Glass-based heat conducting circuit board

A glass-based, circuit board technology, applied in circuit substrate materials, printed circuits, printed circuit manufacturing, etc., can solve problems such as heat dissipation and poor light transmittance, and achieve the effects of simple manufacturing process, reduced packaging costs, and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Manufacture of glass-based copper clad laminate

[0027] Glass and copper foil use epoxy resin as the basic adhesive to produce glass-based copper clad laminates through vacuum hot pressing.

[0028] a. Epoxy resin adhesive formula:

[0029] material name parts by weight A-80 epoxy resin 1000 Dicyandiamide 100 PVB 80 1# Additive 4 2# Additive 4 KH-560 100 filler Appropriate amount solvent 1400

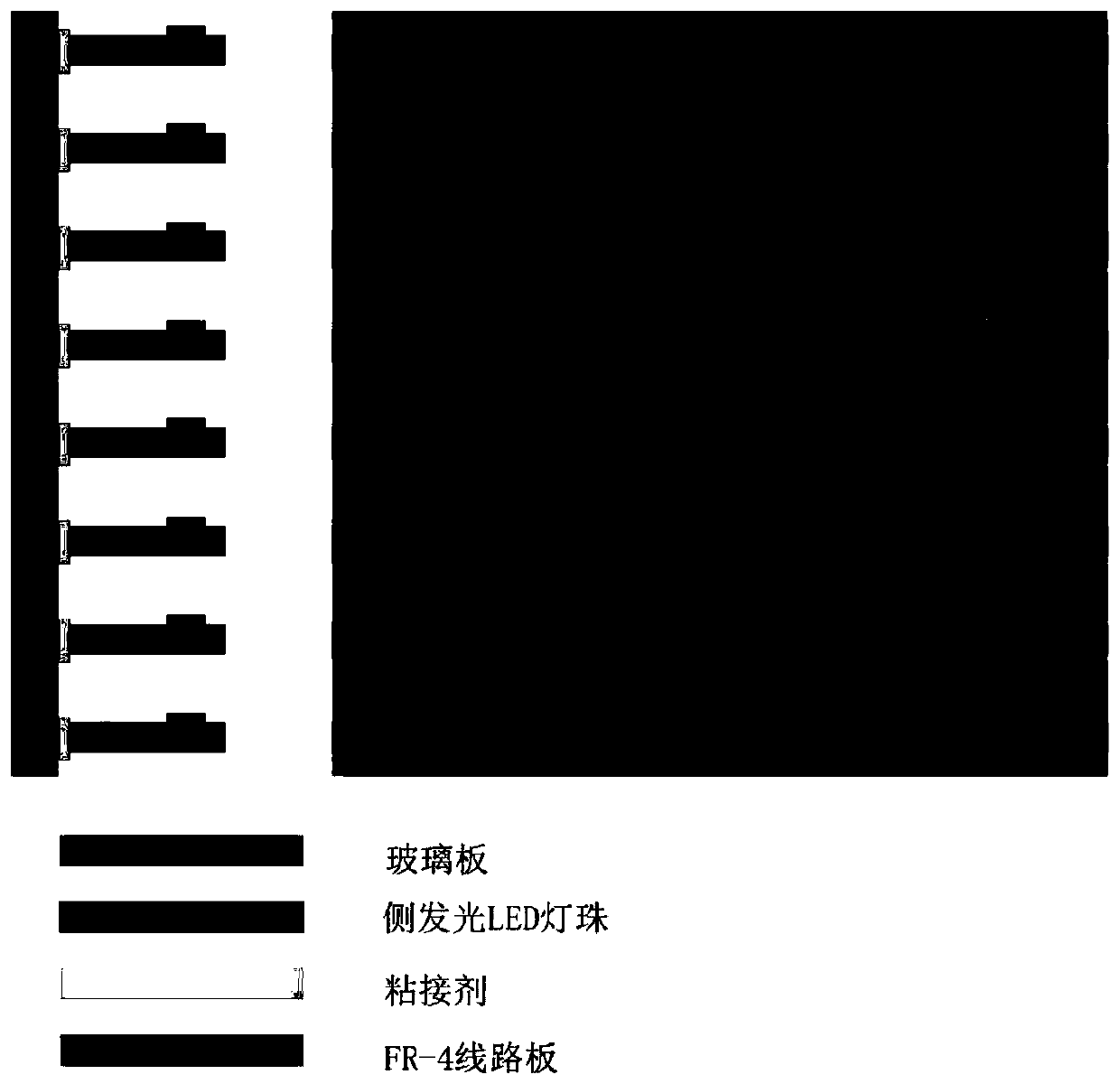

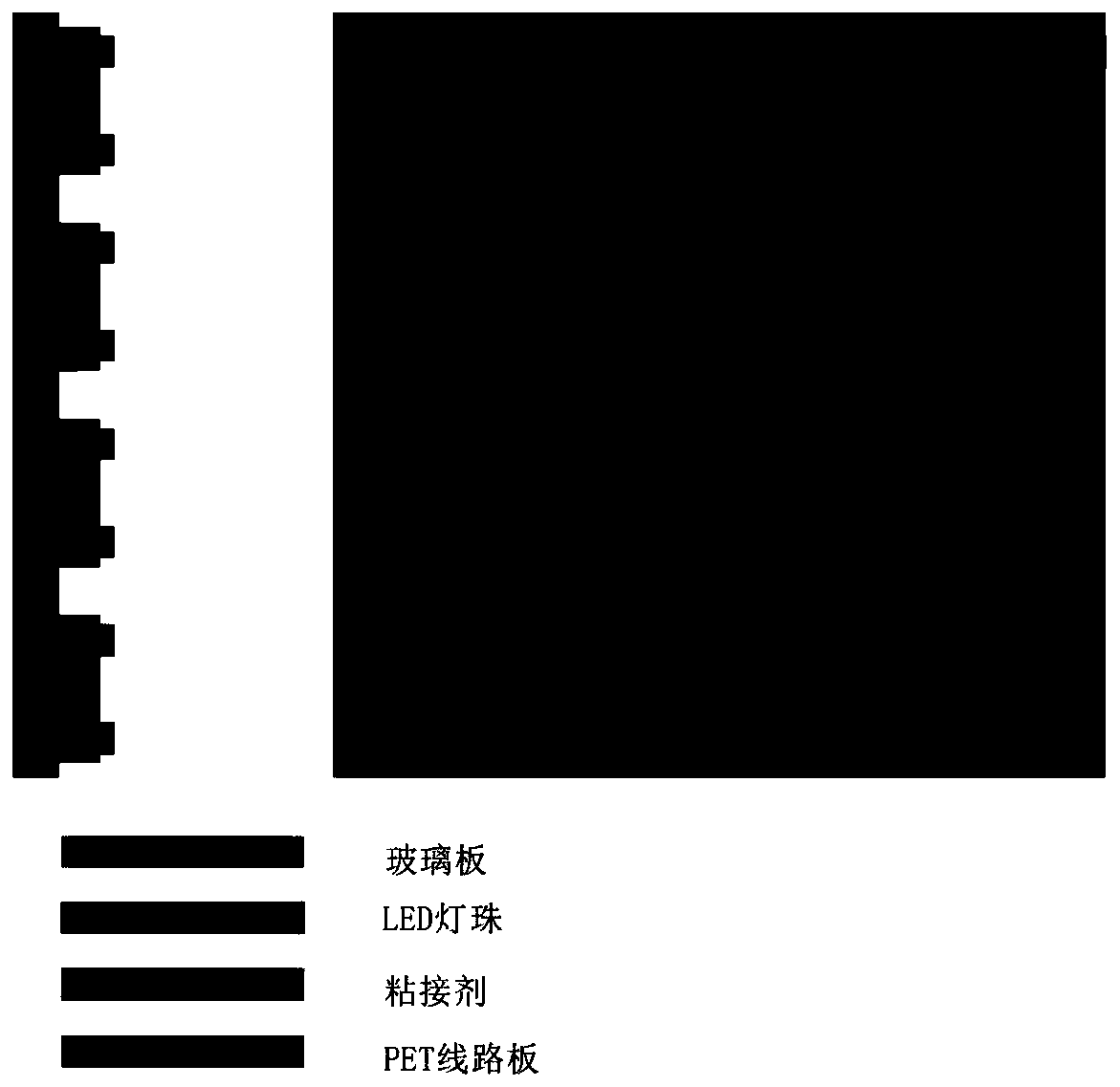

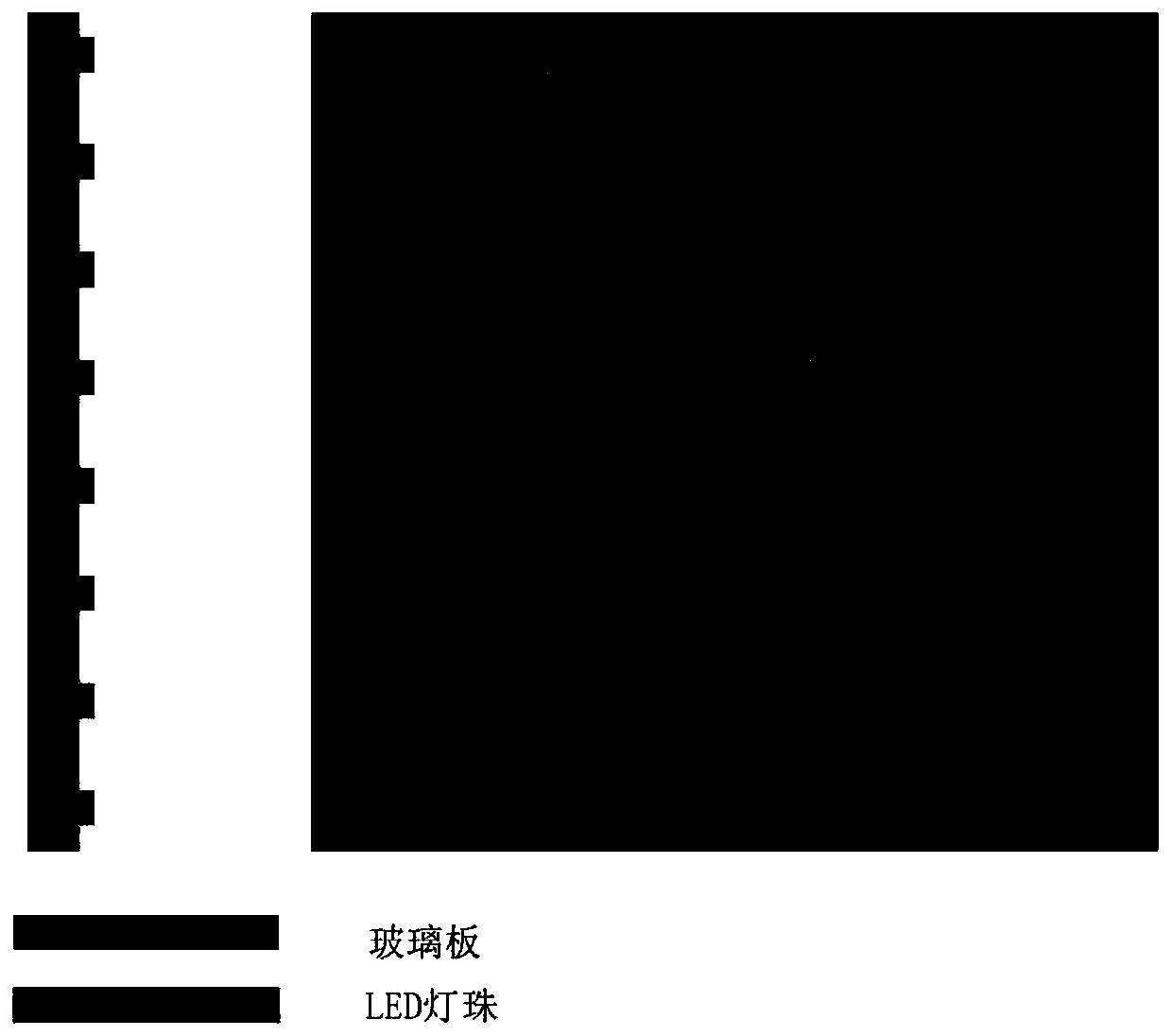

[0030] After the above formula is mixed, stirred and matured, the formula resin is uniformly coated on the copper foil on the resin coating machine. Schematic diagram of the coating resin as Figure 4

[0031] b. Pressed glass-based copper clad laminate

[0032] Place the glass and glued copper foil as shown in the figure below ( Figure 5 ) after being stacked and pressed into a vacuum press.

[0033] c. Manufacture of glass-based circuit boards

[0034] The circuit part is manufactured by the circuit bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com