Cold-chain transportation phase change material and preparation method thereof

A technology of phase change materials and cold chain transportation, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low latent heat of phase change, inability to effectively solve low temperature and high temperature transportation in winter, and poor use effect, etc., to achieve good results Effects of temperature regulation and control, easy control of product quality, and low investment in production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

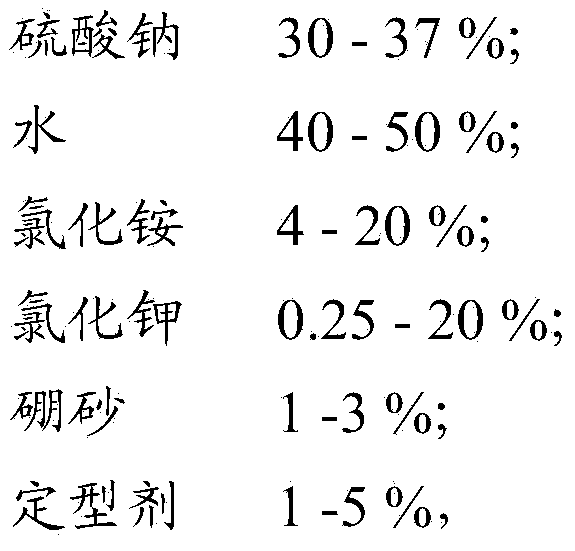

[0023] The phase change temperature of the phase change material for cold chain transportation of the present invention is 2-8°C, and the weight percentage content of each component in the specific embodiment is shown in Table 1:

[0024] Table I:

[0025] components

Example 1

Example 2

Example 3

Example 4

Example 5

30%

30%

33%

31%

37%

water

40%

44%

45%

42%

50%

ammonium chloride

4%

20%

16%

5%

8%

potassium chloride

20%

4%

0.25%

20%

3%

1%

1%

3%

1%

1%

Styling agent

5%

1%

2.75%

1%

1%

[0026] In each embodiment of table one, the sizing agent of embodiment 1 is the mixture of carboxymethyl cellulose sodium, xanthan gum and white carbon black, and the sizing agent of embodiment 2 is the mixture of carboxymethyl cellulose sodium and xanthan gum. Mixture, the fixing ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com