Patents

Literature

169results about How to "Reduce the amount of investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

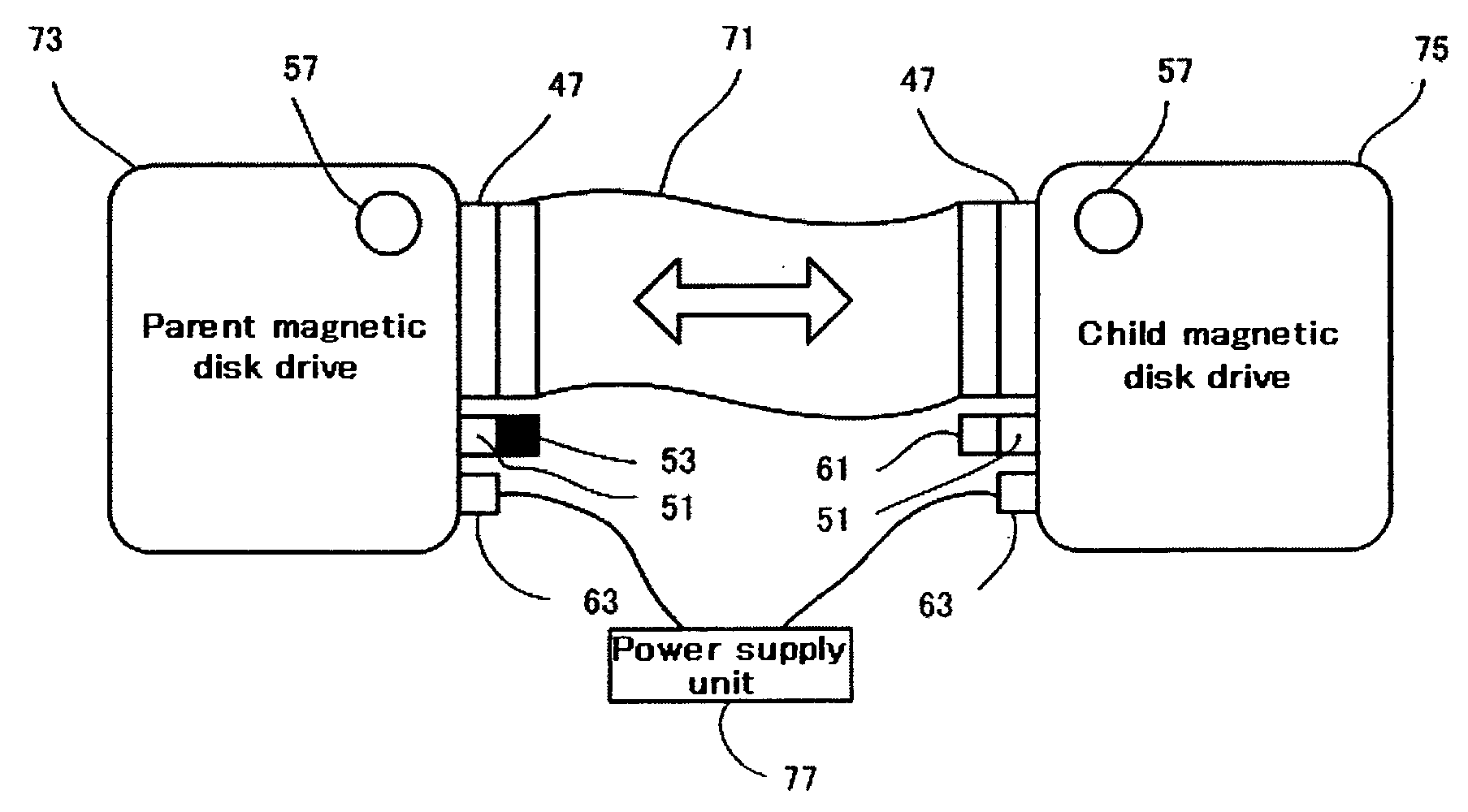

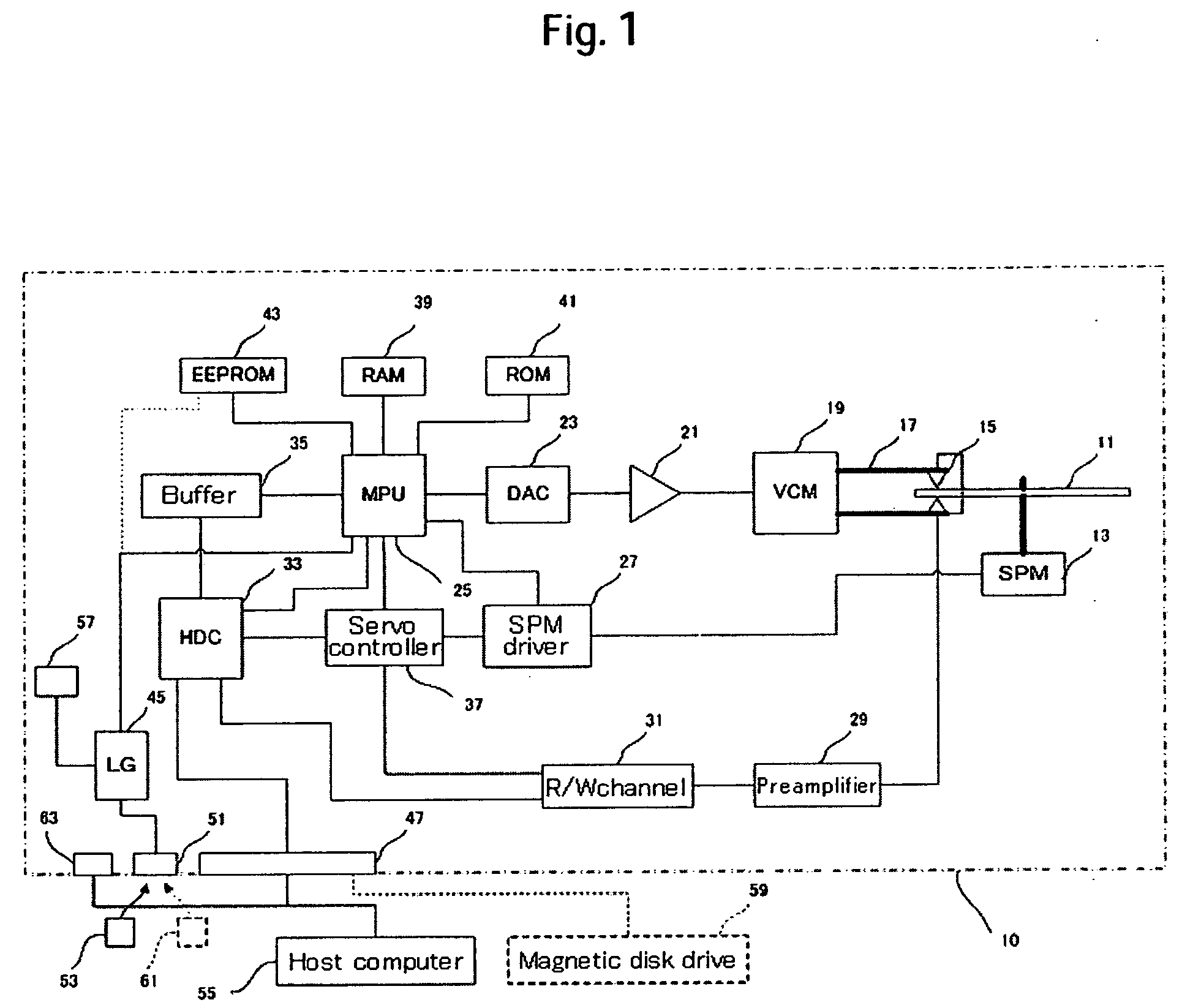

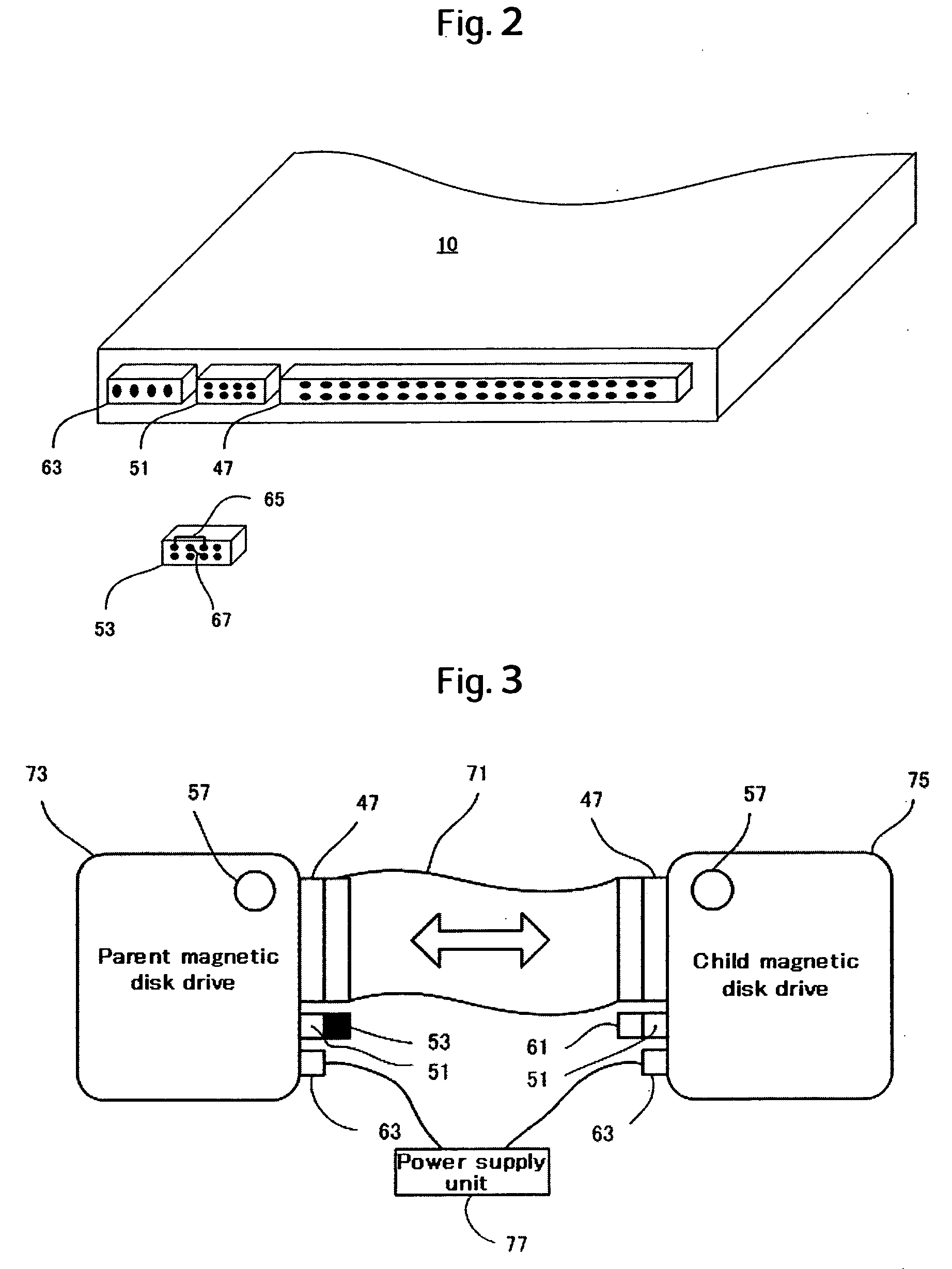

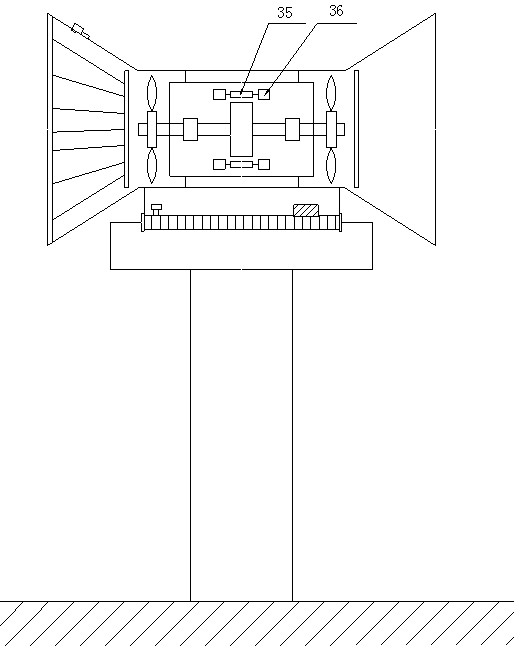

Magnetic disk drive manufacturing method, test/adjustment apparatus, and transport container

InactiveUS20060130316A1Reduce the amount of investmentImprove yieldElectrical transducersCarrier constructional parts dispositionShock absorberElectrical and Electronics engineering

The present invention provides an improved magnetic disk drive manufacturing method that is to be employed during an interval between magnetic disk drive assembly completion and shipment. In one embodiment, a magnetic disk drive has an interface connector. The magnetic disk drive is retained by a shock absorber so that the interface connector is exposed. A testing side connector mounted on a base plate is connected to the interface connector of the magnetic disk drive that is retained by the shock absorber. A host apparatus transfers a test / adjustment program to the magnetic disk drive via the testing side connector. The magnetic disk drive executes the test / adjustment program.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

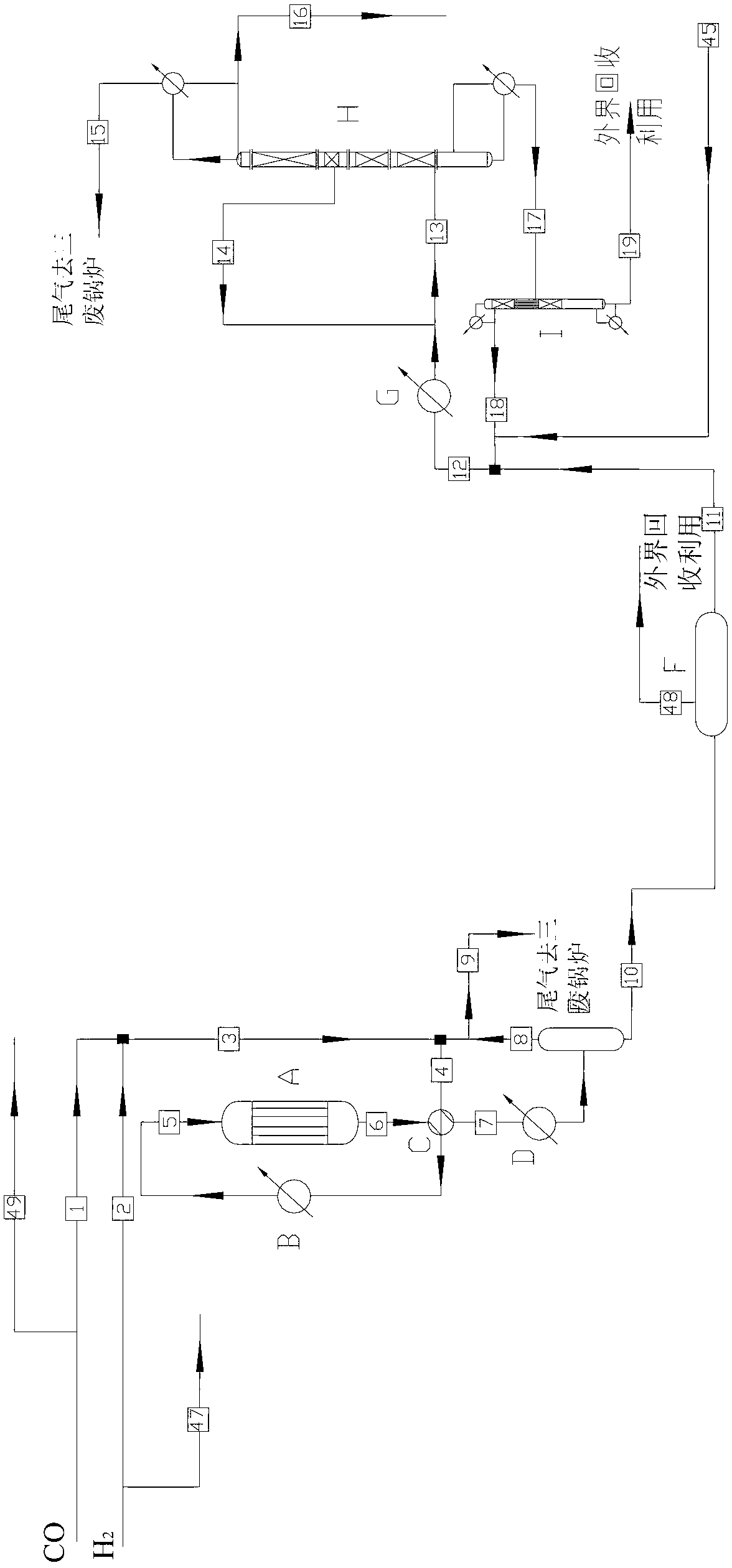

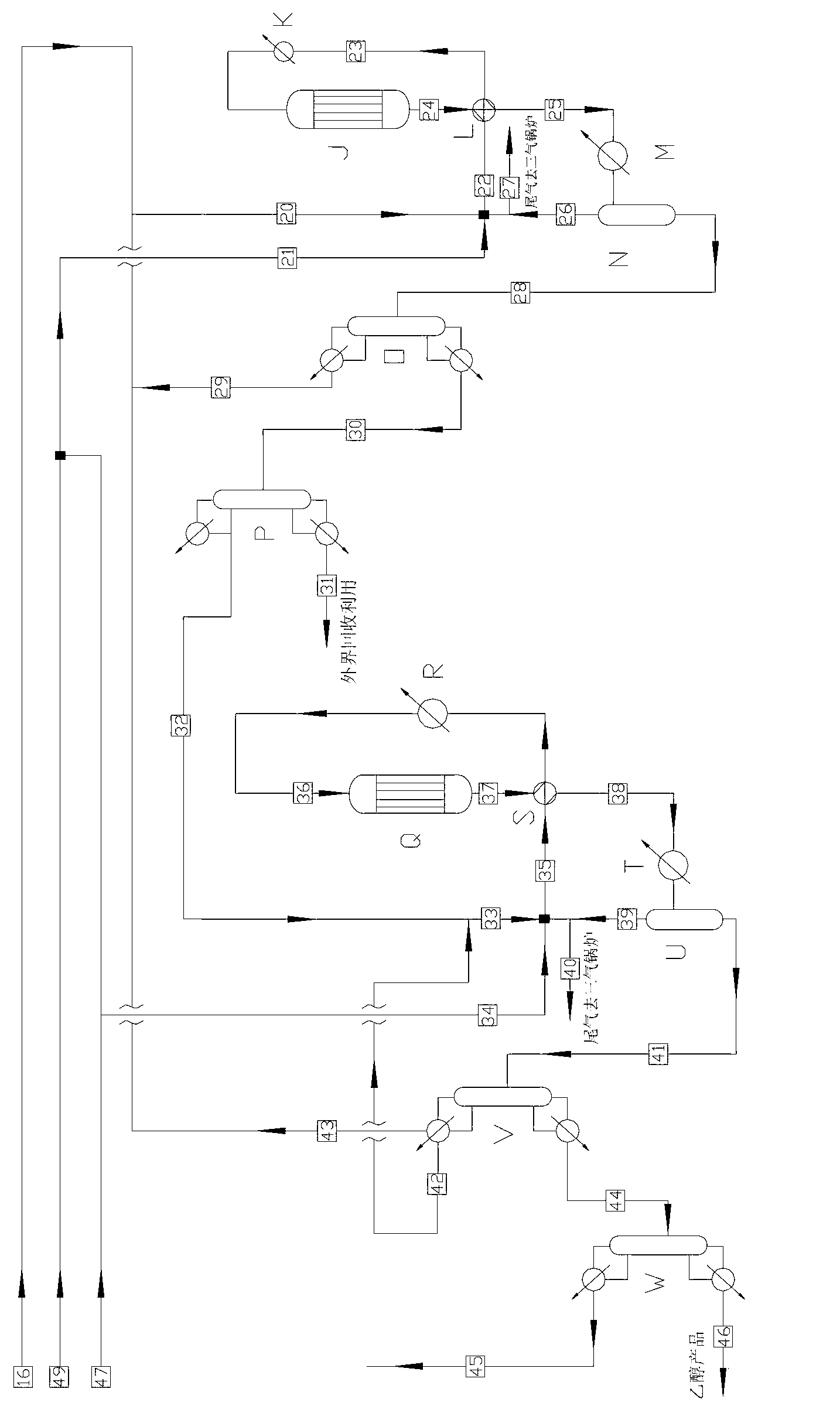

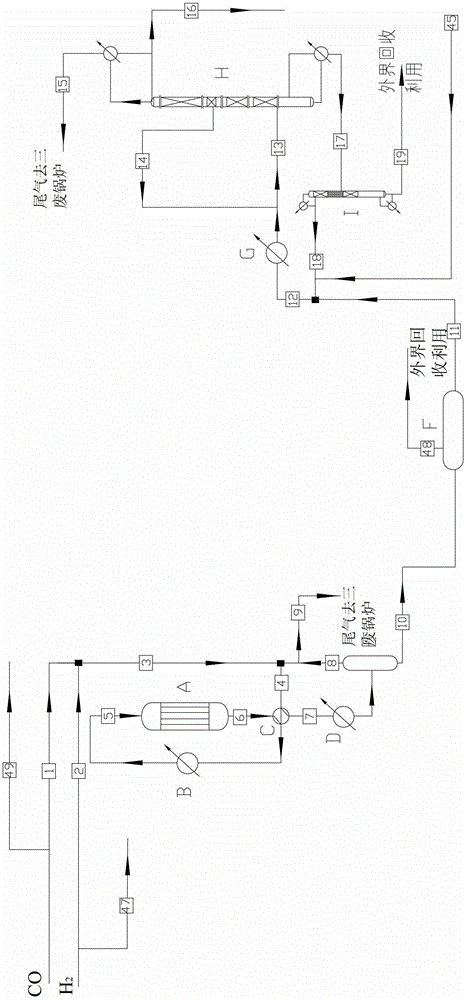

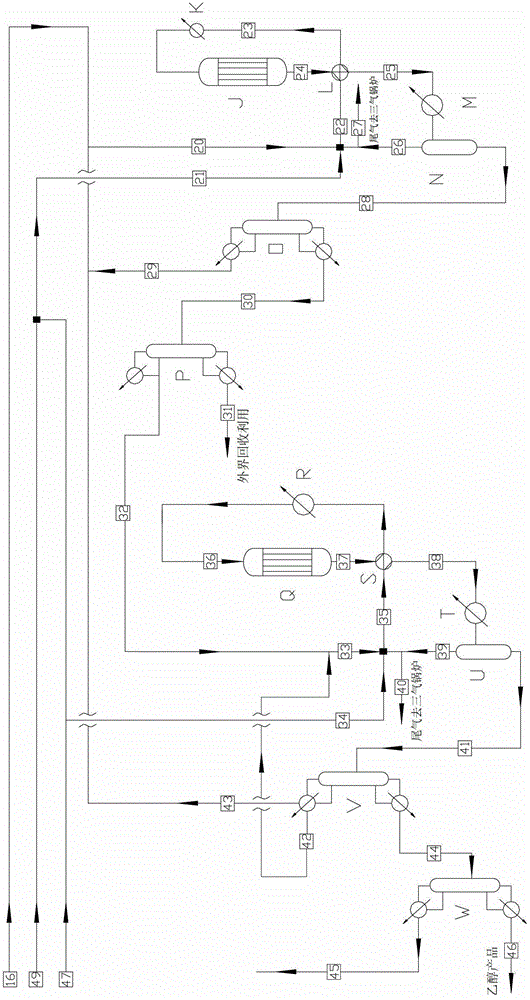

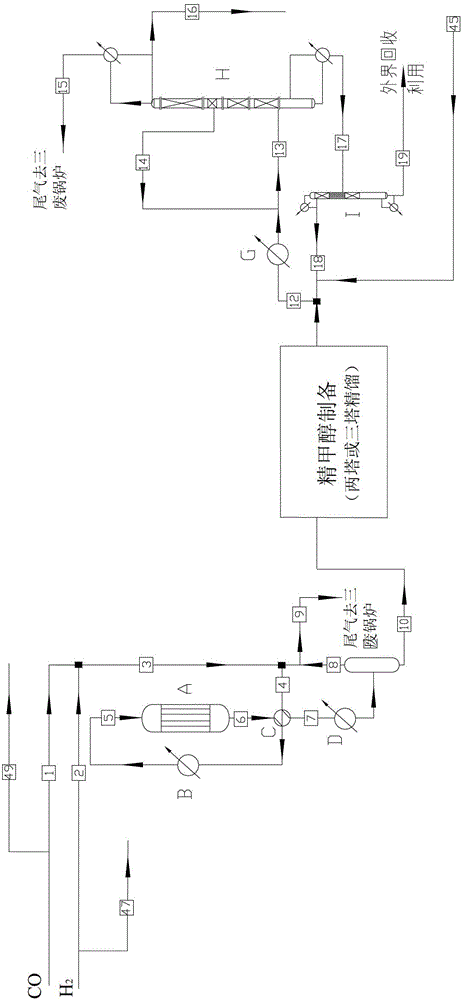

Process for indirectly producing alcohol with synthetic gas and application of process

ActiveCN103012062AReduce energy consumptionMild reaction conditionsOrganic compound preparationHydroxy compound preparationHydrogenMethyl acetate

The invention relates to a process for indirectly producing alcohol with synthetic gas. The process comprises the steps that the synthetic gas formed by mixing industrial carbon monoxide with hydrogen is taken as a raw material to synthesize methanol; methanol is dehydrated to prepare dimethyl ether; dimethyl ether, carbon monoxide and hydrogen are mixed for carbonylation reaction to prepare methyl acetate; methyl acetate is purified and hydrogenated; a hydrogenated product is purified; and an alcohol product is obtained. An adopted catalyst, the process and a device have the characteristics of high conversion per pass and high effective utilization rate of reaction heat; the load of separating a crude product is reduced greatly; the production flow is shortened; and the production energy consumption is reduced greatly.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

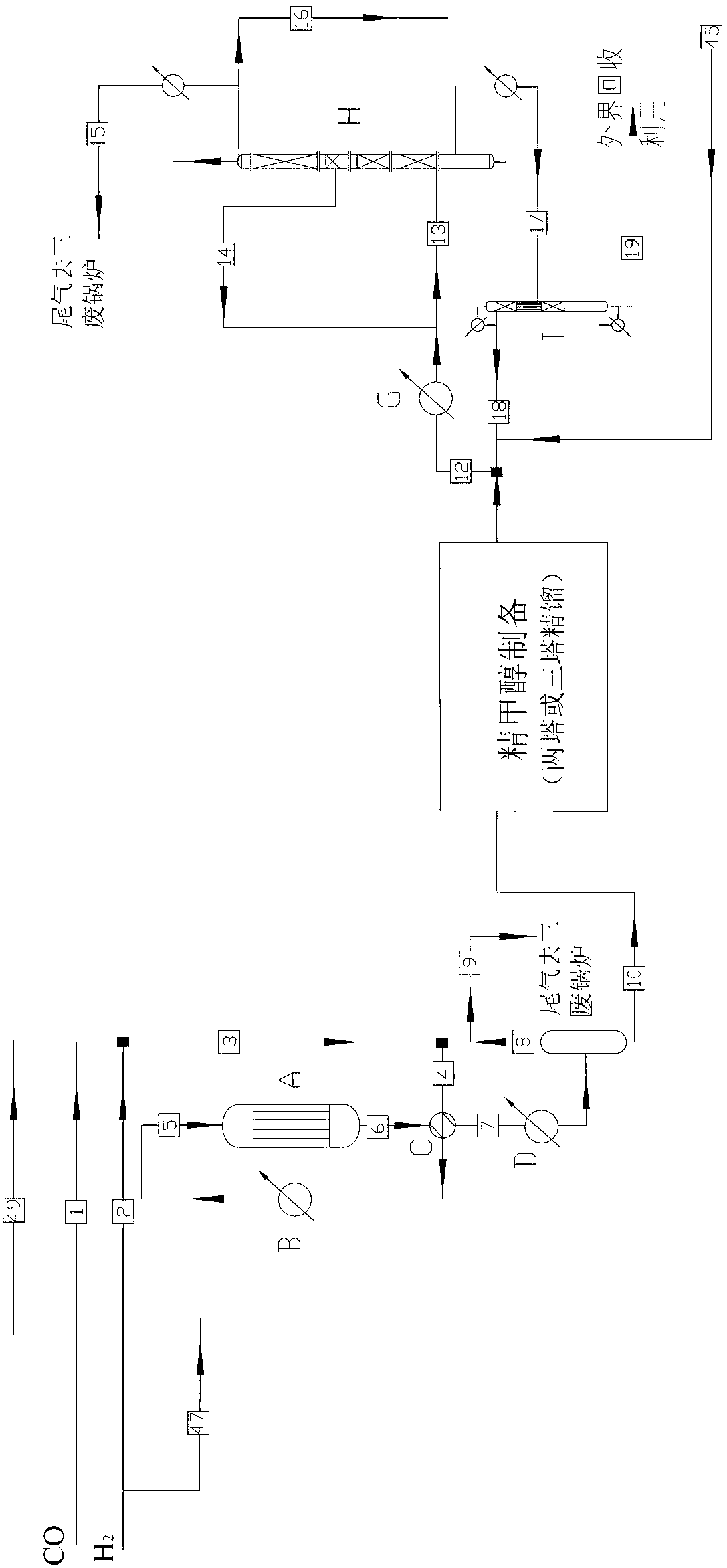

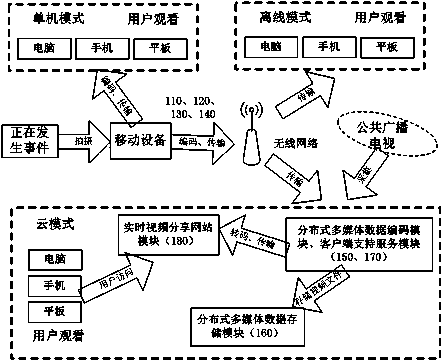

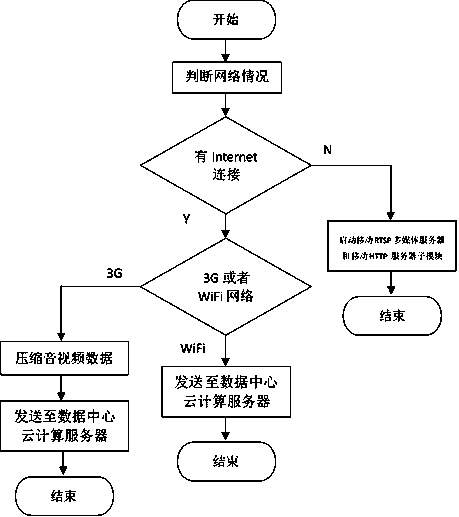

Real-time video sharing platform and method based on mobile cloud computing

ActiveCN103813213AReduce the amount of investmentImprove performanceTransmissionSelective content distributionServer-sideData processing

The invention discloses a real-time video sharing platform based on mobile cloud computing. The real-time video sharing platform comprises a mobile equipment terminal and a cloud computing server side, wherein the mobile equipment terminal comprises an audio / video data processing module, a mobile equipment end working mode switching module, a mobile HTTP (Hypertext Transfer Protocol) server module and a mobile RTSP (Real Time Streaming Protocol) multimedia server module; the cloud computing server side comprises a distributed multimedia data encoding and converting module, a real-time video sharing website module, a distributed multimedia data storage module and a client support server module. A real-time video sharing method based on mobile cloud computing is further disclosed. By adopting the real-time video sharing platform and the real-time video sharing method, the flexibility of video sharing is improved on a user side, and the investment cost is lowered on a platform side. The platform and the method have great application and popularization values.

Owner:NANJING UNIV OF TECH

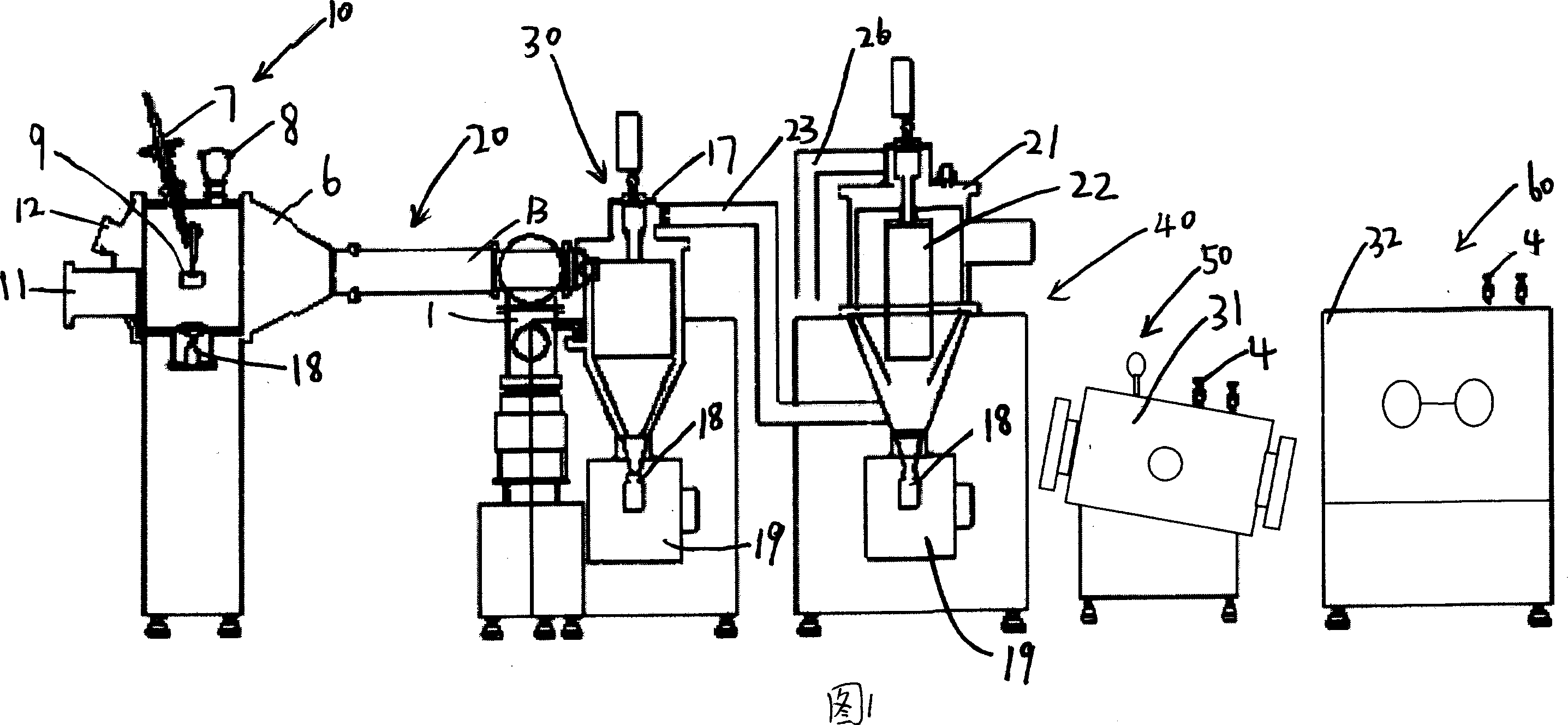

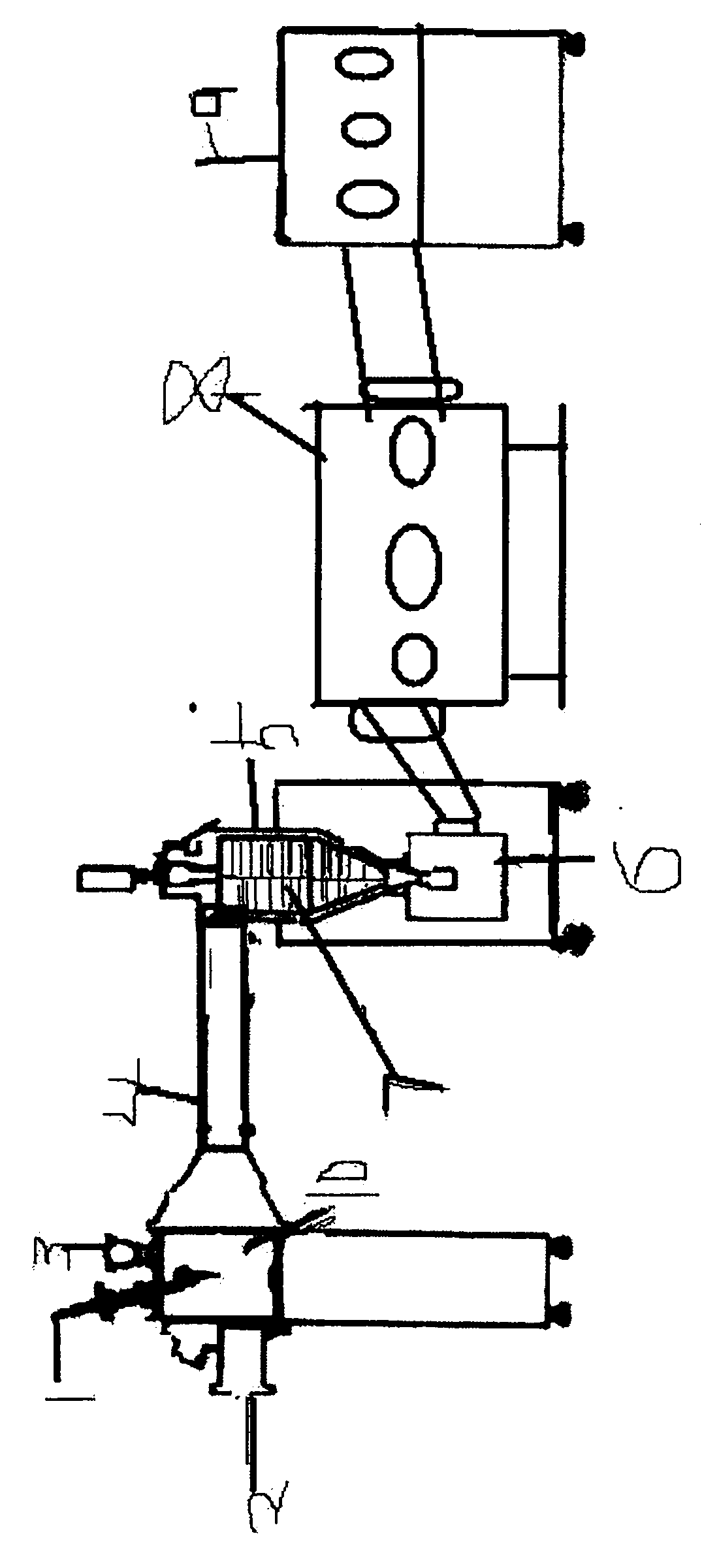

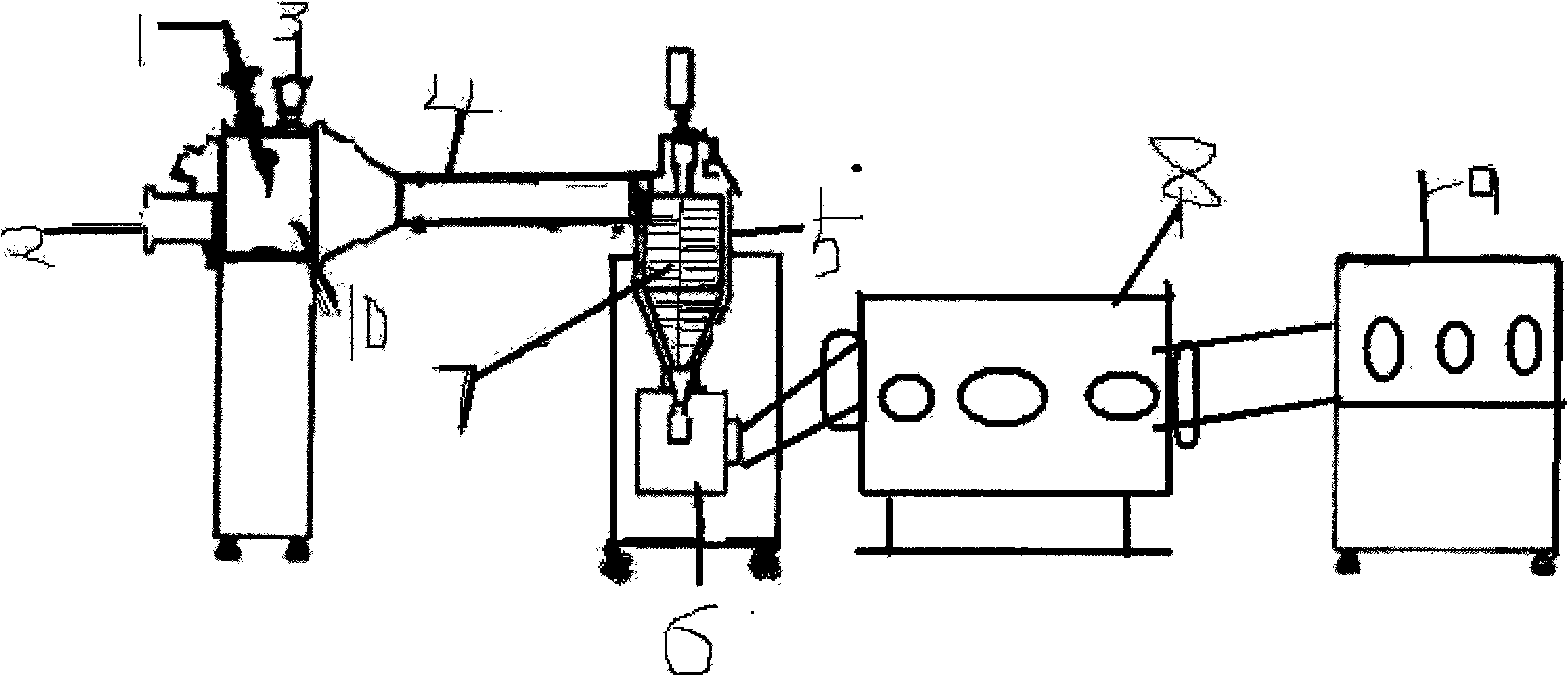

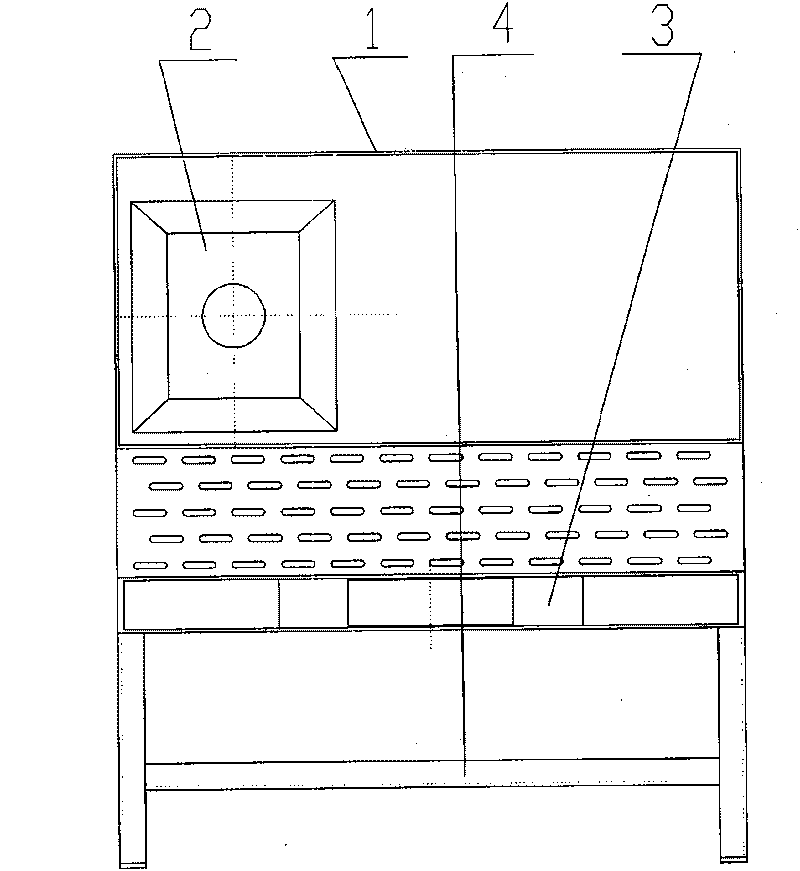

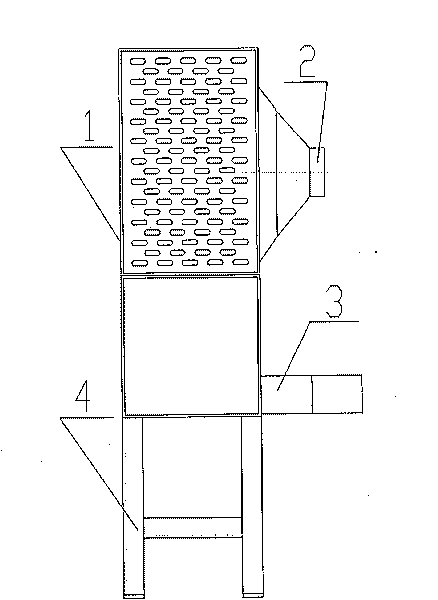

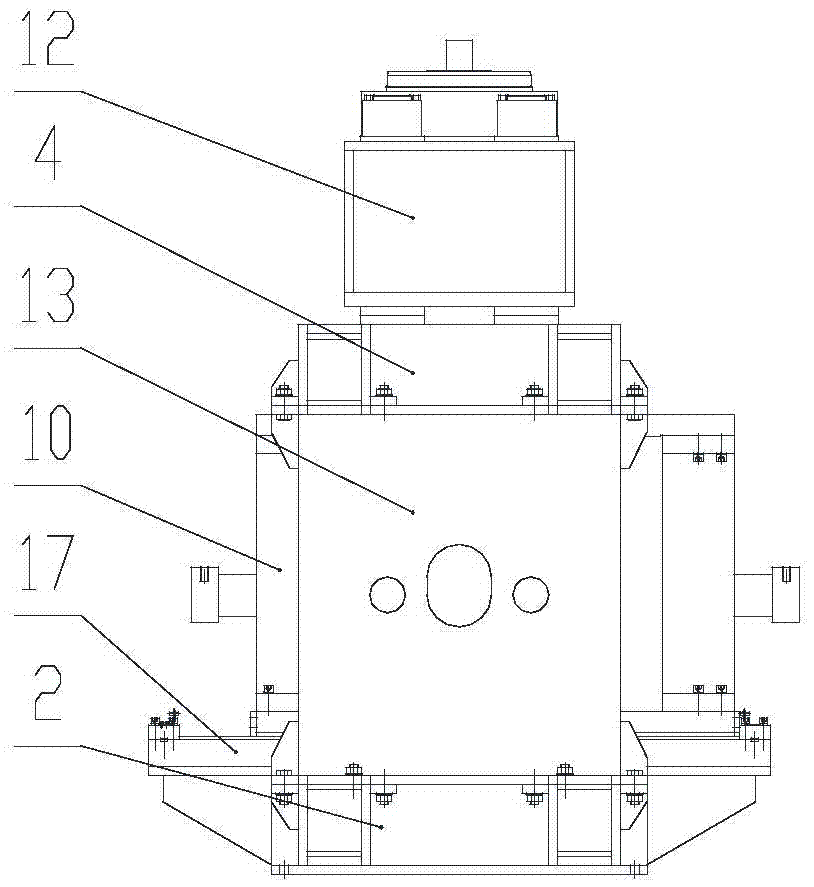

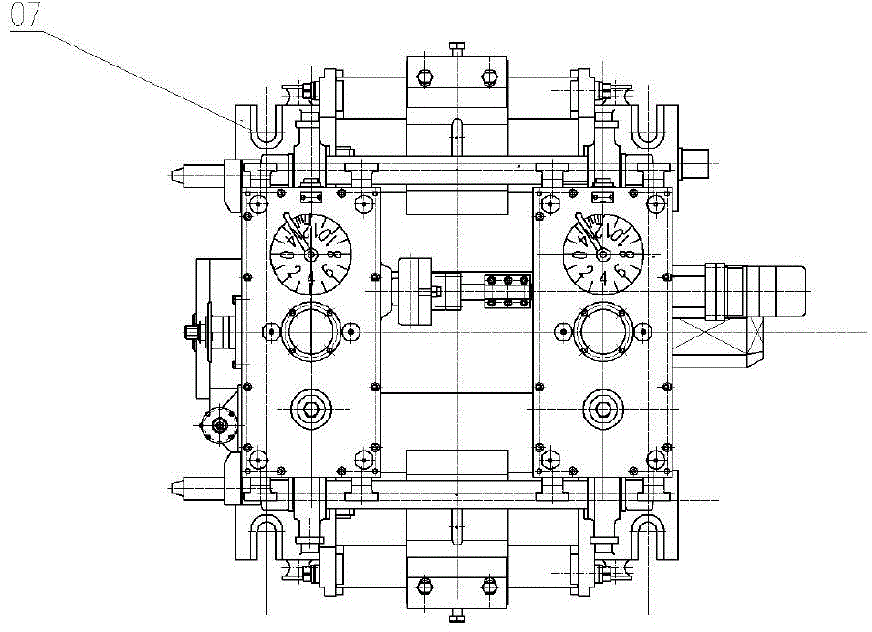

Continuous production apparatus for nano metal powder

The invention discloses a nanometer metal powder continuous producing device, comprising a vacuum measuring aerating system, a plasma / sensitive heating evaporating powder preparing system, a particle controlling system, a nanometer metal powder cyclone grading collecting system, a nanometer powder catching collecting system, a gas cooling circulating system, a water cooling circulating system, an electric controlling detecting system, a metal nanometer powder inactivating system and a powder vacuum packing storing system. The invention has high vacuum and three-gun structure, uses plasma constant-weight packing storing device, and plasma / electromagnetic sensitive evaporation or the like to realize continuous production of nanometer metal powder, change gas component and flux or the like.

Owner:MIYOU GROUP

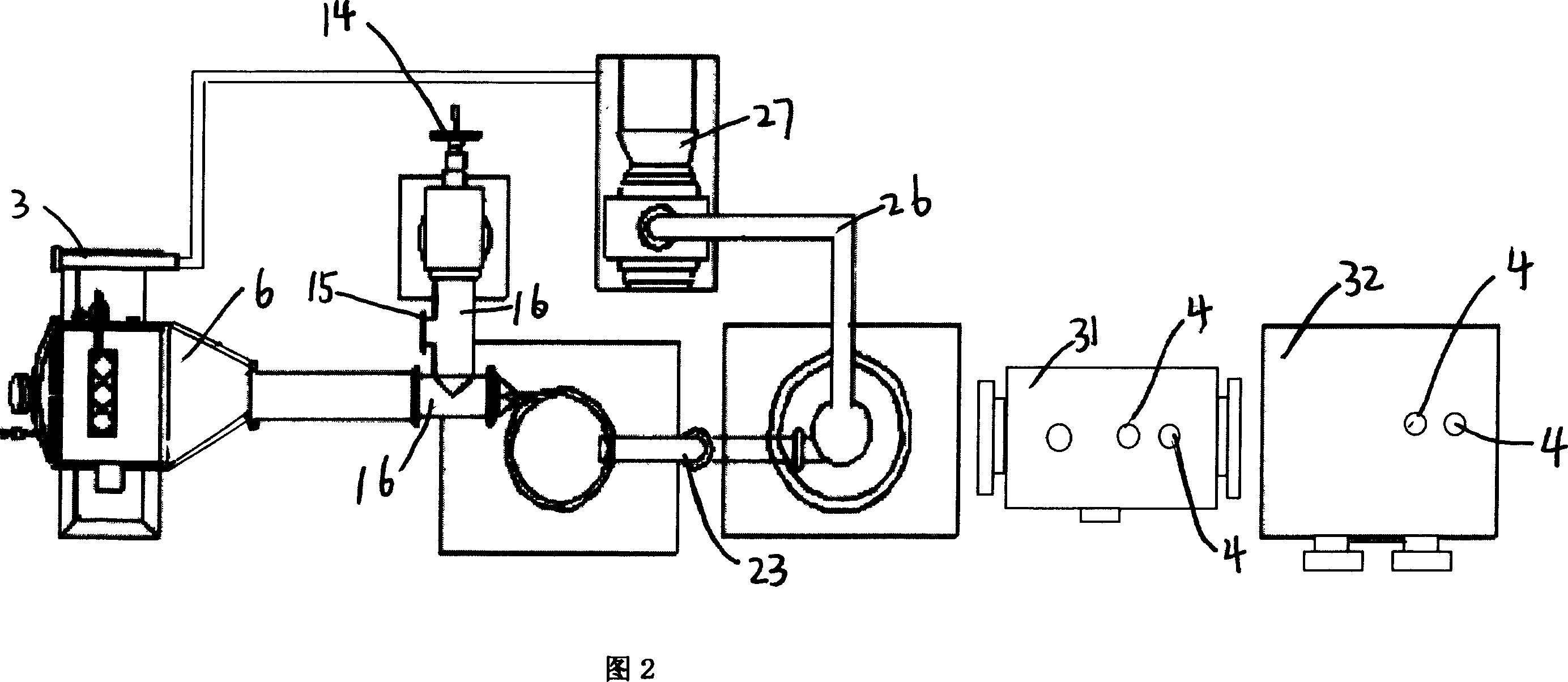

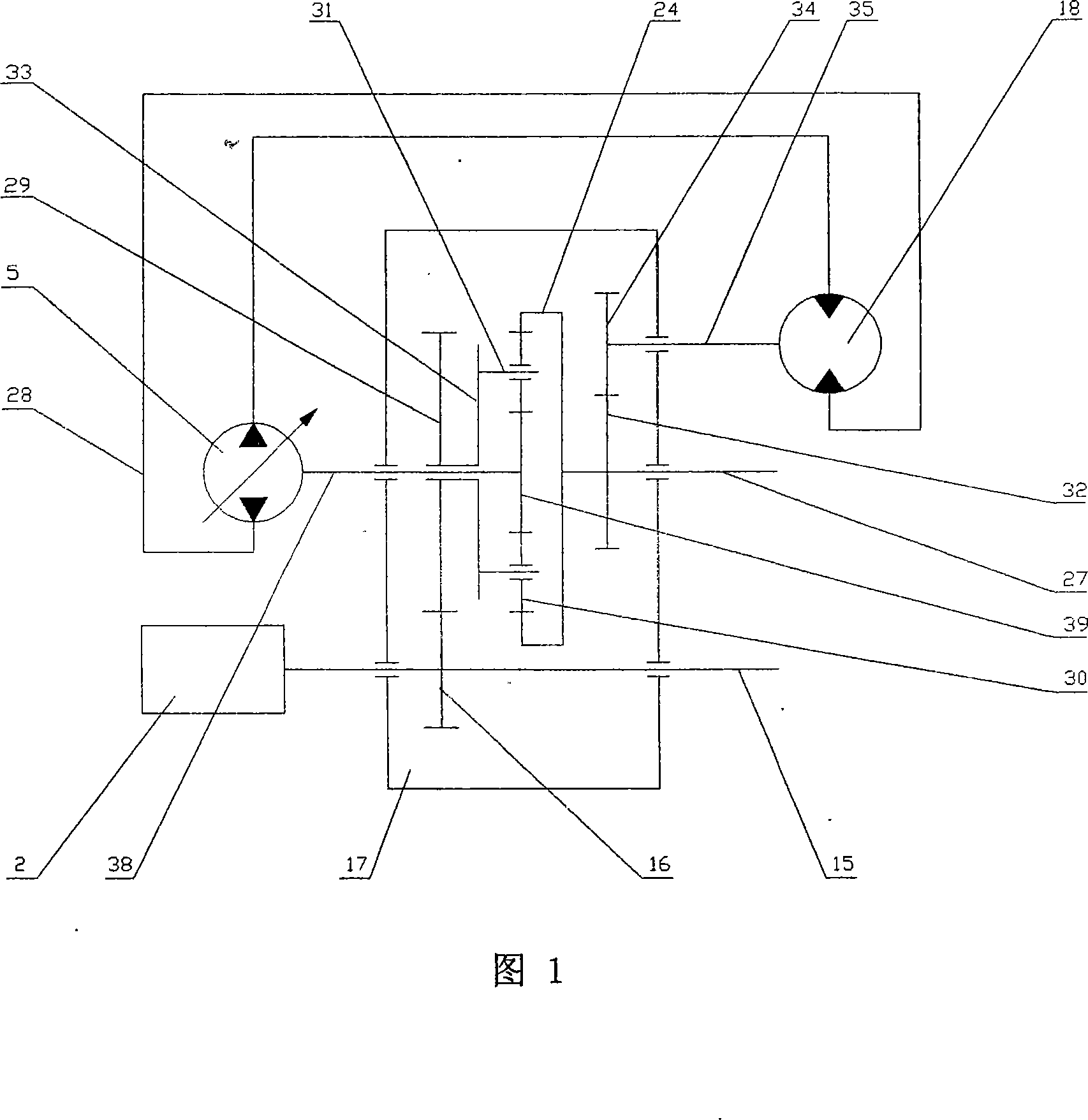

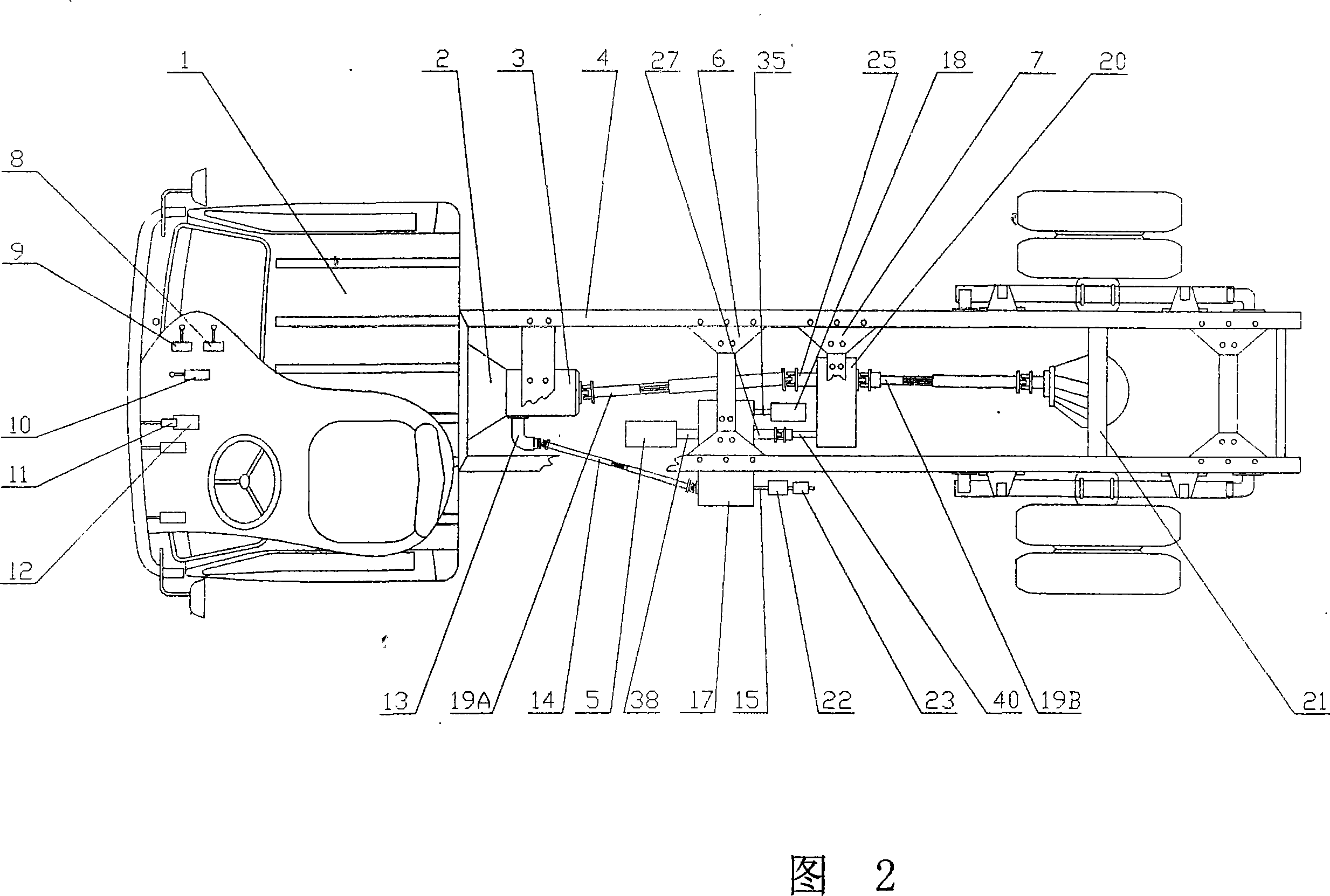

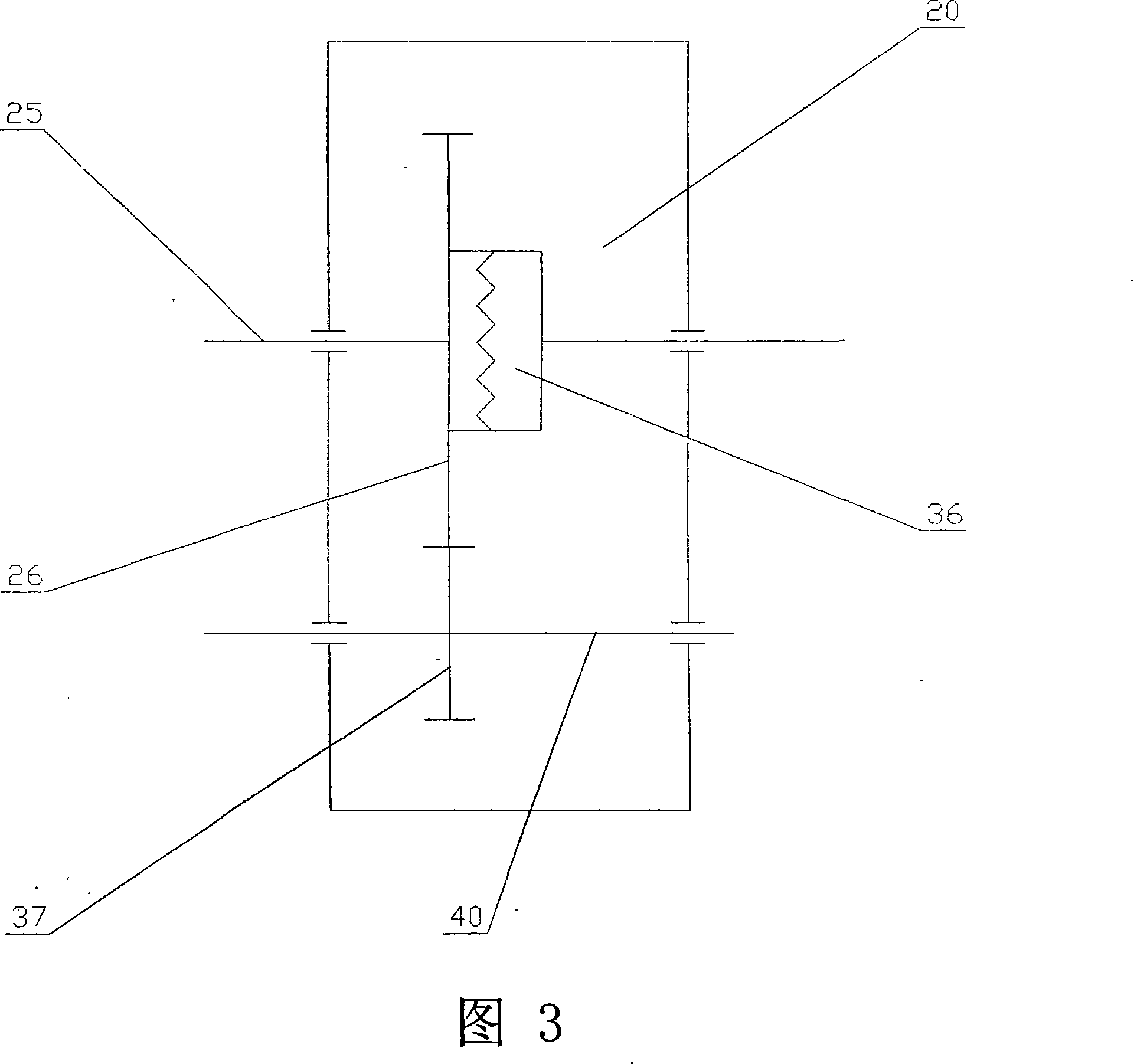

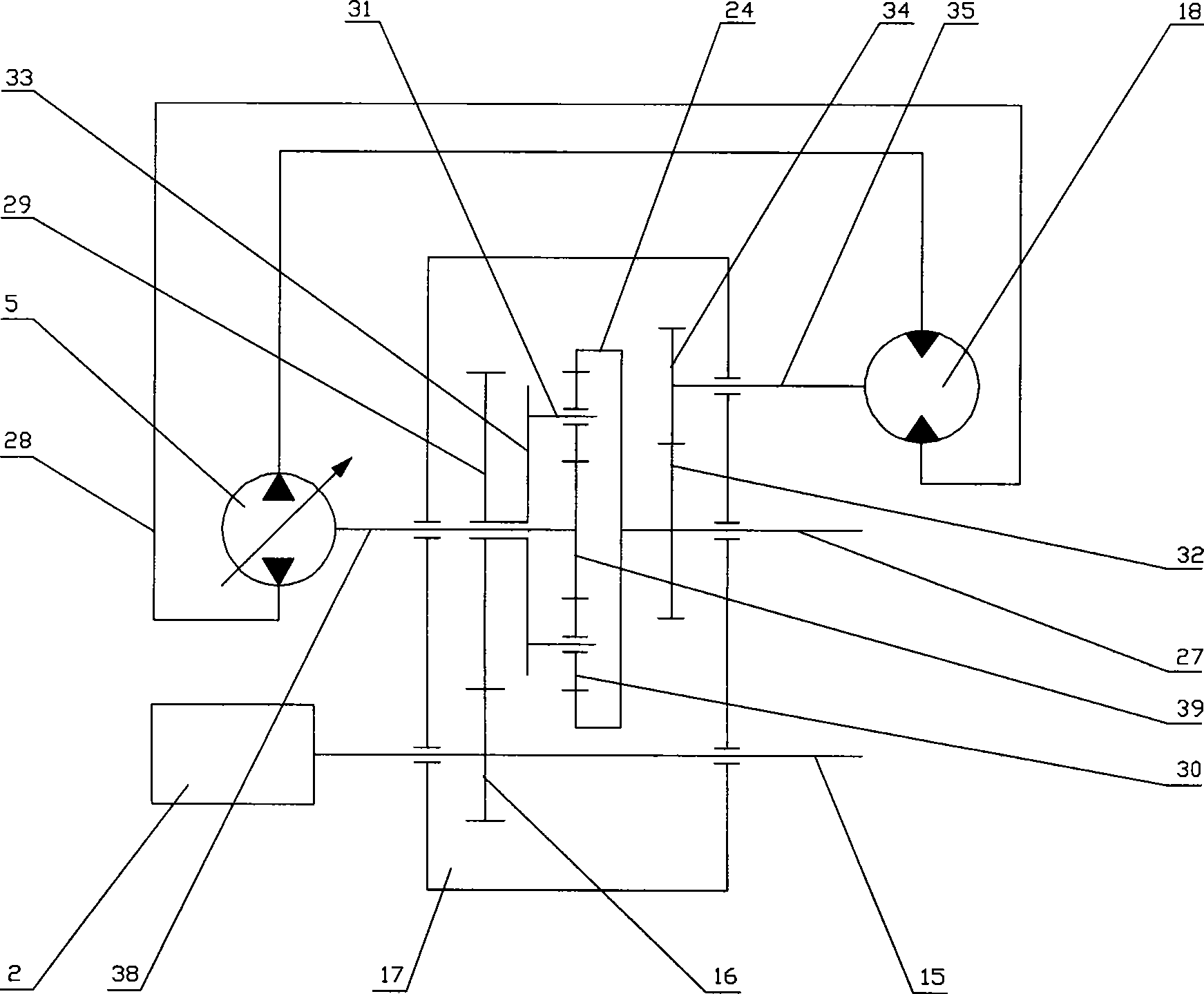

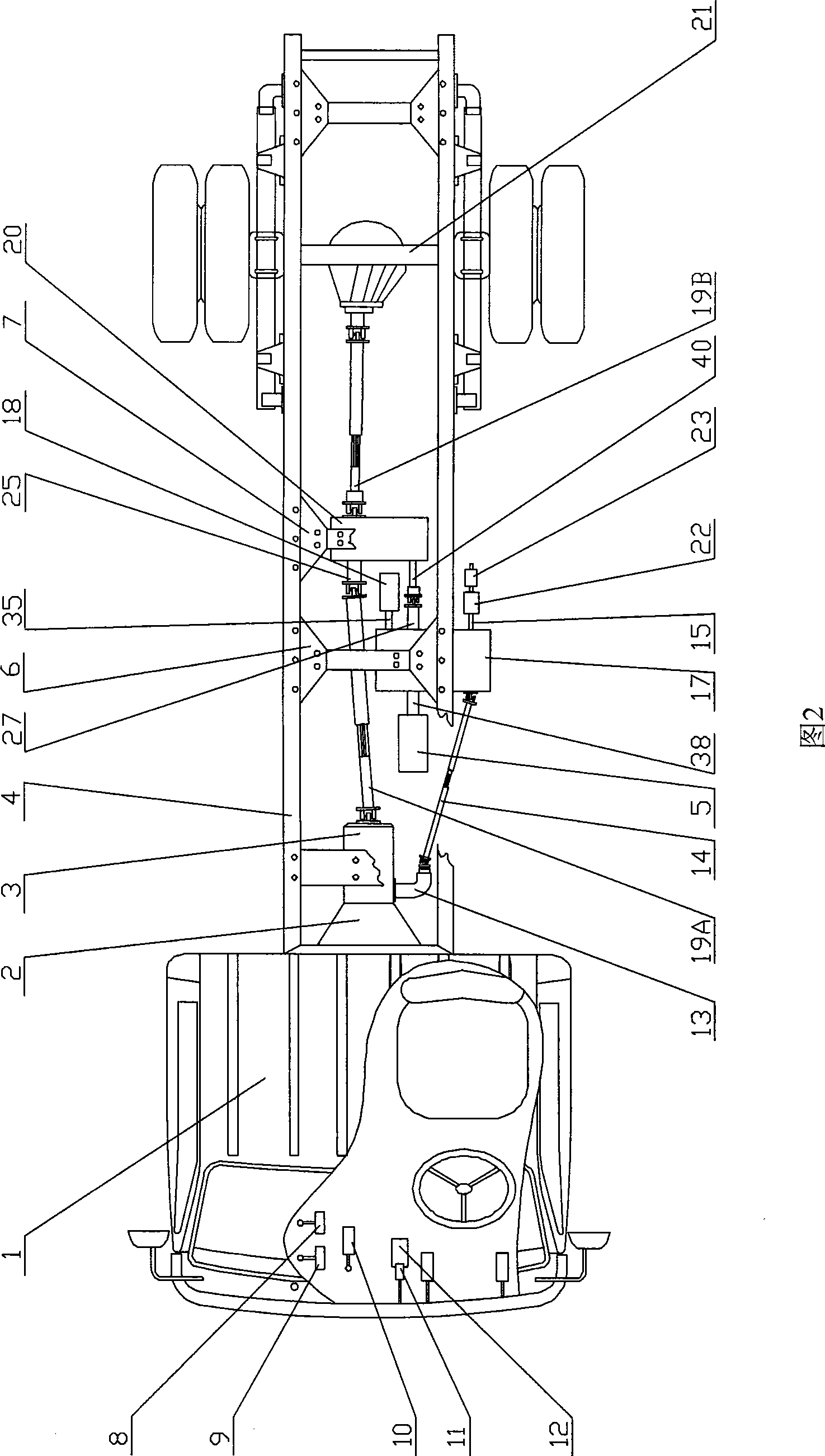

Mechanical-hydraulic compound transmission mechanism

InactiveCN101162043AHigh transmission efficiencyReduce fuel consumptionFluid gearingsControl devicesVariable displacementLow emission

The invention relates to a mechanical-hydraulic composite transmission mechanism, consisting of an engine, a transmission, a planetary gear box, a variable displacement hydraulic pump, a hydraulic motor and a reduction gearbox, wherein, the engine is orderly connected with and drives the transmission and the planetary gear box; a planetary gear mechanism of the planetary gear box distributes the power transmitted by the engine to respectively transmit the variable displacement hydraulic pump and a center wheel; the variable displacement hydraulic pump is orderly connected with and drives the hydraulic motor and a half shaft; the half shaft gathering a mechanical power flow transmitted by the center wheel and a hydraulic power flow transmitted by the hydraulic motor extends out of the planetary gear box to output power; the half shaft is connected with and drives the reduction gearbox and then drives a rear axle to drive an automobile to run. The special automobile refitted with the technology of the invention is a single engine configuration, continuously variable running can be achieved with a mechanical-hydraulic composite transmission mode, meantime, a vehicle device is driven to work with a mechanical transmission mode; a mechanical transmission mode can be converted for fast running, a dynamic system occupies small vehicle space, has a low emission, a high transmission efficiency and a low oil consumption.

Owner:赵宏坚 +1

Novel technology for continuously producing nano powder by using ultra-high temperature plasma and preparation process thereof

InactiveCN101927352AAvoid wastingReduce the amount of investmentEnergy based chemical/physical/physico-chemical processesPlasma techniqueAir volumeCollection system

The invention discloses novel technology for continuously producing nano powder by using ultra-high temperature plasma and a preparation process thereof. The technology is implemented by a device consisting of an electrical control system, a vacuum pumping and measuring system, an gas charging system, an ultra-high temperature plasma heating, evaporating and pulverizing system, a high air-flow cooling and circulating system, a water cooling and circulating system, a nano powder supplementing and collecting system, a powder cleaning system and a vacuum packaging and storing system. High vacuum is adopted in the embodiment of the invention and the method comprises the following steps of: directly heating metal powder by using the ultra-high temperature plasma to form metal vapor quickly; and colliding the metal vapor quickly with high air-flow gas molecules to make the metal vapor loose energy and form clusters by using the high air-flow cooling and circulating system and water cooling circulation, and condensing the clusters into the nano metal powder. Metal hydride nano powder, metal nitride nano powder, metal oxide nano powder and pure metal nano powder can be produced by using different protective gases. Compared with the prior art, the nano metal powder produced by the method has the advantages of difficult agglomeration, simple process, high purity, convenient operation and maintenance, low production cost, easy realization of large-scale industrial production and wide popularization.

Owner:李立明

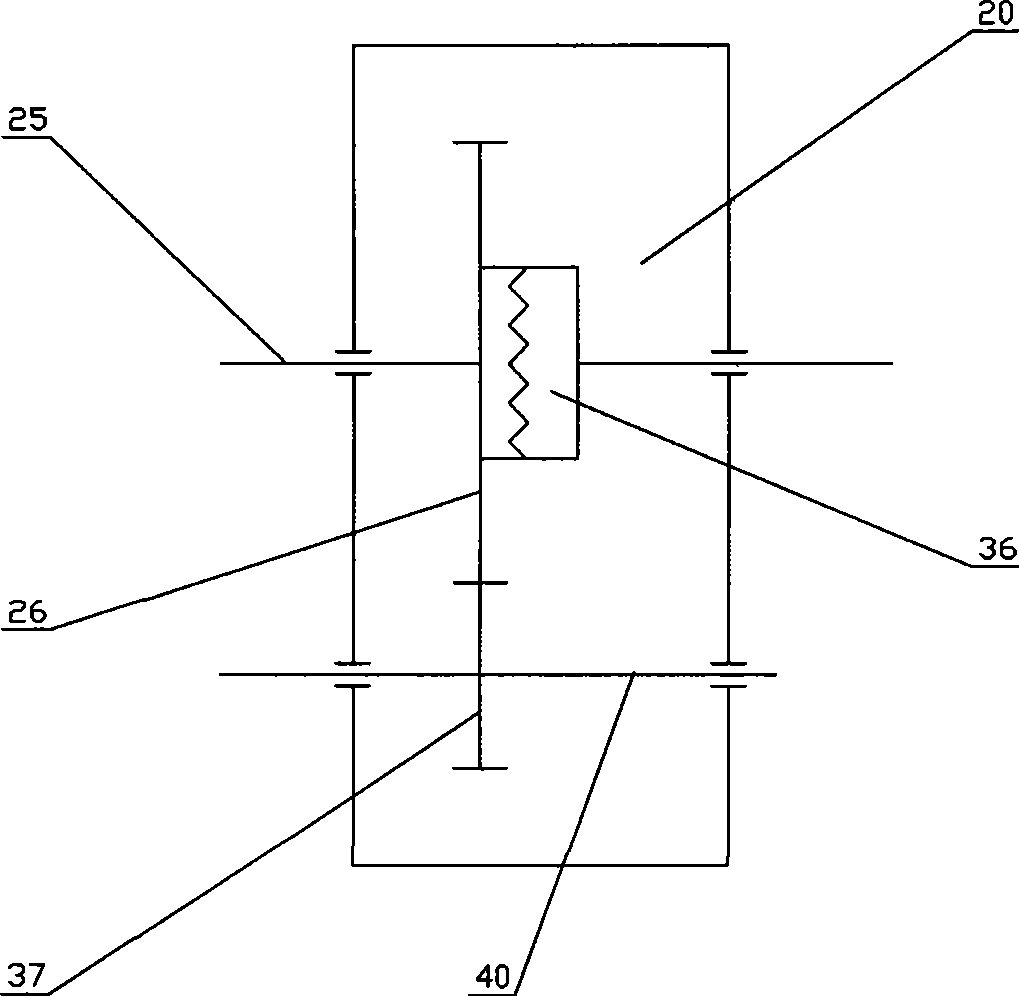

Mechanical and hydraulic combined transmission device

InactiveCN101413572AImprove transmission efficiencyReduce fuel consumptionFluid gearingsControl devicesHydraulic motorPower flow

The invention relates to a mechanical and hydraulic compound transmission device which comprises an engine, a speed changer, a planetary gear box, a hydraulic variable pump, a hydraulic motor and a reduction gearbox; the engine is sequentially connected with the transmission speed changer and the planetary gear box, and a planetary gear mechanism of the planetary gear box distributes the power driven by the motor to respectively drive the hydraulic variable pump and a center gear; the hydraulic variable pump is sequentially connected with a transmission hydraulic motor and a half shaft, the half shaft converges mechanical power flow driven by the center gear and hydraulic power flow driven by the hydraulic motor and protrudes outside the planetary gear box to output the power, and a transmission gear box is connected with the half shaft to redrive a rear shaft to drive a vehicle. A special vehicle refit by the technology with a single-engine configuration can run at a stepless variable speed in a mechanical and hydraulic compound transmission mode, meanwhile, the vehicle can drive a vehicle-mounted operating device in the mechanical transmission mode; during transition, the mechanical transmission mode can be adopted to cause the device to run quickly, the power system occupies little vehicle space, and has low emission, high transmission efficiency and low oil consumption.

Owner:赵宏坚 +1

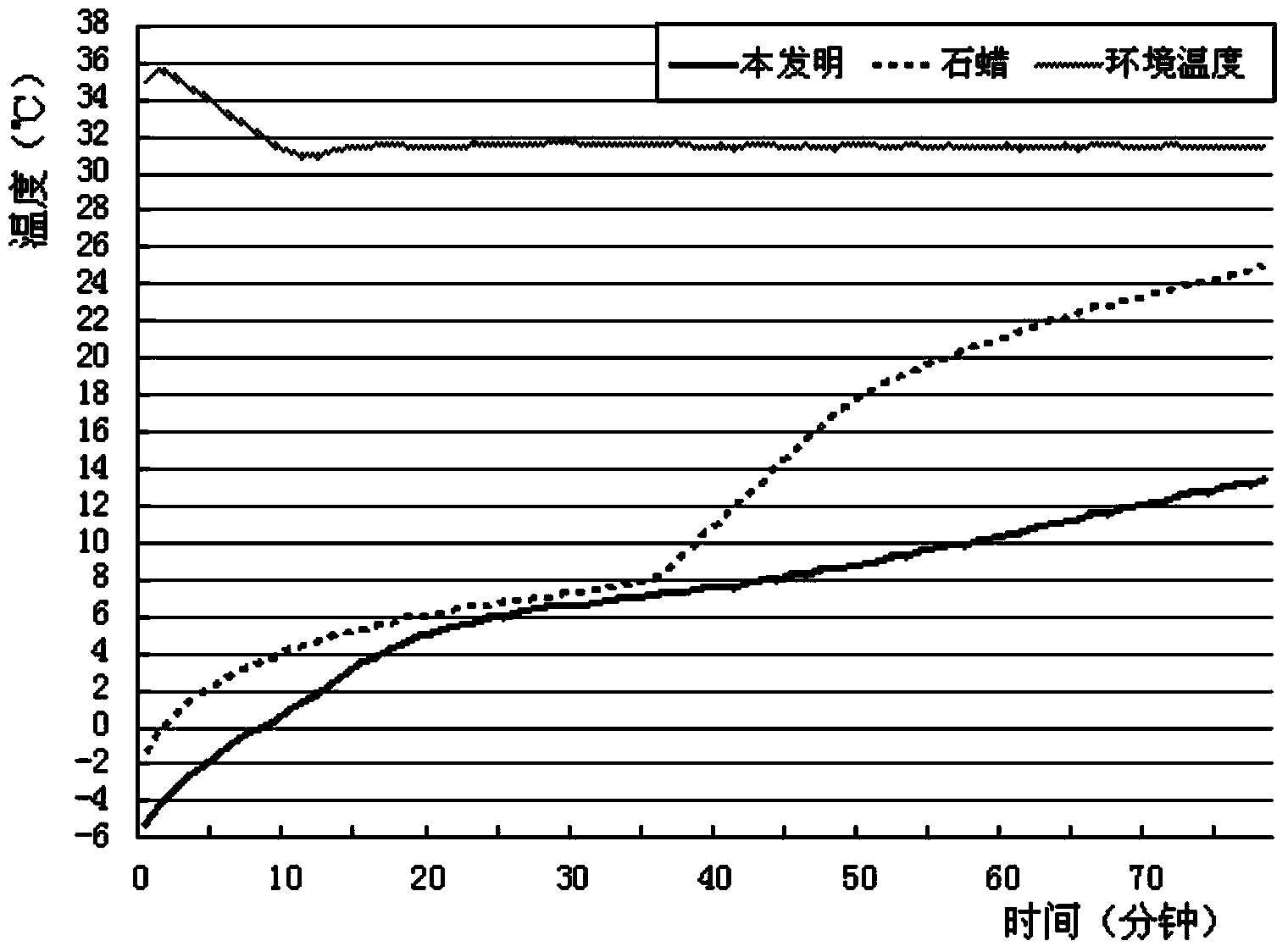

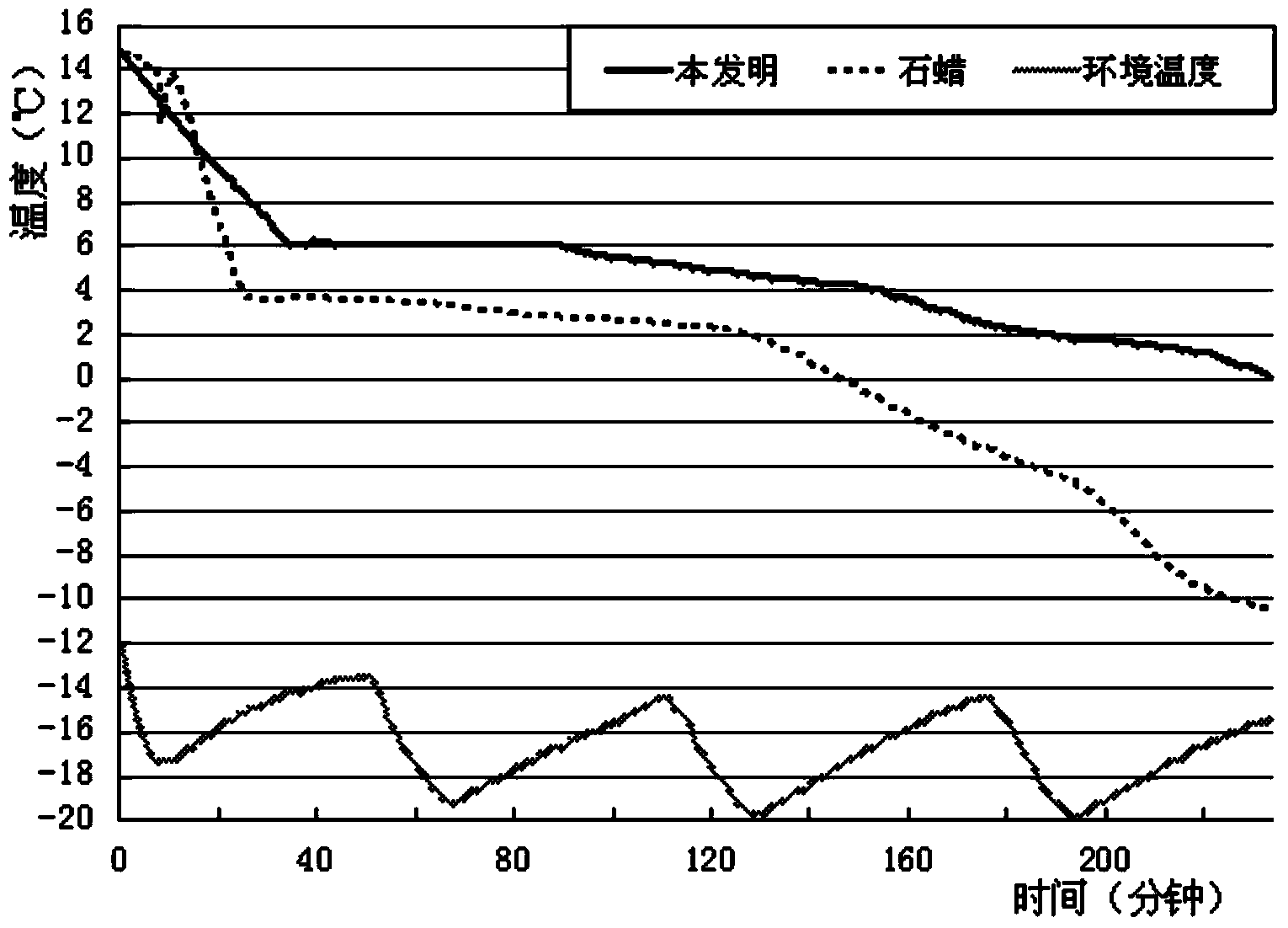

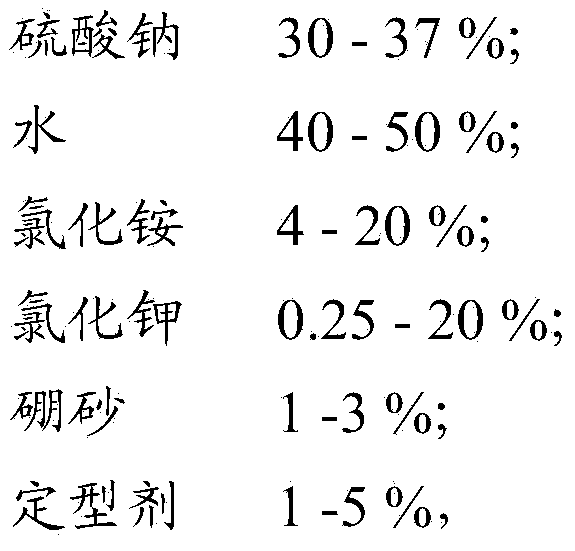

Cold-chain transportation phase change material and preparation method thereof

ActiveCN103756645AStir wellReduce the amount of investmentHeat-exchange elementsCold chainWhole blood product

The invention discloses a cold-chain transportation phase change material and a preparation method thereof. The phase change material is prepared from the following components by weight percent: 30-37% of sodium sulfate, 40-50% of water, 4-20% of ammonium chloride, 0.25-20% of potassium chloride, 1-3% of borax and 1-5% of sizing agent. The preparation method of the phase change material comprises the following steps: A, heating water in the components to 60-70 DEG C, and then adding sodium sulfate to evenly stir, so as to obtain a sodium sulfate solution; B, respectively adding the ammonium chloride, the potassium chloride and borax to the sodium sulfate solution in the step A, evenly stirring, and controlling the temperature of the solution at 60-70 DEG C; C, adding the sizing agent to the solution in the step B, evenly stirring, and filling into a plastic container to store when the temperature of the solution is controlled at 50-60 DEG C. The cold-chain transportation phase change material disclosed by the invention is used for maintaining long soaking time at 2-8 DEG C during cold chain transportation, and the quality of cold chain distribution of drugs, vaccines, blood products and medical devices is ensured.

Owner:益萃健(上海)生物科技有限公司

Novel cotton cultivation method

InactiveCN102783345AImprove labor productivityReduce labor intensityHorticultureUltimate tensile strengthBiology

Seedling raising and transplanting in protected areas can prolong growth period by 30-40 days and promote increase of cotton yield. Traditional seedling raising and transplanting use soil nutrition pots. Manufacturing and transplanting of the soil nutrition pots are labor-consuming, high in labor intensity and low in efficiency. Paper-tube combined filled lightweight substrate and industrially made nutrition pots are used, mechanical seeding and mechanical transplanting are carried out and are development trends of cotton industry in China.

Owner:操宇琳

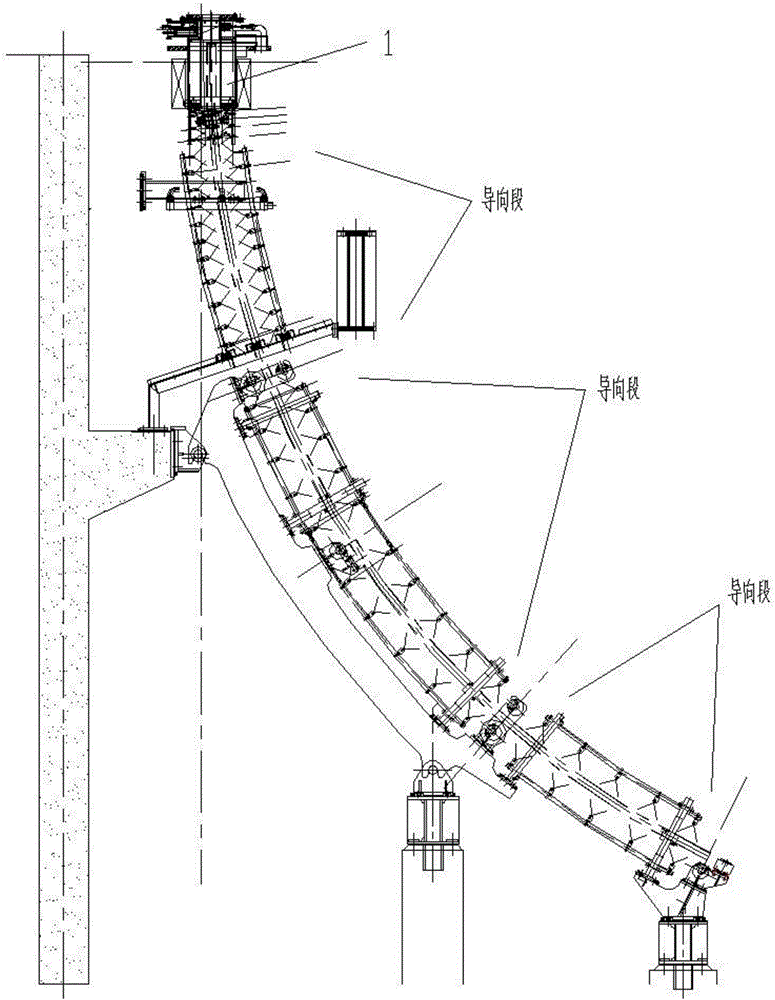

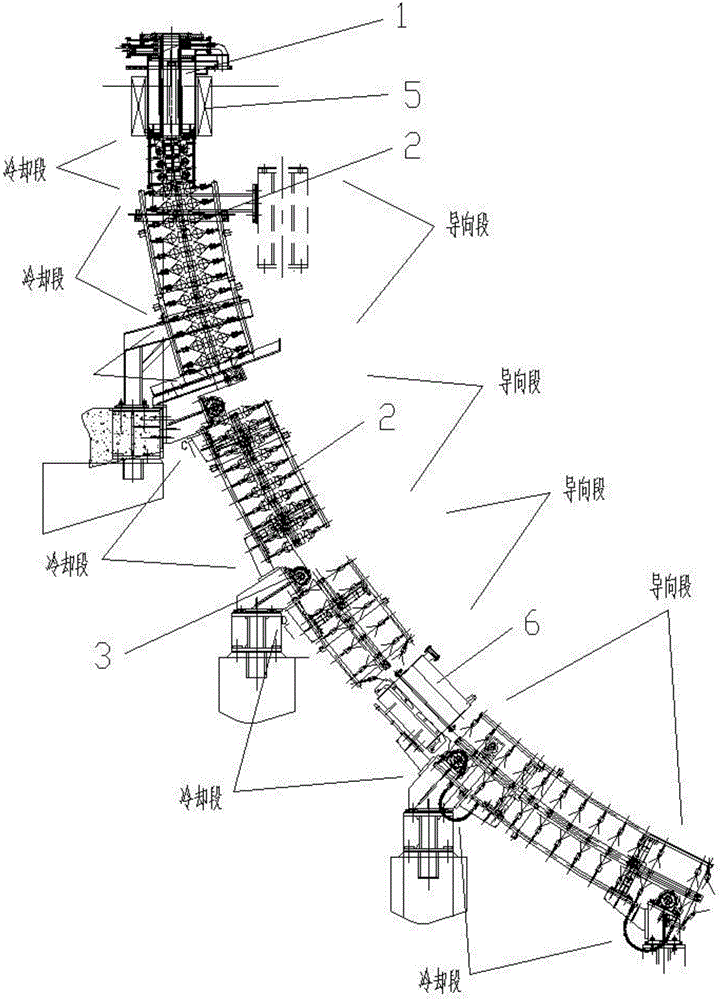

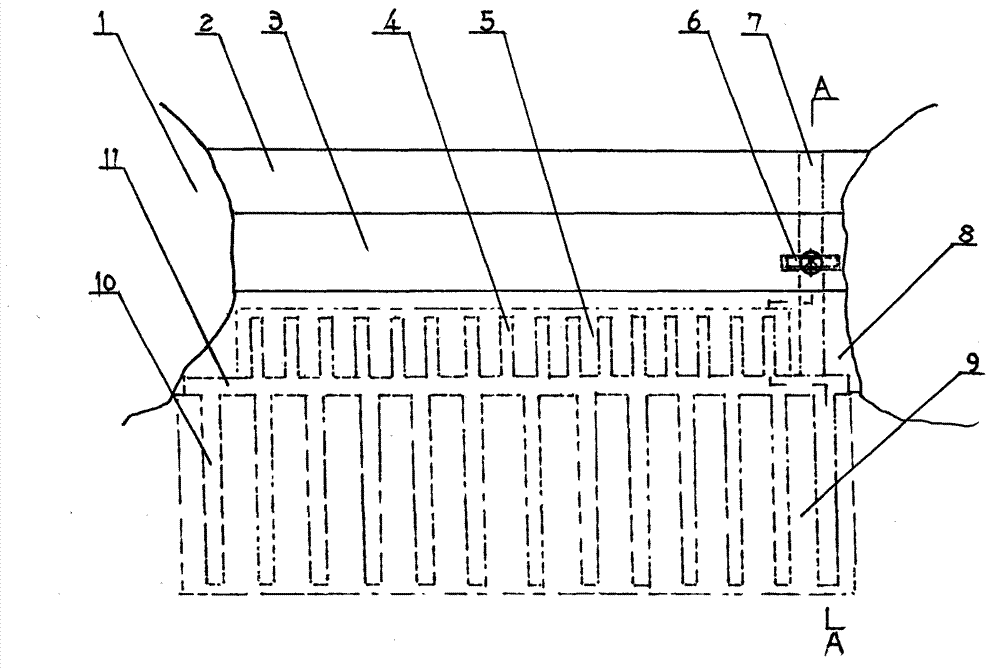

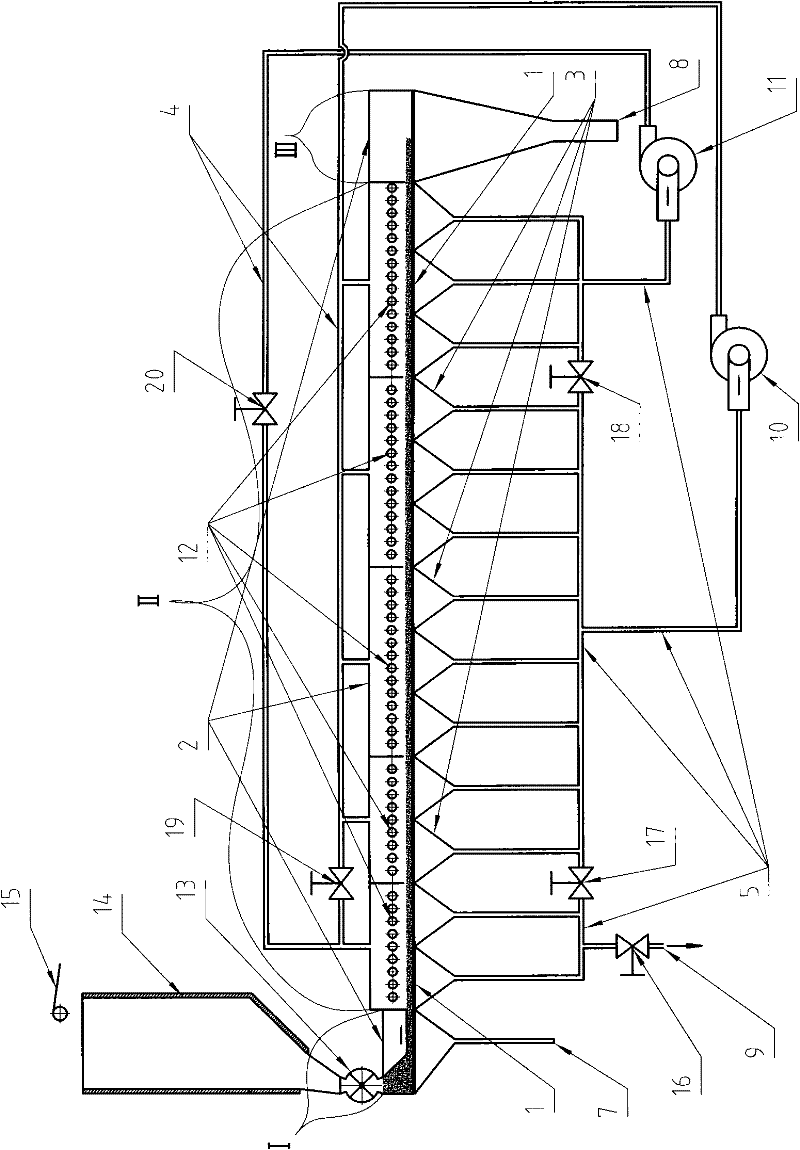

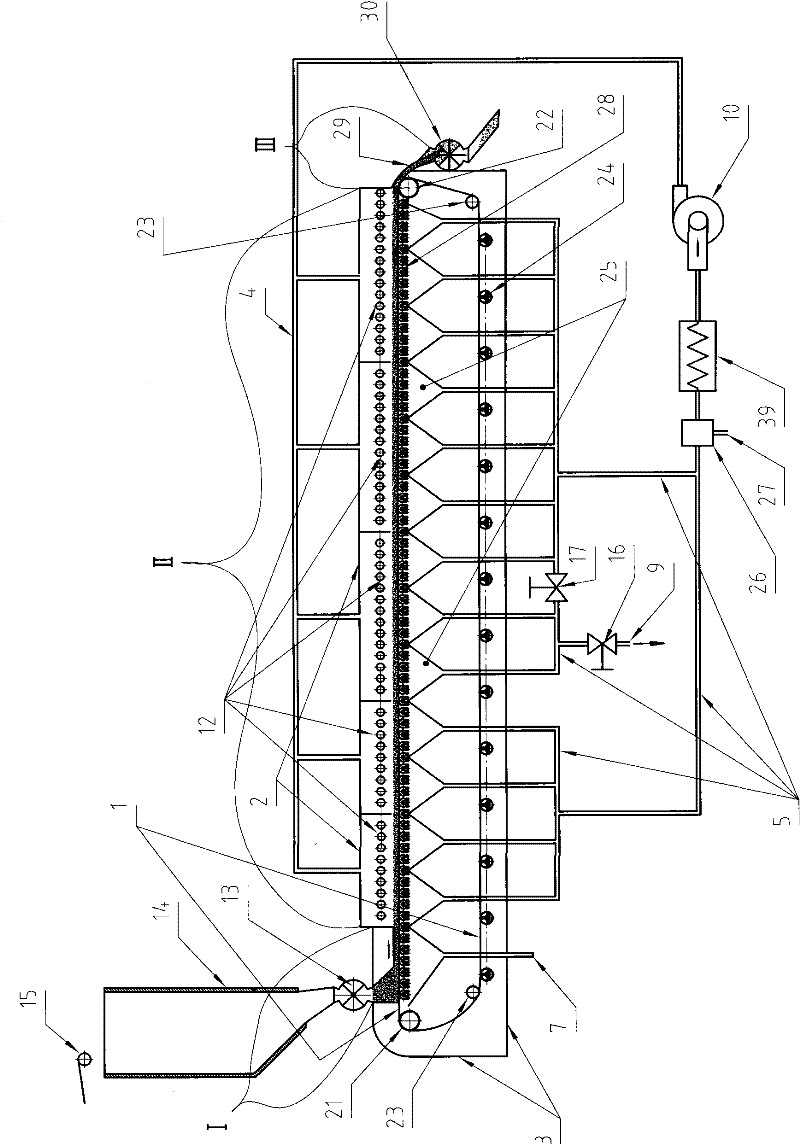

Secondary cooling method and device of high-speed small square billet or small round billet continuous casting machine

InactiveCN106345977AReduce the amount of investmentReduce production and operation costsSpray nozzleAerosol Mist

The invention discloses a secondary cooling method and device of a high-speed small square billet or small round billet continuous casting machine. The method is concretely characterized in that a secondary cooling region is divided into a plurality of guide sections; a plurality of guide sections with the front ends connected with a crystallizer adopt closely arranged roller structures; the rest guide sections adopt single-roller support structures; then, the secondary cooling region is divided into a plurality of cooling sections; the plurality of cooling sections at the front end adopt water spraying nozzles for casting blank cooling, and the rest cooling sections adopt air mist spray nozzles for casting blank cooling. Through section division for corresponding arrangement, the casting blank secondary cooling technology is enabled to meet the requirement of high drawing speed; the problems of great bulging deformation, poor cooling intensity, poor cooling control precision, poor uniformity, high space region temperature returning and the like under the condition of high drawing speed are solved; particularly, the drawing speed is improved; meanwhile, the investment cost and the production operation cost of the continuous casting machine can also be obviously reduced; wide market and application prospects are realized.

Owner:CISDI ENG CO LTD

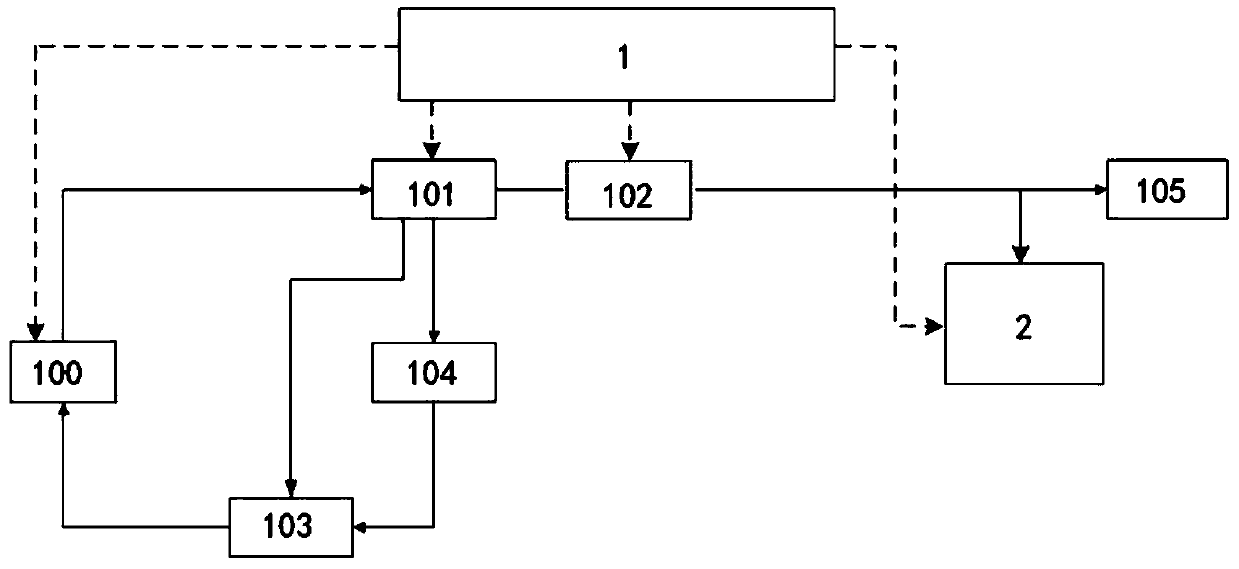

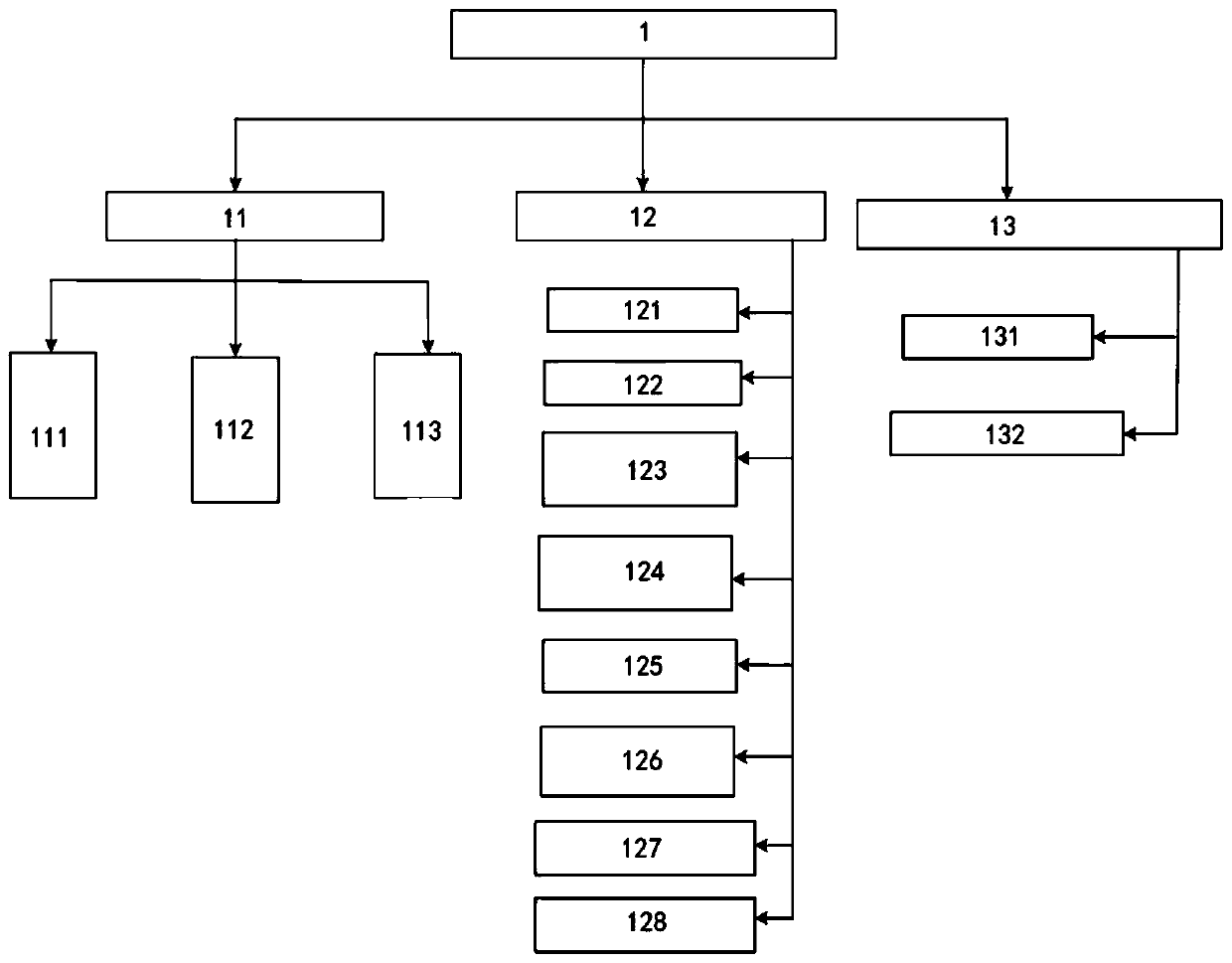

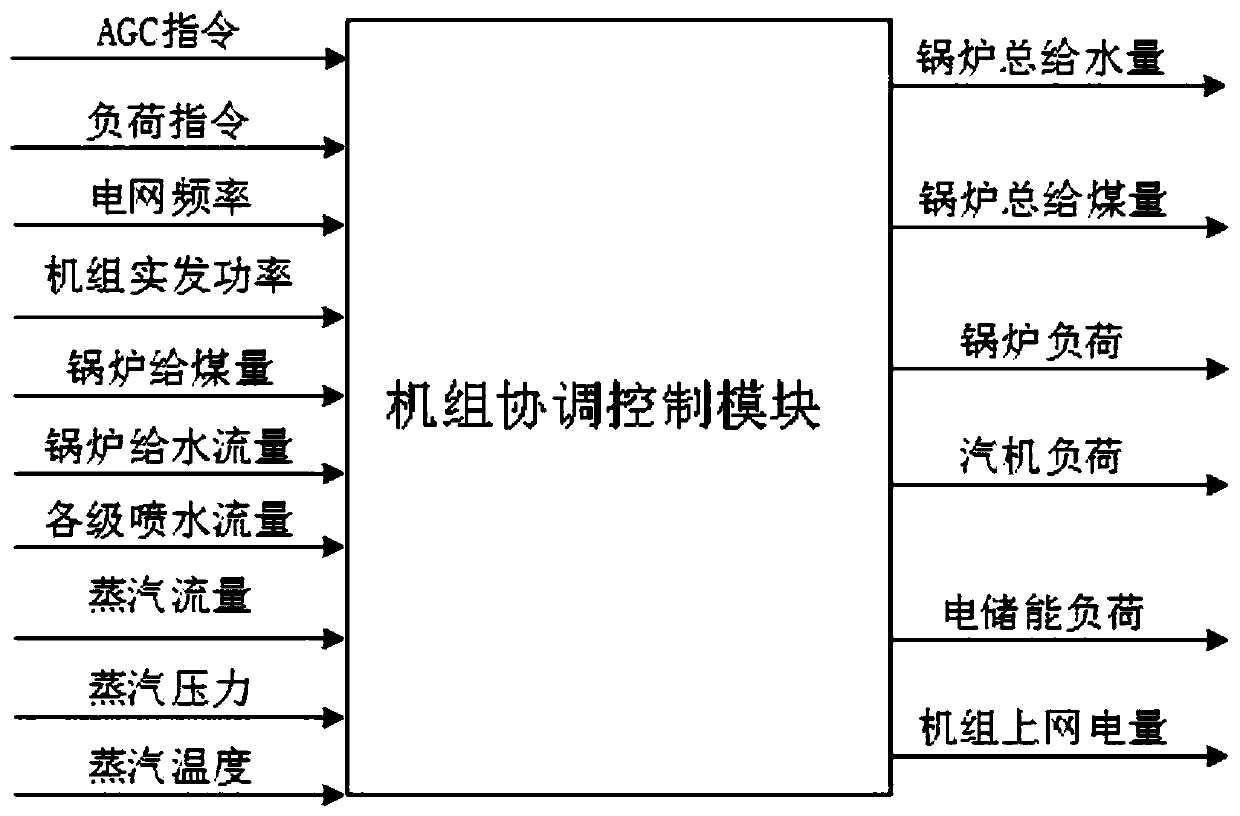

Thermal power generating unit coordinated control peak and frequency modulation system and method

PendingCN111478376AReduce system investmentExtended service lifeSingle network parallel feeding arrangementsAc network load balancingProcess engineeringPower unit

The invention discloses a thermal power generating unit coordinated control peak regulation and frequency modulation system and method. The system comprises a unit coordination control module and an electric energy storage module, the unit coordination control module comprises a boiler coordination control module, a steam turbine coordination control module and an electric energy storage control module. The unit coordination control module is integrated in a thermal power unit central control room control cabinet and is in communication connection with an original CCS and AGC control system ofa thermal power unit, a boiler, a steam turbine, a generator, various operating parameter sensors for electric energy storage and a controller. According to the invention, the unit coordination control module is combined with the electric energy storage module, so that peak-load and frequency-modulation operation of the unit in an AGC commissioning state from 15% to 100% can be realized, the service life of the electric energy storage equipment is prolonged, the average investment of the system is reduced, and the system can be widely applied and implemented in the thermal power industry.

Owner:HEPU ENERGY ENVIRONMENTAL TECHNOLOGY CO LTD

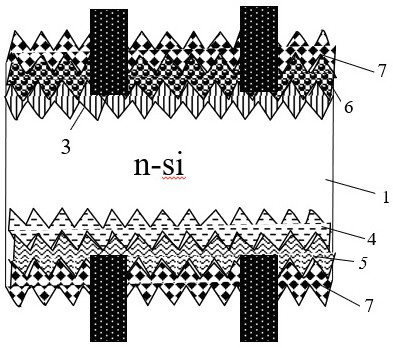

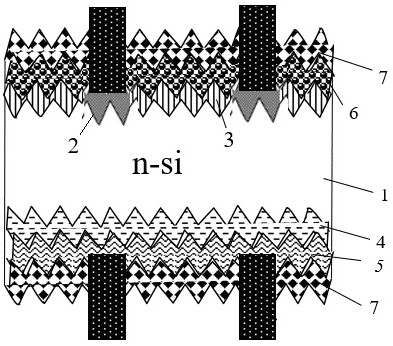

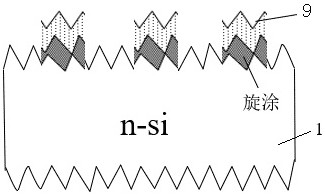

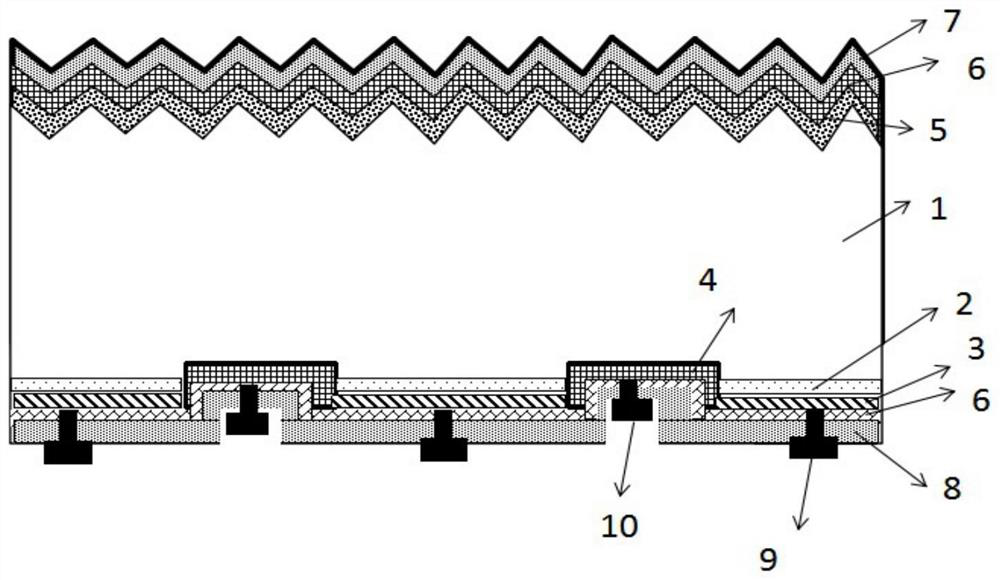

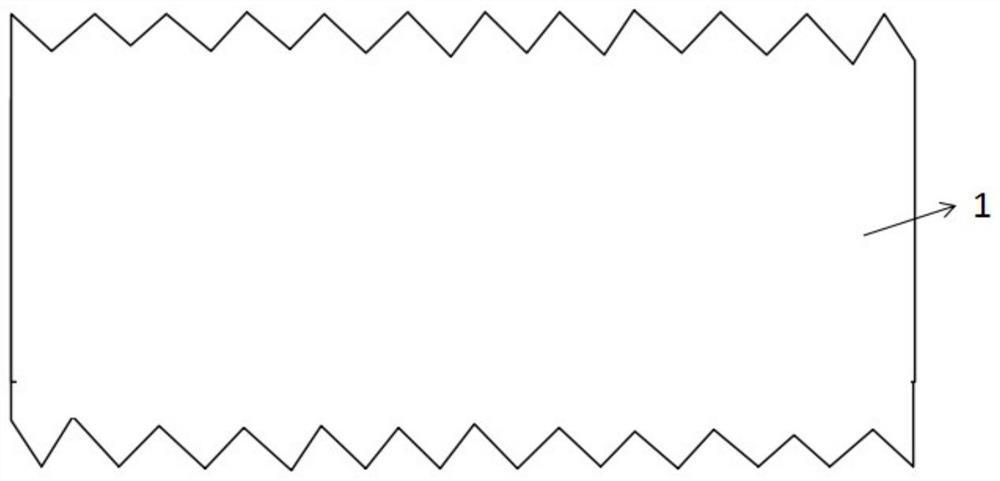

Manufacturing method of N-type TOPCon solar cell

ActiveCN111628047AReduce the amount of investmentAvoid damageFinal product manufacturePhotovoltaic energy generationPhysical chemistrySilicon oxide

The invention relates to a manufacturing method of an N-type TOPCon solar cell. The manufacturing method comprises the following steps: a, double-sided texturing; b, single-sided spin coating; c, single-sided oxidation: forming a boron-containing silicon oxide layer on a spin coating surface; d, forming a heavily doped region substrate and a lightly doped region substrate: forming an organic masklayer for protecting a heavily doped region at a position corresponding to the metal gate line by using a mask mode, completely removing the boron-containing silicon oxide layer and the boron source outside the coverage area of the organic mask layer by using HF, and then removing the organic mask layer; and e, heavy doping and light doping: specifically, completely pushing the spin-coated boron source into the silicon substrate through a tubular low-pressure diffusion method, forming a heavy doping region is formed, carrying out whole-surface source-through deposition to form a lightly dopedregion, and finally, carrying out high-temperature oxidation to form a BSG layer with the thickness of 80-100nm, and then carrying out normal subsequent processes. According to the invention, a boronselective emitter can obtain higher photoelectric conversion efficiency, so that the conversion efficiency of the solar cell is improved.

Owner:常州顺风太阳能科技有限公司

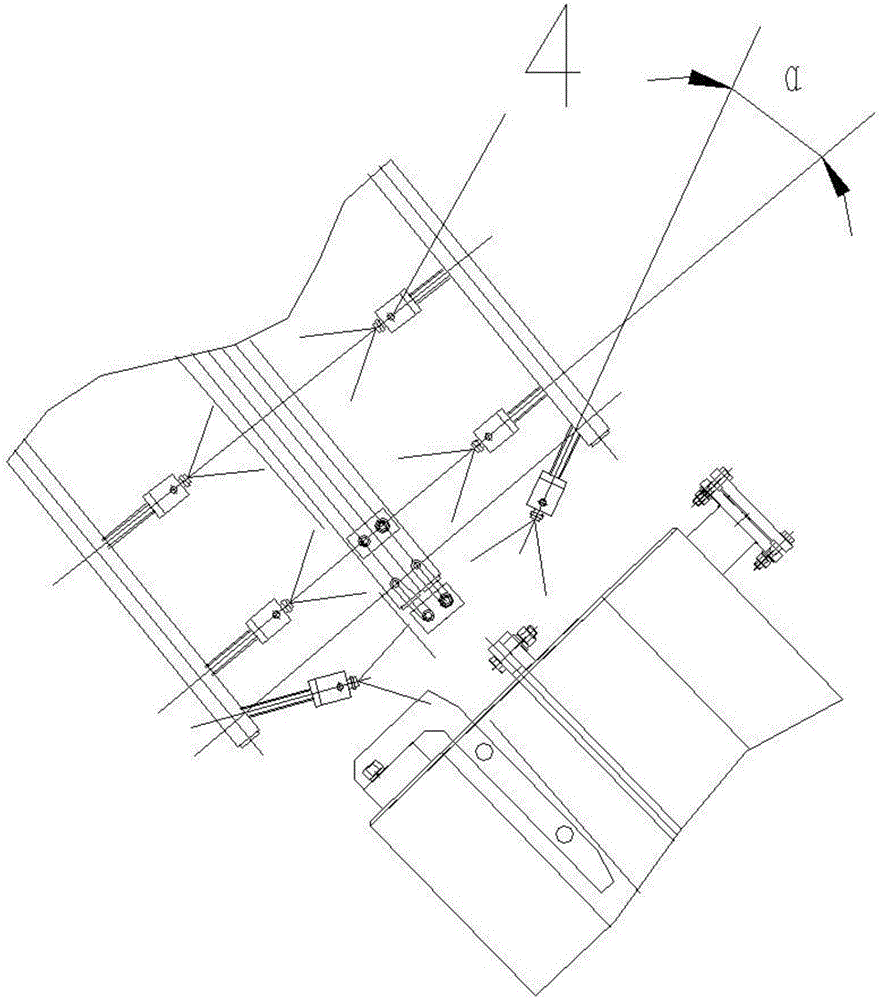

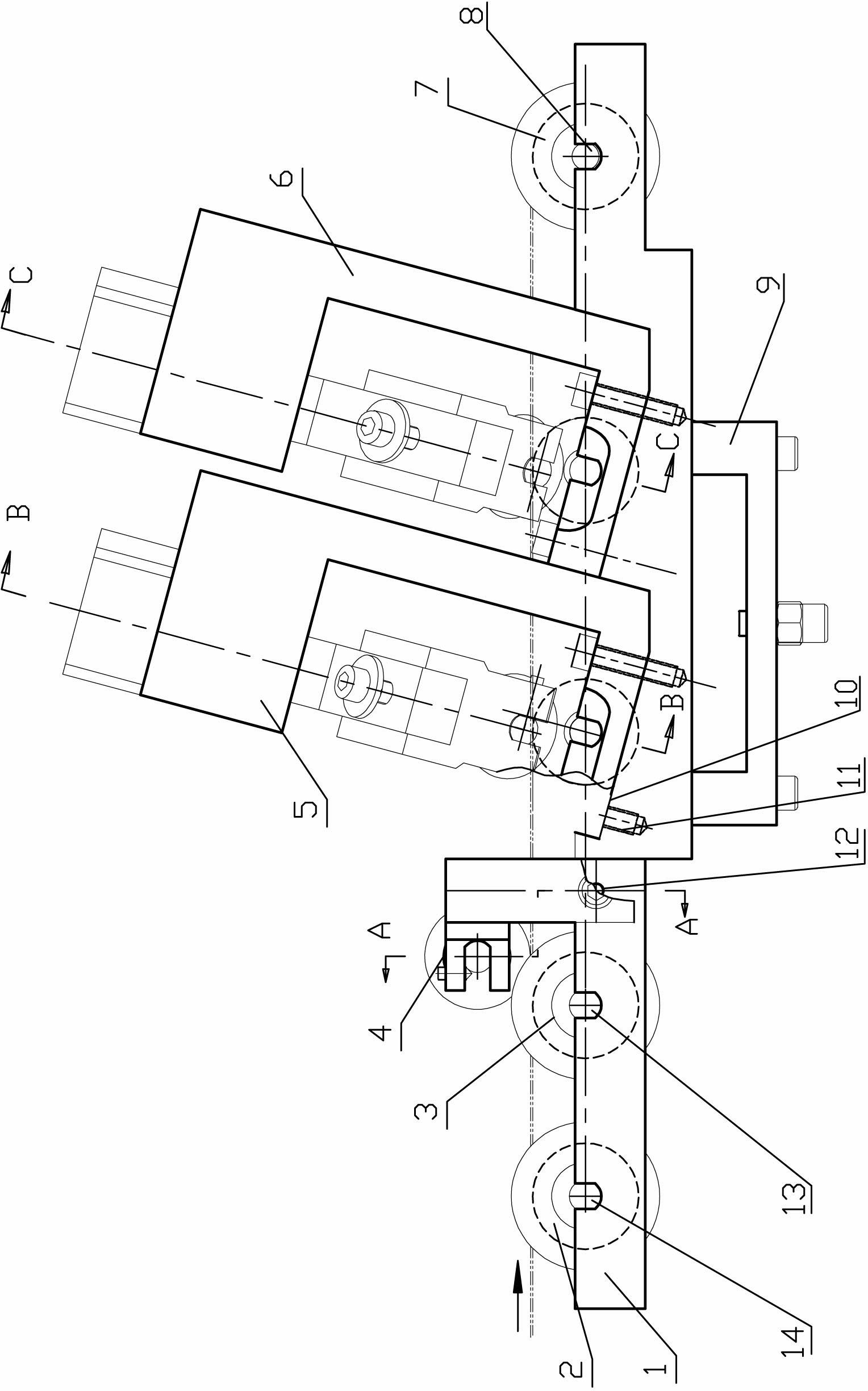

Multi-angle inclined burr removal machine

ActiveCN102275111ASmooth surface treatmentBeautiful surface treatmentEdge grinding machinesProduction lineEngineering

The invention belongs to the technical field of cold rolled steel belt equipment, and particularly relates to a multi-angle inclined burr removal machine. The multi-angle inclined burr removal machine consists of a base and a steel belt input guide wheel, a steel belt conveying riding wheel, a steel belt conveying pinch roller, a steel belt I channel burr removal device, a steel belt II channel burr removal device and a steel belt output guide wheel which are arranged on the base in turn, wherein the steel belt I channel burr removal device consists of a vertical support I, an air cylinder I,a herringbone hanger frame I, two sets of steel belt I channel burr removal rollers which are arranged symmetrically in an inclined mode and a set of steel belt I channel burr removal riding wheels; and the steel belt II channel burr removal device consists of a vertical support II, an air cylinder II, a herringbone hanger frame II, two sets of steel belt II channel burr removal rollers which arearranged symmetrically in an inclined mode and a set of steel belt II channel burr removal riding wheels. The multi-angle inclined burr removal machine has a simple structure, is complete in burr removal and smooth and attractive in a burr removal surface, and is particularly suitable to be applied to production lines of continuous shear steel belts.

Owner:ANSHAN FALAN STEEL STRIP CO LTD

Preparation method of P-type heterojunction full-back electrode contact crystalline silicon photovoltaic cell

InactiveCN111864008ATake advantage ofReduce the amount of investmentFinal product manufacturePhotovoltaic energy generationHeterojunctionEngineering

The invention relates to a preparation method of a P-type heterojunction full-back electrode contact crystalline silicon photovoltaic cell, which comprises the steps of performing double-sided texturing to form a textured structure; performing double-sided oxidation and intrinsic polycrystalline silicon, and then performing phosphorus diffusion to form a tunneling oxidation passivation layer; forming a mask layer on the back surface by using a high-temperature oxidation process; carrying out laser film opening and cleaning on the back surface, and removing intrinsic polycrystalline silicon onthe front surface by utilizing an alkali polishing process; performing boron slurry printing on the back surface, and drying to form a P+ layer; forming a P+ layer on the front surface by adopting boron source doping; removing a BSG mask layer and a PSG mask layer by using HF; removing the redundant polycrystalline silicon layer in an alkali polishing manner; forming a passivation layer from double-sided aluminum oxide, front silicon oxynitride and back silicon nitride; carrying out silk-screen printing to form P+finger and N+finger; and conducting a low-temperature sintering process to complete manufacturing of the cell. According to the invention, the structure of an IBC cell is introduced on the basis of the existing PERC technology, and meanwhile, the structure of the intrinsic amorphous silicon is introduced, so that VOC and ISC can be effectively improved, and the efficiency is greatly improved.

Owner:JIANGSU SHUNFENG PHOTOVOLTAIC TECH CO LTD

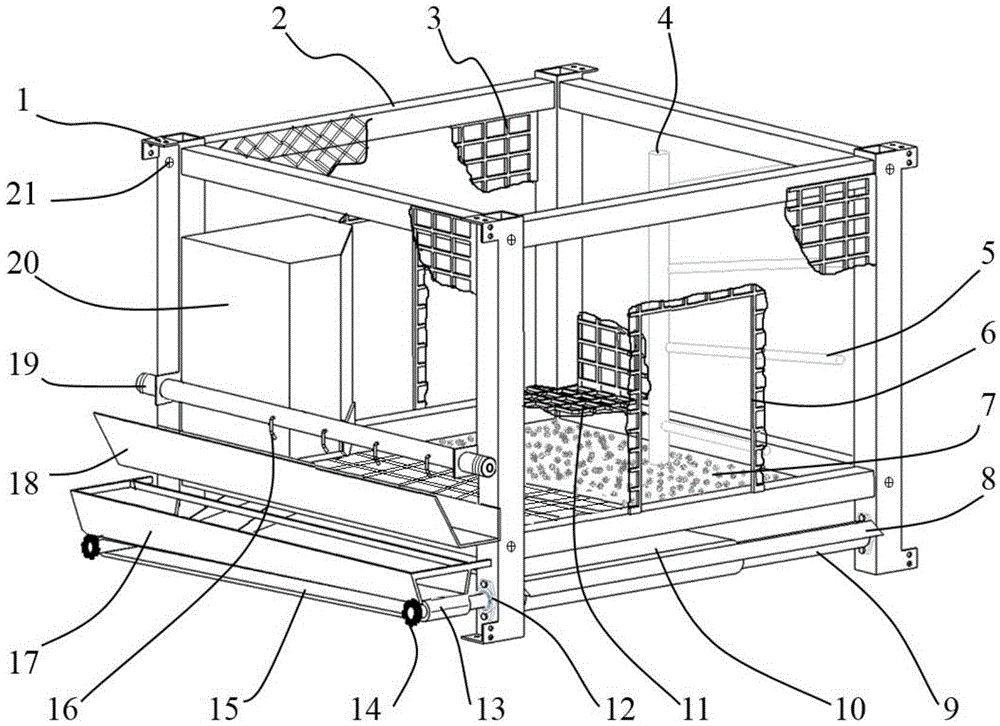

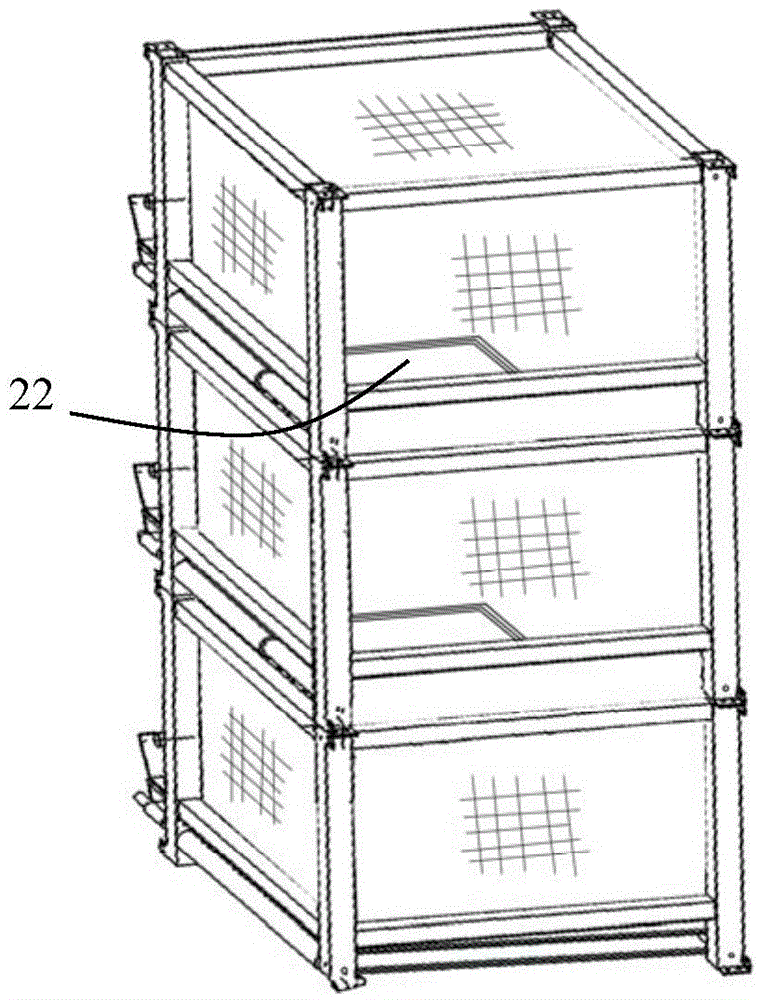

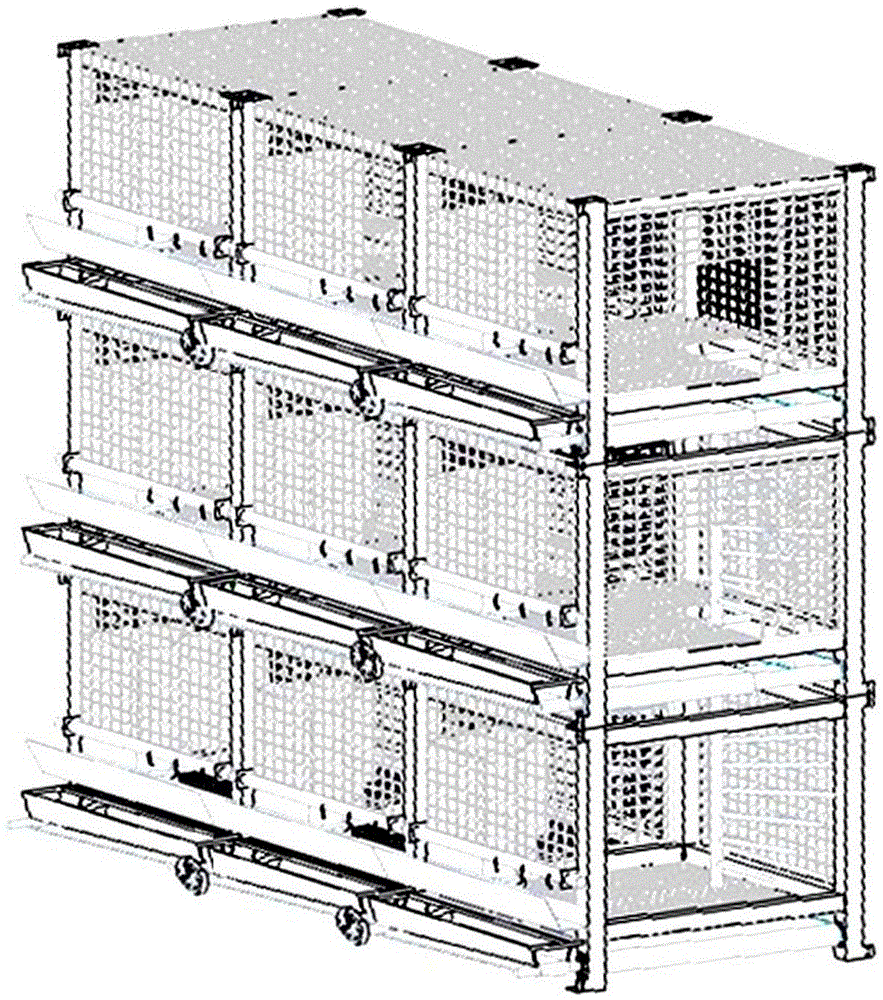

Unitized combined and assembled type egg welfare breeding cage

InactiveCN105638508AHabitat function is goodEfficient use of interior spaceBird housingsAnimal scienceWater drinking

The invention discloses a unitized combined and assembled type egg welfare breeding cage, and belongs to the technical field of livestock machines. The cage comprises supporting legs, a pipe frame, a surface net, perch frame columns, perch bars, a movable door, a manual meadow, a manure scraper, a roller shaft, a manure removal belt, a frame layer, a rolling piece, an egg rolling piece, synchronous teeth, an egg collecting belt, a nipple water drinking device, an egg baffle, a trough, a water drinking pipe, an egg laying box body, a connection pin, an interlayer door and an egg conveying channel. The cage can provide functions of egg collecting, conveying, eating, perching, frame connecting and the like. The cage is complete in structural function, can meet welfare habit behaviors of laying hens such as grabbing for rest, scratching and laying in the cage, can also meet the production requirements for automatic manure removing, egg collecting and the like, and greatly improves the welfare breeding level of laying hens; due to the modularized producing, manufacturing and assembling mode, multiple cages can be connected and assembled, the device manufacturing and investment cost is reduced, the space occupation of a single hen is further increased, and the cage conforms to the development tendency of industrial welfare breeding.

Owner:NORTHWEST A & F UNIV

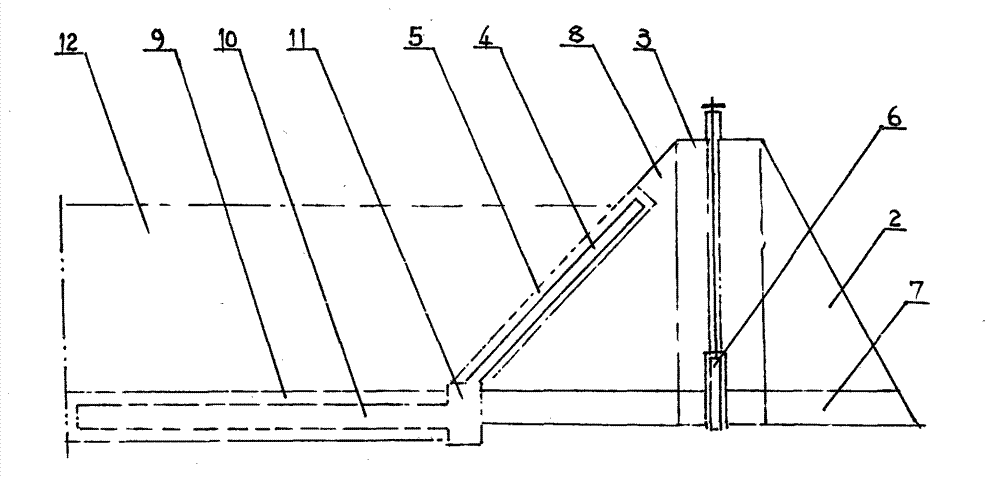

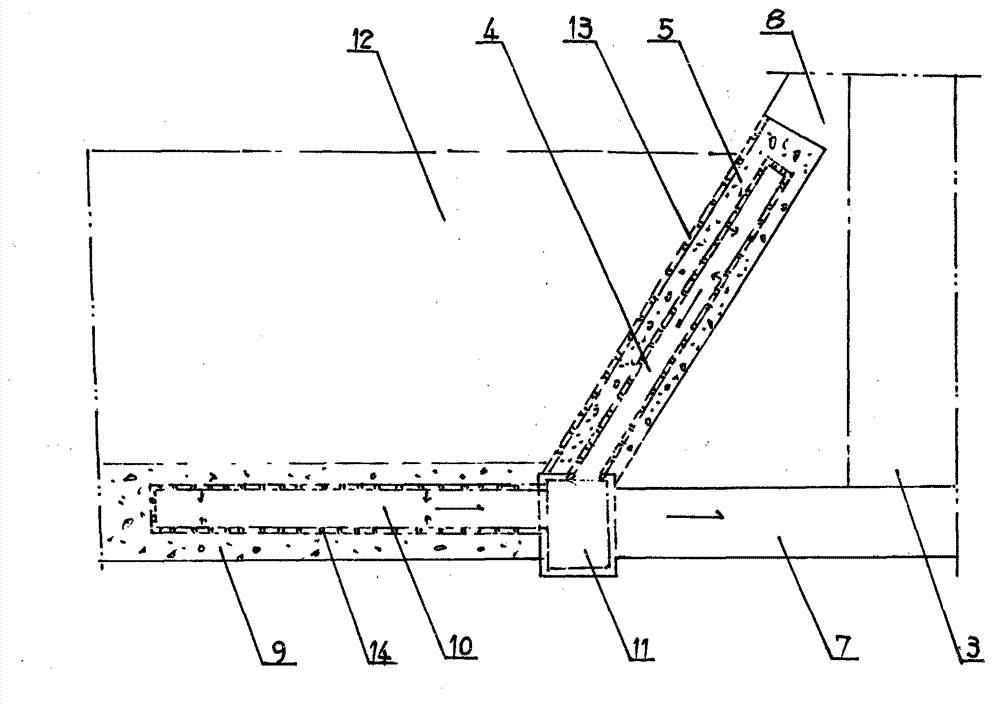

Method for water control and farmland building for environmental protection through water and soil separation and water and soil separation structure

InactiveCN102758417ALess investmentGood soil and water conservationBarrages/weirsDamsTerrainWater pipe

The invention belongs to a method for water control and farmland building for environmental protection through water and soil separation and a water and soil separation structure. The method comprises the following steps of: setting a water control and farmland building area; building a dam body and internal and external dam slope body dam bodies in the water control and farmland building area, and taking the water control and farmland building area enclosed by an external dam slope body and a surrounding hill as a reservoir area; and simultaneously arranging water and soil separation structures at the inner bottom of a reservoir area enclosed by an internal dam slope body and the surrounding terrain and on the internal dam slope body to fast separate turbid water containing a lot of sediment in the reservoir area, leading separated water out of the reservoir area, storing the separated water in a downstream reservoir, and forming farmland by the precipitated sediment. The water and soil separation structure comprises a water permeable sand bed, a water permeable pipe, a water collecting channel and a water drainage channel. The invention can realize fast water and sediment separation for waterflood containing a large amount of sediment in the reservoir area, has double functions of farmland building and water storage to enable the precipitated sediment in the dam to be used for planting and production, and has the advantages of being less in investment and good in water and soil conservation, improving the ecological environment, preventing the occurrence of drought and flood, creating good conditions for the growth of crops, and increasing both production and income.

Owner:黄海宽

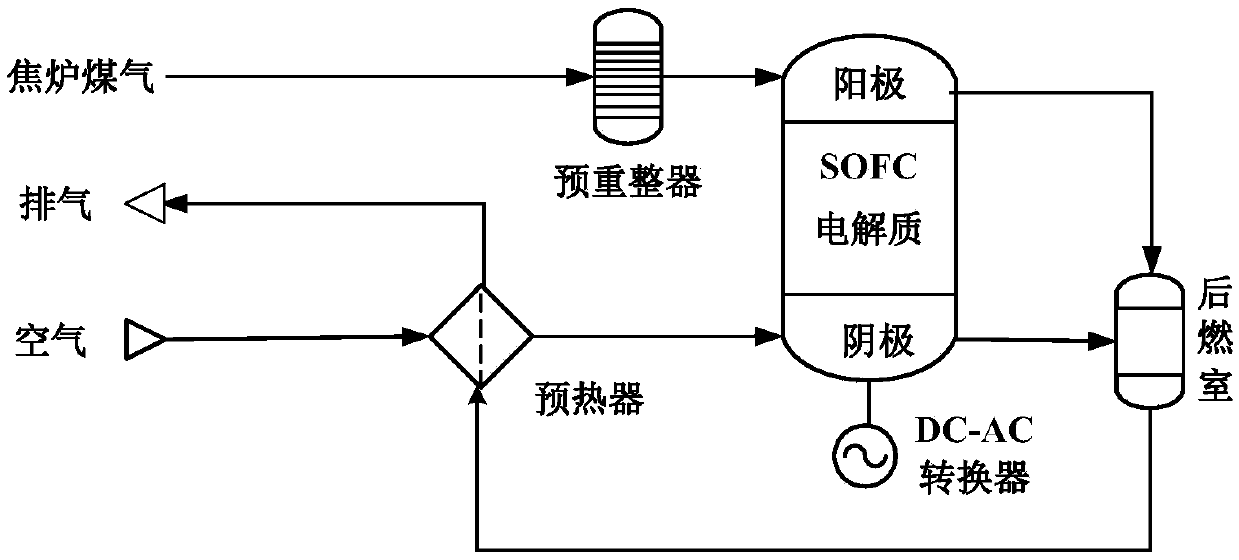

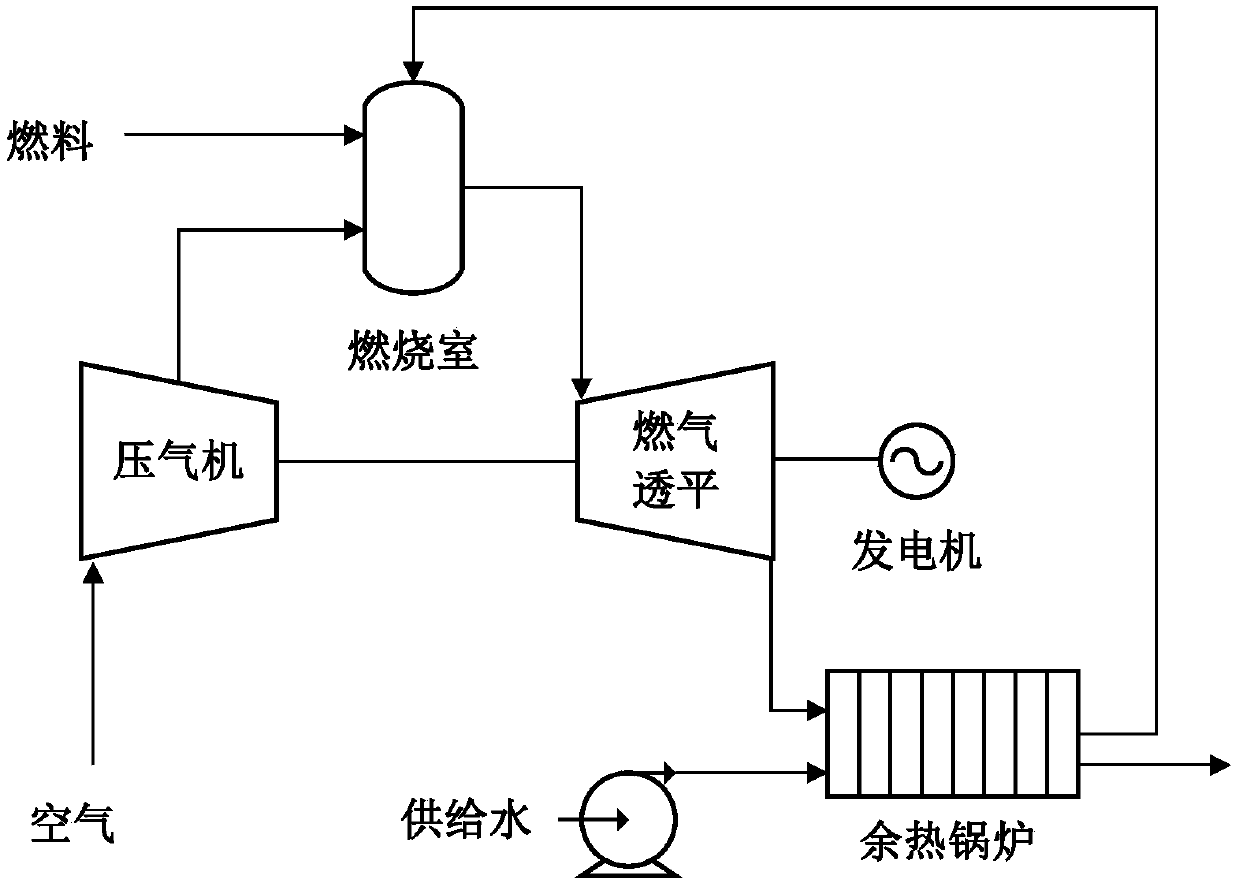

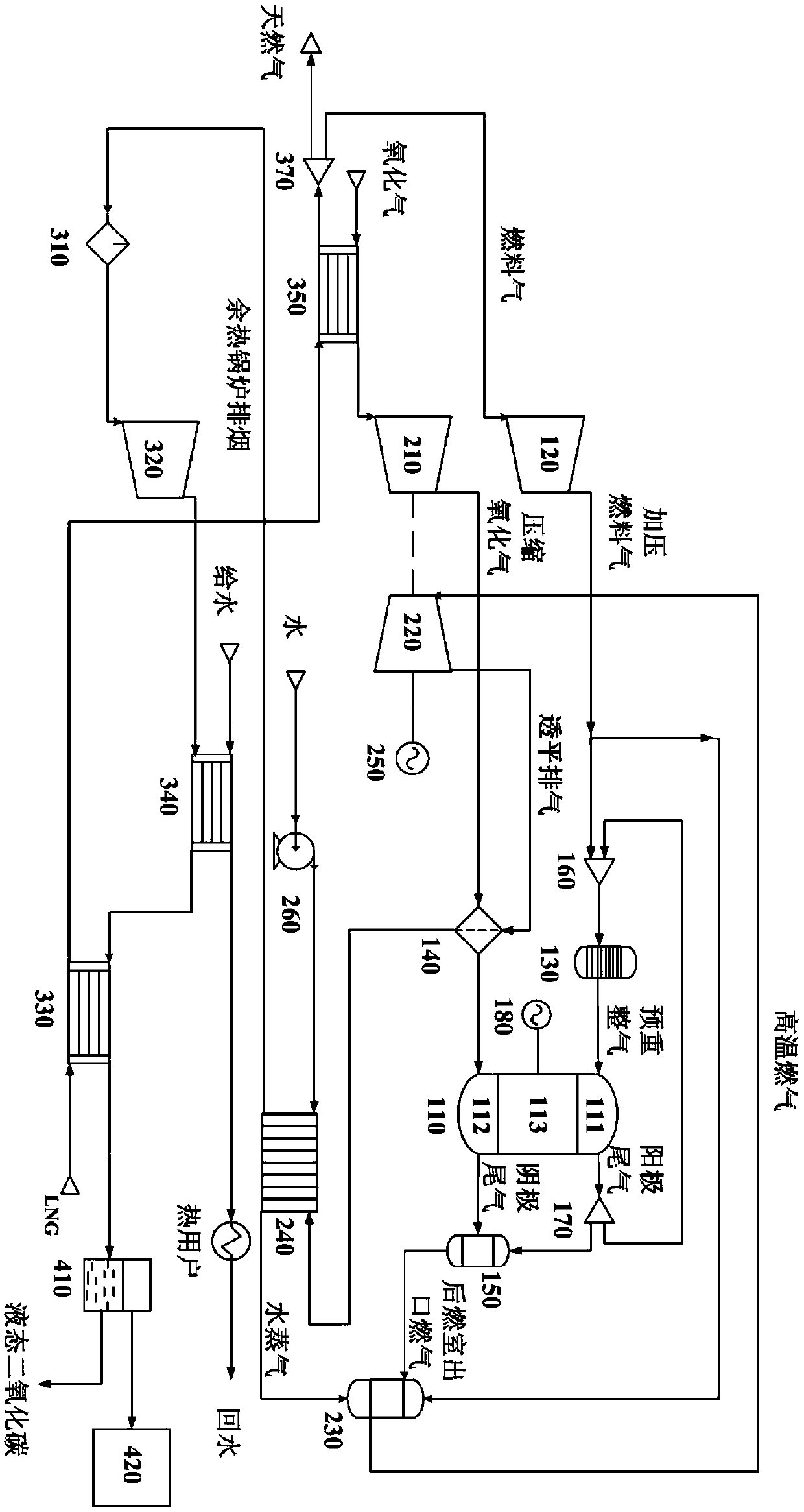

Fuel cell-based distributed energy system using liquefied natural gas as feedstock

PendingCN109065914AReduce the temperatureLow equipment requirementsReactant parameters controlGas turbine plantsSatelliteLiquefied natural gas

The invention provides a distributed energy system based on fuel cell using liquefied natural gas as raw material, which comprises a solid oxide fuel cell subsystem, a steam injection gas turbine subsystem and a liquefied natural gas refrigeration subsystem. An outlet of the fuel compressor is communicated with an inlet of the preformer and an inlet of the combustion chamber respectively; An outlet of the aftercombustion chamber is communicated with an inlet of the combustion chamber; An outlet of the combustion chamber communicates with an inlet of the gas turbine; The heat medium inlet of the waste heat boiler is communicated with the outlet of the gas turbine through the preheater, the heat medium outlet is communicated with the inlet of the first heat release passage of the first condenser, and the cold medium outlet is communicated with the inlet of the combustion chamber. An inlet of the first endothermic passage of the first condenser is in communication with the LNG satellite station, and an outlet of the first endothermic passage is in communication with an inlet of the fuel compressor. The distributed energy system provided by the invention not only optimizes the energy structure but also saves energy and environmental protection, and has important guiding significance for the rational utilization of the energy of the LNG satellite station in China.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

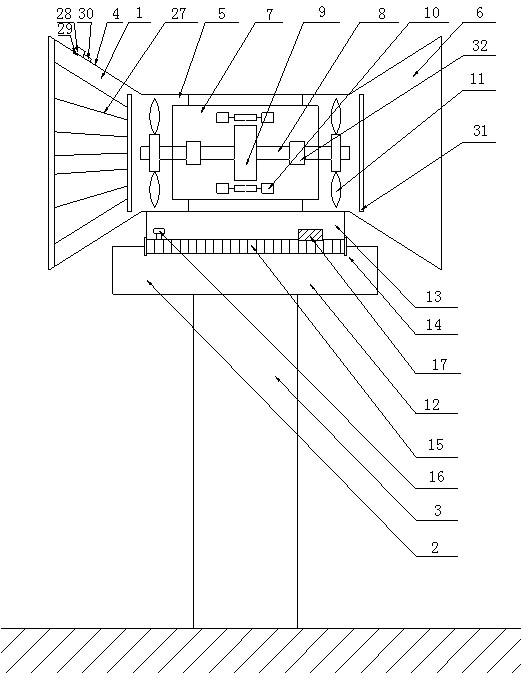

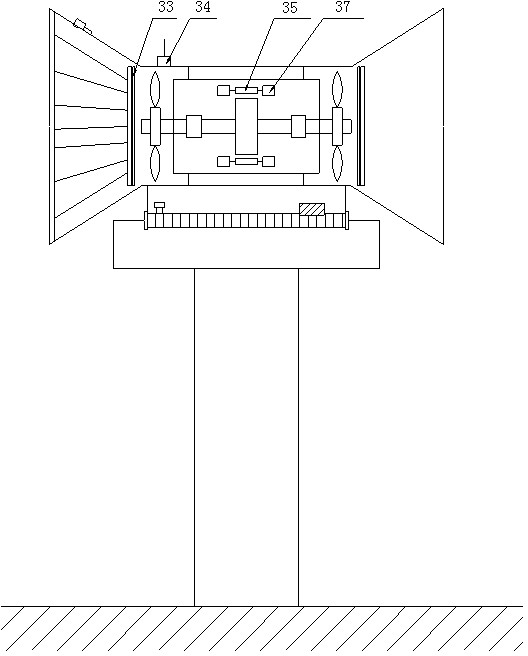

Device for raising and converting fluid energy

InactiveCN102192101ALess investmentAlleviate the energy crisisWind motor controlHydro energy generationImpellerSolar power

The invention relates to a device for raising and converting fluid energy, comprising a flow tube device, a yawing seat and a tower drum, wherein the flow tube device is fixed on the top of the tower drum by virtue of the yawing seat; the flow tube device comprises an incoming flow section, a shrinkage section and a wake flow section; the incoming flow section is arranged towards the incoming flow direction of a fluid; the shrinkage section is arranged between the incoming flow section and the wake flow section; the shrinkage section is internally provided with a cabin; the cabin is internally provided with a transmission shaft, a transmission gear fixed on the transmission shaft and an objective power-consumption unit driven by the transmission gear; and two ends of the transmission shaft are fixedly provided with a group of blade wheels or multiple groups of blade wheels respectively. The device can provide large-scale energy sources to ease the increasing energy source crisis on the earth at present; the device is environmentally-friendly; and wind energy and tidal energy generating sets using the device are reduced in investment, and installation investment per kilowatt is farless than that of the existing fired power, nuclear power, hydropower, solar power, wind power and the like.

Owner:JIANG SU JUYUAN TECH

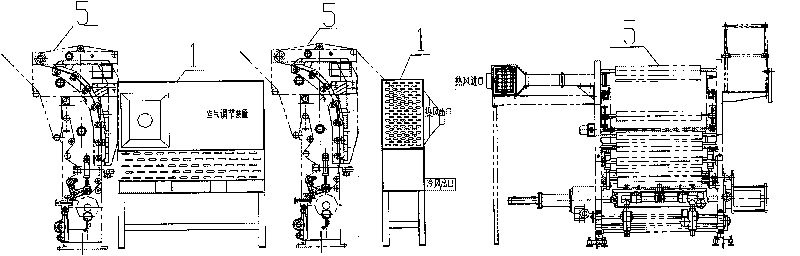

Efficient energy-saving environmental-friendly unit type photogravure press and energy-saving environmental-friendly method

InactiveCN101734002ASimple structureUse to achieveRotary intaglio printing pressPrinting press partsEnvironmental resistancePhotogravure

The invention relates to an efficient energy-saving environmental-friendly unit type photogravure press used for air temperature adjustment of the unit type photogravure press self as well as an energy-saving environmental-friendly method. The photogravure press comprises a unit type photogravure press, an air conditioning plant is arranged between units requiring constant temperature of the unit type photogravure press, a hot wind outlet arranged on the upper part of the air conditioning plant is communicated with an inlet of a drying box body in the unit type photogravure press, a cold wind outlet on the lower part is positioned below the unit in the unit type photogravure press. The invention has the advantages of high cost performance, can realize seamless butt joint with the traditional technology and saves electricity for 56% if compared with products with the same grade on the basis of satisfying the normal function of printing machinery and national environmental protection requirement and has obvious energy saving effect; the environmental impact assessment index is obviously lowered; the efficient energy-saving environmental-friendly unit type photogravure press can realize seamless butt joint with the technology and craft of the existing printing mechanical products under the condition that performance is greatly improved, and also can be used for energy saving modification of printing machinery with low energy efficiency ratio.

Owner:HANGZHOU YUEHUA PRINTING & PACKAGING MACHINERY

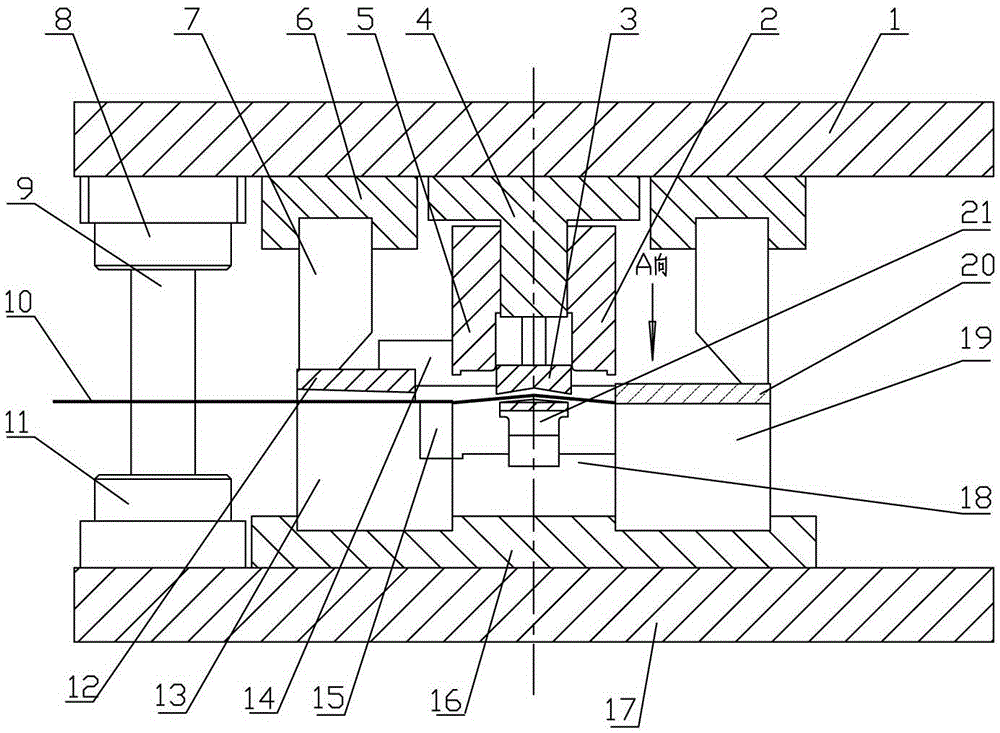

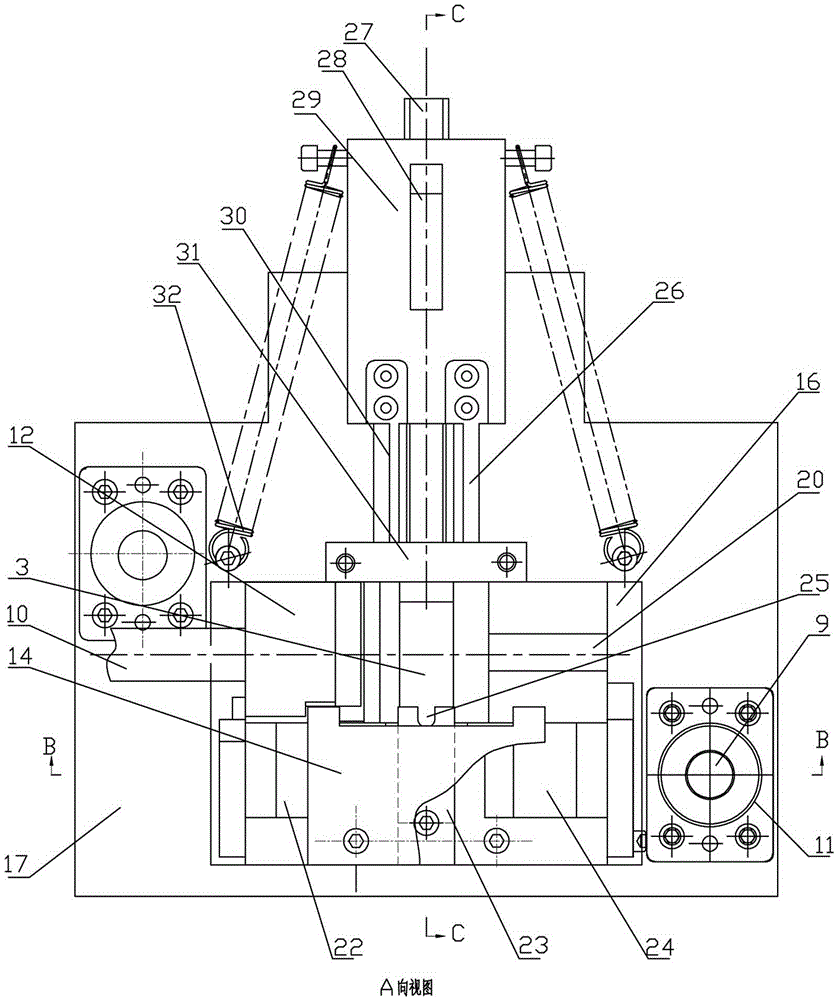

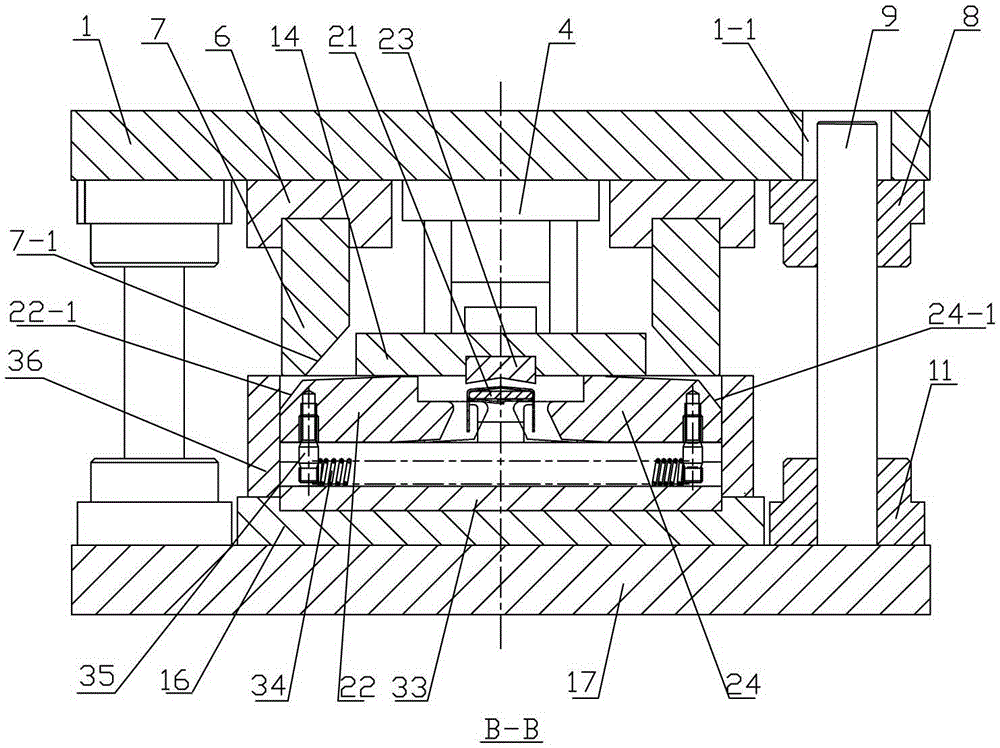

Processing mould for steel strip closed lock catches for packaging

ActiveCN105234288AReduce the amount of investmentImprove productivityShaping toolsProduction ratePunching

The invention belongs to the technical field of processing of steel strip lock catches for packaging and particularly relates to a processing mould for steel strip closed lock catches for packaging. The processing mould comprises an upper mould assembly, a lower mould assembly, a pushing device and two upper mould lifting guide pillar devices, wherein the upper mould assembly is composed of an upper mould plate, a cutter seat, two extrusion block seats, a cover plate seat, a cutter forming compound mould, a profiling upper cover I, two extrusion blocks and a profiling upper cover II; the lower mould assembly comprises a lower mould plate, a base plate, a left cavity block, a right cavity block, a forming lower mould seat, a forming lower mould, a left folding forming pushing block, a right folding forming pushing block, a pushing block reset device, a material feeding press plate and a positioning baffle; and the pushing device is composed of a roller seat, a roller, an inclined vertical plate, a sliding groove block, a left pushing cutter, a right pushing cutter, a straight track, a limiting block and two extension springs. By adopting the processing mould provided by the invention, the continuous production processes of feeding, punching, profiling, forming, taking out and the like of the steel strip lock catches for packaging can be completed by one punching machine, so that the equipment investment is reduced greatly and the production rate is increased.

Owner:ANSHAN FALAN STEEL STRIP CO LTD

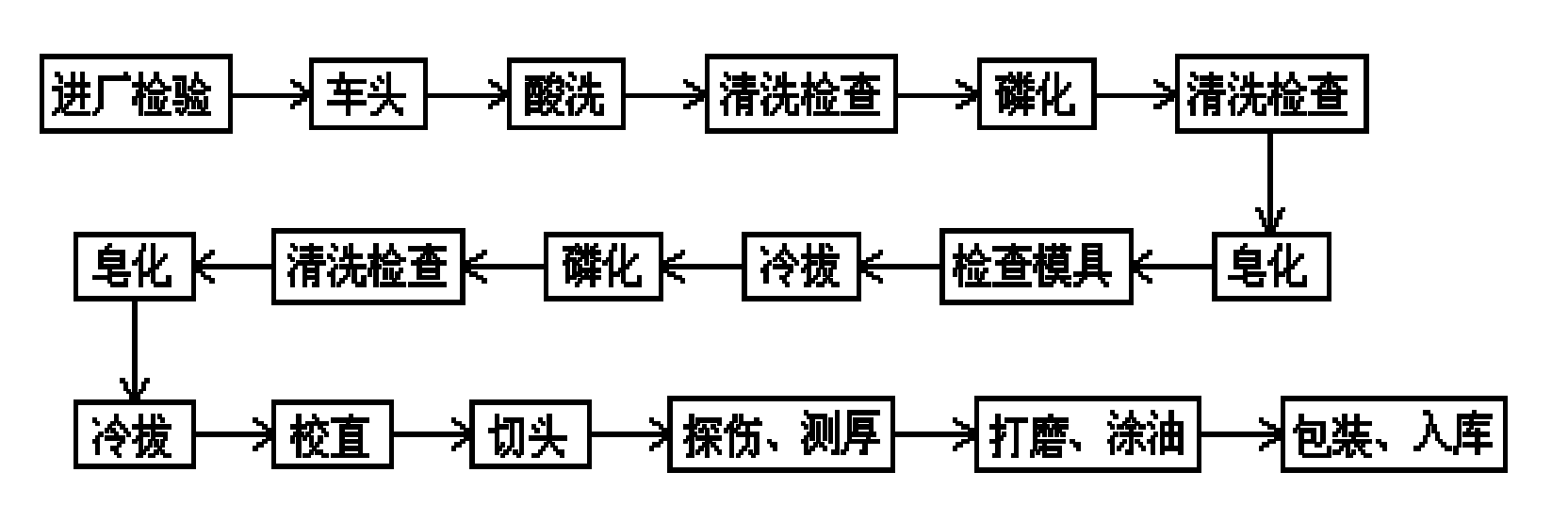

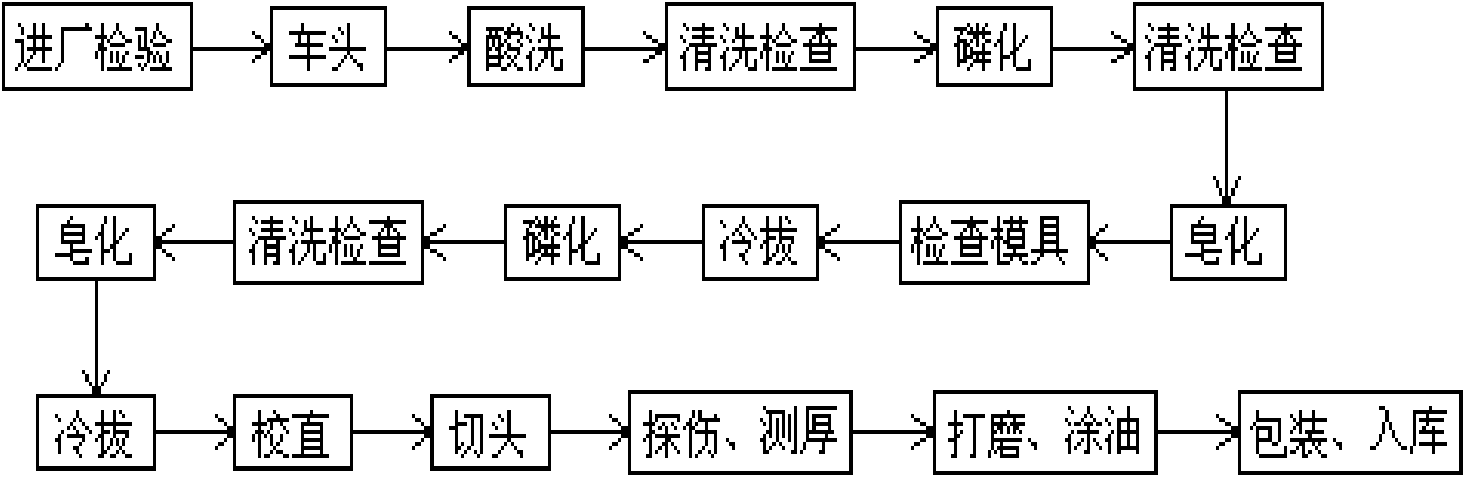

Manufacturing method of gas cylinder steel tube for long-tube trailer

InactiveCN101786112ALow costImprove surface roughnessMetallic material coating processesGas cylinderEngineering

The invention discloses a manufacturing method of a gas cylinder steel tube for a long-tube trailer. The method comprises the following steps of: clamping the trailer head; washing with acid; washing and inspecting; phosphating; saponifying; inspecting a mould; cold drawing; phosphating once again; saponifying once again; and cold drawing once again. The method has less investment and low cost, and the product has high precision and good quality.

Owner:SICHUAN ANJI PRECISION TUBE MFG

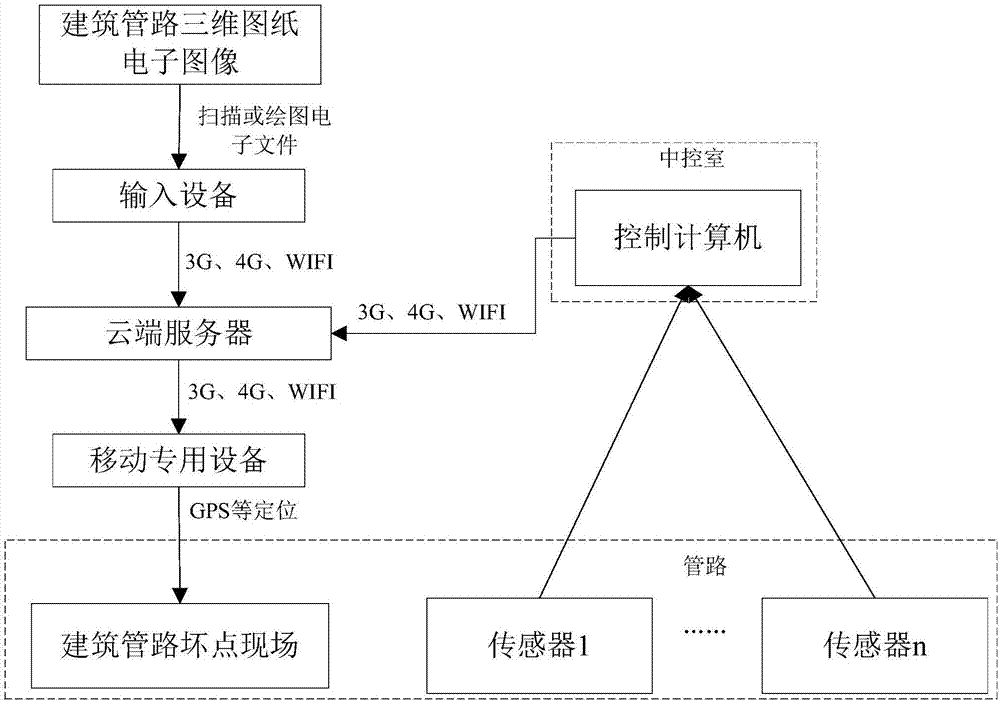

Maintenance management method used for achieving three-dimensional positioning of building pipeline

PendingCN107194480ARapid positioningImprove efficiencyData processing applicationsWireless commuication servicesMaintenance management3d localization

The invention provides a maintenance management method used for achieving three-dimensional positioning of a building pipeline. The method comprises the steps as follows: an electronic image of three-dimensional drawing of the building pipeline is transmitted to a cloud server, and detection sensors are installed at a certain distance on the building pipeline in a building wall, and are electrically connected with a control computer via a signal line; the sensors transmit test signals to the control computer; the control computer finds bad points according to coding, and automatically reports coded data to the cloud server; the cloud server gives an alarm, an alarming site is sent to mobile special equipment with specified maintenance staffs, the cloud server automatically transmits a three-dimensional model of the building pipeline around the bad point of the building pipeline to the mobile special equipment; and the maintenance staff allows the imaging position of the mobile special equipment to be corresponding to the scene position in the building so as to rapidly position the bad point. The method provided by the invention has the beneficial effects that the design can position the bad point position rapidly and accurately, and is simple to operate and low in cost, and can significantly enhance pipeline maintenance efficiency.

Owner:天津晟源宏昱科技有限公司

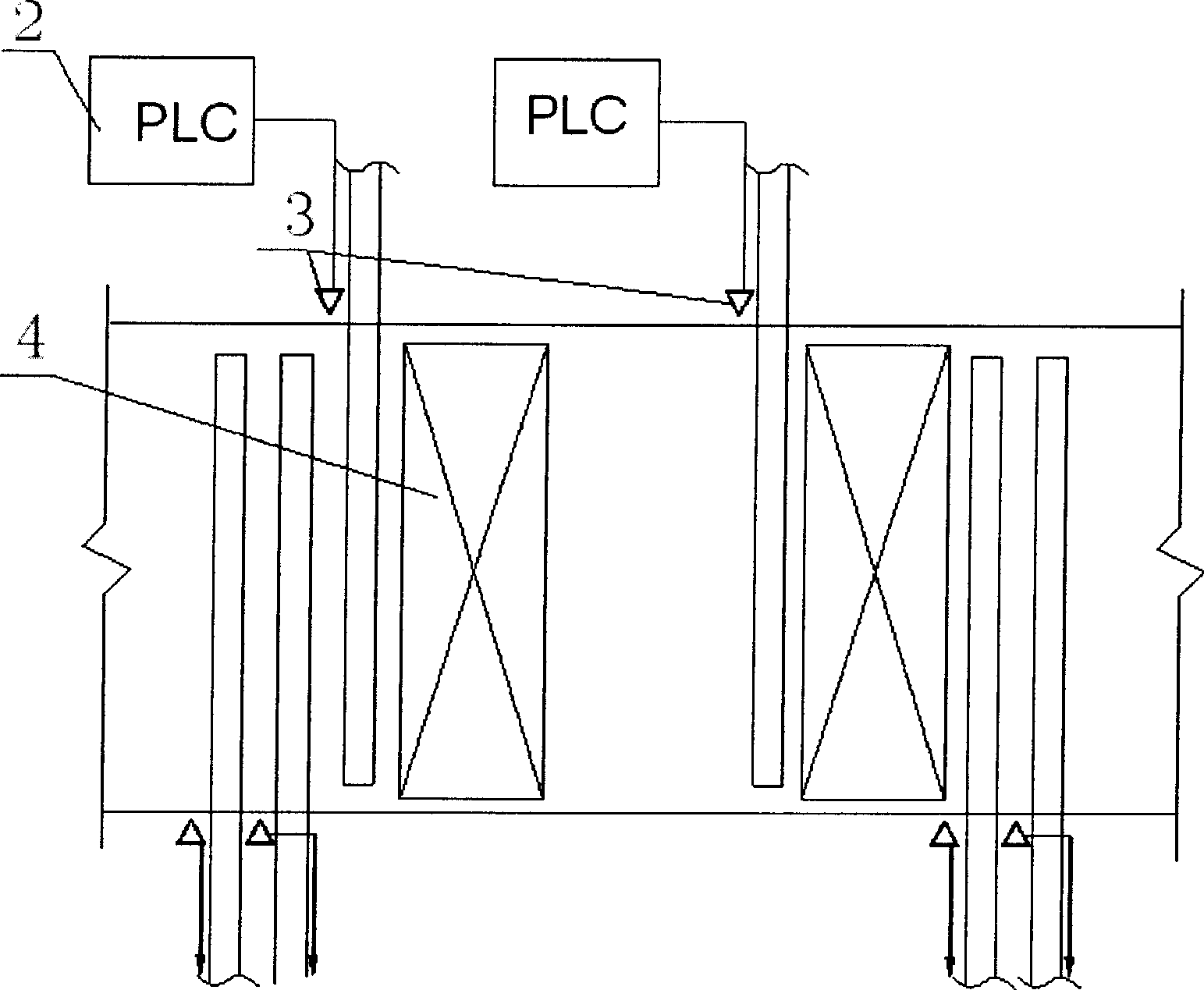

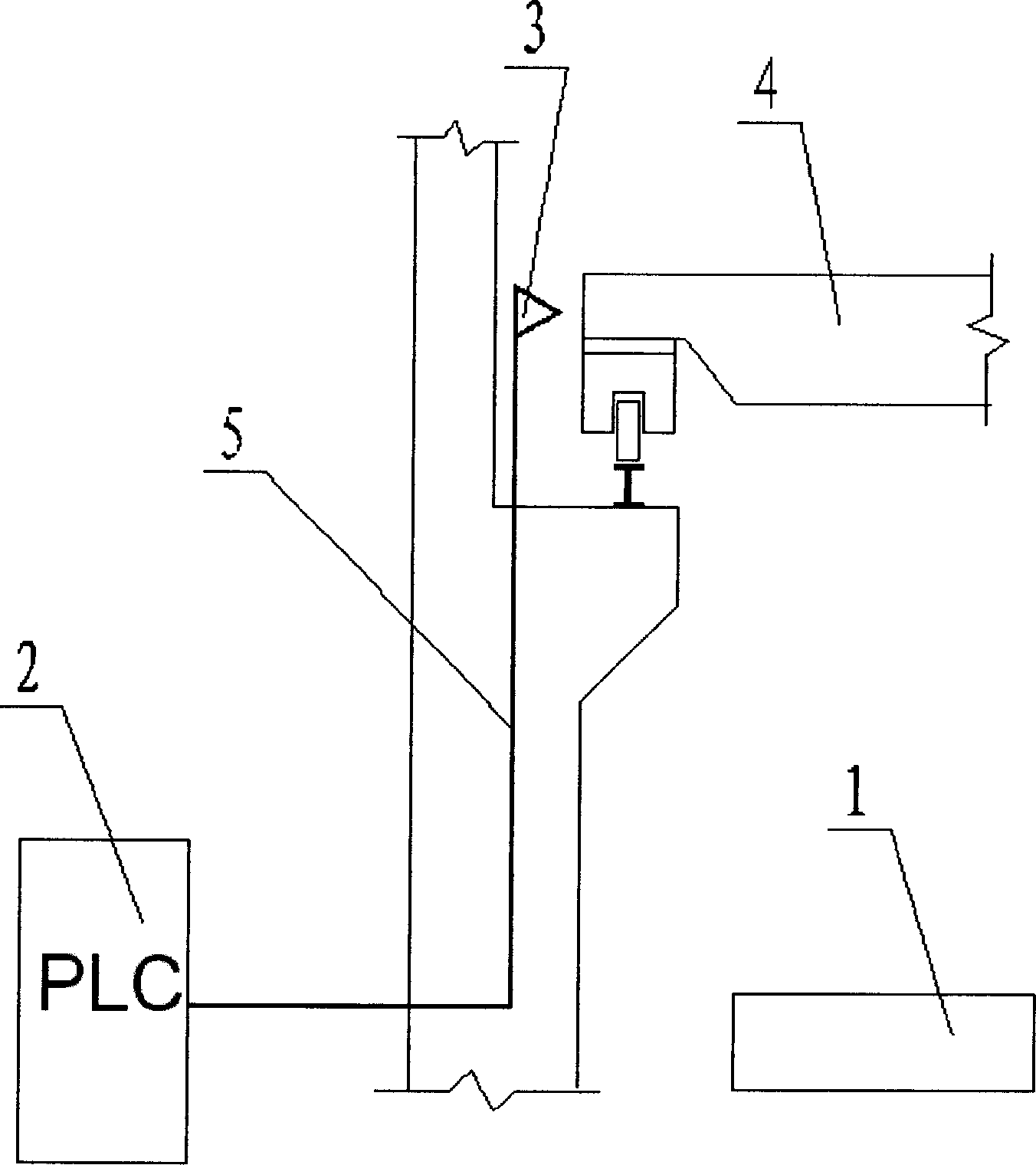

Stacking shop traveller and ground reclaimer interlocking protecting method and apparatus

InactiveCN1773402ASimplify the electrical systemImprove versatilityControl using feedbackProgramme control in sequence/logic controllersOverhead craneReclaimer

The present invention discloses a stacking overhead crane and ground conveyer interlocking protecting method. Said method includes the following steps: using detection switch to detect stacking overhead crane position over the ground coveyer which is controlled by program controller PLC system, transferring the action signal of detection switch to the program controller PLC system of working station to which said ground conveyer is belonged, according to said signal said program controller PLC system can lock said ground conveyer to stop its operation. All the í‹lockingíŒ and í‹releasingíŒ operations can be automatically implemented by PLC system.

Owner:GUIYANG AL-MG DESIGN & RES INST

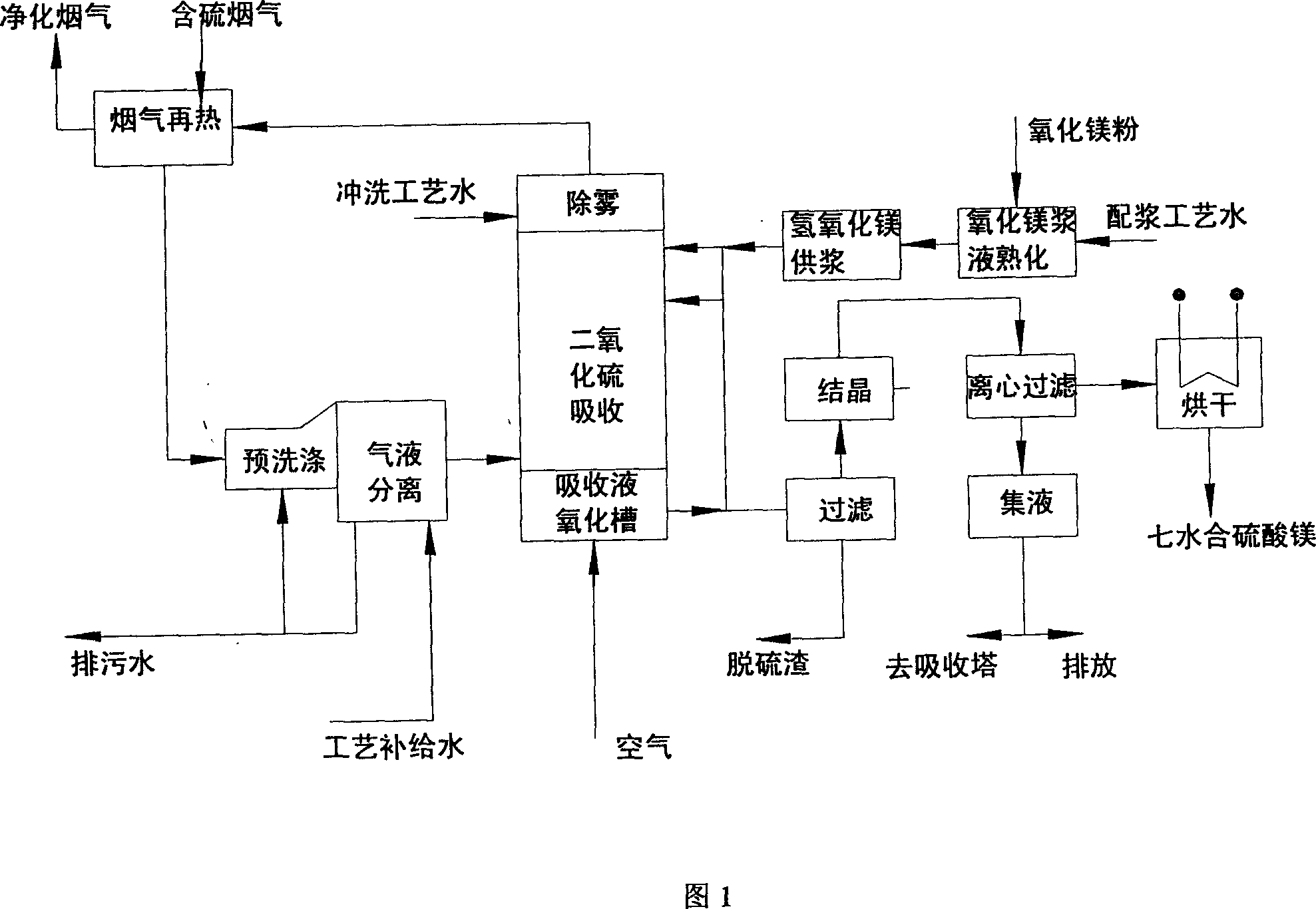

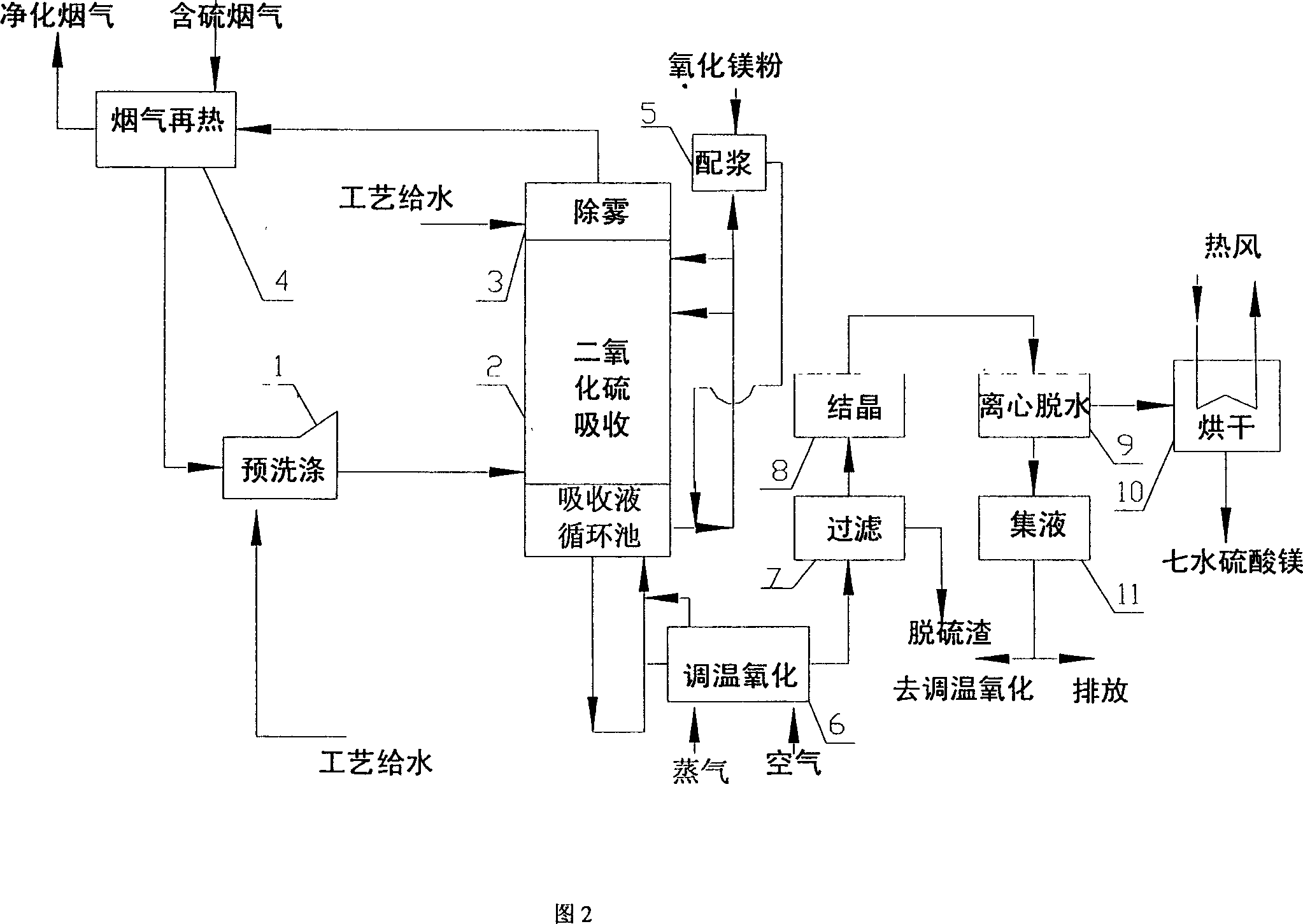

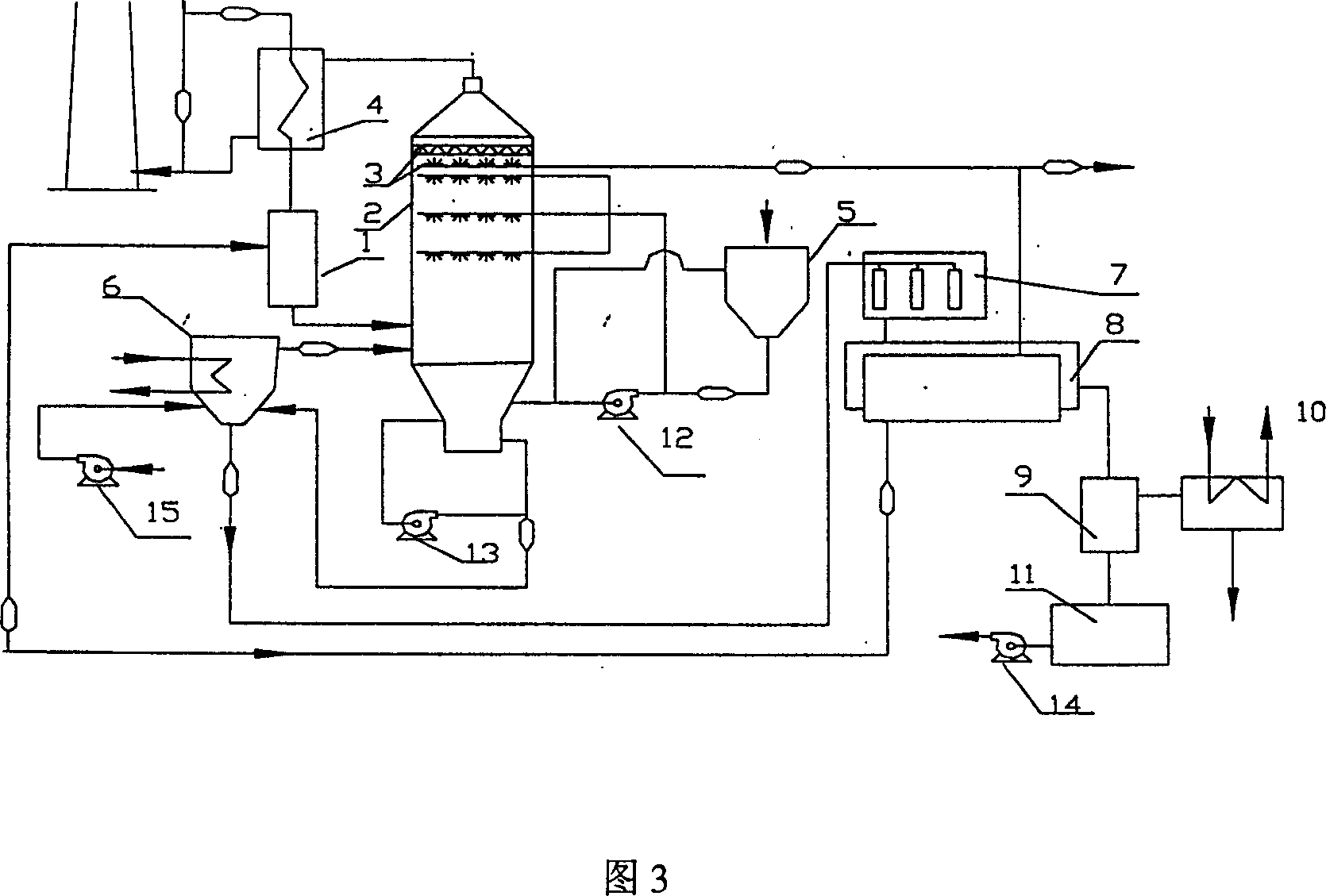

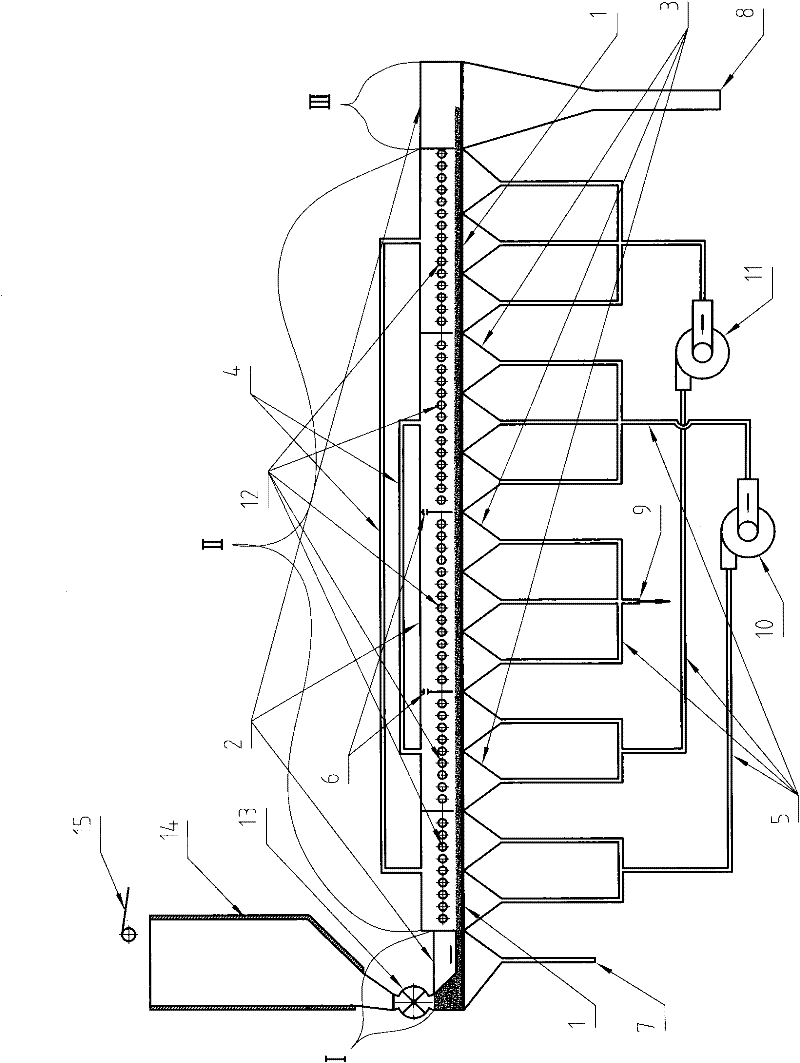

Magnesium oxide flue gas desulfurization and outgrowth thick-slurry method oxidation reclaim process

InactiveCN100335154CMaintain basic advantagesMaintain outstanding progressDispersed particle separationMagnesium sulfatesFlue gasSlurry

The dense-slurry recovery technique for flue gas desulphurization by magnesia comprises: during the process, separating and leading out the dense slurry liquid, blasting air, heating and adjusting the temperature by steam to oxidize the MgSO3 dense slurry as one-time desulphurized product into MgSO4 with concentration achieved industrial level; filtering, crystallizing, and extracting the coarse grain MgSO4.7H2O. This invention is reliable with low cost and high value with the product, even has the yield effect super to industrial production for MgSO4.

Owner:TSINGHUA UNIV +1

Oil shale retorting method as well as dynamic grate type retort furnace for realizing same and application thereof

ActiveCN102051188AAvoid wastingSolve the amount of circulationDirect heating destructive distillationSpecial form destructive distillationCombustible gasProduct gas

The invention provides an oil shale retorting method as well as a dynamic grate type retort furnace for realizing the same and application thereof, belonging to the technical fields of the extraction of shale oil gas from oil shale and the extraction of oil and combustible gas from soft coal. The oil shale retorting method comprises the steps of crushing the oil shale, charging into a furnace, heating, collecting shale retorting gas, collecting shale semicokes and the like and the use of heat-carrying gas. The oil shale retorting method is characterized in that the ratio of the circulating amount of the heat-carrying gas for the retorting furnace in the furnace to the processing amount of the heat-carrying gas for oil-gas extraction is not less than 3.5. By means of the invention, the problems on the separation of circulation amount and the processing amount is solved, and the minimization of the processing amount can be realized; the air injection can also be avoided so that the quality of product gas is improved and particularly the unit heat value of the product gas is improved; and moreover, by means of the high-multiple inner circulation of the heat-carrying gas inside the retorting furnace, the heat loss and the like of the heat-carrying gas in the process can be reduced. Therefore, the oil shale retorting method is particularly suitable for the technical fields of the extraction of the shale oil gas from the oil shale and the extraction of the oil and combustible gas from the soft coal.

Owner:SHANDONG PROVINCE METALLURGICAL ENG CO LTD

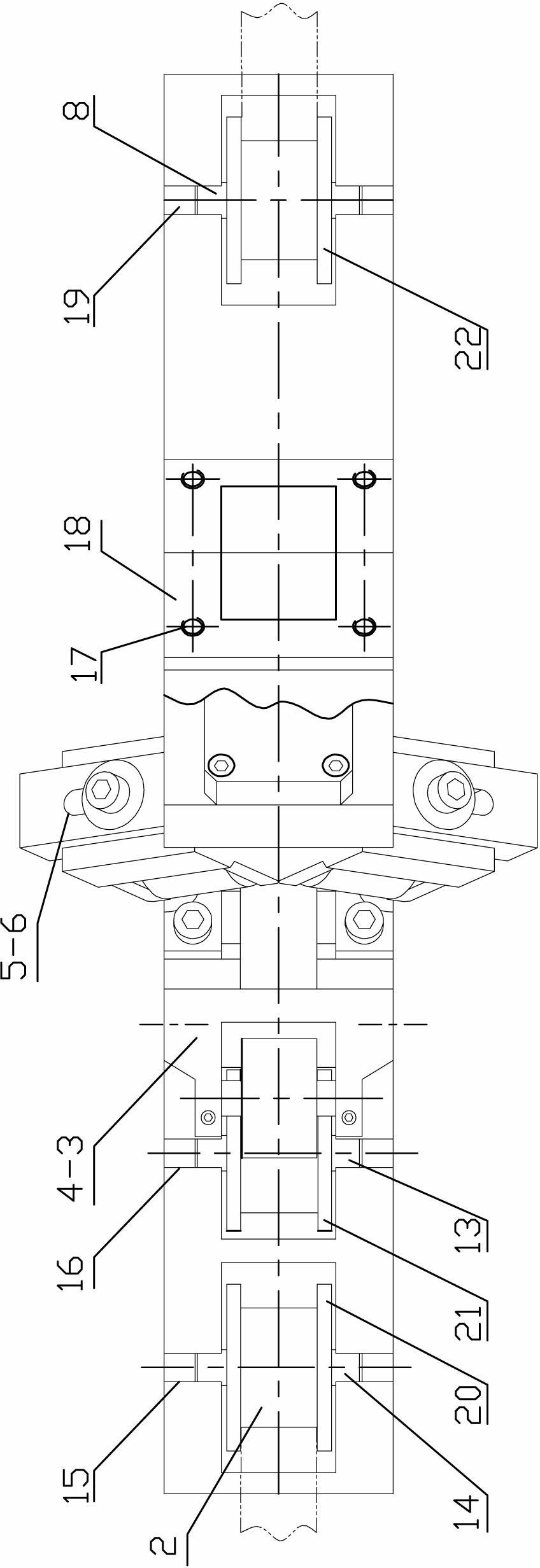

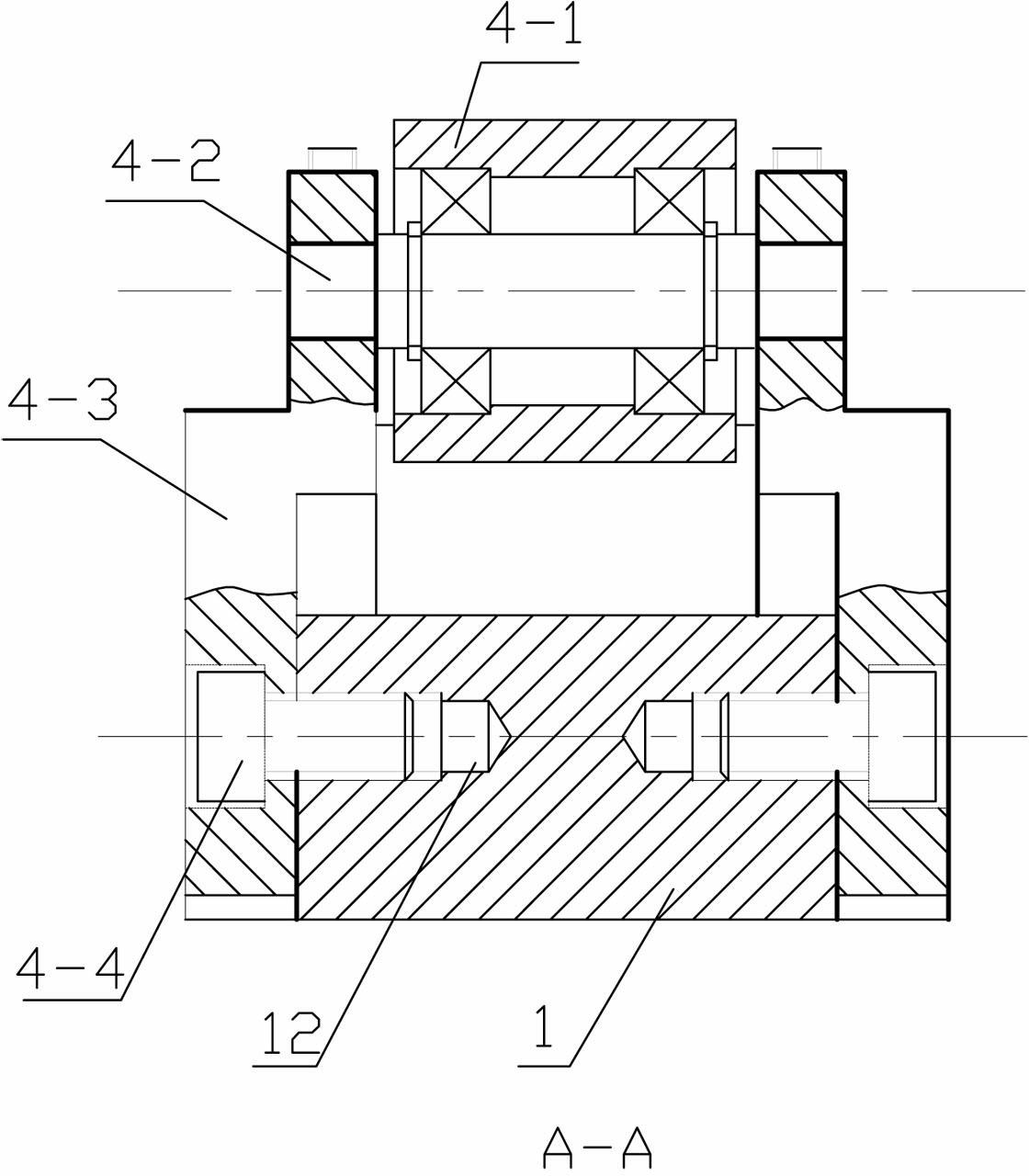

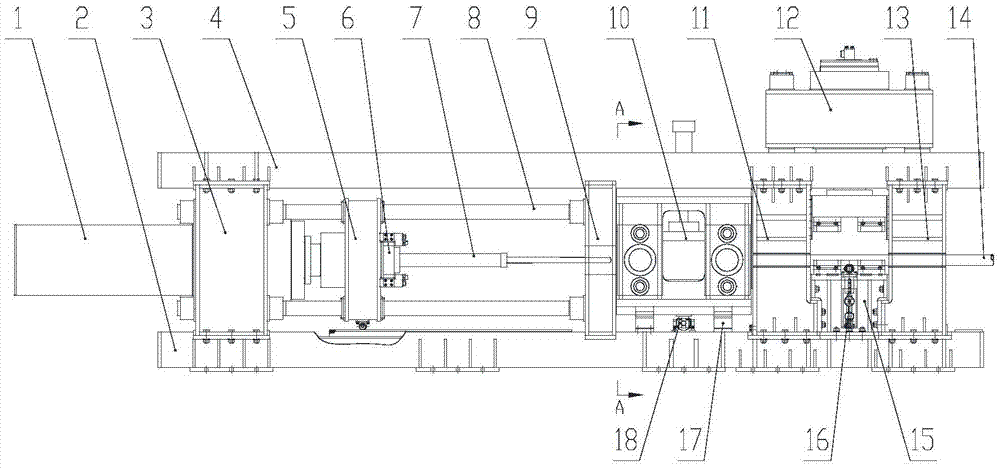

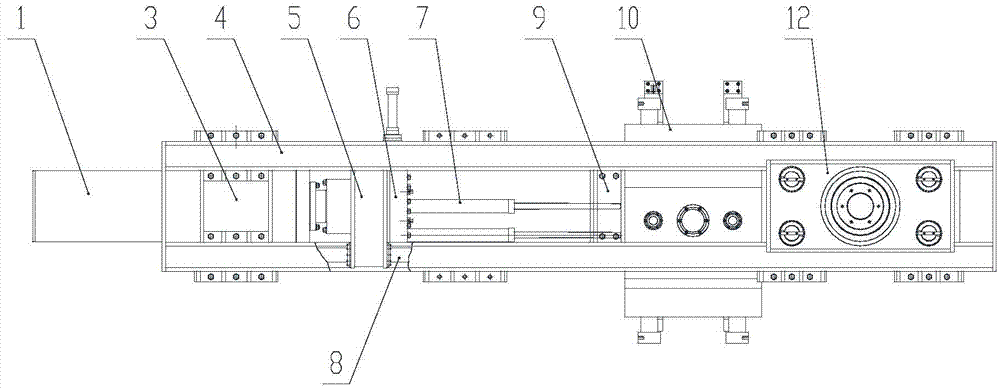

Overall thickening equipment for heavy weight drill rod pipe end

ActiveCN105436374AThickened metal flow line is goodQuality improvementForging/hammering/pressing machinesButt jointMachining

The invention provides overall thickening equipment for the heavy weight drill rod pipe end. The overall thickening equipment comprises a base. The base, a rear beam, a top beam, a middle beam, a rear front beam and a front beam are connected into a frame. An upsetting oil cylinder is connected to the rear beam in a butt joint manner. Guide rods are arranged between the rear beam and the middle beam. The guide rods are sleeved with an upsetting walking beam. One side of the upsetting walking beam is connected with a piston rod of the upsetting oil cylinder, and a punch movement device is arranged on the other side of the upsetting walking beam. A punch is arranged on the punch movement device. A thickening device is arranged between the middle beam and the rear front beam. A clamping device is connected to the rear front beam and the front beam through a connecting rod. A clamping seat is arranged on the rear front beam and the front beam. In the thickening process, a steel pipe is fed into the thickening device, the clamping device clamps the steel pipe to the clamping seat, the upsetting oil cylinder drives the upsetting walking beam to move so as to drive the punch to thicken the end of the steel pipe, the punch returns back after thickening operation is finished, the thickening device releases a thickening die, the steel pipe retracts out of the overall thickening equipment for the heavy weight drill rod pipe end, the metal streamline of produced overall drill rods is good, quality is stable, and the machining cost is low.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Process for indirectly producing alcohol with synthetic gas and application of process

ActiveCN103012062BReduce energy consumptionMild reaction conditionsOrganic compound preparationHydroxy compound preparationHydrogenTechnical grade

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

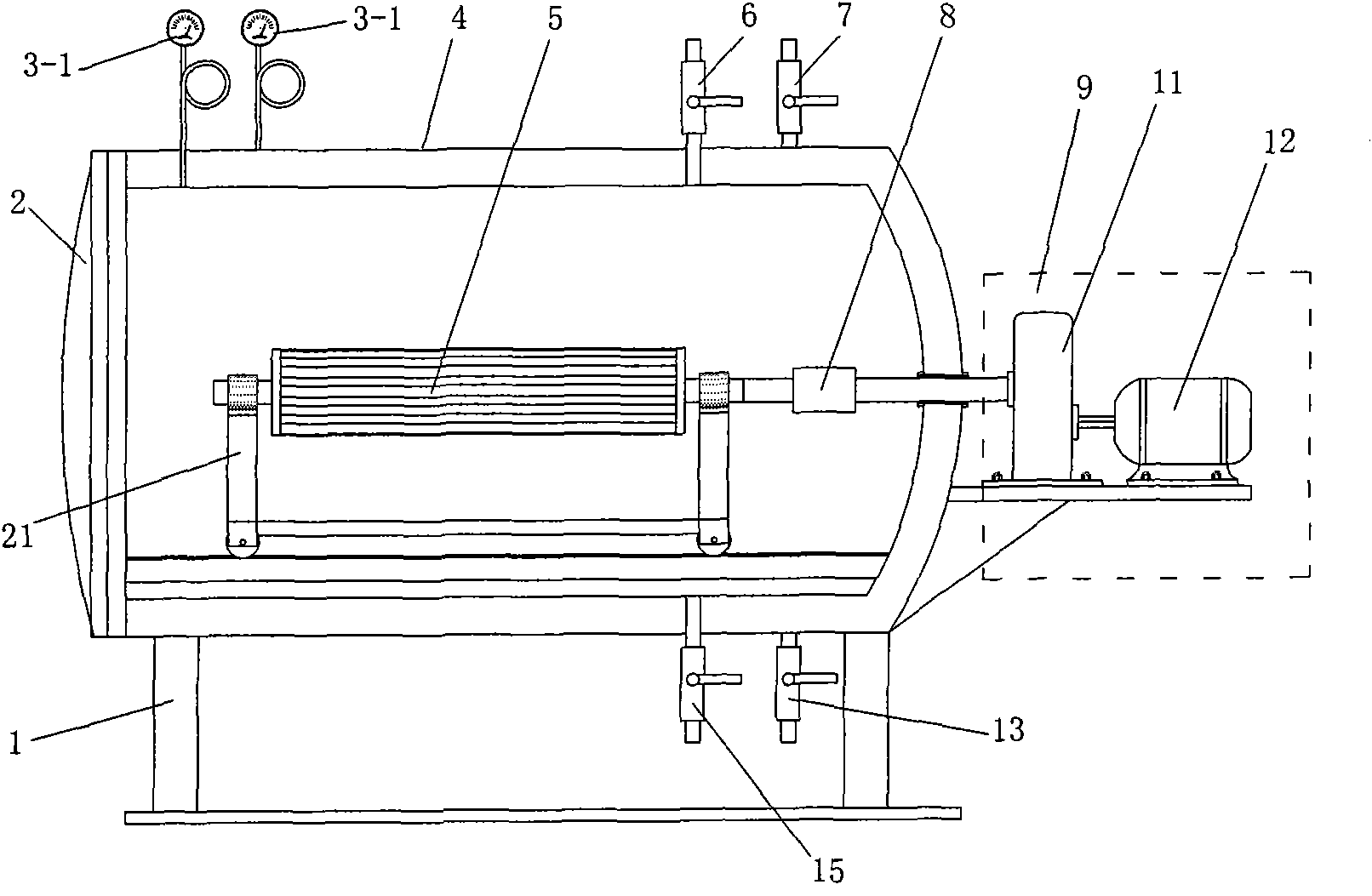

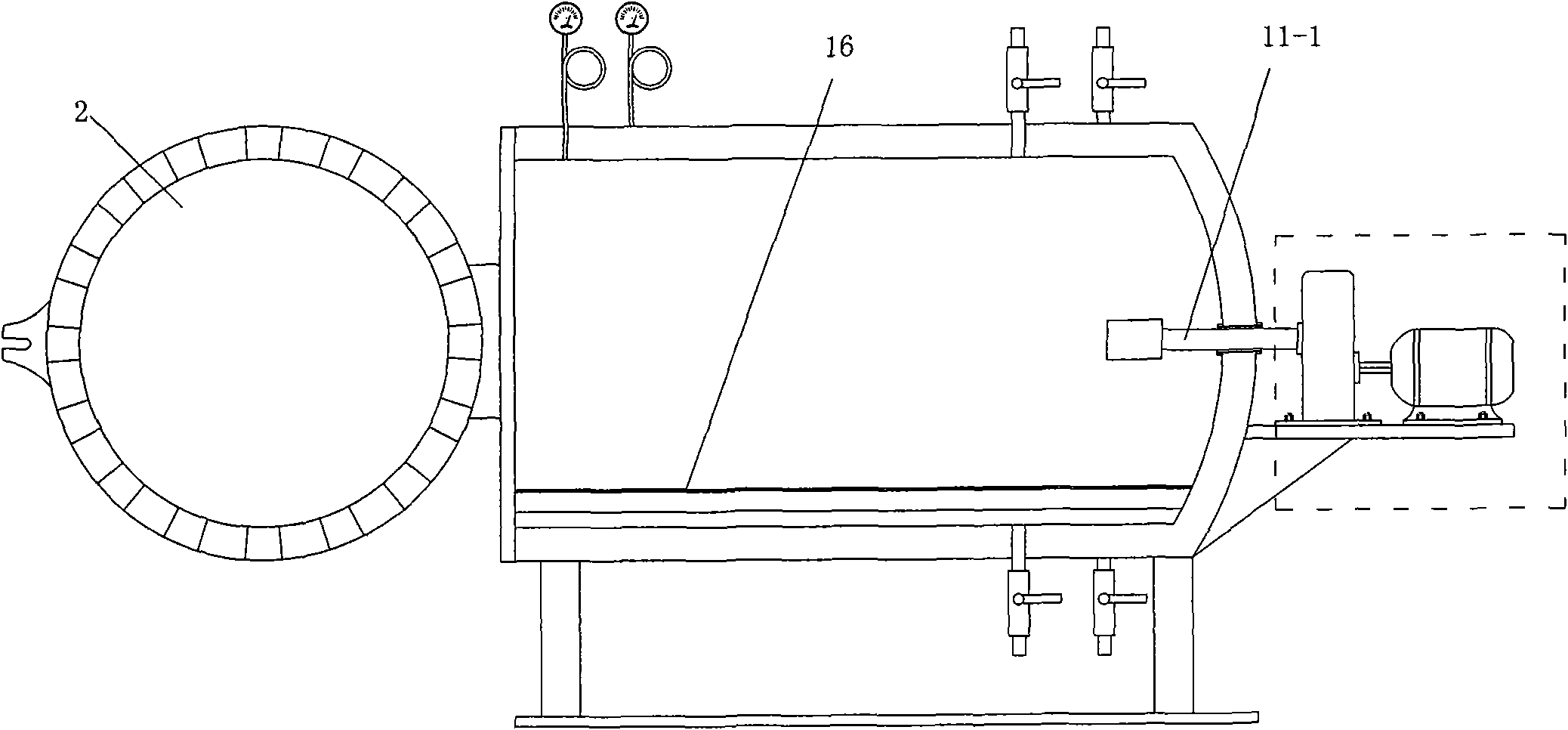

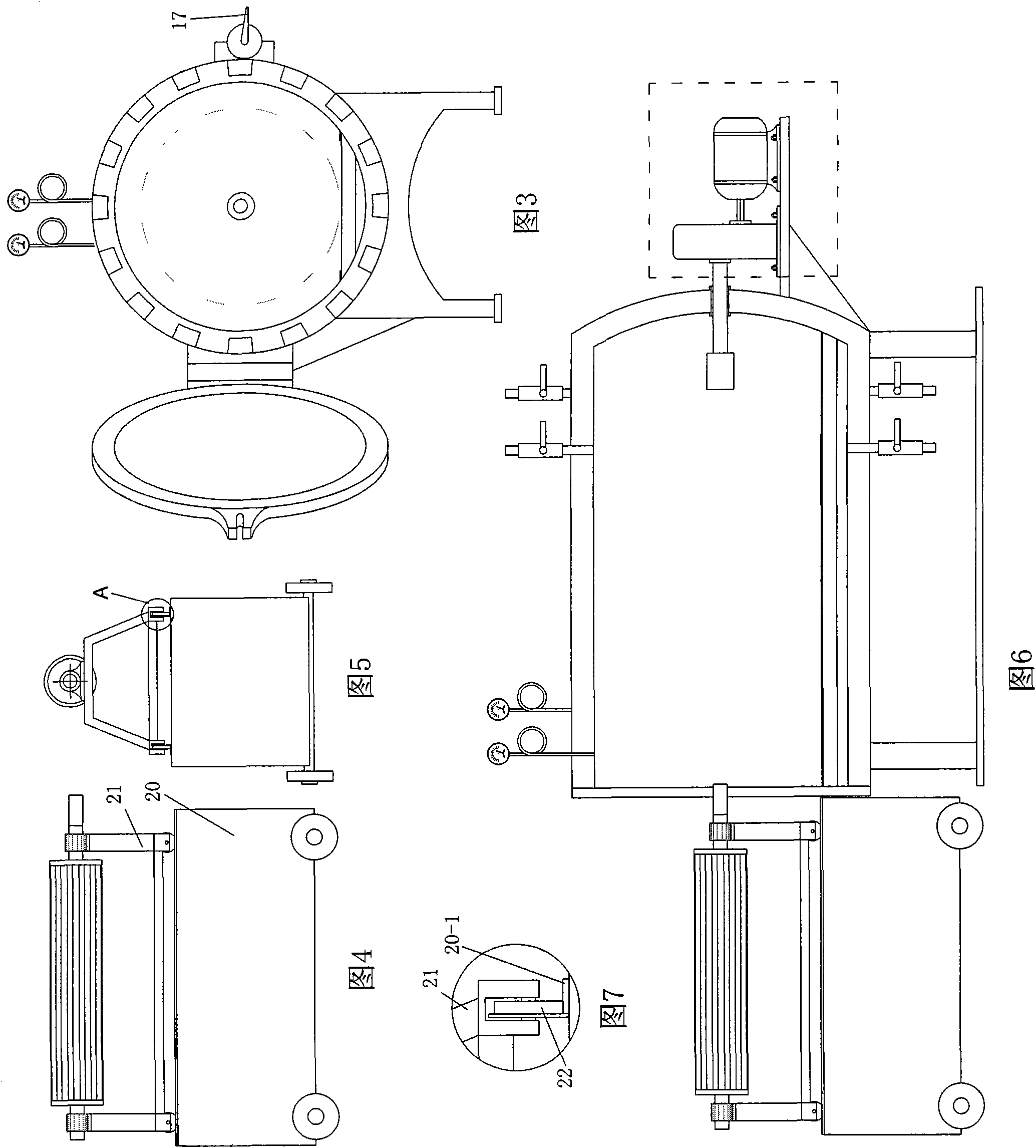

Horizontal fabric rotating steam box

InactiveCN101787629ALower the altitudeReduce labor intensityTextile treatment containersLiquid/gas/vapor textile treatmentCouplingEngineering

The invention relates to a steam box for processing a printed fabric. The technical problem to be solved by the invention is to provide a steam box which is capable of improving the quality of processed products and has the characteristics of low energy consumption, small volume and convenient use. The invention adopts a technical scheme that: the horizontal fabric rotating steam box comprises a cylindrical box body with a cavity and a machine frame supporting the box body; an opening is reserved at one end of the box body and is provided with a seal door; the wall of the box body is hollowed to form a heat-insulating layer; the cylindrical box body is horizontally arranged on the machine frame; and a guide rail and a fabric rotating device capable of entering the cavity along the guide rail are horizontally arranged at the bottom of the cavity and a cloth roller in the device is driven by a driving mechanism to rotate. The fabric rotating device comprises the horizontally arranged cloth roller and a bracket of which the bottom is provided with trolleys. The left end and the right end of the cloth roller are arranged at the upper end of the bracket through a bearing respectively. The right end of the cloth roller is also connected with an output shaft of the driving mechanism through a coupler.

Owner:海宁天怡数码喷墨印花有限公司

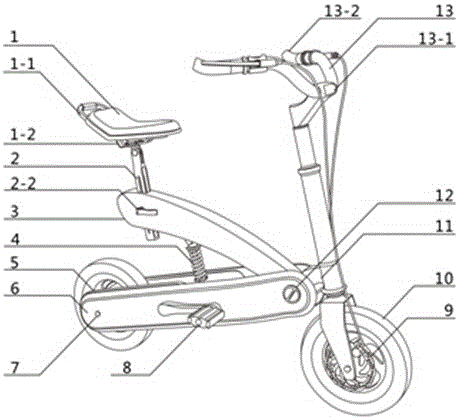

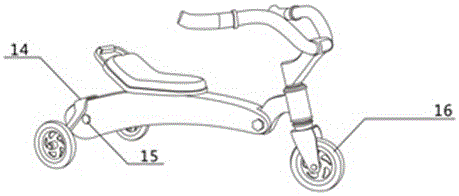

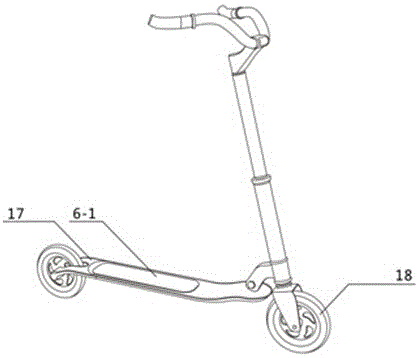

Multifunctional baby scooter

ActiveCN105752242ABeauty machine sizeImprove securityChildren cyclesConvertible cyclesEngineeringDual purpose

The invention provides a multifunctional baby scooter which comprises a dual-purpose saddle, a dual-purpose frame, a lamp-carrying handlebar, a front fork assembly, a disc brake assembly, dual-purpose baffles, tricycle wheels, bicycle wheels and scooter wheels. The dual-purpose frame and the dual-purpose baffles are connected with the front fork assembly through easy-to-detach rotary knobs, and the left dual-purpose baffle and the right dual-purpose baffle are connected with damping springs through supporting pipes. The multifunctional baby scooter has the advantages that through simple combinations, modularized components are transformed into three different types of scooters including the baby tricycle, the baby bicycle and the baby scooter, the service life of the baby scooter product is prolonged, and the concept of environment protection and sustainability is embodied.

Owner:XUZHOU NORMAL UNIVERSITY

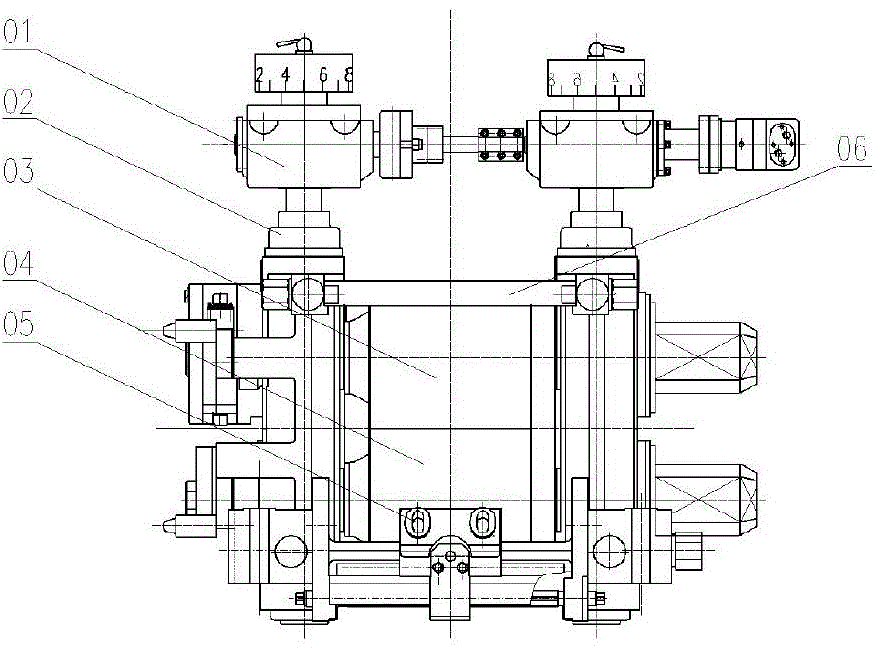

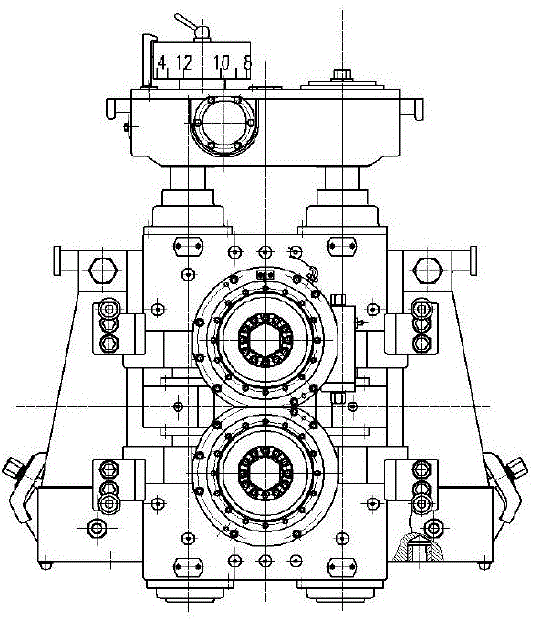

Bars reducing and sizing mill

InactiveCN104889156ACompact structureReduce weightMetal rolling stand detailsRolling equipment maintainenceEngineeringCopper

The invention discloses a bars reducing and sizing mill which is of a short stress line type. The bars reducing and sizing mill comprises a roll-gap adjuster, a pull rod assembly, a frame, a beam, a roll assembly and a guide beam. The roll assembly comprises an upper roll assembly and a lower roll assembly and further comprises a pull rod, butterfly spring absorbers and a spherical anti-axial play device; the butterfly spring absorbers are disposed at upper and lower ends of the pull rod and used for eliminating a gap between the pull rod and a copper nut; the spherical anti-axial play device is used for eliminating an axial gap between the pull rod and a bearing block; the butterfly spring absorbers surround the pull rod; the pull rod assembly allows a central distance of upper and lower rolls of the mill to change by 0.1mm.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com