Horizontal fabric rotating steam box

A kind of fabric, horizontal technology, applied in the field of steam box for processing printed fabrics, can solve the problems of inconvenient work, easy color difference of fabric color, hidden safety hazards, etc., to solve the problem of inconsistent color difference, improve product quality, and reduce height requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

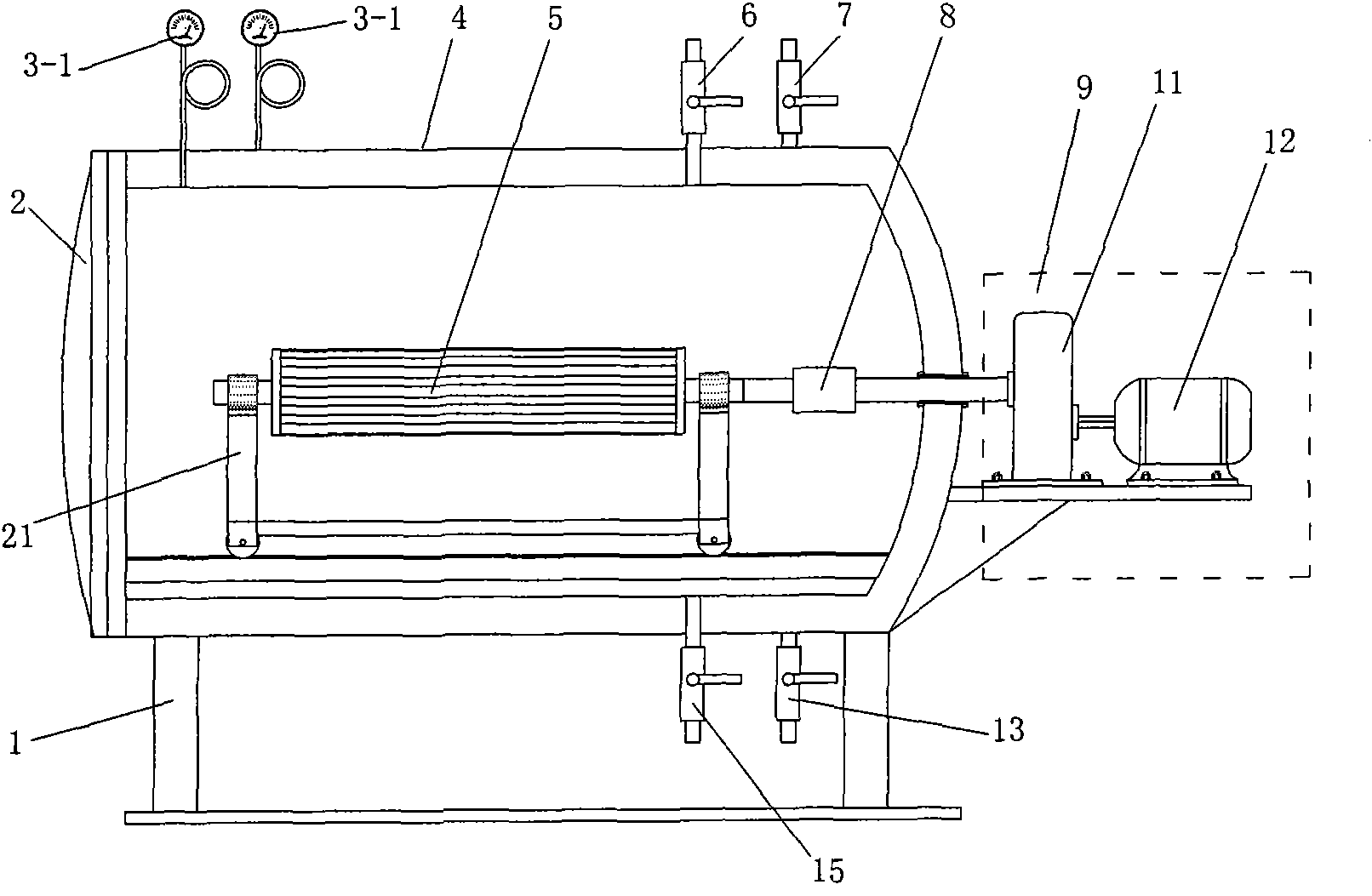

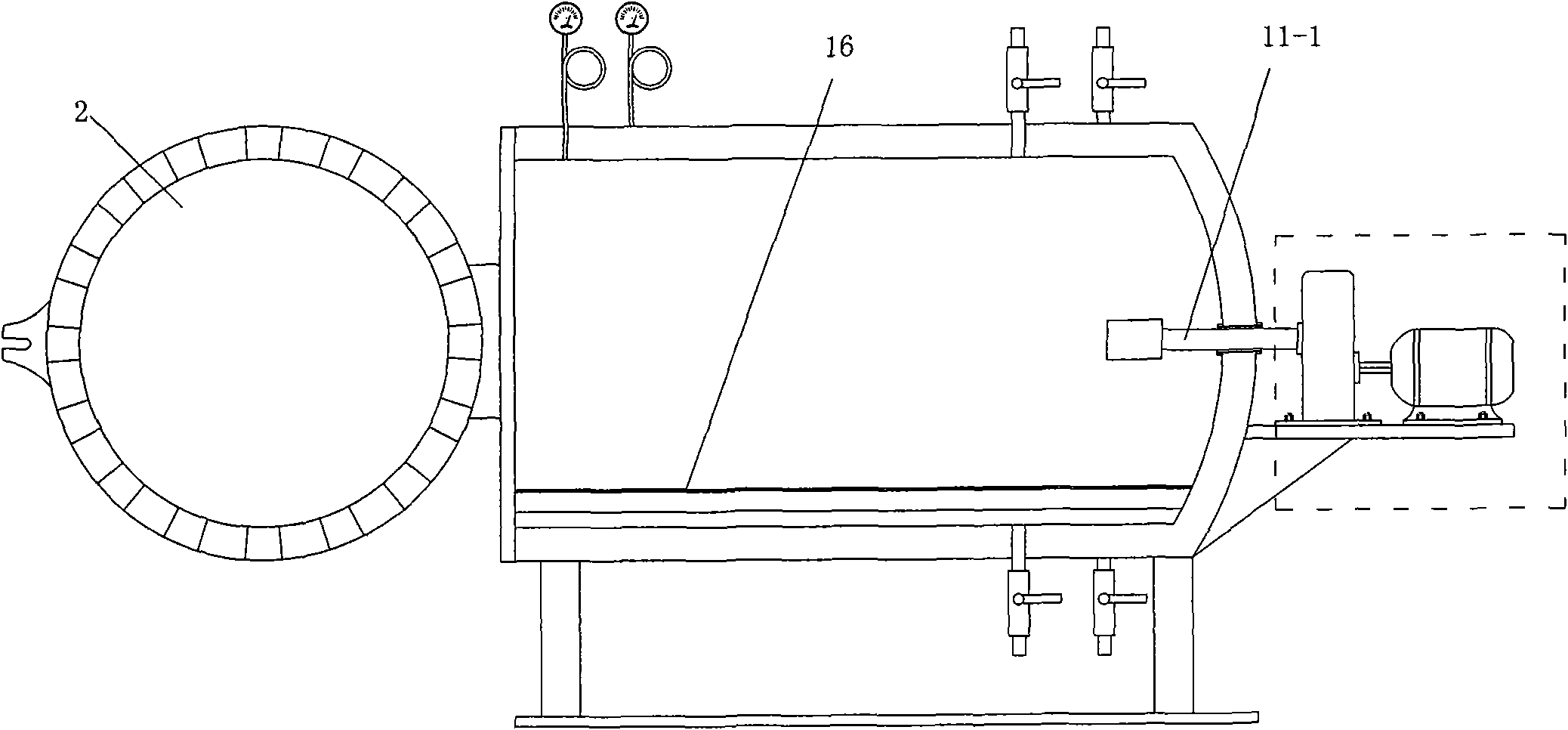

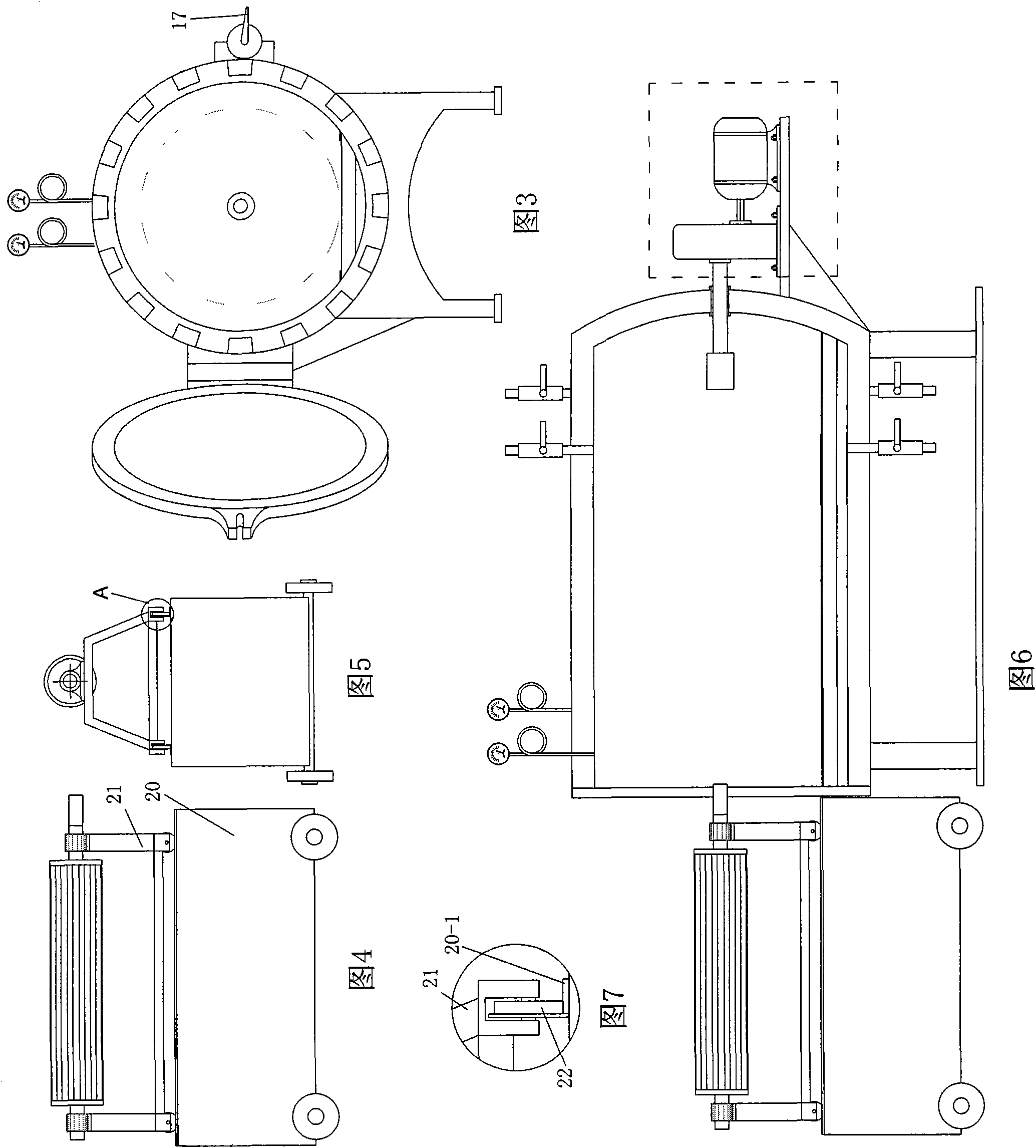

[0019] like figure 1 , figure 2 As shown, the horizontal fabric steamer includes a cylindrical box 4 with a cavity inside and a frame 1 arranged at the bottom of the box; the left end of the box is open and equipped with a sealed door 2 and a sealed door. Device 17 (sealed door structure and sealed door locking device are identical with the structure of existing steamer, do not introduce in detail), the right end of casing is closed; The wall of casing is made hollow to form insulation layer.

[0020] The cylindrical box is horizontally arranged on the frame 1; a guide rail 16 is horizontally arranged at the bottom of the cavity, and there is another fabric rotating device 21 that can enter the cavity of the box along the guide rail. A driving mechanism 9 acts to rotate.

[0021] It can be seen from the figure that the fabric rotating device includes a horizontally arranged cloth rolling roller 5 and a support with rollers 22 (the number of rollers is determined according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com