Preparation method of covalent organic framework composite microspheres with core-shell structures

A technology of covalent organic framework and composite microspheres, which is applied in the field of covalent bond connection preparation, can solve problems such as methods that have not been reported yet, achieve good mechanical stability, reduce height, and the effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of the covalent organic framework composite microsphere of core-shell structure, it comprises the steps:

[0032] 80 mg of silica microspheres, 48 mg of trimesaldehyde, and 82.9 mg of benzidine were uniformly dispersed in 60 mL of dimethyl sulfoxide solvent, ultrasonically mixed for 25 min, and 2 mL of acetic acid was added, and then ultrasonically maintained for 30 min to obtain the obtained Covalent organic framework composite silicon spheres with core-shell structure. Wash with tetrahydrofuran and ethanol several times by centrifugation, and dry the obtained material at 150 °C.

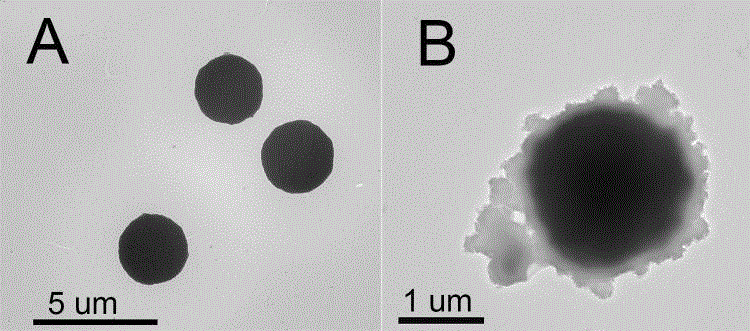

[0033] figure 1 Middle A is the transmission electron microscope image of the silica microspheres in Example 1. It can be clearly seen from the figure that the average particle size of the silica bare spheres with smooth surface morphology is about 2 μm. figure 1 Middle B is the transmission electron microscope image of the covalent organic framework composite microsphere...

Embodiment 2

[0038] The covalent organic framework composite microspheres with the core-shell structure prepared in Example 1 were used as a chromatographic stationary phase, and filled into an empty stainless steel short column with an inner diameter of 2.1 mm and a length of 50 mm by a dry filling method. Sonicated several times with acetone, secondary water and methanol in sequence. When loading the column, one end of the column is connected to a vacuum source, and the other end is equipped with a funnel, and the dry core-shell structure covalent organic framework composite microspheres are slowly fed into it, and the column wall is gently tapped to make the microspheres fall into the column. middle. Ethanol can be added dropwise when filling the microspheres to make them more compact. After the filling is completed, the mobile phase (water:acetonitrile=10:90, v:v) with a flow rate of 0.1 mL / min is used to wash and balance for a long time on the high-performance liquid chromatograph to...

Embodiment 3

[0040] In liquid chromatography (HPLC) mode, acetonitrile:water solution (5:95, v / v) was used as mobile phase A, water:acetonitrile solution (5:95, v / v) was used as mobile phase B, and the chromatographic condition was 55 %B; pump flow rate 0.2 mL / min, detection wavelength 214 nm; mixture of thiourea (20ppm), benzene (100 ppm), toluene (100 ppm), ethylbenzene (100 ppm), naphthalene (100 ppm) Realize efficient and selective separation on the chromatographic column that embodiment 2 makes, its chromatographic separation figure is as follows Figure 6 As shown, the peaks in the chromatogram are 1: thiourea, 2: benzene, 3: toluene, 4: ethylbenzene, 5: naphthalene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com