Preparation method for hollow polymer nanofibers

A nanofiber and polymer technology, which can be used in the manufacture of hollow filaments, single-component synthetic polymer rayon, fiber processing, etc. The effect of repeated use, mild preparation conditions and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

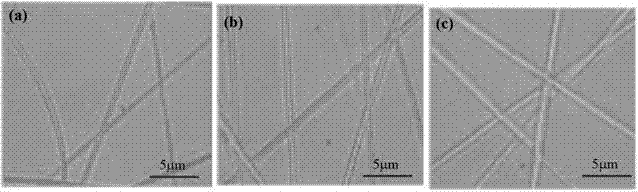

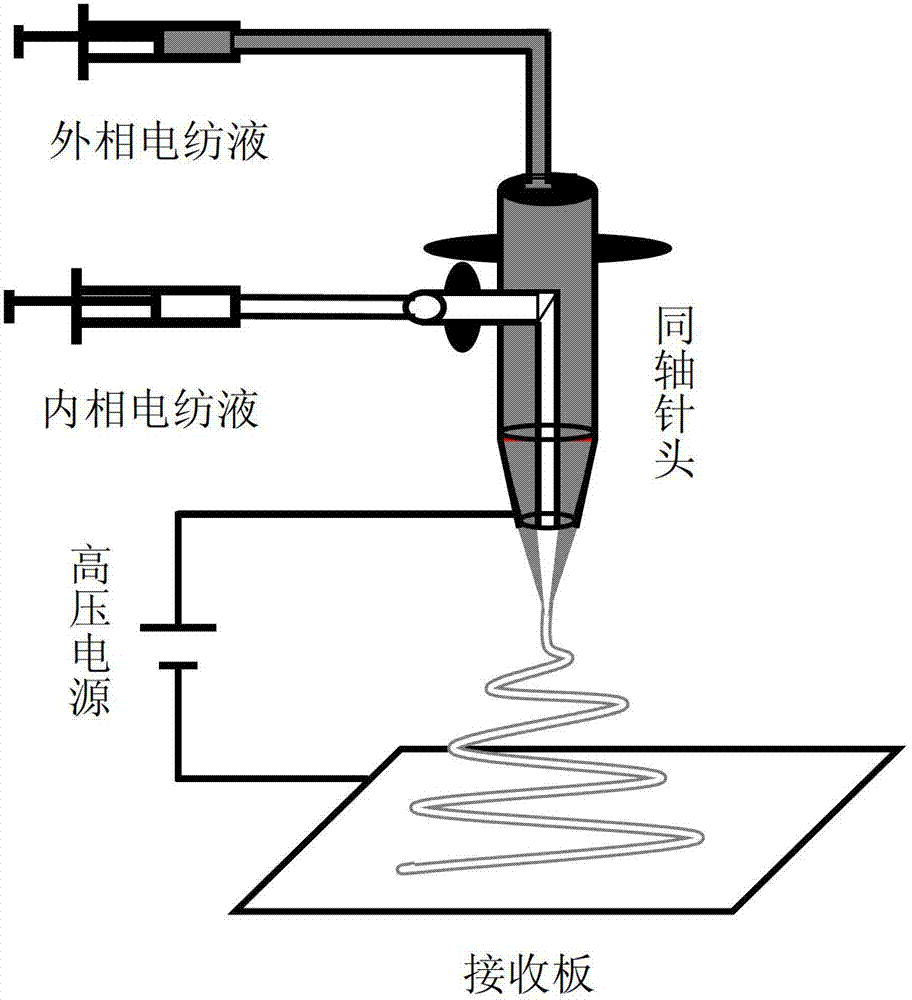

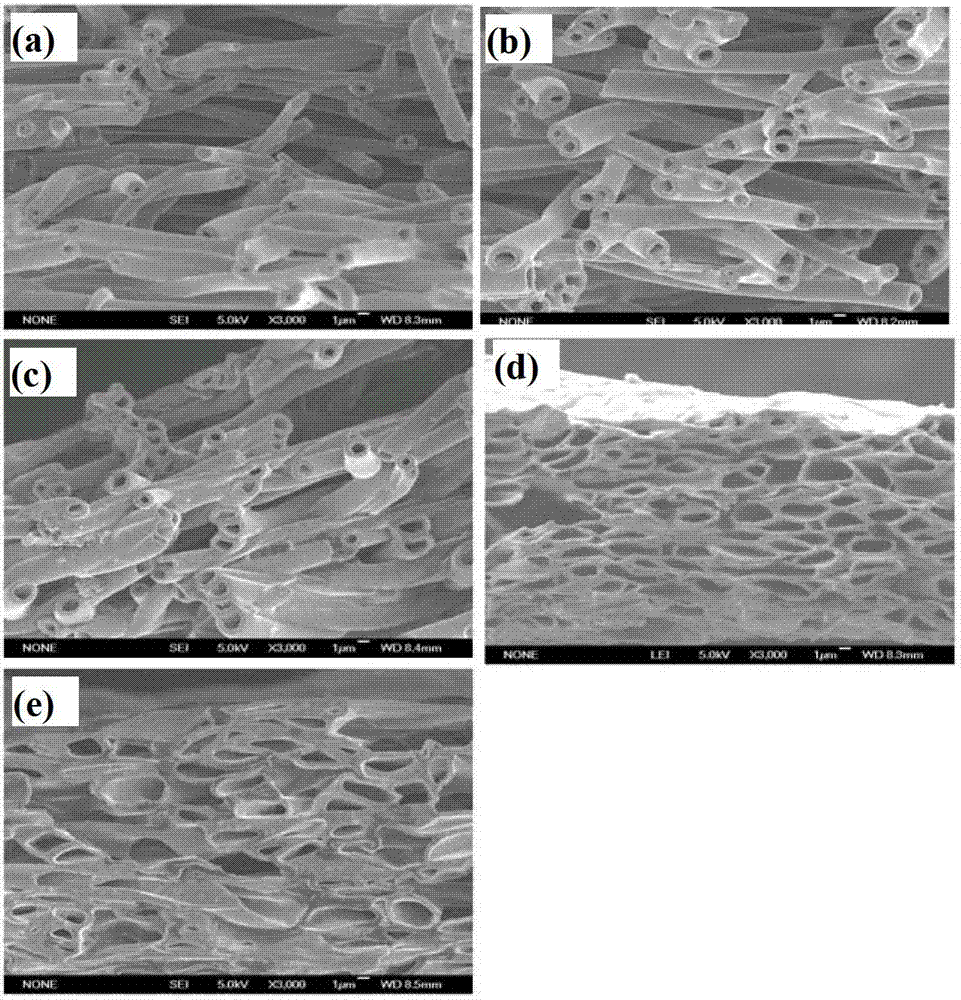

[0035] Thoroughly mix glycerin and water at a volume ratio of 95:5, add to a 5ml injector as the internal phase electrospinning solution for coaxial co-spinning; dissolve polyurethane in N,N-dimethylacetamide, Fully dissolve and make a solution with a weight percentage of 20%, as the external phase electrospinning solution, add it to another 5ml sampler; connect the internal and external phase electrospinning solutions to the inlet of the coaxial electrospinning spinneret through pipelines respectively. Liquid port, connect the liquid outlet of the spinneret to the positive pole of the high-voltage power supply, and use aluminum foil or stainless steel mesh to connect to the negative pole of the high-voltage power supply as a receiving plate. Adjust the distance between the spinneret and the receiving plate to be 15cm, and the voltage to be 15Kv. A syringe pump was used to control the flow rate of the inner phase electrospinning liquid to 0.05ml / h, and the flow rate of the out...

Embodiment 2

[0037] Thoroughly mix glycerin and water at a volume ratio of 95:5, add to a 5ml injector as the internal phase electrospinning solution for coaxial co-spinning; dissolve polyurethane in N,N-dimethylacetamide, Fully dissolve and make a solution with a weight percentage of 20%, as the external phase electrospinning solution, add it to another 5ml sampler; connect the internal and external phase electrospinning solutions to the inlet of the coaxial electrospinning spinneret through pipelines respectively. Liquid port, connect the liquid outlet of the spinneret to the positive pole of the high-voltage power supply, and use aluminum foil or stainless steel mesh to connect to the negative pole of the high-voltage power supply as a receiving plate. Adjust the distance between the spinneret and the receiving plate to be 17cm, and the voltage to be 25Kv. A syringe pump was used to control the flow rate of the inner phase electrospinning liquid to 0.07ml / h, and the flow rate of the out...

Embodiment 3

[0039] Thoroughly mix glycerin and water at a volume ratio of 90:10, add to a 5ml injector as the internal phase electrospinning solution for coaxial co-spinning; dissolve polyurethane in N,N-dimethylacetamide, Fully dissolved and made into a solution with a weight percentage of 25%, as the external phase electrospinning solution, added to another 5ml sampler; the internal and external phase electrospinning solutions were respectively connected to the inlet of the coaxial electrospinning spinneret through pipelines. Liquid port, connect the liquid outlet of the spinneret to the positive pole of the high-voltage power supply, and use aluminum foil or stainless steel mesh to connect to the negative pole of the high-voltage power supply as a receiving plate. Adjust the distance between the spinneret and the receiving plate to be 17cm, and the voltage to be 25Kv. A syringe pump was used to control the flow rate of the inner phase electrospinning liquid to 0.1ml / h, and the flow rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com