Process for preparing shape controllable cuprous oxide micro/nano crystal by electrochemical deposition

A nanocrystal, cuprous oxide technology, applied in chemical instruments and methods, crystal growth, single crystal growth and other directions, can solve the problems of affecting product purity, inconvenient cleaning, etc., and achieves strong operability, high reaction efficiency, and good reliability. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) After grinding and polishing, the glassy carbon electrode was ultrasonically cleaned with ultrapure water for more than 1 h, and then dried naturally to obtain a clean, smooth and bright electrode.

[0024] 2) Prepare CuSO with a concentration of 50mM 4 Pour an appropriate amount of electrolyte solution into the electrolytic cell, ultrasonicate for 20 minutes to eliminate dissolved oxygen, and cool naturally to room temperature.

[0025] 3) After the potentiostat is preheated, select the constant current test method and set the main reaction parameters: the cathode current is 0.005A, and the deposition time is 30s. Afterwards, the three electrodes were respectively connected to the corresponding connection wires of the potentiostat, and the electrodeposition reaction was started at the same time.

[0026] 4) Disconnect the circuit after the reaction, carefully take out the glassy carbon electrode with tweezers, wash it with ultrapure water, put it face up on the fil...

Embodiment 2

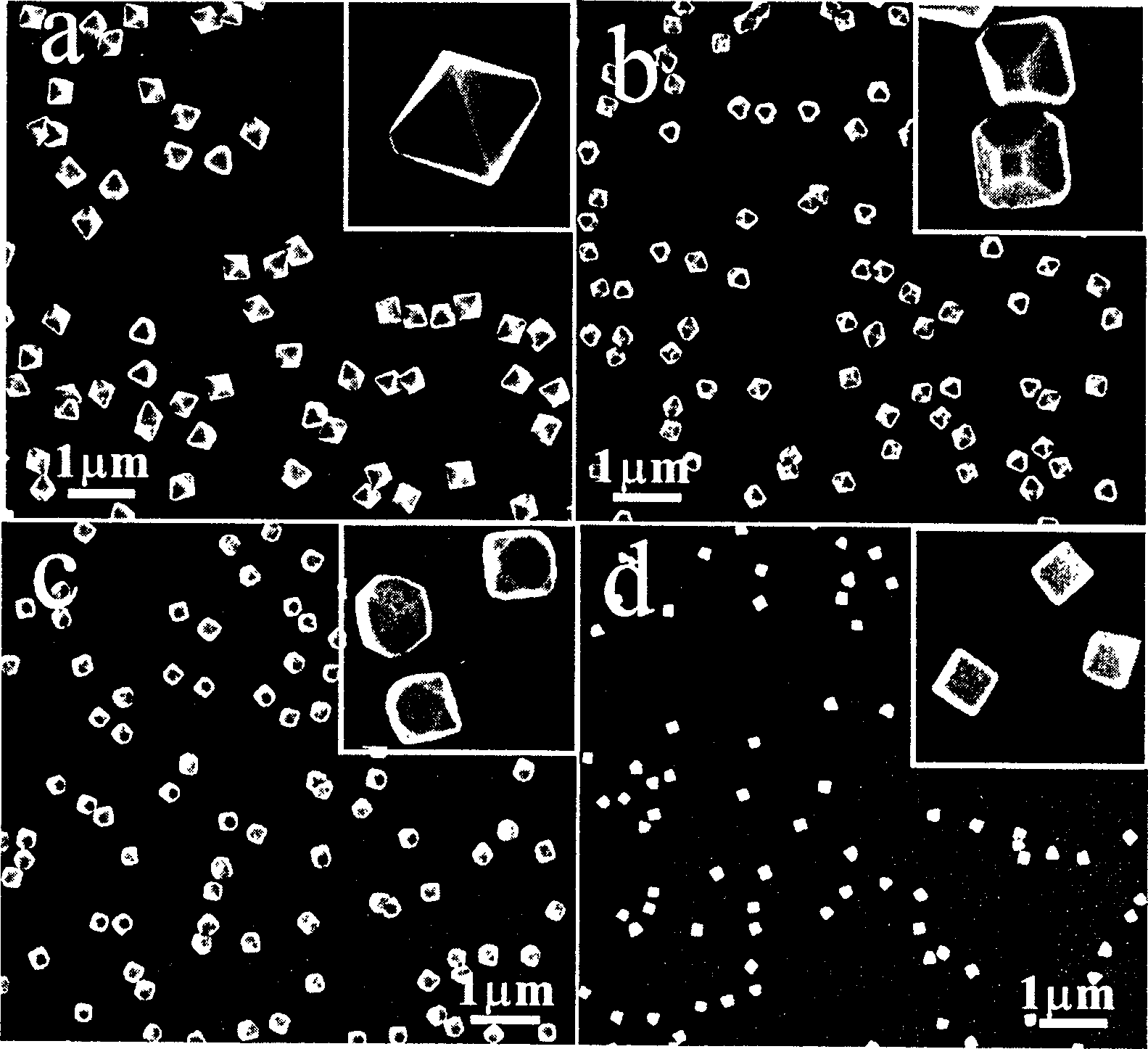

[0029] Prepare CuSO at a concentration of 10mM 4 Electrolyte, all the other preparation methods are the same as embodiment 1, and the product is characterized by SEM (see figure 1b), the typical shape is the structure of cut-off regular octahedron, the average particle size is 250nm, the cut-off angle is 50nm, and the size is uniform and the distribution is uniform. It can be seen from the enlarged SEM image that the surface is smooth and flat.

Embodiment 3

[0031] Prepare CuSO at a concentration of 2mM 4 Electrolyte, all the other preparation methods are the same as embodiment 1, and the product is characterized by SEM (see figure 1 c), the typical shape is a chamfered cubic structure, the average particle size is 170nm, the chamfered angle is 60nm, and the size is uniform and the distribution is uniform. It can be seen from the enlarged SEM image that the surface is smooth and flat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com