Patents

Literature

323results about How to "Not easy to cause pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

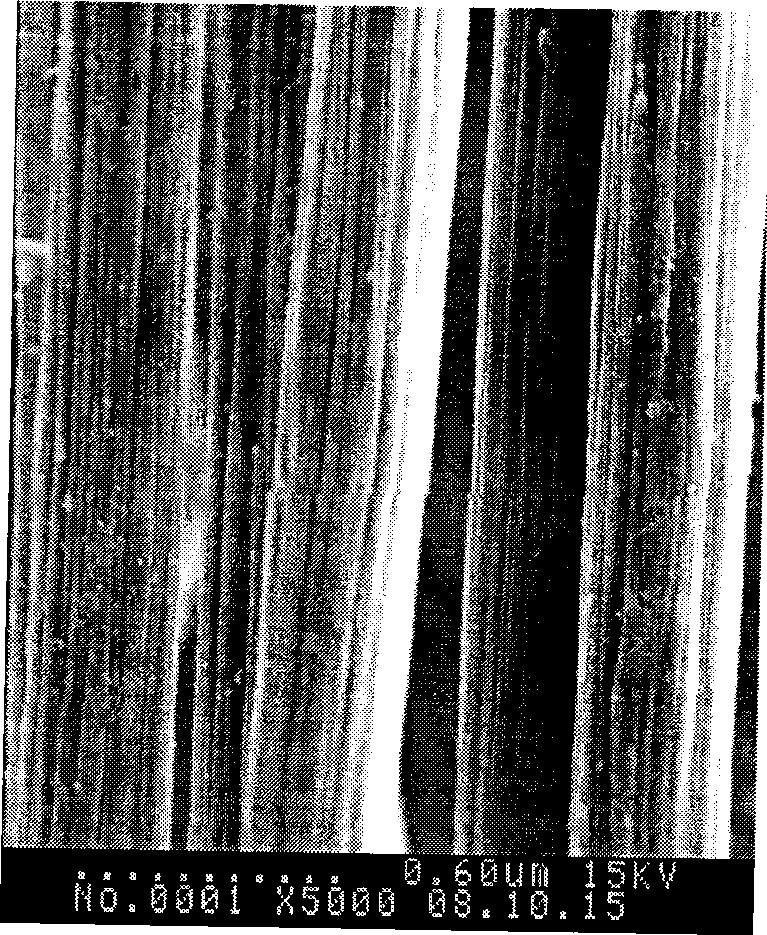

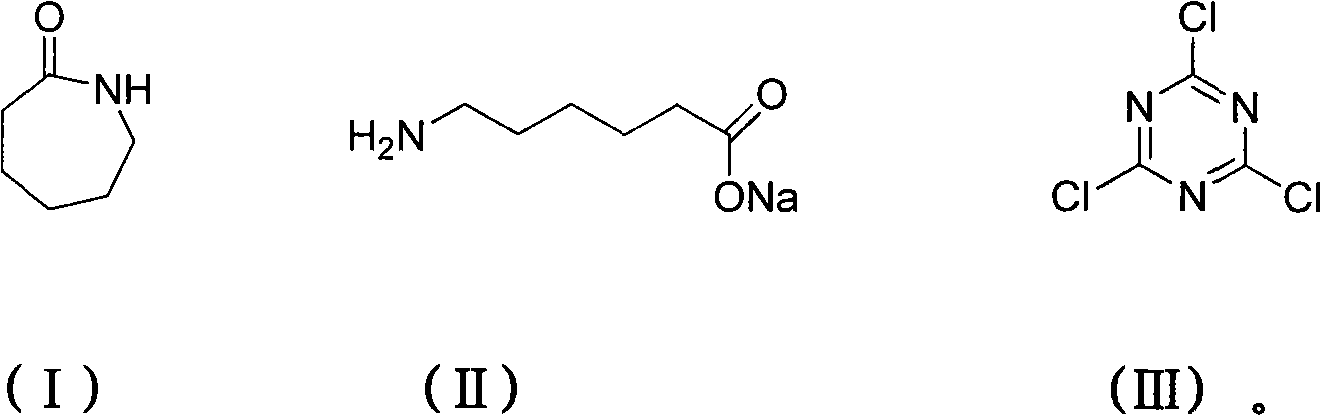

Method for carbon fiber surface modification of plasma coated with nano colloidal sols by plasma treatment

InactiveCN101413209AImprove performanceImprove surface propertiesPhysical treatmentCarbon fibresFiberCarbon fibers

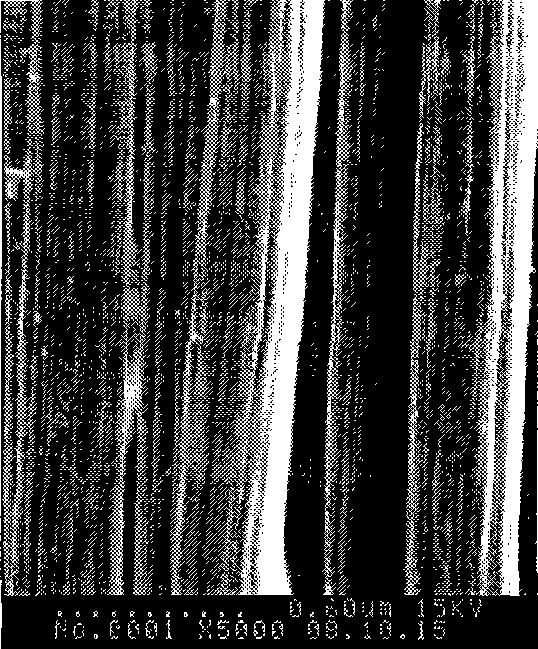

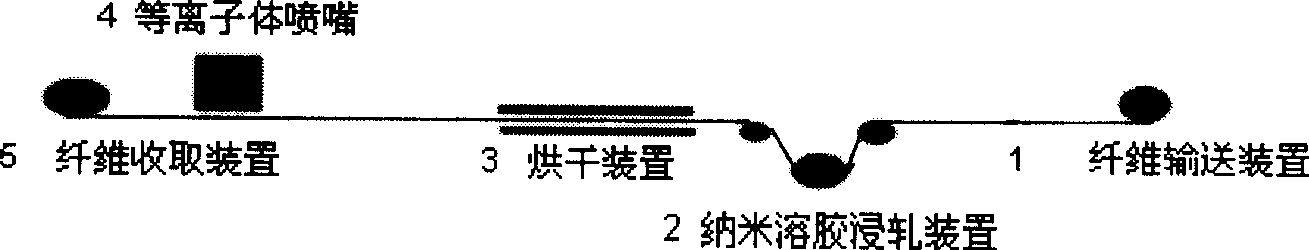

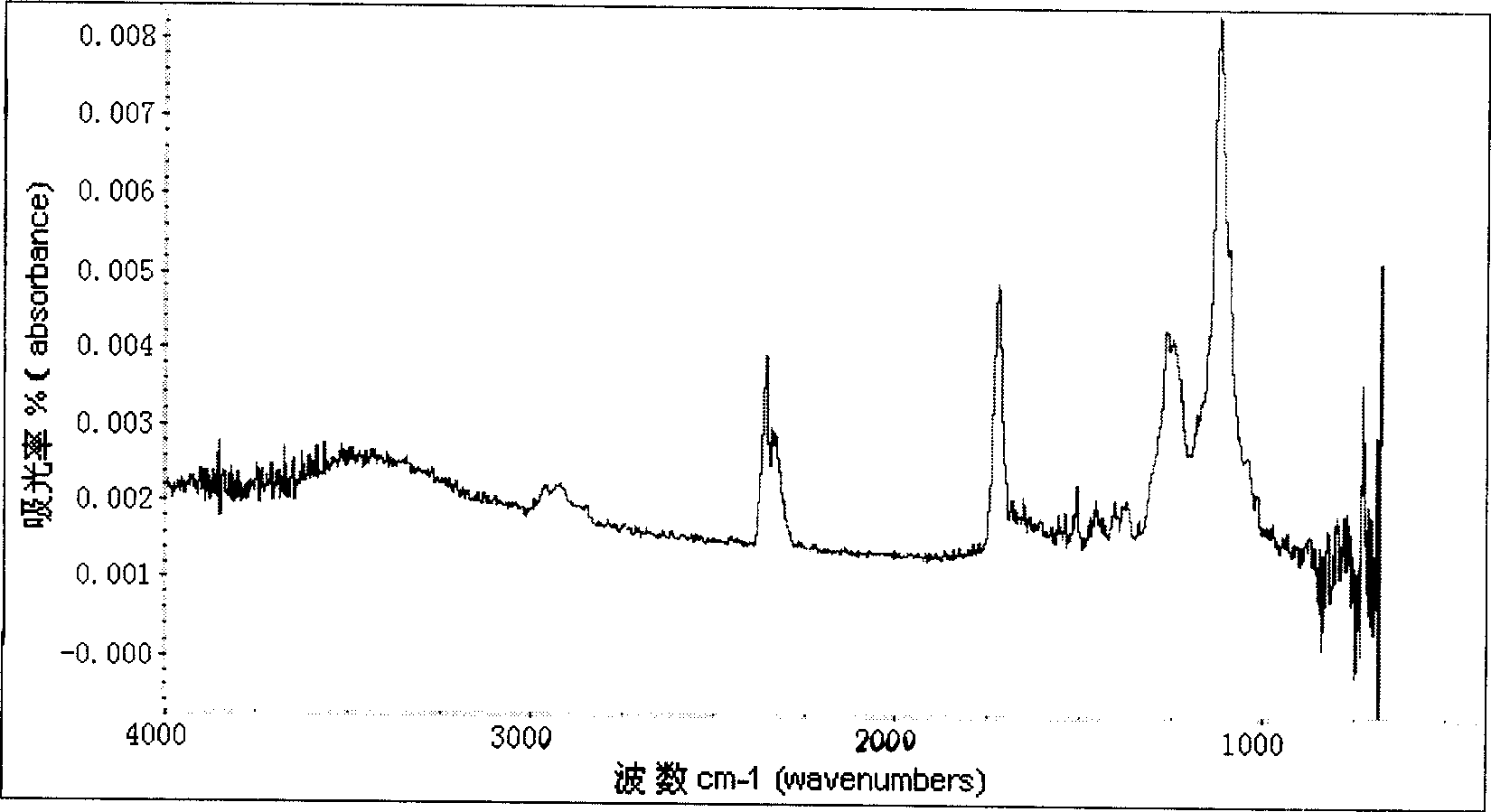

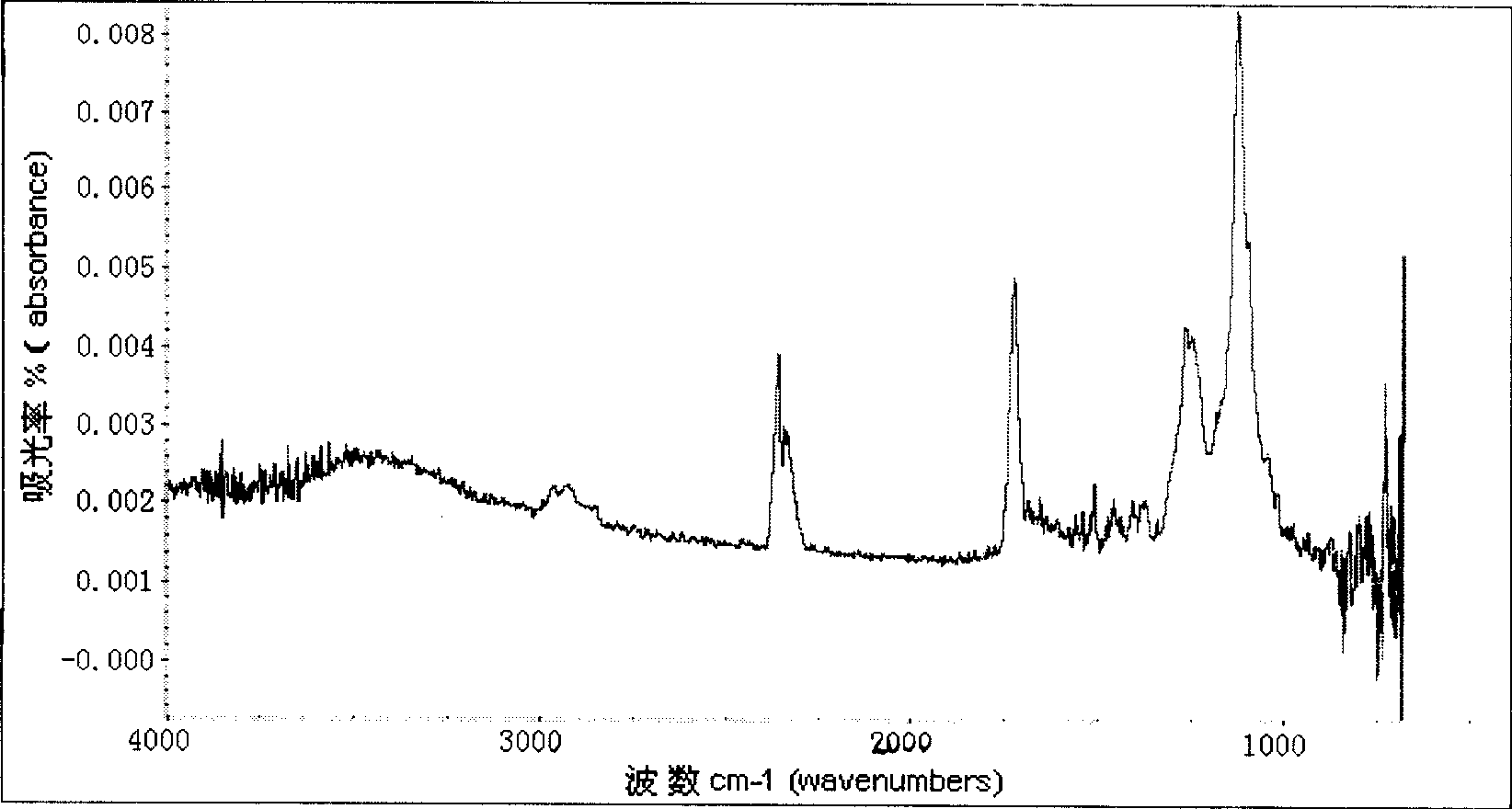

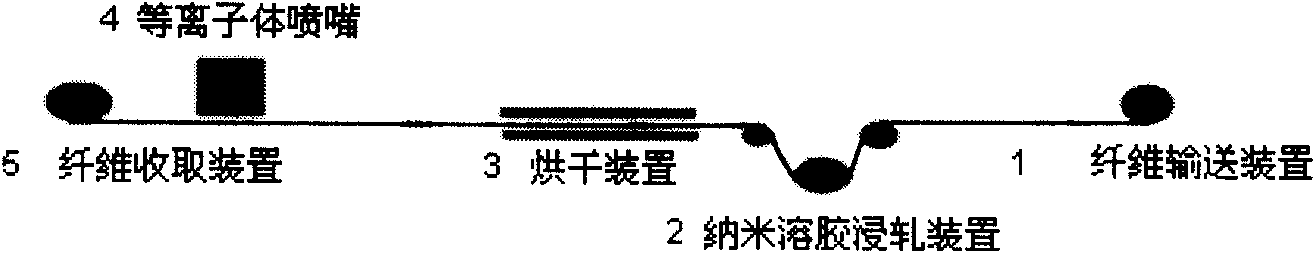

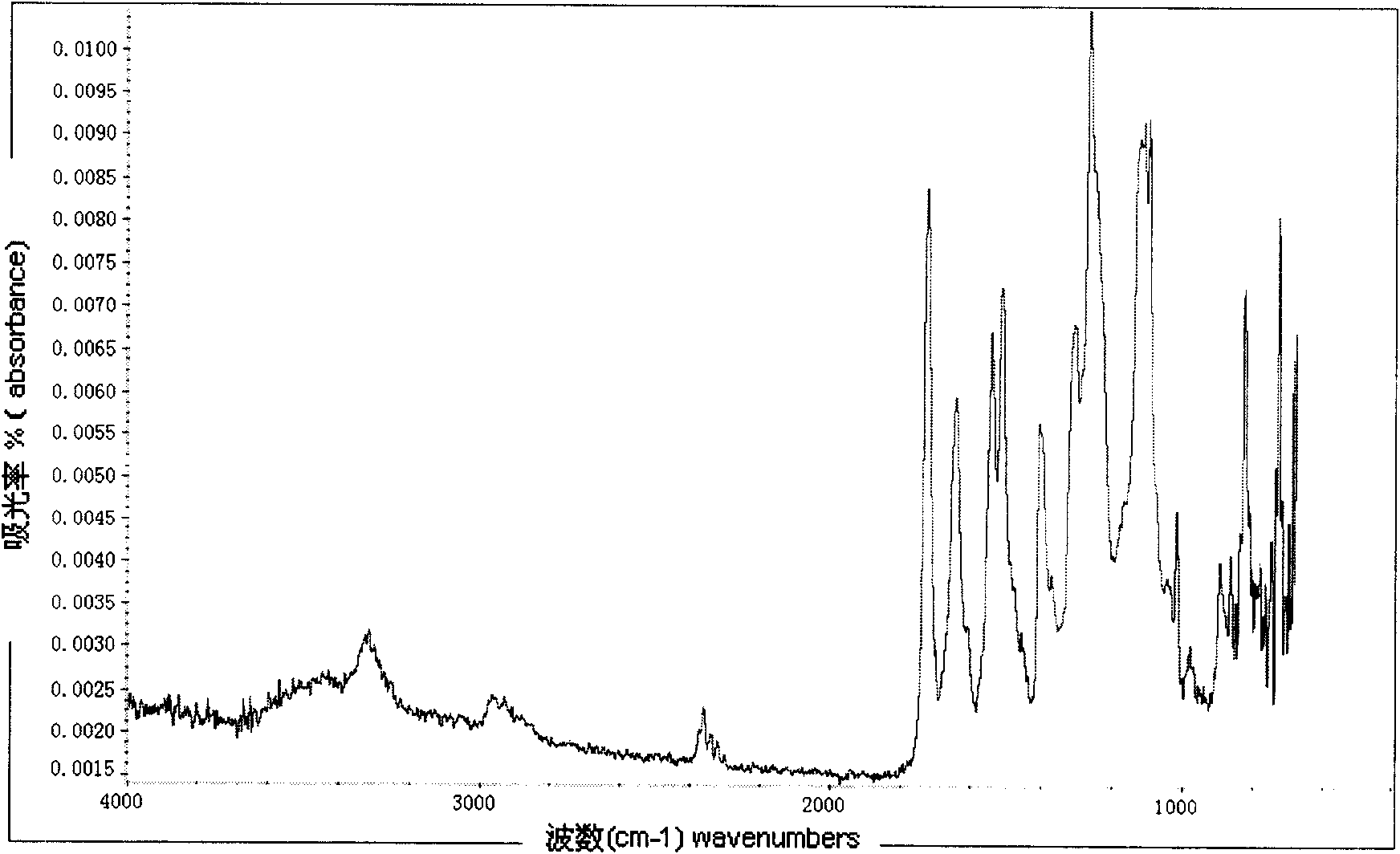

The invention relates to a method for modifying the surface of carbon fiber coated with nano sol through plasma treatment, which comprises the following steps: firstly, nano particles are prepared into an organic solvent, a sol solution of water or a sol solution prepared by hybridization reaction of a precursor solution of organic-inorganic nano particles by the ultrasonic vibrating technology; secondly, the sol solution is coated on the surface of the carbon fiber, treated by means of spray coating and padding, and dried; and thirdly, the dried carbon fiber is placed on a special transport unit for plasma processing equipment and a plasma is sprayed on the surface of the carbon fiber to make the carbon fiber move in the plasma atmosphere, so as to generate surface modification, wherein the treating power is between 10 and , watts, and the treatment time is between 0.5 and 300 seconds. The method can effectively improve the performance of the fiber, improves the molded manufacturability and the overall properties of composite materials of the fiber, has simple technology, quick processing speed, good treatment effect and low cost, is convenient to operate and difficult to cause environmental pollution, can reduce energy consumption, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

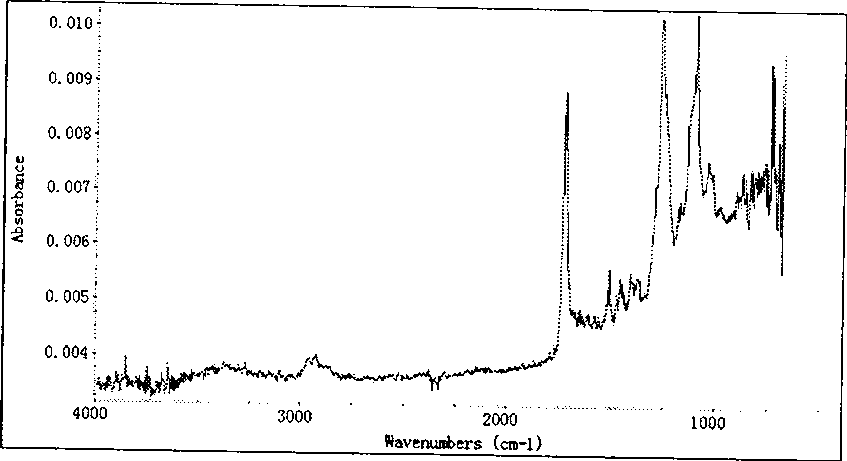

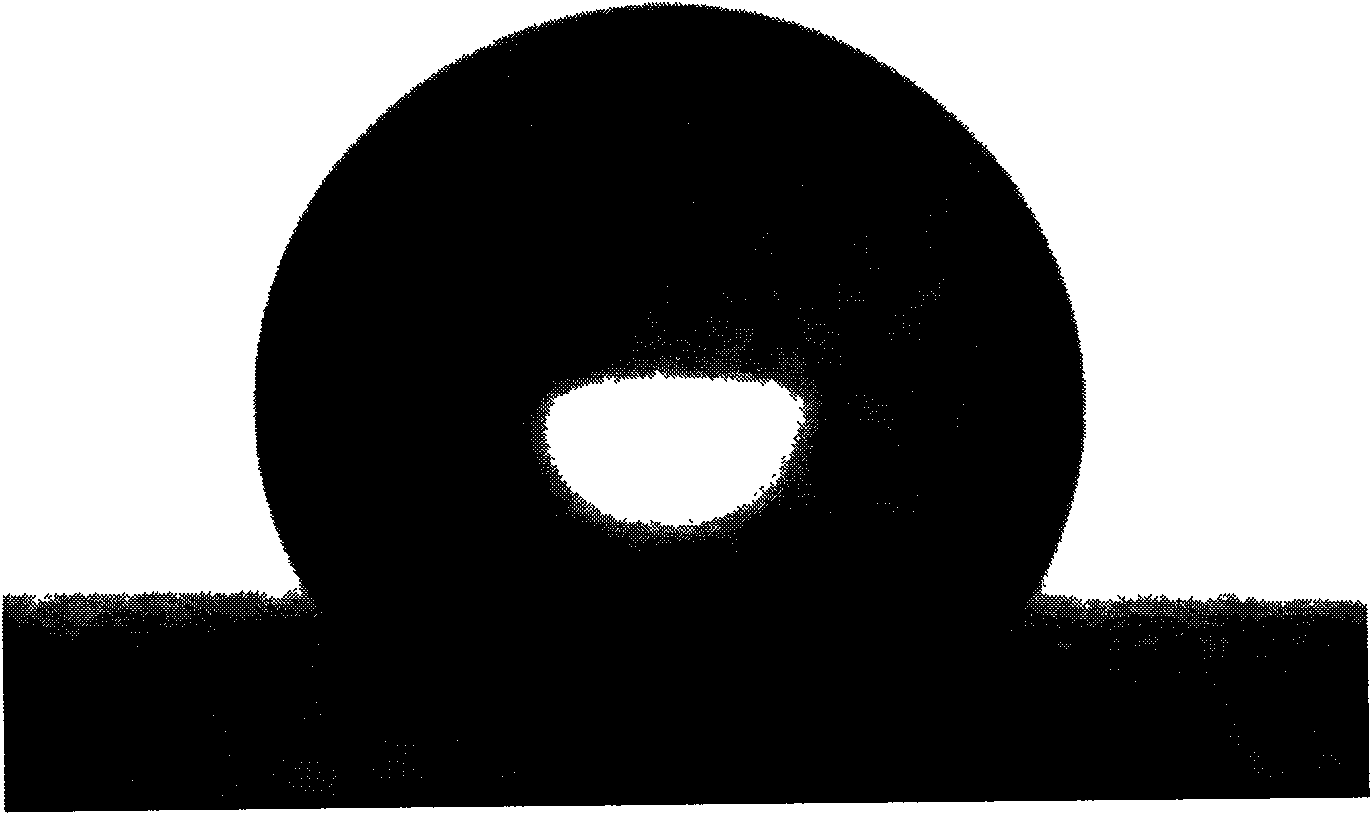

Surface modification method for polytetrafluoroethylene product

ActiveCN101979429AImprove permeabilityImprove wettabilityCoatingsPolyethylene glycolTherapeutic effect

The invention discloses a surface modification method for a polytetrafluoroethylene product. The method comprises the following steps of: coating polyethylene glycol on the surface of the polytetrafluoroethylene product, and then performing surface modification on the polytetrafluoroethylene product coated with the polyethylene glycol by adopting a plasma treatment method. Compared with the prior art, the polyethylene glycol element is introduced on the surface of the polytetrafluoroethylene product so as to effectively improve the surface activity of the polytetrafluoroethylene product, reduce the contact angle, improve the surface energy, remarkably improve the wetting property and the adhesion property of the polytetrafluoroethylene product and keep the polytetrafluoroethylene product for long time; and in addition, the method has little influence on the chemical property of the polytetrafluoroethylene product, has the advantages of convenient for operation, simple process, high processing speed, good treatment effect, low cost, energy conservation and emission reduction, is not easy to cause environmental pollution, and is more suitable for industrialized production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

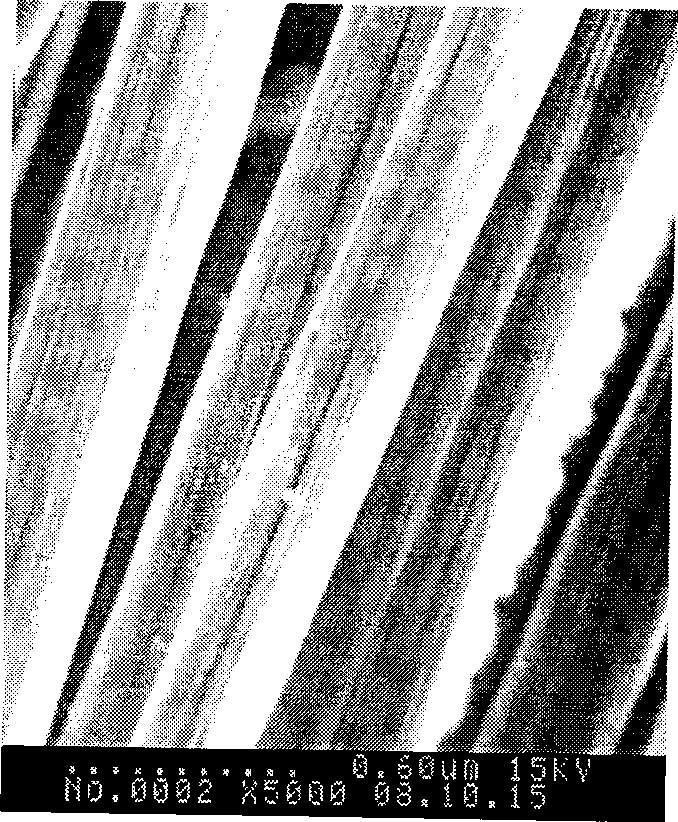

Method for carbon fiber surface modification of plasma coated with silicon dioxide by plasma treatment

InactiveCN101413210AImprove surface propertiesImprove performancePhysical treatmentCarbon fibresFiberCarbon fibers

The invention relates to a method for modifying the surface of carbon fiber coated with nano dioxide sol through plasma treatment, which comprises the following steps: firstly, nano silicon dioxide is prepared into an organic solvent, a sol solution of water or a sol solution prepared by hybridization reaction of a precursor solution of organic-inorganic nano particles and silicon dioxide nano particles by the ultrasonic vibrating technology; secondly, the sol solution is coated on the surface of the carbon fiber, treated by means of spray coating or padding and so on, and dried; and thirdly, the carbon fiber is placed on a plasma transport unit and a plasma is sprayed on the surface of the carbon fiber to generate modification, wherein the treating power is between 10 and 15,000 watts, and the treatment time is between 0.5 and 300 seconds. The method can effectively improve the performance of the carbon fiber, improves the molded manufacturability and the overall properties of composite materials of the carbon fiber, has simple technology, quick processing speed, good treatment effect and low cost, is convenient to operate and difficult to cause environmental pollution, can reduce energy consumption, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

Method for modifying ultrahigh molecular weight polyethylene fiber by plasma treatment

InactiveCN101532244AIncrease infiltration speedImprove wettabilityPhysical treatmentFibre typesFiberPlasma generator

The invention relates to a method for modifying ultrahigh molecular weight polyethylene fiber by plasma treatment. The method comprises that: (1) a nanometer particle of silicon dioxide is prepared into an organic solvent or water solution of sol of which the mass percent is 0.01 to 15 percent, by an ultrasonic shock technique; or (2) a precursor solution of the organic-inorganic nanometer particle is subjected to hybridization reaction with the nanometer particle of silicon dioxide to prepare the nanometer silicon dioxide sol solution; (3) the sol solution is coated on the surface of the ultrahigh molecular weight polyethylene fiber by spraying or padding; and (4) the ultrahigh molecular weight polyethylene fiber is dried at a temperature of 10 to 150 DEG C, and the solvent is collected; and the ultrahigh molecular weight polyethylene fiber is introduced in a plasma atmosphere region by a plasma generator for plasma surface modification. The compound property between the treated ultrahigh molecular weight polyethylene fiber and the organic matrix materials is greatly improved; moreover, the method also has the advantages of simple process, good treatment effect, low cost, environmental protection and low energy consumption.

Owner:DONGHUA UNIV +1

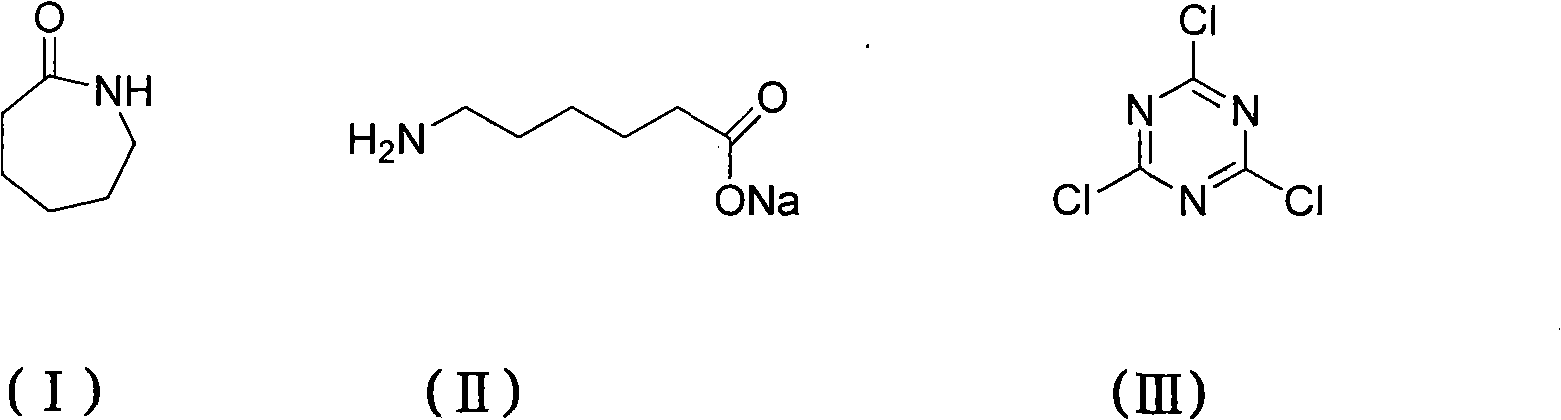

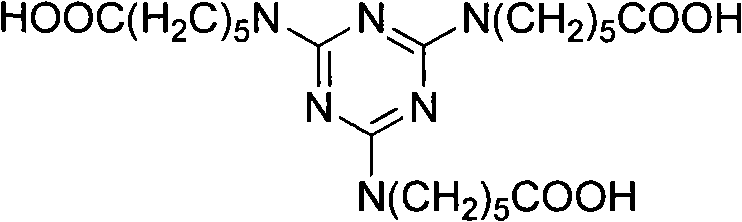

Method for preparing 2,4,6-tri(amino caproyl)-1,3,5-triazine

InactiveCN101973949AThe reaction is easy to operateMild reaction conditionsOrganic chemistryCarboxylic acidSolvent

The invention discloses a method for preparing an organic ternary polycarboxylic acid dustless antirust additive 2,4,6-tri(amino caproyl)-1,3,5-triazine by adopting a one-pot method, which comprises the following steps of: ring-opening caprolactam with alkali to generate carboxylate of aminocaproic acid first; then performing a substitution reaction by the carboxylate of aminocaproic acid and cyanuric chloride; and finally, acidizing with hydrochloric acid to prepare derivatives of organic ternary polycarboxylic acid. The preparation method is free from a toxic organic solvent and employs common water as a solvent for reaction. The preparation method ha the advantages of simple process operation, low production cost and low environmental pollution and is more suitable for large scale industrial production.

Owner:TIANJIN NORMAL UNIVERSITY

Method for modifying nanometer sol ultrahigh molecular weight polyethylene fiber by plasma treatment

InactiveCN101532239AImprove permeabilityHigh chemical activityPhysical treatmentFibre typesFiberTherapeutic effect

The invention relates to a method for modifying a nanometer sol ultrahigh molecular weight polyethylene fiber by plasma treatment. The method comprises that: (1) inorganic nanometer particle is prepared into a sol solution by an ultrasonic shock technique; or (2) a precursor solution of the organic-inorganic nanometer particle is subjected to hybridization reaction with the inorganic nanometer particle to prepare the sol solution; (3) the sol solution is coated on the surface of the ultrahigh molecular weight polyethylene fiber; and (4) the ultrahigh molecular weight polyethylene fiber is dried at a temperature of 10 and 150 DEG C, and the solvent is collected; the ultrahigh molecular weight polyethylene fiber is introduced in a plasma atmosphere region by a plasma generator for plasma surface modification; and the treated ultrahigh molecular weight polyethylene fiber is on-line rolled by an automatic rolling machine. The compound property between the treated ultrahigh molecular weight polyethylene fiber and the organic matrix materials is greatly improved; moreover, the method also has the advantages of simple process, good treatment effect, low cost, environmental protection and low energy consumption.

Owner:DONGHUA UNIV +1

Production method for extracting tryptophan from fermentation liquor by one-step refining

ActiveCN101863822ANot prone to membrane foulingShort filter timeOrganic chemistryFood processingUltrafiltrationSolvent

The invention discloses a production method for extracting tryptophan from fermentation liquor by one-step refining, which comprises the pretreatment of the fermentation liquor. In the method, mycoprotein is filtered off by using a ceramic microfiltration membrane, is decolorized by using an ultrafiltration membrane and is desalted and concentrated by using a nanofiltration membrane; the nanofiltration membrane concentrated liquor is directly decolorized by using activated carbon, the decolorized liquor is subjected to isoelectric point crystallization at a low temperature, and a qualified competitive product is obtained by rinsing with ice water during centrifugal separation; the crystallization mother liquor returns to the nanofiltration membrane for circulation; protein feed with high additional value is prepared by mixing, drying and crushing the ultrafiltration strong liquor and mycoprotein; and nanofiltration strong brine can be used as a culture medium for later use or sold serving as a base fertilizer. The method has the advantages of avoiding adding an organic solvent and an inorganic solvent in the preparation process of a crude product and a fine product, saving the solvent recovery cost, solving the problems of sewage treatment and environmental pollution, along with high utilization rate of the mother liquor, high product quality, and more contribution to industrial production, wherein the total extraction yield of L-tryptophan is 83.5 percent in a 500-ton production line.

Owner:HENAN JULONG BIOLOGICAL ENG CO LTD

Method for modifying Kevlar fiber by treating nano sol through plasma

InactiveCN101575798AImprove permeabilityIncrease infiltration speedPhysical treatmentFibre typesFiberOrganic base

The invention relates to a method for modifying Kevlar fiber by treating a nano sol through plasma, which comprises the following steps: (1) preparing inorganic nano particles into sol solution by ultrasonic oscillation technology; or (2) carrying out a hybridization reaction of precursor solution of organic-inorganic nano particles and the inorganic nano particles to prepare sol solution; (3) coating the sol solution on the surface of the Kevlar fiber; (4) drying the Kevlar fiber at a temperature of between 10 and 150 DEG C, collecting solvent, then introducing the Kevlar fiber in a plasma atmosphere area through a plasma generating device for surface modification treatment by the plasma; and finally, carrying out on-line winding of the treated Kevlar fiber in an automatic winding machine and adjusting the wiring speed of the Kevlar fiber by adjusting the speed range of a winding shaft. The combined performance between the Kevlar fiber treated by the method and the organic base materials is improved greatly; and the method has simple process, good treatment effect, low cost, difficult environmental pollution and reduction of the energy consumption.

Owner:DONGHUA UNIV +1

Soil remediation device used for municipal landscaping

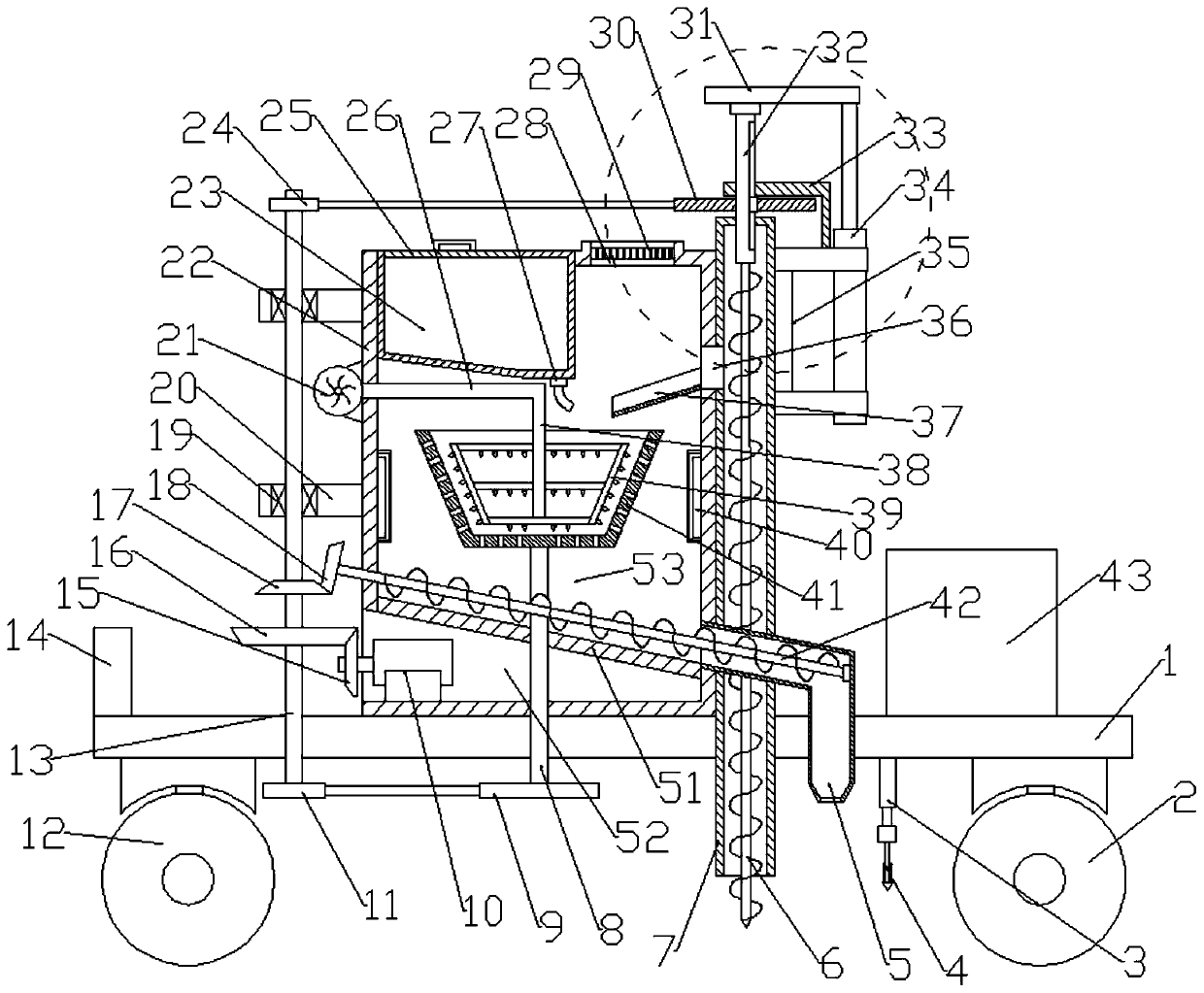

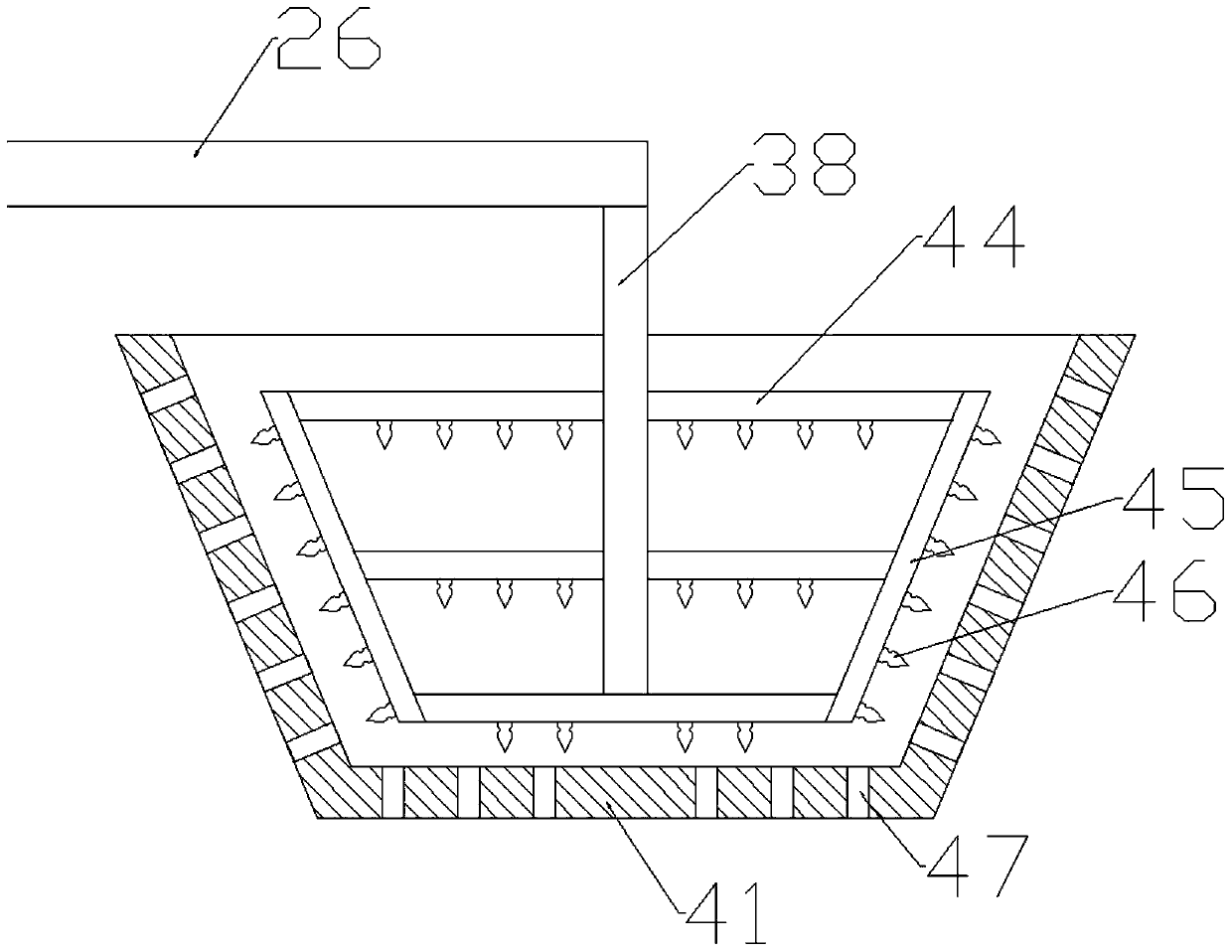

InactiveCN109909288AFast backfillImprove repair effectSoil lifting machinesRotary stirring mixersSoil remediationLandscaping

The invention discloses a soil remediation device used for municipal landscaping. The soil remediation device comprises a loading platform, wherein a soil remediation box is arranged in the middle ofthe upper side of the loading platform; a vertically arranged material lifting barrel is arranged on the right side of the soil remediation box; a spiral soil auger is arranged in the material liftingbarrel; a vertical transmission shaft is arranged on the left side of the soil remediation box; a soil feeding hole is formed between the top of the right side wall of the soil remediation box and the material lifting barrel; the interior of the soil remediation box is divided into a soil remediation cavity at the upper part and a motor chamber at the lower part by a partition board; a rotary drum is arranged in the middle of the soil remediation cavity; discharging holes are uniformly distributed in the side surface and the bottom surface of the rotary drum; a vertical rod is arranged in thecenter of the rotary drum; a stirring and smashing head is arranged on the vertical rod; an agent box filled with a soil remediation agent is arranged on the left of the inner top of the soil remediation cavity, and a gas outlet used for discharging inside gas is formed in the right of the inner top of the soil remediation cavity. According to the soil remediation device, soil is fed automatically, is smashed efficiently, is remedied by heating and is backfilled accurately.

Owner:泰顺县刘志威家庭农场

Preparation method for water treatment microbe immobilization carrier

InactiveCN101560016AMeridian toughness is goodNo osmotic degradationSustainable biological treatmentBiological water/sewage treatmentVacuum pumpPolymer

The invention discloses a preparation method for a water treatment microbe immobilization carrier. The preparation method comprises the following steps: (1) foaming, namely evenly mixing 50 to 100 mass portions of polyether glycol, 10 to 50 mass portions of polymer glycol, 0.1 to 0.3 mass portion of tin catalyst, 0.1 to 0.5 mass portion of amine catalyst, 3 to 9 mass portions of water, 5 to 30 mass portions of blowing promoter and 0.6 to 5 mass portions of foam stabilizer, adding 45 to 60 mass portions of toluene diisocynate, evenly agitating the raw materials, and then pouring the mixture into a die for foaming; (2) tapping through an explosion method, namely adding the foaming materials in a tapping device, carrying out the vacuum pumping on the device to 0.1 to 1 MPa, then filling the device with H2 to 0.1 to 0.5 MPa, filling the device with O2 to 0.2 to 0.8 MPa, and detonating the gases after 10 to 30 minutes of diffusion; and (3) granulation. The method has the advantages of simple process, convenient operation, cleanness and hygiene, and difficulty in environmental pollution. The carrier is widely applied to biological reaction water treatment systems, particularly to sewage treatment systems.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

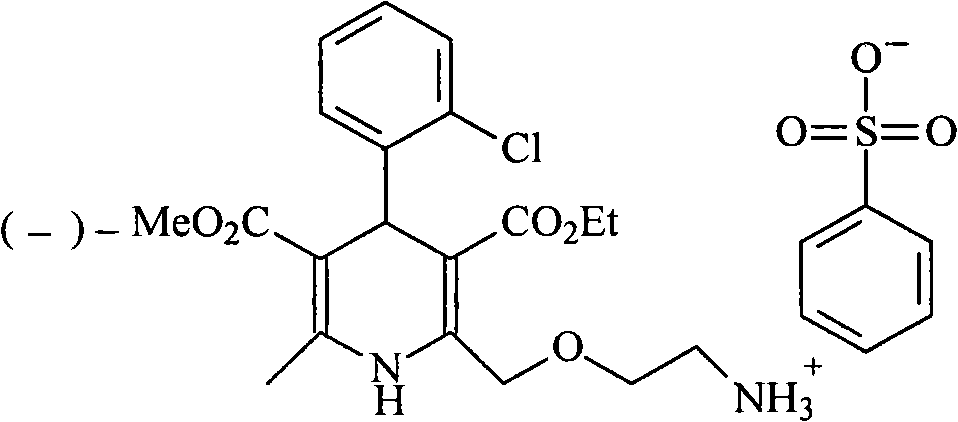

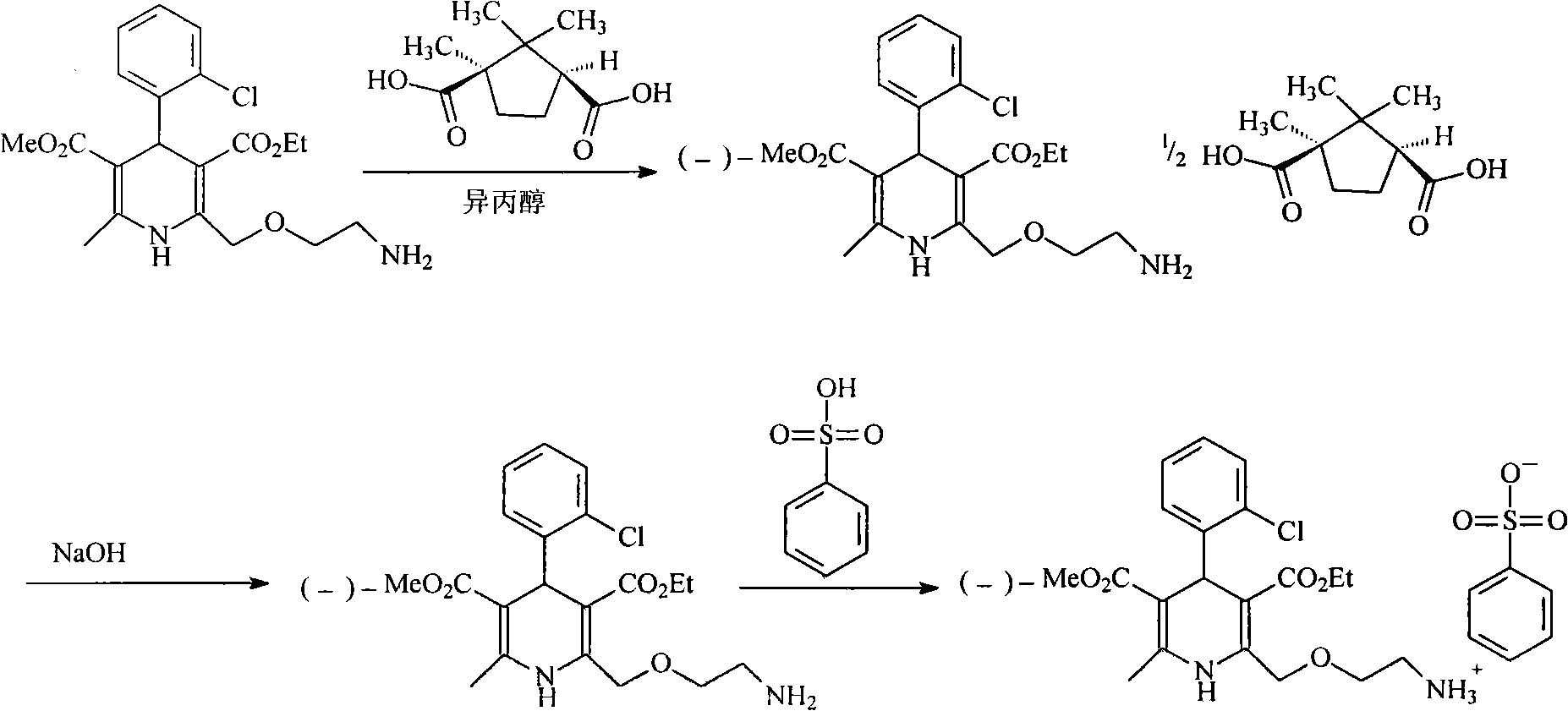

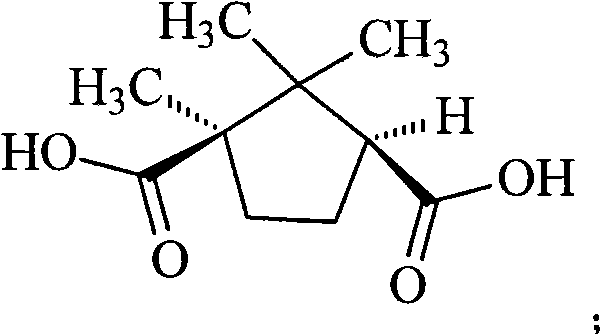

Levamlodipine compound prepared in novel method

InactiveCN101805284AHigh purityNot easy to cause pollutionOrganic chemistryCamphoric acidLevamlodipine

The invention provides a levamlodipine compound prepared in a novel method, which comprises the following steps: producing D-(plus)-levamlodipine camphorate through reaction of amlodipine and D-(plus)-camphanic acid, producing levamlodipine under the effect of sodium hydroxide, and producing the levamlodipine compound through salt forming reaction of the levamlodipine and benzenesulfonic acid. The method adopts a completely novel split reagent D-(plus)-camphanic acid, simplifies reaction procedures and is more suitable for industrial production. Moreover, the method has the advantage of high yield.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

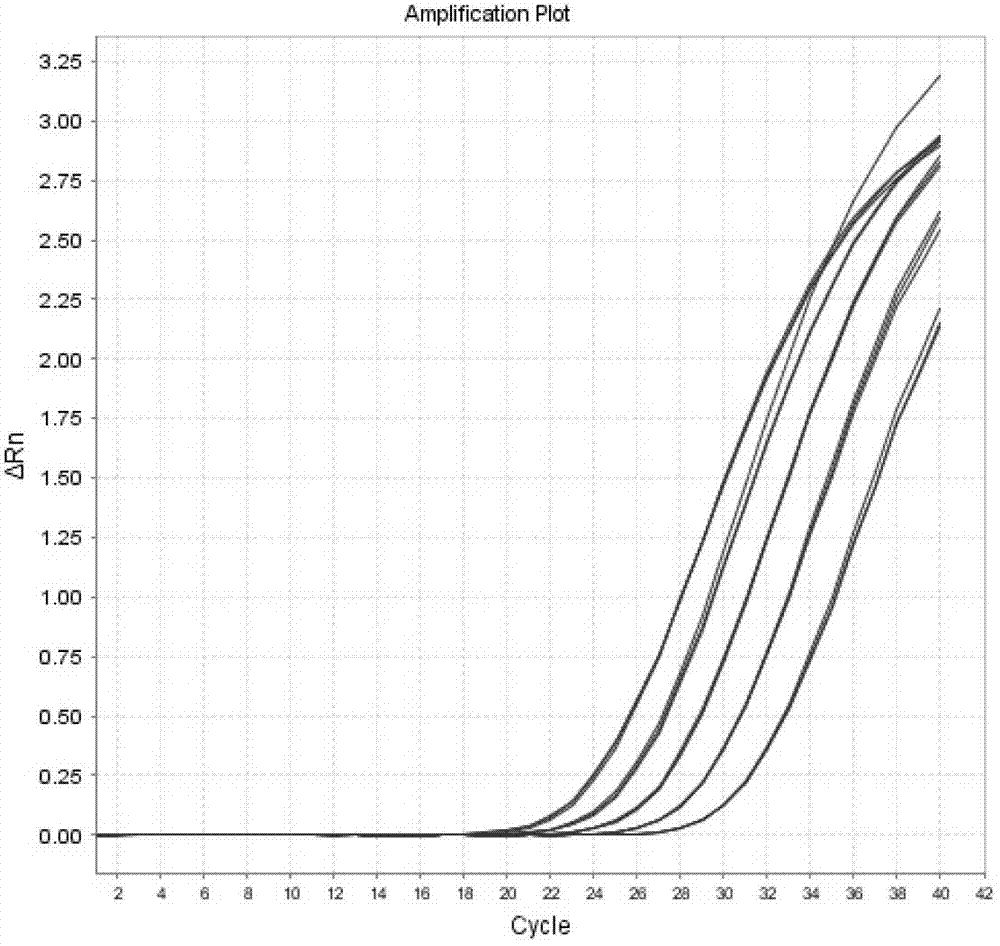

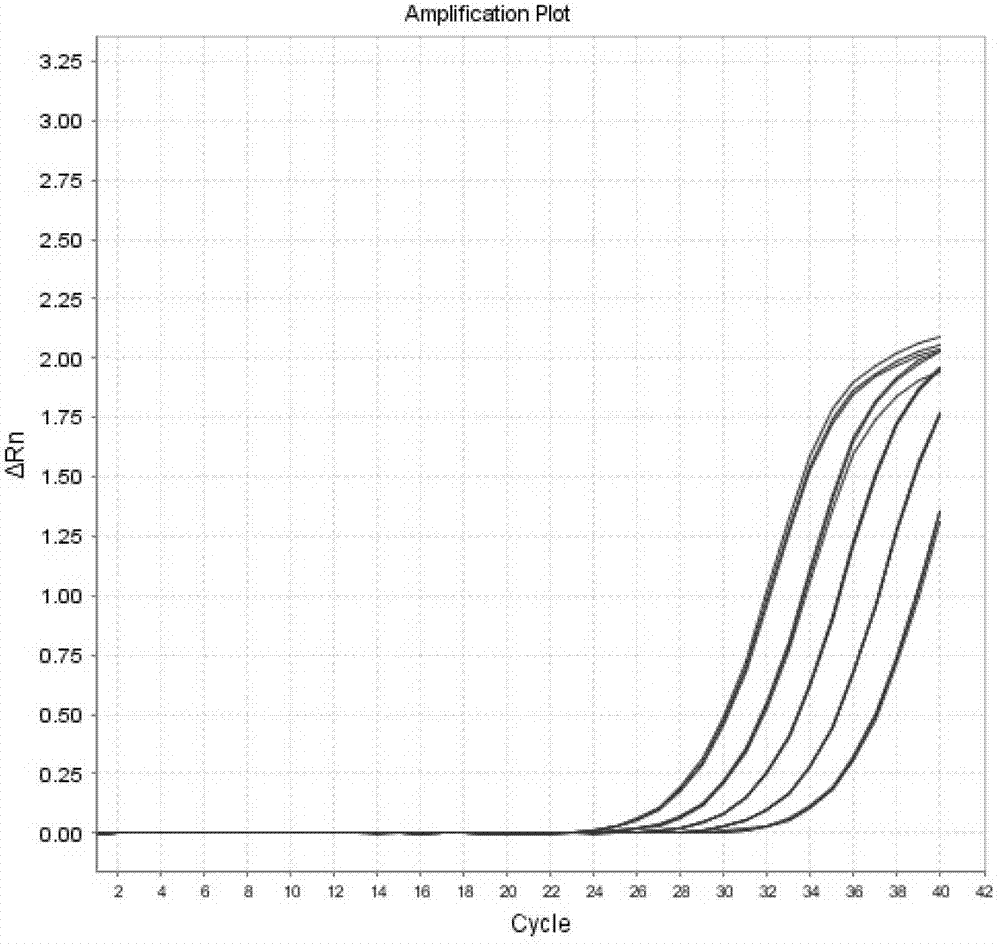

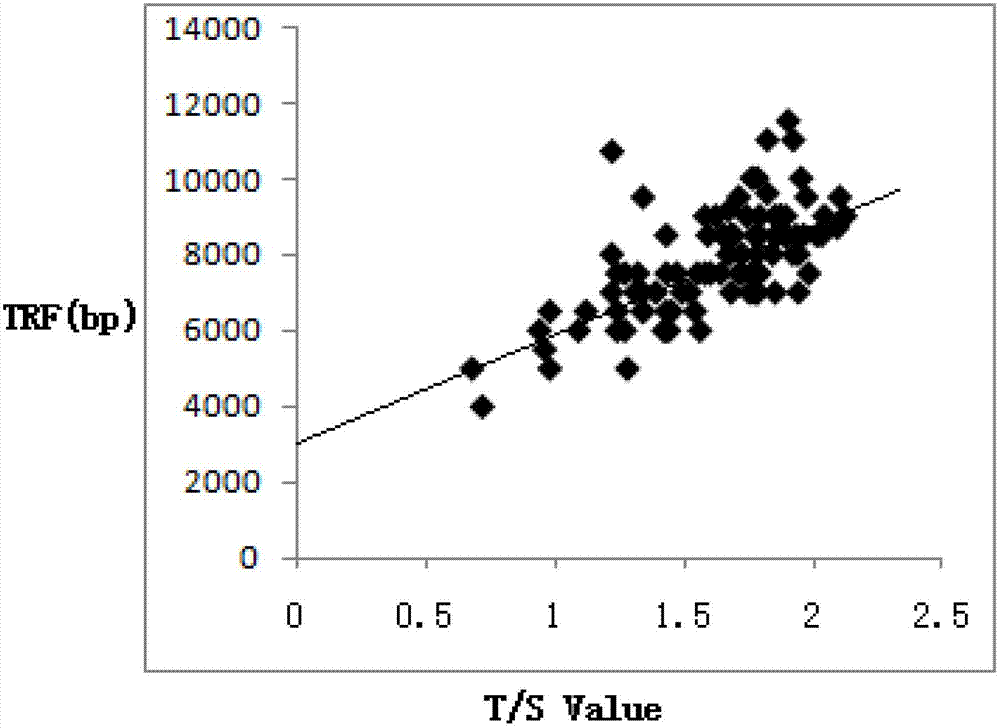

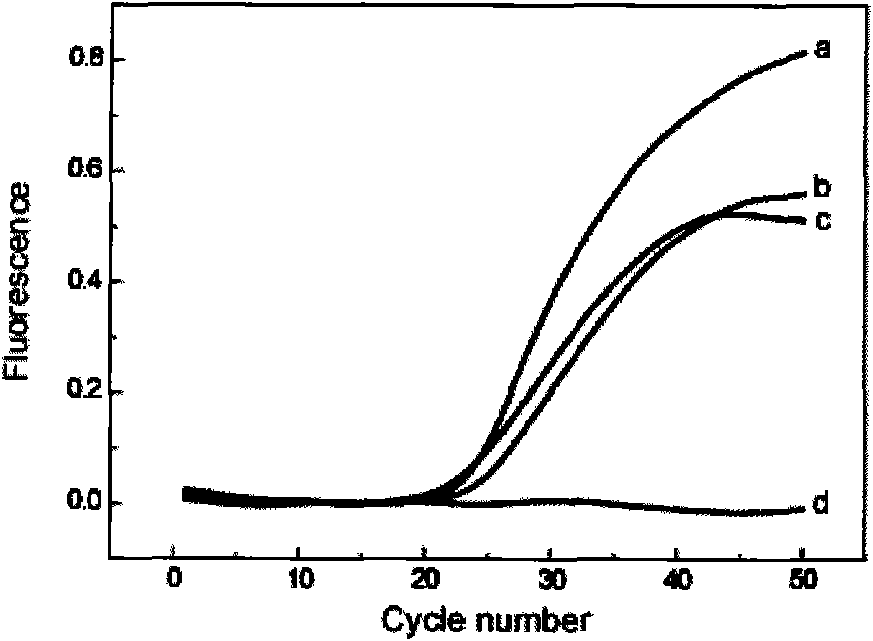

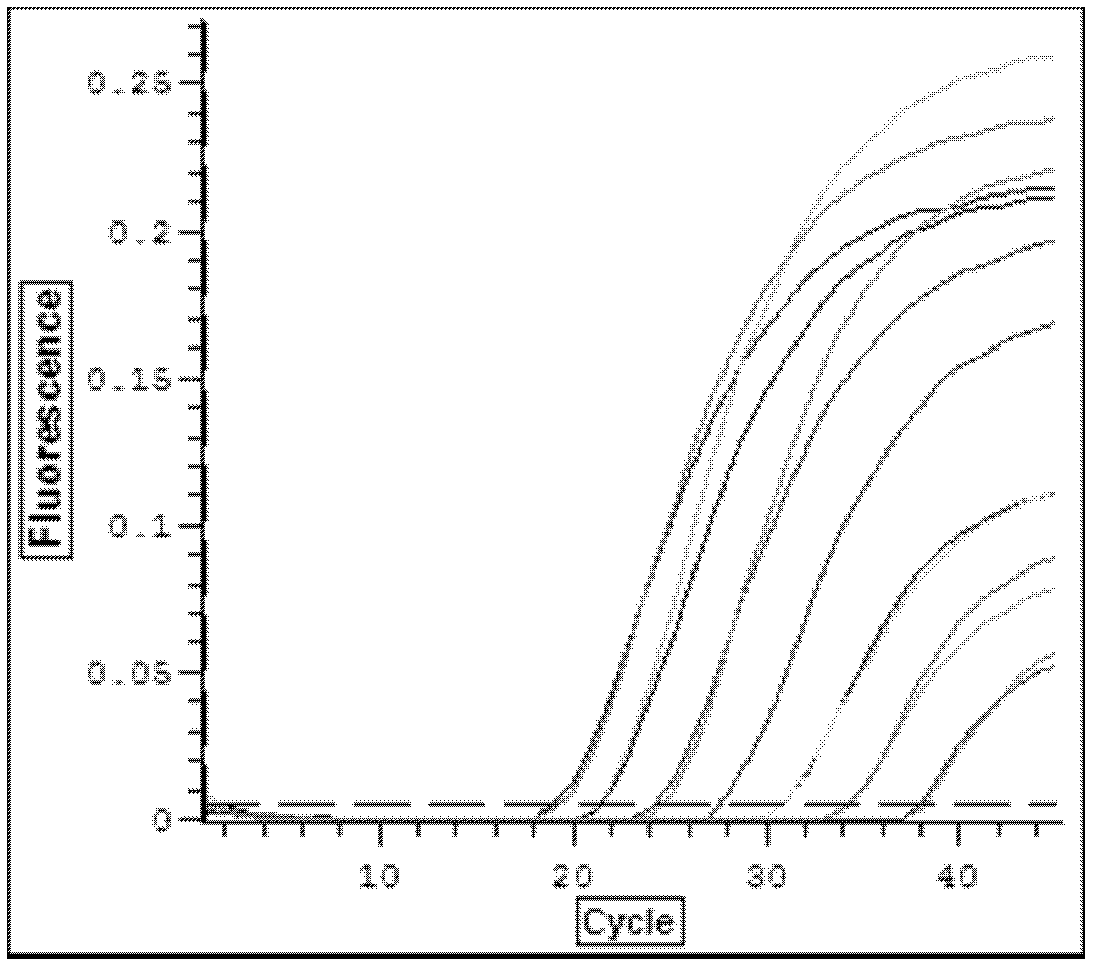

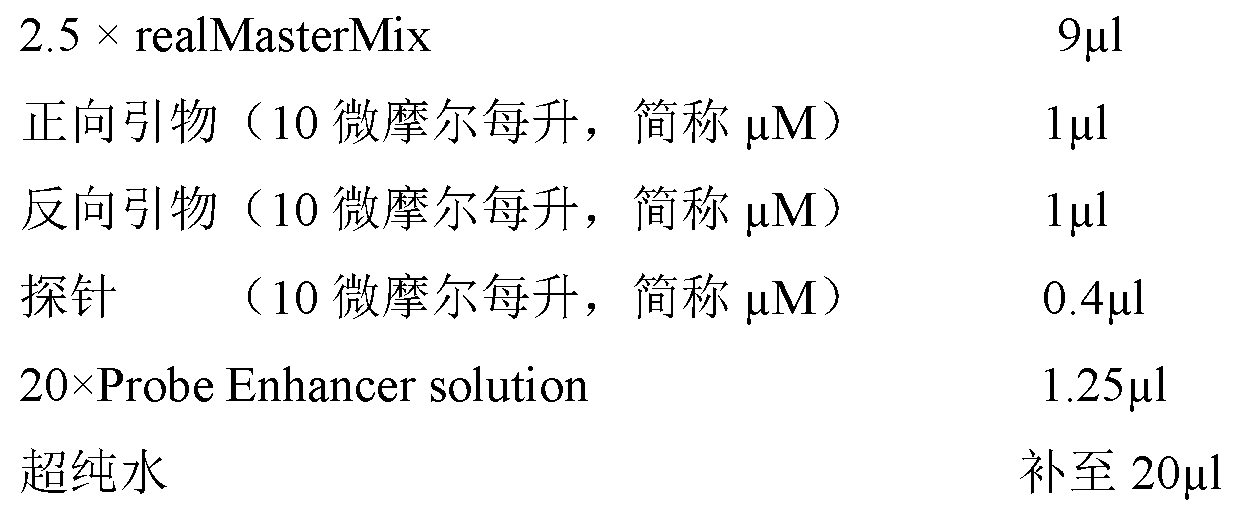

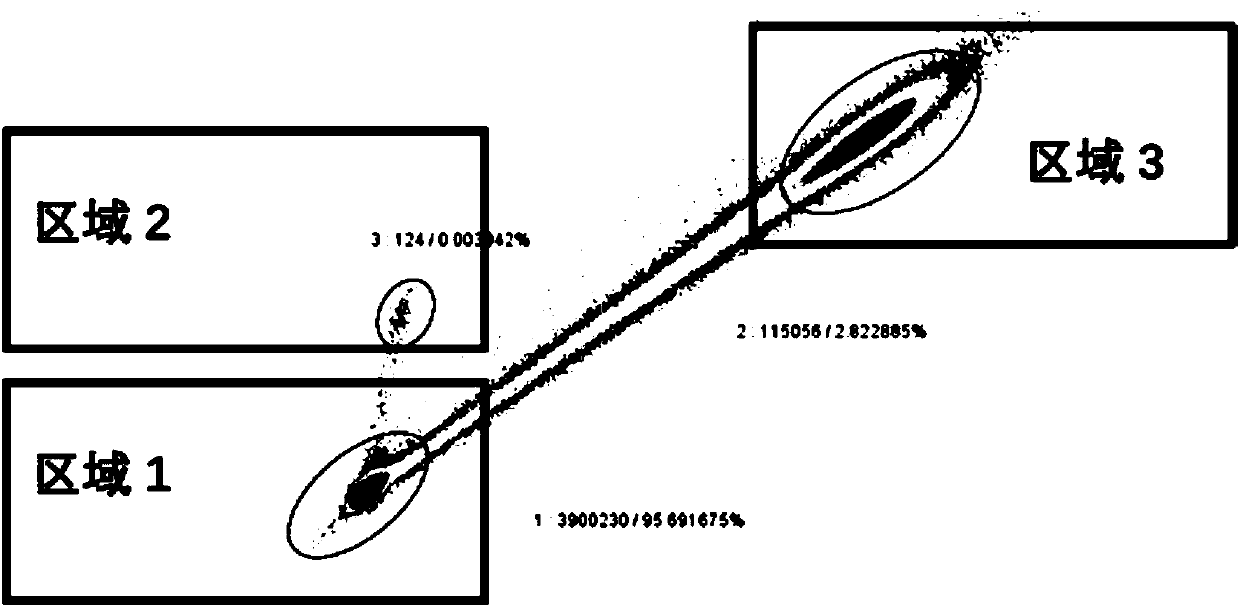

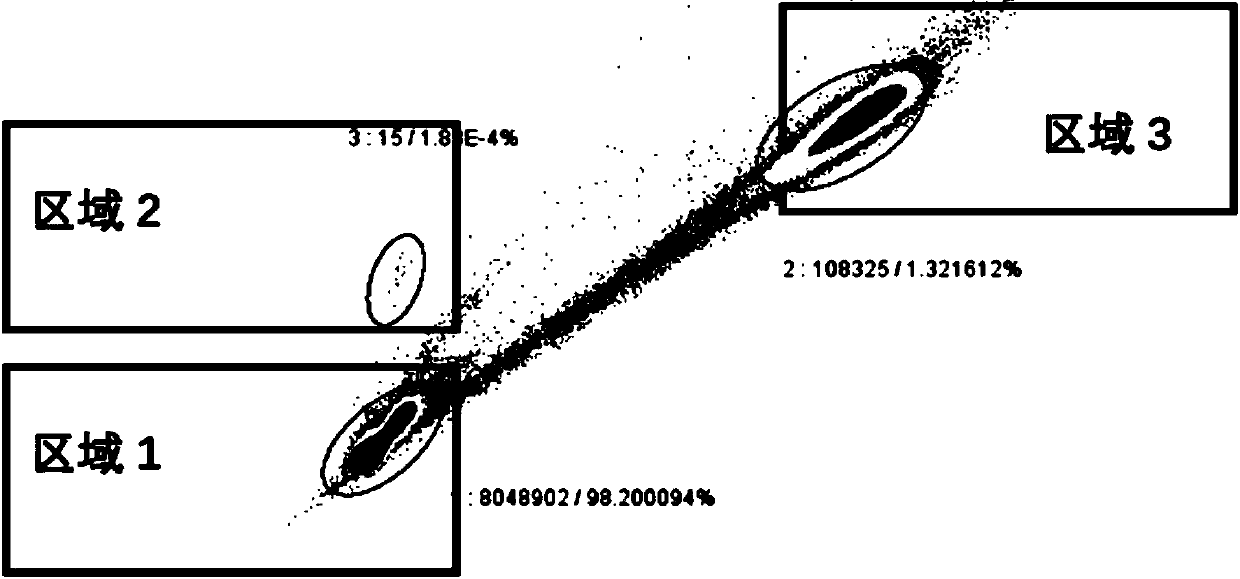

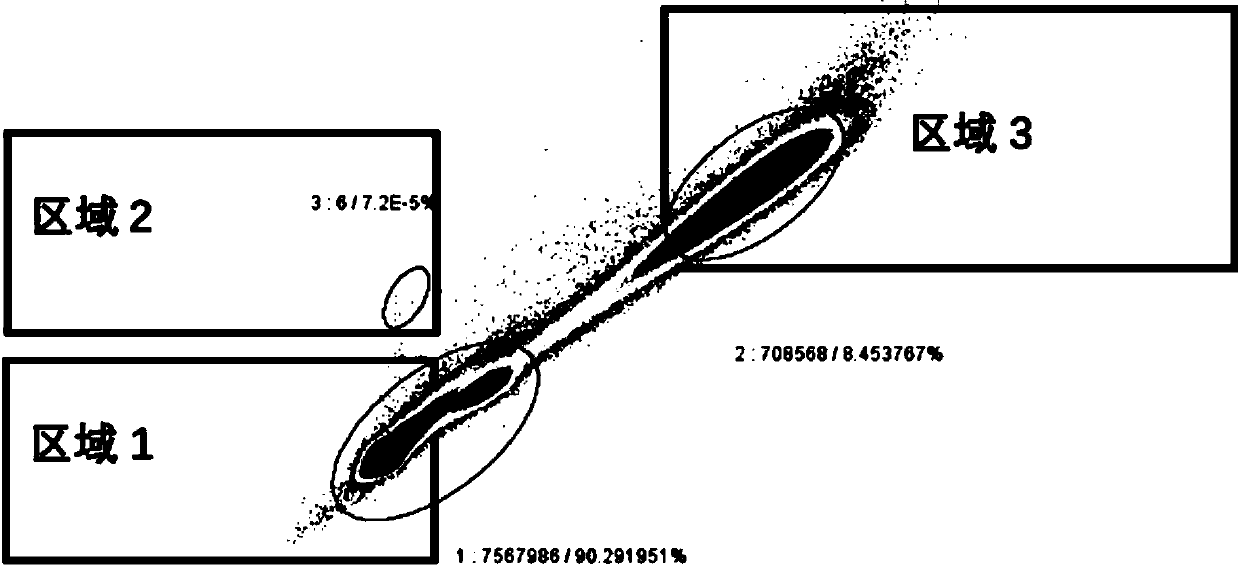

Telomere length detection method based on fluorescent quantitative PCR

InactiveCN103173560AHigh detection sensitivity and fluorescence intensityHigh linear regression coefficientMicrobiological testing/measurementFluorescence/phosphorescenceBiologyLinear regression

The invention provides a telomere length detection method based on fluorescent quantitative PCR. The method comprises the following steps of: extracting genome DNA (deoxyribonucleic acid); carrying out fluorescent quantitative PCR detection, detecting telomere repetitive sequence by using primers SEQ ID NO.1 and SEQ ID NO.2, and detecting 36B4 gene sequence of human acidic ribosomal phosphor-protein PO by using primers SEQ ID NO.3 and SEQ ID NO.4; calculating a relative telomere length T / S; and further calculating the absolute length of the telomere according to the derived formula. In the formula, Eva Green is used as dye, the telomere primers and internal control primers are used for detecting the telomere length by using the fluorescent quantitative PCR method, and the conversion relation between telomere TRF length and the T / S ratio is derived based on the equation of linear regression of large sample analysis, and therefore the telomere length detection method which is suitable for clinic is provided.

Owner:北京海斯凯生物科技有限公司

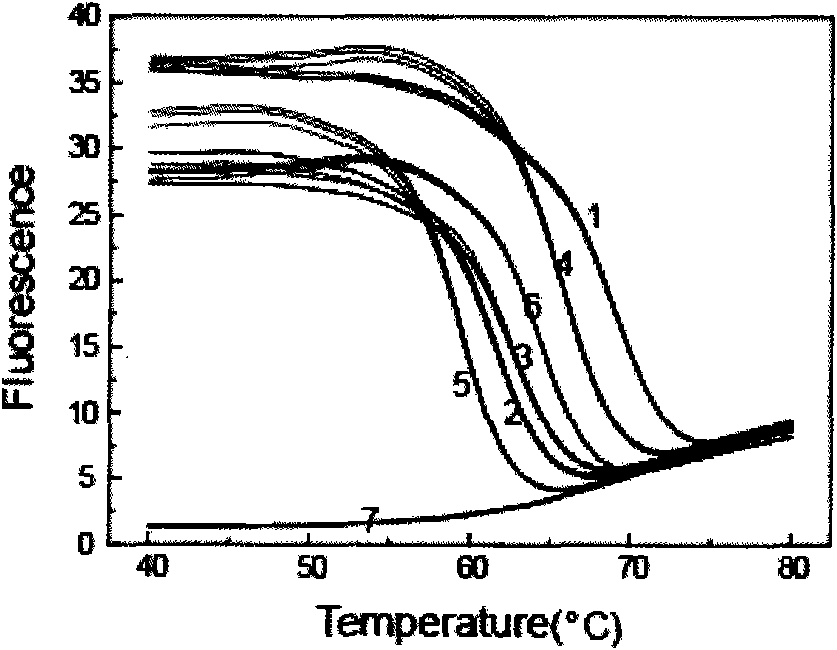

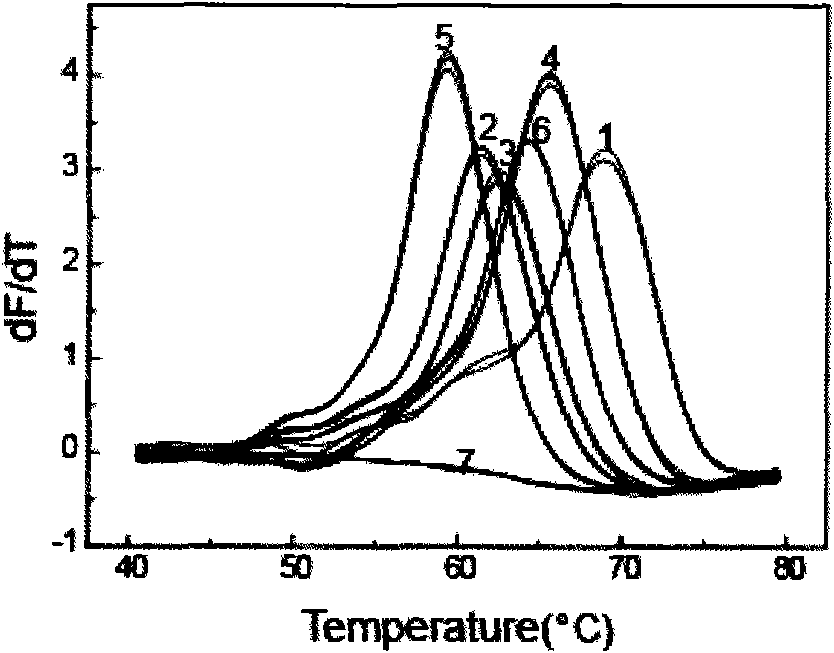

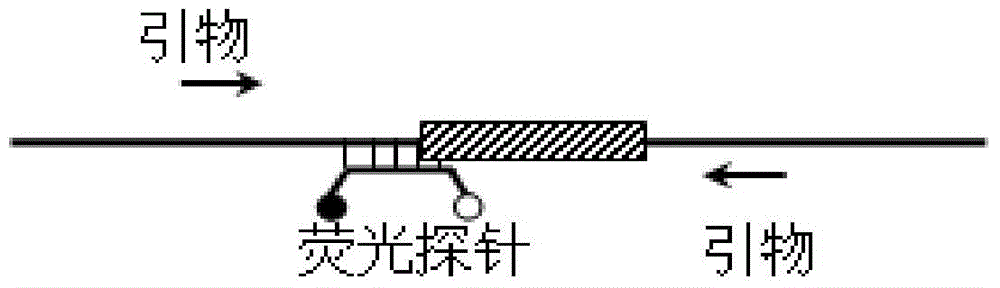

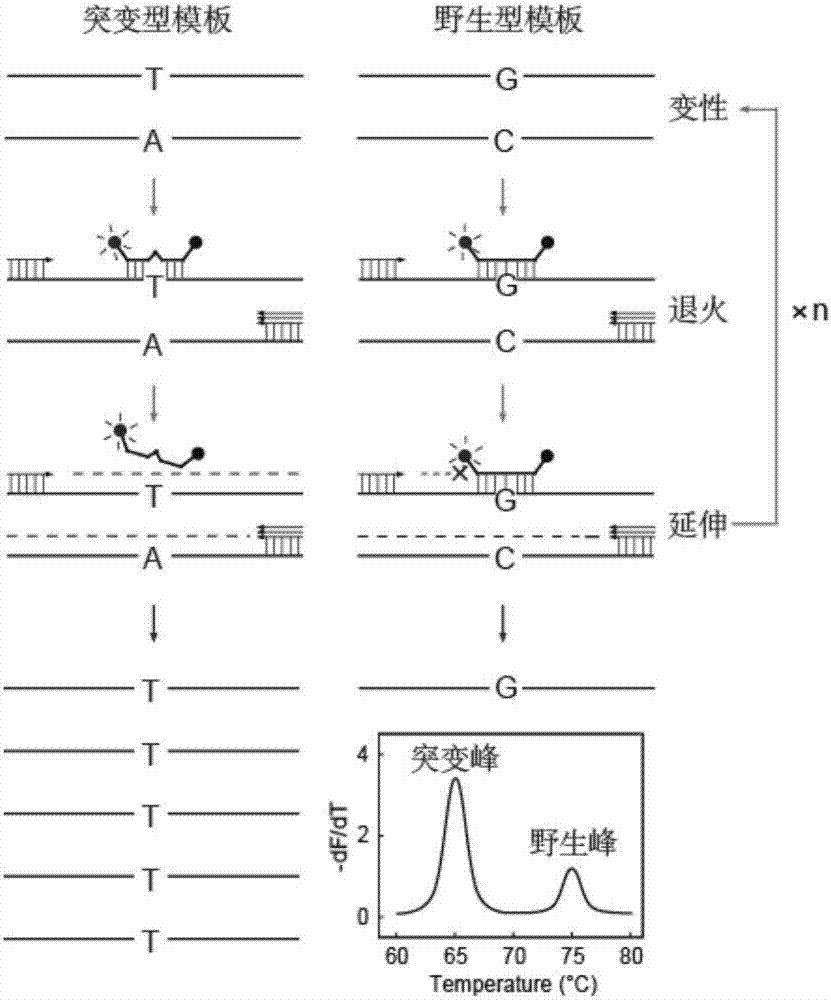

Method for detecting human beta-globin gene mutation

ActiveCN101899499ANot easy to cause pollutionSimple and fast operationMicrobiological testing/measurementFluorescence/phosphorescenceMutation detectionNucleotide sequencing

The invention relates to a method for detecting human beta-globin gene mutation, in particular to a method for detecting the beta-globin gene mutation by a modified molecular beacon melting curve. The method comprises the following steps of: designing and preparing a corresponding modified molecular beacon in region of a beta-globin gene needing mutation detection; designing an upstream primer and a downstream primer on the periphery of the designed modified molecule beacon, and performing PCR amplification on fragments containing the region to be detected by using the upstream primer and the downstream primer; and after PCR amplification is finished, analyzing the melting curve, and judging whether a nucleotide sequence to be detected has the gene mutation and possible mutation types according to the change of the melting point of the modified molecular beacon.

Owner:XIAMEN UNIV +1

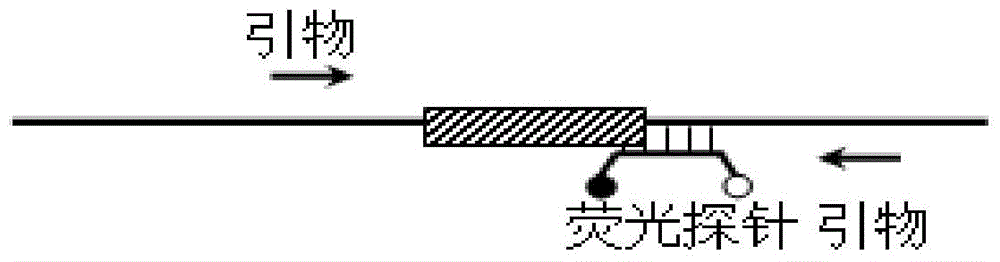

Method for detecting deletion mutation of nucleic acid molecule

InactiveCN104651529ANot easy to cause pollutionSimple and fast operationMicrobiological testing/measurementAfter treatmentReaction system

The invention relates to a method for detecting deletion mutation of a nucleic acid molecule, and particularly relates to a method for detecting deletion mutation of a nucleic acid molecule through a probe melting curve, and a reaction system and kit for detecting deletion mutation of a nucleic acid molecule. The method provided by the invention is accurate and stable, rapid, simple and convenient, free of PCR after-treatment and capable of overcoming defects that the operation is complex, long time is consumed, pollution is easily caused, the detecting flux cannot meet the conventional demand and the like in the prior art, so that the method has a favorable application prospect.

Owner:XIAMEN UNIV

One-tube magnetic bead method for extraction of virus nucleic acid for fluorescent quantitative detection

InactiveCN102605102AImprove cracking capacityThorough and fast lysisMicrobiological testing/measurementMicroorganism based processesFluorescenceMagnetic bead

The invention relates to a one-tube magnetic bead method for extraction of virus nucleic acid for fluorescent quantitative detection, which belongs to the technical field of biological nucleic acid application and includes: firstly, preparing lysis solution, adding the lysis solution and magnetic beads into a tube strip, adding a sample of virus nucleic acid into the tube strip, and mixing well to lead the magnetic beads to fully absorb the virus nucleic acid; secondly, placing magnetic bead mixed liquor on a magnetic carrier, and allowing the liquor to stand for seconds to separate the magnetic beads and solution; and thirdly, rinsing for protein removal and desalination, and drying in air at room temperature. The method is simple and quick, less apt to cause pollution and high in flexibility. By the method, extracting efficiency is high, nucleic acid purity is high, testing repeatability is good, compatibility to amplification reagents is high, production cost is reduced, operation accuracy is improved, and works such as clinical diagnosis, medicolegal identification and the like are facilitated greatly.

Owner:TIANGEN BIOTECH BEIJING

High efficiency and low foam environment-friendly type scouring agent and preparation method thereof

The invention provides a high efficiency and low foam environment-friendly type scouring agent and a preparation method thereof, wherein the scouring agent comprises: 15-25% by weight of dodecyl diphenyl ether sodium disulfonate, 5-15% by weight of C12-16 seconary Alkane Sulphonate Sodium, 15-25% by weight of alkyl polyglucoside, 10-150% by weight of isomeric alcohol ethoxylates, and the balance being water. The concrete steps for preparing the scouring agent, comprising: adding water into a mixture of dodecyl diphenyl ether sodium disulfonate and C12-16 seconary Alkane Sulphonate Sodium, and then mixing the mixture for dissolving; and (2) adding alkyl polyglucoside and isomeric alcohol ethoxylates into the mixture obtained in the step (1), and then uniformly mixing. The product is used as a green environmental protection printing and dyeing auxiliary agent with the advantages of simple technology, environment-friendly formula and excellent performances.

Owner:南通华宇紧固件有限公司

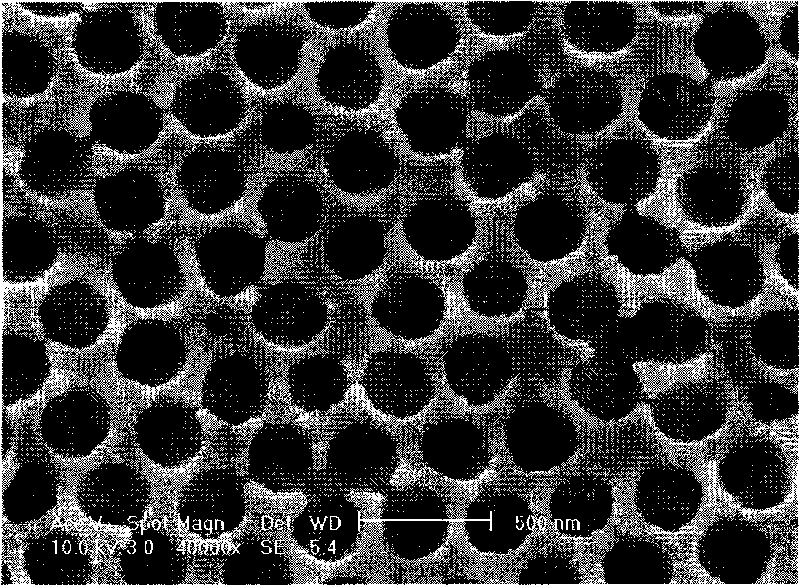

Gas separation functional material and preparation method and application thereof

InactiveCN101695652AHigh mechanical strengthImprove heat resistanceOther chemical processesDispersed particle separationEmulsionIn situ polymerization

The invention belongs to the technical field of nanometer porous materials, and particularly relates to a gas separation functional material, and a preparation method and application thereof. The functional material comprises aqueous inorganic nanoparticles, monodisperse aqueous polymer microspheres and a nonessential auxiliary agent, wherein functional modification groups capable of being combined with gas molecules are modified on the surfaces of the polymer microspheres or (and) the inorganic nanoparticles; a polymer / inorganic nanoparticle composite emulsion with adsorbable gas functional modification groups can be obtained by adopting an in situ polymerization method or a blending method; and after the moisture is volatilized, the polymer and the inorganic nanoparticles are self-assembled to form the gas separation functional material with a nanometer porous structure. The method and the application realize identification, adsorption and adsorption-desorption adjustment of the nanometer porous structure to gas molecules if CO2, H2S, SO2, HCl, Cl2, NO2, H2O, NH3 and the like by regulating and controlling the types of the polymer or (and) the inorganic nanoparticles, the particle diameters and the bore diameters of the functional modification groups, the microspheres and the inorganic nanoparticles on the surface, and the like.

Owner:FUDAN UNIV

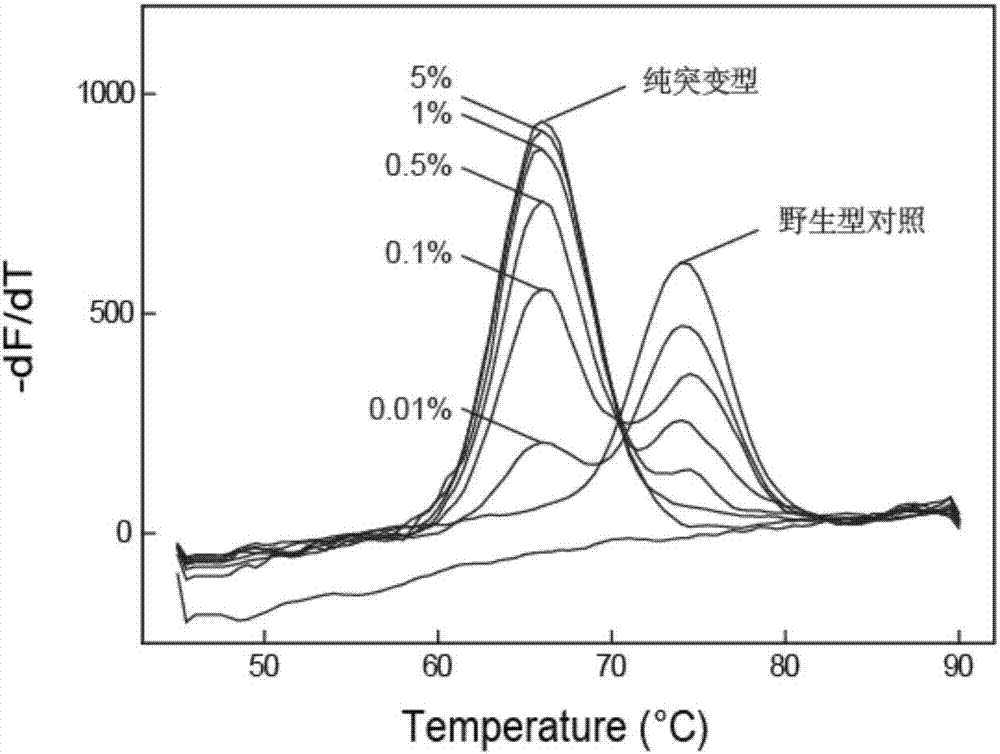

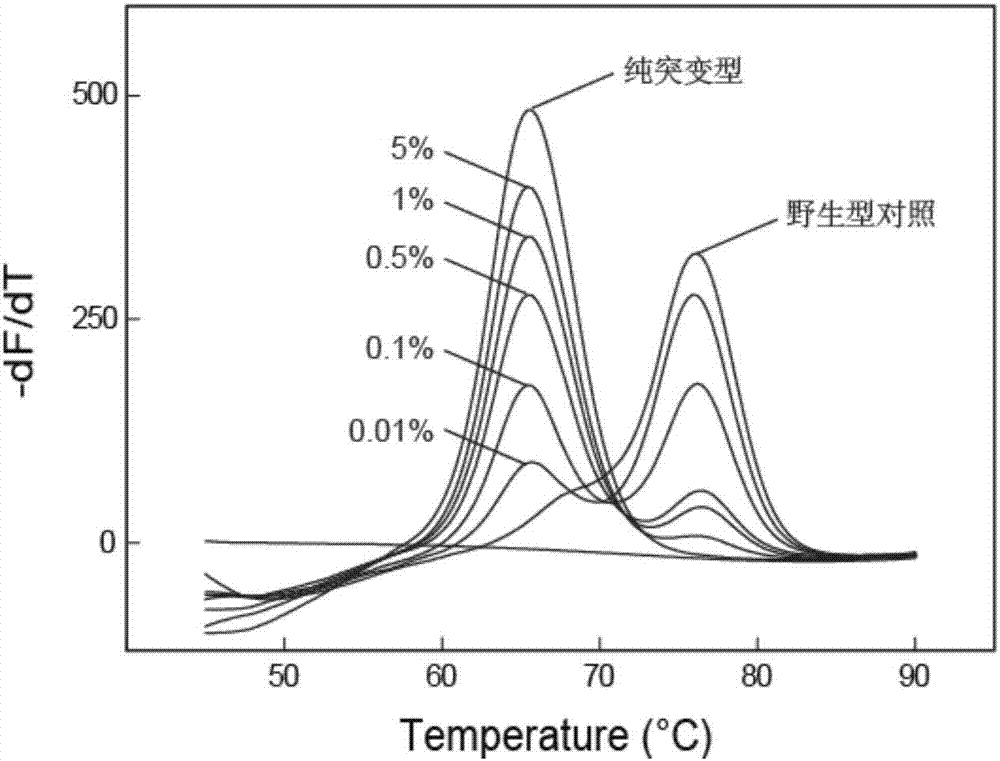

Specific primer probe composition, kit and method for detecting T790M site of EGFR gene

InactiveCN107868828AGood choiceHigh sensitivityMicrobiological testing/measurementDNA/RNA fragmentationFluoProbesWild type

The invention discloses a specific primer probe composition, a kit and a method for detecting a T790M site of an EGFR gene. The kit comprises an upstream primer, a downstream primer, a fluorescent probe I for detecting T790M mutation and a fluorescent probe II for detecting a wild type. For the kit, the primer pair with the specific sequences and the probes with the specific sequences are designedfor the human EGFR gene T790M mutation and reaction systems are optimized. According to the invention, through a method of a Raindropdigital PCR platform, high sensitivity detection on the T790M mutation of the EGFR gene is achieved and the abundance of the mutation is obtained simultaneously; the detection limit can be low to one in 100000. Furthermore, the invention can be used for detecting multi-source samples, comprising tumor tissue samples and ctDNAs, so that the application scope of the kit, reaction systems and method are expanded, and a medication guidance for treatment of patientswith lung cancer T790M mutation is provided.

Owner:中源协和基因科技有限公司

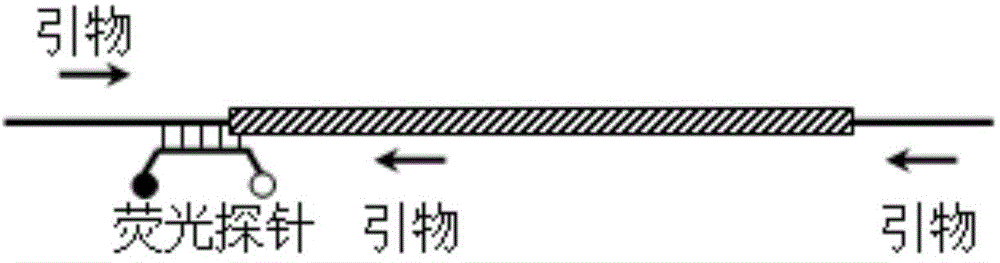

Low-abundance gene mutation detecting method

ActiveCN107034277ANot easy to cause pollutionSimple and fast operationMicrobiological testing/measurementGenes mutationQuenching

The invention relates to low-abundance gene mutation detection. Particularly, the invention provides a method for detecting whether mutation exists in the nucleic acid molecules of a nucleic acid sample to be detected through self-quenching probe melting curve analysis. Besides, the invention also provides a kit comprising a self-quenching probe and primer pairs, and the kit can be applied to implementing the method.

Owner:XIAMEN UNIV

Environmental-friendly water-based fire extinguishing agent and its preparation method

InactiveCN102350032ANot easy to cause pollutionLeave quicklyFire extinguisherWater basedAntiseptic Agent

The invention relates to an environmental-friendly water-based fire extinguishing agent, which comprises: deionized water, an antiseptic agent, a metal antirust agent, a halogen-free fire retardant, a hydrocarbon surfactant, a high efficiency chelating agent, 2-5 parts of an osmotic agent and a high efficiency corrosion inhibitor. The preparation method of the water-based fire extinguishing agentconsists of the steps of: adding deionized water into a dispersing cylinder according to the weight part, then adding the antiseptic agent, the metal antirust agent, the halogen-free fire retardant and the hydrocarbon surfactant, and stirring the mixture uniformly till completely salvation of the mixture; then adding the high efficiency chelating agent, the osmotic agent and the high efficiency corrosion inhibitor, stirring them uniformly till semi-clarity, thus obtaining the finished product. Containing a halogen free fire retardant, the fire extinguishing agent of the invention can be biologically degraded 100%, thus having no pollution to surrounding equipment and space. Containing an osmotic agent, the fire extinguishing agent in the invention can penetrate articles in fire hazards ofclass A, and can penetrate into the inside of combustible articles, so that even if the fire is not completely put out due to a large fire, the part injected with the agent can effectively block a fire source and control the spreading speed of a fire. Therefore, the fire extinguishing agent provided in the invention has excellent flame resistance.

Owner:广东卫斯理化工科技有限公司

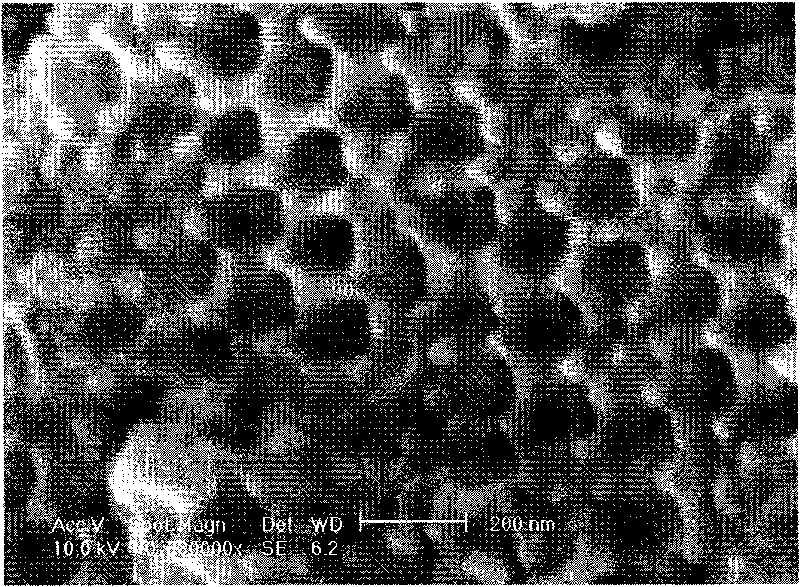

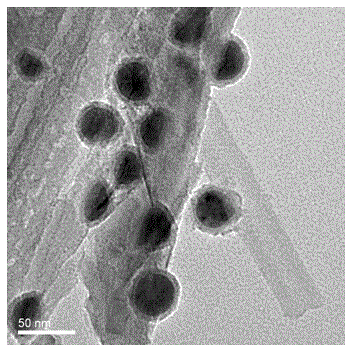

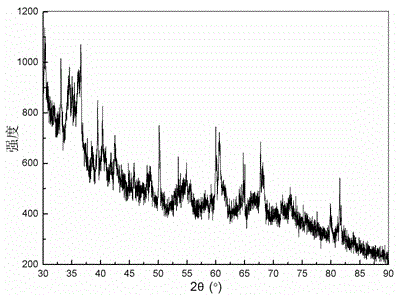

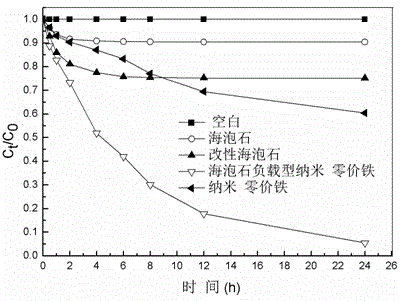

Load-type nano zero-valence iron particle and preparation method therefor

InactiveCN104815982AWidely distributedLow priceMaterial nanotechnologyOrganic fertilisersZerovalent ironSepiolite

The invention discloses a load-type nano zero-valence iron particle and a preparation method therefor. The iron particle takes modified sepiolite as a carrier, and the surface and interior of the modified sepiolite are respectively provided with nano zero-valence iron particles. The preparation method comprises four steps: the preparation of the modified sepiolite; the preparation of modified sepiolite solution containing iron ions; the preparation of nano zero-valence iron solution; and the preparation of the load-type nano zero-valence iron particle. The obtained load-type nano zero-valence iron particle is better in dispersity and reactivity. The preparation method is simple in technology, is convenient to operate, and is simple in needed equipment.

Owner:上海乾堉环境科技有限公司

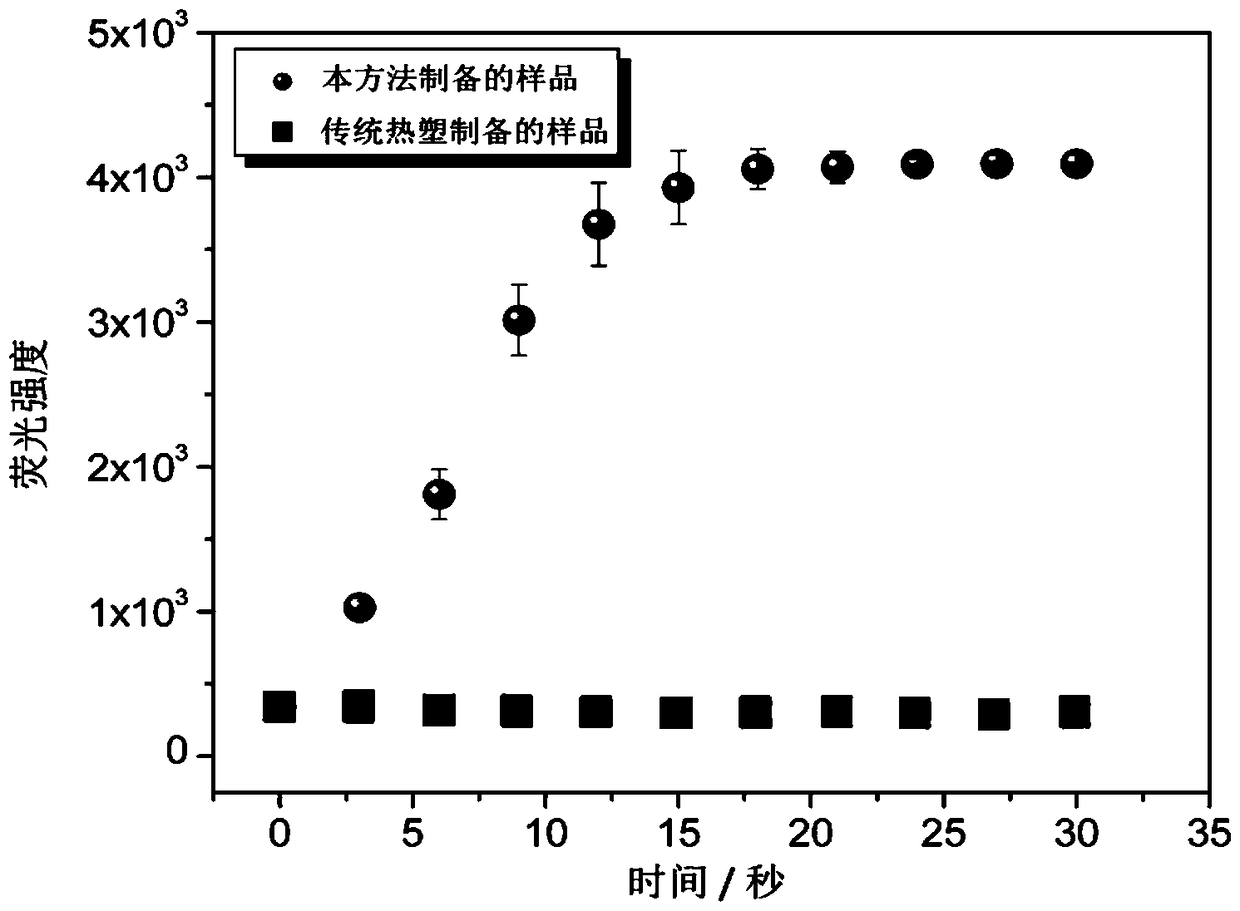

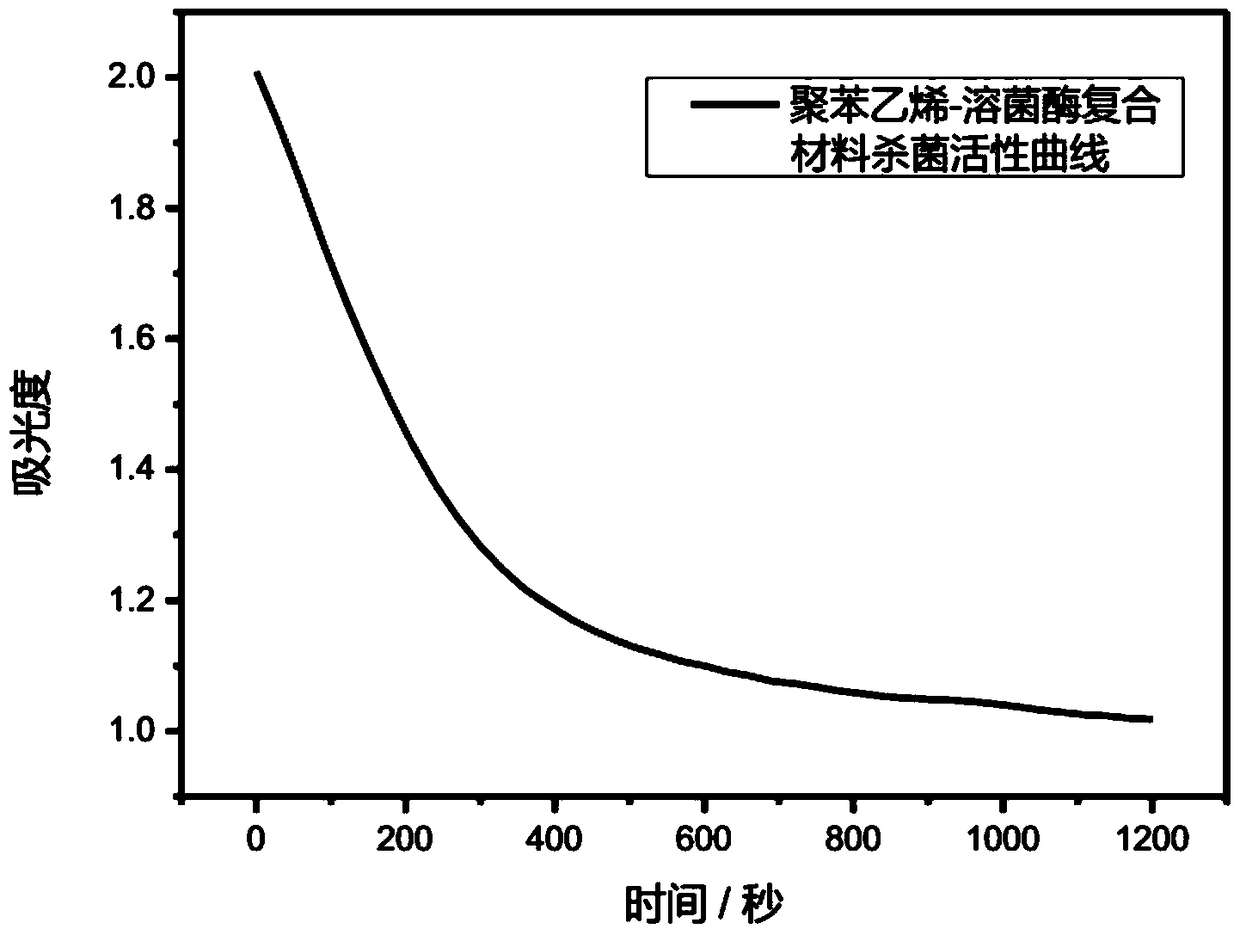

A biocidal plastic

ActiveCN105385056BGood slow-release propertiesNot easy to cause pollutionEnvironmental resistanceRoom temperature

Owner:NANJING UNIV

Flotation gangue subsidence method of alumyte

The present invention relates to the deposition dewatering process of floated tail ore, and is especially the deposition dewatering process of floated tail ore of diaspore type alumyte. The present invention features that into the floated tail ore slurry, sulfuric acid or sulfate, aluminum sulfate, ferrous sulfate, zinc sulfate, copper sulfate, barium sulfate or alum in acidity after hydrolysis is first added to regulate pH value to 6.5-7.5; and polyacrylamide as organic flocculant in the amount of 0.001-0.01 % of the dry tail ore slurry weight is then added for flocculation and deposition. The present invention can raise the concentration of tail ore slurry from 6-11 % to over 25 %, reduce the overflow floated matter to below 1 g / L and make the overflow water capable of being reused.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

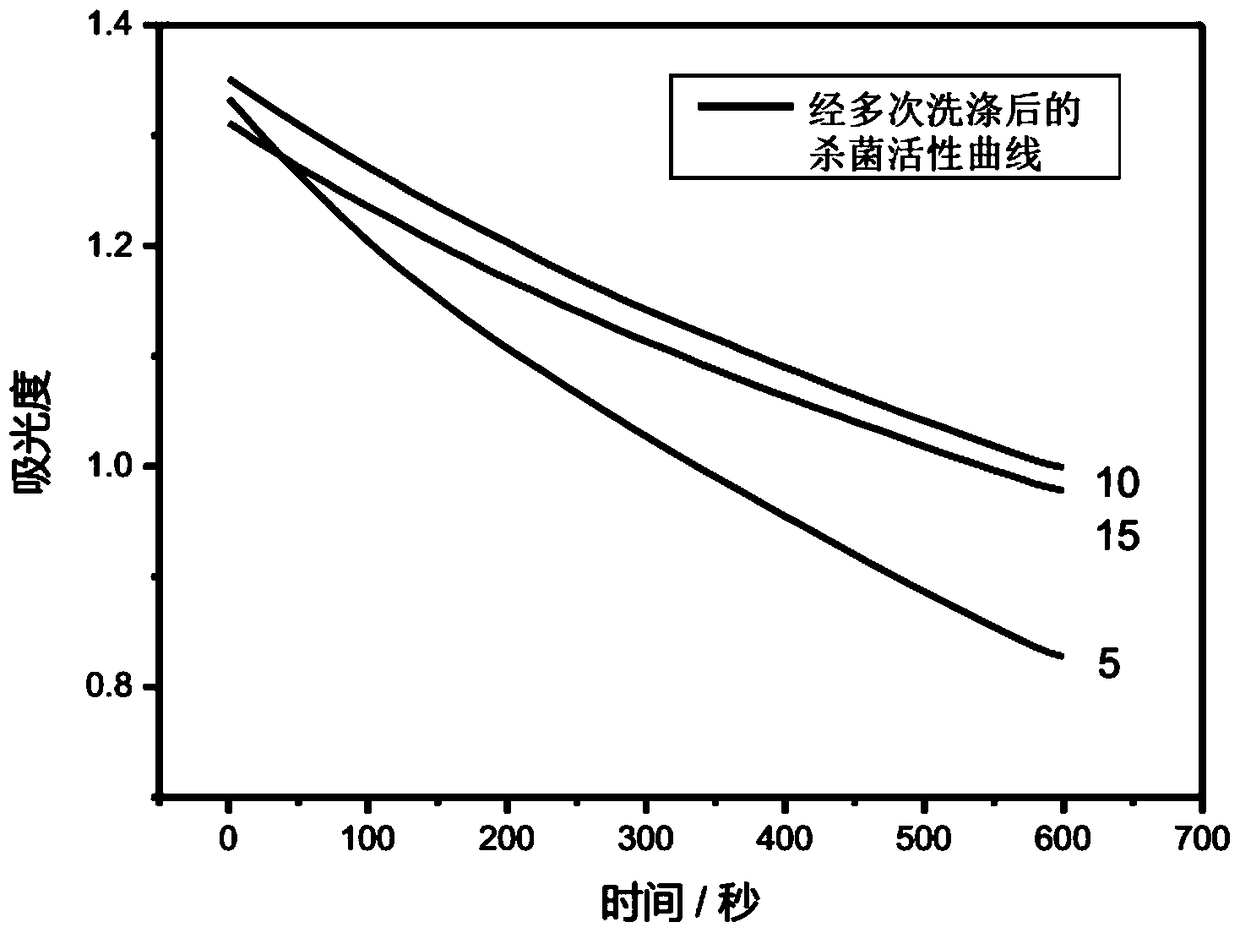

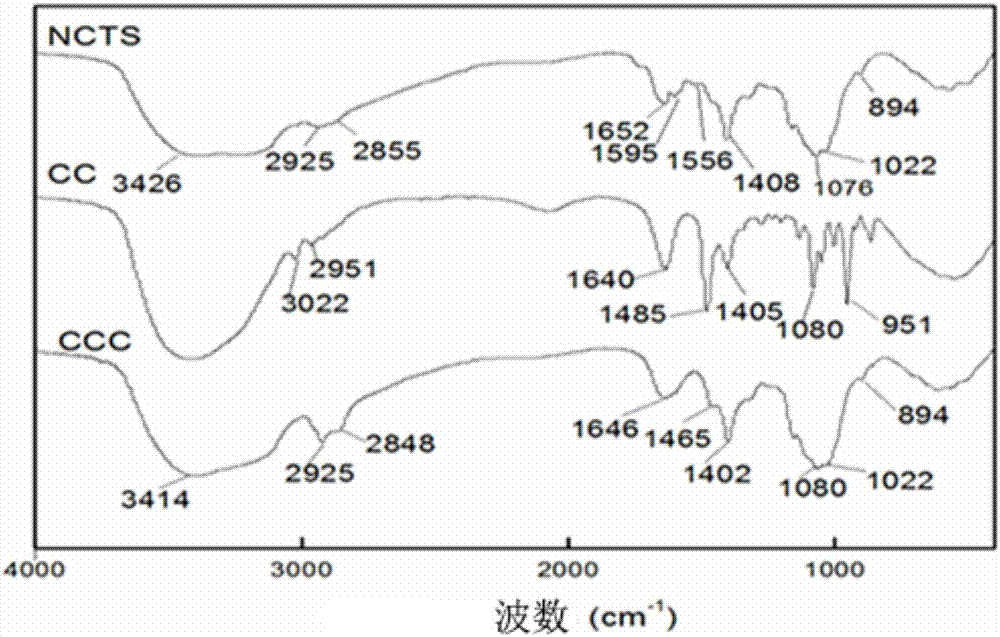

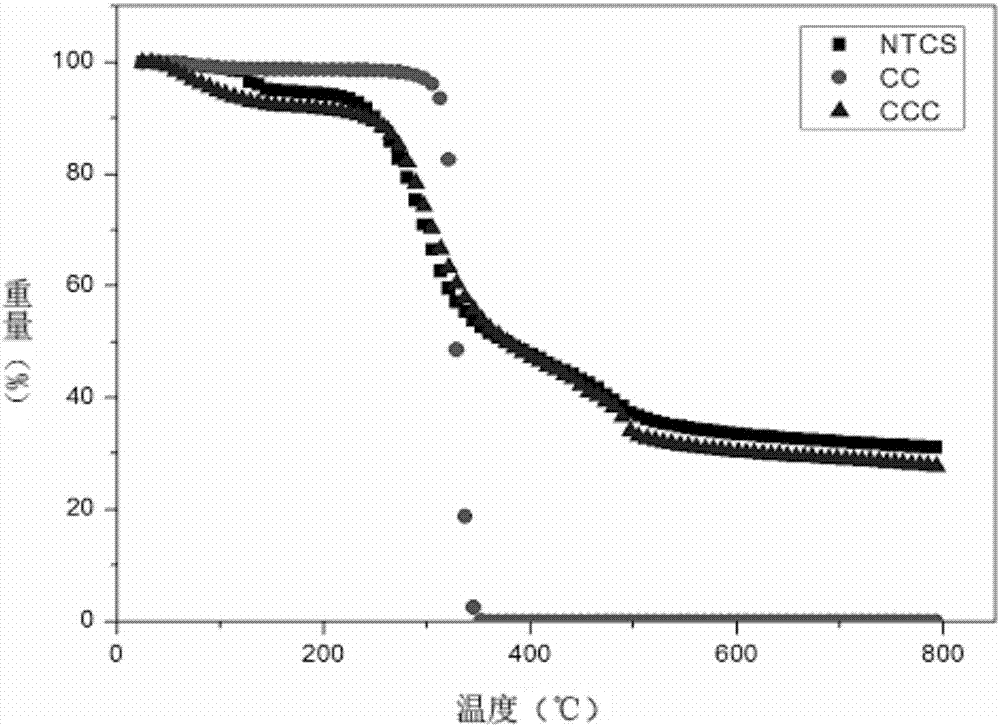

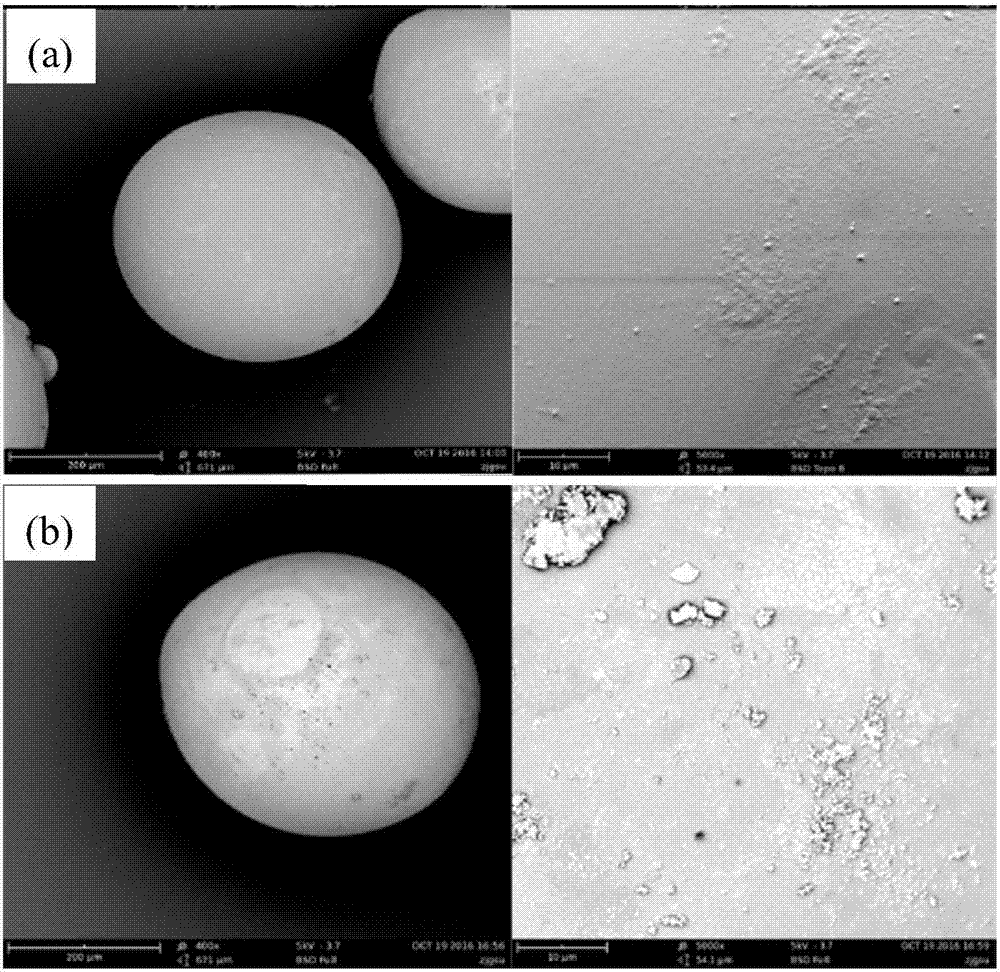

Quaternary ammonium salt modified chitosan microspheres and preparation method and application thereof

ActiveCN107094765ARich reservesLow costBiocideSpecific water treatment objectivesQuaternary ammonium cationChitosan microspheres

The invention discloses quaternary ammonium salt modified chitosan microspheres and a preparation method thereof. The preparation method comprises the following steps: with cross-linked chitosan microspheres as a parent, performing sufficient swelling; adding a ligand choline chloride to regulate the pH value of the system; performing a modifying reaction; after the reaction is finished, performing washing and drying to obtain the quaternary ammonium salt modified chitosan microspheres. The invention also provides application of the quaternary ammonium salt modified chitosan microspheres as a sterilizing agent in drinking water. The quaternary ammonium salt modified chitosan microspheres disclosed by the invention can serve as a novel modified sterilizing agent; the sterilizing effect is enhanced by introducing the quaternary ammonium salt with a good sterilizing effect and carrying positive charges.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

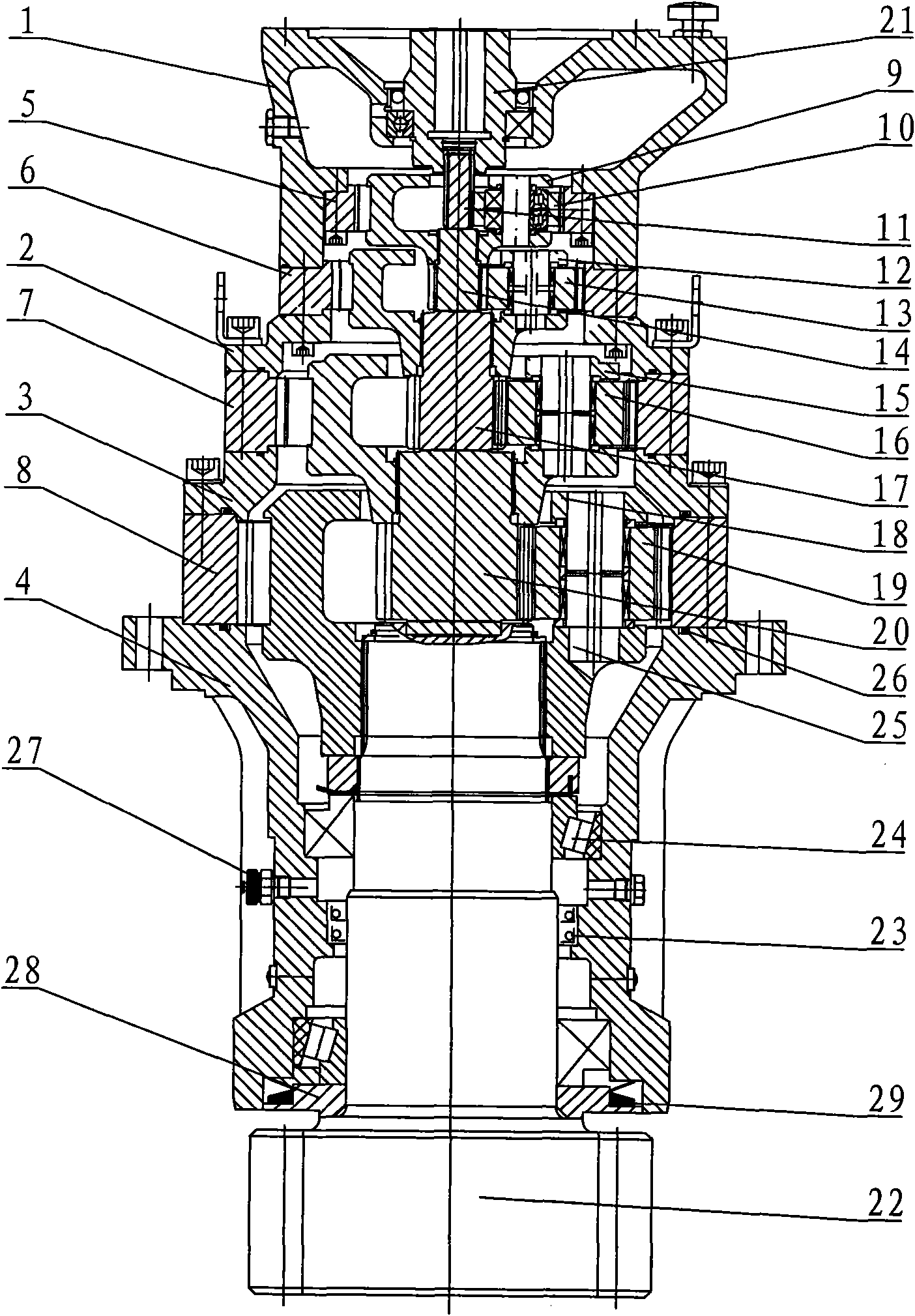

Wind-power generating yaw speed reducer

InactiveCN101649816AReduce wearExtended service lifeEngine sealsToothed gearingsReducerControl theory

The invention relates to a yaw speed reducer of a wind power generator. Four-stage satellite transmission structures are arranged in a box and are connected with each other to be transmitted to an output gear shaft in sequence; a motor flange is connected to the upper end of the box; the output gear shaft is arranged in a support body through an upper bearing and a lower bearing and is sealed by an oil seal base; a first-stage internal gear ring is connected into the motor flange through bolts; a motor input connection sleeve is arranged in the motor flange through a bearing; the number of theinternal teeth of the motor input connection sleeve is the same as the number of the external teeth of a first-stage sun gear; and the internal teeth of the motor input connection sleeve and the external teeth of the first-stage sun gear have the same modulus and the same pressure angle of 20 degrees and are in mutual meshing transmission. The yaw speed reducer has compact structure, reasonable design, good uniform-loading effect, strong bearing and impact resistance capacity, good sealing performance and a uniformly-forced satellite gear meshed with the floating sun gear, is convenient to make and not easy to cause the environmental pollution and runs stably, thereby meeting the requirements of the clients.

Owner:JIANGSU TAILONG MACHINERY GRP CO CO LTD

Method for degrading cellulose by synergic action of mechanical activation and metal salt

The invention discloses a method for degrading cellulose by synergic action of mechanical activation and a metal salt, belonging to the field of biomass energy and fiber chemicals. The method comprises the following steps: (1) crushing cellulose which serves as a raw material, and screening with a screen of 10-200mesh; (2) mixing the crushed and screened cellulose with a metal salt at a weight ratio of 1:(0.001-0.1) uniformly; and (3) adding the materials mixed uniformly into a mechanical activation reactor, adjusting the mechanical activation temperature to 30-90 DEG C, activating the materials mechanically for 10-180 minutes, and taking the obtained cellulose degradation product out of the mechanical activation reactor. Because the cellulose is degraded by synergic action of mechanical activation and the metal salt, the degree of polymerization of the cellulose can be reduced greatly in a mild condition, the accessibility and the reaction activity of the cellulose degradation product can be improved greatly, and hydrolysis and modification reaction of cellulose can be realized. Little energy is consumed in the whole reaction process, the process for degrading cellulose is simple, the production cycle is short, the cellulose is degraded only under the mechanical force of a ball mill, and the requirement for production equipment is low.

Owner:GUANGXI UNIV

Polypropylene nylon plastic alloy for asphalt packaging bag

The invention discloses a polypropylene nylon-plastic alloy for asphalt packaging bags, which comprises the following ingredients (by weight portions): polypropylene 80-95, nylon 5-20, auxiliary agent 0.1-1, and compatibilzer 5-20.

Owner:刘信东

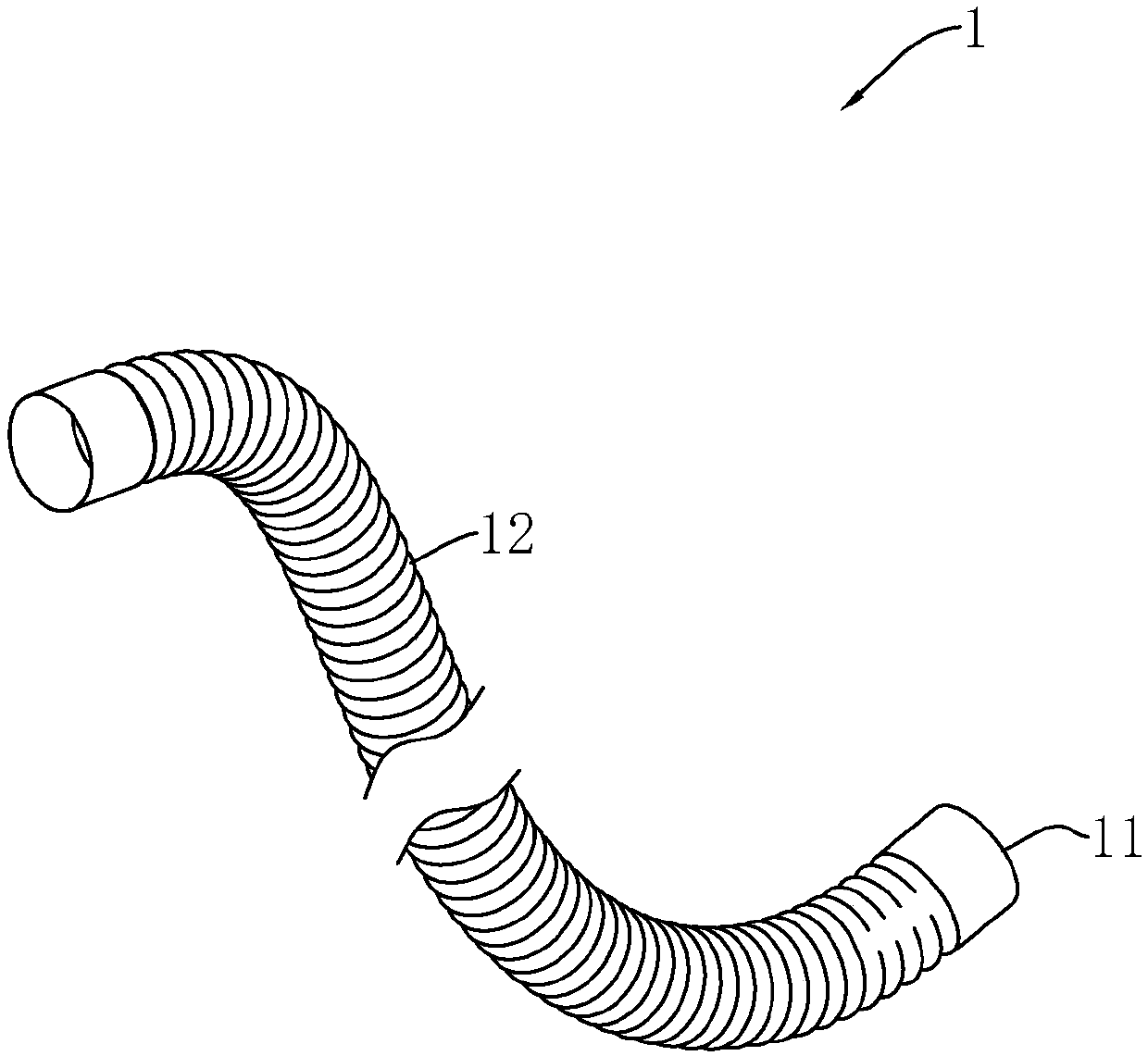

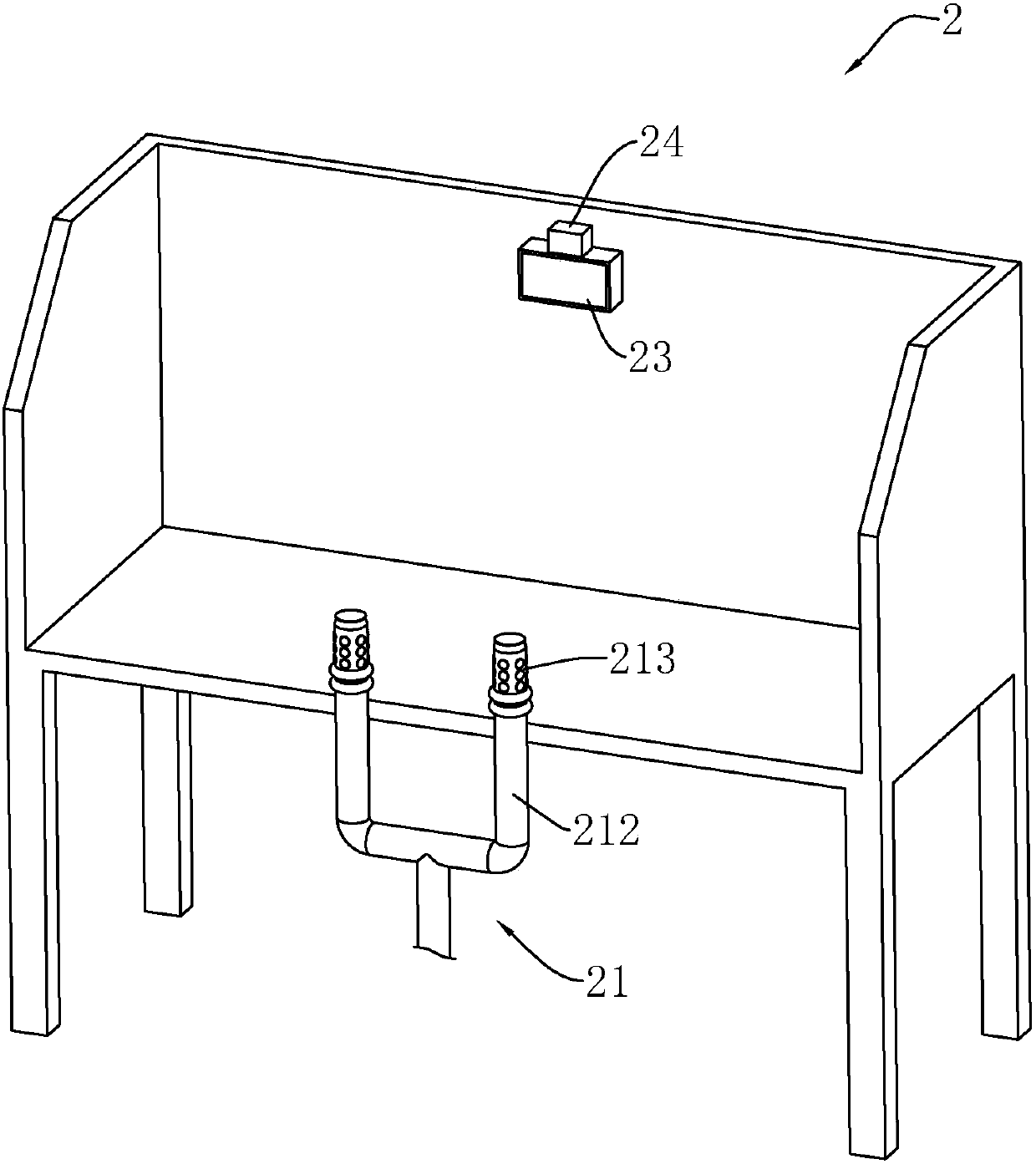

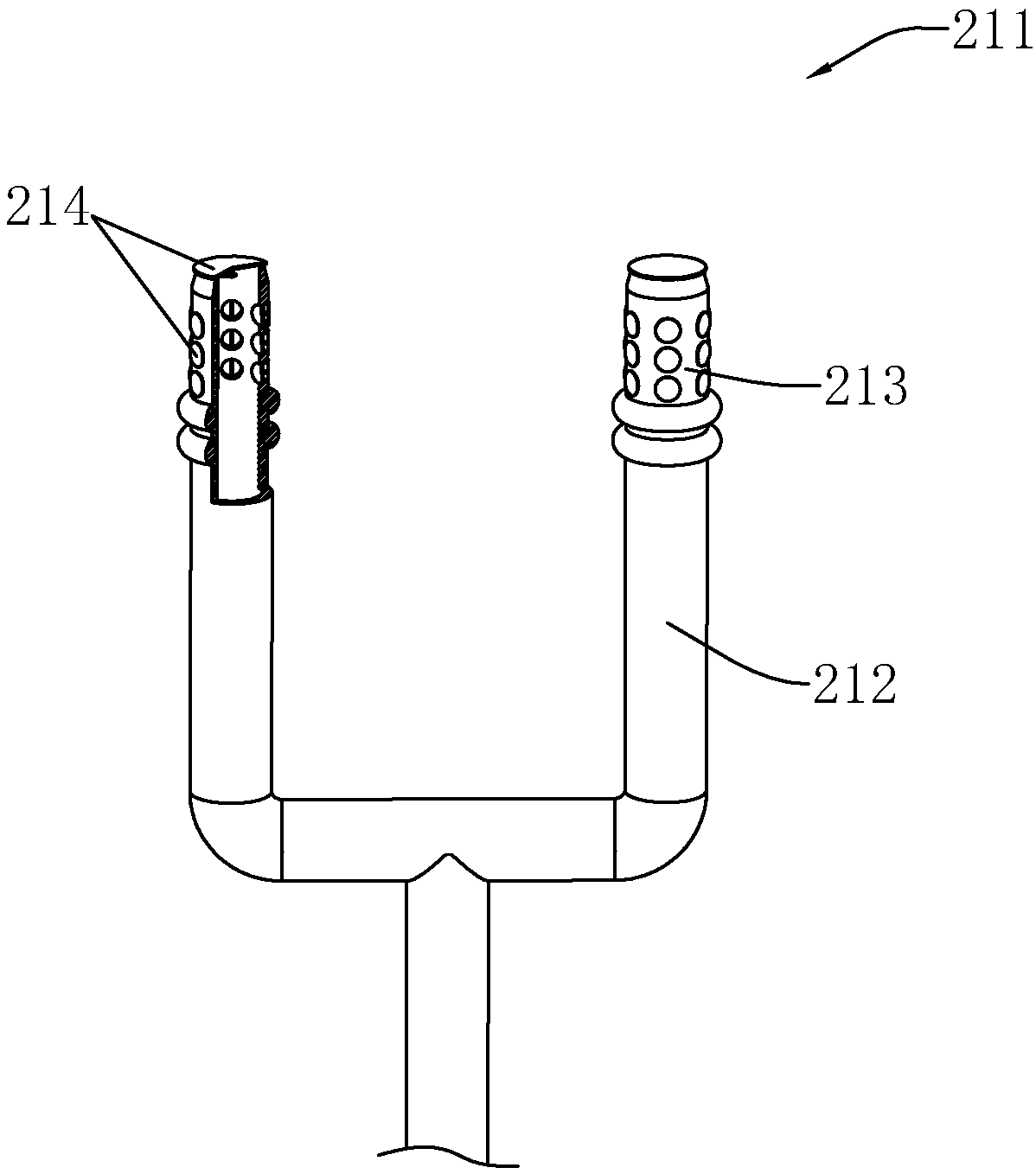

Air tightness detection system

PendingCN107806971AClear judgmentEasy to judgeMeasurement of fluid loss/gain ratePressure senseEngineering

The invention discloses an air tightness detection system and relates to the technical field of bellows air tightness detection. The air tightness detection system includes an air tightness detectiontable, an inflating module, a pressure detection module, a processor, a comparison module and a terminal. According to the scheme, certain pressure intensity is formed in a bellows by filling the bellows with gas, and pressure intensity changes in the bellows are measured through a sensor after the inflation is stopped, to judge whether the bellows leaks air. Besides, a change value delta P is preset through the system, so that a product is automatically judged to be an unqualified product when a value exceeds delta P. The bellows is not polluted in the detection process, the automation degreein the detection process is higher, human input is saved, and the detection speed is quickened.

Owner:重庆赛格尔汽车配件有限公司

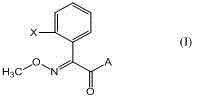

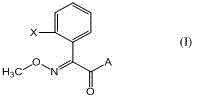

Method for preparing (E)-2-(2-substituted phenyl)-2-methoxyimino acetic acid derivative

InactiveCN104529818AReduce usageNot easy to cause pollutionOximes preparationHydroxylamineHydroxylamine Hydrochloride

The invention relates to a method for preparing a (E)-2-(2-substituted phenyl)-2-methoxyimino acetic acid derivative. The method comprises the following steps: (1) carrying out pinner reaction on a proper raw material acyl cyanide shown in a formula (II) which is shown in the specification and alcohol in an organic solvent in the presence of acid and alkali metal halide to prepare a glyoxylic acid derivative shown in a formula (III); (2) carrying out reaction with hydroxylamine in an organic solvent to generate oxime shown in a formula (IV) and then methylating or oximating by O-methylhydroxyl amine to prepare a mixed isomer of a 2-(2-substituted phenyl)-2-methoxyimino acetic acid derivative; and (3) in the presence of acid, isomerizing in the organic solvent and at a certain temperature range and treating, crystallizing and separating to obtain a target product. According to the method provided by the invention, hydrogen chloride gas is not used, and the method is less in equipment corrosion, hardly causes the environmental pollution, is small in wastewater quantity, convenient to operate and high in synthetic yield and is an environment-friendly chemical synthetic process.

Owner:JIANGSU GENGYUN CHEM CO LTD

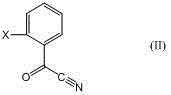

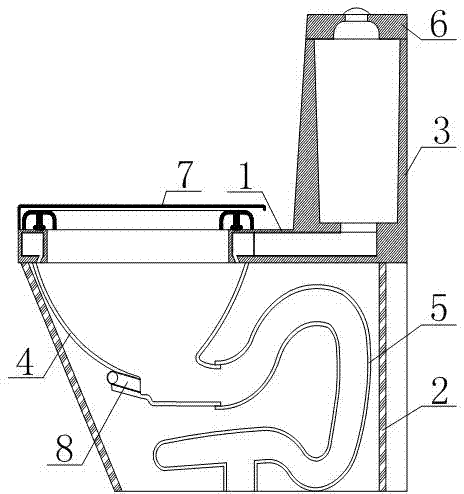

Manufacturing technology for artificial stone closestool

ActiveCN102561494AColor AdjustmentLow profileWater closetsCeramic shaping apparatusManufacturing technologyPolyvinyl chloride

The invention discloses a manufacturing technology for an artificial stone closestool, which comprises the steps as follows: a closestool seat glass reinforced plastic die, an inner container glass reinforced plastic die and a base wooden die are manufactured according to the shapes and sizes of a closestool seat, an inner container and a base, and an artificial stone closestool seat, an artificial stone inner container and a PVC (polyvinyl chloride) base are manufactured according to the dies; a seat ring of the closestool seat and the inner container are connected in a casting manner, and the closestool seat is communicated with a waterway of a water tank and is communicated with the inner container; the base is connected with the closestool seat and then a sewage conduit is communicated with a blowdown hole of the inner container, then a lower opening of the base is sealed up through a PVC plate, and the sewage conduit is led to penetrate through the PVC plate at the bottom of the base; in addition, a water tank cover board is assembled on the water tank after a flushing component is assembled in the water tank of the closestool seat, and then a seat ring cover board of the closestool seat is hinged with the seat ring. Through the adoption of the closestool that is manufactured through the manufacturing technology, energy consumption is low and the emission of waste gas and waste water is small during the manufacturing process, and the manufactured closestool can be recycled.

Owner:SICHUAN XIMA TOILET & BATHROOM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com