Patents

Literature

63results about How to "Increase infiltration speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

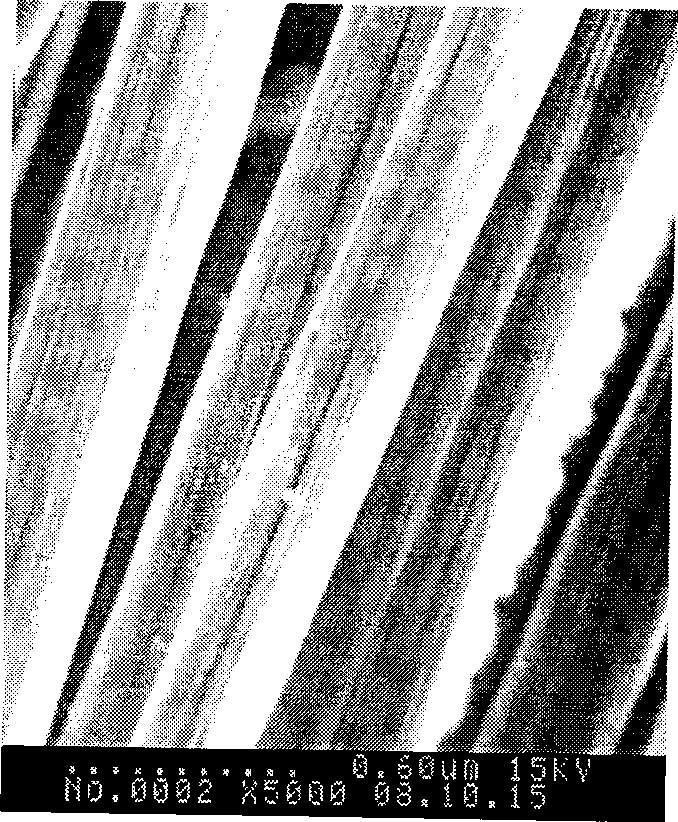

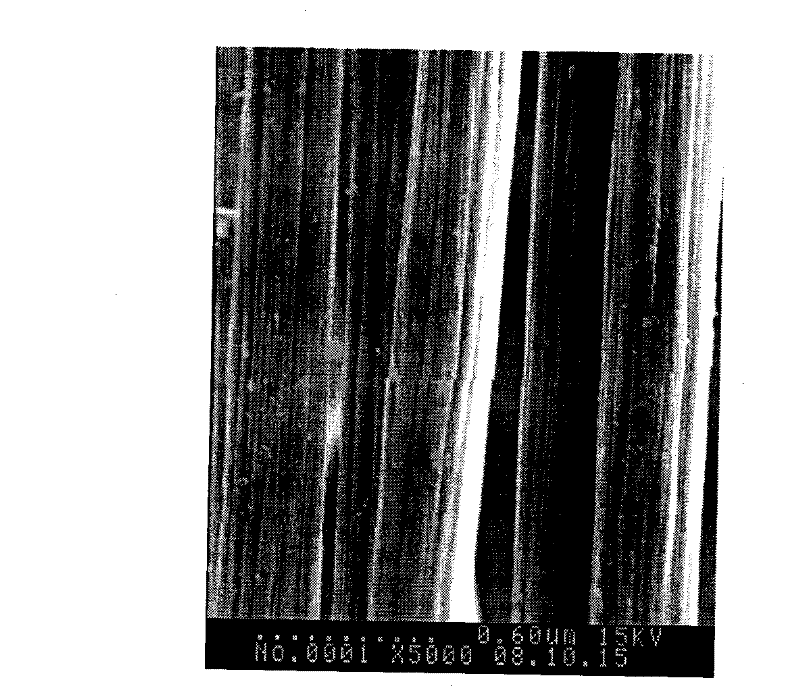

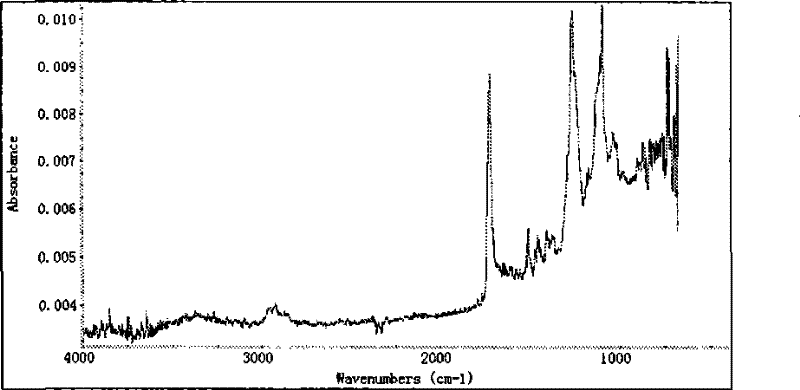

Method for carbon fiber surface modification of plasma coated with nano colloidal sols by plasma treatment

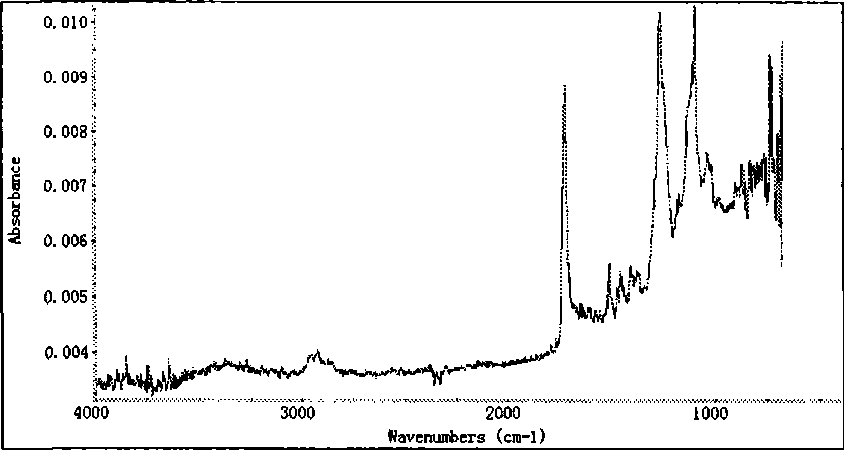

InactiveCN101413209AImprove performanceImprove surface propertiesPhysical treatmentCarbon fibresFiberCarbon fibers

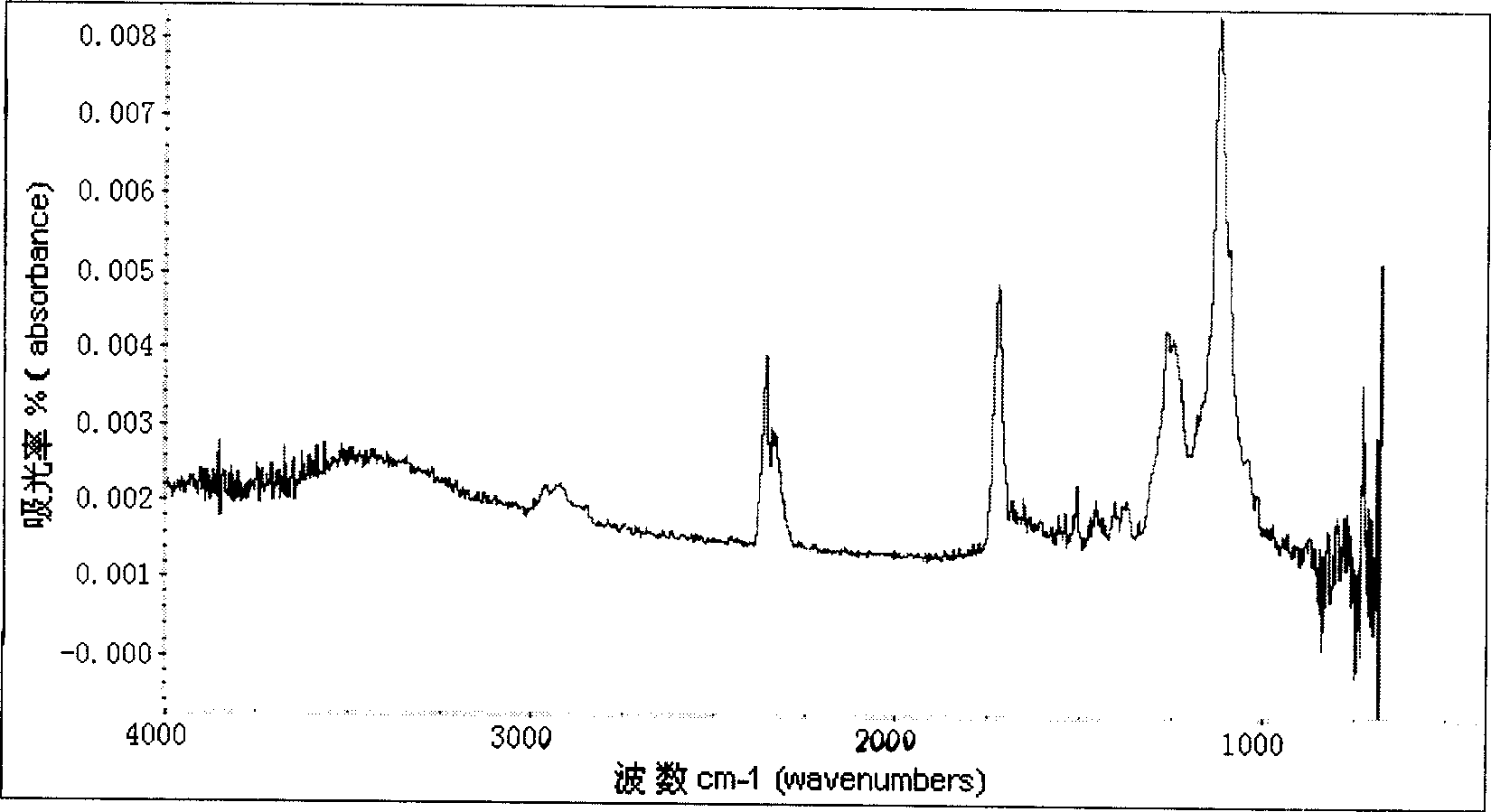

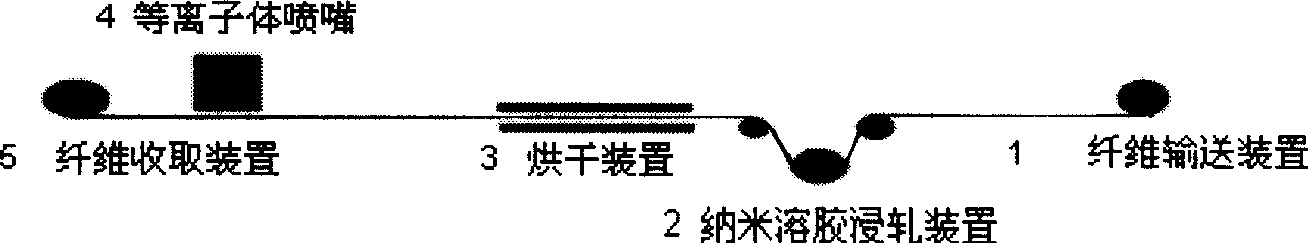

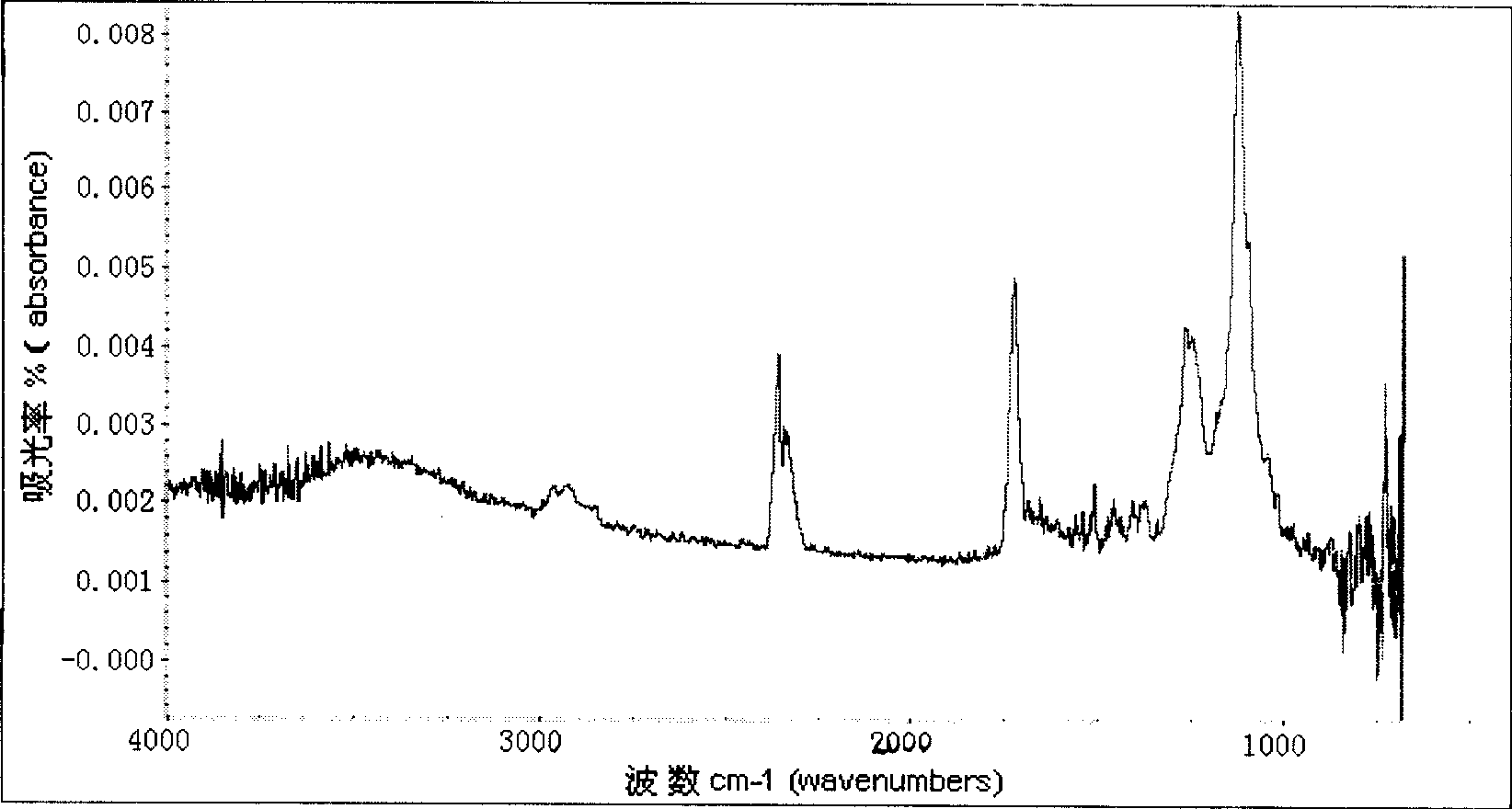

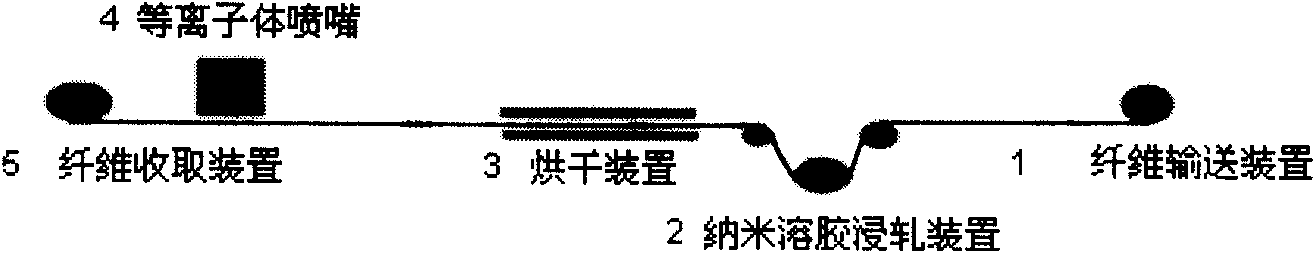

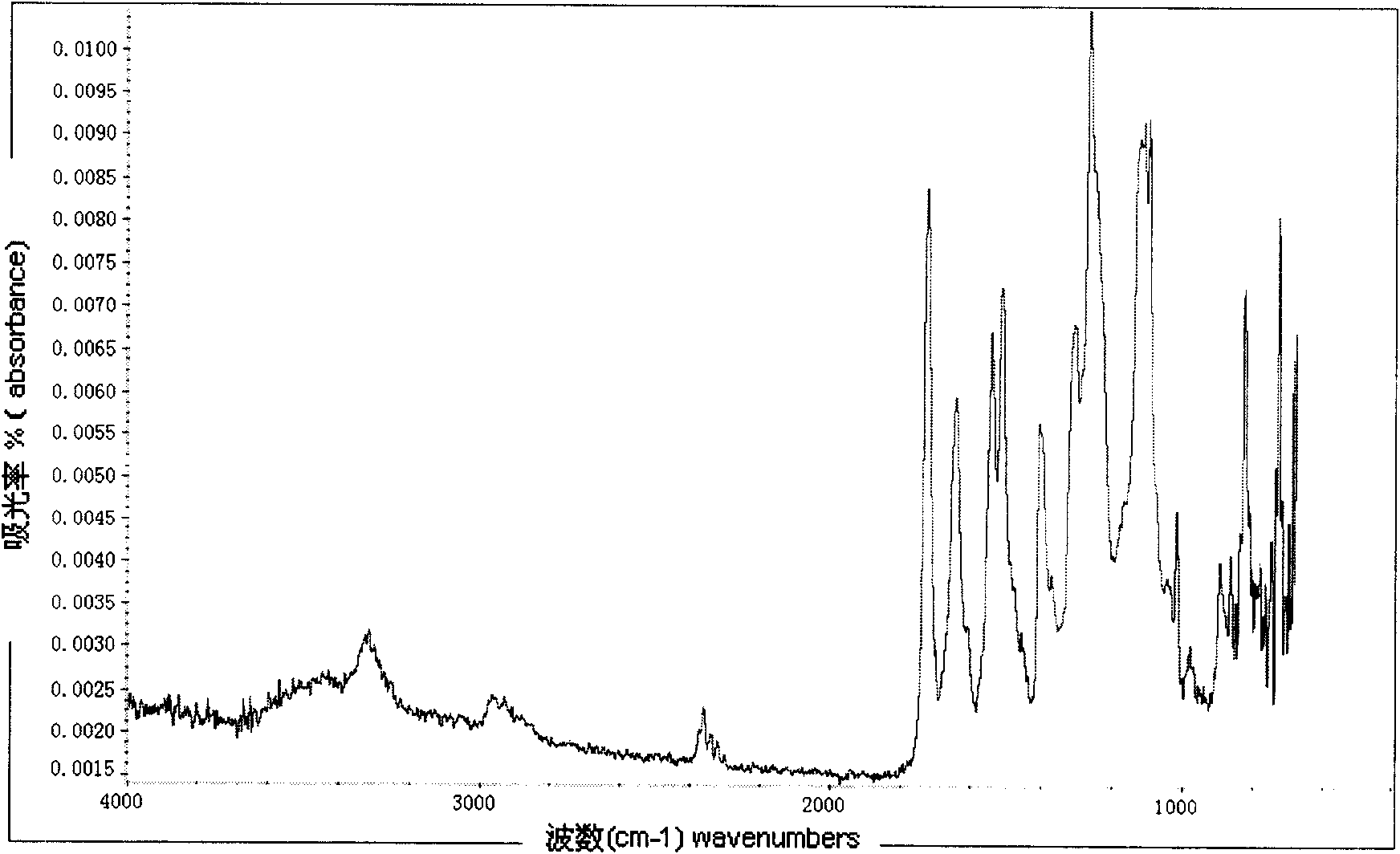

The invention relates to a method for modifying the surface of carbon fiber coated with nano sol through plasma treatment, which comprises the following steps: firstly, nano particles are prepared into an organic solvent, a sol solution of water or a sol solution prepared by hybridization reaction of a precursor solution of organic-inorganic nano particles by the ultrasonic vibrating technology; secondly, the sol solution is coated on the surface of the carbon fiber, treated by means of spray coating and padding, and dried; and thirdly, the dried carbon fiber is placed on a special transport unit for plasma processing equipment and a plasma is sprayed on the surface of the carbon fiber to make the carbon fiber move in the plasma atmosphere, so as to generate surface modification, wherein the treating power is between 10 and , watts, and the treatment time is between 0.5 and 300 seconds. The method can effectively improve the performance of the fiber, improves the molded manufacturability and the overall properties of composite materials of the fiber, has simple technology, quick processing speed, good treatment effect and low cost, is convenient to operate and difficult to cause environmental pollution, can reduce energy consumption, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

Method for carbon fiber surface modification of plasma coated with silicon dioxide by plasma treatment

InactiveCN101413210AImprove surface propertiesImprove performancePhysical treatmentCarbon fibresFiberCarbon fibers

The invention relates to a method for modifying the surface of carbon fiber coated with nano dioxide sol through plasma treatment, which comprises the following steps: firstly, nano silicon dioxide is prepared into an organic solvent, a sol solution of water or a sol solution prepared by hybridization reaction of a precursor solution of organic-inorganic nano particles and silicon dioxide nano particles by the ultrasonic vibrating technology; secondly, the sol solution is coated on the surface of the carbon fiber, treated by means of spray coating or padding and so on, and dried; and thirdly, the carbon fiber is placed on a plasma transport unit and a plasma is sprayed on the surface of the carbon fiber to generate modification, wherein the treating power is between 10 and 15,000 watts, and the treatment time is between 0.5 and 300 seconds. The method can effectively improve the performance of the carbon fiber, improves the molded manufacturability and the overall properties of composite materials of the carbon fiber, has simple technology, quick processing speed, good treatment effect and low cost, is convenient to operate and difficult to cause environmental pollution, can reduce energy consumption, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

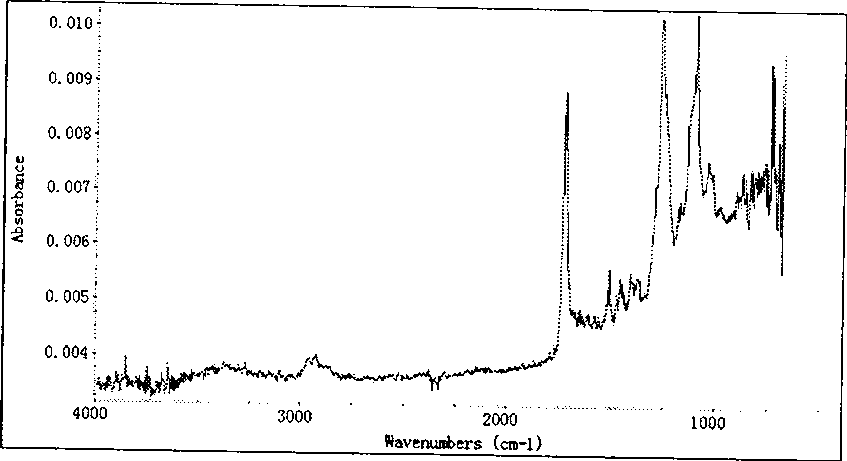

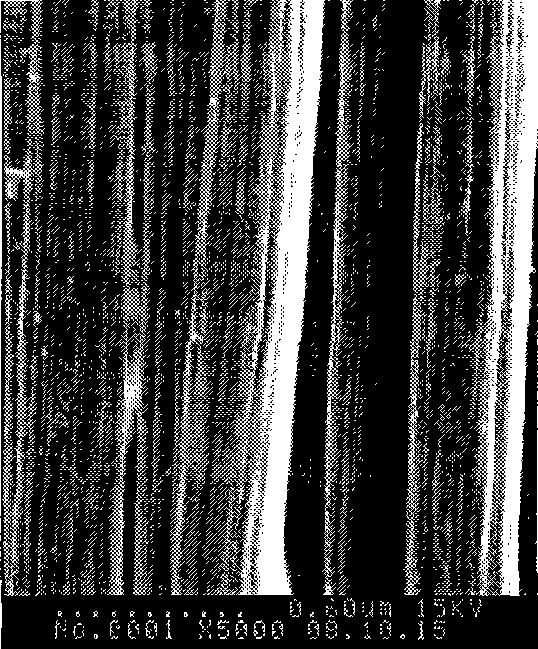

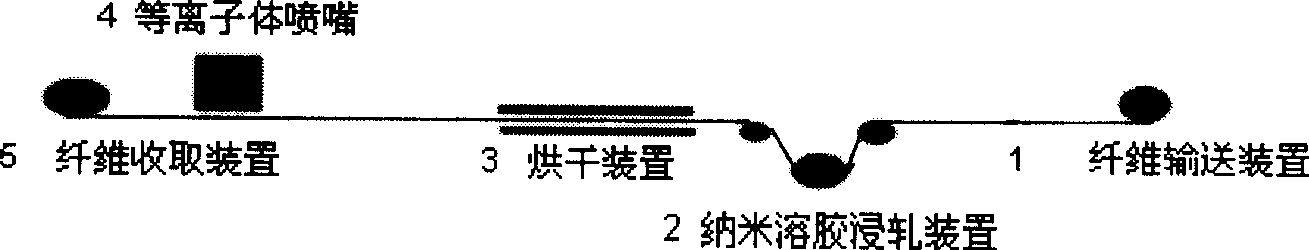

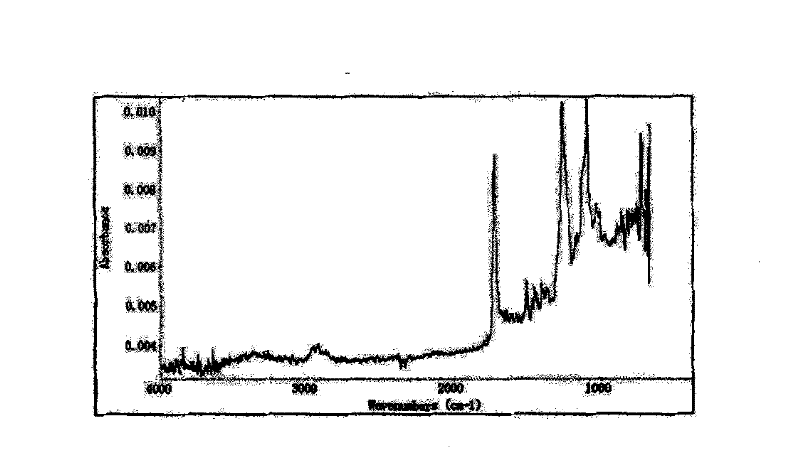

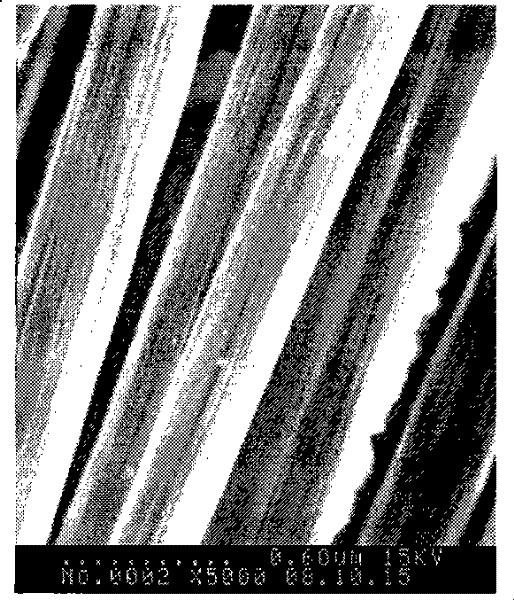

Method for modifying ultrahigh molecular weight polyethylene fiber by plasma treatment

InactiveCN101532244AIncrease infiltration speedImprove wettabilityPhysical treatmentFibre typesFiberPlasma generator

The invention relates to a method for modifying ultrahigh molecular weight polyethylene fiber by plasma treatment. The method comprises that: (1) a nanometer particle of silicon dioxide is prepared into an organic solvent or water solution of sol of which the mass percent is 0.01 to 15 percent, by an ultrasonic shock technique; or (2) a precursor solution of the organic-inorganic nanometer particle is subjected to hybridization reaction with the nanometer particle of silicon dioxide to prepare the nanometer silicon dioxide sol solution; (3) the sol solution is coated on the surface of the ultrahigh molecular weight polyethylene fiber by spraying or padding; and (4) the ultrahigh molecular weight polyethylene fiber is dried at a temperature of 10 to 150 DEG C, and the solvent is collected; and the ultrahigh molecular weight polyethylene fiber is introduced in a plasma atmosphere region by a plasma generator for plasma surface modification. The compound property between the treated ultrahigh molecular weight polyethylene fiber and the organic matrix materials is greatly improved; moreover, the method also has the advantages of simple process, good treatment effect, low cost, environmental protection and low energy consumption.

Owner:DONGHUA UNIV +1

Method for modifying nanometer sol ultrahigh molecular weight polyethylene fiber by plasma treatment

InactiveCN101532239AImprove permeabilityHigh chemical activityPhysical treatmentFibre typesFiberTherapeutic effect

The invention relates to a method for modifying a nanometer sol ultrahigh molecular weight polyethylene fiber by plasma treatment. The method comprises that: (1) inorganic nanometer particle is prepared into a sol solution by an ultrasonic shock technique; or (2) a precursor solution of the organic-inorganic nanometer particle is subjected to hybridization reaction with the inorganic nanometer particle to prepare the sol solution; (3) the sol solution is coated on the surface of the ultrahigh molecular weight polyethylene fiber; and (4) the ultrahigh molecular weight polyethylene fiber is dried at a temperature of 10 and 150 DEG C, and the solvent is collected; the ultrahigh molecular weight polyethylene fiber is introduced in a plasma atmosphere region by a plasma generator for plasma surface modification; and the treated ultrahigh molecular weight polyethylene fiber is on-line rolled by an automatic rolling machine. The compound property between the treated ultrahigh molecular weight polyethylene fiber and the organic matrix materials is greatly improved; moreover, the method also has the advantages of simple process, good treatment effect, low cost, environmental protection and low energy consumption.

Owner:DONGHUA UNIV +1

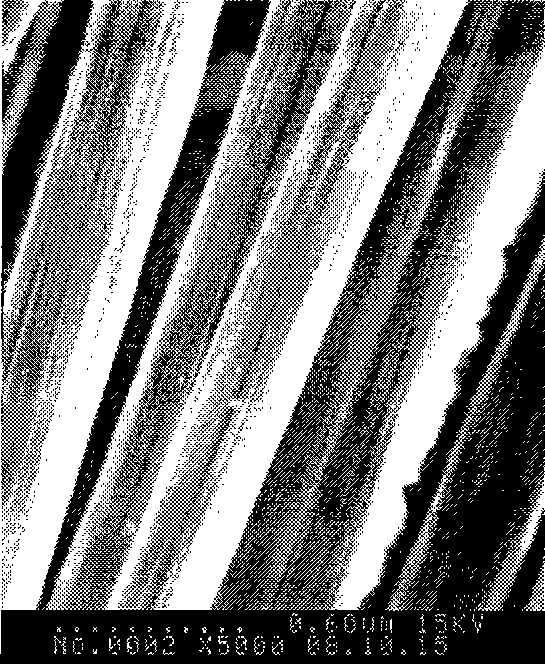

Method for modifying Kevlar fiber by treating nano sol through plasma

InactiveCN101575798AImprove permeabilityIncrease infiltration speedPhysical treatmentFibre typesFiberOrganic base

The invention relates to a method for modifying Kevlar fiber by treating a nano sol through plasma, which comprises the following steps: (1) preparing inorganic nano particles into sol solution by ultrasonic oscillation technology; or (2) carrying out a hybridization reaction of precursor solution of organic-inorganic nano particles and the inorganic nano particles to prepare sol solution; (3) coating the sol solution on the surface of the Kevlar fiber; (4) drying the Kevlar fiber at a temperature of between 10 and 150 DEG C, collecting solvent, then introducing the Kevlar fiber in a plasma atmosphere area through a plasma generating device for surface modification treatment by the plasma; and finally, carrying out on-line winding of the treated Kevlar fiber in an automatic winding machine and adjusting the wiring speed of the Kevlar fiber by adjusting the speed range of a winding shaft. The combined performance between the Kevlar fiber treated by the method and the organic base materials is improved greatly; and the method has simple process, good treatment effect, low cost, difficult environmental pollution and reduction of the energy consumption.

Owner:DONGHUA UNIV +1

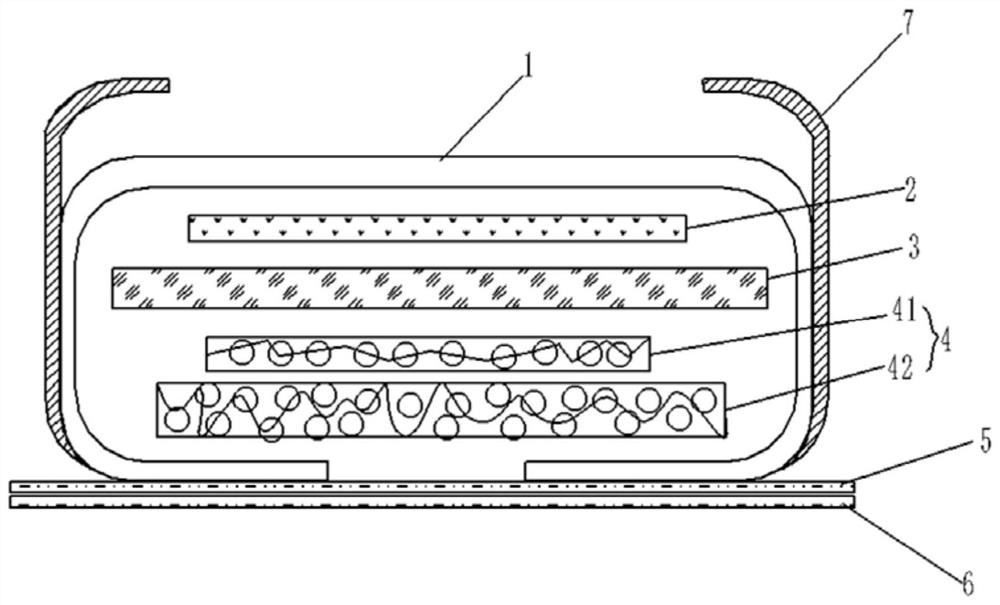

Electrolyte filling device of lithium ion batteries

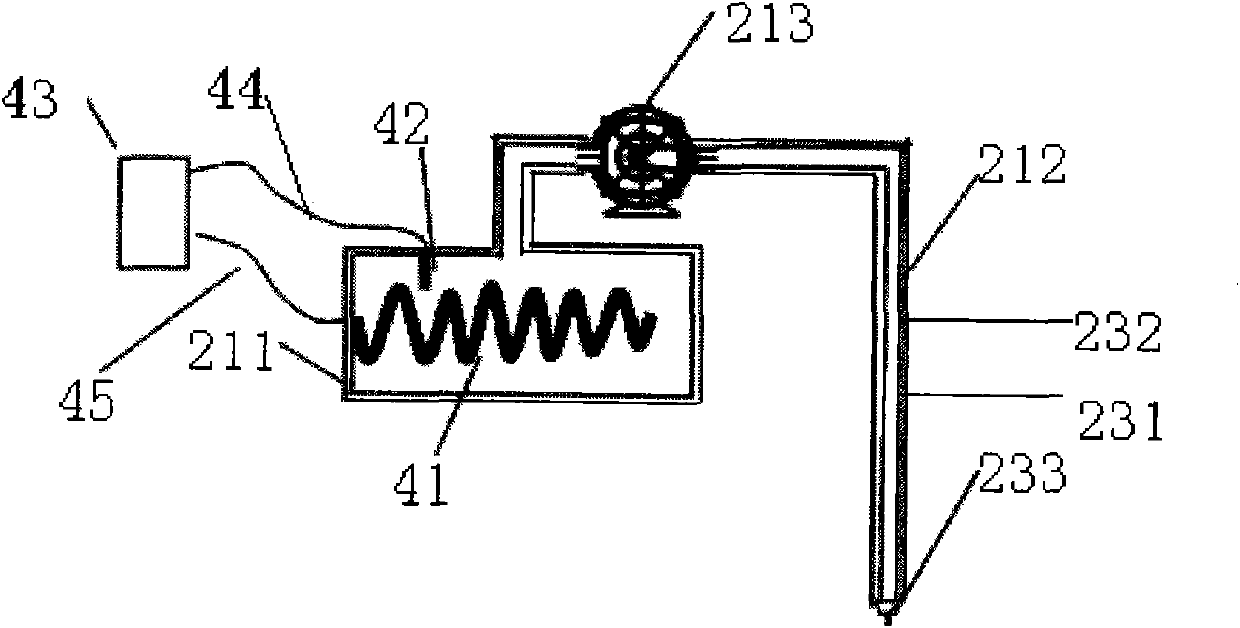

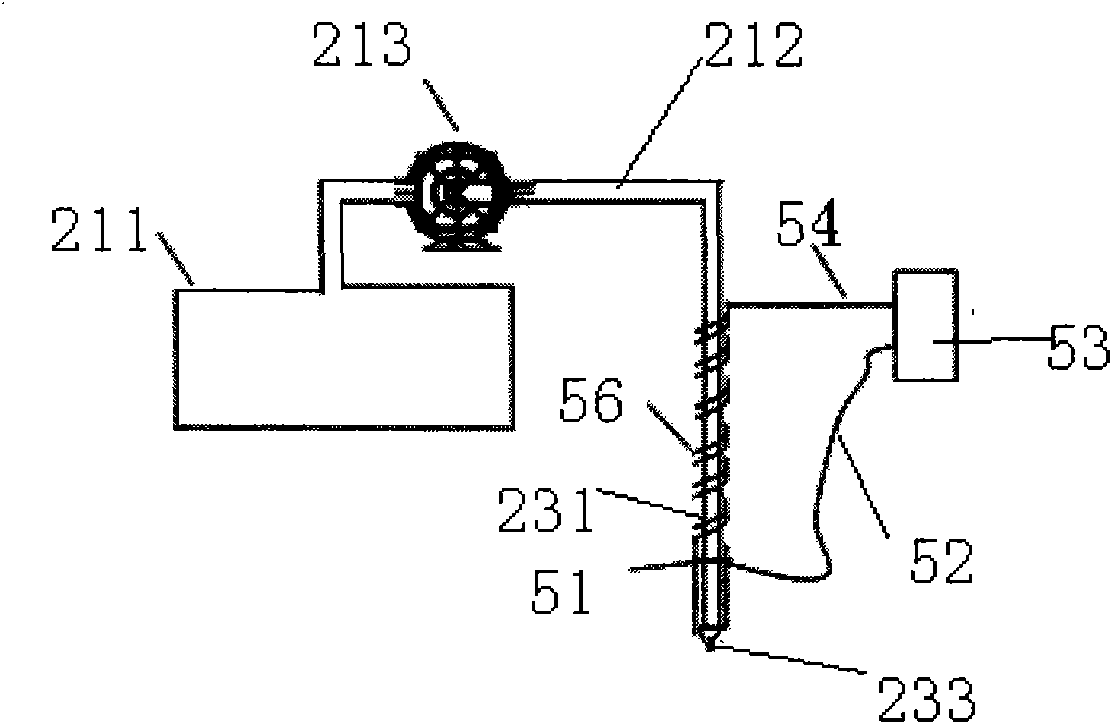

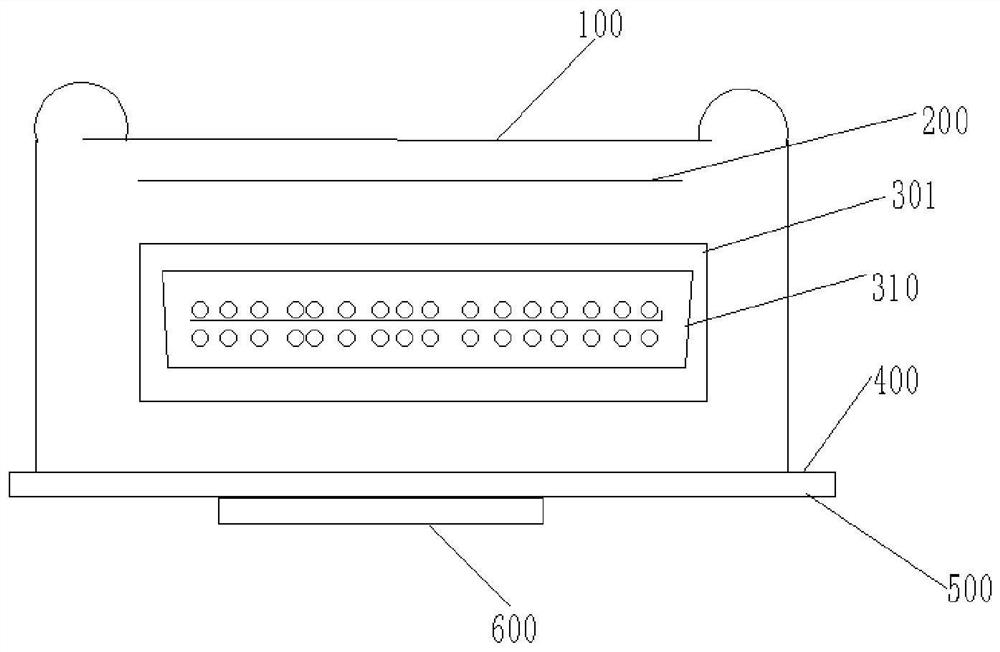

ActiveCN102709511AAccelerate the speed of wetting the membraneHigh speedCell component detailsEngineeringLithium-ion battery

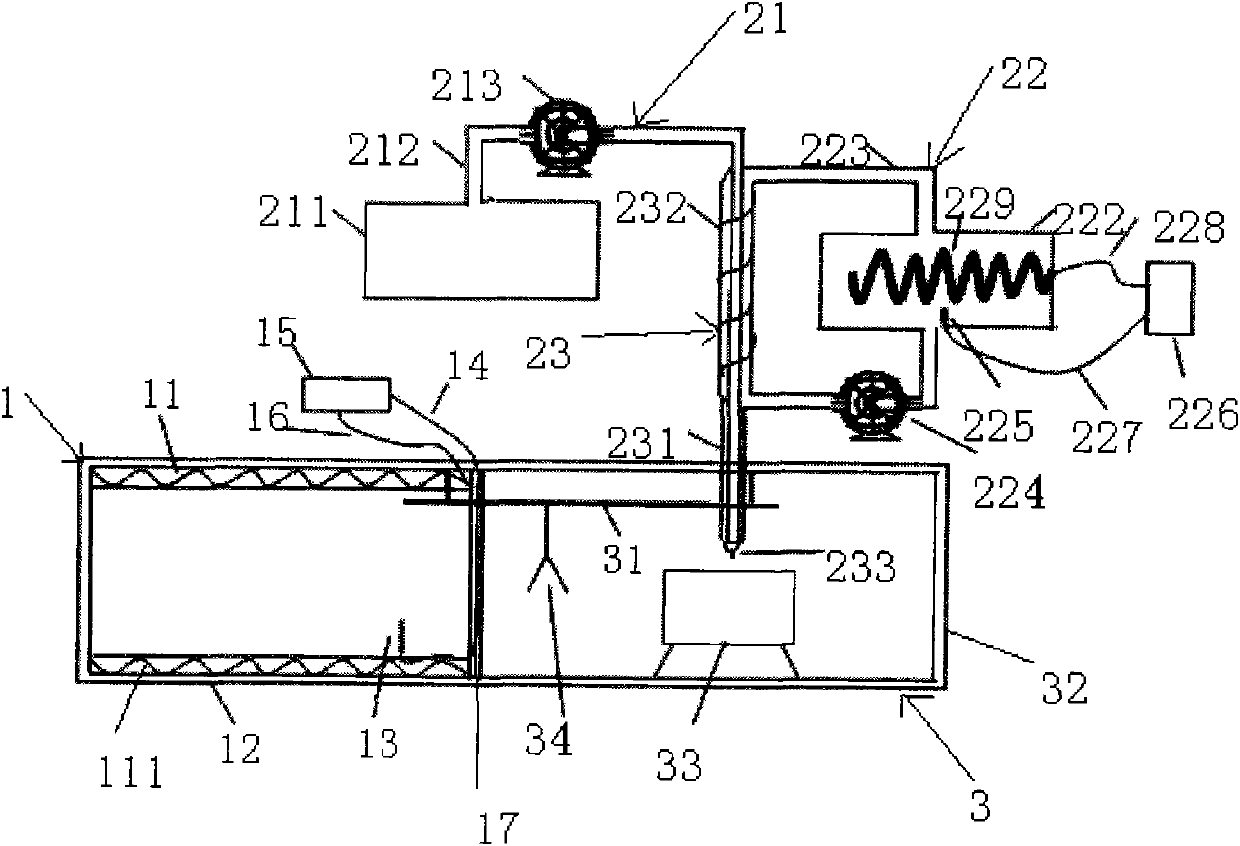

The invention relates to the technical field of lithium ion batteries, in particular to an electrolyte filling device for lithium ion battery electrolyte rapidly infiltrating membranes. The electrolyte filling device comprises an electrolyte filling system, a battery core pre-heating system and / or an electrolyte heating system, wherein the battery core pre-heating system is an upper station of the electrolyte filling system and a battery core outlet is arranged in between the battery core pre-heating system and the electrolyte filling system, and the electrolyte heating system is arranged on the electrolyte filling system. During electrolyte filling process, the battery core and / or the electrolyte is heated to a certain temperature, so that viscosity of the electrolyte is the infiltration process is reduced, and rapid infiltration is achieved. Accordingly, the electrolyte filling device can effectively relieve the problem of slow electrolyte infiltration after electrolyte filling, so that standing time between electrolyte infiltration and formation is reduced, and the production efficiency is improved.

Owner:NINGDE AMPEREX TECH

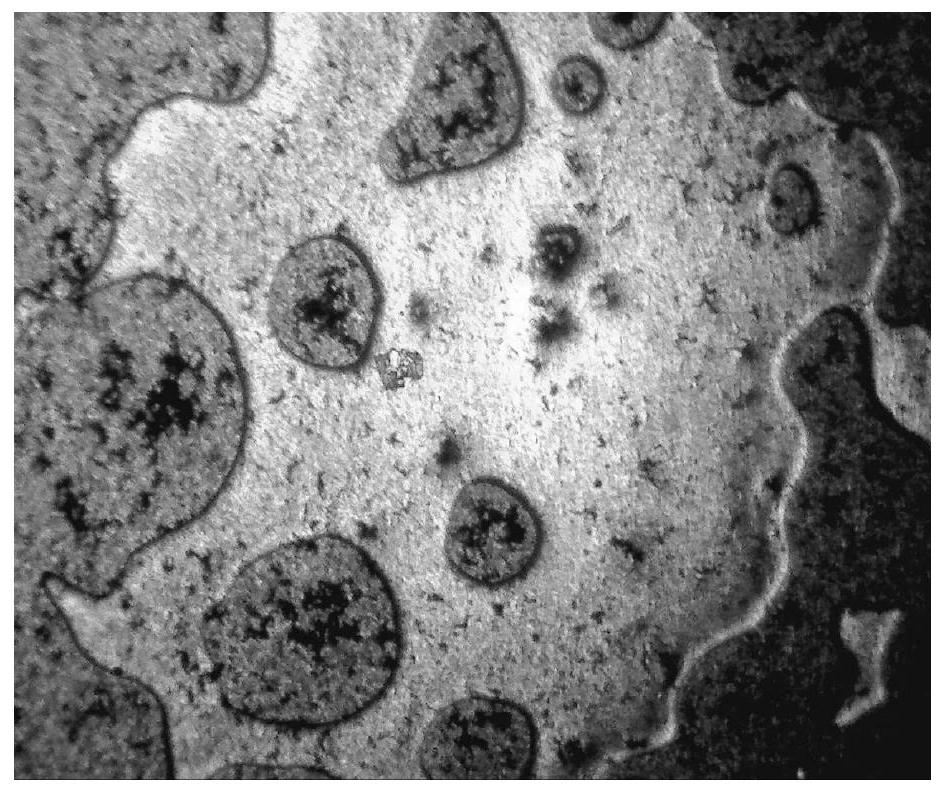

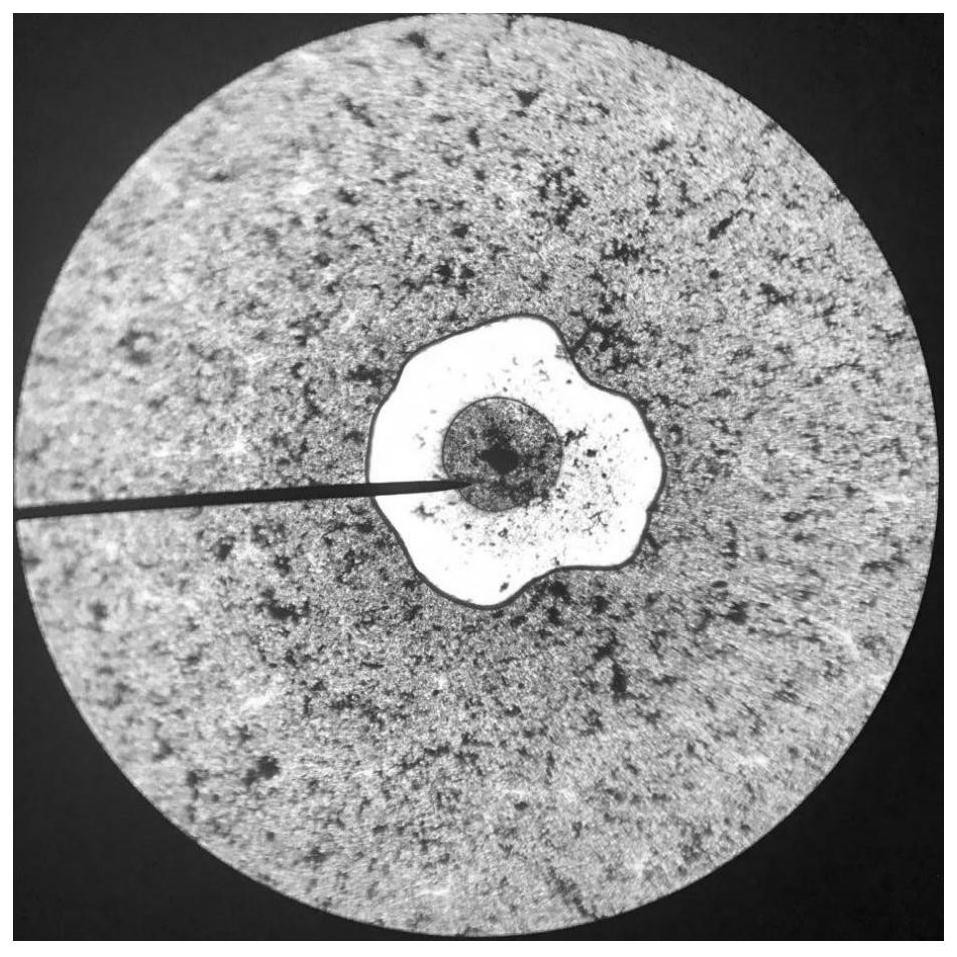

Low-pressure auxiliary infiltration preparation method for high volume fraction C/Cu composite material

The invention relates to a low-pressure auxiliary infiltration preparation method for a high volume fraction C / Cu composite material, which adopts a copper-based composite material and comprises the following steps: short carbon fiber and phenolic resin alcoholic solution are evenly mixed, prefabricated and formed by isostatic cool pressing, and persevere heat and are carbonized under the protection of Ar2; 1-10 percent of Ti, 1-10 percent of Sn, 1-5 percent of Cr, the balanced Cu are added into the carbonized short carbon fiber and phenolic resin alcoholic solution; and alloy pigs are obtained by melting; the alloy pigs are put on a prefabricated part according to a proportion of 4:1 of alloy pig to carbon fiber, pumped to be vacuum in an infiltration furnace and heated to be at infiltration temperature, Ar2 is charged and heat is preserved, infiltration is carried out under the condition of pressure maintaining, and a high content C / Cu composite material is obtained. The invention effectively increases the wetting property, reduces the reaction between alloy liquid and fiber, obtains the C / Cu composite material with high carbon volume fraction of 50-70 percent, decreases the damage to the prefabricated part by surface reaction, and simplifies the preparation process of the C / Cu composite material with high carbon volume fraction.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

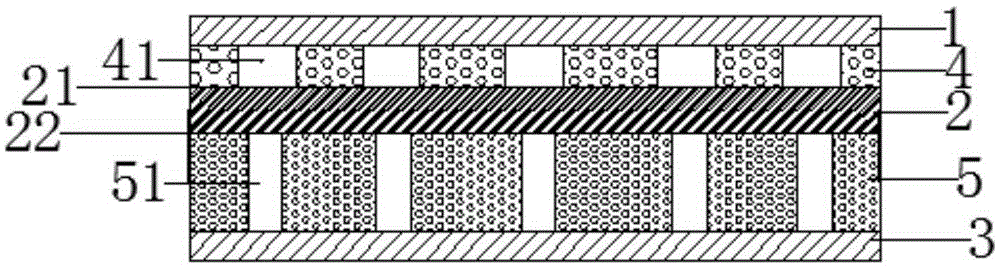

Composite absorbent health product absorbent paper manufacturing method

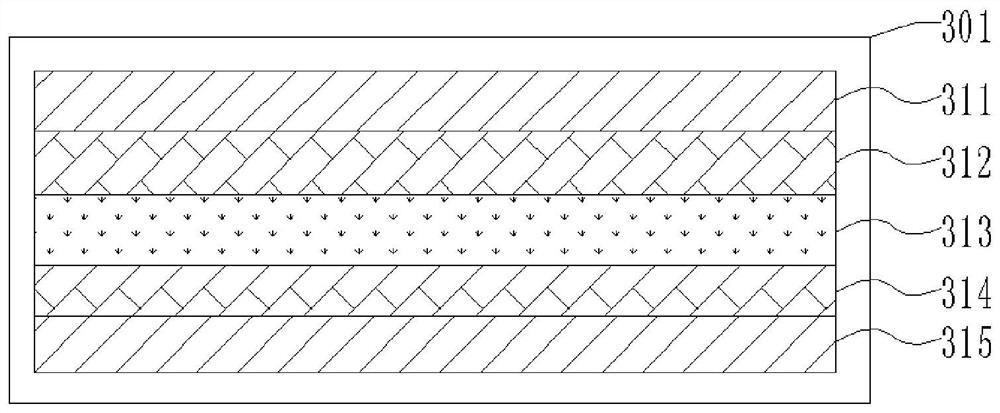

ActiveCN105266975ASimple processSimple and fast operationAbsorbent padsBandagesPaper manufacturingEngineering

The invention provides a composite absorbent health product absorbent paper manufacturing method .The composite absorbent health product absorbent paper manufacturing method comprises steps that, (1), upper high-molecular absorbent resin layers are distributed at a surface on which high-fluffy non-woven fabric is combined with an upper separating layer with a gap, and an upper diversion trench is formed at the gap portion; (2), the high-fluffy non-woven fabric distributed with the upper high-molecular absorbent resin layers is glued with the upper separating layer of which the surface is coated with hot melt adhesive, and the two parts are stitched and rolled; (3), lower high-molecular absorbent resin layers are distributed at a surface on which high-fluffy non-woven fabric is combined with a lower separating layer, and a lower diversion trench is formed at the gap portion; and (4), the high-fluffy non-woven fabric distributed with the lower high-molecular absorbent resin layer is glued with the lower separating layer of which the surface is coated with hot melt adhesive, and the two parts are stitched and rolled. According to the method, the structure of needed equipment is simple, operation is convenient, products manufactured by utilizing the method have properties of small dimensions, simple technology and relatively low cost, moreover, the absorption characteristic is obviously improved, and the core body utilization rate is improved.

Owner:TIANJIN SINOSH NEW MATERIAL TECH

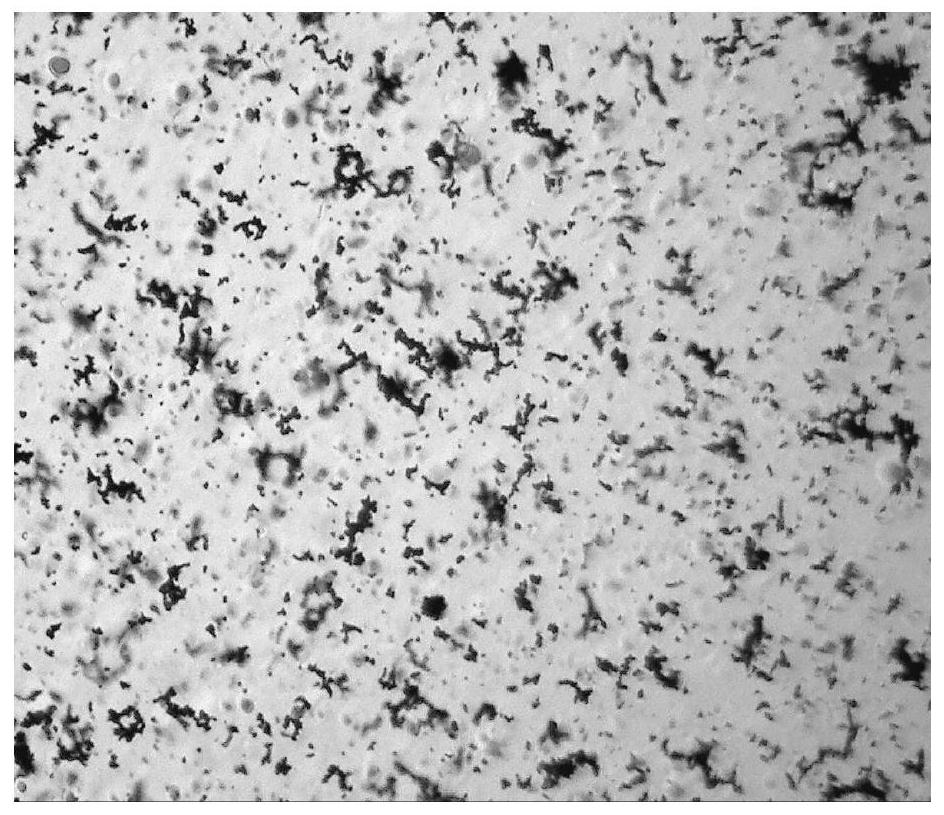

Preparation method of hybrid size for improving basalt fiber performance and modification method

A process for improving the performance of basalt fibers features that an ultrasonic forced continuous coating technique is used for coating hybridized slurry on the surface of each basalt fiber to improve its tension strength and the resistance to high temp. A process for preparing said hybridized slurry is also disclosed.

Owner:哈尔滨工业大学深圳研究院

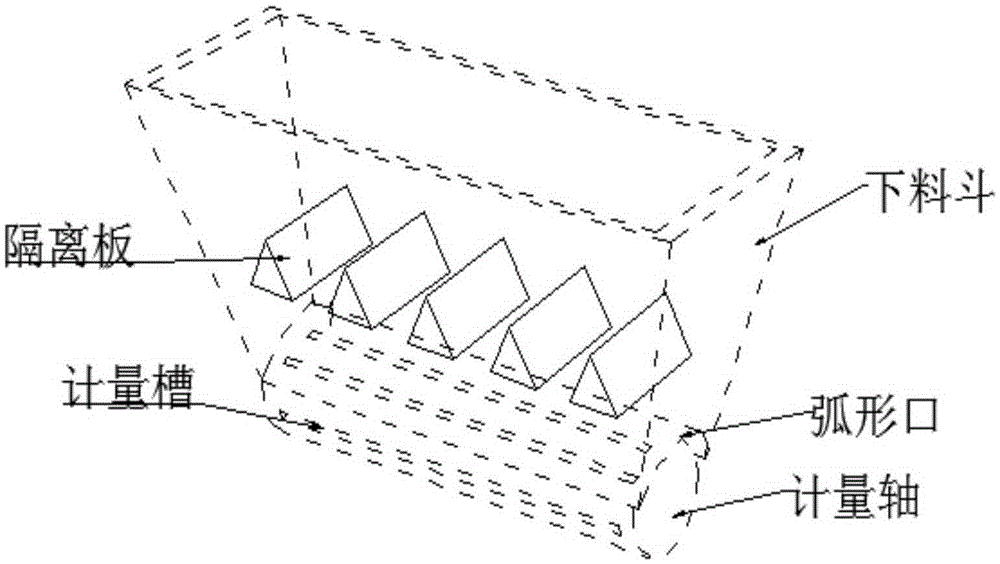

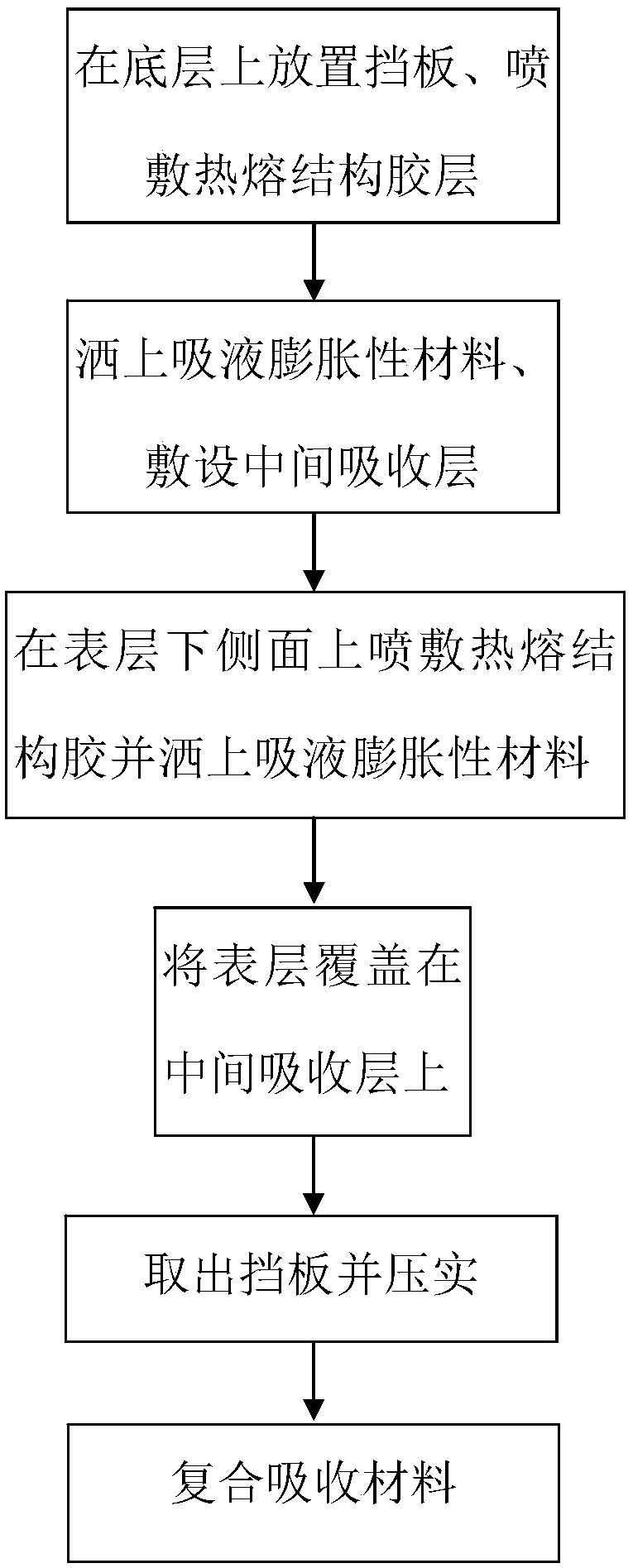

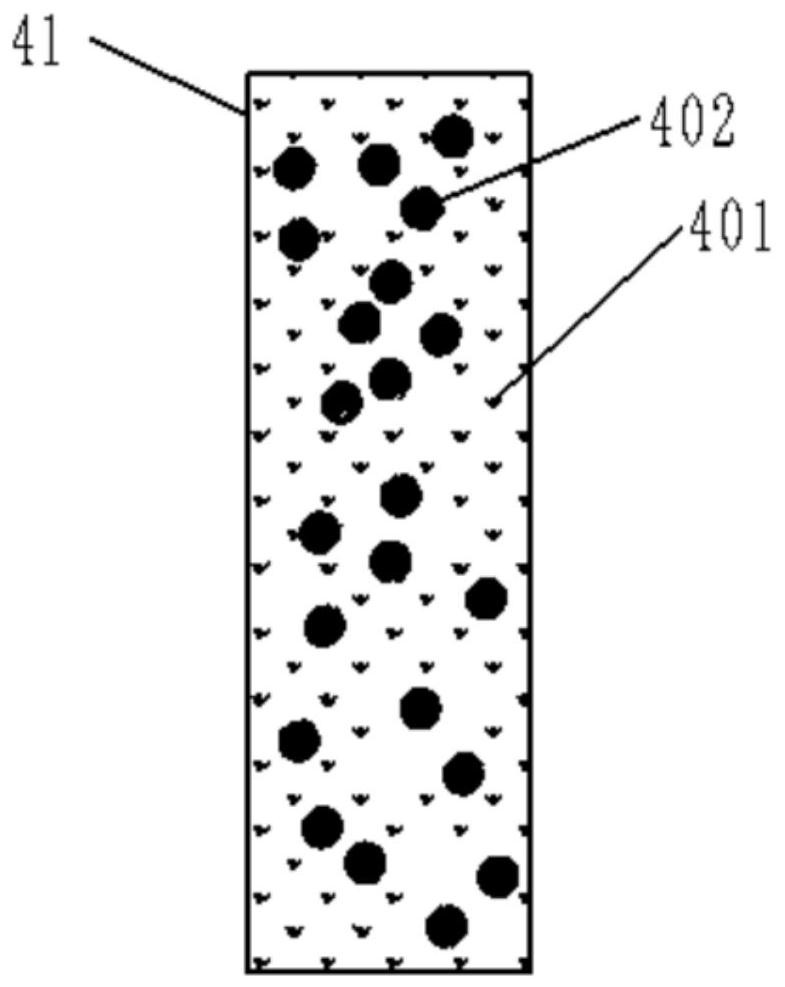

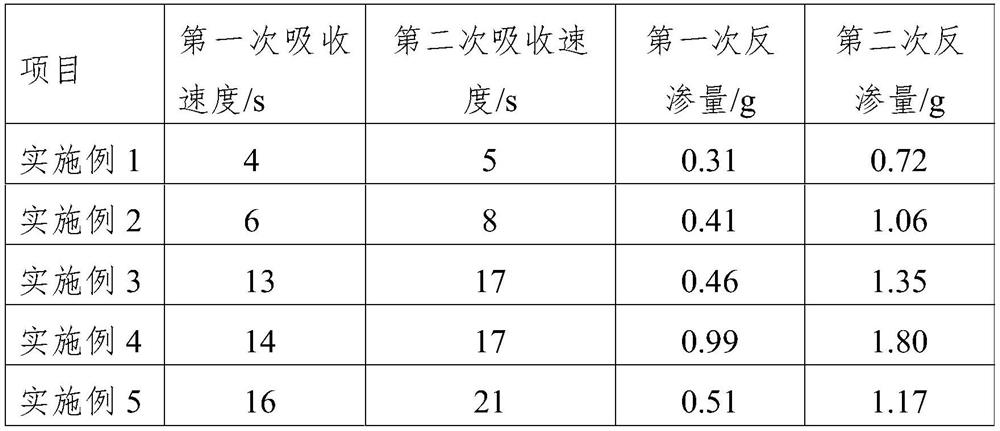

Method for preparing composite absorption core and composite absorption core prepared by method

ActiveCN107625583AImprove drynessLow back seepageSoil-shifting machines/dredgersShearing machinesBond lineComposite material

The invention discloses a method for preparing a composite absorption core and the composite absorption core prepared by the method. The method includes the steps: (1) spraying a first adhesive layeron the upper side face of a bottom layer; (2) sprinkling first imbibition materials for forming a lower water absorption layer on the upper side face of the bottom layer with the sprayed first adhesive layer, and laying a middle absorption layer on the upper portion of the lower water absorption layer; (3) spraying a second adhesive layer on the lower side face of a surface layer, and sprinkling second imbibition materials for forming an upper water absorption layer on the lower side face of a surface layer; (4) covering the middle absorption layer made of materials obtained in the step (2) with materials obtained in the step (3) in such a manner that the side face of the upper water absorption layer is downward; (5) compacting the materials to obtain the composite absorption core. The composite absorption core prepared by the method has the advantages of good dry and comfortable property, avoidance of lumping, fault and hardening in expansion, high liquid infiltration and diffusion speed, less return permeability and the like.

Owner:NUO CHEN CO LTD

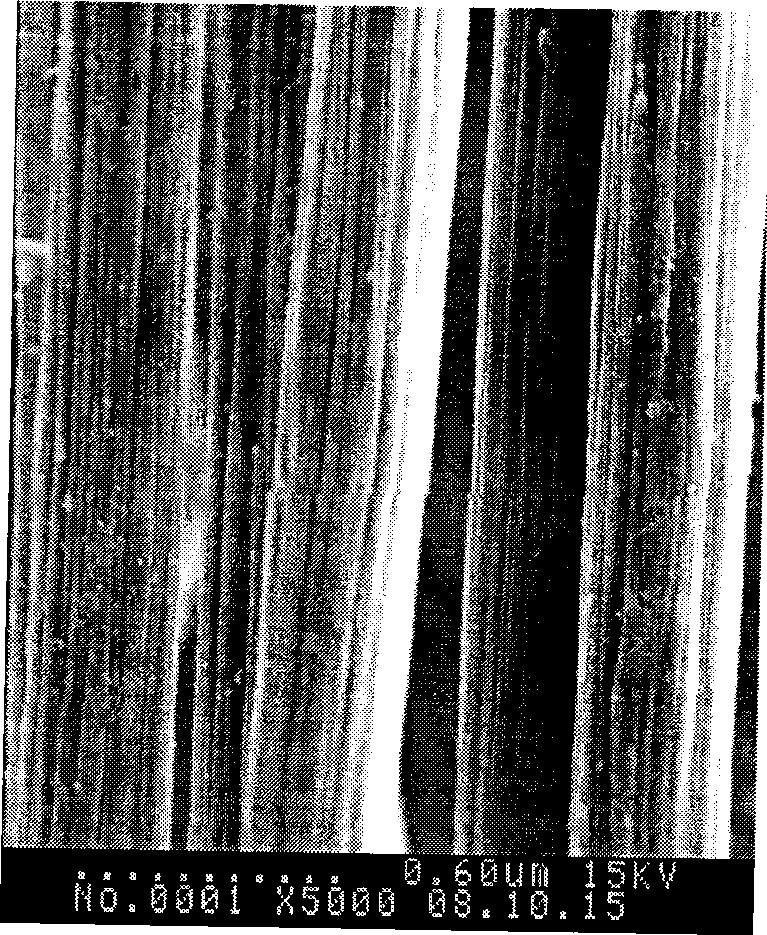

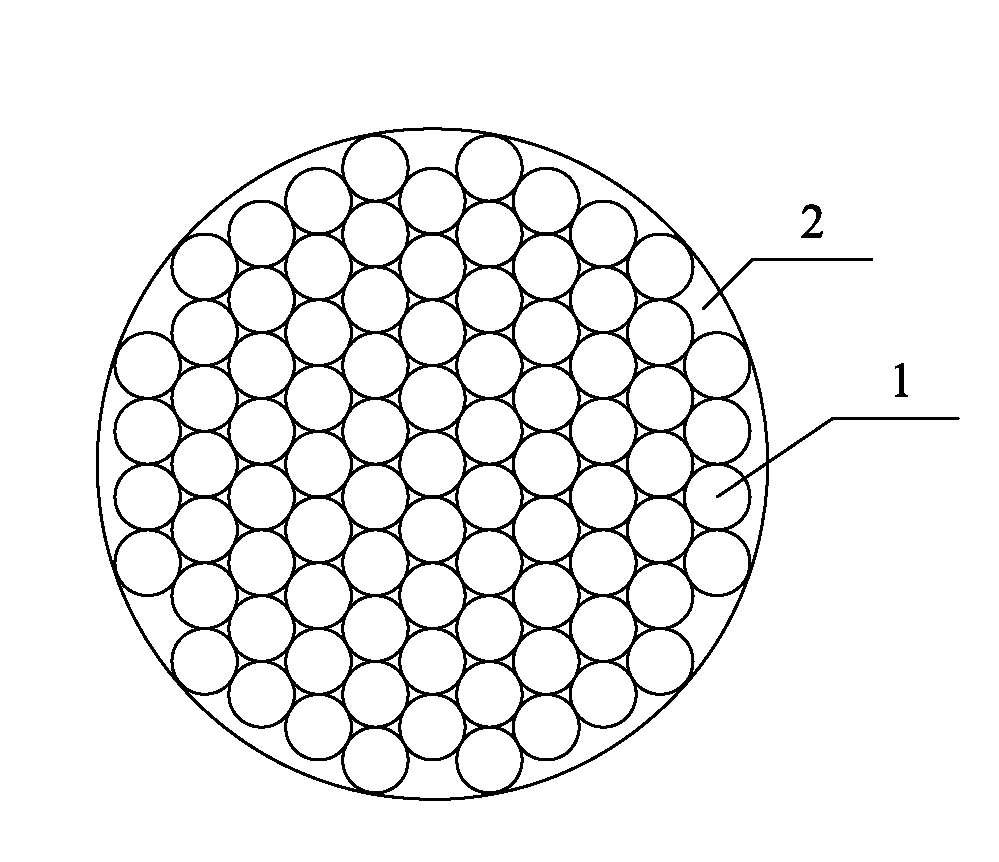

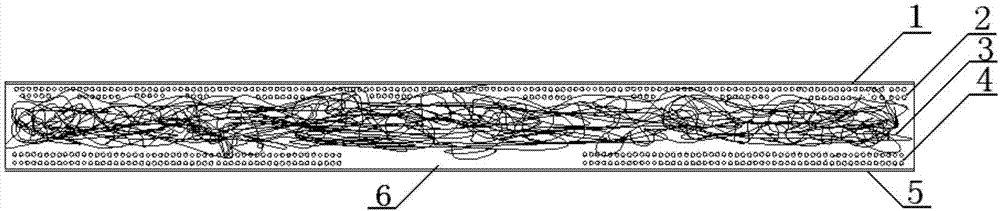

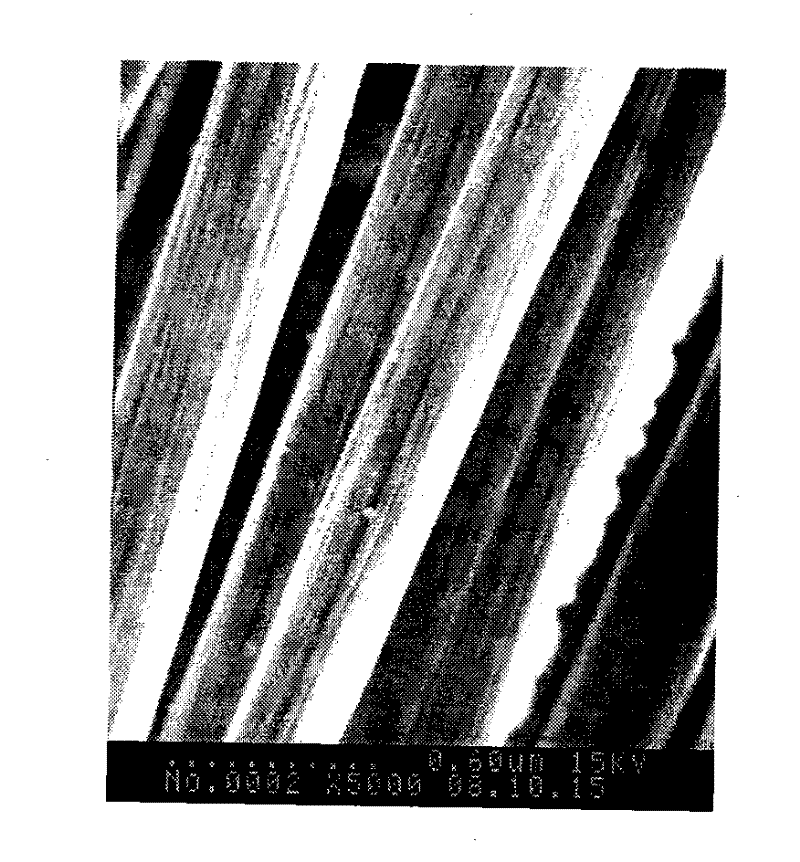

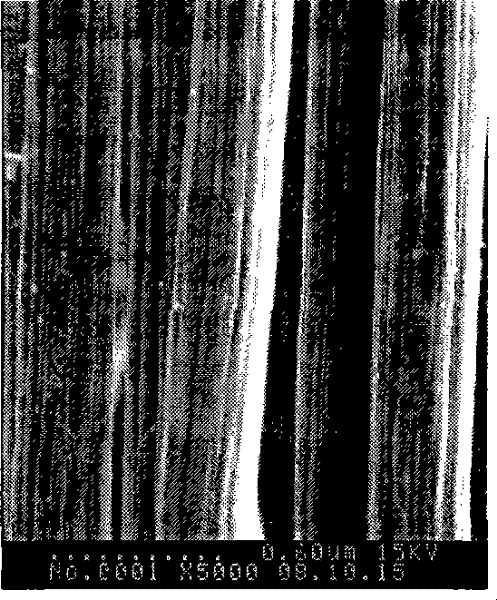

Monofilament-shaped ultrahigh molecular weight polyethylene fiber and continuous preparation method thereof

InactiveCN102797089AImprove wettabilityImprove adhesionPhysical treatmentAdhesivesPolymer scienceWhole body

The invention discloses a monofilament-shaped ultrahigh molecular weight polyethylene fiber and a continuous preparation method thereof. The monofilament-shaped ultrahigh molecular weight polyethylene fiber is formed by adhering 50-570 ultrahigh molecular weight polyethylene fibers to form a whole body in parallel, and a matrix resin layer is coated on an outer wall of the monofilament-shaped ultrahigh molecular weight polyethylene fiber. The continuous preparation method comprises the following steps of: (1) material selection: selecting 50-570 ultrahigh molecular weight polyethylene fibers; (2) performing fiber surface treatment; (3) twisting the fibers to form a single strand; (4) uniformly tensioning the fibers, and removing the static electricity; (5) sizing treatment; and (6) performing heat setting to form the monofilament-shaped ultrahigh molecular weight polyethylene fiber, and finally, winding into coils. According to the monofilament-shaped ultrahigh molecular weight polyethylene fiber and the continuous preparation method thereof, the wear resistance of the fiber is greatly improved on the premise of basically not influencing the strong performance of the fiber, the service life of the fiber can be greatly prolonged, complex special equipment is not required, and the construction cost is low; and moreover, the monofilament-shaped ultrahigh molecular weight polyethylene fiber can be widely applied to the fields of industry, national defense, sports, oceans and the like.

Owner:SHANDONG ICD HIGH PERFORMANCE FIBRES CO LTD

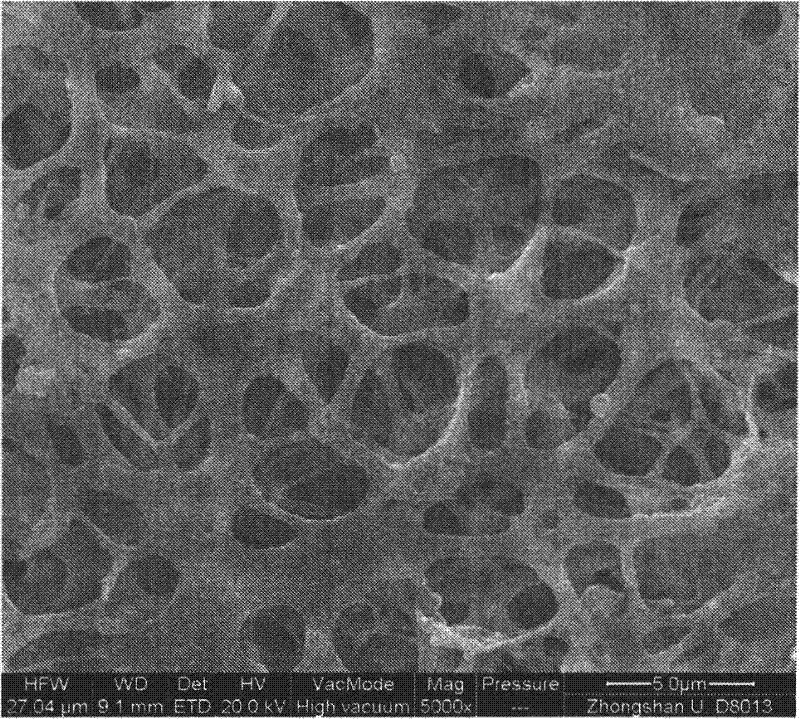

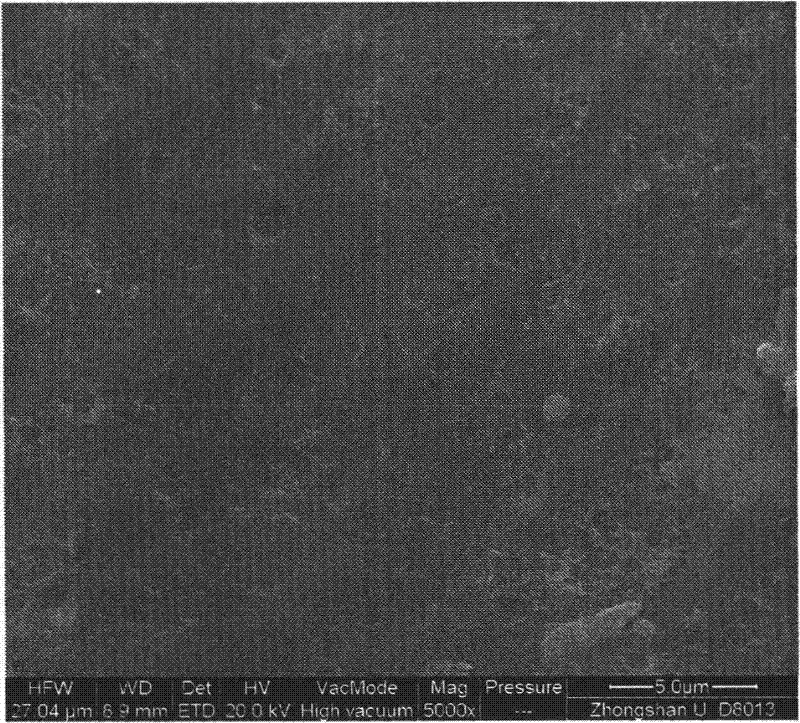

Novel PVC/rubber composite micropore partition board

InactiveCN102130314AIncrease elasticityImprove toughnessCell component detailsPolyvinyl chlorideCompressibility

The invention discloses a novel polyvinyl chloride (PVC) / rubber composite micropore partition board. The composite micropore partition board is characterized by consisting of the following components in percentage by weight: 30 to 80 percent of PVC resin, 0.1 to 20 percent of rubber, 0 to 50 percent of inorganic filling phase and 0.1 to 5 percent of conductive agent. The PVC / rubber composite micropore partition board provided by the invention has compressibility and high strength of plastic and resilience and high toughness of rubber, has good response to the volume change of a polar plate in the charge / discharge process of a battery, can play a good durable role in supporting active substances on the polar plate, effectively controls the separation of the active substances, and remarkably prolongs the service life of the battery.

Owner:SOUTH CHINA NORMAL UNIVERSITY

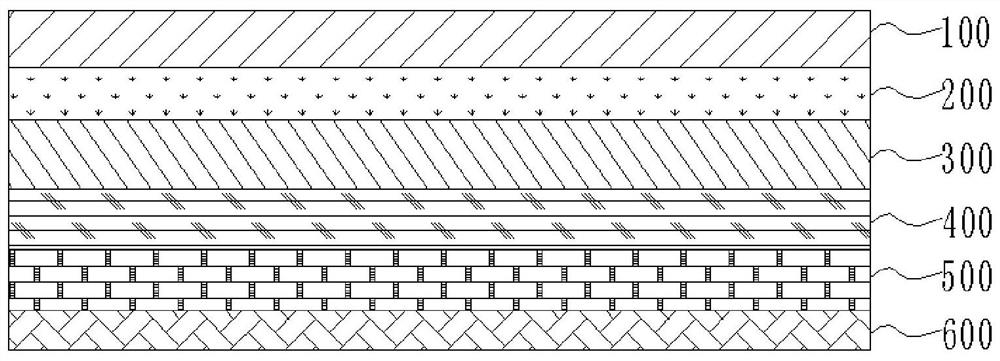

Quick-absorption dry and comfortable type absorption article and manufacturing method thereof

InactiveCN113693831AImprove drynessHelp infiltrationAbsorbent padsBandagesEngineeringNonwoven fabric

The invention provides a quick-absorption dry and comfortable type absorption article and a manufacturing method thereof and belongs to the technical field of hygienic products. The quick-absorption dry and comfortable type absorption article comprises an absorption main body, wherein the absorption main body sequentially comprises a liquid-permeable surface layer, a flow guide layer, a covering layer, an absorption layer, a breathable bottom layer and a bottom film non-woven fabric from top to bottom, wherein the flow guide layer is made of a China-hemp antibacterial material; the covering layer is made of at least one of non-woven fabric or super-absorbent resin absorbent paper; and the absorption layer comprises a first absorption layer and a second absorption layer, the first absorption layer is a convex absorption small core body, and the size of the convex absorption small core body is smaller than that of the second absorption layer. The absorption article provided by the invention has the properties of bacteriostasis, odor removal, high liquid infiltration speed, high absorptivity, good dryness and the like.

Owner:诺宸股份有限公司

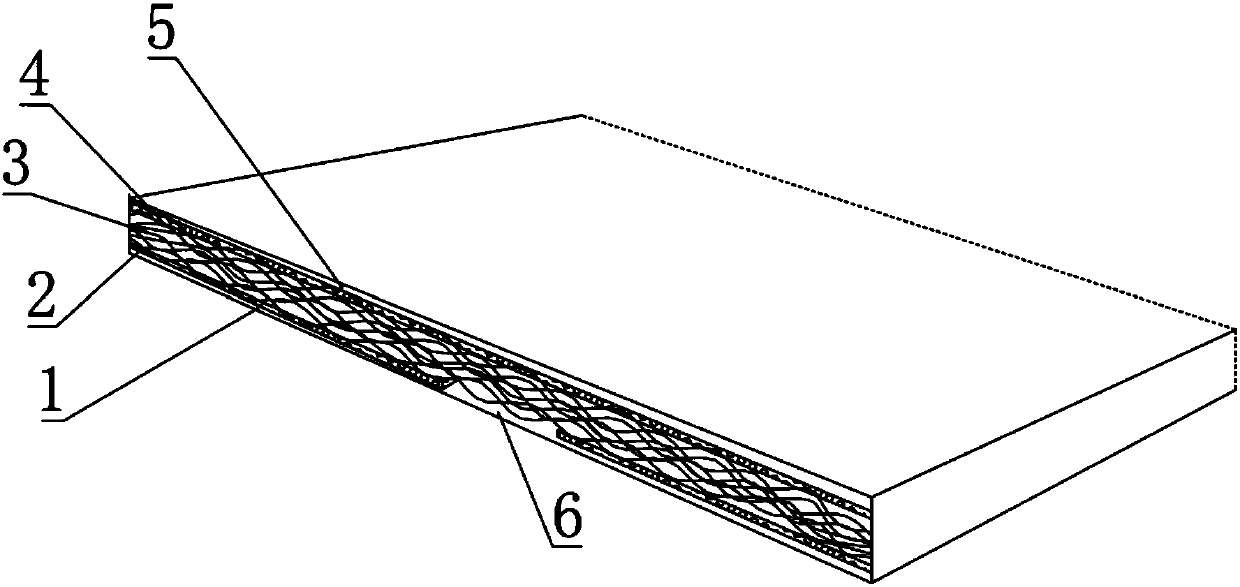

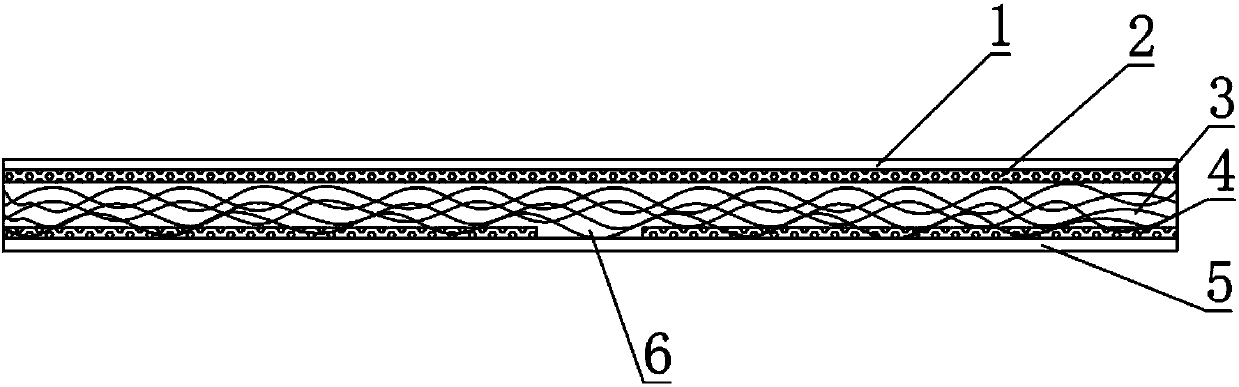

Composite absorption core body provided with imbibition self-expanding type liquid guiding channel and application thereof

ActiveCN107397628AImprove drynessLow back seepageSoil-shifting machines/dredgersShearing machinesSurface layerEngineering

The invention discloses a composite absorption core body. The composite absorption core body comprises a surface layer, an intermediate layer and a bottom layer in sequence from top to bottom. The intermediate layer comprises a water absorption layer made of liquid absorption expansion materials expanding after absorbing liquid, and an imbibition self-expanding type liquid guiding channel is formed in the water absorption layer. The invention further relates to an application of the composite absorption core body in manufacturing of an absorption product, especially a paper diaper. The composite absorption core body has the advantages of being good in drying performance and free of lumping and fracture and other advantages; and especially, the liquid guiding channel has the characteristic of self-expanding after imbibition, so that the composite core body or the absorption product comprising the core body further has the advantages of high liquid infiltration and diffusion speeds, small infiltration return amount and the like.

Owner:诺宸股份有限公司

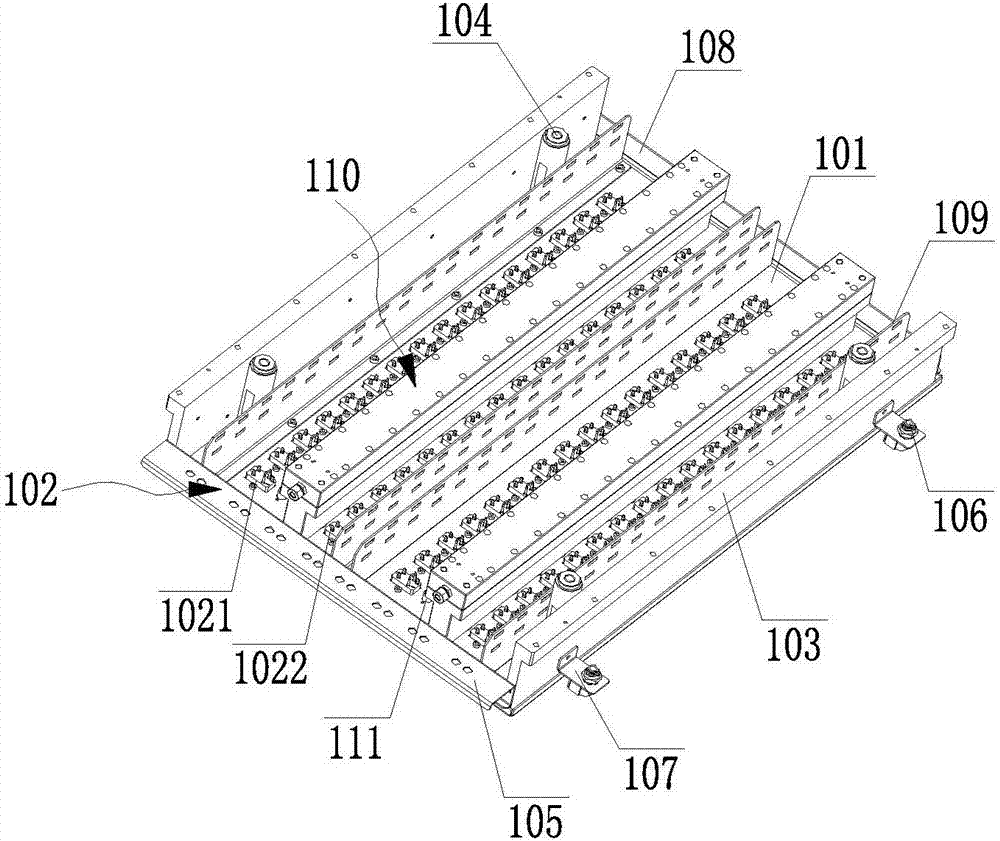

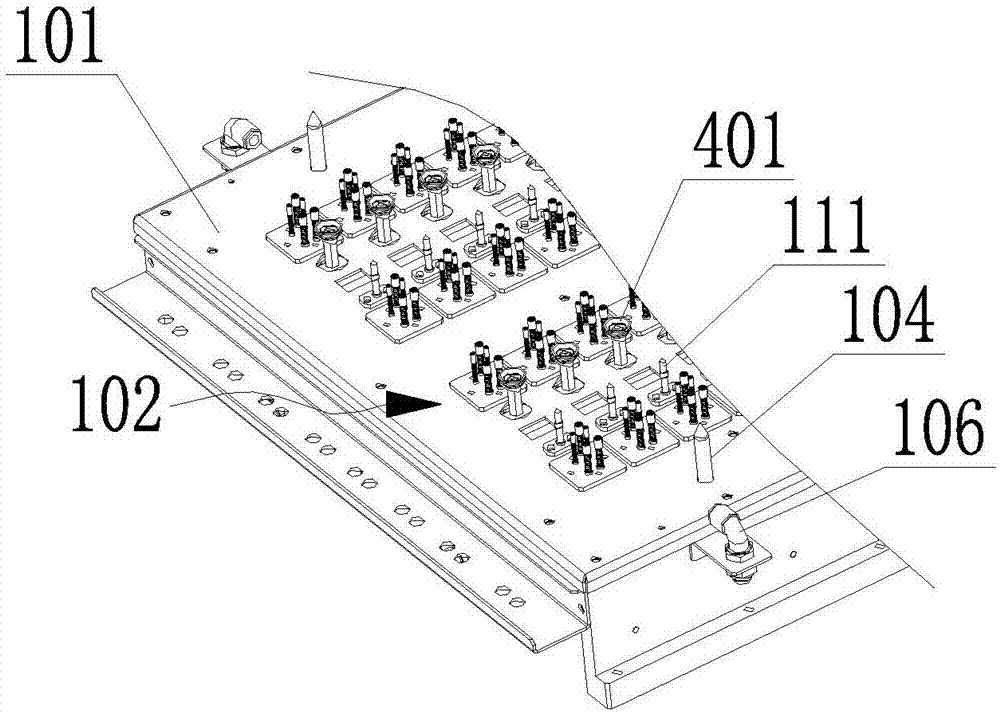

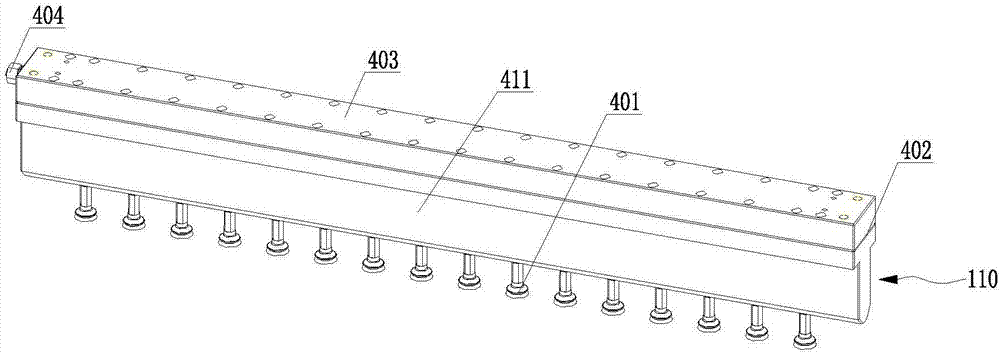

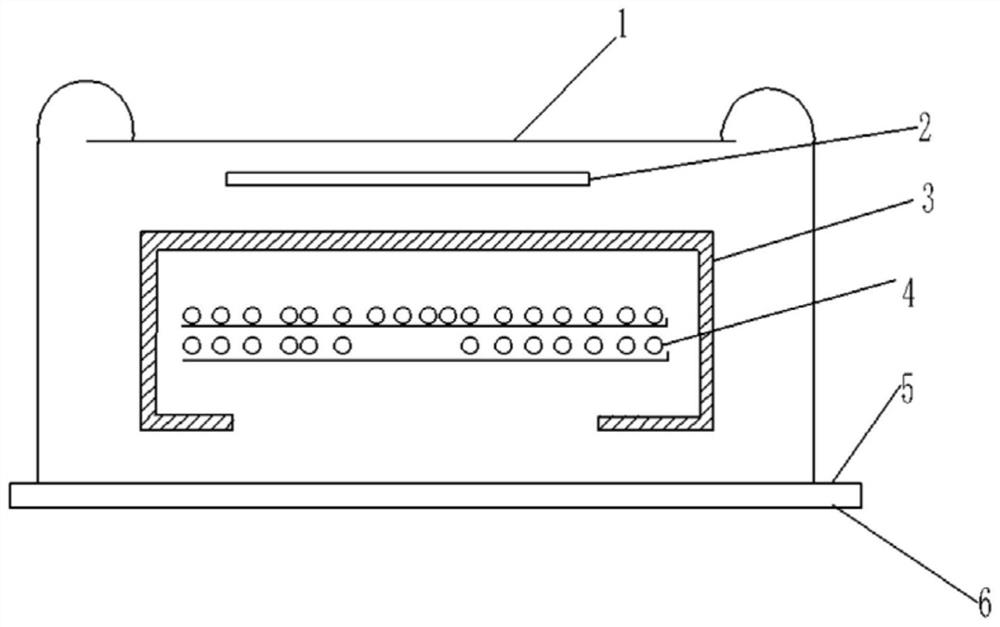

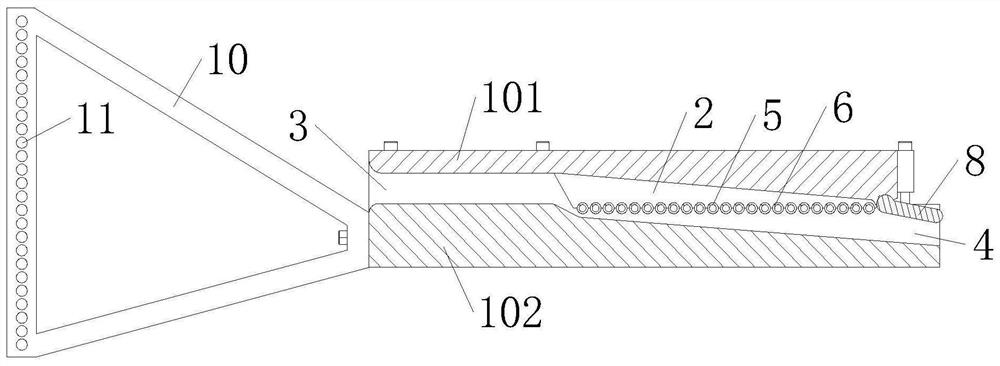

Novel formation needle bed probe module

ActiveCN107275679AWill not polluteImprove the operating environmentFinal product manufactureCell component detailsPressure systemEngineering

The invention relates to a novel formation needle bed probe module, which comprises a baseplate (101). A negative pressure device is disposed between a positive probe (1021) and a negative probe (1022) above the baseplate (101), the negative pressure device passes through the baseplate (101) and is located right above a lithium battery (802) liquid injection port (805) below the baseplate (101) bottom, the negative pressure device seals the liquid injection port (805) to form a negative pressure system. According to the invention, the liquid injection port is sealed in the formation process to form negative pressure, the negative pressure device collects toxic and corrosive gas generated in the formation process, performs centralized treatment, and does not discharge the toxic and corrosive gas into workshops and natural environment, thus improving the operation environment of operation staff, causing no pollution the environment, and being beneficial to environmental protection.

Owner:GUANGDONG HYNN TECH CO LTD

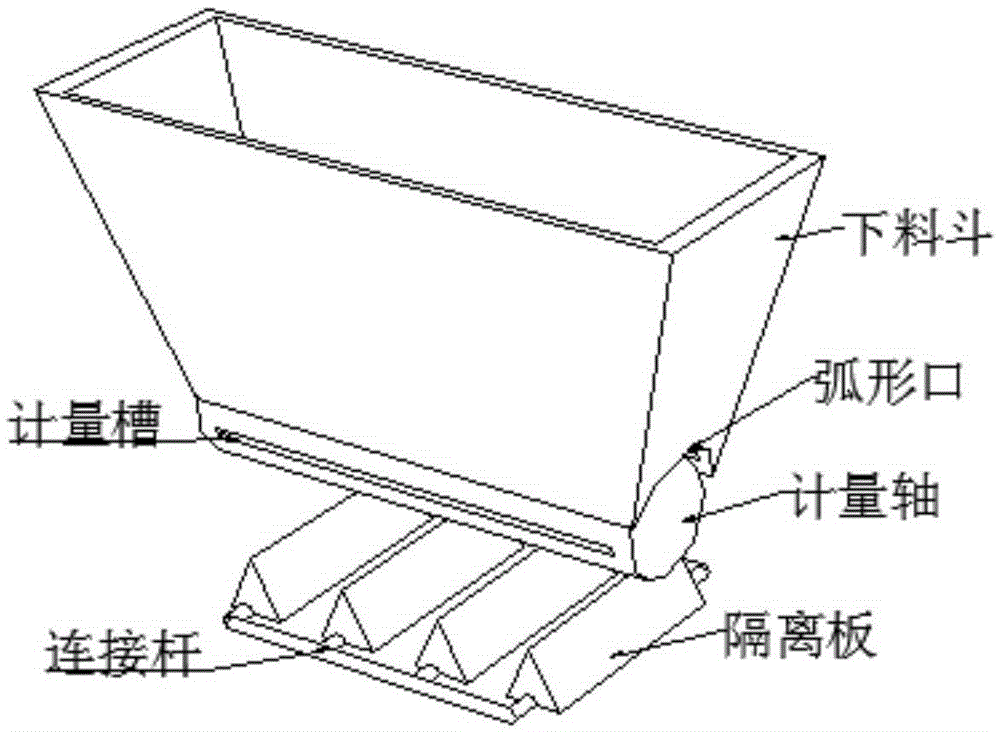

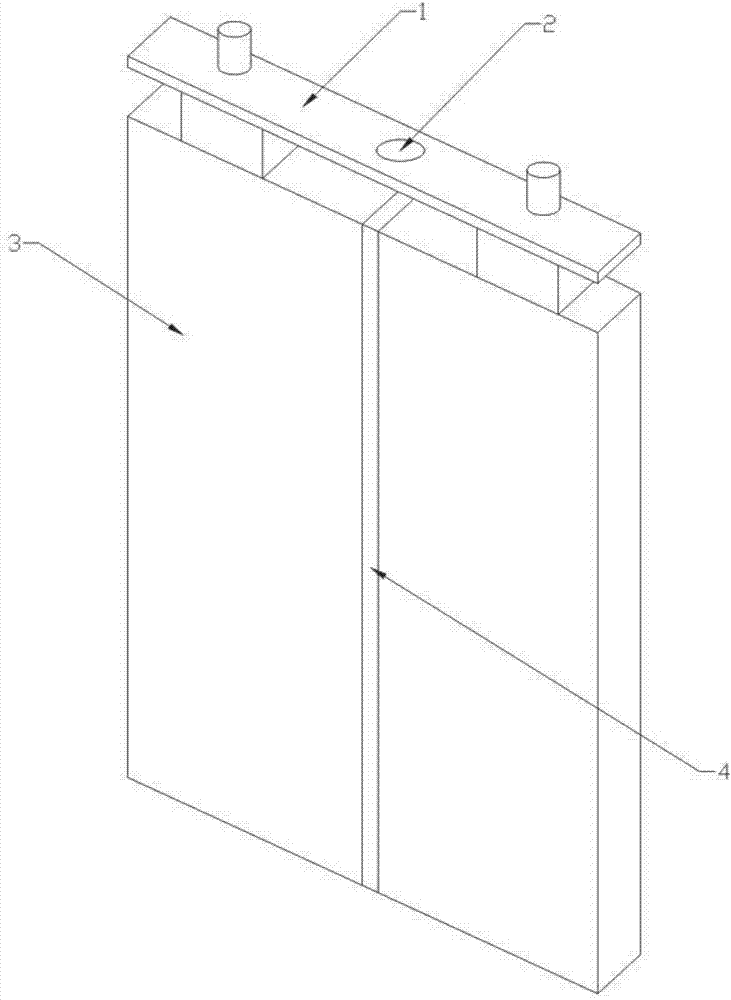

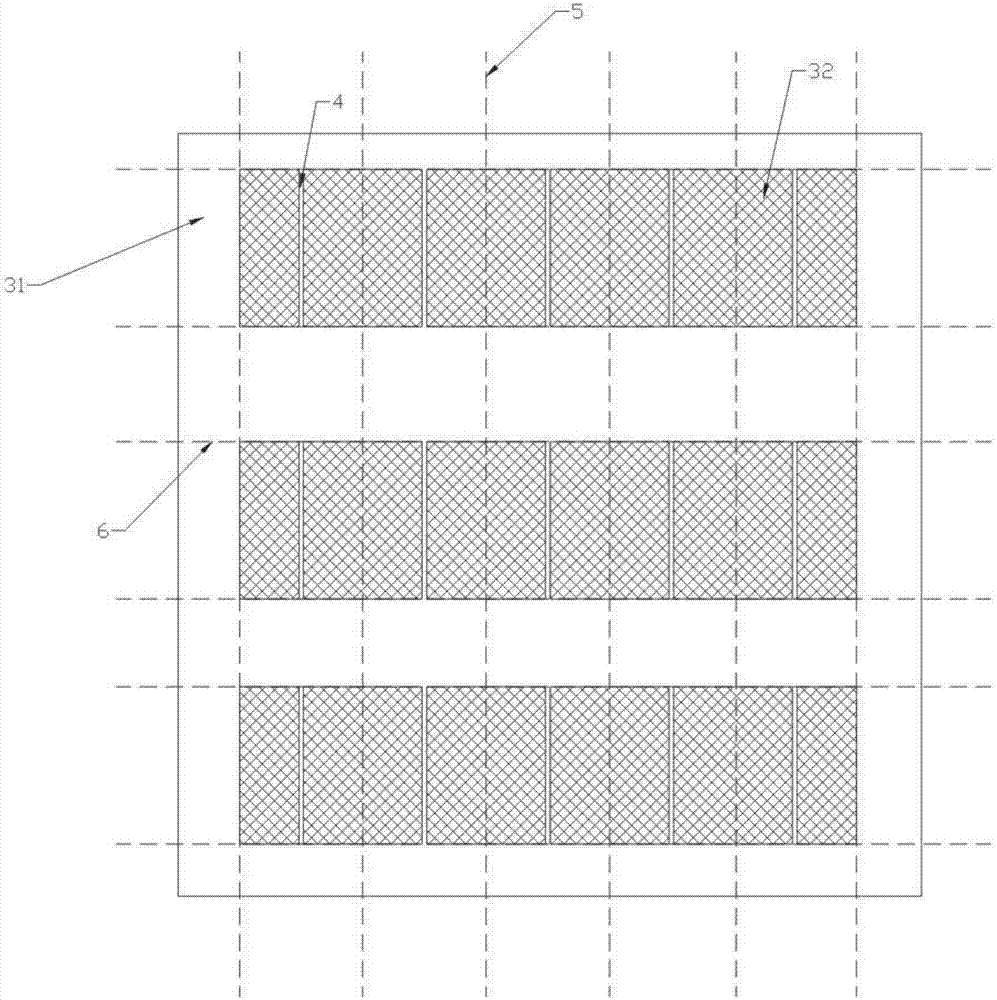

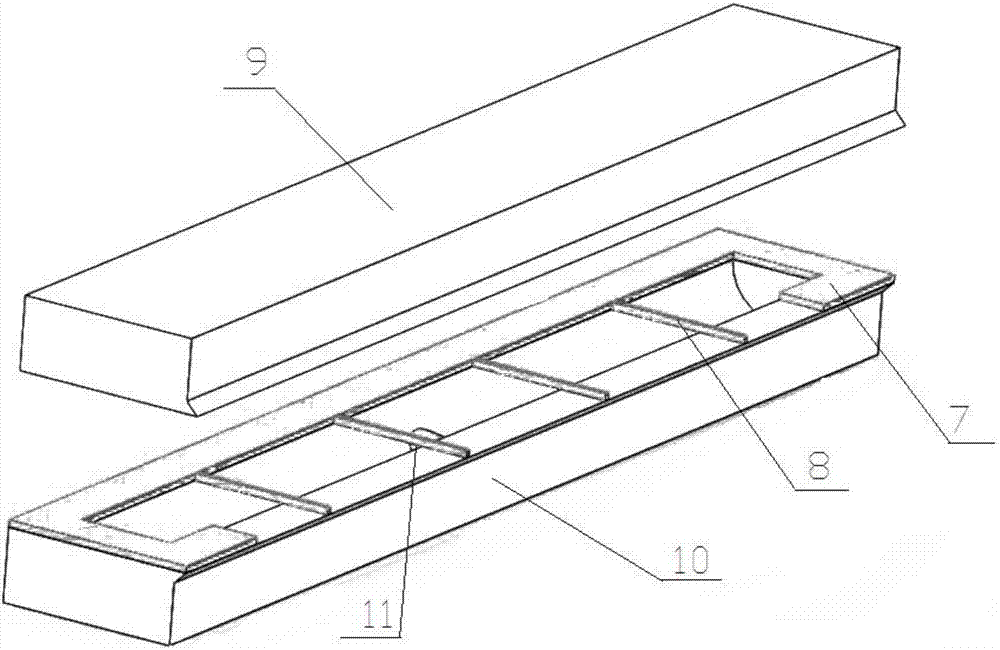

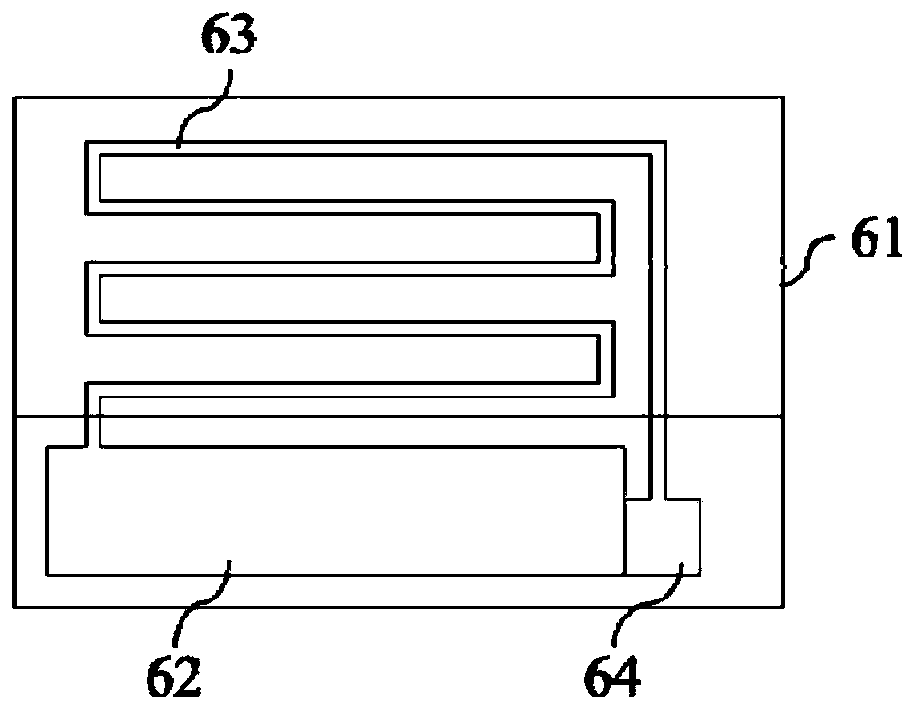

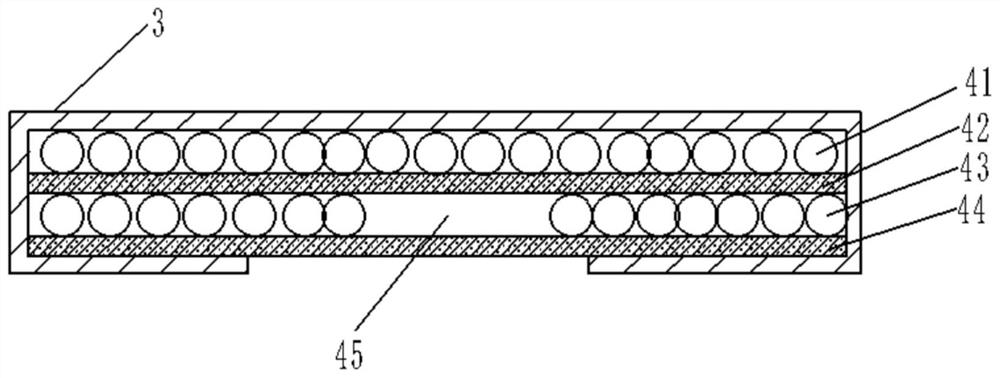

Fast-liquid-injection high-infiltration long-service-life lithium battery and manufacturing method and mold thereof

InactiveCN107403952AExtended service lifeIncrease injection speedFinal product manufactureCell component detailsSlurry coatingLiquid injection

The invention discloses a fast-liquid-injection high-infiltration long-service-life lithium battery and a manufacturing method and a mold thereof. The long-service-life lithium battery comprises a casing and a top cover, wherein the top cover seals a casing opening; a liquid injection opening is formed in the top cover; a plurality of mutually staggered and stacked positive and negative electrode plates are arranged in the casing; diaphragms are separated between the positive and negative electrode plates; each of the positive and negative electrode plates consists of a base plate and a slurry coating layer coating the surface of the base plate; a groove penetrating through the slurry coating layer to reach the base plate is at least formed in the positive electrode plate.

Owner:成都特隆美储能技术有限公司

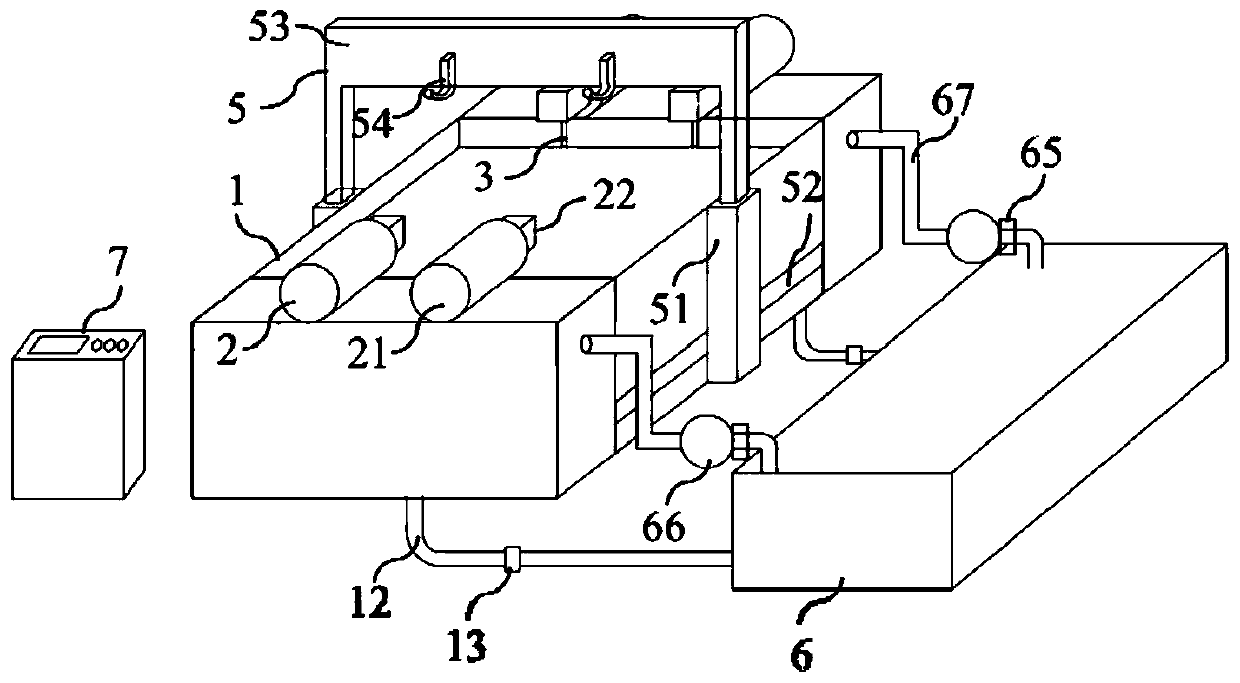

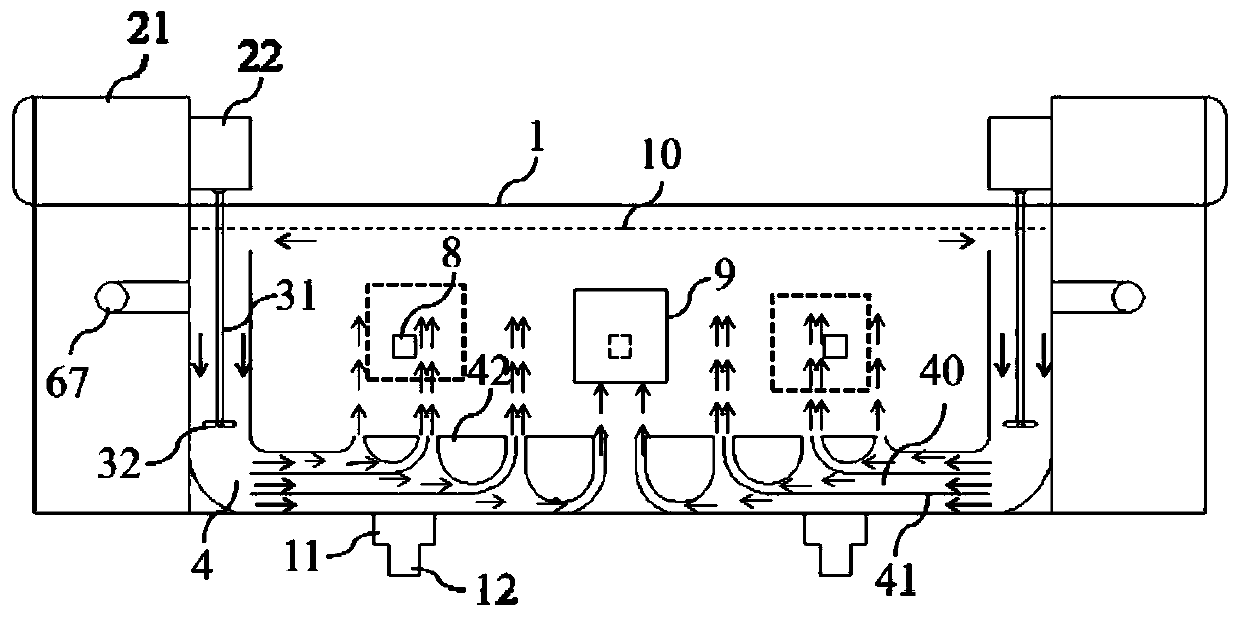

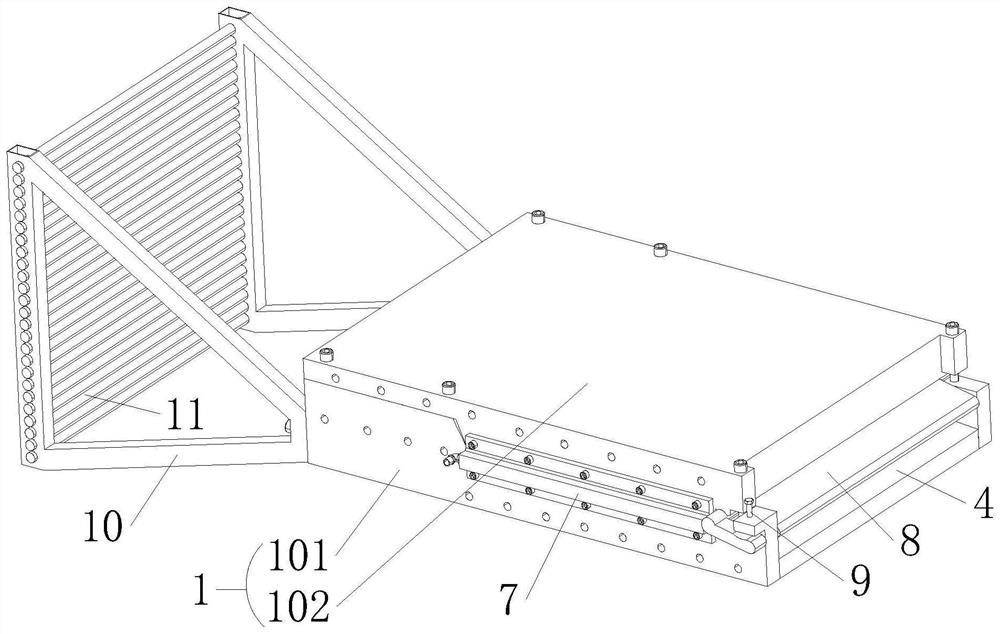

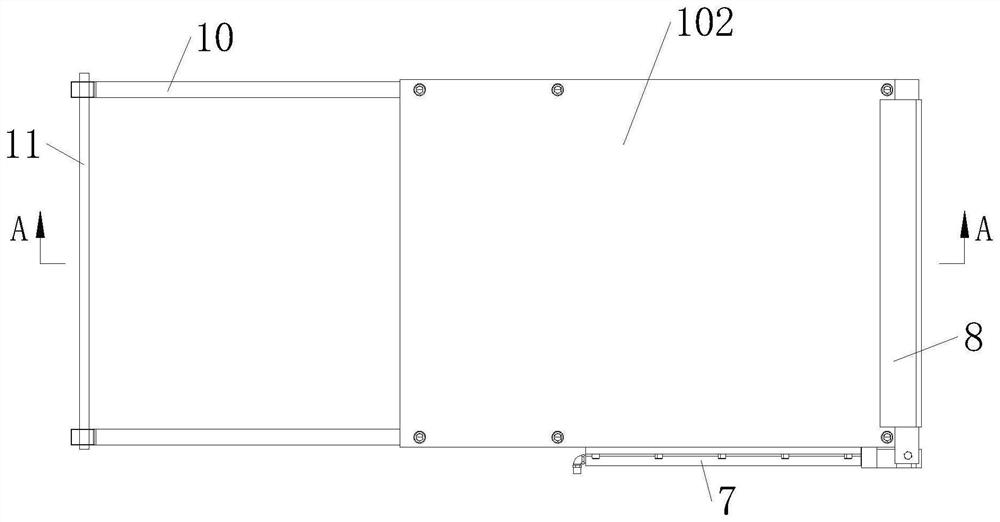

Quenching system and method for box-type workpieces

PendingCN111270054AIncrease infiltration speedSmall footprintFurnace typesHeat treatment furnacesReciprocating motionPropeller

The invention discloses a quenching system and method for box-type workpieces, and belongs to the technical field of heat-treatment quenching equipment. According to the quenching system and method for the box-type workpieces, the quenching system comprises a quenching pool body, a stirring system and a hoisting system capable of hoisting the workpieces back and forth. Stirring devices are symmetrically mounted on the two sides of the interior of the quenching pool body from above. A guide device is arranged between the stirring devices and comprises a plurality of layers of guide plates whichare distributed symmetrically, and a liquid flow in a quenching pool is controlled by means of the thrust of propeller blades in the stirring system and quenching liquid channels formed between the multiple layers of guide plates. A circulating and cooling system is connected to the outside of the quenching pool. When the temperature of a quenching medium is higher than an upper limit of the optimal service temperature, the circulating and cooling system is started to realize circulation and cooling of the quenching liquid.

Owner:马鞍山旭阳机械有限公司

Method for carbon fiber surface modification of plasma coated with nano colloidal sols by plasma treatment

InactiveCN101413209BImprove performanceImprove surface propertiesPhysical treatmentCarbon fibresFiberCarbon fibers

The invention relates to a method for modifying the surface of carbon fiber coated with nano sol through plasma treatment, which comprises the following steps: firstly, nano particles are prepared into an organic solvent, a sol solution of water or a sol solution prepared by hybridization reaction of a precursor solution of organic-inorganic nano particles by the ultrasonic vibrating technology; secondly, the sol solution is coated on the surface of the carbon fiber, treated by means of spray coating and padding, and dried; and thirdly, the dried carbon fiber is placed on a special transport unit for plasma processing equipment and a plasma is sprayed on the surface of the carbon fiber to make the carbon fiber move in the plasma atmosphere, so as to generate surface modification, wherein the treating power is between 10 and , watts, and the treatment time is between 0.5 and 300 seconds. The method can effectively improve the performance of the fiber, improves the molded manufacturability and the overall properties of composite materials of the fiber, has simple technology, quick processing speed, good treatment effect and low cost, is convenient to operate and difficult to cause environmental pollution, can reduce energy consumption, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

Lung moistening and cough stopping peach jam

InactiveCN105767993ASweet and sour tasteSoft tasteFood preservationCheese manufactureSalty tasteVitamin C

The present invention discloses a lung moistening and cough stopping peach jam. The lung moistening and cough stopping peach jam is made from the following raw materials: peaches, pears, white fungus, lily bulbs, tofu, duck eggs, crystal sugar, towel gourd flowers, asparagus schoberioides, Chinese wolfberry roots, common rue herb, cochinchina leafflower herb, solanum melongena roots, herb of bastardtoadflax-like swallowwort, glutinous rice powder, citric acid, and vitamin C. The product tastes sweet and sour, is mellow in fruit flavor and rich in nutrition, and can harmonize blood and stimulate menstrual flow, clear away heat and toxic materials, relieve inflammation and stop pains, harmonize stomach and moisten lungs, and reduce phlegm and relieve cough. The peach jam is abundant in raw materials, comprehensive in nutrition, scientific in compatibility, supplementary to each other, and obvious in lung moistening and cough stopping effects; the tofu is soaked with hot edible salt water, so that the jam is sweet with some salty taste and rich in mouthfeel; the traditional Chinese medicines are crushed, the crushed traditional Chinese medicines are subjected to twice extractions, the active ingredients are fully obtained, so that the traditional Chinese medicines are high in utilization rate and save costs; each of the components are added sequentially into a peach pulp, the raw materials are homogenized and the homogenized material is subjected to low-temperature and long-time sterilization, so that the active ingredients are fully integrated, the bitterness of the traditional Chinese medicines is removed, the mouthfeel is soft, the tissue is delicate, and the peach jam is sour, sweet and palatable, and easy to absorb; and after being filled, the peach jam is subjected to ultraviolet sterilization, the shelf life is prolonged, and the consumption is safe and healthy.

Owner:阜阳市颍州区金湖丰种植农民专业合作社

Method for carbon fiber surface modification of plasma coated with silicon dioxide by plasma treatment

InactiveCN101413210BImprove surface propertiesImprove performancePhysical treatmentCarbon fibresFiberCarbon fibers

The invention relates to a method for modifying the surface of carbon fiber coated with nano dioxide sol through plasma treatment, which comprises the following steps: firstly, nano silicon dioxide is prepared into an organic solvent, a sol solution of water or a sol solution prepared by hybridization reaction of a precursor solution of organic-inorganic nano particles and silicon dioxide nano particles by the ultrasonic vibrating technology; secondly, the sol solution is coated on the surface of the carbon fiber, treated by means of spray coating or padding and so on, and dried; and thirdly, the carbon fiber is placed on a plasma transport unit and a plasma is sprayed on the surface of the carbon fiber to generate modification, wherein the treating power is between 10 and 15,000 watts, and the treatment time is between 0.5 and 300 seconds. The method can effectively improve the performance of the carbon fiber, improves the molded manufacturability and the overall properties of composite materials of the carbon fiber, has simple technology, quick processing speed, good treatment effect and low cost, is convenient to operate and difficult to cause environmental pollution, can reduce energy consumption, and is suitable for industrial production.

Owner:DONGHUA UNIV +1

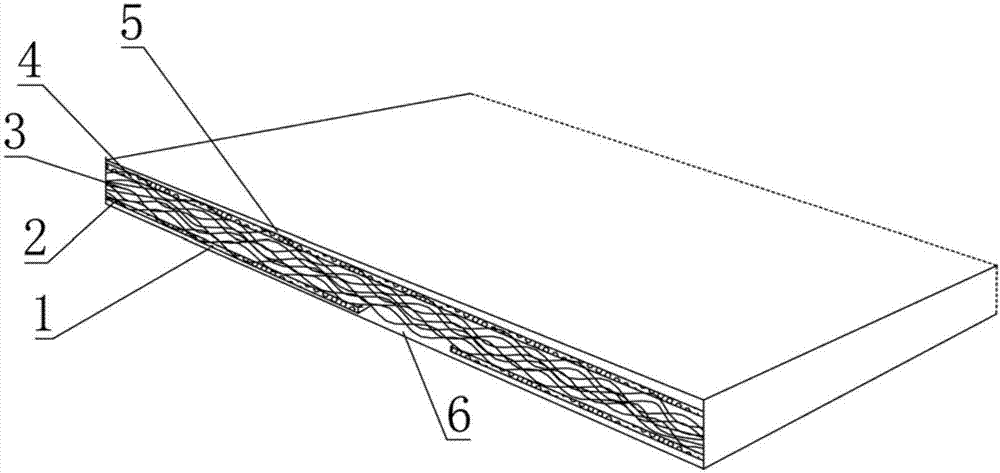

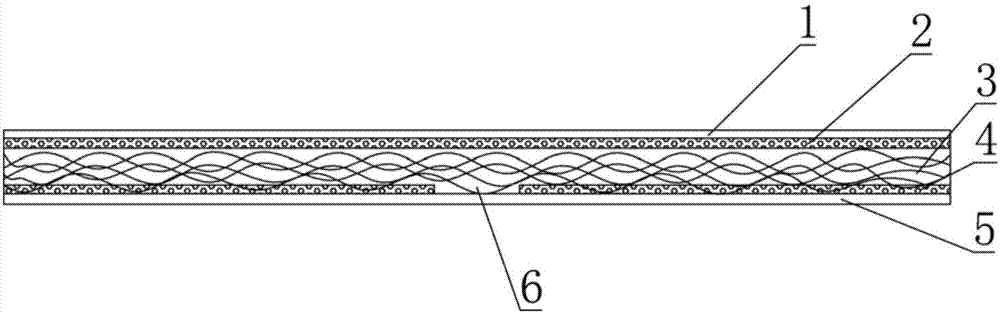

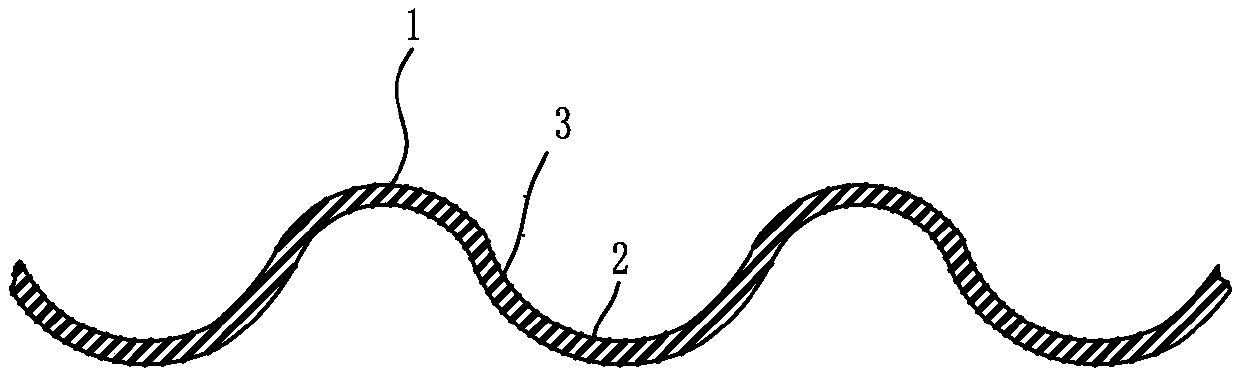

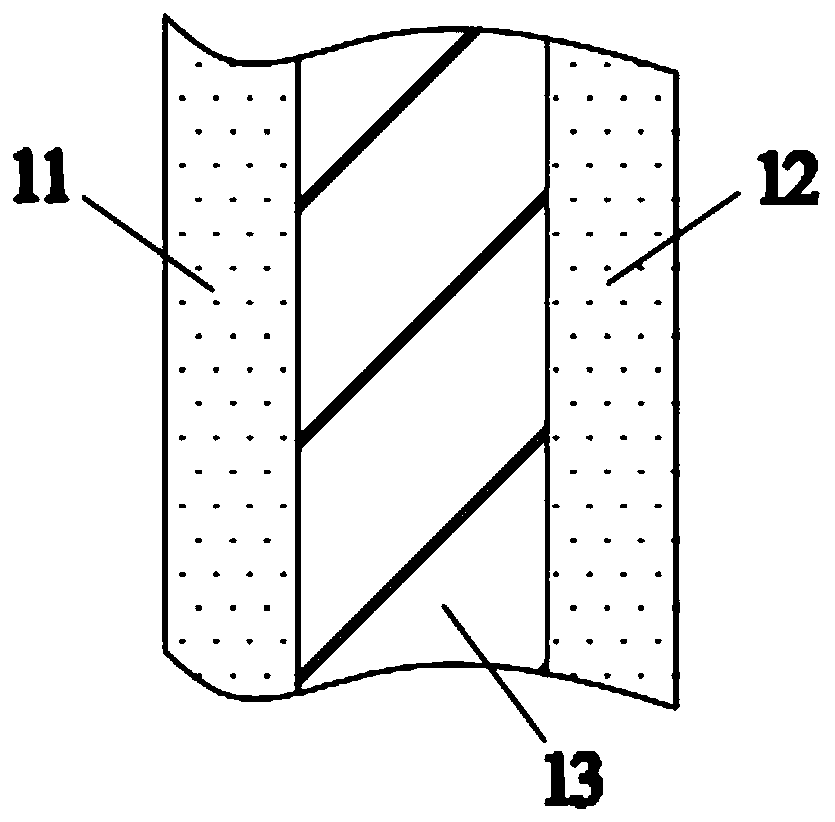

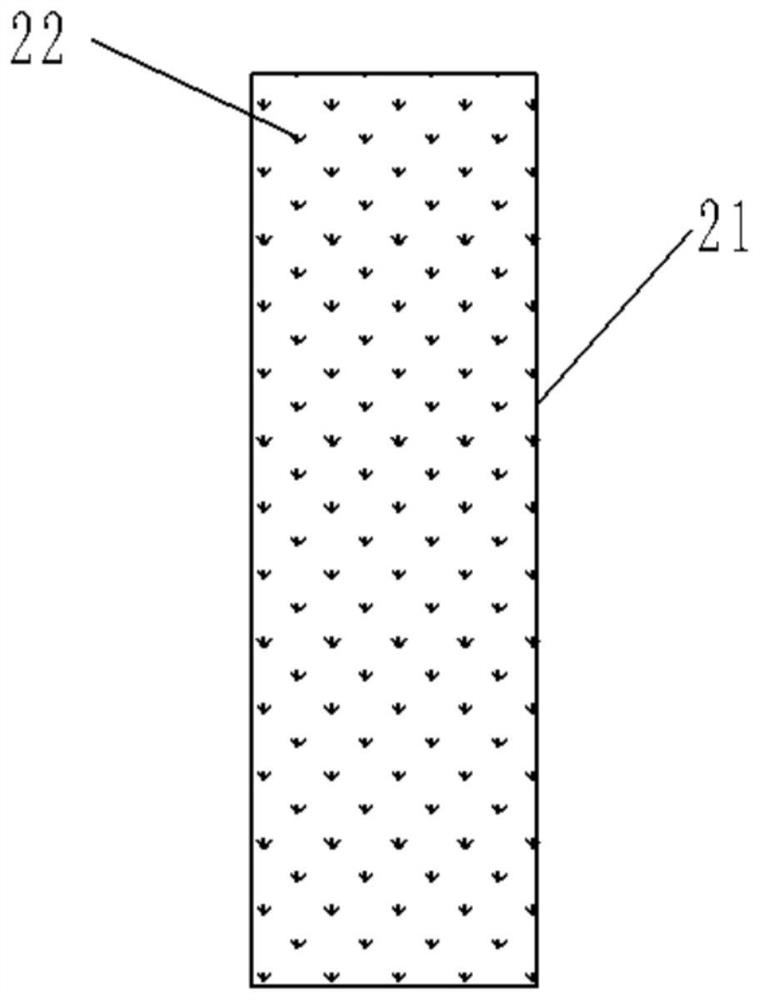

Concave-convex hot-air non-woven fabric and application thereof in paper diaper and paper diaper

ActiveCN107904786AEnhance water absorption and infiltration speedFast absorption and penetrationPattern makingLiquid/gas/vapor removalWoven fabricSurface layer

The invention relates to the field of non-woven fabric materials, in particular to a concave-convex hot-air non-woven fabric. The raw material of the concave-convex hot-air non-woven fabric is repeatedly hydrophilic bi-component fiber, a surface layer is provided with a plurality of hydrophobic convex points protruding upwards, and hydrophilic convex surfaces are arranged between the adjacent convex points. The concave-convex hot-air non-woven fabric has the advantages that the absorption and infiltration speed is high, and the surface layer is dry and comfortable.

Owner:HANGZHOU COCO HEALTHCARE PRODS

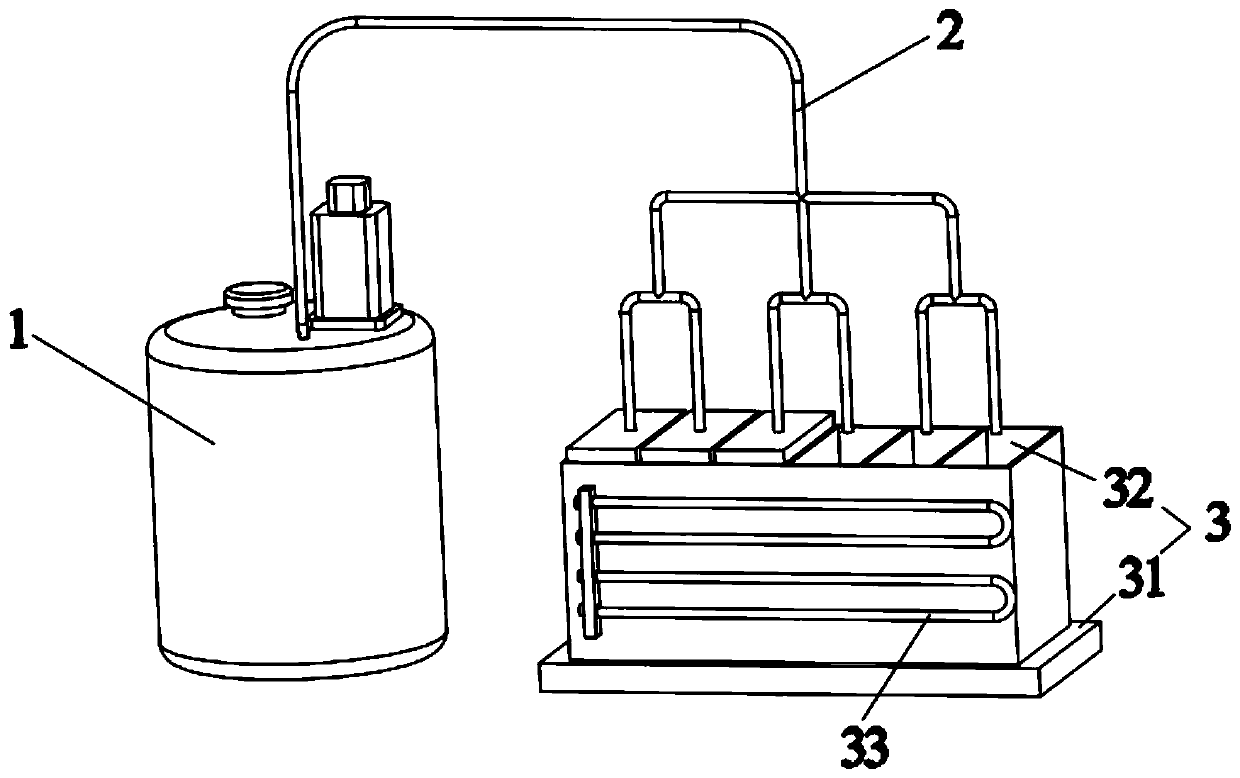

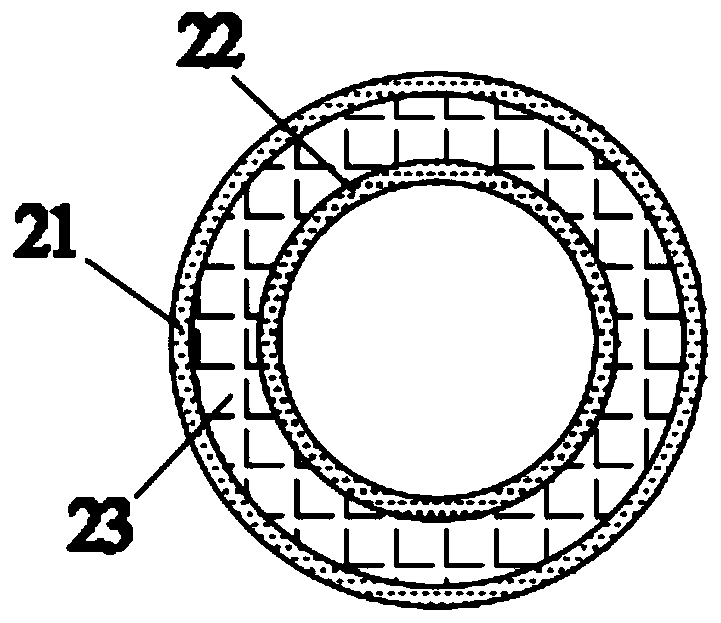

Liquid injection device and method of lithium ion battery

PendingCN110021733AImprove efficiencyImprove stabilitySecondary cellsCell component detailsLiquid storage tankEngineering

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a liquid injection device of a lithium ion battery. The liquid injection device comprises a liquid storage tank, a liquid injection pipe and a fixture, wherein the liquid storage tank communicates with the liquid injection pipe, the liquid injection pipe is arranged on the fixture, the liquid storagetank comprises an outer tank wall layer and an inner tank wall layer, a closed first cavity is formed between the outer tank wall layer and the inner tank wall layer, and a first heating body is arranged in the first cavity. By the first heating body, the liquid storage tank and an electrolyte can be heated, the viscosity of the electrolyte is reduced, and the liquid injection efficiency and theimmersion efficiency of a battery cell are improved; and moreover, the heating stability and consistency of the liquid storage tank also can be improved, and influence on uniform heating of the liquidstorage tank and the electrolyte due to overheat is prevented. Moreover, the invention also discloses a liquid injection method of the lithium ion battery.

Owner:东莞天予天正新能源科技有限公司

A kind of synthetic method of water-absorbing resin

ActiveCN106987075BHigh absorption rateHigh pressure absorption capacityCross-linkAbsorption capacity

Owner:SHANDONG NUOER BIOLOGICAL TECH

Absorption article for inhibiting bacteria and removing odor and manufacturing method thereof

InactiveCN113712739AExtended service lifeIncrease infiltration speedSanitary towelsBandagesBiotechnologyMicrobiology

The invention relates to an absorption article for inhibiting bacteria and removing odor and a manufacturing method thereof, and belongs to the technical field of hygienic products. The absorption article for inhibiting bacteria and removing odor comprises an absorption body, and the absorption body sequentially comprises a liquid-permeable surface layer, an antibacterial and odor-removing layer, a wrapping layer, an absorption layer, a breathable bottom layer and a bottom film non-woven fabric from top to bottom, wherein the antibacterial and odor-removing layer is prepared from an outer wrapping film and an antibacterial and odor-removing material arranged in the outer wrapping film, the outer wrapping film adopts a hydrolyzable film, and the antibacterial and odor-removing material adopts a plant antibacterial and odor-removing extract; and the absorption layer is provided with a flow guide structure. The absorption article disclosed by the invention has the properties of bacteriostasis, odor removal, high liquid infiltration speed, high absorptivity, good dryness and the like.

Owner:诺宸股份有限公司

Mosquito-repelling absorption article and manufacturing method thereof

InactiveCN113520728AGood mosquito repellentEasy to useBiocidePest repellentsBiotechnologyActivated carbon

The invention provides a mosquito-repelling absorption article and a manufacturing method thereof, and relates to the technical field of hygienic products. The mosquito-repelling absorption article comprises a liquid-permeable surface layer, covering cloth, an absorption layer, a breathable bottom layer, a bottom film layer and a mosquito-repelling component which are sequentially arranged in an attached mode; wherein the absorption layer comprises an absorption body and a wrapping layer, and the outer surface of the absorption body is wrapped with the wrapping layer; the covering cloth is formed by compounding PP perforated cloth and wood pulp spunlace non-woven fabric; the mosquito repelling component comprises a natural plant extract, activated carbon and a non-woven fabric used for wrapping the natural plant extract and the activated carbon, wherein the raw material of the natural plant extract comprises any one or a mixture of more of lavender, sweet wormwood, mozzie buster, purple perilla, clove and mint. The absorption article has the advantages of being high in infiltration speed, breathable, high in absorption performance and good in dryness and comfort and has the mosquito repelling performance, and the use performance of the absorption article is improved.

Owner:诺宸股份有限公司

Goat milk powder formula and preparation method thereof

InactiveCN108541765AAvoid rapid spoilageReduce the smellMilk preparationWhey protein powderChemistry

The present invention discloses a goat milk powder formula and a preparation method thereof. The goat milk powder formula comprises the following raw materials in parts by weight: 200-240 parts of fresh goat milk, 5-7 parts of galactooligosaccharide, 12-15 parts of whey protein powder, 0.3-0.4 part of vitamin A powder, 0.1-0.18 parts of vitamin D powder, 0.5-0.7 part of nucleotide, 0.03-0.09 partof milk mineral salt, 3-6 parts dietary fibers, 0.03-0.04 part of xanthan gum, 0.2-0.5 part of lecithin, 0.1-0.13 part of beta-cyclodextrin and 0.021-0.025 part of alkyl furanone. The preparation method of the goat milk powder is as follows: the fresh goat milk is defatted; the defatted goat milk is subjected to flash evaporation and continuous decompression; then parts of the raw materials are added; the materials are homogenized; the homogenized materials are concentrated to obtain a concentrated solution; the dietary fibers and lecithin are mixed and dissolved to obtain coating liquid; thecoating liquid and concentrated solution are cross-sprayed; and then the sprayed materials are dried to obtain goat milk powder. The goat milk powder formula solves problems that the goat milk powderhas goaty flavor and is easy to cause internal heat.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

Static infiltration device for rapid pultrusion of composite material

The invention relates to the technical field of railway track material equipment, in particular to a static infiltration device for rapid pultrusion of a composite material. The static infiltration device comprises a box body, a gum dipping cavity is formed in the box body, and a yarn inlet and a yarn outlet are separately formed in two opposite side surfaces of the box body; and a plurality of parallel yarn guide rods are installed in the gum dipping cavity, are arranged in the horizontal direction and are perpendicular to the pultrusion direction of yarn. According to the static infiltrationdevice, a pre-stress jack can be moved, the angle is adjustable, thus, the pre-stress jack is convenient and easy to install, and high safety and high efficiency are achieved.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

Packaging process of power electronic transformer based on 3D photocuring printing

The invention provides a packaging process of a power electronic transformer based on 3D photocuring printing, and relates to the technical field of transformer packaging. The process comprises the following steps: printing a skeleton network, pouring, applying voltage, applying ultrasonic waves, electrifying, thermally curing and polishing. An epoxy resin printing framework network is adopted to position and fix an iron core and a winding at the first stage of packaging, the winding is effectively prevented from loosening or deforming in the packaging process, epoxy resin containing filler is adopted as a pouring body, the thermal resistance and the expansion coefficient can be remarkably reduced, the heat dissipation performance is improved, and the cracking risk is reduced; the epoxy resin is easy to electrowet a solid in a high-voltage electric field; ultrasonic waves have the characteristic of improving the infiltration capacity, and the infiltration effect of filler-containing resin and a framework network is further improved; the winding is electrified, so that the winding is firstly heated, the casting body is solidified from inside to outside, and external resin is allowed to perform automatic feeding on the shrinkage cavity, so that the internal defects of packaging are remarkably reduced, and the reliability of packaging is improved.

Owner:HEFEI UNIV OF TECH

Novel method for efficiently extractinganthocyanin from black rice

InactiveCN107235951AIncrease added valueRealize full resource utilizationOrganic chemistryUltra high pressureFiltration

The inventiondiscloses a novel method for efficiently extractinganthocyanin from black rice. The method comprises steps of drying ofa black rice raw material, ultra-fine grinding, soaking in a solvent, ultra-high pressure extraction, filtration and centrifugation, ethanol removal, purification by ion exchange resin and freeze drying. The method comprises the following steps: firstly, black rice available in market or broken black rice formed during processing of the black rice is adopted as a raw material, and cells of the black rice are subjected to wall breaking treatment through superfine grinding; then, ultrahigh pressure assisted ethanol extraction is performed, and the ion exchange resin is combined for separation and purification. Extraction efficiency is high, the black rice anthocyanin with higher purity can be prepared, production cost is low, product stability is good, and popularization is facilitated.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Premixing method of conductive glue, conductive adhesive tape and preparation method thereof

PendingCN112680168AIncrease infiltration speedIncrease humidityPolyureas/polyurethane adhesivesEster polymer adhesivesPolymer scienceAdhesive glue

The invention discloses a premixing method of conductive glue. The premixing method comprises the following steps: dispersing first glue with a first preset weight into a solvent, and performing uniform stirring to form a mixed solution A; adding conductive particles into the mixed solution A, and uniformly stirring to form a mixed solution B; and adding the mixed solution B into second glue with a second preset weight to be evenly stirred to form final conductive glue, wherein the second glue and the first glue are the same or different in component. The invention further discloses a preparation method of the conductive adhesive tape adopting the premixing method and the conductive adhesive tape. According to the premixing method, particle clusters formed by coating the conductive particles with glue can be reduced, so that the conductive particles are uniformly dispersed.

Owner:DWELL PHOTOELECTRIC MATERIAL SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com