Composite absorbent health product absorbent paper manufacturing method

A technology for sanitary products and absorbent paper, which is used in absorbent pads, medical science, bandages, etc., and can solve the problems of slow diffusion of body fluids, easy deformation of absorbent cores, and limitation of polymer additions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] A preparation method of composite absorbent paper for absorbent hygienic products, comprising the steps of:

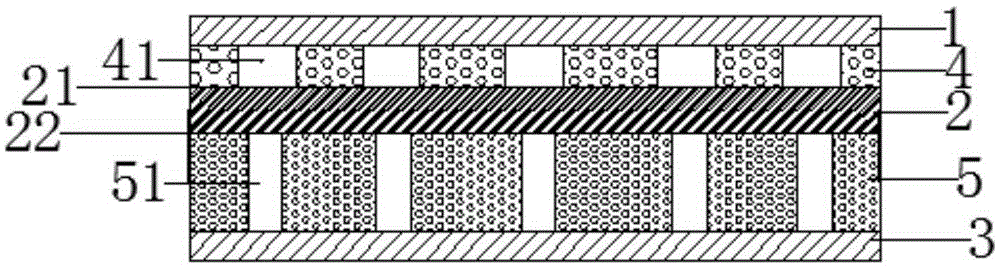

[0057] (1) The upper polymer water-absorbing resin layer 4 passes through the lower hopper and passes through the polymer isolation plate, and then sprinkles it on the surface where the high-loom non-woven fabric 2 and the upper isolation layer 1 are combined, and the upper diversion groove 41 is formed at the interval ;

[0058] (2) The high-loom non-woven fabric 2 sprinkled with the upper polymer water-absorbing resin layer 4 is glued to the upper isolation layer 1 sprayed with hot-melt adhesive on the surface, and then pressed together by pressing rollers;

[0059] (3) The lower polymer water-absorbing resin layer 5 passes through the lower hopper and passes through the polymer isolation plate, and then sprinkles it on the surface where the high-loom non-woven fabric 2 is combined with the lower isolation layer 1, and the lower diversion groove is formed at t...

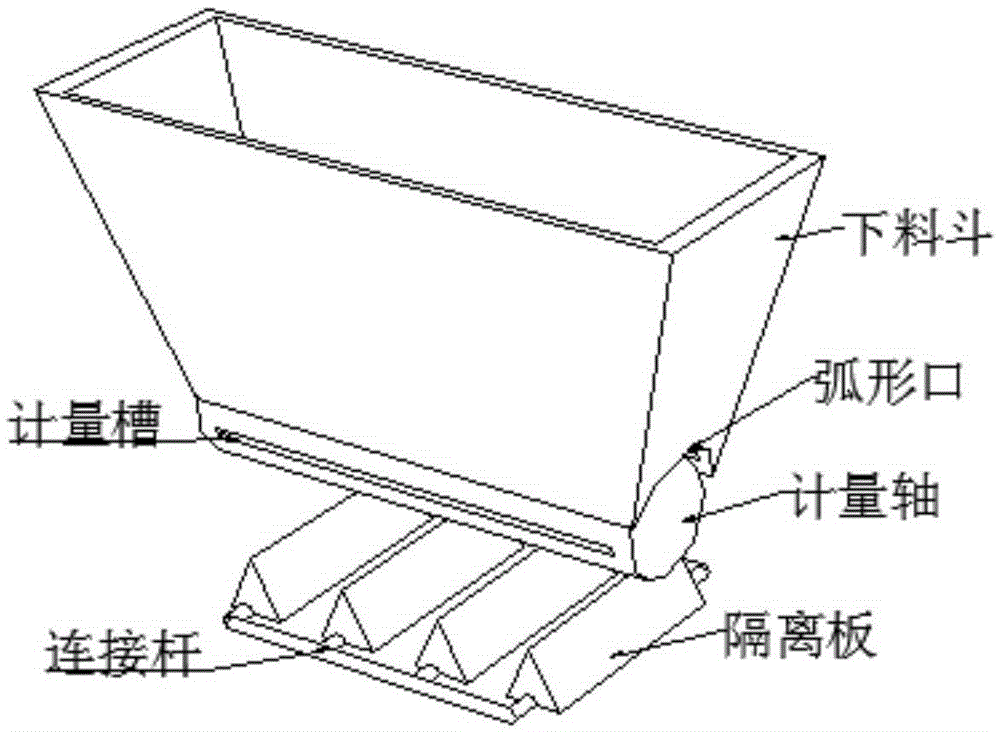

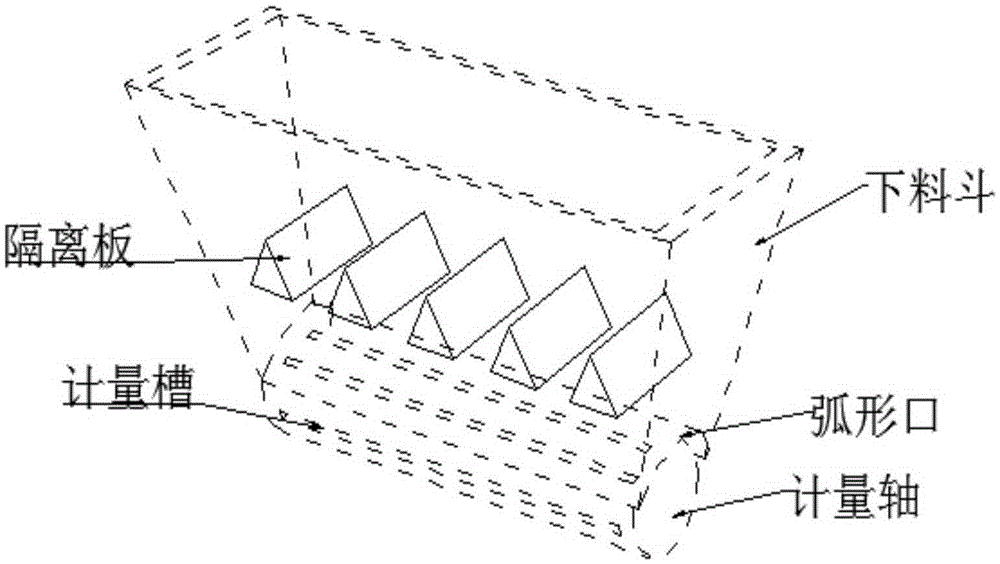

Embodiment approach

[0063] Wherein, the structural diagram of the polymer isolation plate is as follows: figure 2 As shown, since the polymer water-absorbent resin generally needs to pass through the lower hopper, the polymer isolation plate is arranged below the lower hopper. The polymer isolation plate is a triangular prism, and one side of the triangular prism faces the horizontal Directly below, the realization of the different widths of the upper diversion groove and the lower diversion groove in the present invention can adjust the width of the side of the triangular prism facing the side directly below the level, and the width of this side is its The width of the corresponding upper diversion groove or the lower diversion groove, the position of the top view orthographic projection of the side is the position where the upper diversion groove or the lower diversion groove is located, and the side is inseparable from the high canopy. The vertical distance of the woven fabric is 5mm, and the...

Embodiment 1

[0082]

[0083] Among them, Nippon Shokubai W211 polymer water-absorbing resin is selected for the upper and lower polymer water-absorbing resin layers, and the performance indicators are as follows

[0084]

[0085]

[0086] Using a vibrating sieve, select a finer polymer water-absorbent resin with a particle size of 40-60 mesh as the lower polymer water-absorbent resin layer, and select a coarser polymer water-absorbent resin with a particle size of 20-40 mesh as the upper polymer water-absorbent resin layer.

[0087] Wherein, the width of the upper diversion groove is 1.5 cm, the width of the lower diversion groove is 1 cm, and one of the upper diversion grooves is located in the central area of the width direction of the composite absorbent paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com