Patents

Literature

119results about How to "Increase the diffusion length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical vapor deposition preparation method for perovskite solar cell

ActiveCN104393109AEasy to operateImprove film qualityFinal product manufactureChemical vapor deposition coatingHeterojunctionPerovskite solar cell

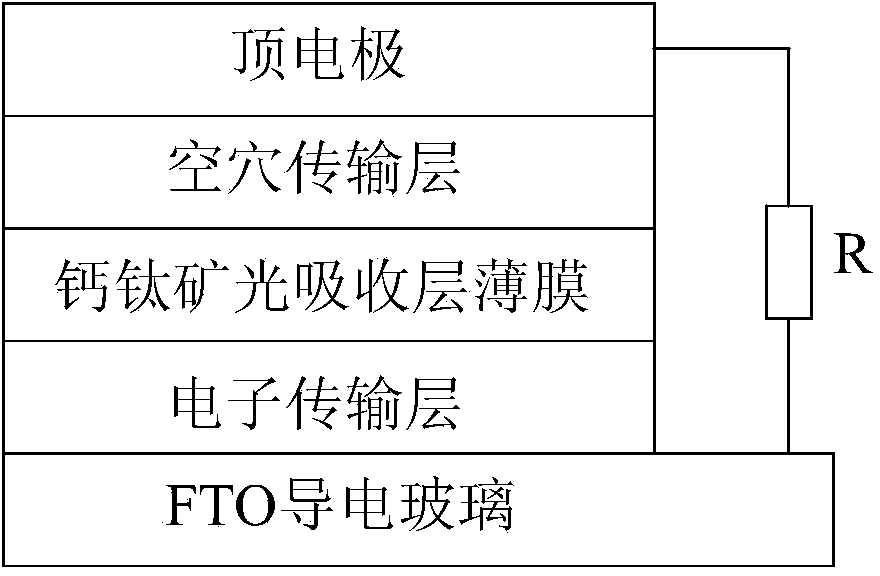

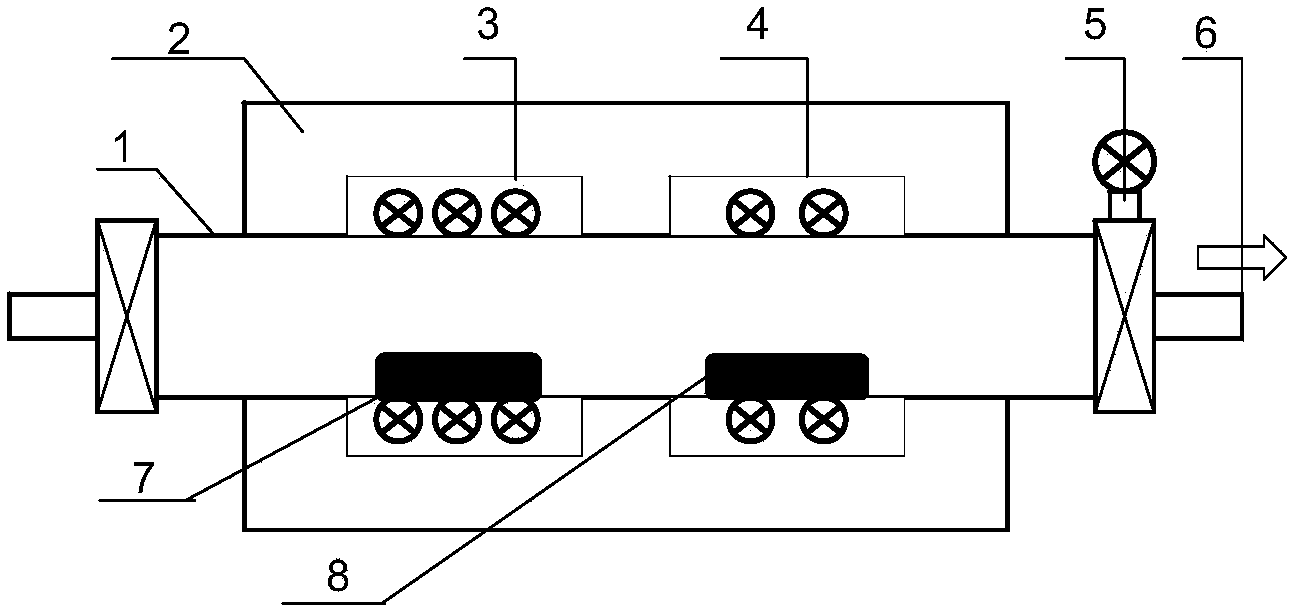

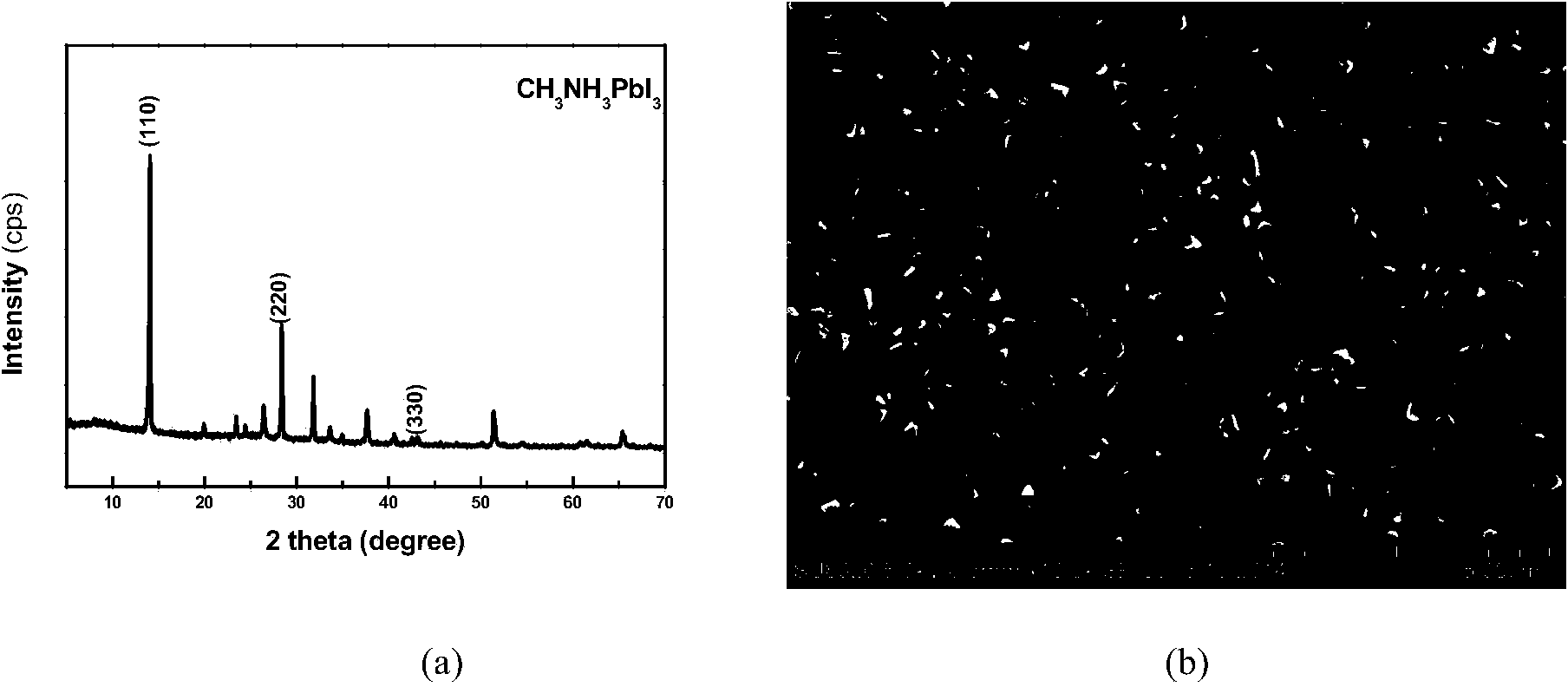

The invention discloses a chemical vapor deposition preparation method for a perovskite solar cell. The preparation method is characterized in that a compact layer TiO2 thin film is deposited on a surface on which the FTO thin film of FTO conductive glass is positioned so as to act as an electron transmission layer; a perovskite light absorption layer thin film is prepared on the electron transmission layer via a chemical vapor deposition method; a hole transmission layer is prepared on the perovskite light absorption layer thin film; and an Ag electrode or an Au electrode is vapor-deposited on the hole transmission layer to act as a top electrode so that the perovskite solar cell is obtained. The preparation method is simple and low in cost. The prepared perovskite light absorption layer thin film is high in quality, excellent in substrate coverage and great in stability and repeatability. Preliminary conversion efficiency of the prepared planar heterojunction perovskite solar cell can be 11%.

Owner:HEFEI UNIV OF TECH

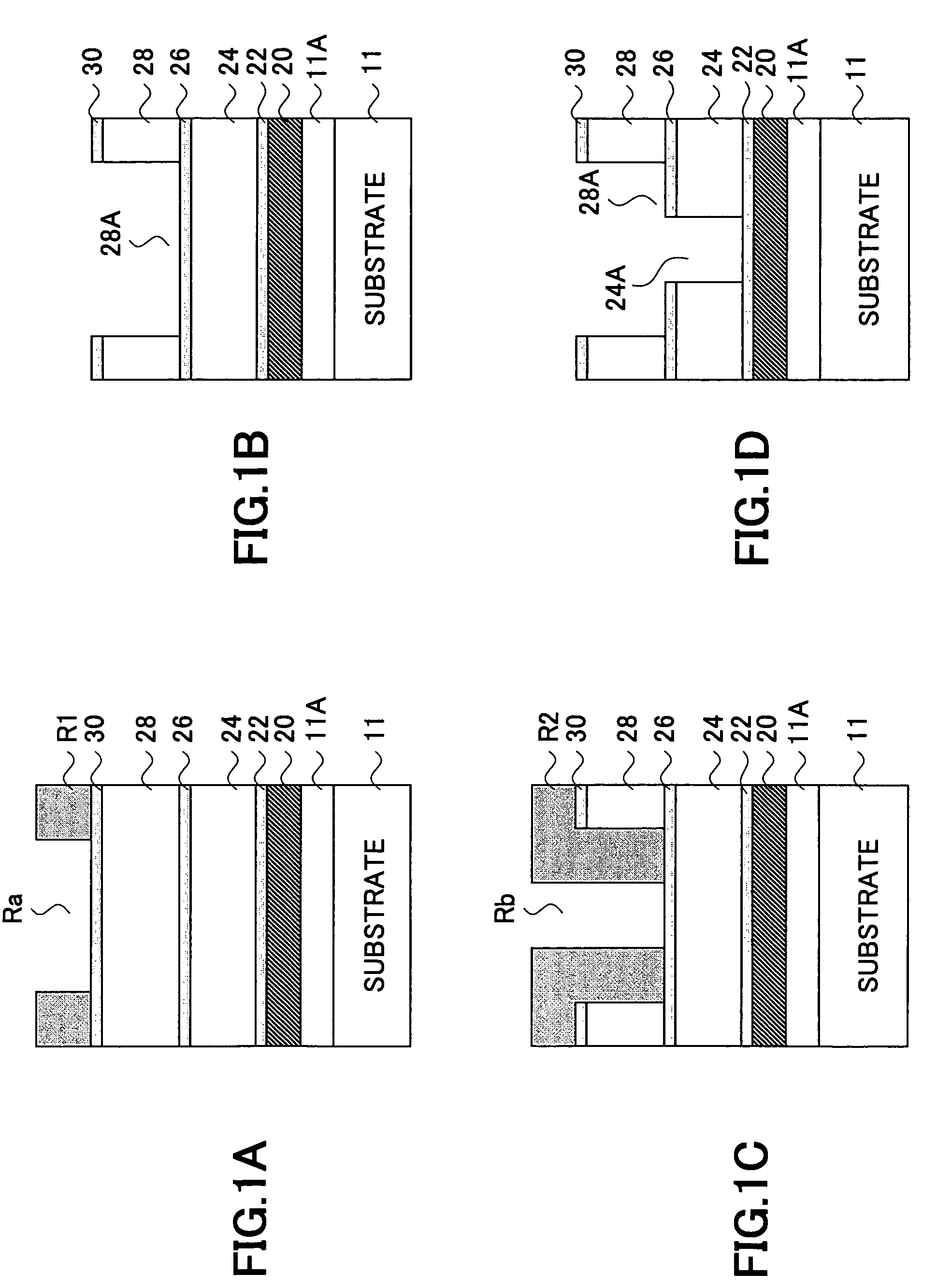

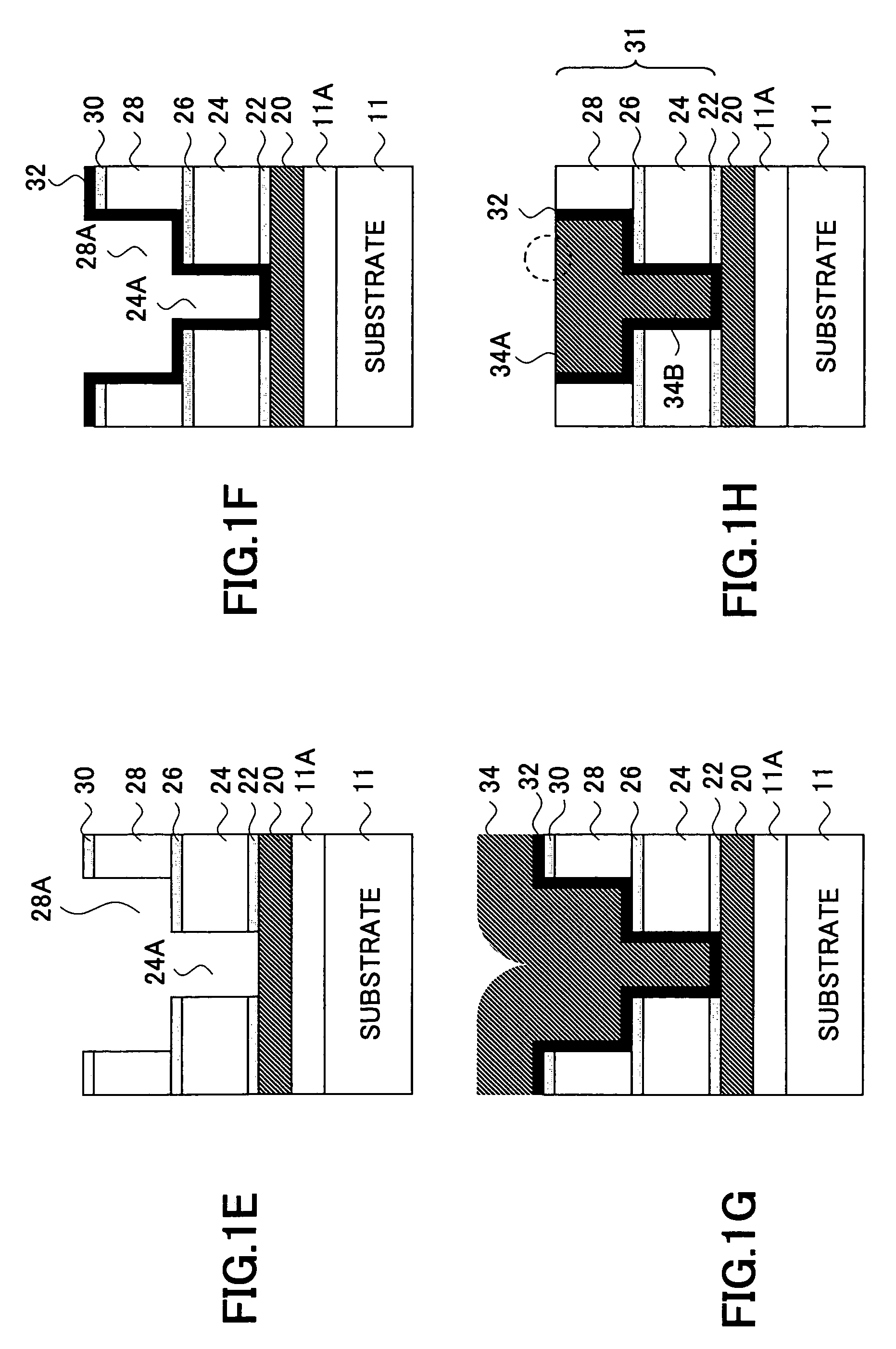

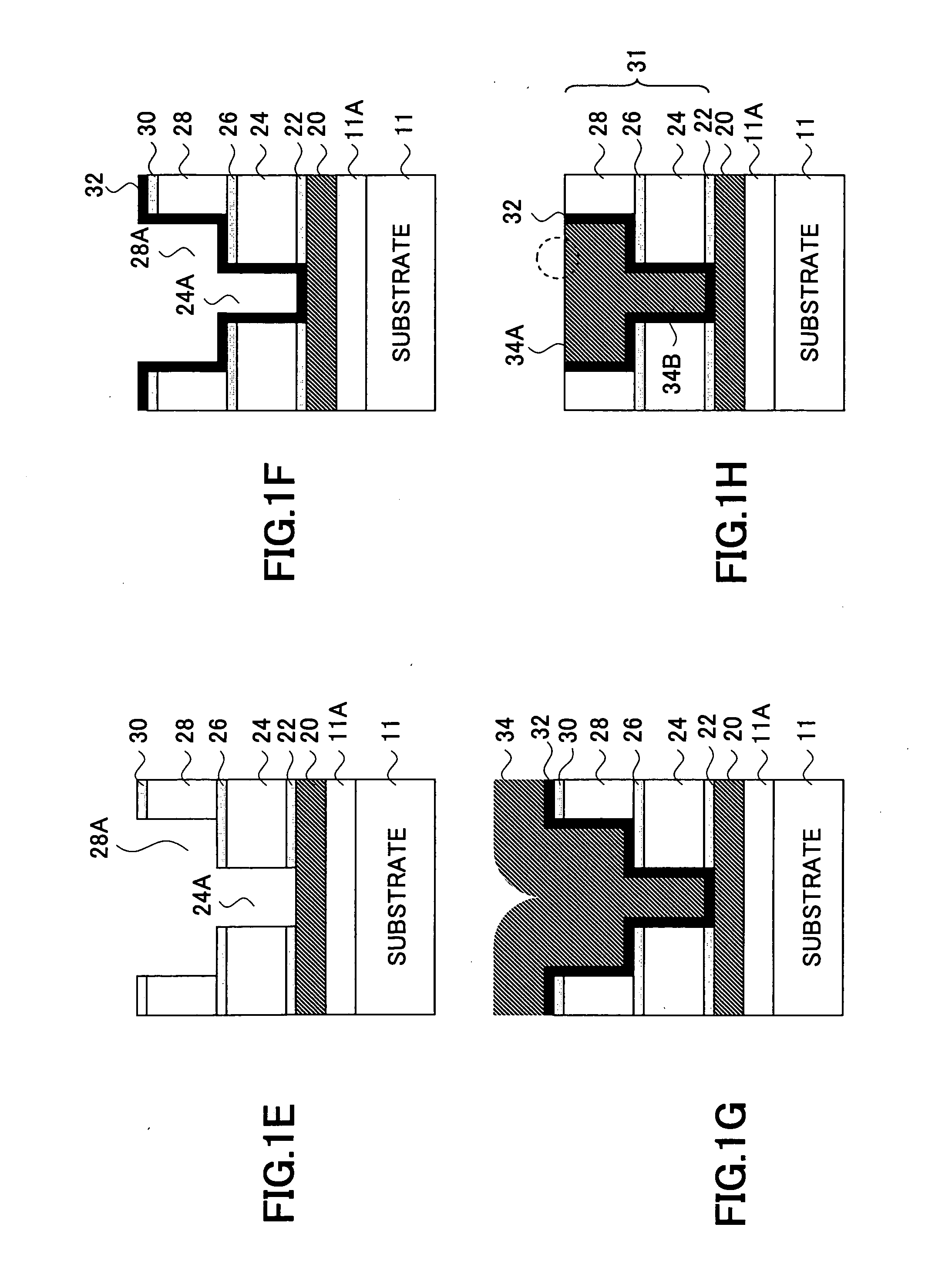

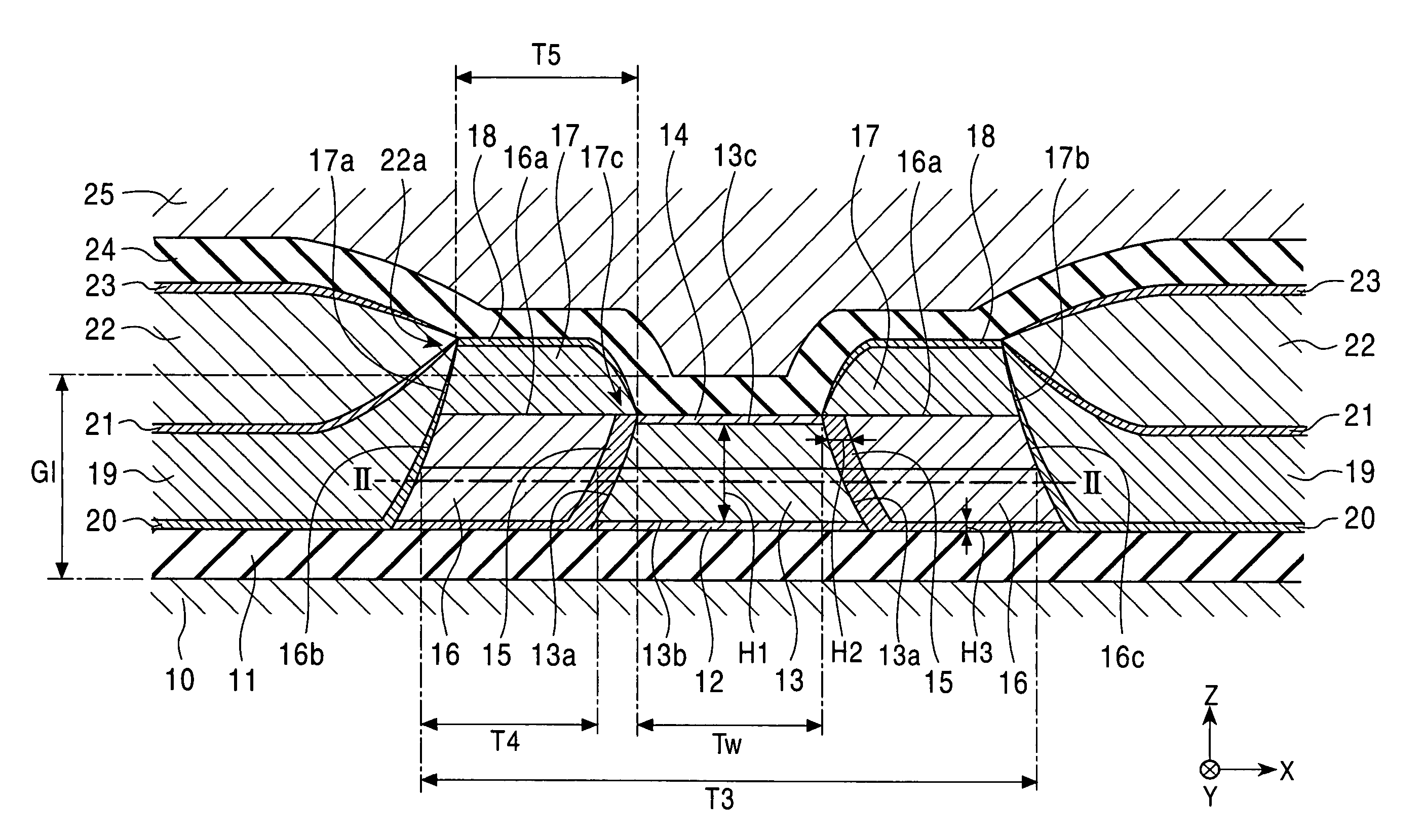

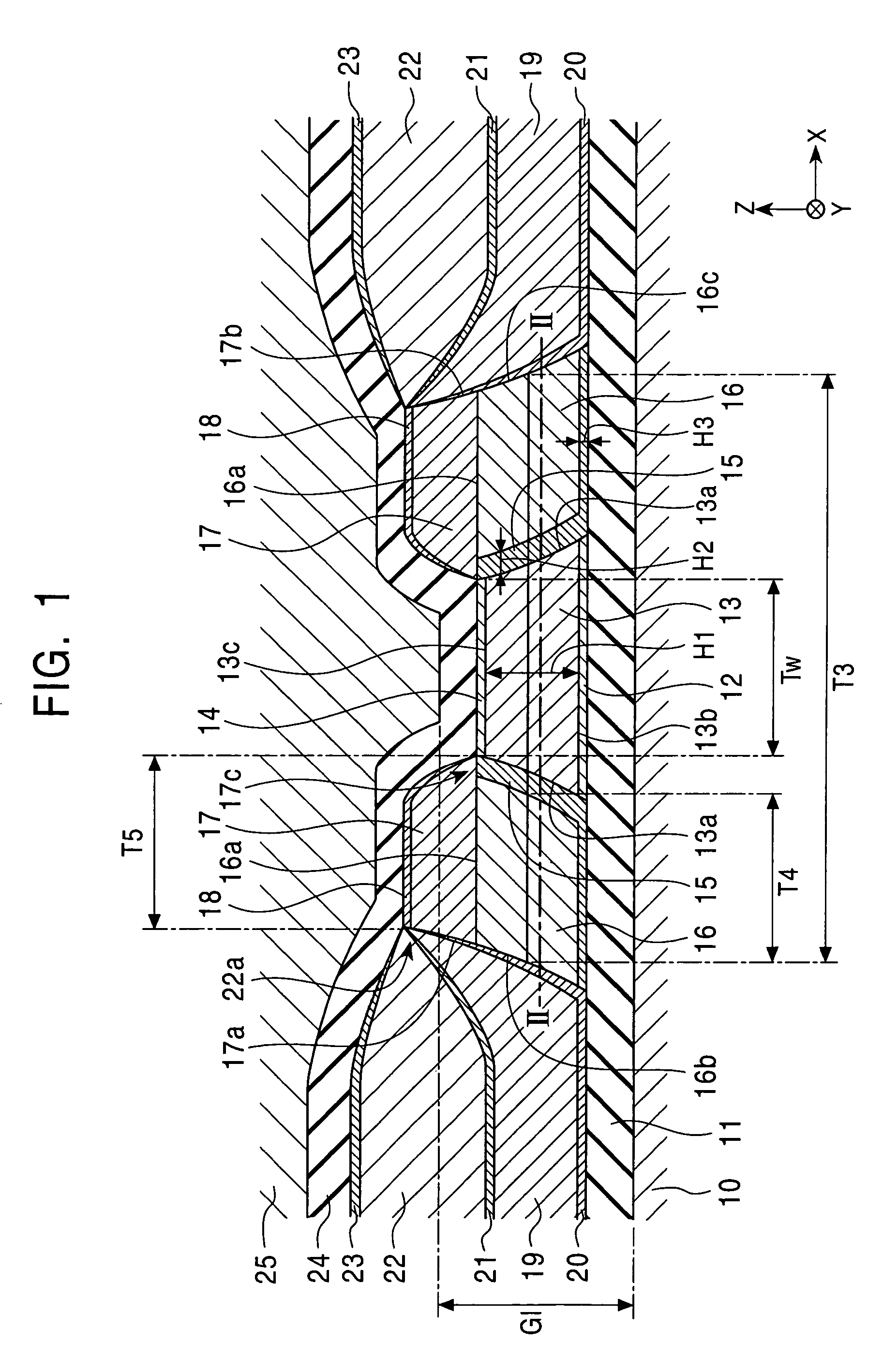

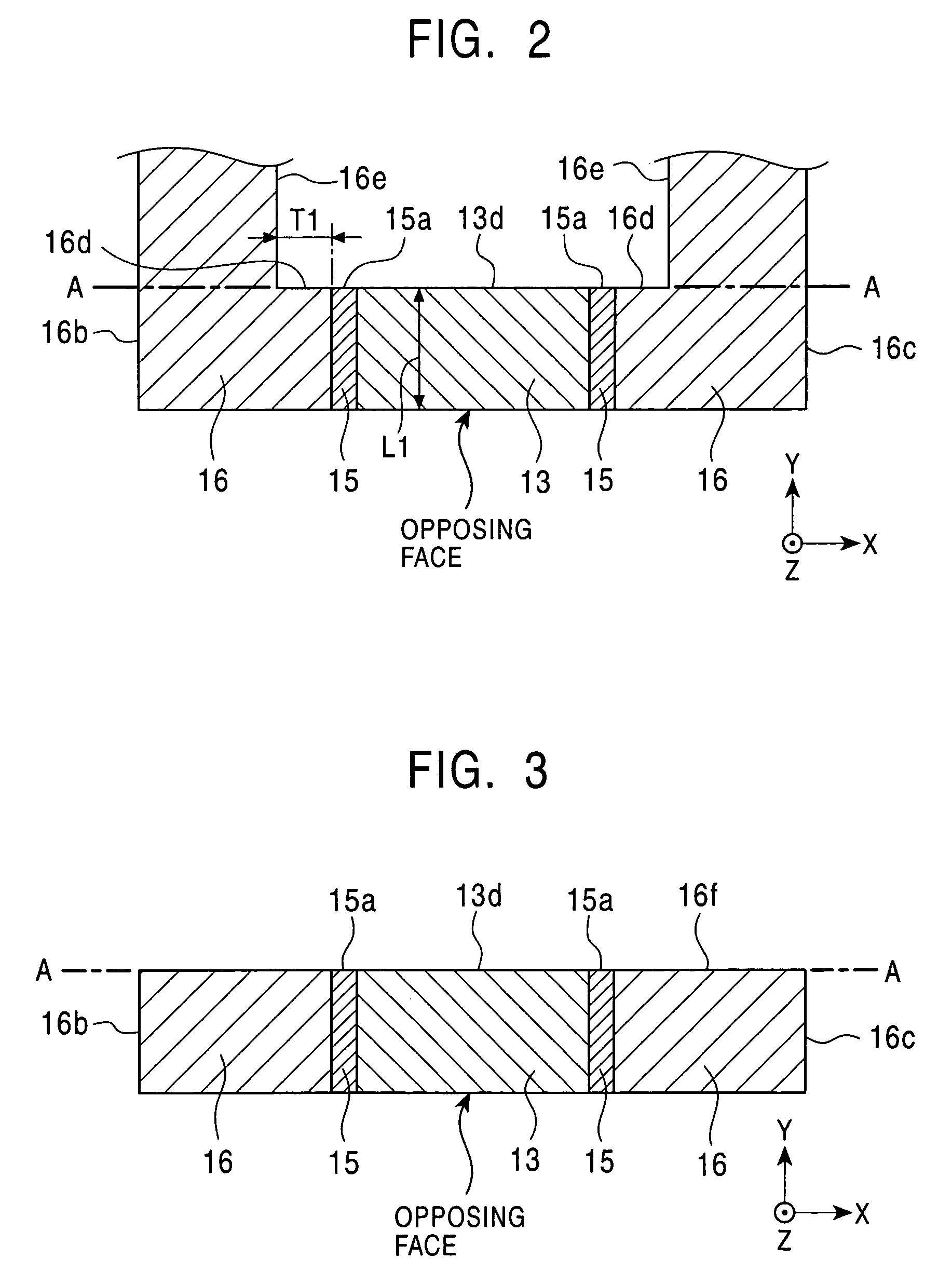

Semiconductor device having a multilayer interconnection structure and fabrication method thereof

InactiveUS7416985B2Increase the diffusion lengthSuppress DiffuseSemiconductor/solid-state device detailsSolid-state devicesEngineeringInterconnection

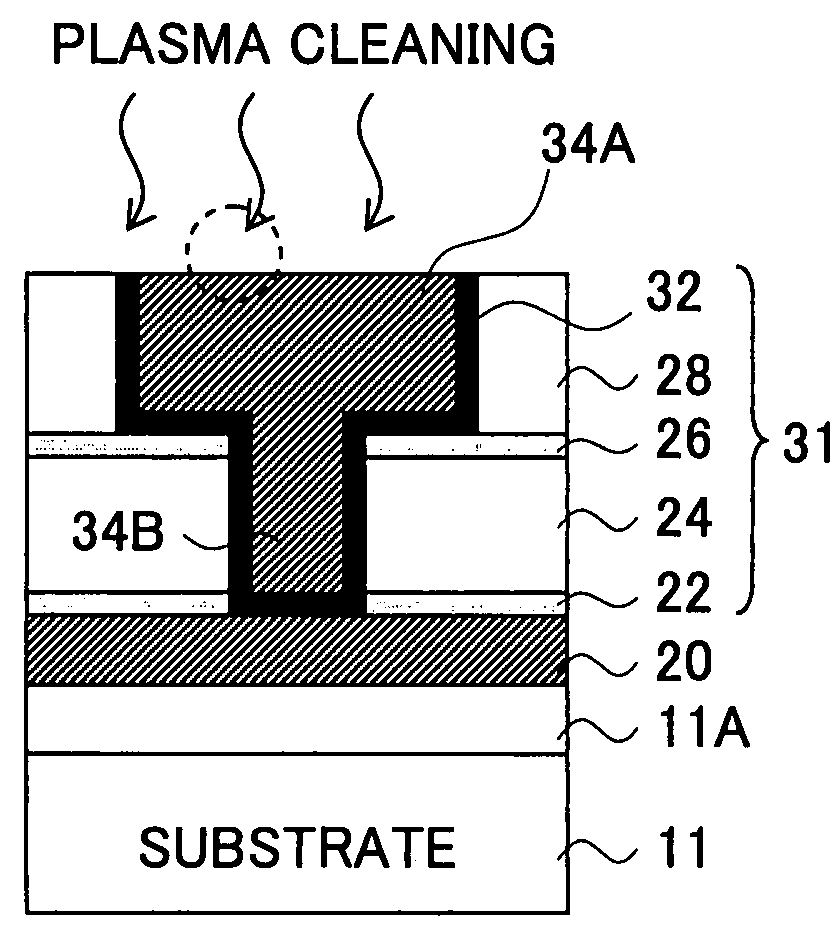

A multilayer interconnection structure includes a first interlayer insulation film, a second interlayer insulation film formed over the first interlayer insulation film, an interconnection trench formed in the first interlayer insulation film and having a sidewall surface and a bottom surface covered with a first barrier metal film, a via-hole formed in the second interlayer insulation film and having a sidewall surface and a bottom surface covered with a second barrier metal film, an interconnection pattern filling the interconnection trench, and a via-plug filling the via-hole, wherein the via-plug makes a contact with a surface of the interconnection pattern, the interconnection pattern has projections and depressions on the surface, the interconnection pattern containing therein oxygen atoms along a crystal grain boundary extending from the surface toward an interior of the interconnection pattern with a concentration higher than a concentration at the surface.

Owner:FUJITSU SEMICON LTD

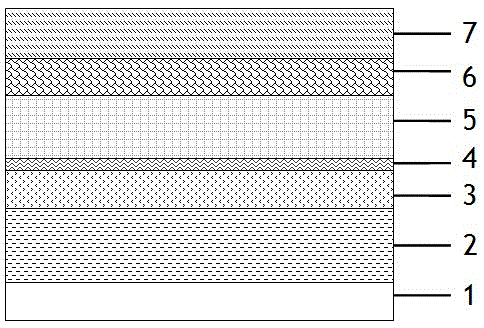

Reciprocal form structure polymer solar cell and preparation method thereof

InactiveCN101577313AAvoid priceLow priceSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionEvaporation

The invention belongs to the technical field of polymer solar cells and particularly relates to a reciprocal form electrode polymer solar cell using TiO2 as an electronic transmission layer, CuPc as a cavity transmission layer and a preparation method thereof. The method includes the steps of: using sol-gel technology to grow a layer of uniform and compact nanocrystal titanium dioxide (TiO2) film on an ITO glass substrate, then spin-coating a layer of P3HT:PCBM solution dissolved by dichlorobenzene, after annealing, using thermal evaporation to grow a layer of CuPc with certain thickness and finally evaporating Au electrode. The polymer solar cell prepared by utilizing the method solves two problems of the traditional polymer solar cell, namely that the mixed solution of 3, 4-EDOT and polystyrolsulfon acid corrode the surface of ITO glass, and the excessive thinness of cathode buffer layer LiF causes the operating process to be difficult to be controlled accurately.

Owner:JILIN UNIV

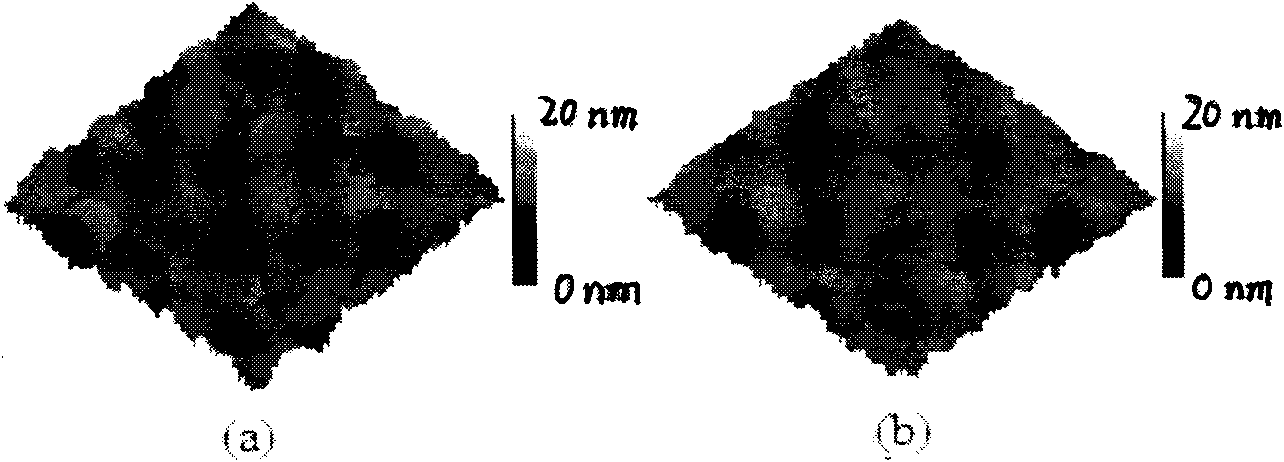

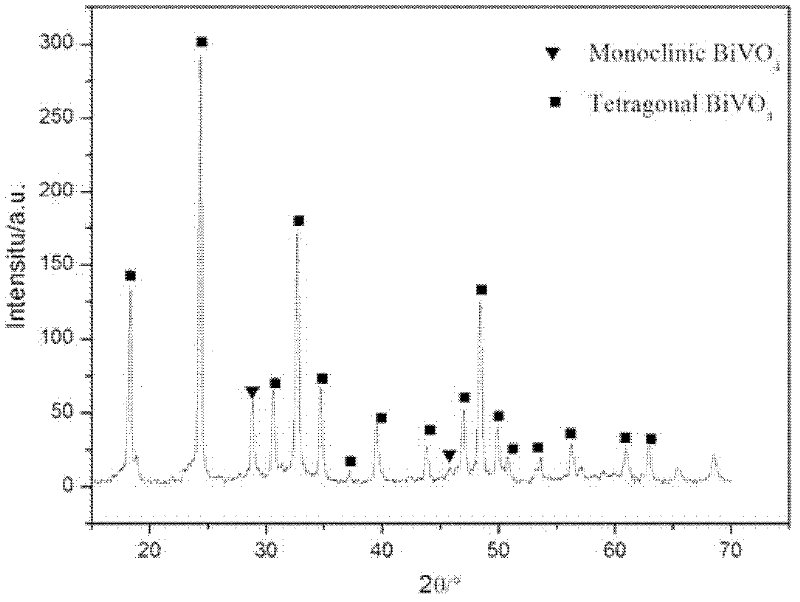

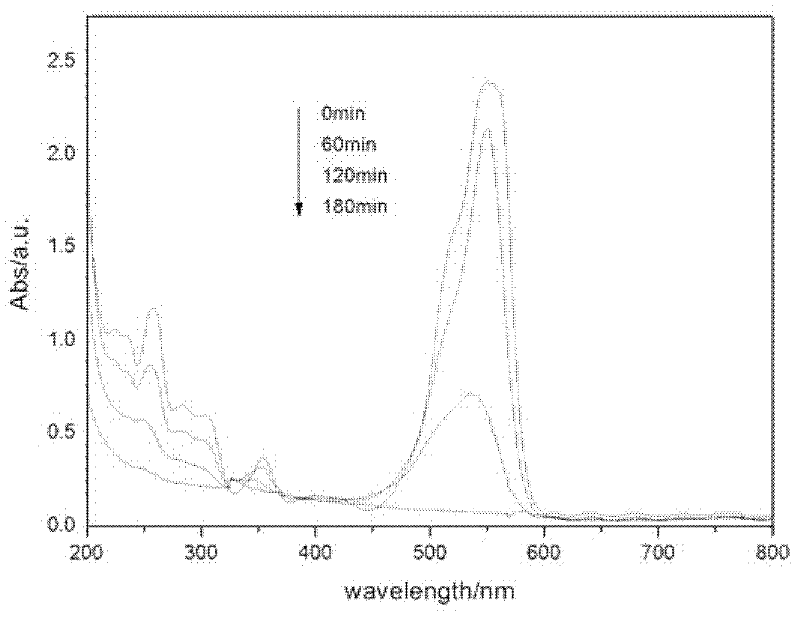

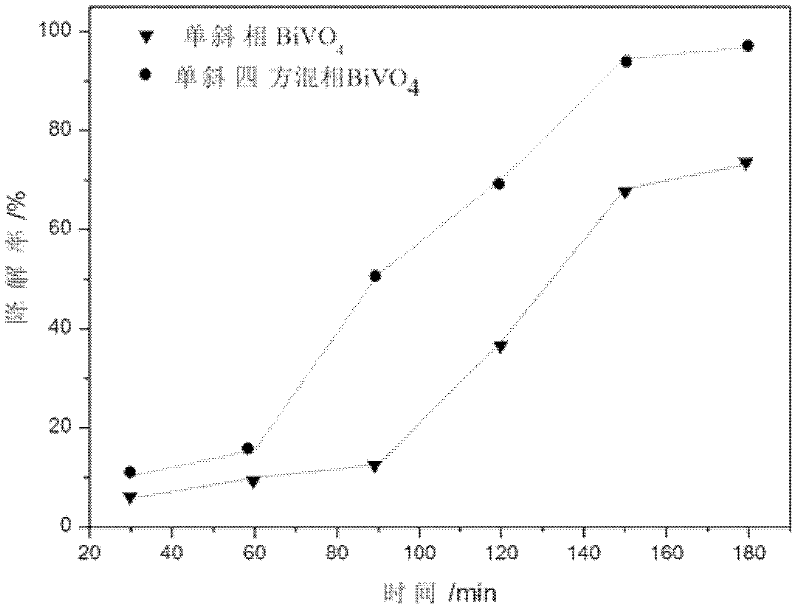

Method for synthesizing monoclinic phase and tetragonal phase mixed high-catalytic-activity bismuth vanadate powder by microwave hydrothermal process

InactiveCN102249305AUniform particle size distributionIncrease the diffusion lengthVanadium compoundsMicrowaveBismuth vanadate

The invention discloses a method for synthesizing monoclinic phase and tetragonal phase blended high-catalytic-activity bismuth vanadate powder by a microwave hydrothermal process, and the method comprises: separately dissolving bismuth nitrate pentahydrate used as a bismuth source and ammonium metavanadate used as a vanadium source in a HNO3 solution and a NaOH solution with a molar ratio of Bi to V being 1:1, adding an appropriate amount of sodium dodecyl benzene sulfonate used as a template agent and NaOH used as a mineralizing agent, and controlling the pH value at 4.6-8.0, microwave hydrothermal reaction temperature at 160-220 DEG C and heat-insulation time at 60-120 minutes to synthesize the monoclinic phase and tetragonal phase blended BiVO4 powder. By adopting the microwave hydrothermal synthesis technique in the invention, high-photocatalytic-activity BiVO4 powder is quickly synthesized. The method as a novel environmentally-friendly rapid synthesis process combines the unique heating characteristics of microwave and the advantages of a hydrothermal method, the process is simple and easy to control, the preparation period is short, the energy is saved, and the resulting powder has uniform particle size distribution and very wide application prospects.

Owner:SHAANXI UNIV OF SCI & TECH

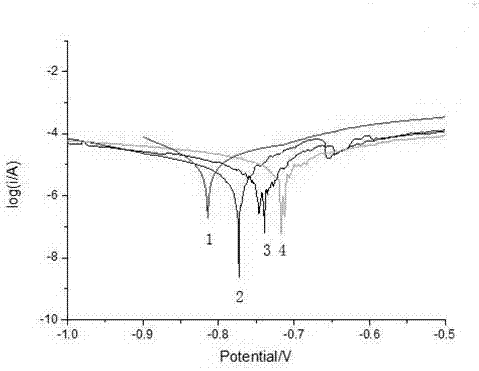

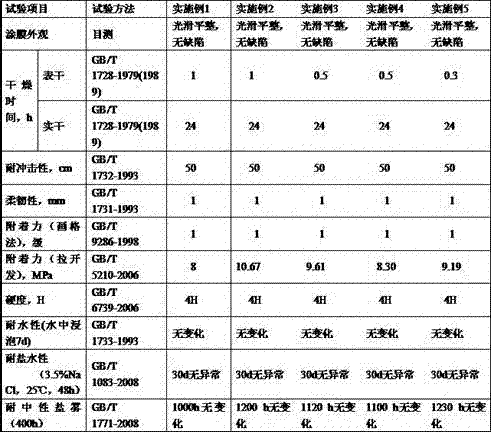

Water-based anticorrosive coating and preparation method thereof

ActiveCN107236437ASimple processEasy to operateAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyWater based

The invention relates to the coating field, and particularly discloses a water-based anticorrosive coating and a preparation method thereof. The water-based anticorrosive coating comprises a component A and a component B. The component A comprises the following components by mass: 15-25 parts of a water-based isocyanate curing agent, 15-55 parts of zinc powder, 1-5 parts of a defoaming agent, 1-5 parts of a wetting dispersing agent, 0.9-2 parts of an anti-sinking thixotropic agent, 0.1-5 parts of a conductive macromolecule / fullerene composite material, 0.5-1 part of a flash-rust resistant agent, 0.5-1 part of a flatting agent, 1-3.5 parts of an adhesive force accelerant, and 5-15 parts of a rust resisting pigment; and the component B comprises the following components by mass: 5-13 parts of methyl methacrylate, 15-25 parts of butyl acrylate, 7-16 parts of styrene, 15-30 parts of an epoxy resin, 1-6 parts of a methacrylic acid, 1-5 parts of acrylamide, 1.5-2 parts of hydroxyethyl acrylate, 0.5-5 parts of an emulgator, 0.5-5 parts of an initiator, 80-130 parts of deionized water, and 0.1-1 part of ammonia water. The water-based anticorrosive coating is prepared by stirring and mixing the prepared component A and component B according to the mass ratio of 8-16:1, and has the advantages of strong shielding property, excellent corrosion resistance, environmental protection, good flexibility and strong adhesive force.

Owner:SHIJIAZHUANG TIEDAO UNIV

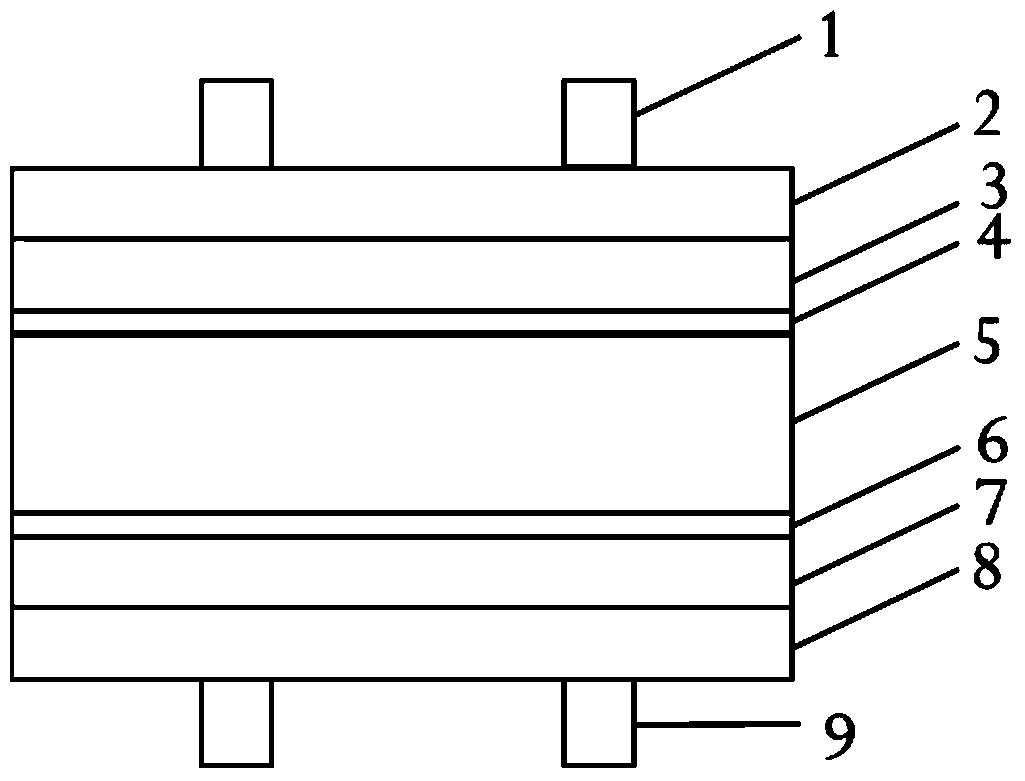

Perovskite solar cell and preparation method thereof

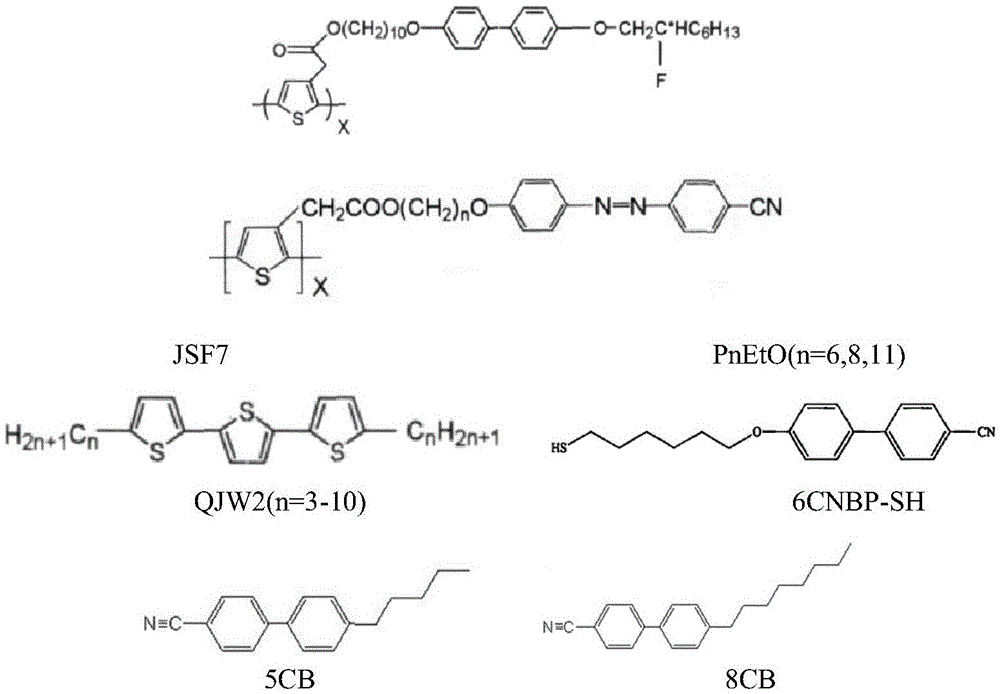

ActiveCN105609641AImprove film morphologyReduce surface defectsFinal product manufactureSolid-state devicesThin film morphologyLiquid-crystal display

The invention relates to a perovskite solar cell and a preparation method thereof. By arranging a liquid crystal layer on the surface of an electron transmission layer or a hole transmission layer, the thin film morphology of the electron transmission layer or the hole transmission layer is improved, the defect on the surface of the electron transmission layer or the hole transmission layer is passivated, the transmission of reverse current carriers is effectively blocked, the electric leakage generation is prevented, the combination probability of electrons and holes which are generated in a perovskite light absorption layer is reduced, and the photoelectric conversion efficiency and the stability of the cell are improved; and meanwhile, the liquid crystal layer is prepared by a low-temperature solution method, and the preparation method is suitably used for roll-to-roll industrial production of the perovskite photovoltaic cell, and is simple in process and low in fabrication cost.

Owner:CHINA LUCKY FILM CORP

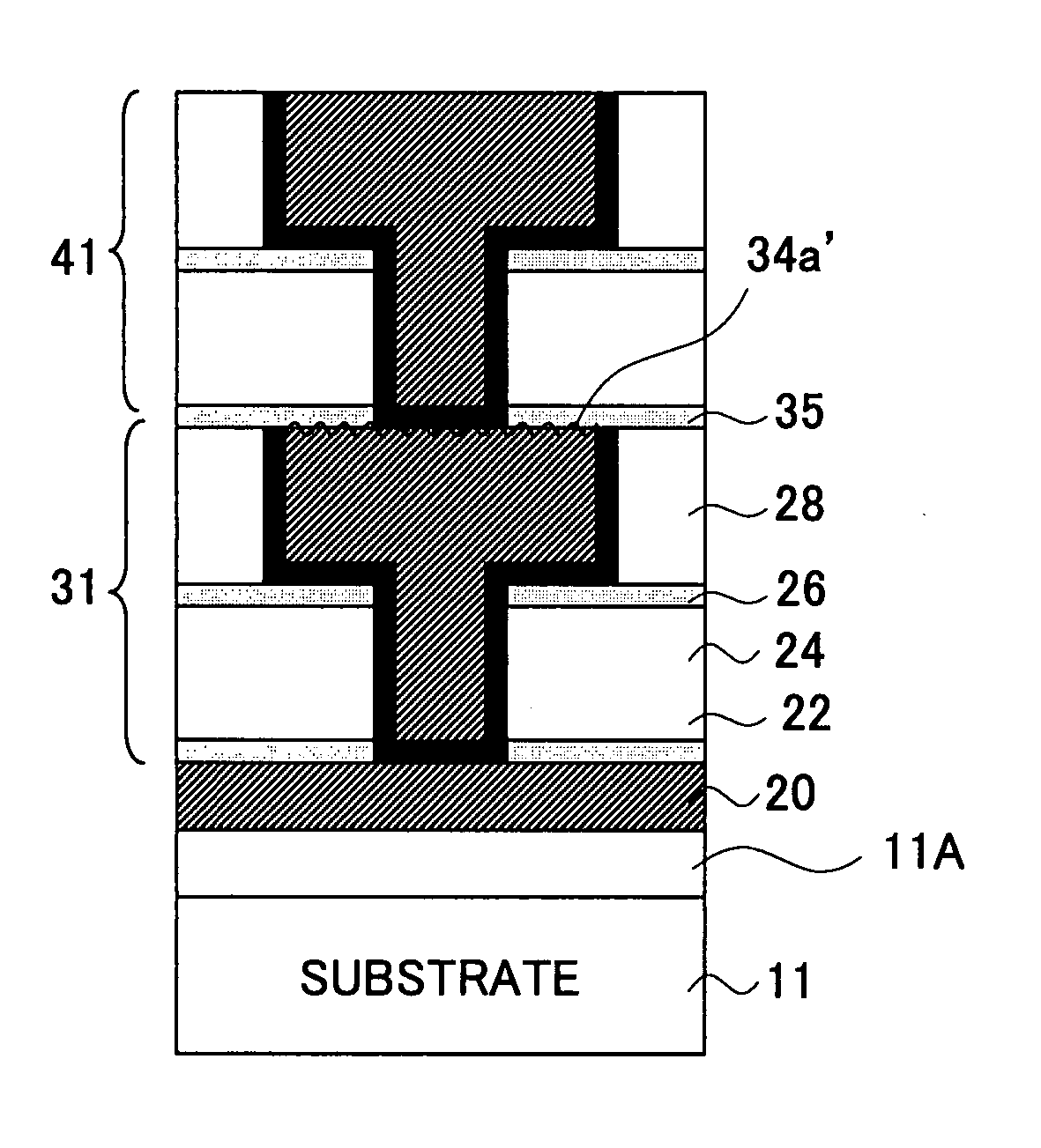

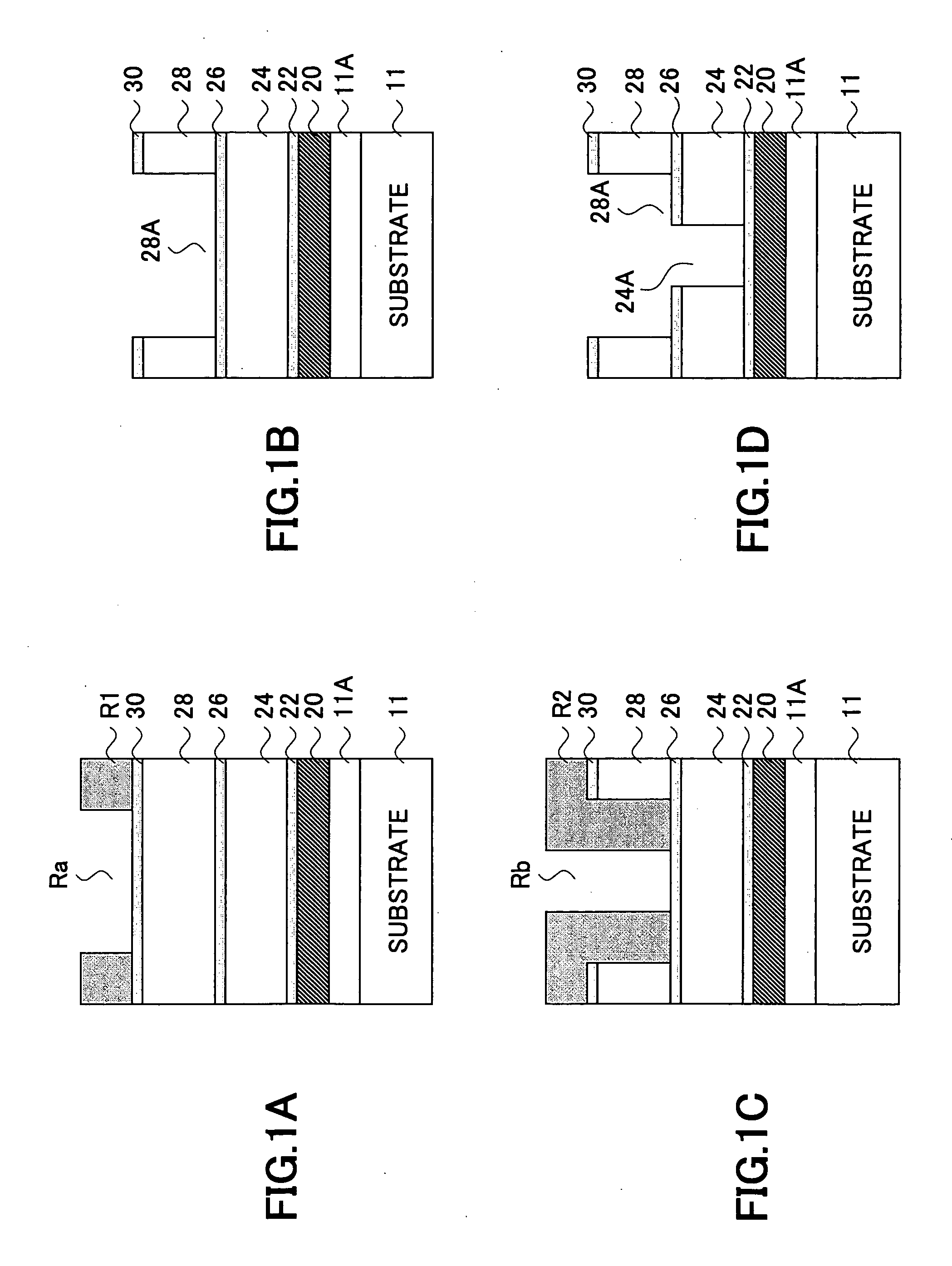

Semiconductor device having a multilayer interconnection structure and fabrication method

InactiveUS20050212137A1Increase the diffusion lengthSuppress DiffuseSemiconductor/solid-state device detailsSolid-state devicesSecondary layerCrystallite

A multilayer interconnection structure includes a first interlayer insulation film, a second interlayer insulation film formed over the first interlayer insulation film, an interconnection trench formed in the first interlayer insulation film and having a sidewall surface and a bottom surface covered with a first barrier metal film, a via-hole formed in the second interlayer insulation film and having a sidewall surface and a bottom surface covered with a second barrier metal film, an interconnection pattern filling the interconnection trench, and a via-plug filling the via-hole, wherein the via-plug makes a contact with a surface of the interconnection pattern, the interconnection pattern has projections and depressions on the surface, the interconnection pattern containing therein oxygen atoms along a crystal grain boundary extending from the surface toward an interior of the interconnection pattern with a concentration higher than a concentration at the surface.

Owner:FUJITSU SEMICON LTD

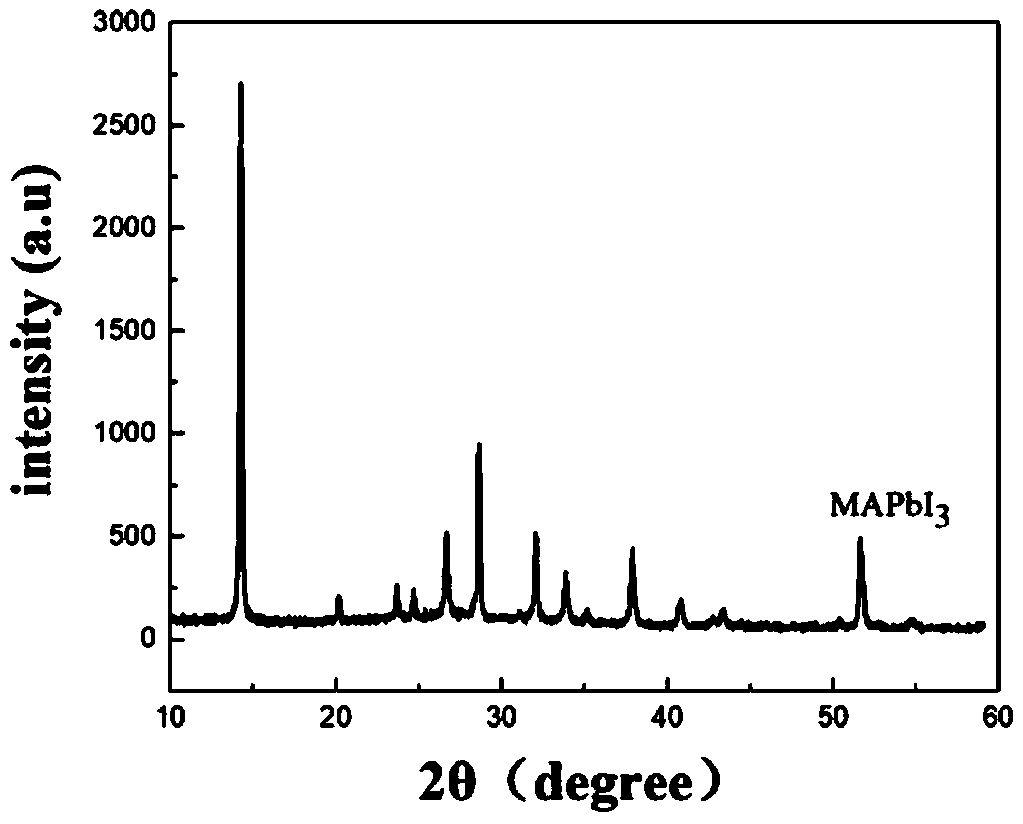

Method for preparing perovskite film, and perovskite solar cell device

ActiveCN108899420AEnhanced carrier mobility and diffusion lengthEnhanced charge transport capabilitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellCrystallite

The invention discloses a method for preparing a perovskite film and a perovskite solar cell device, wherein the method for preparing a perovskite film comprises the following steps: (1) preparing a perovskite precursor solution, then adding anti-solvent diethyl ether to the perovskite precursor solution, and uniformly mixing the anti-solvent diethyl ether and the perovskite precursor solution; (2) dropping the perovskite precursor solution containing the diethyl ether onto the surface of a substrate, performing spin coating, and dropping anti-solvent toluene during the spin coating in order to wash the surface of perovskite; (3) after the spin coating, subjecting an obtained perovskite film intermediate product to thermal annealing treatment to obtain the perovskite film. Adding the diethyl ether to the perovskite precursor solution can control the growth of a perovskite crystal, can prepare a perovskite film having a uniform grain size and low surface roughness, and is beneficial toimproving carrier mobility, a diffusion length, and a charge transport capacity. The perovskite film, when used as an active layer of the perovskite solar cell device, can effectively improve the photovoltaic performance of the device.

Owner:NANJING UNIV OF POSTS & TELECOMM

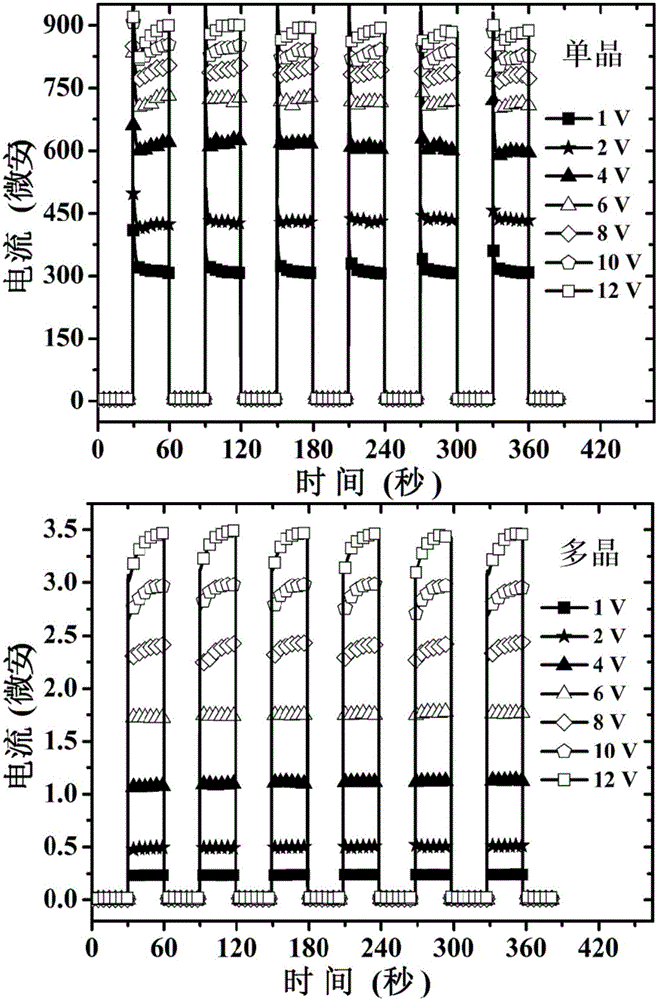

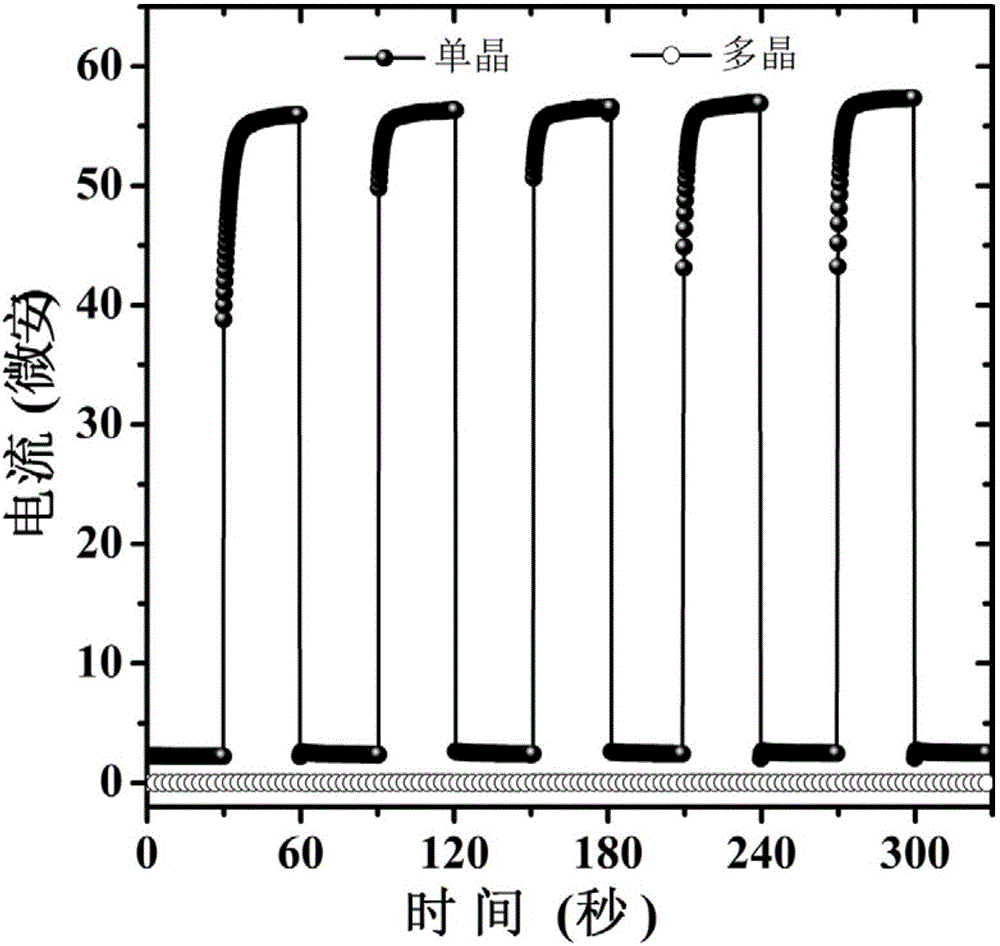

Efficient perovskite monocrystal light detector and preparation method thereof

ActiveCN105870334AHigh carrier mobilityHigh sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSingle crystal

The invention provides an efficient perovskite monocrystal light detector and a preparation method thereof. The efficient perovskite monocrystal light detector comprises a perovskite monocrystal and an interdigital electrode arranged on the perovskite monocrystal. The prepared monocrystal perovskite light detector is simple in structure, high in efficiency, high in response speed, stable in work and long in service life. The light detector has the advantages that the preparation process is simple, the production cost is low, and no expensive instrument equipment is needed. Accordingly, effective utilization of perovskite monocrystal materials is promoted, an existing polycrystal perovskite thin film light detector is replaced, and new technical improvement of light detector application will be produced.

Owner:SHAANXI NORMAL UNIV

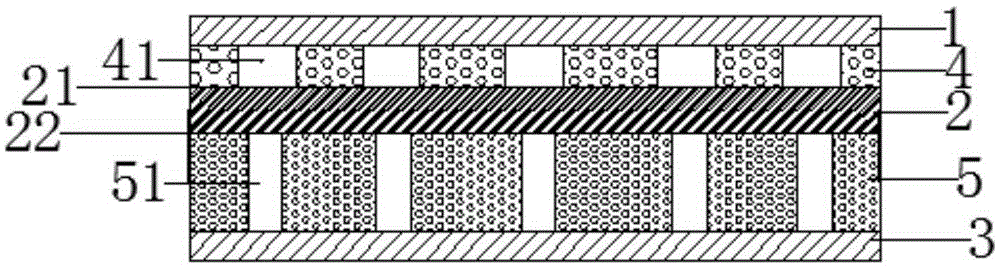

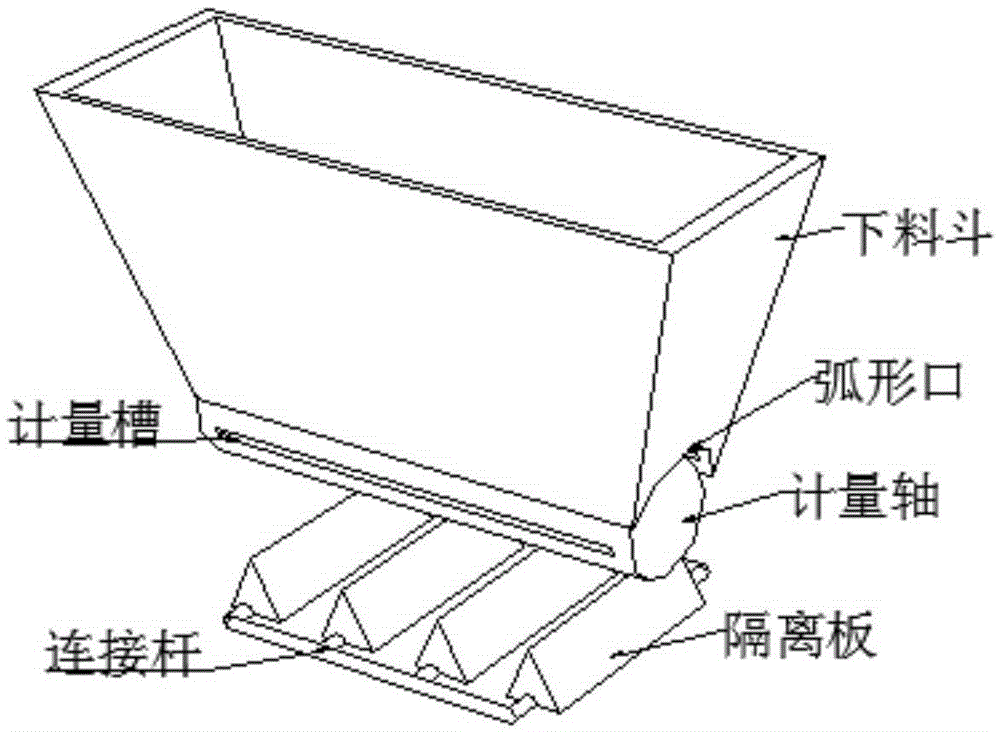

Composite absorbent health product absorbent paper manufacturing method

ActiveCN105266975ASimple processSimple and fast operationAbsorbent padsBandagesPaper manufacturingEngineering

The invention provides a composite absorbent health product absorbent paper manufacturing method .The composite absorbent health product absorbent paper manufacturing method comprises steps that, (1), upper high-molecular absorbent resin layers are distributed at a surface on which high-fluffy non-woven fabric is combined with an upper separating layer with a gap, and an upper diversion trench is formed at the gap portion; (2), the high-fluffy non-woven fabric distributed with the upper high-molecular absorbent resin layers is glued with the upper separating layer of which the surface is coated with hot melt adhesive, and the two parts are stitched and rolled; (3), lower high-molecular absorbent resin layers are distributed at a surface on which high-fluffy non-woven fabric is combined with a lower separating layer, and a lower diversion trench is formed at the gap portion; and (4), the high-fluffy non-woven fabric distributed with the lower high-molecular absorbent resin layer is glued with the lower separating layer of which the surface is coated with hot melt adhesive, and the two parts are stitched and rolled. According to the method, the structure of needed equipment is simple, operation is convenient, products manufactured by utilizing the method have properties of small dimensions, simple technology and relatively low cost, moreover, the absorption characteristic is obviously improved, and the core body utilization rate is improved.

Owner:TIANJIN SINOSH NEW MATERIAL TECH

A gallium nitride-based semiconductor light-emitting tube with a p-type active region

InactiveCN102280547AIncrease the diffusion lengthImprove luminous efficiencySemiconductor devicesDopantOptical property

The invention relates to a gallium nitride-based semiconductor light-emitting tube with a P-type active region, relating to a semiconductor light-emitting tube. A substrate layer, a buffer layer, an N-type layer, an active region, a P-type layer, a P metal electrode, and an N metal electrode are sequentially provided from bottom to top; the P metal electrode is connected to the P-type layer, and the N metal electrode is connected to the N-type layer. The active region is sandwiched between the P-type layer and the N-type layer, and the active region is formed by alternately stacking barrier layers and potential well layers including at least 2 stacking periods, and each stacking period includes One potential barrier layer and one potential well layer, the potential barrier layer is doped with P-type dopant. By introducing a barrier layer containing P-type dopants, the luminous efficiency of the active region of the device is improved, the photoelectric performance of the device is optimized, and the purpose of improving the luminous efficiency of the GaN-based compound semiconductor light-emitting device is achieved.

Owner:XIAMEN UNIV

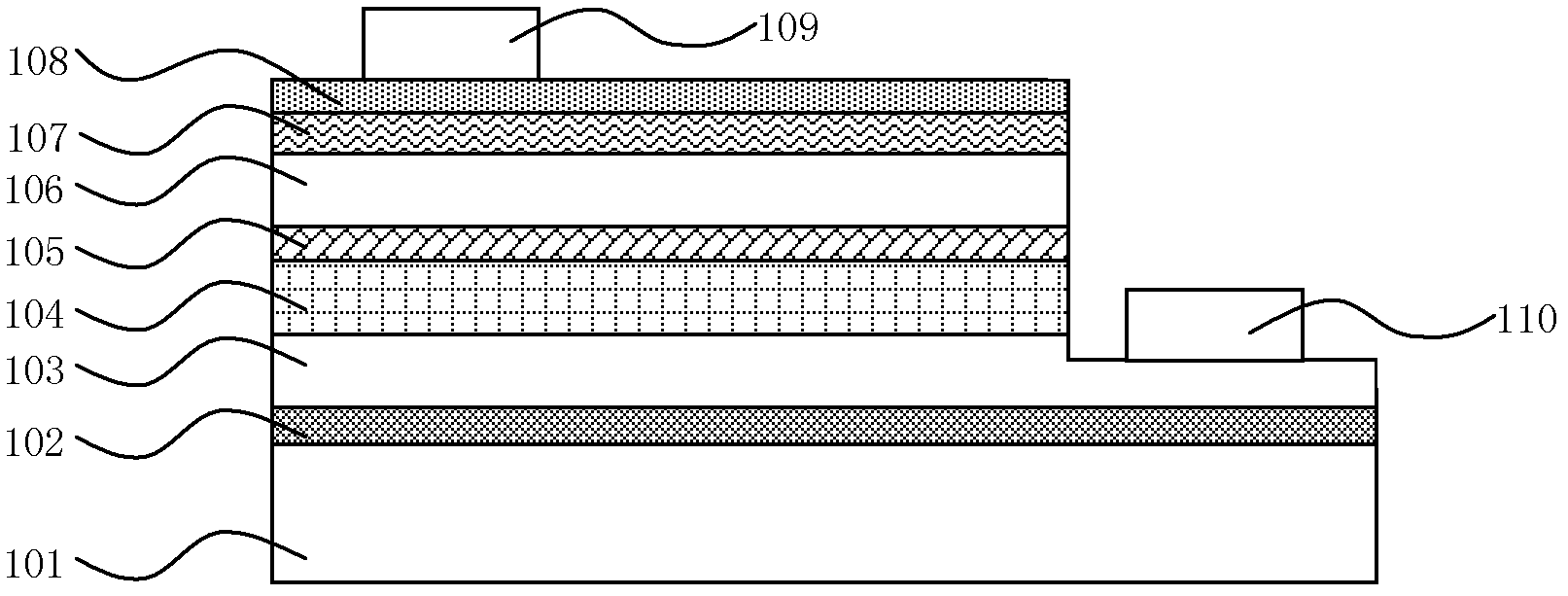

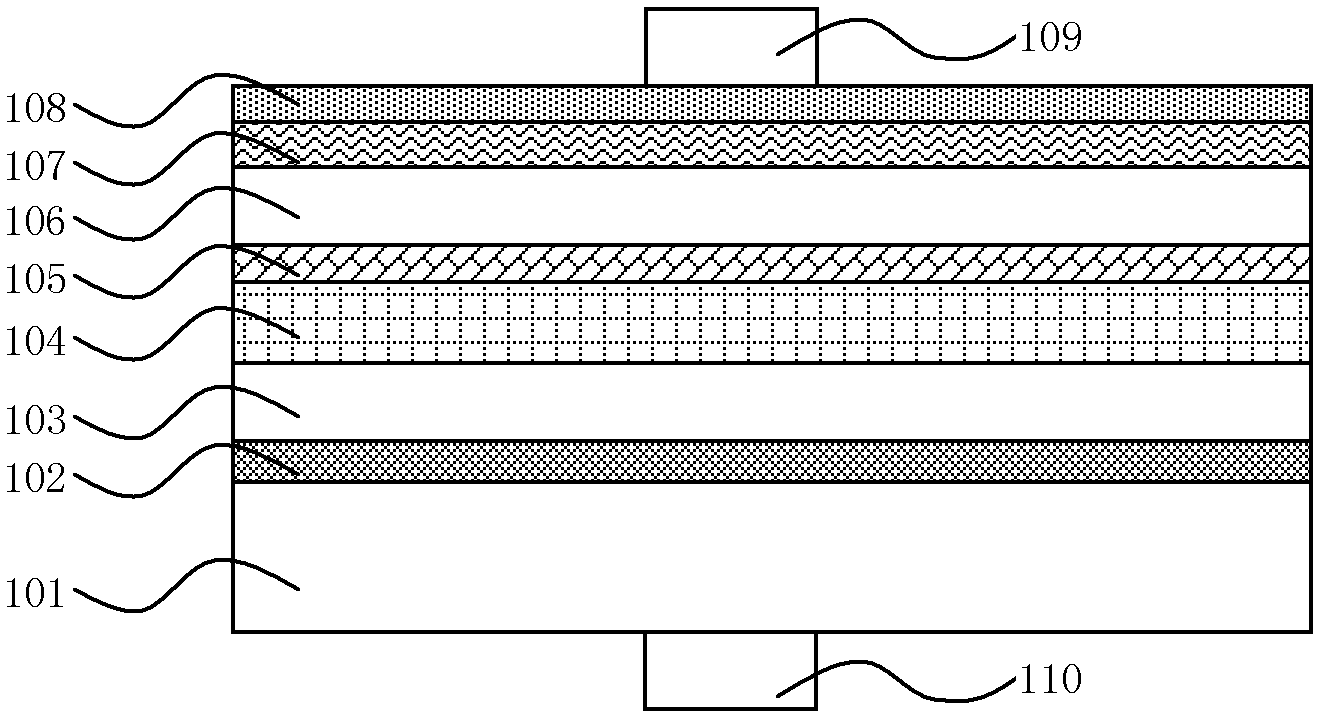

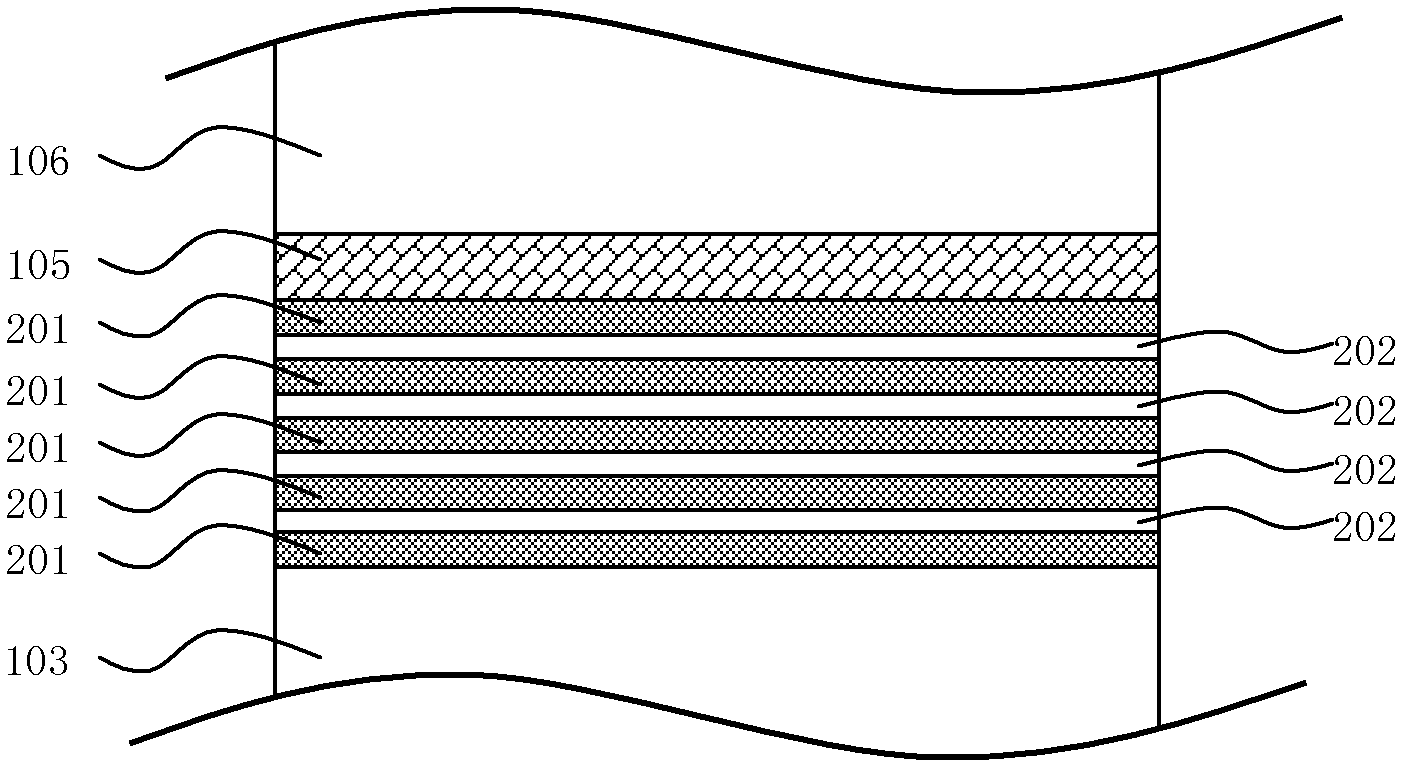

HIT solar cell and preparing method thereof

ActiveCN103904151AReduce usageImprove Plane UtilizationFinal product manufacturePhotovoltaic energy generationAmorphous siliconIntrinsics

The invention provides an HIT solar cell which comprises a P-type polycrystalline silicon substrate (P p-Si). A first intrinsic hydrogenated amorphous silicon layer (i a-Si:H), an N-type hydrogenated amorphous silicon layer (N a-Si:H) and a first transparent conducting thin film layer are sequentially deposited on the front surface of the P-type polycrystalline silicon substrate and the upper surface of the transparent conducting thin film layer is a front face electrode; an intrinsic hydrogenated amorphous silicon layer (i a-Si:H), a P-type hydrogenated amorphous silicon layer (P a-Si:H) and a second transparent conducting thin film layer are sequentially deposited on the back face of the P-type polycrystalline silicon substrate and the lower face of the second transparent conducting thin film layer is a back face electrode. The HIT solar cell greatly reduces cell production cost, the solar cell is not limited by a circular mono-crystalline silicon substrate any more, and the plane use rate of a solar cell module can be effectively improved.

Owner:HEBEI UNIV OF TECH

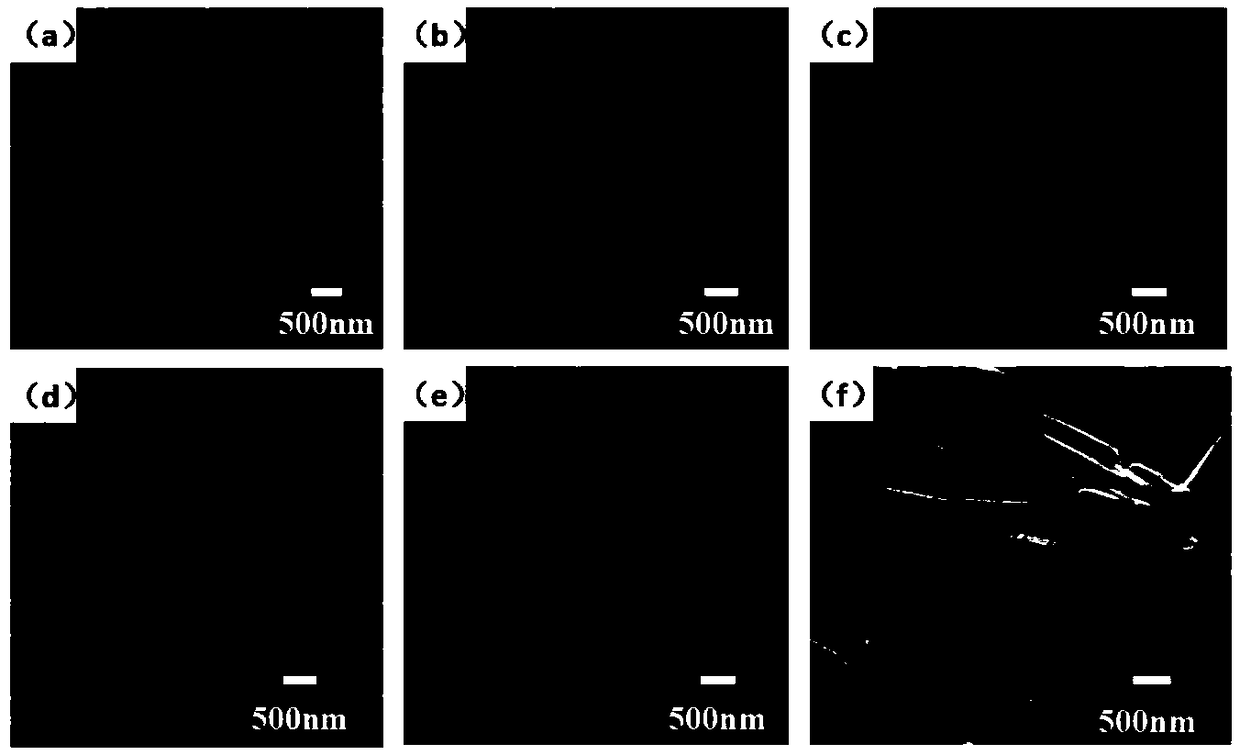

Method for preparing perovskite thin film by dynamic spin coating

ActiveCN108649121AGood repeatabilityEasy to operateSolid-state devicesSemiconductor/solid-state device manufacturingAnti solventPerovskite solar cell

The invention discloses a method for preparing a perovskite thin film by dynamic spin coating. According to the method, a perovskite APbX<3> precursor liquid is directly spin coated on a substrate with a clean surface at high-speed rotation of 4,500-6,000rmp; then an anti solvent is dropwise added to the high-speed spin coated thin film surface at low-speed rotation of 3,000-4,000rmp to obtain a lead halide thin film; and finally, annealing treatment is preformed at a temperature of 80-110 DEG C for 10-30min to obtain the APbX<3> perovskite thin film. The perovskite thin film is prepared by adopting the dynamic spin coating method in the invention; compared with a static spin coating method, the method disclosed in the invention is high in repeatability, simple in operation, high in controllability and wide in applicable range; and the prepared perovskite thin film is high in degree of crystallinity, large in grain size, high in uniformity, free of pin holes, high in coverage rate, lowers trap density for promoting carrier recombination, excellent in photoelectric performance, and has wide application prospect in commercial preparation of a perovskite solar cell.

Owner:NANJING UNIV OF SCI & TECH

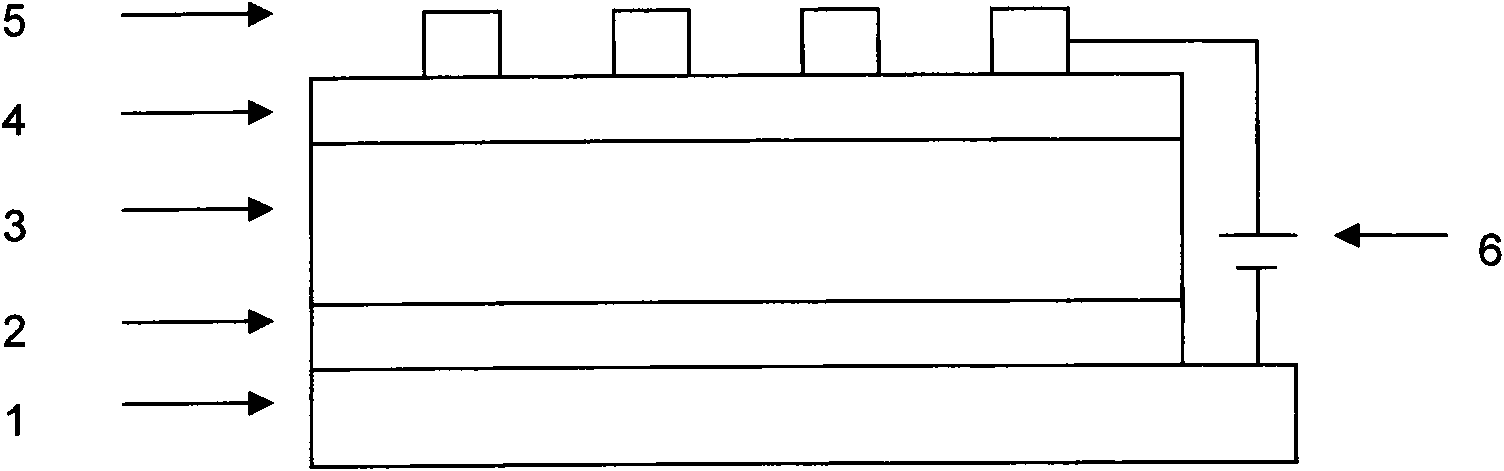

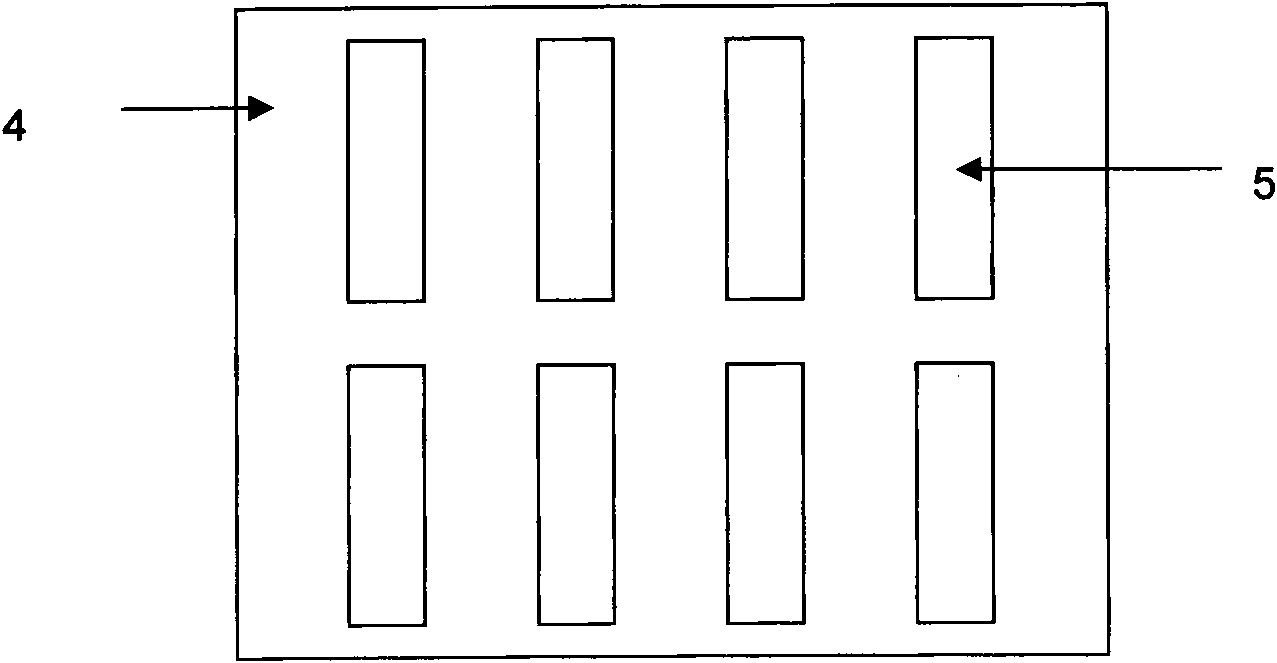

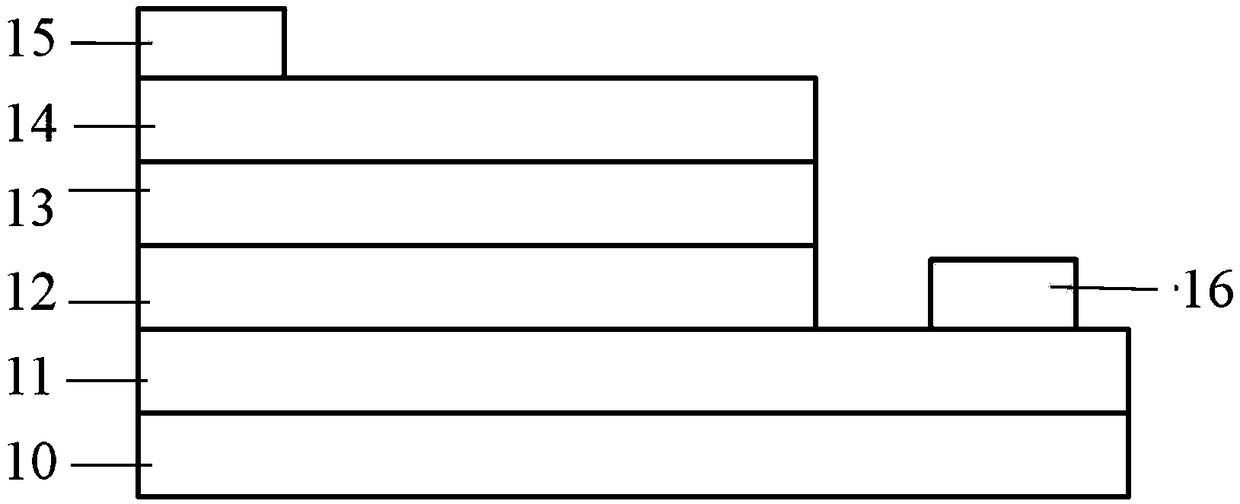

Infrared detector and preparation method thereof

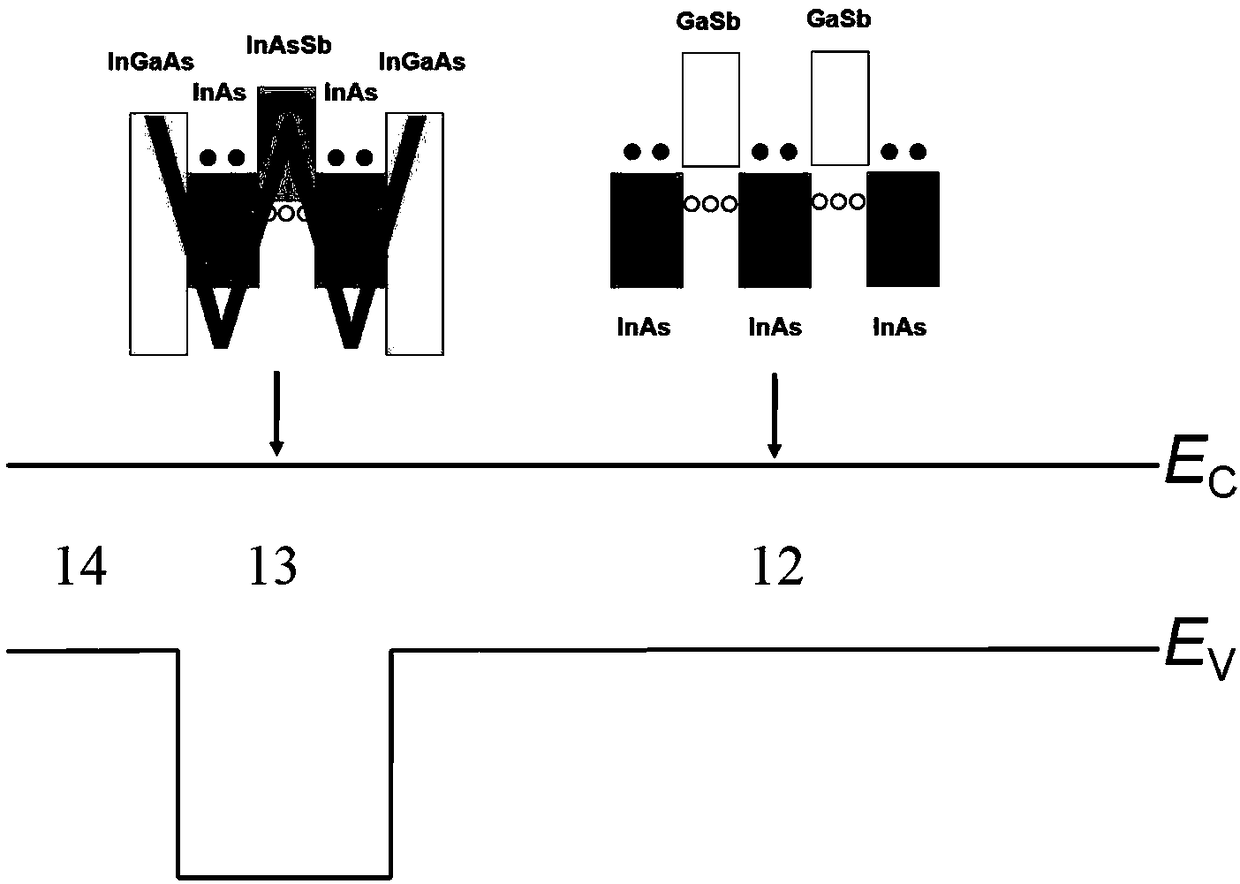

ActiveCN108231926AEasy epitaxial growthEasy to processFinal product manufactureSemiconductor devicesContact layerSemiconductor technology

The invention relates to the field of semiconductor technologies, and particularly relates to an infrared detector. The infrared detector sequentially comprises a substrate, a p-type InAs / GaSb superlattice lower contact layer, a p-type InAs / GaSb superlattice absorption layer, an InGaAs / InAs / InAsSb / InAs / InGaAs superlattice barrier layer and a p-type InAs / GaSb superlattice upper contact layer from the bottom up, and further comprises a lower electrode arranged at the upper end face of the p-type InAs / GaSb superlattice lower contact layer and an upper electrode arranged at the upper end face of the p-type InAs / GaSb superlattice upper contact layer. The infrared detector adopts Al-free InGaAs / InAs / InAsSb / InAs / InGaAs W-type superlattices to serve as a barrier layer, so that the material is easyto perform epitaxial growth, and the long-term stability and reliability are high.

Owner:苏州晶歌半导体有限公司

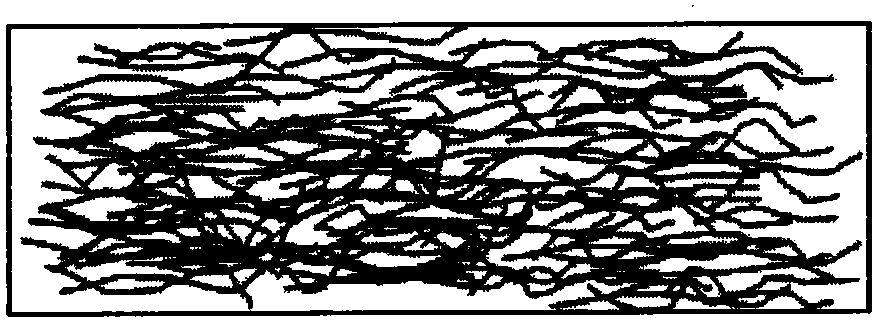

Silk hot-air non-woven fabric

The invention discloses a silk hot-air non-woven fabric which prepared by fine-denier fibers, silk fibers and ES fibers through a hot-air bonding technology.Non-hot melting silk fibers are adopted as the silk fibers, and the melting point of the ES fibers is 130 DEG C.A preparation method of the silk hot-air non-woven fabric comprises the following steps that 1, the ES fibers and the silk fibers are mixed and carded into a web to obtain a fiber web; 2, hot-air bonding reinforcing is performed on the fiber web obtained in the step 1 to obtain the hot-air non-woven fabric; in the carding process of the step 1, the obverse side of the fabric adopts messy carding, and the reverse side of the fabric adopts a dual-carding technology comprising messy carding and vertical carding.The non-woven fabric is comfortable in handfeel, silky and not prone to be fluffed, and the silk fibers can directly make contact with the skin, so that the skin friendliness is achieved; the breakthrough of producing a natural fiber non-woven fabric through a hot-air technology is achieved, the using performance of the silk hot-air non-woven fabric is improved, and the great application prospect is achieved.

Owner:SHANGHAI FENGGE NONWOVEN

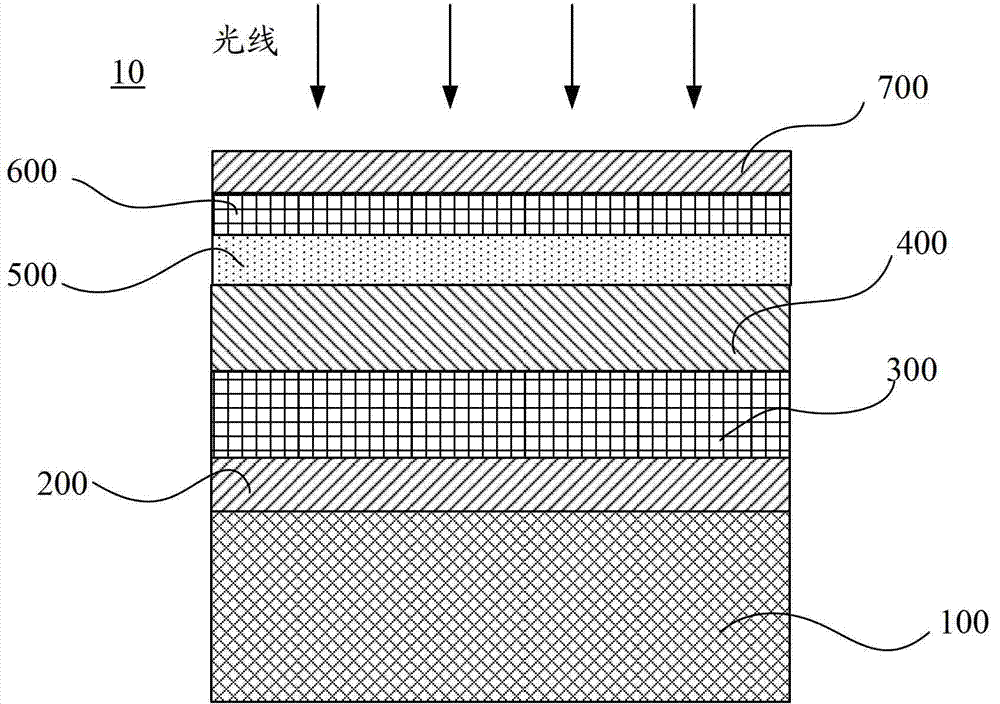

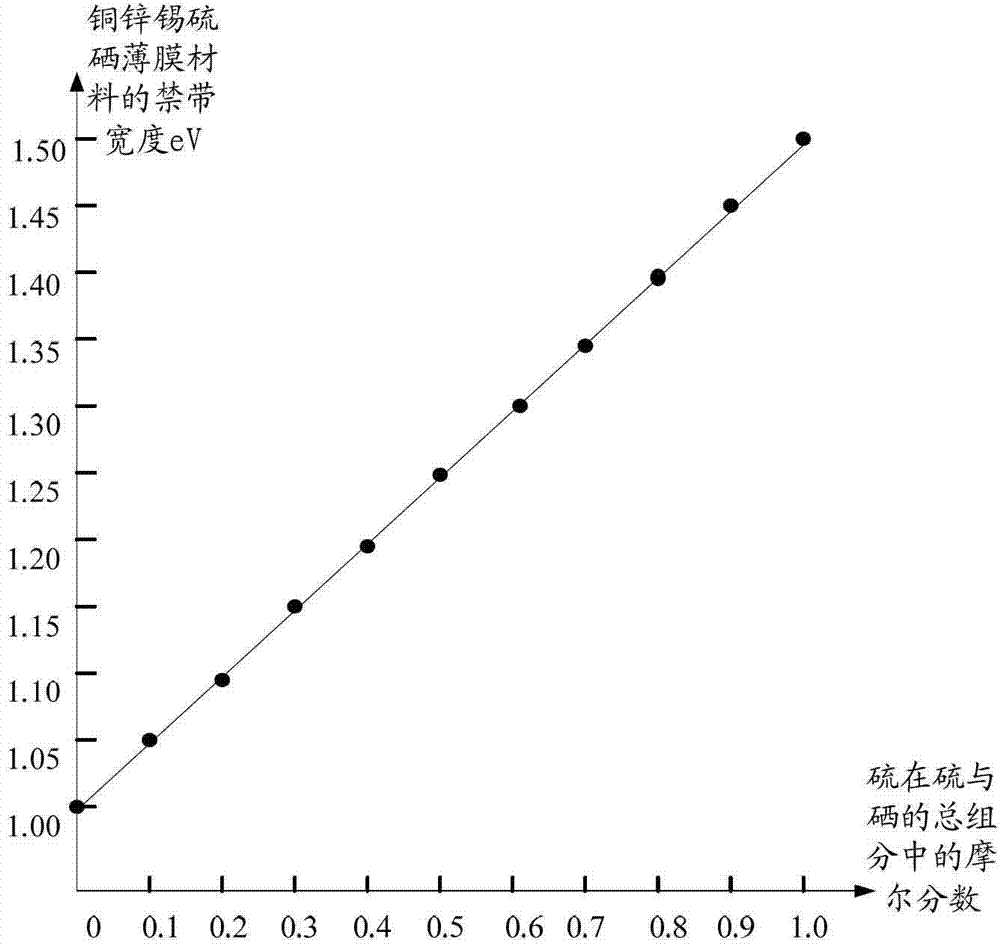

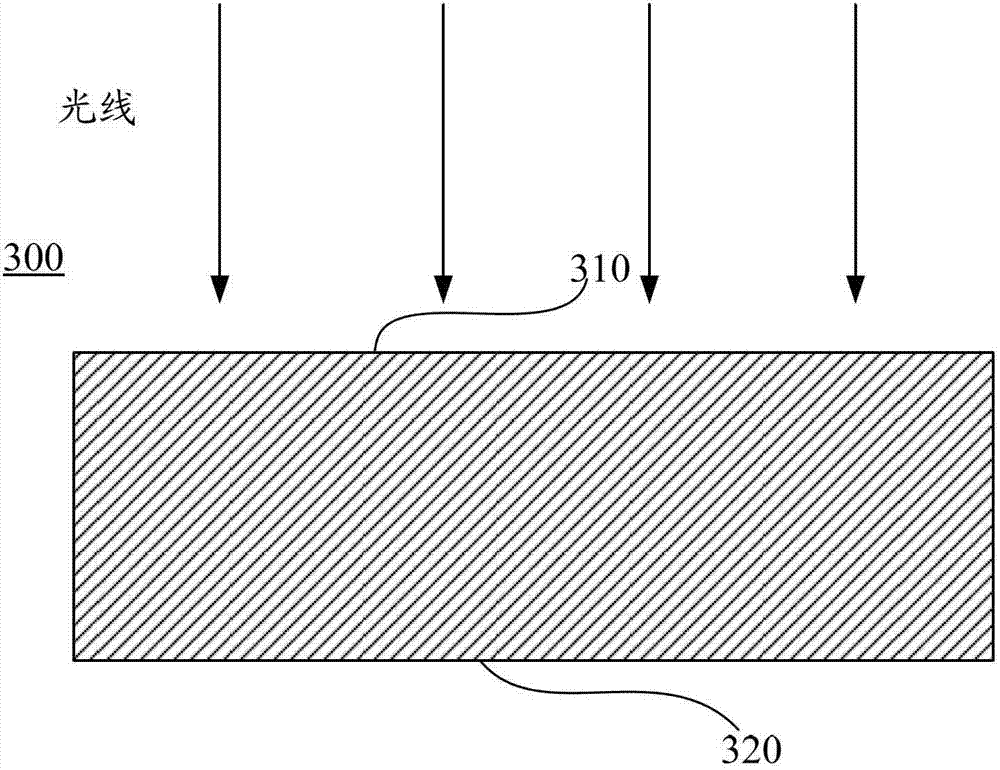

Copper-zinc-tin-sulfide-selenium film and preparation method thereof as well as copper-zinc-tin-sulfide-selenium film solar cell

ActiveCN102769047AAvoid recombinationExtend your lifeFinal product manufactureVacuum evaporation coatingPotential differenceZinc

The invention provides a copper-zinc-tin-sulfide-selenium (CZTSSe) film, which comprises a light-incident surface and a backlight surface opposite to the light-incident surface. The molar ratio of sulfide to selenium in the CZTSSe film is increased gradually along with the direction from the light-incident surface to the backlight surface. The forbidden bandwidth of the CZTSSe film is changed along with the changes of the molar ratio of the sulfide to the selenium in a material. The forbidden bandwidth can cause the generation of potential difference between the light-incident surface and the backlight surface, and photo-induced carriers are driven out of a high recombination area; therefore, recombination among the photo-induced carriers is avoided, and the service liives of the photo-induced carriers are prolonged. The generated potential difference is beneficial to improving the diffusion length of the photo-induced carriers and the collection efficiency of the photo-induced carriers is improved, thus improving the photoelectric conversion efficiency of the cell. The invention further provides a preparation method of the CZTSSe film and a CZTSSe film solar cell.

Owner:SHENZHEN INST OF ADVANCED TECH +1

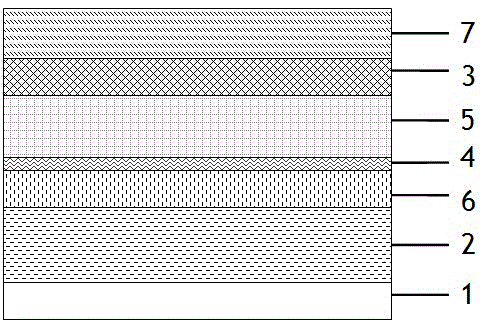

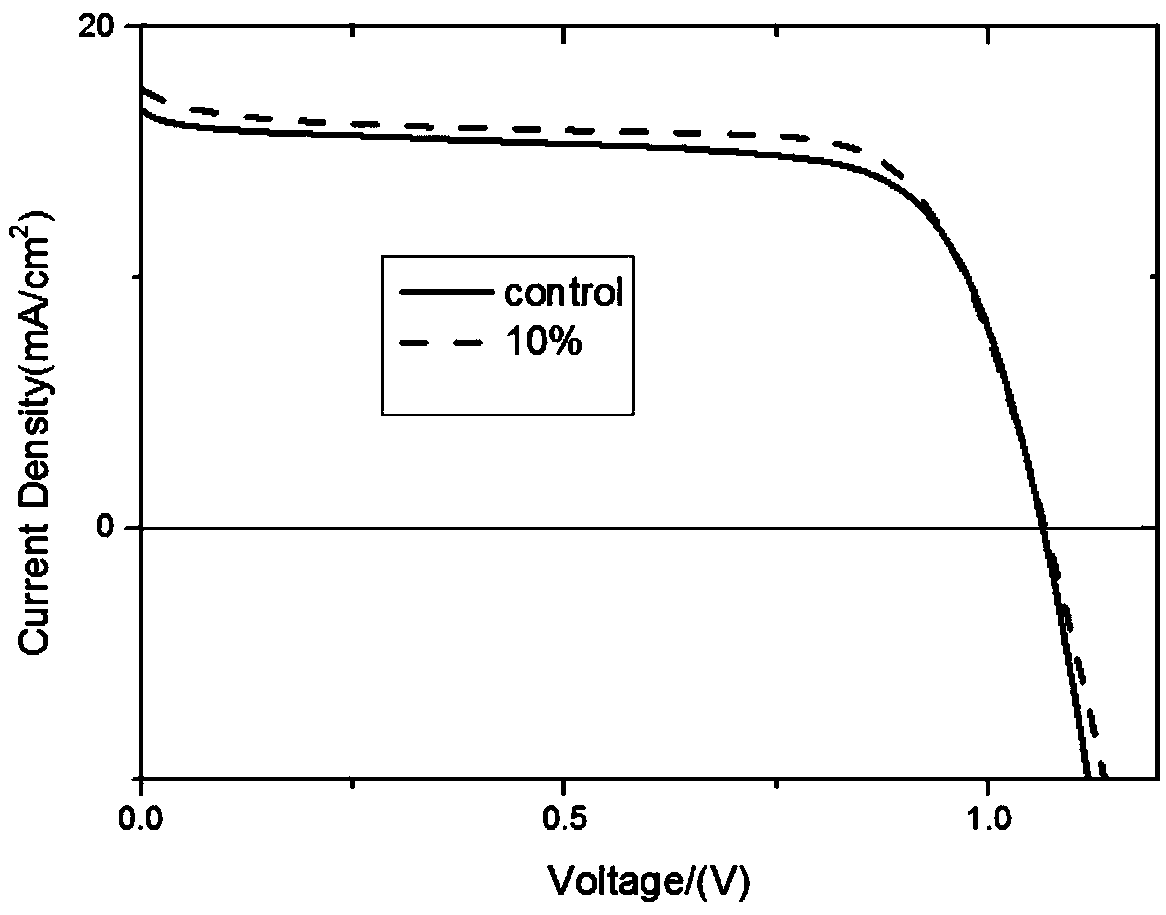

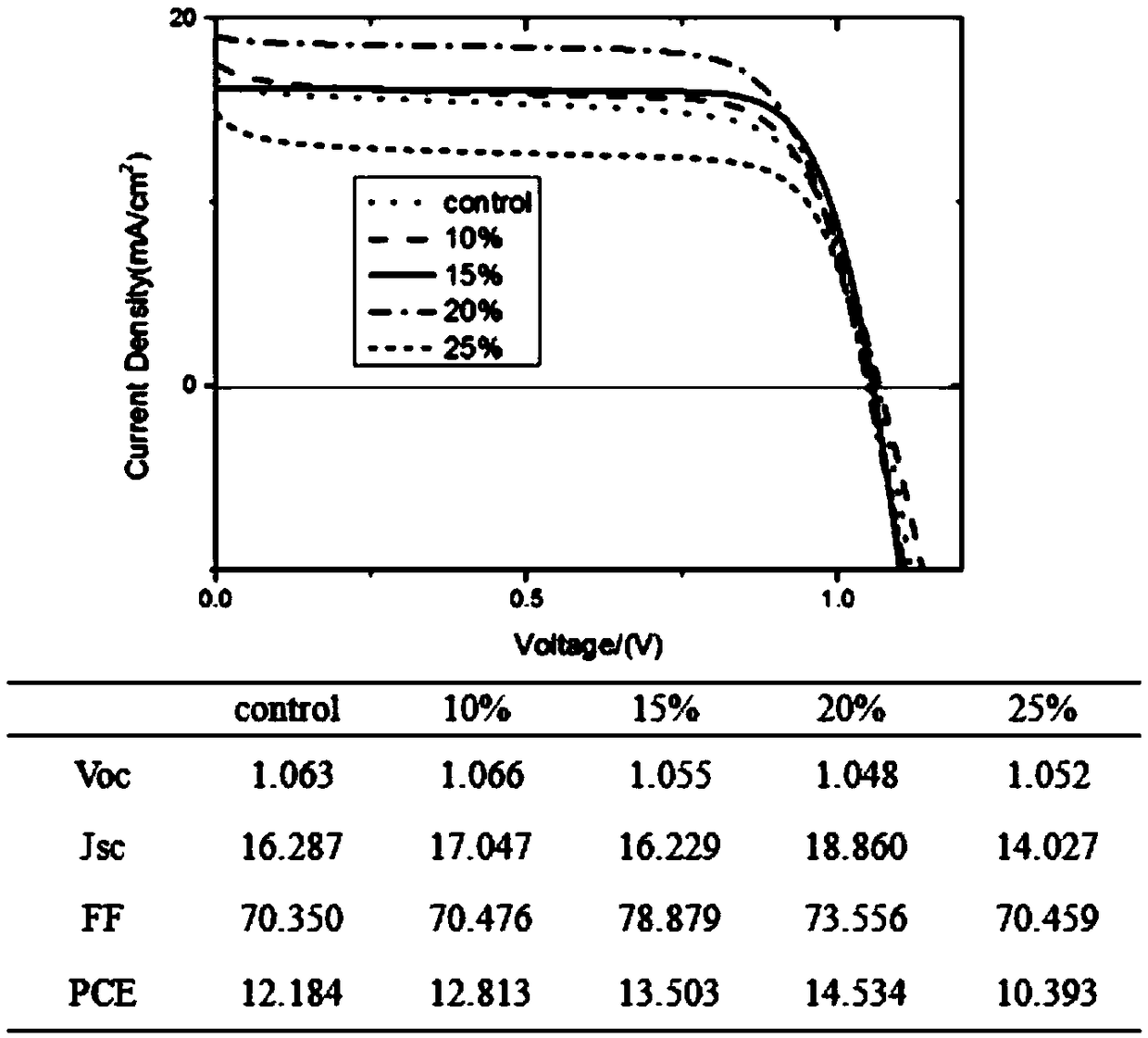

A perovskite solar cell device for modifying a hole transport layer and a preparation method thereof

InactiveCN109244249APromote crystallizationImprove mobilitySolid-state devicesSemiconductor/solid-state device manufacturingCharge carrier mobilityHole transport layer

The invention discloses a perovskite solar cell device for modifying a hole transport layer and a preparation method thereof. the solar cell device comprises a transparent substrate, an anode, a holetransport layer, an absorbing layer, an electron transport layer, amodified layer and a cathode which are sequentially superposed; the invention uses ethanol solution of ethyl acetate to modify the surface of the hole transport layer, so that its surface has some effective groups, which can effectively promote the crystallization of perovskite thin film, It is advantageous to form more flat and compact perovskite thin film, to improve carrier mobility and diffusion length, to improve charge transfer efficiency, to effectively increase short circuit current, to improve device efficiency, so asto improve the performance of solar cells and other light-emitting devices, and has been widely used in the preparation of perovskite battery devices.

Owner:NANJING UNIV OF POSTS & TELECOMM

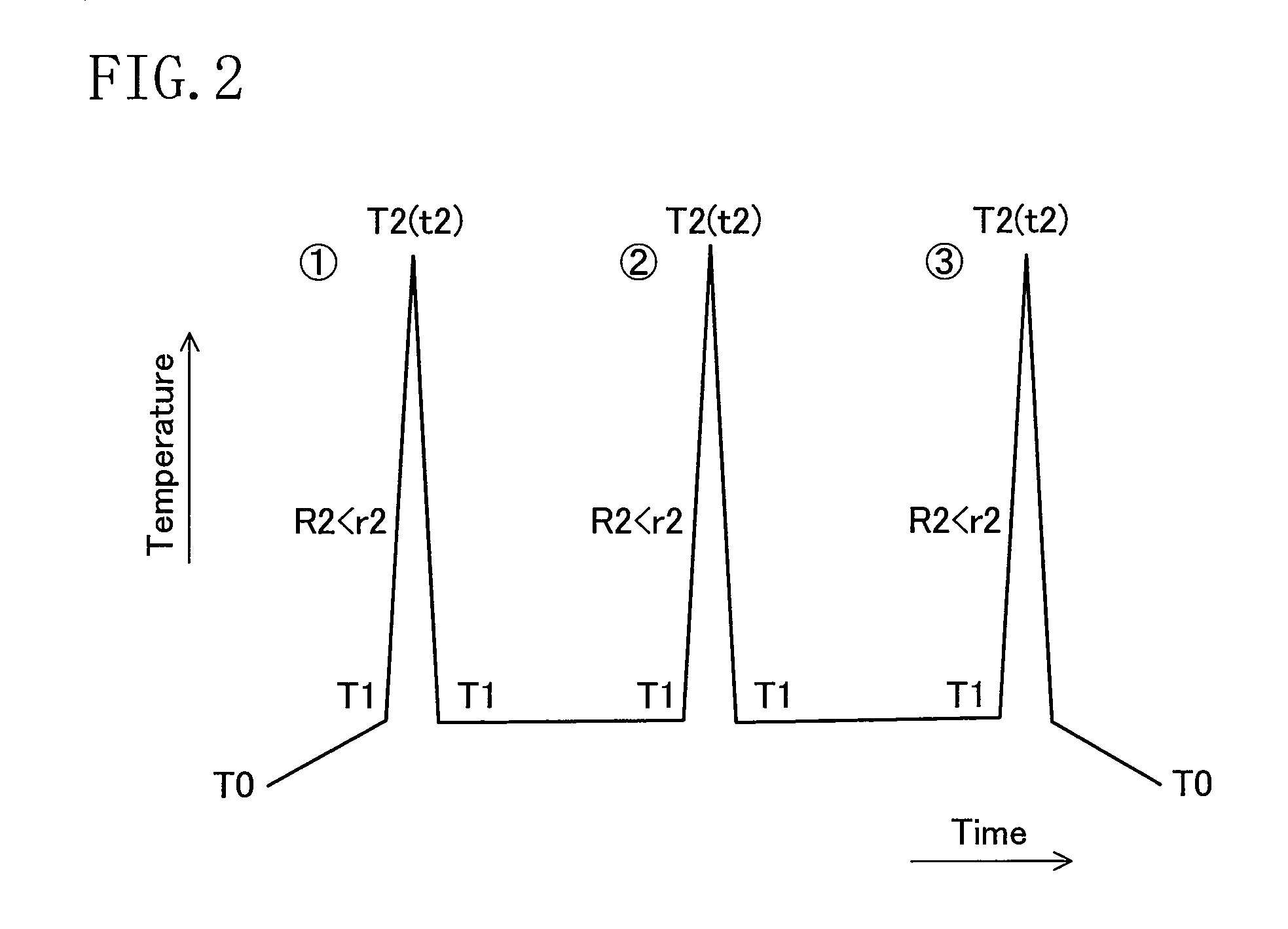

Impurity-activating thermal process method and thermal process appartus

ActiveUS20090197427A1Improve impurity activation rateWithout increasing impurity diffusion lengthTransistorDomestic stoves or rangesArbitrary rateImpurity

A thermal cycle includes: increasing a temperature from an initial temperature to a temperature T1 at an arbitrary rate R1 (° C. / sec); holding the temperature at the temperature T1 for an arbitrary period t1 (sec); increasing the temperature from the temperature T1 to a temperature T2 at a rate R2 (° C. / sec) of 1.0×107 (° C. / sec) or less; and holding the temperature at the temperature T2 for a period t2 (sec) of 50 msec or less. The thermal cycle thereafter includes: decreasing the temperature from the temperature T2 to the temperature T1 at a rate R1′ (° C. / sec) of 1.0×107 (° C. / sec) or less; holding the temperature T1 for an arbitrary period t3 (sec); and decreasing the temperature from the temperature T1 to a final temperature at an arbitrary rate R2′ (° C. / sec). Such a thermal cycle is successively repeated in a plurality of iterations.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

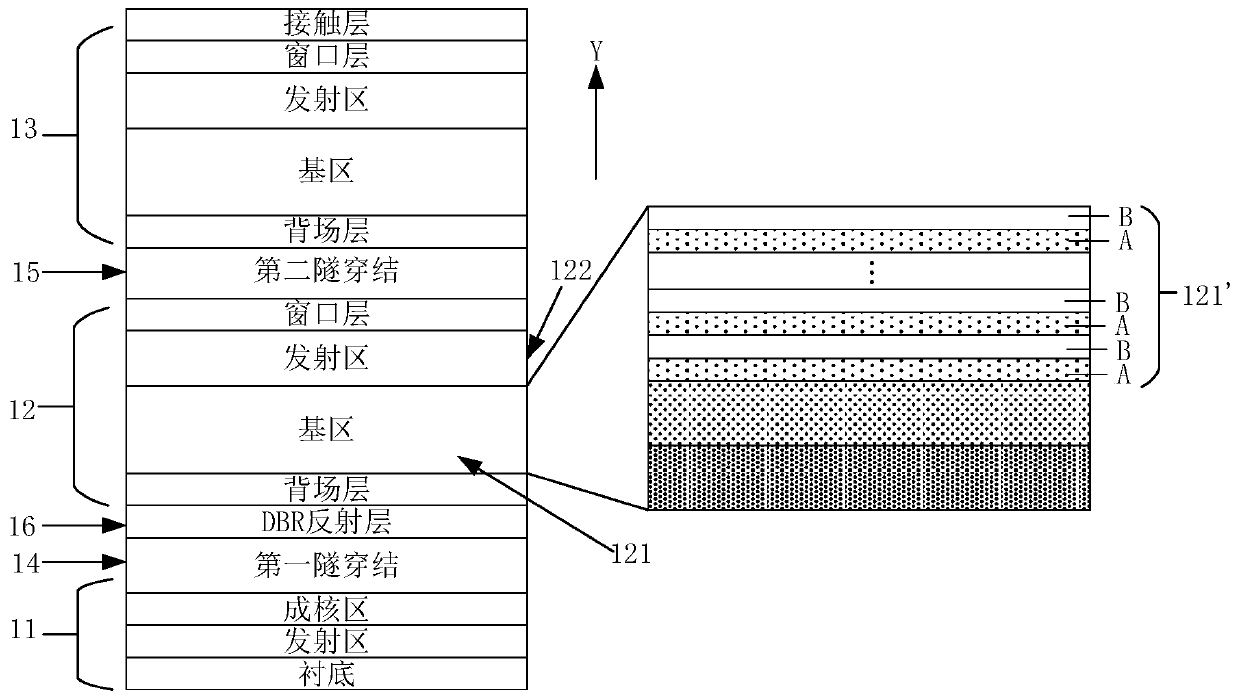

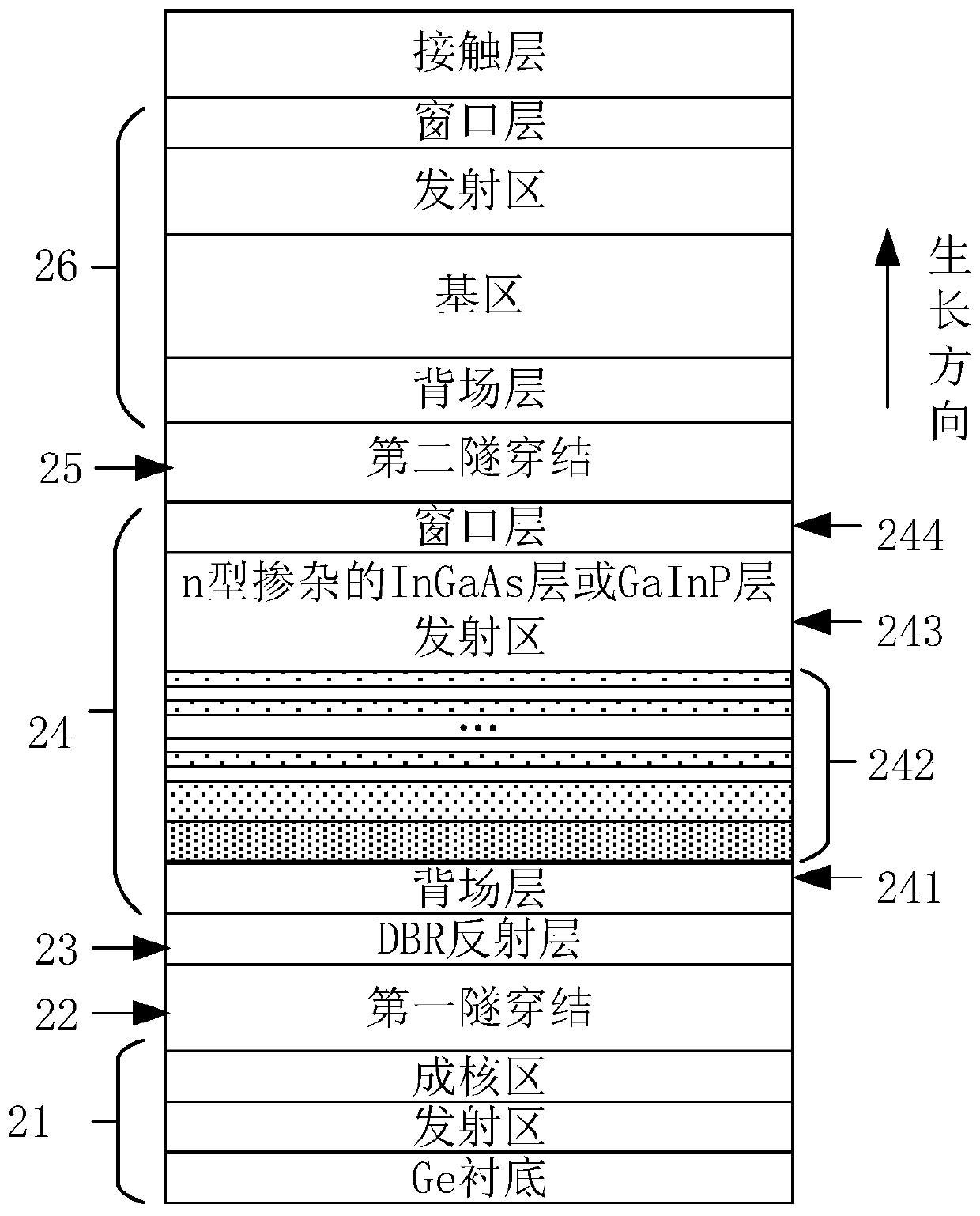

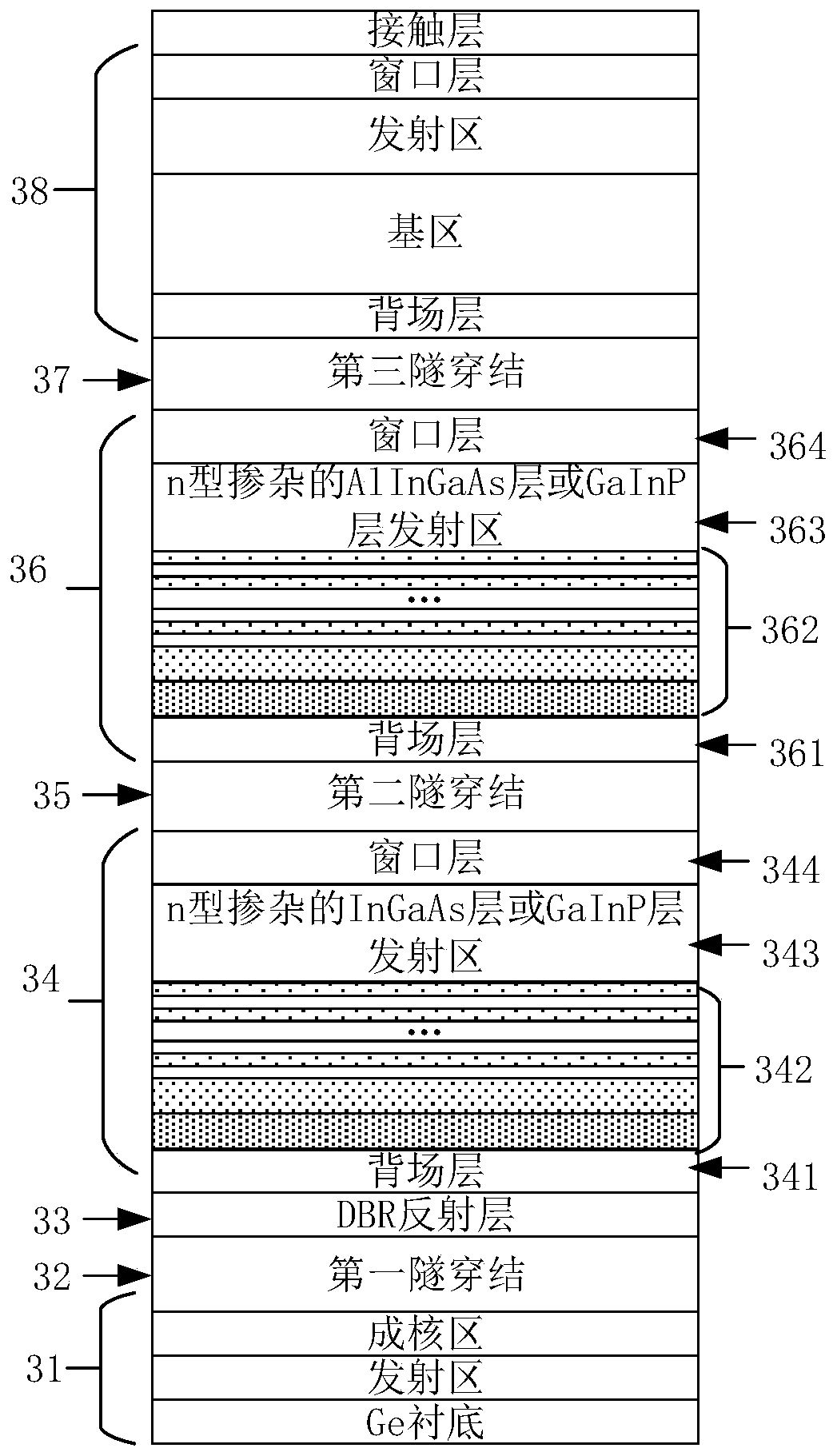

Arsenide multi-junction solar cell and manufacturing method thereof

ActiveCN109860325AImprove performanceImprove radiation resistanceFinal product manufacturePhotovoltaic energy generationCharge carrierNon doped

The present invention provides an arsenide multi-junction solar cell and a manufacturing method thereof. The arsenide multi-junction solar cell comprises at least three-junction sub cells, wherein thebase region of at least one-junction sub cell is an arsenide base region which is formed in a doping gradation mode, in a region with a low dosage concentration, doping layers and non-doping layers are alternately grown to reduce the average carrier concentration, close to a PN-junction region, of the base region, and an inverse proportion relationship of a width and an average carrier concentration in an exhaust region is obtained. Therefore, the technical scheme provided by the invention can increase the thickness of the exhaust region and can improve the collection effect of carriers so asto improve the cell performances, and the base region in the mode increases the migration rate of few of carries through adoption of a mode of alternate growth of the doping layers and the non-dopinglayers so as to increase the diffusion length of few of carriers, finally lives of the carriers and improve the anti-irradiation properties of the cells.

Owner:YANGZHOU CHANGELIGHT

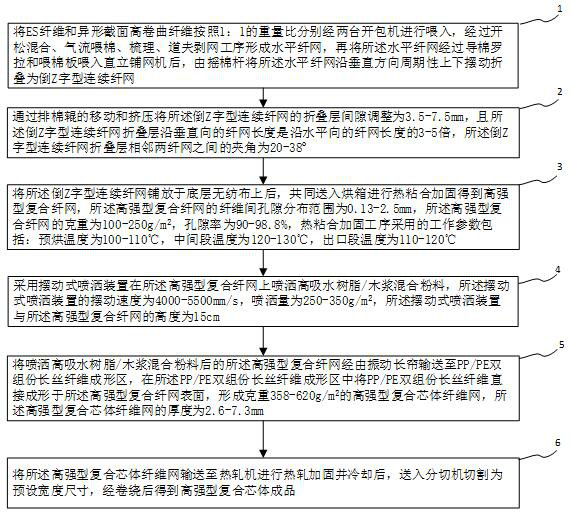

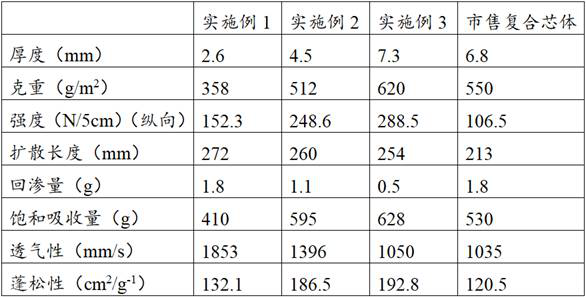

High-strength composite core, preparation method thereof and application of high-strength composite core in baby diapers

The invention discloses a high-strength composite core, a preparation method thereof and application of the high-strength composite core in baby diapers, and relates to the technical field of disposable hygienic products. According to the high-strength composite core and the preparation method thereof, through compounding of PP / PE double-component filament fibers and a high-strength composite fiber net, selection of raw materials of high-crimpness C-type coarse-denier hydrophilic PTT fibers and reasonable matching and common use of super absorbent resin and wood pulp fibers, a processing modeof firstly carrying out thermal hardening and then spraying super absorbent resin / wood pulp mixed powder, innovative design of processing technological parameters, the prepared high-strength compositecore has good toughness, aging resistance, air permeability, moisture penetrability and comfort; the composite core has the advantages of being long in diffusion length, free of hot melt adhesive, high in SAP utilization rate and good in absorption capacity, compared with an existing composite core, the use amount of SAP can be further reduced, and when the composite core is applied to preparation of baby diapers, the fault phenomenon caused by the large amount of urine or the large amount of exercise of babies can be avoided.

Owner:JIAXING UNIV

Low-pressure variable-temperature diffusion method of nanometer textured polycrystalline silicon solar cell

InactiveCN104091857AResolve uneven diffusionSpread evenlyFinal product manufactureSemiconductor/solid-state device manufacturingDiffusion methodsSolar cell

The invention discloses a low-pressure variable-temperature diffusion method of a nanometer textured polycrystalline silicon solar cell, and relates to the technical field of solar cells. The low-pressure variable-temperature diffusion method comprises the steps of cleaning of silicon wafers, vacuumizing, temperature rising, power on, cooling and wafer discharging. The pressure of diffusion gas keeps 0.001-0.8 Pa, the diffusion temperature range is from 600 to 950 degrees, the silicon wafers used are p-type silicon wafers and n type silicon wafers. Low-pressure diffusion and variable-temperature diffusion are combined, the problem of uneven diffusion of the nanometer textured silicon wafers is resolved, molecular movement of a diffusion source is accelerated under a low-pressure condition, an impurity source in a diffusion cavity is distributed evenly, the partial concentration difference on the surfaces of the silicon wafers is small, and an even diffusion environment is created. Meanwhile, inside a nanometer textured structure, the diffusion length of a gas source is large, the response time is short, and it is represented that similar diffusion source atmosphere exists within a certain period of time.

Owner:EOPLLY NEW ENERGY TECH

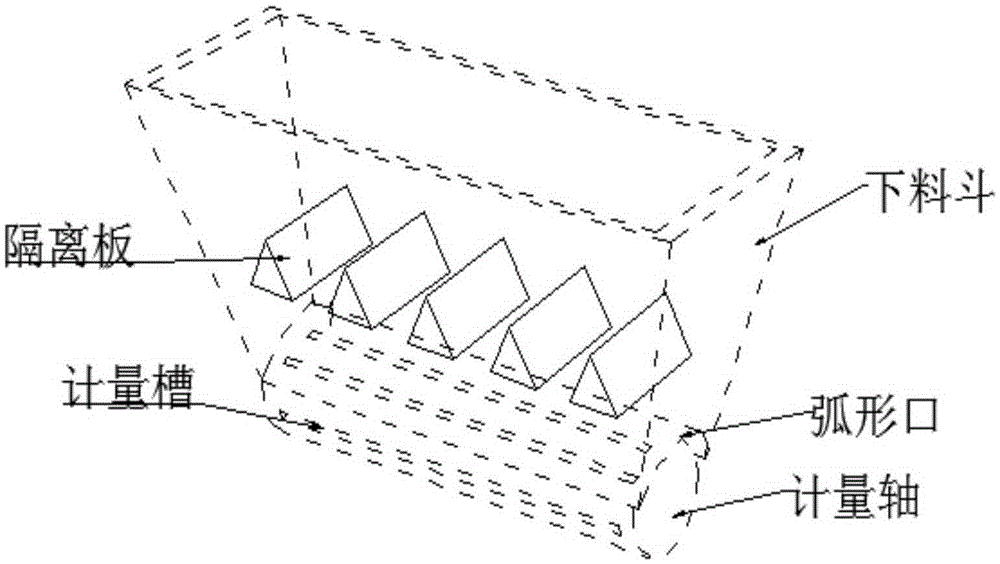

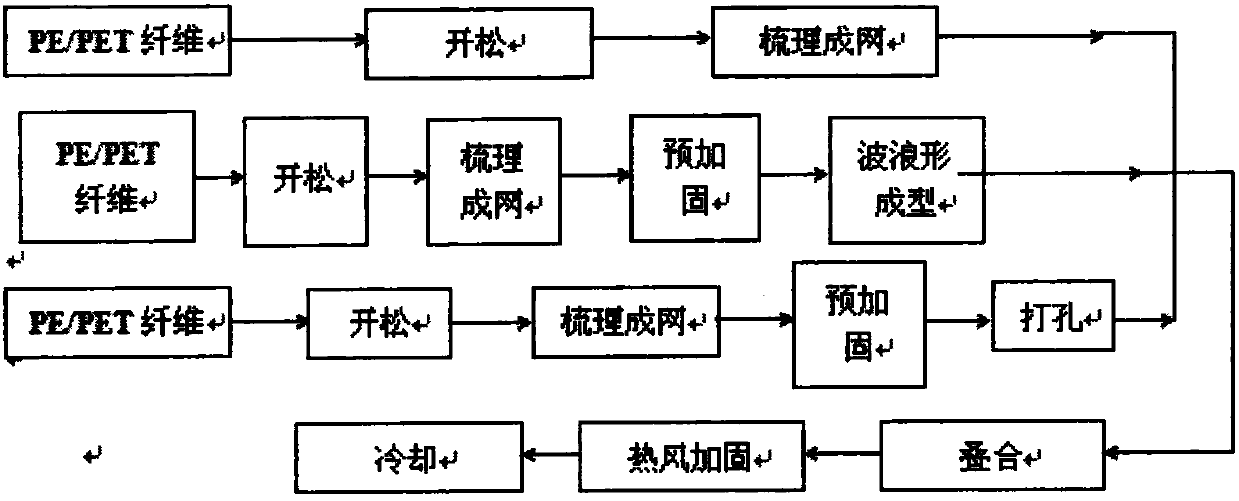

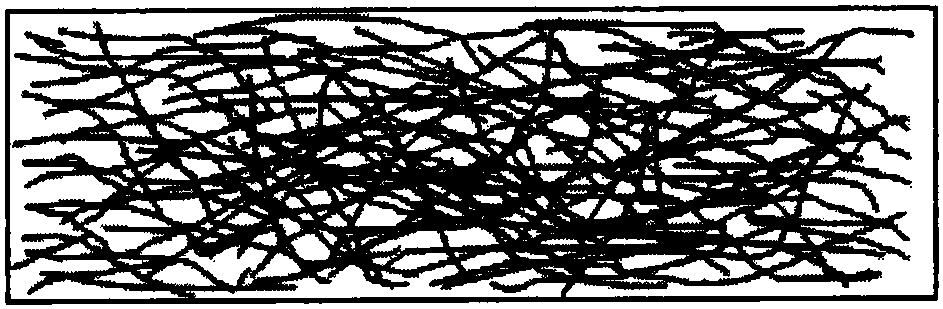

Sandwich structure paper diaper flow guiding layer material and preparation method thereof

ActiveCN107753185AFacilitated DiffusionLarge storage capacitySynthetic resin layered productsAbsorbent padsLiquid diffusionFiber

The invention provides a sandwich structure paper diaper flow guiding layer material and a preparation method thereof. The sandwich structure paper diaper flow guiding layer material is characterizedby comprising three layers of sheets, the three layers of sheets are all non-woven fabrics manufactured by adopting chemical fiber through the hot-blast air penetration bonding non-woven technology, and the three layers of sheets are stacked and bonded from top to bottom to form the sandwich structure; the upper-layer sheet is a longitudinal orienteering fiber net; the middle-layer sheet is a longitudinal orienteering fiber net, and the cross section is in a wavy shape or a sawtooth shape; the lower-layer sheet is a disordered fiber net, and small holes are evenly distributed in the fiber net;the chemical fiber is ES fiber. The prepared flow guiding layer material can shorten the liquid penetration time, increase the liquid diffusion length and increase the liquid storage amount.

Owner:DONGHUA UNIV

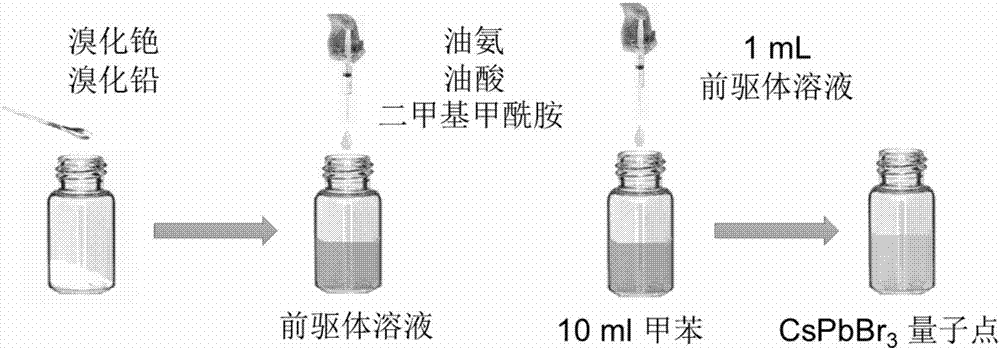

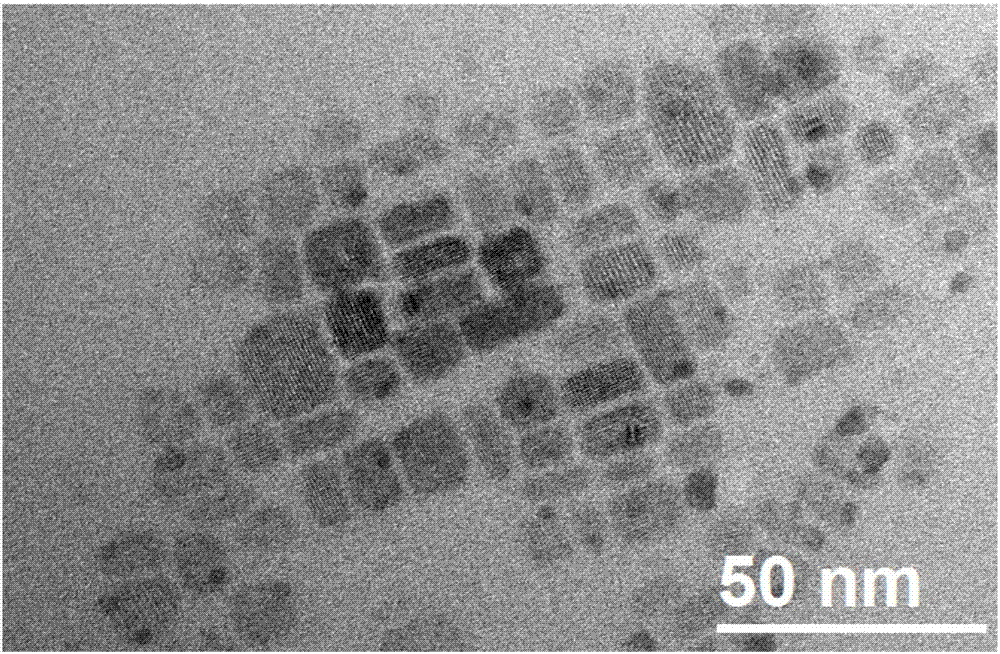

Full-inorganic perovskite quantum-dot CsPbBr3 electric storage device and fabrication method thereof

ActiveCN108010912AEvenly dispersedGood repeatability of electric storage performanceTransistorSemiconductor/solid-state device manufacturingElectricityStatic random-access memory

The invention discloses a full-inorganic perovskite quantum-dot CsPbBr3 electric storage device and a fabrication method thereof. The full-inorganic perovskite quantum-dot CsPbBr3 electric storage device has dynamic random access memory (DRAM) electric storage performance, the application of perovskite quantum dot in the storage device is expanded, the semiconductor device can be favorably applied, the DRAM electric storage behavior is successfully achieved by the fabricated electric storage device having a sandwiched structure, meanwhile, the storage device is simple in fabrication process and good in stability and has the characteristics of good repeatability and frequent bending. The invention provides a new design idea for a flexible electric storage device; and with the flexible electric storage device fabricated by the technology, the DRAM electric storage behavior is successfully achieved.

Owner:SUZHOU UNIV

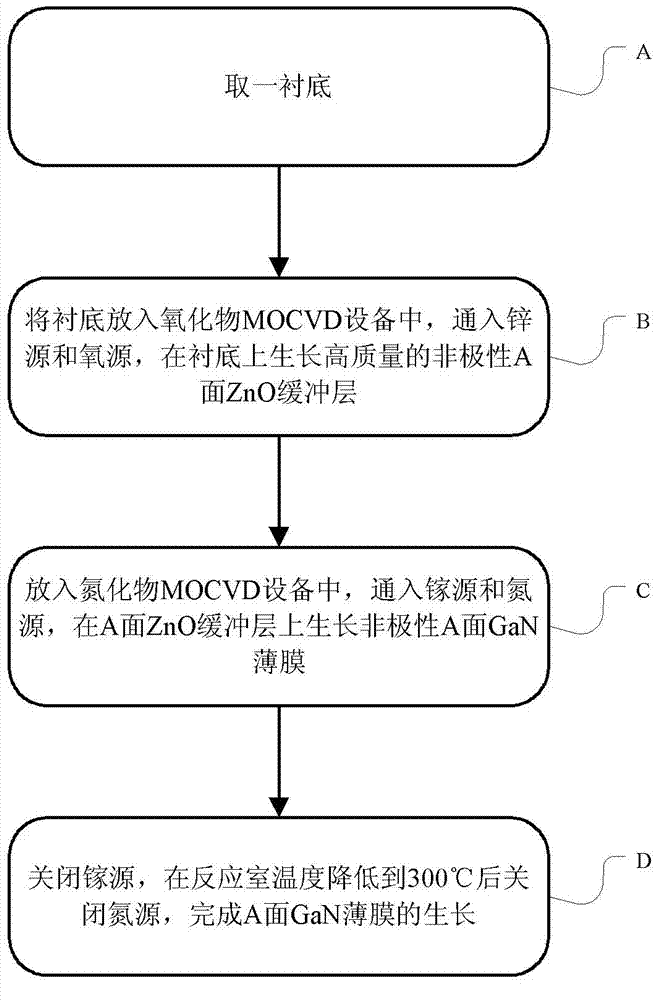

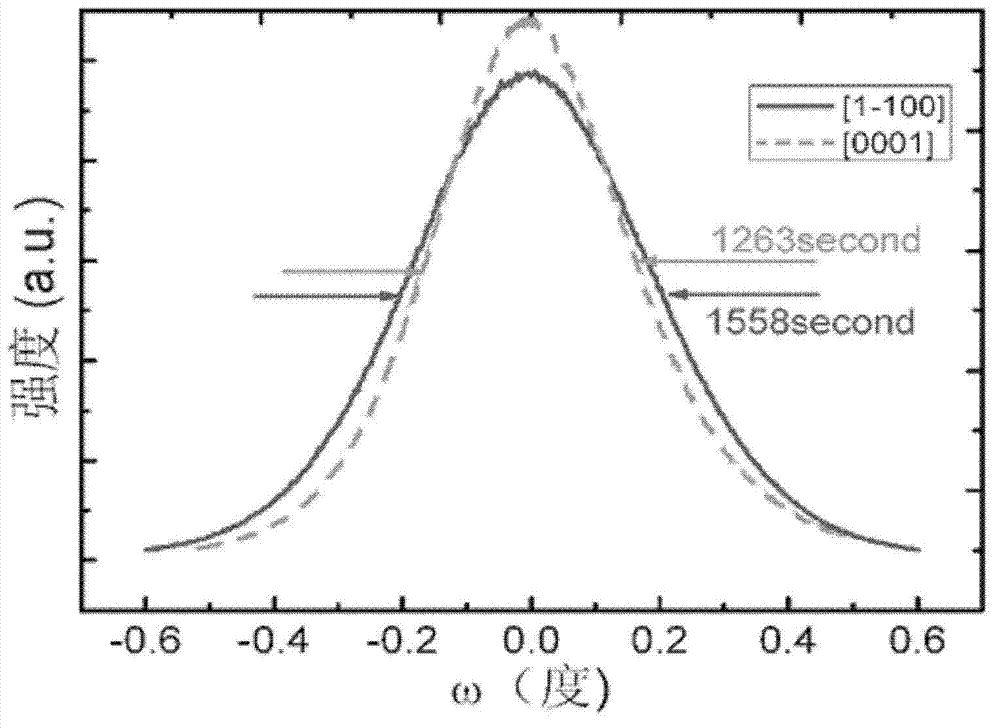

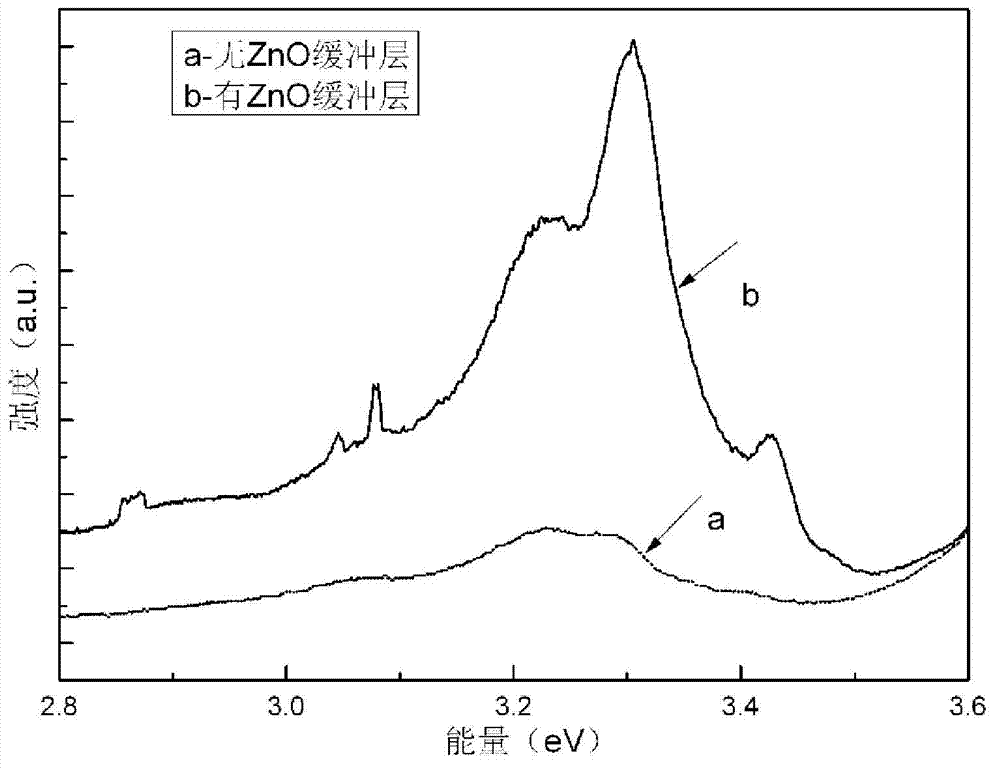

Method for preparing non-polar A face GaN thin film

InactiveCN102903614ALow costFast growthSemiconductor/solid-state device manufacturingLattice mismatchOptoelectronics

The invention provides a method for preparing a non-polar A face GaN thin film. The method comprises the following steps of: preparing an A face ZnO buffering thin film on the surface of a substrate; and preparing the non-polar A face GaN thin film on the prepared A face ZnO buffering thin film. According to the method disclosed by the invention, lattice mismatch and heat lattice mismatch between GaN and the substrate can be coordinated by a ZnO buffering layer, so that the crystallization quality of the prepared GaN thin film is greatly improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

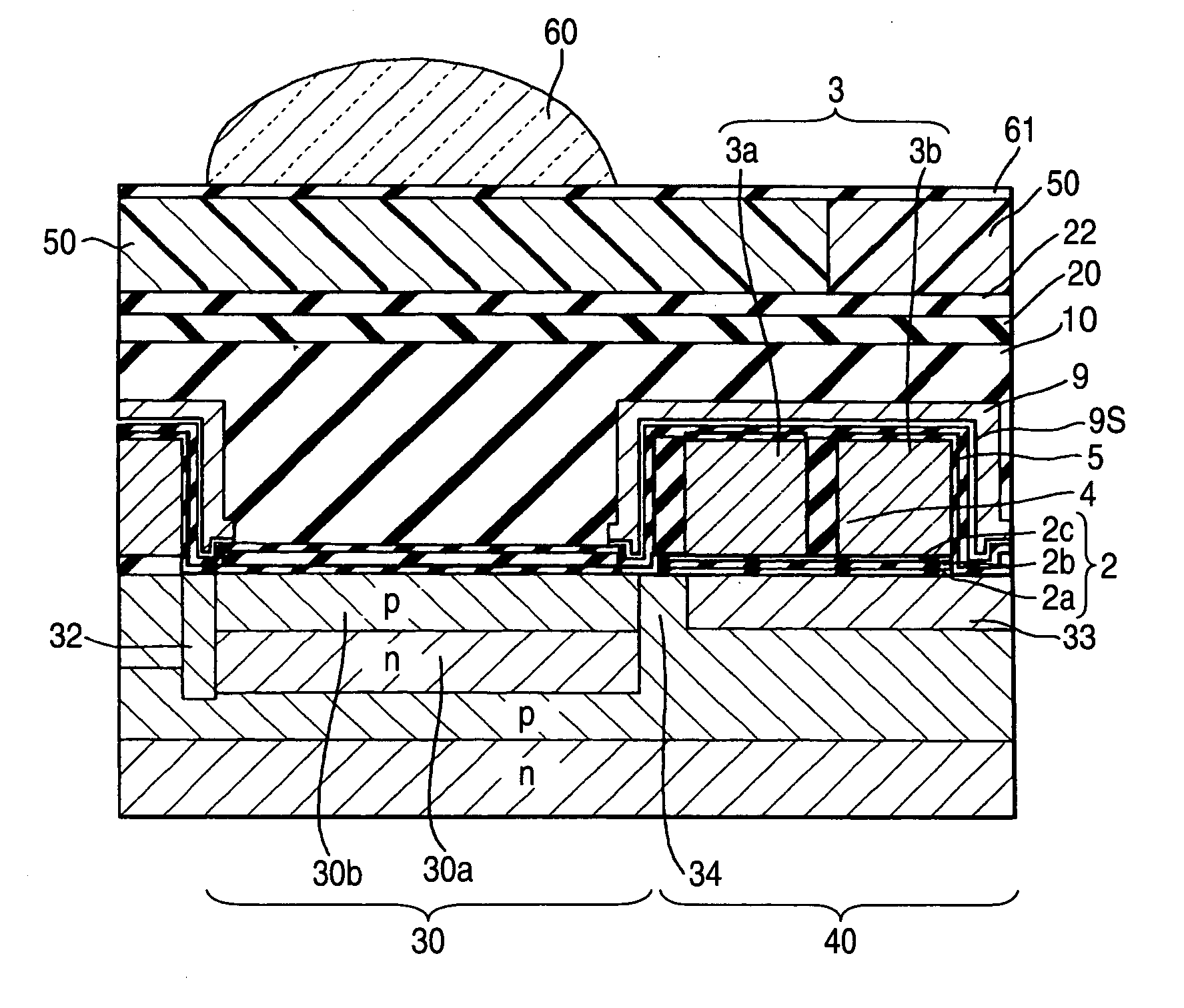

High read output, high sensitivity magnetic sensing element

InactiveUS7428128B2DistanceHigh outputMagnetic-field-controlled resistorsSolid-state devicesHigh current densityNon magnetic

A magnetic sensing element has pinned magnetic layers disposed on the two sides of a free magnetic layer in the track width direction with nonmagnetic conductive layers therebetween, and an electric current flows through these layers in parallel to the surfaces. The back end of the free magnetic layer in the track width direction extends in parallel to the track width direction. The back ends of the nonmagnetic conductive layers are coincident with the reference line drawn by extending the back end of the free magnetic layer. At least part of the back ends of the pinned magnetic layers is coincident with the reference line. Each pinned magnetic layer is shaped so that the region near the nonmagnetic conductive layer and the free magnetic layer has a smaller length in the height direction to achieve higher current density.

Owner:TDK CORPARATION

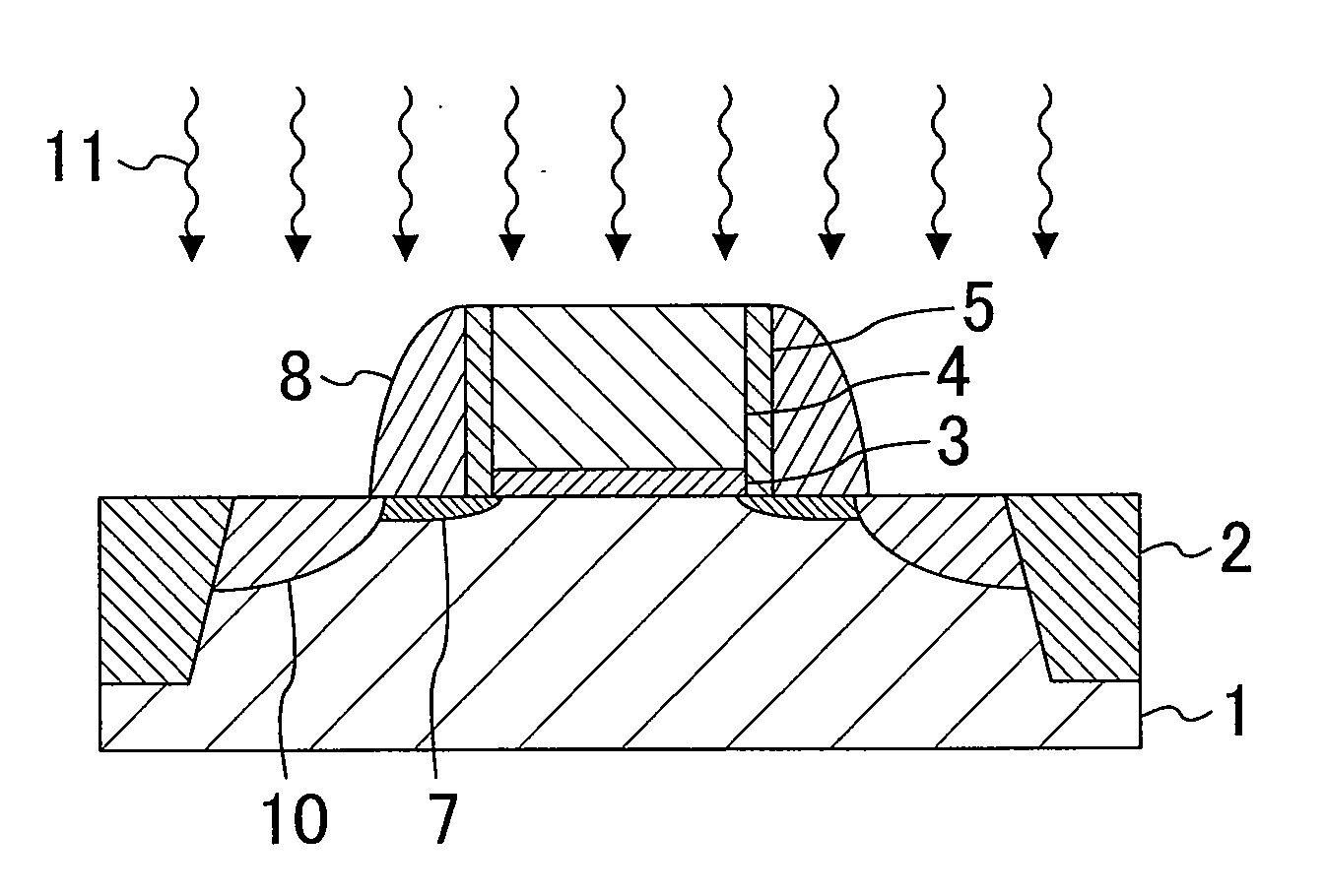

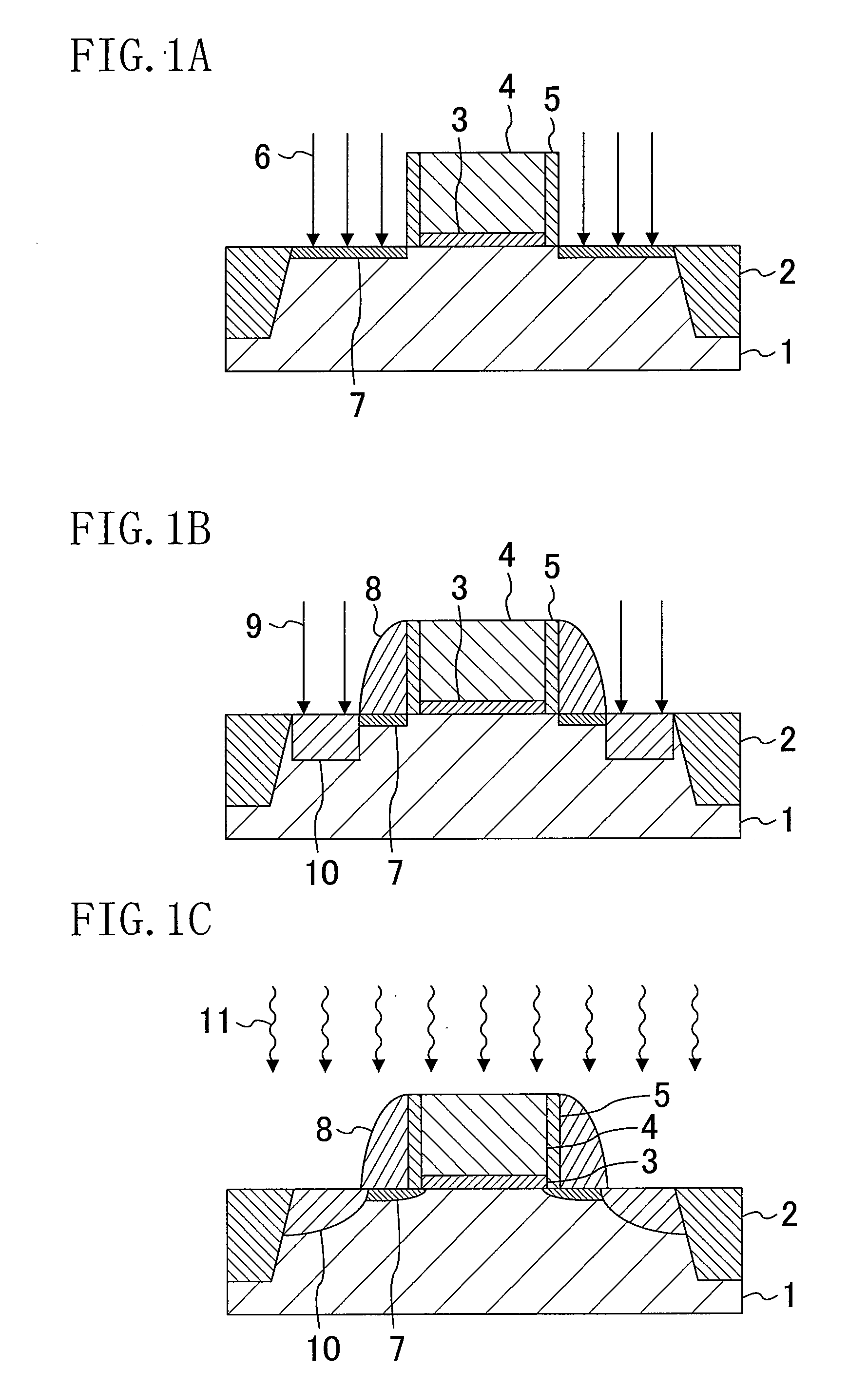

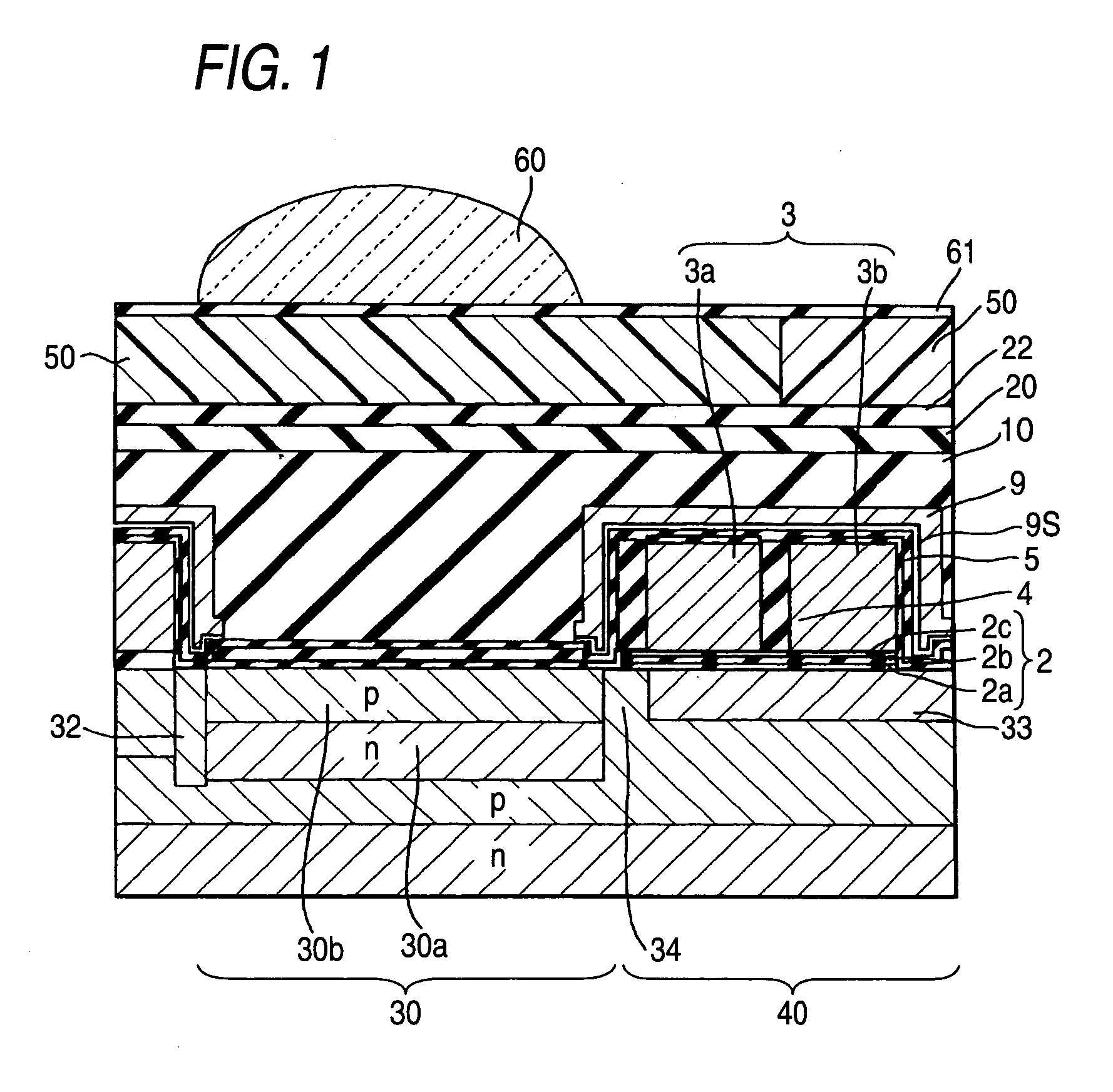

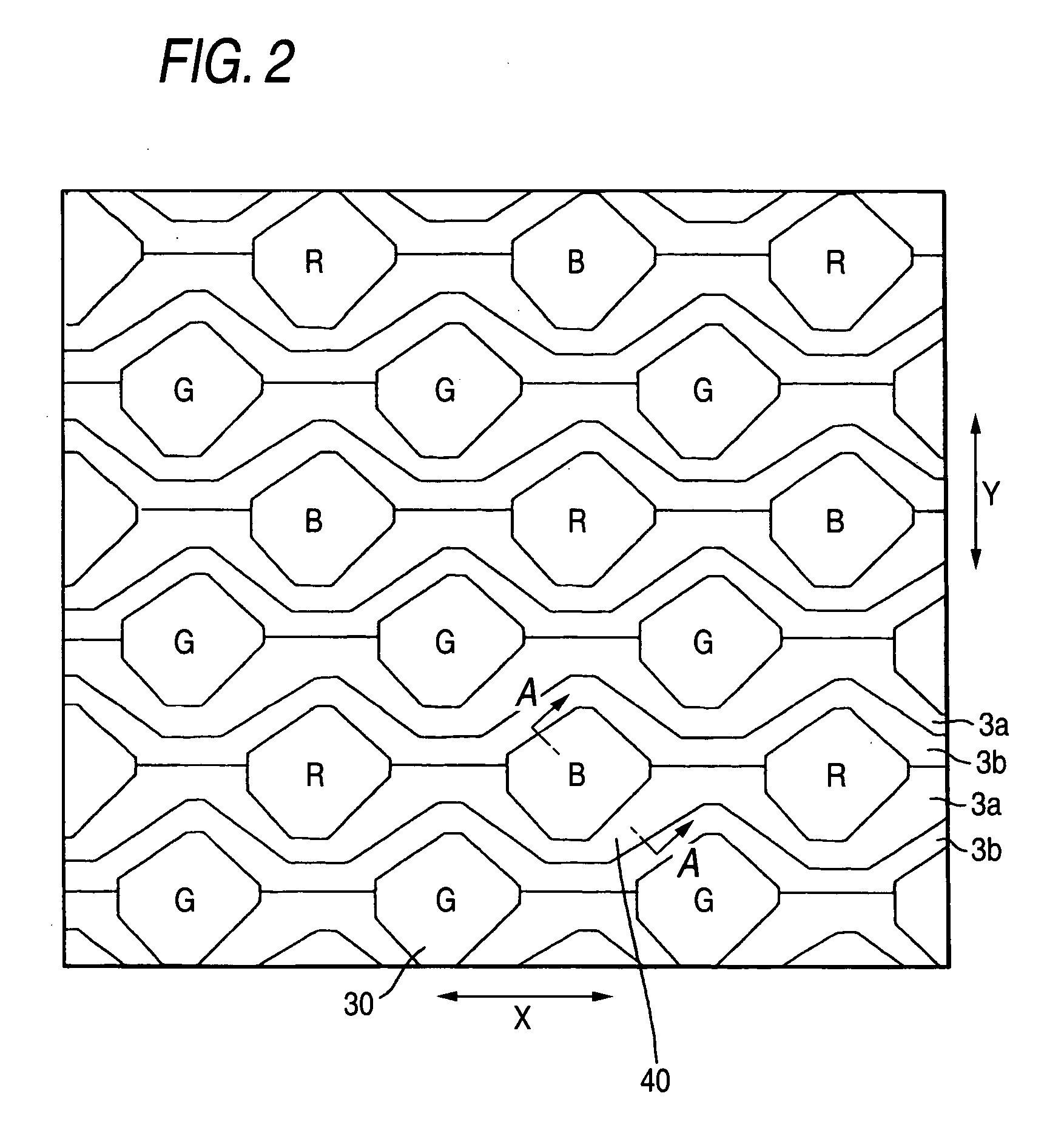

Solid-state imaging device and method for producing the same

InactiveUS20070057286A1Low production costReduce distanceSolid-state devicesSemiconductor/solid-state device manufacturingResistEngineering

A method for producing a solid-state imaging device, which including: a photoelectric conversion section; a charge transfer section having a charge transfer electrode; and an antireflection film covering a light-receiving region in the photoelectric conversion section, wherein forming the antireflection film includes: forming a sidewall on a lateral wall of the charge transfer electrode after forming the charge transfer electrode; forming an antireflection film on a substrate surface where the sidewall is formed; forming a resist on the antireflection film; melting and flattening the resist to expose the antireflection film on the charge transfer electrode; removing the antireflection film by using the resist as the mask; removing the sidewall; covering the charge transfer electrode with an insulating film; and forming a light-shielding film that reaches a level lower than the top surface of the antireflection film, and that surrounds the periphery of the antireflection film.

Owner:FUJIFILM CORP

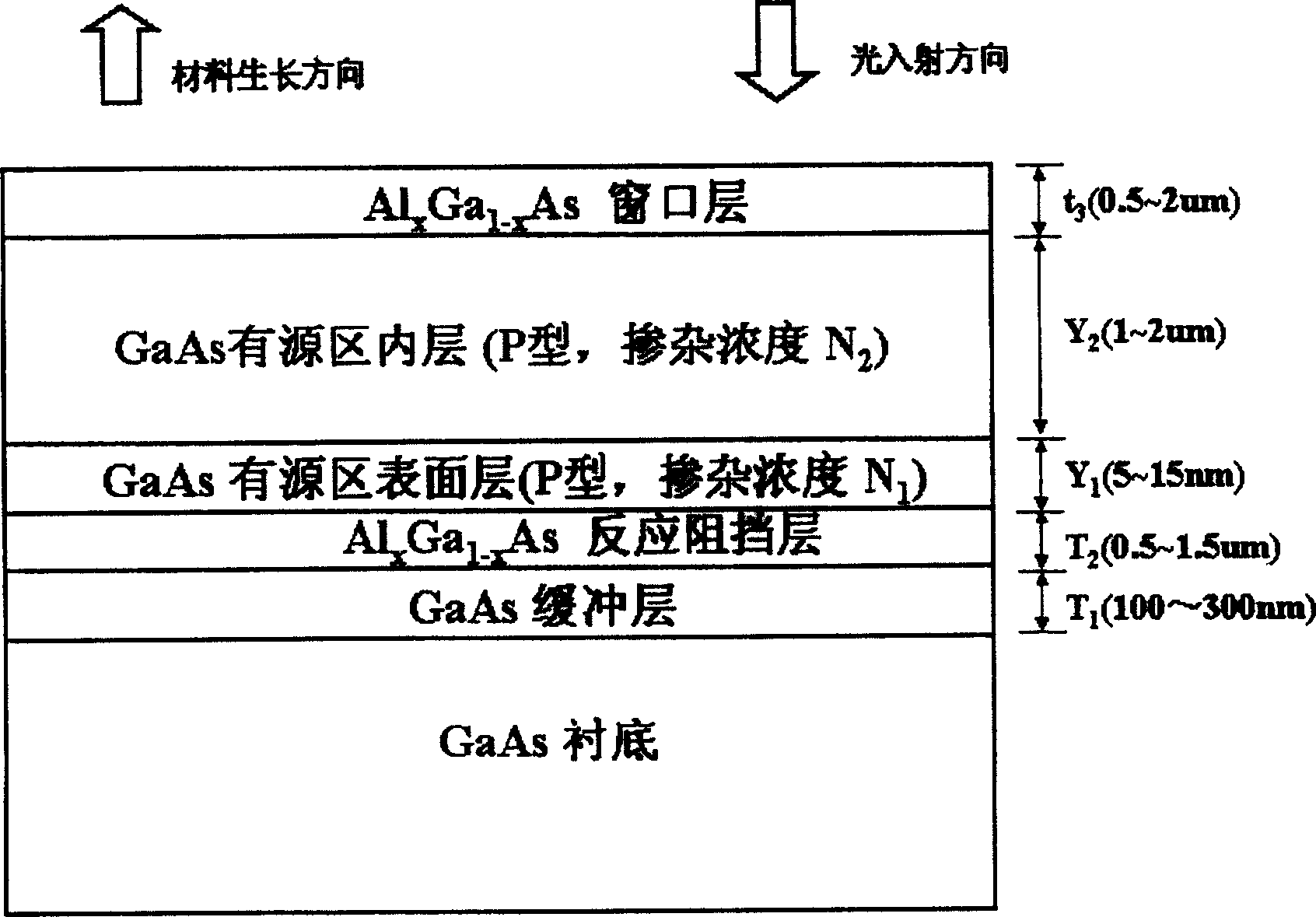

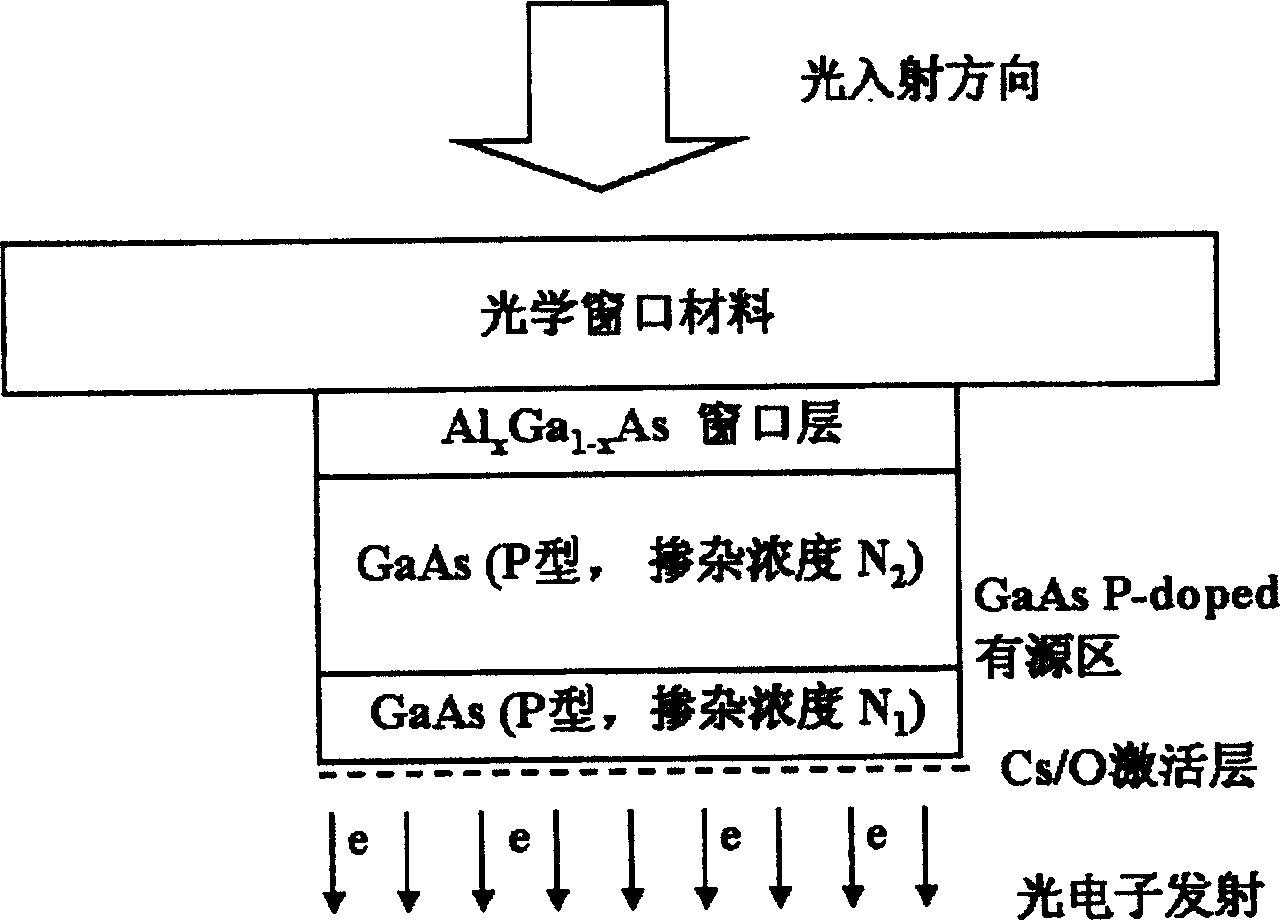

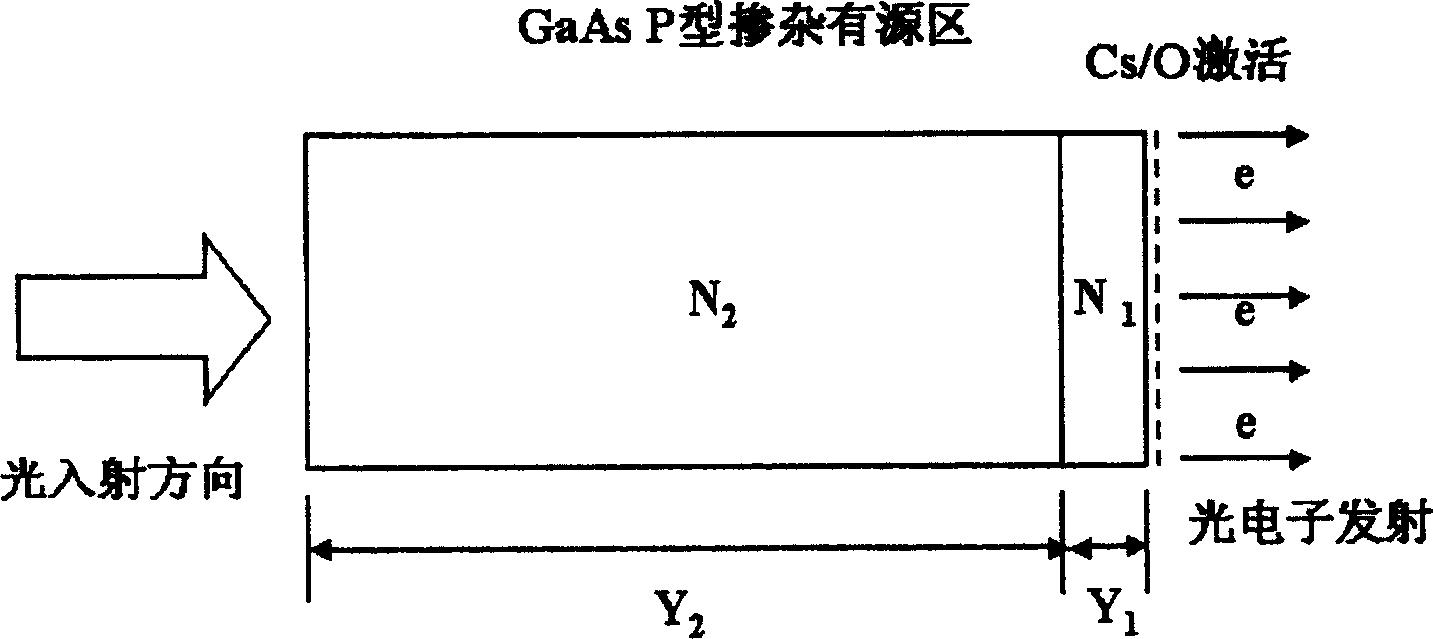

Middle concentration P-type doping transmission type gallium arsenide optical cathode material and method for preparing same

InactiveCN1632898AFew defectsFew dislocationsSemiconductor/solid-state device manufacturingPhoto-emissive cathodesOxygenSource area

This invention relates to semi-conductor material technique used in transparent negative electron affinity gallium arsenide light negative electrode device. This invention source area has two layers of inner layer and surface layer, wherein the inner layer has a window layer outside ad the outside of the surface layer is Se or oxygen actuating layer. The source inner layer is mixed with 1í½8í‡10#+[18]cm#+[-3] in middle concentration and the surface layer is mixed with 5í‡10#+[16]í½1í‡10#+[17]cm#+[-3] in low concentration.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

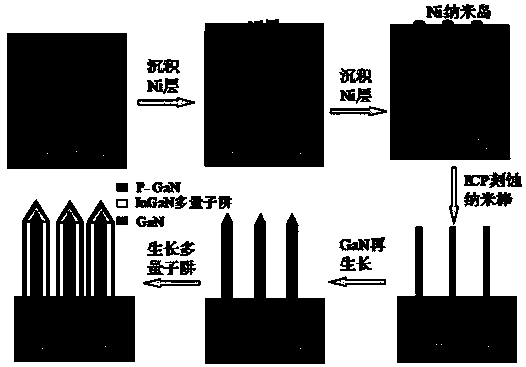

Multi-wavelength GaN-based core-shell nanorod LED device structure and preparation method thereof

The invention discloses a multi-wavelength GaN-based core-shell nanorod LED device structure and a preparation method thereof. A self-organized Ni nano island formed by high-temperature ammonia annealing is used as a template to prepare GaN nanorods with high consistency; a wet etching technology is then used to repair dry etching damage on the nanorod surface, n-type GaN regrowth is carried out on the obtained GaN nanorod array, and a six-sided pillar with a top cone is formed; multi-quantum well layers and P-type GaN layers coating the surfaces of the GaN nanorod array are sequentially stacked to obtain the multi-wavelength GaN-based core-shell nanorod LED device structure. The GaN nanorod array and the multi-quantum well layers and the P-type GaN layers coating the surfaces of the GaN nanorod array form the three-dimensional core-shell structure, which can generate more photons at the same current density and improve the internal quantum efficiency of an LED epitaxial structure. Themethod does not require a patterned substrate, the process cost is low, the preparation is simple and easy to implement, large-scale production is facilitated, and the core-shell nanorod array can bewidely applied to optoelectronic devices and microelectronic devices.

Owner:张士英

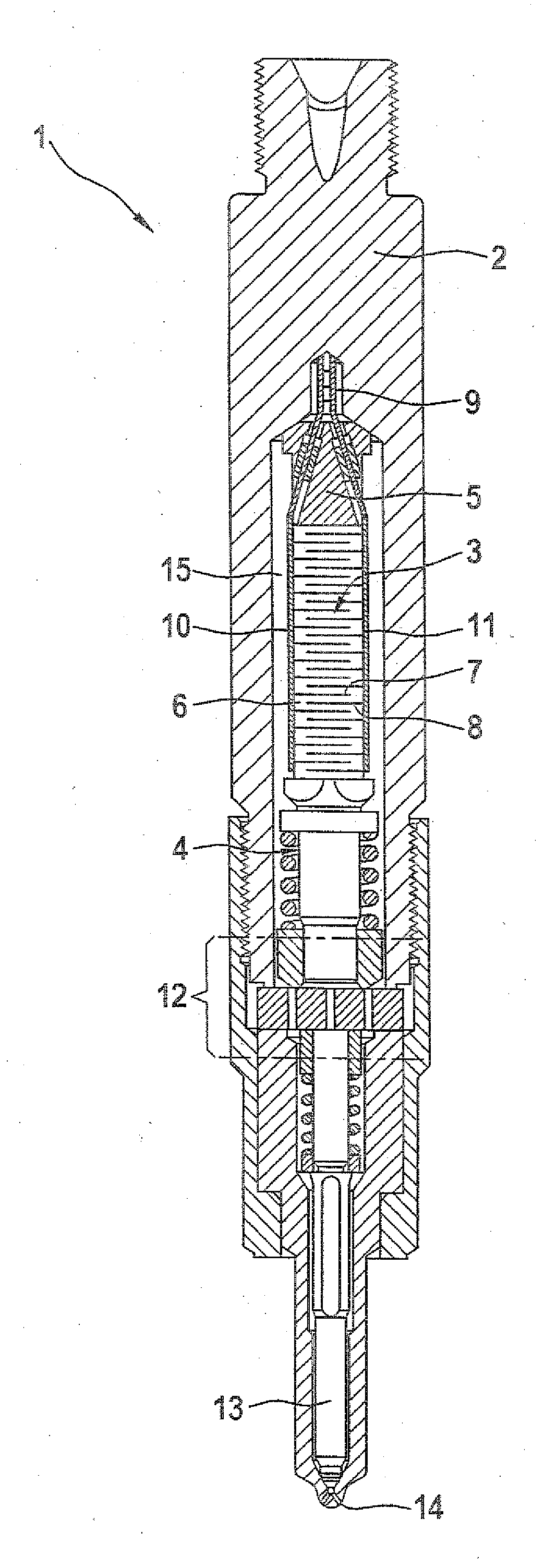

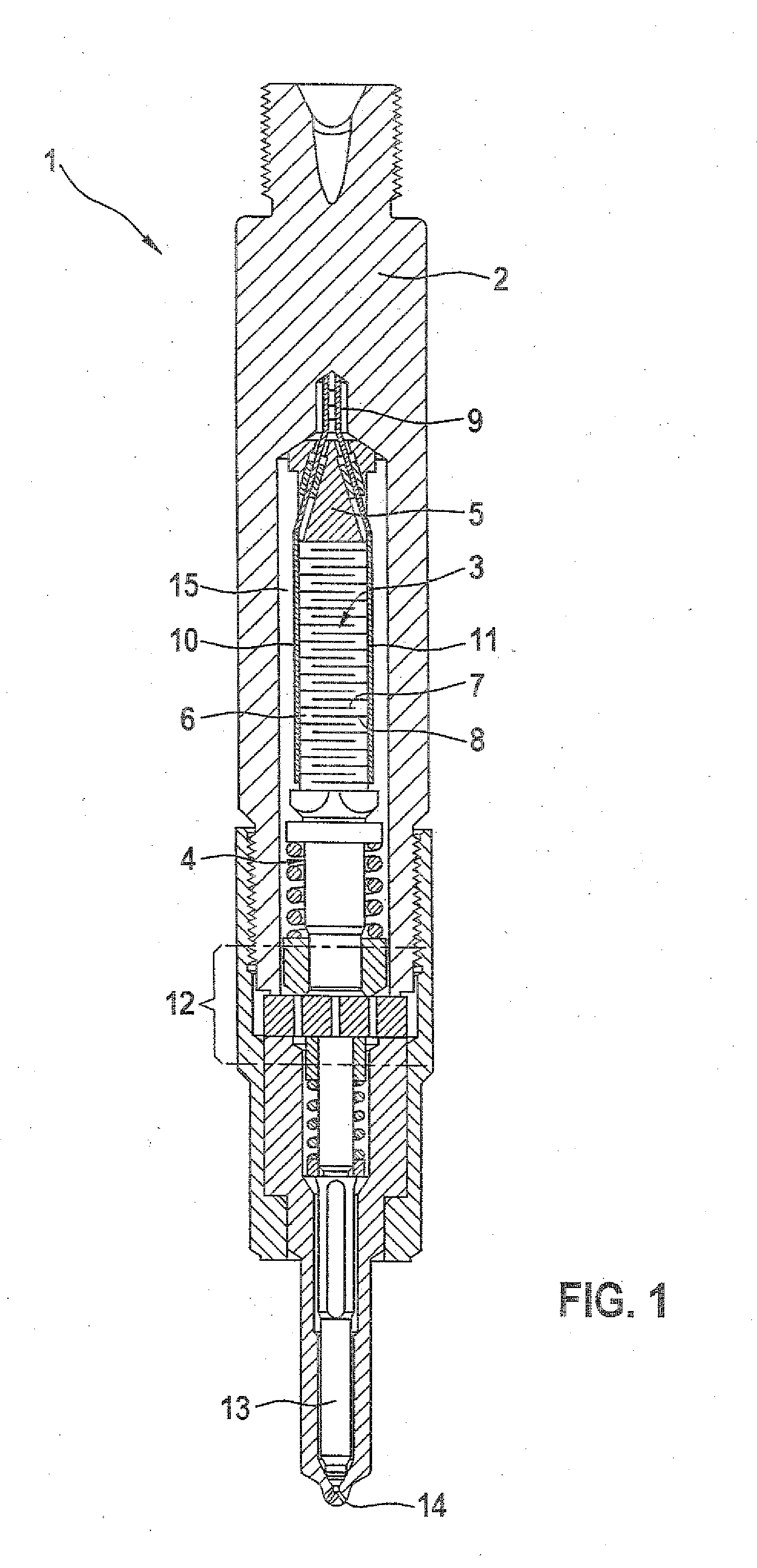

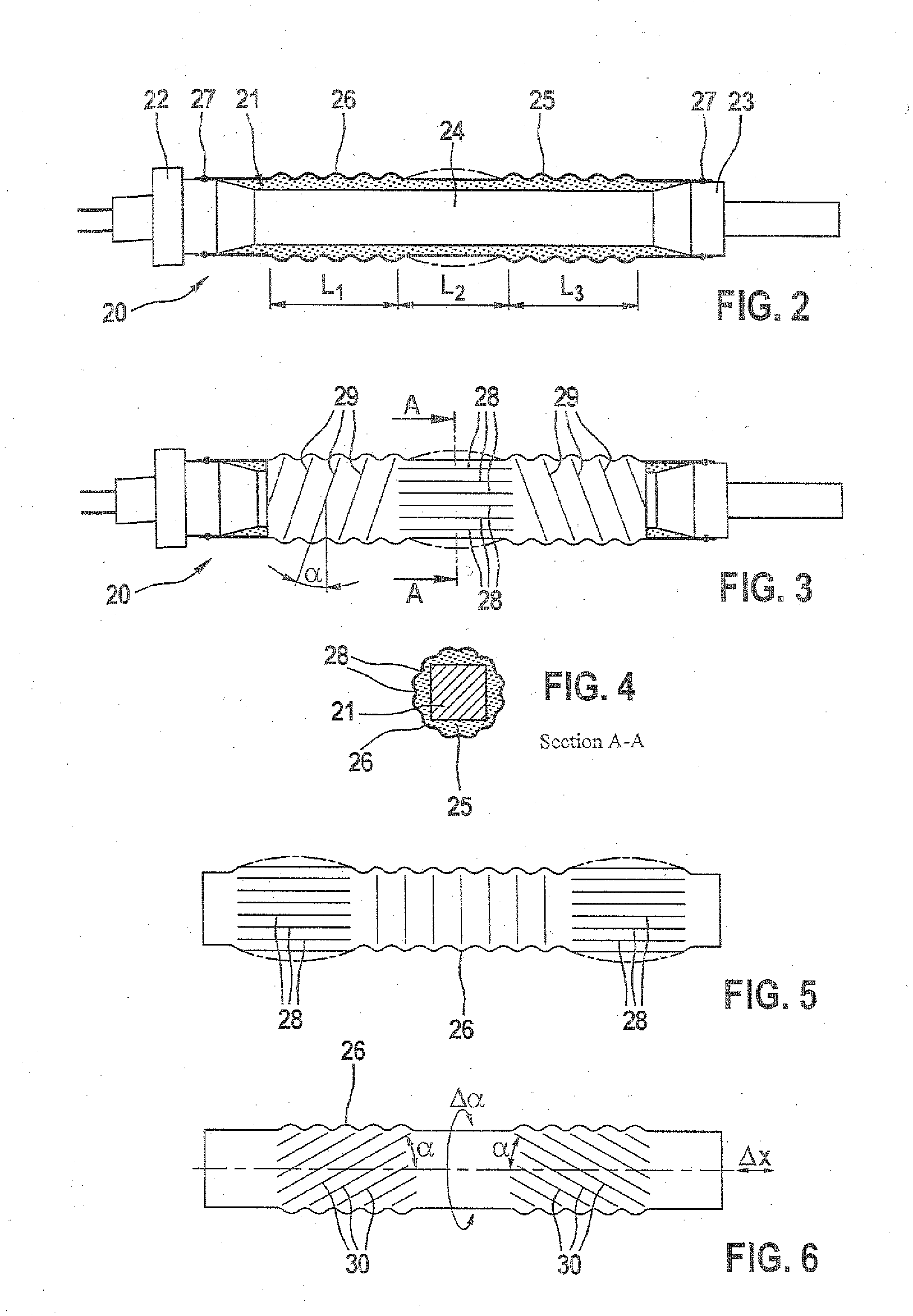

Actuator module with a sheathed piezoelectric actuator

ActiveUS20100163650A1Diffusion length be lengthenDiffusion area be reducePiezoelectric/electrostriction/magnetostriction machinesMachines/enginesPiezoelectric actuatorsInternal combustion engine

An actuator module including a piezoactuator, for example for a piezoinjector for metering fuel in an internal combustion engine, is proposed. The piezoactuator has piezoelements stacked one above another between an actuator head and an actuator foot and is provided with at least one elastomer layer enclosing the piezoelements. The elastomer layer is enveloped by a corrugated bellows or by telescopic tubes, composed of a material that is diffusion-impermeable with respect to a fuel to be metered by the piezoinjector. The corrugated bellows or the telescopic tubes have on their periphery grooves which can absorb expansions of the elastomer layer or of the piezoactuator.

Owner:ROBERT BOSCH GMBH

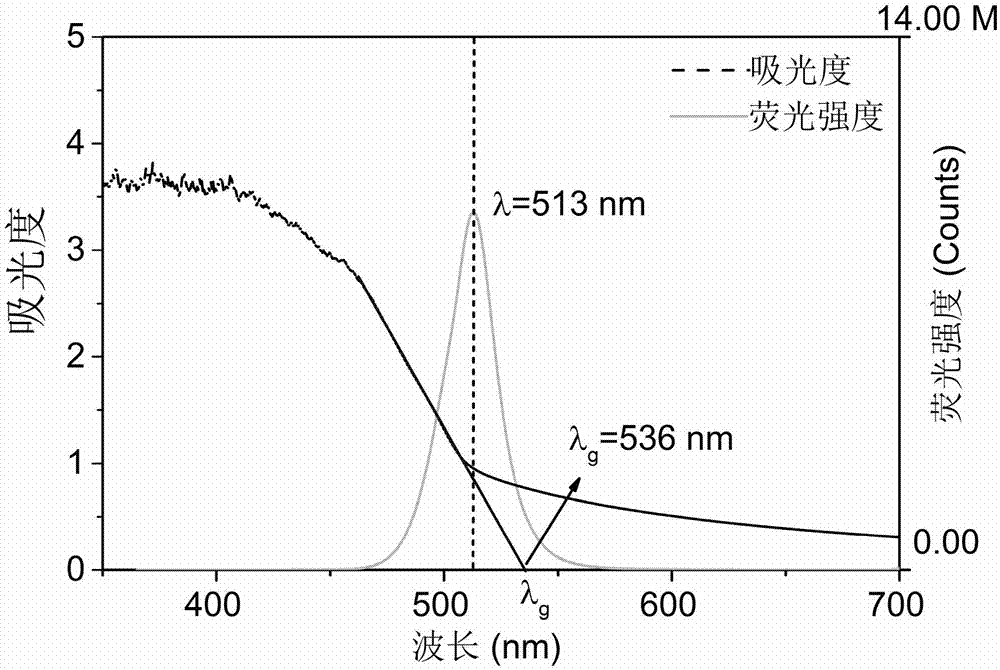

A preparation method of a perovskite miniature laser

InactiveCN109193327ALasingIncrease the diffusion lengthOptical resonator shape and constructionActive medium materialQuantum yieldHigh absorption

The invention relates to a preparation method of a perovskite micro laser, as that method utilize the advantages of high carry migration rate, long diffusion length. The rod or sheet perovskite material with high absorption coefficient and high quantum yield is used as the gain medium of the laser. The perovskite material is pumped by the semiconductor laser array as the excitation light source. The excitation light source makes the perovskite material produce stable spontaneous emission amplification (ASE), and finally the laser output of the target wavelength is realized. The method utilizesthe advantage that the perovskite material can convert 70% of the absorbed light into the emitted light, a low threshold, high conversion efficiency and work wavelength tuning range can cover near infrared to visible light laser devices, and that problems of low conversion efficiency of solid-state laser, serious temperature gain ratio and difficulty in realizing different wave bands laser devices in the prior art are solved.

Owner:CHANGCHUN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com