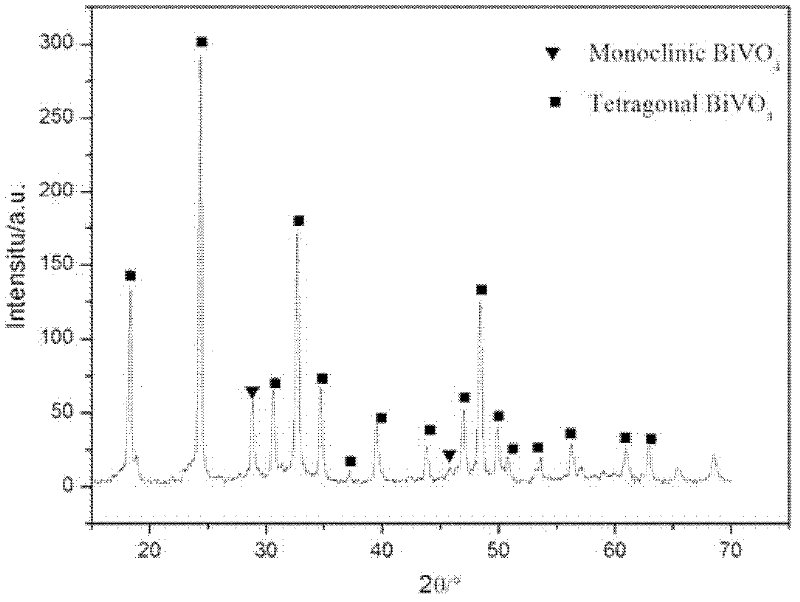

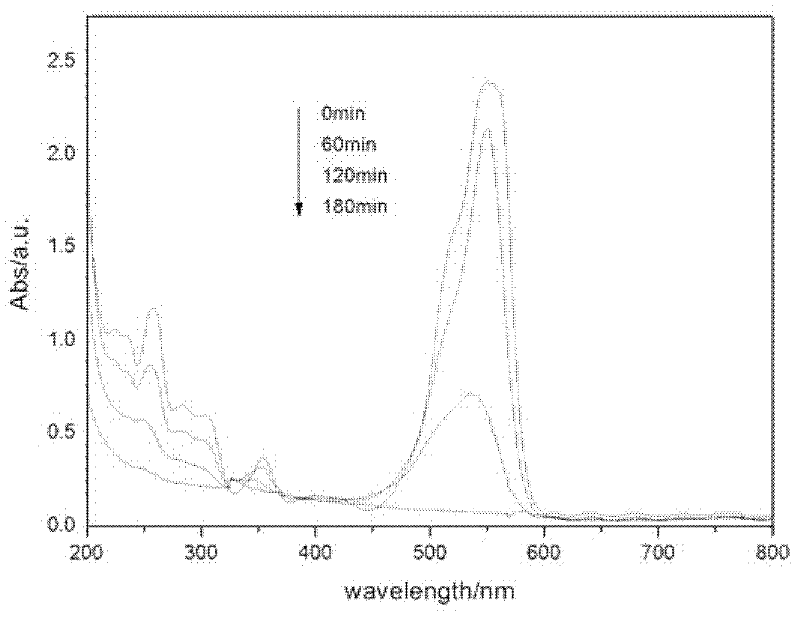

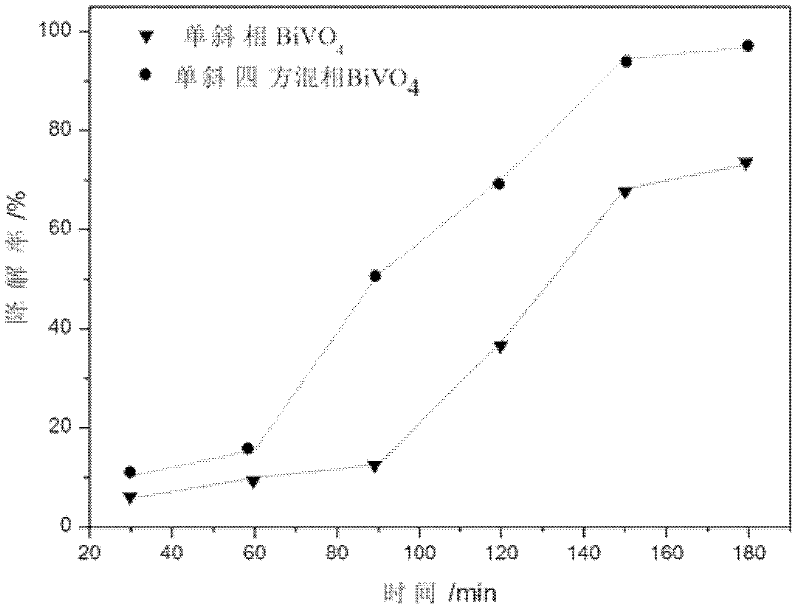

Method for synthesizing monoclinic phase and tetragonal phase mixed high-catalytic-activity bismuth vanadate powder by microwave hydrothermal process

A microwave hydrothermal method, high catalytic activity technology, applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc. problem, to achieve the effect of improving the photocatalytic effect, short preparation period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Add 0.002mol Bi(NO 3 ) 3 ·5H 2 O dissolved in 10 mL of HN0 with a concentration of 2 mol / L 3 solution, 0.002mol NH 4 VO 3 Dissolve in 10mL NaOH solution with a concentration of 2mol / L;

[0028] Step 2: Add 0.15 g of sodium dodecylbenzenesulfonate (SDBS) to the two solutions respectively, and stir for 30 minutes on a magnetic stirrer;

[0029] Step 3: Mix the two solutions evenly, stir on a magnetic stirrer for 30 minutes, and then adjust the pH to 6.07 with NaOH to prepare the precursor solution;

[0030] Step 4: Add the precursor solution into the microwave hydrothermal reactor with a filling ratio of 40%, then place the reactor in a microwave-assisted hydrothermal synthesizer, set the reaction temperature to 180°C, and the holding time to 60 minutes;

[0031] Step 5: After the reaction is completed, cool down, take out the yellow precipitate in the reaction kettle, wash it with deionized water until neutral, then wash it with absolute ethanol, and finall...

Embodiment 2

[0034] Step 1: Add 0.005mol Bi(NO 3 ) 3 ·5H 2 O dissolved in 10mL with a concentration of 4mol / LHNO 3 solution, 0.005mol NH 4 VO 3Dissolve in 10mL NaOH solution with a concentration of 4mol / L;

[0035] Step 2: Add 0.3 g of sodium dodecylbenzenesulfonate (SDBS) to the two solutions respectively, and stir on a magnetic stirrer for 50 min;

[0036] Step 3: Mix the two solutions evenly, stir on a magnetic stirrer for 10 minutes, and then adjust the pH to 7.6 with NaOH to prepare a precursor solution;

[0037] Step 4: Add the precursor solution into the microwave hydrothermal reactor with a filling ratio of 50%, then place the reactor in a microwave-assisted hydrothermal synthesizer, set the reaction temperature to 180°C, and the holding time to 60 minutes;

[0038] Step 5: After the reaction is completed, cool down, take out the yellow precipitate in the reaction kettle, wash it with deionized water until neutral, then wash it with absolute ethanol, and finally dry it at a c...

Embodiment 3

[0041] Step 1: Add 0.01mol Bi(NO 3 ) 3 ·5H 2 O dissolved in 10mL with a concentration of 6mol / LHNO 3 solution, 0.01mol NH 4 VO 3 Dissolve in 10mL NaOH solution with a concentration of 6mol / L;

[0042] Step 2: Add 0.2 g of sodium dodecylbenzenesulfonate (SDBS) to the two solutions respectively, and stir on a magnetic stirrer for 50 min;

[0043] Step 3: Mix the two solutions evenly, stir on a magnetic stirrer for 20 minutes, and then adjust the pH to 4.6 with NaOH to prepare the precursor solution;

[0044] Step 4: Add the precursor solution into the microwave hydrothermal reactor with a filling ratio of 60%, then place the reactor in a microwave-assisted hydrothermal synthesizer, set the reaction temperature to 210°C, and the holding time to 100 minutes;

[0045] Step 5: After the reaction is completed, cool down, take out the yellow precipitate in the reaction kettle, wash it with deionized water until neutral, then wash it with absolute ethanol, and finally dry it at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com