Patents

Literature

442 results about "Scheelite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scheelite is a calcium tungstate mineral with the chemical formula CaWO₄. It is an important ore of tungsten (wolfram). Well-formed crystals are sought by collectors and are occasionally fashioned into gemstones when suitably free of flaws. Scheelite has been synthesized using the Czochralski process; the material produced may be used to imitate diamond, as a scintillator, or as a solid-state lasing medium. It was also used in radium paint in the same fashion as was zinc sulphide, and Thomas Edison invented a fluoroscope with a calcium tungstate-coated screen, making the images six times brighter than those with barium platinocyanide; the latter chemical allowed Röntgen to discover X-rays in early November 1895.

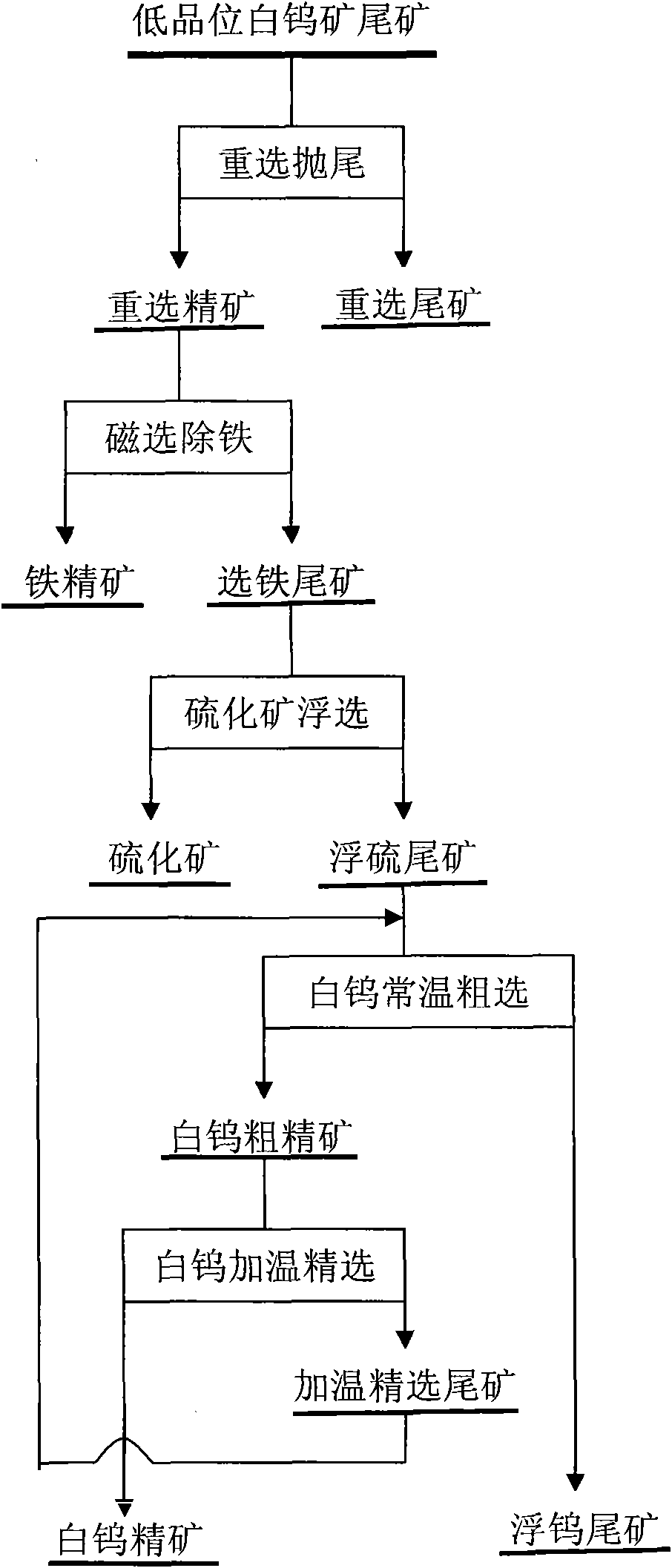

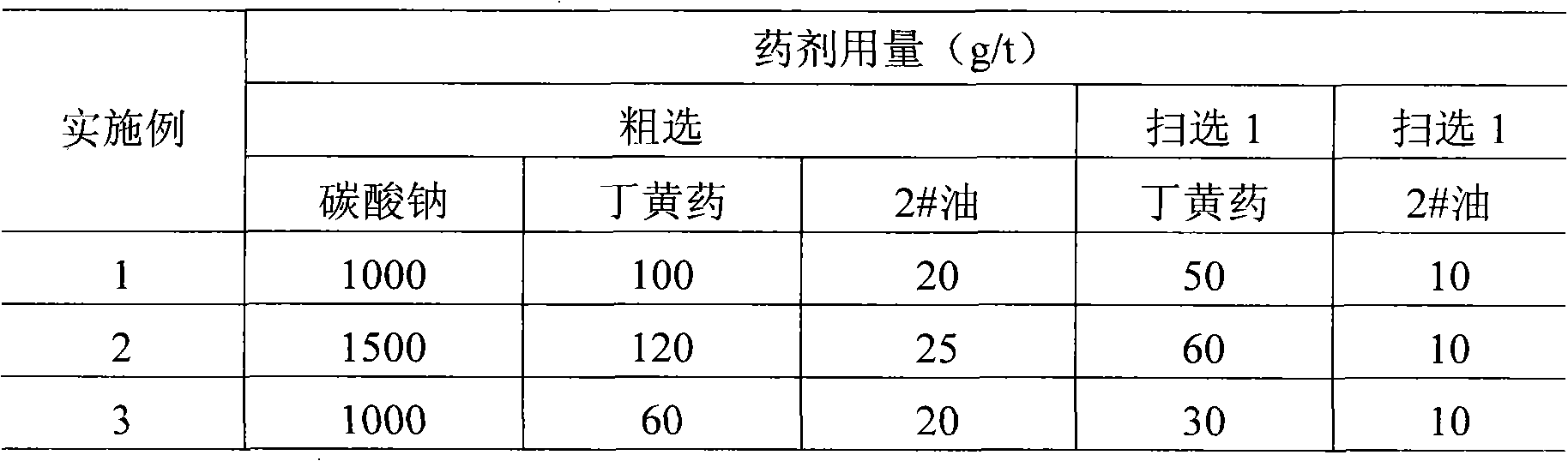

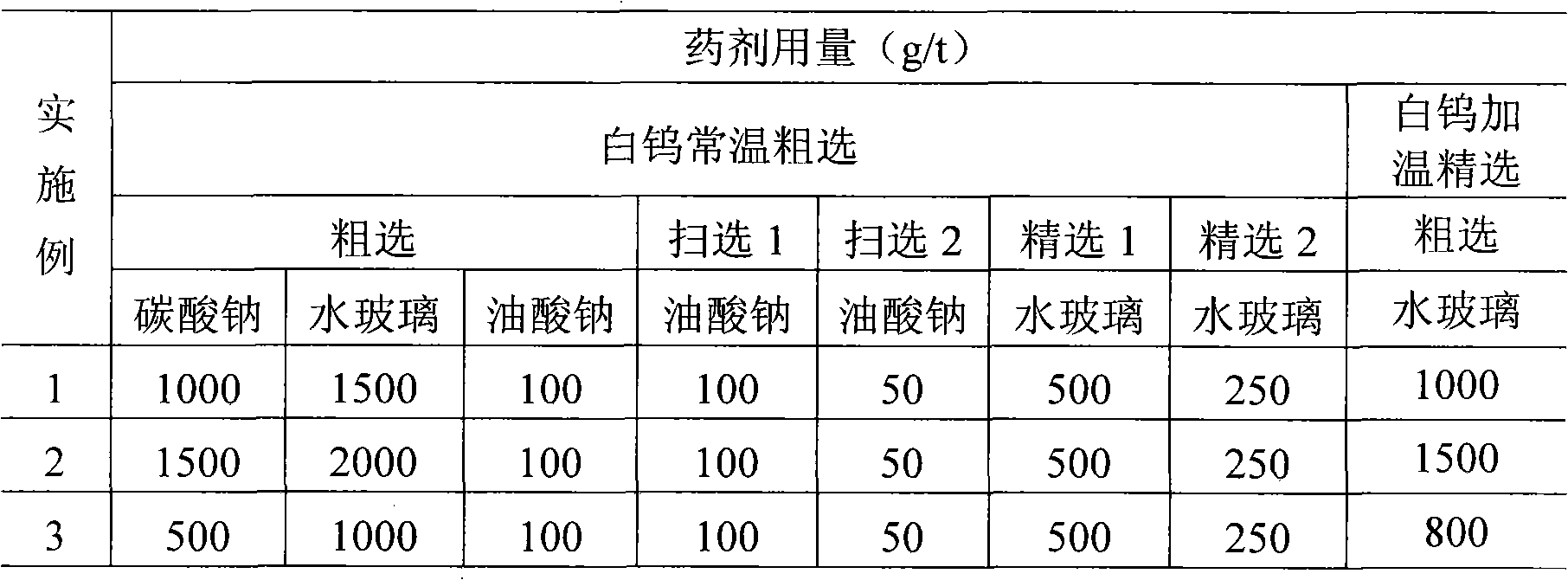

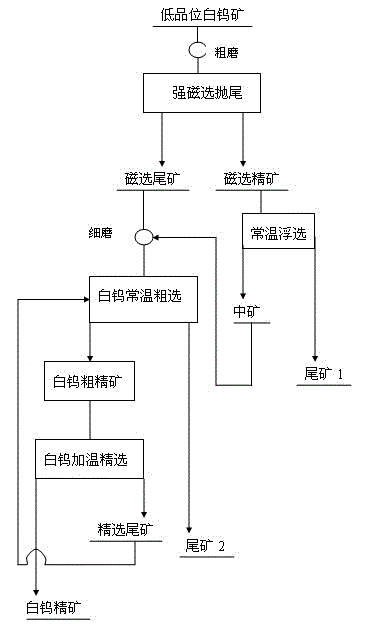

Ore dressing method of low-grade scheelite

InactiveCN101869876AImprove sorting indexImprove the quality of selectionFlotationIron removalLower grade

The invention relates to an ore dressing method of a low-grade scheelite, which is characterized by comprising the following steps: 1. tailing discard by gravity concentration; 2. iron removal by magnetic separation; 3. sulfide ore flotation; 4. normal-temperature rougher flotation of scheelite; and 5. heating concentration of the scheelite. The invention provides a lower-cost ore dressing method for dressing scheelite concentrates from the tailings of the low-grade scheelite. The invention has the characteristics that the comprehensive recovery cost is saved, the beneficiation feed grade of the scheelite is improved, the flotation feed ore quantity is reduced, the dosage of a flotation reagent is reduced, the used ore dressing reagent is more friendly to the environment, and secondary pollution can not be caused. The method of the invention is applicable for low-grade scheelite resources with 0.03 to 0.15 percent of WO3.

Owner:广东省资源综合利用研究所

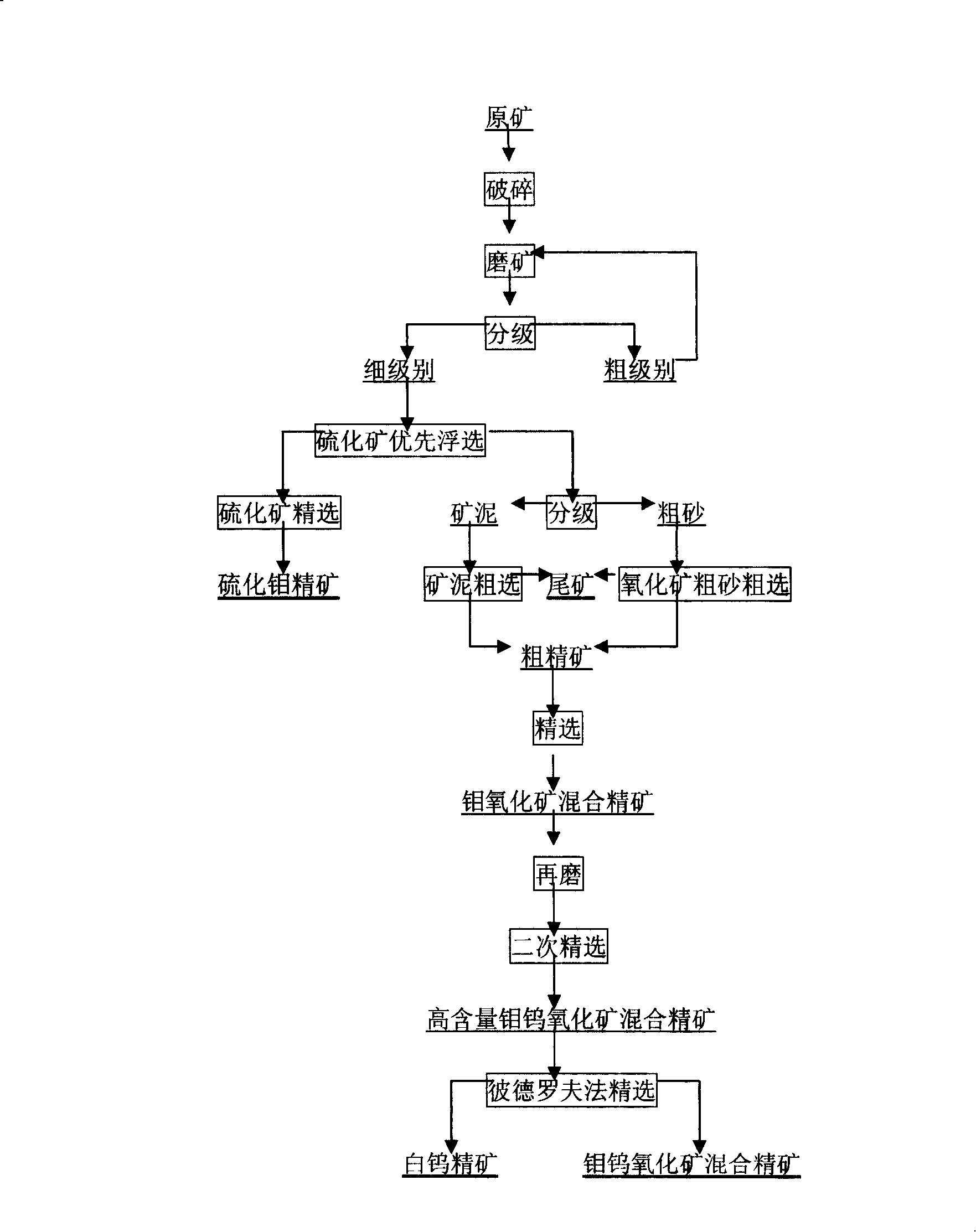

Processing technology for molybdenum and tungsten oxidized ore

InactiveCN101224441AHigh recovery rateResolve recovery rateSievingScreeningLaboratory testFatty acid

The invention discloses a beneficiation process of a molybdenum-tungsten oxide ore. The process of which is that: the liberation degree of ore crushing is higher than or equal to 70%; the flotation of molybdenum sulfide is preferred; the floatation tailing is classified and then a separation of slime and sand is carried out, wherein a slime and sand system takes alkali as the conditioning agent, sodium silicate as the depressant, and emulsified fatty acid as the collecting agent. The rough concentrate obtained from the separation of slime and sand is concentrated after being blended to obtain molybdenum-tungsten oxide ore collective concentrate. The collective concentrate is grounded again and added with the depressant, then a secondary concentrate can be gained through the concentration; the secondary concentrate is concentrated by means of Peter Roph method to obtain scheelite ore and oxidized molybdenum-tungsten beneficiation concentrate. The invention has the advantages that: 1. the invention discloses a beneficiation process flow for treating molybdenum-tungsten oxide ore; 2. the invention solves the difficulty of lowe technical specification of molybdenum - tungsten oxide ore beneficiation; 3. the invention completes laboratory tests and researches and fulfills industrialized implementation for the first time in China.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

Method for decomposing scheelite

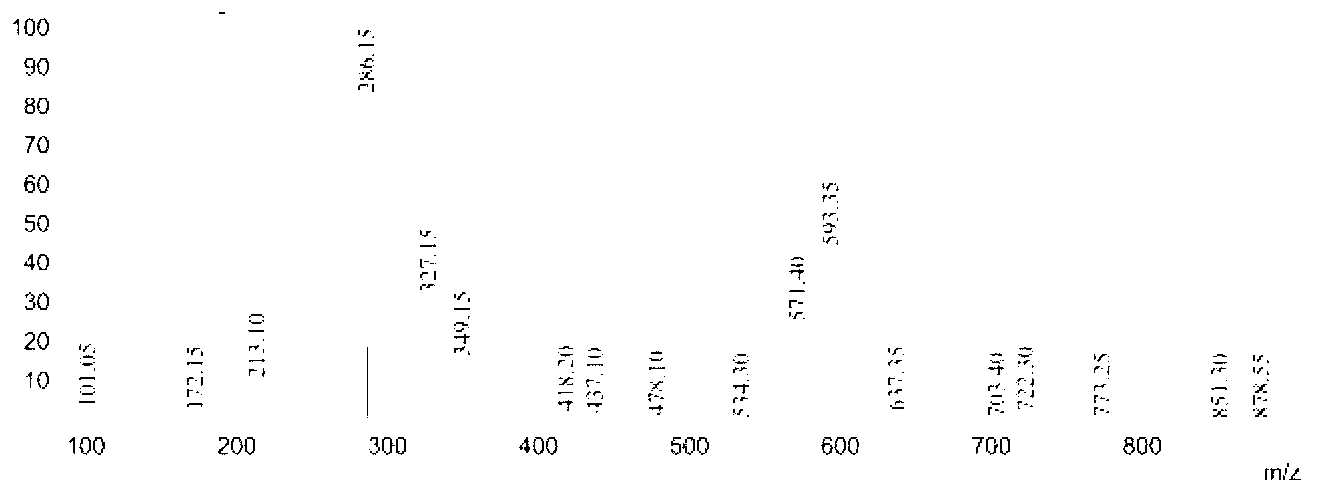

The invention discloses a method for decomposing scheelite. The method has the following specific operations of: preparing the solution of phosphoric acid and adding sulfuric acid; after heating to a temperature required for decomposing, adding the scheelite into a reaction tank for reacting; after finishing reacting, extracting tungsten from a filtrate obtained by filtering; and adding the phosphoric acid and the sulfuric acid to an initial level, and returning for performing mineral leaching. The method has the advantages that: the phosphorus content of the scheelite is not required strictly; floated rough concentrate of the scheelite does not need to be directly conveyed for smelting for removing phosphorus specifically any longer, so the cost of a phosphorus removing agent and the loss of the tungsten are saved; one-step high-efficiency normal-pressure leaching of the scheelite is realized; resource and energy consumption are saved; the decomposition rate of the scheelite can reach over 98 percent; the problem that Cl<-> and HCl in a conventional decomposing process is volatized seriously is solved; the cyclic utilization of the phosphoric acid is basically realized; leaching cost and wastewater discharge amount are reduced extremely; leaching equipment is simple and is convenient to operate; and industrialization is easy to realize.

Owner:CENT SOUTH UNIV

Method for separating and extracting tungsten-molybdenum from mixed solution of tungstate-molybdate

InactiveCN101880780AEfficient separationRealize recyclingProcess efficiency improvementMagnesium saltDecomposition

Owner:CENT SOUTH UNIV

Method for extracting tungsten from scheelite

ActiveCN102021328AReduce lossesLow costProcess efficiency improvementWater dischargeReaction temperature

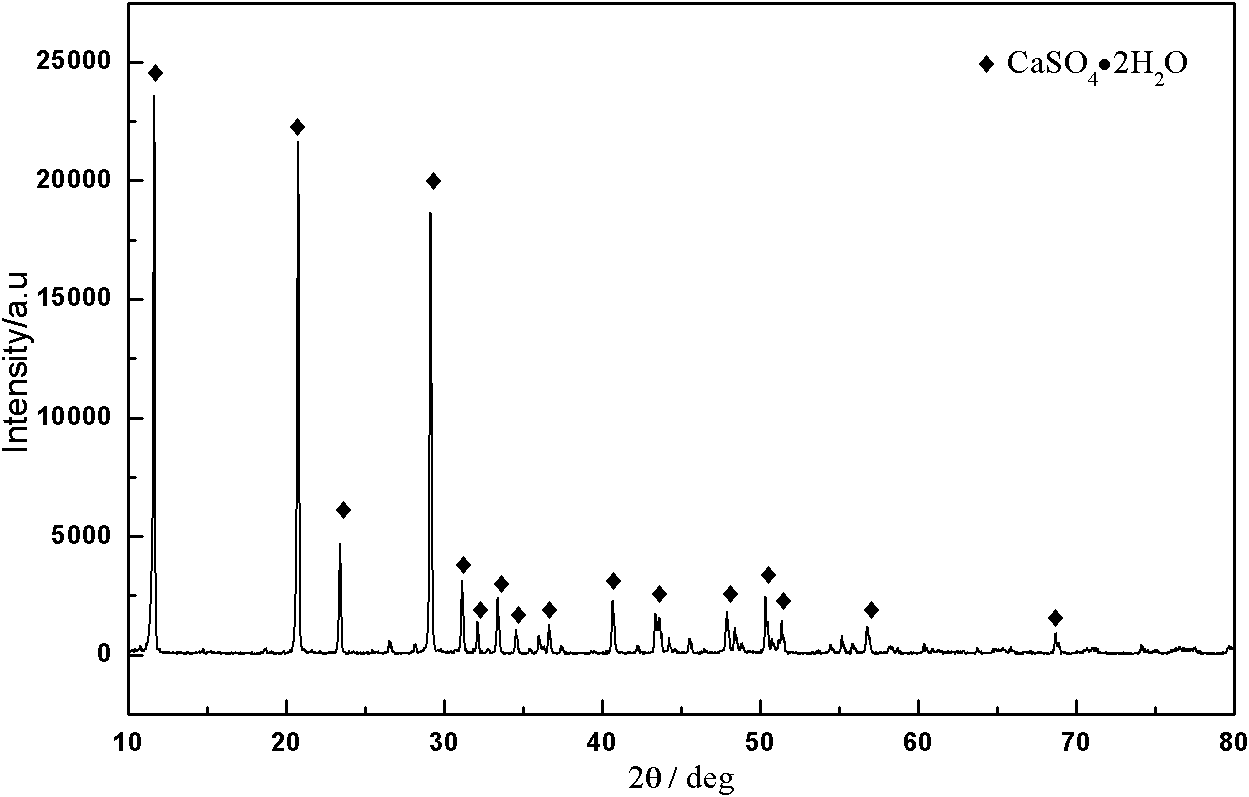

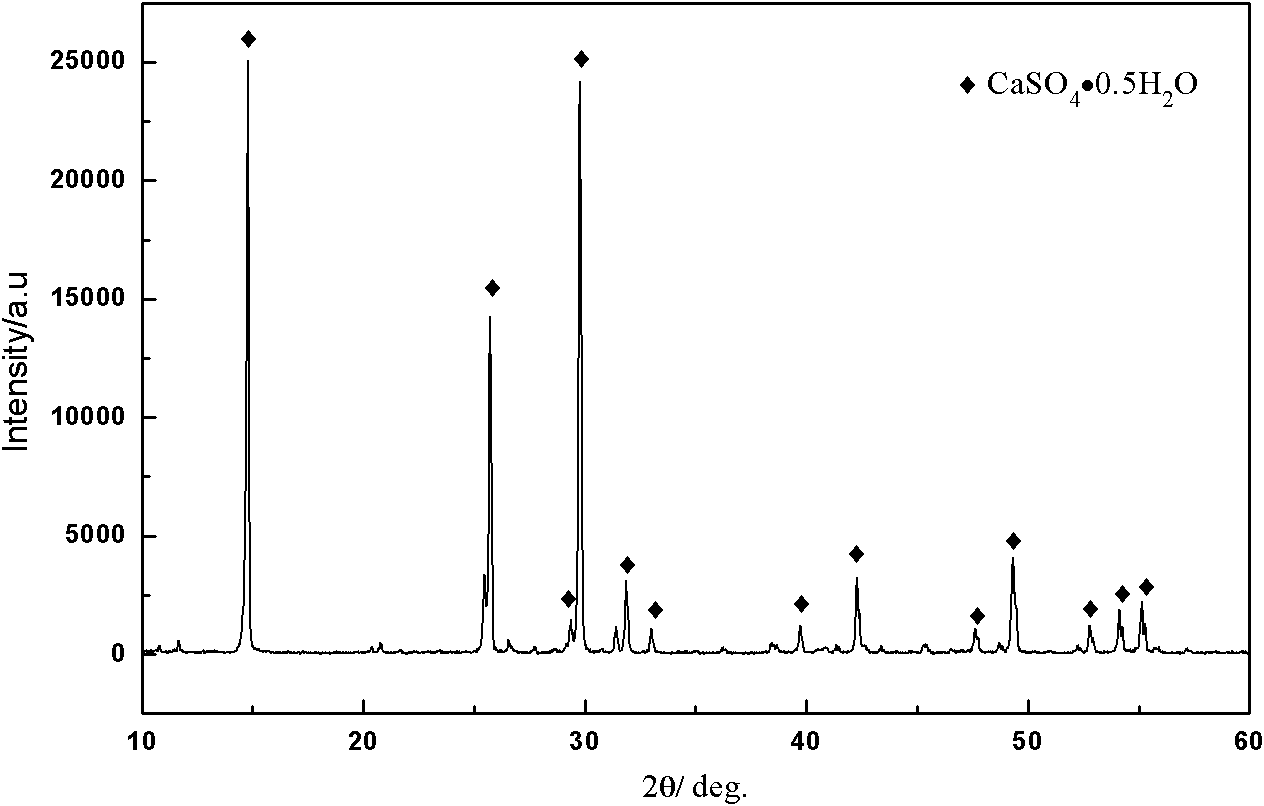

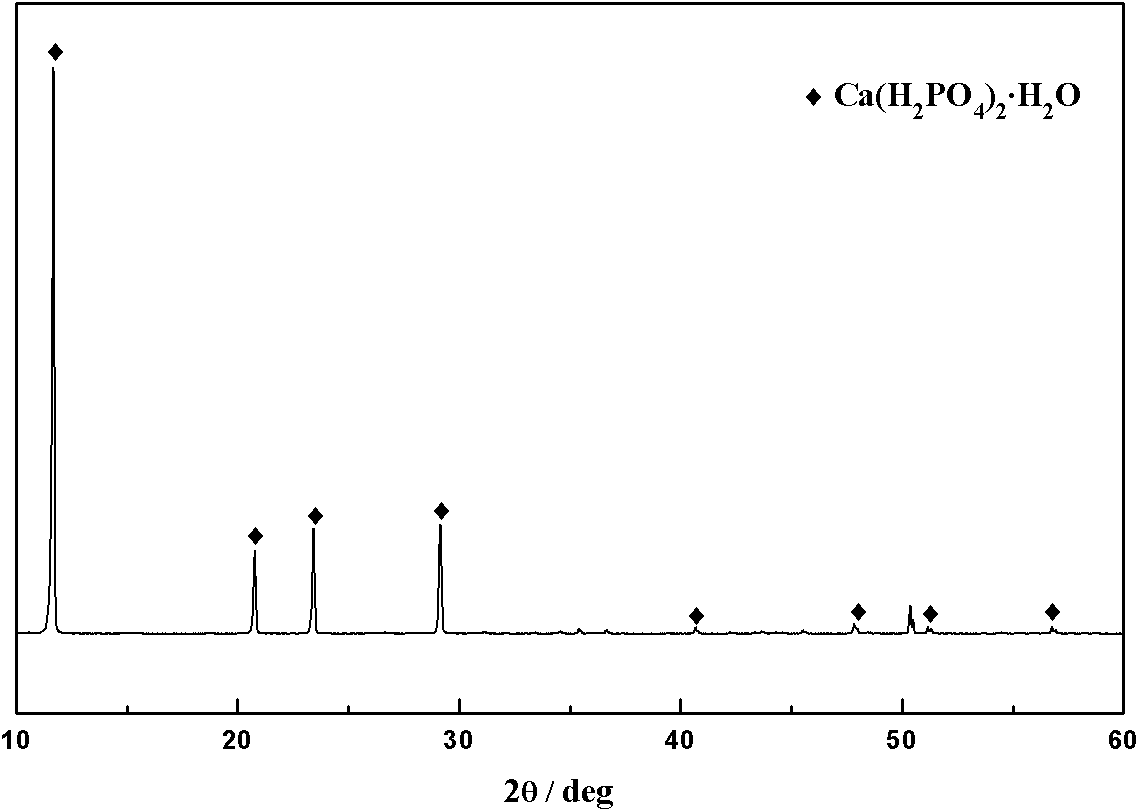

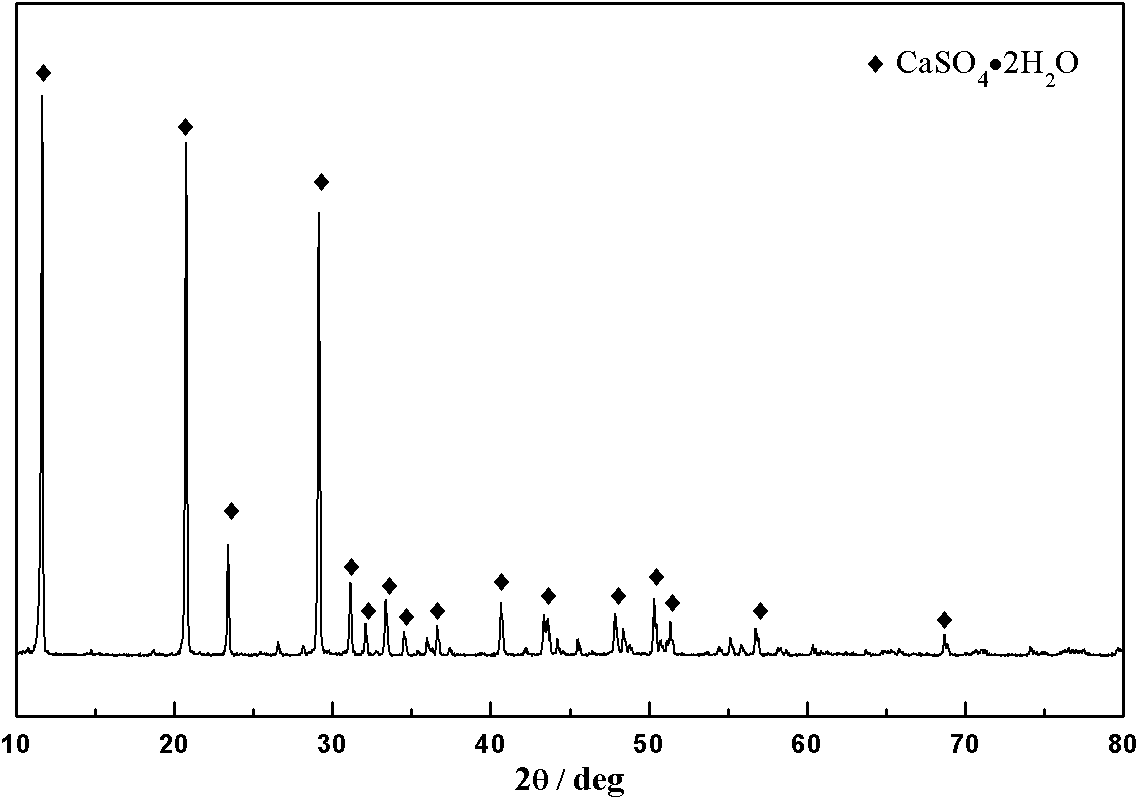

The invention discloses a method for extracting tungsten from scheelite, comprising the following steps of: mixing the scheelite with a mixed solution of phosphoric acid and sulfuric acid for reaction, adding dihydrate gypsum as seed crystals, and controlling the concentration of SO4<2->, the content of P2O5 and the reaction temperature to obtain the dihydrate gypsum with good filtering and washing properties. The invention has the advantages that one-step efficient normal pressure leaching of the scheelite is achieved, thus resources and energy consumption are saved, and the resolution ratio of the scheelite is up to above 98%; the problems of Cl<-> corrosion and serious HCl volatilization are overcome; the cyclic utilization of phosphoric acid is basically achieved, and the leaching cost and waste water discharge are greatly reduced; leaching equipment is simple, is convenient for operation and is easy to realize industrialization; the single and stable dihydrate gypsum is obtained, the filter efficiency of the dihydrate gypsum is high, the washing property of the dihydrate gypsum is good, and the P2O5 content in the washed dihydrate gypsum is reduced to be below 2%, thereby reducing the loss of phosphoric acid; and the passivation phenomenon of calcium sulfate solid film when the tungsten ore is leached is avoided.

Owner:CENT SOUTH UNIV

Method for extracting tungsten from scheelite and producing high-quality calcined gypsum

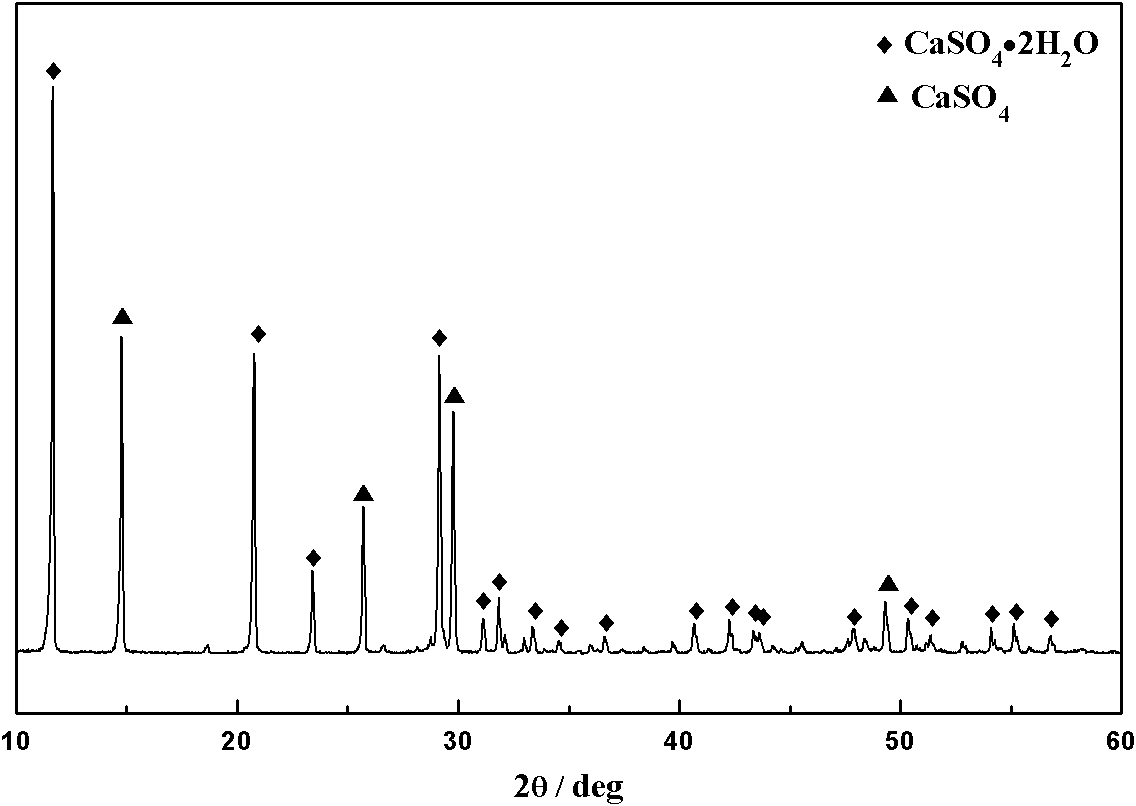

ActiveCN102021329AReduce lossesLow costCalcium/strontium/barium sulfatesProcess efficiency improvementPhosphoric acidSeed crystal

The invention provides a method for extracting tungsten from scheelite and producing high-quality calcined gypsum, comprising the following steps: adding a mixed acid of phosphoric acid and sulphuric acid to decompose scheelite; and after decomposition, adding hydrated gypsum seed crystals to finish the dewatering conversion process of dihydrate gypsum to obtain hydrated gypsum with good properties. The invention has the following advantages: the efficient atmospheric pressure leaching of scheelite is realized, the resource and energy consumption is saved, and the decomposition rate of scheelite can reach over 98%; the serious problems of Cl<-> corrosion and HCl volatilization in the traditional acid decomposition process can be overcome; the recycling of phosphoric acid is basically realized, and the leaching cost and the wastewater discharge are greatly reduced; the leaching device is simple, the operation is convenient and industrialization is easy to realize; the obtained byproduct gypsum has pure quality and can be used to produce gypsum boards, and can be used in retarder, plaster and the like produced by using cement; and due to the recrystallization process, the P2O5 content in gypsum is further reduced to below 0.5%.

Owner:CENT SOUTH UNIV

Method for decomposing scheelite by using phosphoric acid

The invention discloses a method for decomposing scheelite by using phosphoric acid, and the specific operation is as follows: adding the scheelite and phosphoric acid solution into a reaction tank for reaction according to a certain proportion, extracting tungsten from filtrate obtained by filtering after the reaction is finished, further supplementing the phosphoric acid into mother liquor after extracting the tungsten to the initial level, returning for leaching, decomposing filter residue obtained by filtering after the reaction by adopting sulfuric acid so as to recover the phosphoric acid or return the phosphoric acid for recycling. The method has the advantages of having no strict requirement on phosphorus content in the scheelite and eliminating the cost of dephosphorization process step during the ore dressing process; the post-treatment way of extracting the tungsten after the reaction is simple, the remaining solution can be recycled basically, and the pollution can be avoided; the problems of corrosion of Cl- and serious volatilization of HCl (hydrochloric acid) in the traditional acid decomposition process can be overcome; and the normal-pressure leaching of the scheelite can be realized, the energy consumption can be saved, and the decomposition rate can be more than 98%.

Owner:CENT SOUTH UNIV

6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

ActiveCN103301952AImprove flotation recoveryAchieve high flotation separationFlotationReaction temperatureCarboxylic acid

A structural formula of a 6-aliphatic hydrocarbon amido hexyl hydroximic acid collecting agent is represented by a formula (I), wherein R represents C2-C18 aliphatic hydrocarbon group. The preparation method comprises the steps as follows: caprolactam and hydroxylamine hydrochloride or hydroxylamine sulphate are taken as raw materials, methylbenzene is taken as a solvent, the reaction temperature ranges from 80 DEG C to 110 DEG C, the reaction lasts for 1-4 hours, and 6-amino hexyl hydroximic acid is generated; 6-amino hexyl hydroximic acid reacts with C2-C18 fat carboxylic acid at the reaction temperature ranging from 100 DEG C to 160 DEG C for 1-4 hours to generate 6-aliphatic hydrocarbon amido hexyl hydroximic acid, and the product yield can be higher than 91%; and 6-aliphatic hydrocarbon amido hexyl hydroximic acid used in flotation of scheelite, wolframite, tombarthite ore, tin ore, bauxite, titanic iron ore or fluorite ore is taken as the collecting agent, so that the flotation recovery rate can be increased by 3%-10%.

Owner:CENT SOUTH UNIV

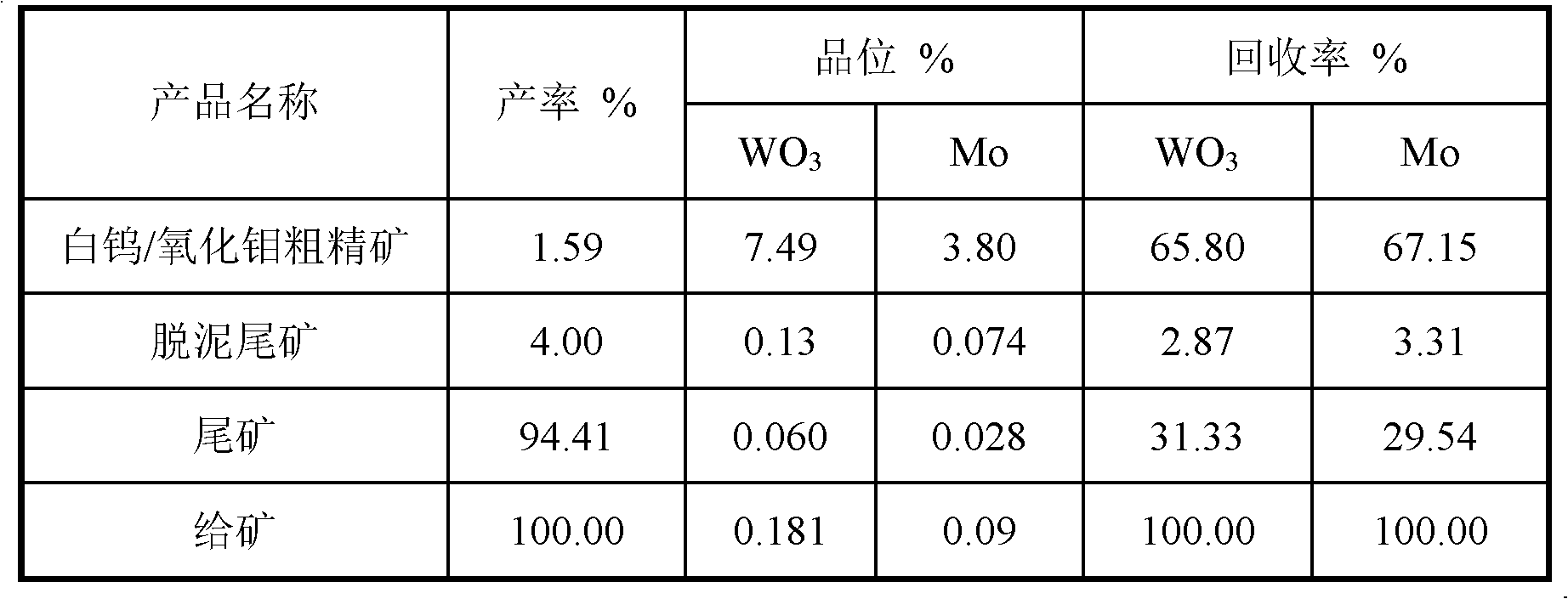

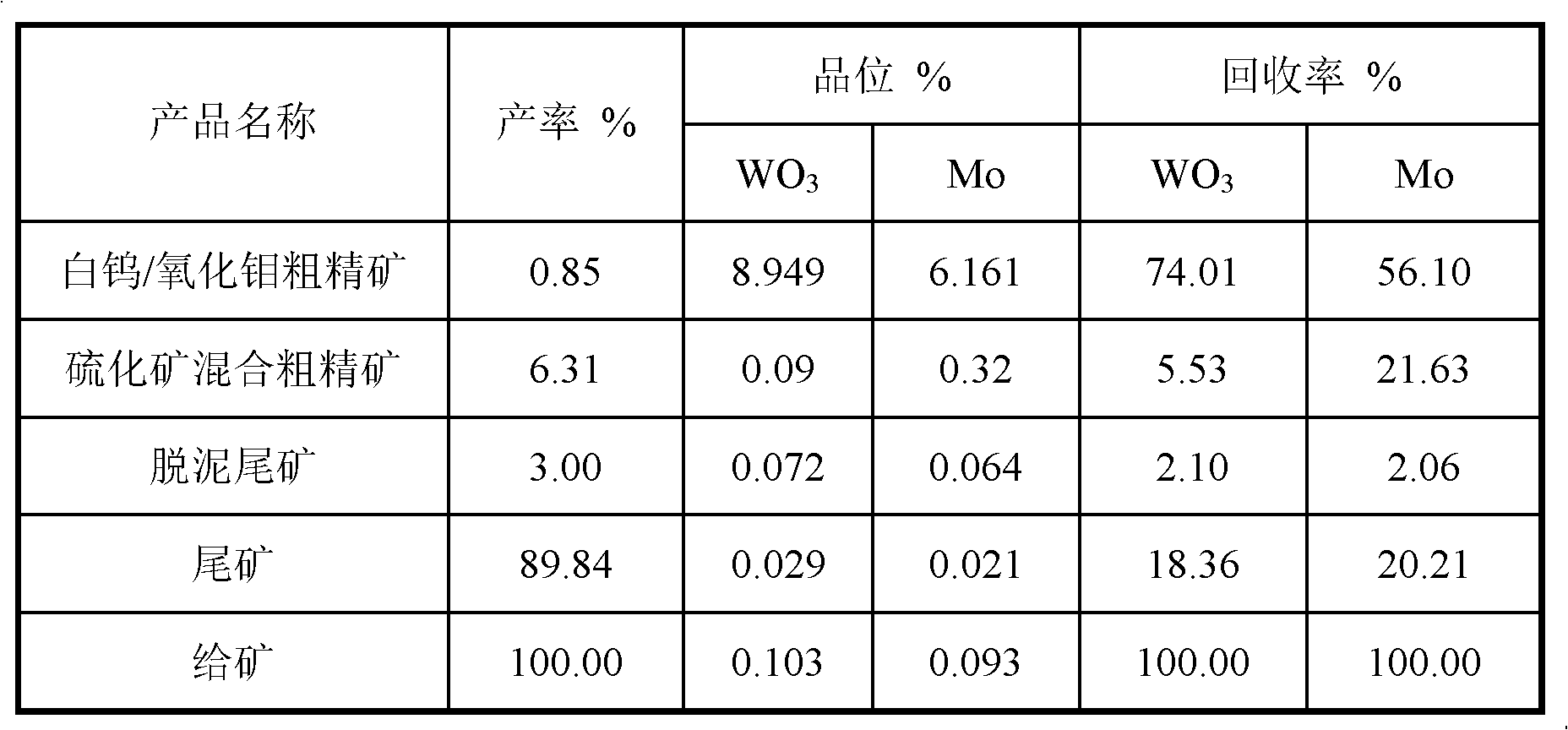

Mineral processing method for recycling scheelite/molybdenum oxide ores from molybdenum sulfide flotation tailings

The invention discloses a mineral processing method for recycling scheelite / molybdenum oxide ores from molybdenum sulfide flotation tailings. The mineral processing method comprises the following steps of: taking the molybdenum sulfide flotation tailings as raw materials and further levigating the raw materials; carrying out reselection and / or flotation and desliming on ore pulp which is levigated according to demands; adding a regulator, an auxiliary inhibitor, an inhibitor and a modified aliphatic acid collecting agent into the flotation tailing pulp; and recycling the scheelite / molybdenum oxide ores at room temperature so as to obtain scheelite / molybdenum oxide ore concentrates after roughing, scavenging and concentrating. The mineral processing method disclosed by the invention has the advantages of simple process flow, low production cost, resource saving, high product level and high recovery.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

Method of producing tungstic acid by closed type hydrochloric acid decompose tunstite

A process for preparing tungstic acid from scheelite by decomposing it by hydrochloric acid in sealed condition includes such steps as adding hydrochloric acid and powered scheelite to reactor, sealing, thermal decomposing reaction while stirring, filter and washing to obtain H2WO4. Its advantages are high productivity, less consumption of hydrochloric acid and energy, and less environmental pollution.

Owner:ZIGONG CEMENTED CARBIDE CORP

Method for comprehensively recovering tungsten and phosphorus from high phosphorus white tungsten ores

ActiveCN102080161ARealize comprehensive utilizationEasy to separate by filtrationProcess efficiency improvementPhosphorus compoundsWater dischargeDecomposition

The invention discloses a method for receiving tungsten and phosphorus from high phosphorus white tungsten ores, which comprises: decomposing the ores by using mixed acid of phosphoric acid and sulfuric acid, wherein phosphorus-containing ore are converted into phosphoric acid, tungsten-containing ore are converted into phosphotungstic acid, and both the phosphorus and the tungsten enter solution; when the total P2O5 mass content in circular leaching filtrate surpasses 30 percent, extracting tungsten from the circular leaching filtrate, extracting phosphoric acid by using a solvent extraction method, reducing P2O5 mass content in the circular leaching filtrate by controlling the extraction rate of phosphoric acid, resupplying sulfuric acid, and returning to newly leached high phosphorus white tungsten ores; and thus, recovering tungsten and phosphoric acid from the leaching filtrate respectively. The method has the advantages of comprehensively recovering tungsten and phosphorus from ores, lowering requirements on tungsten ore raw material, reducing pressure in ore dressing step, ensuring over 98 percent decomposition rate of the white tungsten ore, recycling leaching agent, greatly reducing leaching cost and waste water discharge, along with simple leaching equipment, convenient operation and easy industrialization implementation.

Owner:CENT SOUTH UNIV

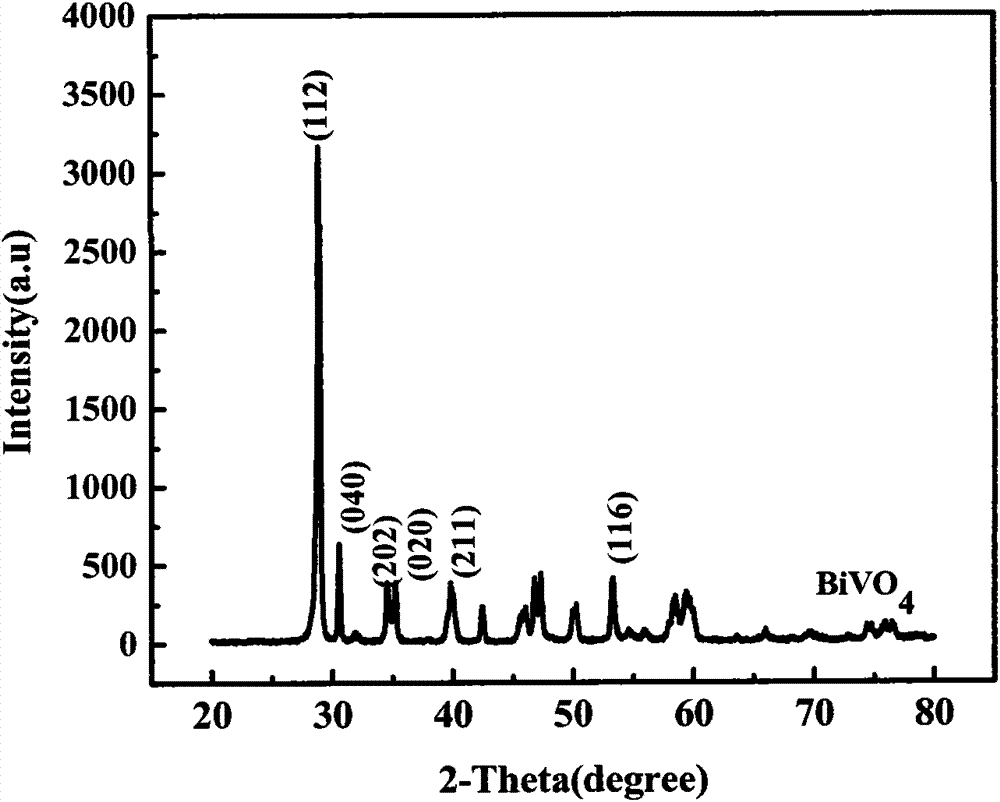

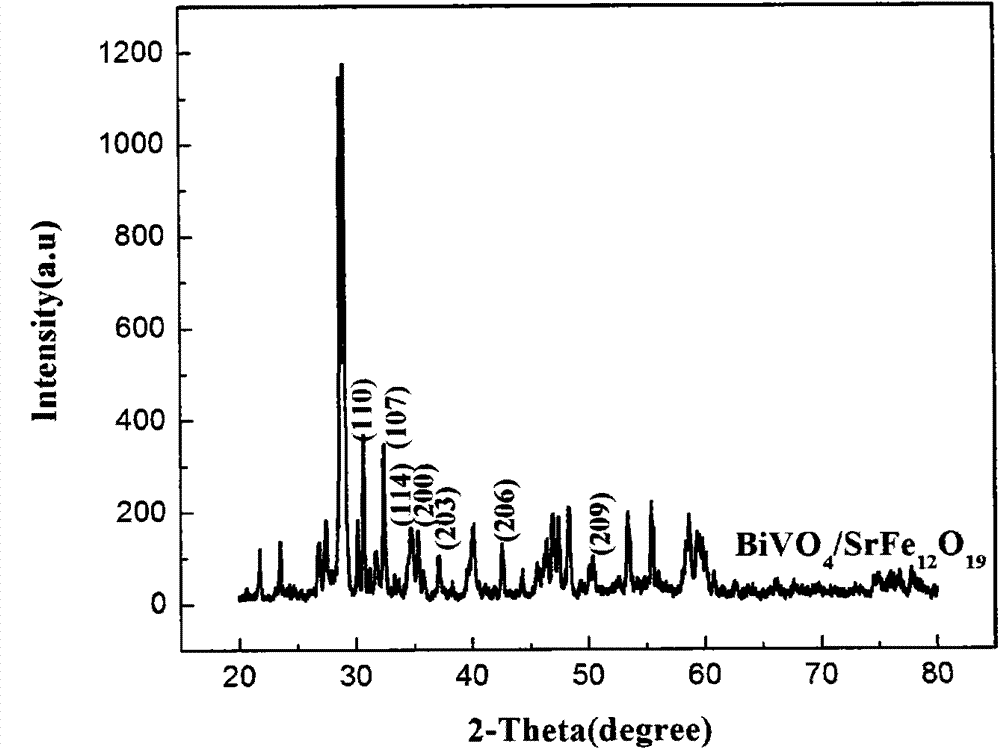

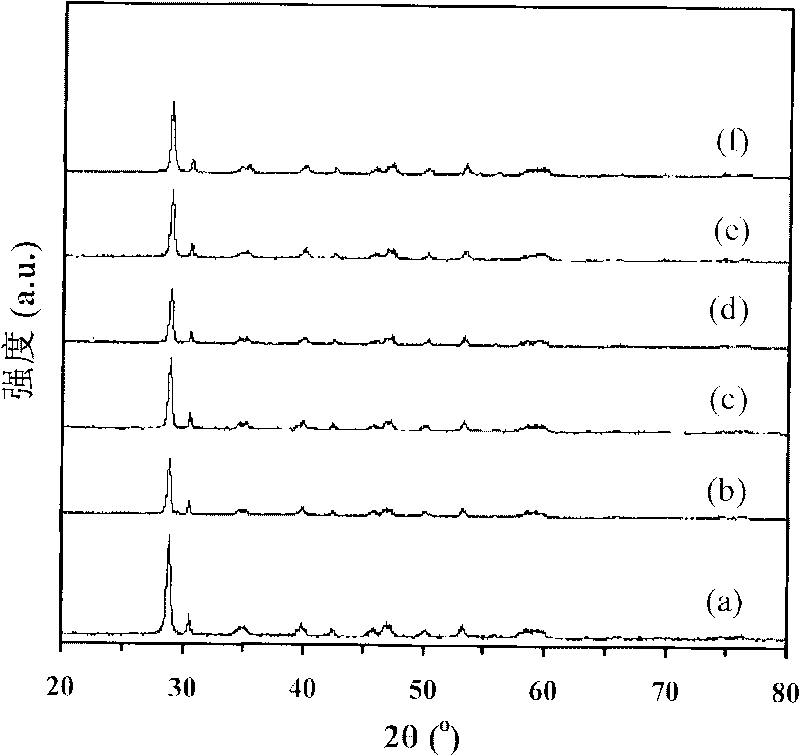

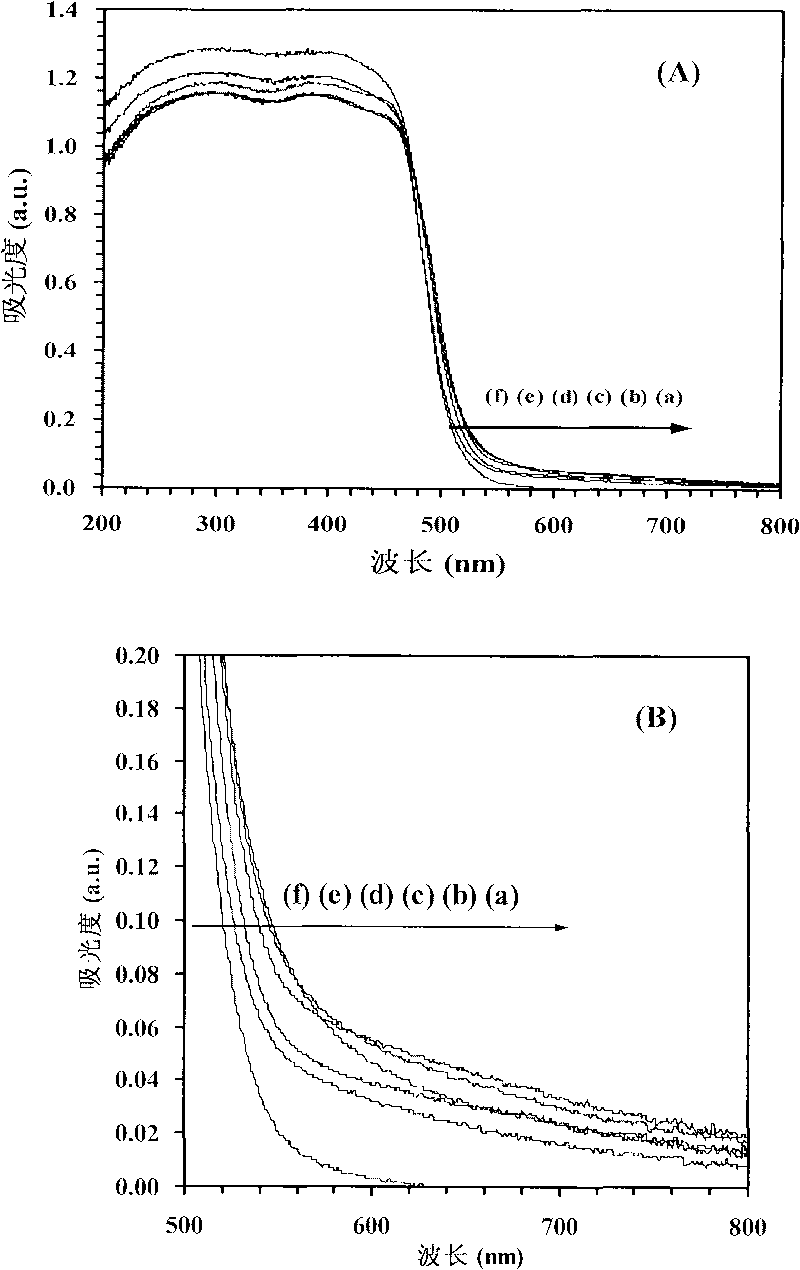

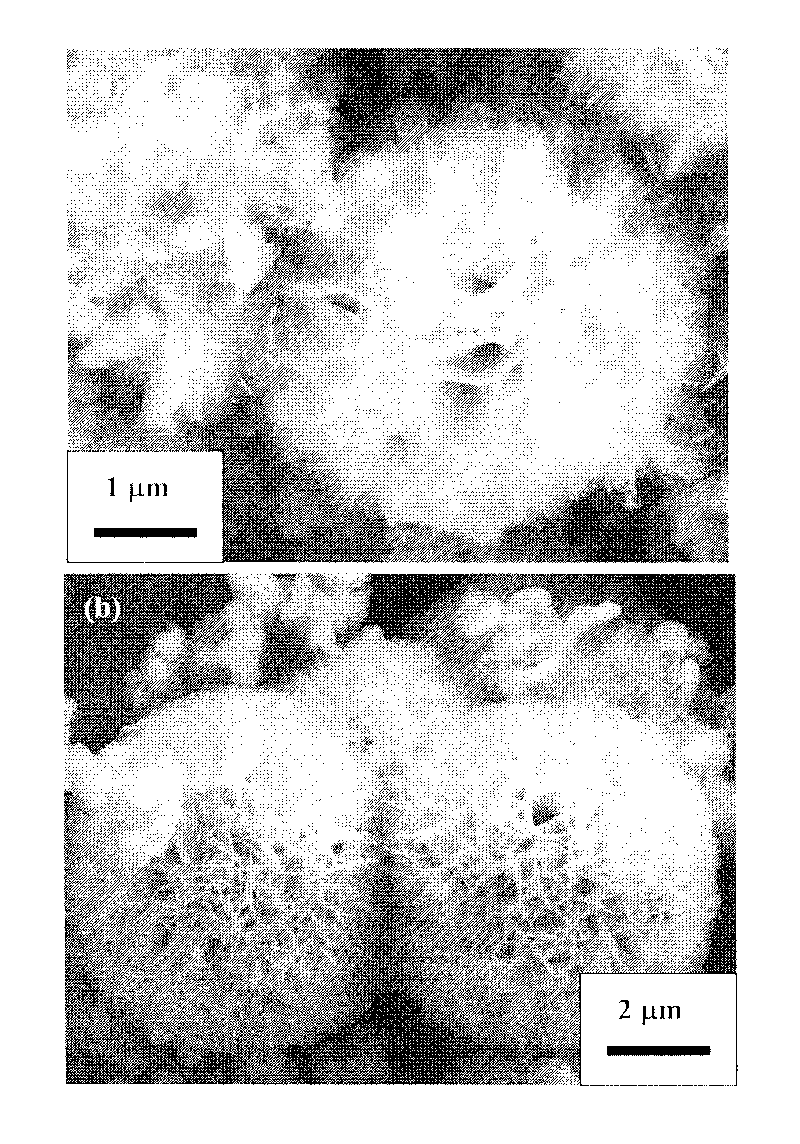

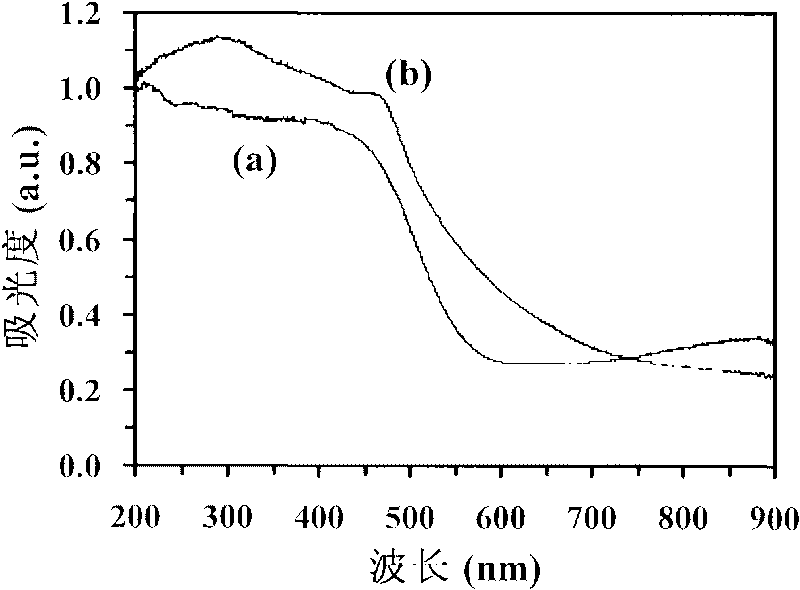

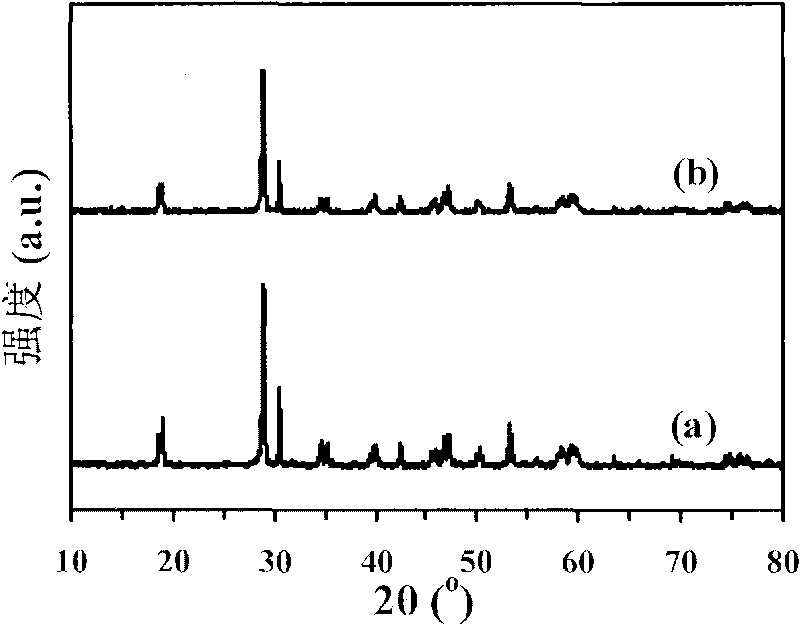

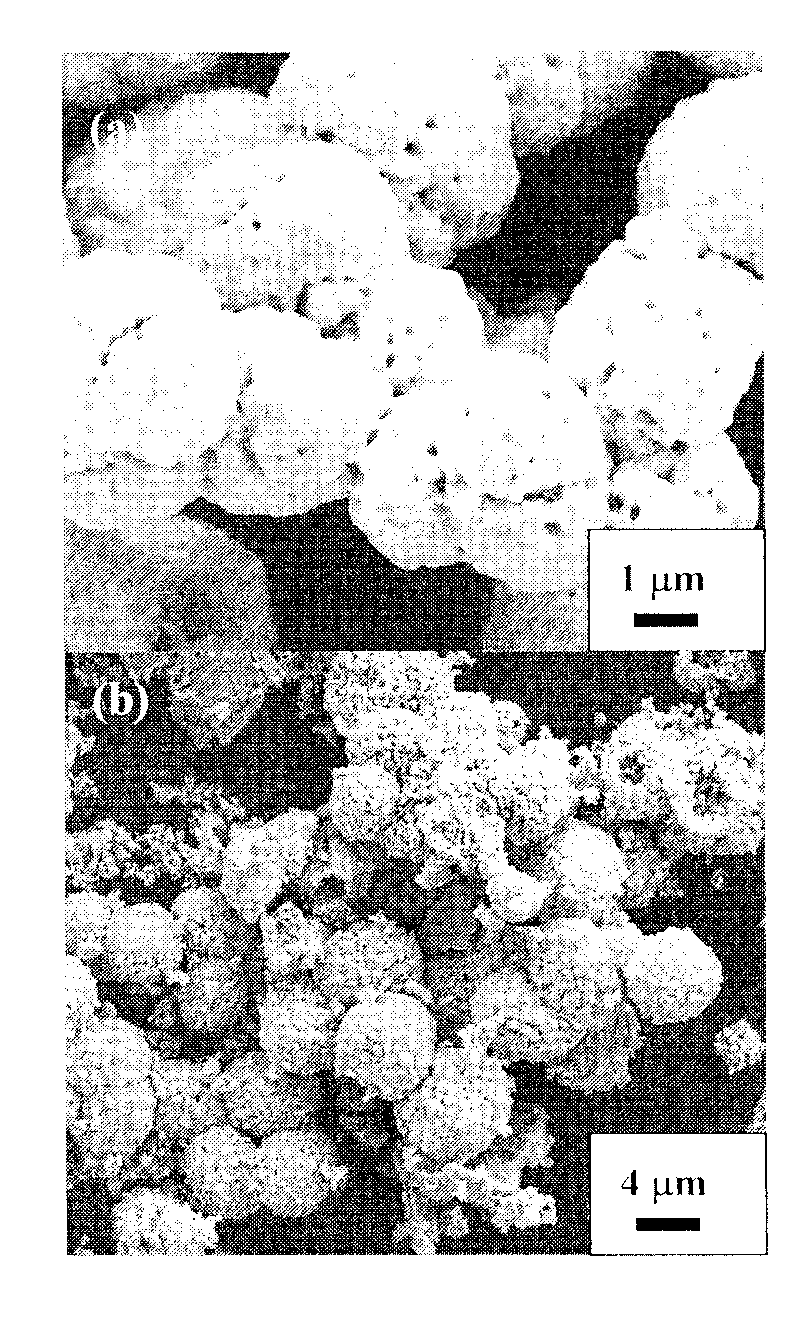

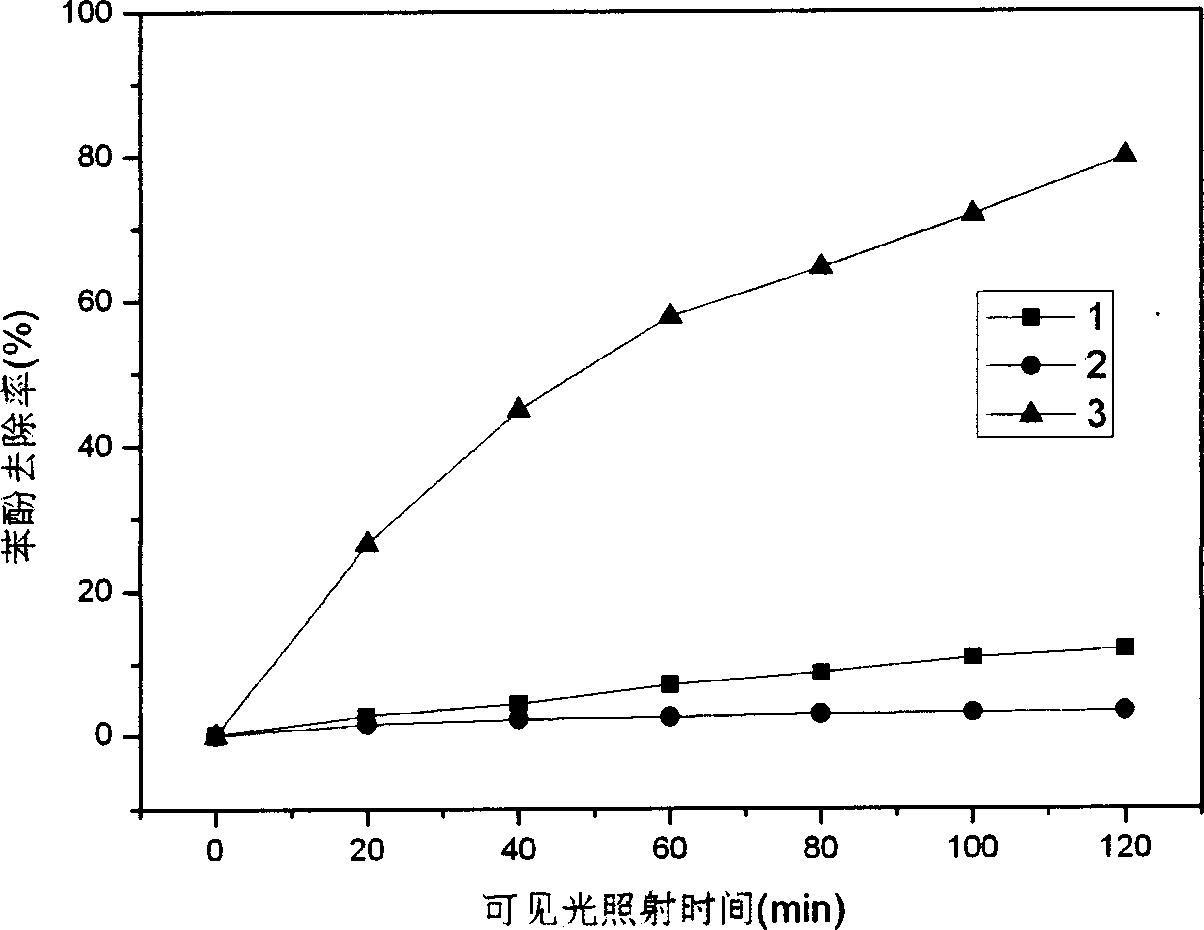

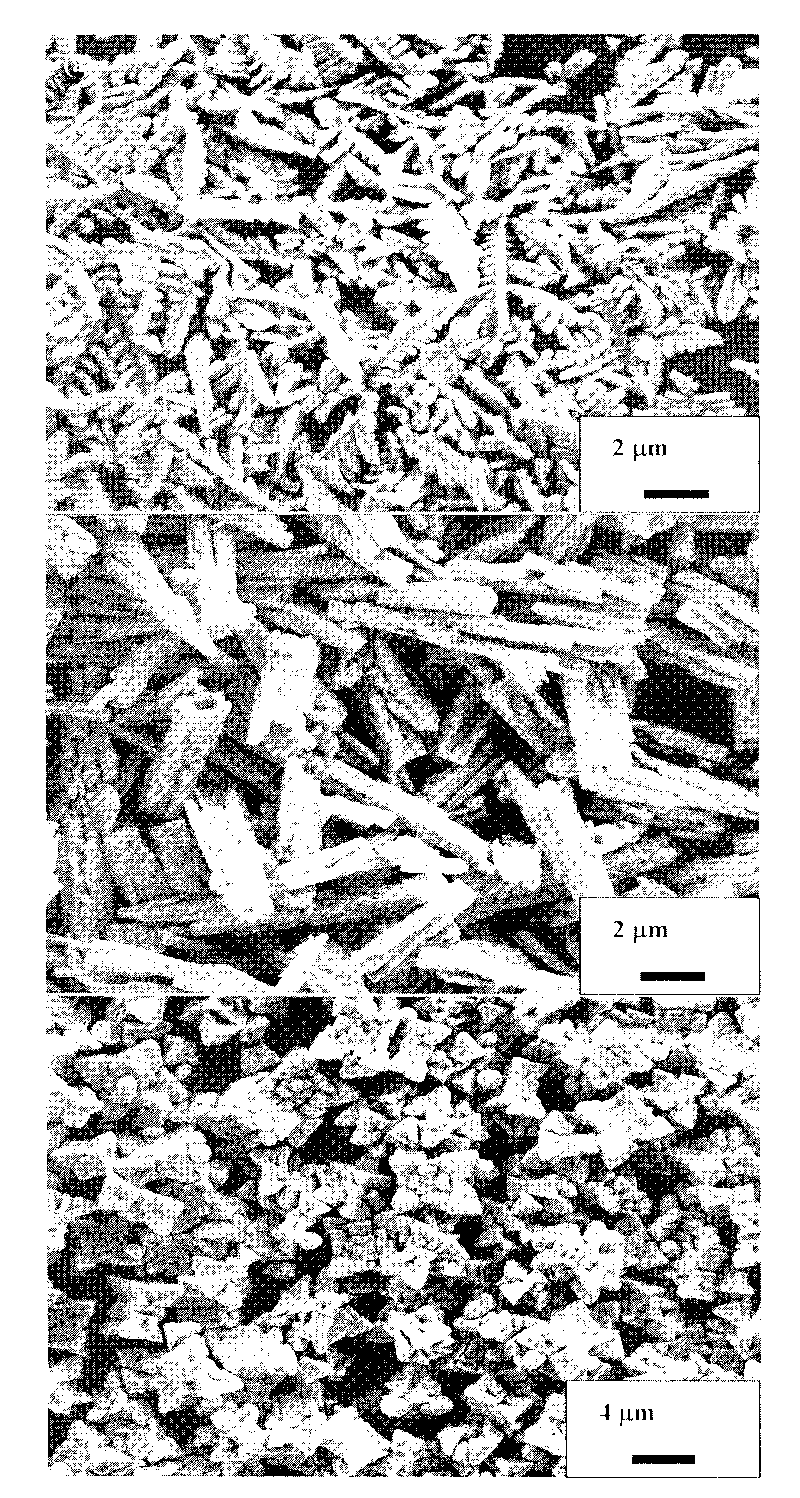

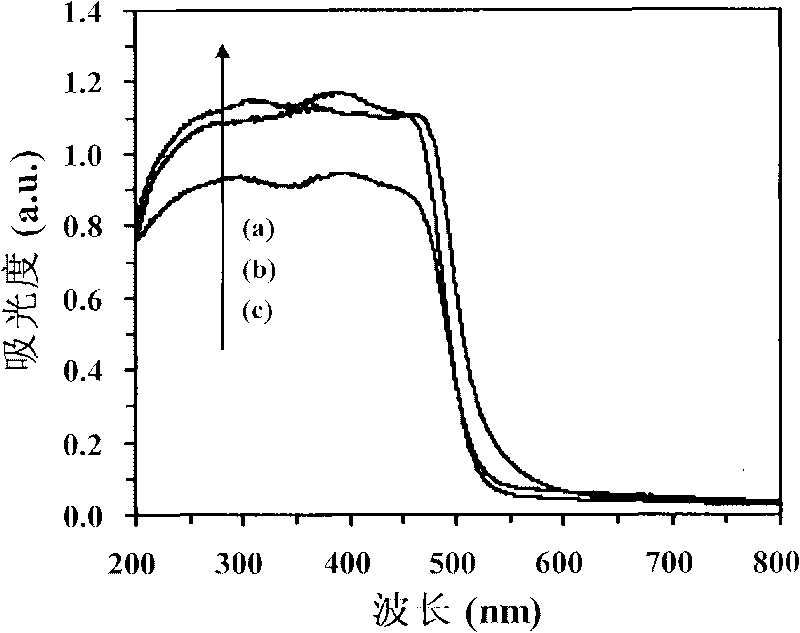

Preparation method for bismuth vanadate composite photocatalyst loaded with strontium ferrite

InactiveCN103480384AThe process steps are simpleReduce manufacturing costMetal/metal-oxides/metal-hydroxide catalystsBismuth vanadateUltraviolet lights

The invention relates to a preparation method for a bismuth vanadate composite photocatalyst loaded with strontium ferrite, and belongs to the field of inorganic catalytic materials. According to the preparation method, bismuth vanadate adopts the structure of scheelite in the monoclinic system; while the degradation rate, of the composite photocatalyst loaded with the strontium ferrite, for methylene blue can reach 93 percent in 5h, the degradation rate, of a similar composite photocatalyst of bismuth vanadate loaded with ferroferric oxide, for the methylene blue can reach 80 percent in 8 h. Moreover, the prepared composite photocatalyst has photocatalysis activity in relatively-wide wavelength range, and can efficiently and cyclically degrade organic pollutants in heteroaromatic dye-type wastewater under the irradiation of ultraviolet light, visible light and natural light through photocatalysis. Meanwhile, the composite catalyst is convenient to recover with the recovery rate not less than 92 percent; the degradation rate, of the recovered composite catalyst, for the methylene blue can reach 60 percent in 5h. The preparation method is simple and has an excellent application prospect.

Owner:CHONGQING UNIV

Method for comprehensively recovering tungsten and fluorine from minerals

InactiveCN102586632AHigh recovery rateImprove solubilitySilicaProcess efficiency improvementDecompositionApatite

The invention provides a method for comprehensively recovering tungsten and fluorine from minerals, namely a mixed acid of phosphoric acid and sulfuric acid is adopted for decomposing complex calcium-containing minerals containing fluorite, scheelite, apatite, and calcite, wherein the fluorite is decomposed to fluorine hydride or silicon tetrafluoride to escape, and absorption treatment is performed for preparing hydrofluoric acid or a fluoride salt; and the scheelite is transformed to phosphotungstic acid to enter into a solution, and filtrate after filtration is supplemented into the consumed sulfuric acid and the phosphoric acid after extraction of the tungsten and returned to the new-round mineral leaching. The method disclosed by the invention has the advantages of comprehensively recovering the fluorine and the tungsten from the minerals, reducing the requirements on the fluorite or the tungsten ore raw material, reducing the pressure on a mineral dressing link, improving the comprehensive recovery rate and simultaneously ensuring the decomposition rate of the fluorite and the scheelite, wherein the decomposition rate of the fluorite is above 98%, and WO3 contained in decomposition slag is reduced to below 0.5%; furthermore, a leaching agent can be recycled, so that leaching cost and wastewater emission are greatly reduced; and the method also has the advantages of simple leaching equipment, convenience in operation and easiness in realization of industrialization.

Owner:CENT SOUTH UNIV

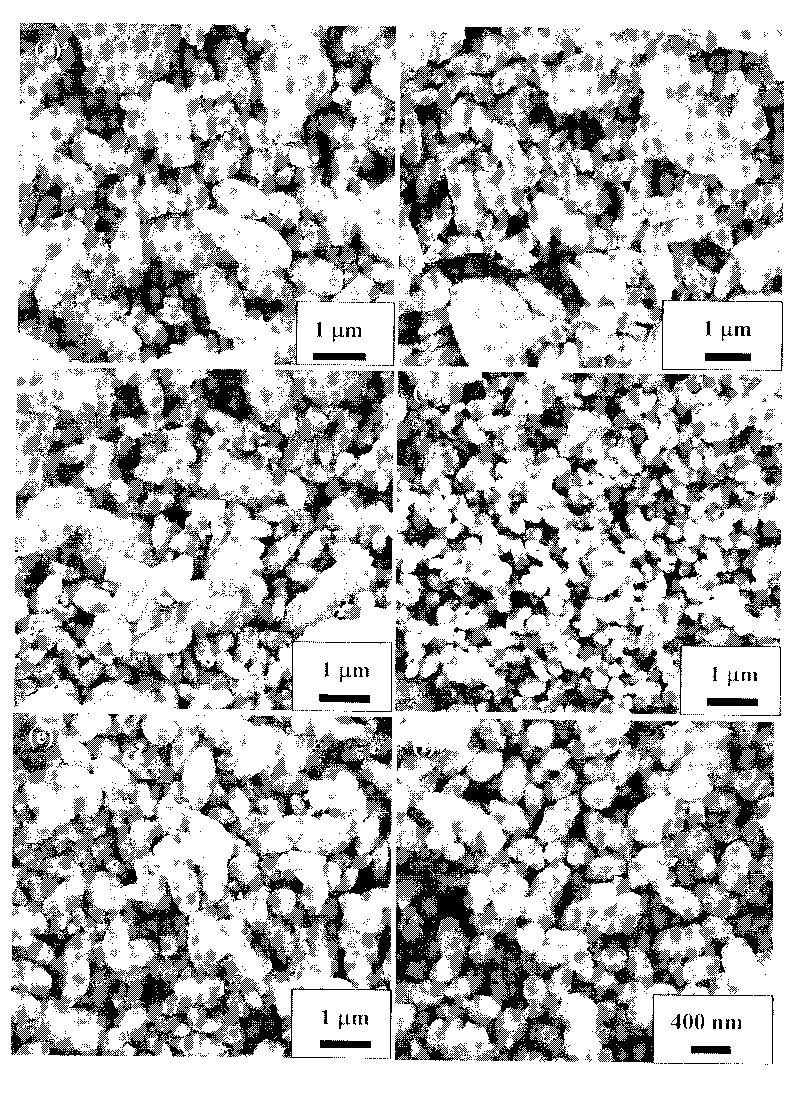

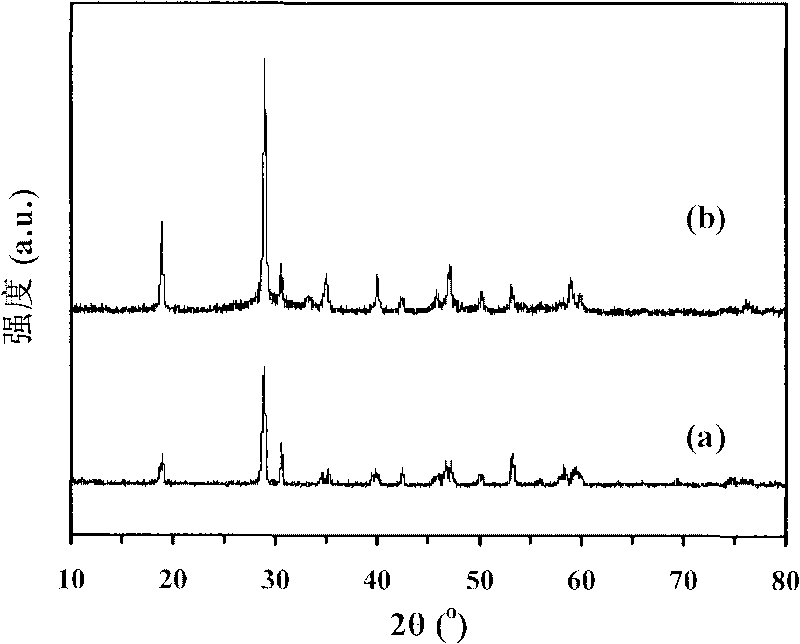

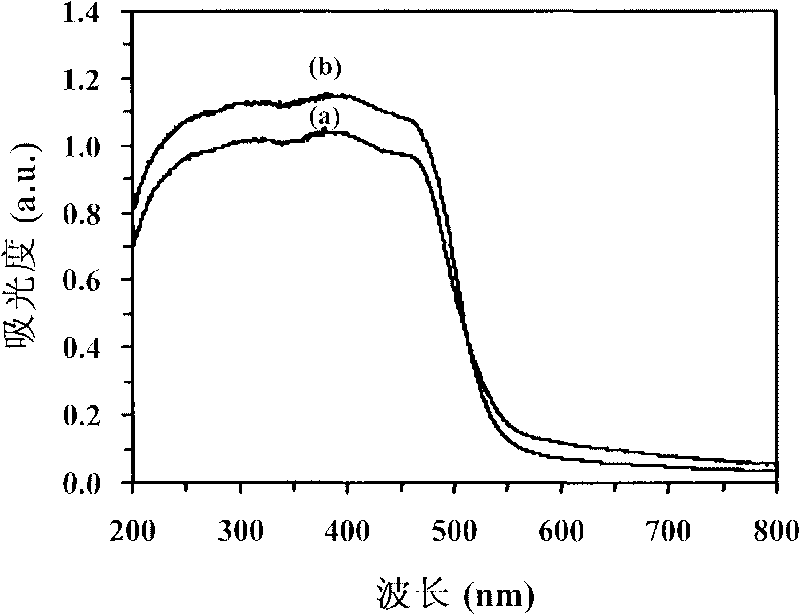

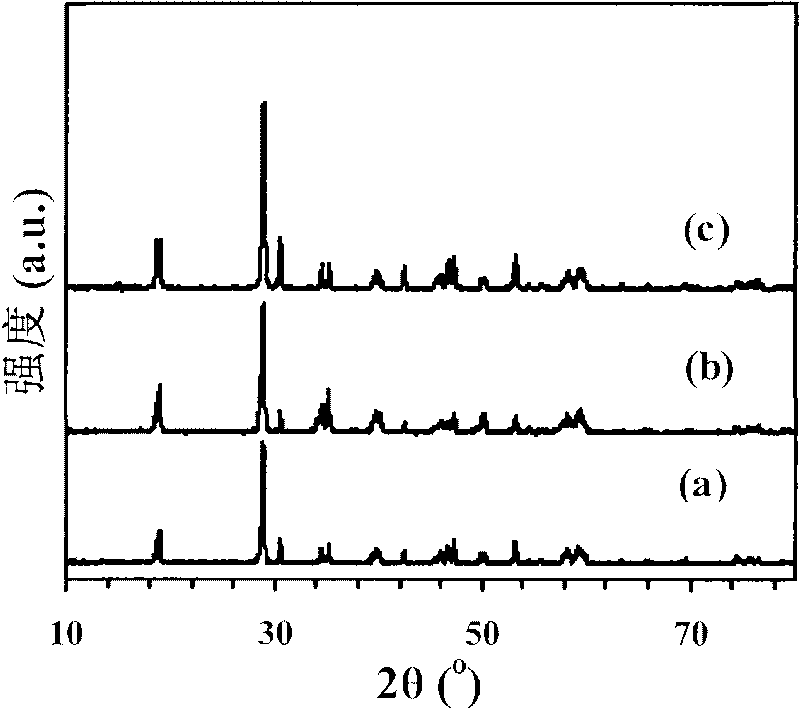

Organic solvent-water heating method for preparing football-shaped mesoporous BiVO4

InactiveCN101746825ASave raw materialsSimple processVanadium compoundsBismuth vanadateAmmonium metavanadate

The invention discloses an organic solvent-water heating method for preparing football-shaped mesoporous BiVO4, comprising the following experimental steps: under the condition of stirring, bismuth nitrate and ammonium metavanadate are dissolved in a mixed solution of ethanol, ethylene glycol, nitric acid and laurylamine (oleylamine or mixed liquid of oleylamine and oleic acid); a sodium hydroxide (2mol / L) alcohol solution of ethanol and ethylene glycol with the volume ratio of 1 to 1 is used to regulate the pH of the solution to be equal to 1.5-3; the mixed solution is transferred in a stainless steel self-pressing vessel (the volume filling degree is about 70%) with a Teflon inner liner and is put in an incubator to carry out organic solvent - water heating treatment for 12h in constant temperature of 100 DEG C; and the mixed solution is naturally cooled to room temperature after taking out. The obtained product after the organic solvent - water heating treatment is filtered, is washed with deionized water and absolute ethanol and is dried for 12h at the temperature of 60 DEG C, and then football-shaped mesoporous BiVO4 micron particles with a monoclinic scheelite structure is obtained. The porous bismuth vanadate obtained by the method has good application prospects in the fields of photocatalysis, electrode materials, pigments, ion conductive ceramic, and the like.

Owner:BEIJING UNIV OF TECH

Surface active agent assisting alcohol-hydrothermal method for preparing anthoid BiVO4

The invention discloses an alcohol-hydrothermal method for preparing anthoid BiVO4. The method comprises the following steps of: under a stirring condition, adding cetylpyridinium chloride as a surface active agent to a mixed solution, wherein the volume ratio of ethanol to glycol to concentrated HNO3 (the concentration is 67 percent) in the mixed solution is 12:12:1, the concentration of the cetylpyridinium chloride is 0.48mol / L; adding Bi(NO3)3.5H2O and NH4VO3 according to the molar ratio of Bi(NO3)3 to NH4VO3 to nitric acid is 1:1:4 after dissolving; adding NaOH powder to control the pH value of the solution to 3-7; transferring the mixed solution into a stainless steel self compression kettle (the volume filling degree is 63 percent) with a polytetrafluoroethylene lining and putting the stainless steel self compression kettle in a thermostat for treating for 12h at a temperature of 100 DEG C; taking out the stainless steel self compression kettle and cooling to room temperature; and after drying an obtained product for 12h at a temperature of 60 DEG C, obtaining BiVO4 micron particles with monoclinic scheelite structures. Bismuth orthovanadate crystals with specific appearances obtained by the method have good application prospects in the field of photocatalysis, electrode materials, pigment, ionic conductive ceramics, and the like.

Owner:BEIJING UNIV OF TECH

Method for preparing hollow spherical porous BiVO4 with aid of surfactant

The invention discloses a method for preparing hollow spherical porous BiVO4 with the aid of a surfactant, which comprises the following steps of: under a stirring condition, dissolving bismuth nitrate and ammonium meta-vanadate in 2 mol / L solution of nitric acid in a molar ratio of bismuth nitrate to ammonium meta-vanadate to nitric acid of 1:1:10; adding polyvinylpyrrolidone (PVP) and carbamide into the mixed liquid in a molar ratio of bismuth nitrate to PVP to carbamide of 1:0.0075-0.0125:3; transferring the mixed liquid to a stainless steel self-pressure reactor of which the lining is teflon and the volume filling degree is 50 percent, and to a thermostat to perform hydro-thermal treatment for 30 hours at the temperature of 100 DEG C; cool a product naturally to room temperature after the product is taken out; drying the product for 24 hours at the temperature of 60 DEG C; and finally calcining the product in a muffle furnace to obtain hollow spherical porous BiVO4 particles with a monoclinic scheelite structure. The method has the characteristics of cheap raw materials, simple process, controllable appearance and crystalline phase structure of the target product particles and the like.

Owner:BEIJING UNIV OF TECH

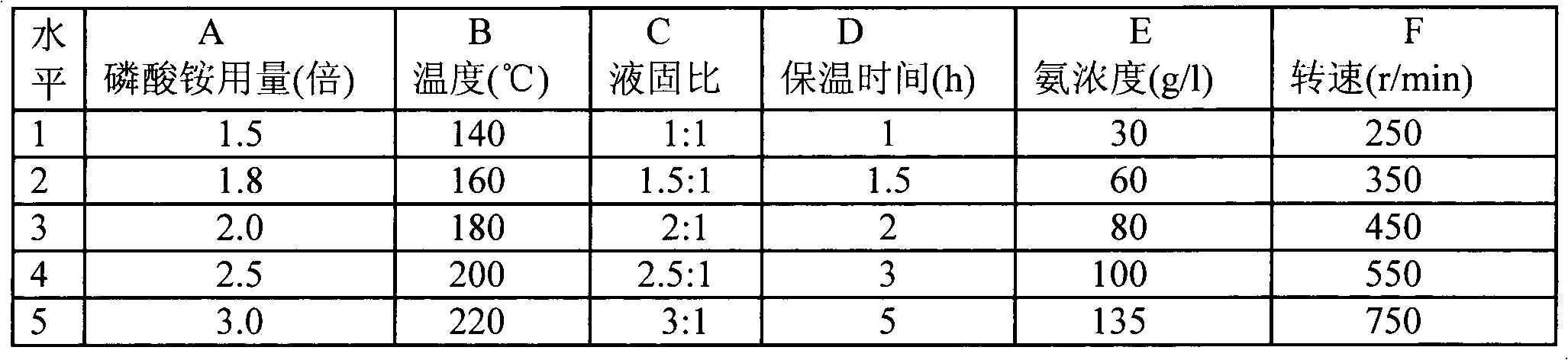

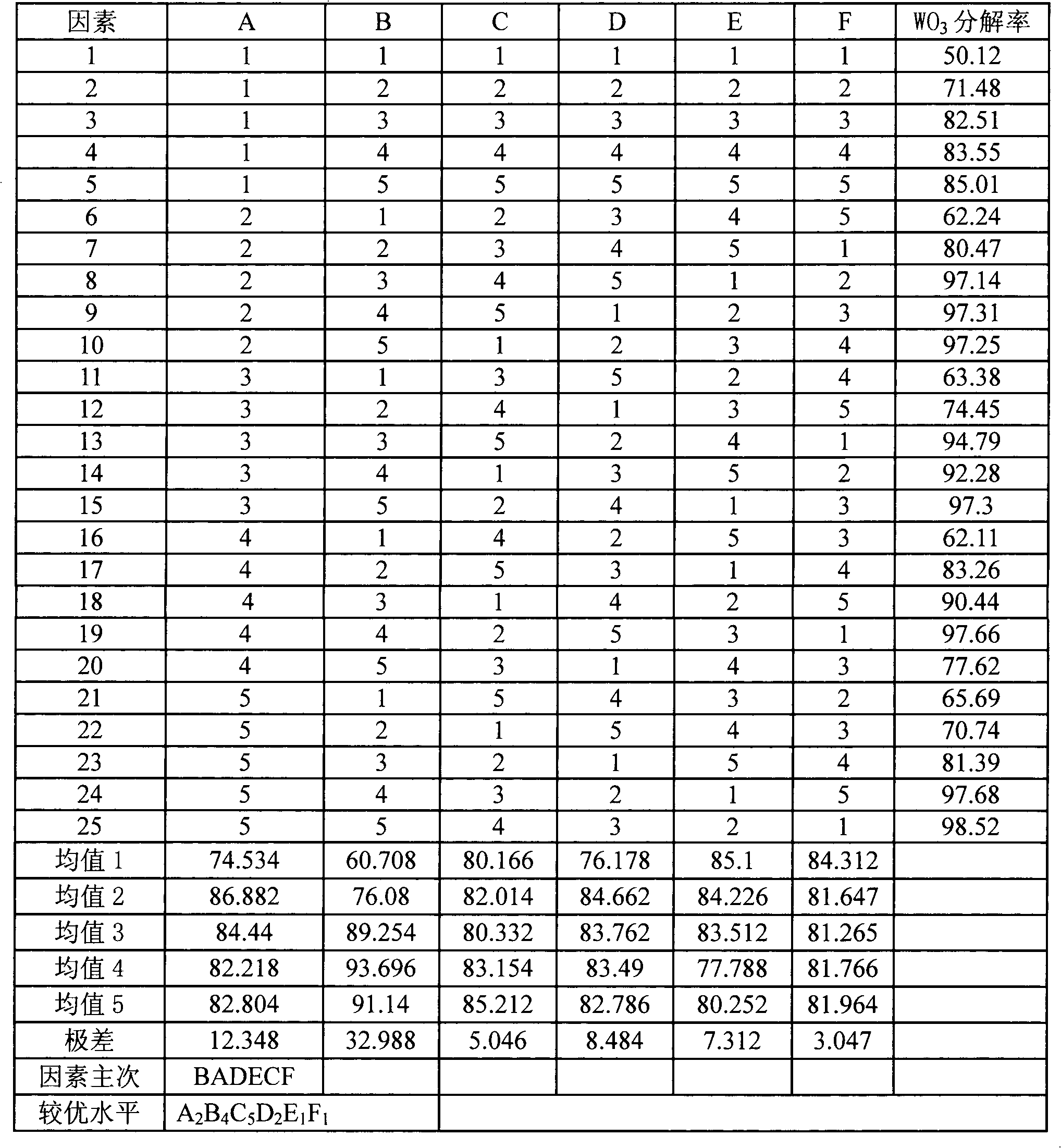

Method for decomposing scheelite with ammonium salts

ActiveCN102154547AEmission reductionReduce auxiliary reagentsProcess efficiency improvementReaction temperatureEconomic benefits

The invention relates to the decomposition technology of scheelite, in particular to a method for decomposing scheelite by adopting ammonium phosphate and liquid ammonia. The method is characterized in that the ammonium phosphate and the liquid ammonia are used as decomposers; the amount of the ammonium phosphate is not less than 1.8 times theoretical amount; the ammonia concentration is not lessthan 30g / l; the reaction temperature is 180-220 DEG C; the heat preservation time is 1.5-5 hours; the liquid-solid ratio is (2:1)-(3:1); and the stirring speed is 25-450r / min. The method has the positive effects of realizing closed cyclic smelting and zero discharge of scheelite, simultaneously lowering the production cost and increasing the economic benefits.

Owner:CHONGYI ZHANGYUAN TUNGSTEN +1

Scheelite beneficiation method

ActiveCN102909130AWith weak magneticEfficient separationFlotationMagnetic separationTotal recoveryMaterials science

The invention discloses a scheelite beneficiation method. The scheelite beneficiation method comprises the steps of: roughly grinding raw mineral with no need of desliming; screening the raw mineral in a sieve with 200-250mu m, roughly grinding the material on the sieve again, carrying out strong magnetic separation and discarding on the mineral under the sieve, wherein mainly magnetic garnets and other magenetic minerals are mainly discarded; carrying out scheelite normal temperature flotation on the nonmagnetic mineral after the nonmagnetic mineral is finely ground; carrying out scheelite warming flotation on concentrate obtained after the rough flotation to obtain scheelite concentrate; and carrying out normal temperature floatation on discarded magnetic concentrate, adding flotation middlings into the nonmagnetic scheelite concentrate to be finely ground. The scheelite beneficiation method aims at the mineral characteristics of the scheelite, the raw mineral contains a large amount of weak magnetism calcium and iron garnet gangue, so the recovery rate can be influenced due to the argillization caused by excessive grinding. The scheelite beneficiation method utilizes a ferromagnetic beneficiation method to effectively separate the magnetic ores, so that the excessive grinding condition is lowered, and the scheelite is preliminarily separated and beneficiated. The scheelite beneficiation method can enhance the mineral grinding efficiency, reduces the mineral grinding energy consumption, enhance the selection grade of the scheelite, reduces the beneficiation amount of the flotation, lowers the dosage of flotation reagents, and enhances the total recovery rate of the scheelite. The scheelite beneficiation method is especially suitable for medium grade and low grade scheelite beneficiation.

Owner:ZHONGXIANG TUNGSTEN IND

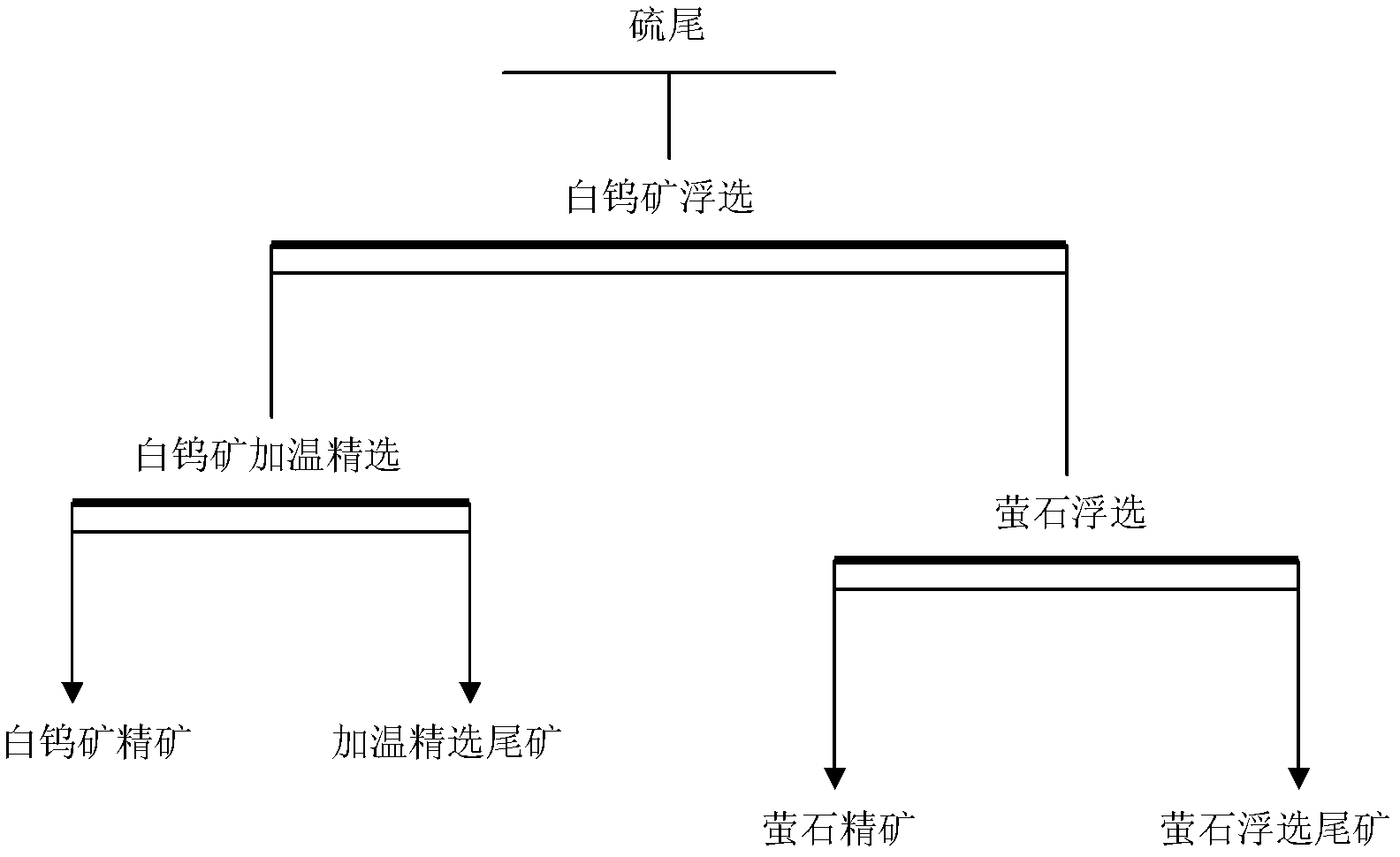

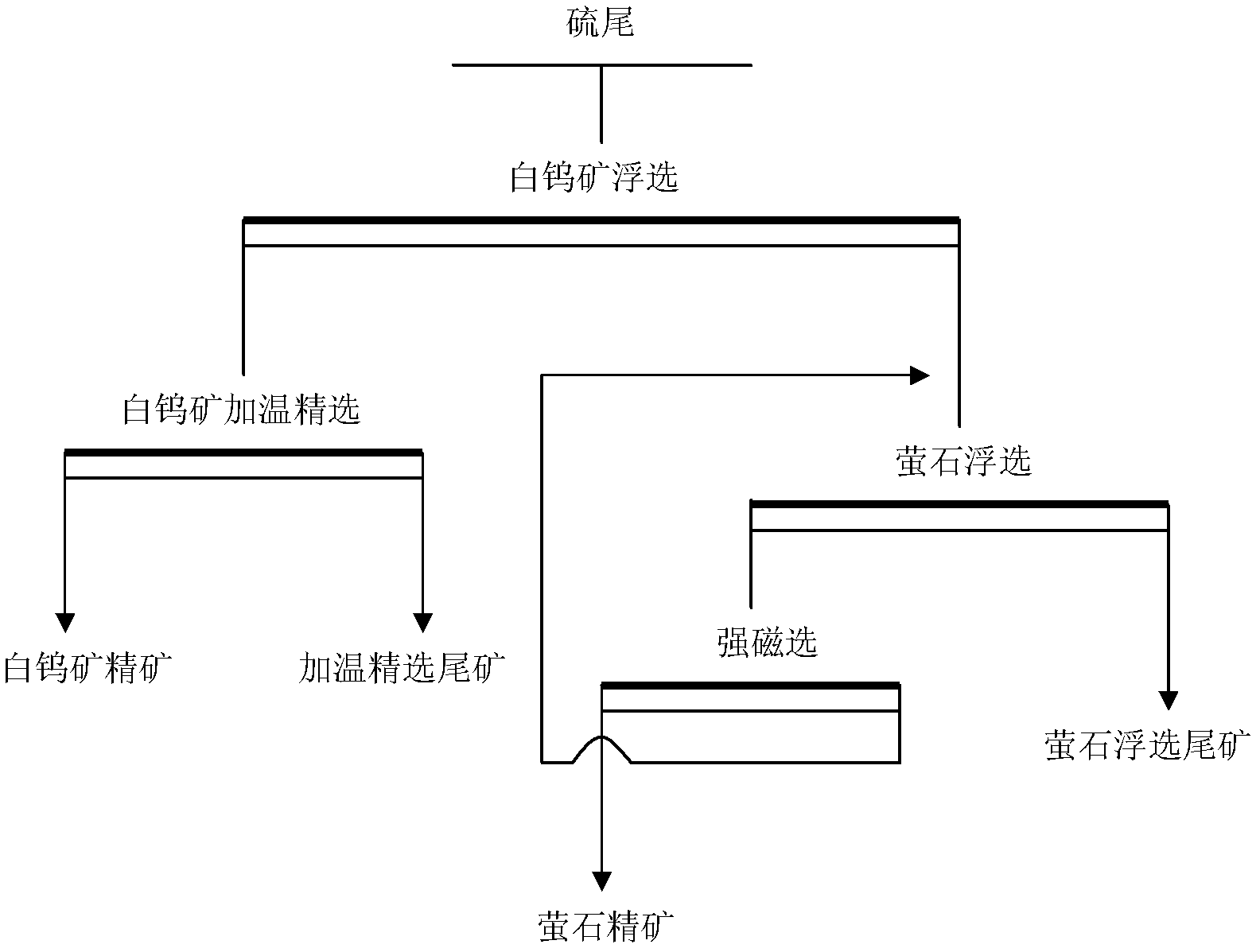

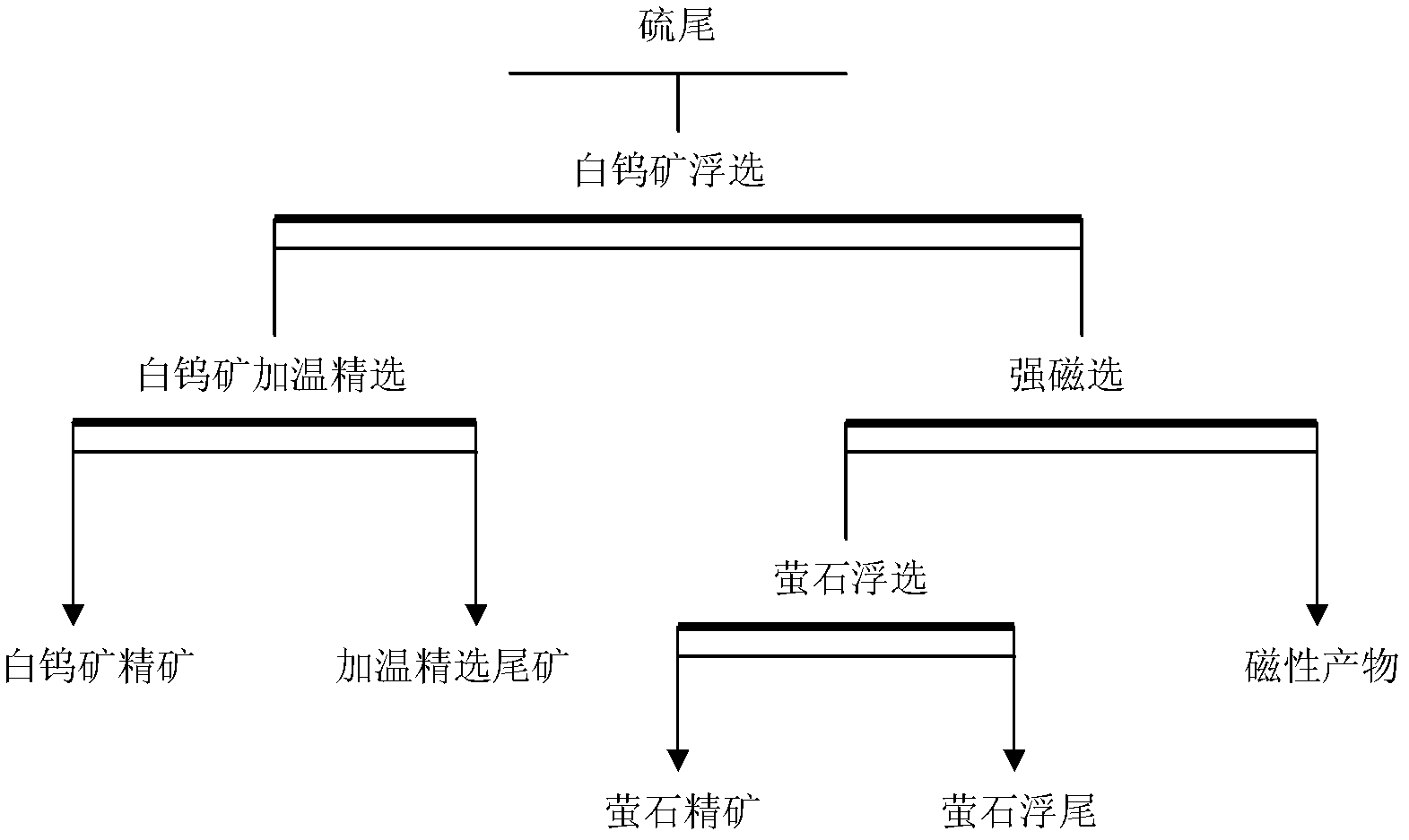

Ore dressing method for separation and recovery of scheelite and fluorite from sulfur flotation tailings of polymetallic ore

InactiveCN102489393AReduce acid consumptionReduce drug consumptionGlass recyclingSolid separationSulfurMaceral

The invention discloses an ore dressing method for separation and recovery of scheelite and fluorite from sulfur flotation tailings of polymetallic ore. The ore dressing method can eliminate the shortcomings caused by a preferential flotation process in the prior art by simultaneously performing bulk flotation on the scheelite and the fluorite and further separating the scheelite from the fluorite, further significantly improve the recovery rate of the scheelite and the fluorite and realize high-efficient recovery of two minerals, namely the scheelite and the fluorite in the polymetallic ore.Furthermore, the scheelite and the fluorite are dressed through a rough concentration bulk flotation and fine concentration separation two-stage process, so that indexes in various stages of operations are convenient to stipulate and control, and quantification of the indexes of the ore dressing process of the scheelite and the fluorite and operation management can be effectively realized.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

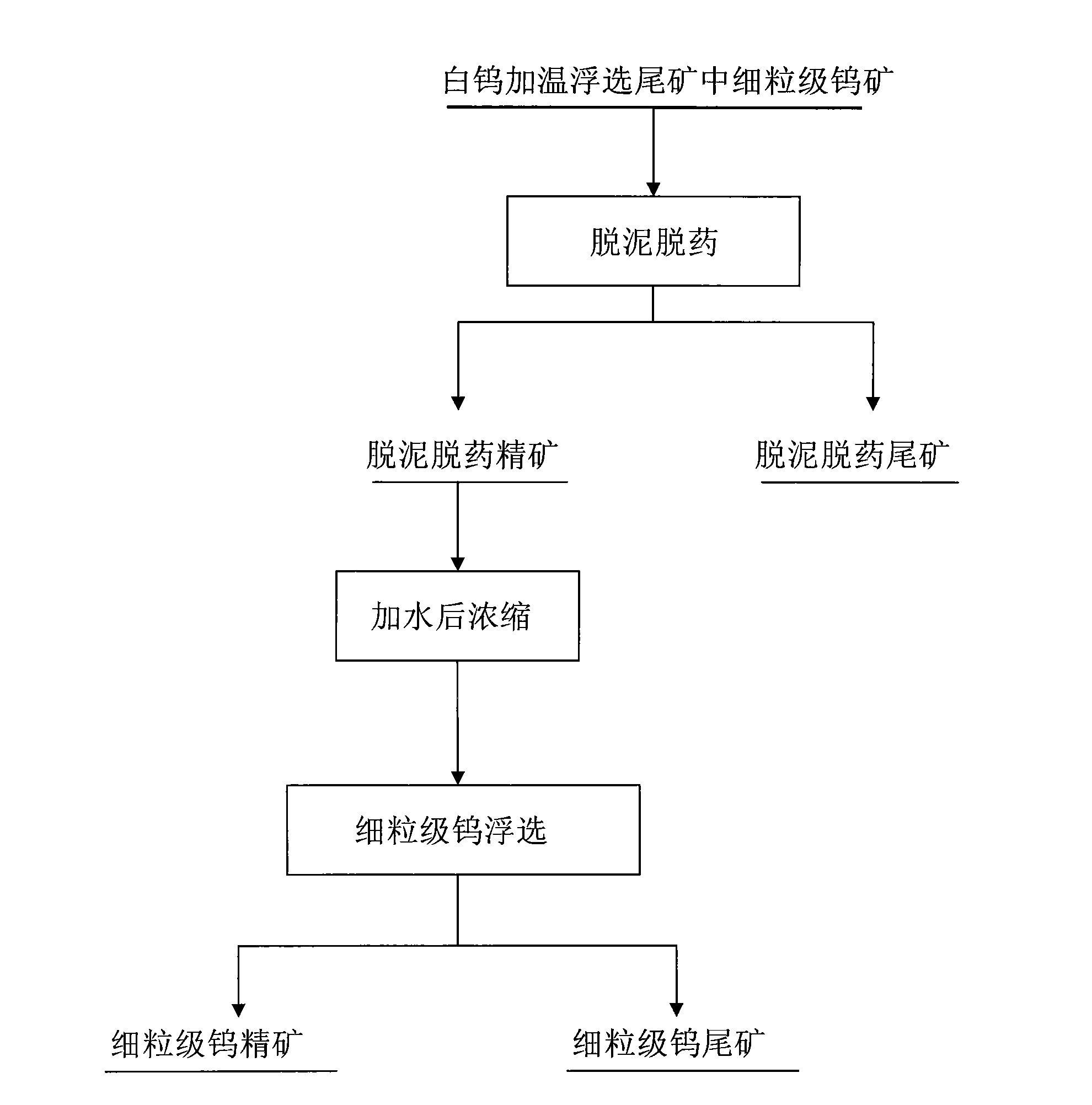

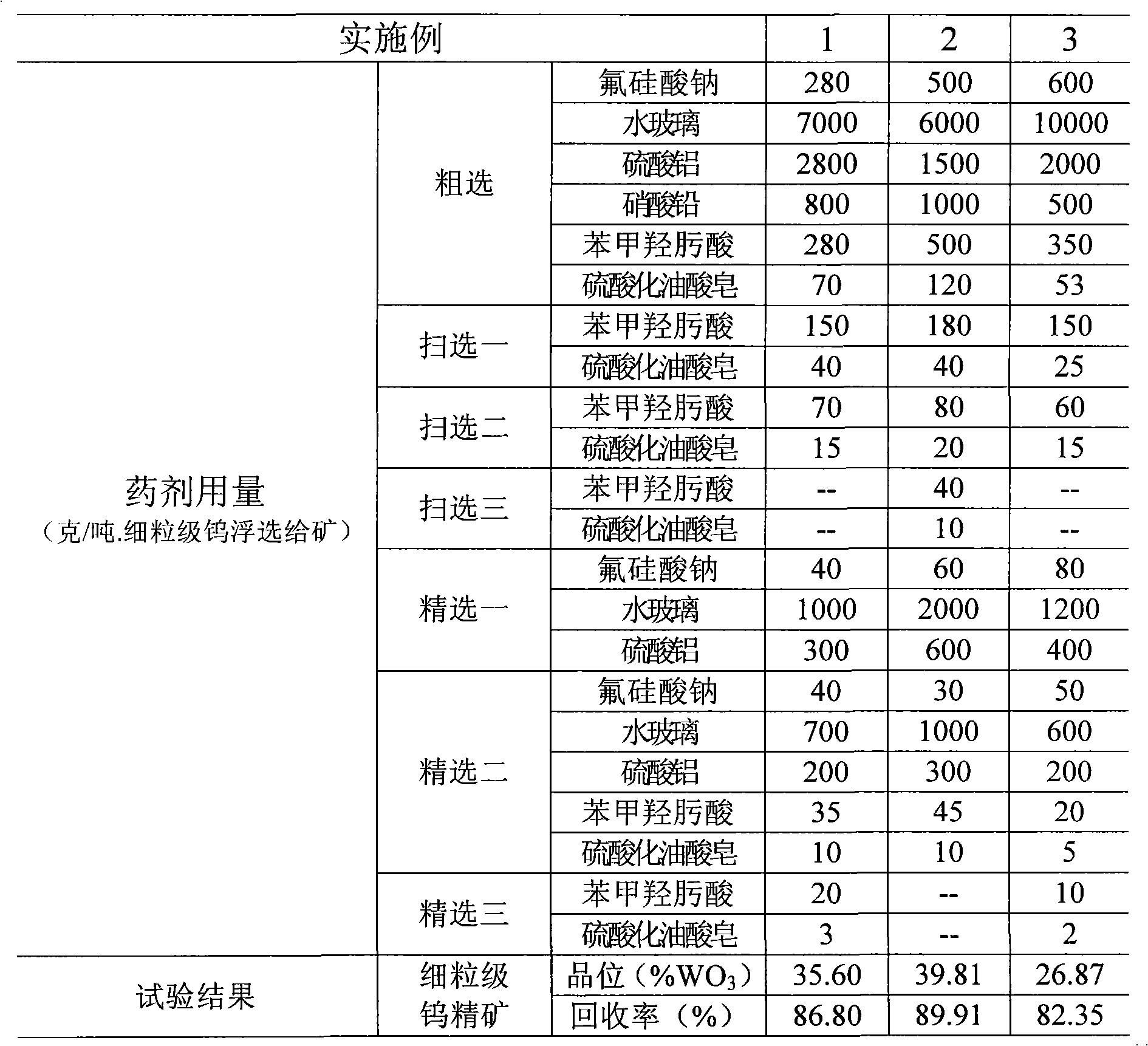

Benefication method for concentrating fine tungsten ore in tailings by warming scheelite

InactiveCN101579653ASimple recycling processThe beneficiation process is stableFlotationWet separationLead nitrateSoluble glass

The invention discloses a benefication method for concentrating fine tungsten ore in tailings by warming scheelite, which is characterized by comprising the following steps in turn: performing desliming and reagent removal; condensing concentrate after desliming and reagent removal, which is added with water, into 26 to 44 percent of pulp density, and controlling the pH of pulp at about 8.5; performing floatation on the fine tungsten ore; adding regulators of sodium fluosilicate, soluble glass, aluminium sulphate and lead nitrate; and adding collecting agents of benzohydroxamic acid and sulfated oleate soap, and performing rough concentration, concentration and scavenging to obtain the fine tungsten ore concentration and fine tungsten tailings. The method has simple recovery process flow, stable benefication process, high tungsten recovery rate, and low cost of reagents; the used benefication reagents do not pollute environment; and tailing water can meet the emission requirement. The method is suitable for the fine tungsten ore, of which the WO3 content is 0.95 to 5.10 percent, the ratio of peanut ore to the scheelite is between 1:9 to 9:1, and the occupancy rate of WO3 metal smaller than 30 microns is more than or equal to 60 percent, and which is subjected to concentration of the tailings by warming the scheelite and then reconcentration of the tailings by a shaker.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

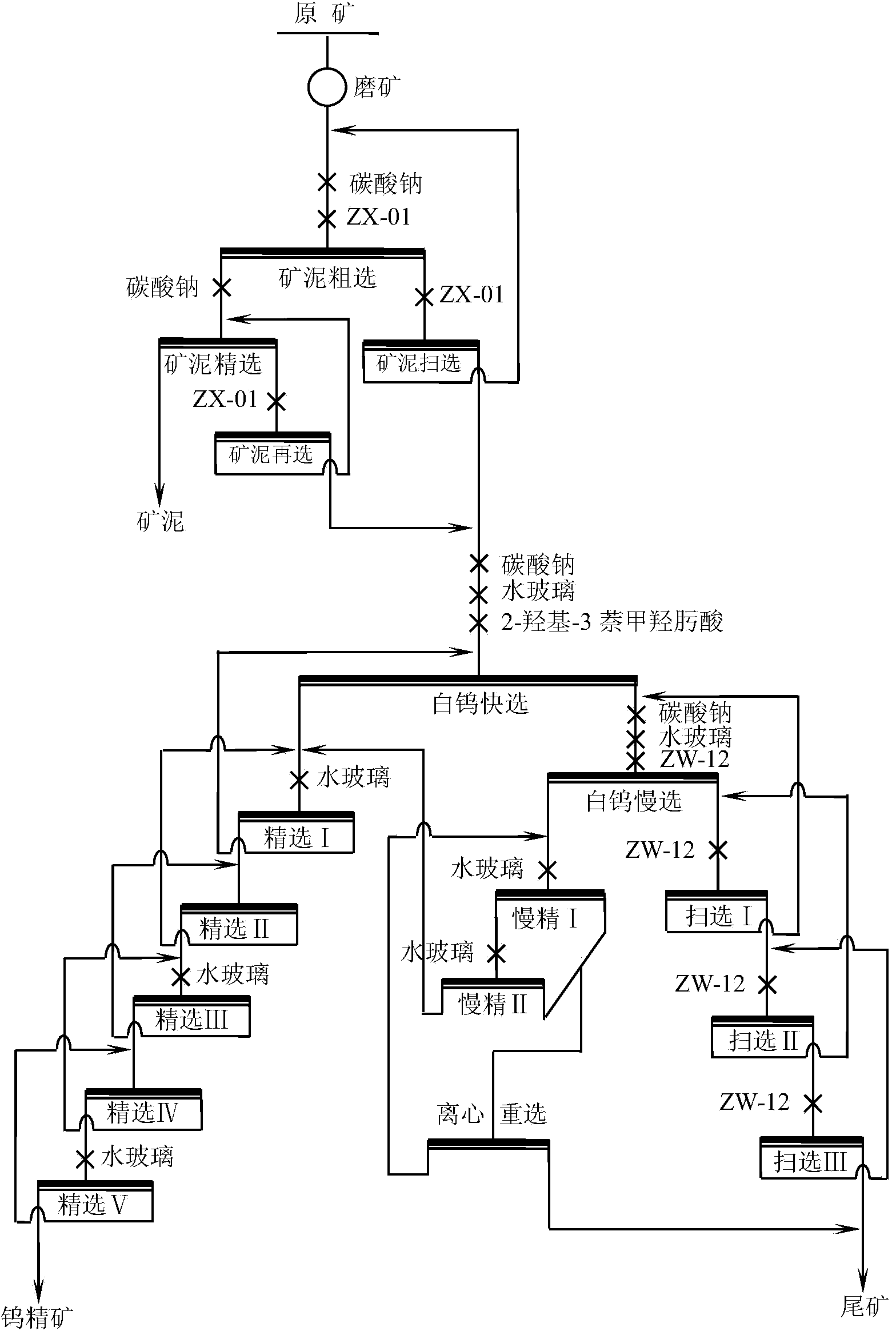

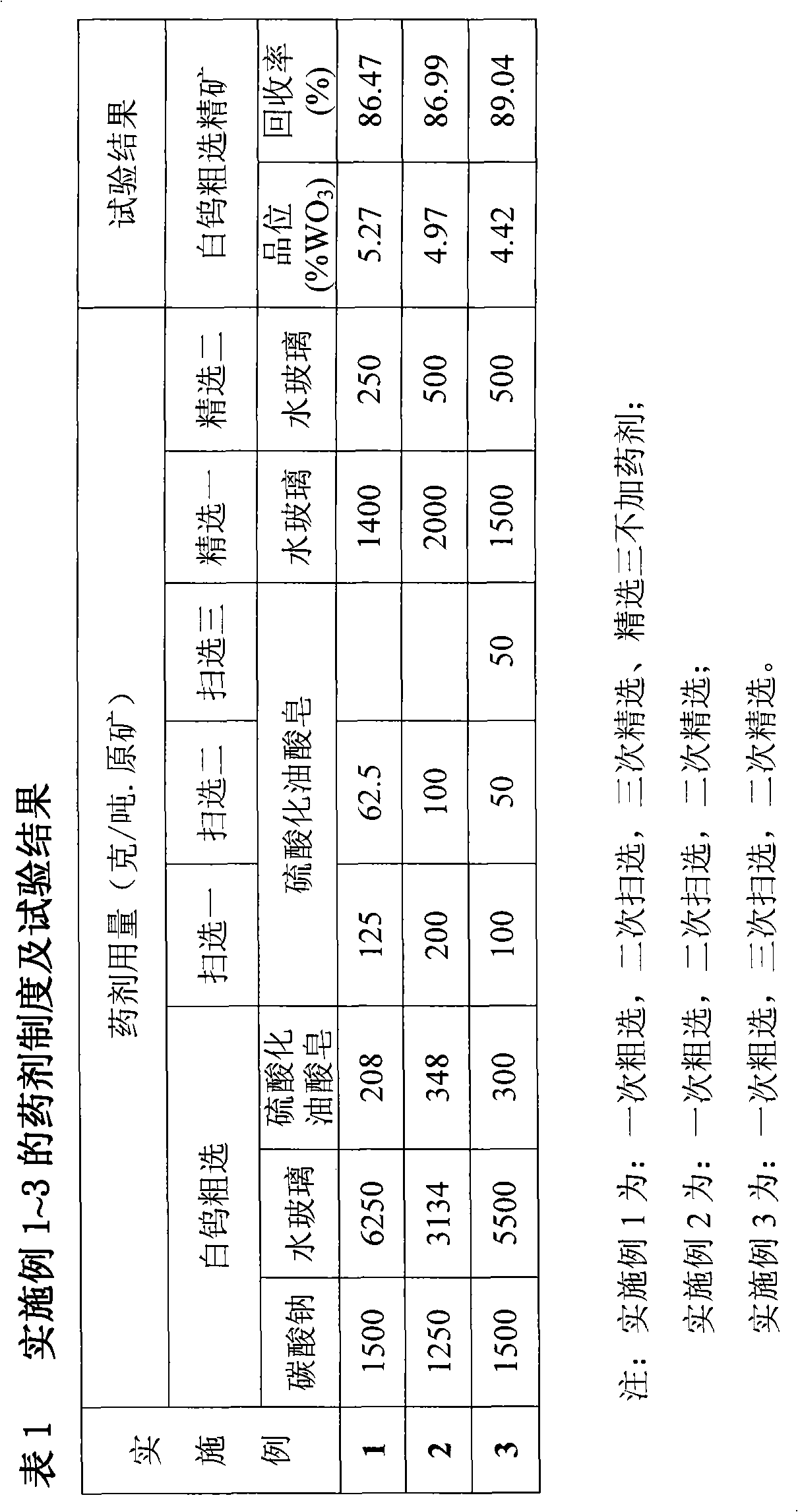

Beneficiation method of refractory low-grade scheelite

ActiveCN104226462AAddressing the Effects of SortingImprove sorting effectFlotationWet separationHydroxamic acidLower grade

The invention provides a beneficiation method of refractory low-grade scheelite. The method adopts slurry collecting agent ZX-01, slurry collecting agent 2-hydroxy-3 naphthoyl hydroxamic acid and slurry collecting agent ZW-12 which have high selective collecting capability; the method comprises the steps of finely grinding raw ore, carrying out slurry flotation, carrying out rapid beneficiation on scheelite, selecting the scheelite, carrying out slow beneficiation on scheelite, slowly selecting the scheelite, carrying out centrifugal reselection on middlings, and the like to finally obtain the scheelite concentrate. The low-grade scheelite sorted by the method is good in sorting indexes; the scheelite concentrate is higher in grade and yield; the beneficiation method of the refractory low-grade scheelite is stable, efficient, good in sorting effect, high in adaptability, high in recovery index and low in production cost, thus being suitable for popularization and application.

Owner:JIANGXI UNIV OF SCI & TECH

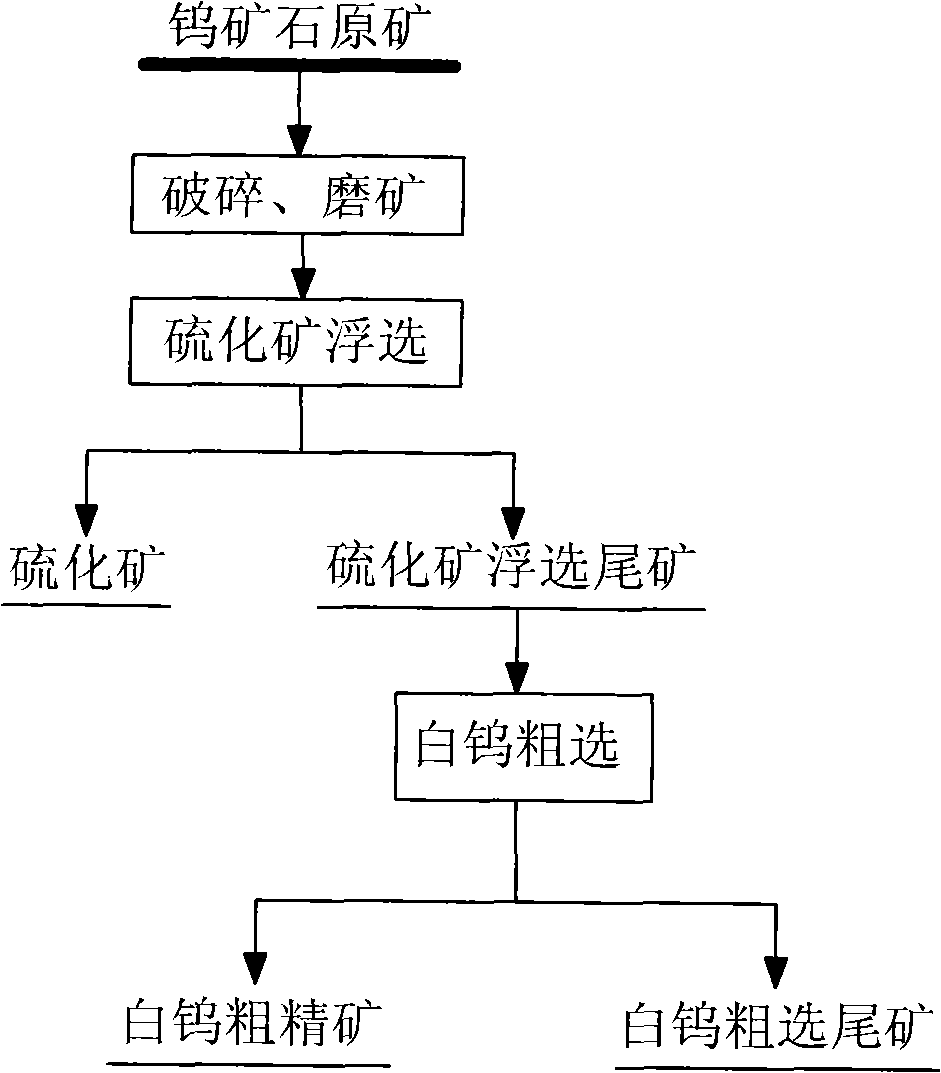

Beneficiation method for recycling scheelite from tungsten ore rich in mispickel

InactiveCN101269353AReduce dosageImprove rough selection indexFlotationSodium silicateMaterials science

The invention relates to an ore dressing method for recycling scheelite from tungsten ore which is rich in arsenopyrite. The method is characterized in that: (1) the flotation of sulphide ore is performed: the tungsten ore is crushed, ground and floated so as to obtain the sulphide ore and sulphide ore flotation tailing which are mainly composed of arsenopyrite; (2) the rough flotation of scheelite is performed: the sulphide ore flotation tailing is mixed with sodium carbonate and sodium silicate, then is added with a collector, namely, sulfating nascent soap; the scheelite concentrate and the coarse ore and the scheelite coarse flotation tailing are obtained by stirring, rough flotation, fine flotation and scavenging. The method provided by the invention is characterized in that the process is simple, the beneficiation reagent has low cost, the recovery rate of tungsten is high, and scheelite concentrate and coarse ore with the recovery rate of tungsten ranging from 80 to 90 percent and containing WO3 which accounts for 4 to 10 percent is obtained.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

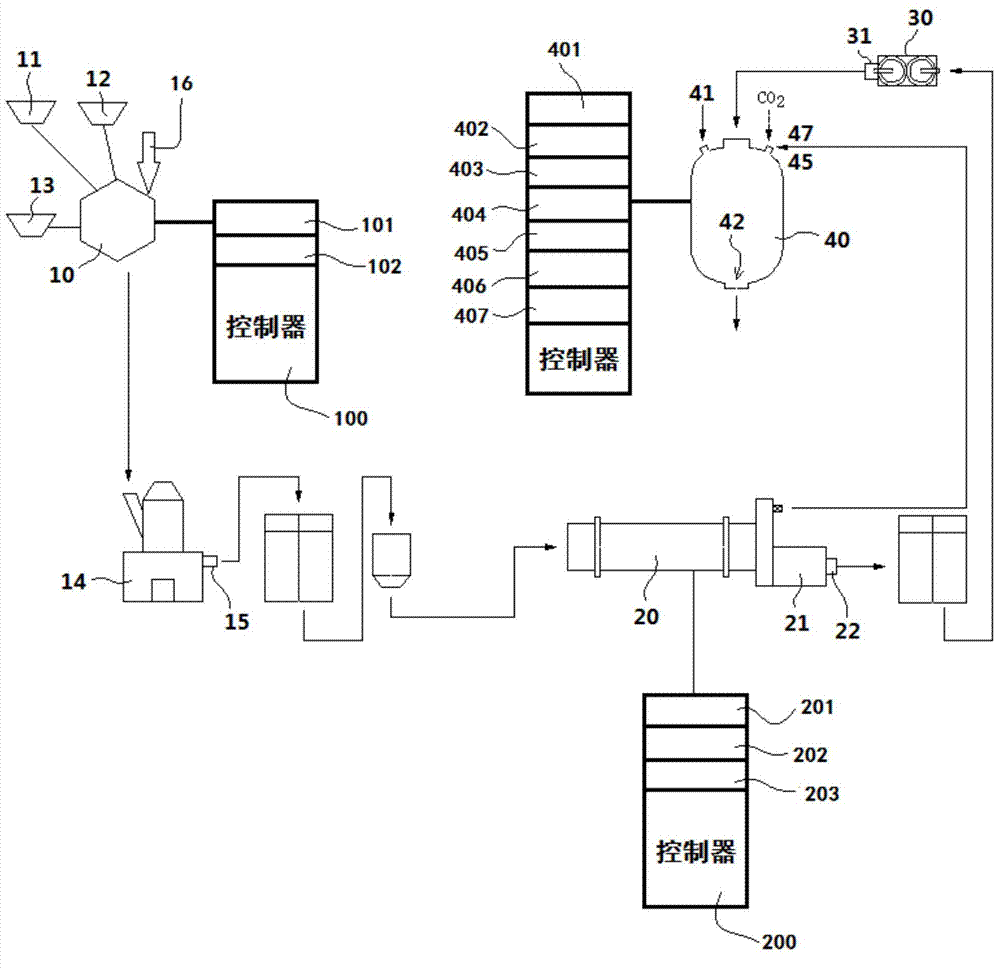

Composite bismuth vanadium photocatalyst supported by cobalt oxide and preparation method thereof

InactiveCN1806915AHigh densityLow costWater/sewage treatment by irradiationDispersed particle separationBismuth vanadateUltraviolet lights

The invention relates the method for preparation of pucherite composite photocatalyst loaded on cobalt oxide. The photocatalyst comprises semi-conductor pucherite particle and cobalt oxide particle. The pucherite is monoclinic crystal system scheelite structure, and the diameter is 100nm-5mum. The grain diameter of cobalt oxide is 10nm-1mum. The mass ratio of cobalt oxide and pucherite is 1-100mg / g. The specific surface area of composite photocatalyst is 0.5-5m2 / g. The said photocatalyst can effectively degrade the noxious and harmful chemical under the ultraviolet light, visible light and natural light radiating. And the photocatalyst is easy to separate and recover.

Owner:SHANGHAI JIAO TONG UNIV

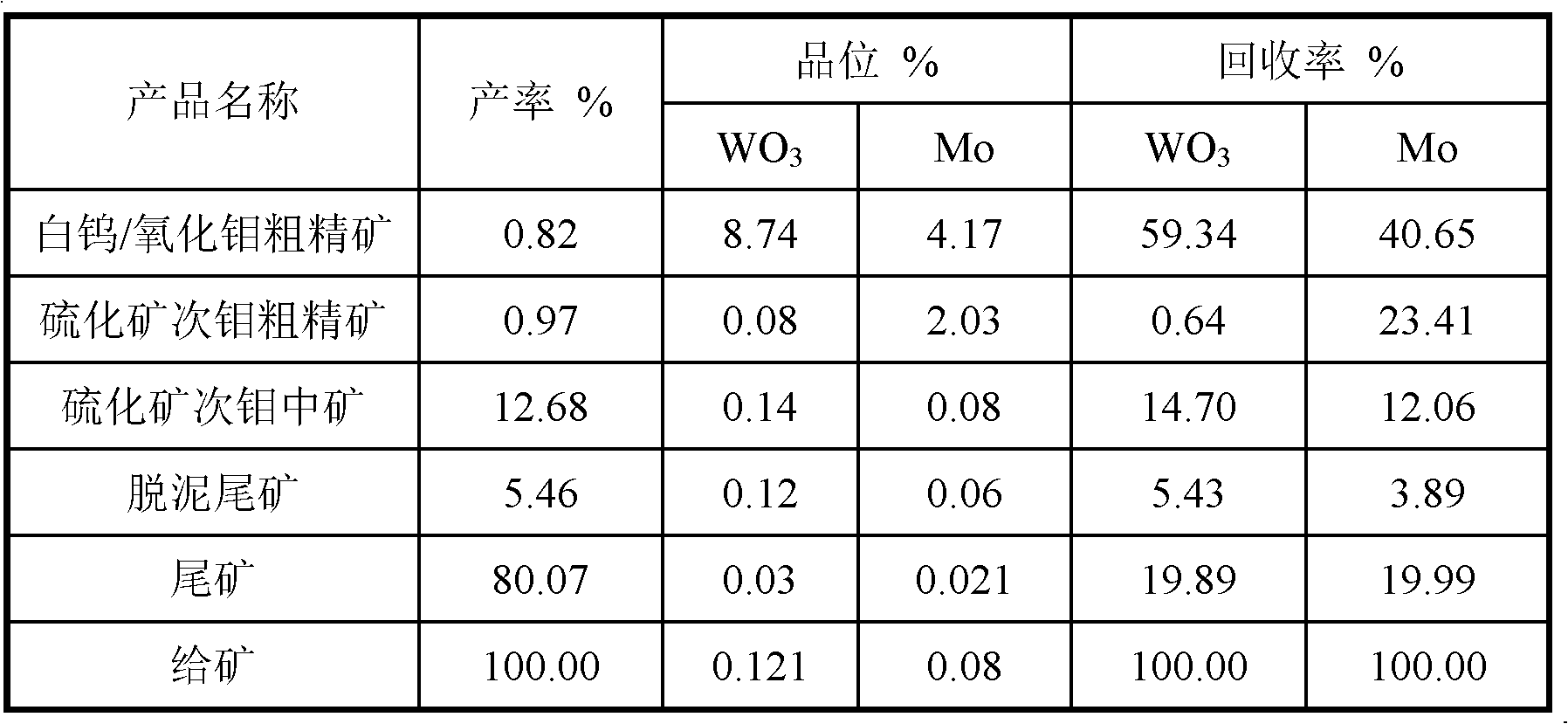

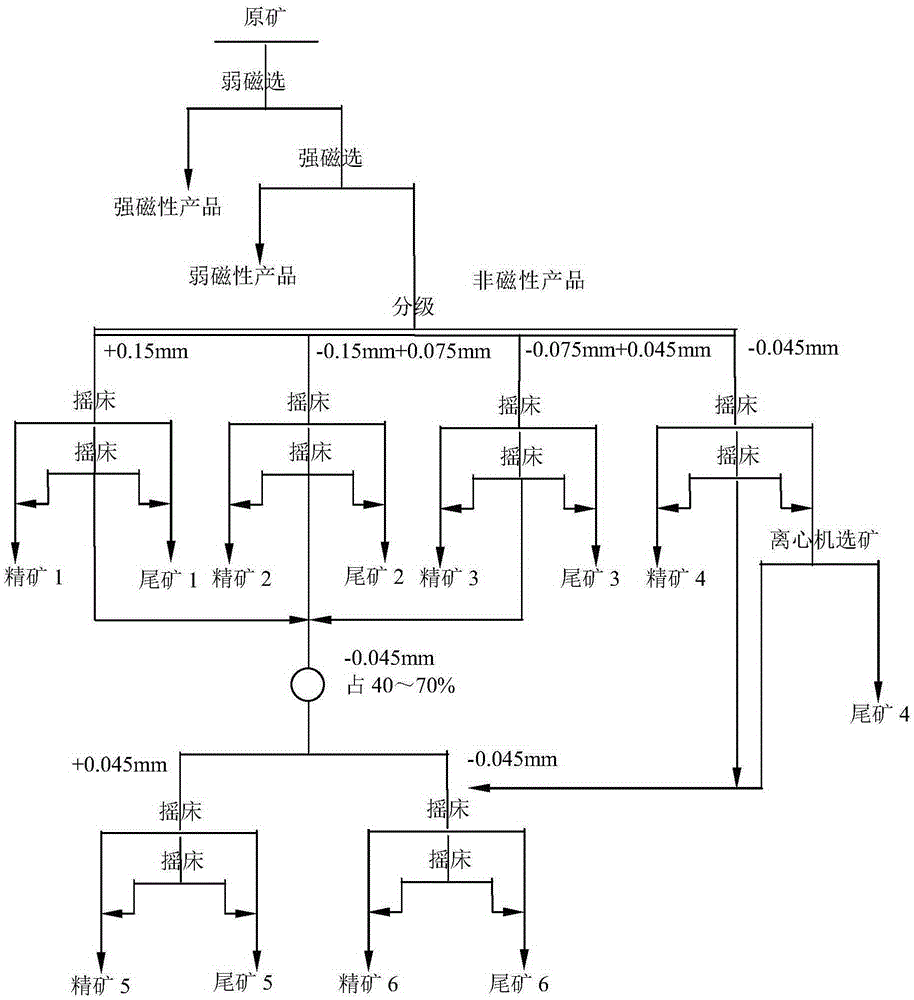

Mineral separation and enrichment method suitable for associated scheelite in molybdenite floatation tailings

InactiveCN105312148AReduce processingImprove sorting efficiencyMechanical material recoveryWet separationEnrichment methodsNon magnetic

The invention provides a mineral separation and enrichment method suitable for associated scheelite in molybdenite floatation tailings. The method includes the steps of low-intensity magnetic separation, high-intensity magnetic separation, non-magnetic ore pulp material size fraction grading, gravity separation, middling regrinding, regrading gravity separation and the like. A high-grade and high-recovery scheelite concentrate product is obtained, the associated low-grade scheelite resource in Cu-Mo polymetallic mixed associated ore is effectively and comprehensively recovered and used. The method can be widely applied to the field of recovering and using the associated low-grade scheelite resource.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Pretreatment method of tungsten mineral materials

ActiveCN104232942AImprove leaching effectAchieve cycleProcess efficiency improvementPretreatment methodDiammonium carbonate

Disclosed is a pretreatment method of tungsten mineral materials. The pretreatment method of the tungsten mineral materials is characterized by including the following steps of raw material preparation and clinker sintering, the raw material preparation includes that the tungsten mineral materials (scheelite, wolframite, scheelite and wolframite mixed mineral and / or tungsten fine silt) are mixed with a certain quantity of calcic substances and mineralizer to be finely ground to obtain raw materials, and the clinker sintering includes that the prepared raw materials are calcinated under special conditions to obtain clinker. The pretreatment method of the tungsten mineral materials has the advantages that the adaptability is wide, and the method is suitable for all tungsten mineral materials, especially scheelite; (2) added calcic substances are cheap and easy to obtain; (3) the calcination temperature is low, the operation is simple, and the industrial application is easy; (4) tungsten in the obtained clinker is good in leaching performance, fully leaching can be achieved by a sodium carbonate solution or an ammonium carbonate salt solution at low temperature, especially when leaching is performed by the ammonium carbonate salt solution, the economical circulation of the solution during APT production can be achieved, and thereby, discharging of wastewater during production can be eliminated.

Owner:CENT SOUTH UNIV +1

Surfactant hydrothermal method for preparing leaf-shaped, tubular and paraphlomis-kwangtungensis-shaped BiVO4

InactiveCN101746823ASave raw materialsSimple processVanadium compoundsHydrogen NitrateAmmonium metavanadate

The invention discloses a surfactant hydrothermal method for preparing leaf-shaped, tubular and paraphlomis-kwangtungensis-shaped BiVO4. The method comprises the steps that: bismuth nitrate, ammonium metavanadate, hydrogen nitrate, and triblock copolymer P123 are resolved in hydrogen nitrate aqueous solution with a concentration of 2mol / L under the stirring condition, then 14 percent of ammonia water by weight is added drop by drop, the pH of the obtained solution is adjusted to 9, the solution containing yellow precipitate is transferred to a stainless steel gravity reactor the lining of which is made from polyfluortetraethylene and is placed and treated in an incubator at a temperature of 180 DEG C for 6 hours, the solution naturally cools down to the room temperature after being taken out, the product obtained after treatment is dried at a temperature of 60 DEG C for 12 hours and then is sintered to obtain the leaf-shaped BiVO4 micron particles with monocline scheelite structure. In the surfactant hydrothermal method, the obtained samples when treated with a pH of 10 in the incubator at a temperature of 180 DEG Care tubular pucherite micron particles with monocline scheelite structure; the obtained samples when treated with a pH of 3 in the incubator at a temperature of 80 DEG C are paraphlomis-kwangtungensis-shaped pucherite micron particles. The surfactant hydrothermal method for preparing leaf-shaped, tubular and paraphlomis-kwangtungensis-shaped BiVO4 are characterized by cheap raw materials, simple process, controllable target product particle shape and crystalline structure, etc.

Owner:BEIJING UNIV OF TECH

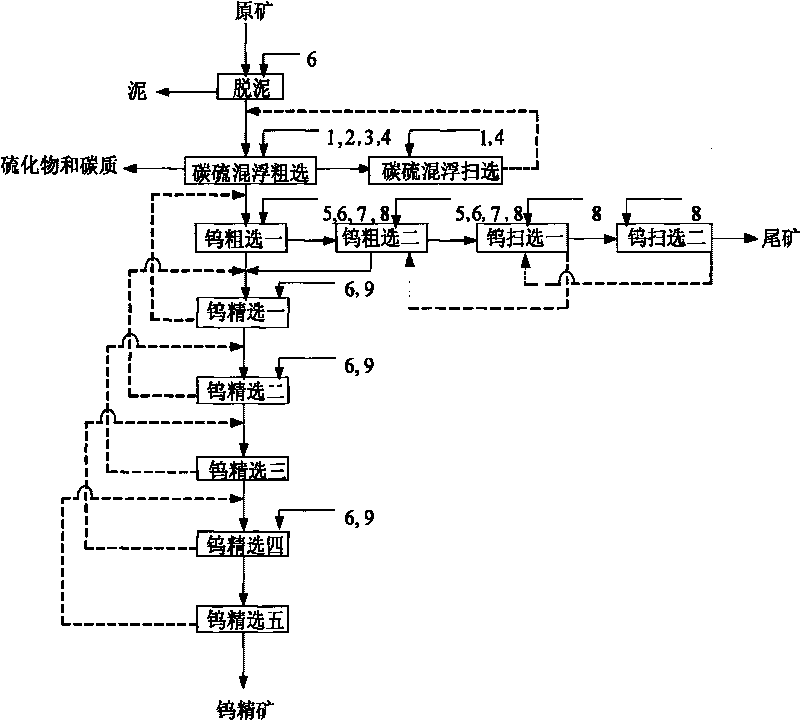

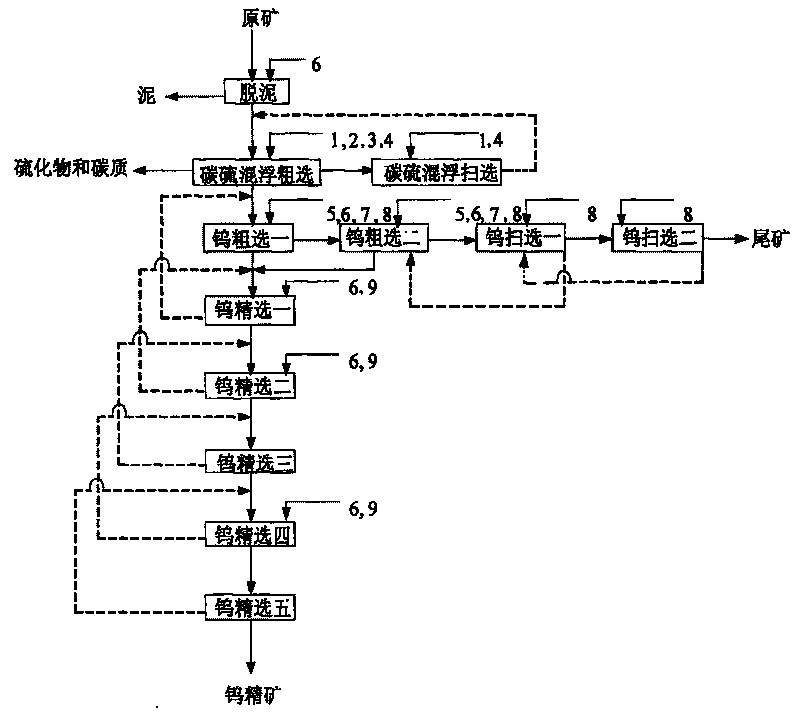

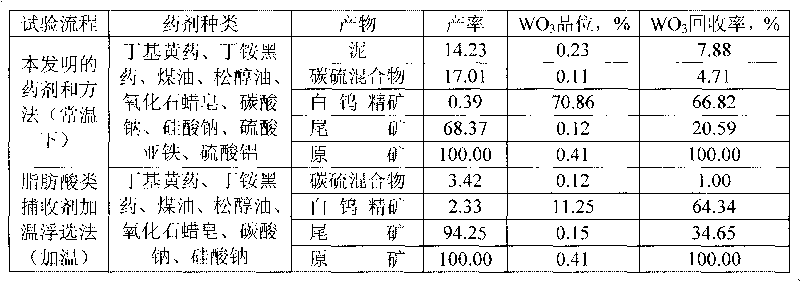

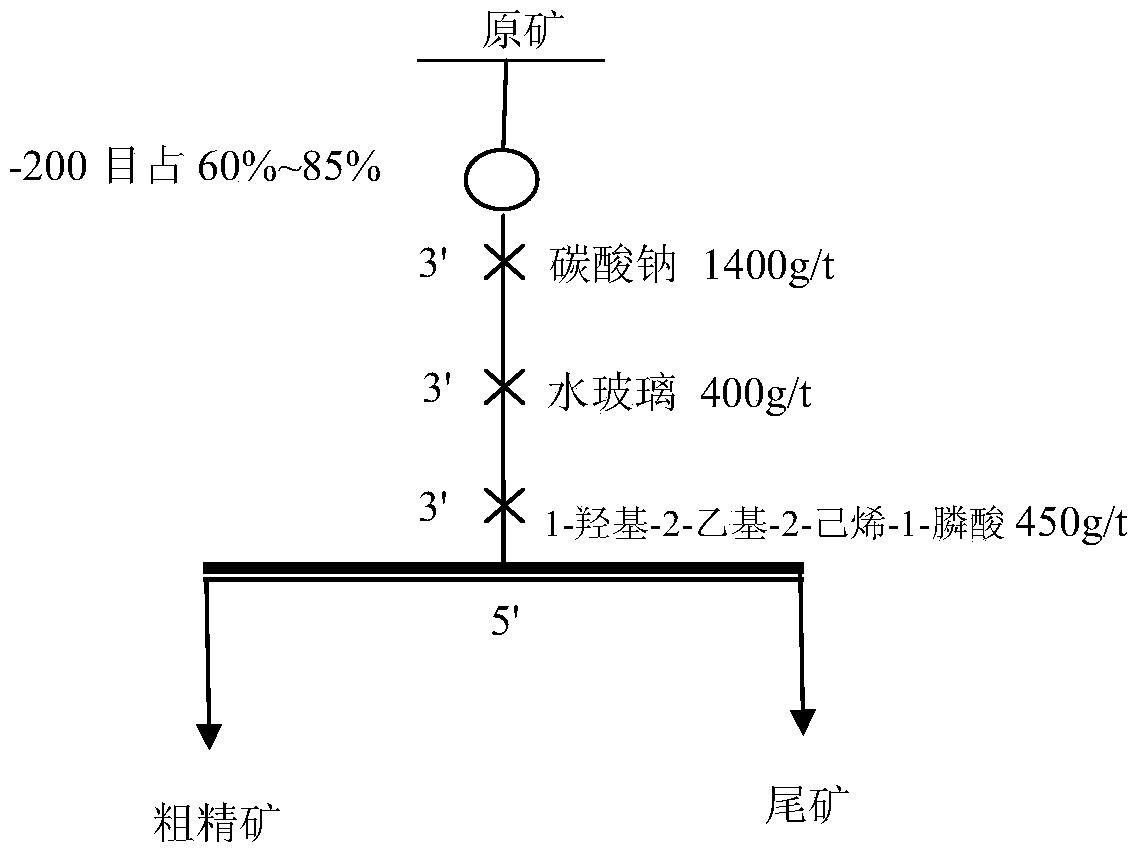

Beneficiation reagent and method for separating scheelite from complex tungsten ore

The invention relates to a beneficiation reagent and a method for separating scheelite from complex tungsten ore; the beneficiation reagent adopts oxidized paraffin soap, kerosene, butyl xanthate, dithiophosphate BA as collectors, adopts sodium carbonate as modifier and terpenic oil as foaming agent, and also adopts one or the combination of Sodium silicate and ferrous sulfate or aluminum sulfate as inhibitor; the method employing the beneficiation reagent for separating scheelite from complex tungsten ore includes: desliming in normal temperature, carbon-sulfide bulk rough floatation, secondary tungsten rough floatation and quintic tungsten concentration, so tailings and tungsten concentrate product are obtained; besides, the invention has the advantages of high sorting efficiency, high yield rate, wide reagent resource, low price, low cost and dosage, simple and reliable process, easy operation and normal temperature working, and is particularly applicable to the beneficiation application of complex tungsten ores.

Owner:ZIJIN MINING GROUP

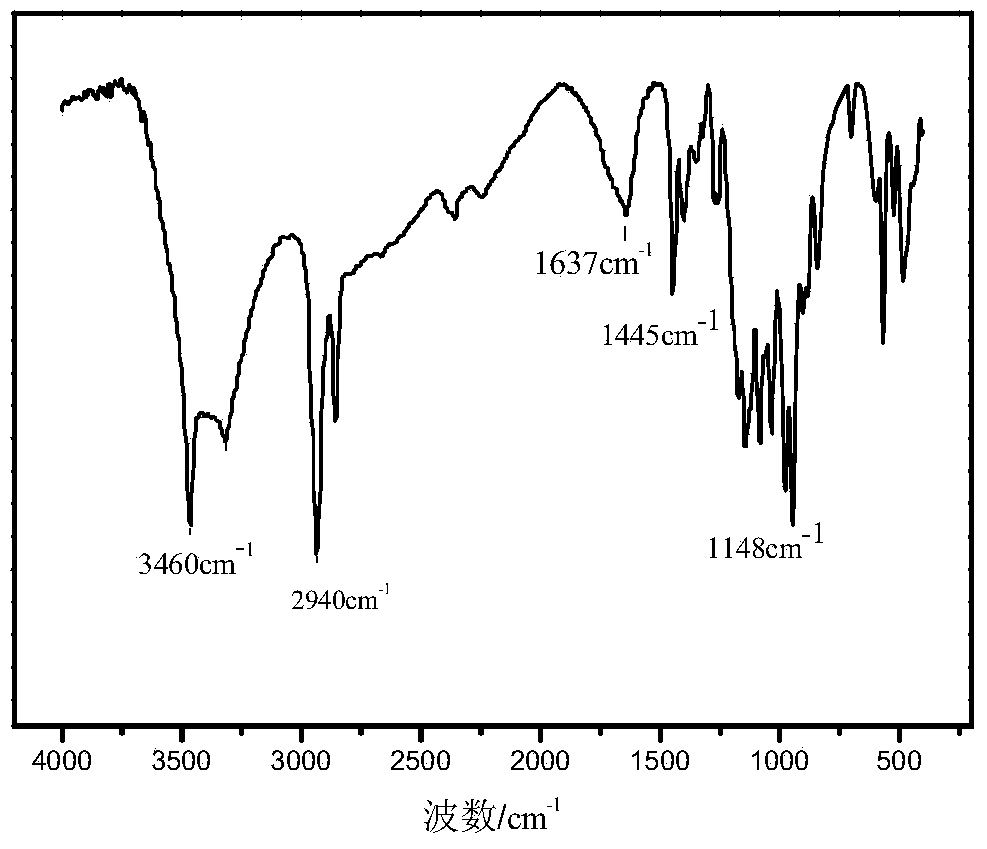

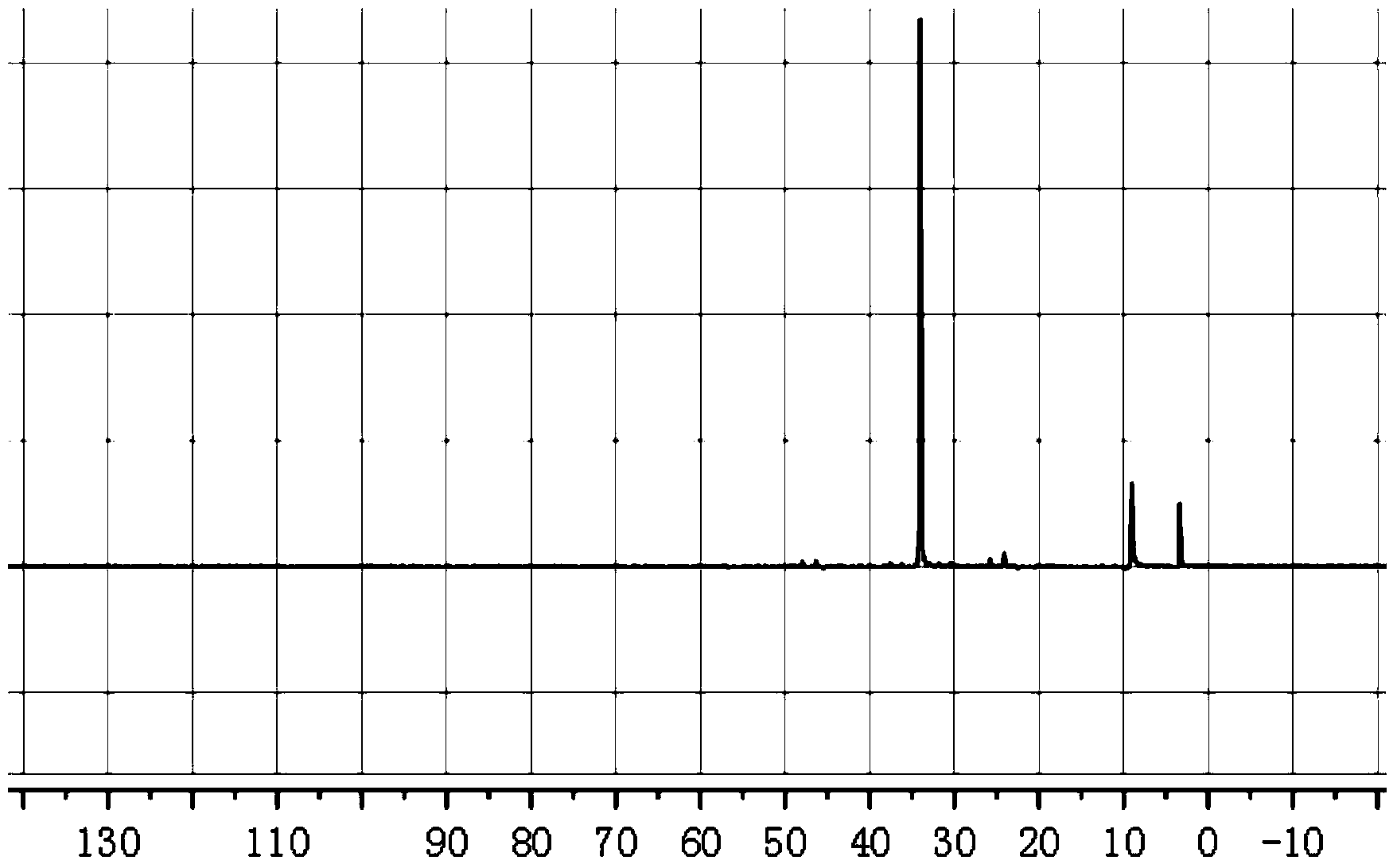

Alpha-hydroxy unsaturated alkylphosphonic acid compound as well as preparation method and application of alpha-hydroxy unsaturated alkylphosphonic acid compound

ActiveCN103613614AConducive to hydrophobizationStrong harvesting abilityGroup 5/15 element organic compoundsFlotationPhosphorous acidRare earth

The invention discloses an alpha-hydroxy unsaturated alkylphosphonic acid compound as well as a preparation method and application of the alpha-hydroxy unsaturated alkylphosphonic acid compound. The alpha-hydroxy unsaturated alkylphosphonic acid compound has the structural formula I as shown in the specification. The preparation method comprises the steps: subjecting 2-ethyl-2-hexenal and hypophosphorous acid or hypophosphite to addition reaction in the existence of an acid catalyst to generate 1-hydroxyl-2-ethyl-2-hexenyl-1-phosphorous acid; subjecting 1-hydroxyl-2-ethyl-2-hexenyl-1-phosphorous acid and an oxidizing agent to reaction to generate 1-hydroxyl-2-ethyl-2-hexenyl-1-phosphonic acid. 30-600g / t of 1-hydroxyl-2-ethyl-2-hexenyl-1-phosphonic acid is used as a flotation collector for bauxite, ilmenite, rutile, scheelite, wolframite, rare earth ores, tin ores, fluorite ores or lithium ores, and the pH value of a flotation solution is controlled at 4-12, so that a target ore and a gangue mineral can be effectively separated.

Owner:CENT SOUTH UNIV

Method for extracting tungsten from wolframite or scheelite and wolframite mixture ore through adding of high-phosphorus scheelite

The invention provides a method for tungsten from wolframite or scheelite and wolframite mixture ore through adding of high-phosphorus scheelite. In the ore grinding process of tungsten mineral raw materials (wolframite or scheelite and wolframite mixture ore), the high-phosphorus scheelite is added, fine grinding and pulp mixing are carried out, and obtained ore pulp is decomposed through phosphoric acid-sulfuric acid; after the reaction is finished, the tungsten is extracted from an obtained leaching agent, then, sulfuric acid is supplemented again, and mineral leaching is carried out again. The method has the advantages that the limitation that a sulfuric acid-phosphoric acid mixing system cannot treat the wolframite and the scheelite and wolframite mixture ore is broken through, and the wolframite and the scheelite and wolframite mixture ore is efficiently decomposed at the constant temperature and constant pressure under the system; phosphorus in the high-phosphorus scheelite can be comprehensively utilized, and meanwhile, the decomposing rate of the tungsten ore can reach more than 97 percent; the added phosphorus can generate phosphoric acid in the decomposing process, the method can be used for making up the phosphoric acid consumed in the decomposing process, energy is saved, and the leaching cost is reduced; and the whole technological process is convenient to operate, and the industrialization is easily achieved.

Owner:CENT SOUTH UNIV

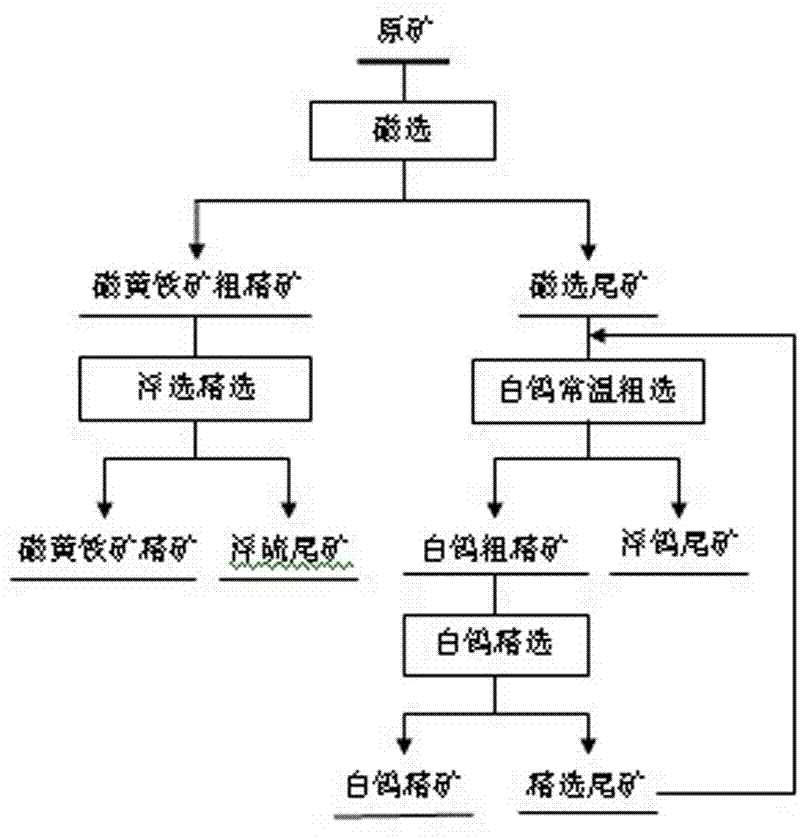

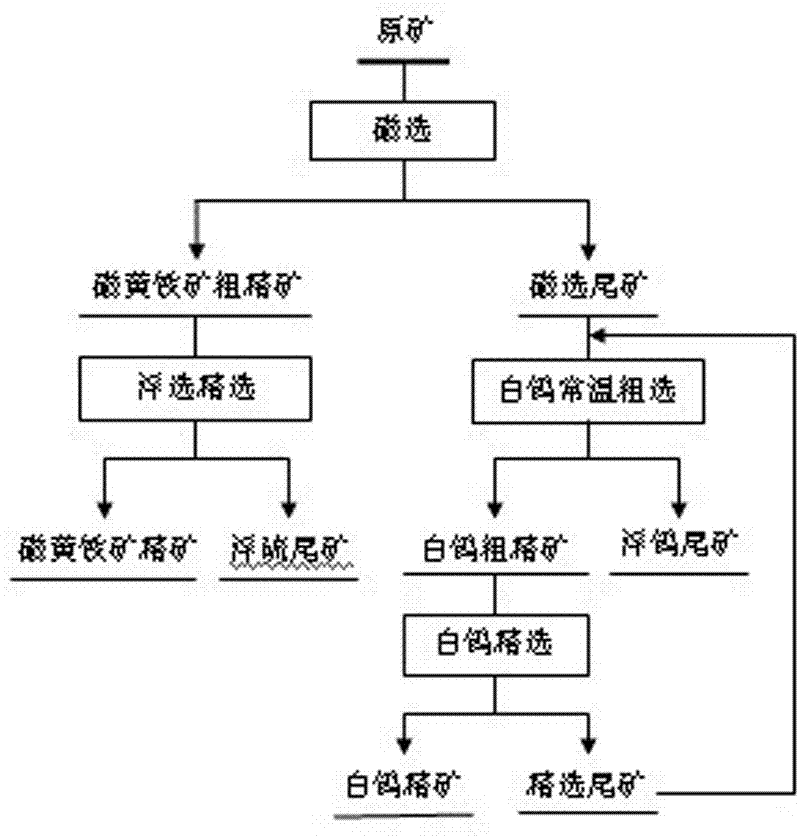

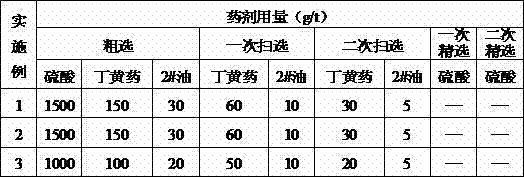

Mineral separation method for scheelite containing rich pyrrhotite

The invention discloses a mineral separation method for scheelite containing rich pyrrhotite, which comprises the following steps of: magnetically separating to obtain pyrrhotite rough concentrates and magnetically separated tailings; roughly separating, secondarily scavenging and secondarily blankly finely separating the pyrrhotite rough concentrates to obtain pyrrhotite concentrates and floating sulfur tailings; roughly separating, secondarily scavenging and secondarily finely separating the magnetically separated tailings to obtain white tungsten rough concentrates and floating tungsten tailings; and concentrating the white tungsten rough concentrates, carrying out floatation at normal temperature or the temperature of 80-100 degrees centigrade to obtain white tungsten concentrates and cleaner tailings. The method disclosed by the invention eliminates the influence caused by the pyrrhotite which is difficultly removed in the traditional flotation method, not only guarantees the quality of the tungsten concentrates but comprehensively recovers the pyrrhotite, and is suitable for mineral separation of the scheelite containing rich pyrrhotite.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com