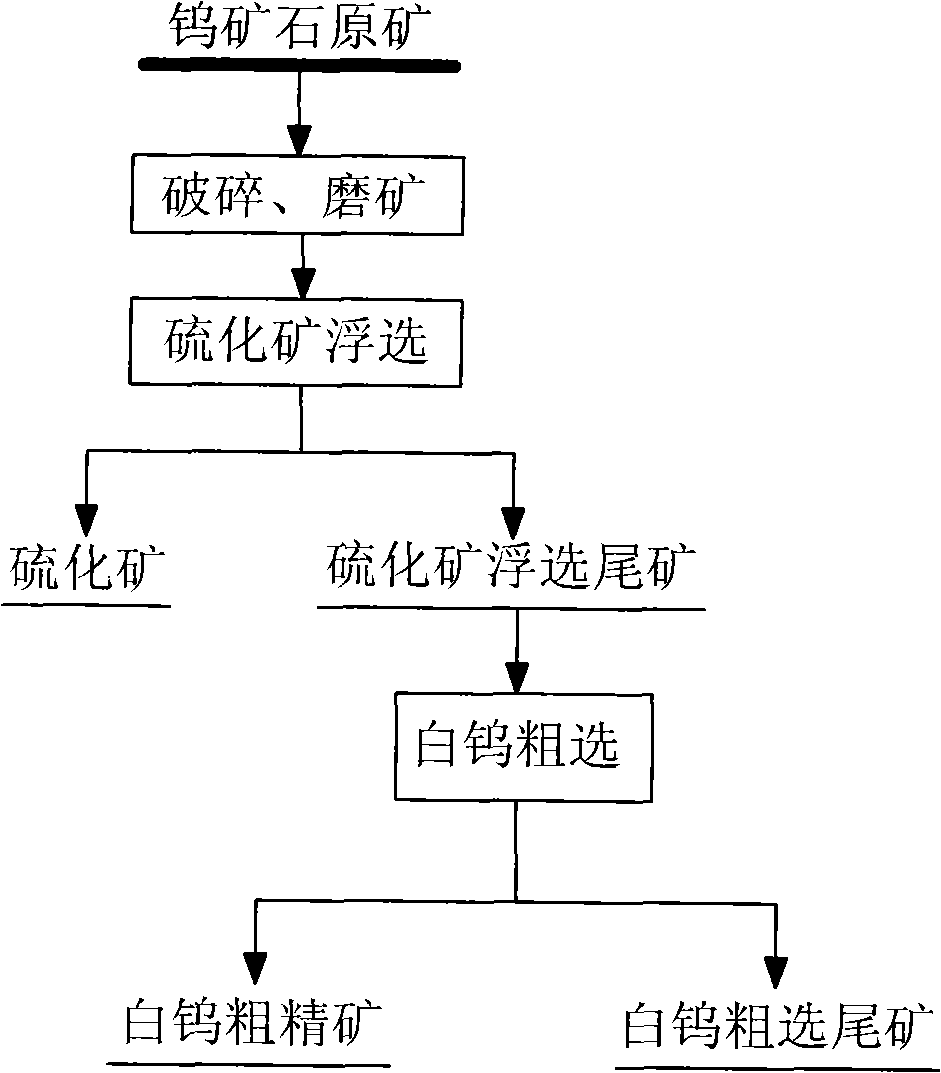

Beneficiation method for recycling scheelite from tungsten ore rich in mispickel

A beneficiation method and tungsten ore technology are applied in the field of beneficiation for recovering scheelite, which can solve the problems of low tungsten beneficiation recovery rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

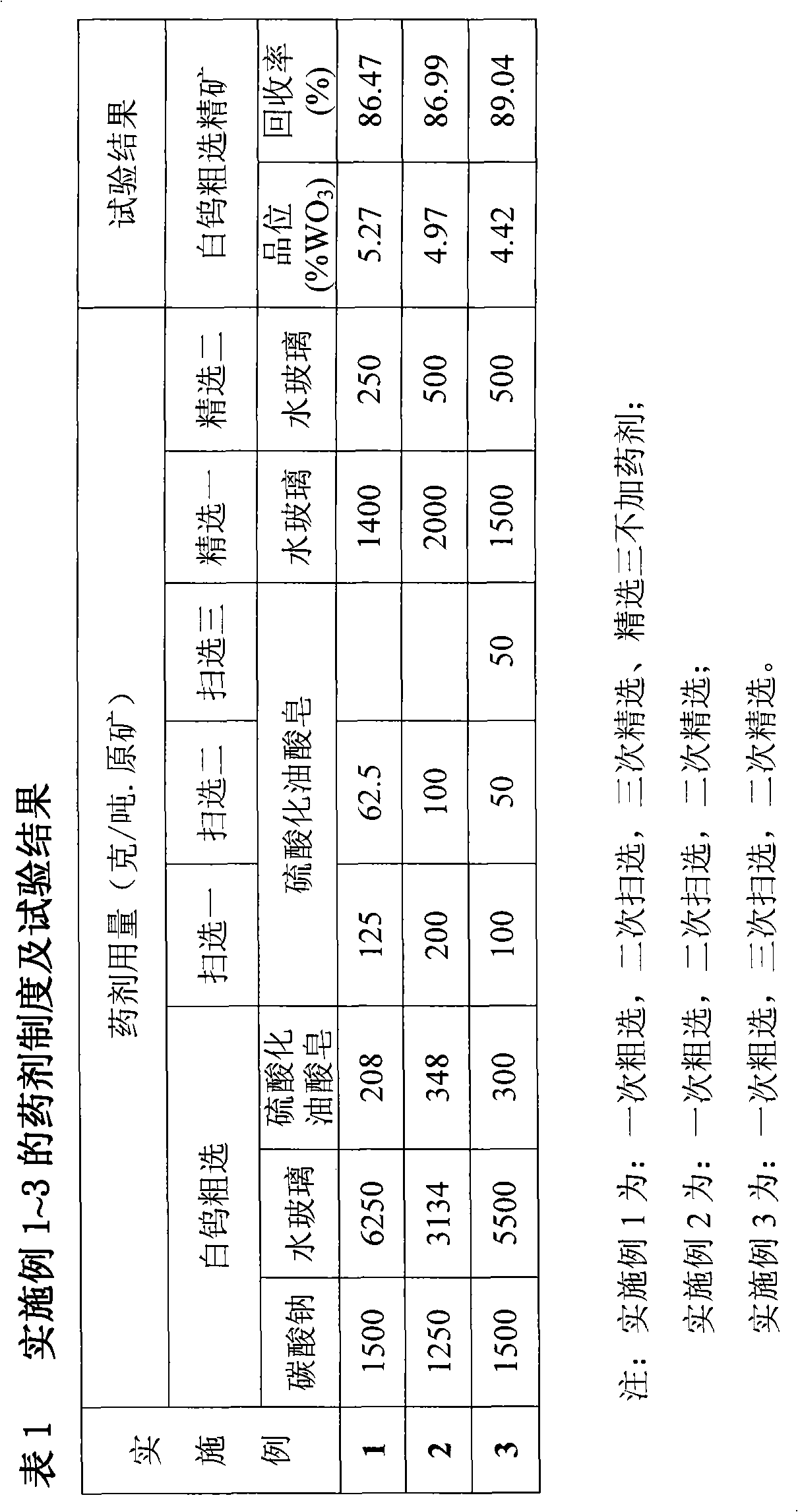

Embodiment 1

[0009] Embodiment 1: Tungsten ore raw ore contains WO 3 0.30%, As 2.86%. According to the pharmaceutical system listed in Table 1, after adding sodium carbonate and water glass to adjust the slurry, add the collector sulfated oleic acid soap, stir for 2 minutes, and go through 1 rough selection, 2 selections, and 3 sweeps to obtain white powder. Tungsten coarse concentrate containing WO 3 5.27%, recovery rate 86.47%.

Embodiment 2

[0010] Embodiment 2: Tungsten ore raw ore contains WO 3 0.36%, As 5.81%. According to the medicament system listed in Table 1, after adding sodium carbonate and water glass to adjust the slurry, add the collector sulfated oleic acid soap, stir for 5 minutes, and after 1 rough selection, 2 selections, and 2 sweeps, white powder is obtained. Tungsten coarse concentrate containing WO 3 4.97%, the recovery rate is 86.99%.

Embodiment 3

[0011] Embodiment 3: Tungsten ore raw ore contains WO 3 0.35%, As 4.82%. According to the medicament system listed in Table 1, after adding sodium carbonate and water glass to adjust the slurry, add the collector sulfated oleic acid soap, stir for 8 minutes, and through 1 rough selection, 2 selections, and 3 sweeps, white powder is obtained. Tungsten coarse concentrate containing WO 3 4.42%, the recovery rate was 89.04%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com