Patents

Literature

118 results about "Diopside" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diopside is a monoclinic pyroxene mineral with composition MgCaSi₂O₆. It forms complete solid solution series with hedenbergite (FeCaSi₂O₆) and augite, and partial solid solutions with orthopyroxene and pigeonite. It forms variably colored, but typically dull green crystals in the monoclinic prismatic class. It has two distinct prismatic cleavages at 87 and 93° typical of the pyroxene series. It has a Mohs hardness of six, a Vickers hardness of 7.7 GPa at a load of 0.98 N, and a specific gravity of 3.25 to 3.55. It is transparent to translucent with indices of refraction of nα=1.663–1.699, nβ=1.671–1.705, and nγ=1.693–1.728. The optic angle is 58° to 63°.

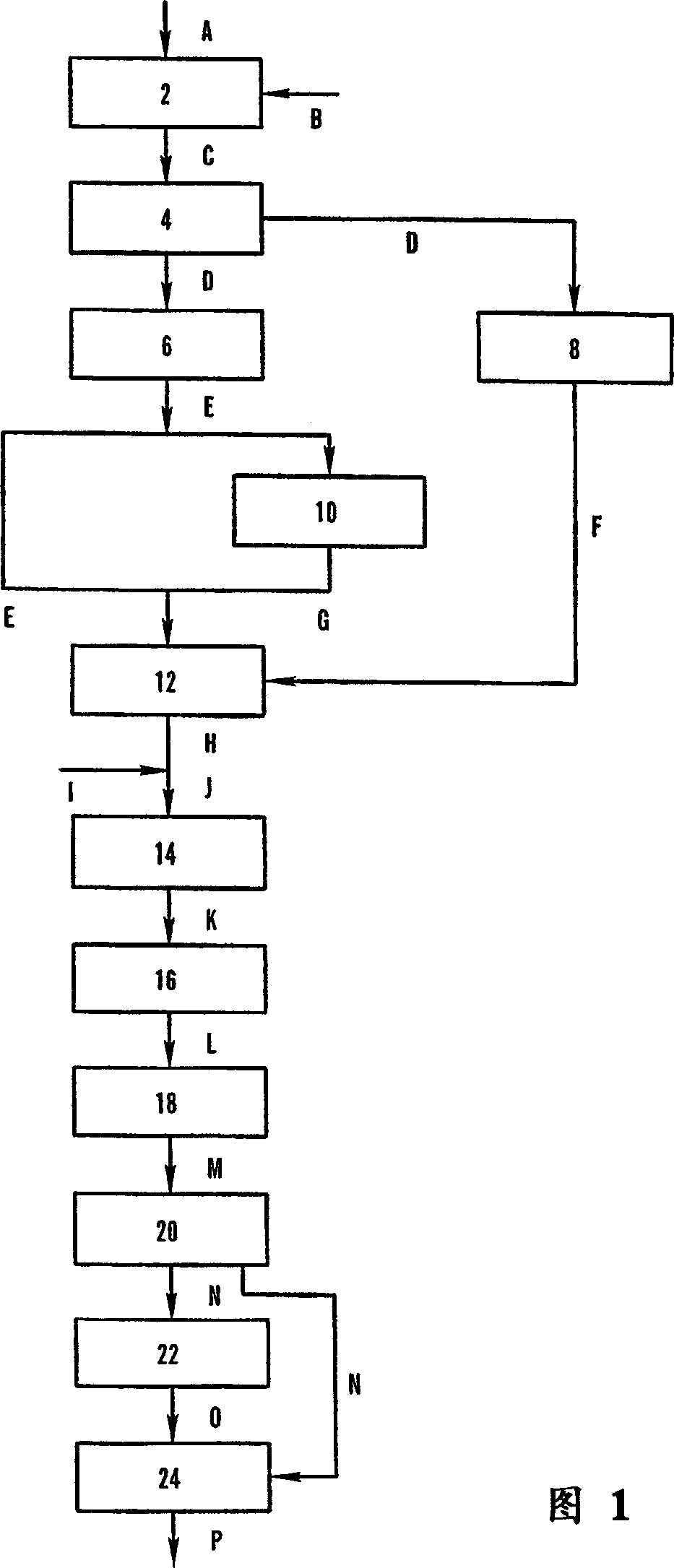

Method for producing microcrystalline glass-ceramics composite board with novel microcrystalline phase

The invention discloses a method for producing a microcrystalline glass-ceramics composite board with novel microcrystalline phase, which is characterized in that the composite board takes diopside-containing pyroxene as microcrystalline phase and the production method thereof comprises the steps as follows: firstly, microcrystalline glass granules are prepared; according to the weight percentage, the microcrystalline glass consist of 50-65% of SiO2, 5-25% of Al2O3, 5-20% OF CaO, 2-10% of MgO, 1-8% of K2O+NaO, 0-1% of Li2O, 0-8% of BaO, 0-8% of B2O3 and the balance of nucleating agent, clarifier and corant with the content ranging from 0 to 20%; secondly, a ceramic palette board is prepared; according to the weight percentage, the ceramic palette board comprises 66-75% of SiO2, 13-23% of Al2O3, 0.3-3% of CaO+MgO, 3-8% of K2O+Na2O and the balance of 0-2% of auxiliary raw material; finally, the raw materials are distributed, sintered and post-processed, thus gaining the finished product of the microcrystalline glass-ceramics composite board. The method has the advantages of low production cost, high product quality, good appearance effect, and the like.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

Low temperature semi-porcelain and its preparation method

The invention relates to a low-temperature semi-ceramic, which comprises: 50-65% clay of Al2O32SiO22H2O, 0-10% fine ceramic waste, 3-20% lithium China stone, 3-25% diopside, 5-20% talc, and 0-15% feldspar. Wherein, breaking the hard material, removing impurity; preparing material according to said weight share; grinding material, ball stone and water as proportion of 1:1.8-2:0.8 for 18-20h; screening off iron from 250 items sieve with residue under 0.2wt%; pressure filtering, forming; colored drawing on blank; glazing; finally, using low-temperature one-time calcination technique at 1020-1030Deg with oxidation atmosphere for 5-6h. This invention has well property, and decreases greatly energy consumption.

Owner:揭阳恒成陶瓷科技有限公司

Iron tailing far-infrared ceramic material and preparation method thereof

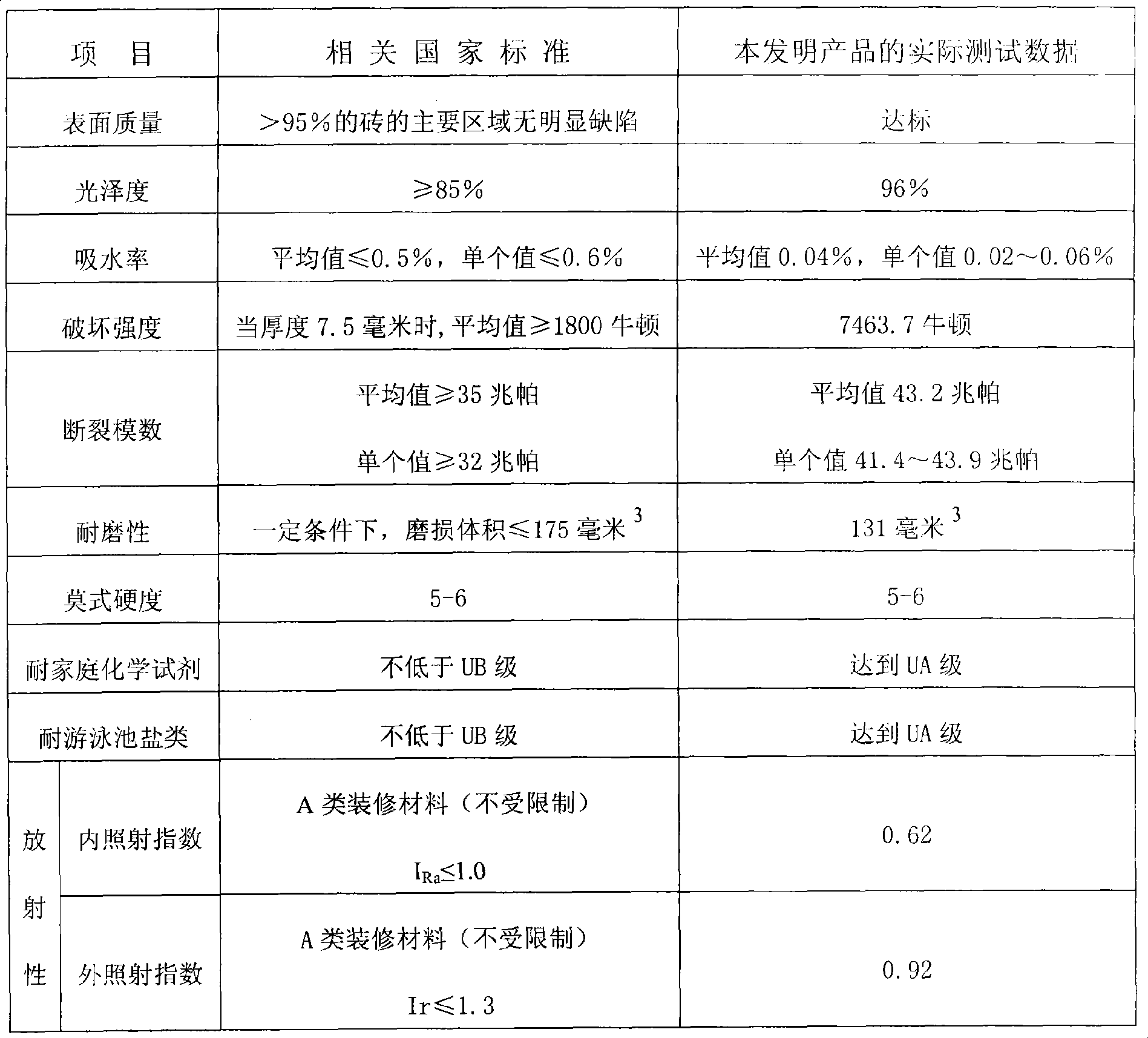

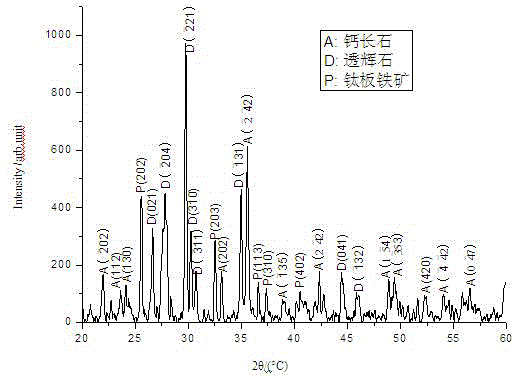

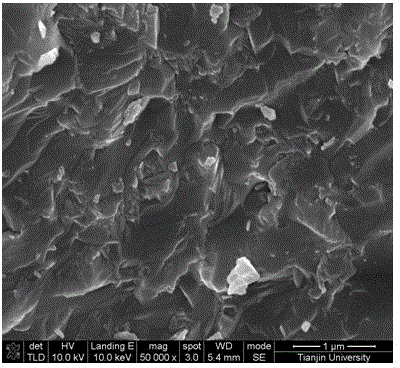

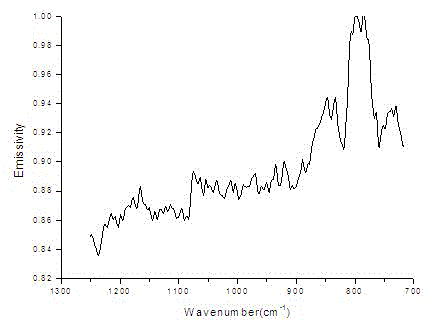

The invention discloses an iron tailing far-infrared ceramic material and a preparation method thereof. The ceramic material is characterized by being prepared from the following components in percentage by weight: 35-75% of iron tailings, 1-9% of clay, 11-25% of silicon dioxide, 11-25% of calcium carbonate and 2-6% of aluminum oxide, wherein the sum of the percentage of the components is 100%; the iron tailing comprises the following main components: 30-35% of SiO2, 20-25% of Fe2O3, 10-15% of Al2O3, 10-15% of TiO2 and a small amount of CaO, Na2O and MgO, and the sum of percentage of the components is 100%; XRD shows that the main components of the ceramic material are anorthite, diopside and titanium sheet iron ore. According to the preparation method, the iron tailing, the clay, silicon dioxide, calcium carbonate and aluminum oxide are used as raw materials, and are subjected to ball-milling, screening, allocation, stirring, drying, mixing, dry pressing forming and sintering, thereby preparing the iron tailing far-infrared ceramic material.

Owner:南京中蓝智能科技有限公司

Alumina-based biologic active ceramic composite material

InactiveCN101250058AImprove mechanical propertiesImprove biological activityCeramic compositeNitrogen gas

The invention relates to an aluminum dioxide substrate biological active ceramic composite material with better mechanical properties and biological activity, belonging to the technical field of bioceramic material, which contains 80-99% of aluminum dioxide and 1-20% of diopside, referring to mass percentage. The preparation method comprises using aluminum dioxide balls to ball grind mixed raw materials, screening the powder material via a screen of 100 meshes to prepare mixed powder, arranging the mixed powder into a graphite mould to be died and shaped, thermally pressing and sintering in nitrogen gas or argon gas, while the sintering temperature is 1400-1500DEG C, sintering pressure is 25-30MPa, keeping the temperature and pressure for 30-40min. Tests prove that the sample immersed in simulated body fluid has much carbonate hydroxyapatite sediment generated at surface and the composite material has better biological activity. The composite material has simple preparation, low material cost, low production investment and wide application for the preparation of artificial bone.

Owner:张木蕃

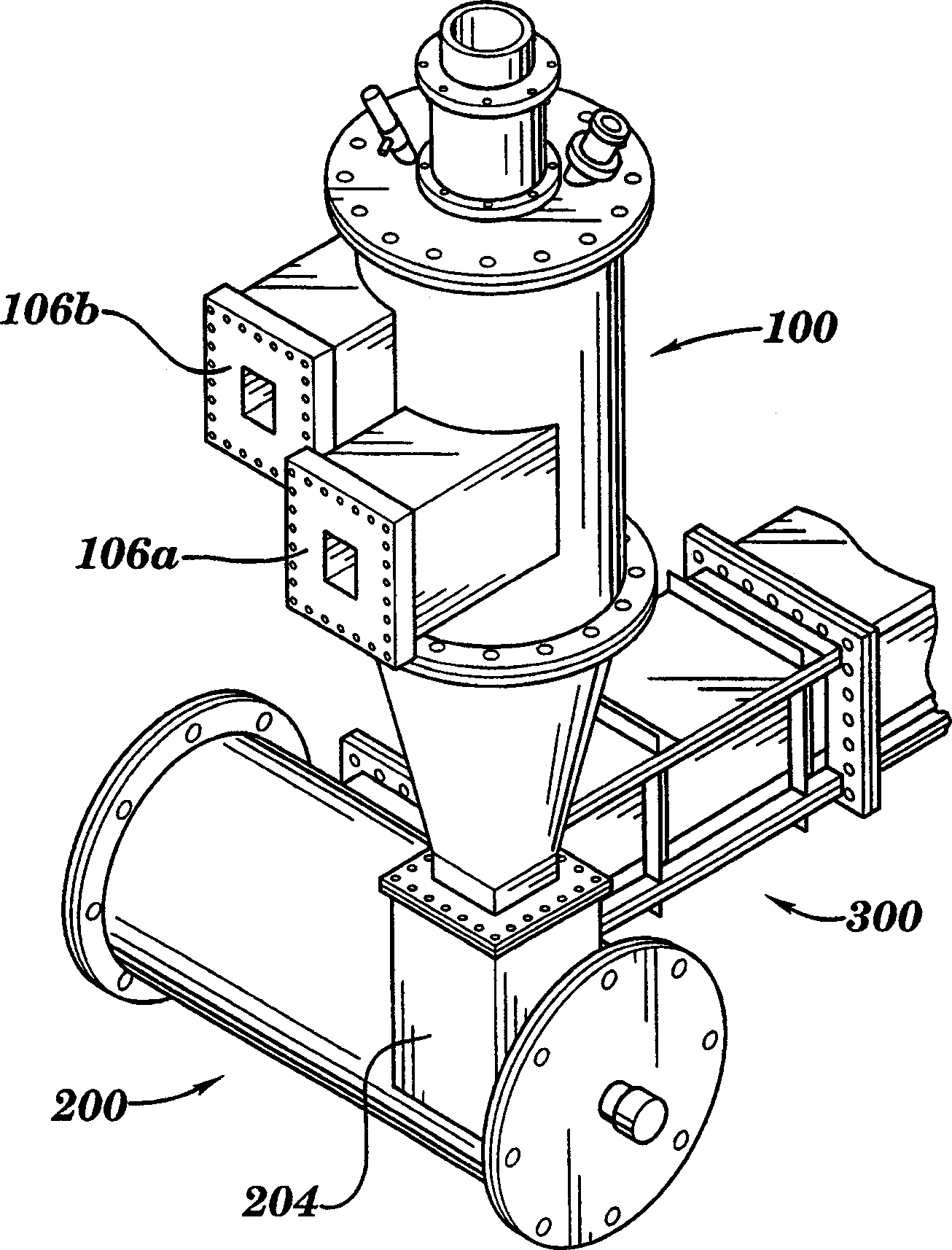

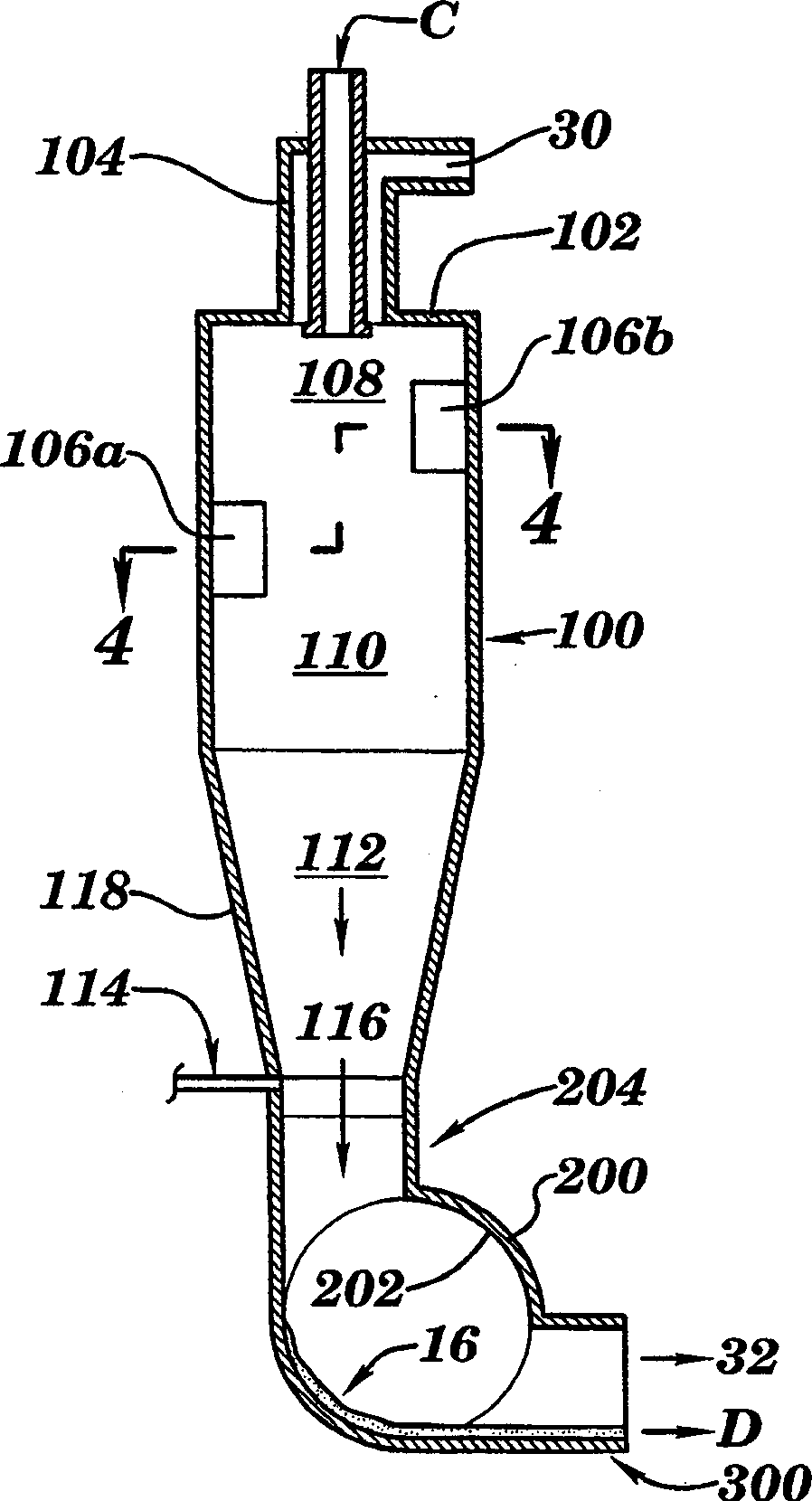

Manufacture of ceramic tiles from industrial waste

The present inveniton relates to a process of forming ceramic tiles having the appearance of tiles produced from clays. The process includes melting a material to form a glass melt, treating the glass melt to produce a solid glass product, grinding the solid glass product to produce glass particles having a particle size of less than 200 microns, mixing the glass particles with a first additive to form a glass power mixture having a composition of 55 to 99 wt.% glass particles and 45-1 wt.% first additive, forming the glass powder mixture into tiles by dry pressing, where the tiles have a primary crystalline phase selected from the group consisting of nepheline, diopside, anorthite, wollastonite, melilite, merwinite, spinel, akermanite, gehlenite, crystalline phases based on iron substitutions in the crystalline phase, and mitures thereof. The process includes a devitrifying step where the solid glass product is devitrified prior tothe grinding step or the glass particles in the tile are devitrified after the forming step.

Owner:沃特克有限公司 +1

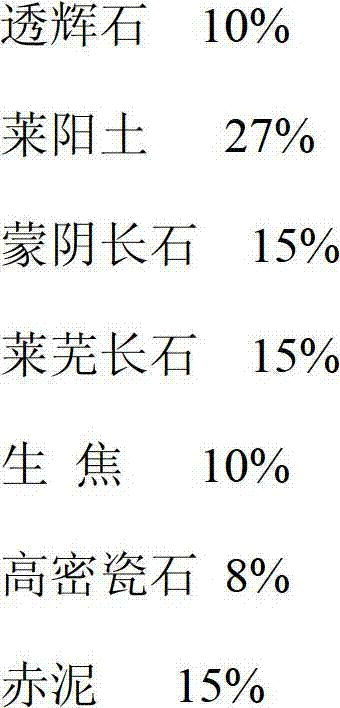

Method for producing architectural ceramic from red mud

ActiveCN102850040AReduce pollutionReduce manufacturing costCeramic materials productionClaywaresHigh densityRed mud

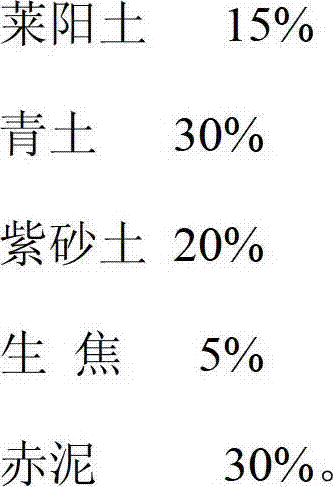

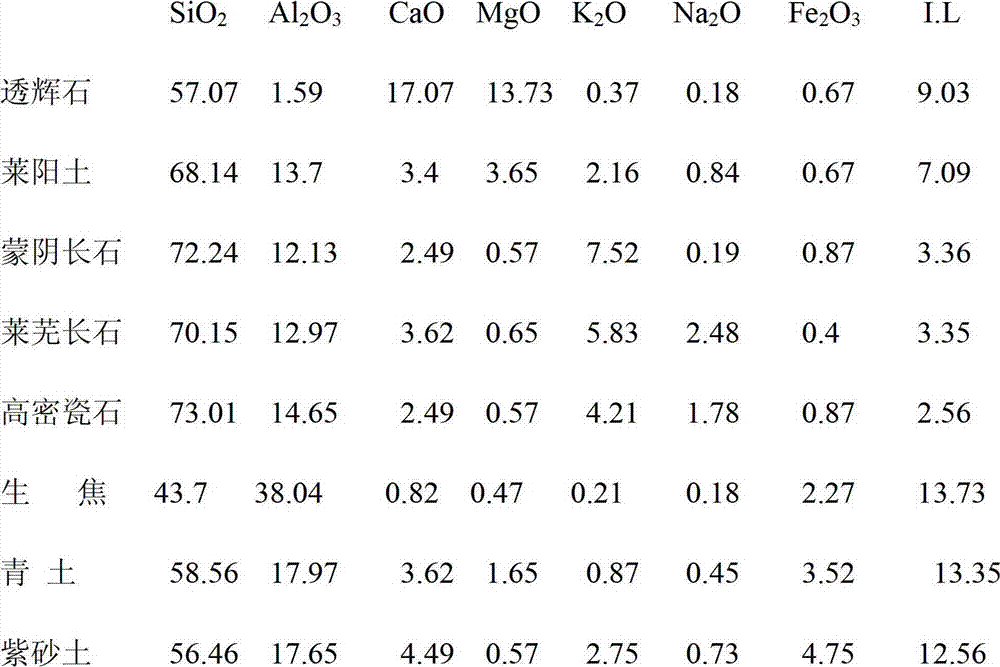

The invention relates to a method for producing architectural ceramic from red mud, belonging to the field of ceramic preparation methods. The invention is characterized in that the archaized tile produced from red mud is prepared from the following raw materials in percentage by mass: 10% of diopside, 27% of Laiyang soil, 15% of Mengyin feldspar, 15% of Laiwu feldspar, 10% of green coke, 8% of high-density porcelain stone and 15% of red mud; and waste billet which accounts for 5% by mass of the total materials is also added. The red mud is added in production, the technological formula can be adjusted to overcome the defects in the red mud, so that the raw materials containing red mud satisfy the technological requirements for producing ceramic tiles and tiles, and the product can satisfy the Chinese standard, thereby changing wastes into valuable substances, utilizing the waste, lowering the production cost and reducing the environmental pollution.

Owner:淄博乐陶仕节能科技有限公司

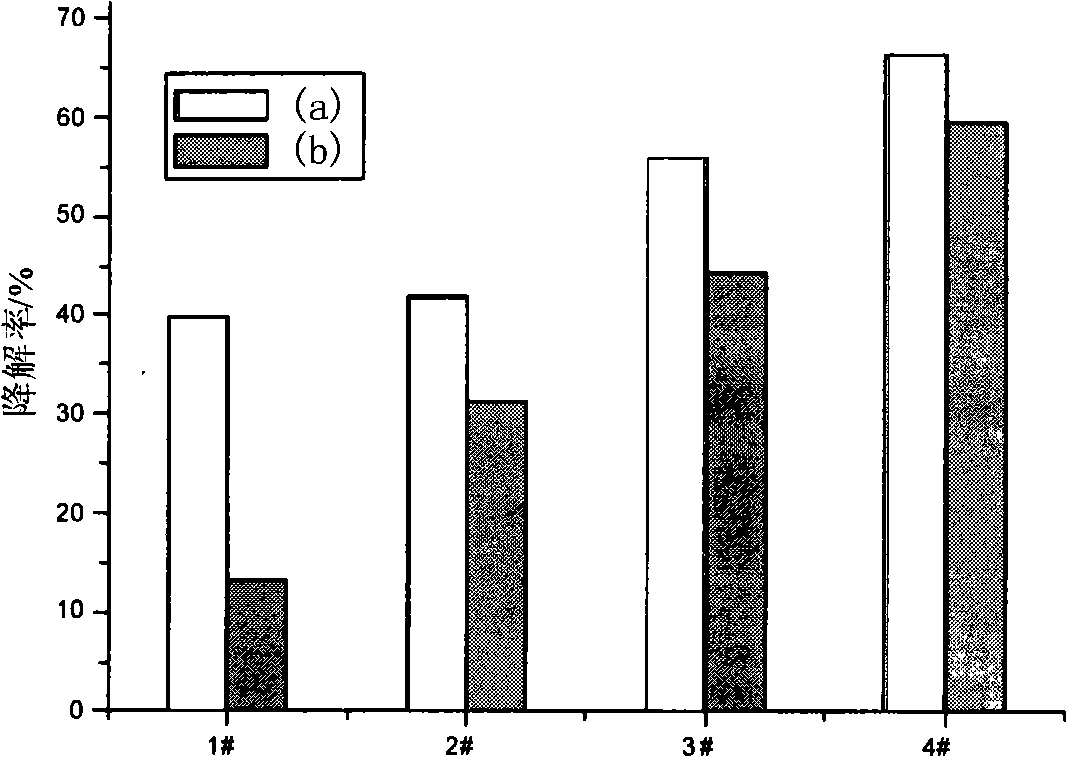

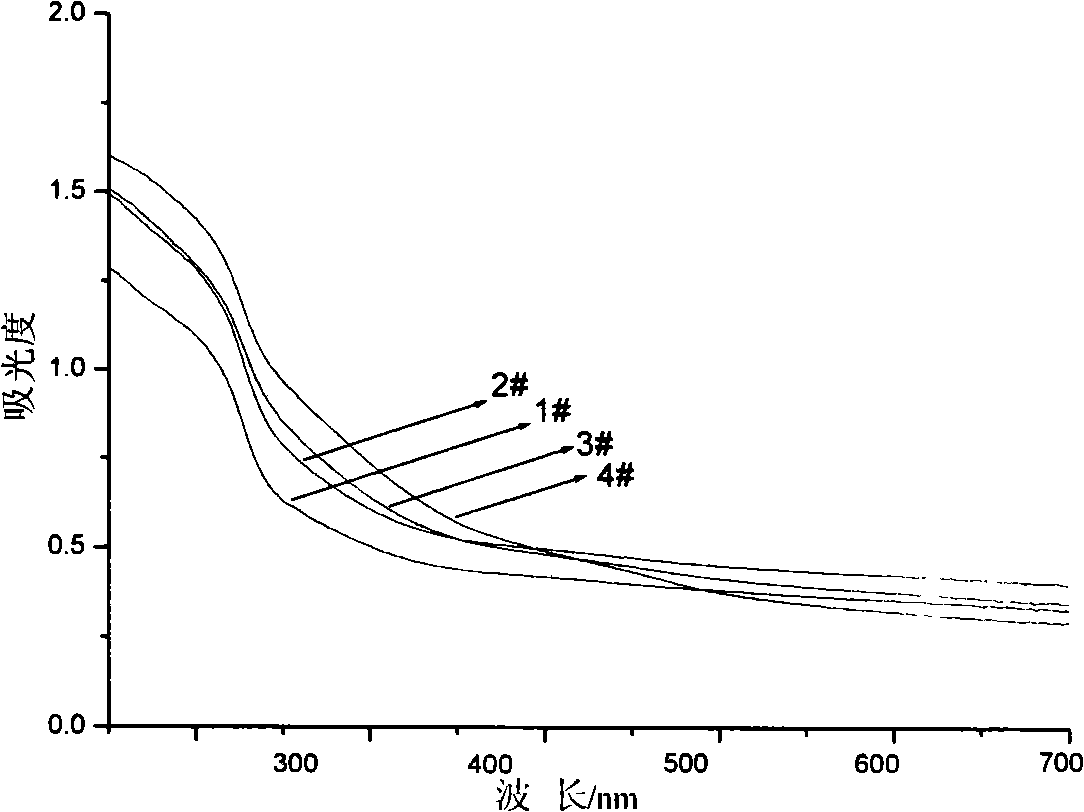

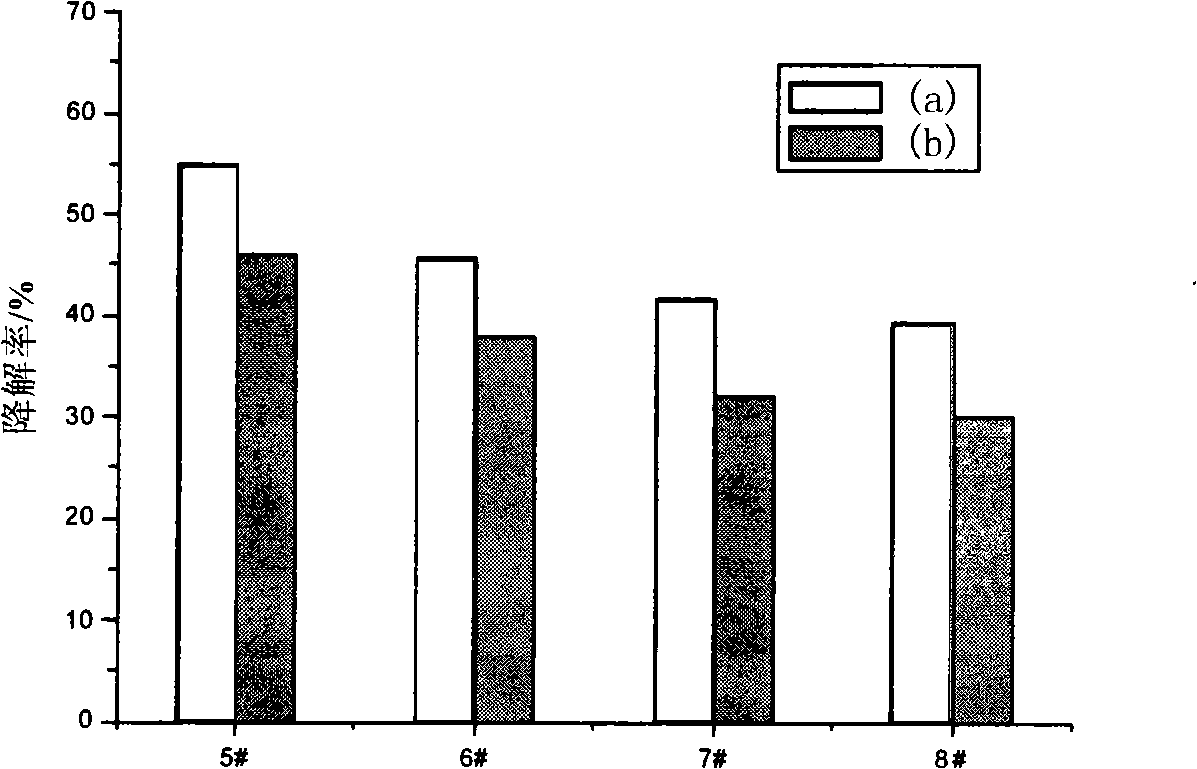

Modified titanium-containing furnace cinder catalyst with visible light catalytic activity and method for producing the same

InactiveCN101402036ASolve pollutionEffective development and utilizationPhysical/chemical process catalystsAbsorption capacitySlag

The invention relates to a modified titanium-bearing blast furnace slag catalyst with visible photocatalytic activity and a preparation method thereof, which belong to the field of material science. The compositions of crystal phase of the catalyst are 33 to 40 weight percent of perovskite, 50 to 59 weight percent of diopside and 7 to 10 weight percent of akermanite-submellite; and the specific surface area is between 9.7 and 20.5 square meters pre gram, and the maximum absorption capacity is between 3.9 and 8.3 milligrams per gram. The preparation method comprises the following steps: firstly, titanium-bearing blast furnace slag is crushed, and titanium-bearing blast furnace slag powder is obtained; secondly, ammonium sulfate is mixed with the titanium-bearing blast furnace slag powder; thirdly, mixture of the titanium-bearing blast furnace slag powder and the ammonium sulfate is grinded; and fourthly, the mixture is roasted for 1 to 4 hours at a temperature of between 300 and 700 DEG C, and is cooled to the room temperature. The STBBFS catalyst prepared by the method has strong photoabsorption and photoresponse when excited by visible light, so that the photocatalyst which is prepared by adoption of the titanium-bearing blast furnace slag as a raw material can utilize visible light sources such as sunlight to effectively photodegrade organic pollutant and inorganic pollutant in the water, and has high energy conversion efficiency.

Owner:NORTHEASTERN UNIV

Functional ceramic tea set

InactiveCN104529420ALong-term radiationGreat tasteDrinking vesselsPesticide residueMolecular cluster

The invention discloses a functional ceramic tea set, and relates to the technical field of ceramic manufacturing, in particular to a functional ceramic tea set capable of radiating negative oxygen ions and far infrared rays for a long time, converting water molecular clusters and adsorbing harmful residues in tea. The functional ceramic tea set is characterized by being mainly composed of 28% of tourmaline, 8% to 10% of quartz, 6% to 8% of diopside, 12% to 16% of medical stone, 12% to 14% of albite, 4% to 7% of hsiuyen jade, 8% to 11% of tremolite, 10% to 13% of rectorite, 5% to 7% of kaolin, 8% of bentonite and the like. The appearance of the functional ceramic tea set is brownish red. The functional ceramic tea set has the functions of radiating negative oxygen ions and far infrared rays for a long time, converting water molecular clusters, having antibacterial and antiseptic effects, adsorbing a trace amount of pesticide residues and heavy metal such as lead, chromium and nickel in tea, resisting and killing mould and carcinogenic bacteria dissolved out of old tea due to inappropriate storage, and the like.

Owner:TANGSHAN LIXIONG FENGHUI MATERIAL SCI & TECH CO LTD

Glass ceramics dielectric material and sintered glass ceramics

The present invention provides a glass ceramics dielectric material, comprising: a crystallizable glass powder in an amount of from 40% to 100% by mass; and a ceramics powder in an amount of from 0% to 60% by mass, wherein the crystallizable glass powder comprises: SiO2 in an amount of from 35% to 65% by mass; CaO in an amount of from 10% to 30% by mass; MgO in an amount of from 10% to 20% by mass; and ZnO in an amount of from 0.5% to 35% by mass, and wherein the material is capable of forming: diopside, CaMgSi2O6, as crystals; and at least one of hardestnite, Ca2ZnSiO7, and willemite, Zn2SiO4, as crystals; and a sintered glass ceramics, comprising: diopside, CaMgSi2O6, as crystals; and at least one of hardestnite, Ca2ZnSiO7, and willemite, Zn2SiO4, as crystals.

Owner:NIPPON ELECTRIC GLASS CO LTD

High-performance wet green sand for steel casting and preparing method thereof

InactiveCN104525841AImprove performanceImprove wet compressive strengthFoundry mouldsFoundry coresBrickTemperature resistance

The invention discloses high-performance wet green sand for a steel casting and a preparing method of the high-performance wet green sand. High-performance wet green sand is composed, by weight, of 40-60 parts of zircon sand, 15-20 parts of sea mud, 10-15 parts of ardealite, 25-35 parts of diopside, 20-30 parts of polyphenyl granule, 5-10 parts of sodium fluoroaluminate, 15-20 parts of coconut shell powder, 10-15 parts of crushed brick powder, 4-8 parts of hydroxypropl xanthan gum, 3-6 parts of sulfonated asphalt powder, 5-10 parts of bitter ling soil, 2-4 parts of calcium sulfite, 3-5 parts of poly aluminum chloride, 4-6 parts of polyoxyethylene, 2.5-4.5 parts of sodium hexametaphosphate, 5-10 parts of modified kaolin and a proper amount of water. The wet green sand is good in comprehensive performance, has the high green compression strength, the high compaction rate and the low thermal expansivity, also has the good high-temperature resistance, ventilating performance and fluidity and can effectively overcome the defects that air holes, scabbing, sand clamping, sand holes and the like can happen on the steel casting, the surface quality of the steel casting is improved, the finished product rate of the steel casting is increased, and the high-performance wet green sand has important economic benefits.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Preparation method for improving firing rate of Nixing pottery

The invention discloses a preparation method for improving firing rate of Nixing pottery, comprising the steps: 1, preparing a preform made from 50-60 parts of Eastern clay, 30-40 parts of Western clay, 6-8 parts of quartz, 2-4 parts of wollastonite, 1-3 parts of illite, 1-3 parts of diopside, and 2-4 parts of calcined talcum powder; 2, performing forming; 3, performing dressing; 4, performing drying; 5, performing decorating; and 6, performing firing: a, firing a decorated preform in a kiln, heating the inside of the kiln to 70-80 DEG C at a temperature rise rate: 30-40 DEG C / h, and holding the temperature for 7-9 h; b, increasing the temperature to 100-120 DEG C at a rate: 40-50 DEG C / h, and holding the temperature or 1-3 h; c, increasing the temperature to 1120-1160 DEG C at a rate: 70-90 DEG C / h, and holding the temperature for 0.7-0.9 h. By modifying a firing process and changing composition of the preform, shrinkage rate and fission rate of the preform are decreased, and the firing rate is increased.

Owner:QINZHOU HUAAN CLAY MODELLING CO LTD

Hydroxy apatite-base composite bioceramic material, and its preparing process

The present invention relates to a composite biological ceramic material using hydroxyapatite as base body and using diopside and alumina as toughening reinforcing body. Its composition includes (by wt%) 58-89% of hydroxyapatite, 0.5-2% of diopside and 10-40% of alumina, and its preparation method includes the following steps: mixing materials, ball-grinding, hot-pressing and sintering, its sintering temperature is 1300-1320 deg.C and sintering pressure is 20-30 MPa, and its heat-insulating and pressure-holding time is 30-60 min.

Owner:SHANDONG UNIV

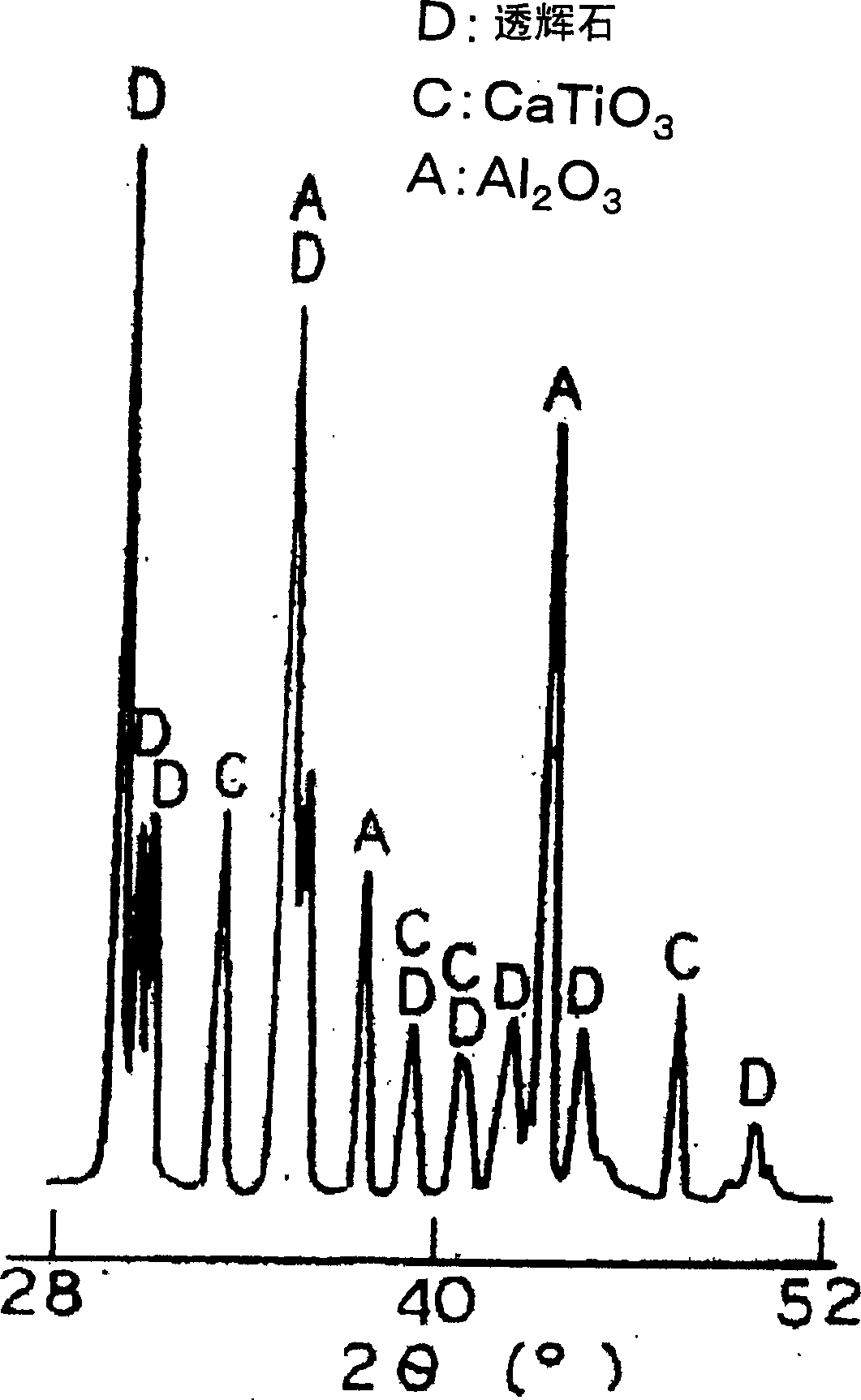

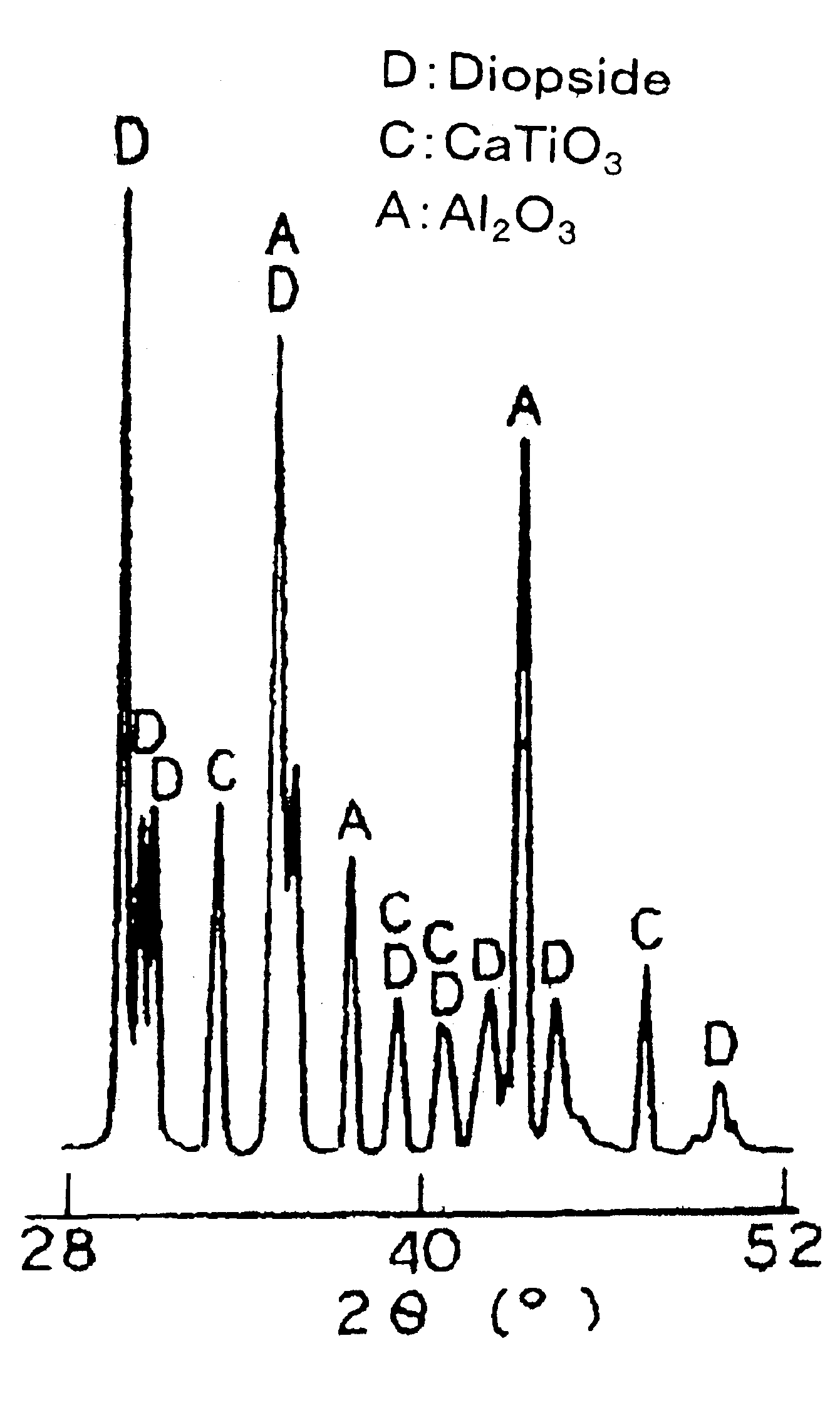

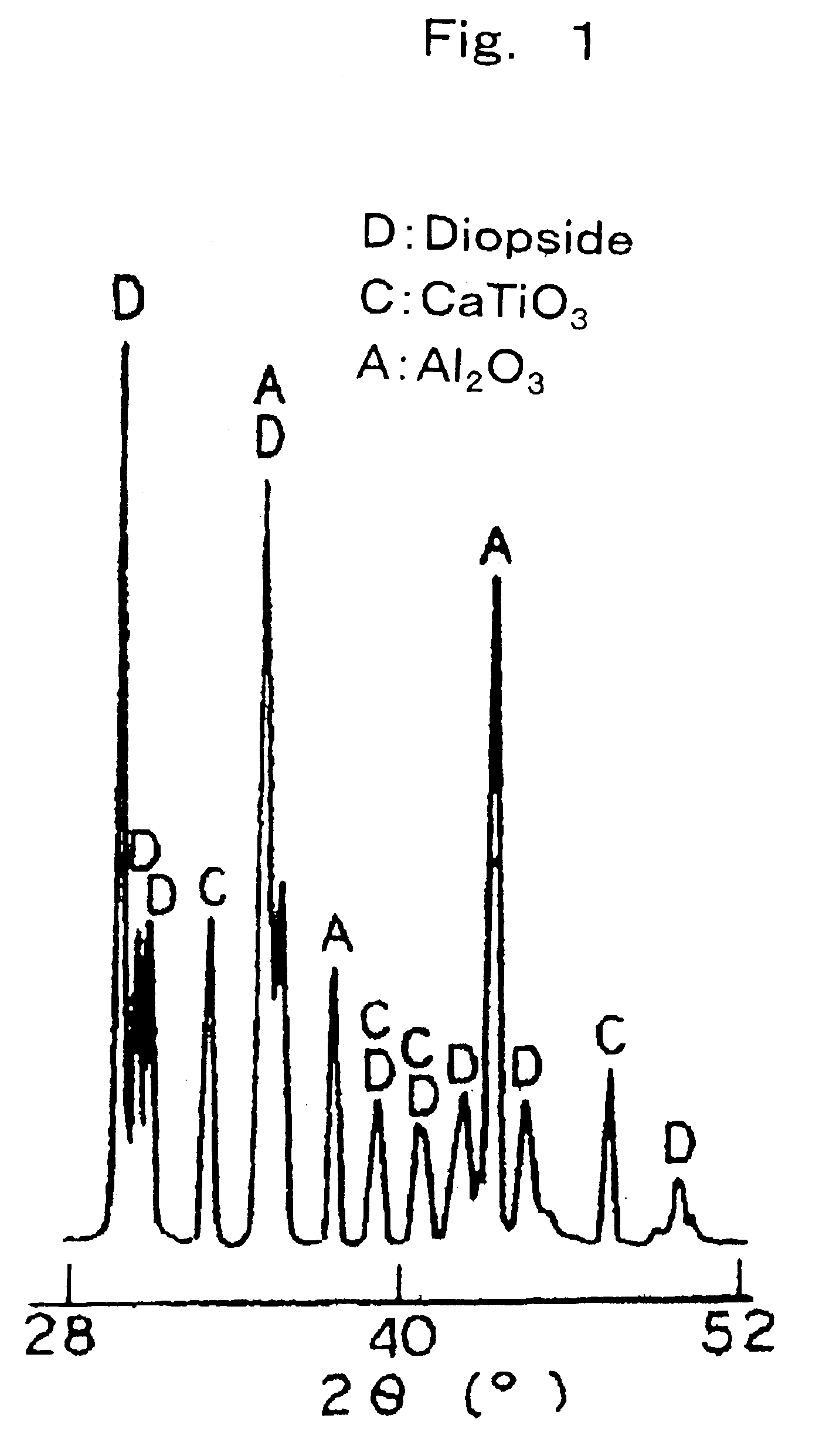

Dielectric ceramic composition and dielectric ceramic

InactiveCN1435390APrevent fadingReduce the rate of bad appearanceCeramicsStrontium titanateDielectric ceramics

The present invention provides a dielectric ceramic composition comprising: 30 to 90% by weight of a crystallized glass powder capable of depositing a diopside crystal, 1 to 40% by weight of a calcium titanate powder, a strontium titanate powder or a mixed powder thereof, and 0 to 60% by weight of at least one kind of a powder selected from the group consisting of Al2O3, TiO2, ZrO2, MgTiO3, BaTi4O9, La2Ti2O7, Nd2Ti2O7, Ca2Nb2O7, SrZrO3 and CaZrO3, and a dielectric ceramics obtained by firing the same.

Owner:KYOCERA CORP

Environment protecting dry brick and its production process

The present invention relates to wall material and its production process. The environment protecting dry wall brick is prepared with base material in 80-90 wt% and colorizing material 10-20 wt%. The base material includes red alumina clay 60-80 wt%, shale 10-30 wt% and flux additive diopside or wollastonite 2-10 wt%; and the colorizing material consists of bottom material and pigment, with the bottom material having the same recipe as the base material and the pigment accounting for 5-20 wt% of the colorizing material. The production process includes forming the colorizing material and the base material in two times into mold with grains, drying, glazing and baking. The produced environment protecting dry wall brick is used in laying building wall without needing decorating and results in excellent outer wall decoration effect.

Owner:WUHAN UNIV OF TECH +1

Primary-side wood-grain brick

The invention belongs to the field of preparation of wood-grain bricks and particularly relates to a primary-side wood-grain brick. The primary-side wood-grain brick comprises a green body, ground glaze and over glaze, wherein the green body is prepared from the following raw materials in percentage by weight: 2-4% of granite, 3-6% of potassic sand, 1-3% of sodium sand, 9-13% of pyrophyllite, 16-20% of kaolin, 13-17% of clay, 18-22% of weathered sand, 10-14% of black mud, 1-3% of black talc, 1-3% of diopside, 2-6% of marble and 4-8% of wollastonite, and the sum of the mass percents of all the raw materials is 100%. The primary-side wood-grain brick has the advantages that the green body is good in texture and difficult in fracture; due to addition of flexible fibers such as tea stems, bamboo powder and the like in the ground glaze, the adhesiveness between the green body and a glaze body can be effectively increased, so that fading is not easy to occur; and finally cedrela sinensis powder and nickel slag are added into the over glaze, so that the obvious anti-corrosion effect can be achieved.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Composite saggar and preparation method thereof

The invention discloses a composite saggar and a preparation method thereof. The composite saggar is prepared from raw materials in parts by weight as follows: 10-13 parts of magnesium mud, 10-12 parts of black talc, 33-35 parts of refractory mortar, 10-12 parts of sand, 4-6 parts of ballstone, 4-6 parts of aluminum powder, 5-7 parts of bauxite, 17-19 parts of refined mud, 90-160 parts of mullite, 22-35 parts of cordierite powder, 8-12 parts of attapulgite, 8-12 parts of calcined kaolin, 8-12 parts of diopside, 1-8 parts of fused magnesite, 1-3 parts of red mud, 1-3 parts of nano aluminum hydroxide sol, 1-3 parts of silica powder and 1-3 parts of reinforced fiber. The thermal stability, compressive capacity, corrosion resistance, low cracking probability and other properties of the saggar are improved by optimizing the raw material composition of the saggar, so that the saggar has the advantages of long service life and light mass. The adopted raw materials are cheap, and the preparation technology is simple, green and environment-friendly and can be industrially implemented.

Owner:衡东县东康瓷业有限公司

Dielectric ceramic composition and dielectric ceramics

InactiveUS6897172B2Prevent discolorationAvoid it happening againCeramicsStrontium titanateDielectric ceramics

The present invention provides a dielectric ceramic composition comprising: 30 to 90% by weight of a crystallized glass powder capable of depositing a diopside crystal, 1 to 40% by weight of a calcium titanate powder, a strontium titanate powder or a mixed powder thereof, and 0 to 60% by weight of at least one kind of a powder selected from the group consisting of Al2O3, TiO2, ZrO2, MgTiO3, BaTi4O9, La2Ti2O7, Nd2Ti2O7, Ca2Nb2O7, SrZrO3 and CaZrO3, and a dielectric ceramics obtained by firing the same.

Owner:KYOCERA CORP

Glass ceramics generated by taking granite tailings as main raw material, and preparation method for glass ceramics

The invention discloses glass ceramics generated by taking granite tailings as a main raw material and a preparation method for the glass ceramics. The glass ceramics comprises the following components in percentage by mass: 4.2 to 4.4 percent of Na2O, 7.0 to 7.3 percent of MgO, 25 to 26 percent of Al2O3, 42 to 47 percent of SiO2, 4.0 to 4.5 percent of TiO2, 2.9 to 3.1 percent of K2O, 7.9 to 8.2 percent of CaO, 0 to 4 percent of MnO2, and 0.5 to 0.6 percent of Fe2O3. According to the glass ceramics, the granite tailings, dolomite, caustic calcined magnesite, aluminum hydroxide, titanium dioxide, sodium carbonate and manganese ore are utilized as raw materials; through a formula design, the content of each component is within the range above; the using amounts of the TiO2, the MnO2 and the Fe2O3 are adjusted, so that the glass ceramics of multiple colors, such as blue grey, brown and dark yellow, can be obtained; the glass ceramics takes diopside as a primary crystalline phase, takes spinel as a secondary crystalline phase, and is high in mechanical property.

Owner:四川一名微晶科技股份有限公司

Molding sand with used sand recycled

InactiveCN105057564AImprove compactionImprove breathabilityFoundry mouldsMould handling/dressing devicesCarboxymethyl starchPyrophyllite

The invention discloses molding sand with used sand recycled. The molding sand is composed of, by weight, 120-130 parts of the used sand, 100-110 parts of quartz sand, 15-20 parts of diopside, 25-30 parts of pyrophyllite, 35-45 parts of plant straw, 30-40 parts of carboxymethyl starch, 20-25 parts of microcrystalline cellulose, 15-20 parts of hydrogenated rosin and 10-15 parts of furfuryl alcohol resin. According to the molding sand, the used sand and waste are reasonably utilized, the direct cost is greatly lowered, and the environment is protected. Besides, the compositions are reasonably matched, and performance is good. The phenomenon of insufficient performance when the used sand is recycled is effectively avoided. The defects of peeling, sand inclusion, sand burning and the like are reduced. The rate of finished castings is increased, and the degree of finish of the castings is improved. The sand removing man-hour is shortened, cost is lowered indirectly, and high economic value is achieved.

Owner:HEFEI CITY TENVER PRECISION CASTING

Diopside phase glass ceramic and preparation method thereof

The invention discloses a diopside phase glass ceramic and a preparation method thereof, belonging to the technical field of building ornament material preparation. A preparation method of the diopside phase glass ceramic comprises the following steps of: taking the following ingredients in percentage by mass: 40-70% of gold mine backfilling, 0-20% of quartz, 18-35% of calcite, 3-8% of borax, 1-3% of ZnO, 0-2% of TiO2, 0.5-3% of Cr2O3, 0-3% of CaF2, 0-3% of Na2SiF6 and 0.5-3% of Sb2O3; mixing and sufficiently grinding, and screening by using a sieve of 60-80 meshes so as to obtain a mixture material; melting the mixture material for 2-5 hours at 1,200-1,500 DEG C, subsequently cooling down to be less than 900-950 DEG C; carrying out heat preservation for 0-2 hours, and subsequently cooling down to be 25-30 DEG C so as to obtain the diopside phase glass ceramic. According to the method, the gold mine backfilling is taken as the main raw material which takes the place of chemical raw materials, so that the waste is changed into wealth, the environmental pollution is reduced, and the production cost of the glass ceramic is lowered. The principal crystalline phase of the glass ceramic prepared by using the method is diopside and a solid solution of the diopside, so that the mechanical strength, the abrasive resistance, the corrosion resistance and the differentiation resistance of a product are improved.

Owner:SHAANXI UNIV OF SCI & TECH

Once-moulded thin-tire ceramic and preparation technology thereof

The invention discloses a once-moulded thin-tire ceramic and a preparation technology thereof. The once-moulded thin-tire ceramic comprises a blank and glaze, wherein the blank comprises the followingraw materials in parts by weight: 16-22 parts of albite, 12-18 parts of montmorillonite, 46-52 parts of a quartz powder, 8-12 parts of rutile, 3-5 parts of a molybdenum ore powder, 1-3 parts of a silica brick powder, 5-8 parts of diopside, 3-6 parts of magnesium oxide, 1-3 parts of light calcium carbonate and 2-5 parts of a sintering aid; the glaze comprises the following raw materials in parts by weight: 10-15 parts of albite, 16-22 parts of red halloysite, 35-46 parts of quartz, 5-8 parts of titanium dioxide, 3-6 parts of a glass powder, 3-5 parts of red jade soil, 1-3 parts of bentonite, 2-5 parts of calcium nitride, 1-3 parts of dysprosium oxide and 1-2 parts of magnesium carbonate.

Owner:CERAMICS SCI & TECH RES INST QUANZHOU +1

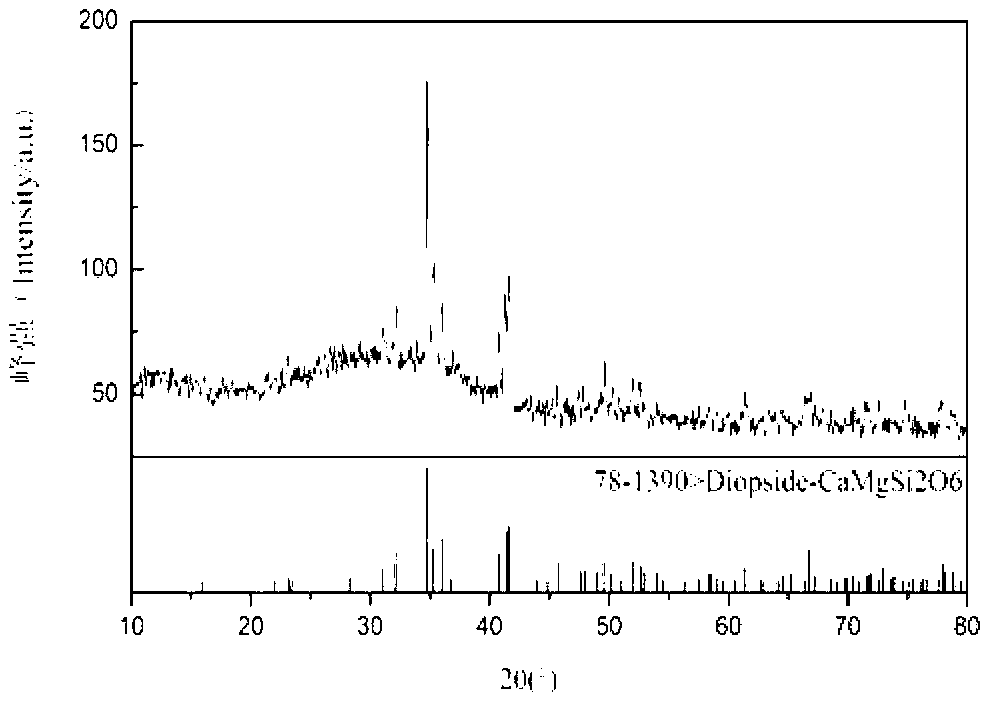

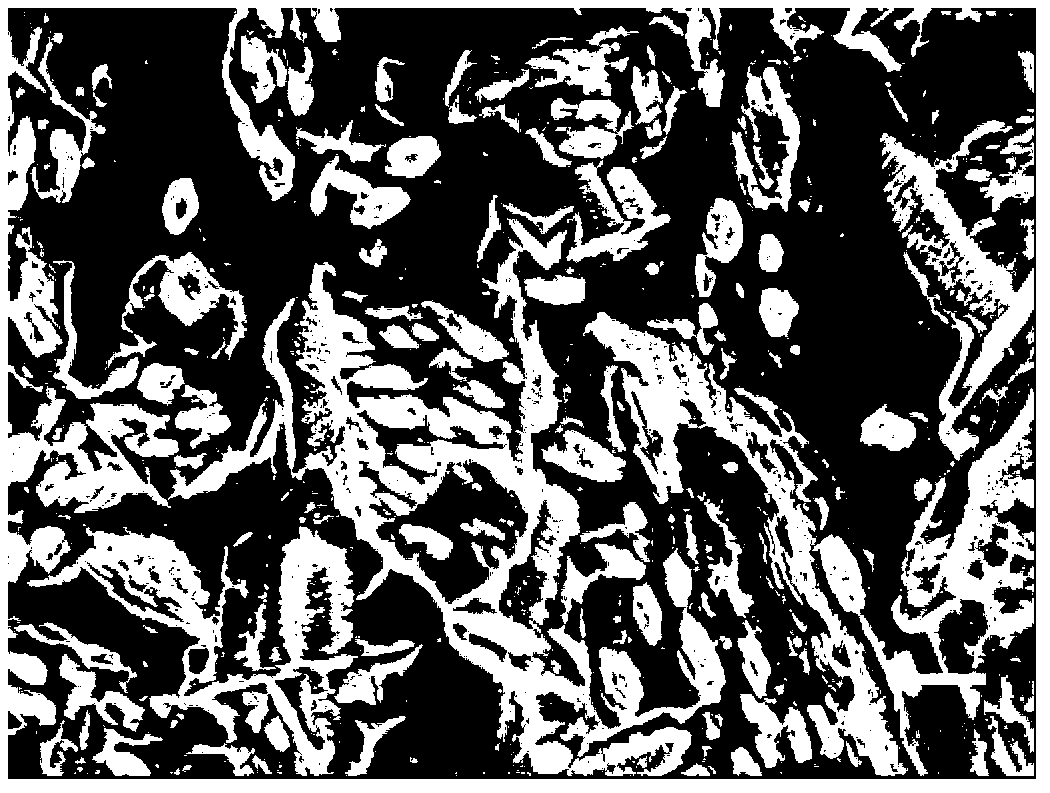

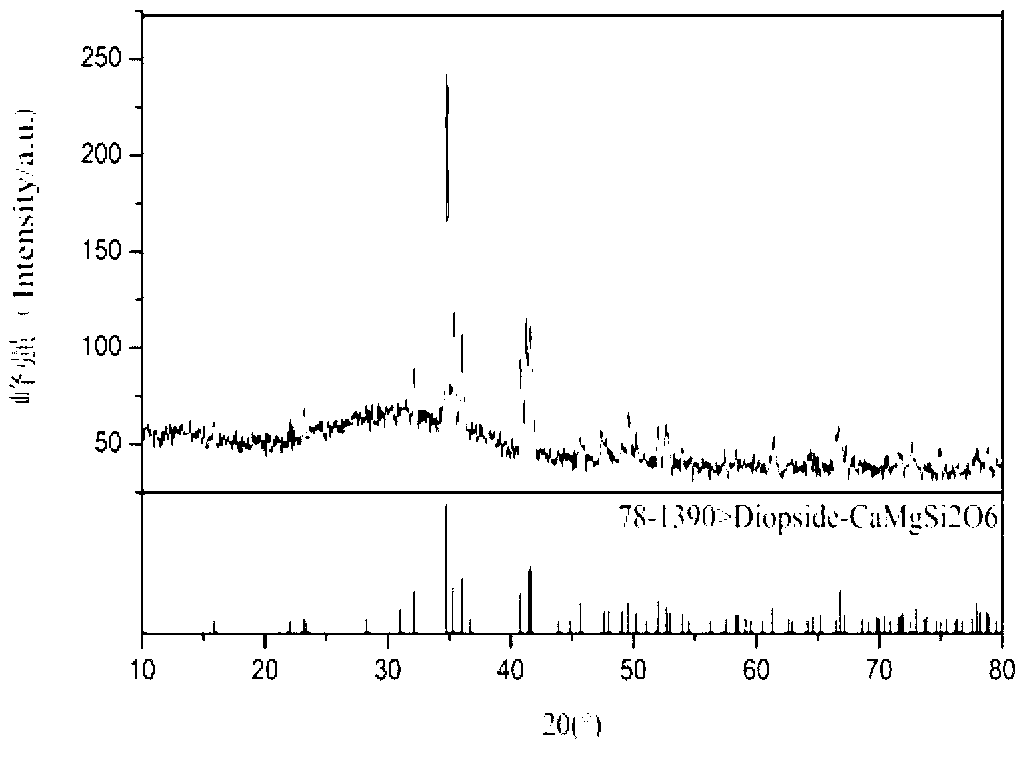

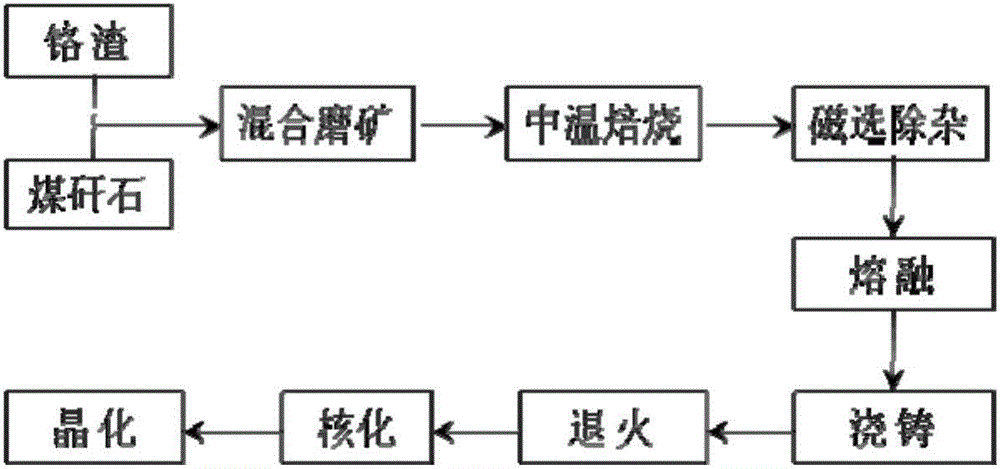

Diopside ceramic glass prepared from chromic slag and coal gangue and preparation method of diopside ceramic glass

PendingCN106673448AIncrease added valueGood for Magnetic Separation RemovalGlass shaping apparatusMolten statePowder mixture

The invention relates to a method for preparing diopside ceramic glass from chromic slag and coal gangue. The method comprises the following steps: mixing and grinding the chromic slag and the coal gangue according to the ratio to obtain a mineral powder mixture; roasting the obtained mineral powder mixture, and enabling Fe2O3 in the mixture to be reduced into Fe3O4 to obtain a roasted mineral powder mixture containing magnetic Fe3O4; carrying out magnetic separation on the obtained roasted mineral powder mixture in a magnetic field so as to remove the Fe3O4 in the mixture, thus obtaining mineral powder mixture subjected to iron removal; putting the obtained mineral powder mixture subjected to the iron removal into a silicon molybdenum rod high-temperature furnace, and heating, melting and homogenizing in a non-oxidizing atmosphere to obtain a molten state mixture; pouring the obtained molten state mixture into a preheated die for forming to obtain base glass; sequentially carrying out annealing, nucleating and crystallization treatment on the obtained base glass to obtain the diopside ceramic glass. According to the method disclosed by the invention, synthetic raw materials are zero cost; a synthesized product, namely the diopside ceramic glass, has higher added value.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Glass-ceramic tiles and preparation method thereof

The invention discloses glass-ceramic tiles. The tiles are prepared from the following components in parts by weight: 10-25 parts of crystalline frit, 10-20 parts of quartz, 5-10 parts of wollastonite, 10-30 parts of diopside, 5-10 parts of anorthite, 5-10 parts of fluorite, 0-1.5 parts of coloring metal oxide powder, 0-5 parts of feldspar and 0-5 parts of clay. The preparation method comprises the following steps: firstly, preparing a powder blank, then performing sheeting forming, performing primary firing, then performing primary polishing, performing secondary firing and finally performingaftertreatment to obtain the finished glass-ceramic tiles. Microcrystalline phases of various oxides are produced from ceramic raw materials under the high temperature condition, oxides of titanium,zirconium or lead are prevented from being used as crystal nuclei, radiation and lead hazards are prevented, and the glass-ceramic tiles prepared with the multiple-sintering method have the characteristics of high surface compactness, high transparency, rich texture, better hardness and wear resistance and the like; meanwhile, fluorite is used as a fluxing agent and a dyeing assistant agent, so that ceramic is not easy to fade.

Owner:安徽磐盛新型材料科技有限公司

Preparation method of environment-friendly alkaline-free fireproof fibers

InactiveCN104557089AMethod securityReliable methodInorganic material artificial filamentsFiberPolymer science

The invention belongs to the field of fireproof fibers and particularly relates to a preparation method of environment-friendly alkaline-free fireproof fibers. The fibers are prepared by preparing raw materials, melting, centrifugally throwing threads or blowing to form fibers by using natural diopside, quartz sands, calcite, coal gangue and phosphate ores as the raw materials. The diameters of the obtained fibers are 1-10 mm and the lengths are 50-200 mm. The fibers have the advantages of high degree of fire resistance, non-combustion property, low shot content, good biodegradability and the like, and are aluminium silicate fiber substitute materials which are widely applied to various thermal equipment and pipelines.

Owner:SHANDONG LIYOUN NEW MATERIAL

Medical porous alumina based ceramic composite material

InactiveCN101757683AImprove mechanical propertiesFacilitate depositionProsthesisCeramic compositeNitrogen gas

The invention belongs to the field of biological ceramic materials, and relates to a medical porous alumina based ceramic composite material. Firstly, 1-8% of calcium fluoride, 90-98% of alumina and 1-5% of diopside are mixed according to the mass percentage, and then the calcium fluoride, the alumina and the diopside are milled by balls to prepare mixed powder; and then the mixed powder material is placed into a graphite mould to be molded and pressed, hot-pressed and sintered in the argon or nitrogen atmosphere, wherein the sintering temperature is 1400 DEG C, the pressuring temperature is 1320 DEG C, the sintering pressure is 30 MPa and the heat preservation and pressure maintaining are carried out for 30 minutes at the sintering temperature. The composite material not only has good mechanical property and bioactivity, but also is distributed with micropores on the surface and is more beneficial to the growth of bone tissues. Simultaneously, the composite material has low manufacture cost and better application prospect in terms of the restoration, replacement and the like of bones of the human body.

Owner:SHANDONG UNIV

Production process of high-transparency glass bottle

The invention provides a production process of a high-transparency glass bottle. The production process comprises the following steps: (1) weighing of the following raw materials: 75-88 parts of silica sand, 1.5-2.8 parts of lithium chinastone, 0.5-2.4 parts of mullite, 2.5-3.8 parts of dolomite, 0.5-3 parts of diopside, 2.8-5.5 parts of potash feldspar, 1.5-3.5 parts of borax, 1.2-2.6 parts of sodium carbonate, 0.05-0.2 part of cerium oxide and 0.01-0.12 parts of yttrium oxide; (2) mixing: ball milling; (3) high-temperature fusion: feeding the mixed powder into a smelting furnace, performingfusion at 1,450-1,480 DEG C, and keeping the temperature for 14-20 h to obtain a glass stock solution; (4) contour machining: after cooling to 1,380-1,400 DEG C, and performing blow-molding; and (5) annealing: transferring glass bottles into an annealing furnace with the temperature of 535-555 DEG C, keeping the temperature for 16-20 min, cooling down to 350-375 DEG C, keeping the temperature for130-150 min, and performing air cooling to the room temperature. The raw materials are reasonable in proportion, the fusion temperature is lower than 1,500 DEG C, and all technological steps work together to ensure that the produced glass bottles are high in transparency, almost free from internal stress, excellent in strength and resistant to shock chilling and shock heating.

Owner:安徽晶晶玻璃制品有限公司

Antique ceramic and preparation method thereof

The invention relates to an antique ceramic. The blank is prepared from the following raw materials: 35-45 wt% of kaolin, 4-6 wt% of peat soil, 6-14 wt% of alkaline earth, 5-7 wt% of quartz, 25-33 wt% of bentonite, 1-3 wt% of diopside, 12-16 wt% of picrolite and 4-6 wt% of fired talcum. The preparation method of the antique ceramic is characterized by comprising the following steps: (1) weighing materials according to the formula, milling the material, balls and water in a ball mill in a mass ratio of 1:2:0.8, passing through a 200-mesh screen, and aging for 2 days; (2) injecting the blank slurry into a mold, demolding after 20 minutes, taking out the blank, drying, repairing and applying water; and (3) firing in a kiln at 900-1000 DEG C in an oxidizing atmosphere for 2-3 hours, converting into a reducing atmosphere, heating to 1150-1230 DEG C, keeping the temperature for 1-2 hours, and finally, naturally cooling to obtain the antique ceramic. The method can directly perform firing without glazing, and thus, is simple in preparation technique. The prepared antique ceramic has the advantages of low cost, natural color, abrasive surface and antique beauty.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Hydroxyl apatite/diopside composite bioceramic material and preparing technique thereof

The invention relates to a compound biological ceramic material with hydroxyapatite as base, diopside as toughening reinforcement and a preparation technique thereof. The compound biological material is prepared with hydroxyapatite and diopside as raw materials. The technical process includes the steps that: 80 percent to 95 percent of hydroxyapatite and 5 percent to 20 percent of diopside are prepared as raw materials by weight percentage, then are subject to the mixed ball milling and are agglomerated at a temperature of 1,300 to 1,320 DEG C and a sintering pressure of 20 to 30MPa in an atmosphere of nitrogen for 30 to 60 minutes. The compound biological ceramic material prepared through the invention not only has low cost, but also has favorable biological compatibility and better mechanical properties such as fracture toughness, bending strength, etc than pure HA, thus having a bright application prospect in the repair and substitution of human bones.

Owner:SHANDONG UNIV

Artistic ceramic tile and its processing techology

InactiveCN1513801AGuaranteed firmnessNot easy to fall offDecorative surface effectsClaywaresAdhesiveDiopside

Owner:张化地

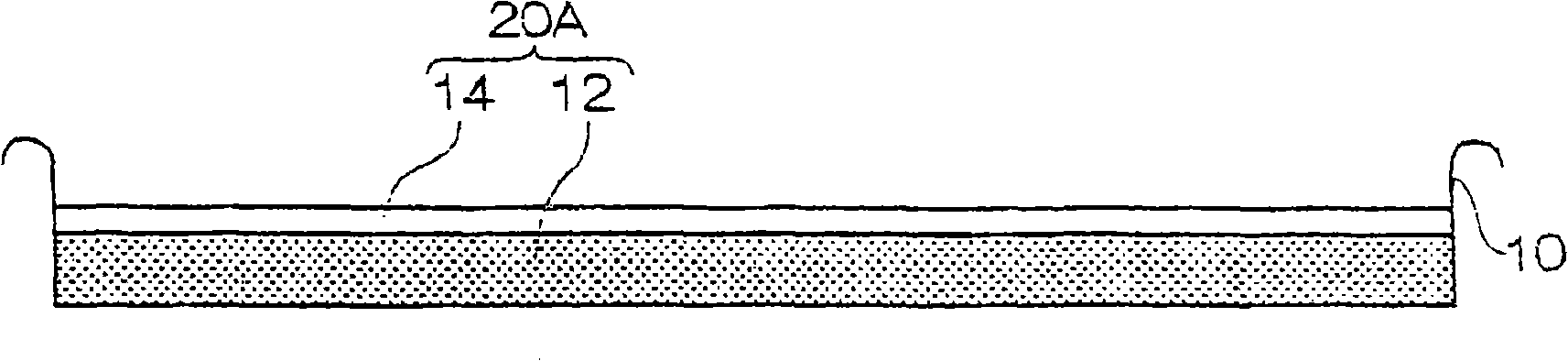

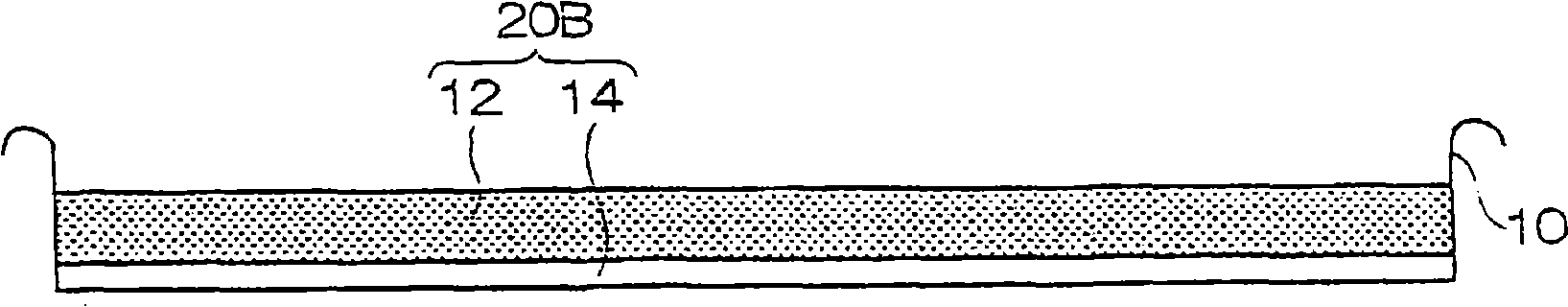

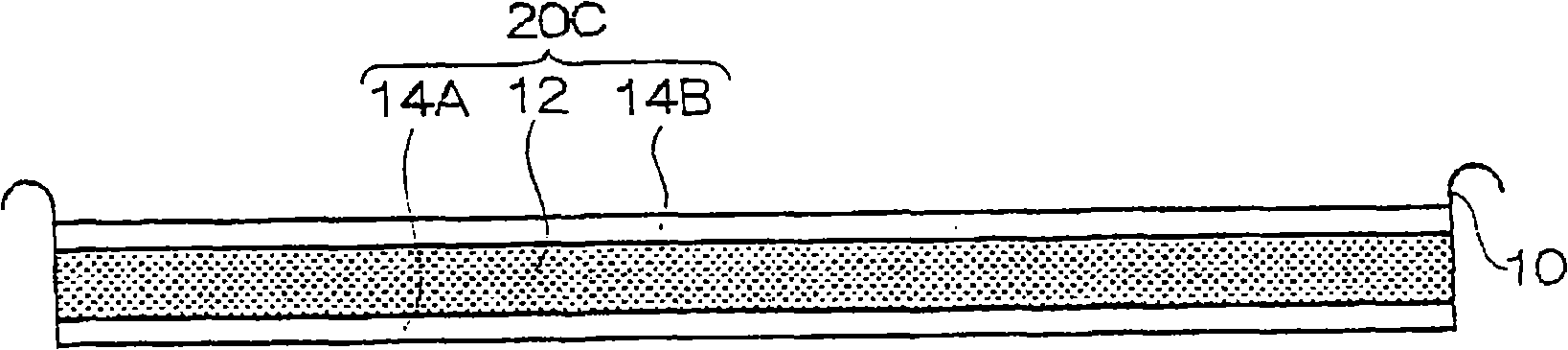

Crystallized glass article having patterns and method of producing the same

The invention provides a crystallized glass product with pattern, which comprises: a crystallized glass layer A formed by sintering multiple small crystallized glass bodies and crystallizing them at the same time; and a crystallized glass layer B formed by arranging a crystallized glass plate B on at least one surface of the crystallized glass layer A while it is in sintering state, and crystallizing the crystallized glass plate B from surface to inner center. The primary crystallization of the crystallized glass layer A is at least one of beta- wollastonite, beta-CaO-SiO2 and diopside, CaO-MgO-2SiO2; while the primary crystallization of the crystallized glass layer B is is at least one of beta- wollastonite, beta-CaO-SiO2 and diopside, CaO-MgO-2SiO2. Besides, the invention further provides a manufacturing method of the crystallized glass product with pattern.

Owner:JIAN QUAN GLASS DEV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com