Dielectric ceramic composition and dielectric ceramic

A technology of dielectric ceramics and compositions, which is applied in the field of dielectric ceramic compositions and dielectric ceramics, can solve problems such as cracking, increasing the temperature coefficient of electrostatic capacity, and failure to obtain conductive properties, so as to prevent bending, deformation, and fading Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

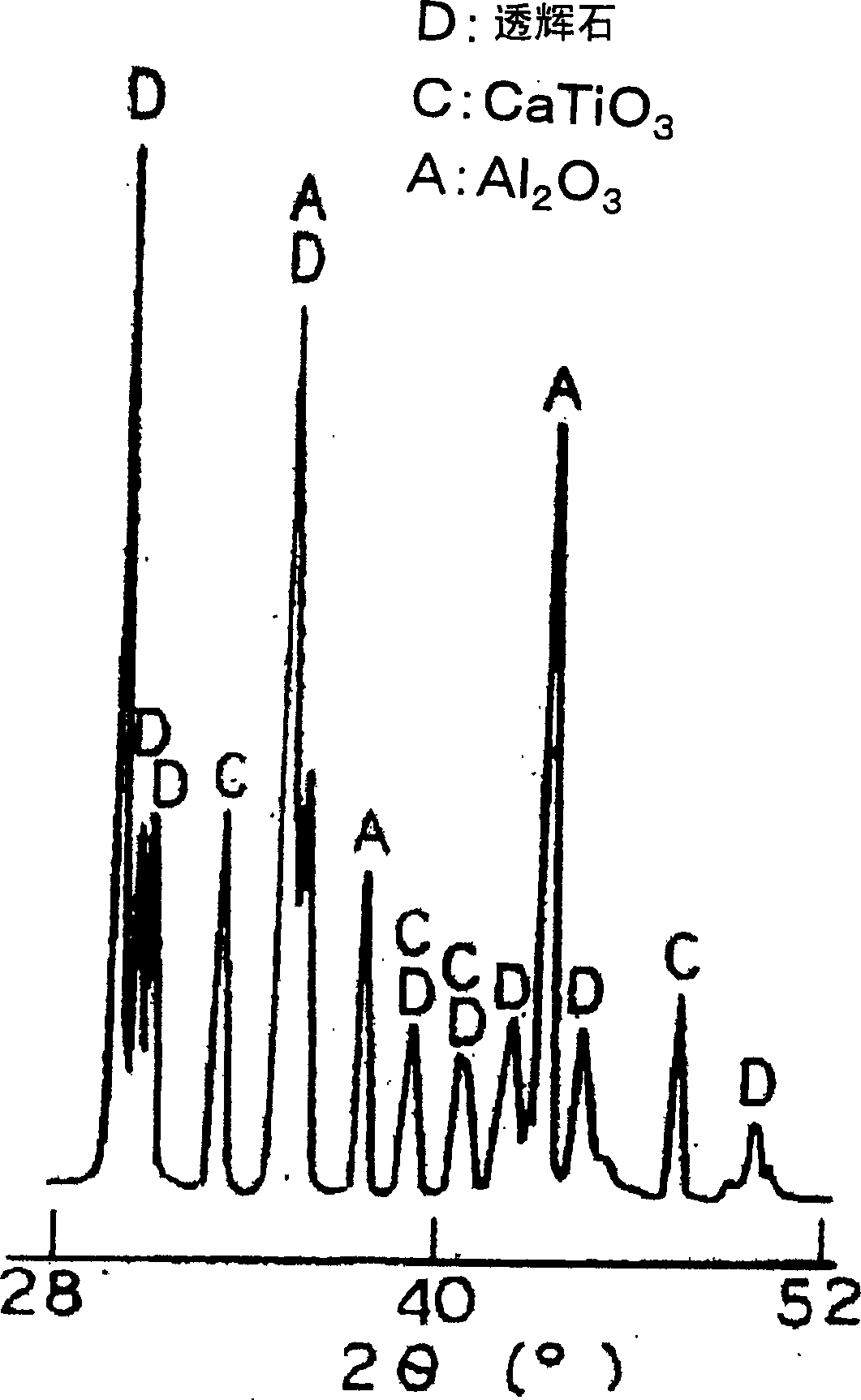

[0053] First, glass frits A and B, which are crystallized glass frits capable of depositing diopside crystals and having an average particle size of 2 μm, were used as glass frits. Glass frit A: 45 wt% SiO 2 -25wt%CaO-15wt%MgO-10wt%ZnO-5wt%Al 2 o 3 Frit B: 49 wt% SiO 2 -28wt%CaO-18wt%MgO-5wt%Al 2 o 3

[0054] Use CaTiO with an average particle size of 2 μm and a purity of 99% or higher 3 Powder and Al with an average particle size of 2 μm each 2 o 3 ,TiO 2 , ZrO 2 , MgTiO 3 , BaTi 4 o 9 , La 2 Ti 2 o 7 ,Nd 2 Ti 2 o 7 , Ca 2 Nb 2 o 7 , SrZrO 3 and CaZrO 3 as a filler. Weigh each component respectively, and mix with water according to the ratio shown in Table 1, when using ZrO 2 The balls were wet-treated in a ball mill for 20 hours to obtain a pulverized mixture having a particle size of 1.5 µm or less.

[0055] As a comparative example, a crystallized glass powder (glass frit C: 50% by weight of SiO2) that cannot deposit diopside crystals was used. 2...

Embodiment 2

[0068] Using the same method as in Example 1, except that the calcium titanate powder used as raw powder in Example 1 was replaced with strontium titanate powder (purity: 99% or higher) having an average particle size of 2 μm, a dielectric material was produced and evaluated. ceramics. The composition is listed in Table 3 and the evaluation results are shown in Table 4.

[0069]

serial number

Glass

ST**

(weight%)

Filler composition (weight%)***

Roasting temperature

℃

components

weight%

AL

Ti

Zr

MT

BT

LT

NT

CN

SZ

CZ

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

*50

51

52

*53

*54

A

A

A

A

A

A

B...

Embodiment 3

[0075] Adopt the same method as embodiment 1, just replace the calcium titanate powder used as raw powder in embodiment 1 with the calcium titanate powder and the strontium titanate powder of 2 μm, 99% or higher purity respectively with average particle size, Fabricate and evaluate dielectric ceramics. The composition is listed in Table 5 and the evaluation results are shown in Table 4.

[0076] Preface

No

Glass

CT**

(weight%)

ST**

(weight%)

Filler composition (weight%)***

temperature

℃

components

weight%

AL

Ti

Zr

MT

BT

LT

NT

CN

SZ

CZ

55

56

57

58

59

60

61

B

B

B

B

B

A

A

58

58

48

48

72

60

55

3

1

1

1

7

4

4

4

6

20

39

1

1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com