Laser engraving method of plastic component

A technology of plastic parts and software, applied in the direction of engraving, decorative arts, etc., can solve the problems of short life, loss of enterprises, individuals, coating peeling, etc., to achieve the effect of short life, personalization, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The operation object of this embodiment is a plastic part including at least one layer of light-transmitting material, including PC, ABS, PMMA and a mixed material of PC and ABS. The said plastic part including at least one layer of light-transmitting material means that it includes a material with a thickness of at least about 0.1 mm. It can also be a double-layer opaque material, that is, a two-color injection molding workpiece, double-layer or multi-layer lamination or bonding Composite workpiece, one or more layers of which are of any color, the outer layer is a layer of light-transmitting material, and the thickness of the light-transmitting layer can be arbitrary. The inner engraving pattern is engraved inside the light-transmitting material layer or between the transparent material layer and its adjacent two layers.

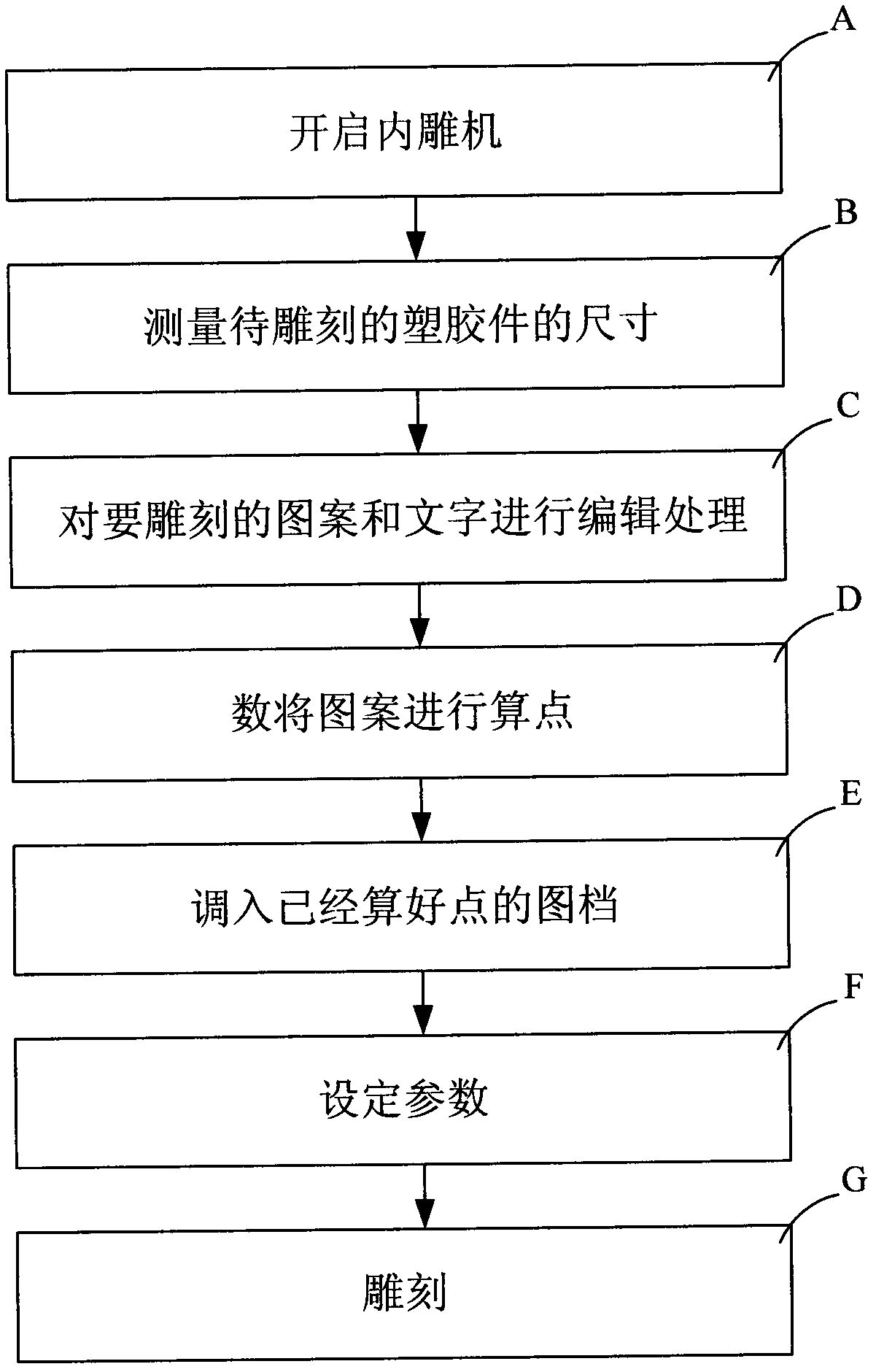

[0033] The specific steps are as follows:

[0034] The first step is to turn on the internal engraving machine and operate the equipment to the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com