Nitryl golden finishing coat with ultra-high adhesive force

A technology of adhesion and nitrate, which is applied in the direction of coating, polyester coating, rosin coating, etc., and can solve problems such as poor adhesion and paint falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A nitro-based finish paint with super adhesion, the weight ratio of components A and B is 1:0.1-0.3 when painting,

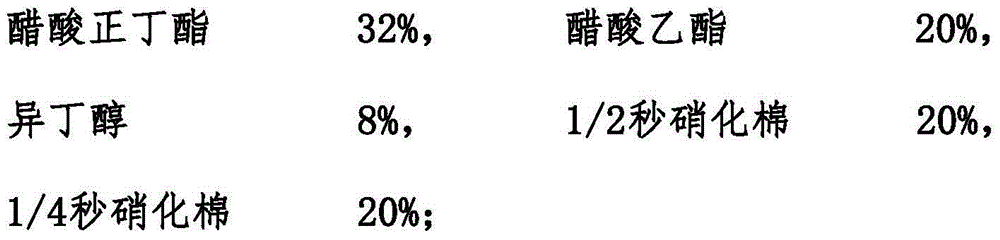

[0030] Preparation of 40% nitrocellulose solution:

[0031]

[0032] Production process: Select a clean dispersion cylinder that meets the requirements, put in 25Kg of n-butyl acetate, 20Kg of ethyl acetate, and 8Kg of isobutanol, start the mixer at a low speed of 500-800 rpm, and then slowly add nitration for 1 / 2 second while stirring Cotton 20Kg and 1 / 4 second nitrocellulose 20Kg, use part of n-butyl acetate 1Kg to clean the side of the tank, disperse at 1000-1200 rpm for 25-30 minutes until the fineness is ≤15um, stop the machine and add the remaining n-butyl acetate 6Kg, Stir for 5-10 minutes at a speed of 600-800 rpm, filter through a 120-mesh filter, and pack into barrels for use.

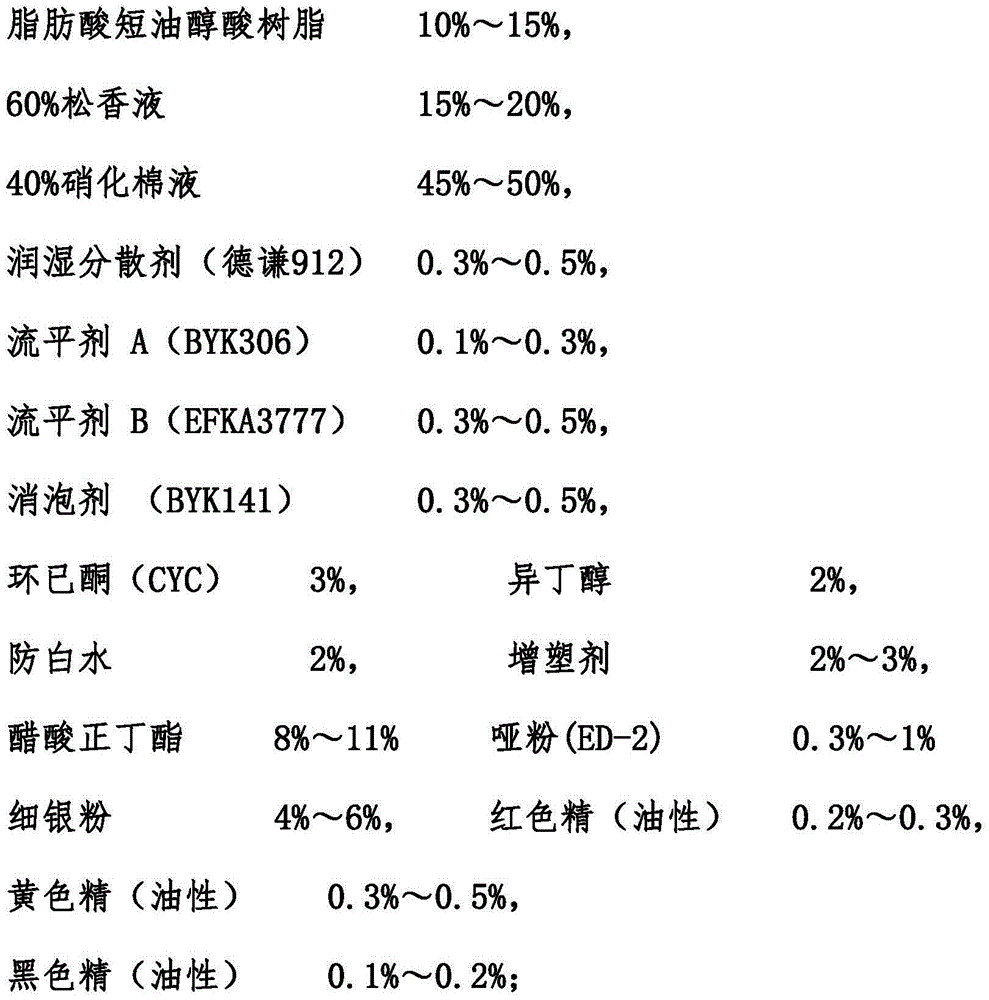

[0033] The weight percentage of the formula of component A:

[0034] Fatty Acid Short Oil Alkyd Resin 10%,

[0035]

[0036] The weight percent of the formula o...

Embodiment 2

[0043] A nitro-based finish paint with super adhesion, the weight ratio of components A and B is 1:0.1-0.3 when painting,

[0044] The weight percentage of 40% nitrocellulose solution:

[0045]

[0046] Production process: Select a clean dispersion cylinder that meets the requirements, put in 25Kg of n-butyl acetate, 20Kg of ethyl acetate, and 8Kg of isobutanol, start the mixer at a low speed of 500-800 rpm, and then slowly add nitration for 1 / 2 second while stirring Cotton 20Kg and 1 / 4 second nitrocellulose 20Kg, use part of n-butyl acetate 0.5Kg to clean the side of the tank, disperse at 1000-1200 rpm for 25-30 minutes until the fineness is ≤15um, stop and add the remaining n-butyl acetate 6.5 Kg, stir for 10 minutes at a speed of 600-800 rpm, filter through a 120-mesh filter, and pack into barrels for use.

[0047] The weight percentage ratio of A component:

[0048]

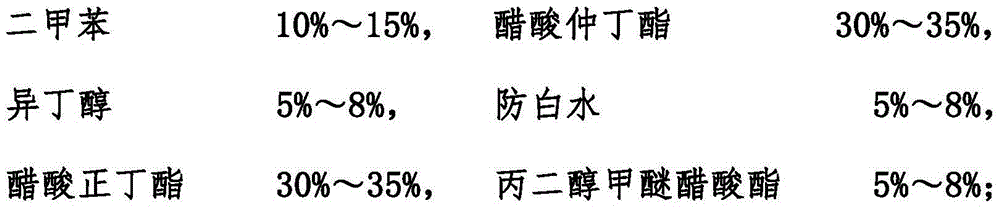

[0049] The weight percentage ratio of component B:

[0050]

[0051] Production process: put i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com