Patents

Literature

78results about How to "Avoid peeling paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

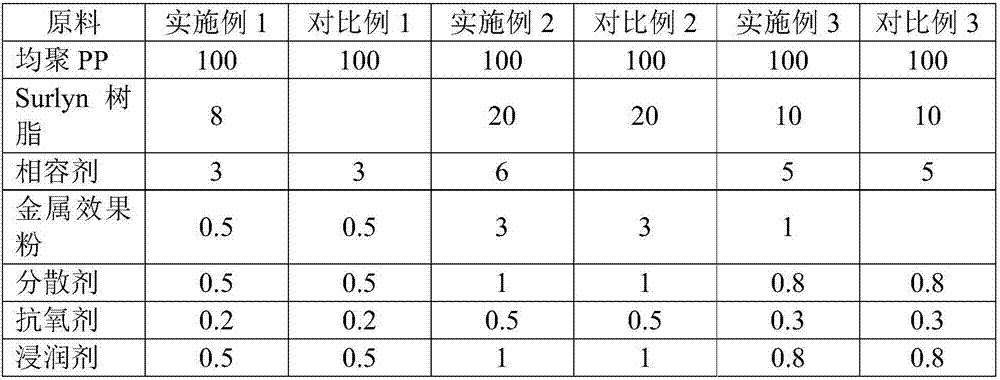

Spray-coating-free scratch-resistant PP alloy material and preparation method thereof

The invention relates to a spray-coating-free scratch-resistant PP alloy material and a preparation method thereof, wherein the spray-coating-free scratch-resistant PP alloy material is prepared from the following raw materials by weight: 100 parts of polypropylene, 5-20 parts of an transparent ionic polymer, 3-6 parts of a compatibilizer, 0.5-3 parts of a metal powder pigment, 0.5-1 part of a dispersant, 0.5-1 part of an infiltrating agent, and 0.2-0.5 part of an antioxidant, the dispersant is formed by compounding polyester grafted modified silicone and polyethylene wax according to a weight ratio of 2:1, and the graft ratio of the polyester grafted modified silicone is 0.8-2%. Compared to the material in the prior art, the material of the present invention has advantages of excellent spray-coating-free metal effect, excellent metal effect powder dispersibility and excellent scratch resistance, can effectively alleviate the flow mark problem of the traditional spray-coating-free metal effect material, is suitable for occasions having high scratch resistance requirements, and can be widely used in vehicles, home appliances, and other fields.

Owner:上海日之升科技有限公司

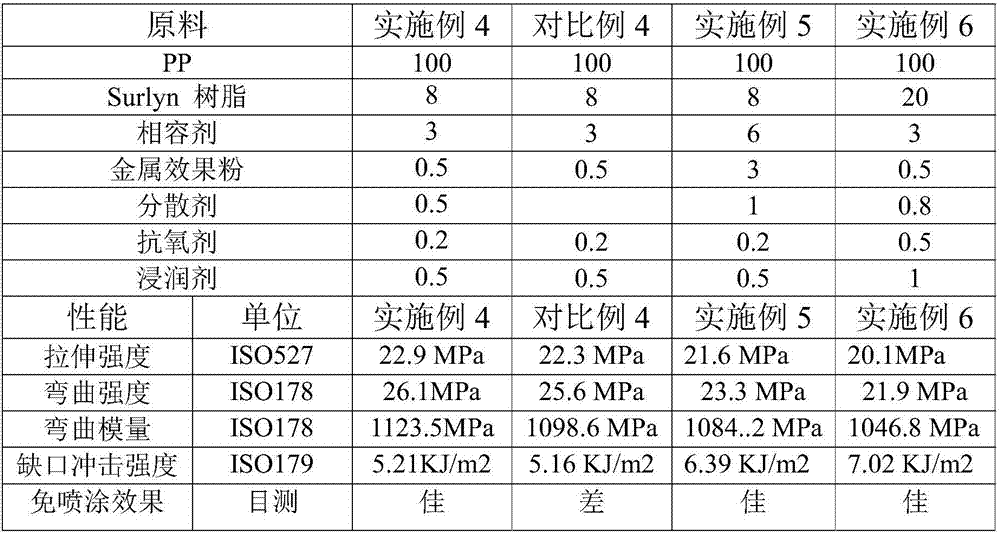

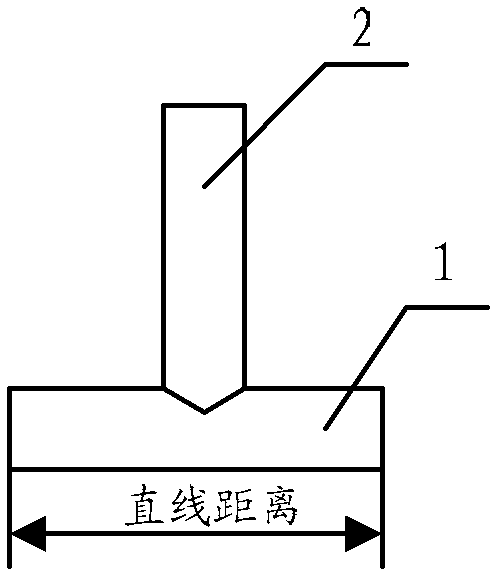

Device and method for detecting glass guide groove of car door assembly

ActiveCN102901418AAddressing Defects That Are Difficult to DetectAvoid peeling paintMechanical clearance measurementsEngineeringAxial distance

The invention provides a device and method for detecting a glass guide groove of a car door assembly, wherein the detecting device comprises a detecting rod, wherein the axial distance of the detecting rod is equal to the longitudinal distance of the glass guide groove, the detecting rod is horizontally put into the glass guide groove, and the detecting rod moves up and down between an upper stop point and a lower stop point of the glass guide groove to detect the longitudinal distance of the glass guide groove. According to the method and device for detecting the glass guide groove of the car door assembly, the size can be detected by the means that the detecting rod moves in the glass guide groove, so that the defect that the glass guide groove is hard to detect can be solved, the operation is easy and simple, and the detection efficiency is high.

Owner:BEIQI FOTON MOTOR CO LTD

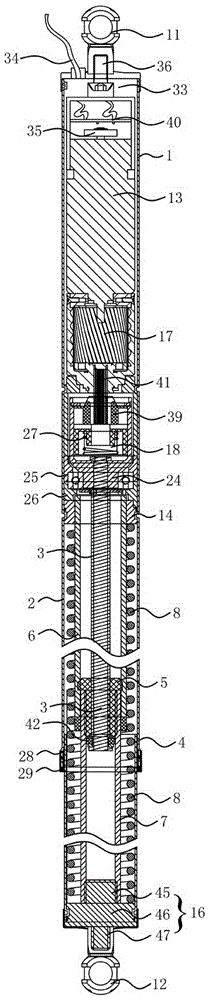

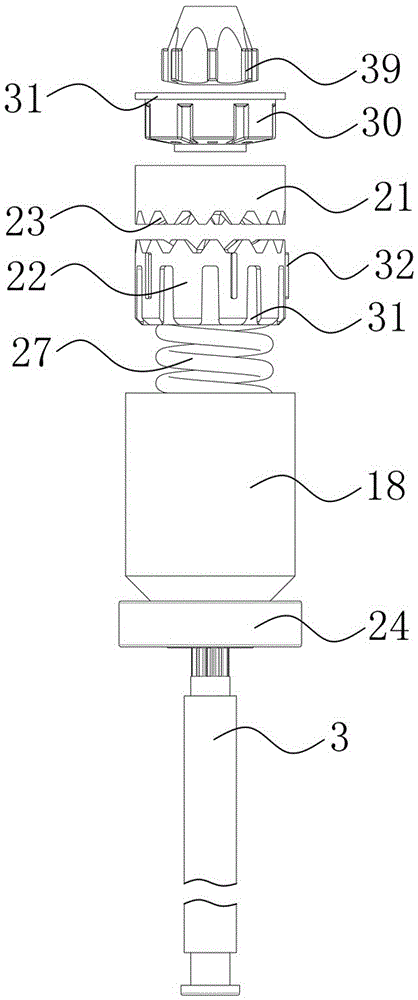

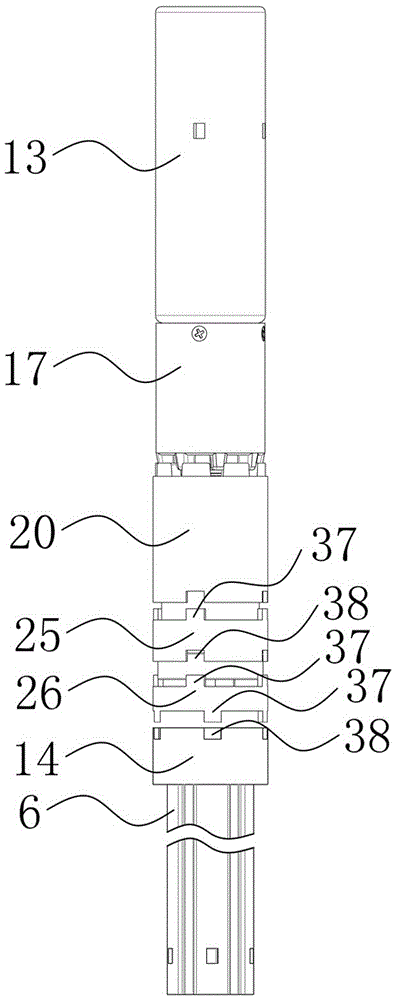

Linear type power operated tailgate supporting rod of car trunk

ActiveCN105696894ARealize automatic openingAchieve closureWing fastenersPower-operated mechanismElectricityBearing capacity

The invention discloses a linear type power operated tailgate supporting rod of a car trunk. The linear type power operated tailgate supporting rod is used for a car, opening and closing of a tailgate can be achieved only through electric connection of a tailgate opening and closing button and a motor, the tailgate does not need to be manually operated, and opening and closing are convenient, rapid and labor-saving. According to the linear type power operated tailgate supporting rod, people and the tailgate can be protected, hand clamping and head bumping caused by tailgate opening or closing or personal injuries, tailgate paint peeling off and the like caused by other objects are avoided, and the linear type power operated tailgate supporting rod has the beneficial effects of being small in size, good in waterproof sealing performance, convenient to mount, reliable in running, large in bearing capacity, low in noise and the like.

Owner:DONGYANG GANTE ELECTRICAL CO LTD

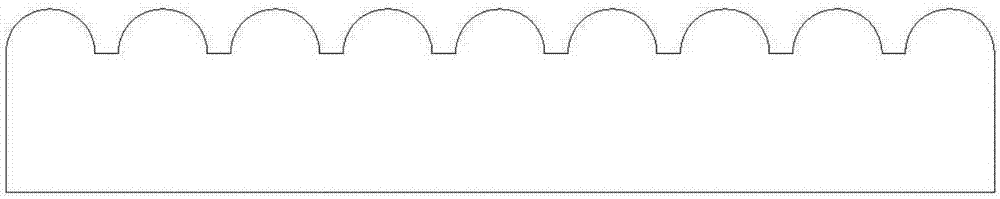

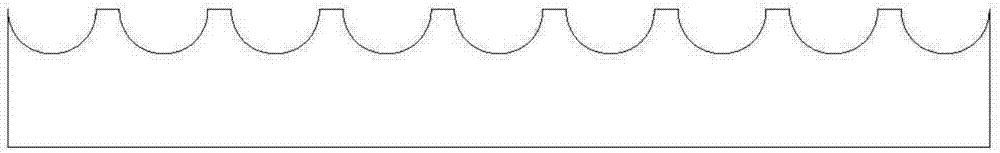

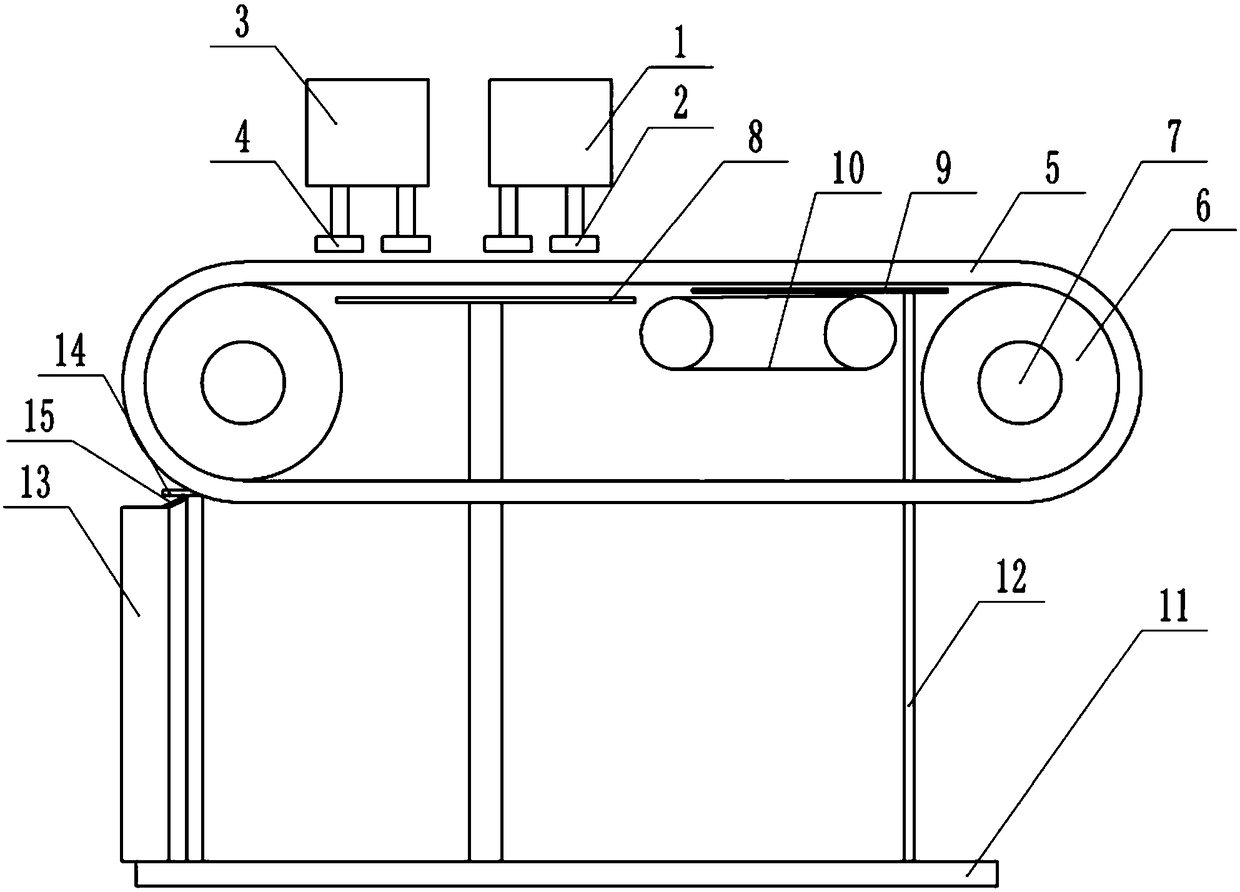

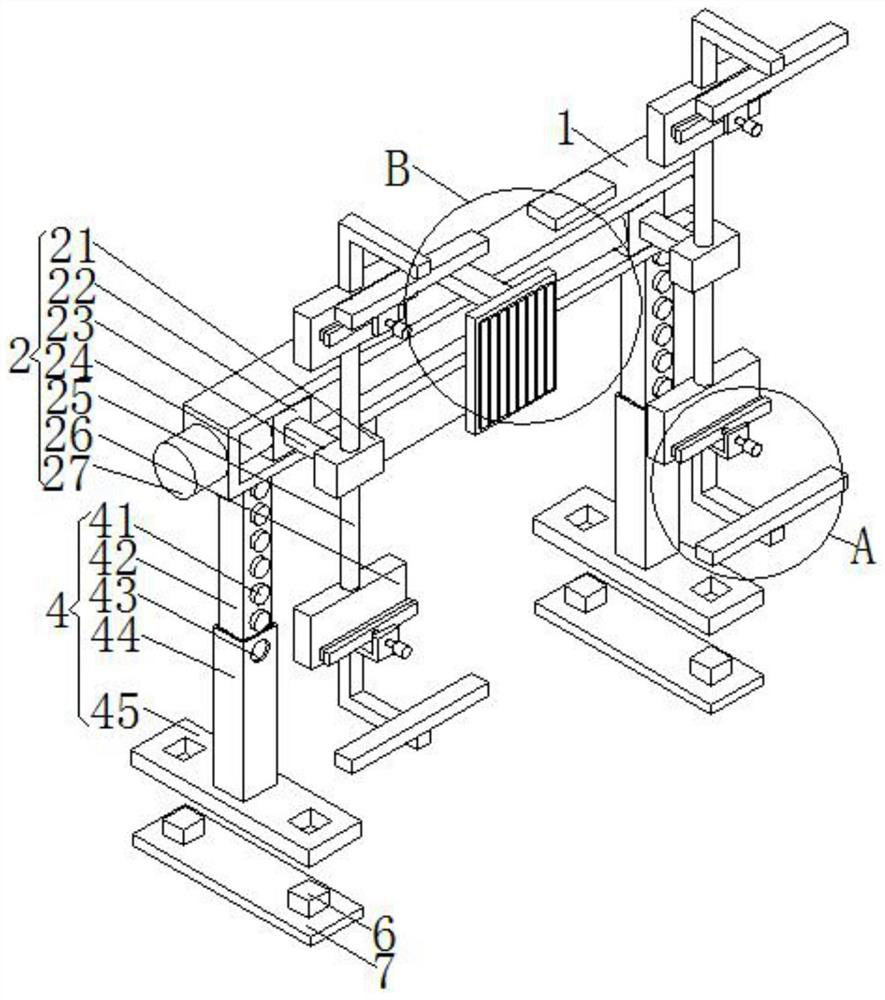

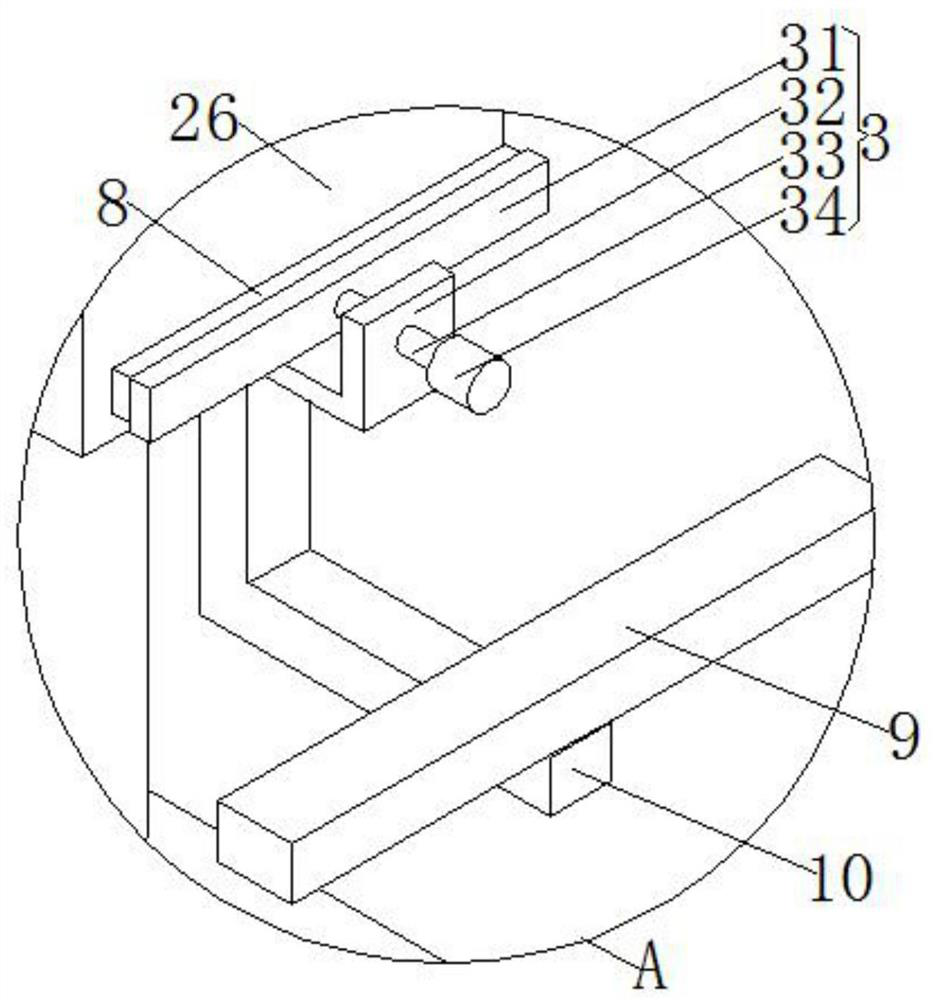

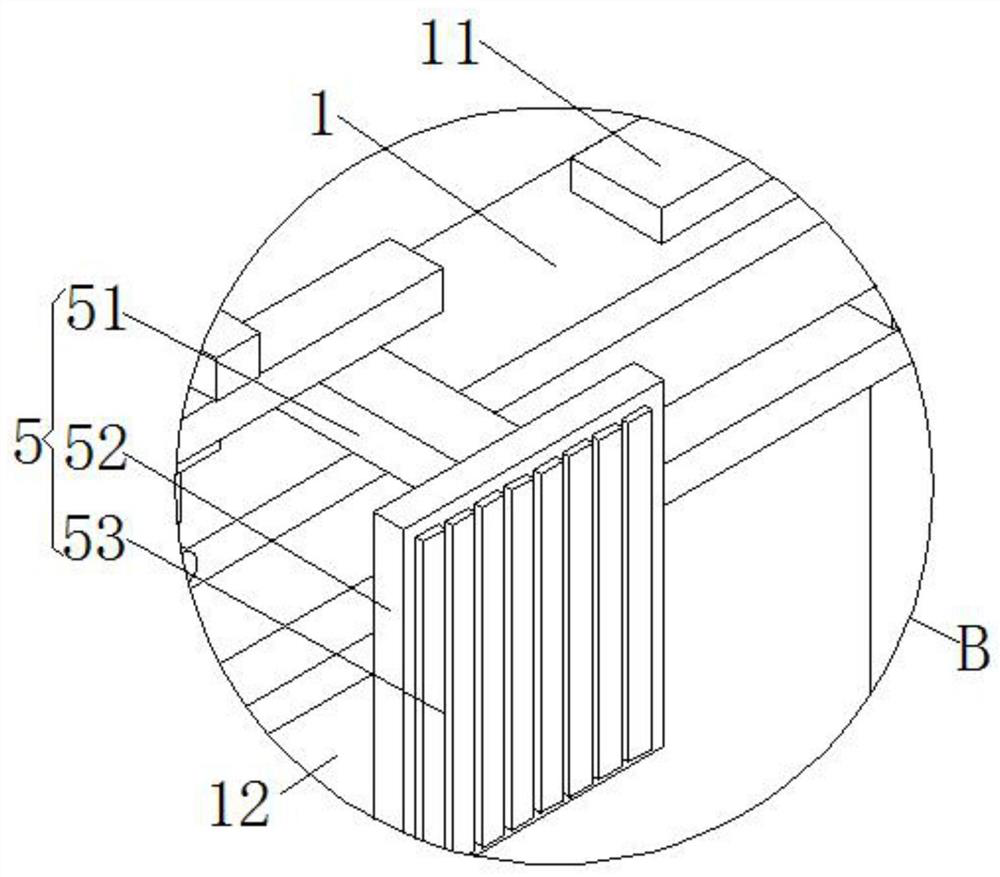

Plastic product surface imitation metal automatic wire-drawing device and process

PendingCN107414637AAvoid damageAvoid peeling paintAutomatic grinding controlGrinding machinesMaterials scienceIndustrial engineering

The invention relates to the technical field of plastic product surface wire drawing, in particular to a plastic product surface imitation metal automatic wire-drawing device and a process. The process comprises the steps that firstly, a plastic product is formed in an injection molding manner through a mould; then the plastic product is subjected to paint spraying treatment; and then the surface of the plastic product is subjected to wire-drawing treatment through the automatic wire-drawing device. According to the device and process provided by the invention, the surface of the plastic product is subjected to wire-drawing treatment, a wire-drawing portion of the plastic product is in an inwards-concave wave shape, the situation that during carrying or transportation or using of the plastic product, the wire-drawing portion is damaged, paint is peeled off, and consequentially the product is probably scraped can be effectively avoided, and the production cost of enterprises is lowered; and in addition, the surface of the plastic product is directly coated with paint after injection molding of the plastic product is completed, then wire-drawing is performed, the gap between every two adjacent wave valleys is not filled with the sprayed paint, and the wire-drawing effect is improved.

Owner:东莞市万协塑胶科技有限公司

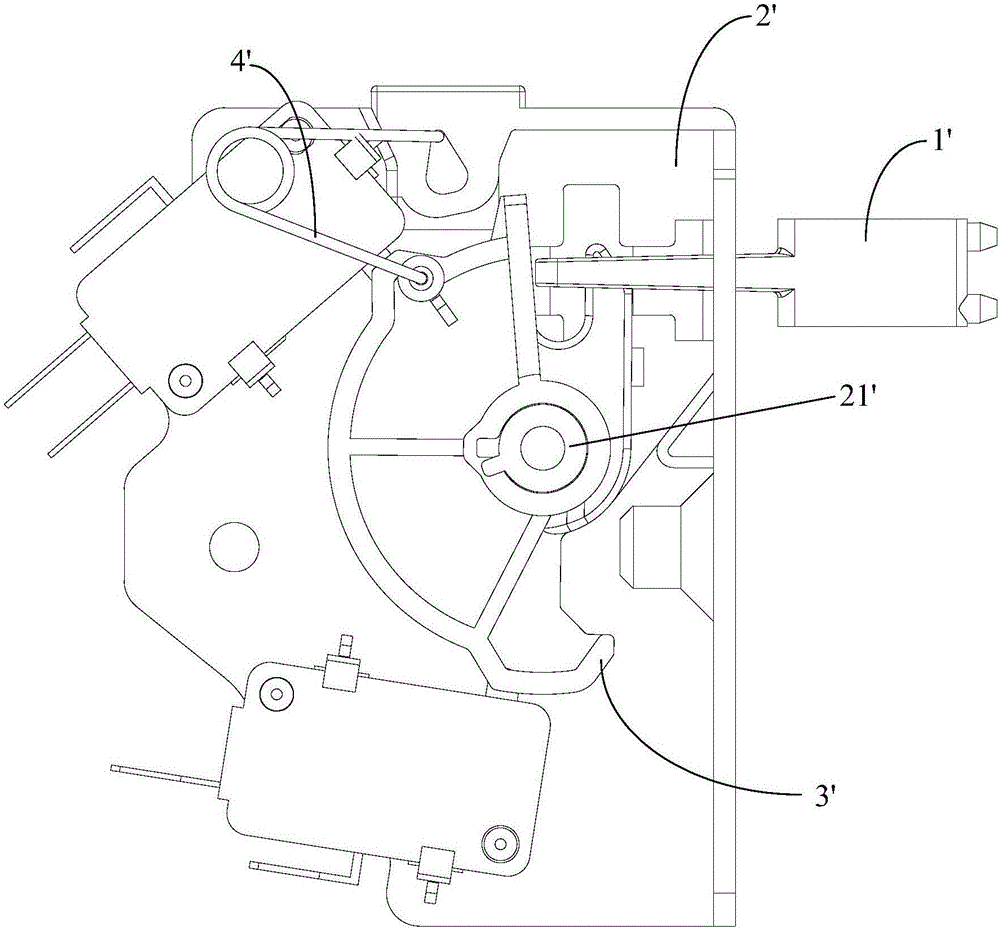

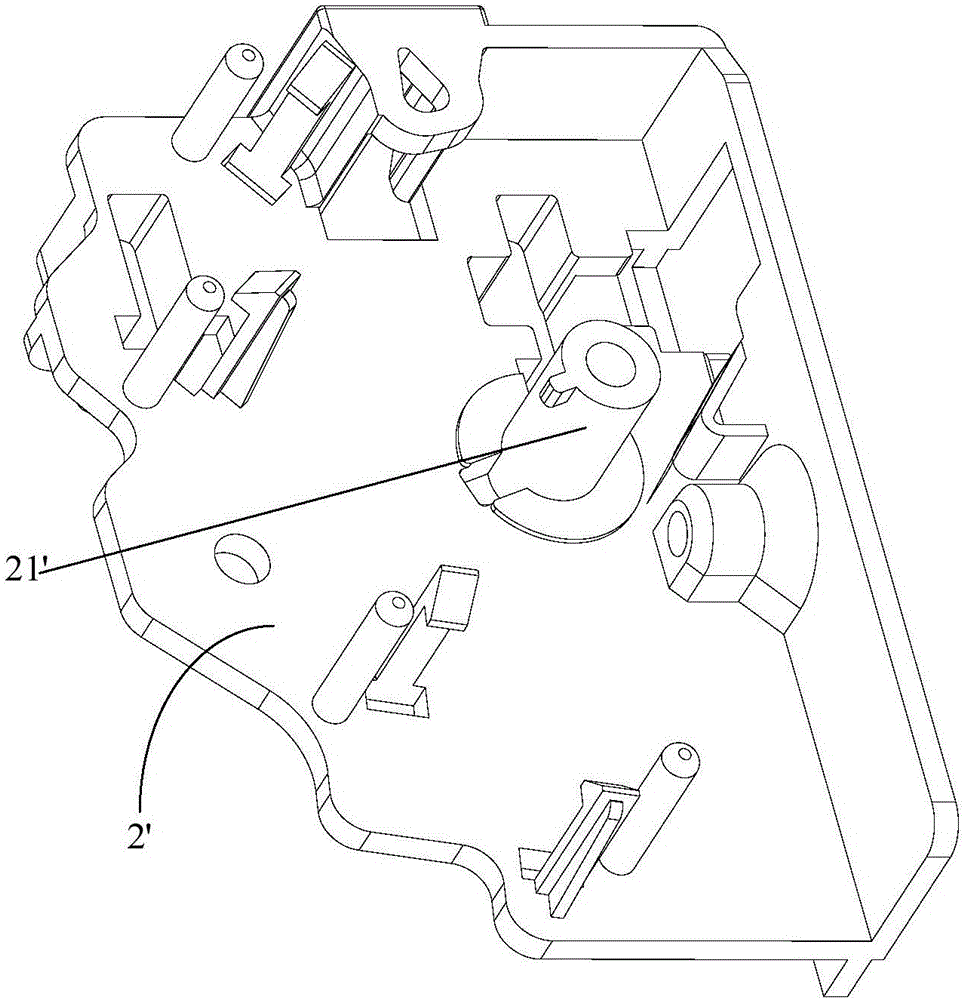

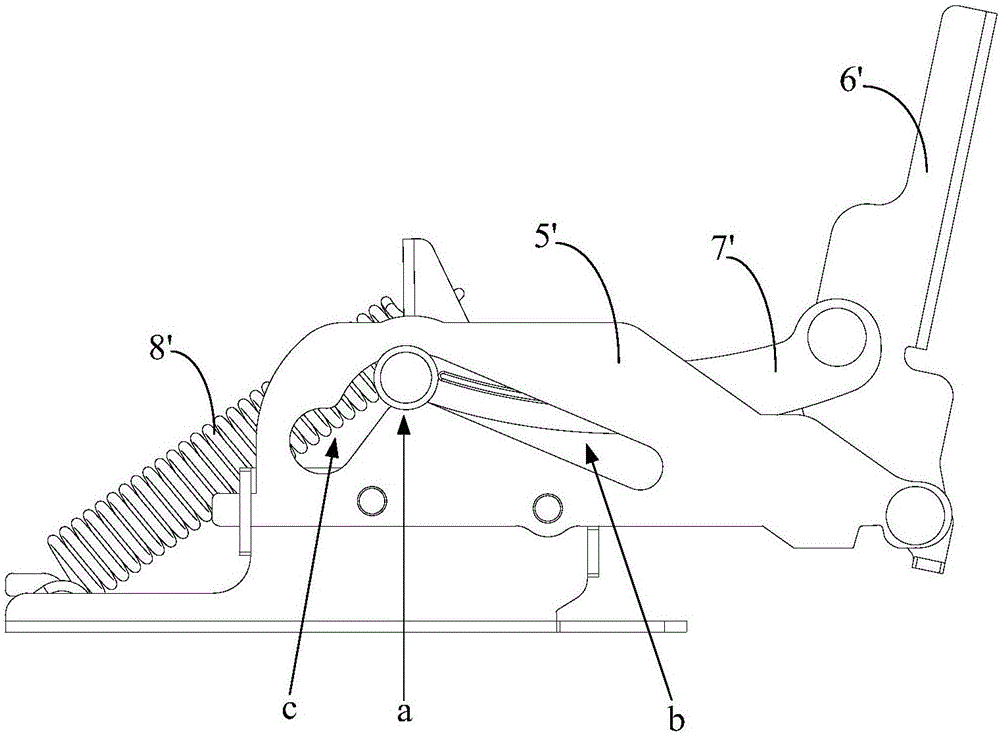

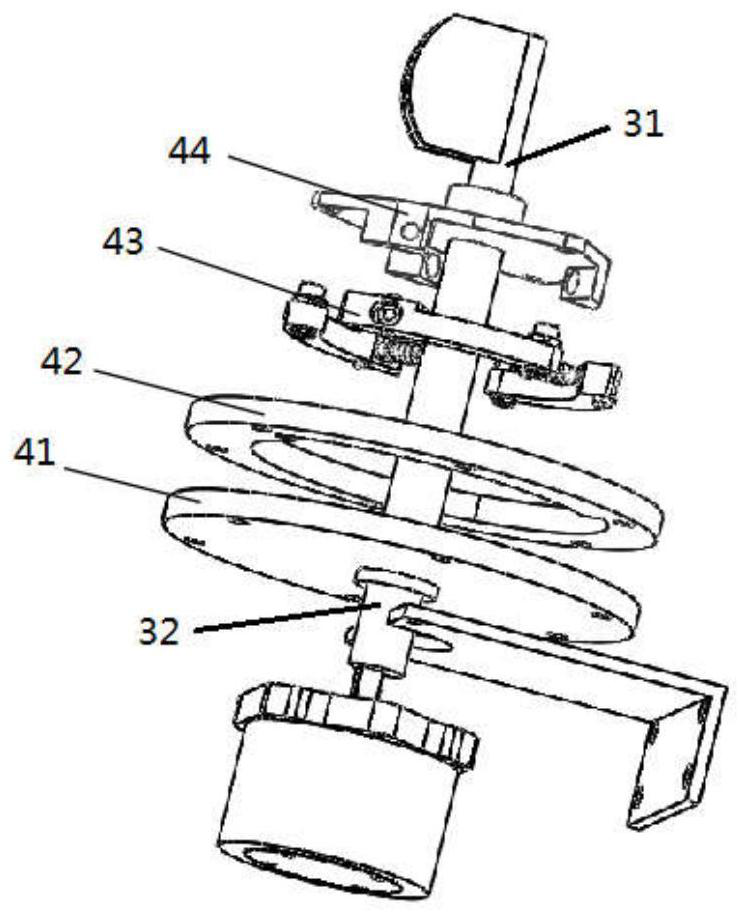

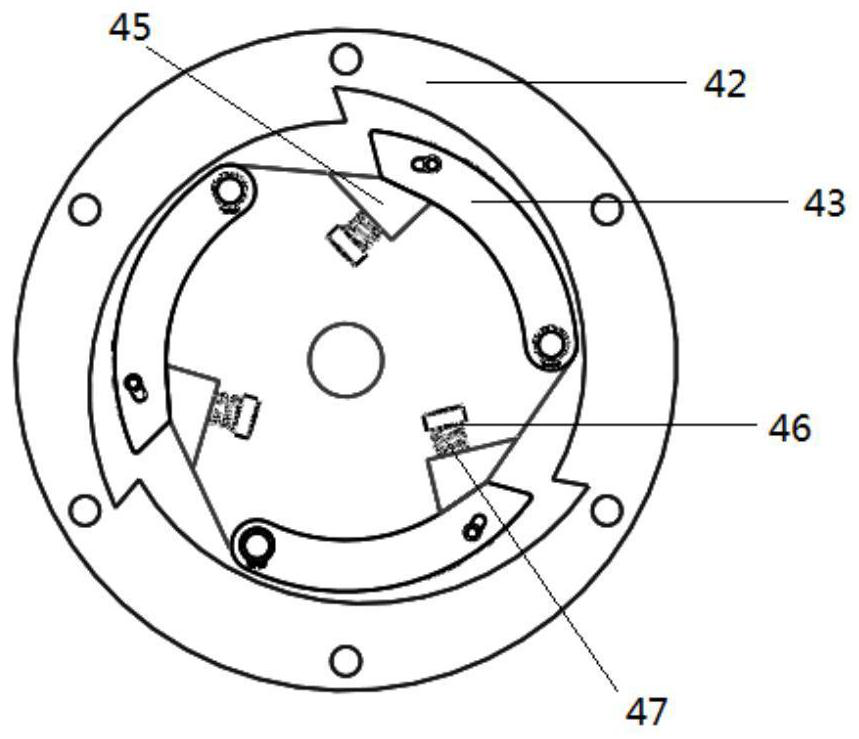

Interlocking assembly and cooking utensil

ActiveCN106812393AReduce momentumReduce shockBuilding locksRoasters/grillsEngineeringMechanical engineering

The invention provides an interlocking assembly and a cooking utensil. The interlocking assembly comprises a door hook, an interlocking support, an interlocking rotary block, a positioning torsional spring and a buffer device. According to the scheme, the buffer device is additionally arranged on the basis of an existing interlocking assembly, a door body is in an open state, the interlocking rotary block is in an unlocking position, and the door hook and the interlocking rotary block are separated; and in the door closing process, the door hook abuts against the interlocking rotary block and then pushes the interlocking rotary block to rotate, the buffer device applies resistance to the interlocking rotary block in the process that the interlocking rotary block rotates to a locking position from the unlocking position, momentum of the door body is reduced so that impact to a box body front plate can be reduced when the door body is closed, and thus the problem that paint of the box body front plate or the door body is peeled off due to the fact that door closing force of a user or a tension hinge is too large is solved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

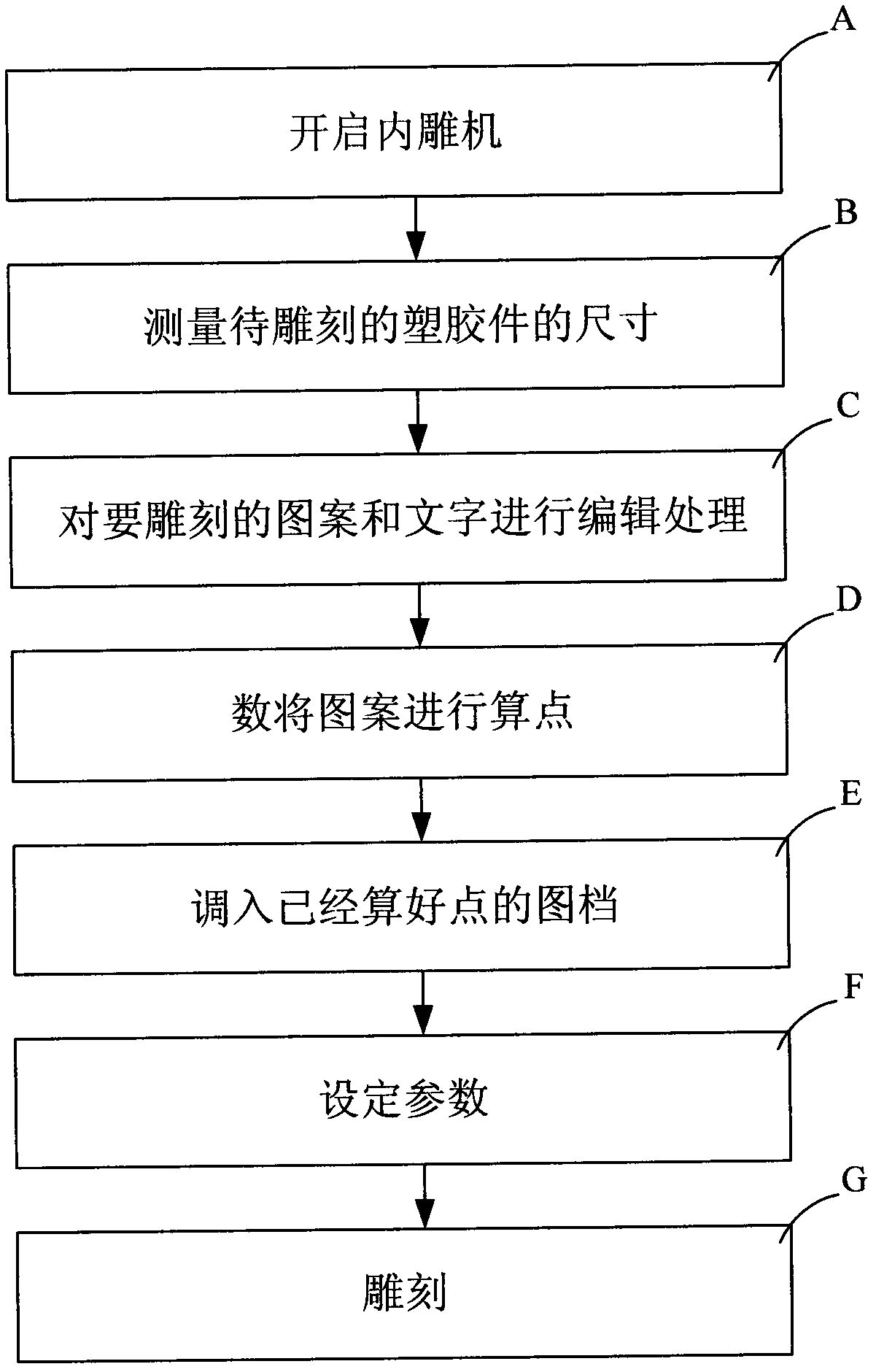

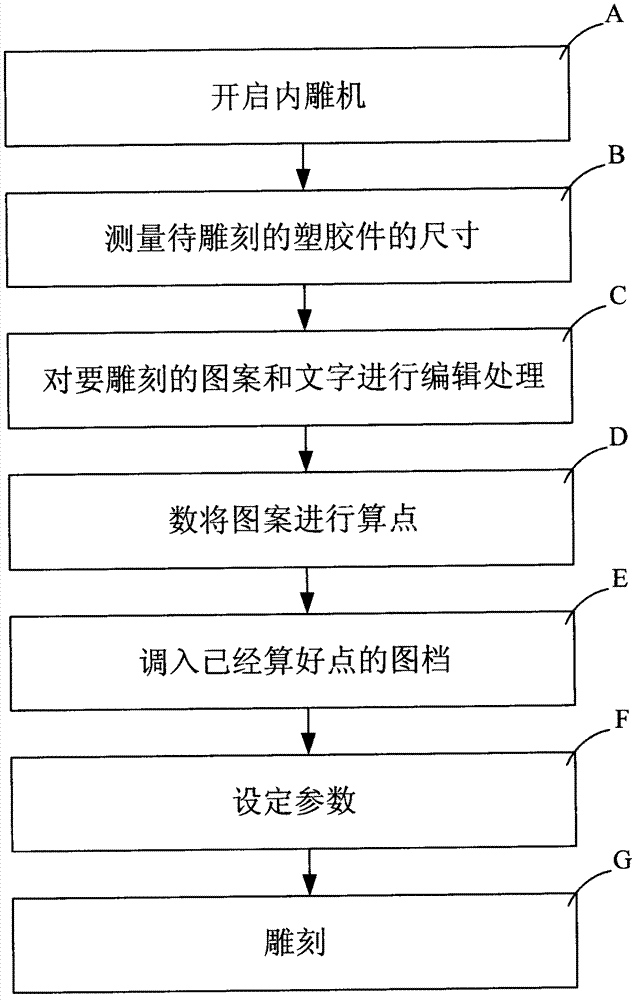

Laser engraving method of plastic component

InactiveCN103029498AAvoid peeling paintInhibit sheddingEngravingEnvironmental resistanceMaterial consumption

The invention relates to a laser engraving method of a product, in particular to a plastic component laser engraving method for engraving any pattern or mark in an elastic workpiece with one layer being lucent. Laser engraving is carried out inside the plastic component at least comprising one layer of transmission material. The method comprises the following steps of starting a laser engraving machine; measuring the size of the plastic component to be engraved; editing the patterns and characters; calculating points of the patterns; calling in a picture file, selecting product dimensional specification and setting parameters; and carrying out the engraving. Due to the adoption of the laser engraving method of the plastic component, not only can the display effect of the patterns and characters of the traditional process be realized, but also the defects of the traditional process such as paint dropping, dropping, color fading, non-abrasion resistance, short service life, easiness for storing dirt, environmental pollution and incapability of individualized production can be solved; and moreover, a novel high-efficient and environment-friendly technique for producing any pattern and character with no material consumption can be realized, and a broad individualized exhibition platform can be provided for the individualized times.

Owner:东莞市光威激光科技有限公司

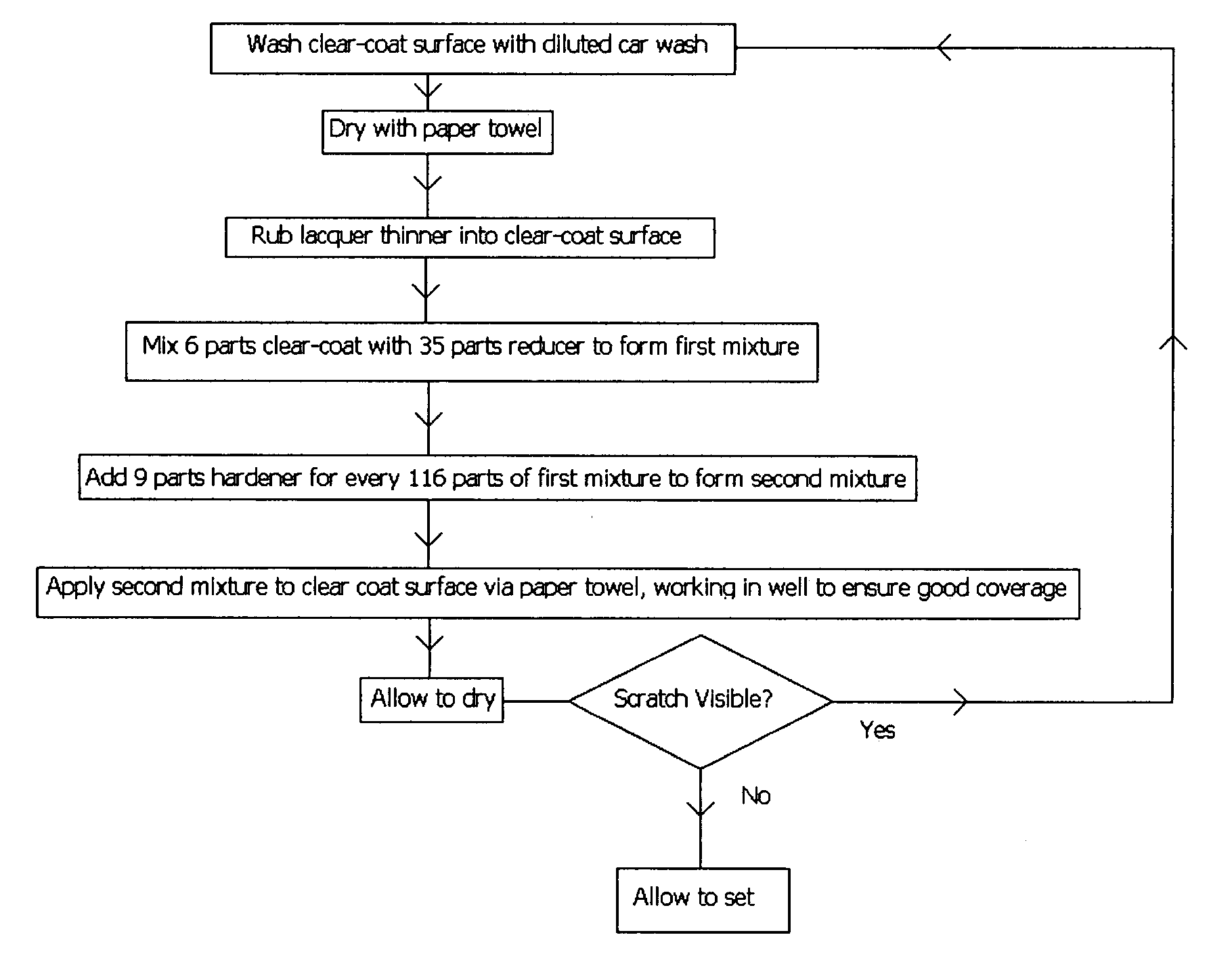

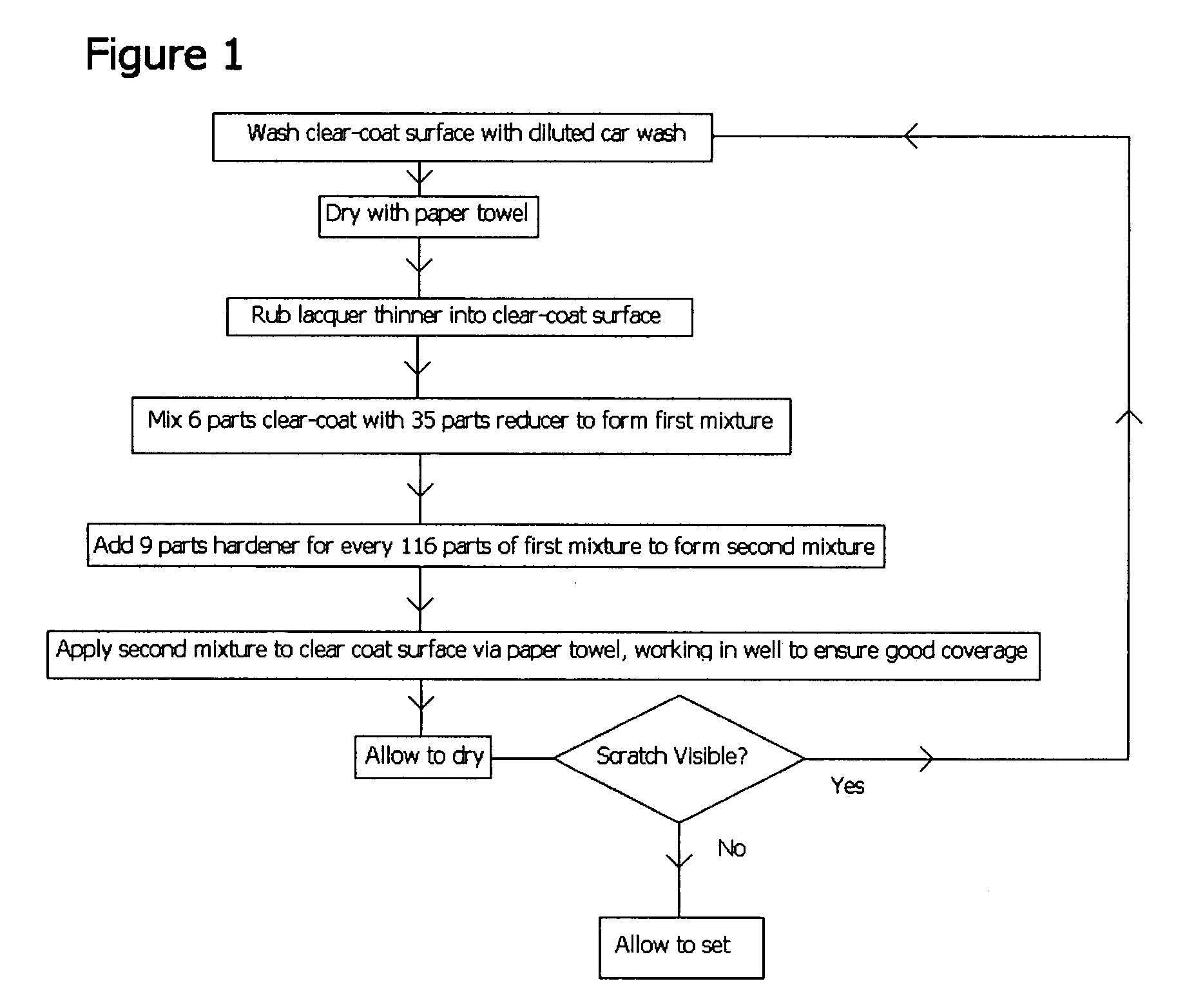

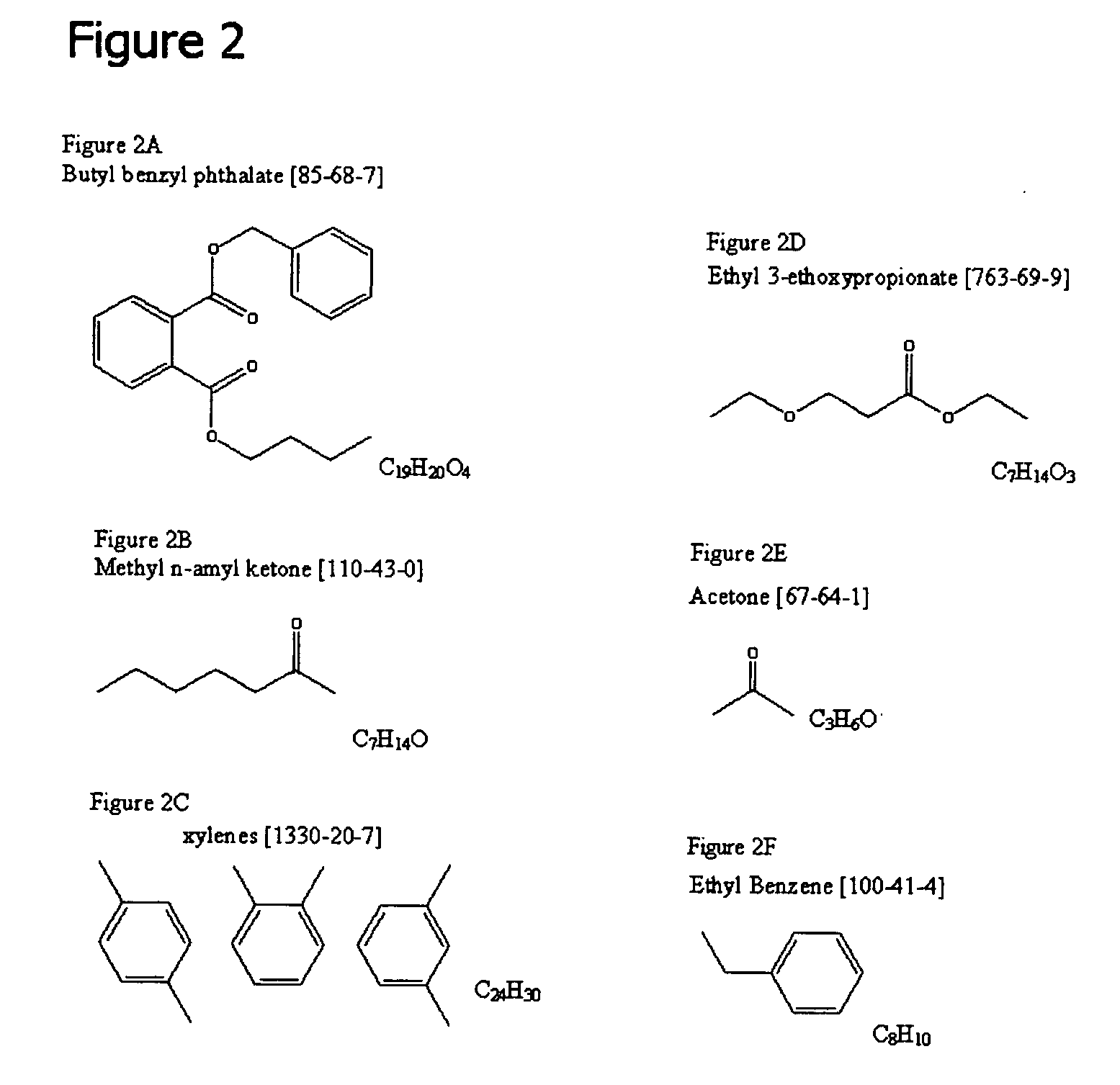

Clear-coat scratch repair composition and refinishing process

InactiveUS20090017199A1Insufficient time for applicationExcessive curing timeLayered productsPretreated surfacesSufficient timeDrying time

The present invention discloses a composition and method for repairing scratches to vehicles and other products which have clear-coat finishes. The composition contains a clear-coat combined with a reducer, to which a hardener is added before application. The threshold proportions of the composition are critical to the composition's effectiveness as they produce a long drying time and a fast cure time. This enables the composition to be worked-into the clear-coat surface for sufficient time to obtain excellent coverage, and to cure quickly after it is applied. The composition can be reapplied as often as desired.

Owner:KOTYAKOV ALEX

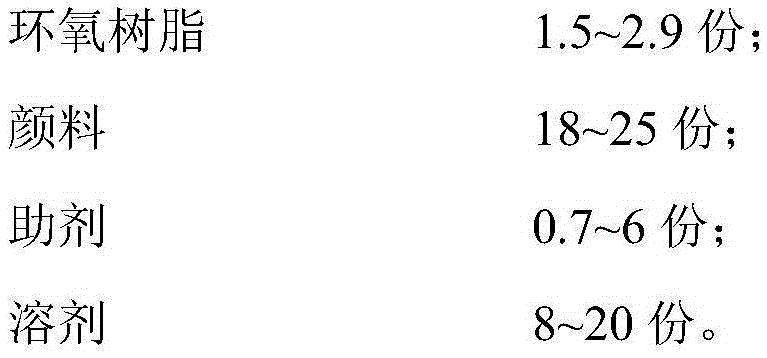

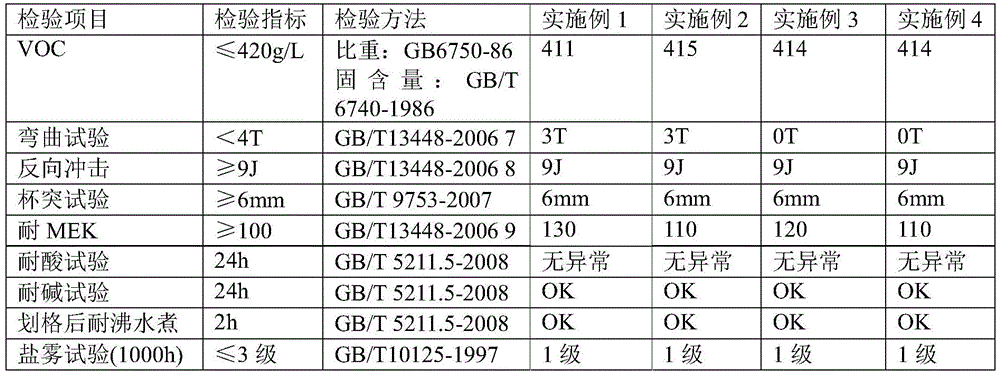

Thick plate polyurethane primer and preparation method thereof

InactiveCN105602435AGood flexibilityHigh resistance to salt sprayAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolyester

The invention discloses a thick plate polyurethane primer which comprises the following ingredients in parts by weight: 17-35 parts of polyester resin, 2-6 parts of amino resin, 2-6 parts of isocyanate, 1.5-2.9 parts of epoxy resin, 18-25 parts of pigment, 0.7-6 parts of an auxiliary agent and 8-20 parts of a solvent. The invention also discloses a preparation method of the thick plate polyurethane primer. The T bend of the thick plate polyurethane primer provided by the invention can reach 0T without cracks, the flexibility is good, and a paint peeling phenomenon is avoided in a processing process; the salt spray resistance is high; by virtue of cooperation of the thick plate polyurethane primer and a polyester topcoat with common performances, the salt spray test achieves grade 1 within 1000 hours; the adhesive force with a substrate and the adhesive force with the topcoat are superior to those of traditional epoxy primer and polyester primer. Compared with the traditional primer, the thick plate polyurethane primer provided by the invention has relatively excellent adhesive force, flexibility and chemical corrosion resistance.

Owner:NIPPON PAINT TIANJIN

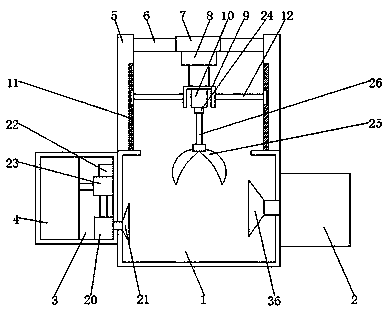

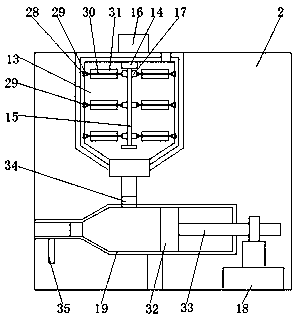

Automobile touch-up painting equipment based on paint peeling-off because of automobile scratching

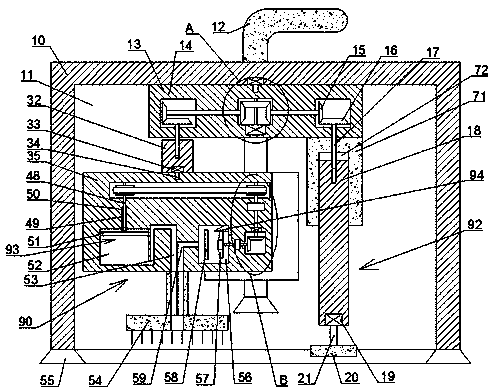

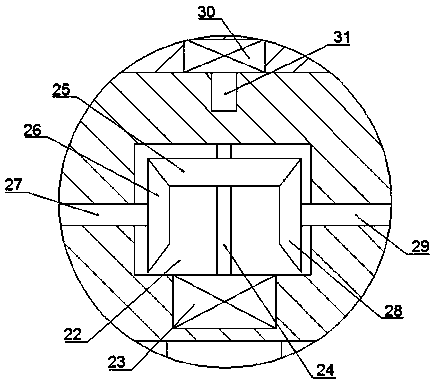

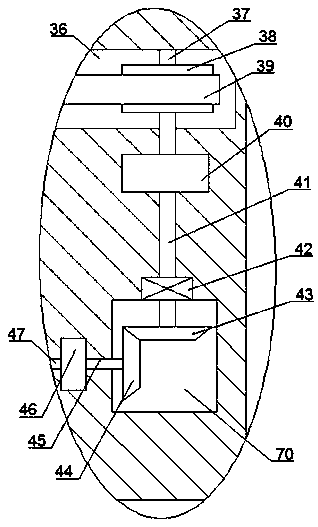

ActiveCN110575936AAvoid unevennessPrevent sprayingPolishing machinesGrinding drivesCleansers skinSpray nozzle

The invention discloses automobile touch-up painting equipment based on paint peeling-off because of automobile scratching. The automobile touch-up painting equipment comprises a casing, wherein the casing is internally provided with a middle cavity; a first rotating block is rotationally arranged at the top of the middle cavity; the bottom center of the first rotating block is symmetrically provided with a cleaning mechanism, a paint spraying mechanism and a polishing mechanism; the cleaning mechanism comprises a cleanser supplying mechanism and a drying mechanism; the paint spraying mechanism comprises a spray gun body and a spray nozzle; the spray gun body is internally provided with a wind cavity; the wind cavity is internally provided with an air pump mechanism; and the spray gun bodyis internally provided with a storage cavity. According to the equipment, the cleaning mechanism cleans the paint peeling-up part of the automobile outer wall; the air pump mechanism provides power for the paint spraying work of a paint spraying machine; the paint spraying mechanism sprays paint to the paint peeling-off part of an automobile; and the polishing mechanism grinds and polishes the paint spaying part.

Owner:WM MOTOR TECH GRP CO LTD

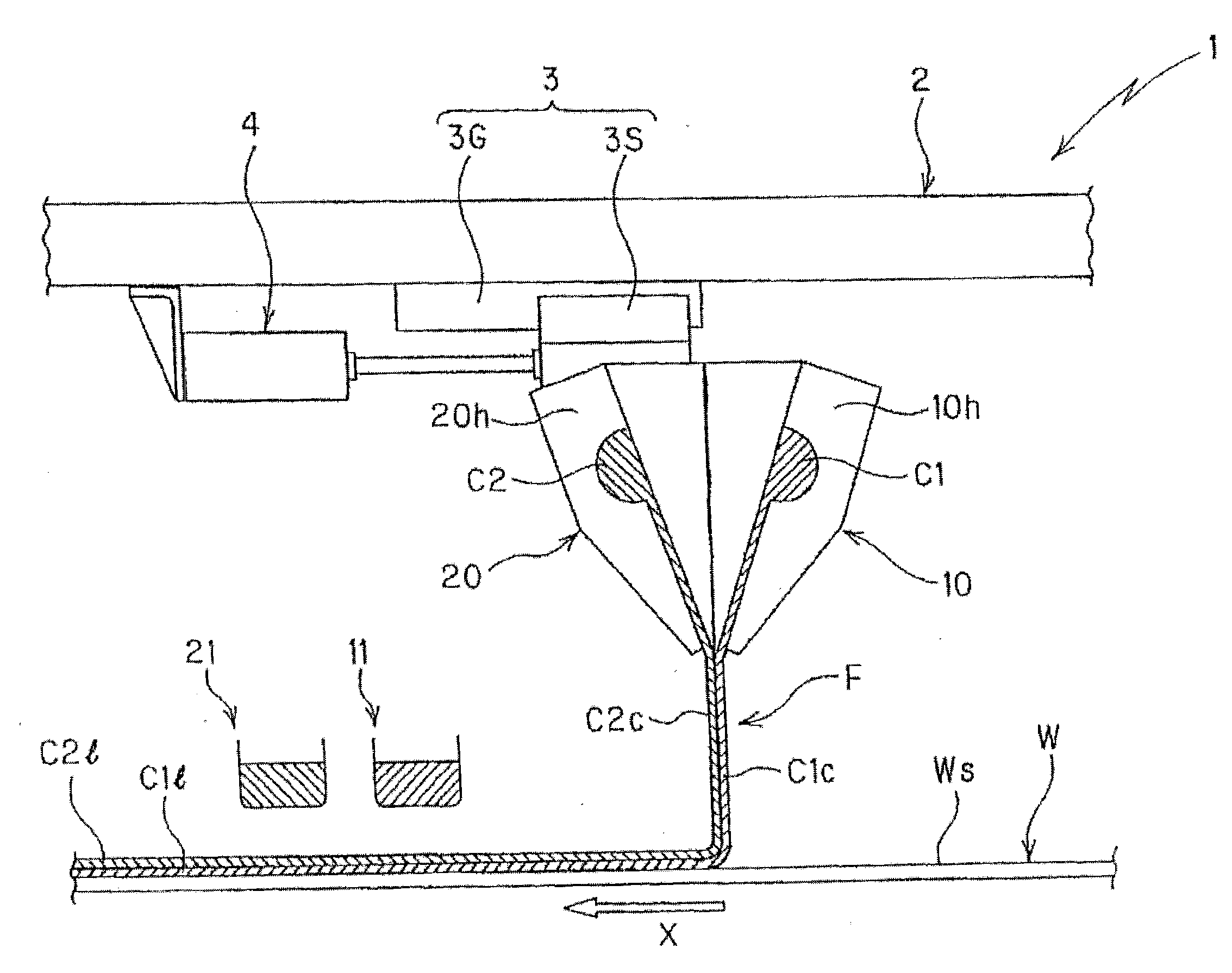

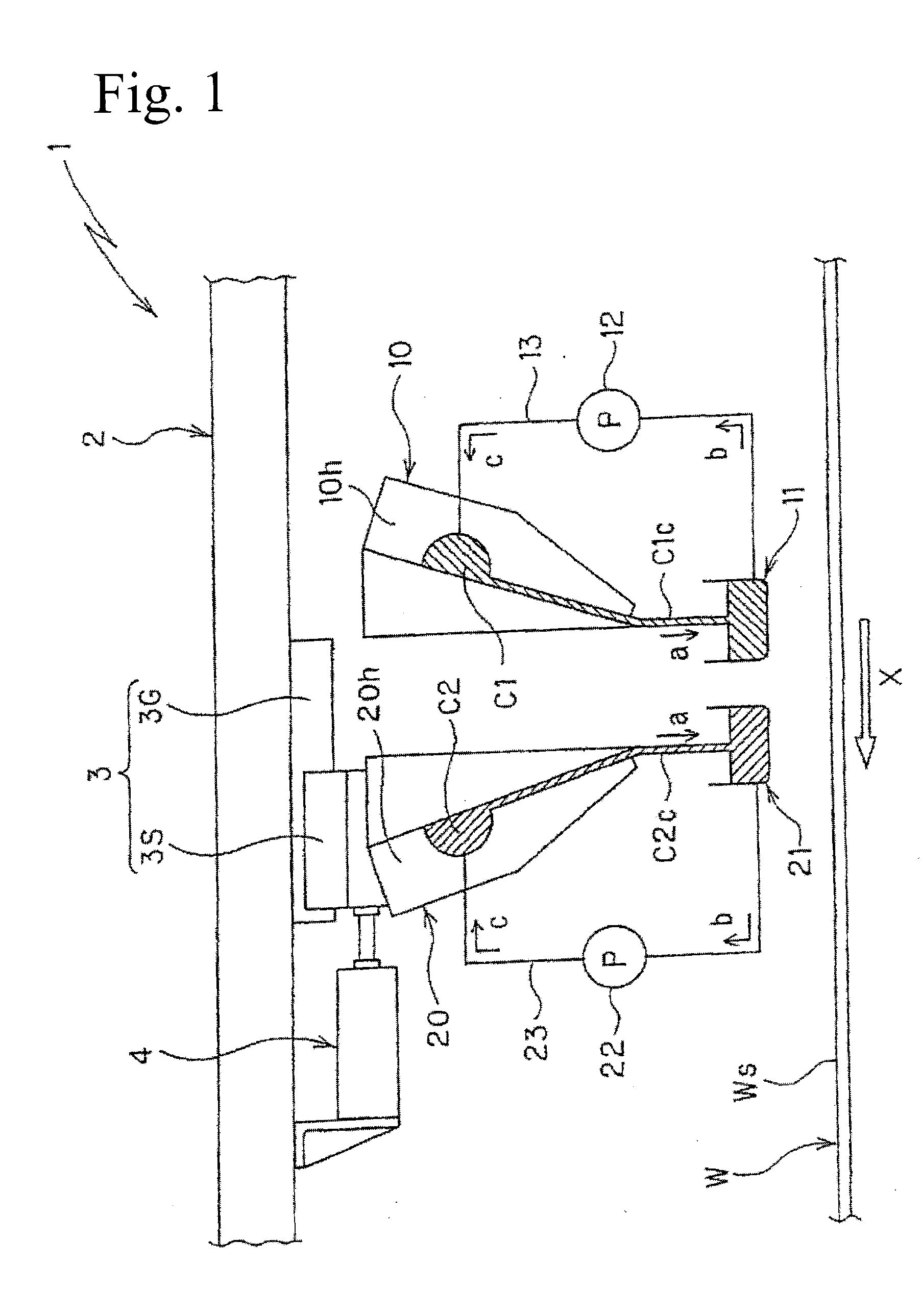

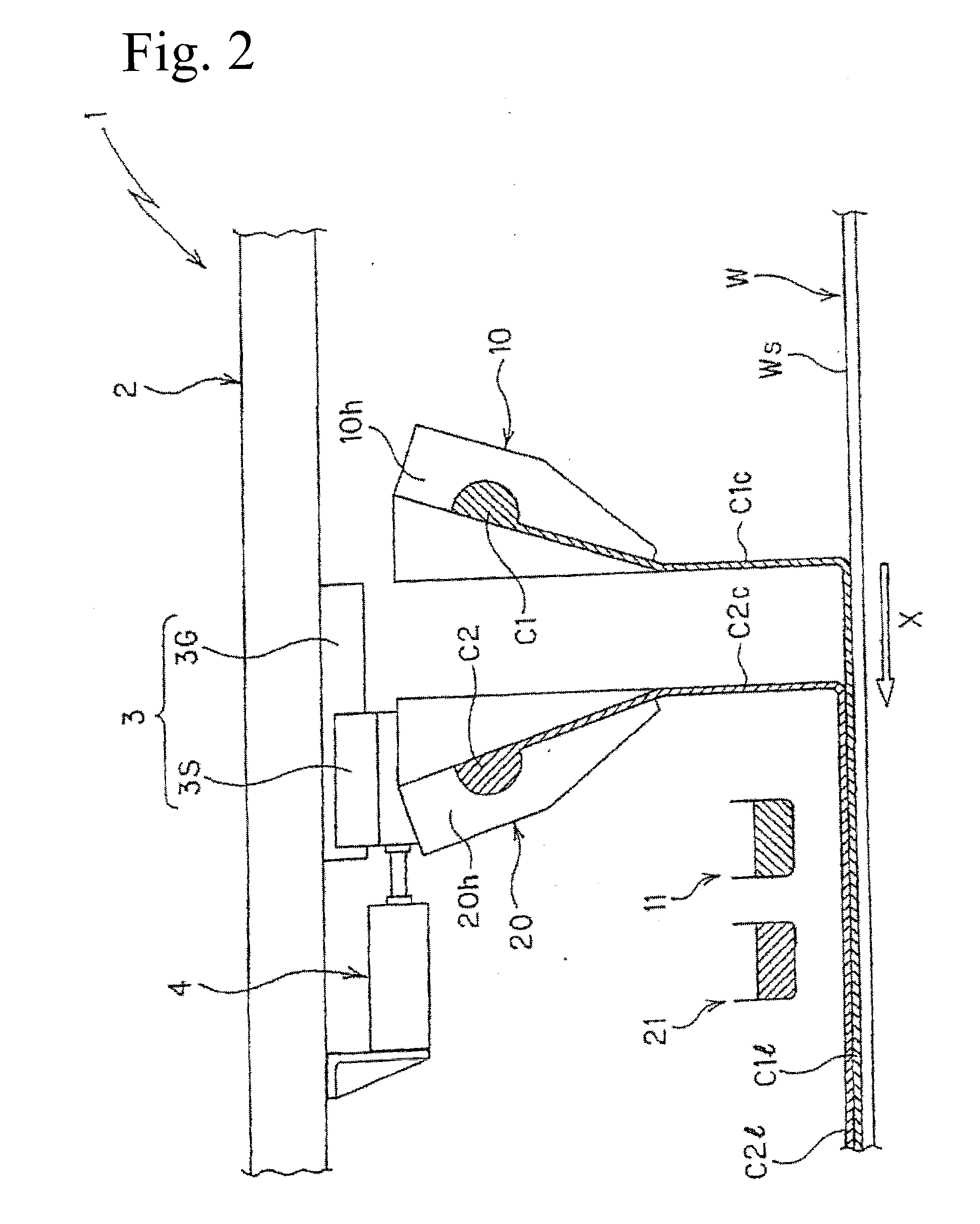

Two-layer curtain coater system

InactiveUS20080178799A1Avoid peeling paintLiquid surface applicatorsLiquid spraying apparatusCoatingNozzle

The present invention provides a 2-layer curtain coater that supplies a 2-layered paint curtain formed from a first paint curtain and a second paint curtain to the surface of a transported web to overcoat a first paint and a second paint in two layers on the surface of the web, the 2-layer curtain coater being able to prevent paint loss during coating preparation. The 2-layer curtain coater includes a first curtain nozzle for the forming of the first paint curtain and a second curtain nozzle for the forming of the second paint curtain and, in addition, in that the first curtain nozzle and the second curtain nozzle are relatively movable between a segregated coating preparation position and a merged coating operation position wherein, in the coating preparation position, the first paint and the second paint are recovered in a state independent of each other by the recovery of the first paint curtain from the first curtain nozzle by way of a first recovery pan and the recovery of the second paint curtain from the second curtain nozzle by way of a second recovery pan and, in the coating operation position, the 2-layered paint curtain is formed from the first paint curtain from the first curtain nozzle and the second paint curtain from the second curtain nozzle to overcoat the first paint and the second paint in two layers on the surface of the web.

Owner:VOITH PATENT GMBH

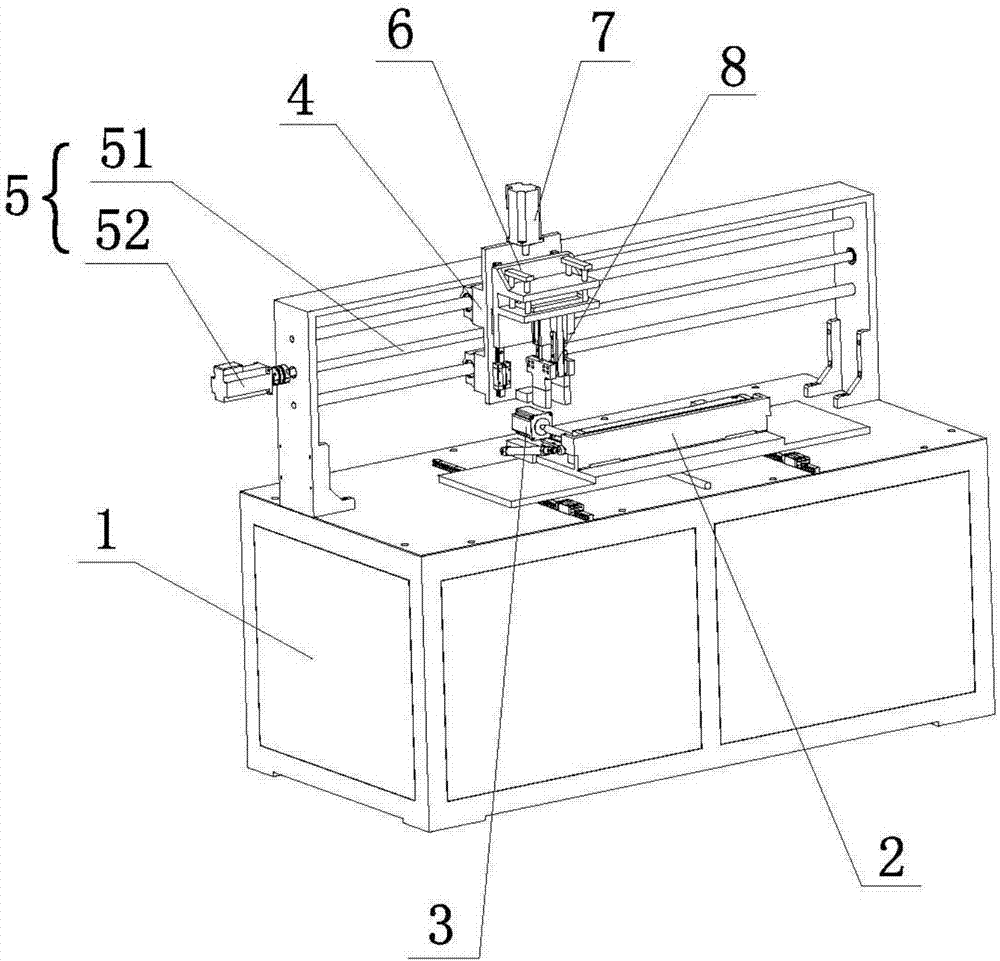

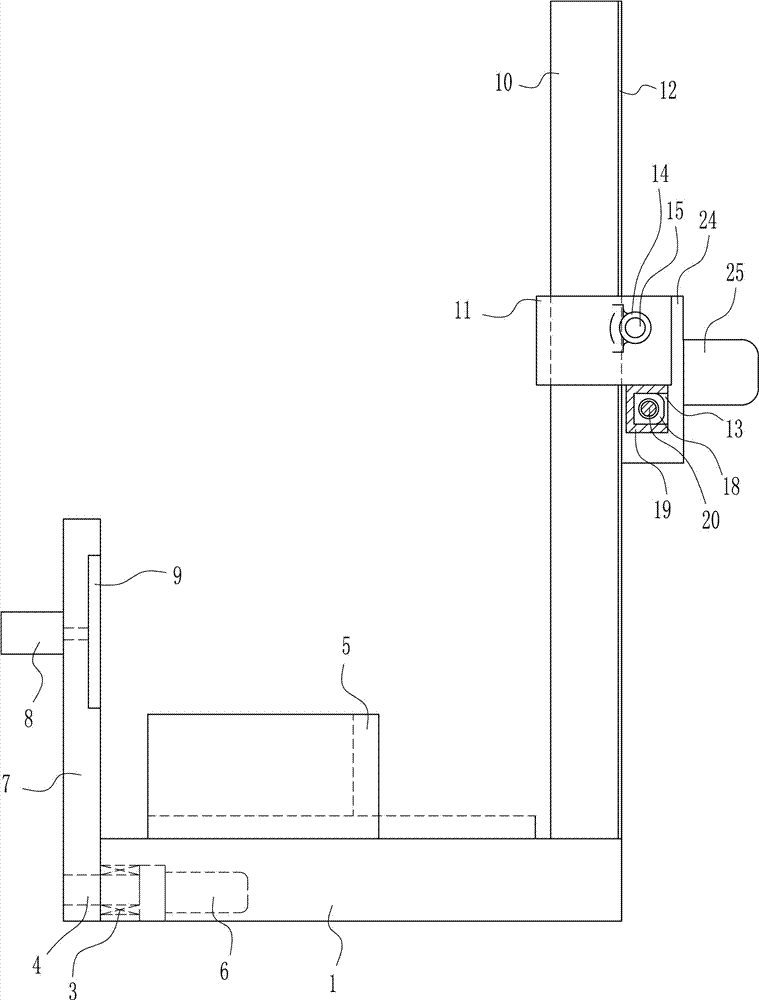

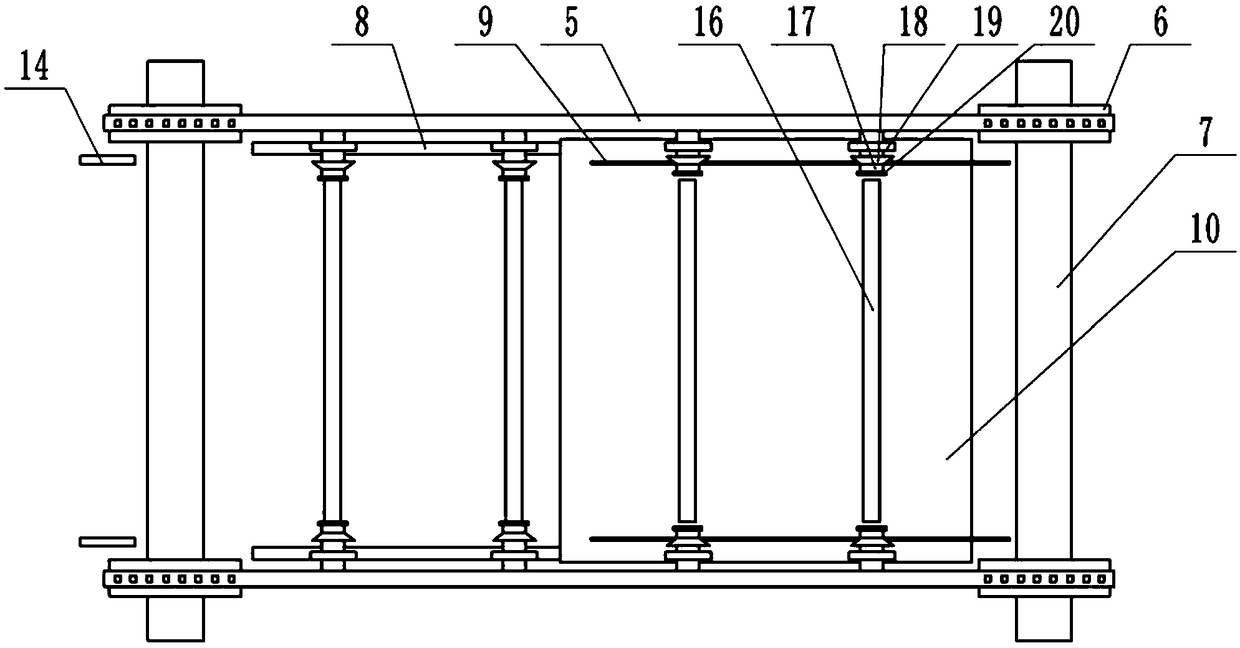

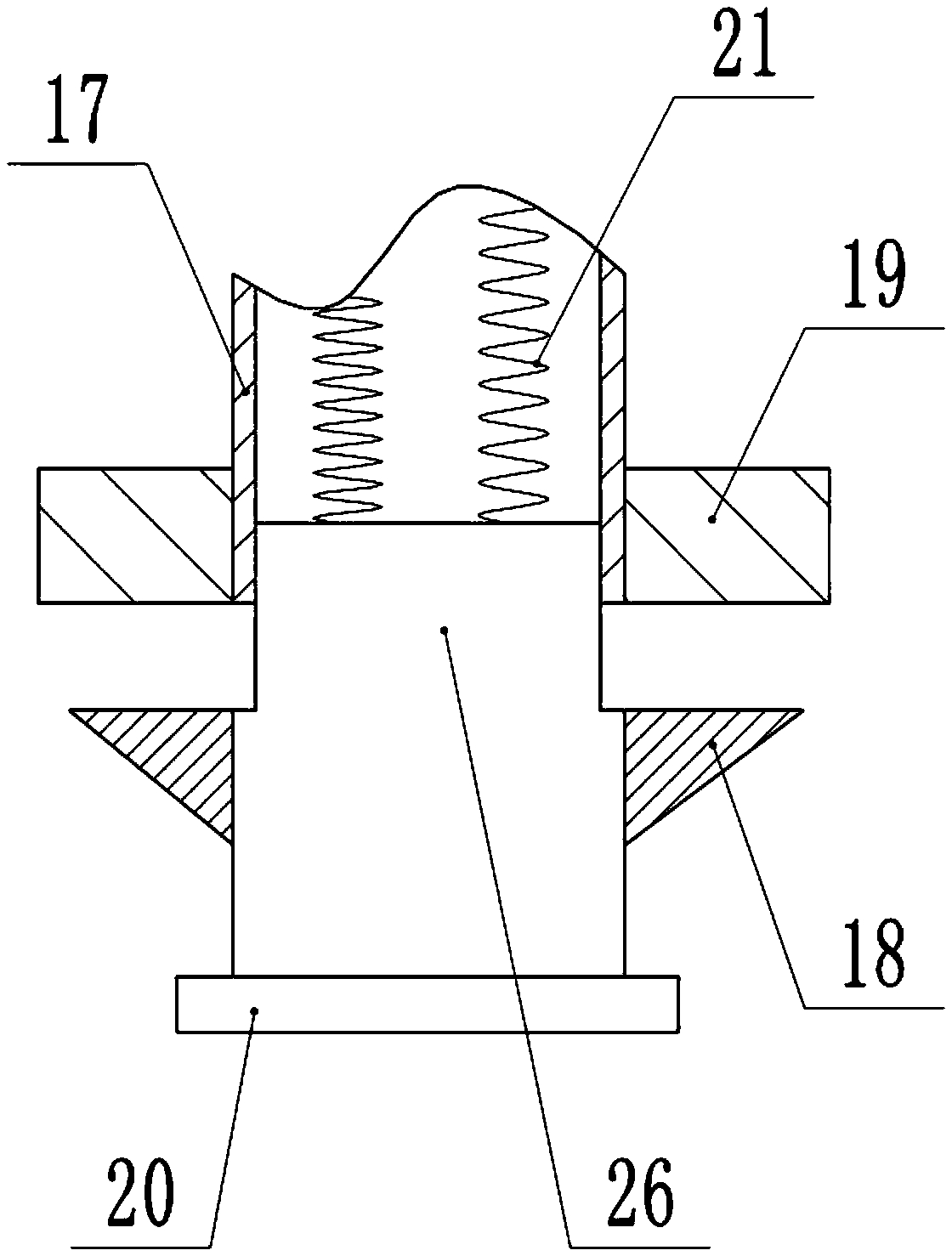

Carving and groove milling device for milling wood door production

ActiveCN106985228AImprove work efficiencyShorten sanding timeProfiling/shaping machinesWood mortising machinesMilling cutterEngineering

The invention relates to a device in the field of woodworking production, in particular to a carving and groove milling device for milling wood door production. According to the technical aims, the carving and groove milling device for milling wood door production can improve the working efficiency, remove machining milling marks, obtain high-requirement surface smoothness, shorten sanding time and prevent paint dropping. In order to achieve the above technical aims, the carving and groove milling device for milling wood door production is provided and comprises a base, rollers, a first bearing block, a first rotating shaft, a positioning device, a first motor, a fixed rod, multiple stages of oil cylinders, a push plate, a sliding column, a sliding base, a rack and the like; and the rollers are evenly installed at the top of the base at intervals in a bolt connecting manner. According to the device, multiple wood doors are placed through the positioning device while wood door carving and groove milling machining is carried out, an opposite direction milling cutter is used in cooperation to achieve secondary refined milling, and therefore the working efficiency is achieved, and the machining milling marks can be removed.

Owner:新昌县云大农业有限公司

Coating construction method of assembly type wall plate

The invention discloses a coating construction method of an assembly type wall plate. The coating construction method includes the following steps that putty is scraped on a wall surface for 1-3 timesto make the wall surface be flat. According to the putty, the weight matching of latex to talcum powder (or large white powder) to 2% carboxymethylcellulose is 1:5:3.5, and the weight matching of polyvinyl acetate emulsion for kitchen, toilet, and shower room to cement to water is 1:5:1. For the first time, waterproof putty is fully scraped transversely through a rubber scraper; for the second time, the waterproof putty is fully scraped vertically through the rubber scraper; for the third time, the putty is filled up through the rubber scraper or the putty is fully scraped through a steel sheet scraper; latex paint is brushed for three times; and in each time, the latex paint is stirred for 5-10 min by using a stirring device. The coating construction method includes the following steps of wall plate cleaning, wall surface cleaning up, wall surface repairing, plate materials inserting connecting, scraping of the putty, and brushing of the latex paint. The coating construction method of the assembly type wall plate is scientific and reasonable in structure, safe and convenient to use; construction operation is facilitated, and working efficiency is improved; the problem of fallingoff of lacquer in seam crossing joints is avoided; adhesion of coating is enhanced and wall plate cracking is avoided; and wholly beauty is enhanced.

Owner:ANHUI DAFU ARCHITECTURAL DECORATION CO LTD

Multifunctional colored pencil core and preparation method thereof

The invention discloses a multifunctional colored pencil core. The multifunctional colored pencil core is prepared from the following raw materials in percentage by weight: 10% of clay, 40% of fine talcum powder, 20% of stearate, 10% of surfactant, 4% of pigment, 6% of sodium carboxymethylcellulose and 10% of micronized refined wax. A preparation method of the multifunctional colored pencil core comprises the following steps: stirring, grinding, storing, pressing, core drying, and end cropping, thereby obtaining the multifunctional colored pencil core. The multifunctional colored pencil core prepared by the preparation method has the advantages that writing on dry materials and wet materials can be realized, if the pencil core is applied to writing on dry paper, the effect of graphite is achieved, and if the pencil core is applied to writing on the wet materials, the effect of a water-soluble colored pencil core is achieved, and therefore, the effect of utilizing one pencil for multiple purposes is achieved.

Owner:LONGKOU YIYOU STATIONERY IND

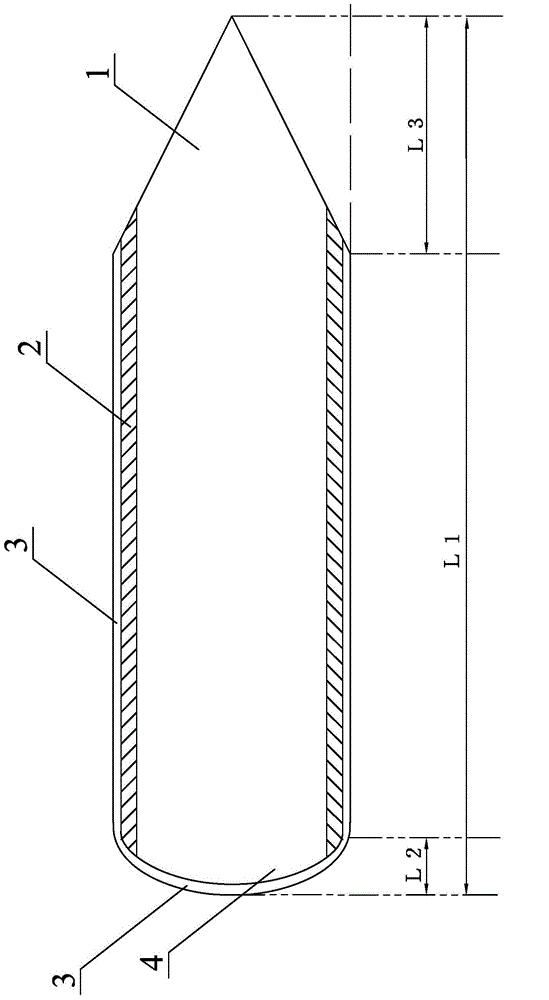

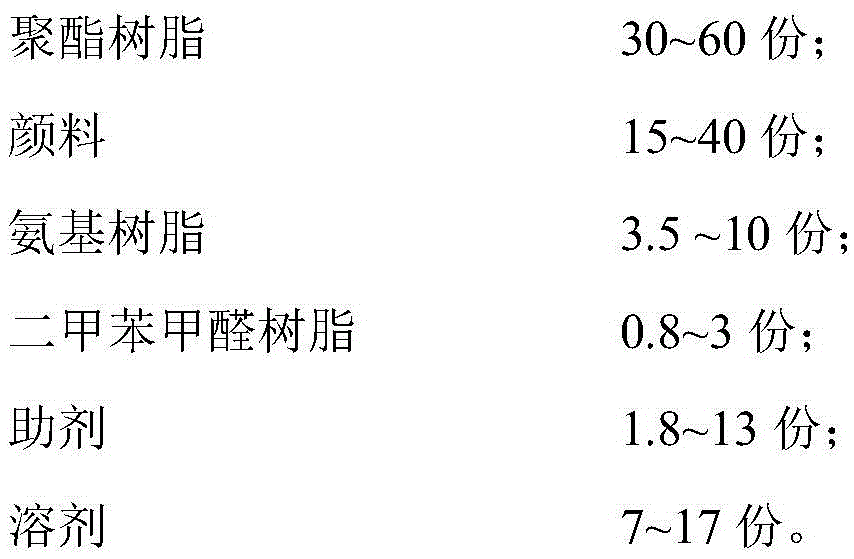

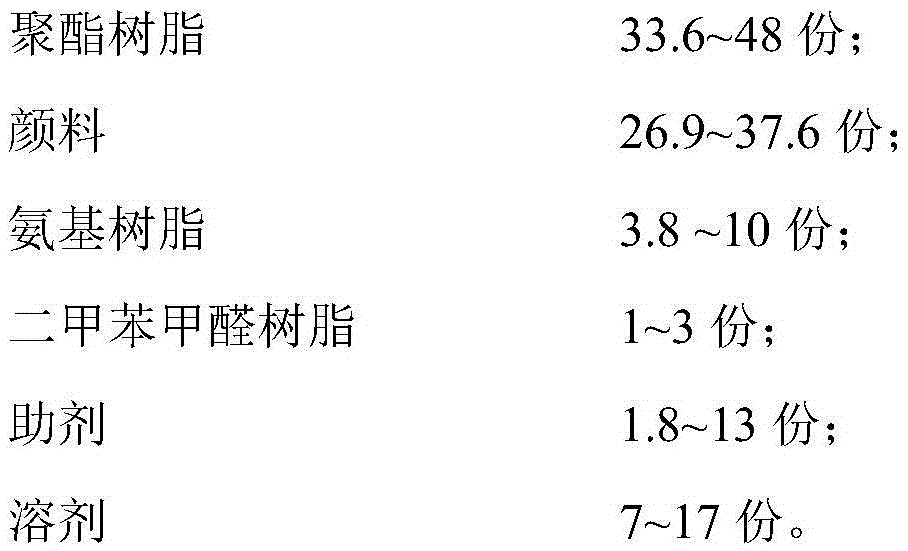

Polyester back coating and preparation method thereof

The invention discloses a polyester back coating, made mainly from the components of following parts by weight: 30-60 parts of polyester resin, 15-40 parts of 15-40 parts, 3.5-10 parts of amino resin, 0.8-3 parts of xylene formaldehyde resin, 1.8-13 parts of aid and 7-17 parts of solvent. The invention also discloses a preparation method of the polyester back coating. Volatile organic matters in the polyester back coating provided by the invention are less than 420 g / l; it is possible for the coating to quickly solidify at PMT (peak metal temperature) 204-232 DEG C; the hardness is up to 6H, compressive strength is excellent, and reverse bonding of the back coating with finish coat is avoided; T-bend performance reaches 4T without peeling, flexibility is good, adhesion is excellent, and peeling-off of the coating is avoided in the processing process; the coating is resistant to more than butanone wipes; the coating can well combine with a foam plate.

Owner:NIPPON PAINT TIANJIN

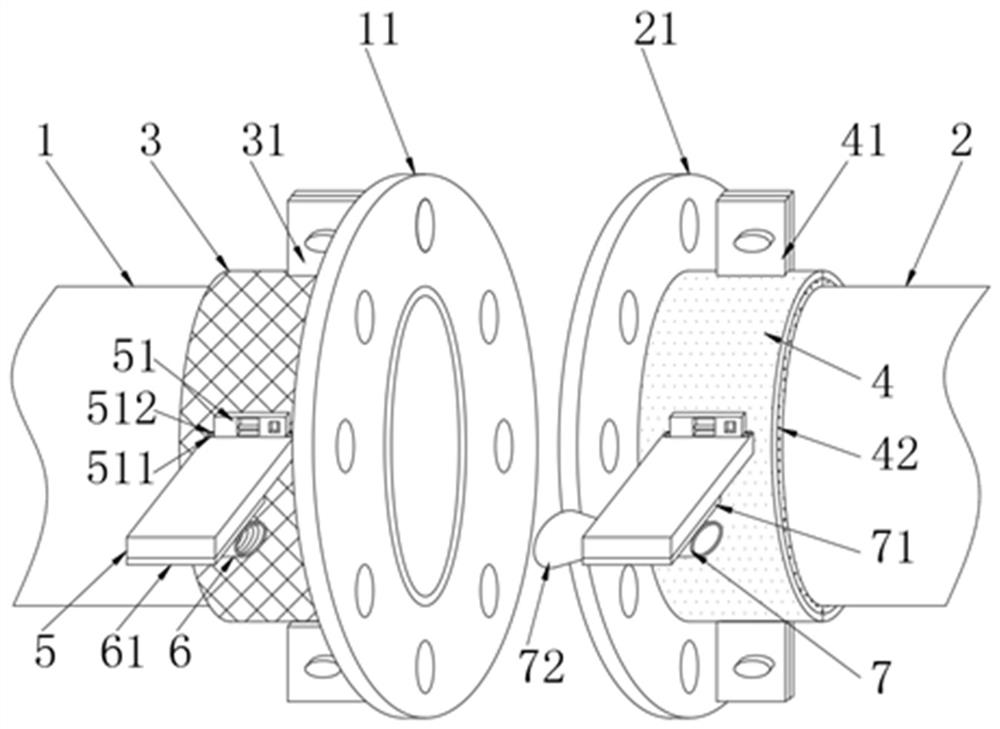

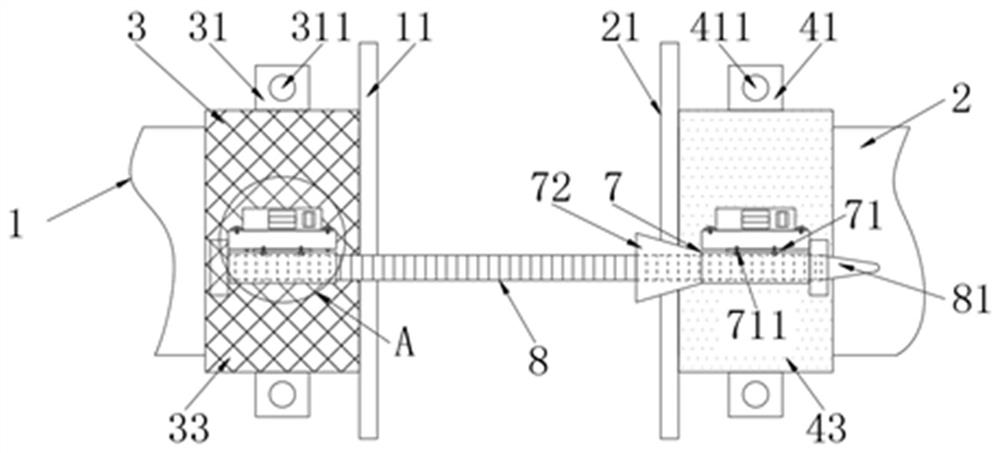

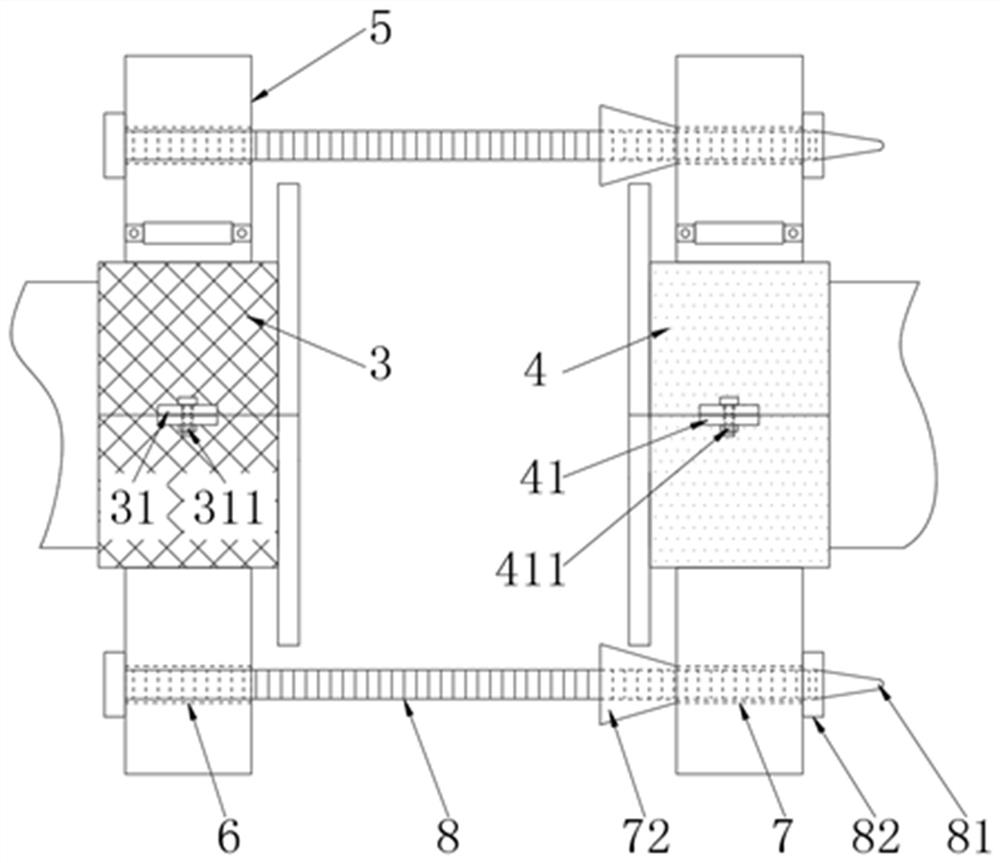

Machine room pipeline equipment integration group splicing method

The invention belongs to the technical field of pipeline installation, and particularly relates to a machine room pipeline equipment integration group splicing method. The method comprises a first pipeline, a second pipeline, a first hoop and a second hoop, a first connecting flange is fixedly welded to one end of the first pipeline, and a second connecting flange is fixedly welded to the end, close to the first connecting flange, of the second pipeline; the first pipeline is detachably connected with the first hoop, the second pipeline is detachably connected with the second hoop, each of theouter wall of the first hoop and the outer wall of the second hoop is fixedly connected with two symmetrically-distributed supporting plates, and the supporting plates are detachably connected with small horizontal rulers. During use, the first hoop on the first pipeline can be matched with the second hoop on the second pipeline, so that the butt joint position of the first connecting flange andthe second connecting flange is quickly found, and the first connecting flange and the second connecting flange are quickly in butt joint; therefore, the high-altitude operation time of constructors is shortened, and the labor intensity of the constructors is reduced.

Owner:CHINA CONSTR FOURTH ENG DIV INSTALLATION ENG

Insulating water-based epoxy self-adhesive paint and preparation method thereof

ActiveCN112724793AImprove high temperature resistanceLight weightFireproof paintsAnti-corrosive paintsPolymer scienceFirming agent

The invention relates to the technical field of epoxy self-adhesive paint, in particular to insulating waterborne epoxy self-adhesive paint and a preparation method thereof. The insulating water-based epoxy self-adhesive paint is prepared from the following raw materials: epoxy resin, a cosolvent, spherical organic silicon resin, a water-based coupling agent, an emulsifier, water, a latent curing agent, a leveling agent, a wetting agent and an antifoaming agent. The self-adhesive paint has the excellent effects of high temperature resistance, smoothness, low specific gravity, water resistance, salt spray resistance and insulation. The preparation method comprises the following steps: adding the spherical organic silicon resin and the coupling agent into water, heating, and carrying out heat preservation reaction to obtain a modifier; dissolving epoxy resin in a cosolvent, heating, adding the modifier and the emulsifier, uniformly stirring, and dropwise adding residual water until the viscosity is reduced in a cliff manner; finally, adding a latent curing agent, a leveling agent, a wetting agent and an antifoaming agent, keeping the temperature, and performing uniform dispersing to obtain a finished product. The preparation method is simple to operate and convenient for batch production.

Owner:ZHEJIANG RONGTAI TECH ENTERPRISE

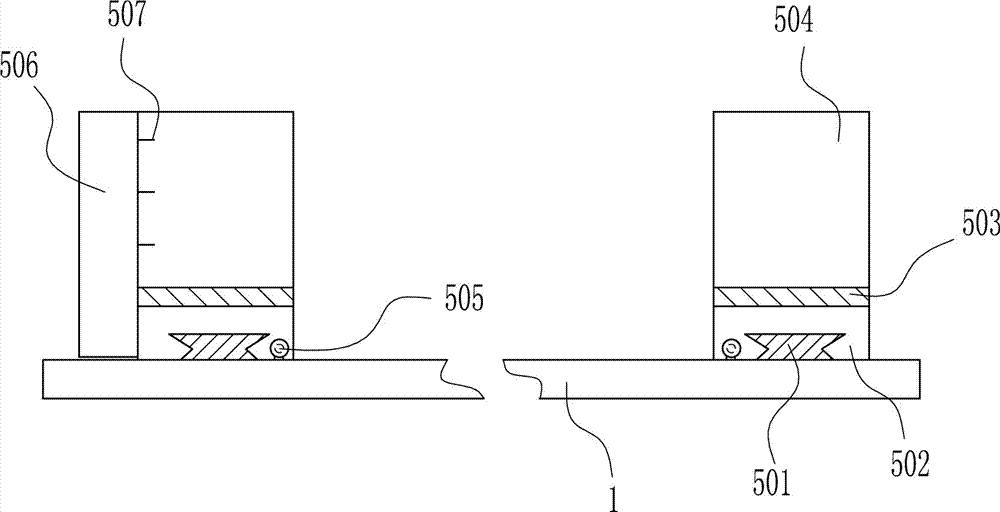

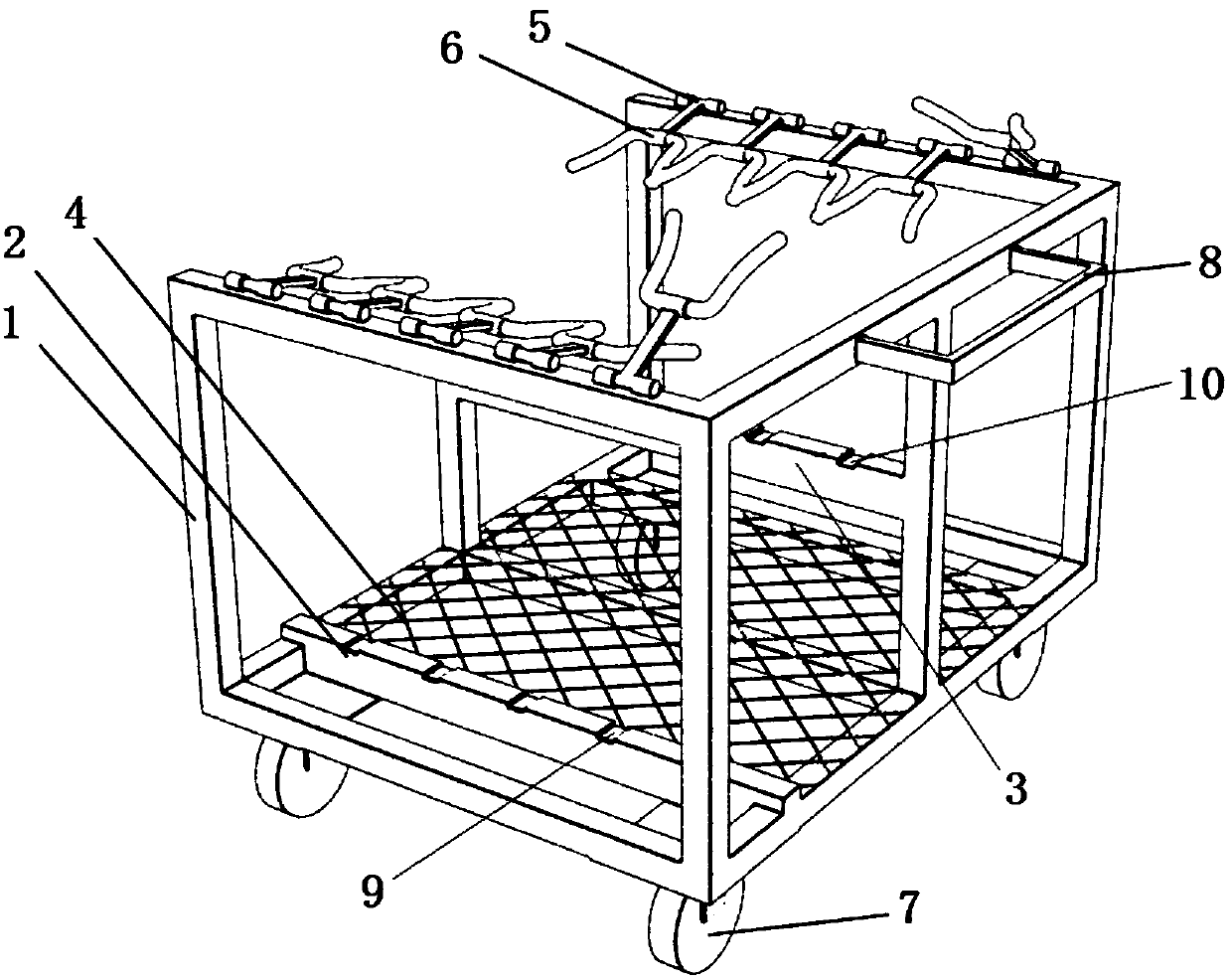

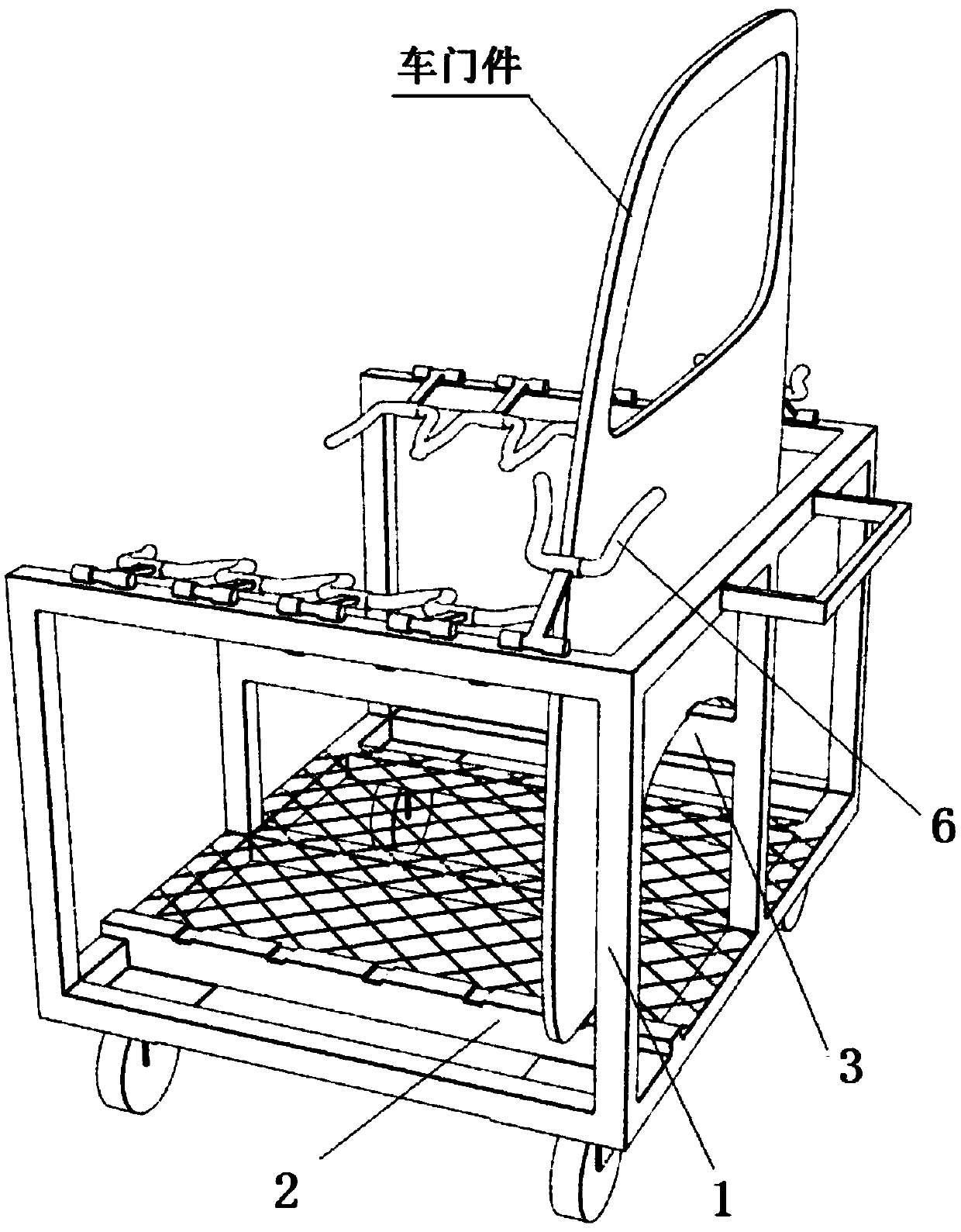

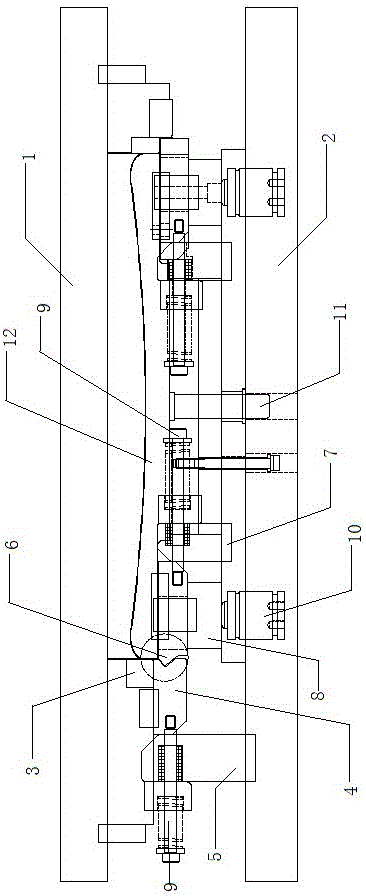

Protective car door component fixing and conveying device

PendingCN107933665AAvoid colliding with each otherAvoid peeling paintSupporting partsHand carts with multiple axesCar doorManufacturing engineering

The invention discloses a protective car door component fixing and conveying device. The device includes a weight bearing frame, two lateral weight bearing supports are symmetrically arranged at the bottom of the weight bearing frame, two first clamping grooves are symmetrically formed in the upper surfaces of the two lateral weight bearing supports, two U-shaped brackets are symmetrically arranged on the two sides of the top of the weight bearing frame, each U-shaped bracket is fixedly connected with a T-shaped rod, and each T-shaped rod is hinged to the top of the weight bearing frame. The weight of each car door component is borne by the lateral weight bearing supports and a middle weight bearing support, and meanwhile the movement of the car door components is limited by the U-shaped brackets, so that each car door component is stably fixed to the weight bearing frame and prevented from colliding other car door components during transportation. Paint on the car door components is prevented from being peeled off or the car door components are prevented from deformation, the influence on the product quality is avoided, and since foam plates do not need to be adopted for package during conveying of the car door components, the environment-friendly production requirement is met; after conveying is finished, the device can be used circularly, and therefore the cost is saved.

Owner:GUIZHOU UNIV

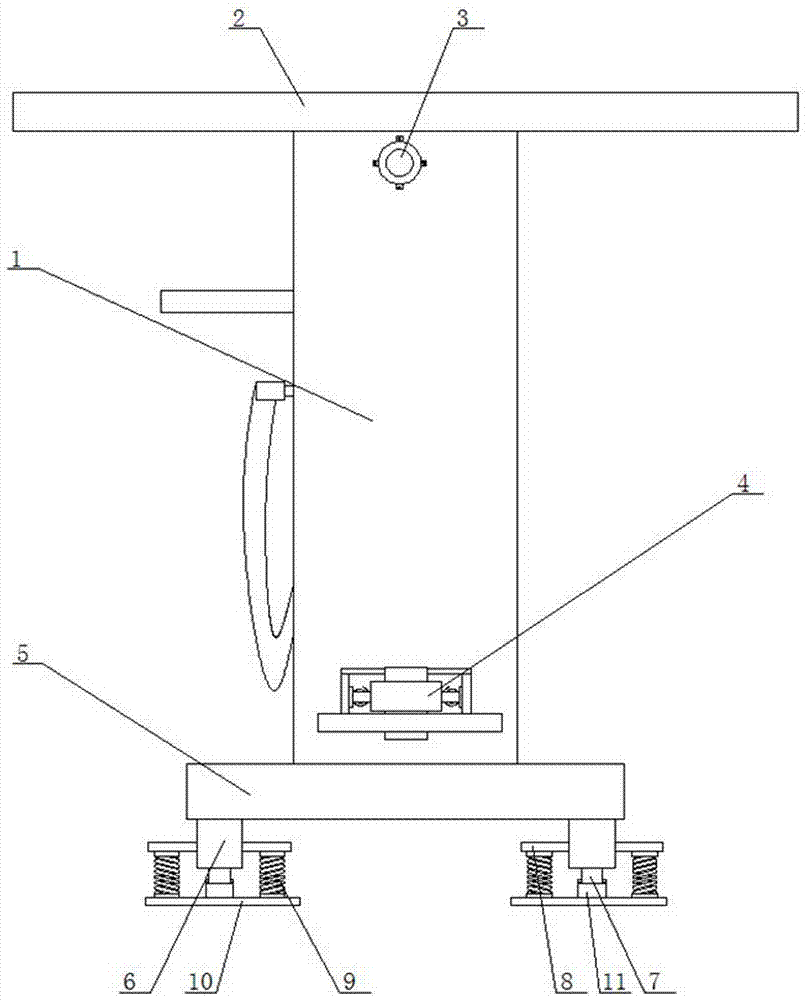

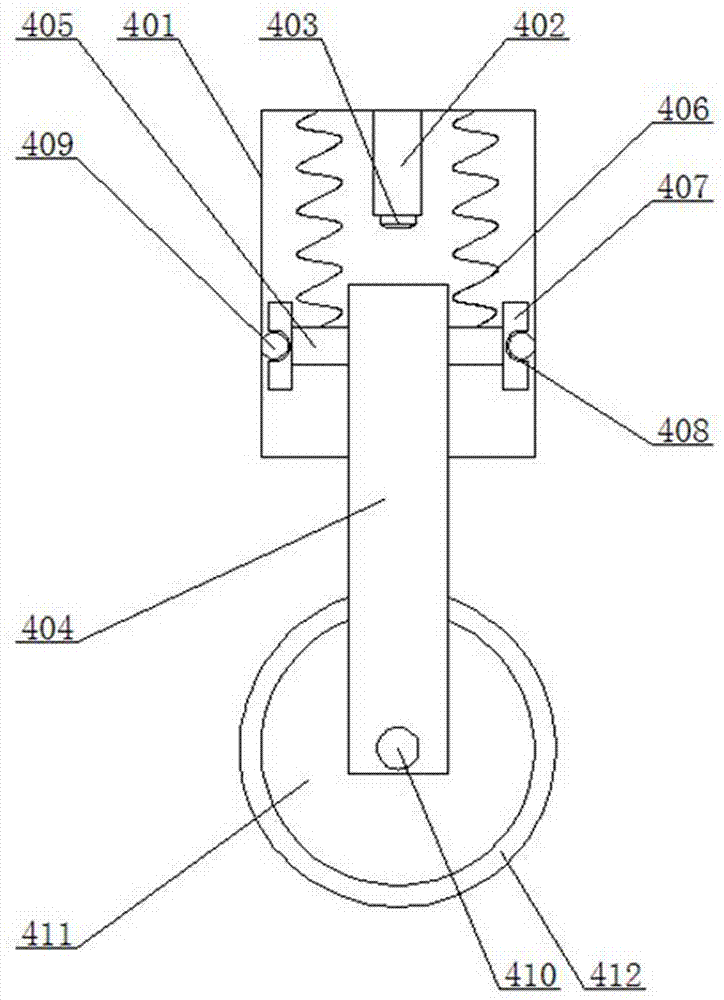

New energy charge pile with reminding function

InactiveCN107962972AReduce breakageAvoid peeling paintCharging stationsElectric vehicle charging technologyNew energyTriggering device

The invention discloses a new energy charge pile with a reminding function. The new energy charge pile comprises a charge pile body. A top plate is arranged on the top of the charge pile body, an alarm is arranged on the front side surface of the charge pile body, a trigger device is arranged at the bottom of the alarm, a main support plate is arranged at the bottom of the charge pile body, support rods are arranged at the bottom of the main support plate, first limit pipes are arranged at the bottoms of the support rods, first auxiliary support plates are arranged on two sides of each supportrod, first springs are arranged at the bottoms of the first auxiliary support plates, and second auxiliary support plates are arranged at the bottoms of the first limit pipes. The new energy charge pile has the advantages that the new energy charge pile comprises the trigger device and the alarm, a movable rod can be pushed by a disc when the disc is squeezed by vehicles, a button switch can be squeezed by the movable rod when the movable rod moves into a limit groove, the alarm can be switched on and started to give an alarm to drivers, accordingly, the new energy charge pile is favorable for reducing the probability of accident occurrence, and the safety of the charge pile body can be improved.

Owner:DIMENSION TECH

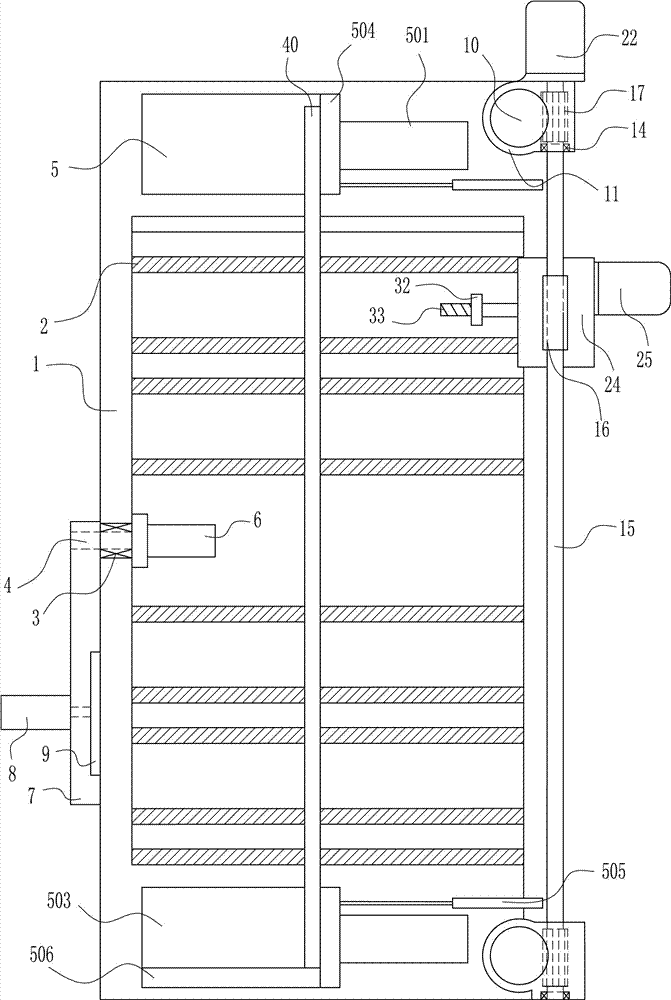

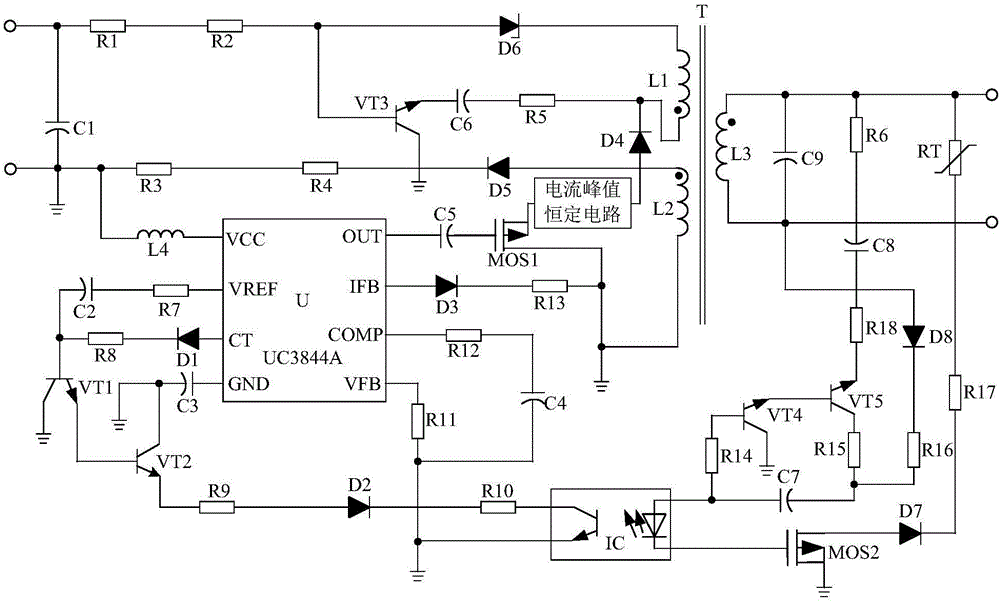

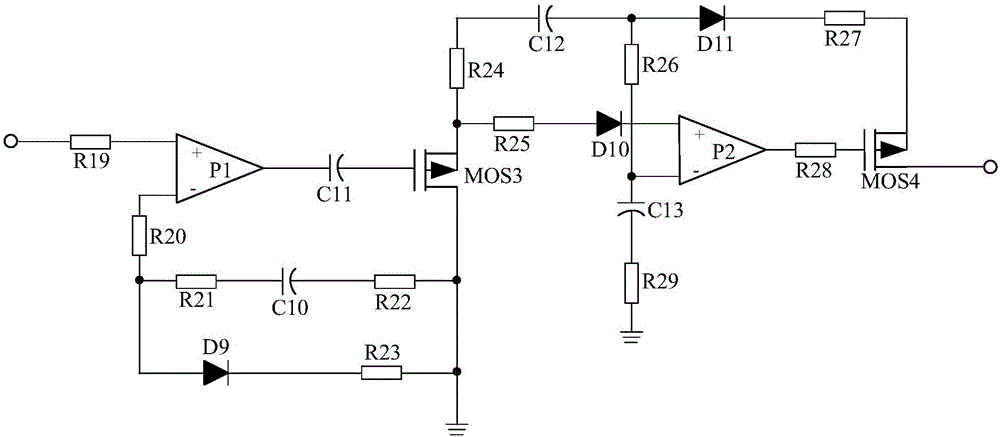

Current peak constant circuit-based switching power supply for leather spray dryer

InactiveCN105978329AGuaranteed stabilityAvoid deformationDc-dc conversionElectric variable regulationOvervoltageTransformer

The invention discloses a current peak constant circuit-based switching power supply for a leather spray dryer. The current peak constant circuit-based switching power supply is characterized by mainly comprising a control chip U, a transformer T, an overvoltage protection circuit, a current adjusting circuit, a field-effect tube MOS1, a polar capacitor C5, a diode D3, a polar capacitor C4, a current peak constant circuit and a photoelectric coupling switching circuit, wherein the current peak constant circuit is connected between the overvoltage protection circuit and a source of the field-effect tube MOS1 in series; and the photoelectric coupling switching circuit is connected with the current adjusting circuit and a secondary induction coil L3 of the transformer T separately. According to the current peak constant circuit-based switching power supply for the leather spray dryer, high-voltage pulses in voltage and high-current ripples in current can be effectively adjusted; and dynamic states of the voltage and the current are kept stable, so that the condition that the current peak constant circuit-based switching power supply can output stable voltage and current is ensured; the stability of the drying temperature of the high-polymer leather spray dryer is ensured; and deformation or a paint failure of a high-polymer shoe material leather surface is effectively prevented.

Owner:CHENGDU SAIPUQI TECH CO LTD

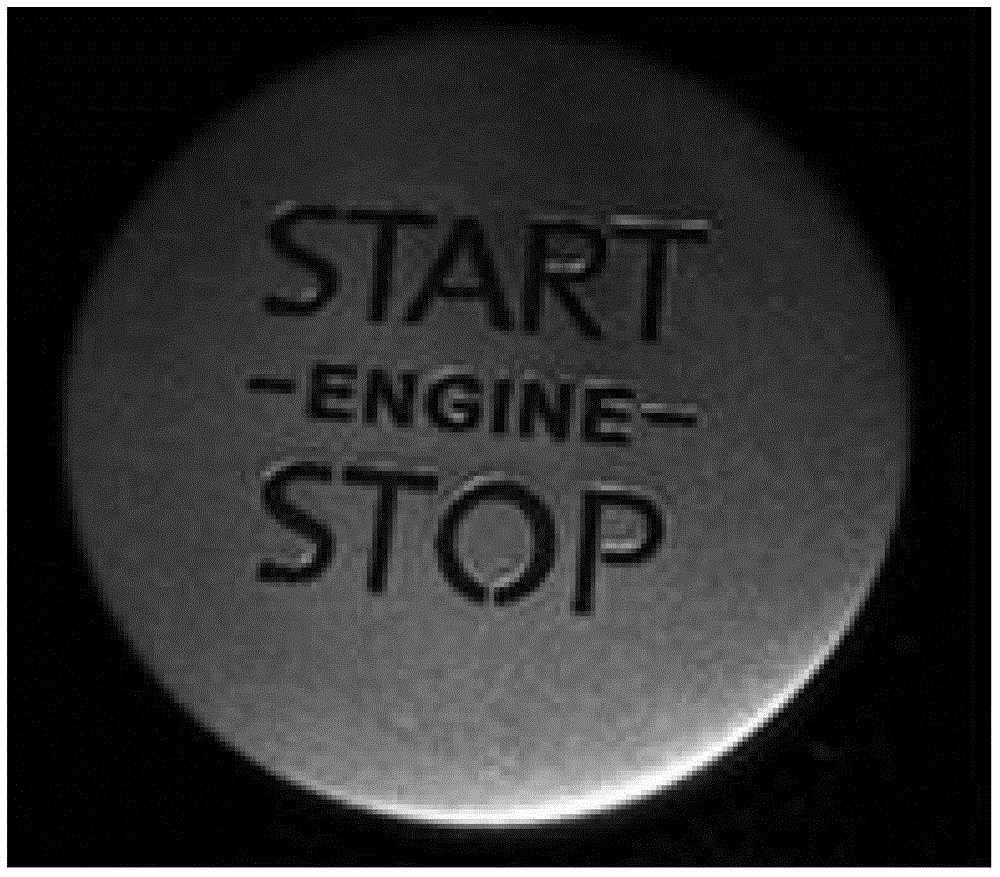

Laser engraving method of plastic component

InactiveCN103029498BAvoid peeling paintInhibit sheddingEngravingEnvironmental resistanceMaterial consumption

The invention relates to a laser engraving method of a product, in particular to a plastic component laser engraving method for engraving any pattern or mark in an elastic workpiece with one layer being lucent. Laser engraving is carried out inside the plastic component at least comprising one layer of transmission material. The method comprises the following steps of starting a laser engraving machine; measuring the size of the plastic component to be engraved; editing the patterns and characters; calculating points of the patterns; calling in a picture file, selecting product dimensional specification and setting parameters; and carrying out the engraving. Due to the adoption of the laser engraving method of the plastic component, not only can the display effect of the patterns and characters of the traditional process be realized, but also the defects of the traditional process such as paint dropping, dropping, color fading, non-abrasion resistance, short service life, easiness for storing dirt, environmental pollution and incapability of individualized production can be solved; and moreover, a novel high-efficient and environment-friendly technique for producing any pattern and character with no material consumption can be realized, and a broad individualized exhibition platform can be provided for the individualized times.

Owner:东莞市光威激光科技有限公司

Paint spraying device for furniture manufacturing

The invention relates to the field of furniture processing, in particular to a paint spraying device for furniture manufacturing. The paint spraying device comprises a main rotation shaft and an auxiliary rotation shaft which are mutually parallel. The main rotation shaft is connected with two main chain wheels, and the auxiliary rotation shaft is connected with two auxiliary chain wheels. Chainsare connected between the main chain wheels and the auxiliary chain wheels. The two chains are connected with clamping mechanisms. The clamping mechanisms on the two chains are right opposite to eachother. Each clamping mechanism comprises a clamping shaft rotationally connected to the corresponding chain, wherein the clamping shaft is fixedly connected with wheels. Guide plates are arranged below the wheels, and the wheels intermittently roll on the guide plates. A paint box and a drying box are arranged above the guide plates, wherein the paint box is connected with sprayers, and the dryingbox is connected with drying heads. According to the scheme, paint spraying is conducted on wood rods, and the wood rod painting efficiency is improved.

Owner:四川三虎家居有限公司重庆分公司

Mold for bending of side of refrigerator door shell

InactiveCN106734623AAvoid deformationAvoid peeling paintShaping toolsEngineeringRefrigerated temperature

Owner:滁州市艾德模具设备有限公司

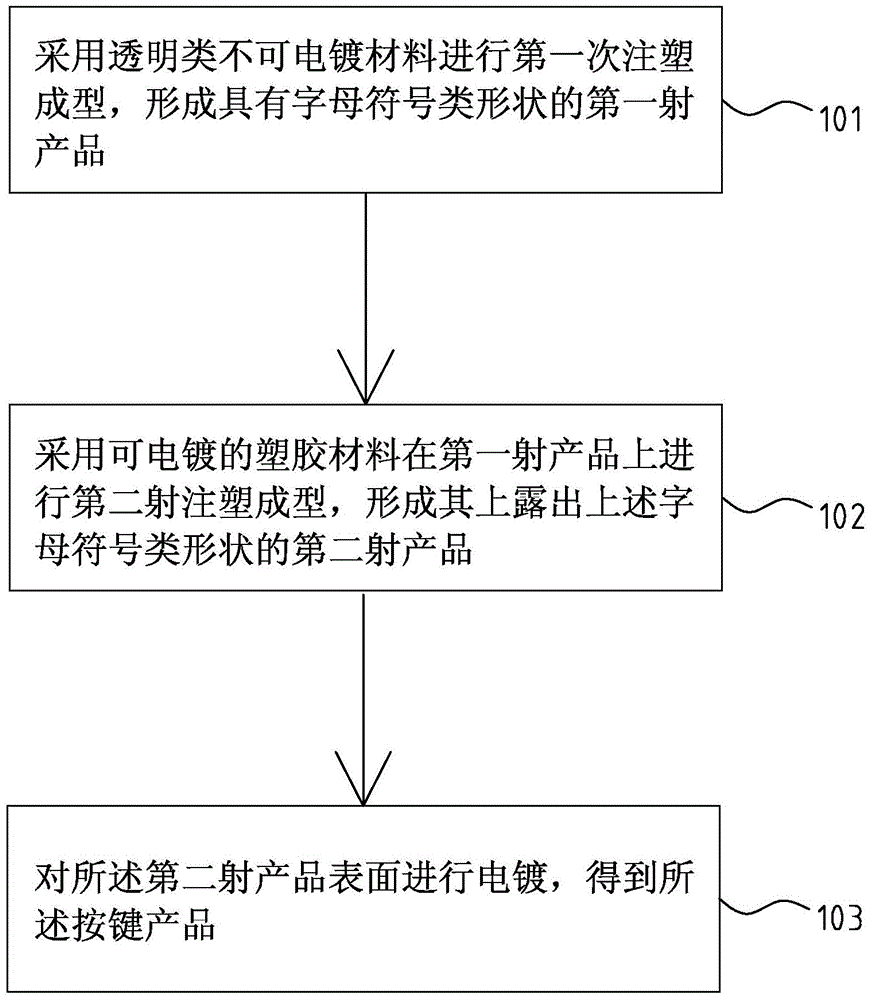

A plastic product manufacturing method and a product of the method

A plastic product manufacturing method and a product of the method are disclosed. The product is an alphabetic symbol key product. The method includes (1) a step of performing first-shot injection molding by adopting a first-shot material to form a first-shot product provided with alphabetic symbol forms, with the first-shot material being a transparent non-electroplatable material, (2) a step of performing second-shot injection molding on the first-shot product by adopting a second-shot material to form a second-shot product, with the alphabetic symbol forms of the first-shot product being exposed on the second-shot product, and the second-shot material being an electroplatable plastic material, and (3) selecting a corresponding plating variety according to appearance requirements, and electroplating the surface of the second-shot product so as to obtain the key product which is the product of the method. The method is simple and efficient in process, short in manufacturing procedure, high in yield, and environmental-friendly in manufacturing procedure. The product is green and high in reliability.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Anti-corrosion surface treatment process for aluminum alloy indication board

PendingCN112813379AHigh hardnessImprove wear resistanceLiquid surface applicatorsSurface reaction electrolytic coatingDc voltageHeat treated

The invention discloses an anti-corrosion surface treatment process for an aluminum alloy indication board. The process comprises the following treatment steps that a, firstly, an aluminum alloy base material is cut according to the mounting size, the rotating speed of a cutting motor is 2500-3000r / min, an indication board blank is formed, then polishing and grinding are carried out on the cut indication board blank, the rotating speed of a polishing and grinding motor is 1800-2000r / min, the polishing and grinding thickness is 0.3-0.5mm, and the indication board is obtained; b, after step a is completed, the polished and ground indication board is subjected to heat treatment; and c, after step b is completed, ion nitriding treatment is carried out on the indication board subjected to heat treatment, firstly a furnace body is connected with an anode, the indication board is connected with a cathode, and hundreds of volts of direct-current voltage is introduced between the anode and the cathode. After the indication board is subjected to corrosion resistance treatment, the hardness, wear resistance, corrosion resistance and oxidation resistance of the indication board in the using process are effectively enhanced, the probability of deformation and damage of the indication board in the using process is reduced, and the service life of the indication board is prolonged.

Owner:徐州润坤铝业有限公司

Hardware part paint spraying device

The invention provides a hardware part paint spraying device. The device comprises a paint spraying box, the right side of the paint spraying box is fixedly provided with a coating box, the left sideof the paint spraying box is fixedly provided with a refrigeration box, a nitrogen box is fixedly arranged on the left side of an inner cavity of the refrigeration box, two supporting columns are fixedly arranged on the top of the paint spraying box, a supporting plate is fixedly mounted on the tops of the two supporting columns, an air cylinder is fixedly arranged on the bottom of the supportingplate, an air rod is fixedly arranged on the bottom of the air cylinder, the bottom of the air rod is fixedly provided with a motor box, and a first motor is fixedly arranged in the motor box. According to the hardware part paint spraying device, through a closed type coating box, impurities are prevented from falling in a material chamber, coating is in the micro-motion state, discharging is convenient, blockage is avoided, a second transmission rod drives a sliding block to slide on a guide rail, a third motor drives a screw rod to rotate, coating is rapidly stirred, bubbles are prevented, and paint spraying effect is prevented from being affected.

Owner:JIANGYIN CHANGJING CAR & SHIP ACCESSORY

Luminous sign production technology based on AB glue carving and surrounding edge injection molding

The invention relates to the field of luminous sign advertisements, in particular to a luminous sign production technology based on AB glue carving and surrounding edge injection molding. The technology includes the following steps that firstly, an acrylic board and other cheap boards such as a PVC foam board are synthesized; secondly, a hollowed groove is carved; thirdly, vacuum defoaming is carried out, and AB glue is injected into the hollowed groove till the hollowed groove is full; fourthly, AB glue carving is carried out; fifthly, the PVC foam board is hollowed out, an original line is marked, and a sign is carved. According to the technology, a common machine is used for carving in the whole manufacturing process and ensures working precision; the adopted boards are good in heat dissipation, and the service life of LEDs can be prolonged to the maximum.

Owner:深圳恒立精工电子科技有限公司

Advertising board with adjustable advertising area

InactiveCN111968552AImprove practicalityAdvertising area adjustableBoardsElectric machineryEngineering

Owner:张得超

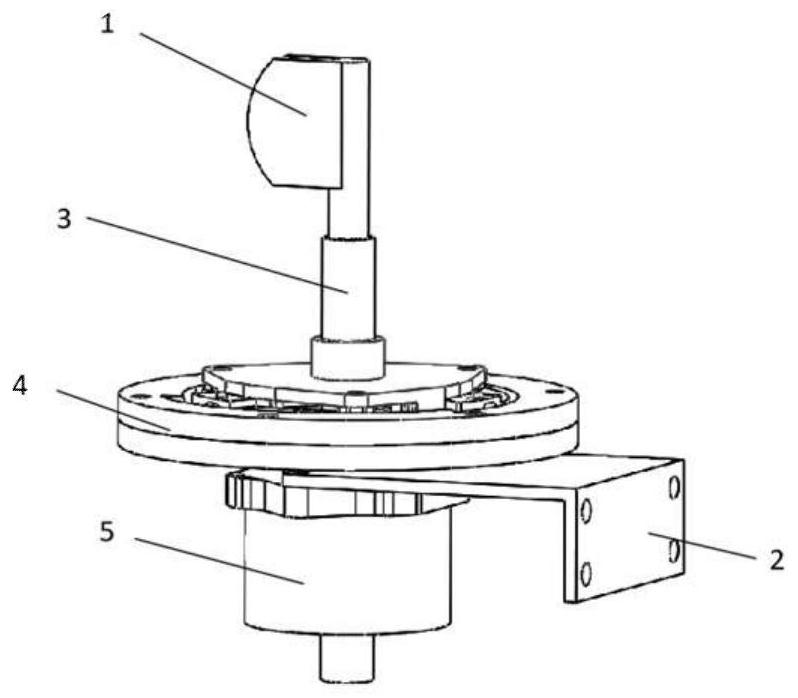

Limiting type automobile door hinge

InactiveCN114412310AAvoid peeling paintLift restrictionsBuilding braking devicesWing accessoriesRatchetEngineering

The limiting type automobile door hinge comprises a movable hinge plate used for being fixedly connected with an automobile door and a fixed hinge plate used for being fixedly connected with the side wall of an automobile body, the movable hinge plate is rotationally connected with the fixed hinge plate through a hinge shaft, and the hinge shaft comprises a shaft rod and a first shaft sleeve which are connected in a matched mode; one end of the shaft rod is fixedly connected with the movable hinge plate, so that the shaft rod and the movable hinge plate synchronously rotate; the first shaft sleeve is arranged on the middle section of the shaft rod and fixedly connected with the fixed hinge plate. A ratchet wheel and pawl mechanism is arranged between the movable hinge plate and the fixed hinge plate, the ratchet wheel and pawl mechanism is installed on the hinge shaft and comprises a fixed disc, an inner ratchet wheel, a pawl and an inertia disc, the fixed disc is fixedly installed on the first shaft sleeve, and the inner ratchet wheel is fixedly connected with the disc face of the fixed disc. The pawls are annularly arranged in an inner cavity of the inner ratchet wheel and movably clamped in tooth grooves of the inner ratchet wheel. The method has the advantage of being capable of reducing personal injury.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

Lacquer thread sculpture protection layer production technology

InactiveCN109109542AAvoid damagePrevent the situationDecorative surface effectsOrnamental structuresMaterials preparationEpoxy

The invention belongs to the technical field of lacquer thread sculpture production technologies, and particularly provides a lacquer thread sculpture protection layer production technology. The technology comprises the following steps of (1) material preparation, wherein multiple kinds of materials are mixed to prepare lacquer mud, and the lacquer mud is made to become a lacquer thread pie material which can be lacquered or shaped; (2) thread twisting, wherein a manual operation method is used for twisting the lacquer mud into lacquer threads of different thickness; (3) shaping, wherein techniques of lacquer thread winding, tying, wrapping, stacking, carving, sculpturing and the like are used for shaping the lacquer threads into a pattern or a shape; (4) decoration, wherein anjin oil is used for foliation decoration. The lacquer thread sculpture protection layer production technology has the beneficial effects that a material made of epoxy is used for protecting the lacquer thread sculpture pattern, the protection strength is high, the situation of lacquer thread sculpture damage or scratches can be effectively prevented, then the situations of lacquer shedding and color losing are avoided, meanwhile, color concentrate in different colors can be added into the epoxy, and different sand-shaped materials can be added to make a lacquer thread sculpture become a decoration or artcraft which has a higher ornamental value at the same time.

Owner:厦门龙承漆线雕有限公司

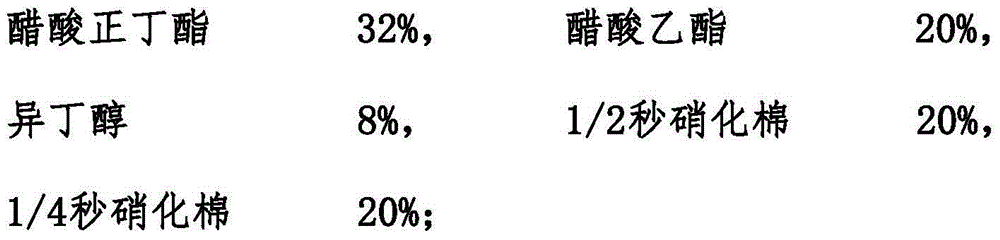

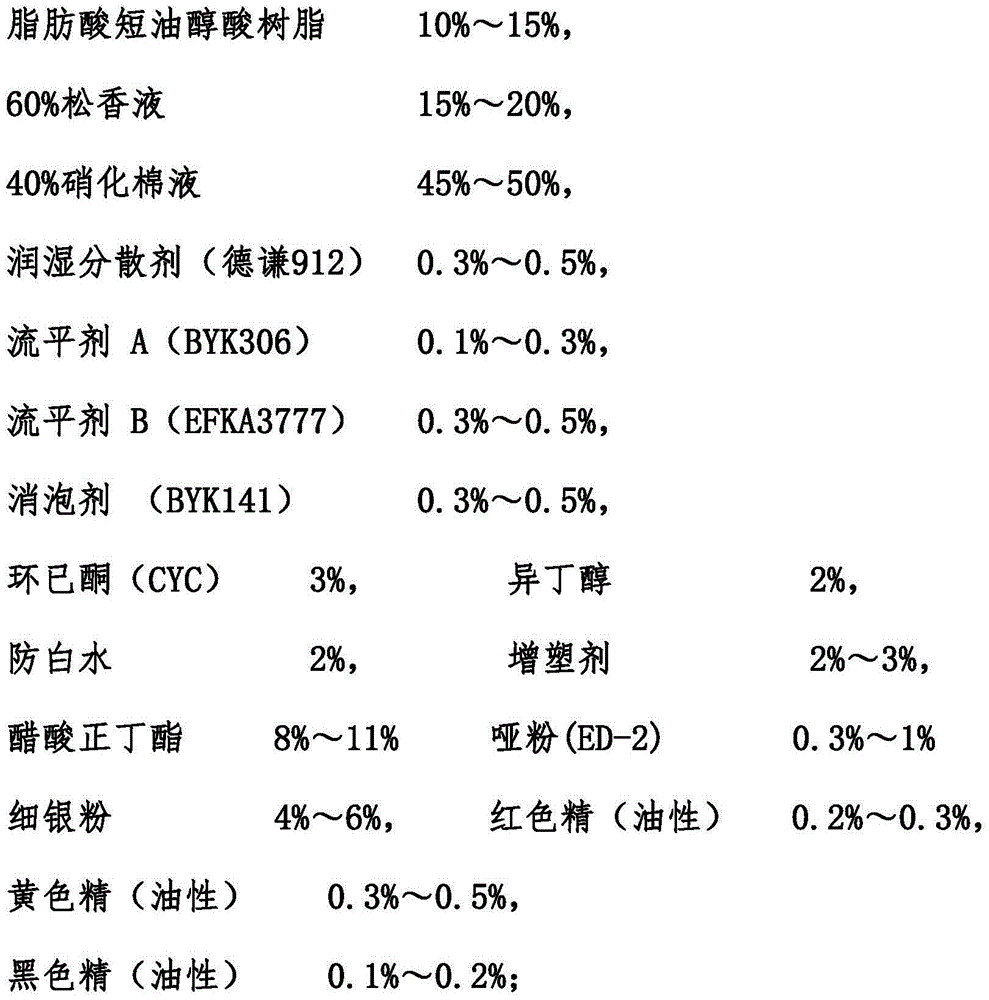

Nitryl golden finishing coat with ultra-high adhesive force

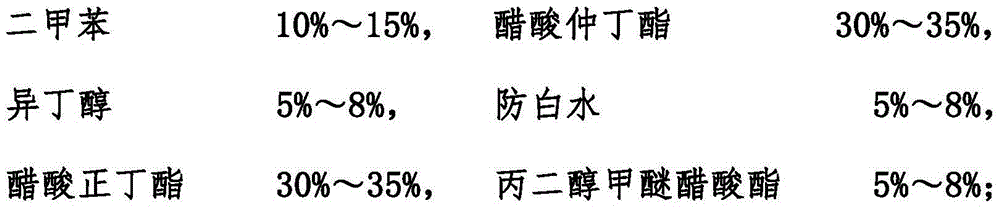

The invention discloses a nitryl golden finishing coat with ultra-high adhesive force. The nitryl golden finishing coat comprises a component A and a component B, wherein during construction, the components A and B are mixed to form a finishing coat to be constructed; the component A comprises fatty acid short-oil alkyd resins, 60 percent of rosin liquid, 40 percent of nitro-cotton liquid, a wetting dispersant, a flatting agent A, a flatting agent B, an anti-foaming agent, cyclohexanone, isobutanol, butoxyethanol, a plasticizer, n-butyl acetate, matt powder, fine silver powder, red essences, yellow essences and black essences; the component B comprises dimethylbenzene, sec-butyl acetate, isobutanol, butoxyethanol, n-butyl acetate and propylene glycol methyl ether acetate. Based on detection and trial certification, the nitryl golden finishing coat is high in adhesion force of coatings, high in covering power, and suitable for coating gold on a grinding-free PU finishing coat.

Owner:GUANGDONG BADESE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com