Device and method for detecting glass guide groove of car door assembly

A glass run channel and detection device technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of difficult detection of the size of the glass run channel, and achieve the effects of easy operation, high detection efficiency, and avoiding paint peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

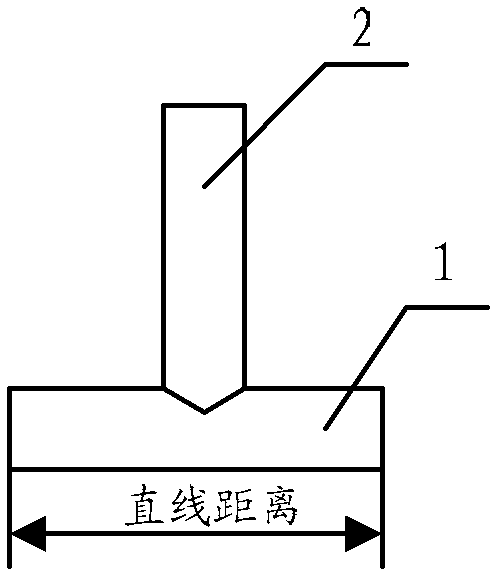

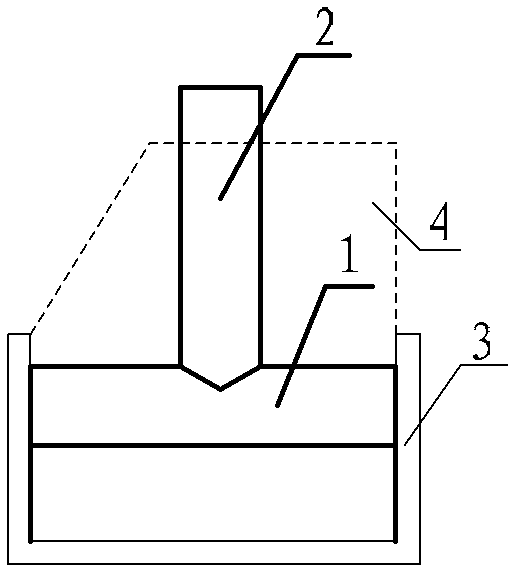

[0019] figure 1 It is a schematic structural diagram of a detection device for a glass run channel of a car door assembly provided in Embodiment 1 of the present invention, figure 2 It is a schematic diagram of the detection state of the detection device for the glass run channel of the vehicle door assembly provided by Embodiment 1 of the present invention. Embodiment 1 of the present invention provides a detection device for a glass run channel of a car door assembly, which includes: a detection rod 1 whose axial distance is equal to the Enter the glass run channel 3, and move up and down between the upper and lower dead centers of the glass run channel 3 to detect the front and back distance of the glass run channel 3. Usually, when designing the glass run channel 3, the size of its front-to-back distance will float within a certain tolerance range, and the length of the detection rod 1 should be set to be equal to the minimum value of the front-to-back distance of the gl...

Embodiment 2

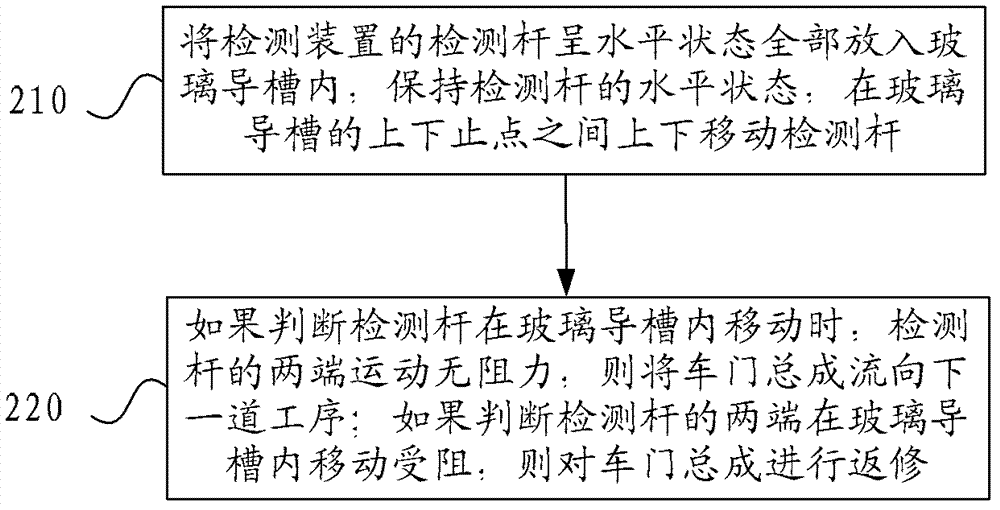

[0026] image 3 It is a schematic flowchart of the detection method for the glass run channel of the car door assembly provided by Embodiment 2 of the present invention. Embodiment 2 of the present invention provides a detection method for the glass run channel of the car door assembly. Please also refer to figure 1 and figure 2 , which includes:

[0027] Step 210, put the detection rod 1 of the detection device in a horizontal state into the glass run channel 3, keep the detection rod 1 in a horizontal state, and move the detection rod 1 up and down between the upper and lower dead centers of the glass run channel 3;

[0028] Step 220, if it is judged that when the detection rod 1 moves in the glass run channel 3, the two ends of the detection rod 1 move without resistance, then flow the door assembly to the next process; if it is judged that the two ends of the detection rod 1 are in the glass run channel 3 If the inner movement is blocked, repair the door assembly.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com