Patents

Literature

55results about How to "Reduce flow marks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

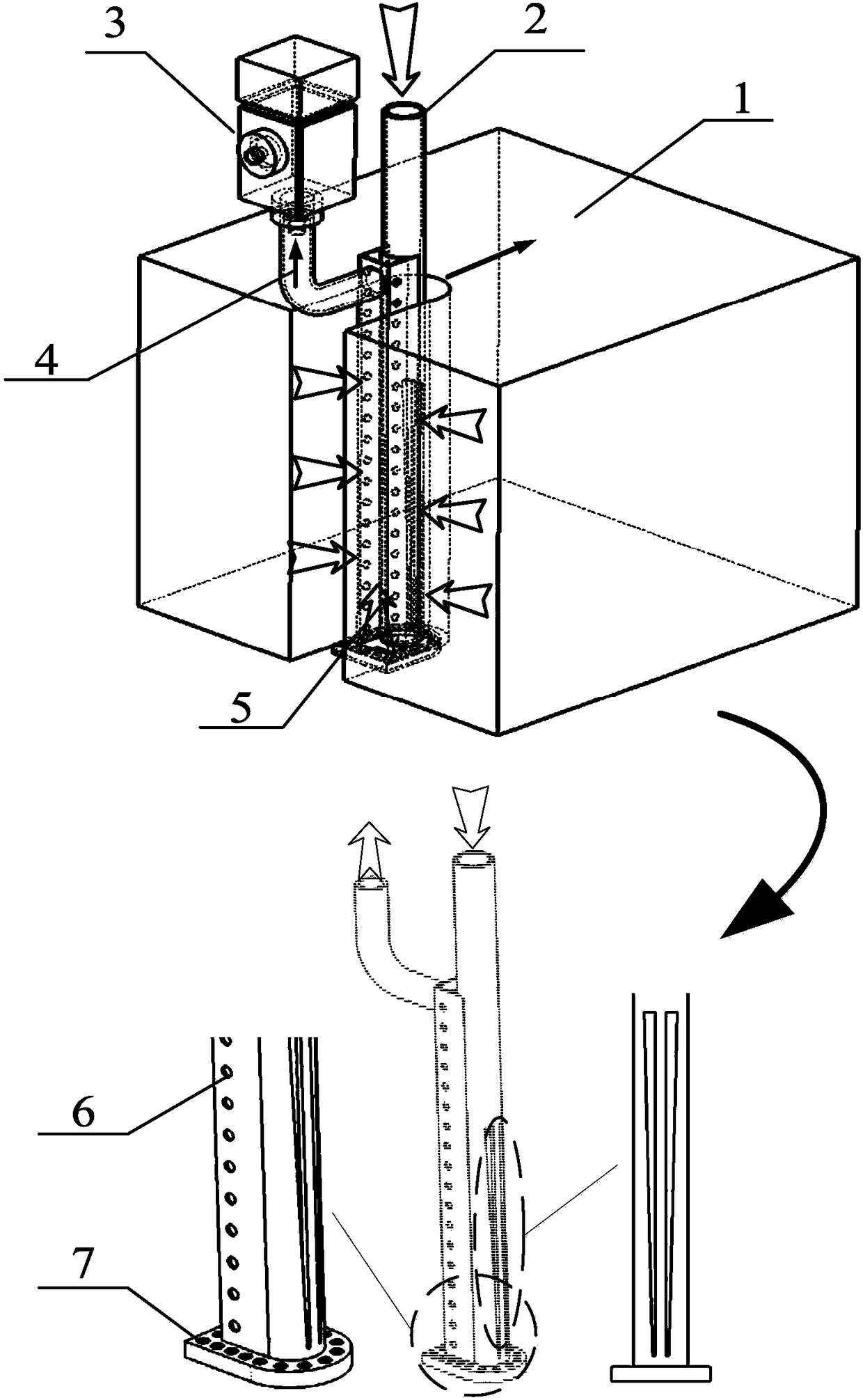

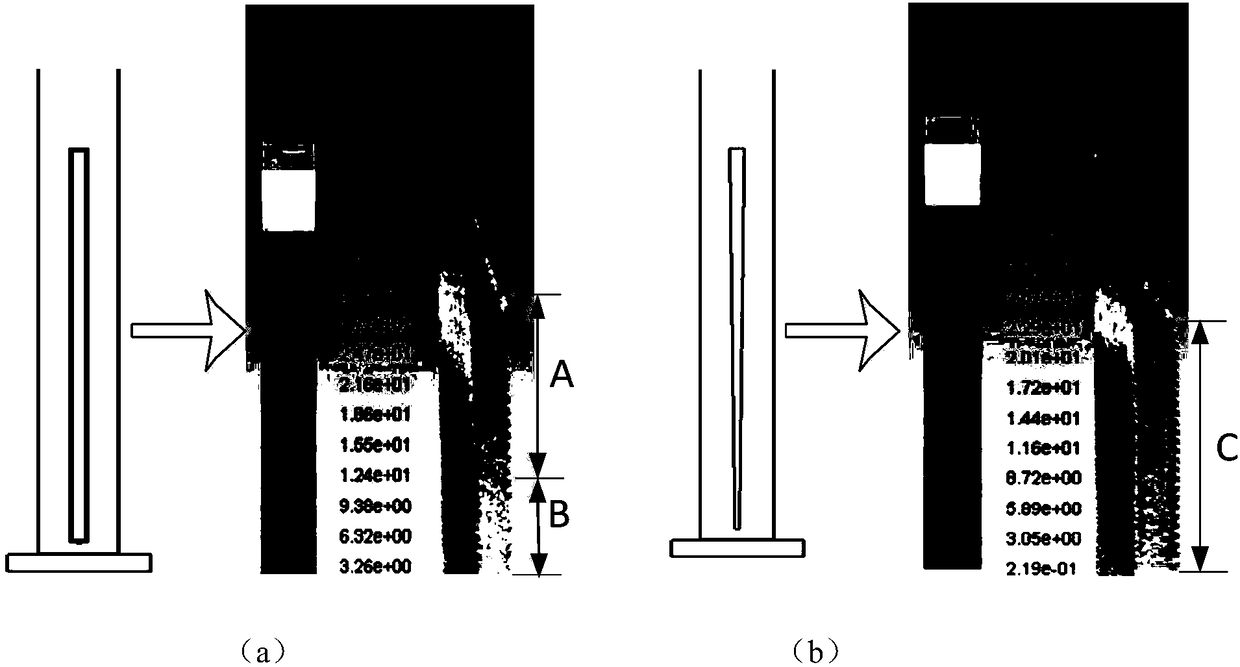

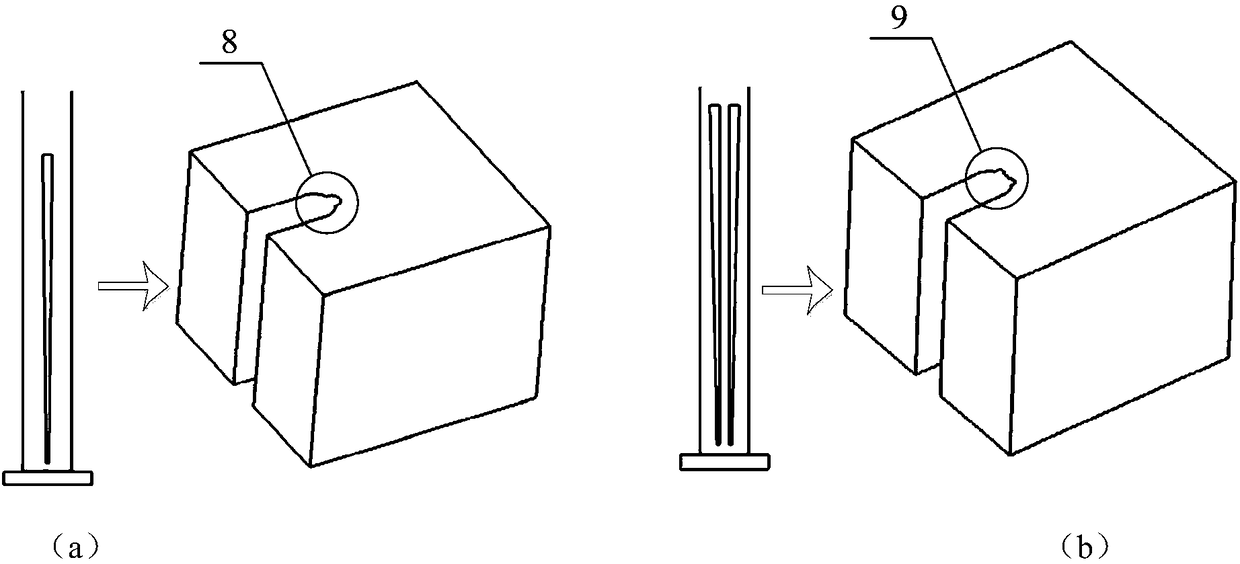

Suction liquid discharge assisted double-narrow-slit electrolytic cutting machining device and method

ActiveCN108161150AUniform flow fieldImproved processing effect and processing speedMachining working media supply/regenerationEngineeringMachine tool

The invention relates to a suction liquid discharge assisted double-narrow-slit electrolytic cutting machining device and belongs to the field of electrolytic machining. The suction liquid discharge assisted double-narrow-slit electrolytic cutting machining device is characterized in that axial and radial suction devices are additionally arranged on a tube electrode cutter, the flow speed of electrolyte in the machining area is increased, so that products are rapidly discharged, and the machining quality is improved; double narrow slits are formed in a tube electrode, so that the machining face, in the advancing direction, of the cutter is more smooth. The suction liquid discharge assisted double-narrow-slit electrolytic cutting machining device comprises a suction pump, an insulated suction pipe, a double-narrow-slit tube electrode, a power source, an electrolyte circulating system, an electrolysis machining machine tool and a work fixture. The suction liquid discharge assisted double-narrow-slit electrolytic cutting machining device has the important significance in improving the flow speed of the electrolyte, rapidly discharging the products and ensuring one-time electrolytic cutting super-thick workpieces (with the thickness larger than 100mm).

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Free-spraying polyamide resin with metal effect, and preparation method thereof

The invention provides a free-spraying polyamide resin with metal effect, and a preparation method thereof. The free-spraying polyamide resin comprises, by mass, 70 to 95 parts of polyamide, 10 to 30 parts of a metal color pigment, 0.1 to 2 parts of a coupling agent, 0.1 to 0.2 part of zinc stearate, and 2 to 8 parts of a lubricating agent. The preparation method comprises following steps: the raw materials are mixed, are delivered into an extruder for melt blending and extrusion, and then cooing, drying, and cutting are carried out so as to obtain the free-spraying polyamide resin with metal effect. According to the preparation method, the metal color pigment is added into polyamide, and accessory ingredients such as the coupling agent and zinc stearate are added, so that the compatibility and dispersity of polymer matrix with the metal color pigment are improved, spraying effect of metal effect of the obtained product is achieved after injection moulding, increasing of production cost and ecological environment pollution caused by spraying are avoided, defects of injection molding products, such as flow lines and weld bond, are reduced, cost is reduced, and application prospect is promising.

Owner:SHANGHAI ZHONGLEI NEW MATERIAL SCI CO LTD

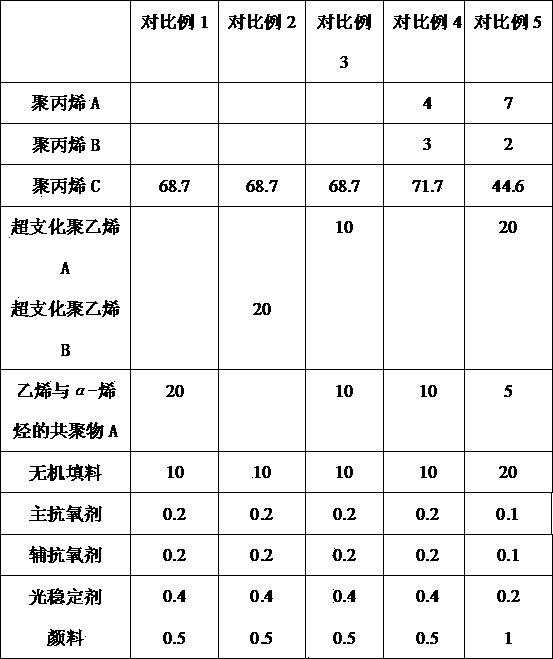

Low-flow-mark low-weld-mark polypropylene composition and preparation method thereof

The invention relates to the technical field of polypropylene compositions, particularly a low-flow-mark low-weld-mark polypropylene composition and a preparation method thereof. The low-flow-mark low-weld-mark polypropylene composition is prepared from the following raw materials in percentage by weight: 55-70% of polypropylene, 10-20% of hyperbranched polyethylene, 5-20% of ethylene-alpha-olefin copolymer, 10-20% of inorganic filler, 0.2-0.4% of antioxidant, 0.2-0.4% of light stabilizer and 0.5-1% of other additives, totaling 100%. The low-flow-mark low-weld-mark polypropylene composition has the advantages of low density, favorable flowability, low flow mark, low weld mark, favorable shock resistance and the like. The preparation method comprises the following steps: mixing the raw materials according to parts by weight in a high-speed stirrer, putting the mixed raw materials in a double screw machine, and carrying out melt extrusion and granulation. The preparation method has the advantages of simple steps and favorable preparation effect, and is easy to operate.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD +2

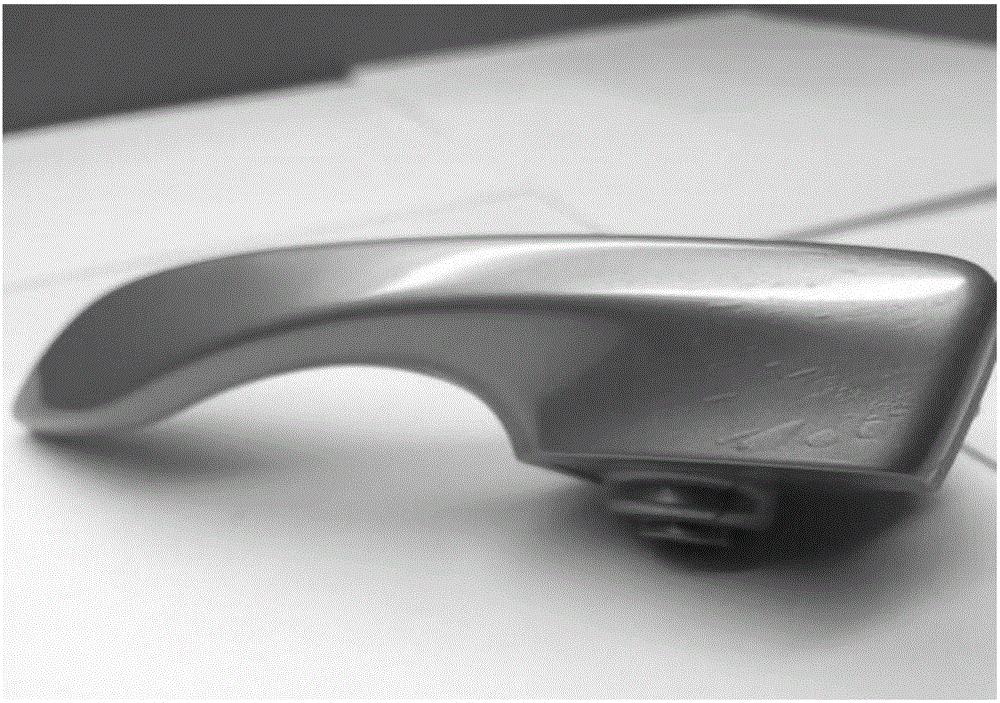

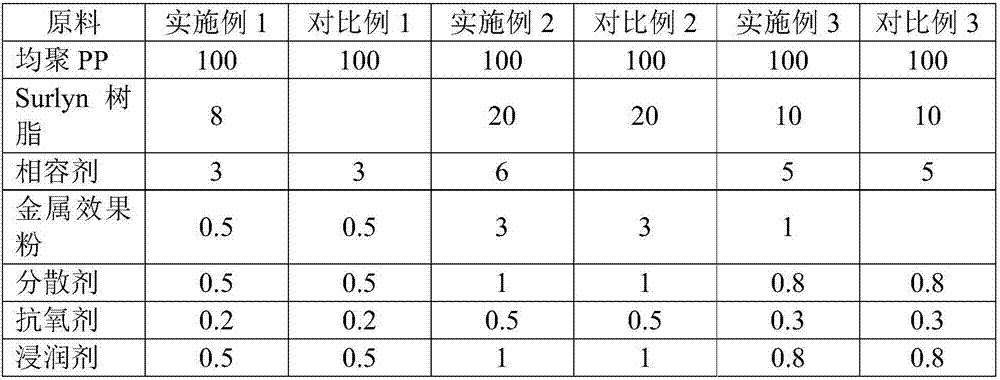

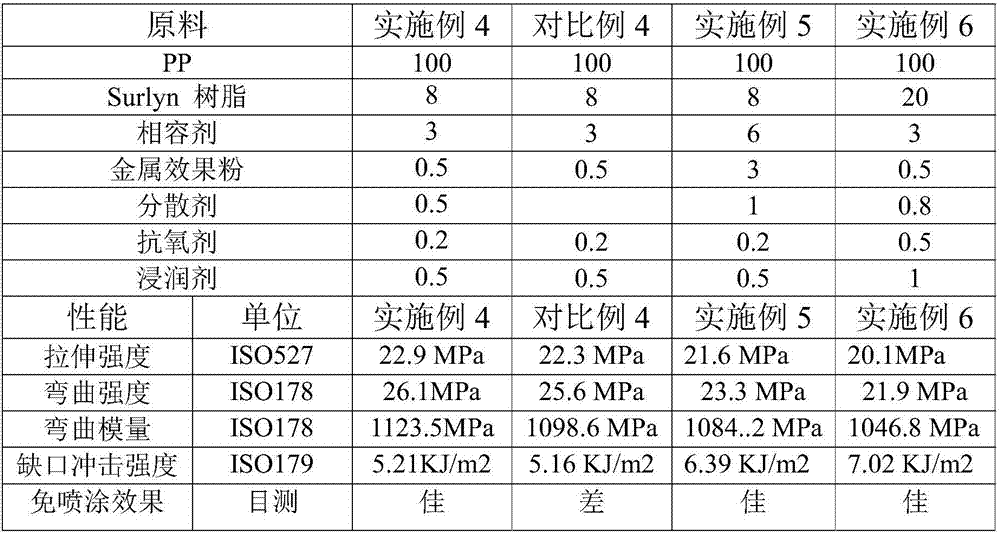

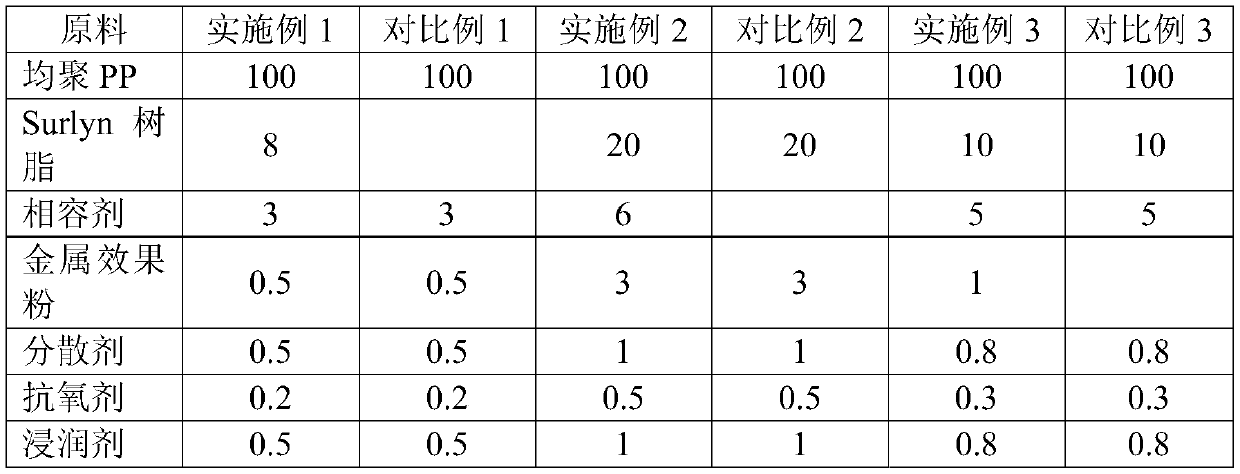

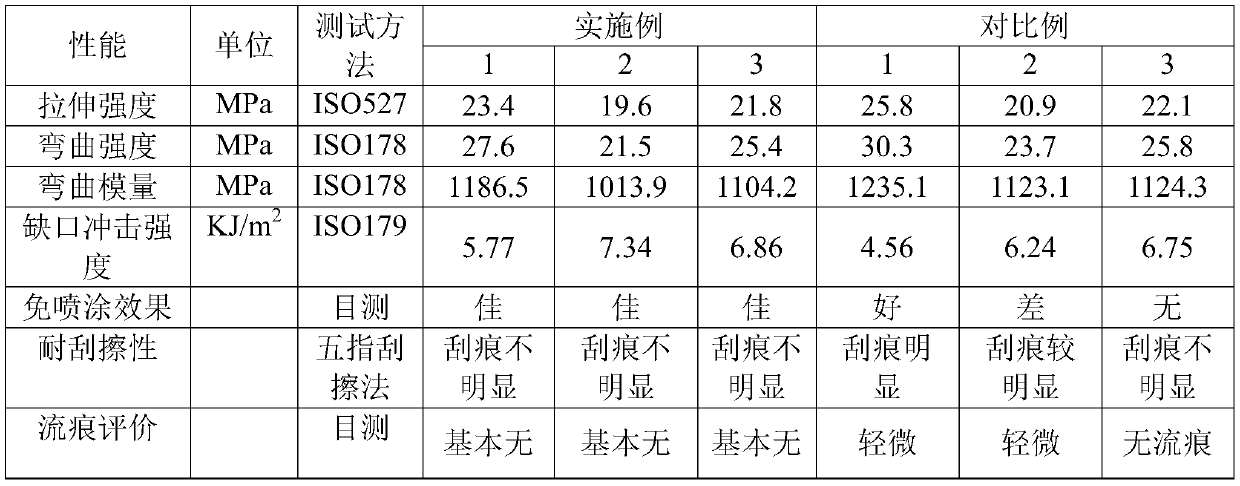

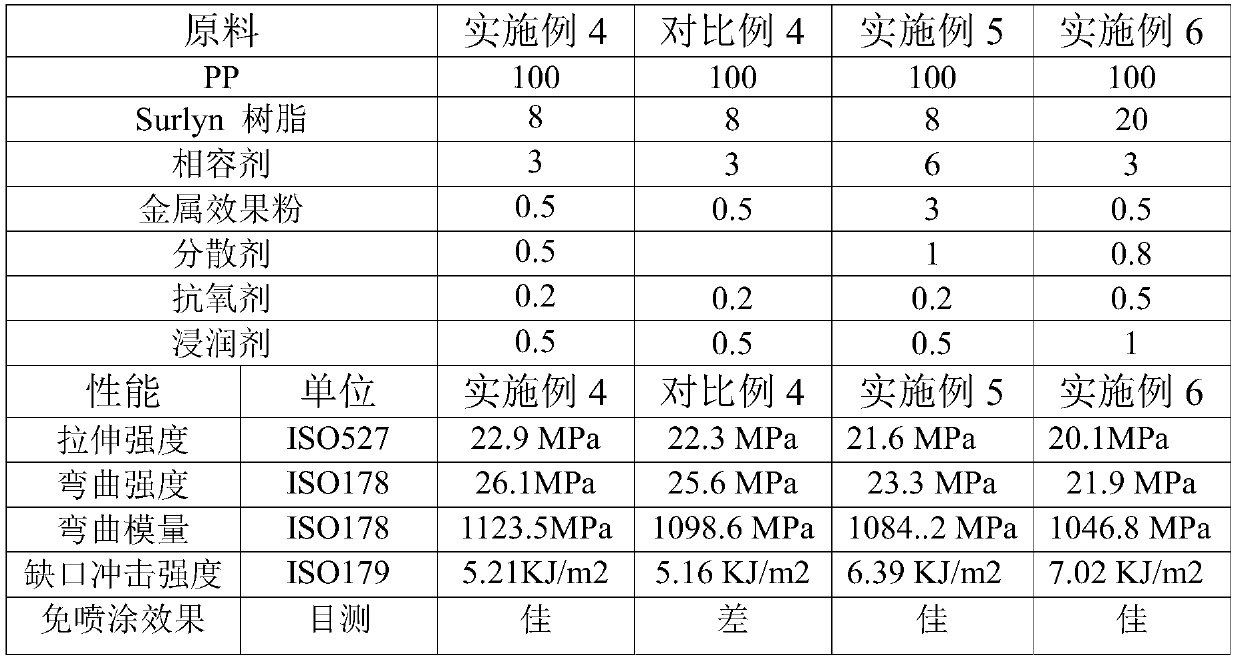

Spray-coating-free scratch-resistant PP alloy material and preparation method thereof

The invention relates to a spray-coating-free scratch-resistant PP alloy material and a preparation method thereof, wherein the spray-coating-free scratch-resistant PP alloy material is prepared from the following raw materials by weight: 100 parts of polypropylene, 5-20 parts of an transparent ionic polymer, 3-6 parts of a compatibilizer, 0.5-3 parts of a metal powder pigment, 0.5-1 part of a dispersant, 0.5-1 part of an infiltrating agent, and 0.2-0.5 part of an antioxidant, the dispersant is formed by compounding polyester grafted modified silicone and polyethylene wax according to a weight ratio of 2:1, and the graft ratio of the polyester grafted modified silicone is 0.8-2%. Compared to the material in the prior art, the material of the present invention has advantages of excellent spray-coating-free metal effect, excellent metal effect powder dispersibility and excellent scratch resistance, can effectively alleviate the flow mark problem of the traditional spray-coating-free metal effect material, is suitable for occasions having high scratch resistance requirements, and can be widely used in vehicles, home appliances, and other fields.

Owner:上海日之升科技有限公司

Production method of alcohol-based flow coating paint for cast iron

ActiveCN103551497AUnique methodLight colorFoundry mouldsFoundry coresCrack resistanceSodium Bentonite

The invention relates to a production method of paint and in particular relates to a production method of an alcohol-based flow coating paint for cast iron. The production method of the alcohol-based flow coating paint for the cast iron comprises the following steps: adding a dissolved rosin liquid and a pretreated bentonite liquid into a dispersing kettle, then sequentially adding ethanol, a combustion-supporting agent, isopropyl alcohol and a thickening agent in residual content, carrying out electric stirring, sequentially adding polyvinyl butyral, a silicate composite suspending agent, a defoaming agent and a surface active agent into the dispersing kettle, regulating the stirring rate to be 500r / min after charging is finished, sequentially adding flake graphite and mullite into the dispersing kettle, regulating the stirring rate after charging is finished, dispersing, sequentially adding quartz powder and white corundum into the dispersing kettle, regulating the stirring rate to be 1200r / min after charging is finished, dispersing for 20 minutes, and discharging. The production method of the alcohol-based flow coating paint for the cast iron is unique, and the produced alcohol-based flow coating paint for the cast iron has the advantages of superior liquidity, good levelling property, high suspension stability, heat shock crack resistance, high temperature stability, sand burning resistance and low gas-forming property.

Owner:共享新材料(山东)有限公司

Water-based paint of lost foam for iron casting, and production method of water-based paint

ActiveCN103447454ARaw materials are uniqueImprove securityFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention relates to a water-based paint of lost foam for iron casting. The water-based paint is characterized by comprising the following raw materials: high bauxite, precious peal powder, brown aluminum oxide, sodium bentonite, polyacrylamide, a polyvinyl acetate emulsion, maltodextrin, silica sol, sodium hexametaphosphate, tributyl phosphate, sodium pentachlorophenate, OP-10 active agent and water. A production method of the water-based paint comprises the steps: pretreating the sodium bentonite, pretreating the polyacrylamide and the maltodextrin, adding the water, the sodium pentachlorophenate, the tributyl phosphate and the sodium hexametaphosphate into a high-speed dispersion kettle, stirring and then sequentially adding the sodium bentonite slurry and a polyacrylamide and maltodextrin pretreatment solution into the dispersion kettle, sequentially adding the polyvinyl acetate emulsion and the silica sol into the dispersion kettle, sequentially adding the OP-10, the high bauxite, the precious pearl powder and the brown aluminum oxide to the dispersion kettle under a stirring state, and conducting high-speed dispersion for 30 minutes after completing the feeding. The water-based paint is unique in the raw materials, environment-friendly, high in coating strength, anti-cracking, good in permeability, and free from carbon lack of castings.

Owner:共享新材料(山东)有限公司

Auxiliary technique capable of increasing graphite mould titanium alloy casting quality

InactiveCN101456061AImprove thermal conductivityLow thermal conductivityFoundry mouldsFoundry coresGraphiteSlurry

The invention relates to an auxiliary process for improving quality of a graphite type titanium alloy casting, which comprises the following steps: before pouring, using Y2O3, adhesive and deionized water to prepare surface slurry for accurately casting titanium according to a ratio of 85:10:5, using a thin brush to evenly coat the surface slurry on the surface of a graphite type core for forming the casting during pouring till fully covering, roasting the graphite type core in vacuum at a temperature of between 900 and 1,000 DEG C after the graphite type core is placed for 1 hour, preserving heat for 2 to 4 hours at a vacuum degree of less than or equal to 10Pa, cooling the graphite type core to be below 300 DEG C along with cooling of a furnace, discharging the graphite type core and then preserving heat at a temperature of between 100 and 200 DEG C in a baking oven, and taking out the graphite type core for standby during pouring. The auxiliary process can use the special surface slurry to fill pores on the surface of graphite, prevents the graphite from attaching to the surface of the casting after pouring, reduces the defects of cold lap, flow mark and the like generated on the surface of the casting, and increases tendency to forming gross shrinkage by the casting.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

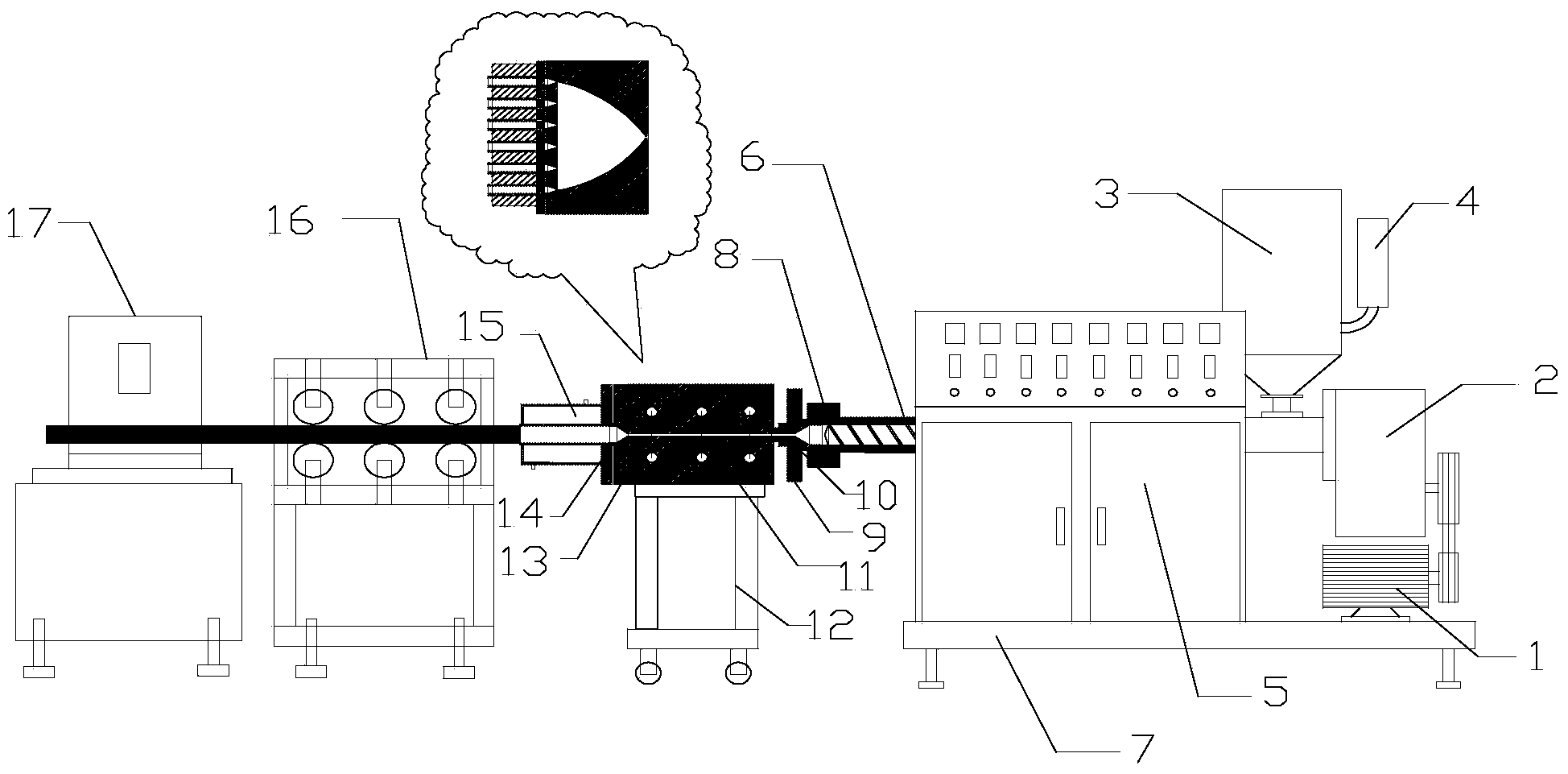

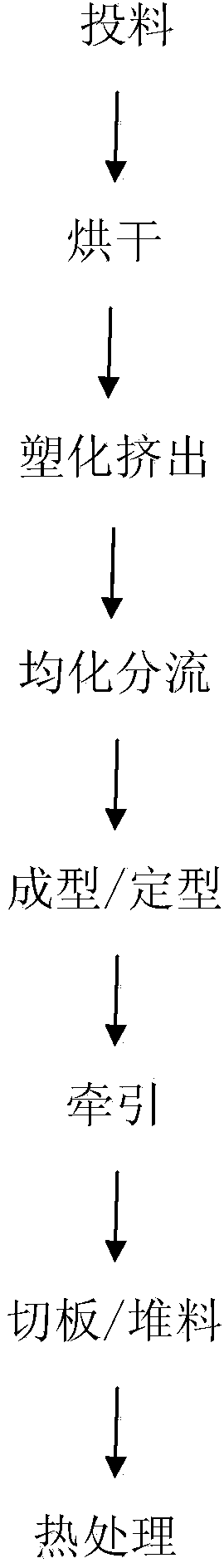

PEEK plastic rod production device and process

InactiveCN103722718AReduced flow marks and scratchesMeet the mechanical propertiesPolyether ether ketoneCompression device

The invention discloses a PEEK plastic rod production device and process. The PEEK plastic rod production device comprises a main machine and an auxiliary machine. The main machine is an extruder and comprises an extruding system, a rotating system and a control system, wherein the extruding system is a gun barrel screw; the rotating system comprises a motor and a reduction box; the control system comprises an electric appliance instrument and an actuating mechanism; the auxiliary machine comprises a mold, a traction machine, an oil temperature machine, a cutting machine and an oven; the mold comprises a main mold, a guide plate, a heat insulation ring, a forming shaping barrel and a cooling water tank; the oil temperature machine is installed on a shaping section of a forming pipe; the traction machine mainly comprises a transmission device, a roller compression device and a brake device, and is installed behind a heat preserving device; the cutting machine is installed behind an outlet of the mold; the oven is a closed box body. The process comprises the steps of charging, drying, plasticizing extruding, homogenizing distributing, forming / shaping, pulling, cutting / stacking and thermal processing.

Owner:深圳市恩欣龙特种材料股份有限公司

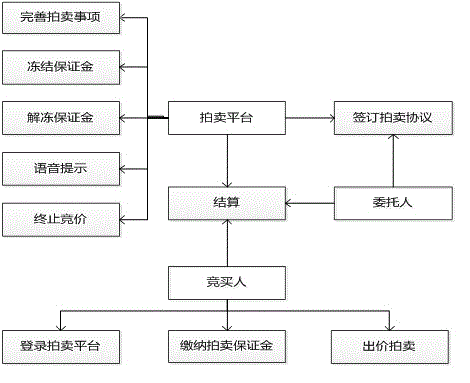

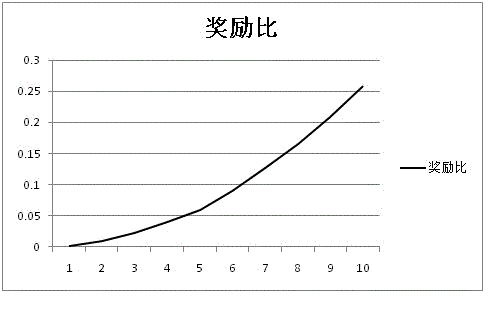

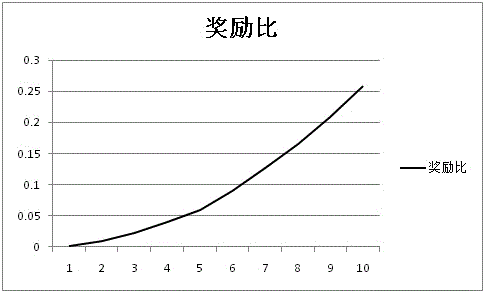

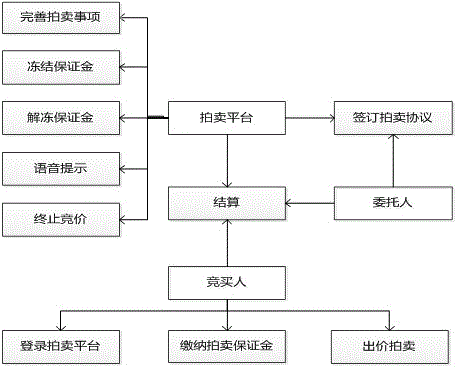

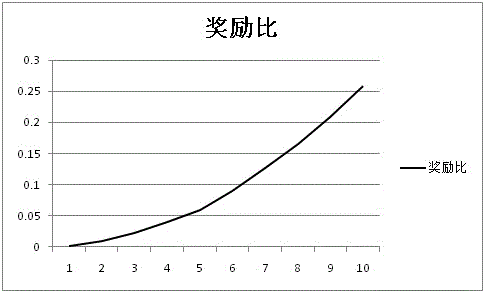

Online auction method and system for establishing bidding reward mechanism

InactiveCN104794650AMaximize the benefitsIncrease auction turnover rateCommerceWeb siteInternet privacy

Disclosed is an online auction method and system for establishing a bidding reward mechanism. The system comprises a client and a server. The client comprises a Unionpay POS (point of services) terminal, an auction website, a handheld terminal and an electronic display screen. The server comprises an auction system background, a Unionpay system, a short message platform and a database. Data are transmitted between the client and the server through a network via the HTTPS (hypertext transfer protocol secure). According to the bidding reward mechanism, a consignor commissions an auctioneer to reward a bidder so that the bidder enjoys part of price differences in bidding steps. The online auction method and system is transparent and strict, safe and reliable, and open and fair, activates the auction market and serves the public and economy.

Owner:胡刚

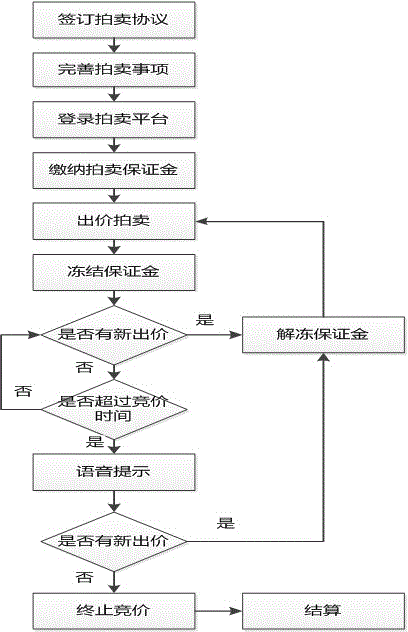

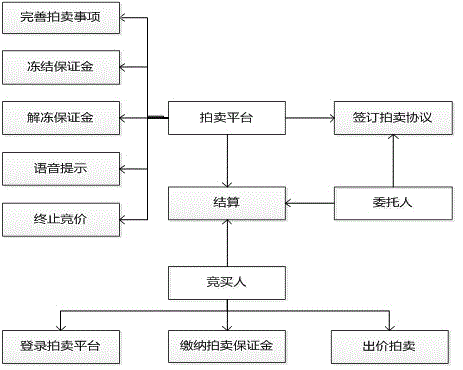

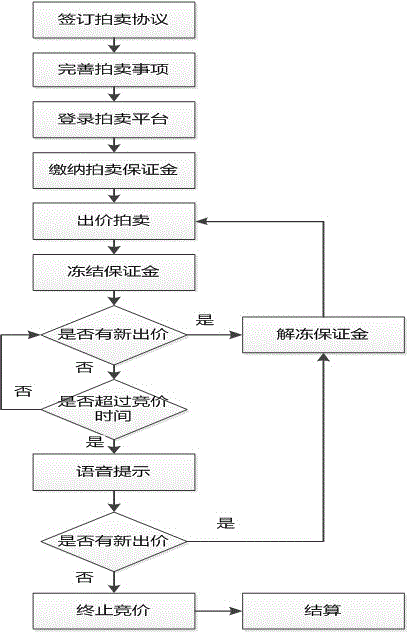

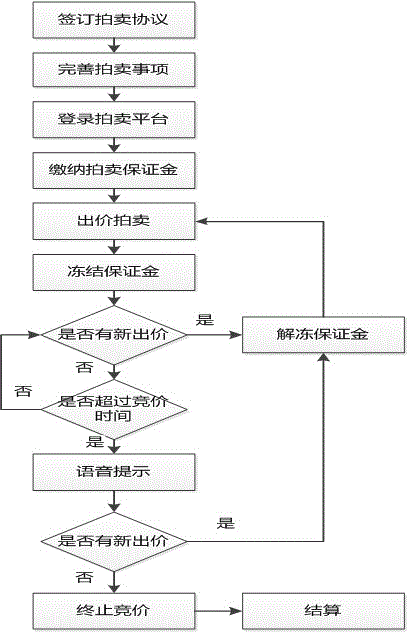

Freezing and unfreezing method and system of auction margin along with bidding behavior

InactiveCN104794651AMaximize the benefitsIncrease auction turnover rateCommerceFinancial transactionComputer science

The invention discloses a freezing and unfreezing method and system of auction margin along with to bidding behavior. In an auction, the auction platform freezes a bidder's margin at the same amount or a certain portion each time when the bidder bids, the margin is not unfrozen until a new bidder bids, and the steps following are similar. By the application of a net-auction system, the auction is more transparent and rigorous, open, fair and impartial. The auction margin is freezing and unfreezing adaptive to the bidding behavior, thereby the security, authenticity, reliability and good faith of auction trade is guaranteed, and the public and economy are served.

Owner:胡刚

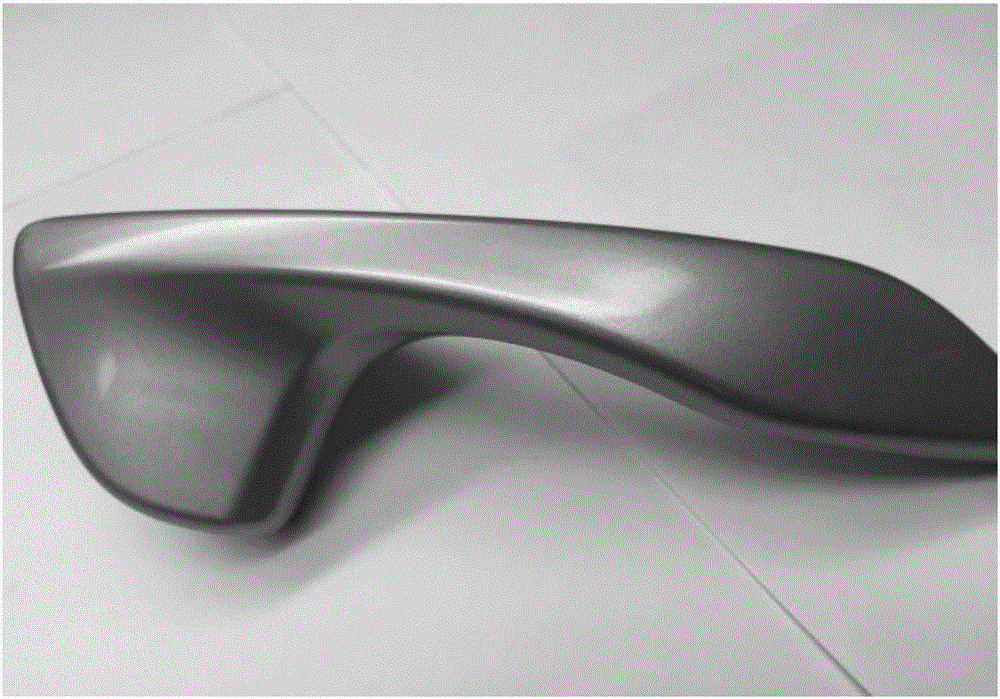

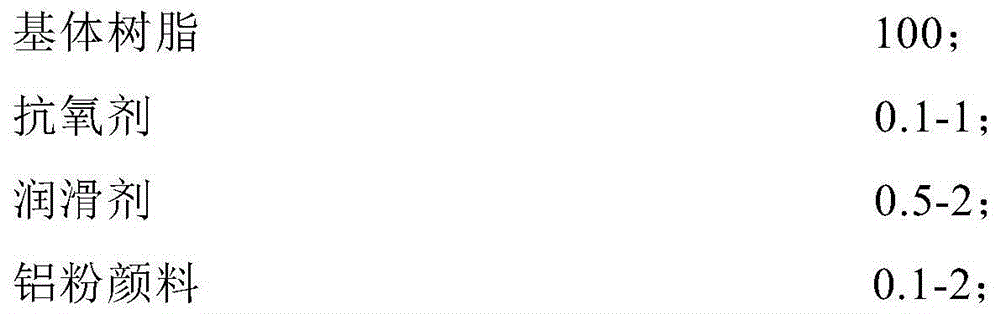

Method for preparing coating-free aesthetic resin with improved appearance

A method for preparing a coating-free aesthetic resin with improved appearance comprises the following steps of: (1) blending the matrix resin, an antioxidant, a lubricant and an aluminum powder pigment together in a weight ratio of 100: (0.1-1): (0.5-2): (0.1-2); (2) stirring and mixing the raw materials in a high-speed mixer and then feeding the mixture into a double-screw extruder, melting and compounding the mixture under conveying, shearing and mixing of the screws, and then performing extrusion, bar drawing, cooling and grain-sized dicing through an opening mold assembled with an ultrasonic device, thereby obtaining the coating-free aesthetic resin with improved appearance. Compared with the prior art, the ultrasonic extrusion method is employed so that the compatibility of the polyester matrix resin with the aluminum powder is improved and the processability of the matrix resin is improved; as a result, weld lines and flow marks of the aesthetic resin formed in the injection molding process are greatly reduced. The method provided by the invention provides technical support for replacing the traditional painting proposal by the green environment-friendly aesthetic resin.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Online auction method and system for establishing bidding reward mechanism

InactiveCN104794652AMaximize the benefitsIncrease auction turnover rateWeb data indexingTransmissionPrice differenceComputer science

Disclosed is an online auction method and system for establishing a bidding reward mechanism. According to the bidding reward mechanism, a consignor commissions an auctioneer to reward a bidder so that the bidder enjoys part of price differences in bidding steps; meanwhile, during auctions, each time when the bidder bids, an auction platform freezes a margin of same amount or certain proportion of amount, the margin is not unfrozen until that another bidder bids, and flowing steps are alike. The online auction method and system is transparent and strict, safe and reliable, and open and fair, activates the auction market and serves the public and economy.

Owner:胡刚

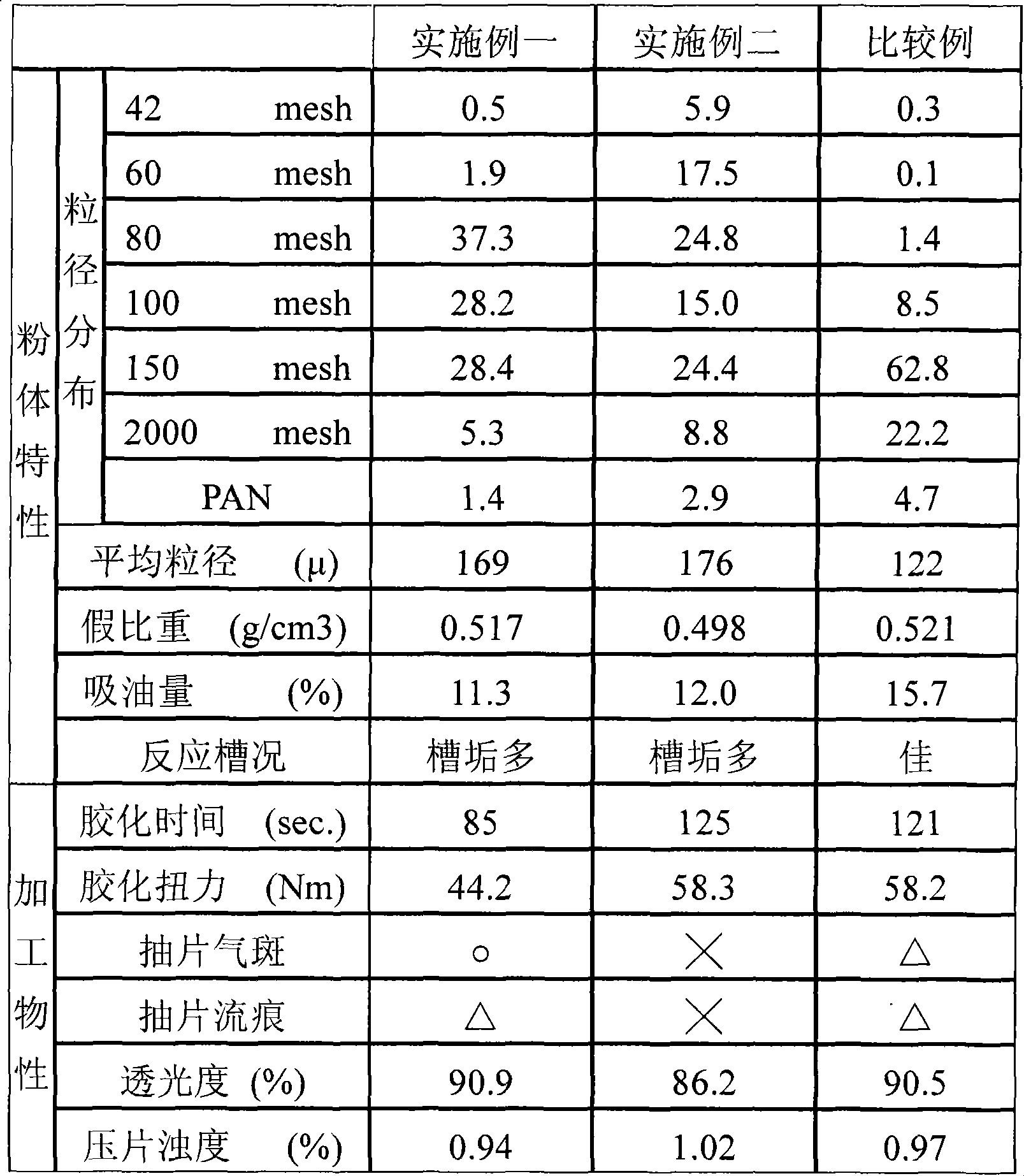

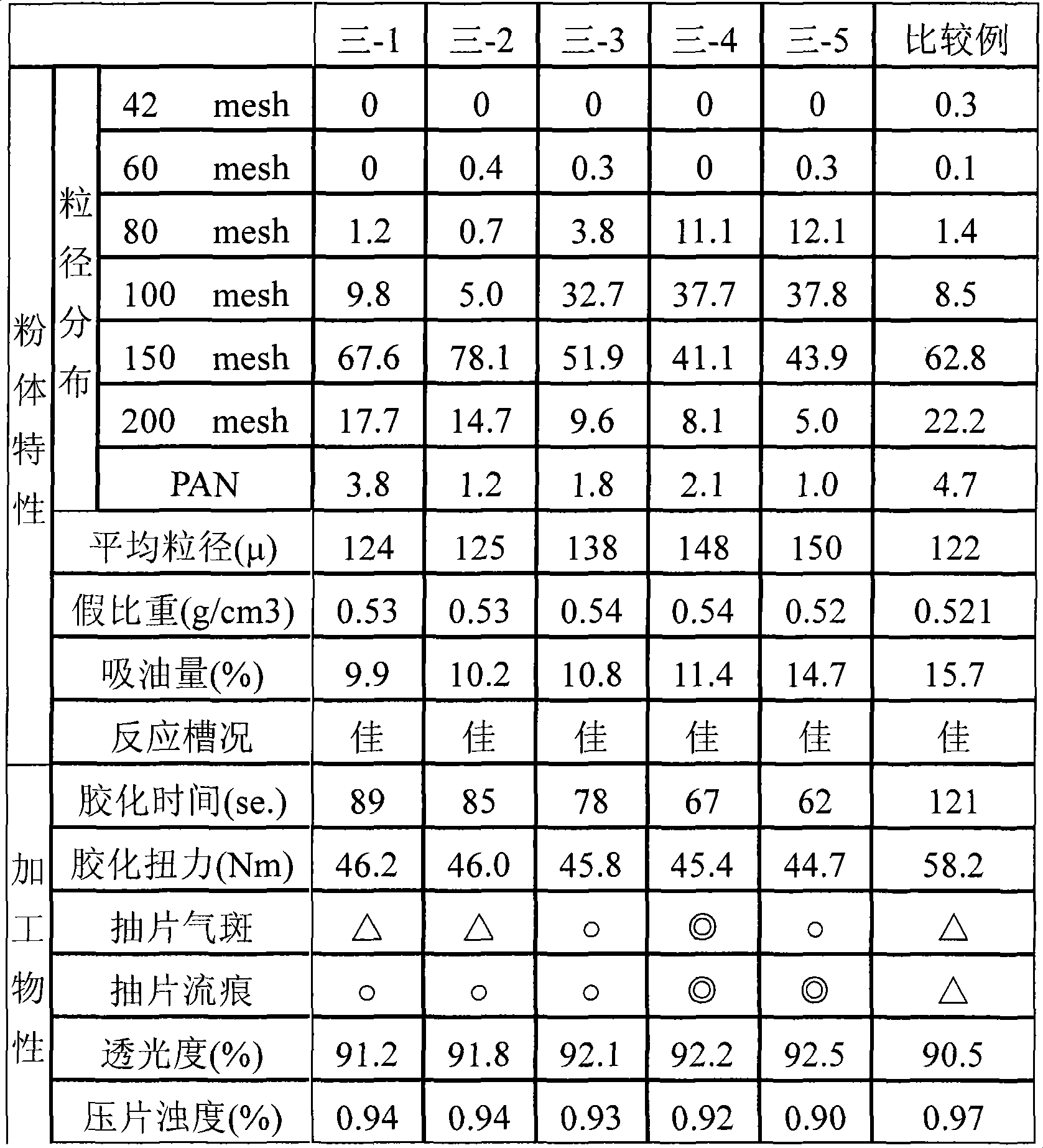

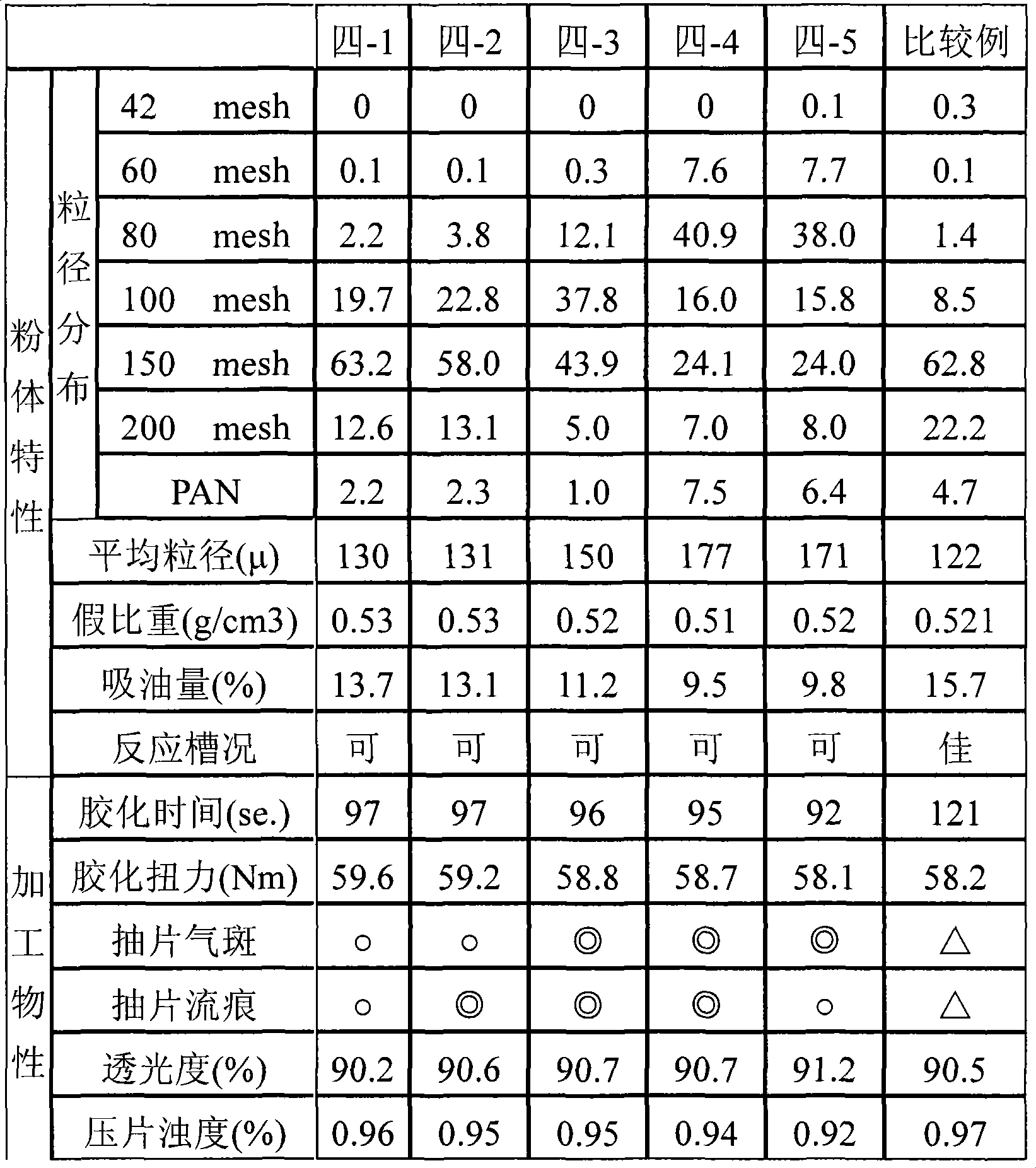

Preparation of functional composite material polyvinylhalogenides resin

The invention provides a functional composite material poly ethylene halide resin, which is prepared by the solution method, the block polymerization method or the suspension polymerization method. The poly ethylene halide resin is prepared through the following steps: (1) providing ethylene halide monomer or multiple polymerization monomers mainly including ethylene halide monomer 90.0 to 99.9 wt% of total composition; and (2) sectionally adding or adding at a time multiple alkyl acrylate monomer or alkyl acrylate / acrylic polymer emulsion / dried substance 10.0 to 0.1 wt% of total composition, and carrying out copolymerization or graft polymerization reaction, wherein the polymerization monomer (ethylene halide monomer or multiple polymerization monomers mainly including ethylene halide monomer) is added in bath or sectionally continuous added, and the multiple alkyl acrylate monomer or alkyl acrylate / acrylic polymer emulsion / dried substance is continuously added during reaction process or is placed into a coincidence tank before reaction.

Owner:FORMOSA PLASTICS CORP

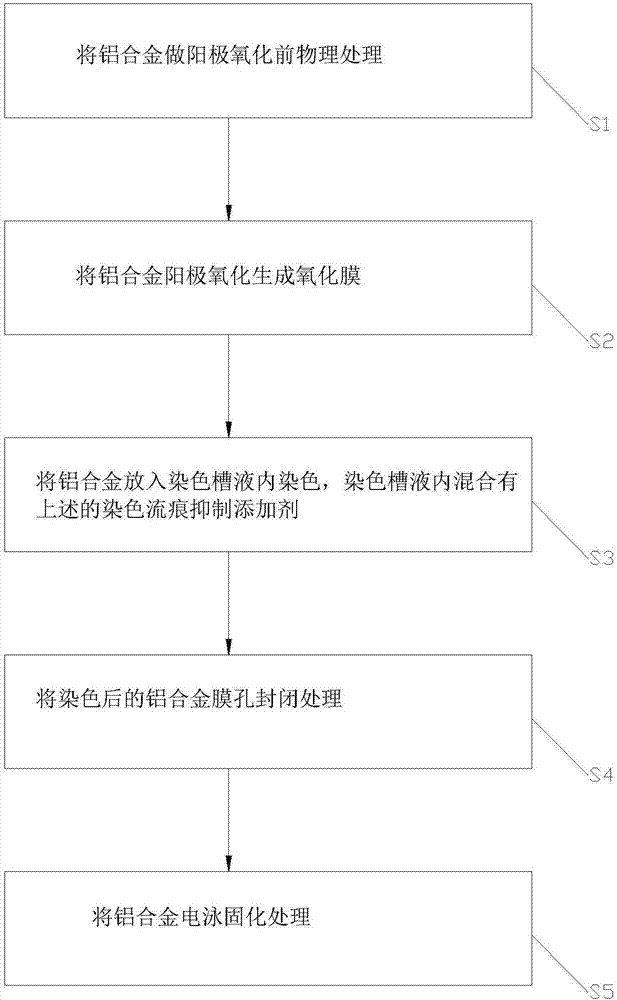

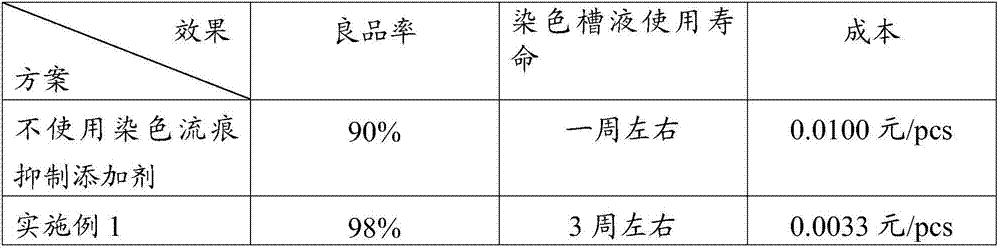

Dyeing flow mark inhibition additive and method for drying aluminum alloy anode

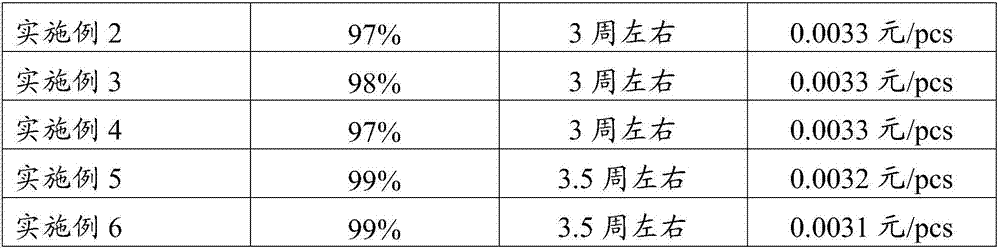

InactiveCN107130278AAvoid foamingInhibit pH instabilitySurface reaction electrolytic coatingSodium acetateMannitol

The invention discloses a dyeing flow mark inhibition additive and a method for drying an aluminum alloy anode. The dyeing flow mark inhibition additive is prepared from the following components in parts by mass: 7.5 to 10.5 parts of nickel acetate, 3.5 to 5.5 parts of sodium acetate, 7.5 to 10.5 parts of polydimethylsiloxane, 3.5 to 5.5 parts of mannitol, 3.5 to 6.5 parts of triethanolamine and 4.5 to 6.5 parts of ammonium sulfate. The dyeing flow mark inhibition additive disclosed by the invention can inhibit conditions of blistering, PH unstability and non-uniform dyeing agent distribution of dyeing bath liquid for oxidization dyeing of the aluminum alloy anode, so that quality abnormities such as flow marks and spots during dyeing are reduced; furthermore, the dyeing capability of dyeing bath liquid can be promoted, and the service life of the dyeing bath liquid for oxidization dyeing of the aluminum alloy anode can be further prolonged from the original one week to about three weeks; and therefore, the bath building frequency is reduced, equipment operation is enhanced, and the dyeing cost is reduced.

Owner:SHENZHEN MENGZHIFANG COMM PROD

Graphite type coating paste for titanium and titanium alloy casting and preparation method thereof, and application of graphite type coating paste for titanium and titanium alloy casting

ActiveCN110899609AChemically stableStrong anti-explosion performance at high temperatureFoundry mouldsFoundry coresGraphiteTitanium alloy

The invention relates to the technical field of casting, and provides a graphite type coating paste for titanium and titanium alloy casting and a preparation method thereof, and application of graphite type coating paste for titanium and titanium alloy casting. The graphite type coating paste comprises the following components: refractory aggregate, a binder, a bonding promoter, a dispersant and an antifoaming agent; the refractory aggregate is composed of zirconium dioxide, titanium dioxide and titanium hydride, wherein the mass ratio of zirconium dioxide to titanium dioxide to titanium hydride is (50-55):(40-45):(1-5). The refractory aggregate of the coating paste provided by the invention does not contain rare and precious metal oxides such as yttrium oxide and hafnium oxide, the graphite type coating paste is low in cost, stable in coating chemical property and high in high-temperature anti-burst performance, and can be applied to graphite mold casting of titanium or titanium alloy, and an obtained casting is low in roughness, thin in pollution layer, few in surface flow marks and free of cracks.

Owner:PANZHIHUA TIANMIN TITANIUM +1

Appearance-improving spraying-free aesthetic resin and its preparation method

Owner:SHANGHAI KUMHO SUNNY PLASTICS

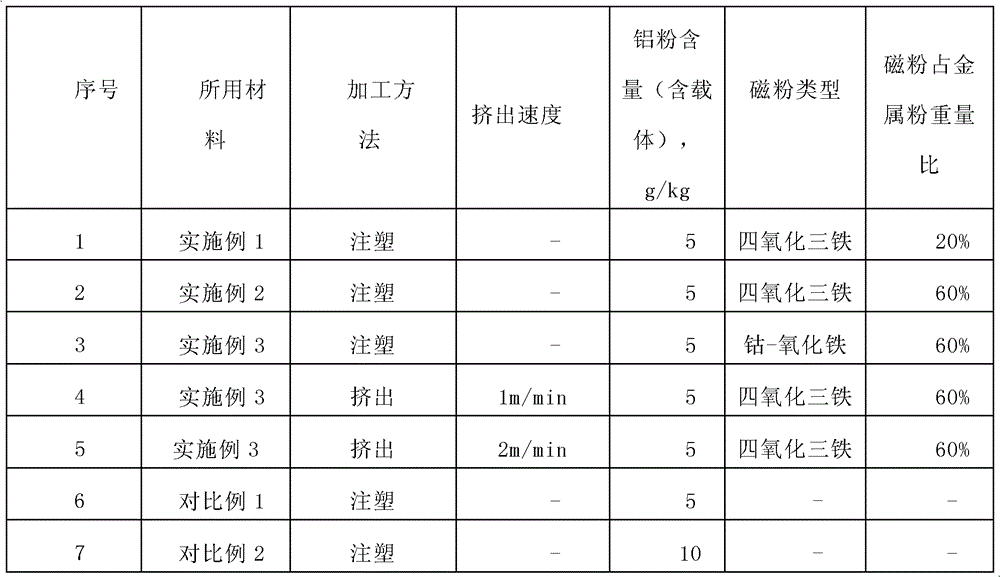

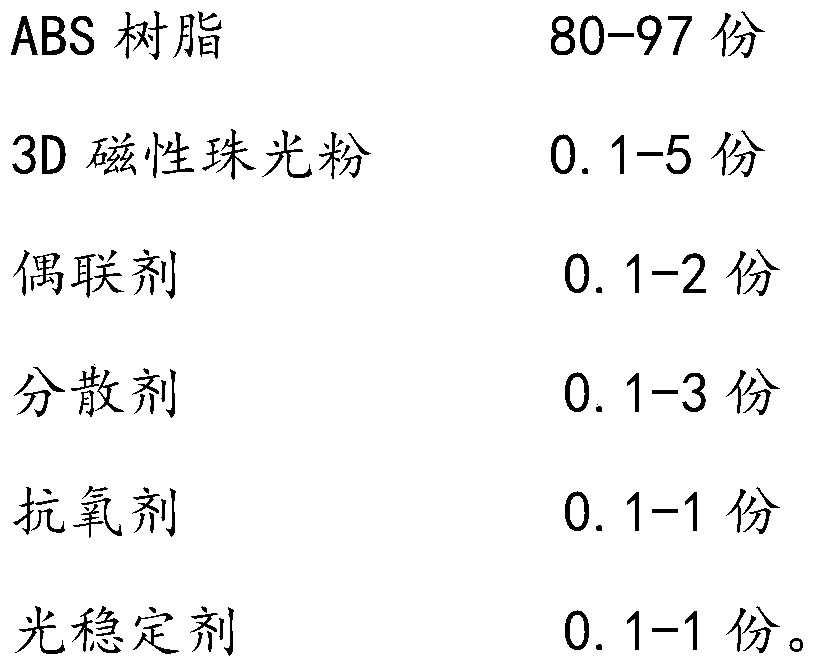

Free-spraying ABS material with 3D pearl effect and preparation method thereof

The invention provides a free-spraying ABS material with the 3D pearl effect and a preparation method thereof. The free-spraying ABS material with the 3D pearl effect is prepared from the components of base material resin, 3D magnetic pearl powder and other processing aids. According to the free-spraying ABS material, the special 3D magnetic pearl powder is added to ABS resin, during injection molding, the magnetic field action of a magnetic injection mold is used, the 3D magnetic pearl powder tends to move towards the surfaces of products, and thus most magnetic materials are concentrated onthe surfaces of the products to form the shiny dreamlike 3D effect; and the free-spraying ABS material with the 3D pearl effect can be applied to products in the fields such as art crafts, toys, homeappliances, automobiles, electronic products, sporting goods and office supplies.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

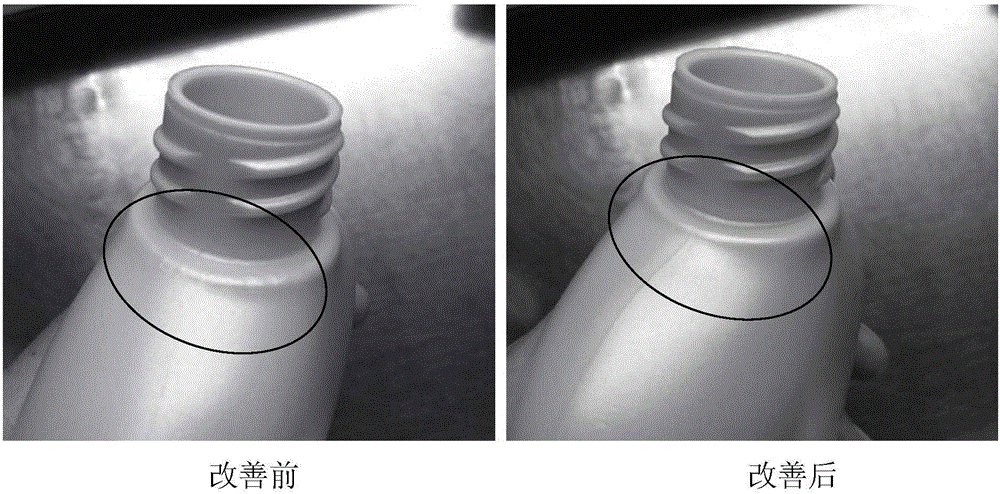

HDPE modified material for improving pearly luster color masterbatch forming line and application of material

The invention discloses an HDPE modified material for improving the pearly luster color masterbatch forming line and application of the material, and belongs to the field of material application. The HDPE modified material is prepared from, by mass, 50-90% of extrusion blow molding grade HDPE and 10-50% of LDPE or LLDPE. The HDPE modified material has the advantages that the effect of improving the pearly luster line and the flow line in forming is good, production efficiency is improved, only a pouring cup needs to be detached to be polished during production, the time for cleaning mold head parts is greatly shortened, and production efficiency is improved; the color and luster of the material are improved, and the material is helpful for improving the pearl luster line and the flow line; the production cost of the product is not increased, and the product performance is not influenced; component compatibility is good, no special requirements exist during machining, so the production cost of the product can not be increased; the mechanical performance of the LDPE is weak, but co-mixture only needs to be used on the outer layer, so the ratio of the co-mixture in the product is small, and the physical performance of the product is not remarkably influenced.

Owner:GUANGZHOU BEAUTY STAR CO LTD

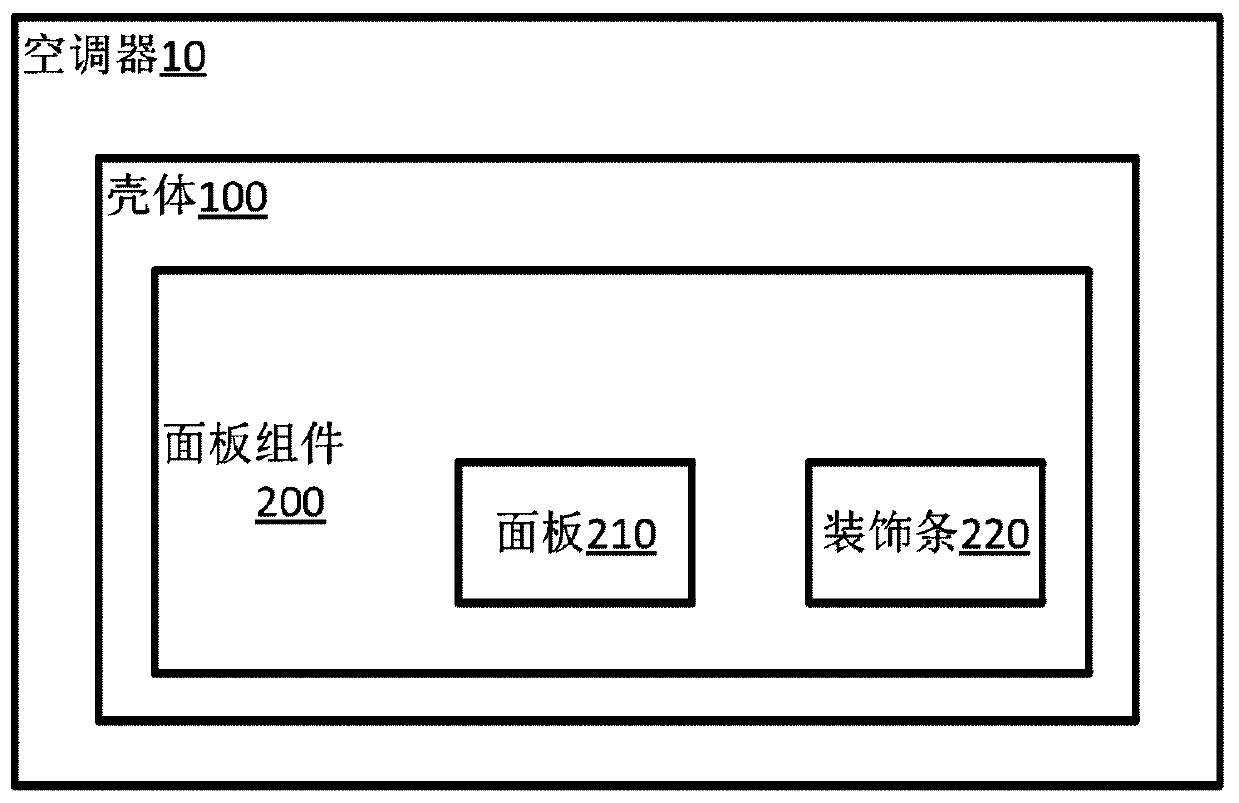

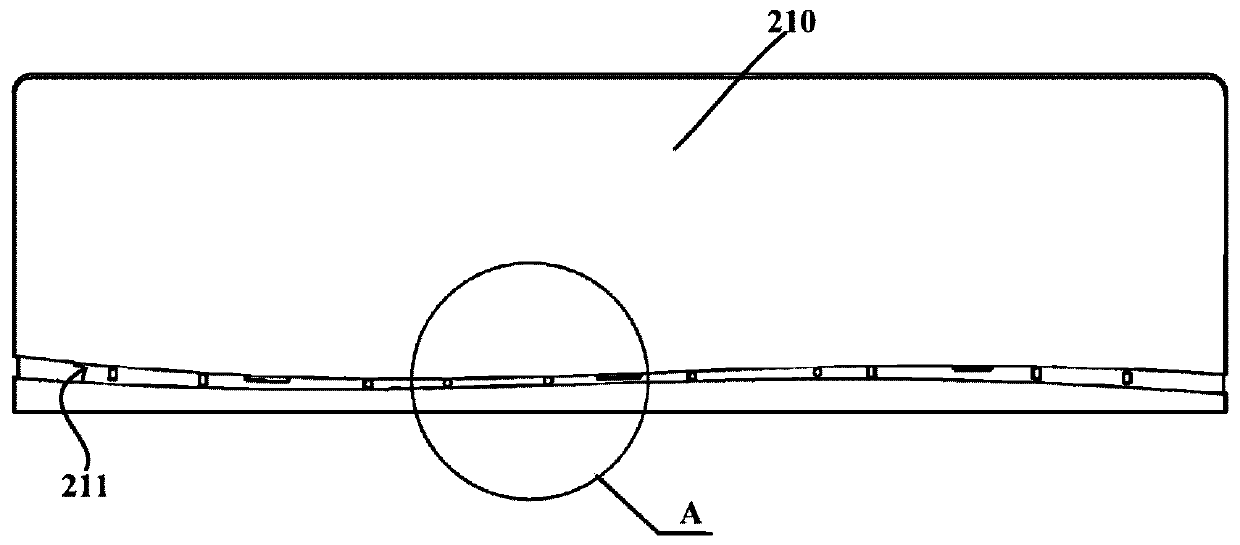

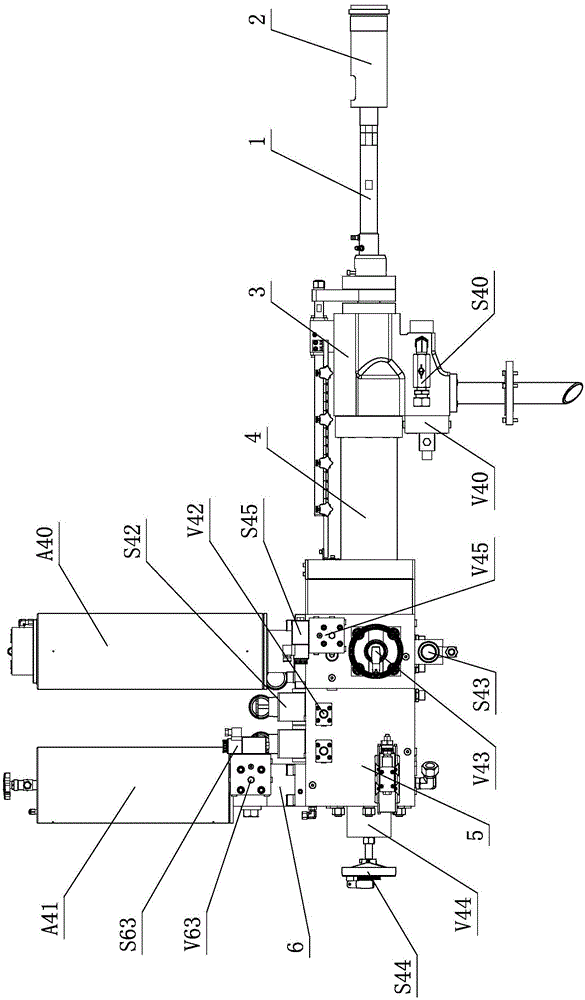

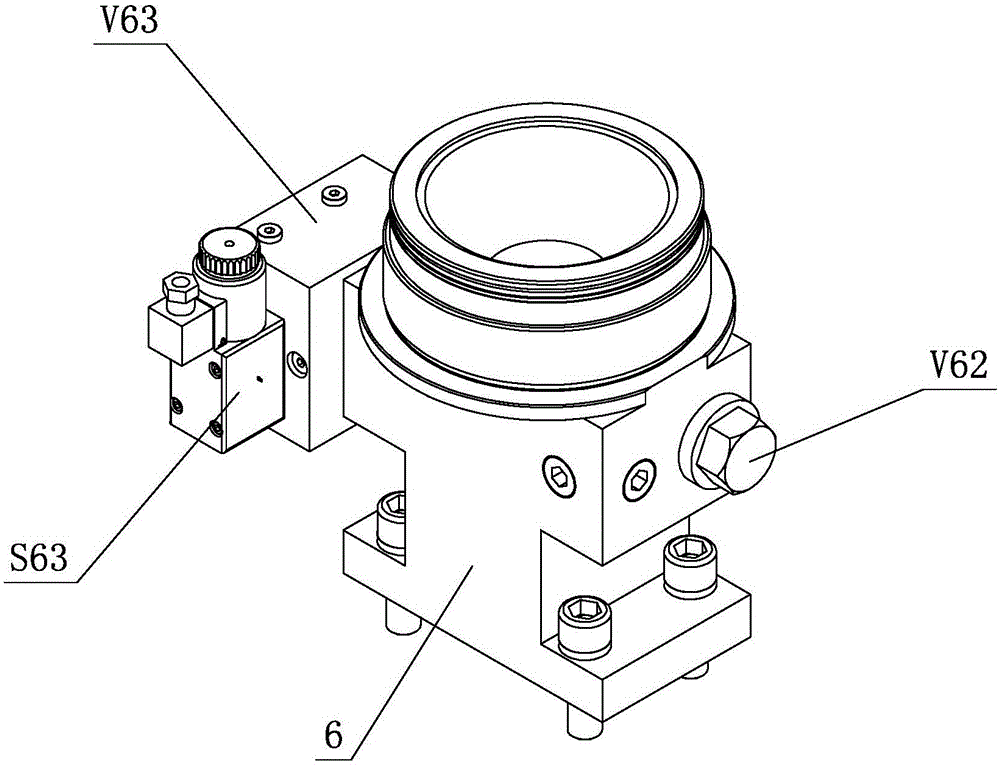

Air conditioner panel assembly and air conditioner

ActiveCN110220292AIncrease smoothnessEnhance metallic color effectHeating and ventilation casings/coversColor effectEngineering

The invention provides an air conditioner panel assembly. The air conditioner panel assembly comprises a panel and a decoration strip, wherein a decoration strip groove is formed in the front surfaceof the panel; the decoration strip is produced through injection molding of a metal texture spraying-free material and is mounted in the decoration strip groove; a plurality of clamping buckles whichare raised backwards are arranged on one side, facing to the decoration strip groove, of the decoration strip; and clamping holes which are in one-to-one correspondence to the plurality of clamping buckles and are matched with the clamping buckles are respectively formed in positions, opposite to the plurality of clamping buckles located in the decoration strip, in the decoration strip groove. According to the air conditioner panel assembly, the size of each clamping buckle in a transverse direction of the decoration strip is smaller than a distance between an upper end surface highest point and a lower end surface lowest point of the clamping buckle in a vertical direction, so that the generation of flow marks on the decoration strip in the injection molding process is generated, so thatthe smoothness degree of the surface of the decoration strip is improved; the process of removing the flow marks is avoided; and the metal color effect of the surface of the decoration strip is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

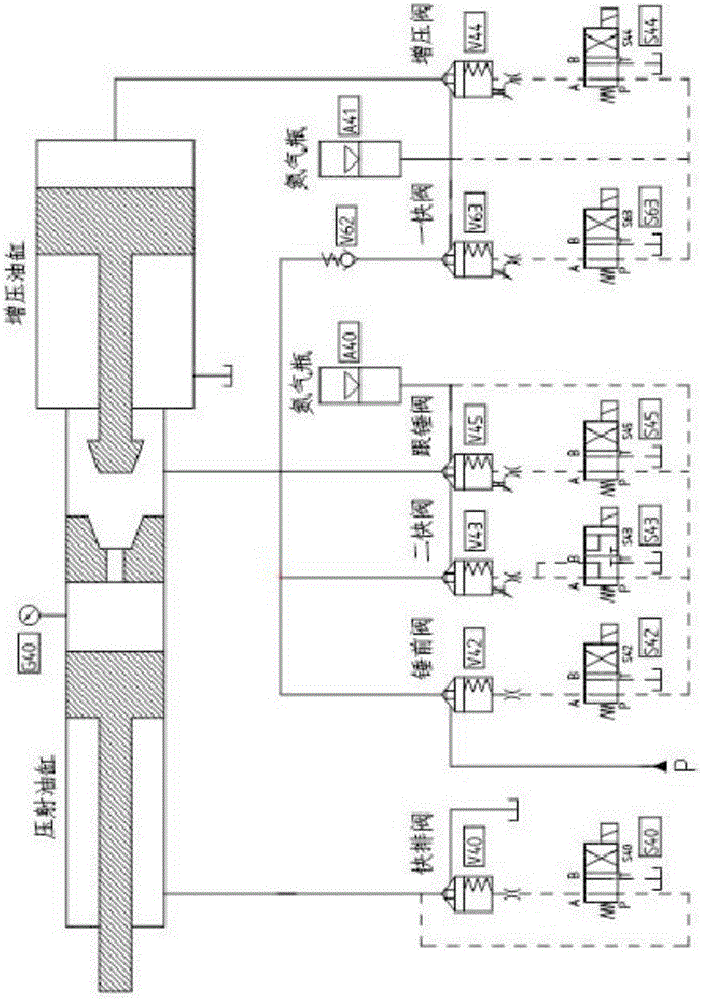

Injection pressure-boosting and speed-increasing structure of die casting machine

The invention discloses an injection pressure-boosting and speed-increasing structure of a die casting machine. The injection pressure-boosting and speed-increasing structure comprises an injection punch, wherein an injection part is arranged at one side of the injection punch; an injection oil cylinder, an injection piston rod and a pressure-boosting oil cylinder are sequentially arranged at the other side of the injection punch; a pressure-boosting cavity is formed between the injection piston rod and the pressure-boosting oil cylinder; and a primarily quick oil path block assembly and a secondarily quick oil path block assembly are arranged on the pressure-boosting oil cylinder. According to the injection pressure-boosting and speed-increasing structure, the speed of the primarily quick action and the secondarily quick action is increased by a design method and a control mode which are combined with a practical production process, so that requirements of producing thin-wall parts such as a magnesium alloy mobile phone middle plate and the like are met, and a common horizontal type cold chamber die casting machine is transformed into a special die casting machine for thin-wall parts represented by the die-cast magnesium alloy mobile phone middle plate; the modified die casting machine can realize that cast pieces are full, less in shrinkage cavities, smooth in surface, good in smoothness, free of flow marks, less in flanges, free of air bubbles and flaws and high in practicability, and meet processing requirements.

Owner:佛山联升压铸科技有限公司

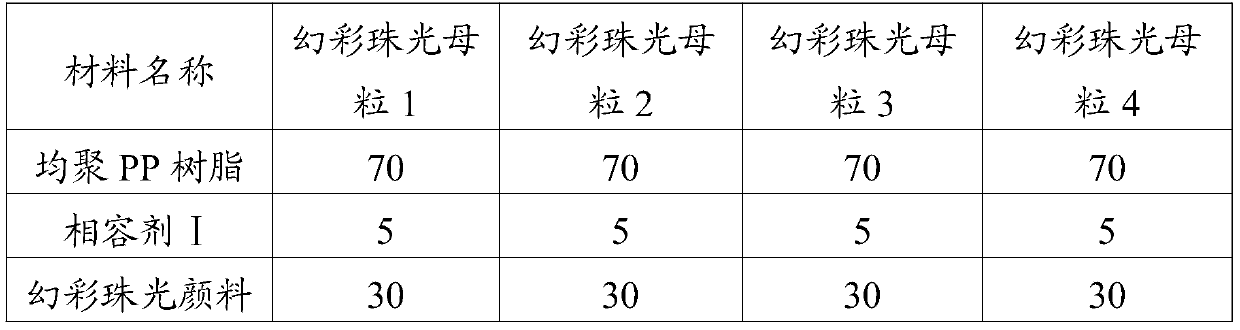

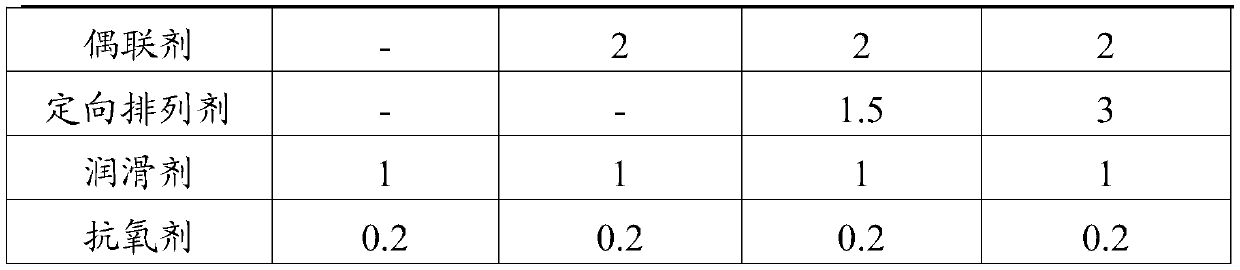

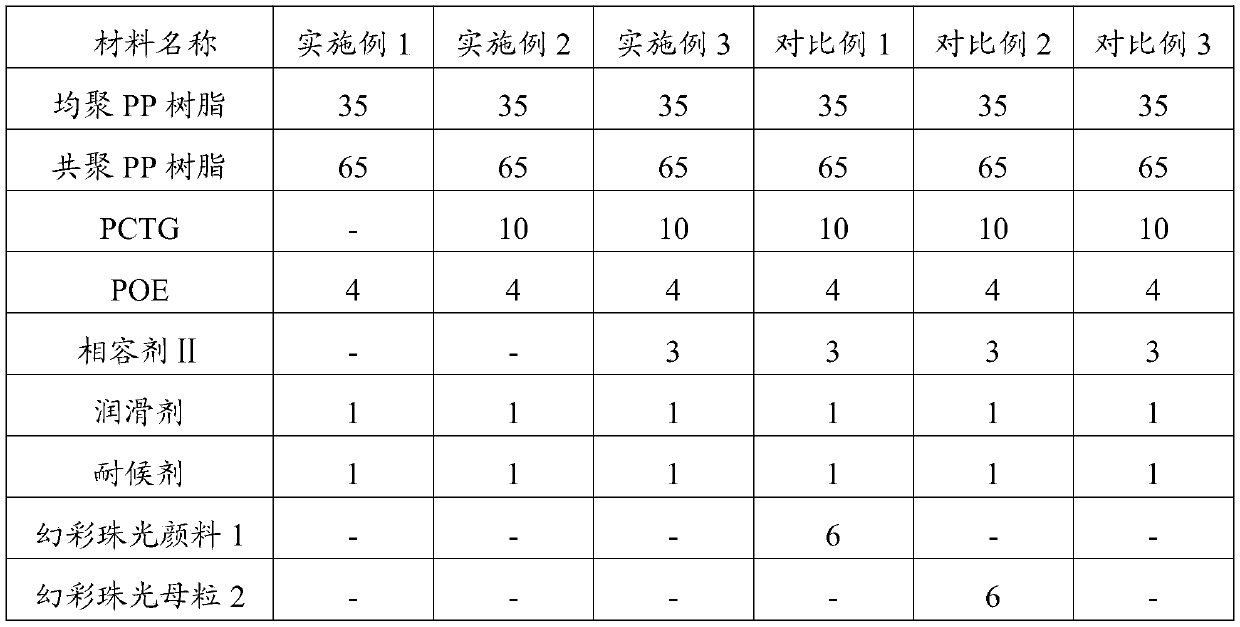

Spraying-free PP/PCTG alloy material with colorful effect and preparation method thereof

The invention relates to the technical field of PP alloy materials, in particular to a spraying-free PP / PCTG alloy material with a colorful effect and a preparation method of the spraying-free PP / PCTGalloy material. The alloy material comprises the following components in parts by mass: 10-35 parts of homopolymerized PP resin, 40-65 parts of copolymerized PP resin, 5-15 parts of PCTG resin, 4-8 parts of a POE flexibilizer, 1-2 parts of a lubricant, 0.5-1.5 parts of a weather-resistant agent, 5-15 parts of a colorful pearlescent master batch and 0-5 parts of a compatilizer II, wherein the colorful pearlescent master batch comprises the following preparation raw materials in parts by mass: 60-90 parts of homopolymerized PP resin, 3-5 parts of a compatilizer I, 10-30 parts of a colorful pearlescent pigment, 1-5 parts of a coupling agent, 1-5 parts of a directional arrangement agent, 1-2 parts of a lubricant and 0.1-0.5 part of an antioxidant. The PP / PCTG alloy material has good impact resistance, and a good colorful effect can be achieved without spraying.

Owner:FOSHAN KAIYUE GRAND SKY PLASTIC TECH CO LTD

A kind of lost foam water-based coating for cast iron and production method thereof

ActiveCN103447454BRaw materials are uniqueImprove securityFoundry mouldsFoundry coresWater basedSodium Bentonite

The invention relates to a water-based paint of lost foam for iron casting. The water-based paint is characterized by comprising the following raw materials: high bauxite, precious peal powder, brown aluminum oxide, sodium bentonite, polyacrylamide, a polyvinyl acetate emulsion, maltodextrin, silica sol, sodium hexametaphosphate, tributyl phosphate, sodium pentachlorophenate, OP-10 active agent and water. A production method of the water-based paint comprises the steps: pretreating the sodium bentonite, pretreating the polyacrylamide and the maltodextrin, adding the water, the sodium pentachlorophenate, the tributyl phosphate and the sodium hexametaphosphate into a high-speed dispersion kettle, stirring and then sequentially adding the sodium bentonite slurry and a polyacrylamide and maltodextrin pretreatment solution into the dispersion kettle, sequentially adding the polyvinyl acetate emulsion and the silica sol into the dispersion kettle, sequentially adding the OP-10, the high bauxite, the precious pearl powder and the brown aluminum oxide to the dispersion kettle under a stirring state, and conducting high-speed dispersion for 30 minutes after completing the feeding. The water-based paint is unique in the raw materials, environment-friendly, high in coating strength, anti-cracking, good in permeability, and free from carbon lack of castings.

Owner:共享新材料(山东)有限公司

Novel hot dip coating low-cost low-energy-consumption aluminum tin alloy containing Ti and Y

InactiveCN108588503AAvoid corrosionReduced service lifeHot-dipping/immersion processesAlloyDip-coating

The invention discloses a novel hot dip coating low-cost low-energy-consumption aluminum tin alloy containing Ti and Y. The alloy comprises the ingredients of, in percentage by weight, 0.3-0.5% of Na,1.5-1.8% of Ti, 0.4-0.8% of Ca, 15.0-22.0 % of Sn, 0.2-0.4% of Y, 0.3-0.5% of Yb, 0.1-0.2% of P and the balance aluminum. By means of the hot dip coating aluminum tin alloy, the key problems that thetechnology in the present hot dip coating alloy field lags behind, product quality is poor, the product cost is high, energy consumption is large, and the like are solved, and in the near future, thealloy will be applied to more fields more widely.

Owner:GUANGZHOU YUZHI TECH CO LTD

Aluminum section bar surface brightening method

InactiveCN109913925AWith cleanReduce production speedAnodisationElectrophoretic coatingsPhosphoric acidColor changes

The invention discloses an aluminum section bar surface brightening method. The aluminum section bar surface brightening method comprises the steps of sand blasting, oil removing, water washing, polishing, oxidizing, coloring, medium-temperature hole sealing and electrophoresis curing, wherein the polishing is performed inside a three-acid polishing tank, the three-acid polishing tank contains theingredients of, in percentage by weight, 65-85% of phosphoric acid, 14-22% of sulfuric acid and 6-8% of nitric acid, the polishing is performed for 20-25 min under the condition of the polishing temperature being 100-110 DEG C, and by means of reduction of the oxidizing temperature and the oxidizing tank sulfuric acid concentration, the oxide film production speed can be reduced, a more uniform and compact oxide film is obtained, and appearance of flow marks in aluminum materials is reduced; and the aluminum materials are not prone to fading when being subjected to the water washing and electrophoresis after being subjected to the coloring and the hole sealing and high adhesion can be obtained when the electrophoresis is performed in a half hole sealing state, and when combination with the electrophoresis is performed, suitable voltage can slow down the paint film coating speed, in addition of an appropriate curing method, dye color changing and coating surface roughness and excessivebrittleness can be prevented, and the coating adhesion is improved.

Owner:佛山市南海区和顺超强铝型材有限公司

A preparation method of spray-free aesthetic resin for improving appearance

A method for preparing a coating-free aesthetic resin with improved appearance comprises the following steps of: (1) blending the matrix resin, an antioxidant, a lubricant and an aluminum powder pigment together in a weight ratio of 100: (0.1-1): (0.5-2): (0.1-2); (2) stirring and mixing the raw materials in a high-speed mixer and then feeding the mixture into a double-screw extruder, melting and compounding the mixture under conveying, shearing and mixing of the screws, and then performing extrusion, bar drawing, cooling and grain-sized dicing through an opening mold assembled with an ultrasonic device, thereby obtaining the coating-free aesthetic resin with improved appearance. Compared with the prior art, the ultrasonic extrusion method is employed so that the compatibility of the polyester matrix resin with the aluminum powder is improved and the processability of the matrix resin is improved; as a result, weld lines and flow marks of the aesthetic resin formed in the injection molding process are greatly reduced. The method provided by the invention provides technical support for replacing the traditional painting proposal by the green environment-friendly aesthetic resin.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

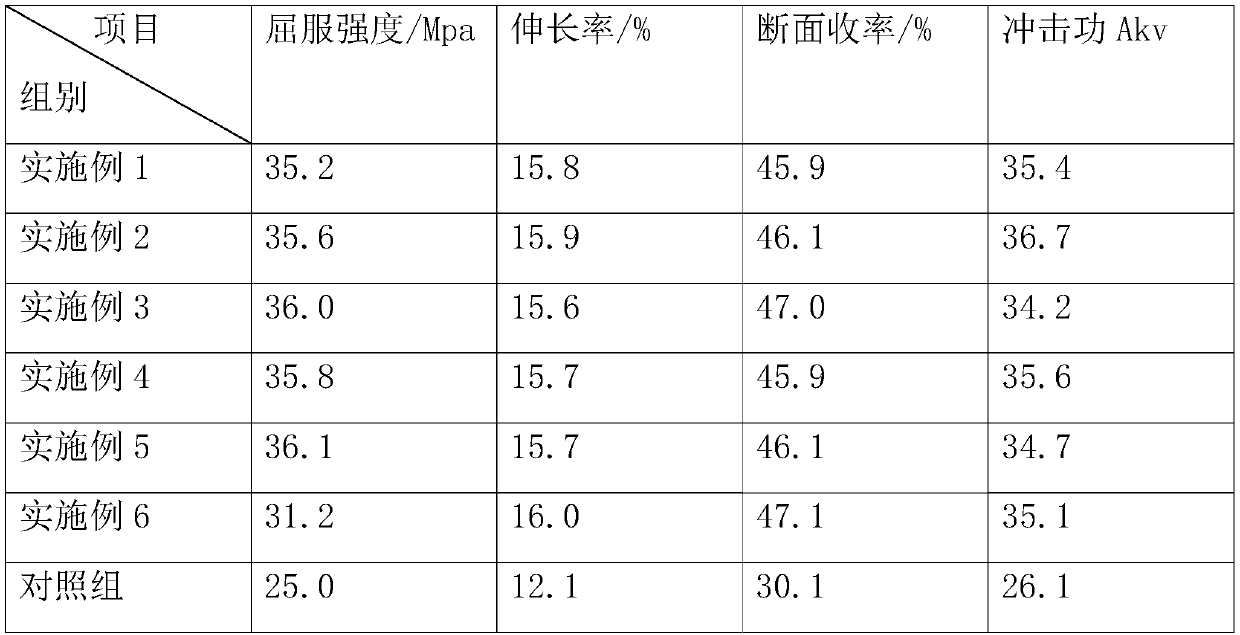

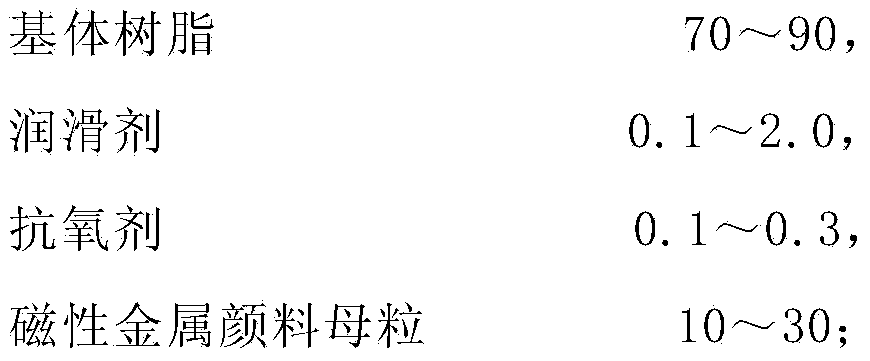

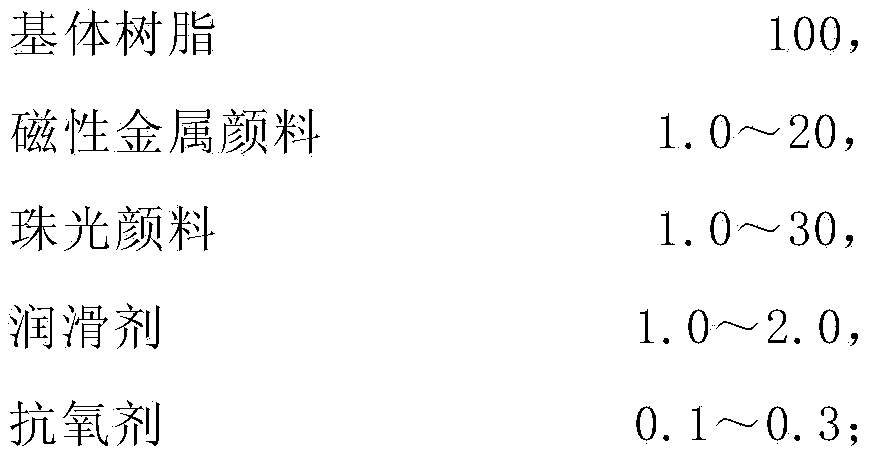

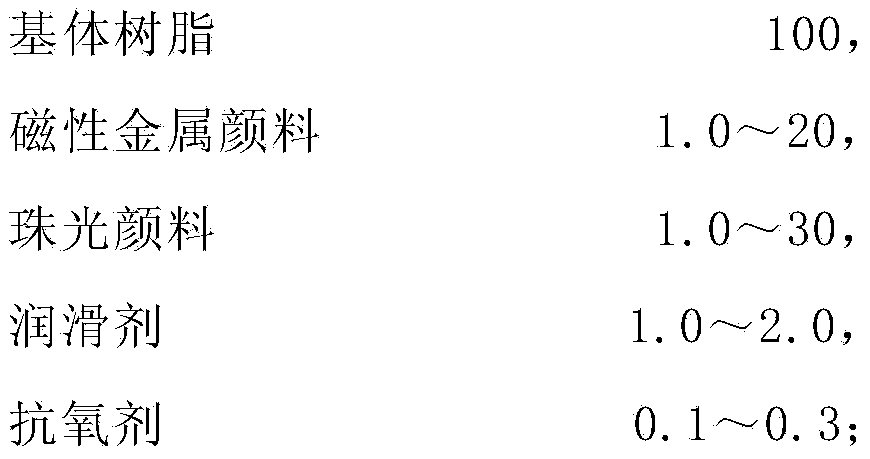

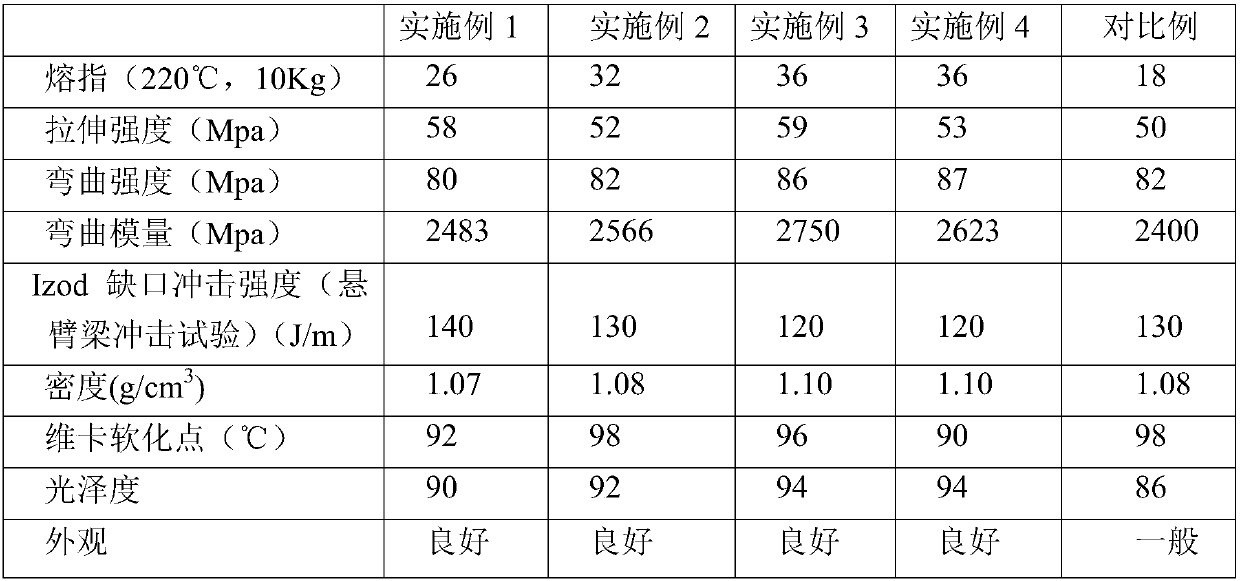

Spraying-free aesthetic resin composition with magnetism and preparation method thereof

The invention relates to a spraying-free aesthetic resin composition with magnetism. The resin comprises the following components in parts by weight: 70-90 parts of matrix resin, 0.1-2.0 parts of lubricant, 0.1-1.0 part of antioxidant and 10-30 parts of magnetic metallic pigment master batch. The magnetic metallic pigment master batch comprises the following components in parts by weight: 100 parts of matrix resin, 1.0-20 parts of magnetic metallic pigment, 1.0-30 parts of pearlescent pigment, 1.0-2.0 parts of lubricant and 0.1-0.3 parts of antioxidant. The preparation method comprises the steps of preparing the magnetic metallic pigment master batch; agitating and mixing the raw materials, extruding, drawing into bars, cooling and cutting into grains to obtain the spraying-free aesthetic resin composition. The spraying-free aesthetic resin composition with magnetism has the advantages that the flow marks and the weld lines occurring in the injection molding or extrusion process of the aesthetic resin containing aluminum powder pigment are effectively reduced, the metal effect of produced parts is enhanced at the same time, the amount of the used aluminum powder pigment is reduced and the cost is saved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

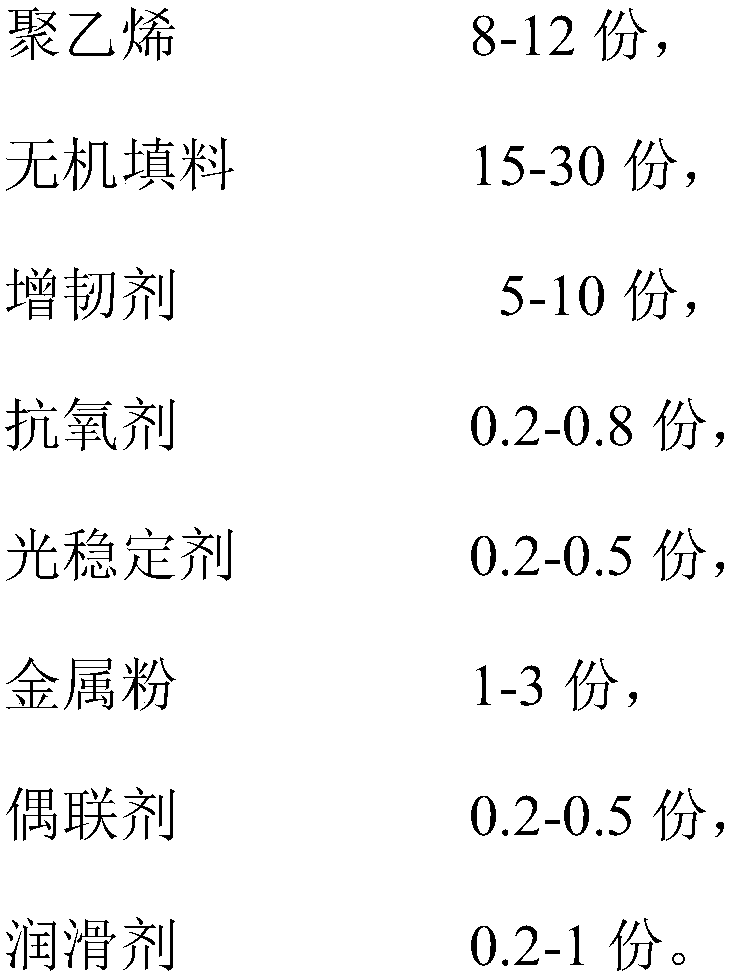

Silver spraying-free polypropylene alloy for lower bumper guard plate and preparation method of alloy

The invention discloses a silver spraying-free polypropylene alloy for a lower bumper guard plate and a preparation method of the alloy. The alloy is prepared by mixing 48-72 parts of polypropylene, 8-12 parts of polyethylene, 15-30 parts of an inorganic filler, 5-10 parts of a toughening agent, 0.2-0.8 part of an antioxidant, 0.2-0.5 part of a light stabilizer, 1-3 parts of metal powder, 0.2-0.5part of a coupling agent and 0.2-1 part of a lubricant and then extruding the mixture for granulating. The polypropylene alloy prepared by means of the method can be matched with a high-gloss mirror surface mold to obtain high gloss and a great appearance with a metal effect without spraying and direct injection molding. Compared with a paint spraying process, the method has the advantages that the cost is greatly reduced, and scrapping caused by a paint shedding problem in a use process of a product is avoided at the same time; a preparation process is simple, and the obtained polypropylene alloy has great comprehensive performance and completely meets the performance requirements of bumpers for materials; meanwhile, a finished product has an obvious metal effect and can be used as a lower bumper guard plate material in cooperation with the high-gloss mold for injection molding.

Owner:HEFEI GENIUS NEW MATERIALS

Novel hot dipping aluminum alloy with hydrogen sulfide and sodium chloride corrosion resistance

InactiveCN108588507AImprove corrosion resistanceUniform compositionHot-dipping/immersion processesCorrosionChloride sodium

The invention discloses a novel hot dipping aluminum alloy with hydrogen sulfide and sodium chloride corrosion resistance. The aluminum alloy comprises the following components in percentage by weight: 0.1-0.2 wt.% of Ba, 0.3-0.5 wt.% of Hf, 0.4-0.6 wt.% of Ca, 1.2-1.5 wt.% of Bi, 0.2-0.4 wt.% of Sc, 0.1-0.2 wt.% of Eu, 0.2-0.3 wt.% of S, and the balance aluminum. The aluminum alloy solves the current situation of backward technologies in the national hot dipping aluminum alloy field at present, and breaks through the bottleneck of restricting the development of hot dipping aluminum steel plate production technologies and equipment in the national high-end field through technology innovation and optimal design. In the near future, the material can be widely applied to more fields.

Owner:GUANGZHOU YUZHI TECH CO LTD

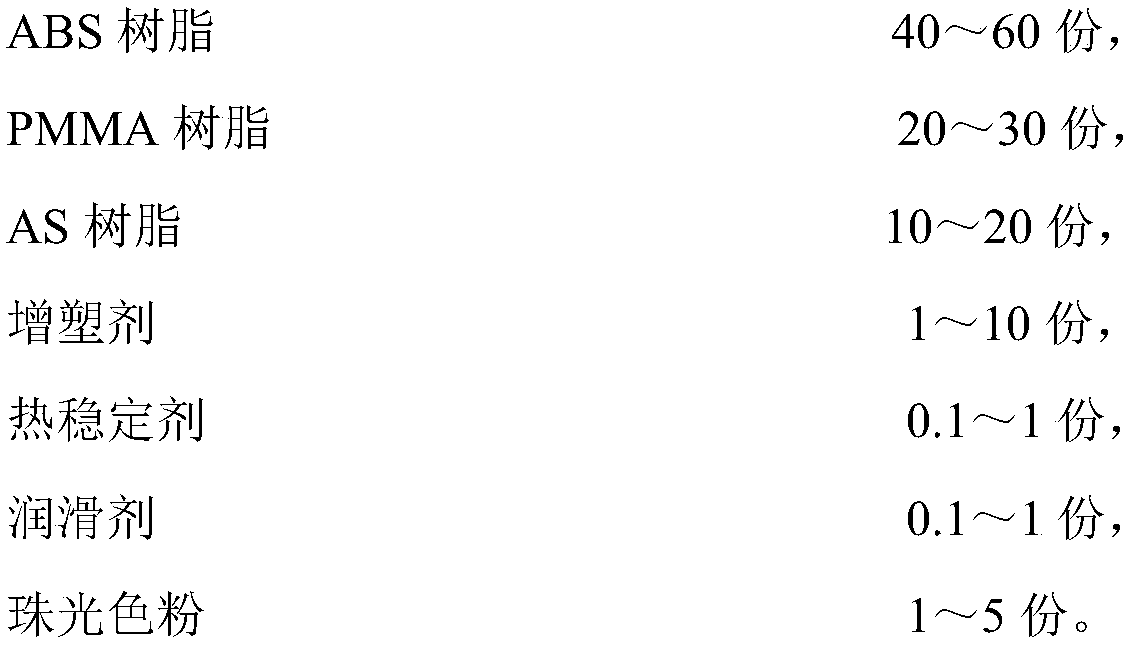

Spraying-free pearlescent ABS material and preparation method thereof

The invention provides a spraying-free pearlescent ABS material and a preparation method thereof. The material is prepared form the following components by weight: 40-60 parts of ABS resin, 20-30 parts of PMMA resin, 10-20 parts of AS resin, 1-10 parts of a plasticizer, 0.1-1 part of a heat stabilizer, 0.1-1 part of a lubricant and 1-5 parts of pearlescent toner. The spraying-free pearlescent ABSmaterial prepared according to the invention has good mechanical properties, greatly saves the cost compared with the previous spraying materials, also is environment-friendly and reliable, and has the characteristics of high mechanical properties, easy machining shaping, etc., especially has good appearance, and can achieve the spraying-free effect.

Owner:HEFEI GENIUS NEW MATERIALS

A kind of spray-free scratch-resistant PP alloy material and its preparation method

The invention relates to a spray-coating-free scratch-resistant PP alloy material and a preparation method thereof, wherein the spray-coating-free scratch-resistant PP alloy material is prepared from the following raw materials by weight: 100 parts of polypropylene, 5-20 parts of an transparent ionic polymer, 3-6 parts of a compatibilizer, 0.5-3 parts of a metal powder pigment, 0.5-1 part of a dispersant, 0.5-1 part of an infiltrating agent, and 0.2-0.5 part of an antioxidant, the dispersant is formed by compounding polyester grafted modified silicone and polyethylene wax according to a weight ratio of 2:1, and the graft ratio of the polyester grafted modified silicone is 0.8-2%. Compared to the material in the prior art, the material of the present invention has advantages of excellent spray-coating-free metal effect, excellent metal effect powder dispersibility and excellent scratch resistance, can effectively alleviate the flow mark problem of the traditional spray-coating-free metal effect material, is suitable for occasions having high scratch resistance requirements, and can be widely used in vehicles, home appliances, and other fields.

Owner:上海日之升科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com