Dyeing flow mark inhibition additive and method for drying aluminum alloy anode

A technology of inhibiting additives and aluminum alloys, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of frequent bath building, easy failure, and decline in dyeing ability, so as to reduce the frequency of bath building and increase the service life , the effect of reducing the cost of dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

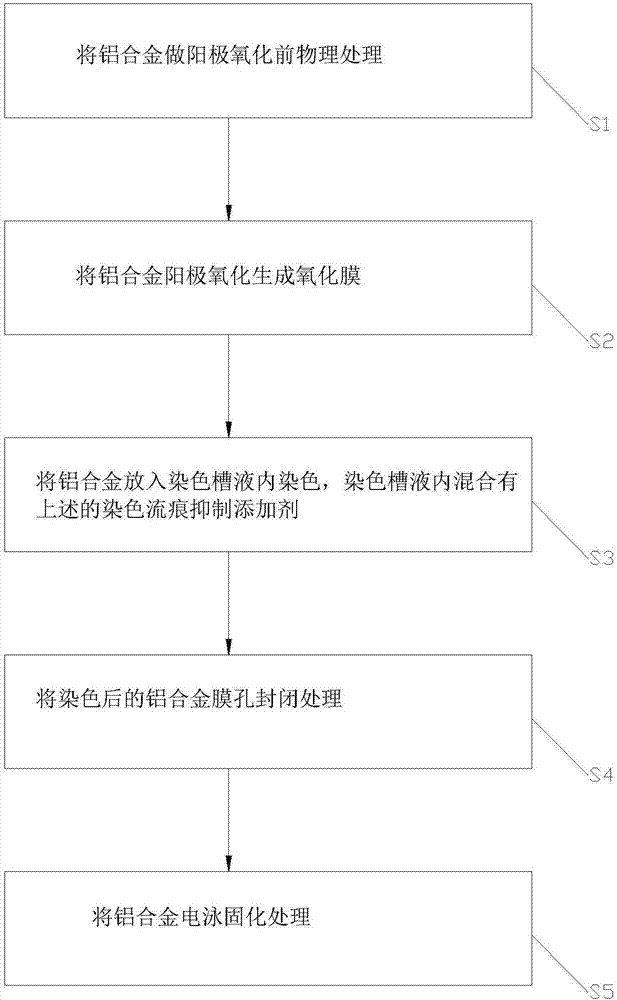

Method used

Image

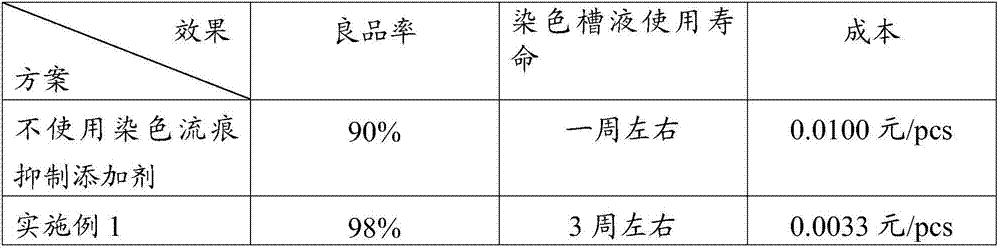

Examples

Embodiment 1

[0033] In Example 1, by mass parts, it includes 7.5 parts of nickel acetate, 3.5 parts of sodium acetate, 7.5 parts of polydimethylsiloxane, 3.5 parts of mannitol, 3.5 parts of triethanolamine and 4.5 parts of ammonium sulfate.

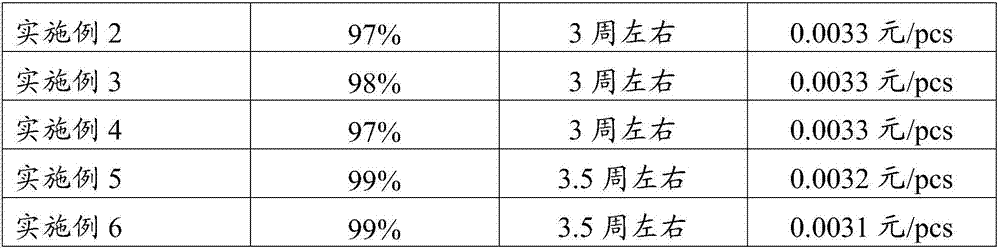

Embodiment 2

[0034] In Example 2, by mass parts, it includes 10.5 parts of nickel acetate, 5.5 parts of sodium acetate, 10.5 parts of polydimethylsiloxane, 5.5 parts of mannitol, 6.5 parts of triethanolamine and 6.5 parts of ammonium sulfate.

Embodiment 3

[0035] In Example 3, in parts by mass, it includes 8 parts of nickel acetate, 4 parts of sodium acetate, 8 parts of polydimethylsiloxane, 4 parts of mannitol, 4 parts of triethanolamine and 5 parts of ammonium sulfate. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com