Patents

Literature

234results about How to "Reduce dyeing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

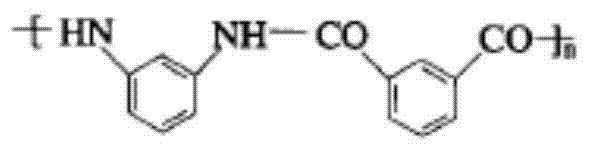

High-temperature high-pressure swelling dyeing method

InactiveCN101191306ASolving Dyeing PuzzlesIncrease profitSucessive textile treatmentsDyeing processPolymer scienceCrystallinity

The invention relates to a high temperature high pressure bulking dyeing method which comprises dyeing and after treatment. By adoption of the dyeing method of the invention, fibers or textile fabrics like aramid fibers, polysulfonamide fibers, polyphenylene sulfides, polybenzimidazole, poly-p-phenylene benzobisoxazole fibers, phenol formaldehyde resins, fibrilia and so on which have high crystallinity and high orientation degree or high glass transformation temperature can be dyed, and fibers after dyeing have the advantages of evenness, bright colors, high dyefastness, improvement of light fastness and little impact on physical properties.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Method for producing modified cation polyester filament and product thereof

ActiveCN102094256ABionic features are obviousLow boiling water shrinkageMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterPolymer science

The invention belongs to the field of manufacture of chemical fibers, in particular to a method for producing a modified cation polyester filament imitating a cellulose fiber. The method comprises the following steps of: preparing modified cation polyester; carrying out melting spinning by aiming at the characteristics of the modified cation polyester to obtain an orientated filament; and carrying out false twisting on the orientated filament under the condition of a special elasticizing process. The invention also provides a modified cation polyester filament prepared with the production method. The cation polyester filament disclosed by the invention has favorable fuzzing and pilling resistance, can be dyed at normal pressure without high-temperature and high-pressure conditions, saves the dyeing cost and has bright color after being dyed and high skin intimacy, and the hygroscopicity is better than that of common cation terylene filament.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Method for producing phosphorus copolymerized flame-retarding terylene high-strength industrial yarns

ActiveCN102199807ADoes not affect the molecular skeleton structureImprove hydrolytic stabilityArtificial filament heat treatmentMonocomponent copolyesters artificial filamentYarnHigh intensity

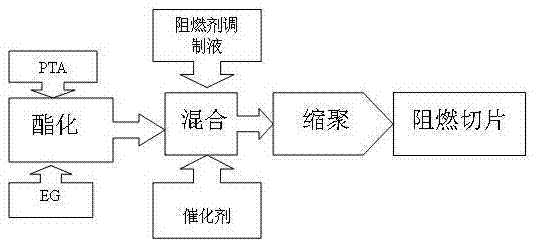

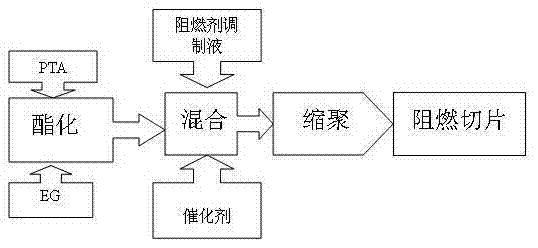

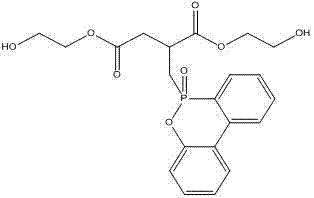

The invention discloses a method for producing phosphorus copolymerized flame-retarding terylene high-strength industrial yarns, which is characterized by comprising the following steps: pumping ethylene glycol (EG) and purified terephthalic acid (PTA) into a pulping kettle according to a molar ratio of 1.15 for pulping; after uniform pulping, transferring the uniform pulp into an esterification kettle for esterification; after the esterification is accomplished, adding blended liquid of a flame retardant, uniformly mixing, and adding the mixture into a polymerization kettle; after the polymerization is accomplished, discharging and cutting to obtain flame-retarding polyester chips with a viscosity of 0.61; feeding the prepared flame-retarding polyester chips into a solid-phase polymerization system, and improving the viscosity to 0.90 to 1.10; and melting at a high temperature into molten spinning solution in a screw extruder, spinning by a spinning component, drawing, and thermally setting to obtain phosphorus copolymerized flame-retarding terylene high-strength industrial yarns. In the invention, a copolymerized flame-retarding modification process is used for flame-retarding modification of the polyester, and the obtained terylene industrial yarns have high strength and a permanent flame-retarding property.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

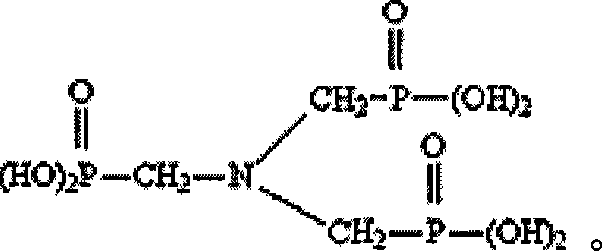

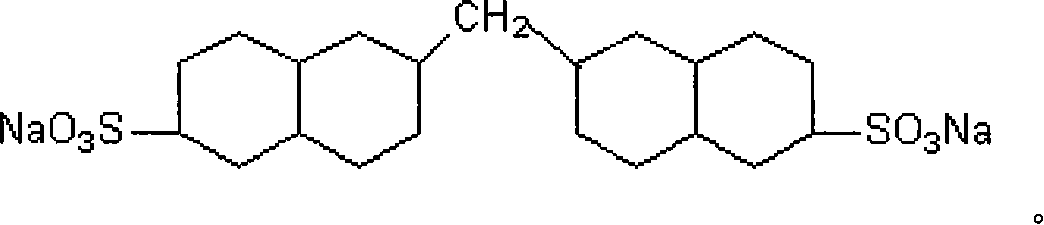

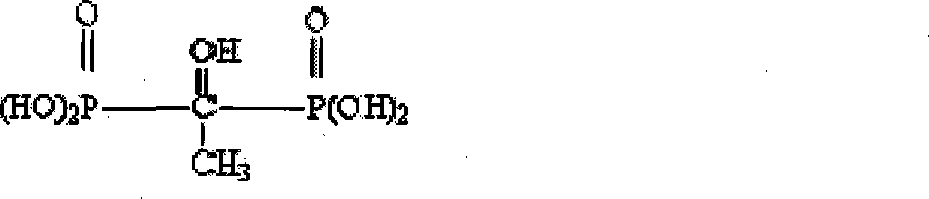

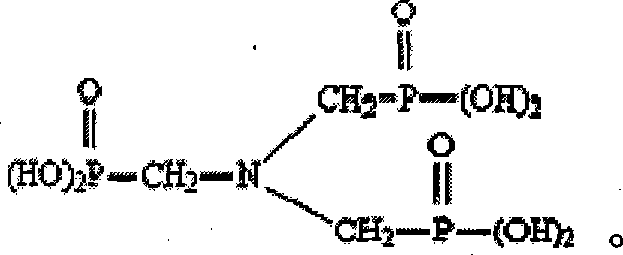

Auxiliary agent of formulation for dyeing Terylene

This invention discloses an aid used in terylene dyeing characterizing in including the following components in weight percentage: acid aid 10-20%, organic phosphonic acid 2-5%, organic carboxylic acid 3-7%, naphthalenesulfonate 10-18%, PEG 400 single oleic acid ester 5-8%, non-ion PAA 0-2%, polytrimethylene polyethenoxy aether 0-3% and water.

Owner:夏建明 +1

High-efficiency environment protection acidic color fixing agent and manufacture method thereof

InactiveCN101245563ARaw material environmental protectionWill not affect healthDyeing processMeth-Hazardous substance

The invention relates to an effective environment protective acid fixing agent that is prepared by a polypropylene acid fixing agent, an addition agent and a solvent which are matched. The polypropylene acid fixing agent is prepared by the following steps: mixing isopropanol, methacrylic acid, 2-acrylamido-2-methylpropane sulfoacid, acrylic acid and sodium persulfate in deionized water to be reacted for 1 to 5 hours at 80 to 90 DEG C and acquiring a reaction product, namely, the polypropylene acid fixing agent by post treatment. The preparation method of the effective environment protective acid fixing agent includes: adding proper water, adding all the materials under the condition of stirring at 40 to 50 DEG C in sequence to be mixed for 2 to 3 hours, uniformly dissolving, filtering, discharging and controlling the pH to be 6 to 7. The materials of the invention are environment-protective, can reduce the treatment cost of waste water and can generate remarkable social and economic benefits.

Owner:杭州下沙恒升化工有限公司

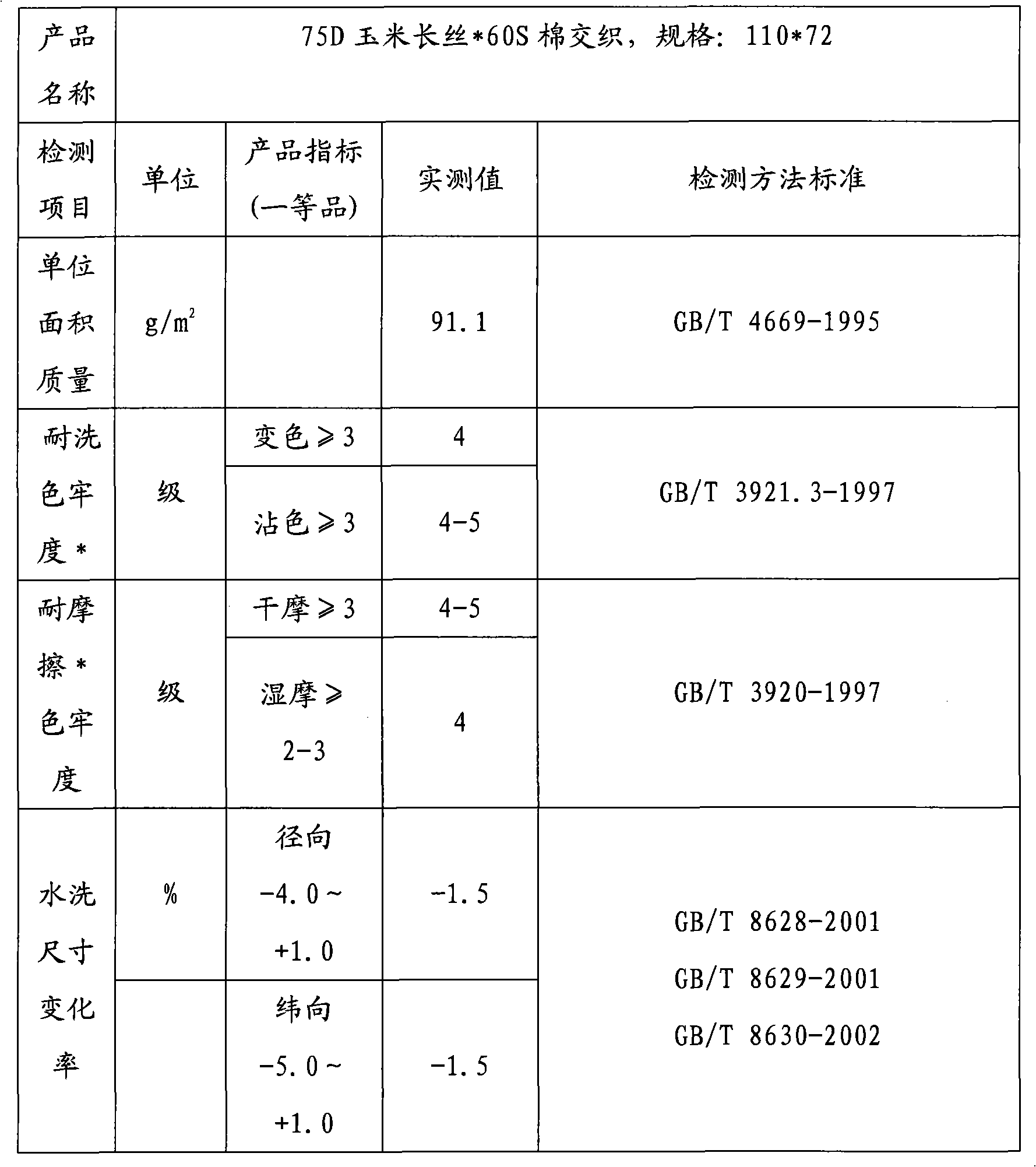

Dyeing and finishing process of corn fibers and cotton blending and mixed fabrics

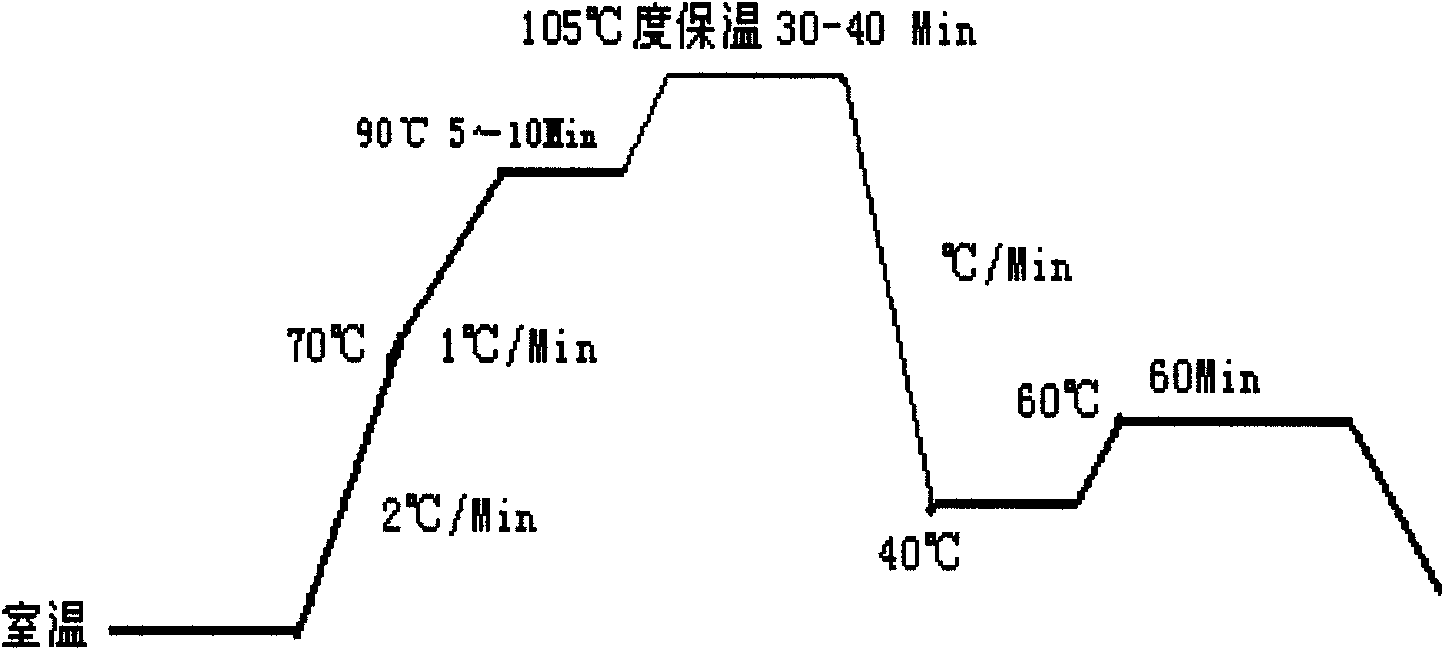

ActiveCN101671947ASufficient sourceNo need for petrochemical resourcesBiochemical fibre treatmentHeating/cooling textile fabricsDisperse dyeDying processes

The invention discloses a dyeing and finishing process of corn fibers and cotton blending and mixed fabrics, comprising the following steps: end stitching of greige cloth, pre-setting, pre-treatment,dyeing, dehydration, post finishing, and warehouse entry inspection. In the pre-setting process, the temperature is 120-130 DEG C and the time is 30-45 minutes; in the pre-setting process, the presetfabrics are placed in an overflow dying machine to conduct desizing and remove the hairiness on the surface of the fabrics; in the dying process, the corn fibers adopt middle temperature type and lowtemperature type dispersing dyes to conduct dying; and in the post finishing process, the dyed fabrics are placed in a 8-12g / L of hydrophilic amino-silicone softener for padding, and then the padded fabrics are dried and stentered and set at 100-120 DEG C. The dyeing and finishing process of corn fibers and cotton blending and mixed fabrics has good coloring rate, ensures the strength and feel ofcorn fibers, and also has significant impact on the industrial development of the textile industry.

Owner:安徽三宝棉纺针织投资有限公司

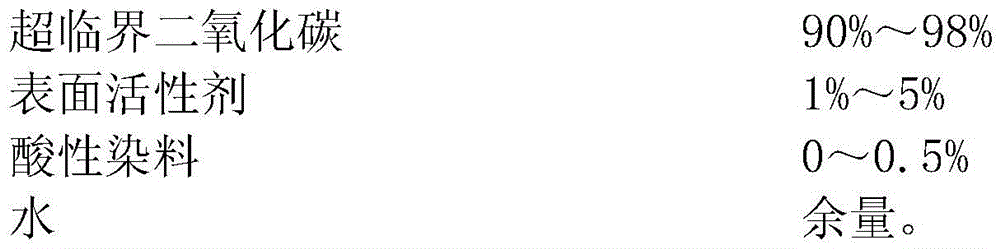

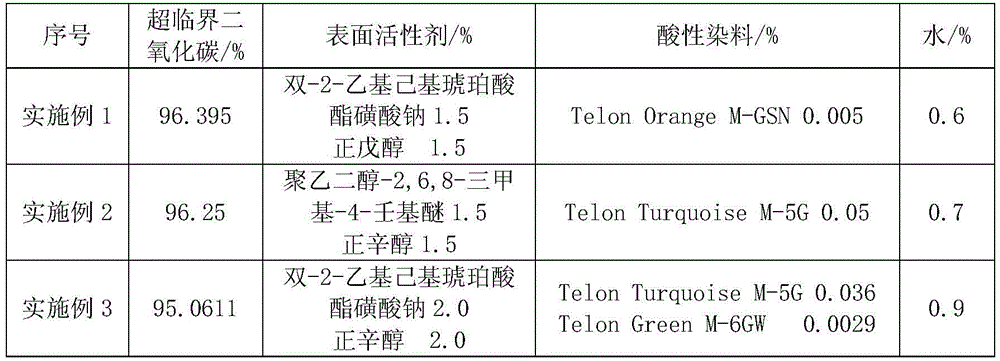

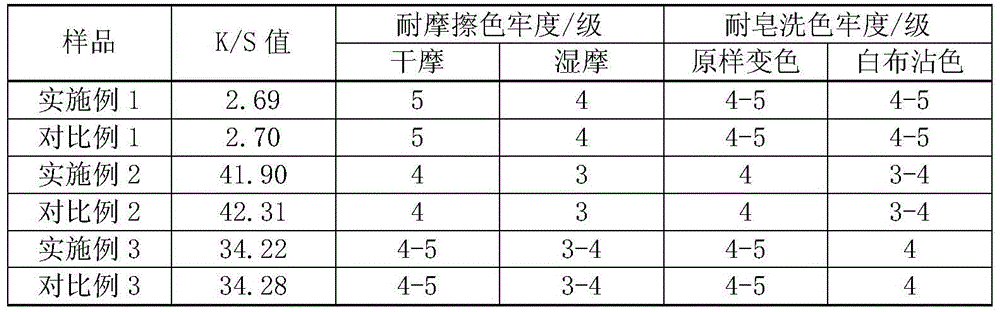

Reverse micelle system and application thereof in acid dye dyeing

InactiveCN105484071AMake up for the inability to dissolve polar substancesReduce dosageDyeing processOrganic solventSolvent

The invention discloses a reverse micelle system and an application thereof in acid dye dyeing. The reverse micelle system is characterized by comprising the following components in percentage by weight: 90%-98% of supercritical carbon dioxide, 1%-5% of a surfactant, 0-0.5% of an acid dye and the balance of water. Supercritical carbon dioxide dyeing is organically combined with reverse micelle dyeing; the supercritical carbon dioxide is taken as a non-polar organic solvent in reverse micelle dyeing due to the fact that the supercritical carbon dioxide is nontoxic, tasteless and not easy to combust and is an environment-friendly chemical solvent; in addition, the system only contains very little water of a reverse micelle-coated soluble dye; the amount of water can be greatly reduced; meanwhile, the carbon dioxide is recovered in the form of gas under the supercritical condition; the non-polar organic solvent, the surfactant and water can be easily separated; and recovery and cyclic utilization are achieved.

Owner:中国纺织科学研究院江南分院 +1

Method for dyeing polyphenylene sulfide fiber or fabric

InactiveCN101824757ADyeing smoothlyRaw materials are cheap and easy to getFibre typesDyeing processDisperse dyePolymer science

The invention discloses a method for dyeing polyphenylene sulfide fiber or fabric. The method comprises the following steps: treating the polyphenylene sulfide fiber or fabric, soaking the polyphenylene sulfide fiber or fabric into a high-temperature high-pressure dyeing machine filled with dyeing solution in a bath ratio of 1: 10-50, heating the polyphenylene sulfide fiber or fabric to between 100 and 140 DEG C at a heating sped of 0.5 to 5 DEG C per minute, preserving the heat and dyeing the polyphenylene sulfide fiber or fabric for 10 to 60 minutes, and performing reductive cleaning, water washing and drying on the polyphenylene sulfide fiber or fabric. Based on the weight of the polyphenylene sulfide fiber or fabric, the dyeing solution comprises 0.5 to 5 percent of disperse dye, 1 to 8g / L of dyeing carrier, 0 to 2g / L of pH adjustor, 0 to 5g / L of levelling agent, 0 to 1g / L of chelated dispersing agent and diluent. The method can successfully dye the polyphenylene sulfide fiber or fabric, has the advantages of high dyeing rate, deep and thick dyed color, good color fastness, soft handfeel, low dyeing cost and simple and feasible use and operation, can be expanded in application of civilian textiles, and is convenient for popularization and application.

Owner:SICHUAN UNIV

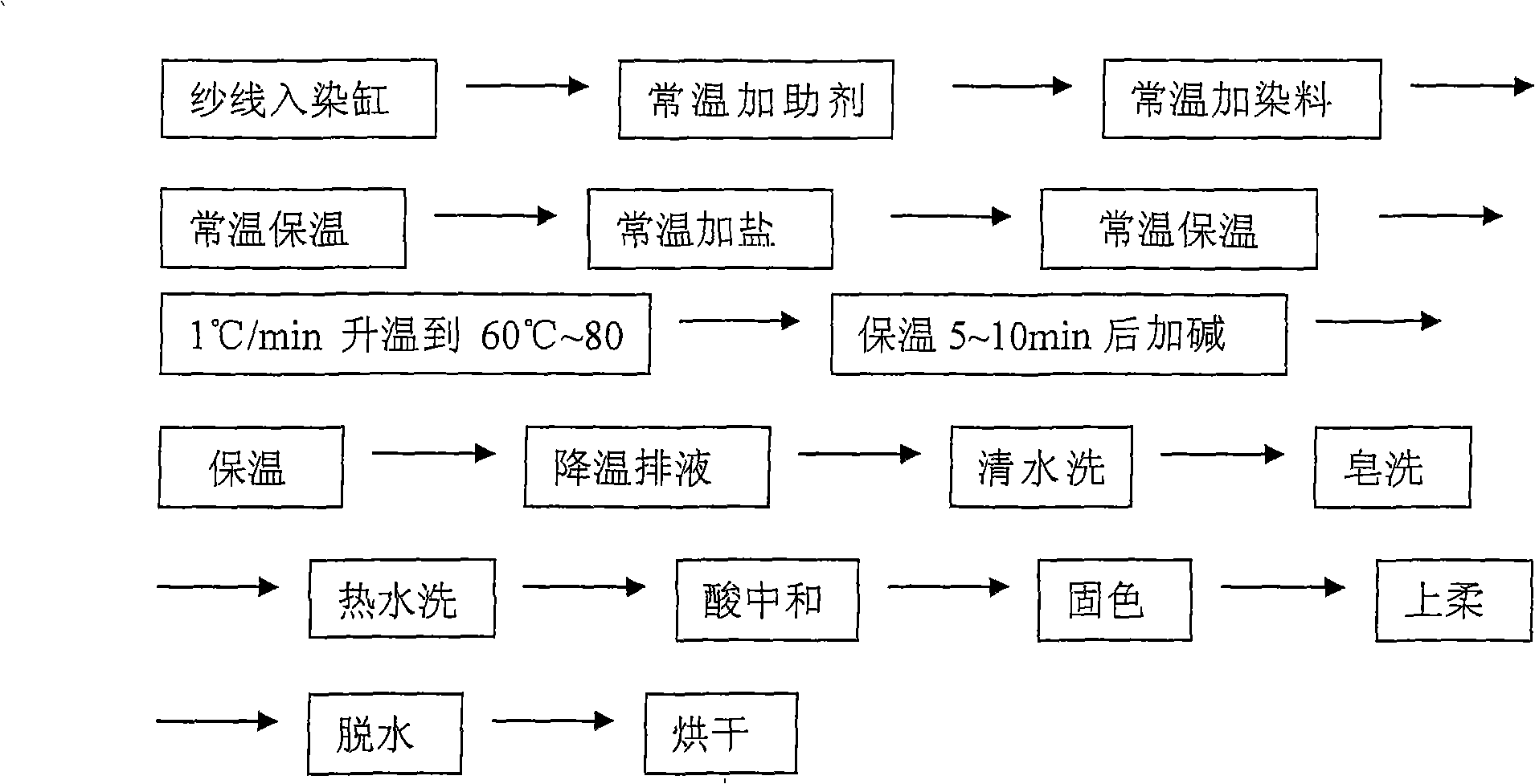

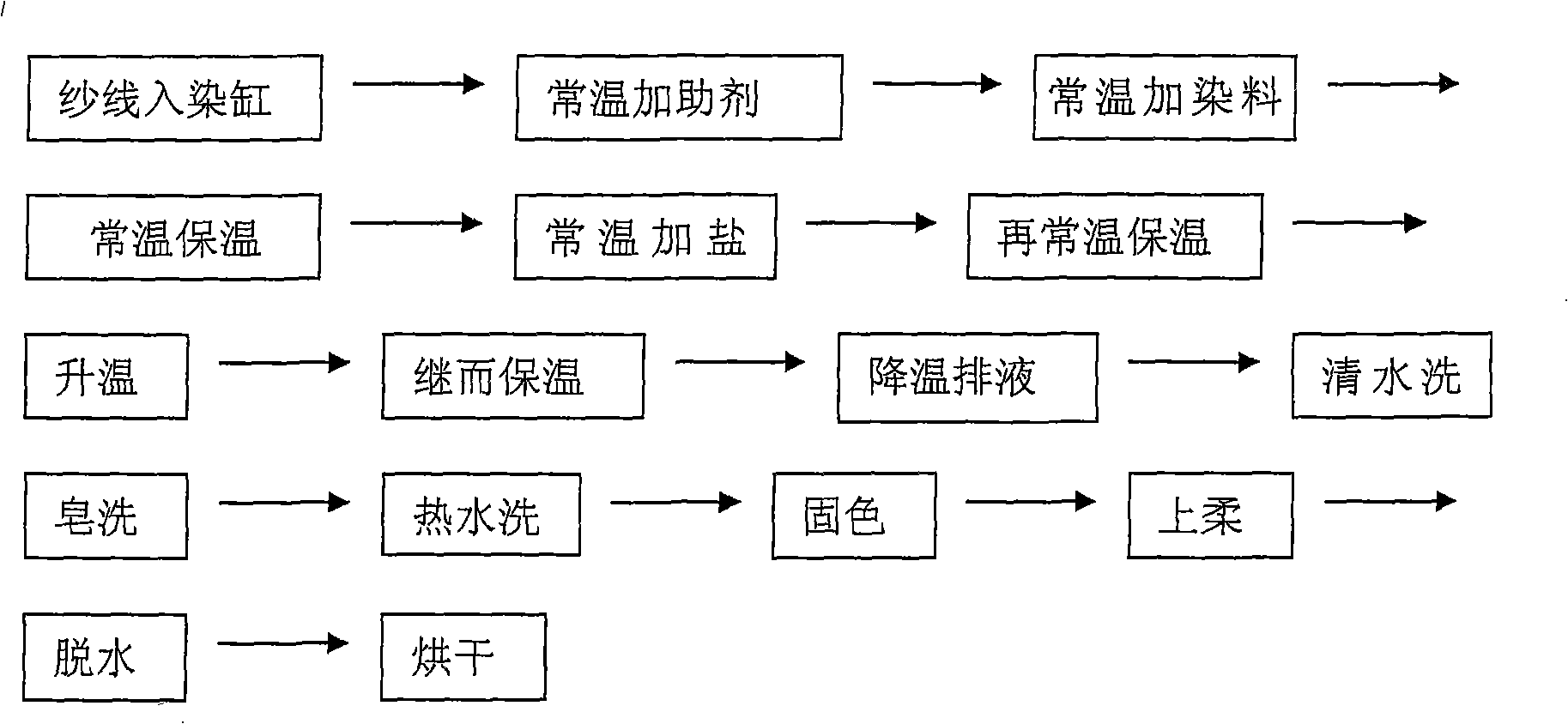

Dyeing process for spun silk

InactiveCN101289810ABe friendlyHigh color fastnessBeaming machinesDyeing processBreaking strengthColour fastness

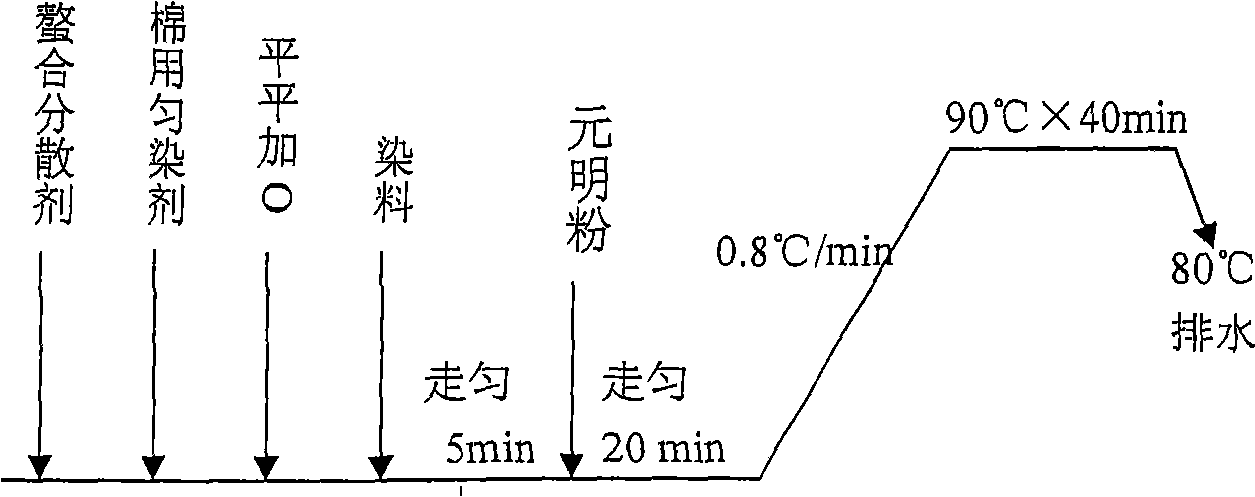

The invention provides a process for dyeing spun silks, belonging to the weaving yarn dyeing technical field. The process comprises the following steps that: spun silk yarns which are ready to be dyed and undergo the pre-dyeing treatment are put in a dye vat, water is added in the dye vat, and the bath ratio is controlled; at the normal temperature, auxiliary agent and cotton-used reactive dyes are added in the dye vat; the dye vat is kept warmth at the normal temperature; at the normal temperature, salt is added in the dye vat; the dye vat is kept warmth at the normal temperature again; the dye vat is heated, and the temperature-rise speed is controlled; the dye vat is kept warmth; finally after sequential steps of temperature drop and liquid discharging, fresh water washing, soap washing, hot water washing, color fixation, upper flexibility, dewatering and drying, dyed spun silk yarns are obtained. The process has the advantages of improving the color fastness of dyed spun silk yarns by one or two levels, having good level-dyeing property, improving the color yield by 20 percent and improving the breaking strength by 5 to 10 percent; because alkali is not used for the color fixation, the process has the advantages of simple process, unnecessary following acid neutralization step, energy conservation and low dyeing cost; because alkalization and acid neutralization steps are not necessary, the process is environment friendly.

Owner:常熟市亨时特染织有限公司

Manufacturing method of anti-biotic and anti-static yarn dyed fabric

The invention relates to the technical field of fabrics, and provides a manufacturing method, having low dye consumption, small environment pollution and small waste water discharge, of an anti-biotic and anti-static yarn dyed fabric. The method comprises the following steps that (1) raw materials are selected; (2) dying is conducted, wherein chitin fibers, white cotton fibers and short chemical fibers are dyed by color master batches; (3) blended yarns are manufactured; (4) mercerization is conducted; (5) warping weaving is conducted; (6) fabric weaving is conducted; (7) anti-biotic finishing is conducted, wherein quaternary ammonium salt solution with the percentage concentration being 15%-18% is prepared, the fabric obtained in the step (6) is dipped in the quaternary ammonium salt solution, the bath ratio is 3:1-6:1, and the dipping time is 40 min-50 min; drying is conducted after dipping, temperature ranges from 65 DEG C to 75 DEG C, and time ranges from 15 min to 30 main; (8) post-finishing is conducted. The fabric manufactured in the method is good in anti-biotic effect, has moisturizing and dry-preventing functions, and does not generate static easily.

Owner:晋江万兴隆染织实业有限公司

Method for producing environment-friendly imitation solid wood color bamboo floor

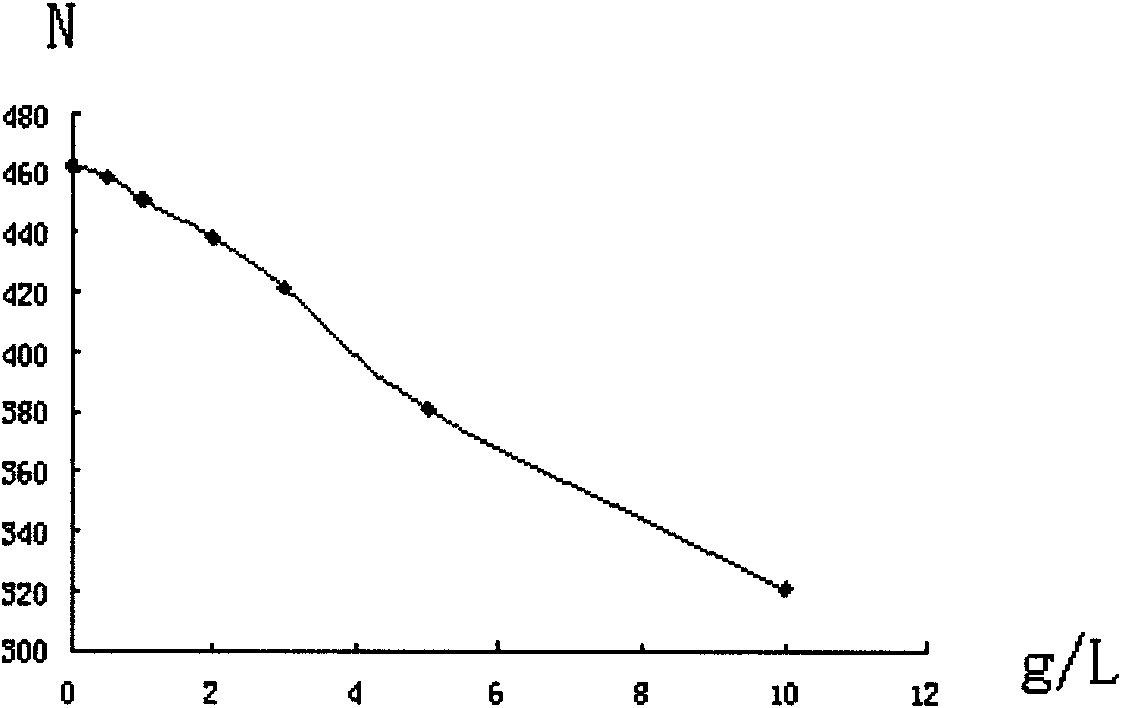

ActiveCN102259365AEmission reductionImprove dyeing effectWood working apparatusSolid woodColor measurement

The invention relates to a method for producing an environment-friendly imitation solid wood color bamboo floor, which comprises the following steps of: (1) establishing a bamboo imitation solid wood dyeing and color matching database, namely matching three primary colors of an acid dye, namely acid yellow, acid red and acid blue, dyeing, performing color measurement, listing the dyeing conditions of the acid dye with the three primary colors and imitation solid wood bamboo dyeing color sample information, and establishing the bamboo imitation solid wood dyeing and color matching database; (2) circularly dyeing bamboo, namely 2.1) selecting a formula, 2.2) establishing a method for calculating the concentration of three primary color matching dye solution, 2.3) preparing the dye solution,2.4) dyeing for the first time, 2.5) measuring the absorbance value of the dye in residual liquid, 2.6) supplementing the dye and a dyeing assistant, and 2.7) repeating the steps 4), 5) and 6) for circular dyeing; and (3) manufacturing the imitation solid wood color bamboo floor, namely impregnating, drying, assembling, gluing and forming in turn to obtain the imitation solid wood color bamboo floor. By the method, the dyeing effect can be enhanced, the simulation degree is high, the consumption of the dye is low, and high environment friendliness is achieved.

Owner:ZHEJIANG FORESTRY ACAD

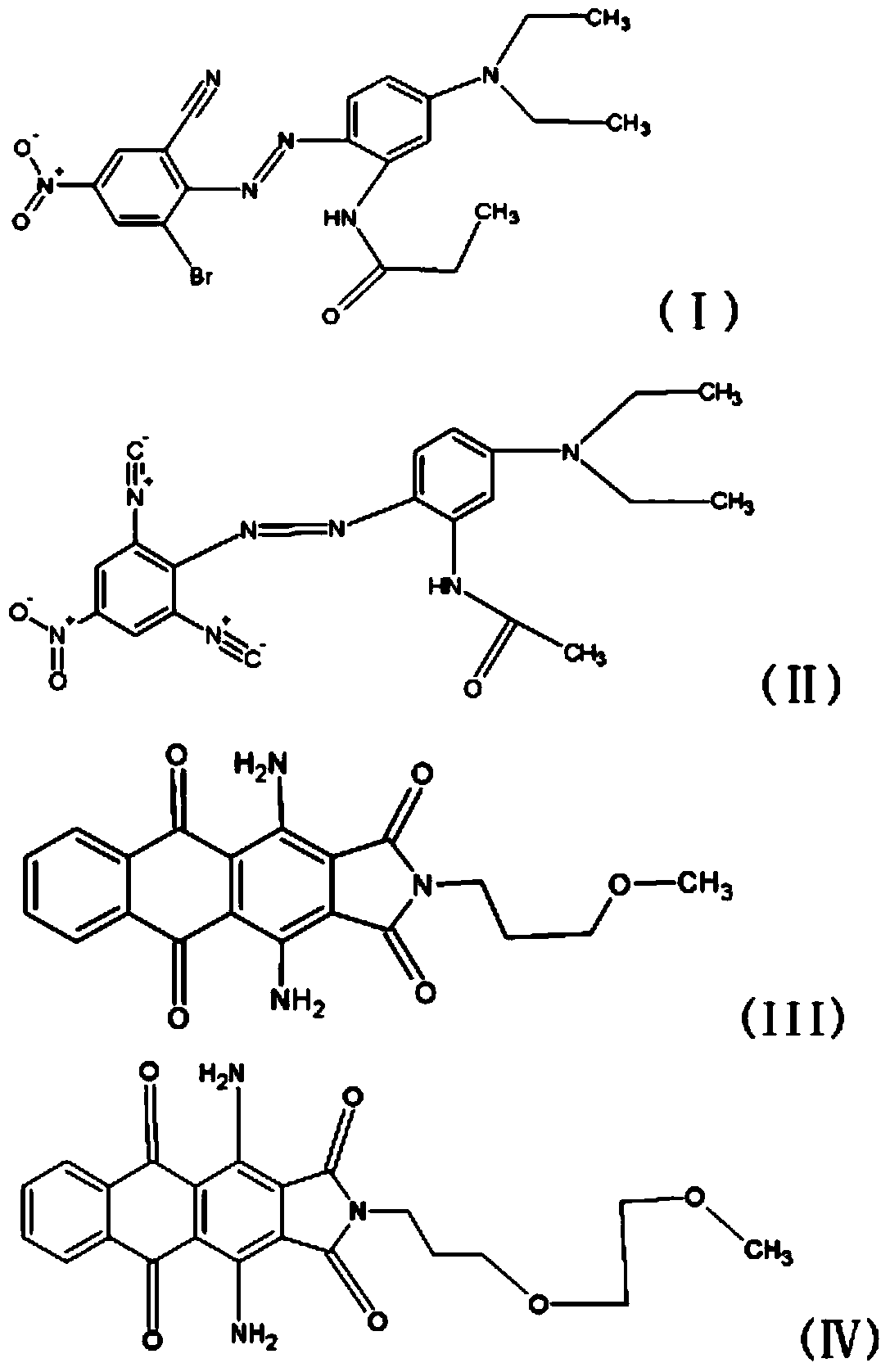

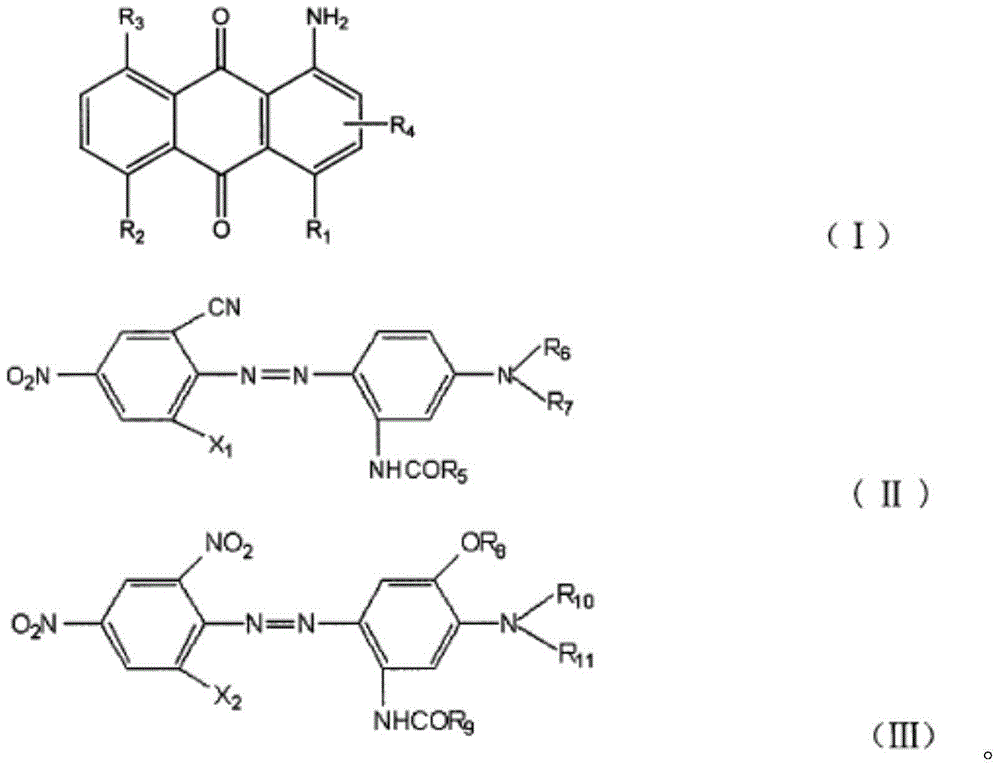

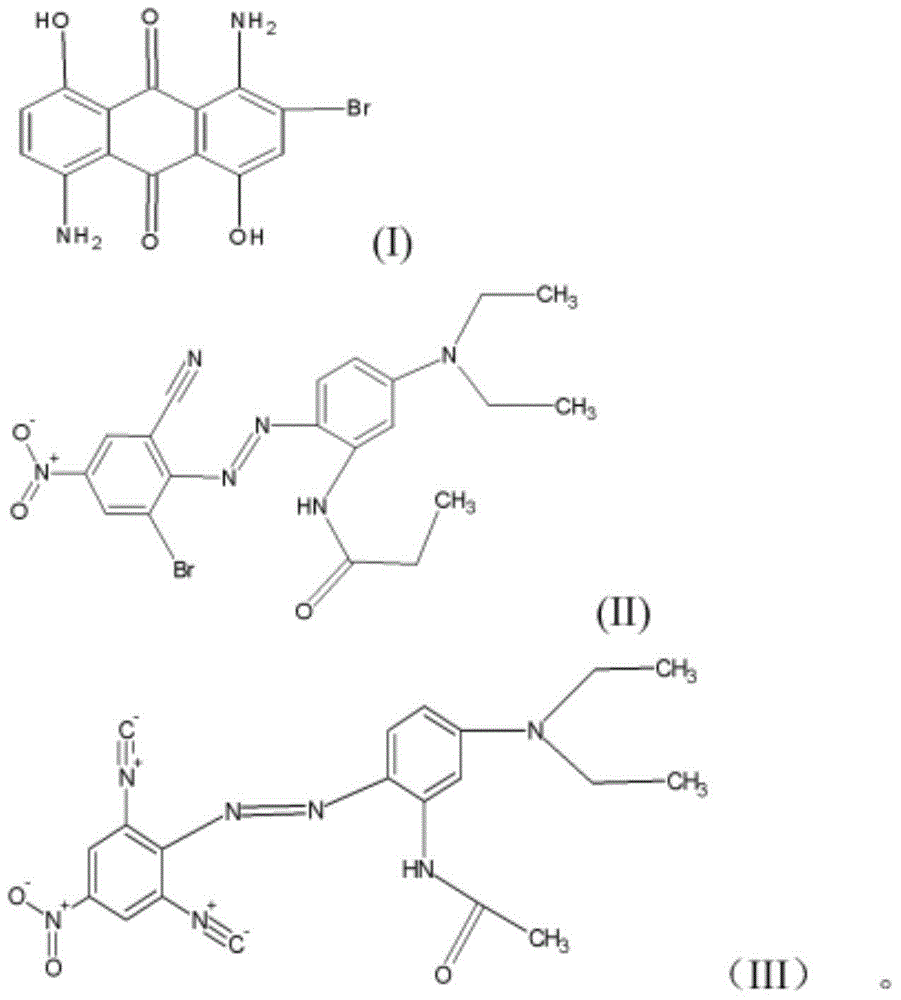

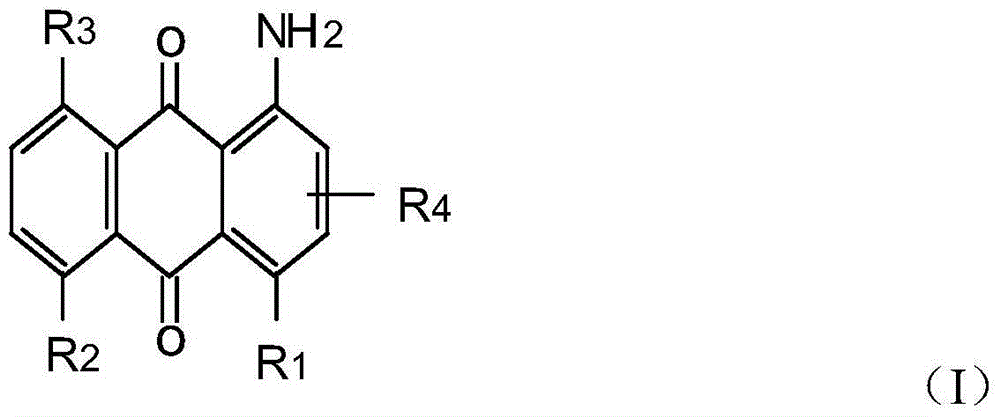

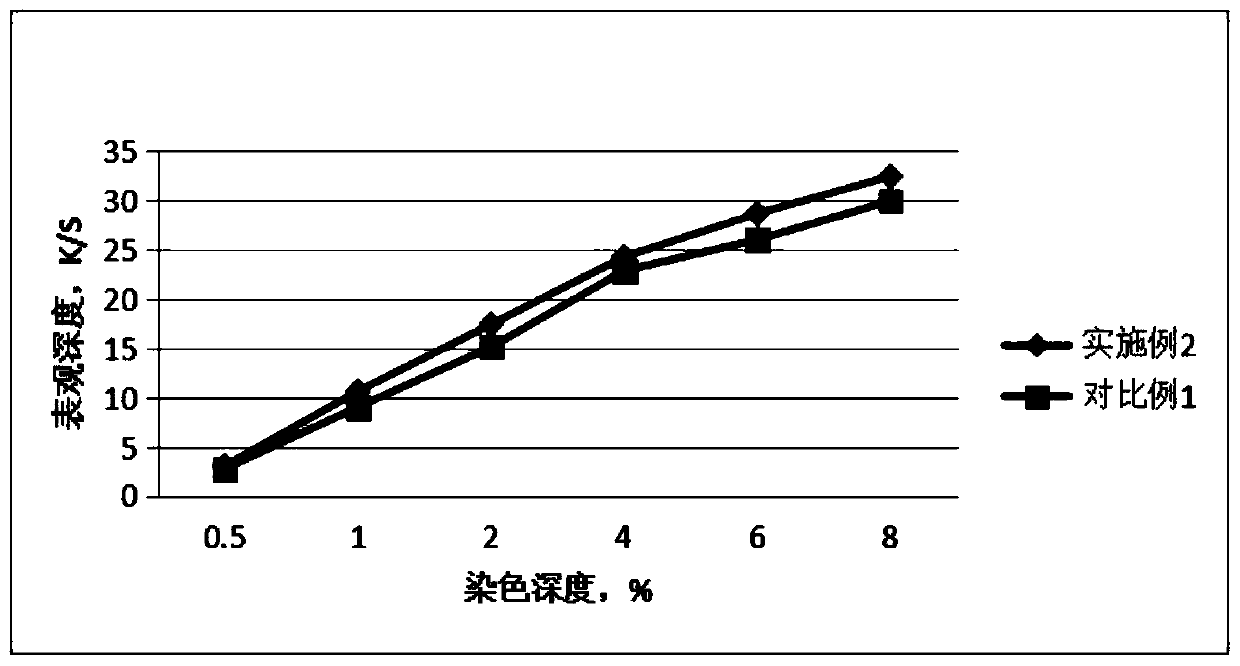

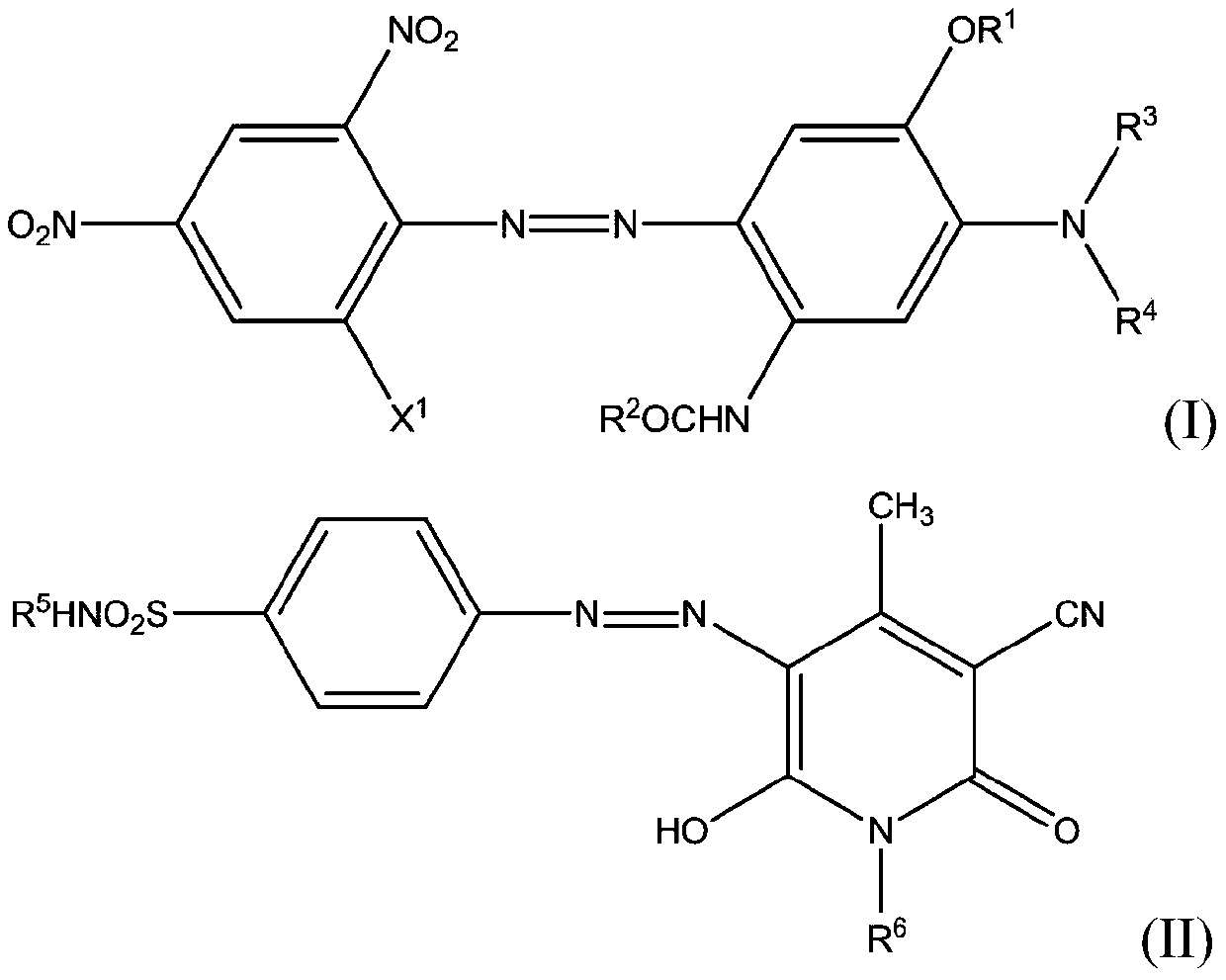

Disperse blue dye composition, disperse dye, and preparation method and application of disperse dye

ActiveCN103613953AGood dyeing depthHigh strengthOrganic dyesDyeing processDisperse dyePhotochemistry

The invention discloses a disperse blue dye composition, mainly comprising a component A and a component B, wherein the component A is at least one of compounds shown by a formula (I), and the component B is a compound shown by a formula (II). The invention also discloses a disperse dye comprising the dye composition and a preparation method and an application of the disperse dye. The disperse dye disclosed by the invention has the advantages of bright color, good deep dyeing property, high strength, good lifting power, good sublimation fastness, excellent fastness to saliva and the like; in particular, the disperse dye has a good printing effect; the printed fabric is clear in outline, thick and bright in color, and better than an expensive C.I. disperse blue 60 dye finished product in dyeing intensity; as a result, the usage amount of the dye can be greatly saved and the dyeing cost also can be saved.

Owner:浙江长征化工有限公司

Transparent lining cloth and its making method

Owner:NITTOBO CHINA CO LTD

Room temperature wool pad dyeing microwave color fixing method

InactiveCN101649563AUniform diffusion rateIncreased diffusion rateDyeing processProduction rateMicrowave

The invention relates to a room temperature wool pad dyeing microwave color fixing method which comprises the following steps: (1) mixing active dye or acid medium-contained dye for wool, cosolvent, areducing agent, a level dyeing agent and a penetrating agent at room temperature and uniformly stirring; (2) padding wool fabrics in the dye liquor, wherein the padding residual rate is 80-120 percent; and carrying out heating color fixation processing, water washing and drying on the wool by a microwave. The invention has simple process, low cost, high productivity, short period, energy saving and environmental protection and is suitable for industrialized production; the level-dyeing performance of dyeing and the planeness of the fabrics are better than those of a common dyeing method, andthe dosage of dyeing auxiliary agents is greatly reduced.

Owner:DONGHUA UNIV

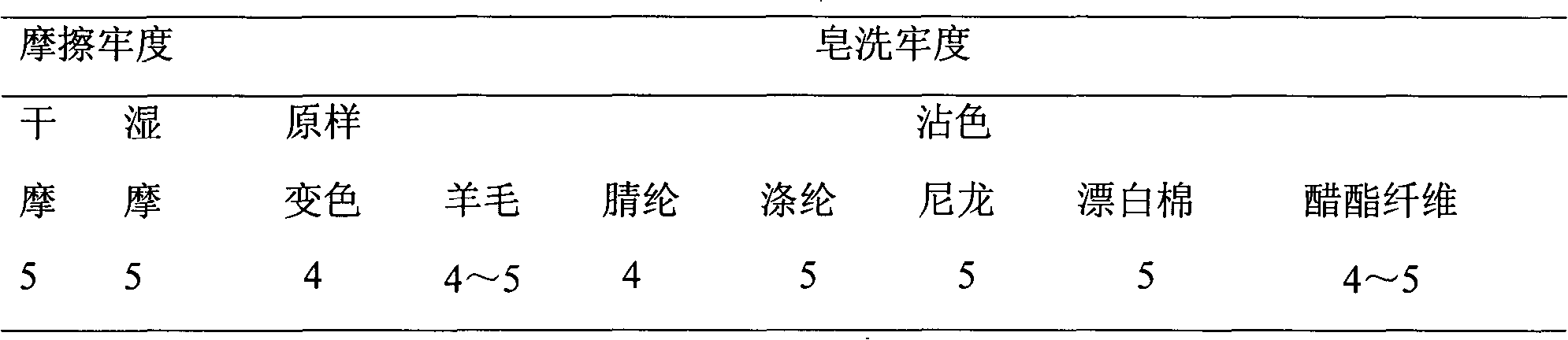

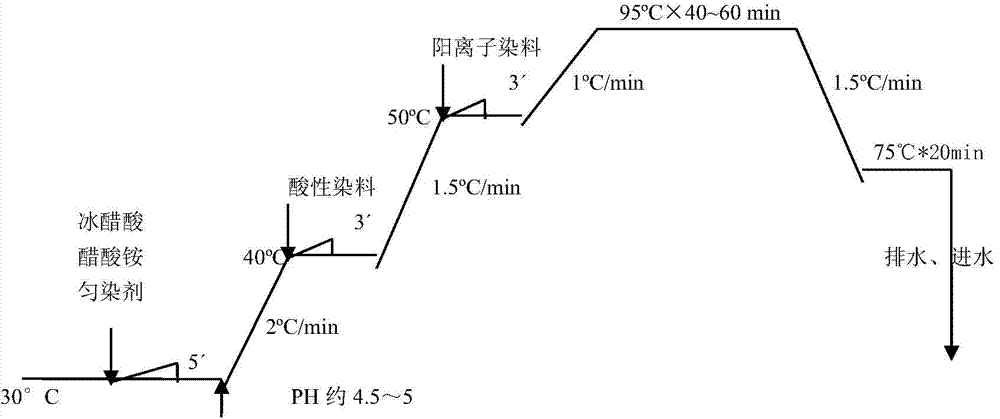

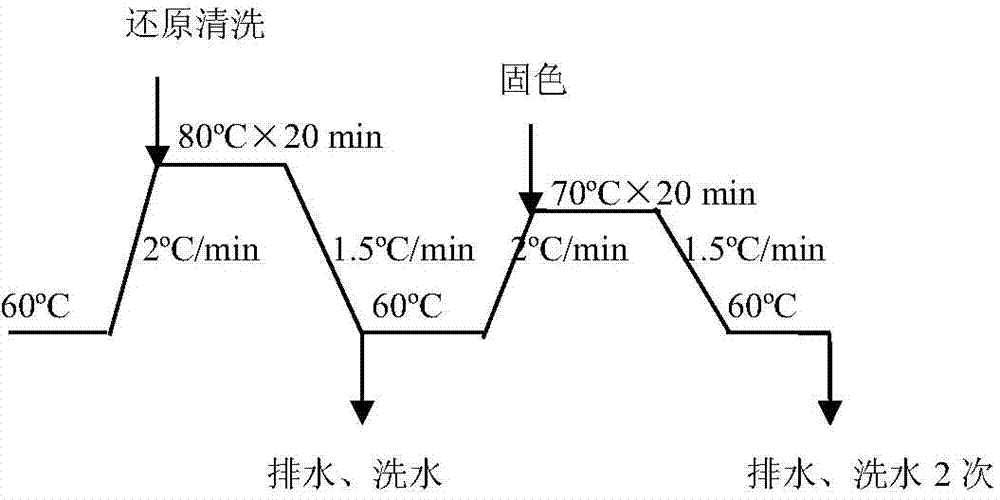

Low-temperature dyeing process of nylon/Dacron elastic knitted fabric

ActiveCN104762839ASolve the difficulties of dyeing and finishingFill in the gaps in coloringDyeing processYarnPolyester

The invention discloses a low-temperature dyeing process of nylon / Dacron elastic knitted fabric. The process comprises the following steps: selecting a low-temperature cationic modified polyester yarn dyed at low temperature as a polyester yarn in raw materials, carrying out dyeing processing on nylon with acid dyes in a same dye bath jar by employing a low-temperature bath dyeing processing process; simultaneously carrying out dyeing processing treatment on polyester with cationic dyes; and in an after treatment process after dyeing, carrying out reduction cleaning on the polyester with an acid reductive cleaning agent. According to the low-temperature dyeing process, by virtue of low-temperature one-bath dyeing, the color fastness can be improved by about 0.5-1.5 grades; the dyeing time can be reduced by over 50%; the water and energy are saved by about 50%; the dyeing cost is saved by about 50%; the nylon does not generate an oxidation phenomenon basically; the reproducibility of the process is relatively good; and the dyeing process has great popularization value.

Owner:上海云鼎纺织品股份有限公司

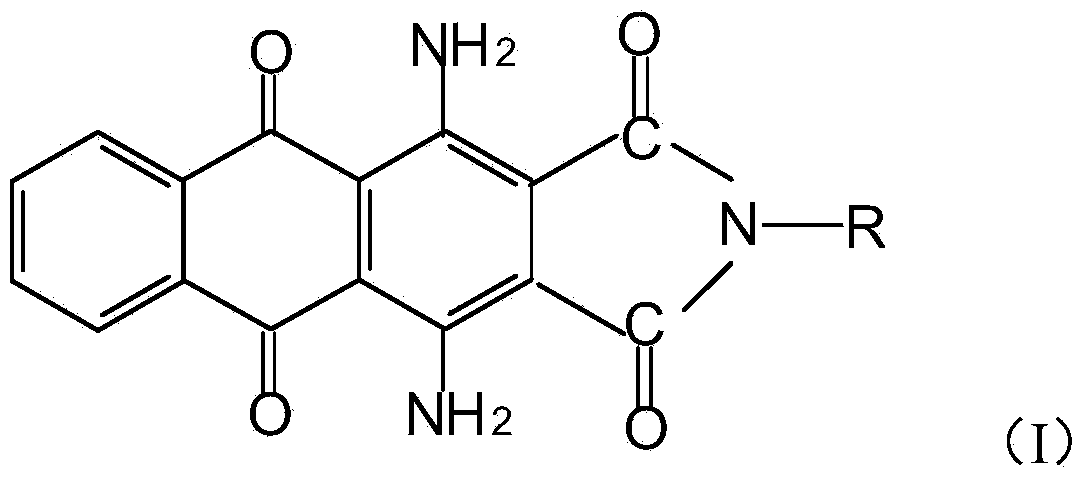

Disperse blue dye composition, disperse dye, preparation method and application

ActiveCN104448928AWith sublimation fastnessGood fastness to perspirationOrganic dyesDyeing processDisperse dyePerspiration

The invention discloses a disperse blue dye composition. The composition is basically prepared from one or more of a component A as shown in a formula (I), a component B as shown in a formula (II) and a component C as shown in a formula (III). Furthermore, a component D as shown in a formula (IV) and a component E as shown in a formula (V) can be selectively added into the disperse blue dye according to requirements. The invention further discloses a preparation method and an application of the composition. The disperse blue dye has the advantages of bright color, good sublimation fastness, good perspiration fastness, good light fastness and the like, the dye cost is relatively low, and pollution is relatively small.

Owner:浙江长征化工有限公司

Non-aqueous solvent composition with temperature control separation performance for active dye

InactiveCN104313920AReduce dyeing costsReduce energy consumptionDyeing processSolvent compositionDyeing

The invention provides a non-aqueous solvent composition with temperature control separation performance for active dye. The composition comprises good solvent of the active dye and poor solvent of active dye, wherein the volume ratio of the good solvent to the poor solvent is 1: (3-20); the good solvent of the active dye is the non-aqueous solvent capable of dissolving the active solvent and not having chemical reaction with the active dye; the poor solvent of the active dye is the non-aqueous solvent not capable of dissolving the active dye and not having chemical reaction with the active dye. The solvent system has advantages that after one dye period is ended, a purpose for separating the solvent can be achieved only by reducing the temperature of the solvent, the two solvents can be automatically separated after the temperature is lowered and can be recycled, and the mixture of the solvent does not need to be separated by adopting the energy-consuming and time-consuming distilling procedure, so that the cycling time is greatly reduced, the energy consumption is reduced, and the dyeing cost is remarkably reduced.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

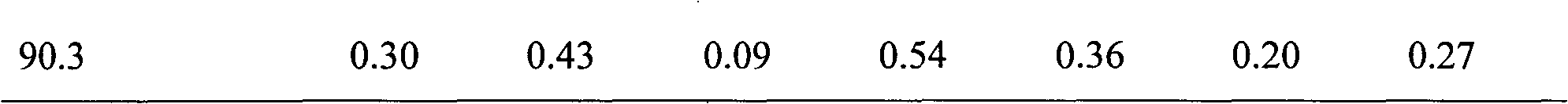

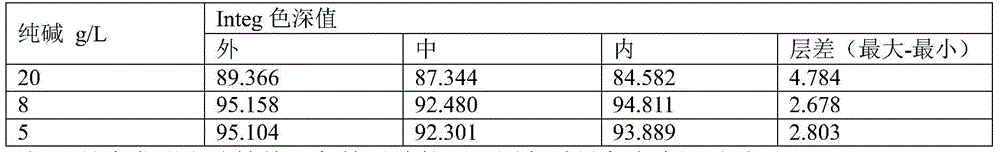

Activated dye low-alkaline dyeing method for black regenerated cellulose fiber cheese

ActiveCN104404797ALower dyeing temperatureReduce alkali consumptionDyeing processAcetic acidWater volume

The invention relates to the field of printing and dyeing, particularly to an activated dye low-alkaline dyeing method for a black regenerated cellulose fiber cheese. The method comprises the steps of pretreatment, dyeing, fixing and follow-up treatment; in addition, low alkaline is adopted in the dyeing and fixing processes and the working procedures are reduced. Therefore, the dyeing temperature of the regenerated cellulose fiber is reduced; the alkaline dosage for dyeing the regenerated cellulose fiber is lowered; the method is simple to operate, short in technical duration, and low in alkaline content in the dyeing waste water, can reduce the dosage of glacial acetic acid for neutralization in the follow-up procedure, lowers washing water volume, saves energy and reduces emission, improves the color fastness of the cheese, and lowers the dyeing cost.

Owner:浙江恒生印染有限公司

Elastic yoga body-shaping fabric and preparation technology thereof

InactiveCN106350928AAvoid bareHigh spandex contentSucessive textile treatmentsWeft knittingMasterbatchYarn

The invention discloses an elastic yoga body-shaping fabric. The elastic yoga body-shaping fabric is of a knitting structure, and is formed by weaving polyester yarns, such as 30D-105D elastic yarns and 50D-300D color yarns, wherein each elastic yarn is a dyeable spandex yarn or a color masterbatch spinning yarn; each polyester yarn is made of polytrimethylene terephthalate. The elastic yoga body-shaping fabric has the characteristics that the content of spandex is high, the weaving technology is simple and matured, the secondary damage is avoided, the white exposing of the spandex is avoided, the dyeing cost is lower, the color fastness is higher, the dirt removal and preventing property is excellent, the dyeing is easy, the hand feel is soft, the elasticity is realized, the elongation is good, and the processing is easy; the dryness and stiffness are realized, the size after shaping is stable, and the application range is wide.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

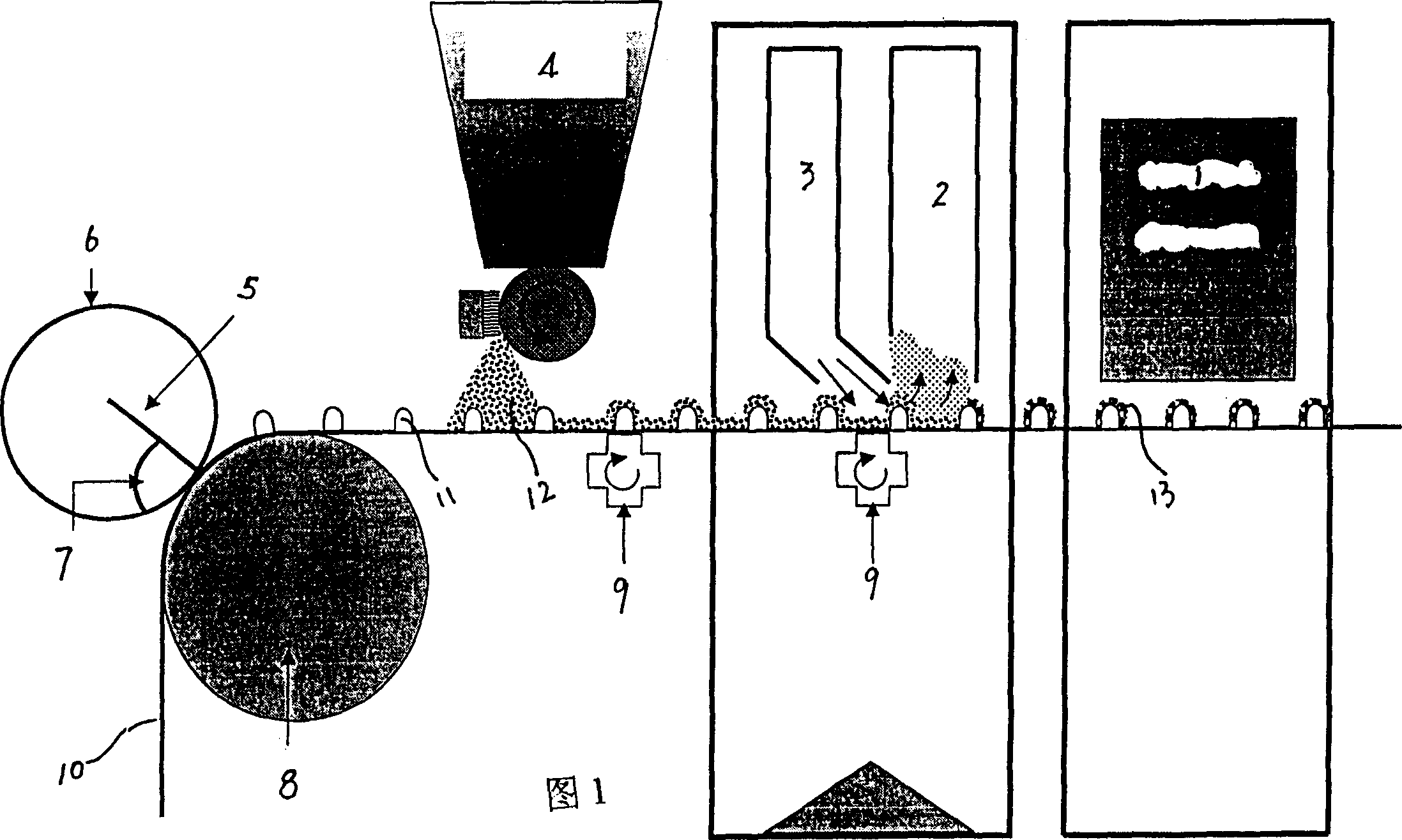

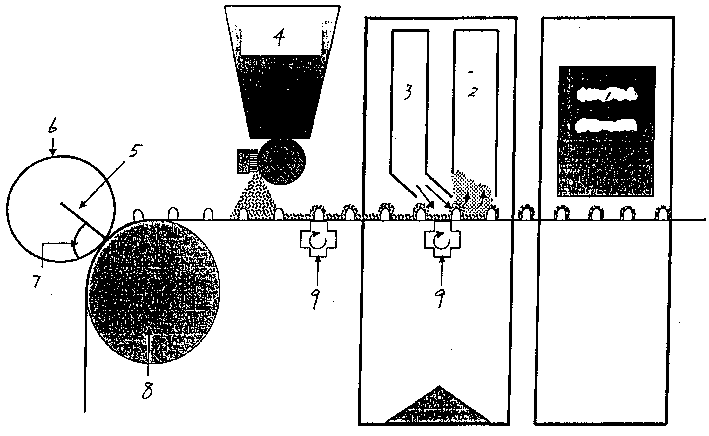

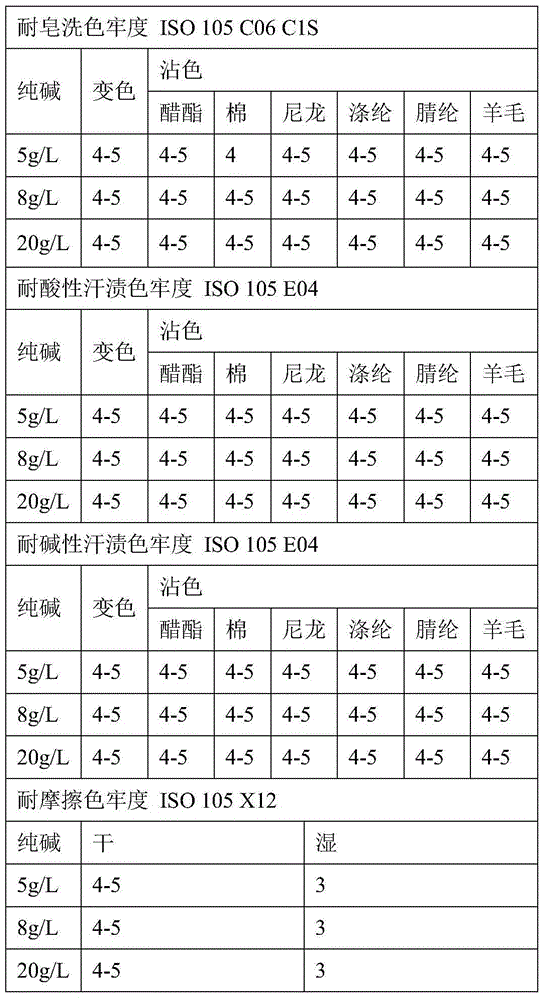

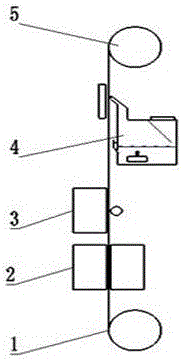

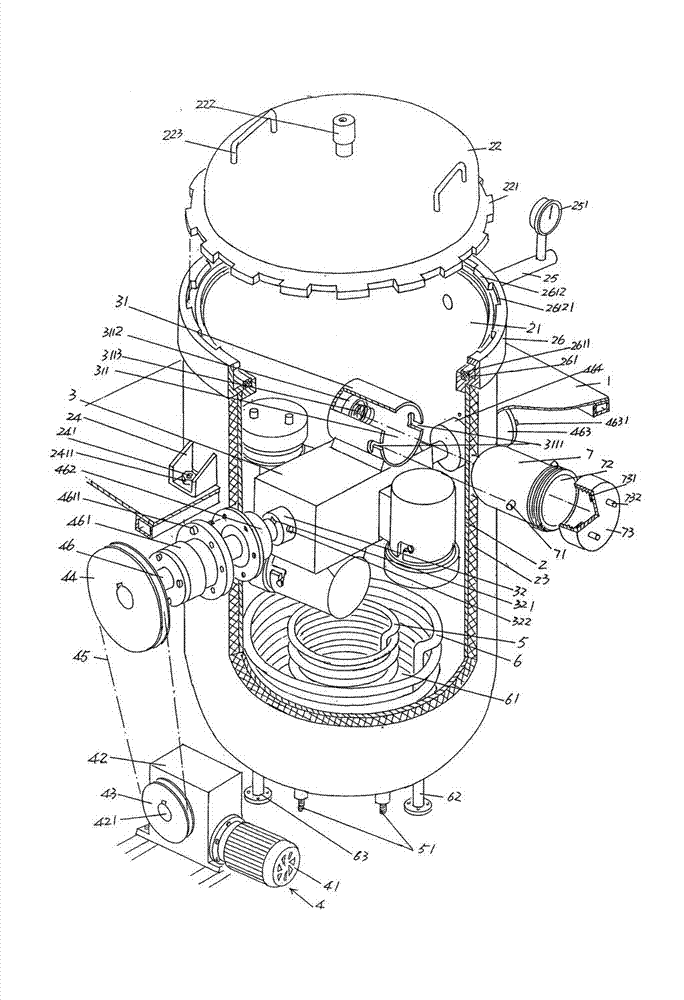

Plasma dyeing system and method

ActiveCN106087315AUniform particlesUniform dyeingSucessive textile treatmentsTextile treatment machine arrangementsGreen environmentWastewater

The invention discloses a plasma dyeing system. The plasma dyeing system comprises an unwinding mechanism for to-be-dyed fabrics, a fabric heating module, a plasma processing module, a dyeing module and a dyed fabric winding mechanism, wherein the fabric heating module, the plasma processing module, the dyeing module and the dyed fabric winding mechanism are sequentially arranged behind the unwinding mechanism. The invention further discloses a dyeing method utilizing the plasma dyeing system. According to the dyeing method utilizing the system, the combination efficiency of the fabrics and dyes can be improved, the dyeing quality of products is improved, non-adsorbed dyes during the plasma dyeing are cyclically used, no wastewater is discharged, green environment friendliness is achieved, the consumption of the dyes, water and eliminating additives are reduced, and compared with the traditional technique, the method provided by the invention has the advantage of lower dyeing cost.

Owner:JIANGSU S&S INTELLIGENT SCI & TECH CO LTD

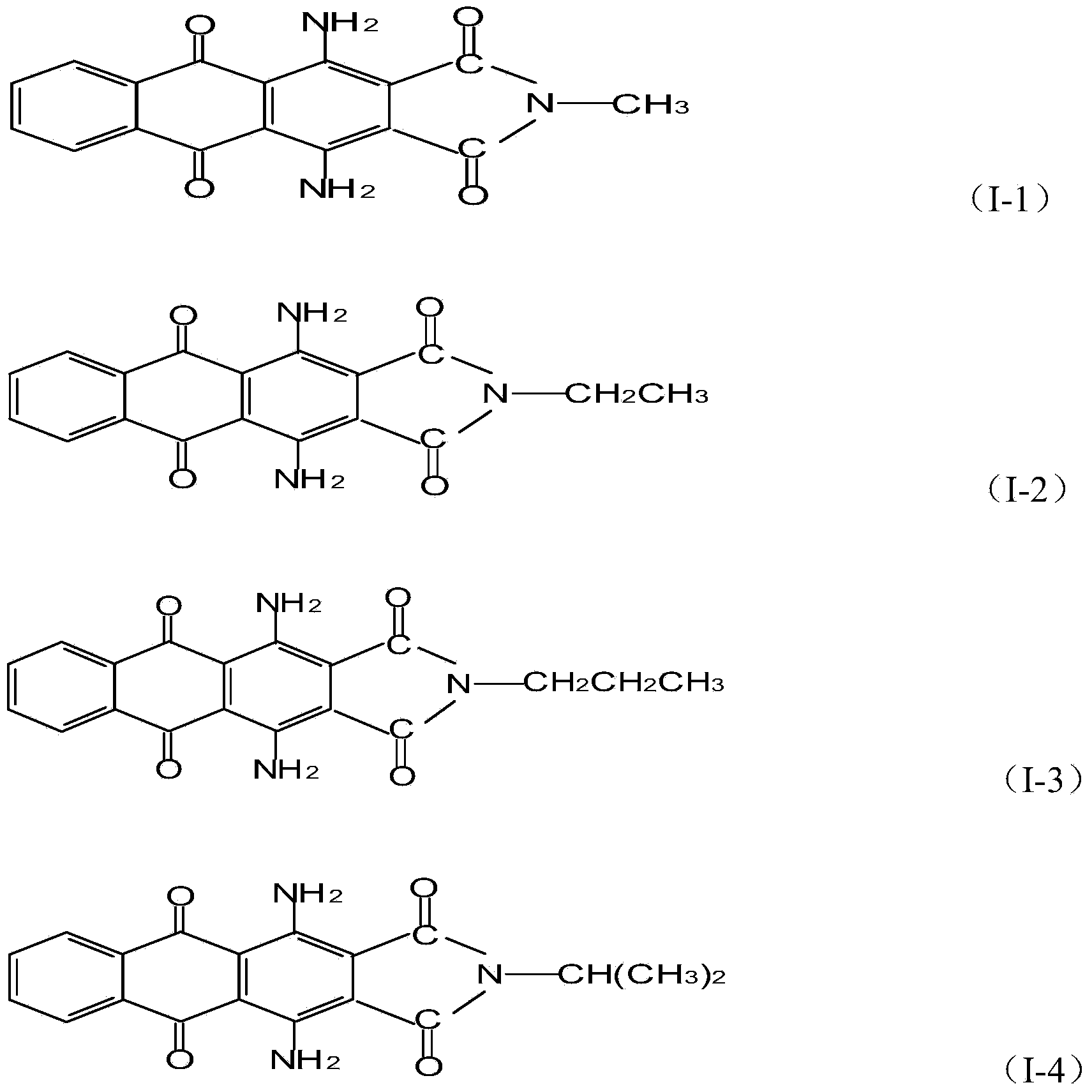

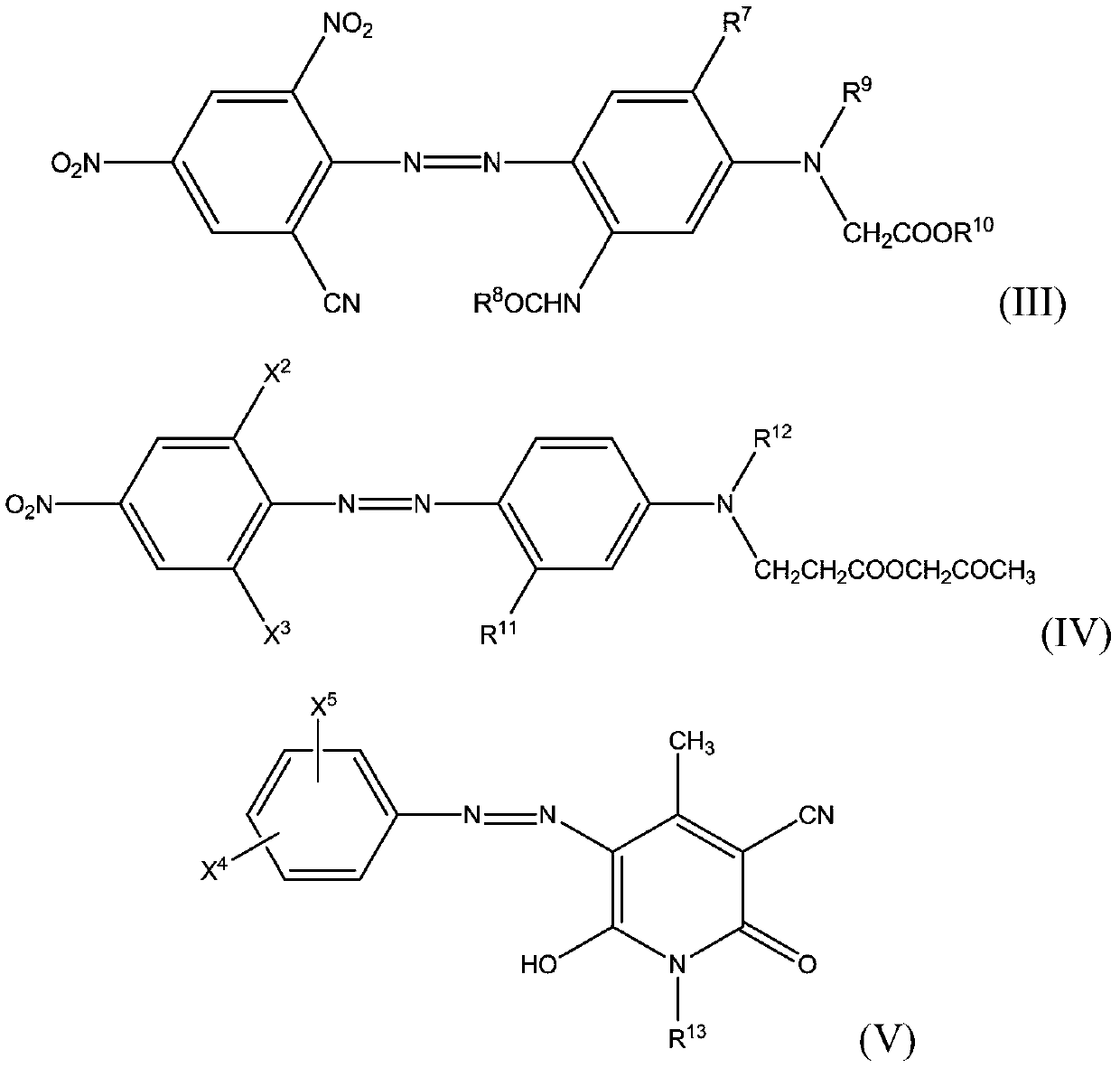

Blue-to-black dispersed dye composition and dye product

ActiveCN110373043AEasy to liftReduce dyeing costsOrganic dyesDyeing processDisperse dyePhotochemistry

The invention discloses a blue-to-black dispersed dye composition and dye product. The blue-to-black dispersed dye composition is prepared from a component A and a component B, wherein the component Ais selected from one or more of compounds shown as a formula (I), the component B is selected from one or more of compounds shown as a formula (II), in the dispersed dye composition, the mass percentage content of the component A is 55-99%, and the mass percentage content of the component B is 1-45%. The blue-to-black dispersed dye composition can further include a component C, and the componentC is selected from following formulas (III) and / or (IV) and / or (V). The invention further provides the blue-to-black dispersed dye product, the blue-to-black dispersed dye product contains the blue-to-black dispersed dye composition and an addition agent, and the weight ratio of the addition agent to the dispersed dye composition is (0.2 to 5):1. The blue-to-black dispersed dye product is appliedto hydrophobic fibrous material printing and dyeing and has the characteristics of excellent color fastness, good dyeing economic efficiency and the like.

Owner:浙江龙盛染料化工有限公司 +1

Preparation method of dyeing assistant

ActiveCN103556505ASimple stepsHigh fastnessDyeing processPigment treatment with macromolecular organic compoundsOrganic dyeMontmorillonite

The invention discloses a preparation method of a dyeing assistant. The preparation method comprises the following steps: (1), swelling 20-40 parts by weight of montmorillonite for 24 hours in distilled water under the room temperature to form montmorillonite suspension; (2), adding aqueous liquor containing 10-20 parts by weight of organic modifying assistant into the montmorillonite suspension; (3), heating up to 60 DEG C-70 DEG C, fiercely stirring and reacting for 3 hours-5 hours; (4), suction-filtering reaction liquor to obtain white precipitates, and washing by using distilled water until no halide ions exist; (5), vacuum-drying the product obtained in the step (4) for 20-30 hours at 60 DEG C-60 DEG C, sealing for storage after grinding and sieving to obtain the dyeing assistant. The dyeing assistant prepared by the preparation method in the invention can be used for improving the dye-uptake and color fastness of dye, improving the dyeing quality, increasing the dye dispersion, preventing dye from generating precipitates, improving the dye utilization rate, lowering the dyeing cost, lowering content of organic dye in printing and dyeing wastewater and reducing environmental pollution. Moreover, the preparation method of the assistant disclosed by the invention is simple in steps and extensive in material resource, and does not cause environmental pollution in a preparation process.

Owner:HAIAN QI HONG TEXTILE TECH CO LTD

Active dye quick salt-free dyeing method of cellulose product

The invention relates to an active dye quick salt-free dyeing method of a cellulose product, and belongs to the technical field of textile printing and dyeing processes. According to the dyeing method, active dye is adopted to prepare a mixed dyeing liquid of carbon tetrachloride, ethanol alcohol and water, and a cellulose product soaked in the mixed dyeing liquid is subjected to quick salt-free dyeing, so that the production efficiency of the cellulose product when the active dye intermittent dip dyeing is adopted can be effectively improved, and the dyeing time can be shortened to a great extend. The method has a relatively low dyeing temperature, has the effects of energy conservation and consumption reduction, and is adaptive to industrial large-scale production. The active dye used in dyeing does not have selectivity for the dye structure, and has good dye adaptability; neutral salt is not additionally added into a dyeing system in the dyeing process, so that the dyeing cost is reduced, labor intensity is reduced, and environmental pollution of water and soil can be relieved. The method is an environment-friendly short-flow dyeing process.

Owner:WUHAN TEXTILE UNIV

Technique for promoting dye permeability and depth of active dye

ActiveCN108103694AIncrease penetration timeAvoid the problem that it is not easy to penetrate into the fiberLiquid/gas/vapor removalTextile storageTextile printerFiber

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a technique for promoting dye permeability and depth of active dye. The dyeing processing flowis pretreatment fabric->dye padding->piling->first drying->padding with fixation fluid->gas steaming-> high temperature soaping->second drying-> post finishing; the piling temperature is 20-26 DEG C and the piling time is 4-10 hours. The method can increase the permeation time of the dye in the inner part of the fabric, avoid the problems that the continuous dyeing padding time is short and the dye is directly dried after dyeing and the dye is not easy to permeate to the inner part of fiber, avoid the problems of too early fixation of dye and fiber due to the mixing of the cold rolling dye andthe fixation fluid and the dye permeability effect of the active dye goes bad, and promote the permeability of dye; the dye can be fully dissolved and absorbed and spread to the fiber; the techniqueis good for the reaction of dye and fiber in the subsequent fixation, and able to improve the dyeing rate and the utilization rate of the dye; through contrast, the dyeing depth can be promoted by about 15%, and the dyeing cost is greatly reduced.

Owner:鲁丰织染有限公司

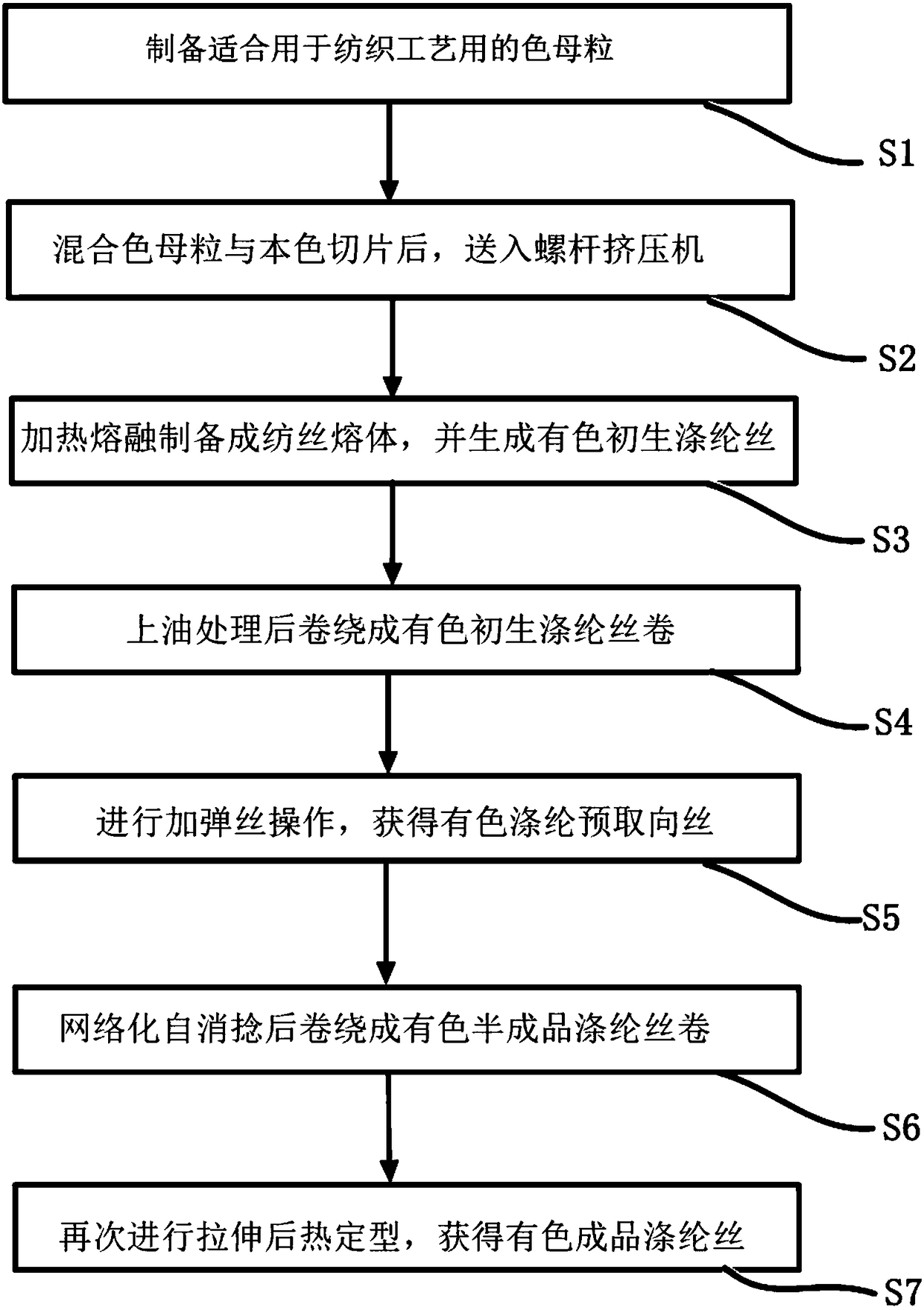

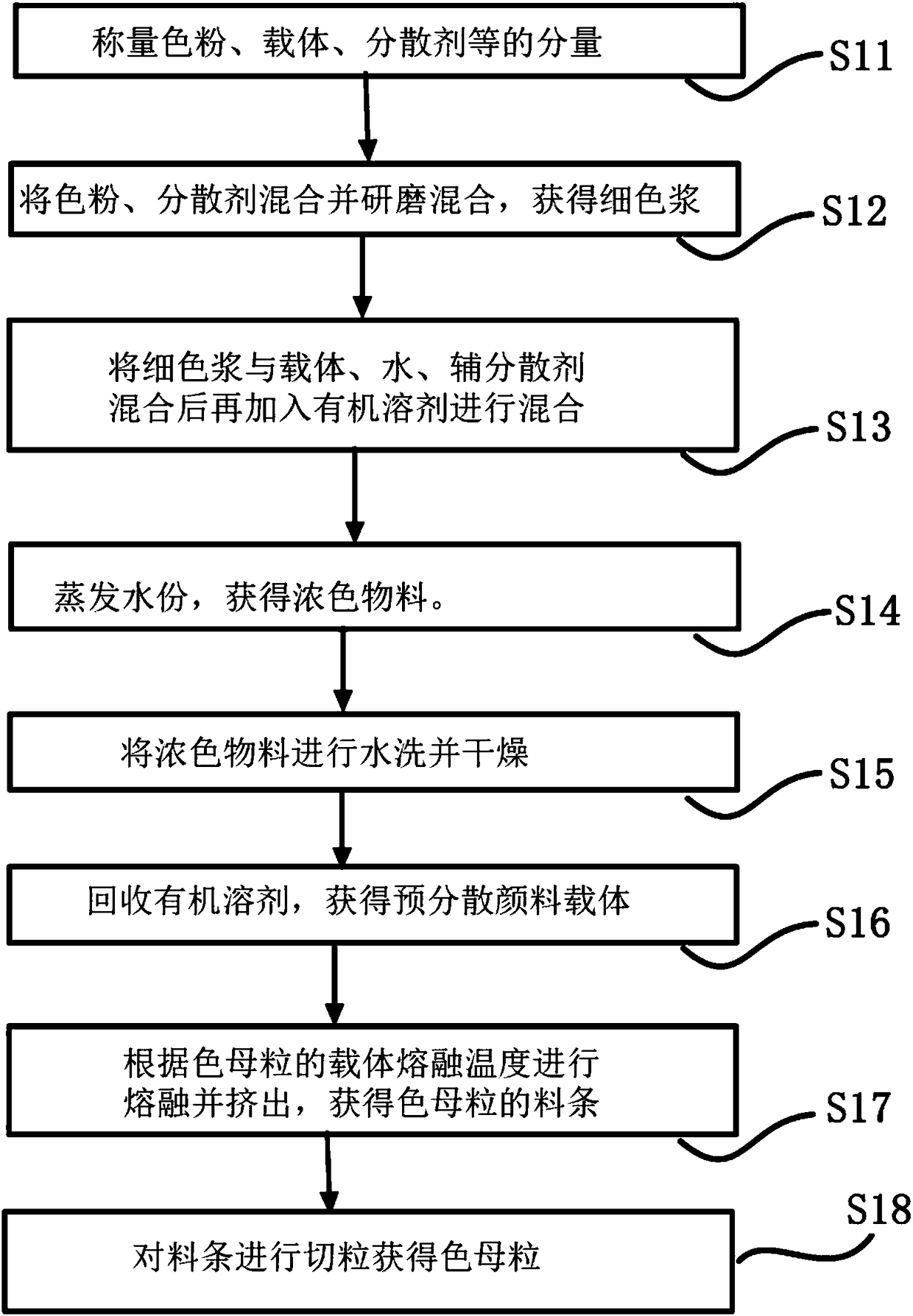

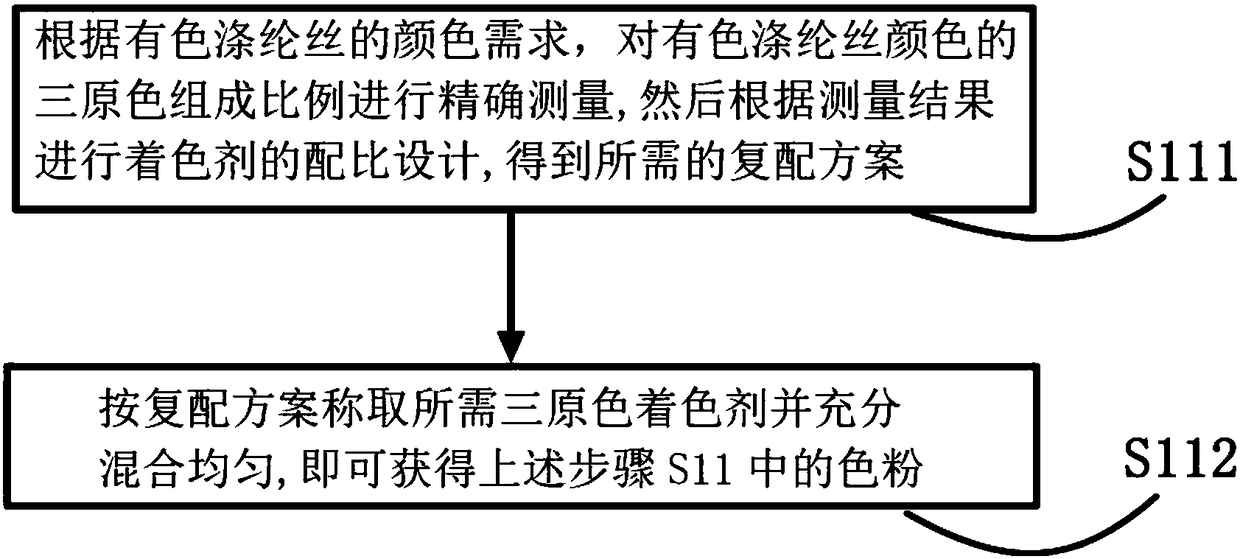

Preparation method of colored polyester yarn

ActiveCN108486659AUniform dyeingSmall color differenceFilament forming substance formingSpinning head liquid feederYarnPolyester

The invention relates to a preparation method of colored polyester yarn. The preparation method comprises the steps that color master batch and natural-color slices are evenly mixed in proportion, areconveyed into a screw extruder and are heated and melted in the screw extruder to be prepared into a spinning melt, the mixture is sprayed out of spinneret orifices and cooled to form colored primarypolyester yarn, and the colored primary polyester yarn is subjected to oiling and wound into a colored primary polyester yarn roll; then, the draw texturing yarn operation is carried out to obtain colored polyester pre-oriented yarn; the colored polyester pre-oriented yarn is subjected to networked self-detwisting to be processed into a colored polyester yarn semi-finished product, and the colored polyester yarn semi-finished product is wound into a colored polyester yarn semi-finished product roll; the colored polyester yarn semi-finished product is drawn again, the re-drawn colored polyester yarn semi-finished product is subjected to heat setting processing at the temperature of 170-210 DEG C, and the colored polyester yarn is obtained. Meanwhile, the invention further relates to a preparation method of the color master batch and the colored polyester yarn.

Owner:江苏苏美达纺织有限公司

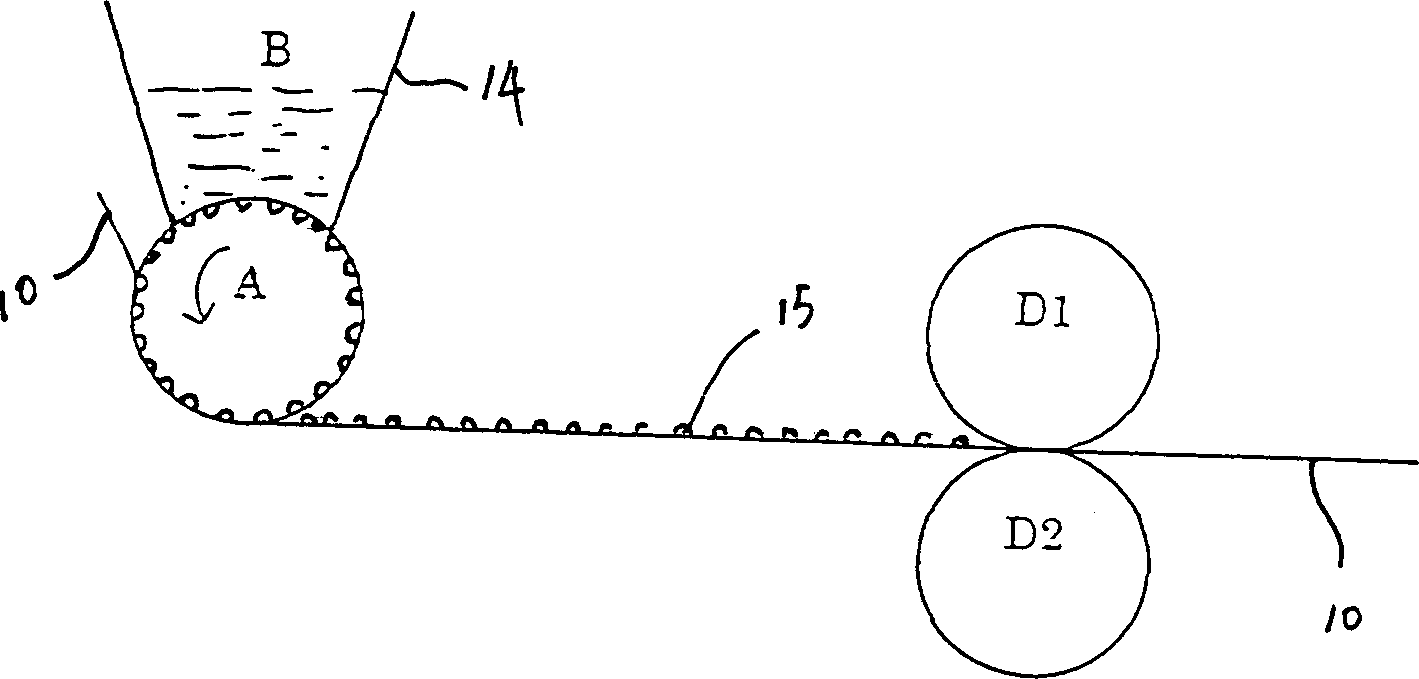

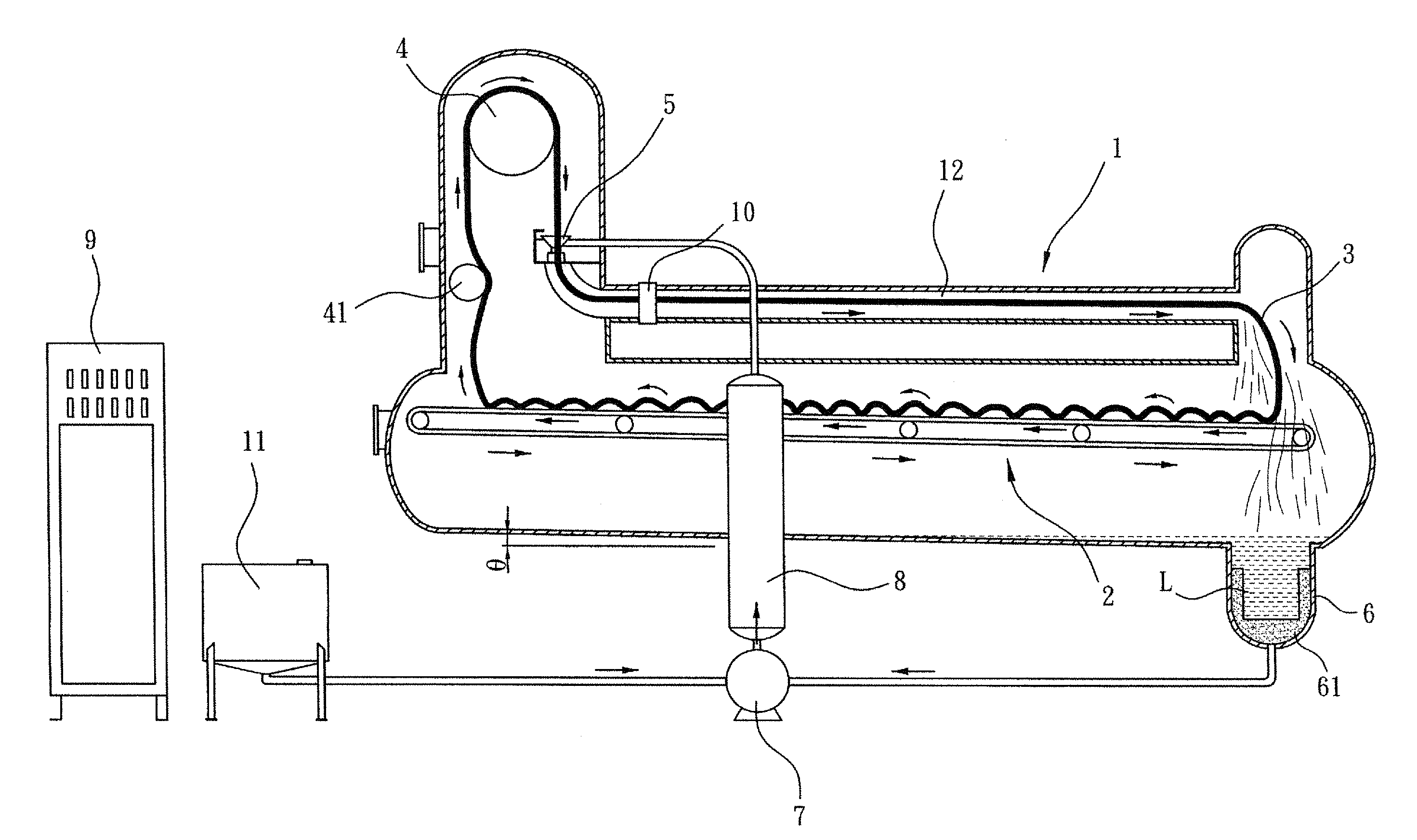

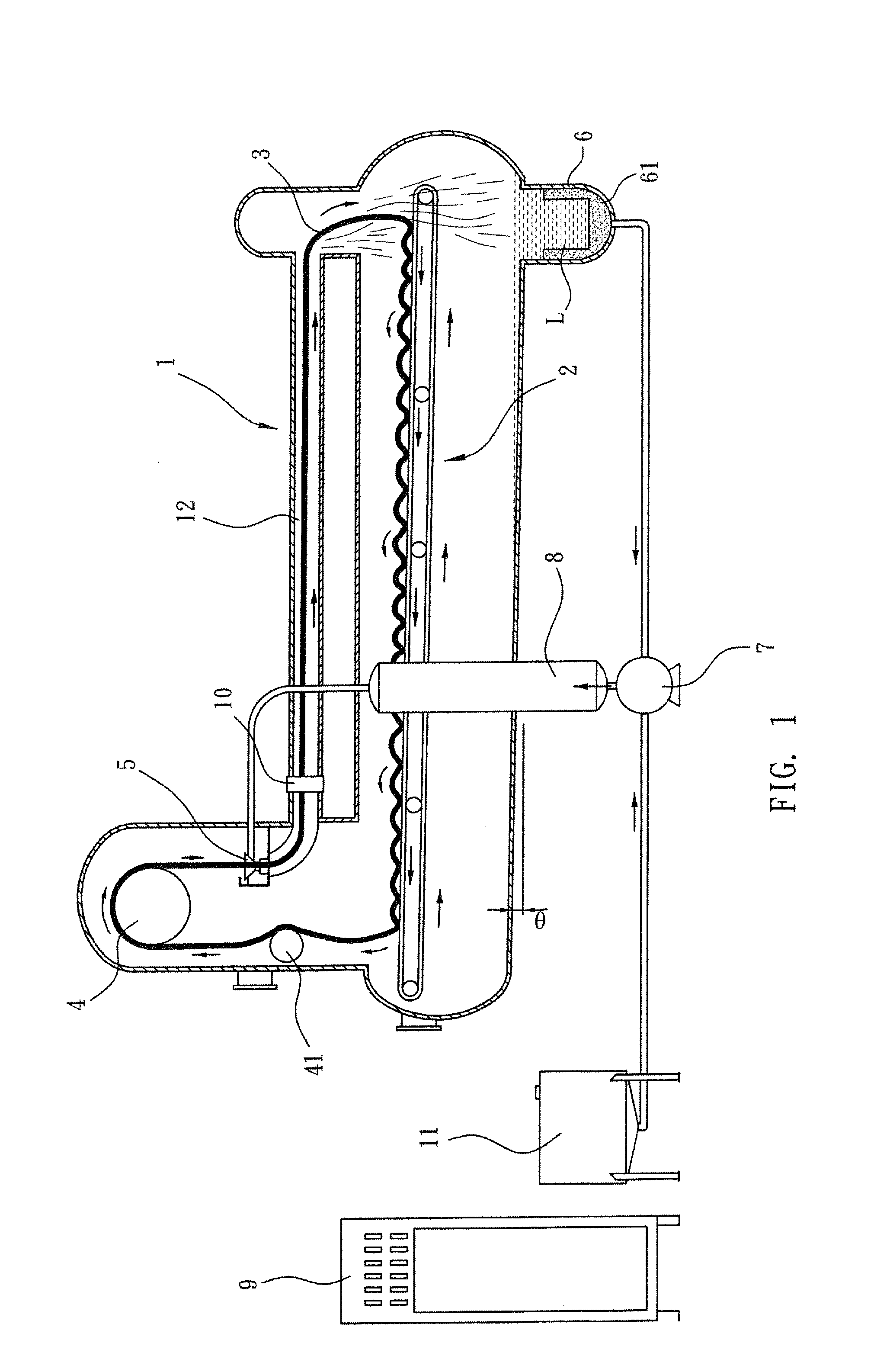

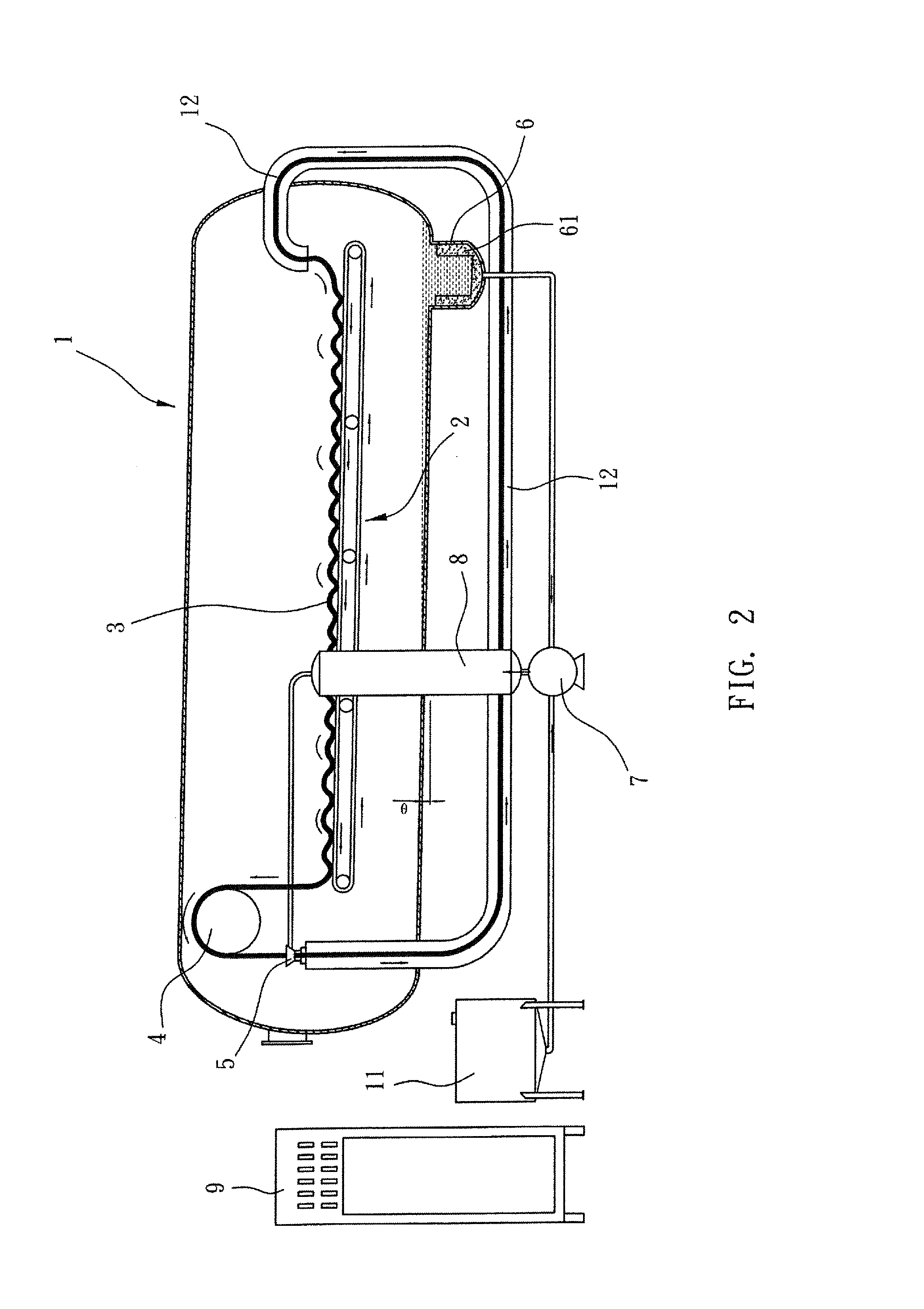

Up-Inclined Coveyor-Driving Fabric Dyeing Machine

InactiveUS20150337471A1Reduce the amount requiredGood effectLiquid/gas/vapor treatment machines driving mechanismsTextile treatment containersLiquid storage tankDyeing

An up-inclined conveyor-driving fabric dyeing machine includes a machine body that is arranged in a front-high-and-rear-low up-inclined configuration. A liquid storage tank is mounted to a bottom of a rear end of the machine body to receive dye liquid falling down from a rear end of a dyeing tube. Thus, the amount of the dye liquid used can be greatly reduced. Further, with such an up-inclined configuration of the dyeing machine, the dyeing tube can be arranged in a horizontal or slightly inclined manner to reduce the heights of a fabric guide roller and the conveyor and thus reduce the distance between the fabric guide roller and the conveyor device, thereby reducing the stretching force and tensile force applied to the fabric during the dyeing process.

Owner:CHANG

Method for dyeing aramid fiber without carrier

ActiveCN103046401AReduce dyeing costsImprove protectionSucessive textile treatmentsTextile treatment machine arrangementsBuffering agentAramid

The invention relates to a method for dyeing aramid fiber without a carrier, belonging to the technical field of spinning, printing and dyeing. The method comprises the following steps of: preparing a dyeing bath: injecting water into a dyeing container, controlling the bath ratio, adding 0.01-15% (by o.w.f) of dye and 5-20g / L of a levelling agent into the dyeing container, and adding a buffering agent to adjust the pH value to 4-6; and dyeing: soaking the aramid fiber into water, removing the water in the aramid fiber, putting the aramid fiber in the dyeing bath, putting the dyeing container into a dyeing machine to dye, controlling the dyeing temperature, time and pressure of the dyeing machine, taking the dyeing container out of the dyeing machine, taking the aramid fiber out of the dyeing container, and washing with water, cleaning by reducing, washing with water and drying in sequence to obtain the dyed aramid fiber. Because the dyeing bath is prepared reasonably, the aramid fiber is soaked before being introduced into the dyeing bath, is dried after being soaked and is dyed under the set dyeing temperature, time and pressure, the defect of using the carrier in the prior art is avoided. The method can not cause pollution to the environment and achieves an ideal aramid fiber dyeing effect, and the aramid fiber dyeing cost is reduced due to the adoption of the method.

Owner:CHANGSHU BAOFENG SPECIAL FIBER +1

Dyeing process of red vegetable dyes

ActiveCN106351033AWith health functionGood colorNatural dyesDyeing processPre treatmentAqueous solution

The invention discloses a dyeing process of red vegetable dyes. The process comprises the following steps: a, treating safflower cakes by an acidic solution, so as to obtain a filter residue A; b, rinsing and filtering the filter residue A by an alkaline solution, so as to obtain a dyeing liquor; c, making a dye C1; d, mixing the dye C1 and a dye C2, so as to obtain a dye D; e, mixing the dye D and a weakly alkaline aqueous solution, so as to obtain a dyeing liquor E1 and a dyeing liquor E2; f, respectively pretreating the heated dyeing liquors (E1 and E2), so as to obtain the dyeing liquors (F1 and F2); g, pretreating a silk fabric, so as to obtain a product G; h, adding the product G into the dyeing liquor F1 for dyeing, so as to obtain a product H; i, adding the product H into the dyeing liquor E2 for dyeing, so as to obtain a product I; j, treating the product I, so as to obtain a finished product J. The dyeing process disclosed by the invention has the characteristics of low production cost, good coloring effect, high color fastness, convenience in large-scale production, and capacities of improving the extraction rate of haematochrome and the impurity removal rate and facilitating safflower storage.

Owner:义乌市惠侬丝服饰有限公司

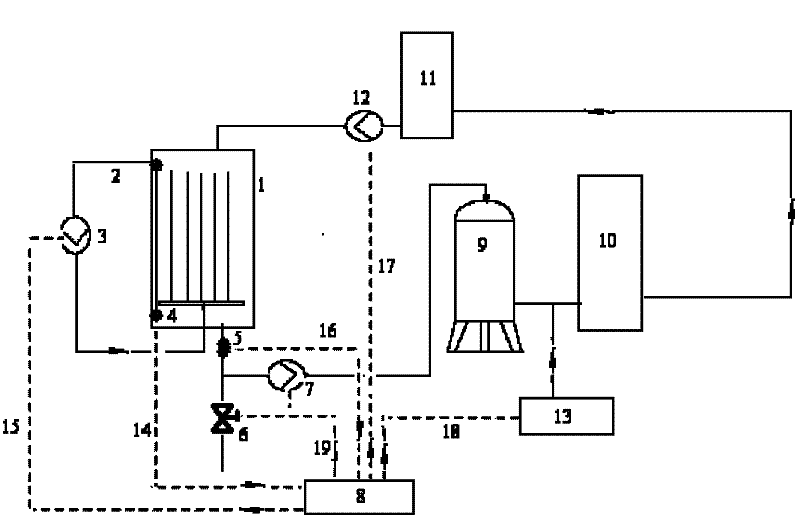

Method for dyeing fabric by using reactive dye and soaping fabric dyed by reactive dye, and equipment

ActiveCN102505388AReduce the number of cylindersReduce processing timeTextile treatment machine partsDyeing processAutomatic controlEngineering

The invention relates to a method for dyeing a fabric by using a reactive dye and soaping the fabric dyed by the reactive dye, and equipment. A hydrolyzed reactive dye in dyeing and soaping liquid is decolorized by a decolorizing technology and then recycled. According to the method, a decolorizing device is connected with soaping equipment in the dyeing and soaping processes, the soaping liquid is forced to pass through the decolorizing device and be subjected to a closed cycle in a dye vat and the decolorizing device during dyeing and soaping, the hydrolyzed dye which is eluted from the fabric in the soaping liquid is continuously adsorbed or decomposed by the decolorizing device, and the eluted hydrolyzed dye is completely removed after the cycle is performed for a certain period of time, so that the process of soaping the fabric dyed by the reactive dye is finished. The used equipment comprises reactive dye dyeing equipment and the hydrolyzed dye decolorizing device which are connected in series with each other, wherein the hydrolyzed dye decolorizing device is provided with an on-line automatic control system which automatically controls the operation of a cycle decolorizing system through a signal output by a chroma detector in the dyeing equipment. The method has the advantages of water and energy conservation, low operation cost and the like.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

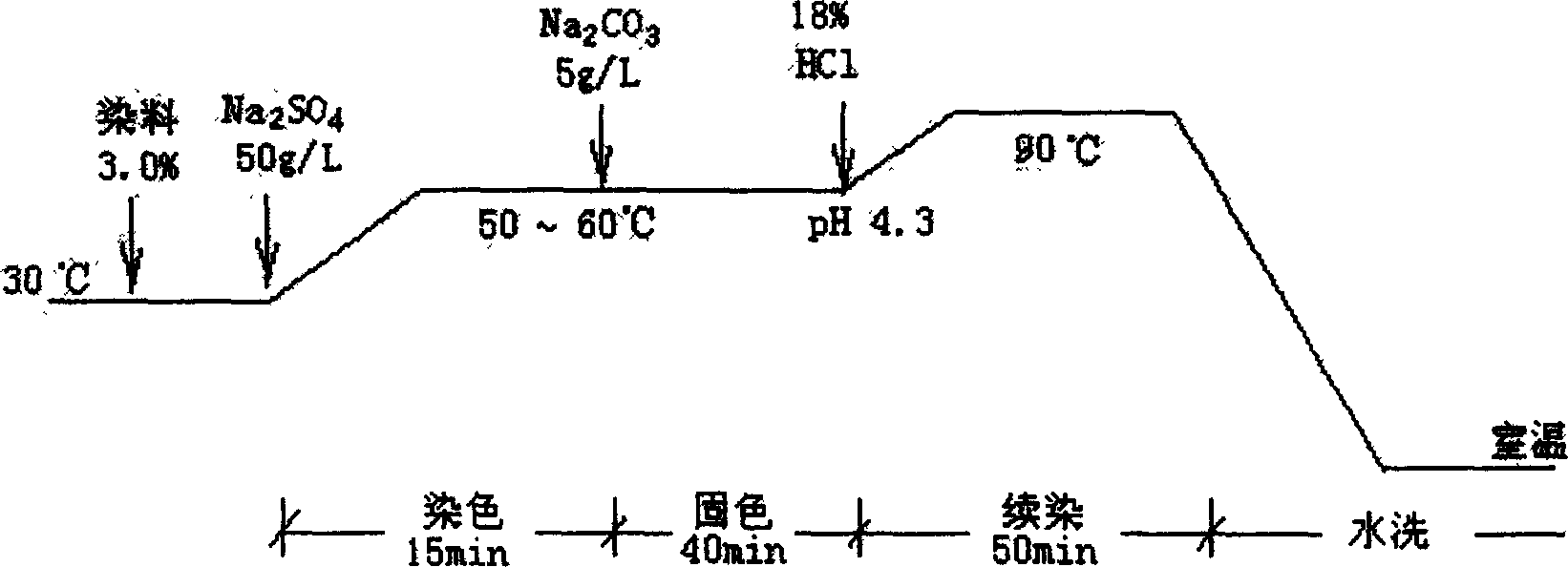

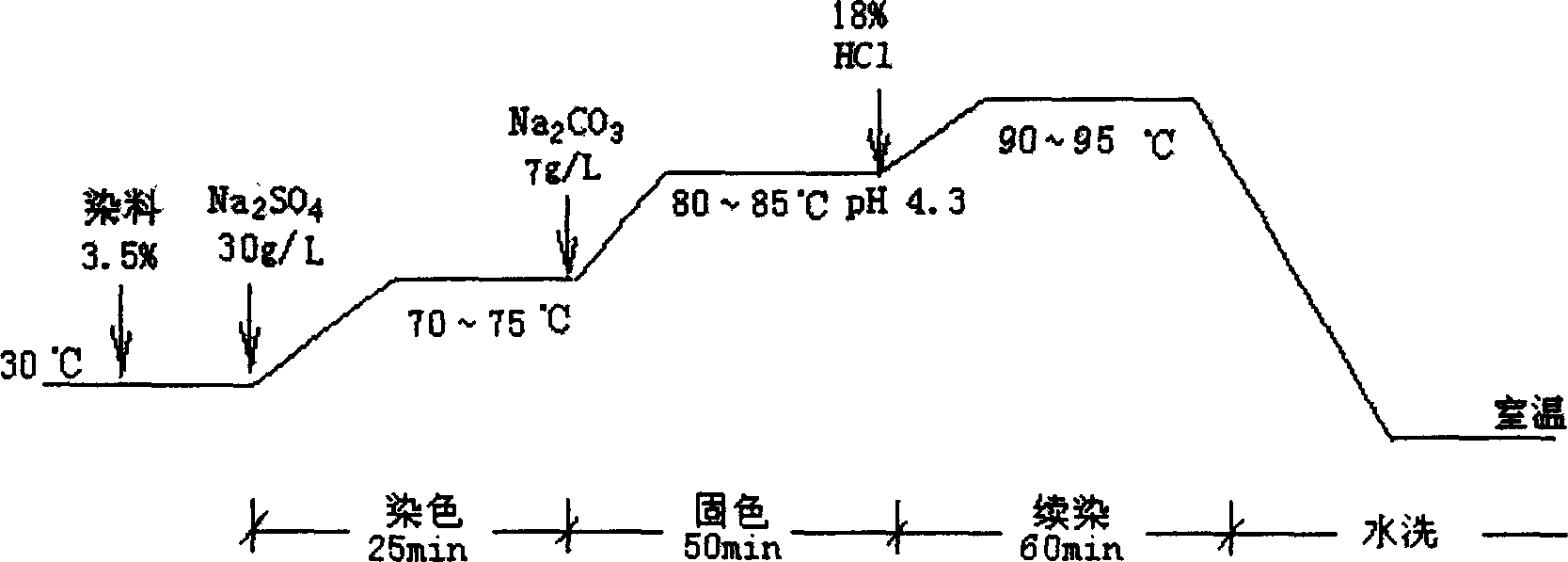

Active, dyestuff modified bath dyeing technology

The present invention relates to a modification bath dyeing technique by using active dyes. Said technique can dye fibre, yarn and fabrics, and includes the following processes: under the alkaline condition utilizing active dyes to dye, fix colour and regulate pH value, and under the acidic condition utilizing acidic dyes to dye, heat-up continuously dye and water-wash, etc. The adoption of said method is applicable to new fibre variety, for example, soybean protein / PVA polyblend fibre can be one-bath dyed by using said method.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com