High-efficiency environment protection acidic color fixing agent and manufacture method thereof

An acidic color-fixing agent and color-fixing agent technology, applied in the field of color-fixing agent for polyamide fiber dyeing and protein fiber dyeing with acid dyes, can solve the problems of high wastewater treatment cost, dyeing defects, and affecting product quality, so as to reduce wastewater The effect of processing cost, improving dyeing quality and saving dyeing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The formula of high-efficiency environment-friendly acid color fixing agent is composed by weight:

[0070] Polyacrylic color fixing agent 40%;

[0071] Penetrant 5%;

[0072] Complexing agent 2%;

[0073] 20% Sodium Hydroxide 1%;

[0074] Organic solvent 8%;

[0075] Water 36%.

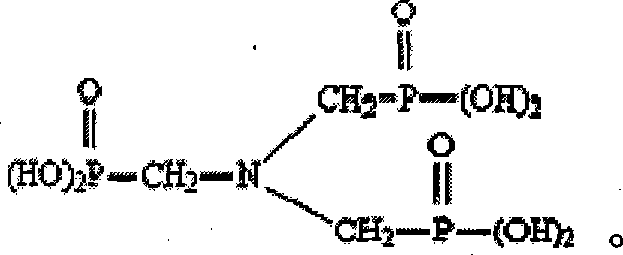

[0076] Wherein, the complexing agent adopts aminotrimethylene phosphonic acid, the penetrating agent adopts sodium butyl diphenyl ether disulfonate, and the organic solvent adopts ethanol.

[0077] Preparation:

[0078] 1. Add an appropriate amount of water, and stir all the materials at 40-50°C according to weight percentage for 2-3 hours, and dissolve and filter evenly. pH is 6-7.

[0079] 2. Among them, the synthesis technology route of polyacrylic acid color fixing agent

[0080] 1) Add 130 grams of isopropanol and 35 grams of deionized water into a four-neck flask, and heat the material to 80 degrees under stirring.

[0081] 2) Insulation, a solution containing 140 grams of metha...

Embodiment 2

[0100] The formula of high-efficiency environment-friendly acid color fixing agent is composed by weight:

[0101] Polyacrylic color fixing agent 40%;

[0102] Polyurethane color fixing agent 8%;

[0103] Penetrant 5%;

[0104] Complexing agent 2%;

[0105] 20% Sodium Hydroxide 1%;

[0106] Organic solvent 8%;

[0107] Water 36%.

[0108] Wherein, the complexing agent adopts aminotrimethylene phosphonic acid, the penetrating agent adopts sodium butyl diphenyl ether disulfonate, and the organic solvent adopts ethanol.

[0109] Preparation:

[0110] 1. Add an appropriate amount of water, and stir all the materials at 40-50°C according to weight percentage for 2-3 hours, and dissolve and filter evenly. pH is 6-7.

[0111] 2. Among them, polyacrylic color fixing agent and polyurethane color fixing agent synthesis technical route (the following examples are the same)

[0112] A, polyacrylic acid color fixing agent synthesis (the following examples are the same):

[0113] ...

Embodiment 3

[0135] The formula of high-efficiency environment-friendly acid color fixing agent is composed by weight:

[0136] Polyacrylic color fixing agent 40%;

[0137] Polyurethane color fixing agent 5%;

[0138] Penetrant 6%;

[0139] Complexing agent 3%;

[0140] 20% sodium hydroxide 2%;

[0141] Organic solvent 5%;

[0142] Water 39%.

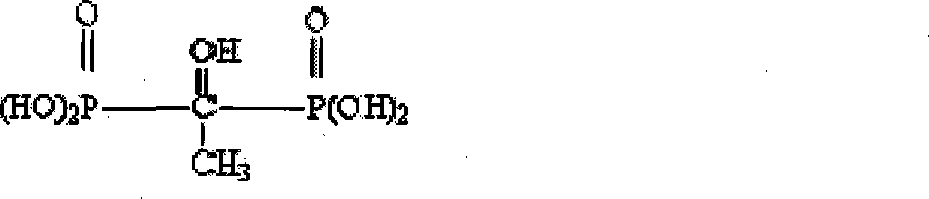

[0143] Wherein, the complexing agent adopts hydroxyethylene diphosphonic acid, the penetrating agent adopts sodium butyl diphenyl ether disulfonate, and the organic solvent adopts ethanol.

[0144] Preparation:

[0145] Add an appropriate amount of water, and stir at 40-50°C to add all the materials in order according to weight percentage and mix for 2-3 hours, dissolve evenly, filter and discharge.

[0146] Dyeing process steps:

[0147] (According to the traditional dyeing process, dyes and auxiliaries are conventional industrial supplies)

[0148] Put water in the dyeing bath, add acid dyes (4% to the weight of the fabric), acid leveling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com