Solidified and modified lignin epoxy resin/ carbon fiber reinforced composite material and preparation method and application

A technology of reinforced composite materials and plain epoxy resin, which is applied in the field of composite materials, can solve the problems that the toughness needs to be further improved, and achieve the effects of enhancing toughness, improving toughness and enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

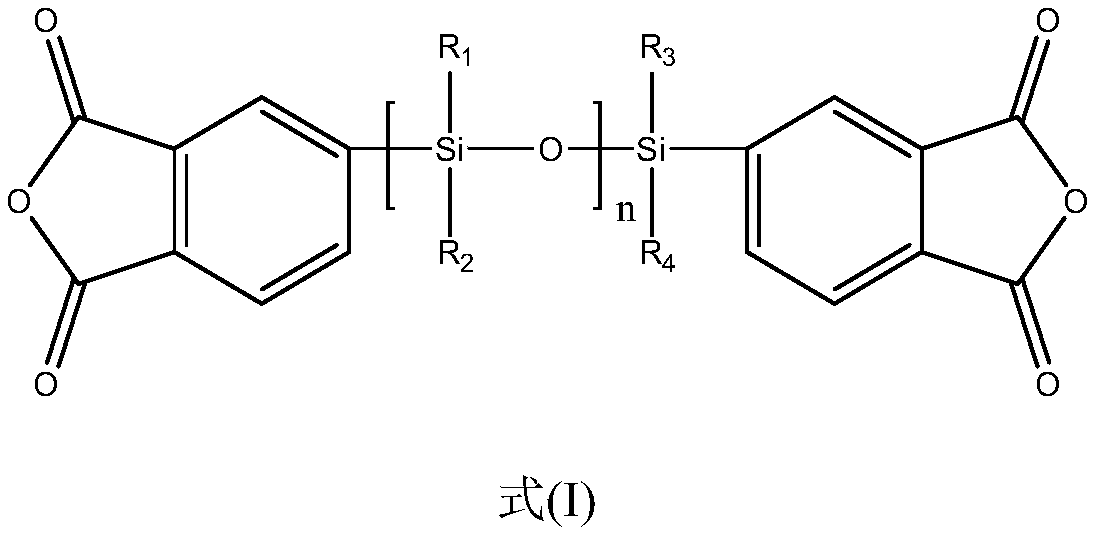

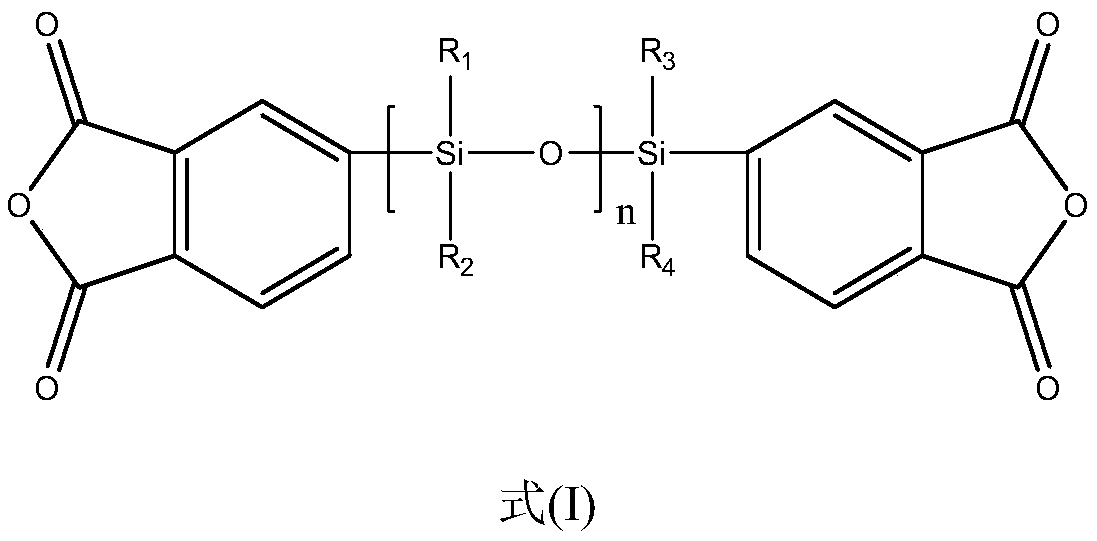

Image

Examples

preparation example 1

[0049] Add 90g of ethylene glycol into the reaction vessel, add 62g of enzymatic lignin and 90g of maleic anhydride under stirring conditions, then add 10g of 50wt% aqueous sulfuric acid as a catalyst, stir and mix thoroughly, and react at 140°C for 4 hours, About 240 g of oil were obtained. Then add 480g of ethylene glycol diglycidyl ether, continue the reaction at 100°C for 2 hours, cool to room temperature, and obtain about 720g of viscous liquid, which is the product lignin epoxy resin, with a viscosity of 10000mPa·s and an epoxy value of 0.41eq / 100g.

preparation example 2

[0051] Add 90g propylene glycol in the reaction vessel, add 62g enzymatic lignin under stirring condition, 1144g phthalic anhydride, then add 10g 55wt% sulfuric acid aqueous solution as catalyst, stir and mix fully, react at 130 ℃ for 5 hours, get Approx. 296g oil. Then add 596g of propylene glycol diglycidyl ether, continue to react at 100°C for 2 hours, and cool to room temperature to obtain about 888g of viscous liquid, which is the product lignin epoxy resin. Its viscosity is 11000mPa·s, and the epoxy value is 0.42eq / 100g.

preparation example 3

[0053] The preparation method is the same as that of Preparation Example 1, except that the epoxy diluent ethylene glycol diglycidyl ether is used in an amount of 456 g. Finally, about 696g of viscous liquid was obtained, namely the product lignin epoxy resin, with a viscosity of 11000mPa·s and an epoxy value of 0.42eq / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com