Patents

Literature

52results about How to "Improve soaping fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

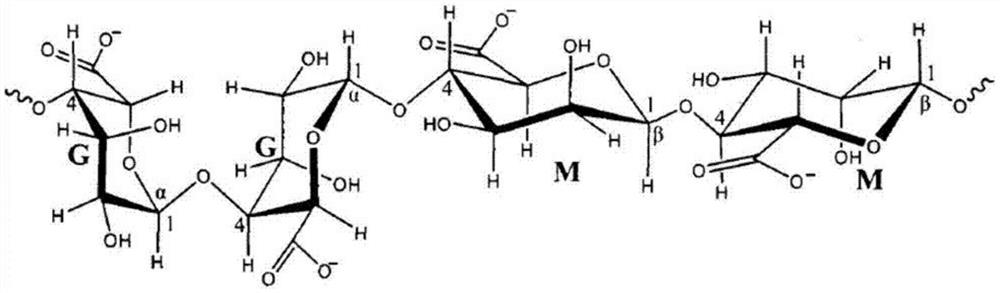

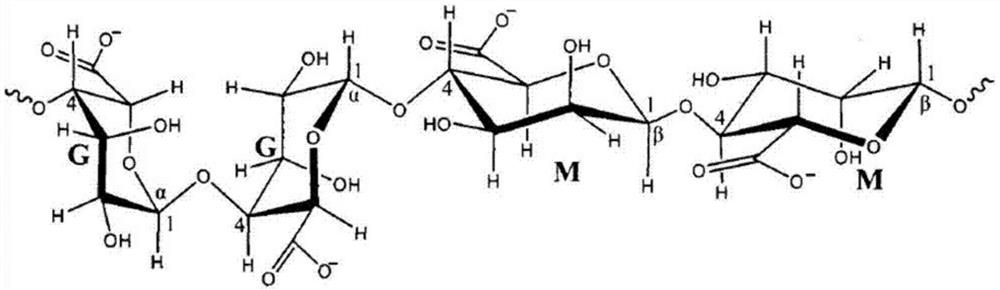

Salt-free dyeing method for calcium alginate fiber

ActiveCN103981744AImprove soaping fastnessGood level dyeingFibre treatmentDyeing processAluminium saltsChemistry

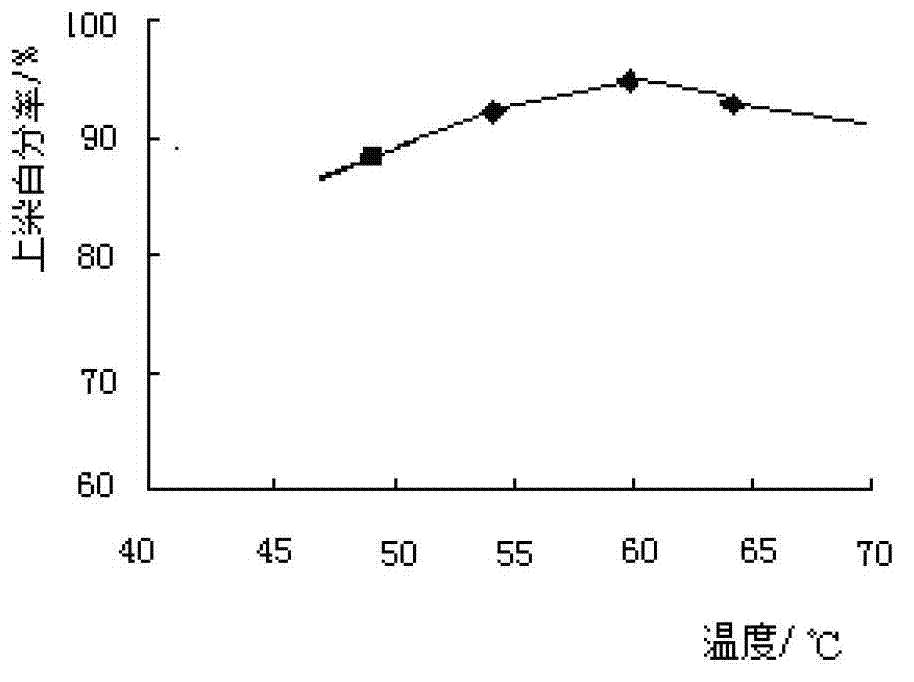

The invention discloses a salt-free dyeing method for calcium alginate fiber, and belongs to the technical field of textile science. According to the method, an aqueous aluminum sulfate solution is adopted to pretreat the calcium alginate fiber to be dyed, then a direct dye is adopted to perform salt-free dyeing, and finally an aqueous calcium chloride solution is adopted to perform fixation. When the method is adopted for dyeing of the calcium alginate fiber, the dye-uptake rate of the dye to the fiber is not less than 90%, the levelling property and the permeability property of the fiber are excellent, and the soaping fastness is not less than the fourth level. The method avoids the use of table salt, acids, alkalis, and other chemical agents, and has characteristics of low cost, less damage to the mechanical properties of the calcium alginate fiber, not more than 10% of the strength loss of the dyed fiber, eco-environment protection, rapid and convenient treatment, recovery and reutilization for dyeing waste water, and zero release.

Owner:QINGDAO TIANYI GROUP

High-efficiency environment protection acidic color fixing agent and manufacture method thereof

InactiveCN101245563ARaw material environmental protectionWill not affect healthDyeing processMeth-Hazardous substance

The invention relates to an effective environment protective acid fixing agent that is prepared by a polypropylene acid fixing agent, an addition agent and a solvent which are matched. The polypropylene acid fixing agent is prepared by the following steps: mixing isopropanol, methacrylic acid, 2-acrylamido-2-methylpropane sulfoacid, acrylic acid and sodium persulfate in deionized water to be reacted for 1 to 5 hours at 80 to 90 DEG C and acquiring a reaction product, namely, the polypropylene acid fixing agent by post treatment. The preparation method of the effective environment protective acid fixing agent includes: adding proper water, adding all the materials under the condition of stirring at 40 to 50 DEG C in sequence to be mixed for 2 to 3 hours, uniformly dissolving, filtering, discharging and controlling the pH to be 6 to 7. The materials of the invention are environment-protective, can reduce the treatment cost of waste water and can generate remarkable social and economic benefits.

Owner:杭州下沙恒升化工有限公司

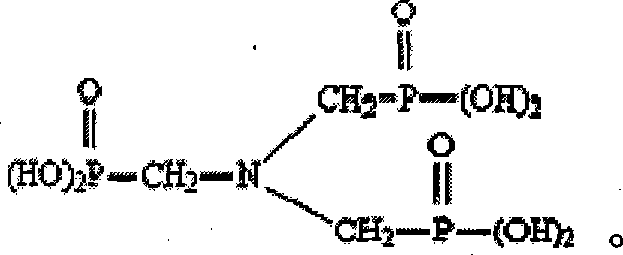

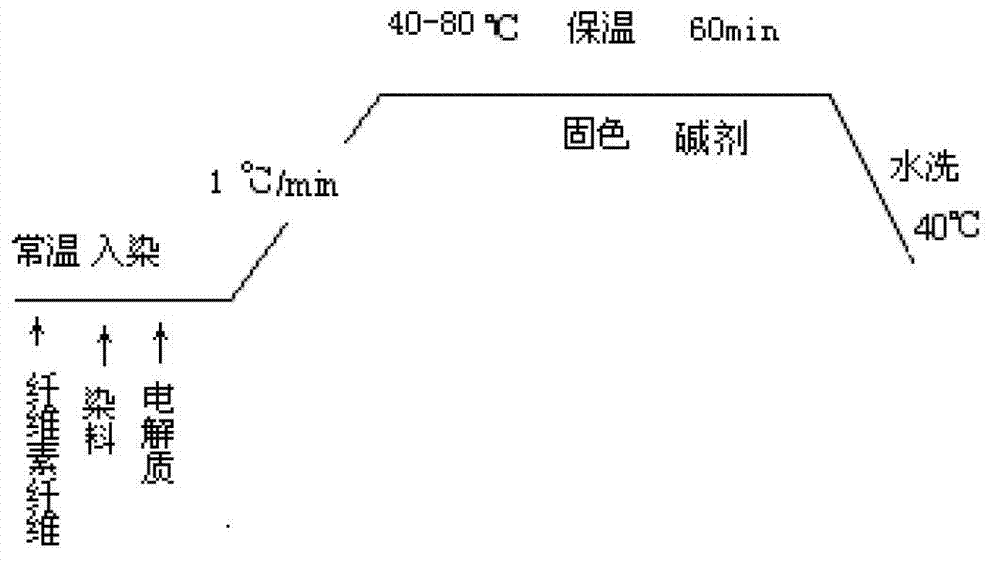

Dyeing method of cellulosic fiber fabric

InactiveCN102817239ASolve the low dyeing rateSolve the fastnessDyeing processVegetal fibresPerformance indexCellulose fiber

The invention discloses a dyeing method of a cellulosic fiber fabric, comprising the following steps of: firstly, performing pretreatment modification on the cellulosic fiber fabric by using chitosan; then, preparing a dye solution; and finally, putting the modified cellulosic fiber fabric in the dye solution for dying. In the dyeing method, the cellulosic fiber fabric is modified by using the chitosan as a deep dyeing agent and then is pretreated at the temperature of 50 DEG C, the modified cellulosic fiber fabric is dyed by using an activated dye, and a color fixing alkali agent is added for fixing the modified cellulosic fiber fabric so that the dye is fixed on fiber. The dyeing rate of the dyed cellulosic fiber fabric can be up to above 90%, and the soaping fastness is improved by 1 level or more than 1 level. The color of the dyed cellulosic fiber fabric is fundamentally in accordance with the color of fiber not dyed by the chitosan, and all performance indexes meet the natural standard.

Owner:XI'AN POLYTECHNIC UNIVERSITY

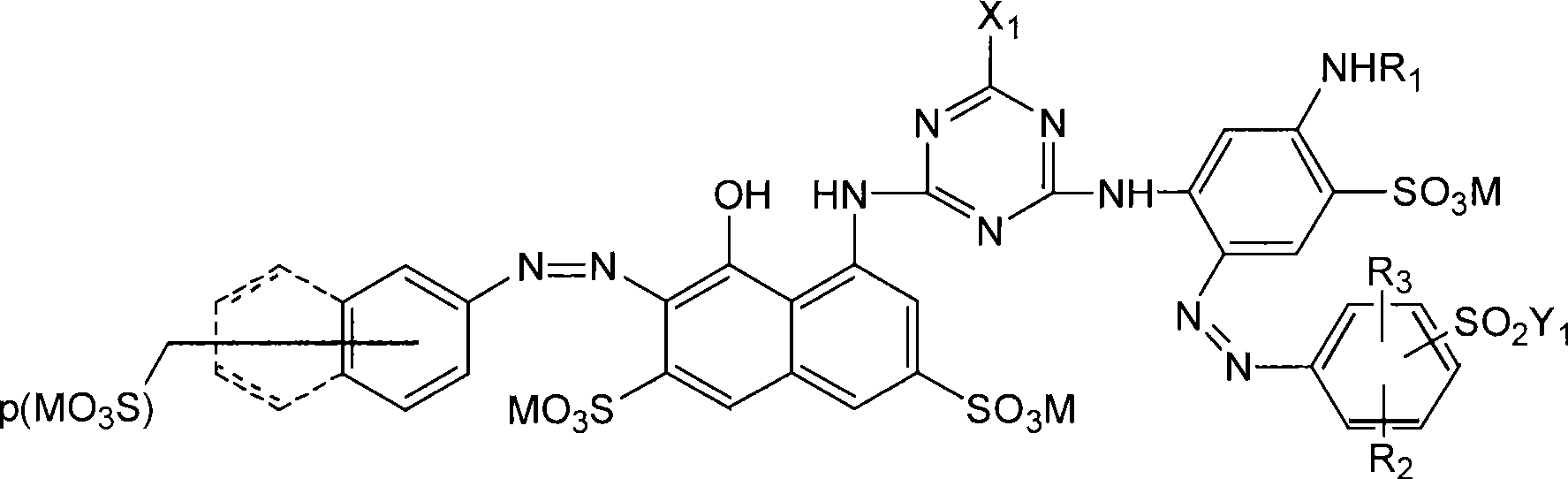

Red reactive dye composition and application thereof

ActiveCN101497747AHigh color fastnessImprove soaping fastnessOrganic dyesDyeing processHuePhotochemistry

The invention provides a red reactive dye compound comprising one or a plurality of known red reactive dye I and red reactive dye II which are mixed together according to a certain proportion. The red reactive dye compound has bright color, wide hue range and excellent various dye fastness. Compared with the red reactive dye I and the red reactive dye II which are the components of the red reactive dye compound, the red reactive dye compound is obviously improved in the color fixation rate, the color promotion rate, the migration property, the different bath ratios during dying and the stability of different electrolyte used. More importantly, compared with the red reactive dye I, the red reactive dye compound is remarkably improved in the light fastness and the fastness to chlorine.

Owner:ARGUS SHANGHAI TEXTILE CHEM

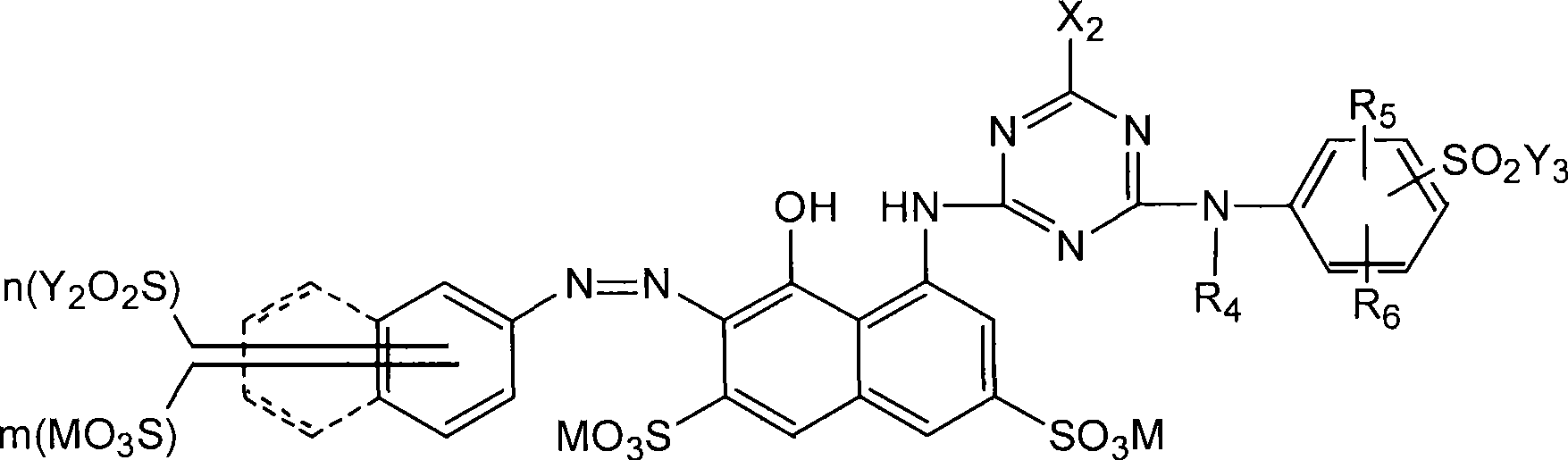

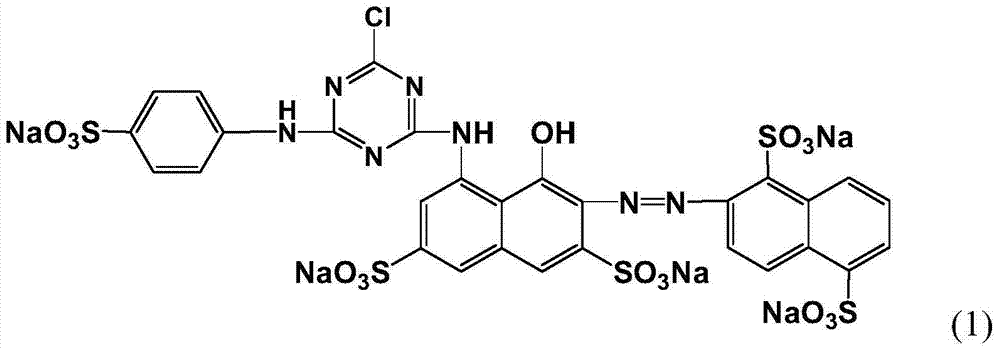

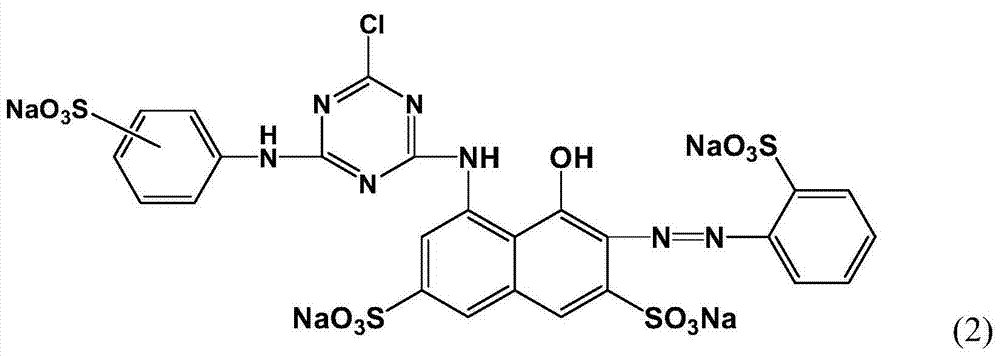

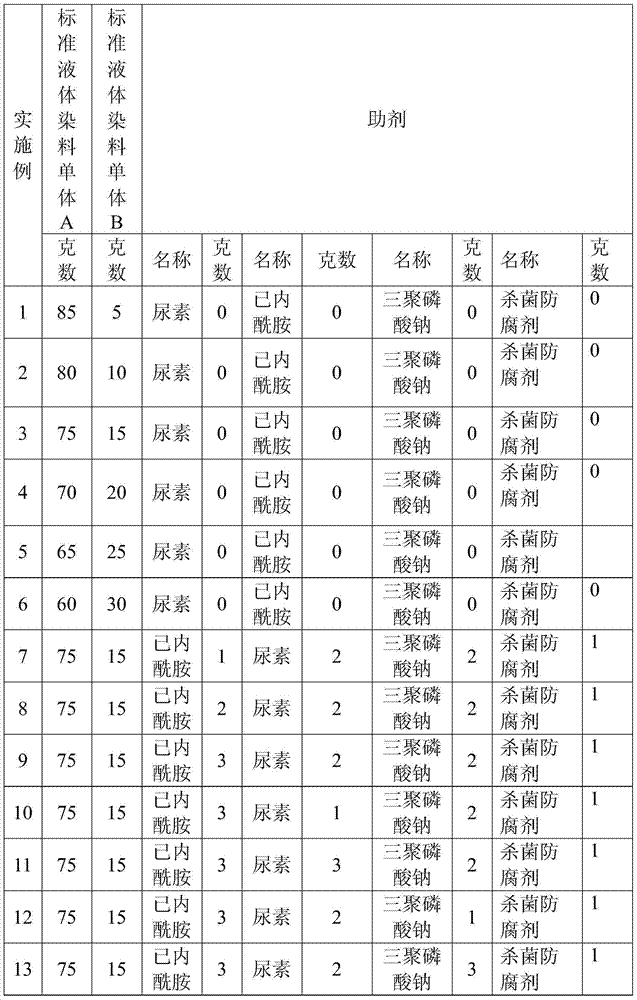

Composite liquid reactive red dye

ActiveCN103694739AGood storage stabilityNot easy to condensationOrganic dyesDyeing processChemical stabilityCaprolactam

The invention discloses composite liquid reactive red dye which consists of the following components in parts by weight: 60-85 parts of a dye monomer A as shown in formula (I), 5-30 parts of a dye monomer B as shown in formula (2), and 1-5 parts of urea, 1-5 parts of caprolactam and 1-5 parts of sodium tripolyphosphate as additives, wherein the sulfonic acid groups in the formula (2) are in meta-positions and para-positions of amino, and the ratio of meta-positions to para-positions is (1:2)-(2:1). According to the composite liquid reactive red dye, monochlorotriazine active dye and improved buffer aids with low reactivity are selected and compounded with aids, the effect of stabilizing dissolution assistance is achieved, the defect that in the prior art the prepared liquid dye is poor in chemical stability is overcome, the liquid dye is prevented from agglomeration or separation in the storage process, and the requirements of the printing and dyeing industry are met.

Owner:ZHEJIANG JINGGUANG IND

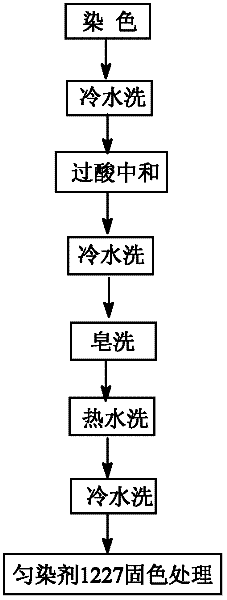

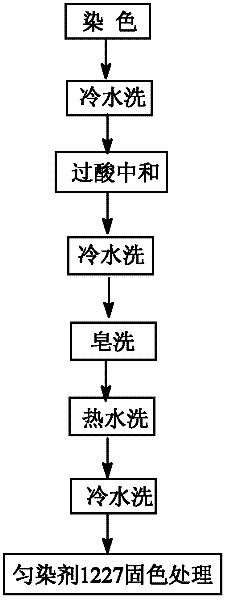

Post-treatment fixation process for fabric dyeing

The invention provides a post-treatment fixation process for fabric dyeing. The process comprises the following sequential steps of: after fabric is dyed by a reactive dye, washing with cold water twice, neutralizing once with 1% of glacial acetic acid at 60 DEG C, washing with cold water twice, soaping with 1% of soaping agent CSP at 80 DEG C for 20 minutes, washing with hot water of 98 DEG C twice, cleaning with cold water, carrying out fixation with 2-4% of acrylon leveling agent 1227 at 45 DEG C for 20 minutes or at 80 DEG C for 20 minutes, then washing with water and discharging the cloth. By adopting the process, the rubbing fastness and water washing fastness indexes of the reactive dye can be effectively improved, and the friction fastness and water washing fastness of the dyed fabric can be further effectively improved.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

Dye for embroidery threads

InactiveCN106634027AImprove soaping fastnessPrevent discolorationNatural dyesDyeing processPterocarpus santalinus extractTragacanth

The invention relates to a dye for embroidery threads. The dye comprises, by weight parts, 1-5 parts of madder extract, 10-15 parts of safflower extract, 5-10 parts of sappan wood extract, 1-10 parts of red sandalwood extract, 15-35 parts of gum tragacanth and aloe extract, 1-4 parts of mordant, 10-20 parts of sodium sulfate and 3-15 parts of nature diatomite. The dye not only does not fade easily, but also is environmentally friendly.

Owner:姚佑灿

Chitosan antibiotic finish method for textiles

InactiveCN106930108AImprove antibacterial washabilityFull penetrationRadio/micro wave fibre treatmentBiochemical fibre treatmentEscherichia coliFiber

The invention discloses a chitosan antibacterial finishing method for textiles. Firstly, it is pretreated, and then the surface of the fiber is activated with a large amount of high-energy electrons, ions and free radicals generated by microwave plasma; , flush the antibacterial finishing agent containing chitosan with a certain temperature into the reaction chamber by using the negative pressure in the reaction chamber to react with the activated clothing for a certain period of time, then dehydrate the finished clothing to maintain the liquid retention rate between 30-60%; and microwave-dried it, finally rinsed with clean water, dehydrated, dried, and packaged. The pure cotton garment of the present invention exhibits good durability after chitosan antibacterial finishing, and after 60 times of soaping, the antibacterial rate of Escherichia coli is still over 80%, and the antibacterial rate of Staphylococcus aureus is over 89%.

Owner:深圳优普莱等离子体技术有限公司

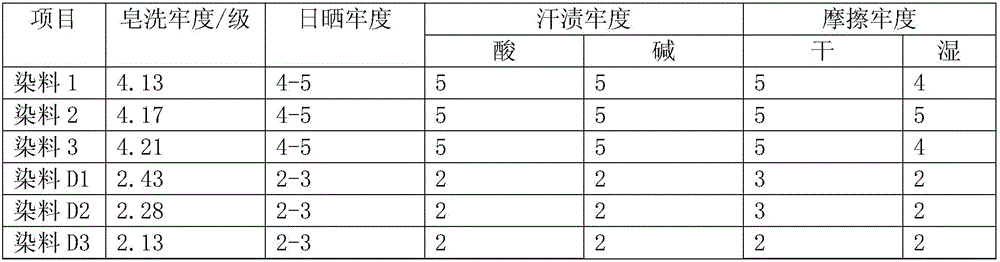

Synthetic method of novel environment-friendly chlorine-resistant color fixing agent

The invention discloses a synthetic method of a novel environment-friendly chlorine-resistant color fixing agent. Epoxy chloropropane, diethylenetriamine and diallylamine serve as the raw materials, and the novel environment-friendly chlorine-resistant color fixing agent is prepared through a reaction. Hydroxyl and imino groups exist in the color fixing agent and can be combined with dye, chloridion of the dye can be closed, and a thin polymer film can further be formed on the fiber surface.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

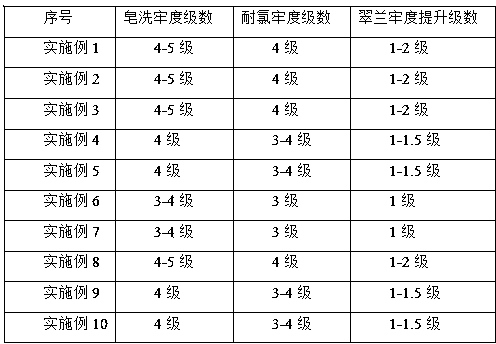

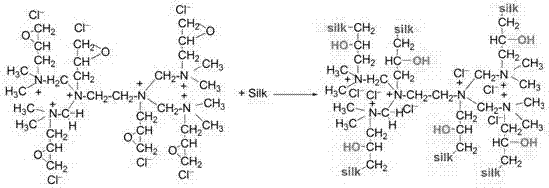

Active cationic modifier and preparation method thereof and method for modifying silk fiber

The invention discloses a preparation method of an active cationic modifier. The preparation method sequentially comprises the following steps of sequentially adding water, ethylenediamine and a formaldehyde water solution into a reaction container, and reacting for at least 30min in water bath at the temperature of 35 to 60 DEG C; cooling the water bath temperature and maintaining to be 35 DEG C,adding a dimethylamine water solution, and reacting for 1h; increasing the water bath temperature to 40 DEG C, adding epichlorohydrin, maintaining the temperature to be 40 DEG C, and reacting for 1.5h, so as to obtain the modifier XS. The modifier XS contains a plurality of active epoxy groups, so that even if a certain amount of epoxy groups is hydrolyzed in the grafting reaction, the cationic modifier is firmly grafted to the silk fiber when one epoxy group and the silk fiber generate the chemical reaction; furthermore, the modifying efficiency of the cationic modifier is high.

Owner:JIANGSU SPCC SILK

Detergent and preparation method thereof

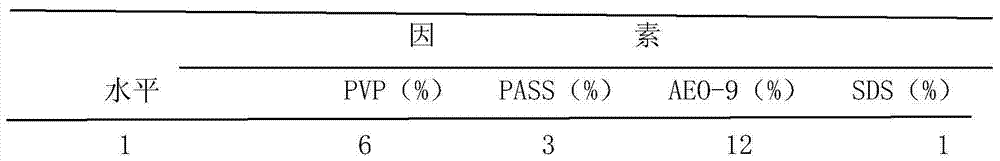

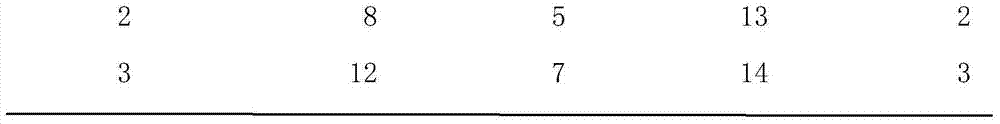

InactiveCN103923753AInhibit back stainingReduce contact areaOrganic detergent compounding agentsNon-ionic surface-active compoundsChemical oxygen demandFatty alcohol

The invention provides a detergent and a preparation method thereof. The detergent is prepared from polyvinylpyrrolidone (PVP), sodium polyacrylate PAAS, fatty alcohol-polyoxyethylene ether AEO-9, sodium dodecyl sulfate SDS, sorbitan laurate PEG-80 and water. The detergent has the functions of strong wetting, permeation, dispersion, emulsion, detergent washing, reprecipitation resistance and other functions, and resists hard water; the stained fastness, the dry friction fastness and wet rubbing fastness of a soaped fabric can be improved, and the color is even and the color is bright; the COD (Chemical Oxygen Demand) of the emitted waste water can also be reduced, the treatment cost of the printing and dyeing sewage can be lowered, and safety and environment protection can be achieved.

Owner:浙江丝之美服饰染整有限公司

Dyeing agent for nylon fabric and preparation method of dyeing agent

The invention discloses a dyeing agent for a nylon fabric and a preparation method of the dyeing agent. The dyeing agent for the nylon fabric comprises the following componnets in parts by weight: 3-6 parts of aluminum sulfate, 15-20 parts of mica powder, 2-6 parts of ethyl acetate, 2-5 parts of dibutyl phthalate, 5-10 parts of sodium dialkyl ester lauryl sulfosuccinate, 15-20 parts of sodium carbonate, 8-15 parts of zinc stearate, 10-20 parts of glycerol, 20-30 parts of blocked isocyanates, 8-14 parts of triethoxy ethyl silane, 20-30 parts of butyl methacrylate, 15-30 parts of dinitroso pentamethylene tetramine, 13-22 parts of iron oxide red, 2-4 parts of a plant extract, 10-15 parts of an initiator, 7-15 parts of an additive, 1-3 parts of a formaldehyde-free dye fixing agent, 1-3 parts of a dye leveler, and 30-50 parts of water. The preparation method is simple, the dyeing effect is good, and the method is green and environmentally friendly.

Owner:SUZHOU CHENHENG WEAVING

Dyeing and finishing technique of cellulose fiber textile

The invention discloses a dyeing and finishing technique of cellulose fiber textile, which sequentially comprises the following steps of: pretreating, dyeing, water washing, neutralizing, soaping and water washing the fiber textile; and the dyeing technique comprises the steps of: under the conditions of 30 DEG C and bath ratio of 1:7-1:15, adding vinyl sulfone type low-temperature dye with the weigh of 2-10% of the textile, and carrying out heat preservation for 10-15min; then, adding anhydrous sodium sulphate and sodium hydroxide which is 1 / 4-1 / 3 of the total weight, and carrying out heat preservation for 10-15min; adding another sodium hydroxide which is 3 / 4-2 / 3 of the total weight, and carrying out heat preservation for 10-15min; and heating to 40 DEG C at the speed of 1 DEG C / min, carrying out heat preservation for 40-60min, and completing the dyeing technique. The dyeing and finishing technique of the cellulose fiber textile has the characteristics of low using quantity of dye, high soaping fastness, low using quantity of alkali color fixing agent, less pollution discharge and reduced cost.

Owner:冯惠英

Binder used for pigment printing of textiles and preparation method thereof

InactiveCN102504090AHigh fastnessImprove film water resistanceDyeing processTextile printerPolymer science

The invention discloses a binder used for pigment printing of textiles and a preparation method thereof. The binder is prepared by seed emulsion polymerization of fatty alcohol polyoxyethylene ether sodium sulfate, diethylaminoethyl methacrylate, methacryloyloxy ethyl acetoacetate, sodium lauryl sulfate, acrylic acid, acrylic ester, ammonium persulfate and deionized water. The binder is free of formaldehyde or alkylphenol polyoxyethylene and has soft hand-feeling and good soaping fastness.

Owner:LIAONING FIXED STAR FINE CHEM

Ultrasonic circulating soaping method used for dyeing by adopting isatis root plant dye

The invention relates to an ultrasonic circulating soaping method used for dyeing by adopting isatis root plant dye. In soaping equipment, ultrasonic waves are adopted, and ozone is introduced; beforefabrics and clothes which are dyed by the isatis root plant dye are put in the soaping equipment, hydrogen peroxide is added into an aqueous solution, and a natural soaping agent HO is added for soaping for 2-20 minutes; a soaping solution is recyclied, and hydrogen peroxide and a natural soaping agent HO are supplemented. The method has the advantages that surface dyeing of dyed textile by adopting the plant dye can be greatly removed, all plant pigments are thoroughly oxidized, parts of water-soluble pigments can be degraded and mineralized, the soaping fastness of the textile dyed by the isatis root plant dye is improved to reach 1-2 grade, and the dry-wet color fastness to rubbing is improved to above 1 grade.

Owner:祝洪哲 +1

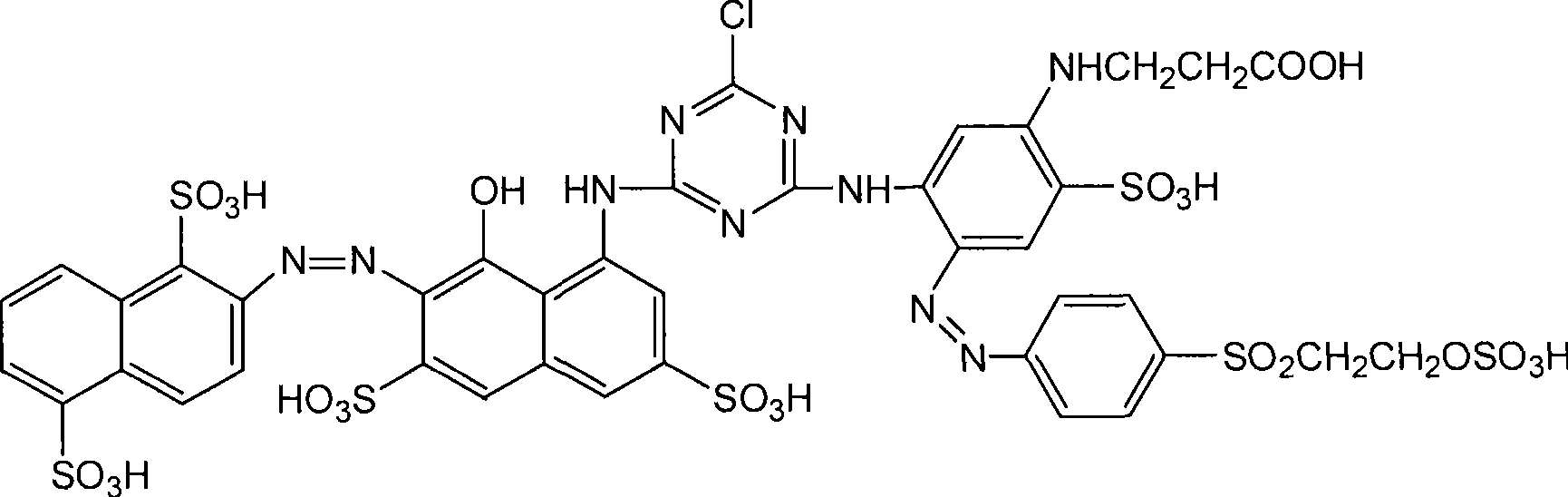

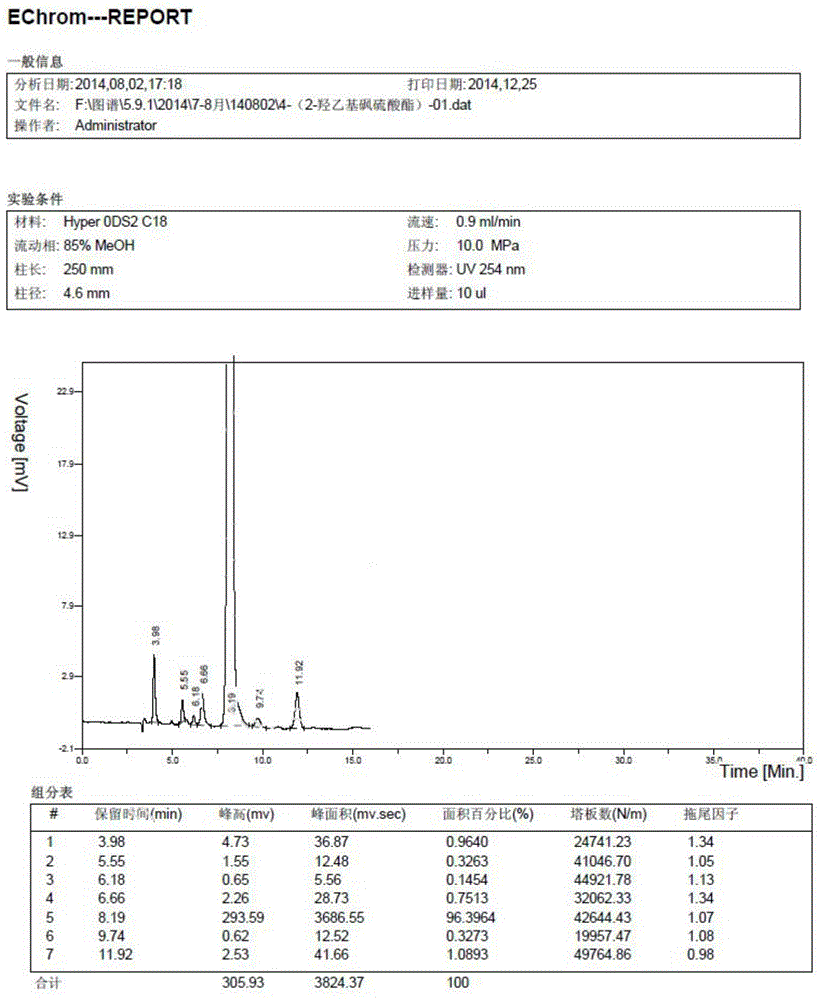

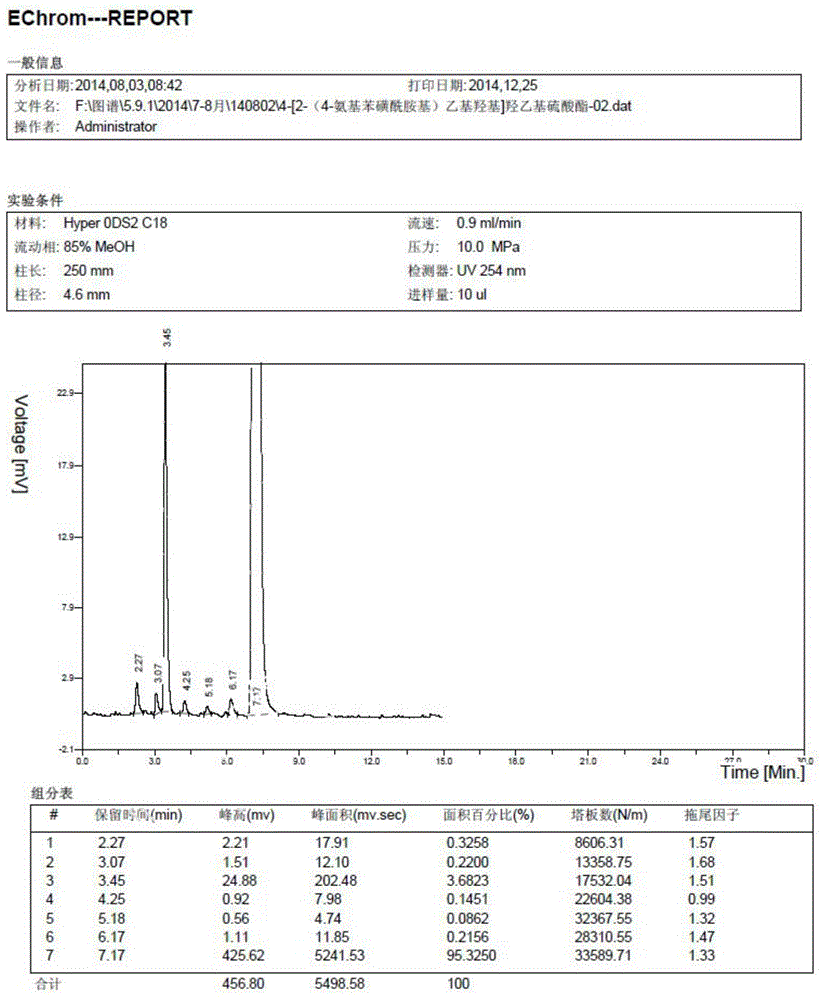

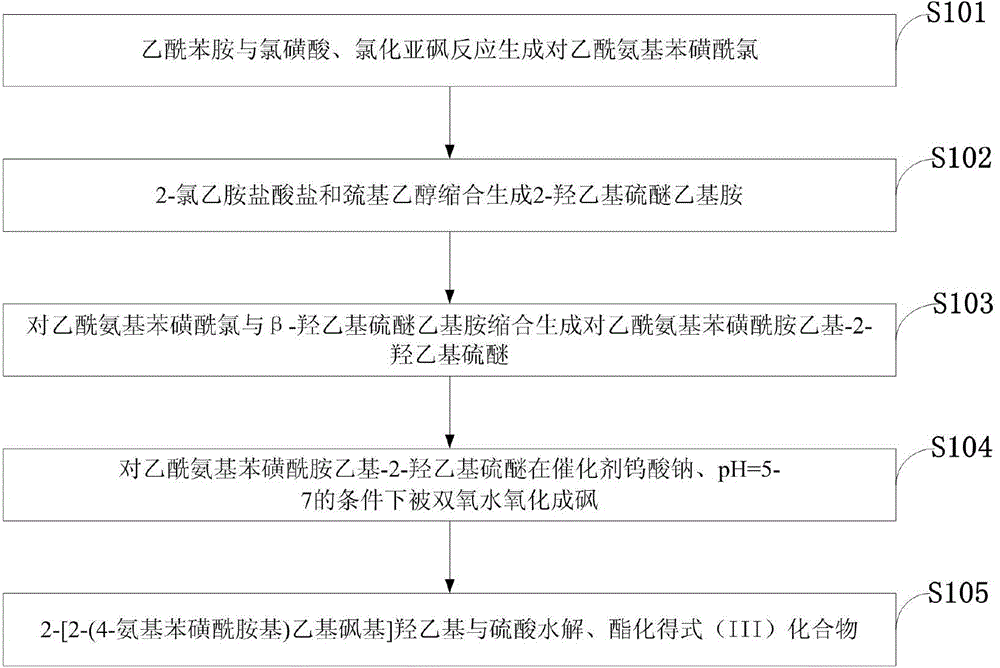

Radical benzene sulfonamide ethyl sulfuryl hydroxyethyl sulfate aniline compound and preparation method thereof

ActiveCN104370780ABright shadeLow directnessReactive dyesSulfonic acid amide preparationAniline CompoundsChemistry

The invention discloses a radical benzene sulfonamide ethyl sulfuryl hydroxyethyl sulfate aniline compound and a preparation method thereof. The preparation method comprises the following steps: reacting acetanilide with chlorosulfonic acid and sulfoxide chloride to generate p-acetamido benzene sulfonyl chloride, and then condensing with sulfide generated through reaction between 2-chlorethamin hydrochloride and mercaptoethanol to obtain sulfur ether, re-oxidizing, etherifying or sulfonating the sulfur ether to obtain 2-[2-(4-amonibenzenesulfonamido)ethyl sulfuryl]hydroxyethyl sulfate or 2-[2-(4-amonibenzenesulfonamido)ethyl sulfuryl] hydroxyethyl sulfate-3-sulfonic acid. Comparing the active radical benzene sulfonamide ethyl sulfuryl hydroxyethyl sulfate aniline compound with 4-(2-sulfonylethanol sulfate)aniline; the synthesized reactive dye has bright colored light, and is low in substantivity, high in dye-uptake rate and fixation rate, less in hydrolysis dye, and excellent in various fastness indexes; especially, the light fastness, the soaping resistant fastness, and rubbing fastness are 0.5-1 level higher than ordinary variety.

Owner:TAIXING JINYUN DYESTUFF

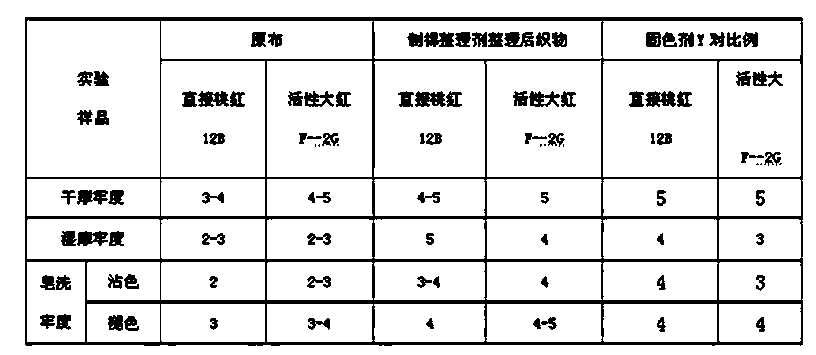

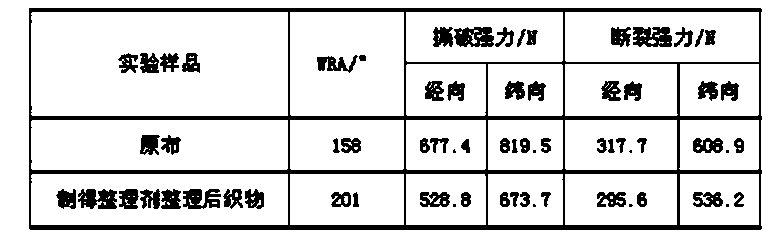

Color-fixing anti-wrinkle finishing agent as well as preparation method and application thereof

InactiveCN104047192ALow water solubilityIncrease intermolecular forcesDyeing processWater soluble polymersRegenerated cellulose

The invention relates to a color-fixing anti-wrinkle finishing agent which is amphoteric water-soluble polymer; the molecular formula of the polymer is (A)x(B)y(C), wherein A refers to an anionic link, B refers to a nonionic link and B refers to a cationic link; x, y and z respectively refer to polymerization degrees of the anionic link, the nonionic link and the cationic link; the ratio of x to y to z is (10-50) to (0-30) to (50-90); the anionic link is derived from a monomer containing adjacent carboxylic acid groups; the nonionic link is derived from a nonionic monomer; the cationic link is derived from a monomer containing cationic quaternary ammonium groups. The invention also relates to a preparation method and application of the color-fixing anti-wrinkle finishing agent. The finishing agent is capable of effectively improving the wet rubbing fastness, the soaping fastness and wrinkle recovery angle (WRA) of the dyed material; the finishing agent is simple and convenient to synthesize, low in cost, good in storage stability, free of release of formaldehyde in the producing and using process, green and applicable to good color-fixation anti-wrinkle treatment on textiles such as colored cotton, hemp, regenerated cellulose and the like.

Owner:YANCHENG PRINTING & DYEING

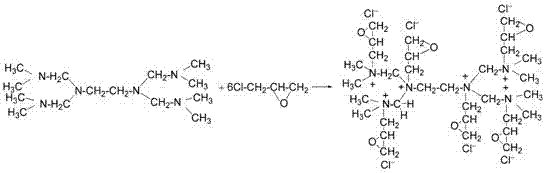

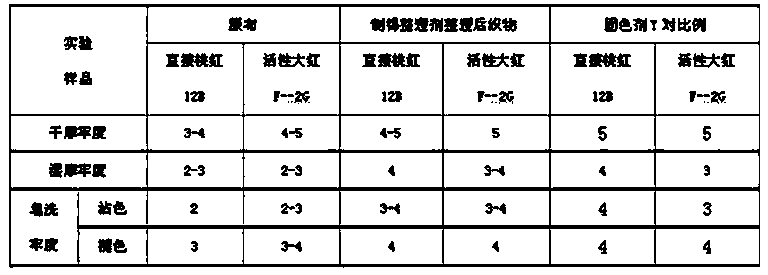

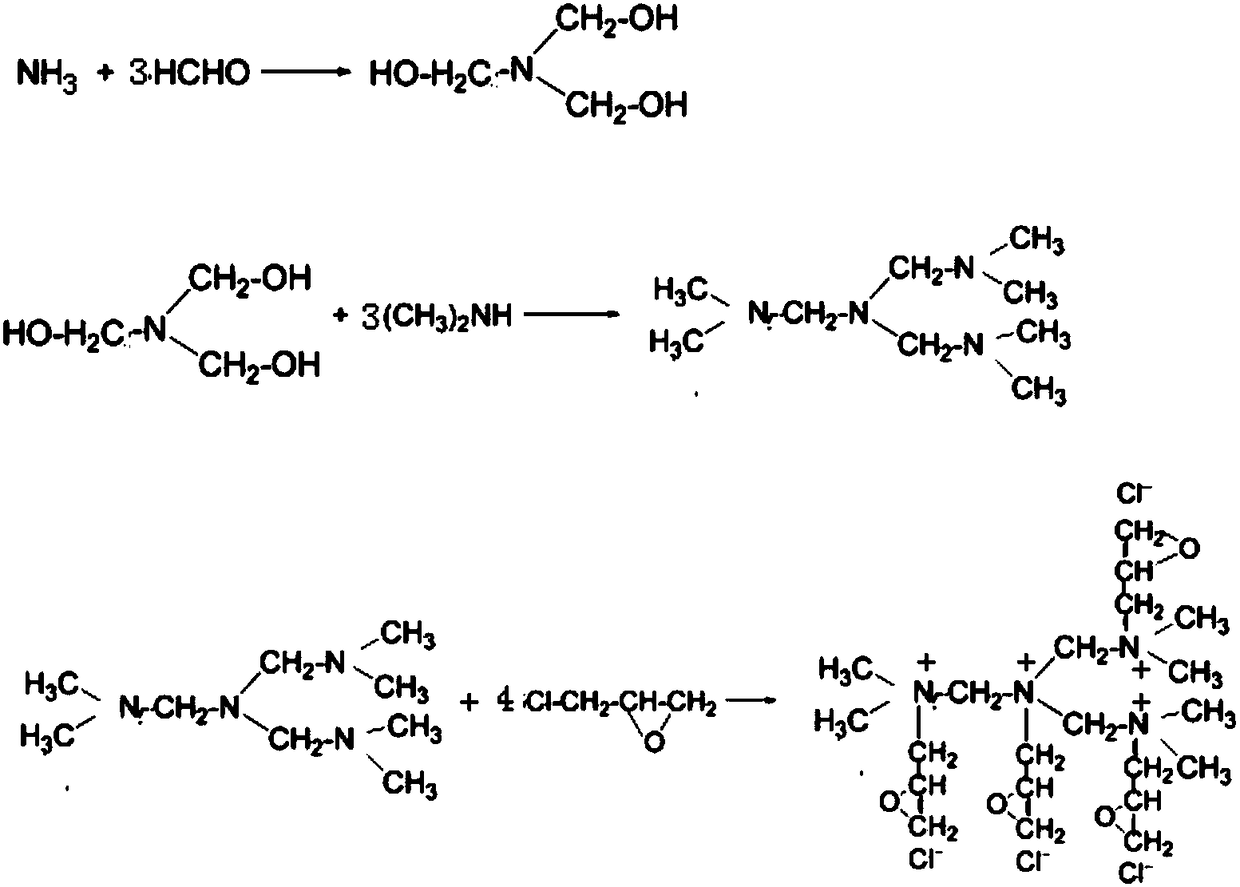

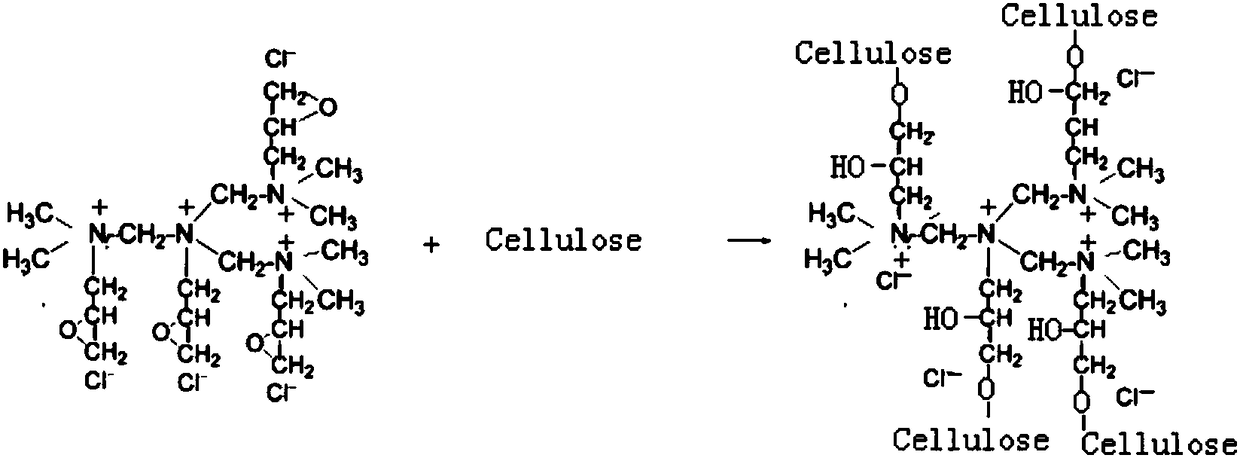

Novel cationic modifier, preparation method thereof, and cotton fiber using modifier

InactiveCN108385415AImprove dyeing effectImprove modification efficiencyOrganic chemistryDyeing processFiberFORMALDEHYDE SOLUTION

The invention relates to the fields of textile chemistry and dyeing and finishing engineering, and especially relates to a novel cationic modifier, a preparation method thereof, and a cotton fiber using the modifier. The modifier comprises, by volume, 100 parts of water, 5 parts of ammonia water with the mass concentration being 25%, 15 parts of an aqueous formaldehyde solution with the mass concentration being 40%, 27 parts of an aqueous dimethylamine solution with the mass concentration being 33%, 21 parts of epichlorohydrin and an aqueous solution of ammonium aminotrimethylene tris(N,N-dimethyl)tetrakis(2,3-epoxypropyl)chloride (XF) prepared through adding 0.5 g of tetrabutylammonium bromide as a phase transfer catalyst into per 100 ml of the water. The modifier can realize multi-time flame retardation, and endows the cotton fiber with a good dyeing property.

Owner:江苏泗水纺织有限公司

Environment protection acidic color fixing agent and manufacture method thereof

InactiveCN101245563BRaw material environmental protectionWill not affect healthDyeing processHazardous substanceSolvent

The invention relates to an effective environment protective acid fixing agent that is prepared by a polypropylene acid fixing agent, an addition agent and a solvent which are matched. The polypropylene acid fixing agent is prepared by the following steps: mixing isopropanol, methacrylic acid, 2-acrylamido-2-methylpropane sulfoacid, acrylic acid and sodium persulfate in deionized water to be reacted for 1 to 5 hours at 80 to 90 DEG C and acquiring a reaction product, namely, the polypropylene acid fixing agent by post treatment. The preparation method of the effective environment protective acid fixing agent includes: adding proper water, adding all the materials under the condition of stirring at 40 to 50 DEG C in sequence to be mixed for 2 to 3 hours, uniformly dissolving, filtering, discharging and controlling the pH to be 6 to 7. The materials of the invention are environment-protective, can reduce the treatment cost of waste water and can generate remarkable social and economic benefits.

Owner:杭州下沙恒升化工有限公司

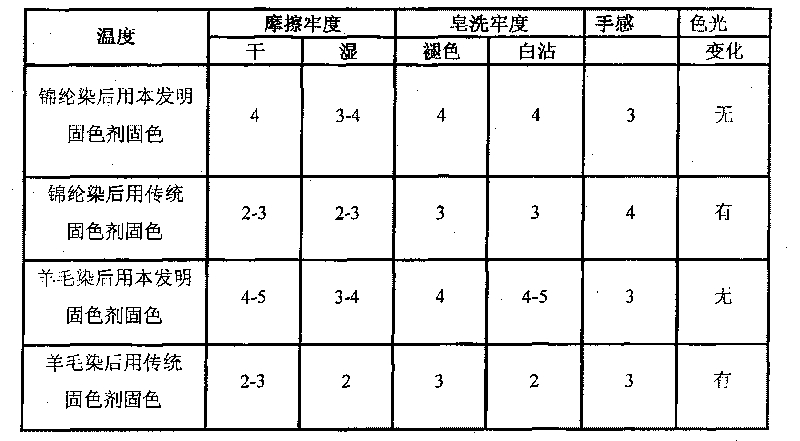

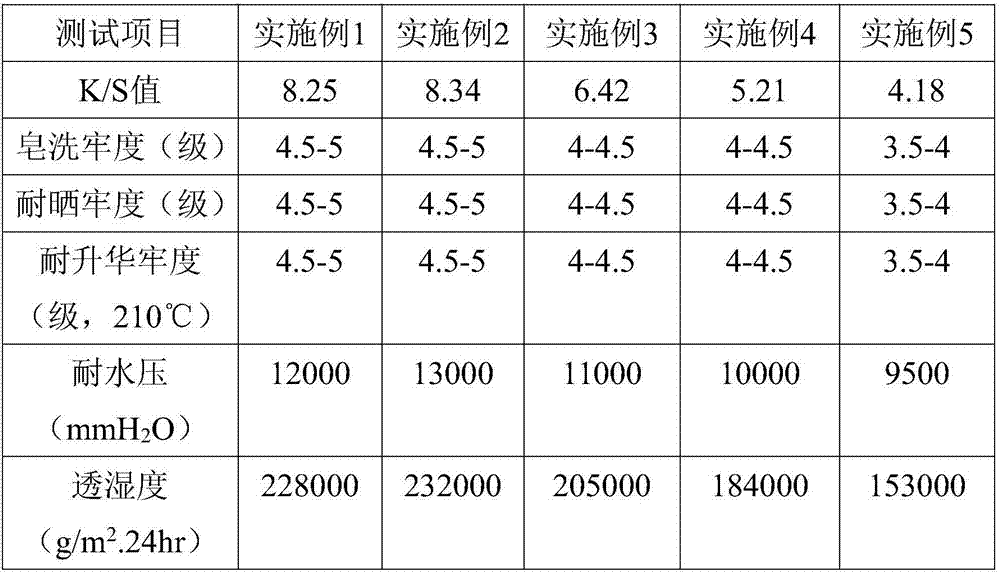

Coloring agent for outer layer nylon fabrics of outdoor sport functional garments

InactiveCN106894243AMeet dyeing requirementsImprove the safety of useDyeing processPolyvinyl alcoholPolyvinyl chloride

The invention discloses a coloring agent for outer layer nylon fabrics of outdoor sport functional garments, and relates to the technical field of functional garment materials. The coloring agent is prepared from the following raw materials in parts by weight: 10 to 15 parts of polyvinyl alcohol resin, 5 to 10 parts of polyoxyethylene, 4 to 8 parts of terpene resin, 4 to 8 parts of polyvinyl chloride paste resin, 3 to 6 parts of an organic dyestuff, 3 to 6 parts of crospovidone, 2 to 4 parts of polytetrafluoroethylene, 2 to 4 p arts of poloxamer, 2 to 4 parts of nano talcum powder, 1 to 2 parts of hydrogenated castor oil, 1 to 2 parts of laurinol polyoxyethylene ether, 1 to 2 parts of epoxidized soybean oil, 0.5 to 1 part of cationic polyacrylamide, 0.5 to 1 part of poly-dimethyl diallyl ammonium chloride, 0.5 to 1 part of dicyclohexyl carbodiimide and 80 to 100 parts of water. The coloring agent disclosed by the invention is easy to color, and is high in soaping fastness, sun-proof fastness and sublimation fastness; the phenomenon of color fading cannot appear in the using process; the coloring agent has excellent waterproof and breathable performance.

Owner:罗碧贤

Cotton warp and polyester weft fabric and processing technology thereof

InactiveCN108754747AThe texture of the cloth surface is clear and crispBeautiful colorSingeingHeating/cooling textile fabricsTextile printerPolyester

The invention belongs to the technical field of textile printing and dyeing, and particularly relates to a cotton warp and polyester weft fabric and a processing technology thereof. A cotton warp andpolyester weft gray fabric is sequentially subjected to singeing, desizing and boiling-off, dry shaping, oxygen bleaching, mercerizing, rolling-drying and dyeing, dyeing and baking, reduction, continuous dyeing and fixation, tentering and softening, and pre-shrinking to obtain the cotton warp and polyester weft fabric. An oxygen bleaching solution comprises NaOH, H2O2, a refining agent EPD-C, a chelating agent SQ-A, a stabilizer OUR-266 and water. The oxygen blenching solution is added into a rolling tank for padding of the cotton warp and polyester weft blended fabric, the liquid carrying rate is controlled to be 55-65%, then the temperature is increased to 98-100 DEG C, and steaming, washing and drying are carried out. The fabric has the advantages that lines of the fabric surface are clear, the color is bright, the fabric is resistant to washing, good in hand feeling and good in water absorption performance, and the soaping fastness reaches the 4th level or above. The invention alsoprovides the processing technology. The production mode is continuous, continuous production of large goods can be realized, and the efficiency is high.

Owner:鲁丰织染有限公司

A kind of salt-free dyeing method of calcium alginate fiber

ActiveCN103981744BImprove soaping fastnessGood level dyeingFibre treatmentDyeing processFiberSalt free

The invention discloses a salt-free dyeing method for calcium alginate fiber, and belongs to the technical field of textile science. According to the method, an aqueous aluminum sulfate solution is adopted to pretreat the calcium alginate fiber to be dyed, then a direct dye is adopted to perform salt-free dyeing, and finally an aqueous calcium chloride solution is adopted to perform fixation. When the method is adopted for dyeing of the calcium alginate fiber, the dye-uptake rate of the dye to the fiber is not less than 90%, the levelling property and the permeability property of the fiber are excellent, and the soaping fastness is not less than the fourth level. The method avoids the use of table salt, acids, alkalis, and other chemical agents, and has characteristics of low cost, less damage to the mechanical properties of the calcium alginate fiber, not more than 10% of the strength loss of the dyed fiber, eco-environment protection, rapid and convenient treatment, recovery and reutilization for dyeing waste water, and zero release.

Owner:QINGDAO TIANYI GROUP

Pure-cotton double-layer jacquard home textile dyeing and finishing method

InactiveCN108130754ASimple production processIncrease lifting powerDyeing processTextile dyeingSulfone

The invention discloses a pure-cotton double-layer jacquard home textile dyeing and finishing method, and belongs to the technical field of pure-cotton fabric dyeing. The method is characterized by comprising the following preparation steps: with a dyeing liquid formula, namely an active dye with two active groups of ethylene sulfuryl and hydroxyl ethylene sulfone sulfate in a main liquid, putting20-50% in percentage by mass of a dye liquid into a dyeing tank, and performing dyeing once; adding the rest dyeing liquid, and performing dyeing once again; adding sodium sulfate, and performing dyeing once; adding alkali powder, and performing dyeing once; adding a soaping agent SN-45, increasing the temperature, and performing dyeing for three times; washing with cold water, adding a neutralization acid, and performing dyeing for three times; performing acid pickling, and discharging a fabric roll. The inventor improves a cotton double-layer jacquard fabric dyeing process, and together with the selected active dye with two active groups of ethylene sulfuryl and hydroxyl ethylene sulfone sulfate in the main liquid, factors such as the soaping fastness, the lifting power of the dye, thedyeing velocity and the curve of the dye, the matching property of the dye, and the like are improved.

Owner:ZIBO DARANFANG SILK GRP

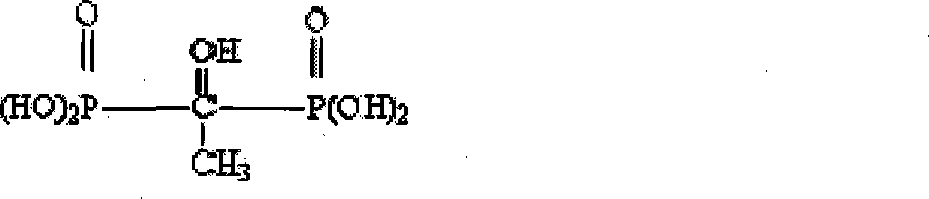

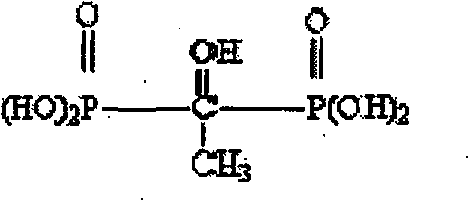

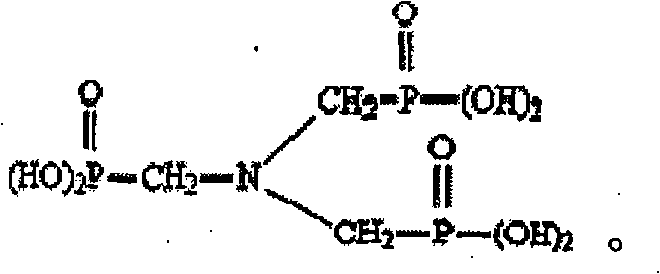

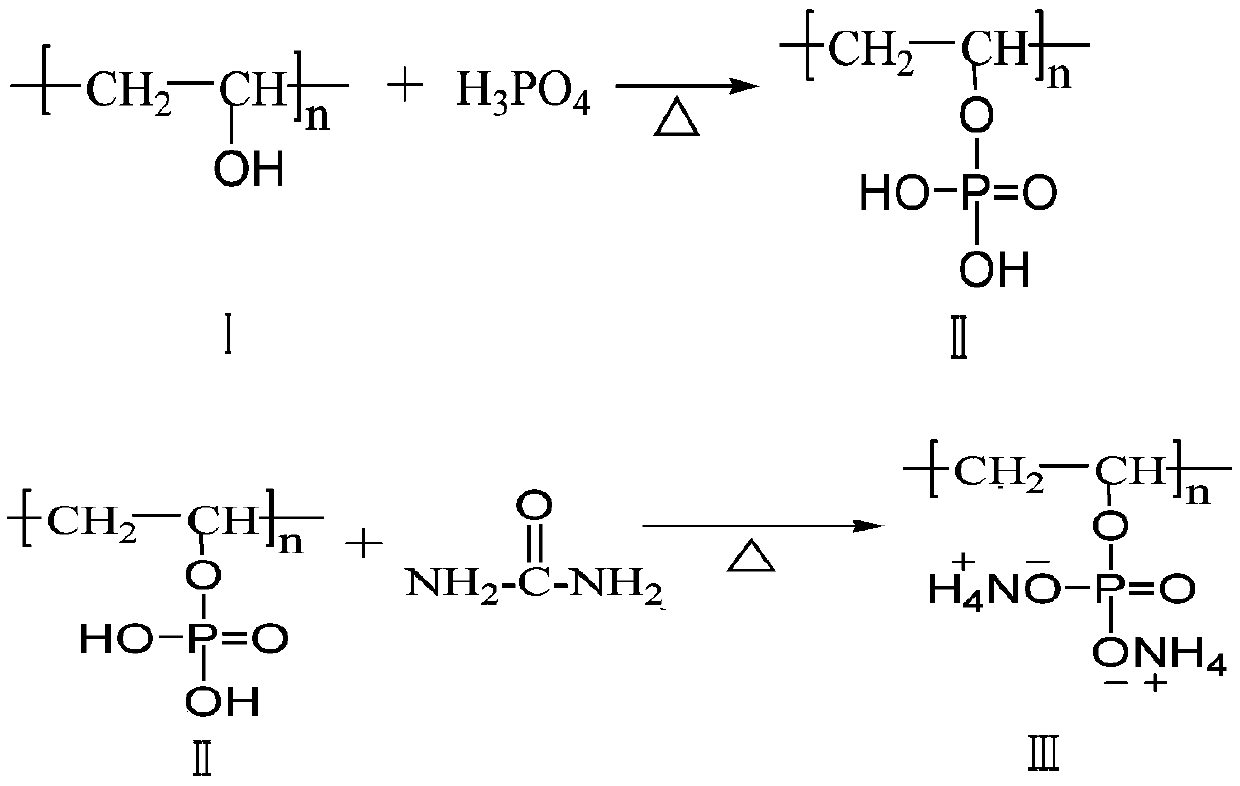

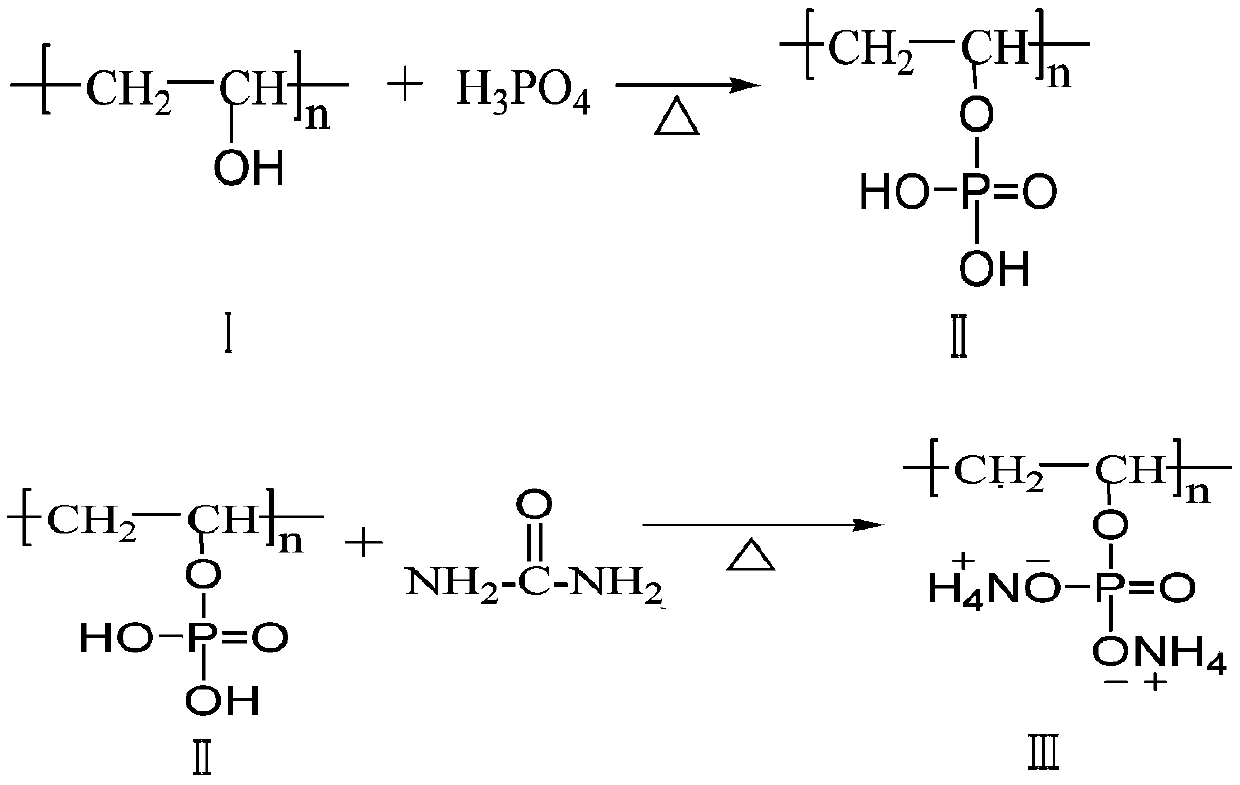

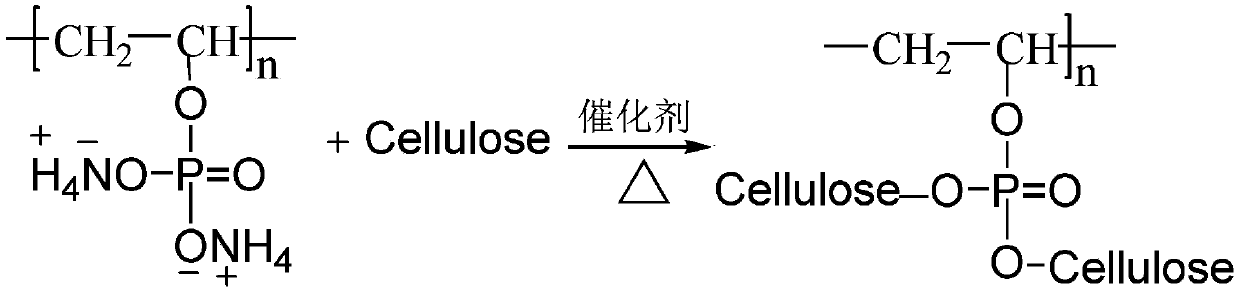

Synthetic method and application of macromolecular activated flame retardant

InactiveCN110283263AImprove soaping fastnessDurableHeat resistant fibresVegetal fibresAlcoholSynthesis methods

The invention discloses synthetic method and application of a macromolecular activated flame retardant. The synthesis method comprises the following steps: heating and dissolving polyvinyl alcohol to prepare a solution with the concentration of 12%, placing the solution in a beaker, adding phosphoric acid, and heating on an electric furnace equipped with a mechanical stirring device to prepare polyvinyl alcohol phosphonate (II); then adding water and urea, and continuing to heat to obtain thick liquid with the pH of 5 to 6, that is, the activated flame retardant ammonium alcohol polyvinyl phosphonate (III). The application of the flame retardant is characterized in that the prepared flame retardant and cotton fabrics are subjected to a grafting reaction under the action of a catalyst dicyandiamide. According to the isynthetic method and application of the macromolecular activated flame retardant, the formaldehyde-free property, durability, and flame retardance of the cotton fabrics are realized, the finished cotton fabrics have durability, and no formaldehyde is released during use.

Owner:张光先

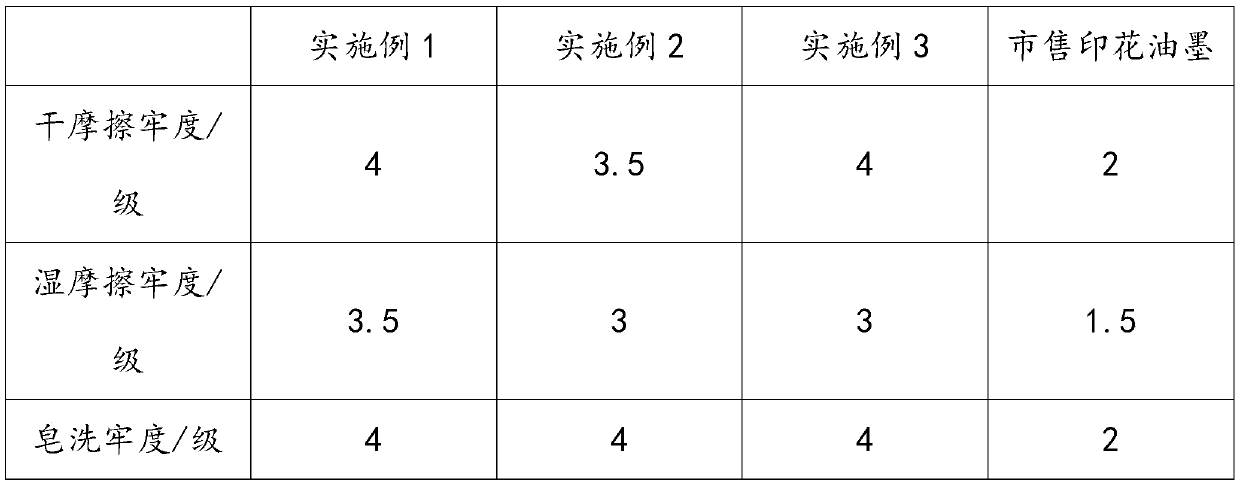

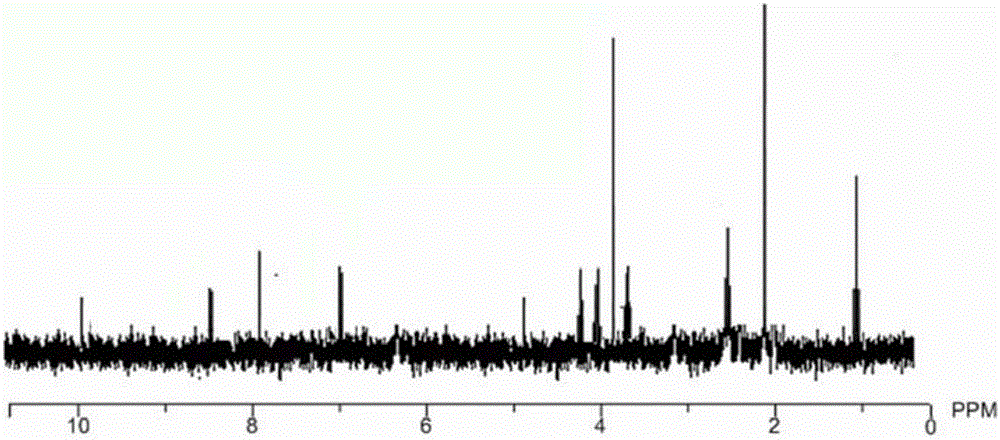

Environmentally-friendly textile printing ink and preparation method thereof

PendingCN109988456AImprove drying rateImprove water resistanceInksDyeing processTextile printerPrinting ink

The invention discloses environmentally-friendly textile printing ink. The ink is prepared from the following raw materials, in parts by weight: 26-32 parts of a polyurethane binding material, 38-44 parts of alcohol-soluble color paste, 2-3 parts of an antibacterial agent, 20-30 parts of a solvent, 10-12 parts of a plasticizer, 1-2 parts of a stabilizer, and 4-6 parts of a rheological auxiliary agent. The invention also discloses a preparation method of the environmentally-friendly textile printing ink. According to the method provided by the invention, polyurethane is used as the binding material of the ink, a compound of ethanol, ethyl acetate and water is used as a solvent of the ink, the antibacterial agent is added into the ink, so that the obtained printing ink is energy-saving and environmentally friendly, has less pollution to the air, and meets modern environmentally-friendly requirements; the antibacterial agent is added, so that the ink has good antibacterial properties; through micro-amount assisted cooperation of auxiliary agents such as the plasticizer and the stabilizer, the mechanical properties and thermal stability of the ink coating can be improved; and the obtained environmentally-friendly textile printing ink has good stability, no color difference, good drying performance and antibacterial activity.

Owner:新昌县丙辰储能科技有限公司

Disperse dye, and preparation method and application thereof

InactiveCN106084874AGood water solubilityLow affinityMonoazo dyesDyeing processDisperse dyeStructural formula

The invention discloses a fluorine-containing disperse dye with high washing fastness, and a preparation method and an application thereof. The structural formula of the disperse dye is shown in the description. The disperse dye contains a hydroxyl group, an ester group and a long molecular chain, has high affinity with fibers, and difficultly migrates to the surface of the fibers, so the disperse dye has high color fastness, can be applied to one-bath two-step process dyeing of polyester cotton, and reduces the process flow; or the disperse dye can be used in polyester / polyurethane elastic fabrics, terylene ultrafine fiber fabrics and terylene fabrics with special after-finishing demands to improve the washing fastness of the fabrics.

Owner:SHAOXING UNIVERSITY

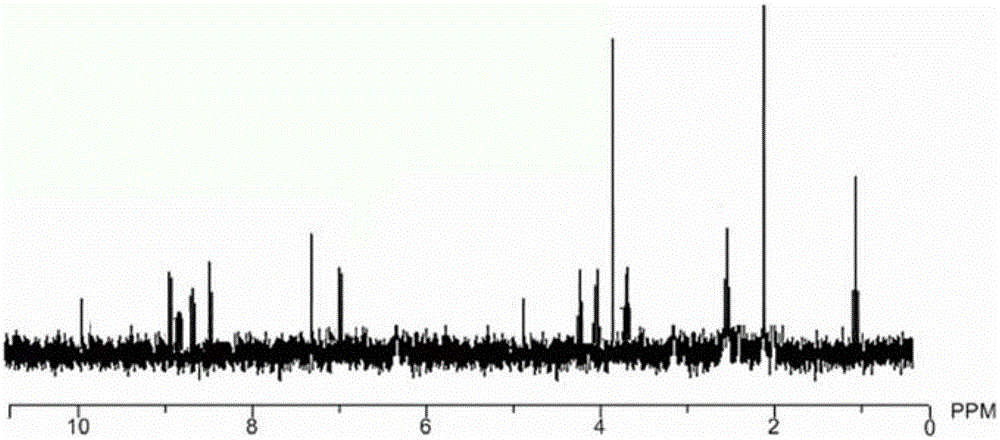

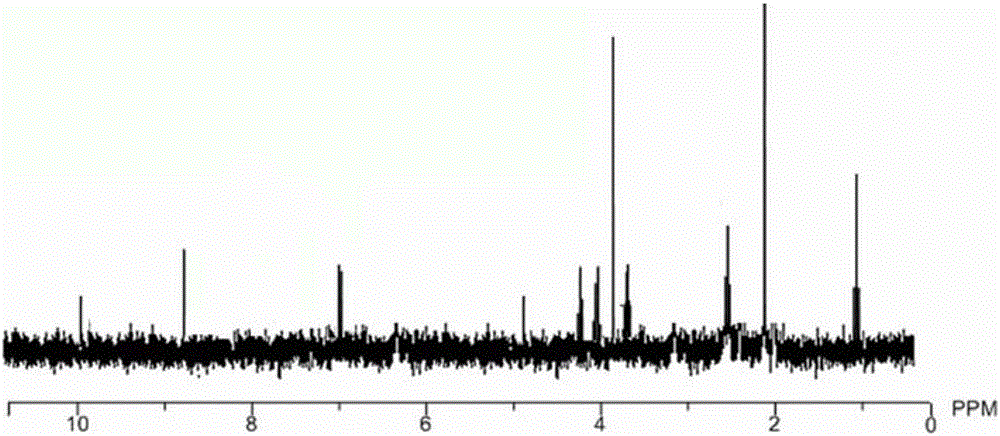

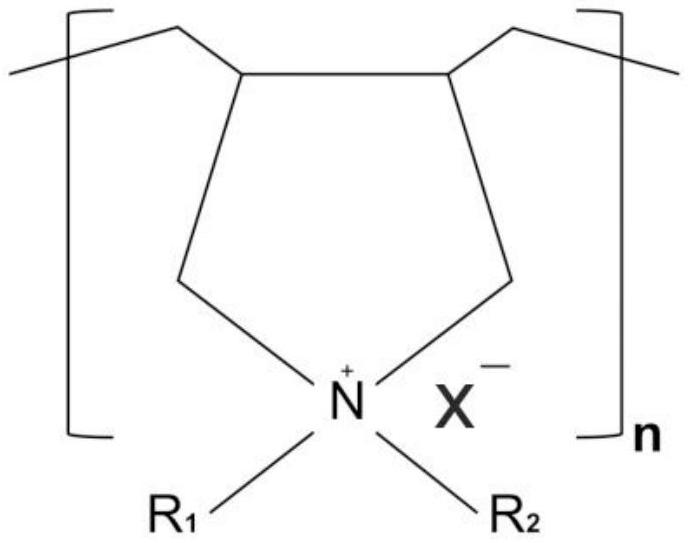

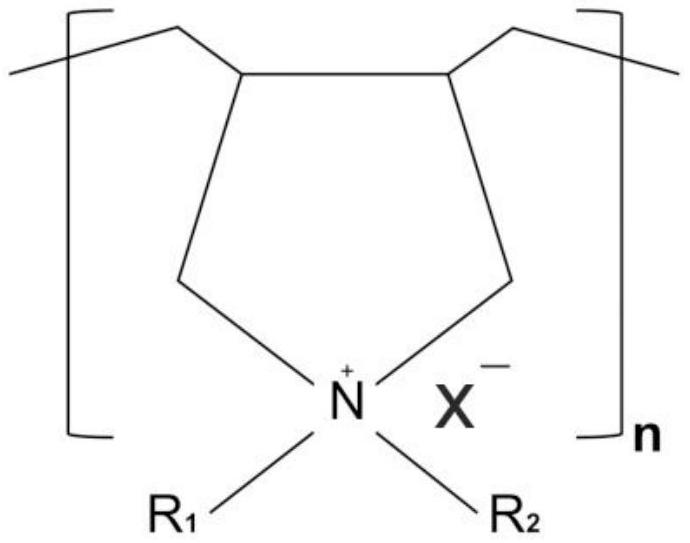

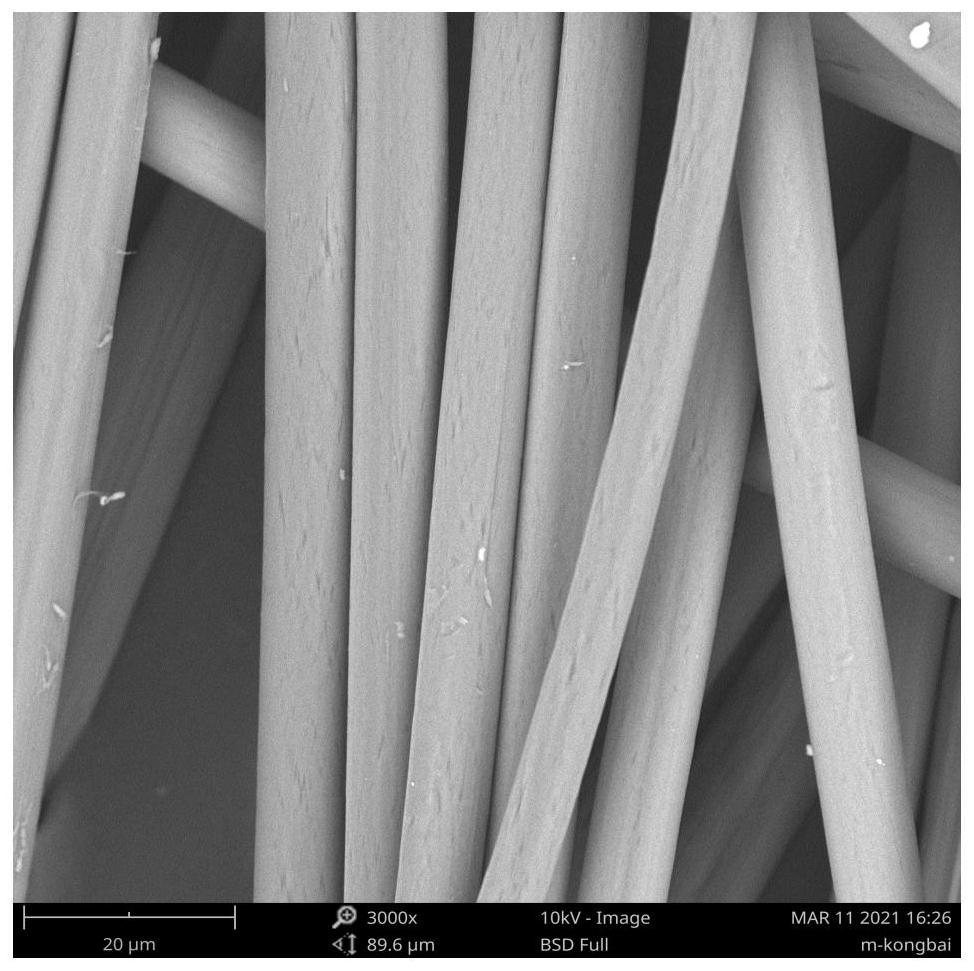

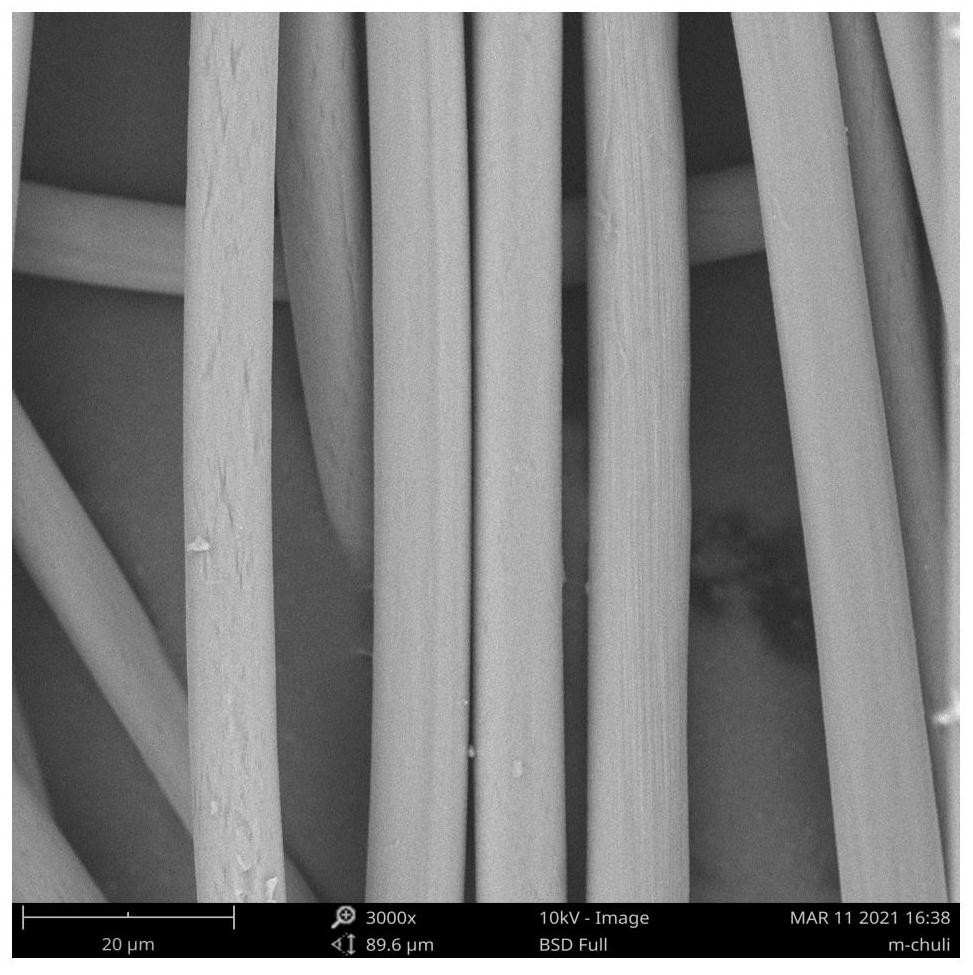

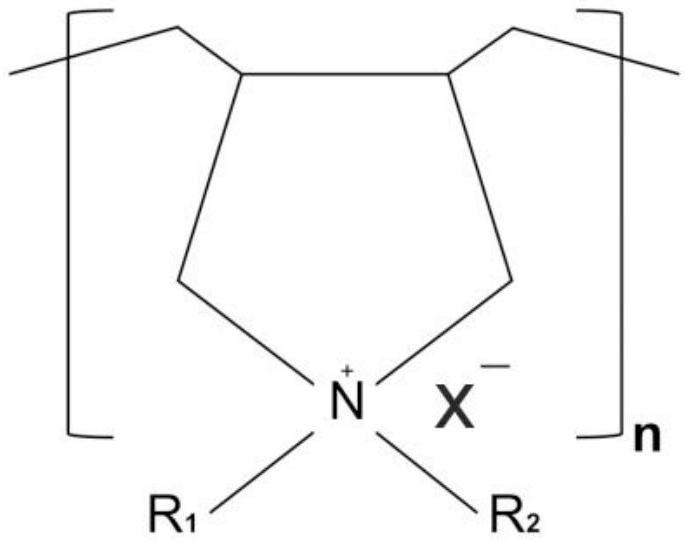

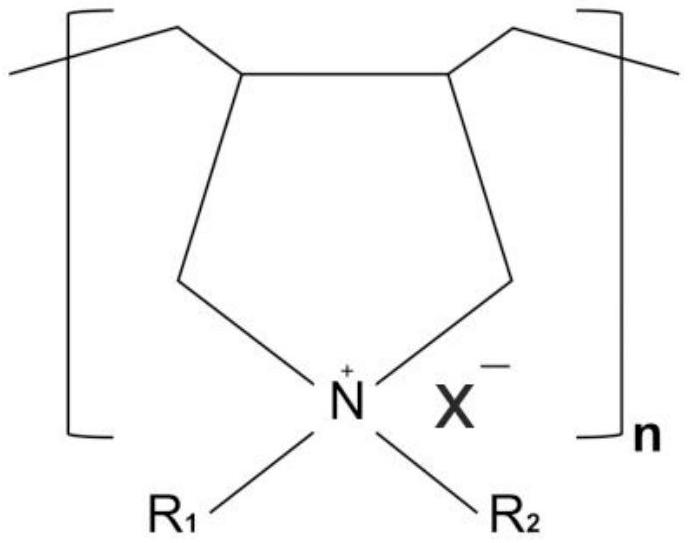

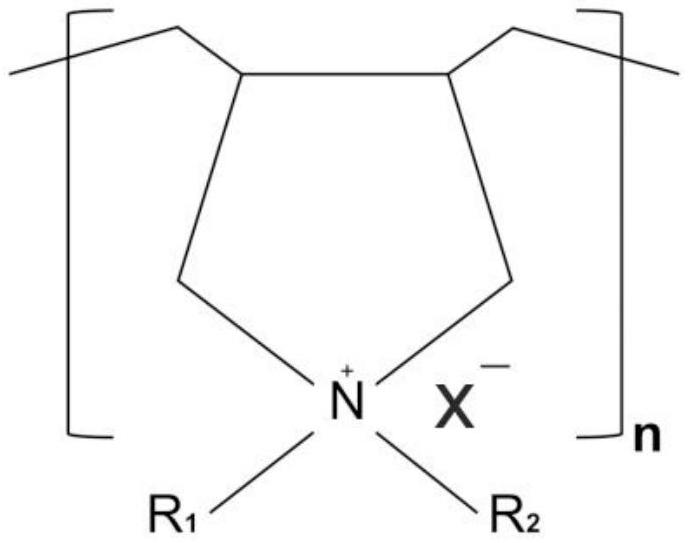

Alginate fiber blended fabric and dyeing method thereof

The invention discloses an alginate fiber blended fabric and a dyeing method thereof, and belongs to the technical field of textile fabric dyeing. The dyeing method of the alginate fiber blended fabric comprises the following steps of S10, pretreating the alginate fiber blended fabric with a five-membered cyclic quaternary ammonium salt polymer; and S20, dyeing the alginate fiber blended fabric obtained in the step S10 by using a dye. The alginate fiber blended fabric obtained through the method is relatively high in dye-uptake rate, low in alginate fiber loss rate, relatively excellent in leveling property and dye permeability and relatively high in soaping fastness.

Owner:QINGDAO UNIV

Alginate fiber and preparation method thereof

ActiveCN113249823AReduce loss rateImprove soaping fastnessAlginate artificial filamentsDyeing processPolymer scienceSpinning

The invention discloses alginate fiber and a preparation method thereof, and belongs to the technical field of textile fabric dyeing. The preparation method of the alginate fiber comprises the following steps of S10, preparing a spinning solution from a raw material containing sodium alginate; S20, extruding the spinning solution obtained in the step S10 into a coagulating bath for coagulating and forming, so that primary fiber is obtained; S30, drafting and washing the primary fiber obtained in the step S20 to obtain the alginate fiber; and S40, immersing the alginate fiber obtained in the step S30 into a treating agent, and carrying out post-treatment, wherein at least one or all of the raw material in the step S10, the coagulating bath in the step S20 and the treating agent in the step S30 comprises or comprise a five-membered ring quaternary ammonium salt polymer. The alginate fiber obtained through the method is relatively high in dye-uptake rate, small in fiber strength damage and relatively high in soaping fastness.

Owner:QINGDAO UNIV

Alginate fiber and dyeing method thereof

PendingCN113249986AReduce loss rateImprove soaping fastnessDyeing processPolymer sciencePolymer chemistry

The invention discloses alginate fiber and a dyeing method thereof, and belongs to the technical field of textile fabric dyeing. The dyeing method of the alginate fiber comprises the following steps of S10, pretreating the alginate fiber by adopting a five-membered ring quaternary ammonium salt polymer; S20, dyeing the alginate fiber obtained in the step S10 by adopting a dye; and S30, carrying out color fixation treatment on the alginate fiber obtained in the step S20 by adopting the five-membered ring quaternary ammonium salt polymer. The alginate fiber obtained through the method is relatively high in dye-uptake rate, small in fiber strength damage and relatively high in soaping fastness.

Owner:QINGDAO UNIV

Coloring agent for garment plus material and preparation method thereof

InactiveCN108385414AGood colorImprove the safety of useDyeing processCarboxymethyl cellulosePolymer science

The invention provides a coloring agent for a garment plus material and a preparation method thereof. The coloring agent is prepared from the following components: polyvinyl alcohol resin, ethyl acetate, dibutyl phthalate, terpene resin, polytetrafluoroethylene, sodium pyrophosphate, carboxymethyl cellulose, initiator, powder, surfactant and deionized water. The coloring agent prepared by the preparation method is easy in coloring and high in soaping fastness, fastness to light and fastness to sublimation, cannot generate a fading phenomenon in a use process, and moreover, has excellent waterproofness and permeability.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com