Novel cationic modifier, preparation method thereof, and cotton fiber using modifier

A cationic modifier and cotton fiber technology, which is applied in the fields of textile chemistry and dyeing and finishing engineering, can solve the problems of unsatisfactory dye uptake rate, inability to dye dark colors, poor dyeing effect of dark colors, etc., and achieve high soaping Effects of high fastness, high dye uptake rate and high graft fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

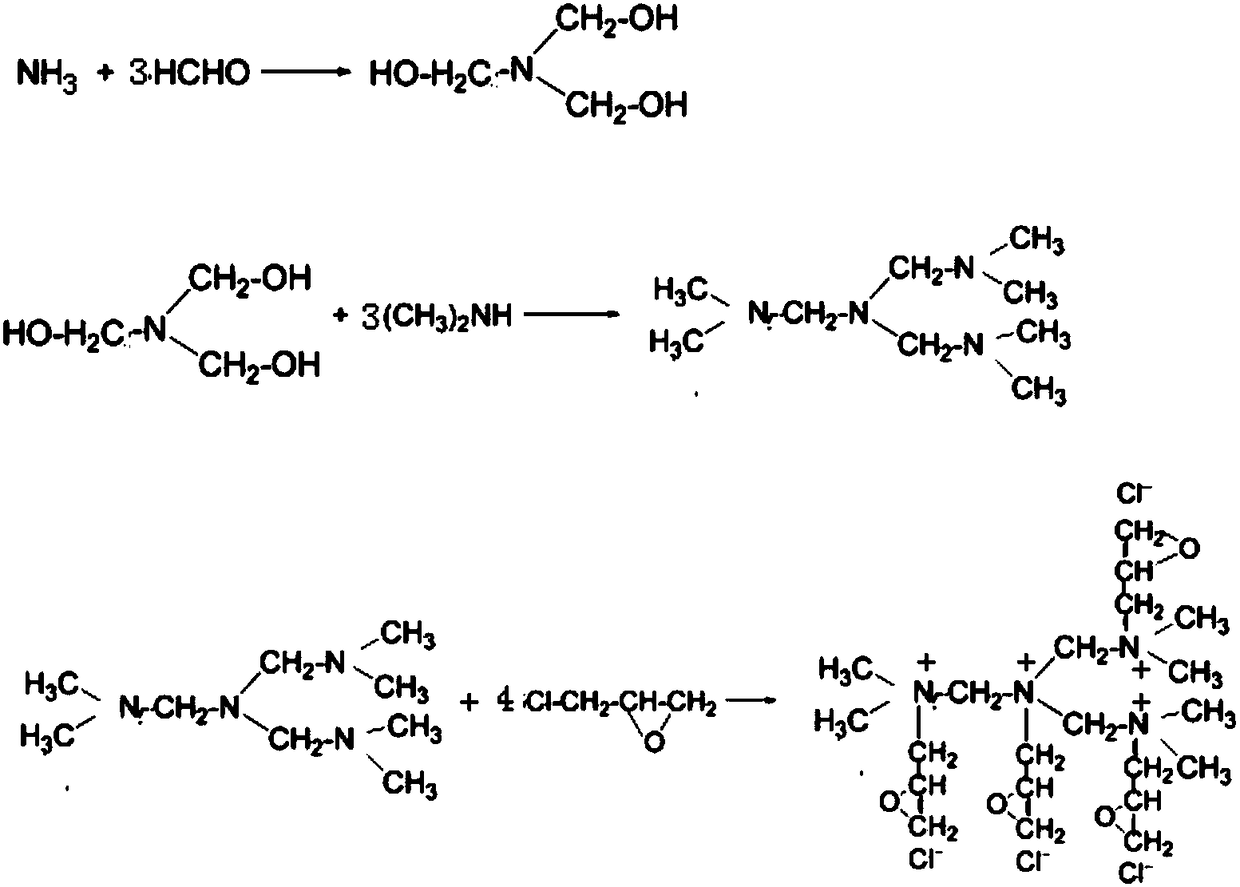

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: successively add water 200ml, 10ml mass concentration 25% ammoniacal liquor, 30ml mass concentration in the round bottom flask of 1000ml (any container all can, here just enumerates), and 30ml mass concentration is the formaldehyde aqueous solution of 40%, be placed in 30 In a constant temperature water bath at ℃, stir mechanically for 30 minutes; then add 54ml of dimethylamine aqueous solution with a mass concentration of 33% and react for 1h; then raise the temperature to 45℃, add 42ml of epichlorohydrin and 1g of tetrabutylammonium bromide as a phase transfer Catalyst, reacted for 1.5h to obtain an aqueous solution of amine trimethylene tris(N,N dimethyl)tetrakis(2,3 epoxypropyl)ammonium chloride (XF).

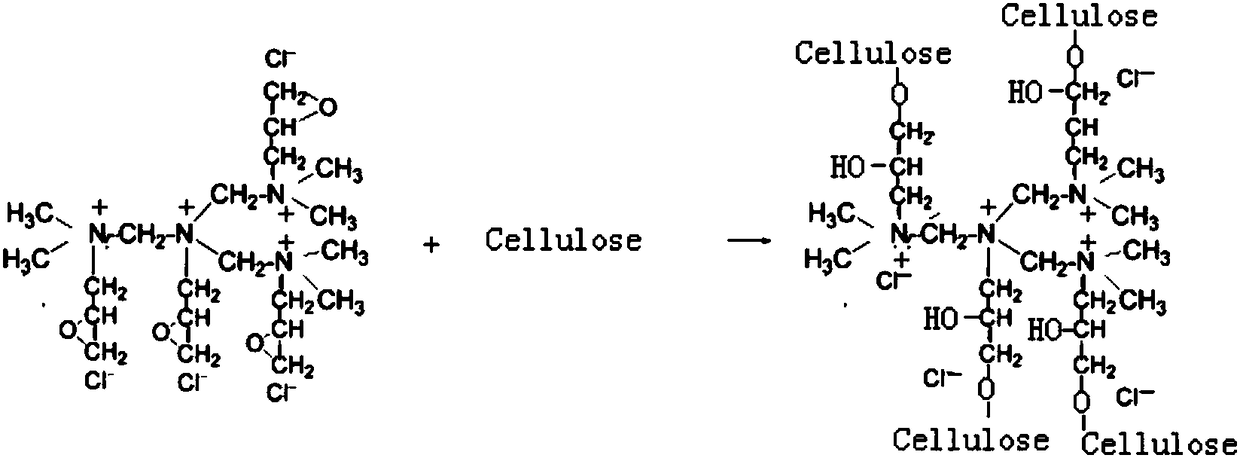

[0034] Prepare XF into an aqueous solution with a mass concentration of 5%, immerse the cotton fiber soaked in hot water into the XF solution at room temperature, the bath ratio is 1:10, soak for 10 minutes, then take out the cotton fiber and roll it in ...

Embodiment 2

[0036]Embodiment 2: in the round bottom flask of 500ml, successively add water 100ml, 5ml mass concentration 25% ammoniacal liquor, 15ml mass concentration be the formaldehyde aqueous solution of 40%, be placed in the constant temperature water bath of 30 ℃, mechanical stirring reaction 30min; Then add 27ml mass concentration of 33% aqueous solution of dimethylamine was reacted for 1h; then the temperature was raised to 45°C, 21ml of epichlorohydrin was added, and 0.5g of tetrabutylammonium bromide was used as a phase transfer catalyst, and the reaction was carried out for 1.5h to obtain the amine trimethylene tri( N,N dimethyl)tetrakis(2,3 epoxypropyl)ammonium chloride (XF) aqueous solution.

[0037] Prepare XF into an aqueous solution with a mass concentration of 6%, immerse the cotton fiber soaked in hot water in the XF solution at room temperature, with a bath ratio of 1:10, and soak for 12 minutes, then take out the cotton fiber and roll it in a padding machine. The liqui...

Embodiment 3

[0039] Example 3: In a 5000ml round bottom flask, add 1000ml of water, 50ml of ammonia with a mass concentration of 25%, and 150ml of formaldehyde solution with a mass concentration of 40%, place it in a constant temperature water bath at 30°C, and react with mechanical stirring for 35min; then add 270ml of dimethylamine aqueous solution with a mass concentration of 33% was reacted for 1h; then the temperature was raised to 45°C, 210ml of epichlorohydrin was added, and 2g of tetrabutylammonium bromide was used as a phase transfer catalyst, and the reaction was carried out for 2.0h to obtain the amine trimethylenetri(N , N dimethyl) tetrakis (2,3 epoxypropyl) ammonium chloride (XF) aqueous solution.

[0040] Prepare XF into an aqueous solution with a mass concentration of 8%, immerse the cotton fiber soaked in hot water in the XF solution at room temperature, with a bath ratio of 1:10, and soak for 12 minutes, then take out the cotton fiber and roll it in a padding machine. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com