Ultralow bath-ratio yarn dyeing machine with three-level vane pump

An impeller pump, ultra-low bath technology, applied in the direction of using small bath ratio liquid textile processing, pump, pump device, etc., can solve the problems of high amount of dye auxiliaries, waste, yarn affecting weaving effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

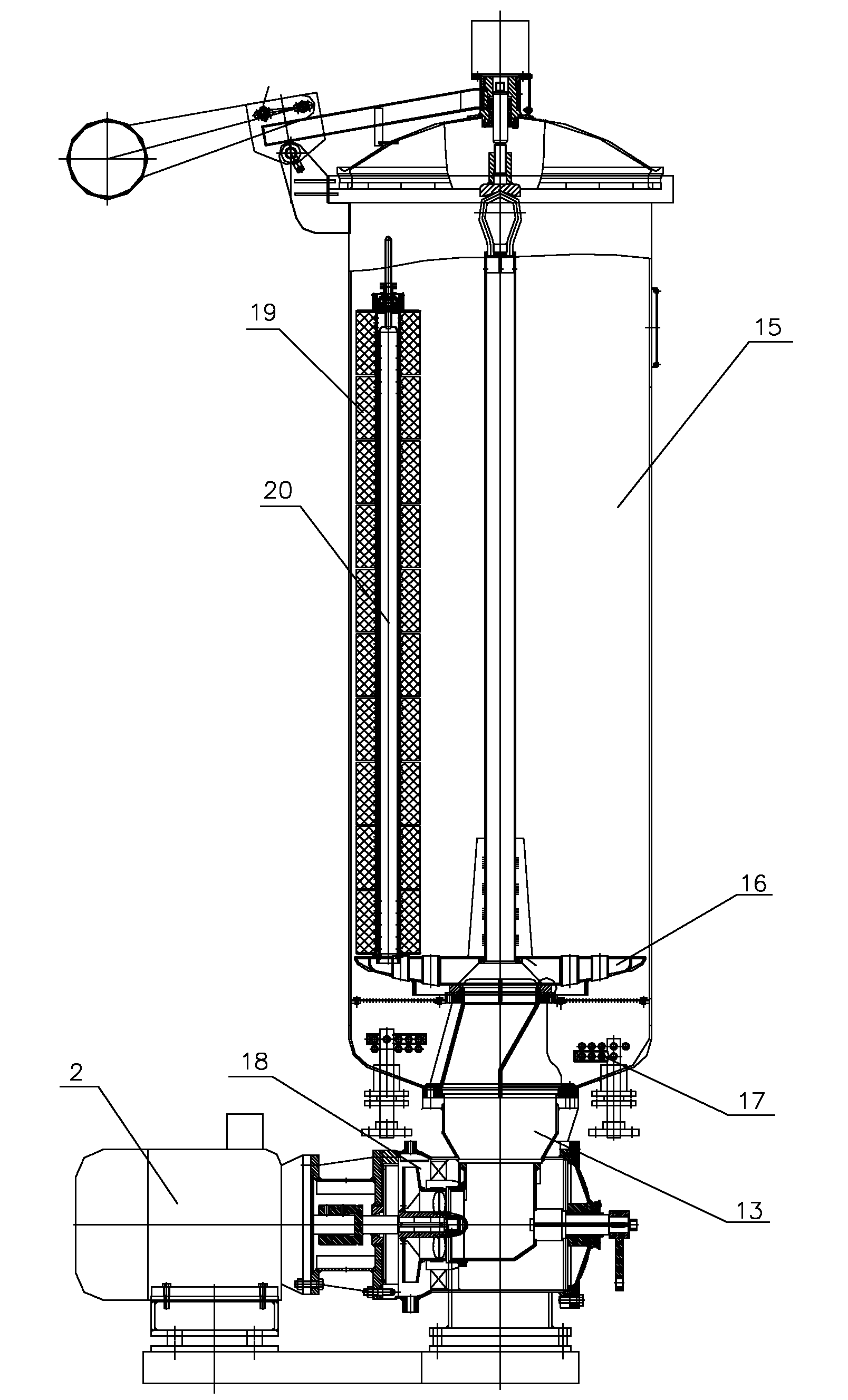

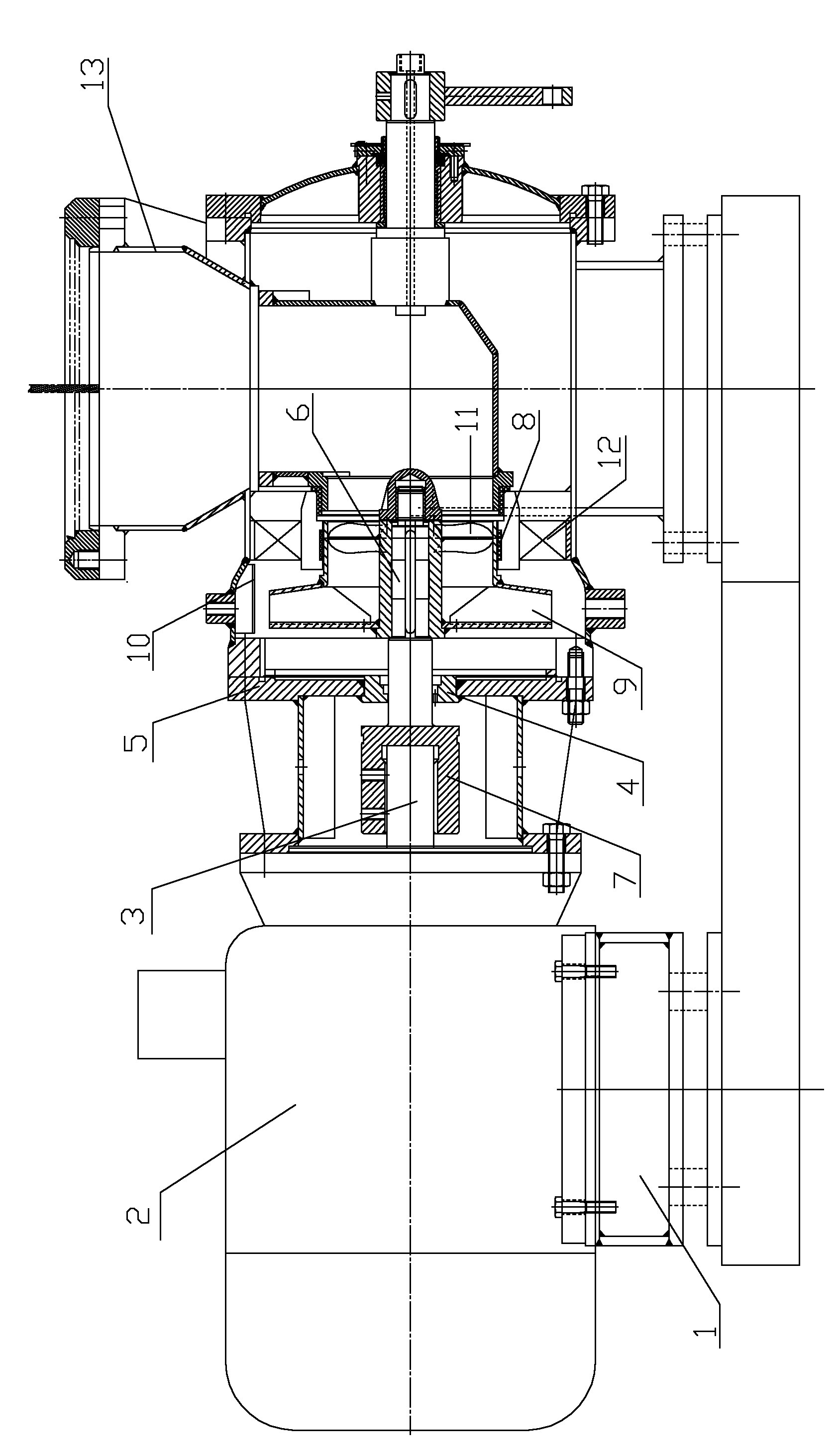

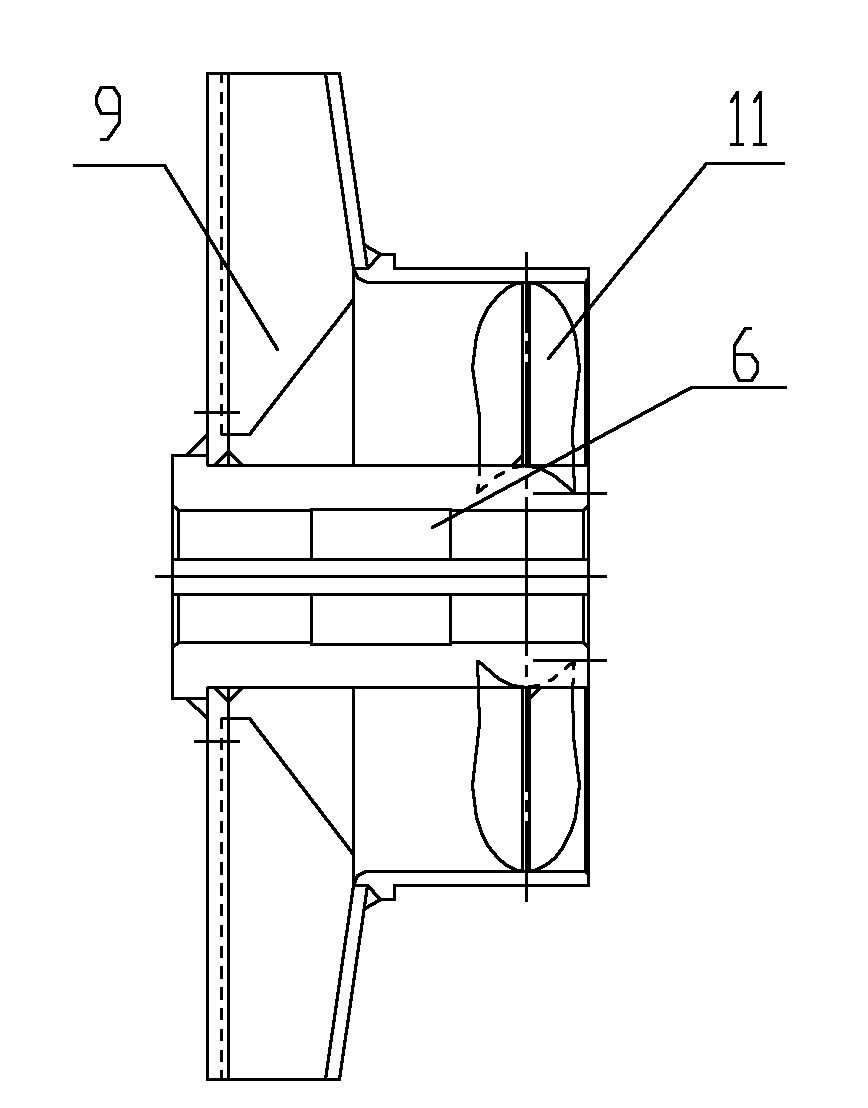

[0079] Such as figure 1 As shown, the ultra-low liquor ratio three-stage impeller pump yarn dyeing machine includes a dyeing vat 15, a creel, an impeller pump 18, and a heat exchange coil 17. The creel is fixed in the dyeing vat 15, and the yarn rod on the creel 20 is hollow, the bottom of the yarn rod 20 communicates with the dye solution output channel in the dye vat 15, the bottom of the creel 20 is the creel disc 16, and the hole on the creel disc 16 communicates with the dye solution input channel in the dye vat 15, and the impeller pump 18 is set Below the entire dye vat 15, the heat exchange coil 17 is arranged at the bottom in the dye vat, and the impeller pump 18 is a three-stage impeller pump, and its pump shaft is coaxially connected with the internal motor shaft. The inlets are connected; the three-stage impeller pump 18 sequentially includes an axial flow stage, a centrifugal stage, and a fixed guide impeller stage along the flow direction of the dye liquor. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com