Patents

Literature

42results about "Textile treatment using short bath ratio liquor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

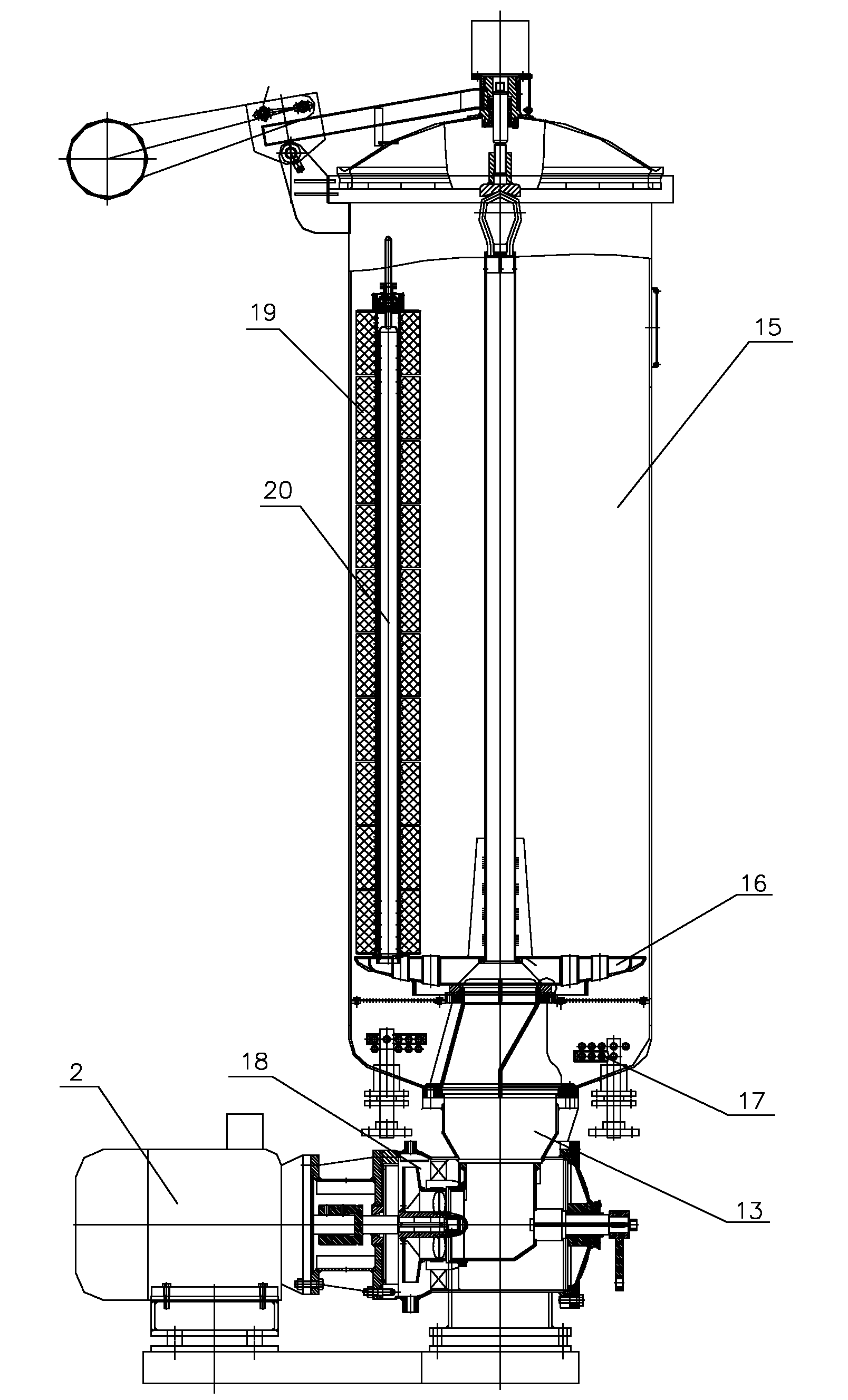

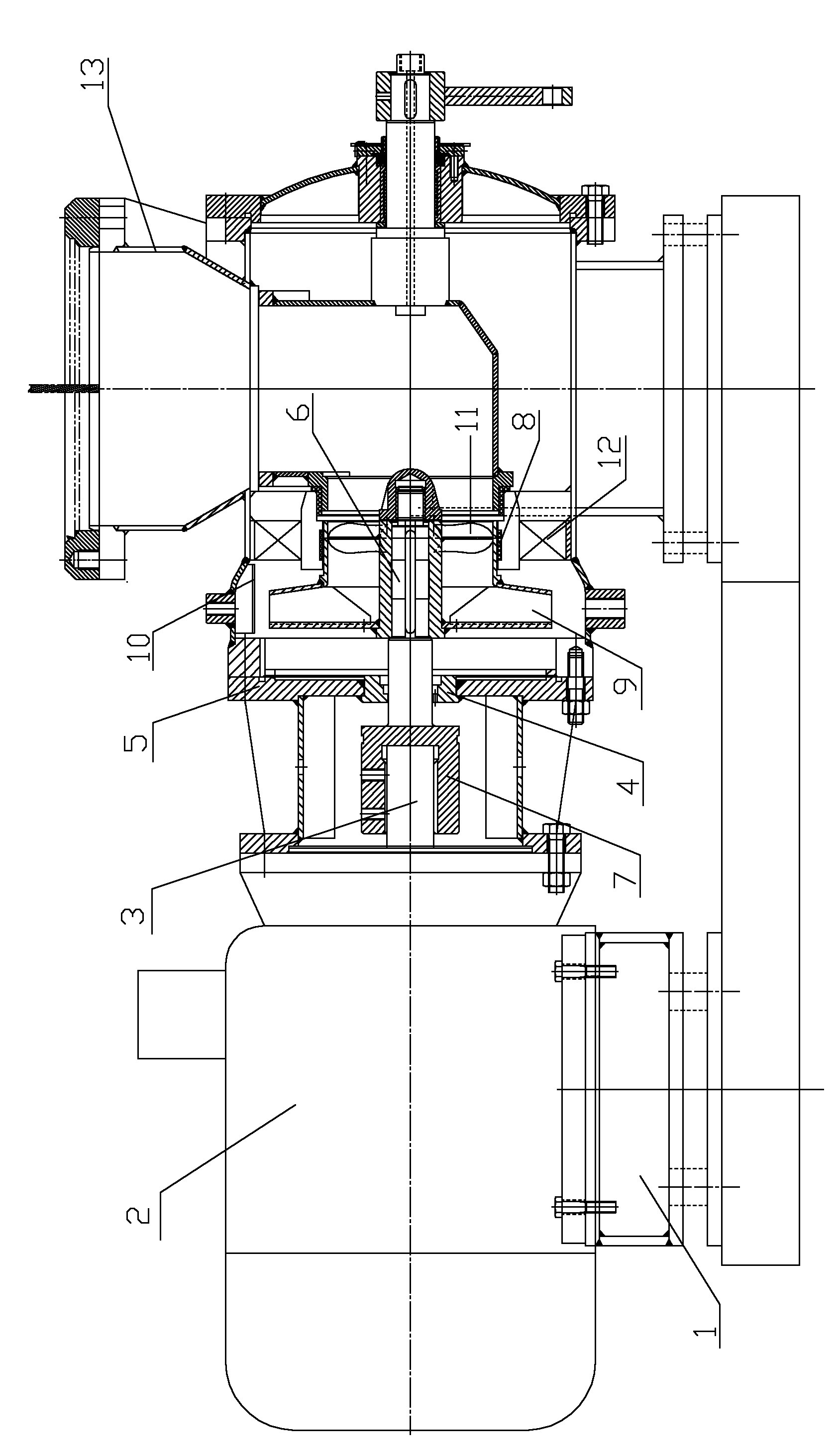

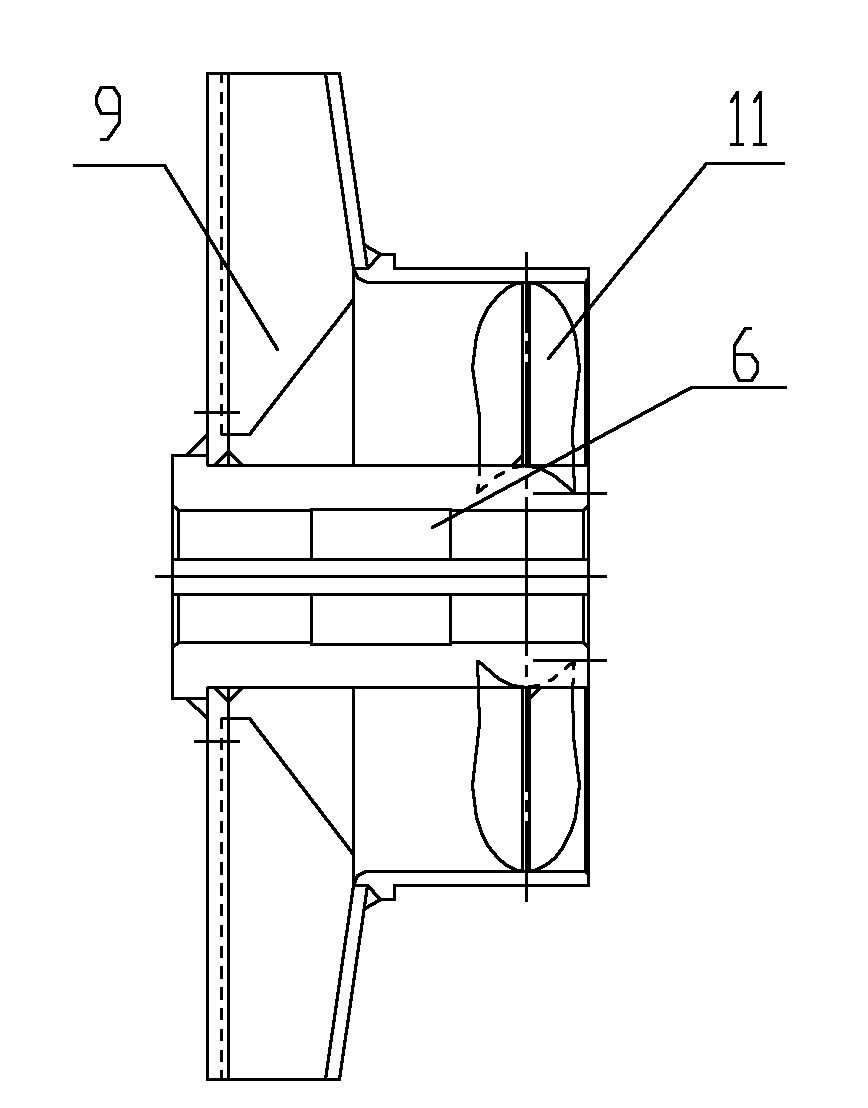

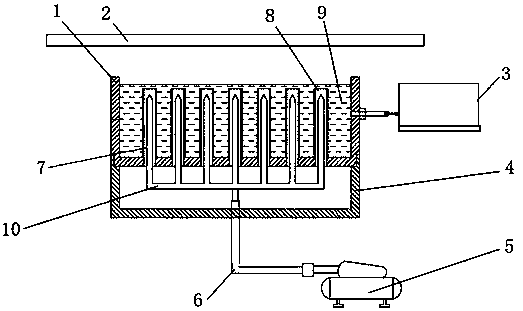

Ultralow bath-ratio yarn dyeing machine with three-level vane pump

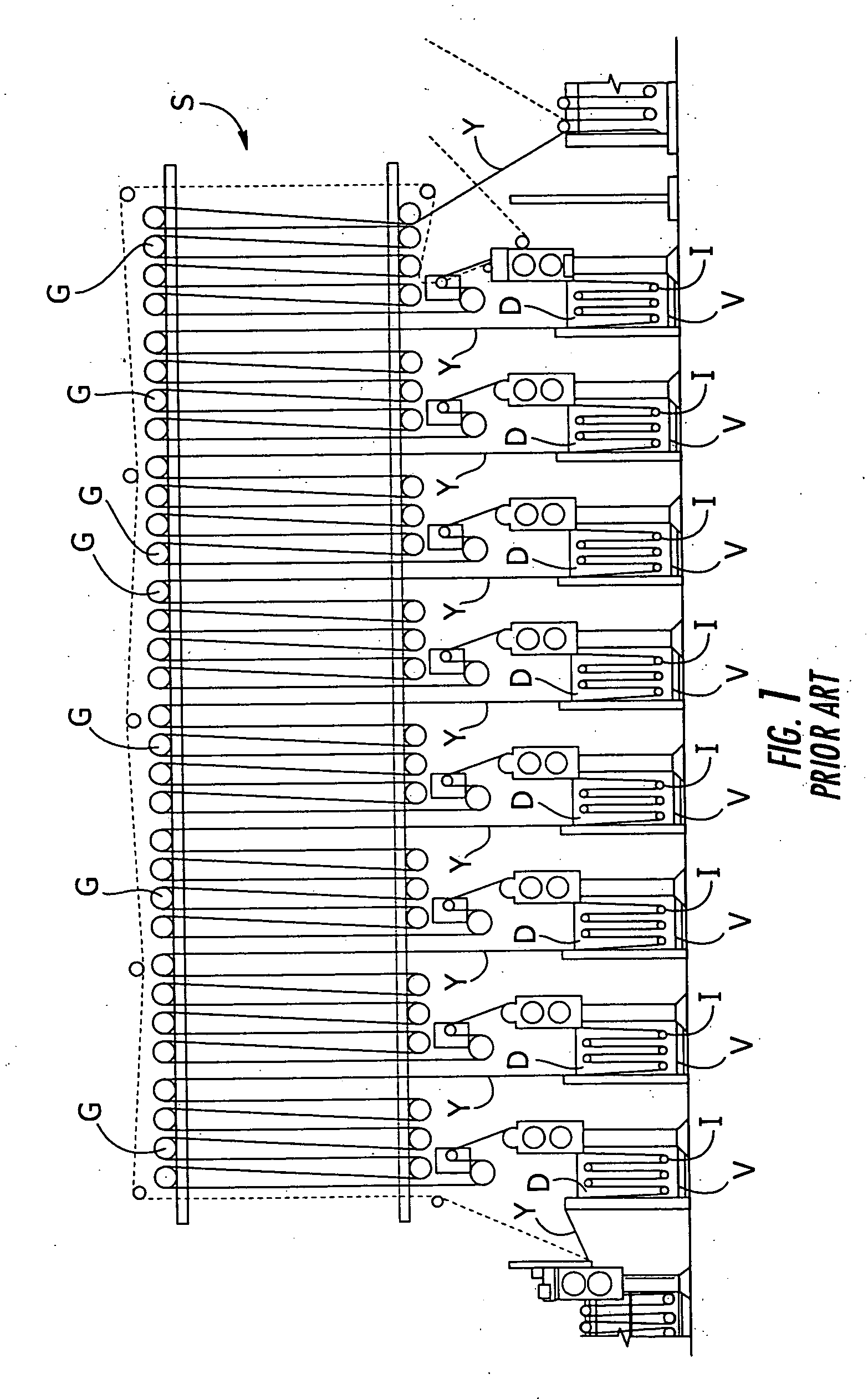

InactiveCN102134793ACycle fastAvoid layer chromatic aberrationTextile treatment using short bath ratio liquorTextile treatment machine arrangementsYarnThree level

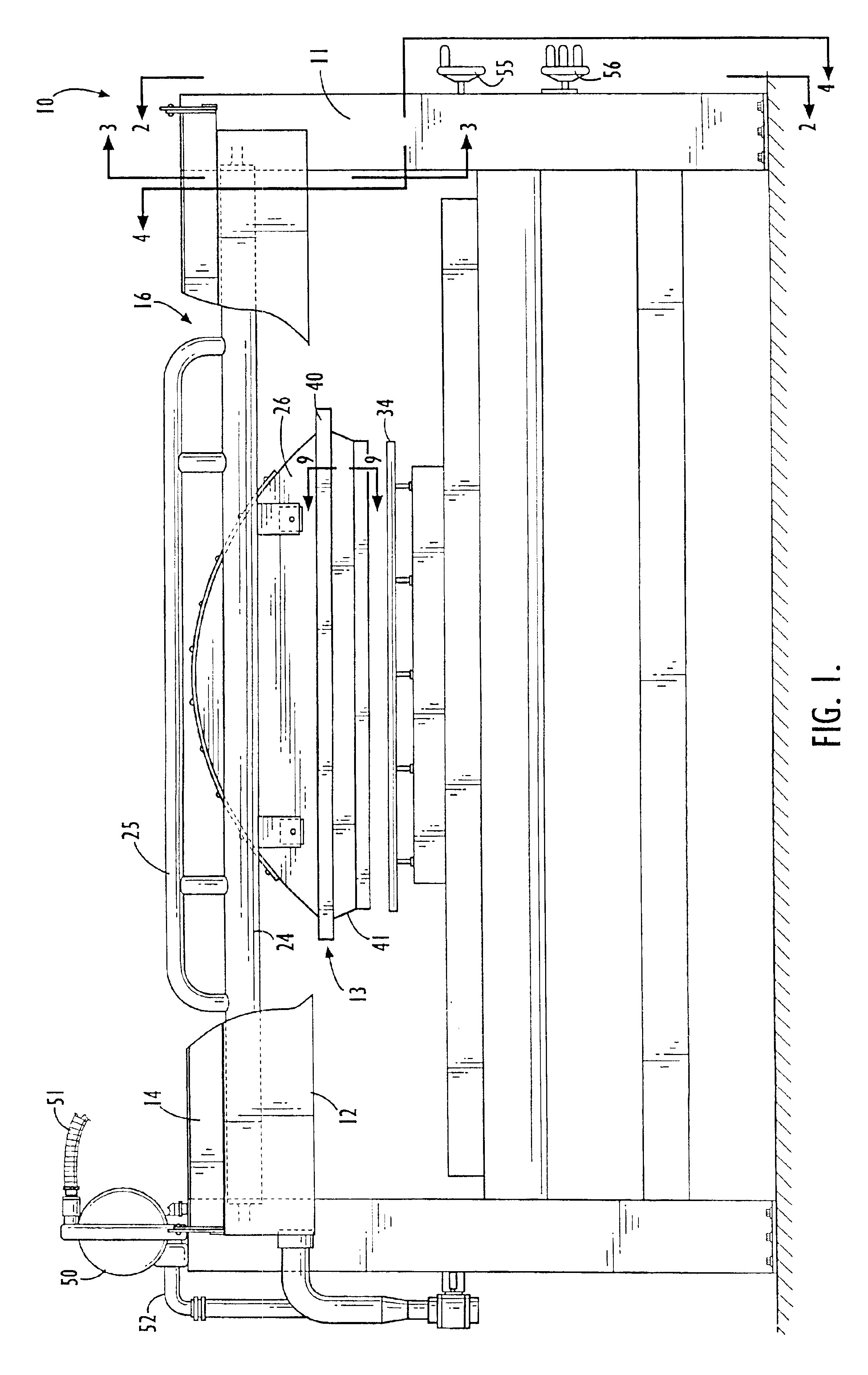

The invention discloses an ultralow bath-ratio yarn dyeing machine with a three-level vane pump, comprising a dye vat, a yarn stand and a vane pump, wherein the bottom of the yarn stand is a yarn stand disk; the yarn stand disk is provided with a hole communicated with a dye liquor input channel in the dye vat; the vane pump is arranged below the whole dye vat and is a three-level vane pump; a shaft of the three-level vane pump is connected with an internal motor shaft coaxially; the dye vat is connected with the inlet of the three-level vane pump; the three-level vane pump comprises an axial flow level, a centrifugal level and a fixed guide vane level; the axial flow level and the centrifugal level are connected with the motor in sequence through the same transmission shaft; dye liquor flows into the axial flow level through an in-flow channel; the dye liquor flowing out of the axial flow level directly enters the inlet of the centrifugal level; and the dye liquor flowing out of the centrifugal level enters an out-flow channel after passing through the fixed guide vane level. During work, the dye liquor in the dye vat does not exceed the yarn stand disk all the time and the bath ratio is lower than 1:3. The ultralow bath-ratio yarn dyeing machine can achieve required lift when the dye liquor in the yarn dyeing machine is lower than a spindle, so as to realize the low bath ratio of the yarn dyeing machine as well as the purpose of saving energy and reducing emission.

Owner:高勋绿色智能装备(广州)有限公司

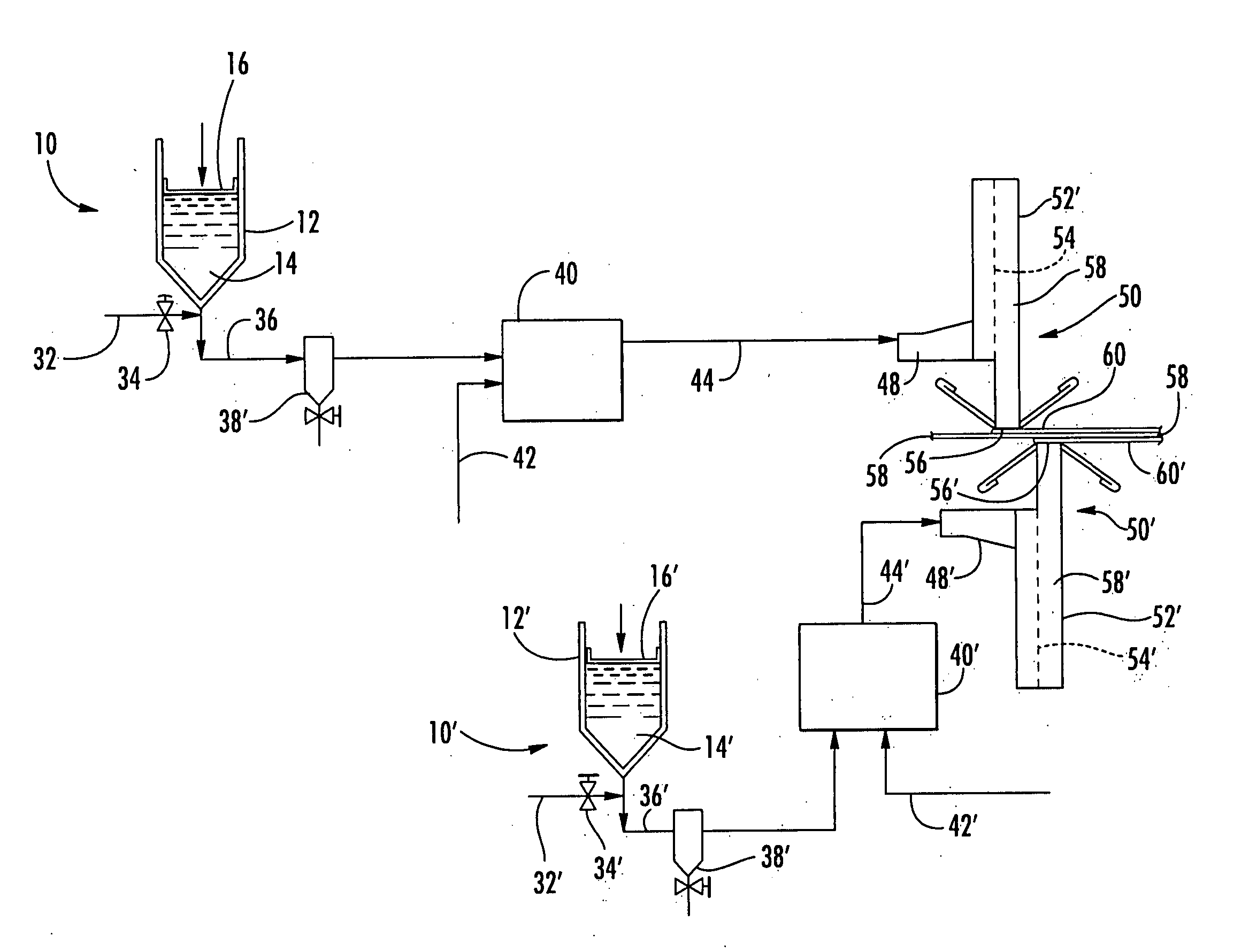

Method and apparatus for dyeing cellulosic textile substrates with an inert leuco state dye and dyed product

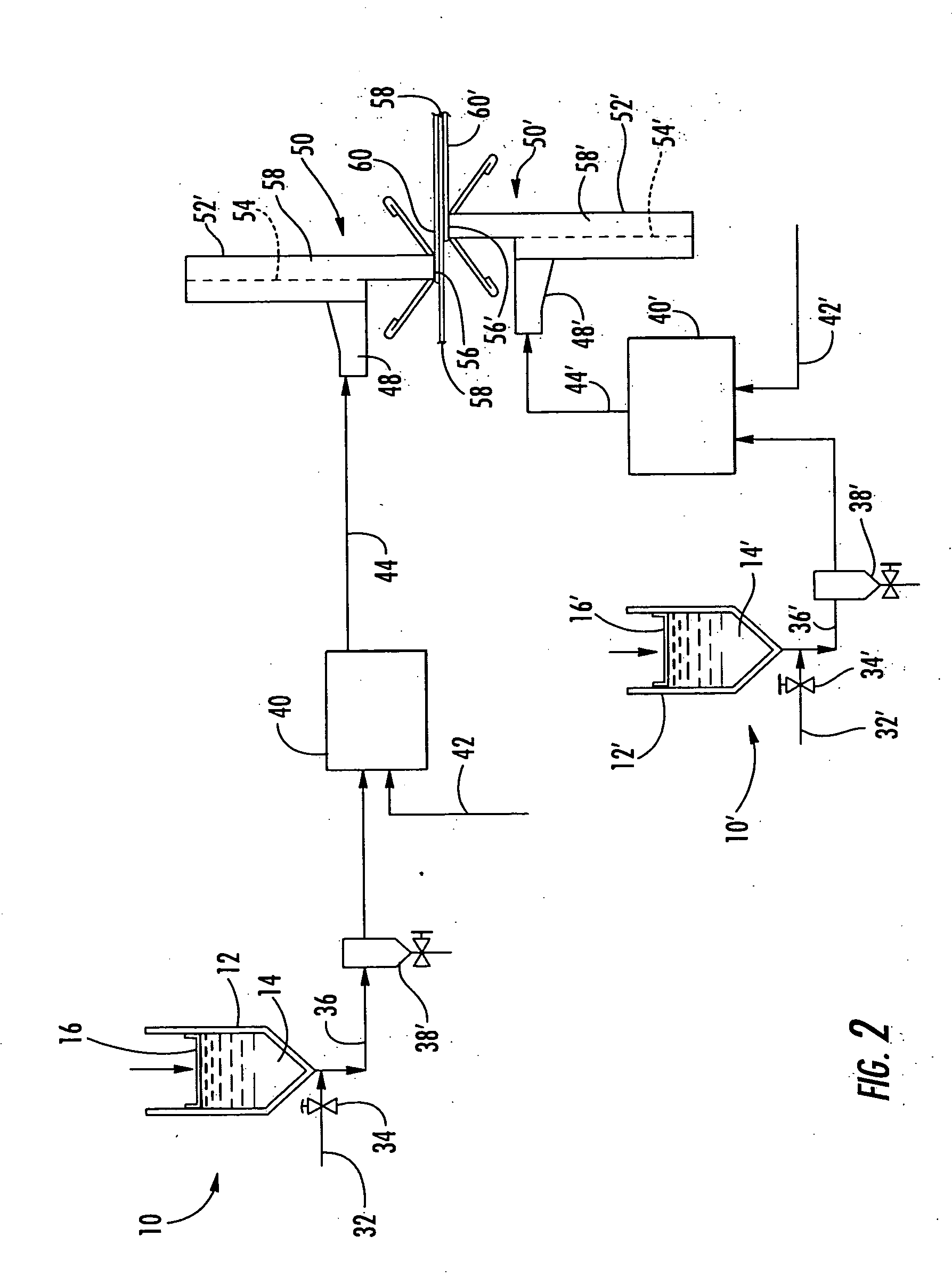

InactiveUS20050241078A1Textile treatment using short bath ratio liquorBleaching apparatusOxygenIndigo dye

Dyeing a cellulosic textile substrate with reduced indigo dye in a leuco state after foaming with an inert gas to maintain the dye isolated from oxidizing substances. Following application of the foam to the substrate, it is exposed to the adjacent atmosphere, with the oxygen in the atmosphere oxidizing the reduced indigo dye to regenerate it and cause it to affix to the textile substrate. A product can be produced using the method and apparatus of the present invention that has different dye characteristics on opposite surfaces of the substrate by applying the indigo dye foam to one surface and another dye, either an indigo dye or some other dye to the opposite surface.

Owner:GASTON SYST INC

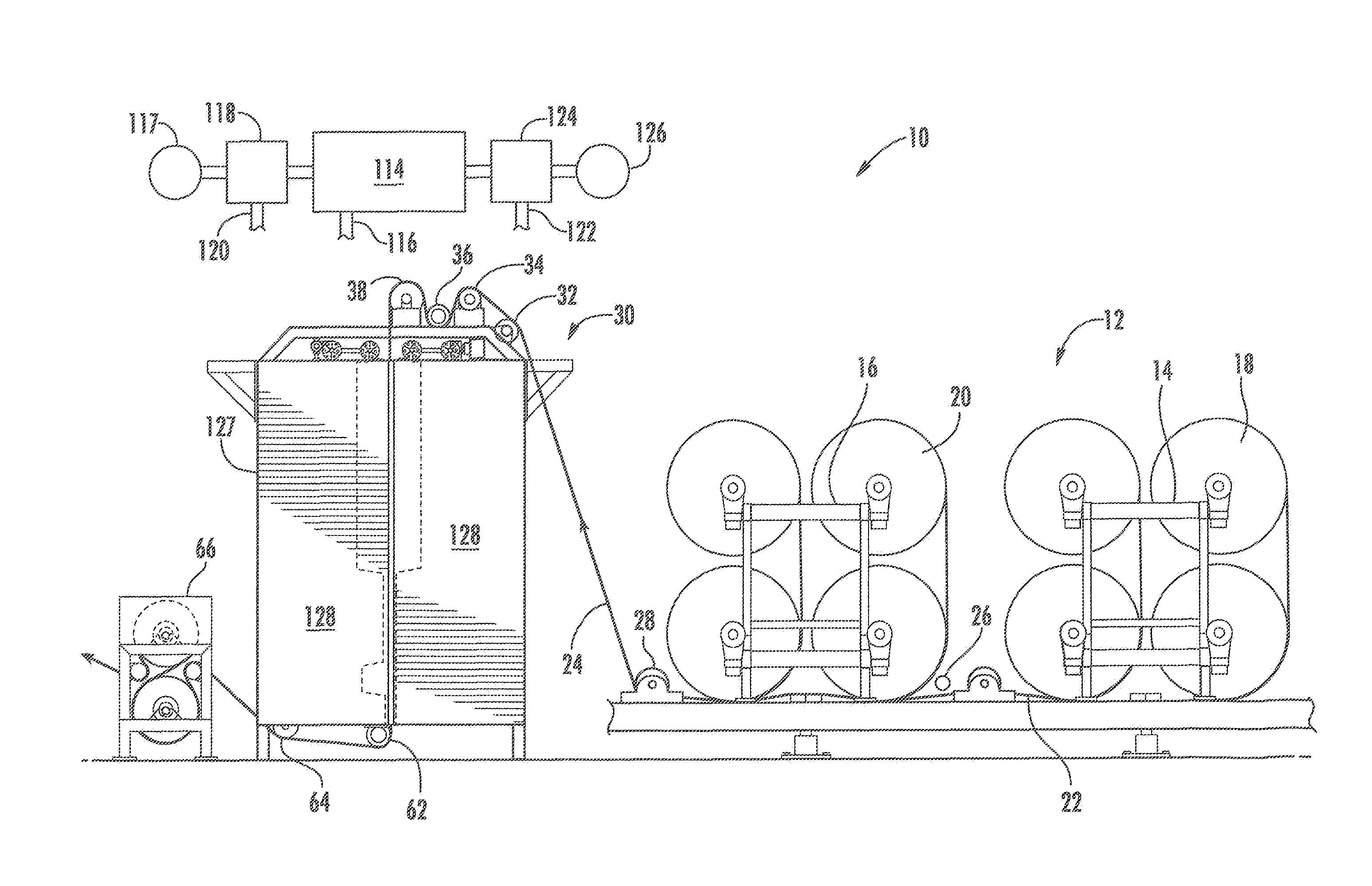

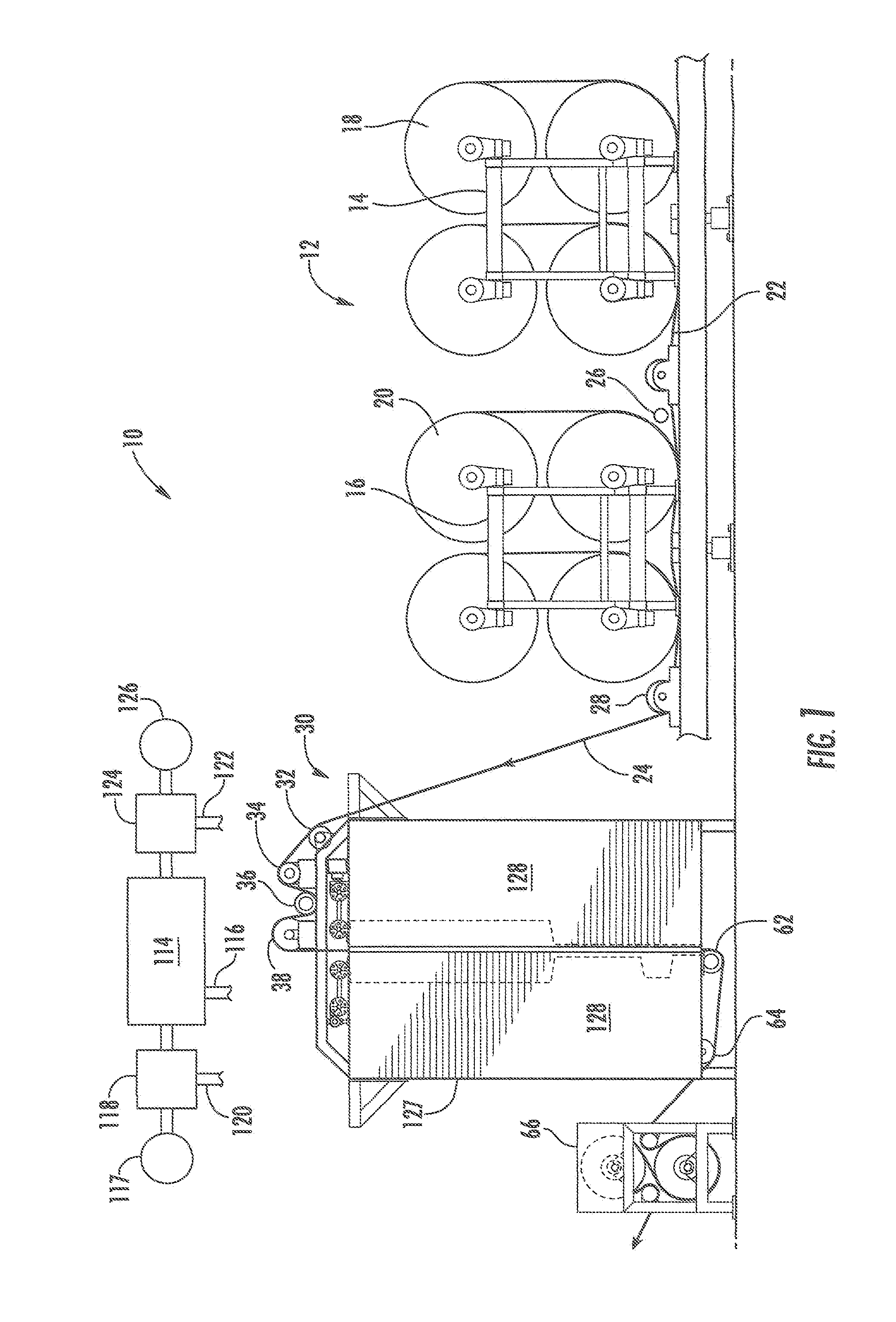

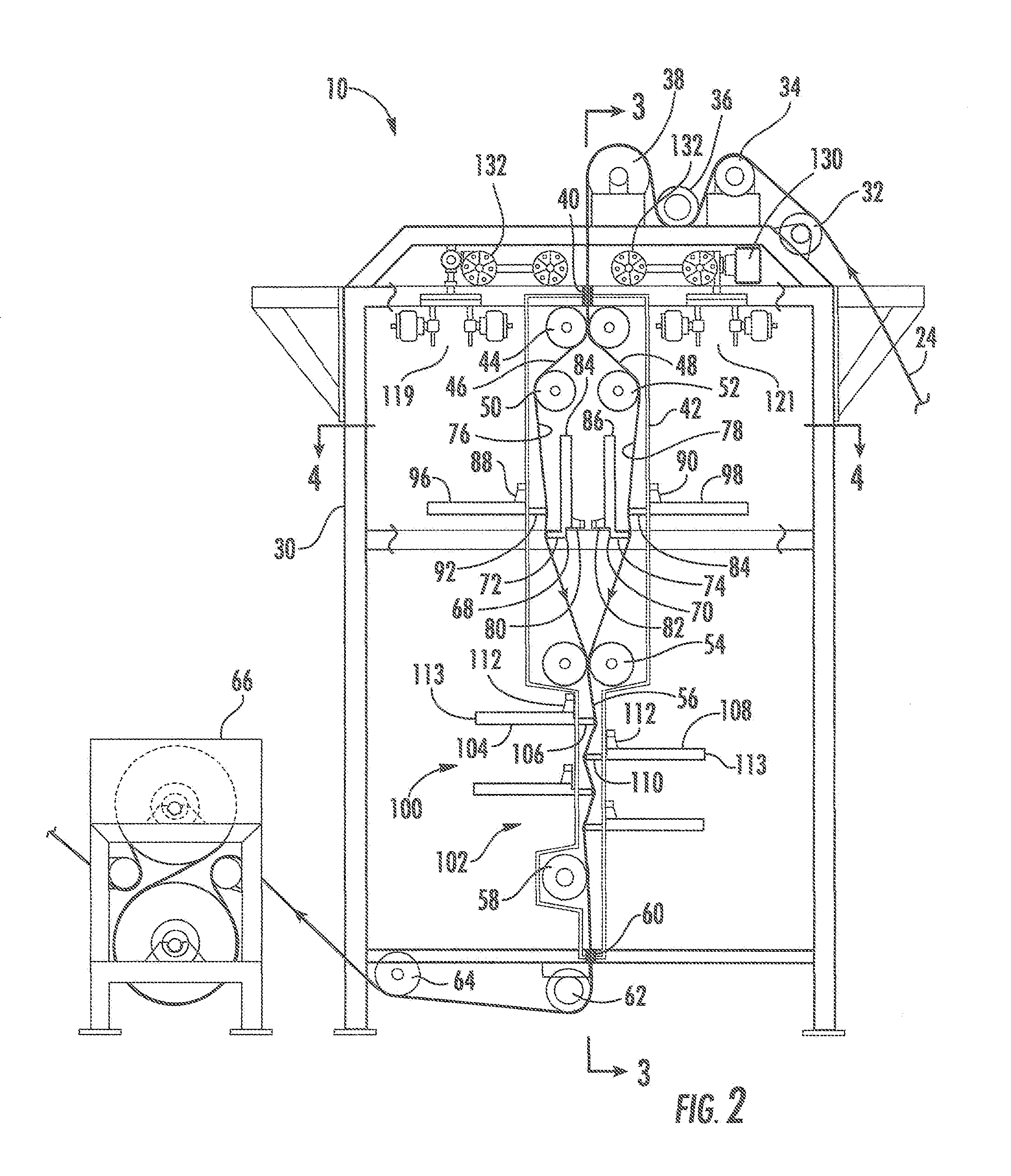

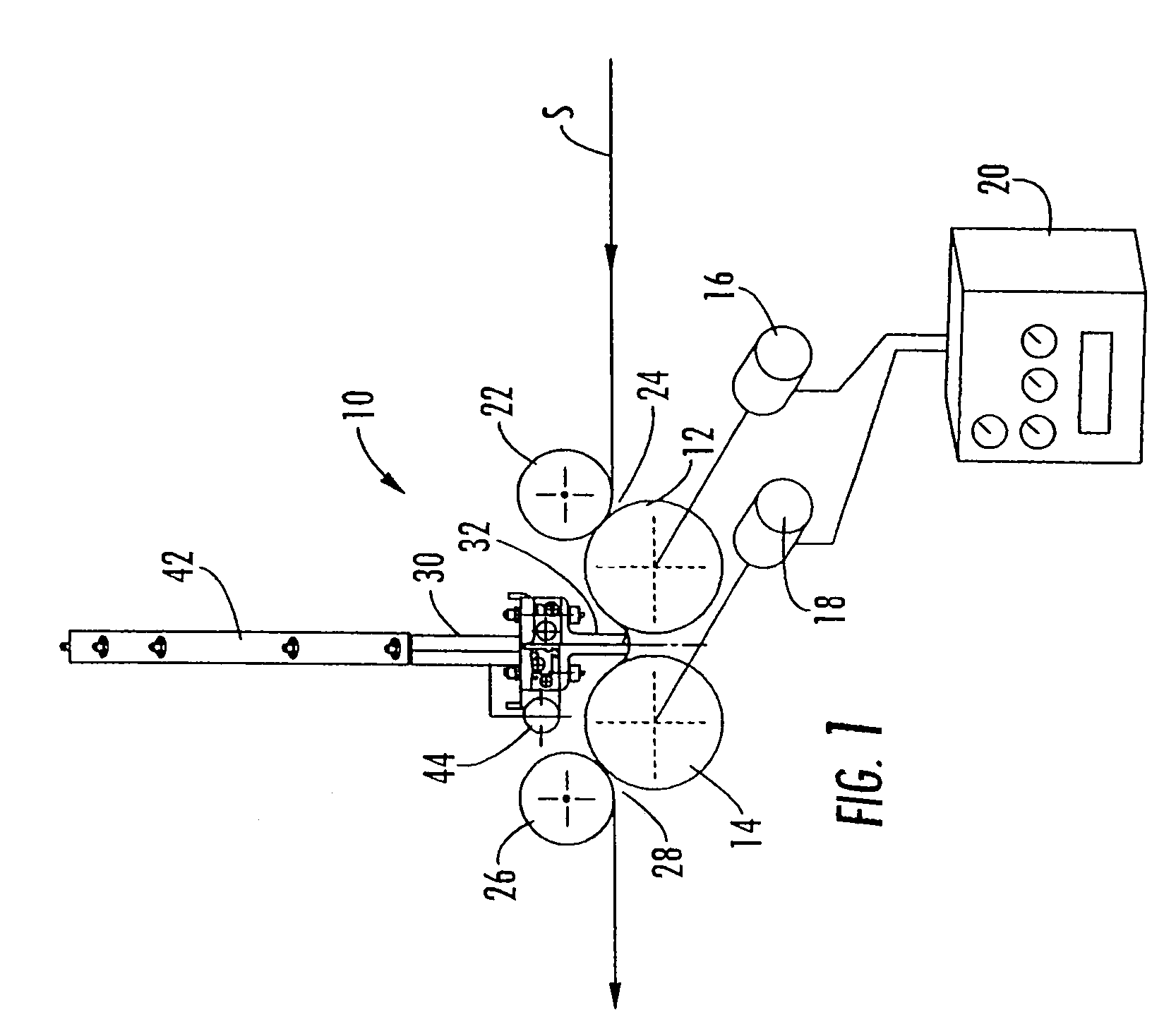

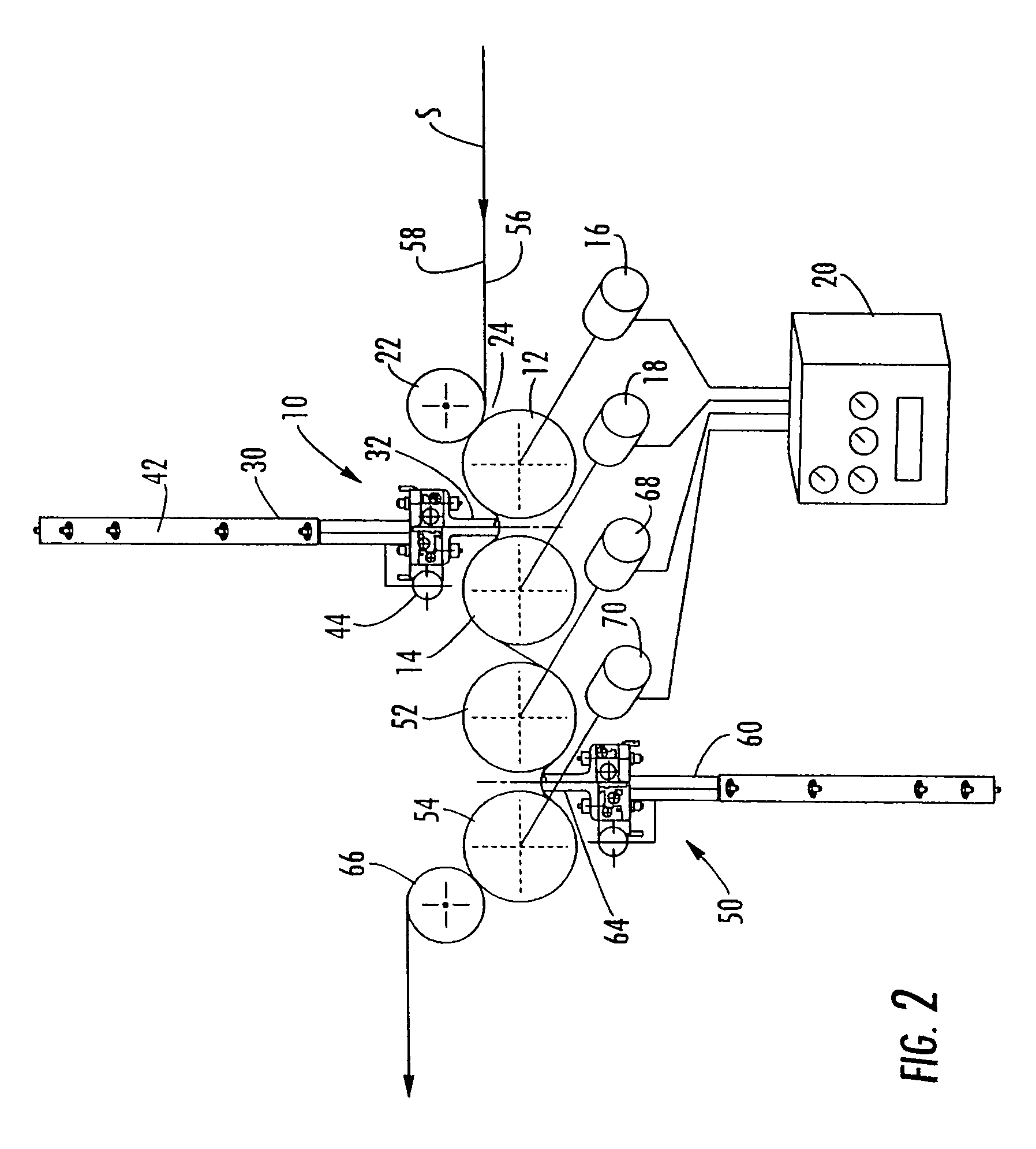

Apparatus for dyeing textile substrates with foamed dye

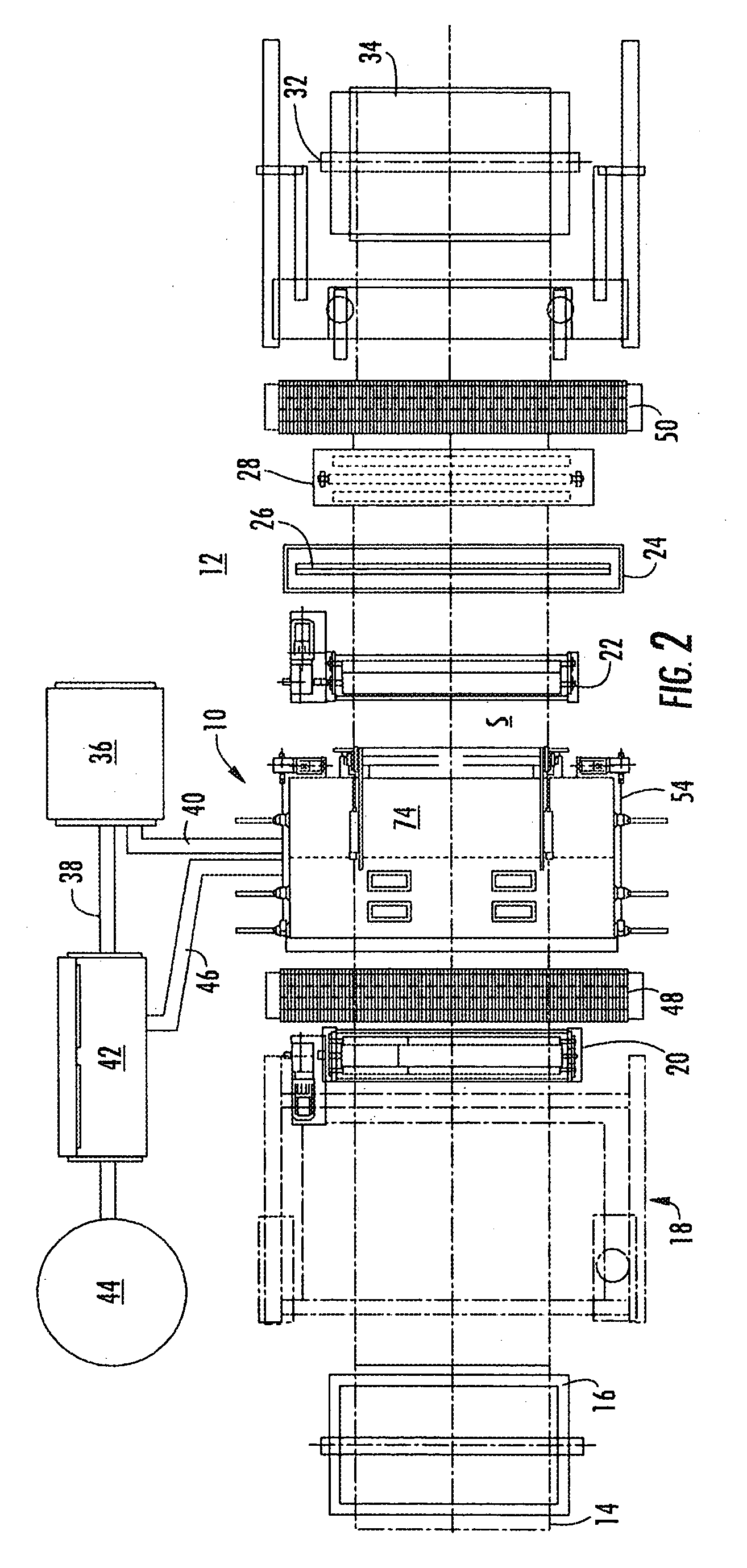

ActiveUS7913524B2Increases the amount of inert nitrogen in the chamber environmentReduce tensionTextile treatment containersOther washing machinesEngineeringIndigo dye

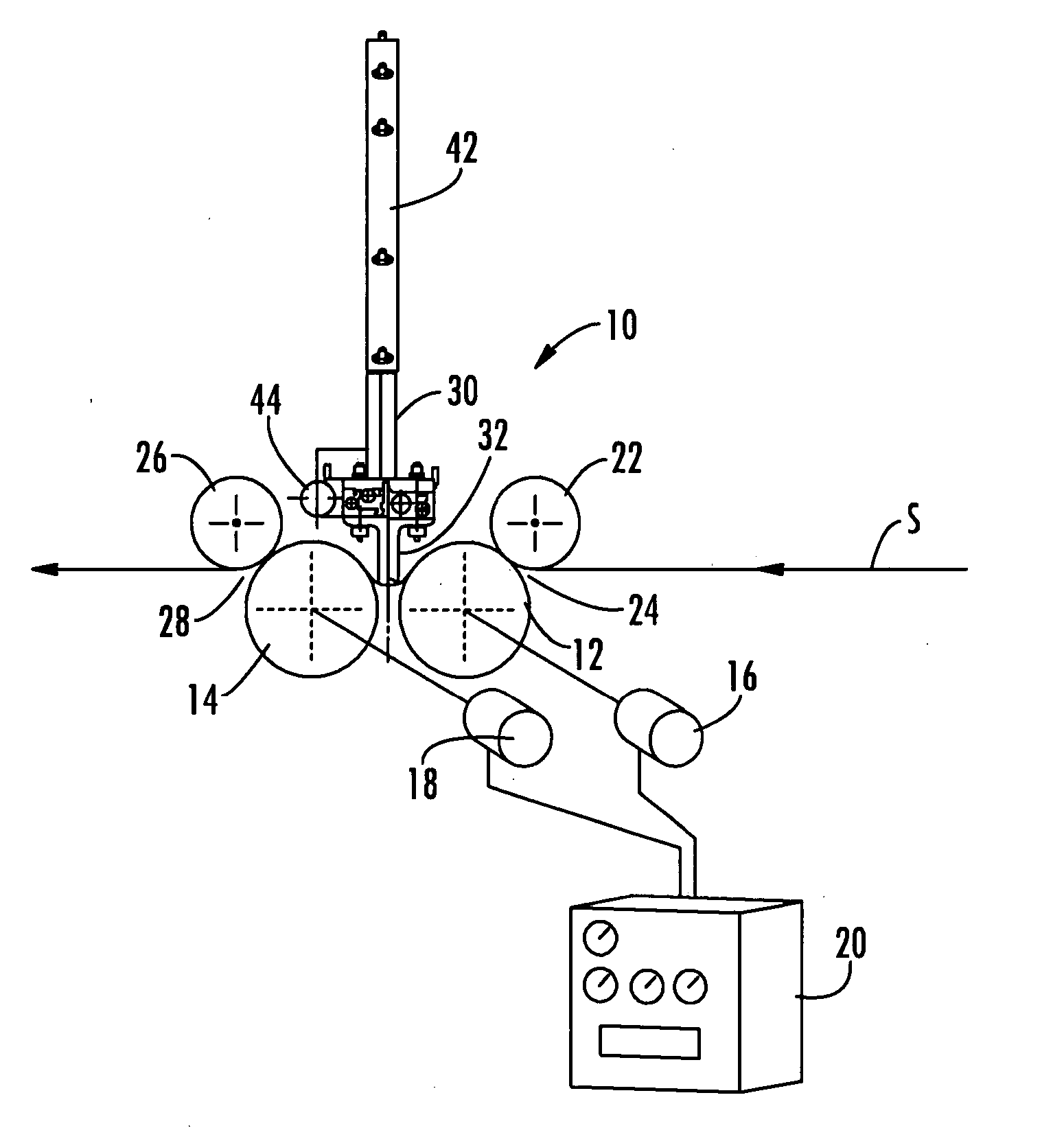

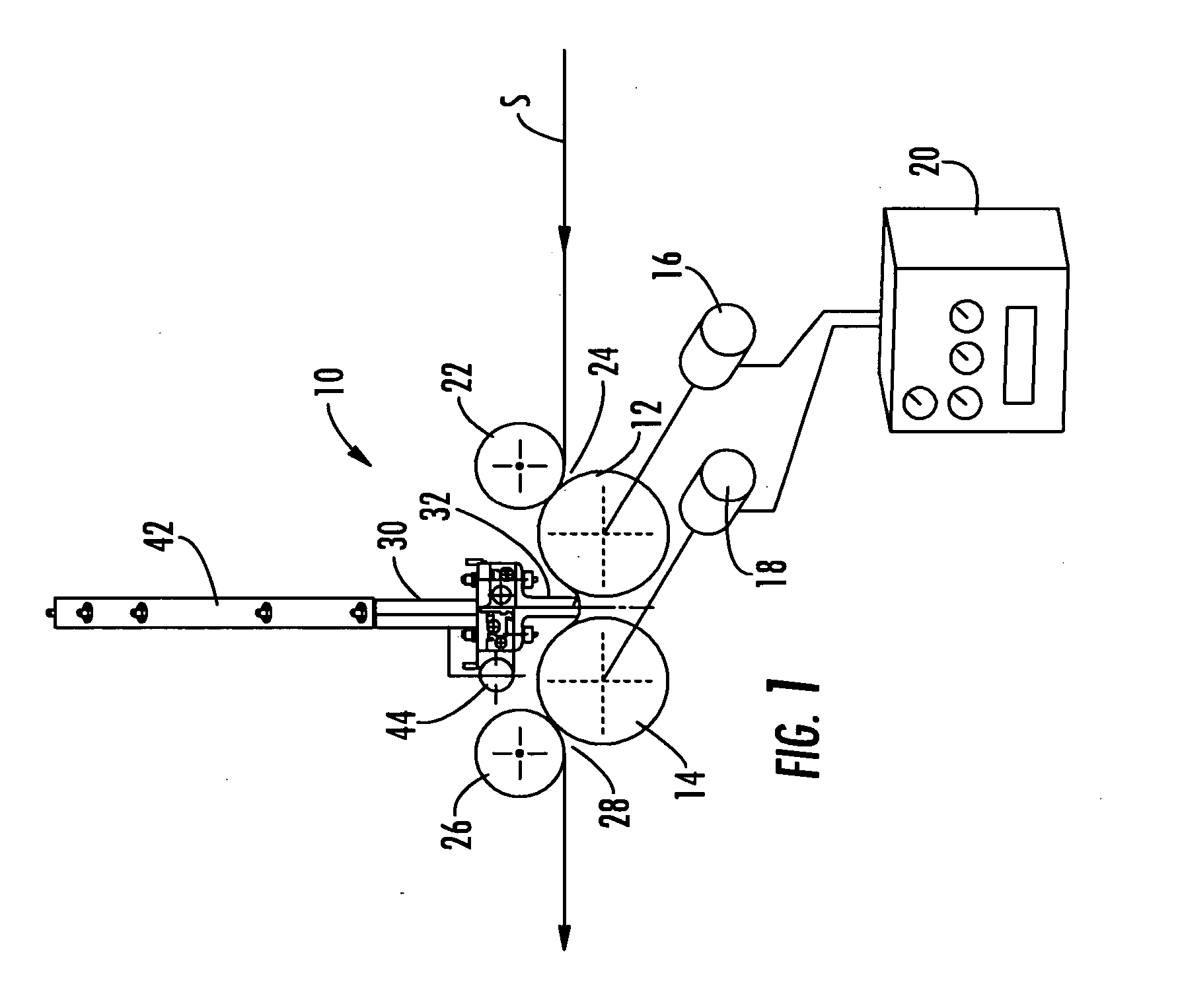

An apparatus for dyeing a textile substrate using a plurality of applicators that each apply an increment of a total dye application. In one form a reduced indigo dye in a leuco-state is applied in an inert atmosphere substantially isolated from oxidizing substances. In another form the foamed dye is applied while open to the atmosphere. In both forms holddown rollers or inverted applicators are located between applicators at decreasing depths to minimize increases in tension as the substrate travels over successive applicator faces.

Owner:GASTON SYST INC

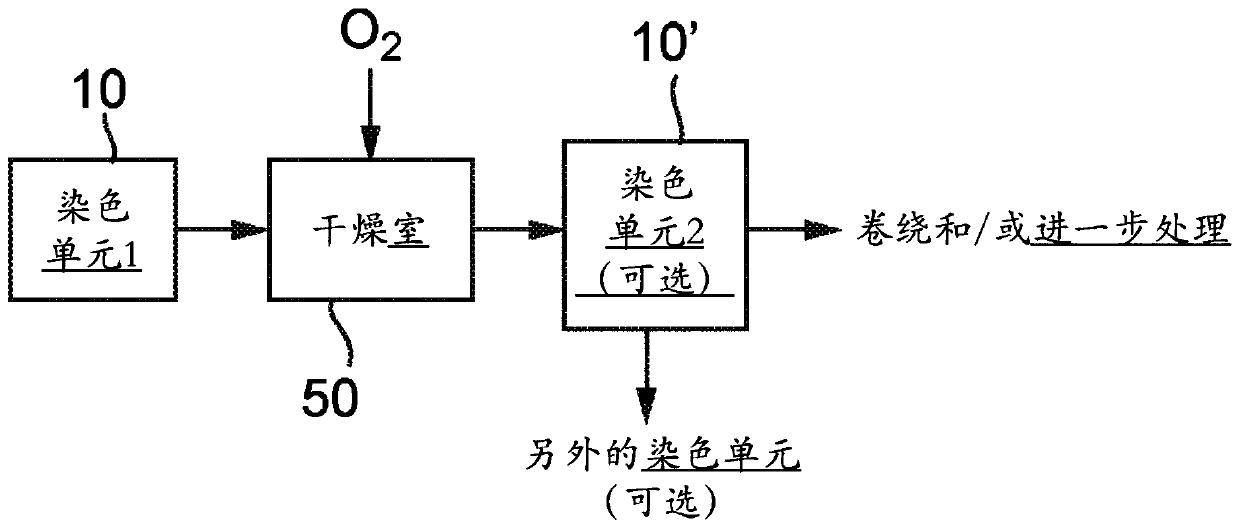

Multiple step dyeing textile with concentrated dye systems

InactiveUS8167958B2Capital costReduce expenditureTextile treatment using short bath ratio liquorLiquid/gas/vapor treatment of indefinite length materialsEngineeringDyeing

The present invention relates to a process for dyeing sheetlike textile materials with a dye, which comprises a concentrated dye system being applied in a total amount of 1% to 25% by weight, based on the textile material, to the textile material in two or more sub-steps and the dye being fixed on the textile material after each and every sub-step.

Owner:DYSTAR COLOURS DISTRIBUTION GMBH

Multi-step process for dyeing textile materials with a concentrated dye system

InactiveCN102149867ALow costReduce overheadFibre treatmentTextile treatment using short bath ratio liquorEngineeringTextile

The present invention relates to a process for dyeing sheetlike textile materials with a concentrated dye, which comprises a concentrated dye system being applied in a total amount of 1% to 25% by weight, based on the textile material, to the textile material in two or more sub-steps and the dye being fixed on the textile material after each and every sub-step.

Owner:DYSTAR COLOURS DEUTSCHLAND GMBH

Apparatus for applying foamed coating material to a traveling textile substrate

InactiveUS6858256B2Facilitate conductionProcess cleaningPretreated surfacesTextile treatment using short bath ratio liquorStop flowViscosity

A coater for applying foamed coating material to a traveling textile substrate including a frame, a flush pan, an applicator having an open slot, a pivot shaft journaled in a pair of support arms that are pivotally mounted to the frame and piston-cylinder mechanisms to move the applicator between an operating position wherein the open slot is adjacent the traveling substrate and a flush position wherein the open slot is adjacent the flush pan by pivoting the support arms and rotating the pivot shaft. Foamed coating material is applied by supporting the traveling substrate between two spaced support elements, contacting the traveling substrate with a foam applicator, and forcing a metered amount of foamed material at least partially into the interstices of the textile substrate before the foamed coating material collapses. A metered amount of foamed coating material is applied onto or into a textile substrate regardless of textile substrate structure and regardless of the viscosity of the coating material. The foamed coating material may be flushed from the coater by stopping flow of foamed material through the applicator, moving the applicator to the flush position, and commencing flow of a flushing fluid through the applicator and into the flush pan. Foamed coating material may also be flushed from the applicator by stopping flow of foamed material through the applicator, commencing flow of a flushing foam through the applicator, stopping flow of flushing foam through the applicator, and commencing flow of a flushing fluid through the applicator.

Owner:GASTON SYST INC

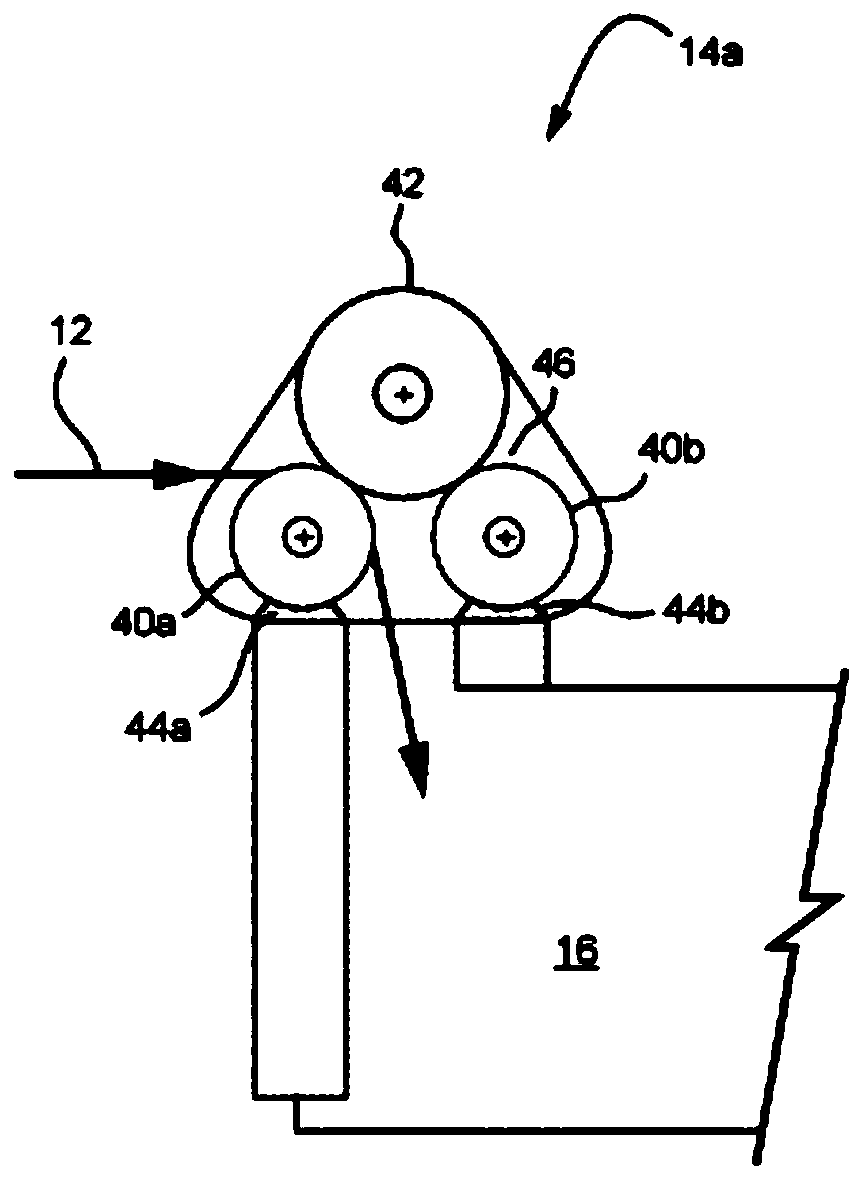

Apparatus and method for applying a foamed composition to a dimensionally unstable traveling substrate

ActiveUS20060102071A1Effective compositionEfficient and effectiveOther washing machinesTextile treatment using short bath ratio liquorEngineeringDistortion

An apparatus and method for applying a foamed composition to a traveling substrate that has a tendency to be dimensionally unstable. A pair of closely spaced driven guide rollers guides a traveling substrate with sufficient roller engagement and controlled tension to minimize dimensional distortion. A foam applicator with a substrate engaging foam dispensing nozzle face is positioned within the space between the rollers to deflect the substrate inwardly between the rollers. The face extends in close proximity to the rollers to minimize the free extent of travel of the substrate between the rollers and the nozzle face. Two pairs of guide rollers and two nozzles may be arranged for applying foamed composition to the opposite sides of the traveling substrate.

Owner:GASTON SYST INC

Method and apparatus for dyeing cellulosic textile substrates with a leuco-state dye

InactiveUS20070266505A1Minimize entryIncreases the amount of inert nitrogen in the chamber environmentTextile treatment using short bath ratio liquorBleaching apparatusCelluloseEngineering

Owner:GASTON SYST INC

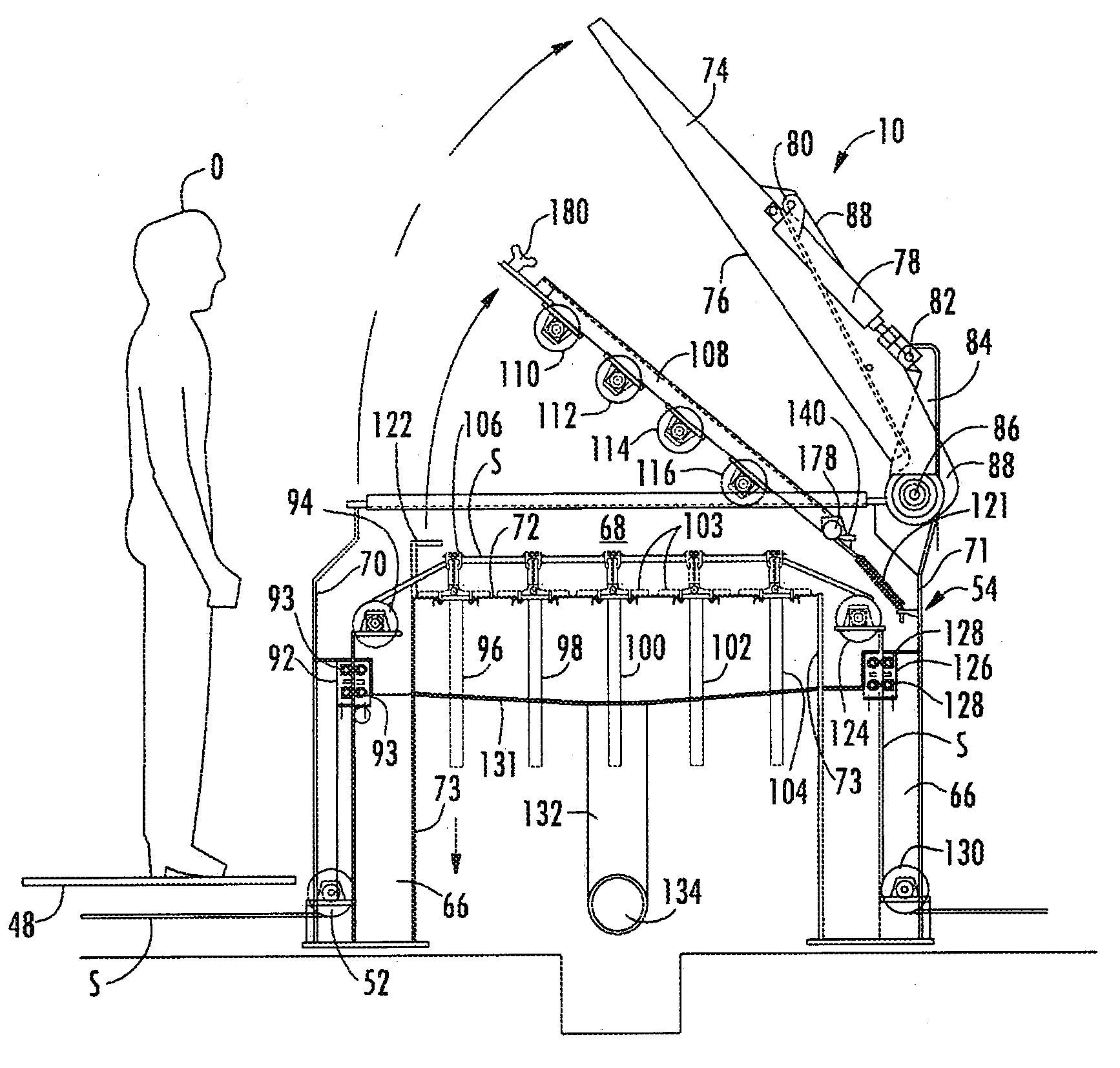

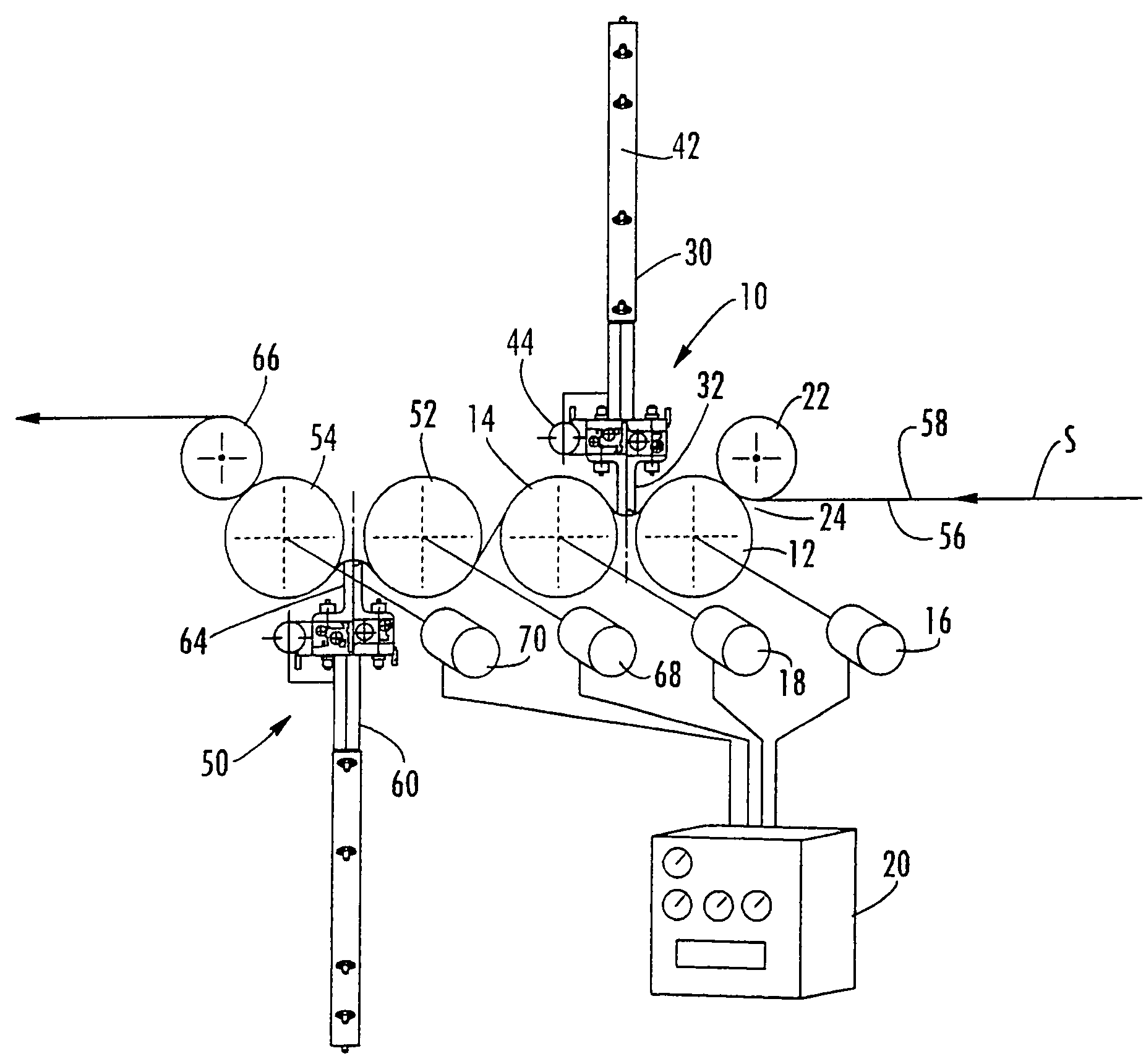

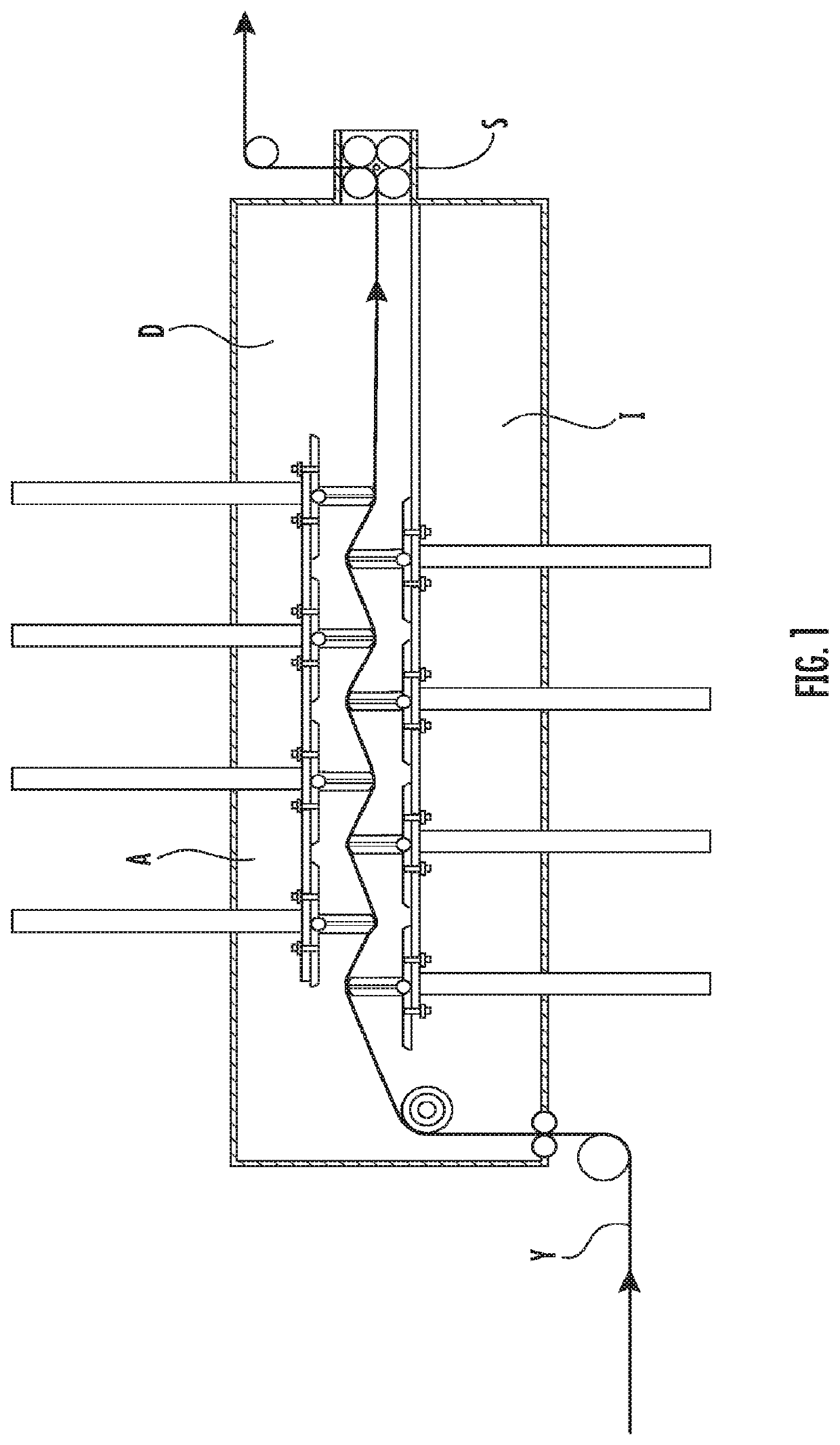

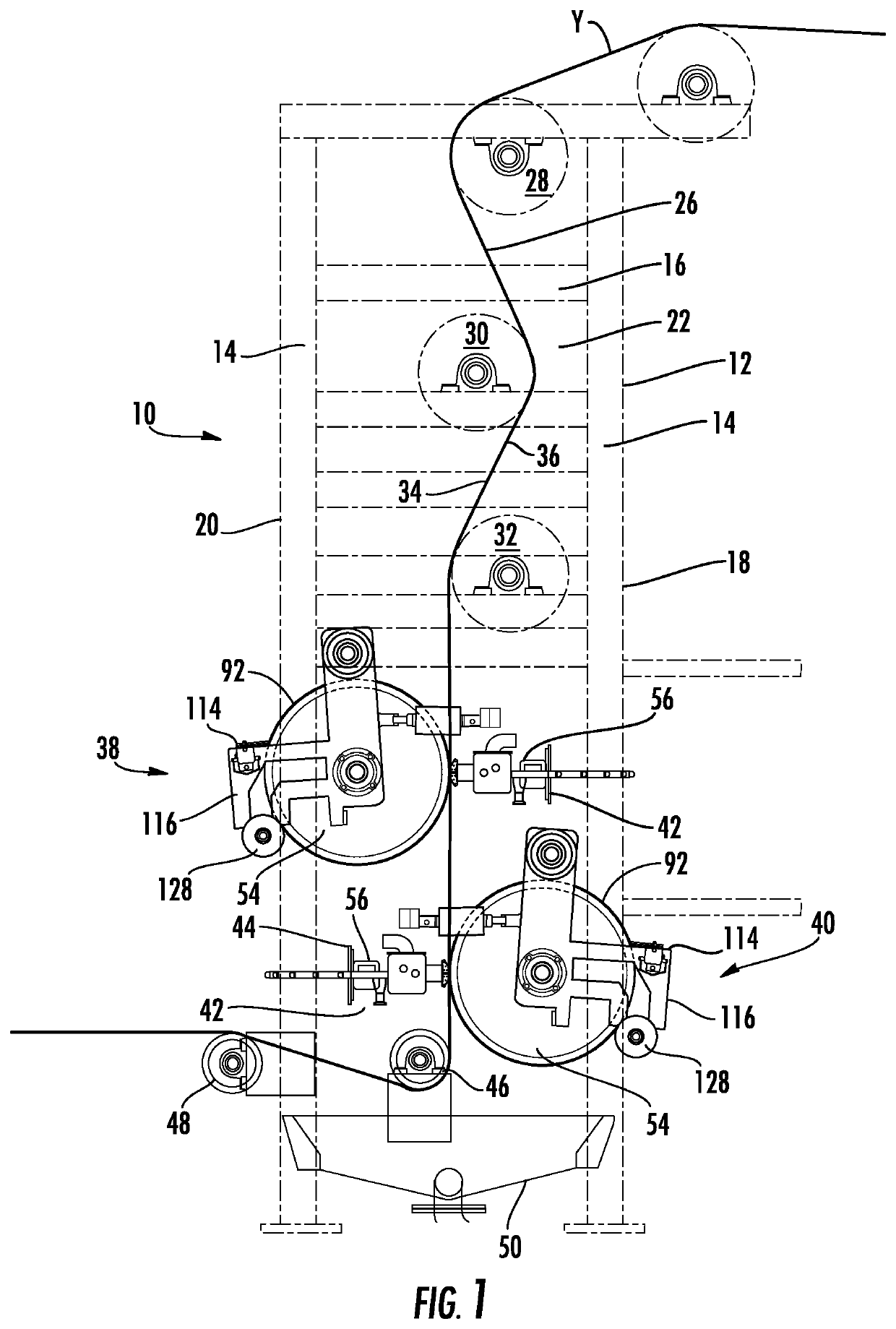

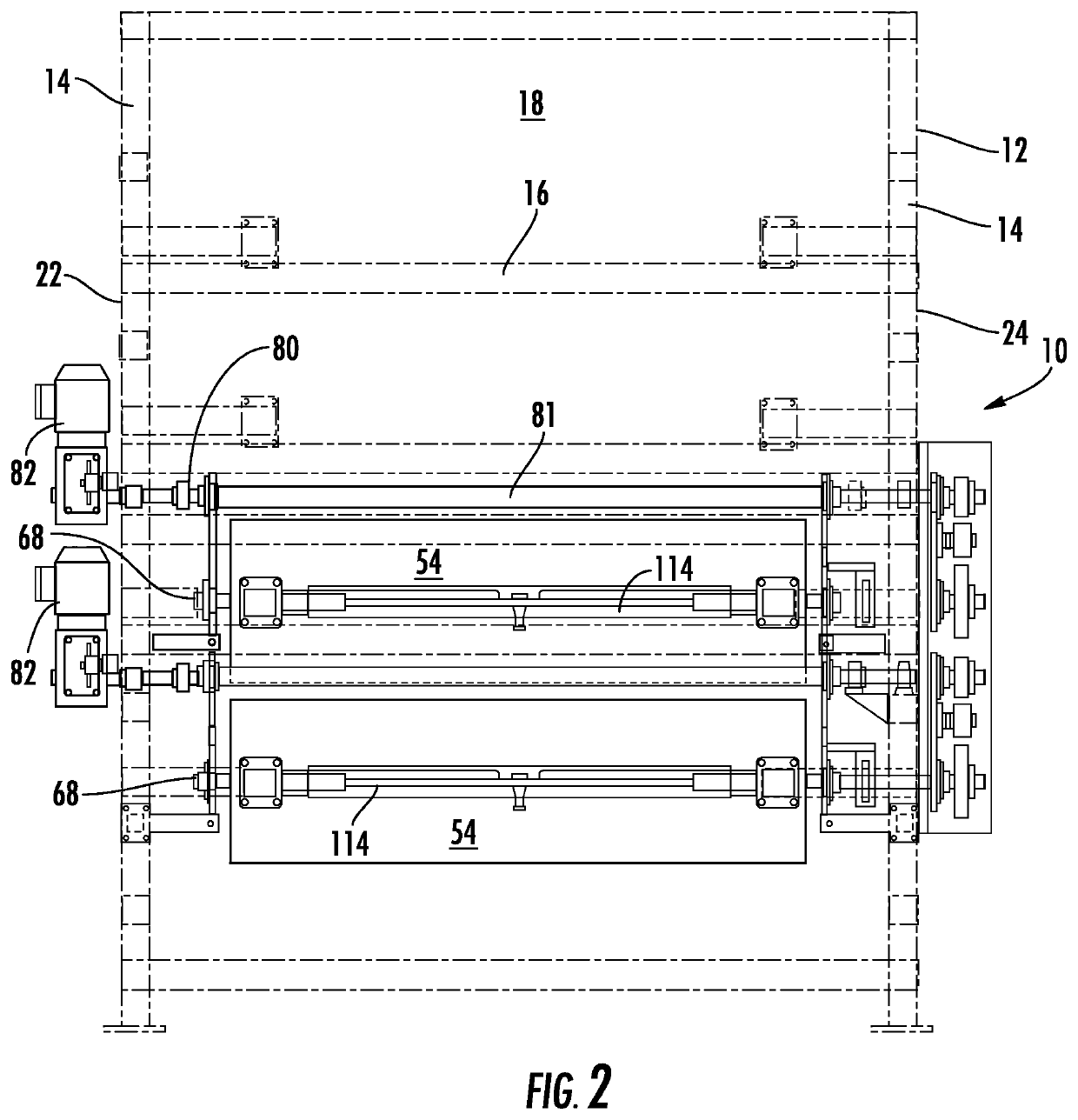

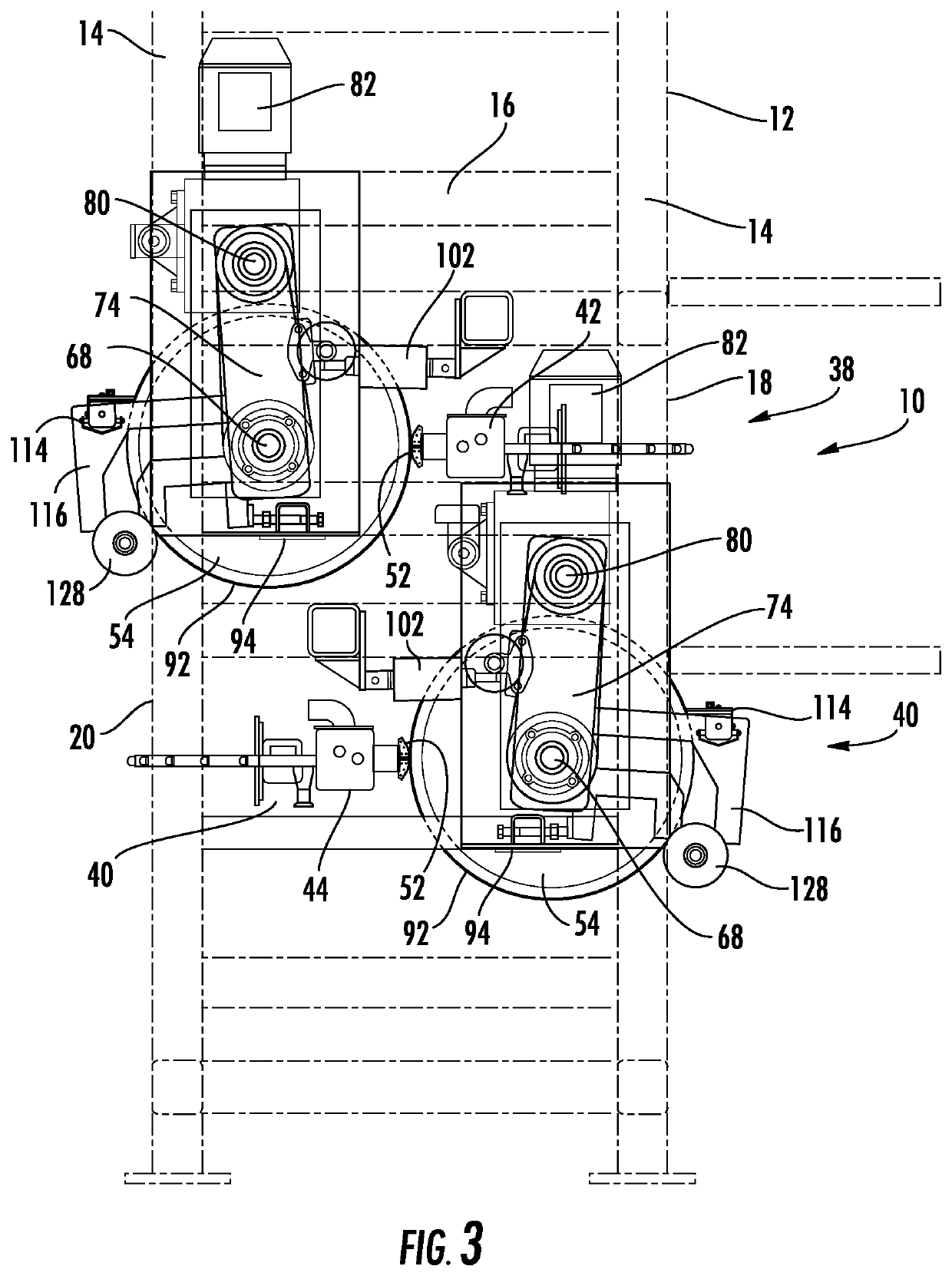

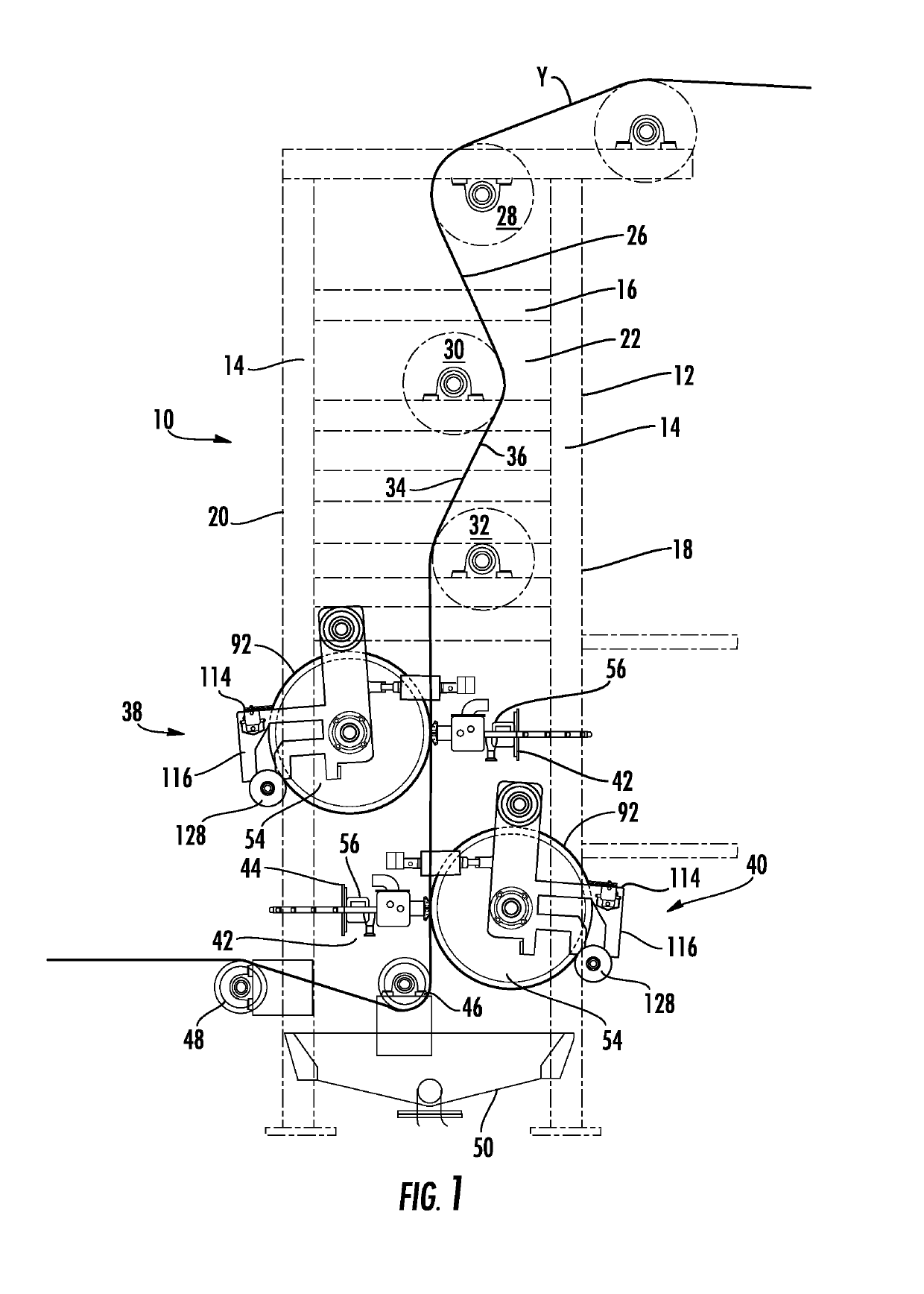

Apparatus and method of foam dyeing a traveling sheet of textile yarn

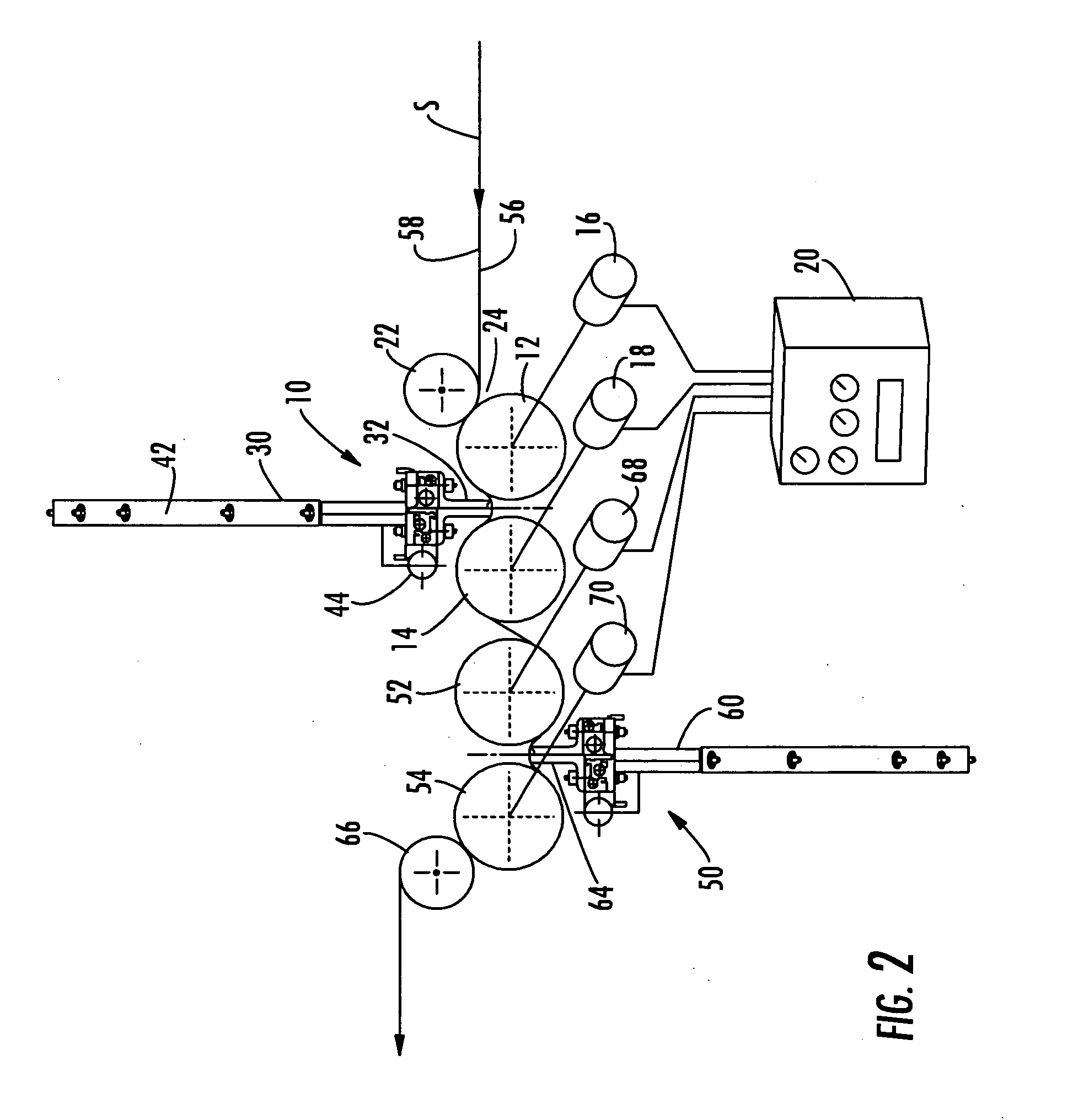

InactiveUS20130283545A1Deepening of shadeKeep in touchOther washing machinesTextile treatment using short bath ratio liquorTextile yarnEngineering

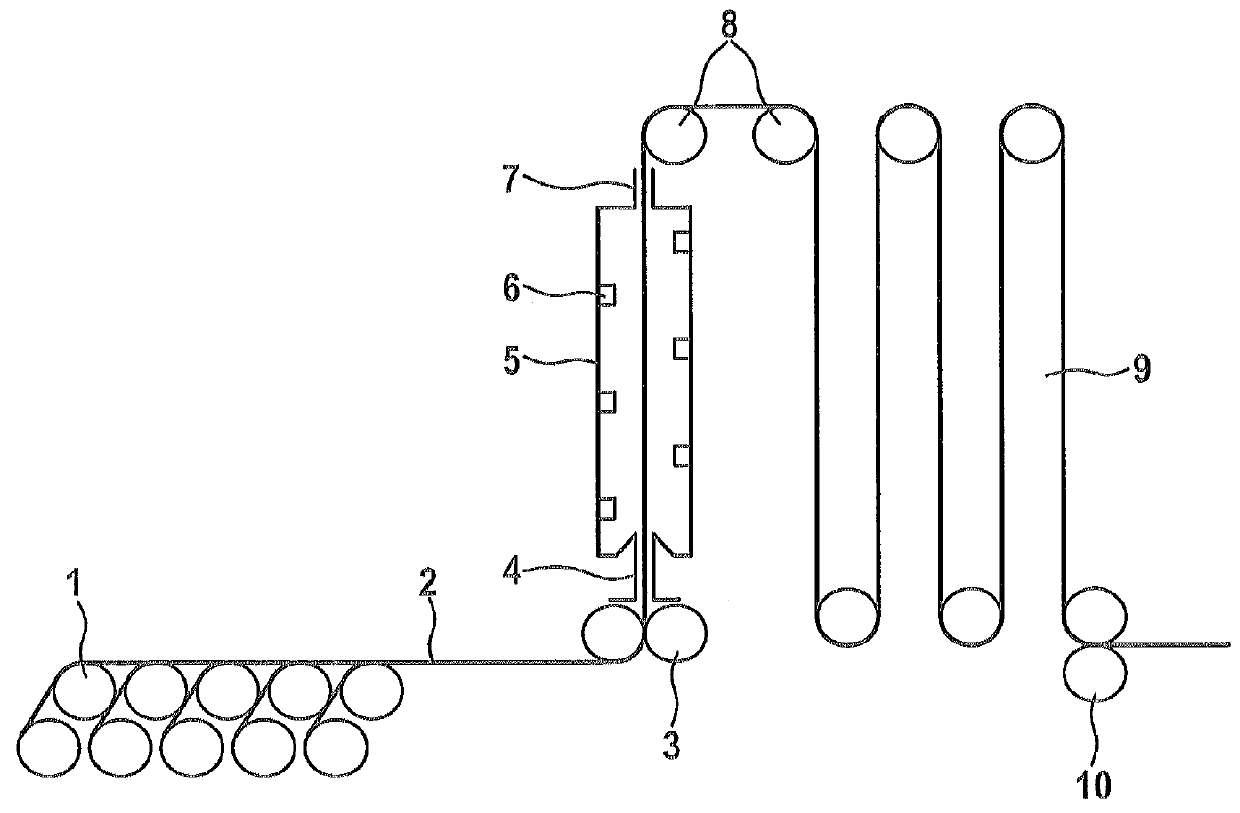

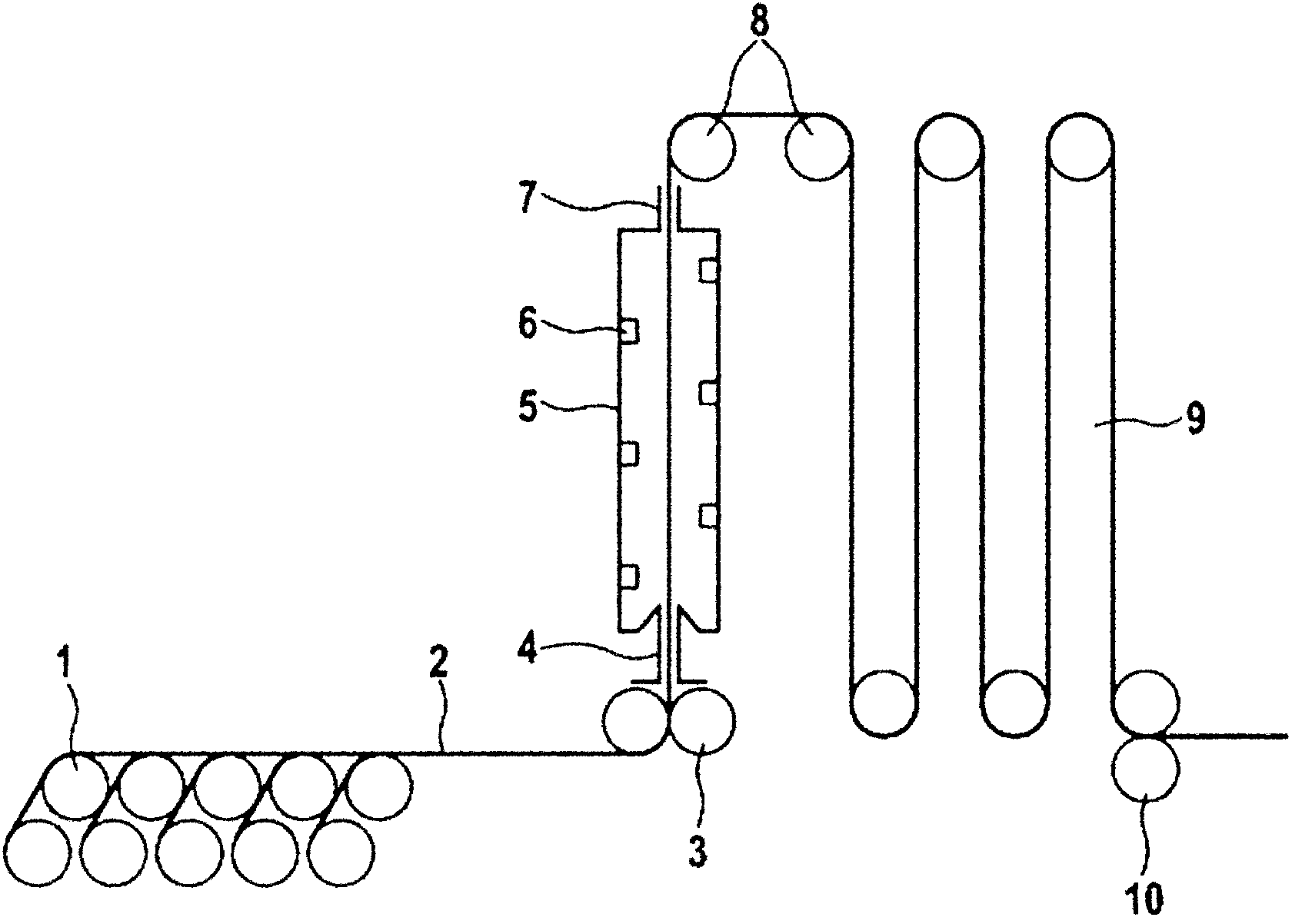

Dyeing a traveling sheet of textile yarn with a dye in foamed condition, and, more particularly, dyeing by separating a traveling sheet of yarn into separate spaced portions and applying foamed dye to the inner facing and outer facing surfaces of the yarns in the spaced portions. Then recombining the spaced portions into a single sheet and further applying foamed dye to the yarn in the recombined sheet.

Owner:GASTON SYST INC

Indigo dyeing process and apparatus and indigo dyed yarns and fabrics made thereby

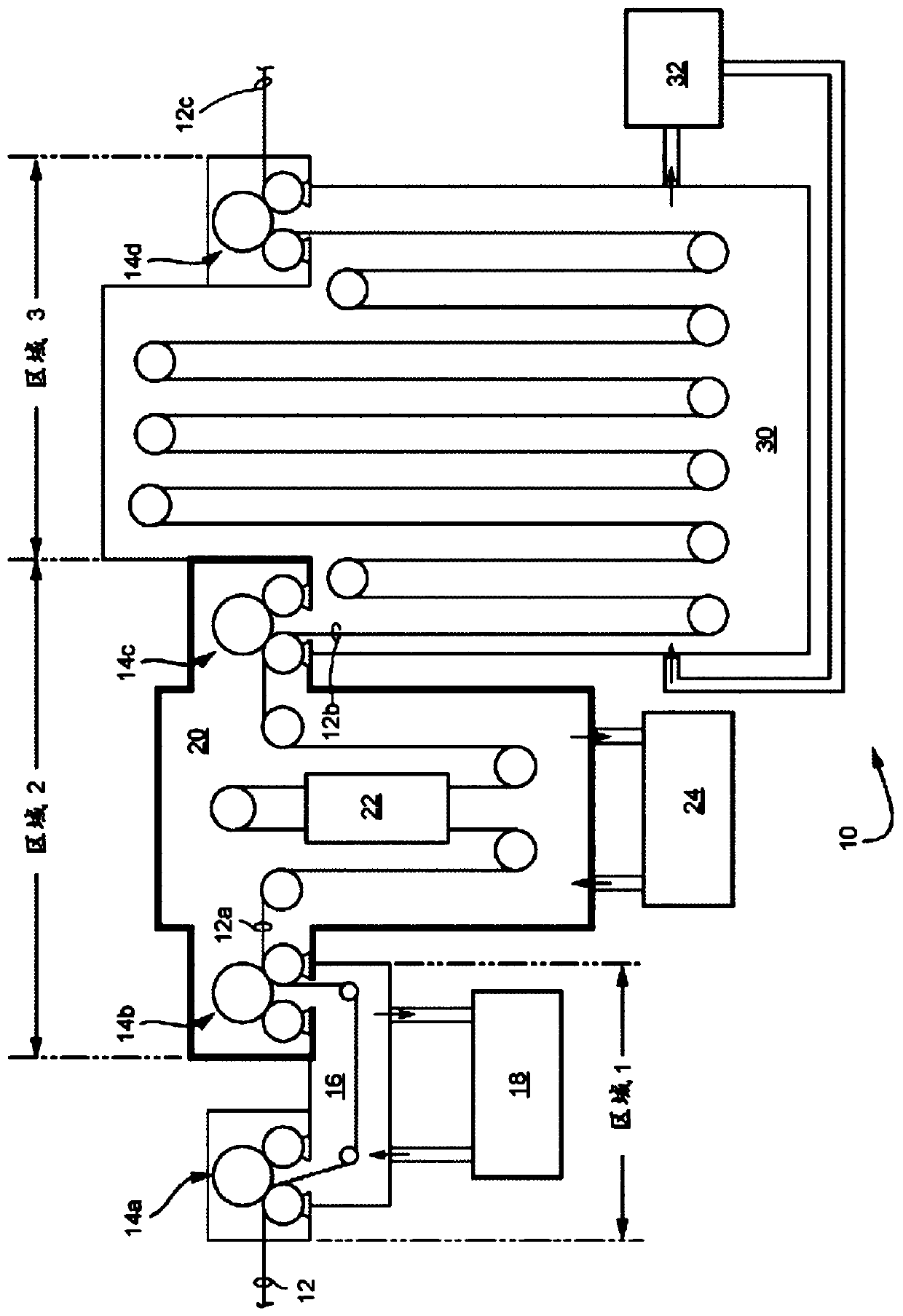

InactiveCN110036075AHigh color fastnessHigh wet friction valueTextile treatment containersSucessive textile treatmentsYarnColour fastness

Processes and apparatus are disclosed which substantially eliminate the formation of oxidized indigo dye before and during dye application onto a natural fiber yarn or fabric while allowing the leuco-indigo dye molecule to diffuse fully into the natural fibers of the yarn where it can fix to the fibers prior to oxidation (i.e., exposure of the leuco-dyed yarns to oxygen). Indigo dyed textile products (e.g., dyed cotton yarns that may be twill woven to form a denim fabric) exhibit exceptionally high colorfastness as determined by the AATCC Crock Test.

Owner:INDIGO MILL DESIGNS LLC

Colored fabric and clothes

InactiveCN101525852AFibre treatmentTextile treatment using short bath ratio liquorCelluloseEngineering

A pad-dyed or foam-dyed, pigment-colored, cellulose-based fabric that does not discolor upon chlorine bleaching of the fabric is provided. The fabric is dyed by grinding pigment colorants of a desired color to an ultra fine size and blending the grinded pigment colorants with one or more binders and, optionally, one or more additives, to form a padding paste. The padding paste is then prepared for pad dyeing or foam dyeing, and the fabric is pad dyed or foam dyed using the prepared padding paste.

Owner:STERLING PRODS

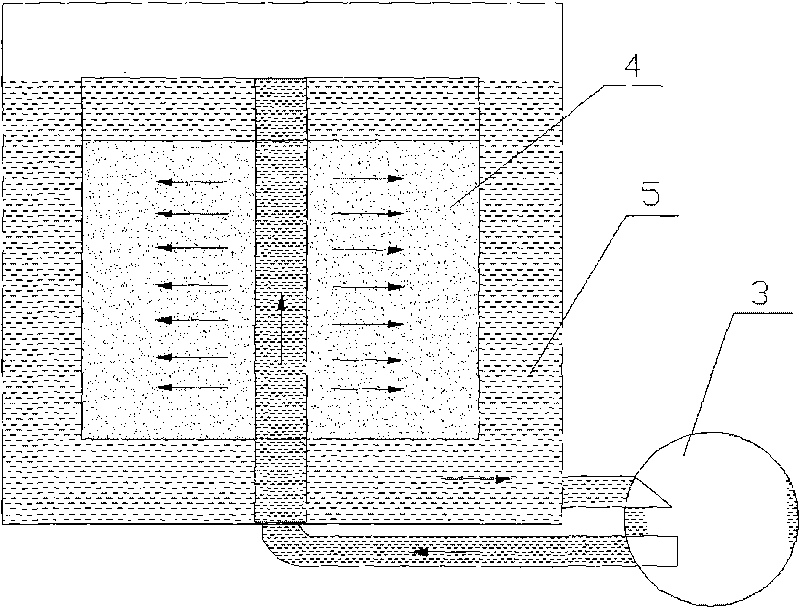

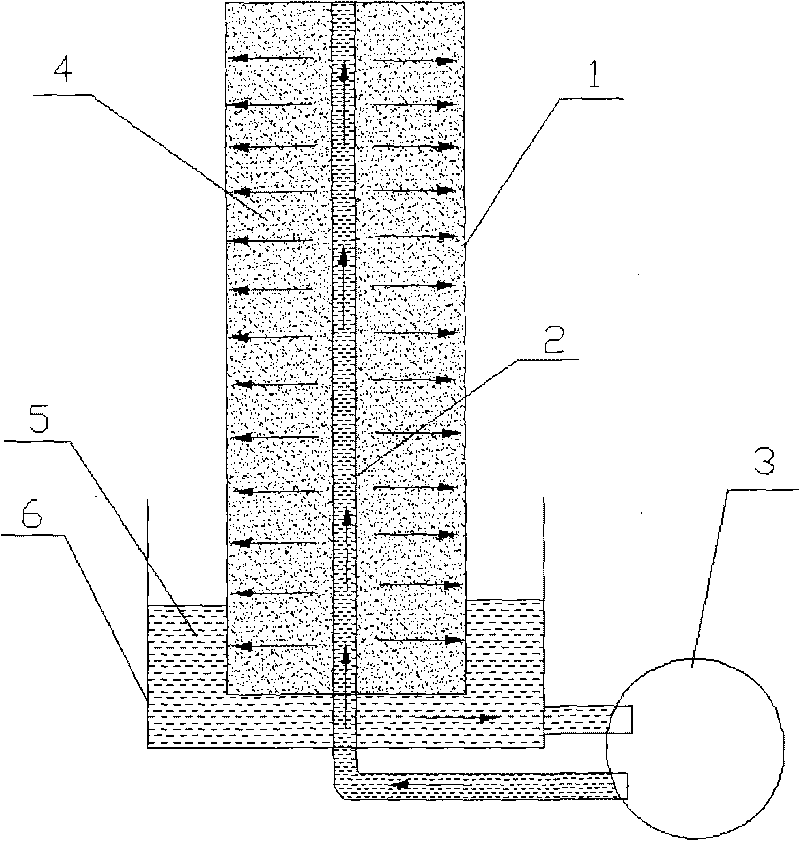

Fiber compressing dipping bath-free dyeing method in super low liquor ratio

InactiveCN101725003AStrong resistanceEmission reductionTextile treatment using short bath ratio liquorTextile/flexible product manufactureYarnFiber

The invention relates to a fiber compressing dipping bath-free dyeing method in a super low liquor ratio. In the method, materials to be dyed are forcedly compressed, and are dyed by flowing dye liquor penetrating the materials to be dyed in a compression state. The compression volume of the materials to be dyed is usually between 0.4 and 0.5g / cm3; and the liquor ratio of the mass of the materials to be dyed to the mass of the used dye liquor is smaller than or equal to 1:2. The method realizes stock dyeing in the super low liquor ratio, reduces water consumption of dyeing and maximum discharge loading, improves the dyeing uniformity, effectively lightens the pollution of sewage to environment, reduces production cost, and can be mainly used for dyeing loose fibers, fiber rods, yarns and the like of various natural or chemical fibers.

Owner:BEIJING SNOWLOTUS GROUP

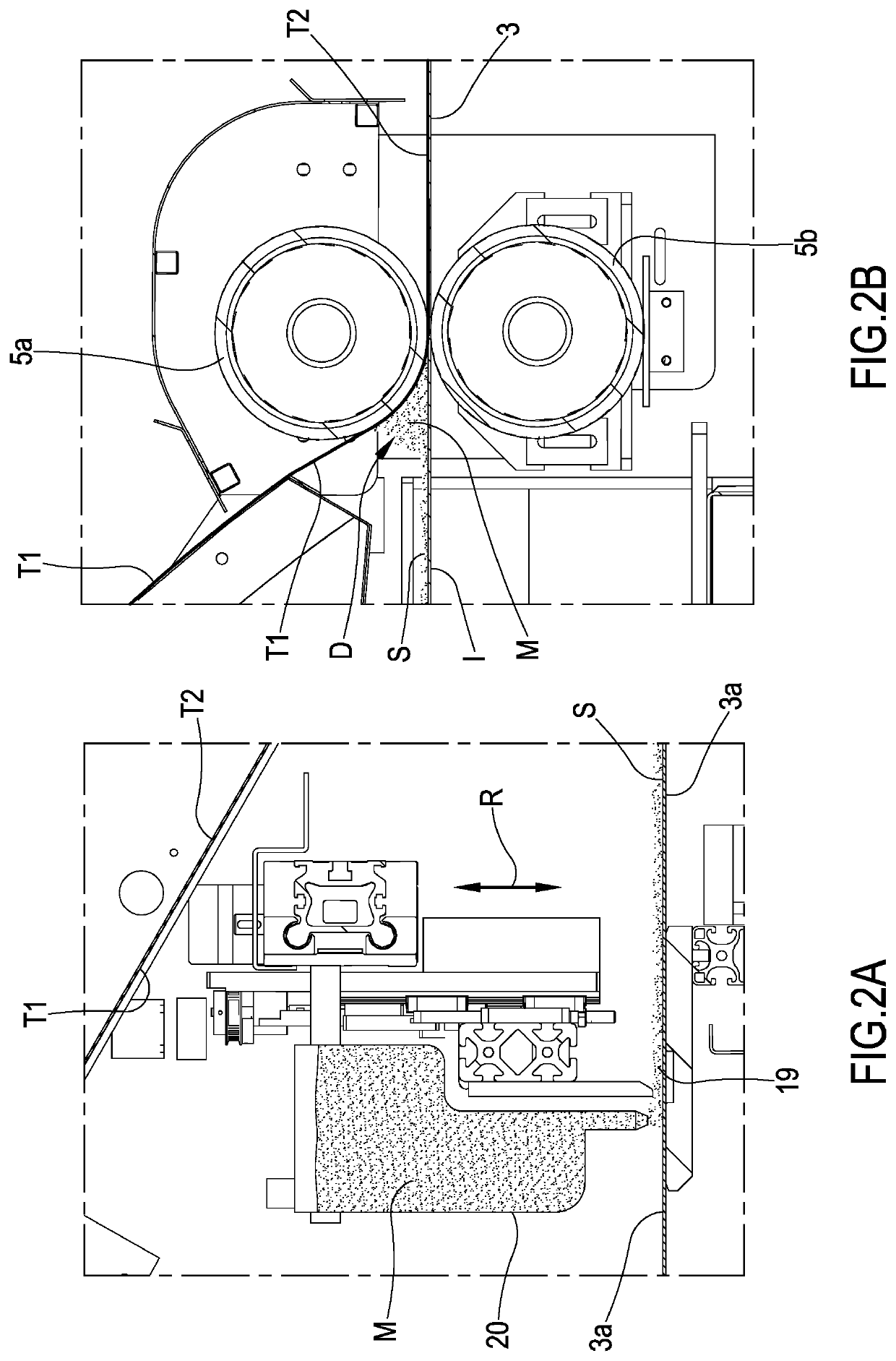

Plant for printing a fibrous material and process of printing said fibrous material

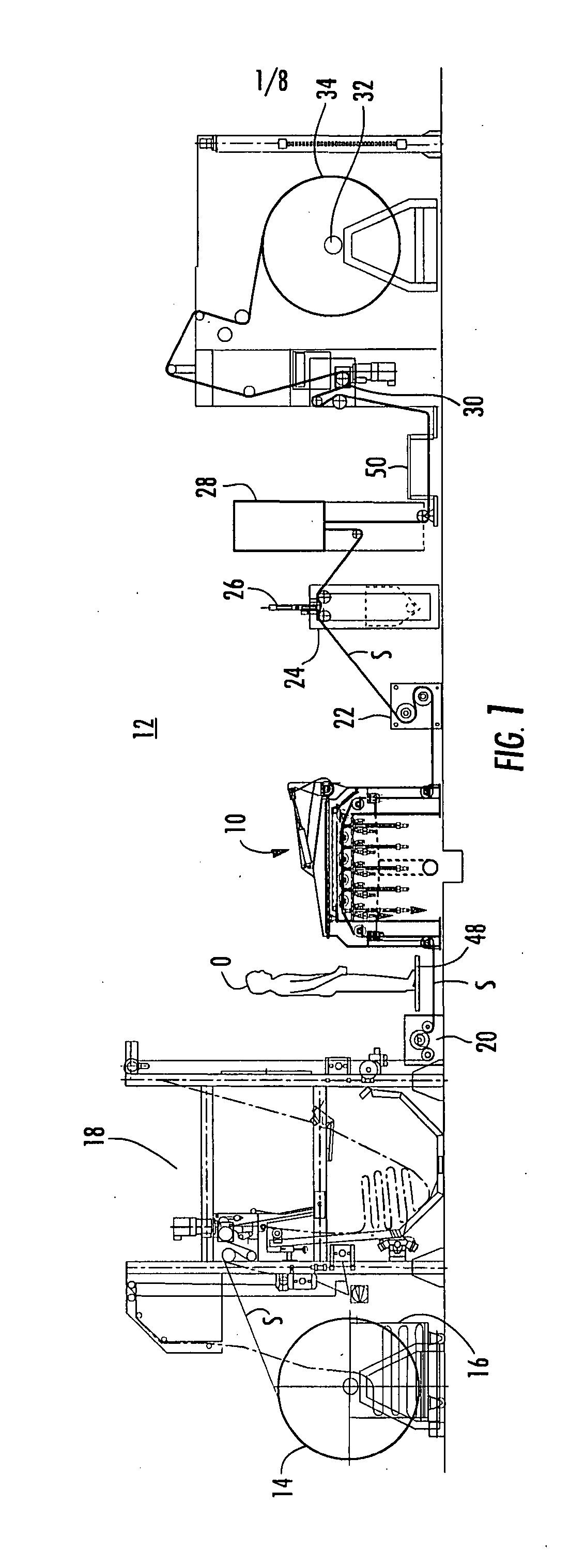

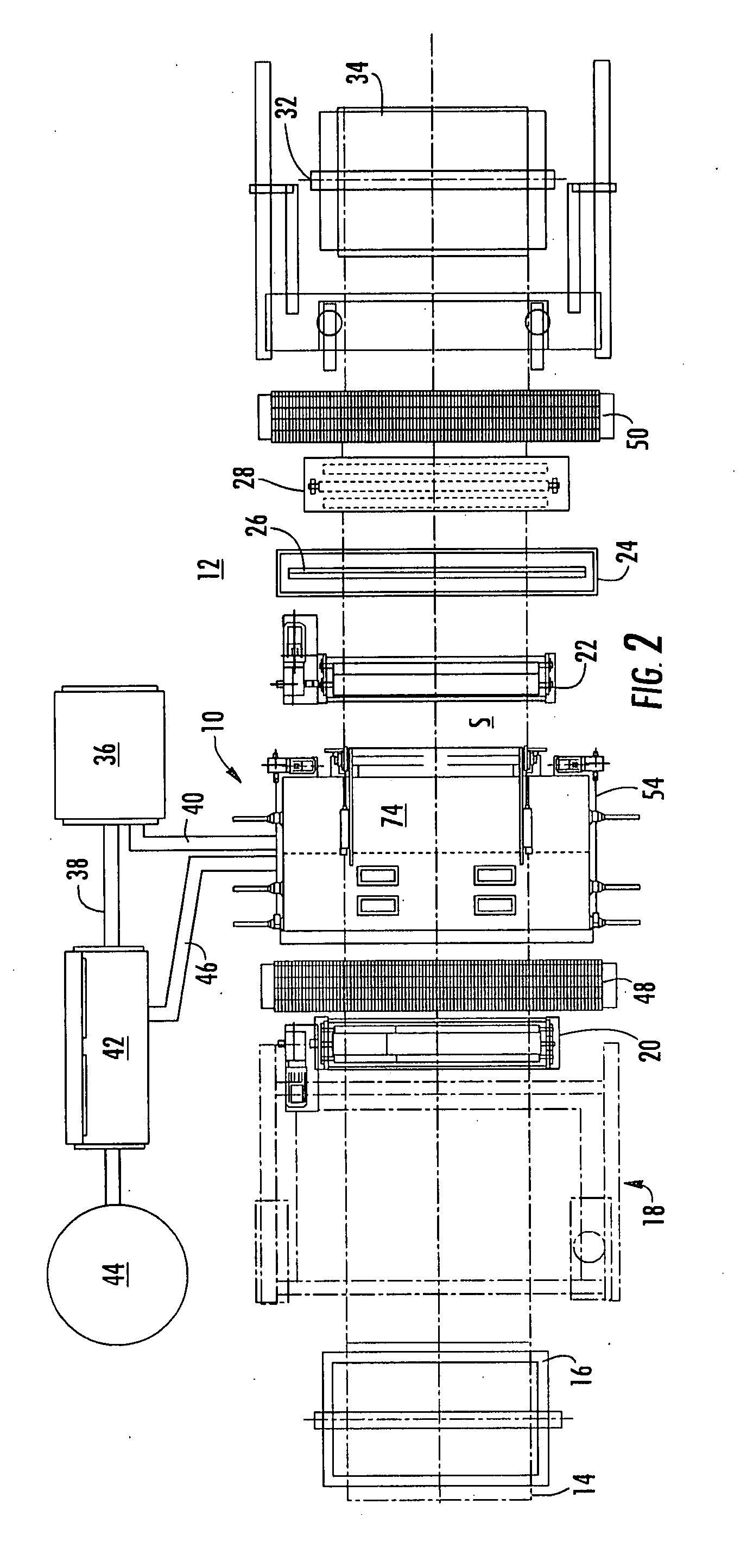

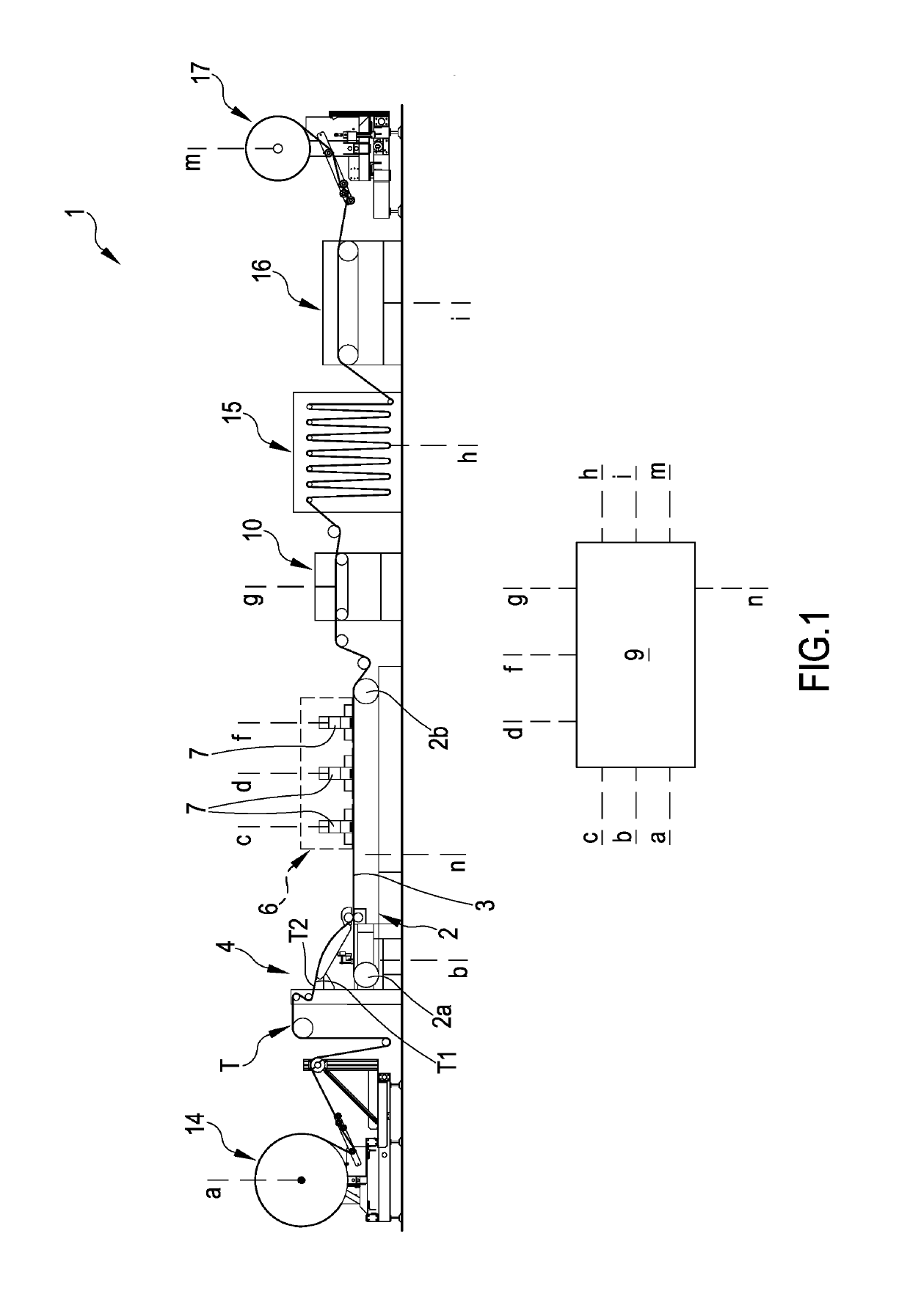

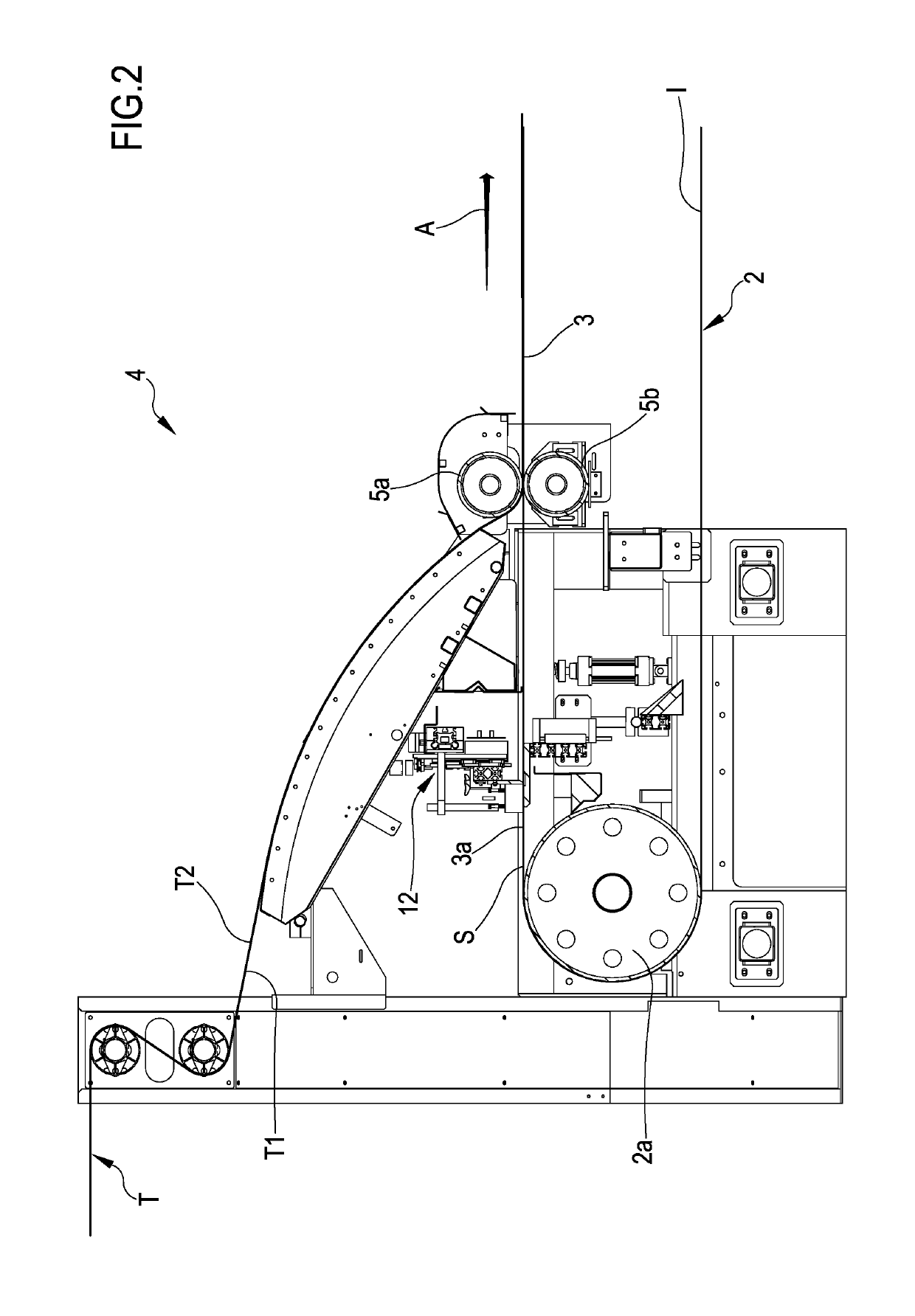

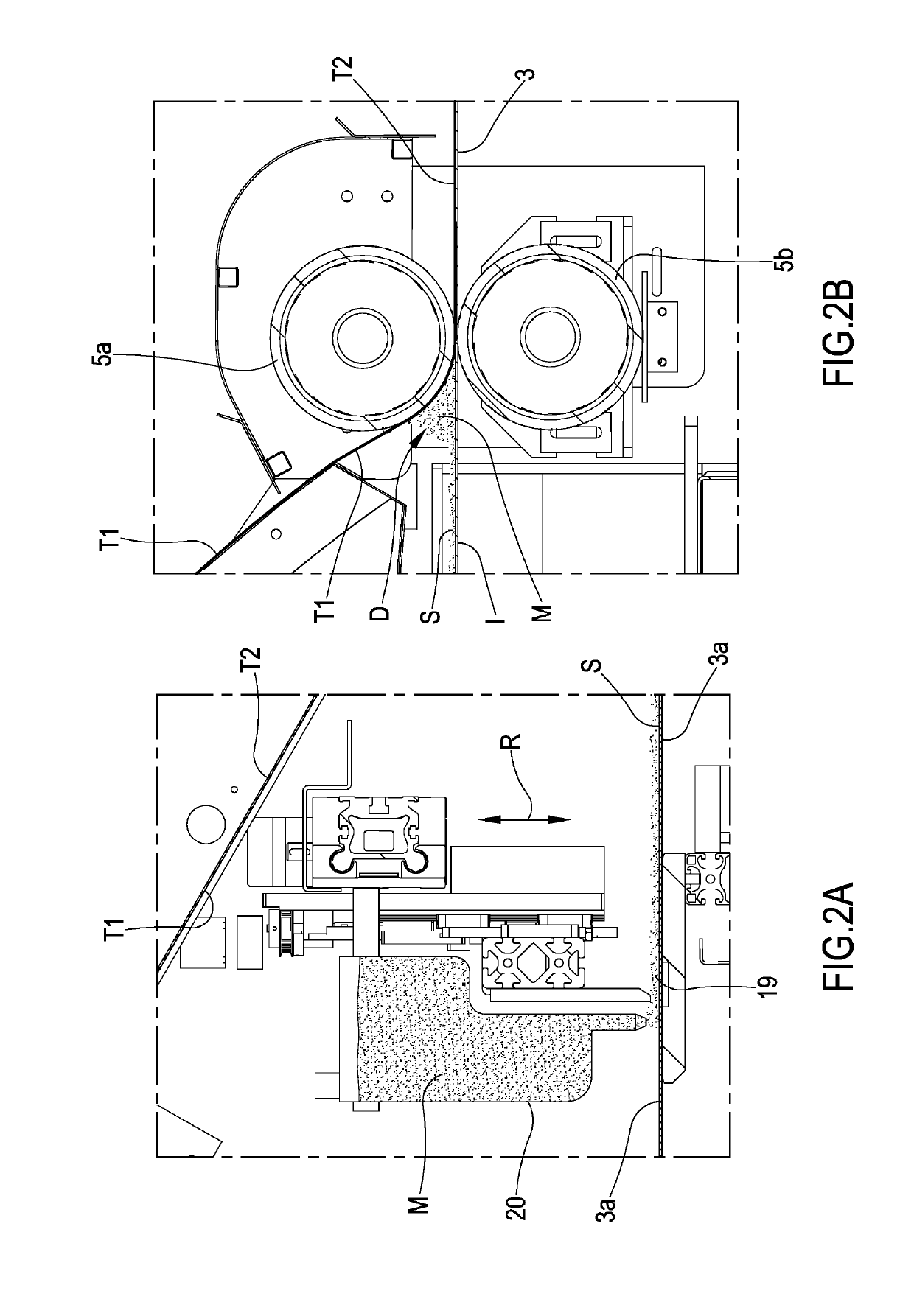

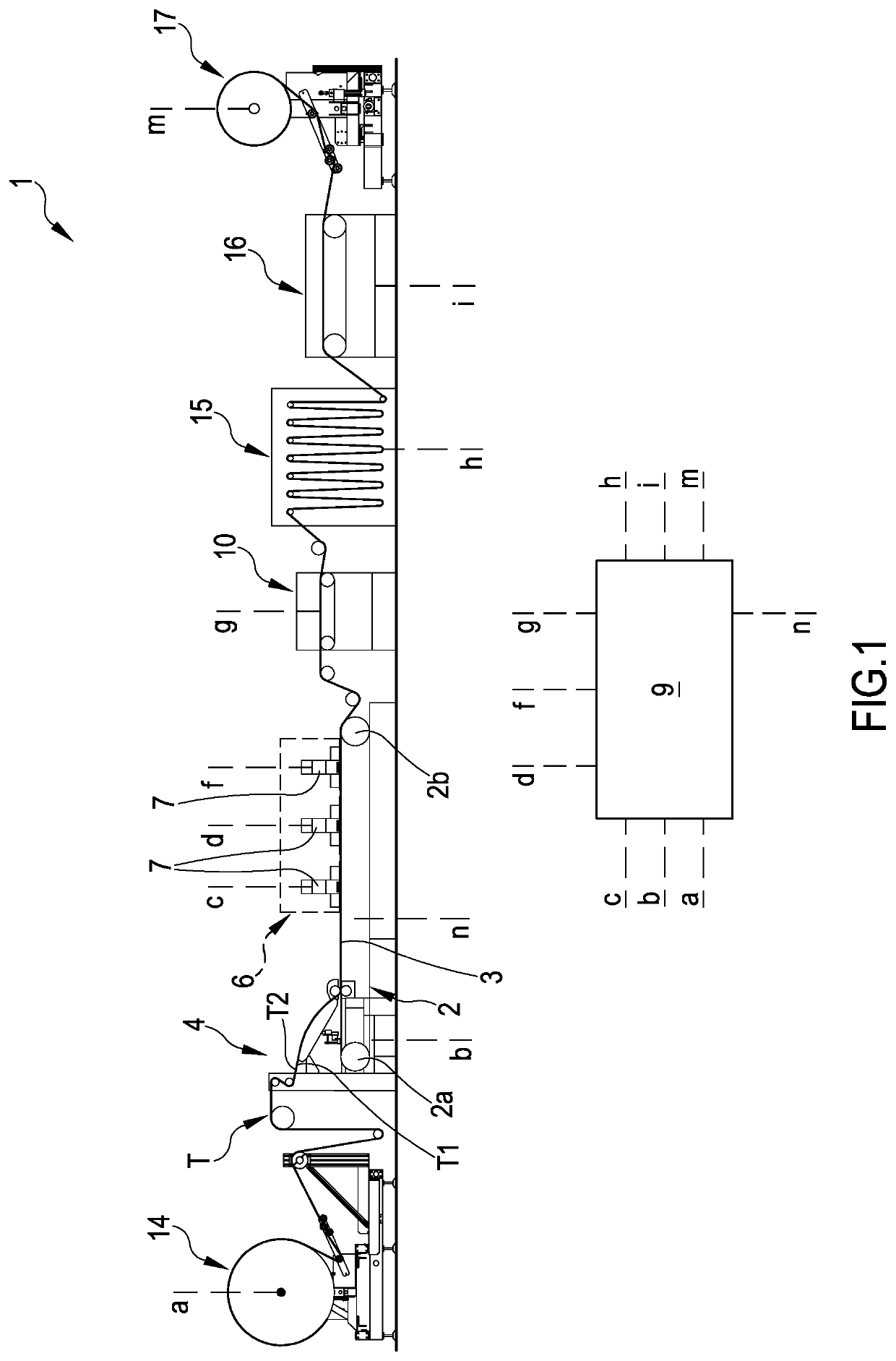

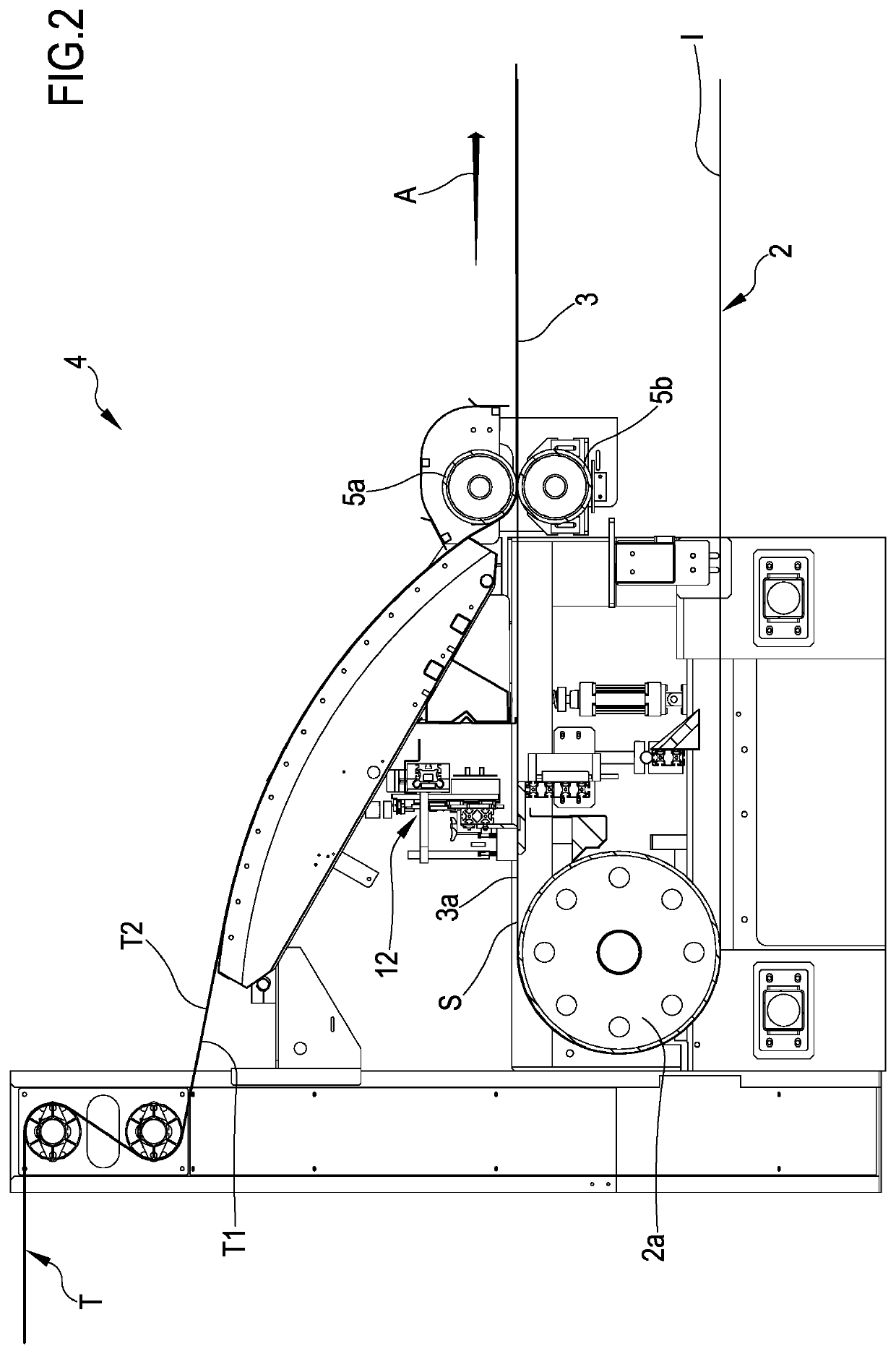

ActiveUS20190275808A1Effective treatmentOptimizationSucessive textile treatmentsDuplicating/marking methodsFiberEngineering

The present invention refers to a plant (1) for printing a fibrous material (T). The printing plant (1) comprises: a station (14) for supplying a fibrous material configured for supplying the fibrous material along a predetermined operative path, a treating station (10) configured for treating the fibrous material with a treatment composition by applying the composition itself on a first side (T1) of the fibrous material (T); and a printing station (6) configured for ink-printing at least part of a second side (T2) of the fibrous material (T) opposite to the first side (T1). Moreover, the present invention refers to a process of printing a fibrous material.

Owner:DOVER EURO SARL

Dyed, bleach-resistant fabrics and garments

A pad-dyed, foam-dyed, or exhaust-dyed pigment-colored, cellulose-based fabric that does not discolor upon chlorine bleaching of the fabric is provided. The fabric is dyed by grinding pigment colorants of a desired color to an ultra fine size and blending the grinded pigment colorants with one or more binders and, optionally, one or more additives, to form a padding paste. The padding paste or pigment paste is then prepared for pad dyeing, foam dyeing or exhaust dyeing, and the fabric is exhaust dyed, foam dyed or pad dyed using the prepared padding or pigment paste. Where the fabric is exhaust dyed or pad dyed, the fabric may be pre-treated by a pre-cationinzation process.

Owner:STERLING PRODS

Apparatus and method for applying a foamed composition to a dimensionally unstable traveling substrate

ActiveUS7431771B2Effective compositionEfficient and effectiveLiquid surface applicatorsOther washing machinesEngineeringMechanical engineering

An apparatus and method for applying a foamed composition to a traveling substrate that has a tendency to be dimensionally unstable. A pair of closely spaced driven guide rollers guides a traveling substrate with sufficient roller engagement and controlled tension to minimize dimensional distortion. A foam applicator with a substrate engaging foam dispensing nozzle face is positioned within the space between the rollers to deflect the substrate inwardly between the rollers. The face extends in close proximity to the rollers to minimize the free extent of travel of the substrate between the rollers and the nozzle face. Two pairs of guide rollers and two nozzles may be arranged for applying foamed composition to the opposite sides of the traveling substrate.

Owner:GASTON SYST INC

Dyeing and Finishing Method for Linen Cotton Textile Fabric with High-shrinkage

InactiveUS20170260687A1Increase fabric 's shrinkageIncrease the fabric's shrinkageTextile treatment containersSucessive textile treatmentsFiberEngineering

A dyeing and finishing method for linen cotton textile fabric with high-shrinkage is described in the present invention, comprises the steps as below: preprocessing, pickling, dyeing and shaping, which can make the fabric with sufficient shrinkage and provide a qualitative sense of linen cotton. Through the above way, in the dyeing and finishing method for linen cotton textile fabric with high-shrinkage provided by the present invention, washing treatment on the fabric by the preprocessing and the pickling before dyeing makes the colorizing more easy and decreases the color difference and colored spot after dyeing, opening the fiber of the fabric and cooling shrinkage during the dyeing process can obtain the unique product style, with a handle more like the linen cotton effect, and a pellet feeling appeared on the cloth cover and the product fabric more like the woven fabric.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

Yarn dyeing process

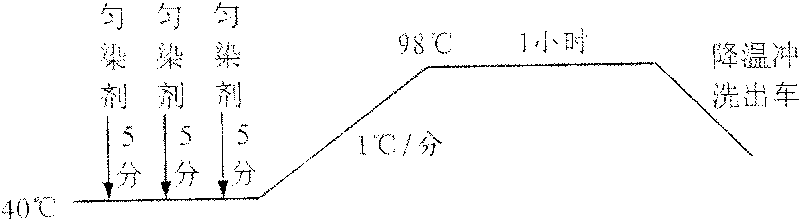

InactiveCN109652936AHigh color fastnessExtended service lifeSucessive textile treatmentsTwo or more solvent application treatmentColour fastnessYarn

The invention provides a yarn dyeing process which includes the steps: firstly, placing yarns on a loosening cylinder to loosen the yarns; secondly, adding the yarns into alkaline liquor to whiten theyarns, and adding stabilizers; thirdly, adding acid to neutralize the whitened yarns, and washing the neutralized yarns; fourthly, stewing the washed yarns at high temperature; fifthly, primarily dyeing the yarns stewed at high temperature; sixthly, steaming the primarily dyed yarns; seventhly, secondarily dyeing the steamed yarns; eighthly, adding the secondarily dyed yarns into a color fixing agent to fix colors of the yarns; ninthly, dewatering and drying the yarns, and baking the yarns. According to the method, primary dye fixation of the yarns is implemented in a steaming manner after primarily dyeing of the yarns is implemented, secondary dye fixation of the yarns is implemented in a baking manner after secondary dyeing of the yarns is implemented, fastness of dyed colors of the yarns is improved, the color of the yarns cannot be easily faded, and the service lives of the yarns are prolonged.

Owner:WUHU FUCHUN DYEING & WEAVING

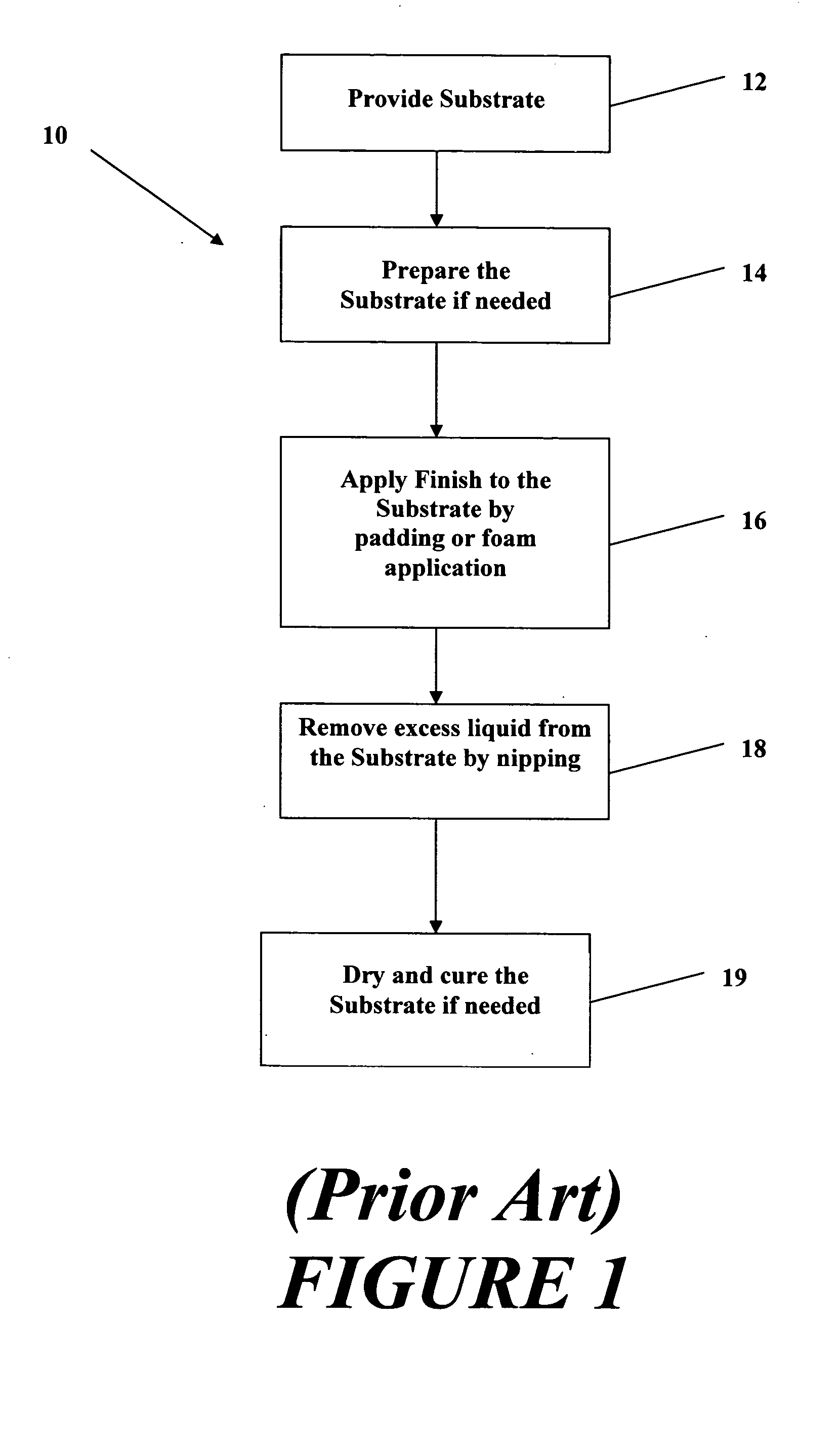

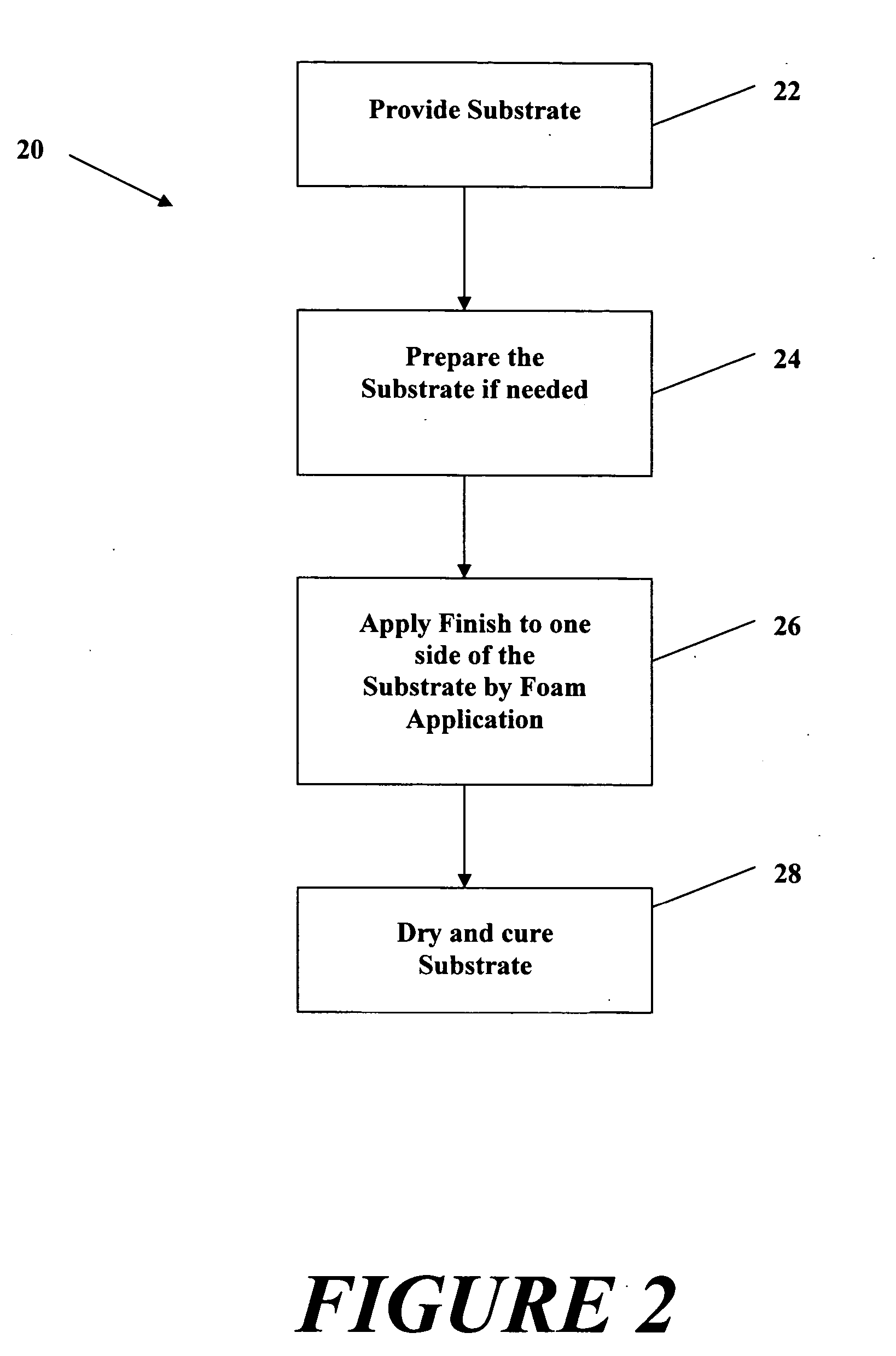

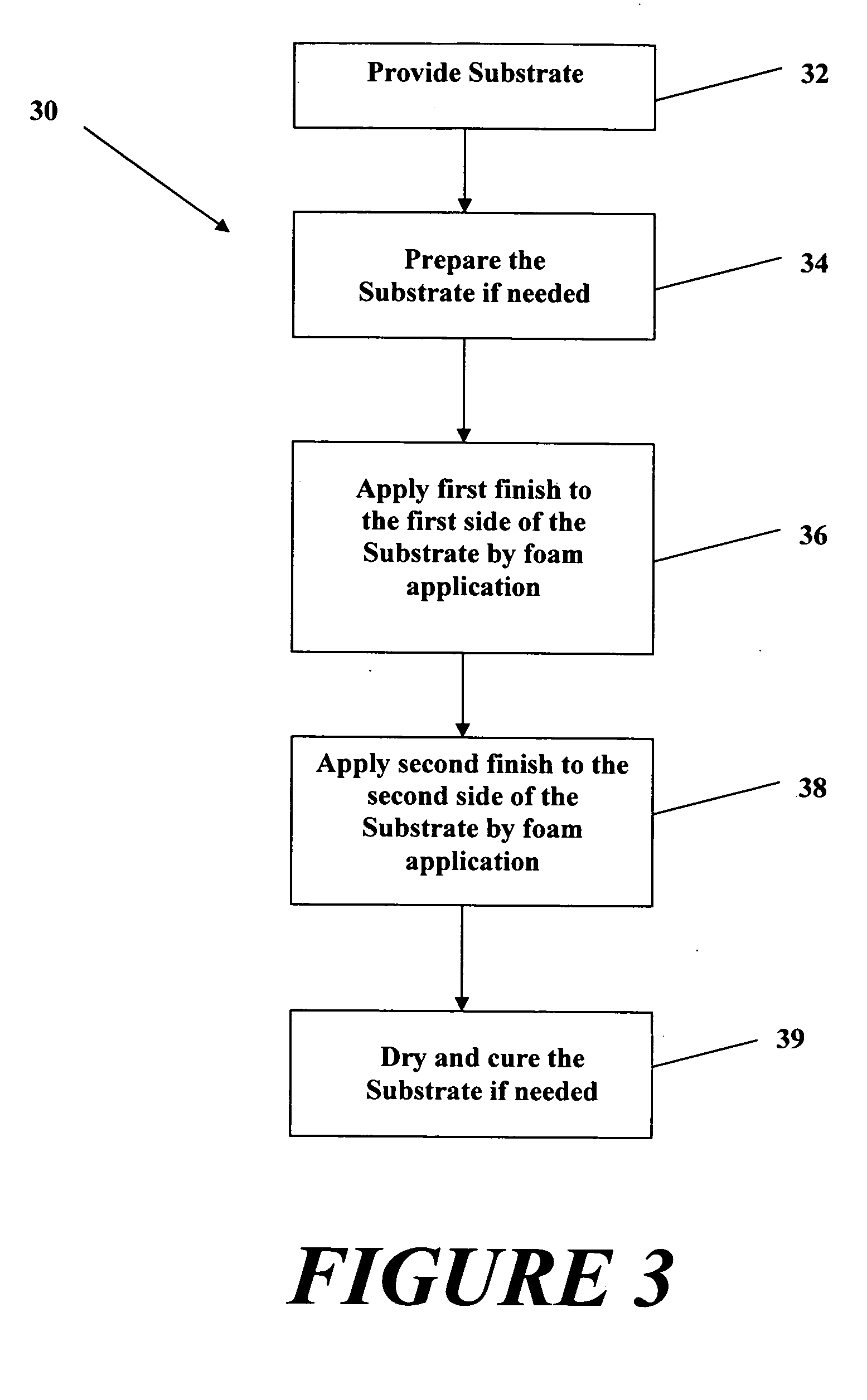

Fabric side-finishing method and products

A process for forming a substrate having a desired performance finish or finishes applied thereto. The process involves applying a foam containing a selected performance finish to a selected substrate side in such a manner that the performance finish is inhibited from transpassing through the substrate to the opposed substrate side. Accordingly, the performance characteristic of the finish is exhibited only on the side of the substrate to which the finish was applied. Additionally, the process may involve applying a second foam having a second distinct performance finish to the opposed side of the substrate in such a manner that only the second side exhibits the characteristics of the second finish. Various parameters used to control transpassing of the finish through the substrate include, singularly and / or in combination, finishing bath chemistry, foam characterization, pH of the finishing bath and freezing moisture that is within the substrate.

Owner:CLARIANT INT LTD

Digital printing system for printing on fabric including foam pretreatment

ActiveUS11390092B2Effective treatmentOptimizationSucessive textile treatmentsDuplicating/marking methodsDigital printingMechanical engineering

Owner:DOVER EURO SARL

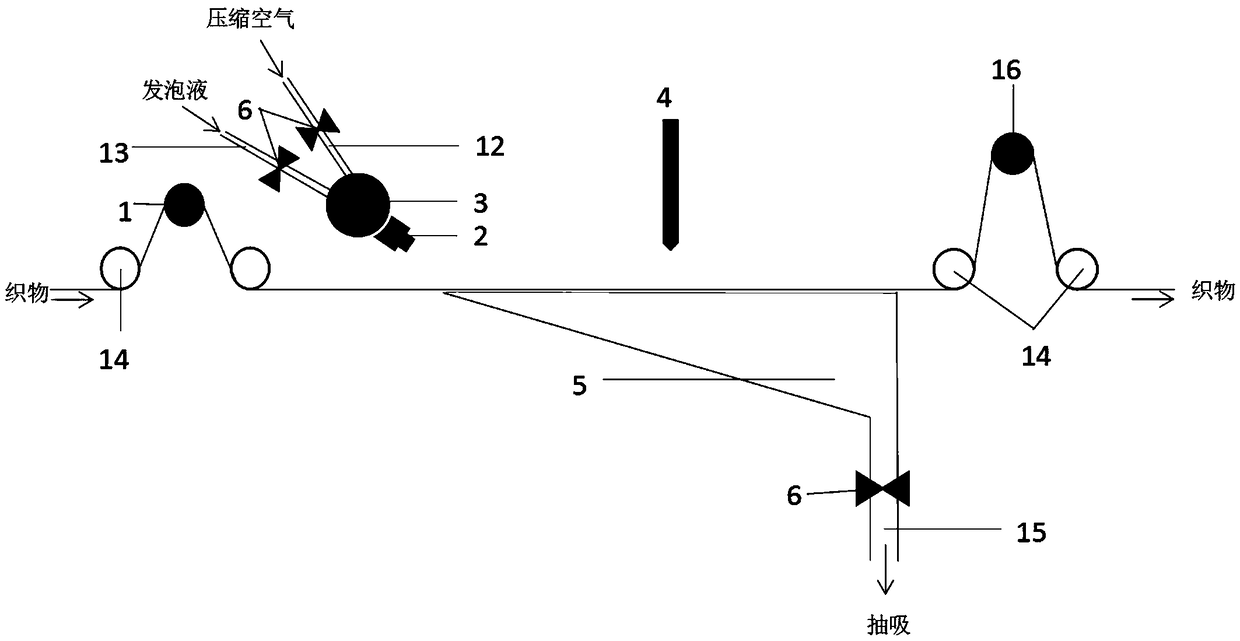

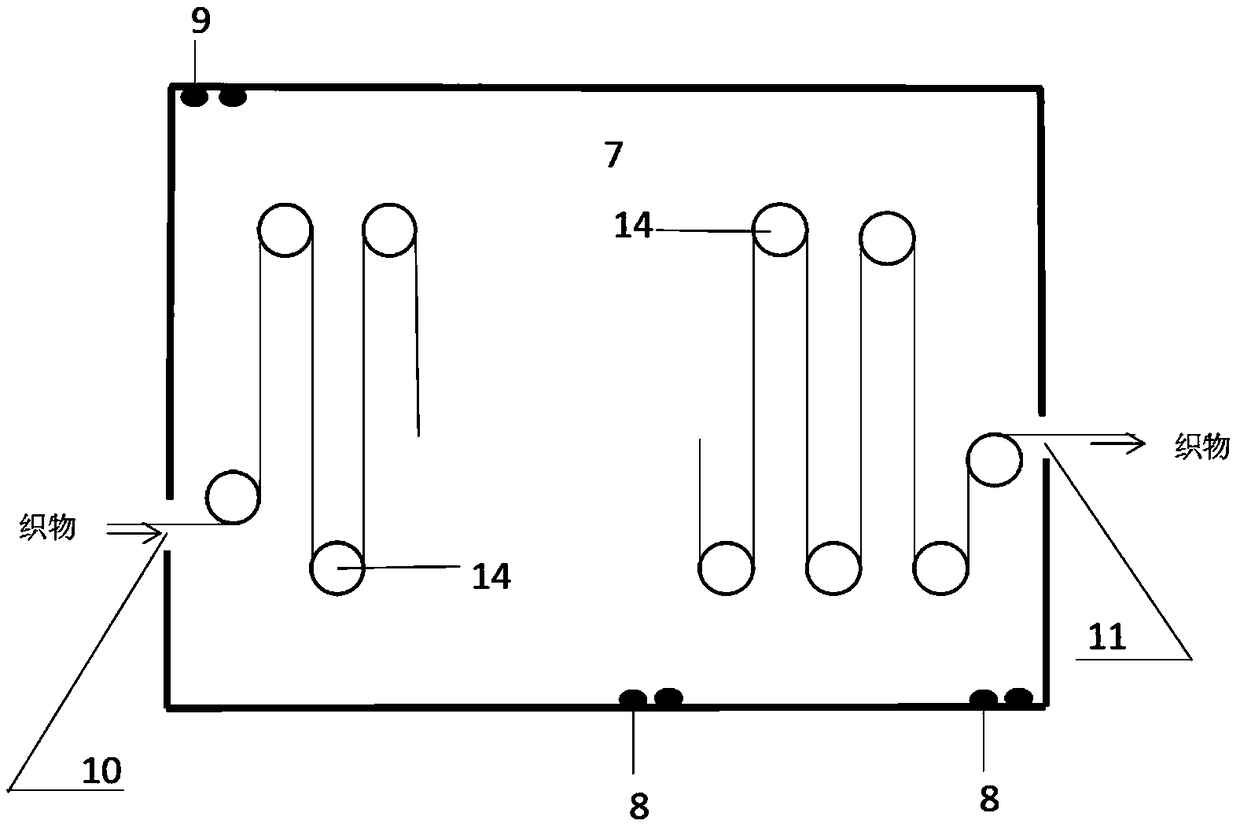

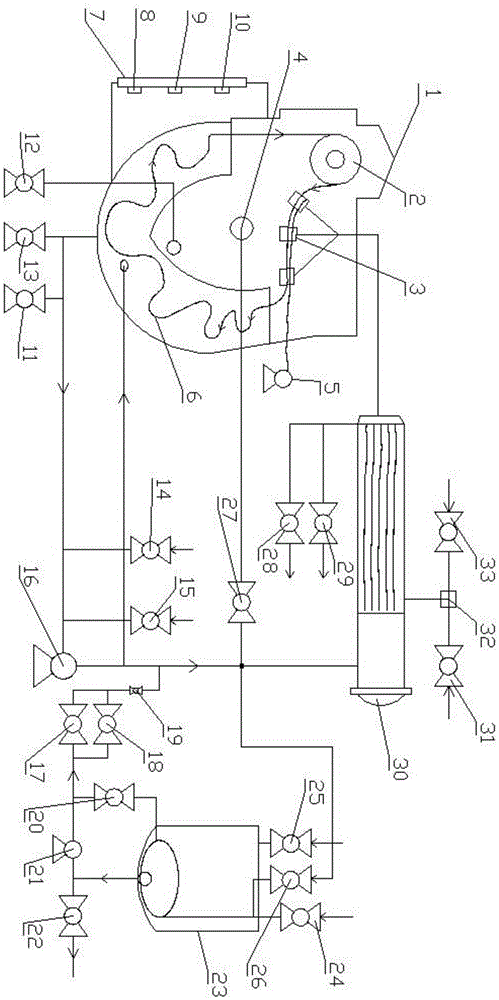

Device for continuous dyeing through bubble wet steaming

PendingCN109402916AHigh color fixing rateReduce hydrolysisSucessive textile treatmentsTextile treatment using short bath ratio liquorEngineeringControl valves

The invention provides a device for continuous dyeing through bubble wet steaming, and belongs to the field of textile dyeing and finishing. The device mainly comprises a bubble applying device, a suction device, a steaming box and a cloth conveying device. The bubble applying device mainly comprises a plurality of spraying guns and a height-limiting plate, and the spraying guns are transversely uniformly arranged along the cloth width; the suction device mainly comprises an inverted suction hood and a control valve; the steaming box mainly comprises a box body and a plurality of cloth guide rollers which rotate synchronously. When dyeing is conducted by using the device, pickup of a fabric obtained before steaming is low to 15-35%, the device is suitable for dyeing cotton fabrics with reactive dyes, the situation that after a high-pickup fabric enters a steaming box, the steaming fixation conditions largely fluctuate is avoided, the fixation rate of the reactive dyes is improved, andcotton fabrics with different dyeing effects can be obtained by adjusting the device and a dyeing process.

Owner:SHANGHAI UNIV

Pad-dyed, bleach-resistant fabrics

A pad-dyed or foam-dyed, pigment-colored, cellulose-based fabric that does not discolor upon chlorine bleaching of the fabric is provided. The fabric is dyed by grinding pigment colorants of a desired color to an ultra fine size and blending the grinded pigment colorants with one or more binders and, optionally, one or more additives, to form a padding paste. The padding paste is then prepared for pad dyeing or foam dyeing, and the fabric is pad dyed or foam dyed using the prepared padding paste.

Owner:STERLING PRODS

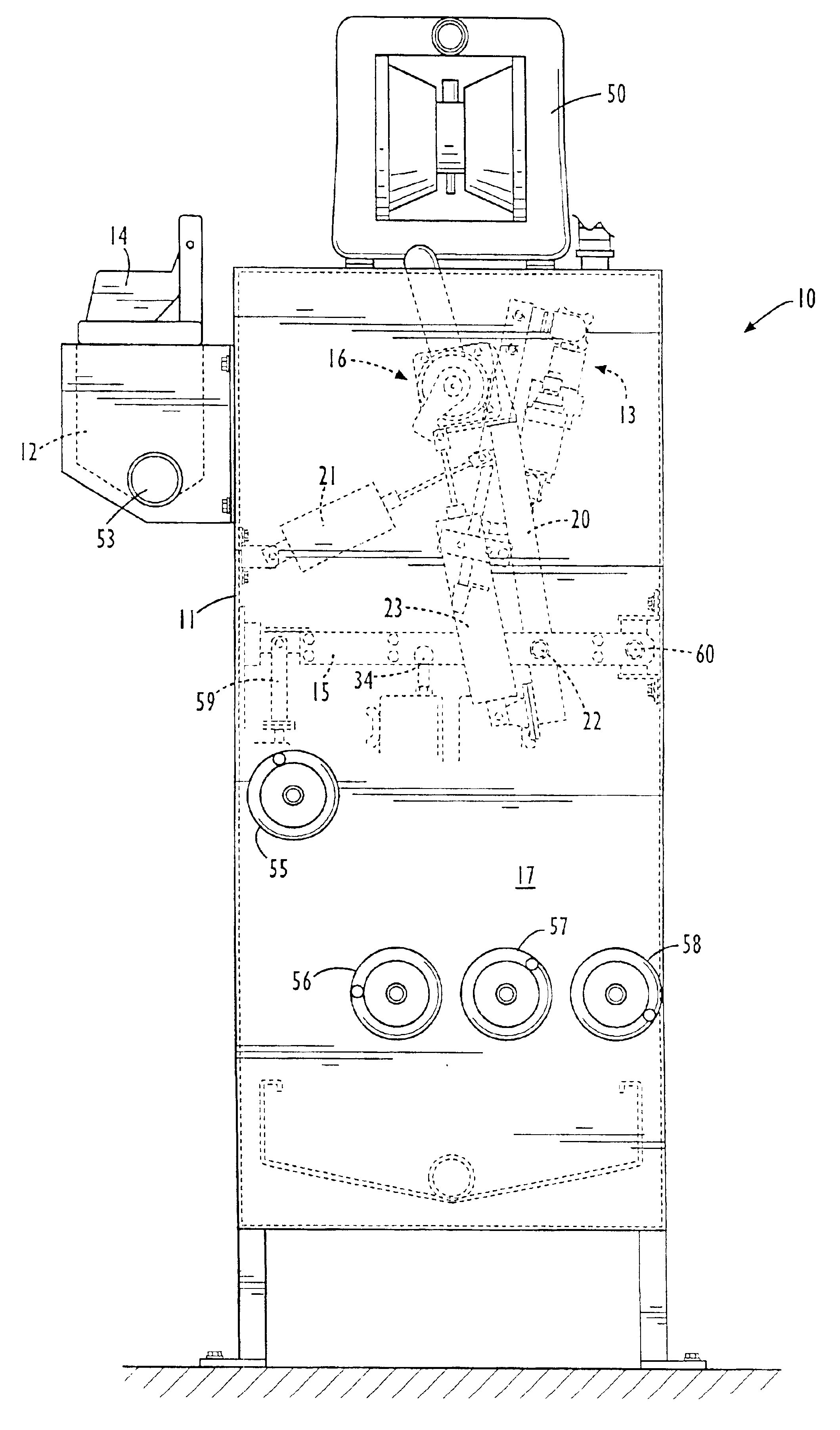

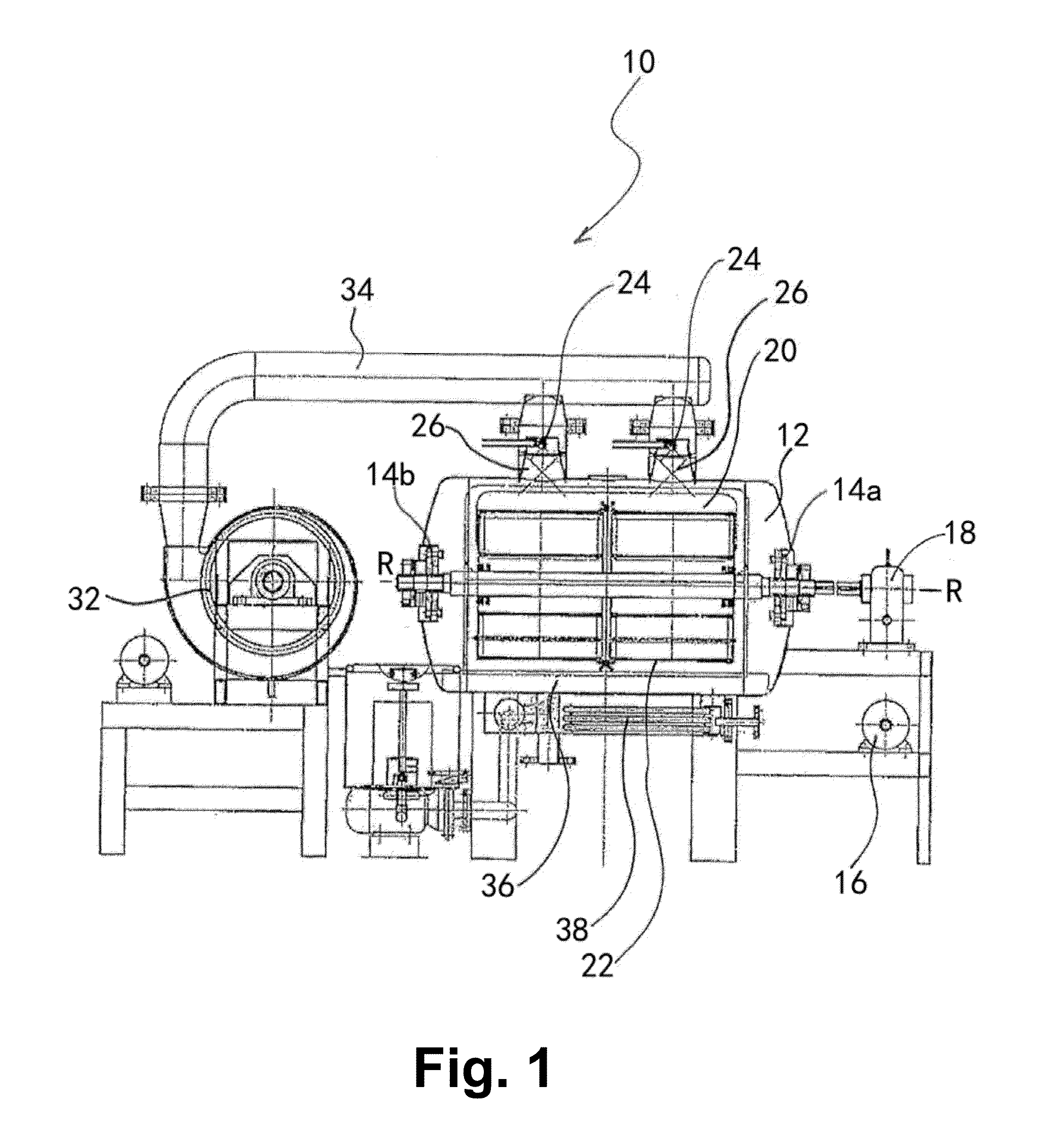

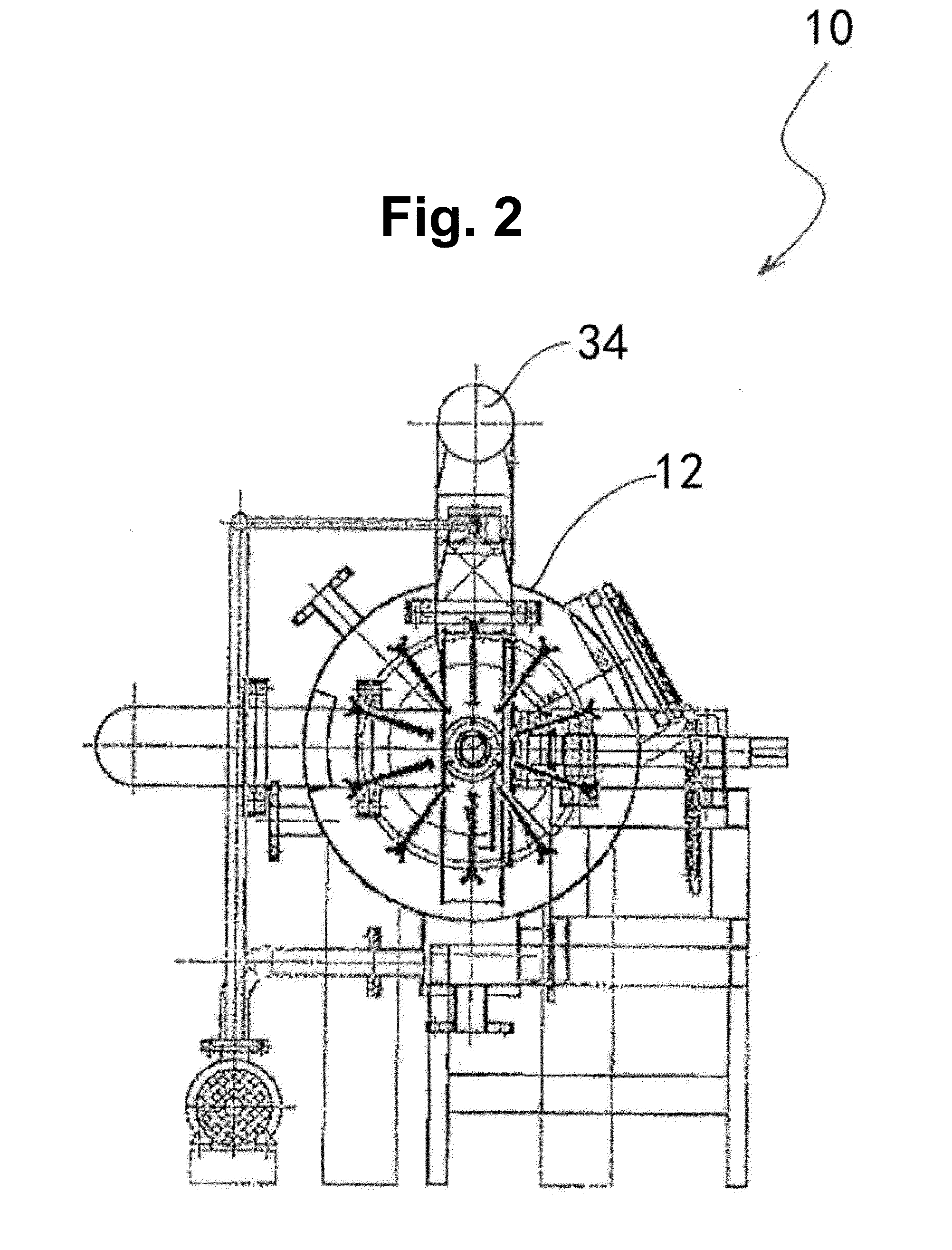

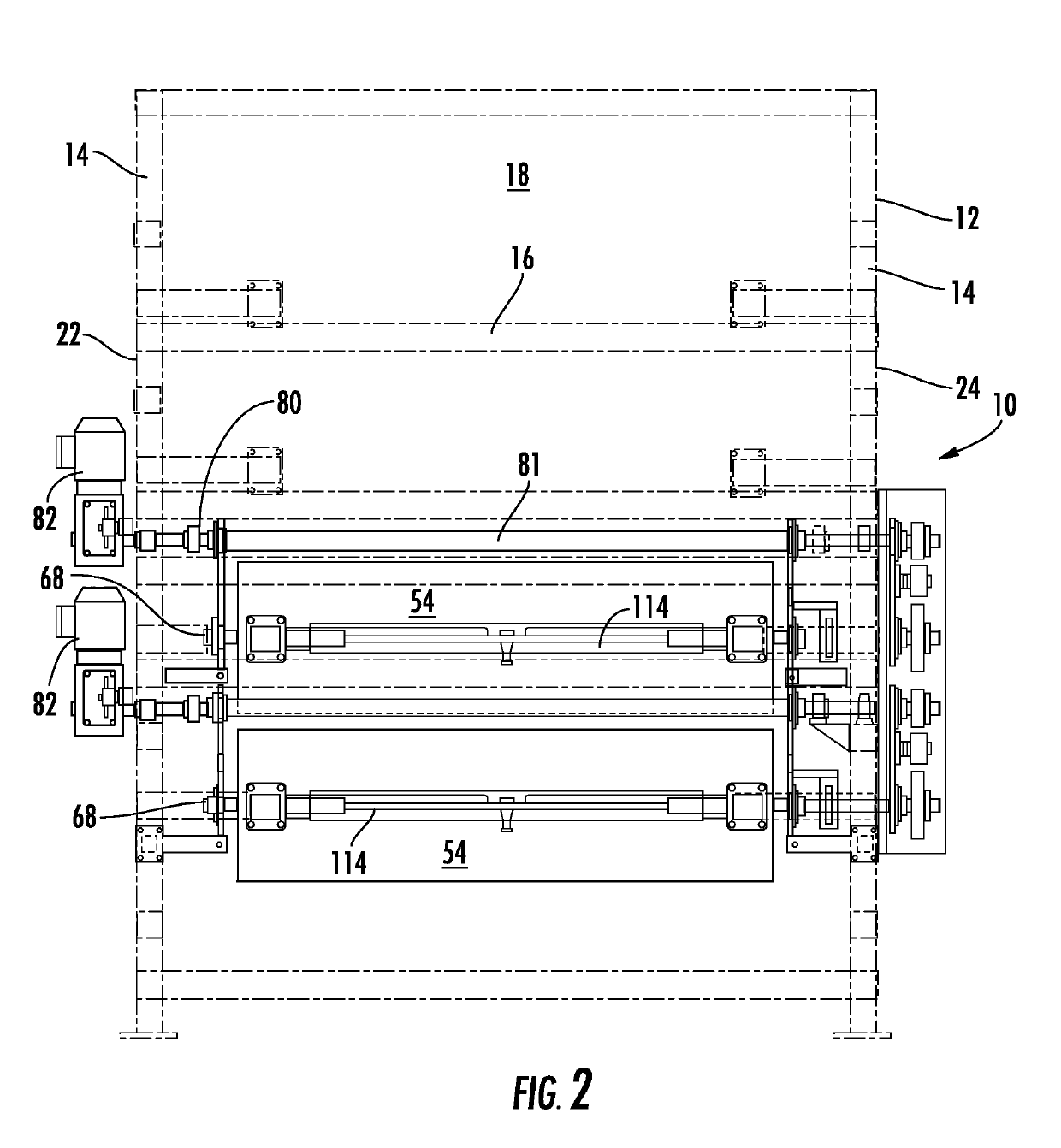

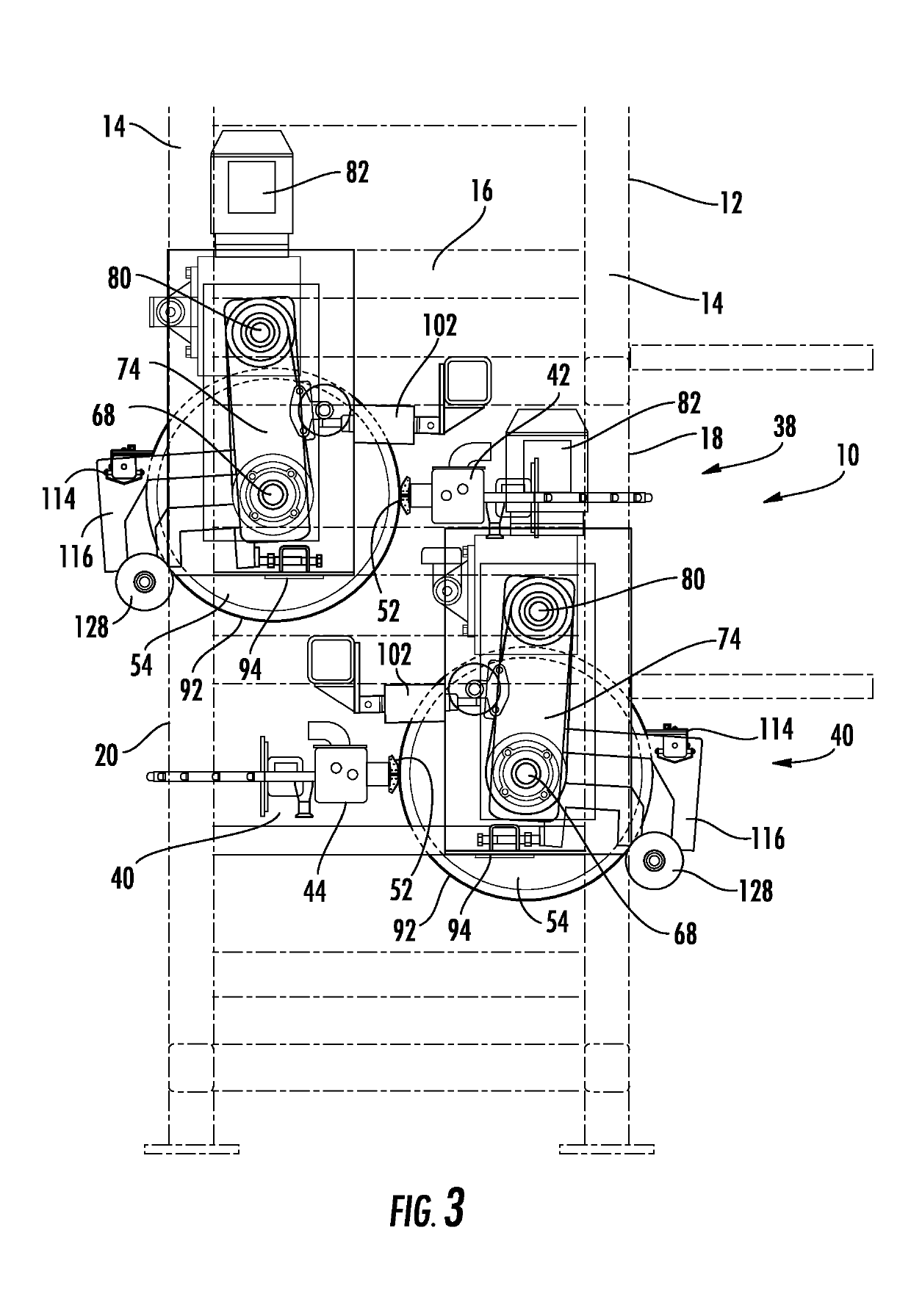

Garment Dyeing Machine

ActiveUS20130219971A1Textile treatment containersTextile treatment using short bath ratio liquorGarment dyerDyeing

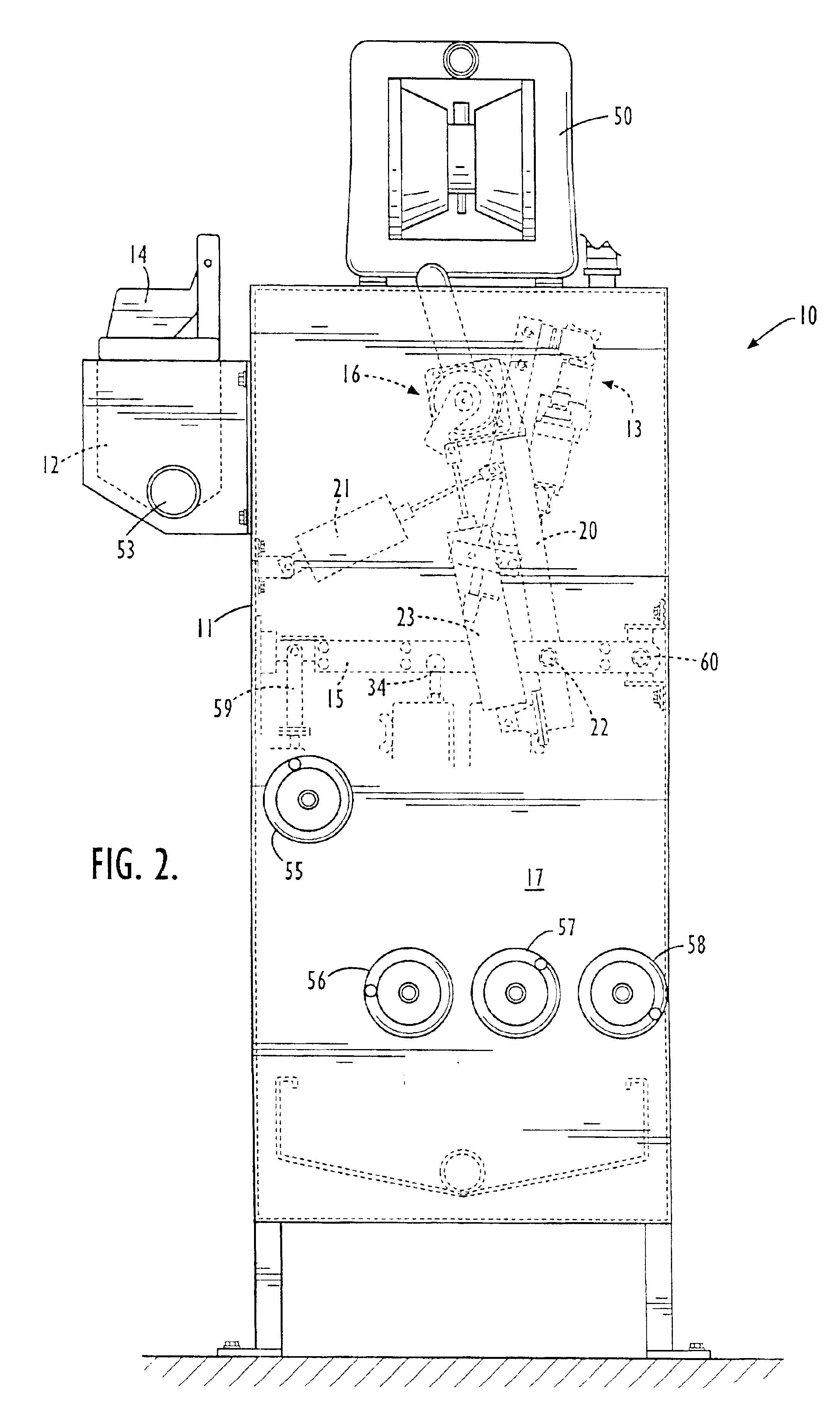

A garment dyeing machine (10) includes a container (12), a roller (22) to which brassieres are releasably attachable, the roller (22) being within the container (12) and rotatable relative to the container (12) about an axis of rotation (R-R), the garment dyeing machine having two nozzles (24) for spraying a dye solution onto the roller (22).

Owner:CLOVER MYSTIQUE CO LTD

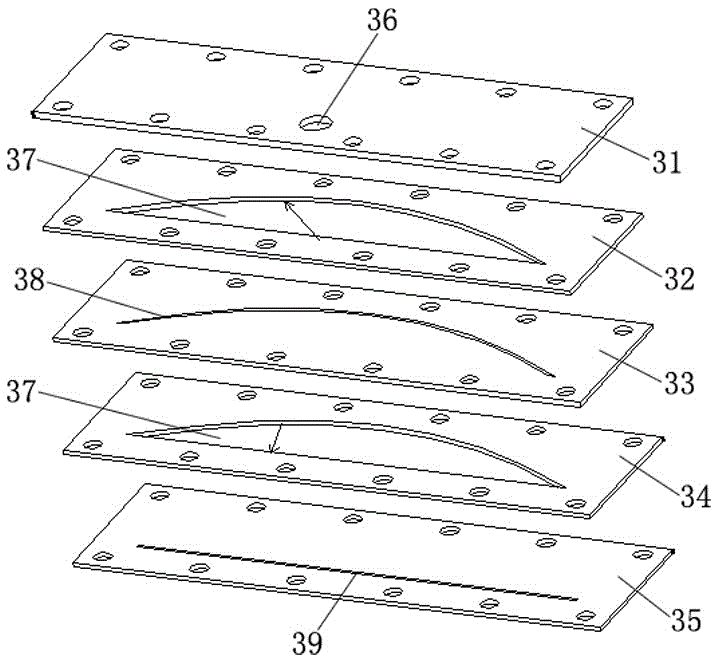

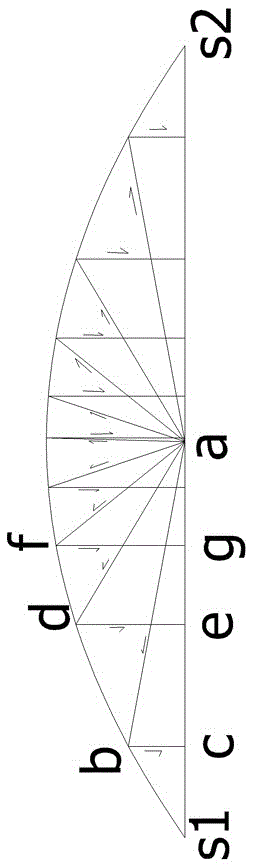

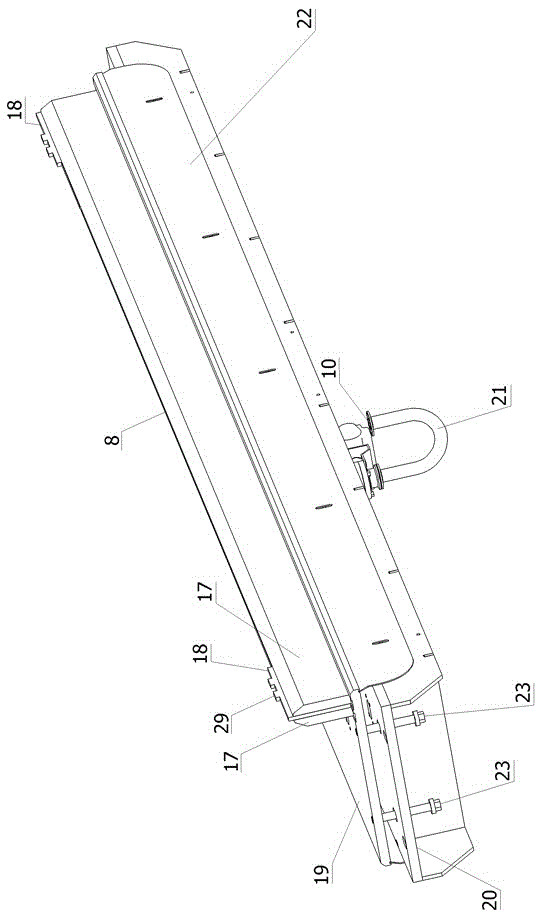

Joint board, foam applying mechanism and foam applying arranging device

PendingCN106436104ANo head and tail chromatic aberrationTextile treatment using short bath ratio liquorTextile treatment carriersEngineeringControl circuit

The invention discloses a joint board, a foam applying mechanism and a foam applying arranging device. The joint board comprises a first board piece, a second board piece, a third board piece, a fourth board piece and a fifth board piece which are sequentially stacked and connected together from top to bottom. The first board piece is provided with a through hole adopted as a foam inlet, the second board piece is provided with an inferior arc arch gap, the third board piece is provided with a front-back through parabolic crack, the fourth board piece is provided with an inferior arc arch gap, and the fifth board piece is provided with a front-back through long-strip-shaped crack adopted as a foam outlet. The joint board can enable the foam conveying path continues to be attenuated uniformly. The foam applying mechanism comprises a supporting frame, the joint board installed on the supporting frame and a long-strip-shaped scraper arranged on the joint board, a knife edge of the scraper is provided with a foam outlet, the foam inlet of the joint board is communicated with a foam input pipe, and the foam outlet of the joint board is communicated with the foam outlet of the scraper. The foam applying arranging device comprises a machine frame, the foam applying mechanism, an edge sealing mechanism and a control circuit.

Owner:上海技楷机电设备有限公司

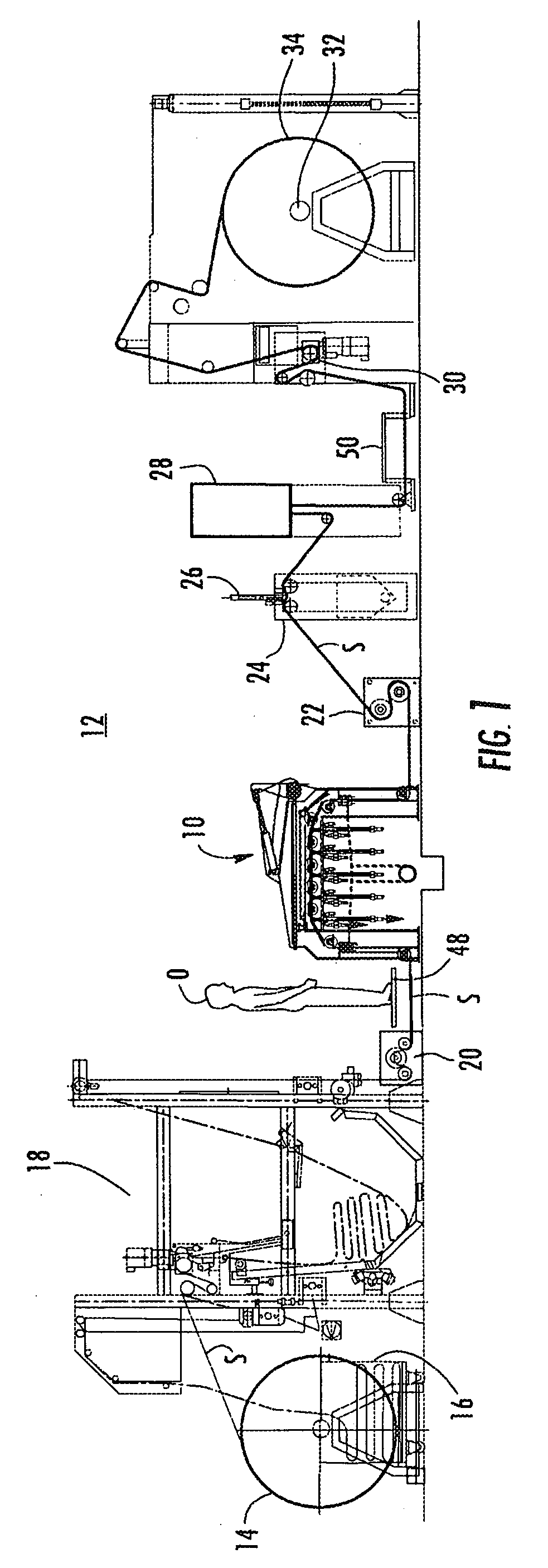

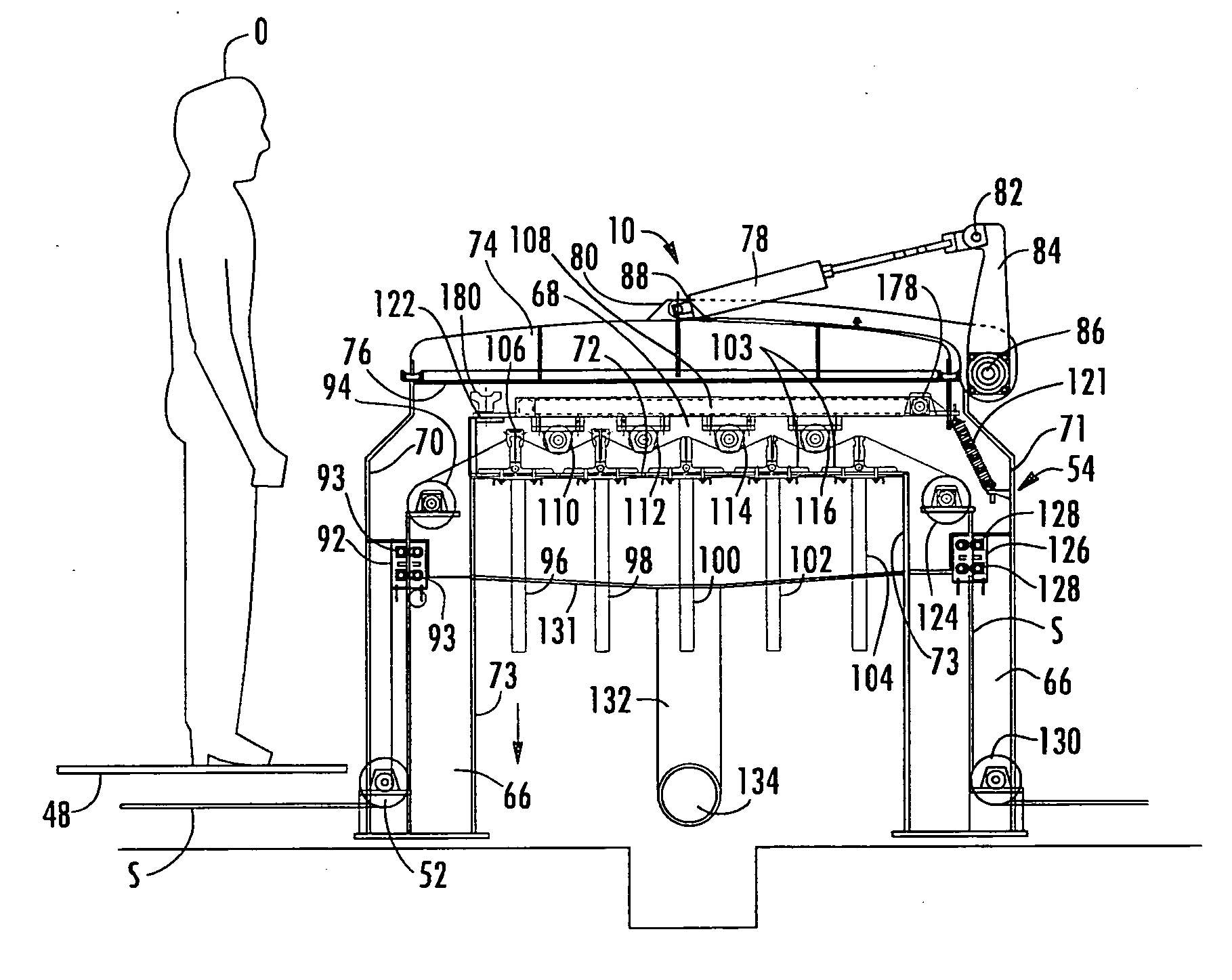

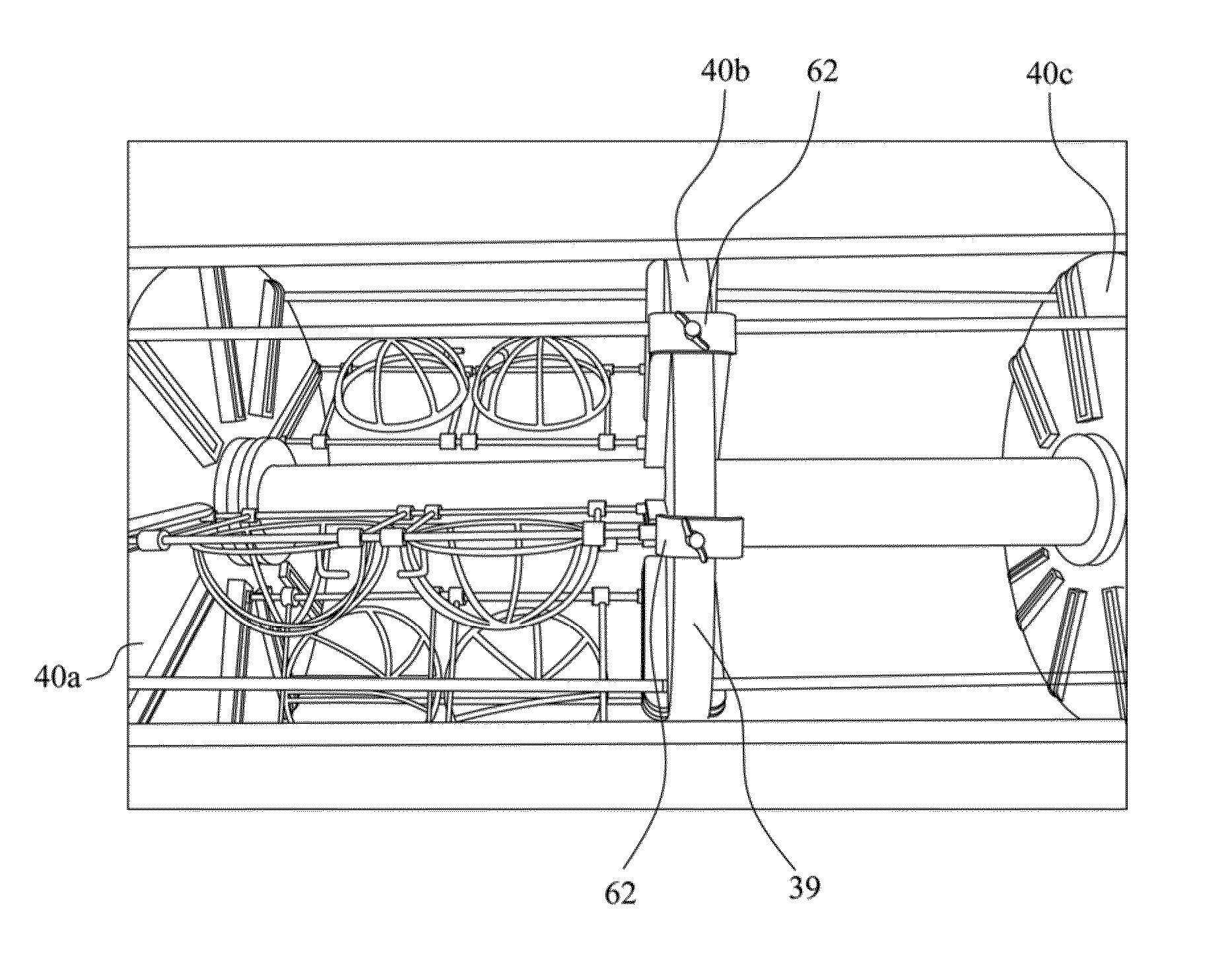

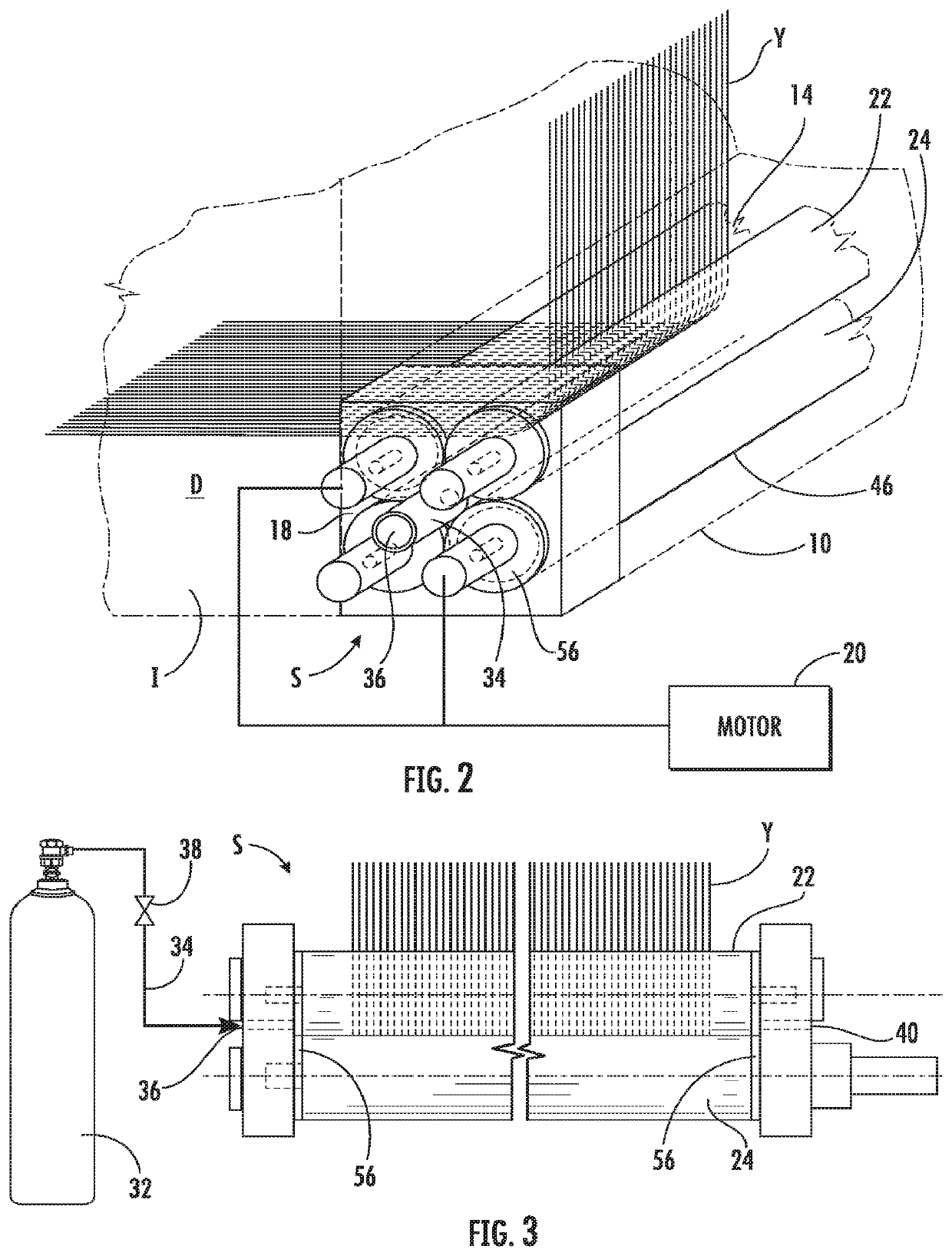

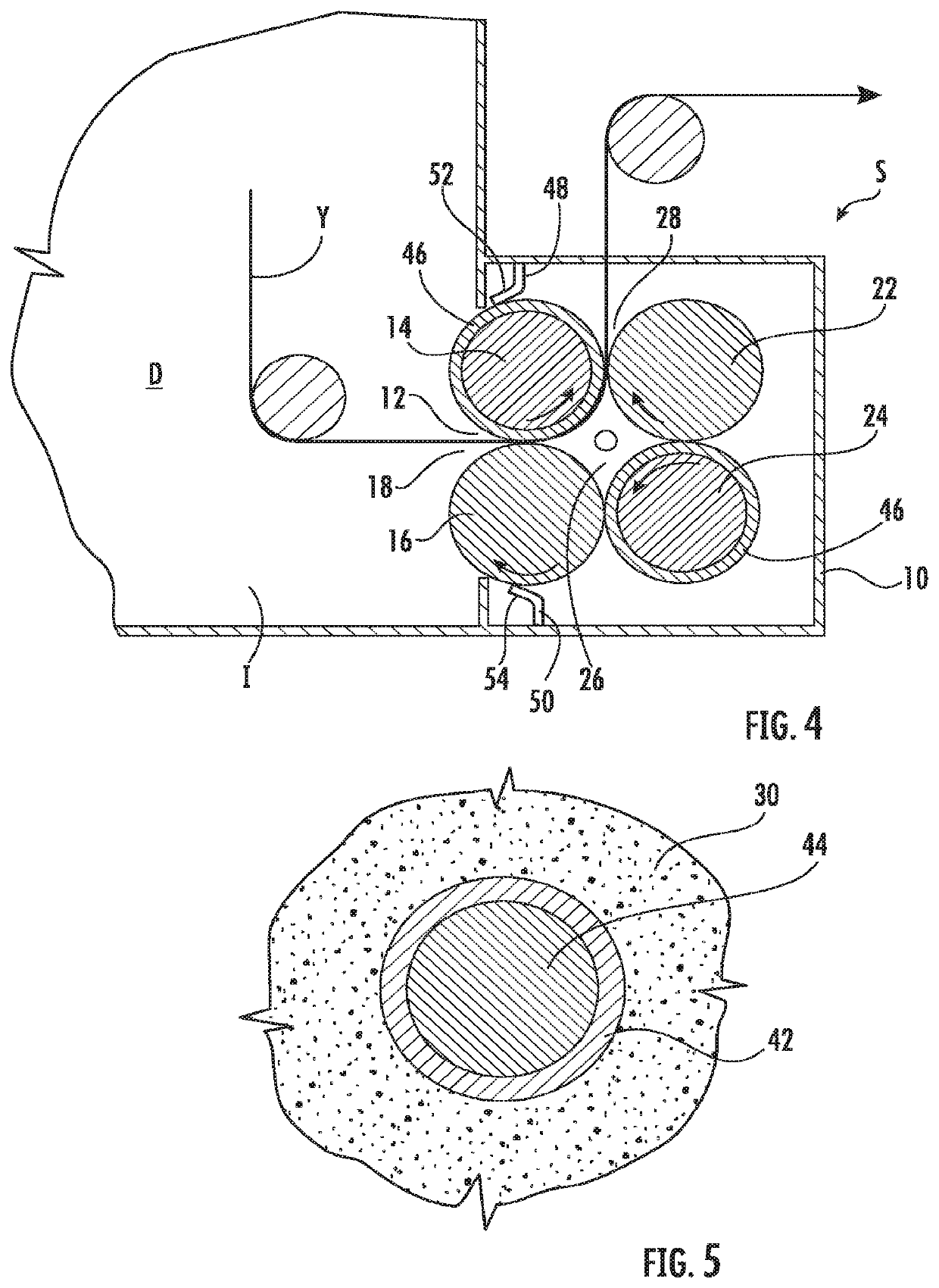

Dye fixing section for an indigo dyeing machine

ActiveUS20200224347A1Textile treatment containersChemical fixing of textilesPolymer scienceTextile yarn

A dye fixing section in a foam indigo dyeing machine for dyeing traveling sheets of textile yarn. The dye fixing section receives traveling sheets of yarn to which indigo dye in leuco form has been applied and penetrated partially through the yarn. Oxygen is applied to the substrate to set the dye at the level of penetration achieved as it enters the dye fixing section, to produce yarns in the sheet with outer dyed rings and undyed cores.

Owner:GASTON SYST INC

Splitting process for modal and cuprammonium rayon

InactiveCN108265439AReduce tensionSave energyTextile treatment using short bath ratio liquorTextile treatment machine arrangementsCuprammonium rayonPulp and paper industry

The invention relates to the technical field of fabric dyeing and finishing, in particular to a splitting process for modal and cuprammonium rayon. The process comprises the following specific steps:a multifunctional dyeing machine with small bath ratio is adopted for processing and comprises a rack, a padder, a cloth guide roller I, a cloth guide roller II and a dye vat, wherein the padder is arranged at one end of the rack, the cloth guide roller I is arranged on the side, opposite to the padder, of the rack, the dye vat is arranged under the rack, a downwards concave liquid storage grooveis formed in the bottom of the dye vat, and the cloth guide roller II is arranged in the liquid storage groove; an acidic splitting solution is added to the liquid storage groove and contains sulfuricacid with concentration of 5-10 g / L, fabric is processed by the multifunctional dyeing machine at 80 DEG C for 60 min, and the bath ratio is 1:3. The multifunctional dyeing machine with small bath ratio is adopted for splitting processing and is low in rotation speed and tension, the fabric is in a loose state, and iron-shine marks and crease marks cannot be produced.

Owner:嘉兴市桑田新材料科技有限公司

Device for applying a foamed treating material under pressure to a traveling sheet of textile yarn

ActiveUS10704174B2Prevent leakageUneven distribution of resistanceLiquid surface applicatorsFilament handlingTextile yarnEngineering

A device for applying a foamed treating material under pressure to a traveling sheet of relatively incompressible textile yarns. A foam applicator unit has a nozzle with a foam dispensing slot facing across one side of the traveling sheet of yarns. A drive roll faces the other side of the traveling sheet of yarns in tangential alignment with the foam dispensing slot. The roll has a resiliently compressible, soft rubber outer layer, which compresses to conform with the surface of the relatively incompressible yarns and presses the traveling sheet of yarns against the applicator surfaces leading to and away from the slot to prevent escape of foam and to prevent passage of foam between yarns to maintain uniform distribution of foam applied to the traveling sheet of yarns.

Owner:GASTON SYST INC

Device for applying a foamed treating material under pressure to a traveling sheet of textile yarn

ActiveUS20190136430A1Minimize abrasion of surfacePrevent leakageLiquid surface applicatorsTextile treatment machine partsTextile yarnEngineering

A device for applying a foamed treating material under pressure to a traveling sheet of relatively incompressible textile yarns. A foam applicator unit has a nozzle with a foam dispensing slot facing across one side of the traveling sheet of yarns. A drive roll faces the other side of the traveling sheet of yarns in tangential alignment with the foam dispensing slot. The roll has a resiliently compressible, soft rubber outer layer, which compresses to conform with the surface of the relatively incompressible yarns and presses the traveling sheet of yarns against the applicator surfaces leading to and away from the slot to prevent escape of foam and to prevent passage of foam between yarns to maintain uniform distribution of foam applied to the traveling sheet of yarns.

Owner:GASTON SYST INC

Shell fabric bubble dyeing device

InactiveCN108130677AGood random color distributionStrong randomnessTextile treatment using short bath ratio liquorEngineeringGas generator

The invention discloses a shell fabric bubble dyeing device. A plurality of foaming pipes are arranged in a dye liquor tank, a pipeline cavity is arranged at the lower part of the dye liquor tank, anair flow main pipe and air flow branch pipes are arranged in the pipeline cavity, the air flow branch pipes are arranged in corresponding foaming pipes, gas generated by a gas generator is conveyed into the air flow branch pipes through the air flow main pipe and gas distribution pipes, the air flow branch pipes are arranged in the foaming pipes, the opening ends of the air flow branch pipes are lower than the upper end of the foaming pipes, gas in the air flow branch pipes rises from the air flow branch pipes to form bubbles in the foaming pipes, and the bubbles slowly rise in the foaming pipe and are broken when rising to the liquid level position of the dye liquor tank. As bubble breaking has the obvious random characteristic, the shell fabric can obtain very good random color distribution after being dyed and has unique artistic value.

Owner:PINGHU YIFANJIA LUGGAGE CO LTD

A method for dyeing knitted fabrics with low active bath ratio

ActiveCN104611952BEasy to useImprove the use of largeLiquid/gas/vapor treatment of propelled fabricsBiochemical fibre treatmentAfter treatmentHigh energy

The invention belongs to the technical field of textile processing and relates to a low activity liquor ratio dyeing method for knitted fabrics. The knitted fabrics are dyed by performing steps such as knitted fabric pre-treatment, dyeing, knitted fabric post-processing and finishing in a low activity liquor ratio dyeing system device. Dyeing; adopts ultra-low pre-treatment liquid level and dye liquid water level adjustment and control technology to achieve energy-saving dyeing; improve traditional knitted fabric overflow dyeing's large water consumption, large use of dyeing materials and additives, and long dyeing time, etc. It effectively solves the problems of high pollution and high energy consumption in knitted fabric dyeing; its overall process is simple, scientific design principle, safe and reliable operation, good energy saving and emission reduction effect, and environmentally friendly dyeing.

Owner:QINGDAO FURUNDA TEXTILE

Methods of treating textiles with foam and related processes

PendingCN112639205AReduce the amount of waterNo inhalation-related problemsFibre treatmentTextile treatment machine partsProcess engineeringChemical products

The present invention offers a new approach to the treatment of garments, including novel compositions and related methods using foam as a carrier of chemical products that are used during the industrial treatment of textiles. Another aspect of the invention relates to methods for reducing total water content necessary in industrial treatment of garments. Another aspect of the present invention relates to processes and methods of forming a foam that can be used for textile treatment.

Owner:KEMIN IND INC

Popular searches

Liquid/gas/vapor treatment of definite length materials Pump installations Liquid/gas/vapor yarns/filaments treatment Non-positive displacement fluid engines Dyeing process Textile treatment by spraying/projecting Sulfur dyes Indigoid dyes Textile treatment cleaning apparatus Textile treatment with treating outlet contect

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com