Patents

Literature

116 results about "Holddown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Holddown works by having each router start a timer when they first receive information about a network that is unreachable. Until the timer expires, the router will discard any subsequent route messages that indicate the route is in fact reachable. It can solve the case where multiple routers are connected indirectly. There are realistic scenarios where split horizon and split horizon with poisoned reverse can do nothing.

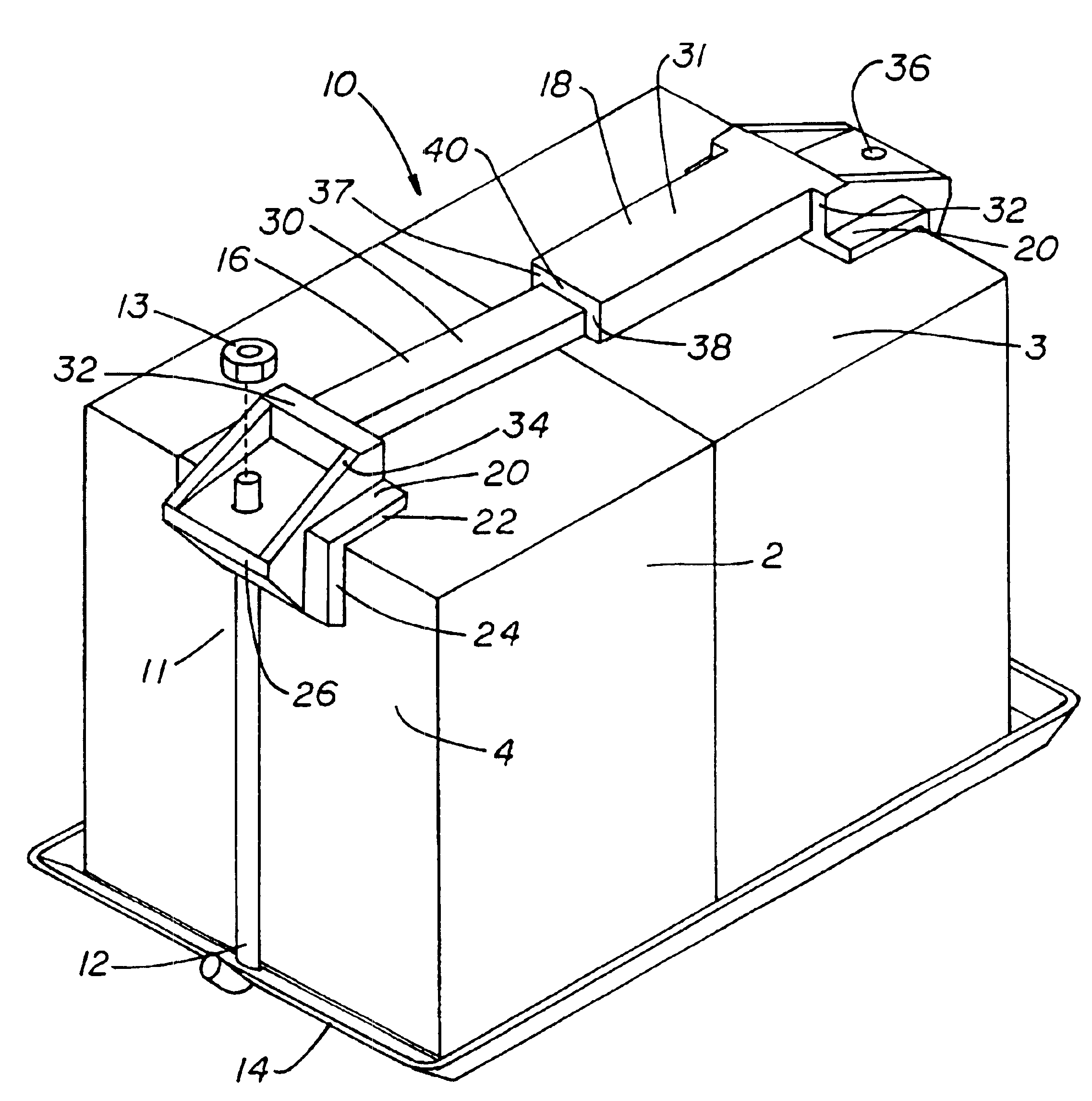

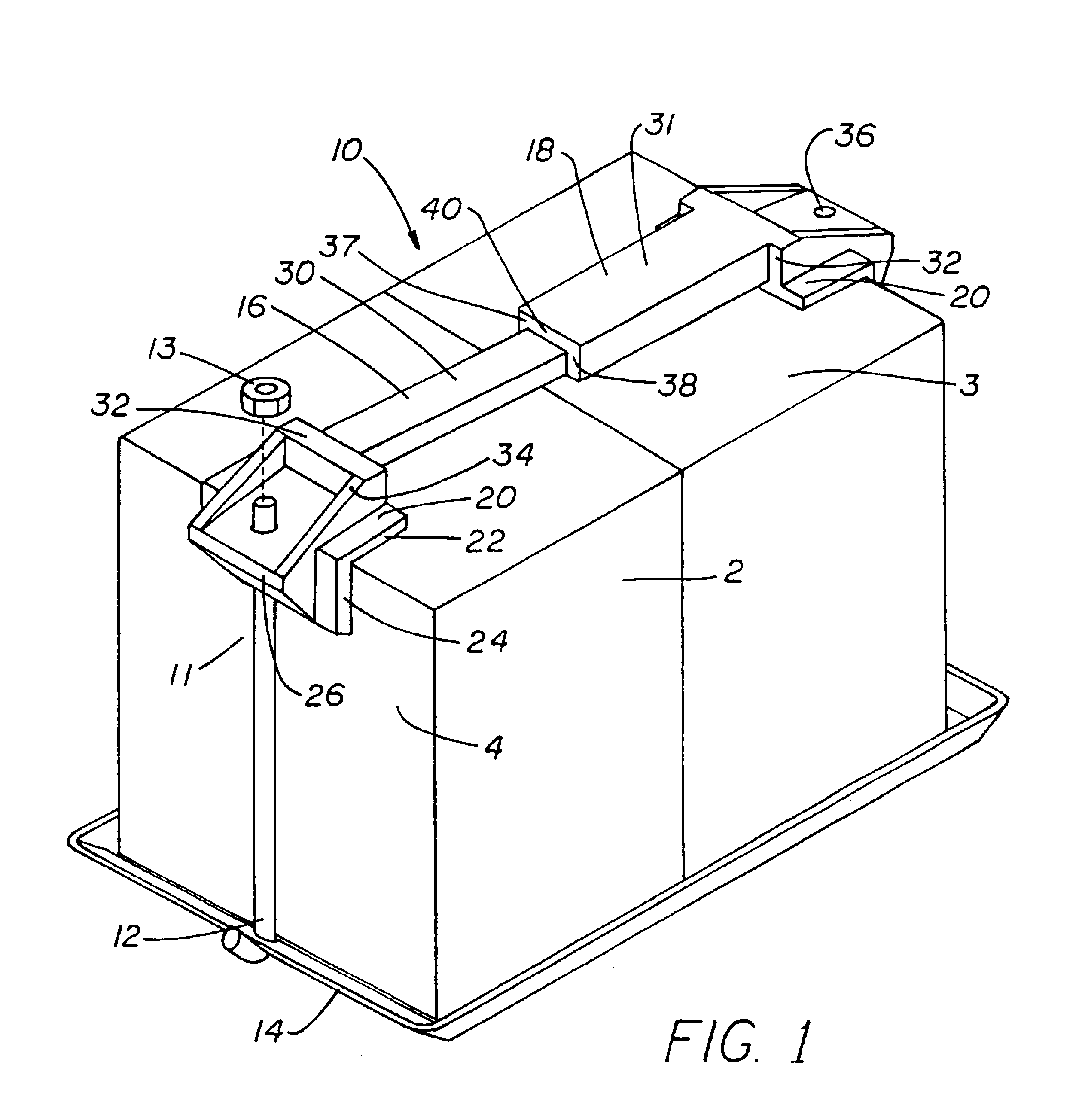

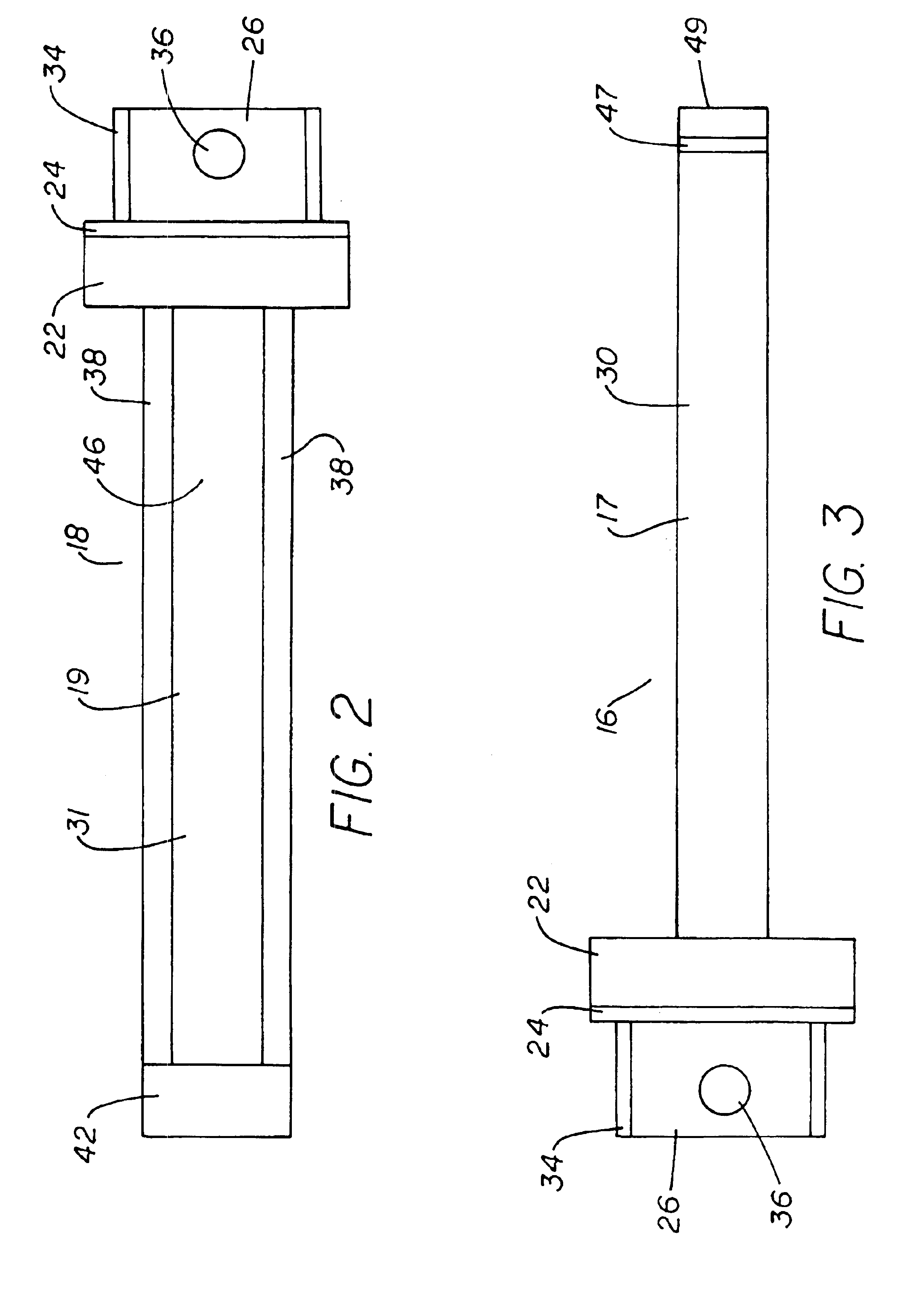

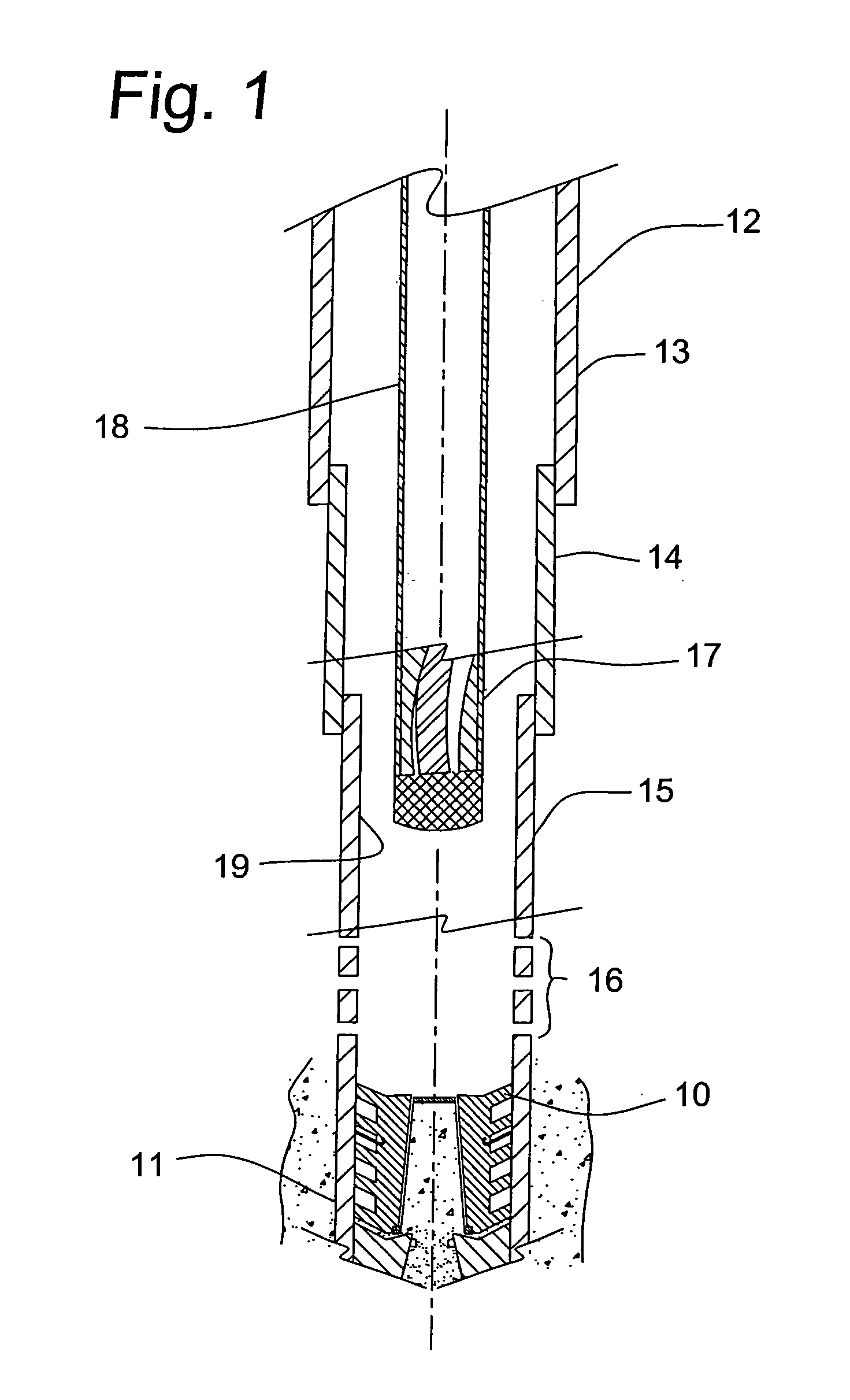

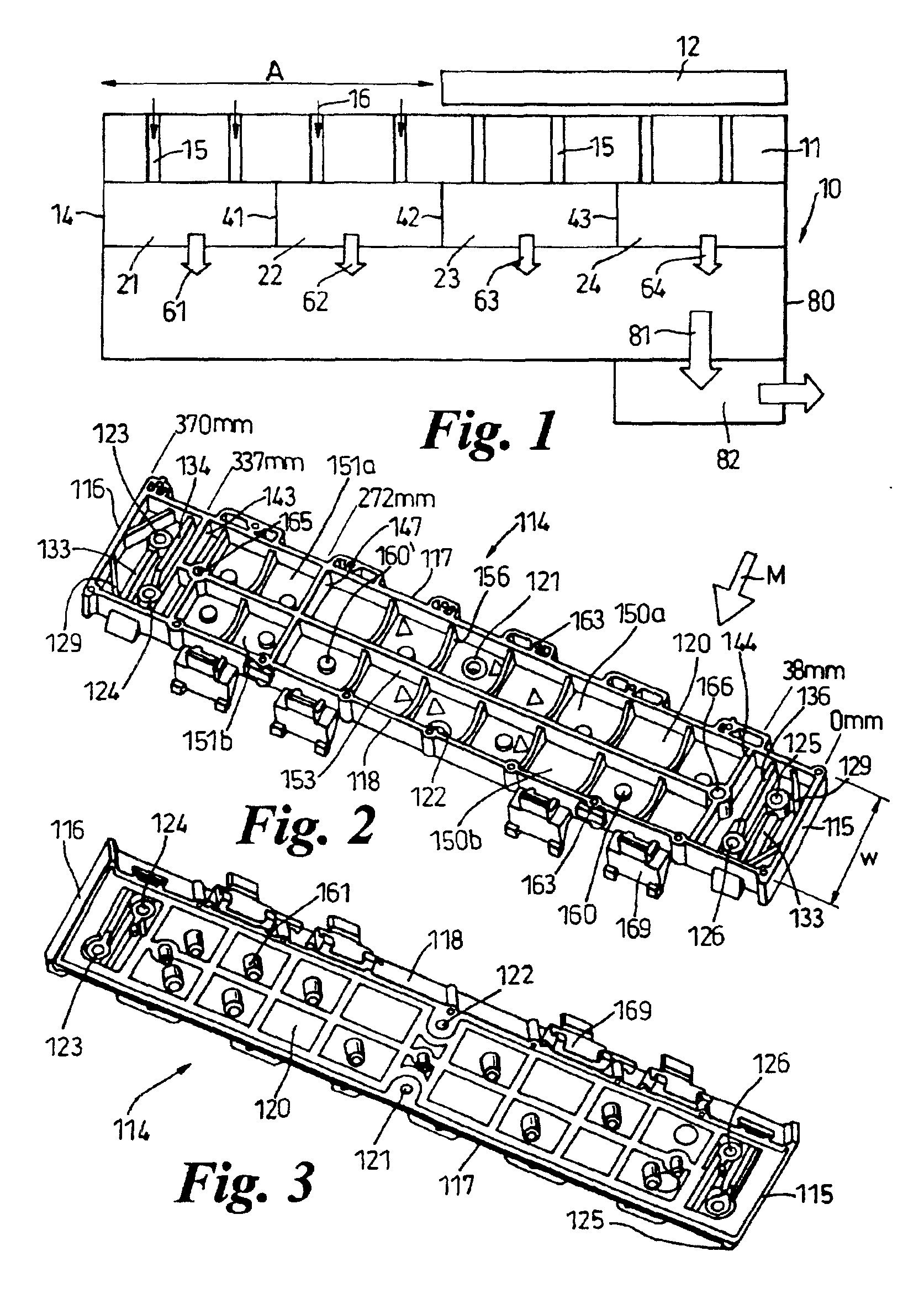

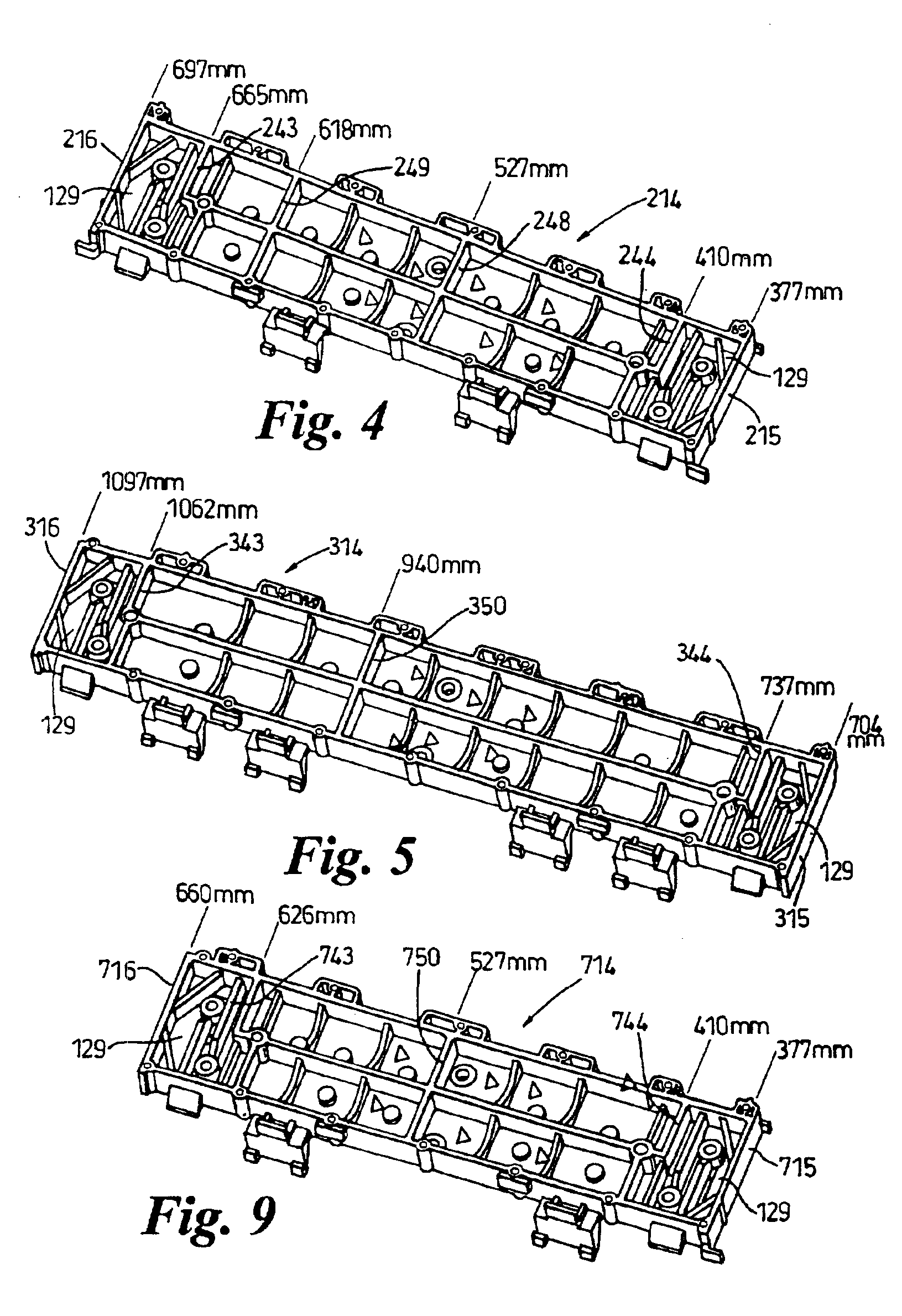

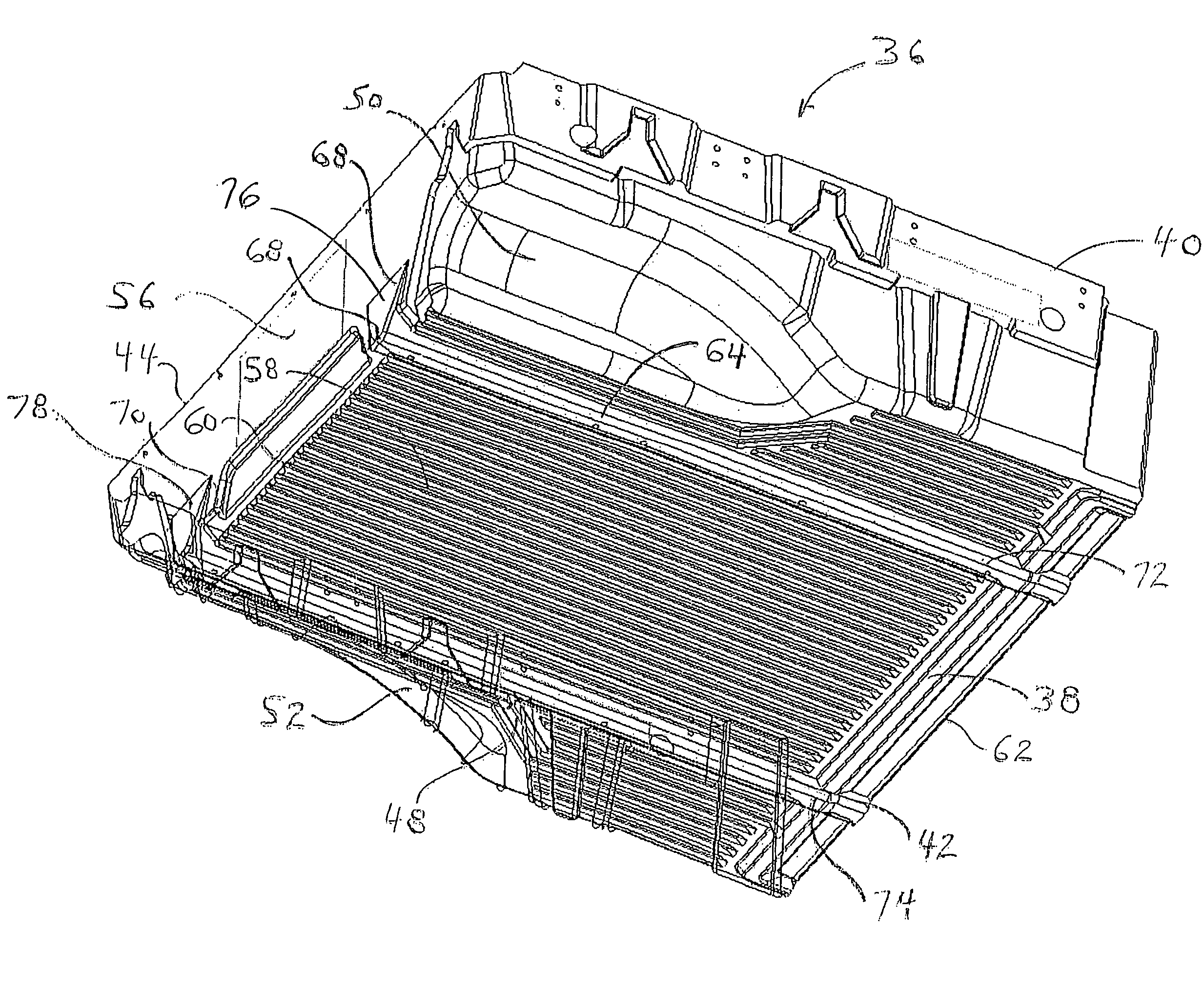

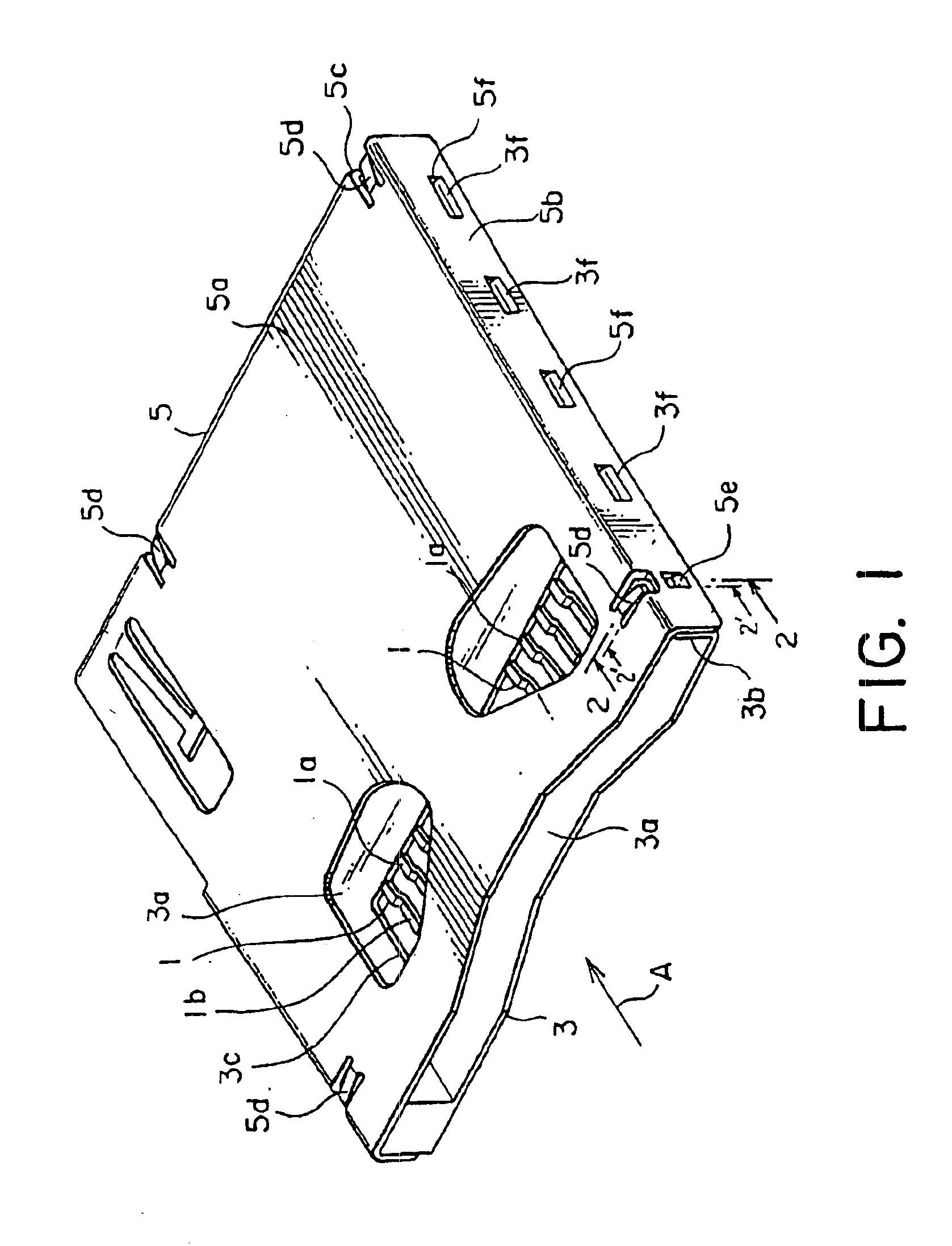

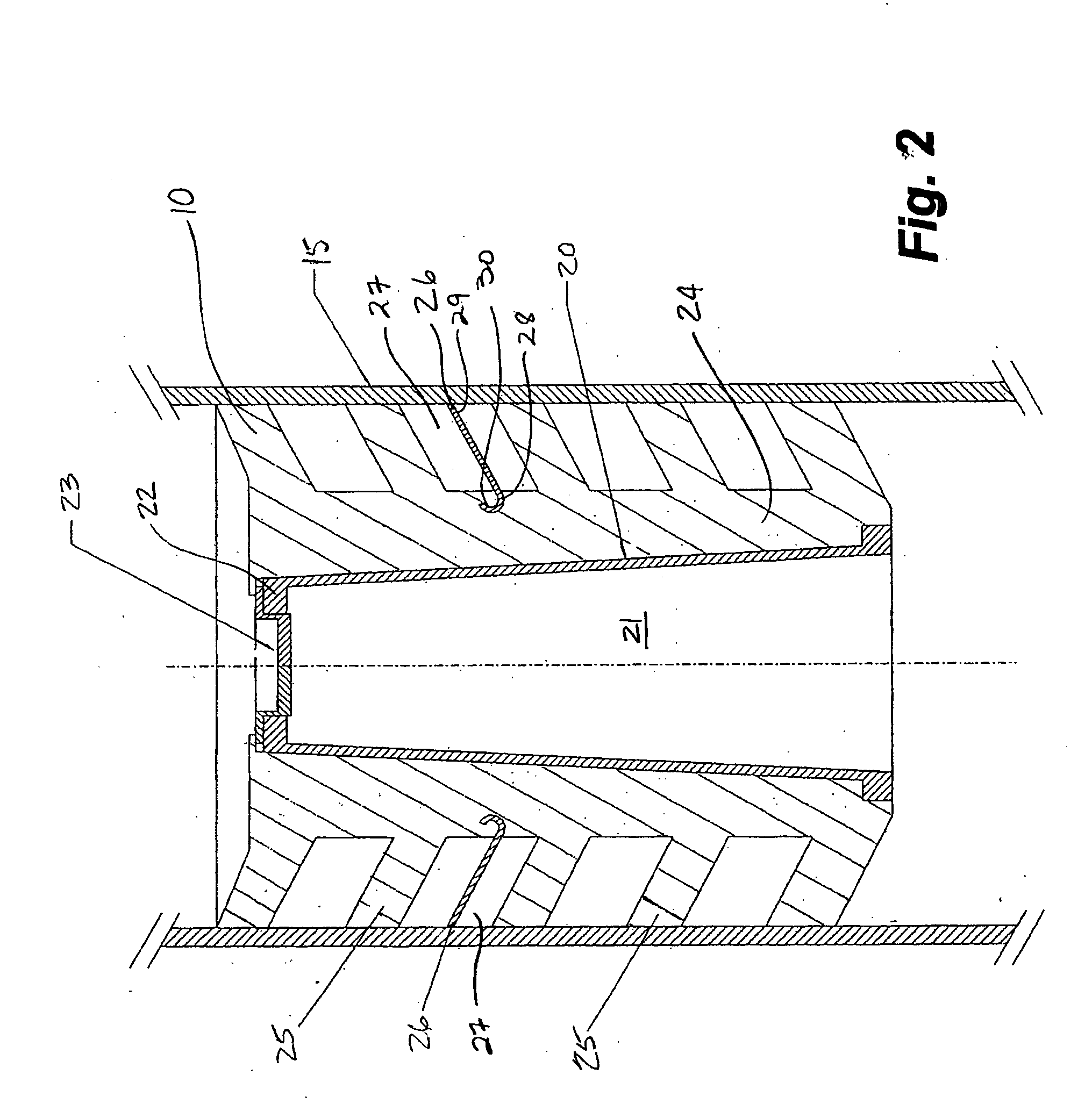

Telescopically adjustable battery holddown

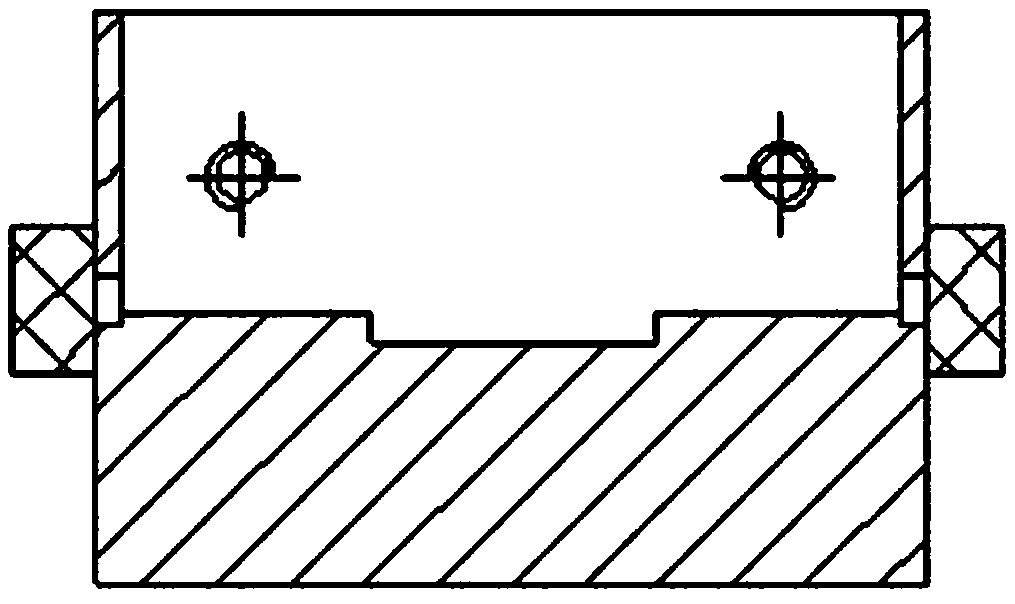

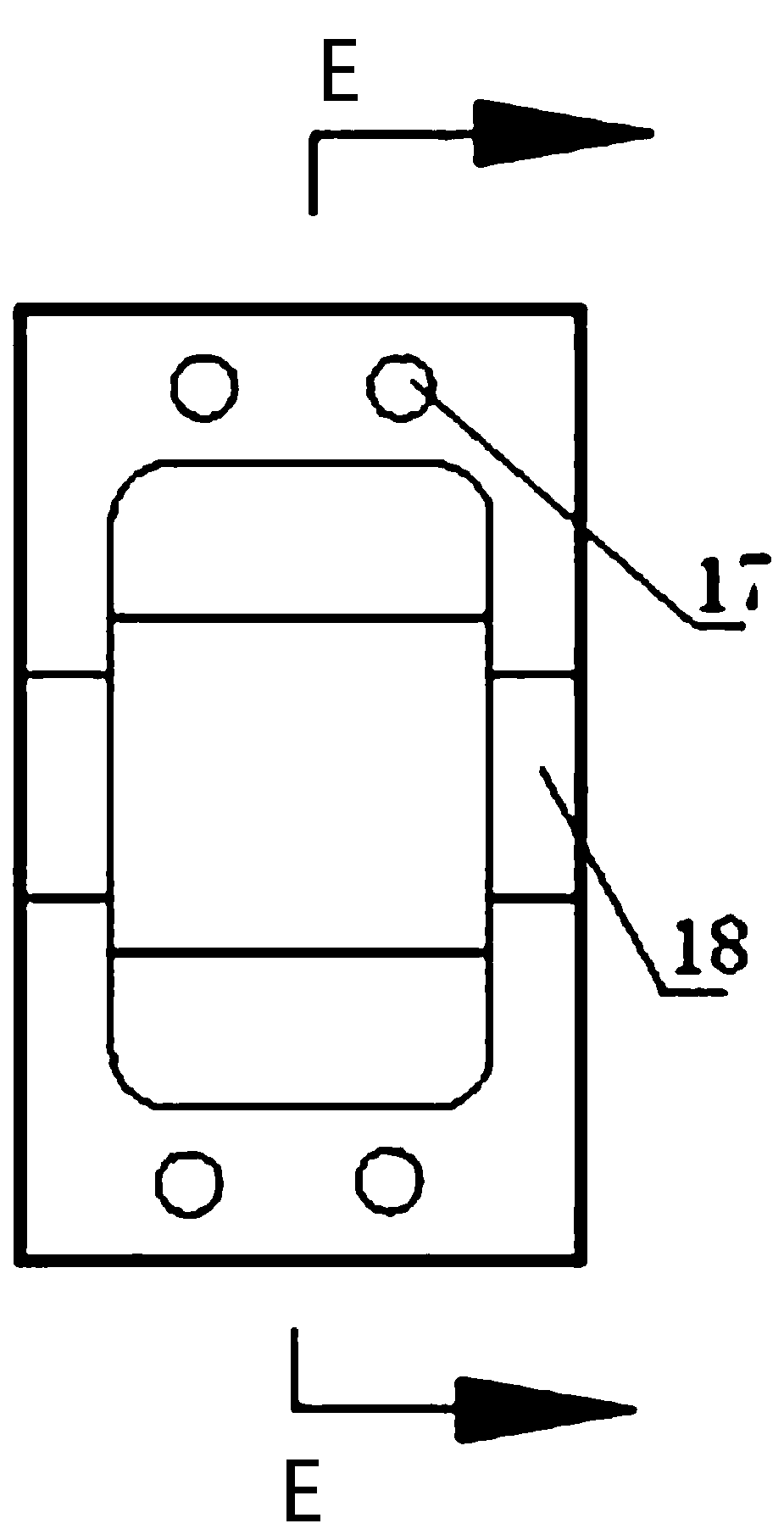

A telescopically adjustable holddown (10) is disclosed including first and second brackets (16,18) and drawing elements (12) adapted to extend between a battery tray (14) and the brackets for drawing the brackets toward the battery tray to hold a battery (2). The brackets each include a generally L-shaped clamp (20) having top (22) and side members (24) for abutting the top (3) and sides (4) of the battery. An ear (26) extends from each side member and includes an aperture (36) for receiving a bolt (12) extending from the battery tray. Each bracket includes a cross rod (17,19) with second cross rod (19) having a cavity (46) for slidably receiving the first cross rod (17). The cavity requires that relative movement of the first and second brackets be substantially along the cavity axis (50) to allow telescopic assembly of the first and second brackets. The brackets are drawn toward the battery tray by tightening nuts (13) on the bolts to prevent relative movement of the brackets.

Owner:QUICK CABLE

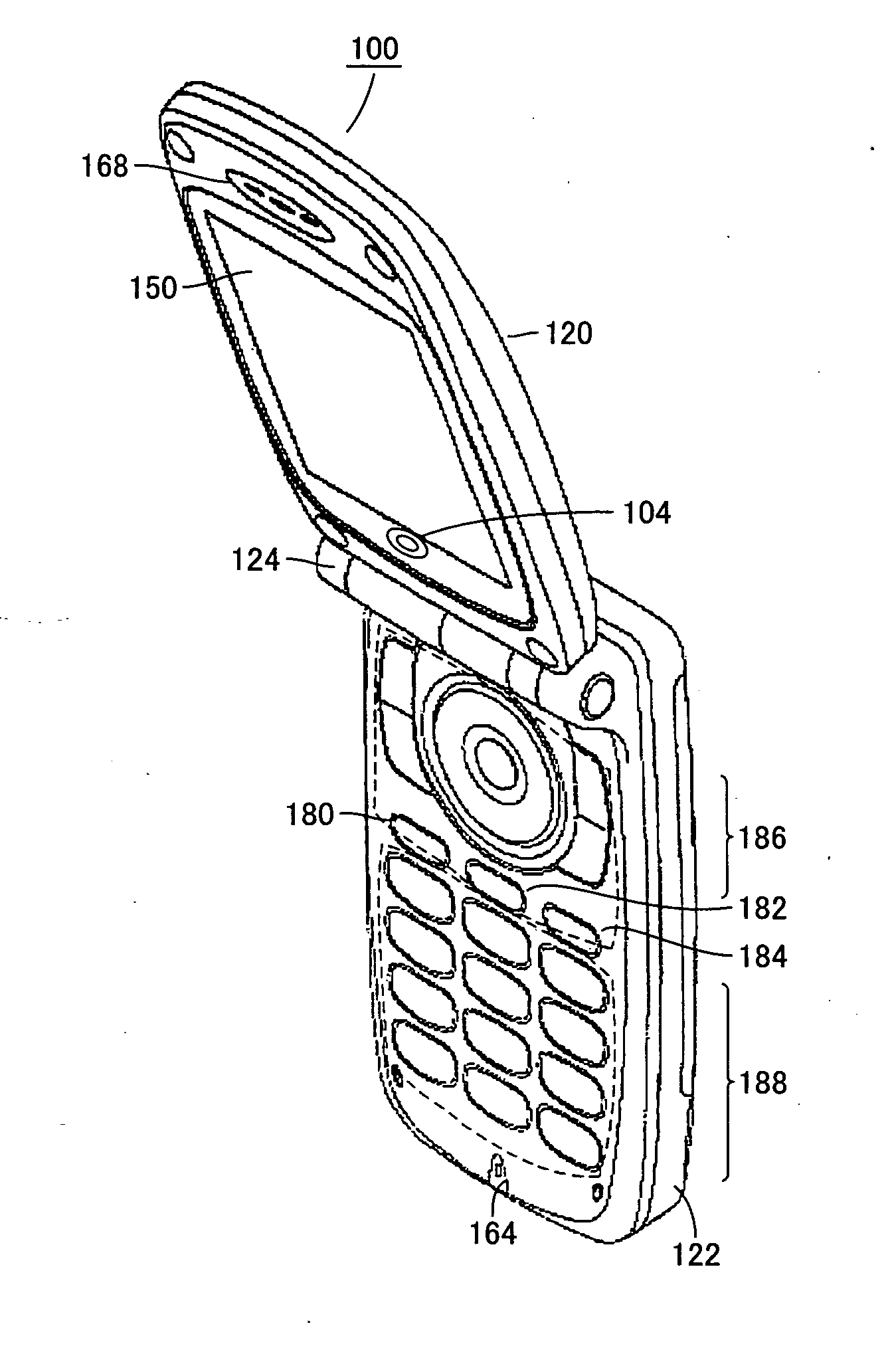

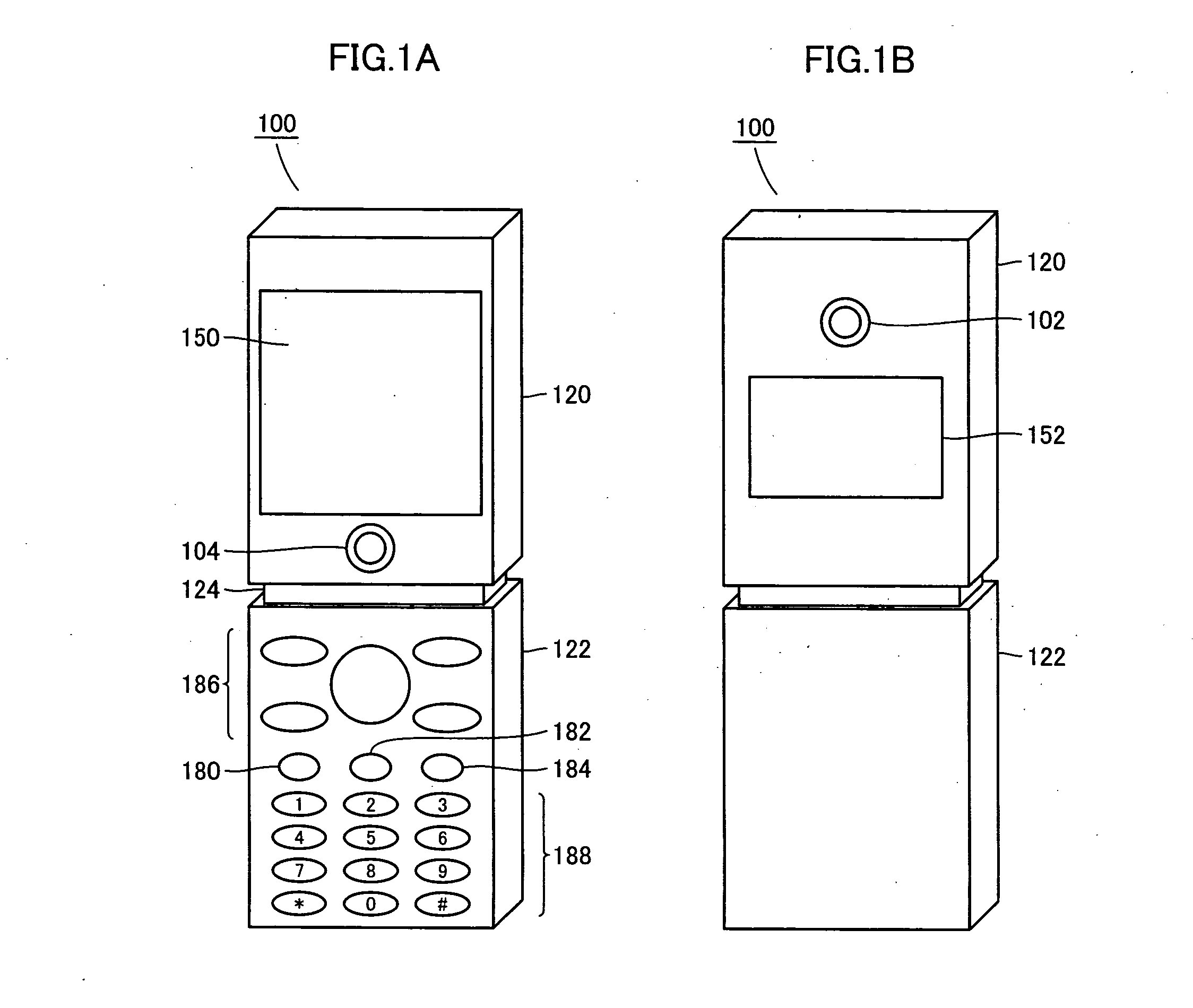

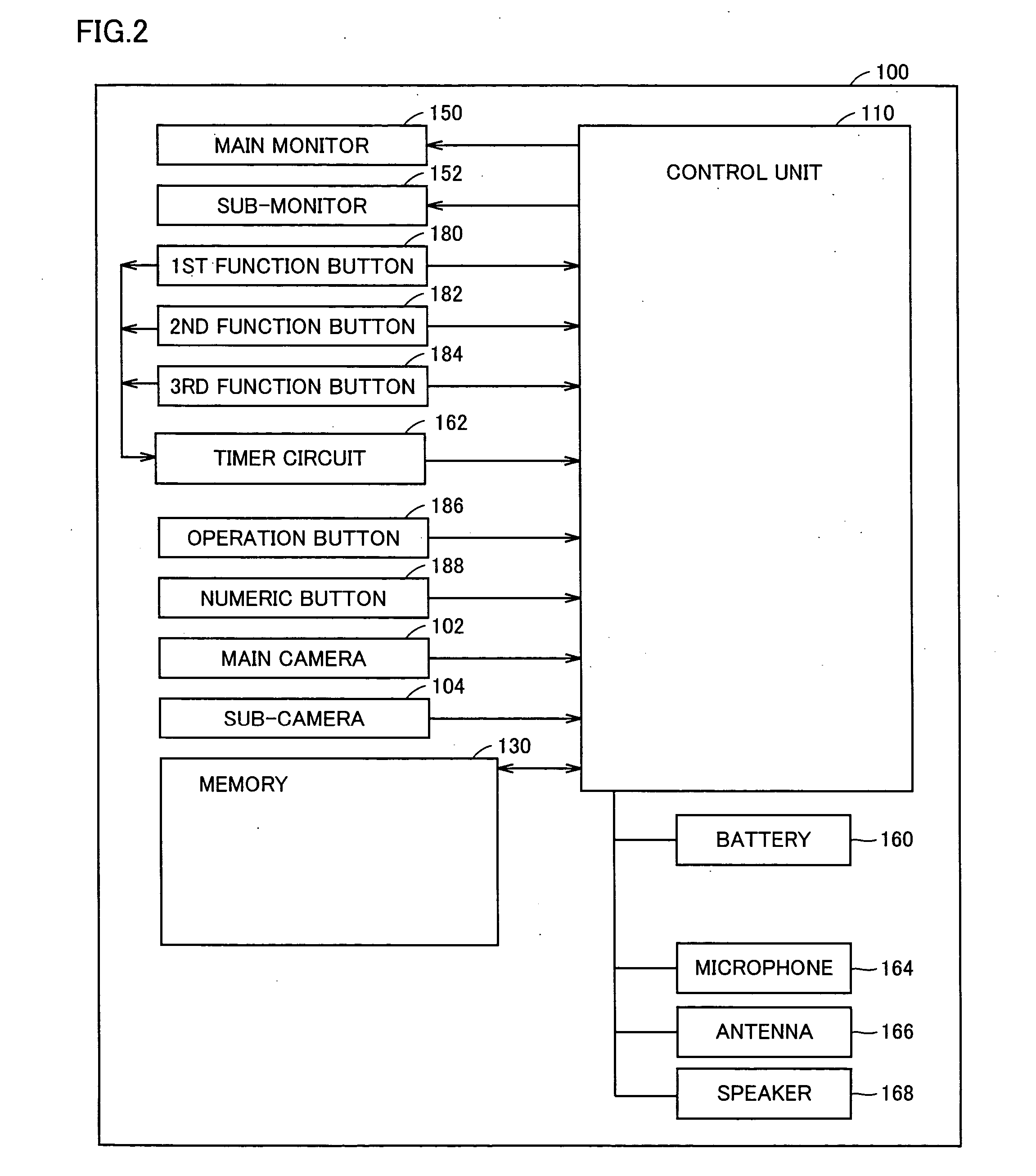

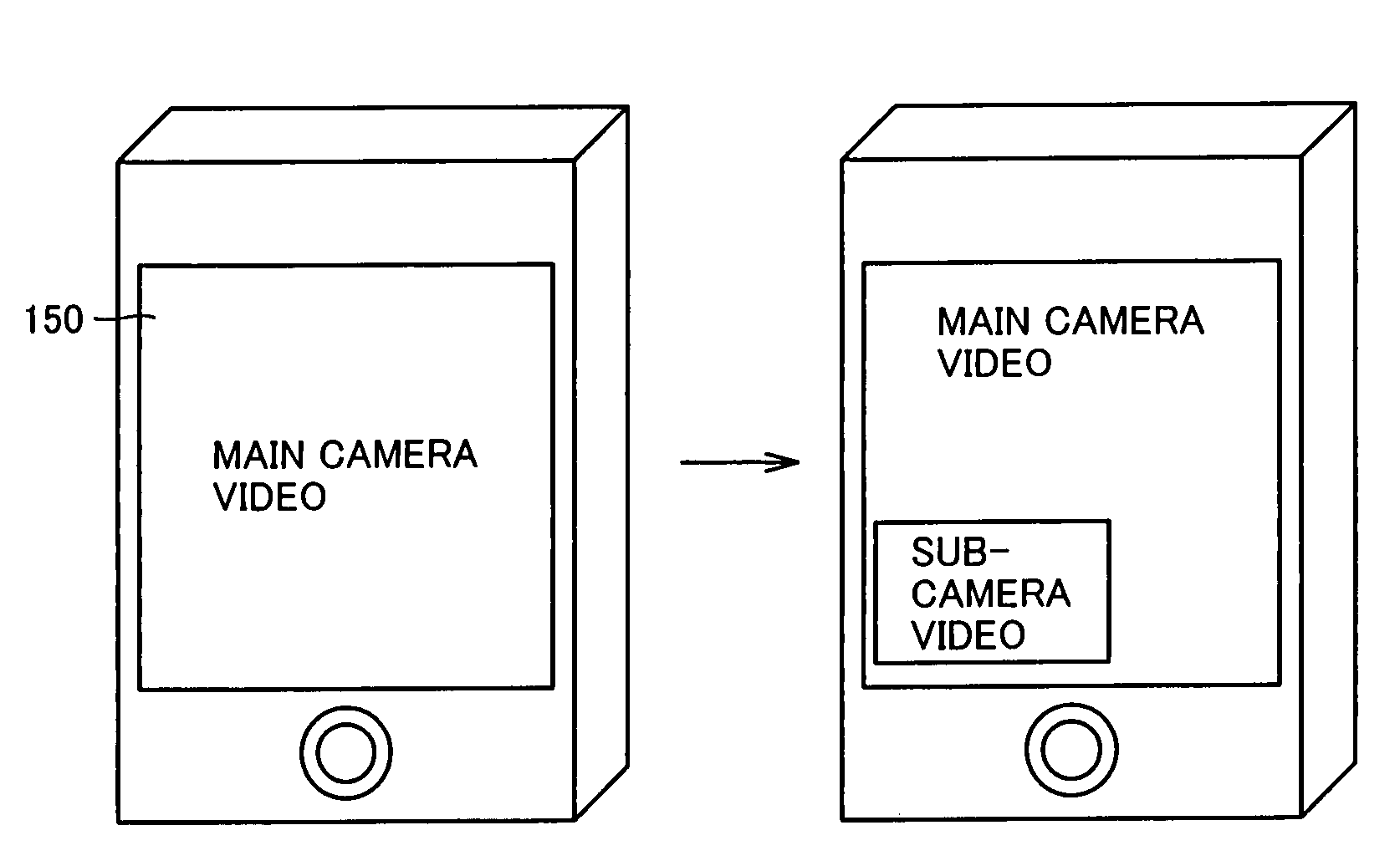

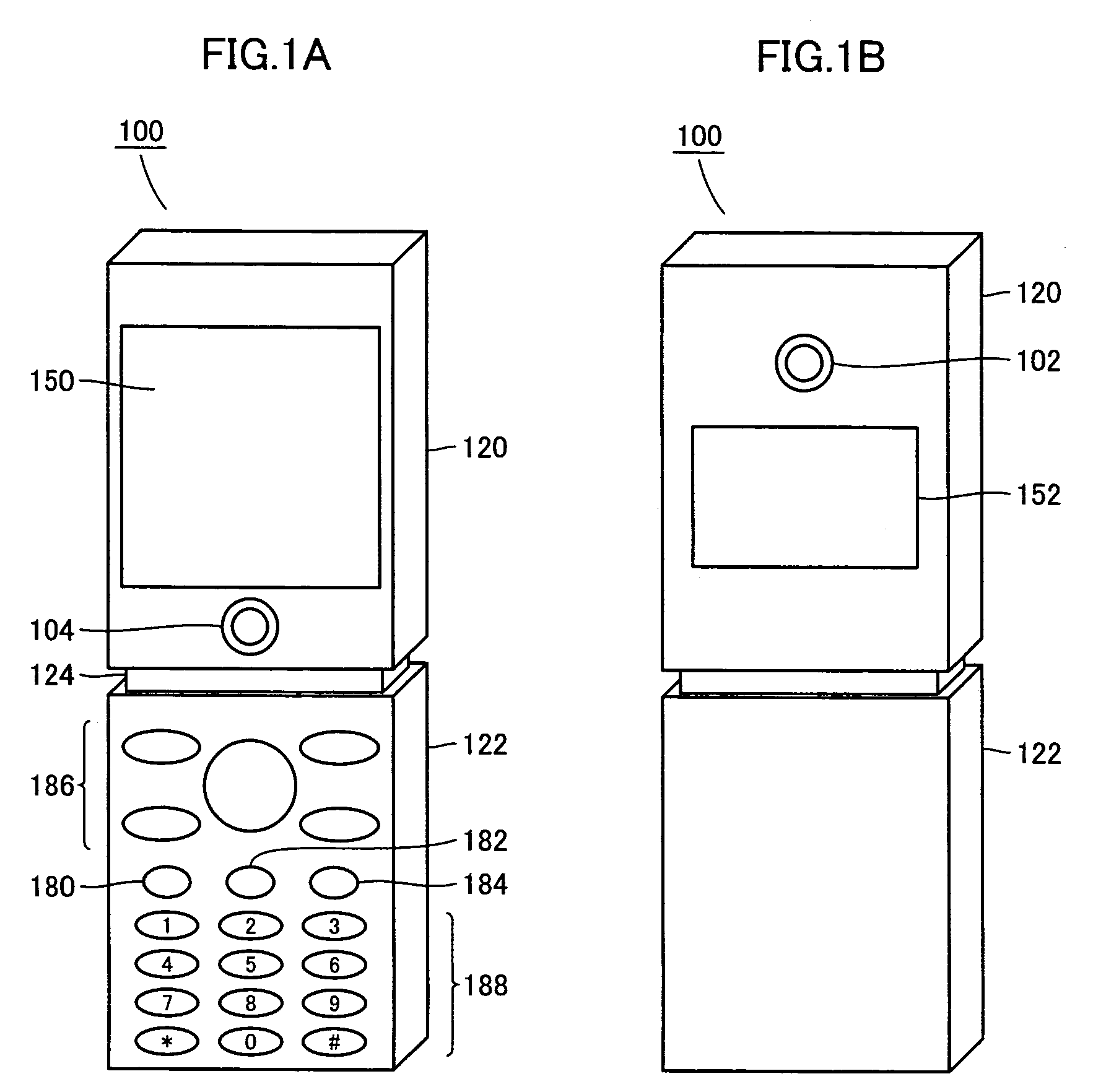

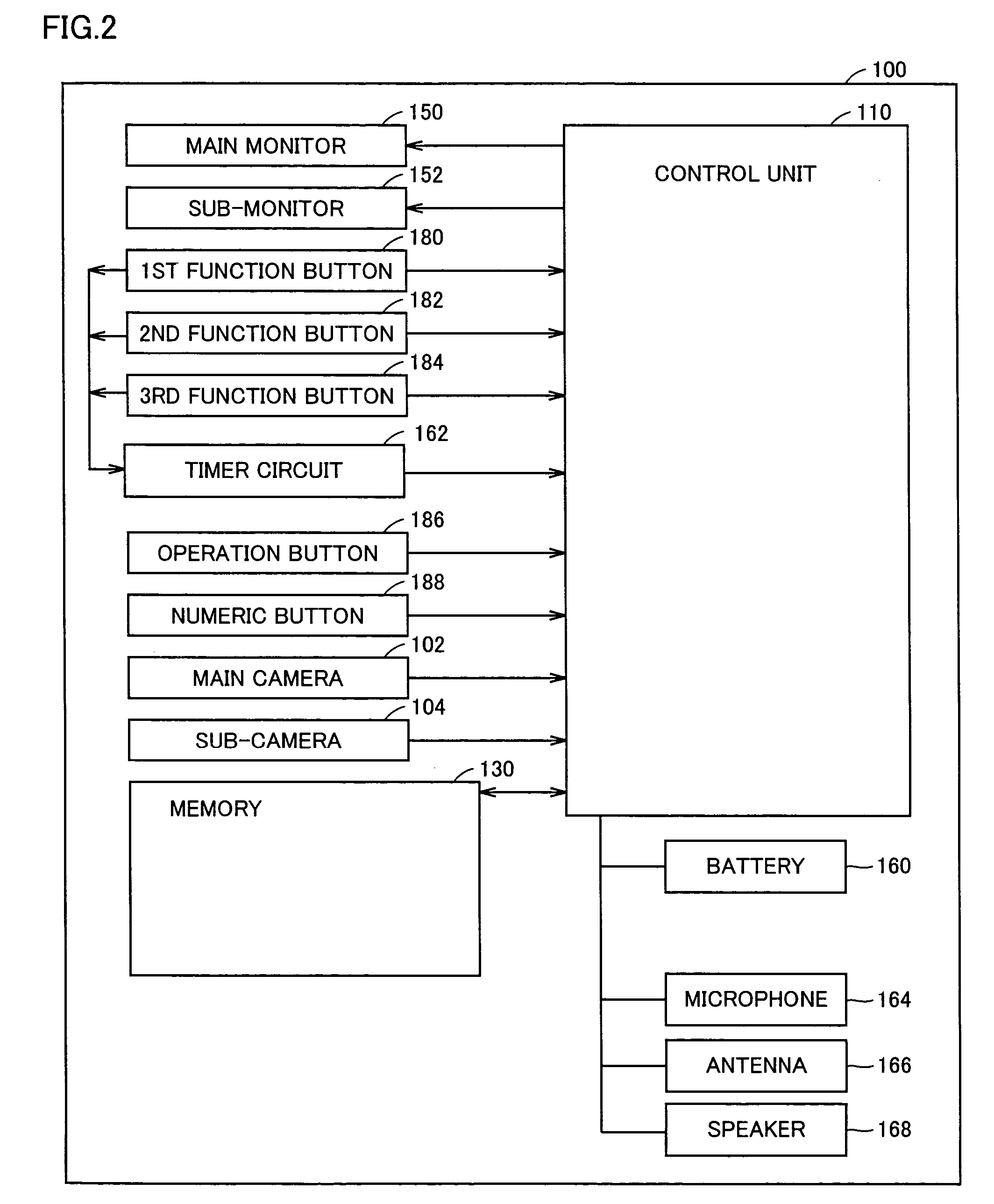

Portable communication terminal switchably displaying pictures based on a plurality of video signal sources

InactiveUS20050134718A1Television system detailsPicture reproducers using cathode ray tubesComputer graphics (images)Signal source

A cellular phone having a plurality of cameras and being able to switch display of a picture without interrupting display for the camera is provided. Processes executed by a control unit of the cellular phone include the steps of measuring a holddown time when holddown of a button is detected; sending the video signal sent from the camera corresponding to a numeric button to a main monitor when a first function button is held down for a holddown time shorter than a predetermined time and the numeric button is held down; and sending the video signal sent from the camera set as a next source to the main monitor when the numeric button is not held down. The processes further includes the step of sending the video signal sent from a main camera to main monitor when the holddown time is longer than the predetermined time.

Owner:SHARP KK

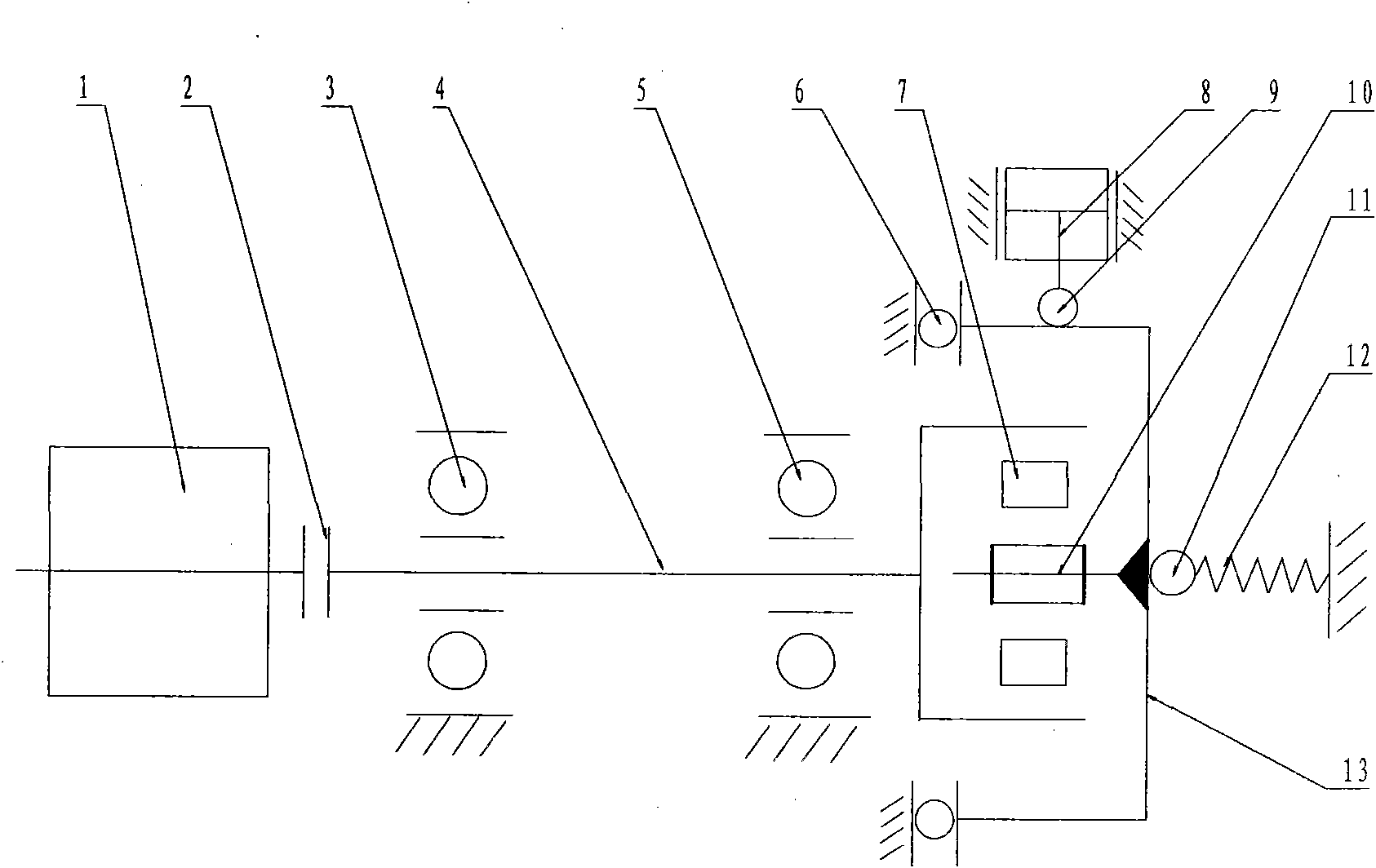

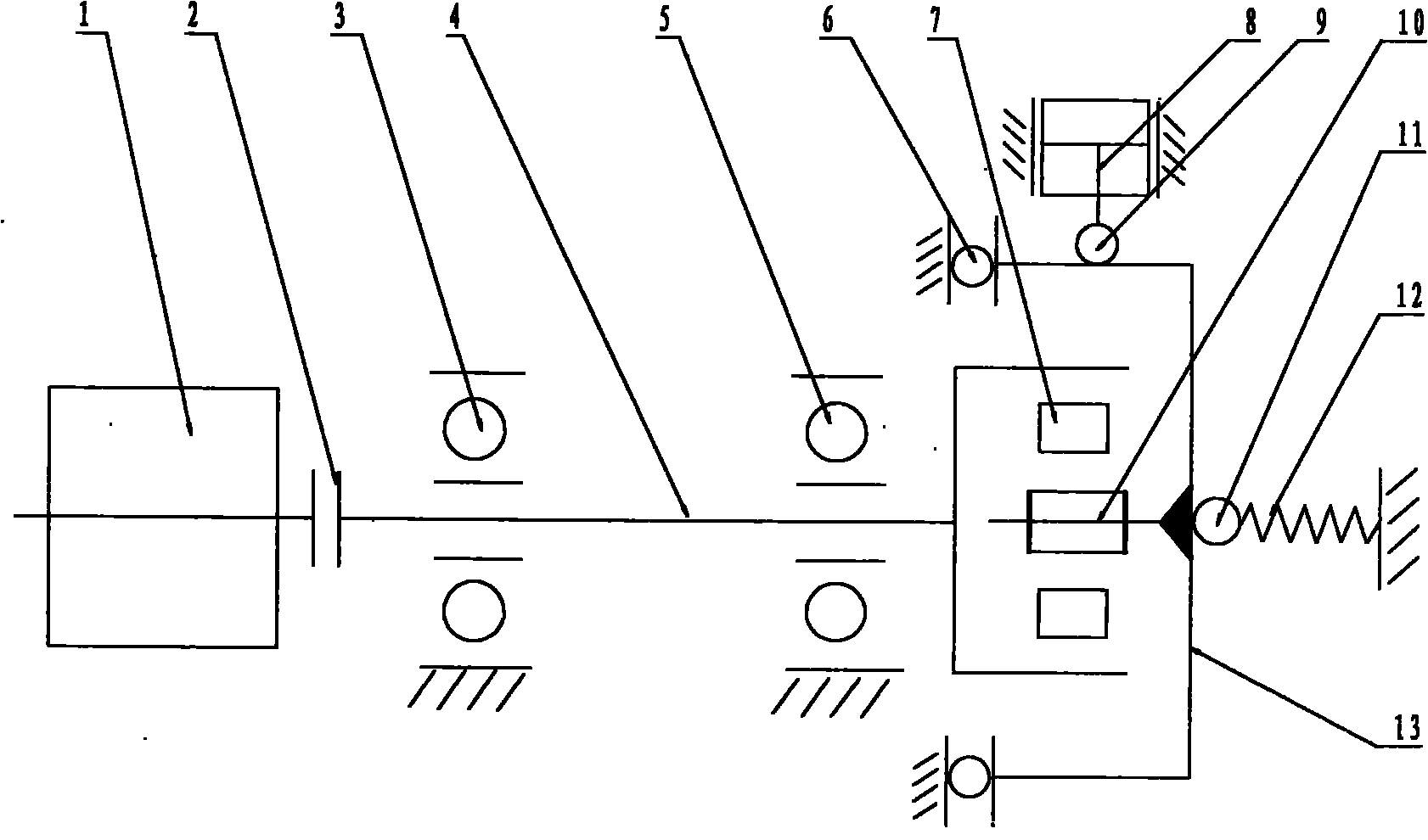

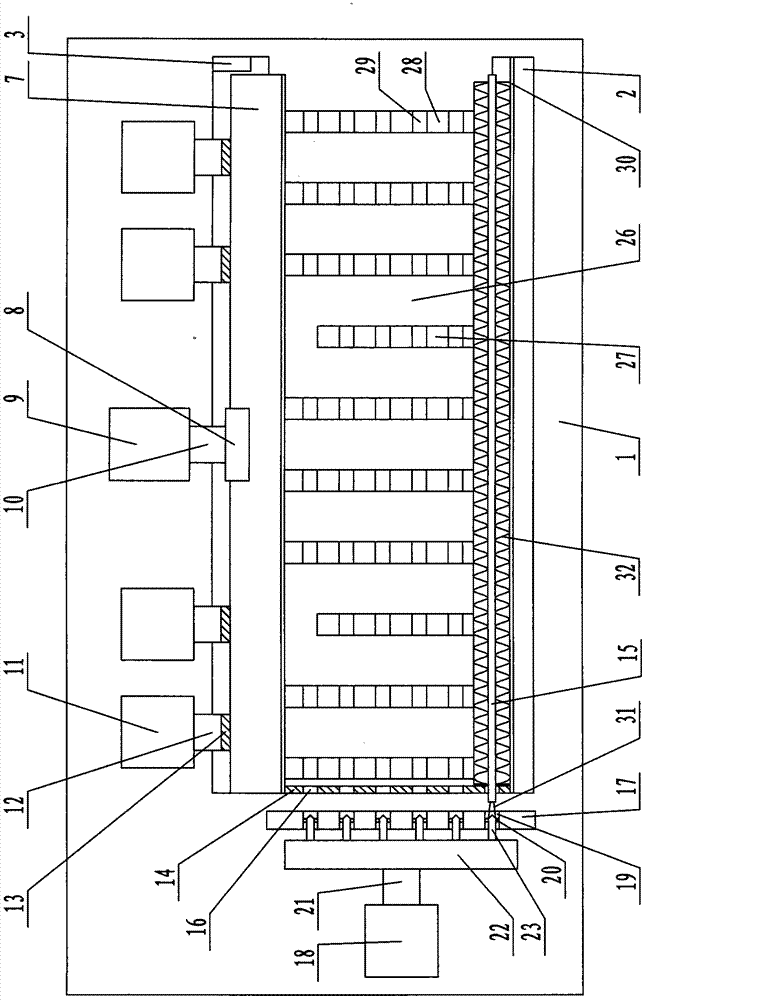

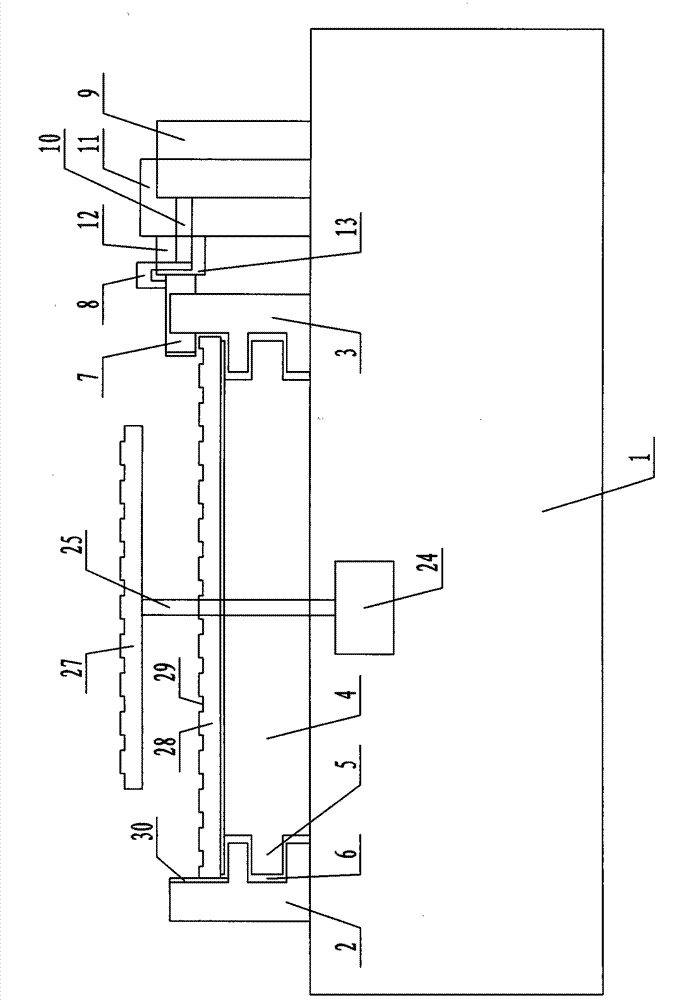

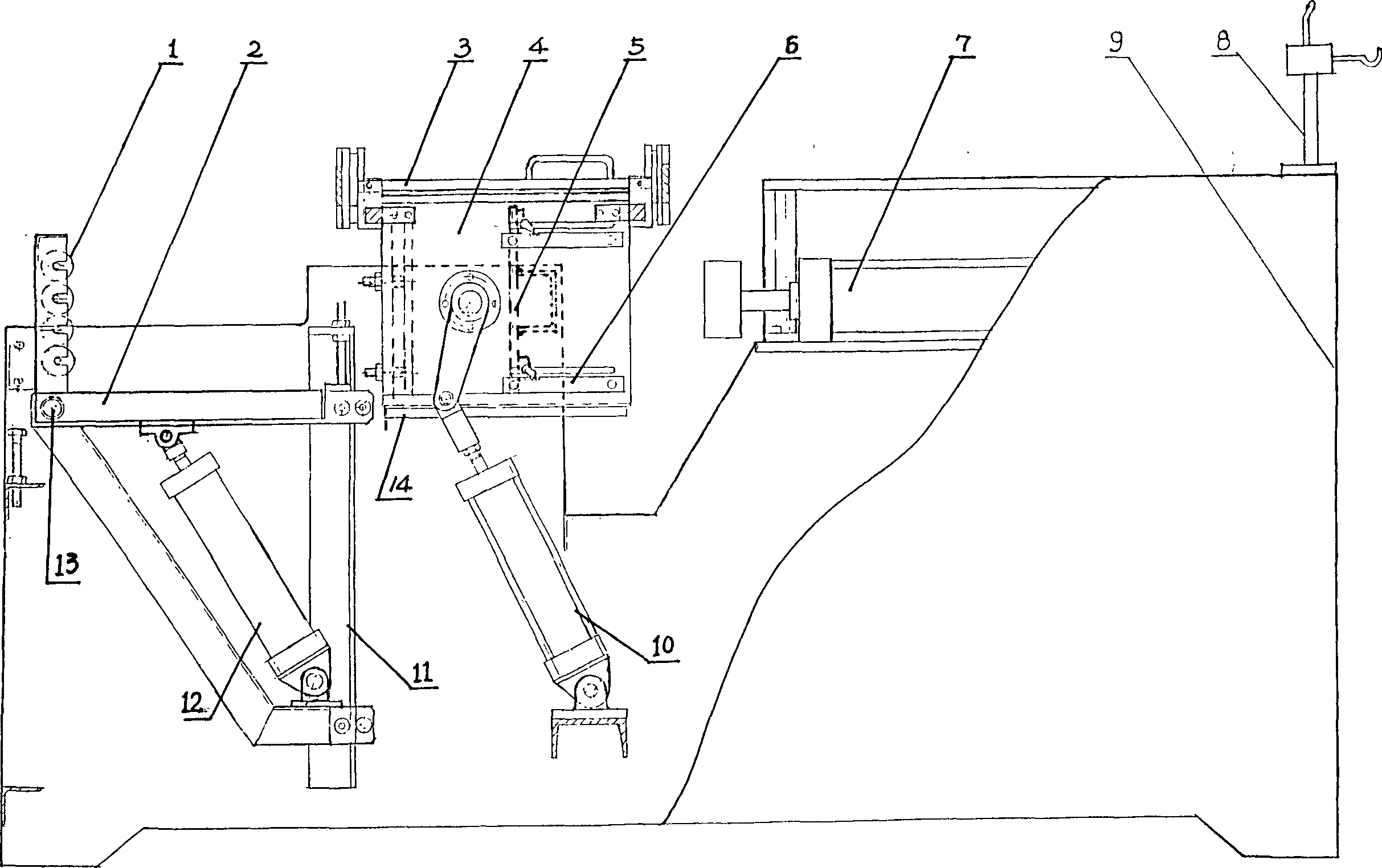

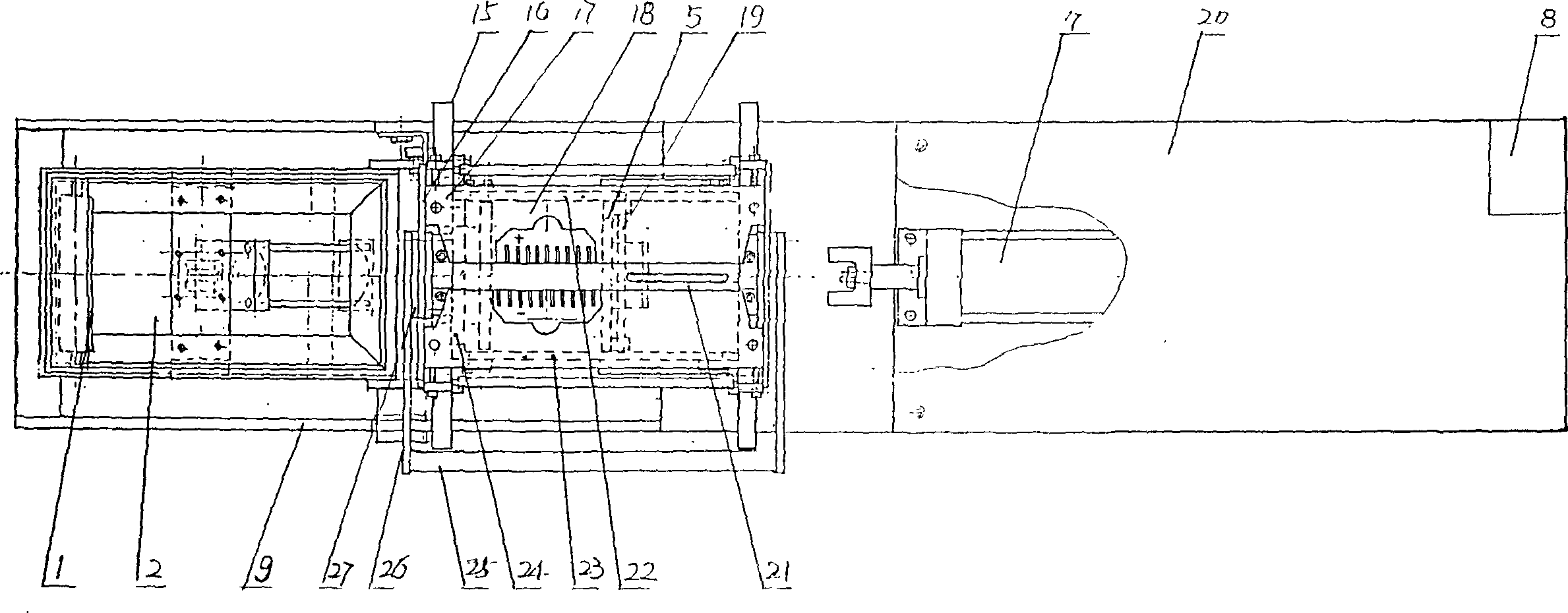

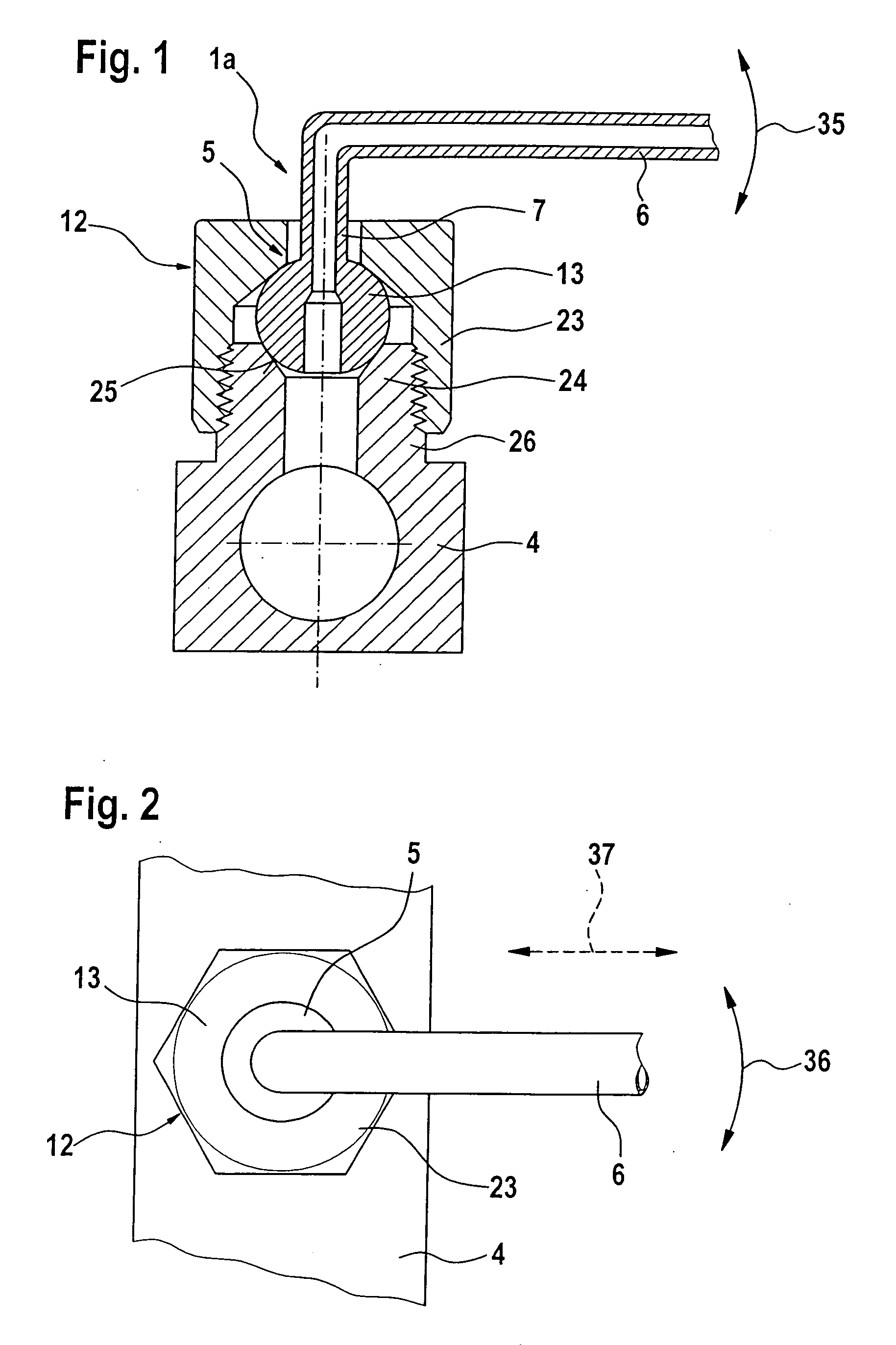

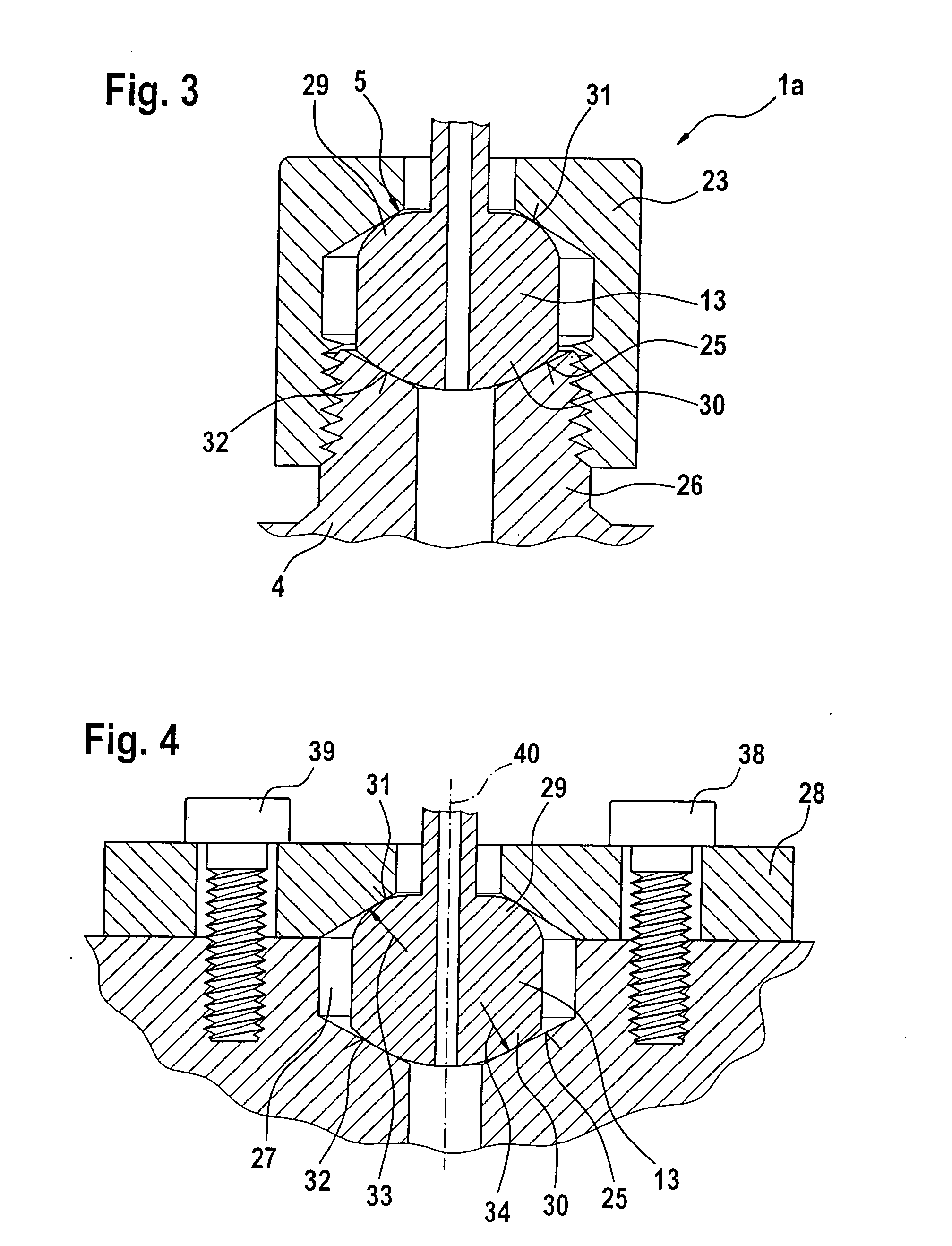

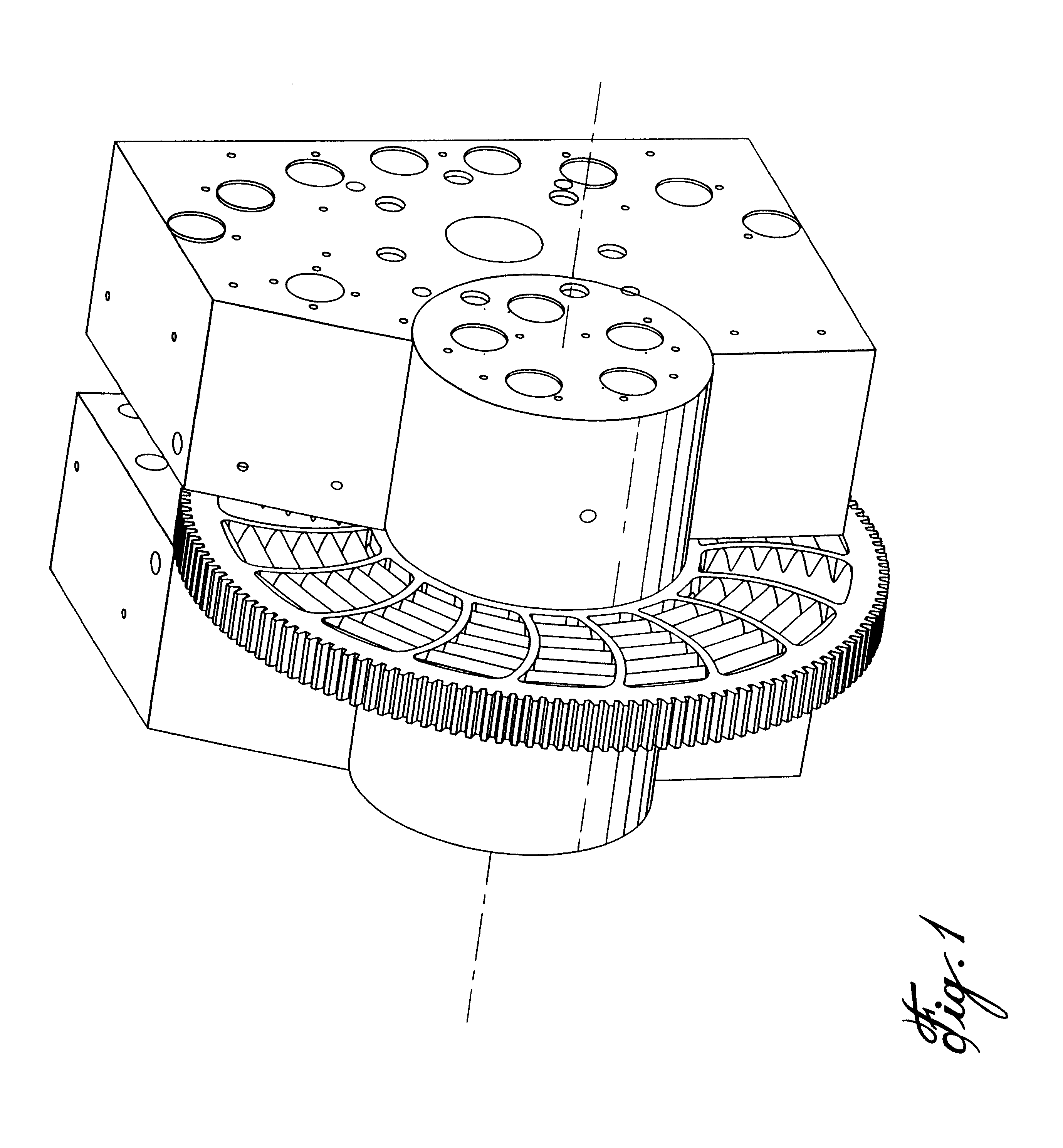

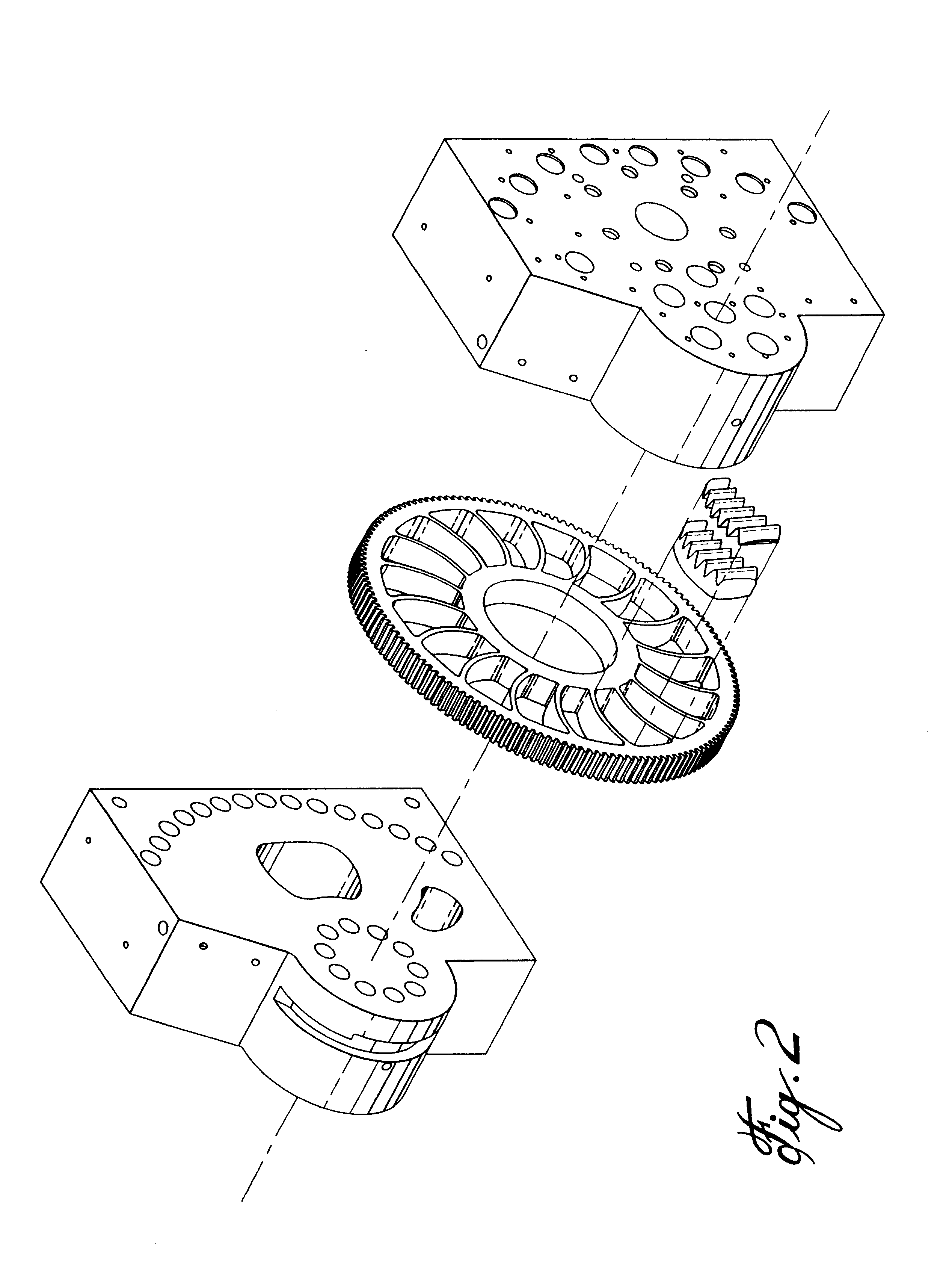

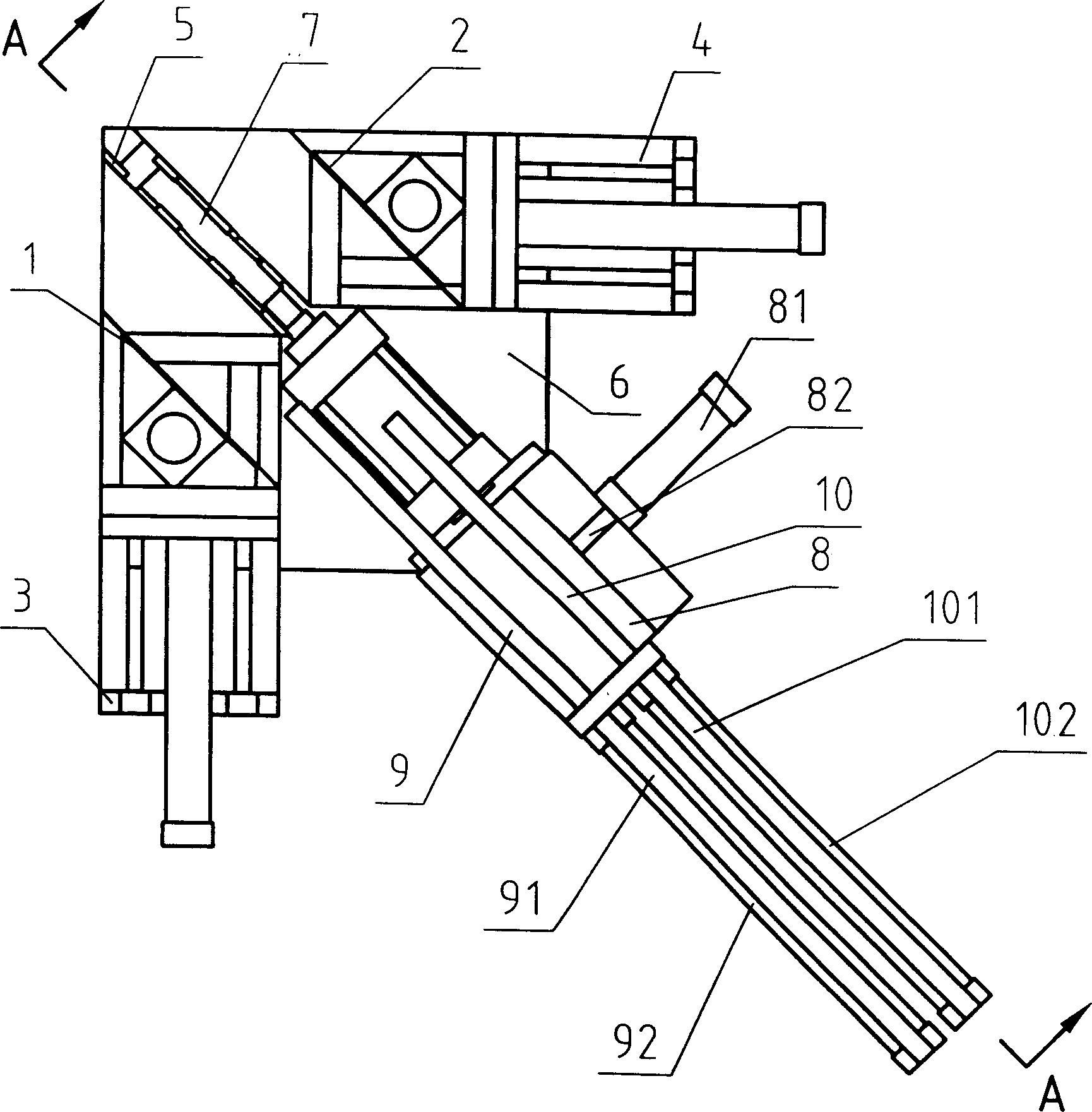

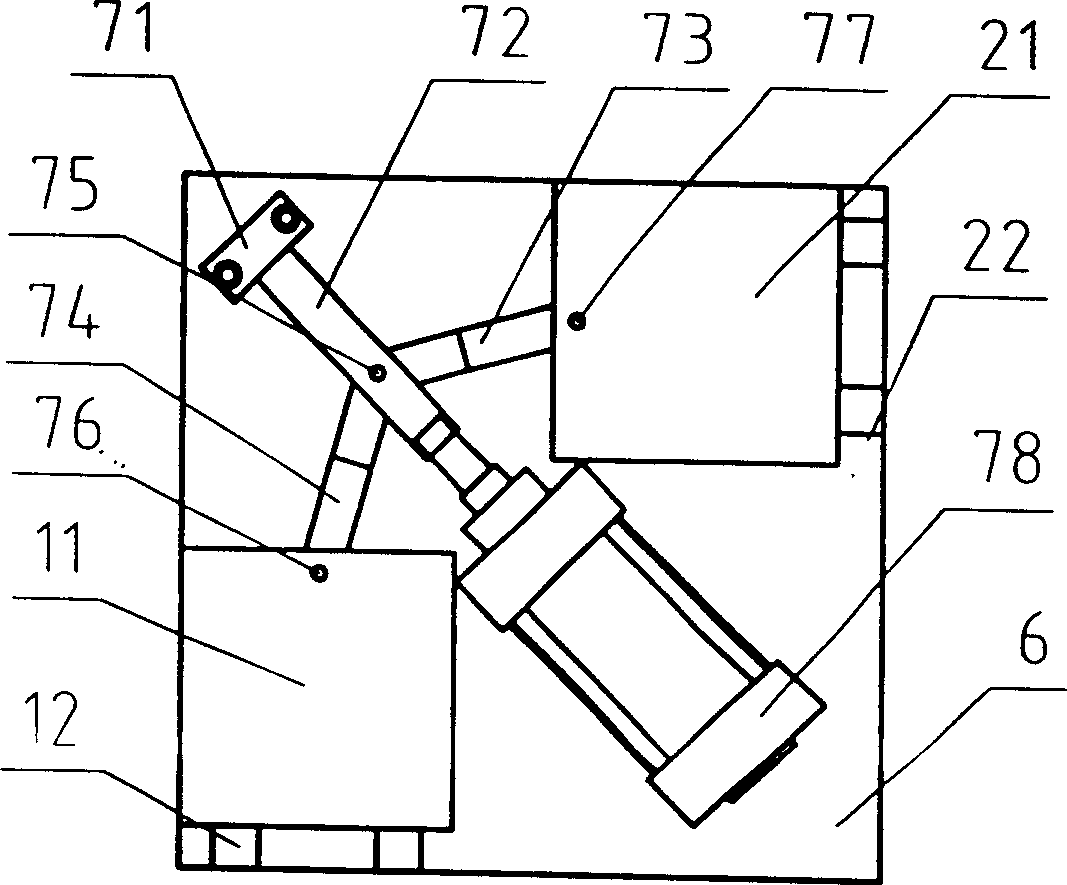

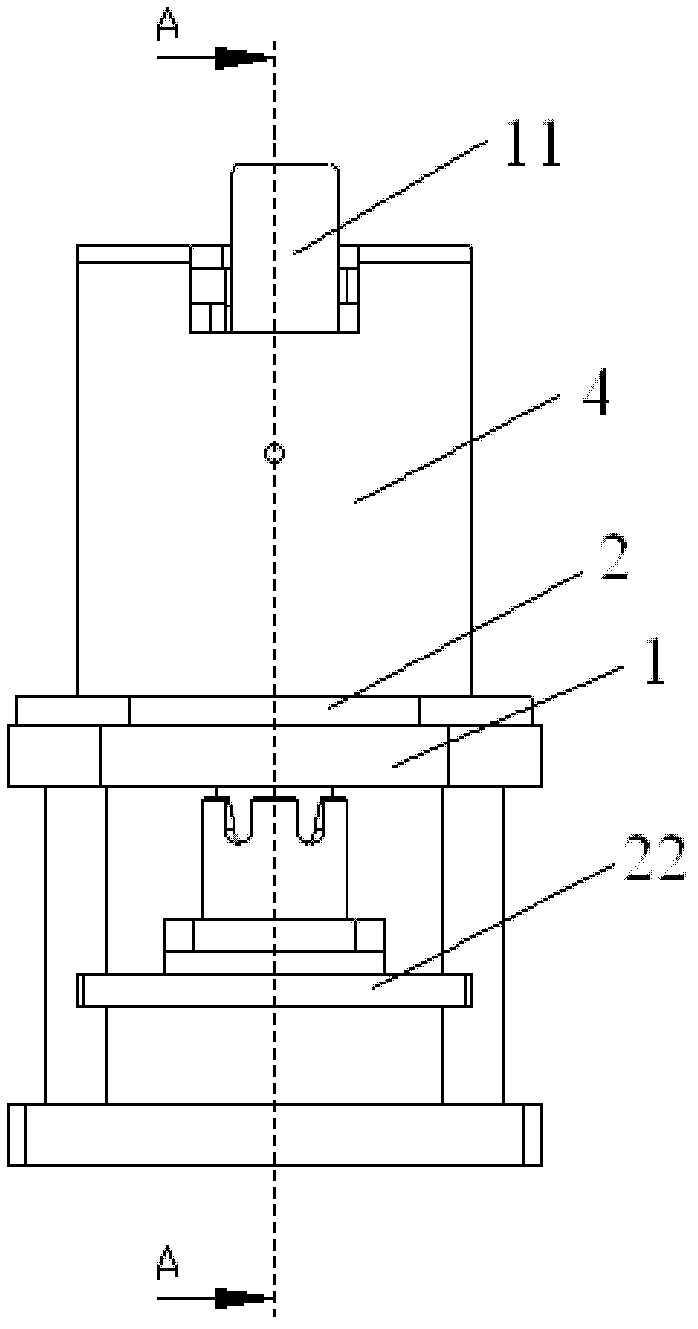

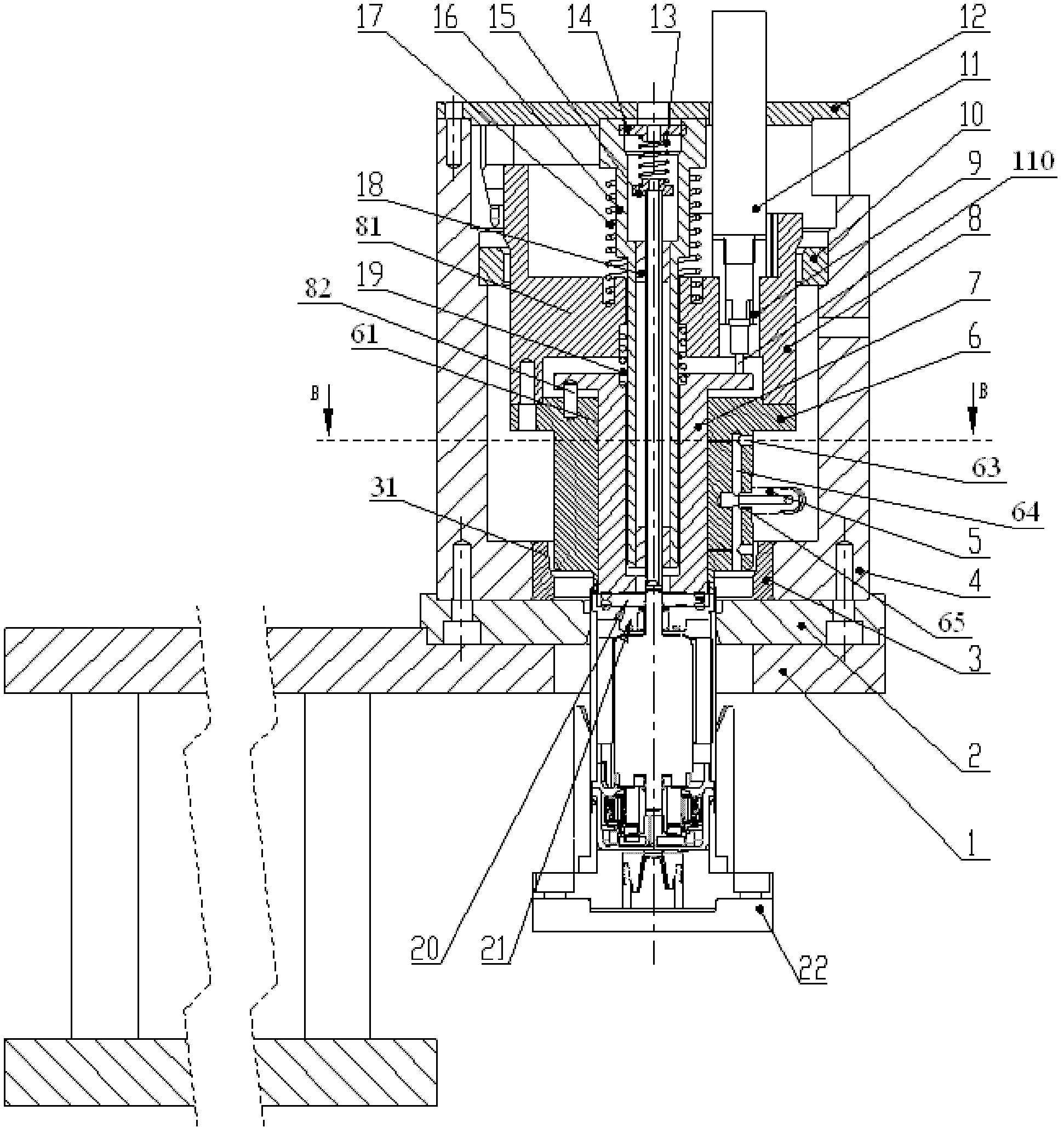

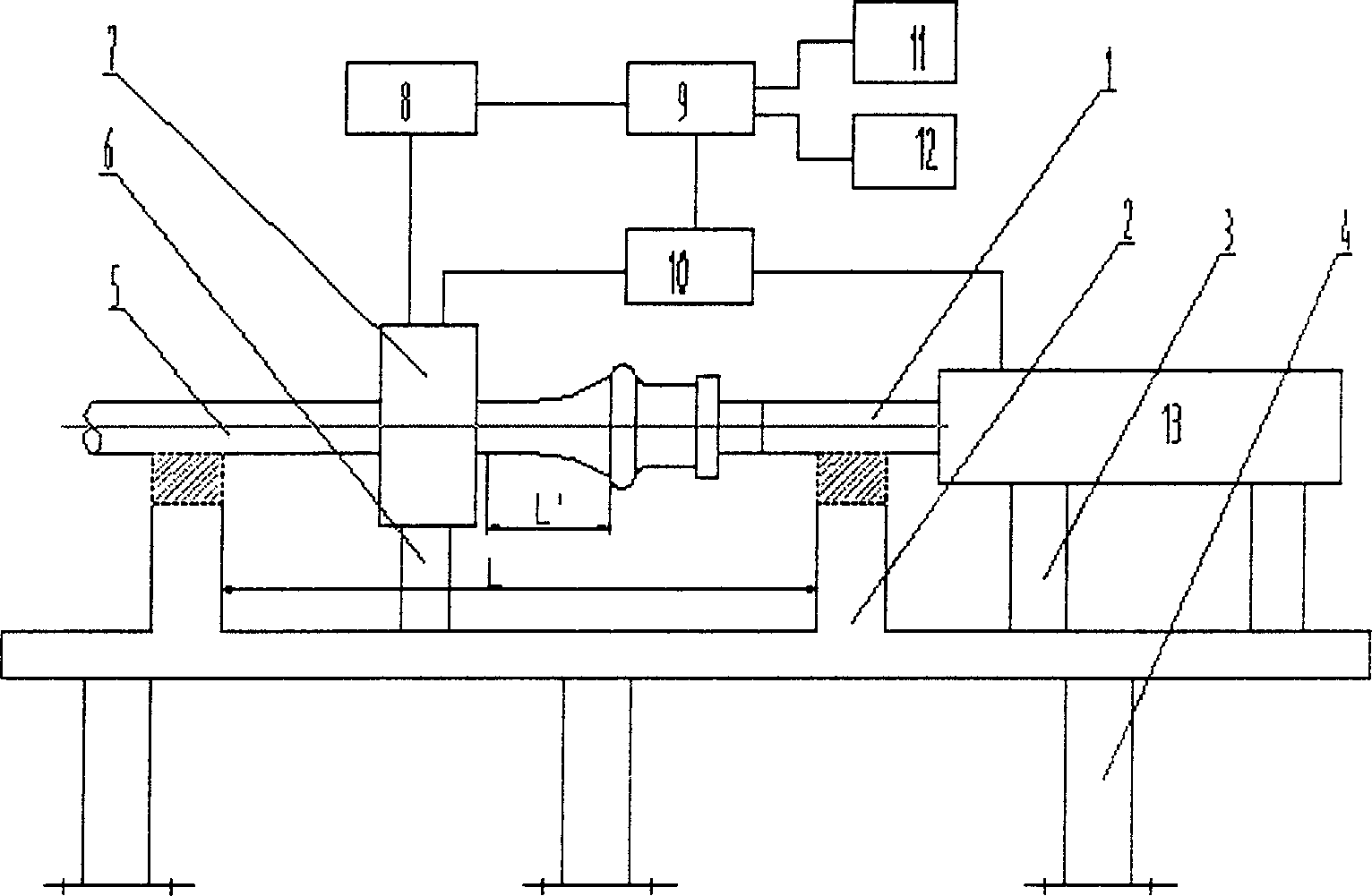

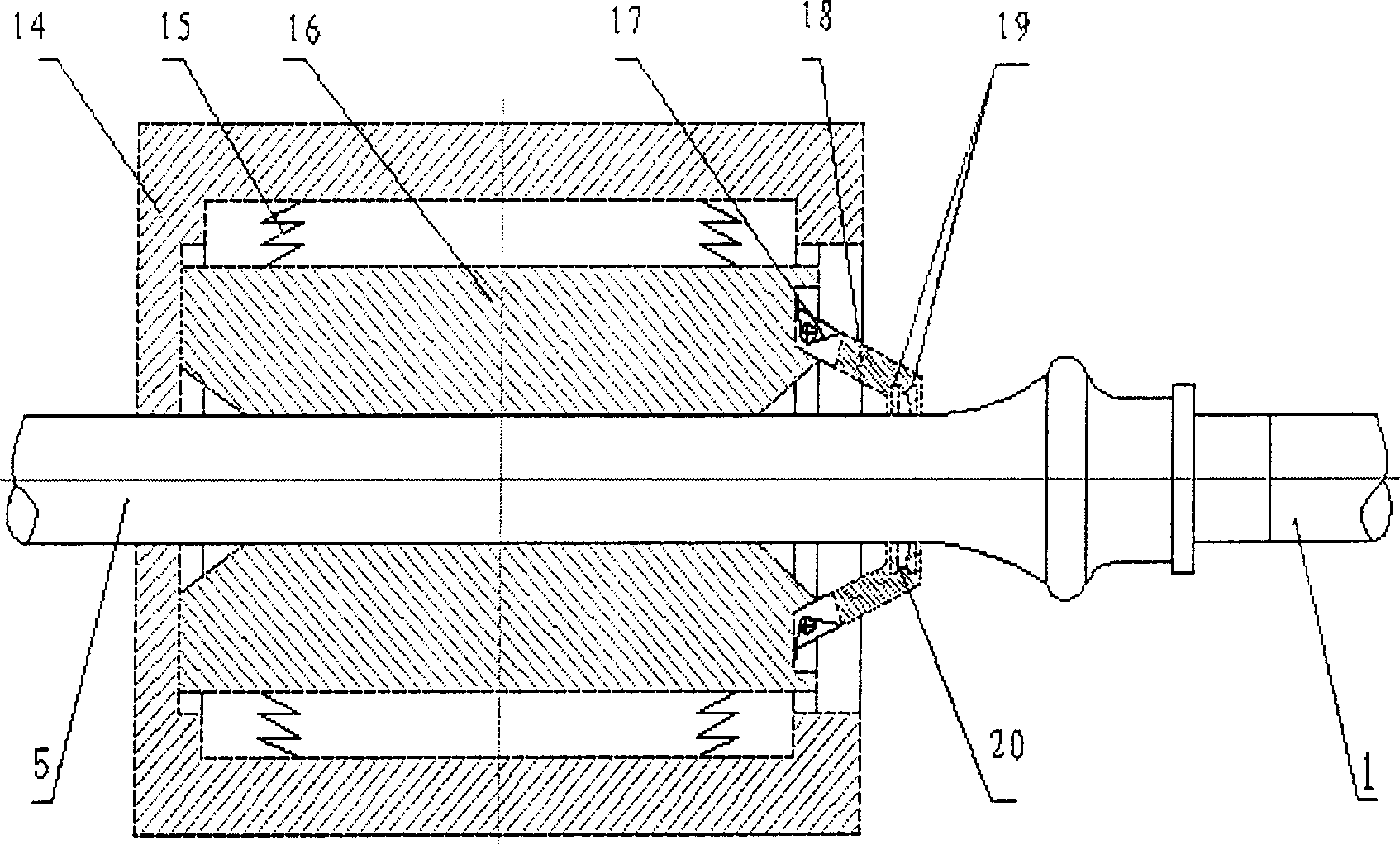

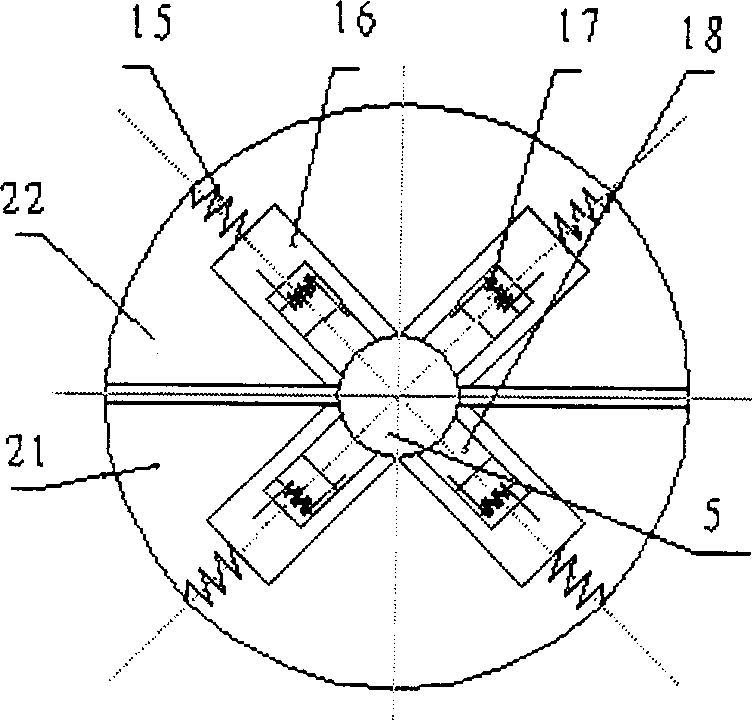

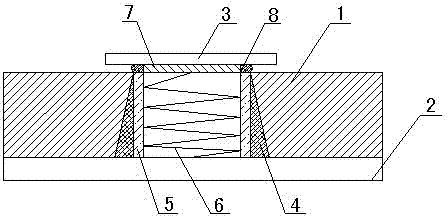

Simulation test method of rotating outer ring/fixed inner ring rolling bearing

ActiveCN101929918AAchieve axial positioningMinimize the interference of radial forceMachine bearings testingCouplingRolling-element bearing

The invention relates to a simulation test method of a rotating outer ring / fixed inner ring rolling bearing. The bearing test device is composed of a drive motor (1), a coupling (2), a rear pivot bearing (3), an outer ring shaft (4), a front pivot bearing (5), a sliding guide rail (6), a loading hydro-cylinder (8), a hinge I (9), an inner ring shaft (10), a hinge II (11), a spring (12) and a loading sleeve (13), wherein the outer ring of a test bearing (7) is installed in a cantilever end outer sleeve of the outer ring shaft; the inner ring of the test bearing is installed on the inner ring shaft; the inner ring shaft is fixed on the loading sleeve; the loading hydro-cylinder directly loads the test bearing in the radial direction by using the loading sleeve; and the axial holddown spring, the sliding guide rail, the hinge II and the like are utilized to realize axial positioning of the test bearing and reduce the interference of the radial force, thereby completely simulating the simulation test method of the rotating outer ring / fixed inner ring rolling bearing. The invention can be used for carrying out property simulation tests on the test bearing according to the velocity spectrum and loading spectrum.

Owner:LUOYANG BEARING RES INST CO LTD

Wiper plug with packer

Owner:TESSIER LYNN P +2

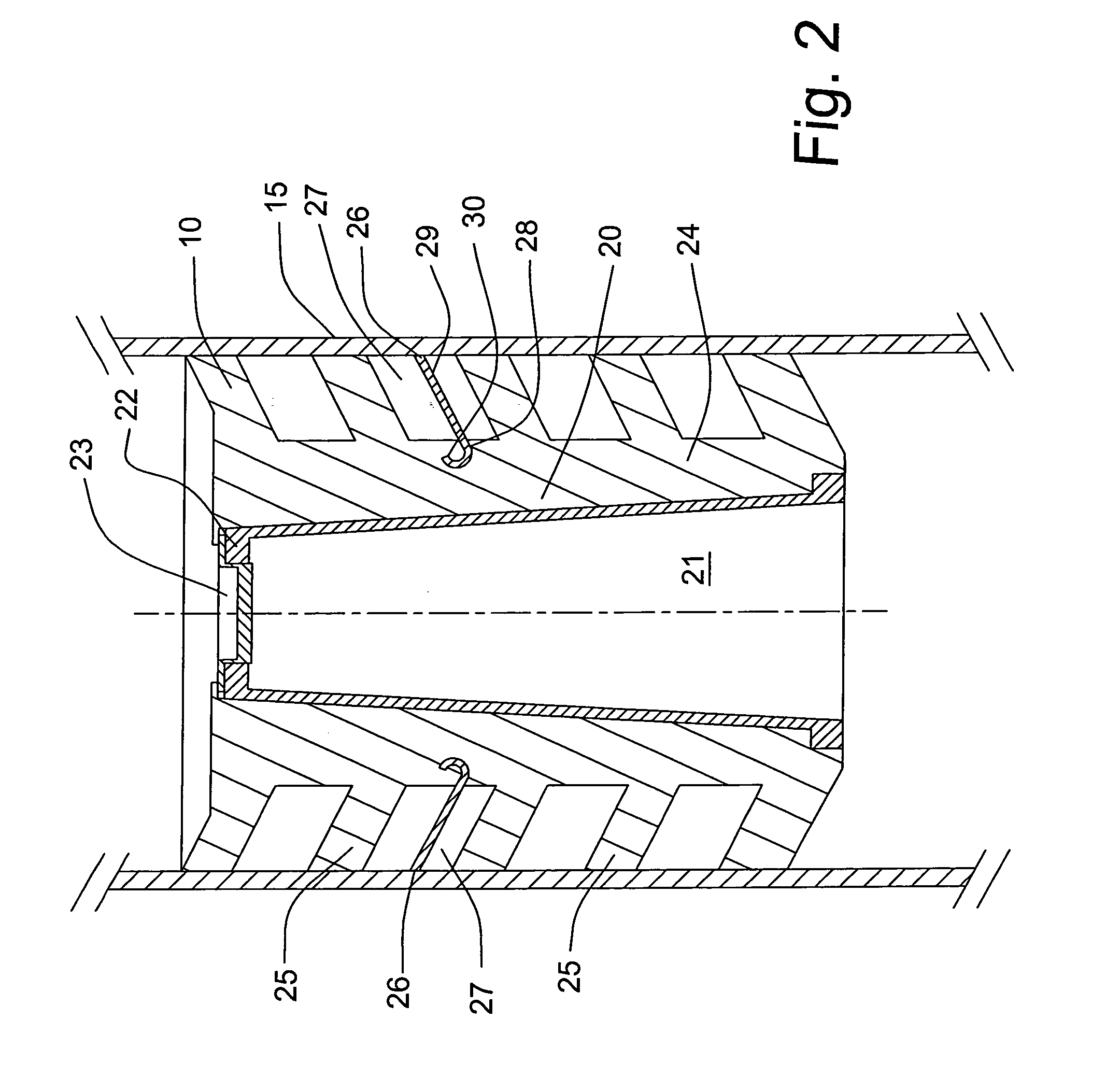

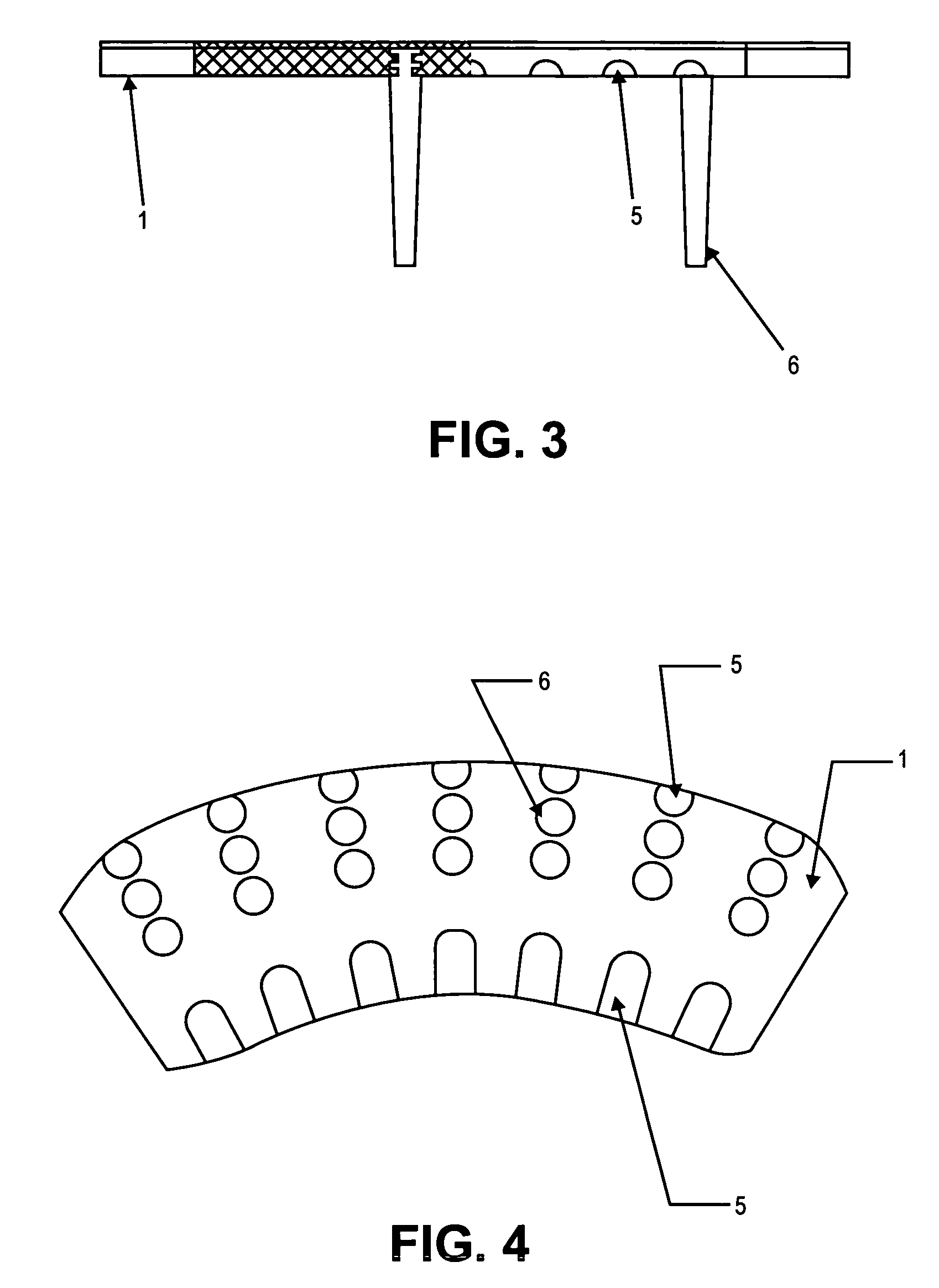

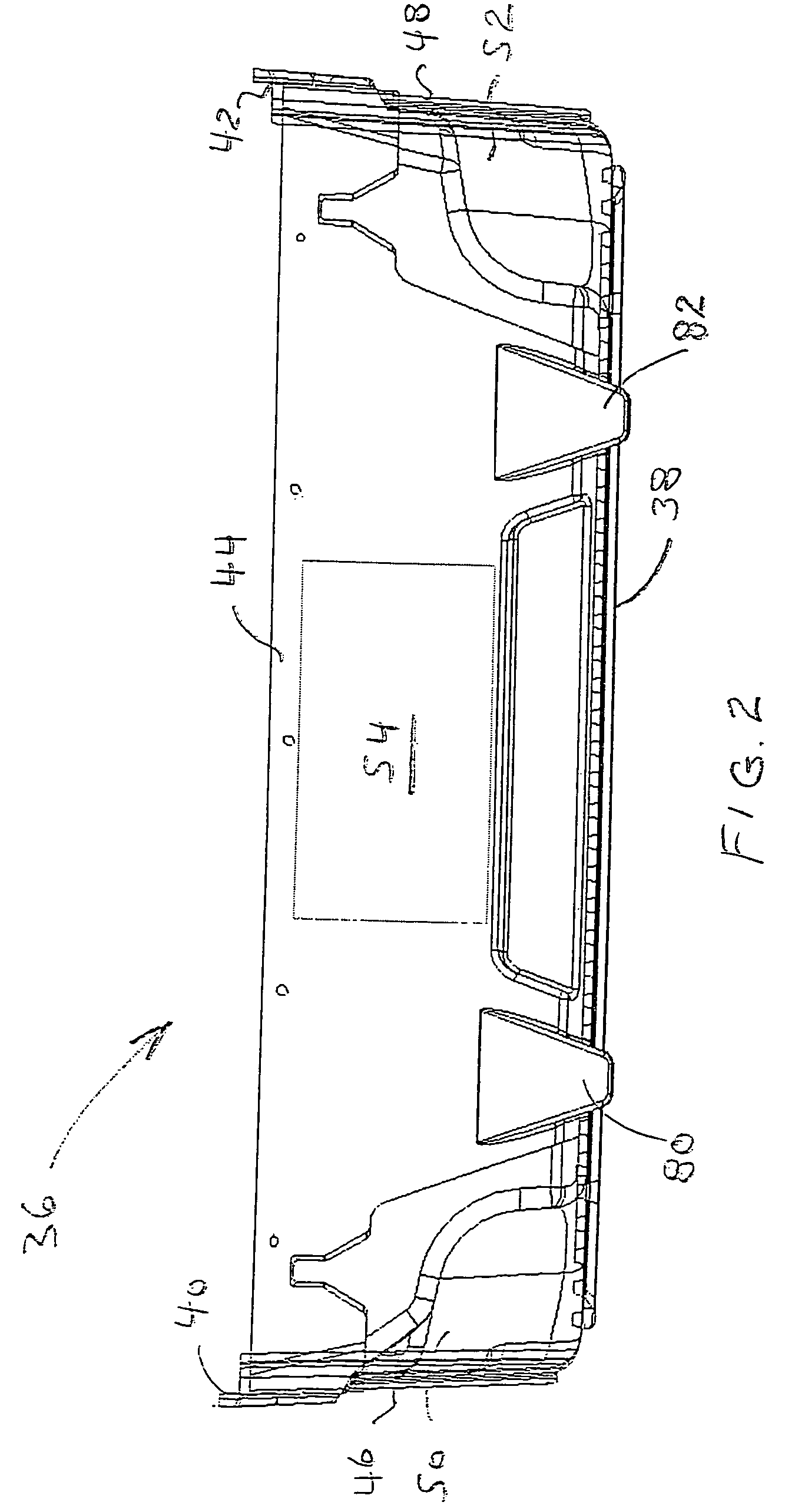

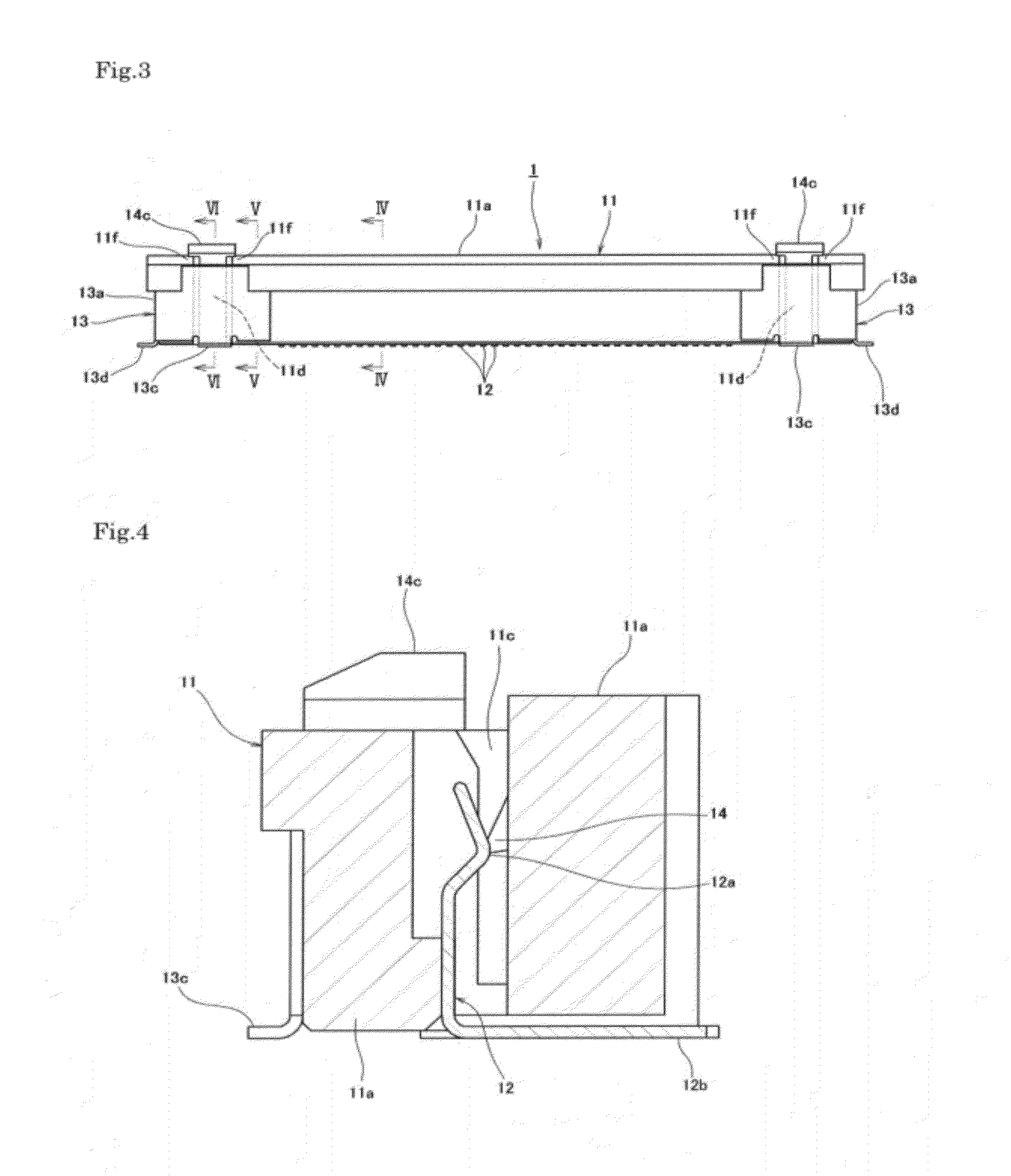

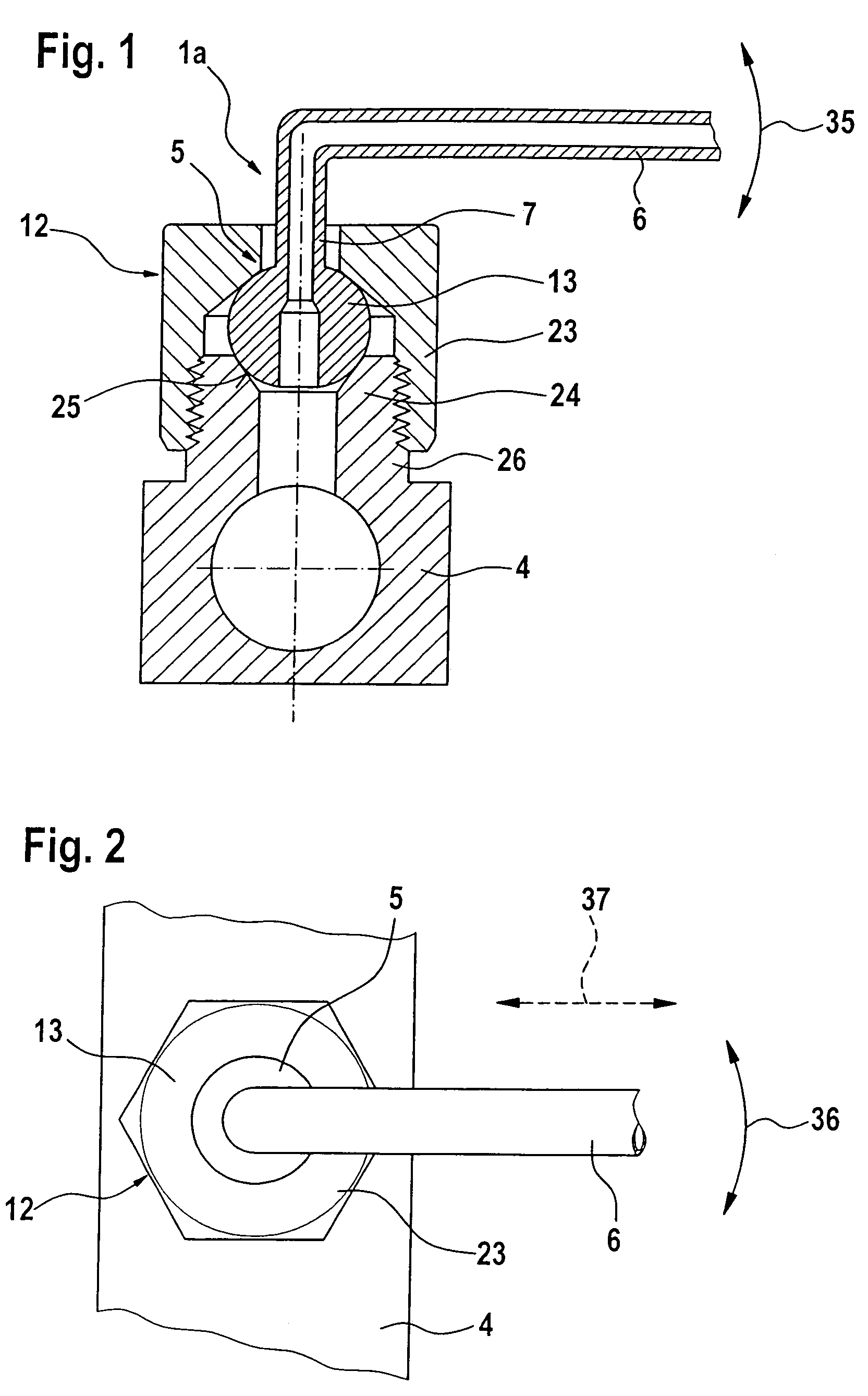

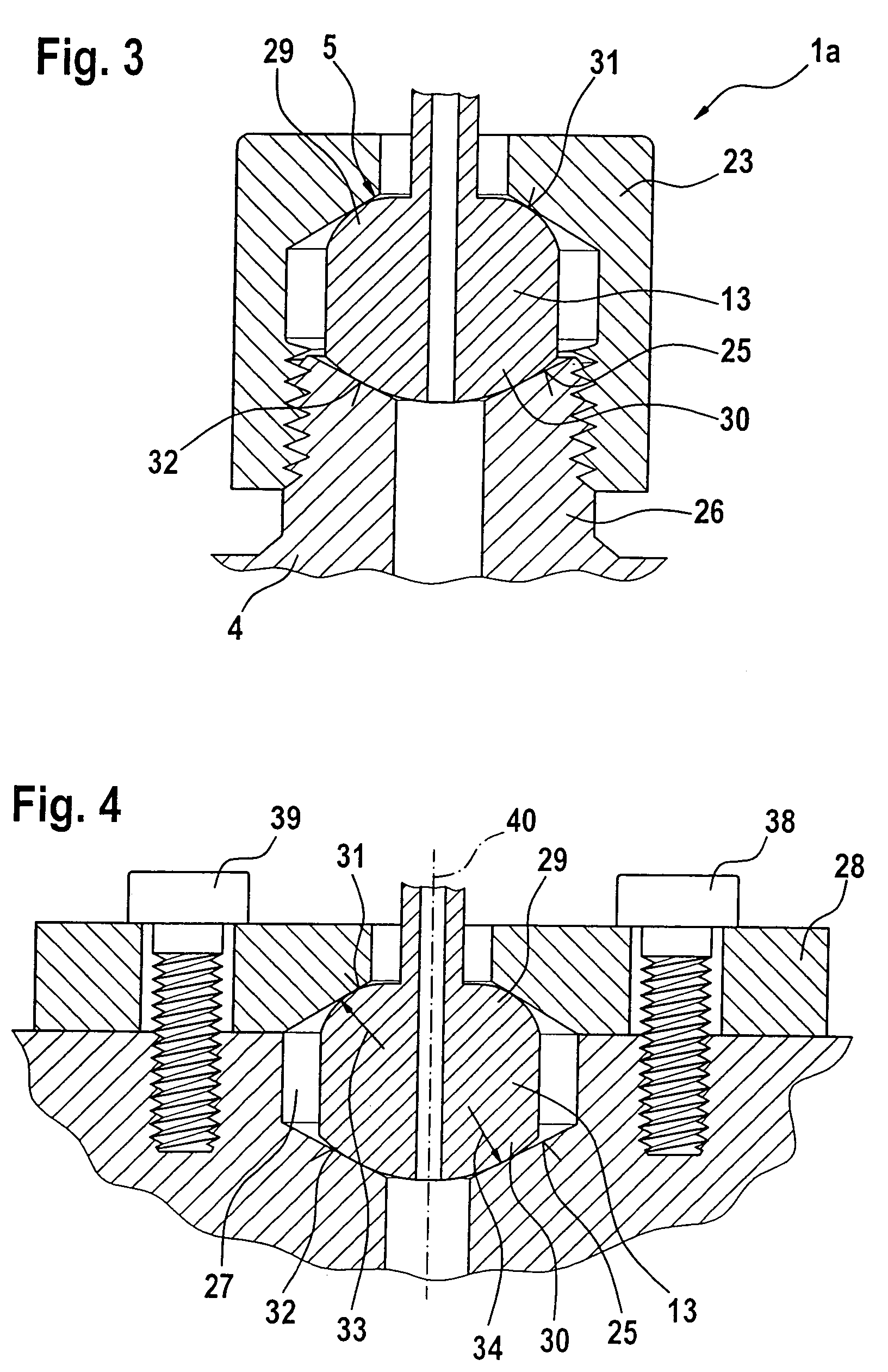

Holddown device for hardcopy apparatus

InactiveUS6927841B2Light weightConveniently madeWork holdersOther printing apparatusLeading edgeEngineering

A media holddown device a plastics vacuum guide attached to a sheet metal vacuum beam, the guide includes vacuum chambers in communication with the beam through openings to control the negative pressures applied to media of varying widths by a fan. Dividing walls are provided between the chambers to maintain the value of the negative pressure larger than a predetermined value, especially for media with conventional widths. An intermediate wall divides the guide into front and rear chambers to increase the control of media leading edges. The number, size and pattern of arrangement of openings are selected to produce desired air flow characteristics.

Owner:HEWLETT PACKARD DEV CO LP

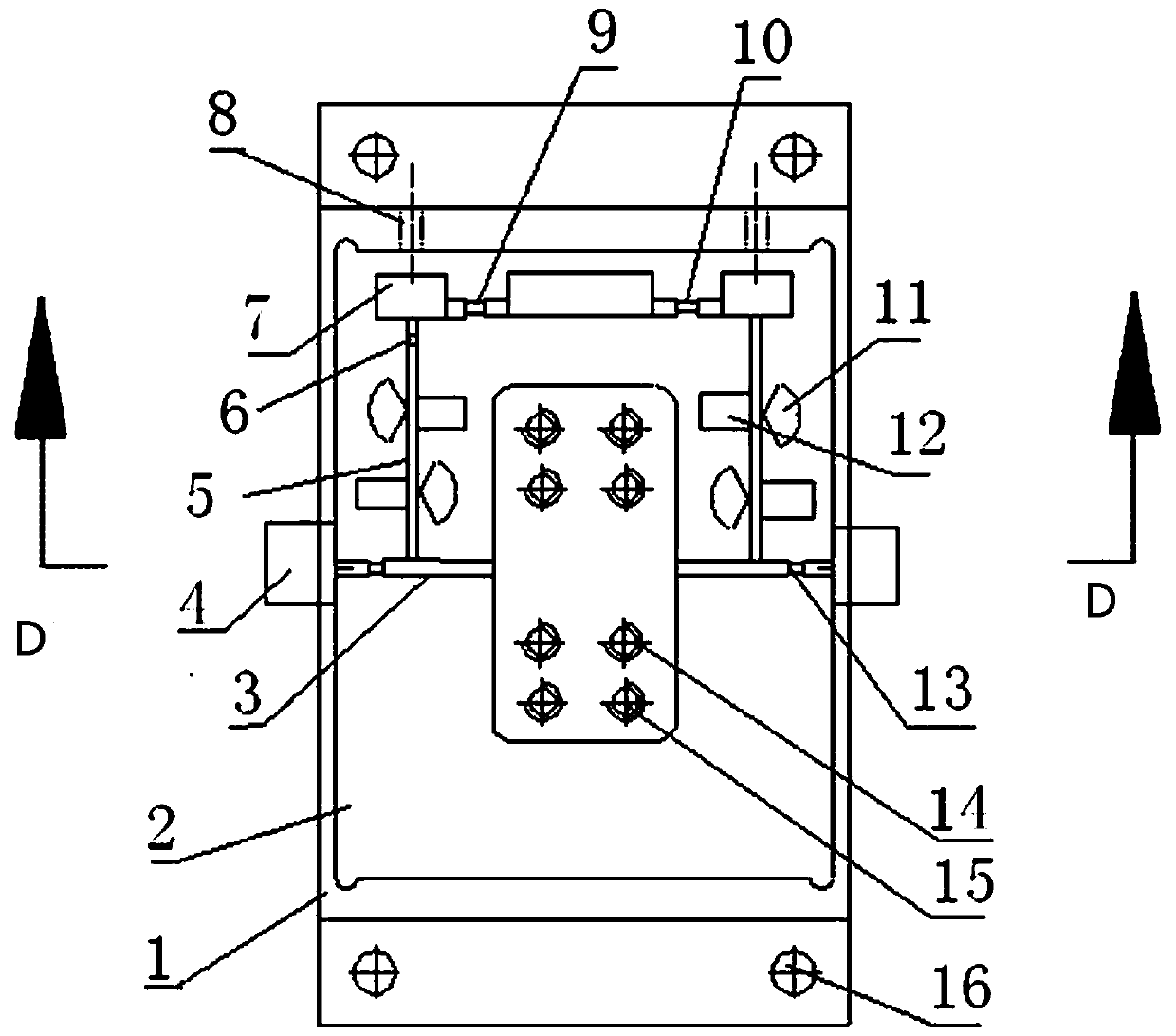

Power-on curing machine for PTC (Positive Temperature Coefficient) heaters

InactiveCN103702463AEasy to installImprove cooling effectHeater elementsEngineeringPositive temperature

The invention discloses a power-on curing machine for PTC (Positive Temperature Coefficient) heaters, which is convenient to operate. The power-on curing machine comprises a bed, a left supporting block and a right supporting block are arranged on the bed, a plurality of middle supporting blocks are arranged between the left supporting block and the right supporting block, a slidable holddown is arranged on the right supporting block, the middle of the slidable holddown is connected with a piston rod of a positioning cylinder through a connecting block, a pole-fixing board and an air cylinder are arranged on the bed by one side of a positioning board, poles are respectively arranged on both sides of each mounting groove, a push board is connected with a piston rod of the air cylinder, a plurality of connecting conductive posts which are matched with the mounting grooves are evenly arranged on the push board, two ejecting cylinders are arranged on the bottom of the bed, piston rods of the two ejecting cylinders pass through the bed and are inserted into a cavity between the two neighboring middle supporting blocks, and ejecting bars which cooperate with a PTC heater are arranged on the top ends of the piston rods of the ejecting cylinders.

Owner:盐城市北蒋电力机械厂

Portable communication terminal switchably displaying pictures based on a plurality of video signal sources

InactiveUS7515193B2Television system detailsPicture reproducers using cathode ray tubesComputer graphics (images)Signal source

A cellular phone having a plurality of cameras and being able to switch display of a picture without interrupting display for the camera is provided. Processes executed by a control unit of the cellular phone include the steps of measuring a holddown time when holddown of a button is detected; sending the video signal sent from the camera corresponding to a numeric button to a main monitor when a first function button is held down for a holddown time shorter than a predetermined time and the numeric button is held down; and sending the video signal sent from the camera set as a next source to the main monitor when the numeric button is not held down. The processes further includes the step of sending the video signal sent from a main camera to main monitor when the holddown time is longer than the predetermined time.

Owner:SHARP KK

Pole group welder for accumulator

InactiveCN1434533ASimple structureEasy to operateFinal product manufactureSecondary cells manufactureEngineeringWelding torch

A accumulator pole-group welder includes an assembly box, welding torch, firing device, holddown cylinder, non-withdrawing device, steering cylinder, crane, cell slot frame, turnover cylinder and a frame in which, the said assembly box right sideplate is movable holddown, the holddown cylinder is put on the frame corresponding to the plate, non-withdrawing device is between the plate and box, on the up-middle part of the frame via the turnover shaft, the turnover cylinder between the box and frame, the mould is above the box, the blow mouth of the cooling device and circular water weir are corresponding to the mould, welding torch and firing device on the frame, the crane on the frame, left to the assembly box, the slot frame on the crane via the turnover shaft, the turnover cylinder is between the slot frame crane.

Owner:温海泉

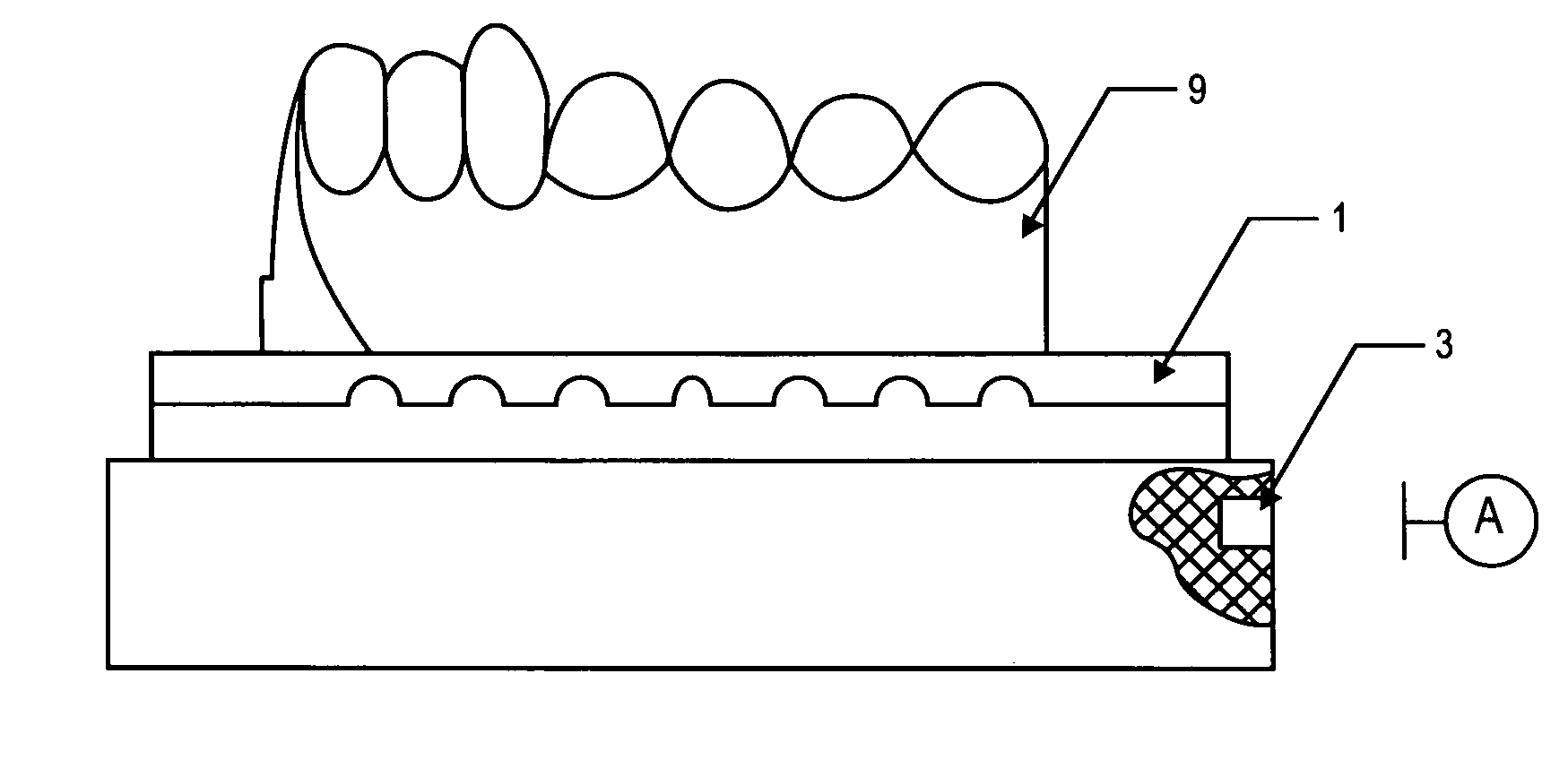

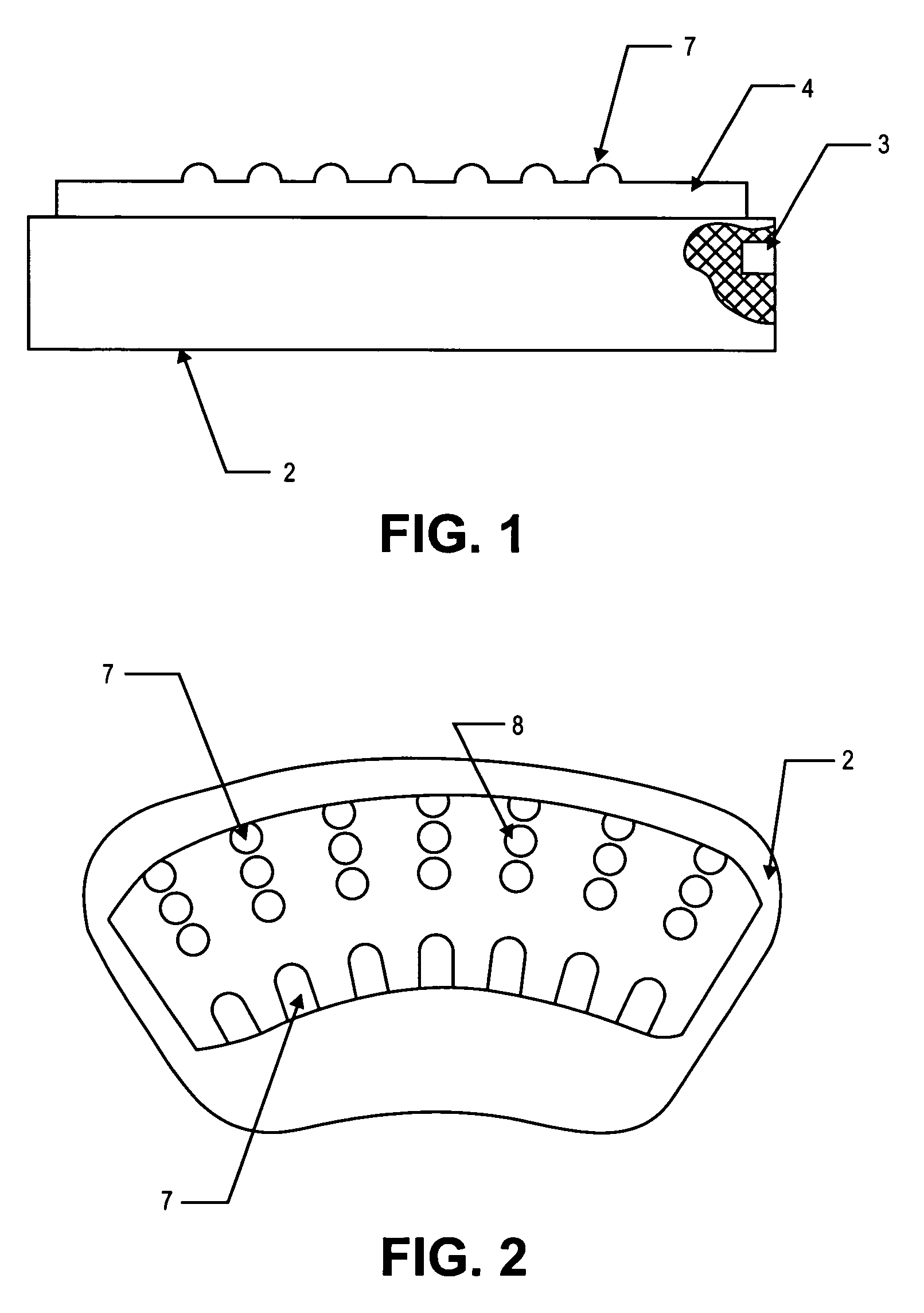

Base assembly for fabrication of false teeth

InactiveUS7192278B2Improve manufacturing precisionShorten production timeImpression capsDental articulatorsDenturesEngineering

A base assembly for fabrication of false teeth includes a base, and a gum-like raised portion is provided on the said base, a plurality of protruding blocks are provided symmetrically and evenly at the interior and exterior arc edges on the raised portion, and positioning holes are provided between two opposite protruding blocks; a removable holddown plate with a configuration corresponding to the said raised portion is provided over the raised portion, and the holddown plate has a flat surface on the upper surface, has the recesses corresponding to the protruding blocks to be engaged with the protruding blocks and the mounting pins corresponding to the positioning holes to be engaged with the positioning holes on the lower surface. The time to fabricate false teeth is largely reduced and the fabrication accuracy of the false teeth is improved by using the base assembly of the present invention.

Owner:QINGDAO DONGHE DENTURE MFG

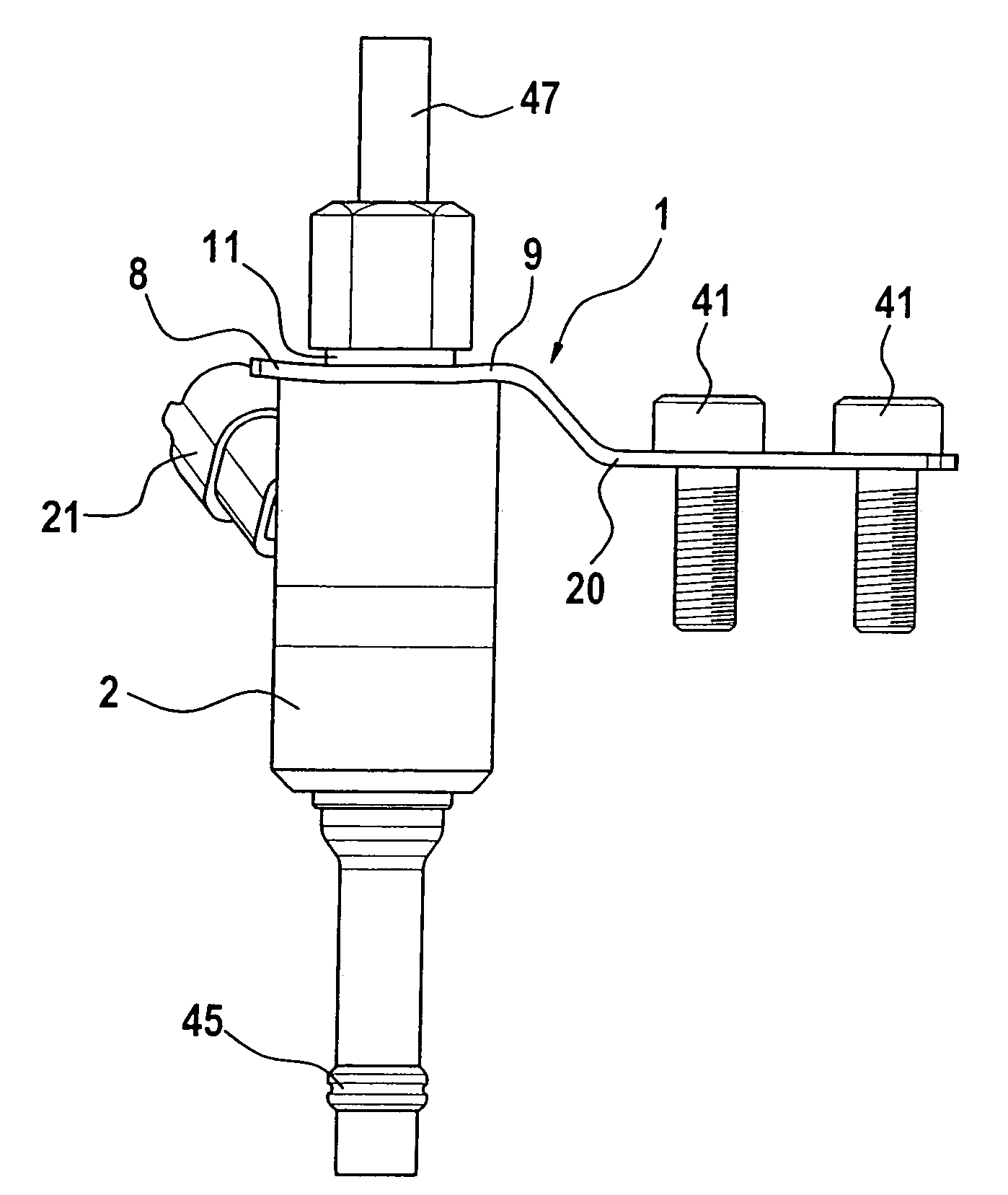

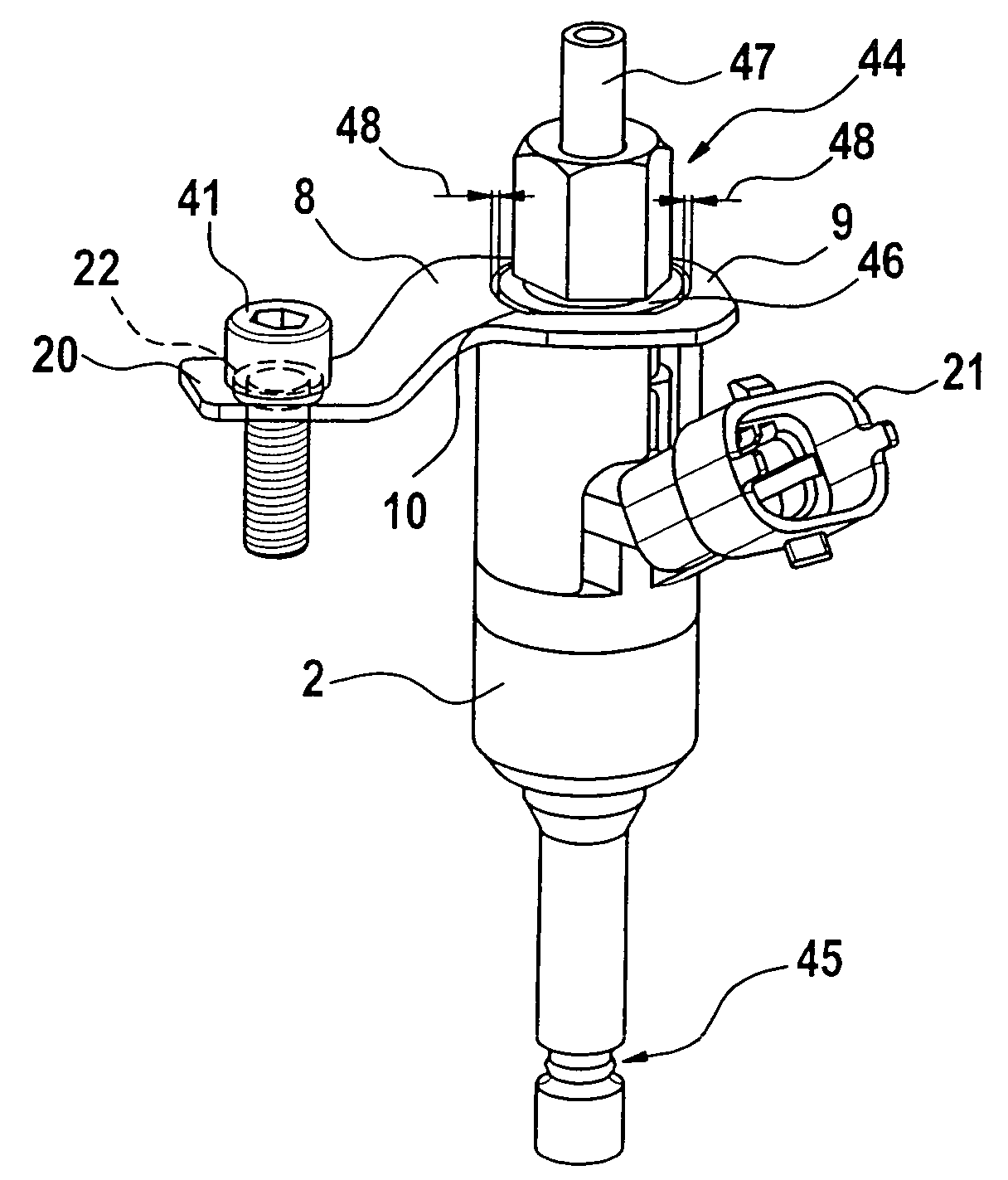

Connector System

InactiveUS20070246016A1Possible to compensateFuel injection apparatusMachines/enginesLine tubingTransverse force

A connector system, free of transverse forces, for a fuel injection valve to be inserted into a receiving orifice into a cylinder head for connection to a fuel distributor line that encompasses a connector to a tubing line leading to a fuel reservoir, has a connecting part for connection to the tubing line. The connector system includes a holddown claw having an elongated opening that completely surrounds the fuel injection valve but allows for a tolerance compensation in the direction of the longitudinal axis of the holddown claw, and provides that the connecting part to the tubing line leading to the fuel reservoir has a tube screw fitting having an end piece. The end piece is embodied so that before the tubing line is screwed down onto the fuel distributor line, it can be moved for tolerance compensation, in a seat on the inflow-side end of the fuel distributor line, in two directions perpendicular to the extent of the tubing line.

Owner:ROBERT BOSCH GMBH

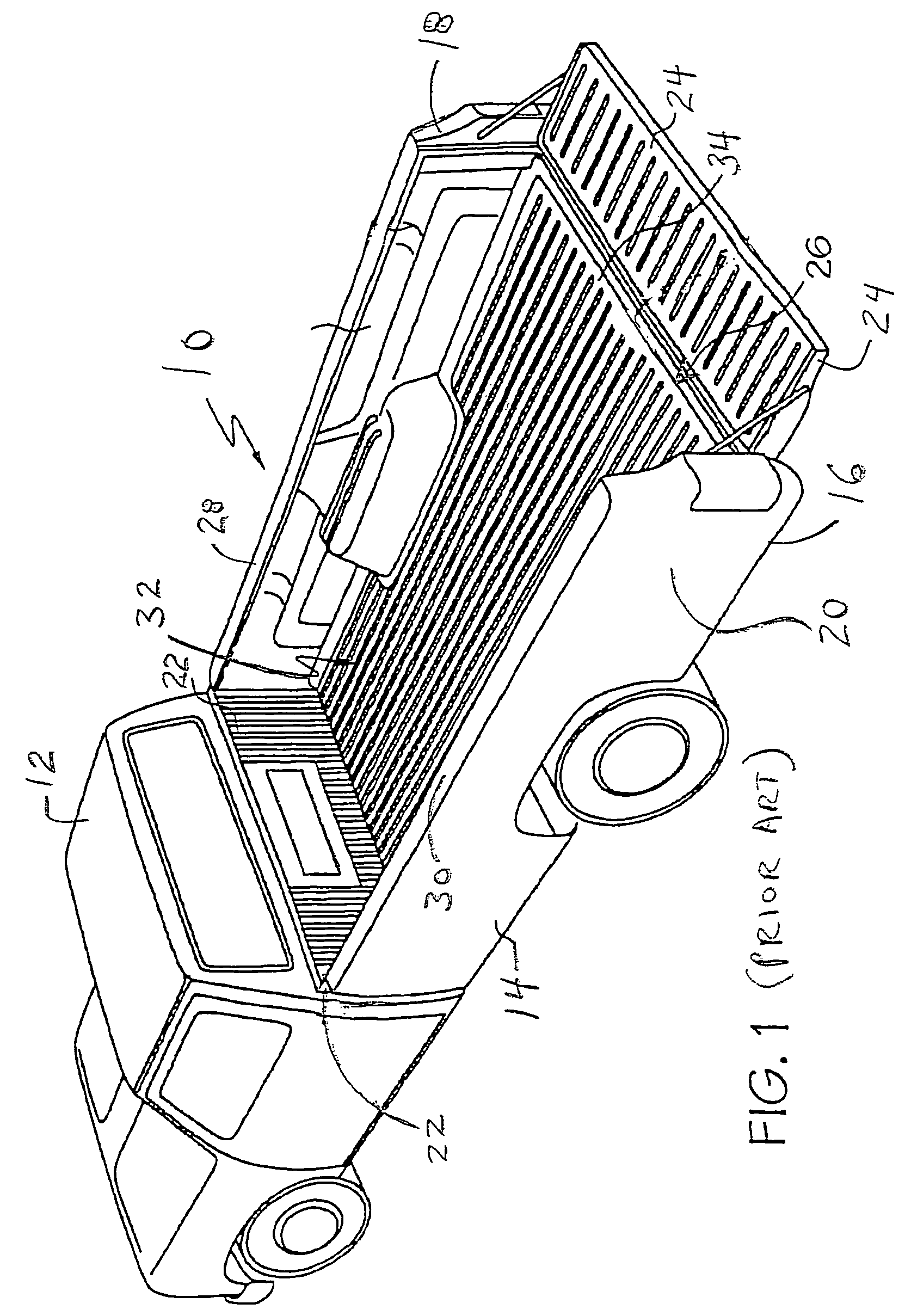

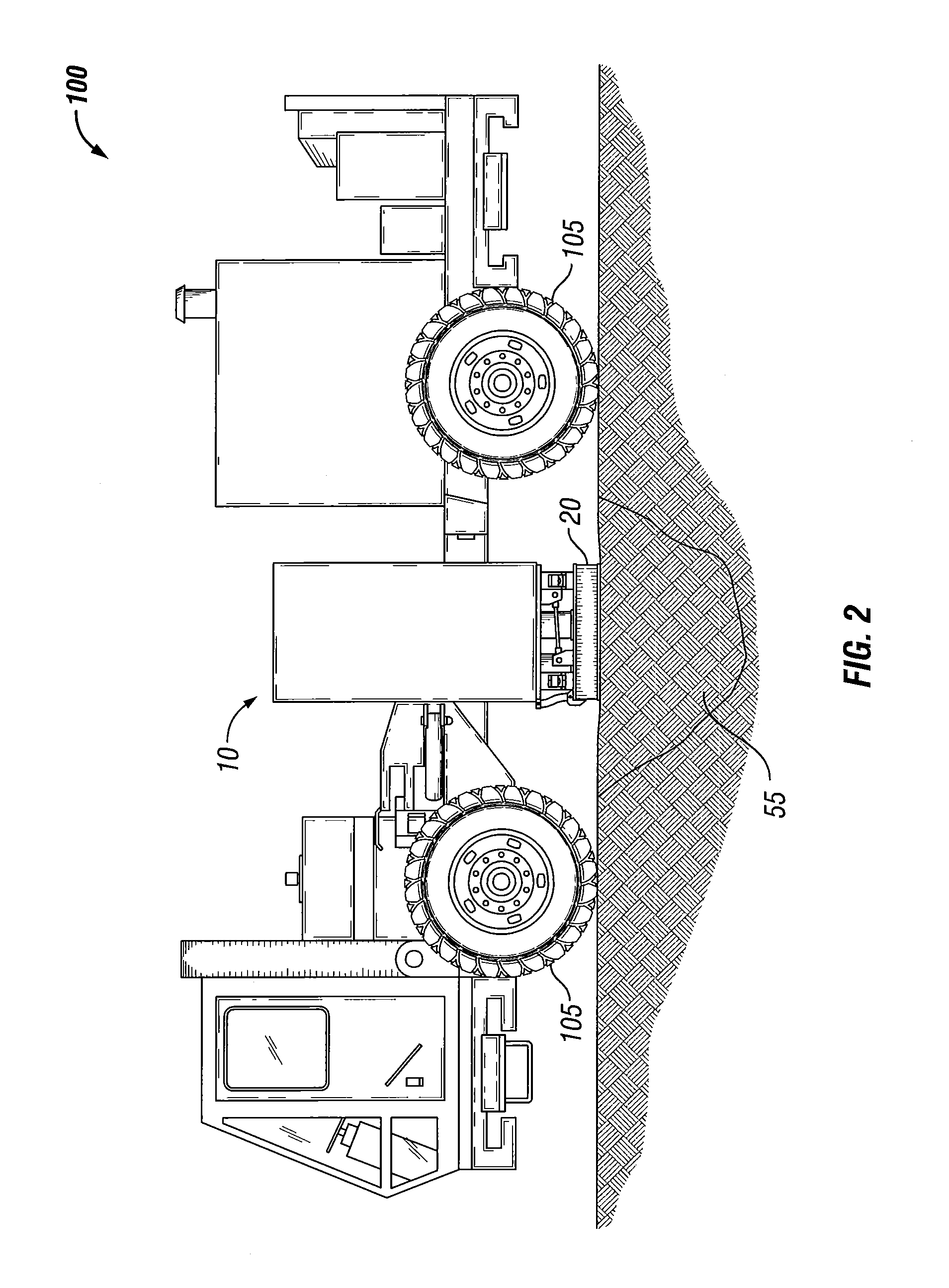

Bed liner rail system for cargo holddown

An essentially flat base of a bed liner is positioned on a vehicle cargo bed. The base includes a forward edge and a rear edge. A plurality of panels extend upwardly from the base. A front panel includes a protrusion projecting beyond the base forward edge. The base includes one or more continuous recessed channels extending from the base rear edge to the protrusion. Each channel includes a continuous track for receiving a movable tie-down device. The tie-down device includes a portion contoured to slide within the track and an anchor portion.

Owner:GERMAN MARK K

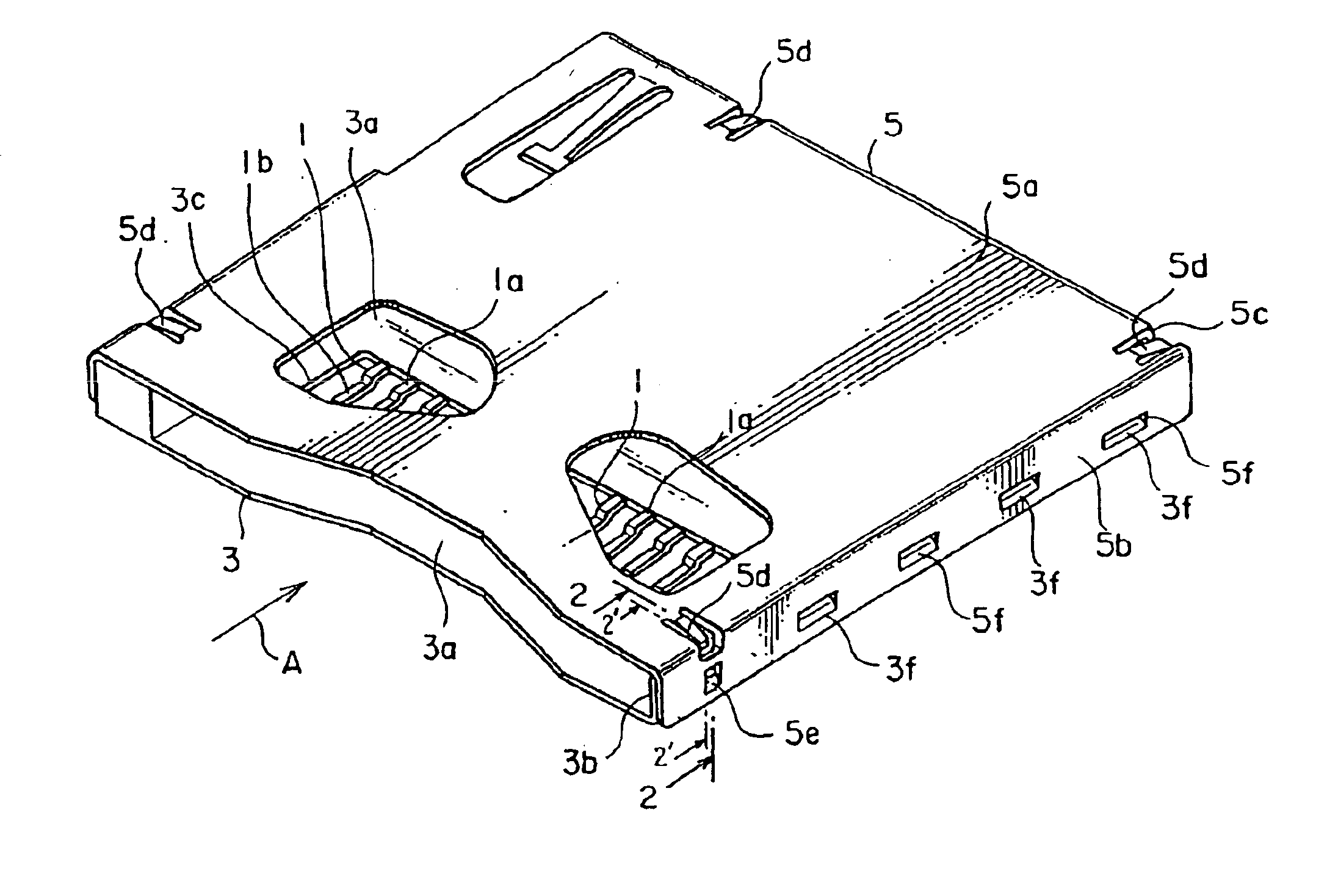

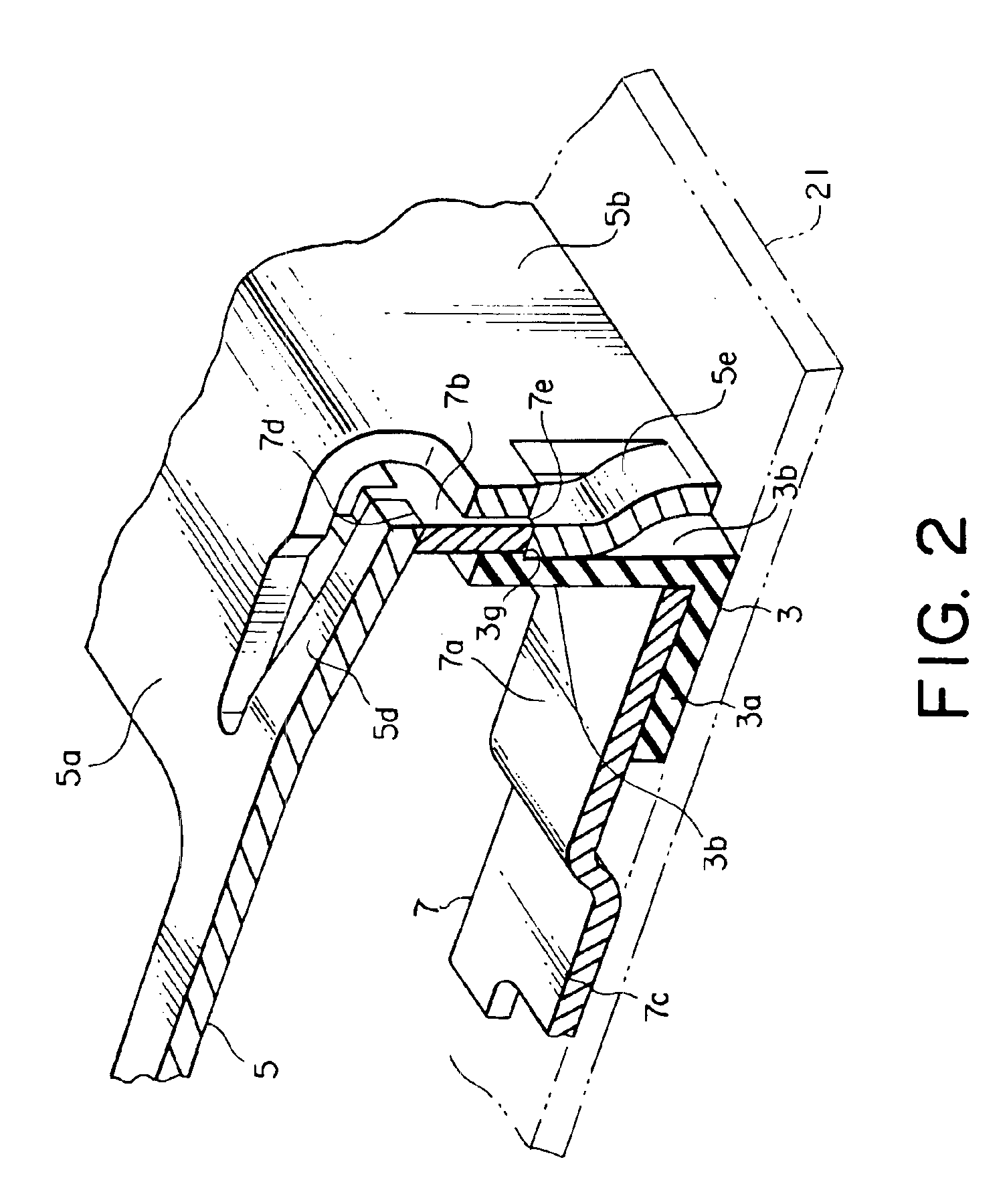

Electrical connector having a holddown for ground connection

InactiveUS6899565B2Reliable weldingFlatness can be impairedTwo-part coupling devicesCoupling protective earth/shielding arrangementsElectrical conductorEngineering

An electrical connector comprises an insulator to be mounted to a substrate, a conductive cover member coupled to the insulator, and a conductive holddown held by the insulator to connect the cover member and a ground conductor portion formed on the substrate. The cover member has first and second cover contacting portions. The holddown has a holddown contacting portion extending to face an outer surface of a side wall portion of the insulator. The holddown contacting portion is clamped between the first and the second cover contacting portions in a direction along the outer surface of the side wall portion.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

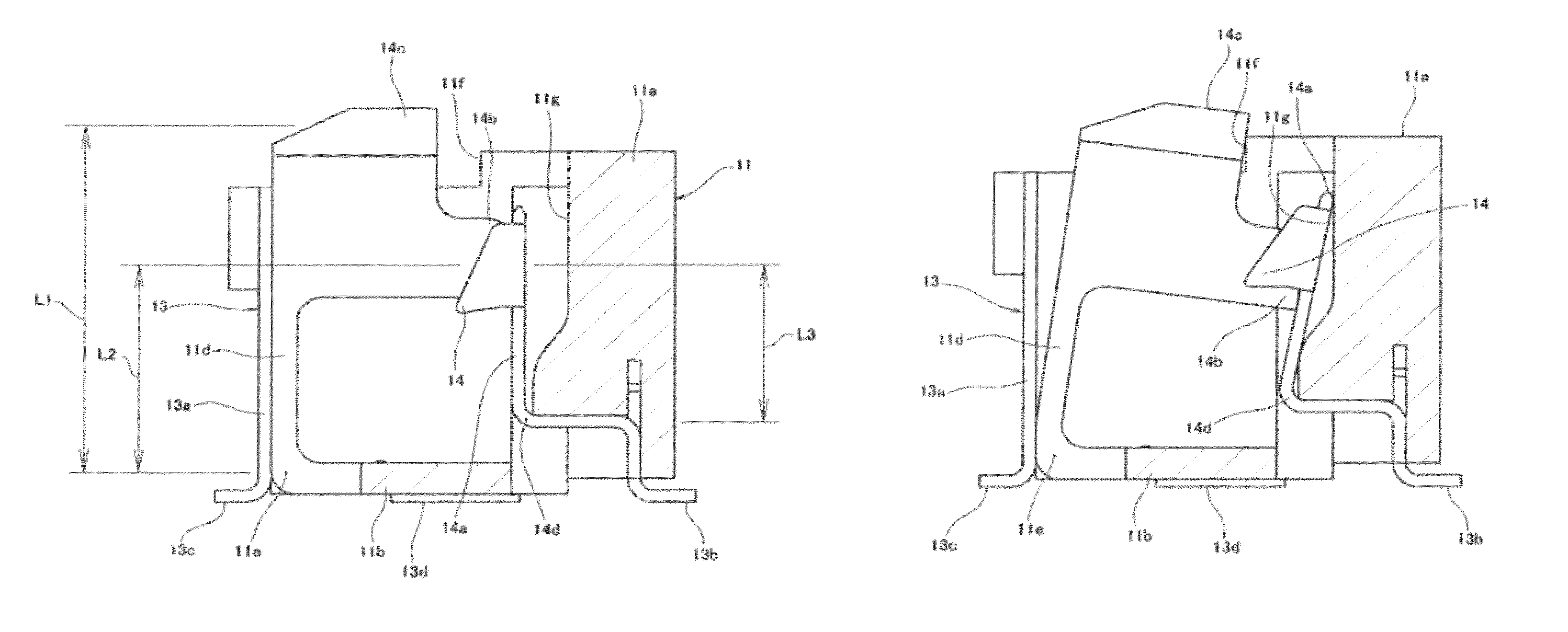

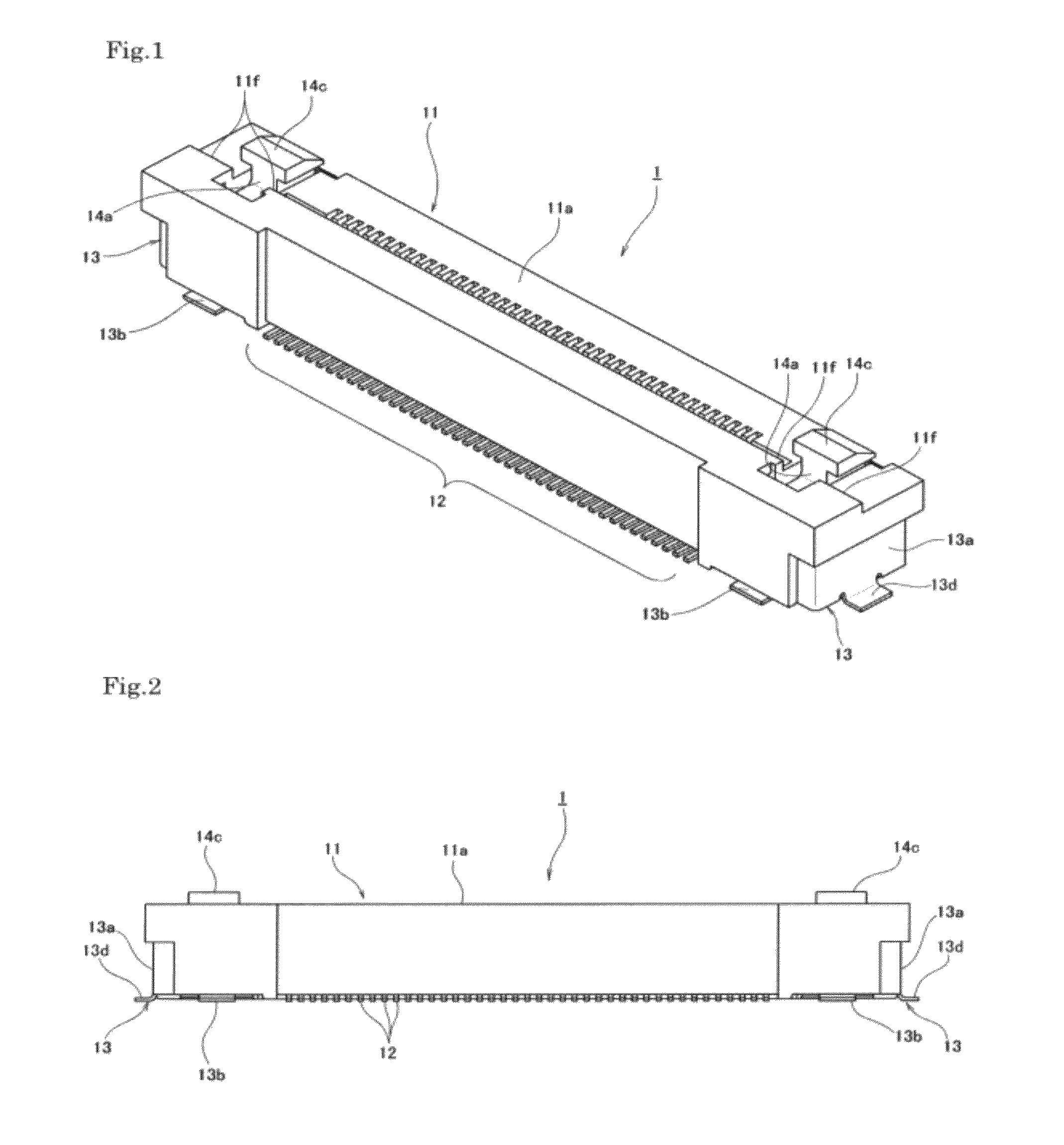

Electrical connector having a board connection leg portion with a locking portion to engage a signal transmission medium and a connector main body with an unlocking portion

InactiveUS8371880B2Improve reliabilityEngagement/disengagement of coupling partsTwo-part coupling devicesElectrical connectorCantilever

A signal transmission medium inserted in a connector main body portion, which can be held and released successfully with a simple configuration, is disclosed. A distal end portion of an elastically-displaceable cantilever-shaped locking arm member formed so as to be integral with a board connection leg portion (holddown) is provided with a locking portion engaged with a portion of the signal transmission medium inserted in the connector main body portion to hold the inserted state. The held state of the signal transmission medium is maintained by elastic action of the locking arm member extending in a relatively-elongated shape from a swinging fulcrum. Simultaneously, an unlocking-action force on the locking portion can be reduced, and an unlocking-operation force is stably received by the board connection leg portion (holddown) fixed to a printed circuit board so that improvement in strength is achieved.

Owner:DAIICHI SEIKO CO LTD

Wave filter for rotary filter

InactiveUS6582598B2Cost effectivenessAllowing cost-effectivenessFrozen sweetsConfectioneryWave shapeFilter media

Owner:ALTER INVEST FUND LP

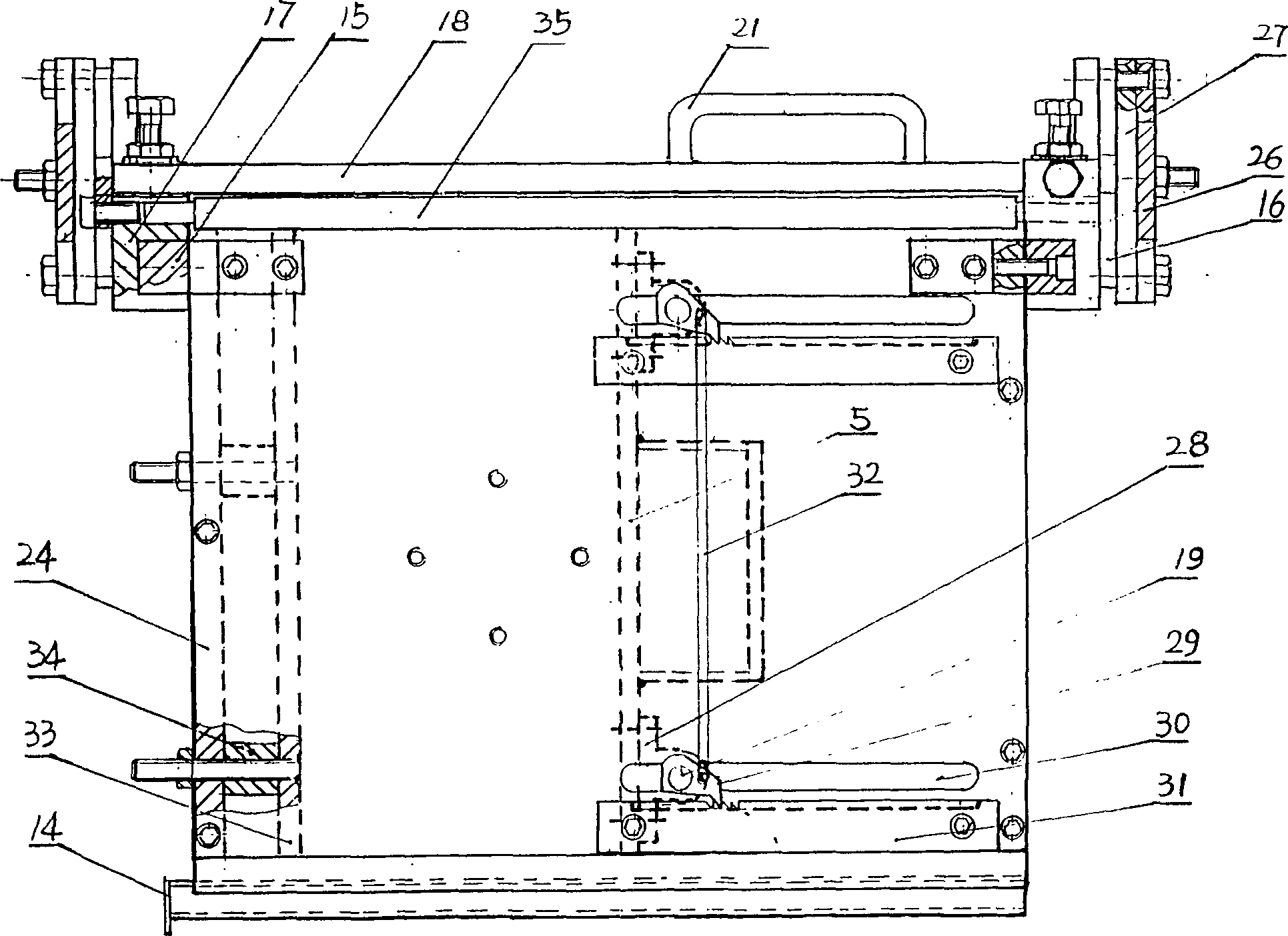

Welding equipment of plastic door-window welding machine

The welding device of plastic door and window welding machine relates to a mechanism of plastic door and window welding machine. Said mechanism includes two holddown pliers devices, positioning heating device and welding melting spacing mechanism, the described two holddown pliers devices are respectively equipped with a set of sliding mechanism fixedly-connected with them, and the described two sliding mechanisms are connected with holddown pliers feeding devices capable of synchromoving with them. Said invention is mainly used on plastic door and window welding machine.

Owner:济南光明机器有限公司

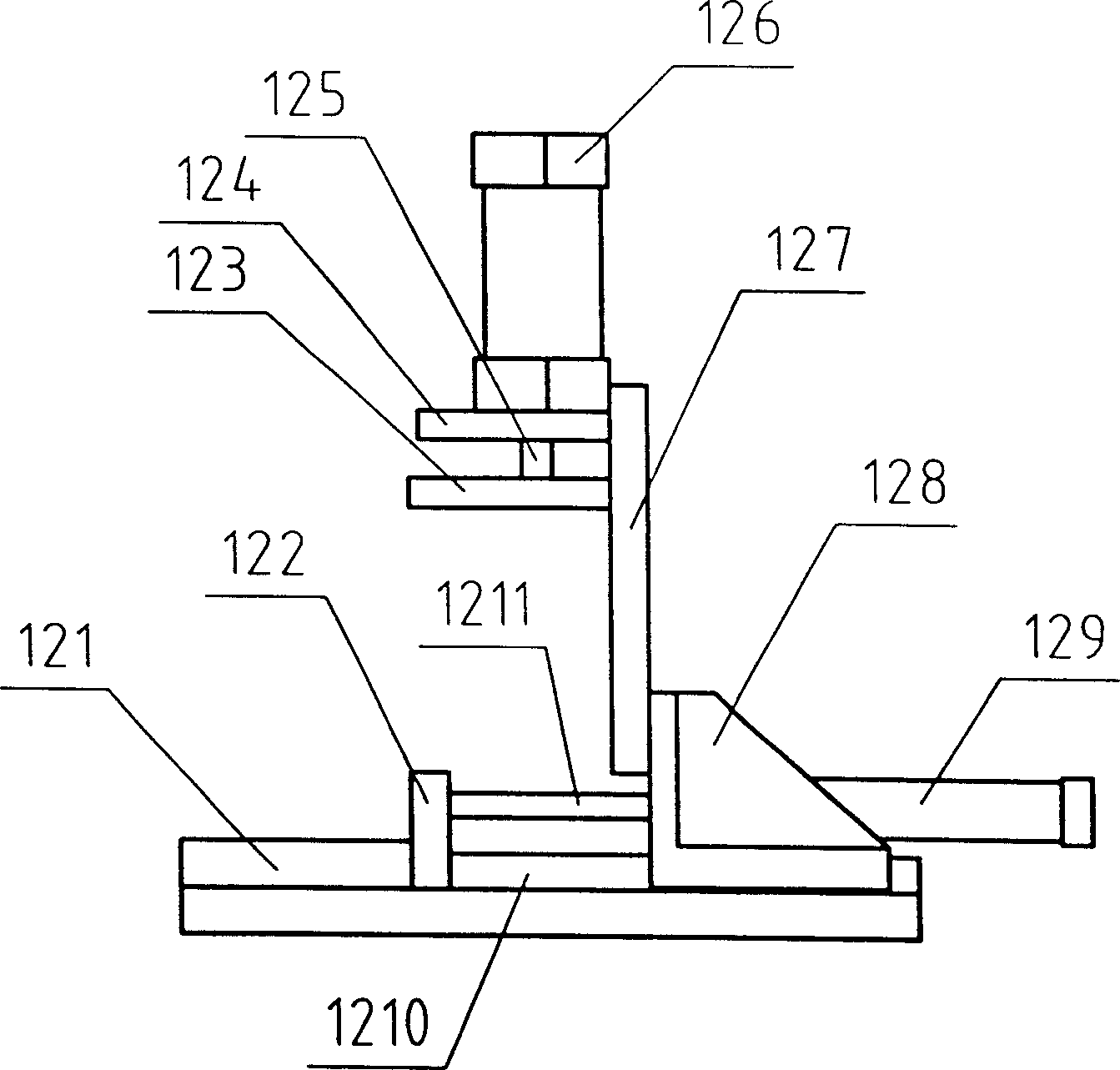

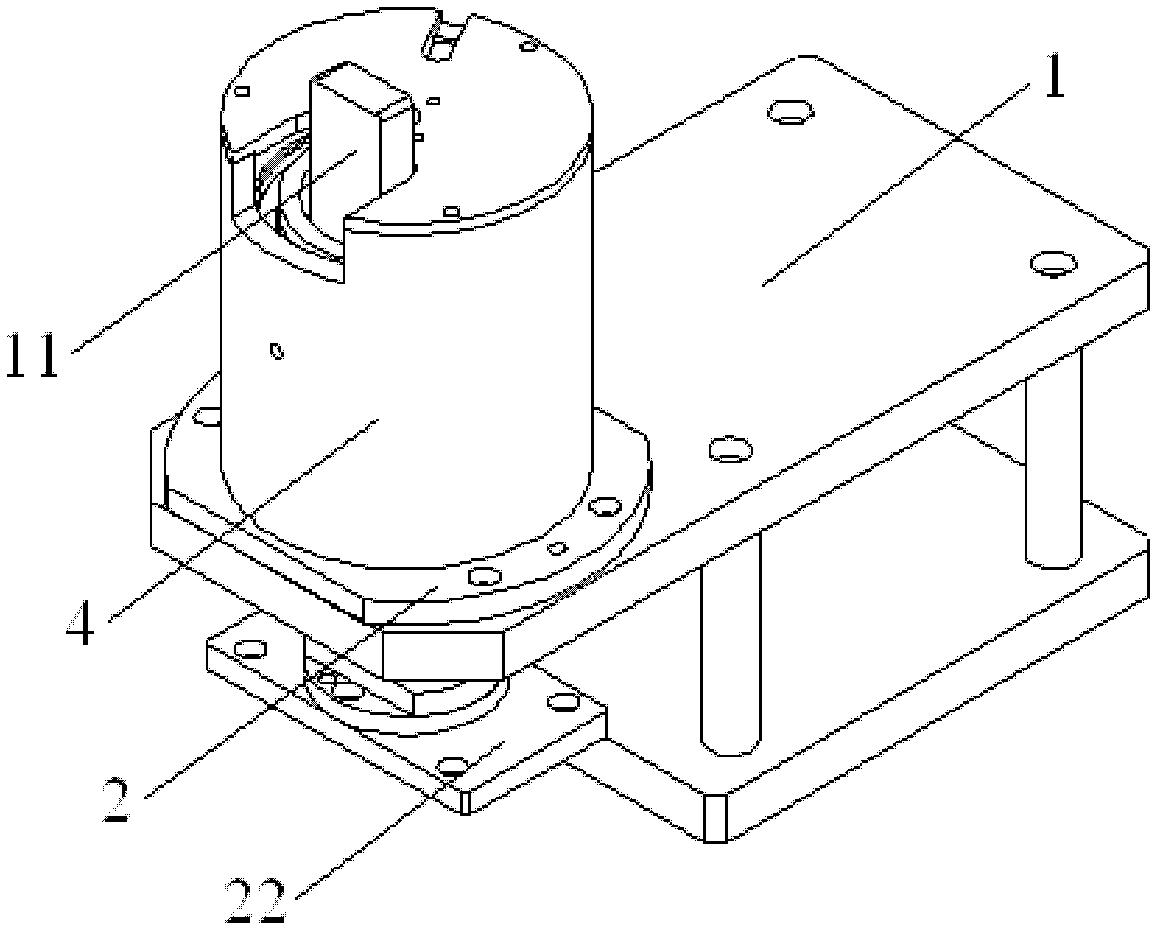

Device for measuring small clearance between end faces of mechanical products

ActiveCN102589505AAchieving Relative MeasurementsRealize precise measurementMeasurement devicesSurface cleaningEngineering

The invention relates to a device for measuring the small clearance between end faces of mechanical products, which is used for measuring the clearance between the parallel upper end faces of a first workpiece and a second workpiece, and the first workpiece is nested in a concave cavity of the upper end face of the second workpiece. The device comprises a supporting plate, a bracket cylinder, a second workpiece holddown piece, a connecting sleeve, a first workpiece holddown shaft, a sensor and a workpiece positioning clamp, wherein the bracket cylinder is fixedly connected onto the upper surface of the supporting plate, the second workpiece holddown piece and the connecting sleeve are arranged in the bracket cylinder in a sliding fit manner, the sensor is provided with a sensing head, and the first workpiece and the second workpiece are clamped at the top of the workpiece positioning clamp. According to the device for measuring the small clearance between the end faces of the mechanical products, the relative measurement of end face clearances is realized through the design of a three-layer annular sleeve structure, and a reference member can be concentric with a measuring column through the introduction of a gas floating support technology, so that two measuring faces are ensured to be parallel, the precise measurement of the small clearance between the end faces is realized, and the minimum value of the clearance between the end faces is ensured to be measured; and furthermore, the function of measured surface cleaning is realized through a blowing rod of the device.

Owner:SHANGHAI KELAI MECHATRONICS ENG CO LTD

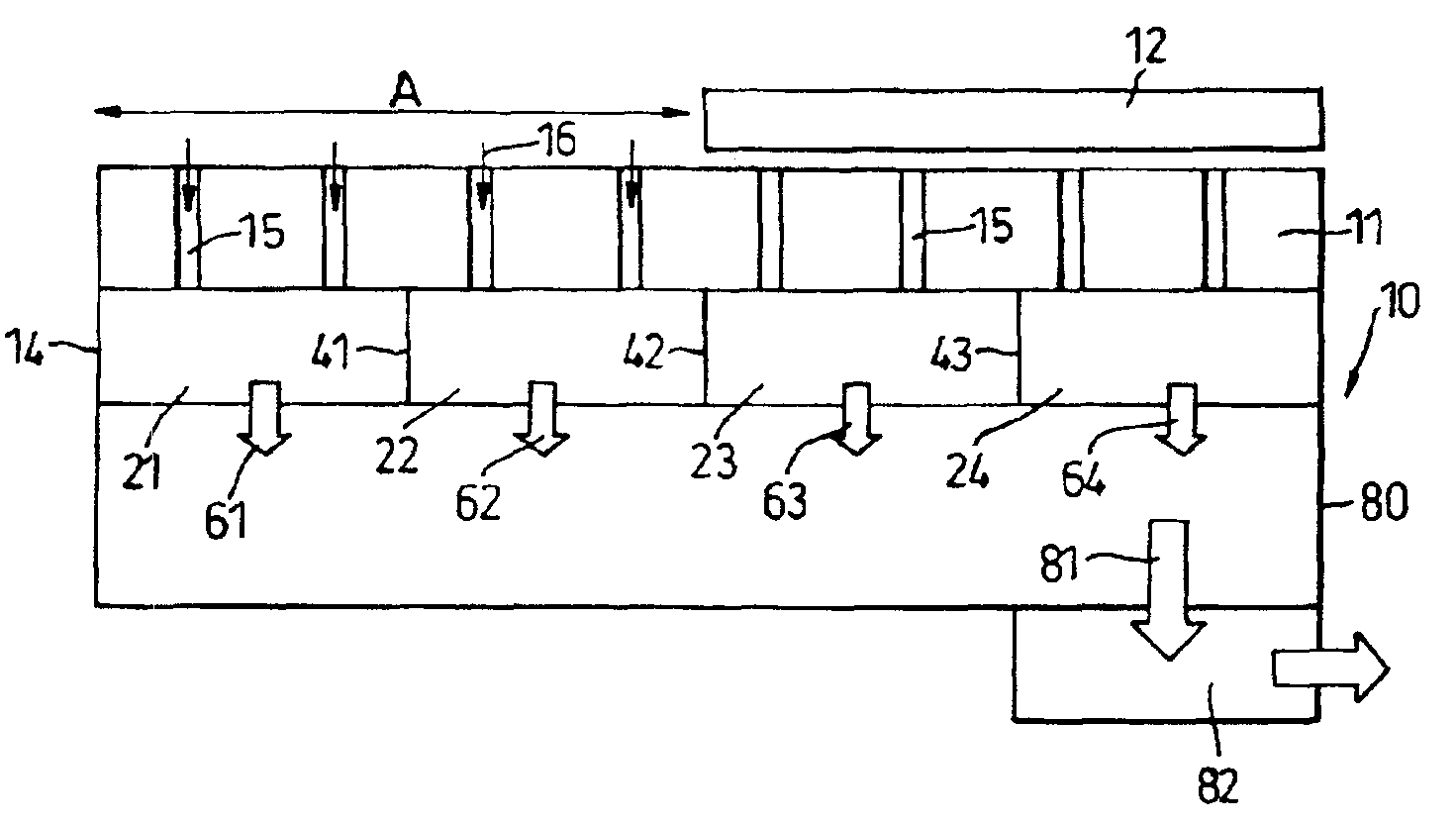

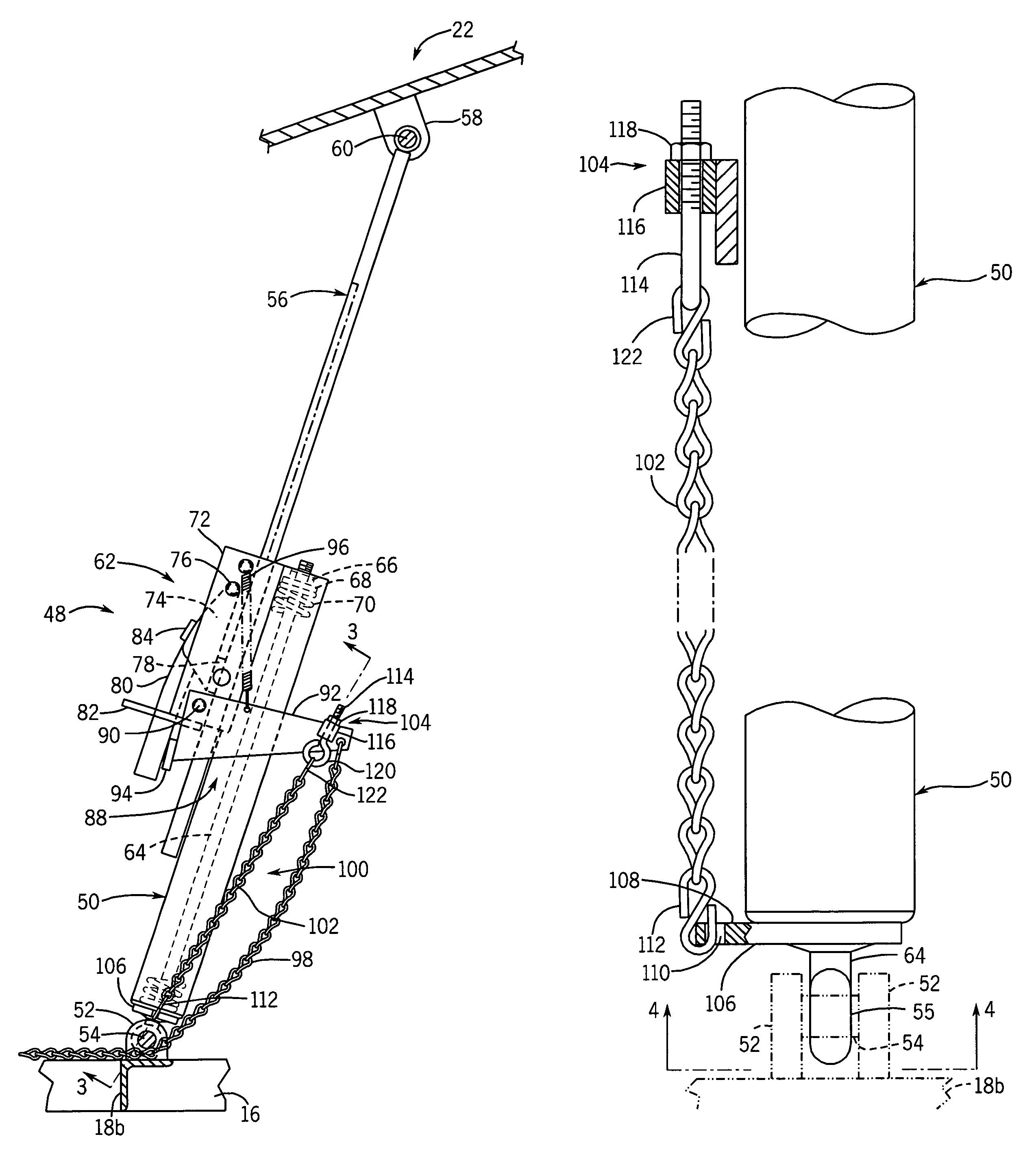

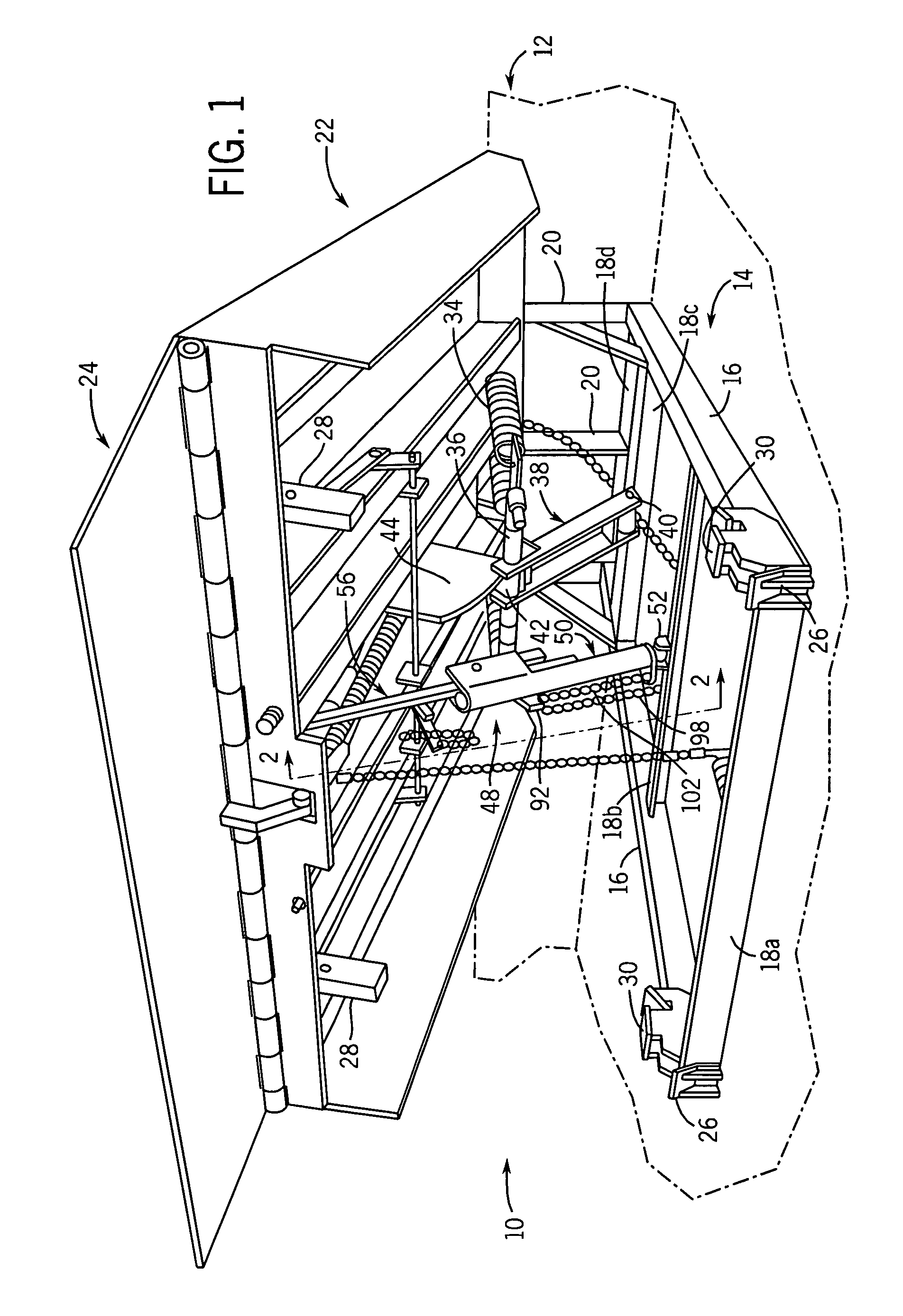

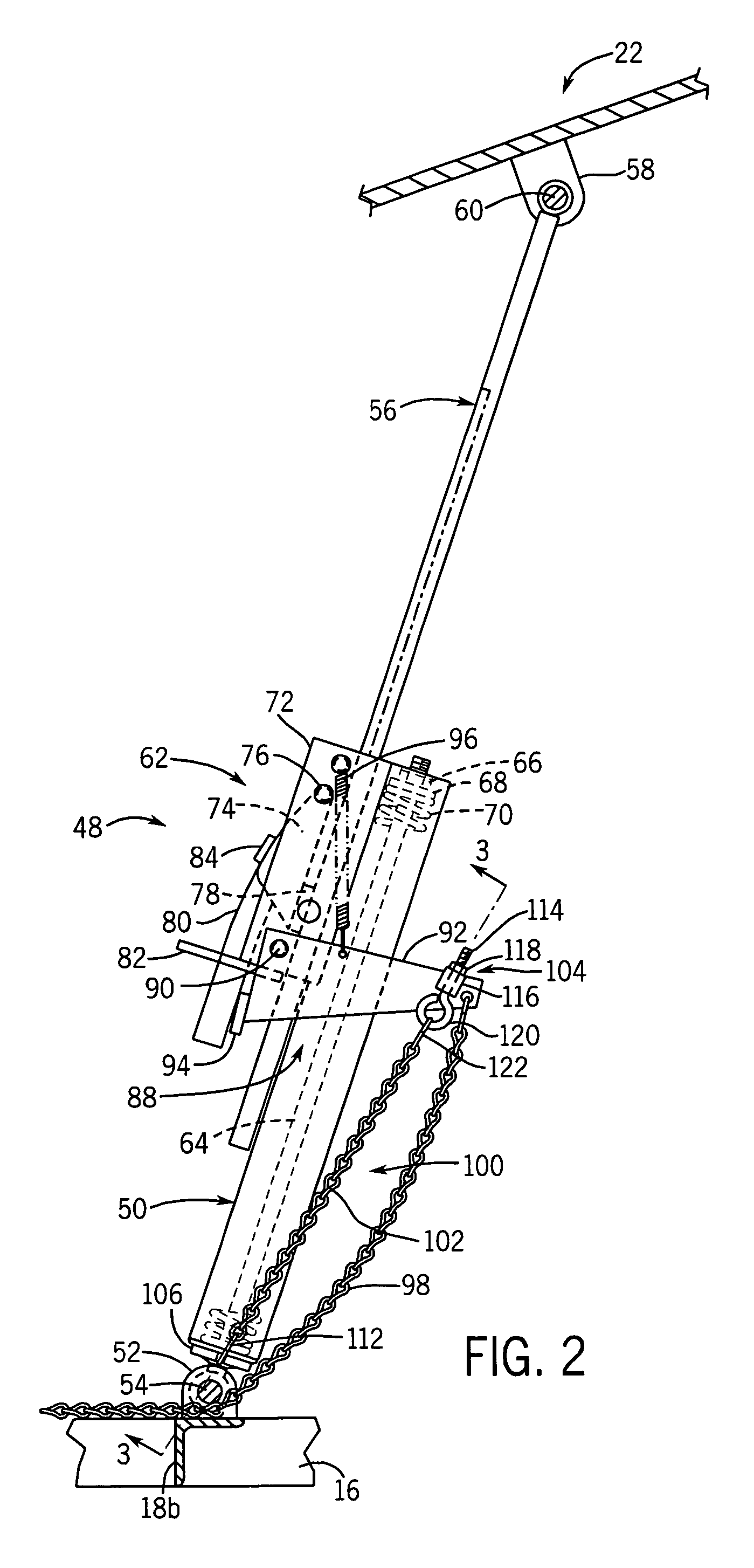

Dock leveler assembly with adjustable automatic release

InactiveUS6973693B1Prevent movementMaintain positionBridgesLoading/unloadingControlled releaseEngineering

A dock leveler assembly includes a base and a ramp that is pivotably movable under the influence of a biasing arrangement to a raised position. The ramp is lowered into engagement with a truck bed, preferably via a lip connected to the outer end of the ramp, and a holddown assembly maintains the ramp in a lowered position during loading and unloading of the truck bed against the force of a biasing arrangement that urges the ramp toward a raised position. The holddown assembly includes an extendible and retractable mechanism which is selectively fixed in position to maintain the ramp in a desired position. A “float” apparatus using a compression spring accommodates a certain amount of vertical movement of the ramp as the truck bed moves up and down during loading and unloading. A release arrangement enables the holddown assembly to be extended and retracted, and includes an automatic actuating arrangement that allows the mechanism to be extended upon application of a selected upward force to the ramp when the ramp is in a lowered position. The automatic actuating arrangement includes a flexible member such as a chain, and an adjustment arrangement for adjusting the inoperative position of the release member so as to control the degree of movement of the release member that is required in order to move the release member to the operative position from the inoperative position. The adjustment arrangement may be in the form of a threaded connection between one end of the actuating member and the release member, for selectively varying the inoperative position of the release member. The purpose of the adjustment is to control the amount of upward force that is required to actuate the release member, in order to avoid premature release and to avoid damage that can occur if the release does not occur until after an excessive upward force is applied.

Owner:MULTI FAB PRODS

Connector system

InactiveUS7461638B2Effective installationPossible to compensateFuel injection apparatusMachines/enginesLine tubingTransverse force

A connector system, free of transverse forces, for a fuel injection valve to be inserted into a receiving orifice into a cylinder head for connection to a fuel distributor line that encompasses a connector to a tubing line leading to a fuel reservoir, has a connecting part for connection to the tubing line. The connector system includes a holddown claw having an elongated opening that completely surrounds the fuel injection valve but allows for a tolerance compensation in the direction of the longitudinal axis of the holddown claw, and provides that the connecting part to the tubing line leading to the fuel reservoir has a tube screw fitting having an end piece. The end piece is embodied so that before the tubing line is screwed down onto the fuel distributor line, it can be moved for tolerance compensation, in a seat on the inflow-side end of the fuel distributor line, in two directions perpendicular to the extent of the tubing line.

Owner:ROBERT BOSCH GMBH

Magnectic-conductive member end-part defect detection device

InactiveCN1405558AReduce labor intensityAvoid labor intensityMaterial magnetic variablesBlind zoneMagnetic poles

A testing device for magnetic conductive components terminal defect resolves the problem of terminal blind zone by ordinary magnet leakge method. The device includes a test part and signal processing part in which two magnetic poles of the magnetizer, test probee and assistant guide rod of the test part are at the same shaft line. The structure of the test probe is a two stage clamping structure in which the first comprises a shell, a spread spring, a holddown and the second has a reed, a detector, Hall units and magnetic focusing plate, the signal process part contains a preprocessor, signal processer, a display and a controller. The assistant guide rod resolves problem of blind zone at the terminal.

Owner:HUAZHONG UNIV OF SCI & TECH

High-isolation microwave test fixture for ultrahigh-power GaN microwave devices

ActiveCN105510648AStable jobImprove isolationMeasurement instrument housingIndividual semiconductor device testingCapacitanceTest fixture

The invention discloses a high-isolation microwave test fixture for ultrahigh-power GaN microwave devices, which belongs to the technical field of testing of semiconductor devices. The high-isolation microwave test fixture comprises a test box body, a PCB (printed circuit board), a holddown, a direct-current bias leading-out terminal and a radio frequency input / output leading-out terminal, wherein the PCB is arranged in the text box body, and the PCB comprises a feed matching circuit and a radio frequency input / output microstrip; the feed matching circuit is divided into two parts, i.e. a grid feed matching circuit and a drain feed matching circuit, the grid feed matching circuit comprises double sector-shaped wires, two RC (Resistor-Capacitor) filter networks, a grid bias resistor and a grid filter capacitor, and the drain feed matching circuit comprises double sector-shaped wires, two RC filter networks and a drain filter capacitor; the direct-current bias leading-out terminal is led out of the feed matching circuit from two feedthru capacitors; the radio frequency input / output leading-out terminal is a coaxial transmission-to-microstrip transmission connector. The invention solves the problem of insufficient isolation of leaked radio frequency signals of a drain electrode existing in the process of ultrahigh-power testing of microwave devices, can prevent a direct-current bias module from being burnt, and ensures the authenticity and effectiveness of test results.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

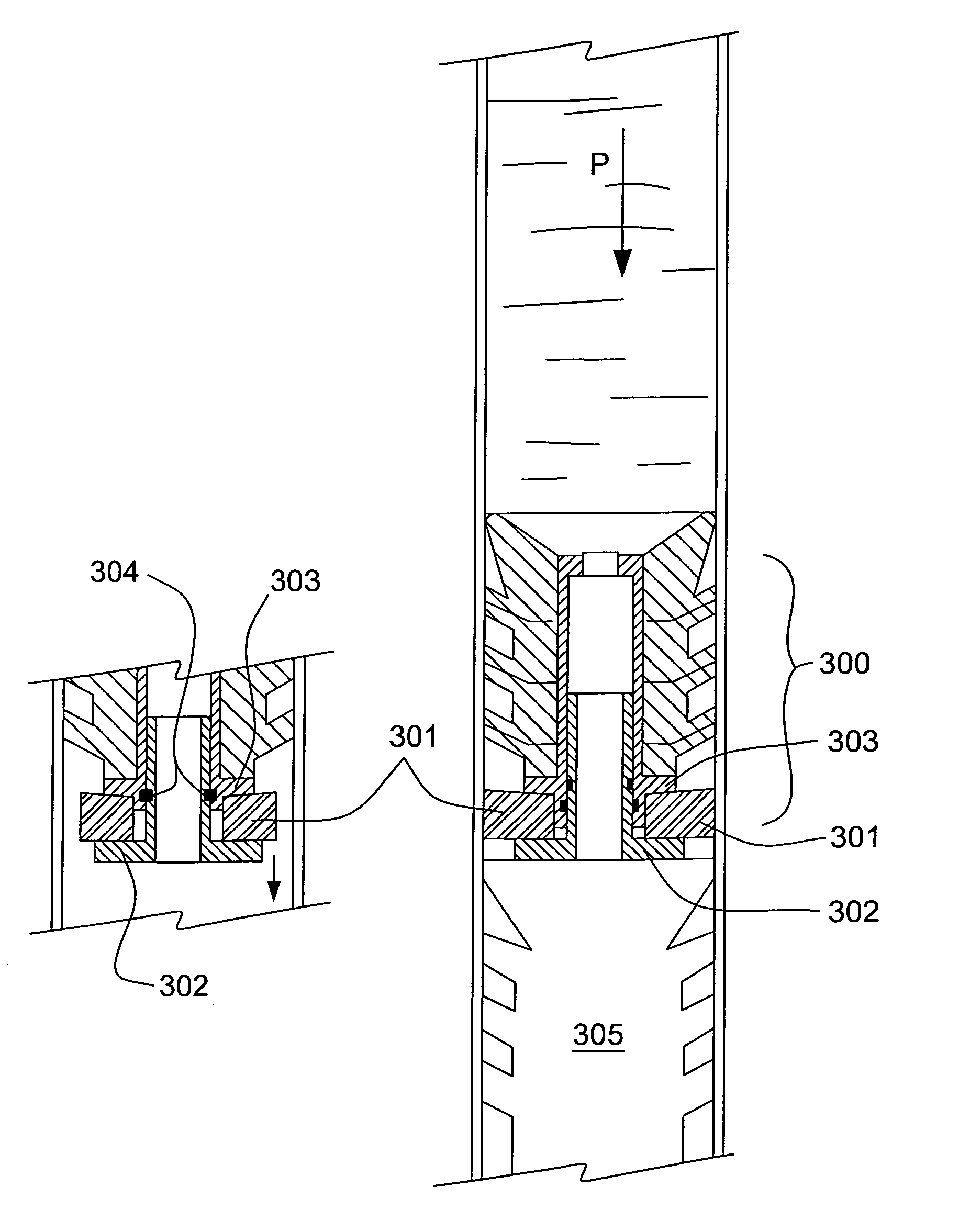

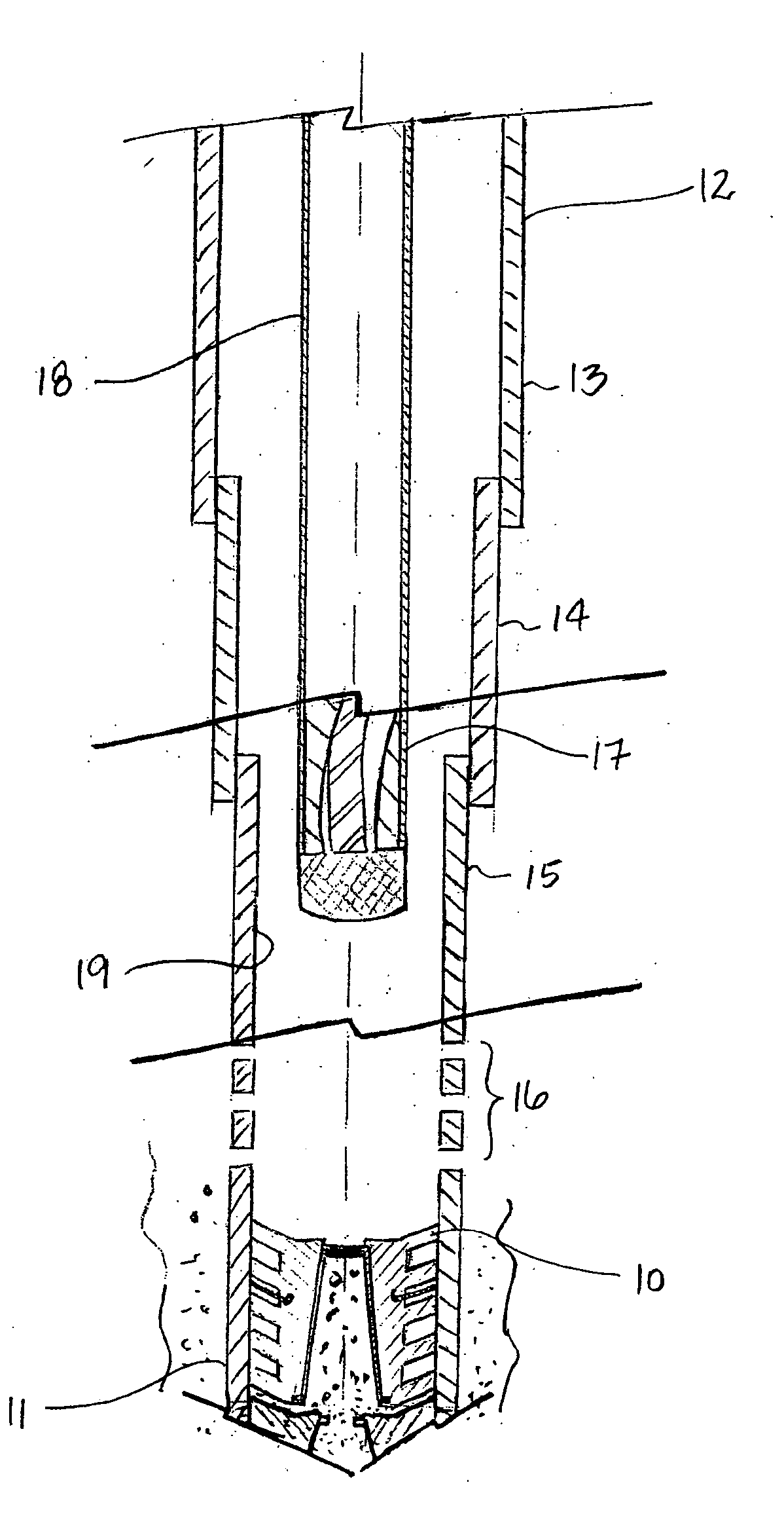

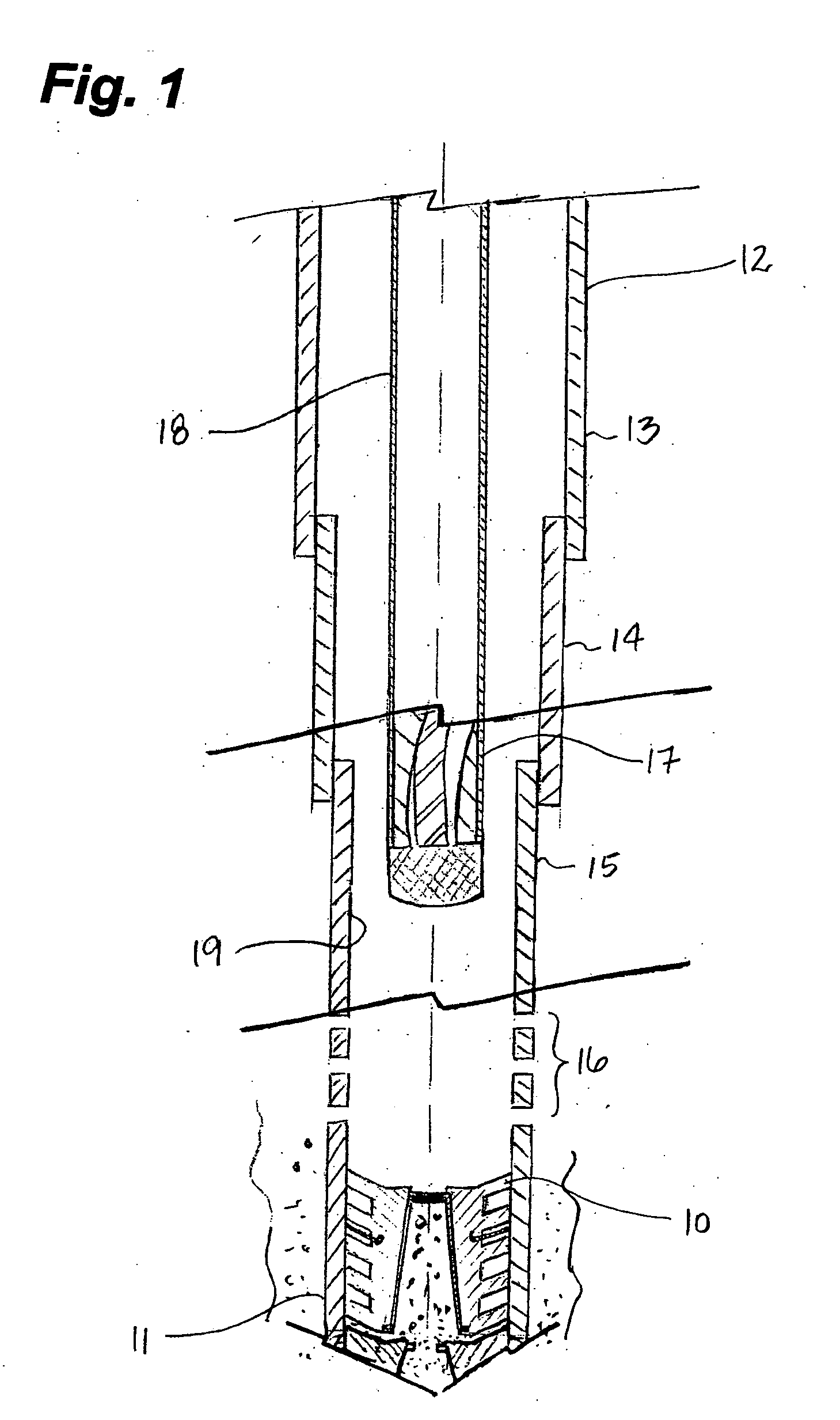

Wiper plug with packer

A self-retaining cementing wiper plug with a packer element has two or more steel or carbide tipped holddown fingers or slips extending radially outward from the plug for engaging the inner surface of the casing and preventing the plug from moving uphole over time and potentially interfering with other downhole apparatus such as a pump. The packer element in the wiper plug is actuated when the plug is supported by an obstruction under the plug and then compressed, the packer being maintained in compression by the holddown fingers.

Owner:TESSIER LYNN P +2

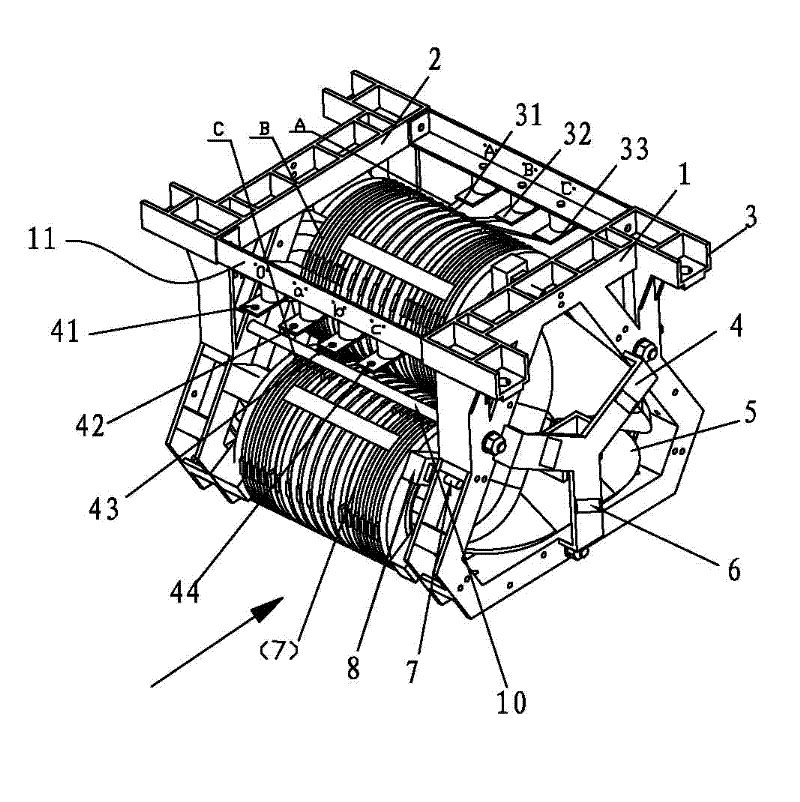

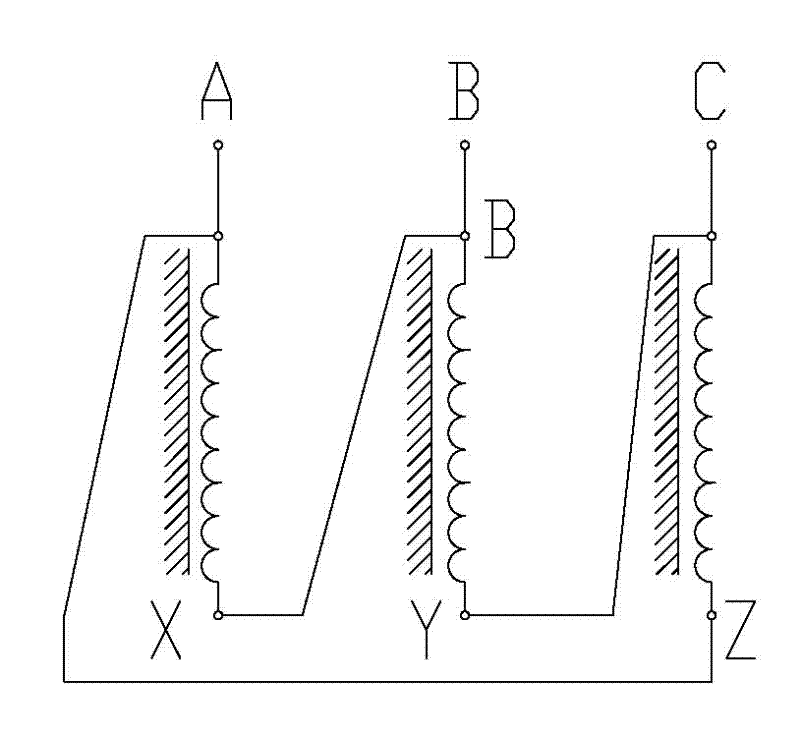

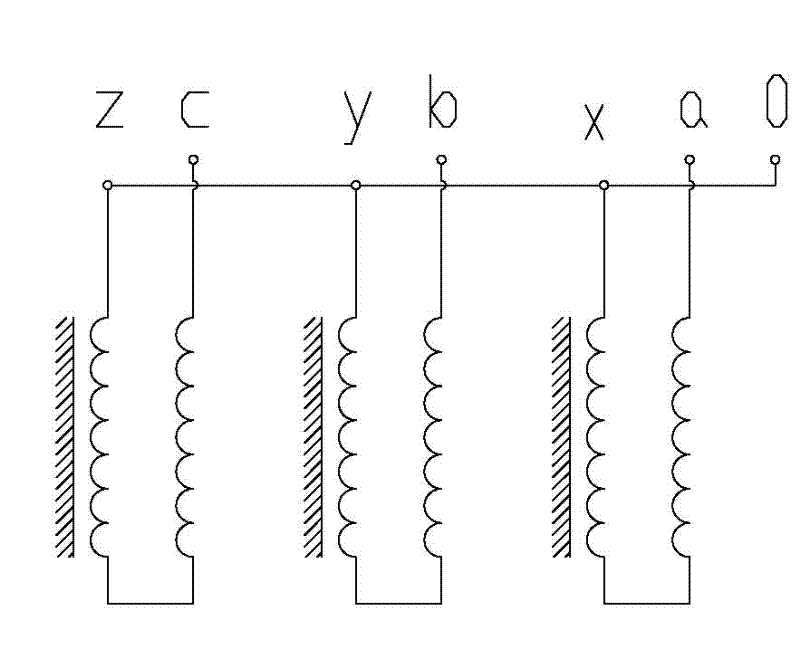

C-class three-dimensional wound core dry-type transformer for suspension installation

ActiveCN102290206AImprove overload capacityStrong volumeTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresShock resistanceSilica gel

A suspension-mounted C-grade three-dimensional wound core dry type transformer comprises an upper clamp, a lower clamp, mounting supports, holddown plates, cores and coils; the cores and the coils are arranged between the upper clamp and the lower clamp; silica gel cushions are arranged on the surfaces of the upper and the lower clamps, which are in contact with the cores, holddown blocks and holddown screws are arranged between the upper end surfaces of the coils and the upper clamp, and holddown blocks are arranged between the lower end surfaces of the coils and the lower clamp; steels are welded together to form approximately triangular frames as the upper and the lower clamps, the upper and the lower clamps are connected together through four compression screws, stay bars are arrangedbetween the coils and the cores, the lower end surfaces of the coils are tightly placed on the upper surfaces of the holddown blocks on the lower clamp, and the coils are then tightly pressed by tightening the holddown screws. Since the structure is adopted, besides the advantages of the conventional dry type transformer, such as safety, environment-friendliness and high overload capability, the main materials also have the characteristics of high insulating and heat-withstanding grades, little no-load loss, small exciting current, little noise, small size, light weight, high shock resistance, attractive appearance and the like.

Owner:GUANGDONG CHANGKAI ELECTRIC CO LTD

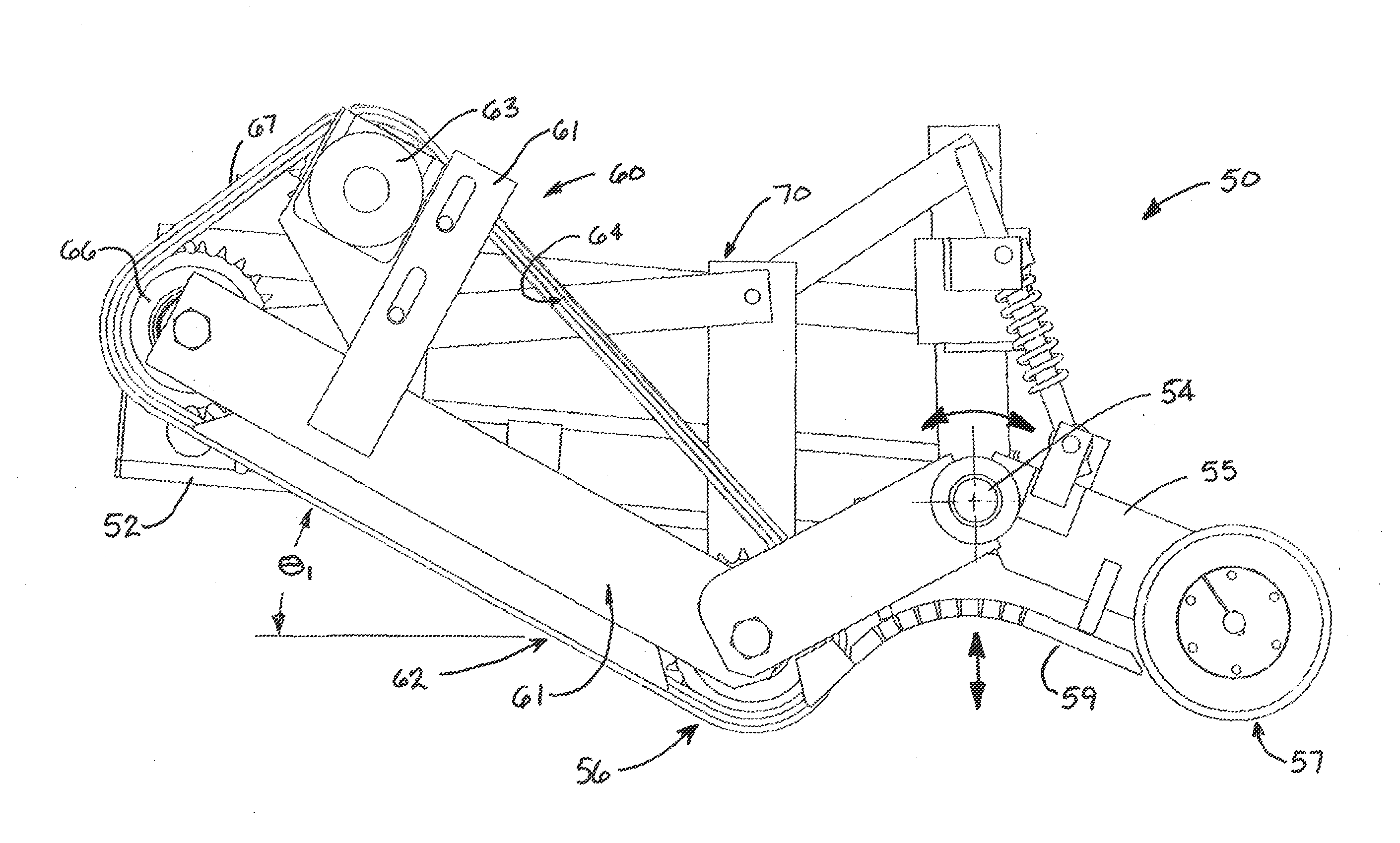

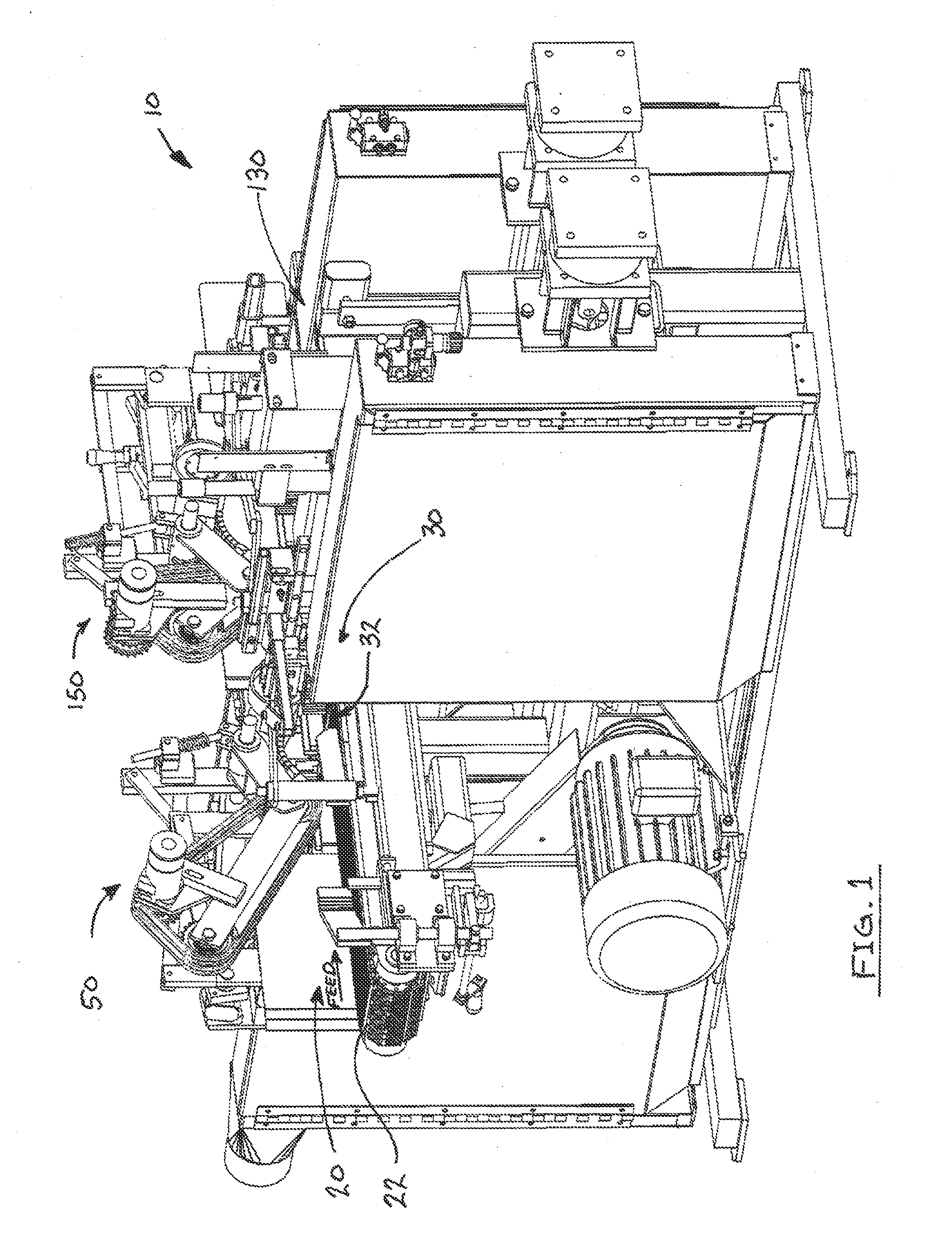

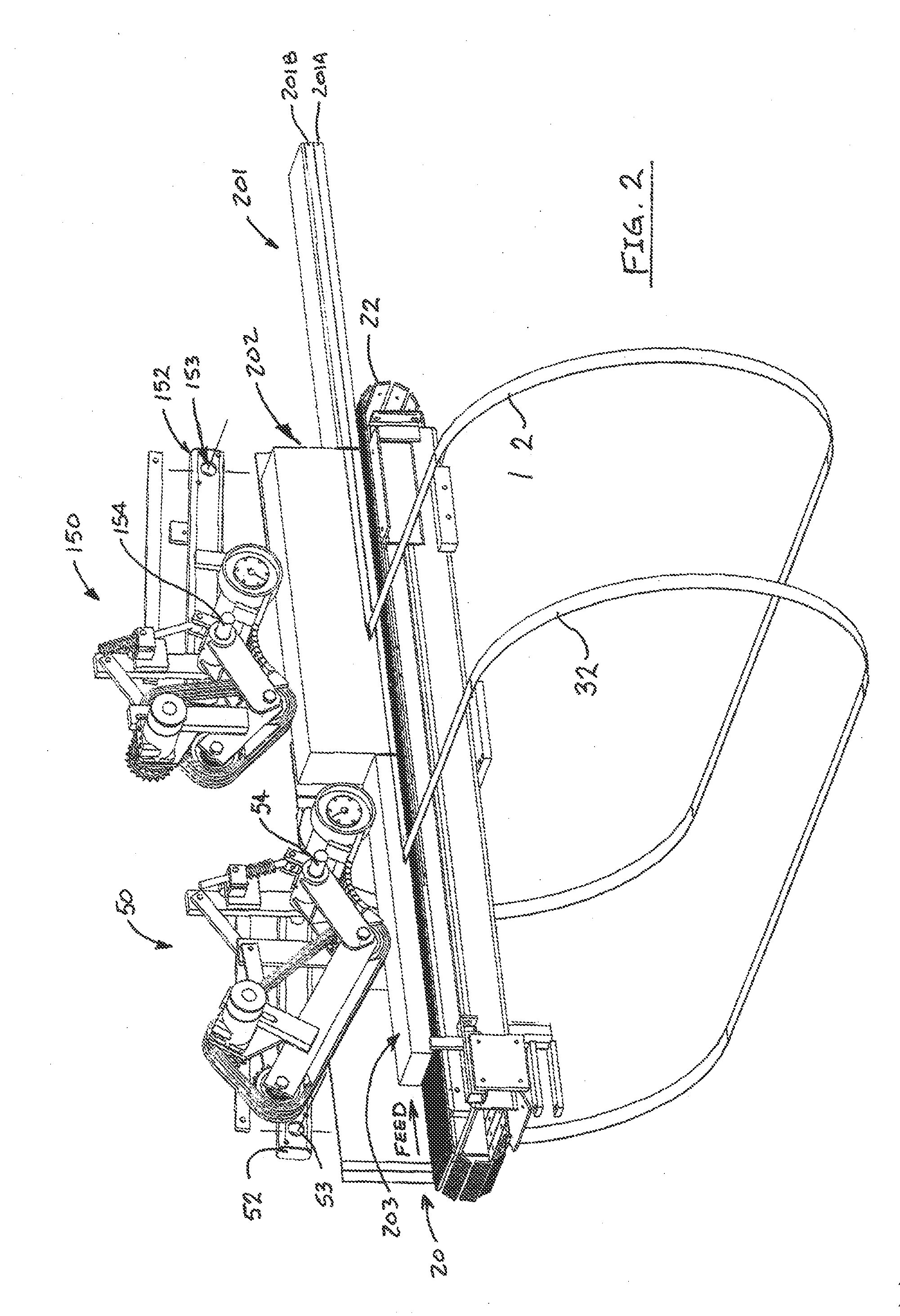

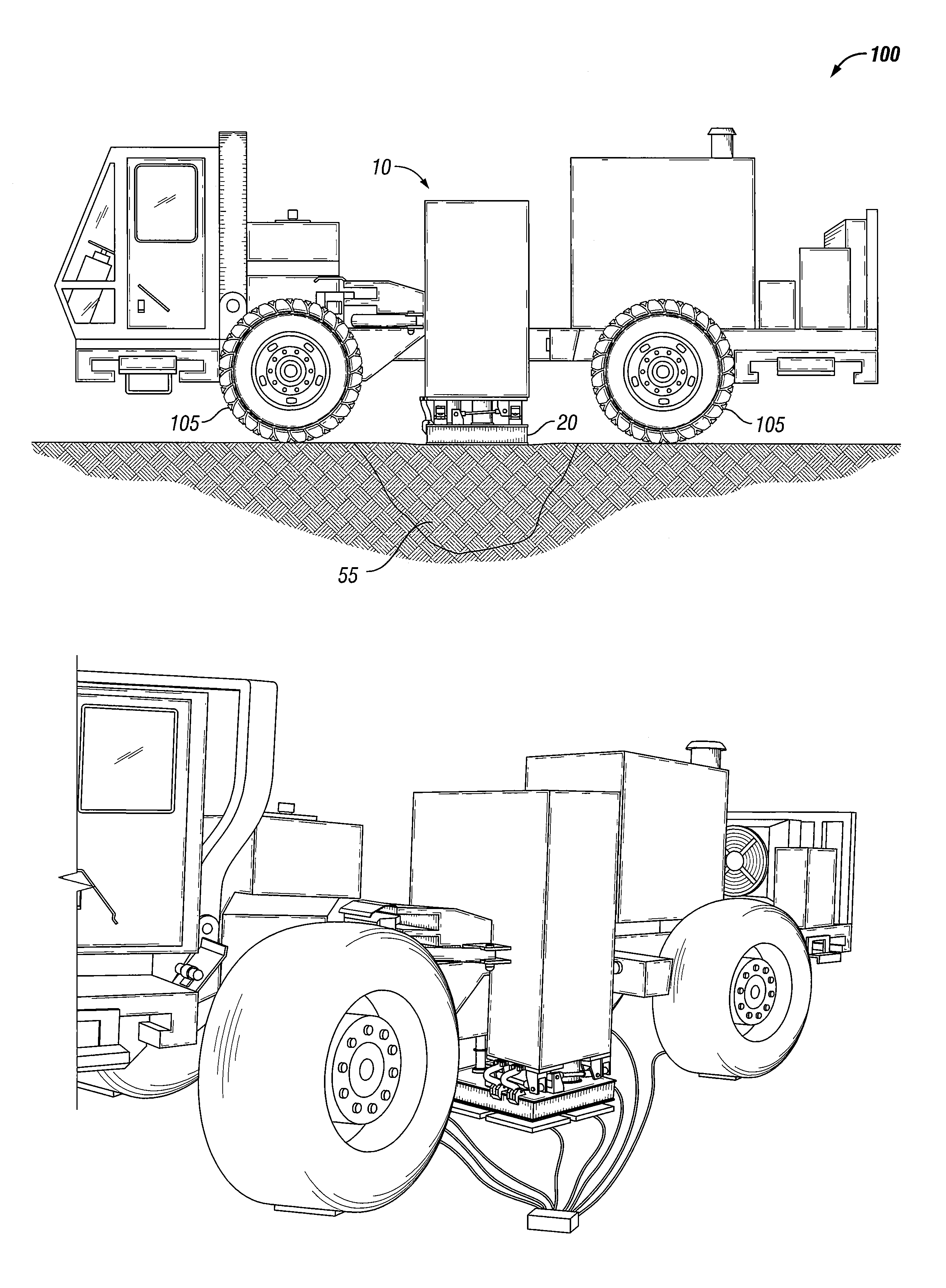

Workpiece holddown apparatus for a bandsaw

ActiveUS20150321379A1Increase productivityIncrease the number ofWood feeding arangementsFeeding devicesBogieTrailing edge

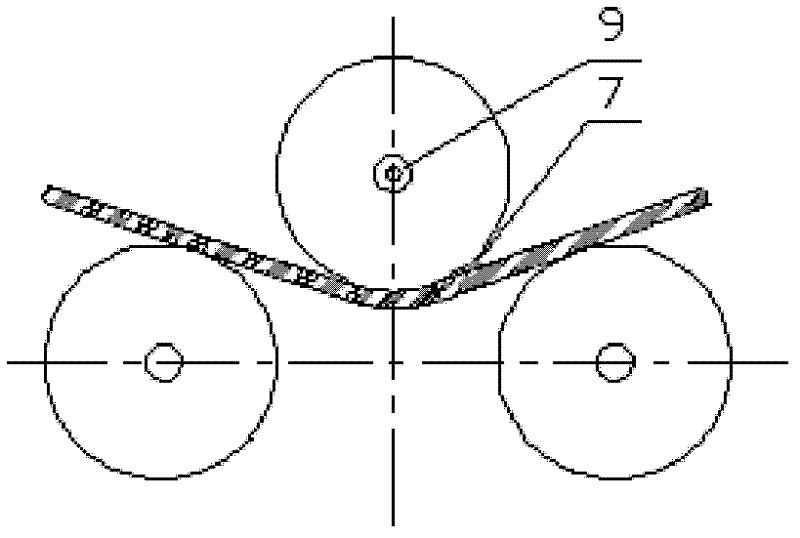

A hold down mechanism for a bandsaw including an upstream wheel positioned upstream of the saw blade and a downstream wheel positioned downstream of the saw blade, each wheel being rotationally connected to a bogie which is in turn supported on a swing arm. The proximity of the upstream and downstream wheels to the saw blade as well as the degree of pivoting motion permitted by the bogie enable a hold down wheel to press the ends if sequential workpieces against a base as the ends pass the saw blade to assure a uniform thickness of the cut workpiece. An angled guide surface is provide upstream from the forward wheel to assist the forward wheel in elevating when a trailing workpiece is significantly thicker than the workpiece preceding.

Owner:KEYSTONE MACHINERY

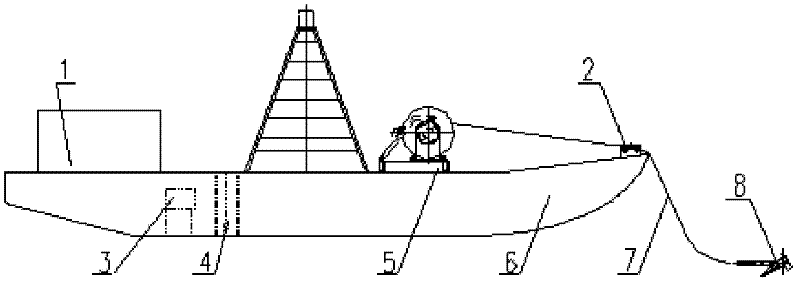

Indicating navigation mark capable of automatically collecting, releasing and tying mooring rope along with changes of water level

InactiveCN102501951ASolve power problemsRealize real-time automatic adjustmentRoute marking with anchored lightshipsCommunication unitNavigation safety

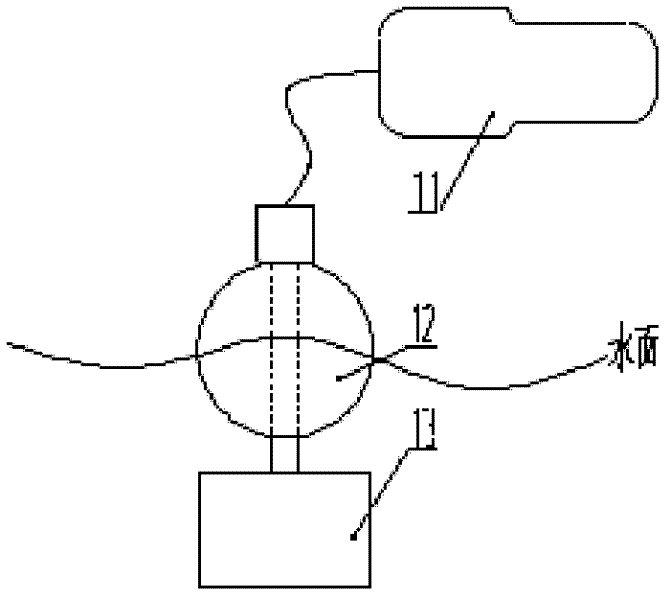

The invention provides an indicating navigation mark capable of automatically collecting, releasing and tying a mooring rope along with changes of the water level, which belongs to the technical field of channel navigation and comprises a power supply device, a rope length measuring device, a control and communication unit, a depth measuring device, a collecting and releasing winch, a navigation mark ship, an anchor rope and an anchor. The rope length measuring device consists of three holddown wheels and photoelectric encoders, and the photoelectric encoders are arranged on end surfaces of the holddown wheels; the depth measuring device comprises an ultrasonic depth finder, a foam floating ball and a depth measuring probe; and the power supply device is fixed onto a deck of a stern of the navigation mark ship, the control and communication unit is fixed to the rear of a body of the navigation mark ship, the rope length measuring device is fixed onto a deck of a bow of the navigation ship, the depth measuring device is fixed to the middle rear of the body of the navigation ship, the collecting and releasing winch is fixed onto a deck of the middle front of the navigation ship, one end of the anchor rope is wound on the collecting and releasing winch, and the other end of the anchor rope penetrates through the rope length measuring device and hinged with the anchor by a standard part. The indicating navigation mark has the advantages that the position of the indicating navigation mark and tension of tying of the mooring cable are automatically adjusted in real time, and navigation safety is guaranteed.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP +2

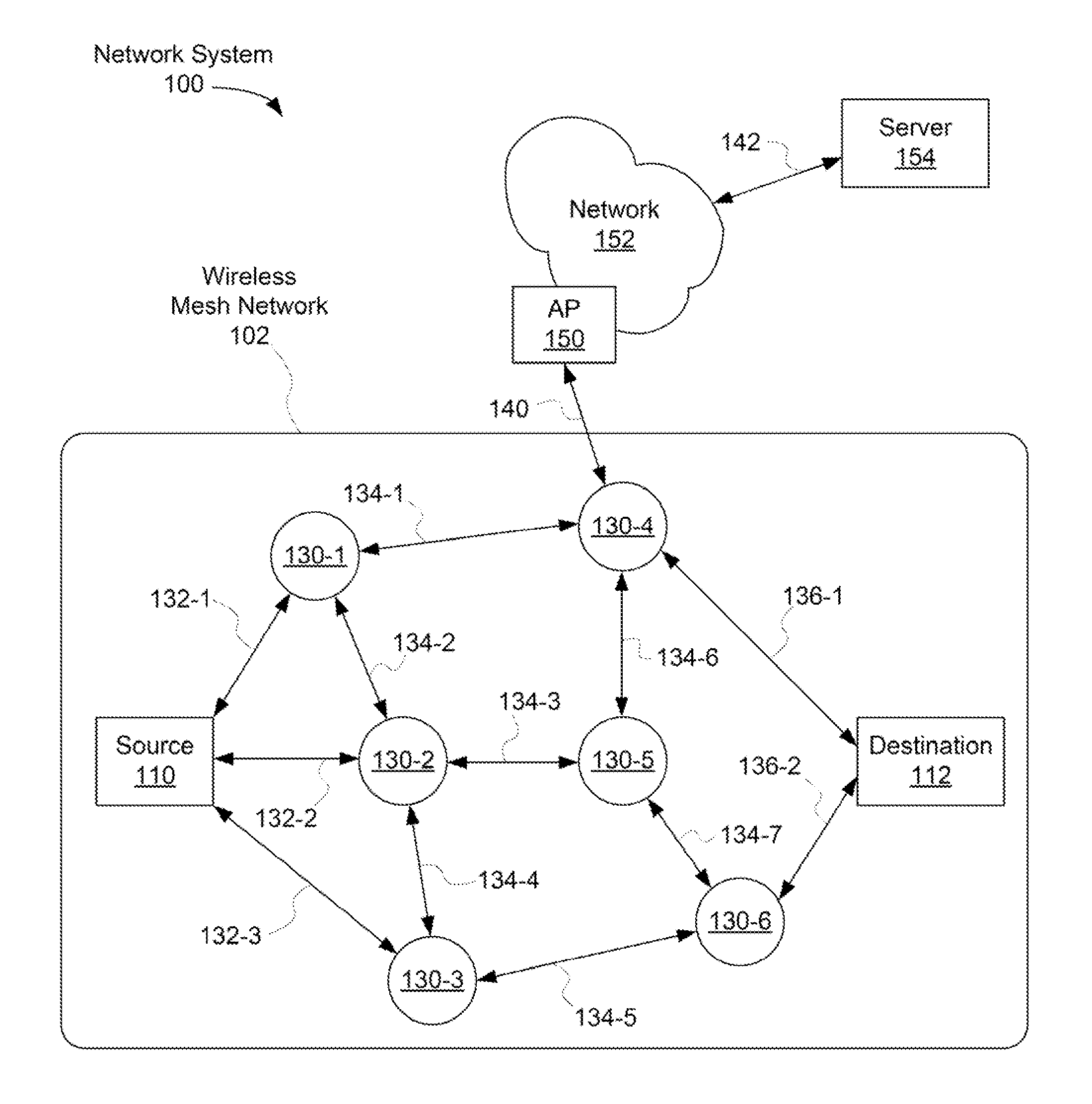

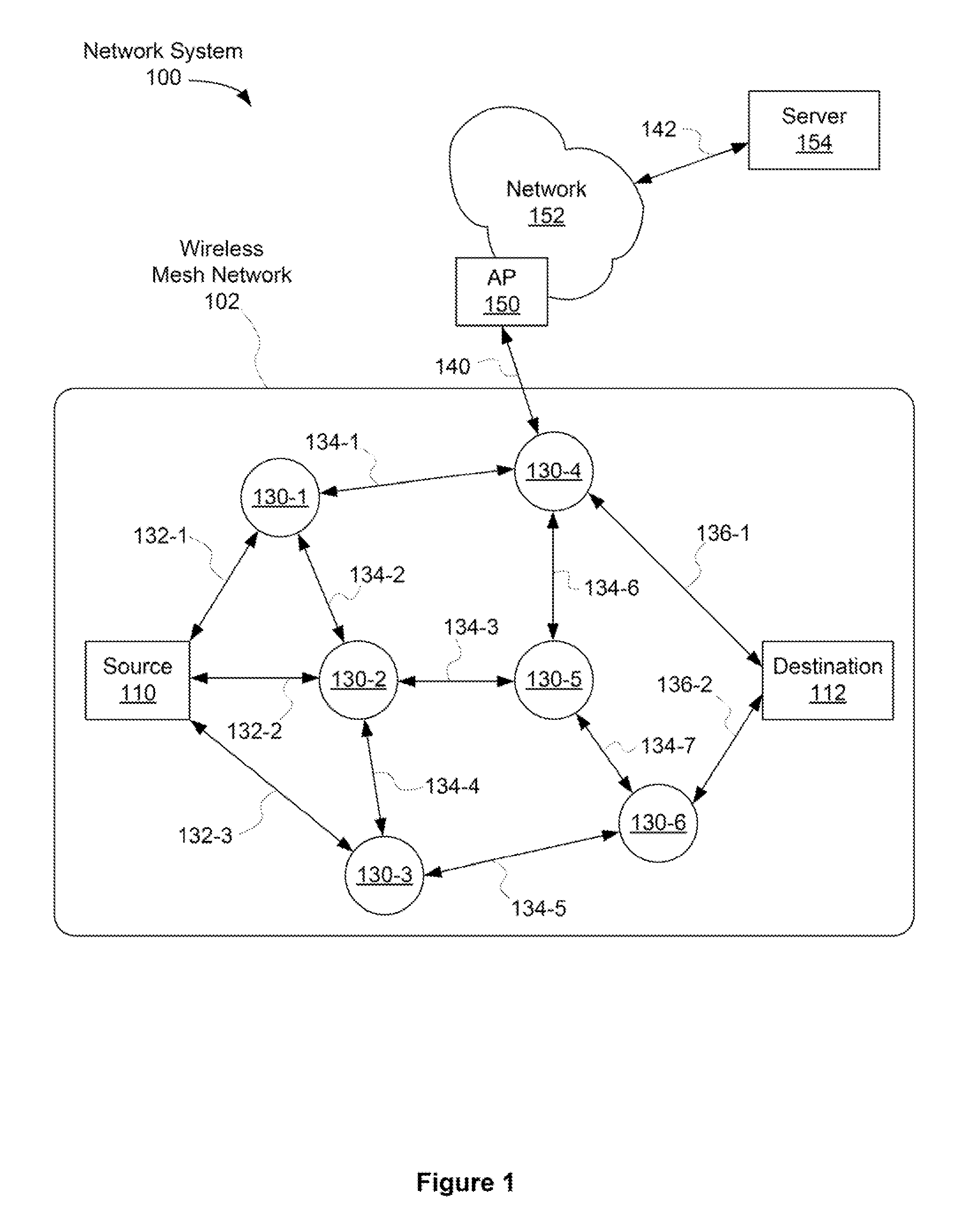

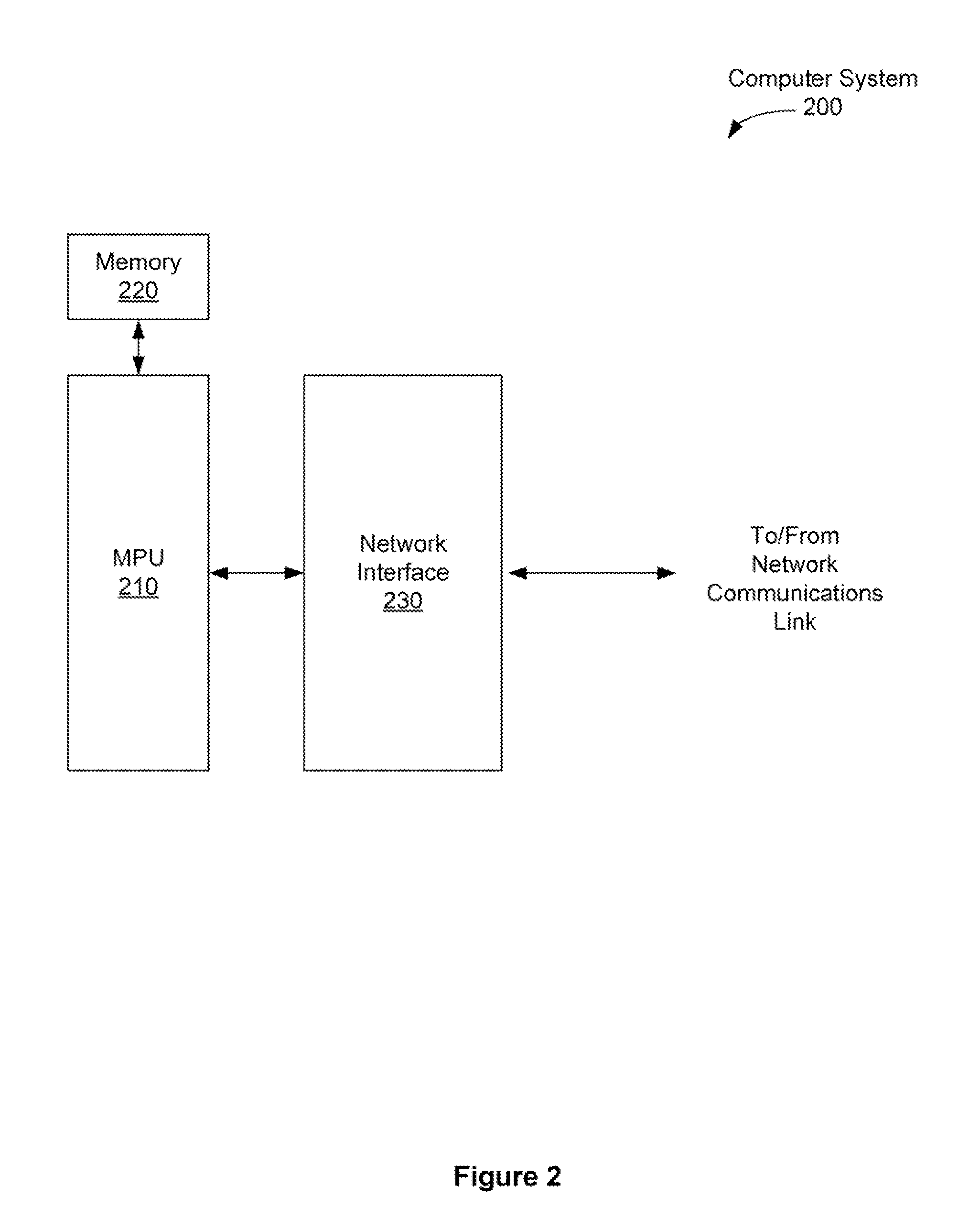

System and method for improving network convergence via adaptive routing techniques

ActiveUS20130155880A1Low costError preventionTransmission systemsNetwork ConvergenceAdaptive routing

One embodiment of the present invention sets forth a technique for a node within a network to adjust one or more routing parameters based on certain network parameters. A node monitors certain network metrics such as the mean time between routing drops. In response to changes in these network parameters, the node changes certain routing parameters, such as the holddown time. The node may store network metrics and associated routing parameters that result in preferred network operating conditions. The node may pre-load these beneficial settings upon the occurrence of a particular condition such as a system reset of the node. Moreover, a node may share these beneficial settings with neighboring nodes on the same network. One advantage of this approach is that cost savings are achieved when a node within a network may be installed without preconfiguring the node with specific routing parameters.

Owner:ITRON NETWORKED SOLUTIONS INC

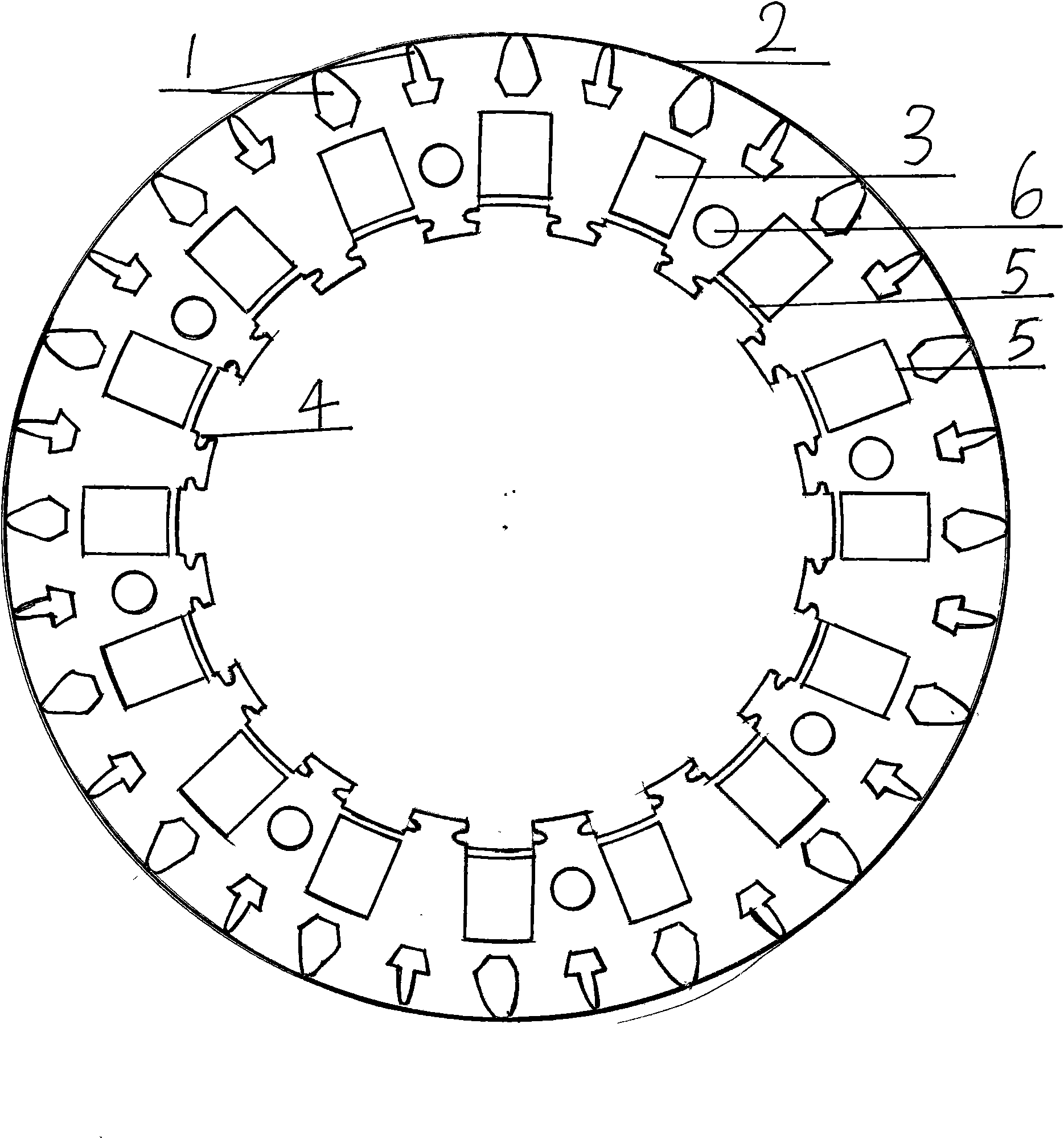

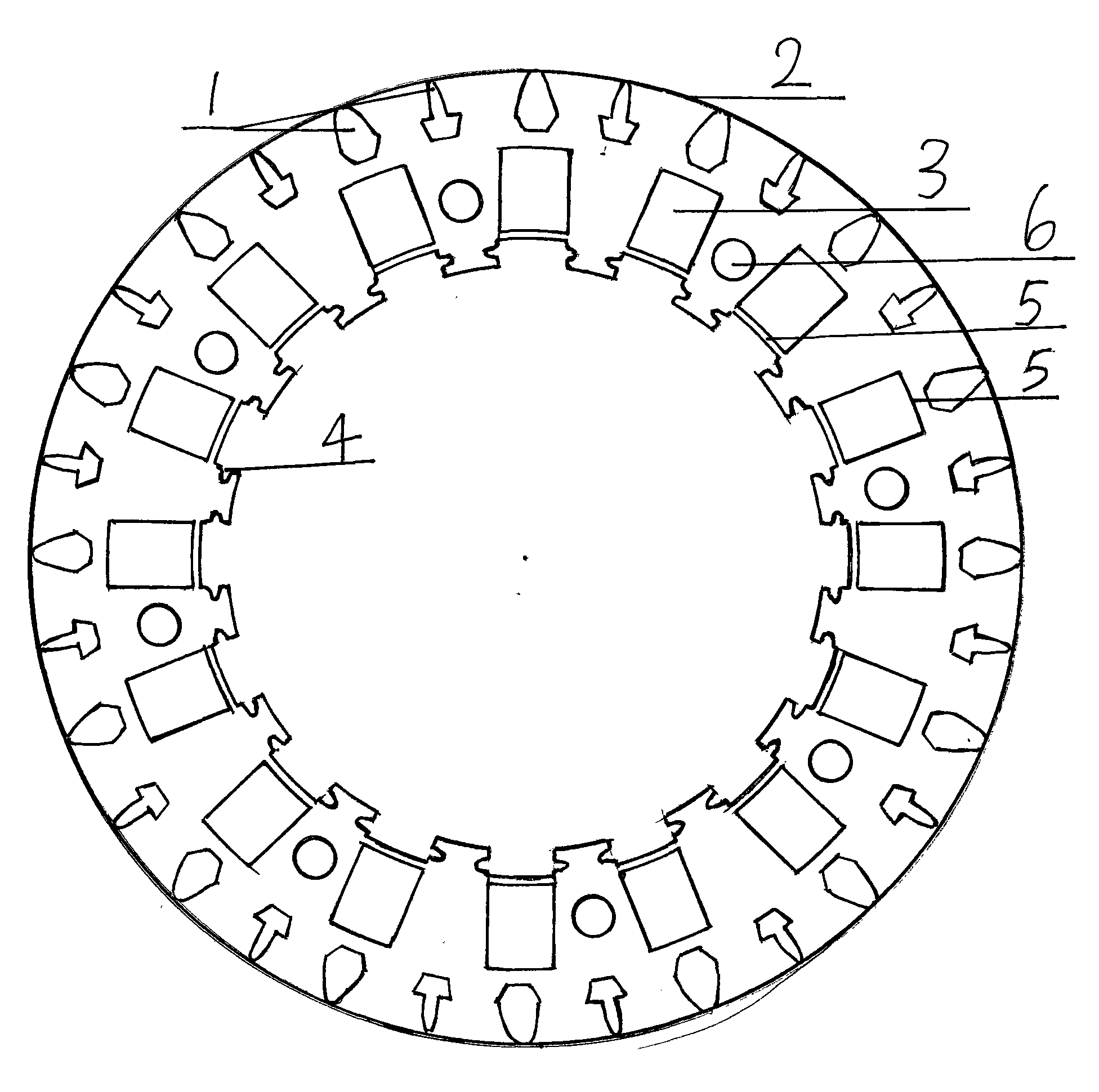

Rotor sheet of asynchronously-started PMSM (permanent magnet synchronous motor)

InactiveCN102170184AImprove punching efficiencyMagnetic circuit rotating partsSynchronous machinesPermanent magnet synchronous motorEconomic benefits

The invention relates to the field of the rotor sheet of a PMSM (permanent magnet synchronous motor), and in particular provides a rotor sheet of an asynchronously-started PMSM. The rotor sheet comprises asynchronously-started cage conducting bar slots, magnetic steel slots and a bolt fixing hole. The sheet does not have an interference spindle hole; the plurality of magnetic steel slots are formed at edges of the inner diameter circumference of the sheet in a punching shear mode, and magnet-isolating magnetic bridges, holddown grooves, asynchronously-started cage conducting bar slots at mouse cage parts at outer diameter edges of the fixed holddown grooves and bolt fixing holes in poles are reserved to constitute a high-intensity rotor sheet of the PMSM without coordination of a heating jacket. The rotor sheet has the beneficial effects that the punching efficiency is high, the labor and time are saved, the number of steel plates is reduced, the residual part without a center can be used for punching other small-size motor rotor sheets, and economic benefits in a motor sheet industry are improved greatly.

Owner:王乃兵 +1

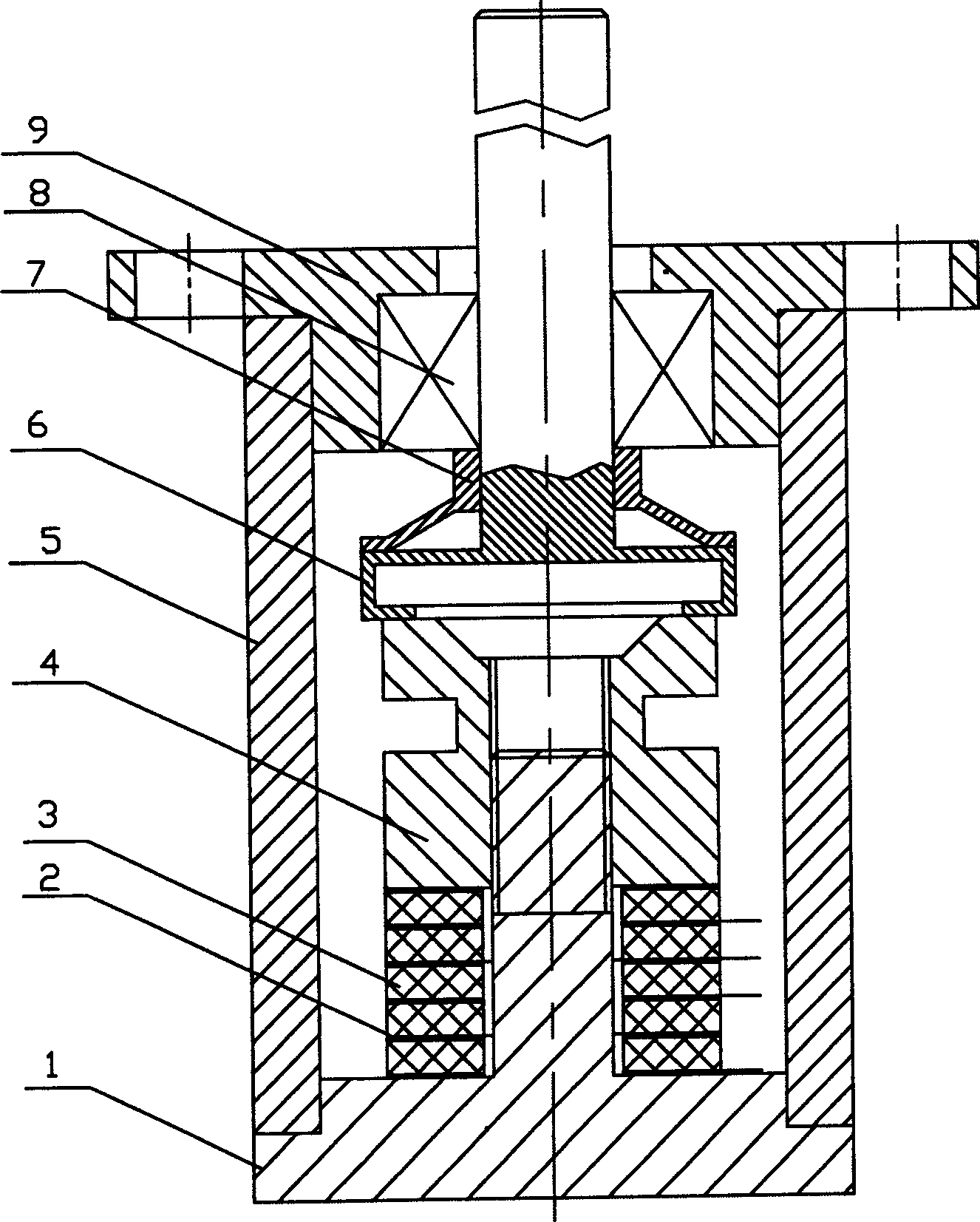

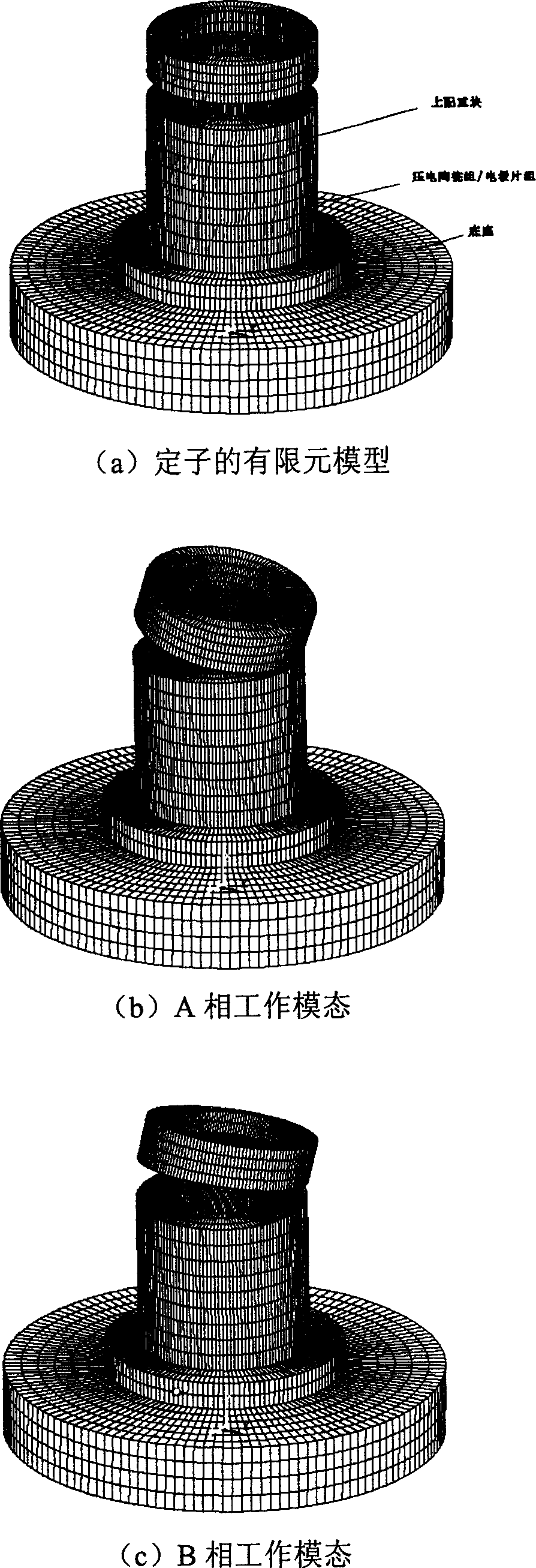

Minitype rod traveling wave type ultrasonic motor

InactiveCN1606227ACompact structureEasy to processPiezoelectric/electrostriction/magnetostriction machinesMicro rodsEngineering

A micro-rod traveling wave supersonic motor is composed of a stator part including screwing tightly the piezoelectric ceramic set and electrode plates by the base and the up balance block with a crew rod on the base. The rotor part is composed of a rotor, a bearing and a disk spring. The shell part is composed of a holddown and a shell. The pre-pressure of the stator and rotor is applied by pressing the disk spring with press blocks. When a certain AC voltage is inlet into the motor in supersonic frequency, the top surface mass points on the top balance block of the stator form elliptic movement, a friction is generated between the rotor and stator since pre-pressure exists between them. The power is output by the rotor shaft.

Owner:JIANGSU FENGKE ULTRASONIC MOTORS TECH

Resilient printed circuit board pad structure

ActiveCN103402307AReliable processingImprove electrical connection reliabilityElectrical connection printed elementsSolderingPrinted circuit board

The invention discloses a resilient printed circuit board pad structure, which comprises an insulating layer and a base, the insulating layer is arranged on the top of the base, a pad is arranged on the top of the center of the insulating layer, the insulating layer is provided with a through hole under the pad, moreover, two triangular reinforcing ribs are respectively arranged on both sides of the inside of the through hole, the inner side of each triangular reinforcing rib is provided with a conductive layer, a spring assembly is arranged in the closed cavity defined by the conductive layers, and a holddown is connected with the top of the spring assembly. The resilient printed circuit board pad structure has the beneficial effects that: pad processing can become reliable, pseudo soldering as the result of the unevenness and sinking of the pad can be prevented, and thereby the reliability of the electric connection of a printed circuit board is enhanced; by adding the triangular reinforcing ribs, the pad structure is reinforced; and supporting force can be provided for the top pad from the bottom for a long time.

Owner:ANHUI BOTAI CIRCUIT TECH

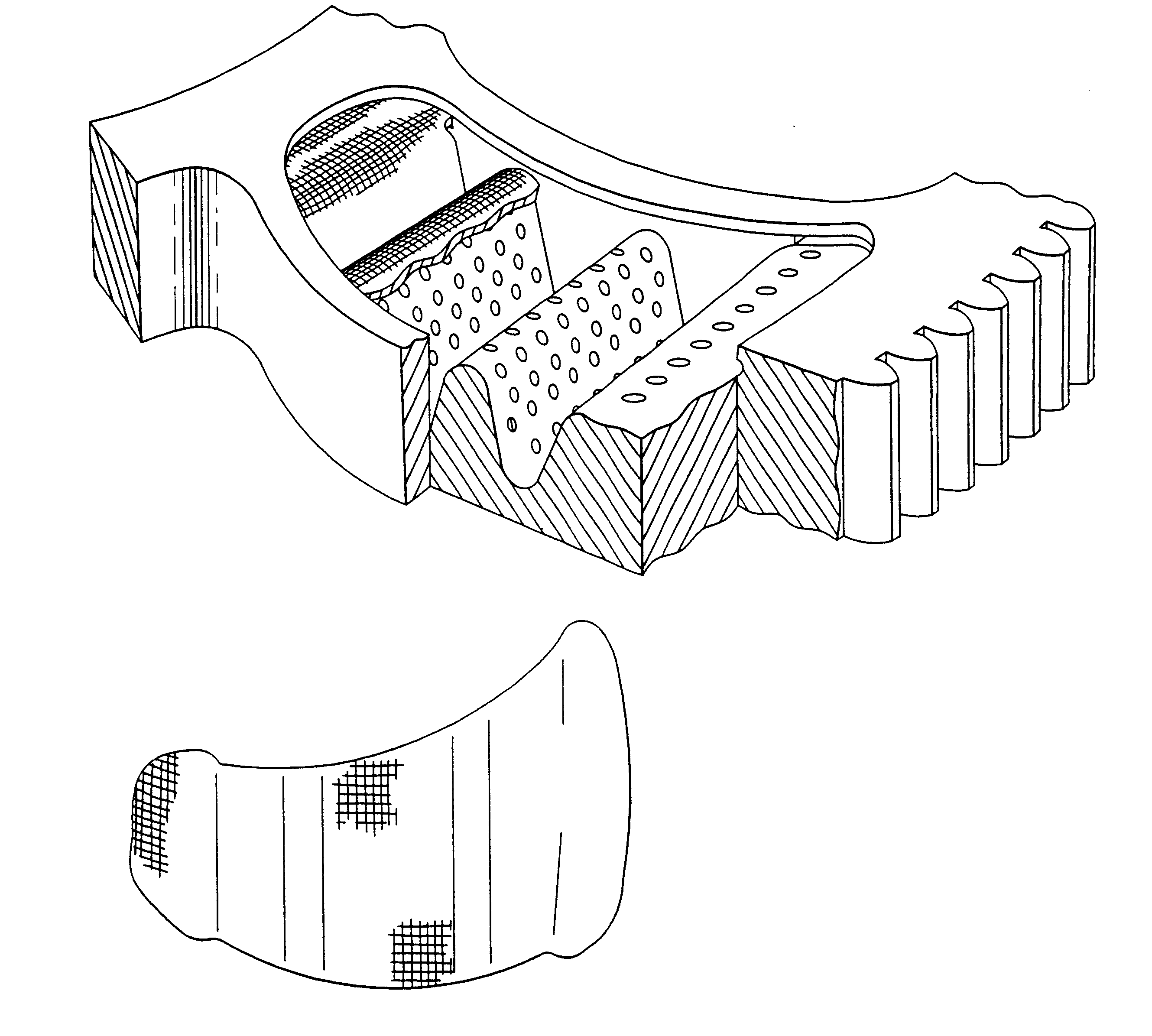

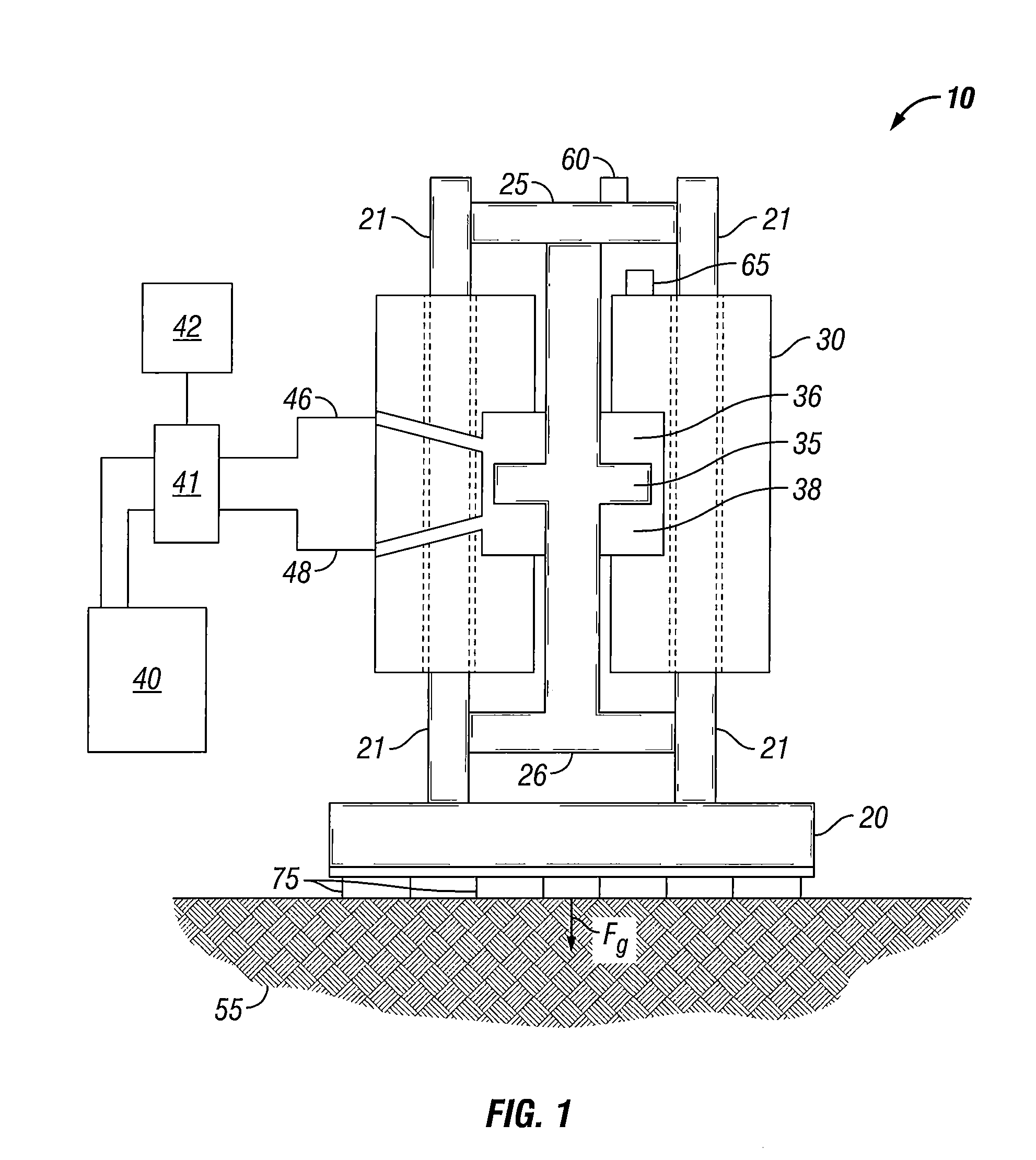

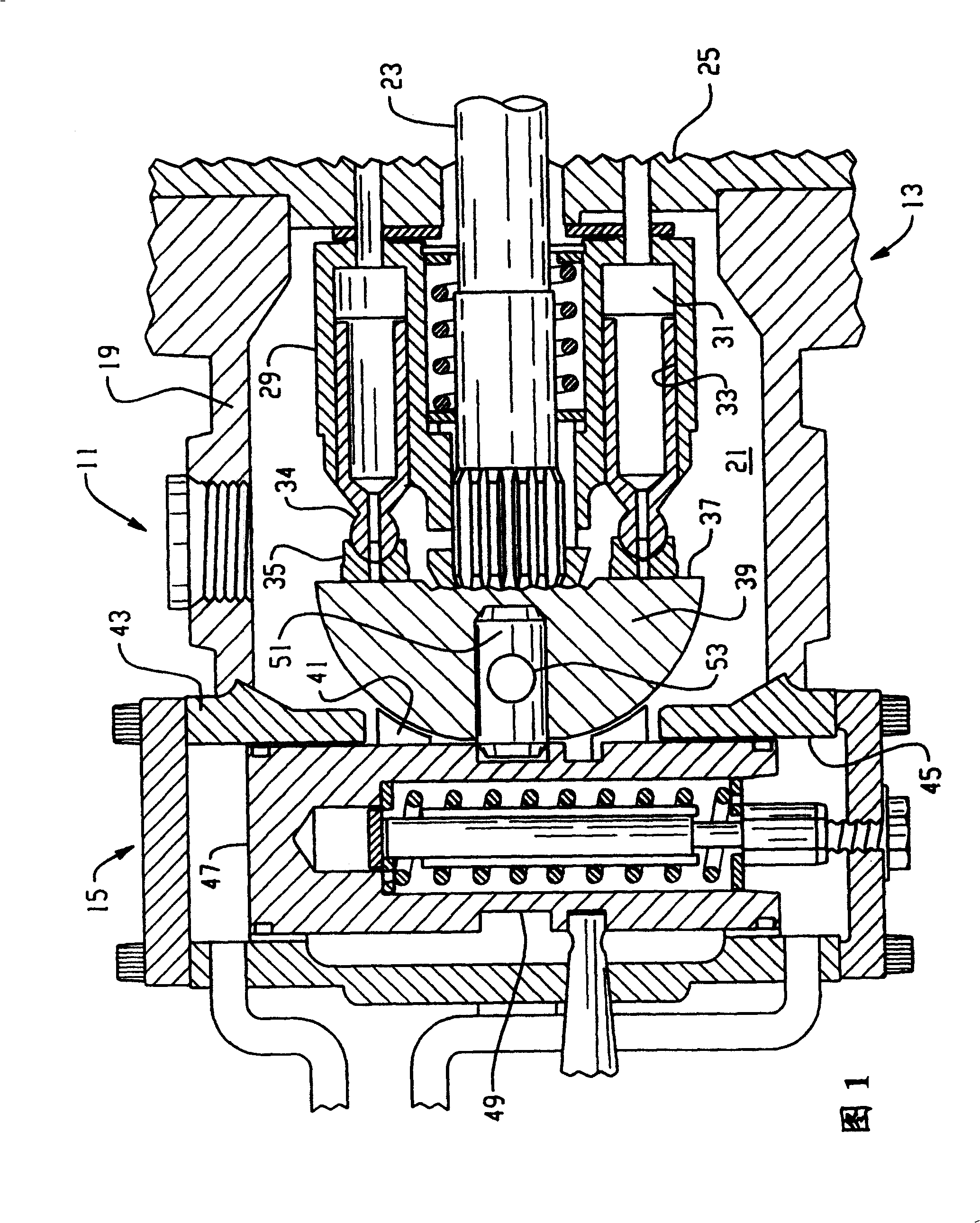

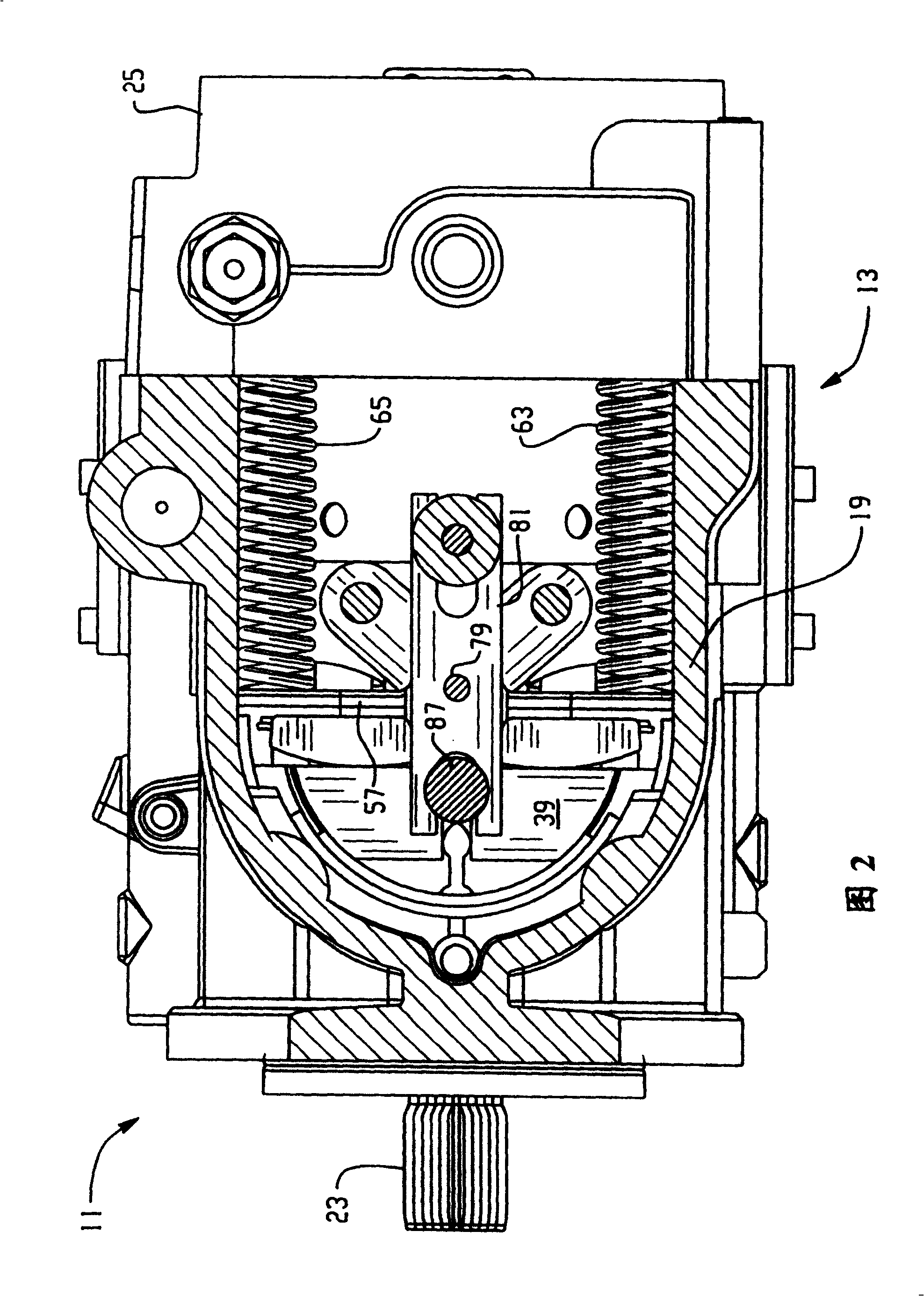

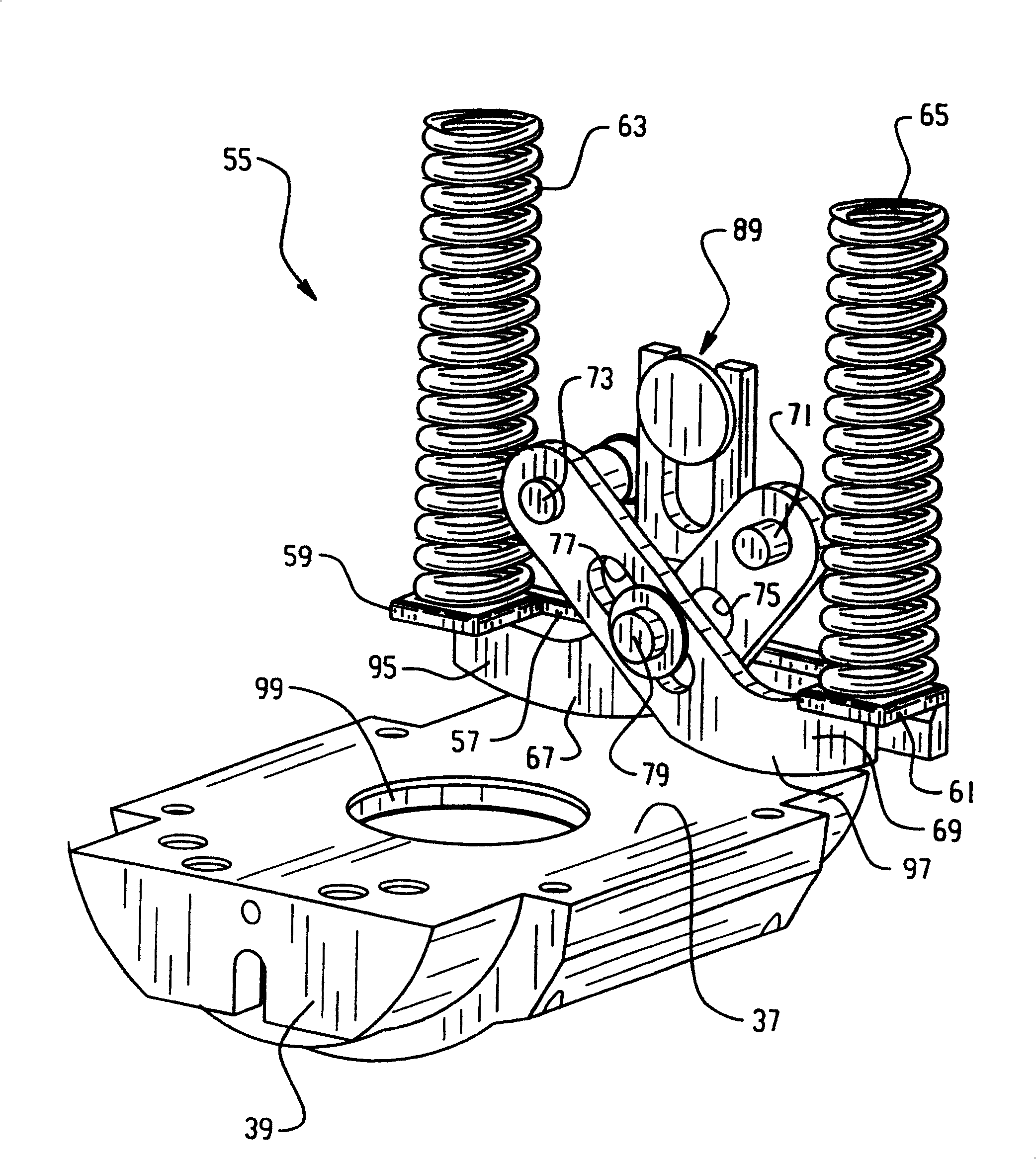

Swashplate holddown and adjustable centering mechanism

InactiveCN100422507CReciprocating piston enginesPositive-displacement liquid enginesTransverse axisCam

A swashplate centering and holddown mechanism for an axial piston unit comprising a cylinder barrel disposed for rotation about an axis of rotation. A cam member is tiltable about a transverse axis and has a swashplate. The swashplate is perpendicular to the axis of rotation, in a neutral position, and has a displaced position. The swashplate centering and holddown mechanism biases the cam member axially toward a cradle surface and pivotably toward the neutral position. The mechanism comprises a pair of arms, each of which defines a pivot location, at one axial end thereof, fixed relative to a pump housing on one side of the axis of rotation, and a swashplate-engaging portion, at the opposite axial end thereof, engaging the swashplate, on the other side of said axis of rotation, when said swashplate is in neutral. A connector is operably associated with the arms, whereby the arms are able to pivot about the pivot locations in a generally scissors-type movement. A pair of springs biases the swashplate-engaging portions of the arms toward the swashplate, whereby, in the absence of an input to tilt the cam member, the swashplate is in engagement with both of said swashplate-engaging portions and is in the neutral position.

Owner:EATON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com