Swashplate holddown and adjustable centering mechanism

A technology of swash plate and fixing device, which is applied in variable displacement engines, liquid variable displacement machinery, reciprocating piston engines, etc., and can solve problems such as shortening the life of springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

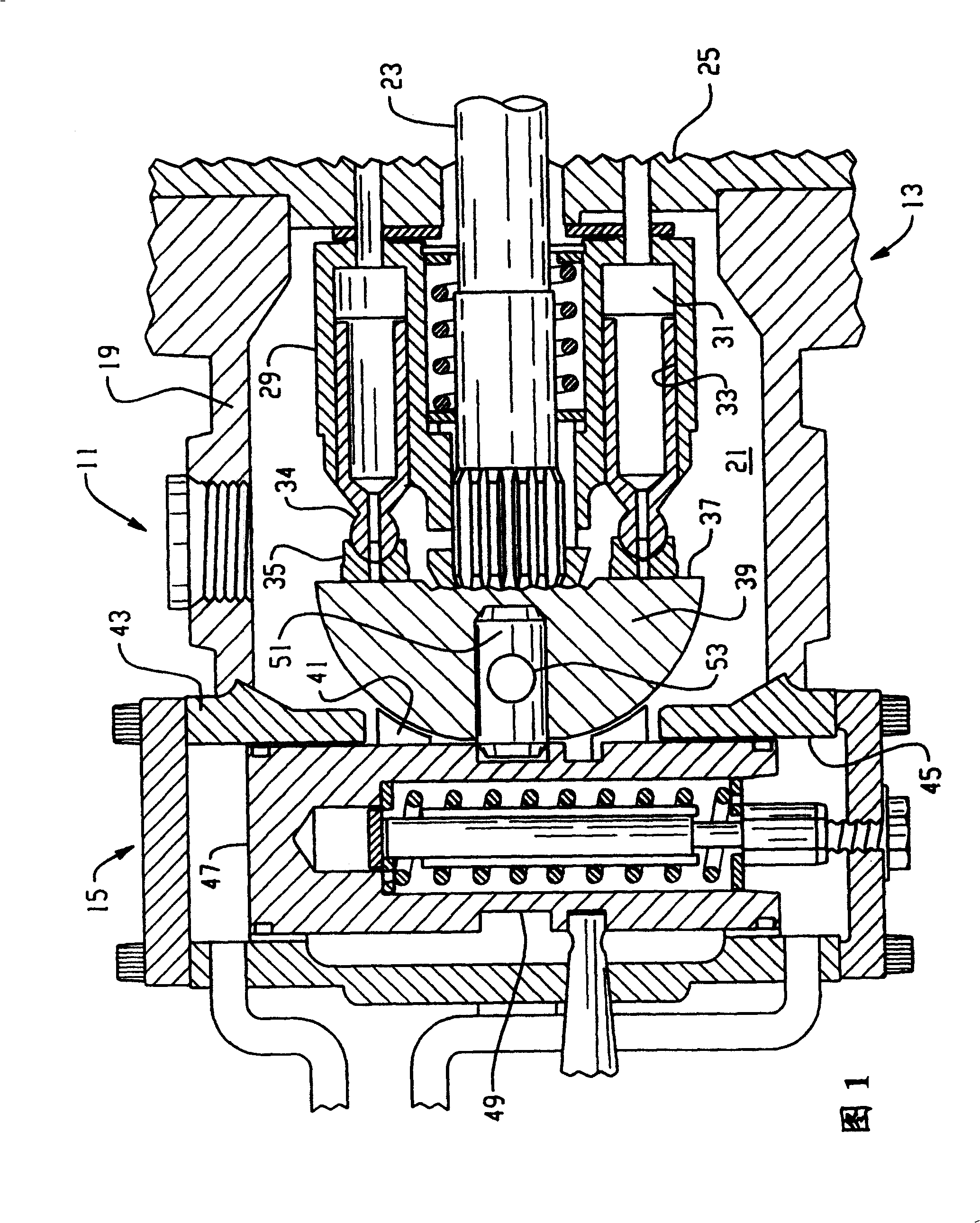

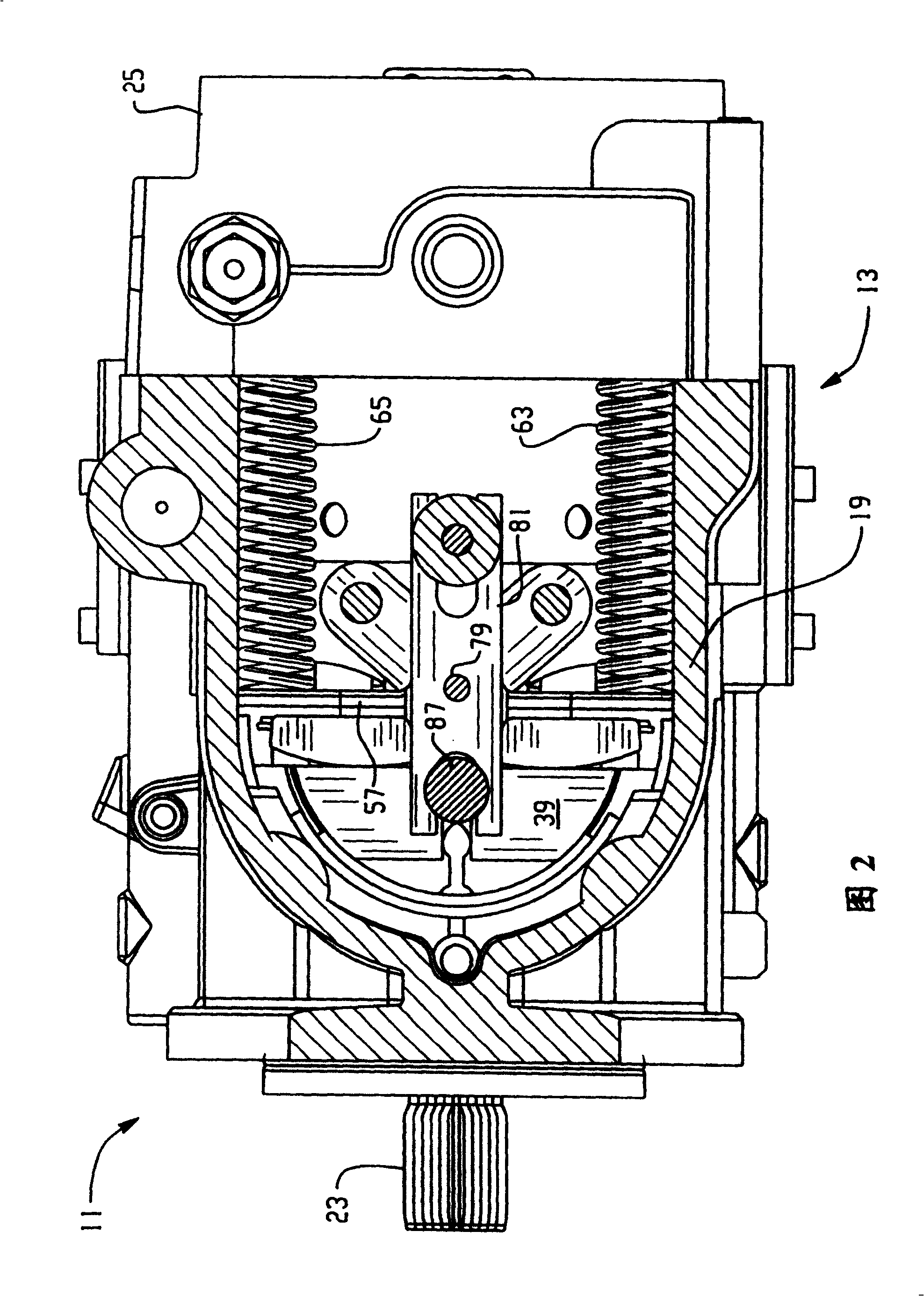

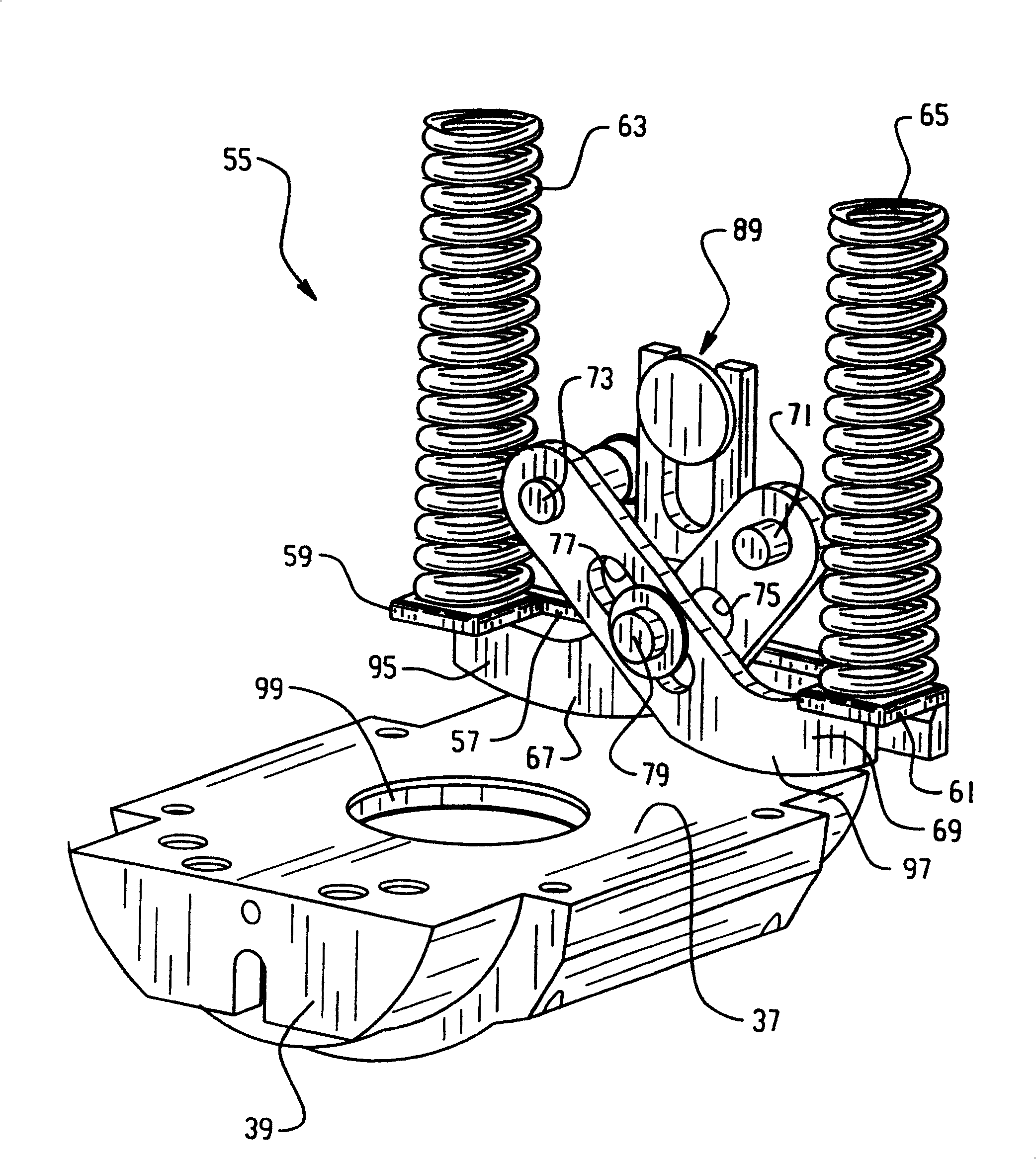

[0019] Referring now to the drawings, which are not intended to limit the invention, there is shown in Figure 1, generally designated 11, a variable displacement axial piston pump to which the invention may be applied. The pump 11 comprises two main parts: a pump element 13 and a hydraulically actuated servo 15 . It should be understood that the invention is not required to use the particular type of pump element 13 shown here, nor does it require a hydraulic type of servo to actuate the pump 11 .

[0020] The pump element 13 includes a pump housing 19 defining an internal cavity or chamber 21 . As known to those skilled in the art, an input shaft 23 extends from the left end in FIG. 1 into cavity 21 (see FIG. 2 ), and then extends through an opening in a port housing 25 to the right end. The port housing 25 is also sometimes referred to as a back plate or end cap. Hereinafter and in the appended claims, the term "housing" may refer to and include both the pump housing 19 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com