Pole group welder for accumulator

A kind of pole group, battery technology, applied in the direction of secondary battery manufacturing, welding equipment, climate sustainability, etc., can solve the problems of low production efficiency, difficult demolding of pole group, unreasonable design, etc., to achieve high production efficiency , reliable performance, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

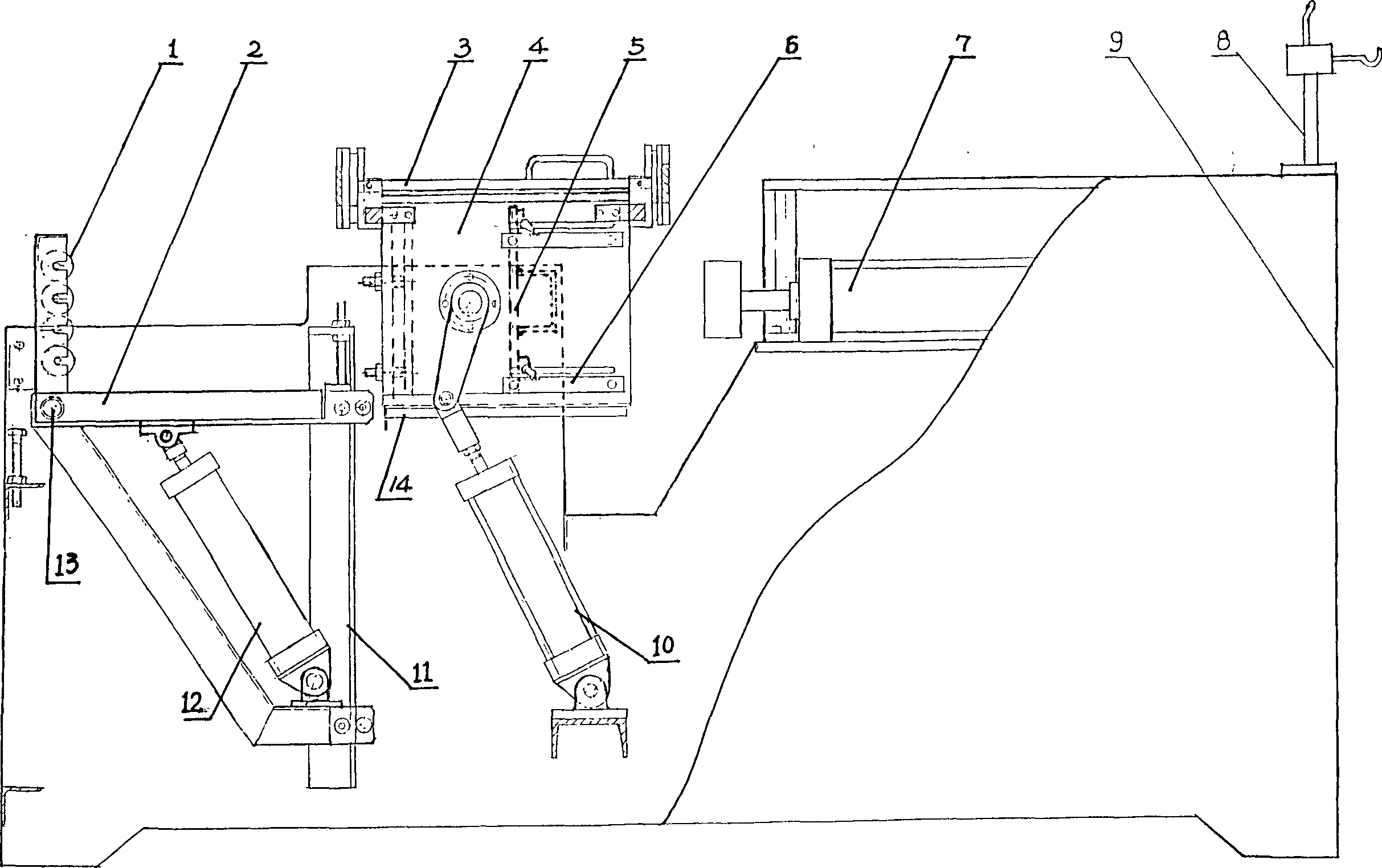

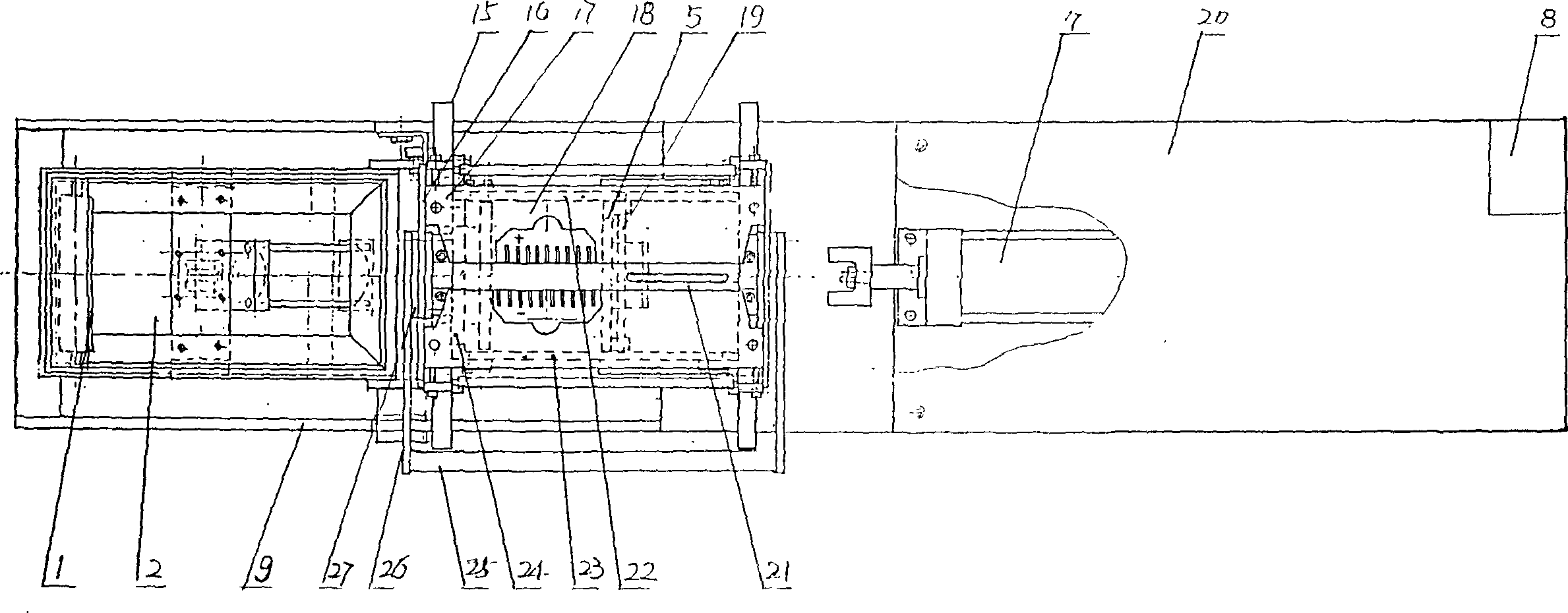

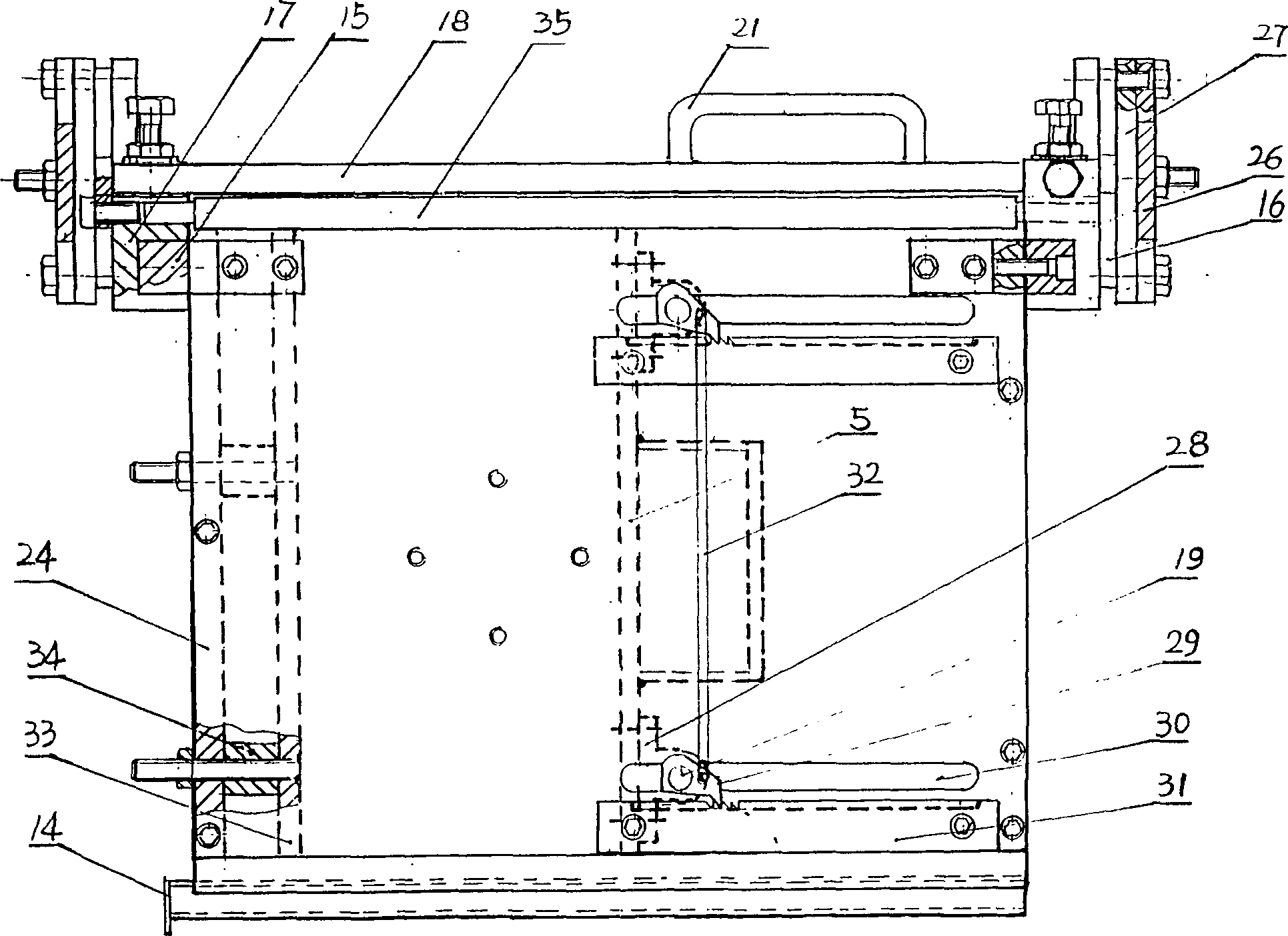

[0013] See attached figure 1 1 is the rolling shaft, 2 is the battery frame, 3 is the welding mold, 4 is the assembly box, 5 is the pressing plate, 6 is the stop device, 7 is the pressing cylinder, 8 is the welding torch and the ignition device, 9 is the Frame, 10 is a steering cylinder, 11 is a lifting frame, 12 is a turning cylinder, 13 is a turning shaft, and 14 is a flashboard. The bottom plate of the assembly box 4 is a movable inserting plate 14, the right side plate of the assembly box 4 is a movable pressing plate 5, and the pressing cylinder 7 is installed on the frame 9 corresponding to the pressing plate 5 to stop the movement. The device 6 is installed between the pressing plate 5 and the assembly box 4, the assembly box 4 is mounted on the middle and upper part of the frame 9 through the steering shaft fixed on the front and rear two side plates, and the steering cylinder 10 is installed between the assembly box and the frame Between them, the welding mold 3 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com