Simulation test method of rotating outer ring/fixed inner ring rolling bearing

A simulation test and rolling bearing technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of small type and quantity, and achieve the effect of low cost, simple and practical test method, and reduced interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

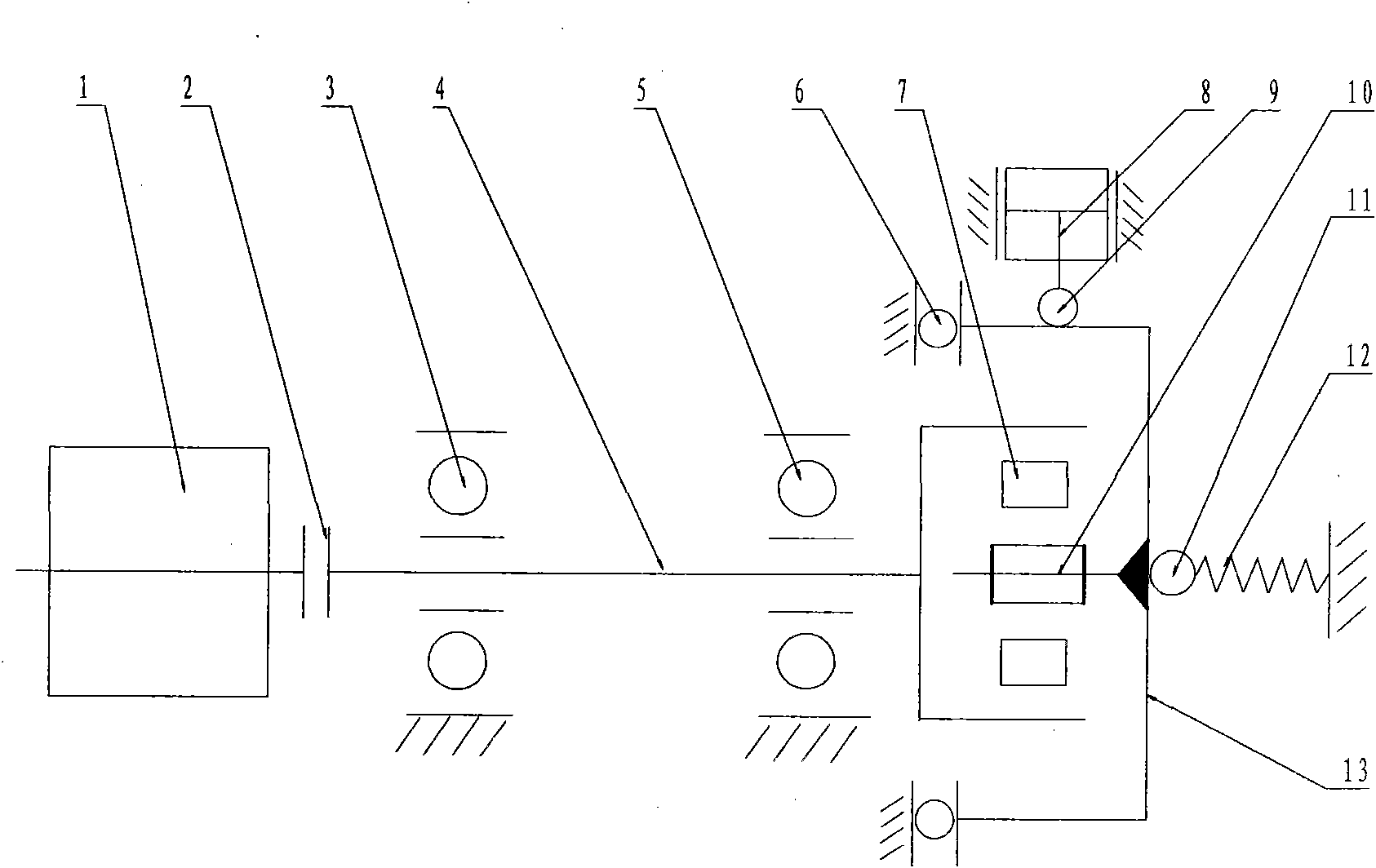

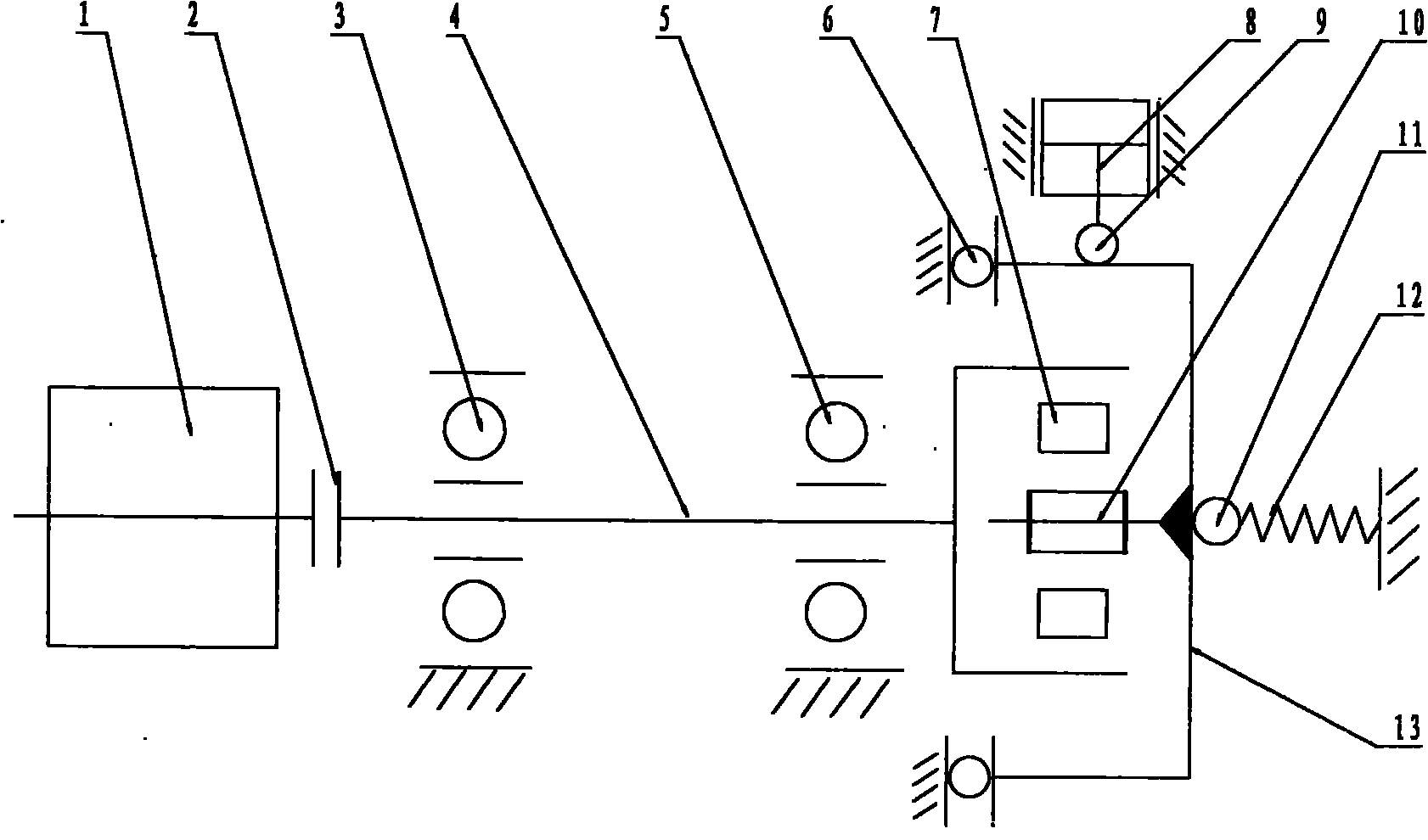

[0017] combine figure 1 , the rolling bearing simulation test method used for the fixed outer ring rotating inner ring of the present invention is equipped with a bearing test device, and the bearing test device is composed of an outer ring shaft system and a loading shaft system.

[0018] The outer ring shaft system is composed of a driving motor 1, a shaft coupling 2, a rear fulcrum bearing 3, an outer ring shaft 4 and a front fulcrum bearing 5.

[0019] The loading shaft system is composed of sliding guide rail 6, loading cylinder 8, hinge I9, inner ring shaft 10, hinge II11, spring 12 and loading sleeve 13.

[0020] The driving motor 1 is connected with the outer ring shaft 4 through the coupling 2, the outer ring shaft 4 is supported by the rear fulcrum bearing 3 and the front fulcrum bearing 5, and the outer ring of the rear fulcrum bearing 3 and the outer ring of the front fulcrum bearing 5 are fixed on the bearing On the base of the test device, a test bearing 7 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com