Patents

Literature

161results about How to "Achieve axial positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

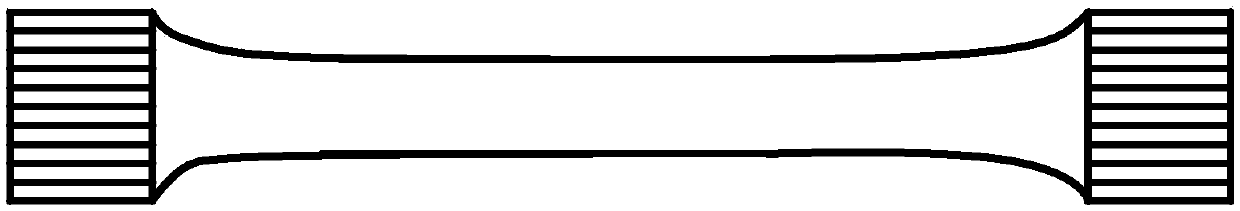

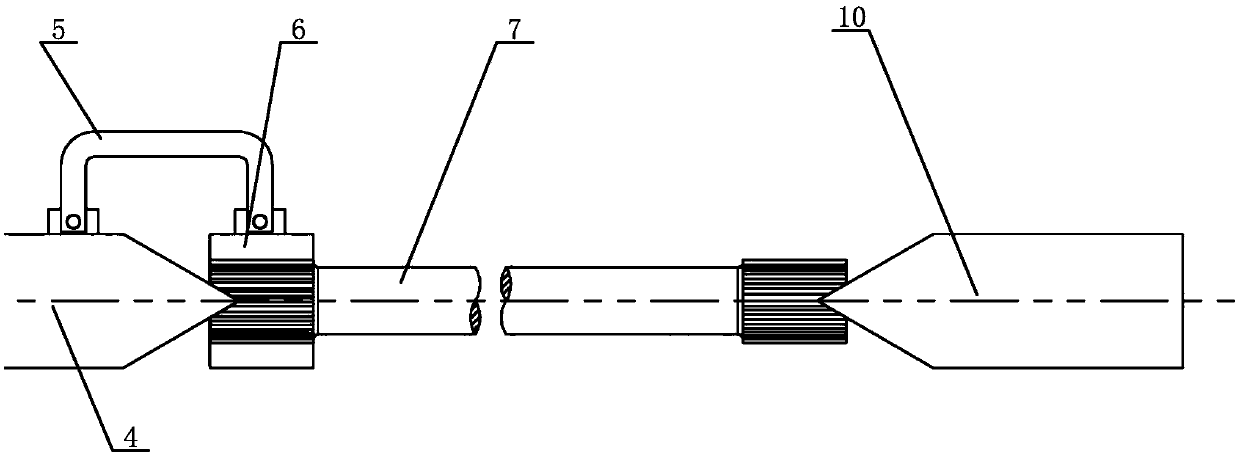

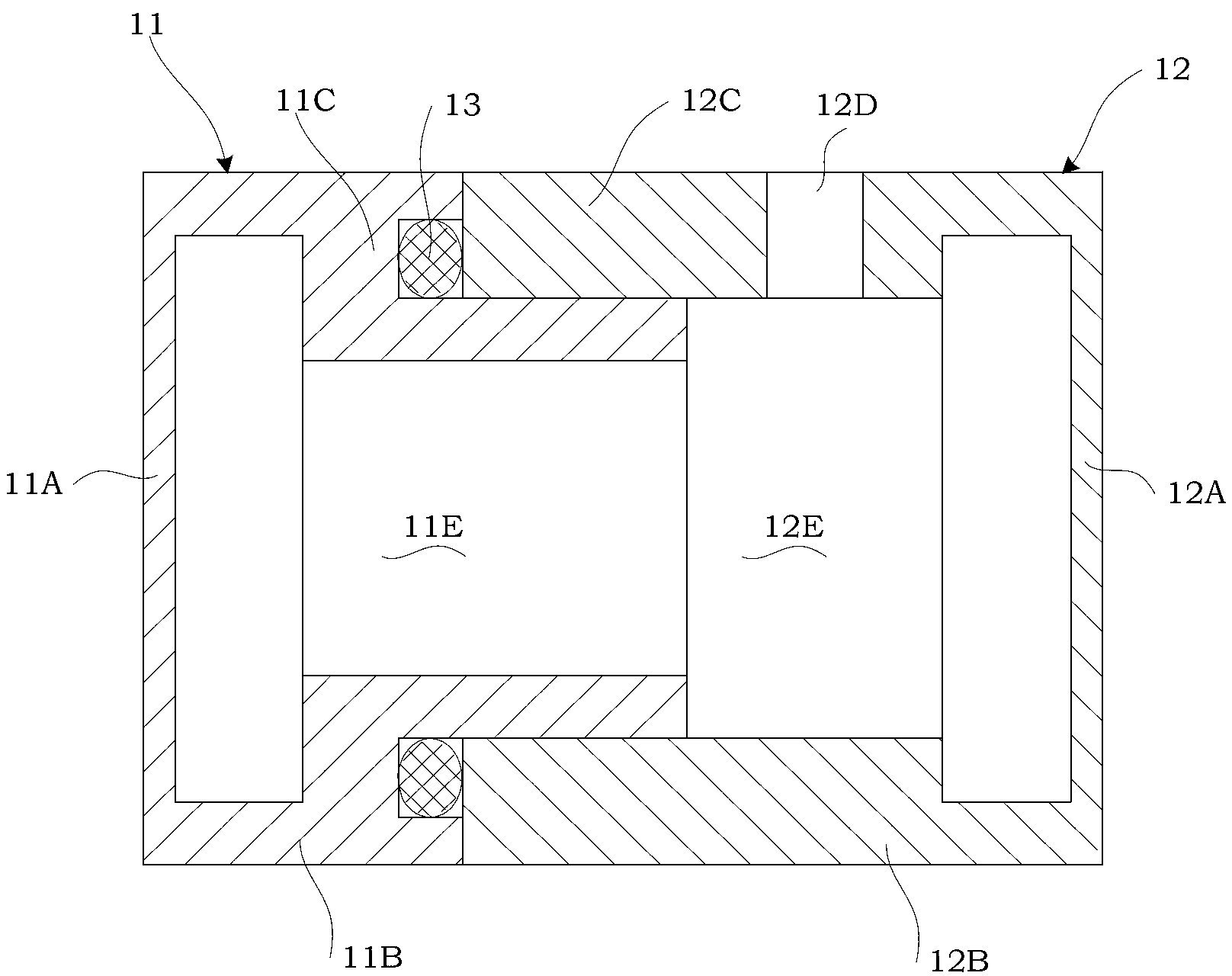

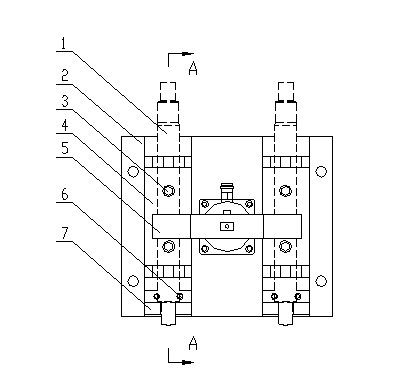

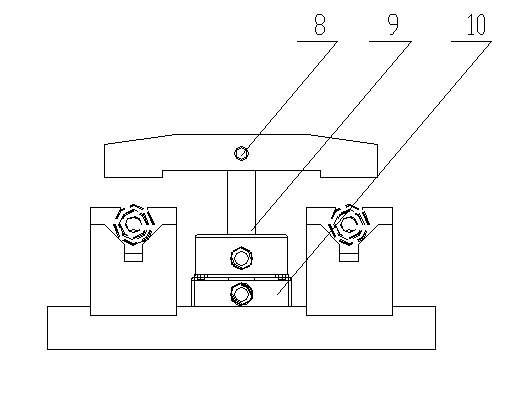

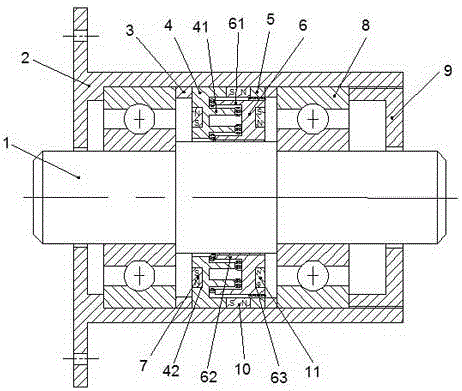

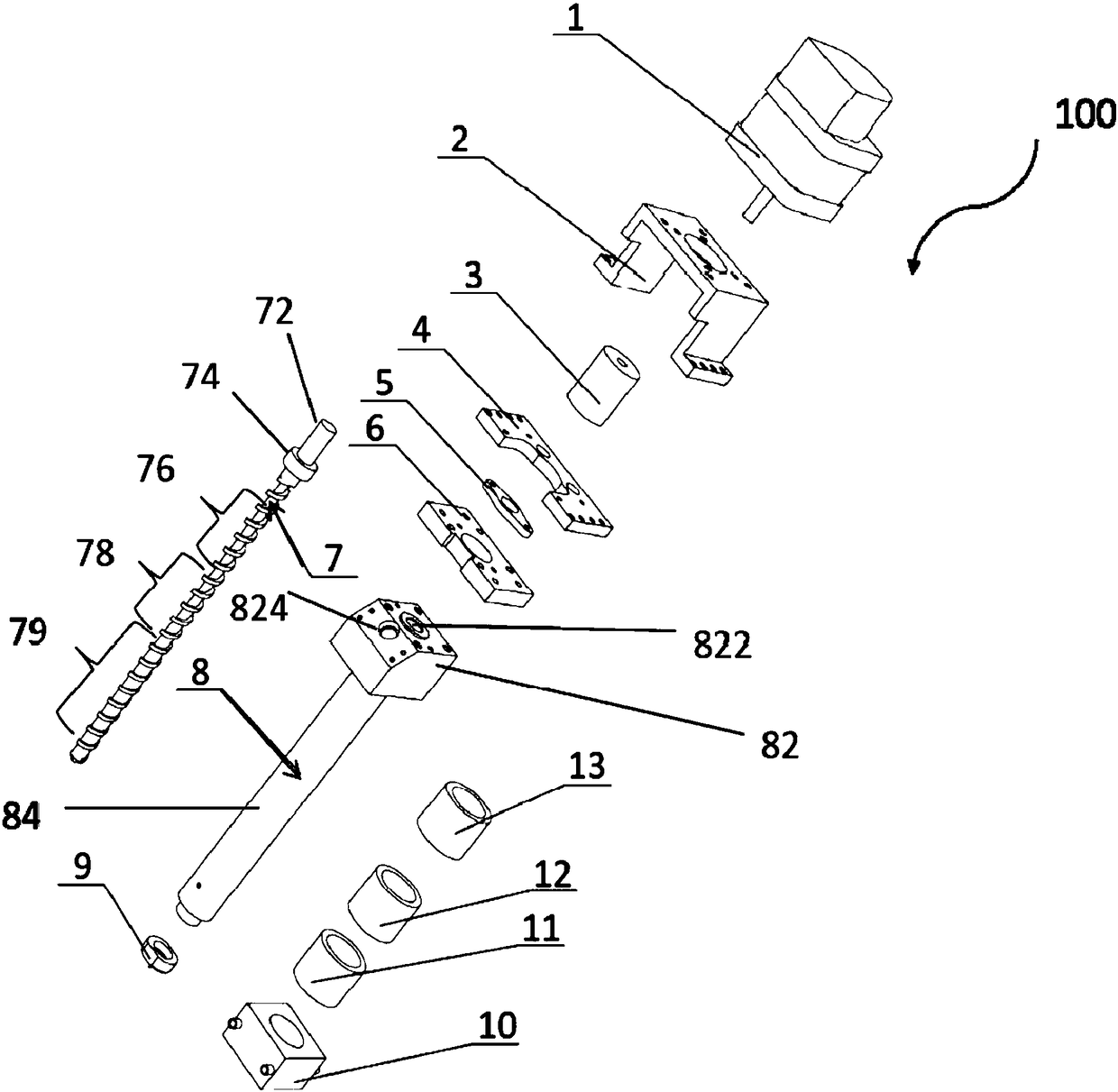

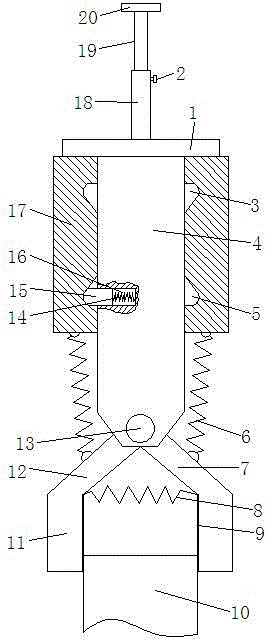

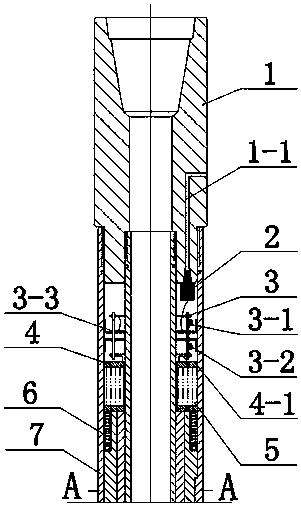

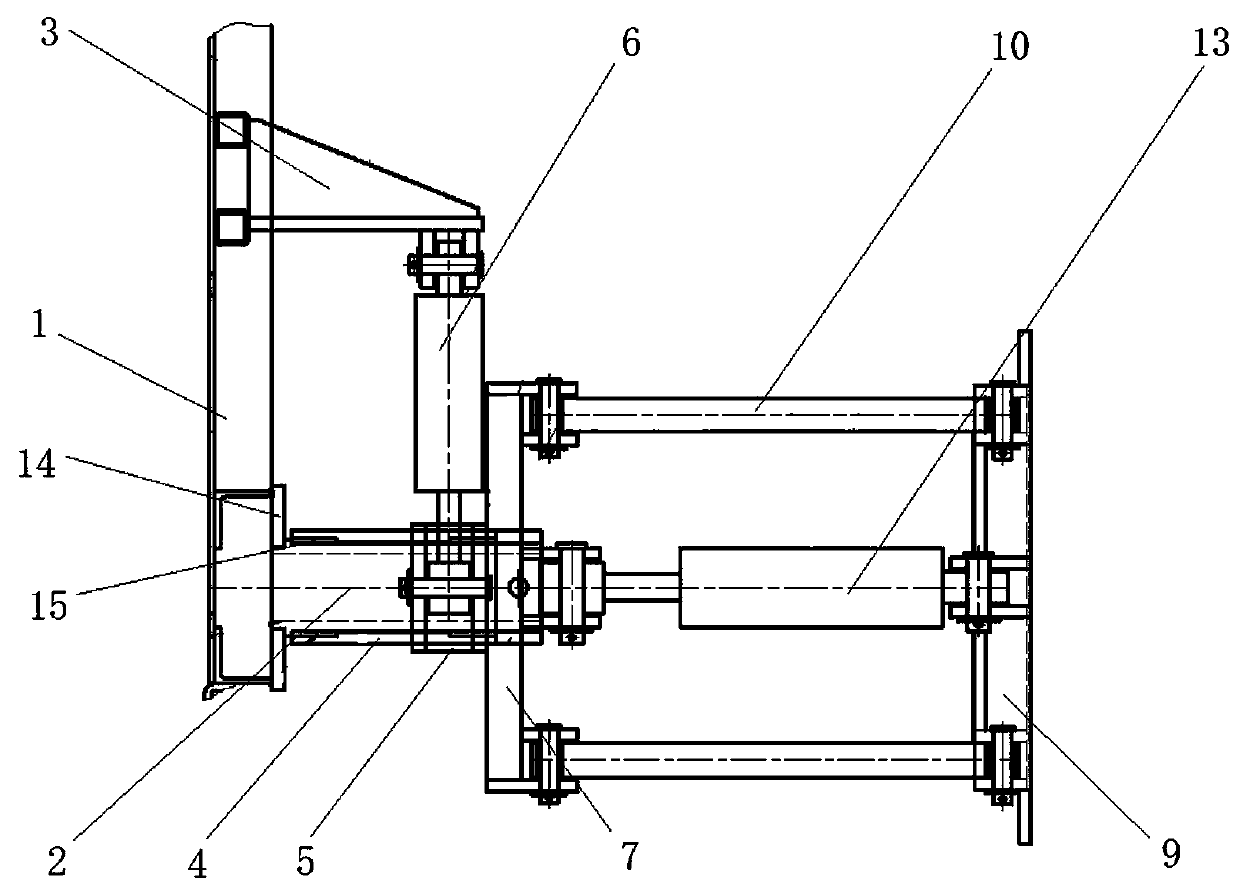

Simulation test method of rotating outer ring/fixed inner ring rolling bearing

ActiveCN101929918AAchieve axial positioningMinimize the interference of radial forceMachine bearings testingCouplingRolling-element bearing

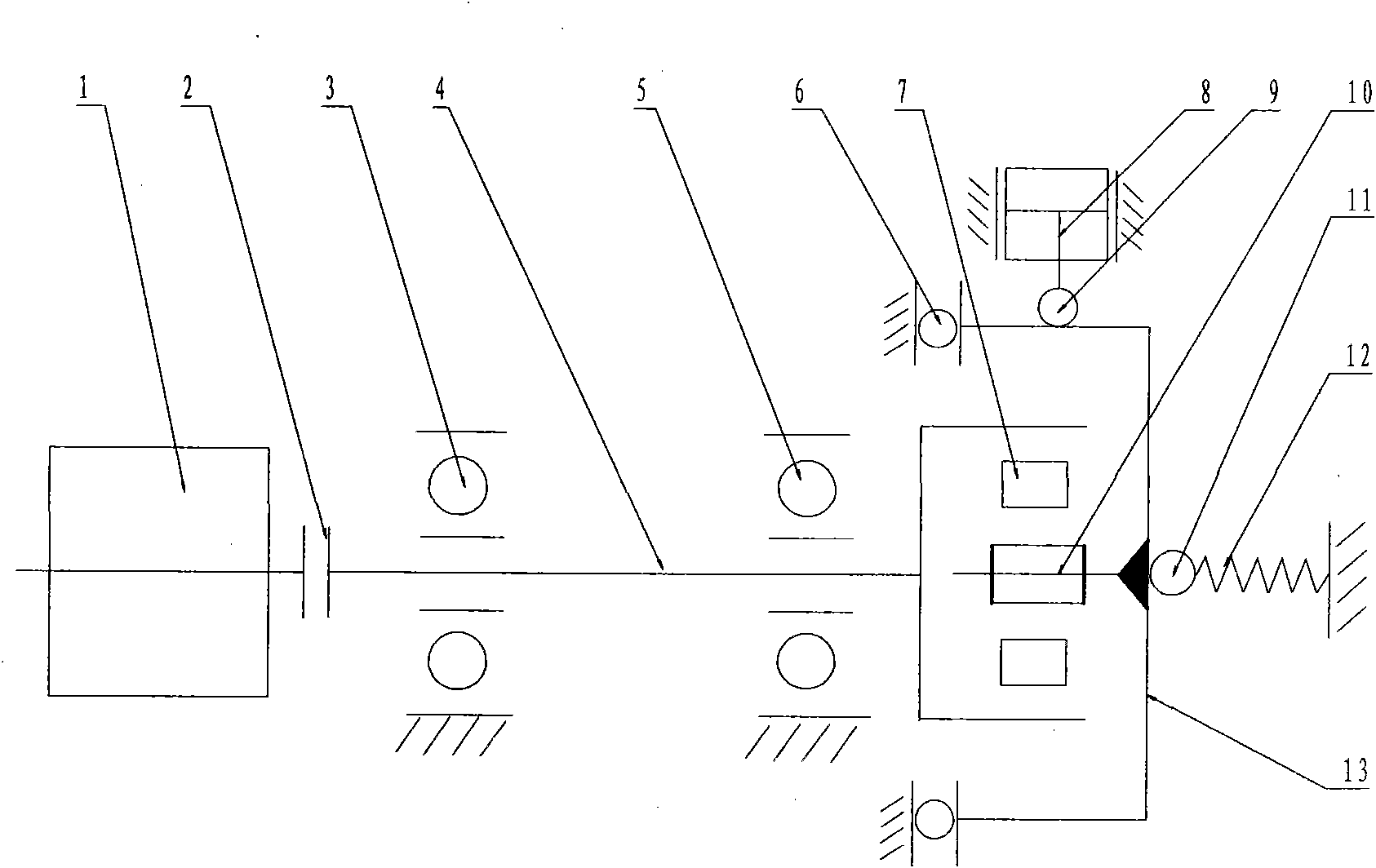

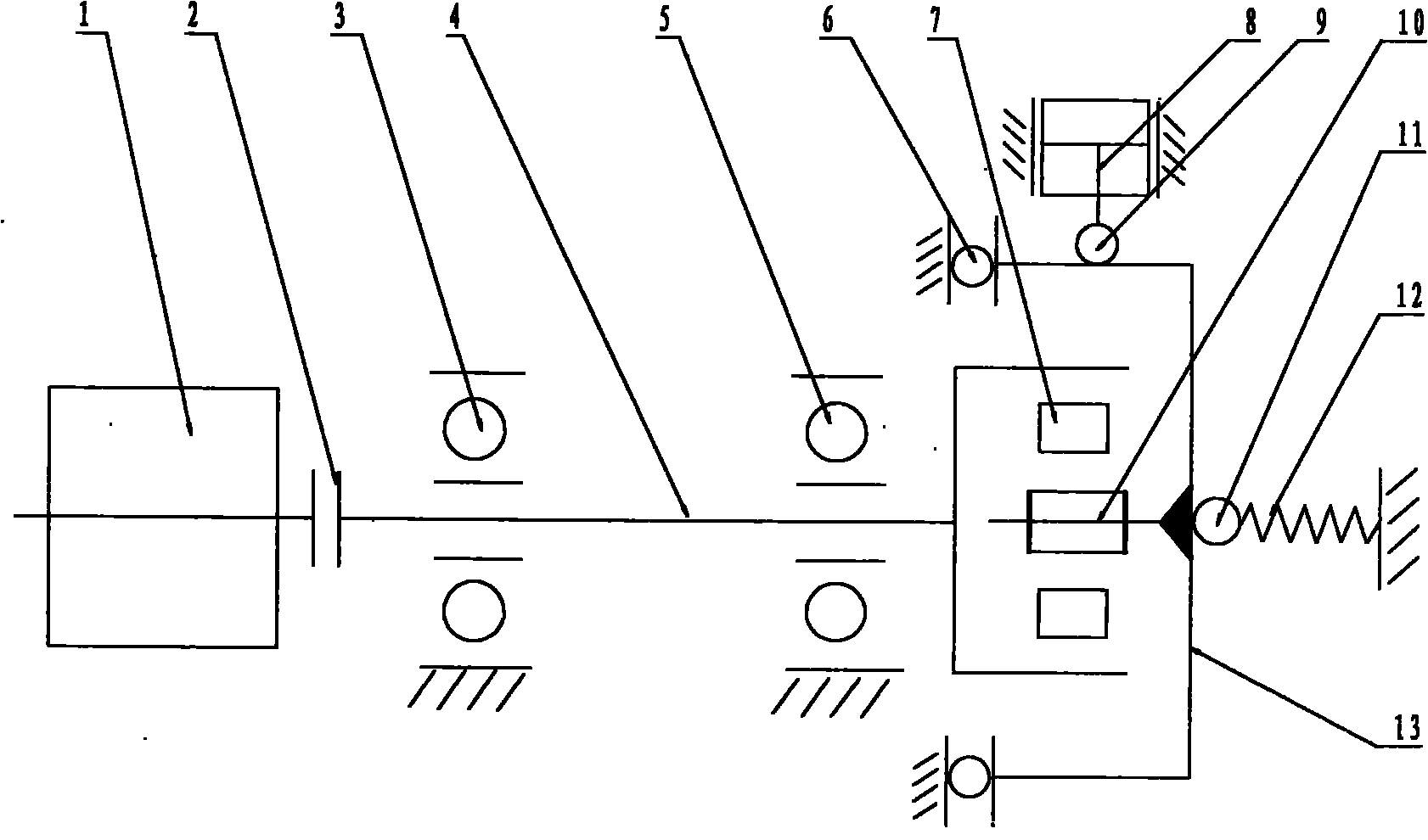

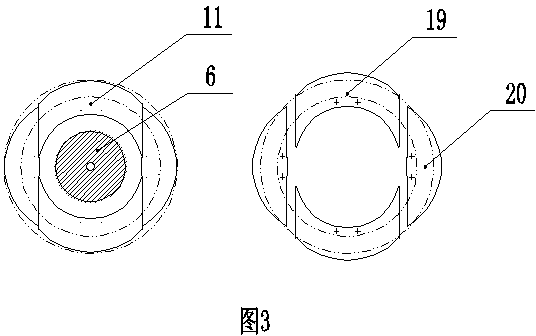

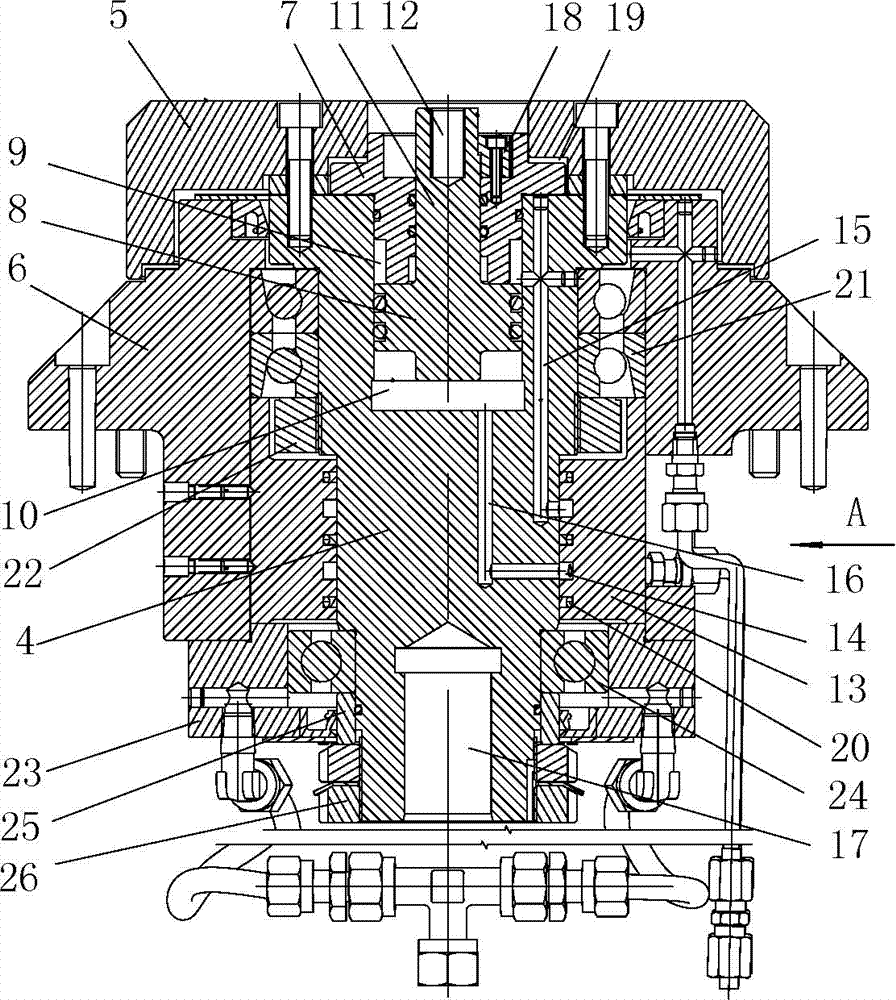

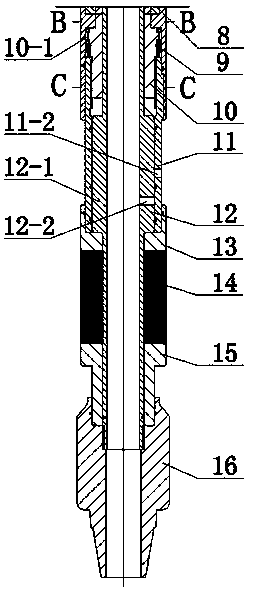

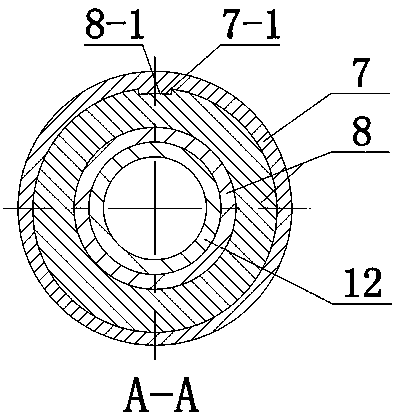

The invention relates to a simulation test method of a rotating outer ring / fixed inner ring rolling bearing. The bearing test device is composed of a drive motor (1), a coupling (2), a rear pivot bearing (3), an outer ring shaft (4), a front pivot bearing (5), a sliding guide rail (6), a loading hydro-cylinder (8), a hinge I (9), an inner ring shaft (10), a hinge II (11), a spring (12) and a loading sleeve (13), wherein the outer ring of a test bearing (7) is installed in a cantilever end outer sleeve of the outer ring shaft; the inner ring of the test bearing is installed on the inner ring shaft; the inner ring shaft is fixed on the loading sleeve; the loading hydro-cylinder directly loads the test bearing in the radial direction by using the loading sleeve; and the axial holddown spring, the sliding guide rail, the hinge II and the like are utilized to realize axial positioning of the test bearing and reduce the interference of the radial force, thereby completely simulating the simulation test method of the rotating outer ring / fixed inner ring rolling bearing. The invention can be used for carrying out property simulation tests on the test bearing according to the velocity spectrum and loading spectrum.

Owner:LUOYANG BEARING RES INST CO LTD

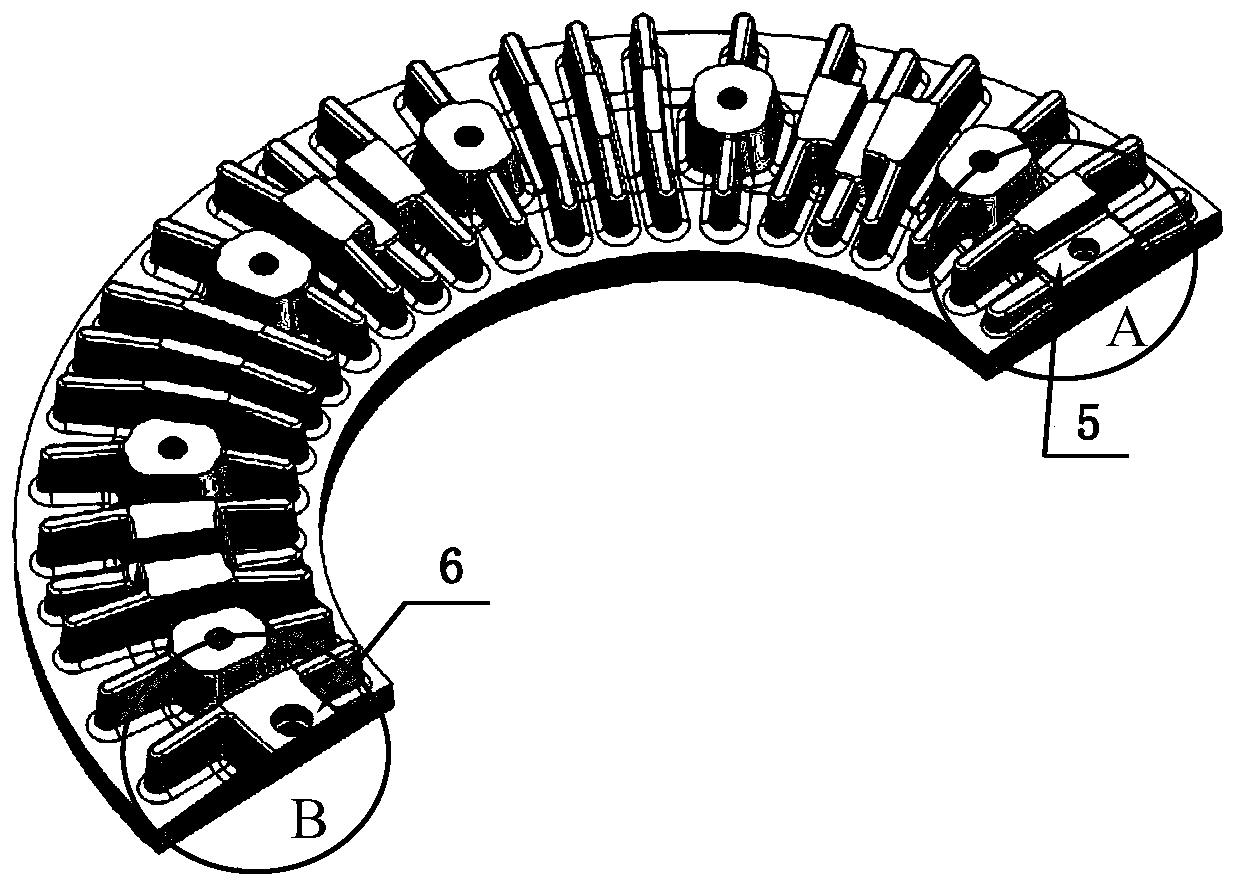

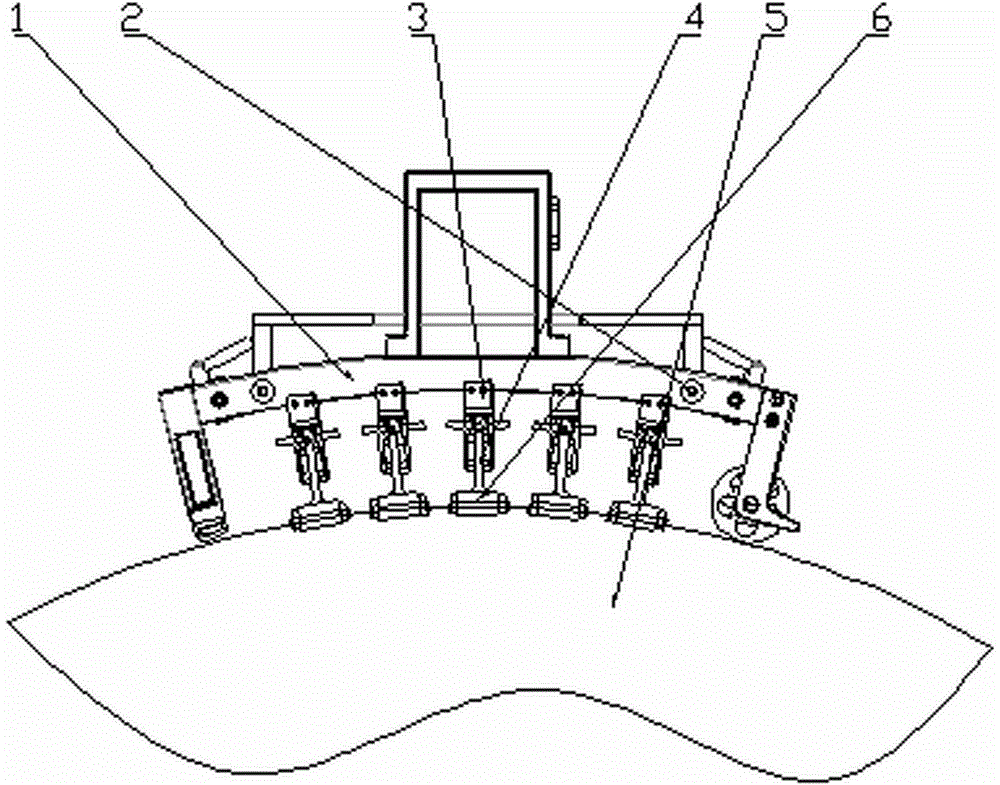

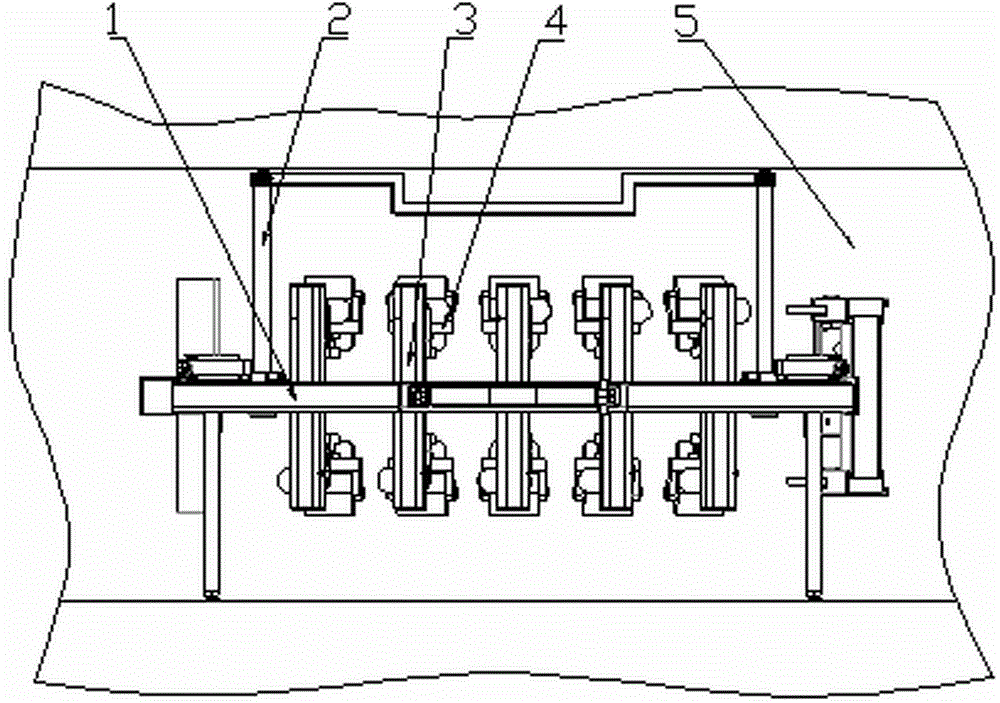

Phased-array ultrasonic nondestructive detection fixture of welding rotor

ActiveCN104597134APrecise alignmentAchieve axial positioningMaterial analysis using sonic/ultrasonic/infrasonic wavesElectric machineryWeld seam

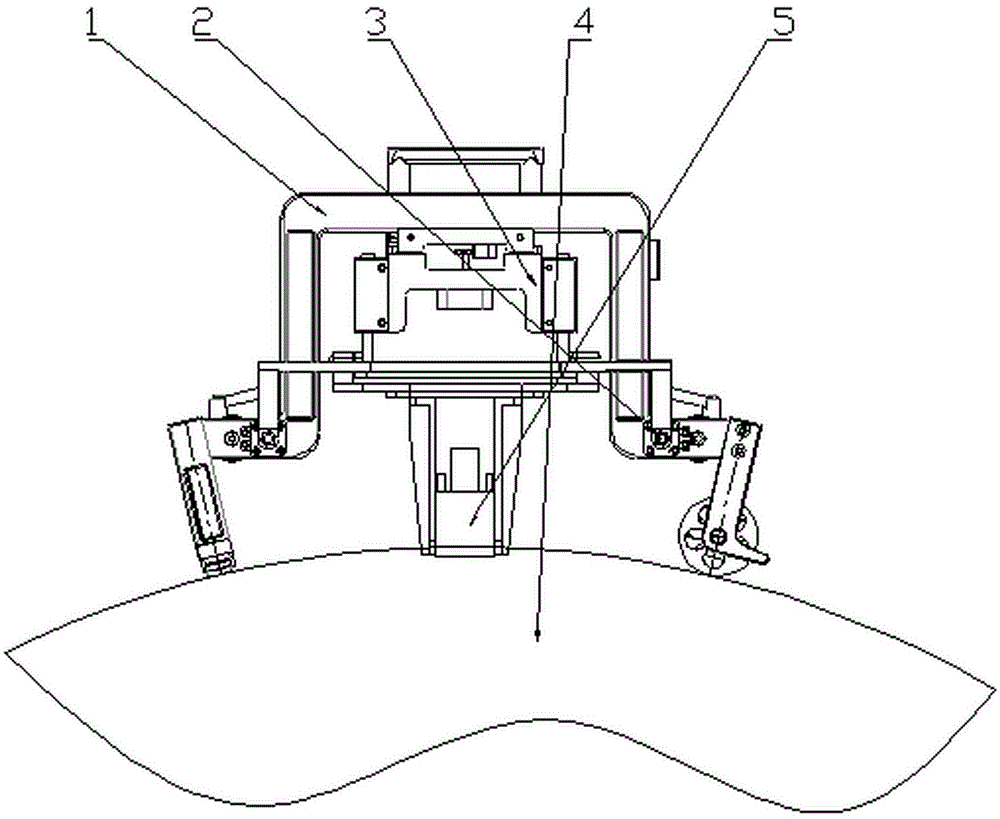

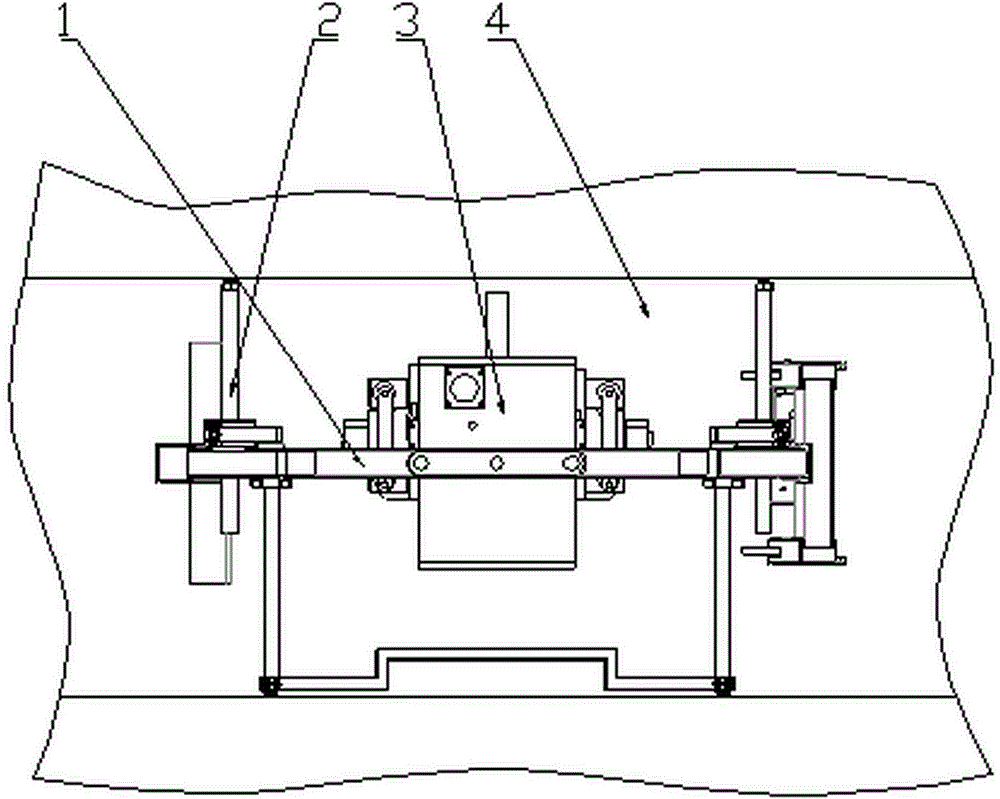

The invention belongs to the field of a detection robot, and particularly relates to a phased-array ultrasonic nondestructive detection fixture for a steam turbine welding rotor, which is used for overcoming the weaknesses of the prior art that no positioning and drive device is arranged and the technical problem of defect caused by detecting the welding rotor seam by utilizing the vision and thickness measuring method. A system mainly comprises an adsorption-type movable platform, a positioning system and a driving clamp. The phased-array ultrasonic nondestructive detection fixture has the advantages that a wedged block is automatically adaptive to the surface angle of the welding rotor by virtue of the rotation degree of freedom of the tail end of the clamp and the elastic force of a spring, and the wedged block is tightly fit to the welding rotor; the transverse movement of the wedged block can be realized by virtue of a drive motor and a transmission mechanism, so that the wedged block can be used for detecting different positions on the surface of the welding rotor; the axial positioning between the wedged block and the welding rotor is realized under the effect of the positioning system, so that the wedged block can be accurately aligned to a weld seam.

Owner:中国东方电气集团有限公司

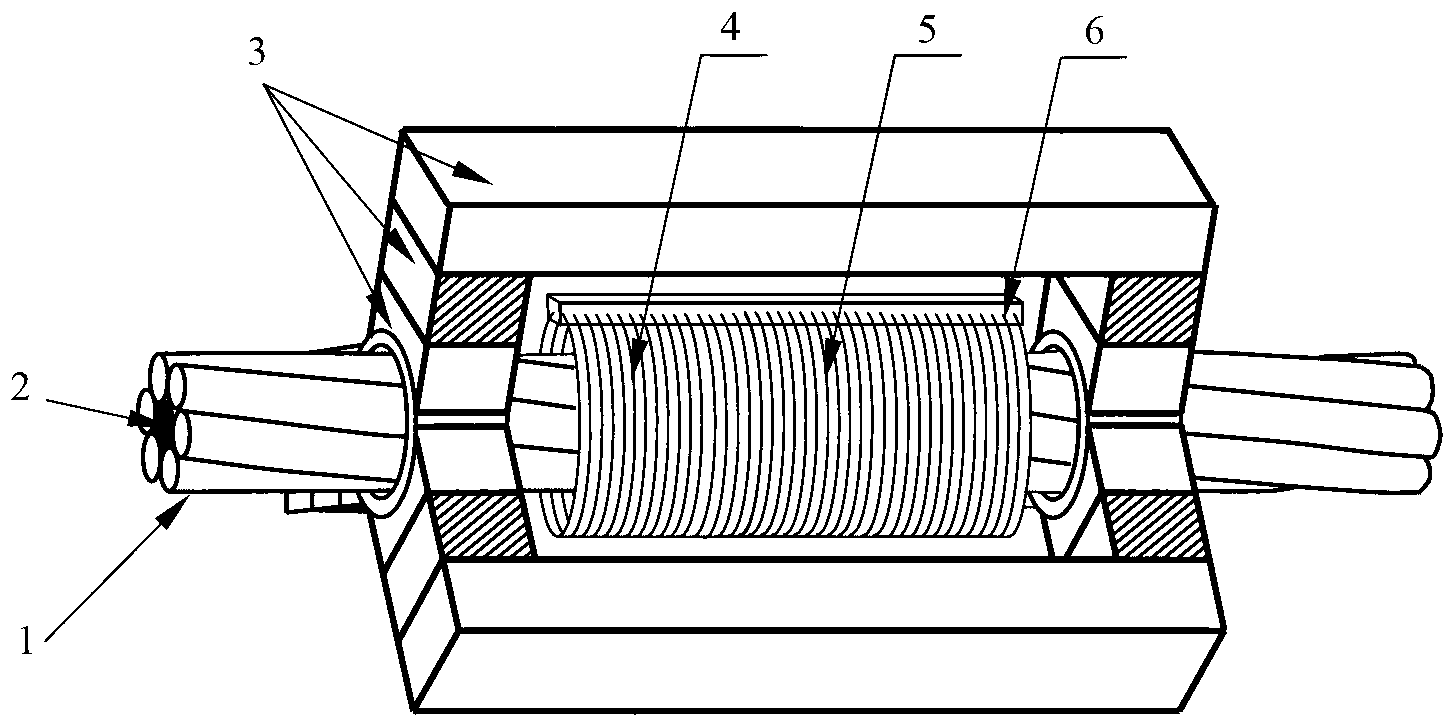

Flexible magnetostriction and eddy integrated sensor for detecting defects of high-voltage transmission line

ActiveCN102841132ARealize full structural defect detectionAchieve axial positioningOptically investigating flaws/contaminationMaterial magnetic variablesEngineeringHigh pressure

The invention relates to a flexible magnetostriction and eddy integrated sensor for detecting defects of a high-voltage transmission line and belongs to the technical field of an electromagnetic acoustic sensor. An outer-layer magnetostriction sensor is printed on a substrate through a flexible printing coil and an inner-layer eddy sensor is printed on the substrate through the flexible printing coil; the flexible printing coil can be coiled into a cylindrical shape and clung to the surface of the high-voltage transmission line so as to form a solenoid coil; after the solenoid coil is clamped and fixed by a connector, the solenoid coil is mounted on a detected transmission line so as to detect the defects; and after the clamped and fixed state is released, the solenoid coil can be detached from the surface of the transmission line. The integrated sensor can be used for stimulating a longitudinal modal ultrasonic guide wave from the transmission line and detecting the defects of the whole structure of the transmission line on the basis of a magnetostriction effect; the integrated sensor also can be used for detecting complex impedance change of a sensor detecting coil due to the defects of the transmission line by utilizing a multi-channel eddy sensor and realizing the peripheral positioning for the defects on the basis of an eddy effect; and meanwhile, the deep positions of the defects in the transmission line can be confirmed on the basis of a surface action of an eddy field.

Owner:BEIJING UNIV OF TECH

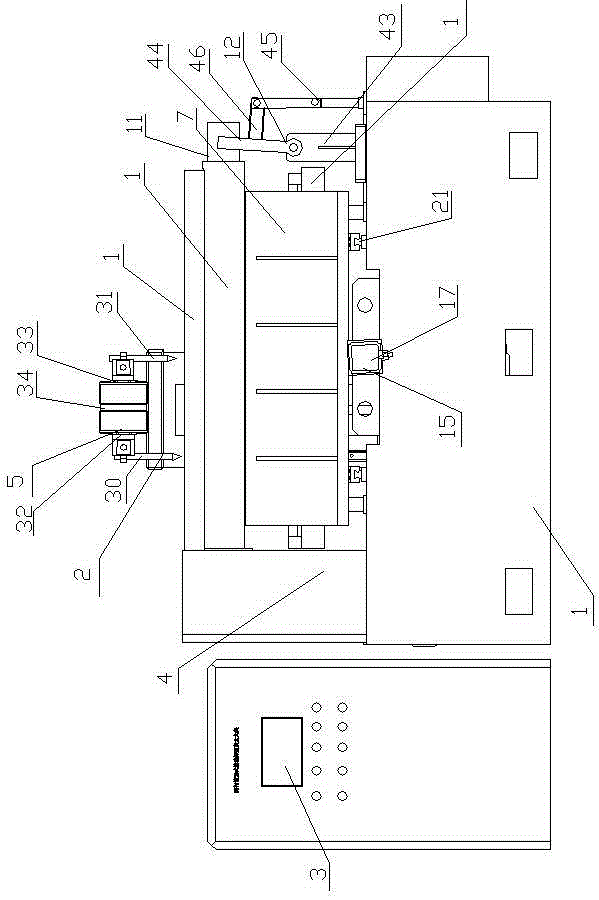

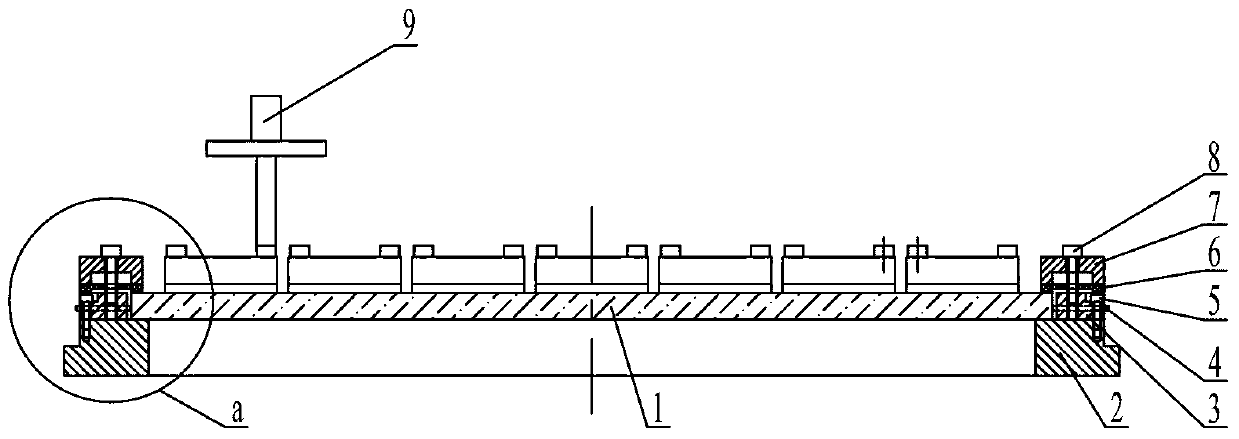

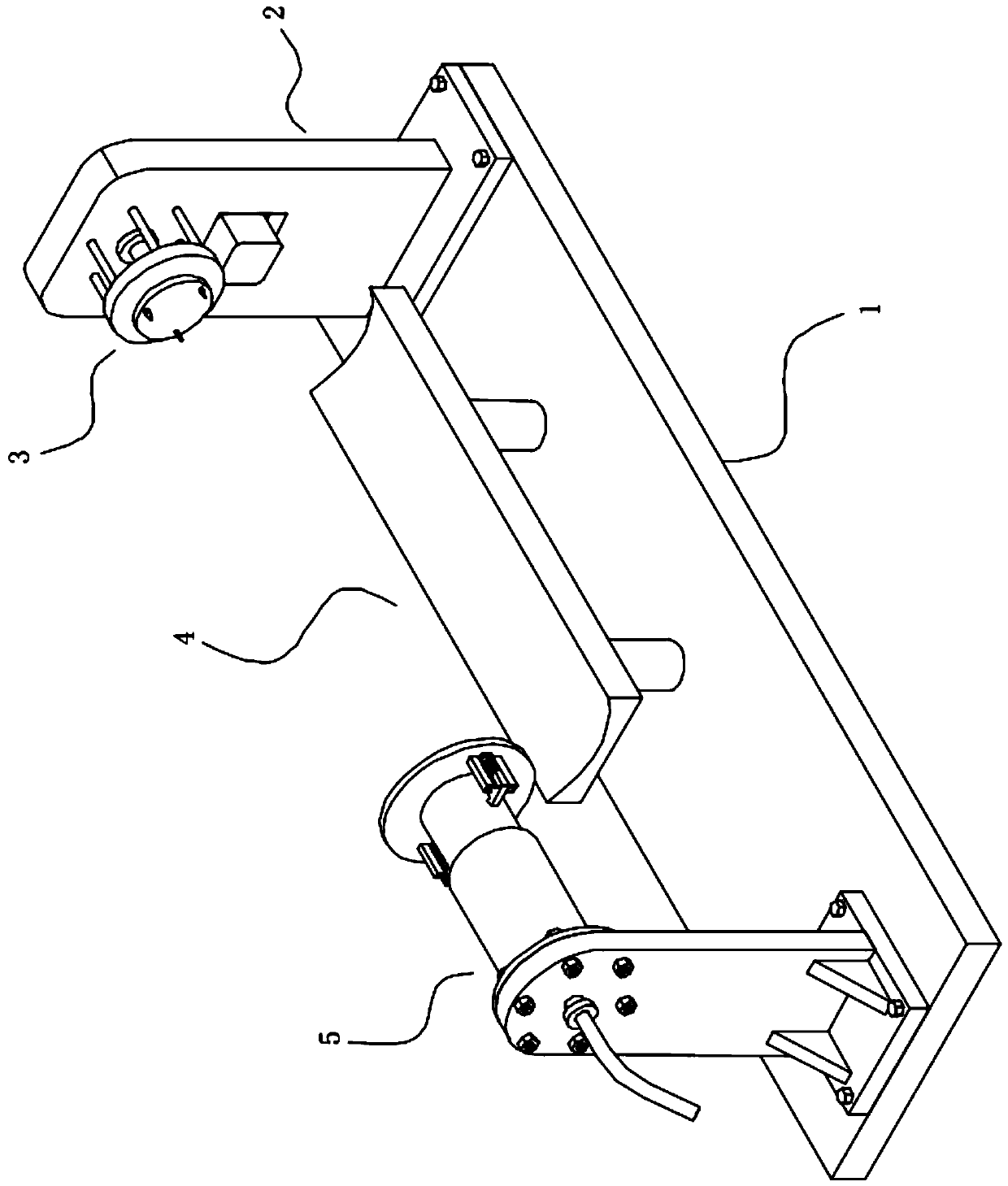

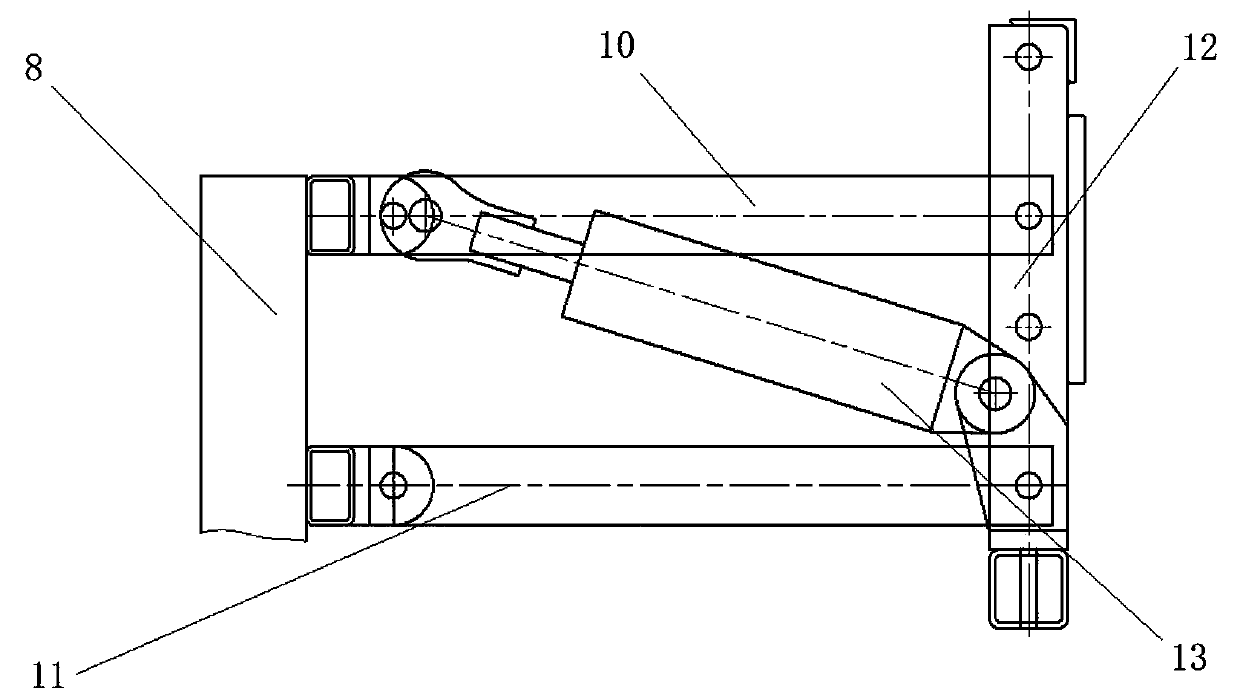

Compound pipe longitudinal joint automatic welding device

InactiveCN105127541AAchieve axial positioningImprove continuityTubular articlesSoldering auxillary devicesKey pressingControl system

The invention relates to the technical field of welding, in particular to a compound pipe longitudinal joint automatic welding device which mainly comprises a double welding gun movement mechanism, a control system, welding power supplies and a welding fixture. The double welding gun movement mechanism is composed of a movable platform, a left welding gun, a right welding gun and a cross sliding frame, wherein the two welding guns are provided with wire feeding mechanisms and welding power supplies respectively. The control system is located on the left side of the welding fixture, and the two welding power supplies are connected with the control system. The welding fixture comprises a welding front-rear symmetric supporting device, a lower supporting device, a supporting mandrel, a pneumatic key pressing device and a precision movement sliding rail. According to the welding device, a double metal compound pipe longitudinal joint with a diameter of 200-500 mm, a length of 1800 mm and a thickness of 4-7 mm can be clamped quickly and reliably, the control system can finish welding device control, welding track planning, welding parameter setting and welding process monitoring, and the double metal compound pipe longitudinal joint is automatically welded.

Owner:JIANGSU JIANGHAI MACHINE TOOLS GROUP

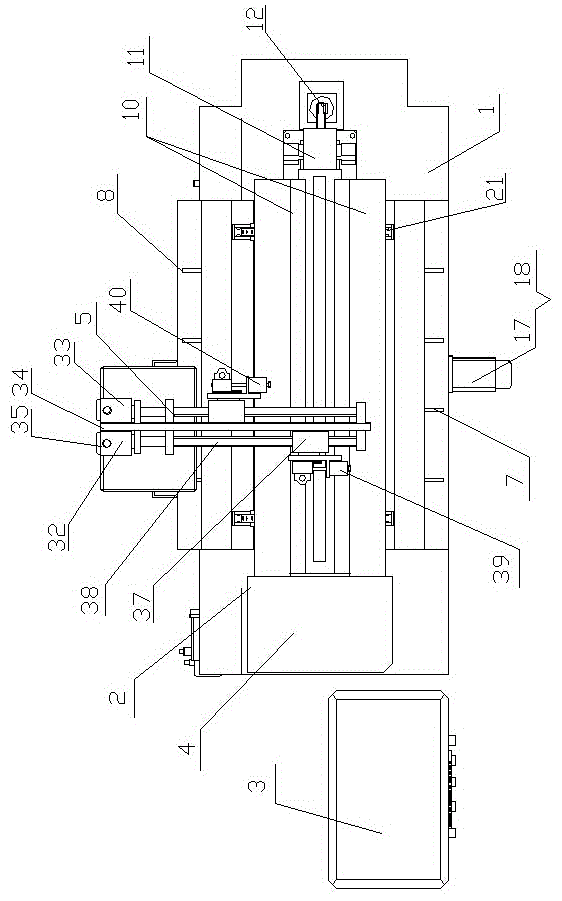

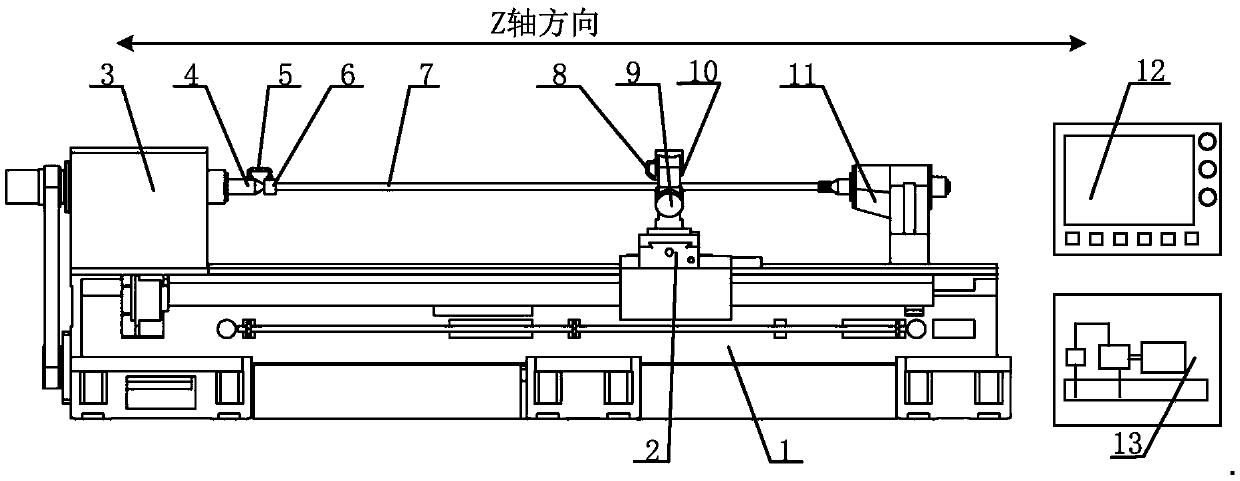

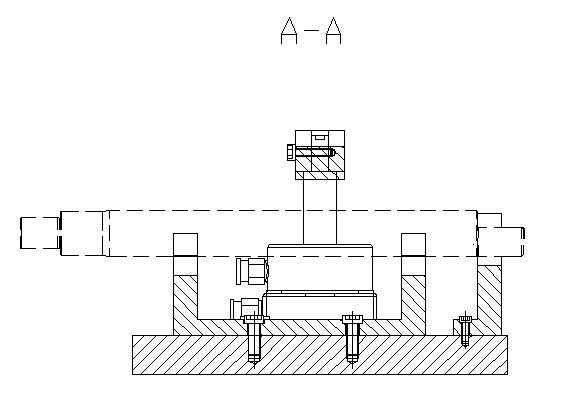

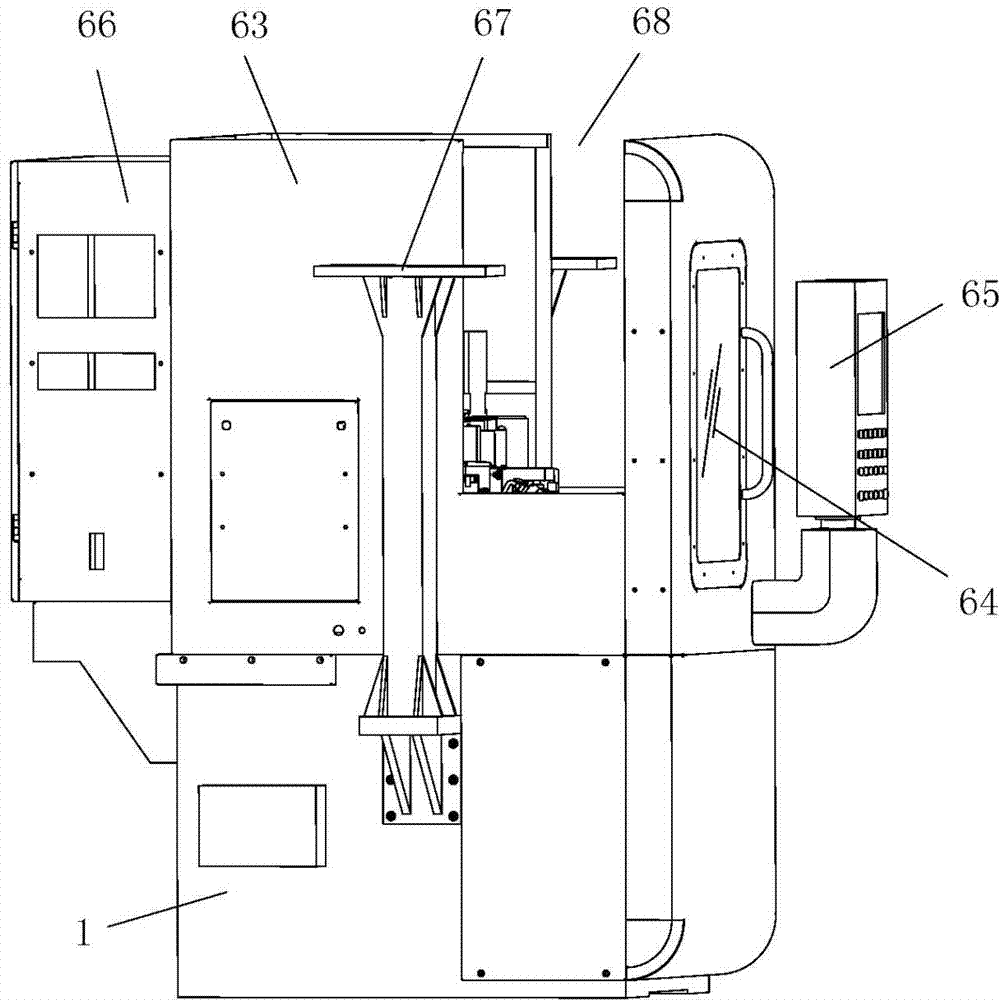

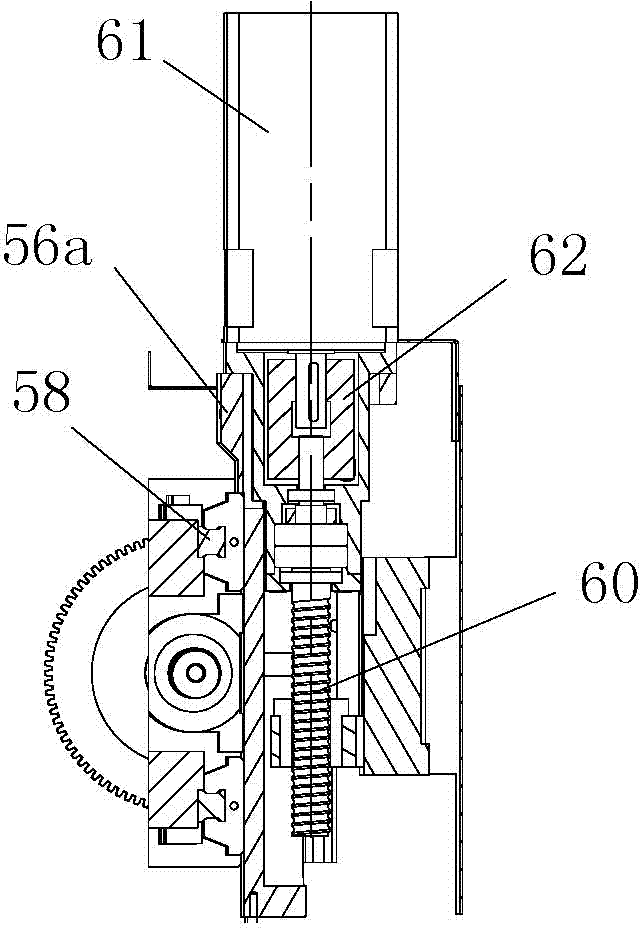

Numerical control rolling machine tool for outer circle rolling of torsion shaft

ActiveCN108673051AFastenedHigh speedWork clamping meansPositioning apparatusHydraulic cylinderEngineering

The invention provides a numerical control rolling machine tool for outer circle rolling machining of a torsion shaft. The numerical control rolling machine tool comprises a machine tool body, an outer circle rolling head, a dual centre locating device, a shifting fork connecting part, an internal spline clamp sleeve, a full closed protection cover, a displacement measurement system, a precise oilmist cooling system, a numerical control system and a hydraulic system. The outer circle rolling head of the machine tool adopts a multi-rolling-wheel symmetric rolling device structure, and when outer circle rolling machining of the torsion shaft is carried out, a workpiece bears multiple equal pressures in the radiation direction; a displacement sensor is mounted in a hydraulic cylinder of theouter circle rolling head, the change value of the rolling diameter in the outer circle rolling process is worked out through the rolling cylinder displacement value fed back by the displacement sensor, and intelligent judgment on the limiting position of the outer circle rolling arc end can be achieved; and the shifting fork connecting part replaces a traditional chuck, a transmission structure is optimized, meanwhile, worker operation is more convenient, the machine tool is more suitable for streamlined production operation, and the rolling machining efficiency is higher.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

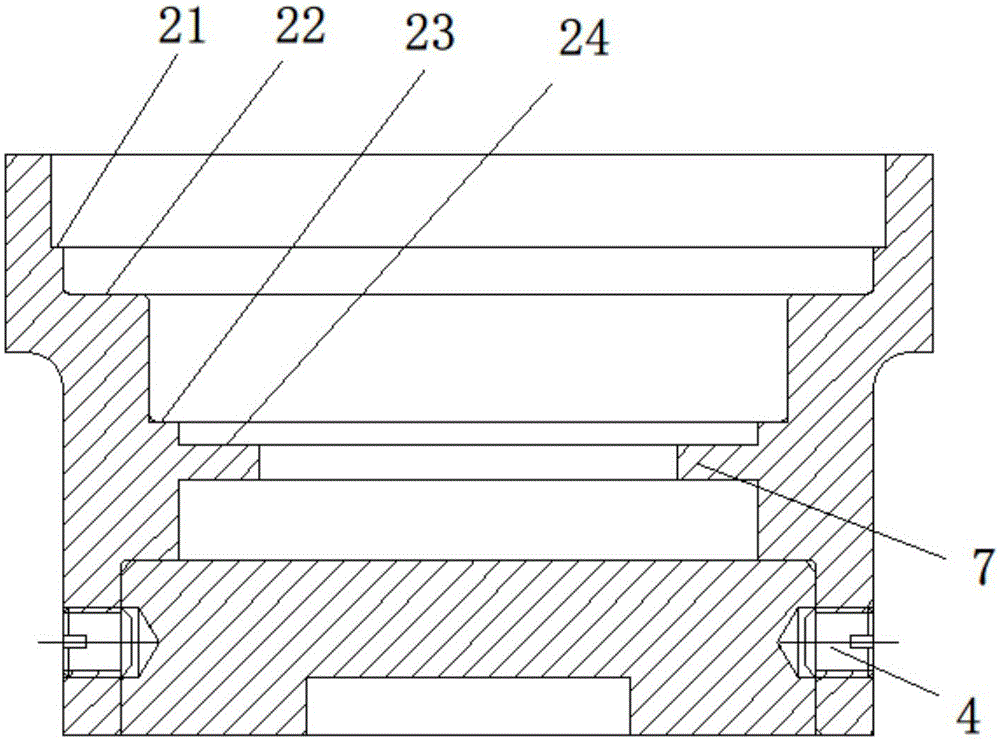

Stepped end face type magnetic fluid sealing device

The invention relates to the field of mechanical engineering sealing, in particular to a stepped end face type magnetic fluid sealing device. The stepped end face type magnetic fluid sealing device comprises a housing, a left pole shoe, a middle pole shoe, a right pole shoe and permanent magnets, wherein the middle pole shoe is installed in the middle of a shaft, and step structures are symmetrically arranged on the left side and the right side of the middle pole shoe in the radial direction. The left pole shoe is installed on the left side of the middle pole shoe, the right pole shoe is installed on the right side of the middle pole shoe, pole teeth I and an annular groove I are arranged on the right end face of the left pole shoe, the pole teeth I correspond to the step side face of the left end of the middle pole shoe, and the annular groove I is formed among the pole teeth I. Pole teeth II and an annular groove II are arranged on the left end face of the right pole shoe, the pole teeth II correspond to the step side face of the right end of the middle pole shoe, and the annular groove II is formed among the pole teeth II. The permanent magnets are installed in the annular groove I and the annular groove II. The sealing device has good sealing properties and can meet the using requirements of working conditions including large gap, high speed, heavy load and the like.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

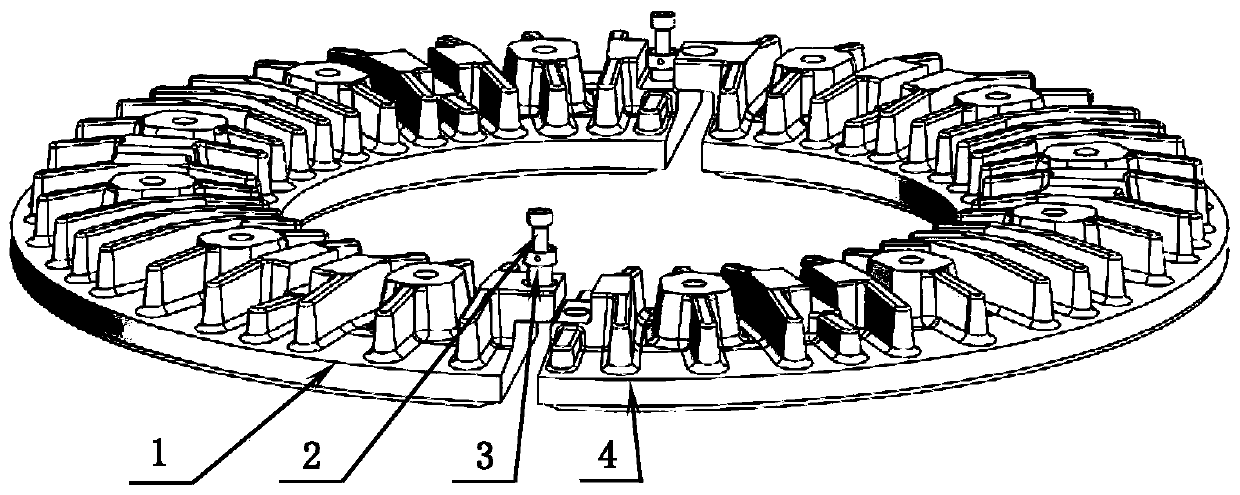

Valve body machining tool clamp for butt welding connection of high-pressure valve

ActiveCN110936196AAccurate clamping and positioningGuaranteed machining accuracyPrecision positioning equipmentPositioning apparatusButt weldingEngineering

The invention discloses a valve body machining tool clamp for butt welding connection of a high-pressure valve. The clamp comprises a clamping rotary disc, a positioning frame is arranged on the clamping rotary disc in a linked mode, the positioning frame comprises an upper positioning plate, a right positioning plate, a lower positioning plate and a left positioning plate which are sequentially connected to form a closed loop, a base used for containing a valve body is arranged on the lower positioning plate in a rotating mode, and a clamping mechanism used for clamping the valve body is arranged on the base; a plurality of positioning holes are formed in the base in the rotating direction of the base, and a positioning mechanism arranged in one positioning hole in a penetrating mode andpositioning the base is arranged on the lower positioning plate. The clamp is firm in clamping, safe, reliable, high in machining efficiency and accurate in clamping and positioning, and the machiningprecision of the valve body is guaranteed.

Owner:CHAODA VALVE GRP

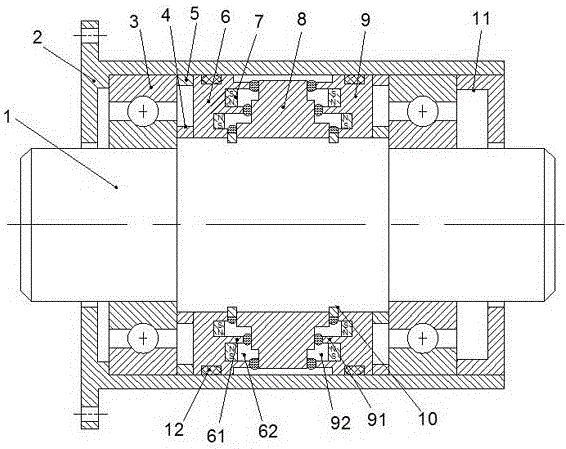

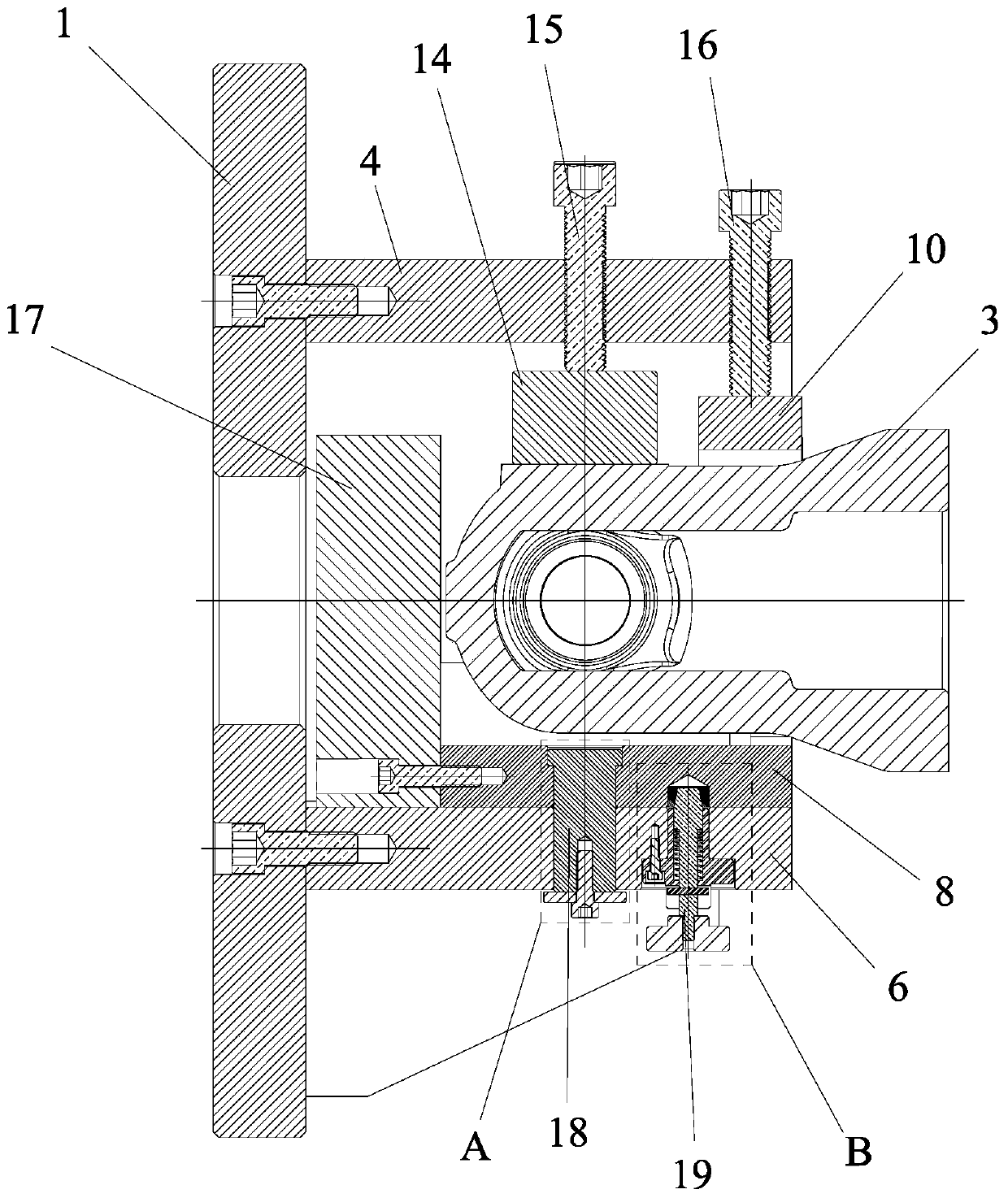

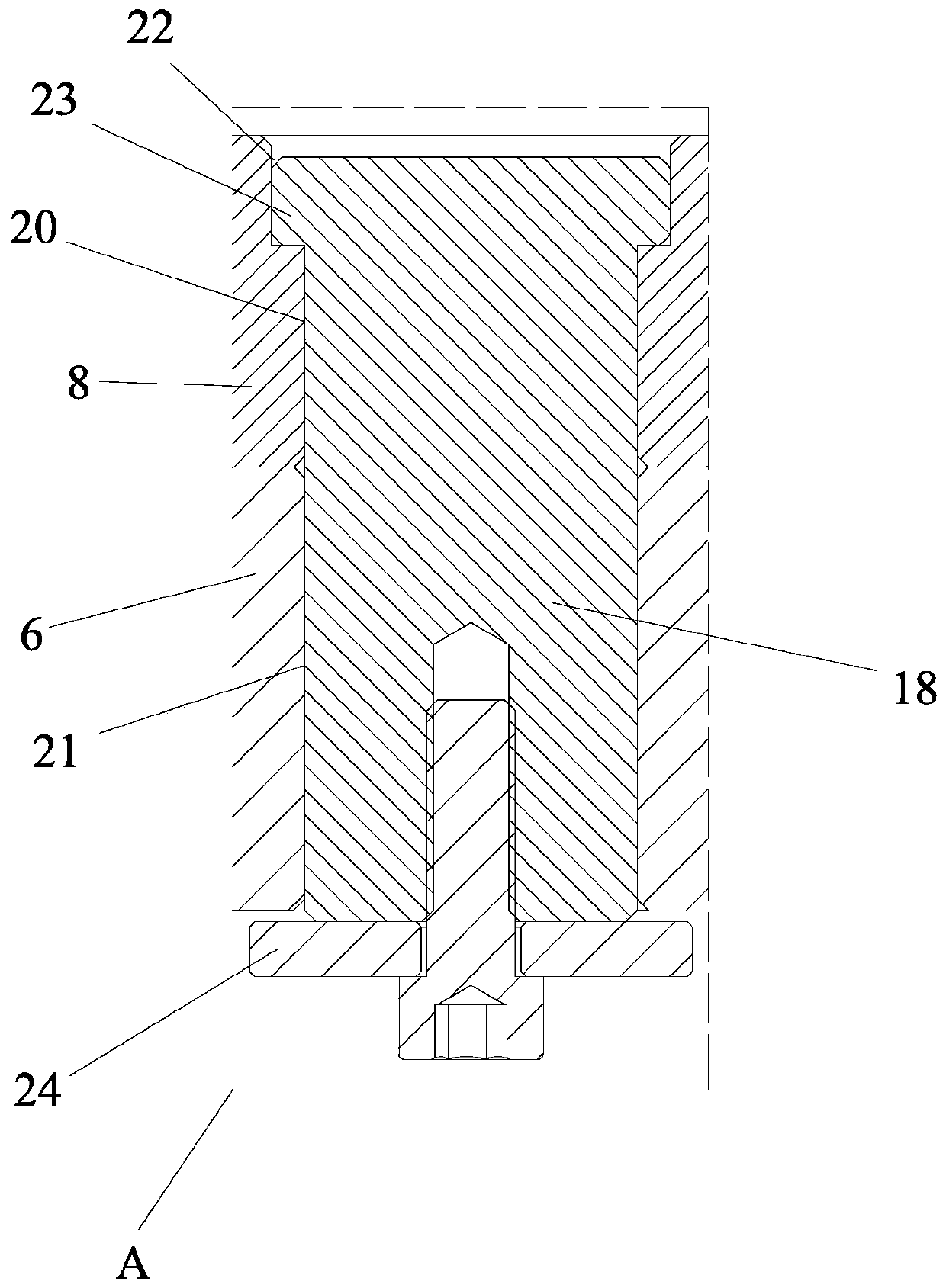

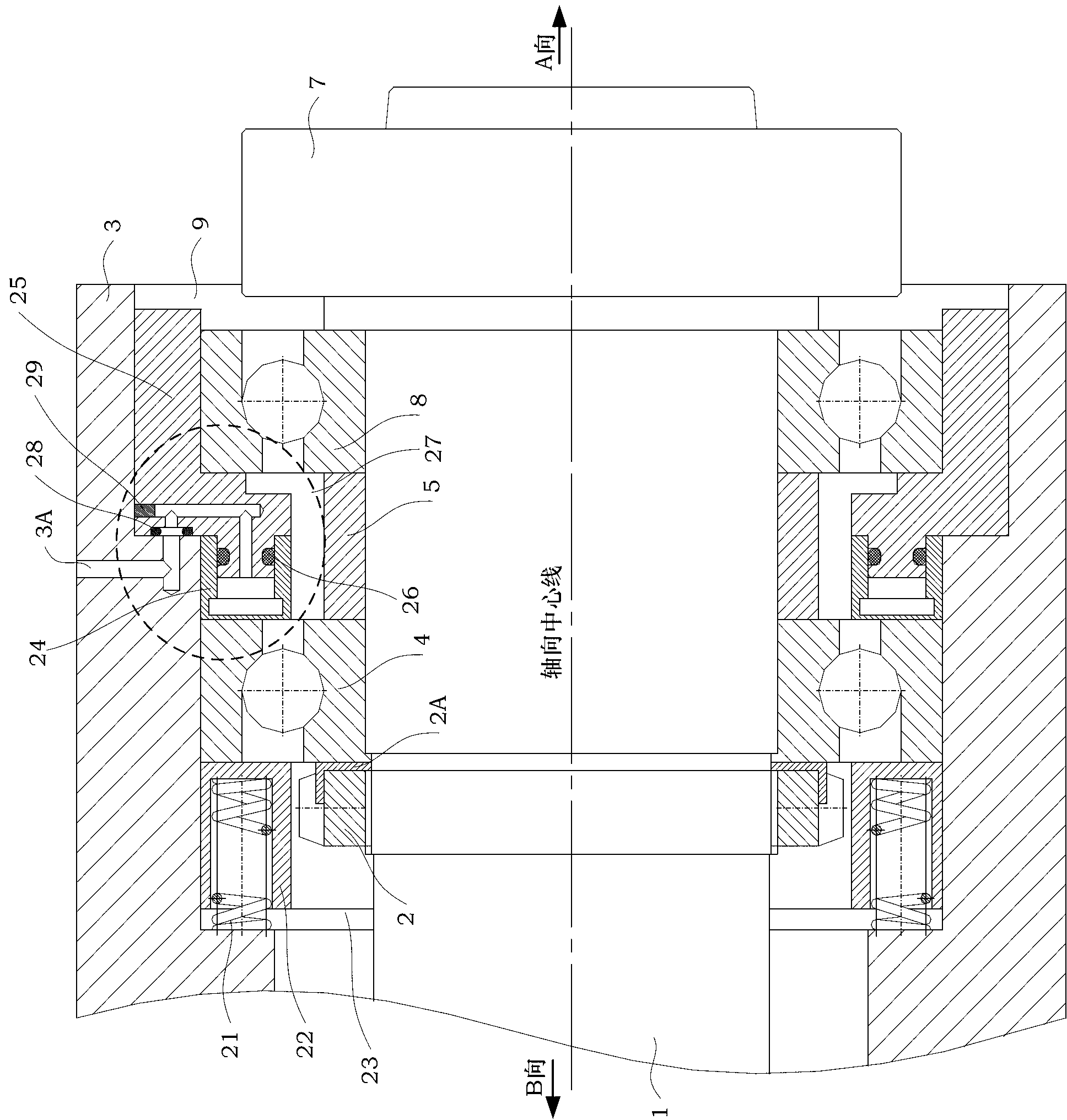

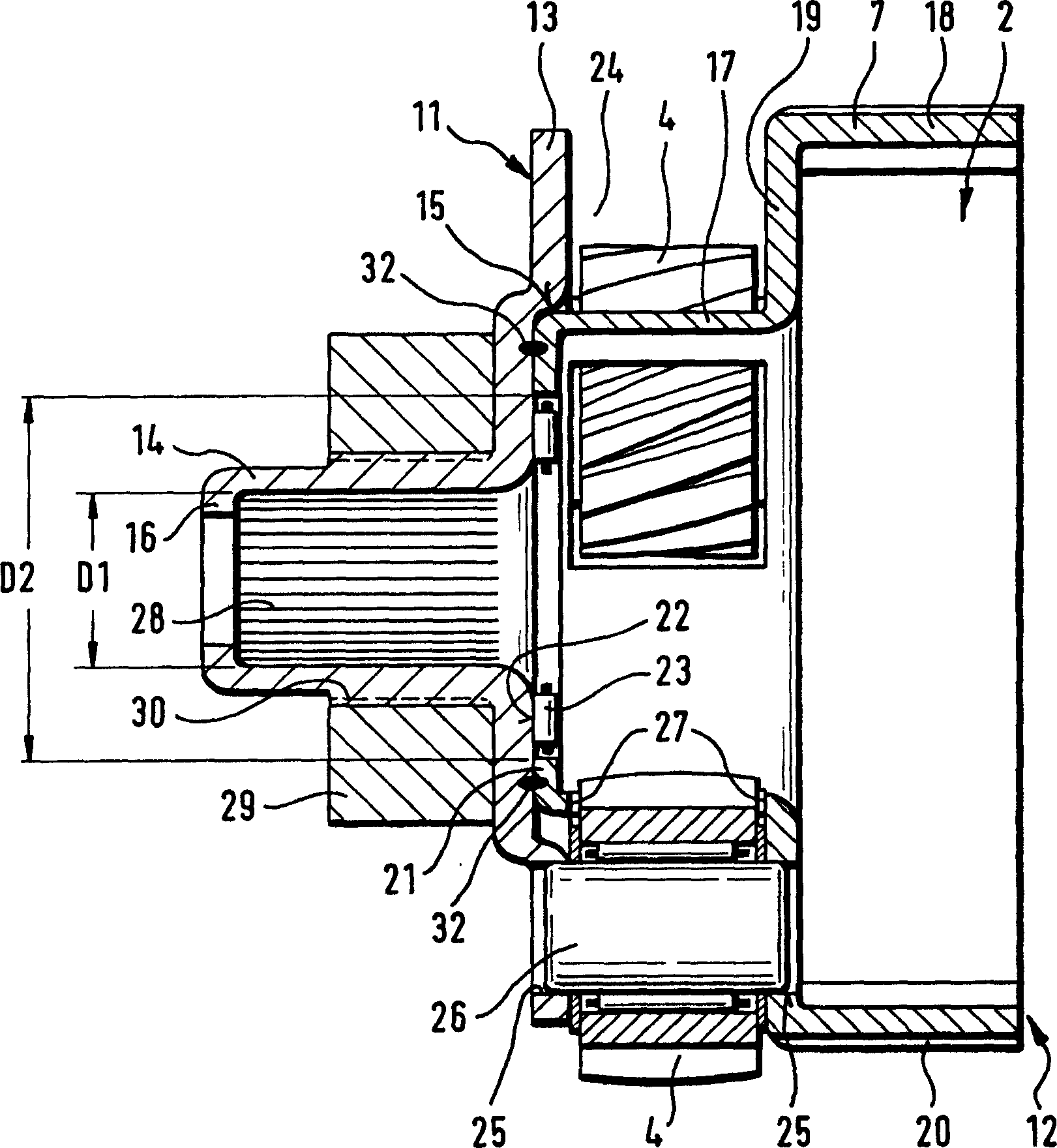

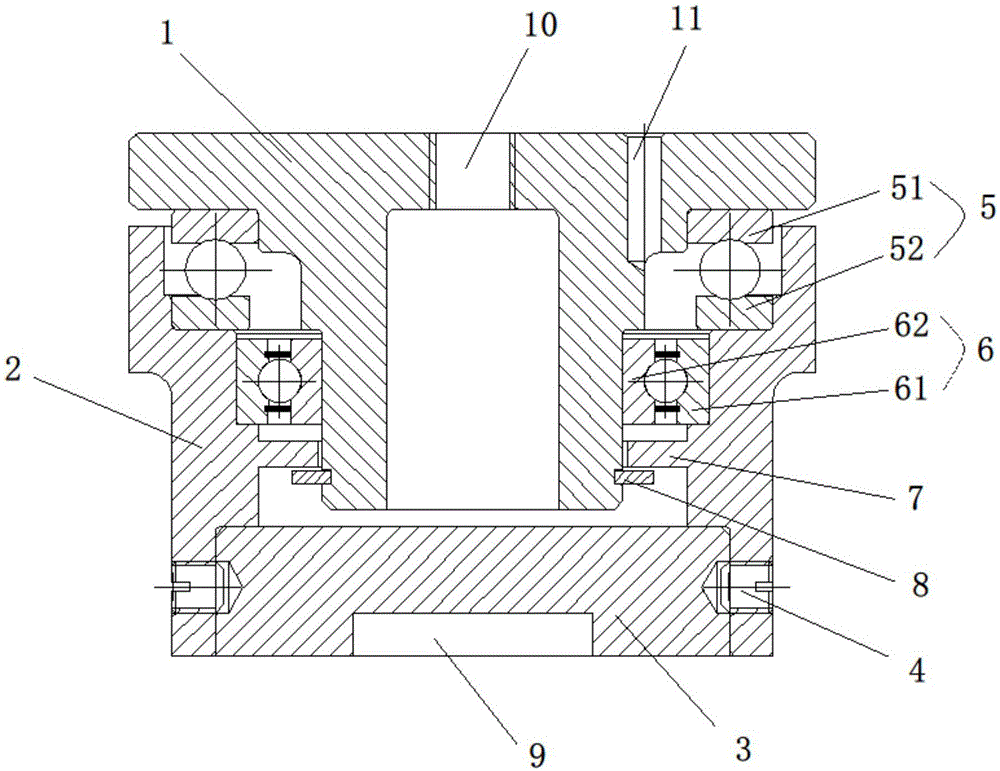

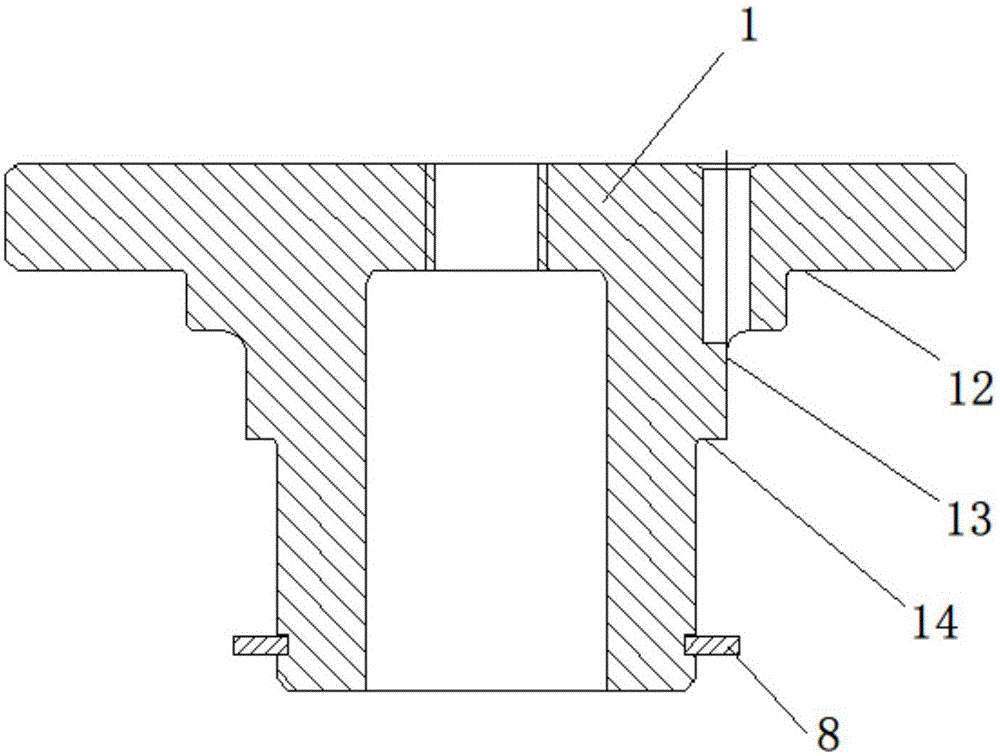

Device capable of improving axial rigidity of main shaft of precision machine tool with adjustable bearing pre-tightening force

InactiveCN103223499AReduce distortionImprove axial stiffnessMetal-working apparatusThin walledLocknut

The invention discloses a device capable of improving axial rigidity of a main shaft of a precision machine tool with an adjustable bearing pre-tightening force. The device comprises a main shaft, a locking nut, a gasket, a box seat, an end cover, a clamp ring, a pre-pressing spring assembly and an improved bearing pre-tightening device, wherein the improved bearing pre-tightening device adopts an annular oil chamber structure formed by transformation of a single-sided thin-walled end surface. The main shaft penetrates through the end cover, the clamp ring, a B bearing, a shaft sleeve, an A bearing, the gasket and the locking nut from one end to the other end sequentially; and the pre-pressing spring assembly and the improved bearing pre-tightening device are mounted between the main shaft and the box seat.According to the device, on one hand, the pre-pressing spring assembly is added on one side of the A bearing to improve the axial rigidity produced when the main shaft moves toward the B direction rightward; and on the other hand, a conventional bearing pre-tightening device mounted between the A bearing and the B bearing is improved, so that on one hand, the improved bearing pre-tightening device can be taken as a support of a D annular oil chamber and an oil way for providing oil, and on the other hand, the improved bearing pre-tightening device can be taken as a support of the B bearing and can achieve radial positioning of the B bearing and axial positioning of the main shaft.

Owner:BEIHANG UNIV

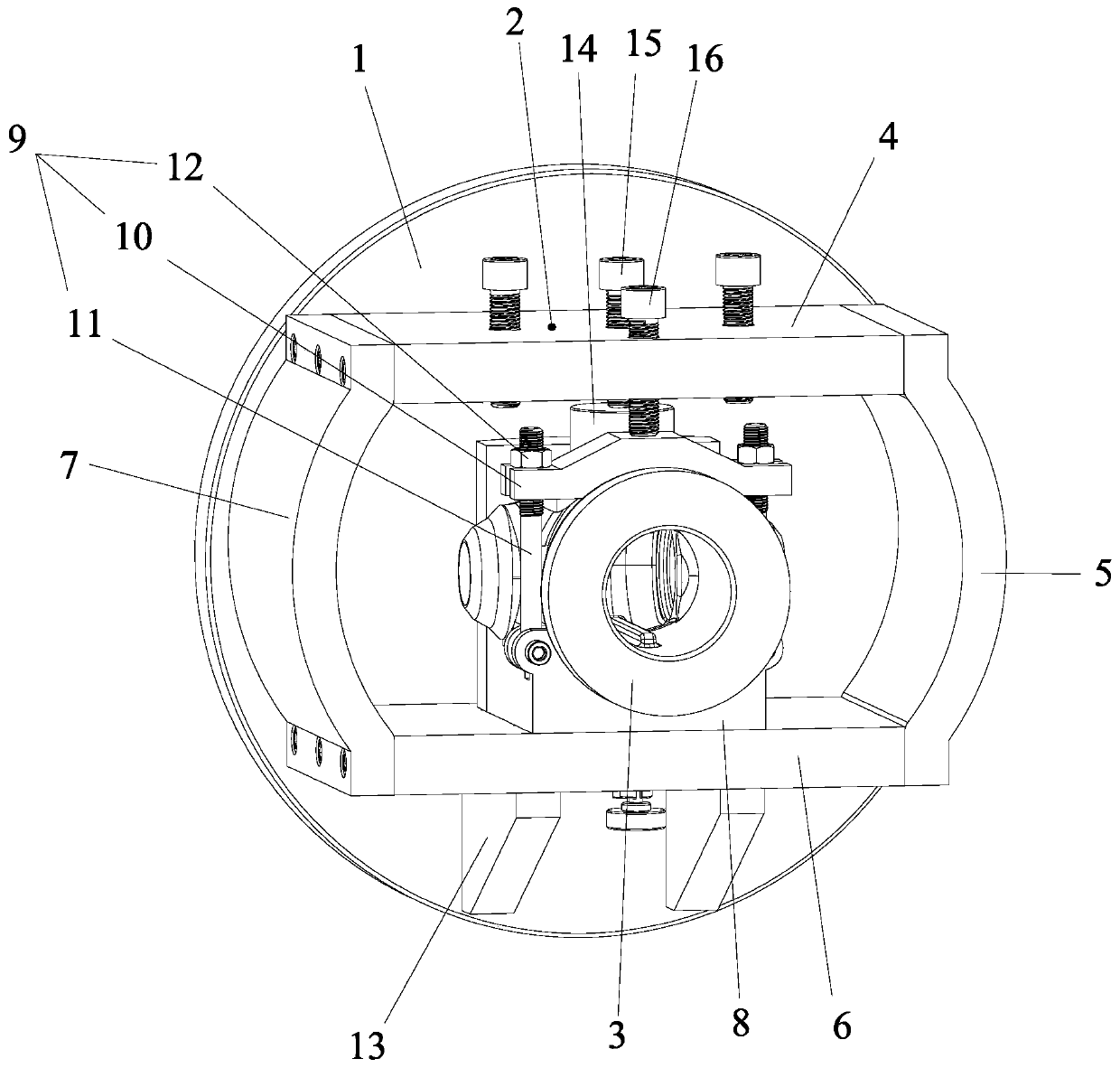

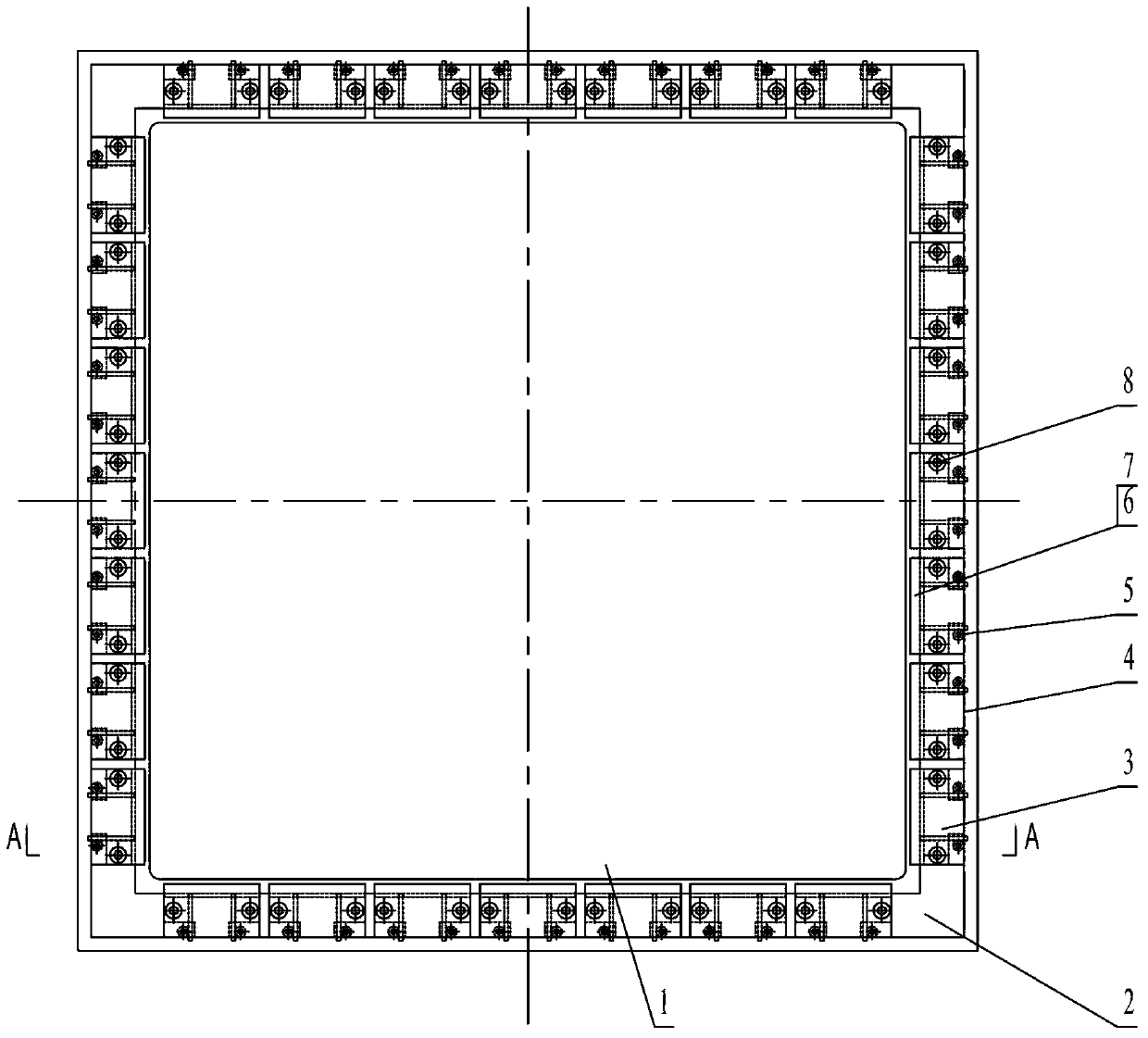

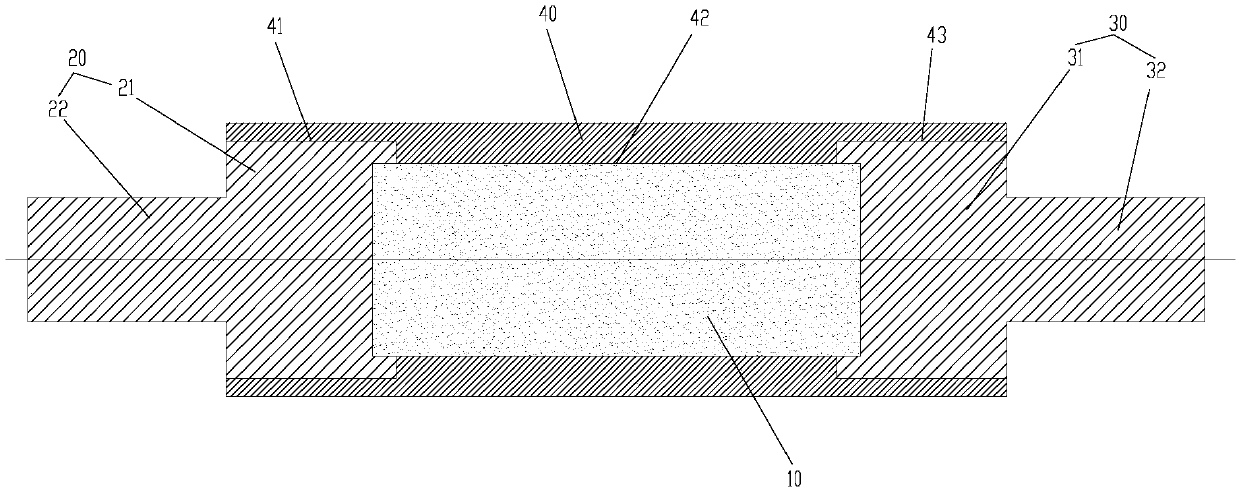

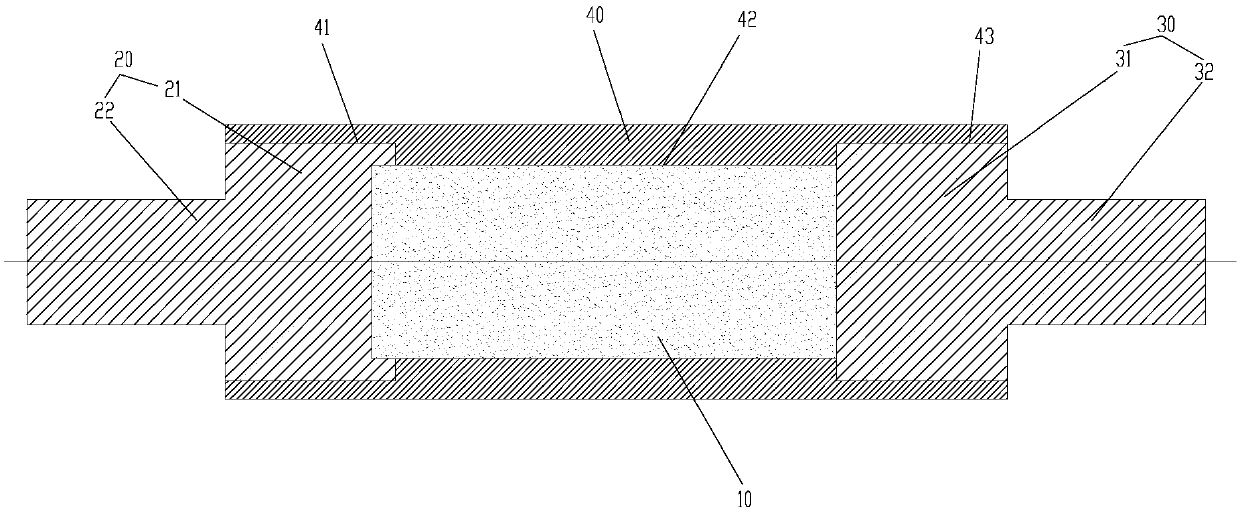

Nonlinear large-aperture optical element clamping device capable of achieving definite value axial load application

ActiveCN103273439AReduce distortionImprove harmonic conversion efficiencyWork holdersMountingsLarge apertureElectrical and Electronics engineering

The invention relates to a nonlinear large-aperture optical element clamping device, in particular to a nonlinear large-aperture optical element clamping device capable of achieving definite value axial load application. The nonlinear large-aperture optical element clamping device capable of achieving definite value axial load application solves the problem that harmonic conversion efficiency of a nonlinear large-aperture optical element is reduced because the nonlinear large-aperture optical element deforms easily under the action of gravity and clamping force. The nonlinear large-aperture optical element is placed on a supporting frame; locating edge blocks are arranged on the periphery of the supporting frame in a distributed mode and are fixedly connected with the supporting frame, plastic staple horizontal installation holes are formed in the locating edge blocks, and plastic staples penetrate through the plastic staple horizontal installation holes and make contact with the nonlinear large-aperture optical element; elastic pressing sheets are arranged on the periphery of a light-facing face of the nonlinear large-aperture optical element in a distributed mode, a rigid pressing sheet is arranged on each elastic pressing sheet, and the elastic pressing sheets and the rigid pressing sheets are connected with the locating edge blocks through load applying screws; a torque wrench acts on the load applying screws. The nonlinear large-aperture optical element clamping device capable of achieving definite value axial load application is applied to experimental schemes for full-circumferential clamping and definite value axial load application of the nonlinear large-aperture optical element.

Owner:HARBIN INST OF TECH

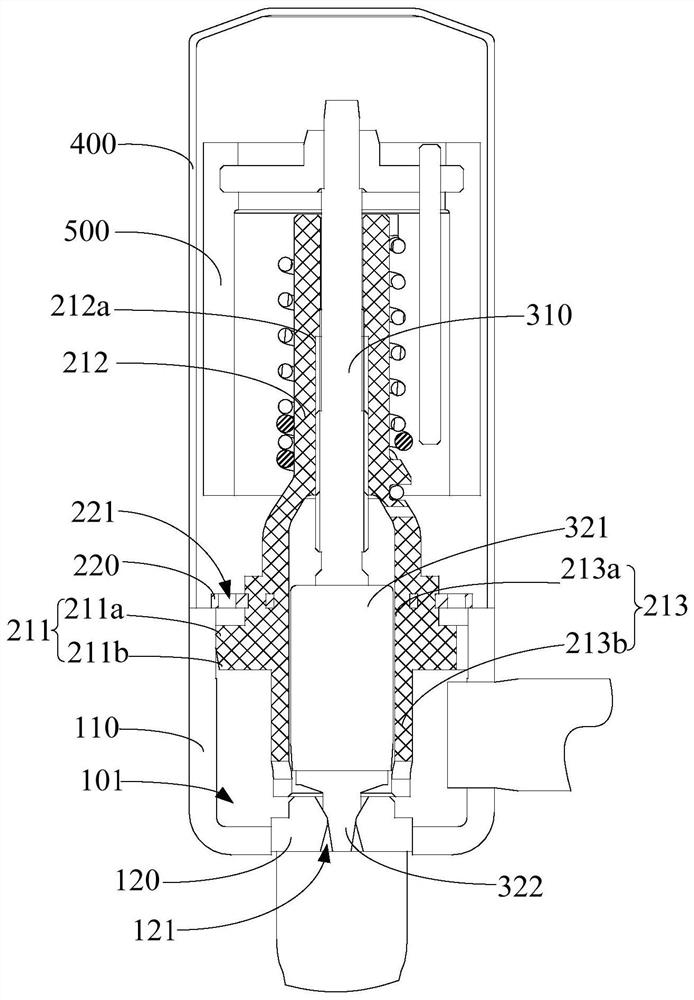

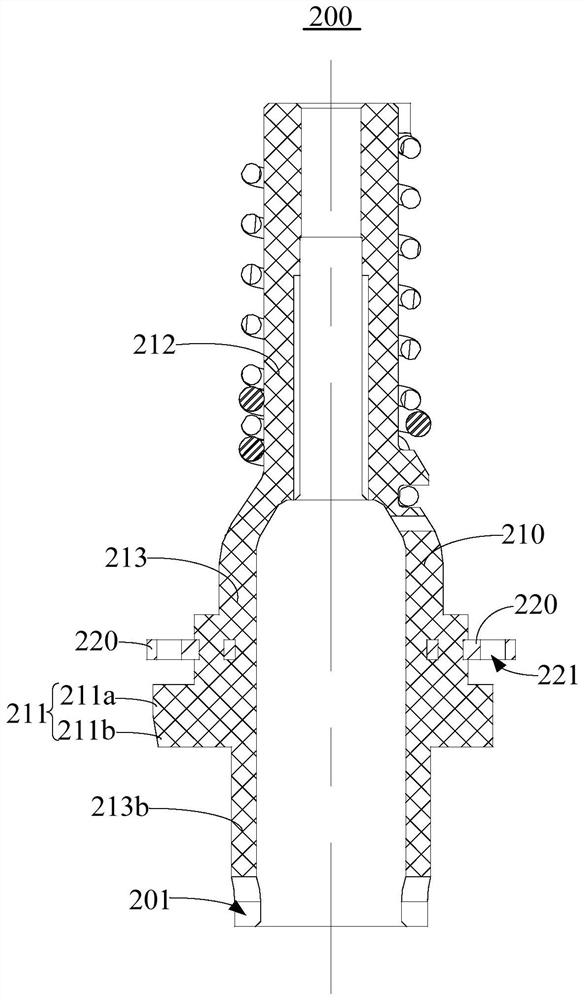

Electronic expansion valve and refrigeration equipment

PendingCN112524261APrevent stuck phenomenonImprove work performanceOperating means/releasing devices for valvesEfficient regulation technologiesEngineeringElectronic expansion valve

The invention discloses an electronic expansion valve and refrigeration equipment. The electronic expansion valve comprises a valve seat, a nut and a connecting piece. The valve seat is provided witha valve cavity, one end of the nut is installed in the valve cavity, an annular positioning part is arranged on the outer wall of the nut in a protruding manner, and the positioning part is connectedwith the cavity wall of the valve seat in an abutting manner to achieve positioning. One end of the connecting piece is fixedly connected with the nut, and the other end of the connecting piece extends away from the nut and is fixedly connected with the axial end face of the valve seat. According to the technical scheme, the electronic expansion valve achieves the function of positioning the nut and the valve seat in the axial and radial directions, the coaxiality of the nut and the valve seat is guaranteed, then the coaxiality of the nut and the valve element seat is guaranteed, the phenomenon that the electronic expansion valve gets stuck is avoided, and the working performance of the electronic expansion valve is improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

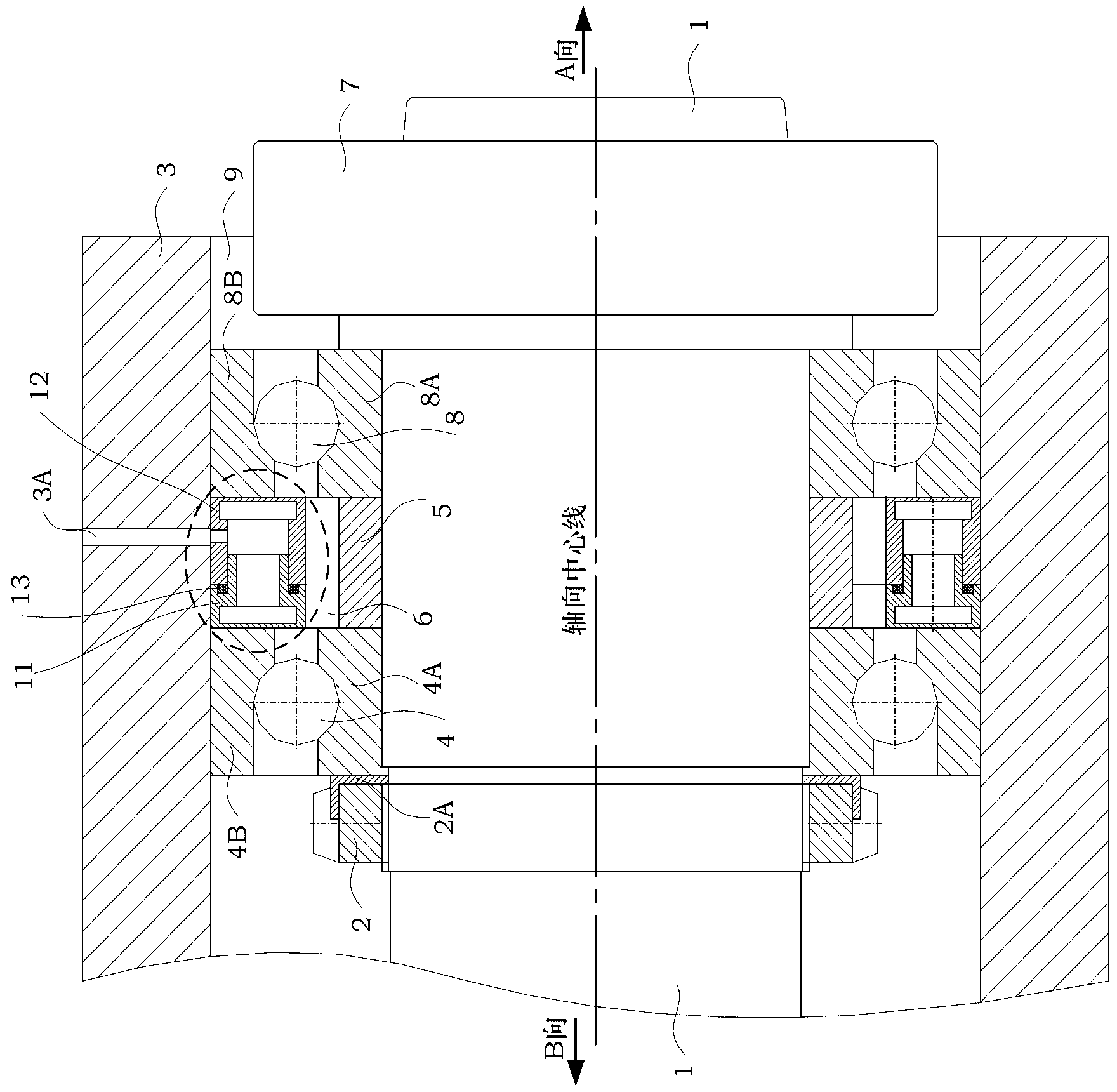

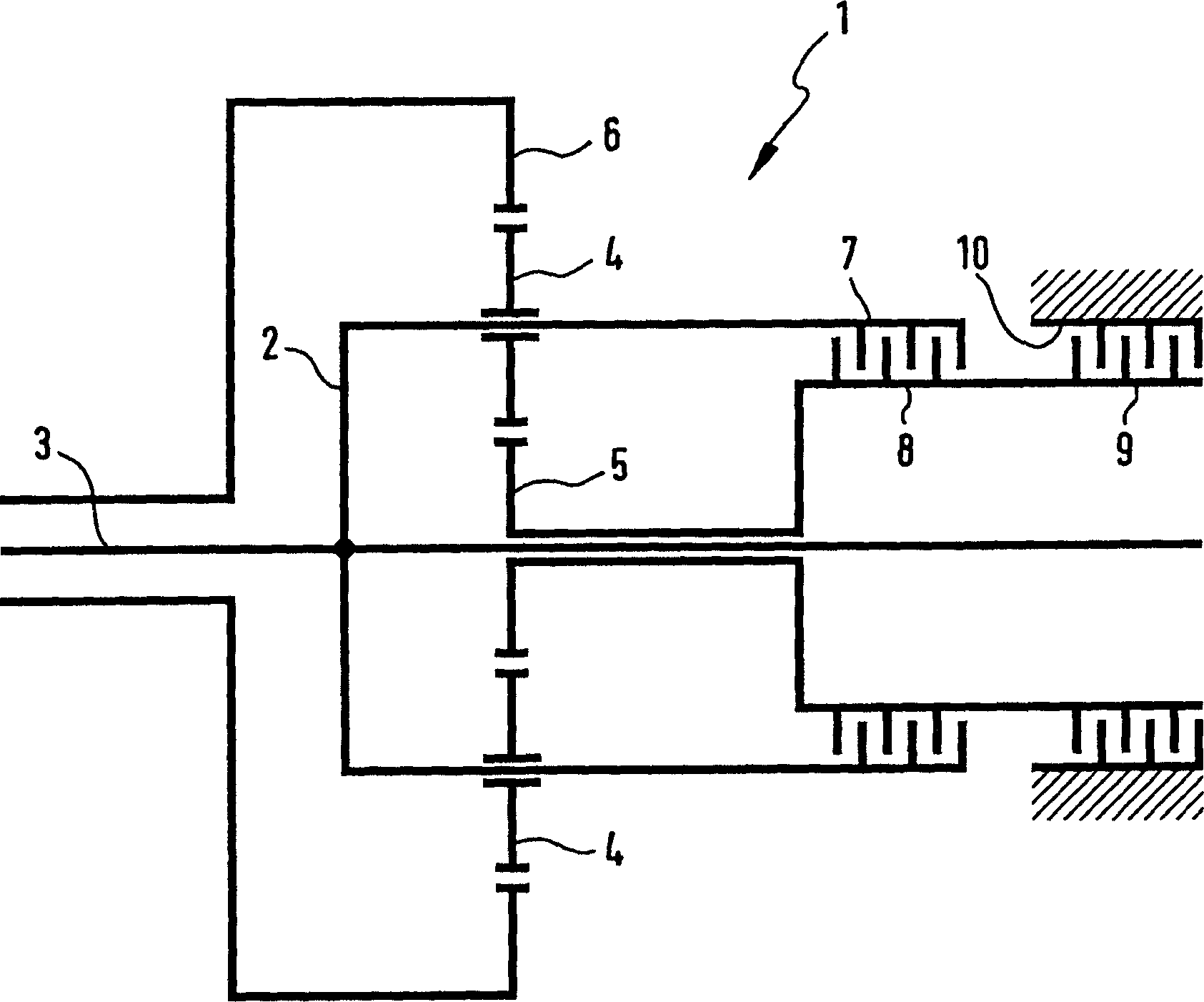

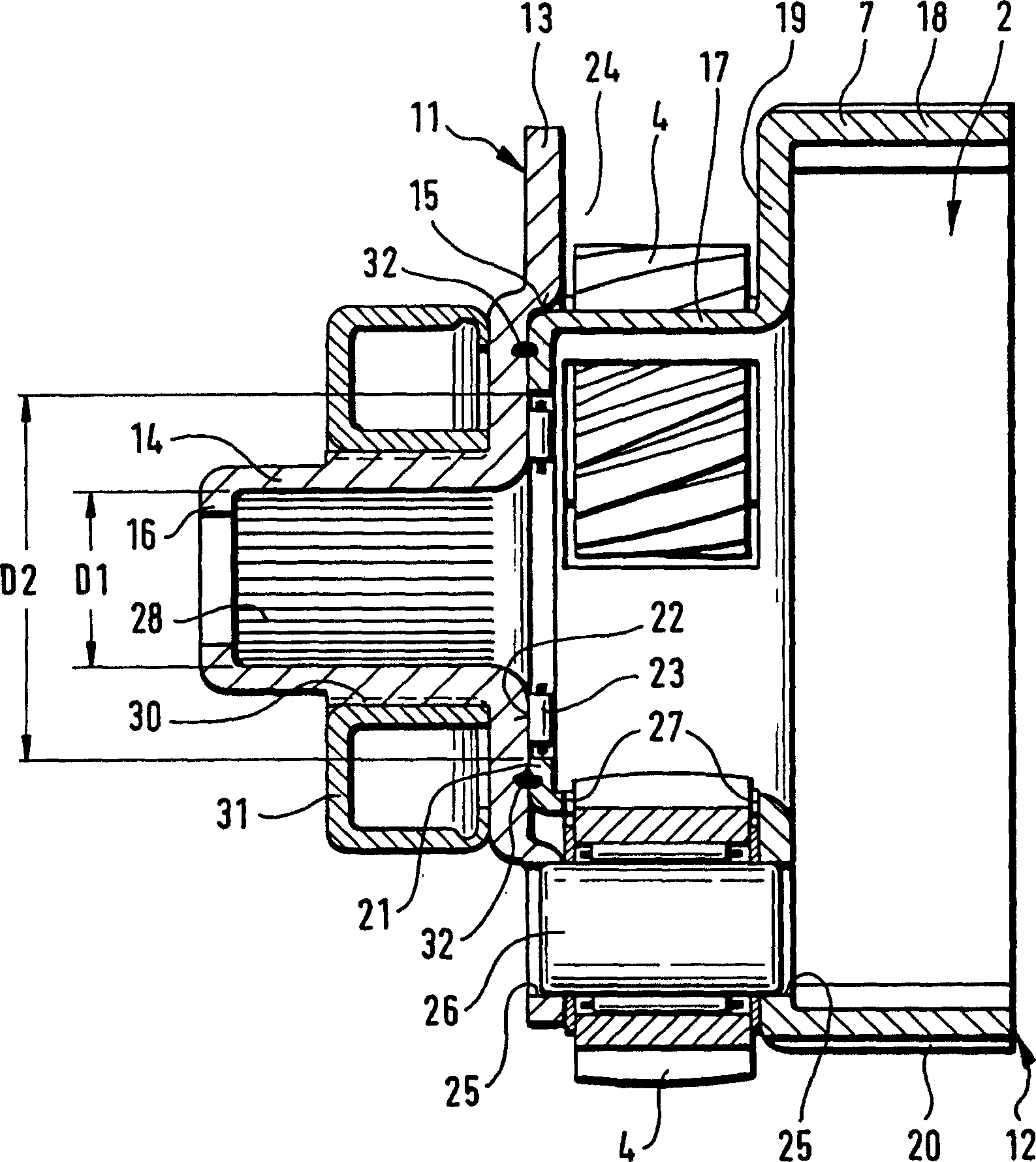

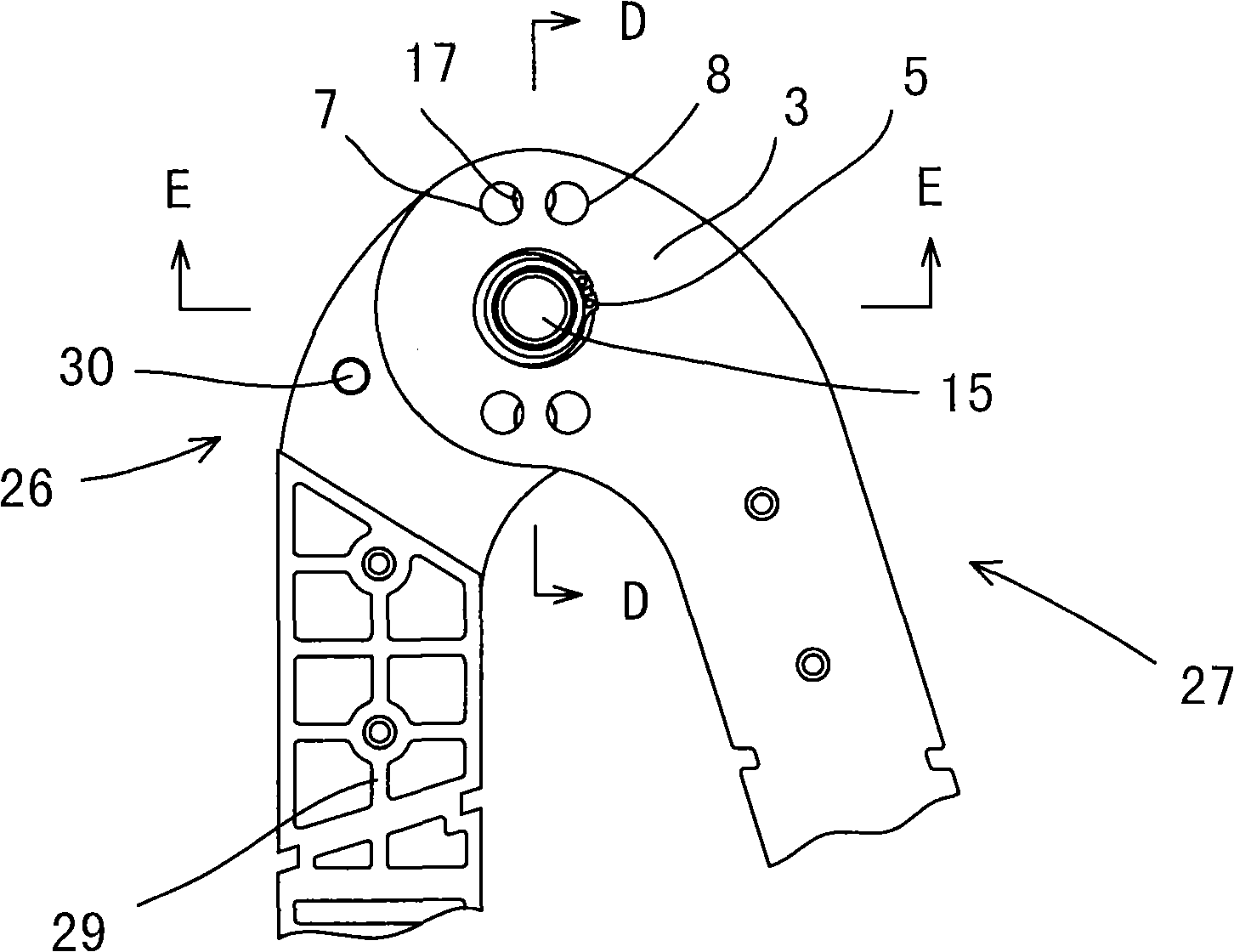

Planet carrier for a gearbox

InactiveCN1829872AAchieve axial positioningIncrease inner diameterGearing detailsAutomatic transmissionGear wheel

A planet carrier ( 2 ) for a gearbox is provided, especially for an automatic transmission or a power-shift gearbox. The planet carrier ( 2 ) includes at least one planet gear ( 4 ) that is in constant contact with a sun gear and an internal geared wheel. The planet carrier ( 2 ) is formed from two parts and includes a single piece flange part ( 11 ) and a single piece cup body ( 12 ) formed in a step-type manner. The two components are rotationally symmetrical or approximately rotationally symmetrical, and are arranged with one at least partially inside the other. The internal diameter of the external part is adapted to the internal diameter of the internal part in an overlapping area. The two components are connected together at contact points. The components are positioned in a precise manner in relation to each other in the axial, radial and peripheral directions based on the construction. The individual components can be produced in a simple and economical manner through deep drawing.

Owner:INA SCHAEFFLER KG

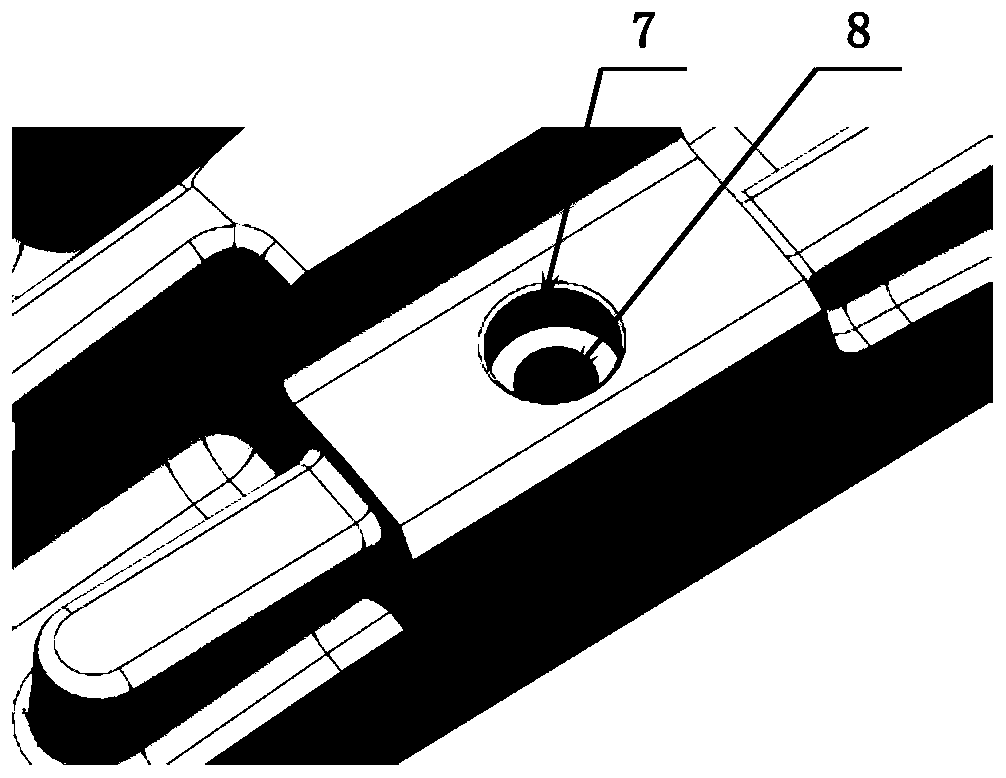

Eccentric shaft machining clamp

InactiveCN103419031AAchieve axial positioningRealize circumferential compression positioningPositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to an eccentric shaft machining clamp which is mainly composed of a base plate, a shaft sleeve positioning device fixed on the base plate and a pressing plate. The eccentric shaft machining clamp is characterized by further comprising a pneumatic device and a guide rod fixed on the base plate. The pressing plate is connected with a moving part of the pneumatic device and moves up and down along the guide rod. When the eccentric shaft machining clamp is operated, a workpiece is placed in the shaft sleeve positioning device on the base plate and axial positioning of the workpiece is achieved. A pneumatic device button is pressed and a pressing head presses till a workpiece rod body portion along the guide rod through the action of the moving part of the pneumatic device. Circumferential pressing and positioning of the workpiece are achieved, and the whole pressing process is easy to operate, short in time, efficient, good in universality as workpieces of the same series can be positioned and clamped through the clamp and capable of greatly meeting the production requirement.

Owner:JIANGSU GANGYANG

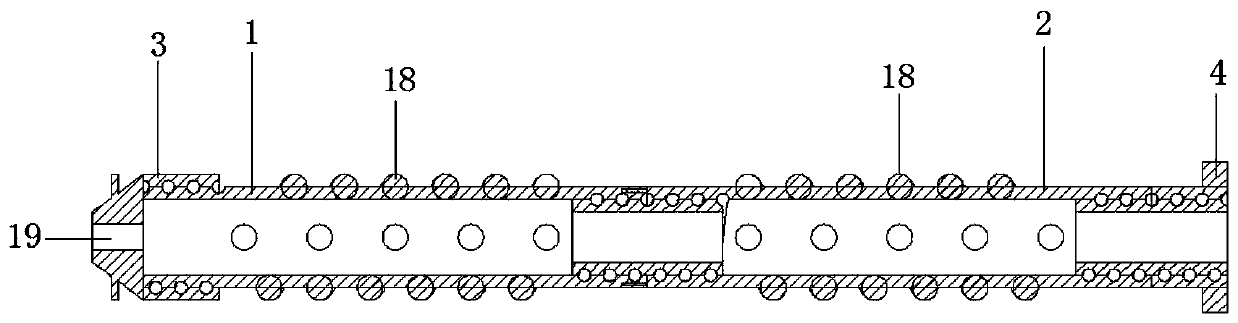

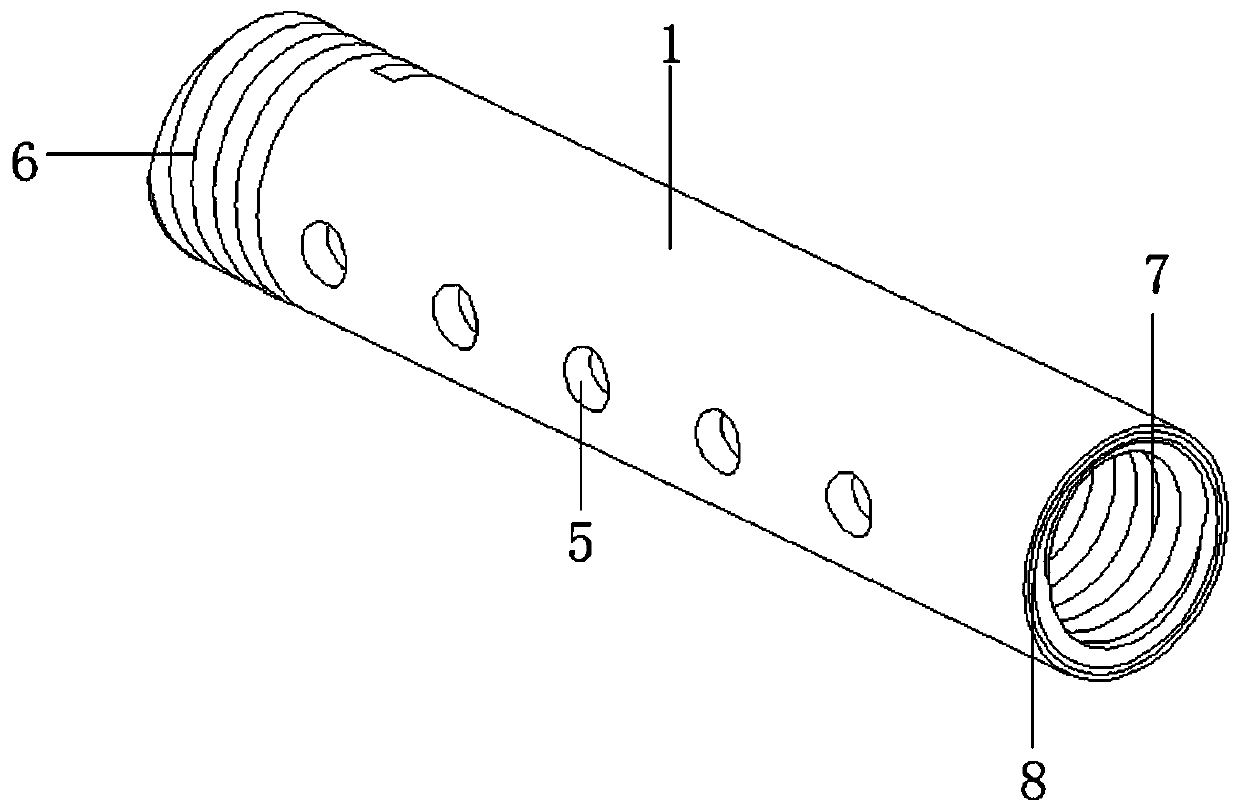

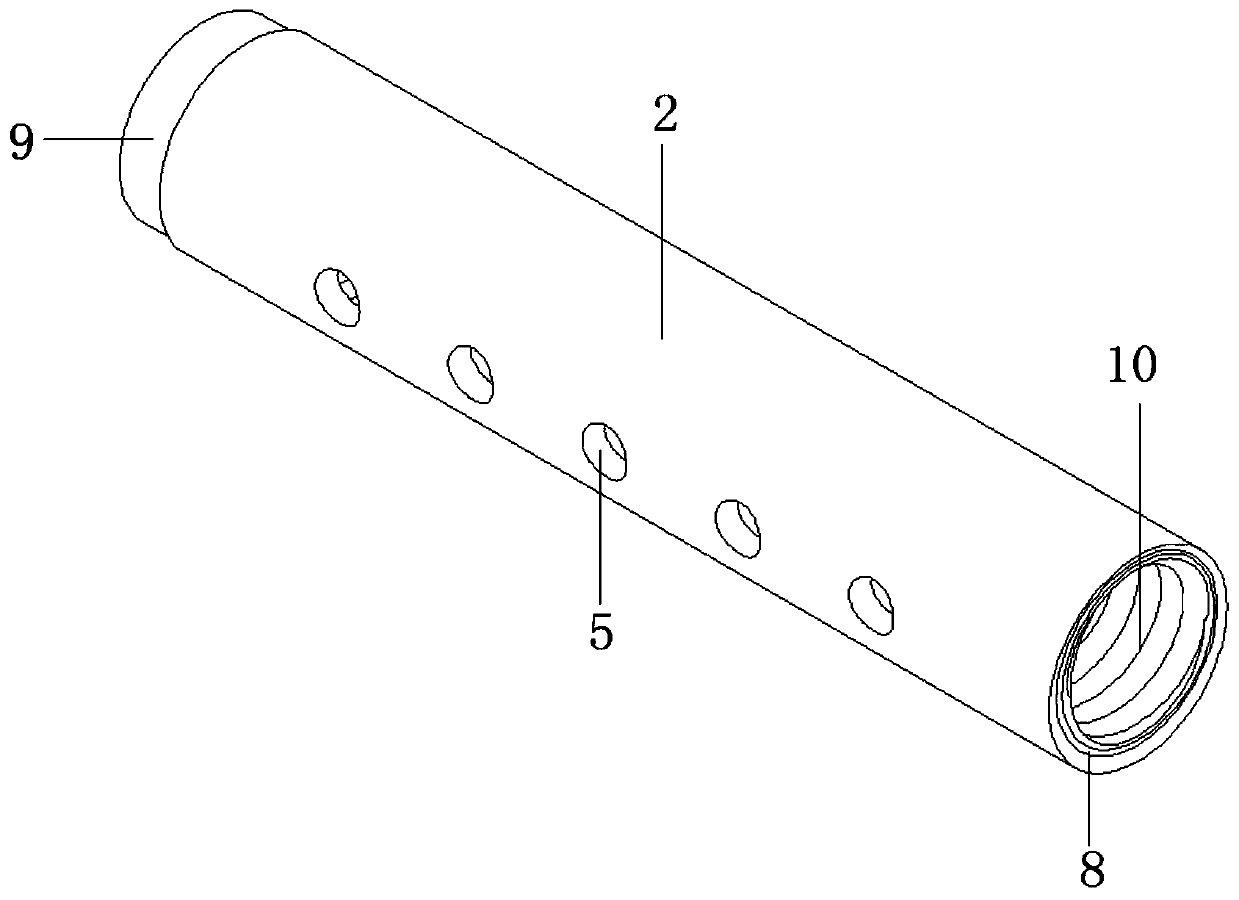

Anchor increasing grouting anchor rod device with adjustable length

PendingCN110656965AAchieve controllableImprove convenienceBulkheads/pilesAnchoring boltsArchitectural engineeringScrew thread

The invention discloses an anchor increasing grouting anchor rod device with the adjustable length. A hollow connecting part is adopted for connecting two grouting anchor rods, a plurality of groutinganchor rods can be selected for assembling according to the specific requirement for the grouting depth, the overall length of the device can be adjusted, meanwhile, a tail anchor head is installed on the end portion of the first section of the grouting anchor rod, the tail anchor head is in detachable thread connection, installing is facilitated, after the drill holes are collapsed, a proper number of grouting anchor rods only need to be connected according to the depth of the collapsed drill holes, the problem that for existing anchor rods with the fixed length, due to depth change of the drill holes, surplus anchor rods need to be sawn off, the utilization rate of the anchor rods is increased, and the material waste is reduced.

Owner:CHANGAN UNIV

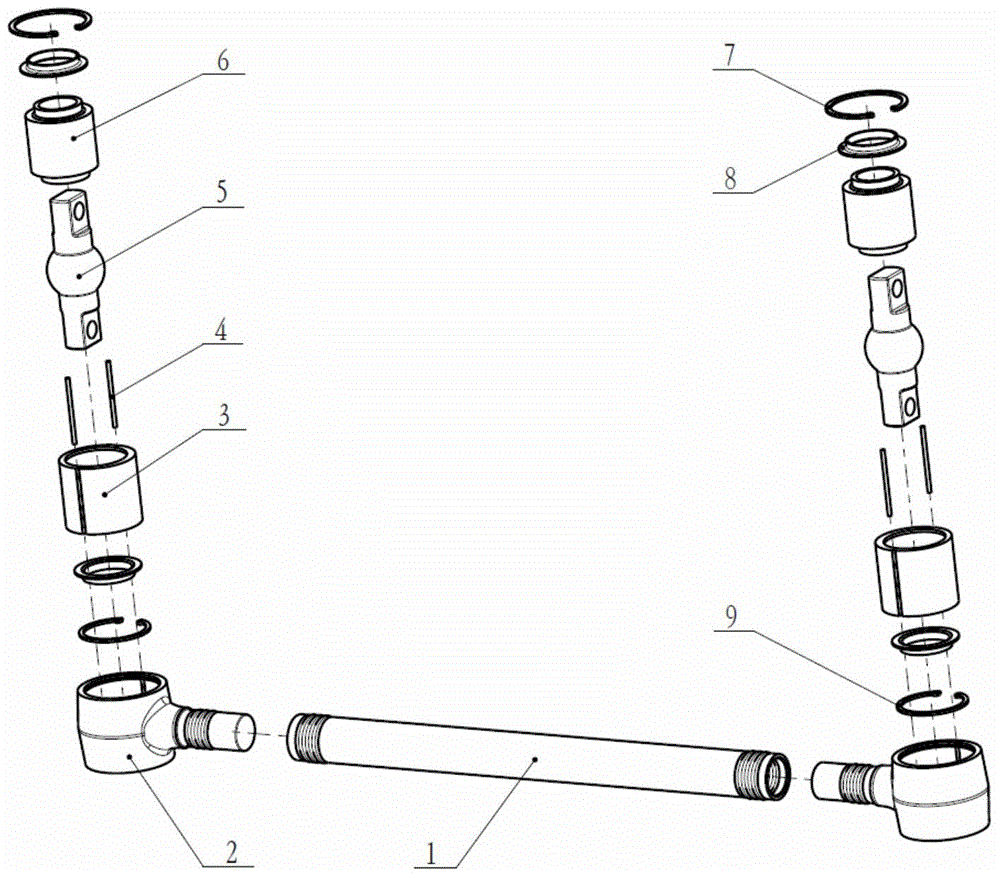

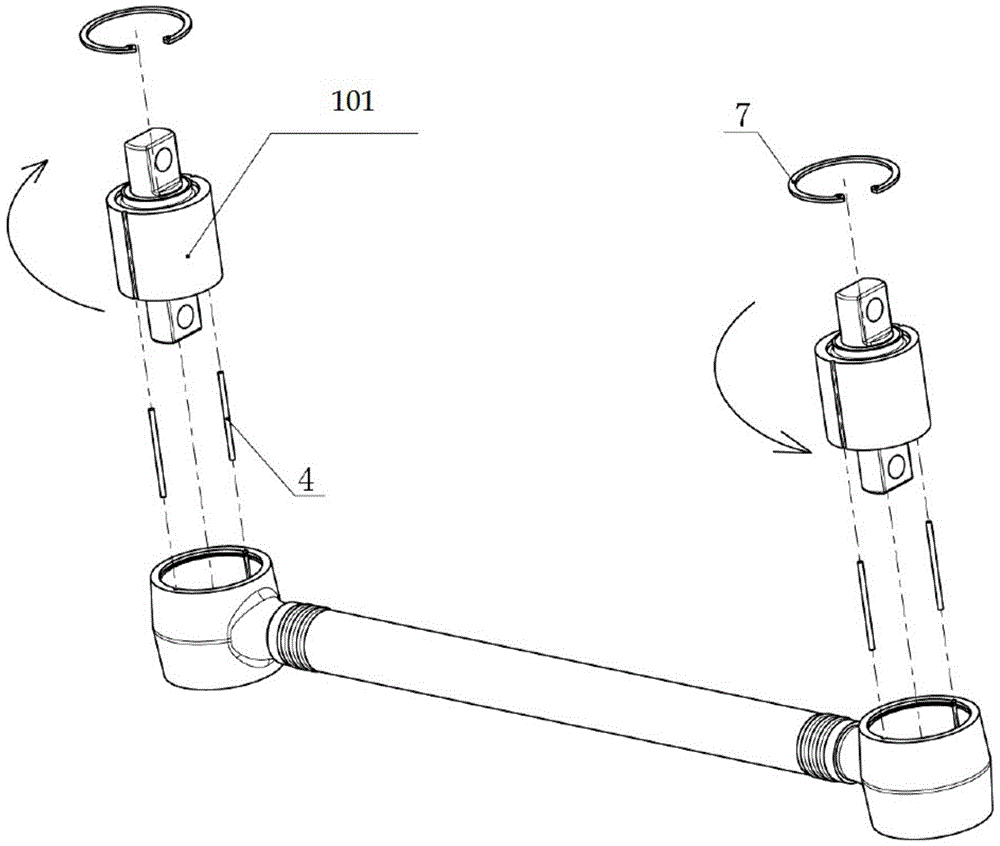

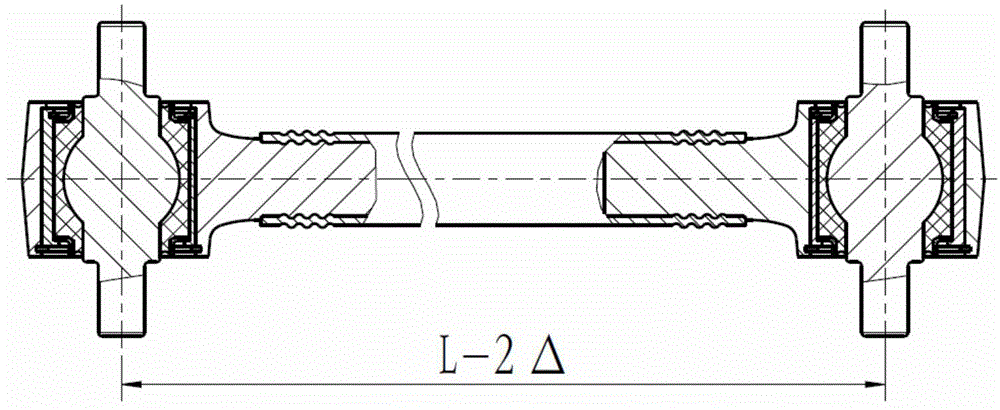

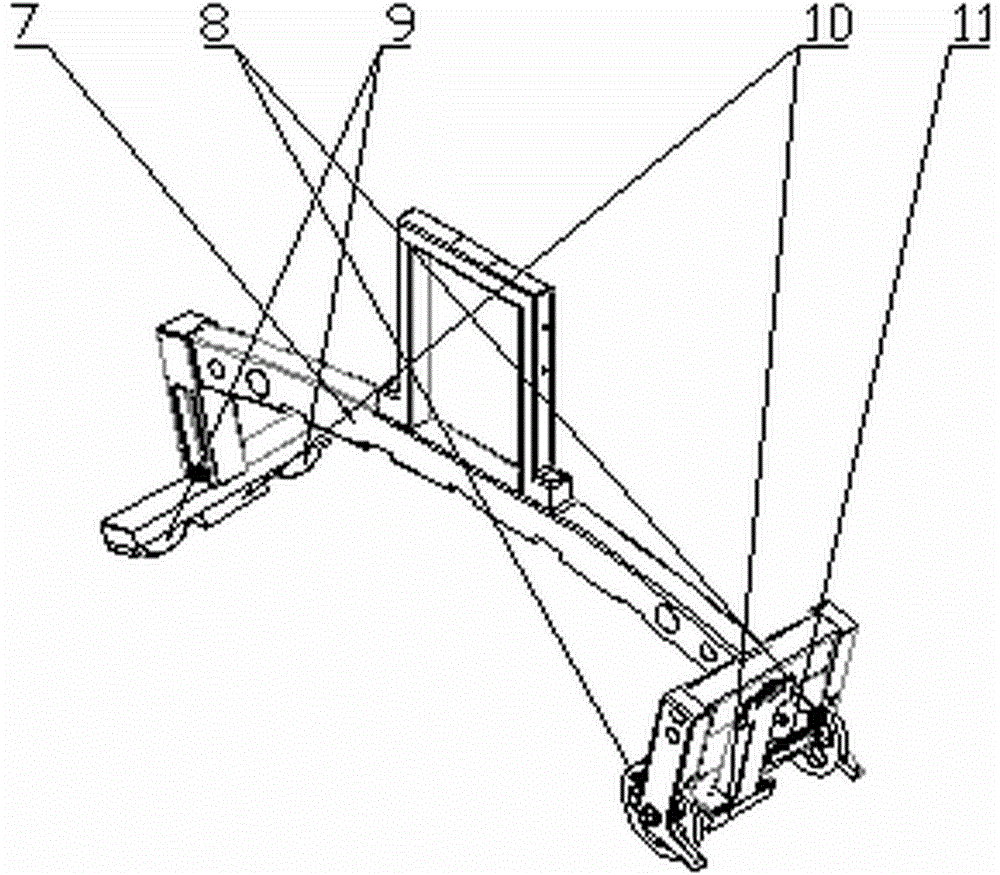

Vehicle thrust rod assembly, adjusting method thereof and vehicle suspension mechanism

ActiveCN105437897AAvoid wastingImprove versatilityPivoted suspension armsAerospace engineeringHinge angle

The invention provides a vehicle thrust rod assembly, an adjusting method thereof and a vehicle suspension mechanism. The vehicle thrust rod assembly is adjustable in length and detachable, thereby being convenient to maintain. The thrust rod assembly is characterized in that two ball head shells are connected to the two ends of a shaft pipe in a hot riveting mode, two eccentric bushings are pressed into the ball head shells at the two ends, positioning of the eccentric bushings in the circumferential direction is achieved through lock pins, and positioning of the eccentric bushings in the axial direction is achieved through flanges and snap springs at the lower ends of shell bodies. End covers are arranged at the two ends of the eccentric bushings, and positioning of the eccentric bushings in the axial direction is achieved through the flanges and the snap springs at the bottoms of the eccentric bushings. The eccentric bushings, the end covers, dabbers and rubber are vulcanized together to form rubber spherical hinges. The multi-stage adjustable function of the length of a thrust rod is achieved by adjusting the circumferential direction arrangement positions of the eccentric bushings in the ball head shells, the actual failure mode frequently occurring of the thrust rod assembly is considered, the eccentric bushings and the ball head shells are connected in a transition matched mode, and the spherical hinges are pressed out and replaced only by dismounting the snap springs when the rubber spherical hinges fail; in addition, the actual use cost is reduced, and the universality degree of parts is improved.

Owner:SHAANXI HEAVY DUTY AUTOMOBILE

Swivel joint

ActiveCN105135109AFlexible rotationAchieve axial positioningAdjustable jointsTurntables/traversersMechanical wearBending moment

The invention discloses a swivel joint which comprises a swivel sleeve and a swivel shaft. The lower portion of the swivel shaft is sleeved with the swivel sleeve. The lower end of the swivel shaft is connected with the swivel sleeve in a rotating manner. A first bearing for providing axial supporting and a second bearing for providing radial supporting are arranged between the swivel sleeve and the swivel shaft. A seat ring of the first bearing is matched with an inner hole of the swivel sleeve. A shaft ring of the first bearing is matched with the swivel shaft. An outer ring of the second bearing is matched with the inner hole of the swivel sleeve. The swivel shaft is sleeved with an inner ring of the second bearing. According to the swivel joint, two bearing pieces are arranged between the swivel shaft and the swivel sleeve, one bearing piece provides axial supporting on the swivel shaft, and the other bearing piece provides radial supporting on the swivel shaft; and bending moment brought by unbalance loading can be overcome, flexible rotating is achieved, mechanical wear is lowered, and the service life of products is prolonged.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

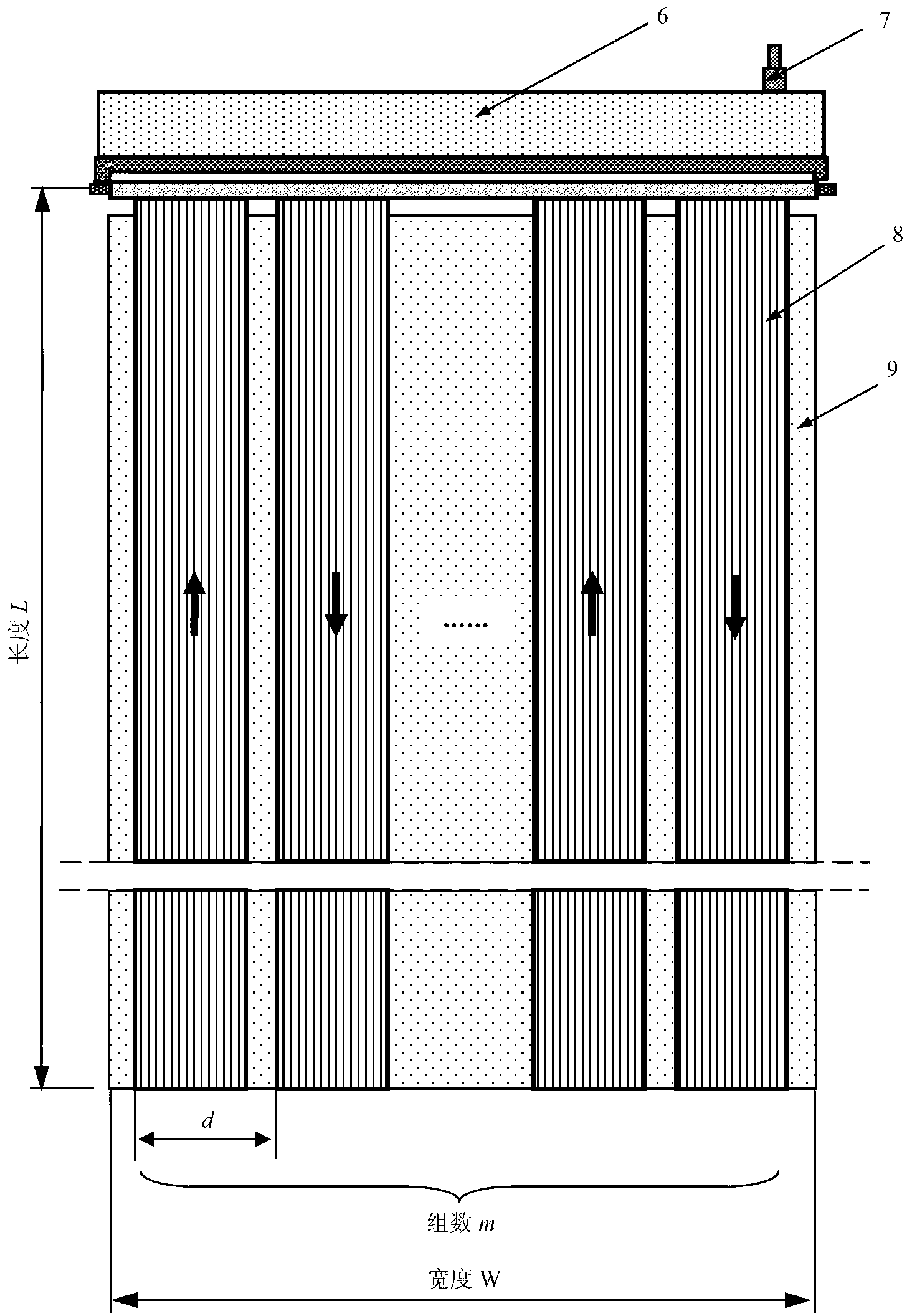

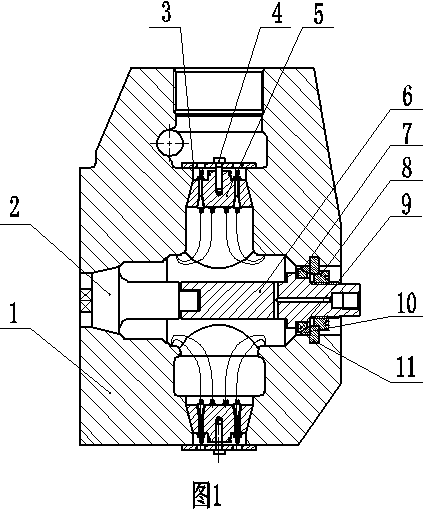

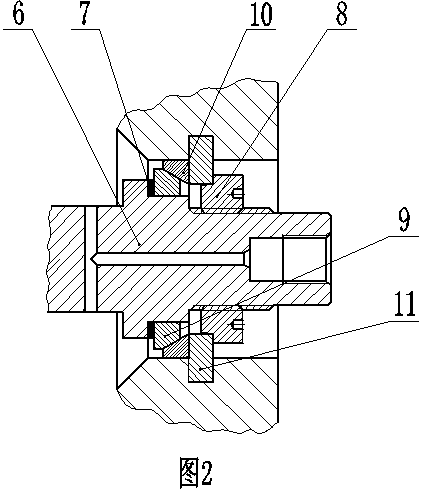

Labyrinth-type magnetofluid sealing device

ActiveCN106015360AAchieve axial positioningPrevent leakageEngine sealsBearing componentsCircular surfaceMagnet

The invention relates to the field of machinery engineering sealing, and concretely relates to a labyrinth-type magnetofluid sealing device. The device comprises a shaft, a housing, a first pole shoe ring, a second pole shoe ring, and a third pole shoe ring; the first pole shoe ring is positioned at the left side of the second pole shoe ring, a pole tooth I is established at the right end of the first pole shoe ring, an annular groove I is established at the left end of the first pole shoe ring, a permanent magnet I is arranged in the annular groove I, a pole tooth II and a pole tooth III are established at the left end of the second pole shoe ring, an annular groove II is established at the right end of the second pole shoe ring, a permanent magnet III is arranged in the annular groove II, the third pole shoe ring is arranged at the external circular surface of the second pole shoe ring, a space is kept between the third pole shoe ring and the first pole shoe ring, a permanent magnet II is arranged in the space, the pole tooth II is positioned over the pole tooth I at the top of the first pole shoe ring, the pole tooth III is positioned below the pole tooth I at the bottom of the first pole shoe ring, and the pole tooth I stretches into the space composed of the pole tooth II and the pole tooth III.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

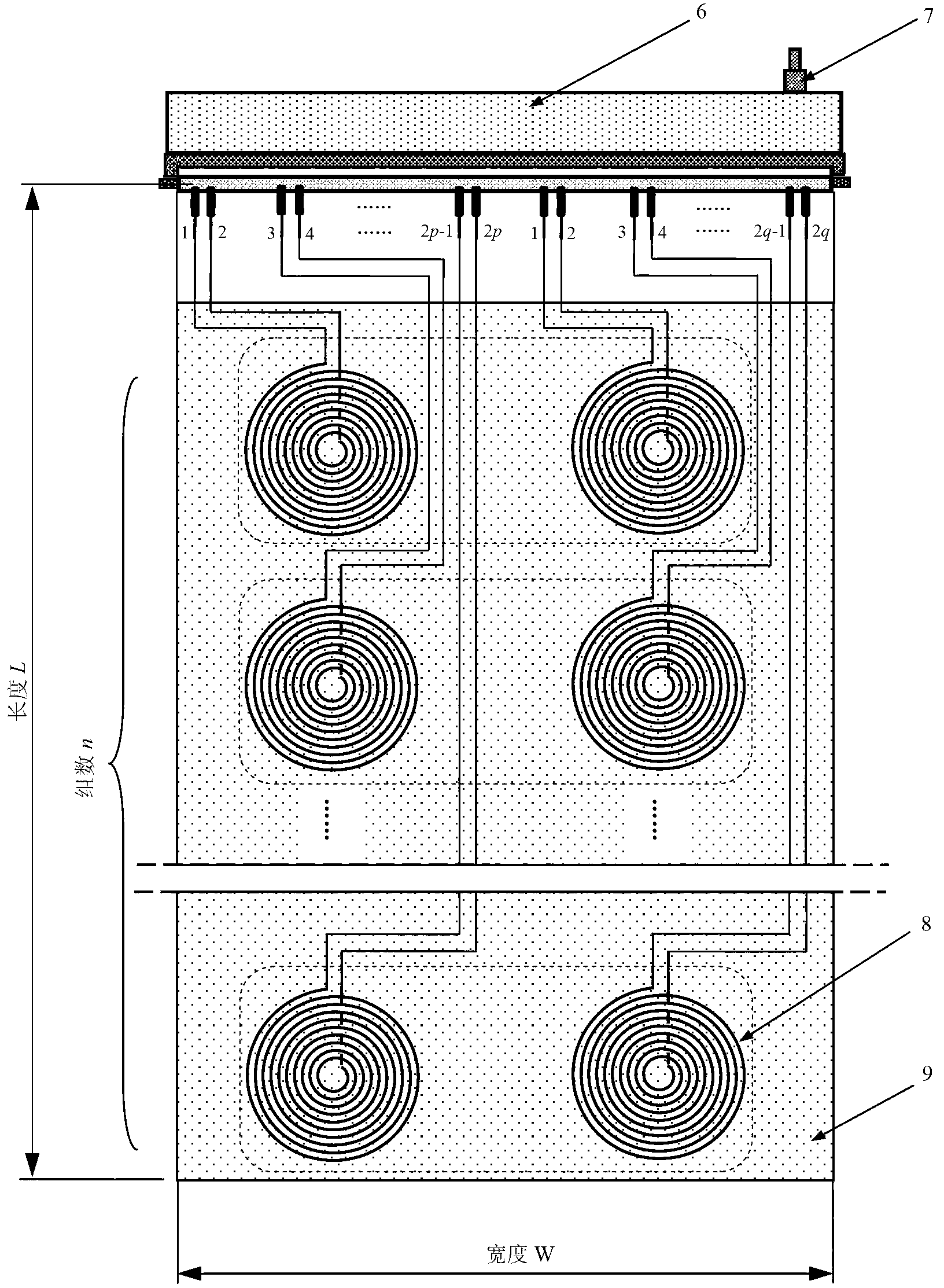

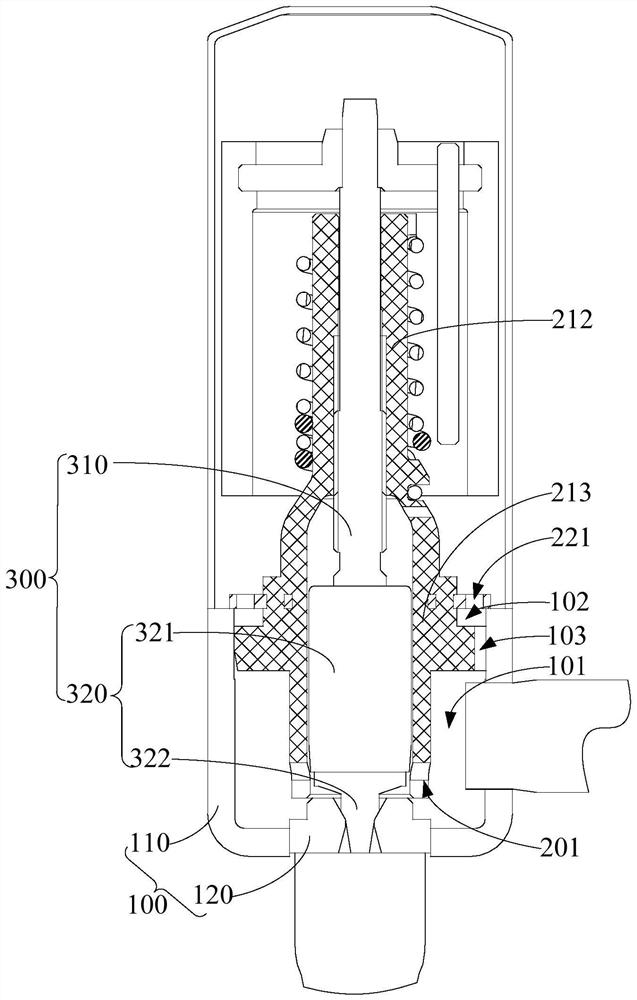

Screw-type extrusion system and 3D printer comprising same

PendingCN108327252AImprove performanceFlexible heating method3D object support structuresApplying layer meansEngineering3d printer

The invention provides a screw-type extrusion system and a 3D printer comprising the same. The screw-type extrusion system comprises a machine barrel, a spray head detachably mounted at the lower endof the machine barrel, a threaded rod rotatably mounted in the machine barrel, one or more heating devices arranged around the outer wall of the machine barrel, and a cooling device arranged around the outer wall of the machine barrel and adjacent to the spray head. By adopting the extrusion system, materials entering the machine barrel can be heated quite flexibly, and especially, the materials can be heated to the quite high temperature in the middle of the machine barrel, so that molecular chains of the materials are fully opened, then the materials are rapidly cooled to the predetermined temperature in the position adjacent to the spray head, and accordingly the materials have viscosity suitable for extrusion forming.

Owner:TSINGHUA UNIV

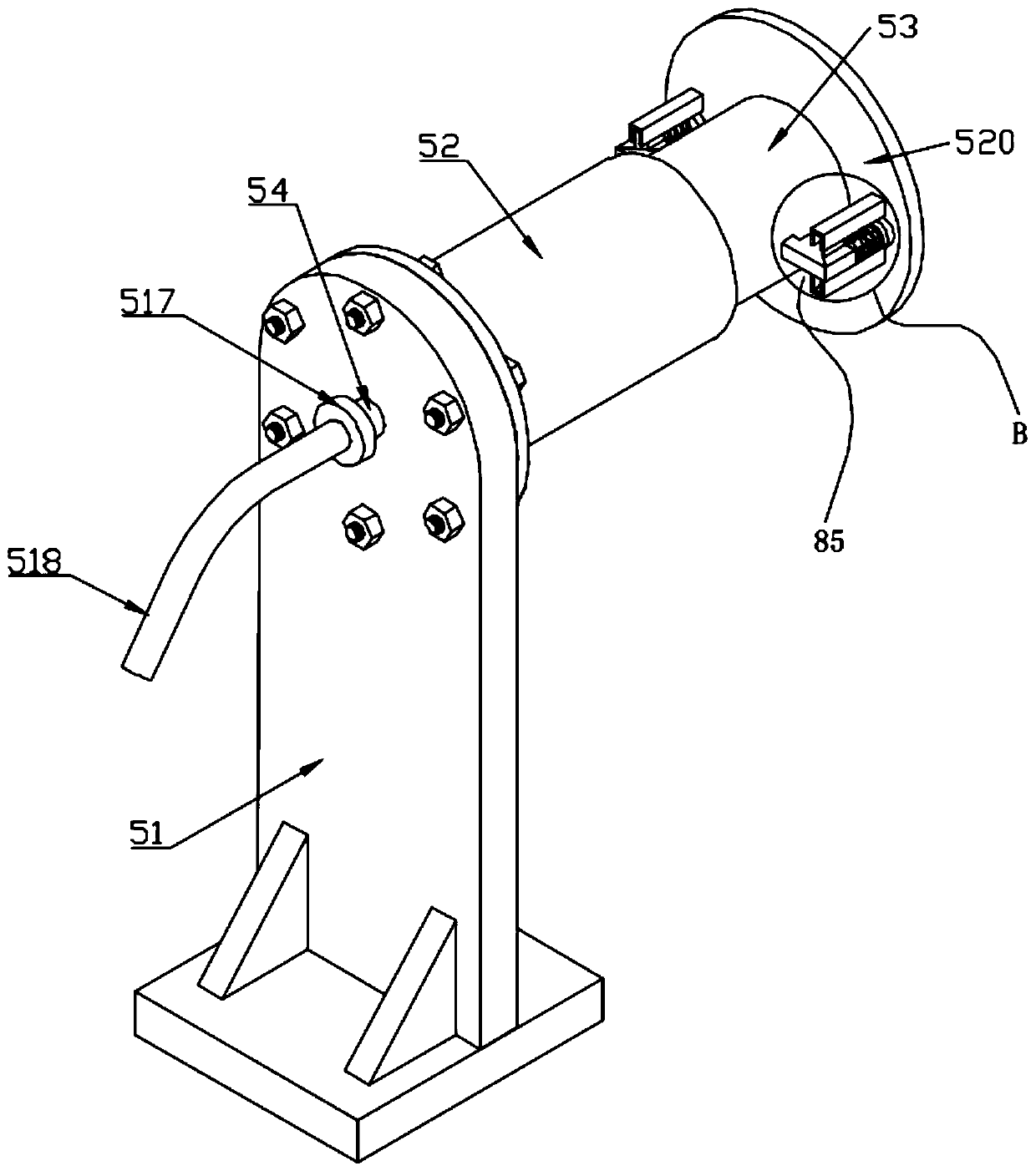

Self-tightening sealing and stress testing device for self-enhancing of ultrahigh-pressure pump head body

ActiveCN103711688AGuaranteed sealing reliabilityReduce local stressPump testingPositive displacement pump componentsCombined usePump head

The invention relates to a self-tightening sealing and stress testing device for self-enhancing of an ultrahigh-pressure pump head body, belonging to the technical field of self-enhancing of a pump head body of an ultrahigh-pressure container. The self-tightening sealing and stress testing device comprises an ultrahigh-pressure pump head body, a horizontal sealed taper rod, a signal lead-out seal taper, a horizontally sealed adjusting rod, an O-shaped seal ring, a signal lead-out rod, an organic glass sealed taper ring, quick-plugging joints, high-strength enameled wires, a strain gauge and a wiring transition plate. All sealing surfaces of the device adopt taper surface hard sealing, the higher the hydraulic pressure in the inner cavity of the pump head body is, the larger the pressure on the sealing surfaces is, and the reliability of sealing under ultrahigh pressure can be guaranteed; in assembling, the sealing of the sealing surfaces in low-pressure or non-pressure state can be controlled by thread pretightening force. The self-tightening sealing and stress testing device has the characteristics of being convenient to install, and convenient and fast to wire. According to the device, the difficulty in testing the stress of the container wall by leading out a wire from the ultrahigh-pressure sealed container can be solved by adopting the combined use of the organic glass sealed taper ring, the O-shaped seal ring and the wire lead-out rod.

Owner:YANGTZE UNIVERSITY +1

Vertical numerically controlled chamfering machine

ActiveCN104511748AReduce volumeMeet chamferFeeding apparatusOther manufacturing equipments/toolsOil distributionDrive motor

The invention discloses a vertical numerically controlled chamfering machine. The machine comprises a body, and a column and a work bench are arranged on the body. A chamfering mechanism and a de-burring mechanism are arranged in the column corresponding to the work bench. Open space is formed above the work bench, and manipulators on an automatic line can take and put work-pieces on the work bench directly. The work bench comprises a spindle, a work platform and a work bench casing. An oil cavity is formed in the upper end of the spindle, a collection disc covers the oil cavity in a seal mode, a piston in sliding fit with the oil cavity is arranged in the oil cavity and divides the oil cavity into an upper oil cavity body and a lower oil cavity body, a through hole is formed in the collection disc, and an extension section extending upwards to penetrate the through hole is formed in the piston. An oil distribution ring fixedly connected with the work bench casing is sleeved on the spindle, two circular oil grooves are formed in the inner wall of the oil distribution ring, two oil channels communicated with the two circular oil grooves respectively are formed in the spindle, and the two oil channels are communicated with the upper oil cavity body and the lower oil cavity body respectively. A connection hole for being connected with a spindle drive motor is formed in the lower end of the spindle.

Owner:CHONGQING MACHINE TOOL GROUP

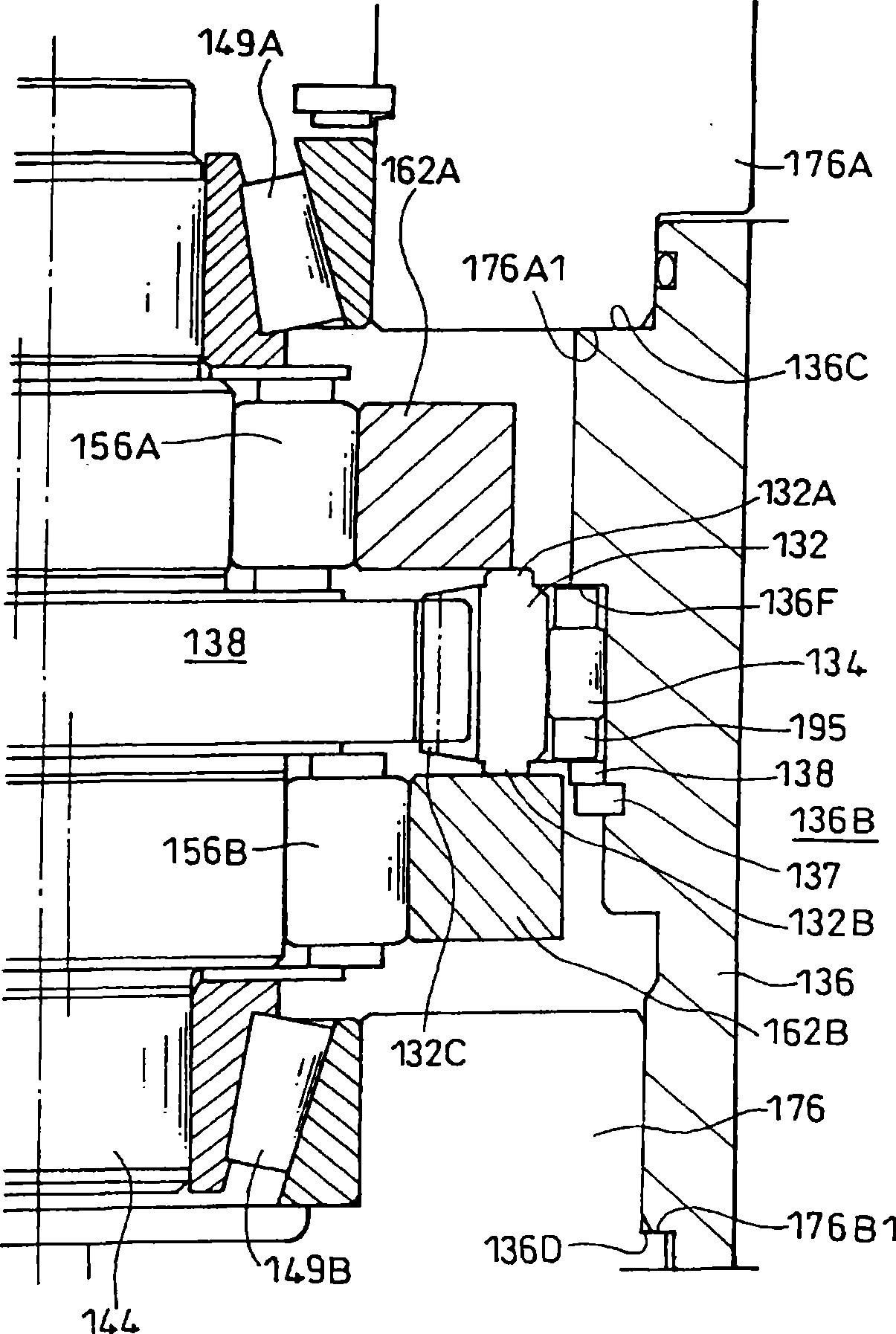

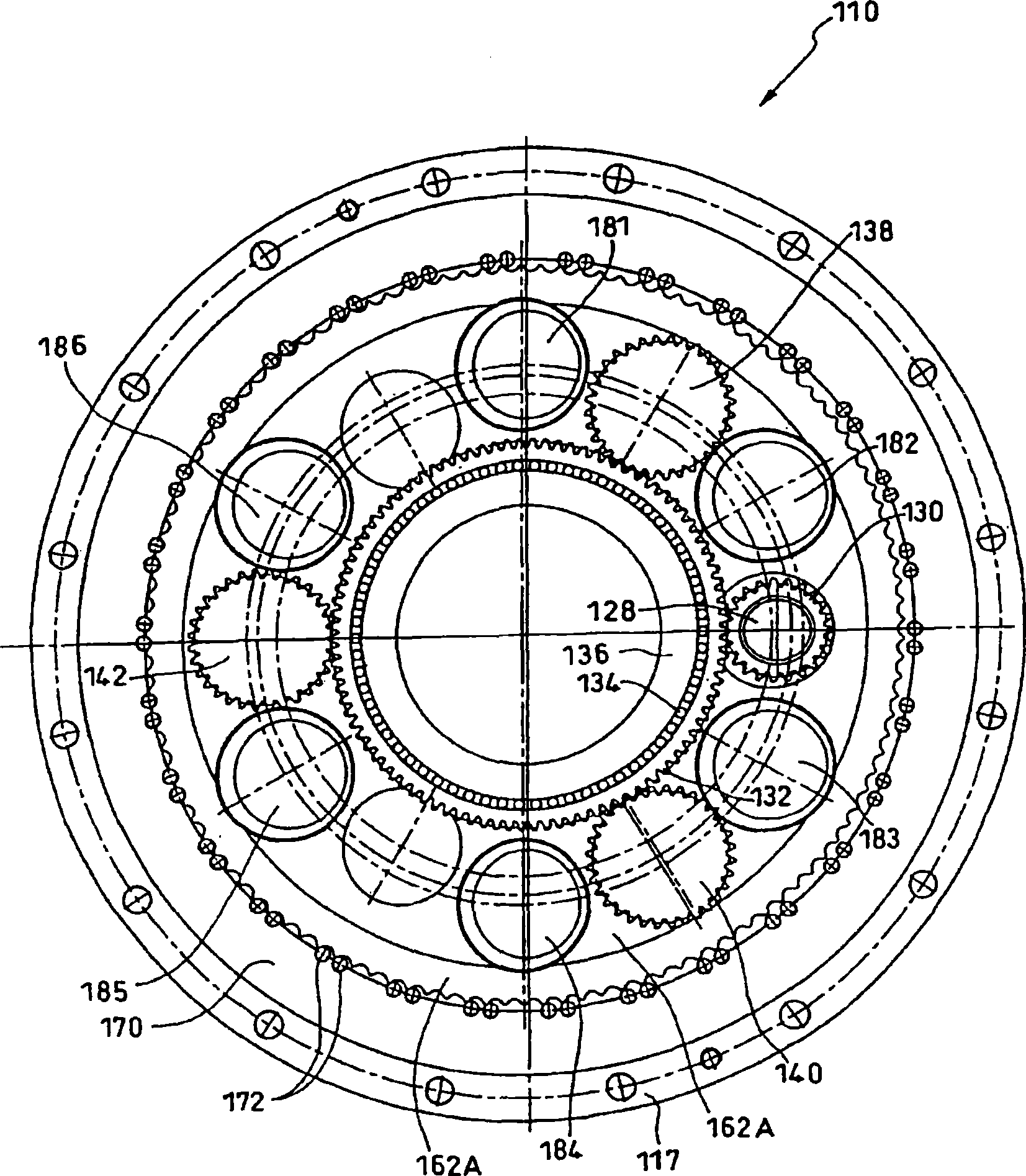

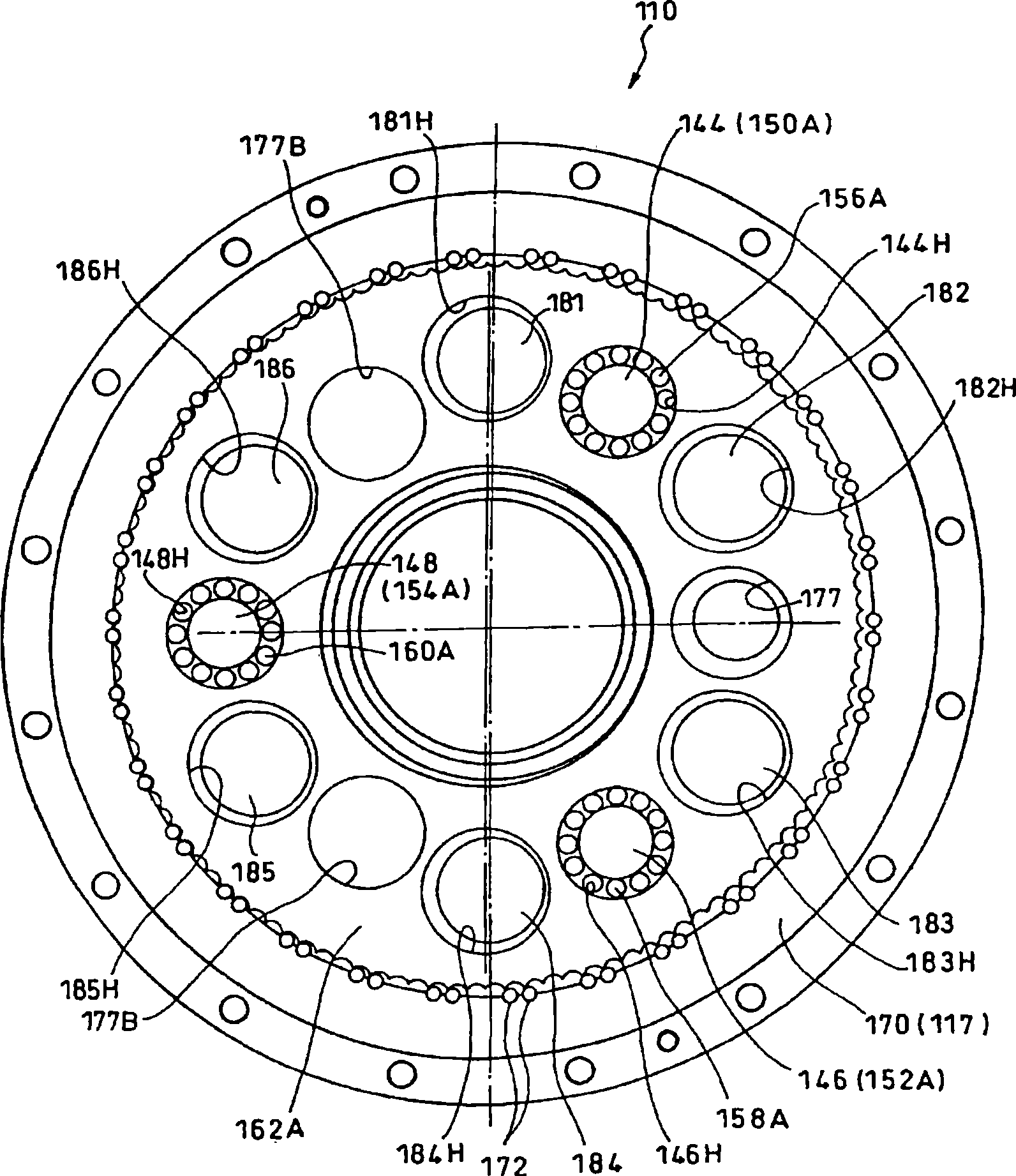

Swinging inner-connected meshed planetary gear structure

The invention provides a swing internal planetary gear structure. While in use, the unfavorable conditions caused by impact between an external gear and a central gear do not happen even the top end face of the central gear is not processed. The swing internal planetary gear structure comprises external gears (162A, 162B) which swing and rotate through eccentric bodies (150A, 150B, 152A, 152B, 154A, 154B); and an internal gear (170) engaged with the external gears. The invention is characterized in that the central gear (132), which is driven by a driving power and drives the several eccentric body shafts (144, 146, 148) synchronously, is axially connected with the external gears so that convex portions (interference prevention portions) (132A, 132B) of the toothed portion (132C) of the central gear is located between the central gear (132) and the external gears; it is characterized in that the convex portions are not contacted with the external gears.

Owner:SUMITOMO HEAVY IND LTD

Tire locking brake for electric power construction transfer vehicle

ActiveCN105109535AReasonable structureEasy to produceHand cart accessoriesEngineeringMechanical engineering

The invention provides a tire locking brake for an electric power construction transfer vehicle. A fixed block and a sliding shaft of the tire locking brake are in clearance fit. The upper end of the sliding shaft is fixedly connected with a drive plate, and clamping supports used in pairs are hinged to the lower end of the sliding shaft. A sleeve is fixed to the upper end face of the drive plate, a telescopic rod with a handle is arranged in the sleeve, and a locking rotary knob is arranged at the upper end of the sleeve. A reset spring A is arranged between the two clamping supports, and reset springs B are connected between the two clamping supports and the lower end of the fixed block respectively. Upper limiting grooves and lower limiting grooves are sequentially formed in the side wall of a through hole in the vertical direction. At least two sets of upper limiting grooves and lower limiting grooves are evenly formed in the side wall of the through hole in the circumferential direction. A ball pin capable of matching the upper limiting grooves and the lower limiting grooves is arranged on the outer side wall of the sliding shaft, a radial mounting groove is formed in the outer side wall of the sliding shaft, and the ball pin is arranged in the radial mounting groove through a reset spring C. The brake can lock and unlock tires of the transfer vehicle.

Owner:STATE GRID SHANDONG ELECTRIC POWER +2

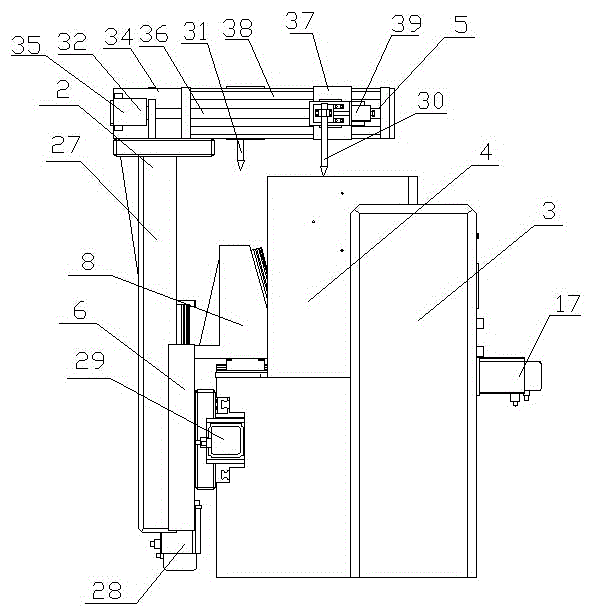

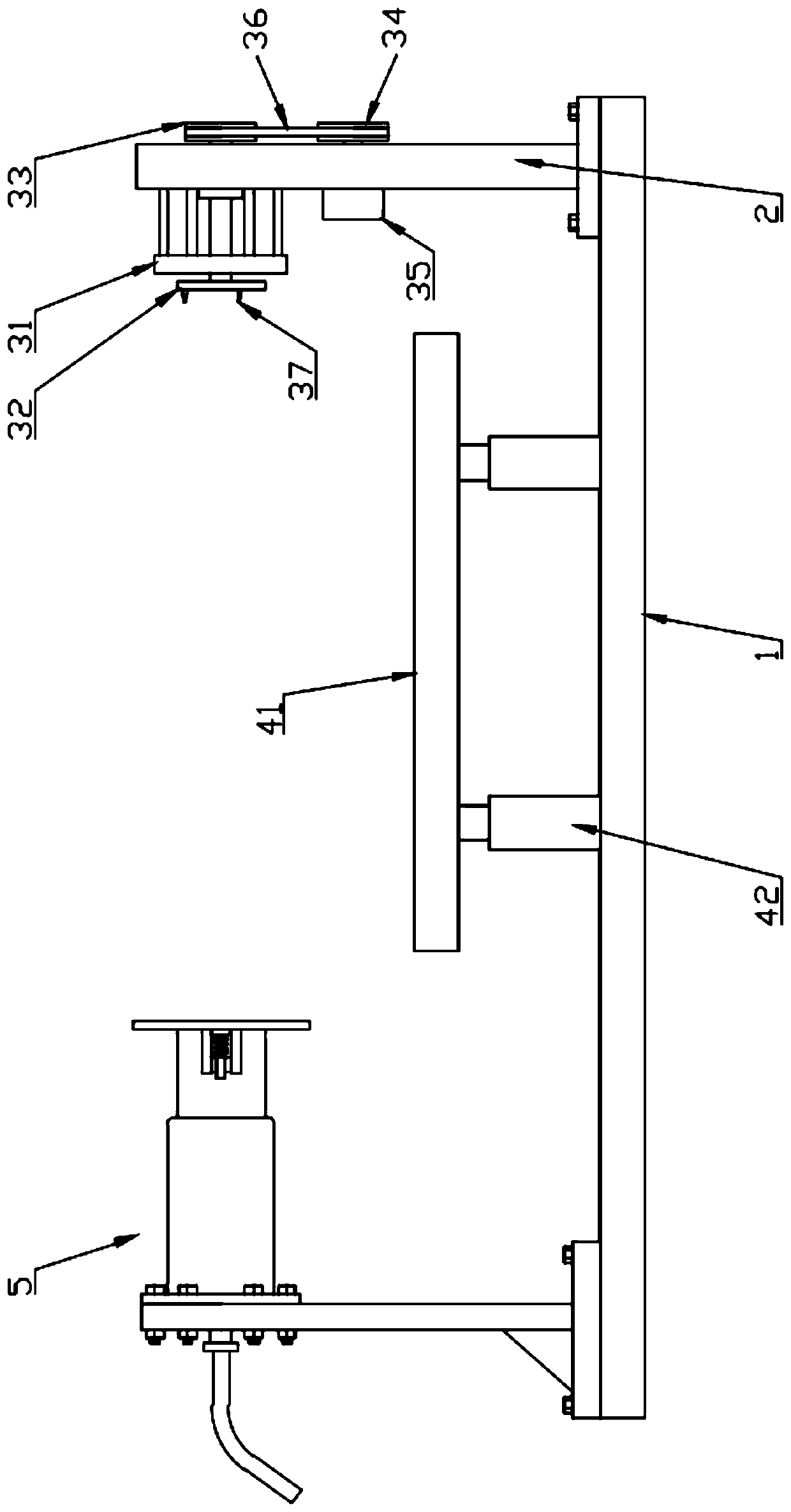

Large-size round timber processing facility for agriculture and forestry

ActiveCN110712254AAchieve axial positioningPrecise positioningMulti-purpose machinesGrinding work supportsAgricultural scienceAgricultural engineering

The invention discloses a large-size round timber processing facility for agriculture and forestry, and relates to the technical field of wood processing. The large-size round timber processing facility for the agriculture and forestry comprises a base, a machine frame, a power assembly, a lifting platform and a locating mechanism. The machine frame and the locating mechanism are installed at thetwo ends of the base correspondingly. The power assembly is installed on the machine frame, cooperates with the locating mechanism and drives a piece of round timber to rotate around the axis of the power assembly. The lifting platform is installed between the machine frame and the locating mechanism and used for achieving feeding and discharging operation of the round timber. By the adoption of the large-size round timber processing facility for the agriculture and forestry, the surface processing treatment work of the large-size round timber is achieved, namely, a driving motor drives the round timber to rotate, the locating mechanism cooperates with a driving disc to achieve the axial locating of the round timber, the clamping and locating operation of one end of the round timber is achieved in the mode that a supporting frame is fixed, and an inner sleeve moves, the process can be achieved under the condition that only the hydraulic oil needs to be fed into the facility, the locating process is simplified, the manpower is saved, the clamping force is more accurate, and the effect of avoiding the round timber rotation situation which happens due to the fact that the torque is excessively high is also achieved.

Owner:芜湖文青机械设备设计有限公司

Rotor shaft assembly, rotor and motor

ActiveCN108054867AAchieve axial positioningAvoid prone to axis misalignment problemsBearing assemblyMagnetic circuitEngineeringMechanical engineering

The invention provides a rotor shaft assembly, a rotor and a motor. The rotor shaft assembly comprises a magnetic core, a first end shaft, a second end shaft and a protection sleeve. A first through hole, a second through hole and a third through hole are formed in the protection sleeve in sequence, the first end shaft penetrates through the first through hole, at least part of the magnetic core is arranged in the second through hole, and the second end shaft penetrates through the third through hole; the minimum distance between the center line of the protection sleeve and the hole wall of the first through hole is a, the minimum distance between the center line of the protection sleeve and the hole wall of the second through hole is b, and the minimum distance between the center line ofthe protection sleeve and the hole wall of the third through hole is c, wherein one or two of a and c are not equal to b. According to rotor shaft assembly, the problem is solved that in the prior art, when the end shafts and magnetic steel of a rotor shaft assembly are assembled, and the axis is not easily centered.

Owner:GREE ELECTRIC APPLIANCES INC

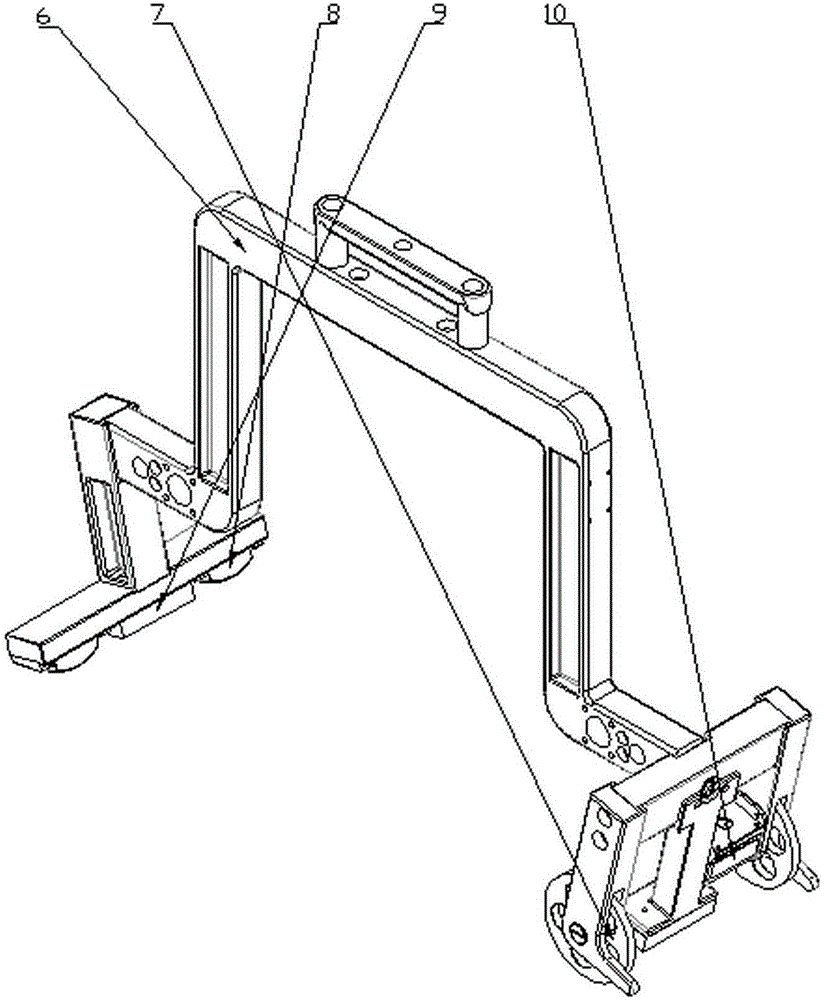

Hinged joint positioning apparatus

ActiveCN101324251AAchieve axial positioningSolve the axial positioning problemPivotsBuilding scaffoldsCircular discEngineering

The invention relates to a hinging and positioning device which comprises a hinging structure. Between a first connector and a second connector, an outer disc and an inner disc pass through a central sleeve, thereby forming the hinging structure; a lock-pin linkage structure comprises a sliding shaft, a spring, a push handle, a pin boss and a pin body, and passes through the central sleeve; two first pinholes are arranged on the outer disc corresponding to the pin body; two second pinholes and two third pinholes are arranged on the inner disc; therefore, an angle positioning structure is formed and has one of three following operating conditions, that is, an included angle formed between the first connector and the second connector is 0 DEG, larger than 0 DEG and less than 180 DEG, or equal to 180 DEG. The device is characterized in that a spherical elastic locating piece arranged in the axial direction on the sliding shaft is utilized to be matched with a locating hole or a concave locating hole on the inner edge of the central sleeve to achieve axial positioning of the sliding shaft from the movement state to the unlock state. According to the technical proposal, an unlock positioning structure is added on the basis of the prior hinging structure and the angle positioning structure of the first connector and the second connector, thereby better solving the axial positioning problem of the sliding shaft relative to the central sleeve in the unlock state, and bring great convenience for use and operation.

Owner:SUZHOU PICA ALUMINUM IND

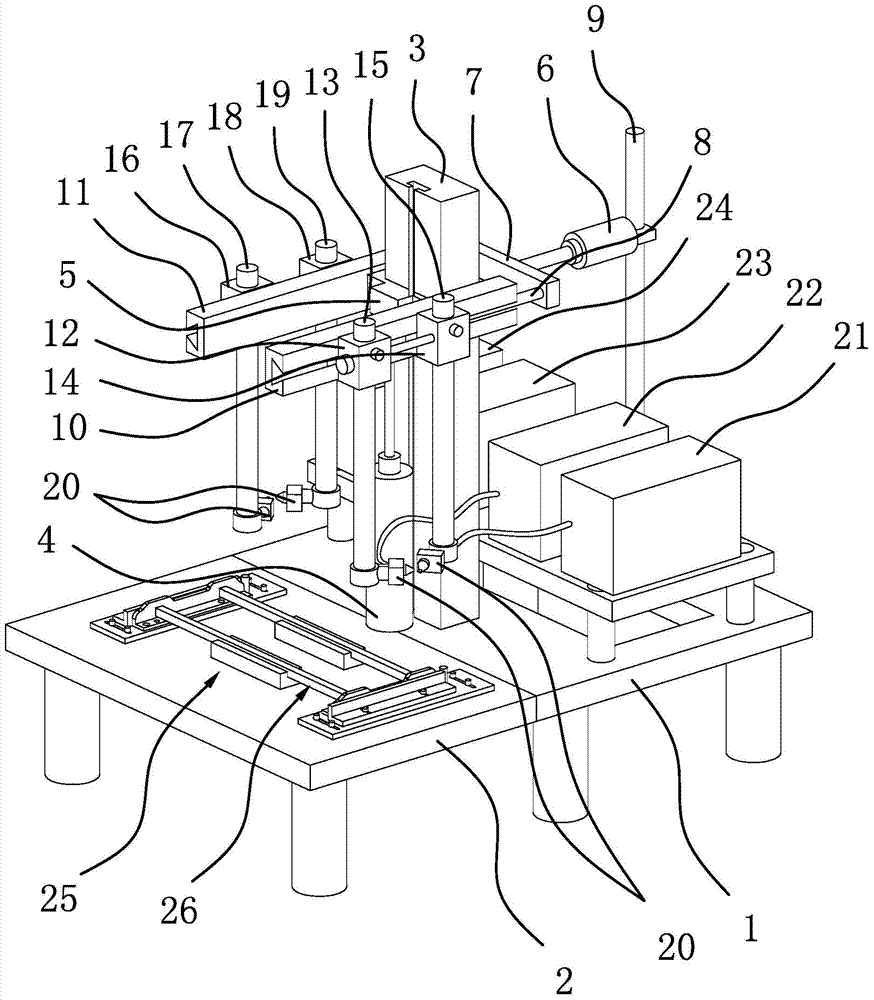

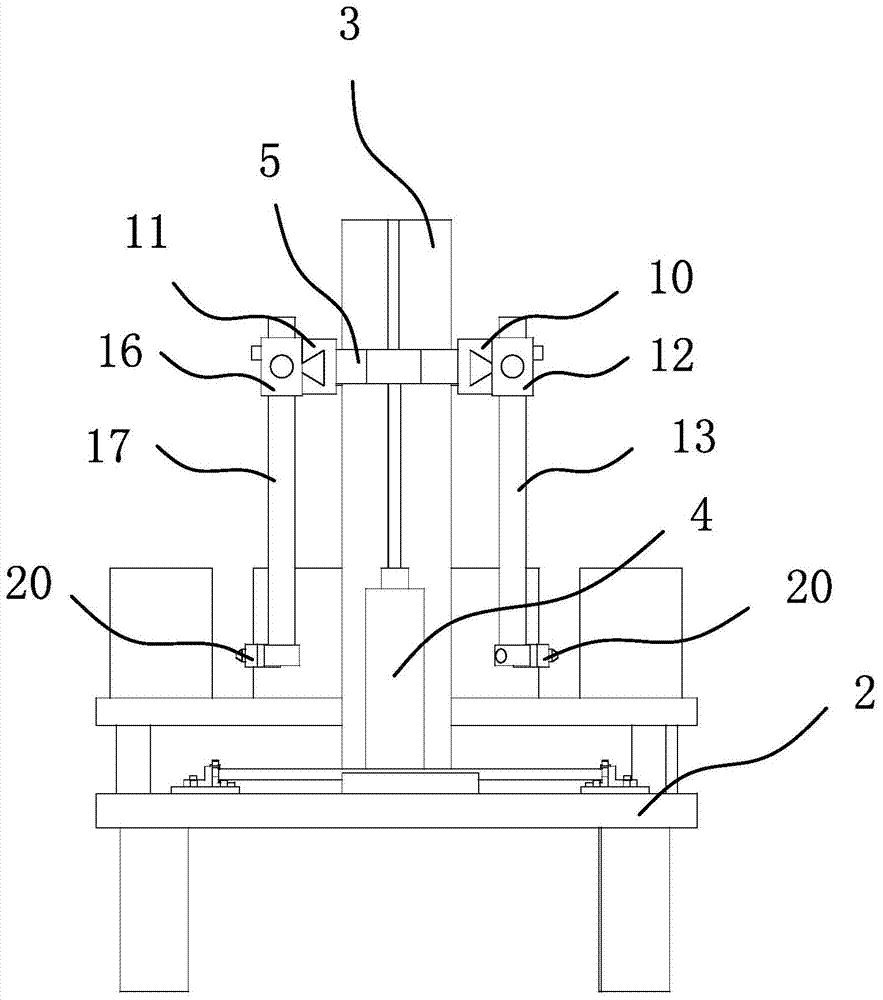

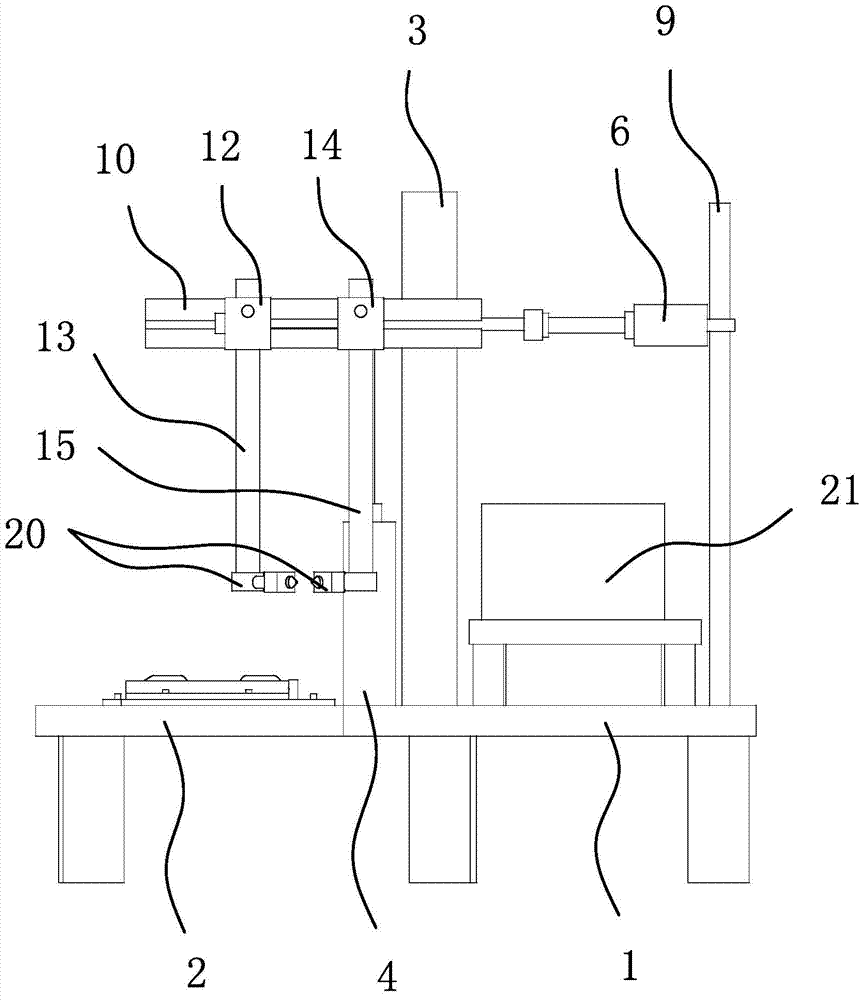

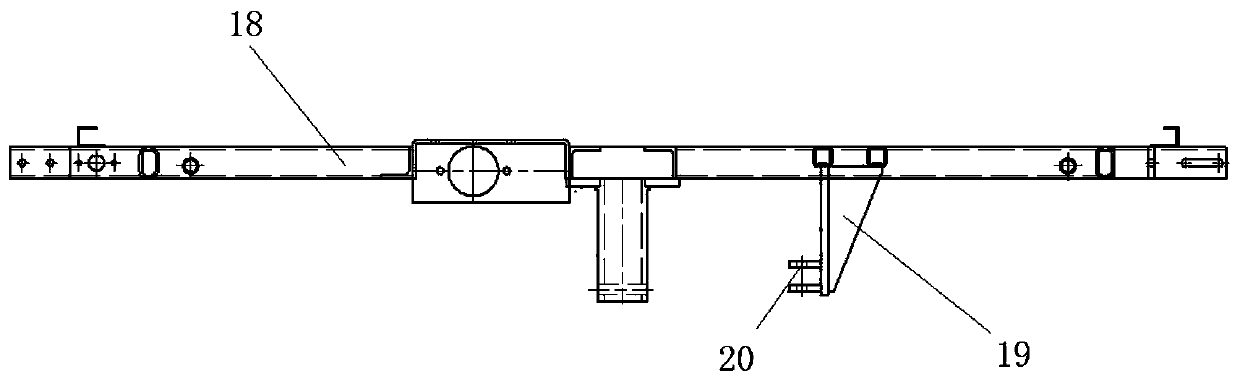

Automatic welding machine with PLC

ActiveCN104708168AAccurate welding positionImprove welding qualityElectrode holder supportersEngineeringWelding

The invention provides an automatic welding machine with a PLC, and belongs to the technical field of machinery. The automatic welding machine solves the problem that in the prior art, the efficiency is low as a rocking chair iron support adopts manual welding. According to the automatic welding machine with the PLC, the rocking chair iron support comprises a first steel ribbon and a second steel ribbon arranged in parallel and a first installing seat and a second installing seat arranged in parallel; the welding machine comprises a rack, a working platform is arranged on the rack, a vertical column is vertically fixed to the working platform, a lifting and dropping block is arranged on the vertical column, and the lifting and dropping block is connected with a first driving mechanism; the working platform is further provided with a positioning device capable of fixing the first steel ribbon, the second steel ribbon, the first installing seat and the second installing seat, and the positioning device comprises a first positioning block and a second positioning block which can circumferentially position the first steel ribbon and the second steel ribbon and further comprises a first positioning ribbon and a second positioning ribbon which can axially position the first steel ribbon and the second steel ribbon. According to the automatic welding machine with the PLC, the automatic welding of the rocking chair iron support can be achieved, and the welding efficiency is high.

Owner:ZHEJIANG FEILI TECH CO LTD

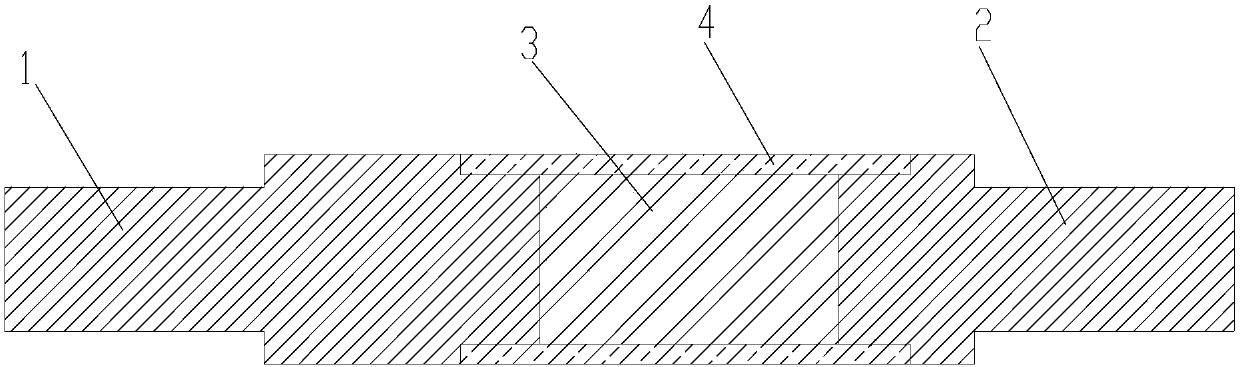

Connection method for split wheel-installed brake disk

ActiveCN110307276AGood assembly interchangeabilityAchieve axial positioningBraking discsEngineeringFlange

The invention provides a connection method for a split wheel-installed brake disk. A disk body A (1) and a disk body B (4) used by the connection method have identical structures. Grooves (5) and flanges (6) are respectively arranged at two ends of the disk body A and disk body B. Locating holes A (7) and threaded holes (8) are formed in the grooves. Counter bores (10) and locating holes B (9) areformed in the flanges (6). Locating sleeves (3) penetrate through the flanges (6) and the grooves (5) in sequence, and radial direction and circumferential direction location of disk body A (1) and disk body B (4) is achieved. Withdrawal holes (13) are formed in the locating sleeves. Inner hexagon screws (2) penetrate through the locating sleeves (3) and are screwed tightly with the threaded holes (8), axial direction location of disk body A (1) and disk body B (4) is achieved, and thus full-constrained reliable connection of displacement of disk body A (1) and disk body B (4) is achieved.

Owner:BEIJING JIAOTONG UNIV

Motor-driven compressive rubber-barrel underground blowout preventer

The invention discloses a motor-driven compressive rubber-barrel underground blowout preventer and belongs to the technical field of underground blowout prevention. The motor-driven compressive rubber-barrel underground blowout preventer mainly comprises a control module, a power module, a communication module and an execution module. A rubber barrel of the execution module herein can be squeezedby a compression barrel, pushed by rotation of a motor, to expand, thereby sealing a shaft annulus; when unsealing is required, the motor rotates reversely to drive the compression barrel to move reversely, and the rubber barrel is released to allow unsealing. The motor-driven compressive rubber-barrel underground blowout preventer is reusable, can respond fast, is suitable for various well types,has good safety and reliability and long life, can be set to establish a new circulation passage between inner and outer annular spaces, thereby facilitating subsequent well killing.

Owner:SOUTHWEST PETROLEUM UNIV

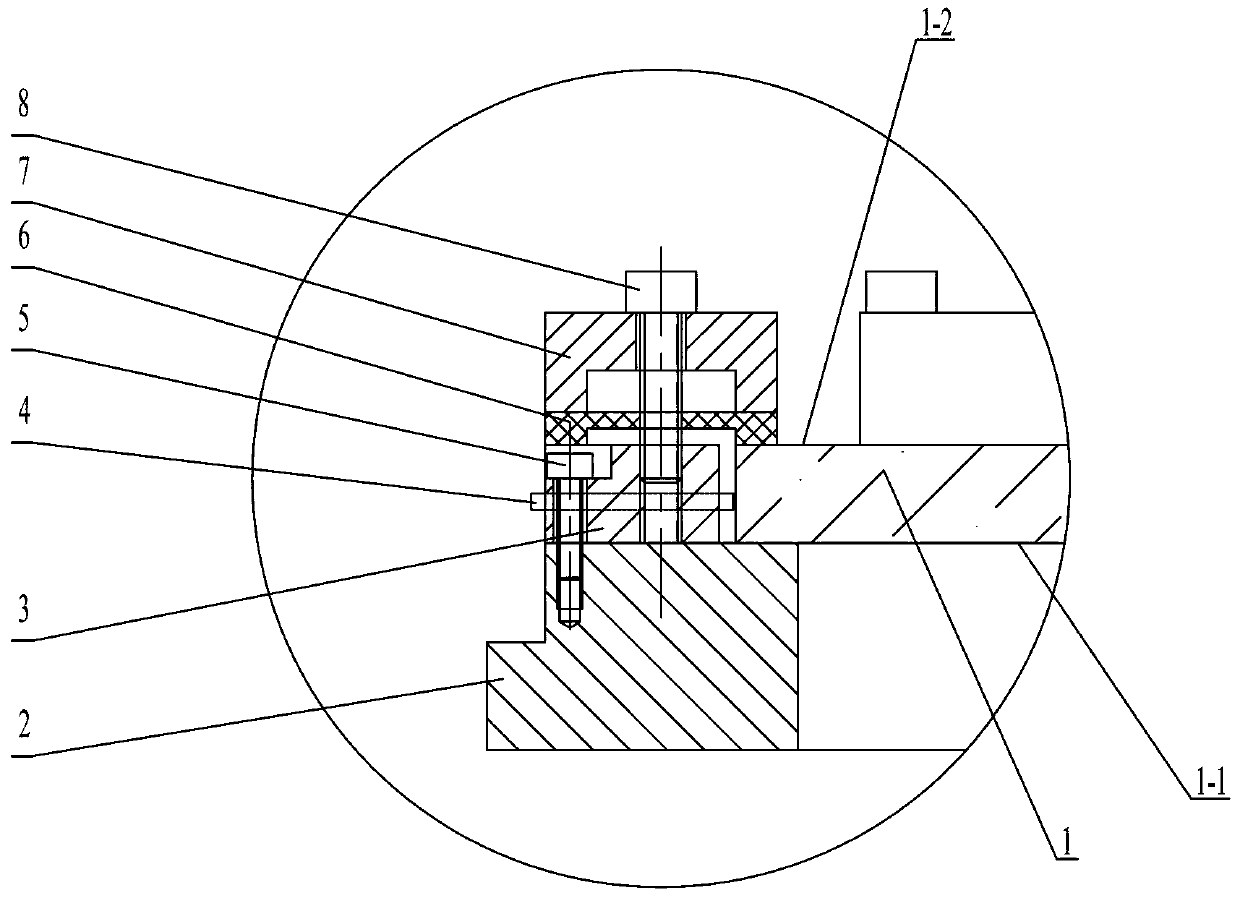

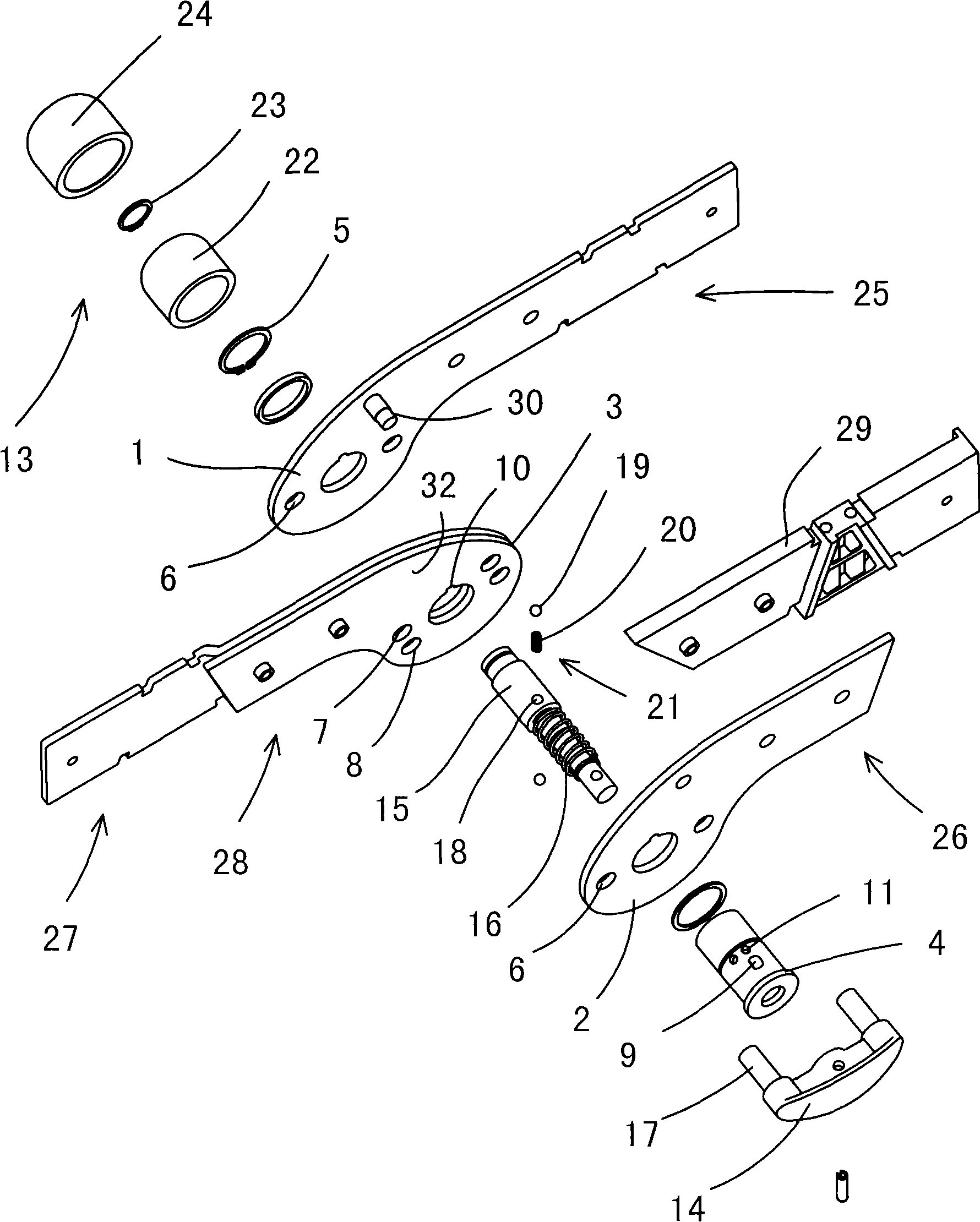

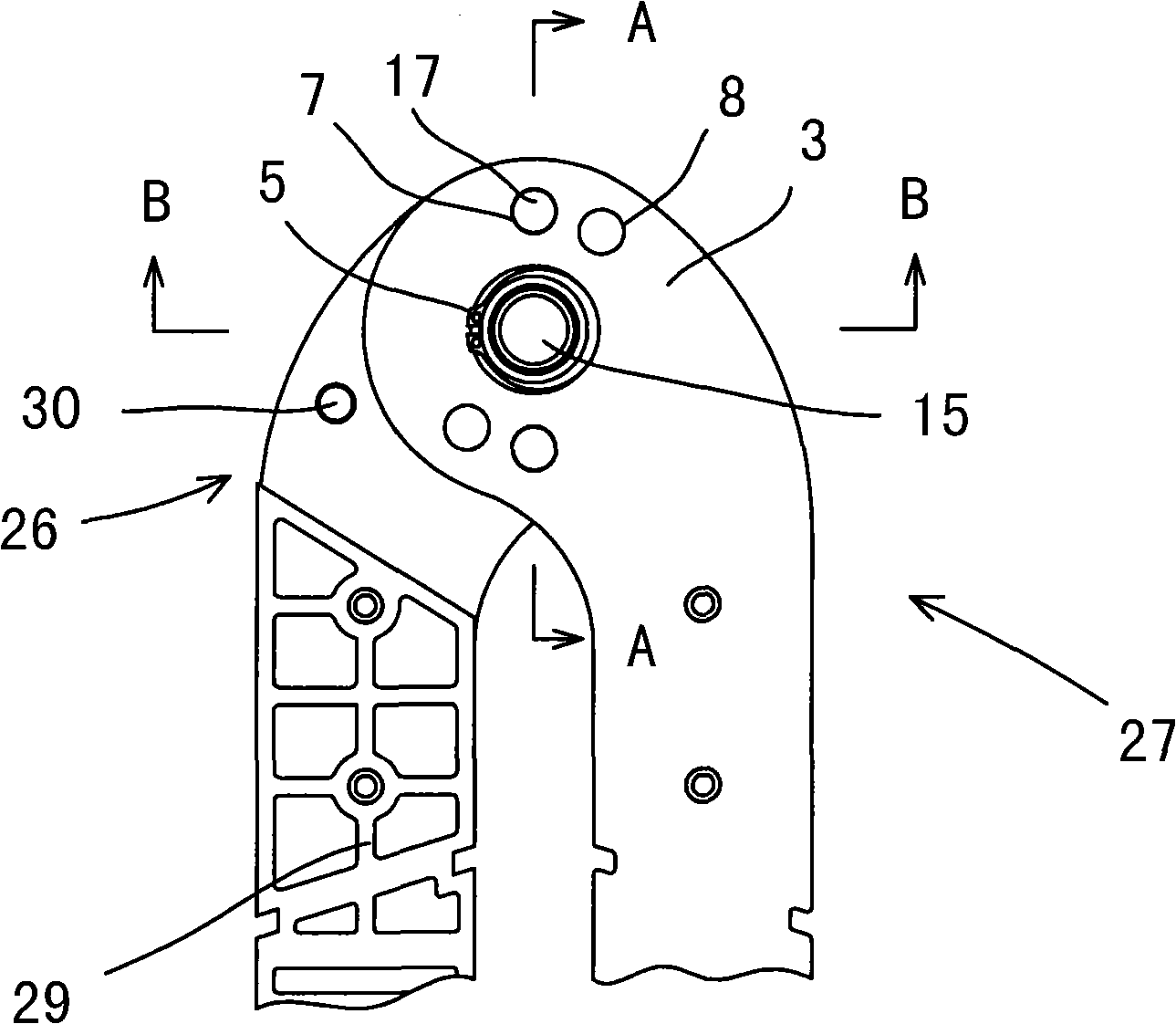

TOFD ultrasonic non-destructive testing self-positioning fixture of welded rotor

ActiveCN104597135APrecise alignmentAchieve axial positioningAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveSpring force

The invention belongs to the field of testing robots and in particular relates to a TOFD ultrasonic non-destructive testing self-positioning fixture of a welded rotor. The fixture comprises an adsorption type mobile platform, a positioning system, a fixture slideway and a self-adaption fixture. The TOFD ultrasonic non-destructive testing self-positioning fixture of the welded rotor is used for clamping a TOFD ultrasonic non-destructive testing wedge block and a probe, the wedge block automatically adapts to surface angle of the welded rotor through two rotational degrees of freedom of the tail end of the fixture and spring force and is tightly pasted with the welded rotor, and axial positioning between the fixture and the welded rotor can be realized under action of the positioning system so that the welded block can accurately aim at a welded joint.

Owner:东方电气集团科学技术研究院有限公司

Omnibearing profile device of swather

PendingCN110972691AFulfill profiling requirementsReasonable and reliable structural designHarvestersAgricultural engineeringStructural engineering

The invention particularly discloses an omnibearing profile device of a swather and solves the problem of stubble cutting flatness of an existing swather during harvesting. A left-right profile mechanism comprises a hollow shaft and a connecting frame, wherein a shaft sleeve is arranged on the outer side of the hollow shaft, a strip-like steel plate is arranged above the shaft sleeve, and a left-right adjusting oil cylinder is arranged at the lower part of the strip-like steel plate; an up-down lifting mechanism comprises front lifting cross beams and back lifting cross beams, a front connecting rod is fixed between the two front lifting cross beams, upper lifting cross beams, lower lifting cross beams and front-back adjusting oil cylinders are arranged between the front lifting cross beams and between the back lifting cross beams, and a back connecting rod is arranged between the back lifting cross beams; and output ends of range sensors and range sensors I are connected with the input end of a controller, and the output end of the controller is connected with input ends of the front-back and left-right adjusting oil cylinders. The omnibearing profile device meets the profile requirement when harvesting crops on land which is uneven left and right and wavy front and back and can realize stubble cutting flatness so as to meet harvest requirements.

Owner:SHANXI AGRI UNIV +1

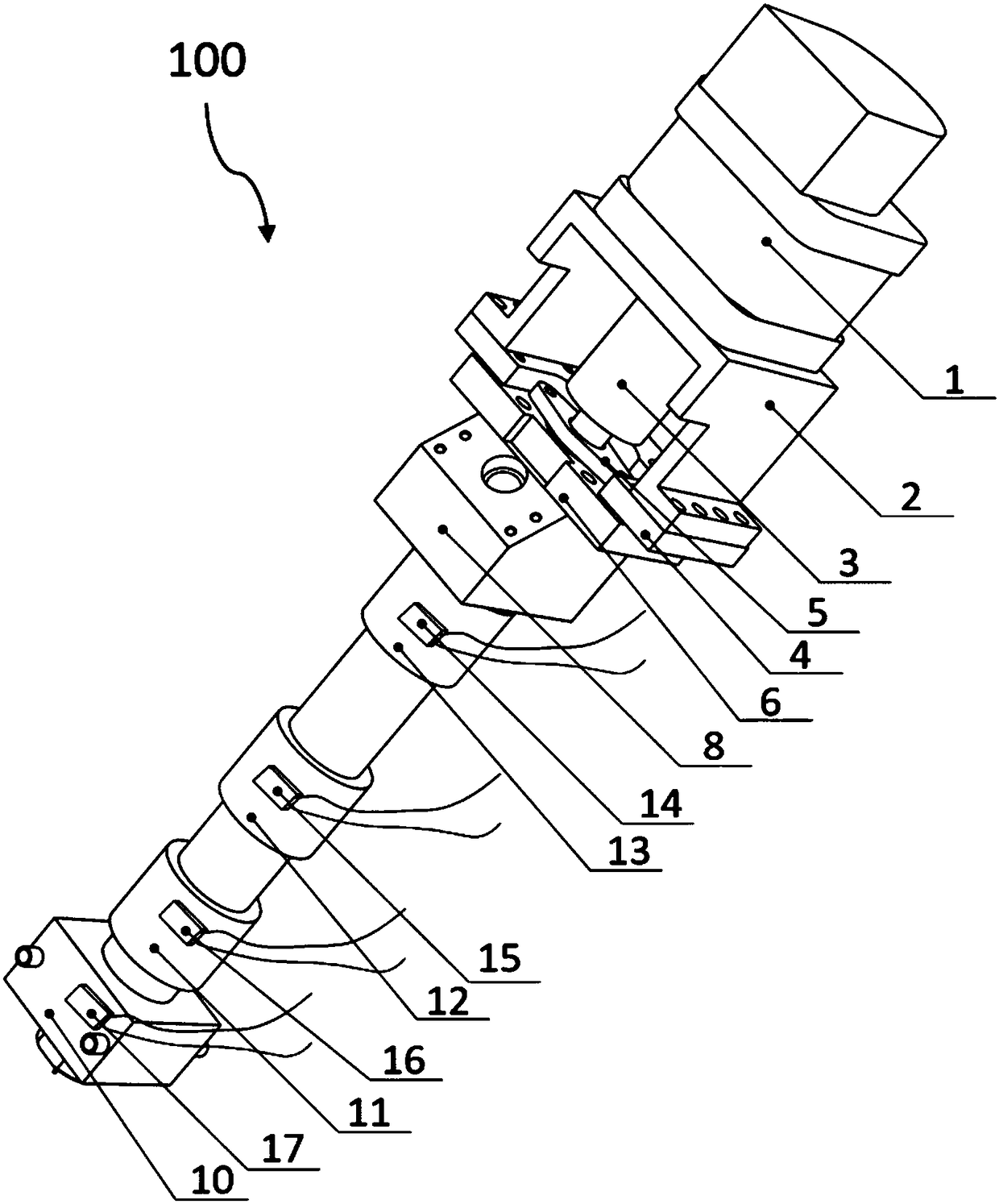

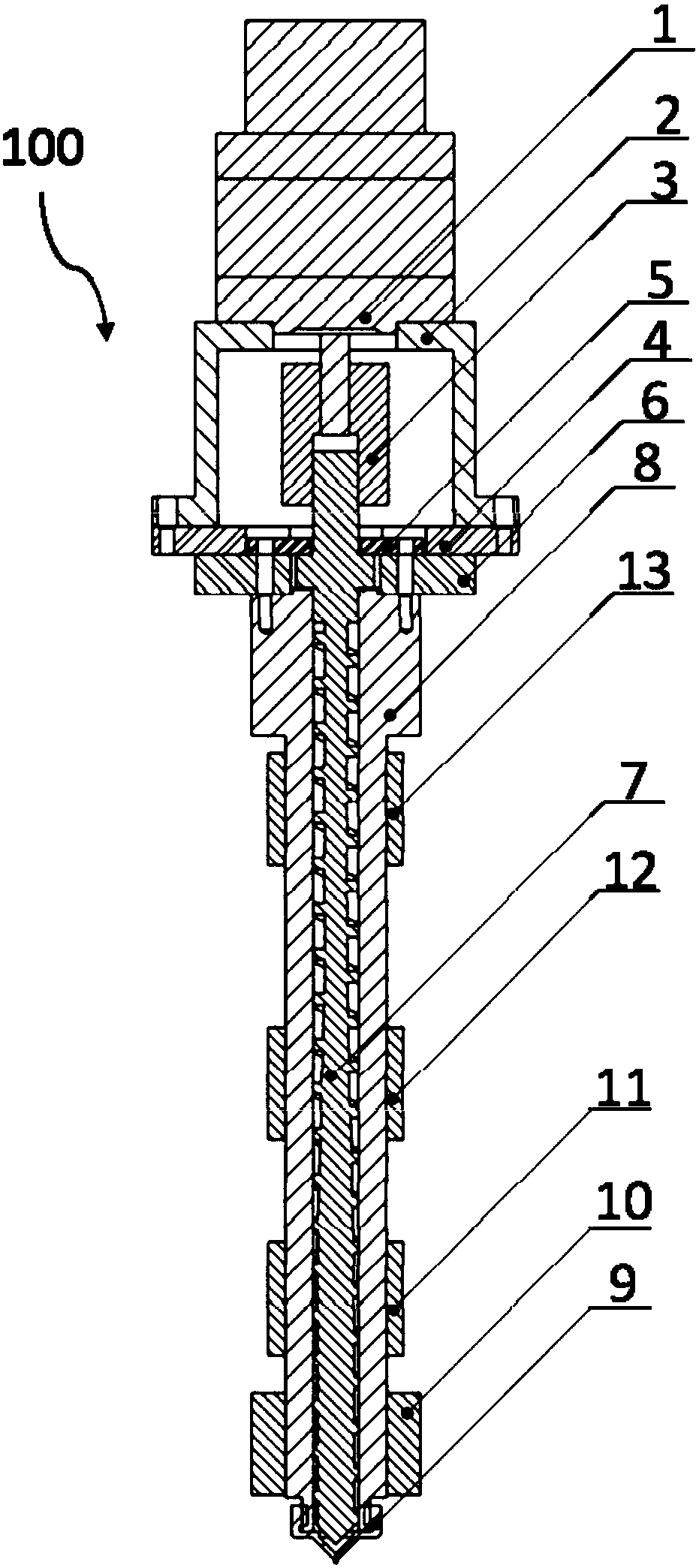

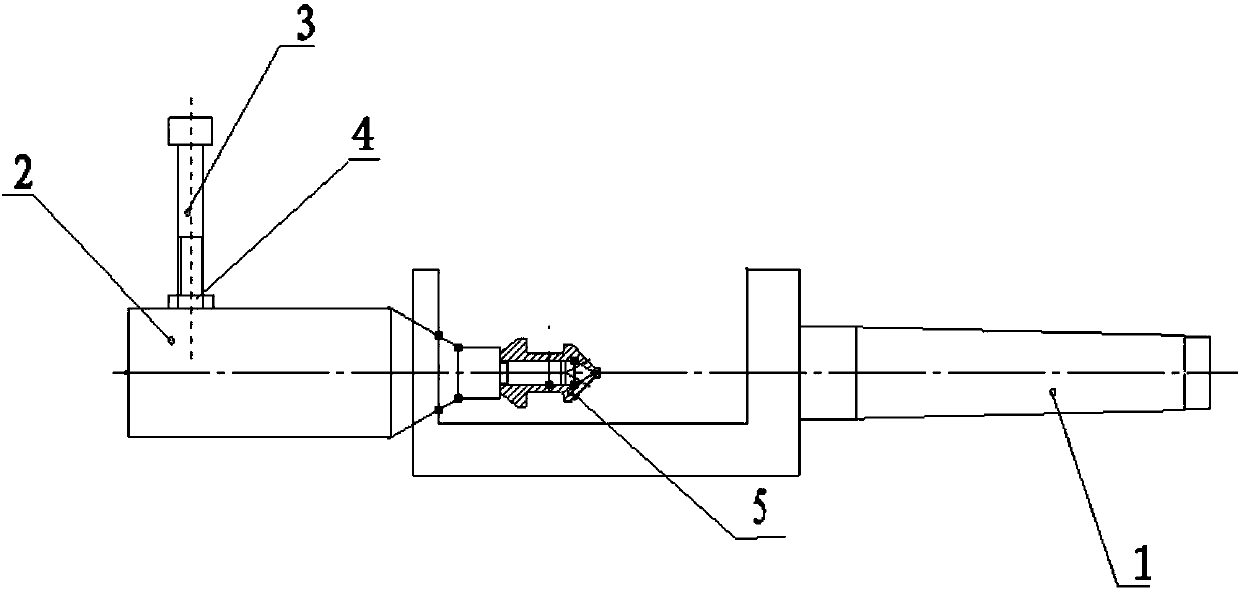

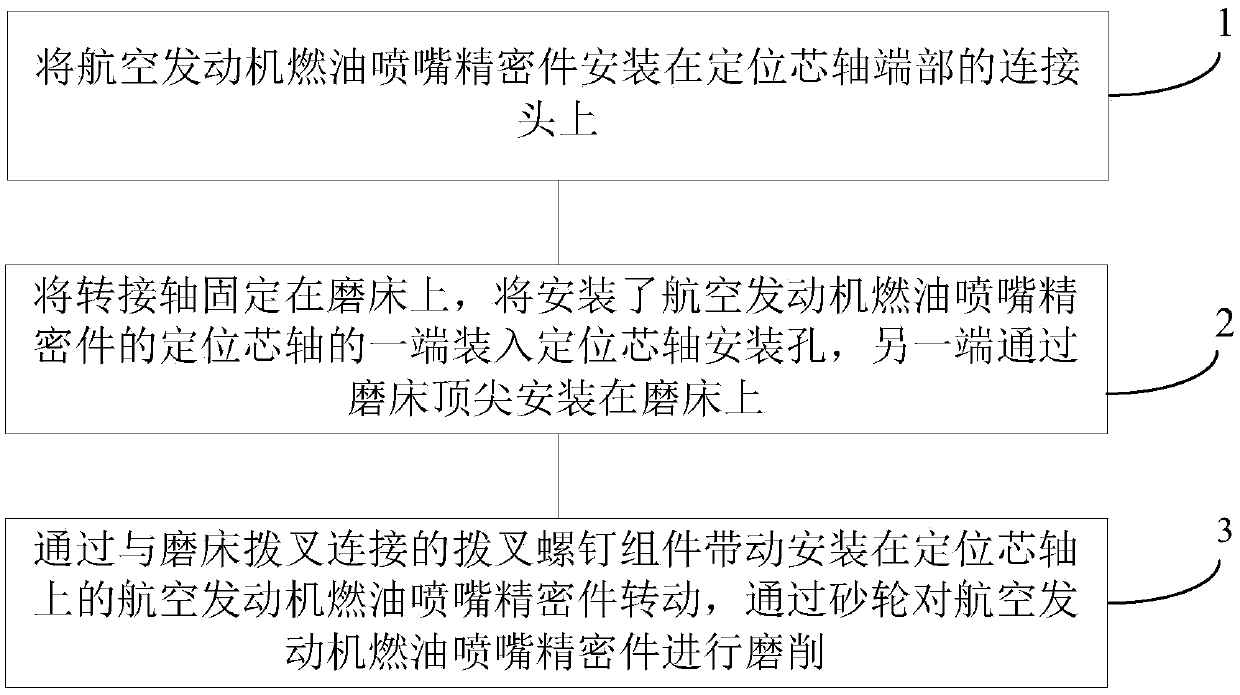

Aircraft engine fuel nozzle precision piece grinding quick-change tooling and using method

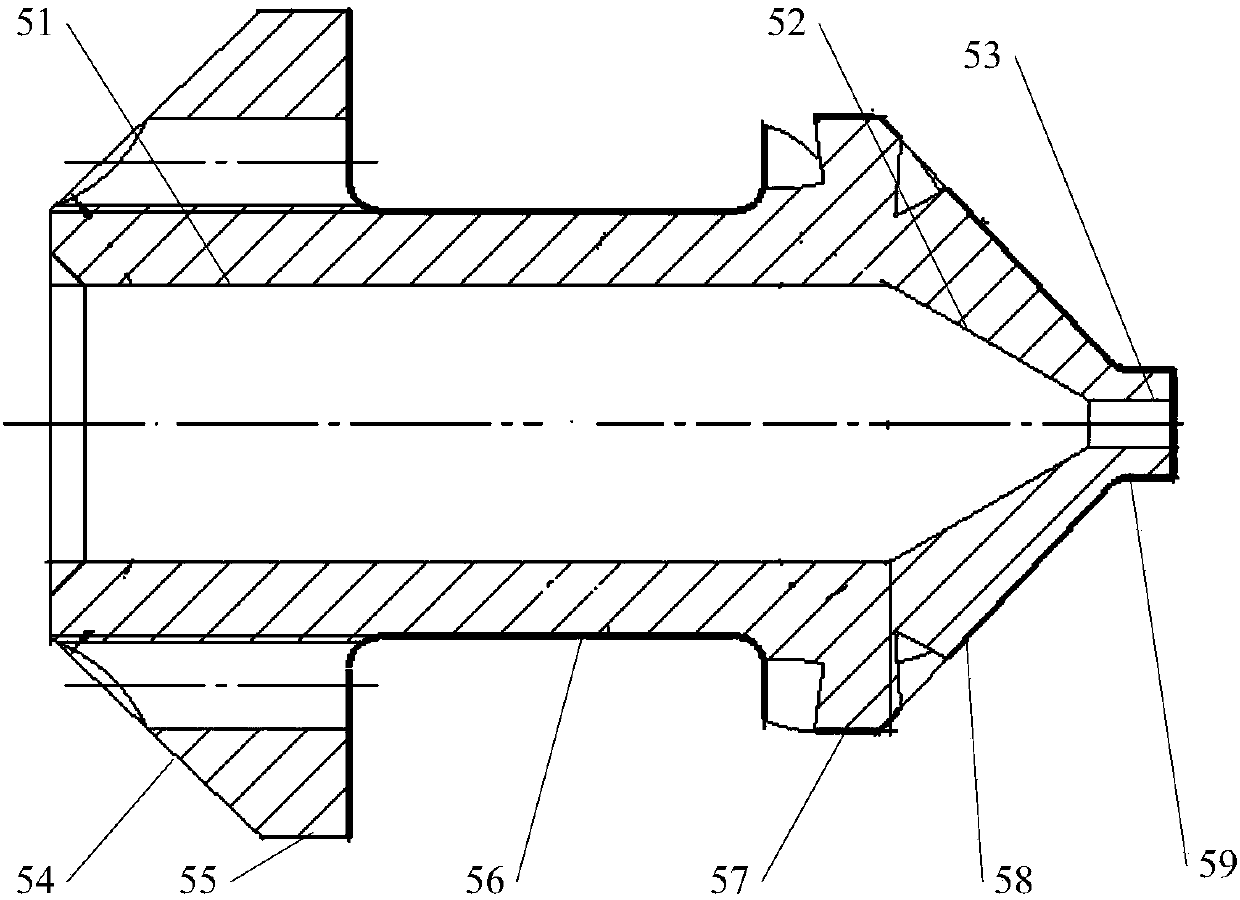

ActiveCN107671640AIncrease productivityGuaranteed operational safetyGrinding machinesGrinding work supportsAviationAero engine

The invention discloses aircraft engine fuel nozzle precision piece grinding quick-change tooling and a using method, and belongs to the technical field of quick-change tooling. The quick-change tooling includes a rotating connecting shaft, a positioning mandrel and a shifting fork screw assembly. An aircraft engine fuel nozzle precision piece to be ground is mounted on the positioning mandrel, and the positioning mandrel and the rotating connecting shaft are connected with and mounted on a grinding machine, so that the fact that quick mounting and clamping of the aircraft engine fuel nozzle precision piece are changed is achieved, the problems that grinding, mounting and clamping of the shape of the aircraft engine fuel nozzle precision piece are high in frequency and low in precision aresolved, repeated centering in the process of mounting and clamping is omitted, the working difficulty of grinding operators is reduced, the production efficiency, machining accuracy and size consistency of the nozzle precision piece are improved, and the running safety of an aircraft engine is ensured.

Owner:AECC AVIATION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com