Vehicle thrust rod assembly, adjusting method thereof and vehicle suspension mechanism

A thrust rod and assembly technology, applied in the field of automobile chassis, can solve problems such as non-adjustable length, and achieve the effects of improving versatility, reducing use costs, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer to those skilled in the art, the present invention will now be described in further detail in combination with preferred embodiments with reference to the accompanying drawings.

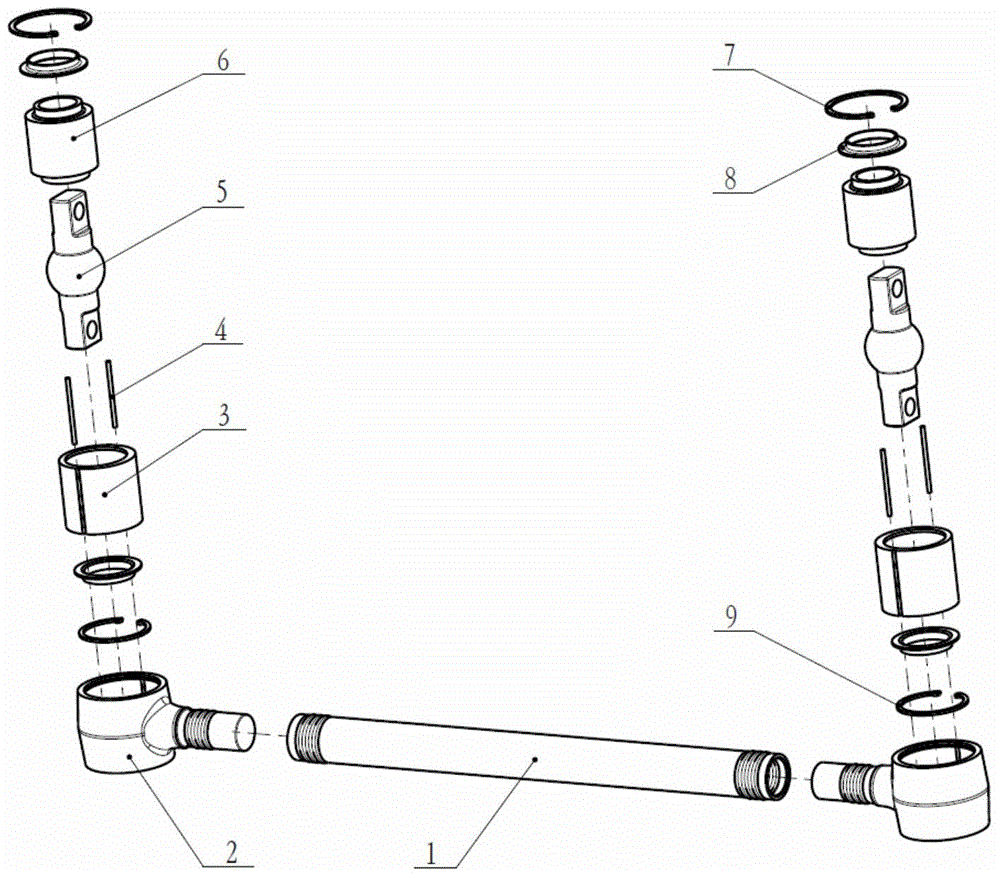

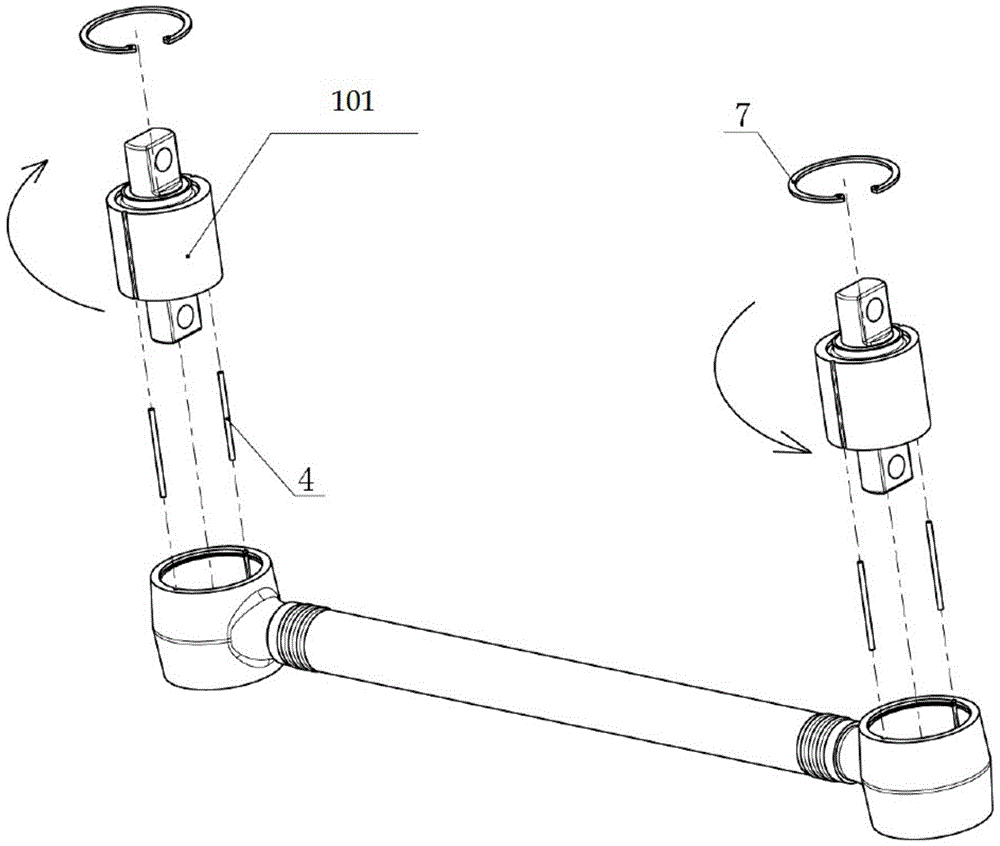

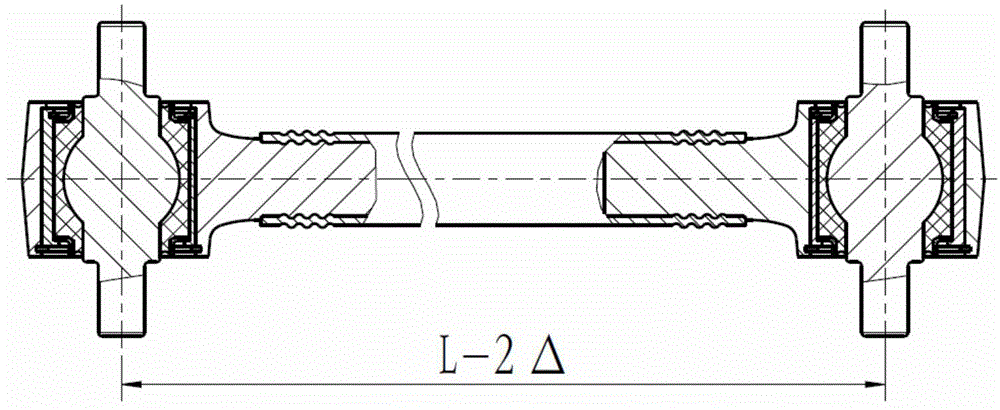

[0029] like figure 1 As shown, the new thrust rod assembly for vehicles according to the present invention includes a shaft tube 1, a spherical shell 2, an eccentric sleeve 3, a lock pin 4, a mandrel 5, a rubber 6, a second retaining spring 7, and an end cover 8 , the first snap ring 9. The spherical head shell 2 is connected with the shaft tube 1 by heat riveting. The eccentric sleeve 3 is pressed into the ball shell 2 at both ends of the assembly, its circumferential positioning is realized by the lock pin 4, and the axial positioning is realized by the flange at the lower end of the ball shell 2 and the retaining spring 7; Use transition fit. The end caps 8 are placed at both ends of the ecce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com