Patents

Literature

190 results about "Thrust lever" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thrust levers or power levers are found in the cockpit of aircraft, and are used by the pilot, copilot, or autopilot to control the thrust output of the aircraft's engines. In multi-engine aircraft, each thrust lever displays the engine number of the engine it controls. Normally, there is one thrust lever for each engine. The thrust levers are normally found in the aircraft's center console, or on the dashboard of smaller aircraft.

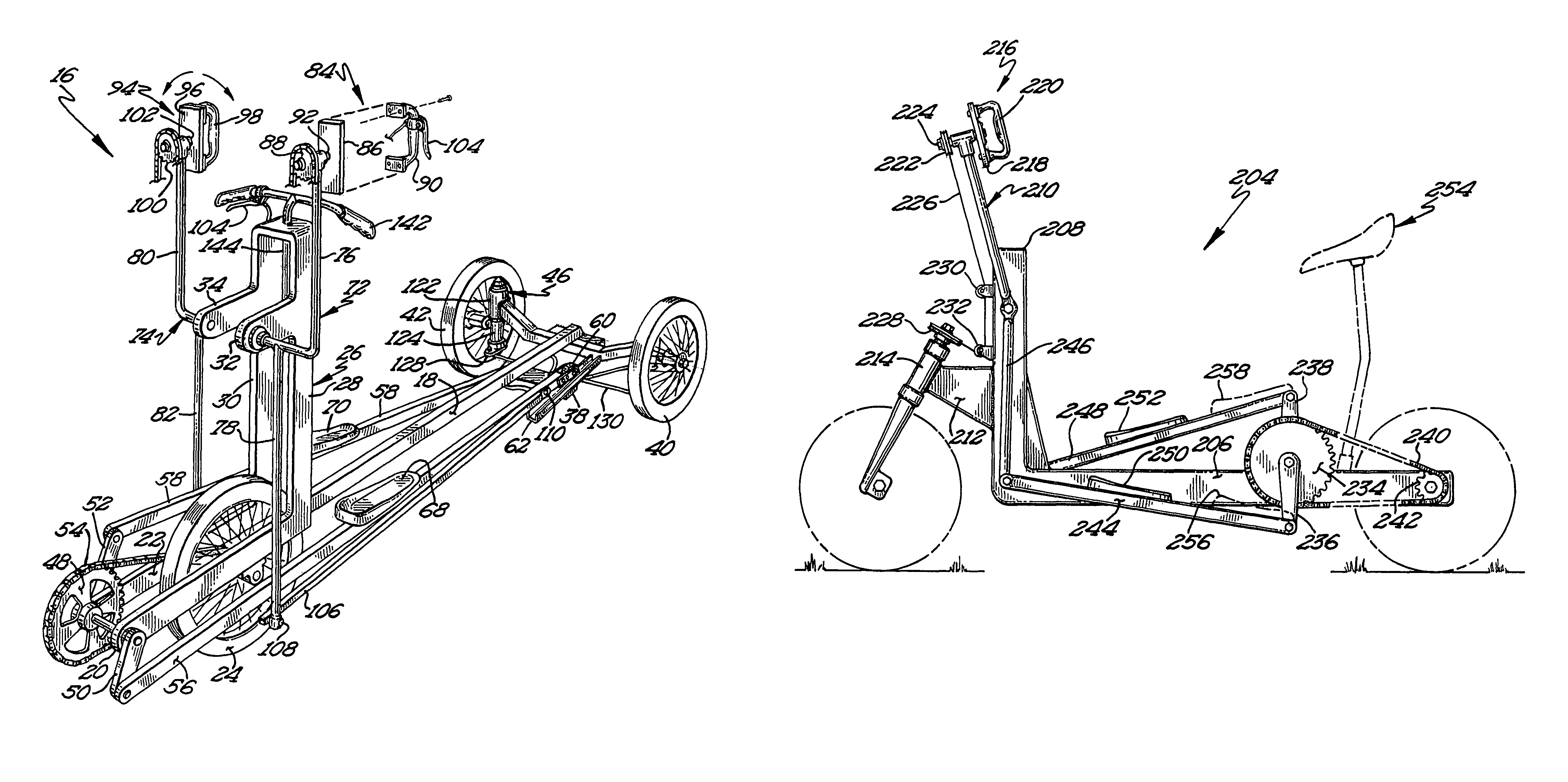

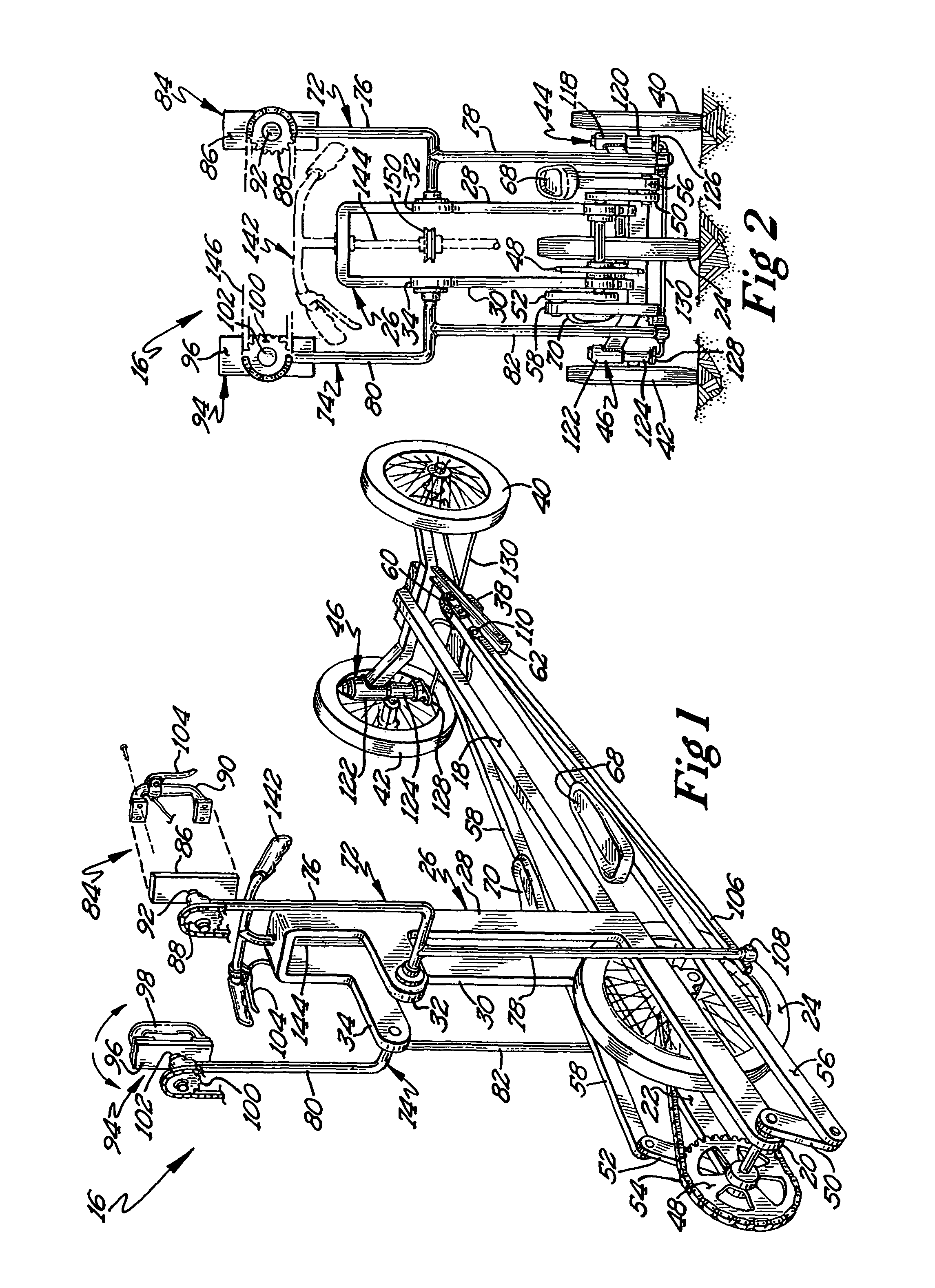

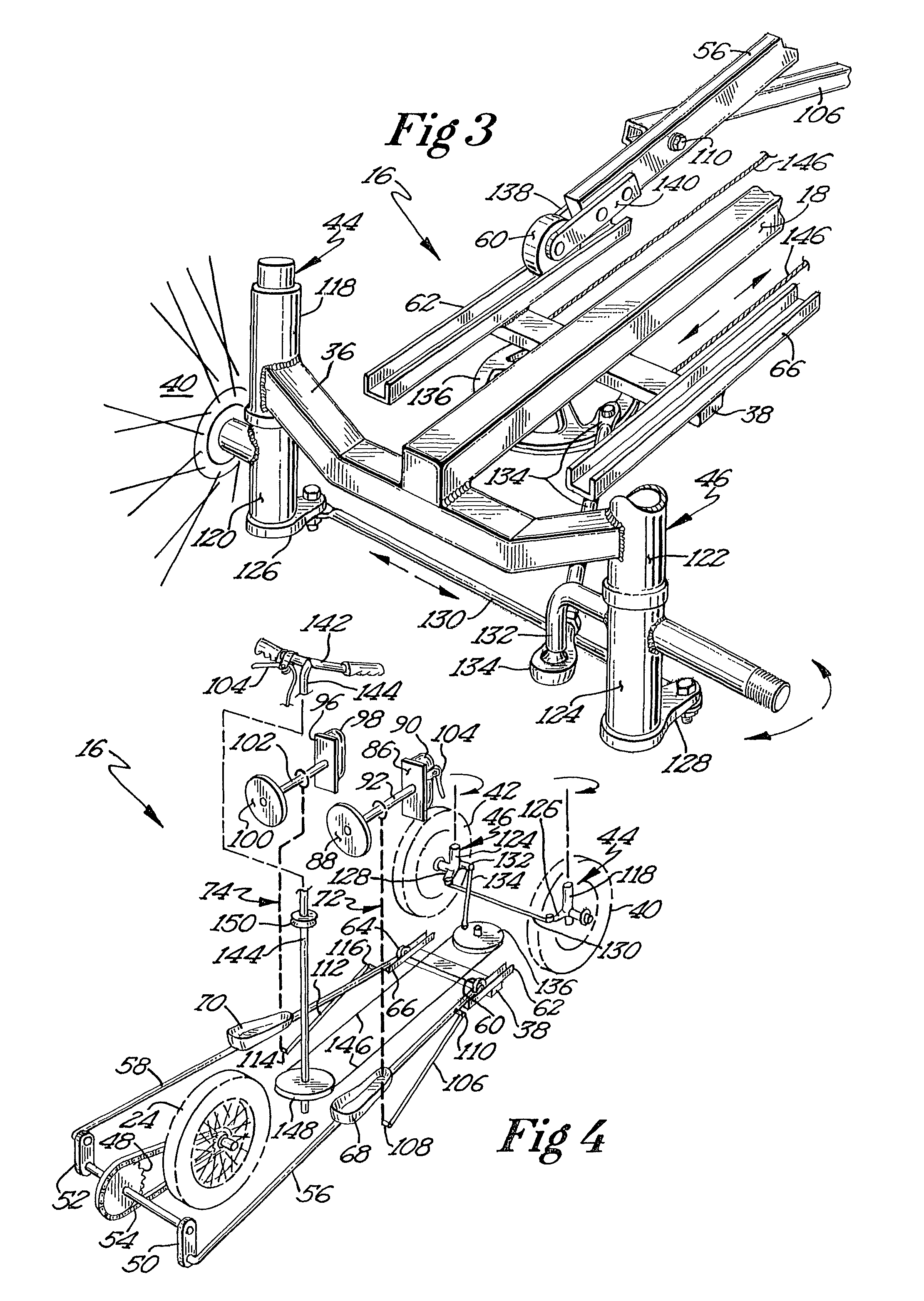

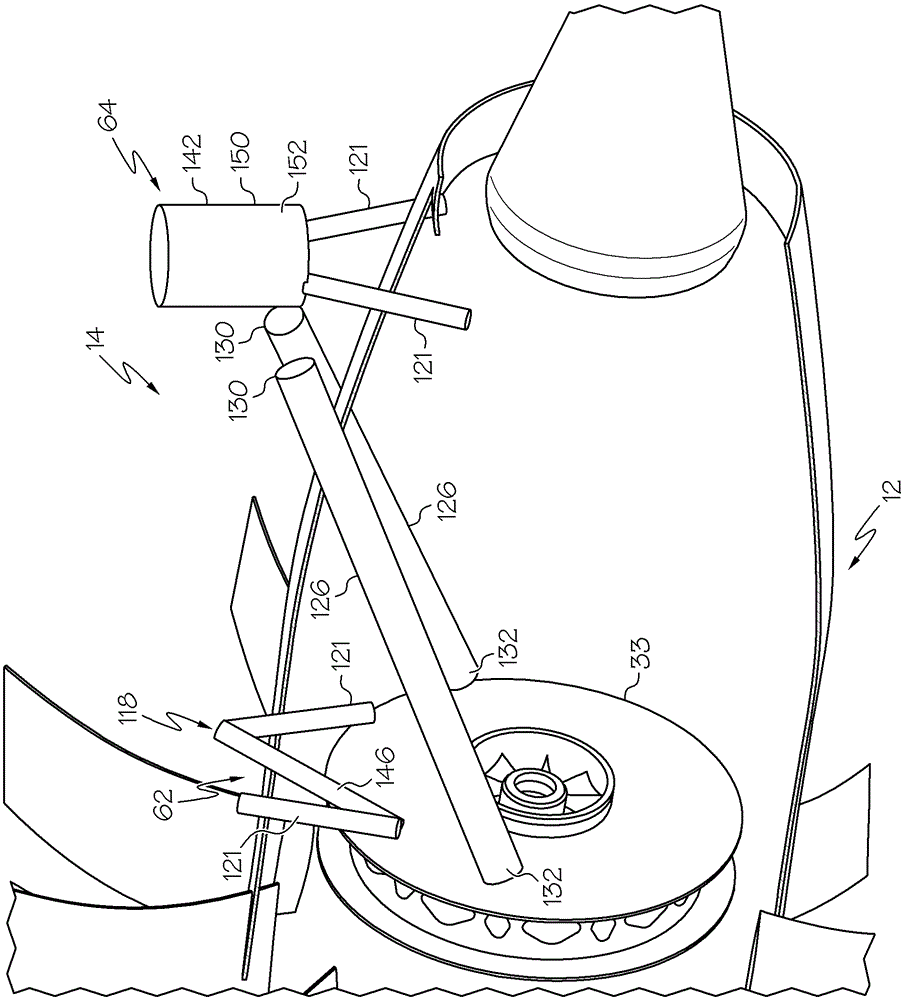

Recreational vehicle with elliptical drive

InactiveUS7967313B1Easy to useExtended service lifeCyclesFoot-driven leversPush and pullReciprocating motion

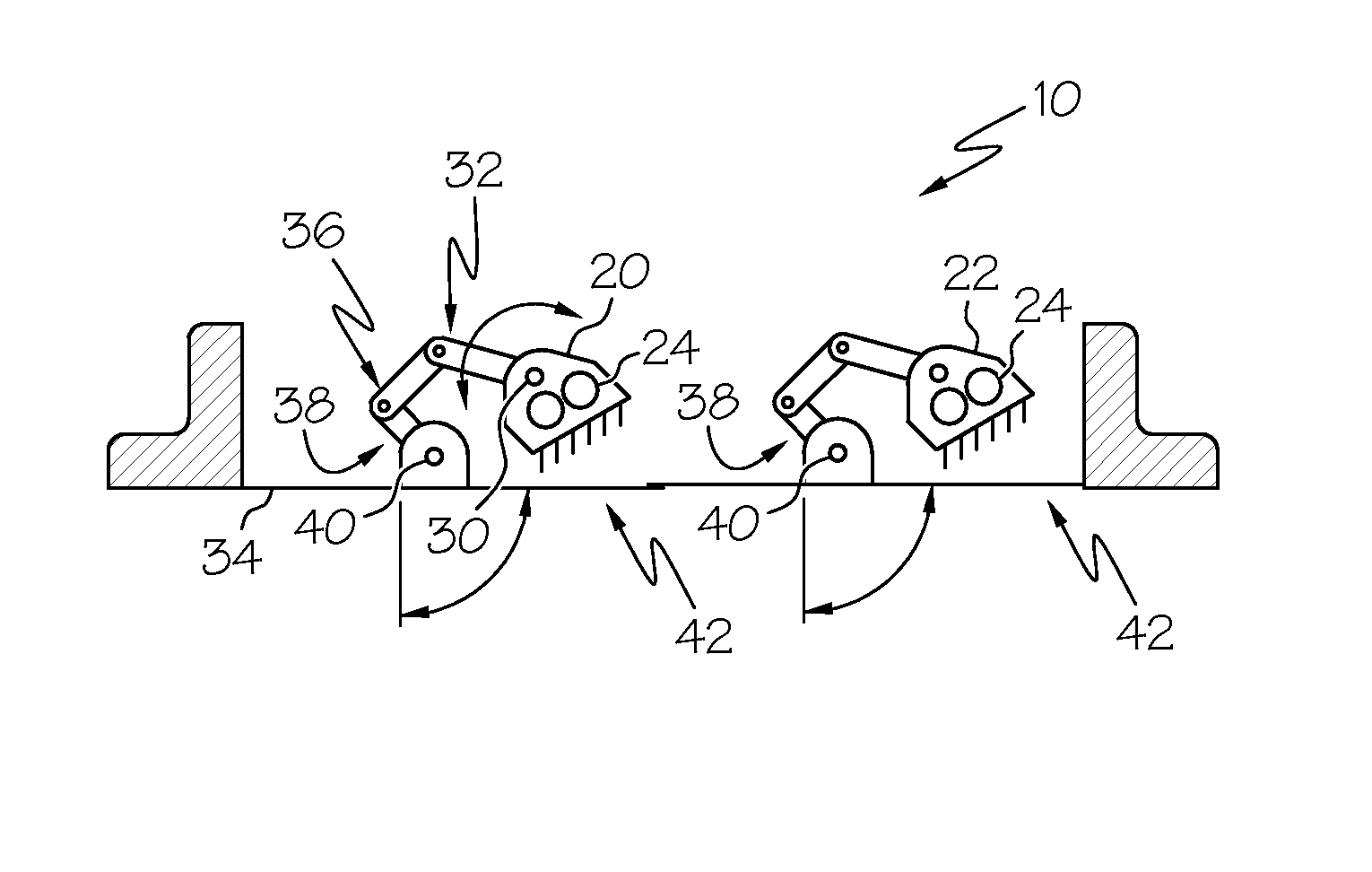

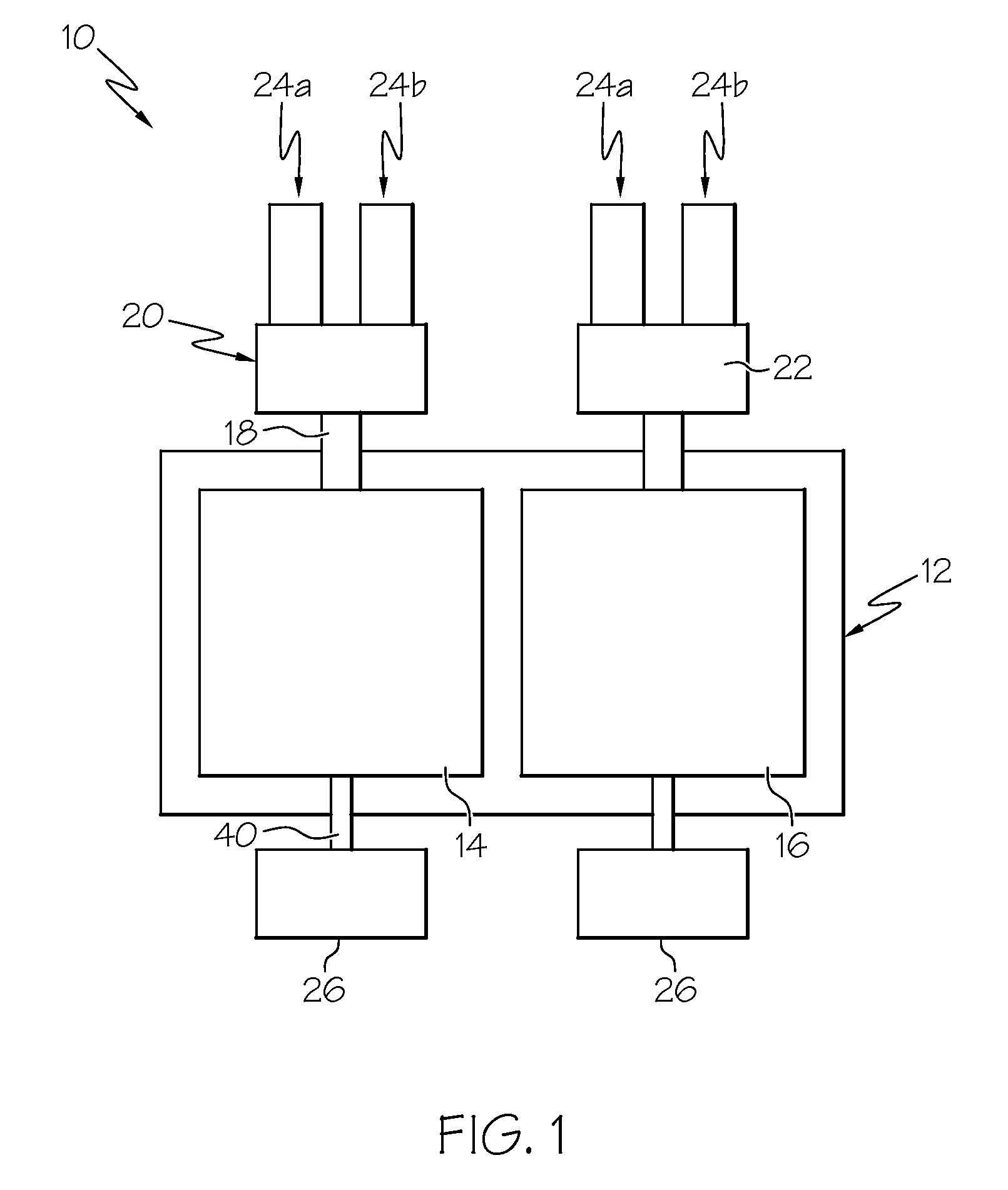

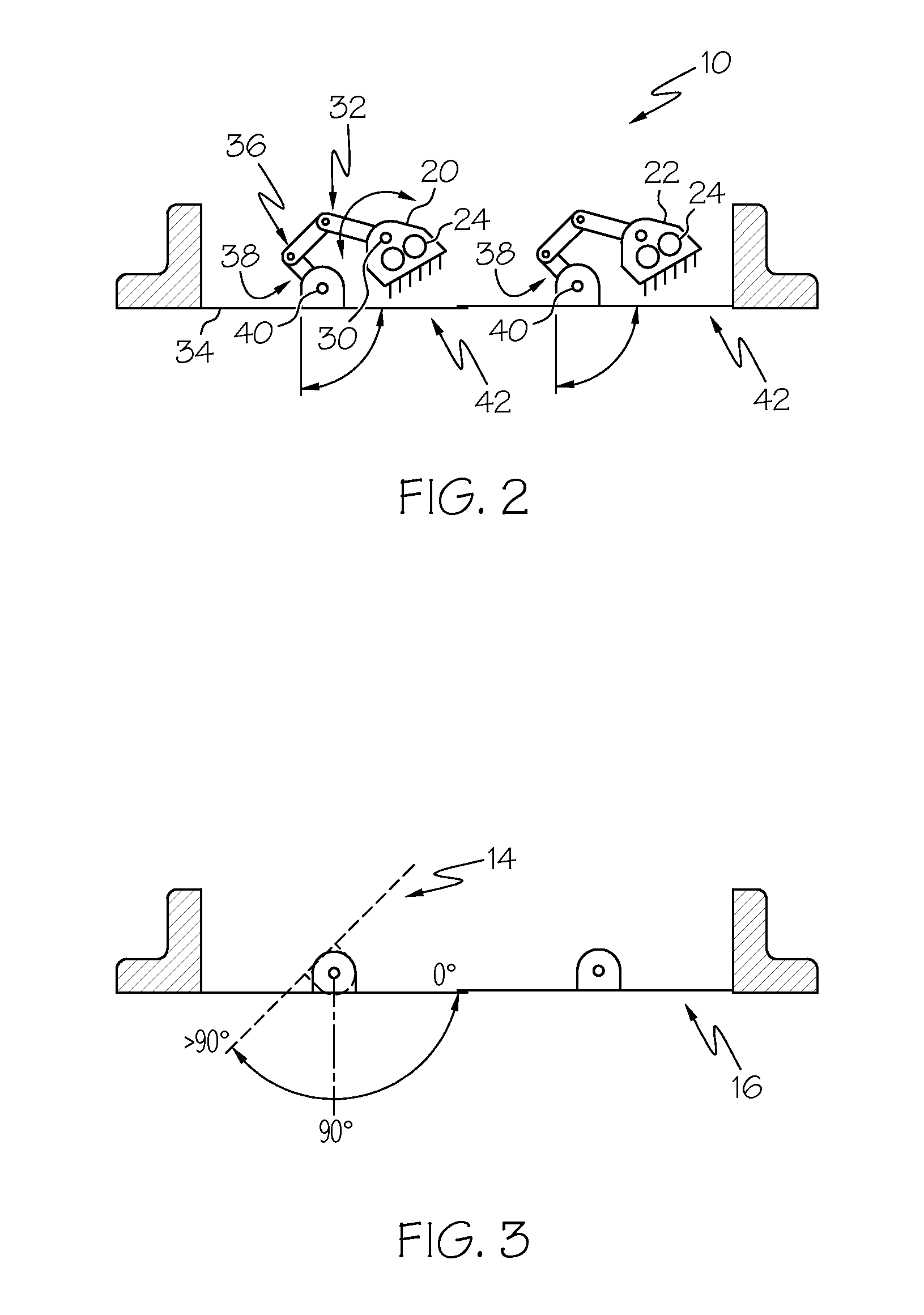

A wheeled vehicle includes a pair of leg driven skis and hand operated levers for simultaneously applying power to a crank and drive sprocket to propel the vehicle. A pair of controllers, one at the top of each thrust lever, include handles that are pushed and pulled to reciprocate the levers and may simultaneously be rotated through wrist and forearm action to steer the vehicle. Auxiliary steering is provided through a handlebar mounted to the vehicle separately from the thrust levers. The skis are operatively coupled to their associated levers, either directly through a pivotal connection or indirectly through an elongate link rotatably coupled at one end to the lever and at the other end to the ski.

Owner:EGGERT WILLIAM E

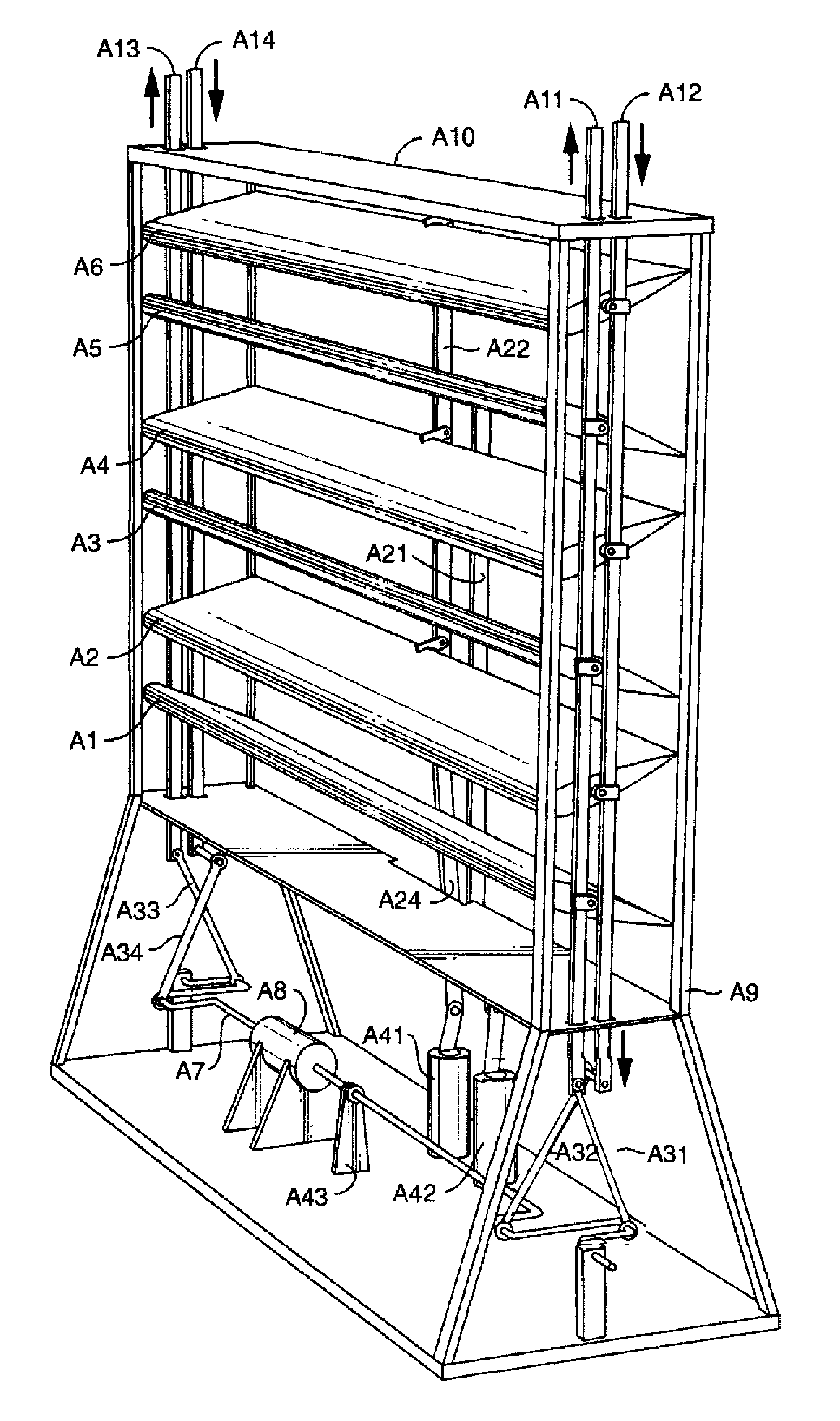

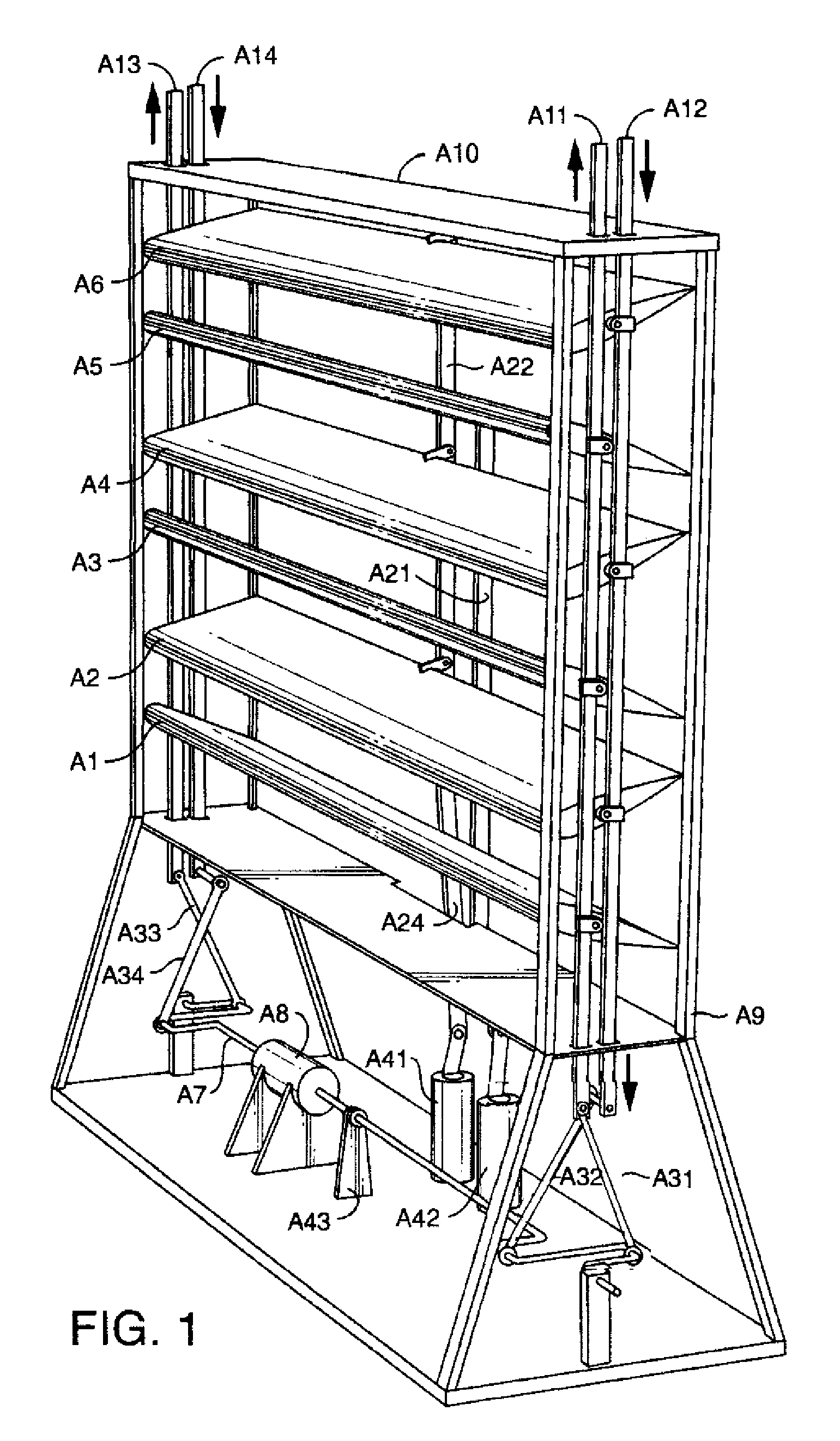

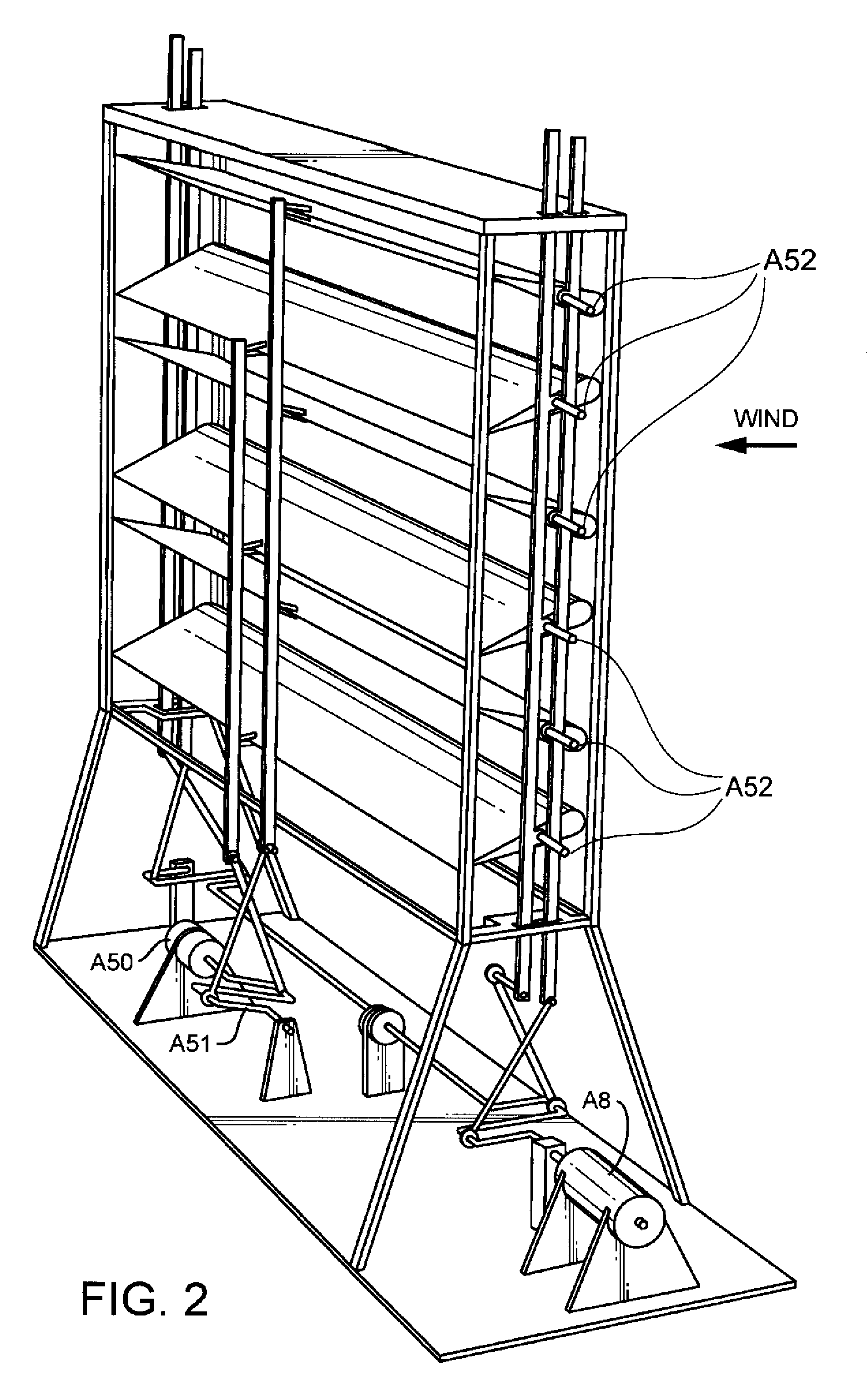

Reciprocating wind-powered transducer employing interleaved airfoil arrays

A reciprocating transducer to convert windpower to electrical energy includes an odd sub-array of blades and an even sub-array of blades, wherein two odd thrust rods are pivotably coupled to the ends of each of the odd numbered blades, two even thrust rods are pivotably coupled to the ends of each of the even numbered blades, an odd tilt rod is pivotably coupled to the trailing edge of each of the odd numbered blades, an even tilt rod is pivotably coupled to the trailing edge of each of the even numbered blades. The tilt rods are moved up and down, thereby changing the attitude of the blades, a crank shaft converts the linear motion of the thrust rods into rotational motion, and a generator converts the rotational motion into electrical power.

Owner:ARNTZ FLOYD

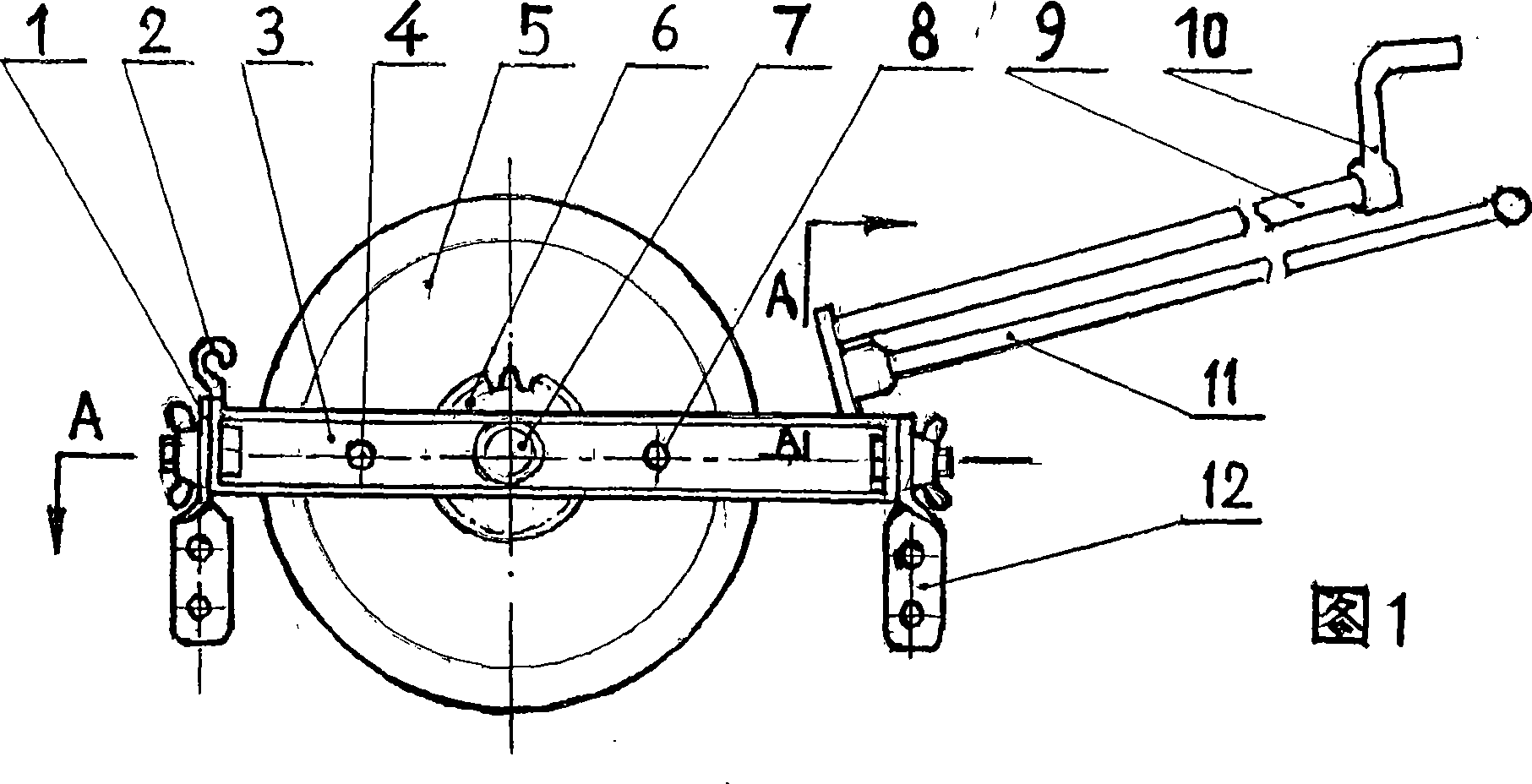

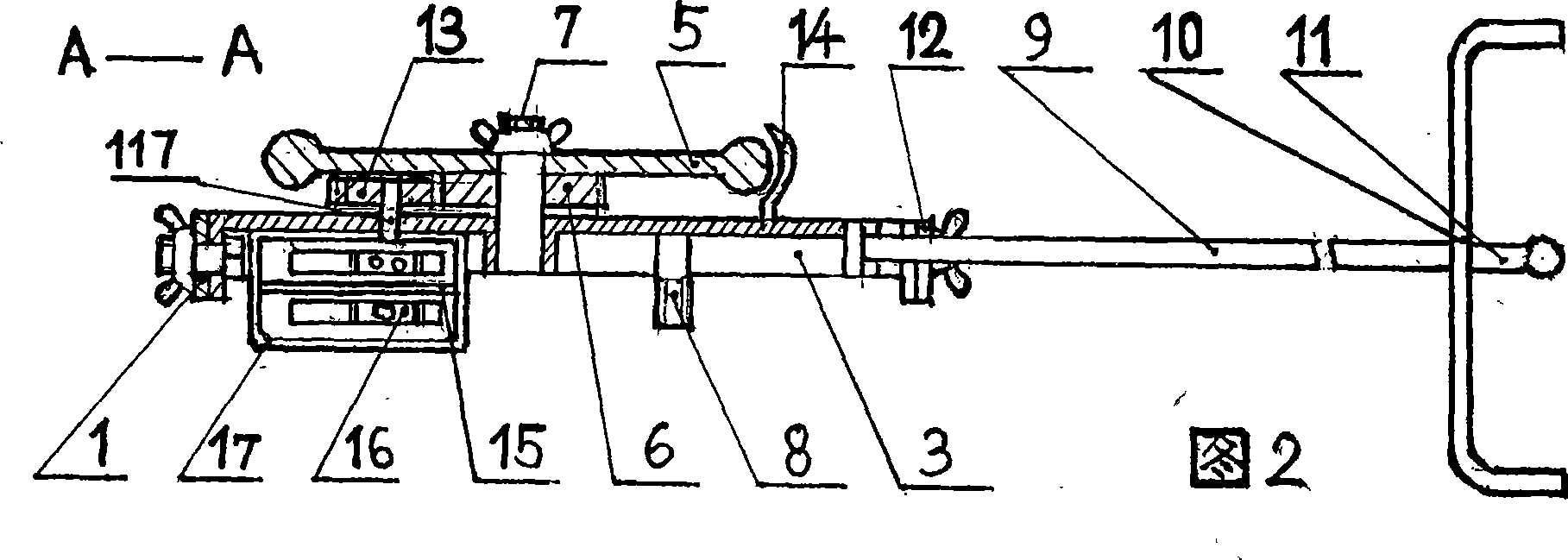

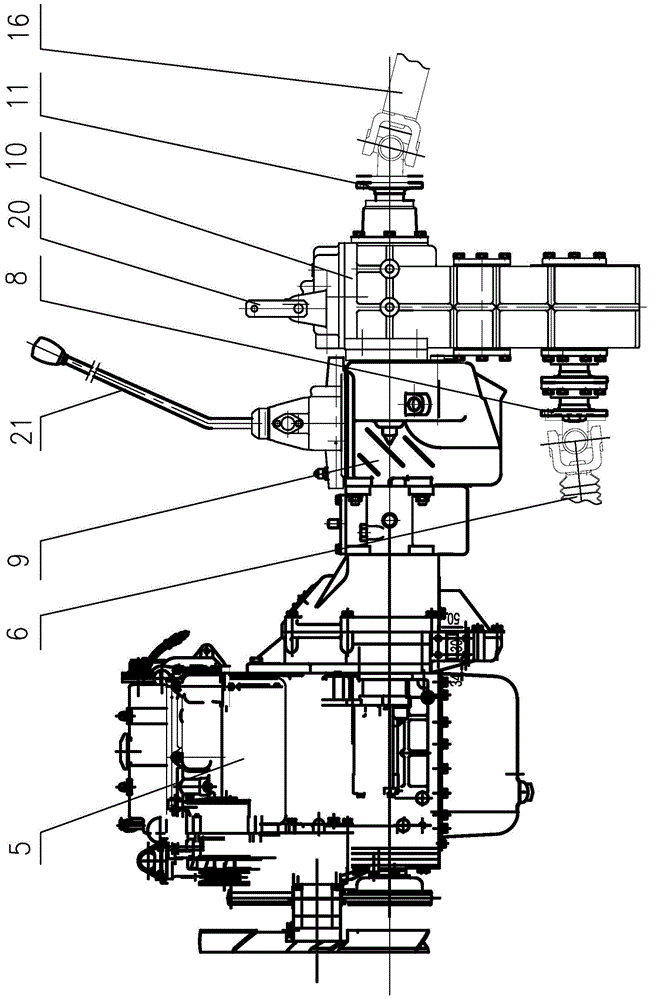

Multipurpose manpower agricultural machinery base part, thrust rod and push-pull belt, and matching component thereof

InactiveCN101434251AEasy loading and unloadingIncrease walking resistanceLoadersSoil-working equipmentsPull forcePush pull

The invention relates to a multifunctional manpower machine basic part, a thrust rod, a pushing and pulling belt and accessories thereof. The basic part comprises a running wheel axle (2) arranged on a single frame (3), a running wheel (5) provided with a driving gear (6) at the end part, an armrest cross-rod (10) fixed tightly on an armrest straight rod (9), a thrust straight rod (11), a front-movable vertical rod (1), a back-movable vertical rod (12), a frame hook (2), a front suspension arm shaft (4), a back suspension arm shaft (8), etc. More than ten kinds of various functional mechanisms, tools and work parts are arranged on the suspension arm shafts and movable vertical rod in a module manner and each kind is provided with different specifications, functions and capabilities so as to lead a user to select parts individually for the mutual coordination without interruption. Particularly, the cooperation between the thrust rod and pushing belt changes the prior manner that hands and arms generate thrust so as to lead the abdomen to get thrust; and the shoulders generate pulling force so as to lead the waist to get pulling force, thereby saving force under the same work load. With a support connecting part, an operator can hold the machine with one hand and also can push the machine to move forward.

Owner:汪新民

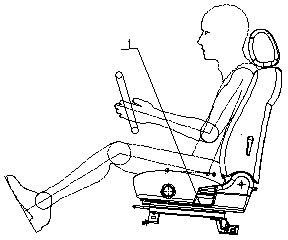

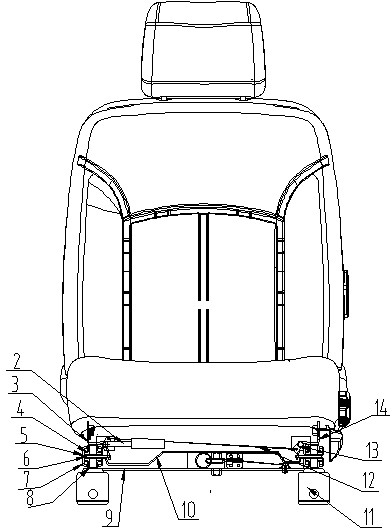

Safe automatic regulation mechanism for automobile seat

The invention discloses a safe automatic regulation mechanism for an automobile seat, which comprises a first sliding mechanism, a second sliding mechanism, a thrust mechanism, a positioning mechanism and a sensing driving mechanism, wherein the first sliding mechanism is used for the forward and backward regulation of the seat position, the second sliding mechanism, the thrust mechanism, the positioning mechanism and the sensing driving mechanism are used for the safety assurance, the first sliding mechanism, the second sliding mechanism, the thrust mechanism, the positioning mechanism and the sensing driving mechanism are all directly arranged on an automobile floor or are all arranged on the automobile floor through transition components, a thrust plate is arranged on a thrust rod of a thrust device and is connected with a sliding part of the second sliding mechanism, a positioning pressing arm of the positioning mechanism is pressed on the thrust rod of the thrust device, the thrust device is locked in an un-pushed state, and a pressure relieving driving arm of the positioning mechanism is connected with the sensing driving mechanism. When an automobile seriously collides, the sensing driving mechanism drives a pressing driving handle, the pressing rod is driven to relieve the locking on the thrust device, the thrust mechanism fast pushes the thrust plate, and the sliding part of the second sliding mechanism drives the seat to backwards move under the effect of the thrust plate.

Owner:CHONGQING QINGANG QINGHONG TECH

Thrust recovery, or other valve, containing two independently actuated doors and control system

A thrust recovery valve has two flaps, with each flap controlled independently via its own rotary actuator. Embodiments of the present invention also provide a cabin pressure control system that includes one or two thrust recovery valves and the controls architecture to efficiently operate the valves. On each thrust recovery valve, only one door can be operated during flight, making less effective area change per unit time (relative to the operating both doors at the same time), allowing higher resolution of valve control. Further, the valve doors can be made such that the primary door that is operated in flight is smaller than the other door (mostly only operated on the ground). Because the doors of the thrust recovery valve can be operated independently, the forward door of each valve can be rotated such that the door creates a ram air “scoop” to ingress air to prevent negative pressure from building up beyond a specified limit.

Owner:HONEYWELL INT INC

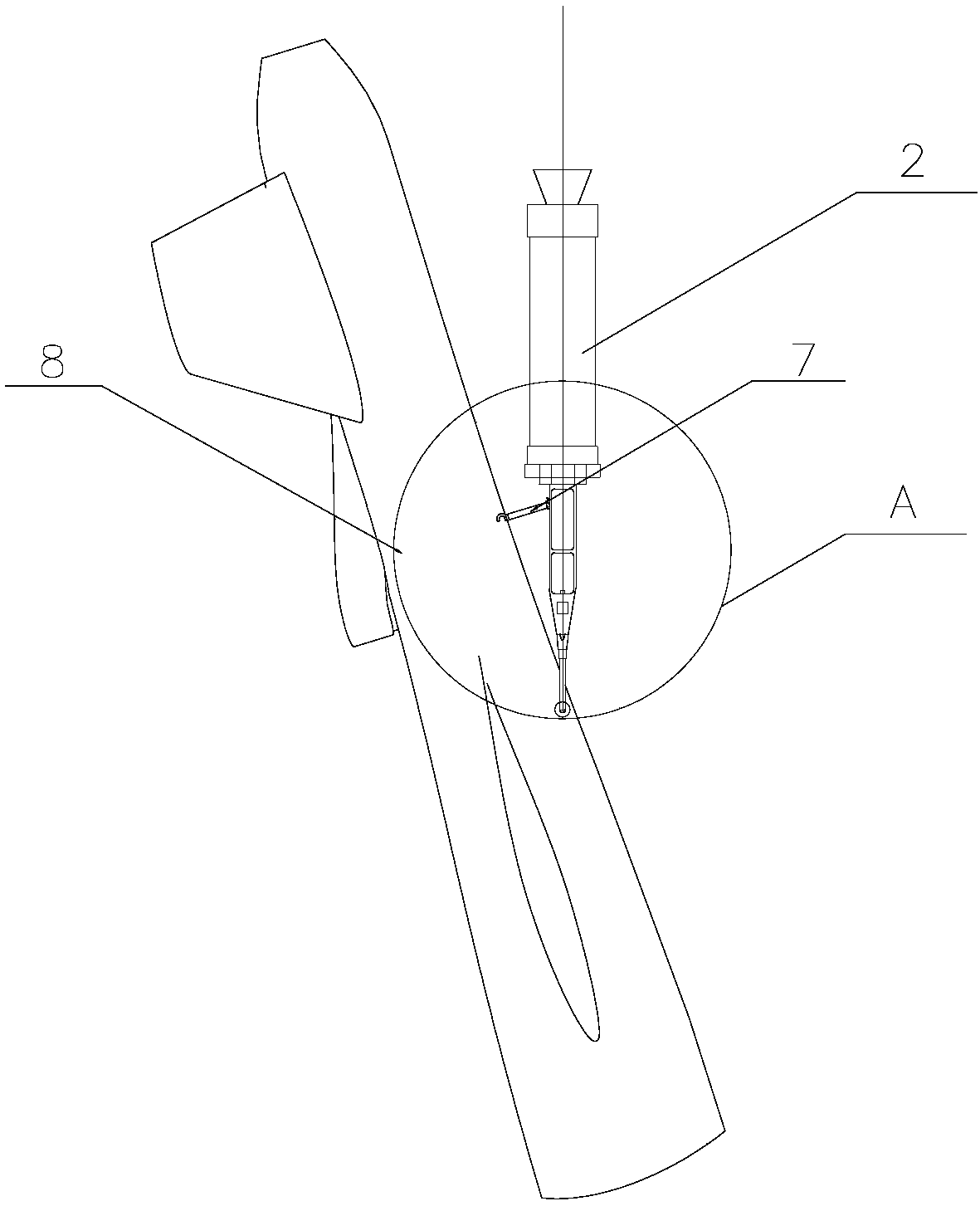

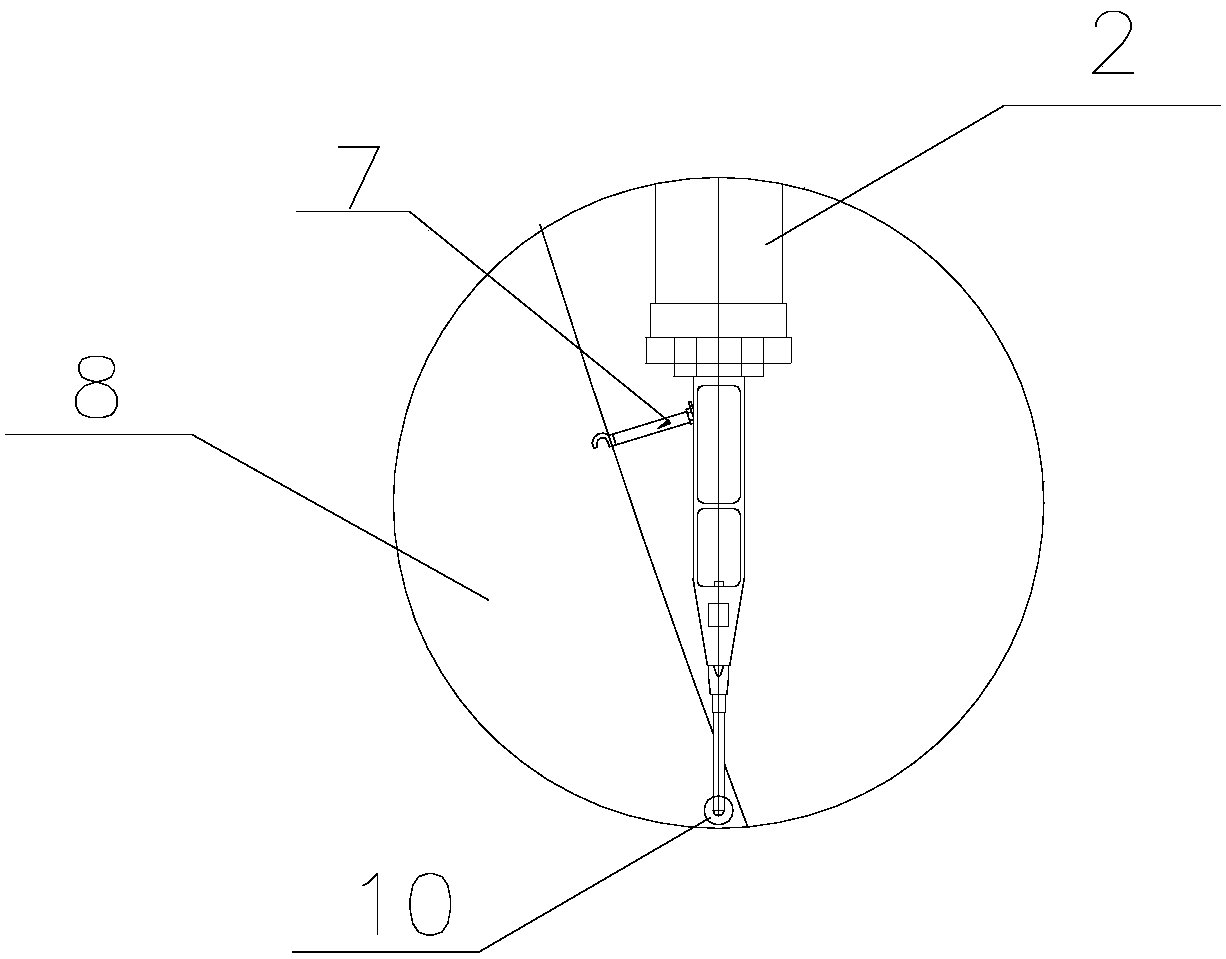

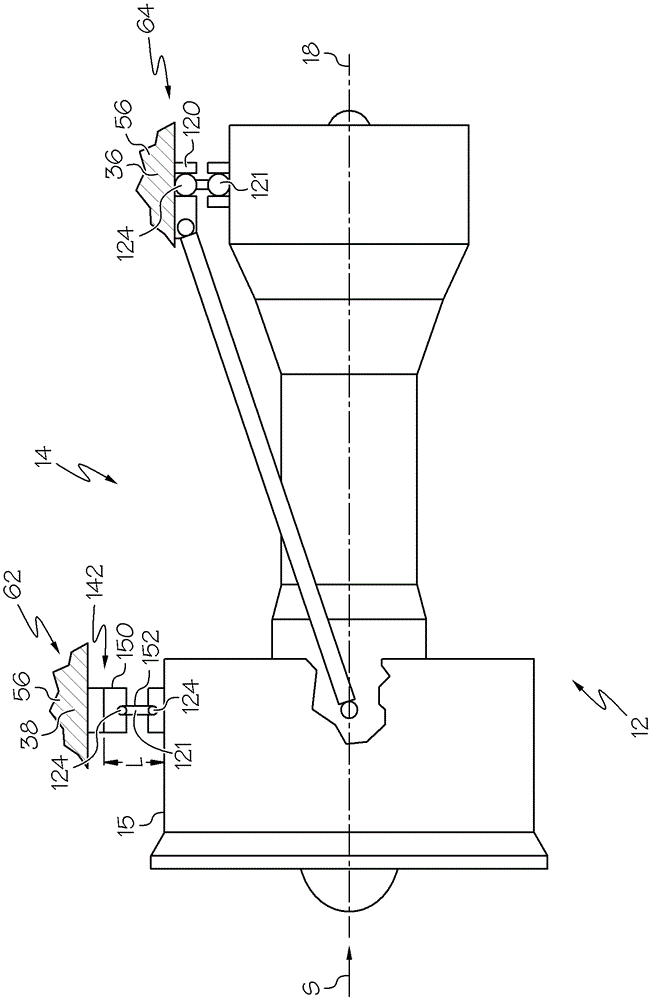

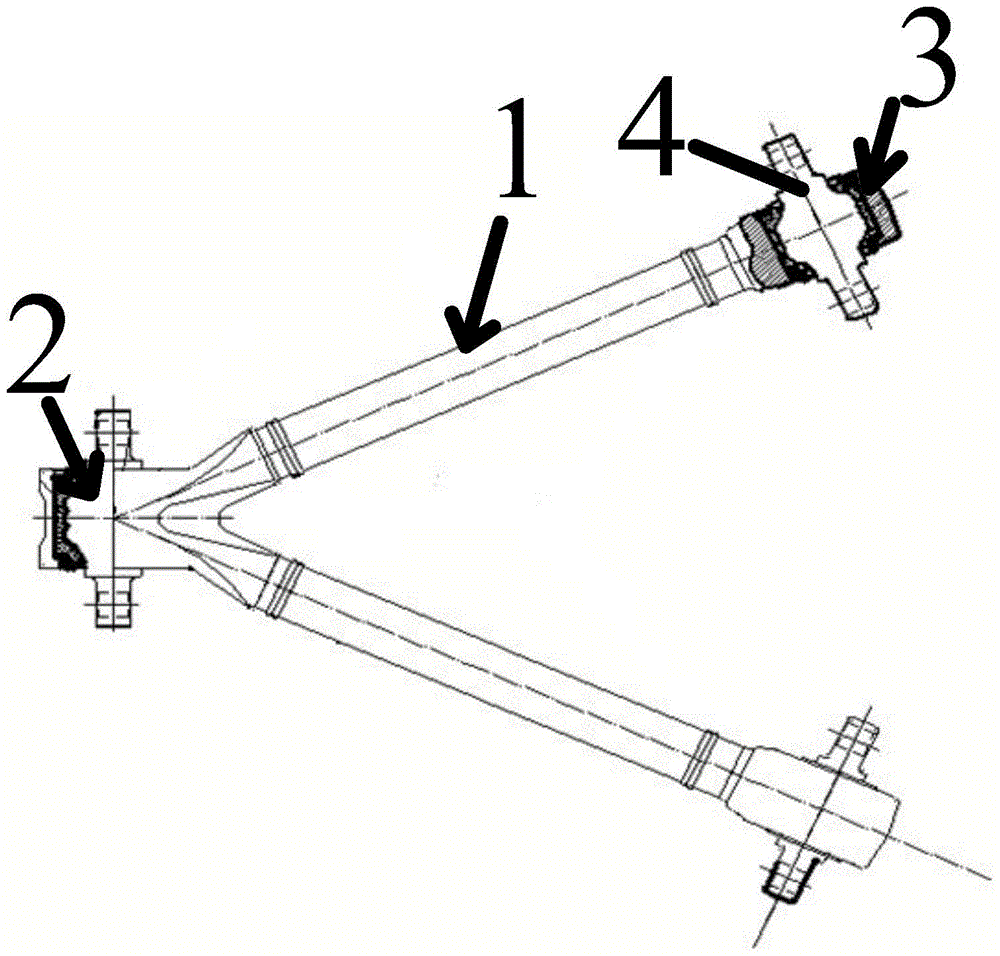

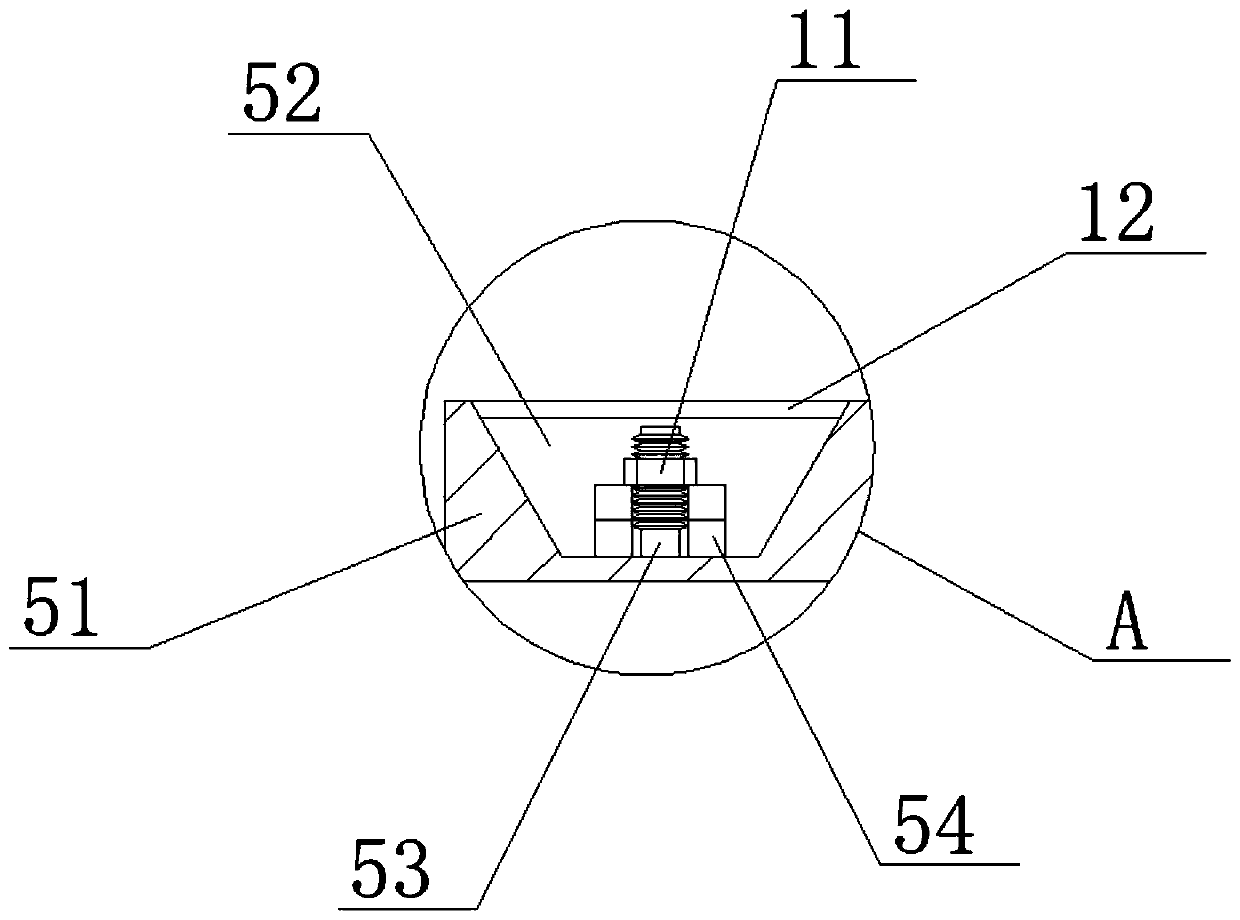

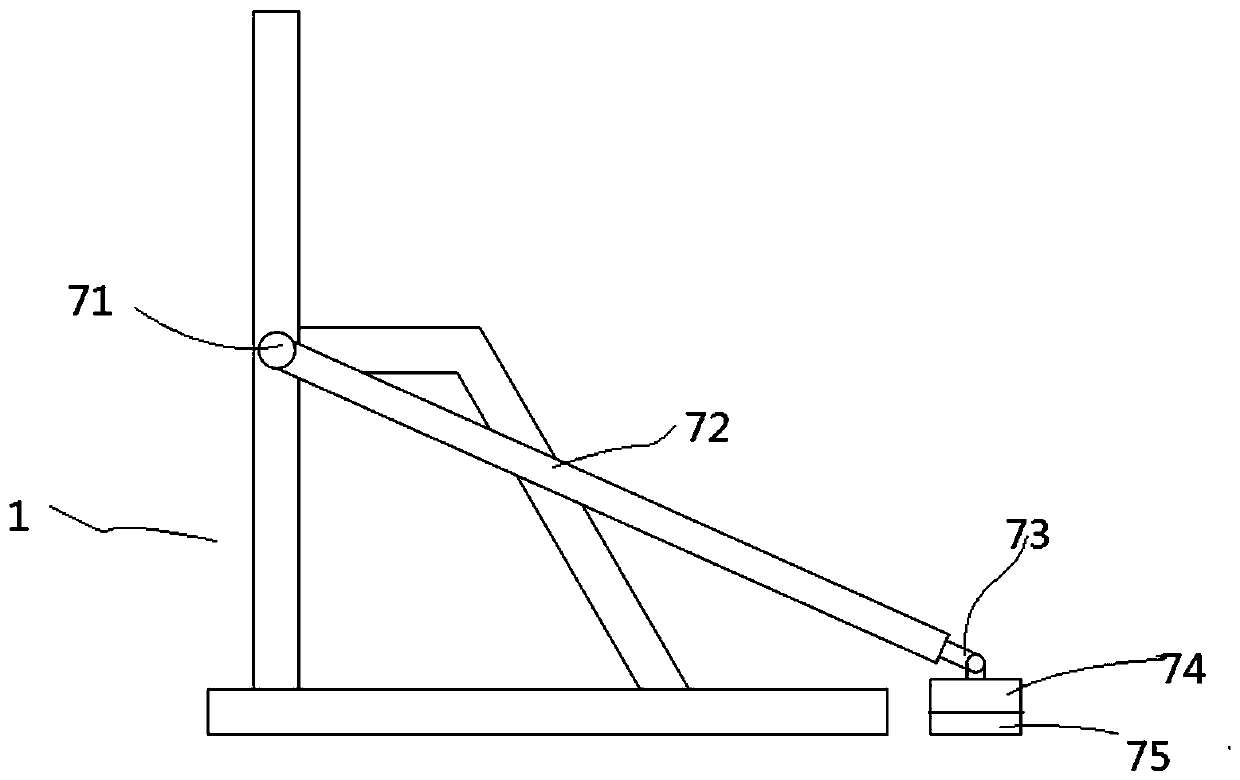

Two-point-type rocket assisting launcher of unmanned aerial vehicle and method thereof

PendingCN107933946AReduce local overloadReduce occupancyLaunching/towing gearFlight vehicleUncrewed vehicle

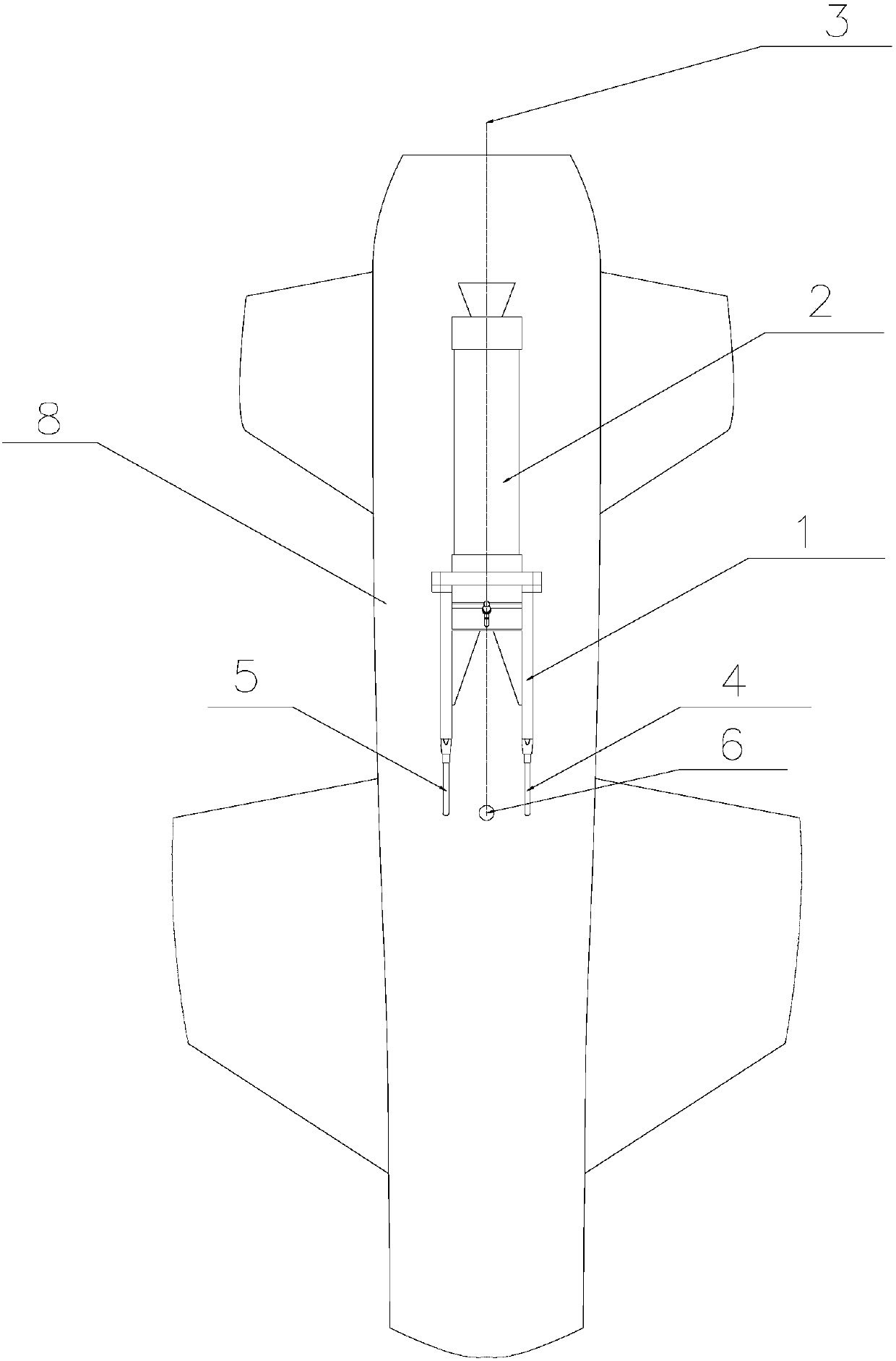

The invention discloses a two-point-type rocket assisting launcher of an unmanned aerial vehicle and a method thereof, and belongs to the field of aircrafts. The two-point-type rocket assisting launcher of the unmanned aerial vehicle comprises a thrust frame for installing a booster rocket and a bottom base and a hanging hook ring which are installed on an unmanned aerial vehicle body. The thrustframe is fixedly provided with two thrust bars and a hanging hook. The bottom base is provided with two ball sockets and a hanging point. The hanging hook is hanged on the hanging hook ring. The top parts of the two thrust bars are supported in the ball sockets. The hanging hook, the thrust bars and the unmanned aerial vehicle body form a triangle supporting structure. The thrust bars transmit a rocket assisting thrust to the unmanned aerial vehicle body through the two ball sockets. The hanging point is used for connecting a sling for determining a thrust line. The thrust frame is further provided with a connecting base used for connecting a thrust line measuring device. The two-point-type rocket assisting launcher of the unmanned aerial vehicle uses a two-point boosting mode, the stabletriangle is formed by two thrust points and one hanging hook point, the gravity is balanced and the influence of the ground effect to the relative position of the rocket and the unmanned aerial vehicle body in a launching initial stage is eliminated, so the accuracy of the relative position between the rocket and the unmanned aerial vehicle body is guaranteed.

Owner:ZHEJIANG UNIV

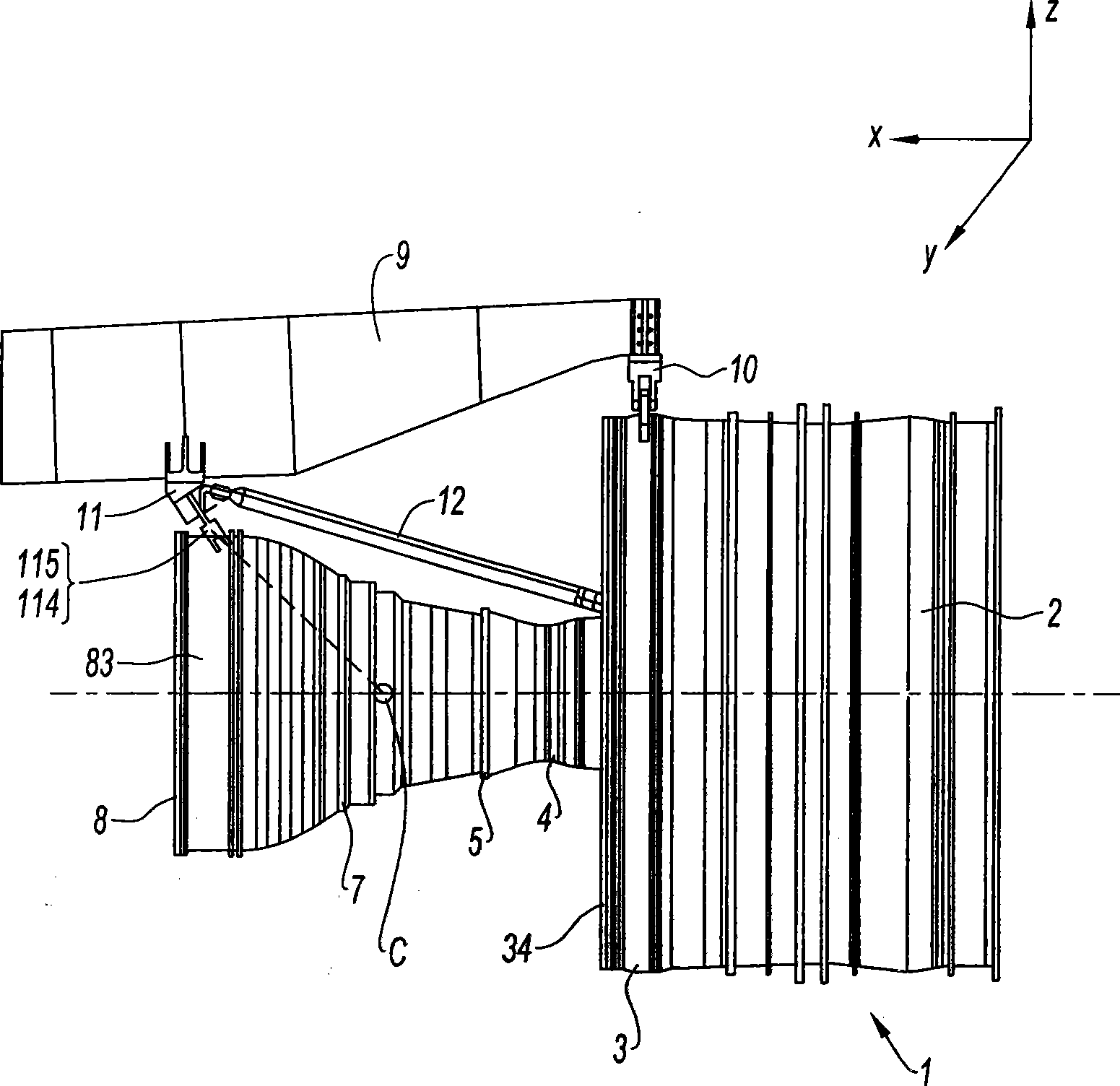

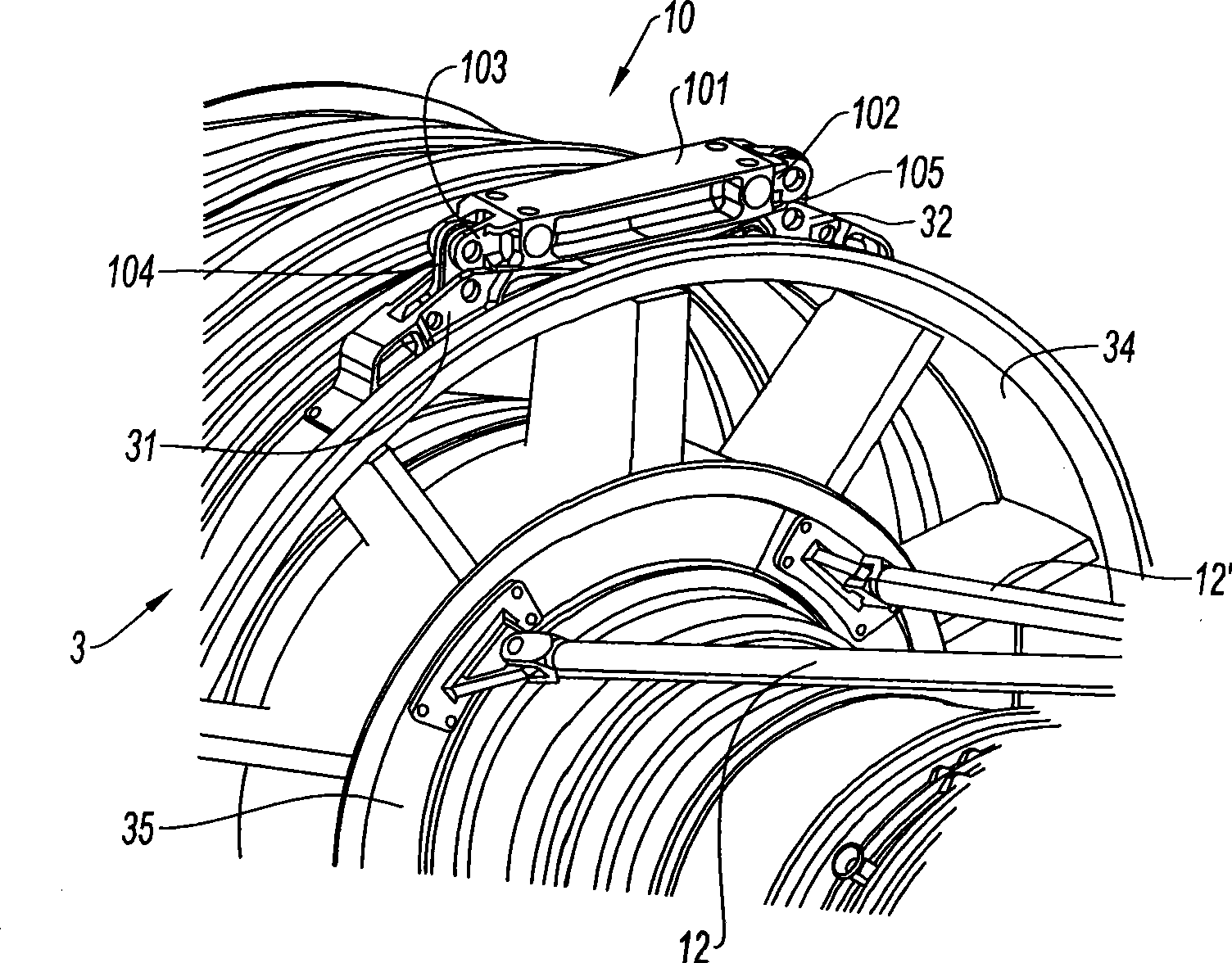

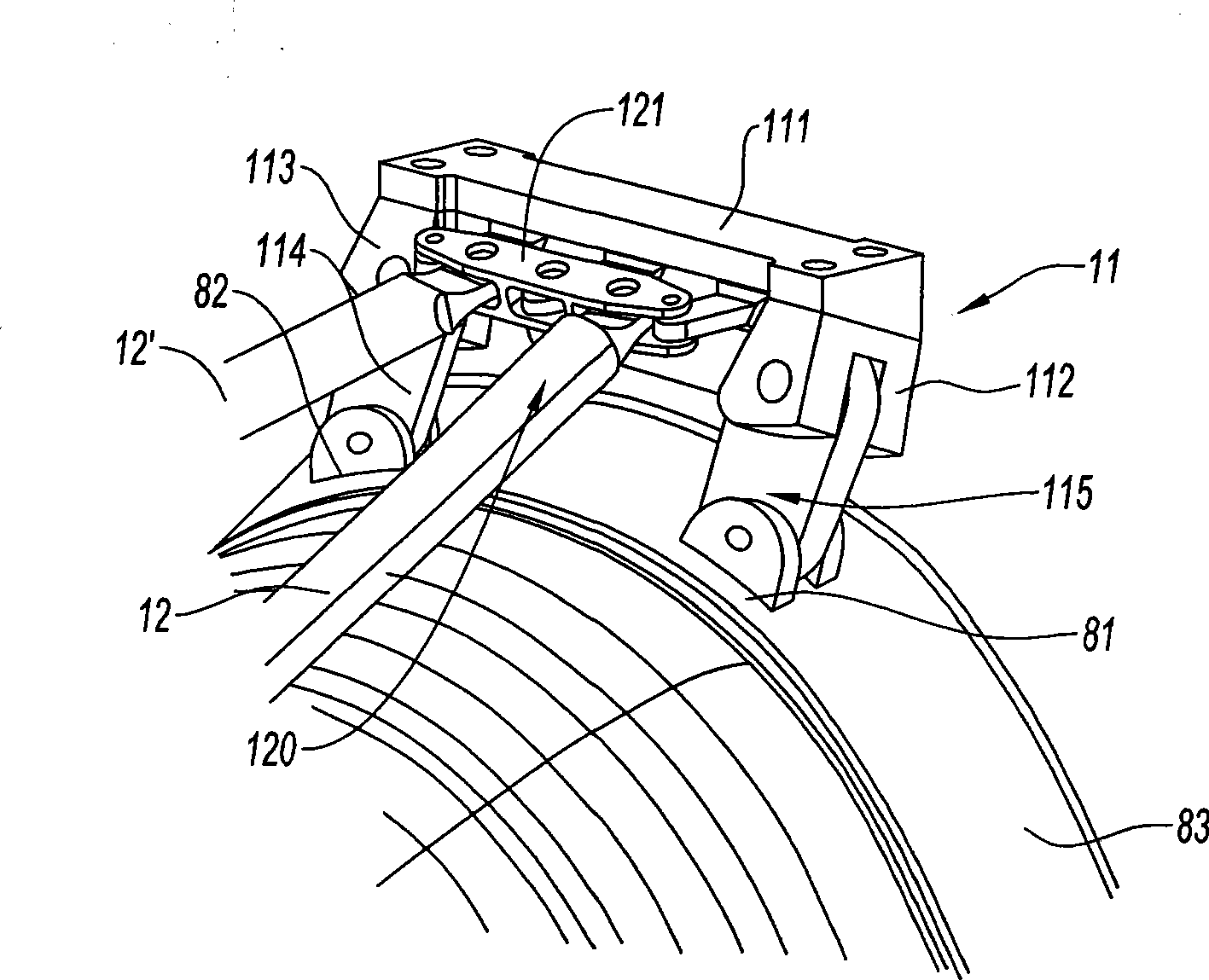

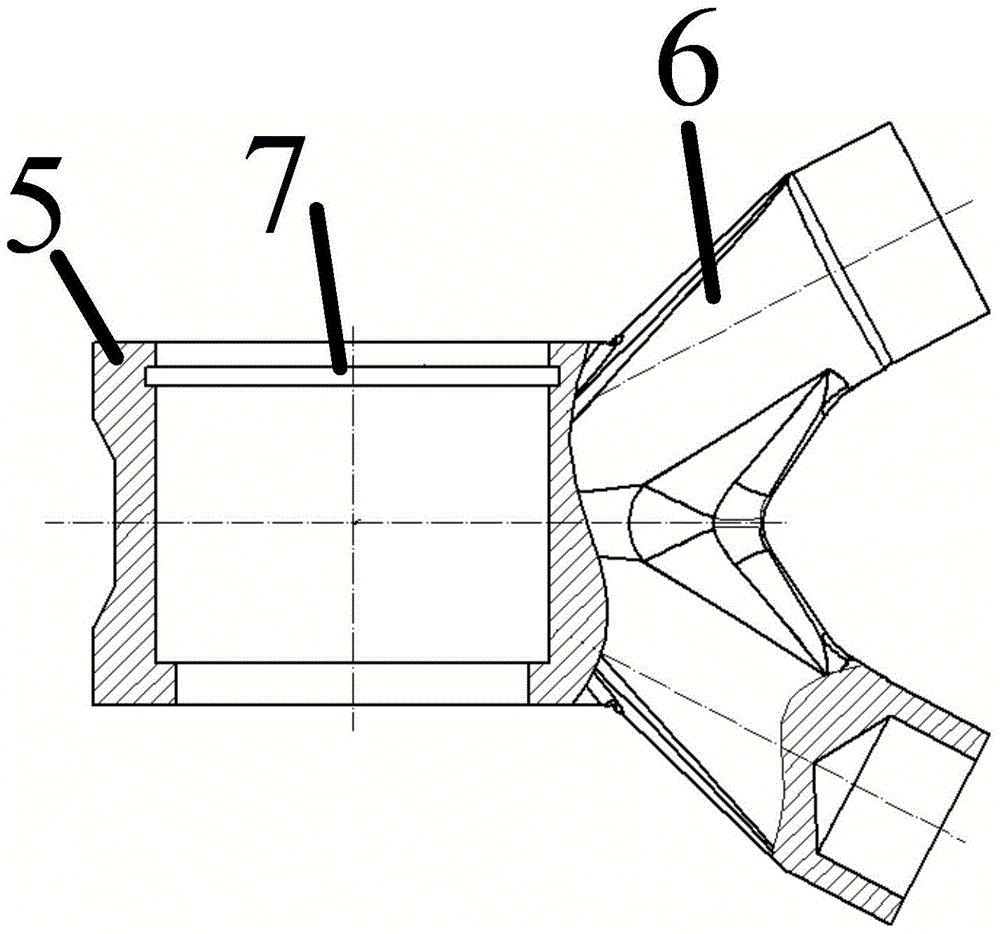

Suspension of a turbojet to an aircraft

ActiveCN101450715AEliminate or at least reduce distortionReduce weightPower plant constructionWeight reductionTurbineTurbojet

The present invention relates to a balance suspension device for mounting a turbine engine on a suspension frame of a plane, the turbine engine comprises a front fan (2), an intermediate case (3) at low stream of the fan, the intermediate case has an external housing and a hub (35) connected together by a radial rod (360, and an exhaust case (8) with a housing (83) on a same axis XX, the suspension device comprises a front connection device (10) on the intermediate case (3), a rear connection device (11), which has at least two link rods (114, 115) connected to the external housing of the exhaust case (8), and a pair of thrust rods (12, 12') fixed on the hub (35) of the intermediate case (3) at their low stream end. The suspension device is characterized in that a plane formed by the two link rods (114, 115) of the rear connection device (11) is inclined with respect ot a plane of the exhaust case (8).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

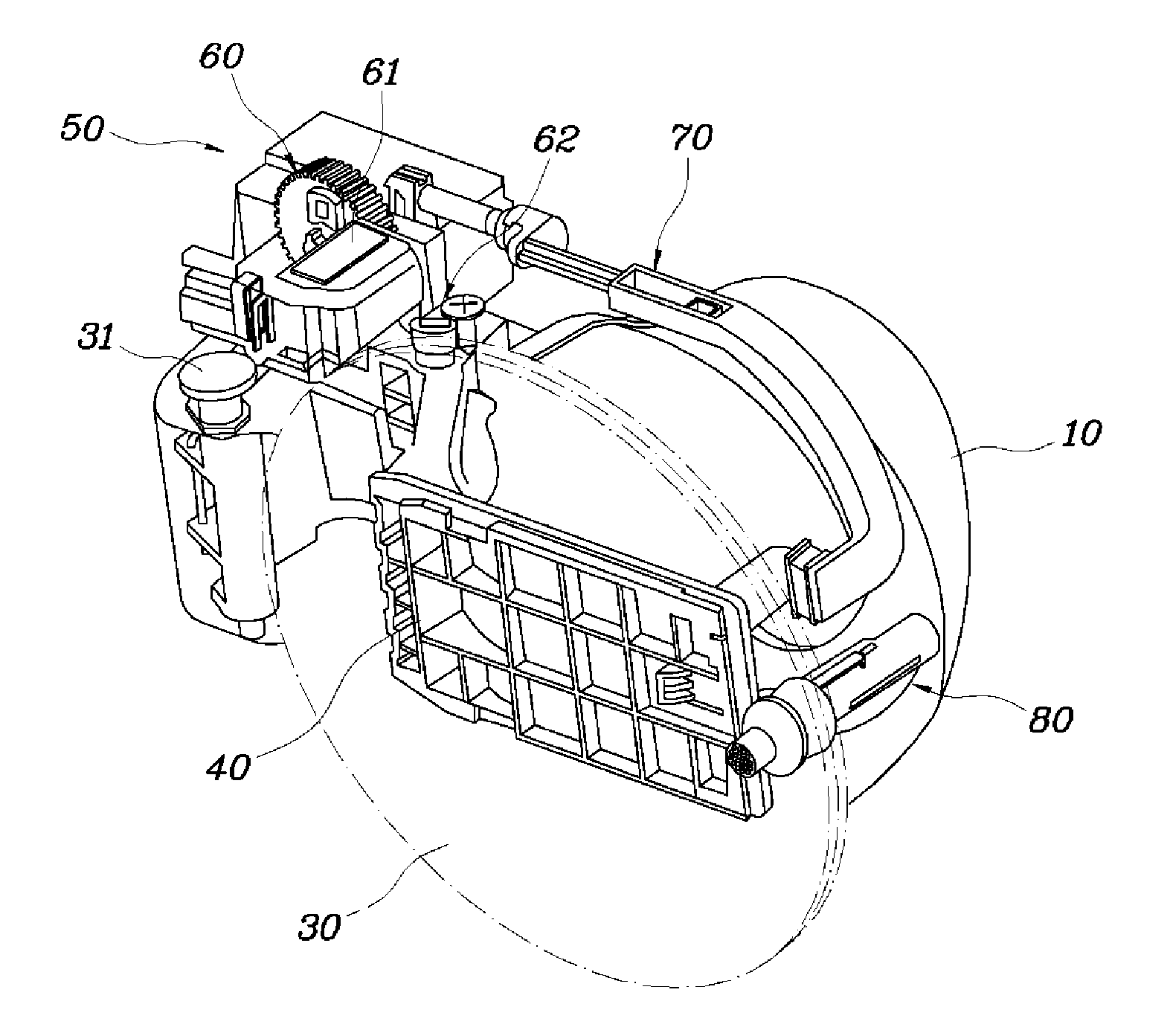

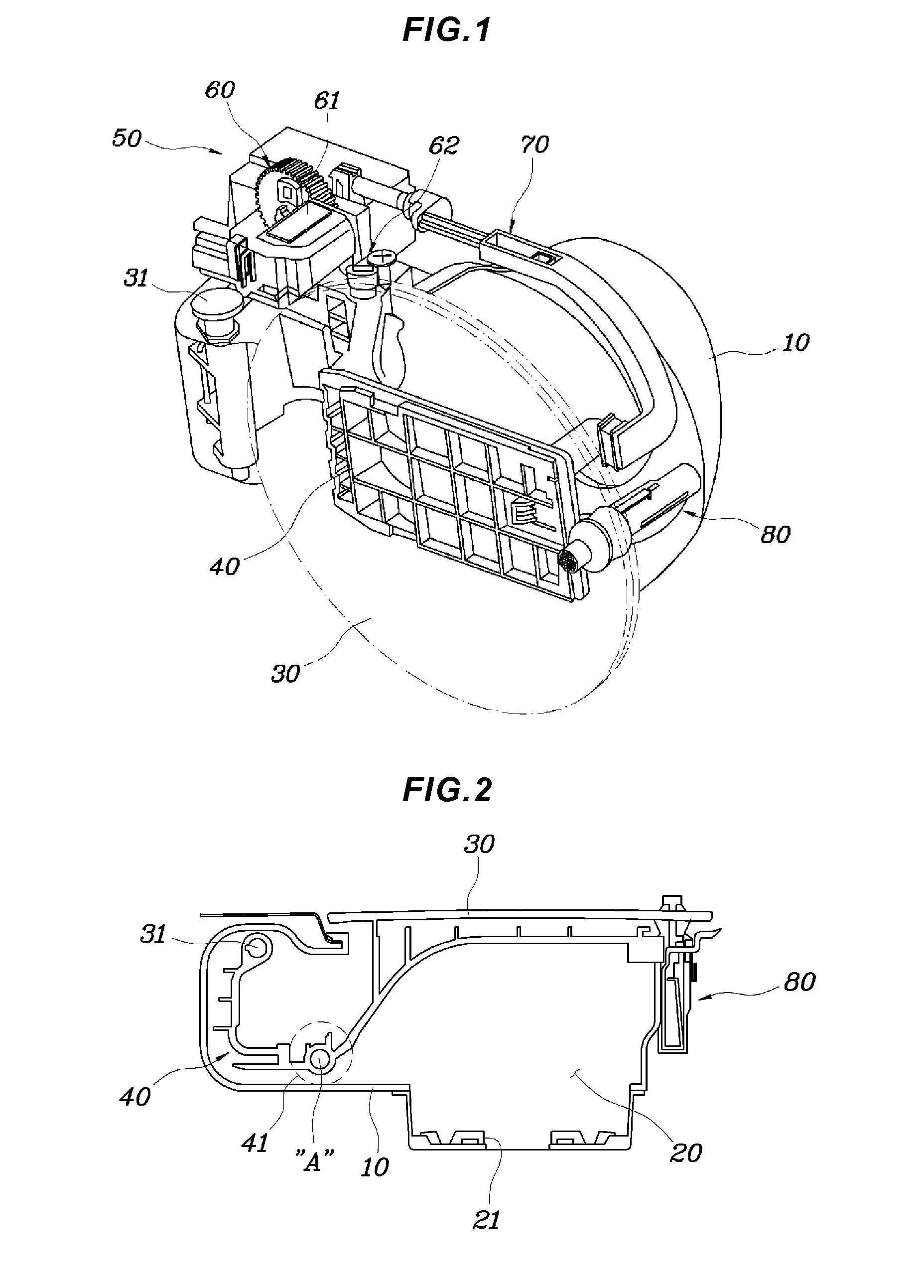

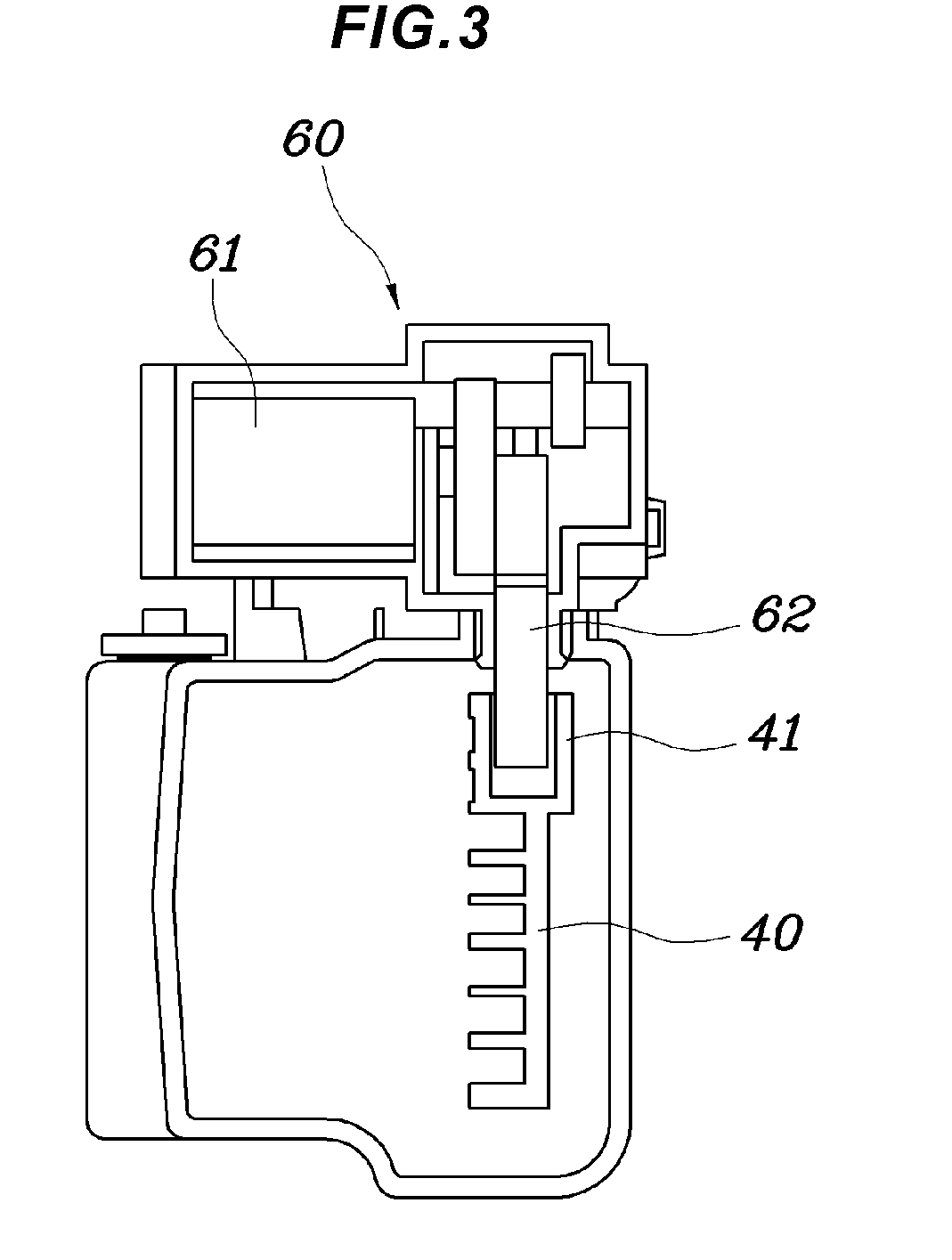

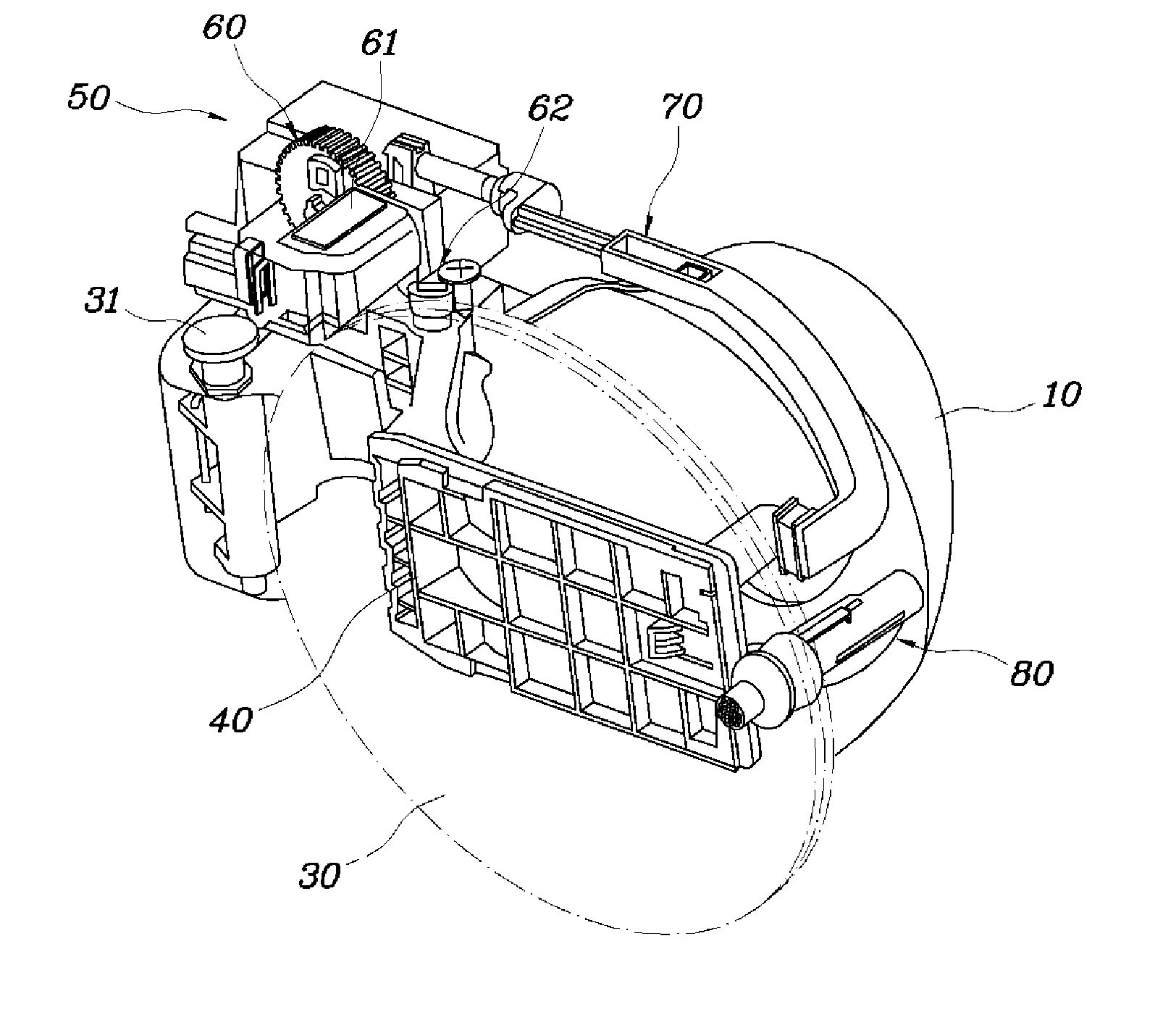

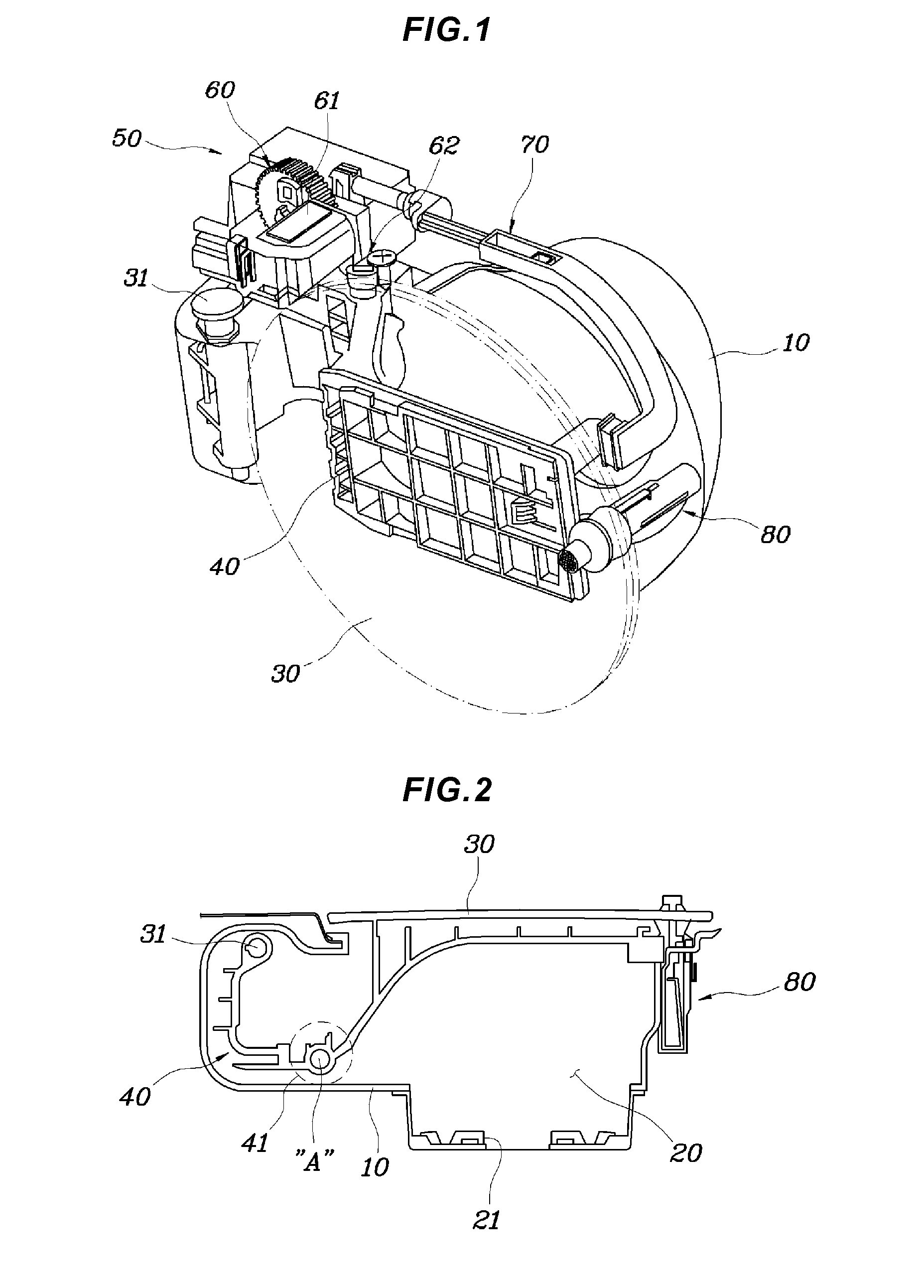

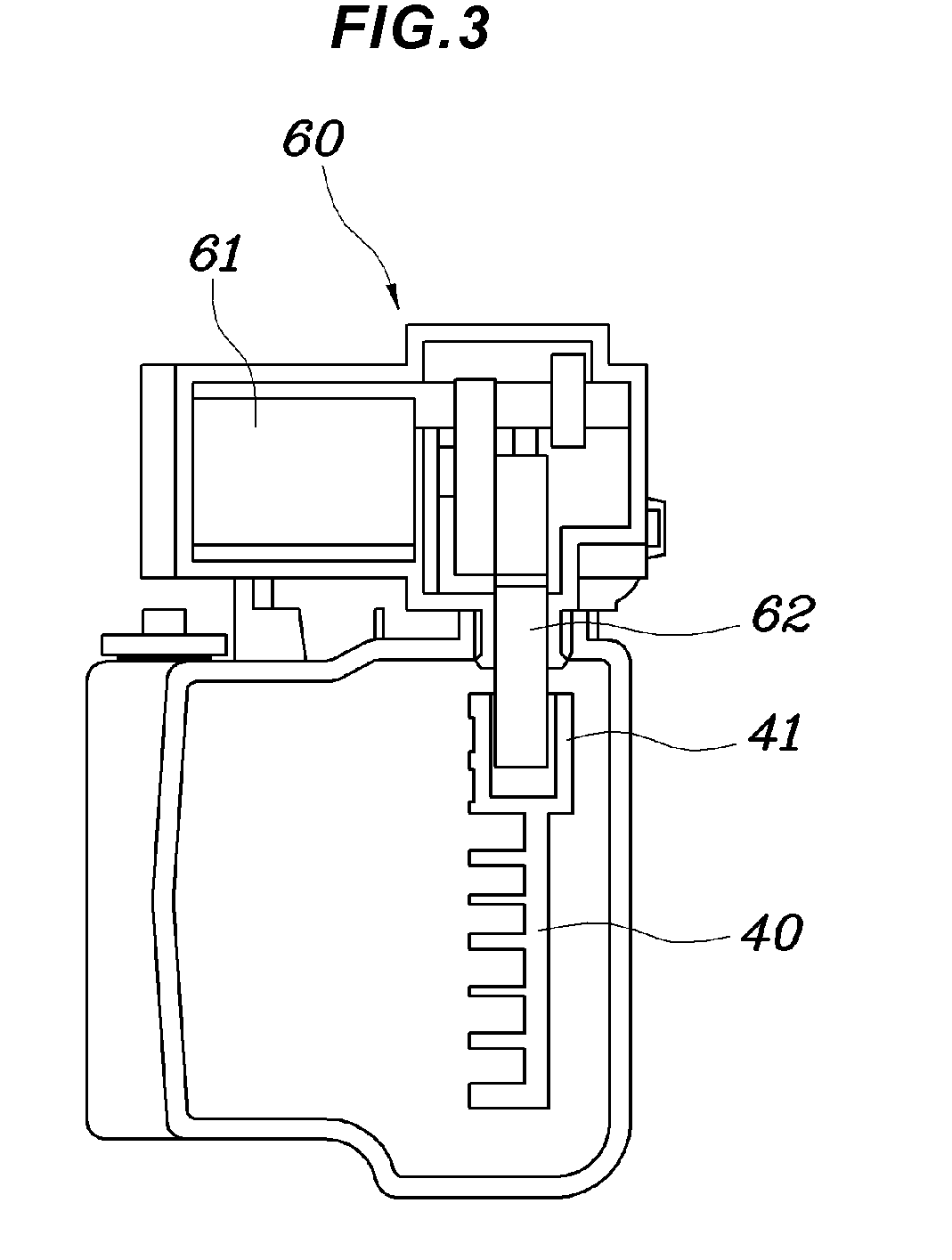

Opening and closing device for fuel door of vehicle

ActiveUS8870241B2Guaranteed uptimeMan-operated mechanismConstruction fastening devicesEngineeringActuator

An opening and closing device for a fuel door of a vehicle including a push type latch device for locking or unlocking the fuel door that may be rotatably mounted to a side of a housing by a hinge unit, may include a locking rod movable by an actuator and selectively locked to a locking slot provided in the hinge unit to which the fuel door may be attached, thereby controlling rotation of the hinge unit, and an anti-thrust lever operated in conjunction with the locking rod actuated by the actuator to selectively support the fuel door so as to prevent the fuel door from being thrust backwards.

Owner:HYUNDAI MOTOR CO LTD

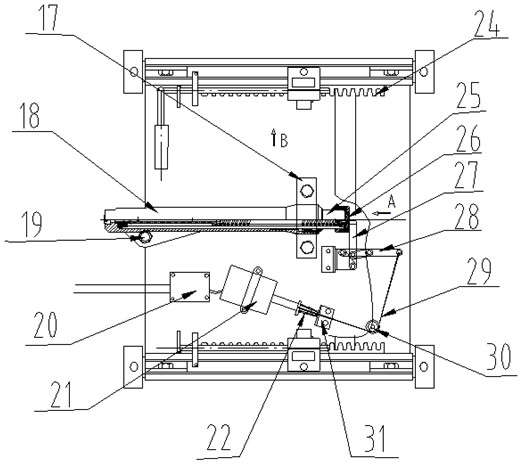

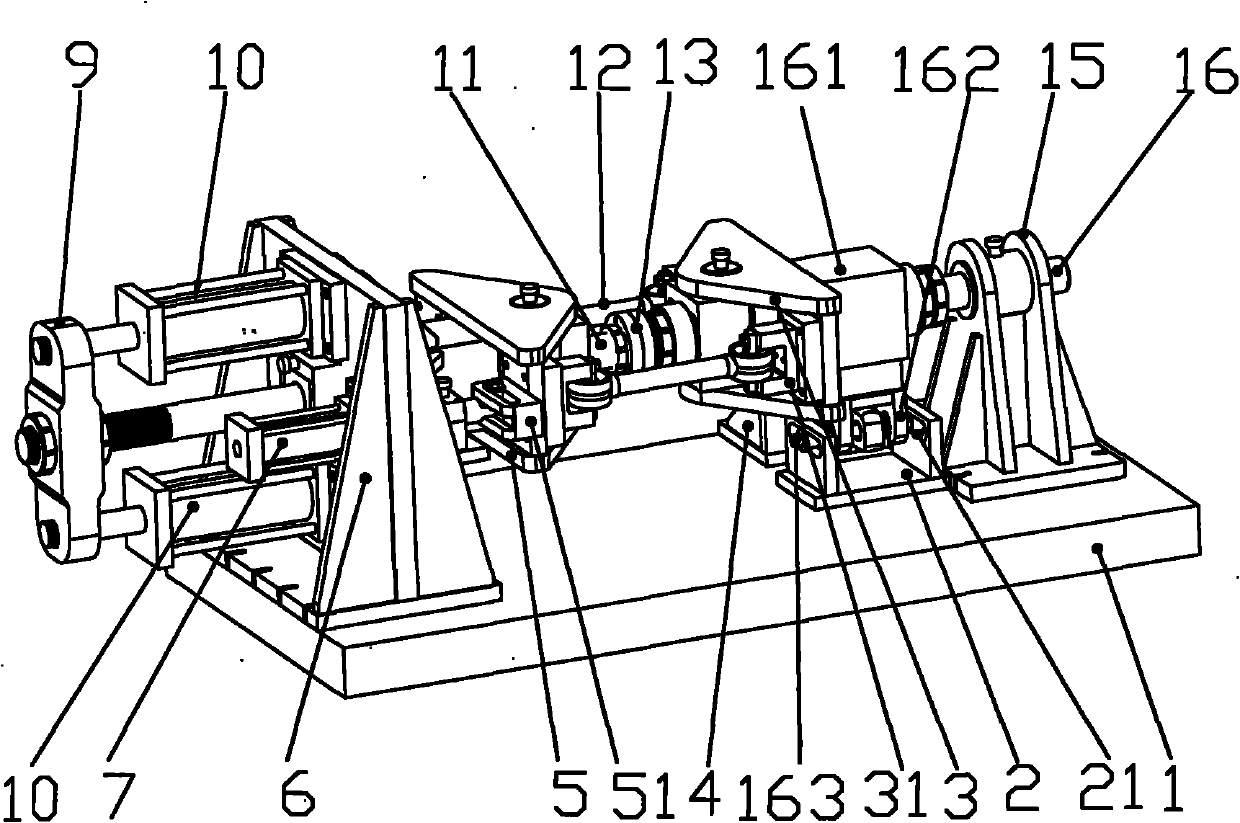

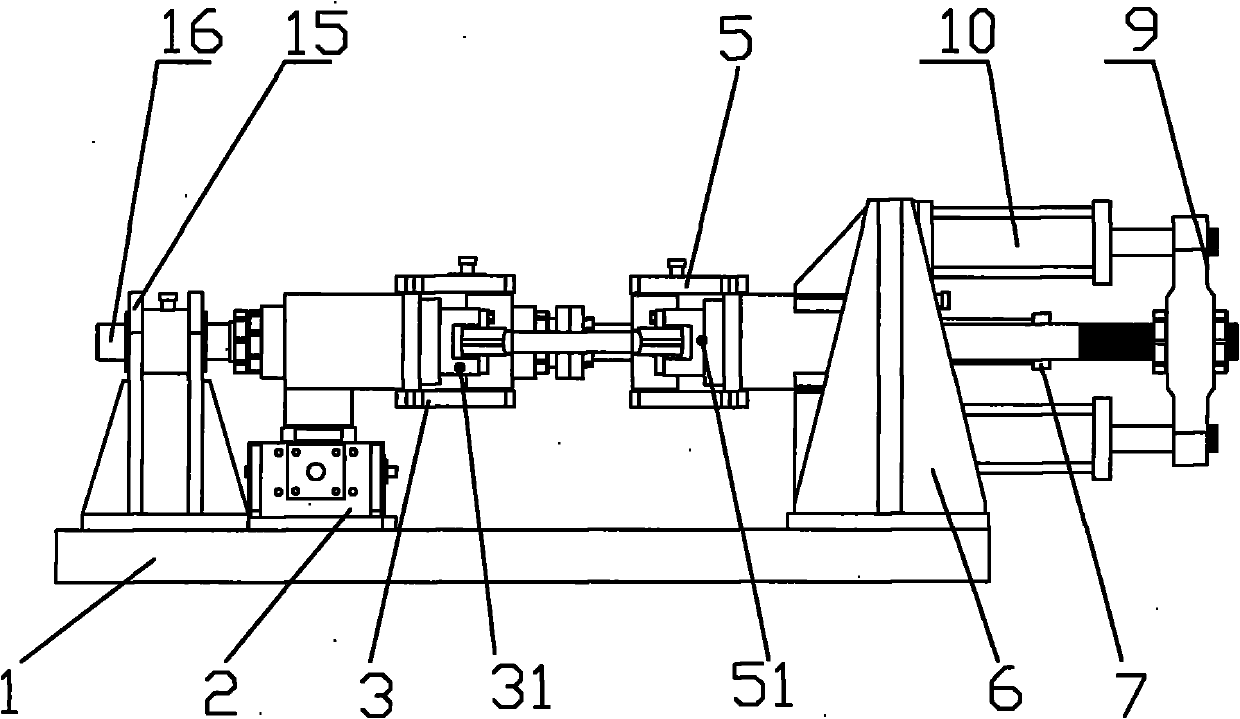

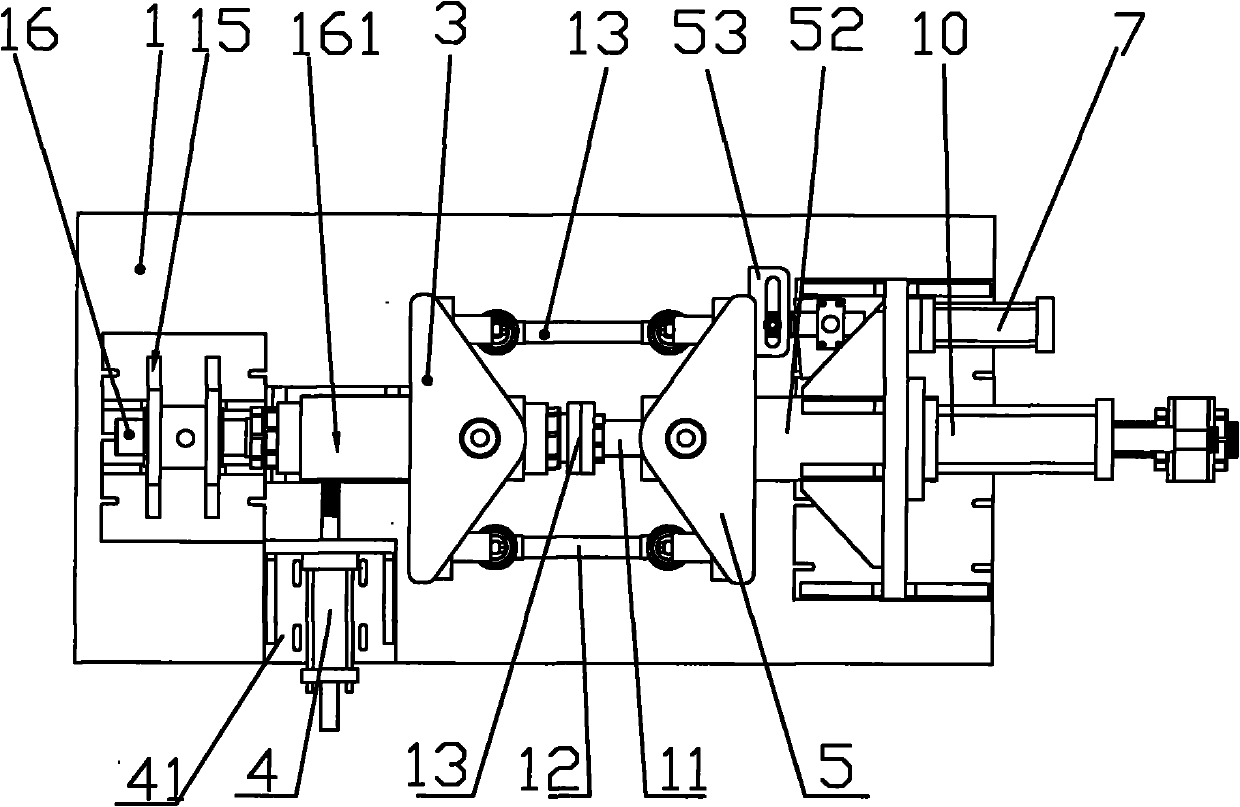

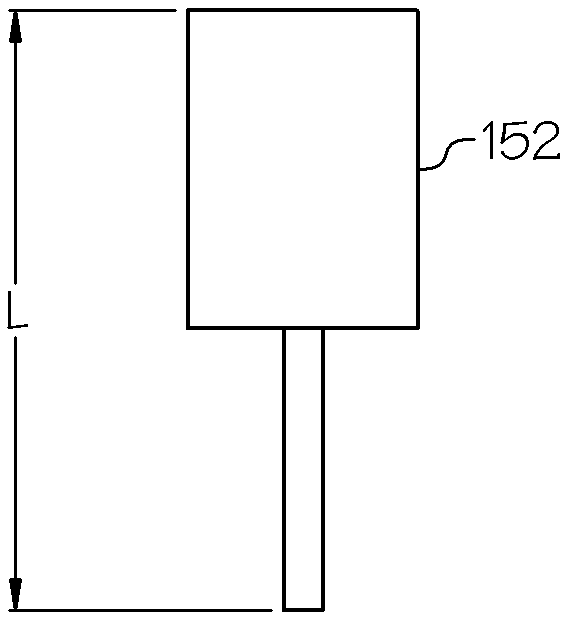

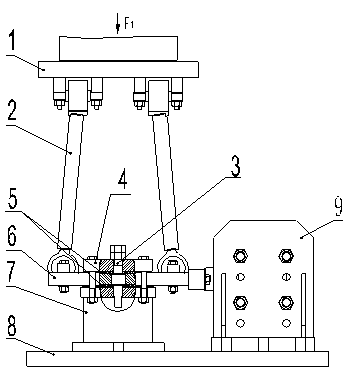

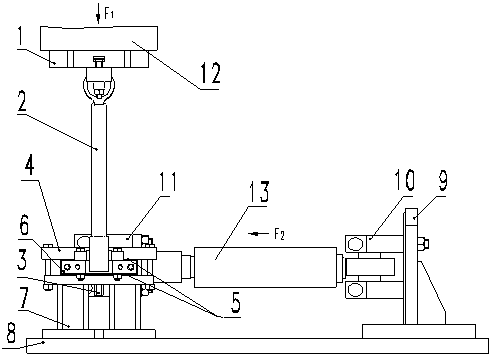

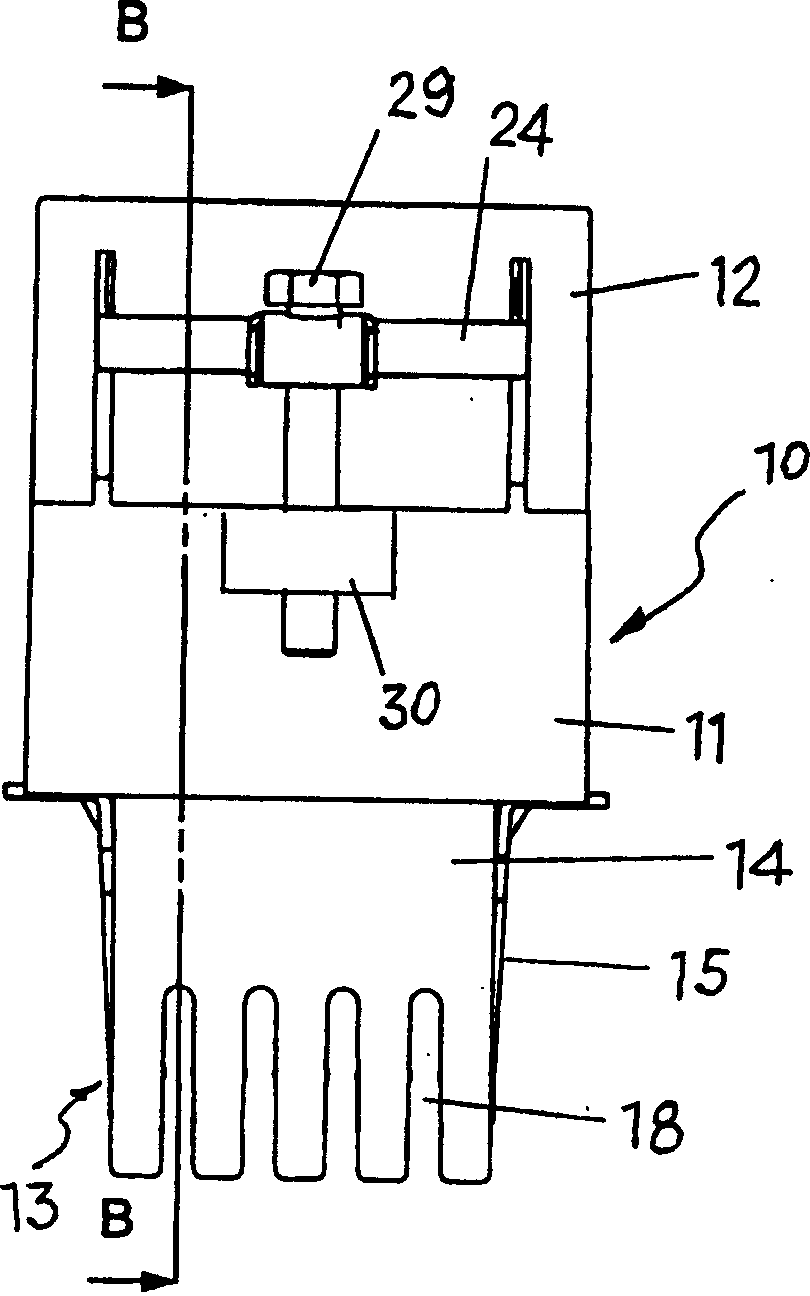

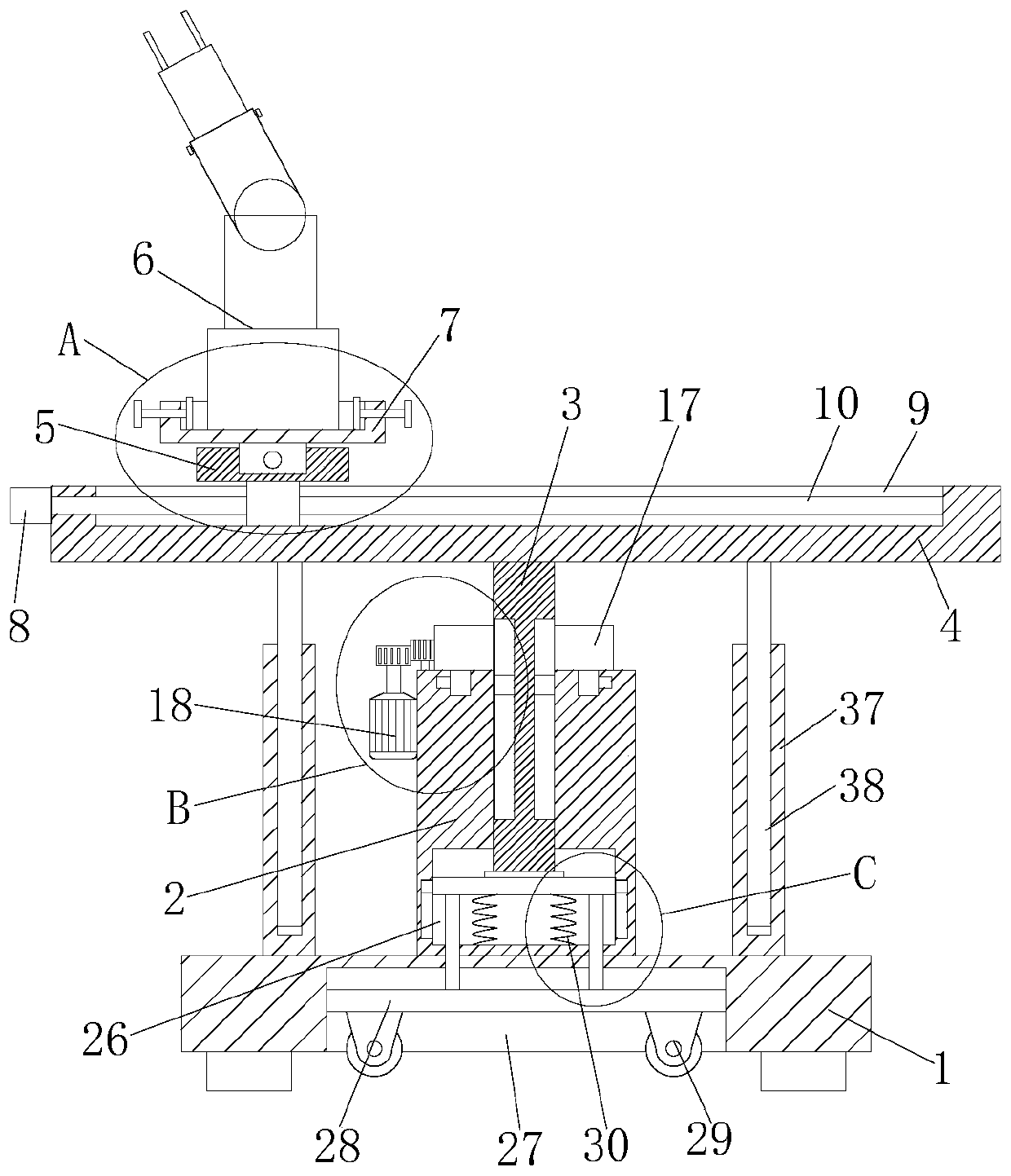

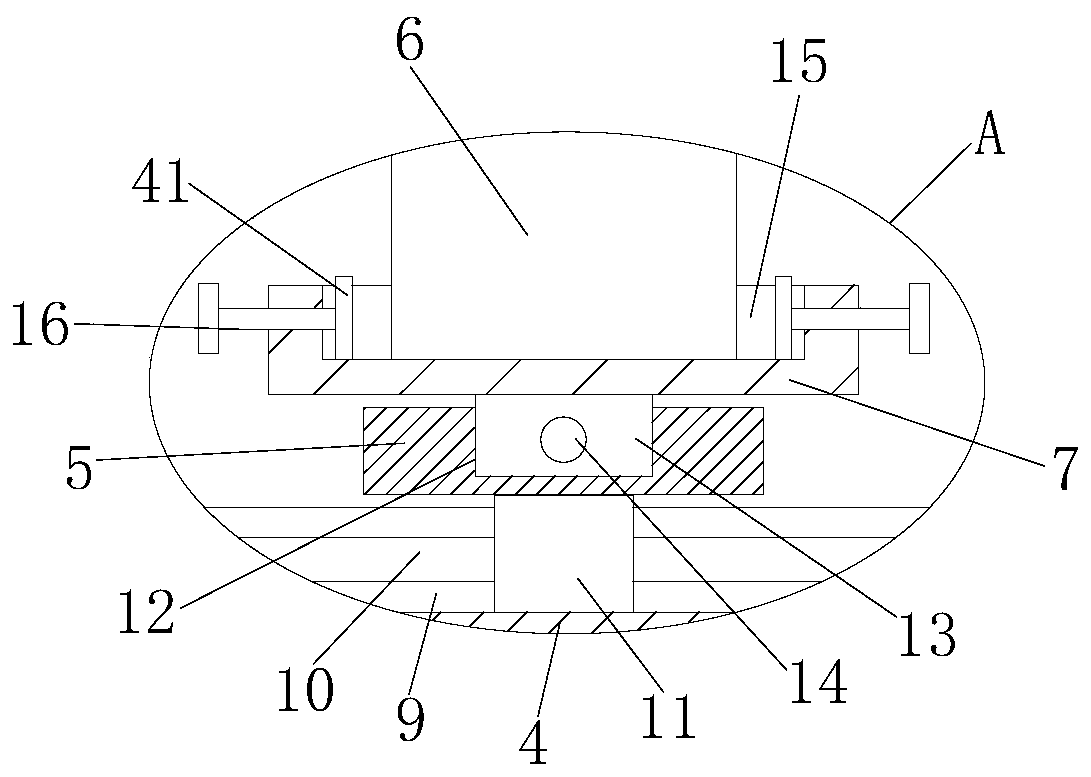

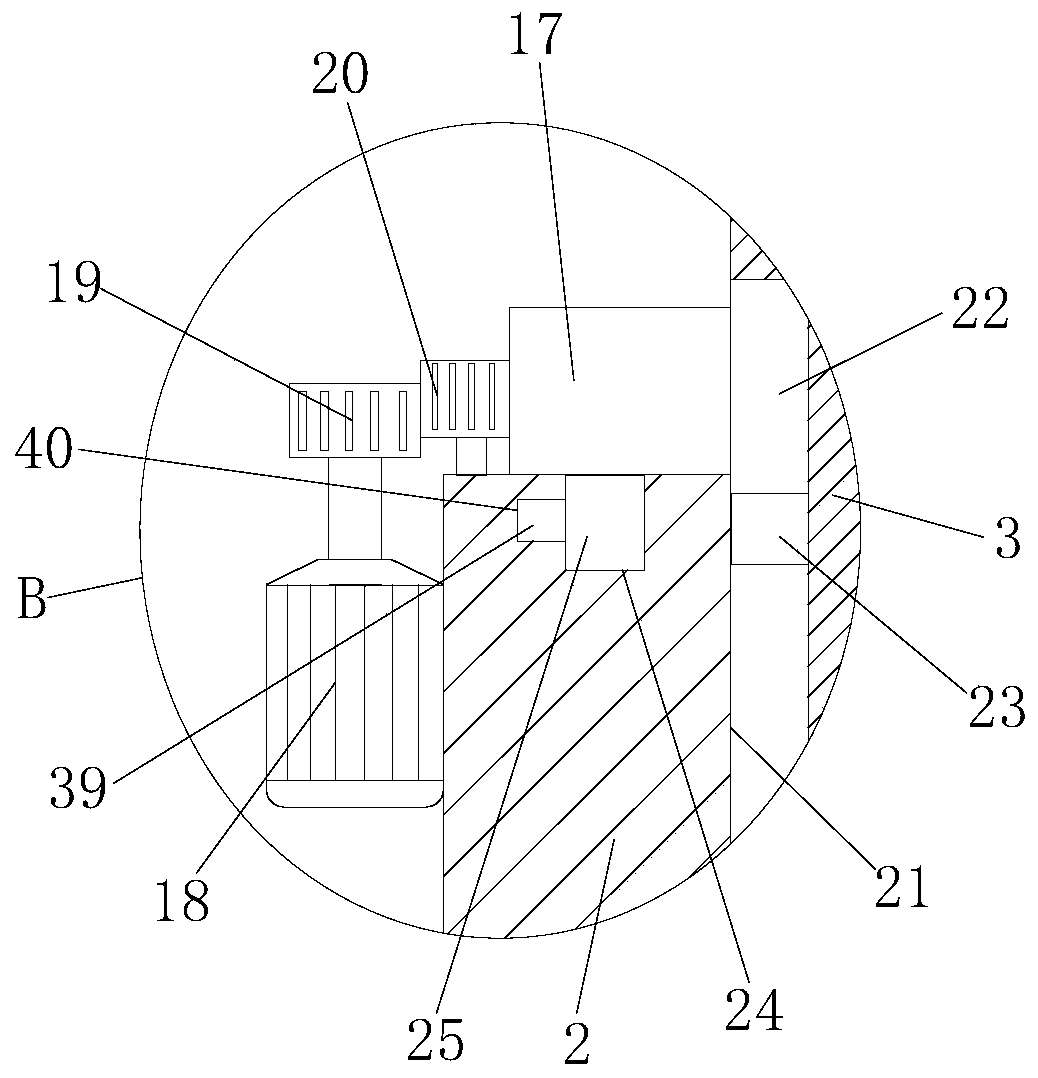

Thrusting rod bench simulation fatigue tester

InactiveCN101995332AReliable fatigue performance dataMachine part testingStructural engineeringWorkbench

The invention relates to the field of automobile parts, in particular to a thrusting rod bench simulation fatigue tester, which comprises a work bench, a front support seat arranged at the front end of the work bench, a rear support seat arranged at the rear end of the work bench, a rear shaft penetrating the rear support seat, a front shaft penetrating the front support seat, a clutch arranged between the rear shaft and the front shaft, a front fixing seat arranged on the inner side of the front shaft, a front rotating triangle arranged at the inner end of the front fixing seat, two front U-shaped connecting seats arranged on the left and right of the front rotating triangle, a rear fixing seat arranged on the inner side of the rear shaft, a rear rotating triangle arranged at the inner end of the rear fixing seat, two rear U-shaped connecting seats arranged on the left and right of the rear rotating triangle, and a pulling plate arranged at the outer end of the front shaft. Due to the structure, the simulation fatigue property can be tested, and reliable fatigue property data is acquired; and the property in three directions can be comprehensively tested according to actual road conditions.

Owner:黄衍国

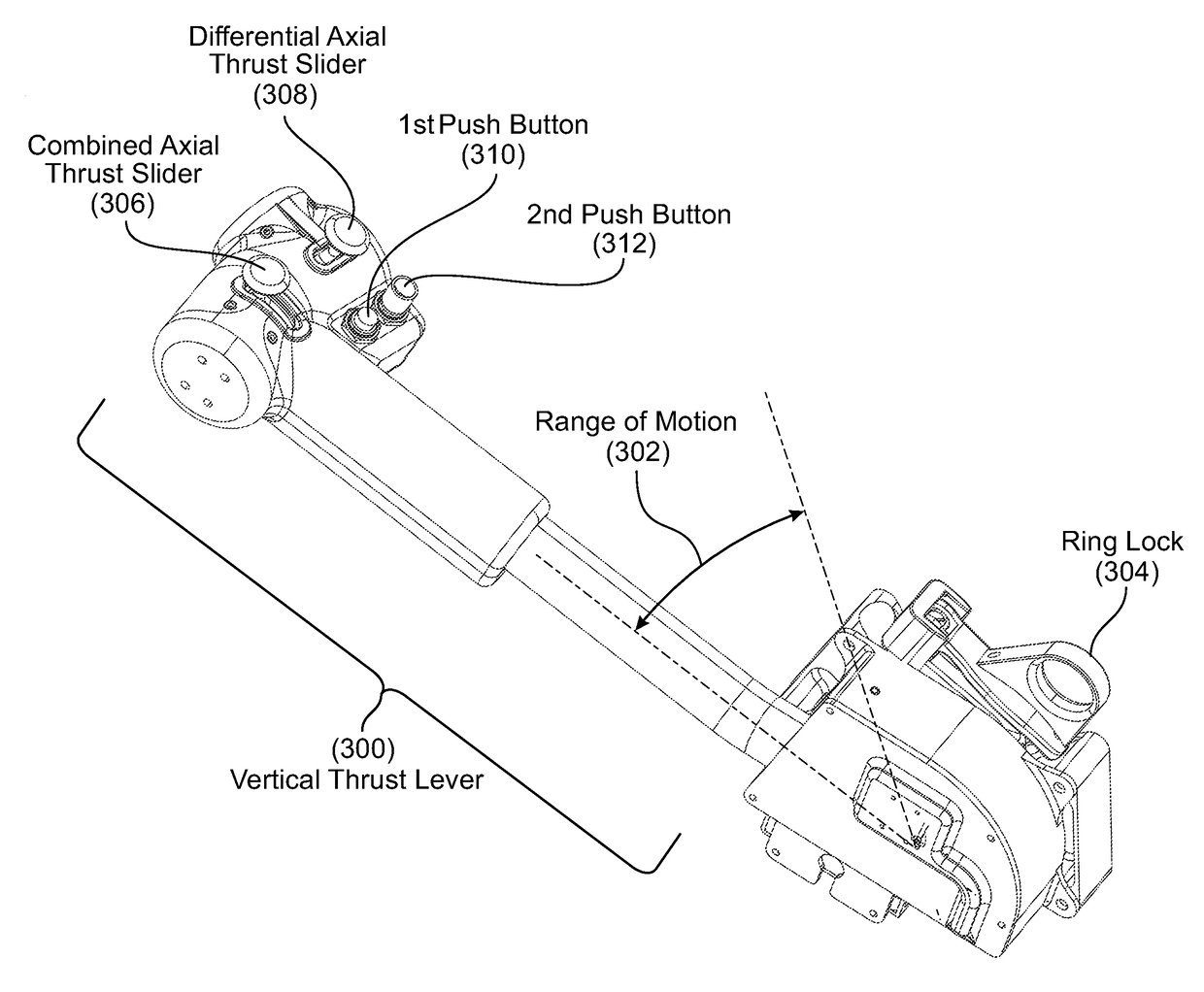

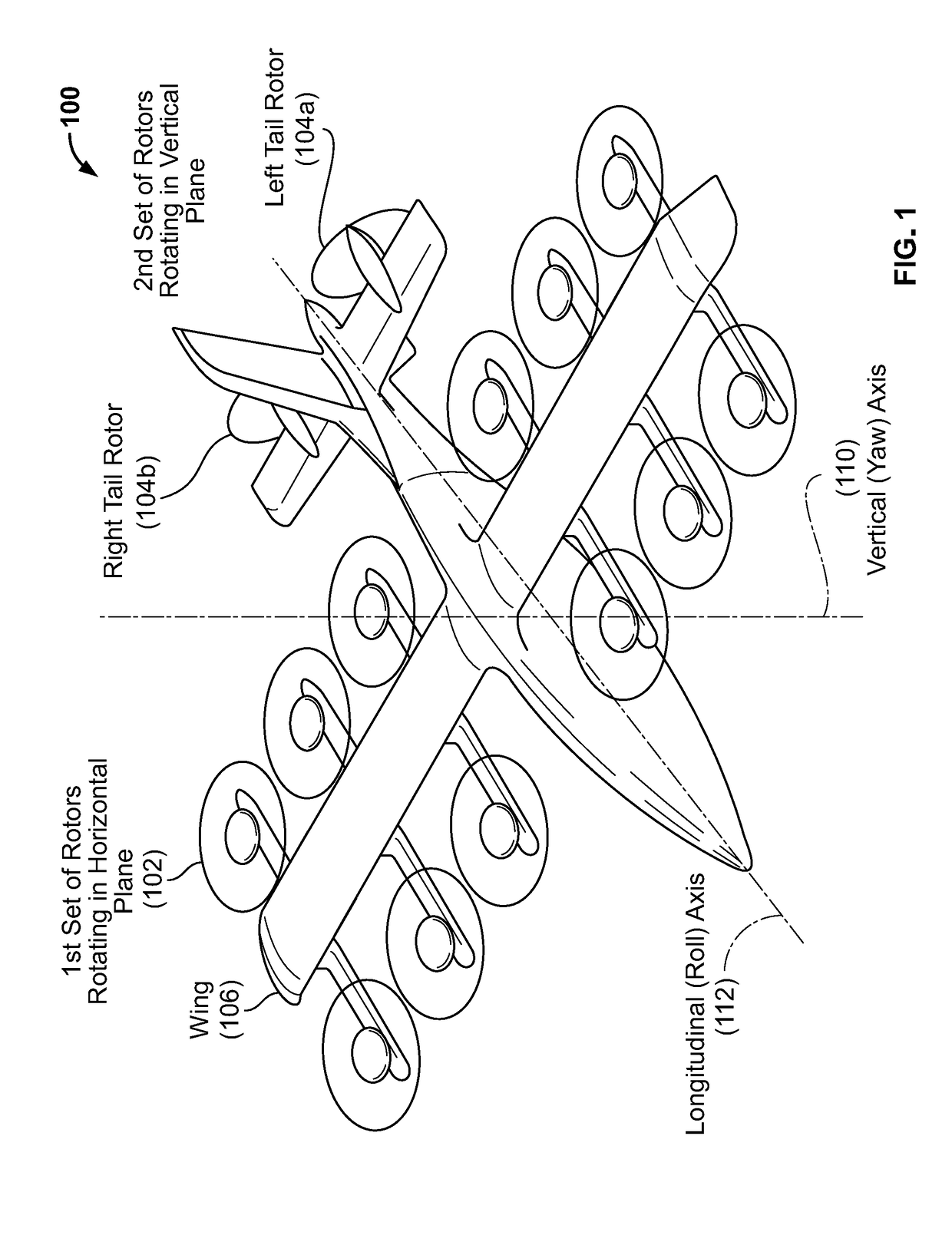

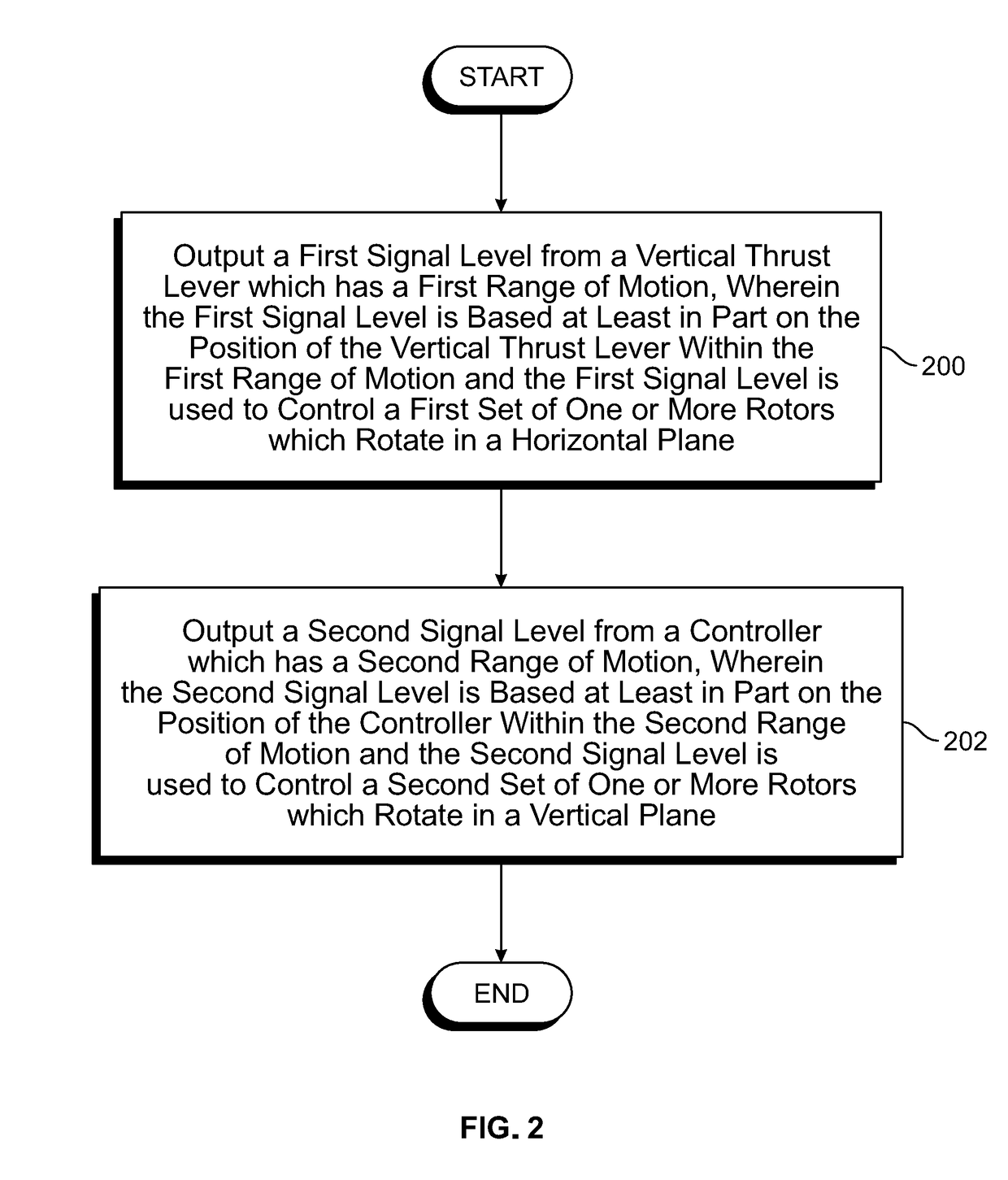

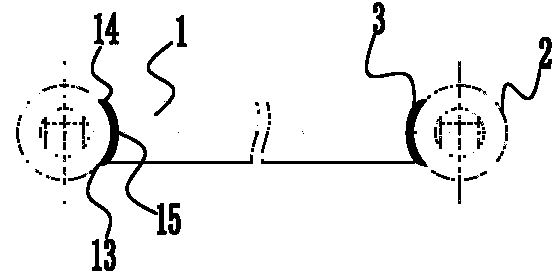

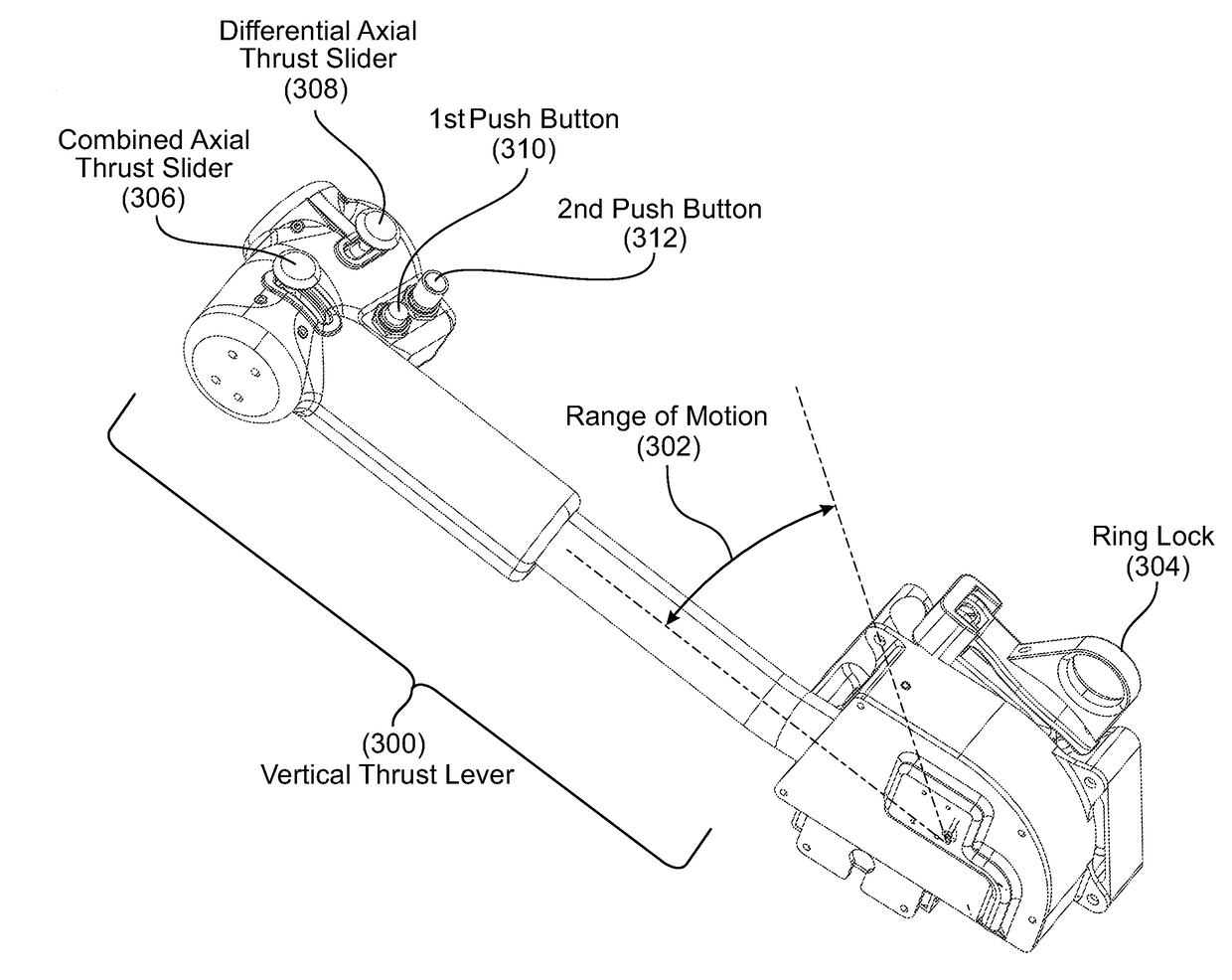

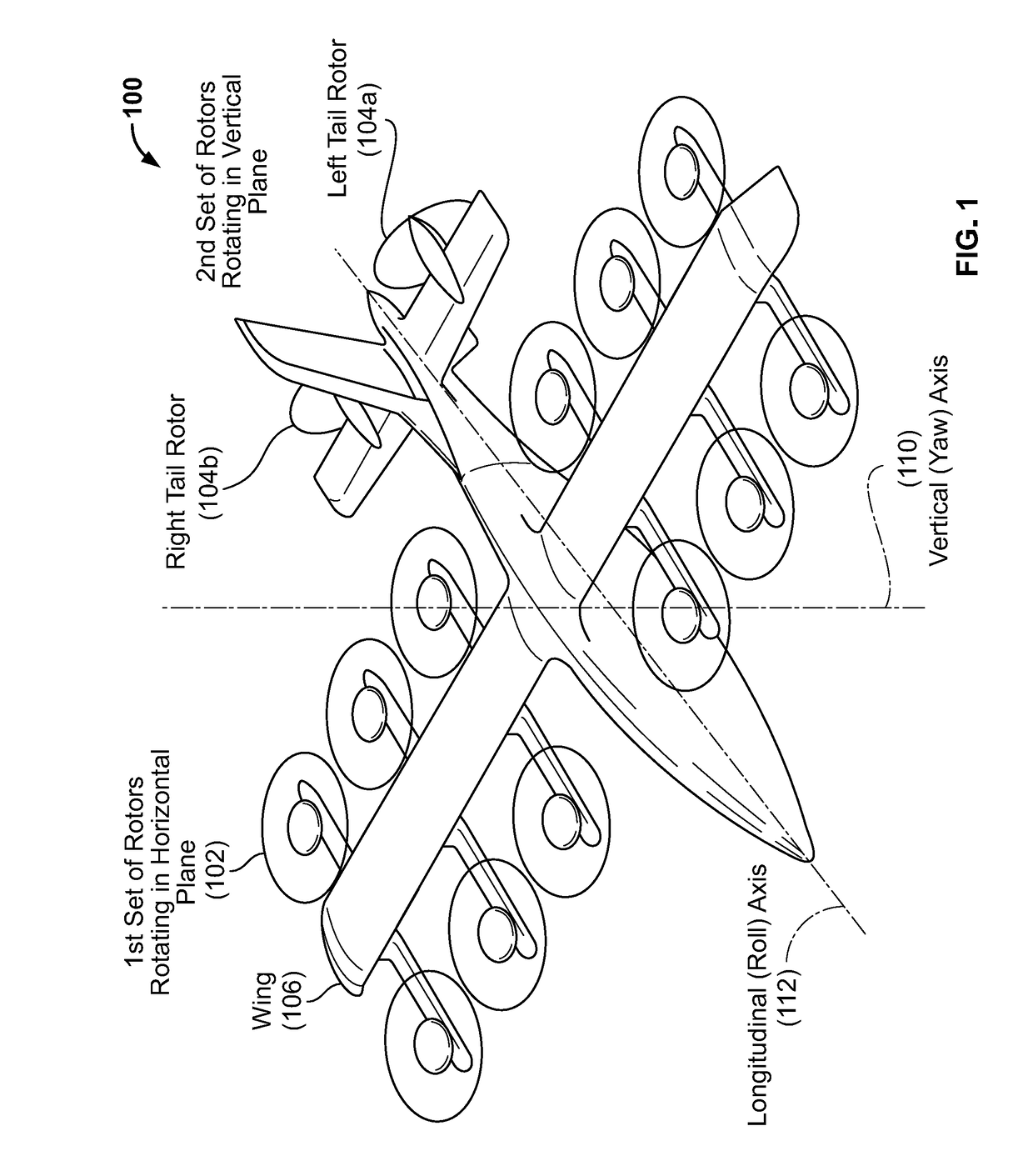

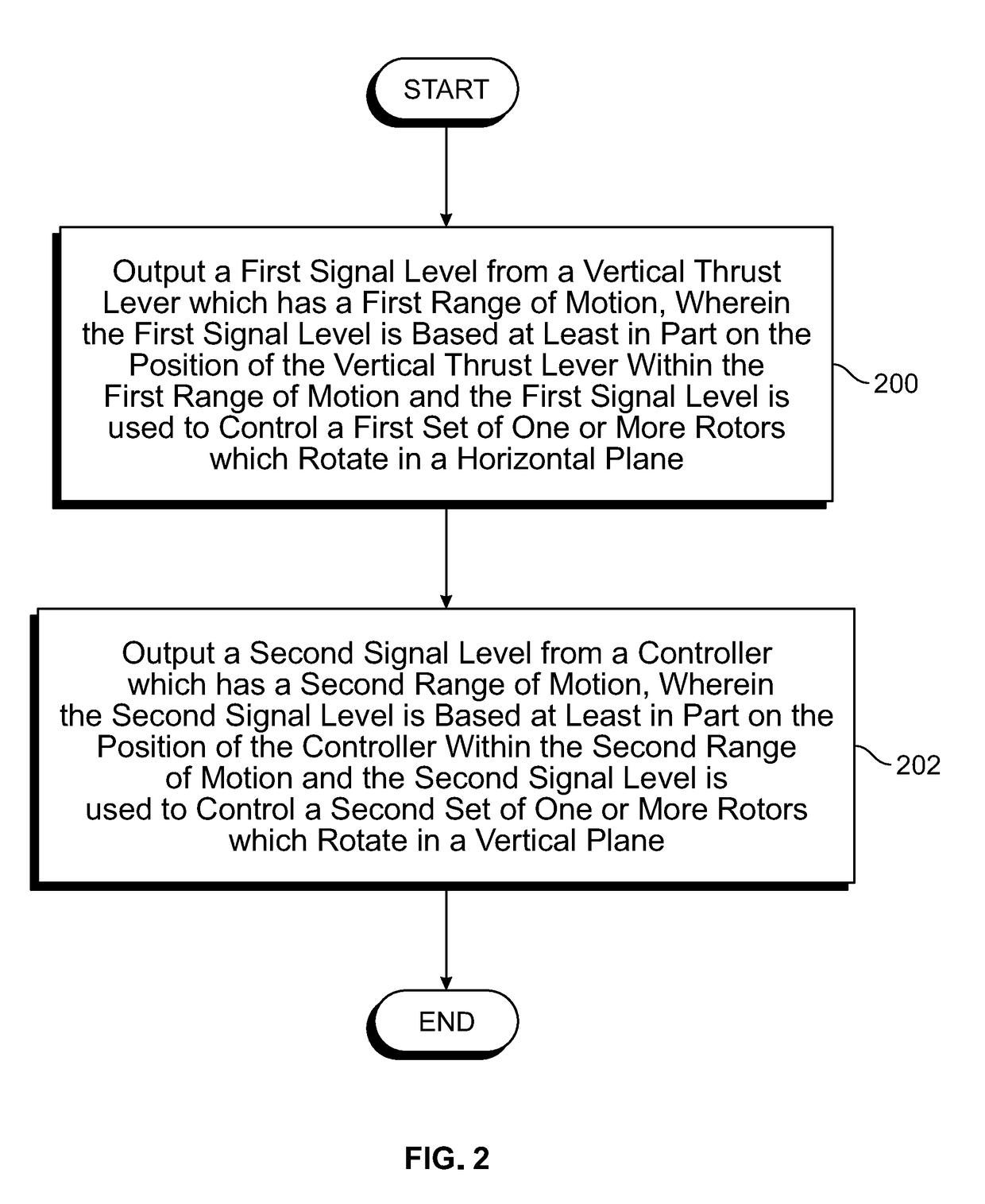

Vertical thrust lever

Owner:WISK AERO LLC

Opening and closing device for fuel door of vehicle

ActiveUS20120313382A1Operational reliability is increasedGuaranteed uptimeConstruction fastening devicesPower transmission/actuator featuresEngineeringActuator

An opening and closing device for a fuel door of a vehicle including a push type latch device for locking or unlocking the fuel door that may be rotatably mounted to a side of a housing by a hinge unit, may include a locking rod movable by an actuator and selectively locked to a locking slot provided in the hinge unit to which the fuel door may be attached, thereby controlling rotation of the hinge unit, and an anti-thrust lever operated in conjunction with the locking rod actuated by the actuator to selectively support the fuel door so as to prevent the fuel door from being thrust backwards.

Owner:HYUNDAI MOTOR CO LTD

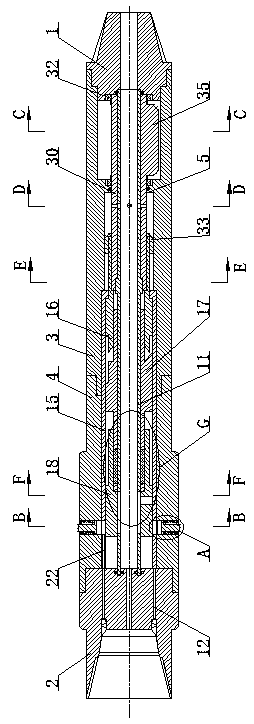

Push-against type rotation guiding tool

PendingCN110725649AImprove reliabilityHigh temperature and high pressure resistanceDirectional drillingUpper jointElectrical control

The invention relates to a push-against type rotation guiding tool, and belongs to the technical field of oil downhole guiding tools. The push-against type rotation guiding tool is composed of an shell, an upper joint, a lower joint and a rotation control device, one end of the shell is provided with the upper joint in a threaded mode, the other end of the shell is provided with the lower joint ina threaded mode, a center pipe is movably mounted in the position, between the upper joint and the lower joint, of the shell, and the rotation control device is mounted between the center pipe and the shell. The push-against type rotation guiding tool is of a purely mechanical structure, compared with control through an electronic control component, the push-against type rotation guiding tool hashigher high temperature, high pressure and high corrosion resistant ability, and therefore, the overall reliability of the push-against type rotation guiding tool is high; and the reference directionof rotation guiding is determined through an eccentric pipe, extending of a thrust rod in all directions is controlled through the rotation control device, the precession direction of a drill bit iscontrolled, compared with electrical control over the precession direction of the drill bit, the technical difficulty in signal does not exist, and the problem that through electrical control over theprecession direction of the drill bit, reliability is poor, and the overall reliability is poor is effectively solved.

Owner:YANGTZE UNIVERSITY

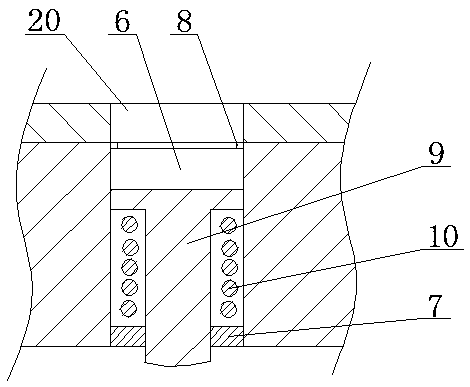

Resistance barrel and method for detecting static loads of engineering pile foundations

ActiveCN104032775AFit tightlySolve the limited numberFoundation testingArchitectural engineeringJackscrew

The invention discloses a resistance barrel and a method for detecting static loads of engineering file foundations. The resistance barrel is characterized by comprising a resistance barrel body, resistance rod plates, propulsion devices and thrust rods; the resistance rod plates and the propulsion devices are arranged in the resistance barrel body and are connected with one another by the thrust rods, holes are formed in the resistance barrel body, the resistance rod plates can be pushed by the propulsion devices to horizontally move along the holes, also can be arranged on the outer side surface of the resistance barrel body, and are drilled into an underground rock and soil layer adjacent to the outer side of the resistance barrel body to enhance upward anti-shifting resistance of the resistance barrel body after the resistance rod plates extend out of the holes of the resistance barrel body or are spread on the outer side surface of the resistance barrel body, and loads can be applied to ground transverse beam counterforce devices via oil jacks by the aid of the resistance barrel, so that static load detection tests can be carried out on the pile foundations. The resistance barrel and the method for detecting the static loads of the engineering pile foundations have the advantages that the resistance barrel is reasonable in structural design and can be operated easily and conveniently, the work efficiency and the safety can be obviously improved during the static load detection tests on the pile foundations, and the like.

Owner:陆剑

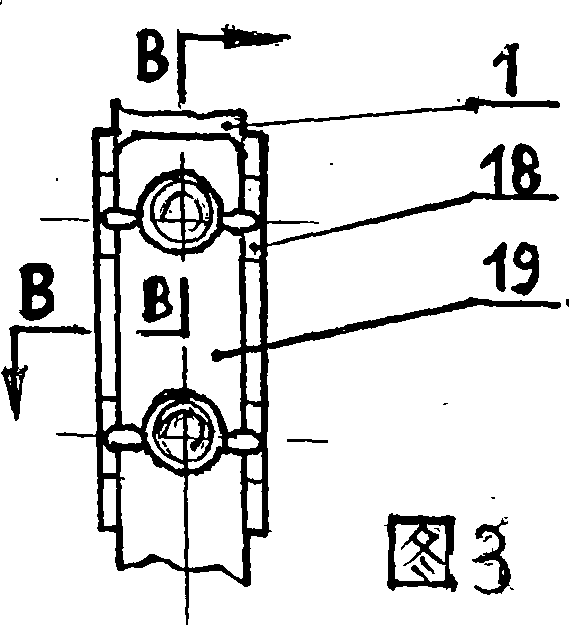

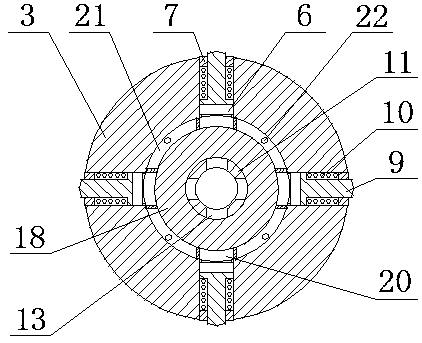

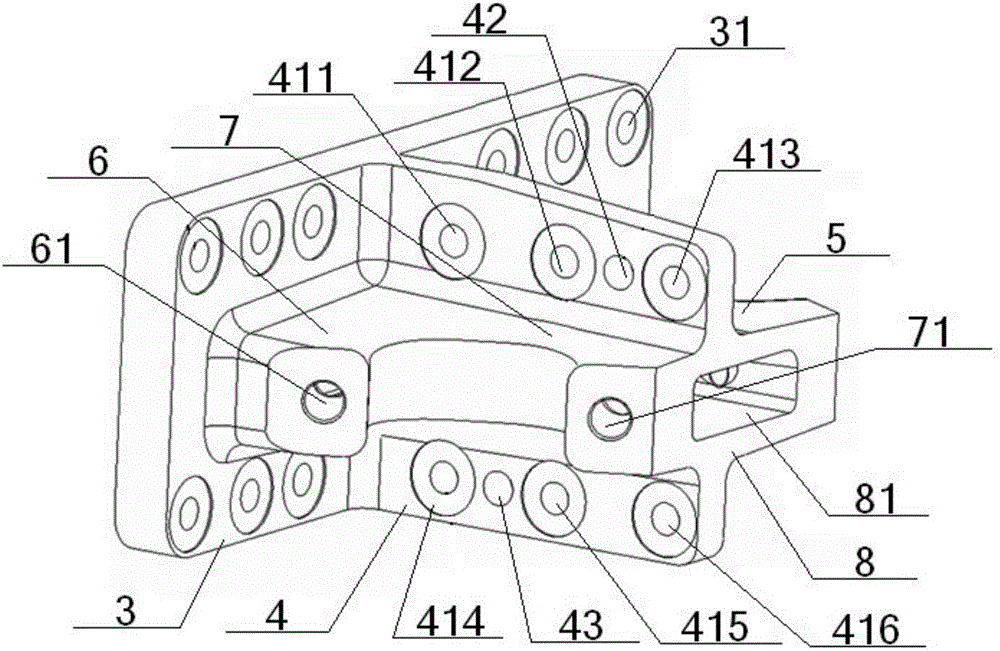

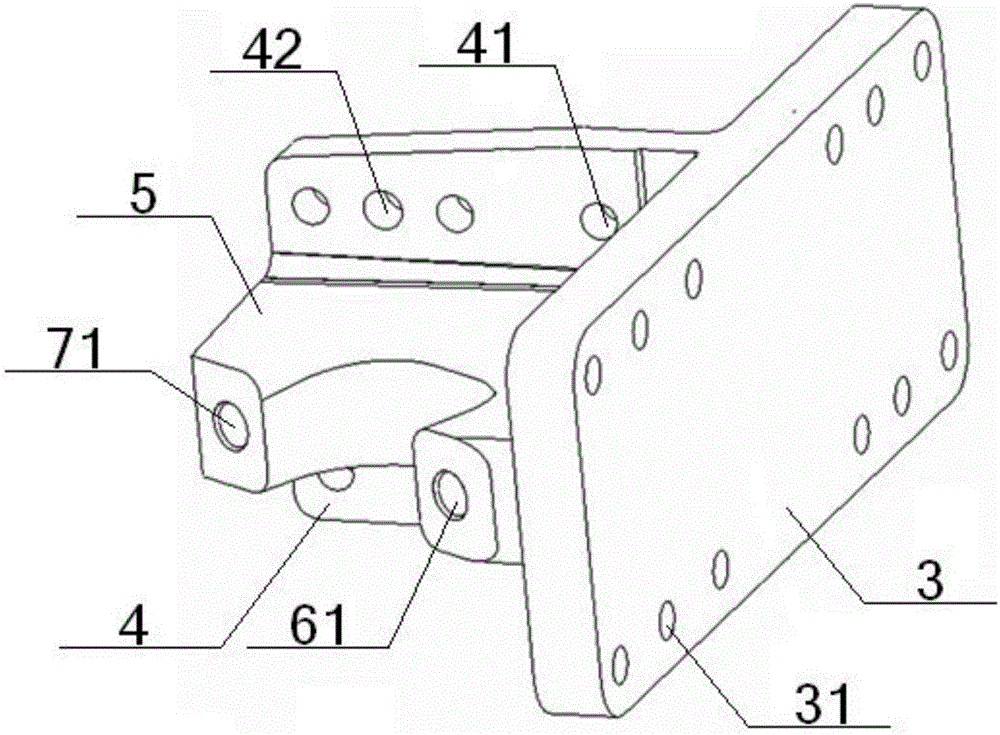

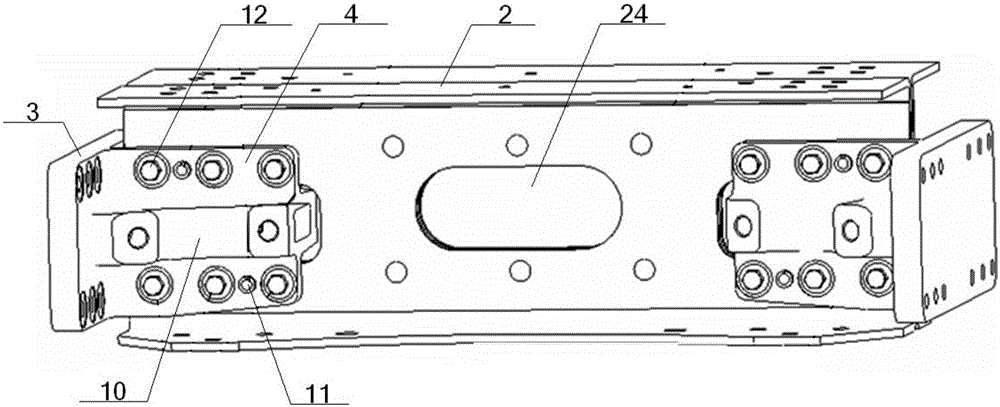

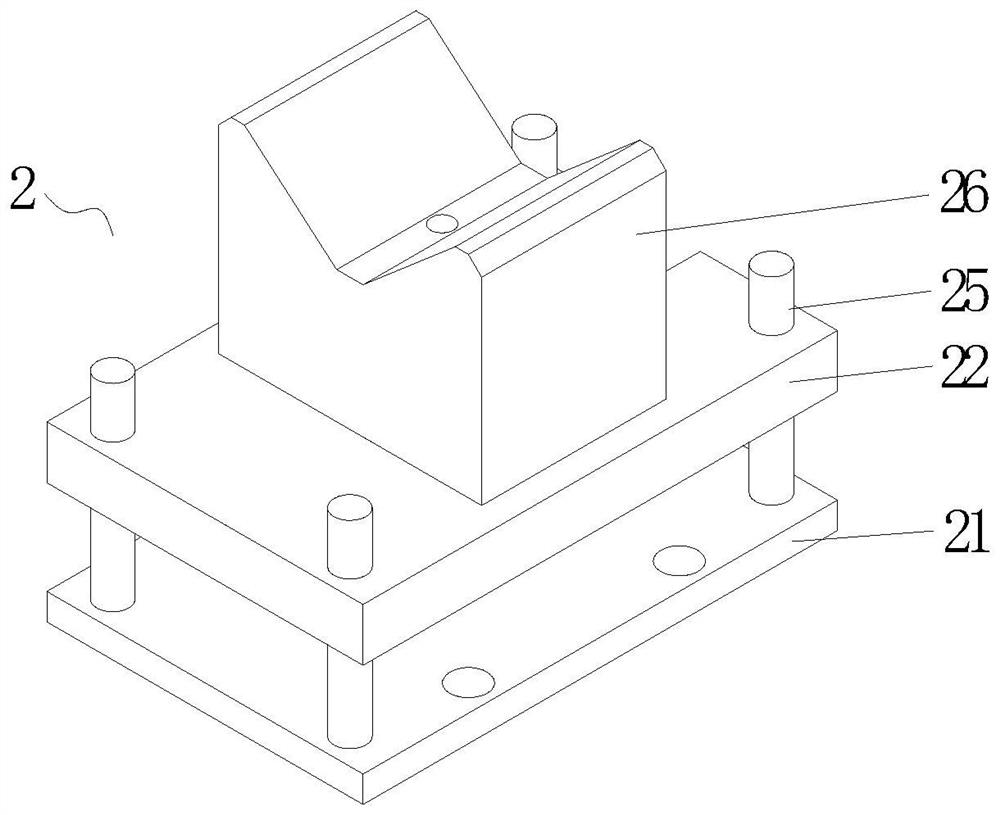

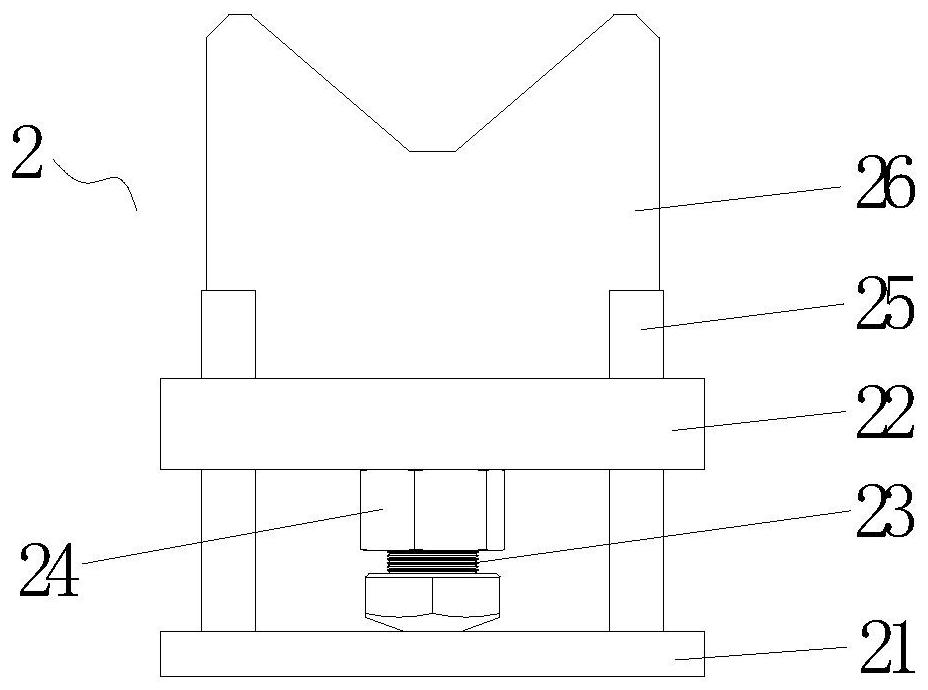

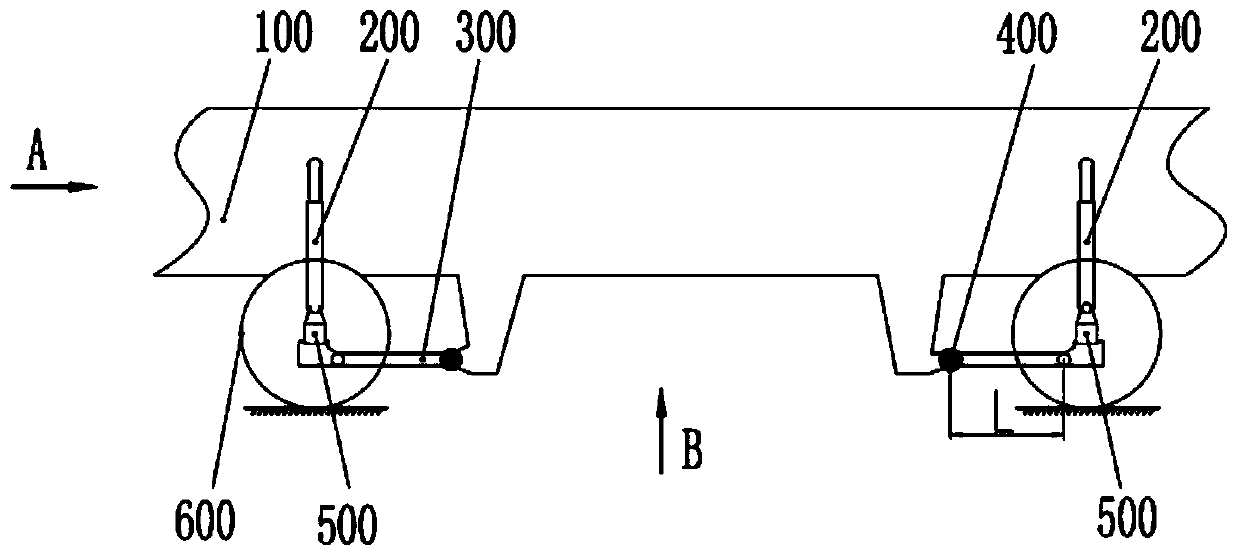

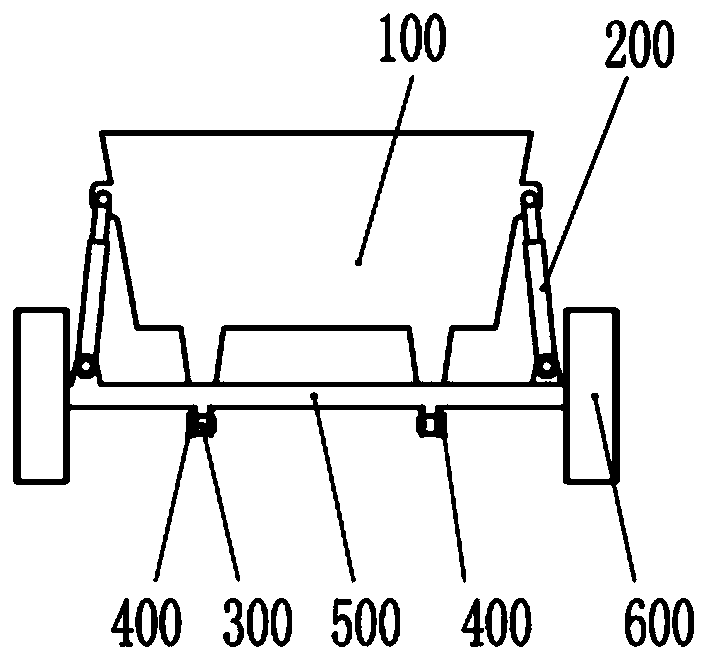

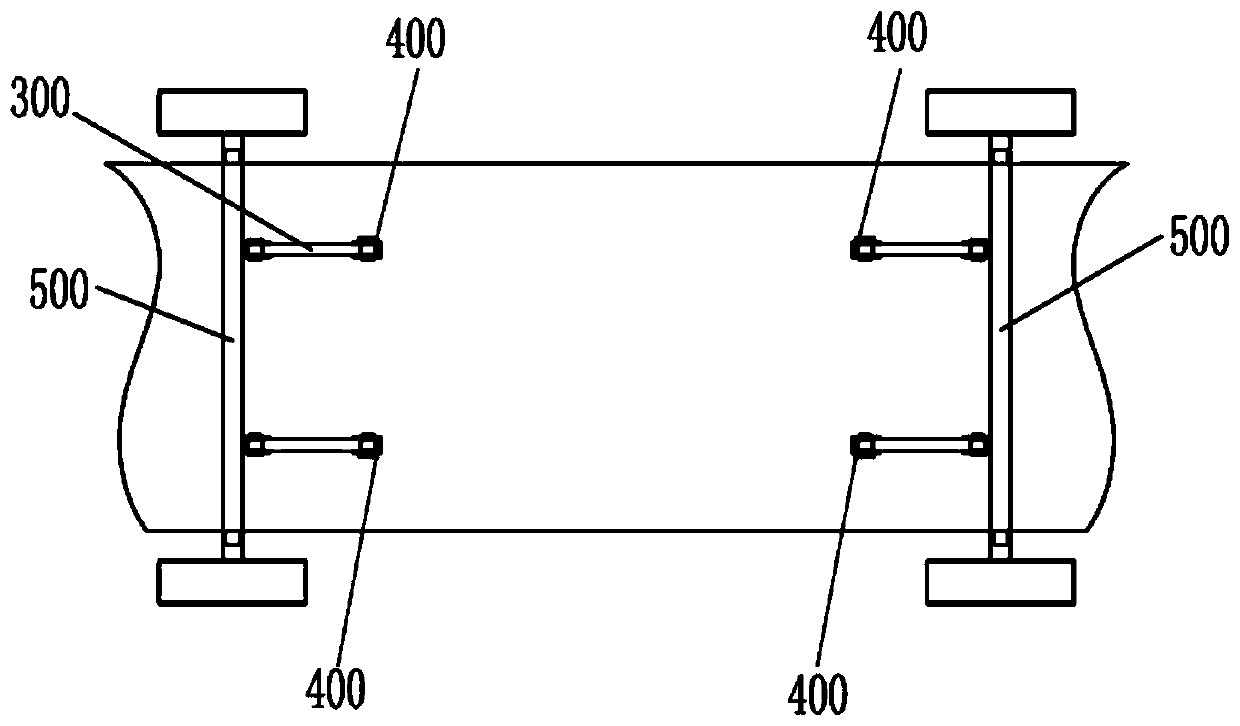

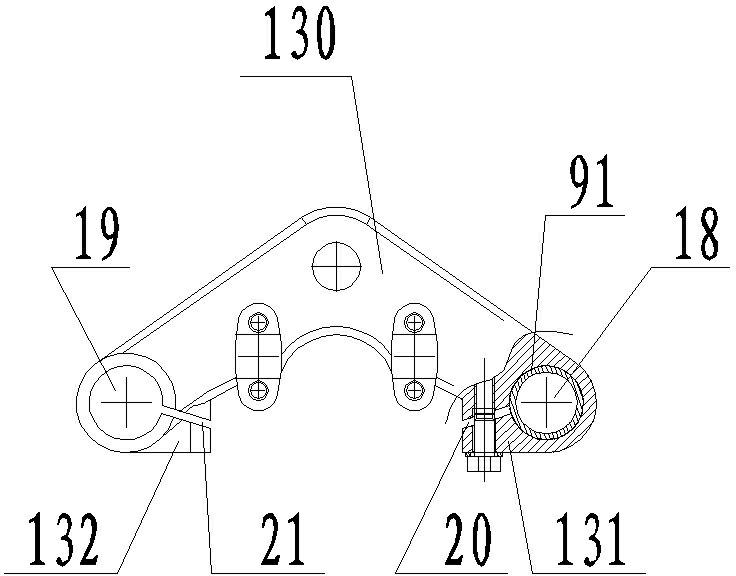

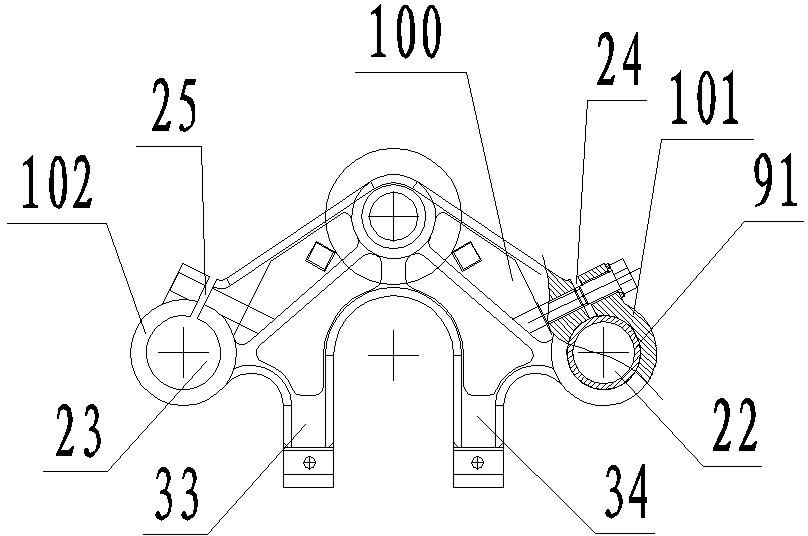

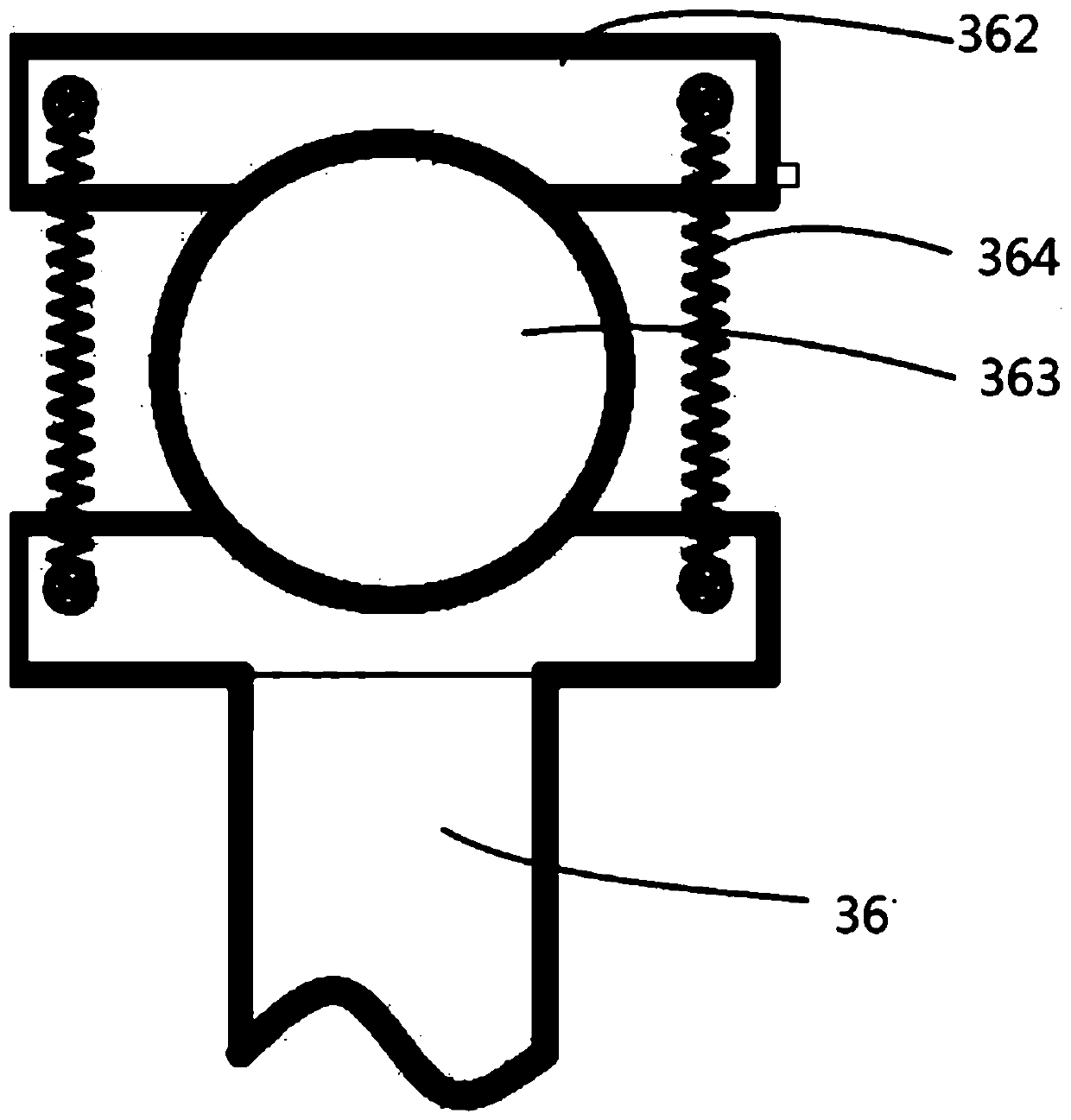

Two-way V-shaped thrust lever upper bracket and bracket beam assembly

ActiveCN105667235AReduce in quantityReduce manufacturing costUnderstructuresPivoted suspension armsIn planeVehicle frame

The invention relates to a two-way V-shaped thrust lever upper bracket. The two-way V-shaped thrust lever upper bracket comprises a longitudinal beam connecting plate, a cross beam connecting plate and two support seats, wherein the middle of the longitudinal beam connecting plate is vertically connected to the bottom of the cross beam connecting plate, the two support seats are respectively arranged between the positive and negative side surfaces of the middle of the cross beam connecting plate and the longitudinal beam connecting plate, the two support seats are in plane symmetry according to the cross beam connecting plate, longitudinal beam bolt holes are formed in the upper and lower sides of the connecting positions of the longitudinal beam connecting plate and the support seats, and cross beam bolt holes and pin holes are formed in the upper and lower sides of the connecting positions of the cross beam connecting plate and the support seats. The upper bracket is combined with U-shaped grooves formed in both ends of a frame cross beam, so as to form a bracket beam assembly. By adopting the design, a thrust lever can be installed in two directions, the quantity of components and parts is reduced, the precision of the installation position is higher, the installation and removal are convenient, the assembly efficiency is higher, and the maintenance convenience is good.

Owner:DONGFENG COMML VEHICLE CO LTD

Arable pitch mounting for aircraft gas turbine engine

ActiveCN105691623AReduce angle of attackGas turbine type power plantsPower plant constructionAviationTemporal information

The light source control apparatus controls drive of multiple light sources included in a light source unit to be used in a state where the multiple light sources are lit. The multiple light sources each include multiple light-emitting elements. The light source control apparatus includes an acquirer acquiring temporal information relating to a temporal change of each of the light sources, an estimator acquiring an estimated lifetime of each of the multiple light sources by using the temporal information, and a controller decreasing, when the multiple light sources include a first light source whose estimated lifetime is shorter than a target lifetime set for the light source unit, a light emission amount of the first light source.

Owner:GENERAL ELECTRIC CO

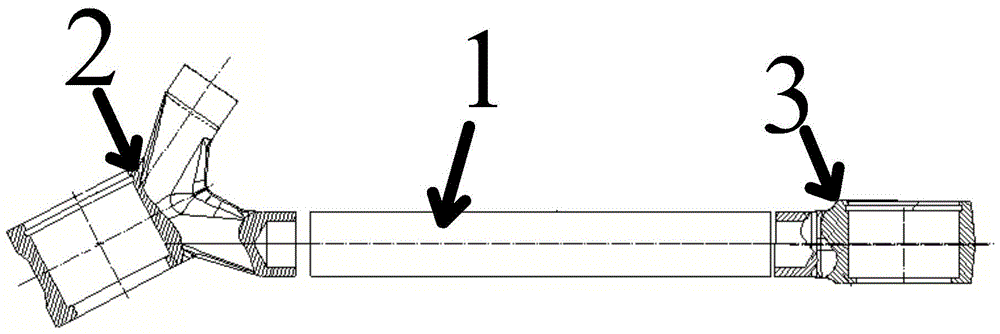

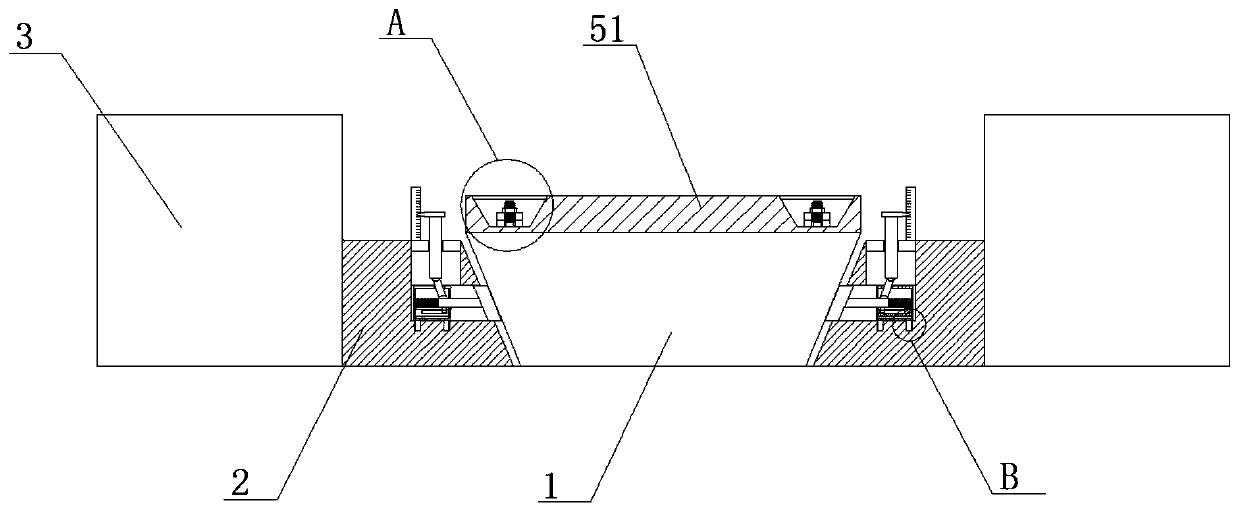

Vehicle thrust rod and assembly process thereof

ActiveCN103350626AGuaranteed use strengthReduce weightWelding/cutting auxillary devicesArc welding apparatusEngineeringEnvironmentally friendly

The invention discloses a vehicle thrust rod and an assembly process of the vehicle thrust rod. The vehicle thrust rod comprises a sleeve and a thrust rod ball head, wherein the connecting position of the sleeve and the thrust rod ball head adopts groove-shaped intersecting connection, and the thrust rod ball head is in a cylindrical structure; the groove-shaped intersecting connection adopts the mode that two end heads of the sleeve are processed into a groove shape intersected with the cylindrical contour of the thrust rod ball head; and the sleeve and the thrust rod ball head are welded together. The assembly process adopts a process of synchronous rotation and welding of two ends, and the sleeve and the thrust rod ball head are connected together through gas shielded welding in the synchronous rotation process of the sleeve and the thrust rod ball head. Under the premise that the using requirement of product is met, the product weight and the manufacturing cost of product are reduced on the basis of the current structure and process, so that automobiles are energy-saving and environmentally-friendly, and the comprehensive benefits are increased.

Owner:BOGE RUBBER&PLASTICS ZHUZHOU CO LTD

Automobile thrust rod

InactiveCN105667234AThe overall structure is simple and reliableHigh strengthPivoted suspension armsBase-materialsVehicle frameThrust lever

Owner:西安德仕汽车零部件有限责任公司 +1

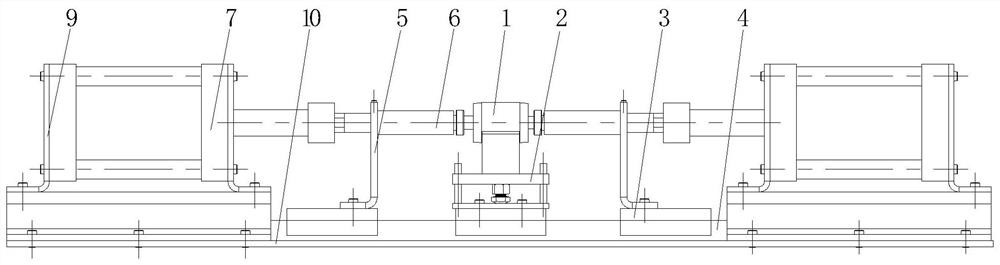

Method and device for testing fatigue of car thrust rod component

ActiveCN102798522ARequirements for implementing simultaneous coordinated loadsMachine part testingRotary stageTest platform

The invention discloses a method and device for testing fatigue of a car thrust rod component. The method for testing fatigue of the car thrust rod component comprises the steps of: mounting two to-be-tested thrust rod components in a test device in pairs, wherein the two to-be-tested thrust rod components are respectively connected with an upper test platform on the test device through a front-end spherical hinge and are fixed with a turntable of the test device through a back-end spherical hinge; mounting the turntable on a lower test platform to enable the turntable to rotate around the axis per se on the lower test platform; connecting the side surfaces of the turntable with a transverse actuator and providing a functional torque enabling the turntable to rotate by the transverse actuator; mounting a vertical actuator on the upper test platform and providing a lengthways tension and compression force by the vertical actuator; applying lengthways tension and compression loads to the thrust rod through the upper test platform by the vertical actuator and meanwhile fixing the transverse actuator on a horizontal base through a tail joint, connecting the transverse actuator with the turntable through an end-part joint, and applying offset and reciprocated torque to the thrust rod component to realize the fatigue test on the thrust rod component.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

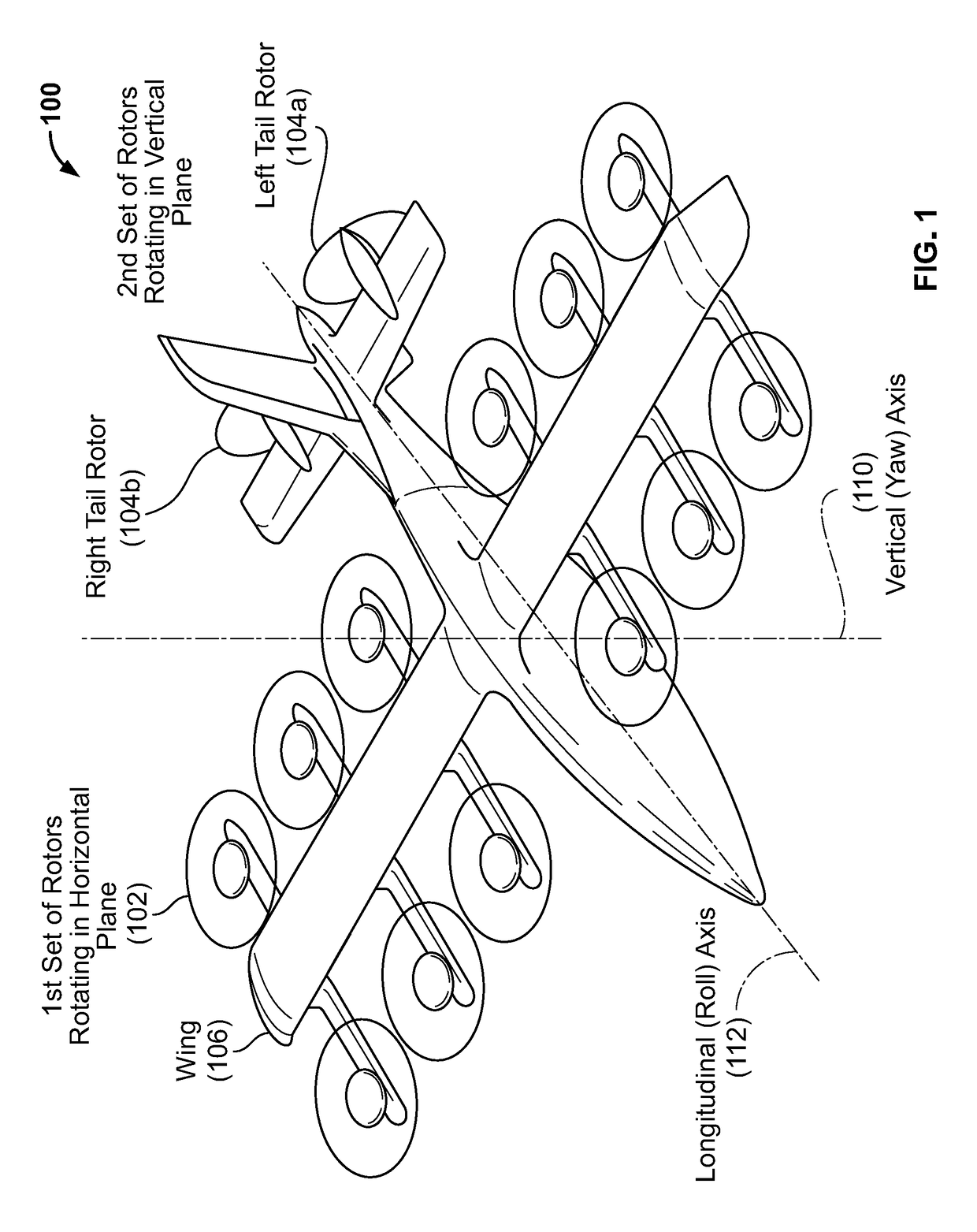

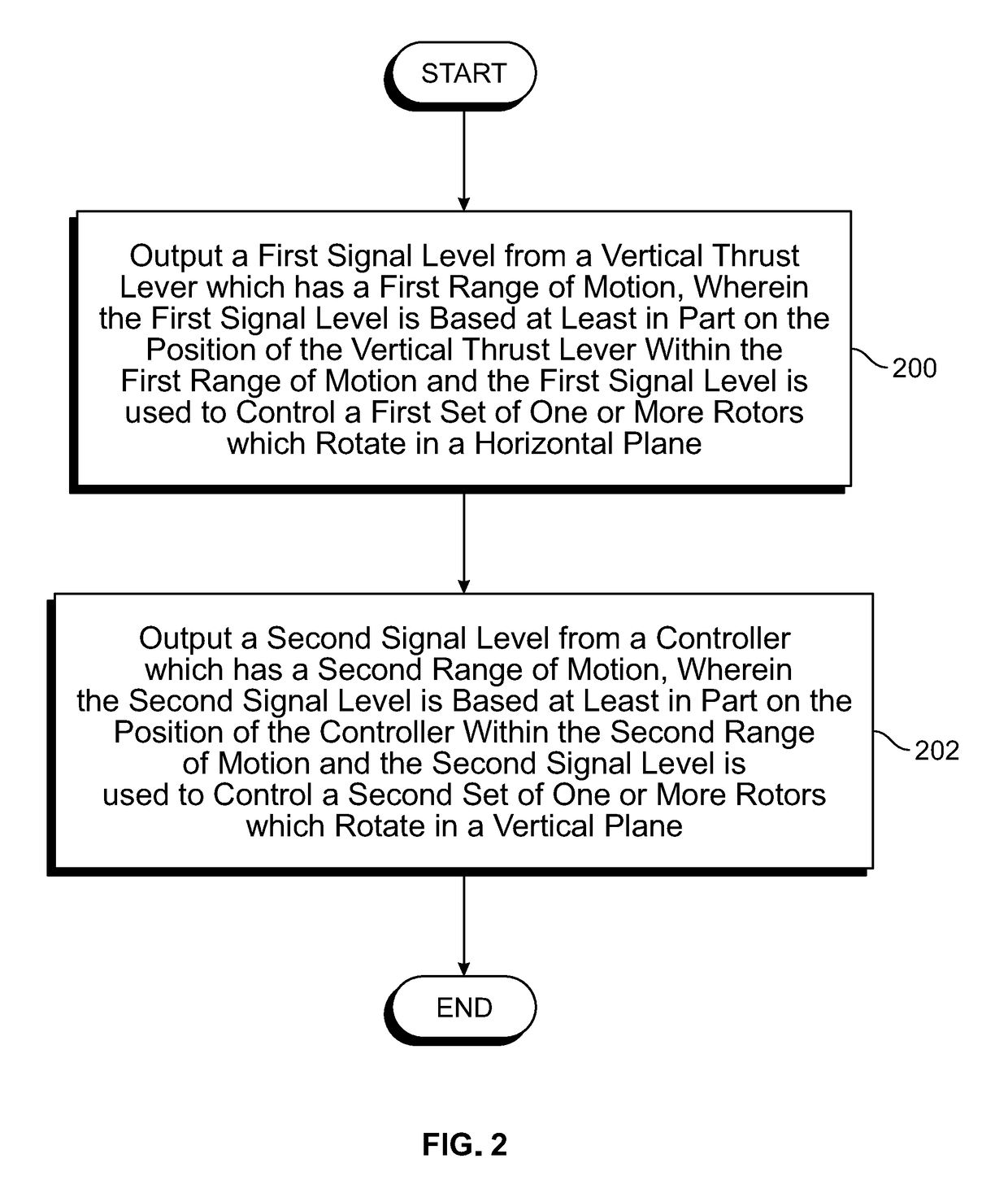

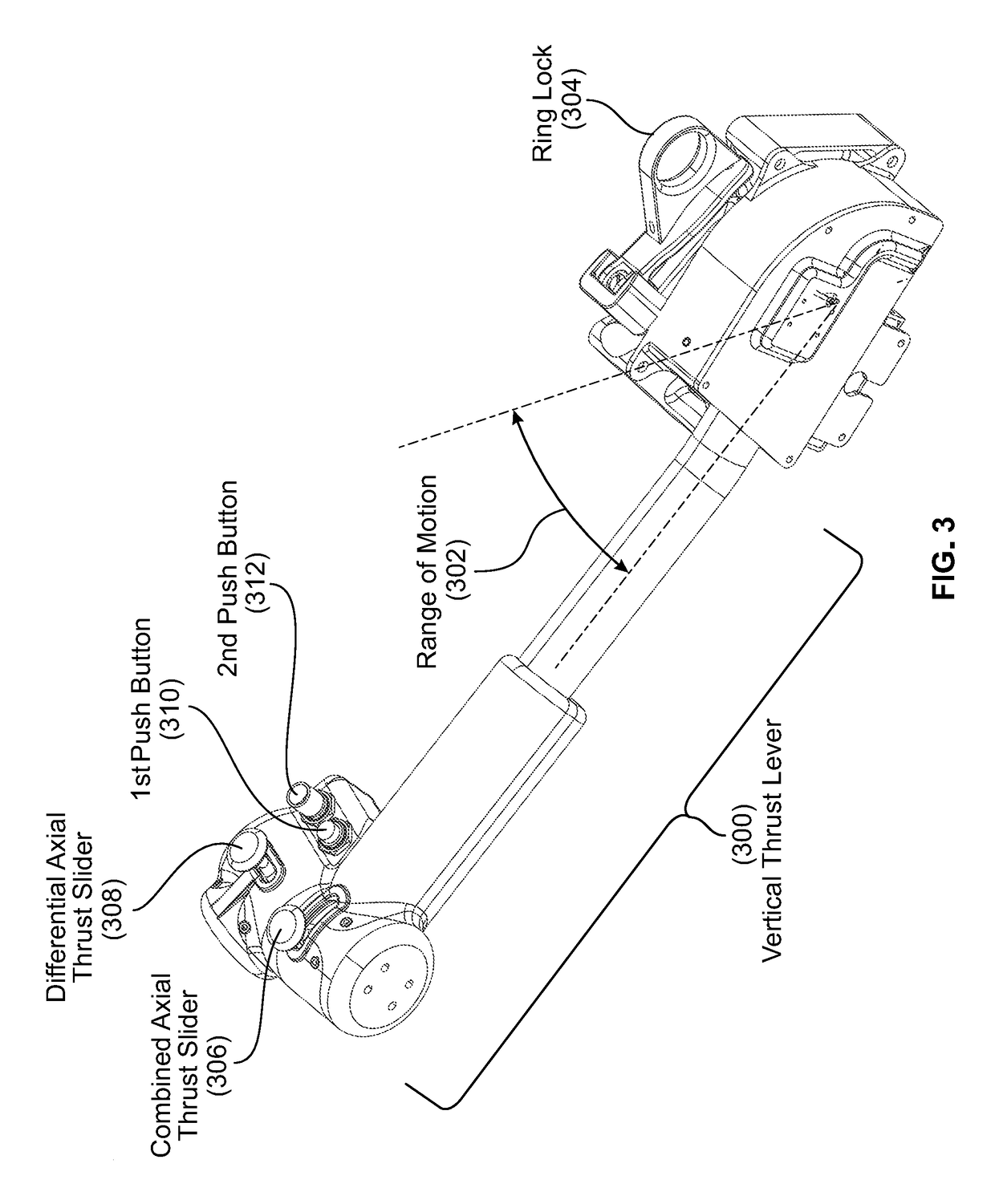

Vertical thrust lever

A lever outputs a first signal level where the first signal level is based at least in part on the position of the lever and the first signal level is used to control a first set of rotors associated with a vertical propulsion system. A thumb controller (coupled to the vertical thrust lever) outputs a second signal level where the second signal level is based at least in part on the position of the thumb controller, the second signal level is used to control a second set of rotors associated with a horizontal propulsion system, and the thumb controller includes a detent associated with a recommended sustained maximum.

Owner:WISK AERO LLC

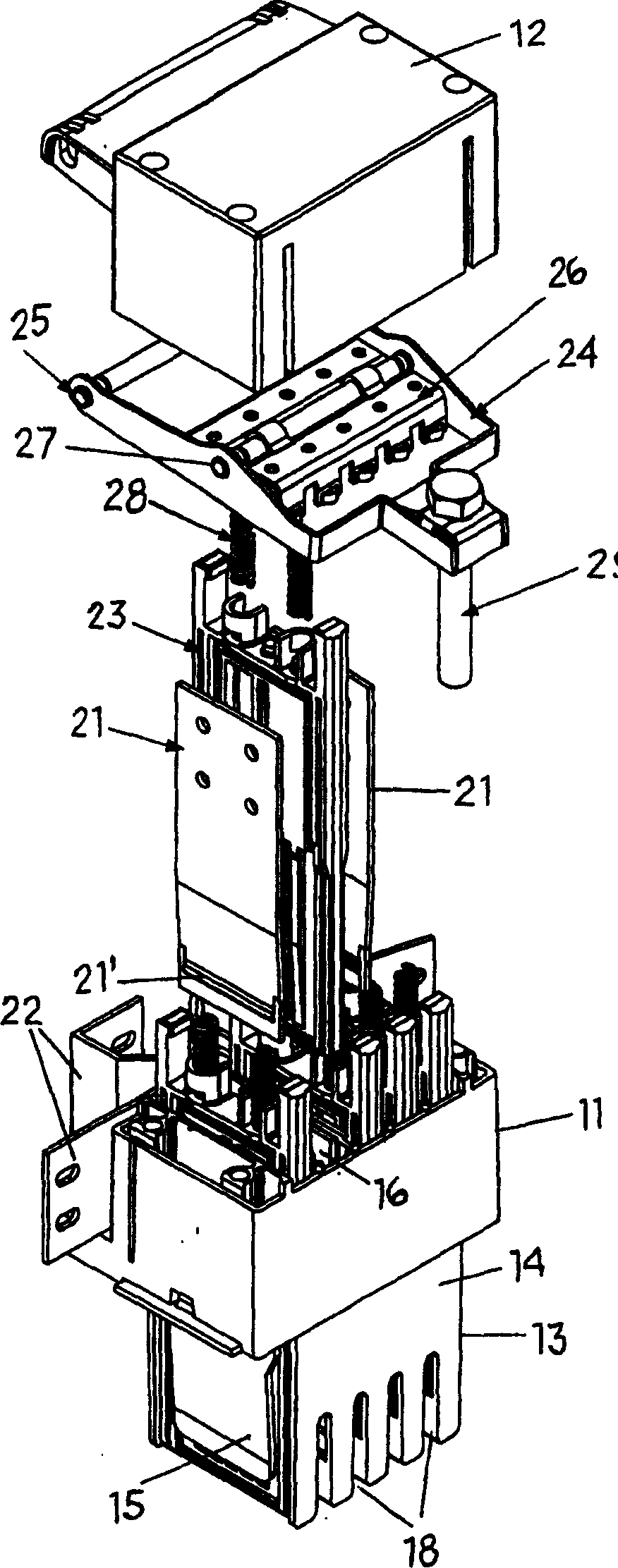

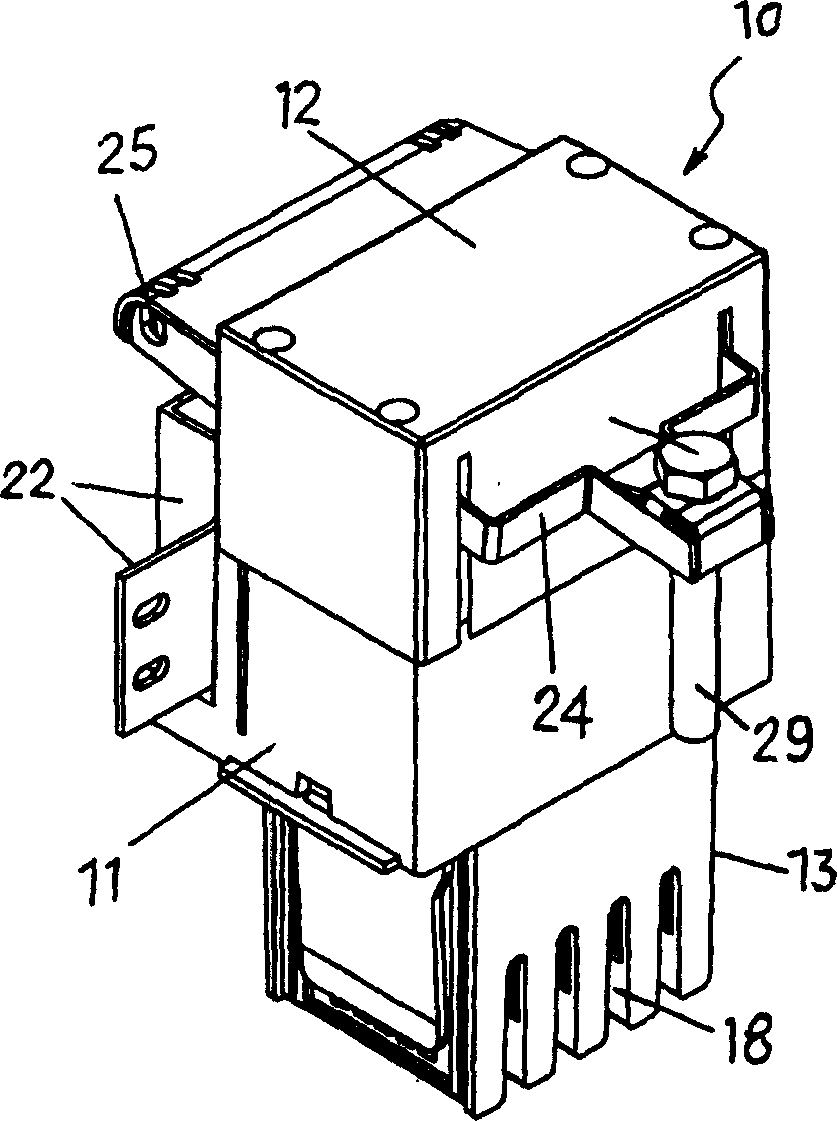

Unit for shunting current from bus bars

InactiveCN1645700AEasy to manufactureImprove performanceVehicle cranksBus-bar installationElectricityElectrical conductor

The invention concerns a unit for shunting current from bus bars which is made up of a body divided internally into sections housing the blade shaped flexible electric contacts(21) which can be flexed between an open and closed position of the conductor elements of a bus bar. The electric contacts can be moved from one position to the other by means of insulated wedges(23) associated with them and which can all be moved axially simultaneously from the outside between a retracted open position and a forward closed position by means of a thrust lever and interposed springs.

Owner:BBI ELECTRIC

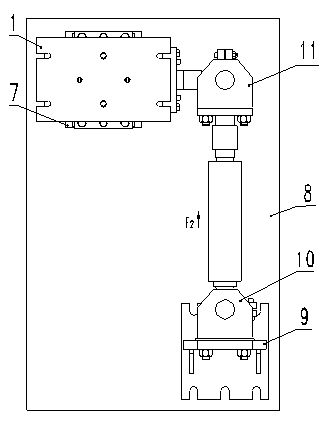

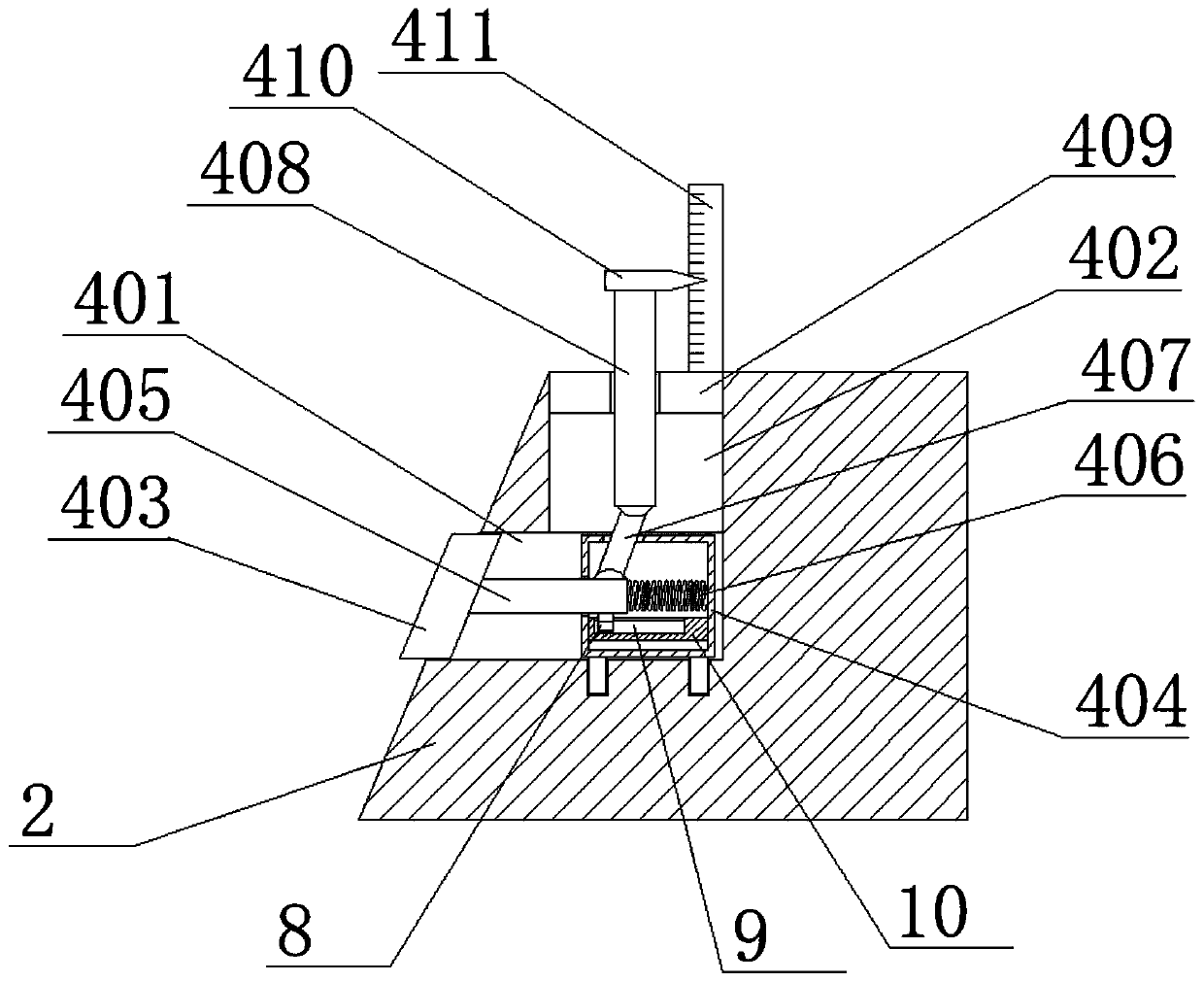

Horizontal bearing pressing system

InactiveCN112372579AImprove press fit accuracyImprove efficiencyMetal-working hand toolsEngineeringCylinder block

The invention relates to a horizontal bearing pressing system. The horizontal bearing pressing system comprises a base; a linear guide rail is fixedly installed in the middle of the base; two air cylinders are symmetrically installed on the two sides of the base; each air cylinder comprises a thrust rod; the end of the thrust rod away from the air cylinder body is fixedly connected with a press-fitting sleeve; three sliding blocks are connected to the linear guide rail in a sliding mode; limiting plates used for fixing the press-fitting sleeve are fixedly connected to the sliding blocks on thetwo sides; and a lifting V-shaped support used for horizontally supporting a rotor is fixedly connected to the sliding block in the middle. The horizontal bearing pressing system achieves simultaneous press-fitting of two bearings, is high in press-fitting precision, high in efficiency, low in cost and wide in application range, and is suitable for bearing press-fitting of different types of rotors and large-scale production lines. According to the invention, the linear guide rail and the sliding blocks which are high in precision are adopted, which ensures that the pressure in the bearing press-fitting process is always kept on the same straight line, and has an obvious effect of reducing shaft deformation caused by radial force borne by the rotor shaft in the press-fitting process.

Owner:湖北梨威机械设备有限公司

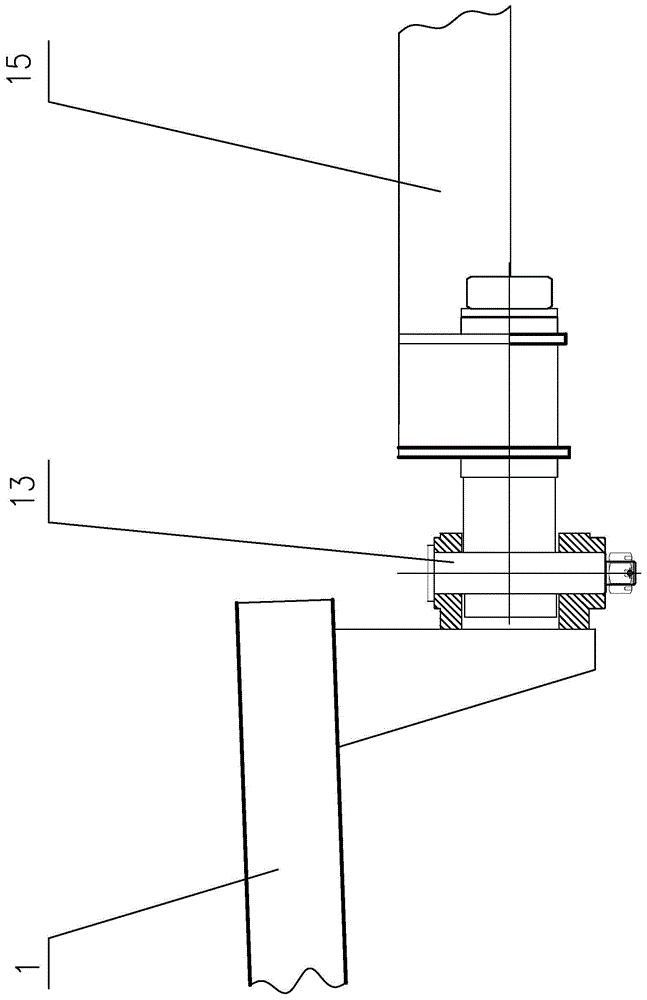

Hydro-pneumatic suspension system, position detection method thereof and engineering vehicle

InactiveCN111251799AThe detection method is simpleMeasurement devicesResilient suspensionsVehicle frameSuspension (vehicle)

The invention provides a hydro-pneumatic suspension system, a position detection method thereof and an engineering vehicle, and relates to the technical field of engineering machinery. The hydro-pneumatic suspension system provided by the invention comprises a frame, an axle, a suspension oil cylinder, a thrust rod and a rotation angle sensor; wherein the frame is connected to the axle through thesuspension oil cylinder, one end of the thrust rod is connected to the frame, and the other end of the thrust rod is connected to the axle; the rotation angle sensor is used for detecting a rotationangle of the thrust rod relative to an initial position and acquiring the suspension state of the hydro-pneumatic suspension system according to the rotation angle. The rotation angle of the thrust rod relative to the initial position is detected through the rotation angle sensor, and the position state of the hydro-pneumatic suspension system is obtained according to the rotation angle, so that the production cost and the maintenance cost in position detection of the hydro-pneumatic suspension system of the vehicle are reduced, the maintenance difficulty is reduced, and the maintenance efficiency is improved.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Vertical thrust lever

A lever outputs a first signal level where the first signal level is based at least in part on the position of the lever and the first signal level is used to control a first set of rotors associated with a vertical propulsion system. A thumb controller (coupled to the vertical thrust lever) outputs a second signal level where the second signal level is based at least in part on the position of the thumb controller, the second signal level is used to control a second set of rotors associated with a horizontal propulsion system, and the thumb controller includes a detent associated with a recommended sustained maximum.

Owner:WISK AERO LLC

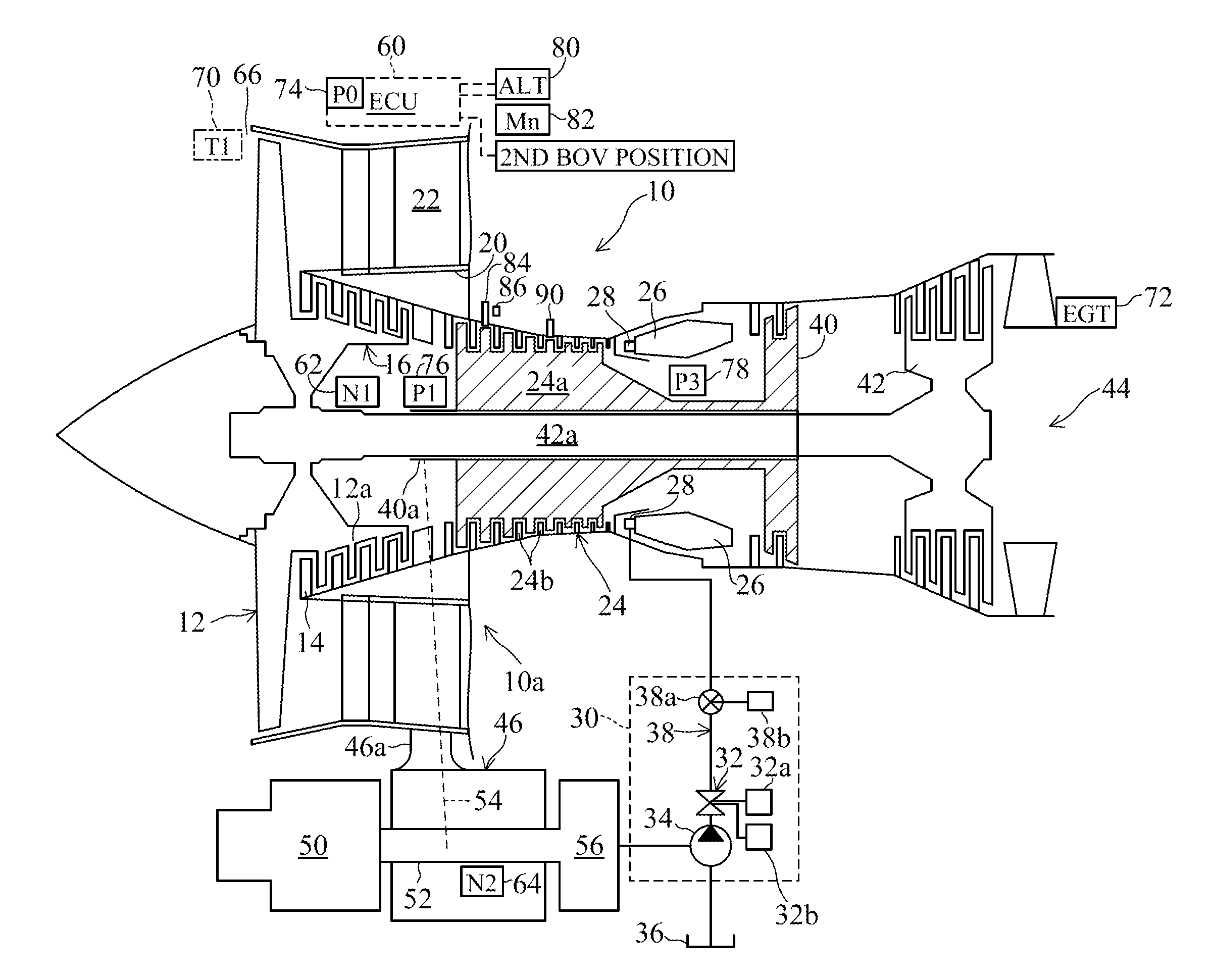

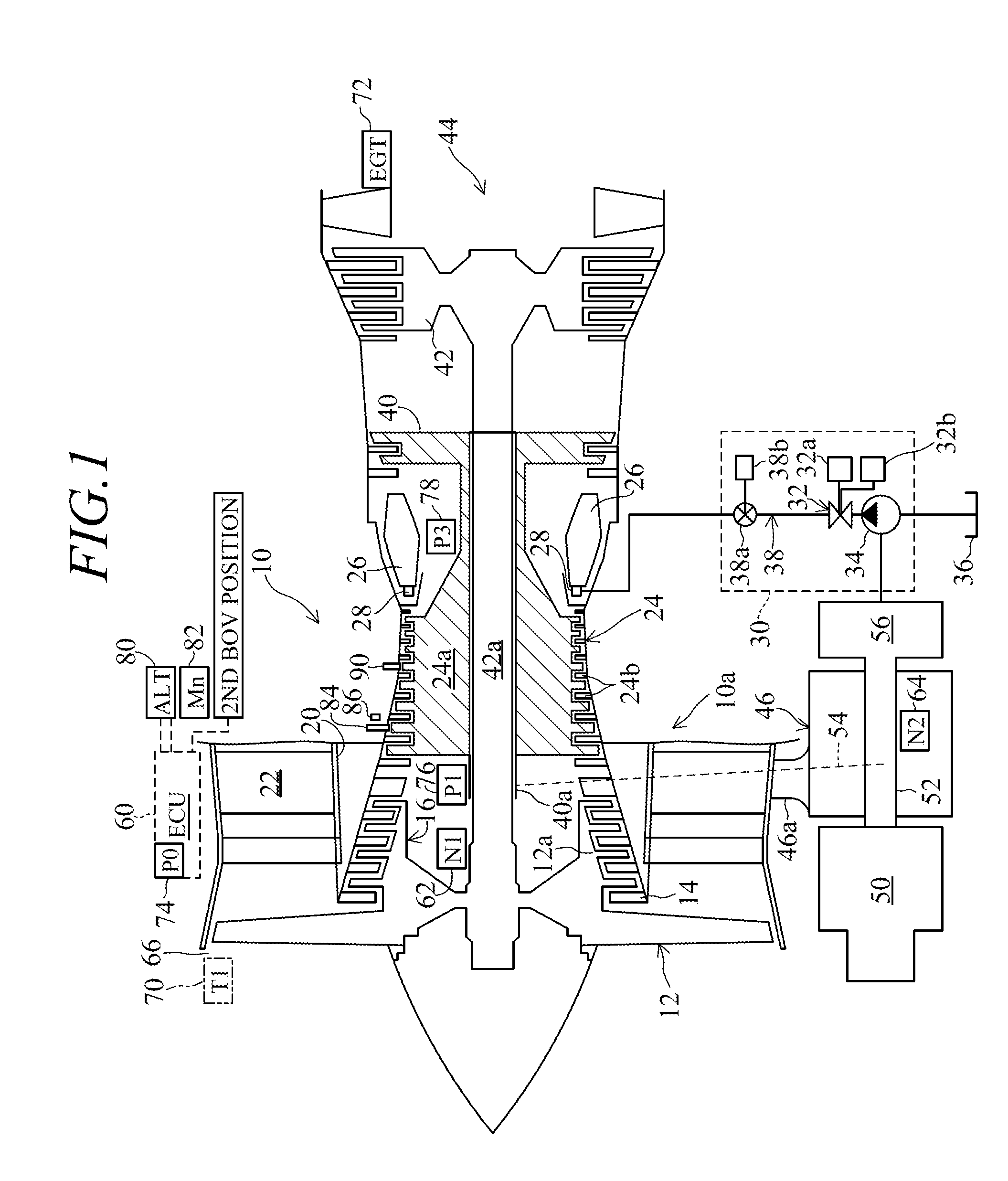

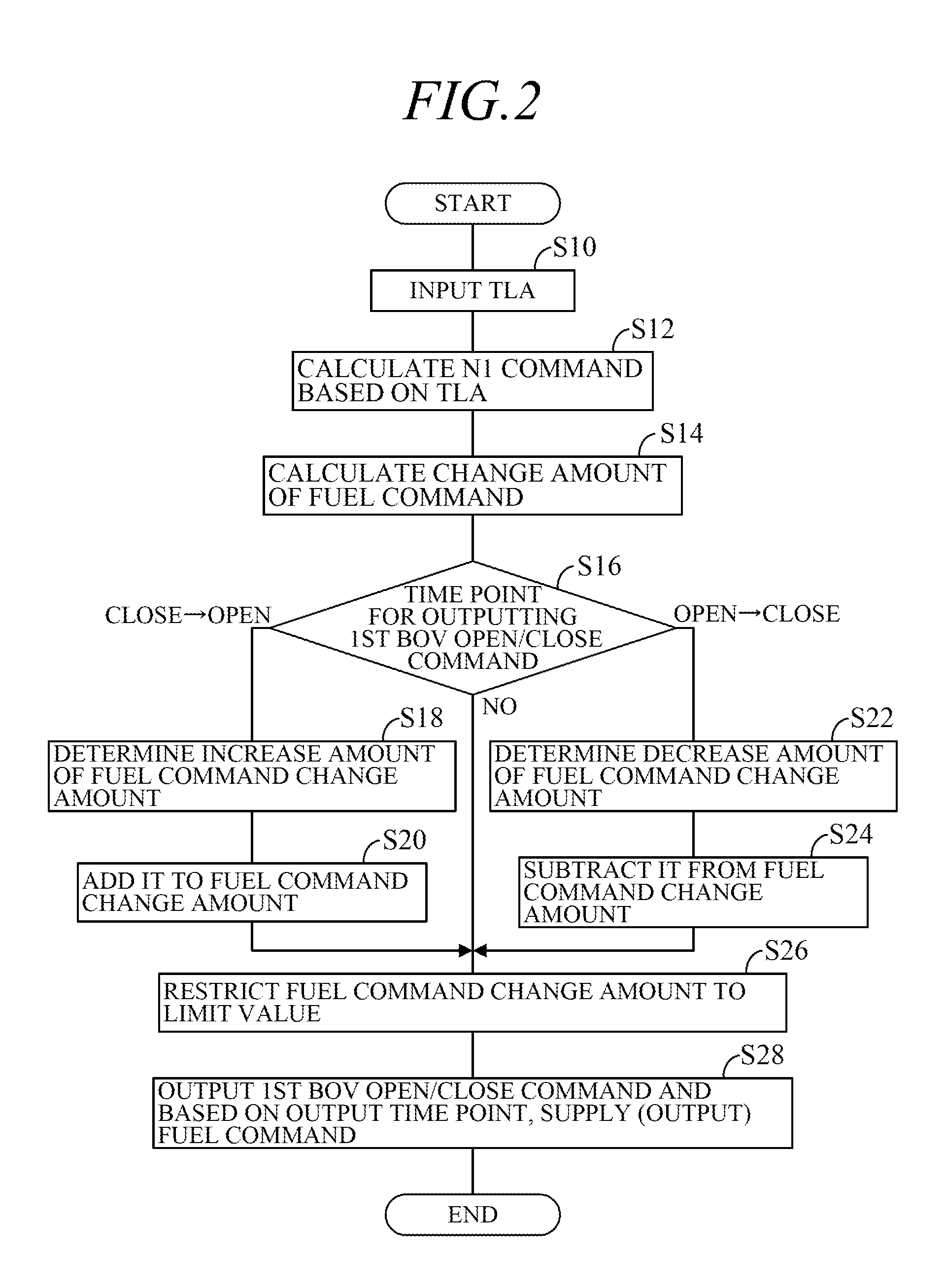

Control apparatus for a gas-turbine aeroengine

ActiveUS20160305346A1Suppress engine thrust fluctuationSuppress fluctuationsGas turbine plantsSpeed sensing governorsHigh pressureTurbine

An apparatus for controlling a gas-turbine aeroengine is configured to calculate a fuel command to supply fuel based on a calculated desired rotational speed of a low-pressure turbine calculated from an operation angle of a thrust lever installed at an aircraft cockpit pilot's seat, determines whether it is a time point for outputting a command to open / close a bleed-off valve equipped at a high-pressure compressor connected to a high-pressure turbine and to supply the fuel command based on the time point when it is determined to be the time point for outputting the command to open / close the bleed-off valve.

Owner:HONDA MOTOR CO LTD

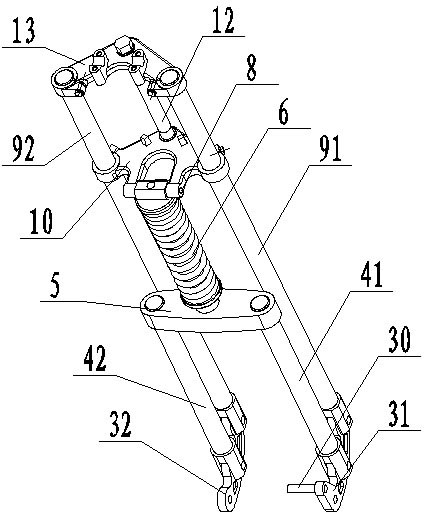

Front shock absorption assembly of motorcycle

InactiveCN102328719AImprove front suspension capacityImprove comfortAxle suspensionsArchitectural engineeringThrust lever

The invention discloses a front shock absorption assembly of a motorcycle, which comprises a left support fork pipe, a right support fork pipe, a damper and a shock absorbing spring arranged on the damper; and the key points of the front shock absorption assembly of the motorcycle are as follows: the left support fork pipe and the right support fork pipe are fixed on an upper connecting plate and a lower connecting plate and are arranged at an interval; the lower end of the left support fork pipe is fixedly connected with a left rotating arm; the lower end of the right support fork pipe is fixedly connected with a right rotating arm; the lower end of the damper is fixedly connected with a thrust rod connecting plate; a left thrust rod and a right thrust rod are respectively arranged at the left end and the right end of the thrust rod connecting plate; the lower end of the left thrust rod is connected with the left rotating arm; the lower end of the right thrust rod is connected with the right rotating arm; and the upper end of the damper is connected with the lower connecting plate through a pin shaft. The shock absorption assembly is low in requirements on the manufacturing process, simple in structure, low in maintenance cost, better in strength and high in reliability, and the processing quality of the shock absorption assembly is easy to control.

Owner:重庆福泰涂装技术有限公司

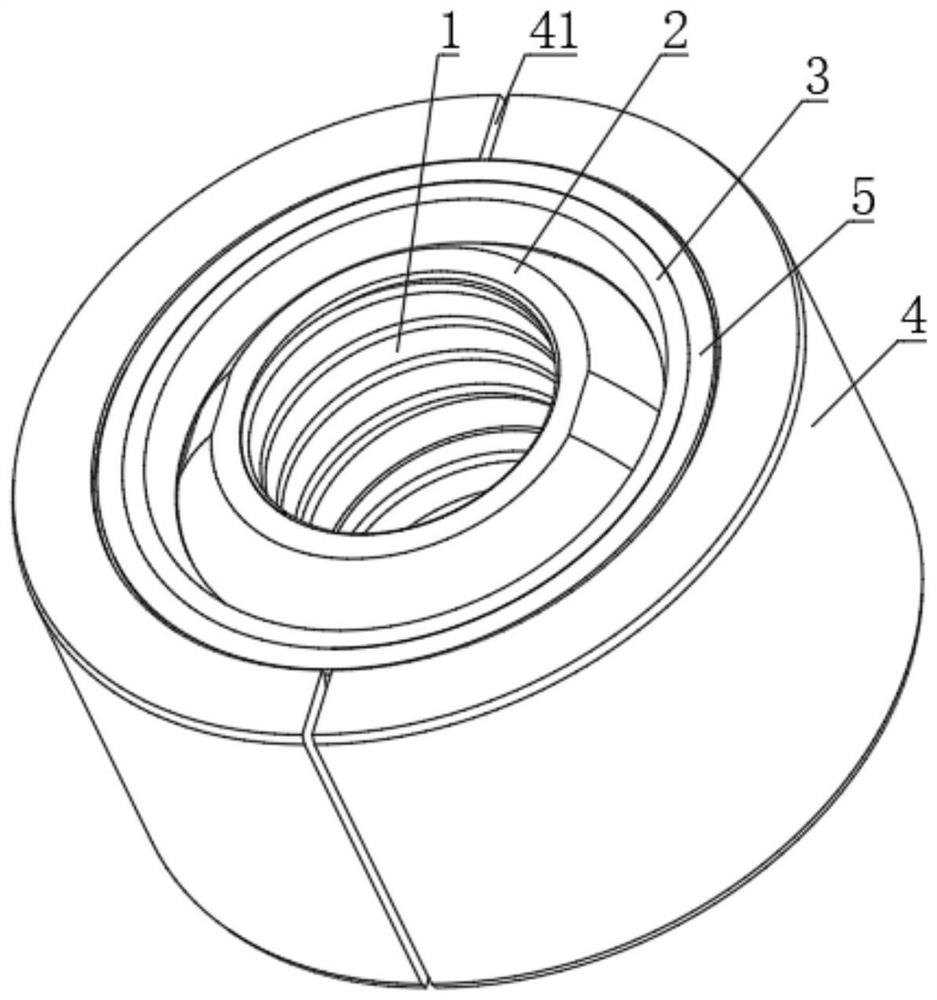

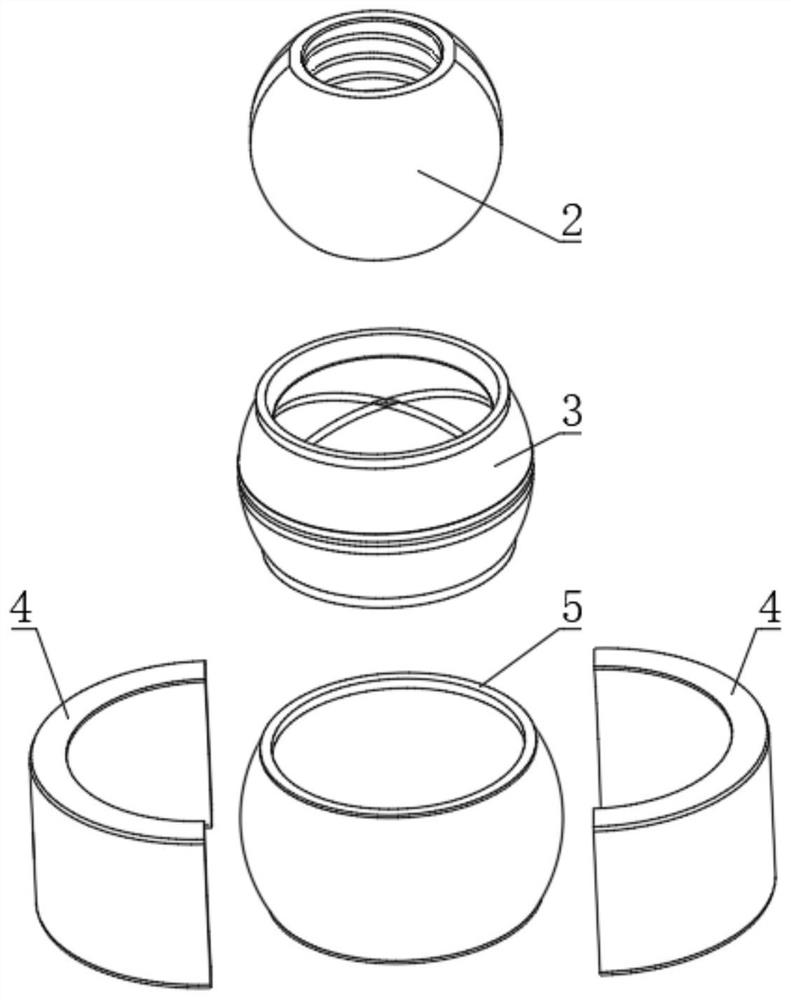

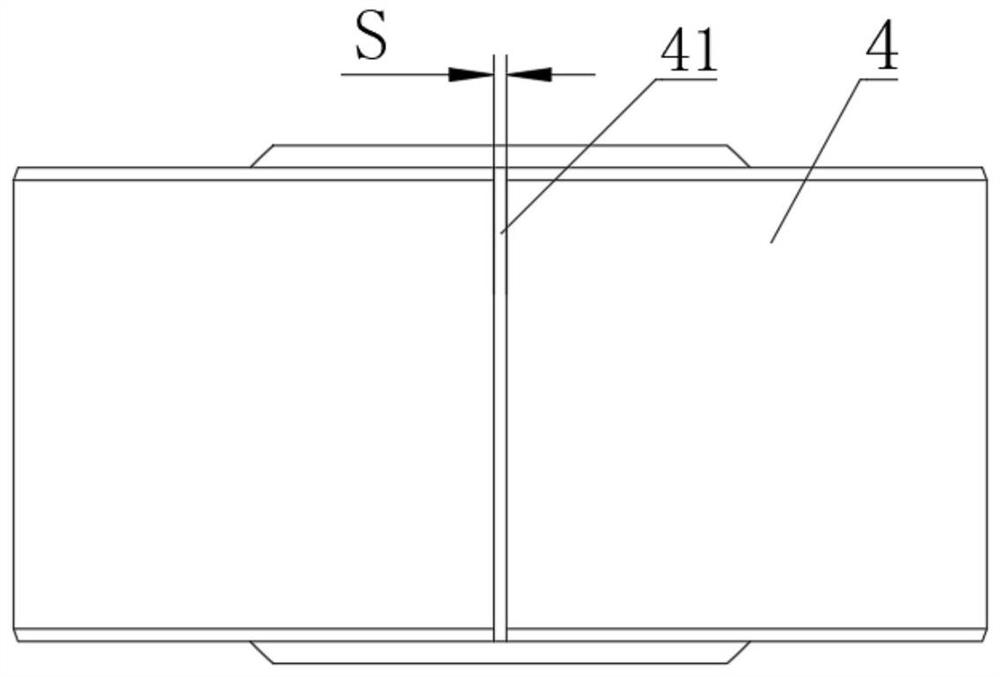

Rigidity-adjustable ball joint and thrust rod assembly

PendingCN112879417AExtended service lifePrevent extrusionPivotal connectionsPivoted suspension armsSuspension (vehicle)Ball joint

The invention discloses a rigidity-adjustable ball joint and thrust rod assembly, and belongs to the technical field of automobile suspension systems. The assembly comprises a thrust rod bracket, a pin shaft, a thrust rod, a ball body, a bearing outer ring and rigidity adjusting sleeves, wherein the ball body is in sliding universal connection with the bearing outer ring; the bearing outer ring is connected with the rigidity adjusting sleeves through an elastic layer; adjusting gaps are formed by the corresponding end faces of the rigidity adjusting sleeves on the two sides; the thrust rod and the rigidity adjusting sleeves are fixedly mounted; and the pin shaft is inserted into a mounting shaft hole and is connected with the thrust rod bracket. Free universal rotation of the thrust rod assembly is achieved through a ball joint, torsion stress of the elastic layer is released, and the elastic layer is only subjected to pressure load; the elastic layer achieves the buffering function of the thrust rod assembly, and the impact load in the force transmission process of the thrust rod is reduced; and the rigidity adjusting sleeves are provided with the adjusting gap, so that rigidity adjustment of the thrust rod assembly is achieved, the reliability of the thrust rod assembly is improved, the service life is prolonged, meanwhile, flexible connection of a suspension system and an axle assembly is achieved, and the comfort of a whole vehicle is improved.

Owner:SINO TRUK JINAN POWER

Civil structure self-adaptive horizontal thrust control device

InactiveCN110886297AReduce control adjustment timeEasy counterweightBridge erection/assemblyExcavationsArchitectural engineeringStructural engineering

The invention relates to the technical field of constructional engineering, and discloses a civil structure self-adaptive horizontal thrust control device which comprises a thrust rod. Supporting blocks are symmetrically arranged on the two sides of the thrust rod. The side, away from the thrust rod, of each supporting block is provided with a civil structure body. A measuring mechanism is installed in each supporting block. A balance weight mechanism is installed at the upper end of the thrust rod. By means of the civil structure self-adaptive horizontal thrust control device, before the weight of the thrust rod meets the thrust requirement, a balance weight on the thrust rod can be rapidly reduced or increased properly according to the deformation of the thrust rod, the horizontal thrustcontrol and adjustment time is shortened, and work efficiency is improved.

Owner:CHANGZHOU INST OF TECH

Device for detecting horizontal load resistance of guardrail on site and using method thereof

PendingCN110068505AOvercoming frictional resistanceImprove detection accuracyMaterial strength using tensile/compressive forcesLoad resistanceMeasuring instrument

Disclosed are a device for detecting the horizontal load resistance of a guardrail on site and a using method thereof. The device comprises a frame, a thrust device, a measuring device and a reactiondevice; the thrust device comprises an adjustable base, a loading device, a horizontal thrust rod and an adjustable support rod; the measuring device comprises a measuring frame, a measuring rod and ameasuring instrument; the measuring frame comprises a pair of adjustable measuring frames, the measuring rod is fixed on the measuring frame, the measuring instrument is fixed on the measuring rod, the measuring frame is in a shape of forward extension, and the measuring rod is placed on a side opposite to a thrust receiving side of the guardrail; the reaction device comprises at least one of a telescopic reaction rod, an anchor reaction hook and a reaction force bracket. The device for detecting the horizontal load resistance of the guardrail on site is convenient to operate, can be carried,assembled and measured by a single person, and can adapt to the measurement of the guardrail in various complicated occasions, and the measuring method is precise, convenient, simple and quick in operation.

Owner:常州华厦建设工程质量检测有限公司 +1

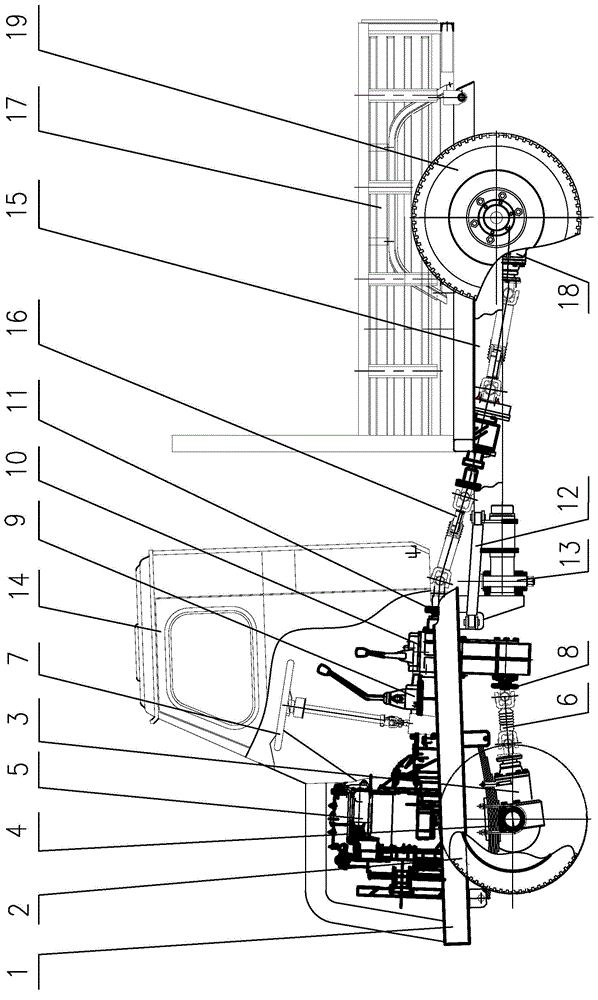

Direct-drive front-rear drive articulated steering-wheeled tractor

ActiveCN104875610AEasy to operateCompact structureDeflectable wheel steeringControl devicesVehicle frameSteering wheel

The invention discloses a direct-drive front-rear drive articulated steering-wheeled tractor. A frame system comprises a front frame and a rear frame connected through a traction pin; a travelling system comprises a front drive axle provided with front wheels and a rear drive axle provided with rear wheels; a power system comprises an engine disposed on the front frame; a transmission system comprises a gearbox, a transfer case, a front transmission shaft and a rear transmission shaft; the gearbox and the transfer case are arranged on the front frame; the engine, the gearbox and the transfer case are directly connected in order; the transfer case is connected with the front drive axle through the front transmission shaft and connected with the rear drive axle through the rear transmission shaft; a steering system comprises a steering gear and a steering thrust bar pushed by the steering gear; the steering thrust bar is connected between the front frame and the rear frame. The direct-drive front-rear drive articulated steering-wheeled tractor has the advantages that the defects of the prior art are effectively overcome, travelling is based on front wheel drive with the auxiliary rear wheel drive, and the tractor is simple to operate, compact in structure, stable in transmission and simple and practical.

Owner:GUANGXI QINZHOU LISHUN MACHINERY

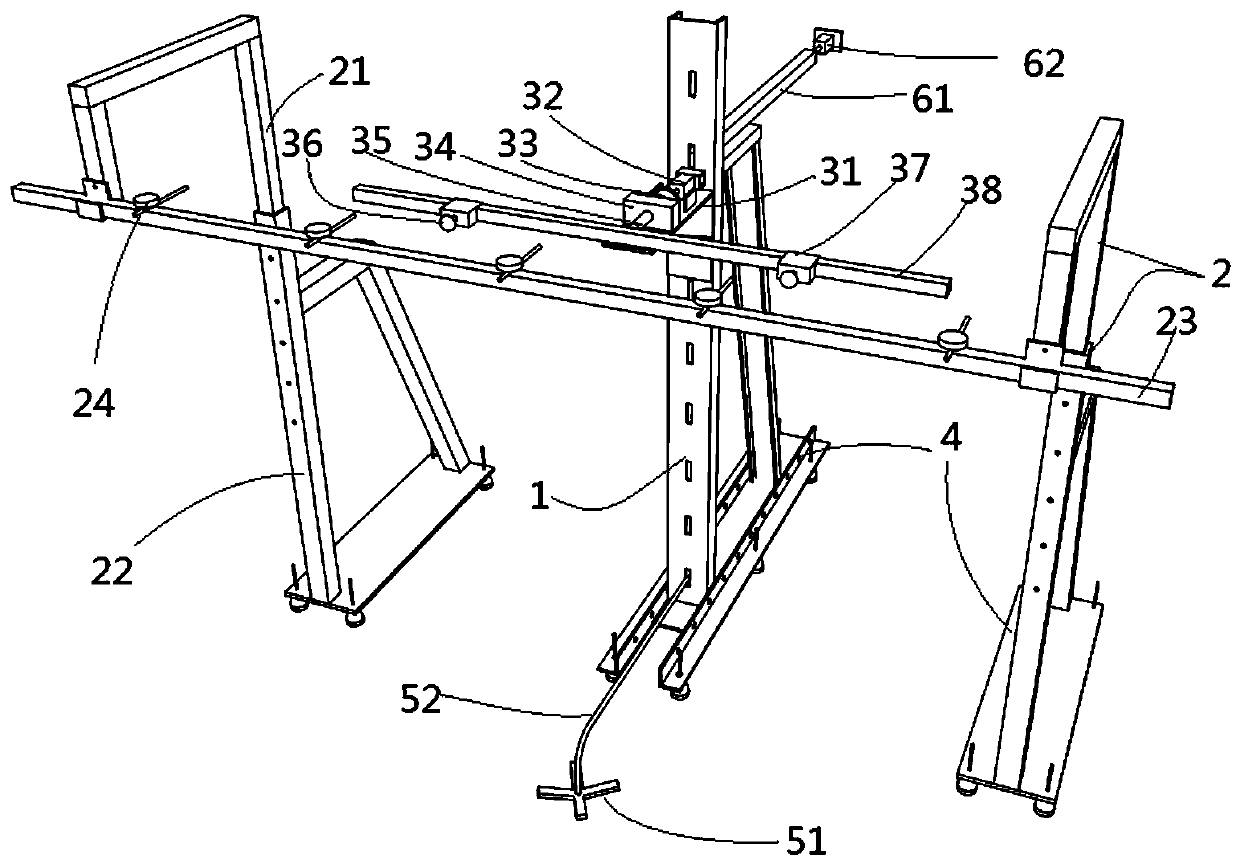

Drive system of mechanical arm

InactiveCN111168644AEasy to installEasy to disassembleProgramme-controlled manipulatorArmsRobotic armEngineering

The invention belongs to the technical field of drive structures of mechanical arms, in particular to a drive system of a mechanical arm. In order to solve the problem that different use needs cannotbe met as an existing drive mechanism is inconvenient in use, is mostly fixed on one position, and is inconvenient to move, the invention discloses the following scheme: the drive system comprises a base and a mechanical arm, wherein the top of the base is fixedly equipped with a stand column; the top of the stand column is movably connected with a pushing rod; the top of the pushing rod is fixedly equipped with a transverse regulating mechanism; a longitudinal regulating mechanism is slidably mounted on the transverse regulating mechanism; a placing disc is slidably mounted on the longitudinal regulating mechanism; a placing slot is formed in the top of the placing disc; the mechanical arm is adaptive to the placing slot; a bottom slot is formed in the bottom of the base; and a bottom plate is slidably mounted in the bottom slot. The drive system is simple in structure, is convenient to operate, can conveniently move and perform height regulation on a drive structure body, can improvestability while used, and can meet different use needs.

Owner:罗厚镇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com