Patents

Literature

202results about How to "Guaranteed use strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stainless steel tube for brake system of rail vehicle and method for producing same

ActiveCN101538684AExtended service lifeReduce manufacturing costFurnace typesHeat treatment furnacesPunchingMolten steel

The invention provides a stainless steel tube for a brake system of a rail vehicle and a method for producing the same. The stainless steel tube comprises the following components in weight percentage: less than 0.030 percent of C, more than 0 percent or less than 1.00 percent of Si, more than 0 percent or less than 1.50 percent of Mn, less than 0.40 percent of P, less than 0.015 percent of S, 10.5 to 12.50 percent of Cr, 0.30 to 1.00 percent of Ni, less than 0.030 percent of N, more than 0 percent or less than 0.10 percent of Cu, 6*(C+N) to 0.75 percent of Ti and Nb, and the balance of Fe and inevitable impurities. The method for producing the stainless steel tube comprises the following steps of: smelting, continuous casting, hot rolling, punching or extruding, and deep processing of the steel tube; the method is characterized in that molten iron is made into molten steel according to the components of the stainless steel tube; at the hot rolling step, the start-rolling temperature is between 1,080 and 1,150 DEG C, and the end-rolling temperature is between 850 and 900 DEG C; and the punching or extruding deformation temperature is controlled to be between 850 and 1,100 DEG C. The stainless steel tube produced by the method has the advantages of good corrosion resistance, good welding, mechanical and cold processing properties, and low price.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

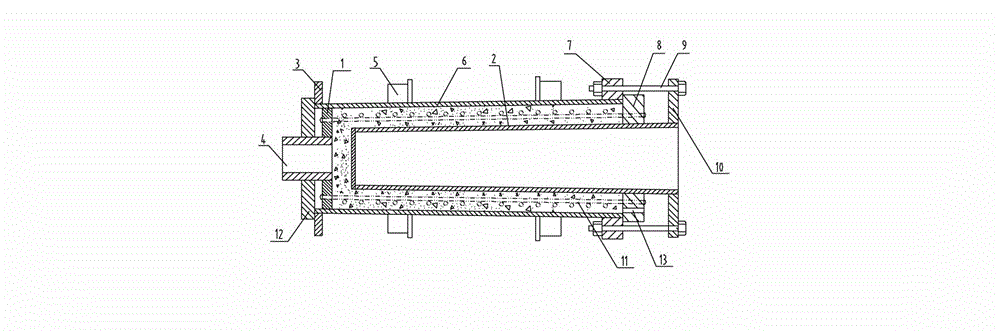

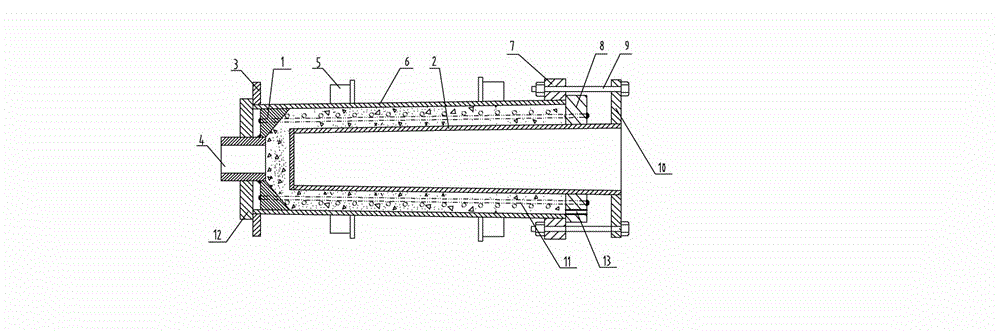

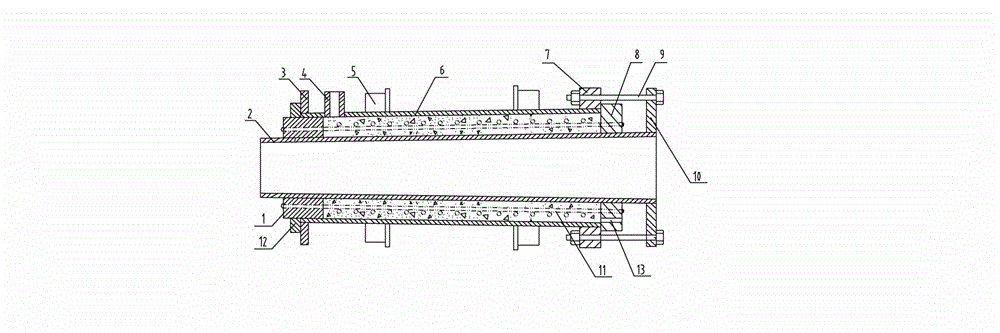

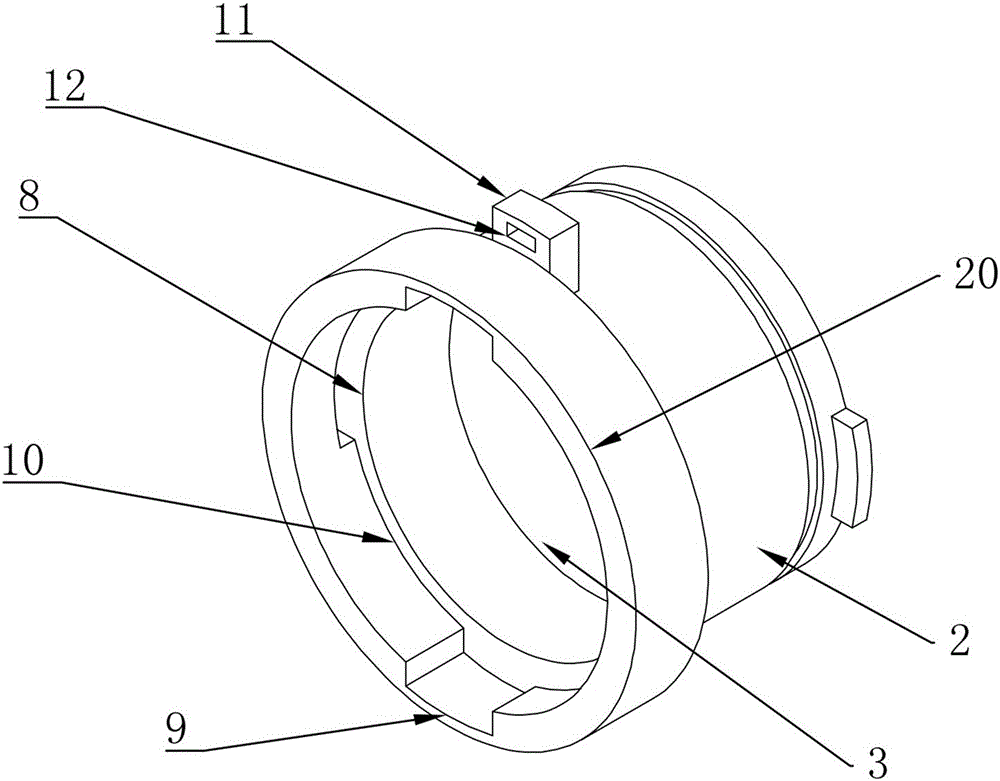

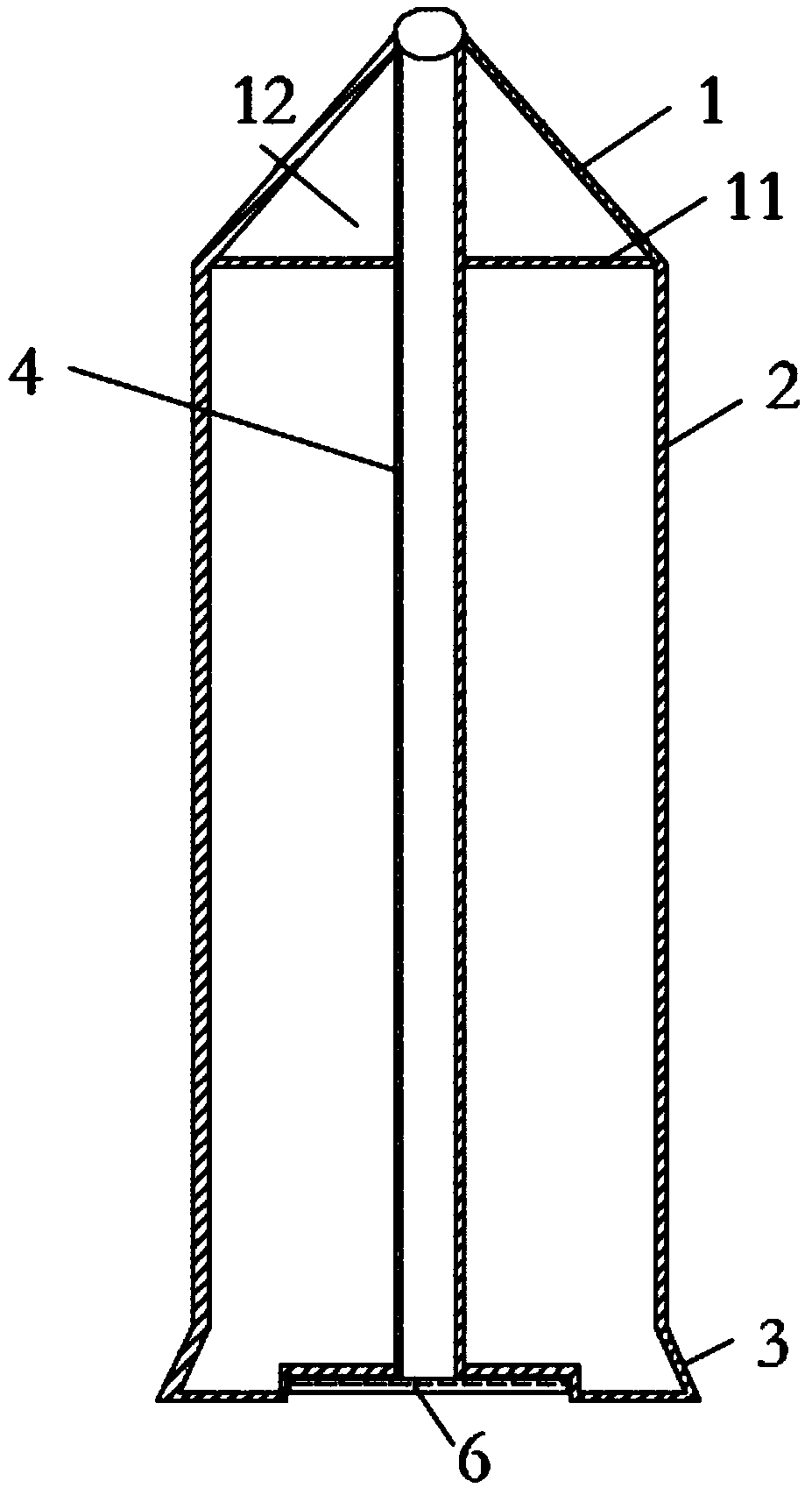

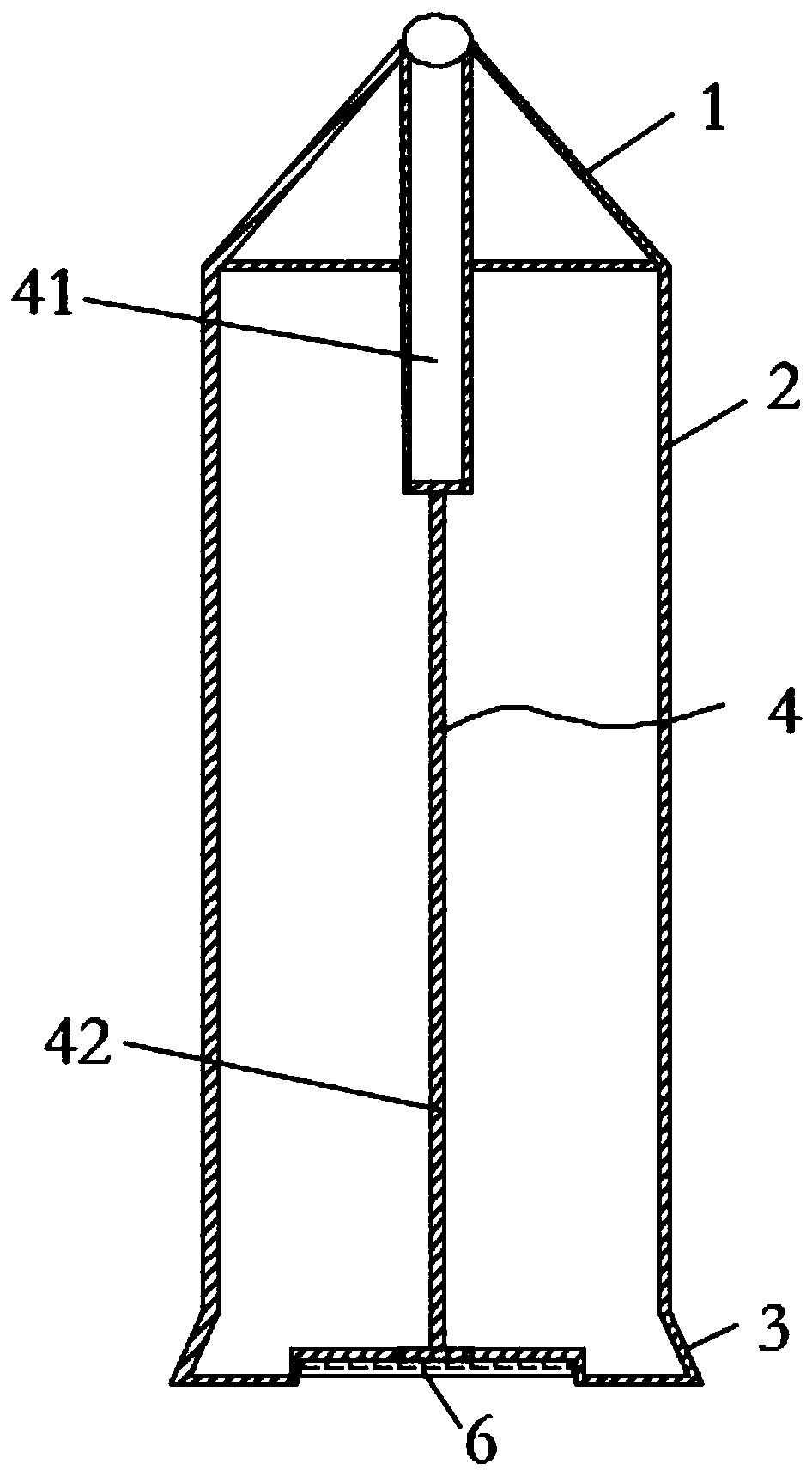

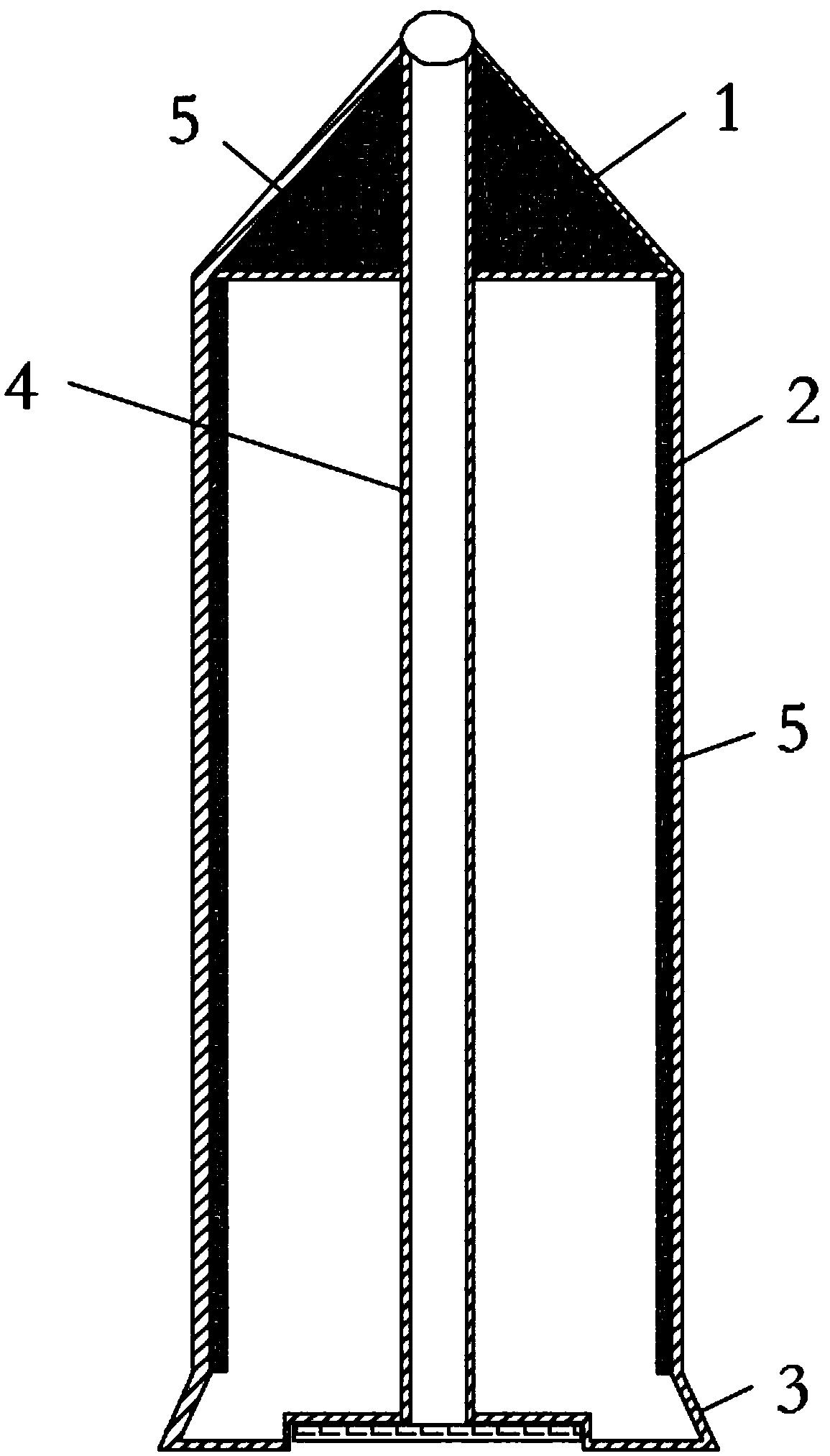

Centrifugal forming die and construction method for high-strength conical cement pole

ActiveCN102941622AImprove internal structural strengthSmooth inside and outsideMouldsPre stressWorking environment

The inventions belongs to the technical fields of manufacture of conical cement electric poles, cements communication poles and cement lamp poles and particularly relates to a centrifugal forming die and a construction method for a high-strength conical cement pole. The centrifugal forming die comprises a conical outer die, a conical inner die, an inner die large-end flange plate, a large-end prestress tensioning ring, an outer-die large-end flange plate, an outer-die small-end flange plate, a die cavity small-end closing plate, one group of running wheels, one group of bolt assemblies, a prestress locking nut, a mortar injecting port and an exhaust port, wherein the conical outer die, the conical inner die, the large-end prestress tensioning ring and the die cavity small-end closing plate form a closed annular die cavity; one group of large-end longitudinal rib inserting holes are formed in the large-end prestress tensioning ring; and one group of small-end longitudinal rib inserting holes are formed in the die cavity small-end closing plate. According to the centrifugal forming die and the construction method disclosed by the invention, the conical cement poles with the advantages of smooth inner and outer surfaces, high internal structural strength and uniformity in wall thickness can be produced. In addition, the wall thickness of the cement poles can be accurately controlled, so that the materials can be saved, the service strength of the pole bodies is ensured and the work environment of the field is improved.

Owner:元工能源科技集团有限公司

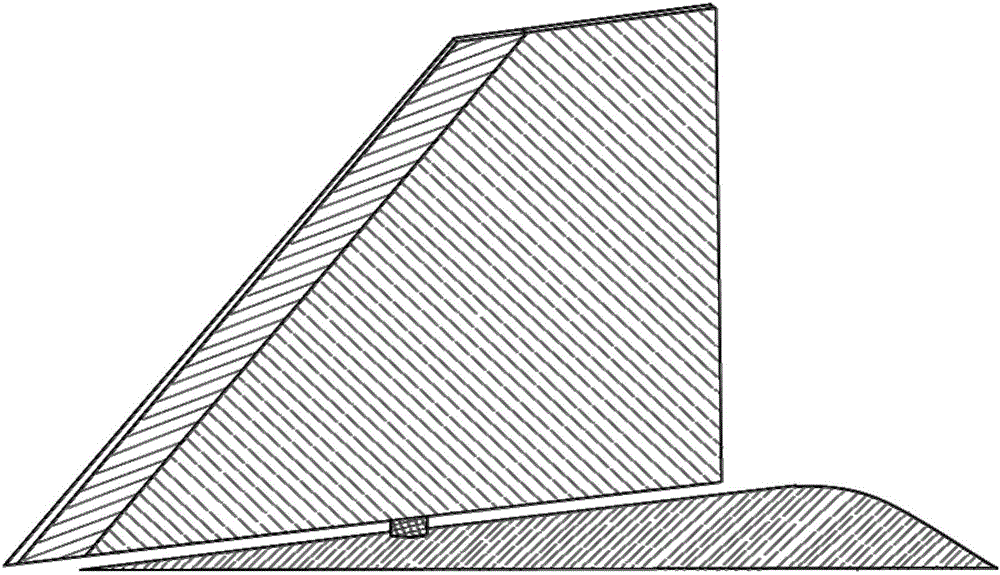

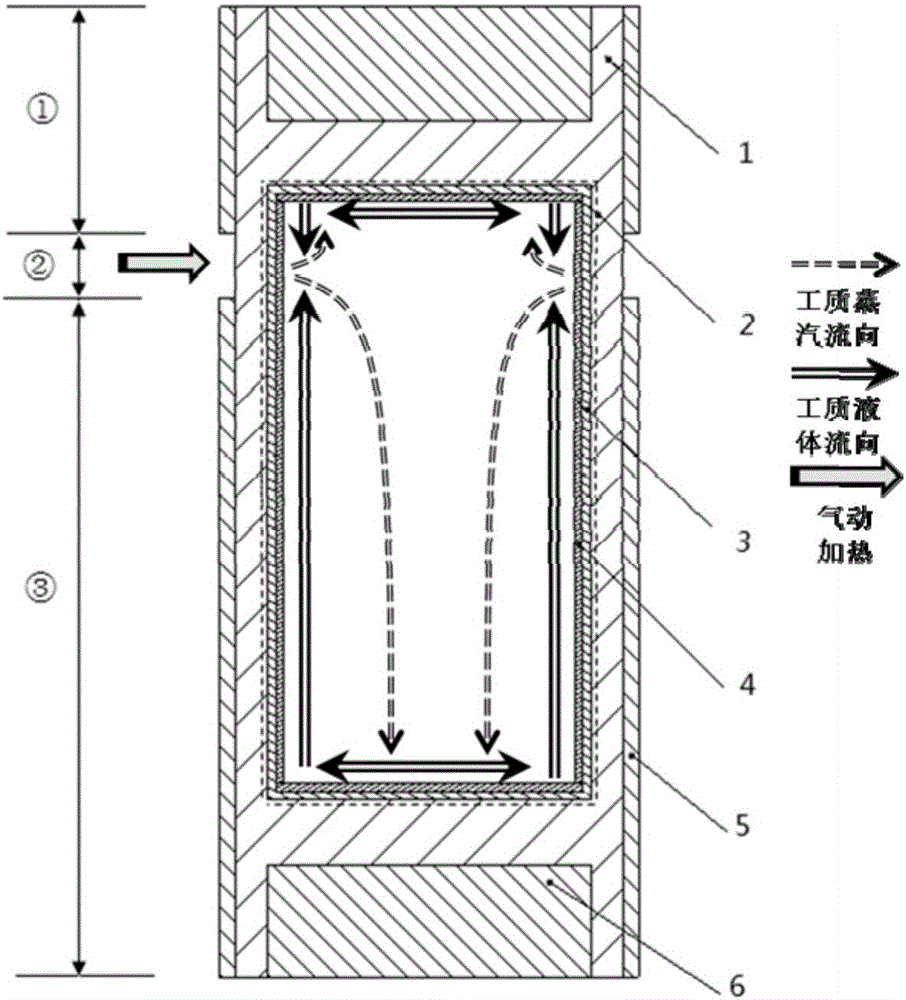

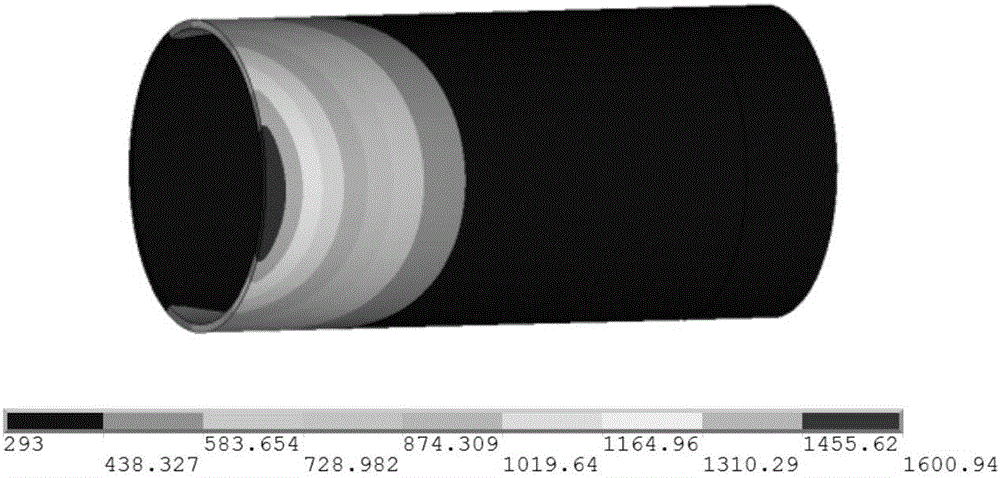

Hypersonic aircraft dredging-type rudderpost heat protection structure

ActiveCN106809375AIsothermalizationImprove thermal stress distributionAircraft controlGround installationsInsulation layerEngineering

The invention relates to a hypersonic aircraft dredging-type rudderpost heat protection structure. The rudderpost is designed as a hollow structure, the upper surface of the hollow cavity is positioned above the rudderpost mounting gap and is isolated from the control surface through a heat-insulation layer, and the lower surface is positioned inside the aircraft body and is isolated from the control actuator through a phase-change material or heat sink. The side wall of the hollow cavity is provided with a channel which is parallel to the rudderpost bus, a capillary core is welded with the surface of the channel, the hollow cavity is filled with a working medium, and the heat quantity of aerodynamic heating at the rudderpost gap is dredged to the inner wall of the whole hollow cavity through the phase change and dispersion of the working medium in the hollow cavity. The part of the rudderpost inside the aircraft body and the external surface of the control surface part are respectively provided with a heat-insulation layer.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Intermediate-carbon high-speed cutting saw blade matrix steel and production method thereof

The invention discloses an intermediate-carbon high-speed cutting saw blade matrix steel and a production method thereof. The steel comprises the following components in percentage by weight: 0.20-0.40% of C, 0.10-0.30% of Si, 0.45-0.63% of Mn, not more than 0.010% of P, not more than 0.005% of S, 0.008-0.020% of Ti, 0.80-1.20% of Cr, not more than 0.005% of N, 0.020-0.050% of Al, 0.10-0.20% of Ni, 0.030-0.050% of V and the balance of Fe and inevitable impurities, wherein Als / N is not less than 30%, Mn +Cr is 1.45-1.85. The production method comprises the following steps of: desulfurizing molten iron, smelting in a converter, carrying out vacuum treatment, casting continuously, hot-rolling continuously, cooling, coiling, leveling, quenching and tempering. Facts prove that the steel has pure steel quality, strong toughness, high wearing resistance and low cost at the same time. The production method of the steel is simple in process and stable in product property.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Production process for plate heat exchanger

InactiveCN106584045AThe production process is simple and effectiveGuaranteed use strengthPunchingEngineering

The invention discloses a production process for a plate heat exchanger. The production process is characterized by comprising the following steps of base plate treatment, base plate cutting, punch forming, punching and trimming, cleaning and drying, assembling, welding, pressure testing and packing; in the welding step, the obtained heat exchange plate set is put into a vacuum furnace and is welded at a high temperature; and after the high-temperature welding is completed, heating is stopped, and the heat exchange plate set which is welded into an integrated structure is kept in the vacuum furnace in a sealed manner and is cooled along with temperature reduction of the vacuum furnace, so that the heat exchange plate set is cooled in the vacuum environment, and accident situations such as the color change are avoided; and in the pressure testing process, the heat exchange plate set is put in the environment under the pressure of 2-3 MPa and subjected to a pressure bearing test. The production process for the plate heat exchanger is concise and efficient, the use strength and the service life of the plate heat exchanger can be guaranteed to the maximum extent, especially for rigid control over welding preparation and conditions, the process is safe and efficient, the quality is excellent, and the high-pressure test is conducted, so that the quality of products is further guaranteed, and the production process is worthy of popularization.

Owner:JIANGYIN YALONG HEAT TRANSFER EQUIP CO LTD

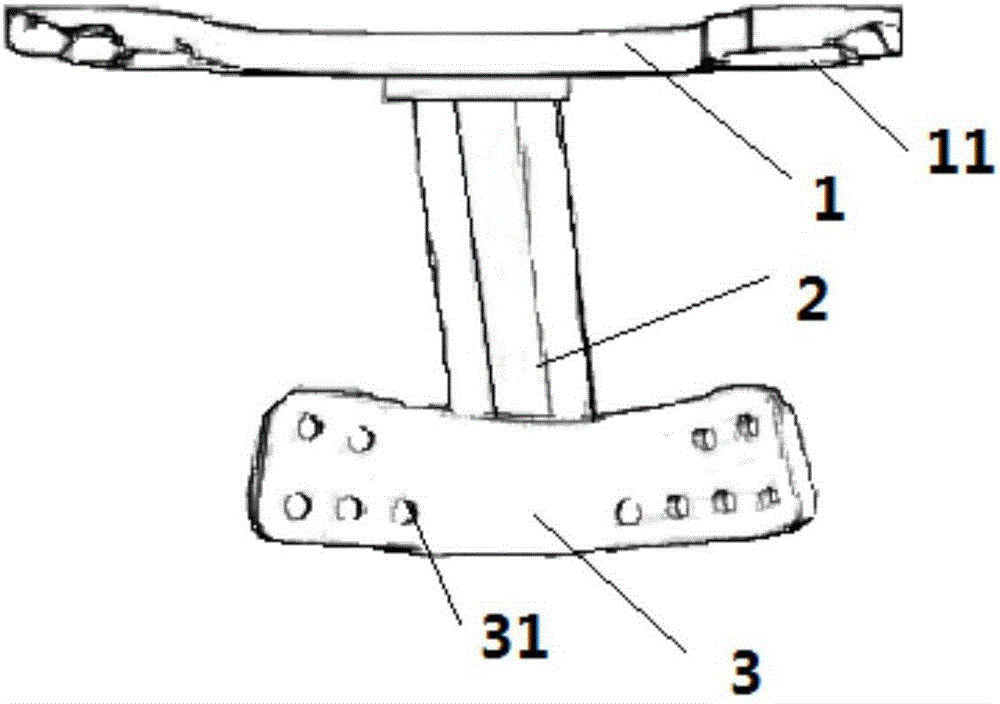

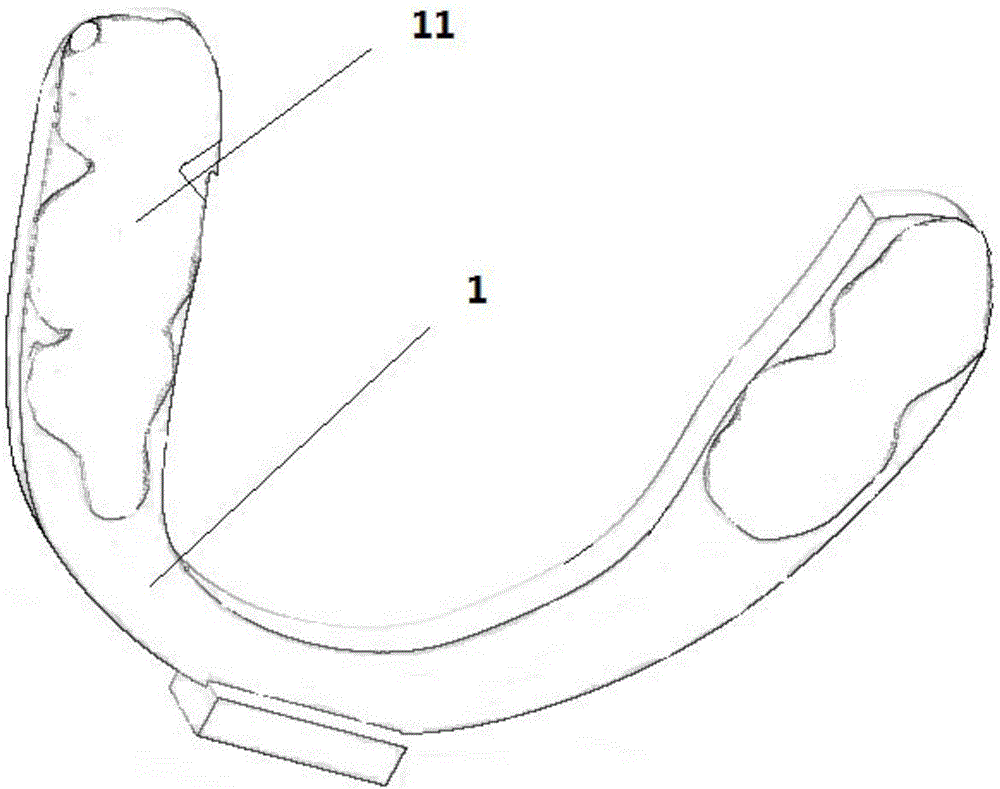

Guide plate for stretching alveolar bone to form bone as well as manufacturing method and using method of guide plate

PendingCN107174361ASimple structureImprove securityDental implantsAdditive manufacturing apparatusAnatomical structuresEngineering

The invention provides a guide plate for stretching an alveolar bone to form a bone as well as a manufacturing method and a using method of the guide plate. The guide plate comprises an occlusal plate, a positioning plate and a guide plate body; the occlusal plate supplied for human occlusion is arranged in a U shape and extends into a mouth of a person from the opening side; the bottom of the occlusal plate is connected with the middle part of the guide plate body through the positioning plate; the guide plate body is wholly arranged in an arch shape, is adhered to the alveolar bone of the person and is provided with two transverse rows of through holes; and an osteotomy line is arranged between the two rows of through holes for capability of accurately stretching the alveolar bone to form the bone directionally, so that the guide plate is particularly suitable for a case of increasing the thickness and the height of the alveolar bone at the same time, can avoid an important anatomical structure, improves the safety of a surgery, guides a doctor to successfully and safely finish the surgery, improves the surgery accuracy efficiency, lightens burdens of the doctor and a patient, in addition, has a simple structure, is liable to manufacture and convenient to apply and is suitable for being popularized and used in a large scale.

Owner:SICHUAN UNIV

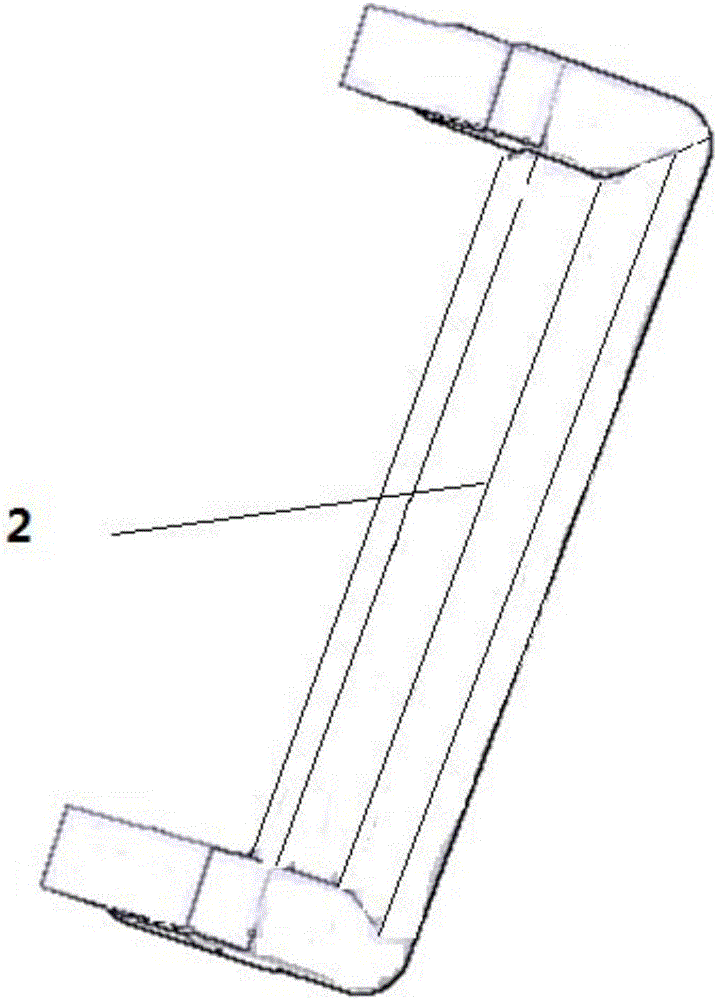

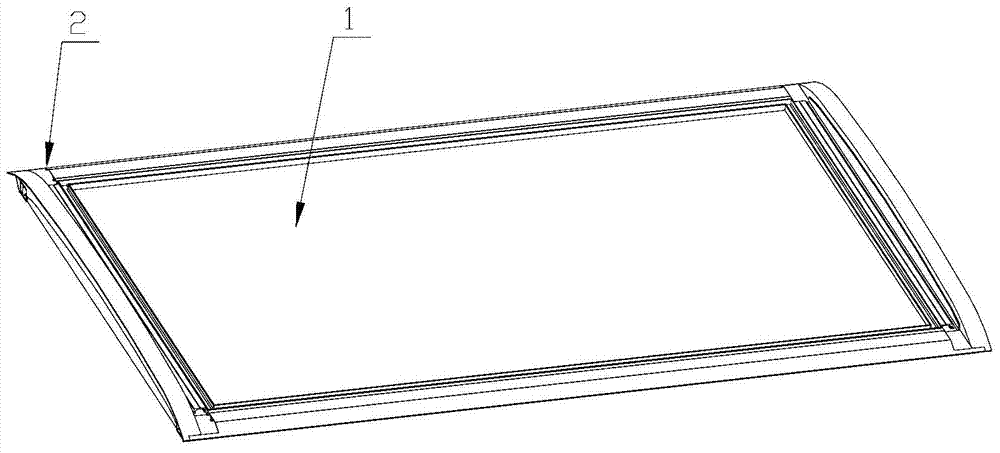

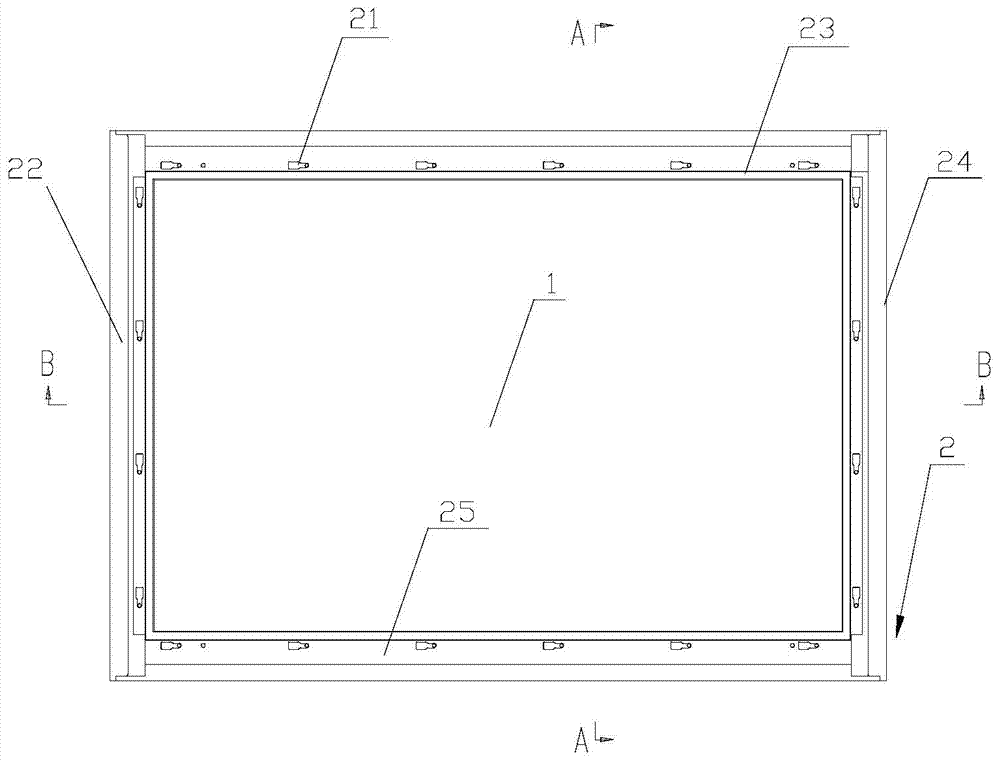

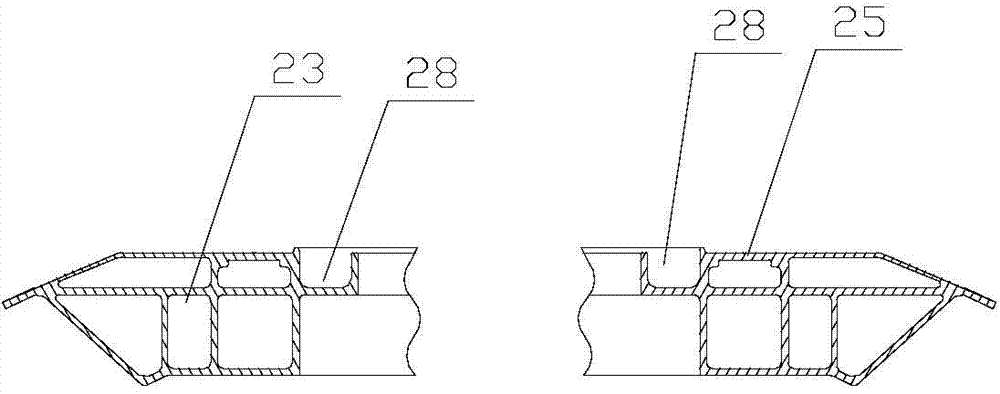

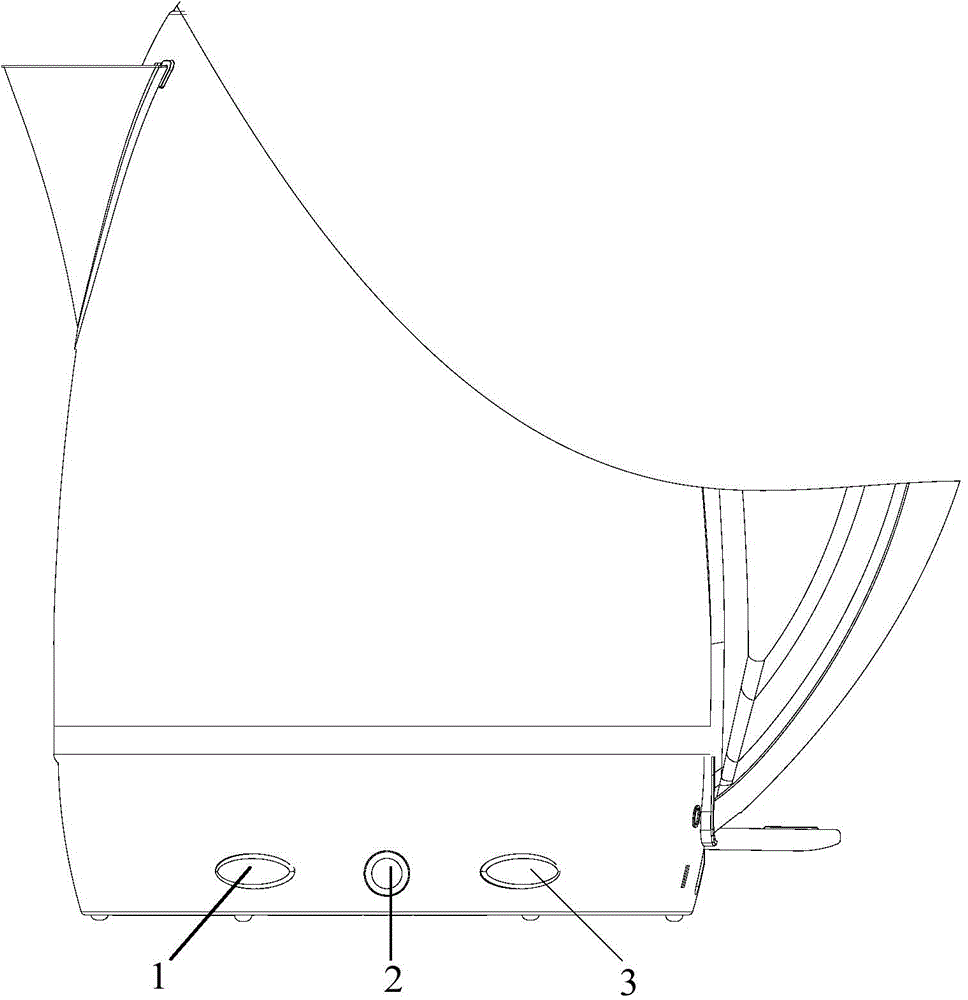

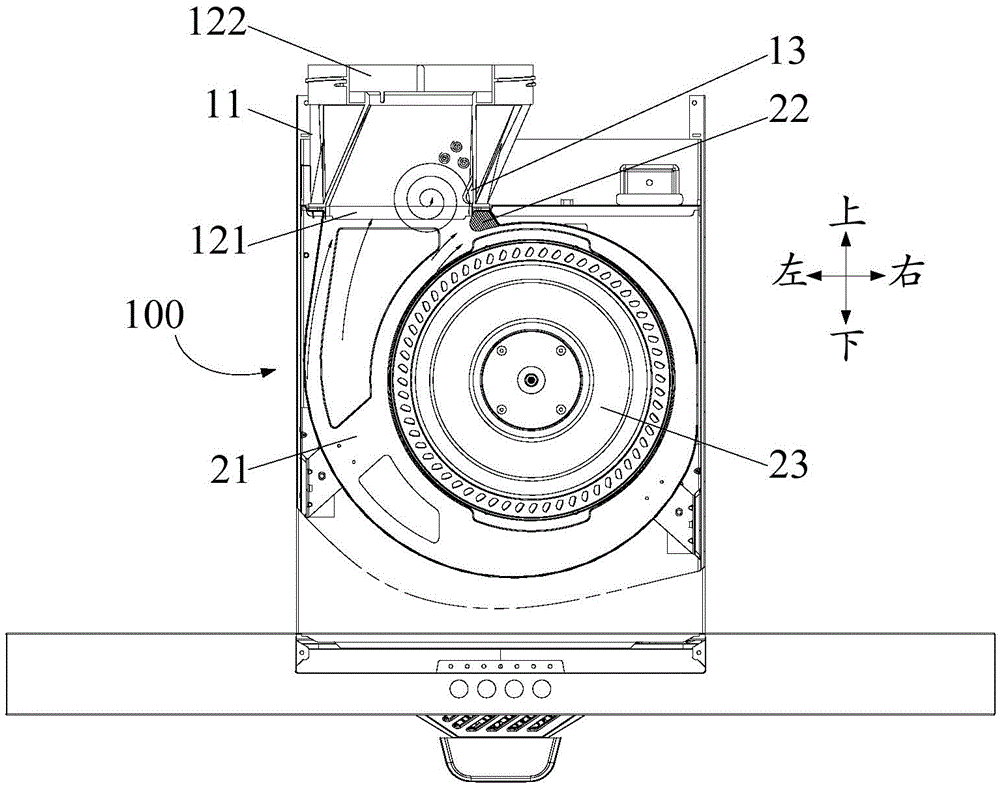

Roof and air conditioner installation seat of railway vehicle

ActiveCN104709303ARealize "sinking" installationDoes not affect the outer contourRailway heating/coolingAxle-box lubricationAerospace engineering

The invention provides a roof and an air conditioner installation seat of a railway vehicle. Sunken installation of an air conditioner can be achieved, the influences on a roof streamline structure are reduced, air resistance and aerodynamic noise are lowered, and the aerodynamic performance of a train is improved. The air conditioner installation seat is arranged on the roof of the railway vehicle and is of a square frame structure, a middle cavity of the square frame structure is used for containing the air conditioner, the four sides of the square frame structure are edge beams made of hollow sectional materials, the inner sides of the edge beams are provided with air conditioner installation positions, the outer sides of the edge beams can be welded to the hollow sectional materials of the roof in an inserted mode, and the top faces of the side beams are each of an arc shape matched with the roof. The middle cavity of the square frame structure is used for containing the air conditioner, the whole air conditioner is conveniently arranged on the roof and cannot protrude out of the roof, sunken installation of the air conditioner is achieved, the influences of air conditioner installation on the roof streamline structure are effectively reduced, air resistance and aerodynamic noise are lowered, and the aerodynamic performance of the train is improved.

Owner:CRRC QINGDAO SIFANG CO LTD +1

Method for preparing high-strength water-permeable brick by compounding gangue steel slag and wheat straw ash

The invention discloses a method for preparing a high-strength water-permeable brick by compounding gangue steel slag and wheat straw ash. The method comprises the following steps: sieving gangue andsteel slag according to grain diameter, with the sieved gangue and steel slag as aggregates on the surface layer and the bottom layer of a water-permeable brick correspondingly, carbonizing wheat straws in a carbonizing furnace, mixing with resin, and performing surface modification on the aggregates on the surface layers. The strength and the wear resistance of concrete can be greatly enhanced within the proper mixing amount range, the specific gravity of the water-permeable brick is greatly reduced, high adaptability in the processes of transportation, construction and the like is achieved,and the effect of synergistically improving the strength and the water permeability of the sand-based water-permeable brick is achieved; for the treatment on the aggregate on the bottom layer, rollerrolling is adopted to reduce the influence on the quality performance of the material caused by physical friction, silt on the surfaces of the aggregates can be shaken off, crack-containing particlescan be completely eliminated, and the forming strength of the brick body can be enhanced; and the concrete water-permeable brick with high strength and excellent wear resistance can be prepared, sintering is avoided, and the use strength and high water permeability of the water-permeable brick can be guaranteed.

Owner:海南华舜泰环保科技有限公司

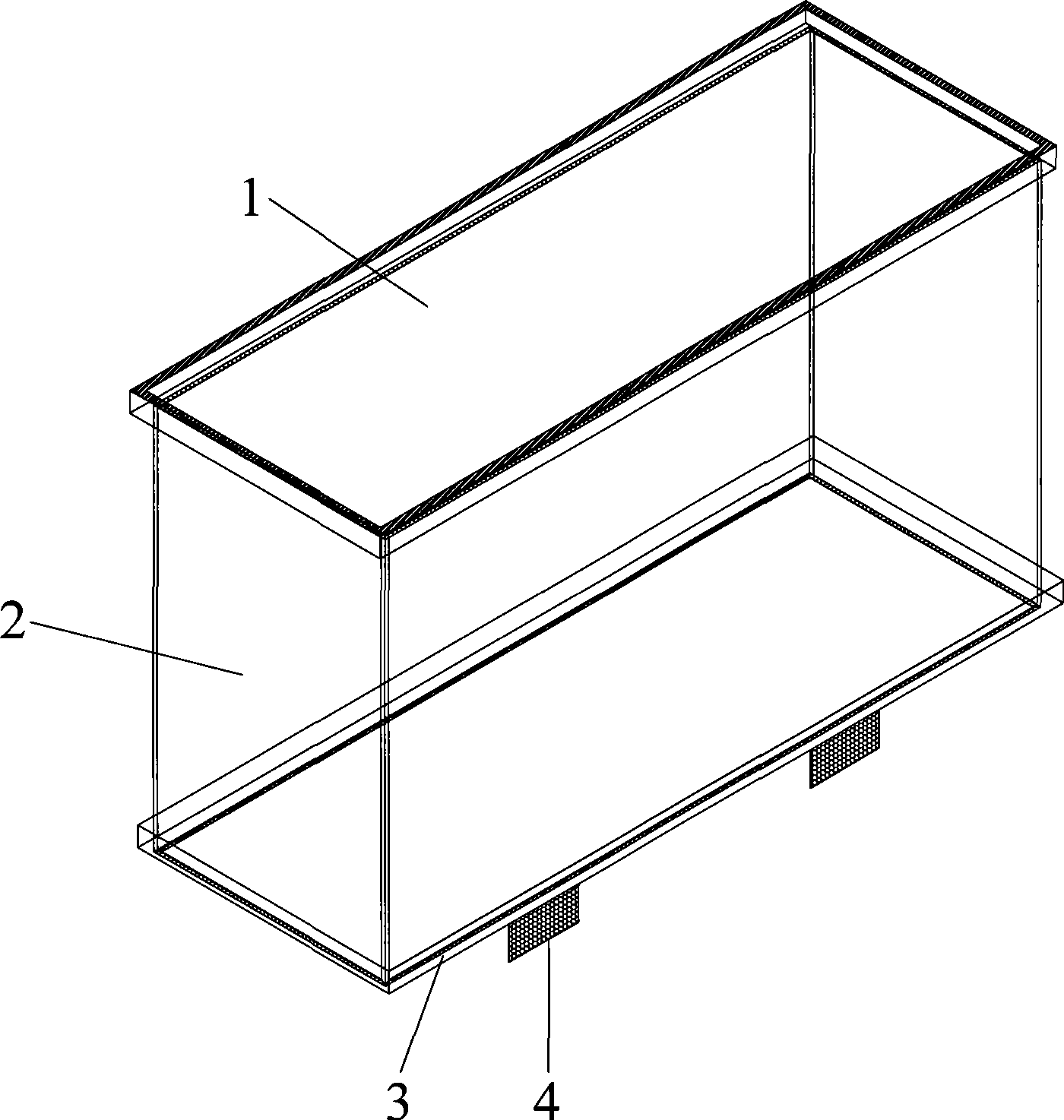

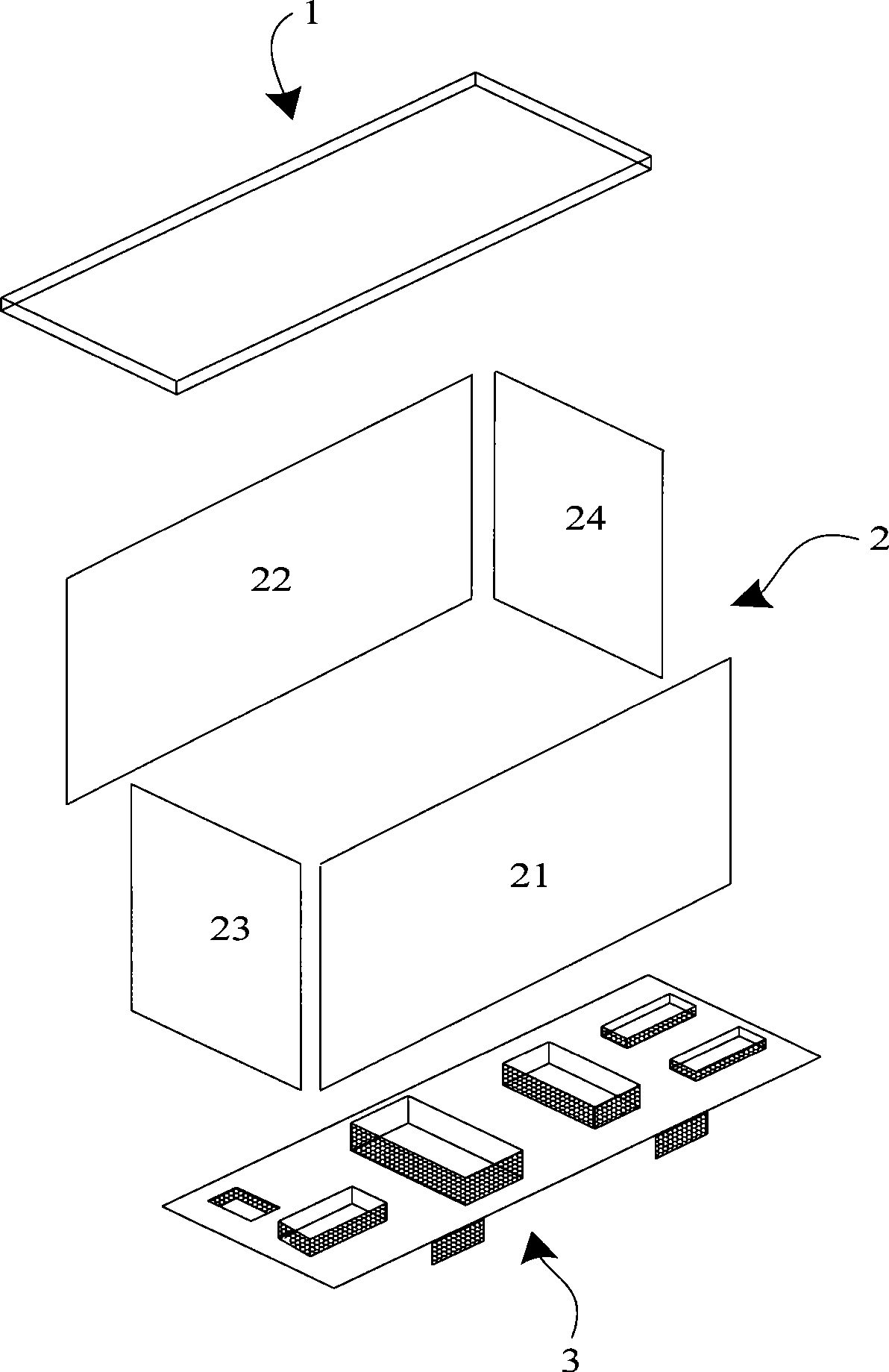

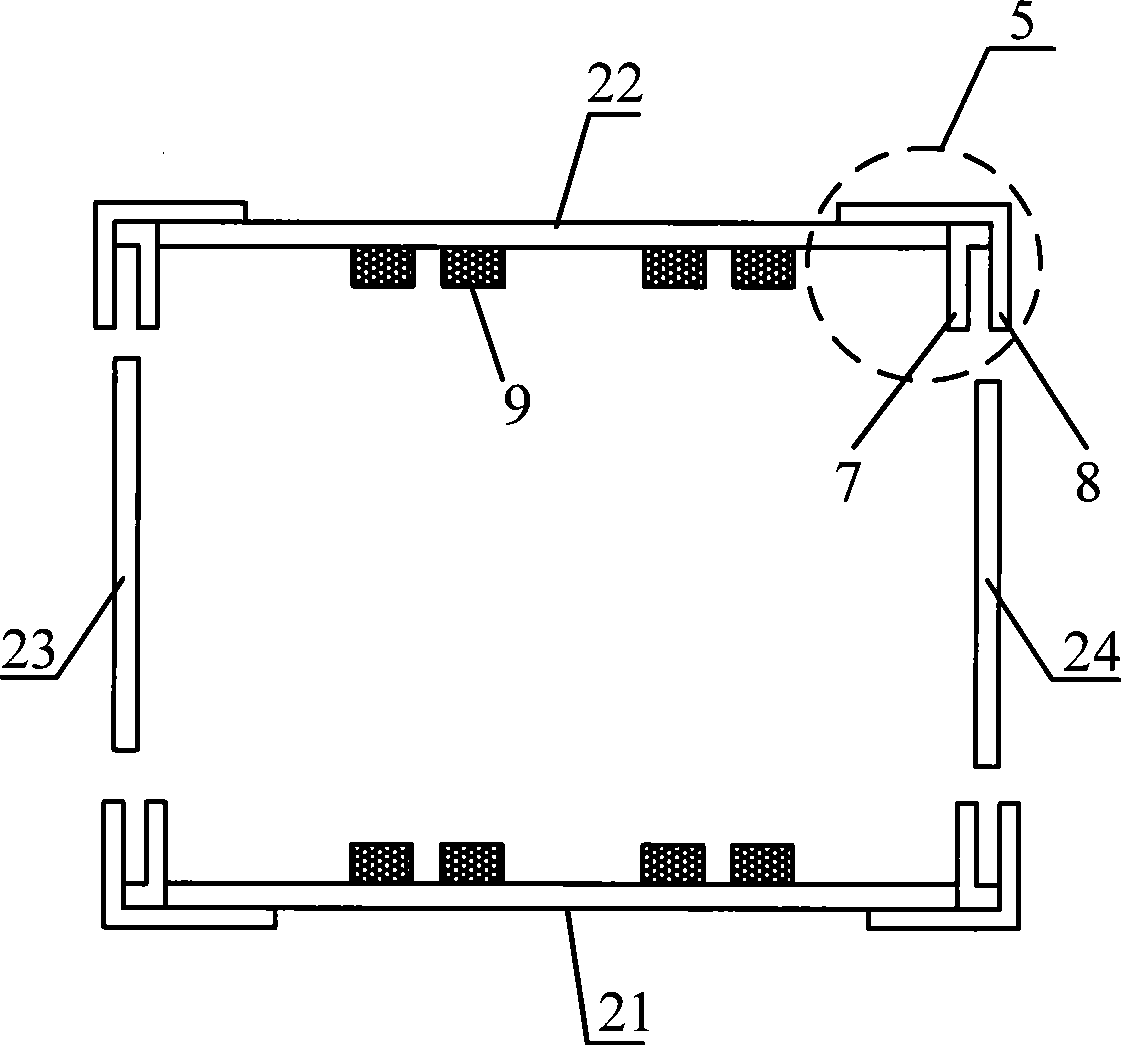

Combination type package container of motorcycle

InactiveCN101391687AGood regeneration performanceImprove aestheticsPackaging vehiclesContainers for machinesCardboardVertical edge

The invention relates to a combination packing box used for motorcycles, comprising a box cover, a box body and a chassis. Wherein, the box body is composed of a front end plate, a back end plate, a left side plate and a right side plate. The upper end of the box body is connected with the box cover while the lower end is connected with the chassis. The box cover, box body and chassis all appears beehive paper board formed by two pieces of cardboard between which the beehive paper is clamped. Outer paper corner beads and inner paper corner beads are adhered on the vertical edges at the ends of the end plates of the box body to form the paper corner-protecting body of right-angle slot style, and one end of the right-angle slot style paper corner-protecting body which links the side plates appears as the slot structure and the corresponding side plates are inserted into the slot. Then the front end plate, back end plate, right side plate and left side plate are connected mutually to form the box body. The combination packing box adopts the block combination style on structure and the box body is formed by inserting and connecting beehive paper boards with compact structure and proper intensity so as to reduce cost and prolong the service life while guaranteeing the intensity; and the processing is easy and both assembling and disassembling are convenient; not only the integrity appearance of the packing box is elegant but the environment protection requirement can be realized; and the application prospect of the combination packing box is prosperous.

Owner:SUZHOU WEIEN HONEYCOMB PRODS

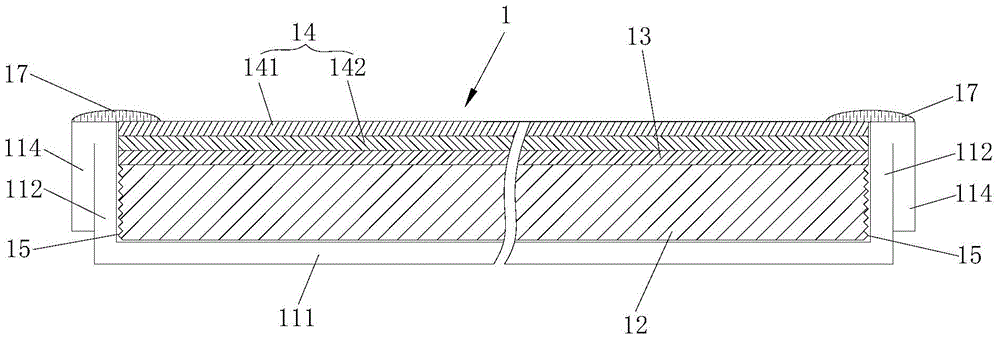

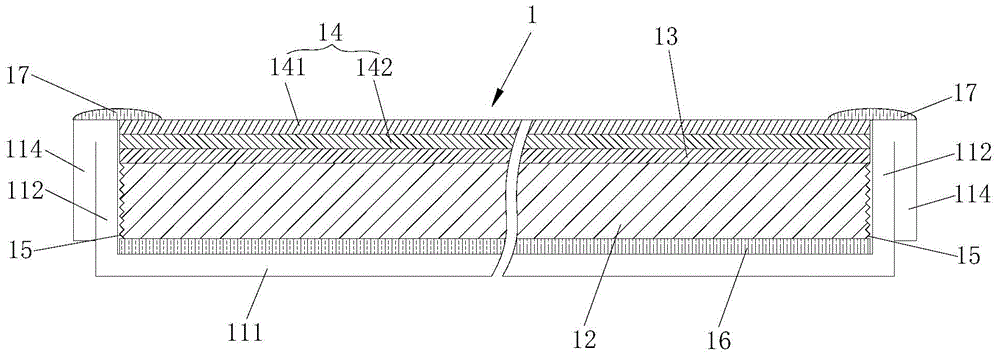

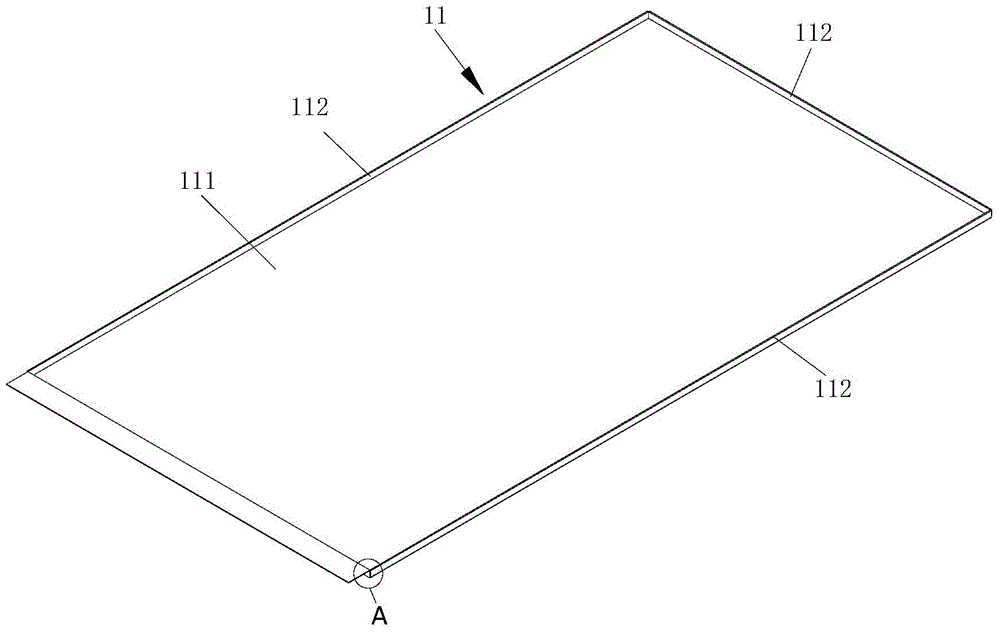

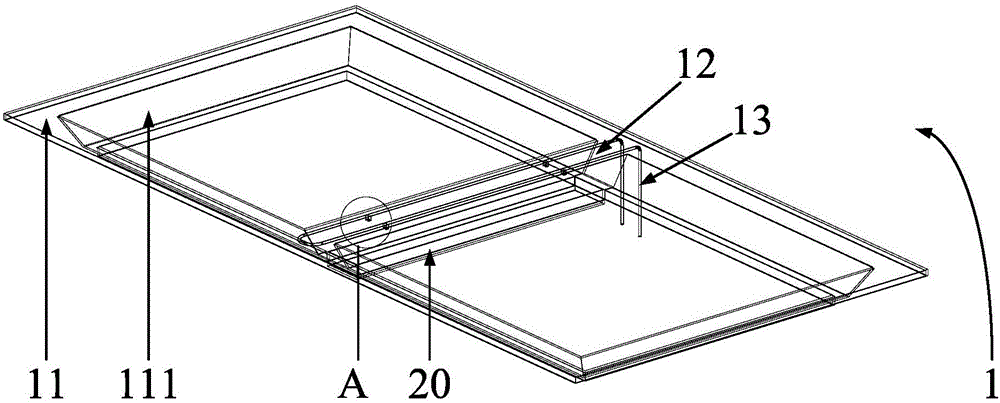

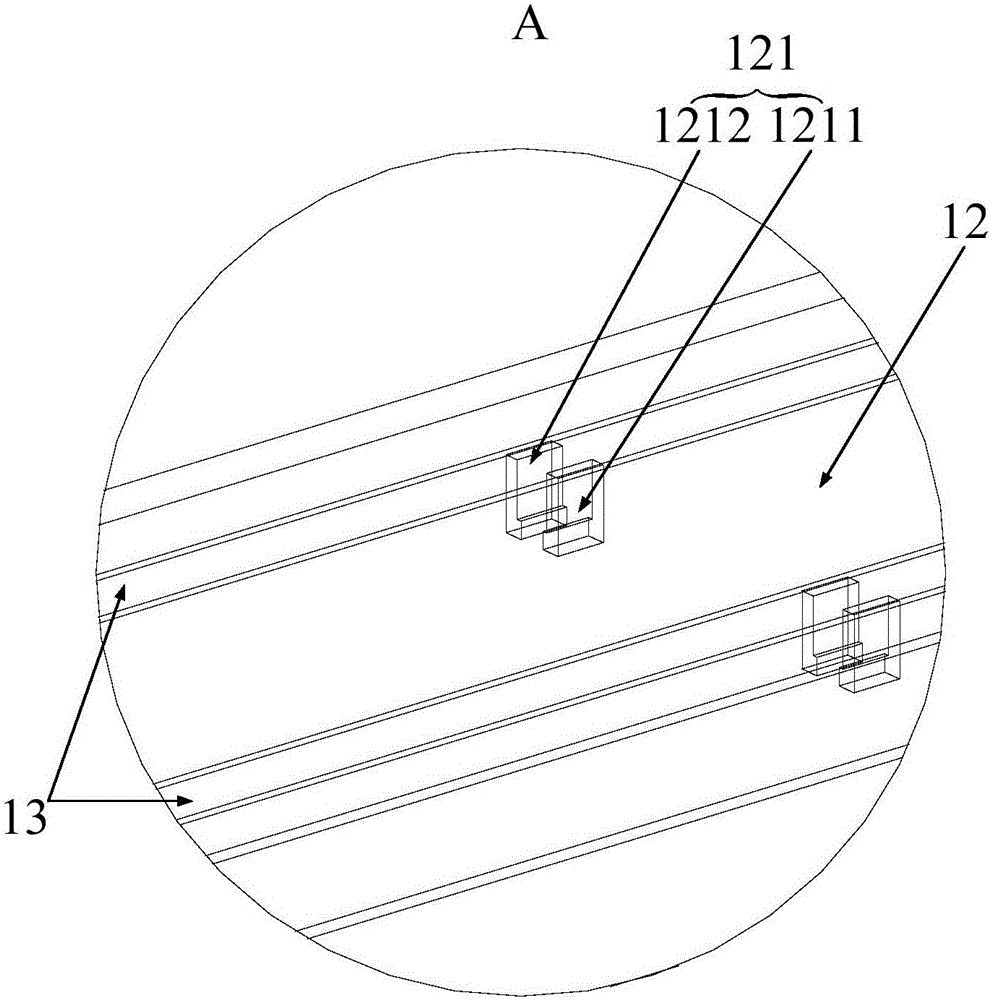

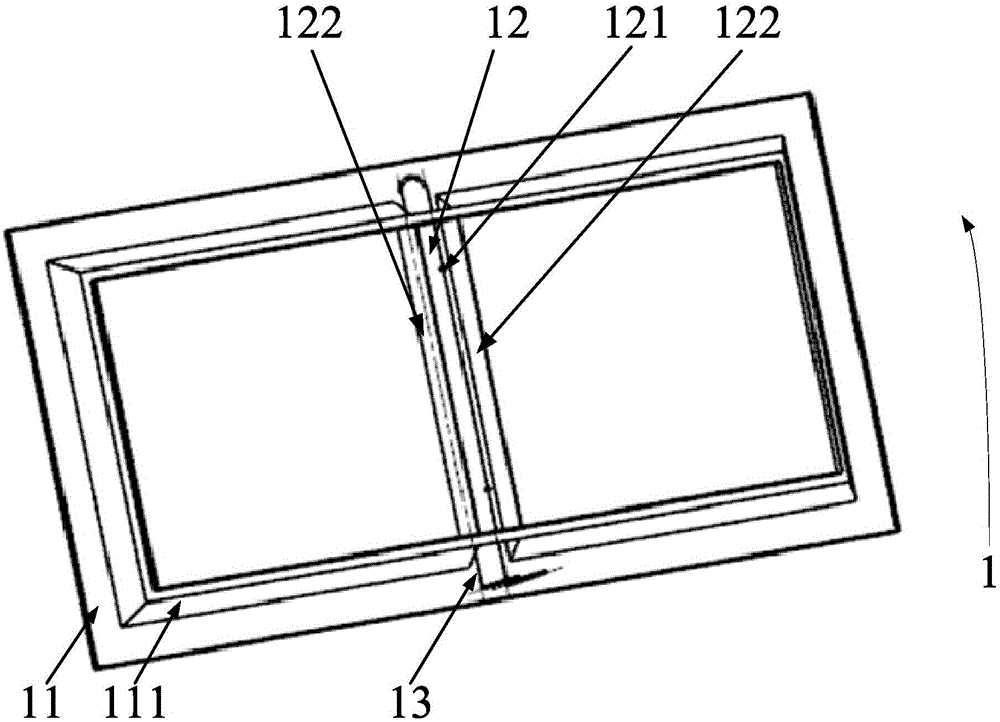

Backlight module and display screen thereof

ActiveCN104879685AUltra-thin designIncrease brightnessLighting support devicesIdentification meansLight guideDisplay device

The invention is applicable to the technical field of display devices, and provides a backlight module and a display screen thereof. The backlight module comprises an iron frame, a light guide plate, a diffusion film and a bright enhancement film set, wherein the iron frame is combined by a bottom plate and four side plates which are enclosed on the bottom plate to form a cavity; the light guide plate, the diffusion film and the bright enhancement film set are laminated in sequence; the side plates are also provided with reinforcing plates in a bending manner; the inner side faces of the four side plates and the bottom plate are provided with reflecting layers; a light emitting circuit is arranged in a gap between the side face of the light guide plate and the side plates of the iron frame; the side face of the light guide plate is provided with prism stripes for reducing the brightness of the edge of the light guide plate. The display screen comprises the backlight module. According to the backlight module provided by the embodiment of the invention, the width of the frame of the backlight module is narrow and the strength is high, the integral strength of the product is guaranteed, and the requirements of the display screen on narrow-side and ultrathin development are met.

Owner:SHENZHEN HUARUIBO PHOTOELECTRIC CO LTD

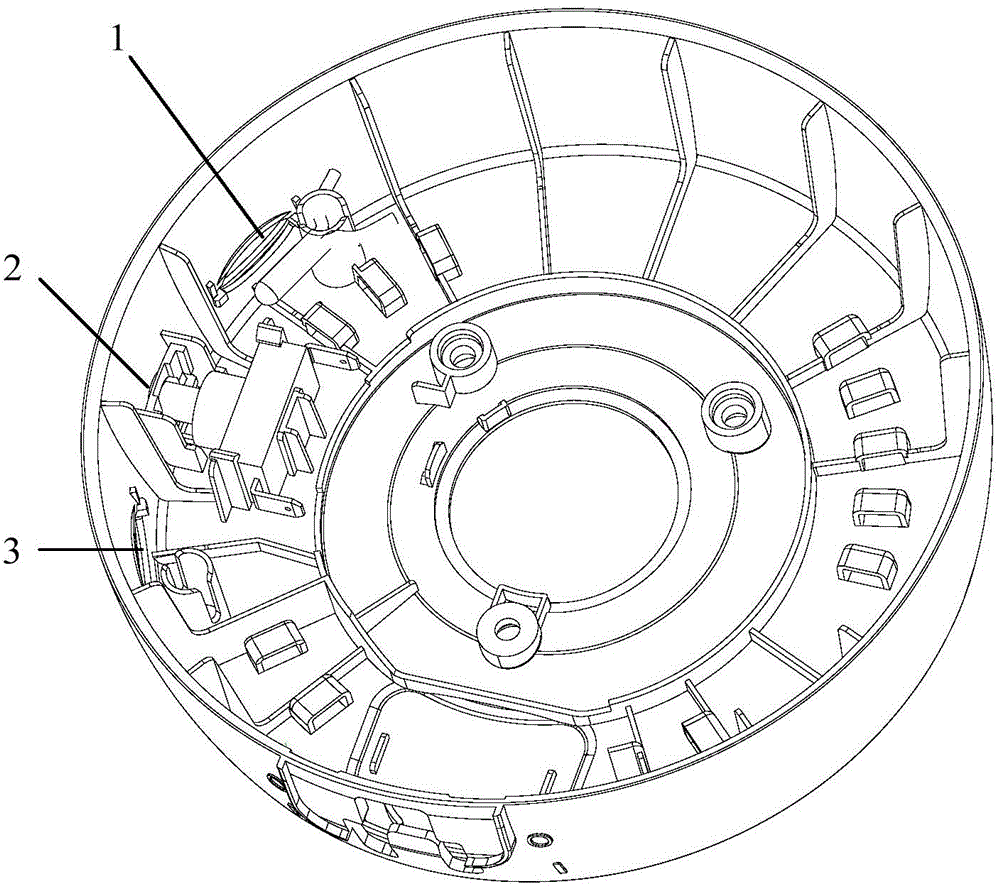

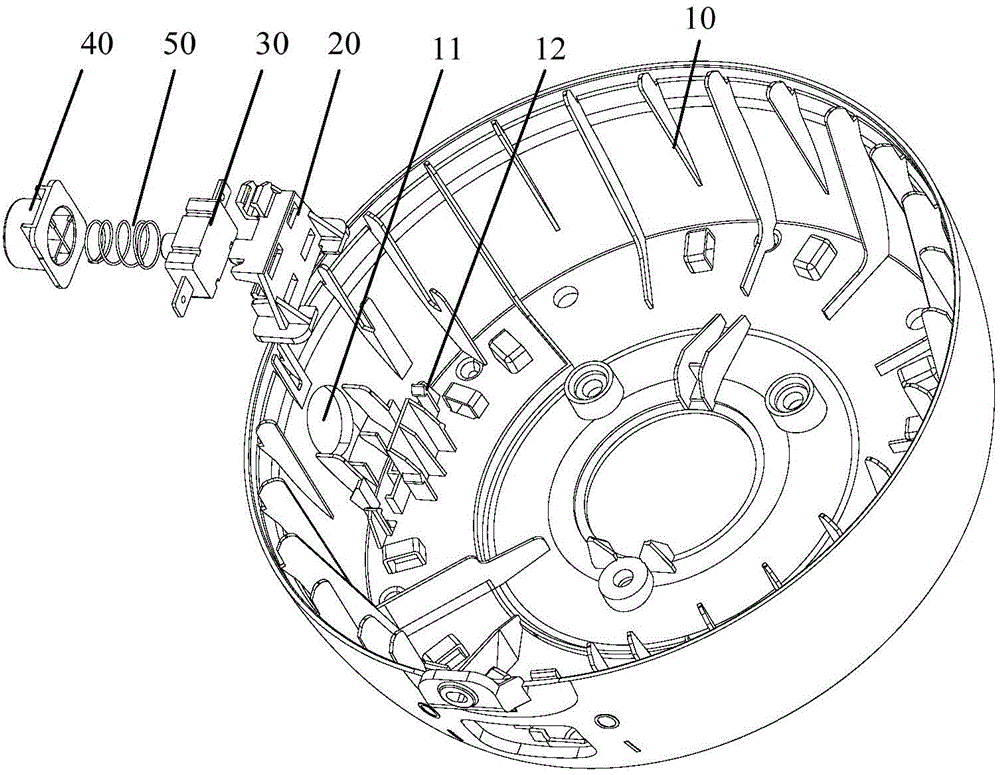

Thermal insulation switch structure and electric kettle

ActiveCN105640348AStable structureSimple structureWater-boiling vesselsThermal insulationEngineering

The invention provides a thermal insulation switch structure and an electric kettle. The thermal insulation switch structure comprises a support assembly and a thermal insulation button. The support assembly is in the bottom cover of the electric kettle. The support assembly comprises a support component and a thermal insulation switch. The thermal insulation switch is assembled on the support component through a button placement structure of the support component. The first end of the thermal insulation button passes through a preset hole of the bottom cover and is in the bottom cover. The first end of the thermal insulation button is provided with an elastic element. The thermal insulation button is connected with the support assembly through the elastic element. Through the technical scheme, the support component and the thermal insulation switch combine to form the support assembly. Compared with the prior art, the position of the support assembly is more flexible, the support assembly is not limited by bottom cover space, and influence of sizes of other components of the bottom cover on the thermal insulation switch is prevented, installation of the thermal insulation switch structure is simplified, so the thermal insulation switch is more stable. A thermal insulation indication lamp cover and the thermal insulation button are combined, and the appearance modeling is simplified, one key operation is simple and clear, and the electric kettle is convenient for a user to use.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Opening frame structure and refrigeration equipment

ActiveCN105928300AReduce usage intensityGuaranteed use strengthLighting and heating apparatusDefrostingMoisture condensationEngineering

The invention provides an opening frame structure and refrigeration equipment. The opening frame structure comprises an opening frame body and a middle beam which is integrally connected with the opening frame body, and an anti-condensation pipe is installed on the middle beam. The opening frame structure is assembled at the opening end of a box container of the refrigeration equipment, and foaming is conducted after the opening frame structure and the box container are assembled. According to the technical scheme, the middle beam and the opening frame structure are integrally connected, so that the middle beam is installed on the box container before conducing foaming, accordingly, the anti-condensation pipe can be easily and directly installed on the middle beam, the situation that in the prior art, the middle beam is installed on the opening frame structure of the box container after box container foaming is conducted, and the anti-condensation pipe is difficult to directly install on the middle beam is avoided, and the installing efficiency is improved; in addition, heat dissipated by the anti-condensation pipe is used to evaporate condensation water condensed on the middle beam, and the problems of icing and moisture condensation of the middle frame are solved; and compared with an anti-condensation middle beam with a heating wire, more energy consumption is reduced through the scheme, and the using cost is reduced.

Owner:HEFEI HUALING CO LTD +1

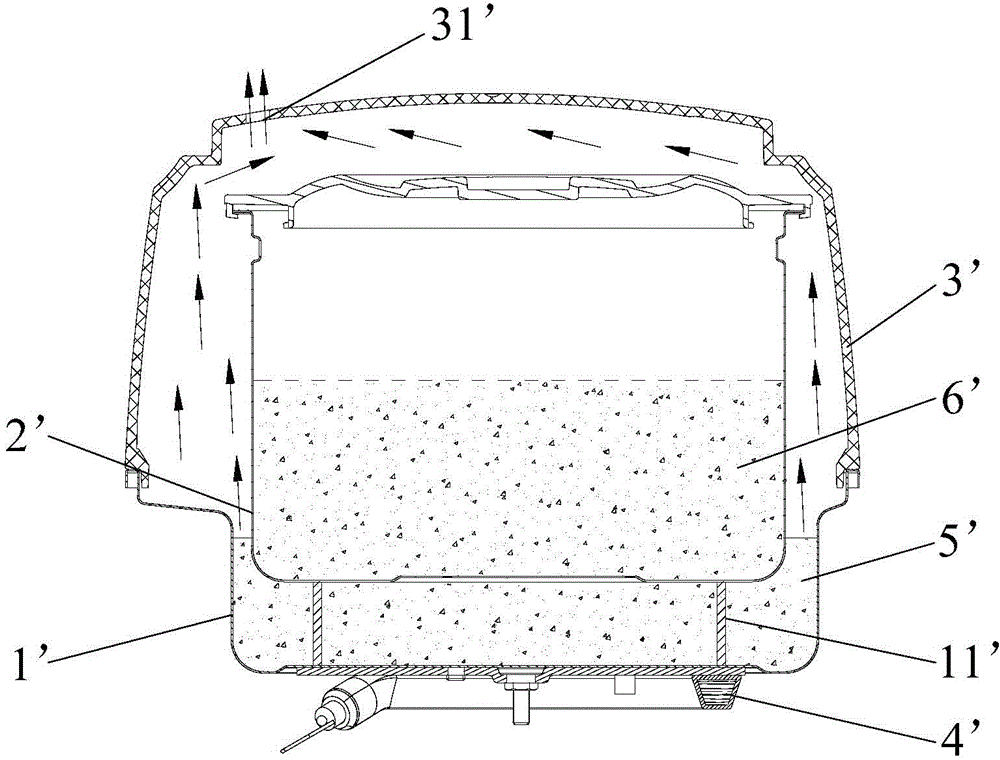

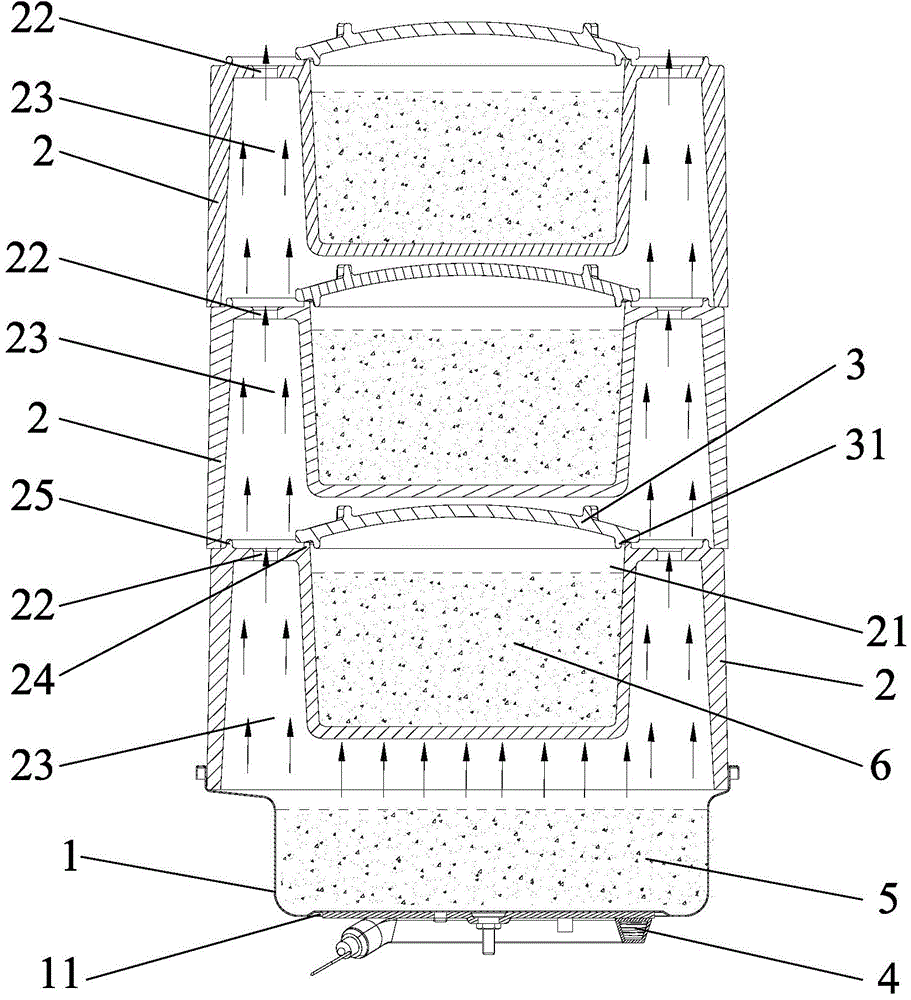

Cookware

InactiveCN105520622AIncrease profitRealize all-round heatingMultiple-unit cooking vesselsWarming devicesEngineeringHeating efficiency

The invention provides a cookware which comprises a water box, a heating device and pot liners. The heating device is used for heating up water in the water box. Each pot liner is a hollow cavity formed by a side plate and a top plate in an encircling manner and provided with one end opening. A containing groove for food is formed in the top plate, and the depth of the containing groove is smaller than the height of the side plate. A steam passage is formed by a gap between the wall of the containing groove and the side plate of the pot liner. At least one steam pores are formed around the opening of the containing groove. High-temperature steam generated from water in the water box heats up the bottom of each containing groove, and can also flow along the steam passage to heat up the wall of the containing groove, so that food in the containing groove is heated completely and heating efficiency is improved. Besides, steam in the steam passage can be exhausted through the steam pores; the opening end of each pot liner is detachably mounted on the water box; and each lid is connected with each containing groove in an opened or closed manner.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

High-flow precious metal channel

ActiveCN111704347AGuaranteed service lifeGuaranteed use strengthForehearthsTank furnacesMaterials scienceGlass production

The invention provides a high-flow precious metal channel, which comprises a molten glass mixed-flow stirring section, at least two molten glass heating; clarifying and cooling sections are connectedin parallel to one end of the molten glass mixed-flow stirring section, and a liquid supply tank is further communicated with the other end of the molten glass mixed-flow stirring section. The methodis mainly used for clarification and homogenization of large-flow high-temperature molten glass in the production process of 8.5-generation or higher-generation TFT glass, and bubble-free and stripe-free high-quality molten glass is provided for the subsequent float forming or overflow forming process.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

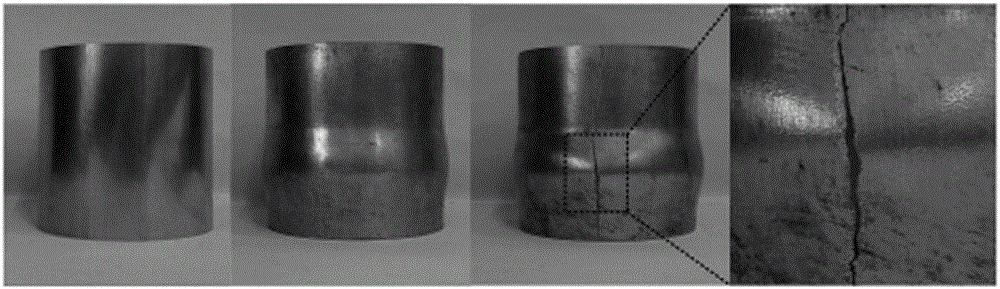

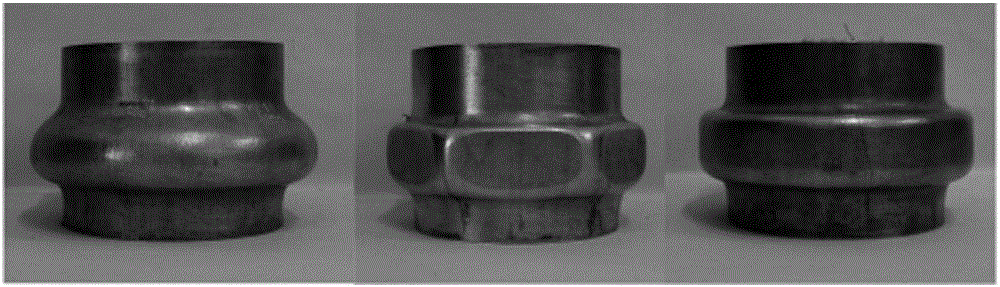

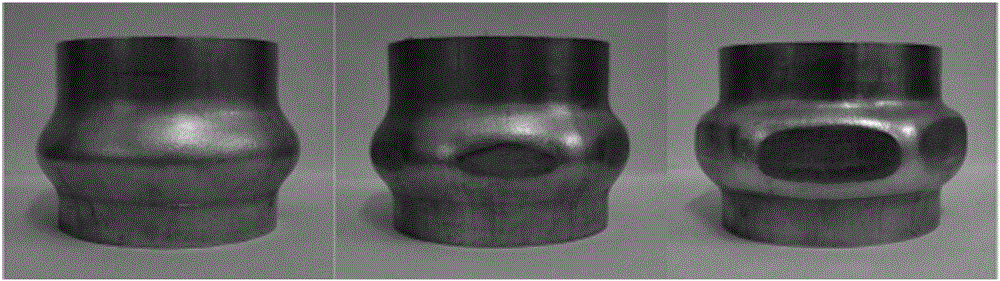

Solution treatment and granular medium cold forming method for high-strength aluminum alloy pipe fitting

ActiveCN105964722ASimple process controlLow input costFurnace typesProcess efficiency improvementSolid particleArtificial aging

Disclosed is a solution treatment and granular medium cold forming method for a high-strength aluminum alloy pipe fitting. Forming of complex parts from a high-strength aluminum alloy extruded pipe at a room temperature is realized through the process of solution treatment, granular medium pressure forming and artificial aging. The process is easy and convenient to control, the input cost is low, product design is flexible, energy consumption is low, production efficiency is high, the size of a target workpiece is precise, and high use strength and stability are achieved. After a pipe blank is subjected to solution treatment, the strength and hardness are lowered, the plasticity is remarkably improved, parts in complex shapes can be formed only at the room temperature, and the bearing capacity requirement for equipment is low. The strength of the formed pipe fitting is low, the strength of the pipe fitting can be recovered to the original state through artificial aging, and the service life of the target pipe fitting is prolonged. Solid granular media are stable in chemical property, environmentally friendly, free of pollution and reusable, and have the characteristic of uneven distribution of internal pressure, and the use strength of the formed pipe fitting is guaranteed while the plastic processing capacity of the pipe blank is improved.

Owner:YANSHAN UNIV

Micro-filtration membrane and preparation method thereof

InactiveCN108097068AGuaranteed use strengthSimple processSemi-permeable membranesFiltration membraneSeparation technology

The invention belongs to the technical field of membrane separation, and concretely relates to a micro-filtration membrane and a preparation method thereof. The micro-filtration membrane is prepared by compounding a membrane casting solution and a non-woven fabric, wherein the membrane casting solution is prepared from the following raw materials in percentage by mass: 10 to 25w% of polyaryletherketone, 1 to 10w% of pore-foaming agent, 5 to 40w% of nonsolvent additive, and 40 to 80w% of solvent. The micro-filtration membrane provided by the invention has good high temperature resistance, acidand alkali resistance and corrosion resistance, and is high in mechanical strength and flux.

Owner:安徽普朗膜技术有限公司

Purification device of automobile tail gas treatment equipment

ActiveCN105673141AEasy to useIncrease profitExhaust apparatusSilencing apparatusActivated carbonUtilization rate

The invention discloses a purification device of automobile tail gas treatment equipment. The purification device comprises a filter drum, wherein the filter drum comprises a plurality of splicing pipes which are spliced with one another; cover panels are arranged in the multiple splicing pipes; through slots are formed in the cover panels, and are staggered from the through slot of the cover panel on the other splicing pipe; filter elements are arranged in the through slots; tail gas enters the purification device from one end of the filter drum and then is discharged from the other end of the filter drum after passing through filter plates on the multiple cover panels; plug blocks are arranged at one-ends of the splicing pipes, and sliding rails capable of rotating after the plug blocks are plugged are arranged on the inner walls of the other ends of the splicing pipes; gaps for letting the plug blocks enter the sliding rails are formed in the sliding rails; stopper blocks for limiting excessive rotation of the plug blocks are arranged in the sliding rails; positioning lugs are further arranged on the splicing pipes; positioning holes are formed in the positioning lugs, and are communicated with one another after mounting is completed; and positioning strips penetrating through the positioning holes are arranged in an outer drum. Therefore, effects of convenience in mounting and improvement of the utilization rate of active carbon are achieved.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

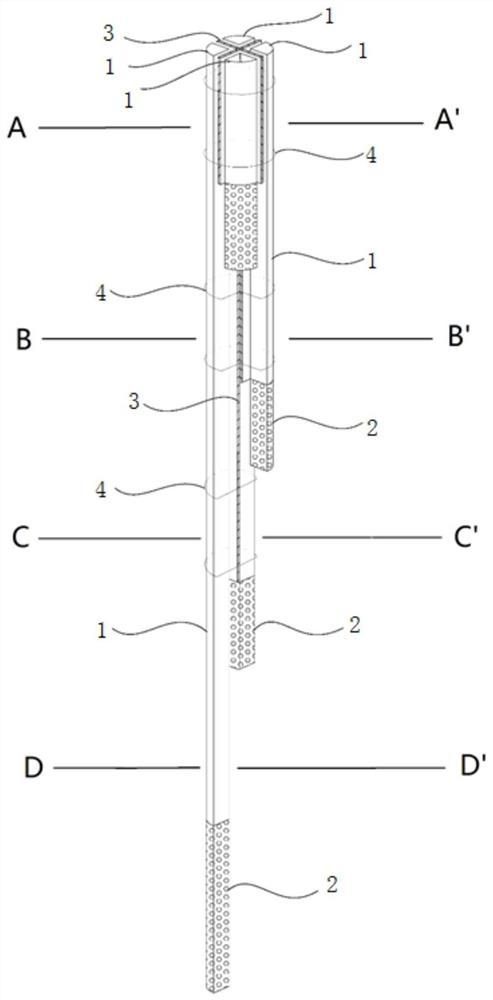

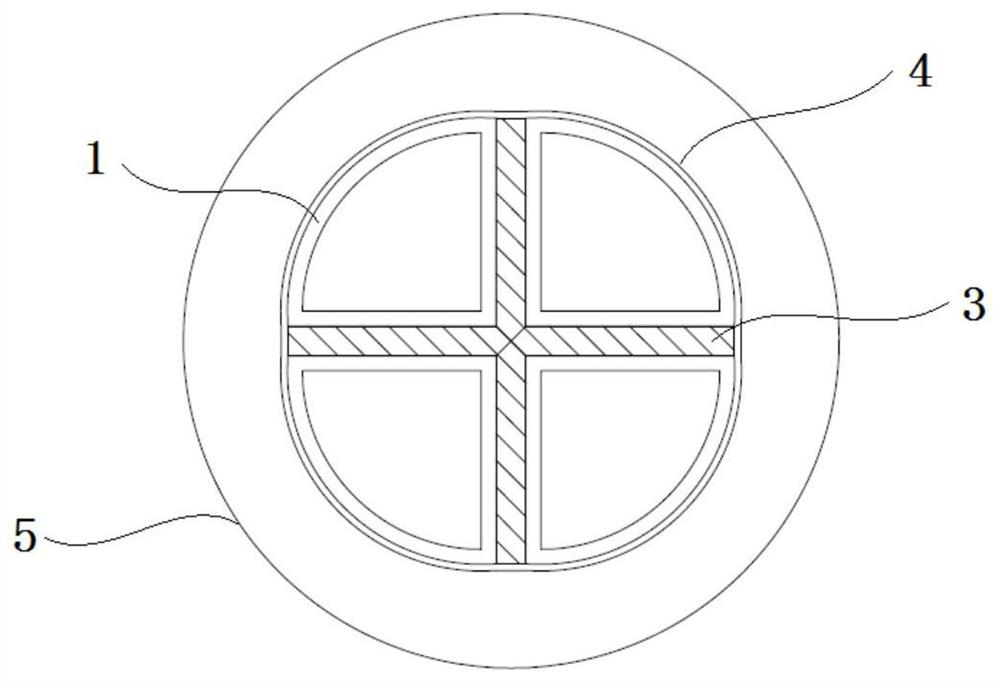

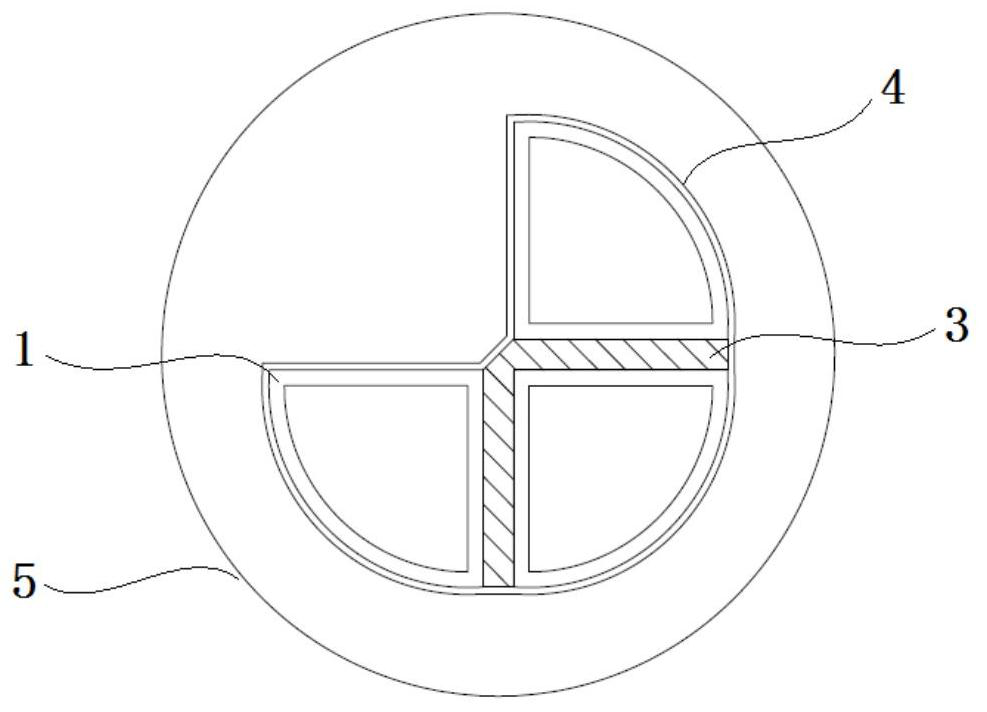

Underground water beam type monitoring well and well completion method

PendingCN113588903AAvoid vertical flow of waterGuaranteed StrengthTesting waterGeological measurementsArchitectural engineeringMechanical engineering

The invention relates to the technical field of underground water monitoring, in particular to an underground water beam type monitoring well, which comprises a plurality of monitoring pipes, wherein the monitoring pipes are jointly inserted into a drill hole, the upper surfaces of the monitoring pipes are flush, the lengths of the monitoring pipes are different, and each monitoring pipe corresponds to a corresponding aquifer; a water stop structure arranged between two adjacent monitoring pipes; filtering structures arranged at the bottoms of the monitoring pipes, wherein the length of each filtering structure is equal to the thickness of a monitoring layer. Due to the fact that the monitoring well only needs to be drilled at a time, each monitoring pipe can correspond to a plurality of aquifers to conduct layered monitoring, construction is convenient, construction efficiency is improved, the number of drilled holes is reduced, construction and management cost is saved, and large-scale engineering application and popularization are facilitated. The invention further provides a well completion method of an underground water beam type monitoring well, gaps among the multiple monitoring pipes are filled with the water stop structures, the multiple monitoring pipes are installed in the same drill hole after being bundled and fixed, and the well completion quality and the monitoring effect are remarkably improved.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

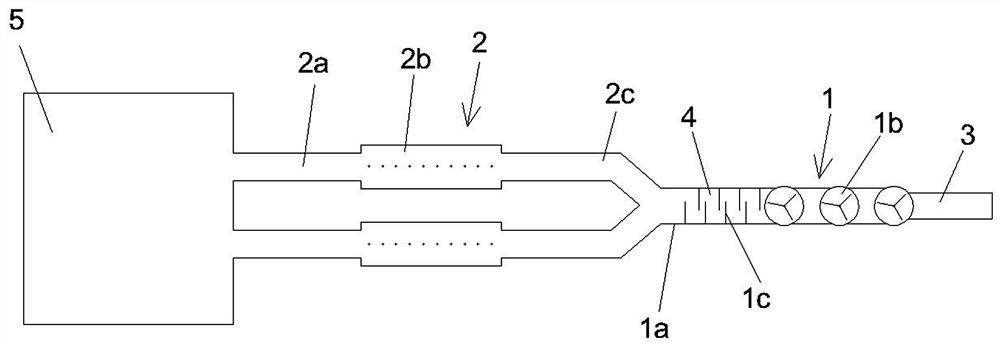

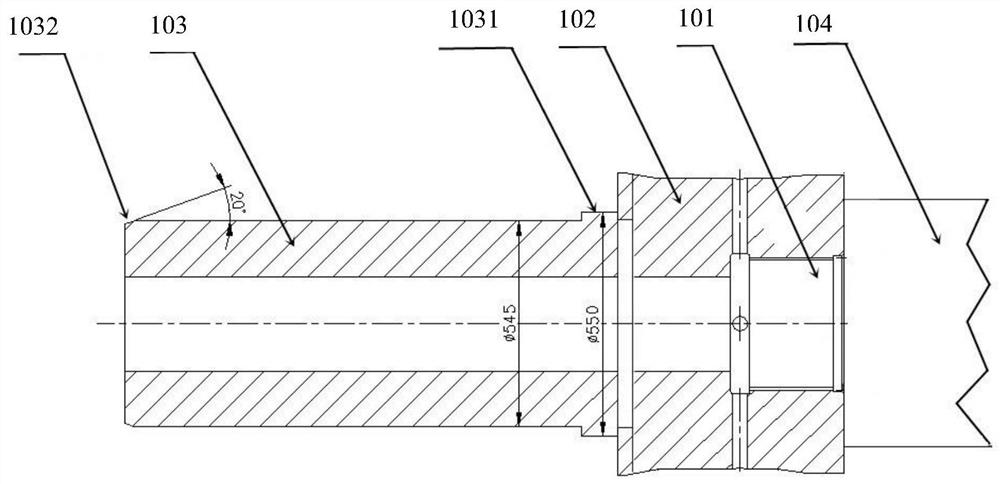

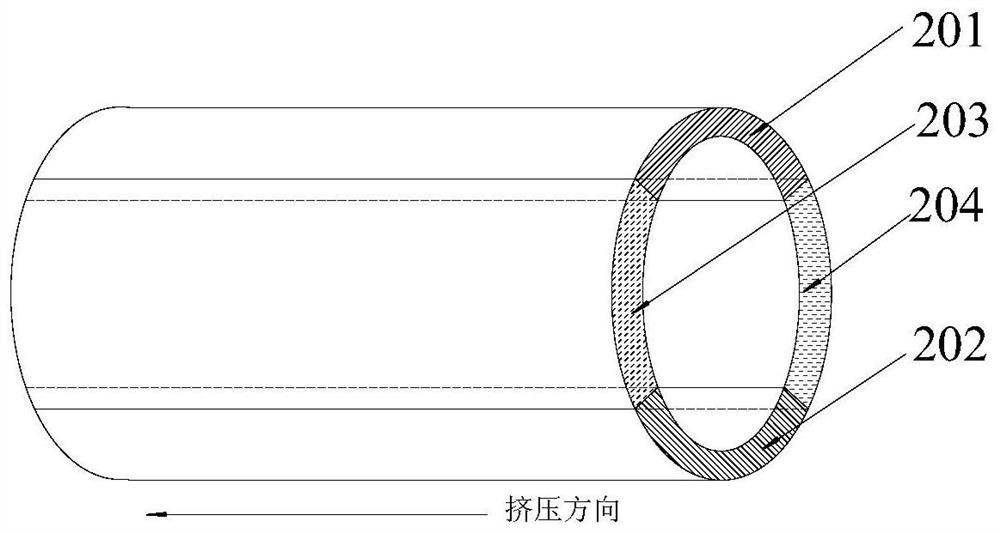

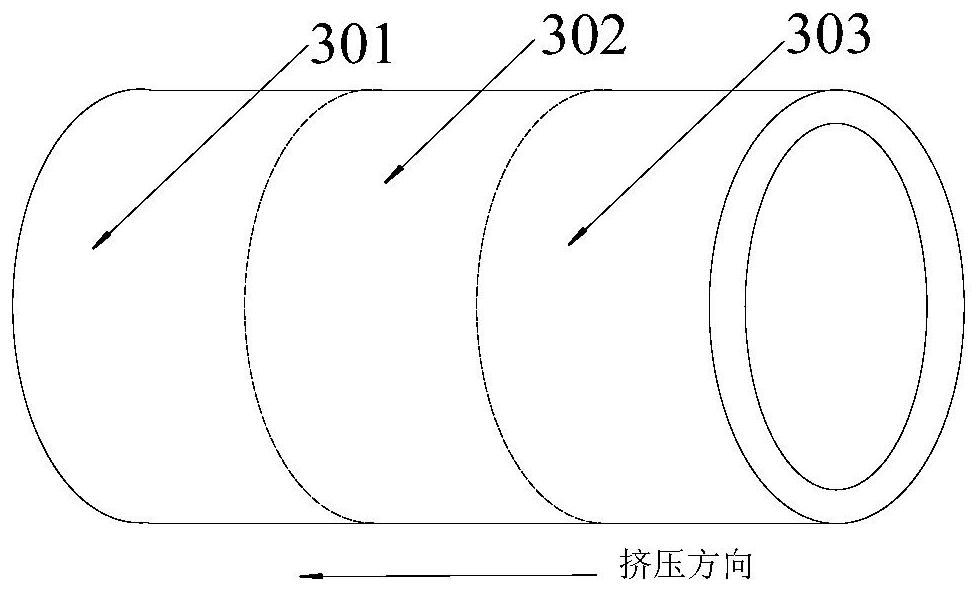

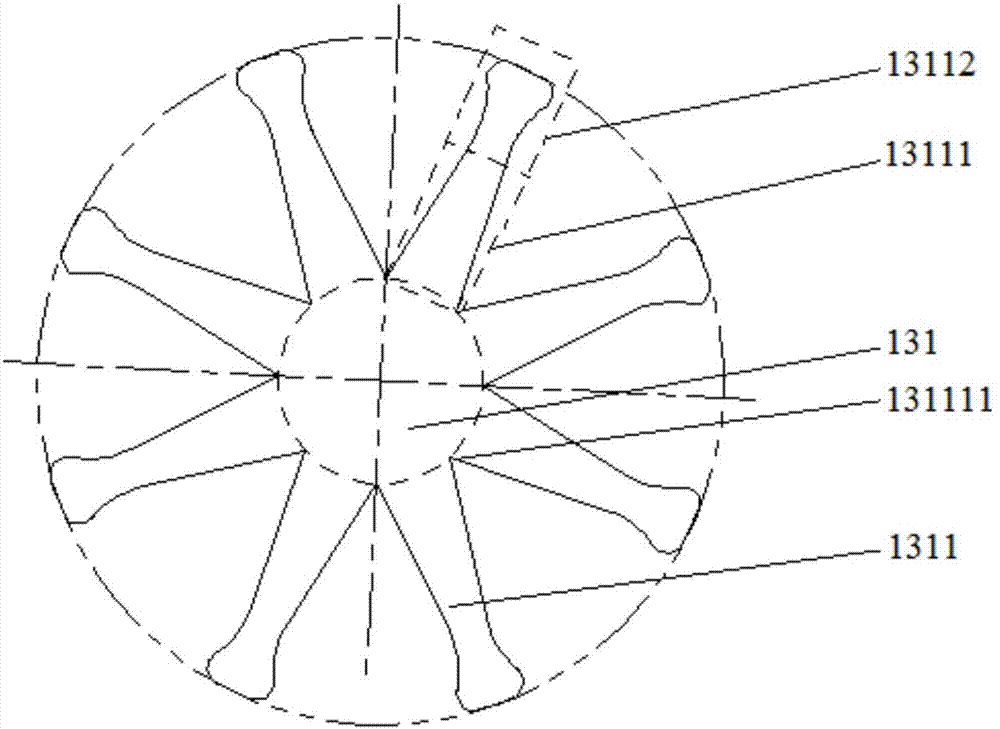

Large-width aluminum alloy ribbed plate, production method thereof and extrusion perforating needle

ActiveCN112547831AInhibition of recrystallizationImprove solid solubilityFurnace typesHeat treatment furnacesIngotMaterials processing

The invention discloses a large-width aluminum alloy ribbed plate, a production method thereof and an extrusion perforating needle, and belongs to the field of aluminum alloy material processing. Theproduction method of the large-width aluminum alloy ribbed plate comprises the steps that an aluminum alloy ribbed pipe is manufactured through casting, preheating and extrusion, cutting and flattening are conducted after quenching, then heat treatment is conducted, and the ultra-wide, high-strength and high-corrosion-resistance large-width aluminum alloy ribbed plate used for a ship body is obtained. In addition, an extrusion perforating needle is provided for extrusion, and compared with extrusion of an aluminum alloy solid cast ingot, the performance can be further improved. According to the production method, the welding pass of friction stir welding adopted in order to achieve large-width aluminum alloy ship plate batch production in the prior art can be avoided, the number of weld joints is reduced, the overall strength and sealing performance of a ship are greatly improved, the production cost is reduced, and the production efficiency is improved.

Owner:NORTHEASTERN UNIV

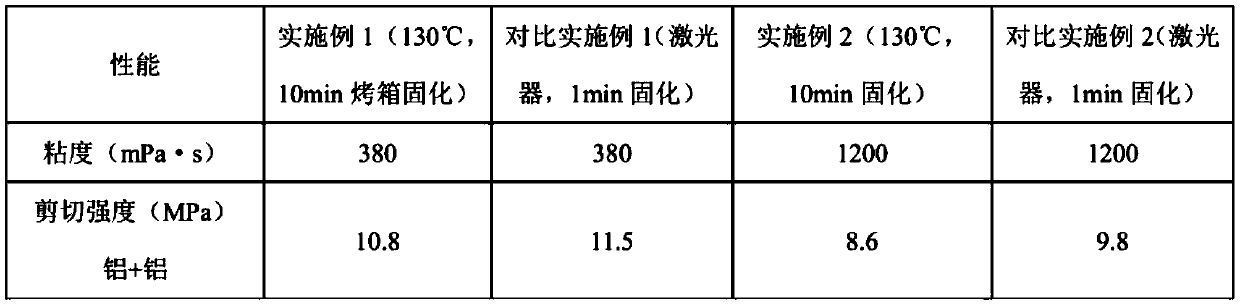

Underfill adhesive and preparation method thereof

InactiveCN111234713AImprove packaging efficiencyImprove reliabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceFirming agent

The invention relates to the technical field of colloidal fillers. The invention particularly relates to an underfill adhesive. The underfill adhesive comprises the following raw materials in parts byweight: 40-50 parts of epoxy resin, 5-40 parts of a curing agent, 10-30 parts of a light-cured monomer and resin, 1-10 parts of a resin toughening agent, 0.1-5 parts of a diluent, 1-5 parts of an initiator, 0.1-0.5 part of a defoaming agent, 0.1-3 parts of a silane coupling agent and 0-1.5 parts of other additives. The underfill adhesive provided by the invention has low viscosity, low shrinkageand low expansion coefficient, can well absorb infrared wavelength emitted by a laser, and can be quickly cured by laser; the invention further provides a preparation method of the underfill adhesive,the preparation method is simple in process and easy to operate, and the prepared underfill adhesive is good in performance.

Owner:SHENZHEN PROSPER DOBOND TECH

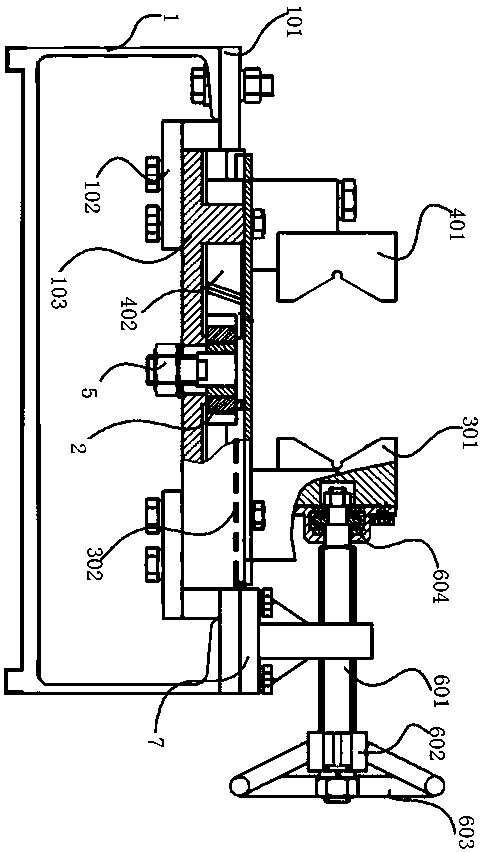

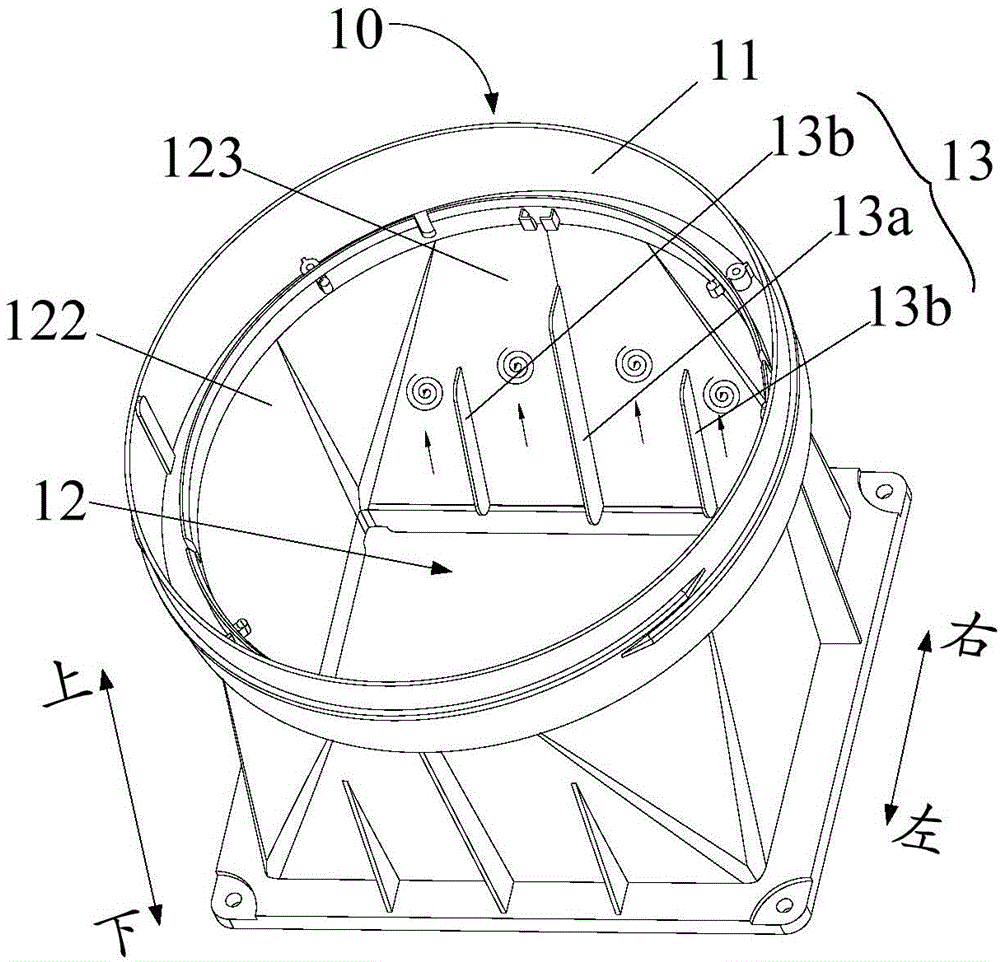

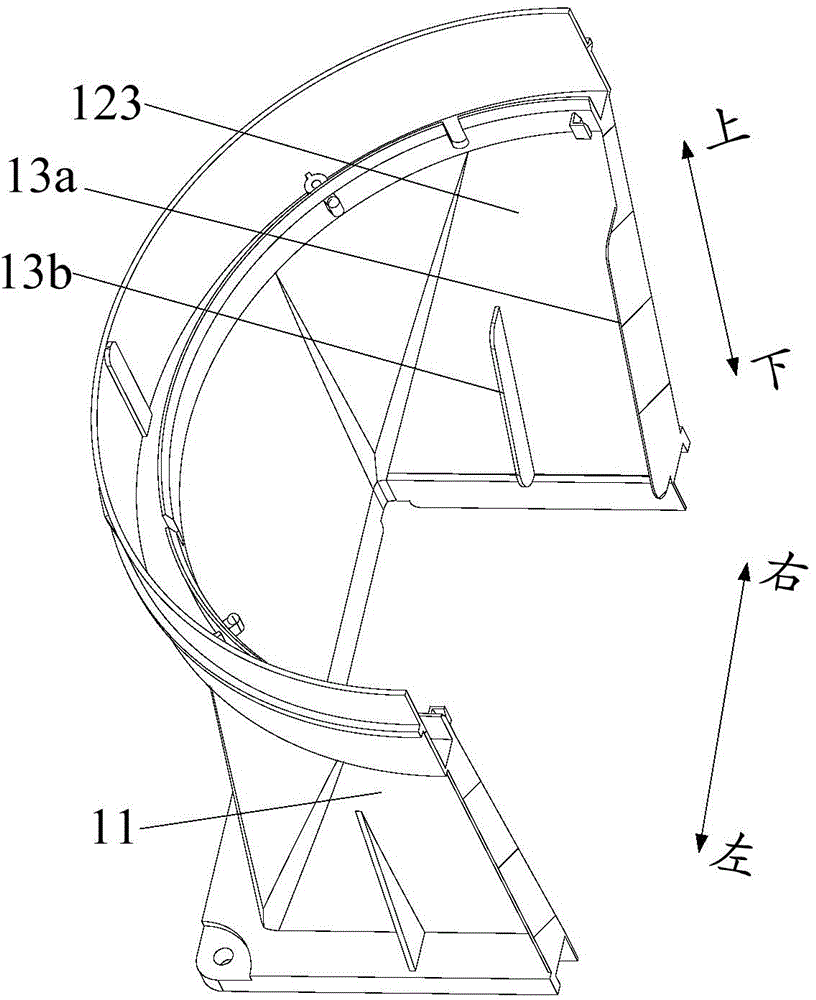

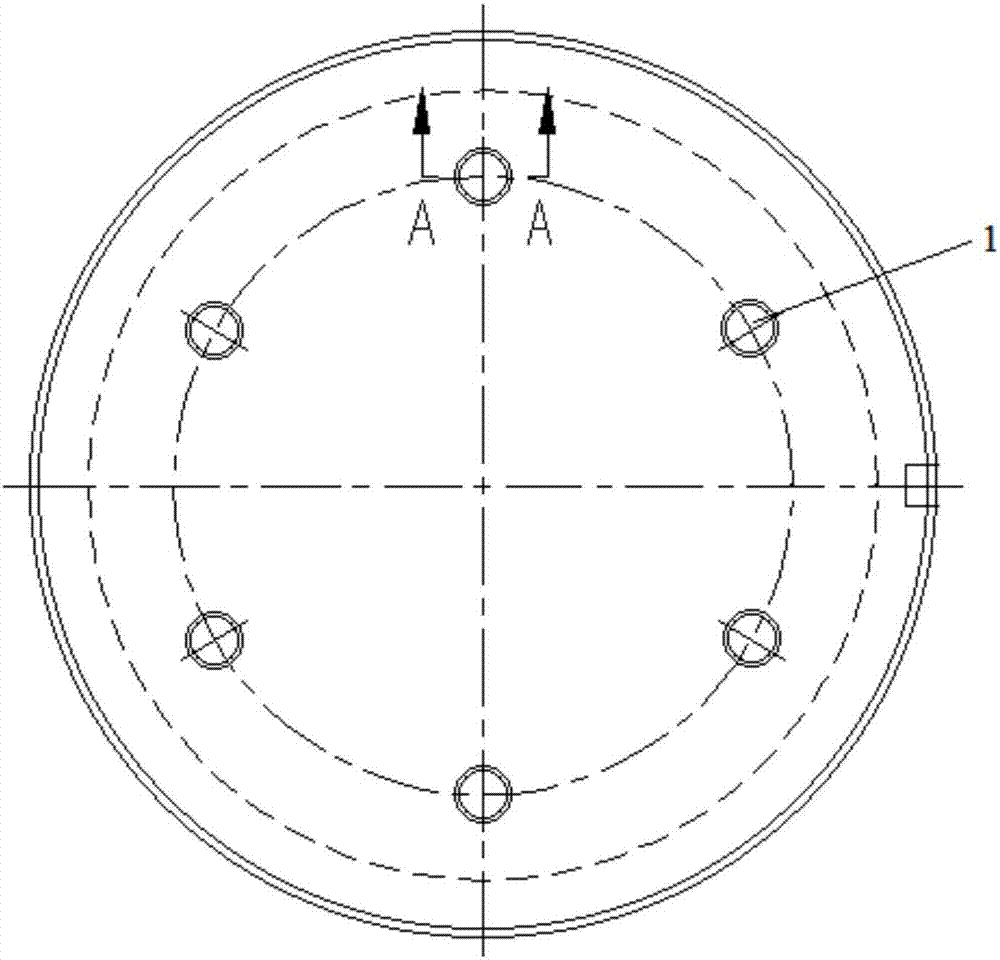

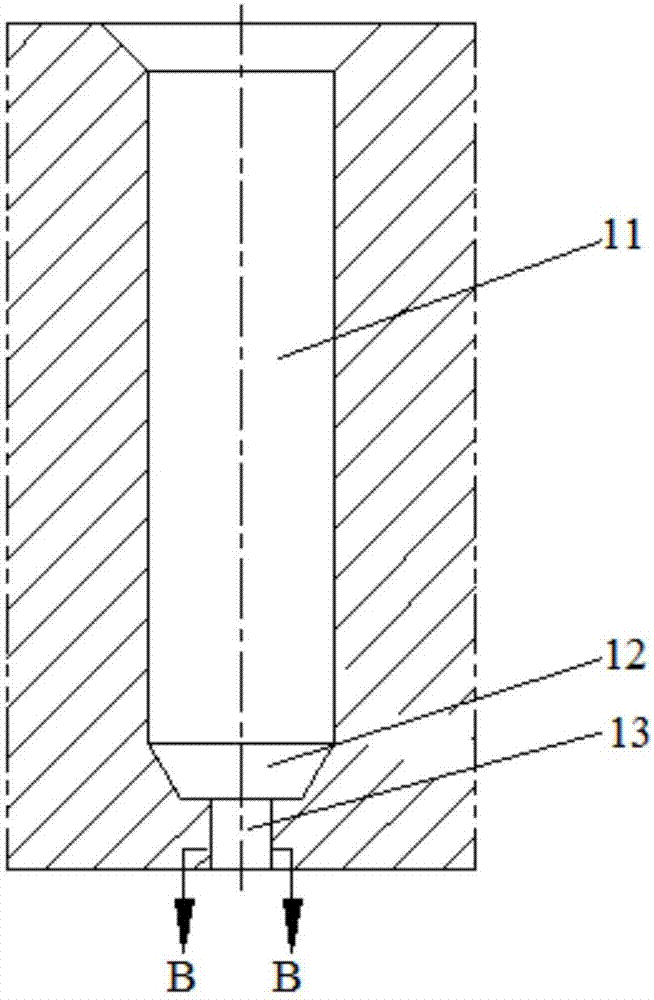

Tube locating device

InactiveCN109382670AReasonable structural designMeet the requirementsPositioning apparatusMetal-working holdersGear wheelElectric machinery

The invention discloses a tube locating device. The tube locating device comprises a support, a regulating gear, a driven unit and a drive unit both arranged on the support, and a power device adaptedto the drive unit; the drive unit comprises a drive V-shaped clamping block, a drive rack fixedly connected with the drive V-shaped clamping block, and a regulating gear adapted to the drive rack; the driven unit comprises a driven V-shaped clamping block, a driven rack fixedly connected with the driven V-shaped clamping block, and a regulating gear adapted to the driven rack; the drive unit drives the driven unit through the regulating gear to move; the power device is in transmission connection with the drive V-shaped clamping block; and the power device comprises a manual regulating screwstructure or a motor power device. The tube locating device is reasonable in structure design, the drive V-shaped clamping block is driven by the power device to move, and the drive V-shaped clampingblock drives the drive rack to drive the regulating gear to rotate, so that the driven rack is driven to move, and the distance of the driven V-shaped clamping block relatively to the drive V-shaped clamping block is driven to be increased to reduced.

Owner:陈振清

Heat-insulation magnesium casting material and preparation method thereof

The invention relates to a heat-insulation magnesium casting material and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: evenly mixing 20-50 wt% of magnesite, 33-63 wt% of mesitite, 0.9-7 wt% of silicon dioxide fine powder, 0.1-2 wt% of sodium polyphosphate and 3-8 wt% of water, thereby obtaining the heat-insulation magnesium casting material. The magnesite is more than one of fused magnesite grains, sintered magnesite grains, fused magnesite fine powder and sintered magnesite fine powder. The invention has the advantages of abundant raw material storage and simple preparation technique; and the prepared heat-insulation magnesium casting material basically has no crack or peel phenomenon, has the advantages of low heat conductivity, high strength, strong alkaline dust and slag corrosion resistance, high melting point and strong alkaline solid and gas slag corrosion resistance, and is beneficial to energy saving and consumption reduction. The heat-insulation magnesium casting material provided by the invention is suitable for liners of high-temperature industrial kilns and containers.

Owner:WUHAN UNIV OF SCI & TECH

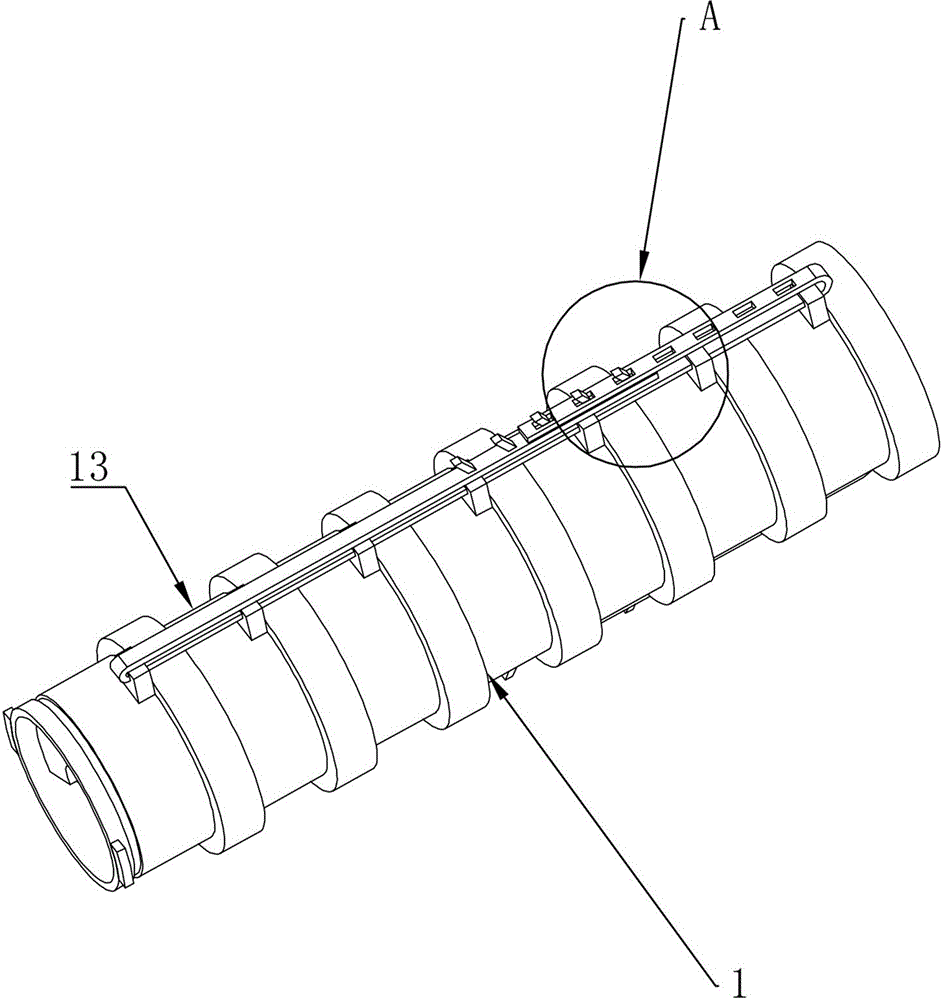

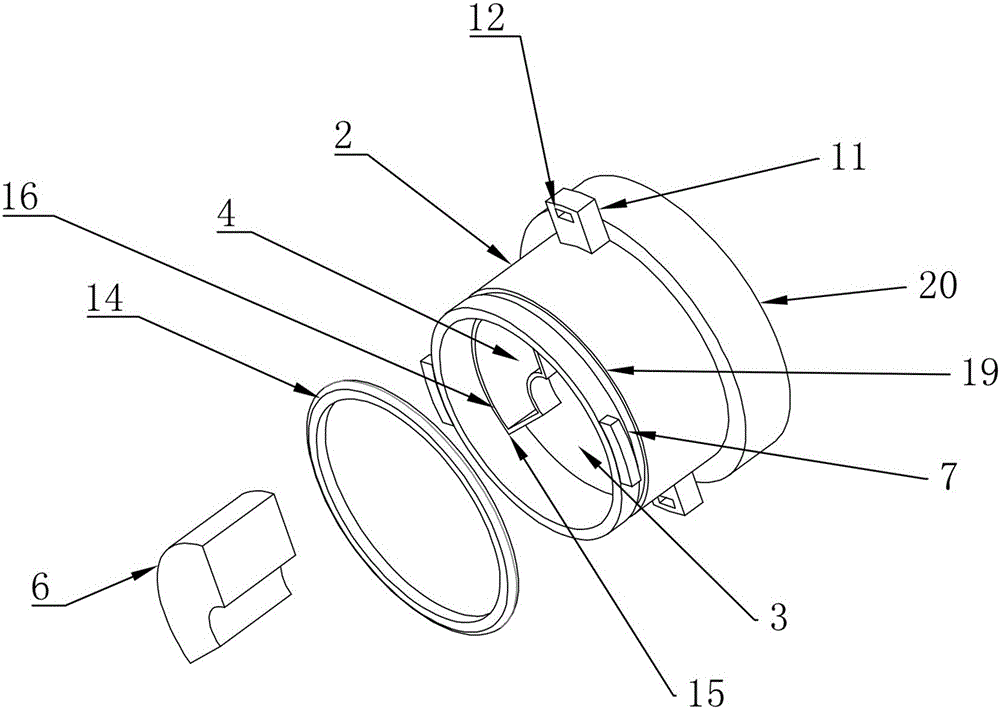

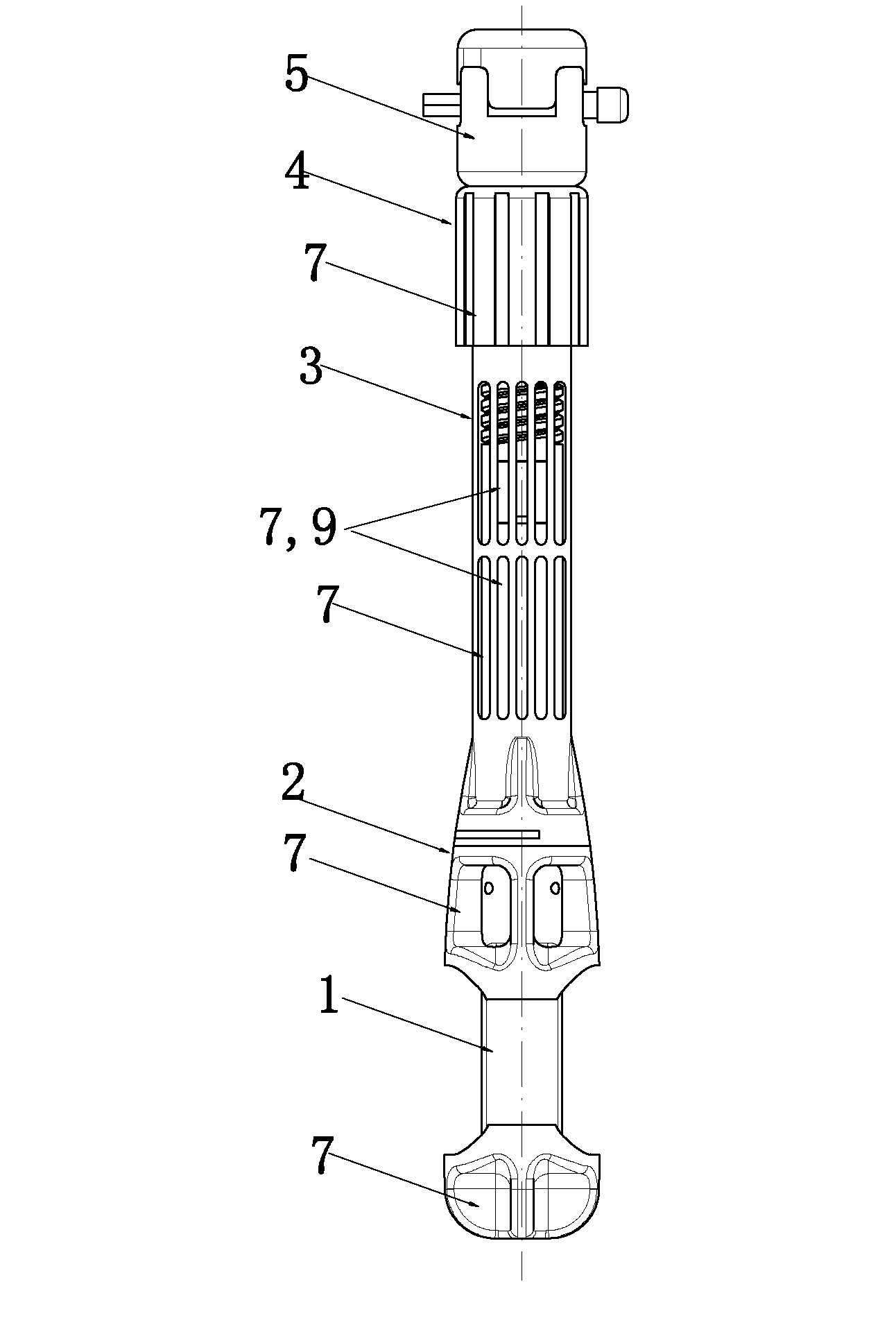

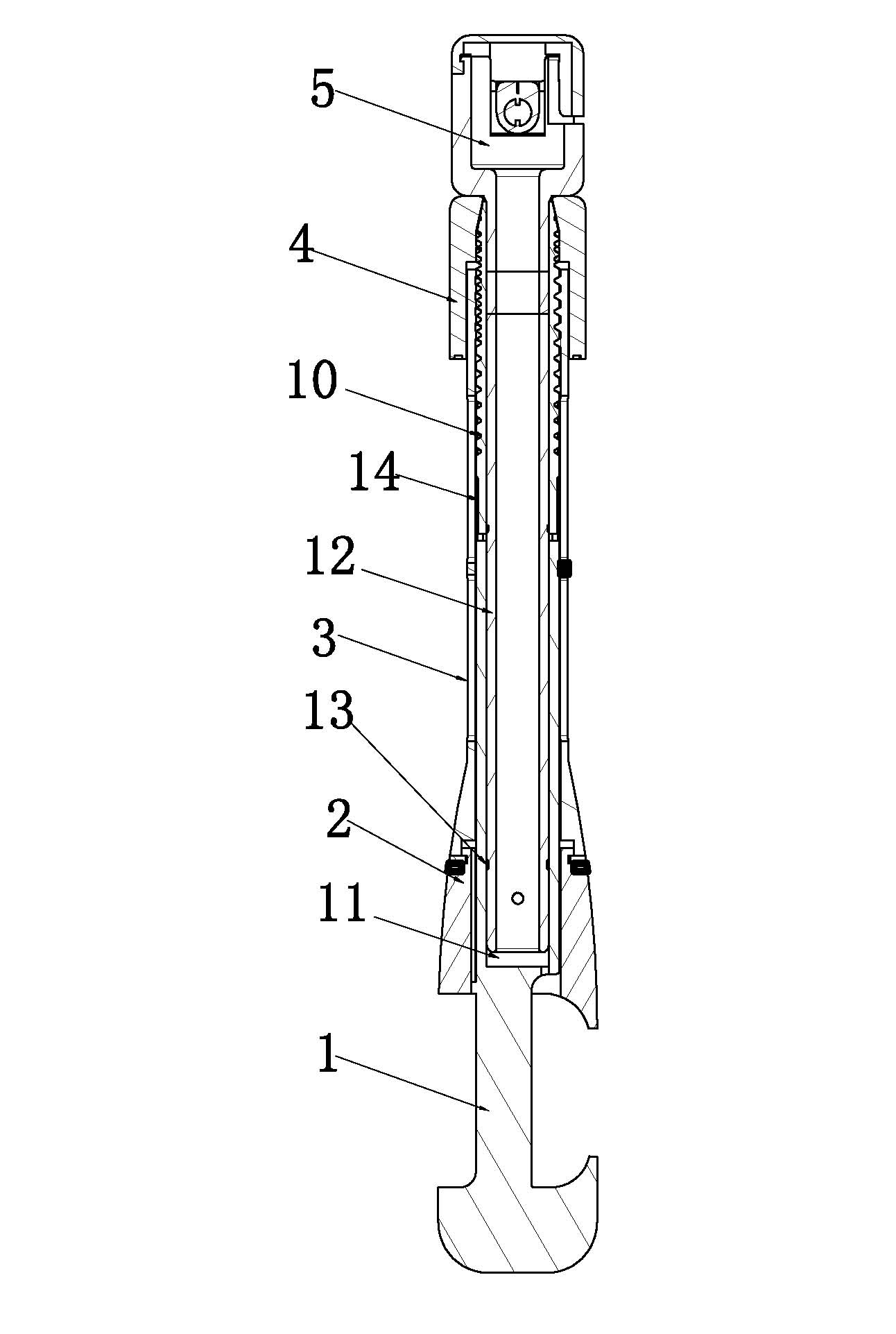

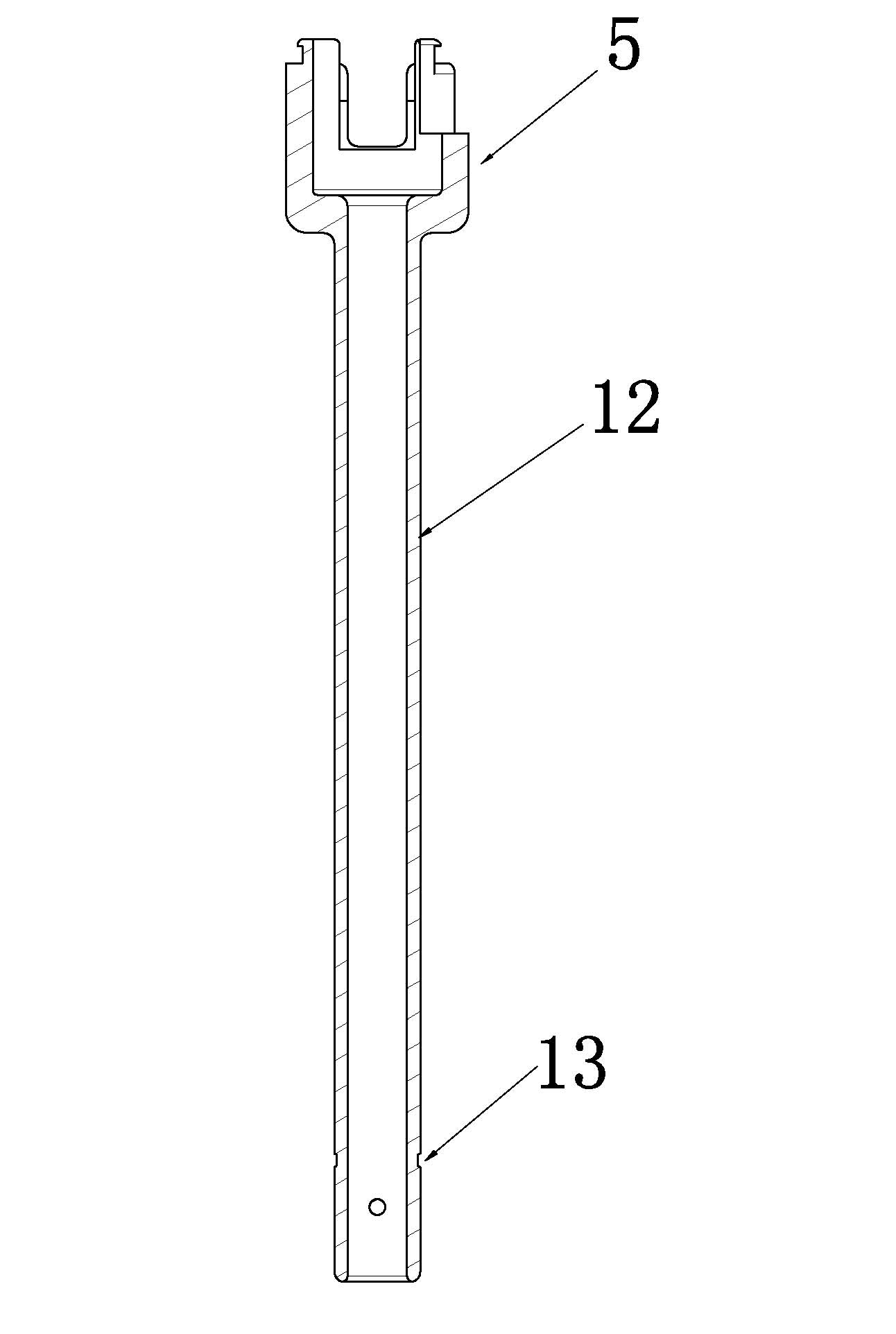

Medical surgical soft tissue dilator

A medical surgical soft tissue dilator comprises a main rod (1), a locking sleeve (2), a locking operating rod (3), a belt winding device locking sleeve (4), a belt winding device (5) and a hook plate (6). A half dovetail groove which matches with a surgical bedside is arranged at the lower end of the main rod (1), another half dovetail groove capable of vertically moving is arranged at the lower end of the locking sleeve (2), the locking operating rod (3) is provided with inner threads matching with outer threads at the upper end of the main rod (1), an inner screw hole which matches with the outer threads of the upper end of the main rod (1) is arranged at the upper end of the belt winding device locking sleeve (4), the lower end of the belt winding device locking sleeve (4) is covered at the upper end of the locking operating rod (3), the lower end of the belt winding device (5) is inserted in an inserting hole at the upper end of the main rod (1), the height of the belt winding device (5) is adjustable, and a belt winding box is disposed at the upper end of the belt winding device (5) and connected with the hook plate (6). The medical surgical soft tissue dilator is characterized in that a limiting groove (13) is arranged on an inserting rod (12) at the lower end of the belt winding device (5), and an elastic jaw (14) is arranged on the main rod (1) and provided with a one-way check bump (15) which is inserted into the limiting groove (13). Structural strength is guaranteed, simultaneously, utilization quantity of materials is greatly reduced, and the medical surgical soft tissue dilator has the advantages of high strength, light weight and convenience in operation and use.

Owner:JIANGSU HAIZE MEDICAL TECH DEV

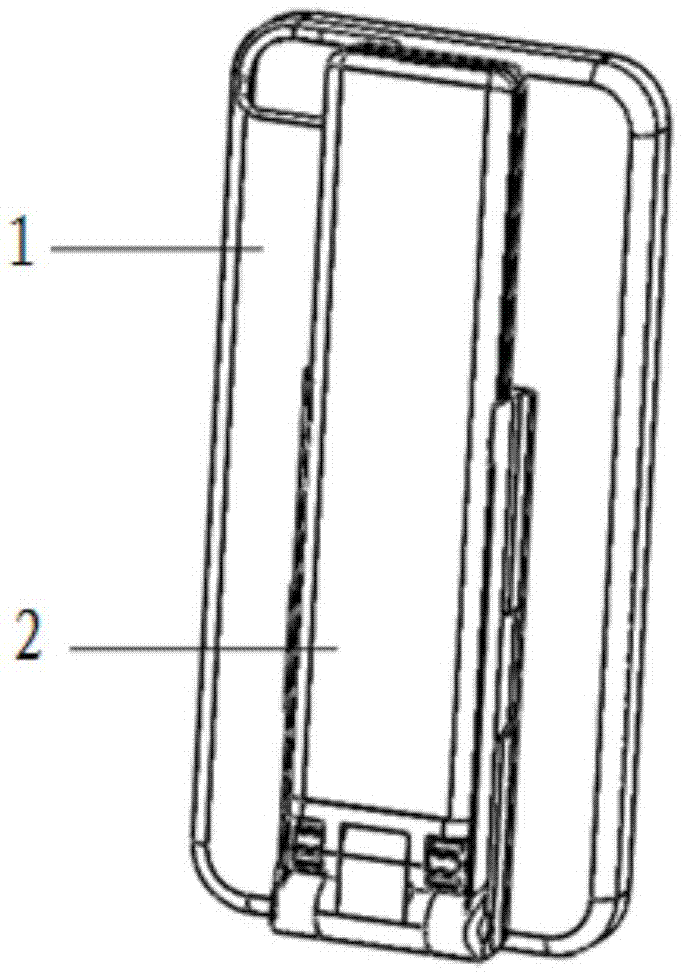

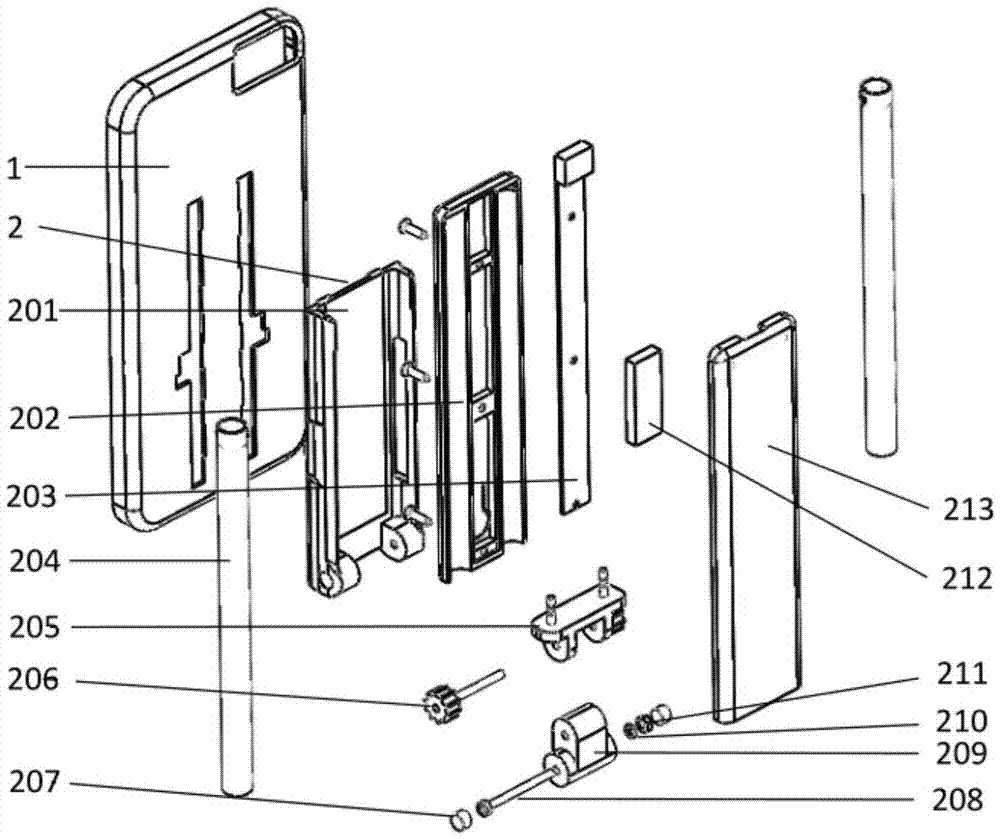

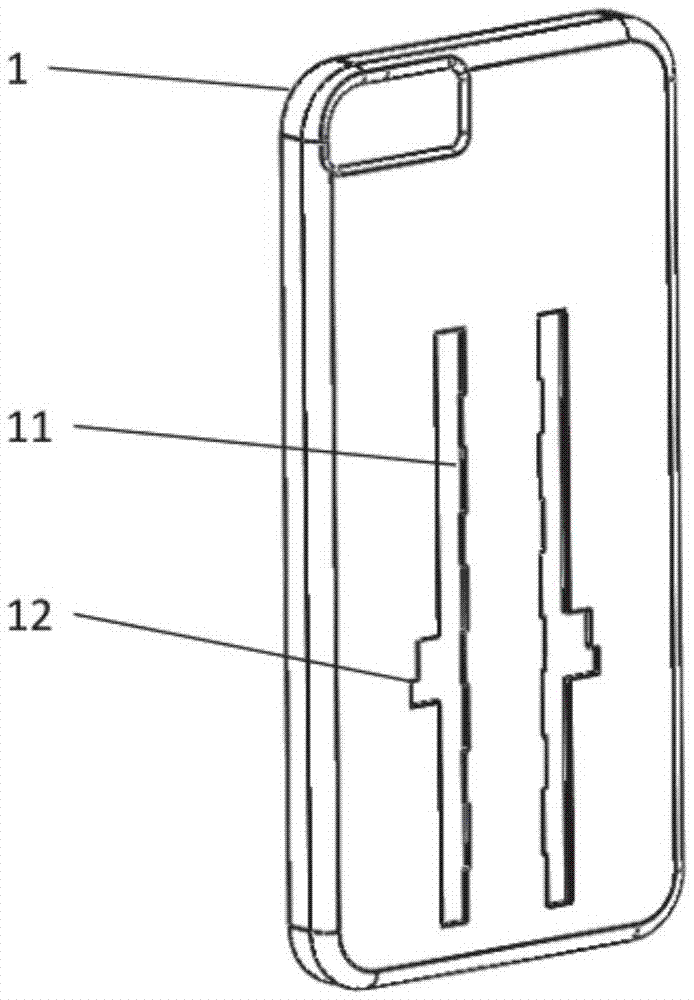

Mobile phone casing having detachable selfie stick

PendingCN107302606AHigh flexibilityEasy to take picturesTelevision system detailsColor television detailsEngineeringElectrical and Electronics engineering

The invention relates to a mobile phone casing and particularly relates to a mobile phone casing having a detachable selfie stick. The mobile phone casing having the detachable selfie stick comprises a mobile phone protection casing, a selfie stick and a support function device; the selfie stick and the support function device comprise a connection port pedestal, a main rotary shaft, an auxiliary rotary shaft, a double-shaft connection rod and a telescopic rod; the connection port pedestal is in fasten cooperation with the back side of the mobile phone protection housing through a detachable port; the telescopic rod is in hinge connection with the double-shaft connection rod through the main rotary shaft; the double-shaft connection rod is in hinge connection with the connection port pedestal through the auxiliary rotary shaft; the telescopic shaft is contained in the connection port pedestal in a contraction state to realize a folding state in a portable manner; the telescopic rod rotates around the main rotary shaft and realizes a support function by forming an included angle with the mobile phone protection housing; when the telescopic rod is in an extending state, the selfie stick function can be realized through rotation of the main rotary shaft and an auxiliary rotary shaft. The mobile phone casing having the detachable selfie stick perfectly integrates functions of the mobile phone housing, the selfie stick, the mobile phone support and a portable cosmetic mirror, realizes one for multiple purposes and is convenient and practicable.

Owner:冷雨泉

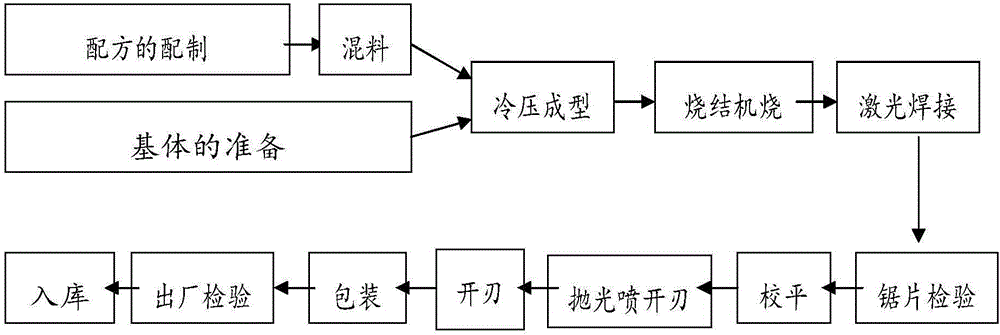

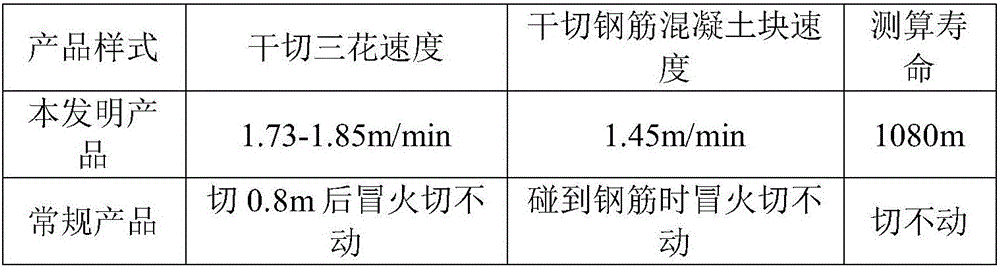

Laser-welding welding diamond circular saw web capable of conducting continuous dry cutting

InactiveCN106112122AGuaranteed use strengthSolve the problems of easy to drop the cutter head and low safety performanceMetal sawing tool makingMetal sawing toolsCircular sawAlloy

The invention discloses a laser welding diamond circular saw blade capable of continuous dry cutting, which relates to Diamond dry cutting saw blades. The present invention includes a carcass and a diamond saw head, the carcass includes the following components in weight percentage: Fe30%-40%, Co-containing alloy powder 25%-35%, Cu20%-30%, Ni8%-12% , Sn2%‑5%, the balance of Cr. The present invention is to manufacture a diamond circular saw blade capable of continuous dry cutting by improving the formula of the saw blade head and using pre-alloyed powder instead of cobalt powder combined with corrugated teeth, and adopting laser welding. It solves the problems of high-frequency welding saw blades that are prone to cutting heads and low safety performance. The design of the matrix components of the saw blade and the reasonable combination of diamonds. In addition, the use of laser welding can effectively ensure the strength of the saw blade and avoid roughness. Use to cause personal injury.

Owner:河北小蜜蜂工具集团有限公司

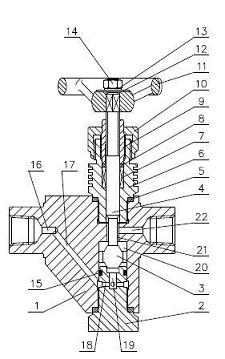

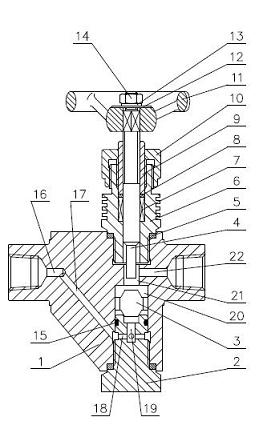

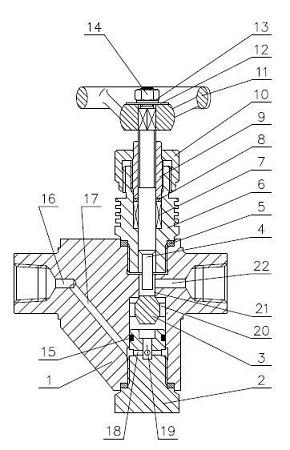

Quick automatic cut-off instrument valve

InactiveCN101832418AReach the sealing specific pressureImprove sealingValve members for heating/coolingEqualizing valvesLine tubingResource saving

The invention relates to an instrument valve, in particular to a quick automatic cut-off instrument valve. The bottom end of a valve rod is plugged in a flow passage hole at a valve cap end; the valve rod is separated from a valve clack; the valve clack is movably installed in a central flow passage hole; a flow passage hole at the valve cap end and a flow passage hole at a valve base end are provided on the valve body, and the diameters of the flow passage holes are less than that of the central flow passage hole on the valve body; the valve clack is in dynamic seal with the flow passage hole at the valve cap end and the flow passage hole at the valve base end to form a sealing pair; and the flow passage hole at the valve base end is communicated with a medium inlet and the flow passage hole at the valve cap end is communicated with a medium outlet to form a medium flow passage. The quick automatic cut-off instrument valve of the invention has simple operation and is cut off by front and back pressure difference of the detected medium rather than by field operating personnel. Maintaining personnel can maintain a display instrument without any treatments, and after the instrument is normal, the quick cut-off instrument valve is opened so that the front pressure and back pressure are in balance. The invention has the advantages of resource saving, environment protection, quick and convenient installation and use, on-line maintenance and safe and reliable operation of pipelines.

Owner:大连高阀泵阀有限公司

Badminton racket carbon fiber handle

InactiveCN108635787AGuaranteed connection strengthGuaranteed connection accuracyStringed racketsFiberCarbon fibers

The invention discloses a badminton racket carbon fiber handle. The handle comprises a taper front sleeve, a handle body and a rear sleeve of a carbon fiber integrated structure, and the carbon fiberhandle further comprises a carbon fiber integrated straight hole structure arranged in the center of the taper front sleeve, the handle body and the rear sleeve; the cross section of the handle body is of a hexagonal structure, and the rear sleeve is provided with a weight adjustable device. The taper front sleeve, the handle body and the rear sleeve of the carbon fiber integrated structure have the advantages of being low in weight and high in strength, and the connecting strength and connecting precision of the carbon fiber handle and a middle rod are guaranteed; the front sleeve and the handle body are internally provided with elastic shock absorption materials, the shock absorption function is achieved, arms of athletes are not prone to ache when the athletes play badminton for a longtime, and use comfort is improved; by means of reinforcing ribs between the integrated straight hole structure and the handle body, the whole strength is guaranteed, the use strength of the carbon fiber handle connected with the middle rod is guaranteed, and it is ensured that the handle is durable and not likely to break off or bend.

Owner:东莞市恒邦企业服务有限公司

Light-weight magnesia brick and preparation method thereof

The invention relates to a light-weight magnesia brick and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: uniformly mixing 30-85 wt% of sintered magnesia, 10-65 wt% of magnesite, 0.5-4 wt% of silicon dioxide fine powder, 0.5-2% of soft clay and 1-3% of binder, carrying out press forming, naturally drying for 24 hours, keeping the temperature of 110-300 DEG C for 8-24 hours, and firing at 1350-1500 DEG C for 3-12 hours to obtain the magnesia brick. The sintered magnesia is granules, fine powder or mixture of granules and fine powder; and the magnesite is granules, fine powder or mixture of granules and fine powder. The light-weight magnesia brick has the advantages of low volume density, low heat conductivity, moderate strength, strong alkaline slag corrosion resistance, high heat-insulating property and high melting point, is beneficial to energy saving and consumption reduction, and satisfies the light-weight requirement of the material. The invention is suitable for the liner of a high-temperature industrial kiln and container.

Owner:WUHAN UNIV OF SCI & TECH

Check valve and smoke exhauster

ActiveCN104990118ATo achieve the purpose of noise reductionReduce dispersionDomestic stoves or rangesLighting and heating apparatusHigh energyEngineering

The invention provides a check valve and a smoke exhauster. The check valve comprises a valve body. A flue is arranged in the valve body. The valve body is provided with a flue inlet and a flue outlet which are communicated with the flue. The end, close to the flue inlet, of the inner wall face of the flue is provided with vortex cutting ribs. The vortex cutting ribs are arranged on the check valve so as to cut large-size and high-energy vortexes formed by soot flowing out of a centrifugal fan of the smoke exhauster at high speed at the flue inlet of the check valve and a centrifugal fan volute tongue, so that the vortexes are dispersed into small vortexes, small in size and easy to dissipate, and the small vortexes are gradually dissipated when flowing in the flue. Accordingly, the problem of noise or vibration caused when vortexes have too high energy and too large size is avoided, and the smoke exhauster noise is reduced.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Rough surface profiled fiber and preparation method and application thereof

ActiveCN107447272AGuaranteed use strengthImprove practicalityFilament/thread formingAbnormal shapedCorrosion

The invention discloses a rough surface profiled fiber and a preparation method and application thereof. The preparation method of the rough surface profiled fiber comprises the following steps of spinning yarns through a profiled spinneret to obtain initial fiber products; performing corrosion treatment on the obtained initial fiber products; performing washing and drying processes to obtain finished fiber products, namely, rough surface profiled fiber, wherein the process of spinning the yarns through the profiled spinneret produces the initial fiber products with the radial cross section in a star shape, then the initial fiber products are corroded, and a number of corrosive pits are formed in the surface of the obtained finished fiber products, namely, the surface obtains certain roughness to further improve condensate performance. The profiled fiber with the corrosive pits in the surface is made of polar polymers, thereby having high water absorbency, the star-shaped structure provides sliding channels for collected water, and meanwhile, the surface roughness can further improve the condensate performance of the fiber.

Owner:北京京盛国泰科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com