Centrifugal forming die and construction method for high-strength conical cement pole

A centrifugal molding and cement pole technology, which is used in the field of cement communication poles, conical cement poles, and cement lamp poles, can solve the problems of difficult control of the wall thickness of cement poles, dirty working environment, and poor quality of the inner wall, etc. The effect of secondary sealing process, high internal structure strength and smooth inner and outer surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

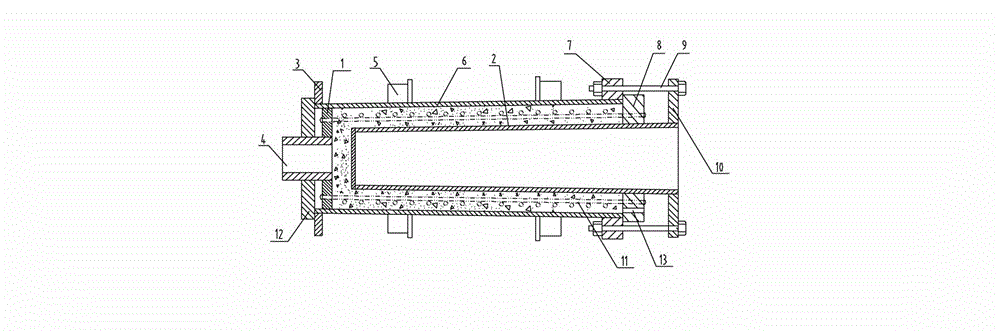

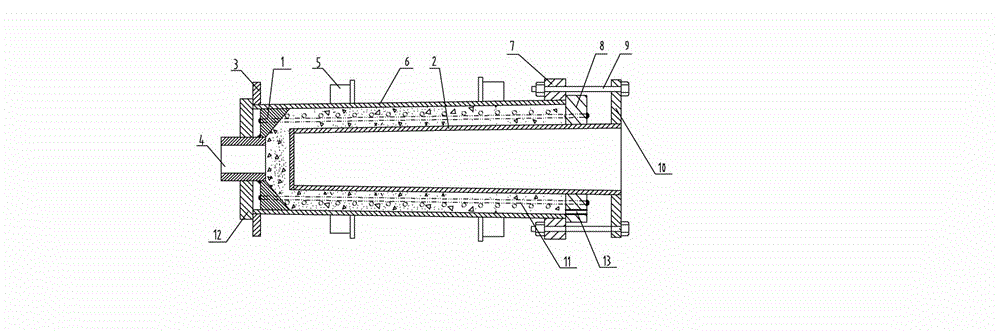

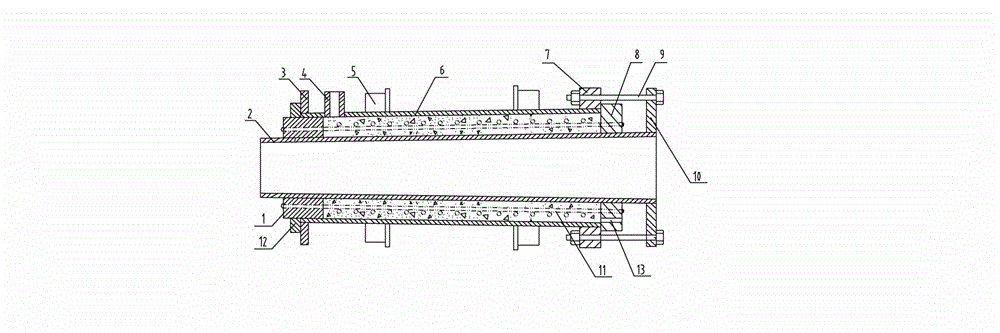

[0027] Such as figure 1 Shown, the centrifugal molding die of high-strength tapered cement rod of the present invention is characterized in that comprising cone-shaped outer mold 6, the cone-shaped internal mold 2 of concentric with this cone-shaped outer mold, and this cone-shaped inner mold The big-end flange plate 10 of the intima fixedly connected to the large-diameter end of the shape inner mold is sleeved on the large-end prestressed tension ring 8 on the large-diameter end of the cone-shaped inner mold 2, which is connected with the cone respectively. The outer mold large end flange plate 7 and the outer mold small end flange plate 3 fixedly connected to the large diameter end and the small diameter end of the cylindrical outer mold, and the mold cavity that is slidingly and sealingly connected with the small end inner hole of the tapered cylindrical outer mold End closure plate 1, a group of running wheels 5 fixedly connected to the outer surface of the cone-shaped out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com