Beam column pouring reinforcement device and process

A technology of pouring reinforcement and beams and columns, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of large consumption of materials, increase of construction costs, and small consumption of materials, so as to improve the strength of internal structures and improve The effect of small construction cost and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

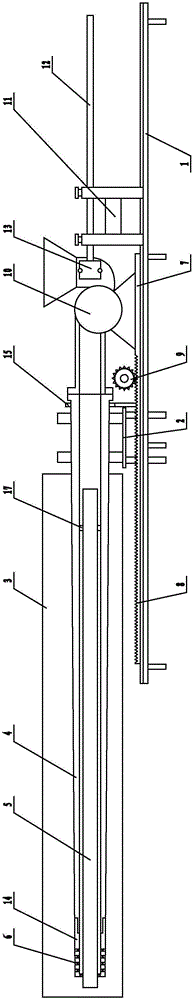

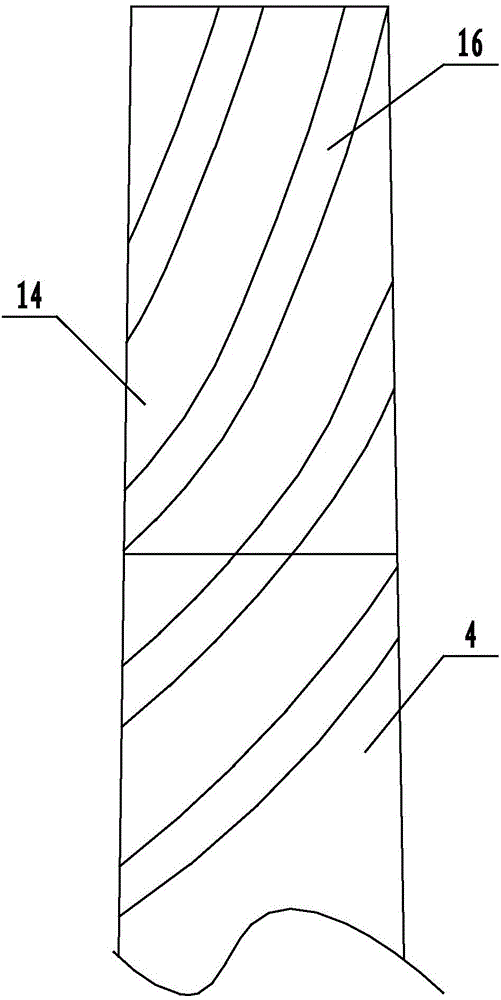

[0023] Embodiment: a kind of beam and column pouring reinforcement device (see attached figure 1 , attached figure 2 ), including support platform 1, stabilizing frame 2, and several pre-embedded pipes 4 preset in casting mold 3. The number of pre-embedded pipes is selected according to construction needs. The diameter gradually increases from the front to the rear. The front end of the embedded pipe is close to the front end of the casting mold, and the rear end of the embedded pipe extends out of the rear end of the casting mold. The rear end of the embedded pipe is movably socketed on the stable frame. The socket holes and the support arms are socketed together with the two socket holes. There is steel bar 5 inside the pre-embedded pipe, the front end of the steel bar is sealed and connected with the front end of the pre-embedded pipe and the front end of the steel bar extends out of the front end of the pre-embedded pipe, the front end of the steel bar is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com