A kind of permeable compressive concrete and preparation method thereof

A concrete and cement technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of affecting the water permeability of permeable concrete, poor structural strength of sand-free porous permeable concrete, and reducing the effective void ratio of aggregate To improve the compactness, ensure the water permeability and improve the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

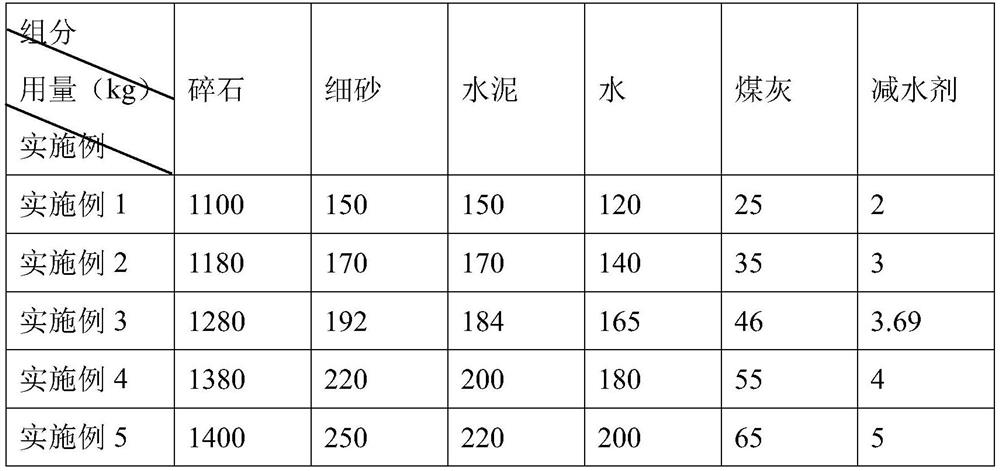

[0034] A kind of permeable compression concrete, its component content is as shown in table 1:

[0035] Table 1

[0036]

[0037] Among them, the crushed stone has a particle size of 25mm, the fineness modulus of fine sand coated with an active calcium oxide layer is 1.5, the cement is sulphoaluminate cement, and the water reducer is polycarboxylate water reducer;

[0038] The coating method of the active calcium oxide layer is as follows: 1) at room temperature, the titanate is completely dissolved in isopropanol to obtain a titanate isopropanol solution, and the molar ratio of titanate to isopropanol is 1: 5; 2) Take activated calcium oxide and place it in the solution, stir to obtain a suspension, the molar ratio of activated calcium oxide to titanate is 0.5:1; 3) Re-stir the suspension to make the activated calcium oxide evenly dispersed , to obtain the dispersion; 4) While performing ball milling on the fine sand, spray the dispersion on the surface of the fine sand i...

Embodiment 2

[0044] A large amount of fly ash concrete, its component content is shown in Table 1;

[0045] Among them, the crushed stone has a particle size of 25mm, the fineness modulus of fine sand coated with an active calcium oxide layer is 1.5, the cement is sulphoaluminate cement, and the water reducer is polycarboxylate water reducer;

[0046] The coating method of the active calcium oxide layer is as follows: 1) at room temperature, the titanate is completely dissolved in isopropanol to obtain a titanate isopropanol solution, and the molar ratio of titanate to isopropanol is 1.25: 5; 2) Put the activated calcium oxide in the solution and stir to obtain a suspension, the molar ratio of activated calcium oxide to titanate is 0.6:1; 3) Re-stir the suspension to make the activated calcium oxide evenly dispersed , to obtain the dispersion; 4) while carrying out ball milling treatment on the fine sand, the dispersion liquid is sprayed on the surface of the fine sand in a mist spray mode...

Embodiment 3

[0052] A large amount of fly ash concrete, its component content is shown in Table 1;

[0053] Among them, the crushed stone has a particle size of 25mm, the fineness modulus of fine sand coated with an active calcium oxide layer is 1.5, the cement is sulphoaluminate cement, and the water reducer is polycarboxylate water reducer;

[0054] The coating method of the active calcium oxide layer is as follows: 1) at room temperature, the titanate is completely dissolved in isopropanol to obtain a titanate isopropanol solution, and the molar ratio of titanate to isopropanol is 1.5: 5; 2) Put the activated calcium oxide in the solution and stir to obtain a suspension, the molar ratio of activated calcium oxide to titanate is 0.75:1; 3) Re-stir the suspension to make the activated calcium oxide evenly dispersed , to obtain a dispersion; 4) while carrying out ball milling treatment on the fine sand, spray the dispersion on the surface of the fine sand in a mist spray mode, the spray pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com