Patents

Literature

2600results about How to "Improve densification performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

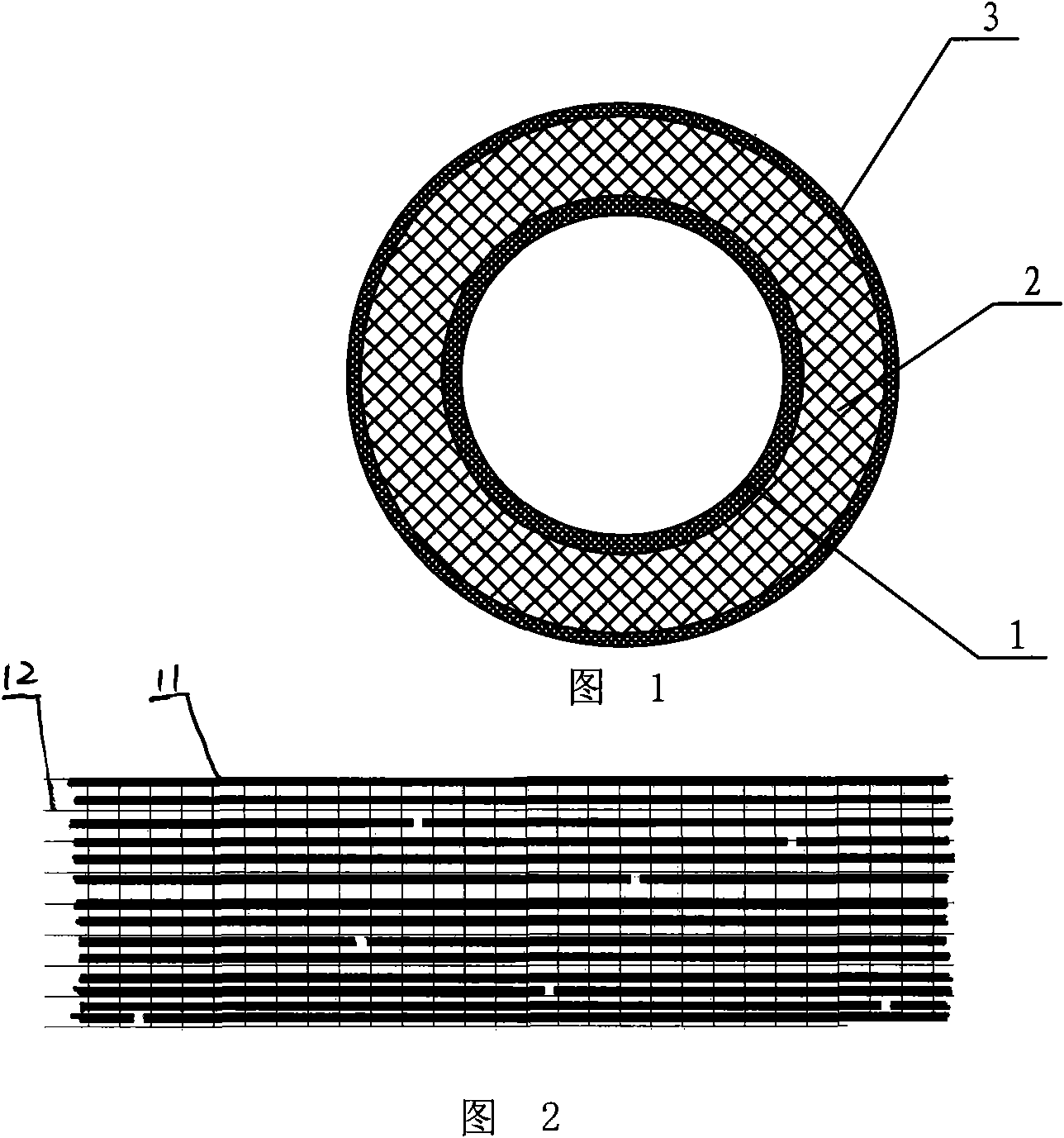

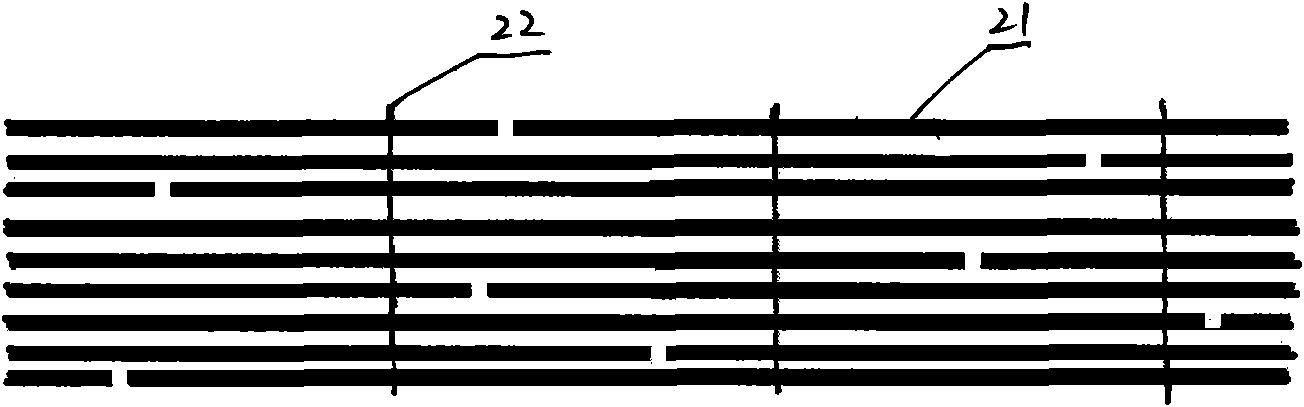

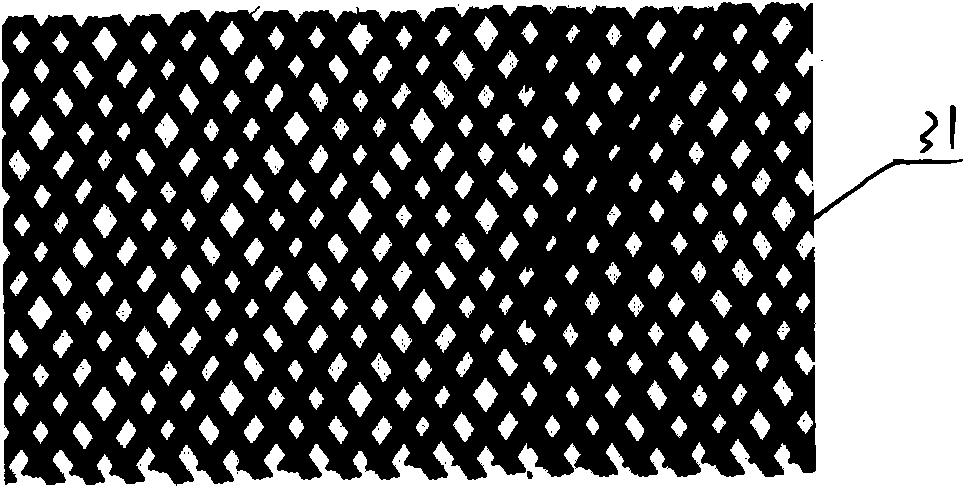

Preparing method of bamboo fiber winding composite tube

InactiveCN101571213ALow costImprove toughnessLiquid surface applicatorsVeneer manufactureSteel tubePre treatment

The invention discloses a preparing method of a bamboo fiber winding composite tube. The existing polyvinyl chloride tubes, polyethylene tubes, glass steel tubes and glass steel sand tubes consume a great amount of petroleum resources, and pollute environments. The invention provides the preparing method of the bamboo fiber winding composite tube. The preparing method comprises the following steps: preparing an inner liner layer; pre-treating bamboo fiber, connecting the bamboo fiber into a continuous bamboo fiber strip by a method of liner cloth adhesion or sewing or weaving, and rolling the bamboo fiber strip into a roll; preparing a reinforcing layer, installing the coiled bamboo fiber strip on a winding machine to unwind, coating resin on the bamboo fiber strip through a resin tank, winding the bamboo fiber strip on an inner liner layer of a straight tube mould more than two circles, and forming the reinforcing layer after curing; preparing an outer protective layer. The preparing method uses the winding machine to perform the machine production, so the production efficiency is high, the compactness of the bamboo fiber is enhanced, and the strength of the product is enhanced.

Owner:XINJIANG GUANGSHUI PIPE

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Water-based primer-topcoat braking paint and preparation method thereof

The invention relates to a water-based primer-topcoat braking paint and a preparation method thereof. The braking paint comprises the following materials by weight percentage: 30-40 of water-based acrylic resin, 2-10 of amino resin, 1-3 of neutralizing agent, 2-5 of compound rustproofing pigment, 1-3 of tinting pigment, 10-20 of filling agent, 0.1-0.5 of defoaming agent, 0.1-0.5 of flatting agent and 25-40 of deionized water, wherein the water-based acrylic resin is a free radical polymerization resultant which comprises the following materials by weight percentage: 10-30 of monomer containing hydroxy acrylic acid, 5-20 of monomer containing carboxyl acrylic acid, 2-8 of internal crosslinking monomer, 20-40 of other acrylic acid monomer, 15-30 of phenyl ethylene monomer, 1-5 of evocating agent and 40-50 of alcohol ether latent solvent. When the paint is prepared, the dispersion and the abrading condition of the pigments and the filling agents are reasonably controlled to ensure that each component of the paint fully plays the respective function. The paint ensures the corrosion prevention effect and the decoration of a coating and realizes the combination of a primer and a topcoat.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

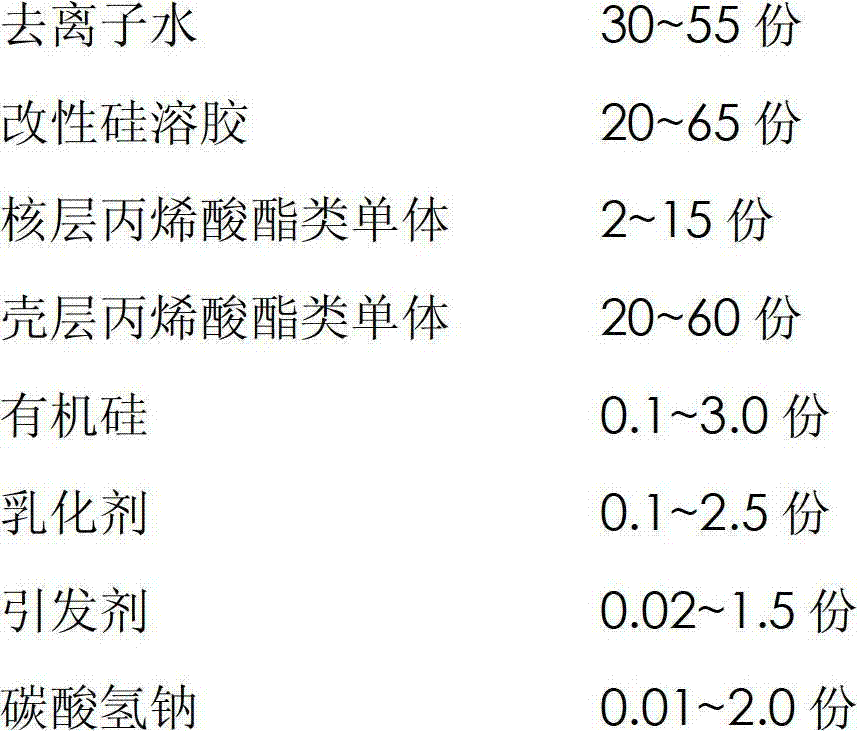

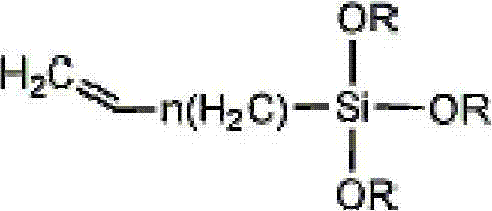

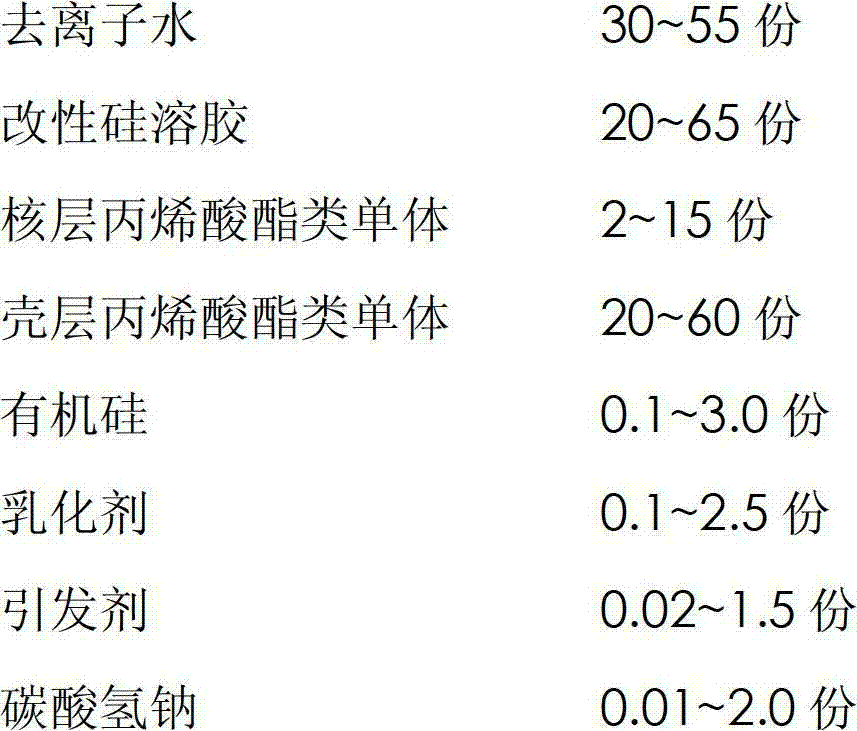

Organosilicon modified silica sol/polyacrylate composite emulsion and its preparation method

InactiveCN102731735AGood repeatabilityComposite emulsion has excellent performanceCoatingsSolventIon

The invention discloses an organosilicon modified silica sol / polyacrylate composite emulsion and its preparation method. The emulsion comprises the following raw materials, by mass, 30-55 parts of deionized water, 20-65 parts of a modified silica sol, 2-15 parts of a core acrylate monomer, 20-60 parts of a shell acrylate monomer, 0.1-3.0 parts of organosilicon, 0.1-2.5 parts of an emulsifier, 0.02-1.5 parts of an initiator, and 0.01-2.0 parts of sodium bicarbonate, wherein the Si (by SiO2) content in the organosilicon modified silica sol / polyacrylate composite emulsion is 15-25% by mass. The emulsion which has an excellent appearance is a white emulsion with obvious blue lights. A coat of the emulsion is transparent and smooth, and has a hardness reaching 5-6H and an adhesion being 0-1 level. The coat has an excellent water resistance, so the coat does not have whitening and foaming phenomena after immersed in water for 7-10 days; the coat has no changes after resisting neutral salt fog for 15-20 days; and the solvent wiping resistance of the coat can pass an MEK test 180-200 times.

Owner:SOUTH CHINA UNIV OF TECH

Marine anticorrosive coating

InactiveCN104087126AImprove anti-corrosion performanceGood flexibilityAnti-corrosive paintsPolyurea/polyurethane coatingsHigh resistanceEpoxy

The invention discloses a marine anticorrosive coating. The marine anticorrosive coating consists of the following components in percentage by mass: 30-40 percent of film forming matter, 21.5-33.8 percent of pigment filler, 6.2-15.4 percent of aids and 30-42.3 percent of solvent, wherein the film forming matter consists of 16-23 mass percent of water-based phenolic epoxy resin and 14-16 mass percent of waterborne polyurethane; the pigment filler comprises graphene; the solvent is deionized water. The marine anticorrosive coating has high corrosion resistance, high flexibility, high wear resistance, high oil and aging resistance and good antirust performance. The film forming matter integrates high adhesion force, high strength, low shrinkage rate and high corrosion resistance of the water-based phenolic epoxy resin as well as high flexibility, wear resistance, oil and aging resistance and good film-forming performance of the waterborne polyurethane.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

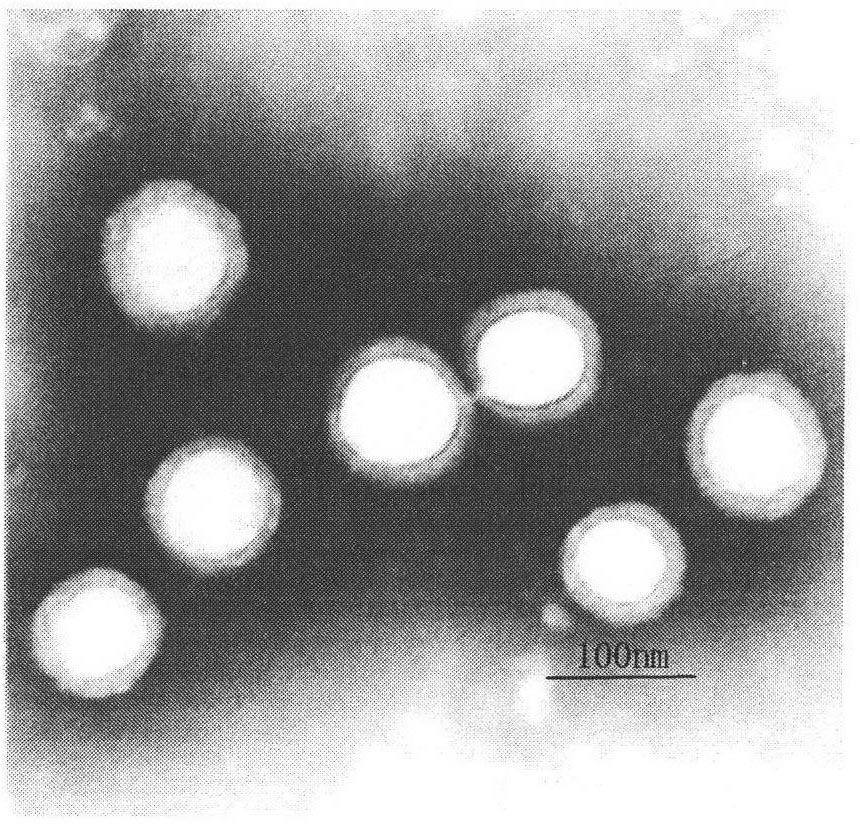

Preparation method of essence microcapsules

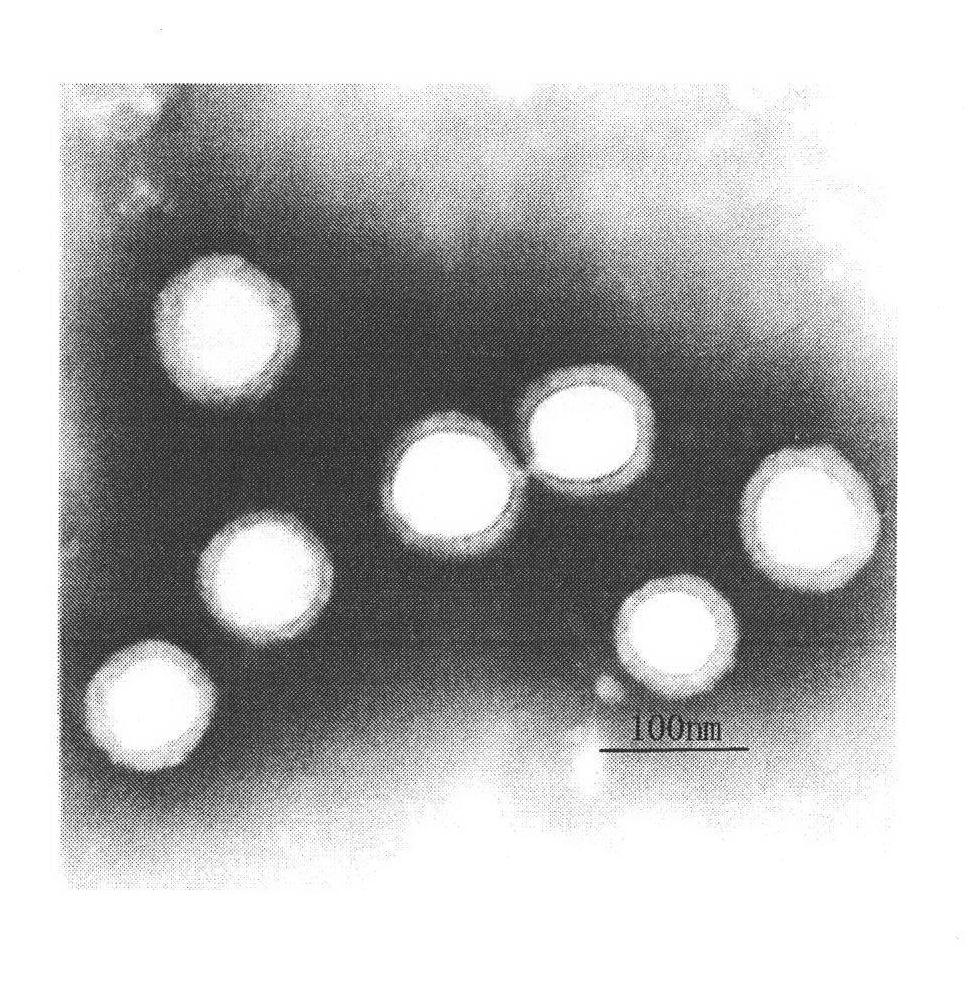

InactiveCN102039108AGood chemical stabilityHigh mechanical strengthEssential-oils/perfumesMicroballoon preparationTextile fiberEthylic acid

The invention discloses a preparation method of essence microcapsules. The preparation method comprises the following steps: (1) dissolving chitosan in acetum; (2) adding emulsifier and essence into the chitosan acetum for high-speed emulsification and dispersion to obtain the chitosan essence emulsion; (3) adding the mixed solution of sodium alginate and sodium tripolyphosphate dropwise into the chitosan essence emulsion; (4) adjusting the pH value of the system to 5-7 with NaOH solution to obtain the condensed essence microcapsules; and (5) adding cross-linking agent into the condensed essence microcapsule system to perform chemical cross-linking process on the condensed essence microcapsules to obtain the essence microcapsules. For the essence microcapsules prepared according to the method disclosed by the invention, as chemical cross-linking process is implemented on the walls of the capsules, the density of the capsule walls and the resistance to the solution alkalinity / acidity are improved, and the application stability of the essence microcapsules is increased; moreover, with small size, the capsules can easily permeate into textile fiber, and the water-washing resistance of the textile fiber is greatly improved.

Owner:广州市戴文高分子材料科技有限公司 +1

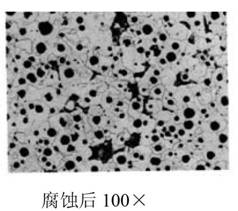

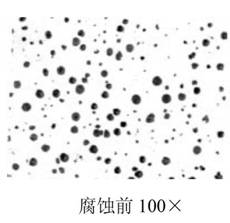

Smelting method for medium-thin wall cast-state nickel-free low-temperature ductile cast iron

ActiveCN102690986AImprove densification performanceImprove roundnessIntermediate frequencyStress relief

The invention relates to a smelting method for medium-thin wall cast-state nickel-free low-temperature ductile cast iron. The medium-thin wall cast-state nickel-free low-temperature ductile cast iron comprises the following chemical components in percentage by mass: 3.5-4.1 percent of C, 1.7-2.2 percent of Si, 0.10-0.25 percent of Mn, not more than 0.035 percent of P, not more than 0.020 percent of S, 0.015-0.030 percent of Re, 0.025-0.045 percent of Mg, 0-0.20percent of Cu, less than 0.1 percent of residual element, and Fe in balancing amount. The medium-thin wall cast-state nickel-free low-temperature ductile cast iron is obtained by mixing furnace materials and carrying out high-temperature smelting in an intermediate-frequency furnace, modularization and inoculation treatment and casting and heat-insulating treatment on the mixed furnace materials. Cast iron products obtained by adopting the smelting method disclosed by the invention obtain normal-temperature mechanical property and low-temperature mechanical property under the cast state conditions; complex medium-thin wall parts are required to be subjected to low-temperature stress relief annealing; and simple medium-thin wall parts are free from being annealed, so that the production cost is greatly reduced, the production period is greatly shortened and the production efficiency is increased.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Method for controlling center porosity of large section heavy rail steel casting blank

The invention relates to the technical field of ferrous metallurgy, in particular to a method for controlling the center porosity of a large section heavy rail steel casting blank. The method comprises the following steps of controlling the superheat degree of medium-package molten steel; controlling the pulling speed in the normal pouring process; pressing down the final solidification end in the pouring process; setting the stirring strength and stirring frequency of electromagnetic stirring of a crystallizer; setting the stirring strength and stirring frequency of electromagnetic stirring at the final solidification end; controlling the cooling water yield and the secondary cooling specific water yield of the crystallizer. The center porosity of the large section heavy rail steel casting blank produced by adopting the method can be effectively controlled, and the remaining internal quality of the casting blank can be effectively guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Composite bonding wear-resistant castable refractory

The invention relates to a composite bonding wear-resistant castable refractory, which can be used for high-temperature kiln engineering. The amorphous castable refractory which is normal in coagulation, quick in hardening, low in porosity, high in strength and high in abrasive resistance is prepared from silica sol serving as a bonding agent, aluminate cement serving as a curing agent, alumina micro powder and wollastonite which serve as a compact agent, heat resistant steel filters serving as a reinforcing agent and corundum and alumina which serve as an aggregate. The composite bonding wear-resistant castable refractory is suitable for positions such as air pipeline elbows for the cogeneration of cement kilns, cyclone cones and linings for triple air pipe gates which are easy to wear in high-temperature kilns.

Owner:ANHUI RUITAI NEW MATERIALS TECH

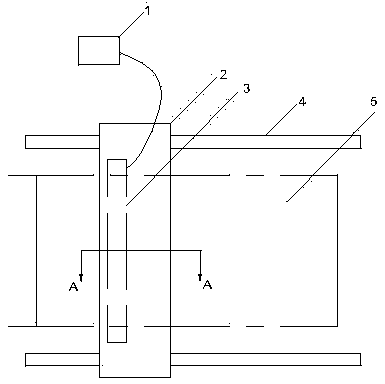

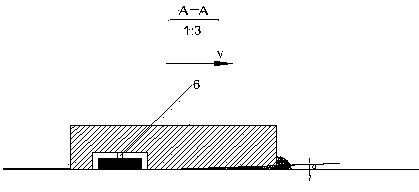

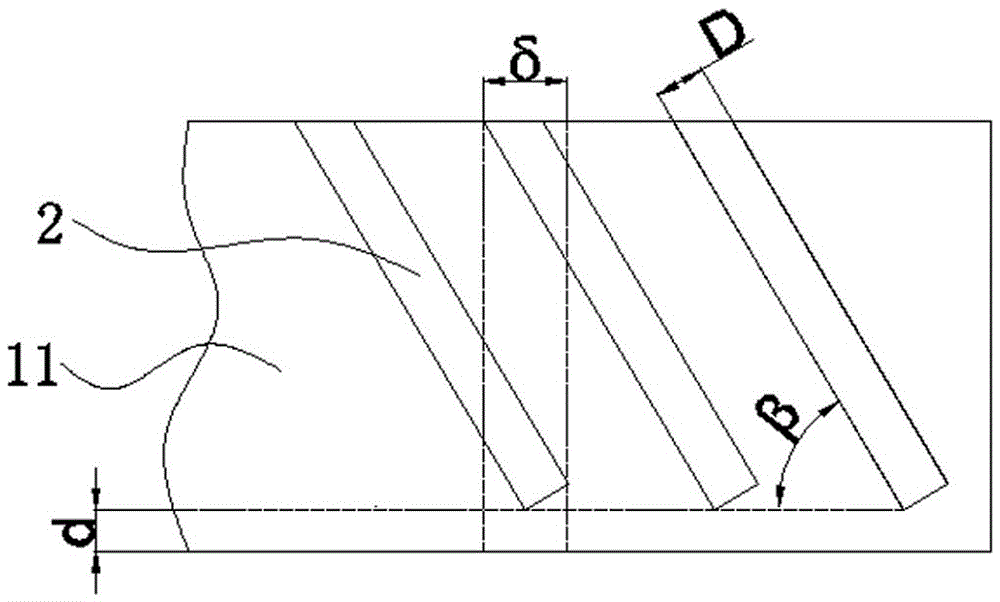

Additive manufacturing device composite powder compacting and spreading device and method

ActiveCN104043830AImprove mechanical propertiesImprove densification performanceIncreasing energy efficiencyMechanical propertyAdditive layer manufacturing

The invention discloses an additive manufacturing device composite powder compacting and spreading device and method. The powder spreading device comprises a pressure powder spreading machine and a vibration system, wherein the pressure powder spreading machine is provided with a coating surface with a certain inclined angle and used for spreading a powder material, and the vibration system is used for vibrating and compacting the spread powder material. According to the powder spreading device, due to the fact that the pressure powder spreading machine is provided with the coating surface with the certain inclined angle, in the powder spreading process, after loose powder enters the included angle formed between the coating surface and a powder spreading plane, the heated loose powder is mutually extruded through the gradually-decreasing space, and then gaps between the powder become smaller; the vibration system vibrates and pressurizes the extruded powder, distribution arrangement of the gaps between the extruded powder is stabilized, namely, rebound of the spread powder is reduced, the powder material is elastically deformed and then the flat-spread powder is compacted, so that compactness of three-dimensional forming products is improved, and mechanical performance of the three-dimensional forming products is further improved.

Owner:HUNAN FARSOON HIGH TECH CO LTD

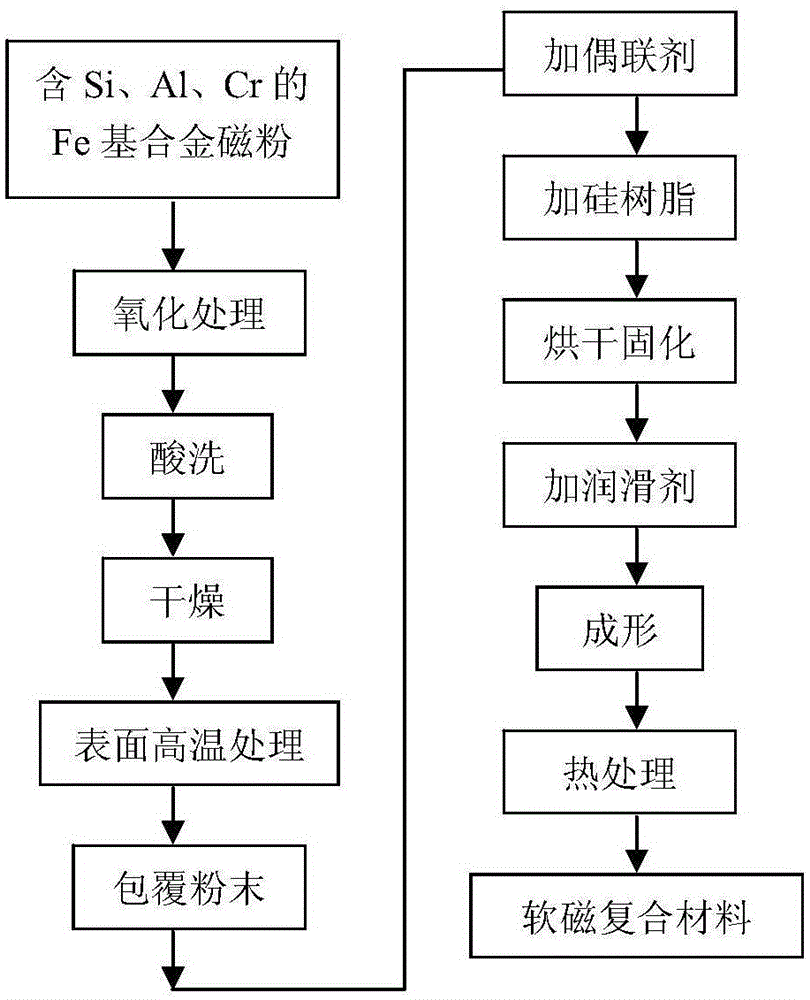

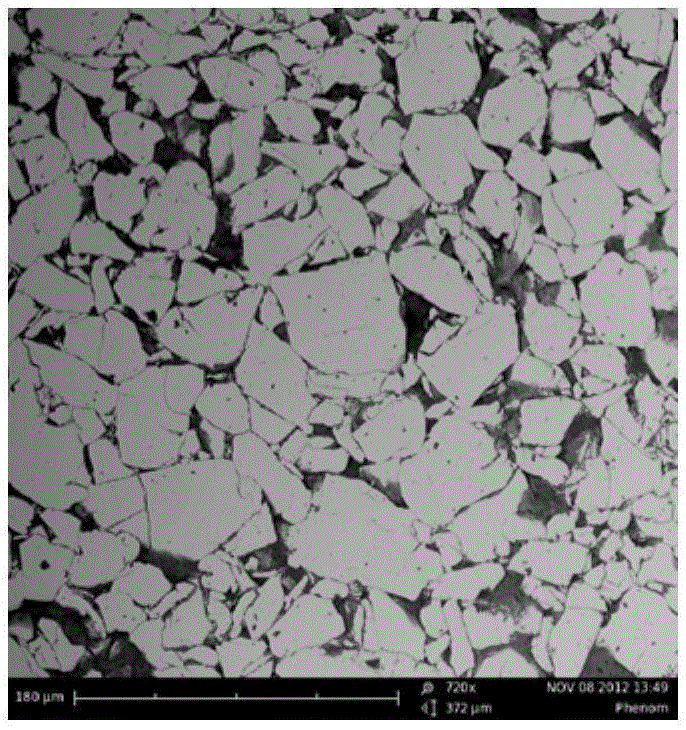

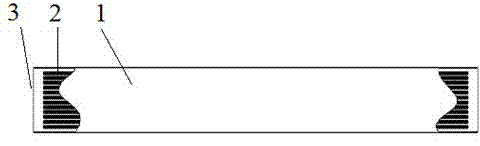

Coating method iron-based magnetically soft alloy powder and preparation method of soft magnet composite material

ActiveCN105149574AHigh resistivityImprove compactnessInorganic material magnetismMagnetic powderOxide

The invention relates to a coating method for iron-based magnetically soft alloy powder and a preparation method of soft magnet composite material. The coating method for iron-based magnetically soft alloy powder comprises the following steps: carrying out accelerated oxidation on iron-based magnetic metal powder at high temperature, forming an oxide layer on the surface of the powder and then carrying out acid pickling, thus obtaining powder with surface coated with SiO2, Al2O3 and Cr2O3 oxides. The preparation method of the soft magnet composite material comprises the following steps: adding coupling agent, silicon resin and lubricating agent to the coated powder, carrying out pressing forming, and then carrying out annealing heat treatment, thus obtaining the soft magnet composite material. According to the invention, the advantage that an oxide produced in reaction of elements including Si, Al and Cr contained in the iron-based magnetically soft alloy powder with oxygen is high in electrical resistivity, small in thermal expansion coefficient and steady in chemical performance and can resist high temperature is fully utilized; the adopted coating technology is to produce a coating layer in situ on the surface of the alloy magnetic powder, and is simple in process, easy to operate and low in cost; the metal soft magnet composite material prepared by adopting the method disclosed by the invention has good magnetic property and frequency stability.

Owner:CENT SOUTH UNIV

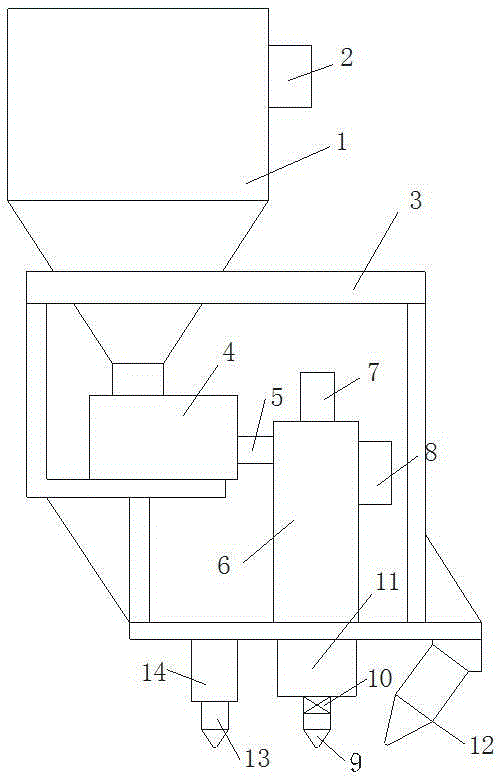

3D printing device integrating material supplying, fluxing and crystal leveling assistance

ActiveCN105383060AImprove densification performanceImprove bindingAdditive manufacturing apparatusCeramic shaping apparatusSize changeEngineering

A 3D printing device integrating material supplying, fluxing and crystal leveling assistance comprises a support, a material bin, a first forced feeding mechanism, a second forced feeding mechanism, an auxiliary heating head and a crystal leveling assistance vibrating head, wherein the material bin, the first forced feeding mechanism, the second forced feeding mechanism, the auxiliary heating head and the crystal leveling assistance vibrating head are all mounted on the support. The material bin, the first forced feeding mechanism and the second forced feeding mechanism are sequentially connected. A nozzle is connected to a discharging outlet of the second forced feeding mechanism, and a heating device is arranged at the discharging outlet. The auxiliary heating head and the crystal leveling assistance vibrating head are arranged at the bottom of the support and located in front of and behind the nozzle respectively. The device is easy to operate, stable, reliable and convenient to maintain; the compactness of formed workpieces in the 3D printing process is improved, interlayer bonding of the formed workpieces is good, and the cost is low; through material selection, size changes and process adjustment of corresponding components, the device can be suitable for fused deposition of powder materials of different types.

Owner:JINAN LUYANG TECH

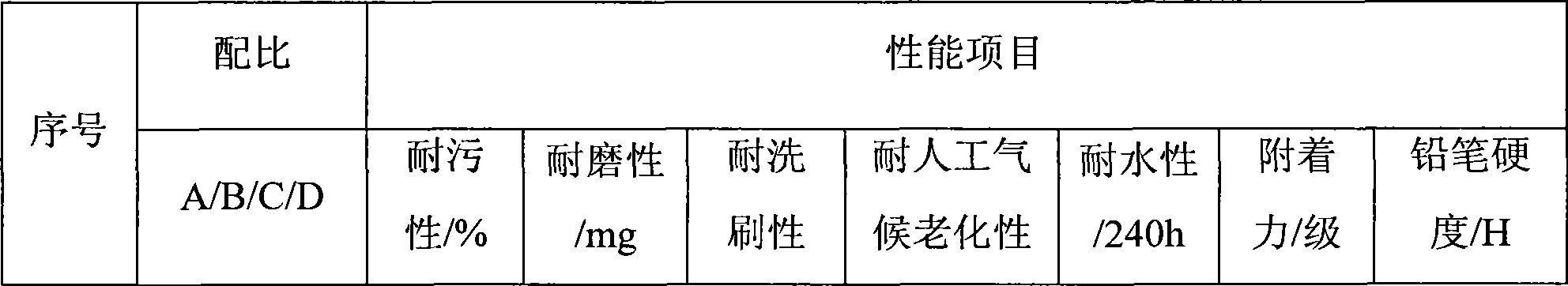

Silicon- and fluorine-containing epoxy (meth) acrylate UV-curing composite coating and preparation method thereof

The invention discloses a silicon and fluorine-containing epoxy (meth) acrylate UV-curing composite coating, comprising the following ingredients of: epoxy (meth) acrylate, polyhedral iligomeric silsesquioxane, fluorine-containing (meth) acrylate, an active diluent monomer, a photoinitiator and an auxiliary agent. Such a composite coating, with excellent fouling resistance, corrosion resistance, weather resistance, abrasive resistance, water resistance, fouling resistance and dynamic performance, is an environmentally friendly coating which is suitable for building material, optical fiber wrapping and the coating of the surface of metal element.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

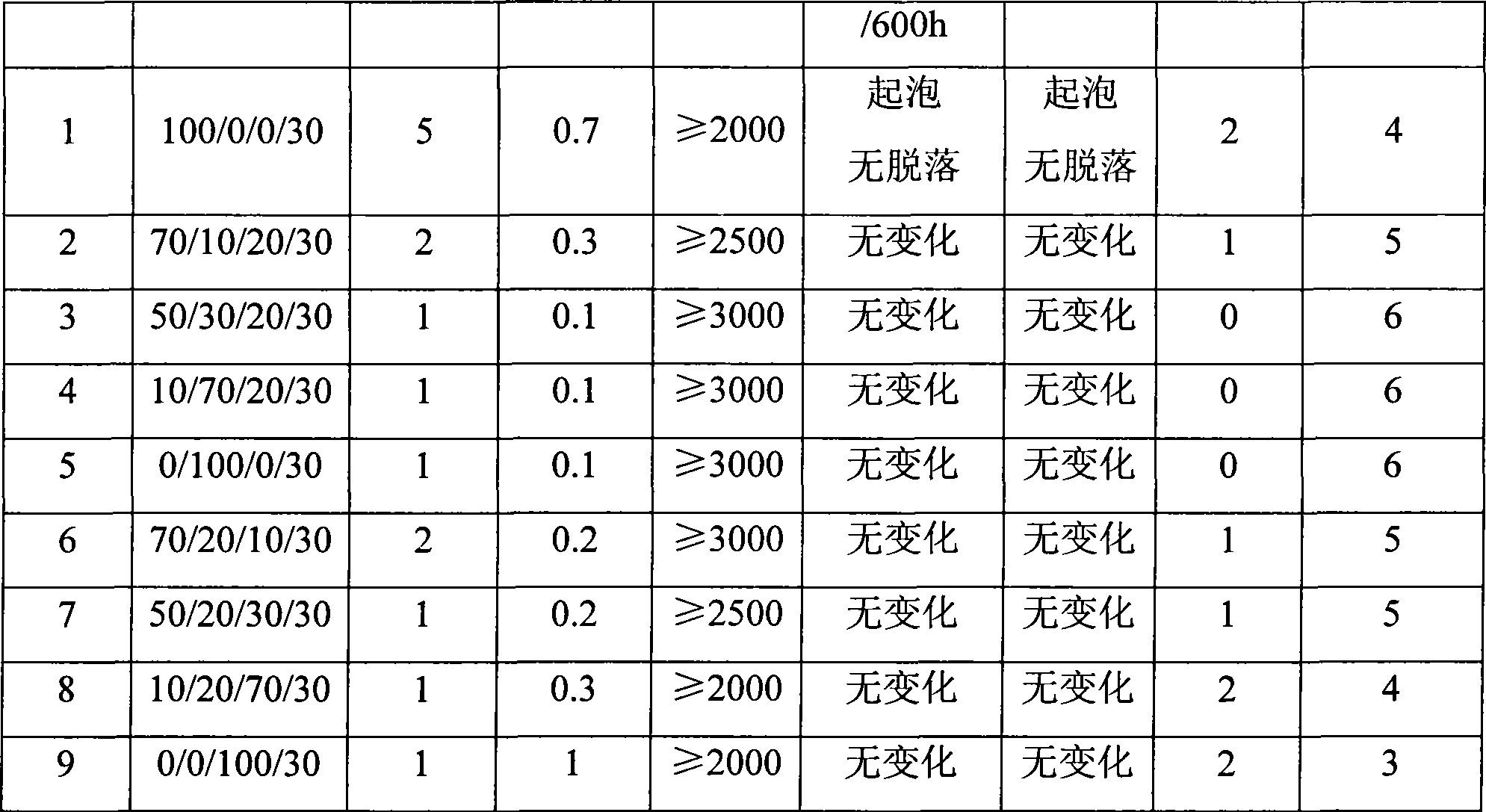

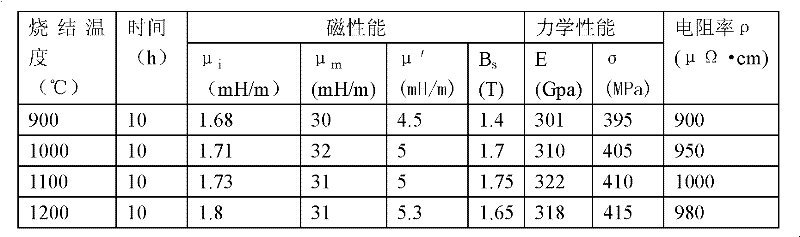

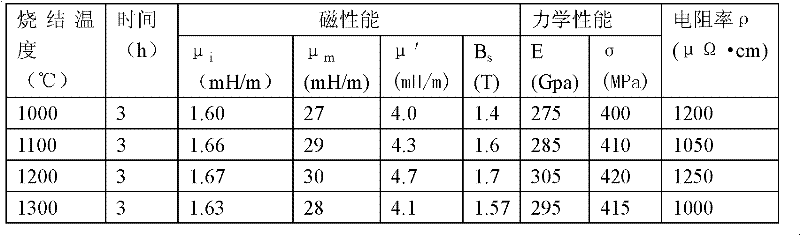

Sintered composite soft magnetic material and method for preparing same

ActiveCN102651264ALower sintering temperatureImprove compactnessInorganic material magnetismRare-earth elementMagnet

The invention relates to a sintered composite soft magnetic material and a method for preparing the same. The material comprises a metal soft magnetic material, a soft magnetic ferrite and a low-melting-point soft magnetic alloy, wherein the metal soft magnetic material is formed by at least one of an Fe-Ni system, an Fe-Co system, an Fe-Co-V system, an Fe-Al system and an Fe-Al-Me system (Me is one or more than two of Co, Cr and Mo), the soft magnetic ferrite is formed by at least one of an Mn-Zn system, an Ni-Zn-based, an Li-Zn system and a Cu-Zn system, and the low-melting-point soft magnetic alloy is an Re-Fe-M system alloy (Re comprises one or more of 17 rare earth elements including Sc and Y, and M is one or more of metal elements including B, Al, Si, Ti, V, Cr, Mn, Co, Cu, Mo, Ni, Zn, Ga, Nb, Ta and W). The method for preparing the soft magnetic material formed by the components has the advantages that cold pressing and then sintering or hot pressing or spark plasma sintering are selected, and the soft magnetic material not only overcomes the low resistivity of the metal soft magnetic material and the low magnetic induction of the ferrite, but also maintains the excellent performance of the metal soft magnetic material and the soft magnetic ferrite.

Owner:GRIREM ADVANCED MATERIALS CO LTD

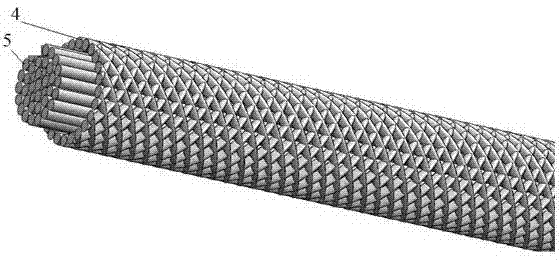

Novel graphite composite grounding material and preparation method thereof

ActiveCN103490180ASolving Corrosion ProblemsIncrease contact areaContact member manufacturingConnection contact member materialYarnCorrosion resistant

The invention discloses a novel graphite composite grounding material and a preparation method thereof. The novel graphite composite grounding material is in the shape of a rope or stranded wire, and comprises a composite graphite yarn inner core and a composite graphite yarn knitted layer wrapped outside the composite graphite yarn inner core, wherein the composite graphite yarn inner core is a composite graphite yarn bundle composed of a plurality of first composite graphite yarns or a single first composite graphite yarn; each first composite graphite yarn is prepared by twisting a first composite graphite belt; the composite graphite yarn knitted layer is prepared by knitting a second composite graphite yarn; and the second composite graphite yarn is prepared by twisting a second composite graphite belt. The graphite composite grounding material disclosed by the invention has the advantages of corrosion resistance, favorable conductivity, high flexibility, low price, precise soil association and the like, and is easy for transportation; since the price is low, artificial theft destroy can be avoided; and the graphite composite grounding material is suitable for the fields of transformer stations, overhead transmission line towers, tall buildings and all other projects in need of electric grounding.

Owner:WUHAN HONGMEN ELECTRICAL TECH CO LTD

Stainless heat-resistant alloy steel seamless steel tube and preparation method thereof

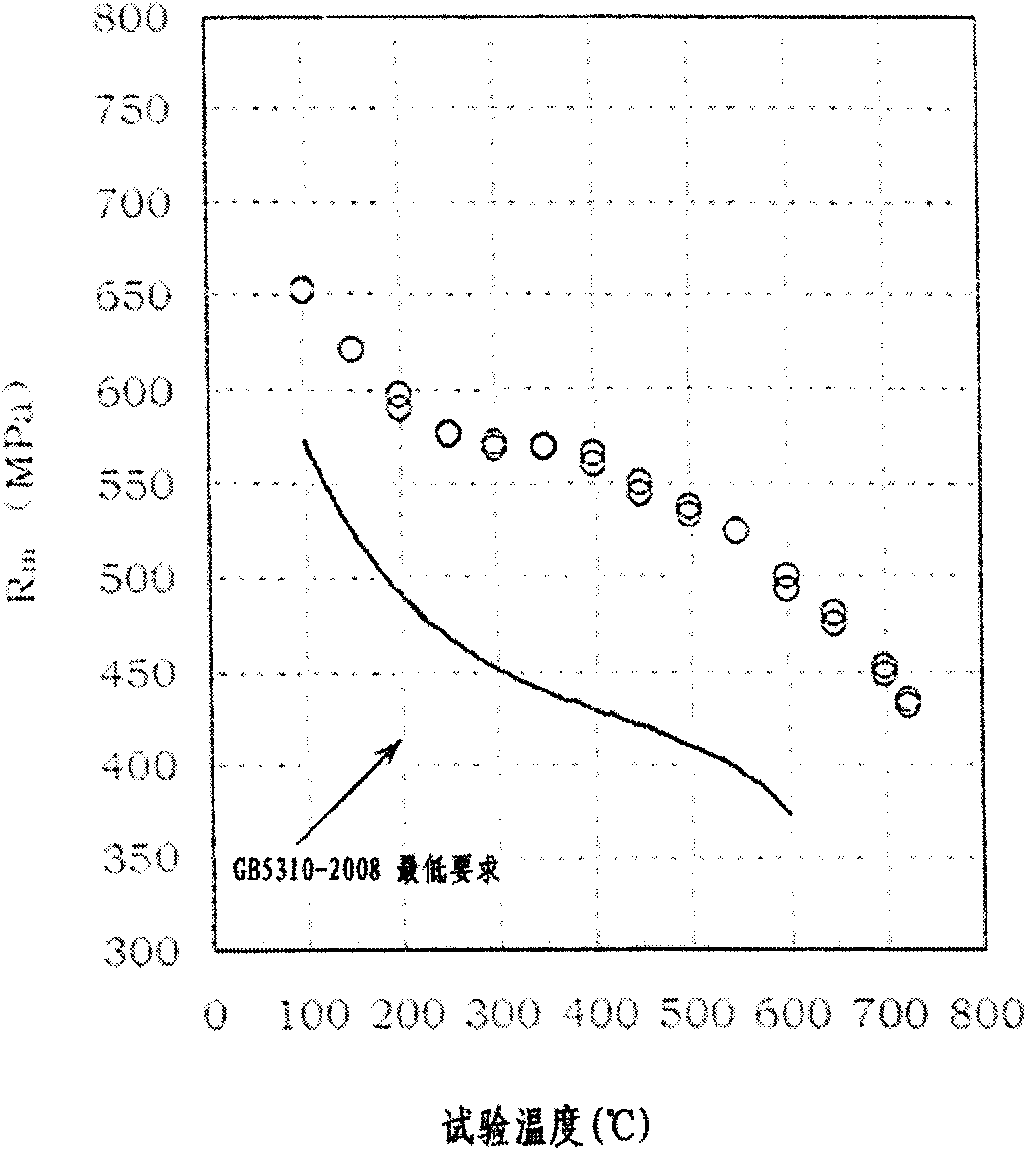

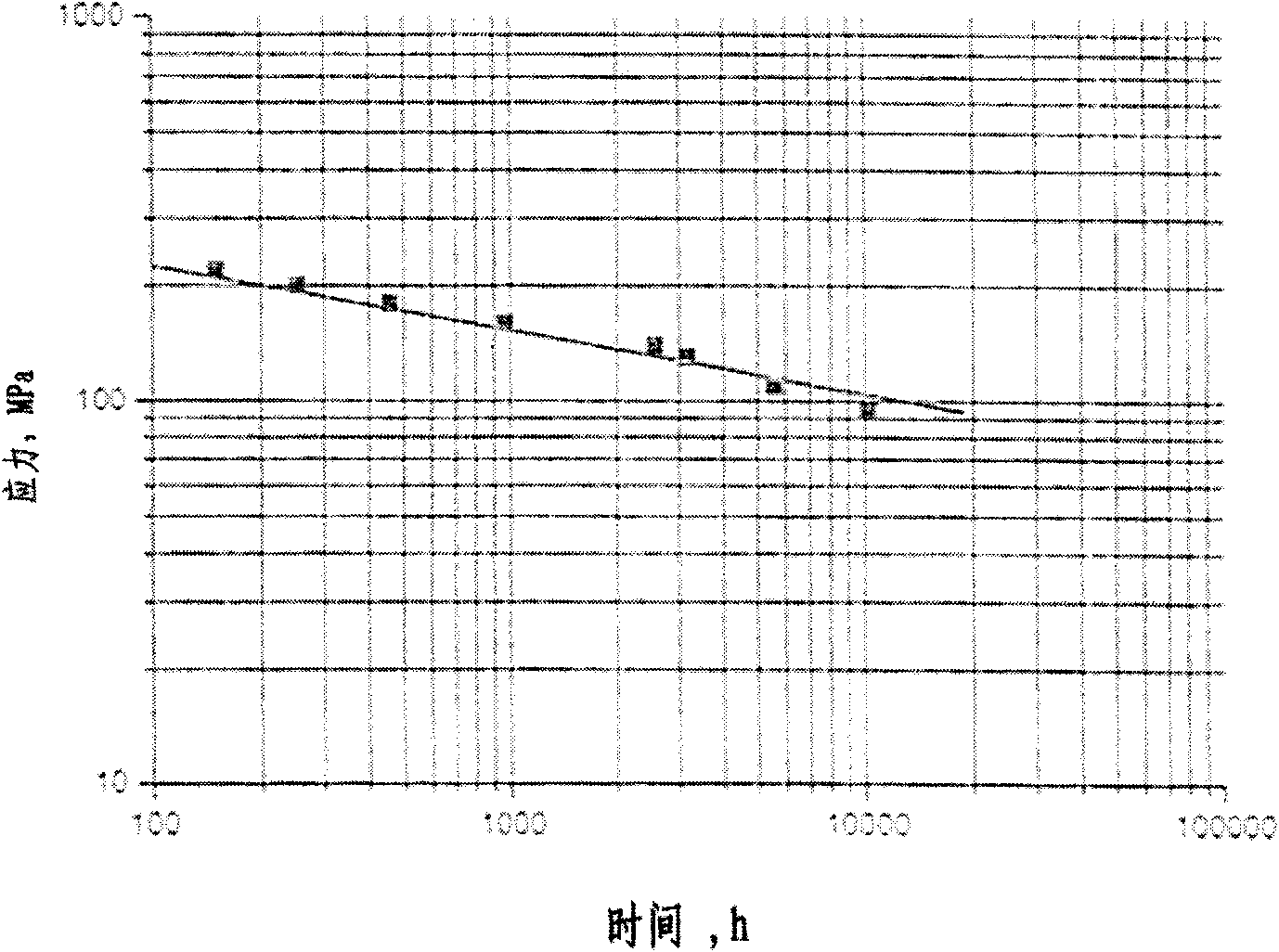

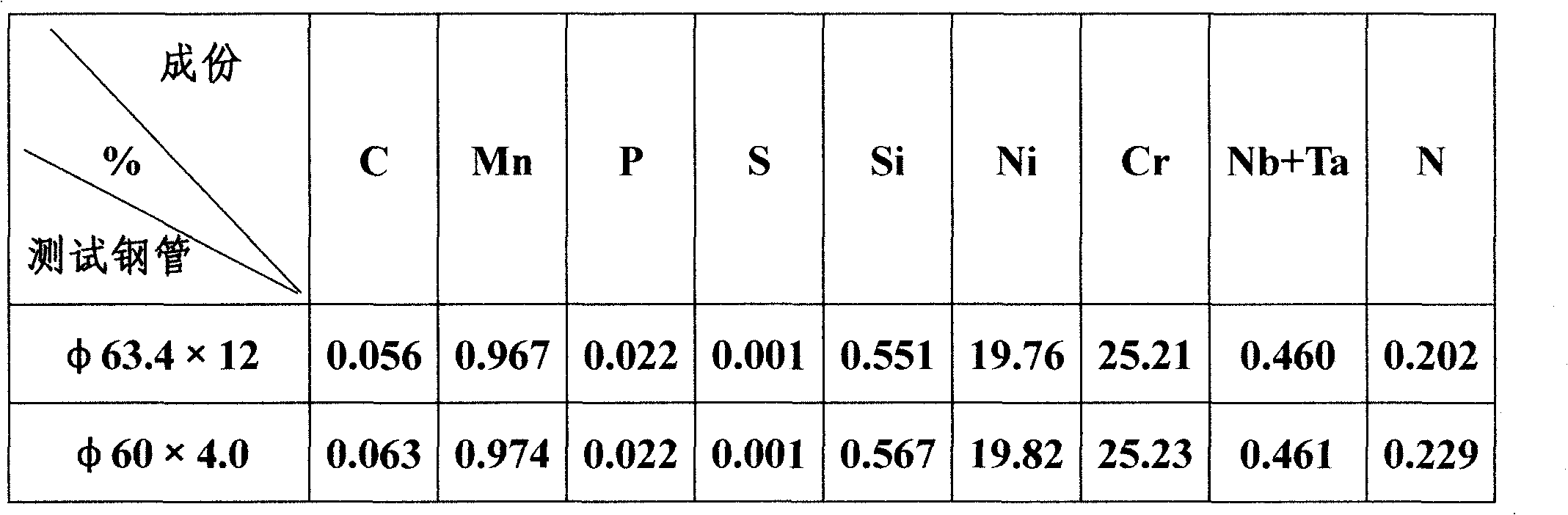

InactiveCN101665891AEvenly preheated at low temperatureImprove densification performanceProcess efficiency improvementElectric furnaceAutomatic controlPower station

The invention relates to a stainless heat-resistant alloy steel seamless steel tube and a preparation method thereof. The seamless steel tube comprises the following chemical compositions by weight percent: 0.04-0.10% of C, 0.75% or less of Si, 2.00% or less of Mn, 0.03% or less of P, 0.03% or less of S, 17.00-23.00% of Ni, 24.00-26.00% of Cr, 0.20-0.60% of Nb+Ta, 0.15-0.35% of N and the balance Fe and inevitable trace elements. The preparation method of the invention adopts hot extrusion and cold rolling, computer automatic control solution heat treatment and other advanced technologies. Theproduct of the invention has excellent mechanical performance, high temperature resistant and corrosion resistance and various technical indexes of the product all meet or exceed Chinese relevant technical standards, thus successfully providing a new kind of qualified tube for the ultra supercritical power station boiler.

Owner:ZHEJIANG JIULI HI TECH METALS

Preparation of nano silicone-acrylate core shell type composite latex for latex paints

InactiveCN101921360AThe polymerization process is stableGuaranteed yieldCoatingsChemistryWeather resistance

The invention relates to a preparation method of nano silicone-acrylate core shell type composite latex for latex paints. The preparation method solves the problem that latex paints prepared from the common latex is insufficient to meet the demands of people at the performance aspects of water resistance, weather resistance, pollution resistance and the like, and simultaneously reduces the restraint degrees of a region domain and a time and season domain for latex construction. In the preparation method, active organic silicon and acrylate monomers are mainly used as raw materials, and then the nano silicone-acrylate core shell type composite latex using polyacrylate as a core and using silicone-acrylate composite resin as a shell is synthesized by adopting a monomer pre-emulsifying process and a seed semi-continuous latex polymerization method, so that the preparation method has the advantages of stable polymerization process and convenient large-scale production. When used for preparing the latex paints of outer walls, the synthesized latex can greatly improve all performance of the latex paints, also solve the conflicts between the lowest film-forming temperature and film hardness and simultaneously realize the unification of the cost and the performance.

Owner:SHAANXI UNIV OF SCI & TECH

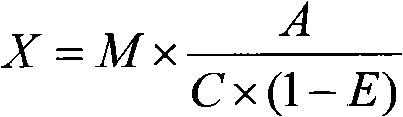

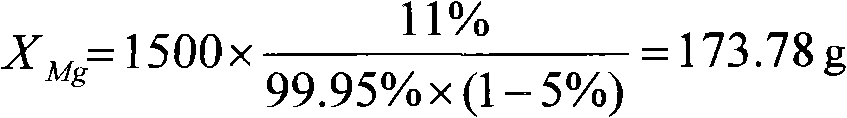

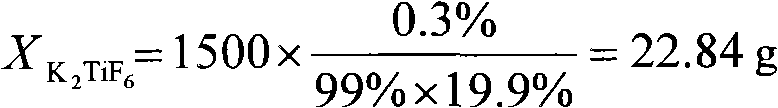

Method for preparing nano tungsten-copper-rare earth composite powder

The invention discloses a method for preparing nano tungsten-copper-rare earth composite powder, in particular a method for preparing nano tungsten-copper-rare earth composite powder by adopting gelling-spraying drying-high-temperature instant decomposition technology. In the invention, in order to improve the granularity, uniformity and compactness of the tungsten-copper composite powder and the comprehensive performance of the material, reduce the power consumption of the production and shorten the production period, micro rare earth alloy elements are added into a mixing process of the original solution of the invention to thin the crystal particles and improve the compactness of the sintered powder, and the novel high-temperature instant decomposition technology is used to restrain the growth of the crystal particles, reduce the energy consumption and copper consumption and improve the uniformity of the tungsten-copper composite powder. The method for preparing the nano tungsten-copper-rare earth composite powder has the characteristics of short production period, low energy consumption and copper consumption, improved granularity, uniformity and compactness of a product and improved comprehensive performance of the material.

Owner:YUNTAI CEMENTED CARBIDE GANZHOU

High-toughness casting aluminum alloy and preparation method thereof

Owner:宁波旭润铝业有限公司 +1

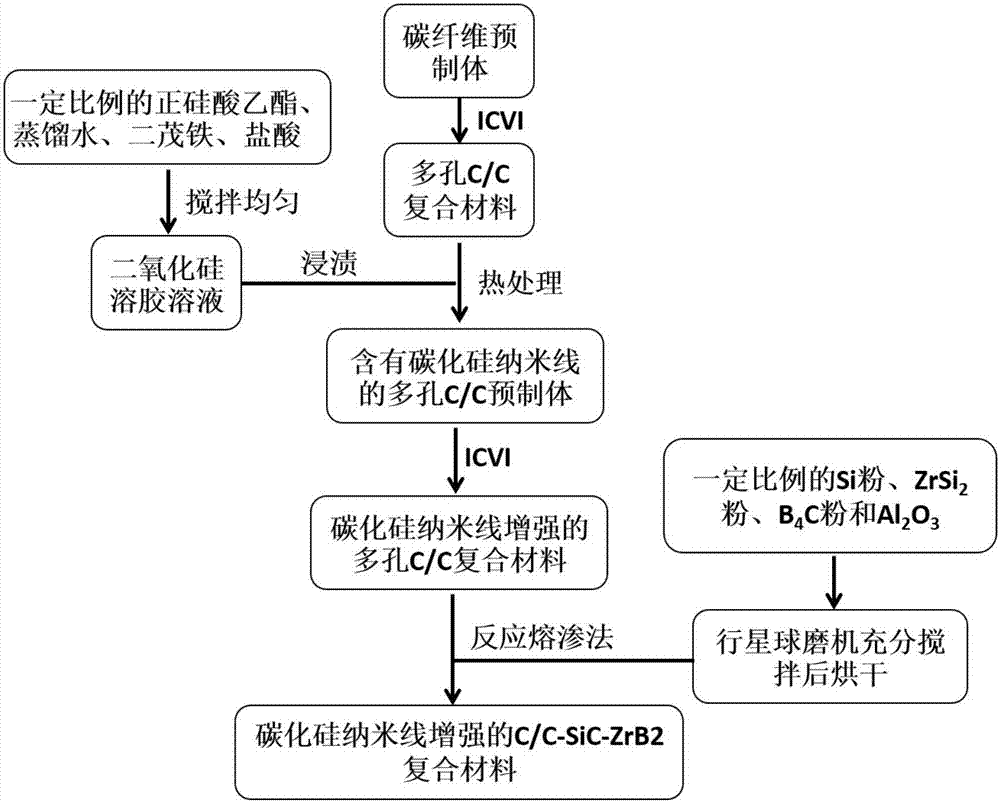

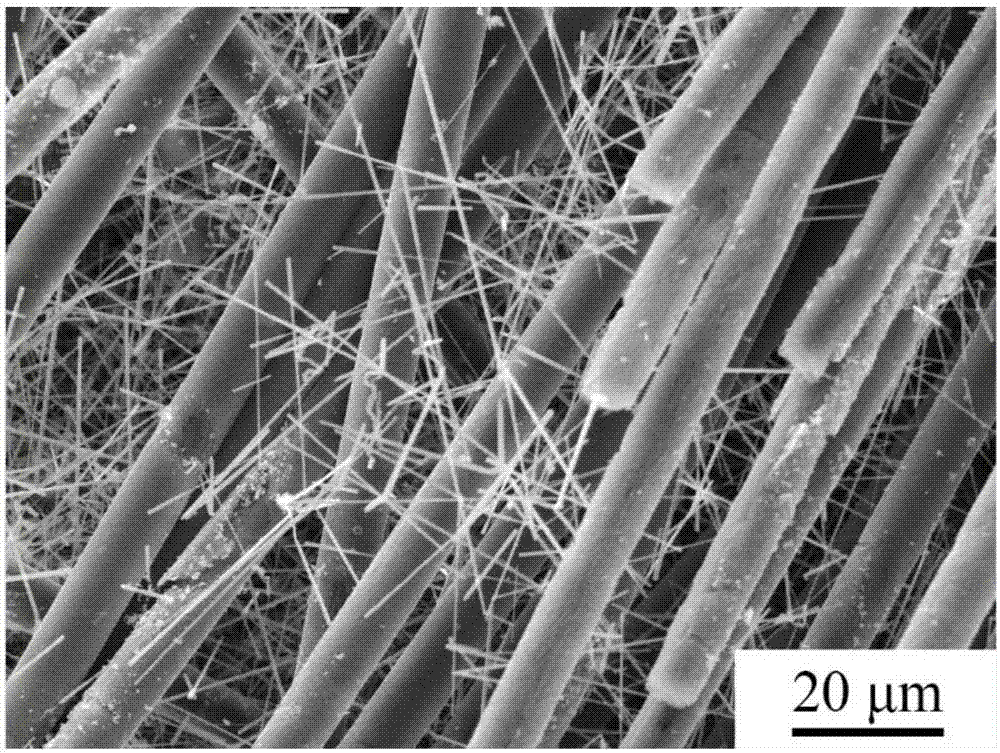

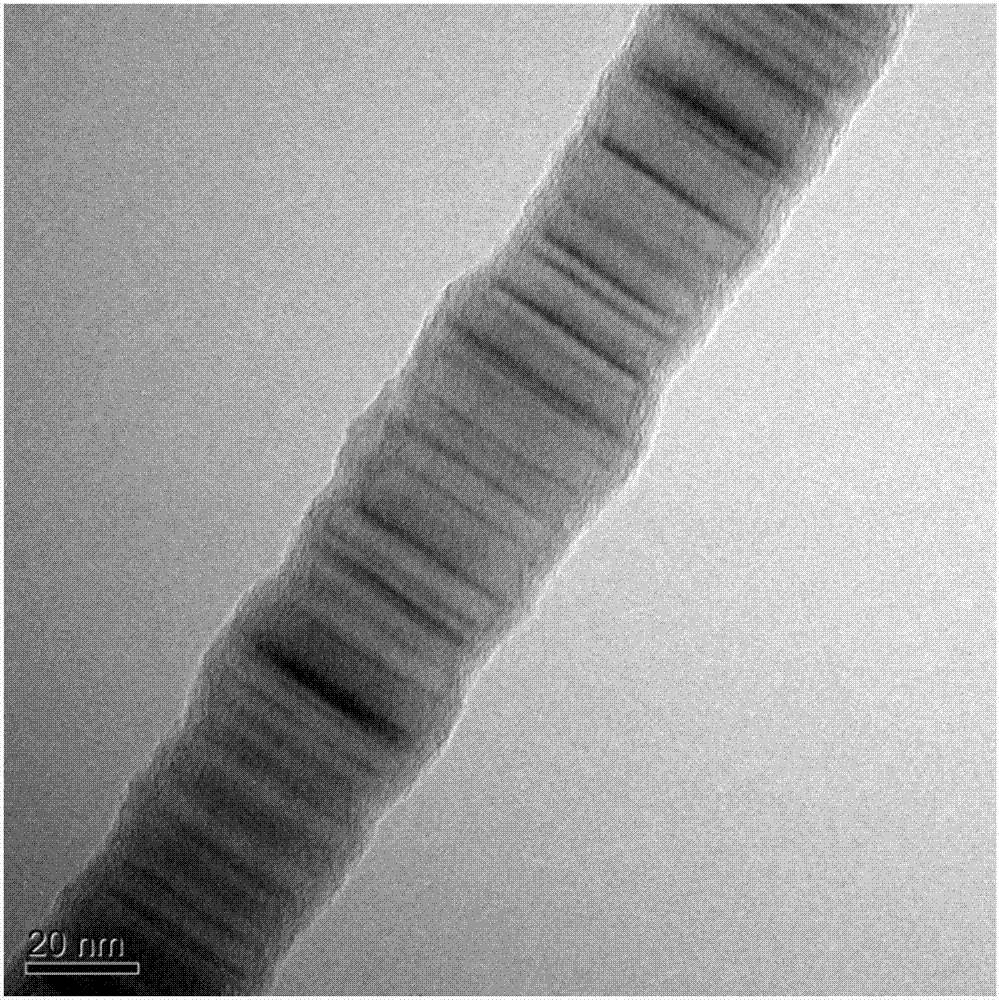

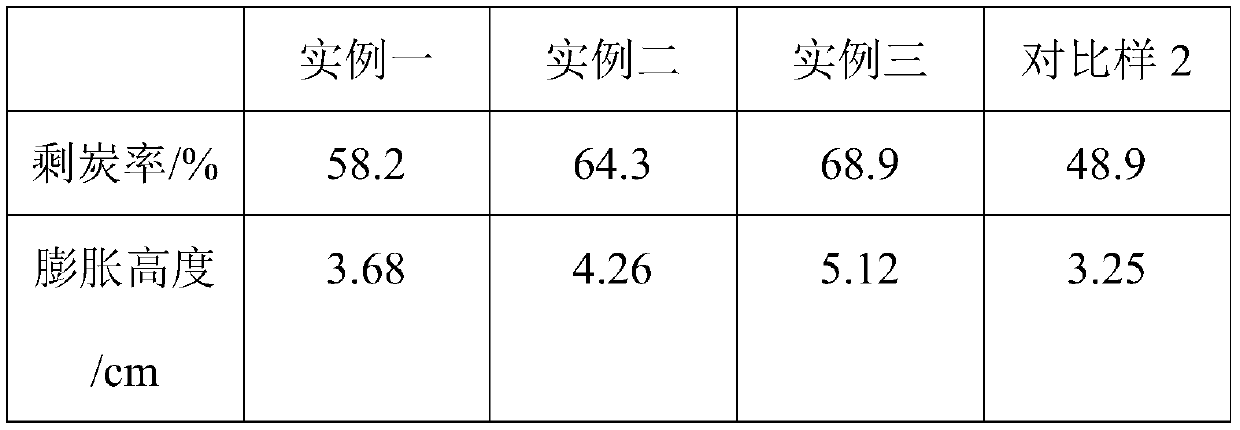

Preparation method of silicon carbide nanowire enhanced C/C-SiC-ZrB2 ceramic-based composite material

The invention relates to a preparation method of a silicon carbide nanowire enhanced C / C-SiC-ZrB2 ceramic-based composite material. A pretreated carbon fiber prefabricating body is thermally treated to obtain a silicon carbide nanowire. The silicon carbide nanowire prepared by a sol-gel carbon-thermal reaction method is evenly distributed at the inner part of a porous carbon / carbon composite material. Subsequently, pyrolytic carbon deposited in an isothermal chemical vapor deposition furnace is coated at the surface of the silicon carbide nanowire, thus the dropping, growing and rupture of the silicon carbide nanowire in the following reaction and infiltration processes are effectively avoided. A ceramic-based composite material carbon fiber, a silicon carbide nanowire and a pyrolytic carbon middle layer after reaction and infiltration are not eroded by a high-temperature metal bath and are well preserved; thus the physical performance of the composite material can be improved. Compared with the C / C-SiC-ZrB2 ceramic-based composite material without adding the silicon carbide nanowire, the bending strength and the fracture toughness property of the silicon carbide nanowire enhanced C / C-SiC-ZrB2 ceramic-based composite material are improved by 26.9-41.3% and 45.2-59.1% respectively.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

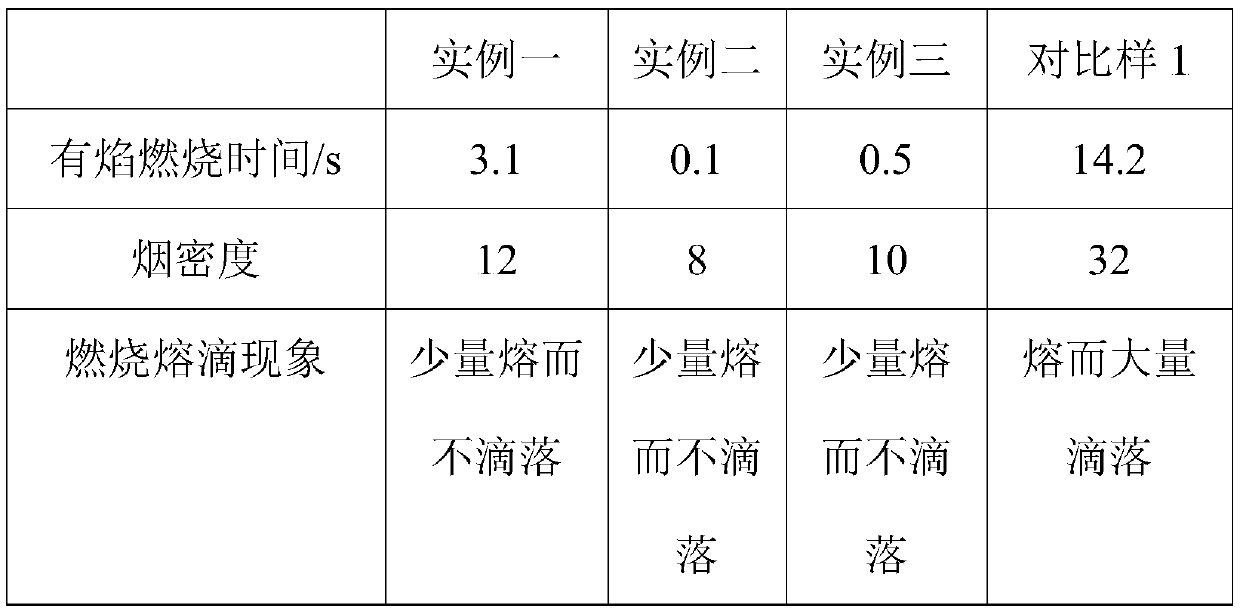

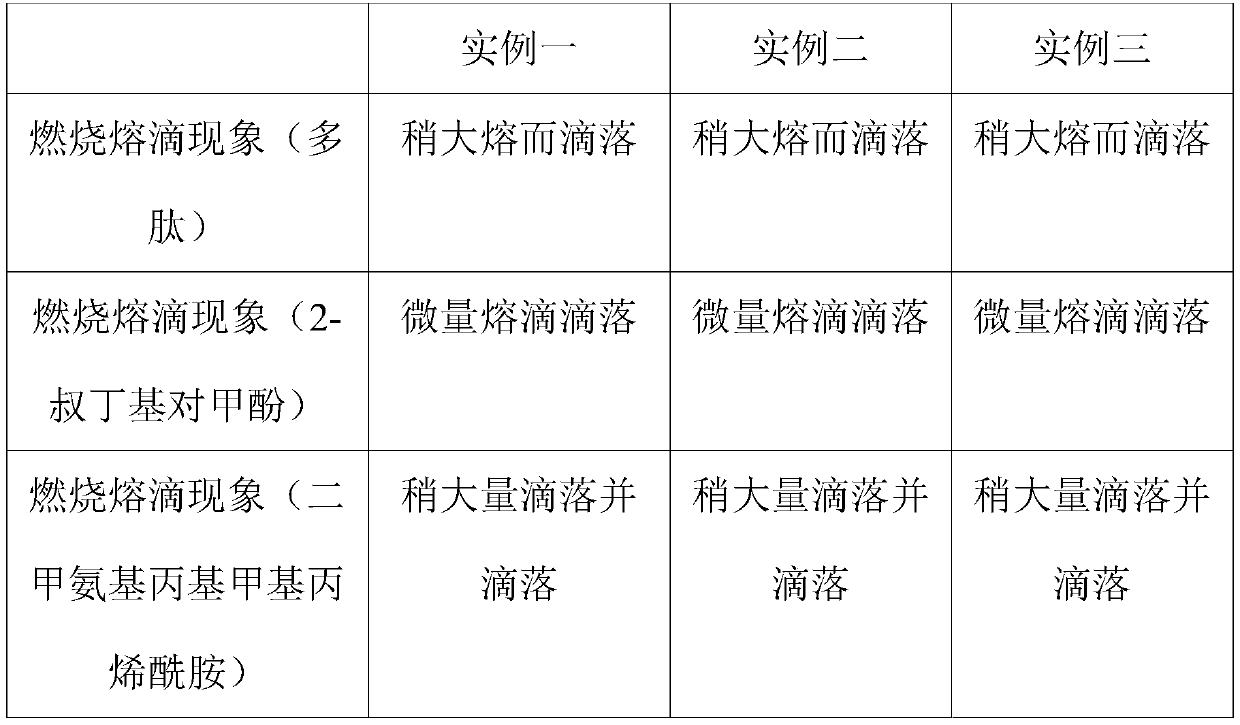

Nitrogen-phosphorus expanded type flame retardant and preparation method for application in aqueous polyurethane coating

ActiveCN110343413AImprove flame retardancyKeep the original natureFireproof paintsGroup 5/15 element organic compoundsChemistrySodium methoxide

The invention relates to preparation of a nitrogen-phosphorus expanded type flame retardant and a method for application in preparing an aqueous polyurethane coating. The method comprises the following steps: mixing dimethyl phosphate, and alkali catalysts, namely sodium methoxide and acrylamide, performing a reaction so as to obtain an intermediate, adding a charcoal formation agent and a substance A, keeping the pH value of the solution to 6.5-7.0 in the stirring process, further adding a substance B and a substance C, performing a continuous stirring reaction, and performing concentration so as to obtain the nitrogen-phosphorus expanded type flame retardant; and preparing the aqueous polyurethane coating from the nitrogen-phosphorus expanded type flame retardant. By adopting the flame retardant provided by the invention, flame can be rapidly choked, and the flame retardancy of the nitrogen-phosphorus expanded type flame retardant can be improved by releasing smoke, controlling flamecombustion time and controlling densities of charcoal layers. In addition, the nitrogen-phosphorus expanded type flame retardant is grafted with polyurethane, so that the flame retardancy of the polyurethane can be further improved.

Owner:YANTAI UNIV

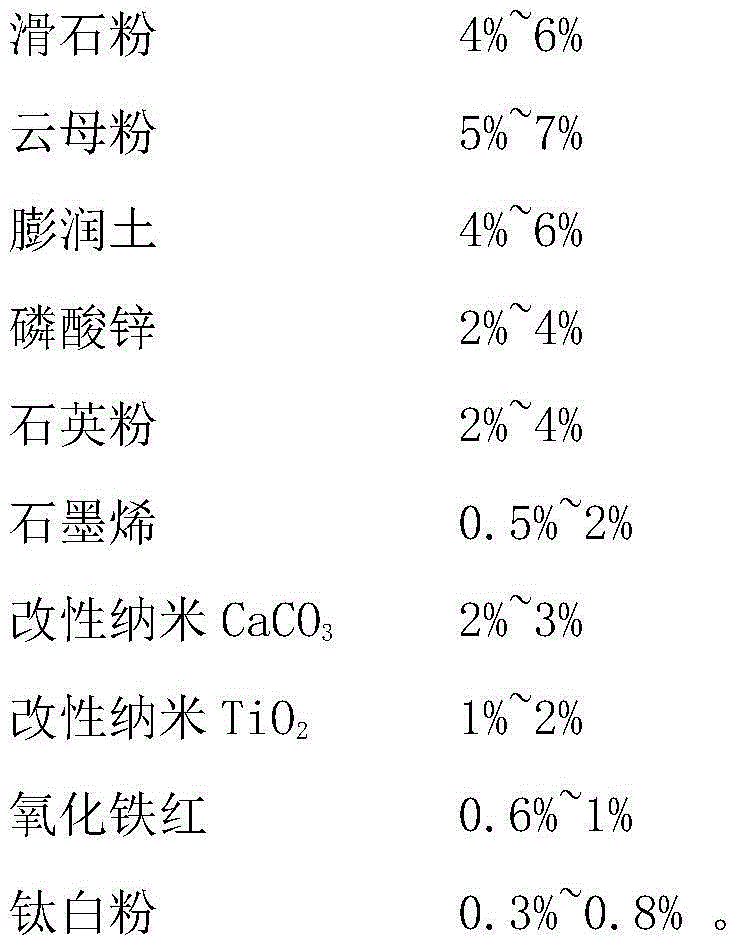

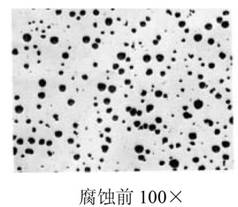

Concrete structure heavy-duty nano composite coating and protection method

The invention relates to a heavy anti-corrosion nano composite coating and a protection method for a concrete structure. The protection method belongs to a method for protecting the reinforced concrete structure. The heavy anti-corrosion nano composite coating for the concrete structure has a three-layer structure and comprises nano modified epoxy sealing coatings, a nano modified epoxy micaceous iron oxide intermediate paint and a nano modified fluorine-containing polyurethane finish or a fluorine-containing polysiloxane finish from inside to outside in turn. By adoption of the nano composite coating protection technology to perform anti-corrosion coating on the concrete structure, the anti-corrosion service life can reach more than 20 years, and the adhesion of the coating can be doubled compared with a common anti-corrosion coating; the coating has better impact resistance, sediment incrustation resistance, weathering resistance and flexibility; and the construction method is simple, and easy to popularize and apply, and has low cost.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

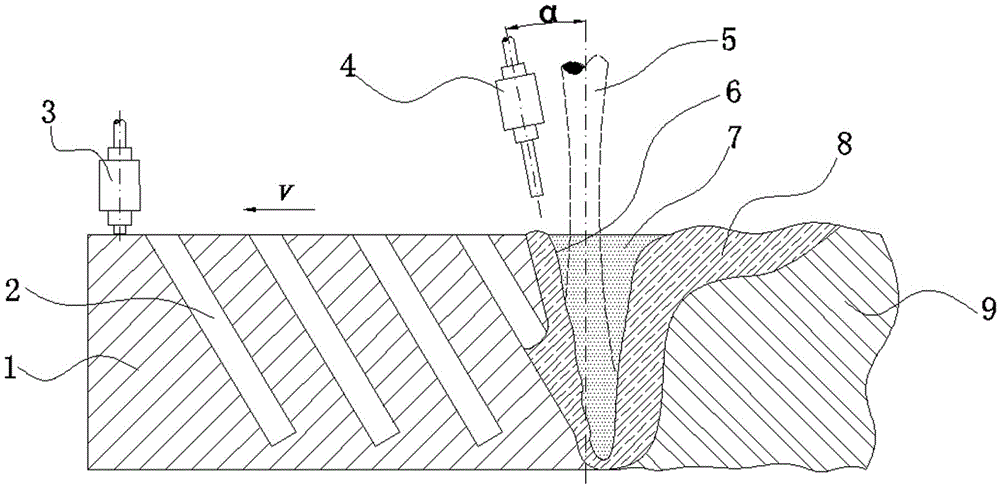

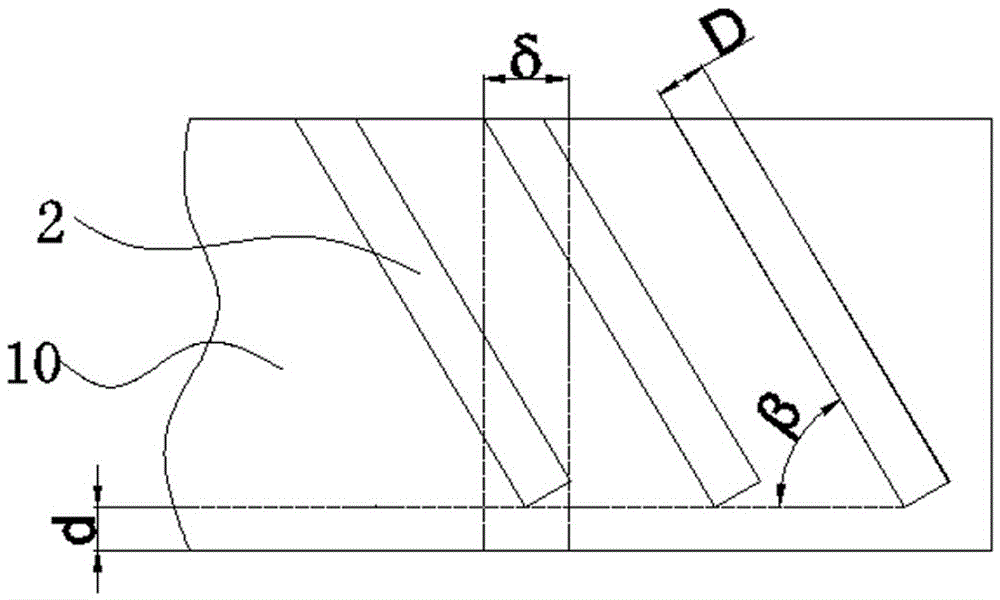

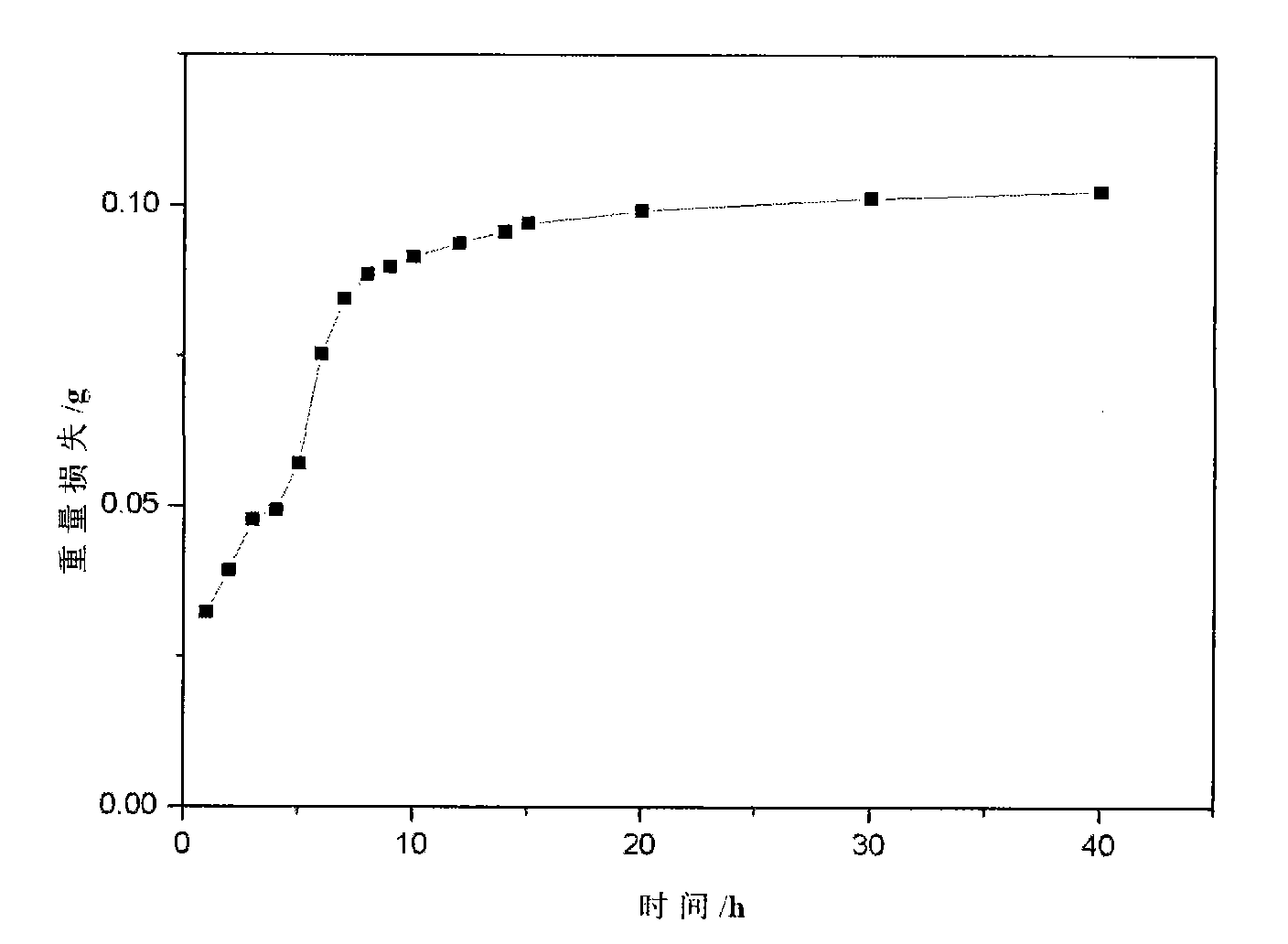

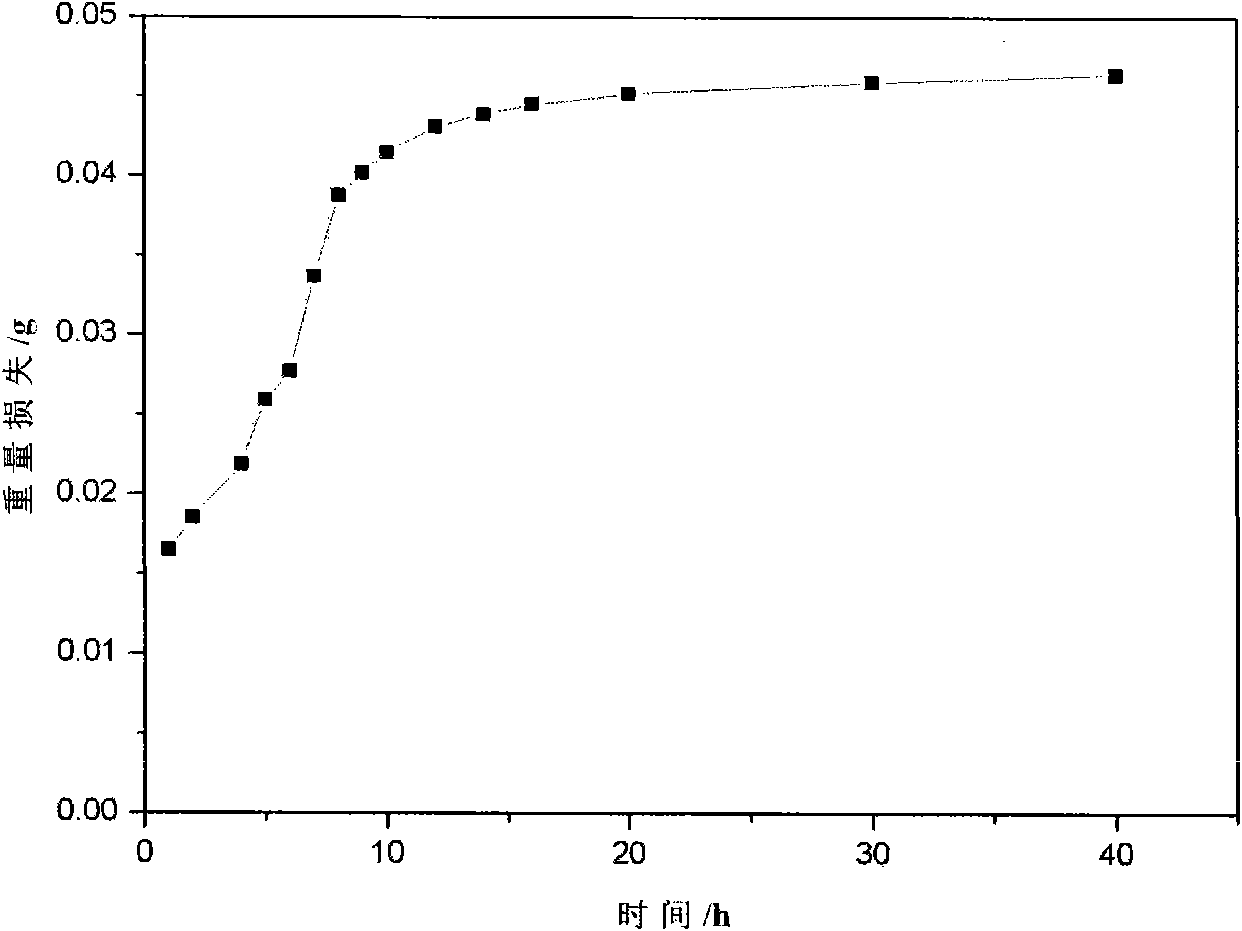

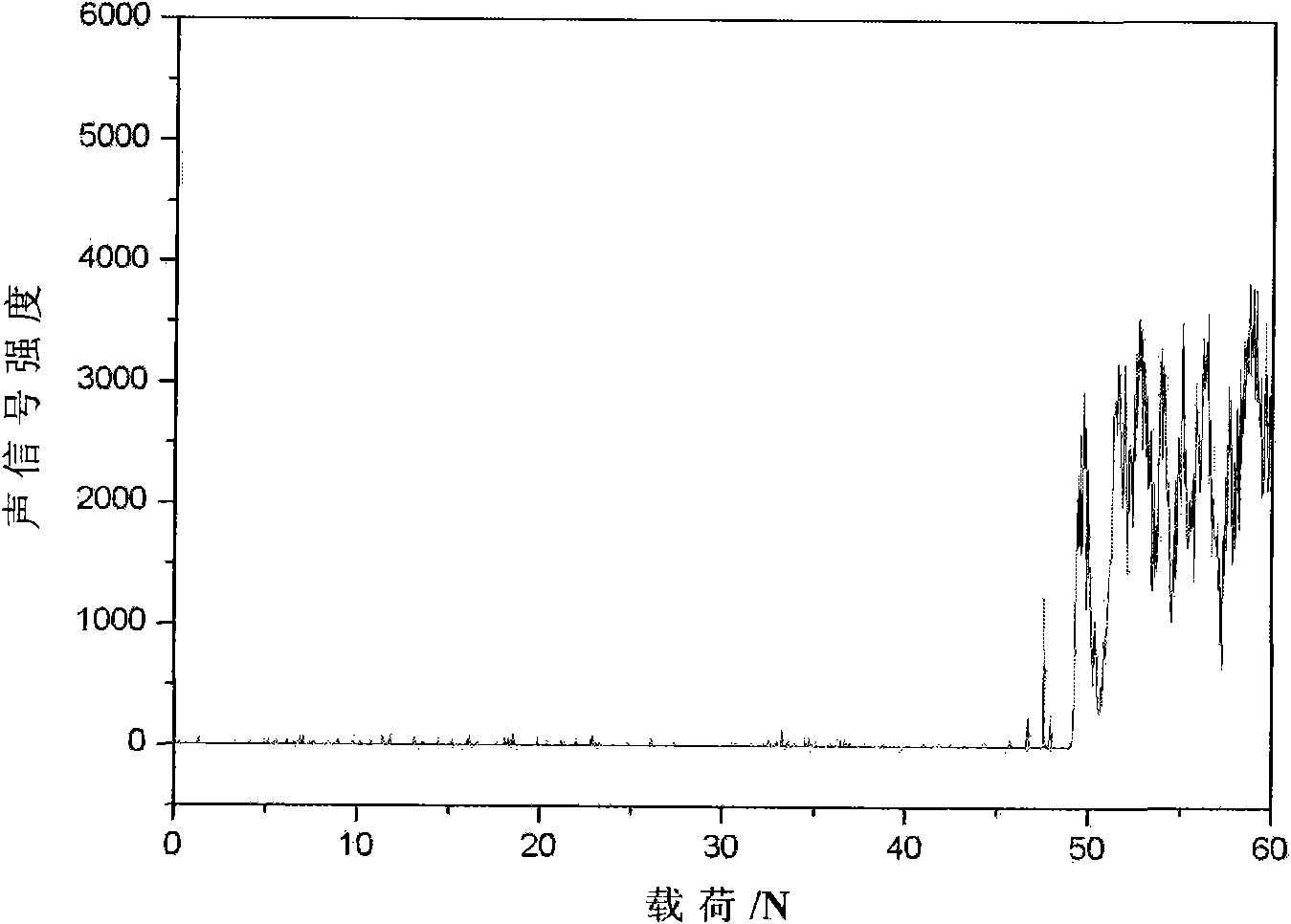

Method for deep penetration laser welding of plate under assistance of ultrasound

ActiveCN105583523AWide range of process parametersReduce crater depthWelding/soldering/cutting articlesMetal working apparatusSmall holeWeld bead

The invention relates to a method for deep penetration laser welding of a plate under the assistance of ultrasound. The method is characterized by comprising the following steps that firstly, first base metal (10) and second base metal (11) are machined to form butt joint end faces, and a series of inclined semicircular grooves are machined; secondly, the first base metal (10) and the second base metal (11) are in butt joint and are clamped, and a series of inclined blind holes are formed in a weld bead; thirdly, a first ultrasonic amplitude-changing rod (3) is pressed to the upper surface of a workpiece to be welded; fourthly, a second ultrasonic amplitude-changing rod (4) is fixed to one side of a laser welding head; fifthly, an ultrasonic generation device is started, the ultrasonic frequency is adjusted; sixthly, a laser beam (5) perpendicularly irradiates the upper surface of the workpiece, and the welding process is completed under continuous ultrasonic vibration; and seventhly, after welding is completed, ultrasonic vibration is maintained for 1-2 minutes. In the method, due to the pre-formed inclined blind holes and ultrasonic vibration, weld joint root leakage caused by molten pool downward flowing driven by local evaporation back flushing pressure of the front edge walls of the small holes is avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Enamel and preparation method thereof

The invention provides enamel, which comprises a substrate and a ceramic glaze layer enamel-fired on the substrate, wherein the ceramic glaze layer is prepared by firing ceramic glaze powder which contains 60 and 90 weight percent of glass frit, 5 to 18 weight percent of crushed sand, 3 to 12 weight percent of clay, 0.3 to 5 weight percent of borax and 0.3 to 5 weight percent of soda ash. The enamel has excellent physiochemical performance such as low sintering temperature, corrosion resistance and the like. The method for preparing the enamel has the advantages of obtaining an enamel coating with high bonding strength and acid and alkali corrosion resistance at lower sintering temperature, solving the problem of substrate deformation, saving energy, and reducing production cost.

Owner:CHERY AUTOMOBILE CO LTD

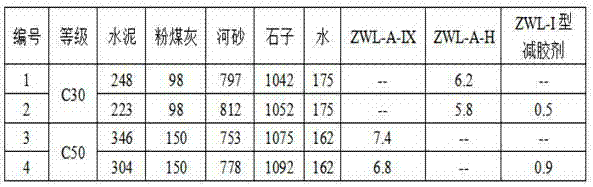

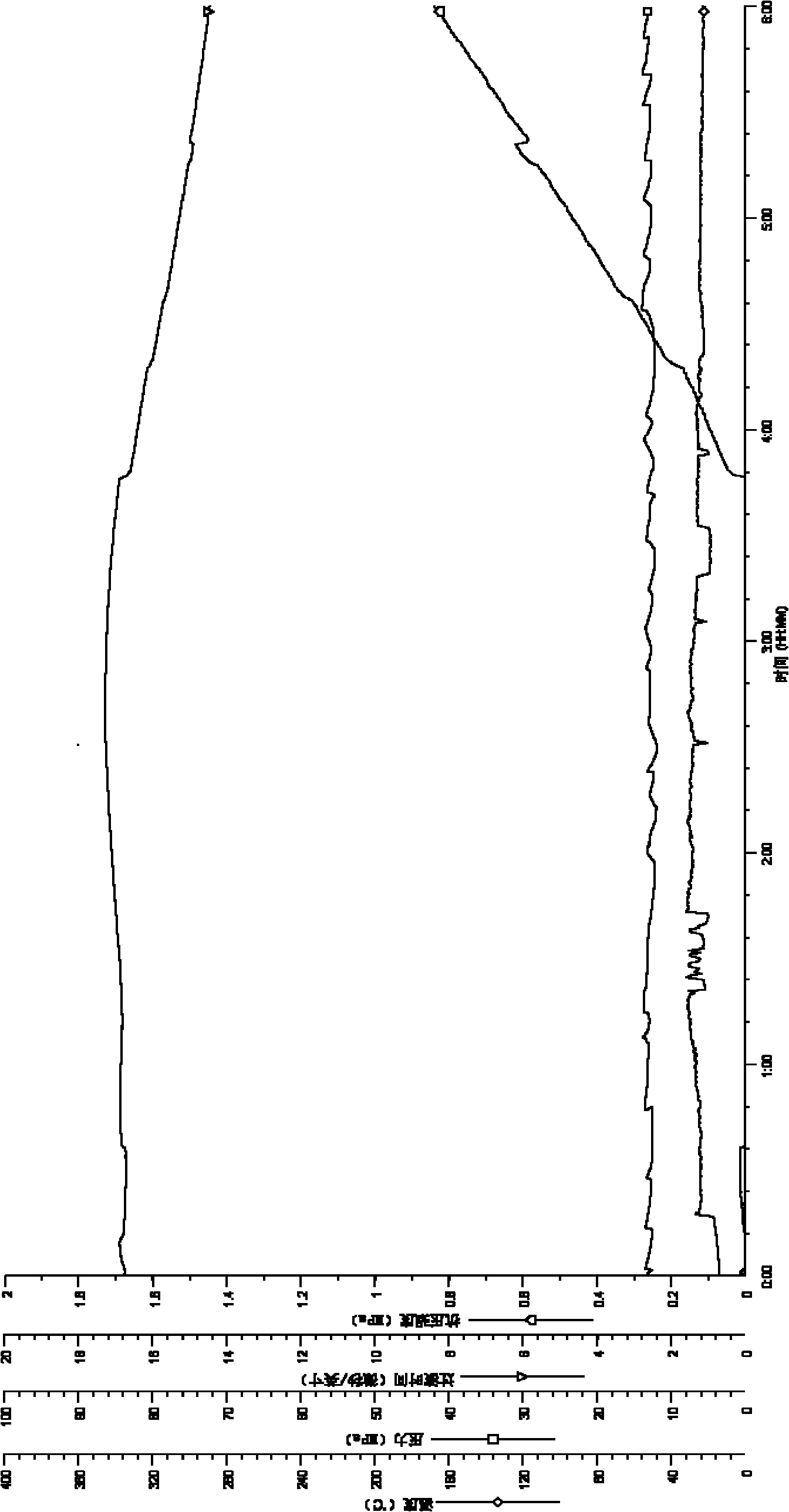

Concrete gel reducing agent

ActiveCN104119014ARefined particlesImprove initial flow propertiesThree-dimensional spaceUltimate tensile strength

The invention relates to a concrete gel reducing agent which comprises the following formula components in percentage by weight: 1%-3% of phosphonic acid ramifications A, 2%-5% of hydroxy aromatic compounds B, 8%-13% of alkylamine C and the balance of water, wherein the total amount of the phosphonic acid ramifications A, the hydroxy aromatic compounds B and the alkylamine C is 15%. A part of organic substances contained in the concrete gel reducing agent used as a novel concrete additive have molecular structures with three-dimensional spaces and have higher micro dispersion property on cement. If the gel reducing agent is doped into concrete, cement particles are sufficiently refined under the condition that the usage amount of the cement is reduced, the initial flowing property of the concrete is improved, and the hydration degree of a cement mineral is enhanced by promoting the hydration of ferrite which is more difficult to hydrate, so that the early strength is enhanced, the later strength of the cement is effectively excited and the compactness of the concrete is enhanced.

Owner:浙江五龙新材股份有限公司

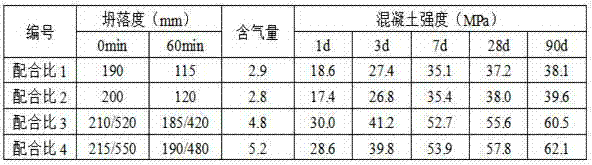

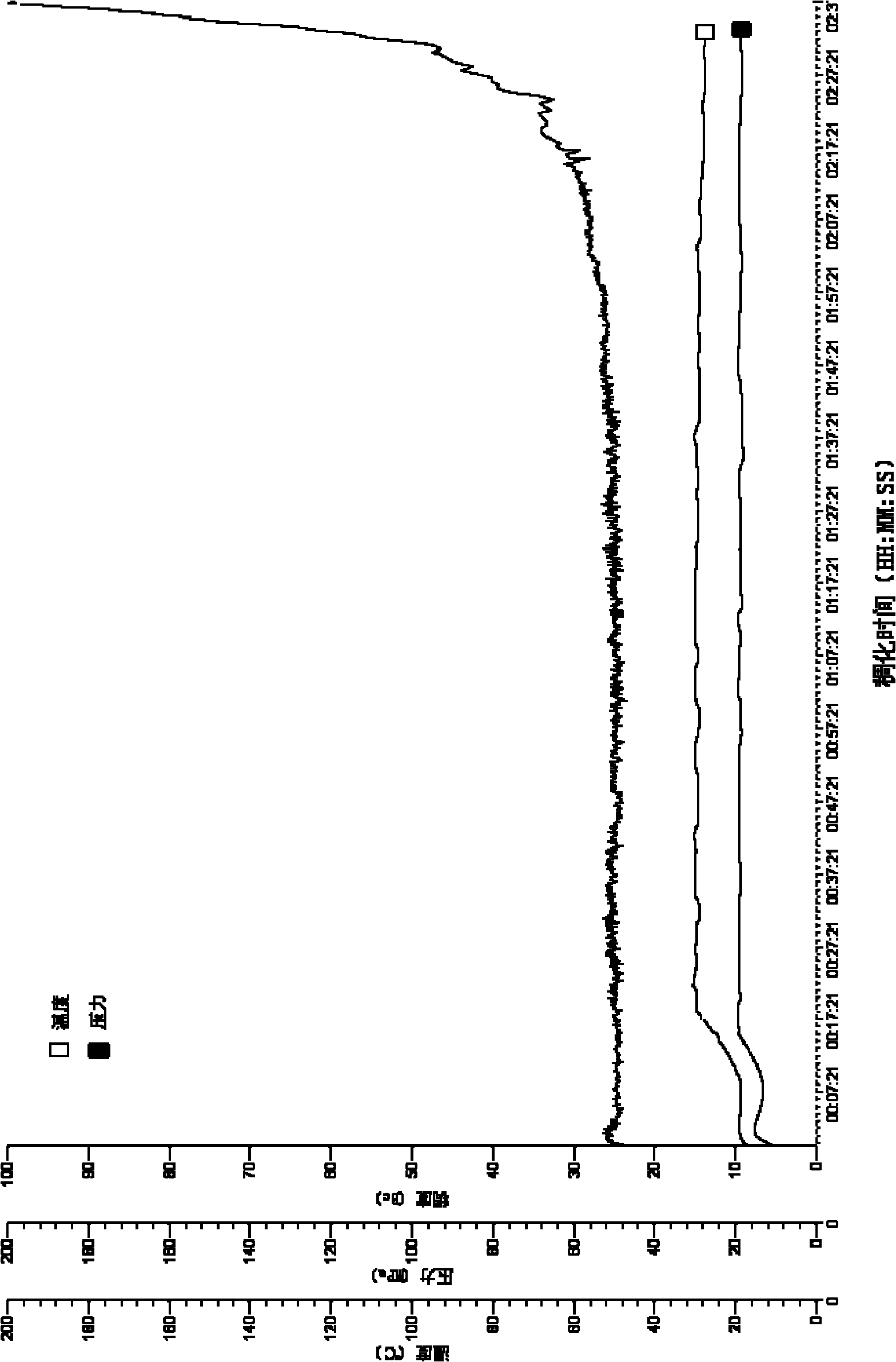

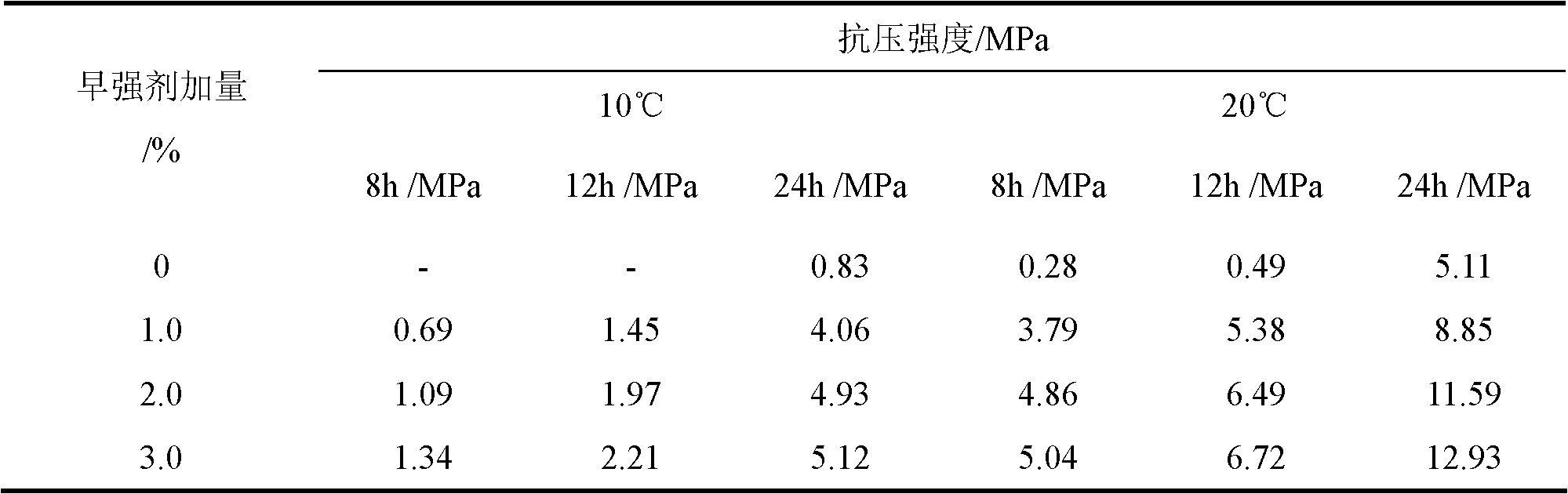

Deepwater cementing low-temperature early strength agent

InactiveCN101864285APromotes hydration processImprove compactnessDrilling compositionTriisopropanolamineCement paste

The invention relates to a deepwater cementing low-temperature early strength agent. The low-temperature early strength agent comprises the following components in percentage by weight: 33 to 66 percent of alkali metal bromides, 6 to 16 percent of sodium metaaluminate, 15 to 35 percent of alkali metal hydroxides, 8 to 15 percent of silicon dioxide and 0.8 to 1.5 percent of alcamines organics, wherein the alkali metal bromides are a mixture of one, two or more of NaBr, KBr and LiBr; the alkali metal hydroxides are NaOH, KOH or a mixture of the NaOH and KOH; and the alcamines organics are triethanolamine, triisopropanolamine or a mixture of the triethanolamine and triisopropanolamine. The deepwater cementing low-temperature early strength agent has small influence on rheological behaviour of cement paste at low temperature, can prompt the cement paste to be solidified rapidly at low temperature and reach higher early strength, shortens the thickening time of the cement paste at lower temperature and can well meet the requirements of the cementing construction of a surface casing under the conditions of low temperature, shallow gas and the like.

Owner:SOUTHWEST PETROLEUM UNIV

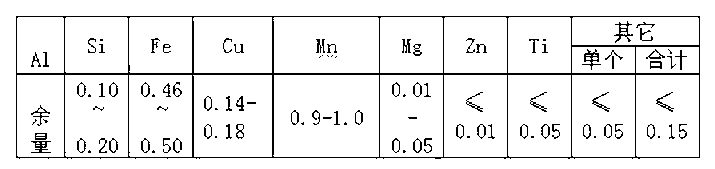

Alloy cathode foil which is special for capacitor and produced by continuous roll casting method and preparation method

ActiveCN102796922AReduce consumptionShort production processElectrolytic capacitorsMetal rolling arrangementsAlloyCapacitor

The invention relates to alloy cathode foil which is special for capacitors and produced by a continuous roll casting method, and the alloy cathode foil is characterized in that the foil comprises the following chemical components by mass fraction: 0.10-0.20% of Si, 0.46-0.50% of Fe, 0.14-0.18% of Cu, 0.9-1.0% of Mn, 0.01-0.05% of Mg, not more than 0.01% of Zn, not more than 0.05% of Ti, and the balance of Al. The preparation method comprises the following steps: a. producing a roll-casting roll; b. rolling the roll-casting roll, that is, roll-casting a 7.5 mm roll-casting plate into 5.0 mm, performing uniform annealing, roll casting to orderly obtain a dimension of 2.5 mm, 1.25 mm, 0.7 mm, and 0.5 mm, performing intermediate annealing, roll casting to orderly obtain a dimension of 0.24 mm, 0.15 mm, 0.09 mm, and 0.062 mm so as to obtain the finished product. The method shortens the production flow, and simplifies the production process, and the obtained aluminium foil has good quality.

Owner:新疆天山盈达碳素有限公司

Silicon carbide reinforced aluminum-based composite material and preparation method thereof

The invention discloses a silicon carbide reinforced aluminum-based composite material and a preparation method thereof. The silicon carbide reinforced aluminum-based composite material is prepared from the following raw materials in percentage by volume: 20 to 25 percent of 325-mesh silicon carbide powder and the balance of 500-mesh Al-30Si alloy powder. According to the silicon carbide reinforced aluminum-based composite material, the silicon carbide powder and the Al-30Si alloy powder which have properly matched particle sizes are easily combined closely in the pressing and sintering process, defects such as air holes and cracks are avoided and the compactness of the composite material can be improved. In addition, by the preparation method of heating, pressurizing and keeping temperature stepwise according to set programs under the vacuum condition, slowly cooling together with a furnace to room temperature under the vacuum and high pressure conditions and removing the pressure, the metallurgical bonding of the reinforcement and the matrix is further improved, the defects such as air holes and cracks are avoided and the performance is high.

Owner:HENAN UNIV OF SCI & TECH

Drilling fluid for shale hydrocarbon reservoir exploration

InactiveCN104610941AInhibition of hydrationPrevent collapseDrilling compositionWell drillingPotassium silicate

The invention provides a drilling fluid for shale hydrocarbon reservoir exploration. The drilling fluid is based on water, and comprises 4-6wt% of bentonite, 2-5wt% of potassium silicate, 0.2-0.5wt% of a coating inhibitor, 0.2-1.5wt% of a flow pattern regulator, 4-6wt% of a fluid loss additive, 2-3wt% of a shale caving inhibitor, 2-3wt% of a plugging agent, 0.5-1wt% of a filter cake surface modifier, 2-4wt% of a lubricant and 0.4-0.6wt% of a pH value regulator. The drilling fluid has the characteristics of good plugging property, strong inhibition, good lubricity and stable high temperature performances to shale hydrocarbon reservoir stratums, and is suitable for the exploration of shale hydrocarbon reservoirs.

Owner:CHINA PETROCHEMICAL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com