Stainless heat-resistant alloy steel seamless steel tube and preparation method thereof

A technology of seamless steel pipe and production method, which is applied to furnace types, furnaces, electric furnaces, etc., can solve the problems of restricting the production and development of ultra-supercritical power station boilers, untimely supply, insufficient resources, etc., and achieves stable and qualified chemical composition. The effect of preventing secondary pollution and accurate process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with embodiment.

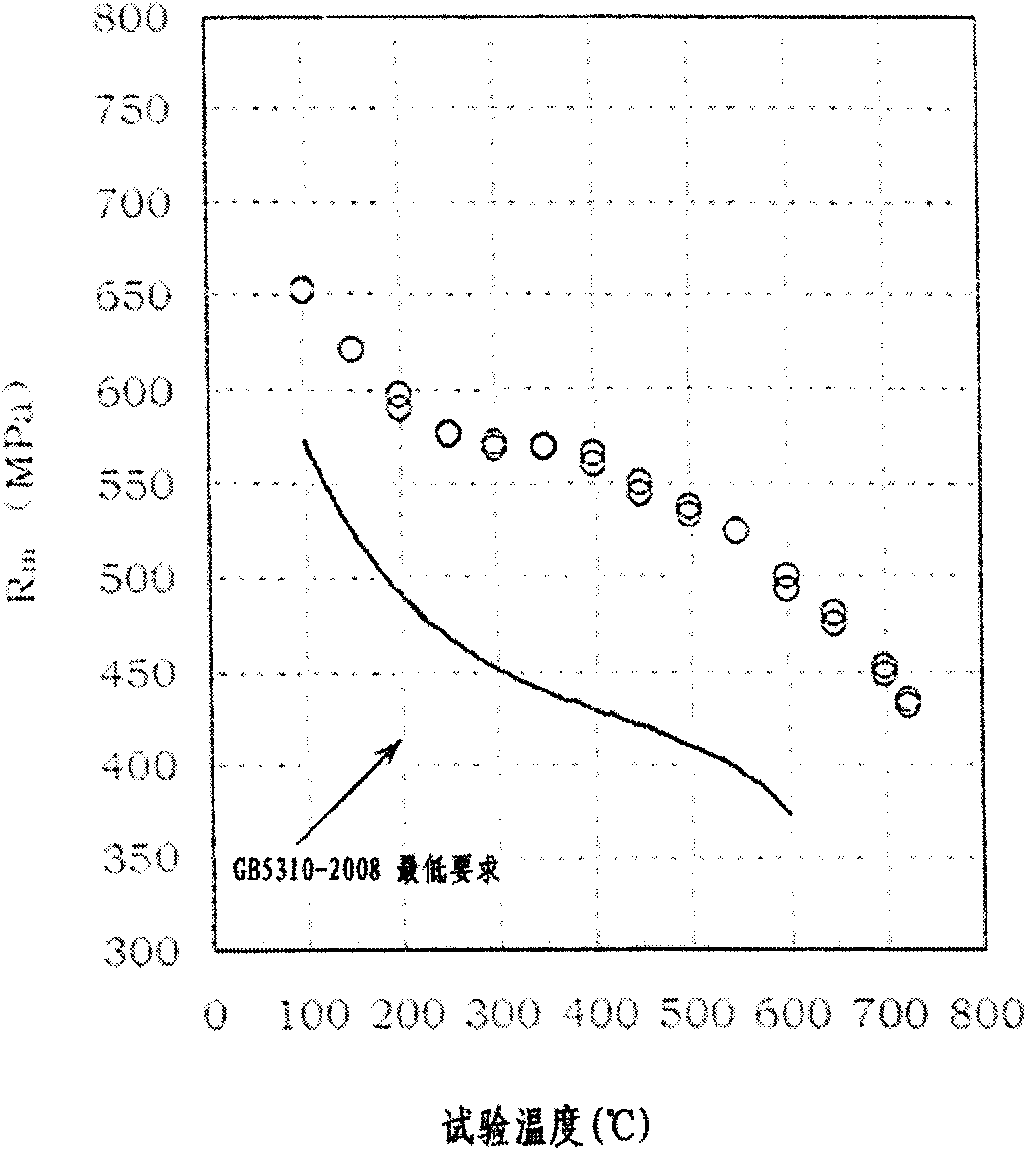

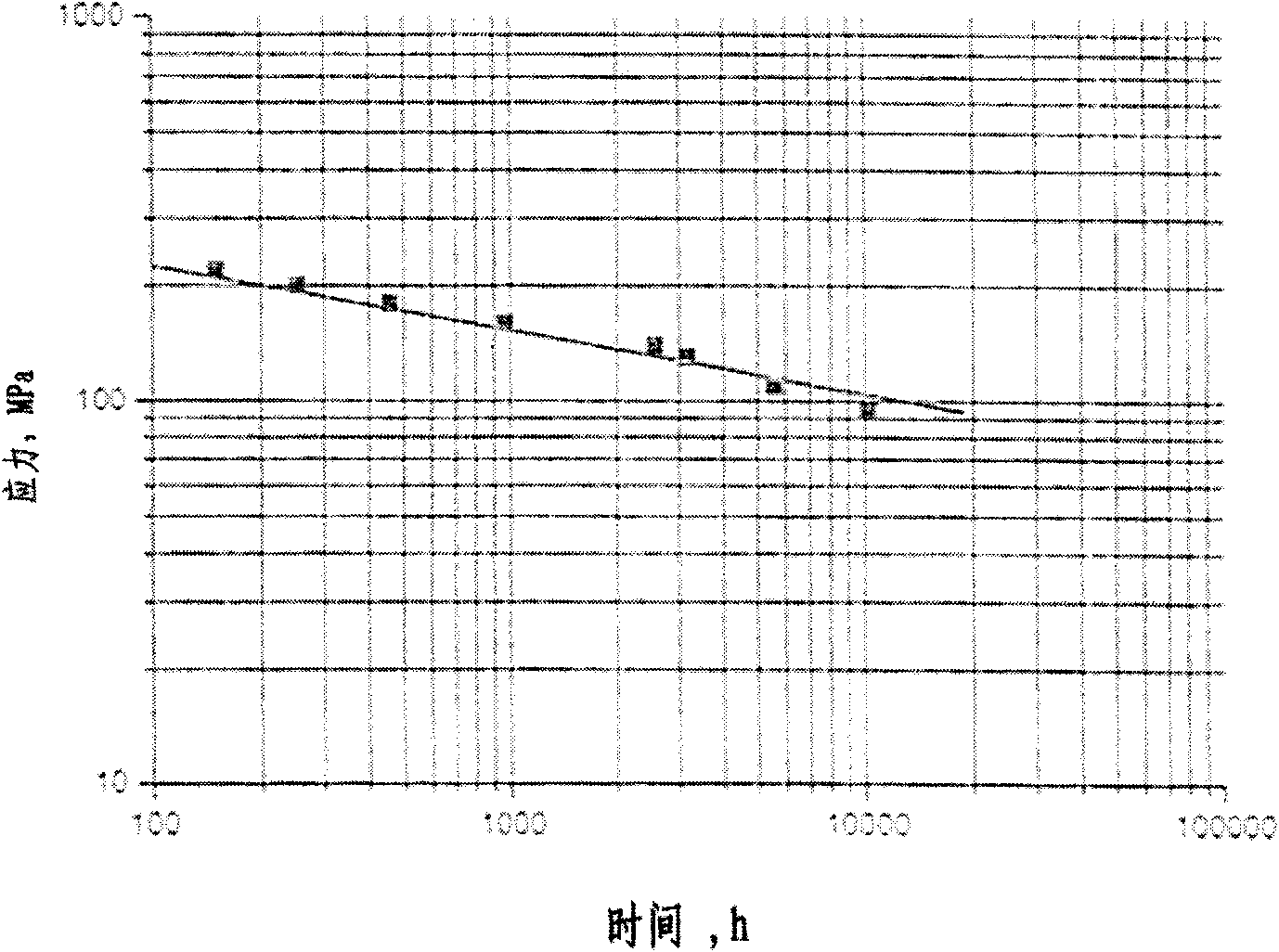

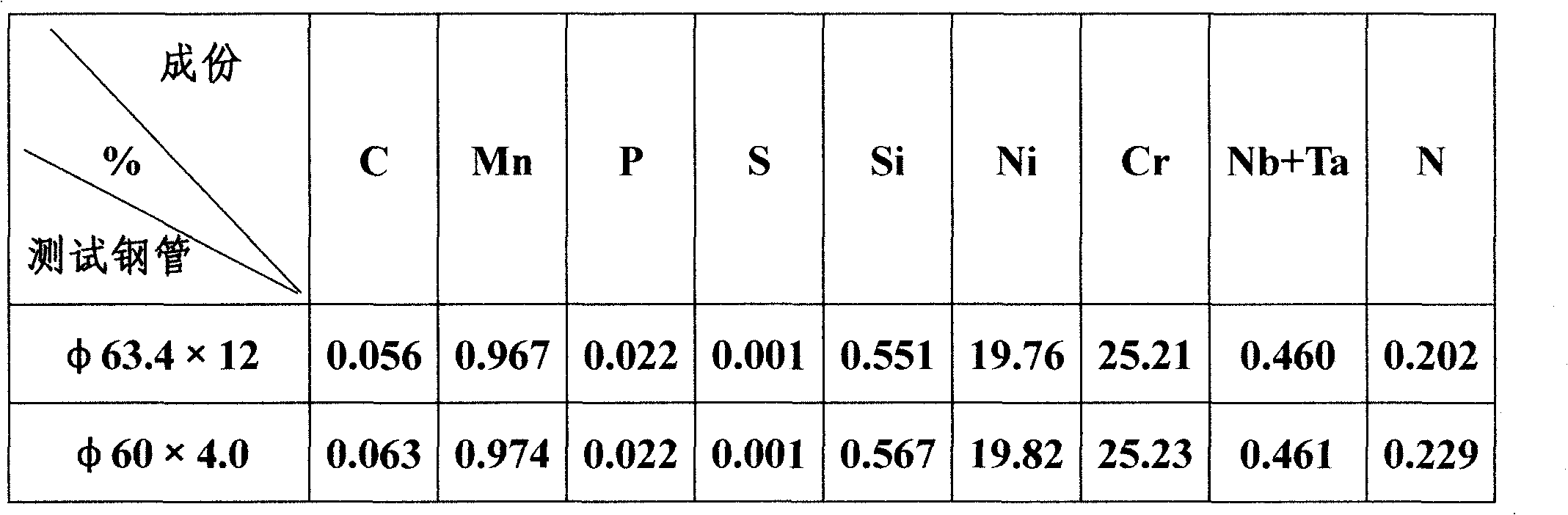

[0018] A stainless heat-resistant alloy steel seamless steel pipe that is especially suitable for ultra-supercritical power plant boilers. The used pipe billet bar is Ф210mm, and its chemical composition is calculated by weight percentage: C 0.04~0.10, Si≤0.75, Mn ≤2.00, P≤0.03, S≤0.03, Ni 17.00~23.00, Cr 24.00~26.00, Nb+Ta0.20~0.60, N 0.15~0.35, the balance is Fe and unavoidable trace elements.

[0019] The production method of the stainless heat-resistant alloy steel seamless steel pipe comprises the following process steps:

[0020] Tube billet bar → acceptance → straightening → cutting head and tail → peeling → segmentation → drilling → end face processing → grinding → cleaning → preheating → primary heating → lubrication → reaming → secondary heating → lubrication → extrusion Mother pipe → water quenching → straightening → sawing → pickling → inspection → rough cold rolling → oil removal → so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com