Alloy cathode foil which is special for capacitor and produced by continuous roll casting method and preparation method

A kind of alloy negative electrode, capacitor technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

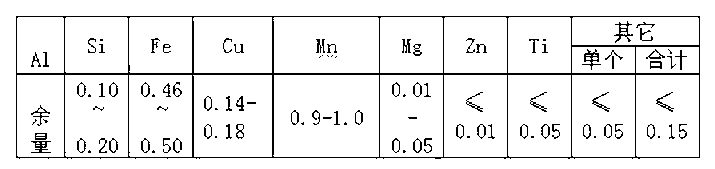

[0038] Example 1: 0.041mm thick alloy negative electrode foil for capacitors

[0039] a. Production of cast-rolled coils

[0040] The chemical composition mass fraction of the cast-rolled coil is as follows: Si: 0.10%, Fe: 0.46%, Cu: 0.18%, Mn: 0.9%, Mg: 0.01%, Zn: 0.01%, Ti: 0.05%, and the balance is Al;

[0041] The production process of cast-rolled coils is: furnace preparation→furnace material preparation→furnace loading→melting→stirring and slag removal→composition adjustment→in-furnace treatment (first refining)→converter and standing (second refining)→removal Air box degassing and slag removal → filter box dual-channel dual-stage ceramic filter plate filter slag removal → casting and rolling into cast-rolled coils, and the regulations on waste in the furnace charge preparation are: use 1XXX series pure aluminum group for waste, and the total input amount of waste ≤35% (of which secondary waste should be ≤30%), primary aluminum ingots ≥65%.

[0042] b. Cold foil rolli...

Embodiment 2

[0045] Example 2: 0.038mm thick alloy negative electrode foil for capacitors

[0046] a. Production of cast-rolled coils

[0047] The chemical composition mass fraction of the cast-rolled coil is as follows: Si: 0.13%, Fe: 0.48%, Cu: 0.15%, Mn: 0.93%, Mg: 0.02%, Zn: 0.005%, Ti: 0.03%, and the balance is Al;

[0048] The production process of cast-rolled coils is: furnace preparation→furnace material preparation→furnace loading→melting→stirring and slag removal→composition adjustment→in-furnace treatment (first refining)→converter and standing (second refining)→removal Air box degassing and slag removal → filter box dual-channel dual-stage ceramic filter plate filter slag removal → casting and rolling into cast-rolled coils, and the regulations on waste in the furnace charge preparation are: use 1XXX series pure aluminum group for waste, and the total input amount of waste ≤35% (of which secondary waste should be ≤30%), primary aluminum ingots ≥65%.

[0049] The length of th...

Embodiment 3

[0053] Example 3: 0.027mm thick alloy negative electrode foil for capacitors

[0054] a. Production of cast-rolled coils

[0055] The mass fractions of the chemical components of the cast-rolled coil are as follows: Si: 0.16%, Fe: 0.49%, Cu: 0.16%, Mn: 0.95%, Mg: 0.03%, Zn: 0.005%, Ti: 0.03%, and the balance is Al;

[0056] The production process of cast-rolled coils is: furnace preparation→furnace material preparation→furnace loading→melting→stirring and slag removal→composition adjustment→in-furnace treatment (first refining)→converter and standing (second refining)→removal Air box degassing and slag removal → filter box dual-channel dual-stage ceramic filter plate filter slag removal → casting and rolling into cast-rolled coils, and the regulations on waste in the furnace charge preparation are: use 1XXX series pure aluminum group for waste, and the total input amount of waste ≤35% (of which secondary waste should be ≤30%), primary aluminum ingots ≥65%.

[0057] The leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com