Patents

Literature

219results about How to "Eliminate shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling center porosity of large section heavy rail steel casting blank

The invention relates to the technical field of ferrous metallurgy, in particular to a method for controlling the center porosity of a large section heavy rail steel casting blank. The method comprises the following steps of controlling the superheat degree of medium-package molten steel; controlling the pulling speed in the normal pouring process; pressing down the final solidification end in the pouring process; setting the stirring strength and stirring frequency of electromagnetic stirring of a crystallizer; setting the stirring strength and stirring frequency of electromagnetic stirring at the final solidification end; controlling the cooling water yield and the secondary cooling specific water yield of the crystallizer. The center porosity of the large section heavy rail steel casting blank produced by adopting the method can be effectively controlled, and the remaining internal quality of the casting blank can be effectively guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

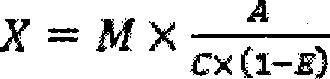

Aluminum-silicon series deforming alloy and manufacturing method thereof

The present invention discloses aluminum silicon deformable aluminum alloy and the preparation method thereof. According to the weight percentages, the alloy contains 9.0-12.6 percent of silicon, 1.5-4.0 percent of copper, 0.3-0.6 percent of magnesium, 0.1-3.5 percent of bismuth, less than 0.30 percent of iron, less than 0.20 percent of zinc, less than or equal to 0.15 percent of impurity, and aluminum as the residual. The raw material is molten and fined in a reflecting smelting furnace, after Al-Sr intermediate alloy modification to the alloy liquid, cast rods are obtained through semi continuous casting, and after hot extrusion and deformation to the cast rods, the aluminum silicon deformable aluminum alloy is produced through forging and T6 heat treatment. After adding the element bismuth into the alloy, the present invention greatly enhances the wear-resisting performance of the alloy, leads the alloy to have self lubricating property, prolongs the service life of the product produced with the alloy, reduces the use cost, and leads the alloy to have the tensile strength of above 390 MPa, the elongation rate after breaking of 6 percent, and the hardness degree of 136-141 HB. The present invention is mainly used for producing vehicle components of wheels, pistons, bearings, and two-side swash plates of vehicles and motorcycles which have high demands on the intensity, the toughness and the abrasion resistance.

Owner:李贞宽 +1

Crack controlling means for laser deposition formed metal parts

InactiveCN1737197AImprove coagulation stateImprove liquidityMetallic material coating processesLaser beam welding apparatusClosed loop feedbackClosed loop

The invention relates to a crack-controlling method of metal parts by laser melting formation in laser material processing domain, which comprises closed-loop control of fused bath temperature, which comprises the two specific steps of exerting closed-loop feedback control on fused bath temperature by using optical imaging system and PID control device with calorific radiation transmitted from melting zone and adjusting horsepower of laser, and introduction of ultrasonic vibration, which comprises the specific steps of introducing ultrasonic vibration under the piece of work when forming by laser melting. The invention can deduce residual stress and crack, improve structure and can be used in multiple relative domains such as forming, manding and surface peening by laser melting.

Owner:SHANGHAI JIAO TONG UNIV

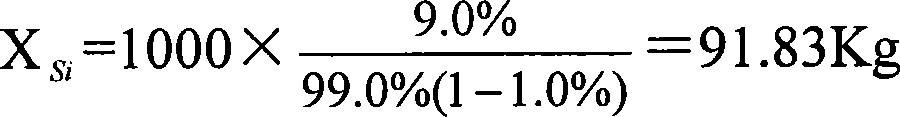

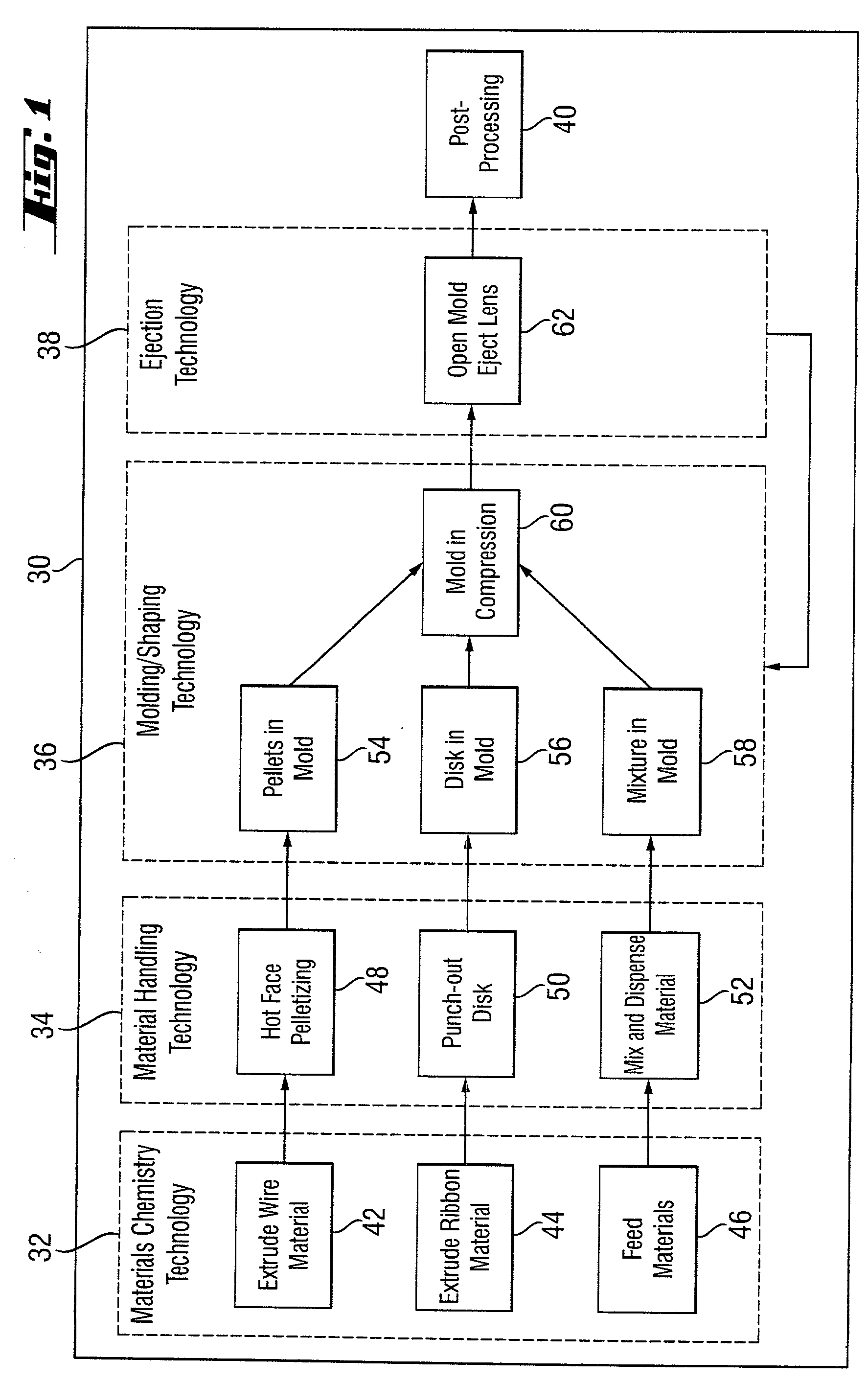

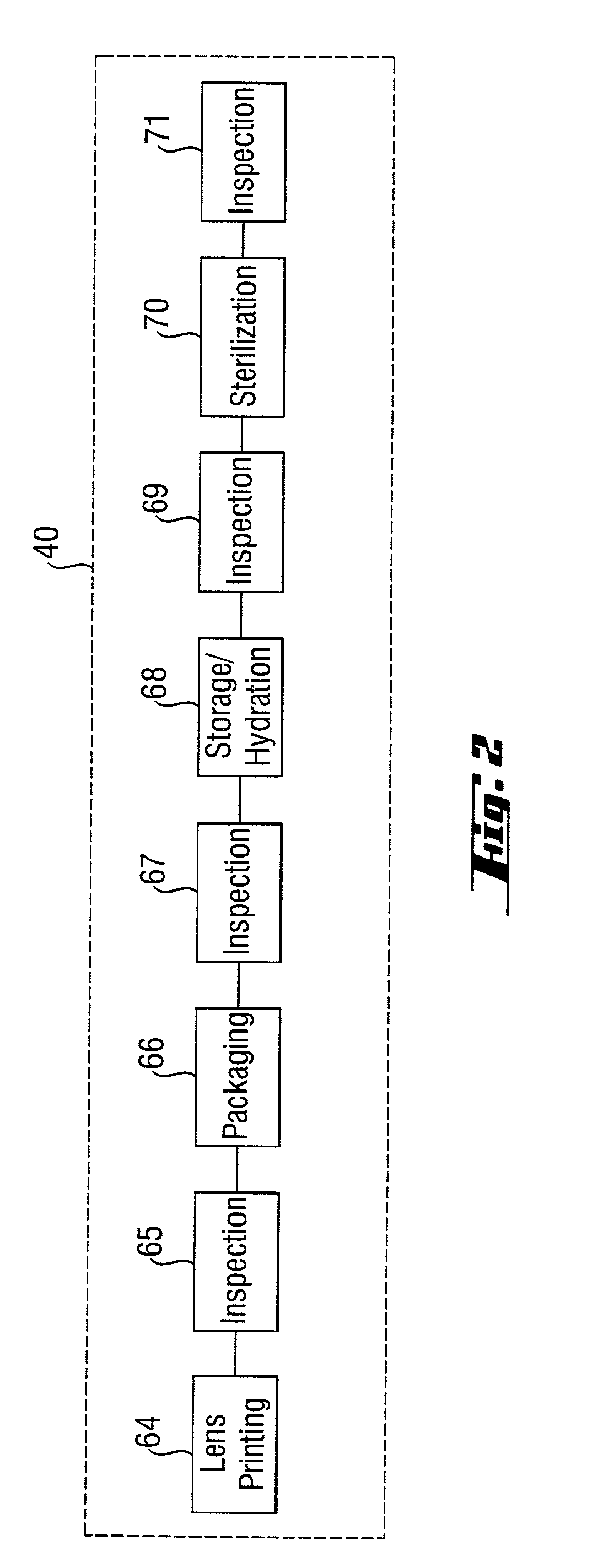

Lens manufacturing process

InactiveUS20020153623A1Suitable for processingImprove automationOptical articlesOptical partsCompression moldingThermoforming

A process for manufacturing ophthalmic lenses is described. This process has several phases, including raw material processing, material metering and dispensing, the material shaping, and ejection / de-molding. The material-shaping phase can utilize various molding processes including compression molding, thermoforming, reaction injection molding, or injection molding. The process allows re-use of the shaping molds / dies and can be automated.

Owner:NOVARTIS AG

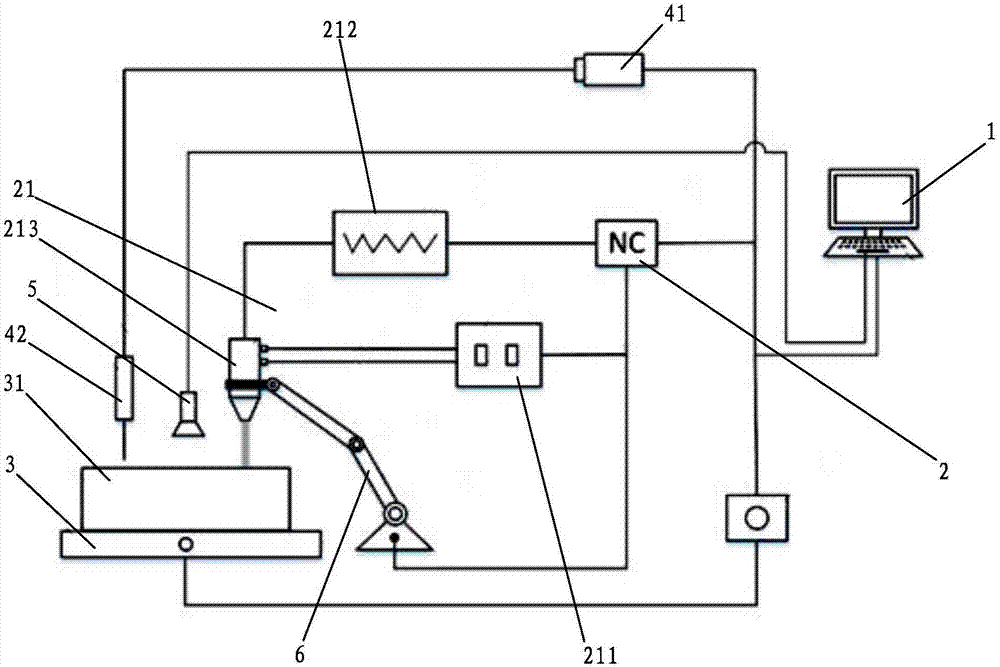

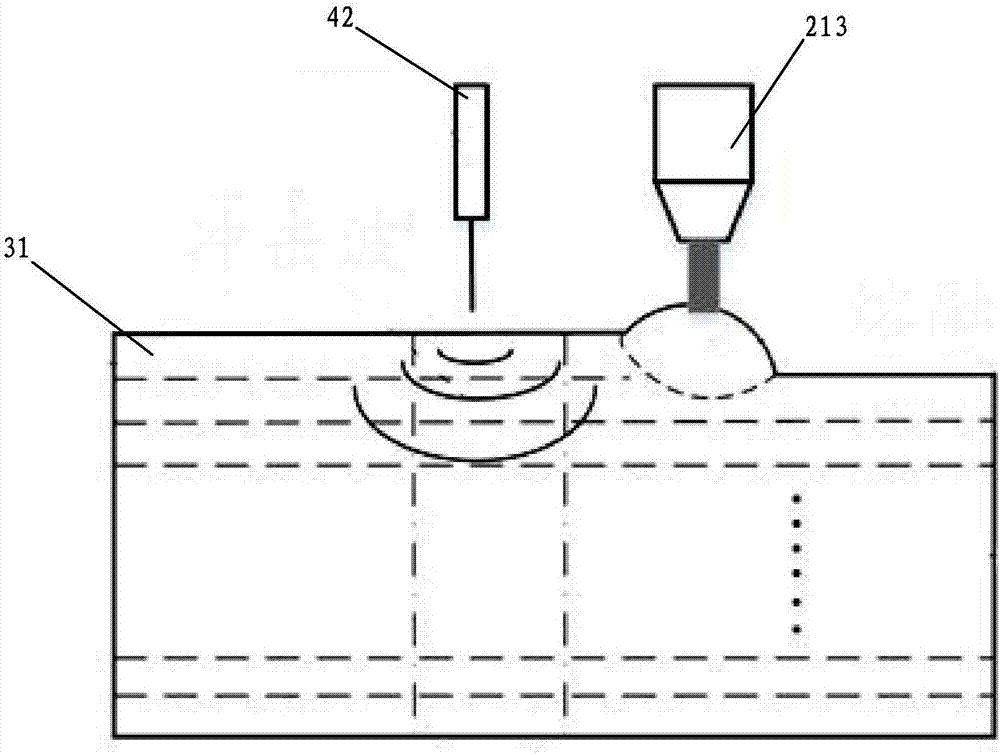

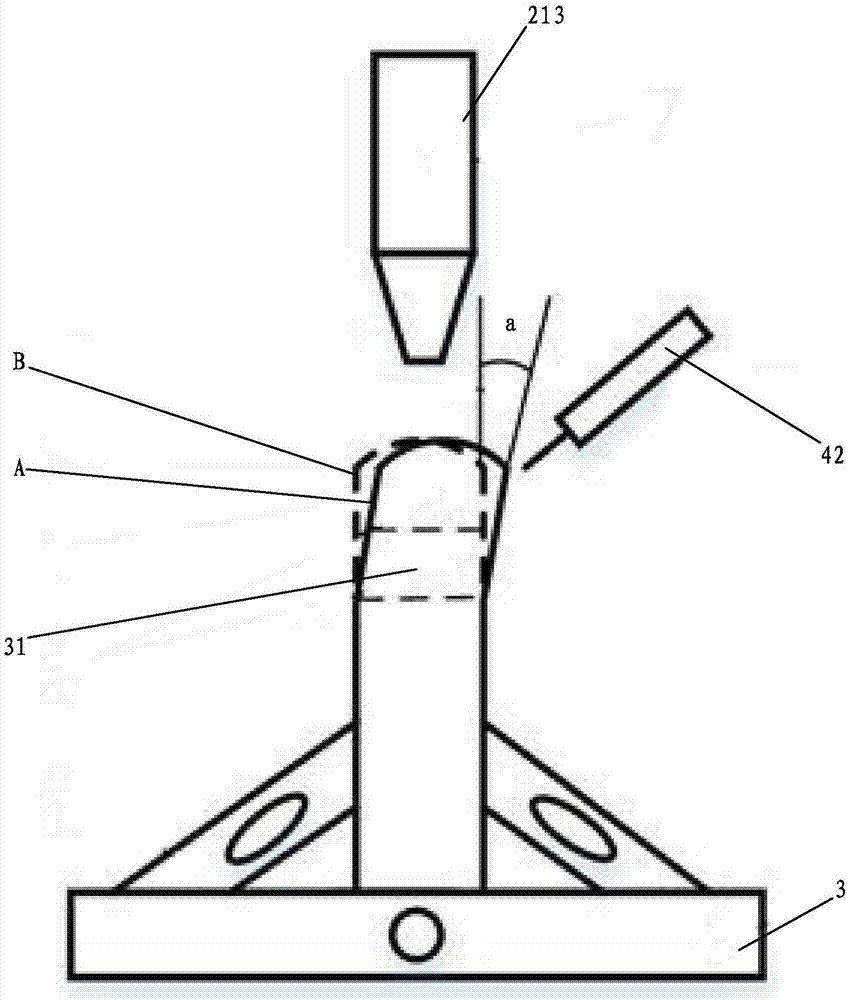

Rapid electric arc fused deposition and laser shock forging combined part forming method and device

ActiveCN107262930AGrain refinementGuaranteed forming qualityAdditive manufacturing apparatusArc welding apparatusNumerical controlEngineering

Owner:GUANGDONG UNIV OF TECH

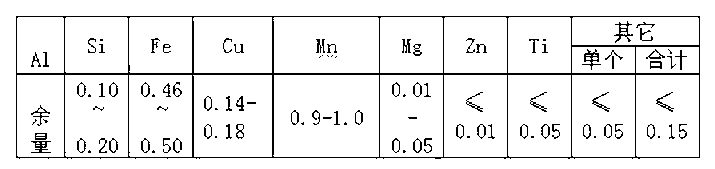

Alloy cathode foil which is special for capacitor and produced by continuous roll casting method and preparation method

ActiveCN102796922AReduce consumptionShort production processElectrolytic capacitorsMetal rolling arrangementsAlloyCapacitor

The invention relates to alloy cathode foil which is special for capacitors and produced by a continuous roll casting method, and the alloy cathode foil is characterized in that the foil comprises the following chemical components by mass fraction: 0.10-0.20% of Si, 0.46-0.50% of Fe, 0.14-0.18% of Cu, 0.9-1.0% of Mn, 0.01-0.05% of Mg, not more than 0.01% of Zn, not more than 0.05% of Ti, and the balance of Al. The preparation method comprises the following steps: a. producing a roll-casting roll; b. rolling the roll-casting roll, that is, roll-casting a 7.5 mm roll-casting plate into 5.0 mm, performing uniform annealing, roll casting to orderly obtain a dimension of 2.5 mm, 1.25 mm, 0.7 mm, and 0.5 mm, performing intermediate annealing, roll casting to orderly obtain a dimension of 0.24 mm, 0.15 mm, 0.09 mm, and 0.062 mm so as to obtain the finished product. The method shortens the production flow, and simplifies the production process, and the obtained aluminium foil has good quality.

Owner:新疆天山盈达碳素有限公司

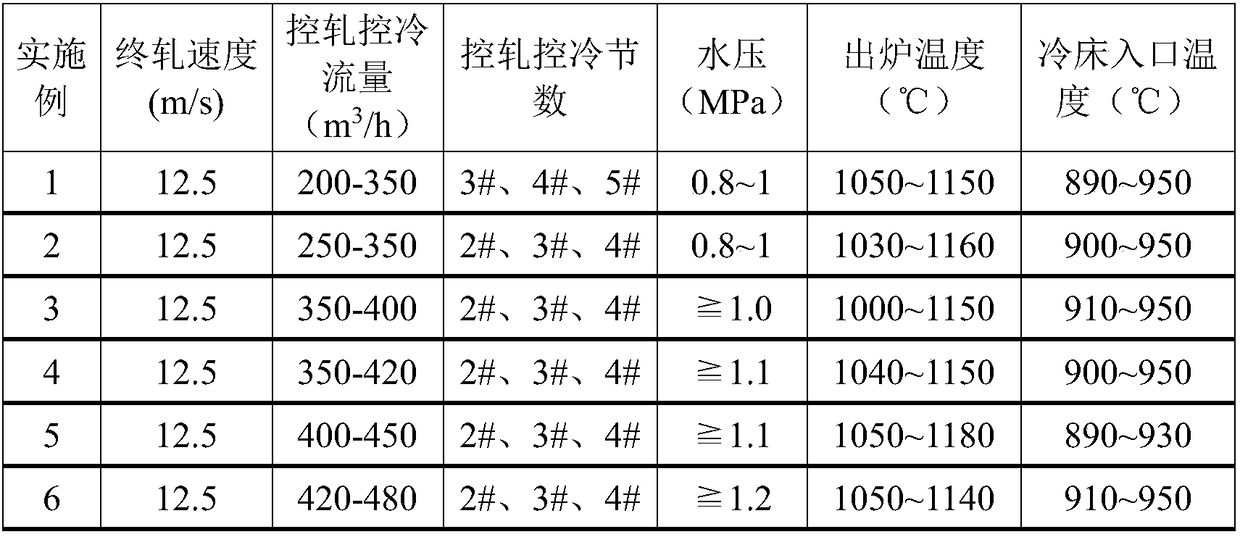

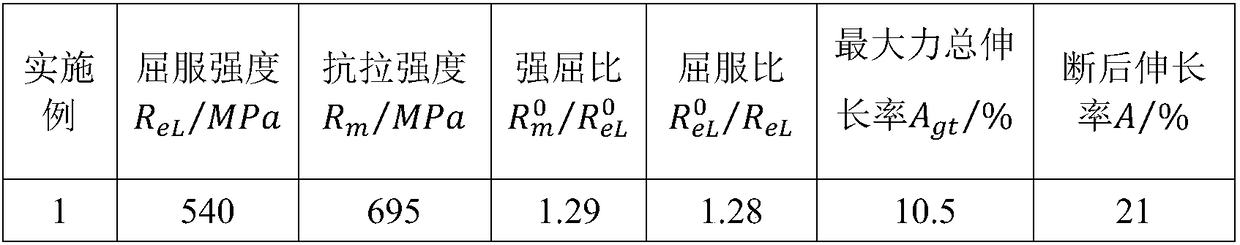

Steel bar with high weather resistance, low cost and seawater corrosion resistance and production process

ActiveCN108251746AGood weather resistanceLow costProcess efficiency improvementWeather resistanceRebar

The invention provides a steel bar with high weather resistance, low cost and seawater corrosion resistance and a production process. The steel bar comprises the following elementary compositions of,by weight, 0.04%-0.10% of C, 0.10%-0.50% of Si, 0.5%-1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 2%-4% of Cr, 0.3%-0.5% of Cu, 0.2%-0.6% of Ni, and the balance Fe and inevitable impurities. According to the steel bar, the mechanical property meets the requirement of the steel bar for corrosion resistance, the aging strain is low, and the corrosion rate is lower than 70% that of common steel bars. The technical path of the process comprises a 70-ton ultrahigh-power electric furnace, LF ladle refining, deoxidation and alloying after steel discharging, argon blowing, continuous casting of165 square billets at four streams by four machines, a heat accumulating type stepping heating furnace, 18 non-twist tandem mills, controlled-rolling and controlled-cold cooling, finishing, packagingand storage.

Owner:福建三宝钢铁有限公司

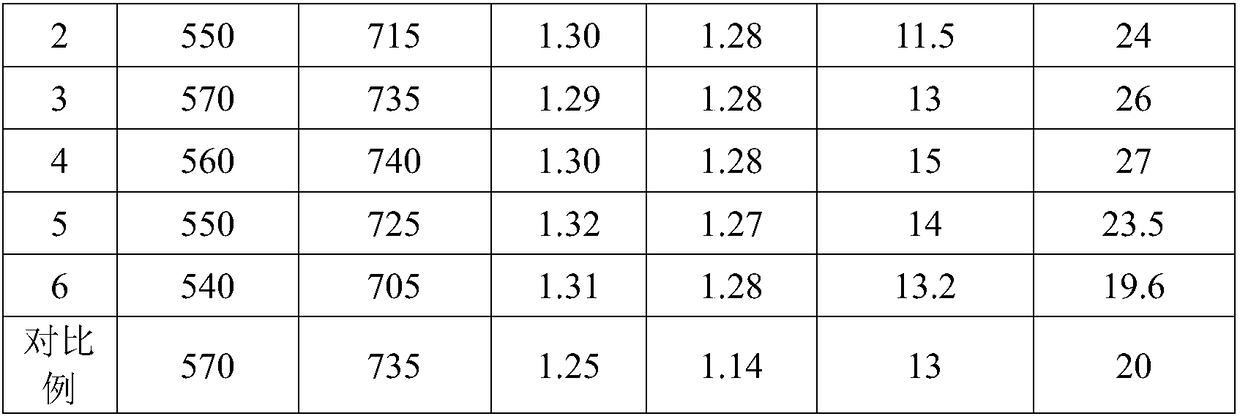

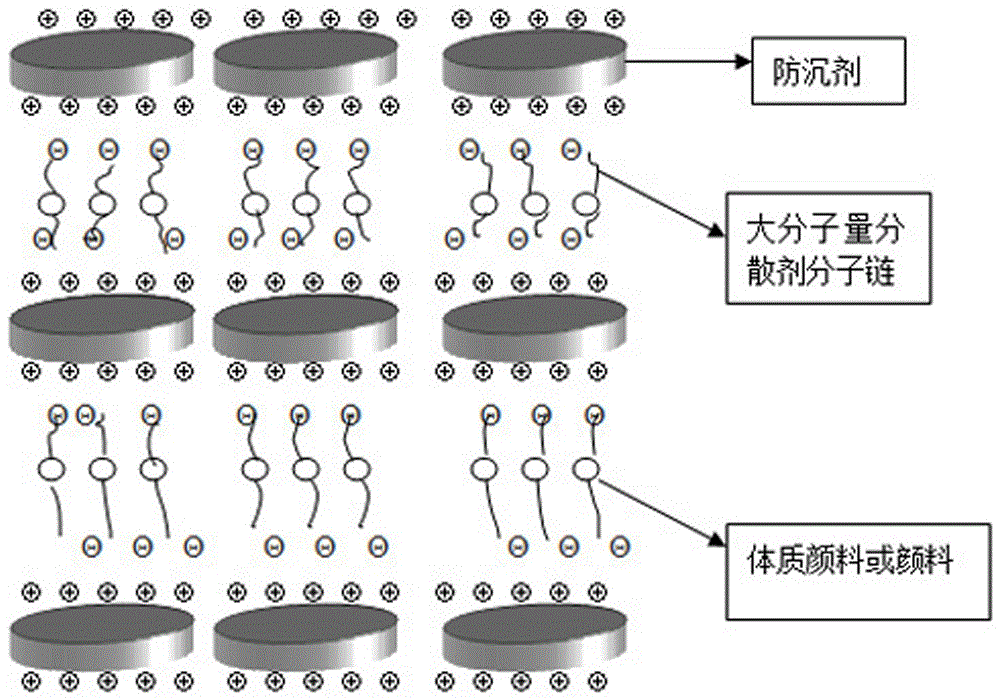

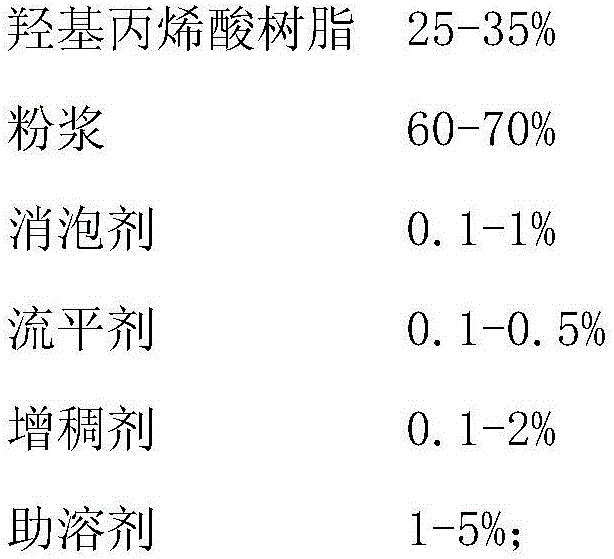

Automobile water-based dual-component middle coating excellent in performance and preparation method thereof

The invention discloses an automobile water-based dual-component middle coating excellent in performance and a preparation method thereof. The water-based middle coating is composed of a component A and a component B. The component A is composed of hydroxy acrylic resin, powder syrup, auxiliaries and cosolvent, wherein powder syrup contains deionized water, amine neutralizer, auxiliaries, extender pigment and pigment. The component B is composed of a curing agent, auxiliaries and cosolvent. After being put in according to the formula of the powder syrup of the component A, materials are dispersed at a high speed for 15 min and then enter a grinding machine to be ground till the granularity is smaller than 30 micron, then powder syrup is obtained, and hydroxy acrylic resin, powder syrup, auxiliaries and cosolvent are evenly mixed to obtain the component A. The component A and the component B are mixed in certain proportion, viscosity is adjusted by adding deionized water, and a middle coating film is obtained through spraying construction. By means of the water-based middle coating, the water-based performance of the automobile middle coating is achieved, the VOC content is greatly decreased, and excellent comprehensive performance is achieved.

Owner:GUANGDONG YATU CHEM

Oxidation-resistant alloying grey cast iron and preparation method thereof

The invention discloses an oxidation-resistant alloying grey cast iron and a preparation method of the oxidation-resistant alloying grey cast iron. The cast iron comprises the following components by mass percentage: 3.0-3.2% of C, 1.8-2.0% of Si, 0.50-0.70% of Mn, 0.10-0.50% of Cr, 0.20-0.30% of Ni, 0.03-0.50% of Mo, 0.5-3.0% of Al, 0.05-0.08% of Sr, 0.005-0.15% of Zn, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of melting raw materials, culturing and processing, and pouring, wherein the tapping is carried out at 1450 to 1550 DEG C after melting; the molten iron is processed by being flushed in a ladle and cultured and processed along with the flow, and then slagged and casted. According to the oxidation-resistant alloying grey cast iron provided by the invention, the organization of the grey alloying cast iron material is structured by distributing 6-8 grades of D type graphite with little graphite of A type on a ferrite substrate, so that higher toughness, high heat conductivity and high-temperature oxidization resistance can be achieved, and good casting technical performance can be ensured as well; and the oxidation-resistant alloying grey cast iron can be applied to manufacturing a glass die and a light alloy metal type casting die which can bear the heat impacting of high-temperature formed liquid and cold-heat alternating stress for a long time.

Owner:SUZHOU DONGHAI GLASS MOLD

Manufacturing method for casting metal lithium target

InactiveCN105349952AEliminate stomataEliminate shrinkageVacuum evaporation coatingSputtering coatingLithiumLiquid metal

Provided is a manufacturing method for casting a metal lithium target. A casting die for metal lithium is prepared according to the needed size, a stainless steel liner tube is located in the middle of the die, and cooling liquid can be injected into the stainless steel liner tube; liquid metal lithium is injected into a sandwich layer between the die and the stainless steel liner tube, and after the liquid metal lithium is solidified and formed, a metal lithium rotating target of the target size is formed through outline processing. The bottom-to-top directional solidification manner is adopted, the process is simple and convenient, and the high-purity metal lithium target which is small in grain size and high in compactness can be manufactured by eliminating air holes and shrinkage cavities in the metal lithium target. Casting conditions are optimized in the casting process, the flaw detection yield of the metal lithium target can be increased, and therefore the metal lithium target can be better applied to electrochromic glass.

Owner:GEMCH MATERIAL TECH SUZHOU

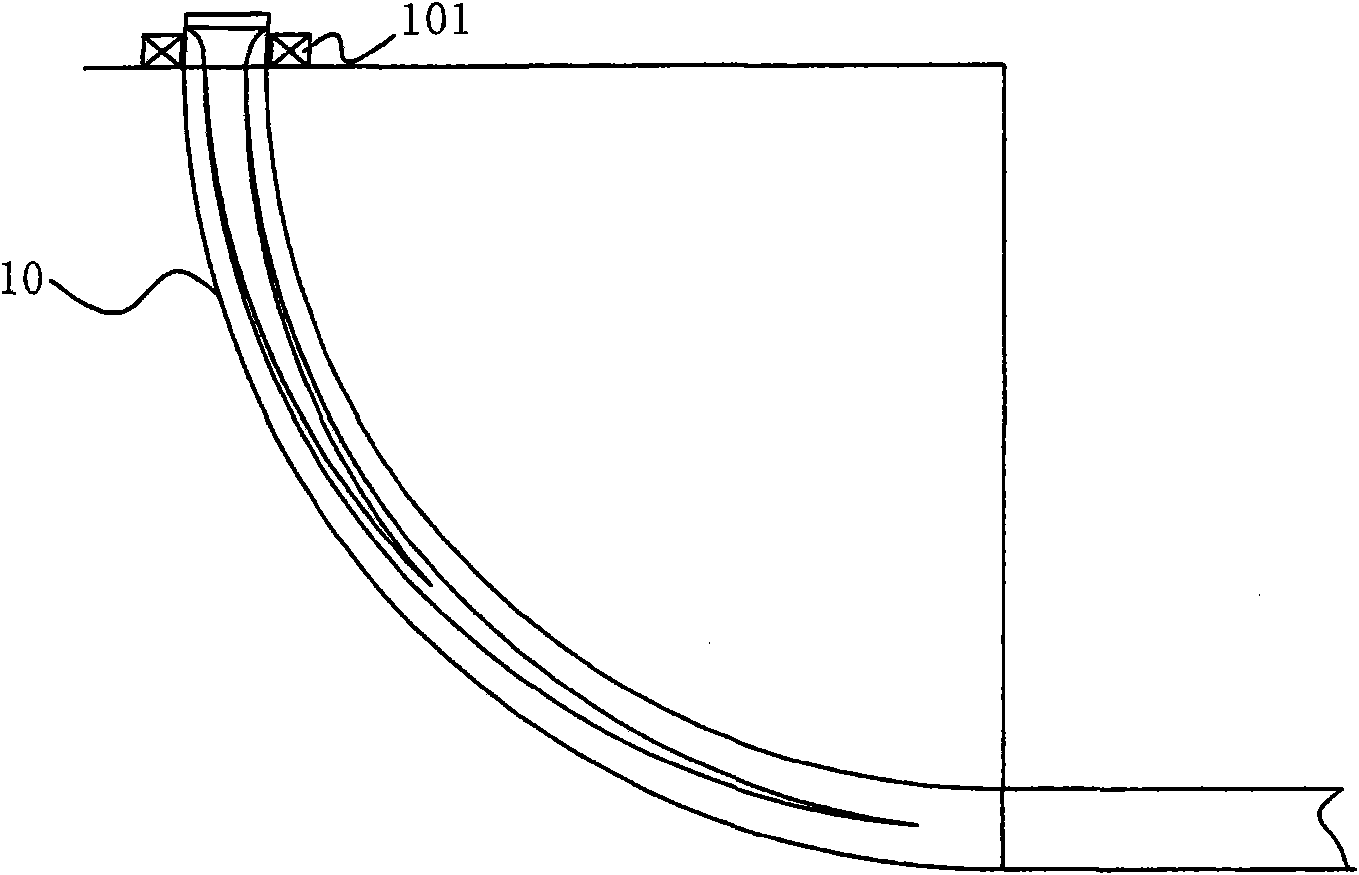

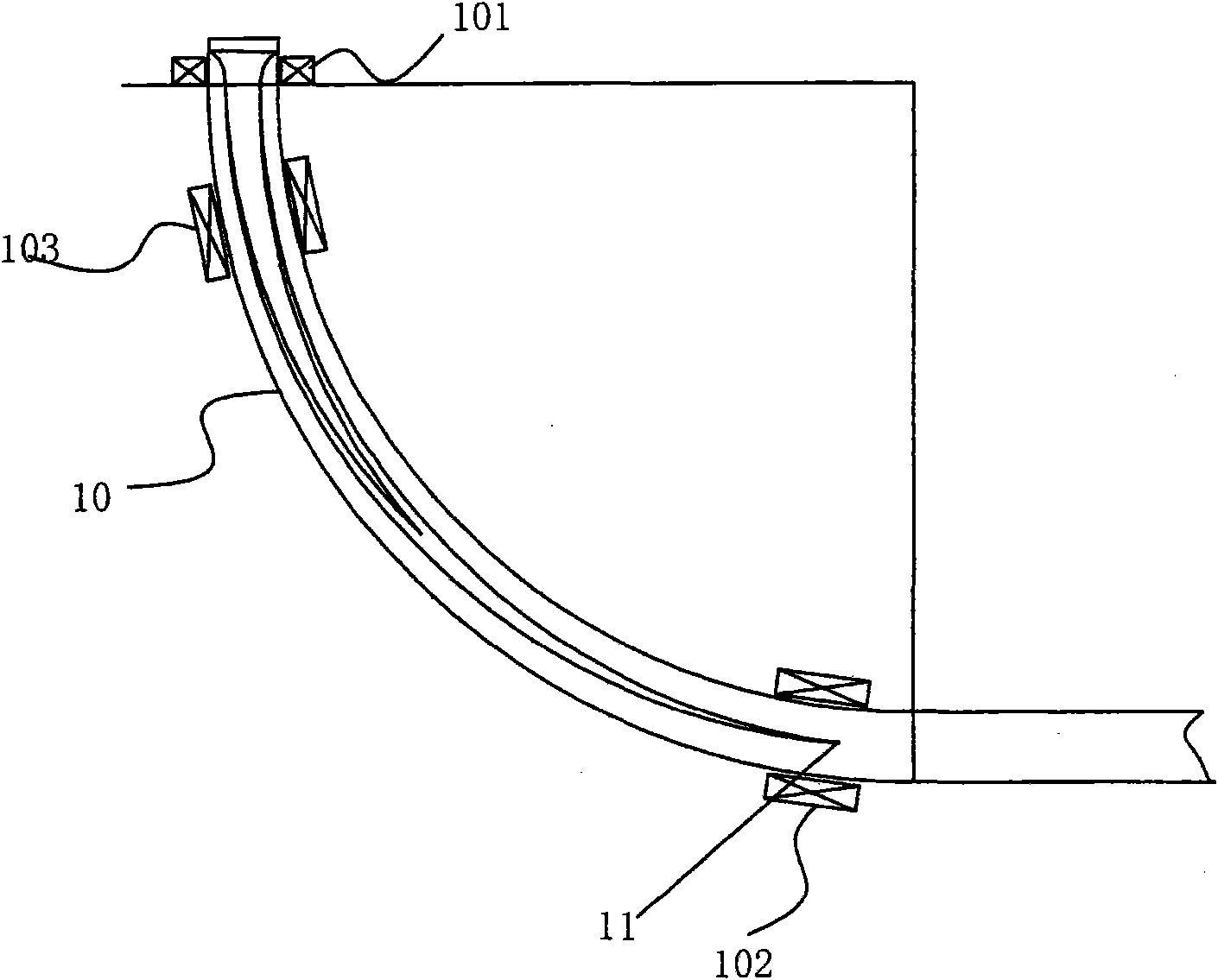

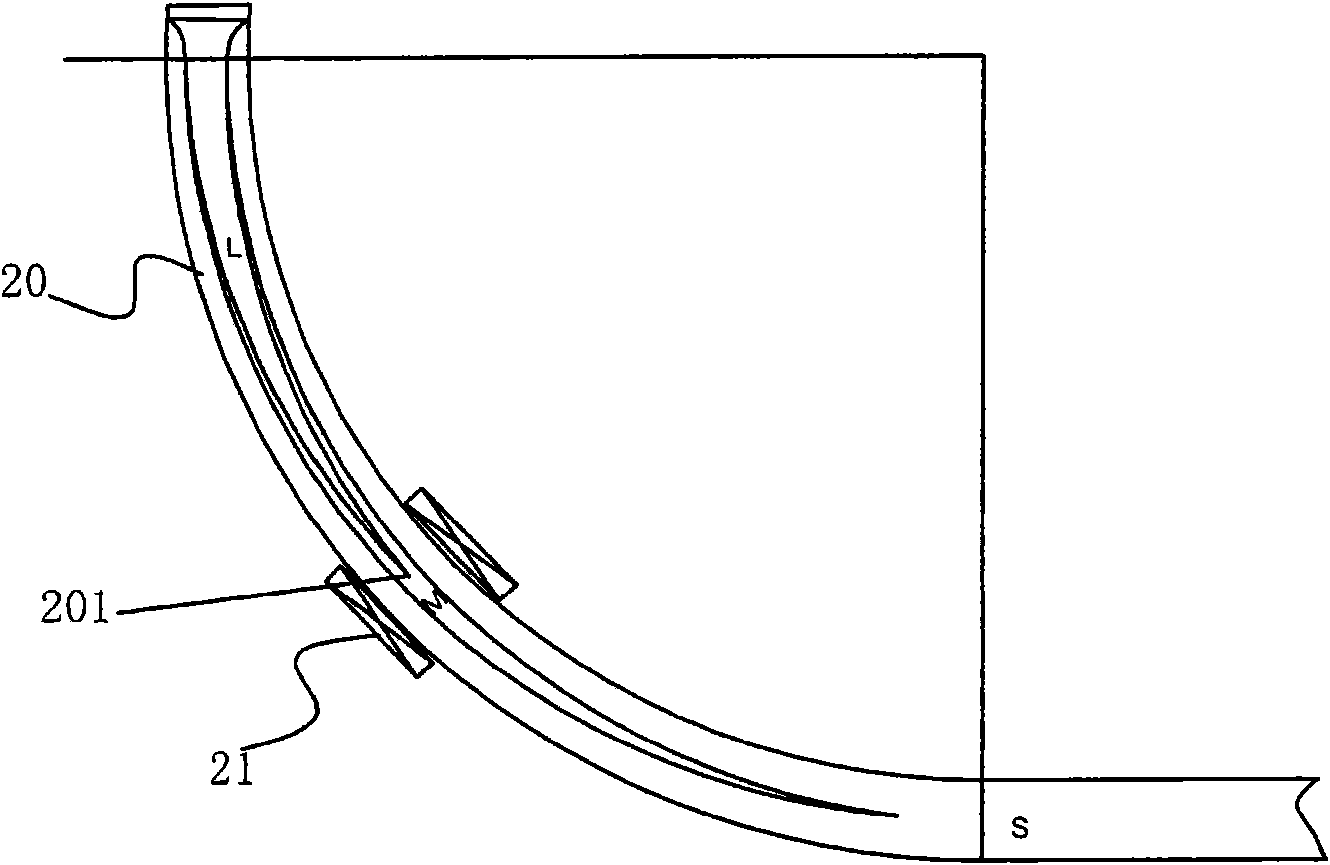

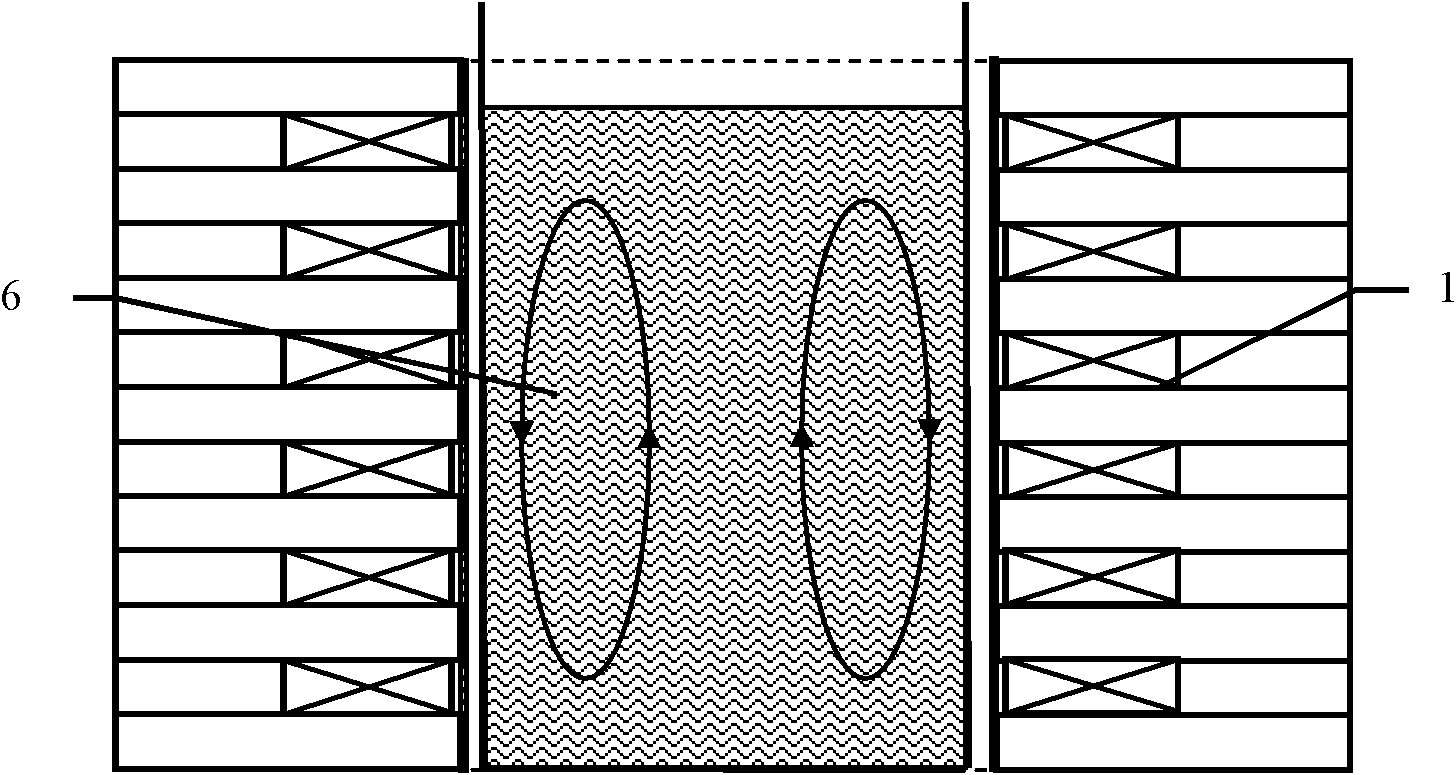

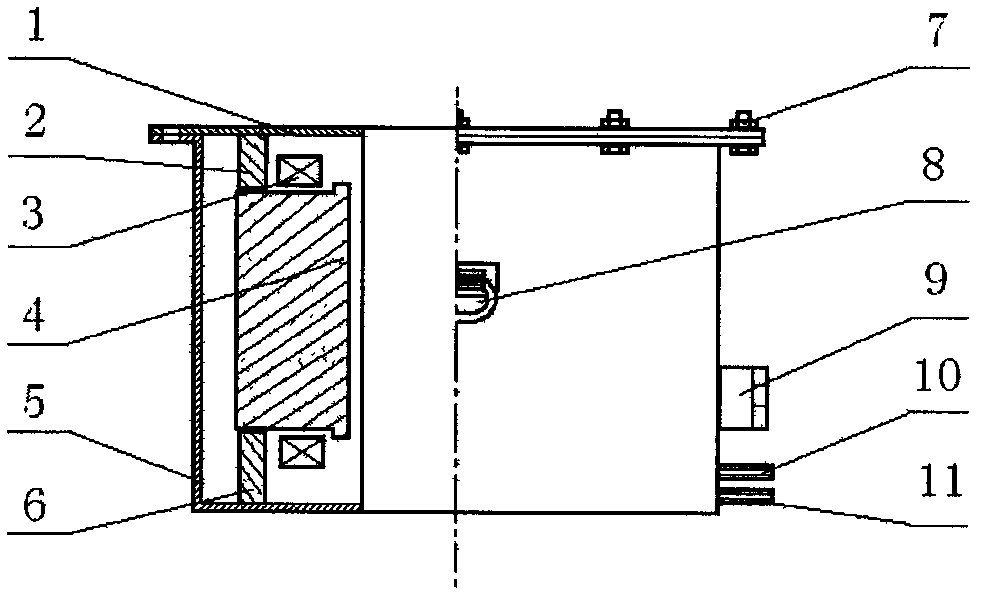

Method for improving internal organization of casting blank of continuous casting machine and electromagnetic stirring device

The invention provides a method for improving the internal organization of a casting blank of a continuous casting machine and an electromagnetic stirring device, wherein the method is as follows: atthe tail end of a continuous casting bank liquid core on a secondary cooling zone of the continuous casting machine, carrying out electromagnetic stirring and generating forward and reverse alternantspiral rotating force which causes molten steel to rotate and flow along the casting direction of the continuous casting machine and appends static pressure to a solid-liquid phase zone of the tail end of the liquid core. The method and the electromagnetic stirring device of the invention can provide enough molten steel for supplying the volume contraction during the solidification of the liquid core and eliminating shrinkage cavity and loose, thus increasing the quality of the continuous blank.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Method in use for conticaster for controlling solidification structure of casting block

A method for the conticaster to control the solidified structure of cast blank includes providing a HF pulse power supply with positive and negative electrodes, inserting its negative electrode into the molten steel in the crystallizer or tundish of conticaster, electrically connecting its positive eletrode with the steel base of conticaster, and conticasting while regulating the voltages, current and frequency to improve the performance of cast blank.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

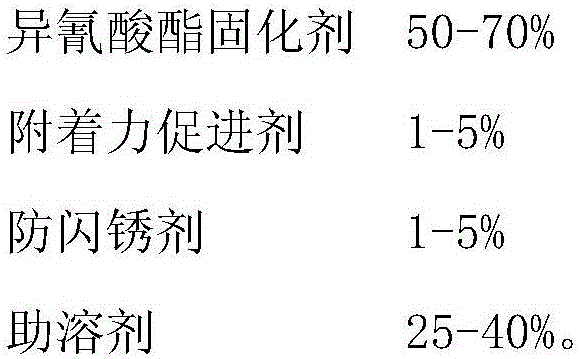

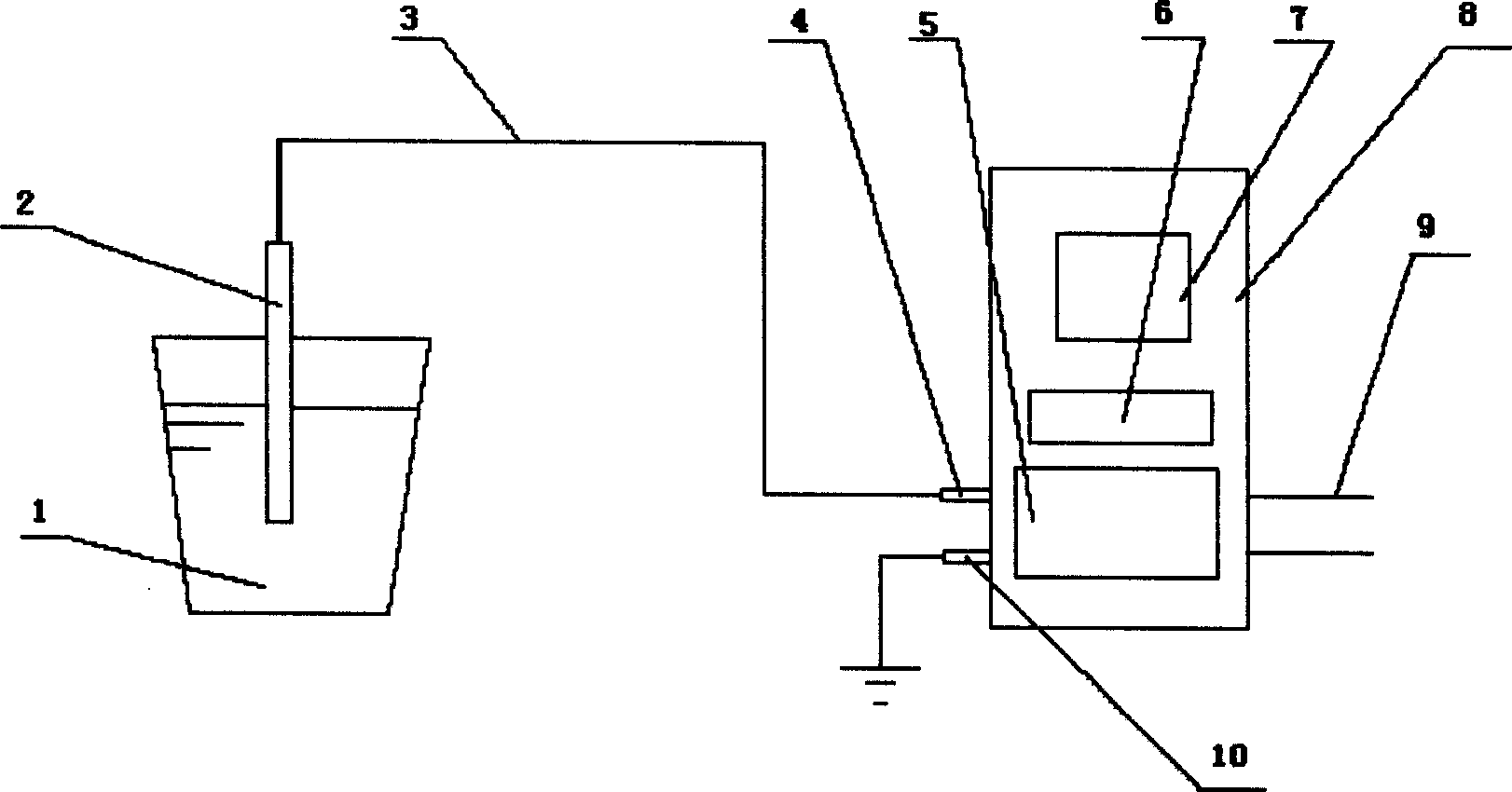

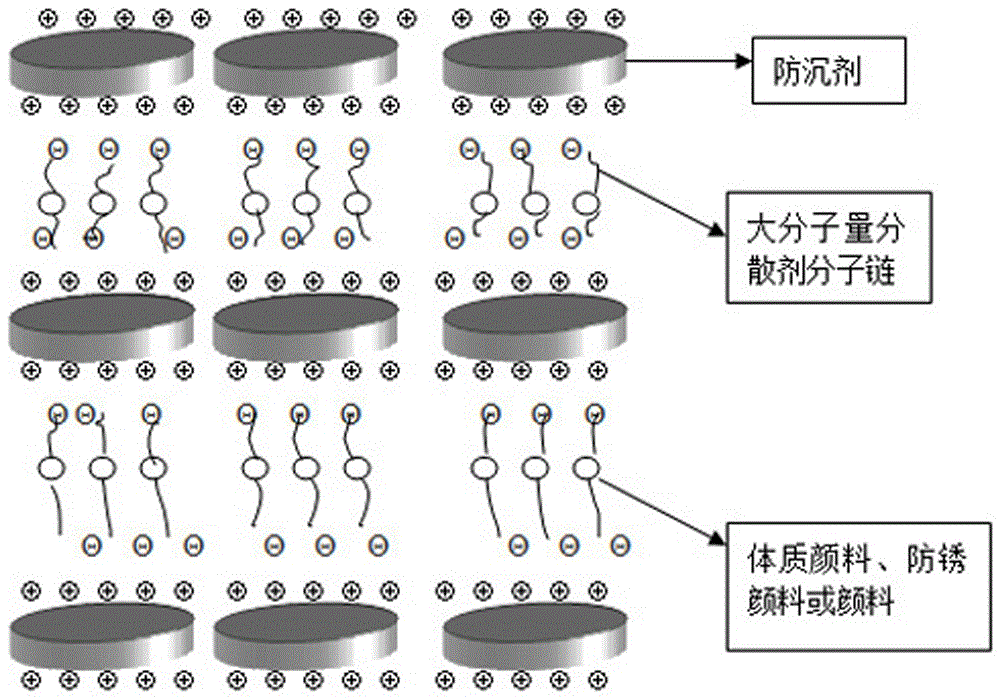

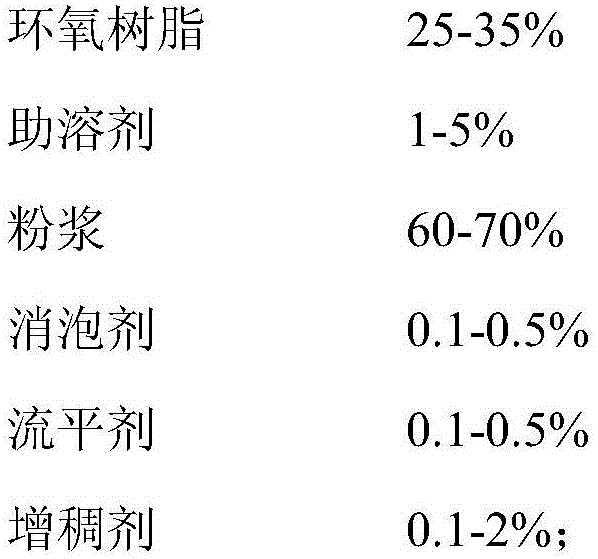

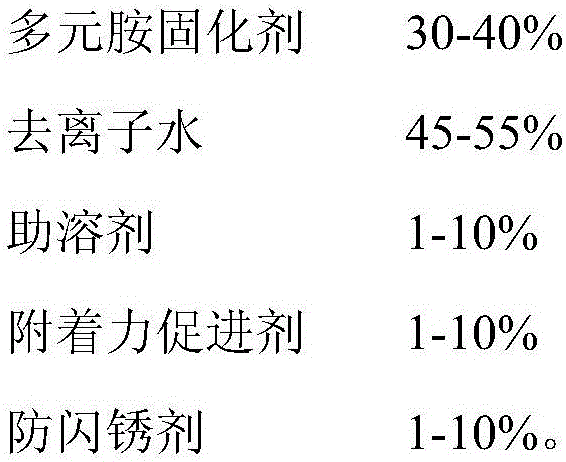

Automobile water-based two-component epoxy primer with excellent performance and preparation method thereof

The invention discloses an automobile water-based two-component epoxy primer with excellent performance and a preparation method thereof. The water-based epoxy primer involved in the invention is composed of a component A and a component B. The component A is composed of epoxy resin, a cosolvent, powder slurry and assistants, wherein the powder slurry includes deionized water, additives, extender pigment, anti-rust pigment and pigment. The component B contains a polyamine curing agent, deionized water, a cosolvent and assistants. The preparation method includes: conducting charging according to the powder slurry formula of the component A, then performing high speed dispersion for 15min, then bringing the materials into a sand mill to conduct grinding to fineness of less than 30 micrometers to obtain the powder slurry, mixing epoxy resin, the cosolvent, the powder slurry and the assistants evenly to obtain the component A, mixing the component A with the components B in certain proportion, adding deionized water to adjust viscosity, and carrying out spray coating to obtain an epoxy primer film. The water-based epoxy primer provided by the invention not only realizes aquation of automobile epoxy primer and great reduction of the VOC content, but also has excellent comprehensive performance.

Owner:GUANGDONG YATU CHEM

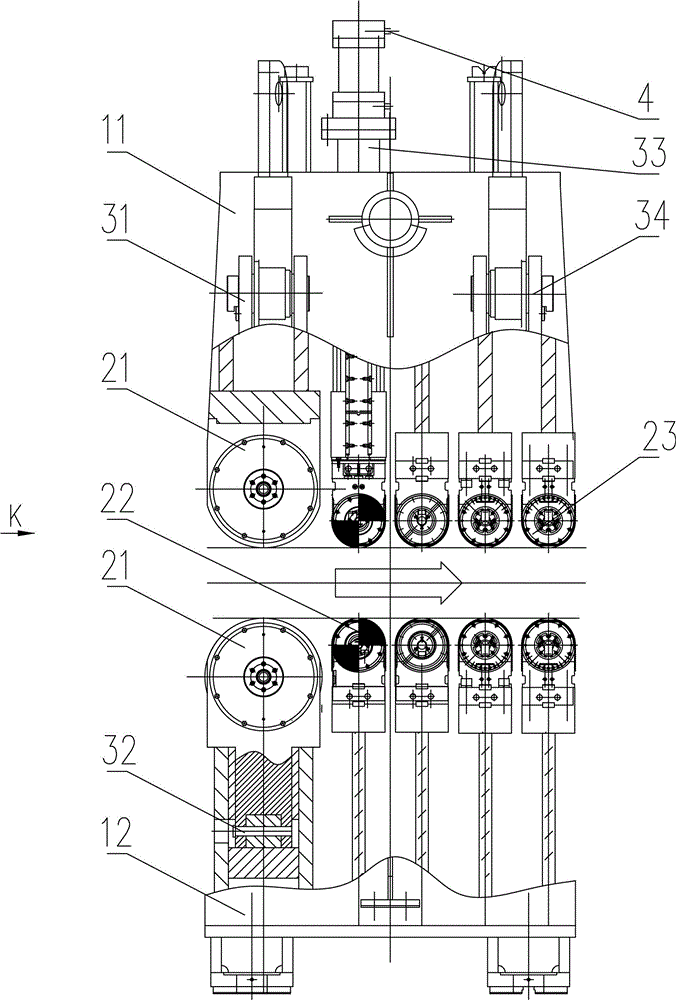

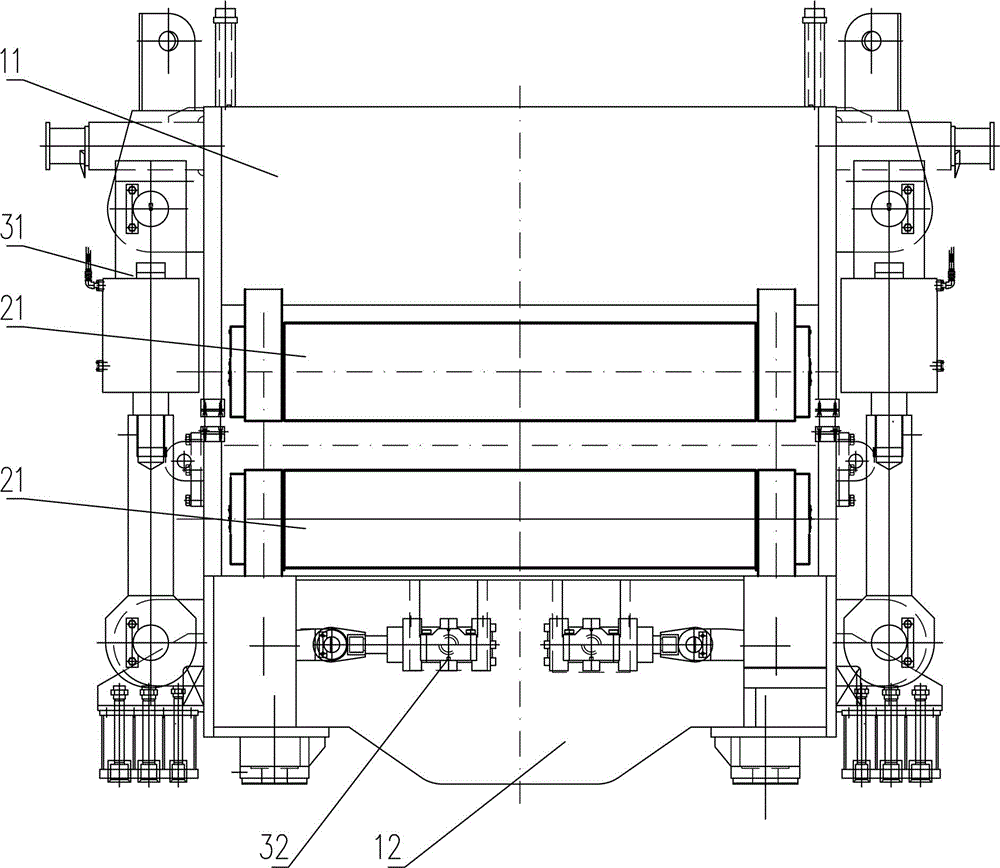

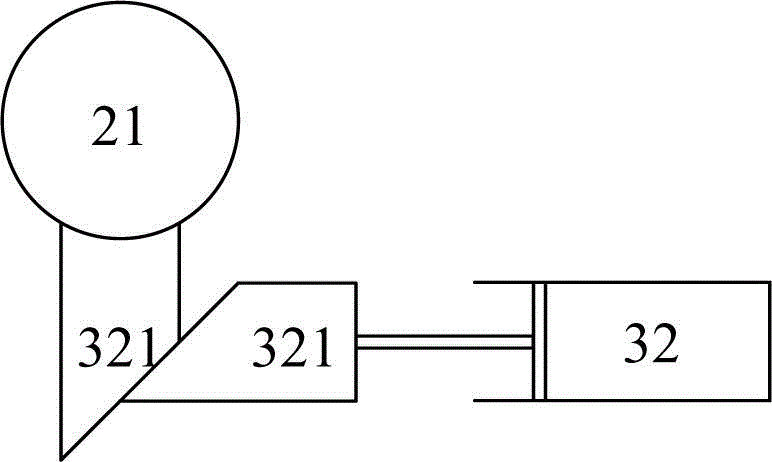

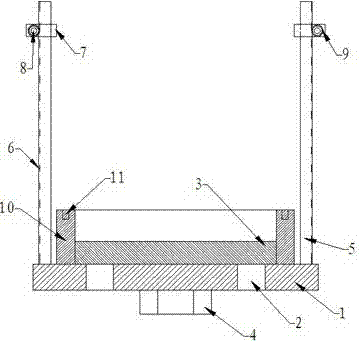

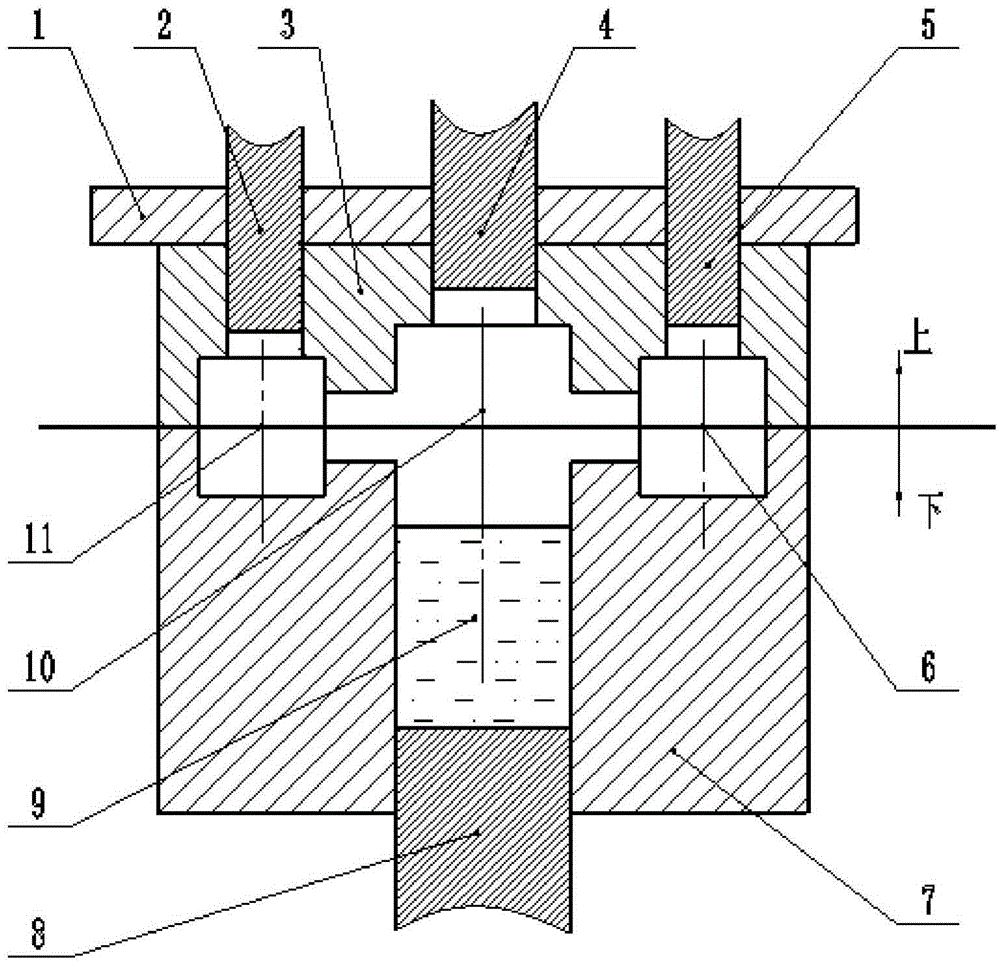

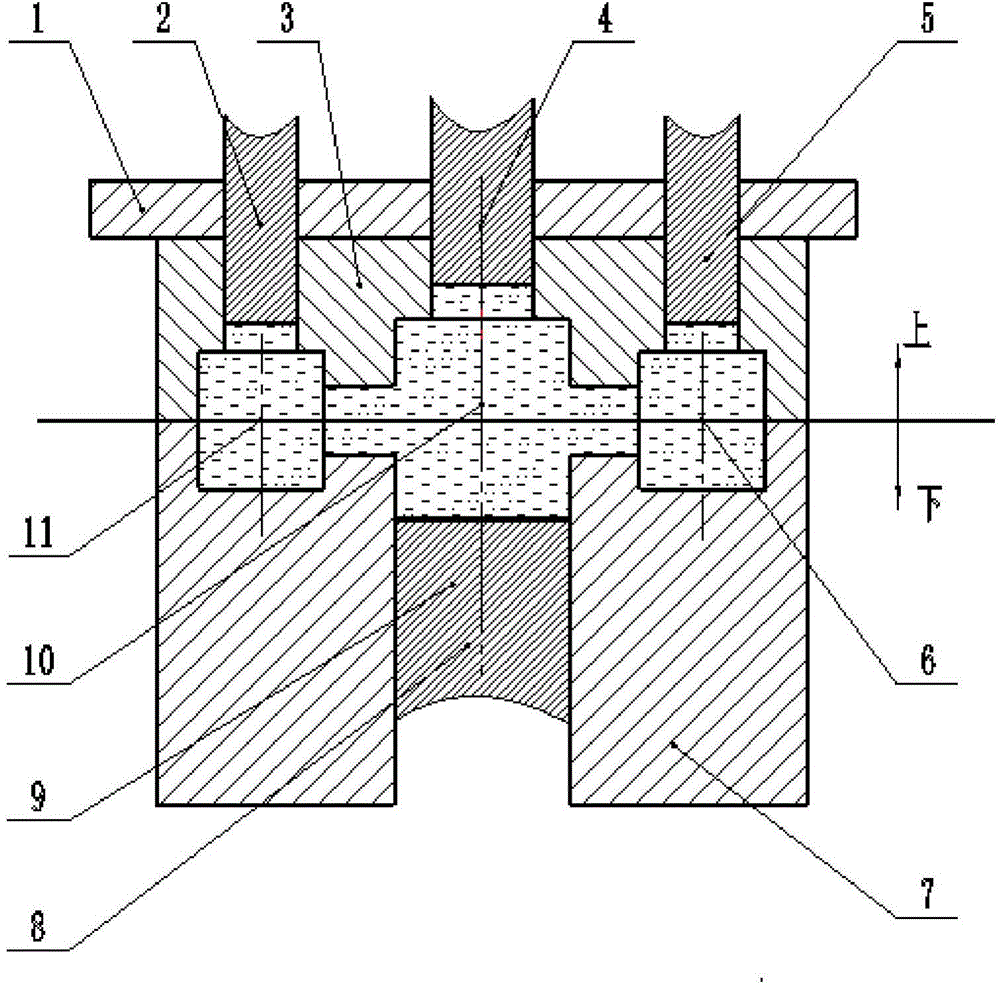

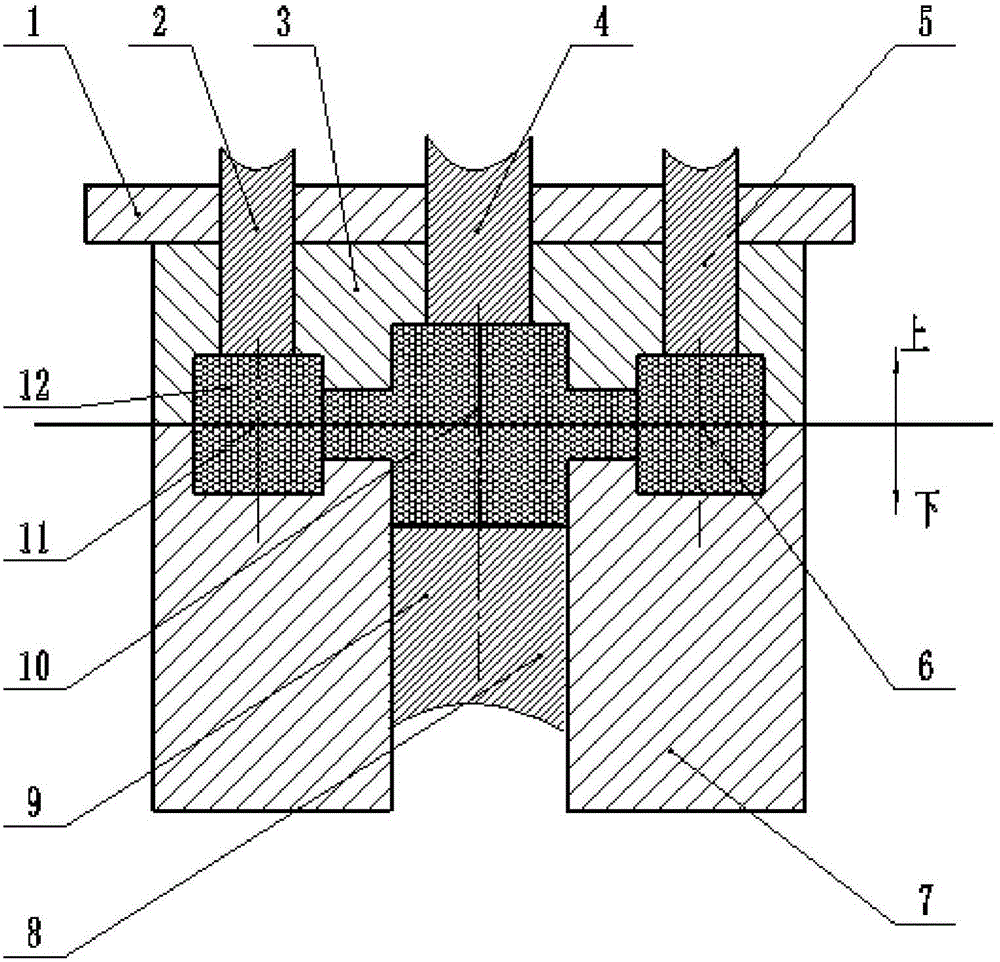

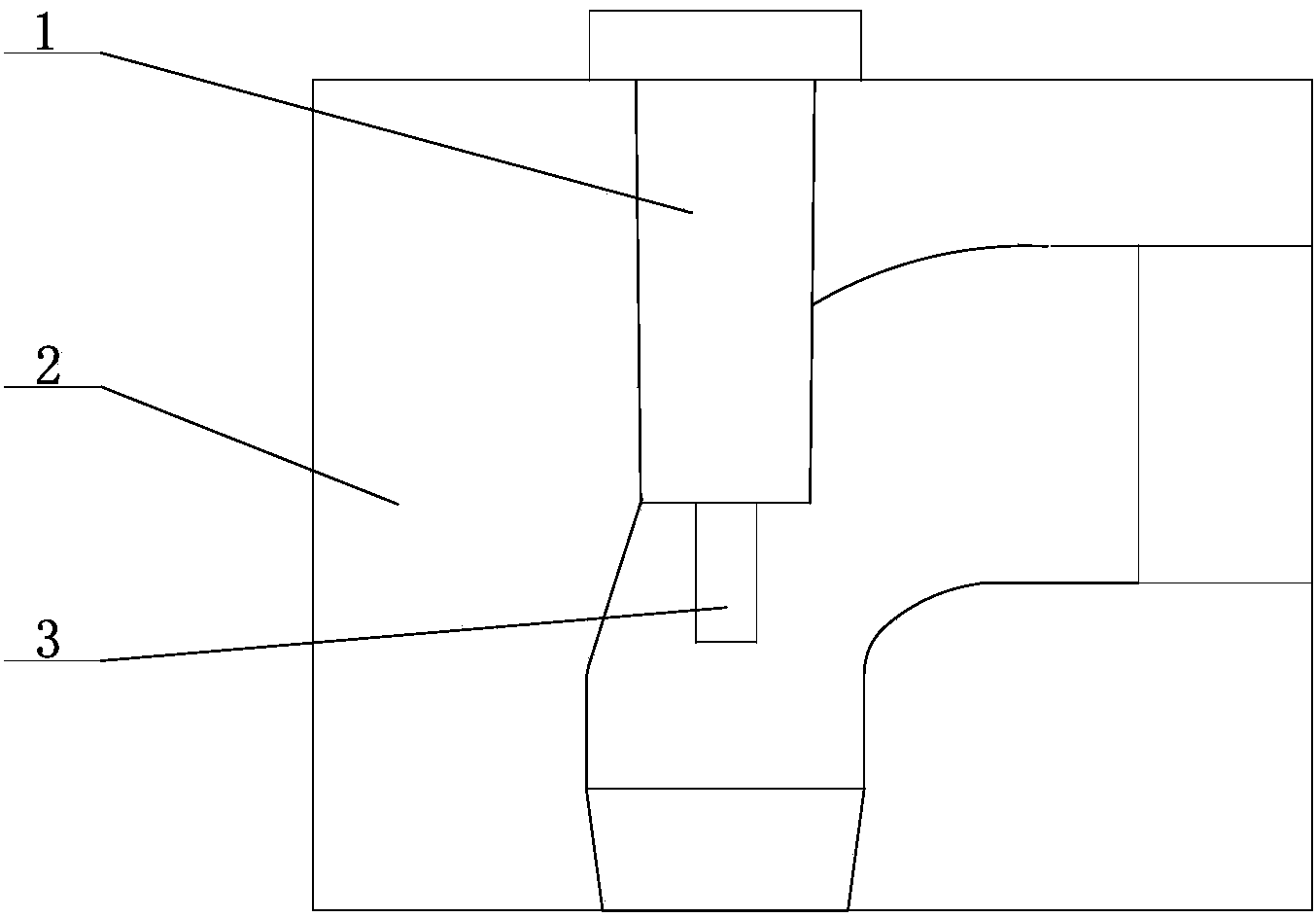

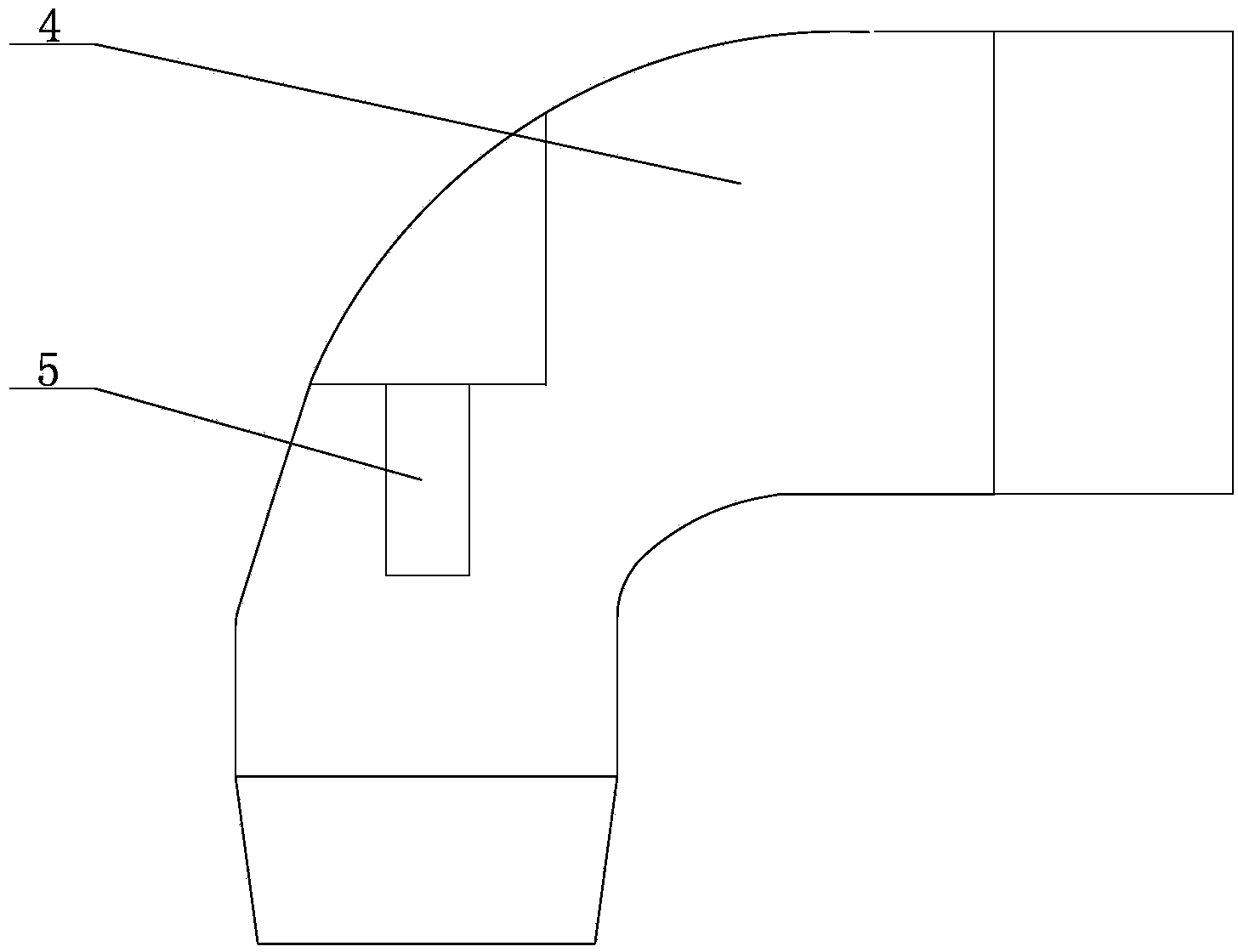

Heavy reduction sector section used for overcoming plate blank looseness and shrinkage defects and application method thereof

The invention relates to the field of accessory equipment used for conducting posttreatment or postprocessing on cast blanks on site during metal continuous casting, in particular to a heavy reduction sector section used for overcoming the plate blank looseness and shrinkage defects and an application method thereof. The heavy reduction sector section used for overcoming the plate blank looseness and shrinkage defects comprises an upper frame (11) and a lower frame (12) and is characterized by further comprising a pair of big loose rolls (21), a pair of driving rolls (22), at least three pairs of small loose rolls (23), big loose roll reduction oil cylinders (31), horizontal oil cylinders (32), a driving roll reduction oil cylinder (33) and a water pipe (4). The application method of the heavy reduction sector section used for overcoming the plate blank looseness and shrinkage defects is characterized in that the method is implemented in the following steps that a casting blank is pulled into the sector section; extrusion is conducted, specifically, the rolling reduction no less than 10 mm is applied to the casting blank; and the casting blank is pulled out of the sector section. According to the heavy reduction sector section used for overcoming the plate blank looseness and shrinkage defects and the application method thereof, the quality of the casting blank is high, and the looseness and shrinkage defects barely occur.

Owner:BAOSTEEL ENG & TECH GRP

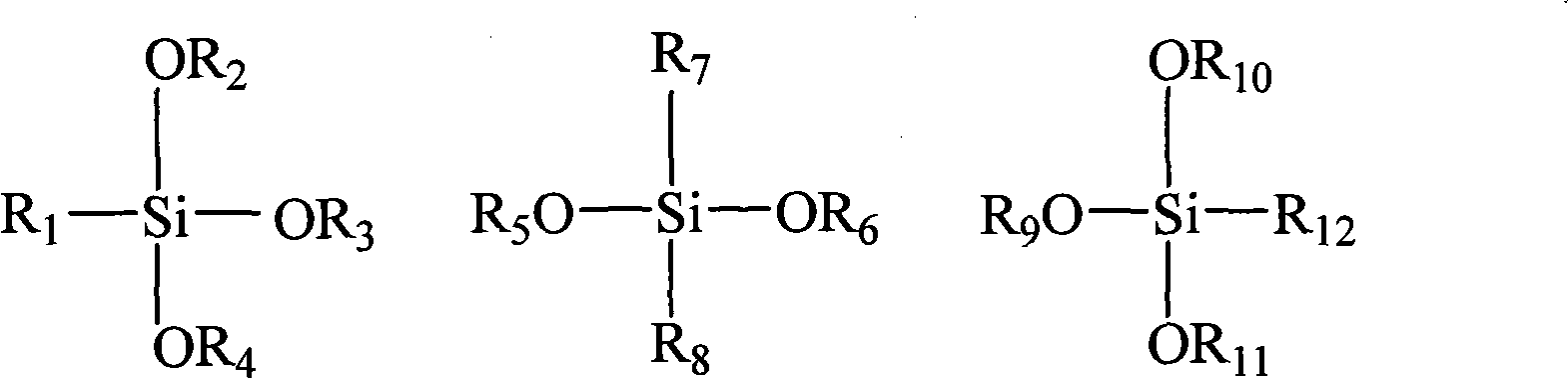

Coating and optical element

The invention provides a coating. The coating is formed by the following steps of: performing hydrolytic condensation on a first mixture comprising three-functionality-degree silane, linear siloxane, an organic silicon coupling agent, and an organic hydrophilic solvent, adding a second mixture comprising nano water-based silica sol and a curing agent, and coating and curing. The invention also provides an optical element. The optical element comprises a transparent base material and a coating which is positioned on the surface of the transparent base material and provided by the invention. The coating comprises the nano water-based silica sol, so that the toughness, hardness and abrasive resistance of the coating are improved and the coating has high adhesion to the base material.

Owner:BYD CO LTD

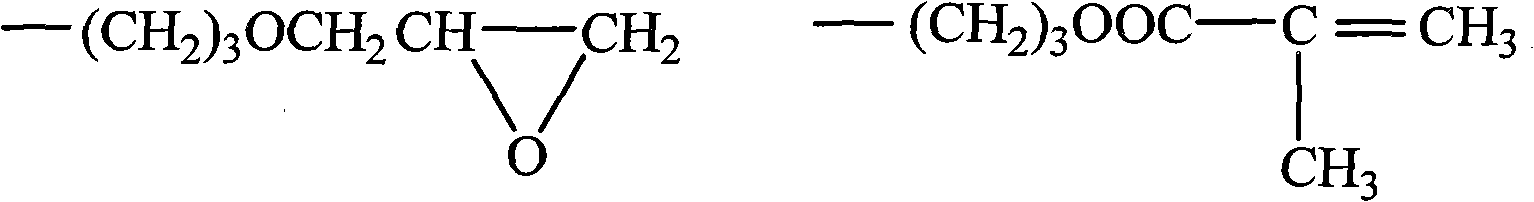

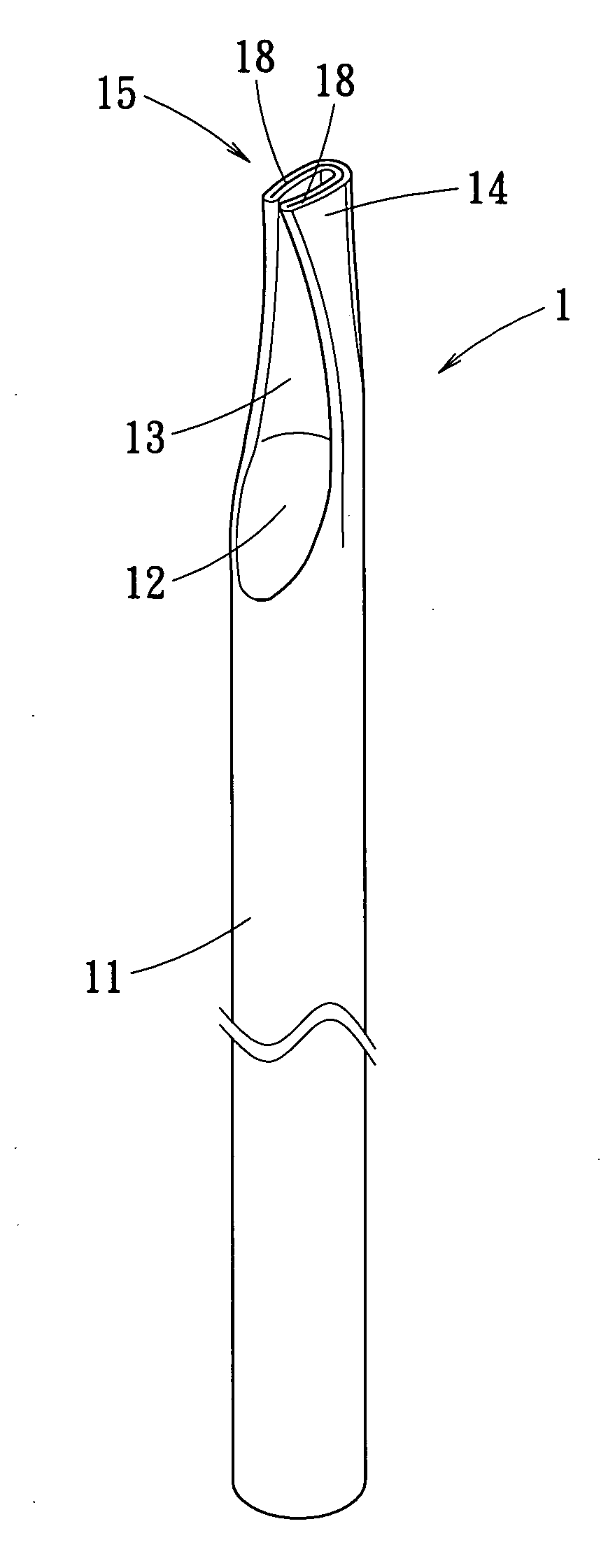

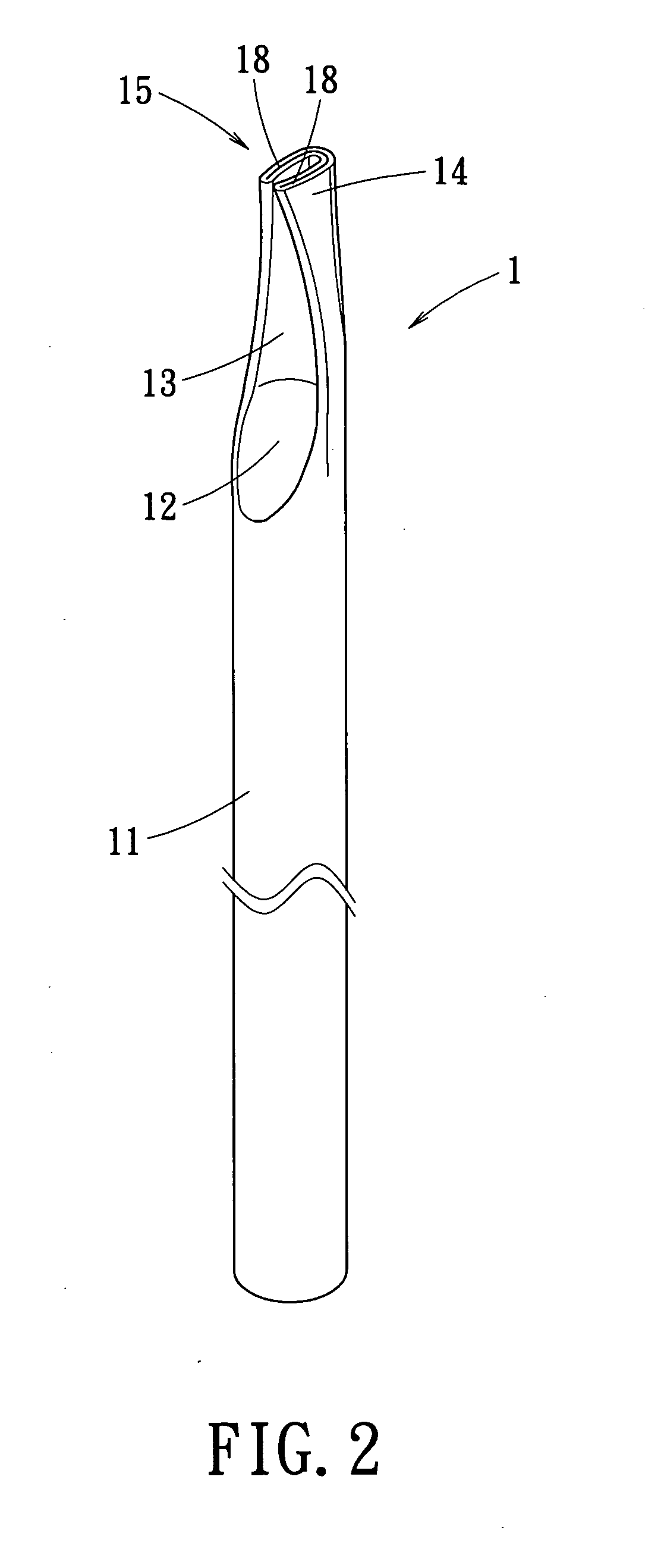

Circular tubular heat pipe having a sealed structure closing a distal opening thereof

InactiveUS20050051301A1Shorten welding timeReduce areaIndirect heat exchangersHeat pipeElectrical and Electronics engineering

A circular tubular heat pipe has a sealed structure closing a distal opening thereof. The improvement of the sealed structure provides a concave wall portion formed on the heat pipe adjacent to the distal opening. A pressed recess portion is formed on the concave wall portion adjacent to the distal opening, the heat pipe being formed to have a overlapping wall at the pressed recess portion. A volume reduced portion is formed on the pressed recess portion adjacent to the distal opening. A sealed welding portion is formed on the volume reduced portion at the distal opening, thereby reducing an area of the sealed welding portion. As the formation of the pressed recess portion and the volume reduced portion reduces the area of the sealed welding portion, the shrinking process is eliminated, and the welding time of the heat pipe with a large diameter is shortened.

Owner:HSU HUL CHUN

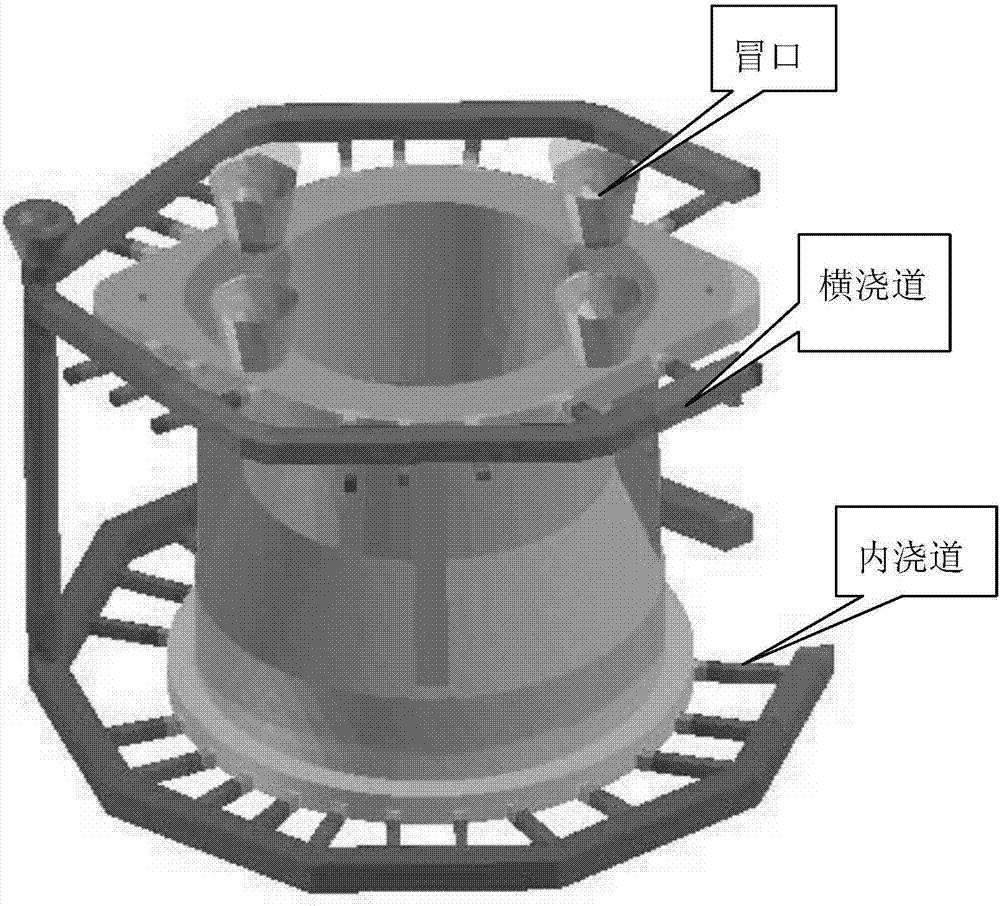

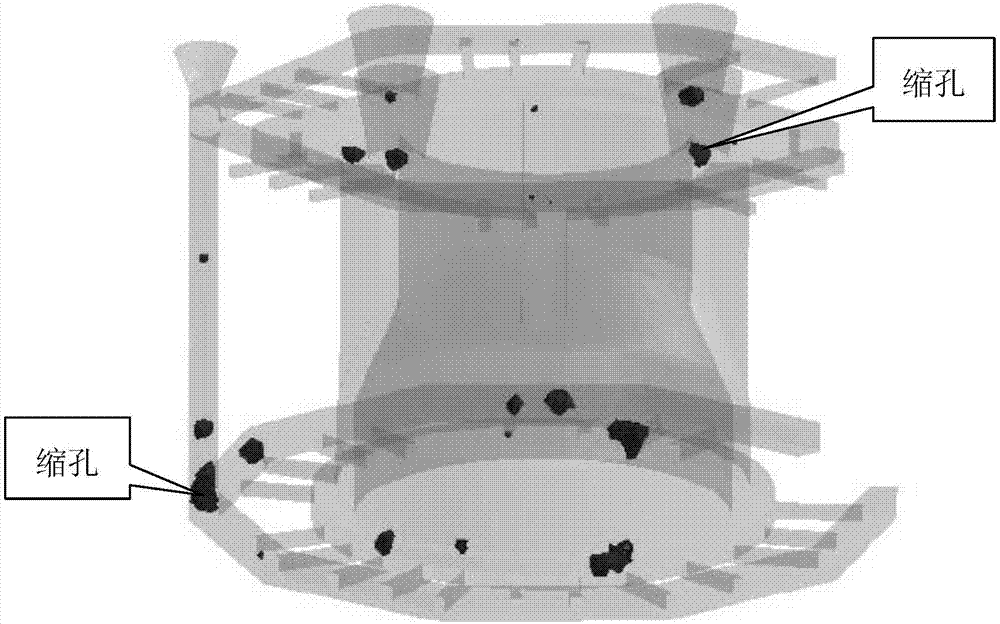

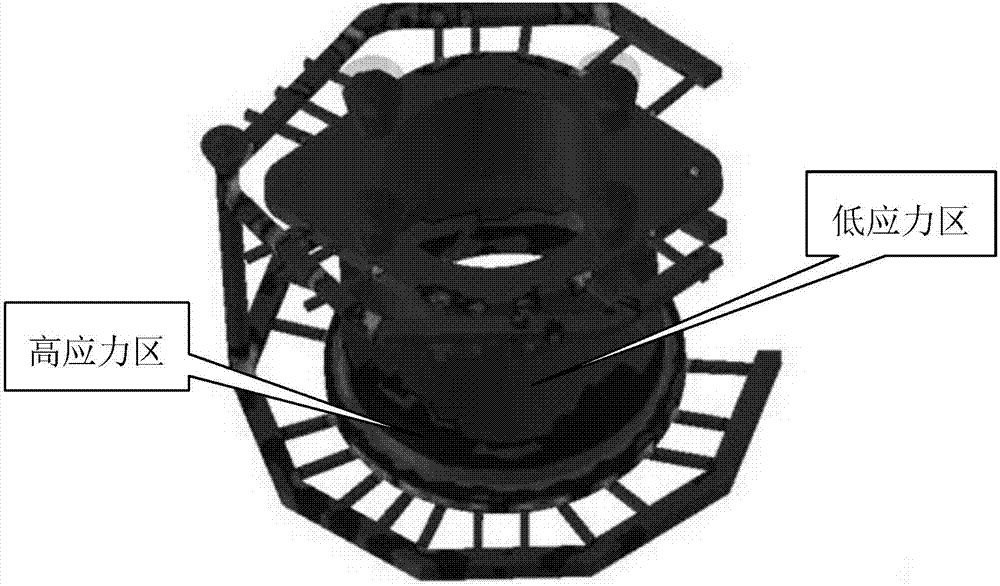

Casting system capable of eliminating detects of ZG35 valve casting and design method thereof

PendingCN107159845AEliminate shrinkageEliminate crack defectsFoundry mouldsFoundry coresDesign methodsMaterials science

The invention discloses a casting system capable of eliminating detects of a ZG35 valve casting and a design method thereof. The casting system comprises risers, a gating system and a chilling block. The gating system adopts a step-type gating system and comprises a sprue cup, a straight gate, a bottom layer ingate and an upper layer ingate. The sprue cup is used for pouring of molten metal liquid and connected with the straight gate. The straight gate is connected with the bottom layer ingate and the upper layer ingate. The chilling block is arranged at a hot spot at the bottom of the casting. The risers comprise the top risers and the side riser. The top risers are arranged over a flange on the top of the casting, and the side riser is arranged on the side face of a flange at the bottom of the casting. According to the casting system, the defects of shrinkage, dispersed shrinkage and cracking of the ZG35 valve casting can be effectively eliminated, the rate of finished products is increased, and mechanical performance of the ZG35 valve casting is improved.

Owner:HEBEI UNIV OF TECH

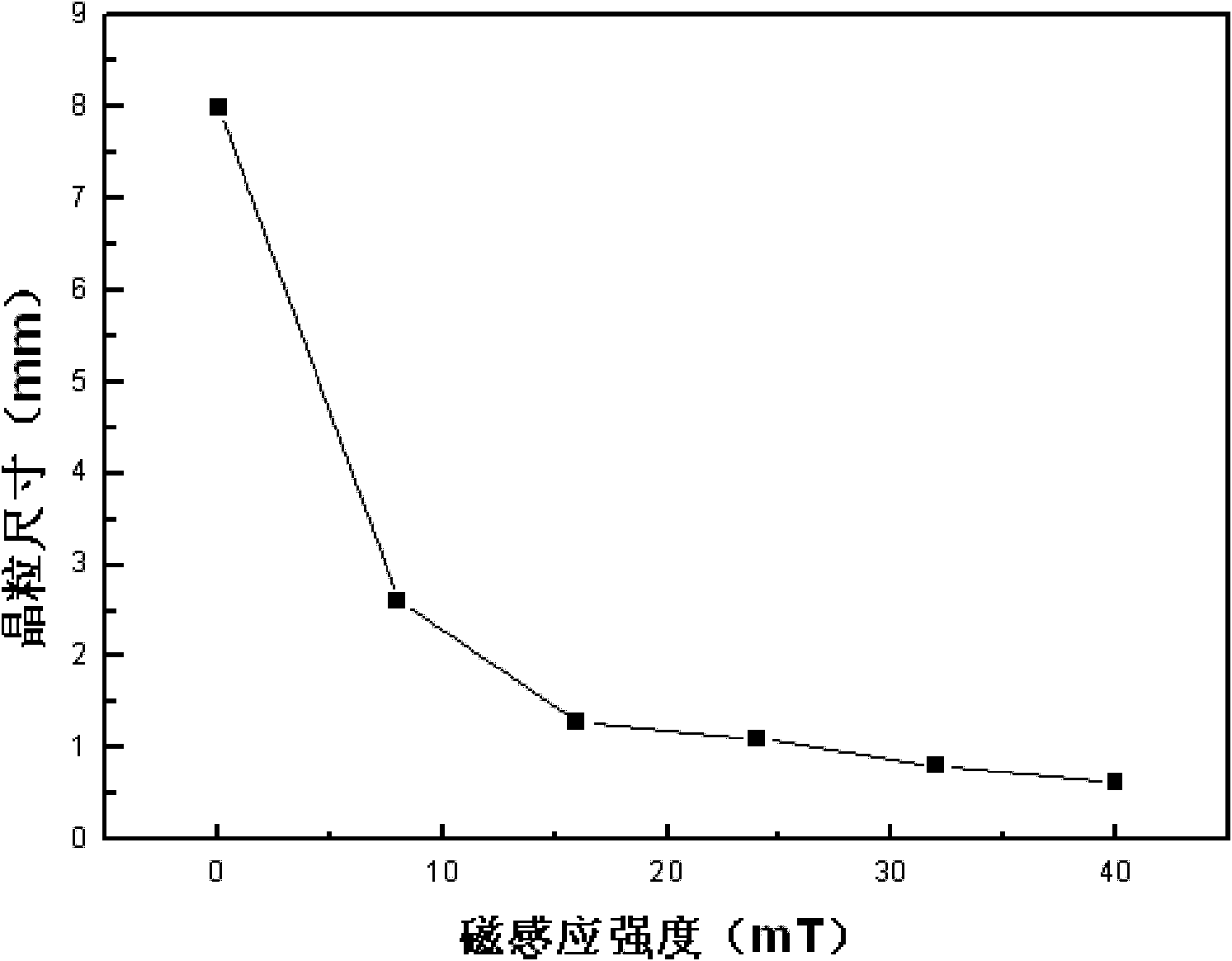

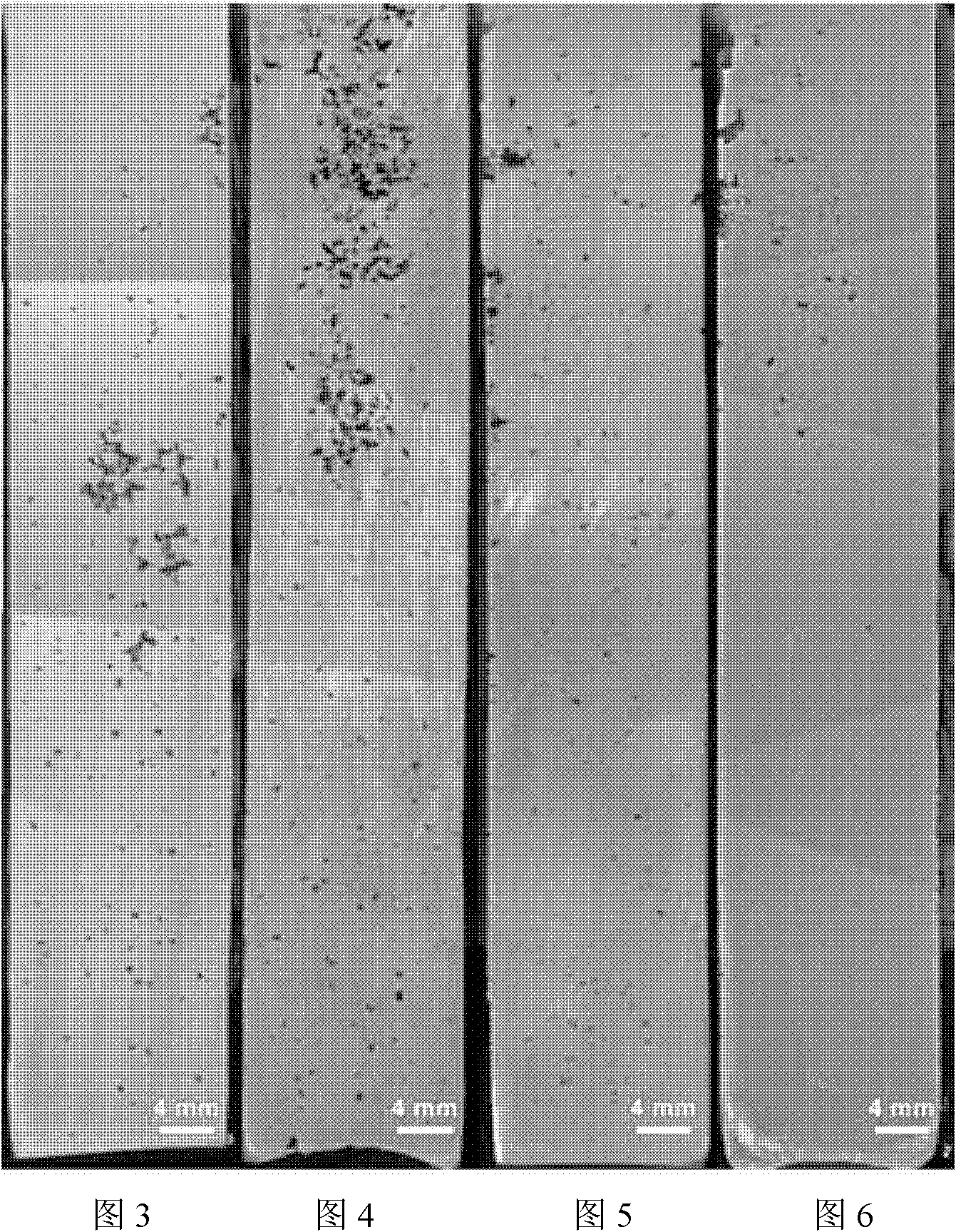

Precision casting method for refining aluminum alloy by using adjustable traveling wave magnetic field

The invention relates to a precision casting method for refining aluminum alloy by using an adjustable traveling wave magnetic field, belonging to the technical field of casting. The invention aims to solve the technical problems of high cost and difficulty in control in the process of grain refining and compacting for changing the properties of aluminum alloy in the prior art. The method provided by the invention comprises the following steps: 1. heating to melt aluminum alloy, and carrying out heat preservation,, thus obtaining an aluminum alloy molten mass; and 2. putting a casting mold, which is made of a non-magnetic material, in a traveling wave magnetic field inductor, turning on the traveling wave magnetic field inductor, adjusting the magnetic field intensity of the traveling wave magnetic field inductor, injecting the aluminum alloy molten mass obtained in the step 1 into the casting mold, and applying a traveling wave magnetic field, of which the magnetic field direction is vertically downward and the magnetic induction intensity is 32-500mT, onto the aluminum alloy molten mass to solidify the aluminum alloy under the traveling wave magnetic field, thereby completing the precision casting of the aluminum alloy. The method provided by the invention is easy to control and low in cost; and by utilizing the method provided by the invention, the obtained alloy crystal grains are fine, bubbles and voids can be effectively reduced, and the metal feeding capacity in the solidification process can be enhanced.

Owner:HARBIN INST OF TECH

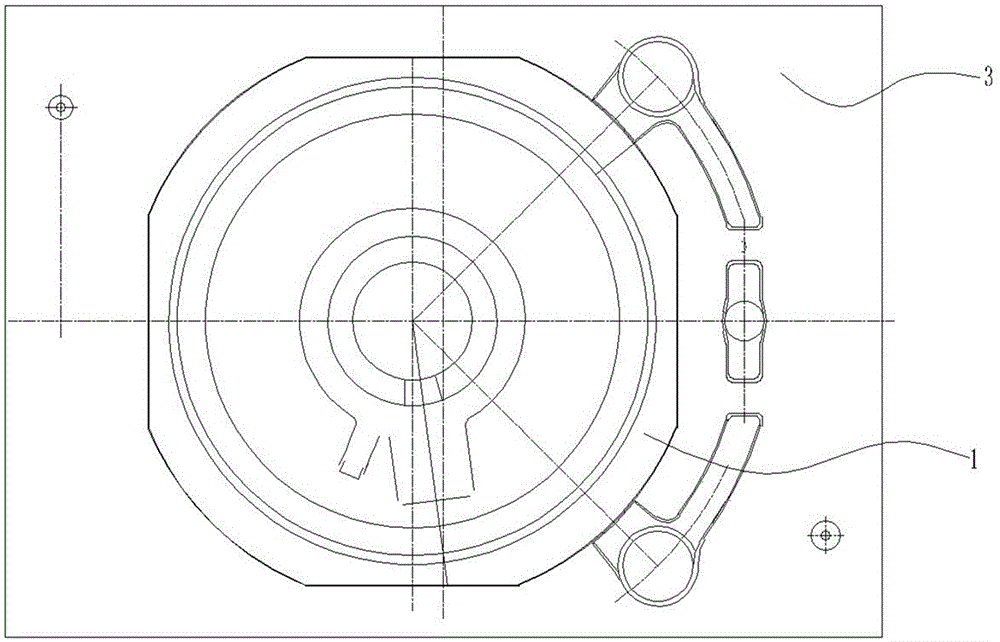

Processing and demoulding mechanism for automobile mould

InactiveCN103934934ASave human effortLow shrinkageStripping-off devicesForging/hammering/pressing machinesEngineeringMechanical engineering

The invention discloses a processing and demoulding mechanism for an automobile mould. The mechanism comprises a fixing plate, a rotary clamp, a plurality of lifting rods, a support plate and a push plate, wherein a plurality of push plate holes are formed in the fixing plate; the rotary clamp is connected with the fixing plate and positioned at the bottom of the fixing plate; the lifting rods are connected with the fixing plate and provided with a gear groove and correspondingly provided with a lifting device; the lifting device is provided with a motor and a gear; the support plate is a regular polygon with a hollow center and connected with the fixing plate; the push plate is matched with the support plate and has the same shape as the hollow center of the support plate. By virtue of the manner, the processing and demoulding mechanism for the automobile mould realizes automatic demoulding, reduces manpower, improves the production efficiency, eliminates shrinkage cavities, reduces shrinkage porosity or even eliminates shrinkage porosity.

Owner:SUZHOU YIQUN MOLD

Multi-point pressurizing type hydraulic die forging method

The invention discloses a multi-point pressurizing type hydraulic die forging method. The method comprises the steps of S1, adjusting the position and travel of each feeding pressing head to make ensure the feeding pressing head is at each corresponding hot spot position of a component and the travel of each feeding head is more than the density compact compression amount of the corresponding hot spot position; S2, pouring molten liquid under a temperature exceeding the temperature of liquid phase line of alloy into a die cavity or a pressing cavity which communicates with the die cavity; S2, fast closing the die, and applying a locking force to lock the die; S4, pressurizing the molten alloy to enable flowing and filling in the whole die cavity; S5, sequentially or synchronously applying a force to each hot spot position of the component and the pressing cavity to enable the molten alloy at the hot spot position to be fast solidified and subjected to rheological feeding until completely solidifying; S6, releasing all pressures, opening the die and removing the component. With the adoption of the method, the problem of liquid forging of large complex component can be effectively solved; the method has the advantages of being small in investment, free of shrinkage defect in the component, stable in product quality, and wide in applicable scope.

Owner:BEIJING JIAOTONG UNIV

Aluminum alloy material as well as preparing method and application thereof

InactiveCN104561698AImprove welding performanceImprove toughnessStructural componentNonferrous metal

The invention relates to an aluminum alloy material, in particular to an aluminum alloy material with high strength, high toughness and high welding performance as well as a preparing method and application thereof, and belongs to the field of nonferrous metal materials. The aluminum alloy material comprises the following components in percentage by mass: 0.55-1.0% of Mg, 0.40-0.80% of Si, 0.05-0.25% of Bi, 0.10-0.45% of Re and the balance of Al and unavoidable impurities. The aluminum alloy material has the characteristics of high strength, high toughness and high welding performance, and can be used as the raw material of pressure pipelines, porous flat flow pipes for air conditioner heat radiators and box structural components of rail vehicles.

Owner:ZHEJIANG LEXIANG ALUMINUM

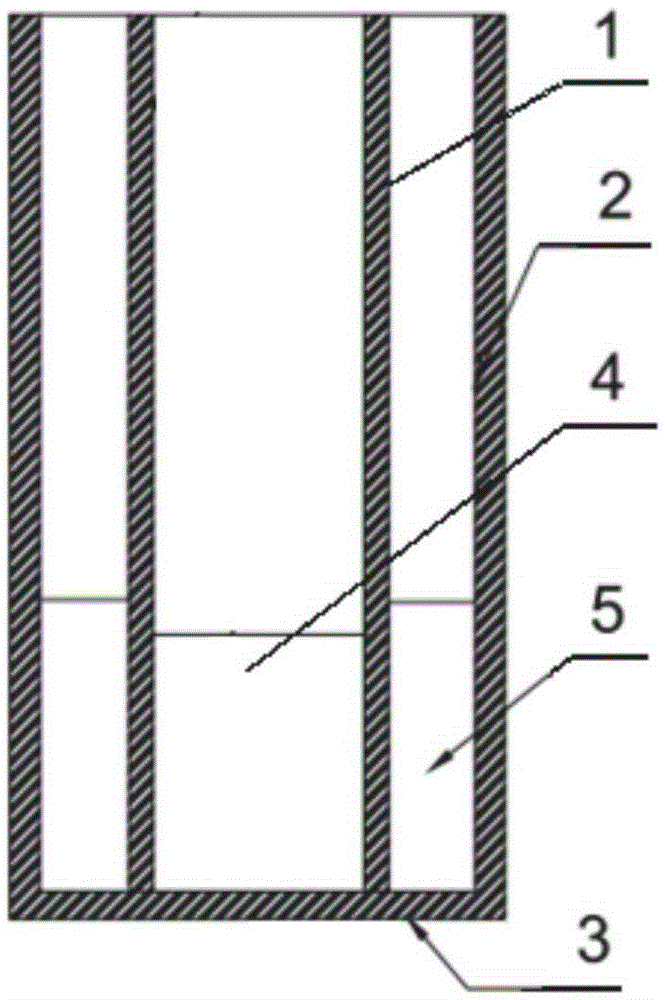

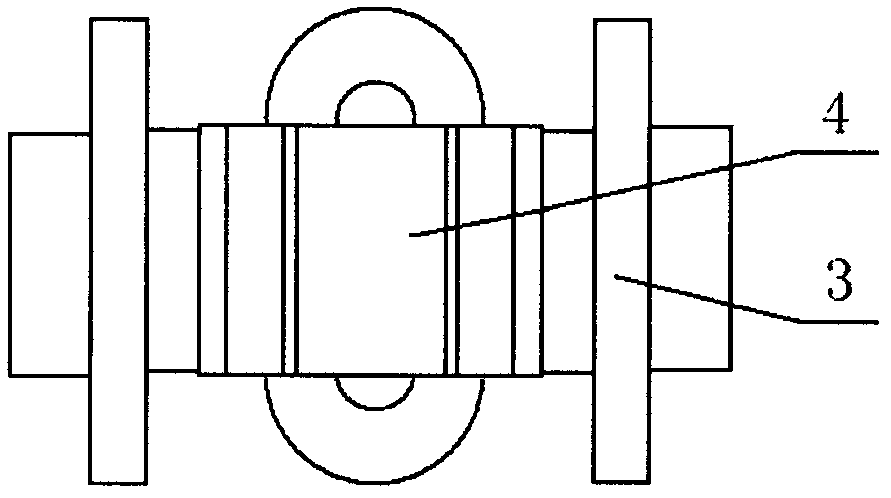

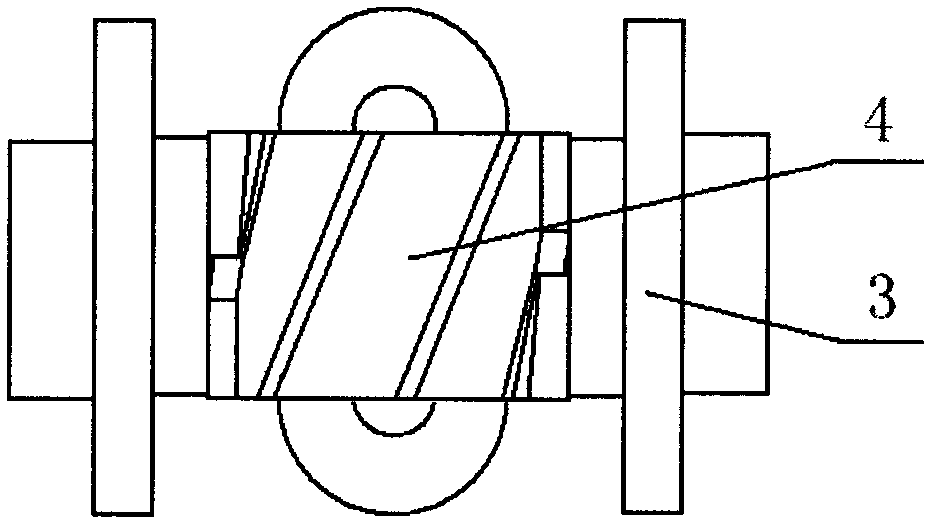

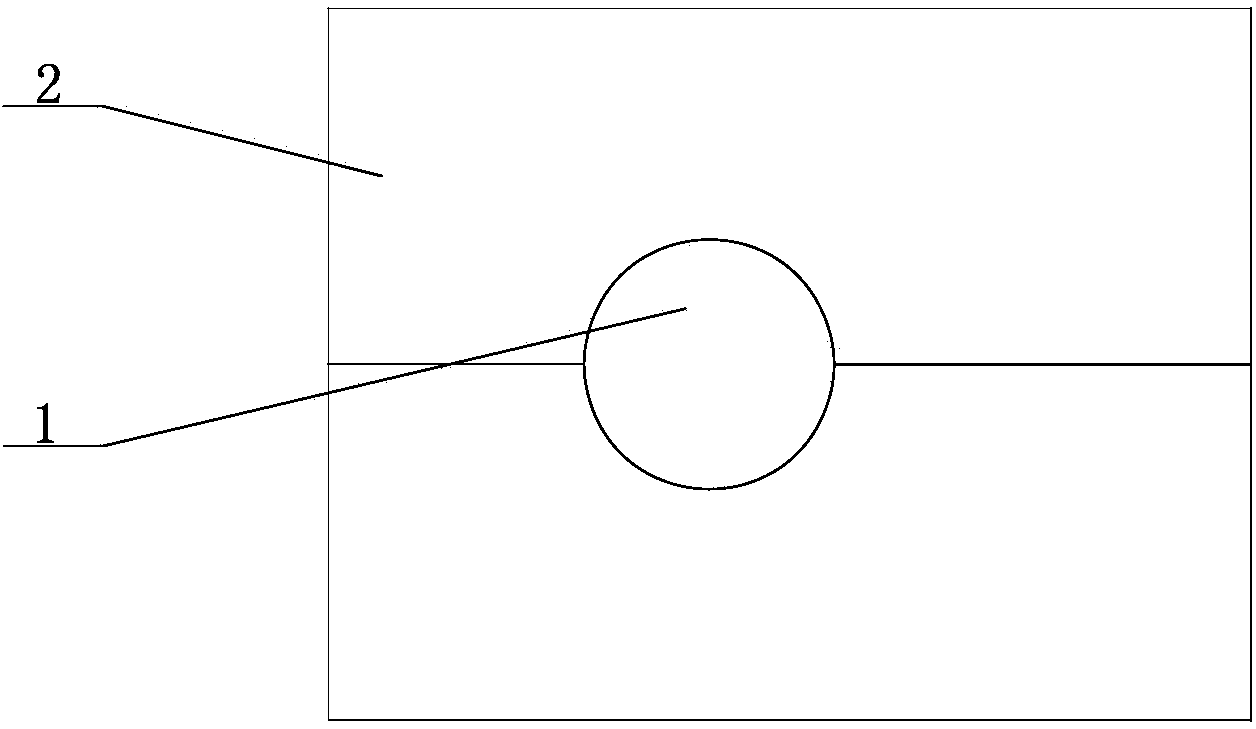

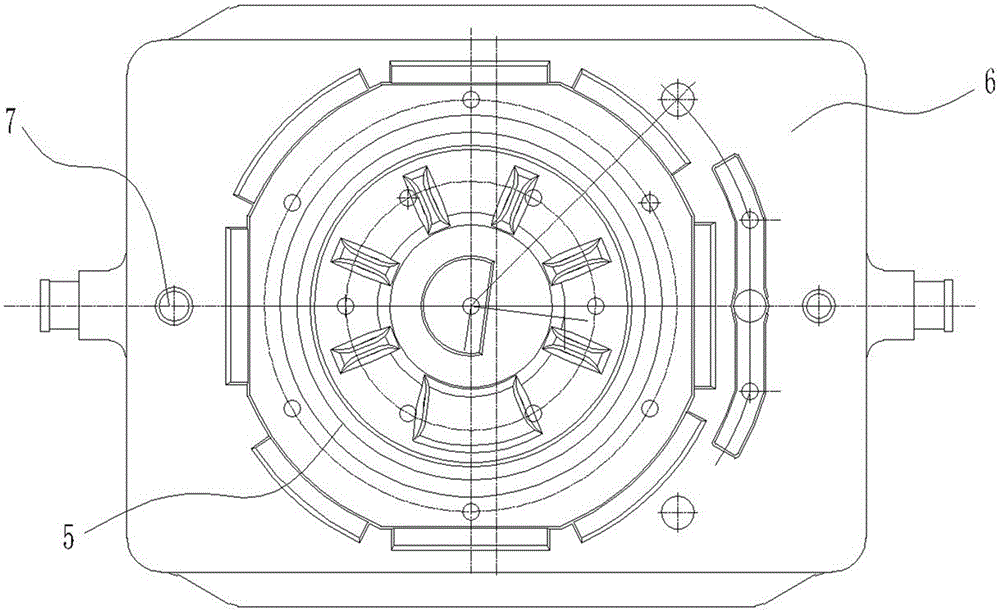

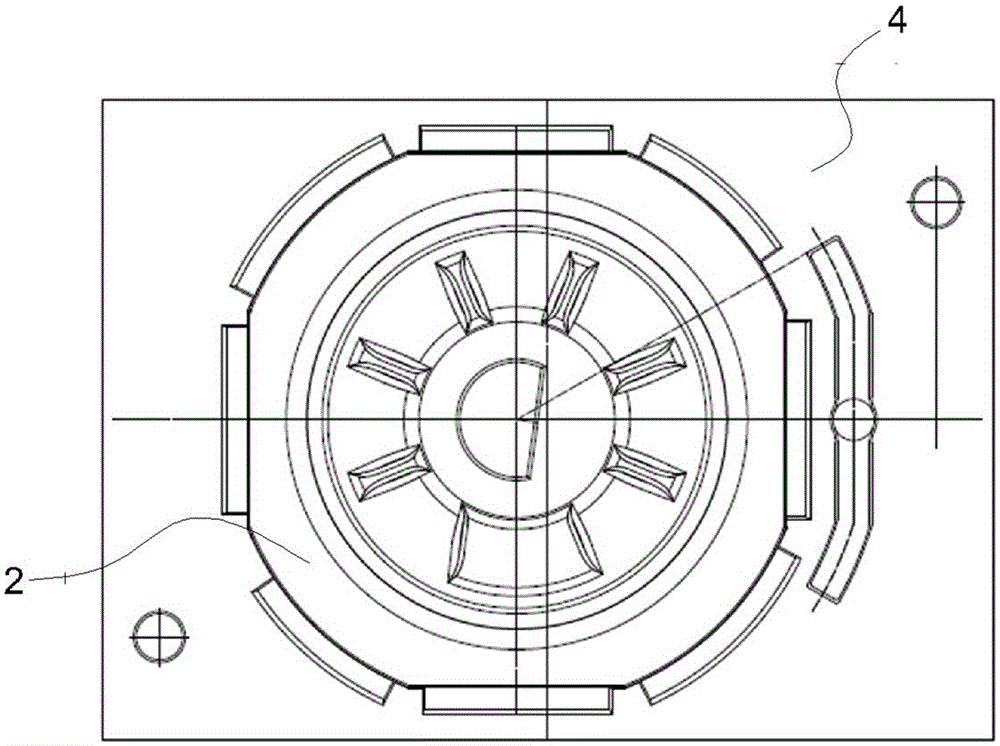

Helical electromagnetic stirring device

ActiveCN102825245AIncrease the axial grain rateReduce or even eliminate shrinkageSemi solidEngineering

The invention discloses a simple and effective helical electromagnetic stirring device capable of fully stirring molten metal. The helical electromagnetic stirring device comprises an electromagnetic induction system, a power supply system, a cooling system and a box body (5), wherein the electromagnetic induction system consists of a magnet yoke group and coils (3) sleeved on the magnet yoke group; the helical electromagnetic stirring device is characterized in that the magnet yoke group consists of a magnet yoke back part (12) and a plurality of magnet yoke end planes (4) connected with the magnet yoke back part; and the magnet yoke end planes (4) are arranged in a tilted manner opposite to the magnet yoke back part (12). According to the helical electromagnetic stirring device, the stirring device can be applied to metal continuous casting, semi-solid state continuous casting and directional solidification processes.

Owner:ANGANG STEEL CO LTD

Method for improving self-feeding capacity of high and thick large-cross section casting blank

ActiveCN102161090AAchieving radial self-feedingImprove the interface heat transfer coefficientState of artDiameter ratio

The invention relates to the field of casting blank manufacturing, in particular to a method for improving the self-feeding capacity of a high and thick large-cross section casting blank, and can solve the problems that the center quality of the thick large-cross section casting blank is poor, cracks are generated on the surface of the thick large-cross section casting blank, and the rejection rate is high in the prior art. The method comprises the following steps of: controlling external cooling conditions of different solidification stages of the casting blank to quickly solidify the outer surface of the casting blank to form a shell, establish strength and prevent surface cracks from being generated; performing heat preservation and slow cooling on the surface of the casting blank to keep a large area of a core part in a pasty area, wherein a solidification layer on the outer surface of the casting blank is kept at a higher temperature so that plastic deformation is realized; and performing simultaneous solidification and solid-phase movement in the subsequent solidifying and shrinking process of the casting blank to fulfill the aim of radial self-feeding of a deformable metal at a high temperature so as to eliminate the internal shrinkage cavities and surface cracks of the casting blank and obviously improve the looseness until the internal looseness of the casting blank is eliminated. The method is applicable to the high and thick large-cross section casting blank, particularly to a thick large-cross section casting round blank and a thick large-cross section casting square blank of which the height-diameter ratio is high and the axial looseness cannot be improved through riser feeding.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

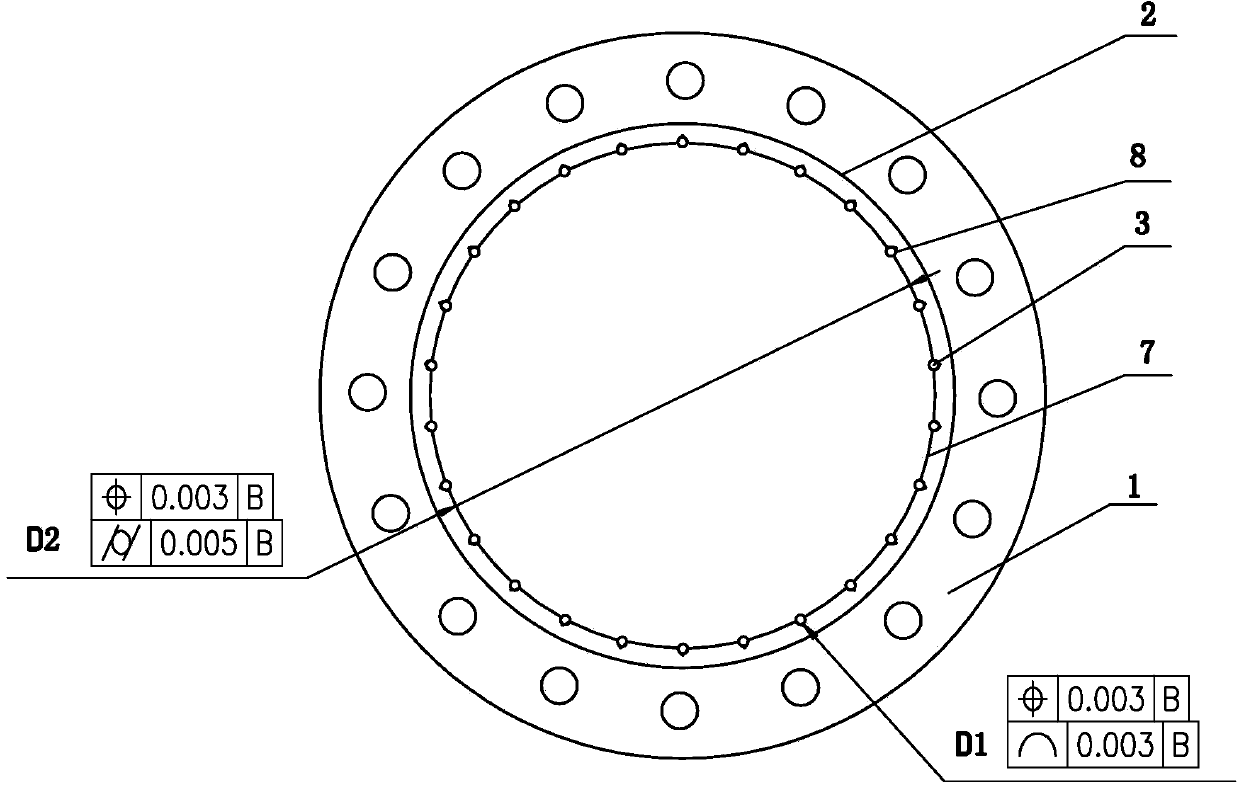

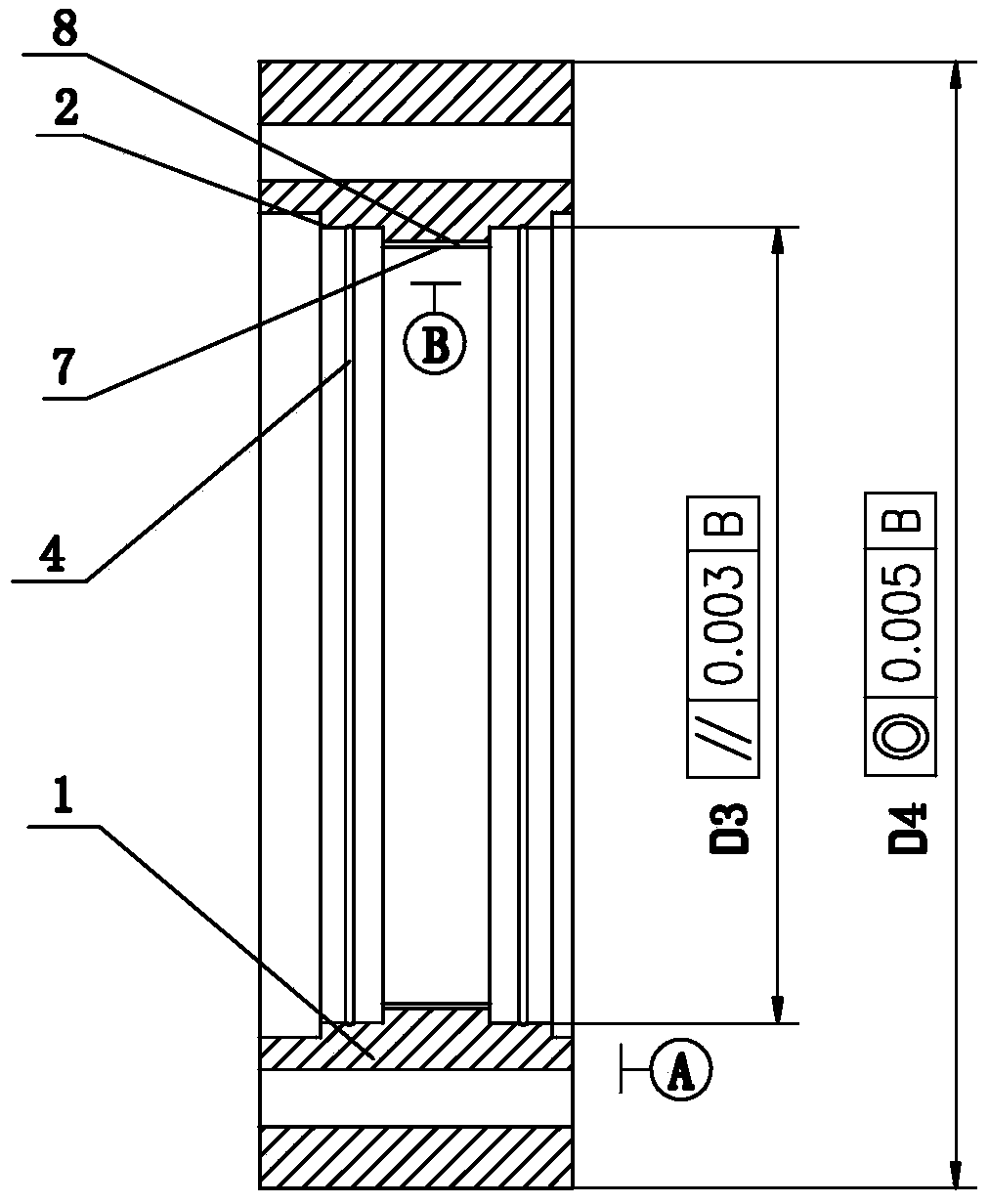

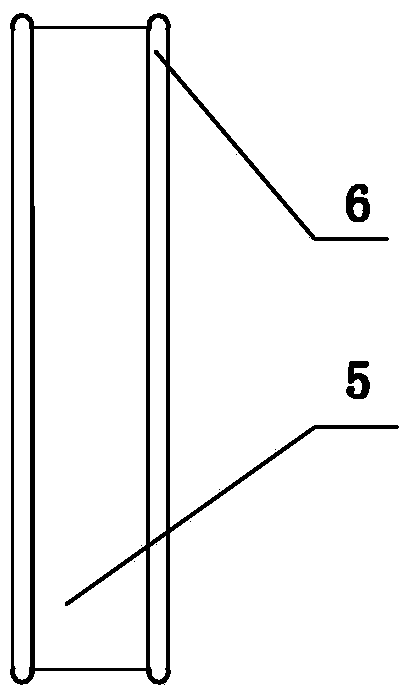

Processing technology of robot RV speed reducer needle gear shell

The invention discloses a processing technology of a robot RV speed reducer needle gear shell, and belongs to the technical field of robot RV speed reducer processing. The processing technology includes the steps that precise casting or forging is carried out on a needle gear shell blank; the needle gear shell blank is clamped after the surface of the needle gear shell blank is machined, and the rotation center of the needle gear shell blank is taken as a positioning reference; the end face of the needle gear shell blank, a bearing position of a roller pin bearing and bearing positions of two main bearings are machined; finish machining is carried out on the inner surface of the roller pin bearing according to the positioning reference; finish machining is carried out on a roller pin groove in line contact with a roller pin of the roller pin bearing according to the positioning reference; inner grooves are simultaneously machined in the bearing positions of the two main bearings in a finish machining mode according to the positioning reference; finish machining is carried out on the outer surface of the needle gear blank. The needle gear shell machined according to the steps improves machining precision and the parallelism degree of the bearing positions of the main bearings, guarantees coaxiality, the position degree and cylindricity of the main bearings after installation, achieves one-time clamping, can meet requirements of multiple process parameters, improves machining precision and installation precision of the needle gear shell, reduces accumulated errors, meets the high-precision requirements, and prolongs service life.

Owner:SHANDONG SHKE MACHINERY MFG

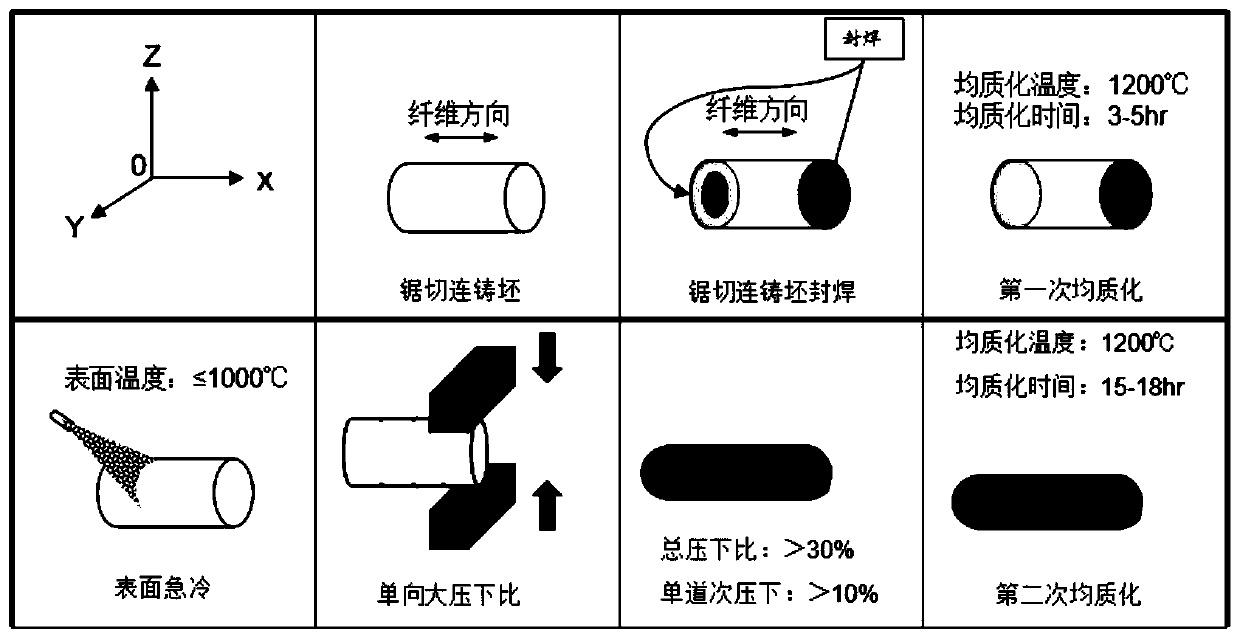

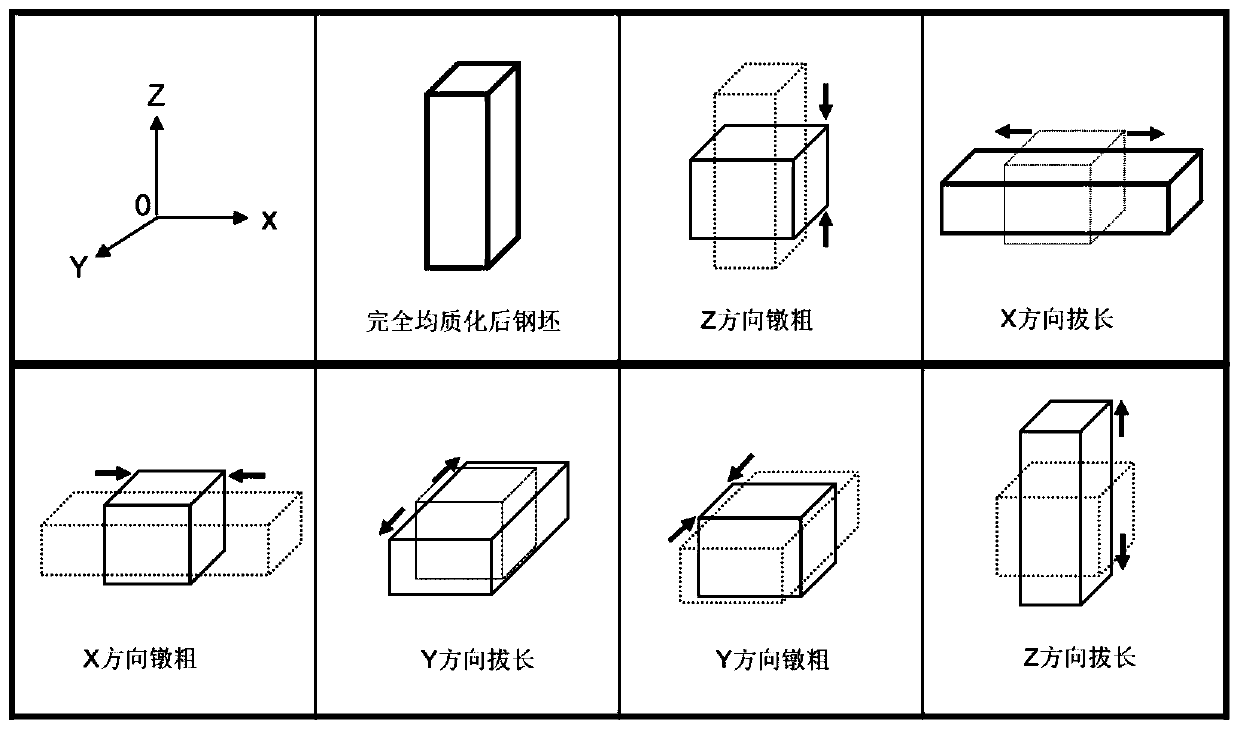

Method for producing hot work mold steel adopting continuous casting billet direct forging

ActiveCN109894473AQuality improvementUniform qualityTemperature control deviceWork treatment devicesDecompositionCarbide

The invention provides a method for producing hot work mold steel adopting continuous casting billet direct forging. The method specifically comprises the steps that end face seal welding or overlaying is performed on a sawed and cut continuous casting billet, after that, first-time homogenization is performed, and the homogenization is performed for 3-6 h with the temperature being 1150-1320 DEGC; the surface of the continuous casting billet after the first-time homogenization is quenched to 1050 DEG C or below to perform one-way large press down ratio deformation, and second-time homogenization is performed for 10-20 h with the temperature being 1150-1320 DEG C; three-way forging is performed on the steel billet after the second-time homogenization; the initial forging temperature of the three-way forging is 1250 DEG C or below, and the final forging temperature is 800-950 DEG C; and a product is obtained through grain refining and annealing. According to the method for producing the hot work mold steel adopting the continuous casting billet direct forging, by means of organic combination of continuous casting billet special treatment, the two times of homogenization and two times of the forging, kinetic conditions favorable to diffusion of carbon and alloy elements are created, and continuous casting billet central continuity loose pores and other defects, decomposition liquid chromatography carbides and banded structures generated by dendritic segregation are completely eliminated.

Owner:江阴华润制钢有限公司

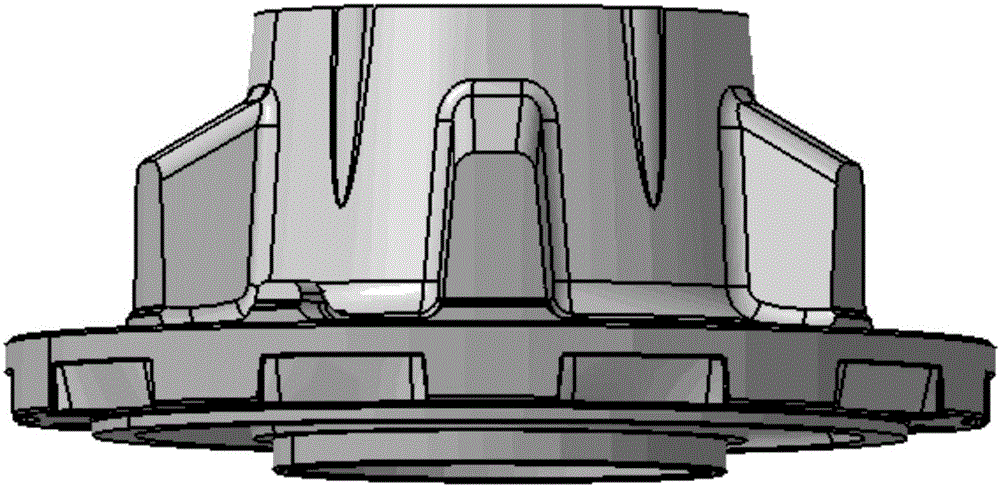

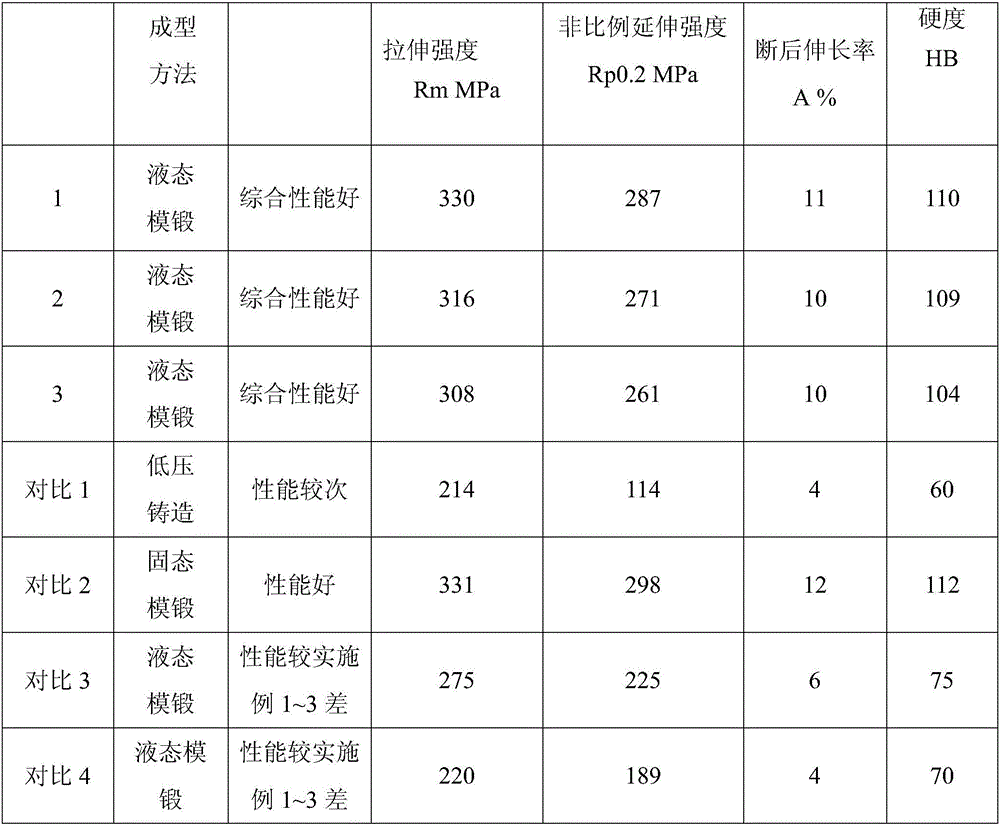

Liquid forging technology method for 6061 material commercial vehicle aluminum alloy shaft head

ActiveCN106319305AImprove metallographic structureEliminate shrinkageRare-earth elementSurface finishing

The invention discloses a liquid forging technology method for a 6061 material commercial vehicle aluminum alloy shaft head. The method mainly comprises the following steps of alloy component optimizing, smelting, melt purifying, liquid forging forming, demolding, trimming, hole tapping, heat treatment enhancing, machining and surface treatment. Firstly, components of elements in a 6061 alloy are optimized, a proper number of rare earth elements Gd and Sm and a proper number of elements Hf are added in a matched manner, and the vehicle shaft head is prepared through combination of the liquid forging technology; and through optimization of the chemical components of the alloy and the melt purifying technology, the metallographical structure of the alloy is improved, and shrinkage, loosening, air holes, cracks and other inner defects of products are greatly removed. The appearance quality of the shaft head product is obviously improved, the inner defects are obviously reduced, the production efficiency is high, the process is short, the technology cost is low, energy is saved, environment pollution is little, and economic benefits and social benefits are obvious.

Owner:辽宁忠相铝业有限公司

Method for casting vermicular graphite cast iron cylinder cover of diesel engine

ActiveCN104308079AStrong maneuverabilityStable productionFoundry mouldsFoundry coresCast ironDiesel engine

The invention belongs to the field of methods for casting a large-size diesel engine vermicular graphite cast iron cylinder cover, and in particular relates to a method for casting a vermicular graphite cast iron cylinder cover of a diesel engine. The method comprises the following steps: (1) manufacturing an air passage core box; (2) manufacturing an air passage sand core; (3) soaking in a coating; (4) inserting a graphite rod into a positioning hole of the air passage sand core; (5) removing rest sand cores and air passage sand cores of the cylinder cover; (6) casting the cylinder cover. The method is simple and high in operability, stable production can be achieved under the condition of molten iron control fluctuation, the rejection rate of the vermicular graphite cast iron cylinder cover of the diesel engine is reduced, the problems that the position of a guide rod hole of the vermicular graphite cast iron cylinder cover is loosened or the hole is shrunk are avoided, the leakage of a guide tube hole is controlled to be within 2%, and the casting quality of other parts is not affected. The economic loss of companies is reduced, and the manufacturing cost is lowered.

Owner:ZICHAI POWER CO LTD

Method for casting end cap of non-transmission end of traction motor on subway locomotive

InactiveCN105108070AEliminate shrinkageEliminate defects such as cracksFoundry mouldsFoundry coresTraction motorMaterials science

The invention relates to a method for casting an end cap of a non-transmission end of a traction motor on a subway locomotive. According to the method, a sand faced permanent iron molding technology is adopted. Through the sand faced permanent iron molding technology, a cavity which is in the shape of a complete end cap of the non-transmission end is obtained, and four cores are fed to directly cast a part of the end cap of the non-transmission end, appearance and inner quality of castings are improved effectively, scrappage of the castings is reduced, weight of the castings is reduced by 16%, production efficiency is improved greatly, and a large amount of time and cost of labor and equipment are saved. By the method, the cost is reduced by 28%. Moreover, the method is simple and practical, obvious in economic benefit, wide in market prospect and suitable for most of enterprises.

Owner:侯马市晋烽机械铸造有限公司

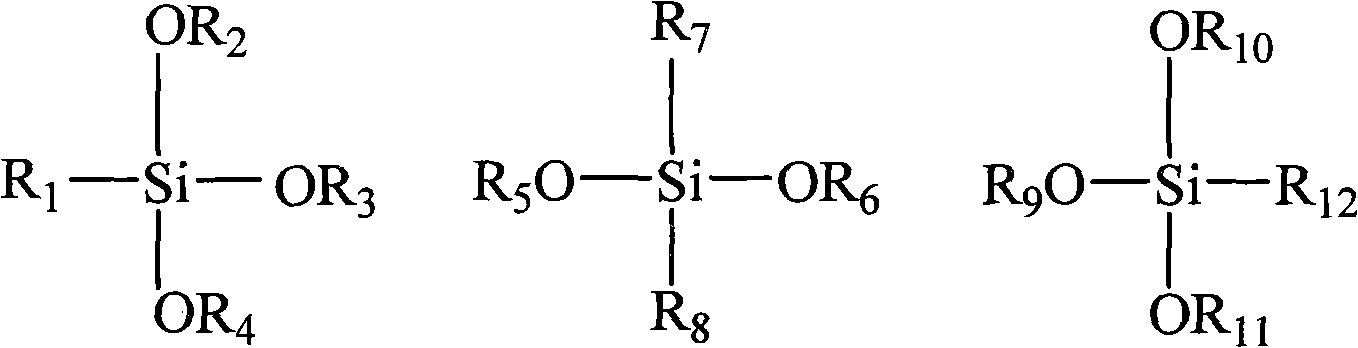

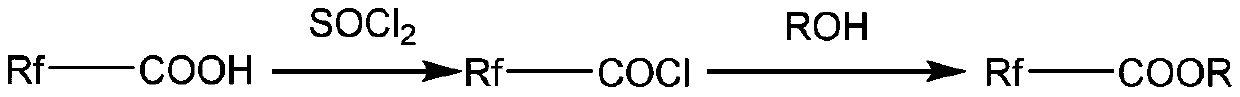

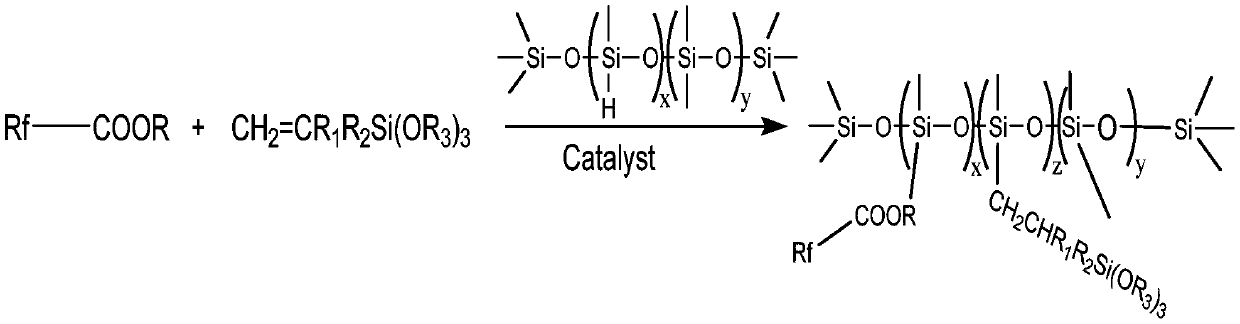

Perfluoropolyether modified polysiloxane coating aid, preparation method thereof and coating

InactiveCN111234237ASpread evenlyEliminate shrinkageAntifouling/underwater paintsPaints with biocidesPolymer sciencePtru catalyst

The invention discloses a perfluoropolyether modified polysiloxane coating aid, a preparation method thereof and a coating. Perfluoropolyether acrylate reacts with siloxane containing carbon-carbon double bonds and hydrogen-containing silicone oil under the action of a catalyst to obtain the perfluoropolyether modified polysiloxane coating aid, wherein a feeding molar ratio of perfluoropolyether acrylate to siloxane containing carbon-carbon double bonds to hydrogen-containing silicone oil is (1-9):(1-9):1, and perfluoropolyether acrylate is obtained by reacting perfluoropolyether acyl chloridewith a hydroxyl-containing acrylate compound according to a feeding molar ratio of 1:(1-1.5). Perfluoropolyether carboxylic acid, a hydroxyl-containing acrylate compound, siloxane containing carbon-carbon double bonds and hydrogen-containing silicone oil carry out reactions to prepare the perfluoropolyether modified polysiloxane coating aid. The problem that phenomenon such as cavity shrinkage, uneven spreading, wrinkled surface, cracking, rough and uneven surface, and the like, easily happens in the coating process of a fluorine-silicon coating agent with a high fluorine content is solved, the fluorine-silicon coating agent can be evenly spread on a hard base material, and better hydrophobic, oleophobic and antifouling effects can be achieved on the surface of the base material.

Owner:东莞泰岳先进材料有限公司

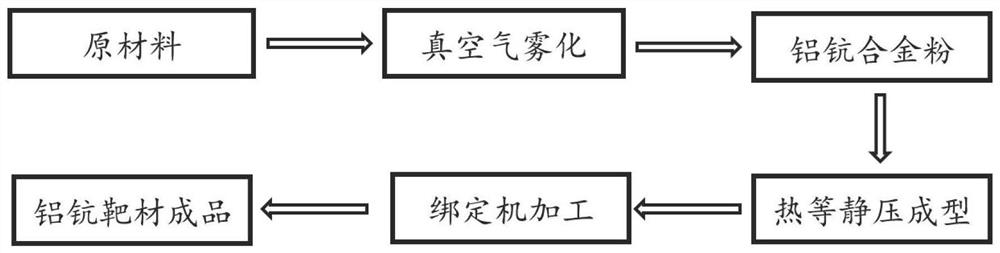

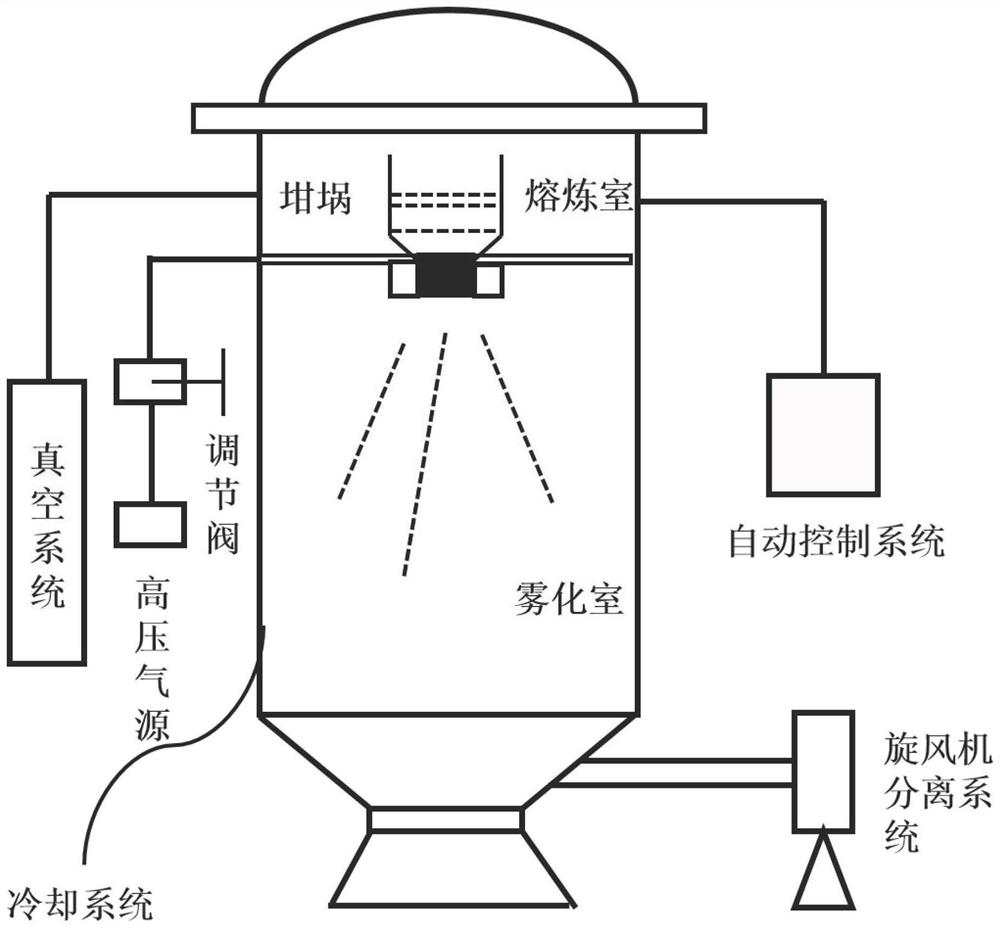

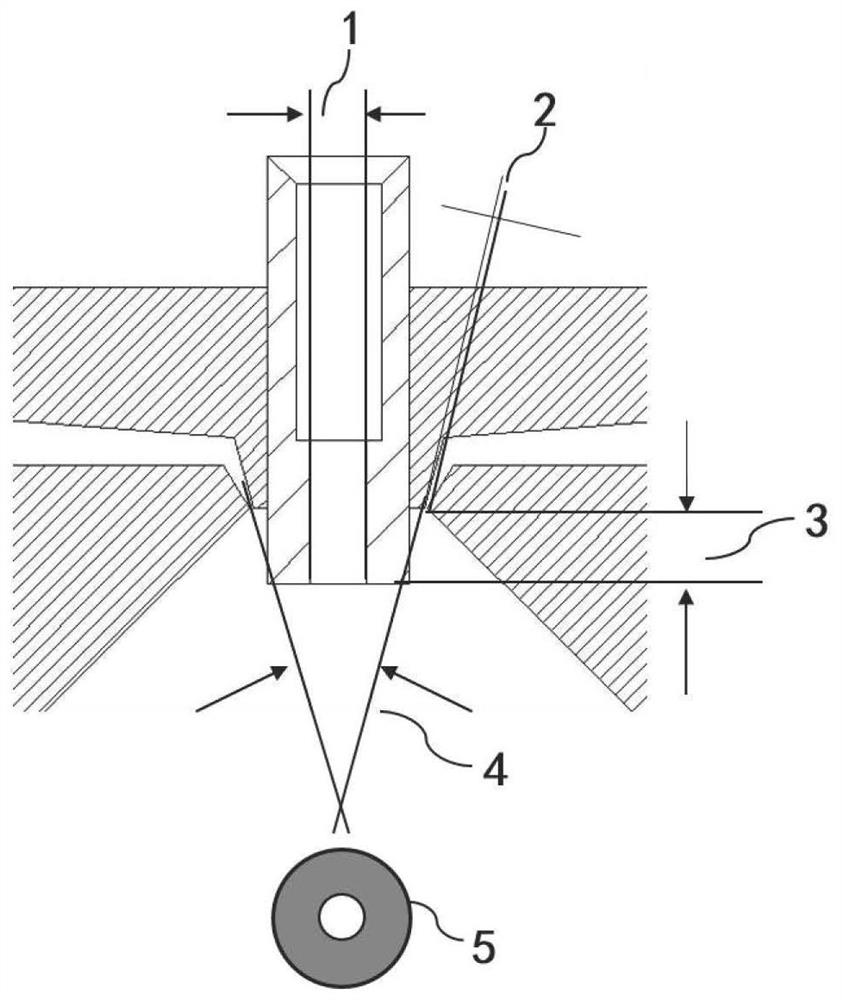

Preparation method of aluminum-scandium alloy sputtering target material

InactiveCN111636054AReduce oxygen contentHigh degree of densificationVacuum evaporation coatingSputtering coatingGrain structureHot isostatic pressing

The invention provides a preparation method of an aluminum-scandium alloy sputtering target material, and relates to the technical field of target material preparation. The preparation method of the aluminum-scandium alloy sputtering target material comprises the following steps that an aluminum source and a scandium source are mixed, and vacuum melting is conducted on an obtained aluminum-scandium alloy ingredient to obtain a molten aluminum-scandium alloy liquid; vacuum gas atomization is conducted on the molten aluminum-scandium alloy liquid by using an inert gas flow to obtain aluminum-scandium alloy powder; outer sheathing and hot isostatic pressing molding are sequentially conducted on the aluminum-scandium alloy powder to obtain an aluminum-scandium alloy sputtering target blank; and the aluminum-scandium alloy sputtering target blank is bound and machined to obtain an aluminum-scandium alloy sputtering target material. According to the method, the vacuum gas atomization is conducted by using the inert gas flow, contact between the molten aluminum-scandium alloy liquid and oxygen is isolated, the prepared aluminum-scandium alloy powder is high in sphericity degree, low in oxygen content, and uniform in grain structure, particle size and microstructure, and the aluminum-scandium alloy sputtering target material obtained by utilizing hot isostatic pressing molding is highin density, uniform in chemical component, and free of the defects such as segregation.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com