Patents

Literature

140 results about "Ferrite substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferrite substrates are obtained for partially magnetized substrates in the direction. of wave propagation and vertically magnetized substrates with variable DC. magnetic field. The obtained results are applied to analyze variable phase shifters, controlled resonators, and impedance matching.

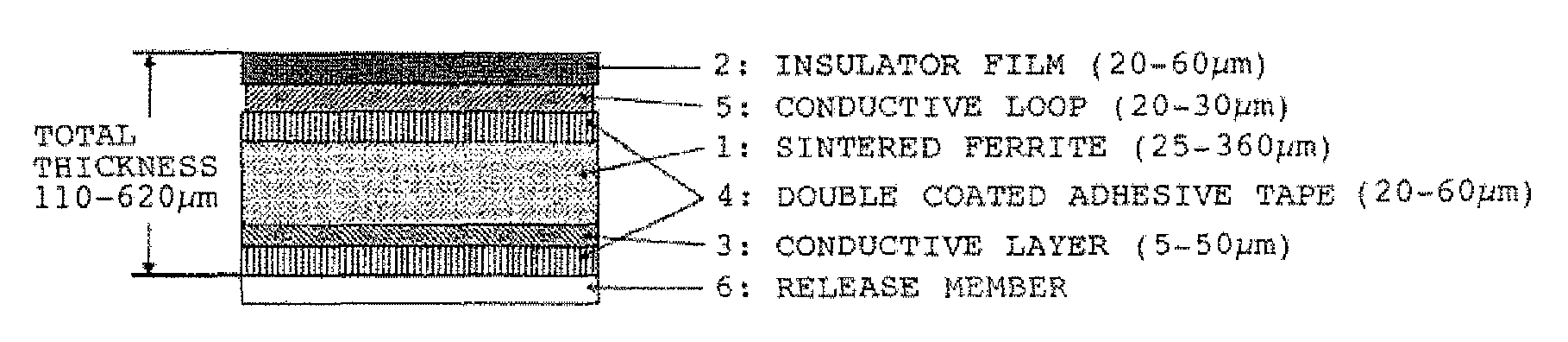

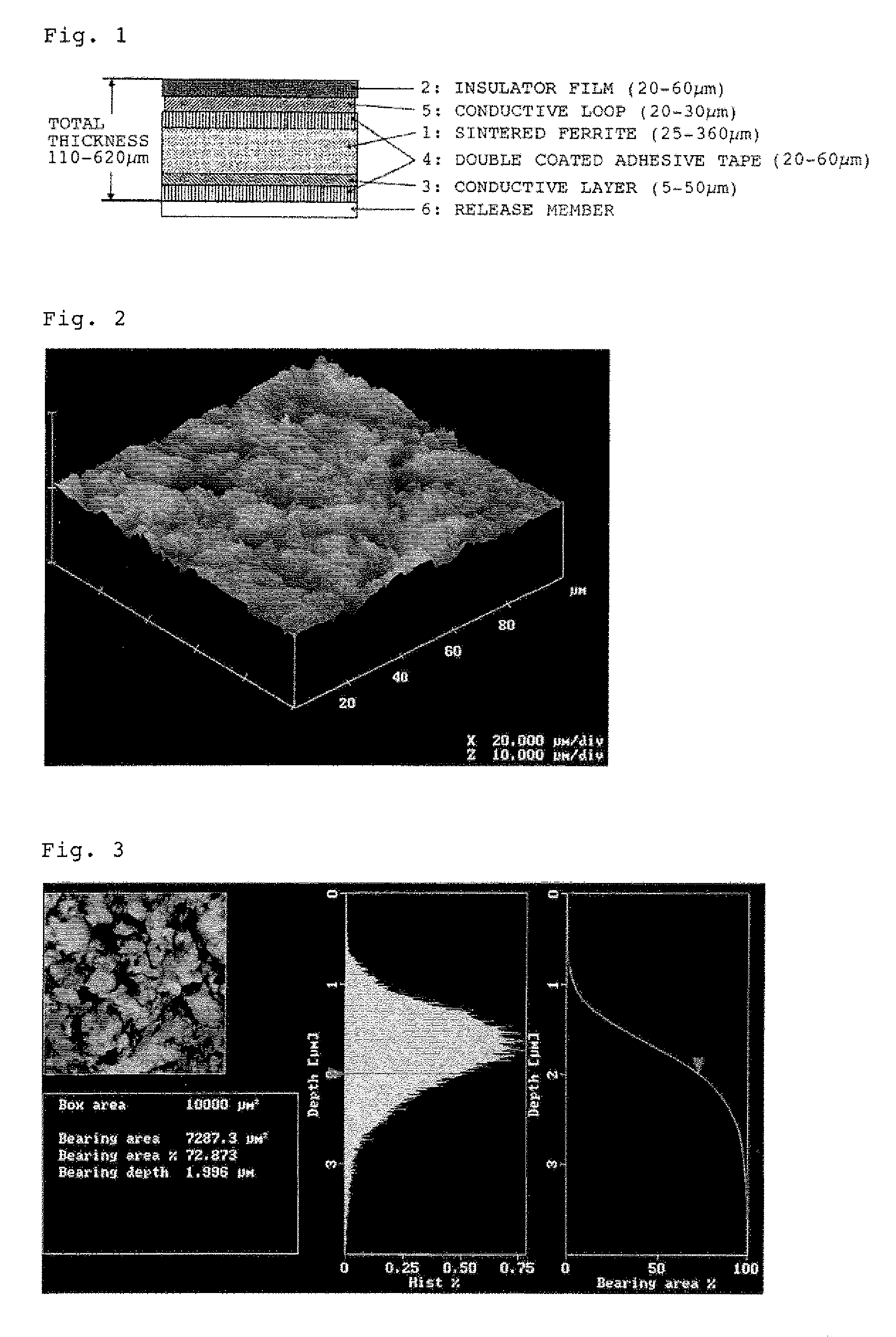

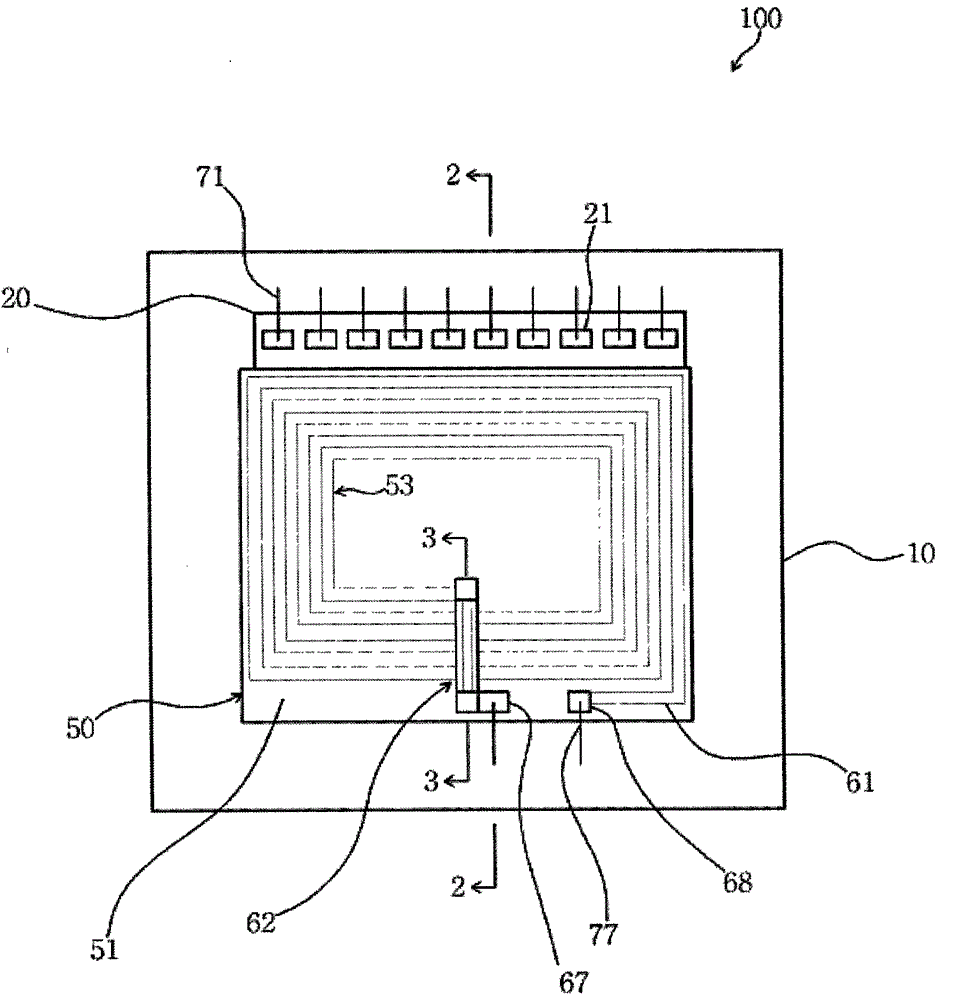

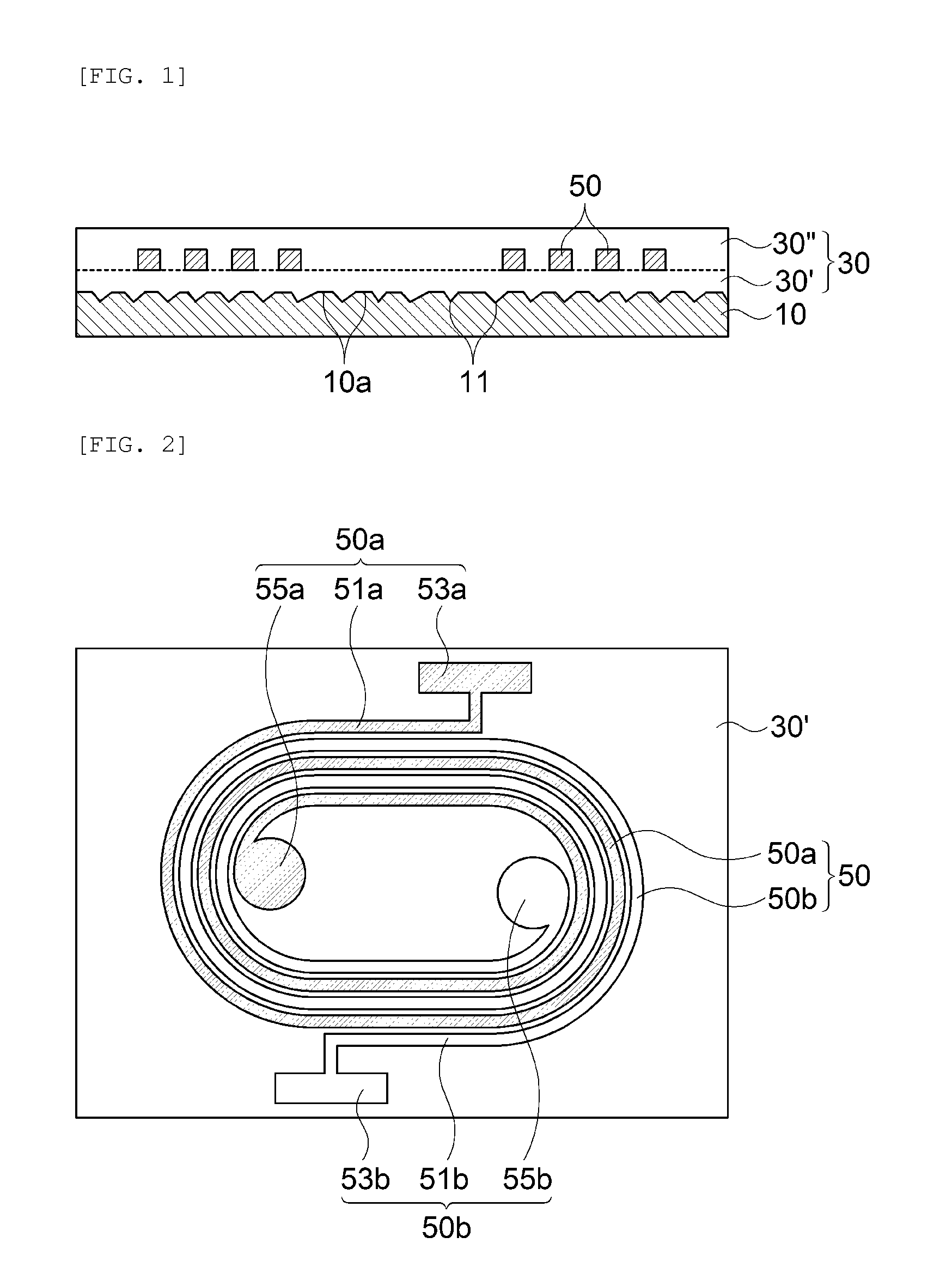

Molded ferrite sheet, sintered ferrite substrate and antenna module

ActiveUS20080224937A1Eliminate procedureReduce instabilityLoop antennas with ferromagnetic coreAntenna supports/mountingsOccupancy rateFerrite substrate

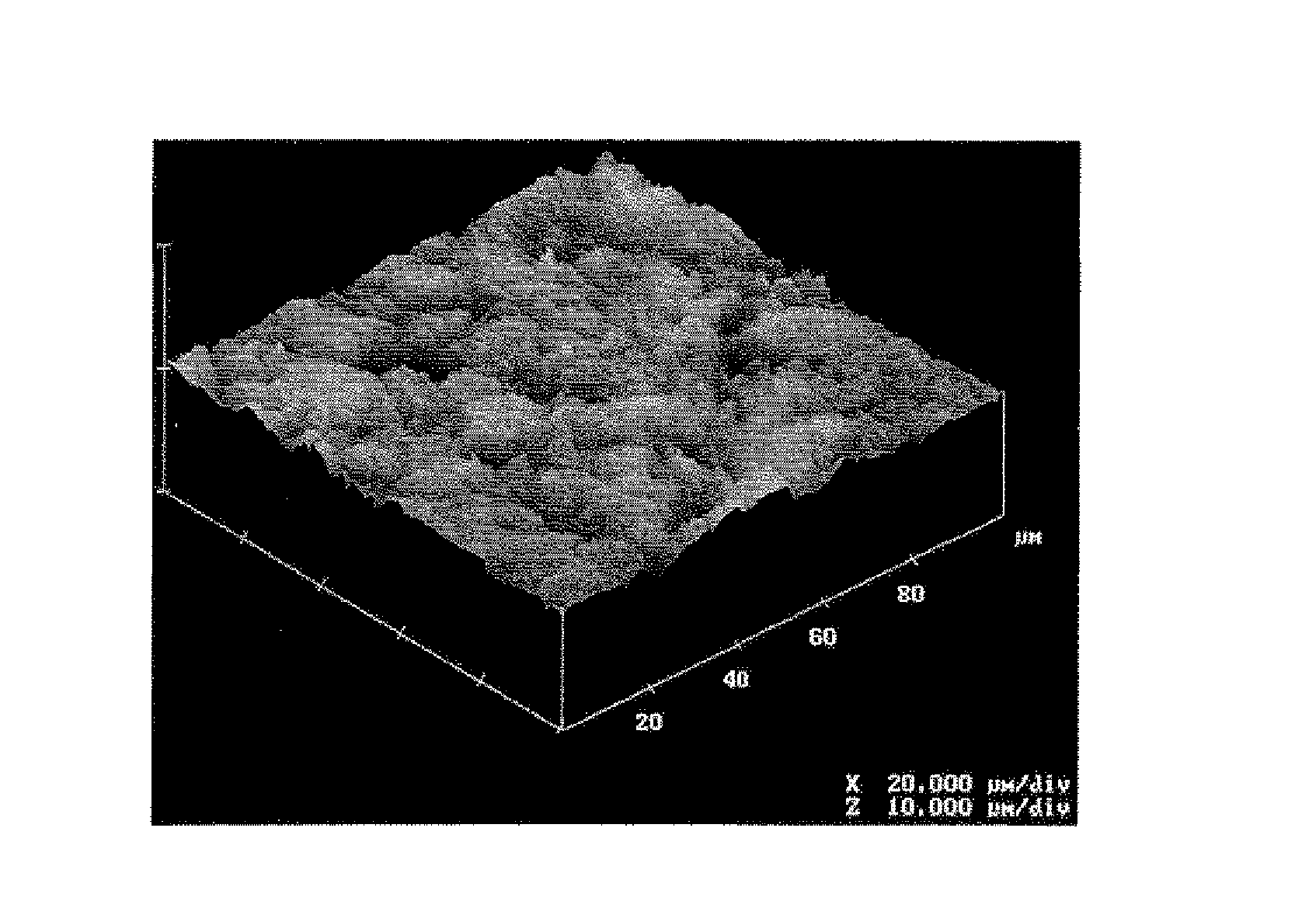

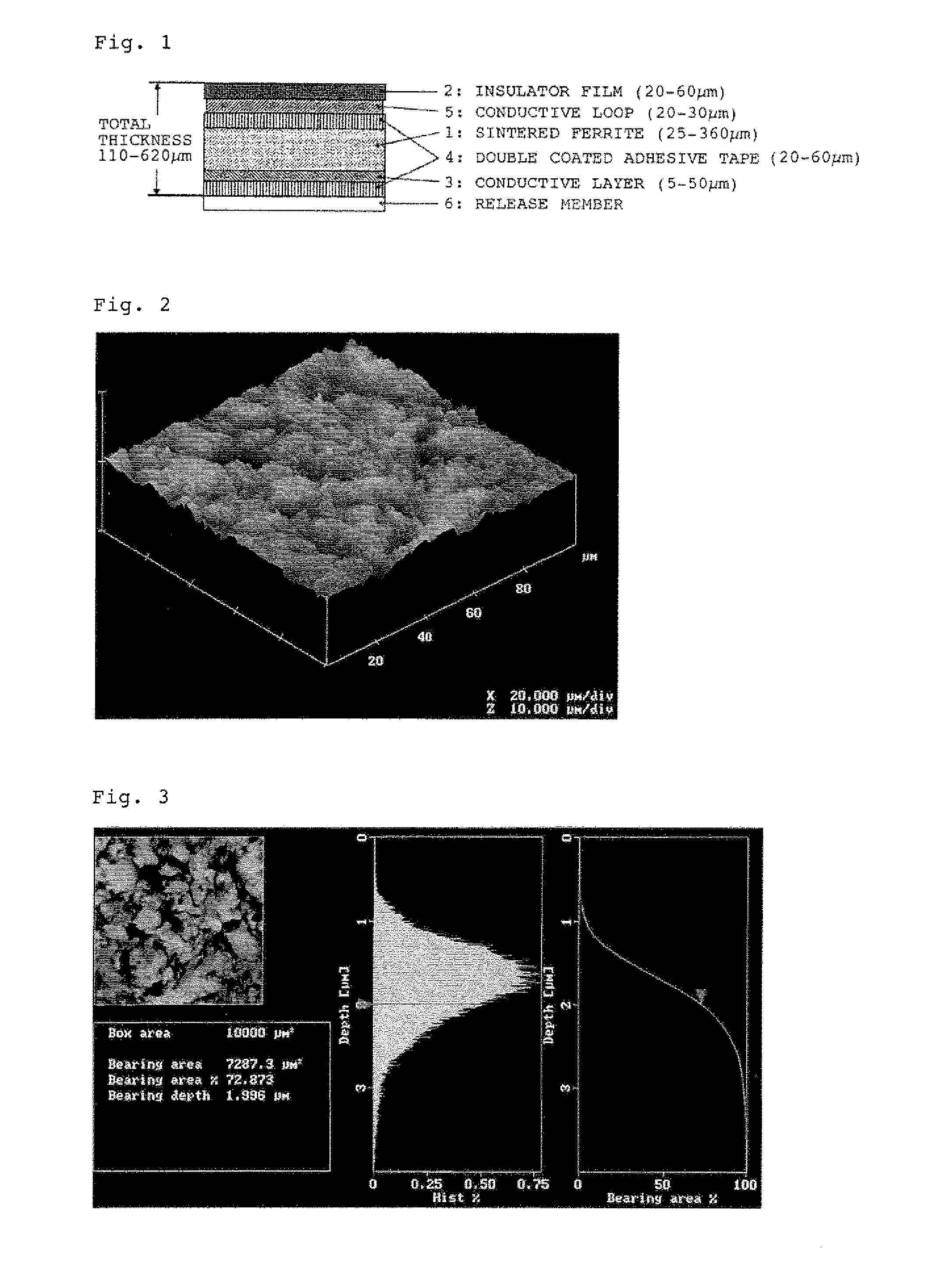

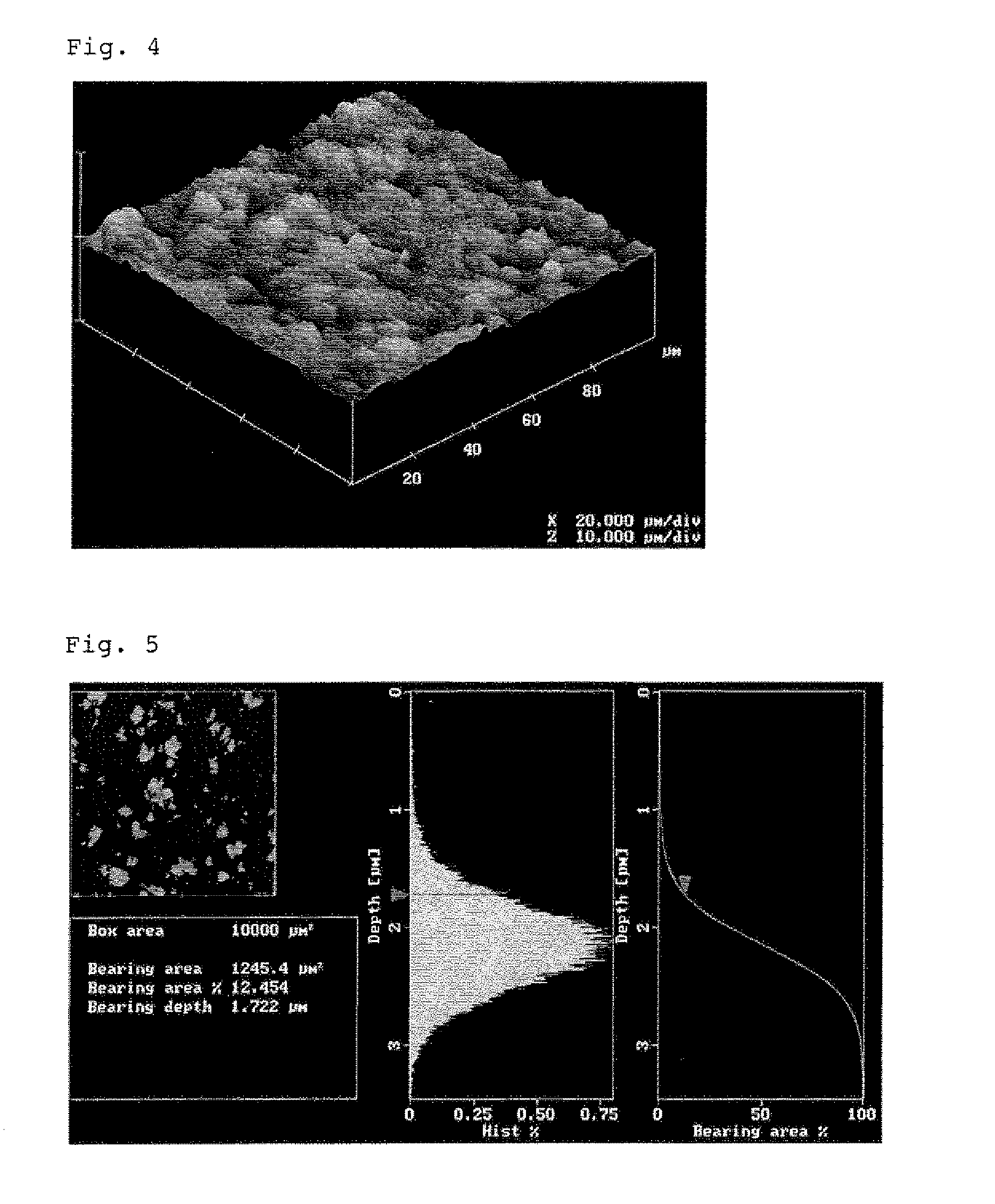

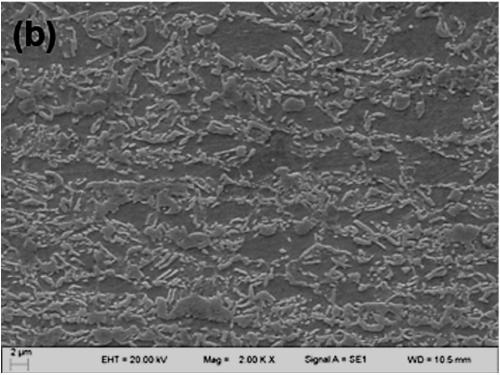

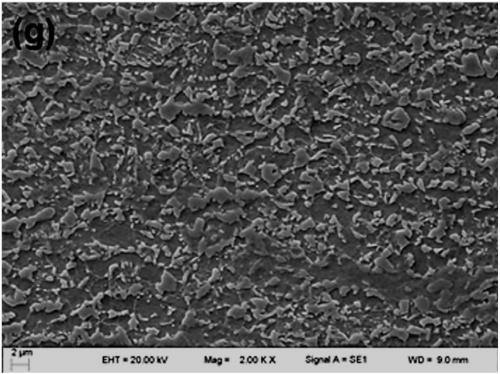

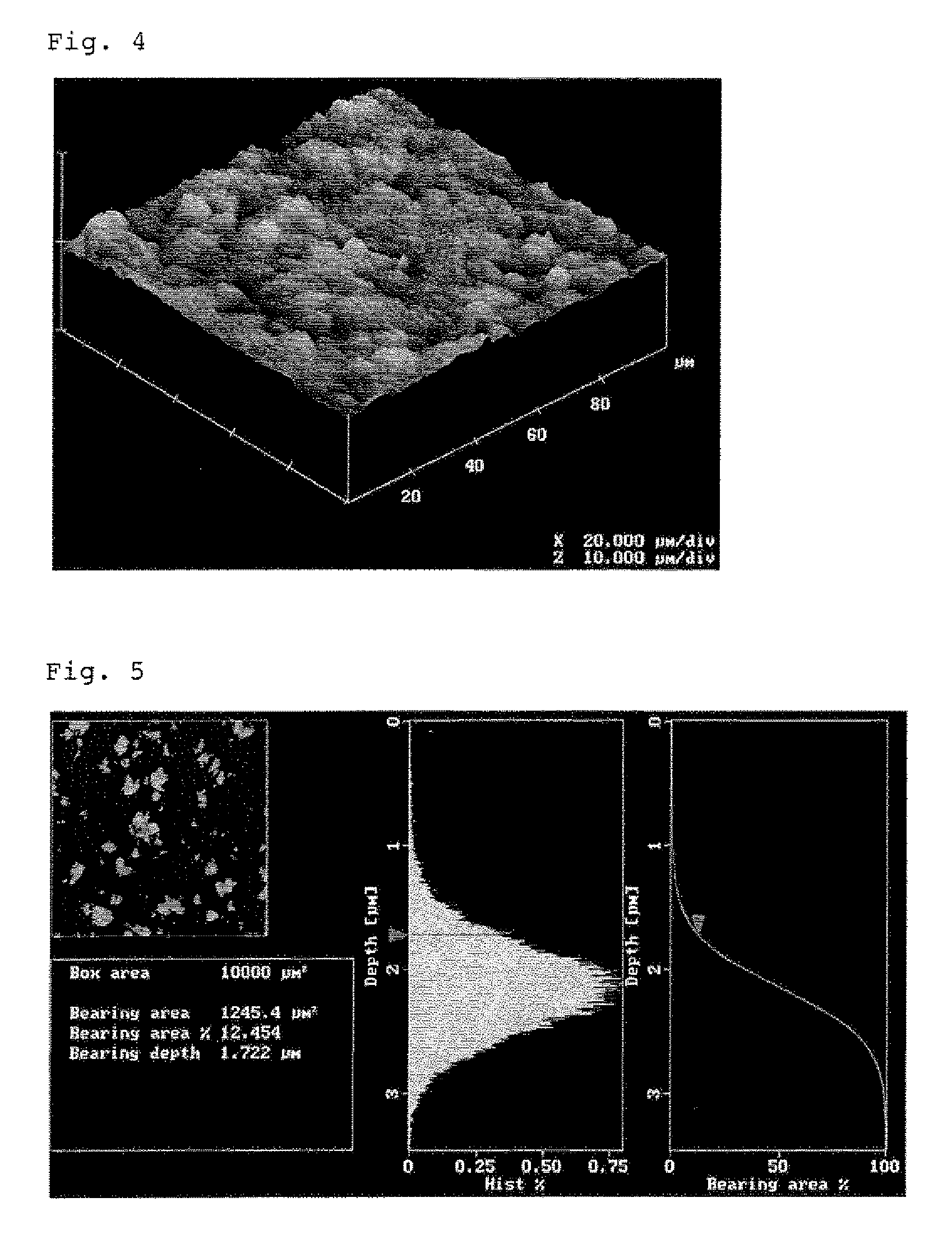

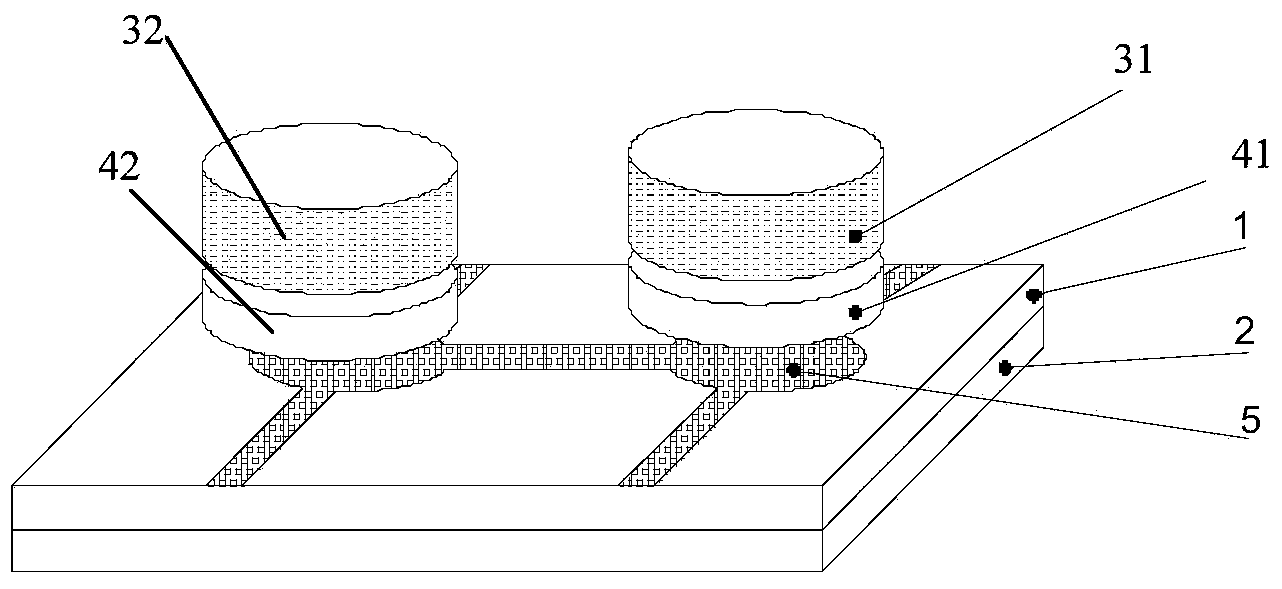

The present invention relates to a molded ferrite sheet having opposing surfaces and a thickness in a range of 30 μm to 430 μm, at least one surface of said opposing surfaces having the following surface roughness characteristics (a) to (c):(a) a center line average roughness is in a range of 170 nm to 800 nm,(b) a maximum height is in a range of 3 μm to 10 μm, and(c) an area occupancy rate of cross-sectional area taken along a horizontal plane at a depth of 50% of the maximum height in a square of side 100 μm is in a range of 10 to 80%.

Owner:TODA IND

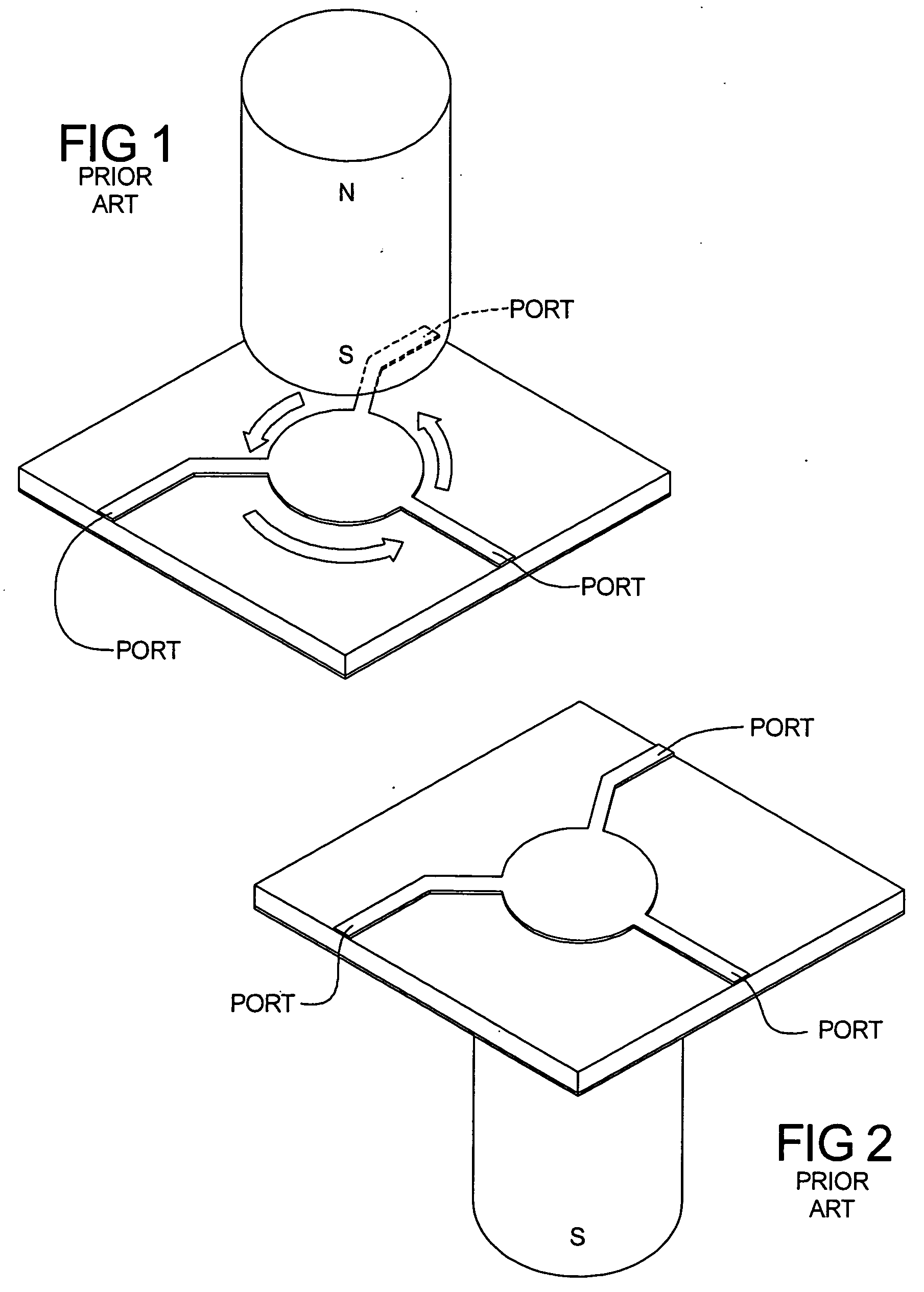

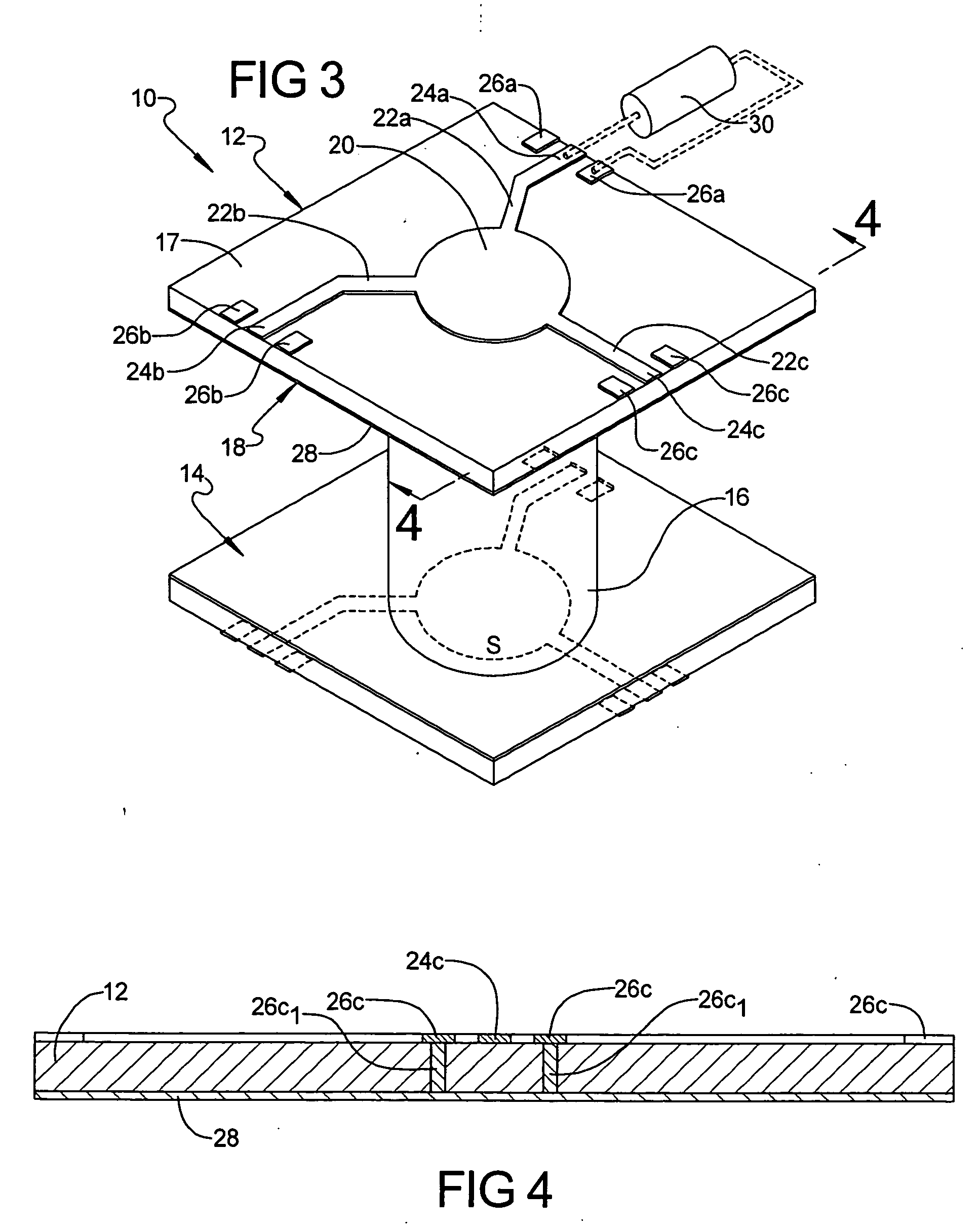

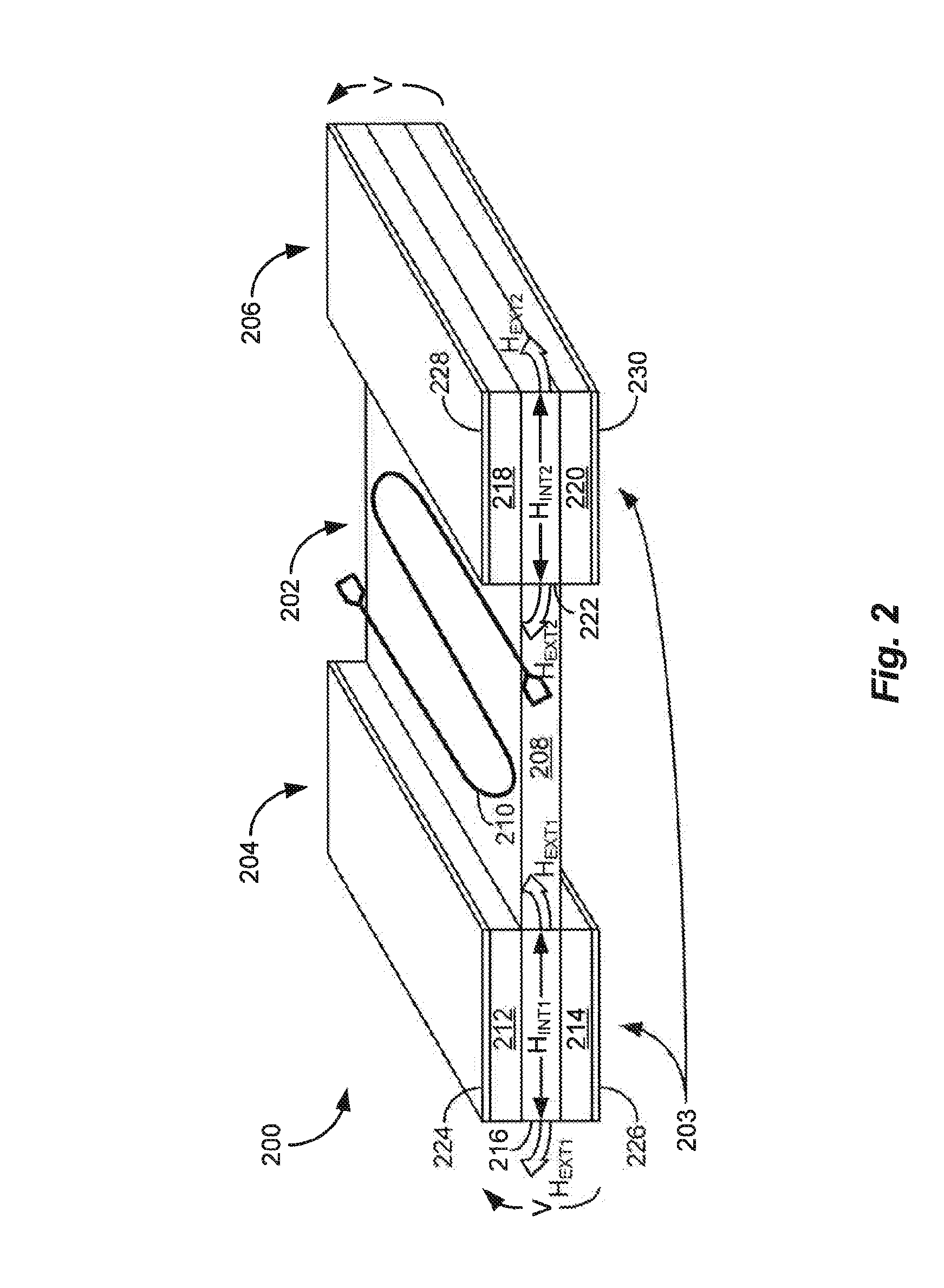

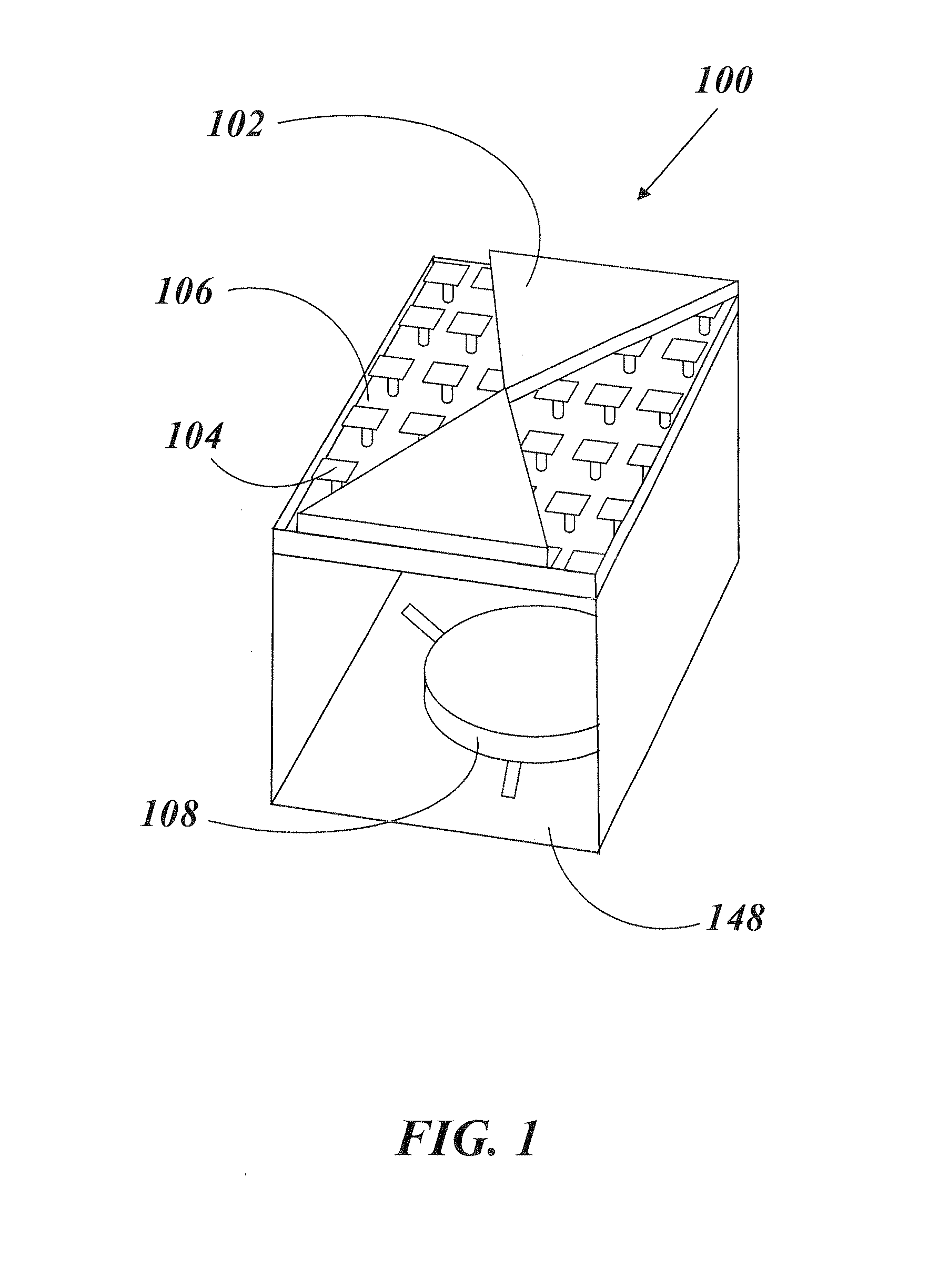

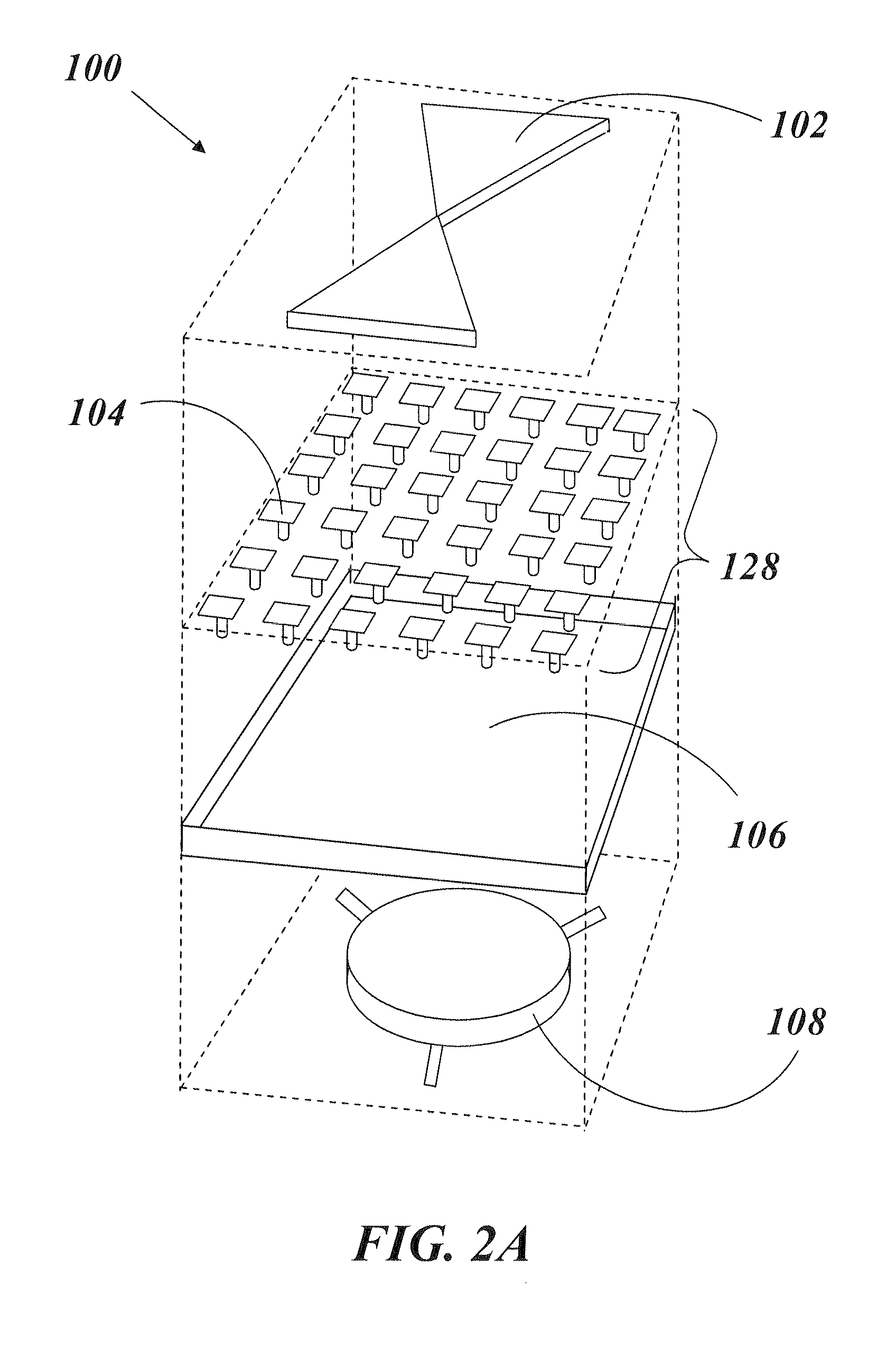

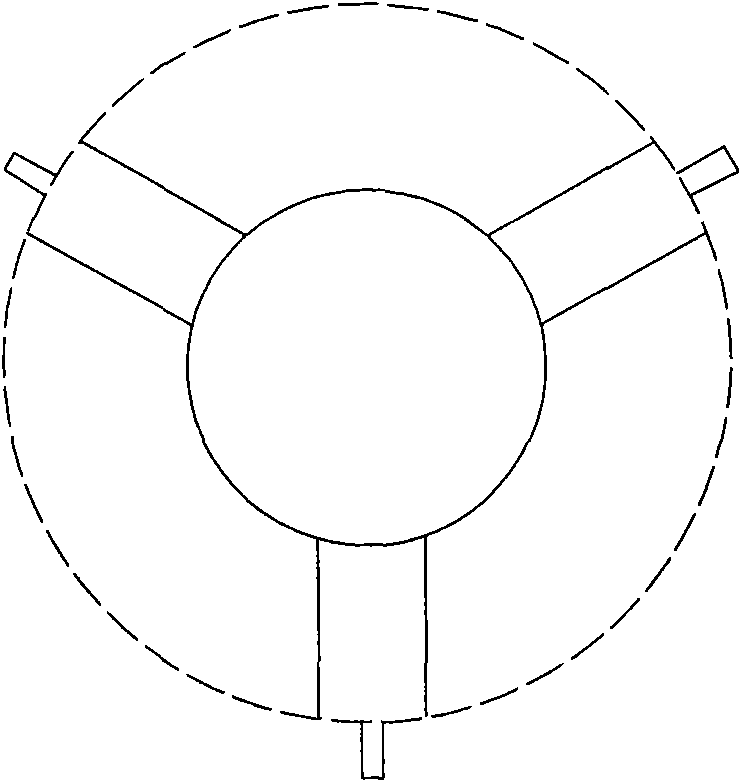

Multi-channel circulator/isolator apparatus and method

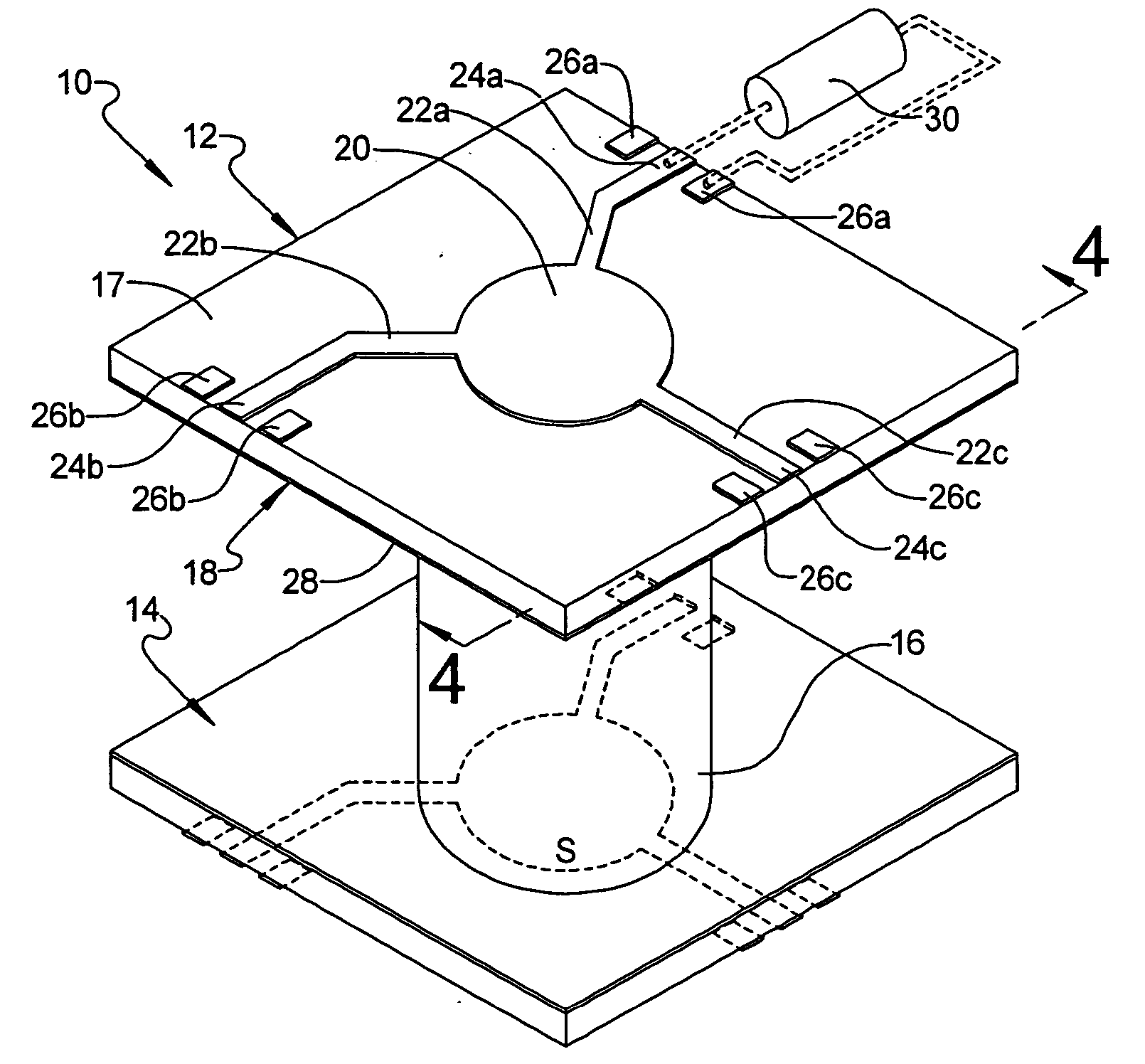

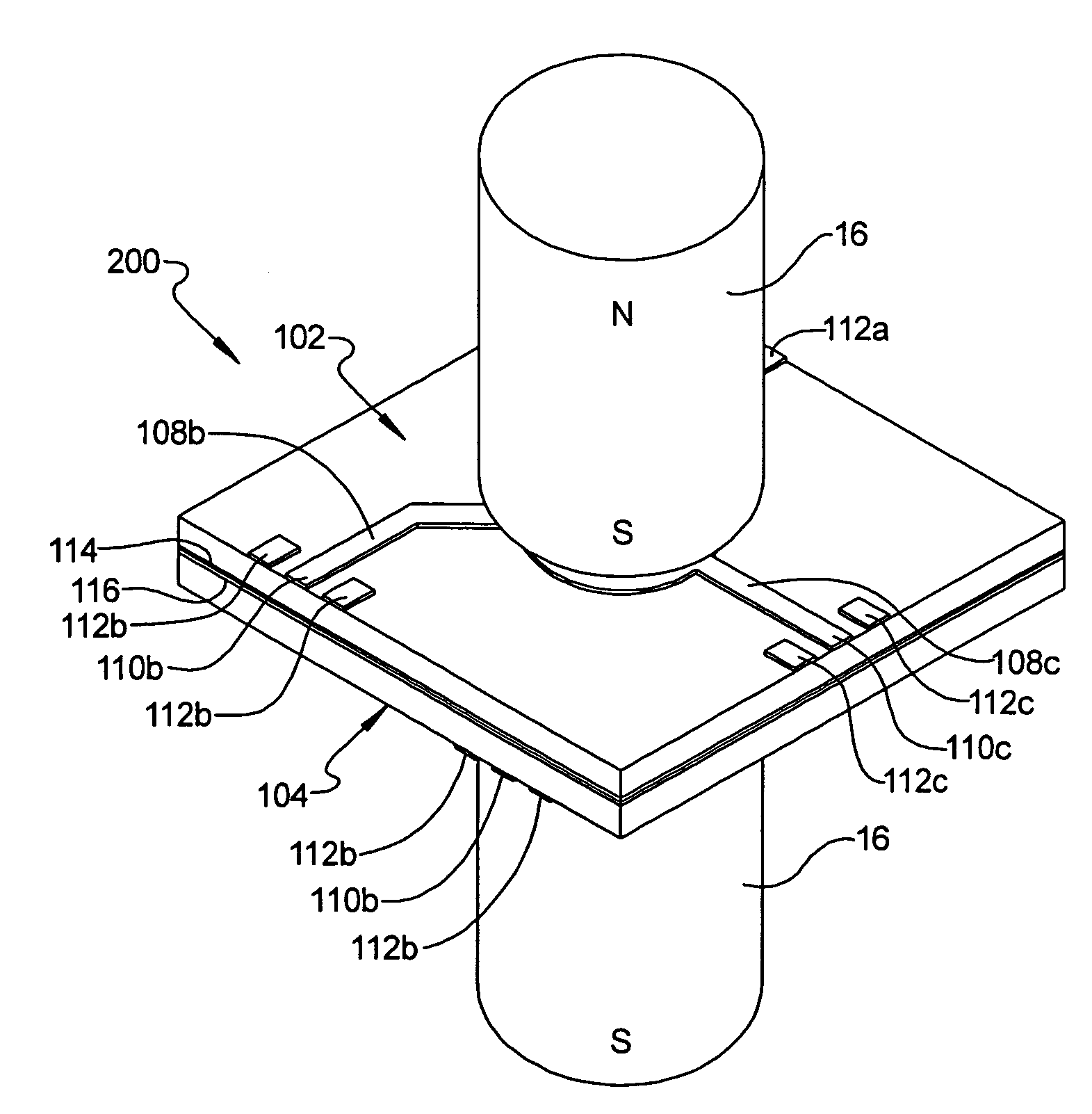

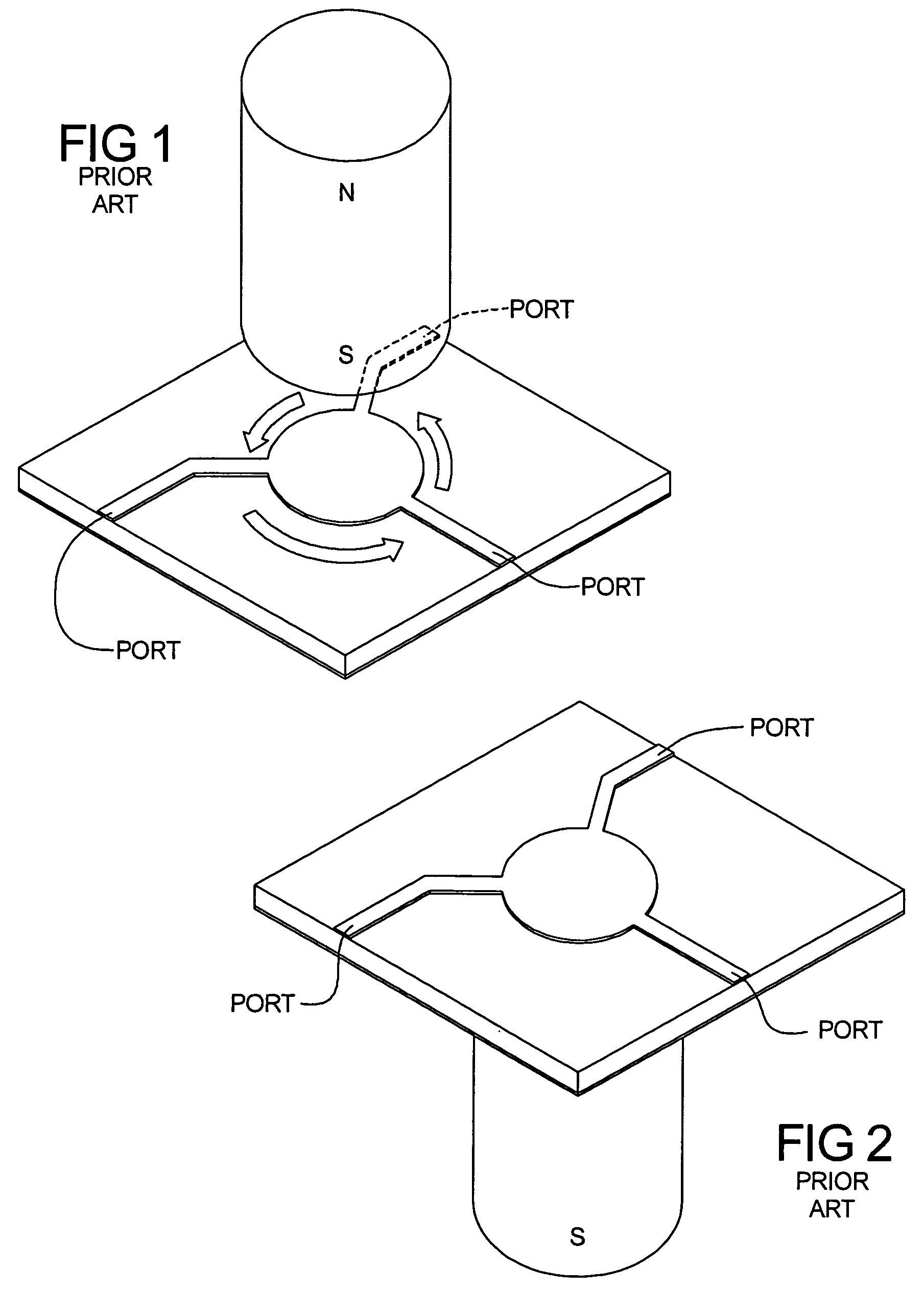

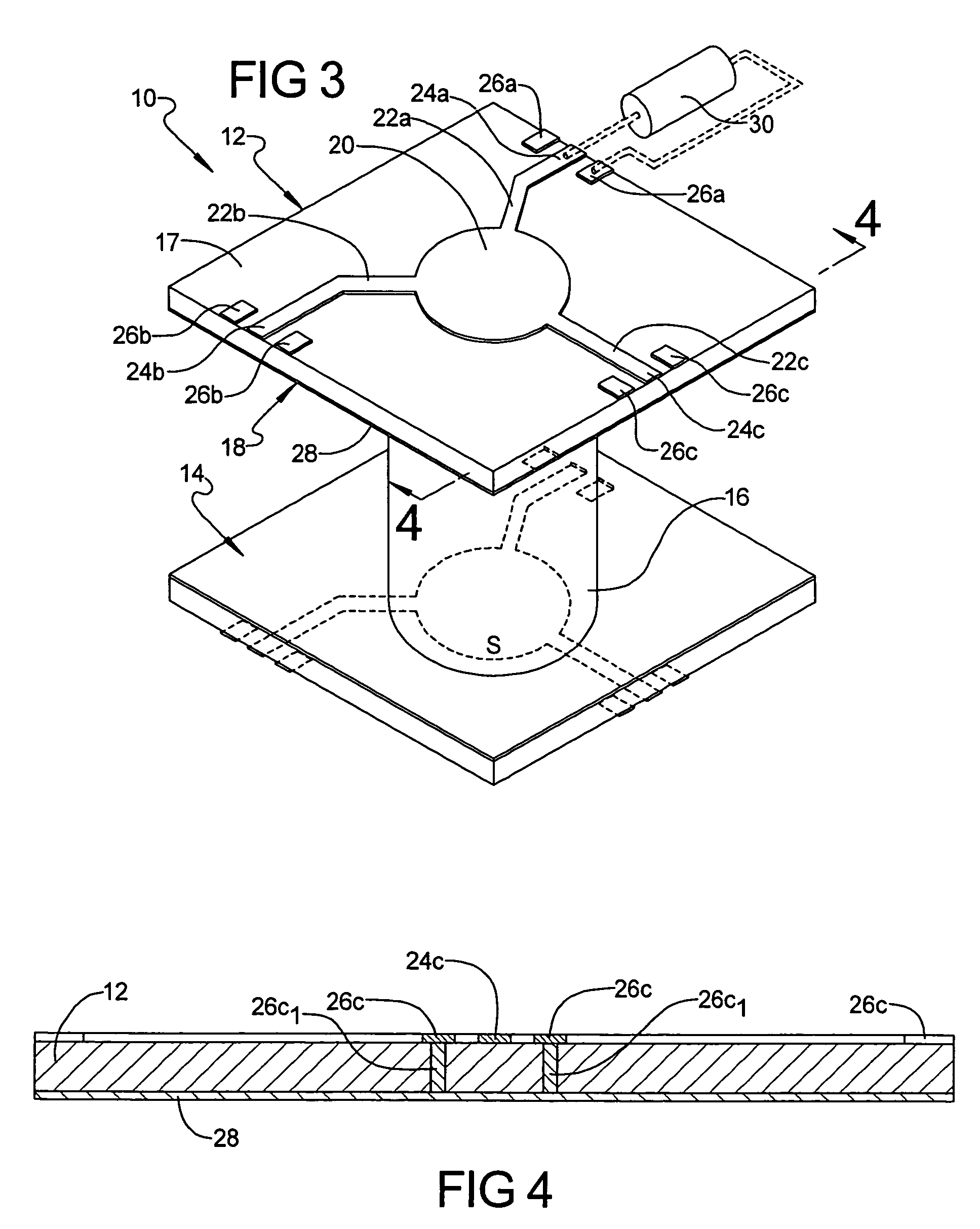

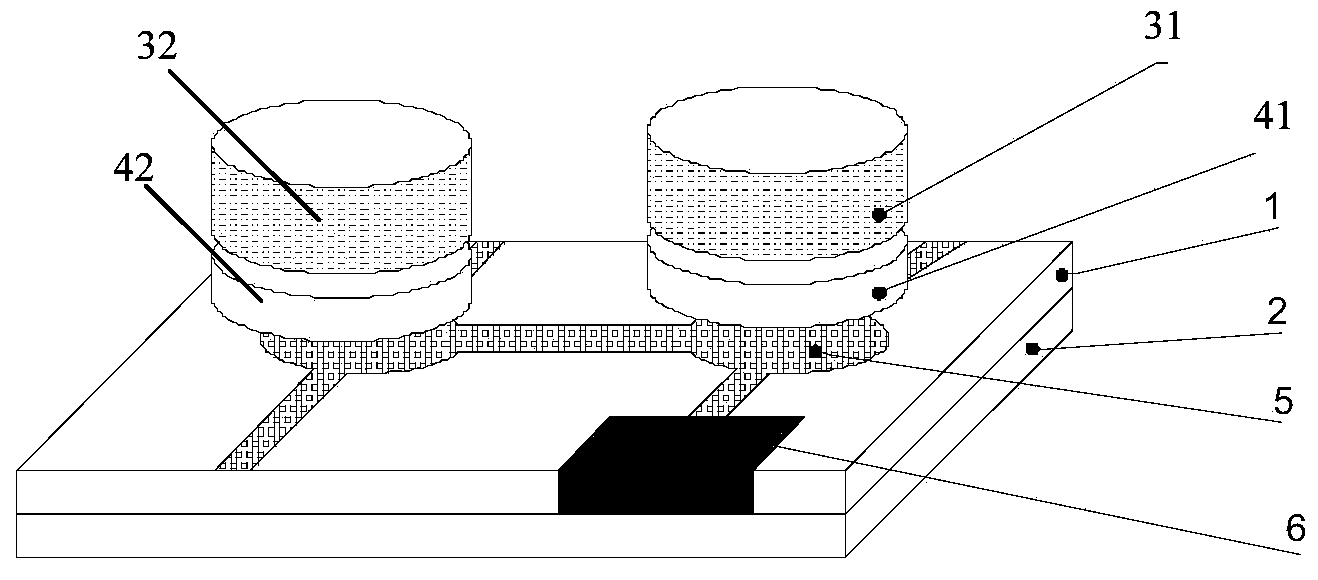

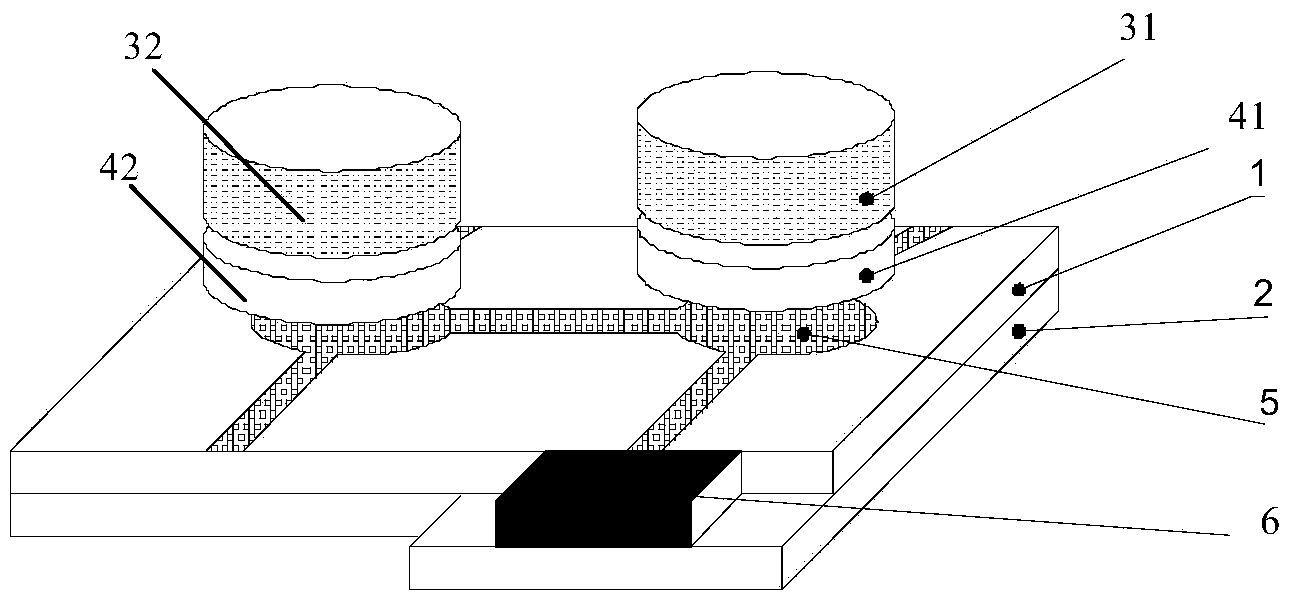

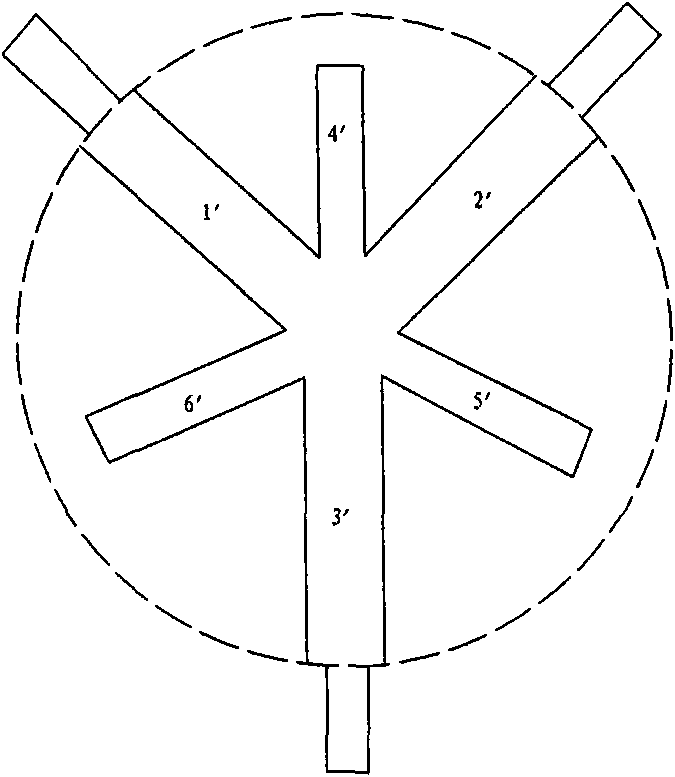

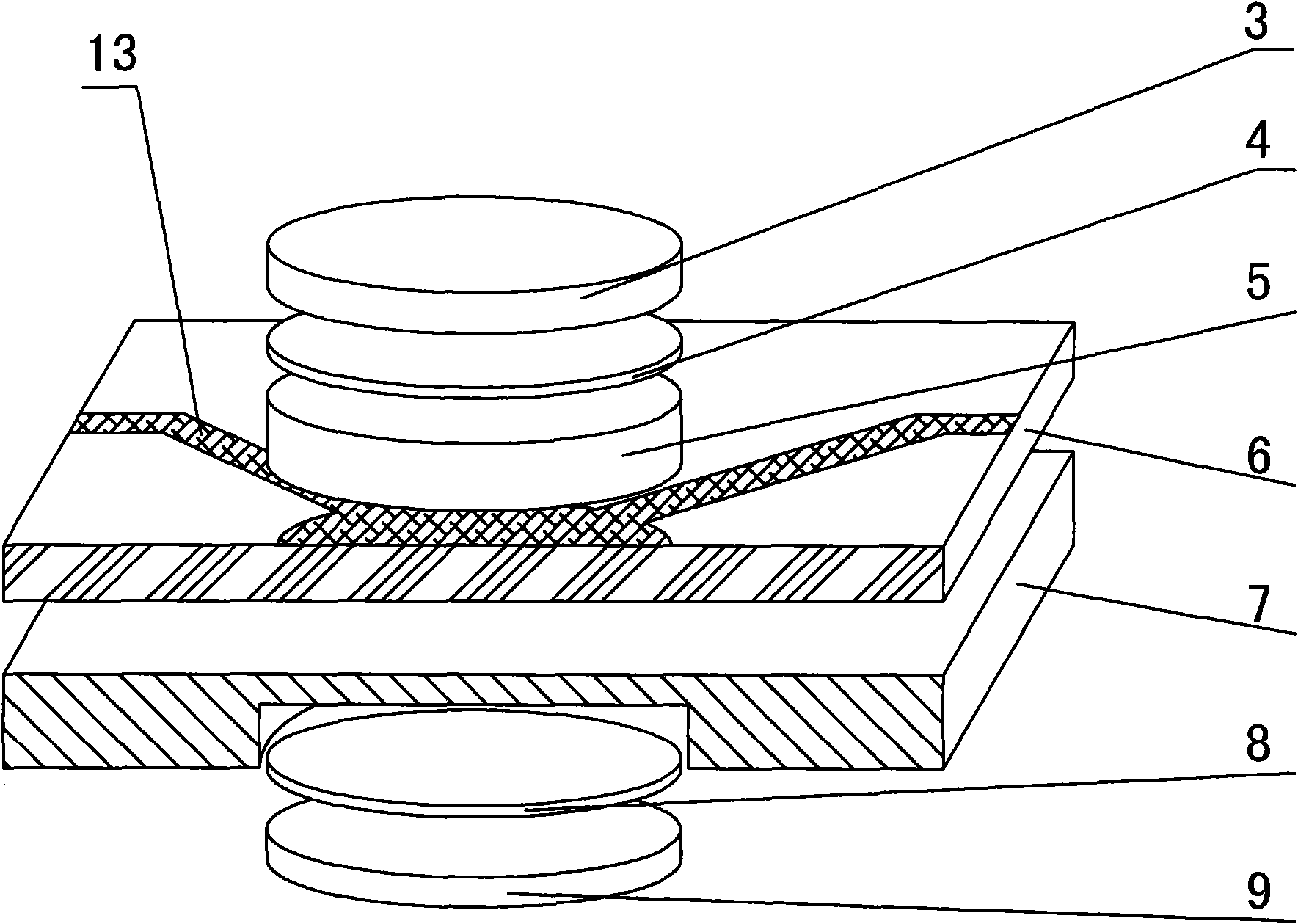

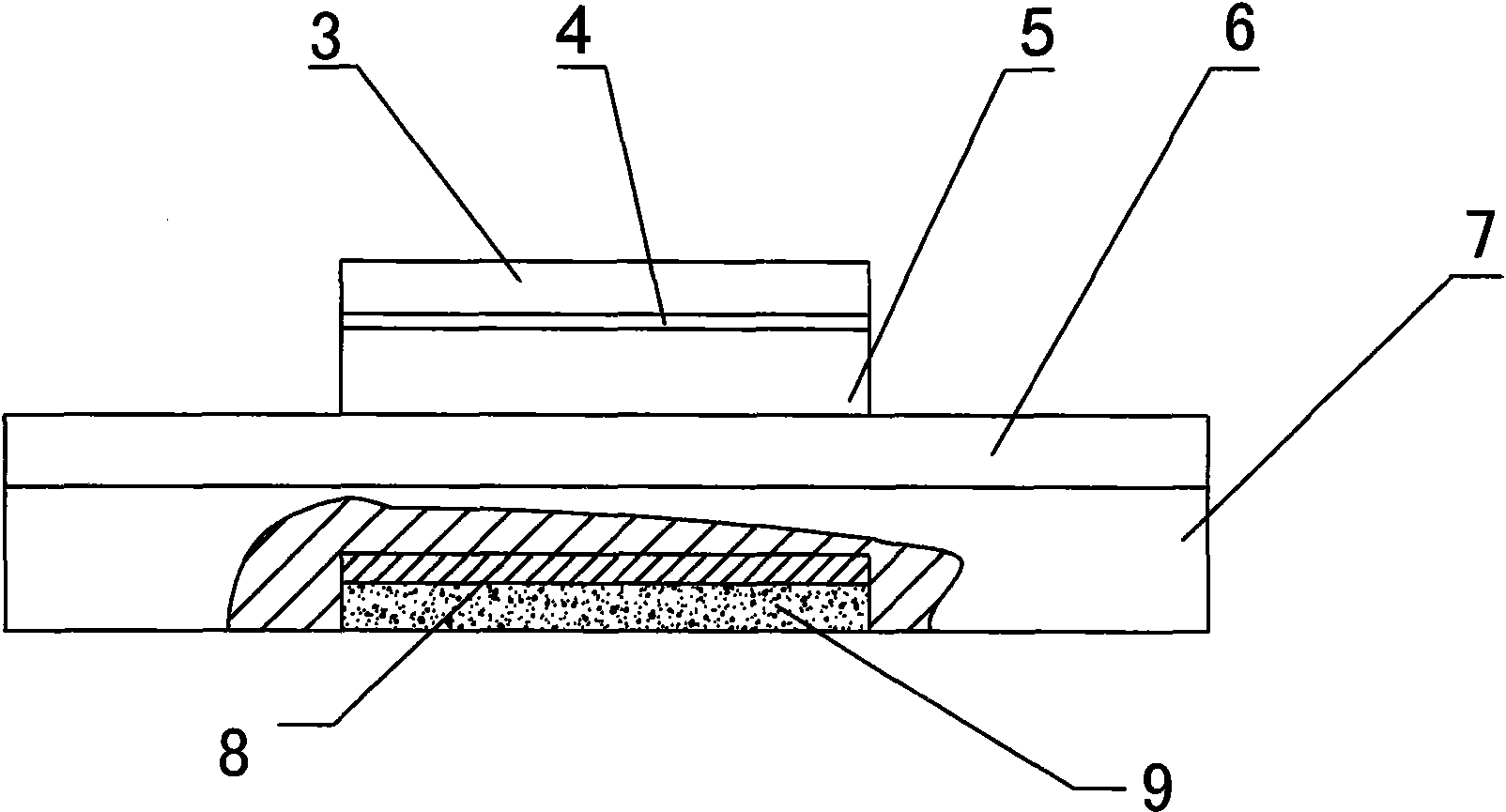

A multi-channel circulator or isolator well suited for use in phased array antennas or other RF devices where space and packaging constraints make the implementation of a conventional circular or isolator difficult or impossible. The multi-channel circulator / isolator can be configured as an isolator by the inclusion of one or more load resistors at one of its ports. In various configurations two or more ferrite substrates are provided that each provide a plurality of transmission ports. One or more permanent magnets are used to simultaneously provide the magnetic flux field through both of the substrates. The substrates can be configured such that they are spaced apart by a small distance, or positioned face to face in contact with one another. One or a plurality of magnets can be used depending upon RF requirements. Each substrate forms an independent electromagnetic wave propagation channel that limits the propagation of RF energy between its ports in one direction only.

Owner:THE BOEING CO

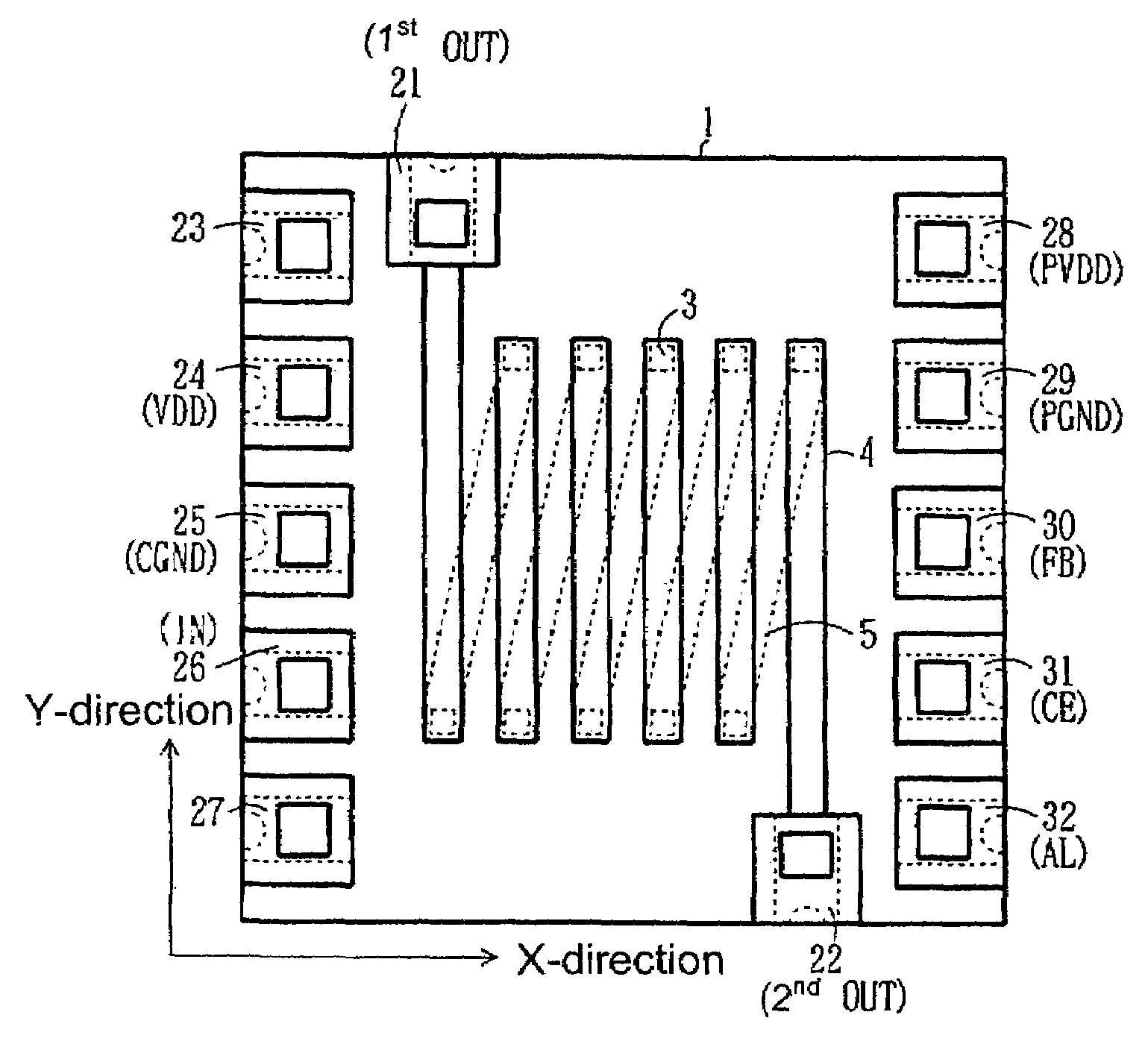

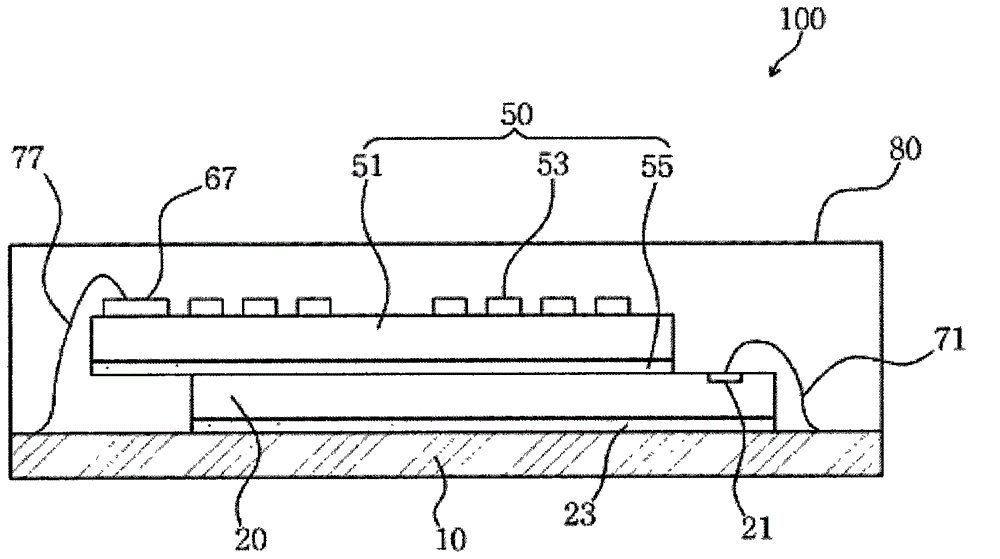

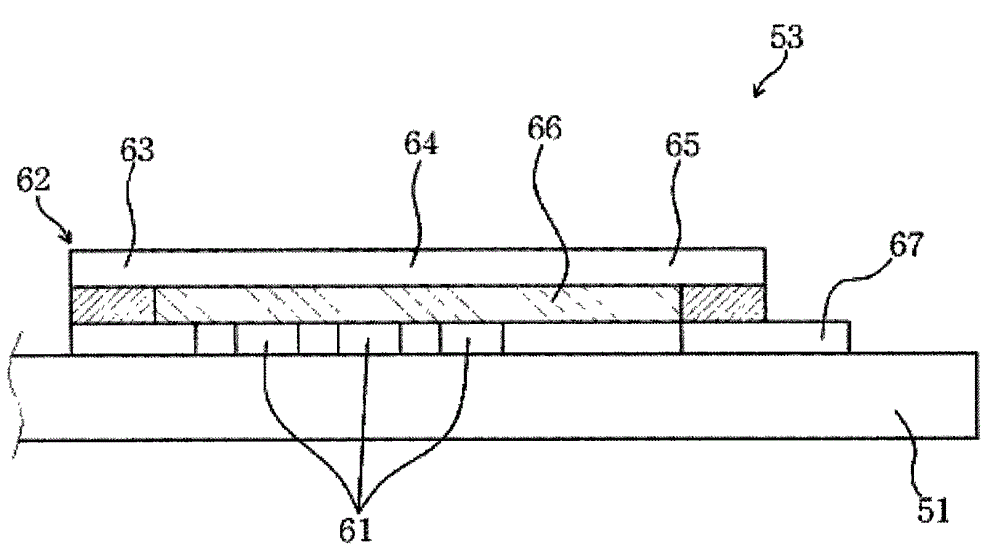

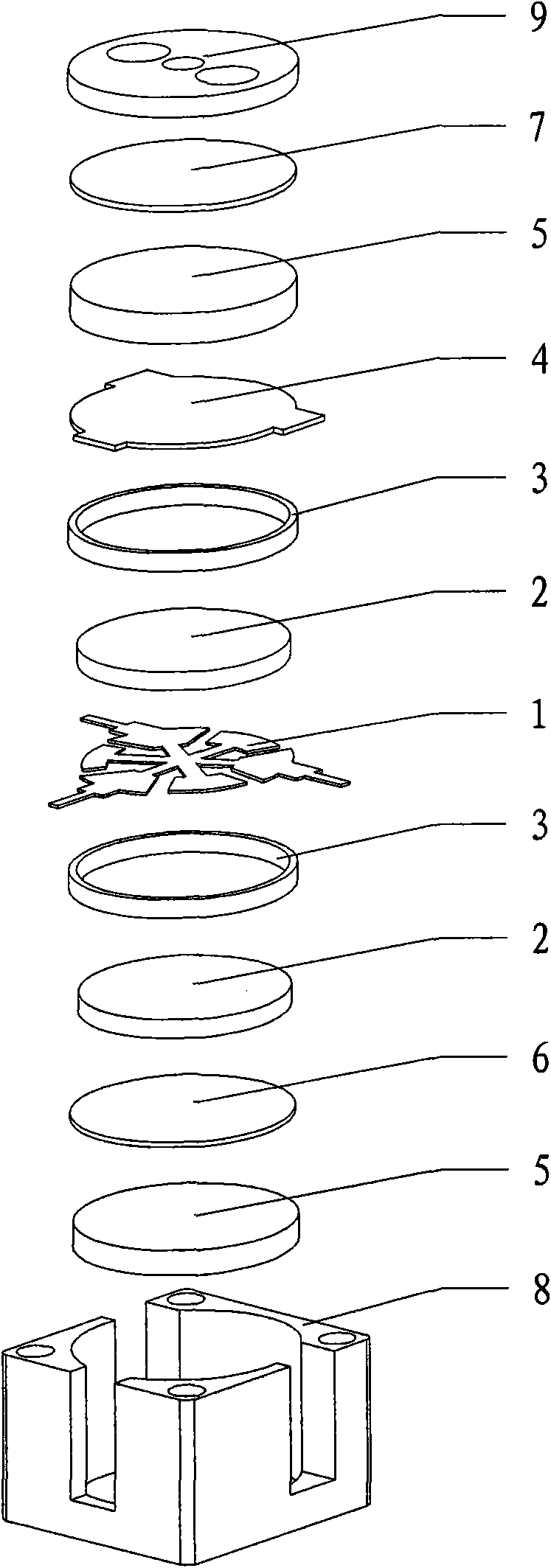

Micro electric power converter

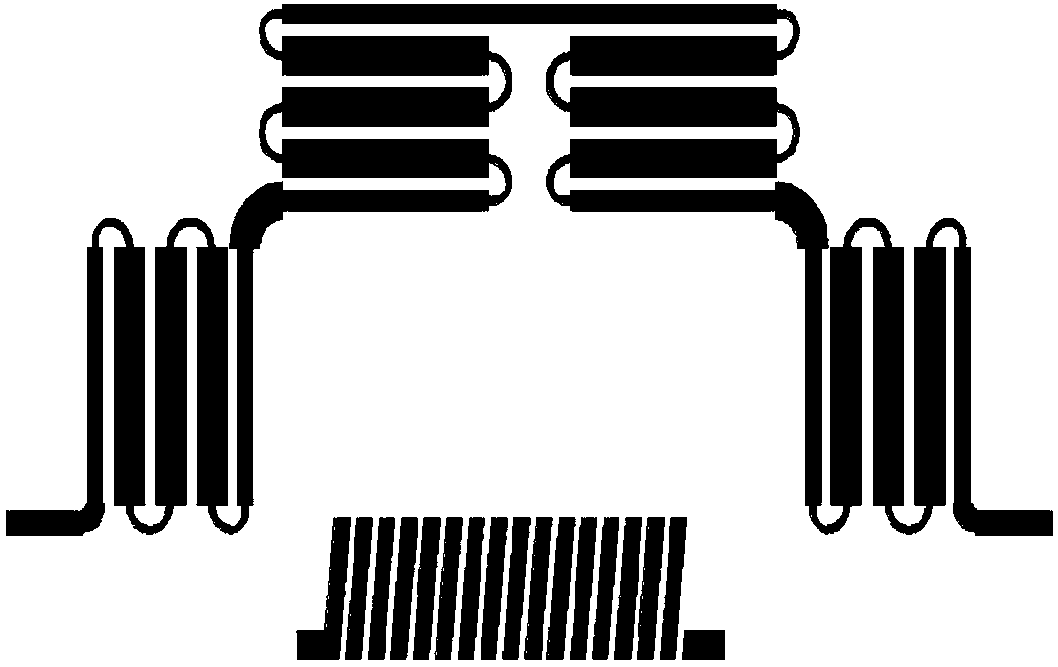

ActiveUS7268659B2Easily causedLow densitySemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsFerrite substrateElectrical conductor

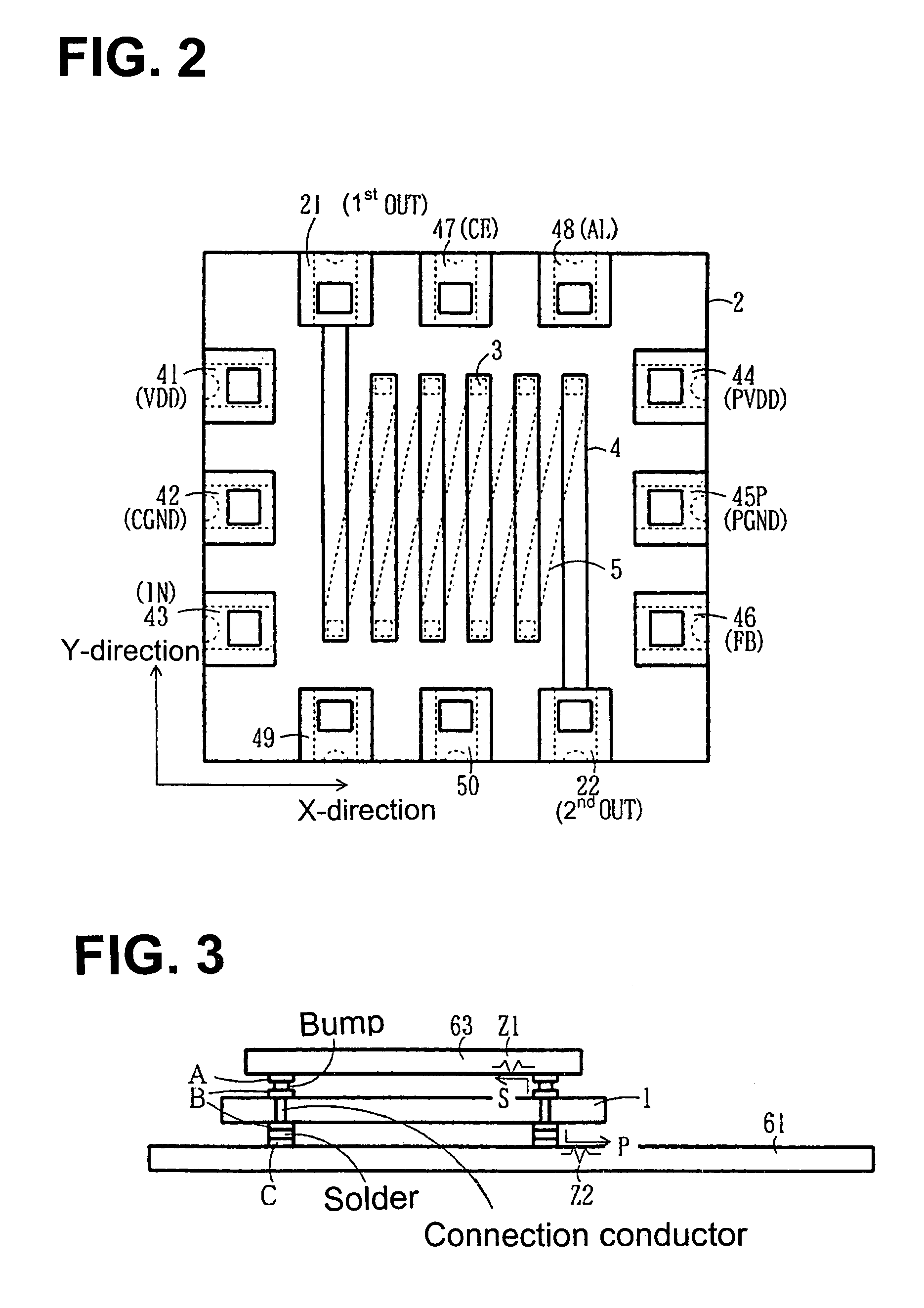

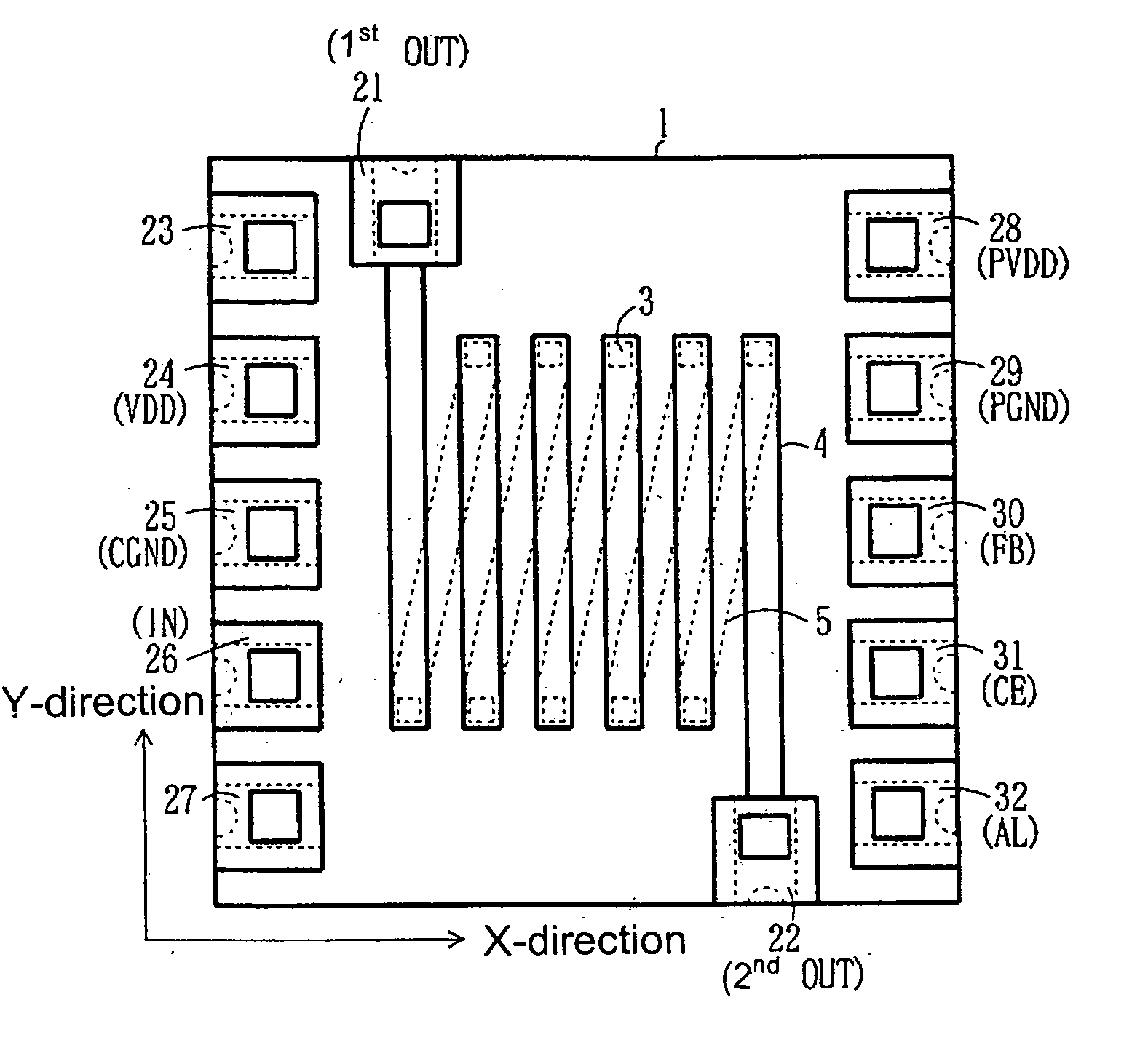

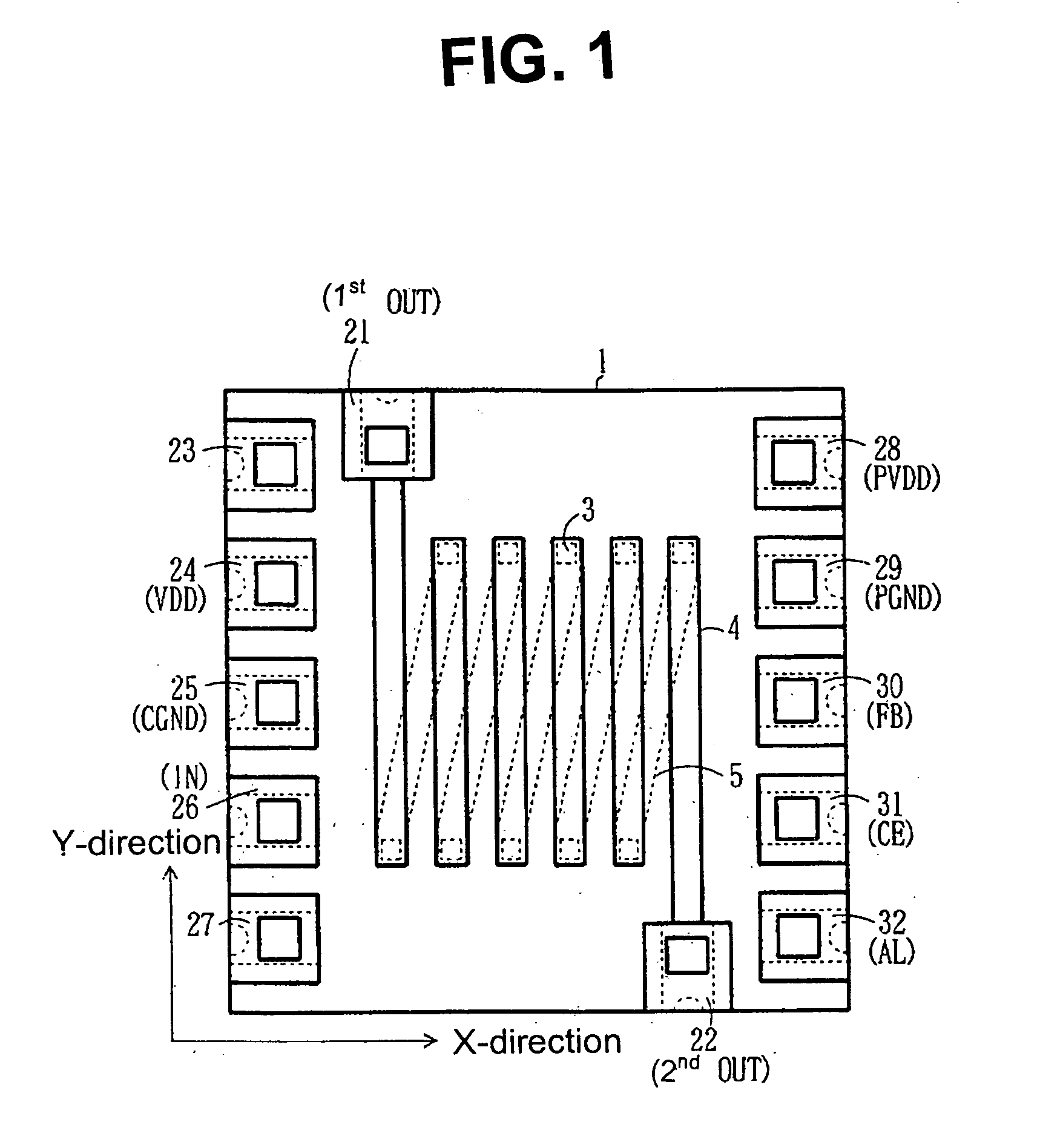

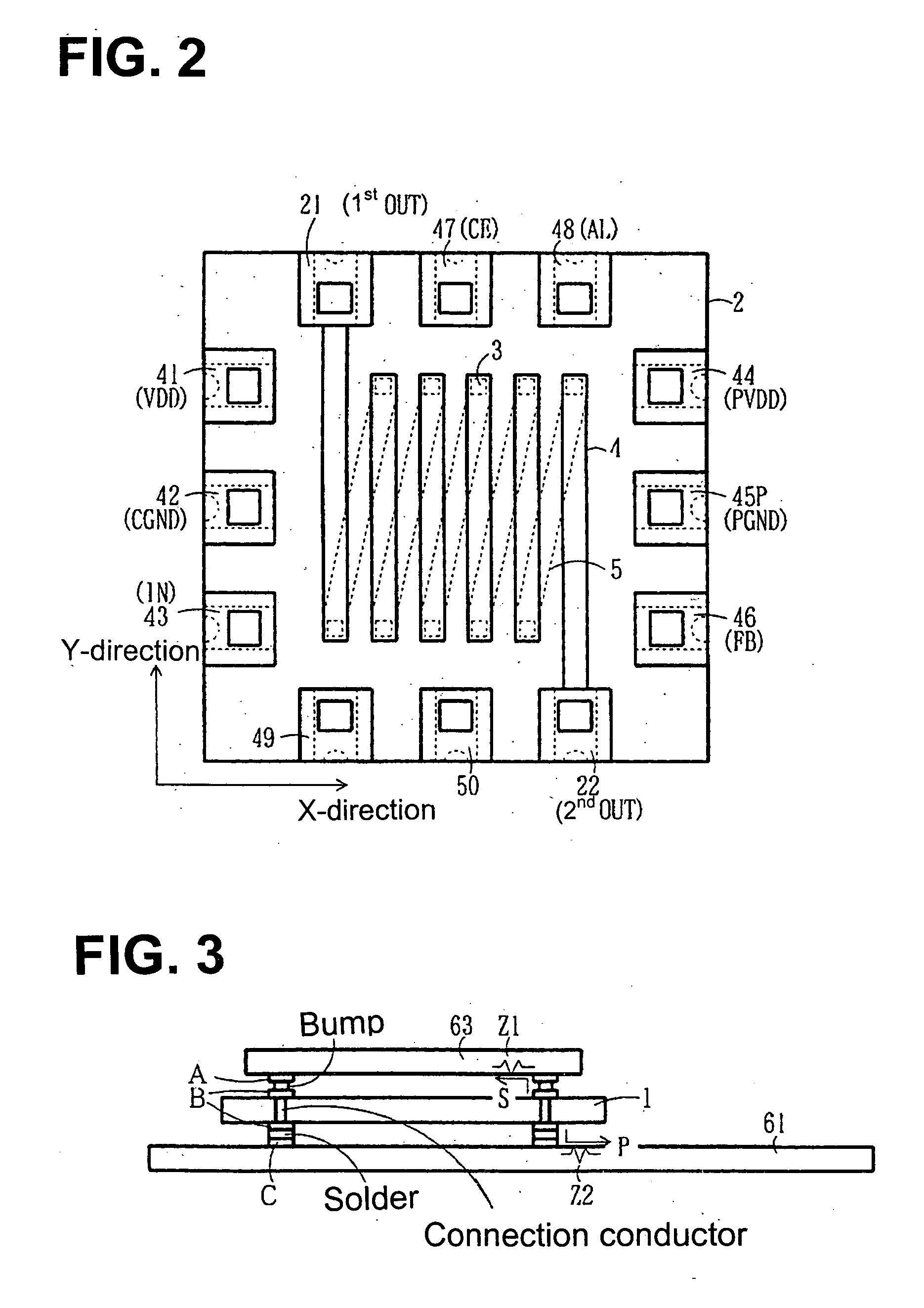

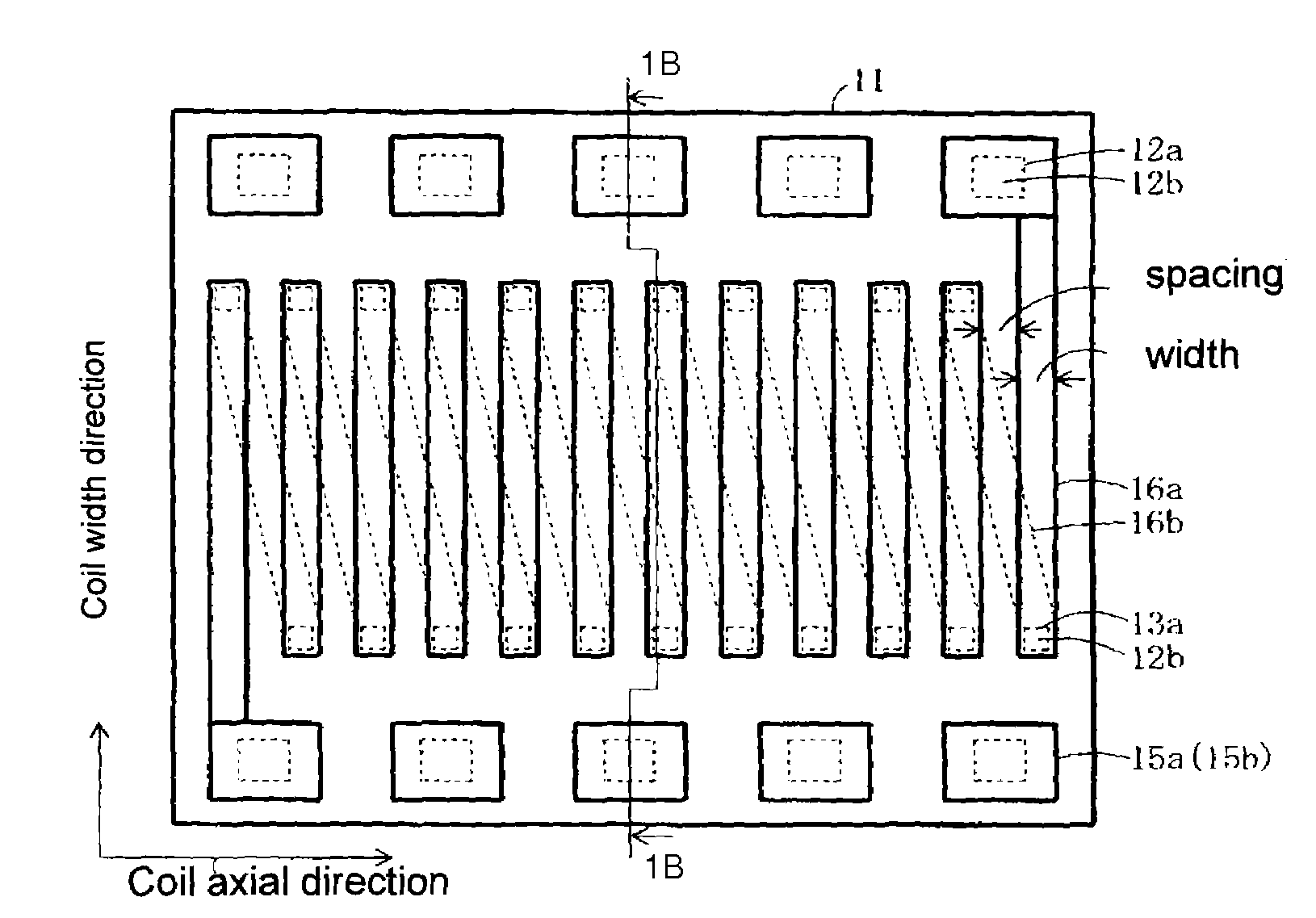

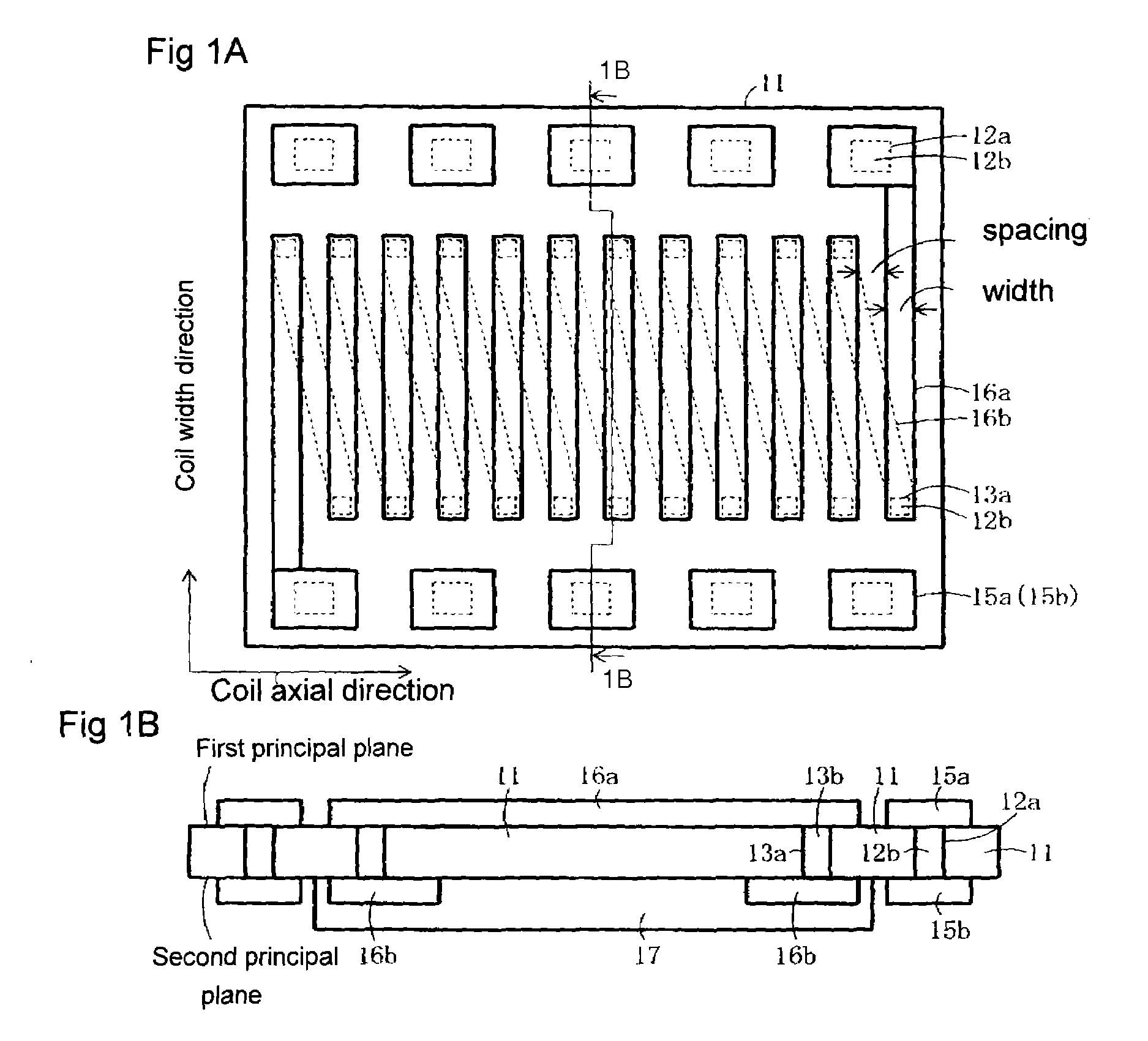

A thin film magnetic induction element includes a ferrite substrate, a coil provided across the ferrite substrate and including connection conductors and coil conductors, and terminals provided on perimeter portions of the substrate. Terminals capable of being adversely affected by an induced magnetic flux, such as a VDD terminal, a CGND terminal, an IN terminal, a PVDD terminal, a PGND terminal, an FB terminal, a CE terminal, and an AL terminal are arranged along the Y-direction of the substrate, in which the magnetic flux density is low. Terminals substantially incapable of being adversely affected by an induced magnetic flux are arranged along the X-direction of the substrate, in which the magnetic flux density is high. A micro electric power converter having the thin film magnetic induction element is less susceptible to circuit malfunctions.

Owner:FUJI ELECTRIC CO LTD

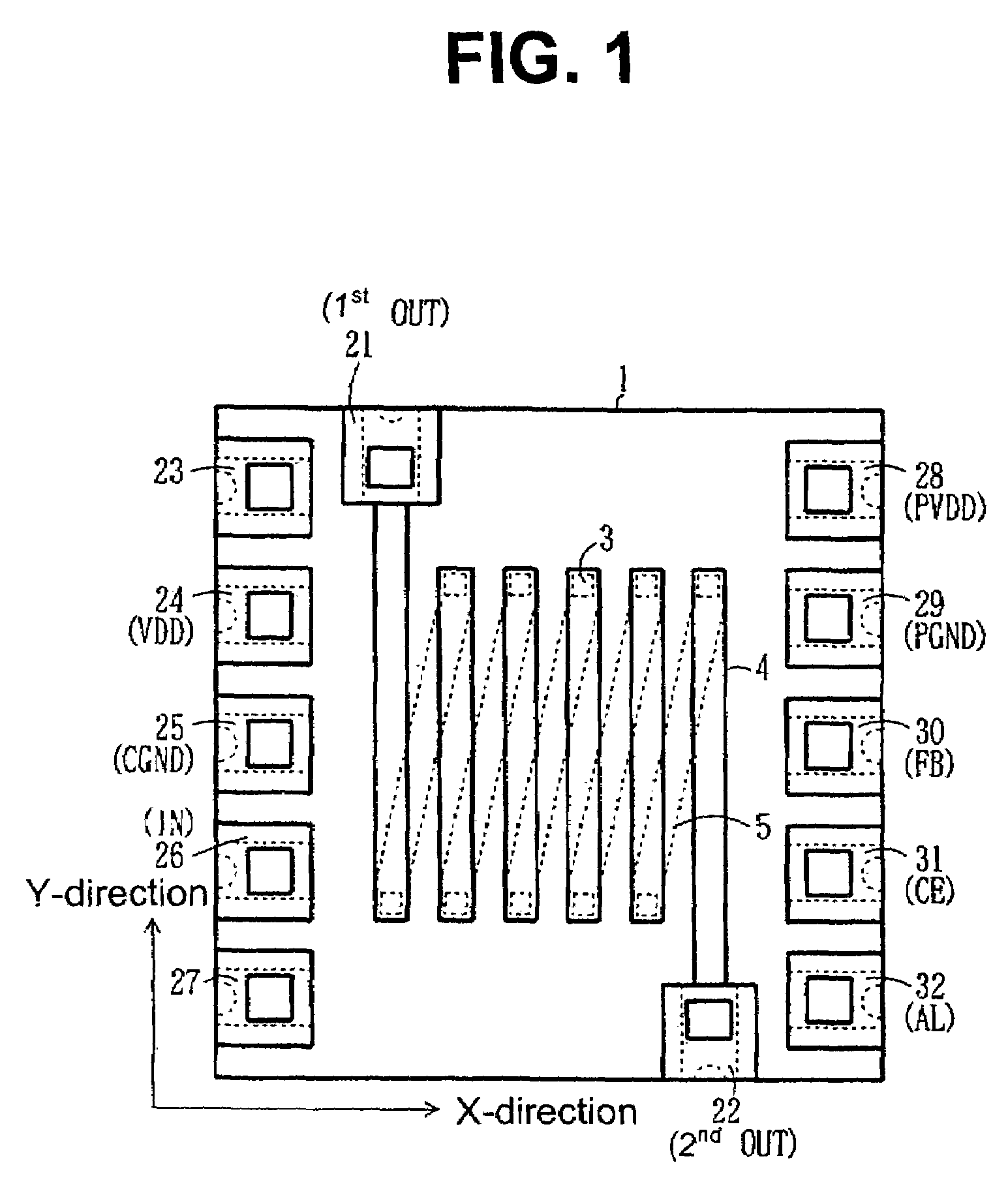

Micro electric power converter

ActiveUS20060227518A1Decrease in magnetic flux densityAvoid failureSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsFerrite substrateElectrical conductor

A thin film magnetic induction element includes a ferrite substrate, a coil provided across the ferrite substrate and including connection conductors and coil conductors, and terminals provided on perimeter portions of the substrate. Terminals capable of being adversely affected by an induced magnetic flux, such as a VDD terminal, a CGND terminal, an IN terminal, a PVDD terminal, a PGND terminal, an FB terminal, a CE terminal, and an AL terminal are arranged along the Y-direction of the substrate, in which the magnetic flux density is low. Terminals substantially incapable of being adversely affected by an induced magnetic flux are arranged along the X-direction of the substrate, in which the magnetic flux density is high. A micro electric power converter having the thin film magnetic induction element is less susceptible to circuit malfunctions.

Owner:FUJI ELECTRIC CO LTD

Composite substrate type microstrip circulator

Owner:BEIJING INST OF RADIO MEASUREMENT

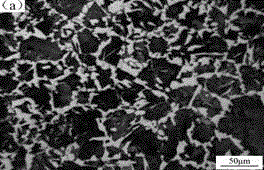

780MPa-level low-carbon and low-alloy TRIP steel and rapid heat treatment method thereof

ActiveCN109943769AShort timeShorten the timeFurnace typesHeat treatment furnacesFerrite substrateAlloy

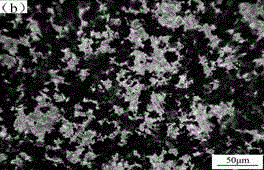

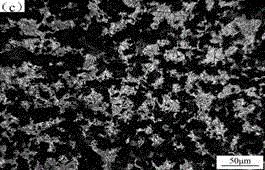

The invention provides 780MPa-level low-carbon and low-alloy TRIP steel and a rapid heat treatment method thereof. The steel comprises the following chemical components in percentage by mass: 0.16-0.22% of C, 1.2-1.6% of Si, 1.6-2.2% of Mn, and the balance Fe and other inevitable impurities. The method comprises the steps of rapidly heating, maintaining temperature within short time, and rapidly cooling. According to the steel and the method, the recrystallizing and phase changing processes in the heating and the phase change process in cooling are controlled, thus a three-phase structure thatbainite and austenite are uniformly distributed on a ferrite substrate can be obtained; the average crystal grain size of bainite and austenite is 1-3 microns; bainite is of a submicron particle form; austenite is of an island uniformly-distributed equiaxial crystal grain form; the whole three-phase structure comprises 35-75% by volume of bainite, 10-60% by volume of ferrite, and 5-15% by volumeof austenite; with the adoption of the rapid heat treatment, the mechanical performance of the material is improved while the heat treatment efficiency is improved; and the material performance area range is expanded.

Owner:BAOSHAN IRON & STEEL CO LTD

Oxidation-resistant alloying grey cast iron and preparation method thereof

The invention discloses an oxidation-resistant alloying grey cast iron and a preparation method of the oxidation-resistant alloying grey cast iron. The cast iron comprises the following components by mass percentage: 3.0-3.2% of C, 1.8-2.0% of Si, 0.50-0.70% of Mn, 0.10-0.50% of Cr, 0.20-0.30% of Ni, 0.03-0.50% of Mo, 0.5-3.0% of Al, 0.05-0.08% of Sr, 0.005-0.15% of Zn, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of melting raw materials, culturing and processing, and pouring, wherein the tapping is carried out at 1450 to 1550 DEG C after melting; the molten iron is processed by being flushed in a ladle and cultured and processed along with the flow, and then slagged and casted. According to the oxidation-resistant alloying grey cast iron provided by the invention, the organization of the grey alloying cast iron material is structured by distributing 6-8 grades of D type graphite with little graphite of A type on a ferrite substrate, so that higher toughness, high heat conductivity and high-temperature oxidization resistance can be achieved, and good casting technical performance can be ensured as well; and the oxidation-resistant alloying grey cast iron can be applied to manufacturing a glass die and a light alloy metal type casting die which can bear the heat impacting of high-temperature formed liquid and cold-heat alternating stress for a long time.

Owner:SUZHOU DONGHAI GLASS MOLD

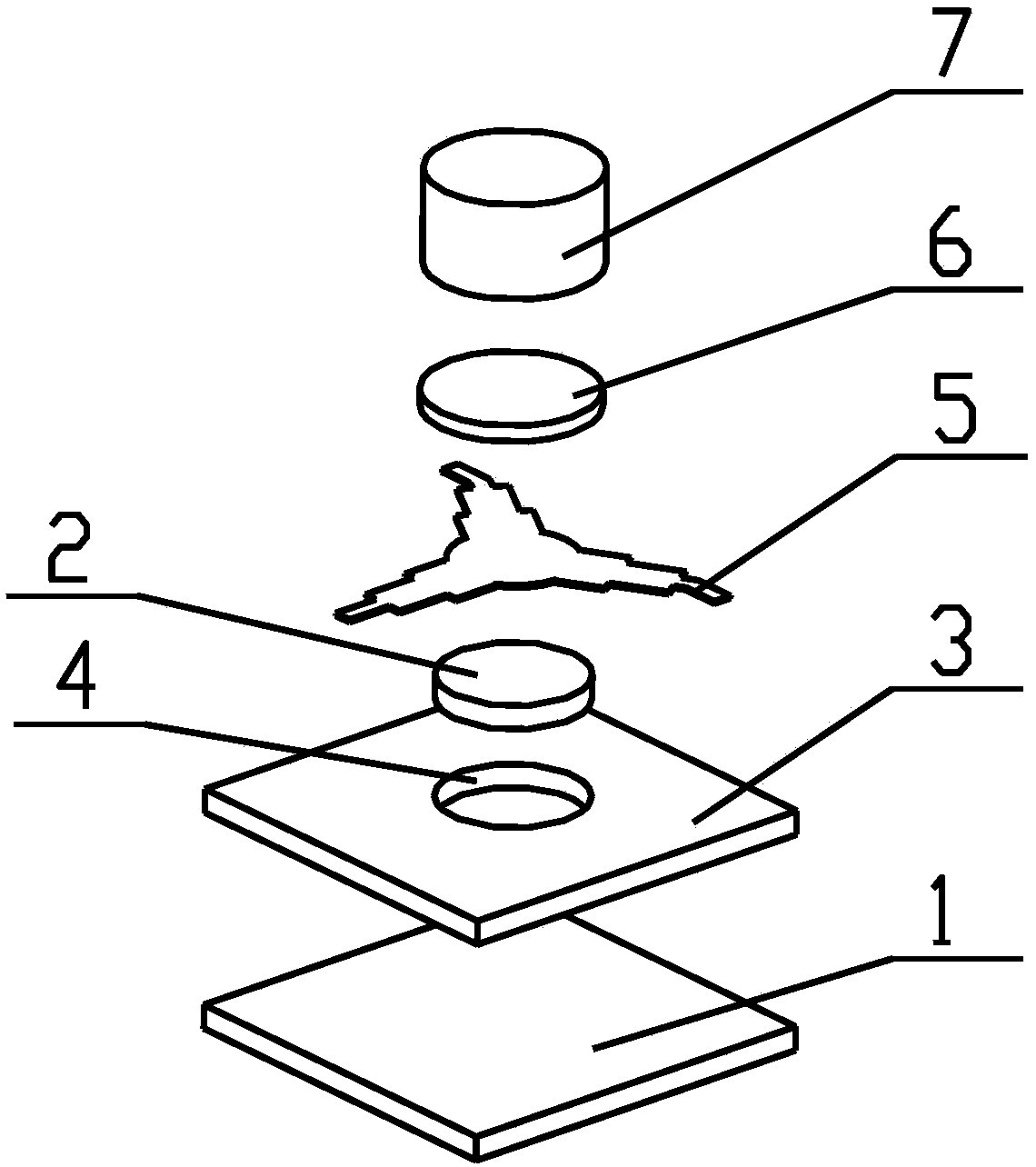

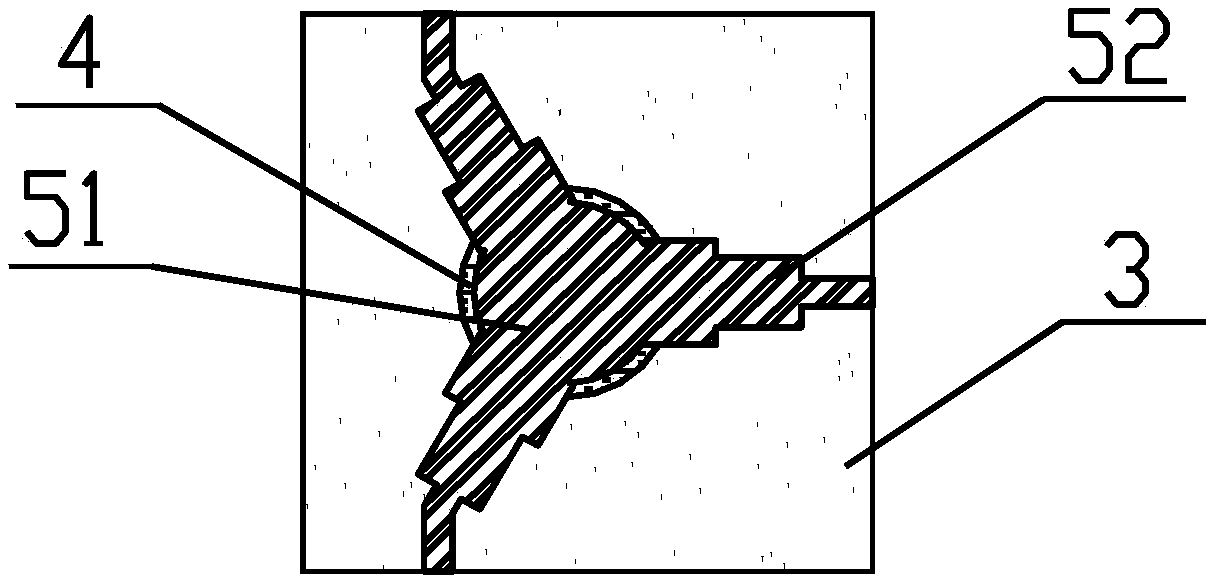

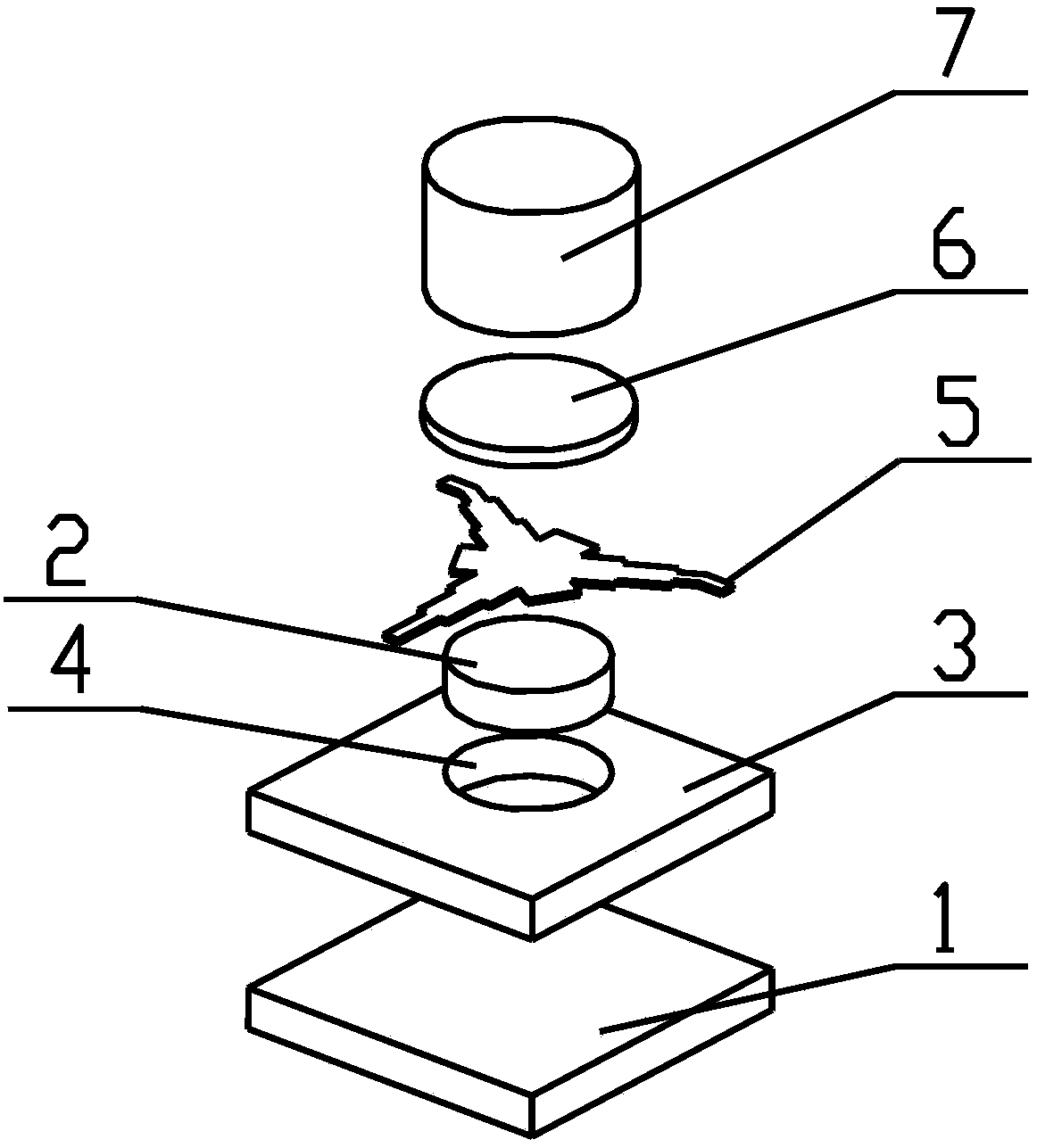

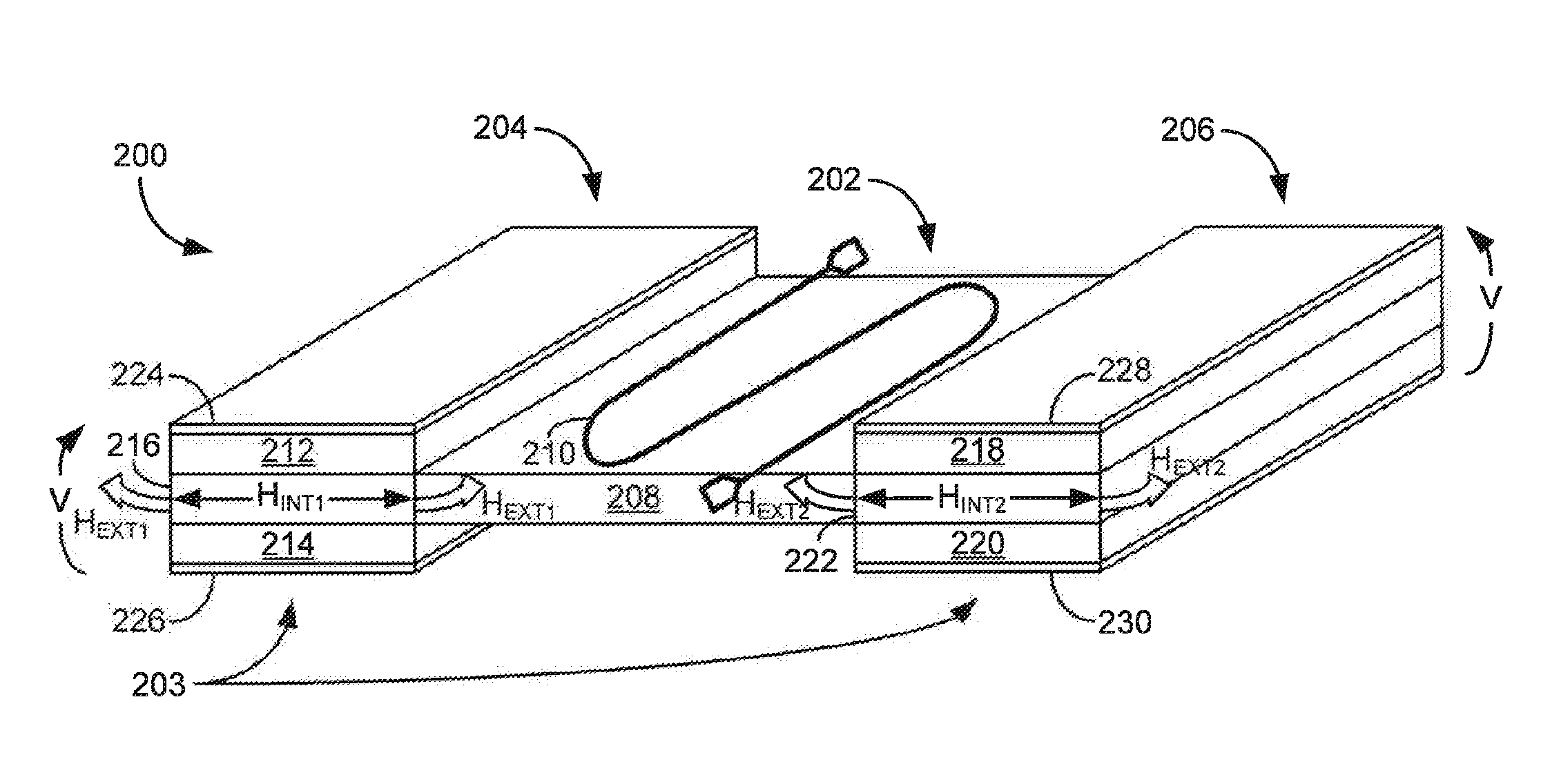

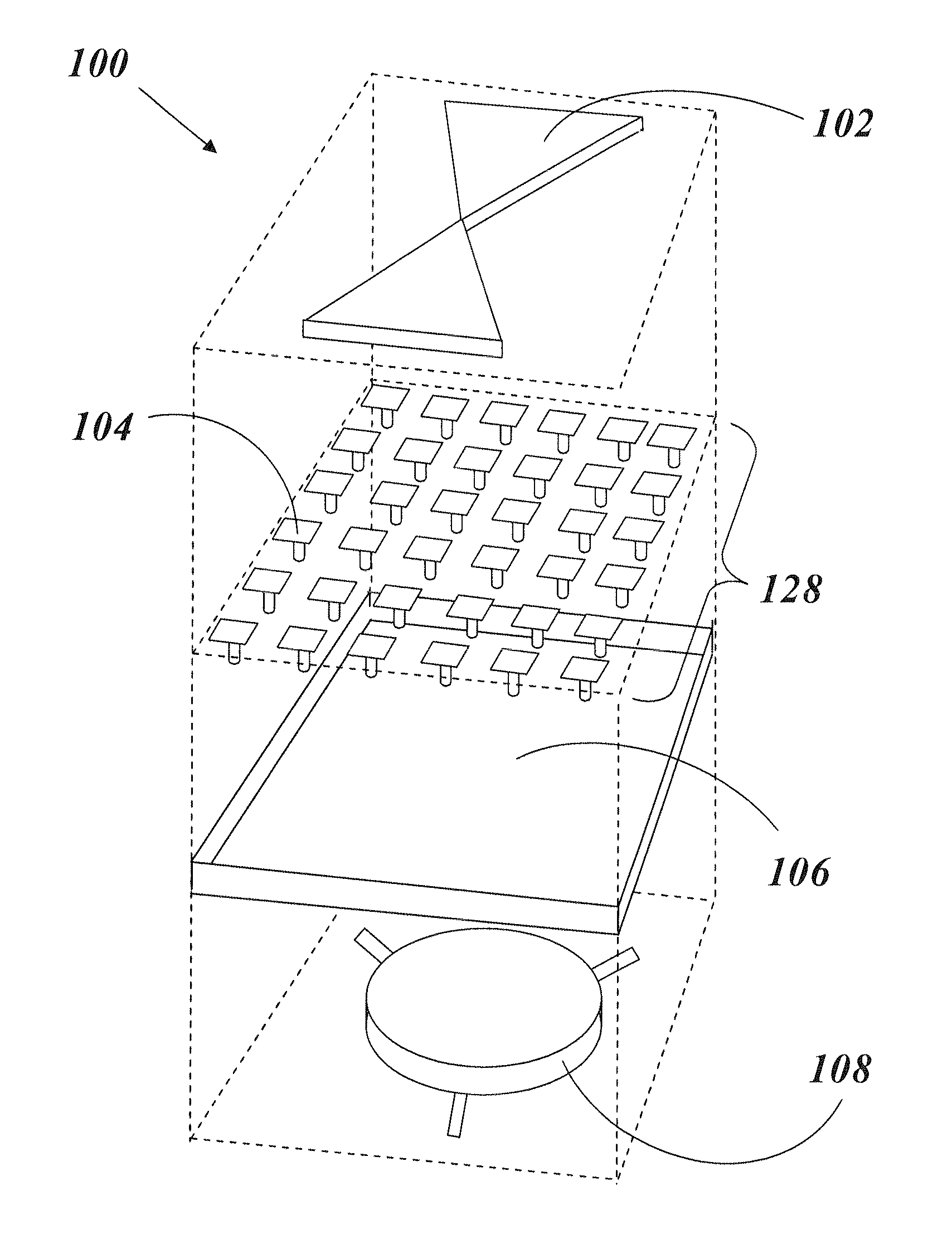

Multi-channel circulator/isolator apparatus and method

A multi-channel circulator or isolator well suited for use in phased array antennas or other RF devices where space and packaging constraints make the implementation of a conventional circular or isolator difficult or impossible. The multi-channel circulator / isolator can be configured as an isolator by the inclusion of one or more load resistors at one of its ports. In various configurations two or more ferrite substrates are provided that each provide a plurality of transmission ports. One or more permanent magnets are used to simultaneously provide the magnetic flux field through both of the substrates. The substrates can be configured such that they are spaced apart by a small distance, or positioned face to face in contact with one another. One or a plurality of magnets can be used depending upon RF requirements. Each substrate forms an independent electromagnetic wave propagation channel that limits the propagation of RF energy between its ports in one direction only.

Owner:THE BOEING CO

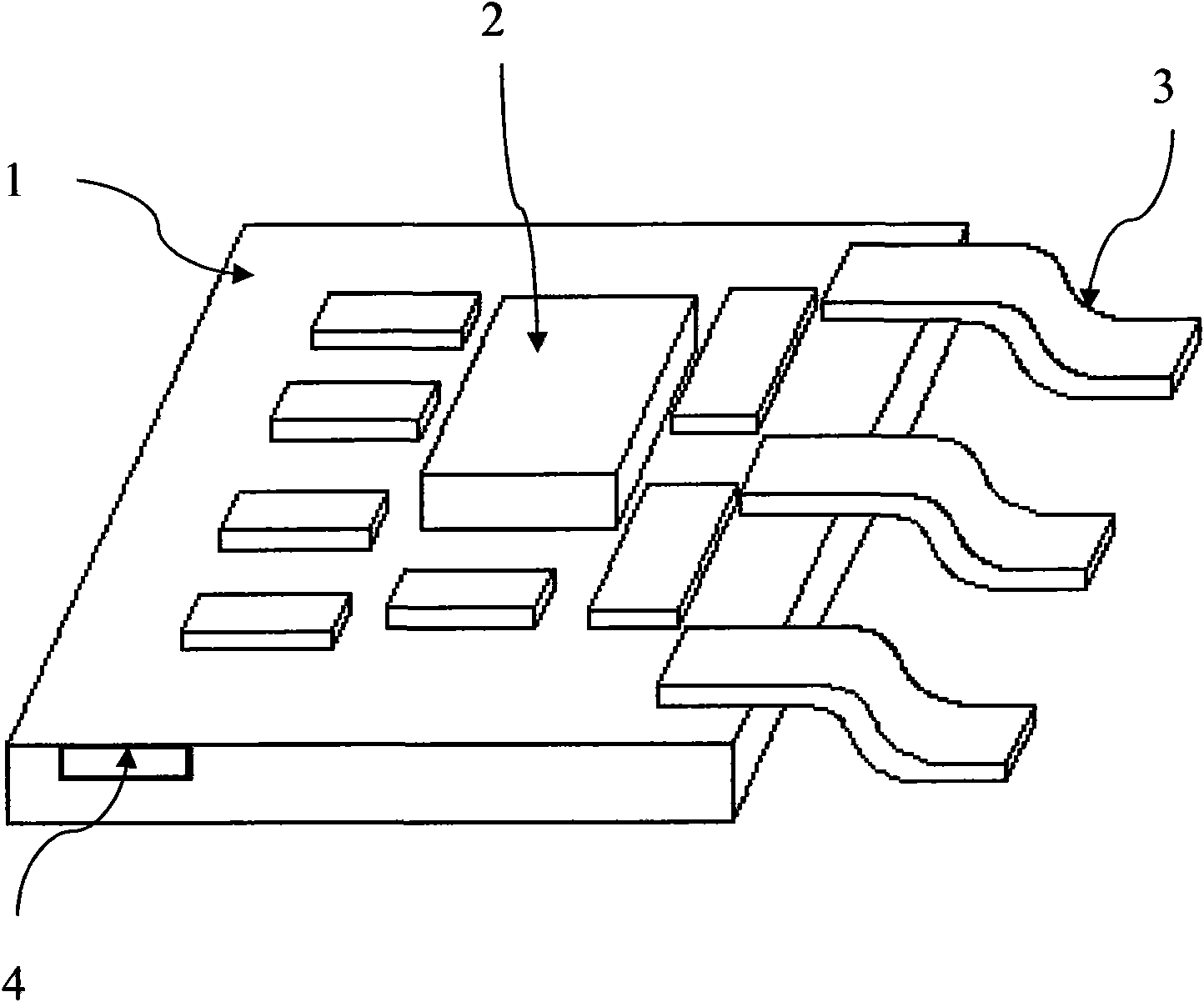

Microminiature power converter and thin film magnetic induction device thereof

ActiveUS20080136575A1Reduce induced voltageTransformers/inductances coils/windings/connectionsSolid-state devicesFerrite substrateElectrical conductor

A microminiature power converter includes a thin film magnetic induction device including a ferrite substrate and a solenoid coil conductor extending along the first and second principal planes of the substrate with the conductor extending through through-holes formed in the substrate to form a coil configuration. Electrodes are positioned near the peripheral region of the substrate and are collectively arranged at least one along the direction parallel to the axis of the solenoid coil formed by the conductor. The length of the coil can be increased to increase the inductance value of the coil. Gaps or grooves are provided near or in the peripheral region of the ferrite substrate to reduce induced voltage appearing in the electrodes.

Owner:FUJI ELECTRIC CO LTD

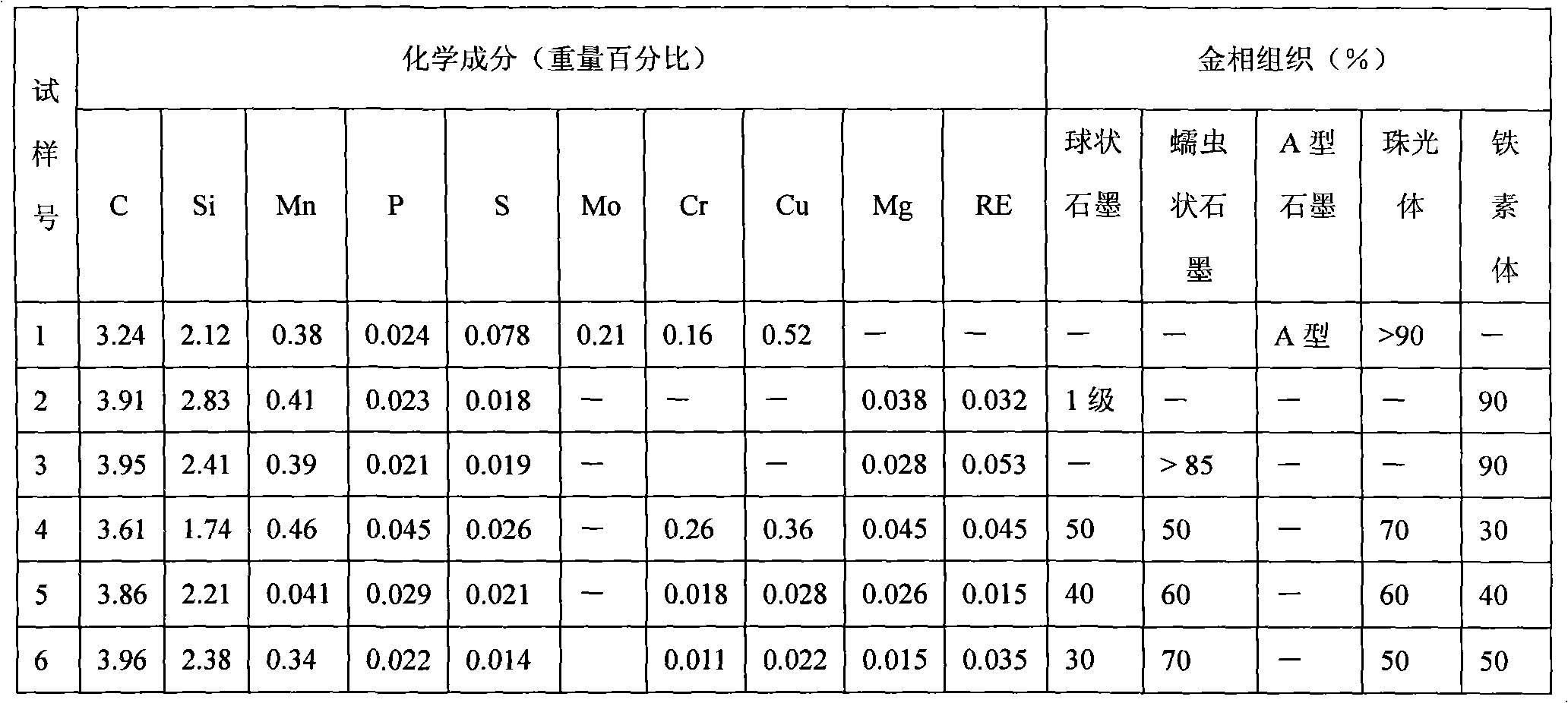

Cast iron for cast-iron brake drum

ActiveCN101967601AOvercome the contradiction of low thermal conductivityReduce toughnessBraking membersFerrite substrateChemical composition

The invention relates to an overweight heavy truck, in particular to cast iron for a cast-iron brake drum of the overweight heavy truck running on mountain roads or slopes and requiring frequent braking. Based on the chemical components of HT250, ferrite spheroidal graphite cast iron and ferrite vermicular iron, the chemical components of the cast iron are redesigned and comprise C, Si, Mn, P, S, Cr, Cu, Mg, RE and Fe; and the cast iron of which the spheroidal and vermicular graphite is distributed on a pearlite and ferrite diphase substrate simultaneously is obtained. The coexisting spheroidal and vermicular graphite replaces the A type graphite or single spheroidal graphite or single vermicular graphite in the traditional cast iron for the cast-iron brake drum; and the pearlite and ferrite diphase substrate replaces the single pearlite or ferrite substrate in the traditional cast iron for the cast-iron brake drum. The high-temperature strength of the brake drum is enhanced, the thermal fatigue resistance of the brake drum is improved and the service life of the brake drum is prolonged.

Owner:JILIN UNIV

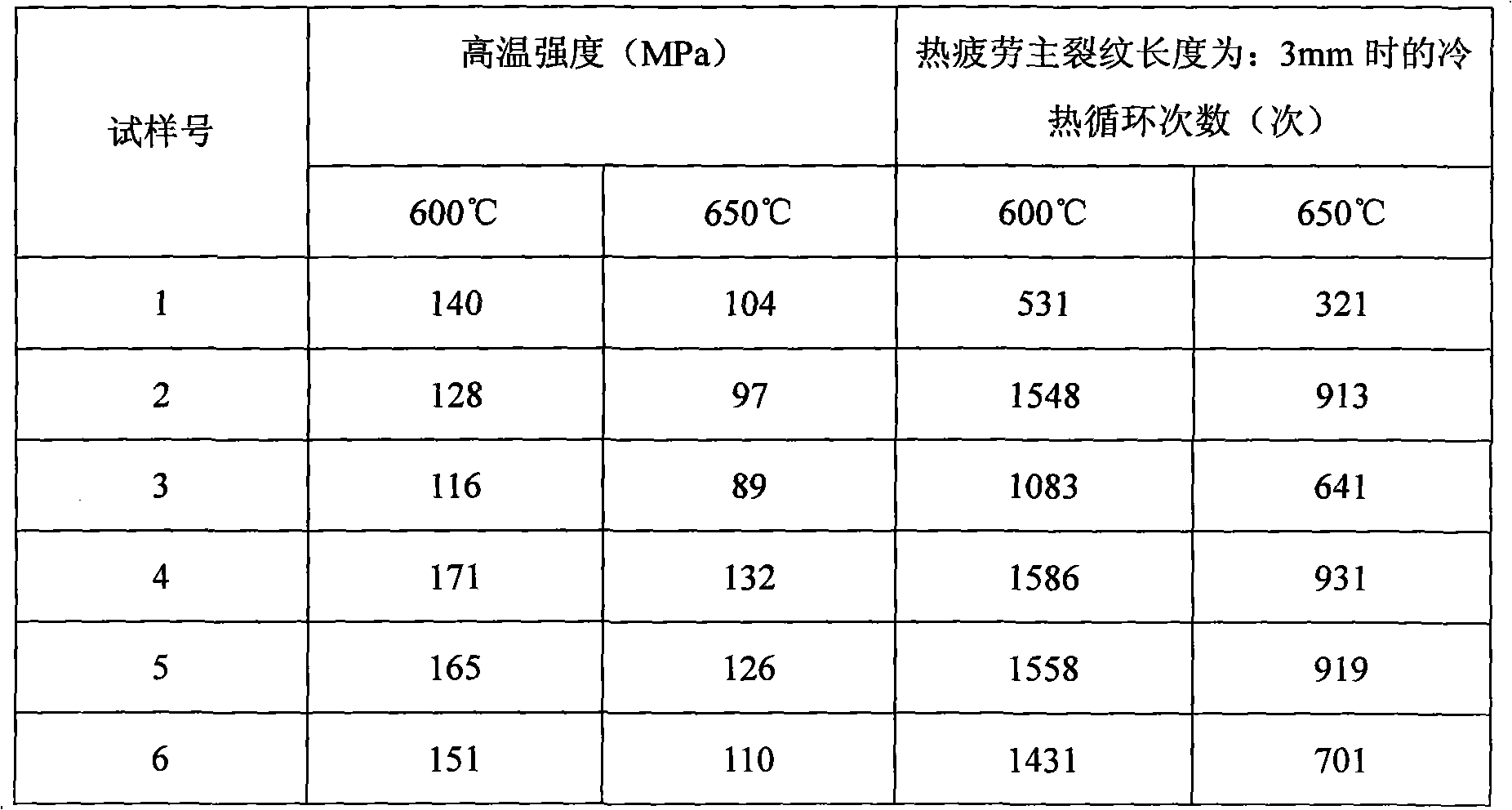

V-N microalloyed high-toughness large-specification steel angle and production method thereof

ActiveCN103911549AOptimizing the formulation of chemical ingredientsExcellent performance indexTemperature control deviceFerrite substrateProduction line

The invention relates to a V-N microalloyed high-toughness large-specification steel angle and a production method thereof. The V-N microalloyed high-toughness large-specification steel angle is composed of the following chemical components in percentage by weight: 0.14-0.20% of C, 0.20-0.50% of Si, 1.30-1.55% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.009-0.016% of N, 0.06-0.10% of V, 0.015-0.030% of Als and the balance of Fe. According to the formula of the chemical components and in a large-scale profile steel production line, the crystalline grains are thinned by controlling the parameters of continuous casting and rolling processes, and a cementite in a pearlite is distributed in a form of granules or in a short-rod form by use of a rapid controlled cooling process, and fine vanadium carbonitride or vanadium oxide particles are scattered and distributed on a ferrite substrate, and therefore, the purpose of improving the strength and the low-temperature toughness of the large-specification steel angle is reached; the mechanical property indexes of the V-N microalloyed high-toughness large-specification steel angle meet the standard requirements of Q460E.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

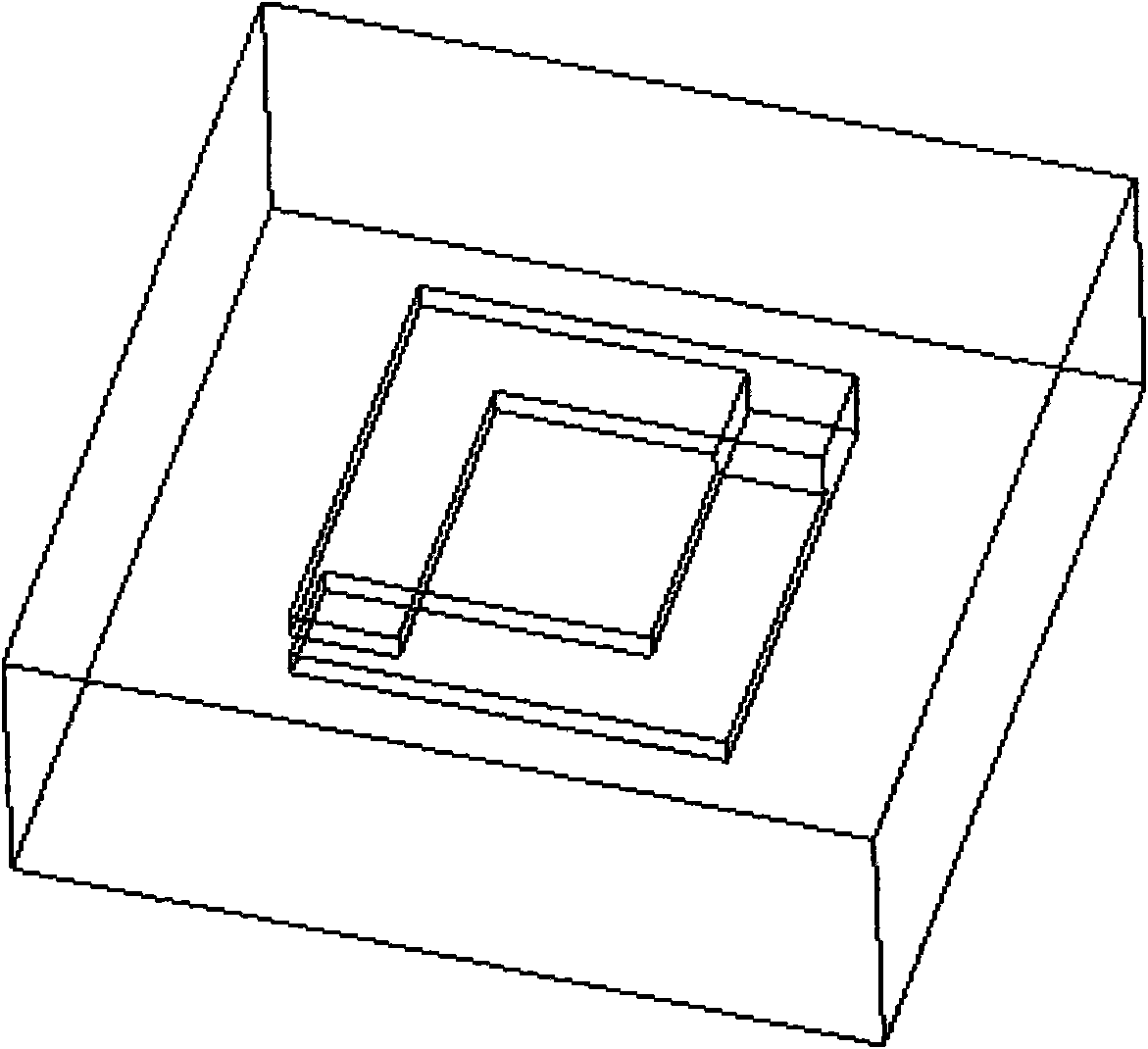

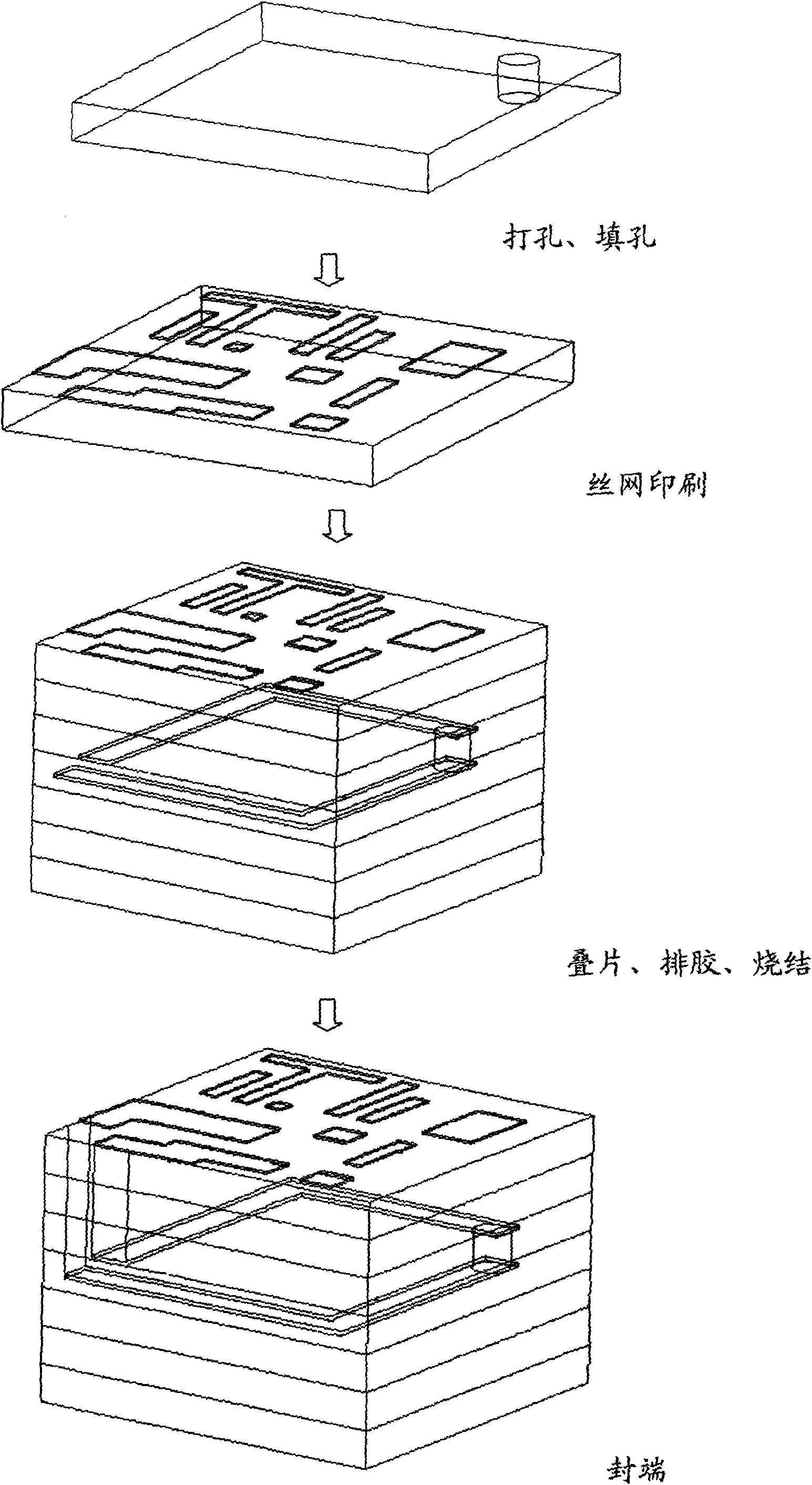

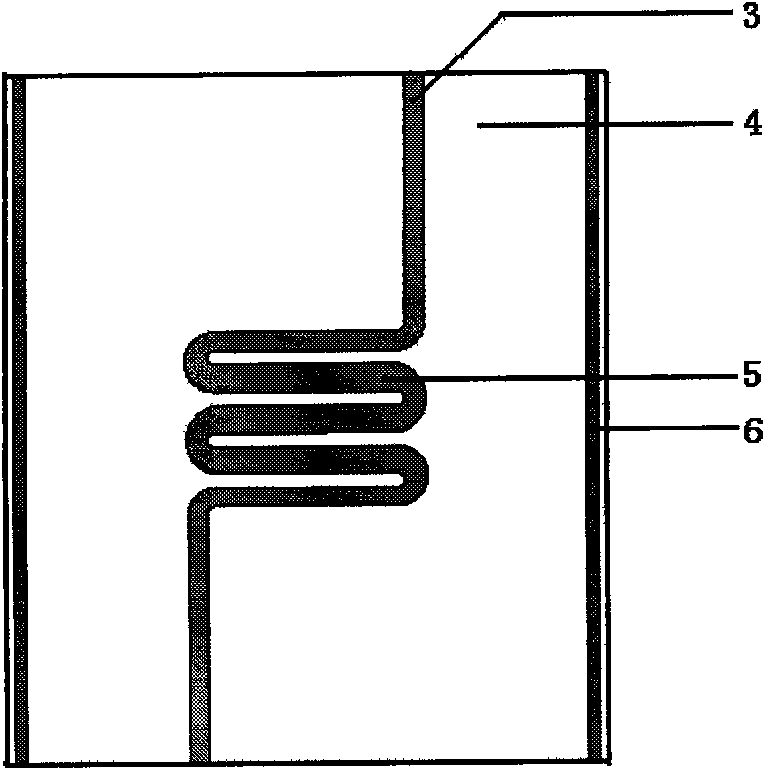

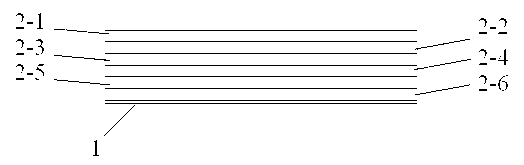

Substrate and magnetic device integrated DC-DC converter and preparation process thereof

InactiveCN101651404AAvoid errorsReduce volumePrinted circuit assemblingPrinted electric component incorporationFerrite substrateElectrical conductor

The invention discloses a substrate and a magnetic device integrated DC-DC converter. A magnetic device is integrated in a circuit substrate of the converter, and a surface electronic circuit is arranged on the surface of the substrate, wherein the substrate is a ferrite substrate, and the magnetic device is a conductor coil in a shape like the Chinese character of 'hui' and forms a closed inductor with ferrites around the magnetic device; both ends of the conductor coil extend to the side of the substrate, and the conductor coil and the surface electronic circuit are connected through a sealing end at the side face. The conductor coil of the converter is embedded in the substrate, and the substrate is a carrier of the magnetic device and the surface electronic circuit, thereby realizing the passive integration of the magnetic device and the circuit substrate and ensuring that the substrate also has the functions of the magnetic device. A separated inductor or transformer is not neededto be arranged in an assembly process, thereby greatly reducing the overall volume of a power module.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Manufacturing method for automobile transmission gear

The invention discloses a manufacturing method for an automobile transmission gear, and relates to the field of manufacturing of automobile parts. The method comprises the following steps: (1) blank forging, (2) spheroidizing annealing, (3) turning machining, (4) hobbing, (5) gear shaving, (6) carburization, (7) quenching and tempering and (8) grinding machining. According to the method, spheroidizing annealing treatment is adopted, so that the cutting performance of the gear is improved, a structure with spheroidized or granular carbide uniformly distributed on a ferrite substrate is obtained for preparation for subsequent heat treatment; a gas carburization method is adopted, and volatile kerosene is used as a carburizer, so that carburization effects are effectively improved, the thickness of a carburized layer is increased, the surface of the gear is hard and wear-proof, and high toughness of the core of the gear is maintained; quenching and tempering heat treatment is adopted after carburization, so that the carburization effects are further consolidated, and the mechanical performance of the gear is improved.

Owner:JIANGXI UNIV OF TECH

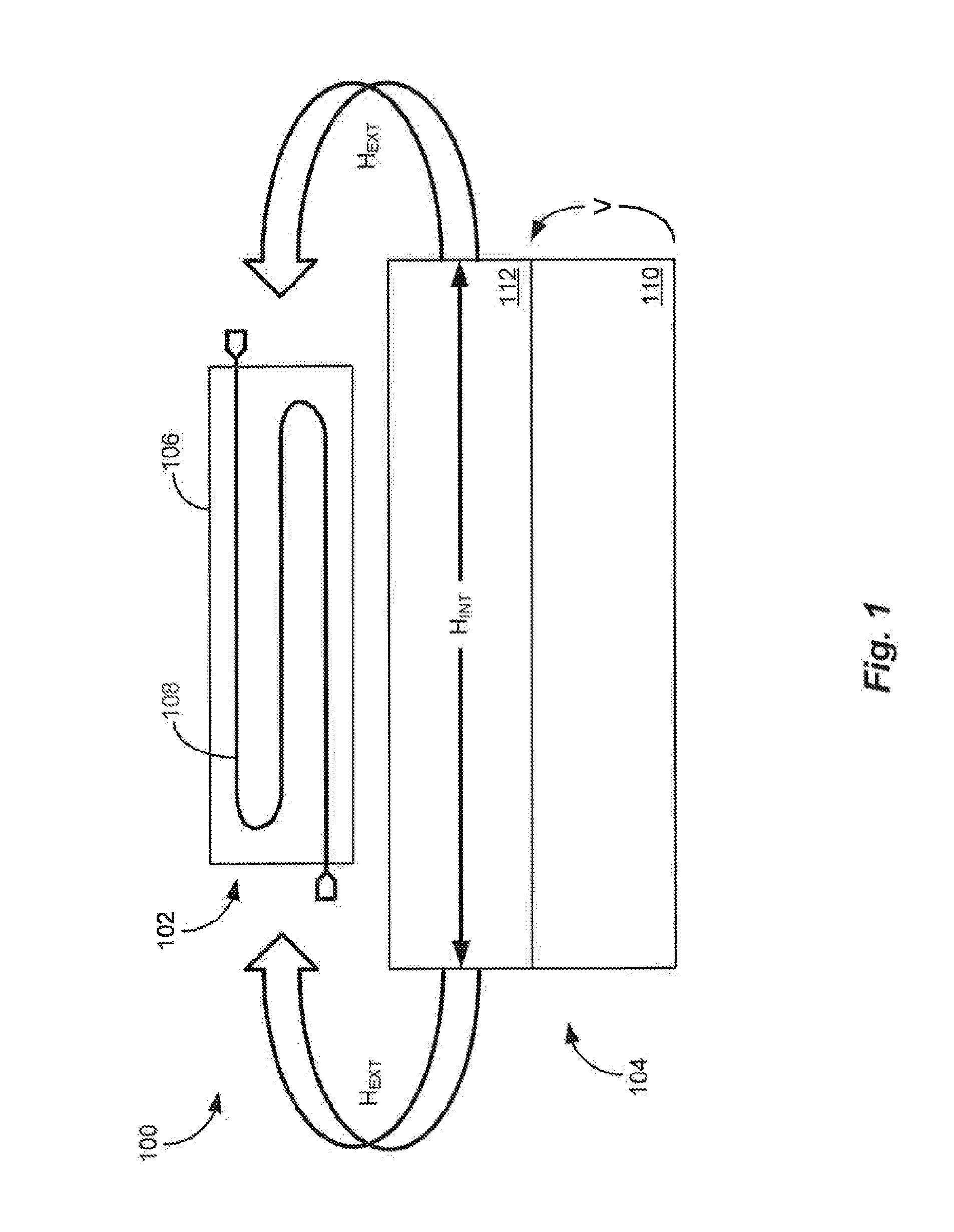

Voltage Tuning of Microwave Magnetic Devices Using Magnetoelectric Transducers

InactiveUS20120293023A1Reduced DC power consumptionShort response timePiezoelectric/electrostriction/magnetostriction machinesWaveguide type devicesFerrite substrateMicrowave

Tunable microwave magnetic devices that provide increased performance with reduced size, weight, and cost. The disclosed microwave magnetic devices are voltage-tunable devices that include ferrite substrates. To tune the devices, the magnetic permeability of the respective ferrite substrates is varied by external, voltage-tuned, magnetic fringe fields created by one or more magnetoelectric (ME) transducers.

Owner:NORTHEASTERN UNIV

Stripline-style ferrite phase shifter based on LTCC technology

ActiveCN101557024AAchieve integrationReduce volumeWaveguide type devicesFerrite substrateDielectric substrate

Owner:东莞成电创新电子科技有限公司

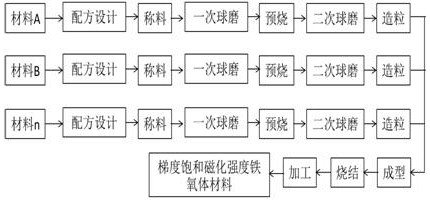

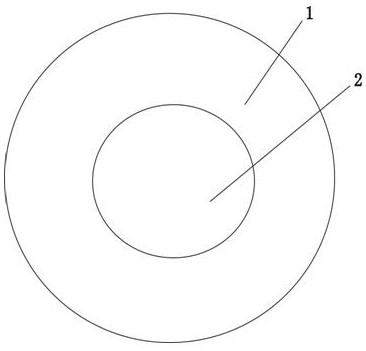

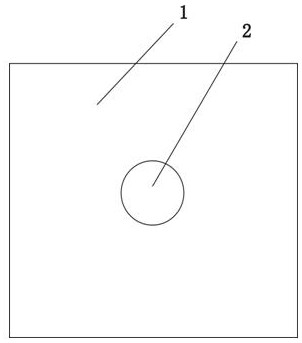

Microwave ferrite material with gradient saturation magnetization intensities, ferrite substrate prepared from microwave ferrite material and preparation method of ferrite substrate

ActiveCN111620682AHigh bandwidthReduce volumeInorganic material magnetismInductances/transformers/magnets manufactureFerrite substrateChemical composition

The invention discloses a microwave ferrite material with gradient saturation magnetization intensities. The chemical composition of the raw materials of the material is Bi<h>Gd<k>Y<3-h-k-(a+c+2d+f)>Ca<a+c+2d+f>SnInZr<c>V<d>Al<e>Ge<f>Fe<5-a-b-c-d-e-f-delta1>O<12> and Ni<1-x+y-z>Zn<x>D<y>Sn<y>Co<z>Mn<m>Fe<2-2y-m-n-delta2>O<4>, wherein a is no less than 0 and no more than 0.5, b is no less than 0 and no more than 0.5, c is no less than 0 and no more than 0.5, d is no less than 0 and no more than 1.0, e is no less than 0 and no more than 1.0, f is no less than 0 and no more than 0.5, h is no less than 0 and no more than 1.5, k is no less than 0 and no more than 0.7, x is no less than 0 and no more than 0.5, y is no less than 0 and no more than 0.15, z is no less than 0 and no more than0.06, m is no less than 0 and no more than 0.1, delta is an iron deficiency amount, delta1 is larger than or equal to 0.02 and smaller than or equal to 0.3, and delta 2 is larger than or equal to 0.02and smaller than or equal to 0.2. The raw materials form at least two different saturation magnetization intensity areas on a substrate; the saturation magnetization intensity gradients on the microwave ferrite substrate with gradient saturation magnetization intensities can be randomly combined within the range of 47 kA / m to 414 kA / m; different saturation magnetization intensity areas can be inany shape; the problems of miniaturization and integration of microwave devices and the technical problems of miniaturization, high isolation and low insertion loss of frequency doubling and triple frequency broadband devices are solved through combination of saturation magnetization intensities of different gradients; and the preparation method is reasonable in process and suitable for application and popularization.

Owner:中国电子科技集团公司第九研究所

Antenna module having reduced size, high gain, and increased power efficiency

InactiveUS8395552B2Reduce weight and sizeImprove power efficiencySimultaneous aerial operationsAntenna supports/mountingsFerrite substrateBarium hexaferrite

A broadband integrated circulator antenna (BICA) module for receiving and transmitting signals with high efficiency and high gain. The BICA can have a bandwidth of over 70% of a radar band and can operate in frequencies from UHF to S-band and above. The BICA has a stack configuration that includes a low profile antenna, a reflecting layer or a metamaterial substrate layer, and a circulator. The circulator is placed proximal to antenna, which greatly reduces the size of the BICA. The circulator can be a stripline Y-junction ferrite circulator and the antenna can be a coaxial center fed bow-tie antenna. The reflecting layer or metamaterial substrate layer can comprise electronic bandgap metamaterial and a high permeability ferrite substrate. The high permeability ferrite substrate can be cobalt substituted Z-type barium hexaferrite.

Owner:METAMAGNETICS +1

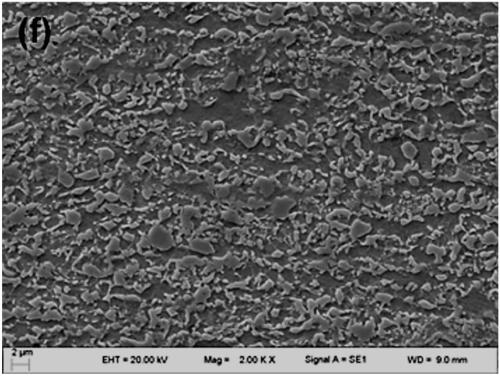

Molded ferrite sheet, sintered ferrite substrate and antenna module

ActiveUS7910214B2Eliminate procedureReduce instabilityLoop antennas with ferromagnetic coreAntenna supports/mountingsFerrite substrateOccupancy rate

The present invention relates to a molded ferrite sheet having opposing surfaces and a thickness in a range of 30 μm to 430 μm, at least one surface of said opposing surfaces having the following surface roughness characteristics (a) to (c):(a) a center line average roughness is in a range of 170 nm to 800 nm,(b) a maximum height is in a range of 3 μm to 10 μm, and(c) an area occupancy rate of cross-sectional area taken along a horizontal plane at a depth of 50% of the maximum height in a square of side 100 μm is in a range of 10 to 80%.

Owner:TODA IND

Ferrite substrate cleaning technology method based on neutral solution

ActiveCN103624028AEasy to recycleEfficient removalCleaning using liquidsFerrite substrateOrganic solvent

The invention relates to the field of micromachining, in particular to a ferrite substrate cleaning technology based on a neutral solution. The technology includes the following steps that a substrate side and a non-exposed face are ground, a substrate is horizontally placed in an utensil, a cleaning agent is used for carrying out ultrasonic treatment on the substrate in an ultrasonic cleaning machine; the substrate is placed in a ceramic crucible and flushed with hot water; microcleaning is carried out on the surface of the substrate. The ferrite substrate cleaning technology based on the neutral solution has the advantages that impurities such as oil contamination can be effectively removed, reaction with the ferrite substrate does not exist, in addition, alcohol and ketone anhydrous organic solvents are easy to recycle and the environment will not be polluted.

Owner:SOUTHWEST INST OF APPLIED MAGNETICS

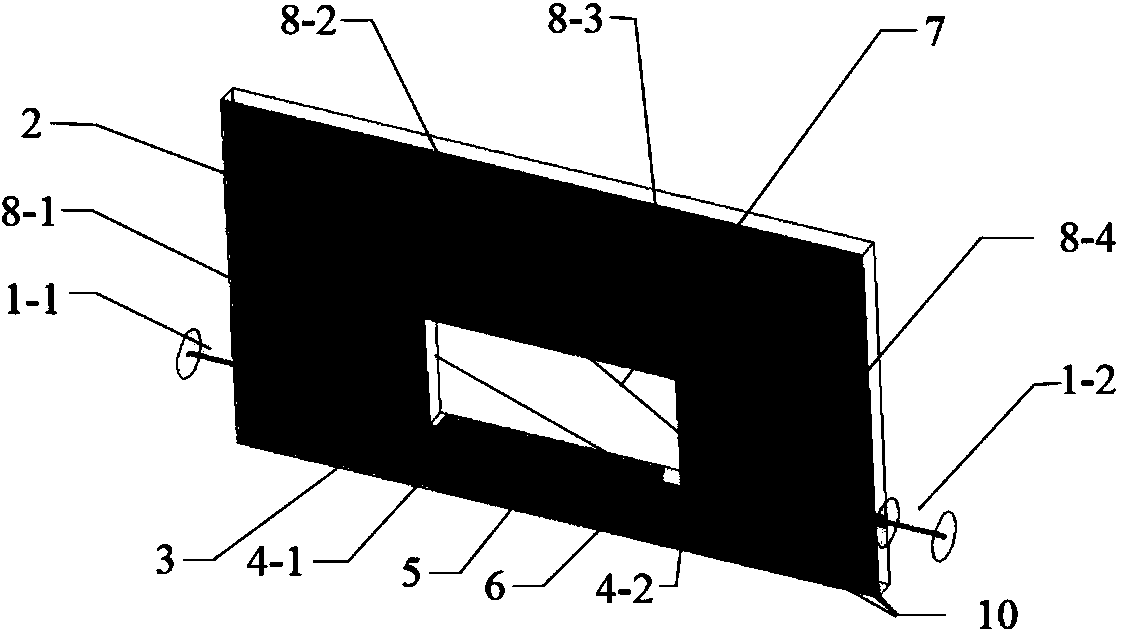

Two-junction microstrip circulator with magnetic shielding case and assembly formed by same

InactiveCN103647126AGood magnetic shielding functionSimple structureWaveguide type devicesFerrite substrateDielectric substrate

The invention relates to a two-junction microstrip circulator with a magnetic shielding case and an assembly formed by the same and belongs to the technical field of magnetic materials and devices. The two-junction microstrip circulator with the magnetic shielding case comprises a soft magnetic alloy bottom plate and a ferrite substrate positioned above the soft magnetic alloy bottom plate, wherein the upper surface of the ferrite substrate is provided with a double-junction circulation microstrip circuit, and the lower surface of the ferrite substrate is provided with a grounding metal layer. Permanent magnets are arranged above the geometric center of the junction circulation microstrip circuit, the magnetic shielding case is arranged above the permanent magnets, lower dielectric substrates are arranged among the permanent magnets and the two-junction circulation microstrip circuit to separate the permanent magnets from the two-junction circulation microstrip circuit, and upper dielectric substrates are arranged among the permanent magnets and the magnetic shielding case to separate the permanent magnets from the magnetic shielding case. The magnetic shielding case is formed by bending the edge of a soft magnetic flat plate alloy material downwards, the bottom of the bent edge of the magnetic shielding case does not contact with the ferrite substrate, the smallest horizontal enclosure dimension of the magnetic shielding case is larger than the largest distance between outer edges of the two permanent magnets and smaller than the side length of the ferrite substrate. The two-junction microstrip circulator with the magnetic shielding case has a good magnetic shielding function, and is simple in structure, stable in performance, convenient to produce and debug and capable of meeting application needs of increasing miniaturization and high integration.

Owner:CHENGDU ZHILI MICRO TECH

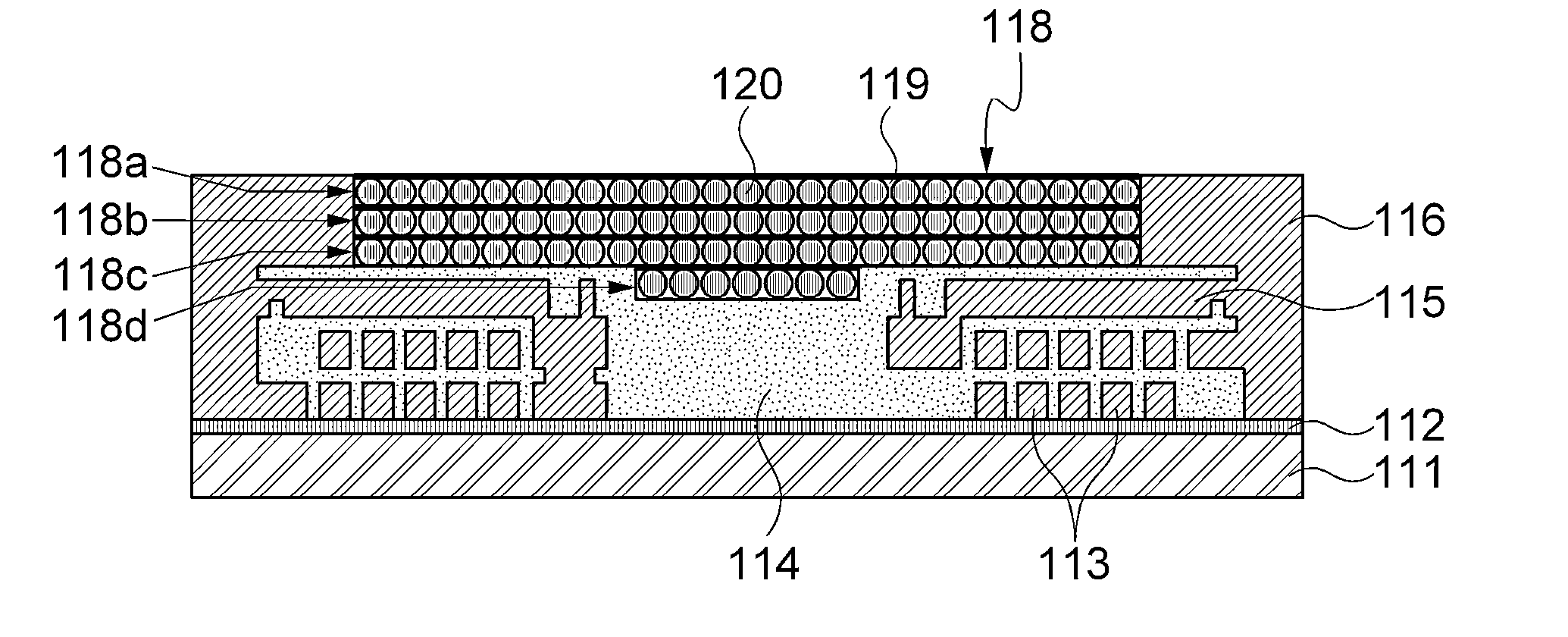

Semiconductor package comprising ferrite antenna for near filed communication and manufacturing method thereof

InactiveCN104425434ASuppresses the problem of antenna performance degradationImprove performanceSemiconductor/solid-state device detailsSolid-state devicesFerrite substrateAntenna radiation patterns

The present invention relates to a semiconductor package having a ferrite antenna for a near field communication (NFC), and a method of manufacturing the same. A semiconductor package according to the present invention includes a printed circuit board, a semiconductor chip, a ferrite antenna for NFC, first and second bonding wires, and a resin sealing part. The semiconductor chip is attached to one surface of the printed circuit board. The ferrite antenna, which is attached onto the semiconductor chip, includes a ferrite substrate of a ferrite material having the low surface attached onto the semiconductor chip, and an antenna pattern formed on the top surface of the ferrite substrate. The first wire connects the semiconductor chip and the printed circuit board electrically to each other. The second wire connects the antenna pattern of the ferrite antenna and the printed circuit board electrically to each other. And, the resin sealing part seals the semiconductor chip, the ferrite antenna, and the first and second bonding wires formed on the printed circuit board.

Owner:BARUN ELECTRONICS CO LTD

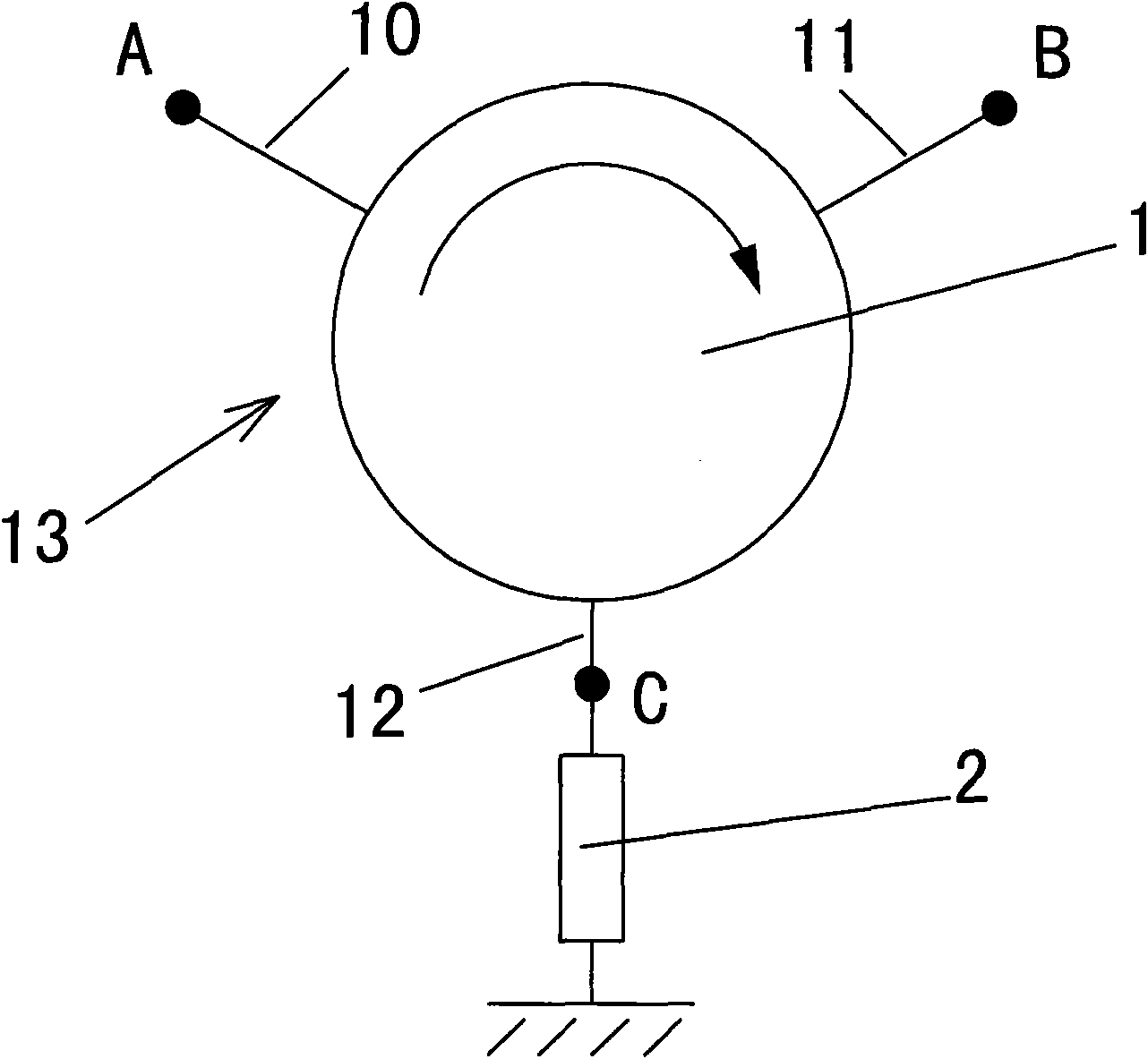

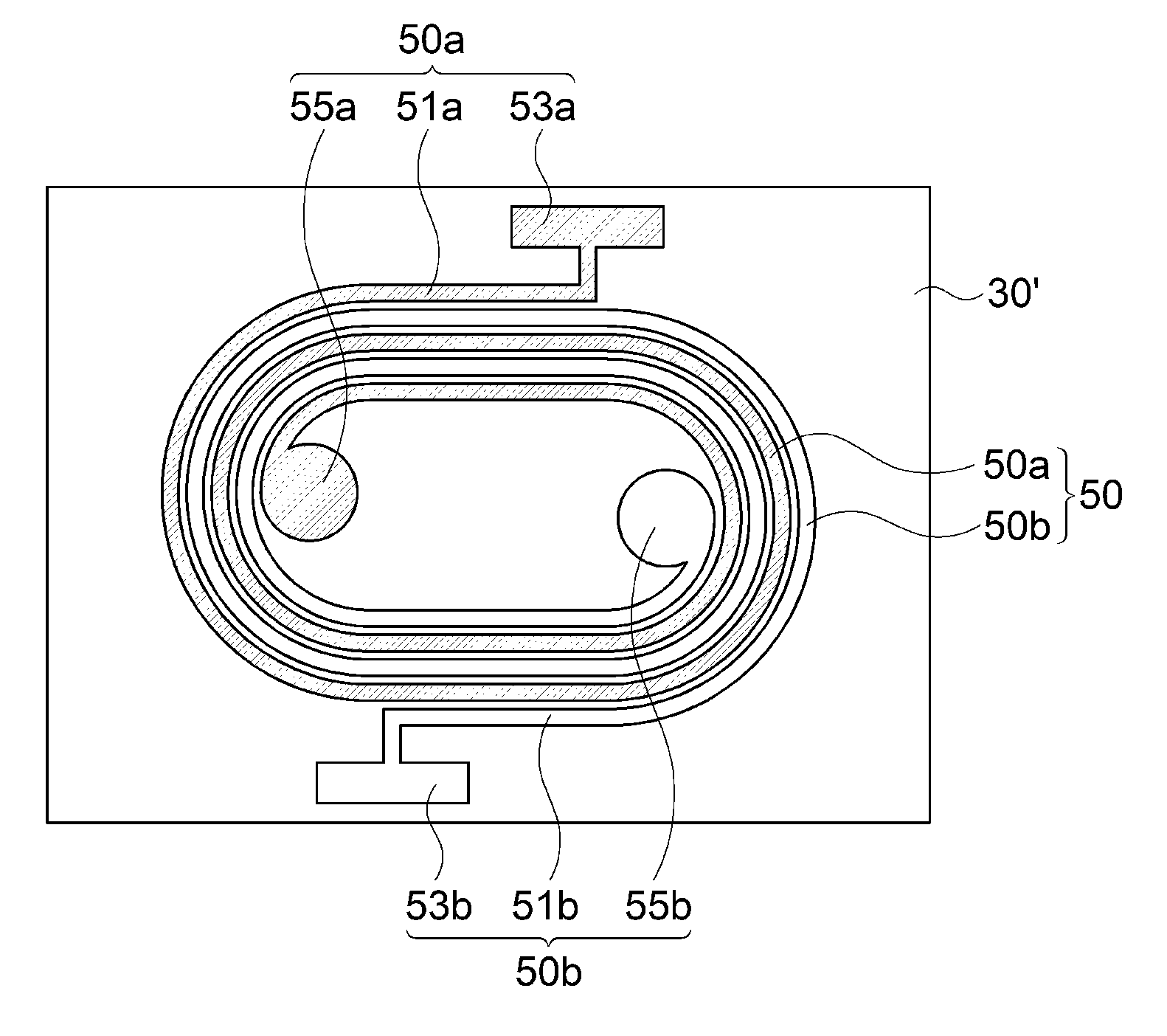

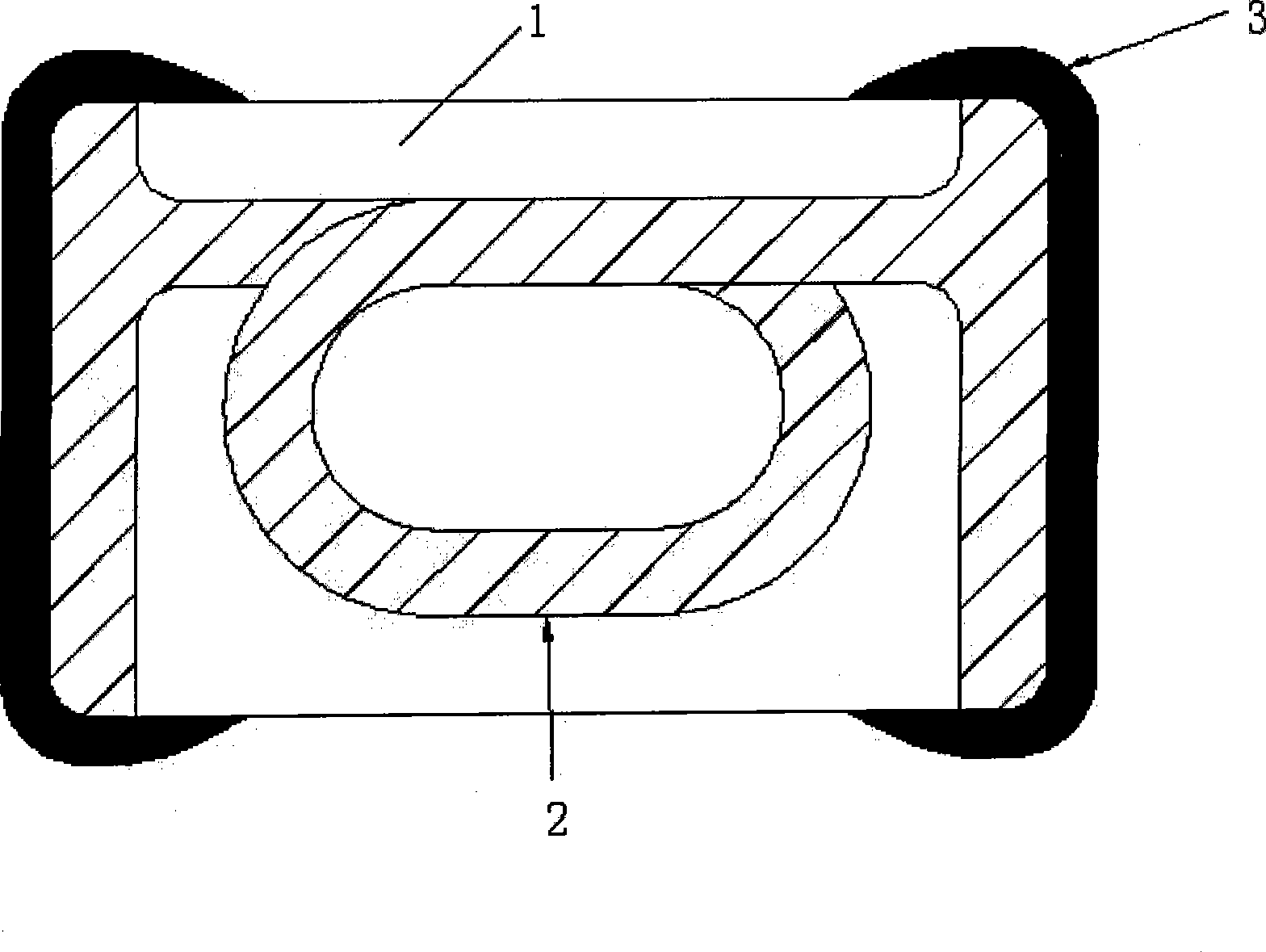

Circulator

ActiveCN101621148AReduce lossReduce operating frequencyWaveguide type devicesFerrite substrateElectrical conductor

The invention discloses a circulator which comprises a cavity, wherein a center conductor and ferrite substrates are arranged in the cavity, and a cover plate is arranged at the outermost layer of the cavity; both sides of the center conductor are provided with the ferrite substrates; the center conductor is provided with a big Y branch line and a small Y branch line which are arranged at intervals; and the port of at least one of the Y branch lines is provided with a section of short capacitive transmission line, thereby being equivalent to an L / C matching network. The circulator is based ona double-Y node circulator, a section of short capacitive transmission line is extended from the port of at least one Y branch line, thereby being equivalent to the quasi-concentrated parameter L / C type matching network to replace a Y branch line forming a Y type transmission line in the prior art, thus the circulator is miniaturized. Under the same performance, the working frequency of the circulator is lower than that of the prior circulator, the loss is small, and the radius of the disk of gyromagnetic material of the circulator can be reduced to be half of that of the disk of gyromagneticmaterial of the prior conductor.

Owner:HUAYANG TECH DEV

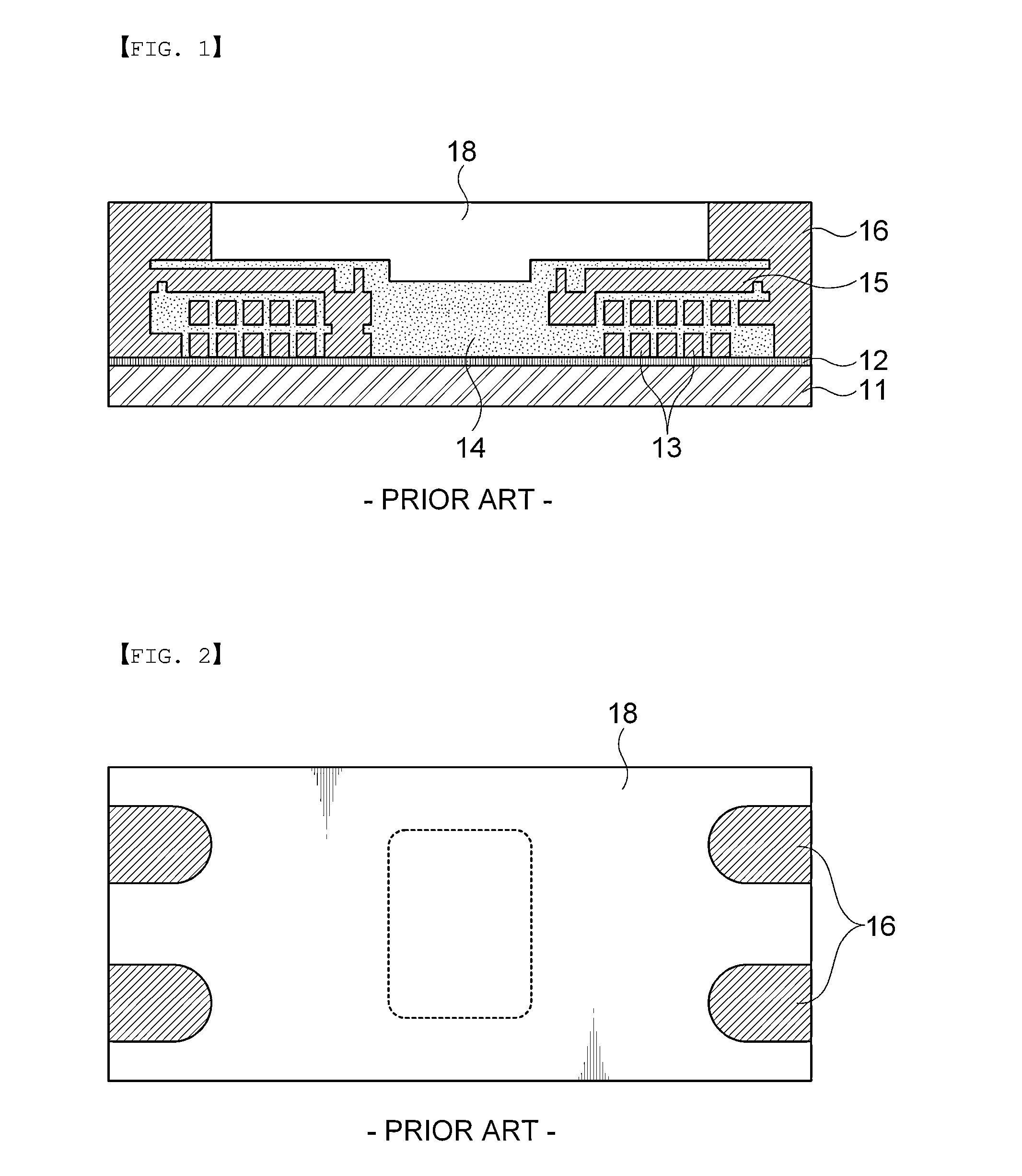

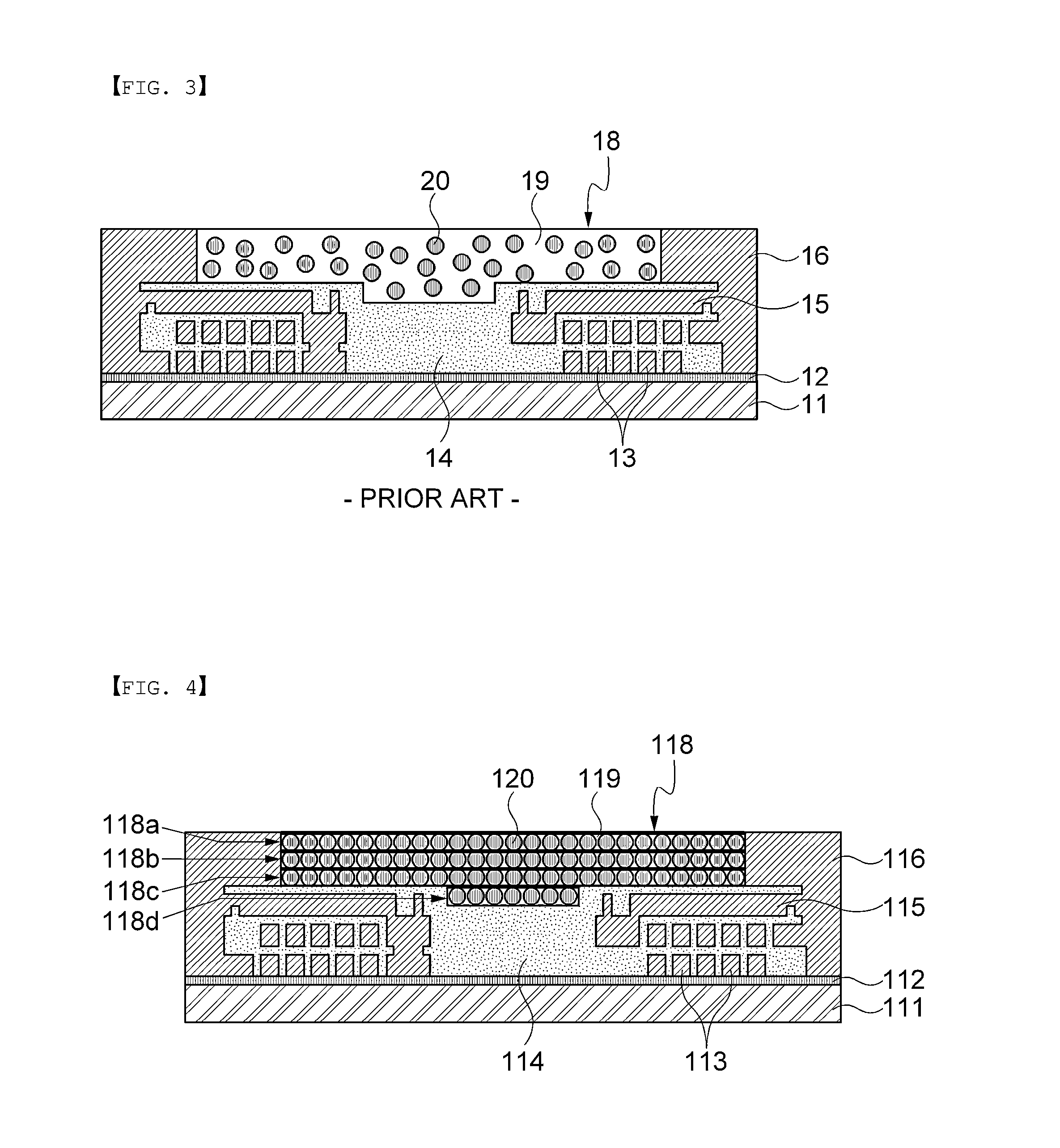

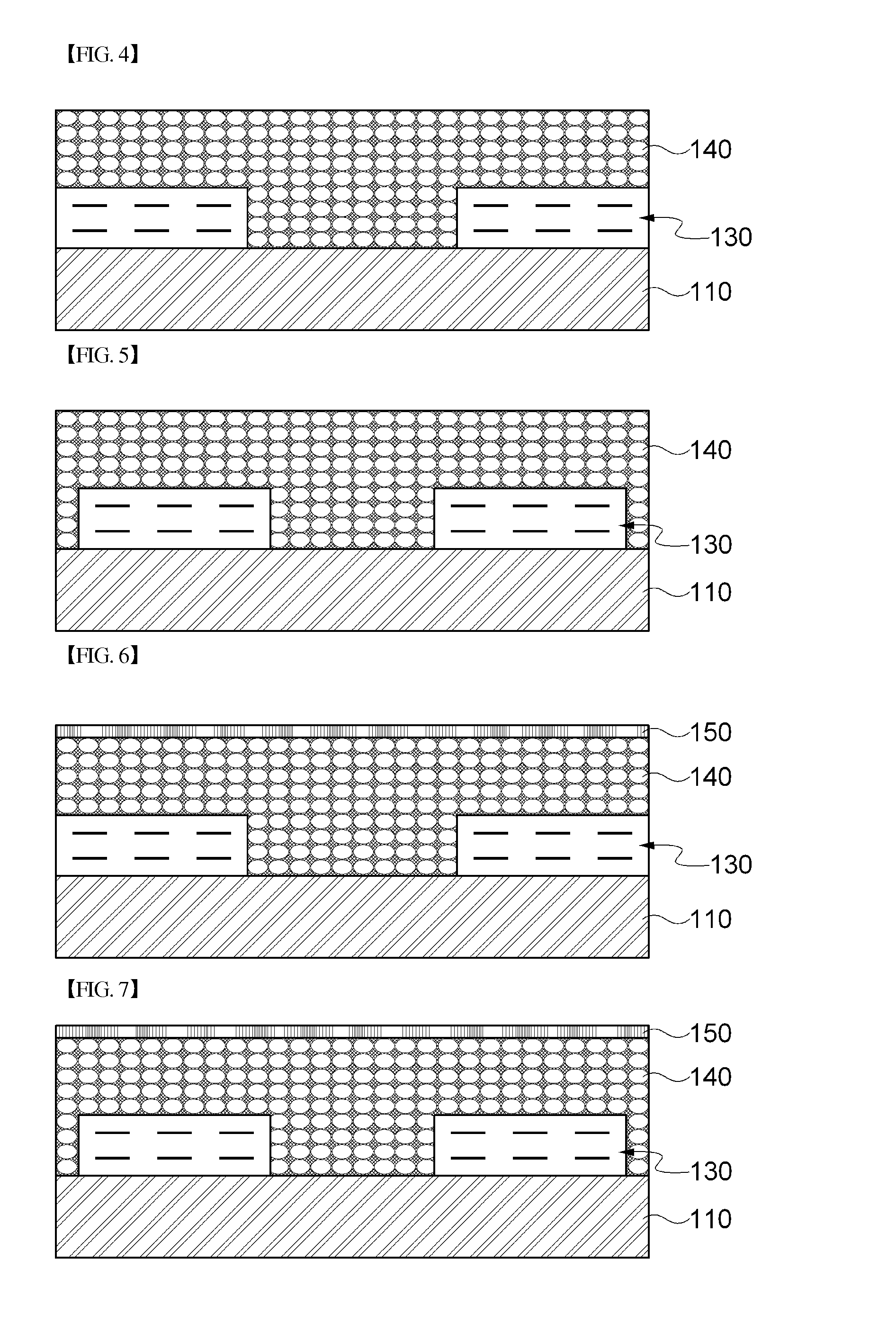

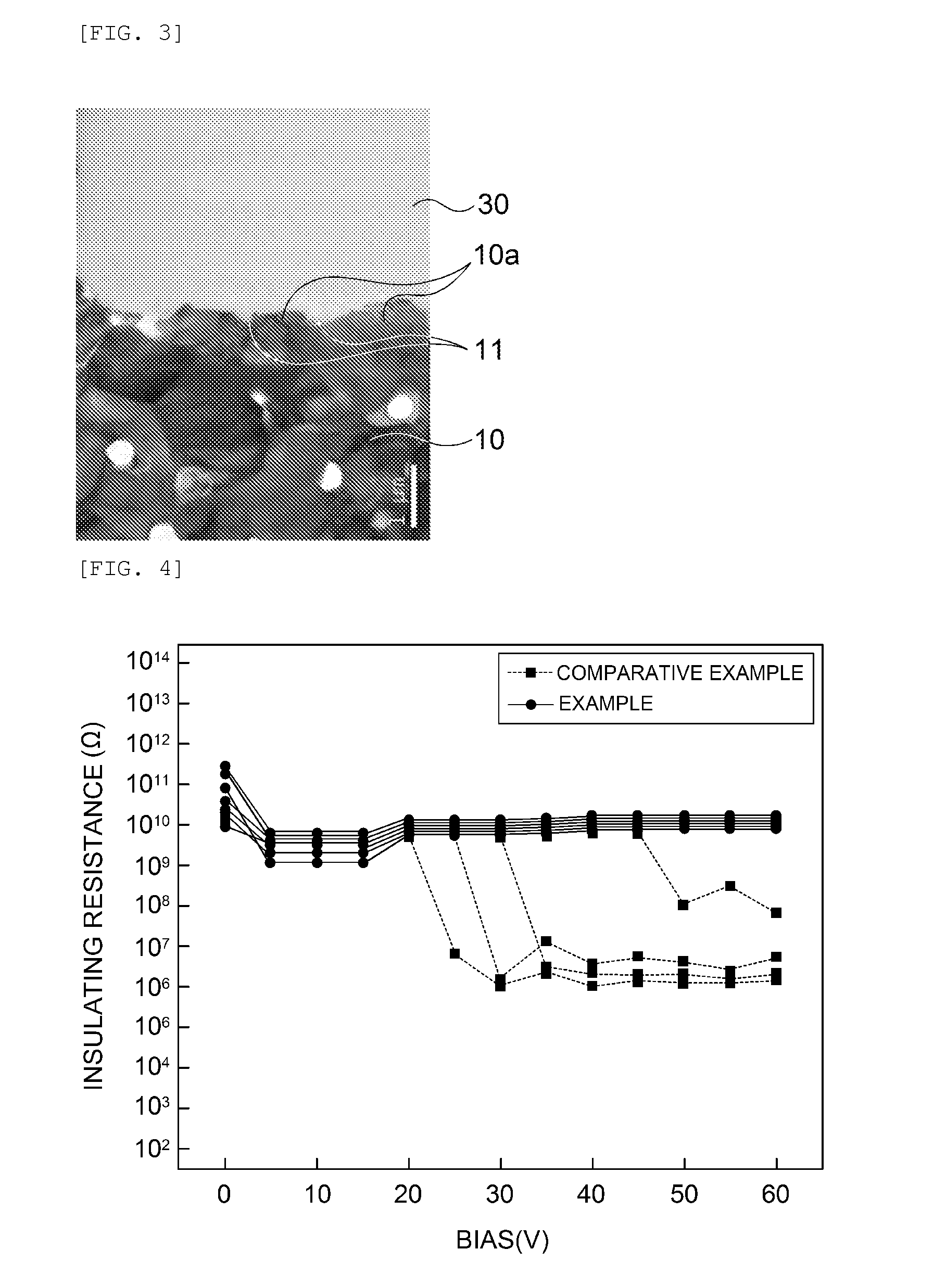

Common mode noise chip filter and method for manufacturing the same

InactiveUS20140145797A1Improve reliabilityImprove breathabilityMultiple-port networksInductances/transformers/magnets manufactureFerrite substrateInternal stress

Disclosed herein are a common mode noise chip filter and a method for manufacturing the same, the common mode noise chip filter including: a ferrite substrate; coil patterns formed on the ferrite substrate; and a ferrite-polymer complex layer formed on the result substrate having the coil patterns formed therein, wherein the ferrite-polymer complex layer has a multilayer structure, so that the ferrite-polymer complex layer filling an inner space of the substrate having inner coil patterns is formed to have the multilayer structure but not a single-layer structure, thereby lowering internal stress, and thus improving reliability of the common mode noise chip filter as a product.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Filter chip element and method of preparing the same

ActiveUS20140132366A1Avoid noiseIncreased impedance valueMultiple-port networksInductances/transformers/magnets manufactureFerrite substrateElectromagnetic shielding

Disclosed herein is a filter chip element including a ferrite substrate, internal coil patterns formed on the ferrite substrate; and a ferrite composite layer filled between the internal coil patterns formed on the ferrite substrate, wherein the ferrite composite layer includes foaming resin, thereby increasing magnetic permeability and a Q value which are important characteristics of a filter chip element for noise prevention among electromagnetic shielding components.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

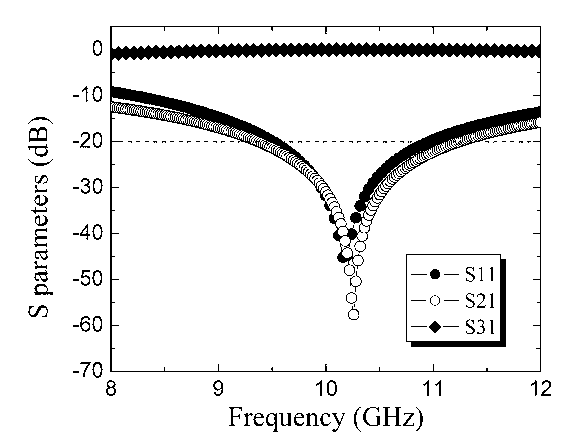

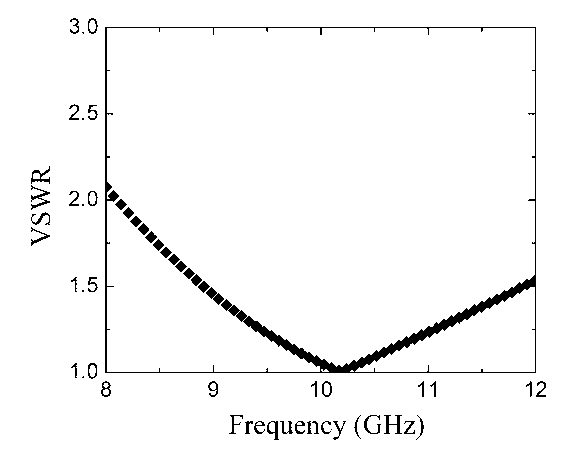

Wideband microstrip isolator

InactiveCN101552366ABroadbandBest parameter combinationWaveguide type devicesFerrite substrateMicrowave

The invention relates to a wideband microstrip isolator, which comprehensively considers the effects of electromagnetic parameters of a ferrite substrate, central working frequency and a bias field, and provides a best parameter combination. The microstrip isolator effectively solves the resistance matching problem, has the advantages of small volume, light weight, capable of being plastered, etc., realizes the wideband of the microstrip isolator and can be widely applied to the field of microwave communication field.

Owner:江苏灿勤科技股份有限公司

X wave band laminated slice type micro-strip ferrite circulator

InactiveCN103022609AAdapt to miniaturization development requirementsImproving Impedance MatchingWaveguide type devicesFerrite substrateMicrowave

The invention discloses an X wave band laminated slice type micro-strip ferrite circulator and belongs to the field of microwave ferrite devices. The circulator comprises a metal grounding layer, a ferrite substrate group, a disk knot, a small Y arm and a large Y arm. Structural form of a ferrite substrate is changed on the basis of a double-Y structure, a laminated slice type structure is used to build gradient electromagnetic parameters, so that impedance matching is improved, loss is reduced, isolation is increased and the like. Insertion loss of a device can be lowered to below 0.1dB, isolation is increased to above 50dB, and standing wave ratio is lowered to below 1.05. In addition, a impedance matching circuit of the device is smaller in size, so that integration of microwave circuits is facilitated, and the miniaturization development requirements of micro-strip ferrite circulators is adapted.

Owner:彭龙

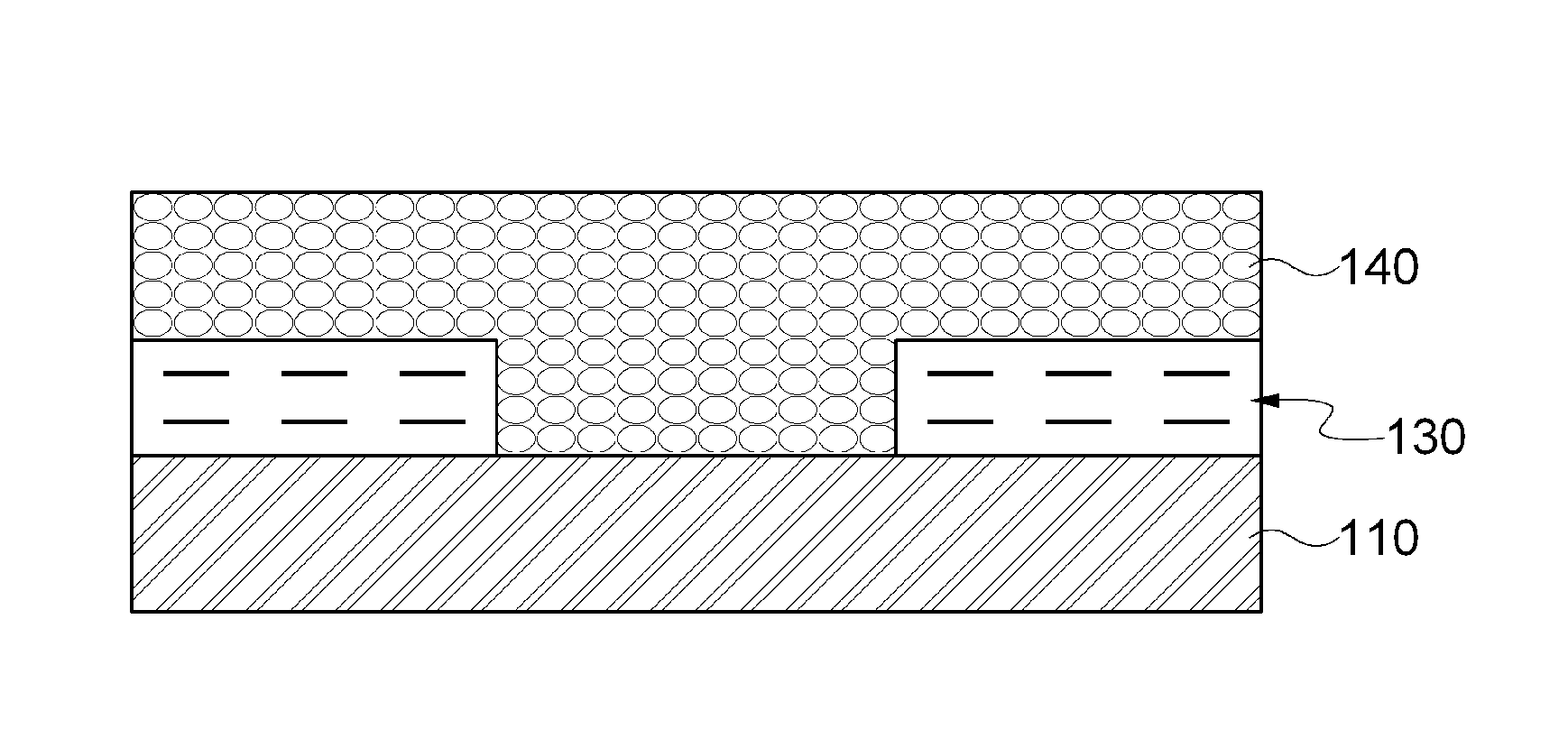

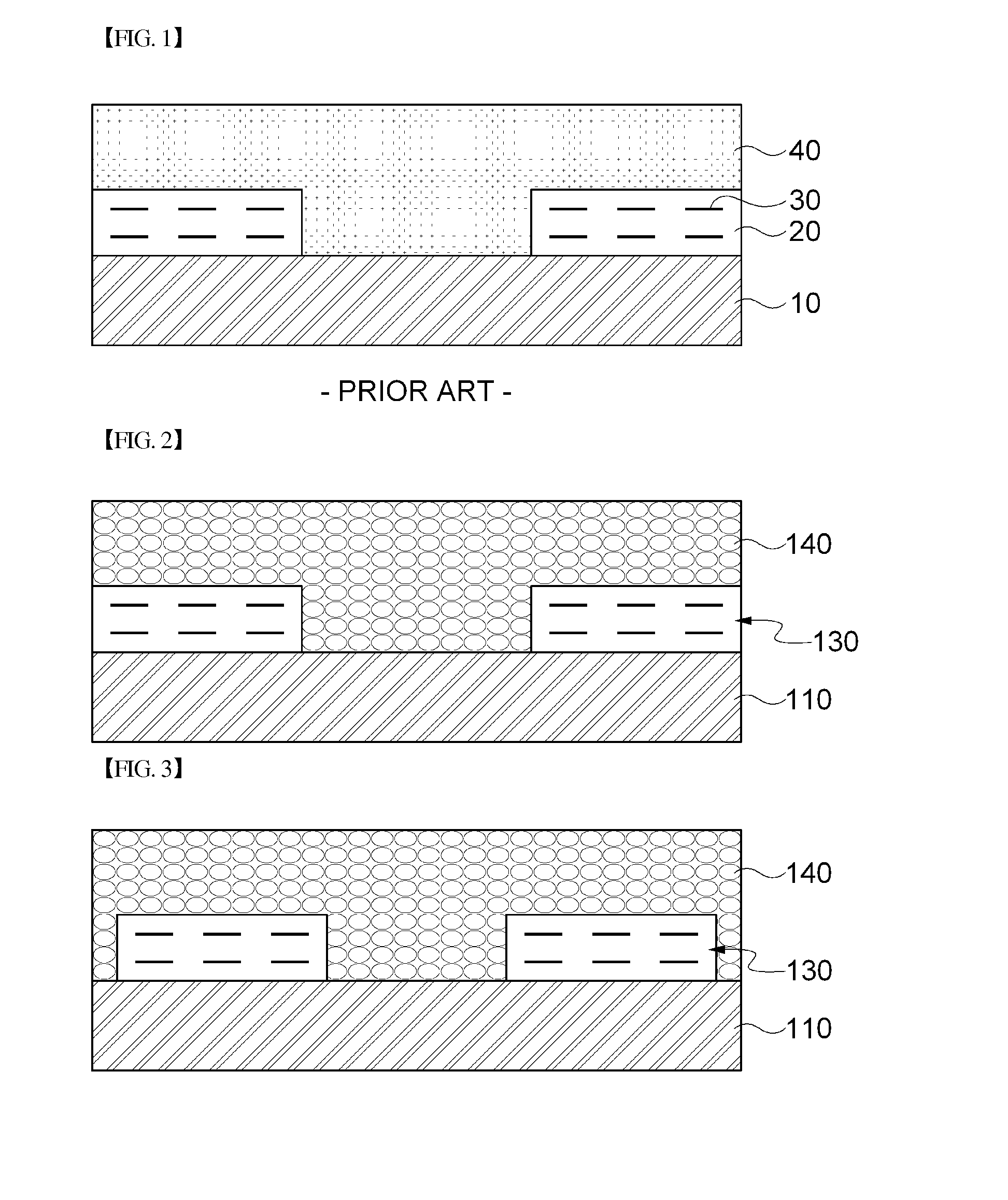

Thin-type common mode filter and manufacturing method thereof

InactiveUS20160012956A1Improve interface adhesionTransformers/inductances coils/windings/connectionsConductive/insulating/magnetic material on magnetic film applicationFerrite substrateSurface roughness

Disclosed herein are a thin-type common mode filter and a manufacturing method thereof. According to an exemplary embodiment of the present invention, a thin-type common mode filter includes: a ferrite substrate having an upper surface on which irregular surface roughness is formed; an insulating layer formed on the upper surface of the ferrite substrate; and a conductive coil pattern formed in the insulating layer to be spaced apart from the upper surface of the ferrite substrate. Further, a manufacturing method of a thin-type common mode filter is proposed.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

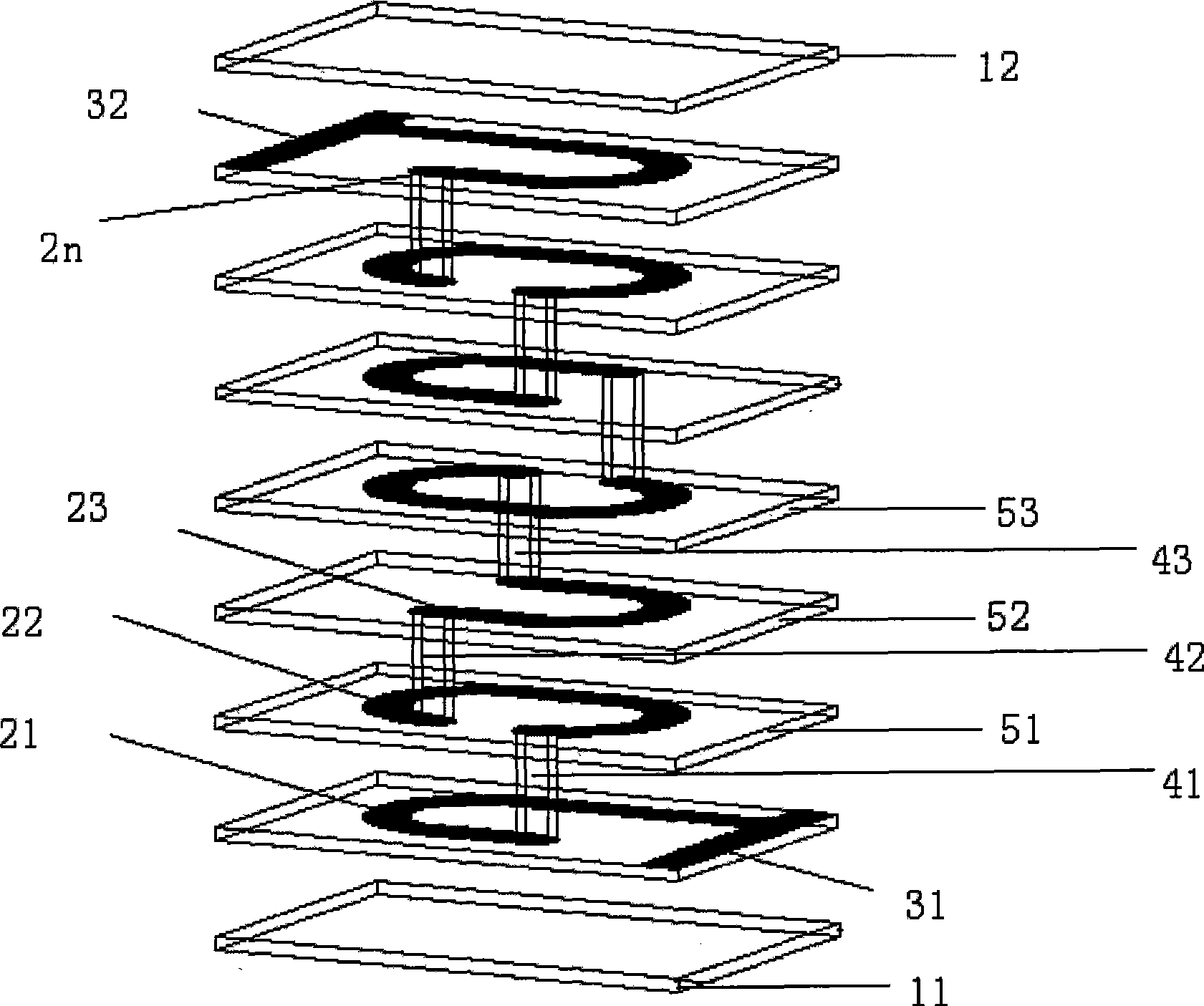

Inductor and manufacturing method thereof

ActiveCN101521087ACompositeTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresFerrite substrateEngineering

The invention is suitable for the field of electronics, and provides an inductor and a manufacturing method thereof. The inductor comprises a ferrite substrate, a conductive coil arranged in the ferriThe invention is suitable for the field of electronics, and provides an inductor and a manufacturing method thereof. The inductor comprises a ferrite substrate, a conductive coil arranged in the ferrite substrate, and terminal electrodes which are positioned at two end parts of the ferrite substrate and used for electrically connecting with the conductive coil. The conductive coil comprises a plurte substrate, and terminal electrodes which are positioned at two end parts of the ferrite substrate and used for electrically connecting with the conductive coil. The conductive coil comprises a plurality of layers of electrode patterns which are connected layer upon layer spirally. The layers of the electrode patterns are electrically connected through electric connecting elements to form a spirality of layers of electrode patterns which are connected layer upon layer spirally. The layers of the electrode patterns are electrically connected through electric connecting elements to form a spiral ellipse-like shape. In the inductor provided by the invention, the conductive coil adopts an ellipse-like spiral structure so as to make the inductor realize the specific inductive characteristic aal ellipse-like shape. In the inductor provided by the invention, the conductive coil adopts an ellipse-like spiral structure so as to make the inductor realize the specific inductive characteristic and the impedance characteristic and integrates the inductor and beads into a whole.nd the impedance characteristic and integrates the inductor and beads into a whole.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

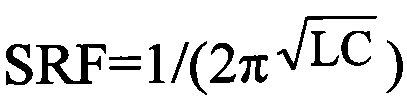

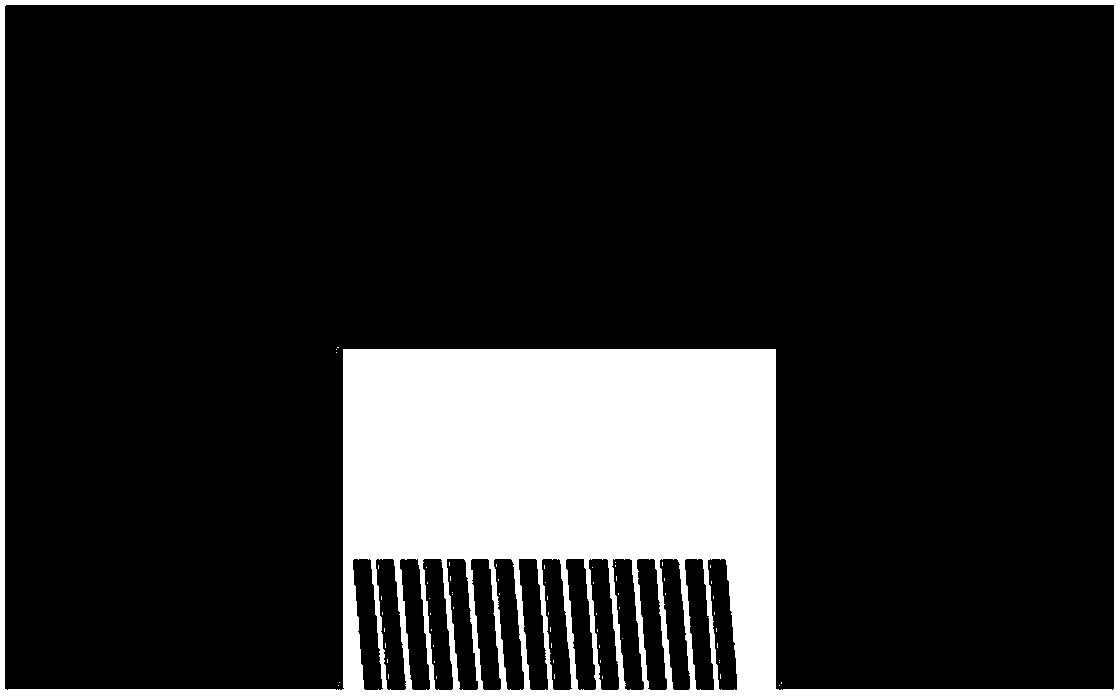

Microstrip line phase shifter based on LTCC technology

InactiveCN104201442ALow insertion lossLarge average power capacityWaveguide type devicesFerrite substrateCoupling

The invention provides a microstrip line phase shifter based on LTCC technology. The microstrip line phase shifter comprises a rectangular ferrite substrate, a first coupling curved segment, a second coupling curved segment, a third coupling curved segment, a fourth coupling curved segment, a solenoid and a bonding pad, and is characterized in that, the center of the rectangular ferrite substrate is provided with a rectangular substrate window; the fourth coupling curved segments are distributed on the upper surface of the substrate, wherein the first and fourth coupling curved segments are respectively positioned on the ferrite substrate on two sides of the wide side of the substrate window, and the second and third coupling curved segments are arranged on the ferrite substrate on one side of the long side of the substrate window in parallel, the solenoid is arranged on the ferrite substrate on the other side of the long side of the substrate window and forms a winding structure with the ferrite substrate, and the head end and tail end of the winding structure are connected to the bonding pad through wires. The microstrip line phase shifter has the advantages of low insertion loss and large average power capacity, a magnetization cycle is integrated into the ferrite substrate, so that the volume of the common ferrite phase shifter is significantly reduced, and miniaturization of the phase shifter is facilitated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Process method for treating 65Mn steel material through ECAE (Equal Channel Angular Extrusion)

The invention discloses a process method for treating a 65Mn steel material through ECAE (Equal Channel Angular Extrusion). The material is subjected to extrusion treatment by adopting a specific process and utilizing a plurality of moulds, so that original pearlite structures in the material are plastically deformed greatly; cementite structures in pearlites are damaged; cementites are uniformly dissolved in an ultrafine grain ferrite substrate structure; finally, an equiaxial ultrafine grain structure is formed. The material structure is improved, the performance is improved, and the material is more applicable to agricultural mechanical tillage and soil preparation machines.

Owner:HENAN AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com