Composite substrate type microstrip circulator

A technology of composite substrates and circulators, which is applied in waveguide devices, electrical components, circuits, etc., to achieve the effects of reducing loss, easy preparation and assembly of devices, and ensuring tight integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

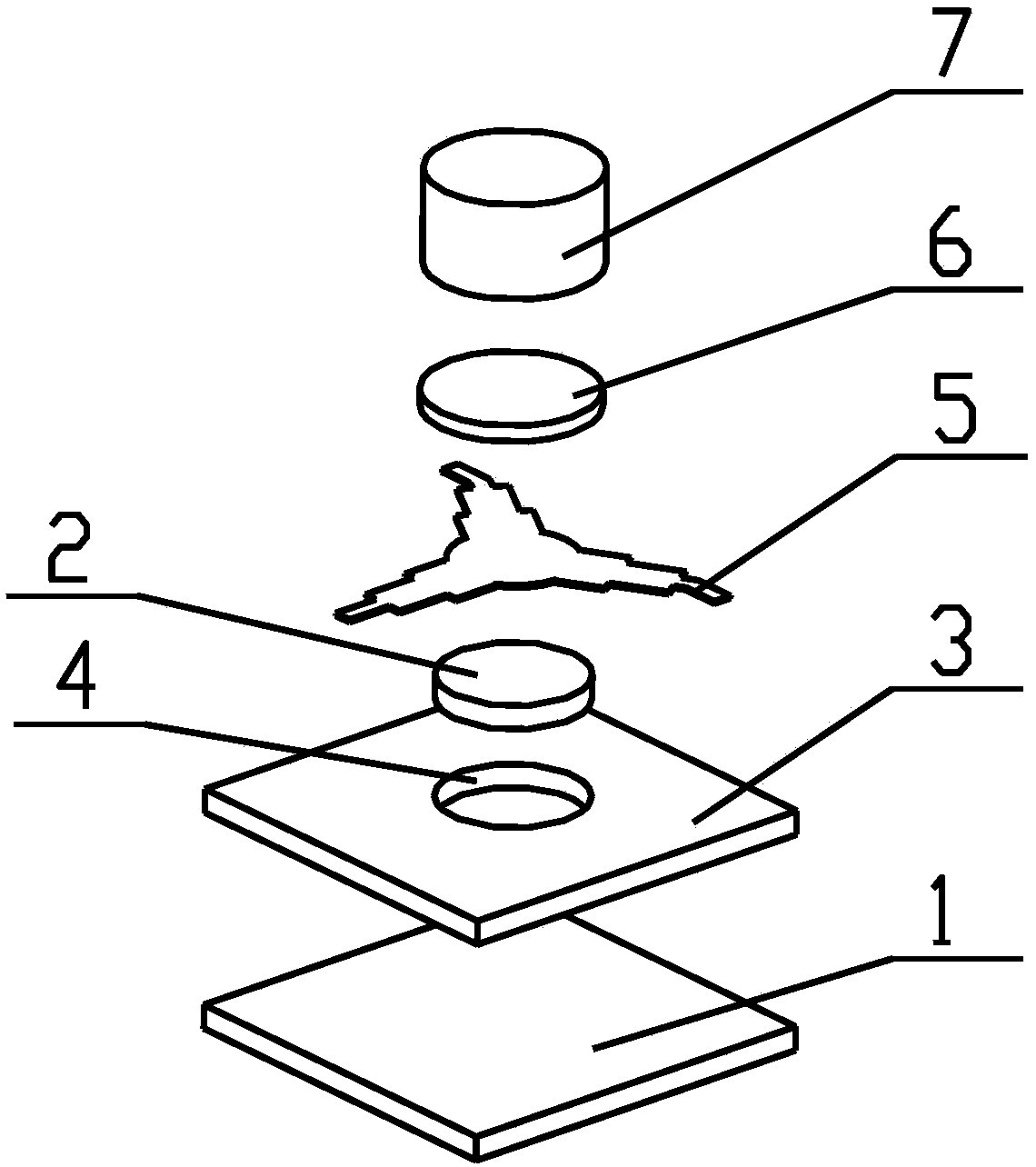

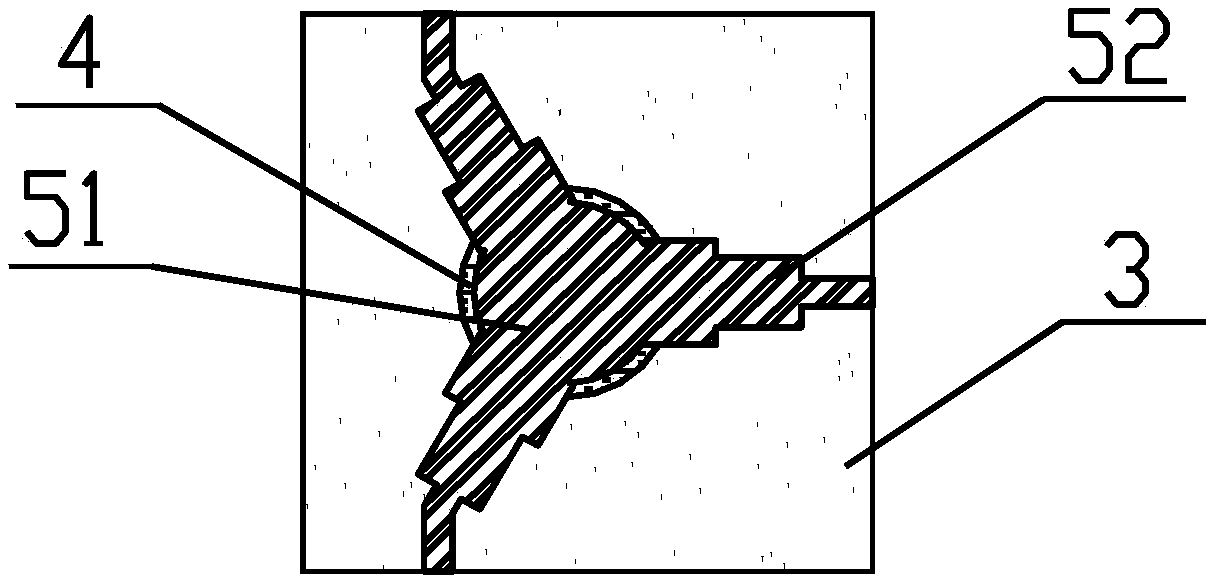

[0038] Such as figure 1 with figure 2 As shown, the specific implementation of the composite substrate microstrip circulator works in the C-band, with a center frequency of 4.5GHz; the dielectric substrate in the composite substrate is made of high dielectric constant composite ceramics, and the thickness of the dielectric substrate is 0.5mm. The dielectric constant of the substrate is about 40; the through hole on the dielectric substrate is prepared by mechanical drilling technology, and the through hole is circular with a diameter of 3.05 mm; the ferrite substrate in the composite substrate is circular with a diameter of 3.05 mm. 3mm, dielectric constant 13, saturation magnetization 1500Gs.

[0039] During the preparation process, the circular ferrite substrate is embedded in the through hole on the dielectric substrate, and the sealing glass is filled in the gap between the ferrite substrate and the dielectric substrate. Through low-temperature co-firing, the ferrite subst...

Embodiment 2

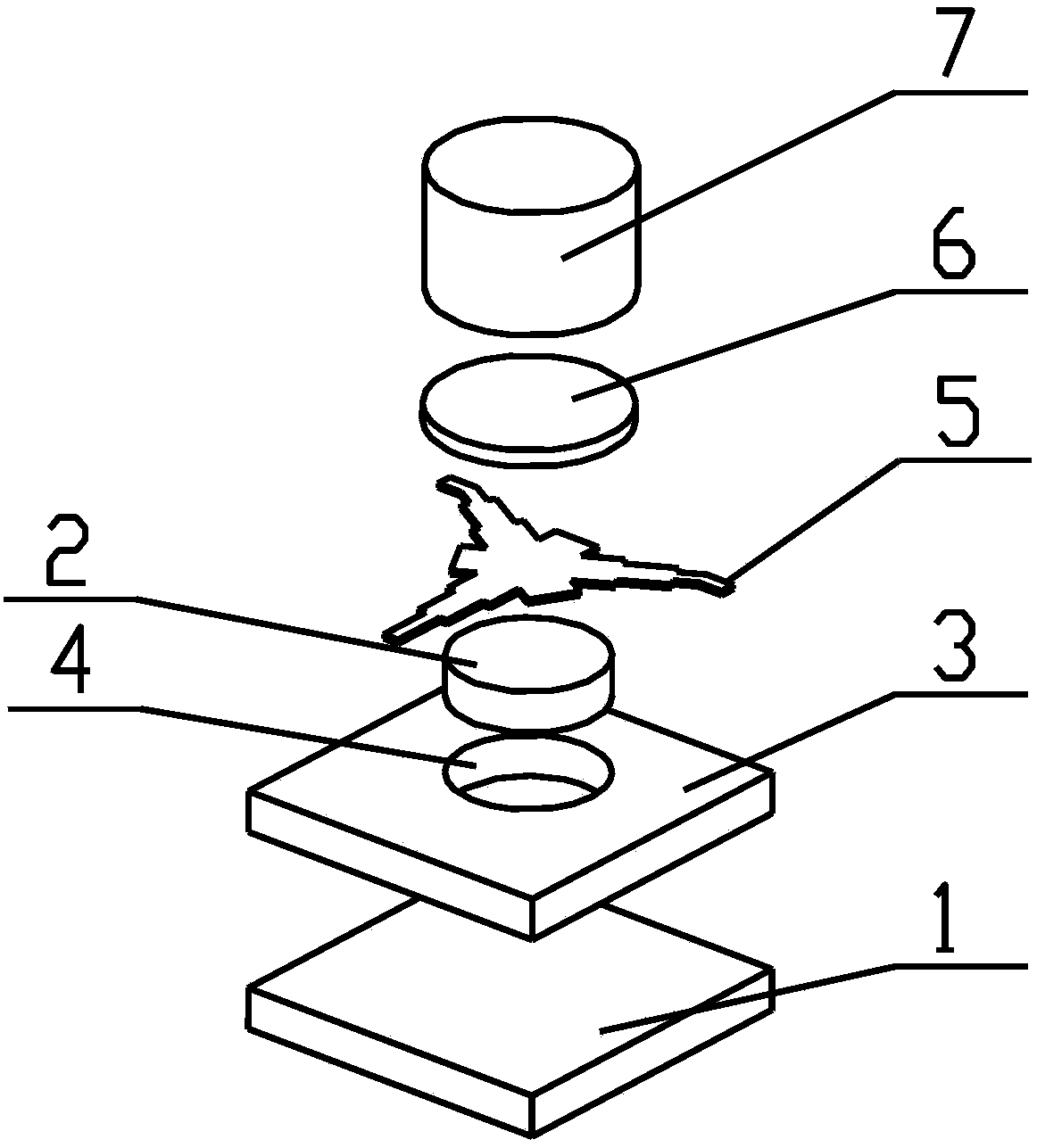

[0047] Such as image 3 with Figure 4 As shown, the specific implementation of the composite substrate microstrip circulator works in the X-band, with a center frequency of 9.5GHz; the dielectric substrate in the composite substrate is made of high dielectric constant composite ceramics, and the thickness of the dielectric substrate is 0.5mm. The dielectric constant of the substrate is about 40; the through hole on the dielectric substrate is prepared by mechanical drilling technology, and the through hole is circular with a diameter of 1.65 mm; the ferrite substrate in the composite substrate is circular with a diameter of 1.65 mm. 1.6mm, dielectric constant 12.5, saturation magnetization 2200Gs.

[0048] During the preparation process, the circular ferrite substrate is embedded in the through hole on the dielectric substrate, and the sealing glass is filled in the gap between the ferrite substrate and the dielectric substrate. Through low-temperature co-firing, the ferrite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com