Patents

Literature

71results about How to "Realize integrated molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material casing containing inward-flanging windows, forming die and forming method

ActiveCN108501398AGood for weight lossHigh structural efficiencyDomestic articlesMicrowaveEngineering

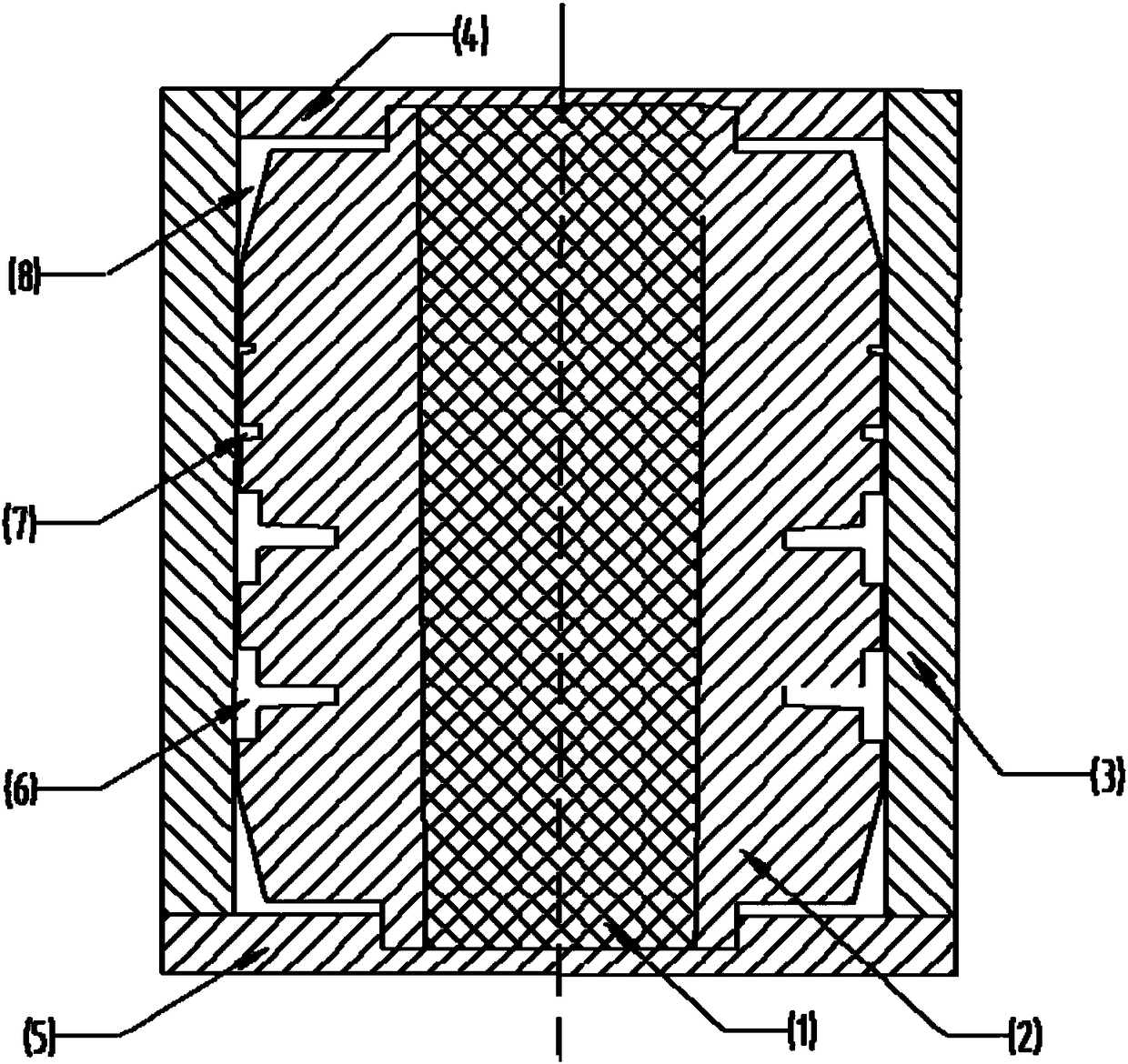

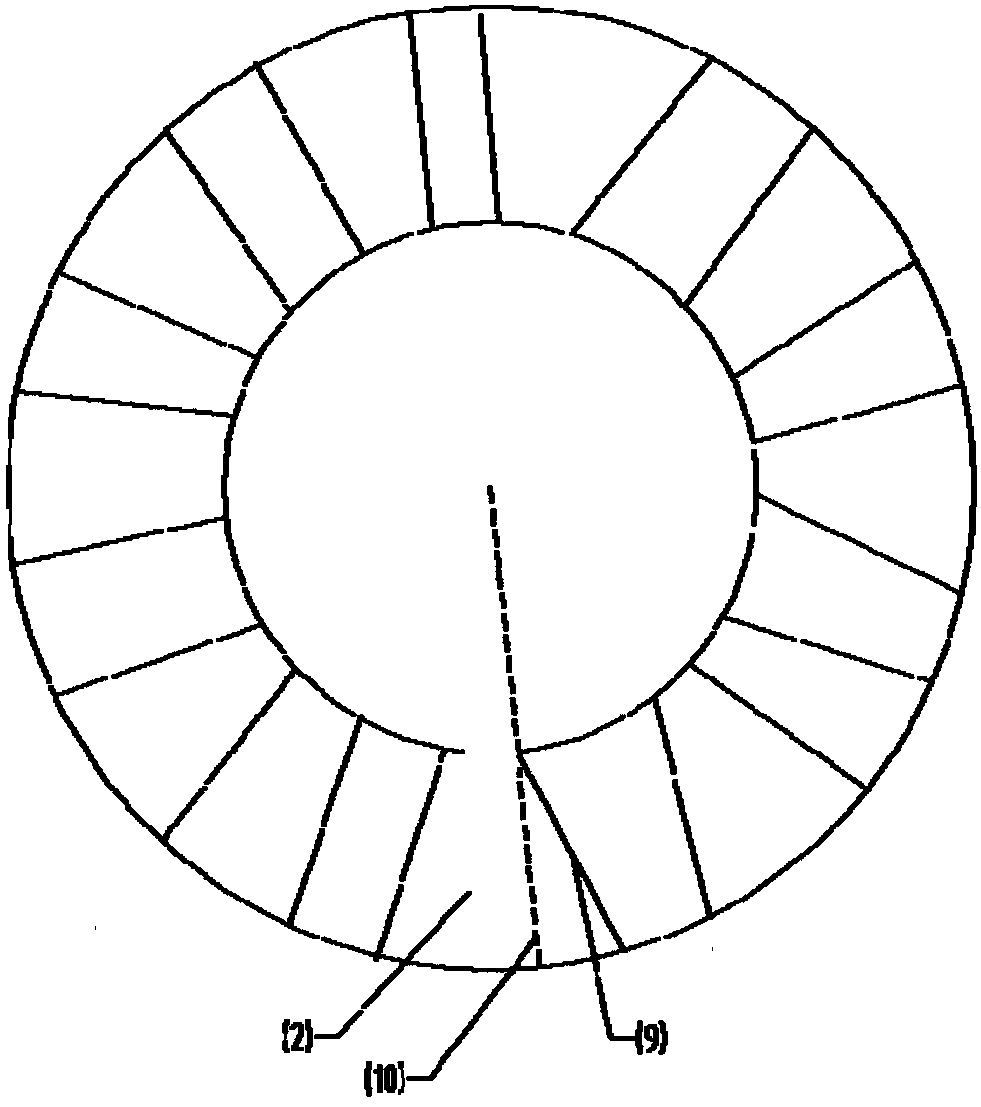

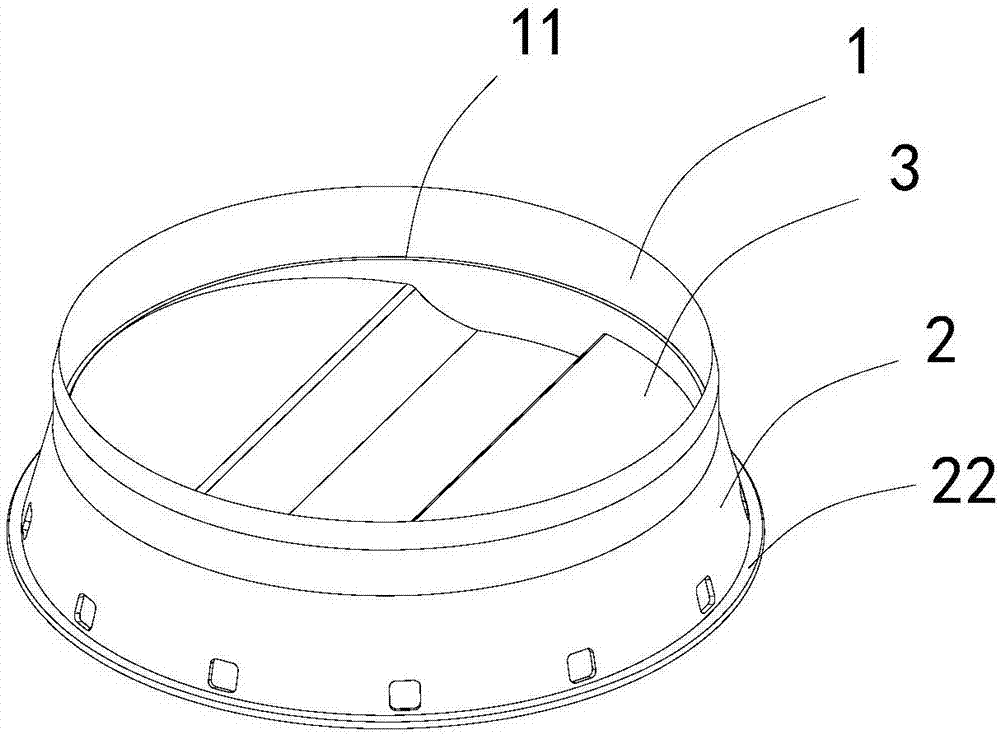

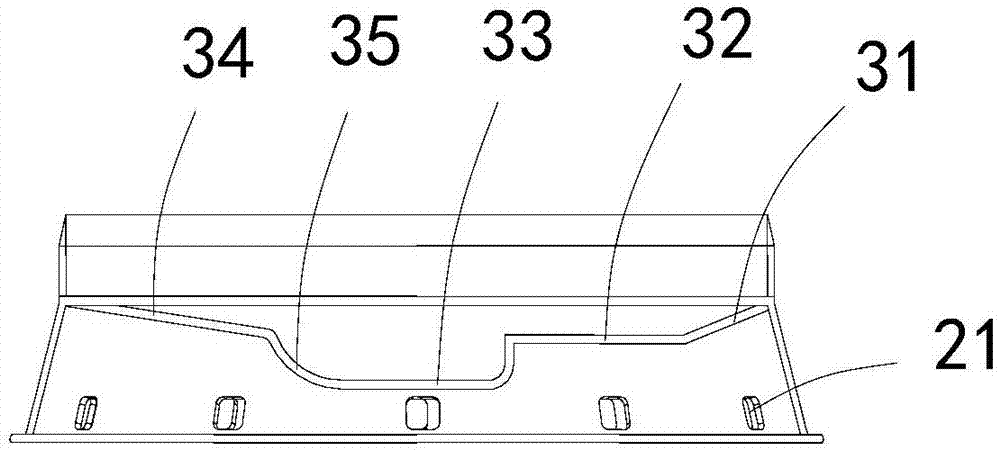

The invention relates to a composite material casing containing inward-flanging windows, a forming die and a forming method. The whole casing is of a cylindrical or conical rib-skin structure, and ischaracterized in that the skins at the upper side and lower side of the structure are flanged inwards along the radial direction to form an upper end framework and a lower end framework of the casing;the side surface of the structure is provided with an even number of windows towards the interior of the cylinder, and the inner walls of windows are in a step shape; every two windows are symmetrically distributed along the center of circle at the circumference; the casing is of an integrated forming structure. The composite material casing has the advantages that the inward-flanging windows andthe composite material casing with the rib-skin structure are integrally formed, so that the weight of the composite material member is reduced, and the structure efficiency is improved; the composite material casing is suitable for manufacturing the composite material member of the rib-skin structure containing the inward-flanging windows; by adopting the integrated structure, the weight is light, the strength is high, and a microwave absorbing and transmitting unit can be formed after a functional material is introduced into the integrated window; by adopting the structure type, the wide application prospect in the fields of anti-counterfeiting, hiding and the like of aircrafts is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

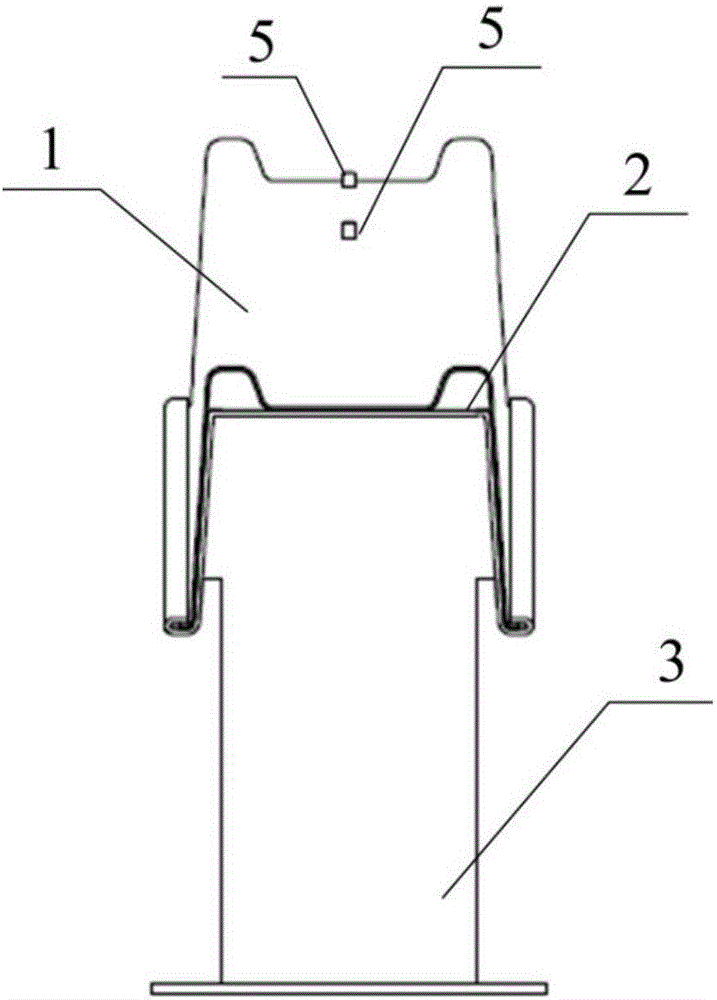

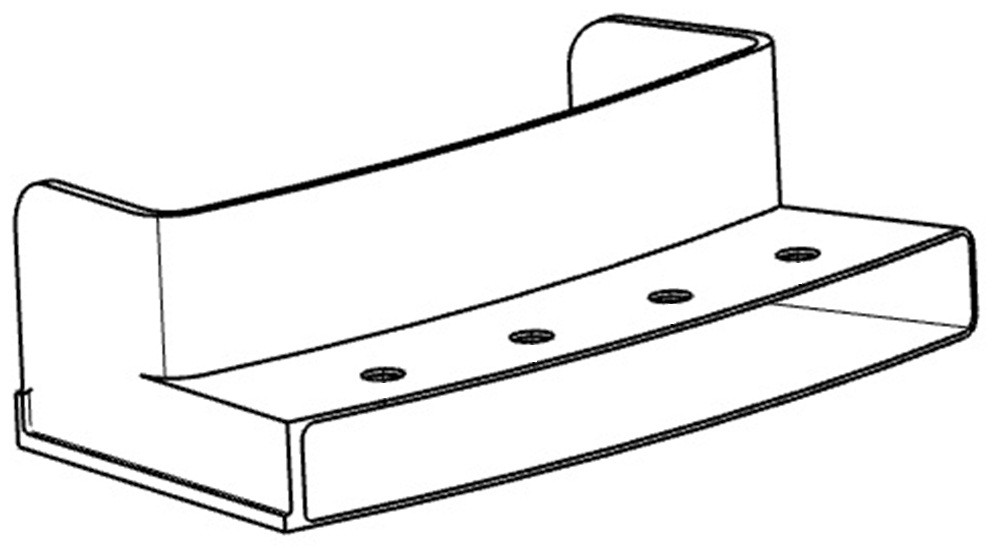

Bumper device integrally formed by metal/composite material

The invention discloses a metal / composite material integrated bumper device, which belongs to the technical field of automobile lightweight and collision safety. The bumper device comprises a bumper beam metal outer panel, a bumper beam composite material inner panel, an energy-absorbing box, a composite material inner panel reinforcing rib and a composite material lock buckle. Based on the design concept of lightweight and modularized automobiles, the invention comprehensively utilizes the characteristics of strong metal bearing capacity, high specific strength of composite materials, good impact energy absorption and complex geometry, and adopts advanced direct injection molding and adhesion integration Made by molding process. The integrally formed automobile bumper device has high integration, shortens the assembly process, has good economic benefits, and is easy to popularize. The use of composite materials reduces the weight of the bumper, realizes lightweight, reduces vehicle fuel consumption, reduces exhaust emissions, designs and manufactures a rib structure with good load-bearing capacity, and improves the collision safety of the vehicle bumper.

Owner:BEIHANG UNIV

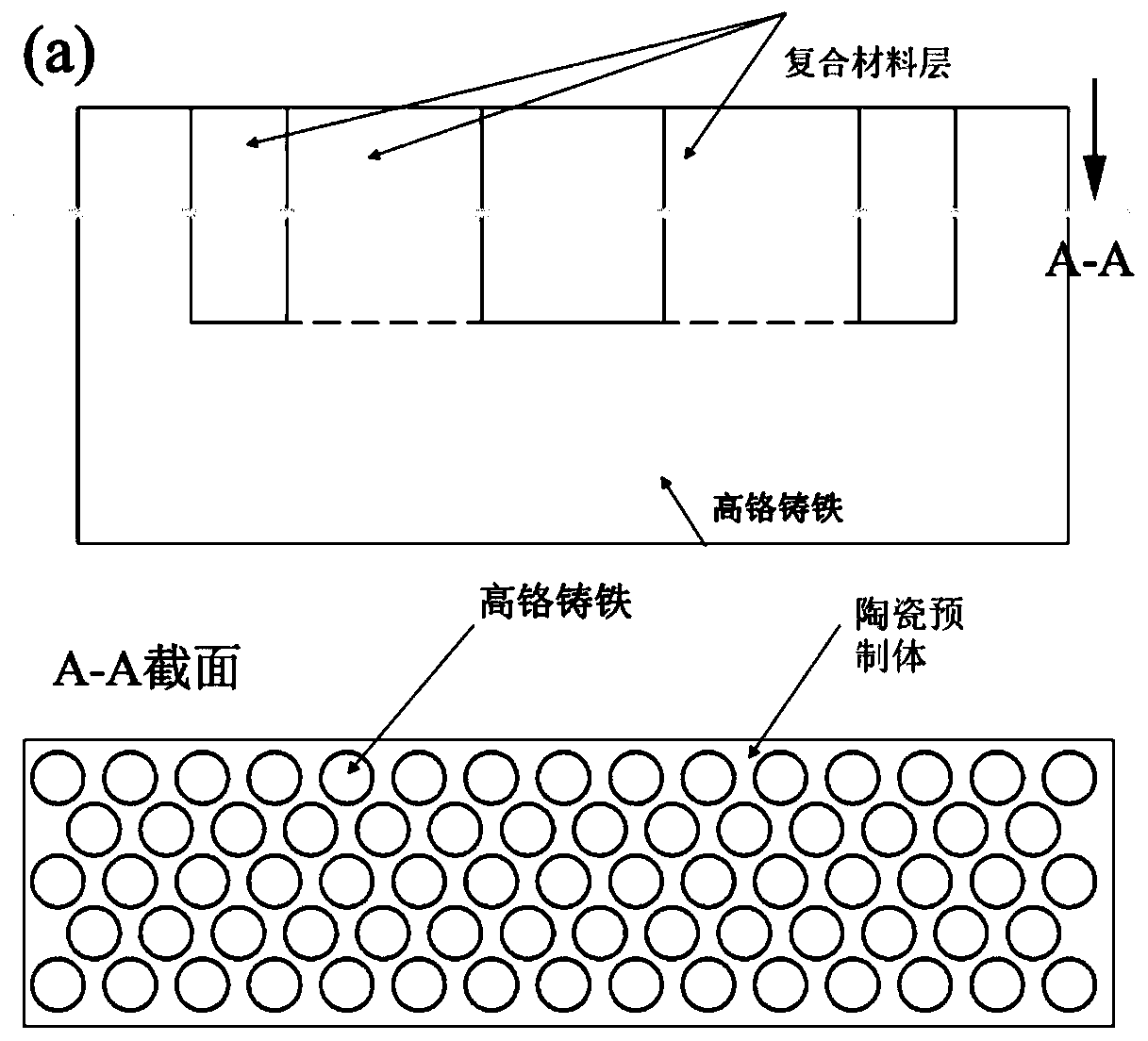

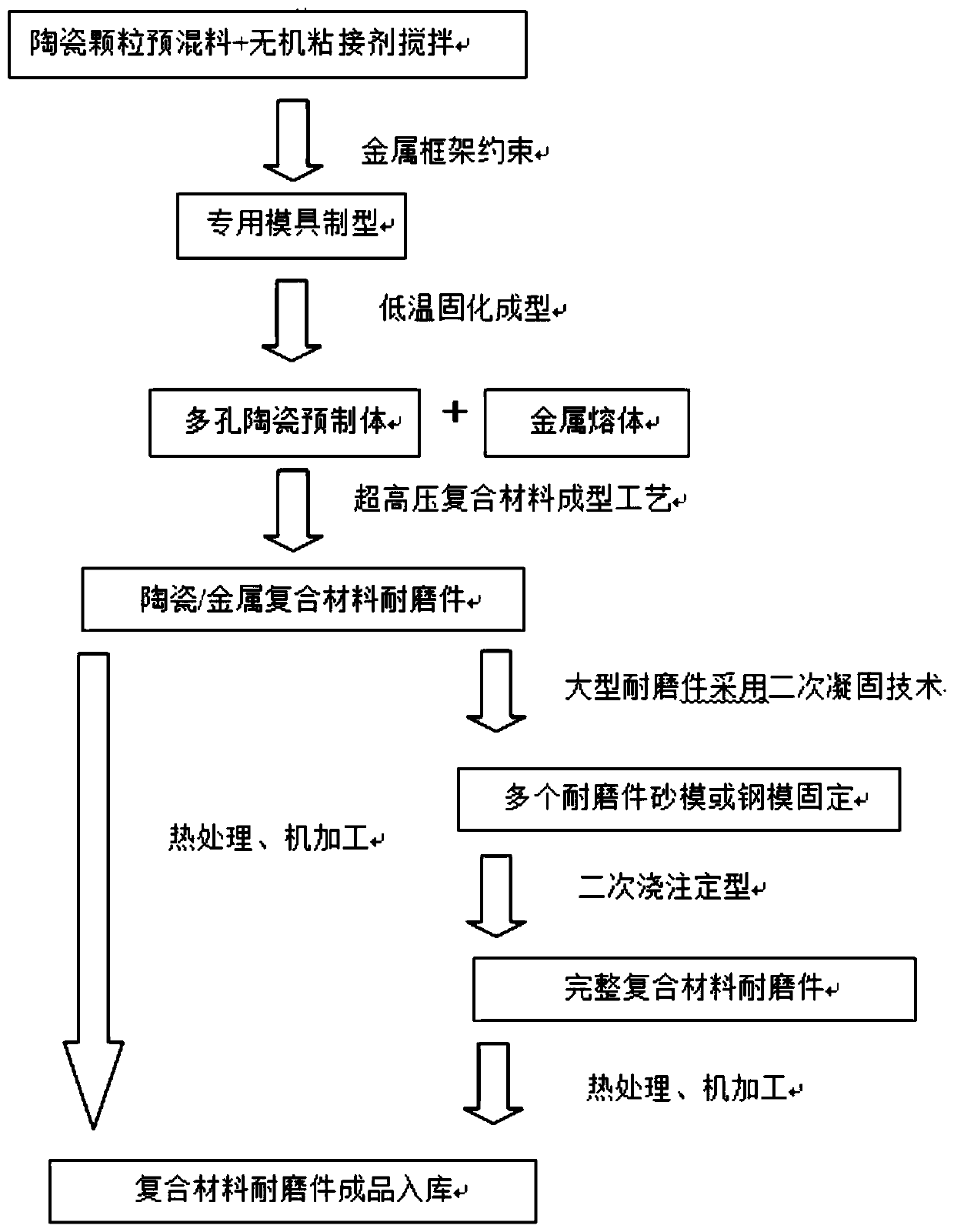

Preparation method of wear-resistant composite material and preparation method of wear-resistant composite material casting

The invention relates to a preparation method of a wear-resistant composite material and a preparation method of a wear-resistant composite material casting, and belongs to the technical field of novel material preparation. The preparation method of the wear-resistant composite material casting comprises the step that under the condition that the pressure intensity is 10 MPa to 200 MPa, a metal melt and a porous ceramic prefabricated body subjected to preheating treatment are subjected to high-pressure compound molding in a metal mold. A high-pressure compound molding process is used for pressing the porous ceramic prefabricated body and the metal melt; a metal matrix structure is refined; meanwhile, the ceramic and metal interface bonding strength is improved, so that a metal matrix tightly wraps ceramic particles; and the wear-resistant performance of the composite material is greatly improved.

Owner:SONGSHAN LAKE MATERIALS LAB

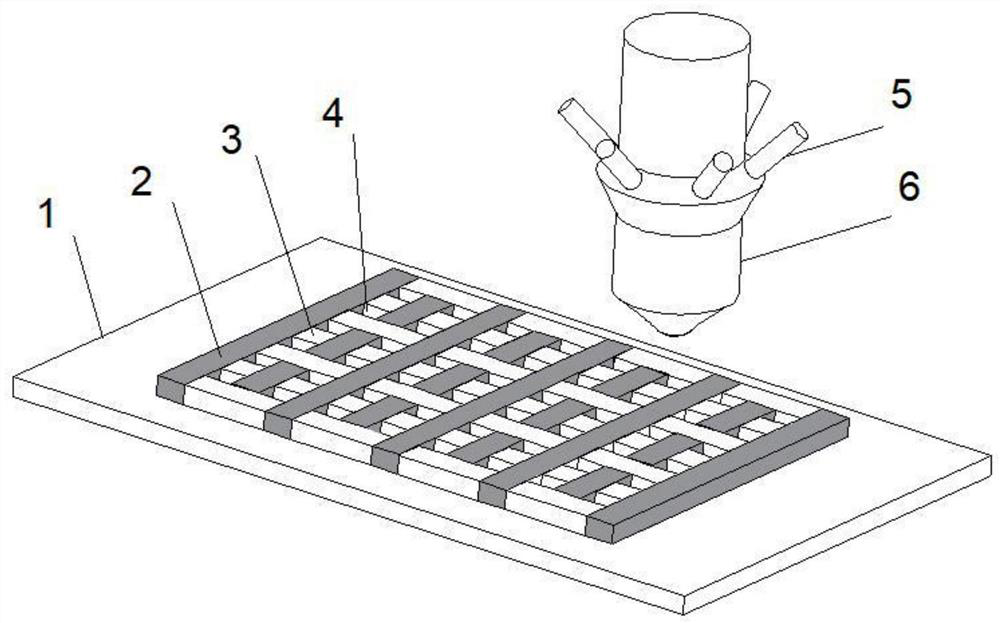

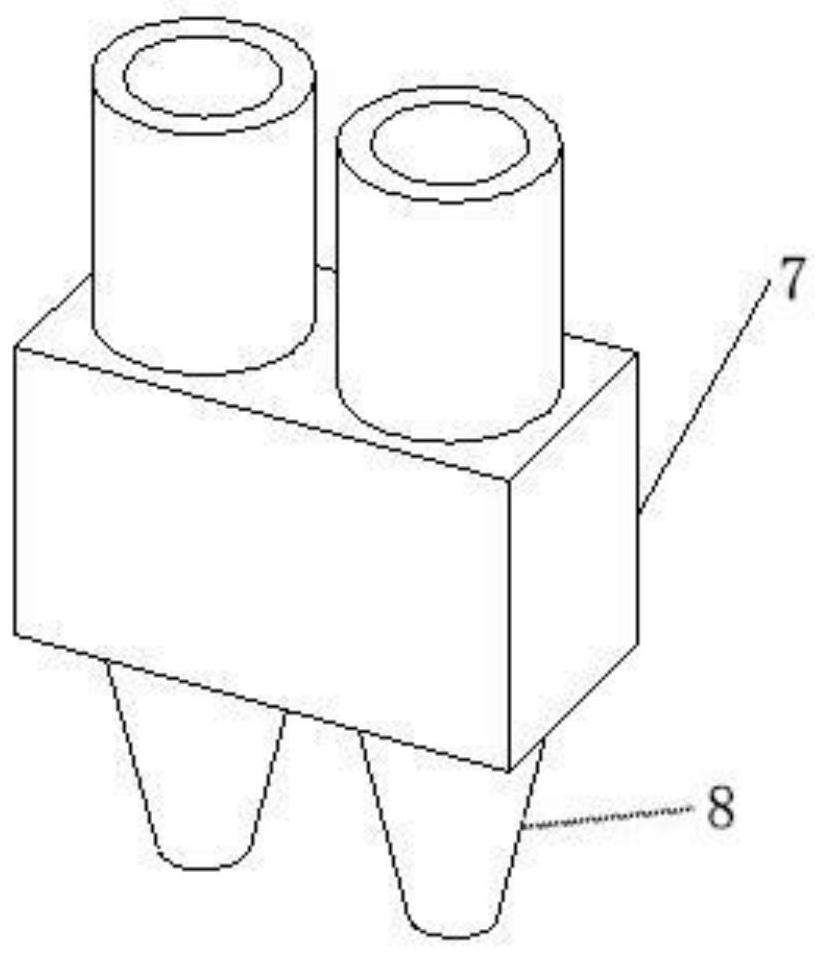

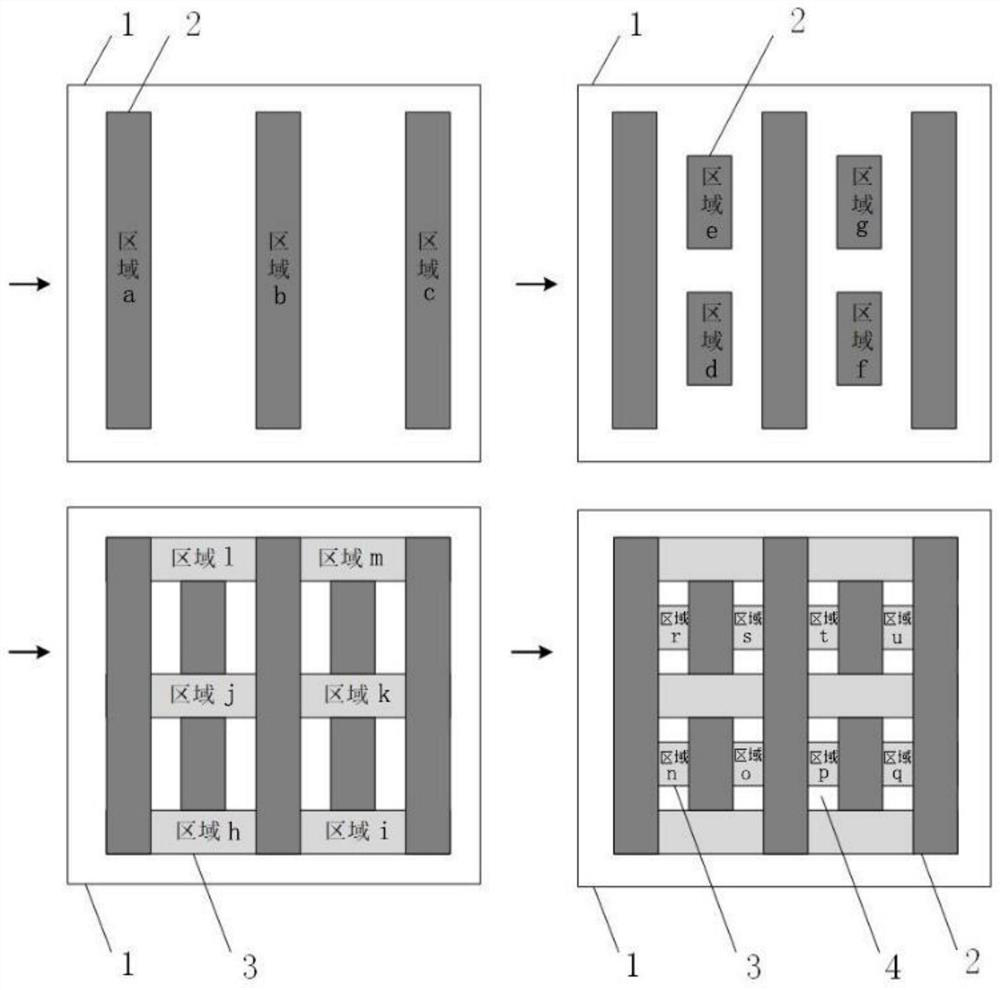

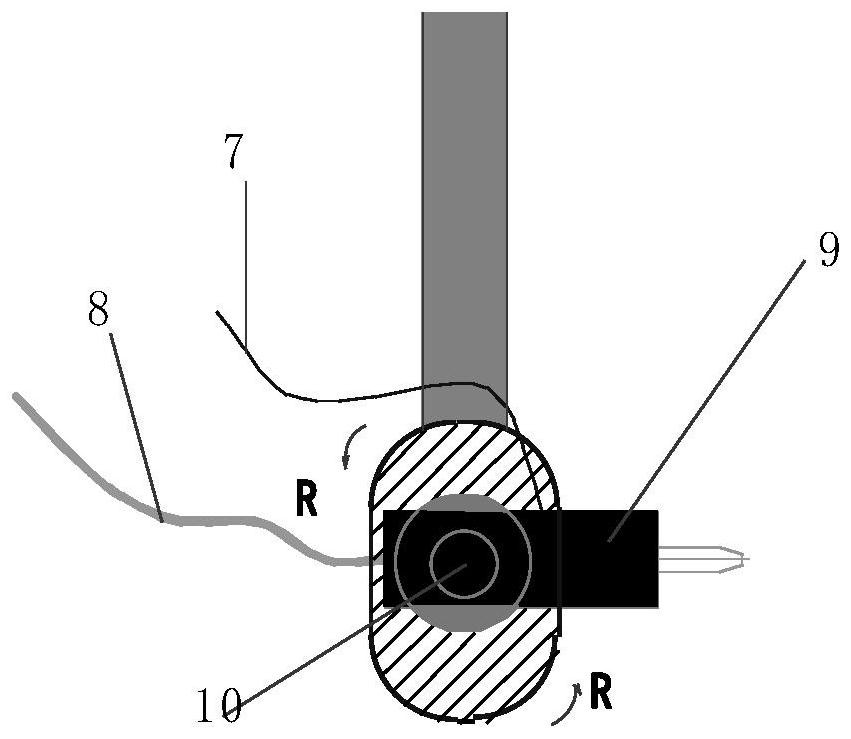

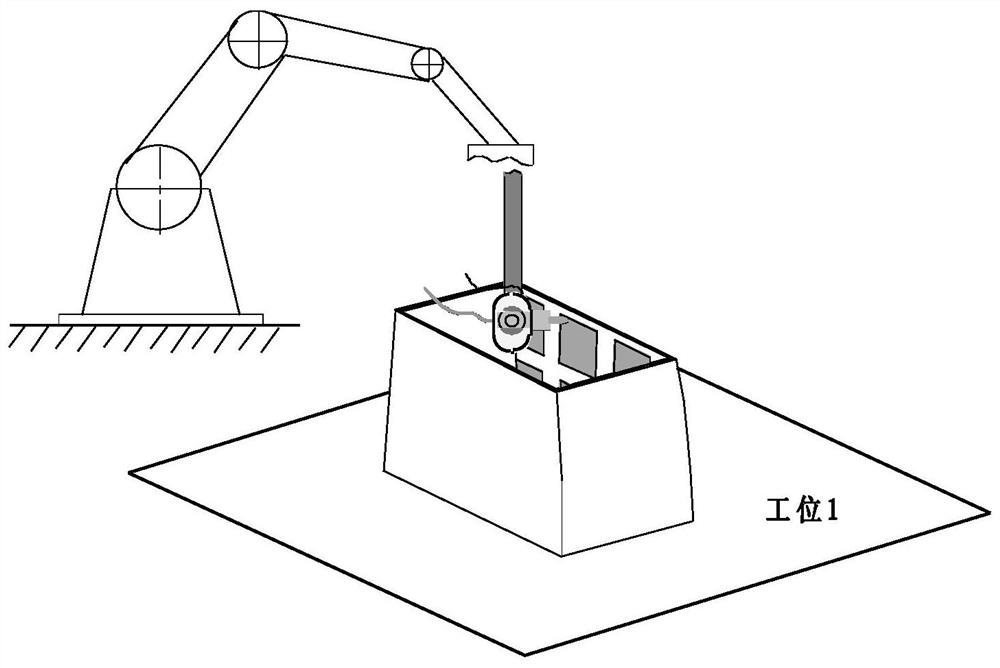

Additive manufacturing method of lightweight rigid-flexible coupled heterostructure

ActiveCN113386343AAchieve anti-fatigueAnti-fatigueAdditive manufacturing apparatusIncreasing energy efficiencyHeterojunctionStructural unit

The invention provides an additive manufacturing method of a lightweight rigid-flexible coupled heterostructure. The method comprises the following steps of (1) selecting a raw material of a soft material and a raw material of a hard material for additive manufacturing according to heterostructure design and intermiscibility and hardness difference characteristics of the materials; (2) selecting a substrate material according to two heterogeneous materials to be subjected to additive manufacturing forming, and then carrying out cutting based on a size, surface polishing and cleaning treatment on a used substrate; (3) manufacturing structural unit bodies of the hard material and the soft material on the substrate in a regional additive manufacturing mode; and (4) integrally taking down the grid-shaped heterostructure which is subjected to additive manufacturing and is provided with structural gaps from the substrate by using linear cutting or machining. The additive manufacturing method is simple in preparation process and low in raw material cost, the prepared heterostructure has the properties of light weight, good toughness, impact resistance and the like, material-structure-property integrated design and manufacturing forming are achieved, and the production efficiency is improved.

Owner:JILIN UNIV

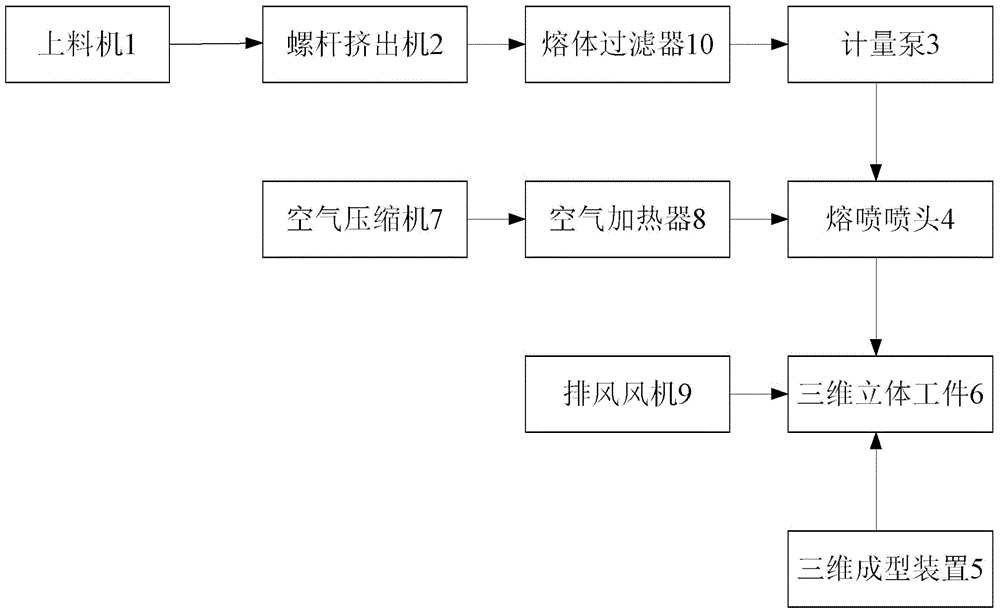

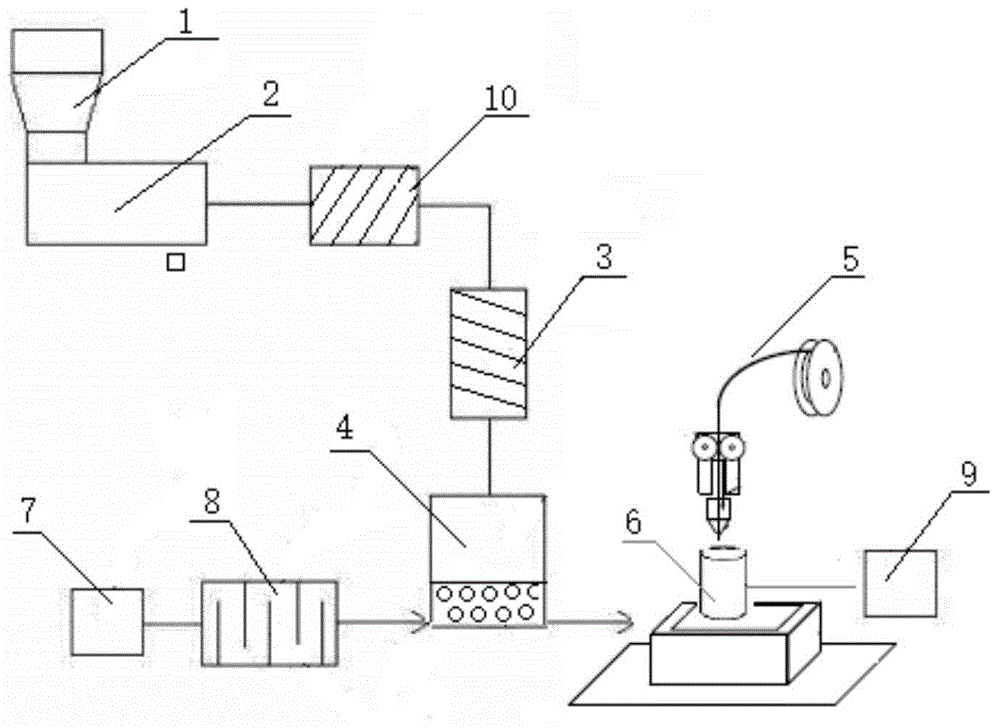

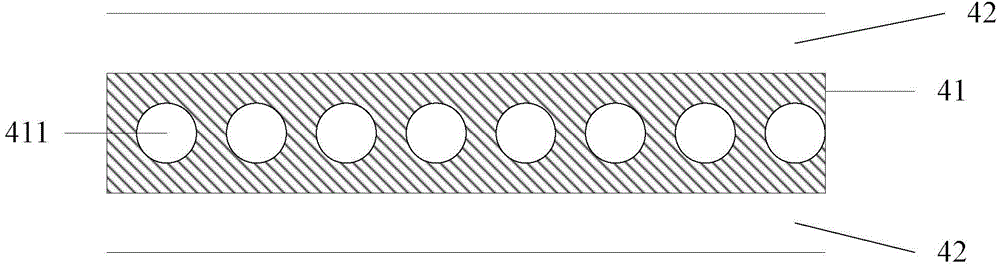

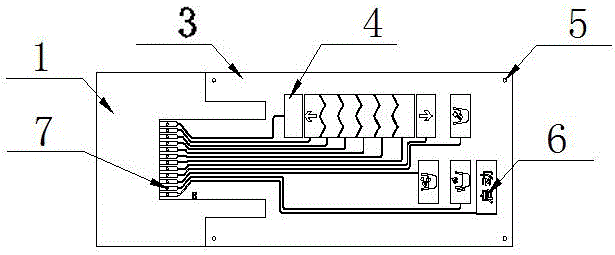

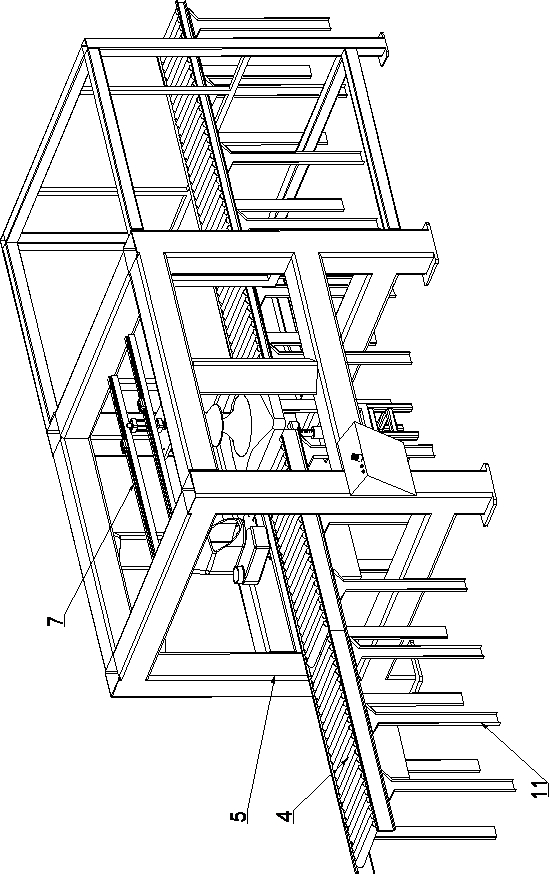

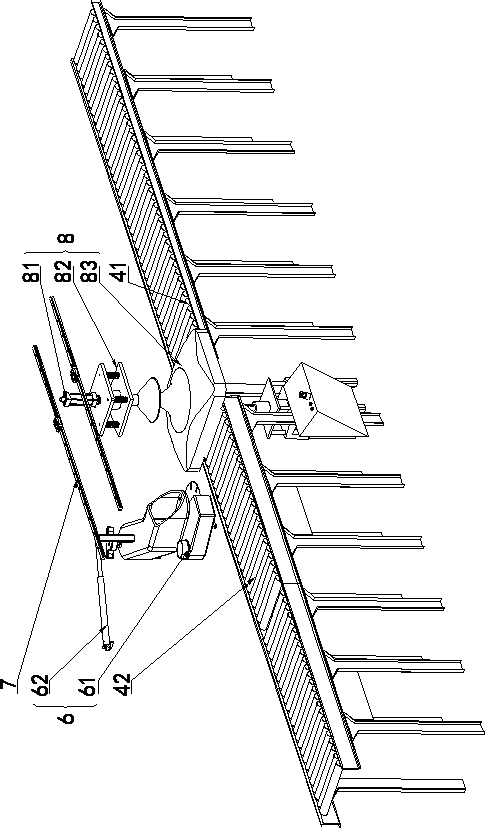

Three-dimensional flexible material molding system and method

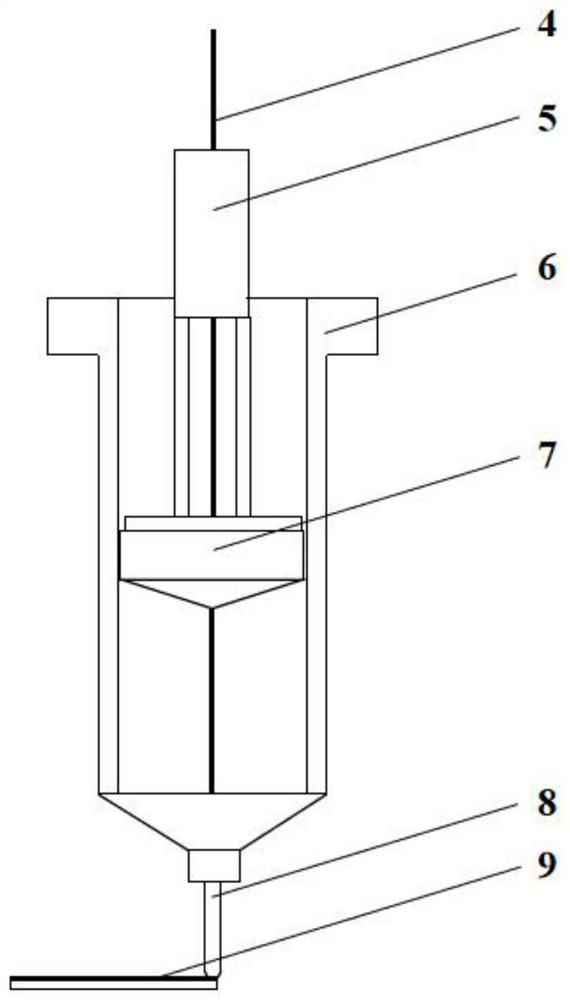

ActiveCN104149338AEasy to printRealize production and processingAdditive manufacturing apparatusAdditive manufacturing with liquidsAir compressorMelt blowing

The invention provides a three-dimensional flexible material molding system and a three-dimensional flexible material molding method. The system comprises a feeder, a screw extruder, a metering pump, an air compressor, an air heater, a three-dimensional molding device, a melt-blowing nozzle and a solidification molding device, wherein the feeder is used for feeding molten polymers; the screw extruder is used for extruding the molten polymers; the metering pump is used for controlling the number of the molten polymers flowing into the melt-blowing nozzle; the air compressor is used for compressing air; the air heater is used for heating the compressed air; the three-dimensional molding device is used for processing and molding a three-dimensional workpiece for supporting a flexible material; the melt-blowing nozzle comprises a spinneret plate communicated with the metering pump and an air flow hole communicated with the air heater; a melt hole is formed in the spinneret plate; thin molten polymer flows are blown to the three-dimensional workpiece and are drawn into melt-blowing fibers through the air flow hole to be agglomerated on the three-dimensional workpiece; the solidification molding device is communicated with the three-dimensional workpiece and is used for solidifying the melt-blowing fibers agglomerated on the three-dimensional workpiece to generate the flexible material. According to the system and the method, the flexible material can be conveniently and quickly printed.

Owner:INVENTECSHANGHAI TECH +2

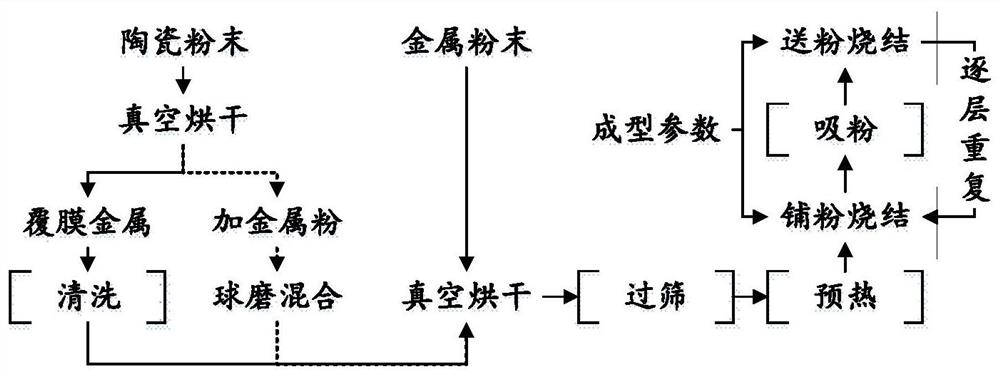

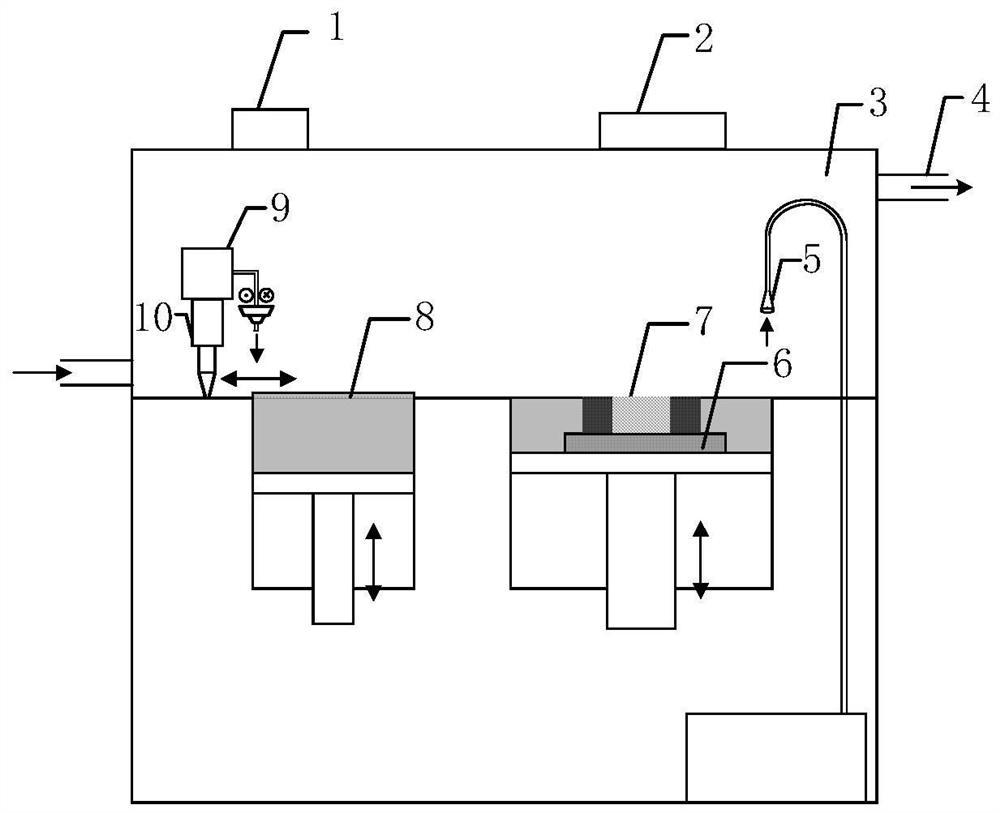

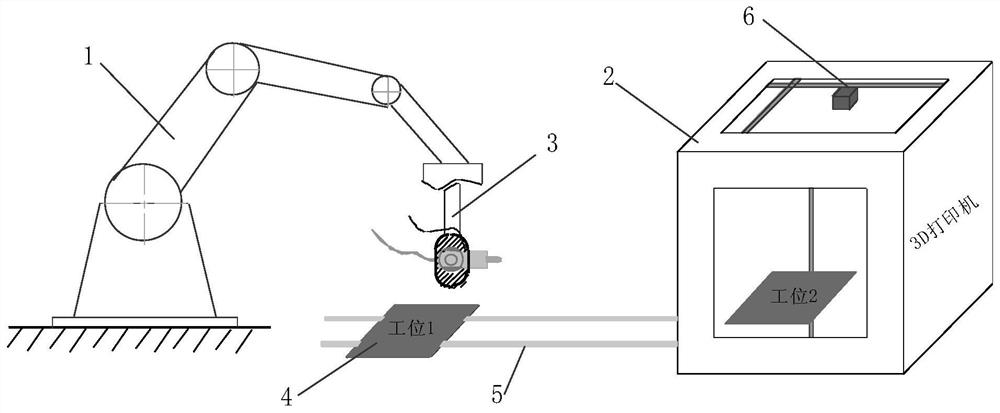

Multi-material additive manufacturing forming system and method

ActiveCN112705731ASolve printing process compatibility issuesRealize printingAdditive manufacturing apparatusCeramic shaping apparatusPumping vacuumAdditive layer manufacturing

The invention discloses a multi-material additive manufacturing forming system and method. The system comprises a laser system and a cavity as well as a base plate, a heating system and a gas exchange system, wherein a powder absorbing system, a power feeding system, a powder spreading system, a working cylinder and a plurality of powder storage cylinders are arranged in the cavity; the powder absorbing system is used for absorbing excessive raw material powder; the powder spreading system can be movably arranged in the cavity for feeding raw material powder in some of the powder storage cylinders into the working cylinder; the powder feeding system can be movably mounted on the powder spreading system for feeding raw material powder provided by the rest of the powder storage cylinders into the working cylinder; the base plate and the heating system are arranged in the working cylinder; and the gas exchange system is used for performing vacuum-pumping on the cavity and injecting protective gas. The additive manufacturing method can be utilized to realize metal / ceramic multi-material integrated forming, so that the printing process compatibility problem caused by great difference of different powder properties can be solved.

Owner:XI AN JIAOTONG UNIV

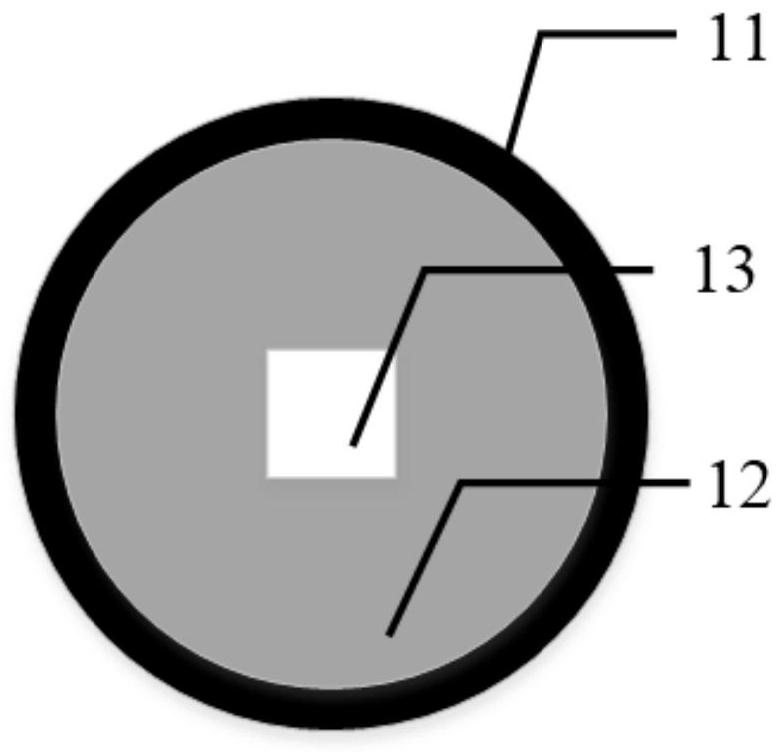

Gas diffusion layer for proton exchange membrane fuel cell and preparation method of gas diffusion layer

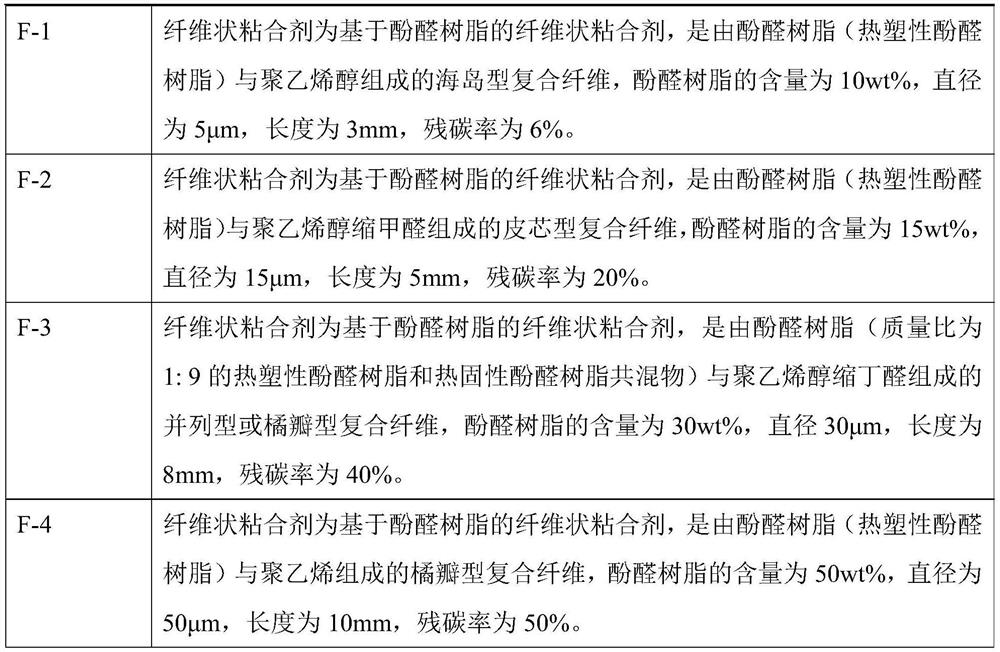

ActiveCN113555563ASolve the problem of low carbon residual rateSolve for uniformityCell electrodesChemical/biochemical paper treatmentFiberCarbon fibers

The invention relates to a gas diffusion layer for a proton exchange membrane fuel cell and a preparation method thereof, and the method comprises the following steps: carrying out papermaking and drying on a carbon fiber suspension mainly composed of a fibrous adhesive, water, a dispersant and carbon fibers with different length-diameter ratios to obtain carbon fiber raw paper, carrying out carbonization and graphitization treatment under the protection of nitrogen or inert gas to obtain the gas diffusion layer for the proton exchange membrane fuel cell; the fibrous adhesive being a composite fiber or a blend fiber composed of phenolic resin and other resin; the finally prepared gas diffusion layer for the proton exchange membrane fuel cell having pore gradient, and the layer with the minimum pore diameter being an intrinsic microporous layer. According to the method, the step of impregnating the base paper with the resin is omitted, integrated forming of the carbon paper and the microporous layer can be achieved, subsequent coating preparation of the microporous layer is omitted, the process is simple, and the cost is reduced.

Owner:DONGHUA UNIV

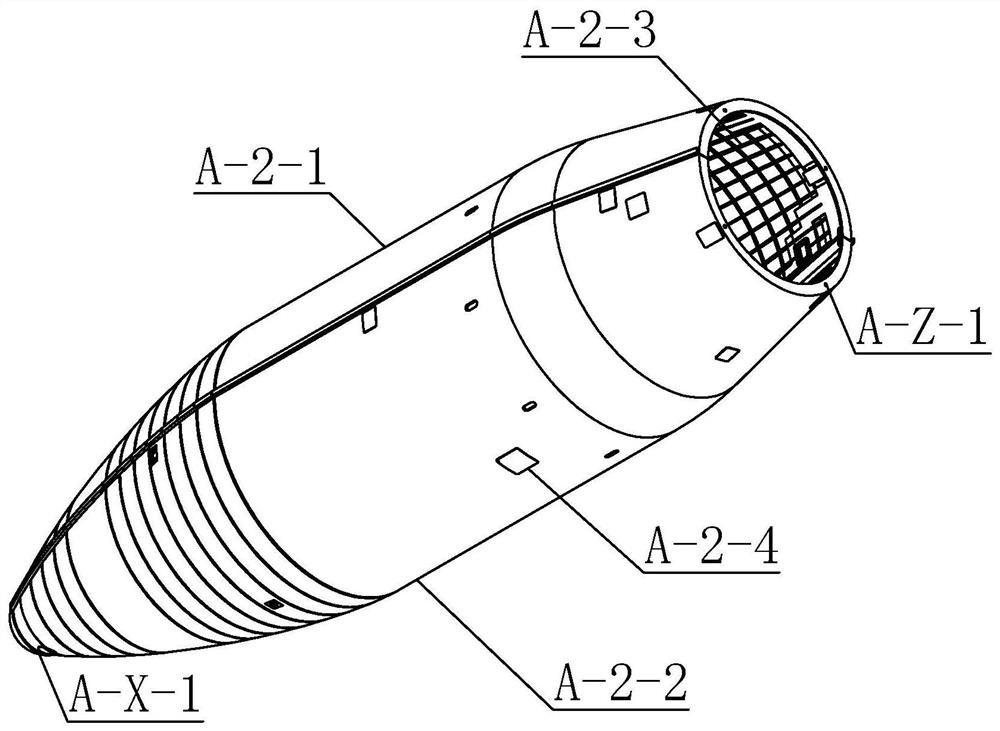

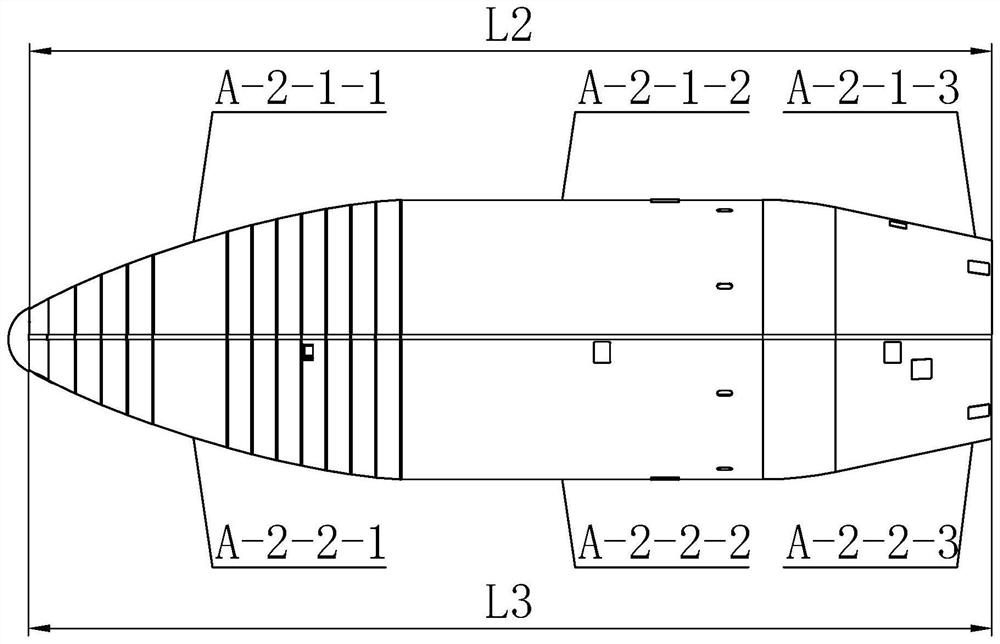

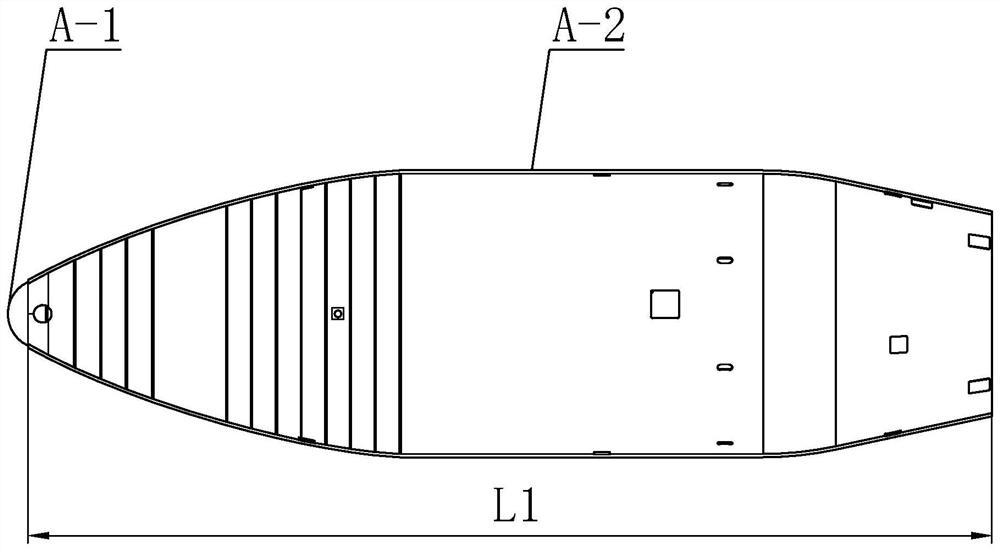

Carbon fiber composite fairing, forming mold and forming method thereof

The invention discloses a carbon fiber composite fairing, a forming mold and a forming method thereof, and relates to the technical field of carbon fiber composite forming. The problems that an existing fairing structure form used for being matched with a rocket cannot meet the requirements for high performance and light weight of spaceflight in rocket upgrading and updating projects in China are solved. An end cap of the carbon fiber composite fairing is installed on the head portion of a shell through a plurality of connecting pieces, the shell is cut along the horizontal plane where a shaft is located to form an I-quadrant half cover or an III-quadrant half cover of the same structure, the I-quadrant half cover is detachably connected with the III-quadrant half cover through a plurality of connecting pieces, and reinforcing ribs are arranged on the inner side faces of the I-quadrant half cover or the inner side faces of the III-quadrant half cover; and the reinforcing ribs are of a grid reinforced structure, and a plurality of explosive bolt box installation openings are formed in the side faces of the I-quadrant half cover or the side faces of the III-quadrant half cover . The forming mold and the forming method are used for forming the carbon fiber composite fairing, and the requirements for the high performance and the light weight of the spaceflight in the rocket upgrading and updating projects in China are met.

Owner:HARBIN FRP INST

Connecting method of stephanoporate inner core and compact outer shell

The invention discloses a connection method of porous belly core and compact shell, the method is that: choose metal A and B powder in the range of negative 80 to positive 500 items, blend according to atom ratio 1 / 1, then put into a mixer to mix evenly, then package the A,B metal mixing powder into a compact tube made of metal A directly, after 2.5 to 5.0 MPa mould pressing and forming, weld in vacuum at 350 to 1200 DEG C. for 1 to 2 hours; wherein, the spreading speed of metal B in the metal A is large than that of the metal A in the metal B, the porous material is AB alloy, the compact material is metal A. With the method of powder metallurgy, the invention uses little alloy which can produce Kirkendall effect and welding swelling during welding, to finish welding spreading welding, and makes two parts connected into a whole body without air leakage and has good sealing performance, which can realize the integration forming of the porous material and the compact material, and has simple technics and lowers the production cost greatly.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for manufacturing GH5188 engine heat screen through selective laser melting technology

ActiveCN113770382ASolve internal defectsRealize integrated moldingAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMetallic materials

The invention discloses a method for manufacturing a GH5188 engine heat screen through a selective laser melting technology, and belongs to the technical field of metal material additive manufacturing. According to the technical scheme, the method for manufacturing the GH5188 engine heat screen through the selective laser melting technology comprises the steps that model processing is conducted; the raw material, GH5188 alloy powder, is taken and subjected to drying treatment; the GH5188 alloy powder is fed in a powder cabin of selective laser melting forming equipment after being dried, a base plate is selected, the base plate is fixed to a workbench, the GH5188 alloy powder is fetched through a scraper, the GH5188 alloy powder is repeatedly laid on the base plate in a trial mode, the whole base plate is completely paved with the powder, a forming cabin is locked, the forming cabin is vacuumized and filled with inert gas for protection, and meanwhile the base plate is preheated; a heat screen part is printed; stress relief annealing, support removal, hot isostatic pressing and heat treatment are conducted on the formed heat screen part; and the performance of the sample is detected. According to the method, integrated forming of the heat screen part is achieved, the number of weld joints is reduced, and welding cracking caused by welding is avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

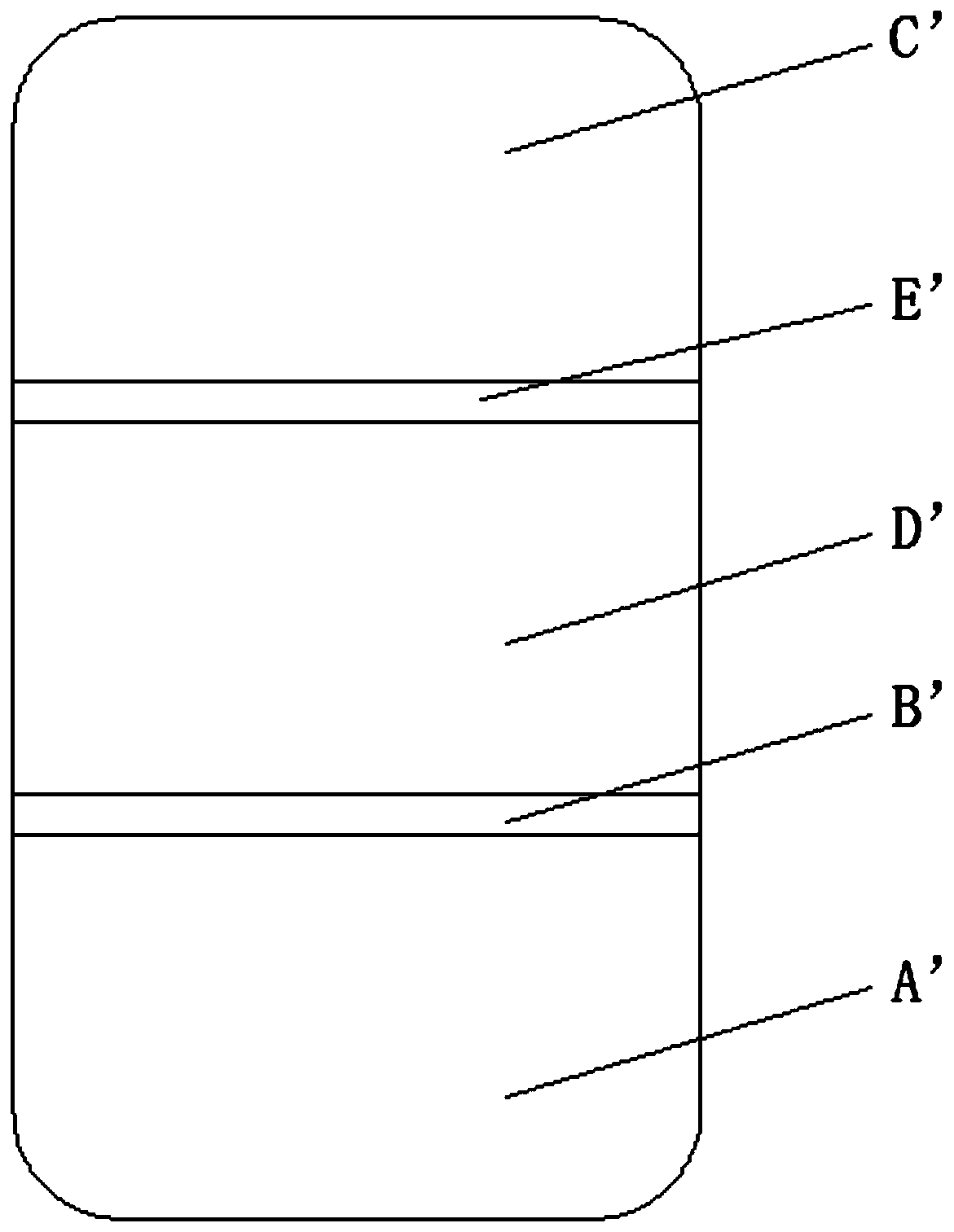

Preparation method of material and/or color gradient mobile phone shell

InactiveCN111491055ARealize integrated moldingSolve the size problemAdditive manufacturing apparatusTelephone set constructionsProcess engineeringMobile phone

The invention relates to a preparation method of a material and / or color gradient mobile phone shell. The preparation method comprises the following steps: S1, preparation of various feeds for 3D printing according to a 3D printing model; S2, mobile phone shell blank printing: dividing the mobile phone shell blank into a plurality of printing areas according to the distribution of materials in the3D printing model, and carrying out continuous printing on the plurality of printing areas to obtain a mobile phone shell blank; S3, degreasing: degreasing the green body to obtain a degreased part;and S4, sintering: sintering the degreased part to form a final product. According to the invention, multiple material printing technologies and indirect printing are combined to realize integrated molding of the mobile phone shell, and the size problem caused by assembly is avoided.

Owner:CHANGZHOU GIAN TECH

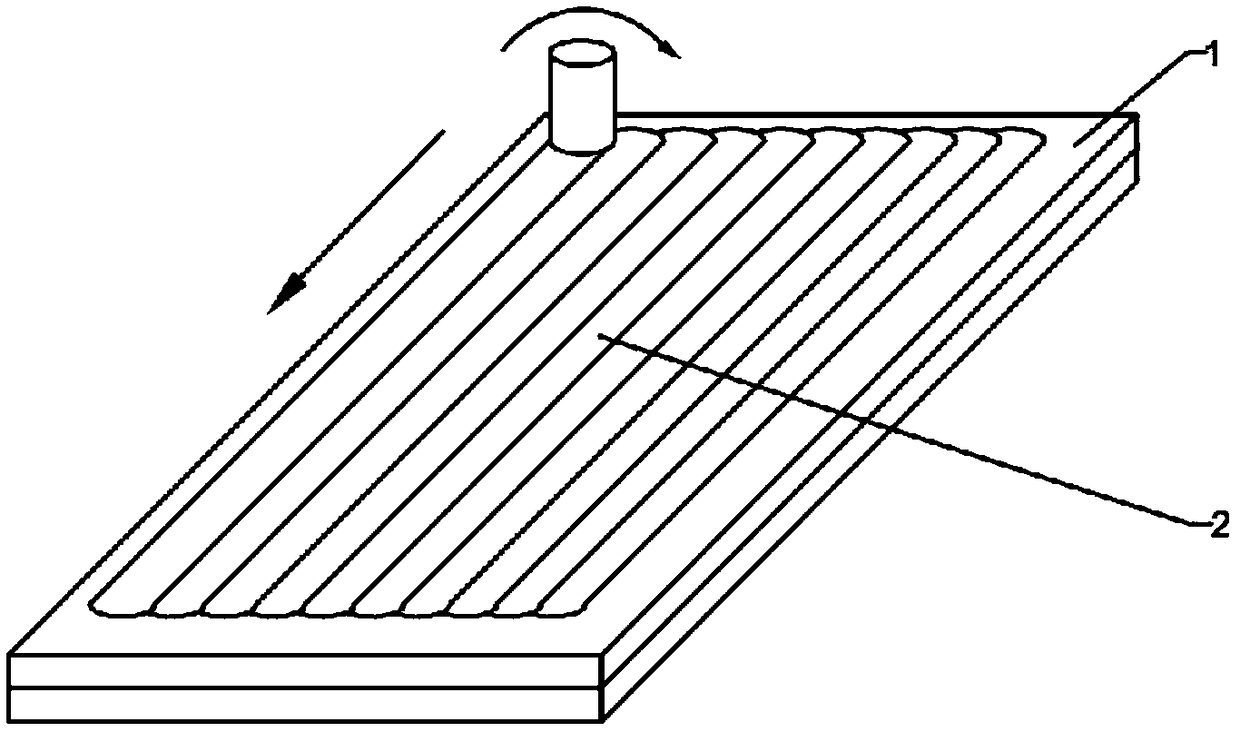

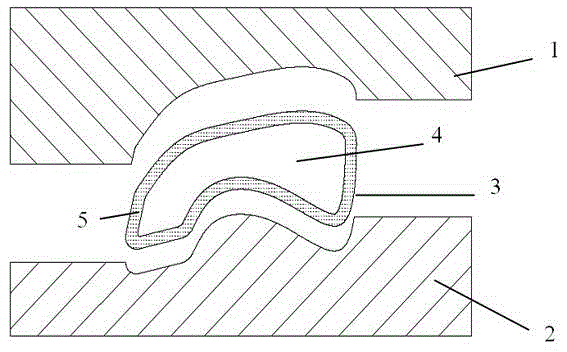

Forming method for foam aluminum part with complex curved face

The invention discloses a forming method for a foam aluminum part with a complex curved face. The forming method includes that steps that S1, a stamping die is provided, and the stamping die includesa convex die, a concave die, and a heating assembly; S2, two stacked metal plates are provided, a foaming agent and a stabilizer are evenly distributed between the two metal plates, and stirring friction welding is adopted to conduct multi-pass welding treatment on the two stacked metal plates to obtain a foam aluminum prefabricated body; S3, a heating mechanism or the heating assembly using the stamping die is provided to heat and insulate the foam aluminum prefabricated body in the S2; and S4, the heated foam aluminum prefabricated body is transferred to the stamping die, die closing is carried out, the foam aluminum prefabricated body is subjected to stamping and forming, die opening is carried out, the convex die is moved to be at a distance from the concave die, and the heating assembly is started to heat the foam aluminum prefabricated body, so that the foam aluminum prefabricated body completes remaining foaming action to obtain the foam aluminum part with the complex curved face. According to the forming method for the foam aluminum part with the complex curved face, not only can any desired curved face forming parts be formed, but also the whole process has short durationand low cost.

Owner:WUHAN UNIV OF TECH

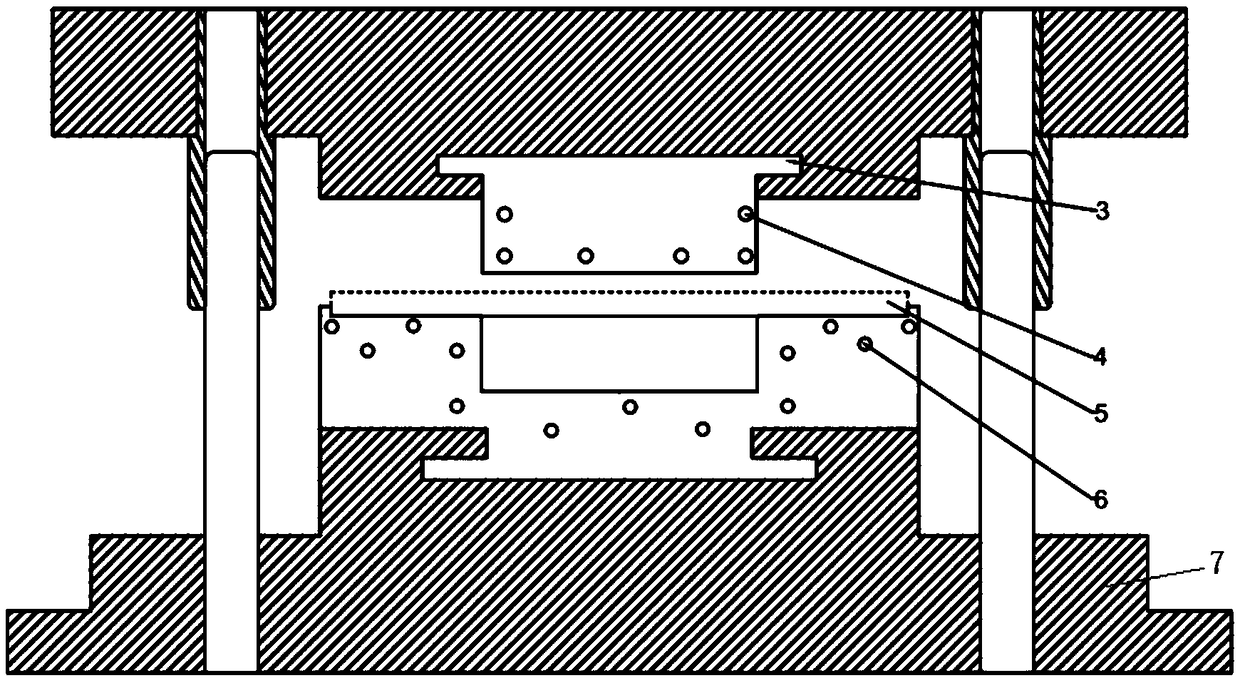

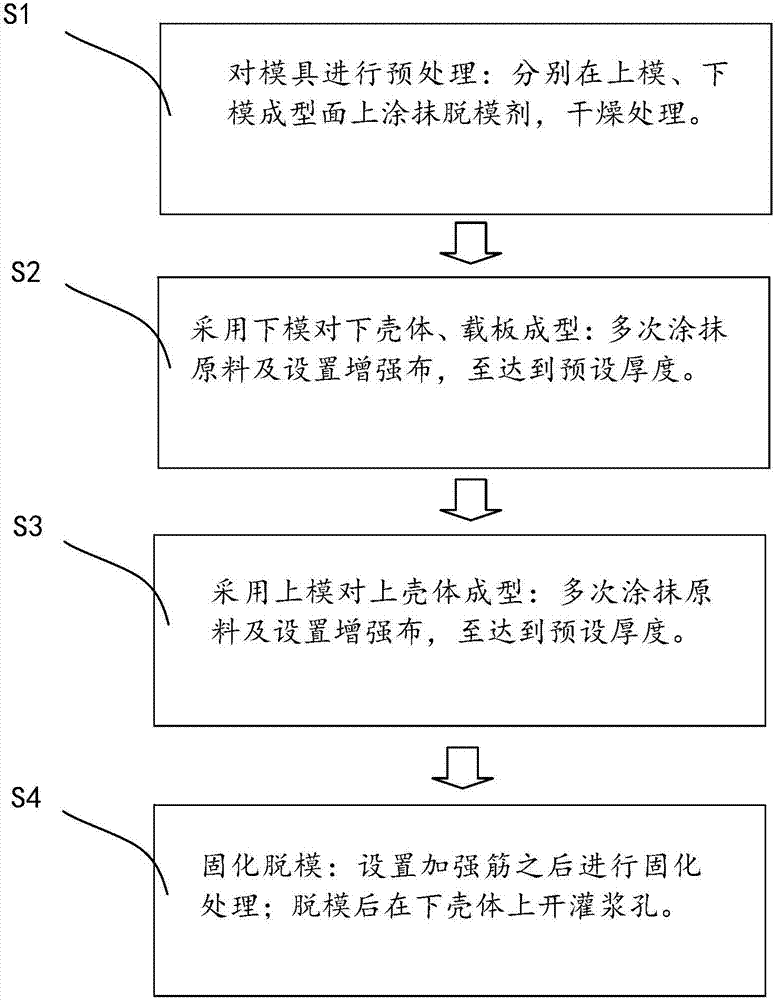

Manufacturing technology for integrally prefabricating base of pump station

InactiveCN107984594AGuaranteed integrityHigh strengthSewerage structuresCeramic shaping apparatusManufacturing technologyWastewater

The invention provides a manufacturing technology for integrally prefabricating a base of a pump station. The base comprises an upper housing and a lower housing, wherein a loading plate is arranged between the upper housing and the lower housing. The manufacturing technology comprises the steps of S1, preprocessing a die, wherein the die comprises a lower die for forming the lower housing and theloading plate, and an upper die for forming the upper housing; and coating forming surfaces of the upper die and the lower die with release agents; S2, forming the lower housing and the loading platethrough the lower die; and uniformly brushing raw materials on the forming surface of the lower die; S3, arranging the upper die corresponding to the lower die; enabling the forming surface of the upper die to be in contact with a product surface of the lower housing; and brushing the raw materials on the forming surface of the upper die; and S4, curing and releasing the dies, namely, correspondingly separating out the upper die and the lower die from the cured and formed base. The manufactured base is designed to form a self-cleaning structure which promotes the discharging of wastewater mixture; the base is high in intensity, and high in adaptability, and thus the waste draining performance of the whole pump station is improved.

Owner:CRI (GZH) CO LTD

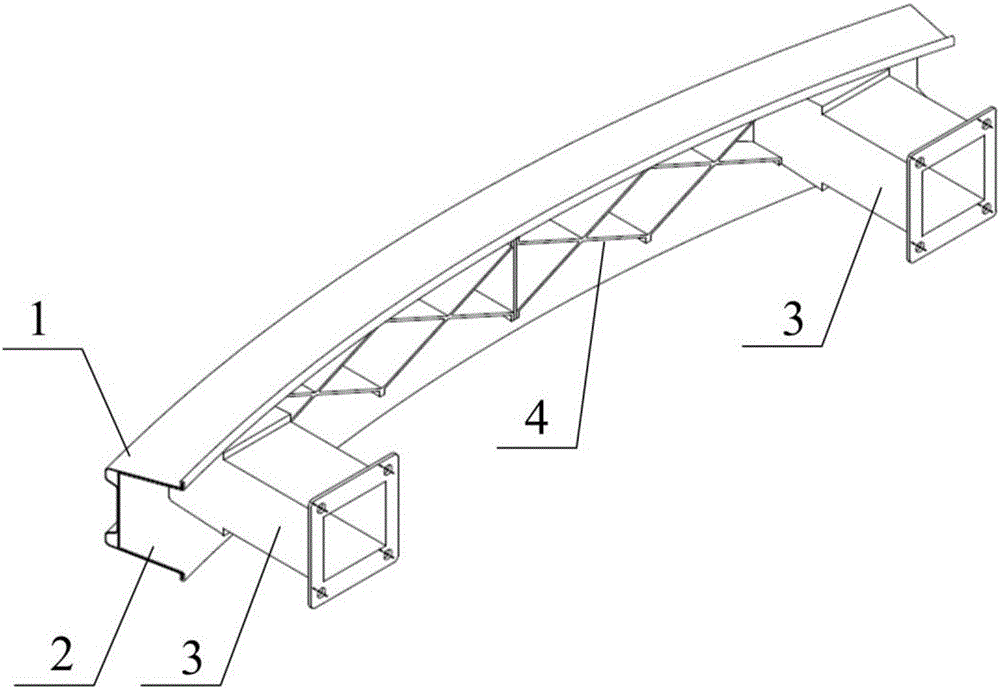

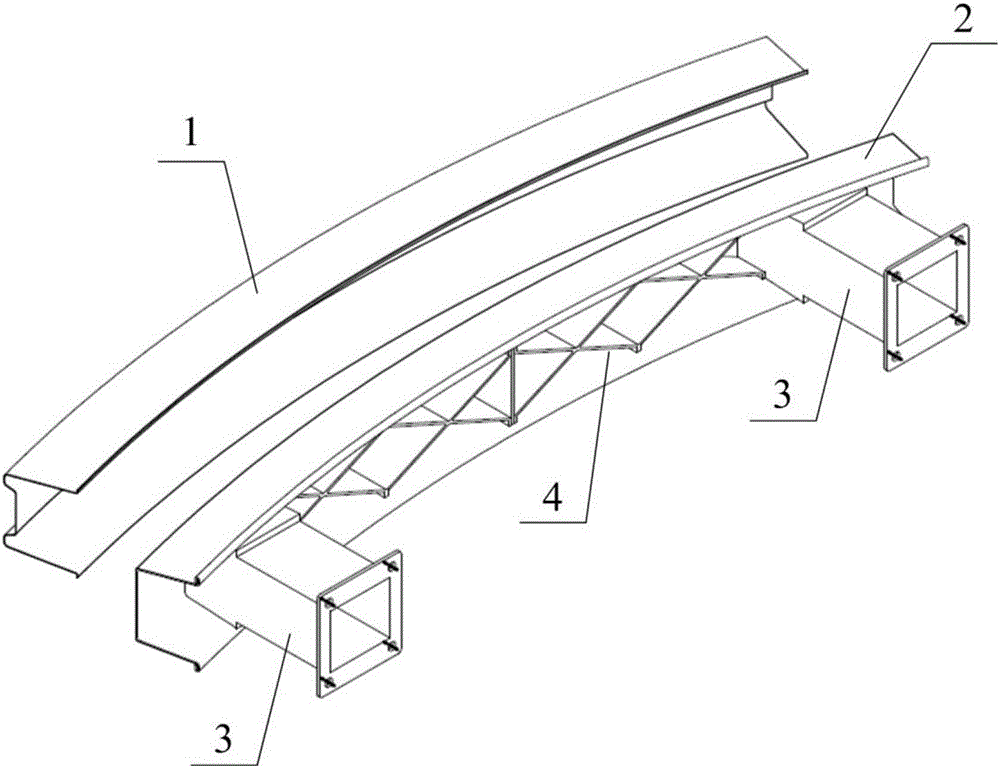

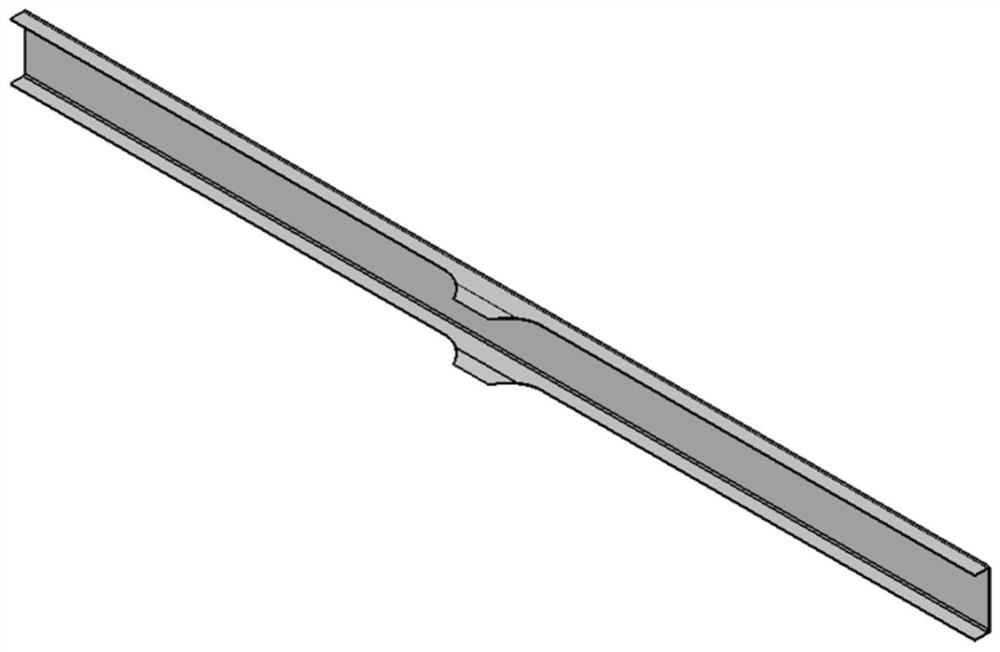

Composite material integrated frame beam and manufacturing method

PendingCN112173062AReduce in quantityRealize integrated moldingFuselage framesAircraft assemblyFlight vehicleStructural engineering

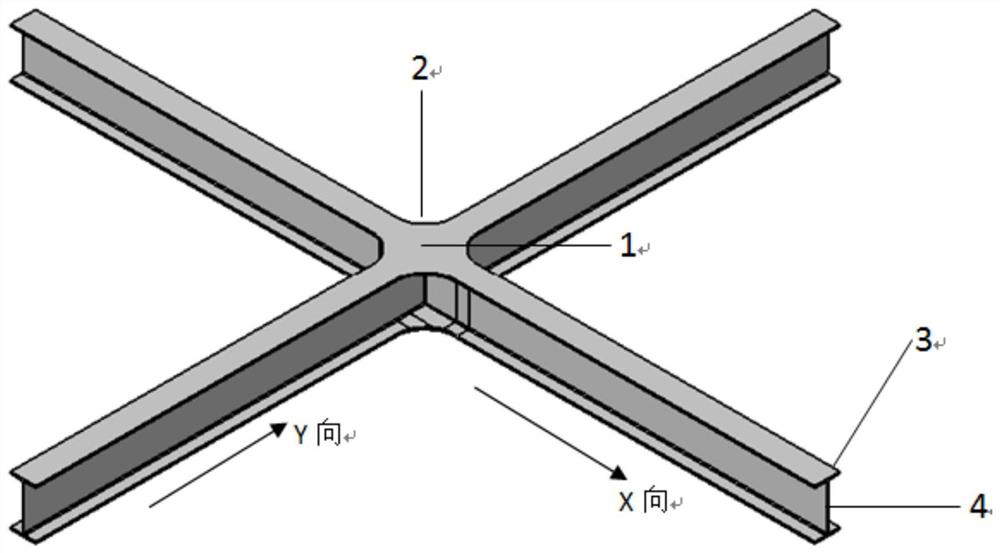

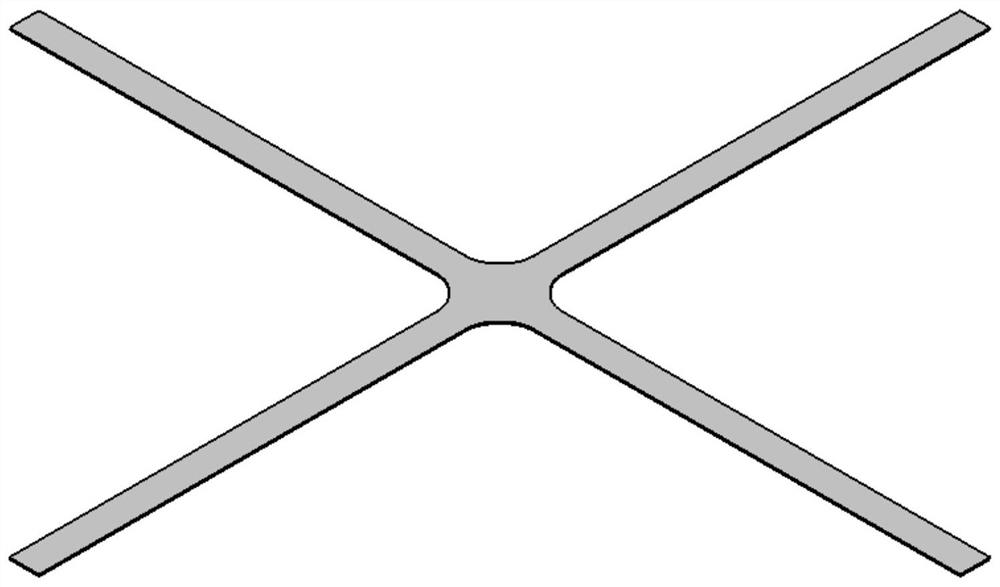

The invention belongs to the technical field of aircraft structure design, and discloses a composite material integrated frame beam and a manufacturing method, the integrated frame beam is of a cross-shaped structure as a whole, one direction of the cross-shaped structure is the X direction, and the other direction of the cross-shaped structure is the Y direction; the integrated frame beam comprises an upper cross-shaped pavement layer, a middle cross-shaped pavement layer and a lower cross-shaped pavement layer. Wherein the middle cross-shaped paving layer comprises a paving layer with an I-shaped cross section in the X direction and a paving layer with an I-shaped cross section in the Y direction; wherein the paving layer with the I-shaped cross section in the X direction comprises two continuous composite fabrics with C-shaped cross sections, and the paving layer with the I-shaped cross section in the Y direction is a discontinuous composite fabric and comprises a left half paving layer and a right half paving layer; and both the left half part paving layer and the right half part paving layer consist of two continuous composite fabrics with C-shaped sections. And a sewing process is used in the intersection area. According to the integrated frame beam, integrated forming can be achieved, layering can be avoided, and the strength is guaranteed.

Owner:CHINA HELICOPTER RES & DEV INST

Injection molding process for flexible switch

ActiveCN106541538ARealize Capacitive Sensing FunctionRealize integrated moldingDomestic articlesCoatingsPunchingWorking environment

The invention discloses an injection molding process for a flexible switch. The injection molding process comprises the following steps that firstly, printed PET films are placed into a cutting die for punching, and during punching, positioning holes at the two ends of sheets are placed onto cutting die positioning holes with the diameter being 2 mm for punching; secondly, roasted plastic grains are placed into a storage barrel, wherein according to roasting parameters for roasting of the plastic grains, the roasting temperature is 80 DEG C, and the roasting time is 2 H; thirdly, parameters of an injection molding machine table are set, punched PET panel films are placed into a front die cavity, and the front faces of the sheets make contact with the front die cavity; and fourthly, ITO films and the PET films are integrated through injection molding, and production is completed. Under the working environment of an IMD product, a capacitive sensing function is achieved, and the application range of the product is widened; adhesive attaching is not needed, and integral forming is achieved; and the product is attractive and practical, and the sensing effect is excellent.

Owner:南通振群电子有限公司

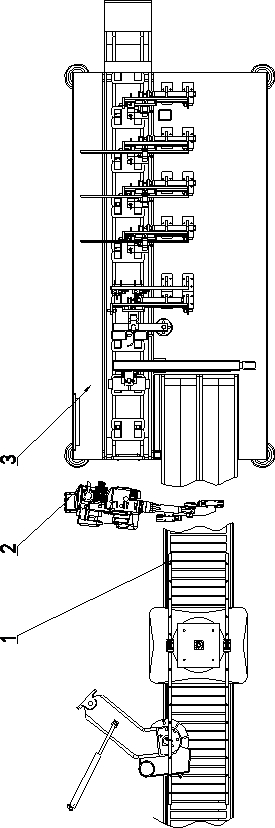

A comprehensive processing machine

ActiveCN111390569BHigh geometric accuracyQuality improvementMetal sawing devicesMeasurement devicesNumerical controlControl cell

The invention discloses a comprehensive processing machine, which comprises a material reduction processing module, an allocation control module and an additive manufacturing module arranged in sequence along the conveying direction of workpieces; the material reduction processing module includes a frame and is arranged on the frame The cutting device; the additive manufacturing module includes a workbench and a welding device arranged on the workbench; the deployment control module includes a batching device; also includes a numerical control module; the numerical control module includes a display unit, a control unit, A contour detection unit for monitoring the shape change trend of the workpiece during the process of adding and subtracting materials, an ultrasonic micro-forging unit for monitoring internal defects of the workpiece during the process of adding and subtracting materials, and a molten pool monitoring unit for detecting the state of the molten pool of the welding device ; The control unit is electrically connected with the cutting device, welding device and batching device. The invention has the advantages of further improving production efficiency, saving working space, reducing the manufacturing difficulty of complex structural parts and realizing integral molding of parts.

Owner:FOSHAN NANHAI FUDA PRECISION MACHINERY

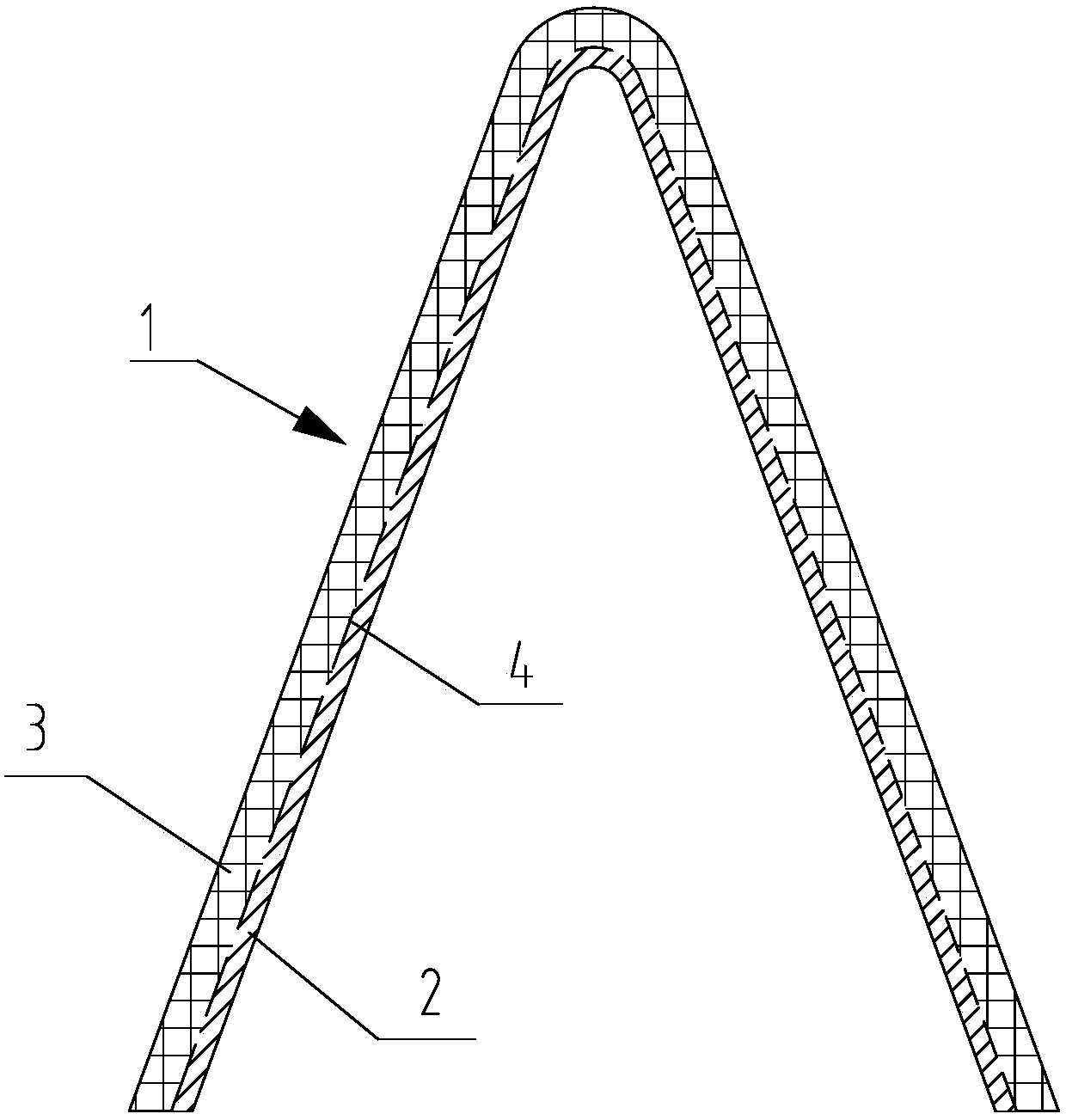

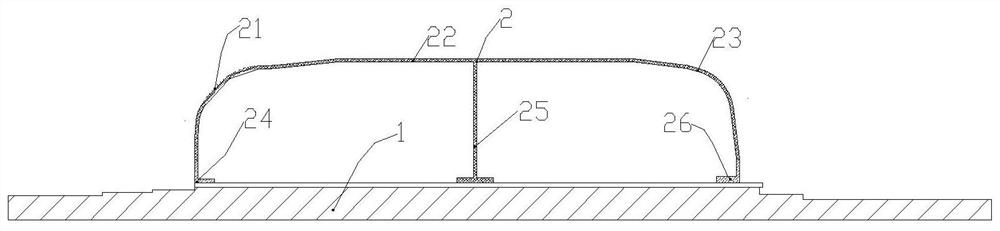

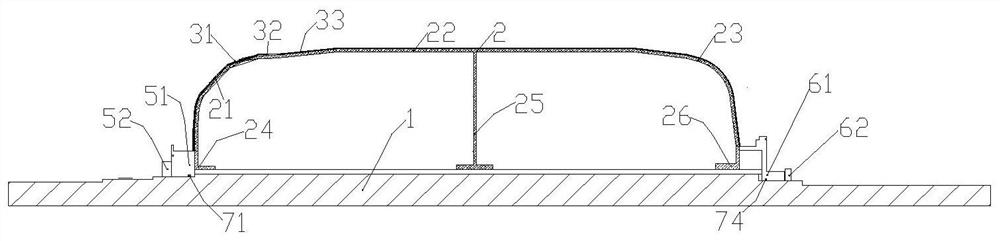

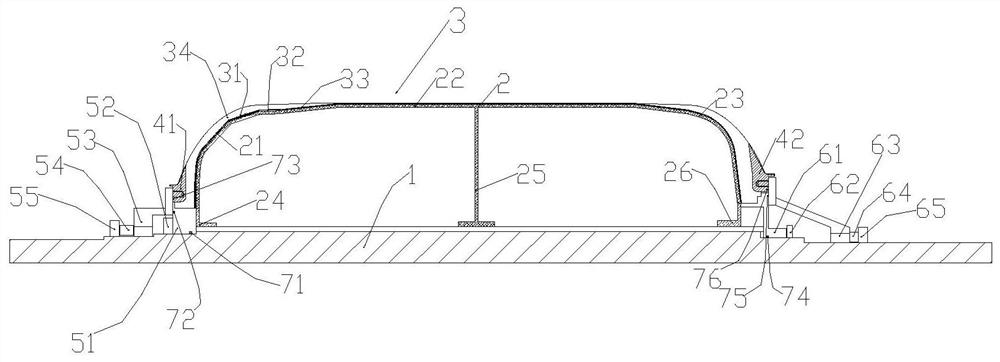

Broadband wave-transparent double-layer composite ceramic radome cover body and preparation method thereof

ActiveCN106129615BGuaranteed strength performanceGuaranteed electricityRadiating element housingsComposite ceramicBroadband

The invention discloses a cover body of a broadband wave-transmitting dual-layer composite ceramic antenna cover and a fabrication method for the cover body. The fabrication method for the cover body of the broadband wave-transmitting dual-layer composite ceramic antenna cover comprises the following steps of 1) weaving a shaped fabric; 2) pre-processing the shaped fabric; 3) impregnating an outer layer of the shaped fabric; 4) performing integral impregnation; 5) repeating to perform integral impregnation in the above step of 4) for two or three times; 6) sintering an intermediate blank; 7) roughly processing a cover body blank; 8) repeating to perform integral impregnation in the above step of 4) on the roughly-processed cover body blank for one time, and performing high-temperature sintering; and 9) finely processing an initial cover body. The shaped fabric of the cover body of the dual-substrate composite ceramic antenna cover is formed by laying and integratedly stitching a hollow quartz fiber fabric, a hollow quartz fiber felt and a solid quartz fiber fabric, the integral formation of the dual-layer composite ceramic antenna cover can be achieved, thus, the connection strength and the assembly accuracy of the cover body are improved, and the production cost is reduced.

Owner:湖北三江航天江北机械工程有限公司

Preparation method of cubing

The invention relates to a preparation method of a cubing. The preparation method comprises the following technological steps: design and processing of a mold: the mold is divided into an upper mold and a lower mold which are both provided with a glue injection opening and an exhaust glue outlet; laying: tailored fibre cloth is respectively laid inside a cavity of the upper mold and a cavity of the lower mold so as to obtain two preforms, the two preforms are respectively sealed, vacuum-pumping is carried out, resin is injected through the glue injection opening, and solidification is carried out; and the edge of the solidified mold is coated with an adhesive layer, the mold is closed, and demolding is carried out after the adhesive layer is solidified so as to obtain a hollow fiber gauge product. Integral forming of the cubing can be realized. The preparation method has technical advantages of simplified technology, simple process, short production cycle and the like. In addition, production cost of the cubing is lower, and the cubing is lighter.

Owner:东莞市海旭新材料技术有限公司

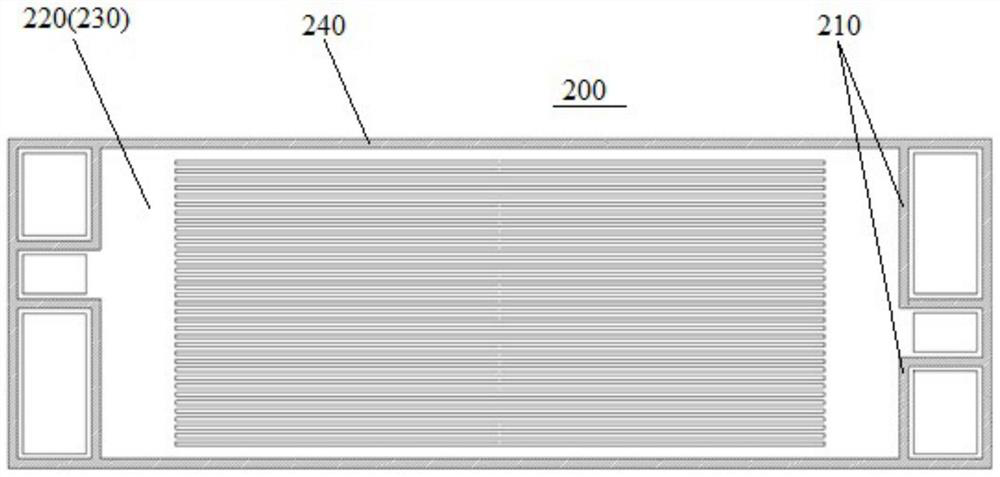

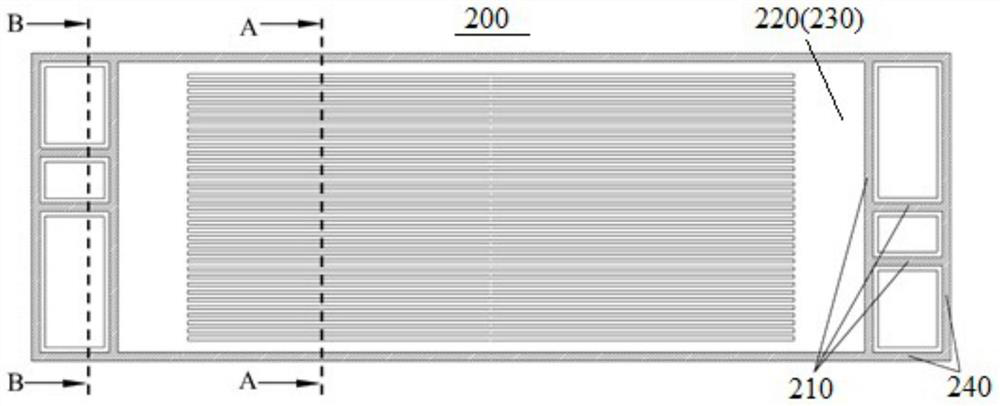

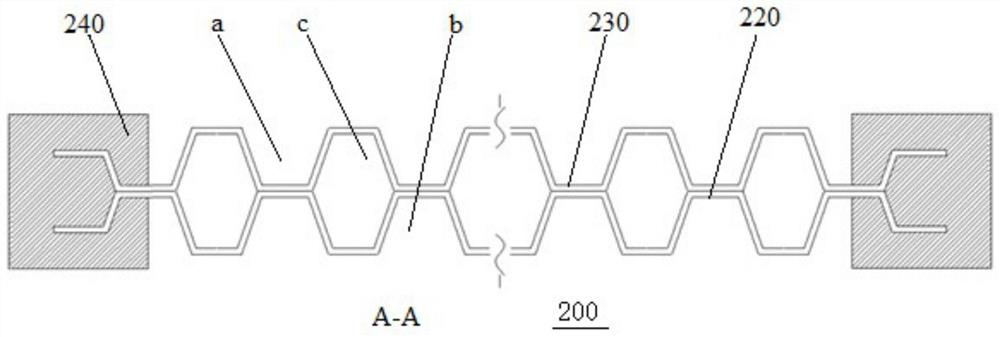

Bipolar plate assembly, manufacturing process, cell stack and fuel cell vehicle

ActiveCN113745563ASimple structureAvoid seal failureFinal product manufacturePropulsion by batteries/cellsFuel cellsManufacturing technology

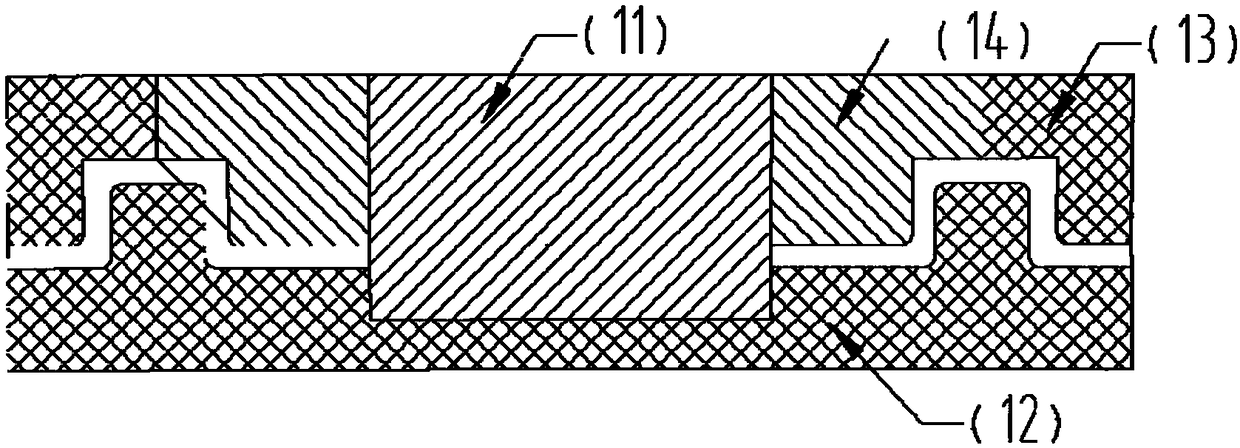

The invention discloses a bipolar plate assembly, a manufacturing process, a cell stack and a fuel cell vehicle, and aims to solve the technical problems of high production cost, long preparation period and low yield of an existing bipolar plate manufacturing process, and the technical problems of poor durability and sealing performance of a prepared bipolar plate. The bipolar plate assembly comprises a cathode plate, an anode plate and a sealing assembly, wherein the cathode plate and the anode plate are attached in a posture that flow channel openings are opposite and are fixed into a whole through the sealing assembly; the sealing assembly comprises an outer frame insulation sealing ring wrapping a containing cavity and an inner frame insulation sealing ring wrapping a sealing groove, and the protruding height of the outer frame insulation sealing ring and the protruding height of the inner frame insulation sealing ring are both larger than the protruding height of flow channels. The cathode plate and the anode plate are connected into a whole through the integrally-formed sealing assembly, and the sealing assembly serves as a welding wire, so that the welding step in an existing bipolar plate manufacturing process can be omitted; and a plate sealing ring and a gas field side sealing ring are integrally formed, so that the sealing performance is good.

Owner:DONGFENG MOTOR GRP

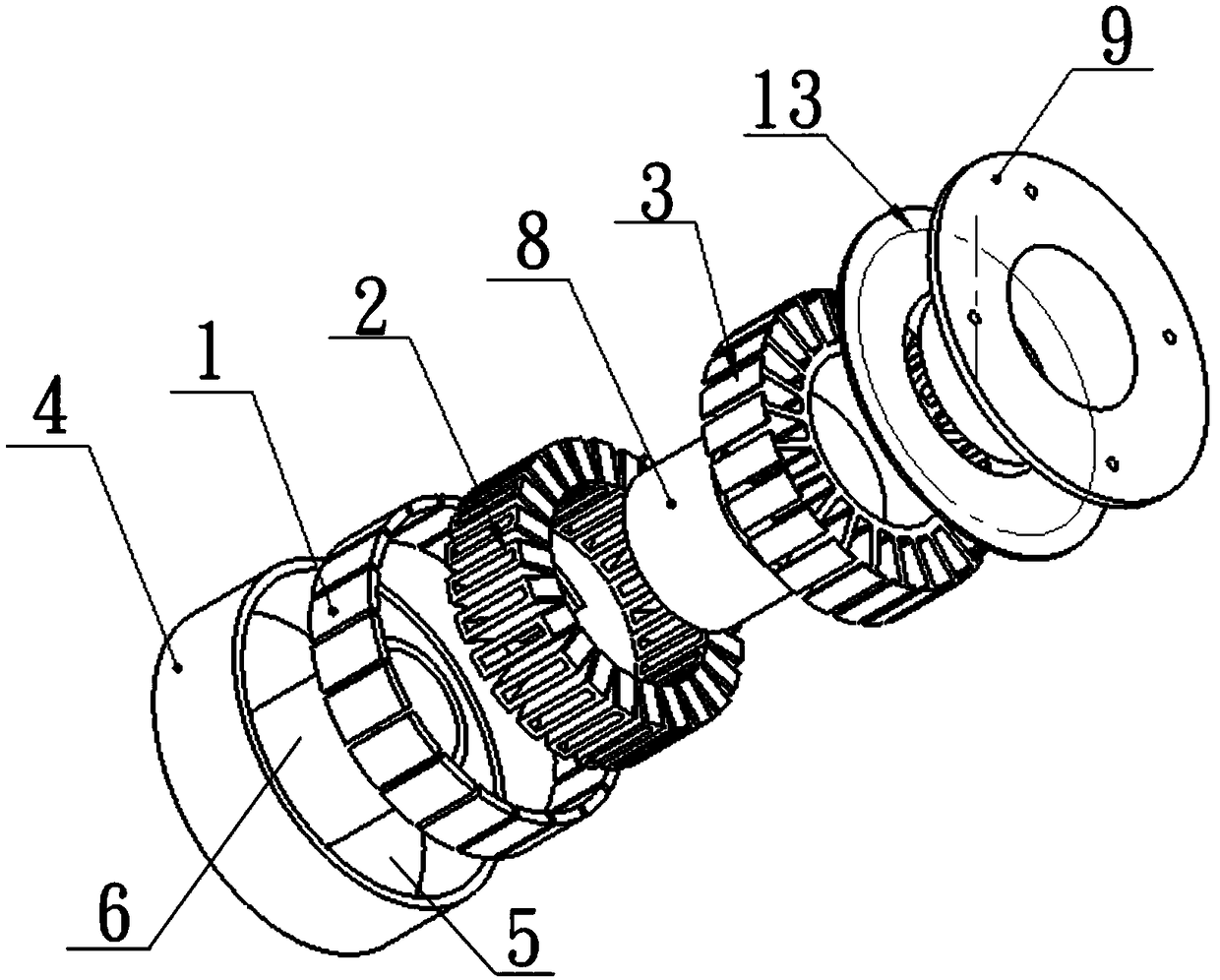

A brushless DC motor with hollow shaft

PendingCN109149890AHigh precisionReduce the difficulty of assemblyMagnetic circuit rotating partsMechanical energy handlingStatorMagnet

A brushless DC motor with hollow shaft, the motor includes a magnet, coils and stator cores, the motor further comprises a barrel, At one end of that barrel, a rotor end cover is formed to extend inward, A middle part of that rotor end cover is formed with a hollow, the hollow edge extends in a direction perpendicular to the rotor end cover to form a hollow shaft body, the hollow shaft body and the cylinder body are mutually parallel, Between that hollow shaft body and the cylinder body is for a magnet accommodating the magnet, A space between the coil and the stator core, a hollow shaft rotorshell integrally formed between the cylinder, the rotor end cover and the hollow shaft body, and the motor support comprises a bearing end portion extending inwardly to form a nesting portion, wherein a support portion is formed on the nesting portion, and an inner side of the stator core rests on the support portion. The invention improves the precision of the parts, reduces the assembly difficulty, improves the assembly efficiency, realizes the integrated molding, and reduces the cost.

Owner:SHENZHEN HENGDRIVER MOTOR CO LTD

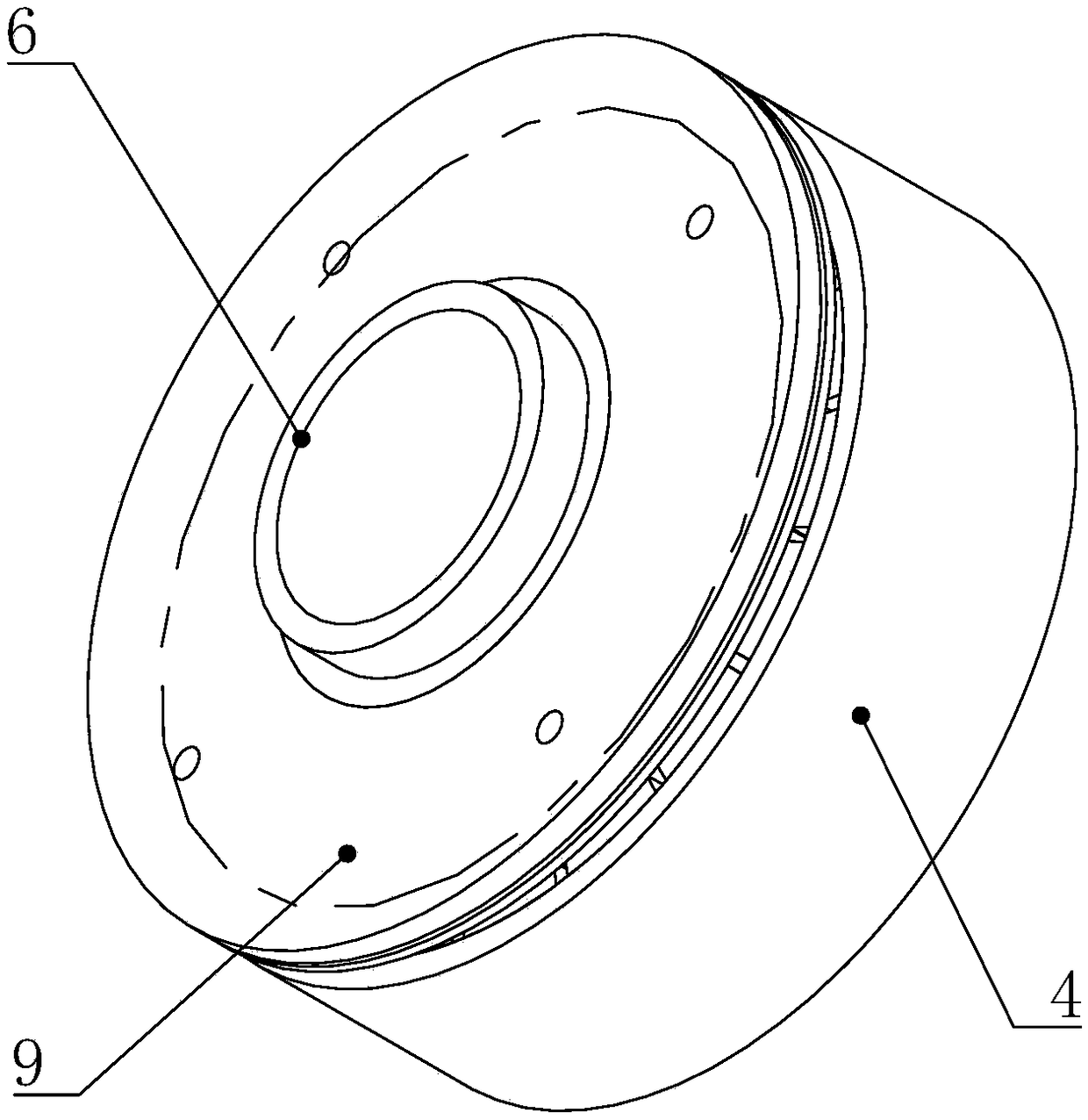

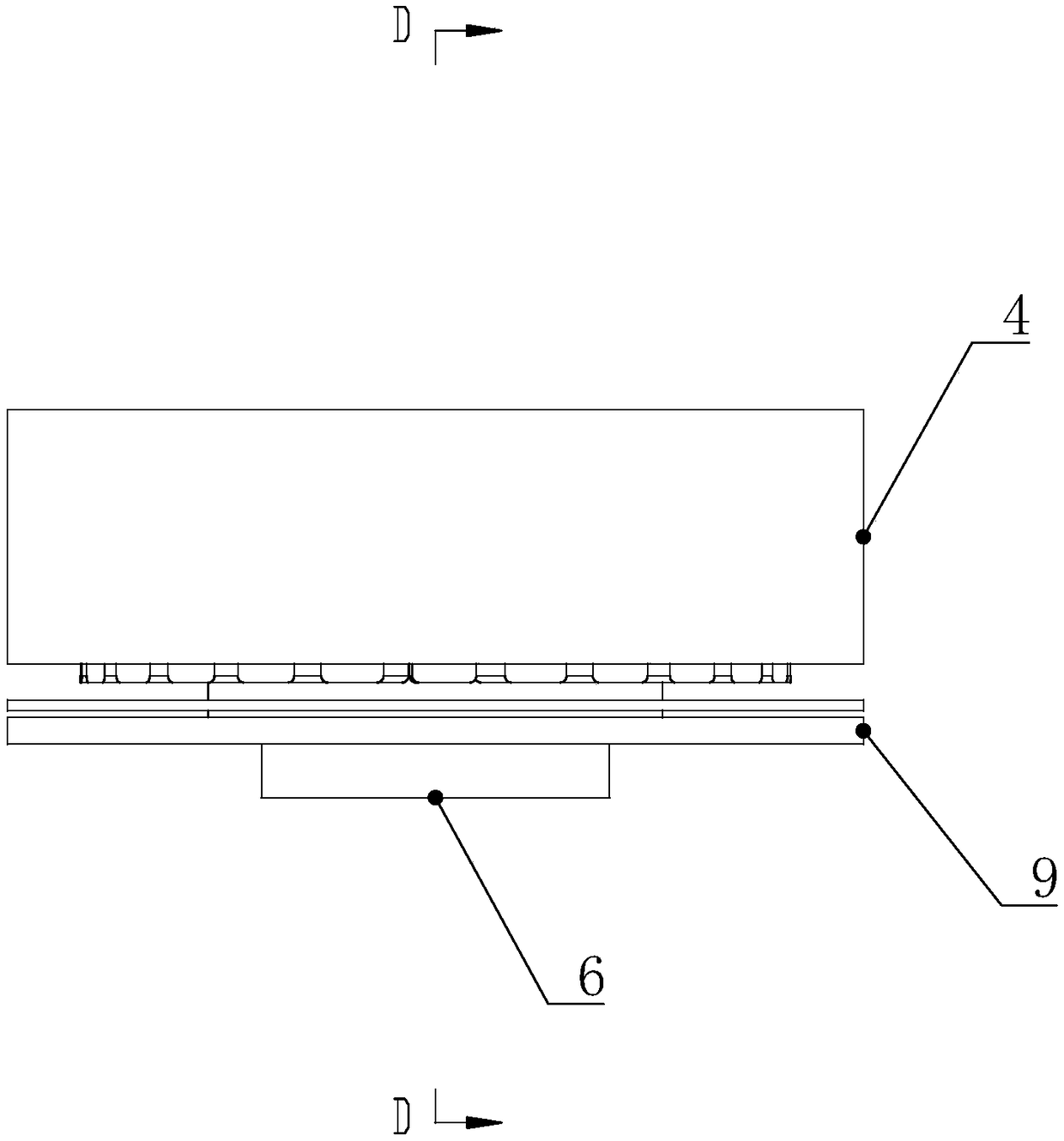

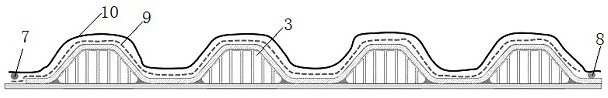

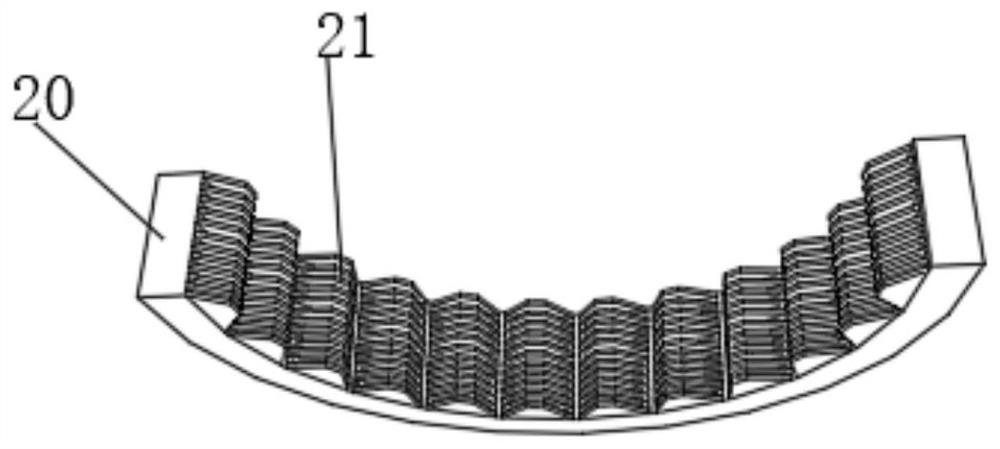

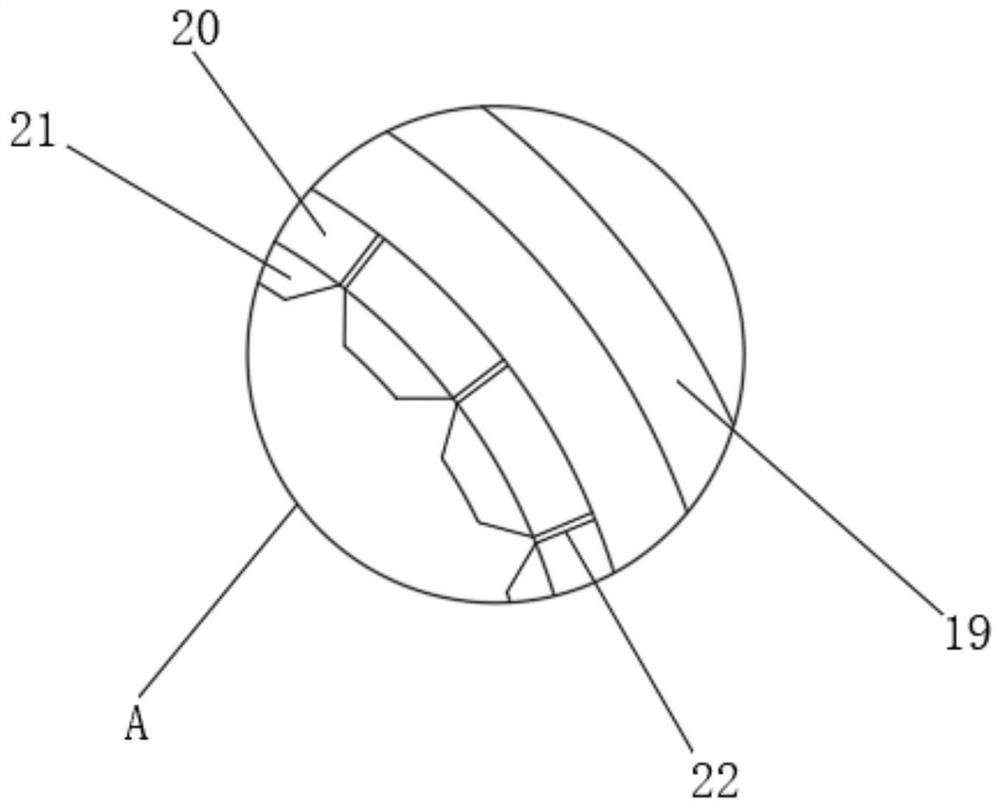

Foam sandwich cap type stiffened wallboard structure and integrated forming method

PendingCN113772076AImprove stress resistanceHigh bonding strengthFuselage bulkheadsWeight reductionUltimate tensile strengthBoard structure

The invention discloses a foam sandwich cap type stiffened wallboard structure and an integrated forming method, and belongs to the technical field of composite material manufacturing. According to the method, a dry fabric, a trapezoidal foam sandwich which is grooved and punched in advance and a one-way filling core material are laid and assembled on a skin female die tool, an assembled prefabricated body is prepared, and then the prefabricated body is subjected to integrated impregnation and curing through a vacuum resin flow guide process; wherein, the interface between the skin and the foam sandwich is completely filled with the impregnated resin, the flow guide holes formed in the foam sandwich are also filled with the resin to form resin columns, and the resin columns evenly distributed in the foam sandwich improve the pressure resistance of the foam sandwich material. Besides, the resin penetrating between the resin columns and the skin and the core material also improves the bonding strength between the skin and the core material. Therefore, the manufacturing period and cost of the cap-shaped stiffened wall plate can be obviously reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

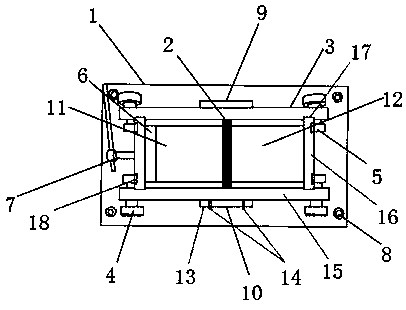

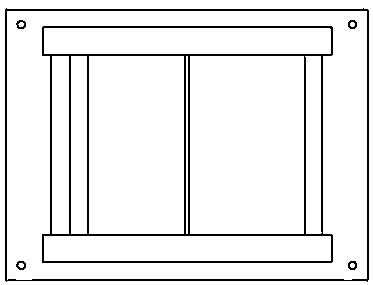

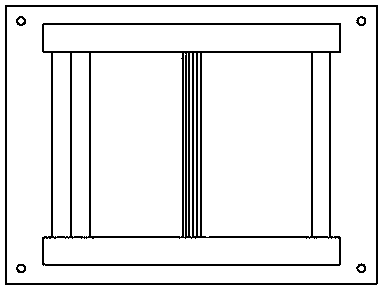

Molding mould capable of adjusting concrete interlayer bonding thickness and test method thereof

PendingCN108760442AAvoid disturbing effectRealize integrated moldingPreparing sample for investigationRoad engineeringRoad surface

The invention relates to a molding mould capable of adjusting the concrete interlayer bonding thickness and a test method thereof, and belongs to the technical field of road engineering in traffic engineering. The mould comprises structures such as a base, a thickness adjusting steel plate, a rectangular mould frame, an adjusting screw, a fixing nut, a propelling plate, an adjusting screw rod, a leveling bolt, a fixing block and a counterforce frame. Different concrete mixing materials are added manually, the thickness between the different concrete materials and the interlayer bonding material can be precisely controlled, the conformity of the size of the materials of each structural layer is maintained, integral forming of the interlayer bonding material and the concrete structural layercan be simply, conveniently and rapidly achieved, meanwhile a test piece can be convenient to dismount and mount, the disturbance of human factors to the interlayer bonding capability can be avoidedto the maximum extend, and accordingly the bonding ability between road surface material layers can be accurately reflected.

Owner:BROADVISION ENG CONSULTANTS

Method for preparing bamboo-resin integrated material for bamboo weaving

InactiveCN107511898AChange structureRealize integrated moldingWood treatment detailsCane mechanical workingFiberResin microsphere

The invention discloses a method for preparing a bamboo-resin integrated material for bamboo weaving. Bamboo chip filaments are subjected to steps of alkalization, acetylization, resin injection, surface treatment and the like, the structures of bamboo fibers are changed to a certain degree, nano-scale resin microspheres are introduced through a pressurization impregnation method, the characteristics of resin and the bamboo fibers are efficiently combined, integration forming of the bamboo filaments and the resin is achieved, and the defect that a bamboo plastic material prepared through a traditional method is insufficient in toughness is overcome. The bamboo-resin integrated material can directly serve as a bamboo weaving material, the prepared material is flexible and smooth and easier to shape, corrosion resistance and water resistance both are improved, and the additional value of bamboo weaving products is improved.

Owner:FUNAN NATURE ARTS & CRAFTS

Structure and function integrated flexible structure and mold thereof

The invention relates to a structure and function integrated flexible structure and a mold thereof. The structure and function integrated flexible structure comprises a core shaft, a heat insulation air bag, a sealing connection system and an inflation pressure stabilizing system, wherein the heat insulation air bag is of a cylindrical structure with the core shaft as a center shaft, and end sockets with gradually-shrunk openings are arranged at the two ends of the heat insulation air bag; the sealing connection system is arranged at an opening of the sealing head and is used for sealing the heat insulation air bag and connecting an external device; and the inflation pressure stabilizing system is connected to the sealing connection system and used for inflating the heat insulation air bag and maintaining the air pressure in the heat insulation air bag to be stable. The mold comprises a core shaft and an assembly shell, the core shaft is used as a center shaft of the assembly shell, and the two ends of the core shaft extend out of the assembly shell. The flexible structure can serve as a winding core mold in the winding forming process, after a combustion chamber shell is formed, the mold can be detached, the flexible structure does not need to be disengaged, and the flexible structure can serve as a heat insulation structure of the combustion chamber shell.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

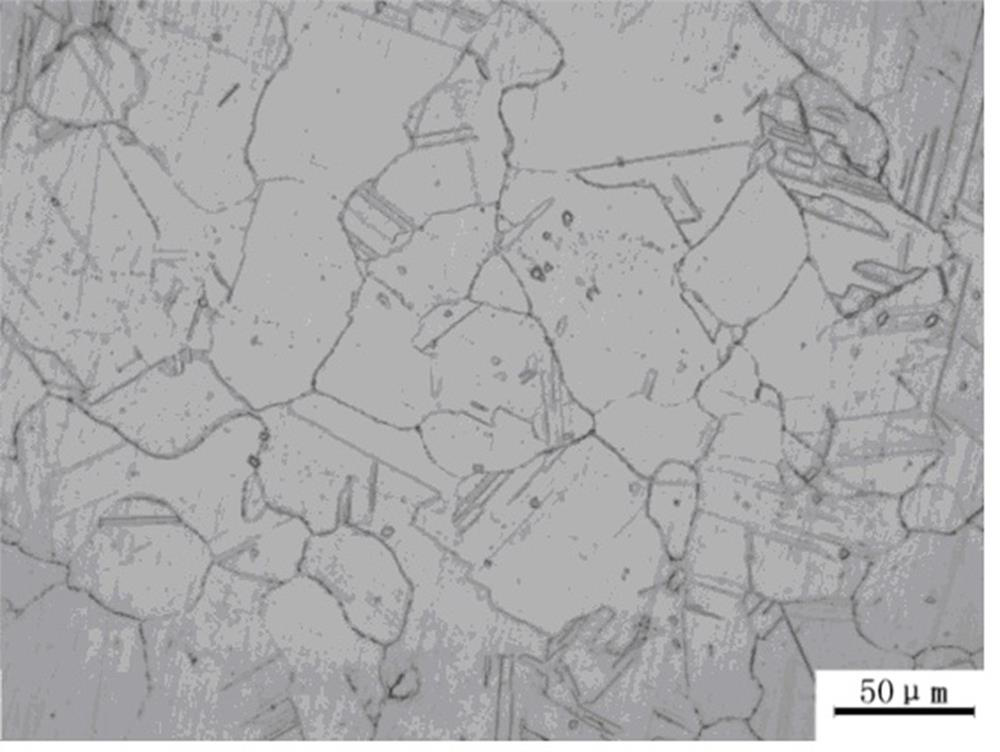

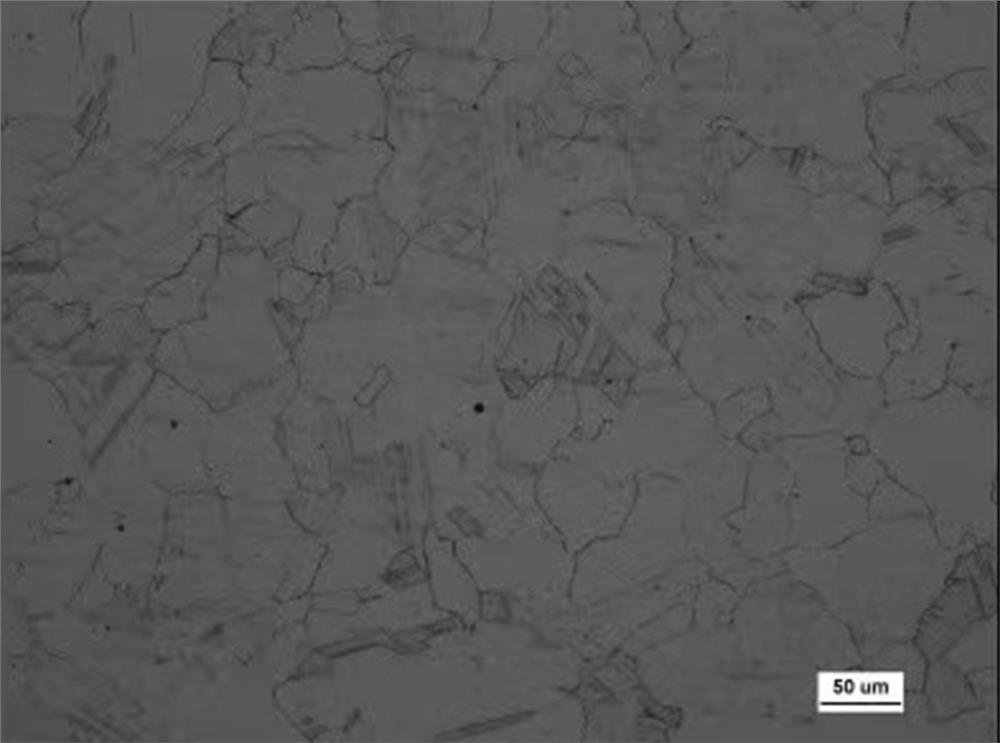

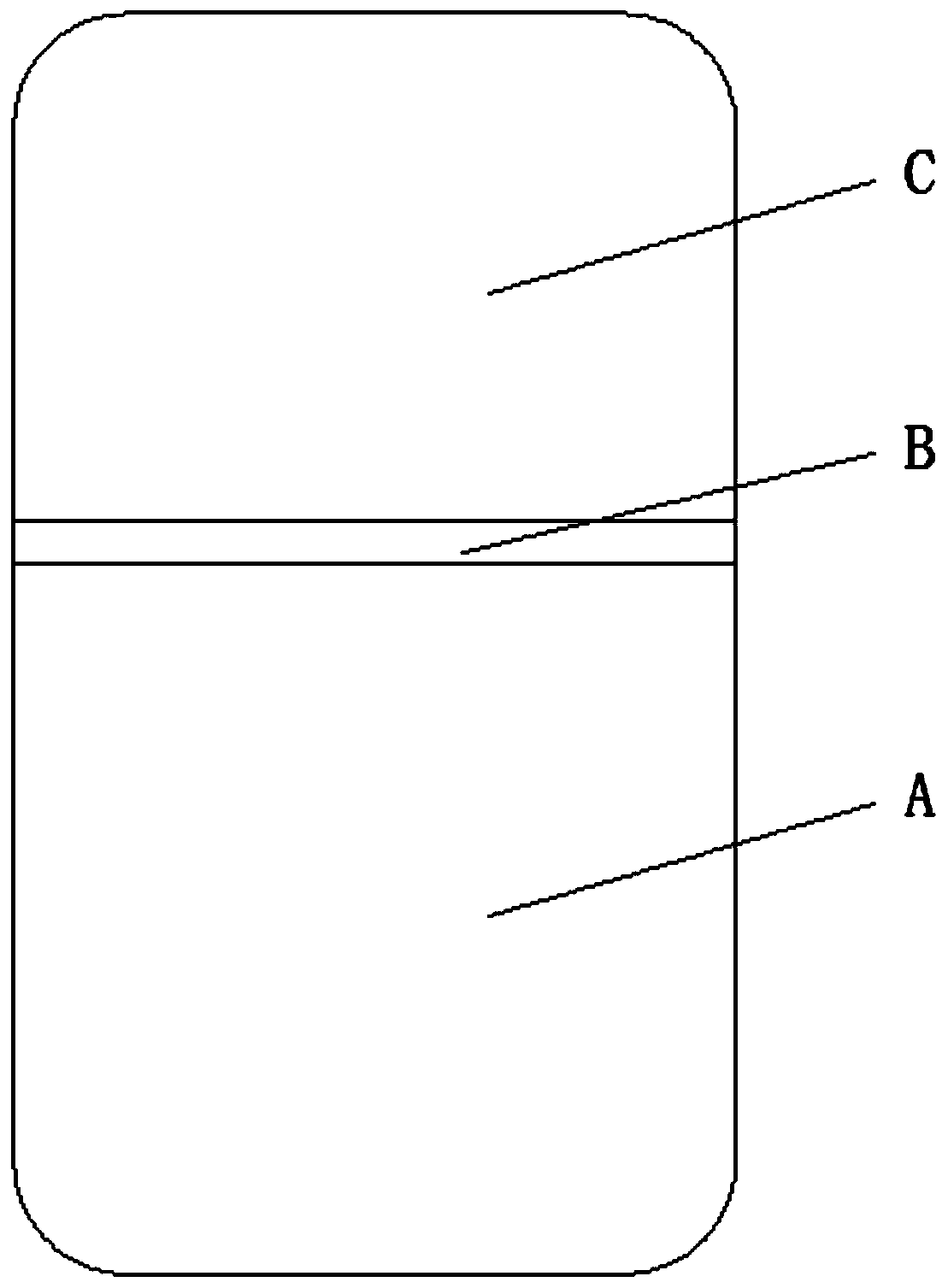

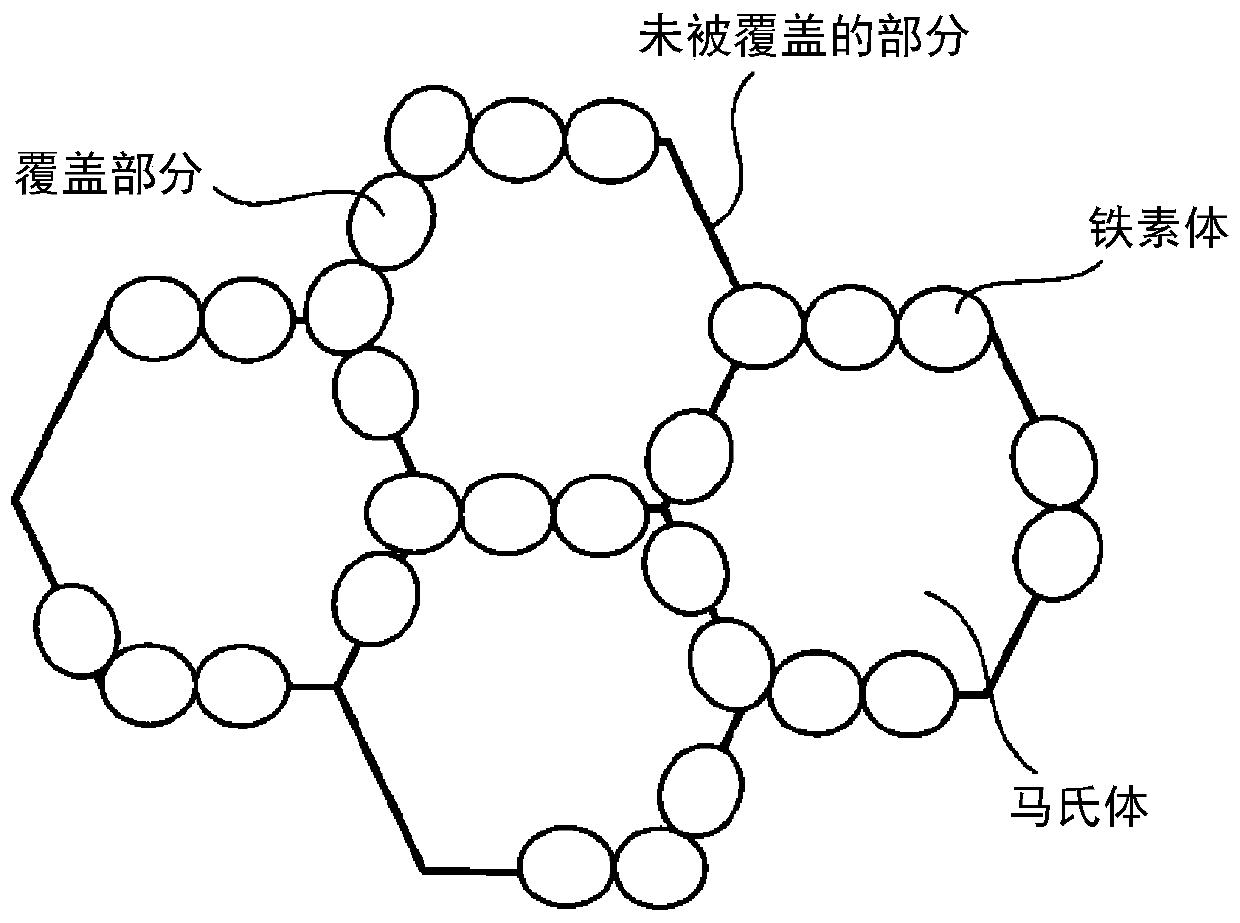

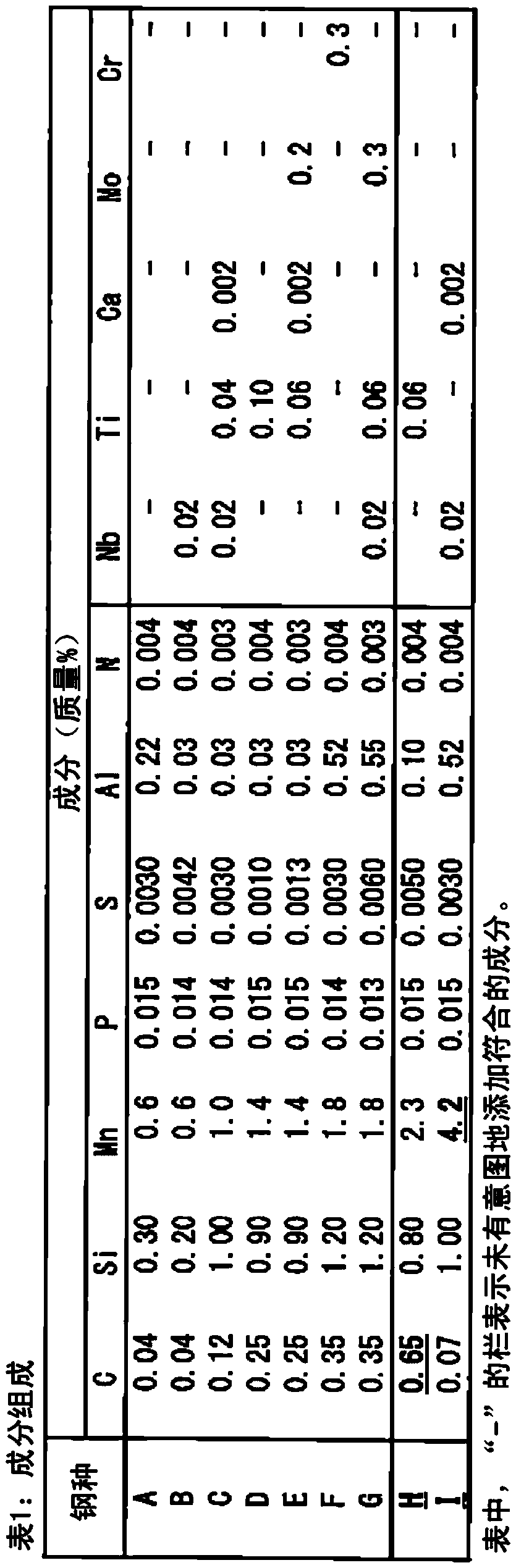

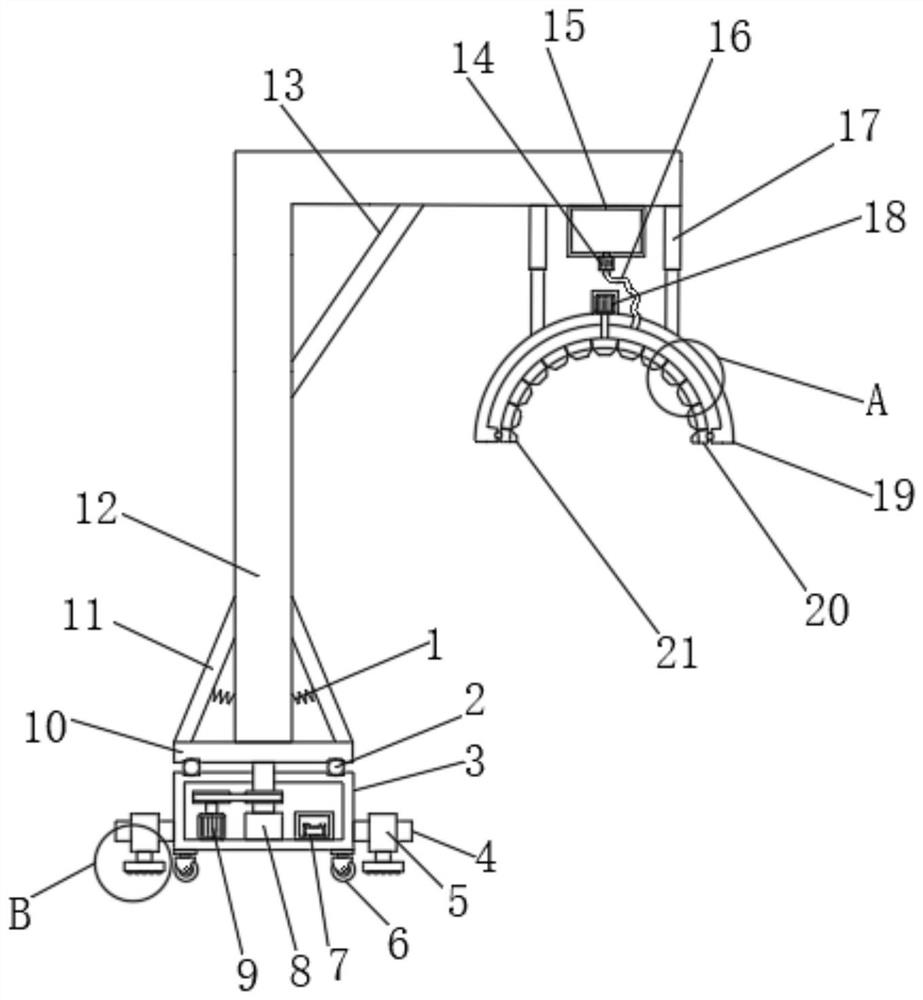

Hot-rolled steel sheet and manufacturing method therefor

ActiveCN110785507AHas tensile strengthAchieve lightweightFurnace typesHeat treatment furnacesMetallurgyMartensite

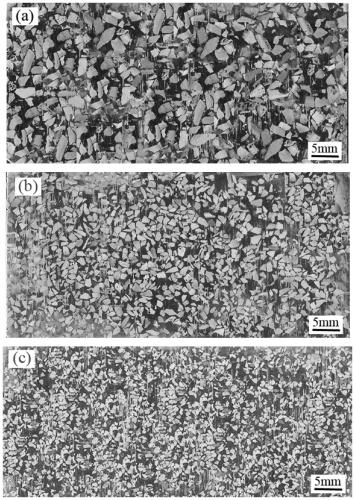

Provided is a hot-rolled steel sheet that has a prescribed composition and that includes a two-phase structure in which a martensite phase has a structural fraction of 10-40% in terms of area fraction, and in which a ferrite phase has a structural fraction of at least 60%, wherein ferrite grains have an average grain diameter of at most 5.0 um, and the coverage factor of martensite grains by the ferrite grains is more than 60%. Also provided is a hot-rolled steel sheet manufacturing method comprising: a step for achieving, in the last three rolling stands, a rolling load of at least 80% of that of an immediately-preceding rolling stand, and an average rolling temperature of 800-950 deg c; and a step for forced-cooling a steel sheet and then rolling up the steel sheet, wherein the forced cooling starts within 1.5 seconds of the termination of rolling to cool down the steel sheet to 600-750 deg c at an average cooling rate of at least 30 deg c / sec, and then the steel sheet is subjected to spontaneous cooling for 3-10 seconds, and then further cooled down to 200 deg c or lower at an average cooling rate of at least 30 deg c / sec.

Owner:NIPPON STEEL CORP

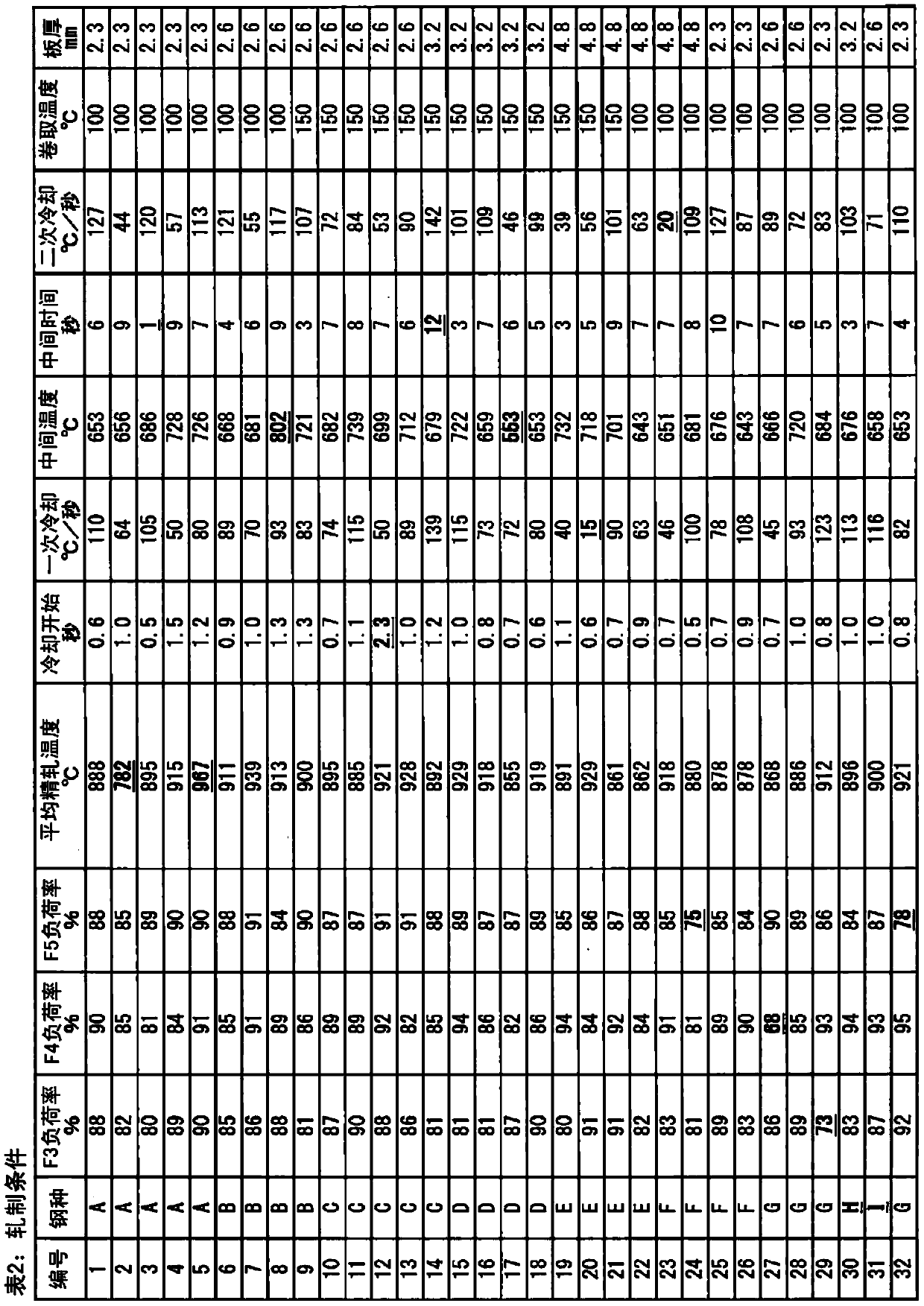

Metal die hot working one-time forming device

InactiveCN106493302AReduce labor intensityLow technical levelFoundry mouldsFoundry coresHydraulic cylinderHot work

A metal die hot working one-time forming device is characterized by comprising an upper core installation base, an upper core, jetting nozzles, a right hydraulic cylinder, sliding grooves, a lower core, a protrusion, a lower core installation base, sliding blocks, a left hydraulic cylinder and dead heads, wherein the device is of a symmetrical structure, the left hydraulic cylinder and the right hydraulic cylinder are arranged on the two sides of the device, the left hydraulic cylinder and the right hydraulic cylinder are connected with the jetting nozzles through connecting pins, the sliding blocks are installed below the hydraulic cylinders and installed in the sliding grooves of the lower core installation base on the lower portion of the device, the protrusion is arranged on the center portion of the lower core installation base and sleeved with the lower core, the upper core is arranged at the corresponding position above the lower core, the upper core is installed on the upper core installation base, the dead heads are arranged on the inner sides, making contact with the lower core, of the two sides of the lower core installation base, and the dead heads make contact with the jetting nozzles in the outer sides. The metal die hot working one-time forming device has the beneficial effects that the structure is reasonable, integrated forming is achieved, operation is easy, the labor intensity of workers is lowered, the needed technical level of the workers is lowered, time and labor are saved, the cost is relatively low, and the quality of a cast product can be guaranteed.

Owner:刘勇

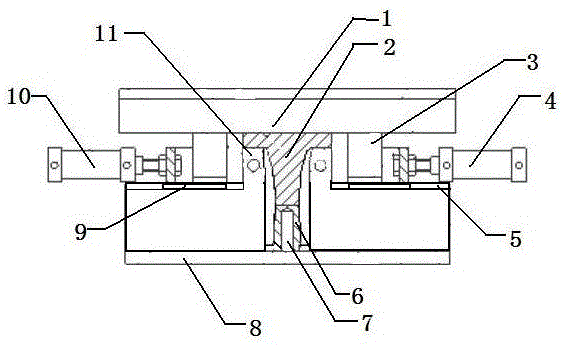

Shrub ball pruning device for landscaping

InactiveCN111758413AReduce pollutionRealize integrated moldingHedge trimming apparatusCuttersAgricultural engineeringLandscaping

The invention belongs to the technical field of gardens, particularly relates to a shrub ball pruning device for landscaping, and aims to solve the problems that a pruning device in the patent is simple in design structure and poor in pruning effect, dust cannot be removed in a pruning process, and dust flying is easily caused to influence the surrounding environment. According to the scheme, theshrub ball pruning device comprises equipment box; a bearing seat is fixed to the inner wall of the bottom of the equipment box through screws; a rotating rod is connected to the inner wall of the bearing seat through a bearing; the top end of the rotating rod is sleeved with a rotating disc; a supporting column of an L-shaped structure is fixed to the outer wall of the top of the rotating disc through screws; an electric telescopic rod is fixed to the outer wall of the bottom of the end, away from the equipment box, of the supporting column through screws; and an outer fixed ring is fixed toone end of a piston rod of the electric telescopic rod through screws. According to the shrub ball pruning device, integrated forming of pruning is achieved, and meanwhile, flying dust can be removedin a pruning process, so that pollution of the dust to the garden environment can be reduced, and the body health of people is guaranteed.

Owner:吴槚婷

3D printing composite material flexible strain sensor based on auxetic structure and preparation method thereof

PendingCN114413744AIncreased degree of fractureSignificant change in resistance signalElectrical/magnetic solid deformation measurementIncreasing energy efficiencyComposite materialStrain sensor

The invention relates to a 3D printing composite material flexible strain sensor based on an auxetic structure and a preparation method thereof, the flexible strain sensor structure comprises a sensing element embedded in one side of an elastic film, and the other side of the elastic film is printed with an auxetic structure support; according to the preparation method, size parameters of each structure of the sensor are designed according to an application scene, then composite materials used by each structure are prepared respectively, the sensor structure is obtained through integrated printing forming of multi-material 3D printing equipment, and finally the flexible strain sensor is obtained through high-temperature curing. According to the invention, the tension-expansion structure support reinforced by the composite material enables the flexible strain sensor to generate a stronger expansion effect in the transverse direction when the flexible strain sensor is stretched in the longitudinal direction, thereby improving the strain sensitivity and reliability of the sensor; and multiple materials are integrally formed by using a 3D printing process, so that the manufacturing process is greatly simplified, and the manufacturing cost is reduced.

Owner:XI AN JIAOTONG UNIV

Device and process method for preparing base material and inner surface metallization circuit based on 3D printing integration

ActiveCN108811355BEasy to manufactureShort preparation cycleConductive pattern formationGraphicsComputer printing

Owner:西安瑞特三维科技有限公司

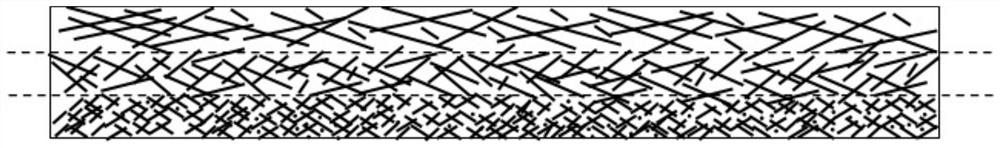

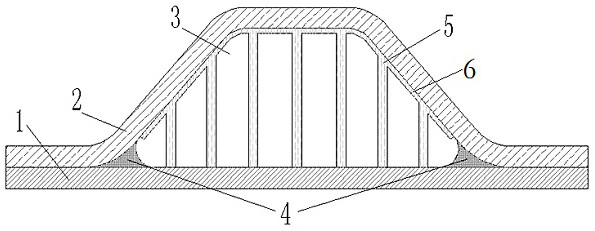

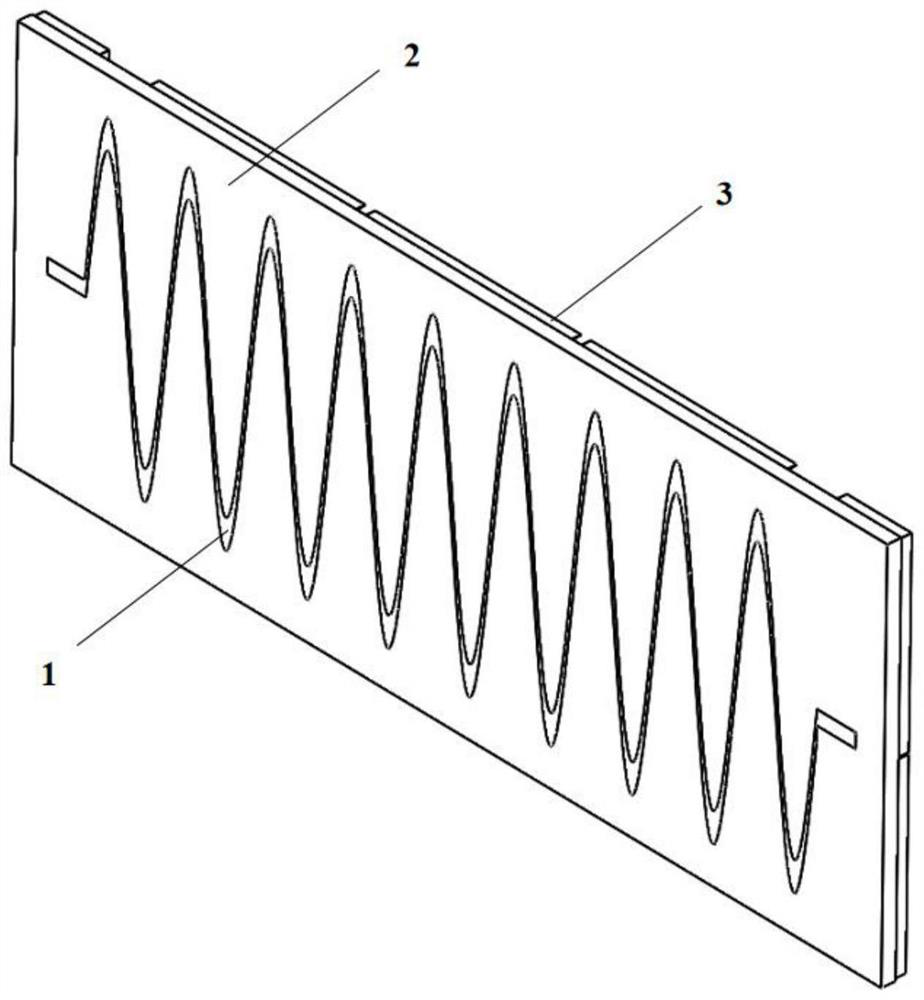

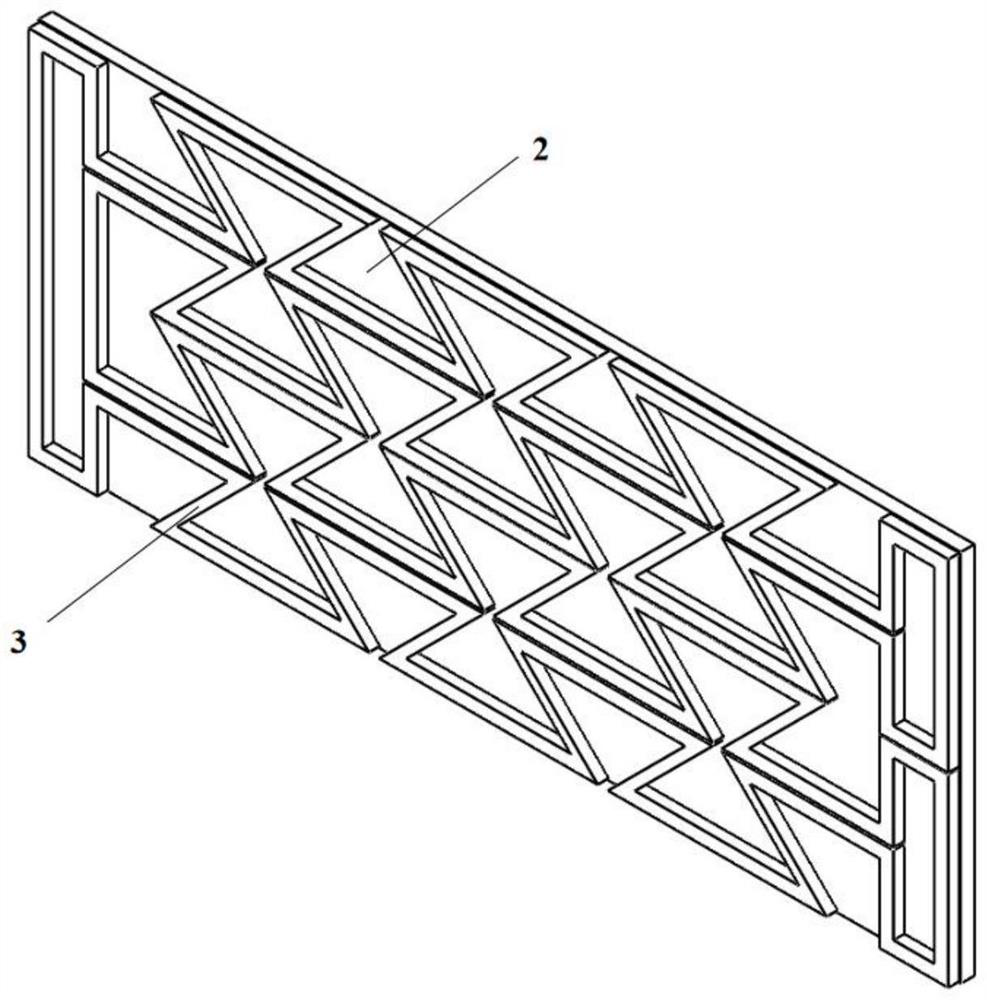

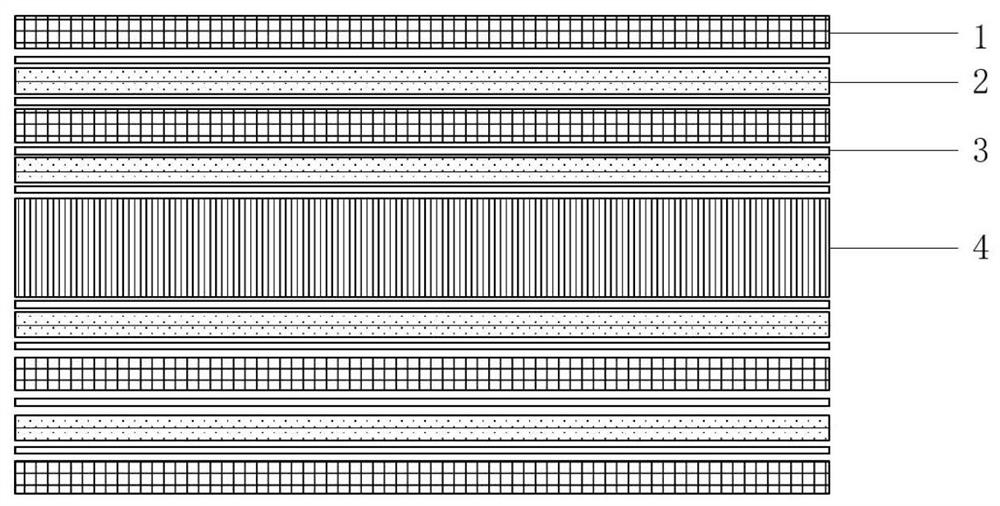

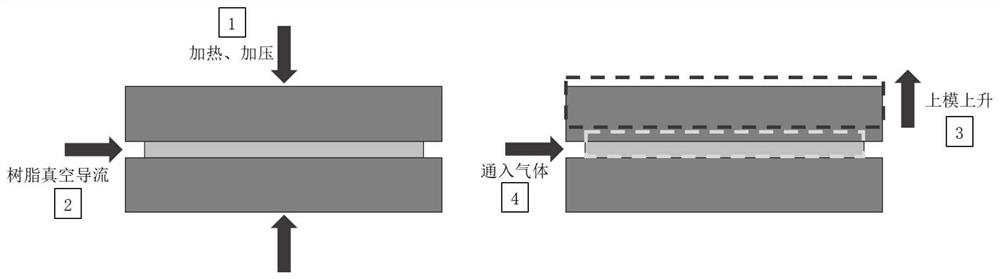

Integrated forming method of super-hybrid panel/three-dimensional woven hollow interlayer composite material

The invention discloses an integrated forming method of a super-hybrid panel / three-dimensional woven hollow interlayer composite material. The method comprises the following steps: 1) carrying out surface treatment on an aluminum alloy sheet; (2) laying the aluminum alloy thin plate, continuous fiber prepreg, a hot melt adhesive film and a three-dimensional woven hollow prefabricated body layer by layer according to the design sequence; (3) impregnating the three-dimensional woven hollow prefabricated body through a resin vacuum flow guide process, releasing pressure, and lifting an upper mold of a mold for a certain distance; and 4) introducing hot air into a vacuum bag, closing a vacuum valve port after the three-dimensional woven hollow prefabricated body is bulged, and standing and curing. By combining a hot mold pressing process, a resin vacuum flow guide process and an air pressure forming process, the problems that pile warp of the three-dimensional woven hollow prefabricated body is incompletely stood and the standing height is not uniform are effectively solved. Integrated forming of a flat plate part and a curvature part of the super-hybrid panel / three-dimensional woven hollow interlayer composite material is achieved efficiently at low cost, and therefore the manufacturing requirement of a composite plate in the rail transit industry is met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com