Device and process method for preparing base material and inner surface metallization circuit based on 3D printing integration

A 3D printing and 3D printer technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as inability to prepare electronic circuits, and achieve the effects of simplifying the manufacturing process, reducing manufacturing costs, and shortening the manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0038] Basic principle of the present invention is:

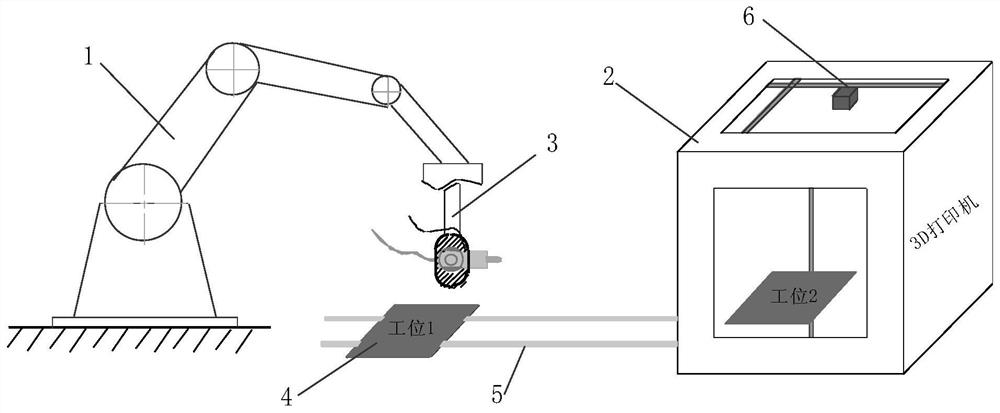

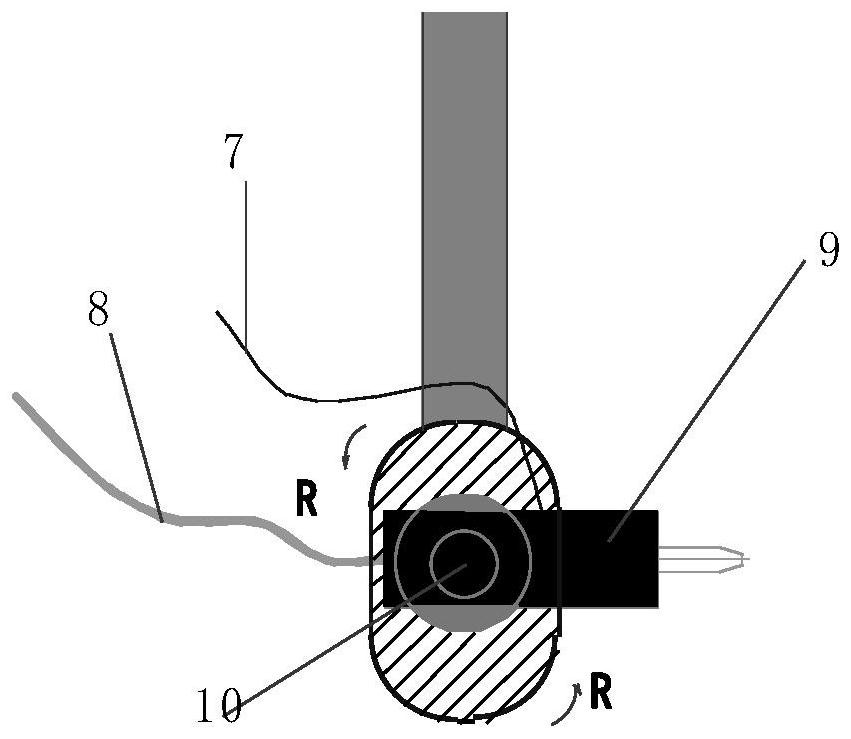

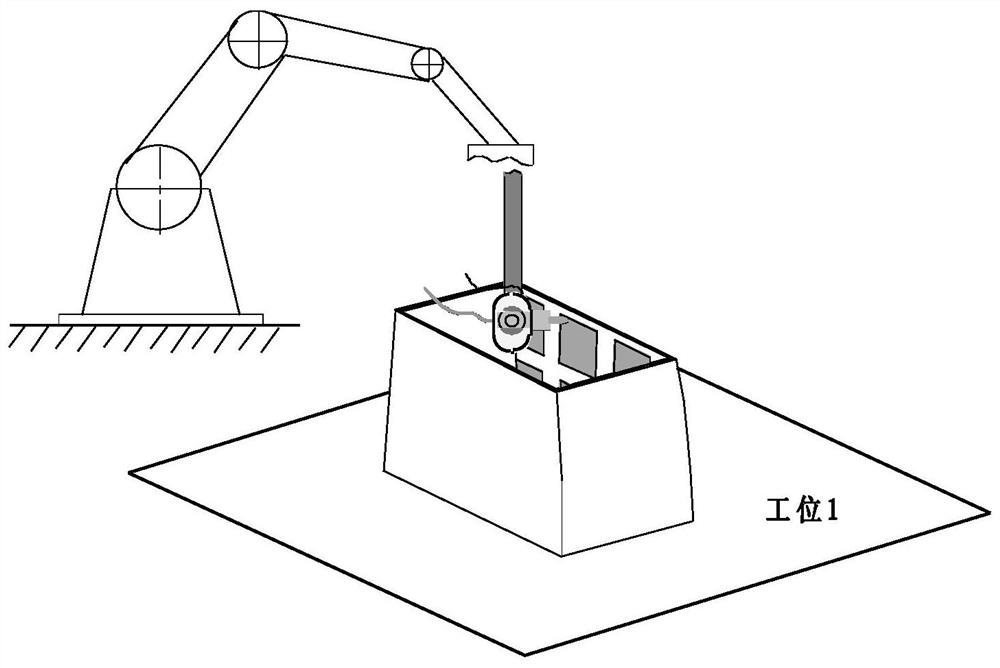

[0039] A 3D printer with three-axis movement is configured with a specific print head such as an inkjet or a melt extrusion head to print and form the base material. After setting a pause action when printing at a certain height, the printing platform is moved from the station through the slide rail. 2 Move to station 1. At this station, the mechanical arm system is used to extend the part of the device with the inkjet printing head into the inner cavity of the printed substrate (if the inner cavity opening is small, only rotate to control the inkjet head to adjust the angle), by controlling the rotation device Adjust the angle of the print head, start the printing action, and print the conductive paste on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com