Patents

Literature

432results about How to "Avoid Positioning Effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

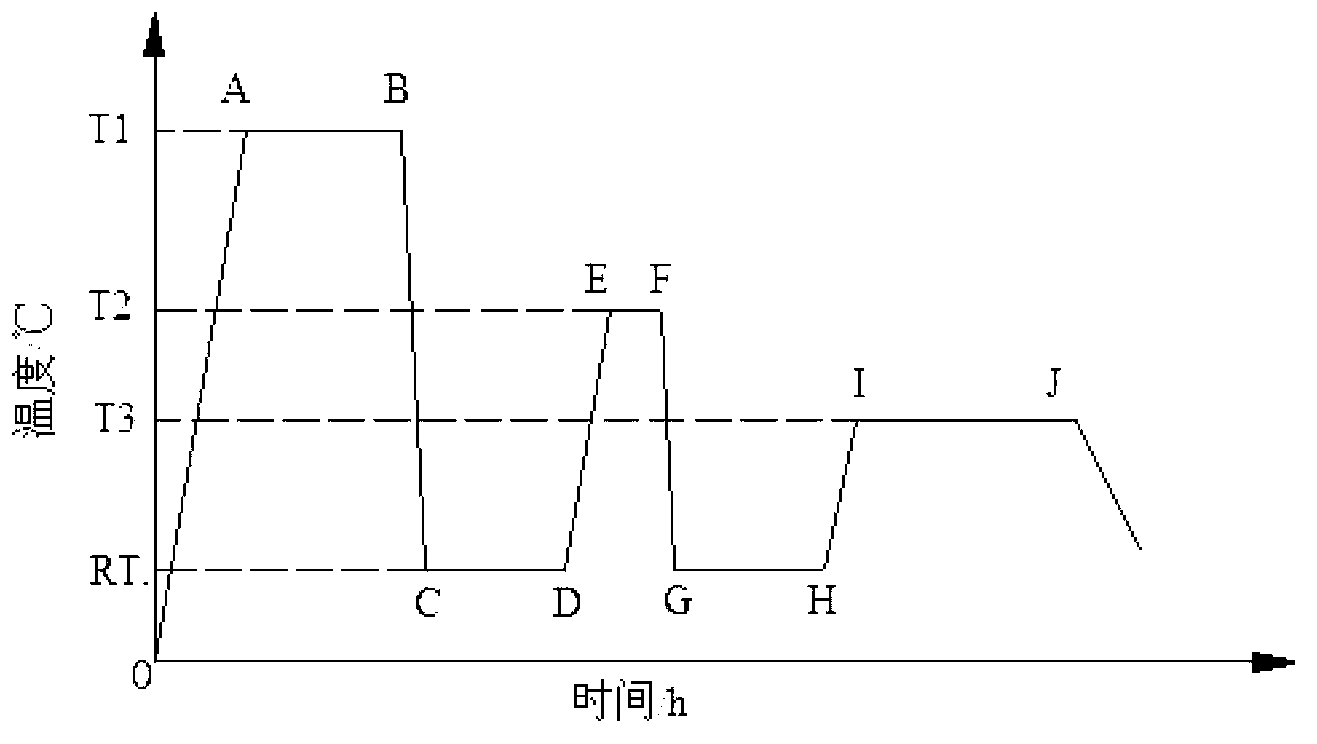

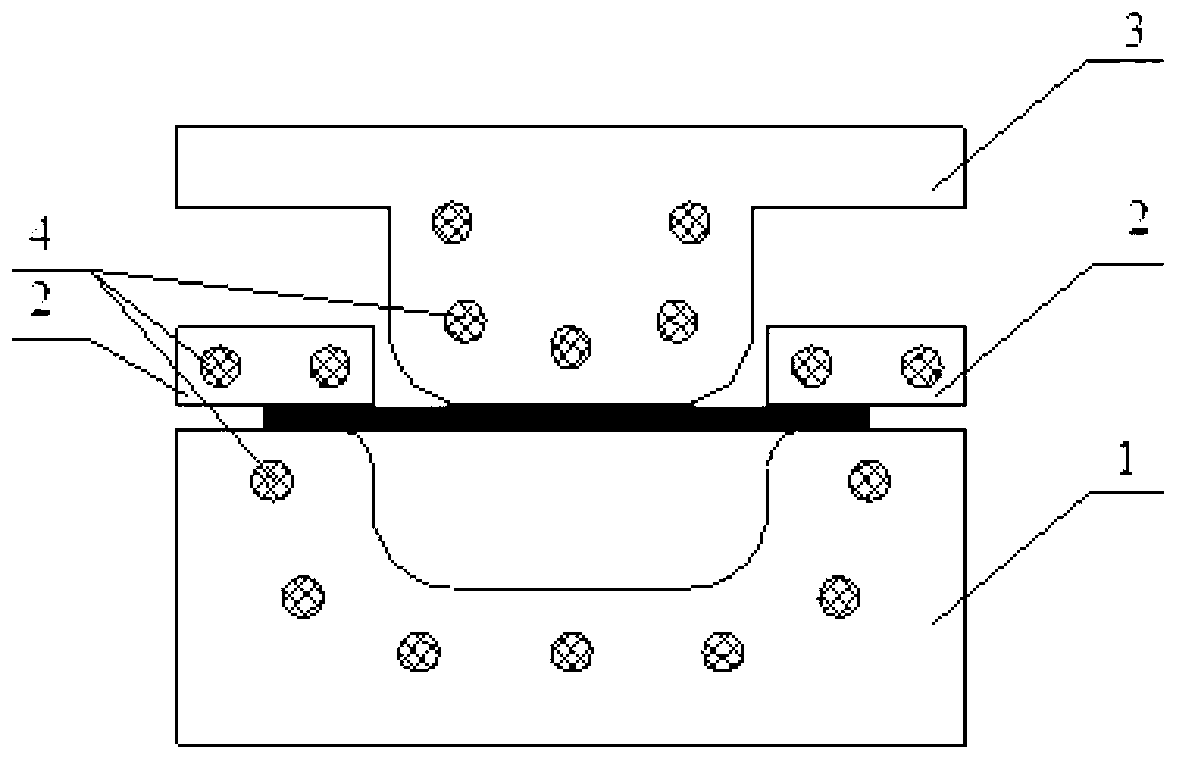

Heat forming method for aluminum alloy sheet metal part after solid solution and water quenching

InactiveCN102974675AGuaranteed shape and size accuracyAvoid quick transfersShaping toolsSize changeSupersaturated solid solution

The invention discloses a heat forming method for an aluminum alloy sheet metal part after solid solution and water quenching, relates to a heat forming method for a heat-treatable strengthening aluminum alloy sheet metal part and aims at solving the technical problems that existing heat-treatable strengthening aluminum alloy is large in shape and size change in the process of heat treatment after the heat-treatable strengthening aluminum alloy is formed first, heat melting forming and cold mold quenching technique requires transfer locating and forming to be fast, in an aluminum alloy sheet metal part cold-hot compound mold forming method, control on temperature of an aluminum alloy slab is difficult, in-mold cooling and quenching speed after forming is slow and not beneficial for obtaining a supersaturated solid solution, requirements for forming equipment are high, and the like. The forming method includes the flowing steps: carrying out the solid solution and the water quenching to the aluminum alloy slab, then, placing the aluminum alloy slab in a hot-state mold to carry out secondary heating, and carrying out aging treatment after pressing forming. According to the heat forming method for the aluminum alloy sheet metal part after the solid solution and the water quenching, the requirements for the forming equipment are not high, precision of shape and size of the aluminum alloy sheet metal part is high, strength is greatly improved, and the heat forming method for the aluminum alloy sheet metal part after the solid solution and the water quenching is suitable for the heat-treatable strengthening aluminum alloy such as 2000 series aluminum alloy, 6000 series aluminum alloy and 7000 series aluminum alloy.

Owner:HARBIN INST OF TECH

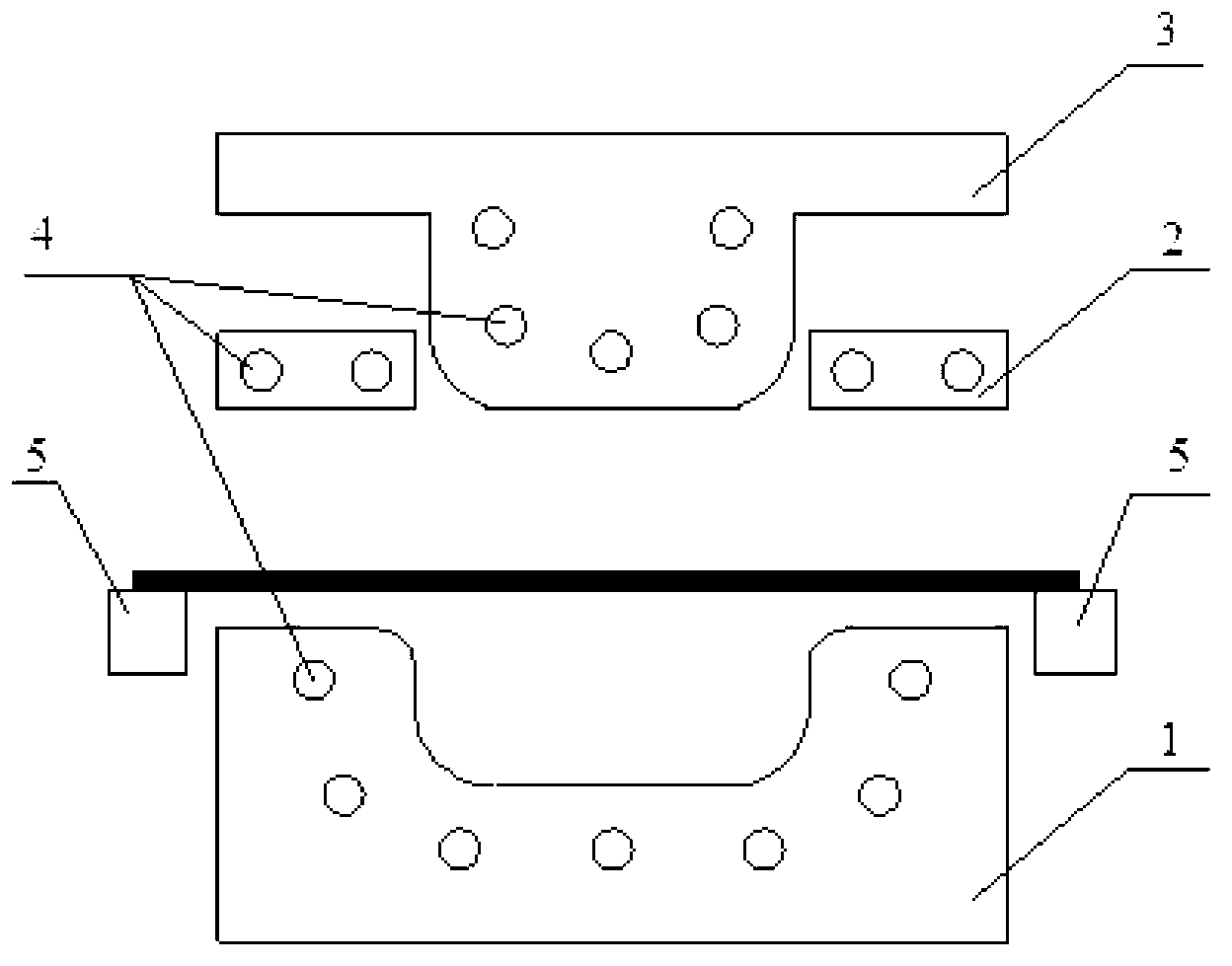

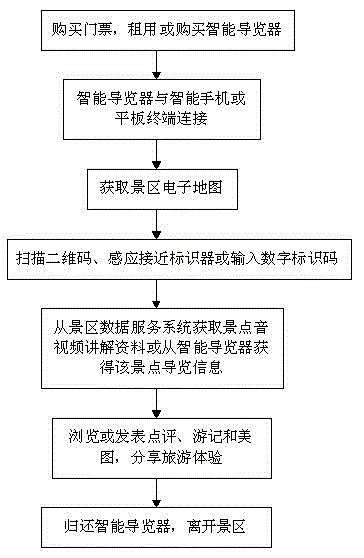

Scenic spot self-help tour system and scenic spot self-help tour method based on mobile Internet

InactiveCN104680440ASolve the needs of explanationEnable self-guided toursData processing applicationsSensing record carriersTablet computerGeolocation

The invention discloses a scenic spot self-help tour system and a scenic spot self-help tour method based on a mobile Internet. The system comprises a scenic spot identification system, a user terminal, a scenic spot data service system, and an intelligent navigator. A PC terminal and a notebook access the scenic spot data service system via the Internet. A smart phone or a tablet computer terminal identifies a two-dimension identification code, a proximity identification device or a digital identification code of the scenic spot identification system, and accesses video and audio explanation information in the scenic spot data service system via a wireless network. The smart phone or the tablet computer terminal is further connected with the intelligent navigator through a data line interface, and looks up navigation information of a scenic spot in the intelligent navigator. According to the invention, accurate location information of a scenic spot is judged by using the smart phone or the tablet computer terminal to scan the two-dimension identification code, sense a proximity identification device signal or input the digital identification code, and the video and audio explanation information of the scenic spot is acquired by accessing the scenic spot data service system or directly accessing a rented intelligent navigator, thus realizing self-help tour guide.

Owner:CHENGDU GUOHENG INFORMATION SECURITY TECH +1

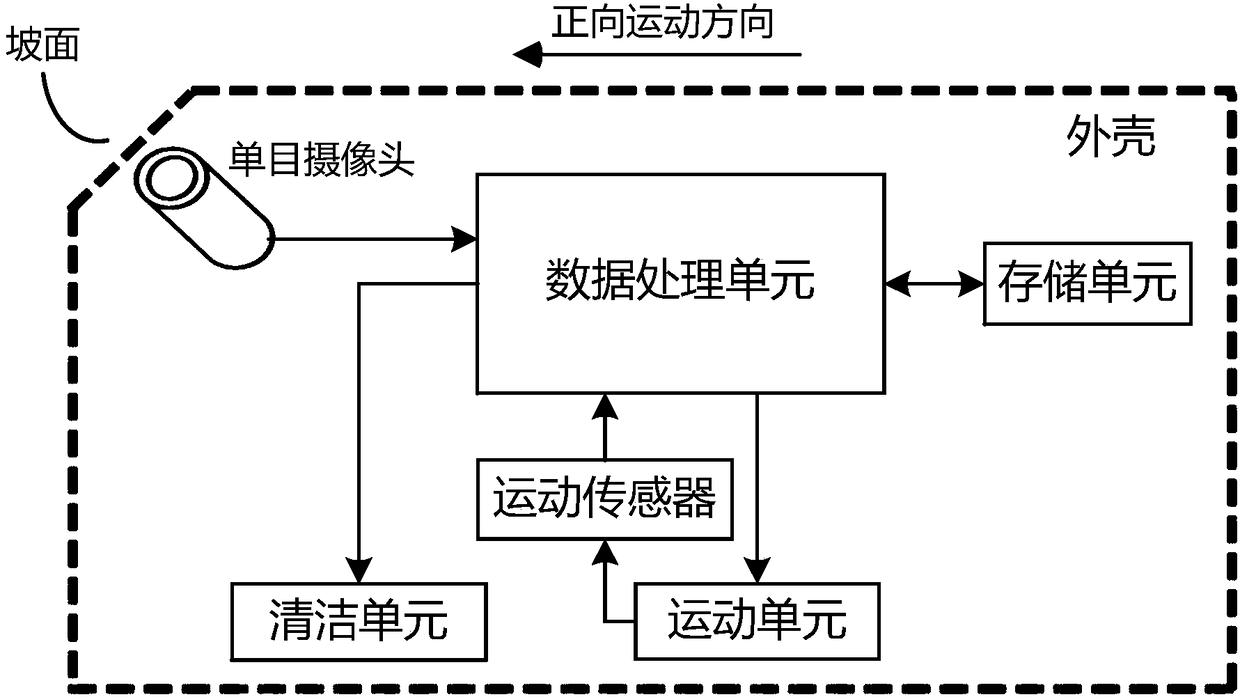

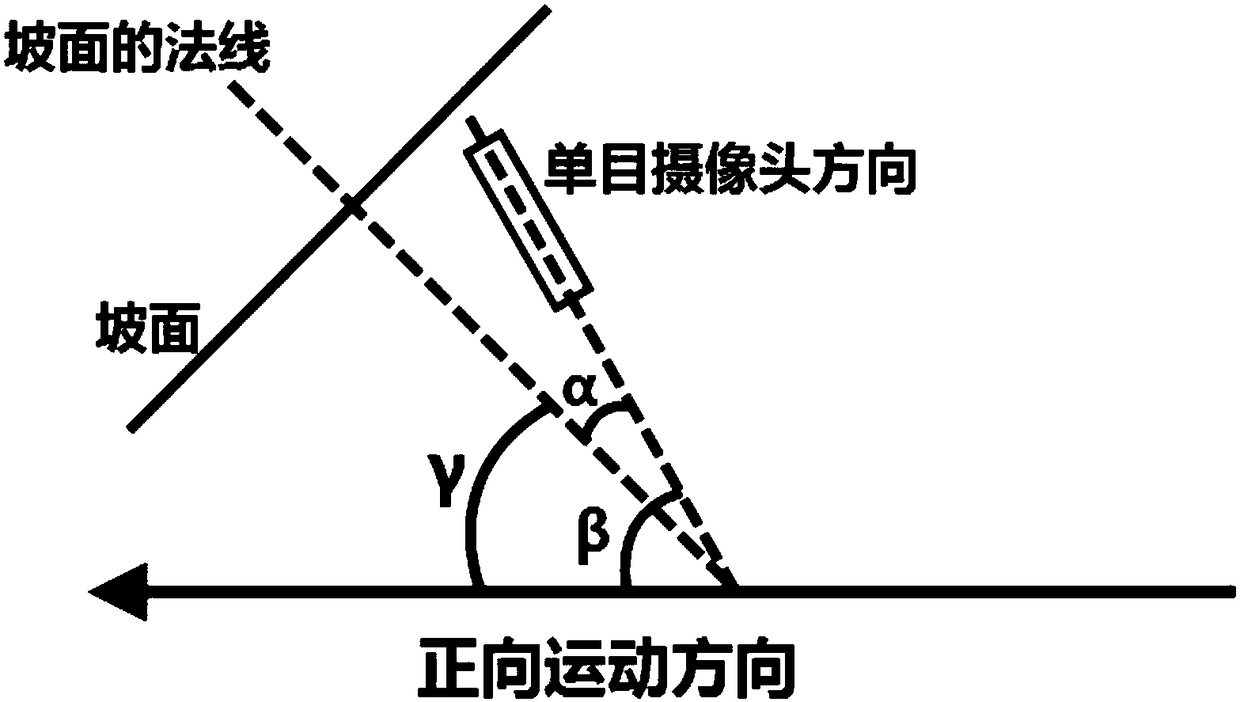

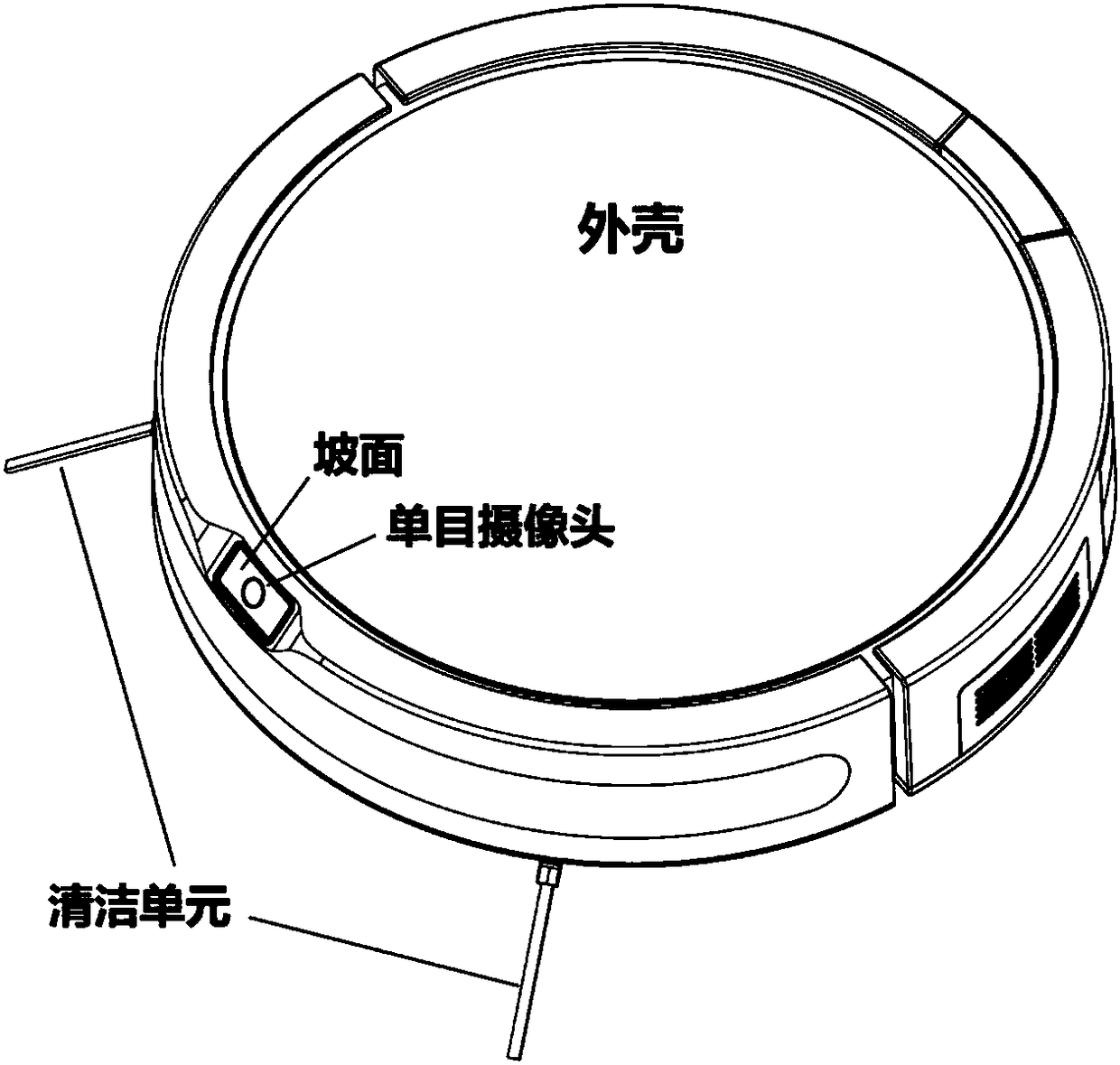

Cleaning robot

ActiveCN108247647AEasy to identifyImprove the effect of obstacle avoidanceAutomatic obstacle detectionProgramme-controlled manipulatorAcute angleEngineering

The invention provides a cleaning robot which comprises a motion unit, a motion sensor, a monocular camera, a storage unit, a data processing unit, a cleaning unit and a shell. The motion sensor acquires motion parameters of the cleaning robot in the motion process. The monocular camera is used for shooting images and is arranged in a slope face which is located at the front end of the shell and inclines upwards in the forward motion direction, the monocular camera and the slope face are approximately in the same direction, and an acute angle is formed by the direction of the monocular cameraand the forward motion direction of the cleaning robot. The data processing unit is used for acquiring the images shot by the monocular camera and the motion parameters of the motion sensor, carryingout locating, mapping and route planning on the cleaning robot and controlling the motion unit to operate according to a planned route. According to the cleaning robot, the simple-structure monocularcamera with the elevation angle being an acute angle is arranged, the accuracy of locating and mapping of the cleaning robot is improved, and therefore the route planning / navigation effect is improved.

Owner:SUGAN TECH BEIJING

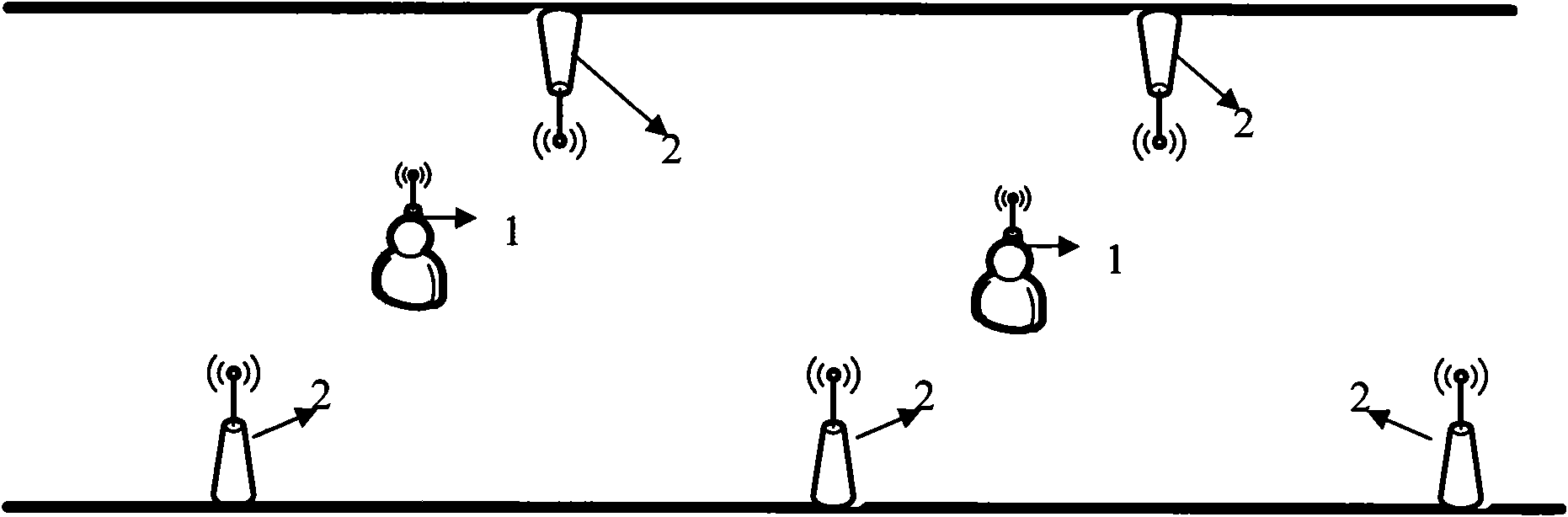

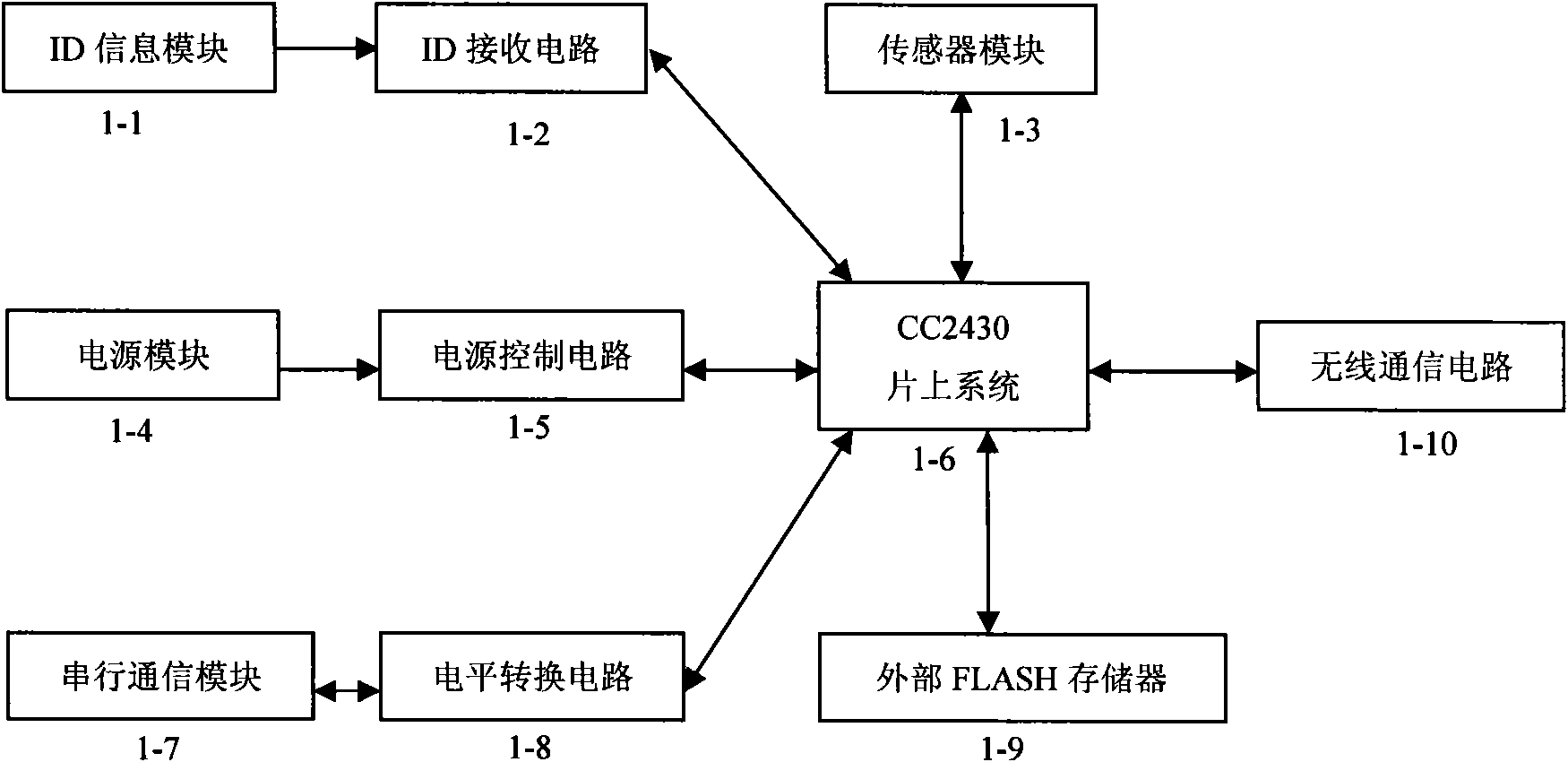

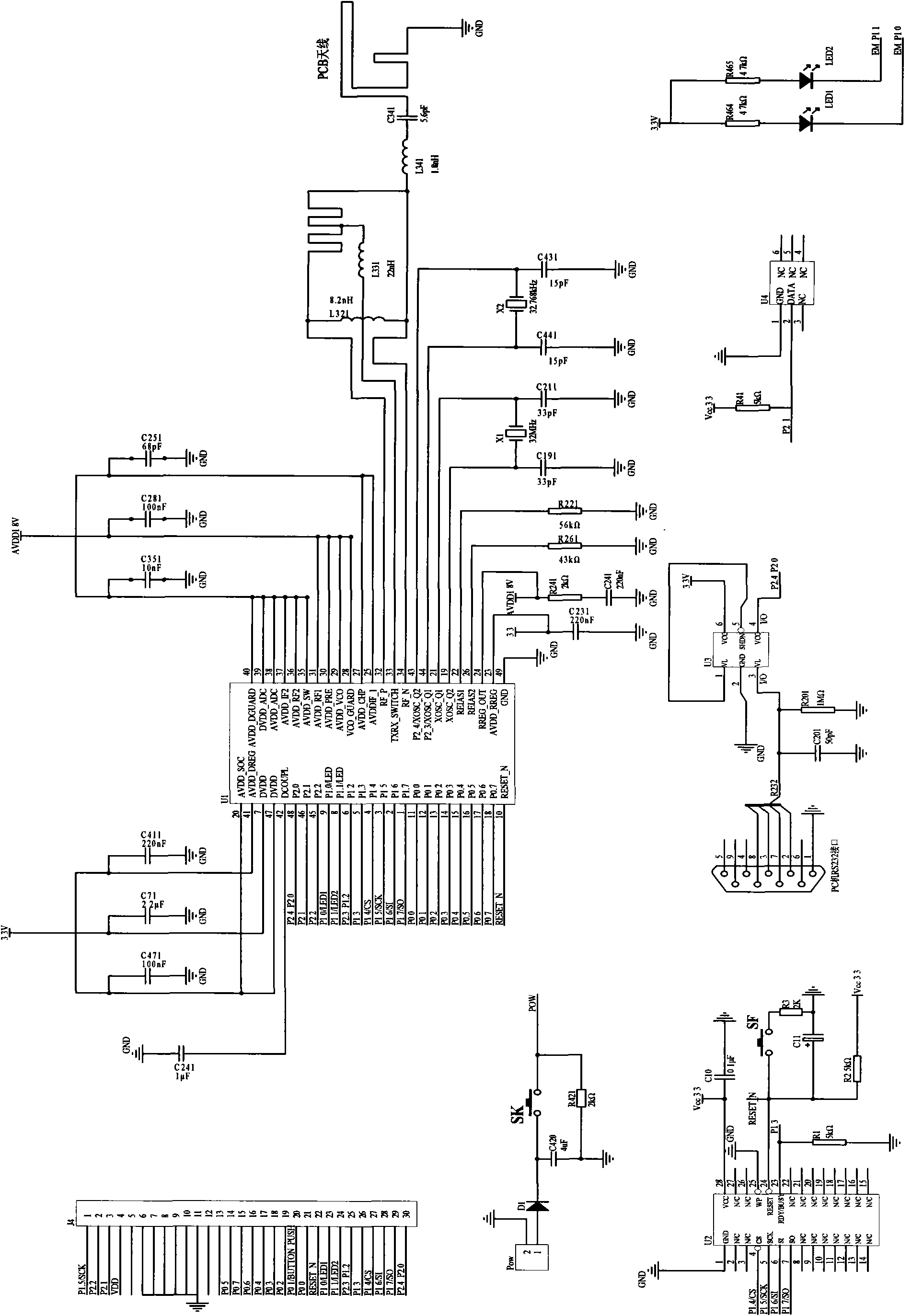

Wireless sensor network node device used in underground coal mine

InactiveCN101621431AReduce energy consumptionExtended life cycleMining devicesNetwork topologiesLine sensorTunnel wall

The invention discloses a wireless sensor network node device used in an underground coal mine, which belongs to a hardware platform for personnel positioning and environmental monitoring based on a wireless sensor network in the underground coal mine. The wireless sensor network node device used in the underground coal mine is provided with wireless sensor fixed nodes (1) and wireless sensor mobile nodes (2); the sensor fixed nodes (1) are placed on a tunnel wall from space to space in the underground coal mine; and the sensor mobile nodes (2) are worn by mining personnel. The device has the following advantages: 1) the device has high positioning accuracy, and the mobile nodes carried by the personnel transmit wireless signals to communicate the approaching fixed nodes so as to determine the position of the device and improve the positioning precision; 2) both the wireless sensor fixed nodes and the wireless sensor mobile nodes have the capacity of bidirectional communication so as to accurately position the position of the personnel; 3) the design cost of the wireless sensor nodes is comparatively low, large amount of nodes can be arranged, and drain regions and blind points of positioning and monitoring are avoided; and 4) the arranged wireless sensor fixed nodes do not need wire connection, so the cost is low.

Owner:CHINA UNIV OF MINING & TECH

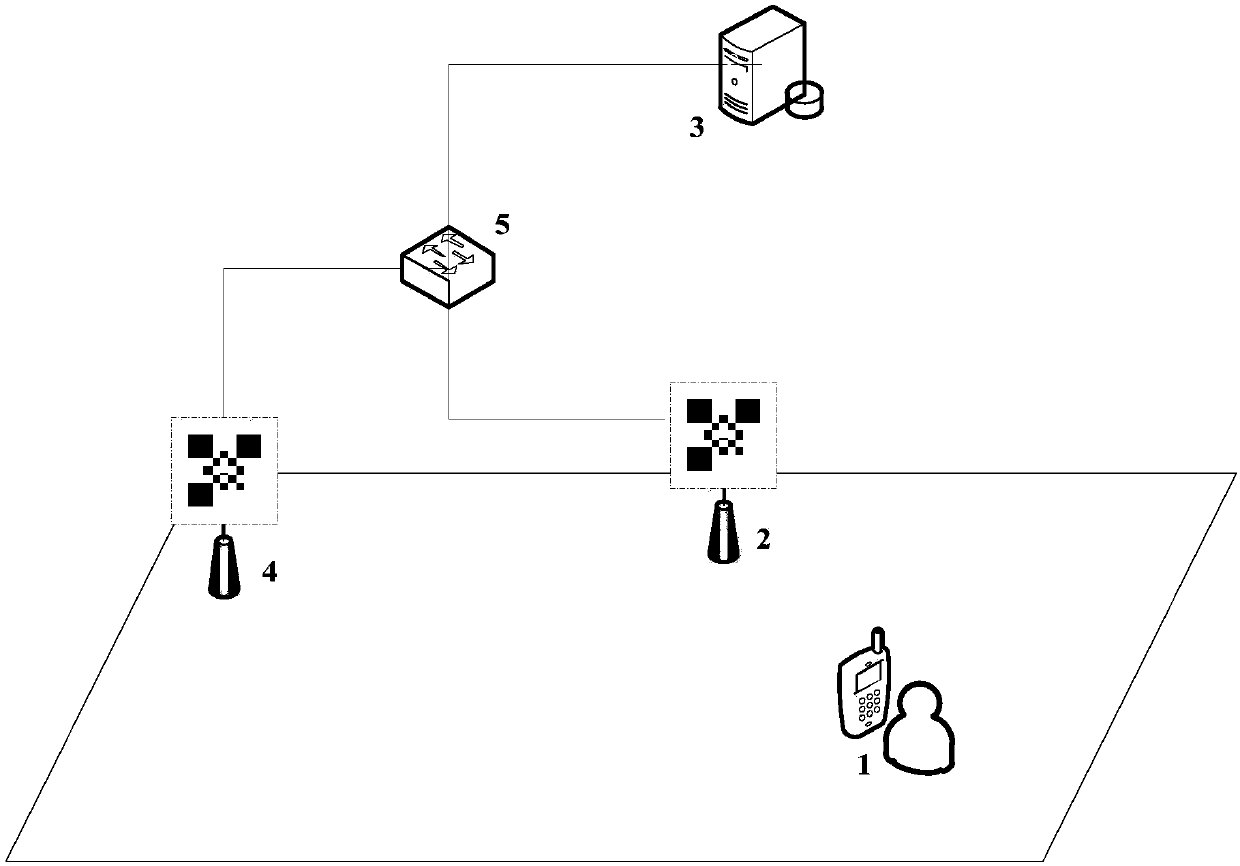

Outdoor auxiliary positioning method, system and device based on optical tag

ActiveCN107734449AAvoid Positioning EffectsAvoid interferenceLocation information based serviceGeolocationComputer science

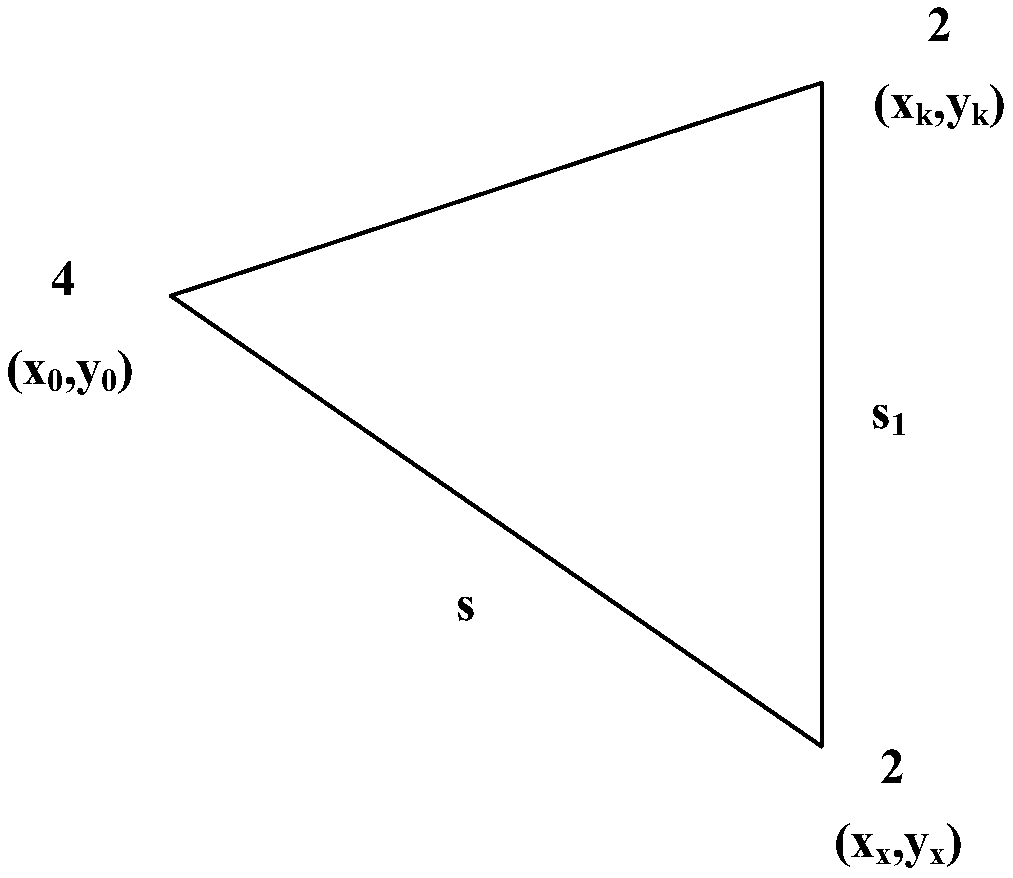

The present invention discloses an outdoor auxiliary positioning method, system and device based on an optical tag. The method comprises the following steps: arranging at least two optical tag anchorpoints within a to-be-positioned range, wherein each optical tag anchor point displays ID information thereof, and a camera on a to-be-positioned device acquires the ID information displayed by each optical tag anchor point; obtaining geographical position information of each optical tag anchor point by using the ID information; measuring a distance between the to-be-positioned device and each optical tag anchor point by the optical tag; and calculating geographical position information of the to-be-positioned device according to the geographical location information of each optical tag anchorpoint, and the distance between the to-be-positioned device and each optical tag anchor point. The method, system and device provided by the present invention can realize outdoor positioning, and have high anti-interference ability and high positioning accuracy.

Owner:SHAANXI WHYHOW INFORMATION TECH CO LTD

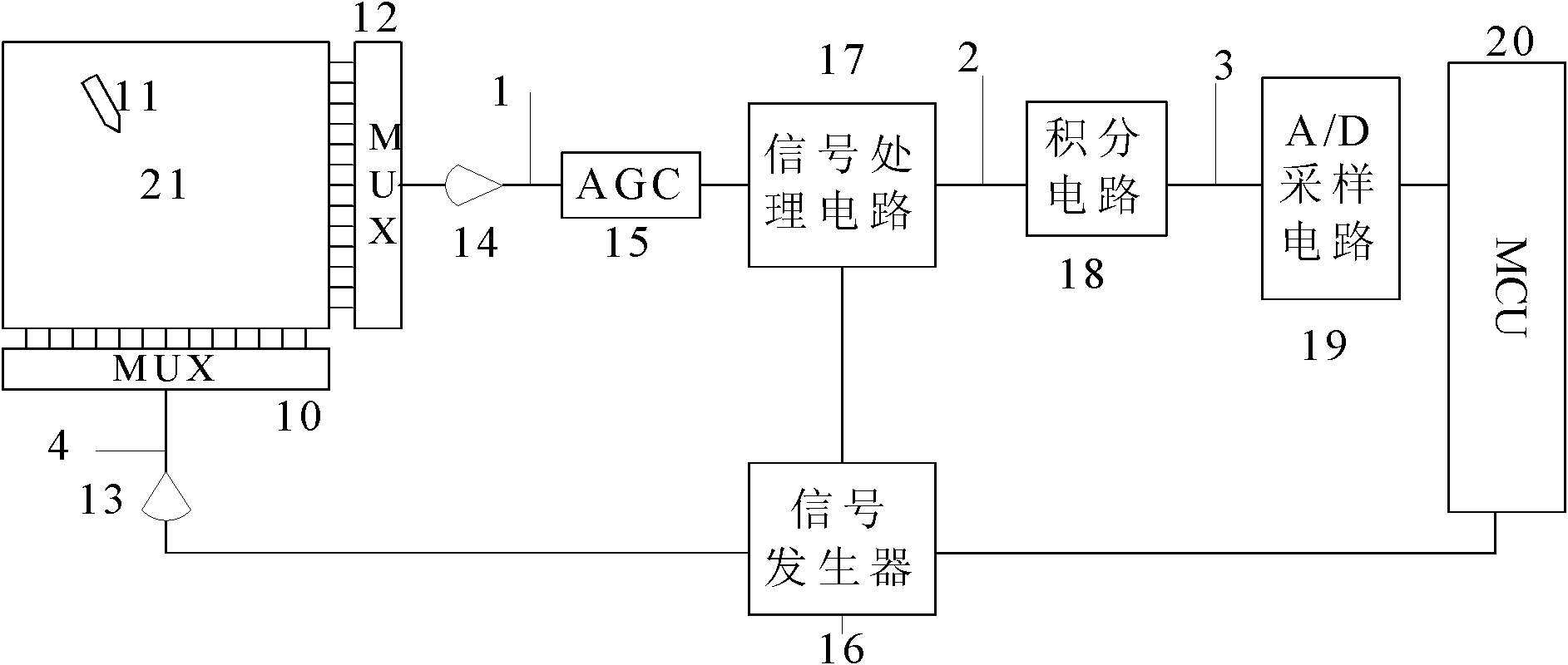

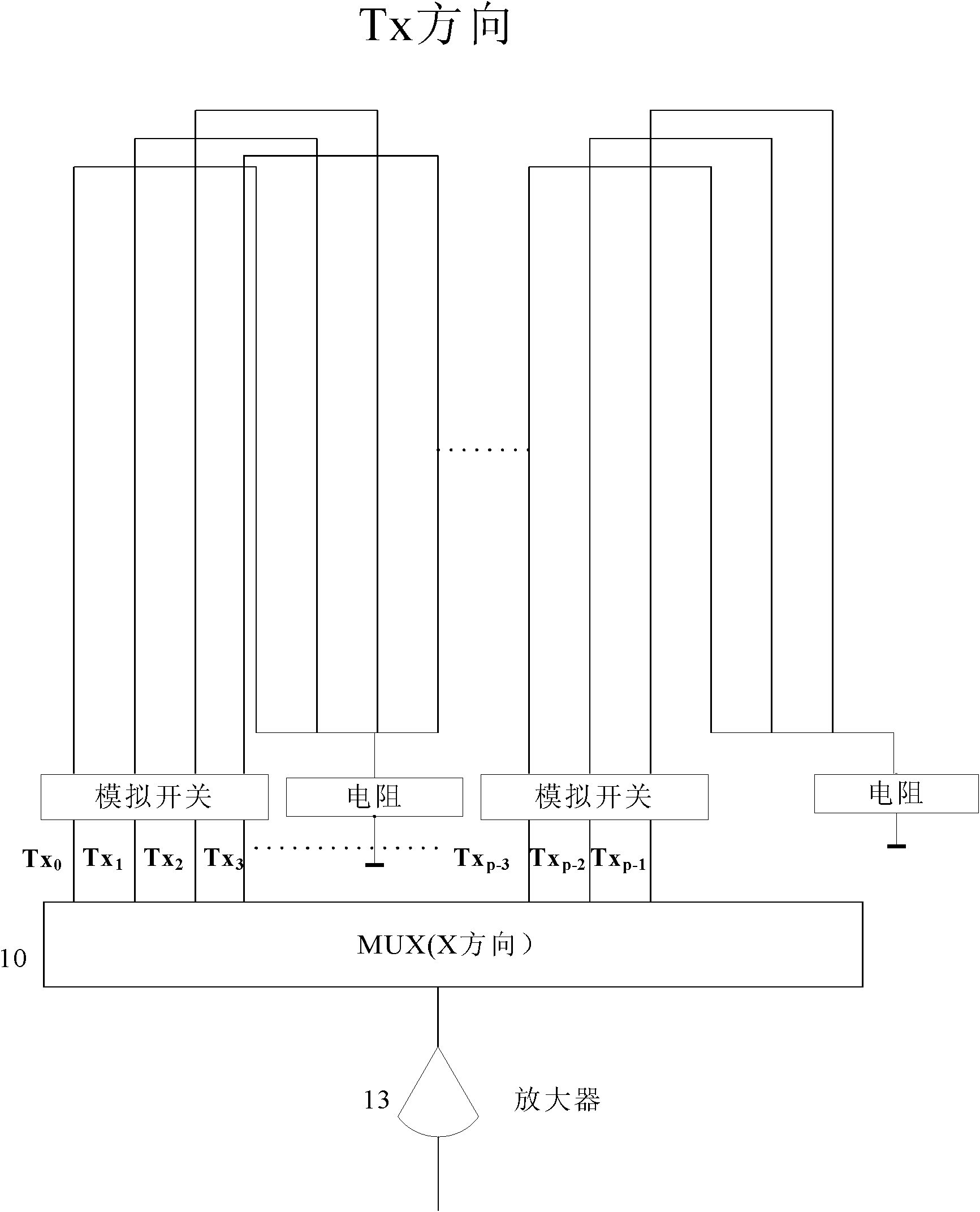

Electromagnetic induction device and touch positioning method thereof

ActiveCN102141867APrecise positioningRapid positioningInput/output processes for data processingTransmitter coilEngineering

The invention discloses an electromagnetic induction device and a touch positioning method thereof, belonging to the field of electromagnetic handwritten input. The touch positioning method provided by the invention comprises the following steps of: simultaneously gating at least two groups of transmitter coils and receiving coils for scanning, detecting and recording an electromagnetic pen signal; primarily positioning an electromagnetic pen according to the maximum value of the detected electromagnetic pen signal and a coil combination corresponding to the maximum value after all boundary transmitter coils and boundary receiving coils in an antenna plate zone are scanned; and accurately positioning the electromagnetic pen according to the coil combination corresponding to the maximum value of the electromagnetic pen signal if the maximum value of the electromagnetic pen signal is smaller than a preset initial positioning threshold value, or else processing the combination of the receiving coils and the transmitter coils corresponding to the maximum value of the electromagnetic pen signal to confirm the position of the electromagnetic pen. The method provided by the invention can be adopted to rapidly realize the accurate positioning of the electromagnetic pen and can effectively avoid the problems of contact loss, delayed positioning, and the like when the electromagnetic pen rapidly moves.

Owner:BEIJING HANWANG PENGTAI TECH CO LTD

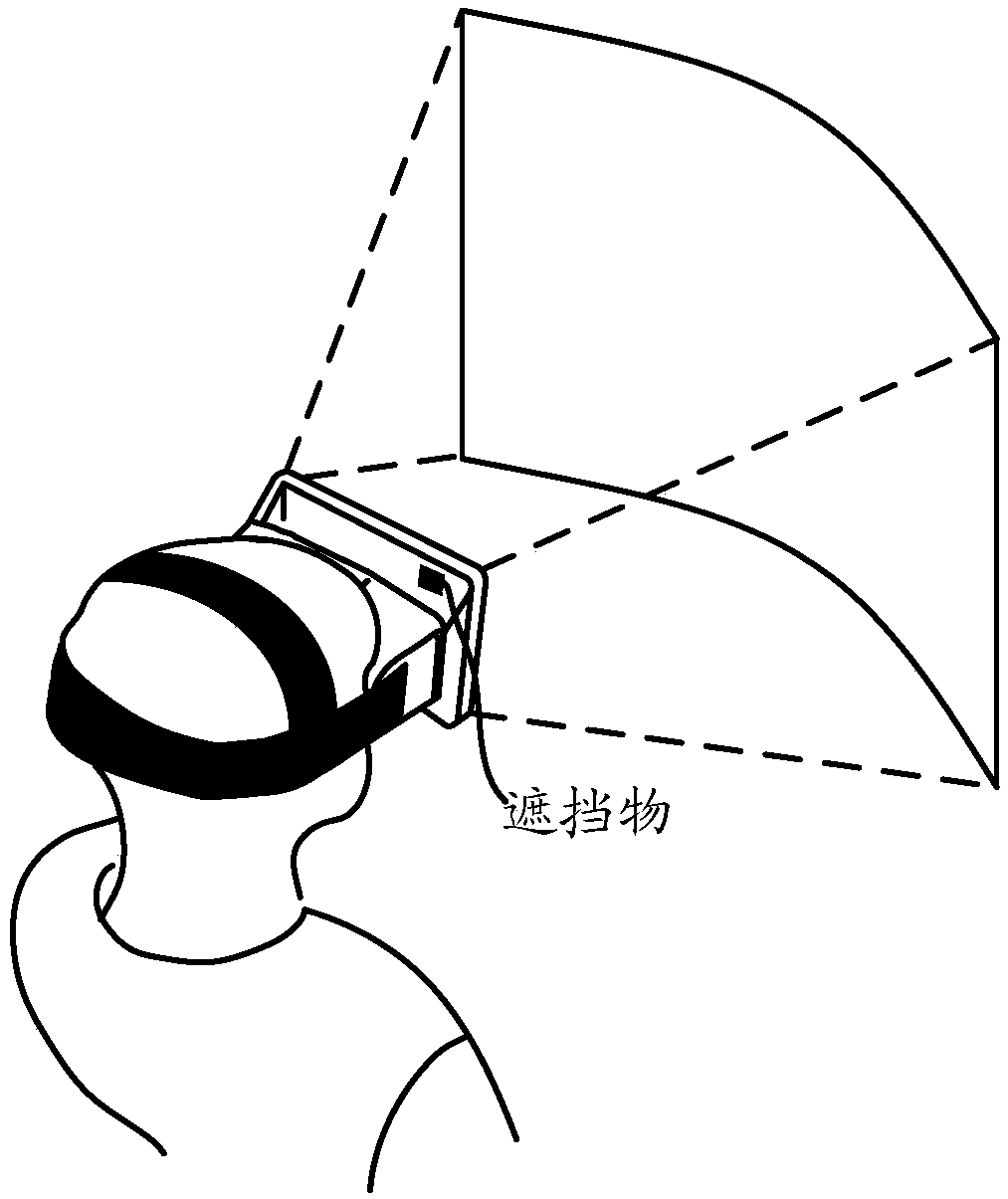

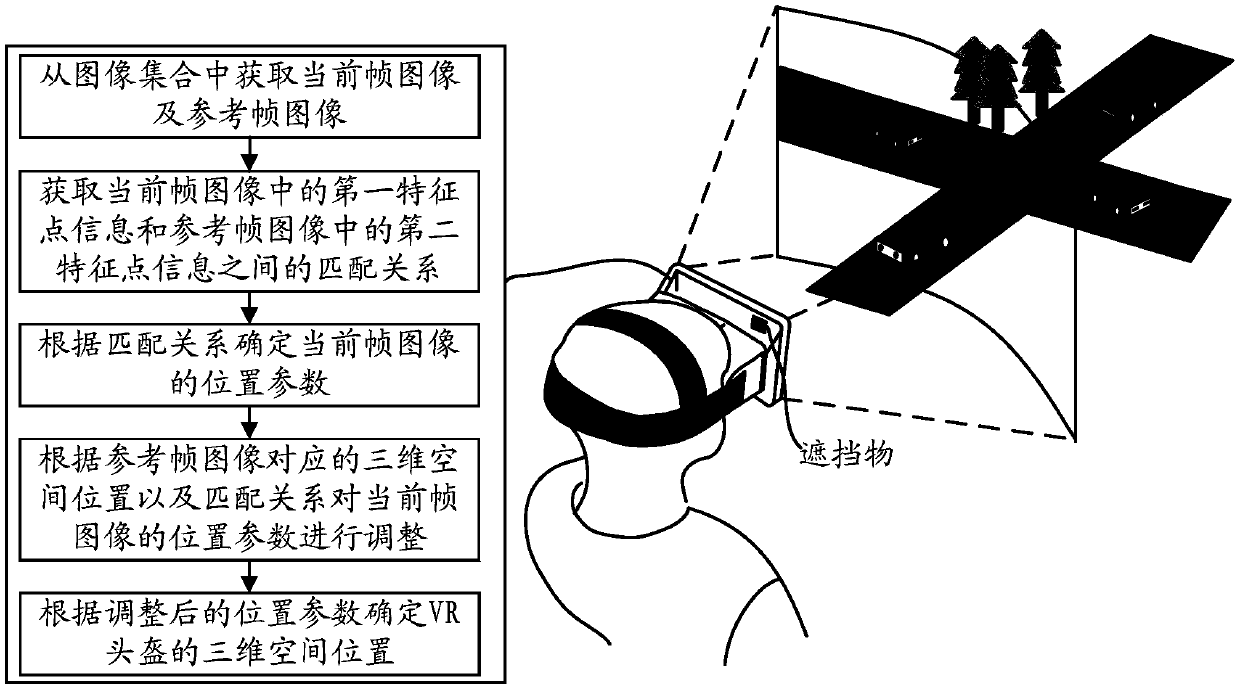

Image-based relocation method and device, terminal, and storage medium

ActiveCN109544615AImprove accuracyIncrease success rateImage enhancementImage analysisPattern recognitionComputer graphics (images)

The embodiment of the invention discloses an image-based relocation method and device, a terminal and a medium, wherein the method comprises the following steps: obtaining a current frame image and areference frame image from an image set; Extracting first feature information from the current frame image and extracting second feature information from the reference frame image, and obtaining a matching relationship between the first feature information and the second feature information; Determining a position parameter of the current frame image according to the matching relationship, the position parameter comprising a rotation parameter and a displacement parameter; Adjusting a position parameter of the current frame image according to a three-dimensional spatial position correspondingto the reference frame image and the matching relationship; determining The three-dimensional spatial position of the terminal according to the adjusted position parameters. The embodiment of the invention can improve the success rate of repositioning and the accuracy of the repositioning result.

Owner:SHENZHEN TENCENT INFORMATION TECH CO LTD

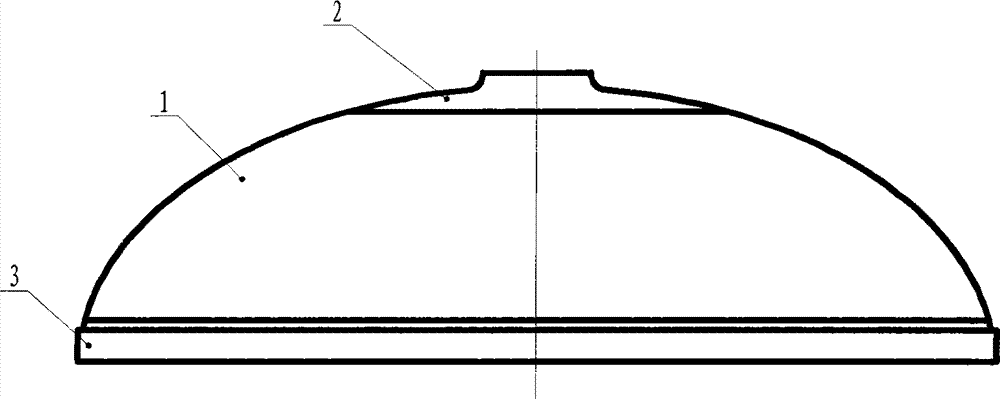

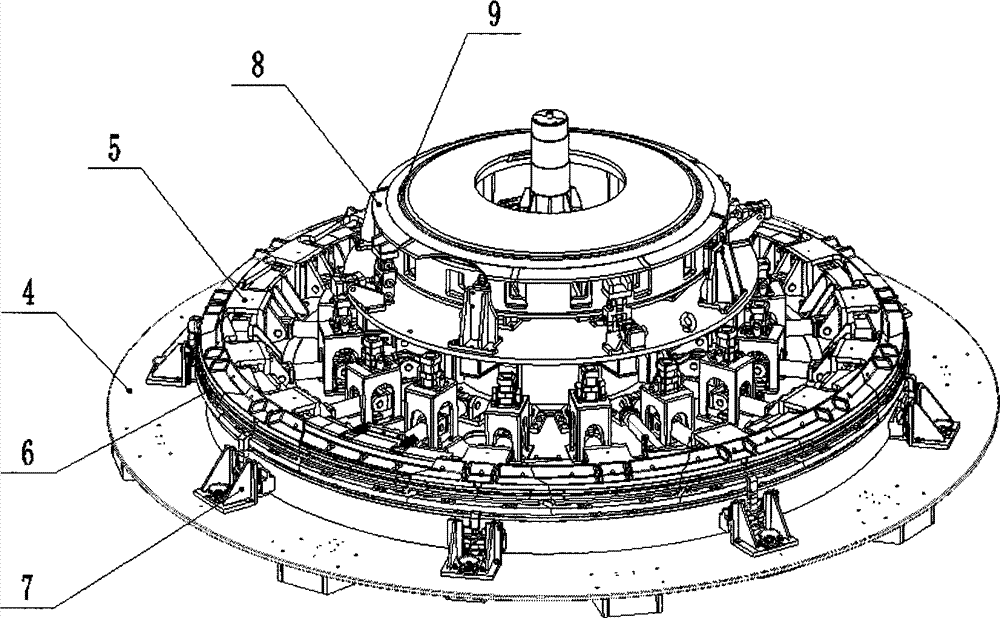

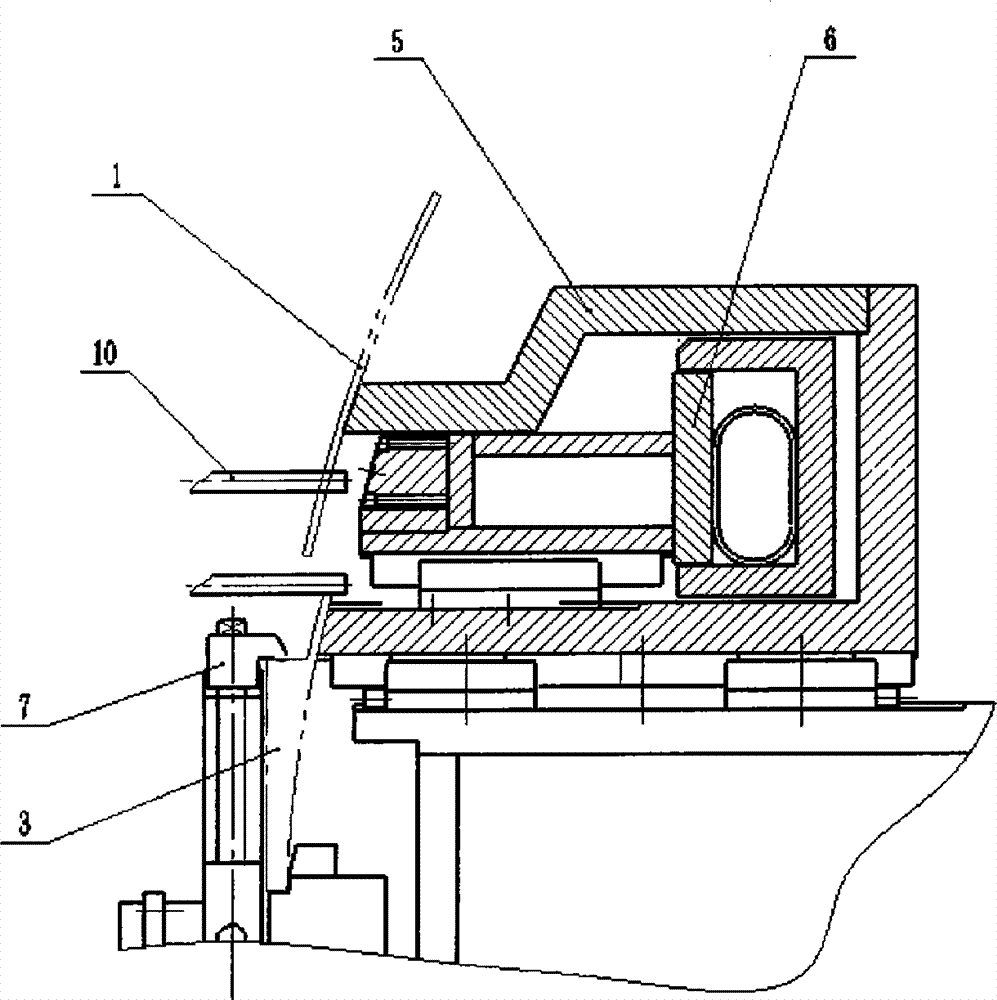

Milling and welding integrated device for upper and lower circular seams in bottom of storage box

ActiveCN104772626AReduce in quantityAvoid the trouble of shrinking and difficult to get out of the mold tireWelding/cutting auxillary devicesOther manufacturing equipments/toolsEngineeringWelding

The invention relates to a milling and welding integrated device for upper and lower circular seams in the bottom of a storage box. The device consists of a tool main body, an air cylinder inner supporting mechanism, an air bag inner supporting mechanism, a fork type ring lifting mechanism, a milling inner holder supporting mechanism, a welding back lining supporting mechanism and a circular seam outer pressing mechanism. The device disclosed by the invention has the advantages of guaranteeing accordant standards of milling, assembling and welding tools, preventing repeated assembly and location and effectively guaranteeing the product quality; by integrating milling, assembly and welding, the device has the advantages of reducing the steps of lifting, regulating, aligning, pressing and the like for replacing a work station, effectively shortening the production period, greatly improving the efficiency, also reducing the amount of tools and lowering the production cost. The air bag inner supporting mechanism has a telescopic function and can be used for preventing a trouble that a work piece is difficultly separated from a mold due to shrinkage after being welded.

Owner:AMET WELDING AUTOMATION TECH BEIJING

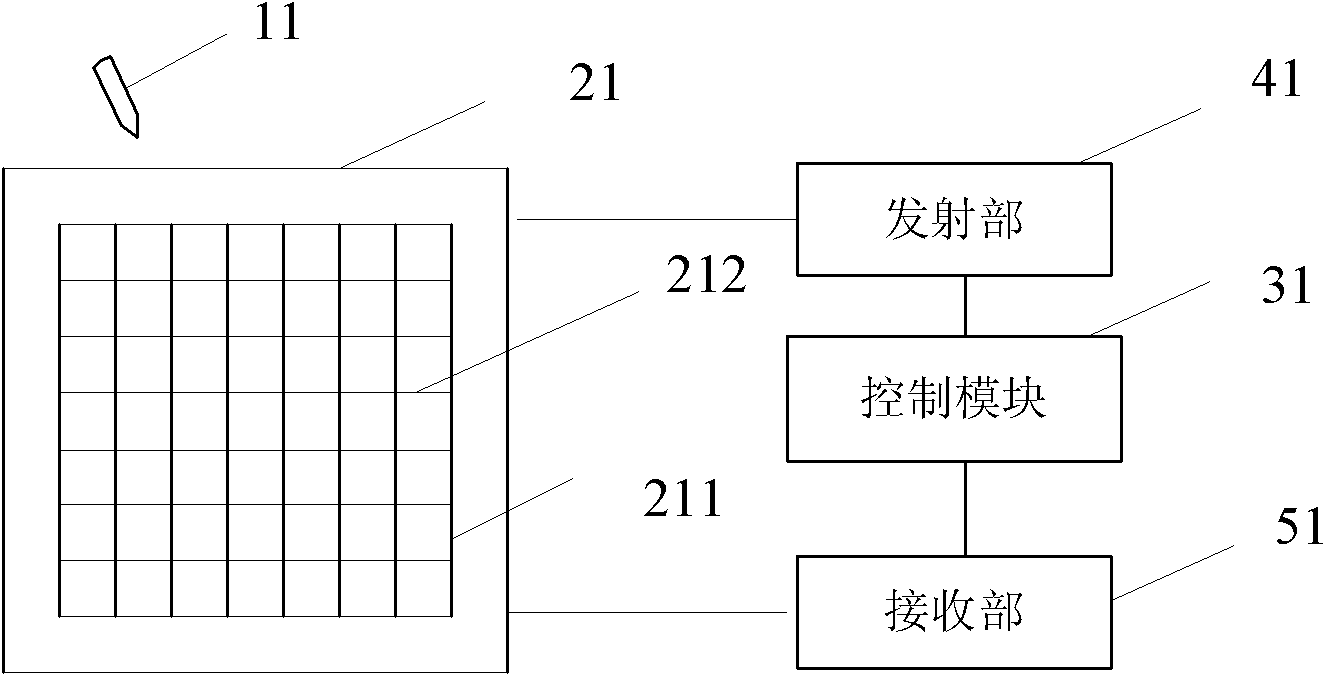

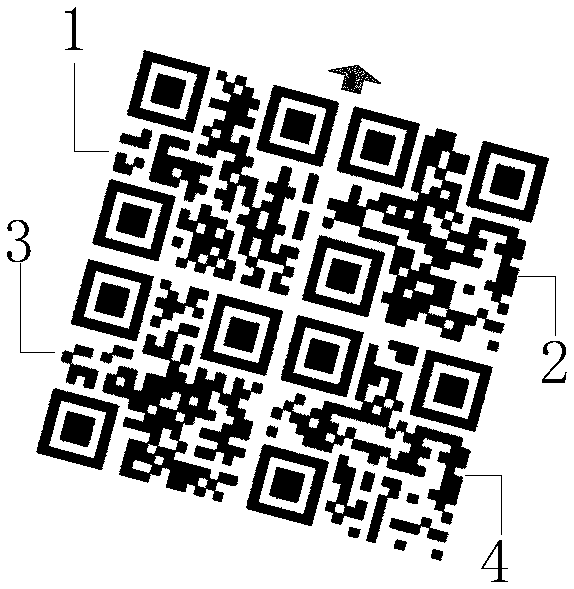

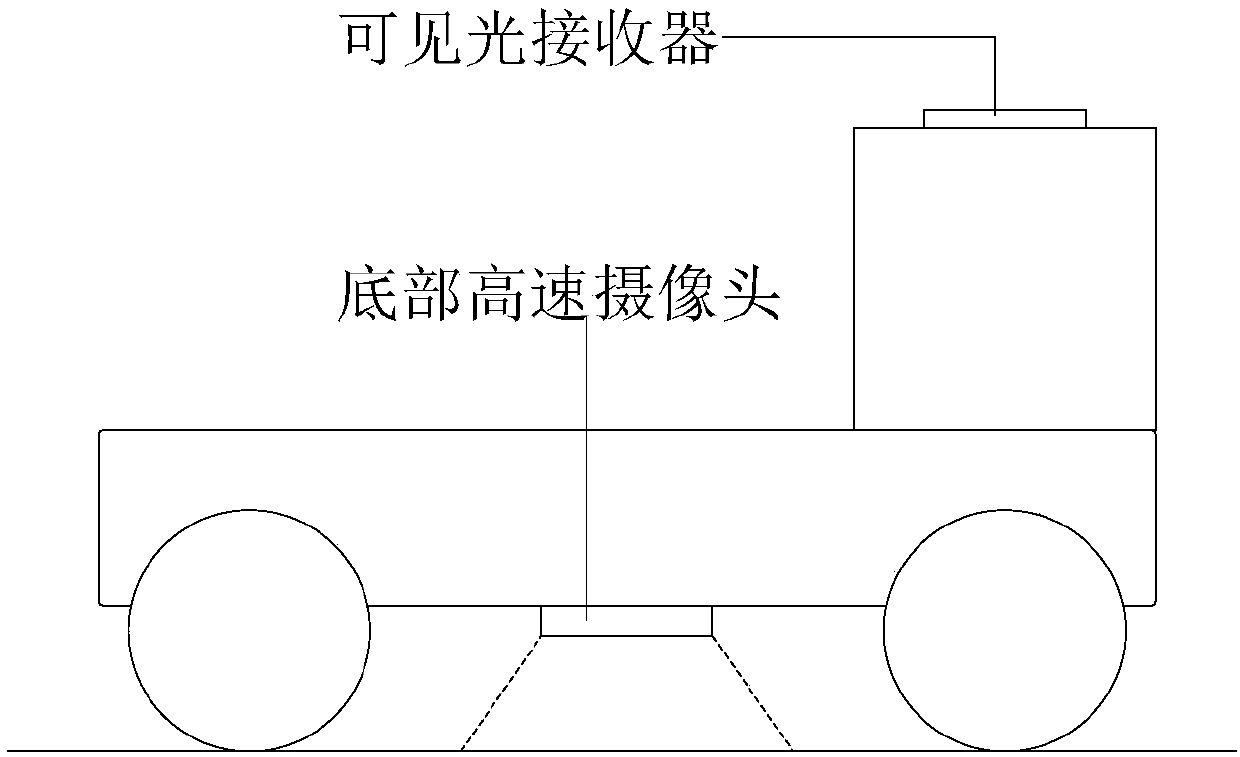

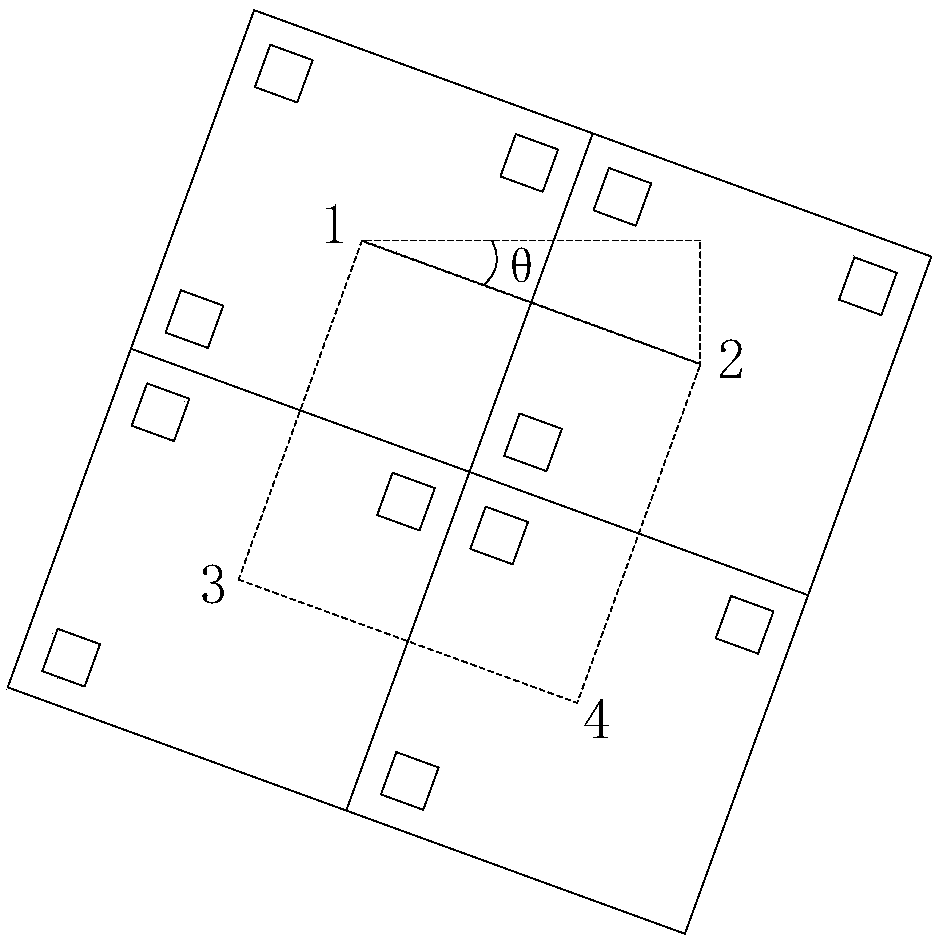

Indoor AGV navigation method and system based on QR code guidance and visible light positioning

PendingCN107943051ALow costHigh precisionPosition/course control in two dimensionsEngineeringImage capture

The invention discloses an indoor AGV navigation method and system based on QR code guidance and visible light positioning. A QR code label is attached to the node of an AGV moving path, so that whenthe AGV moves to the position near the node, a QR code image captured by a high-speed camera can be analyzed to obtain the moving direction of the next step. The AGV can be positioned in real time through the RSS positioning method based on the visible light communication technology when the AGV moves between two nodes, and deviation can be prevented. The visible light communication positioning isadded when QR code recognition technology is used for navigation. The problem that the AGV is deviated from the direction due to lack of positioning information between QR codes which are too long indistance when only QR code navigation is used is avoided. An indoor AGV navigation positioning method which is low in cost is provided.

Owner:SOUTH CHINA UNIV OF TECH

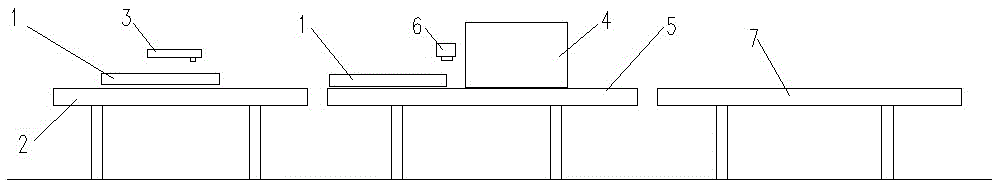

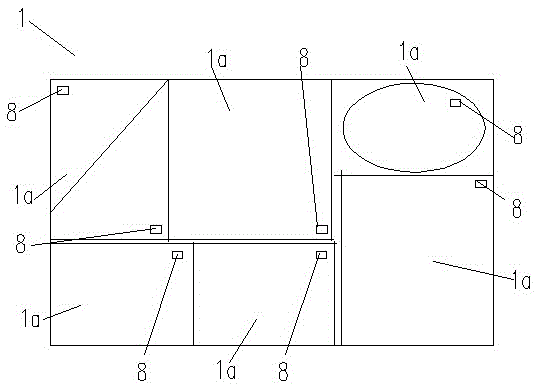

Glass cutting method and device

ActiveCN105541098AFacilitate flexible secondary processingIncrease productivityGlass severing apparatusGlass productionControl systemCutting glass

The present invention discloses a glass cutting method, a two-dimensional code is set on a glass substrate before glass cutting, two-dimensional code information is read before the glass cutting, and inputted into a control system, the control system interprets the two-dimensional code information and generates a cutting path according to interpretation information, and a cutting device cuts the glass substrate according to the cutting path. According to the method, different sizes and different shapes of glass to be cut can be optimized and arranged, the utilization rate of the glass substrate can be improved, the workload of manual input of parameters can be reduced, the relative position of the two-dimensional code on the cut glass is more precision, production efficiency of the glass subsequent processing can be improved, mixed production of different specifications of glass can be achieved, positional deviation increase, large glass size scattering difference and other defects caused by a plurality of times of repeated positioning can be avoided, and flexible secondary processing of the glass can be facilitated. The present invention also discloses the glass cutting device for cutting the glass substrate by use of the method.

Owner:LUOYANG LANDGLASS TECH CO LTD

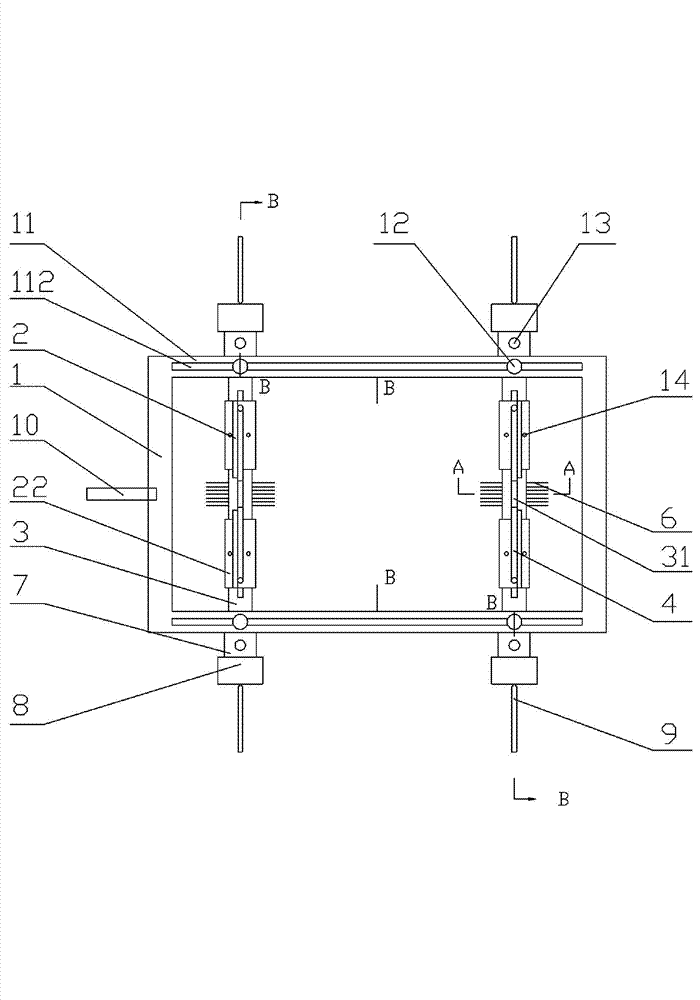

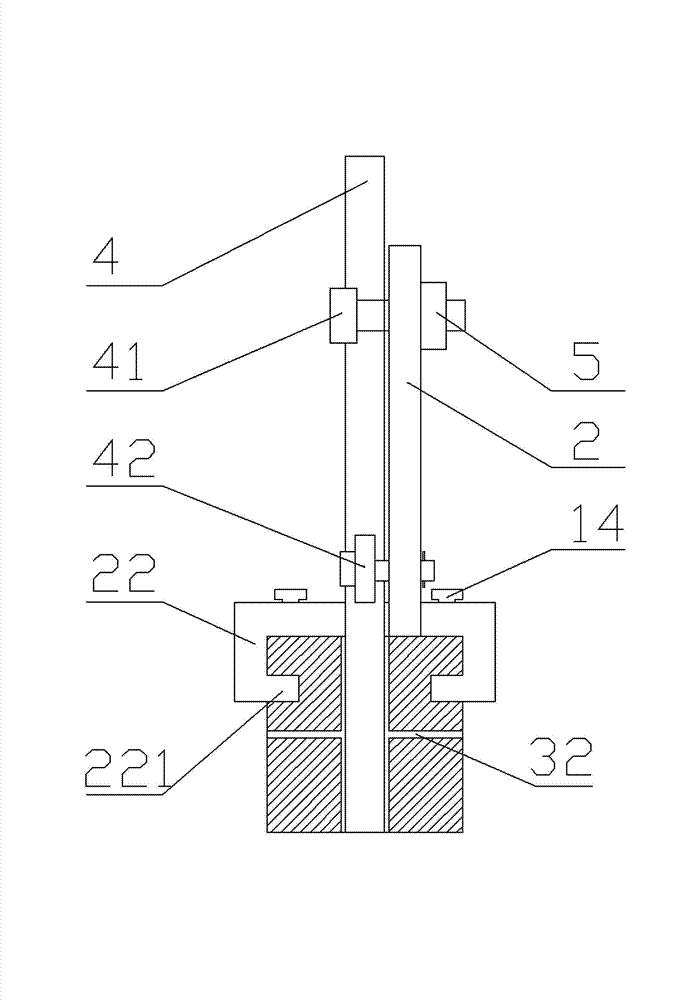

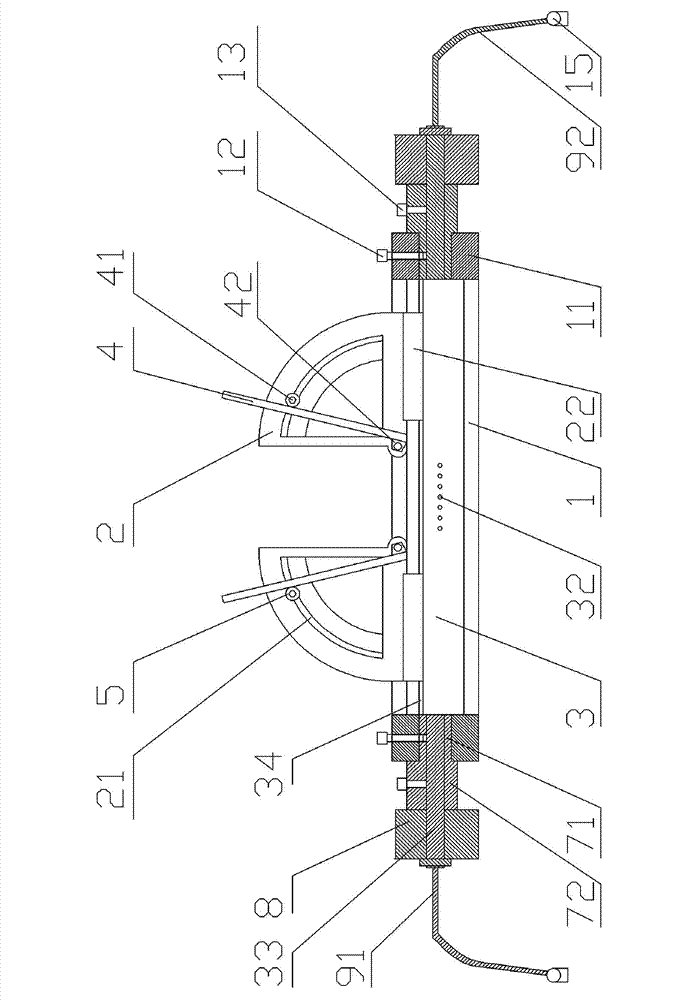

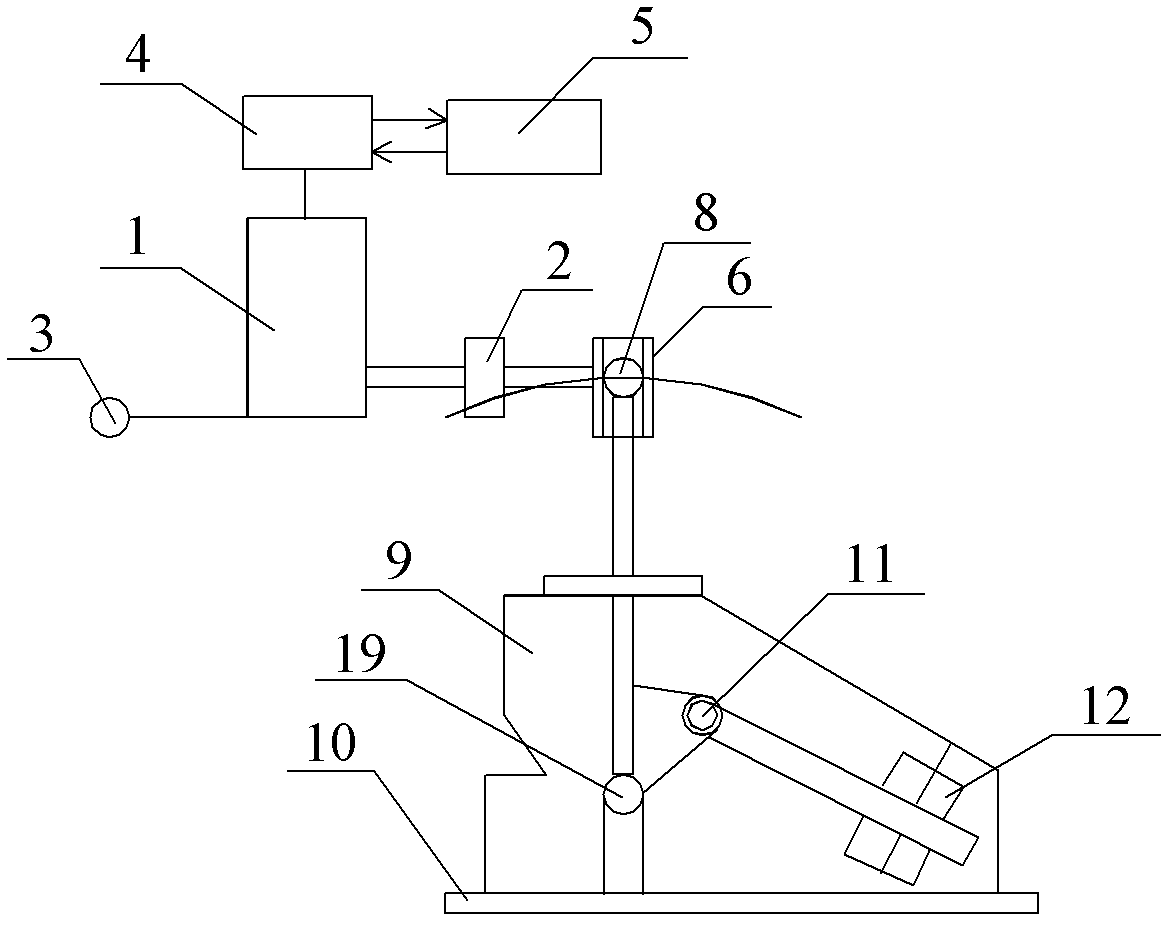

Three-dimensional positioning and guiding device for penetrating vertebral pedicle through skin

InactiveCN103083092ASurgical stabilizationAvoid Positioning EffectsDiagnosticsSurgical needlesVertebral pedicleNeedle guide

The invention discloses a three-dimensional positioning and guiding device for penetrating a vertebral pedicle through skin. The three-dimensional positioning and guiding device for penetrating the vertebral pedicle through the skin comprises a base, dip angle measuring devices and a measuring device supporting rod, wherein guiding grooves are arranged in length wise frame edges of the base, two dip angle measuring devices are matched on the measuring device supporting rod in a sliding mode, and an arc-shaped guiding groove is arranged in each dip angle measuring device. A bar-shaped hole is arranged in the measuring device supporting rod, a puncture needle guiding tube is in hinge joint with the dip angle measuring devices, and the puncture needle guiding tube penetrates through the bar-shaped hole. A guiding pin is arranged on the puncture needle guiding tube and is matched with the arc-shaped guiding grooves, marking needle fixing holes are arranged in the middle portion of the measuring device supporting rod, and two ends of the measuring device supporting rod are cylindrical segments. The measuring device supporting rod is matched with the guiding grooves in a sliding mode through sliding blocks, the cylindrical segments of the measuring device supporting rod extend out of the sliding blocks and are connected with a positioning rod, and the positioning rod is in the same plane with the measuring device supporting rod and the puncture needle guiding tube. The three-dimensional positioning and guiding device for penetrating the vertebral pedicle through the skin is capable of three-dimensional positioning and guiding and shortening the operation time, high in efficiency, accurate in guiding and capable of improving the achievement ratio of operation.

Owner:张忠荣

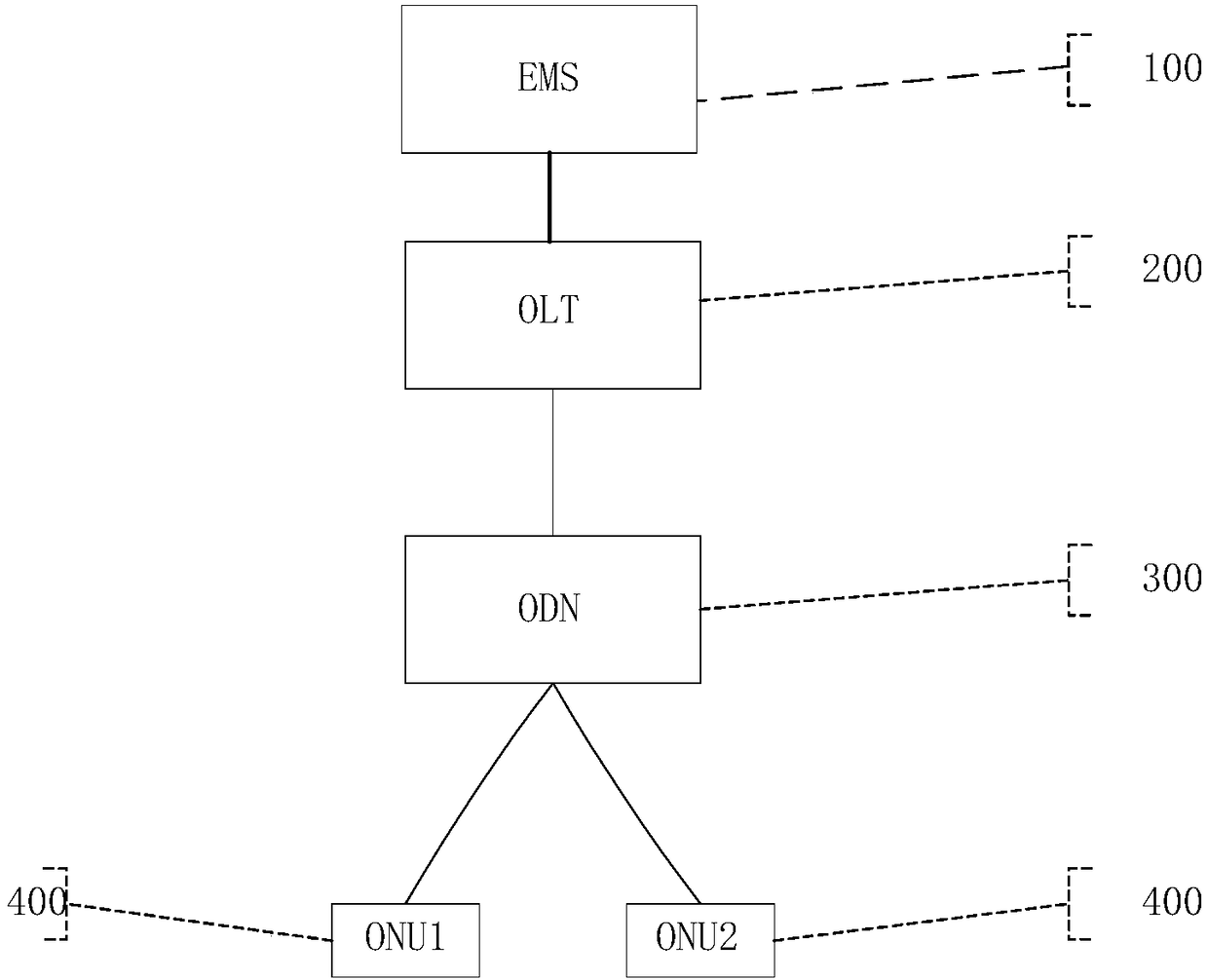

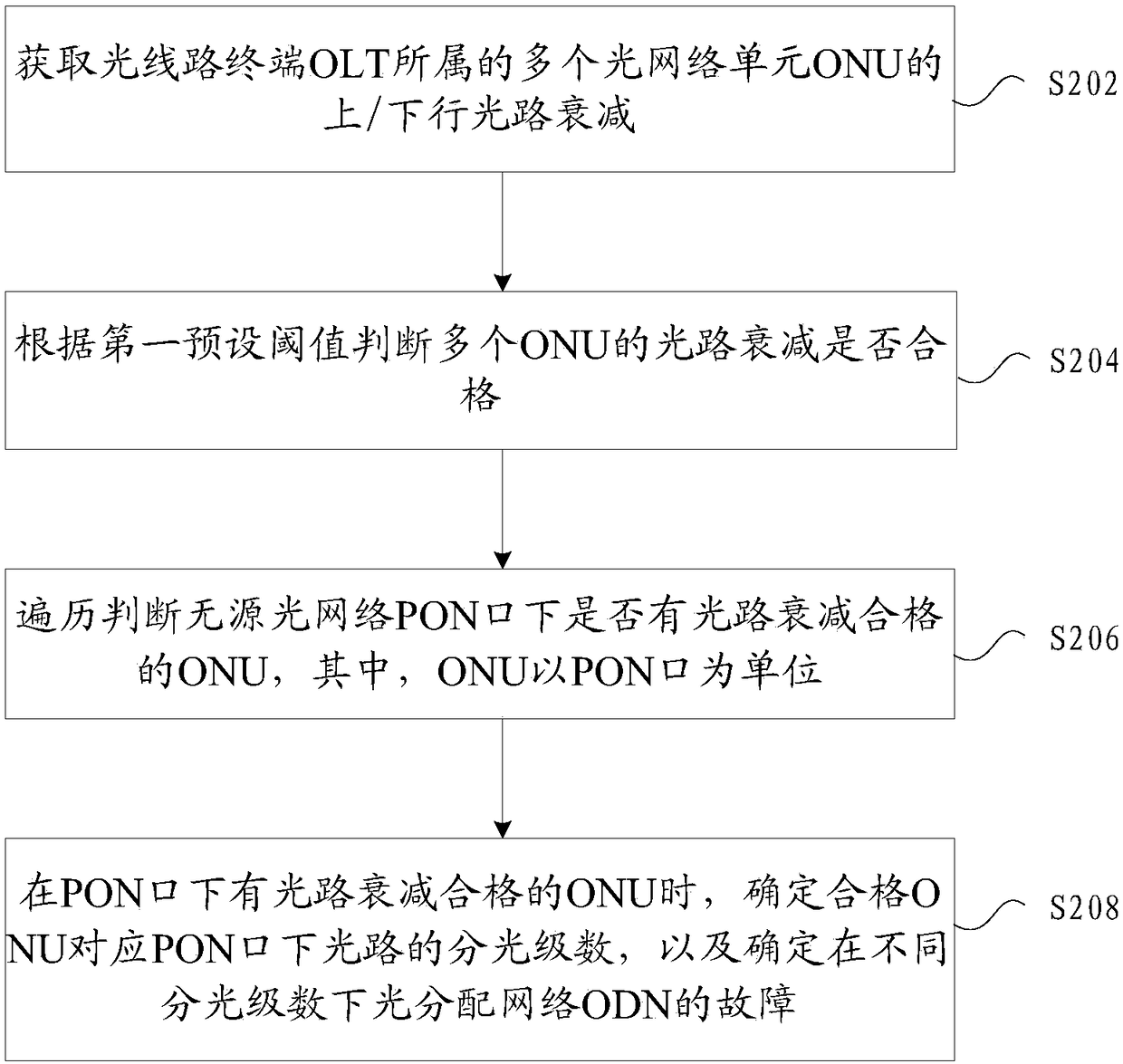

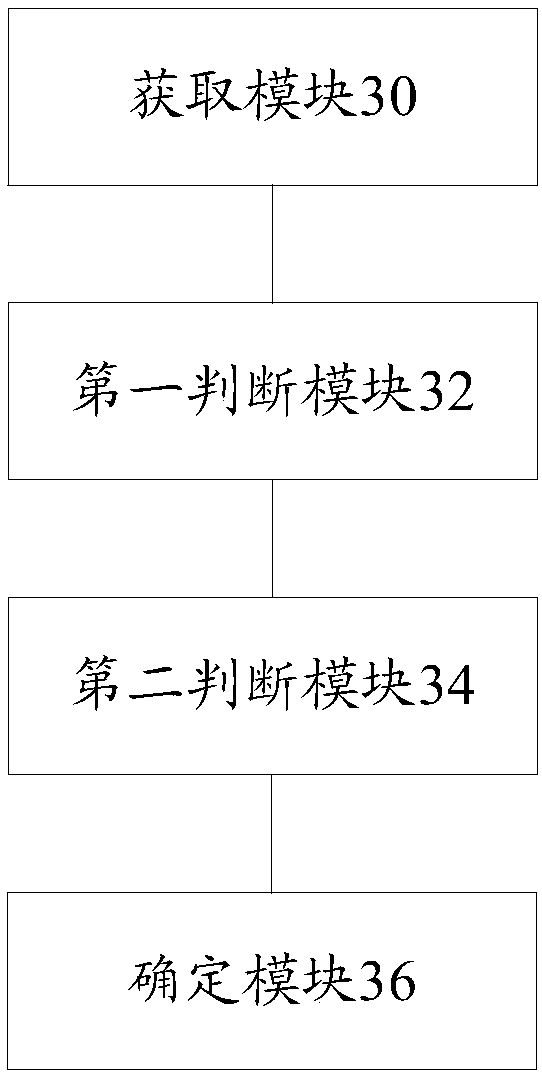

Fault detection method for optical distribution network, device and passive optical network system

ActiveCN108964756AFix technical inefficienciesAvoid Positioning EffectsMultiplex system selection arrangementsElectromagnetic transmissionUltrasound attenuationEngineering

The present invention provides a fault detection method for an optical distribution network, a fault detection device for an optical distribution network and a passive optical network system. The method includes the following steps that: the uplink / downlink optical path attenuation of a plurality of optical network units (ONU) to which optical line terminals (OLT) belong is acquired; whether the optical path attenuation of the plurality of ONUs is qualified is judged according to a preset threshold; the PON ports of a passive optical network are traversed, so that whether ONUs with valid optical path attenuation exist under the PON ports of the passive optical network can be judged, wherein the ONUs adopt the PON ports as units; and if the ONUs with valid optical path attenuation exist under the PON ports, the number of light splitting stages of optical paths under the PON ports corresponding to the valid ONUs is determined, and the fault of the optical distribution network (ODN) underdifferent light splitting stages are also determined. With the method of the invention adopted, the technical problem of low efficiency in determining the faults of the ODN in the prior art is solved.

Owner:ZTE CORP

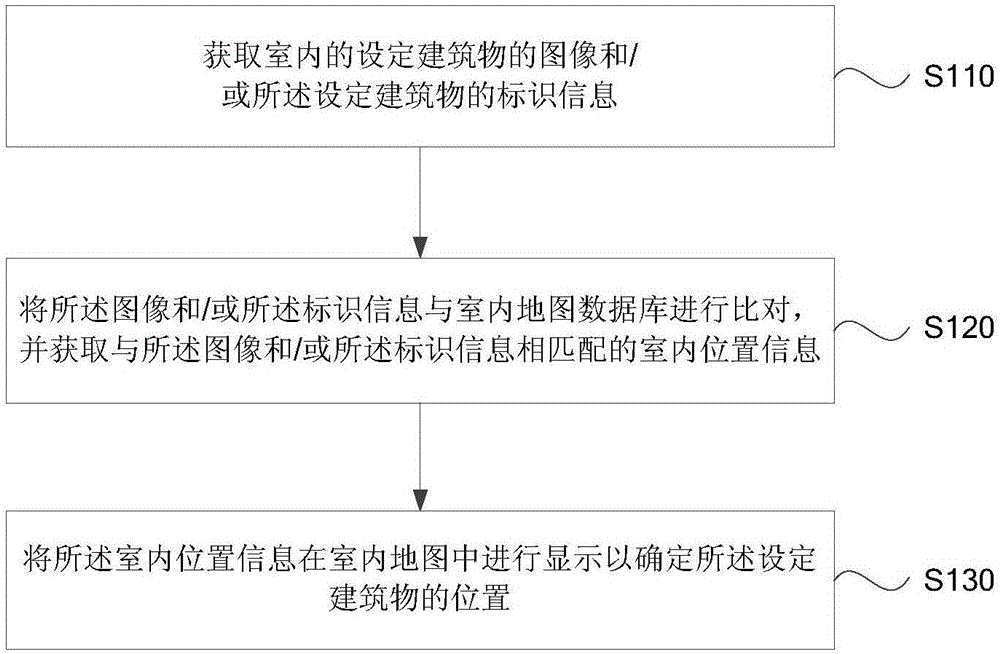

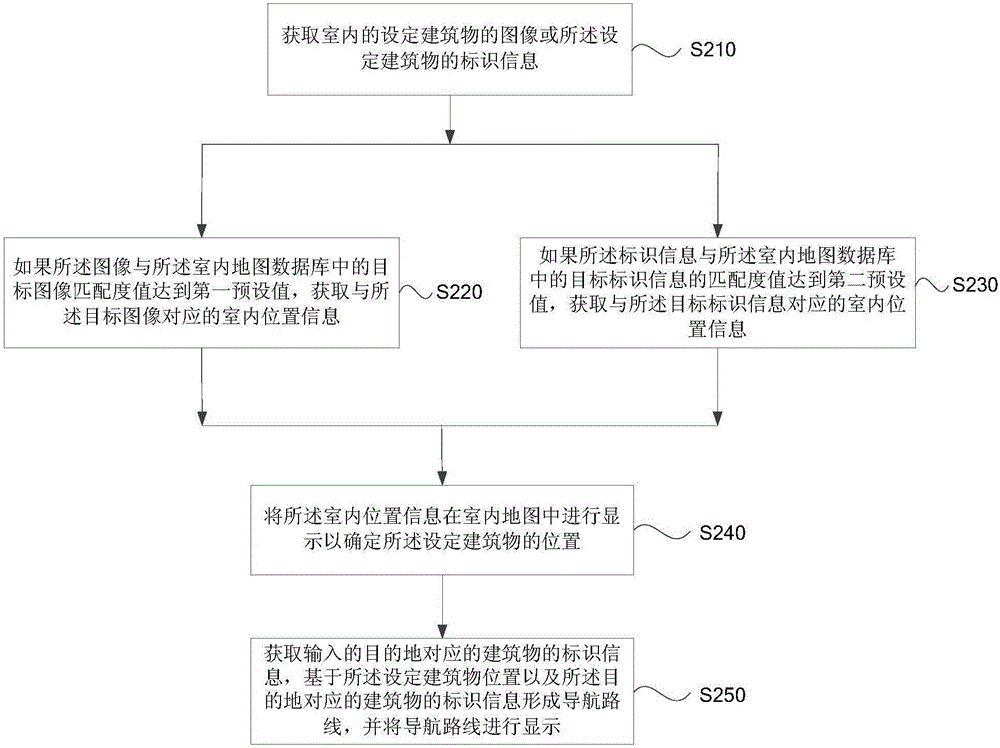

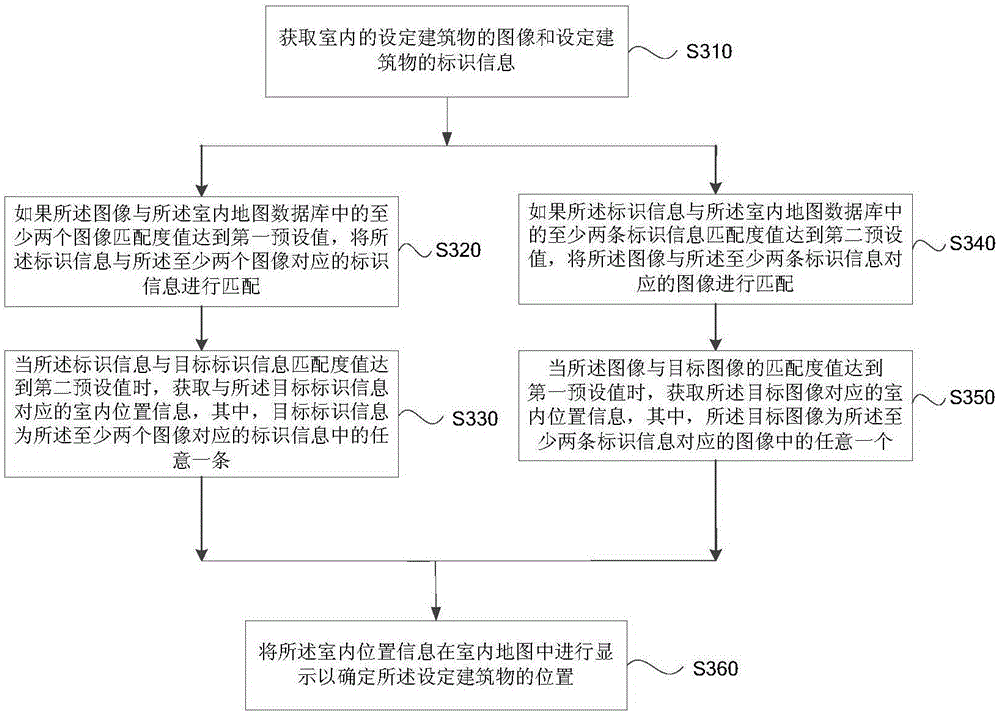

Indoor positioning method and device as well as terminal

InactiveCN106153047AAvoid Positioning EffectsImprove accuracyNavigational calculation instrumentsComputer terminalComputer science

The embodiment of the invention discloses an indoor positioning method and an indoor positioning device as well as a terminal and relates to the technical field of positioning. The method comprises the following steps: acquiring an image of an indoor set building and / or identification information of the set building; comparing the image and / or the identification information with an indoor map database and acquiring indoor position information matched with the image and / or the identification information; and displaying the indoor position information in an indoor map so as to determine the position of the set building. With the adoption of the embodiment of the invention, the influences on positioning, caused by the fact that a signal in a positioning process is instable, can be avoided and the positioning accuracy is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

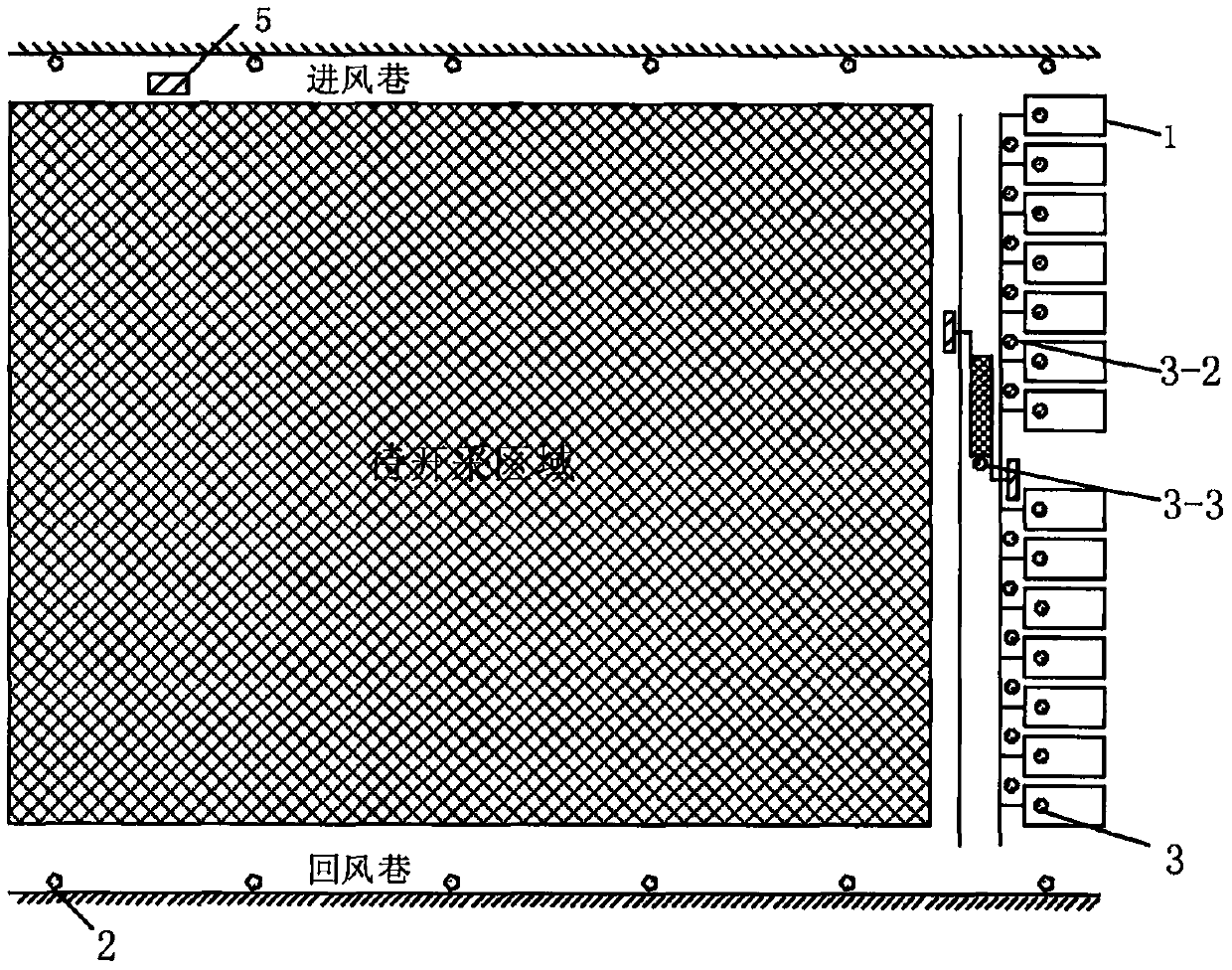

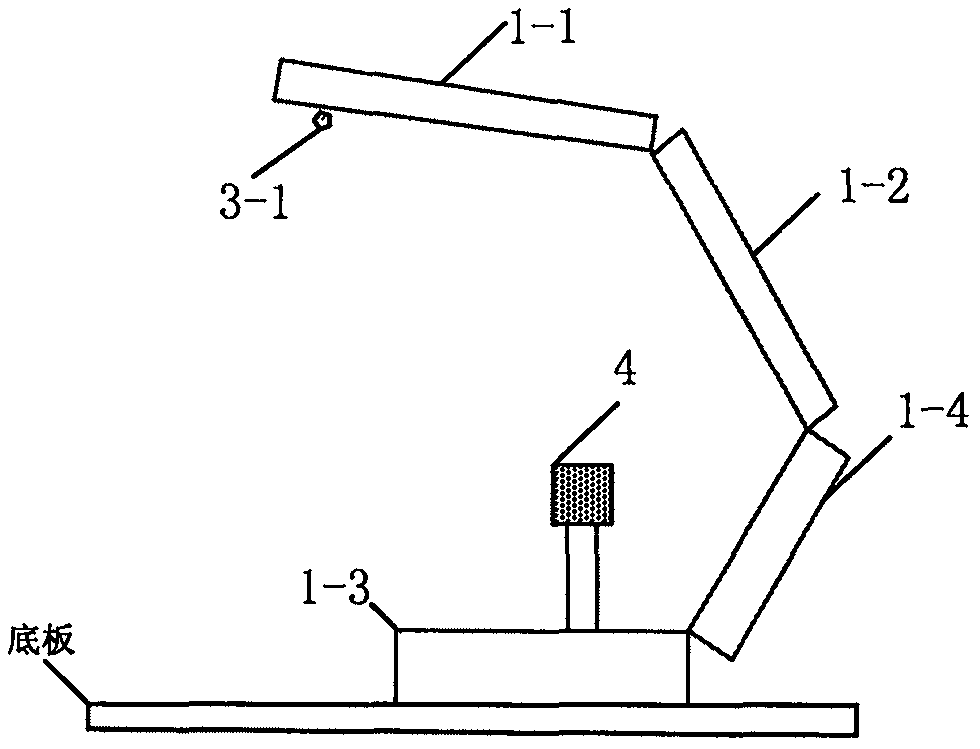

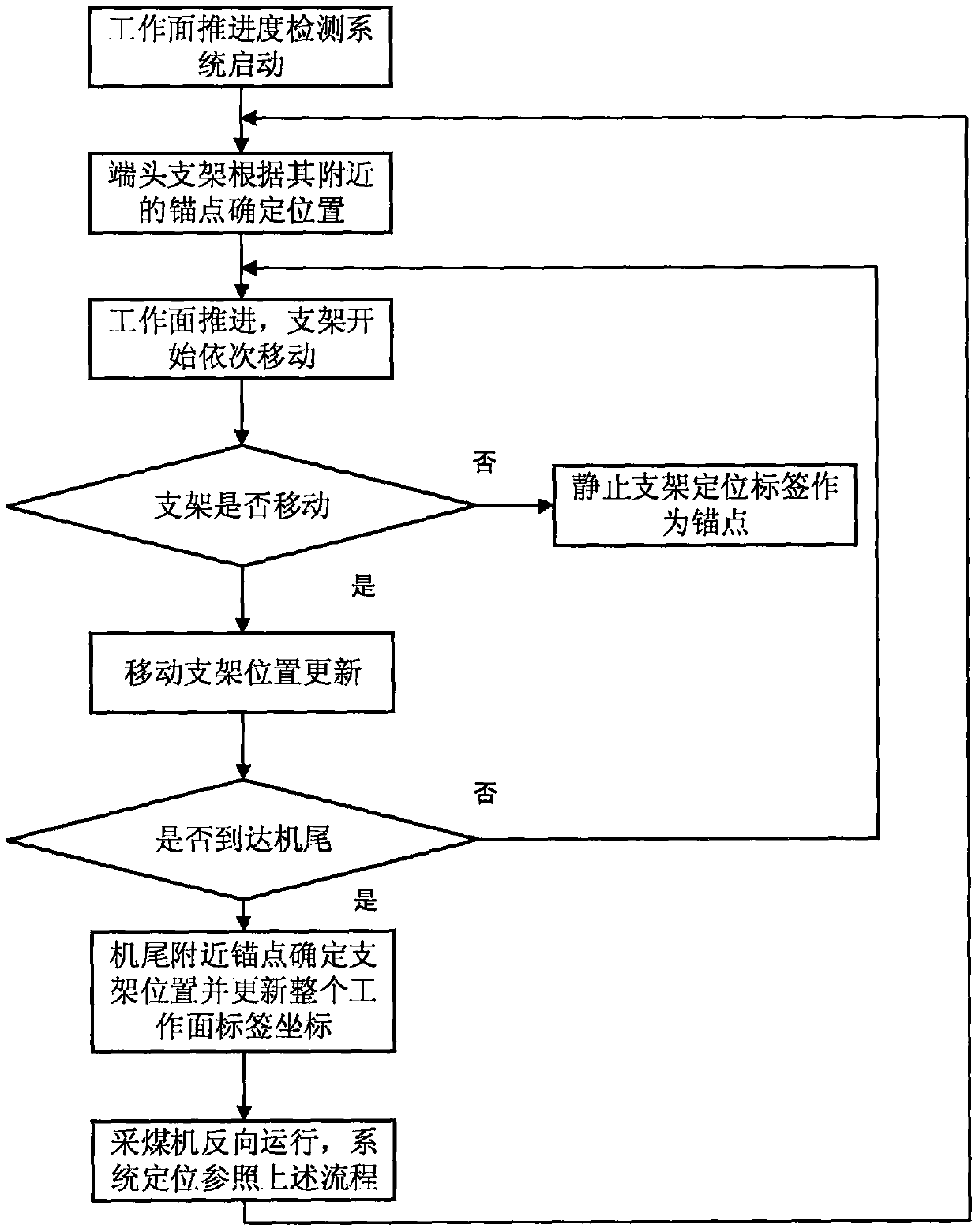

Fully mechanized mining face advancing degree detection system and method

ActiveCN107905846AAvoid human involvementSmall sizeMining devicesPosition fixationCoal miningEnvironmental geology

The invention discloses a coal mine fully mechanized mining face advancing degree detection system and method. The coal mine fully mechanized mining face advancing degree detection system is composedof positioning anchor points, positioning tags, positioning controllers, a master control system and the like. The positioning anchor points are fixedly installed on the rock walls of an air intake roadway and an air return roadway at equal distances, the positioning tags and the positioning controllers are deployed on a hydraulic support, a coal mining machine and the like, the distances betweenevery two positioning nodes are measured, distance measurement data are transmitted to a main control computer by the positioning controllers through communication network, the positions of the equipment in the mining face advancing process are worked out by the main control computer according to the data, and therefore automatic detection can be achieved in the mining face advancing process.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD +1

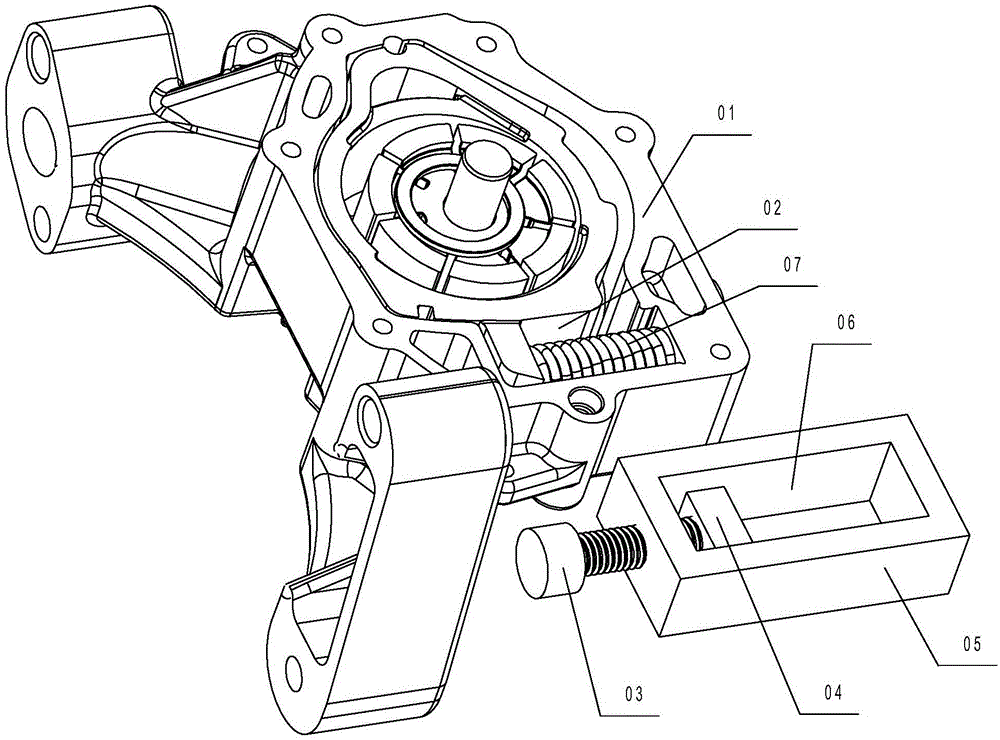

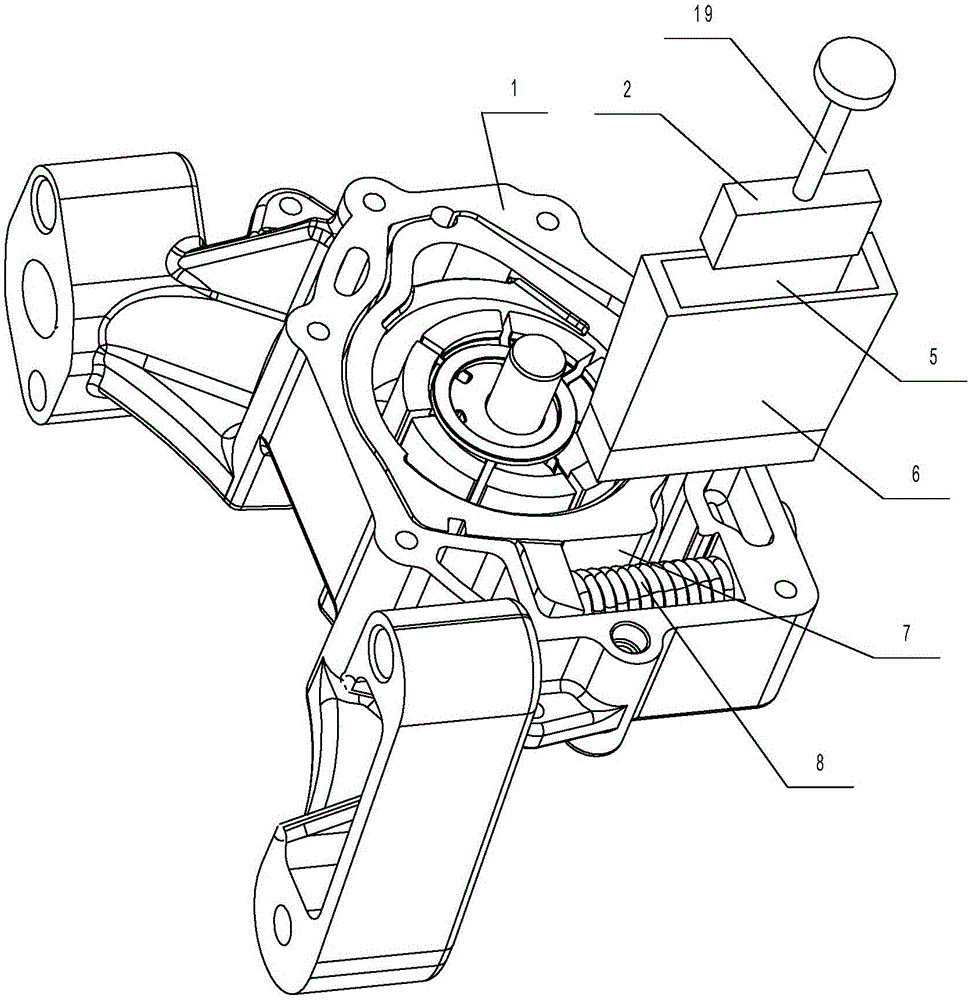

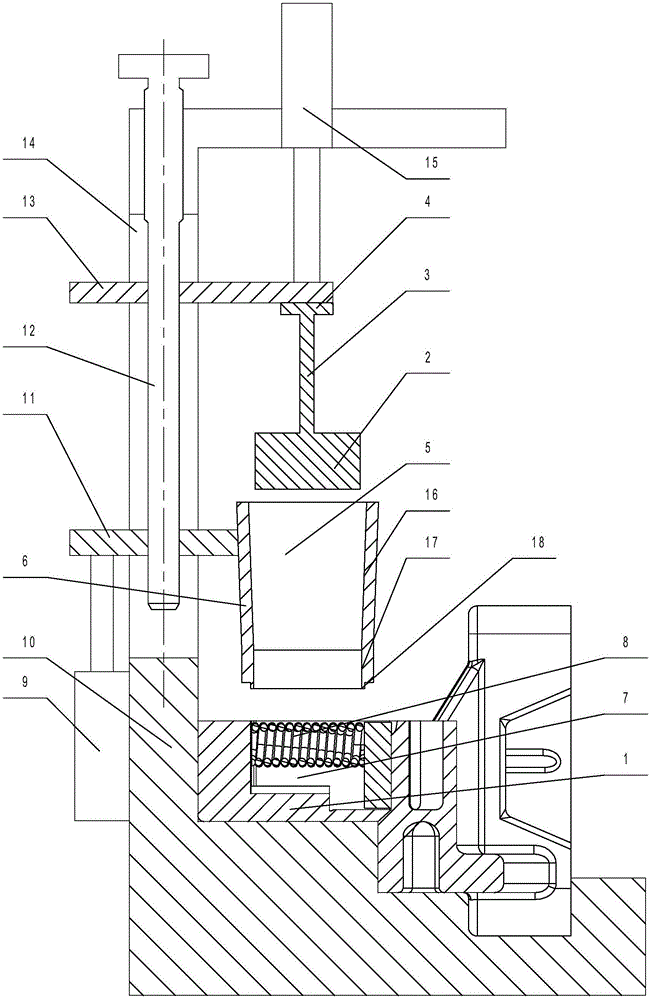

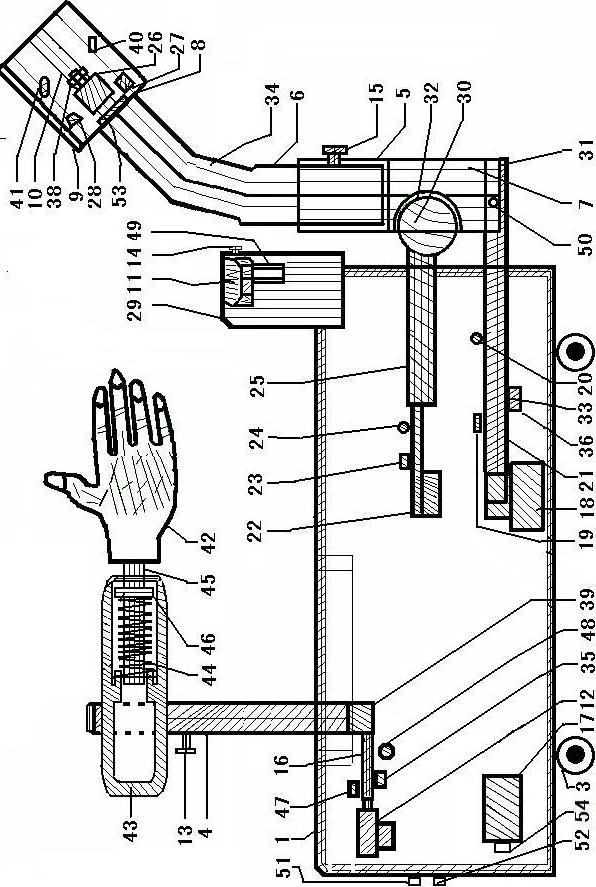

Mounting device for spring in oil pump

ActiveCN105081750AEasy to installAvoid positionMetal working apparatusEngineeringMechanical engineering

The invention discloses a mounting device for a spring in an oil pump. The device comprises a press-in seat (6), and a pressing block (2) for pressing the spring (8) into a spring mounting groove (7) in the oil pump (1); a press-in through hole (5) for storing and compressing the spring (8) is formed in the press-in seat (6); the cross section of the press-in through hole (5) is shaped like a rectangular hole; the sidewalls of two ends of the upper section of the press-in through hole (5), in the length direction of the spring (8), are bevels (16); the lower end of the press-in through hole (5) is positioned right above the spring mounting groove (7), and the space between the sidewalls of two ends of the press-in through hole is reduced from top to bottom; a driving structure for pressing in is arranged at the upper end of the pressing block (2). According to the device adopting the structure above, the position of the spring is fixed relative to the oil pump during transferring, so that the phenomena of position deviating and inaccurate positioning can be avoided, the spring can be mounted conveniently, and as a result, the assembling efficiency can be greatly improved.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

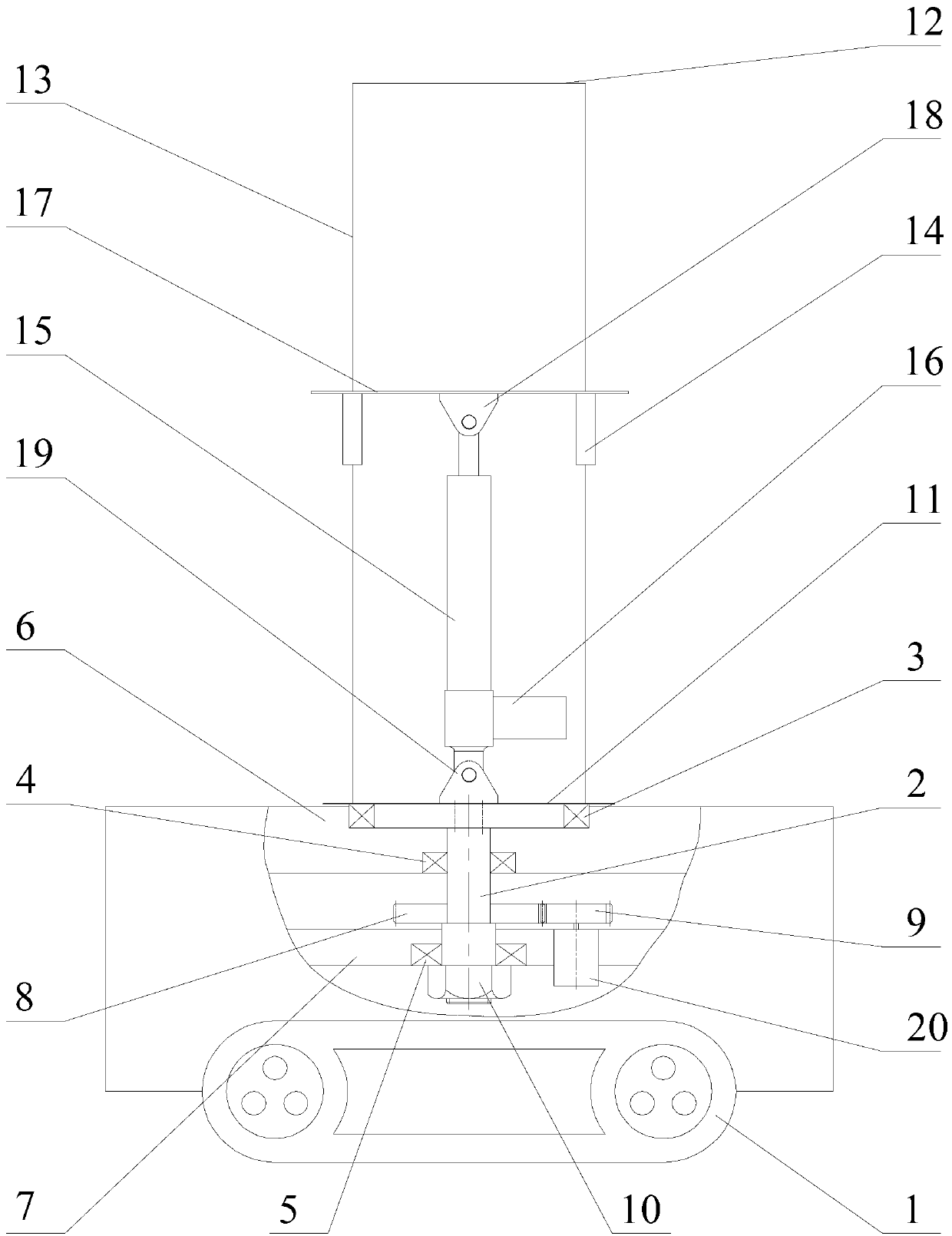

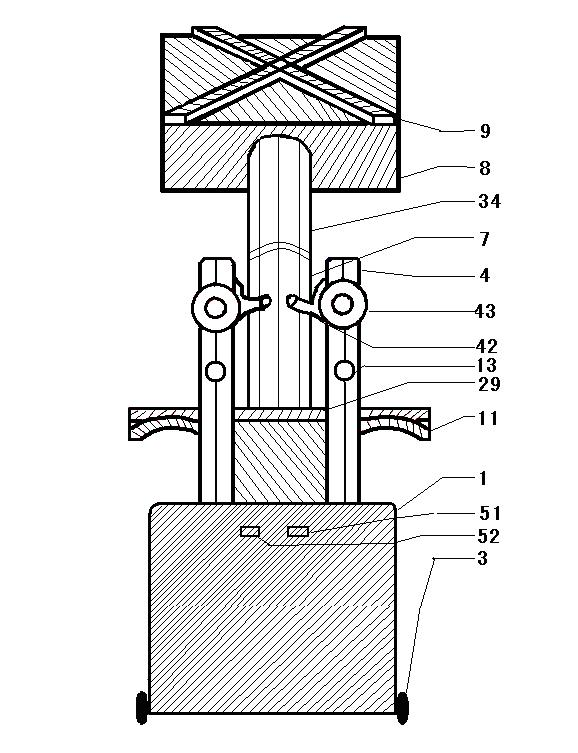

Movable and rotatable lifting platform used for picking agricultural products

ActiveCN103270849AImprove rigidityImprove general performancePicking devicesControl systemAgricultural engineering

The invention discloses a movable and rotatable lifting platform used for picking agricultural products. The movable and rotatable lifting platform comprises a walking mechanism, a rotating mechanism, a lifting platform body and a control system. The rotating mechanism comprises a rotating machine frame, a main shaft, a bearing set, a bearing seat board set, a gear set and a rotating driving motor, wherein the main shaft is connected with the bearing set in a matched mode, the bearing set is fixed on the bearing seat board set, the rotating driving motor transmits rotating power to the main shaft through the gear set, the rotating driving motor is installed on the rotating machine frame, the top end of the main shaft is fixedly connected with the lifting platform body, the bottom of the rotating machine frame is connected with the walking mechanism, and the control system is in signal connection with the rotating driving motor and the lifting platform body. The movable and rotatable lifting platform has the advantages of being capable of bearing larger loads and capsizing moment, small in motion resistance, high in motion precision, large in motion stroke, strong in universality of parts, convenient to produce and maintain, low in manufacturing cost, and the like. Large-load and mass mechanized harvesting of crops can be achieved only through that a corresponding agricultural harvesting operation device is arranged on the movable and rotatable lifting platform.

Owner:SOUTH CHINA AGRI UNIV

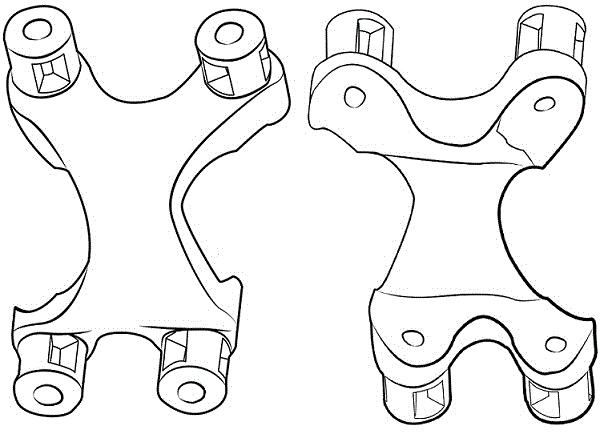

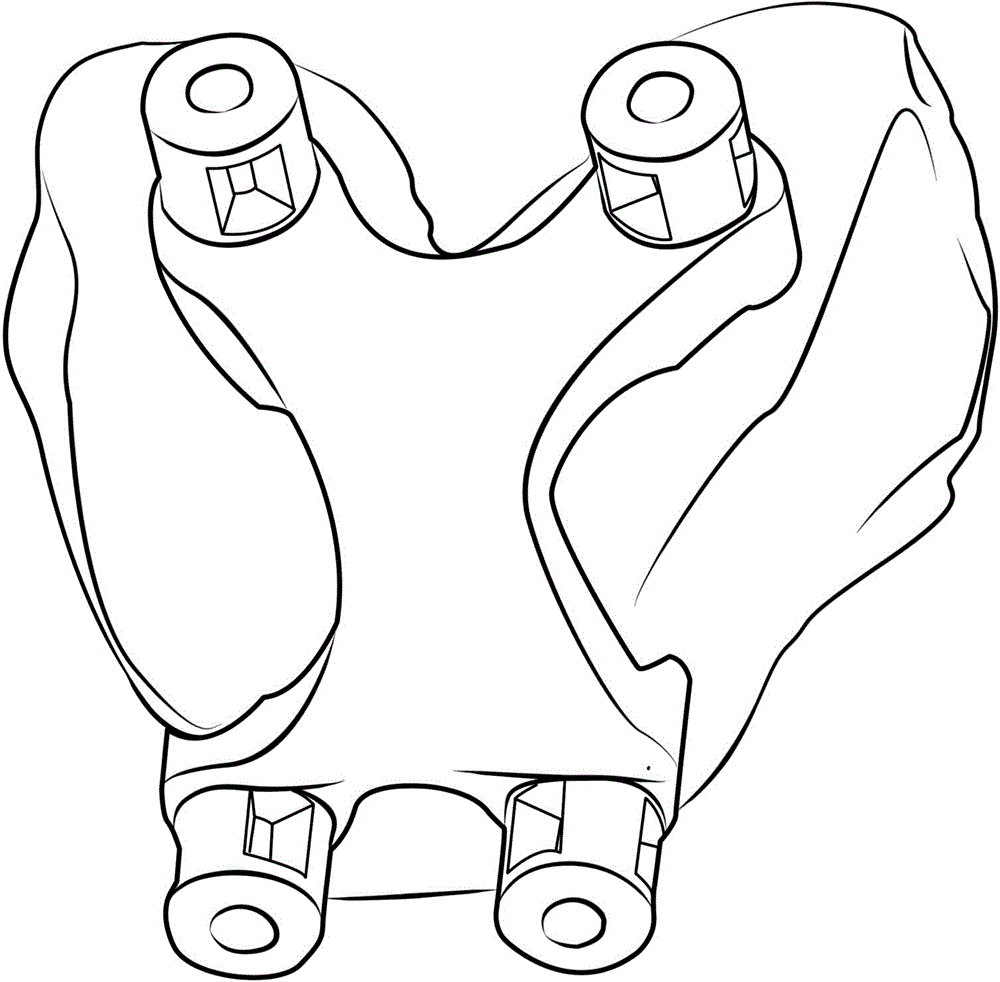

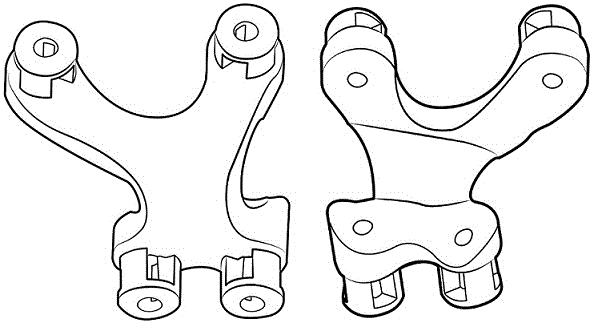

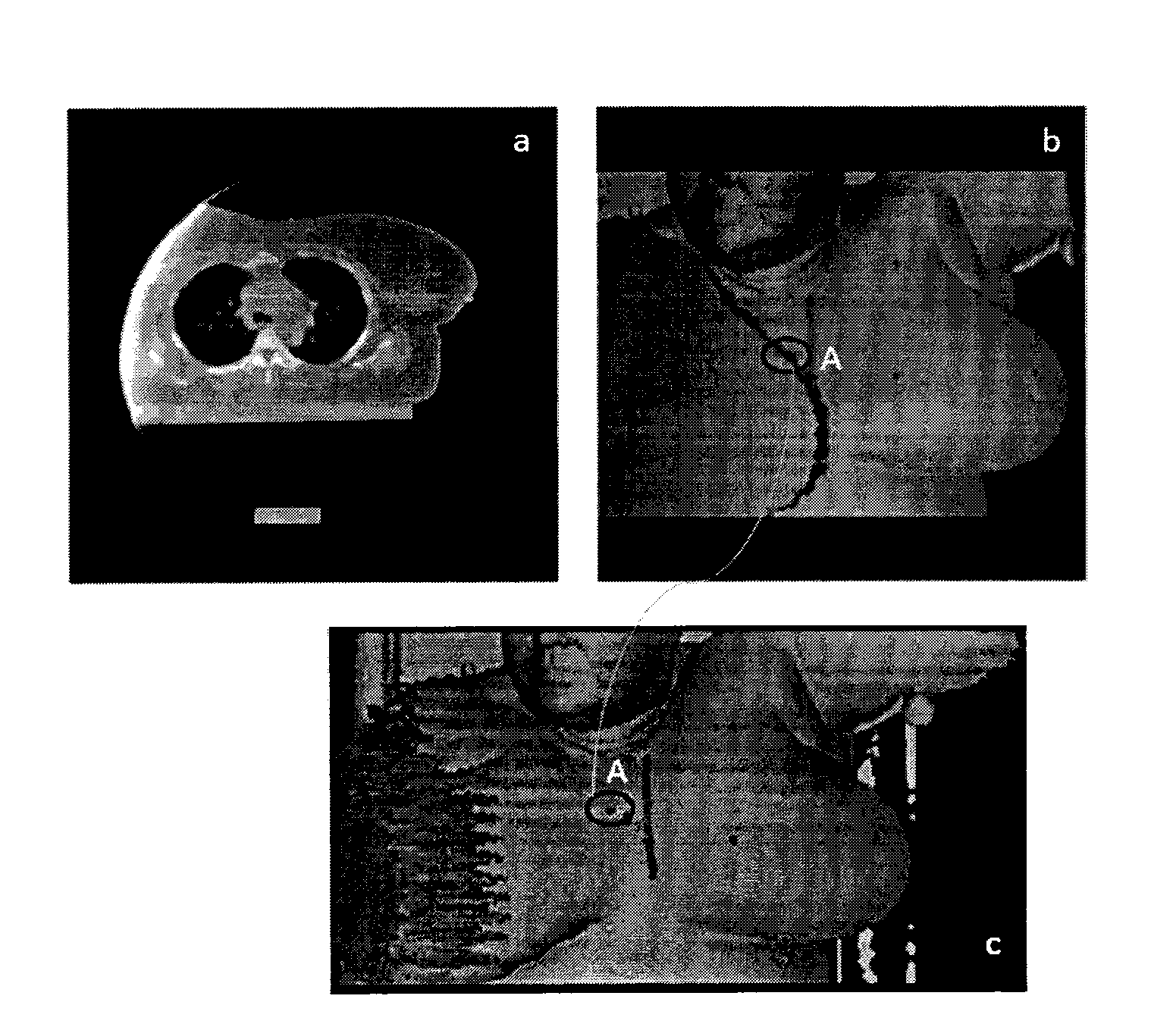

Personalized minimally-invasive knee joint positioning guide plate based on medical image

The invention discloses a personalized minimally-invasive knee joint positioning guide plate used for knee arthroplasty and manufactured on the basis of medical image three-dimensional reconstruction and computer-aided design technologies, 3D (three-dimensional) printing or other machining methods, and particularly relates to accurate determination of a positioning joint surface. Firstly, a patient skeleton model is reconstructed on the basis of a two-dimensional medical image; preoperative planning is performed on the reconstructed model, and important parameters such as a lower extremity force line, a femoral rotation axis and an osteotomy reference point are determined to simulate osteotomy and prosthesis implantation; a positioning sheet (single positioning type and composite type) is determined and designed with the results. The positioning sheet is used for positioning with a local positioning principle by means of local area jointing, so that over-positioning and positioning instability are avoided; meanwhile, the wound area is reduced to the maximum extent. A dissection point is positioned through the reconstructed model, so that the lower extremity force line can be reconstructed accurately, and accurate osteotomy is realized.

Owner:SHANGHAI XINJIAN MEDICAL TECH

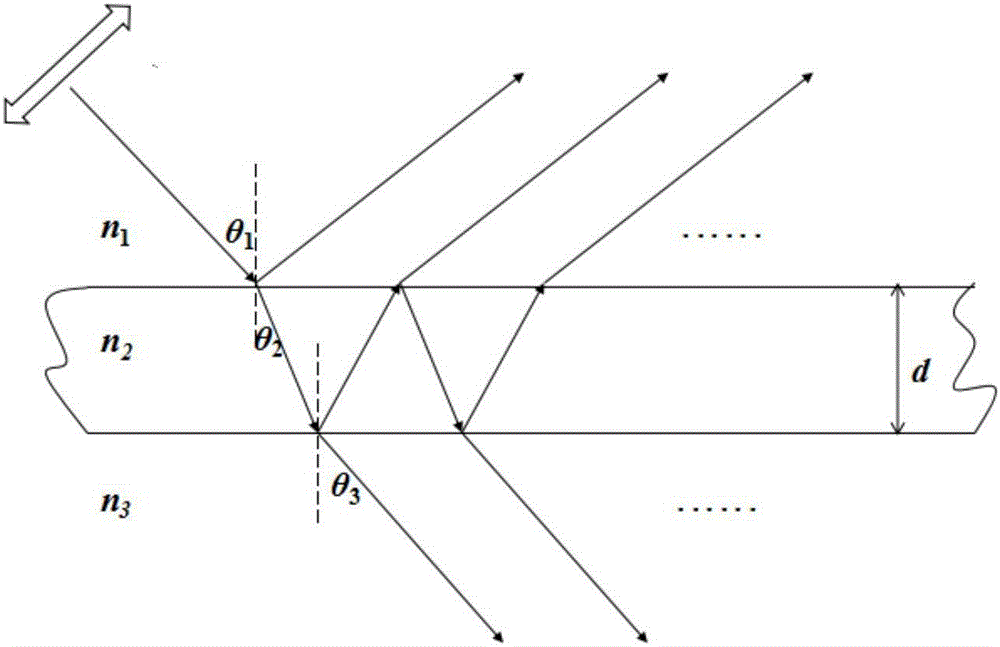

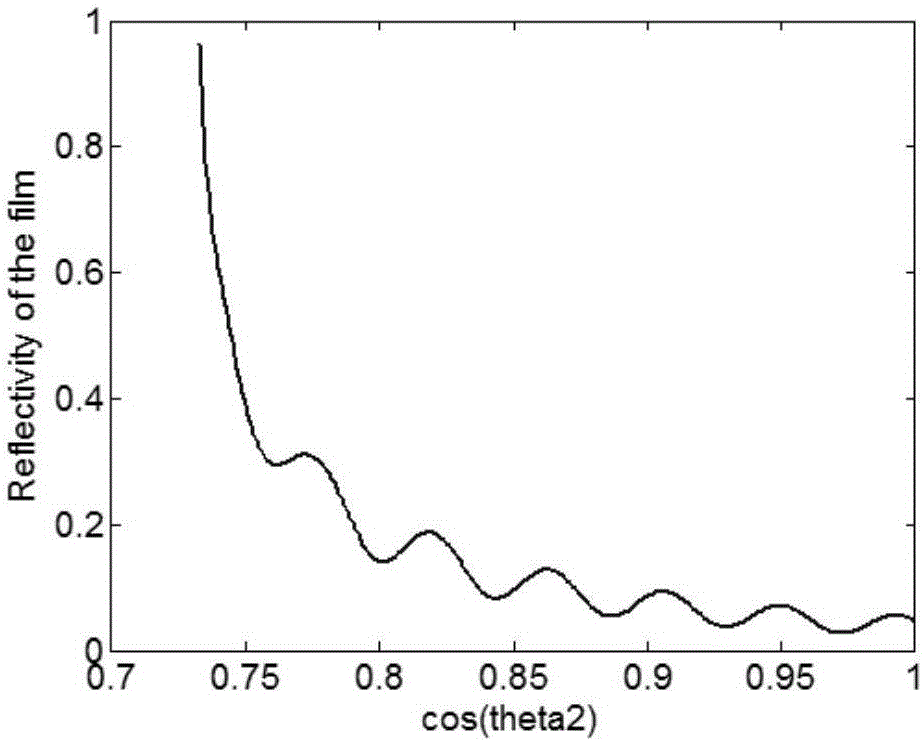

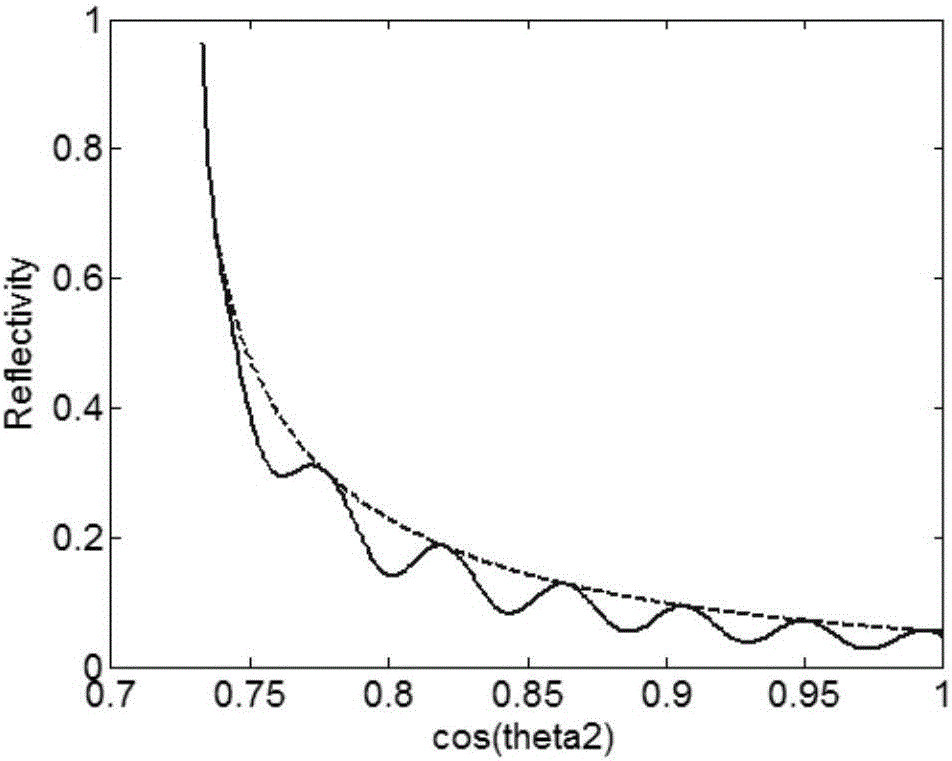

Thin film thickness measurement method and system

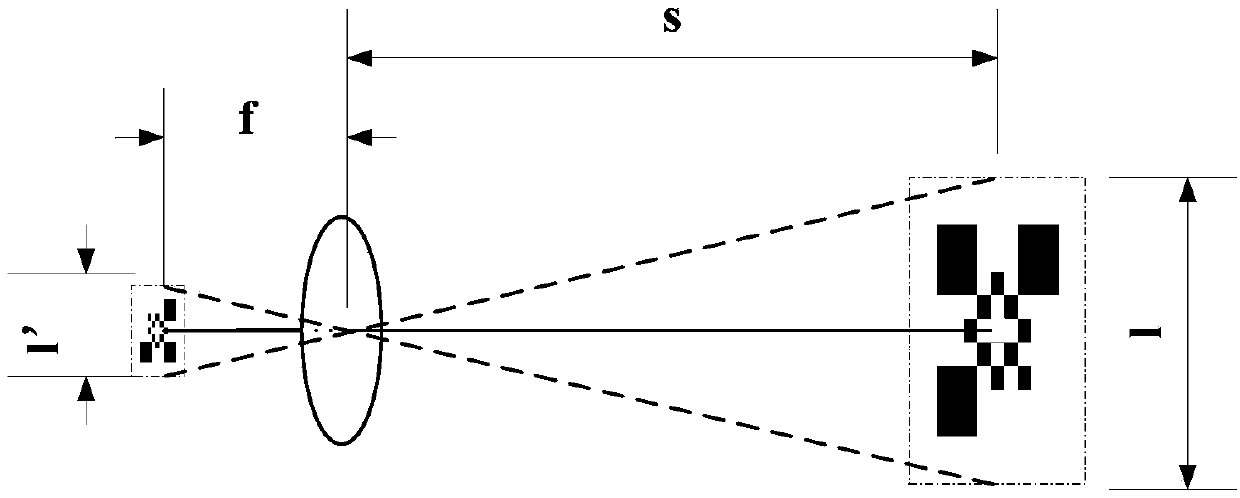

InactiveCN106441125AAvoid Streak CountsAvoid Positioning EffectsUsing optical meansShaped beamLight beam

The invention discloses a thin film thickness measurement method and system. The thin film thickness measurement system comprises a lighting optical device, an imaging optical device and a thin film thickness analyzing device, and is characterized in that the lighting optical device is used for generating a cone-shaped beam and projecting the cone-shaped beam to a point on the thin film surface of a sample; the imaging optical device comprises a focusing lens and an image acquisition module; the focusing lens projects light reflected from the surface of the sample to the image acquisition module according to the sequence of an incidence angle from small to large, the image acquisition module detects to acquire reflection intensity information of the beam at the surface of the sample and builds a relation curve between the reflectivity and the incidence angle according to the reflection intensity information; and the thin film thickness analyzing device builds a function of the reflectivity and a refraction angle cosine value by utilizing the relation curve between the reflectivity and the incidence angle and a Snell's law, and acquires the thin film thickness of the sample through performing Fourier transform and analysis on the function. The thin film thickness measurement system is not only high in measurement accuracy, but also simple, compact and stable in light path, low in cost and easy to realize online measurement.

Owner:HUAIYIN TEACHERS COLLEGE

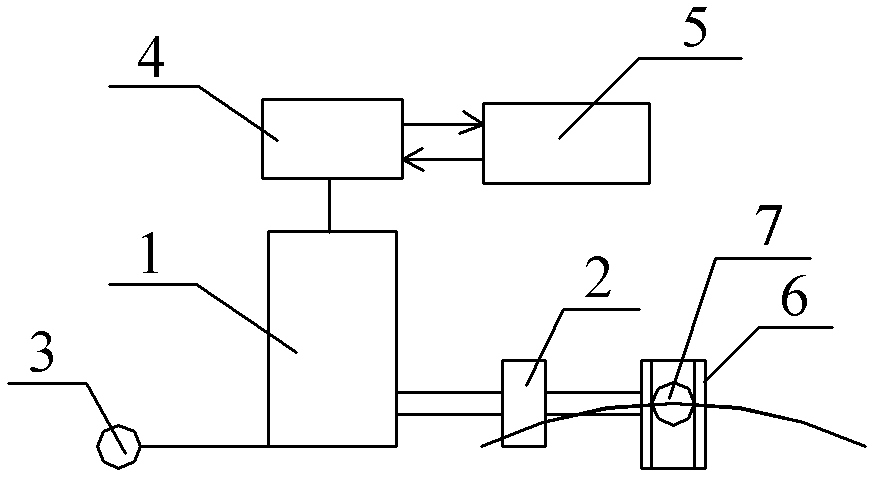

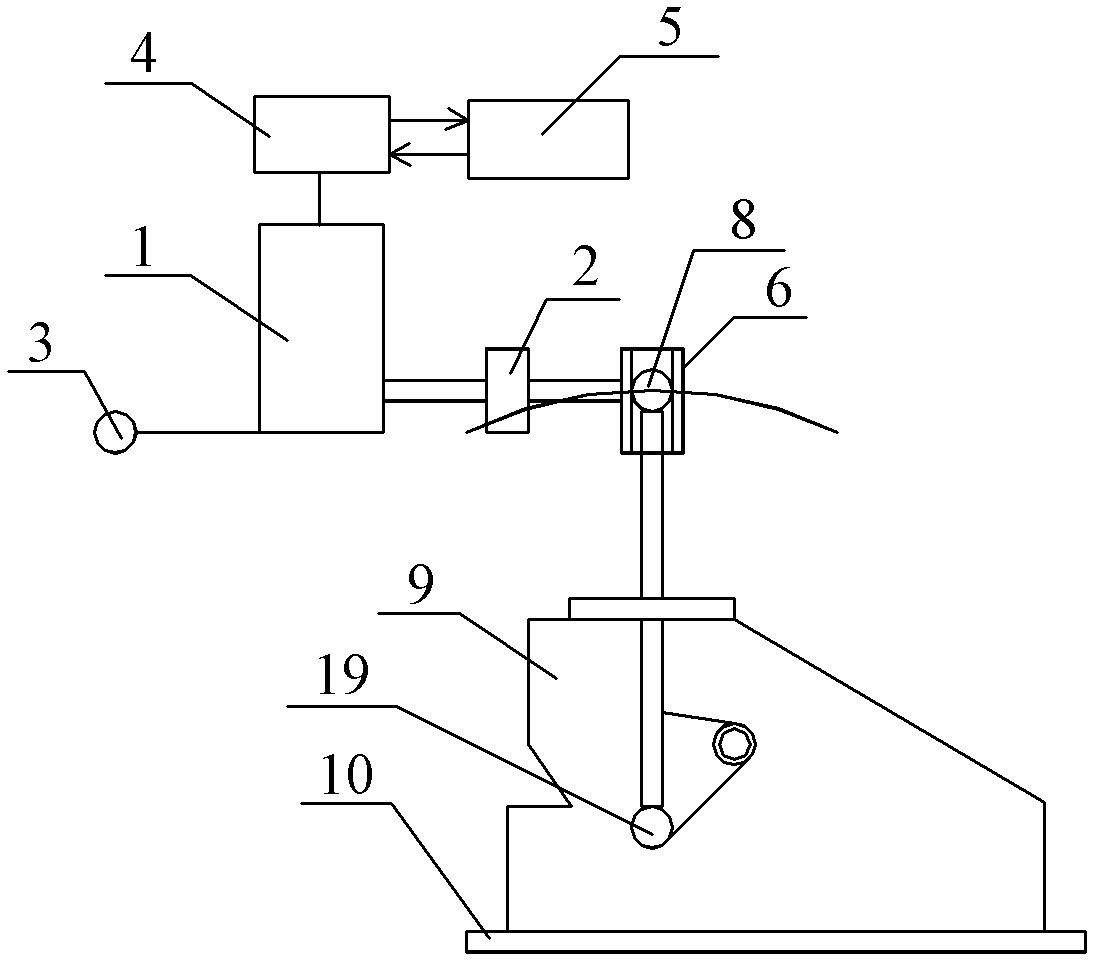

Testing device and testing method for automobile gear shifting system performance

ActiveCN103217285AEasy to changeEliminate potential safety hazardsMachine gearing/transmission testingObservational errorTest fixture

The invention discloses a testing device and a testing method for automobile gear shifting system performance. The testing device comprises a working platform and a gear shifting system to be tested, wherein the gear shifting system to be tested is fixedly arranged on the working platform. The testing device is characterized in that the testing device further comprises a six-shaft industrial robot, wherein the six-shaft industrial robot is connected with a force sensor, a displacement sensor and a controlling unit, the controlling unit is connected with a testing unit in a bi-directional mode, the force sensor is further connected with a fixture, and the fixture is nested outside a measuring ball head of the gear shifting system to be tested. According to the testing device for the automobile gear shifting system performance, a working curved-line moving process of a gear shifter can be simulated precisely, measuring errors generated in a rectilinear motion are avoided, manufacturing cost is low, and the range of application is wide. In addition, due to the fact that the position of the gear shifting system in a finished automobile coordinate system is precisely converted in a user coordinate system, precise location is conduced, the influences by a manufacturing error and a location error and an attitude error in modular system construction are effectively avoided, measuring precision is ensured, testing parameters are comprehensive, and adaptability is strong.

Owner:上海思晋智能科技有限公司

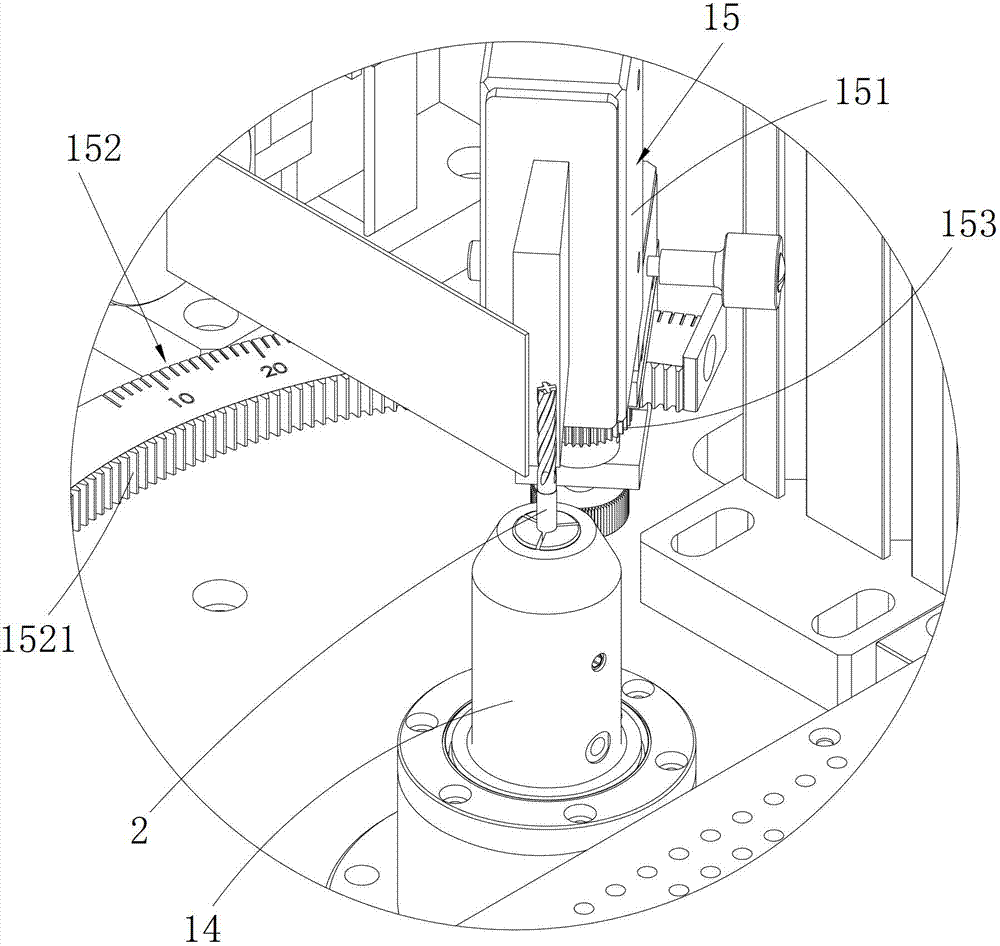

Automatic cutter detection equipment

InactiveCN102901443AImprove detection efficiencyAvoid Positioning EffectsMeasurement/indication equipmentsUsing optical meansEngineeringMechanical engineering

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

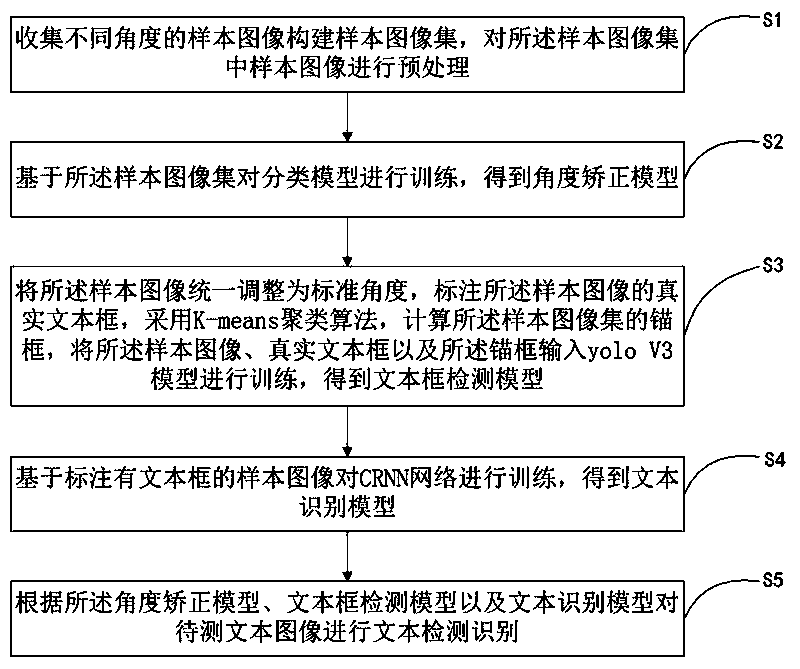

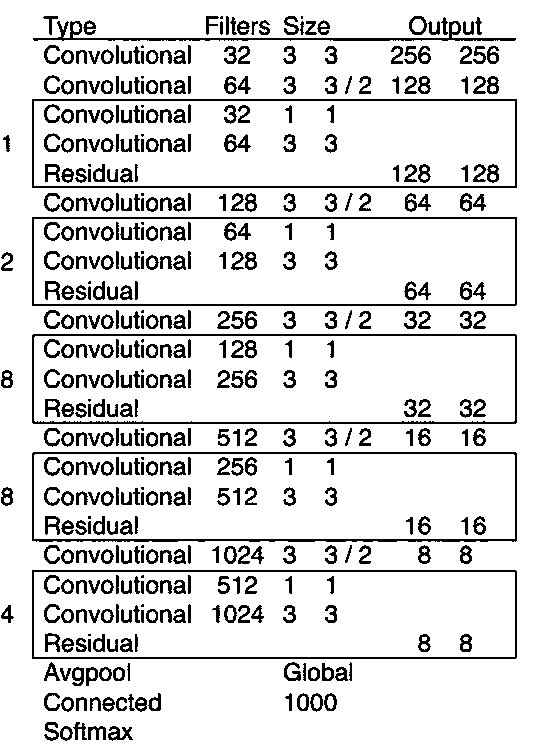

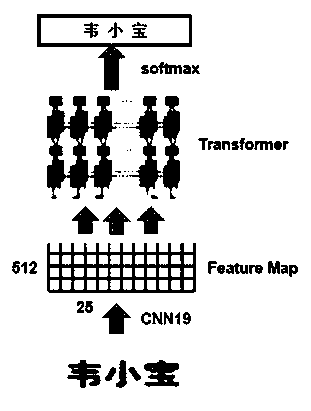

Text detection and recognition method and system and computer equipment

ActiveCN111401371ATime to reduce difficultyAvoid Positioning EffectsCharacter and pattern recognitionCluster algorithmText detection

The invention relates to a text detection and recognition method and system and computer equipment. The method comprises the following steps: collecting sample images at different angles to constructa sample image set; training the classification model based on the sample image set to obtain an angle correction model; uniformly adjusting the sample images into standard angles, labeling real textboxes of the sample images, calculating anchor boxes of the sample image set by adopting a K-means clustering algorithm, and inputting the sample images, the real textboxes and the anchor boxes into ayoloV3 network for training to obtain a textbox detection model; training the CRNN based on the sample image marked with the textbox to obtain a text recognition model; and performing text detection and recognition on the to-be-detected text image according to the angle correction model, the textbox detection model and the text recognition model. According to the method, the low-end training difficulty of the yoloV3 network is reduced, so the text detection and recognition efficiency is improved.

Owner:中邮消费金融有限公司

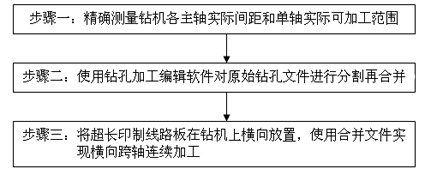

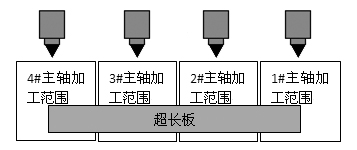

Method for transverse shaft-crossing drilling of drilling machine

InactiveCN101947659AReduce scratchesAvoid Positioning EffectsPrinted circuit manufacturePrinted circuit boardMachining

The invention relates to the field of manufacturing of printed circuit boards, in particular to a method for transverse shaft-crossing drilling of a drilling machine. The method comprises the following steps of: measuring, namely measuring the interval between every main shaft of the drilling machine and an actual machinable range of a single shaft; merging a file, namely partitioning an original drilling file by using drilling editing software, and merging the partitioned original drilling file to form a merged file for the transverse shaft-crossing drilling; and machining, namely transversely placing an overlong printed circuit board on the drilling machine for continuous transverse shaft-crossing machining by using the merged file. The method for the transverse shaft-crossing drilling of the drilling machine has the advantages of continuously finishing drilling the overlong printed circuit board on a common multi-shaft drilling machine at one time, avoiding repeatedly positioning by pins and operation of disassembling and assembling plates, reducing scratches on the plate surface, guaranteeing the drilling precision, simultaneously improving the production efficiency and product passing rate to the utmost.

Owner:GCI SCI & TECH

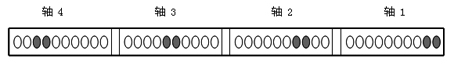

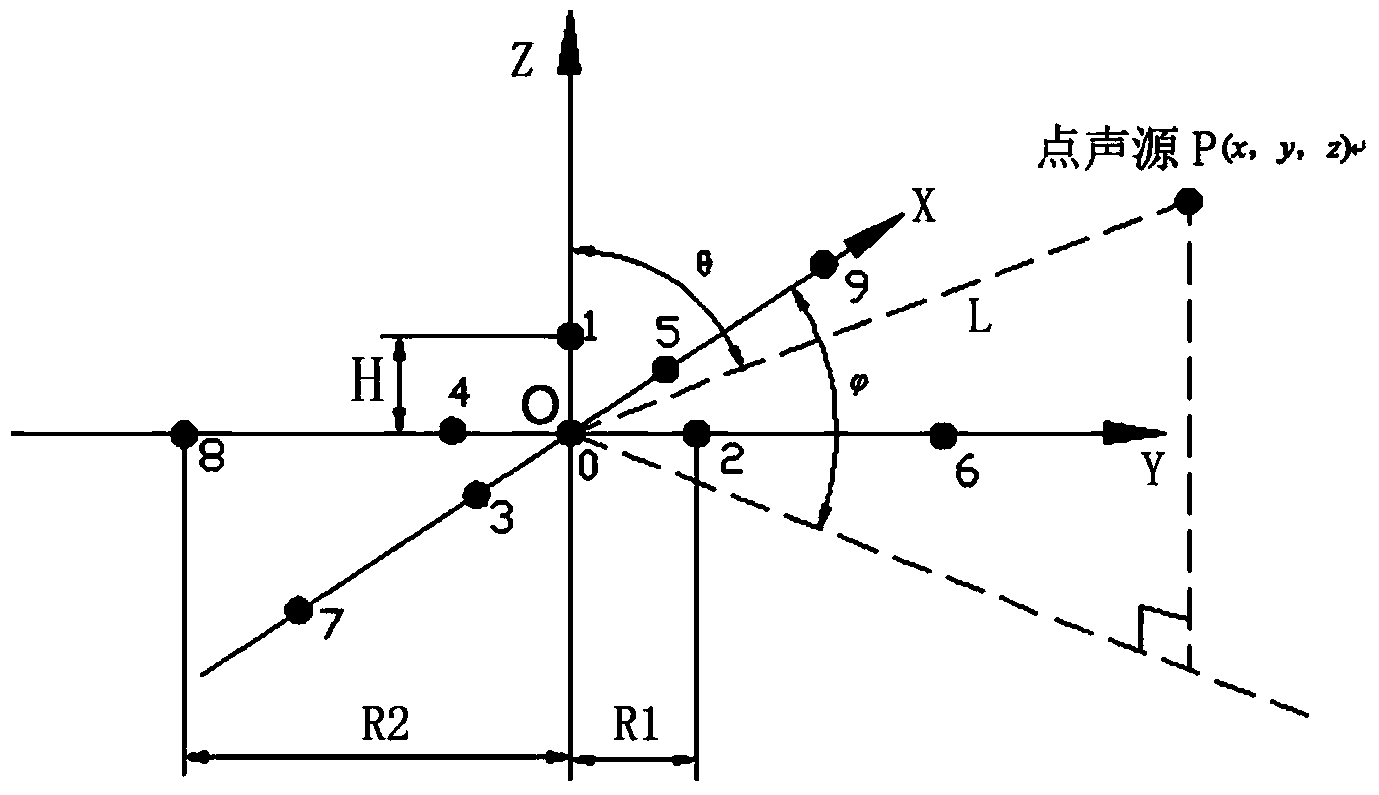

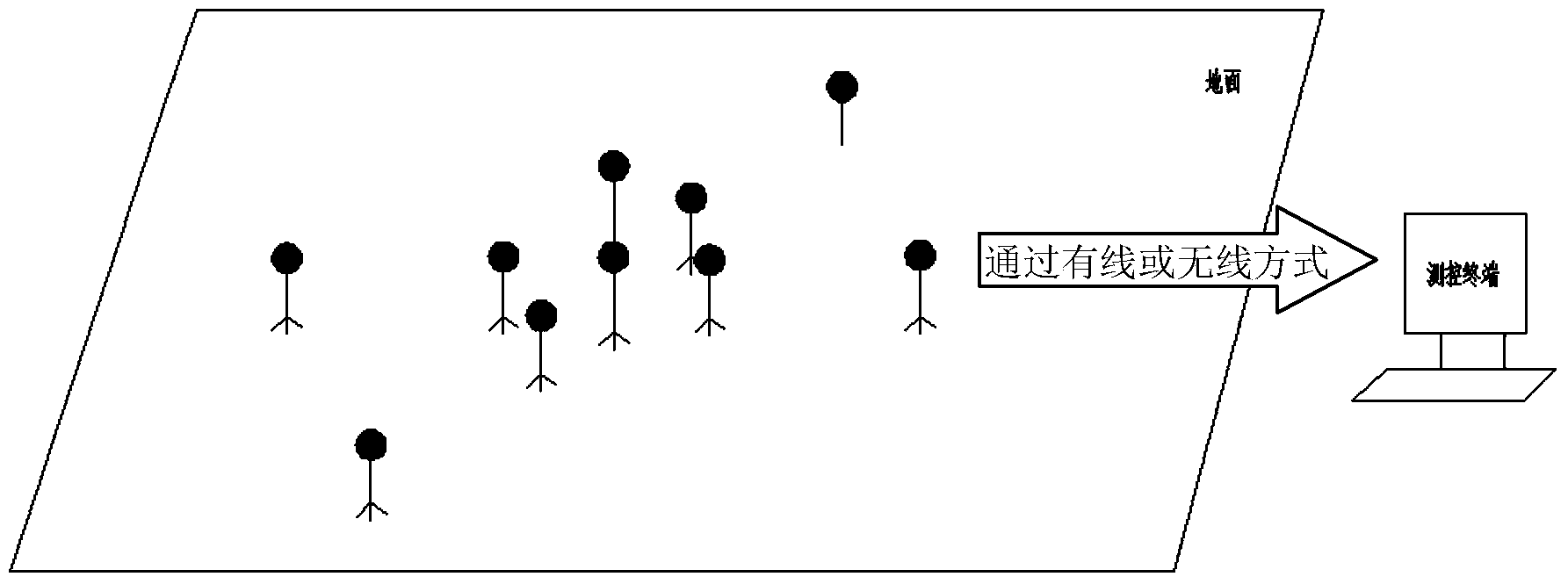

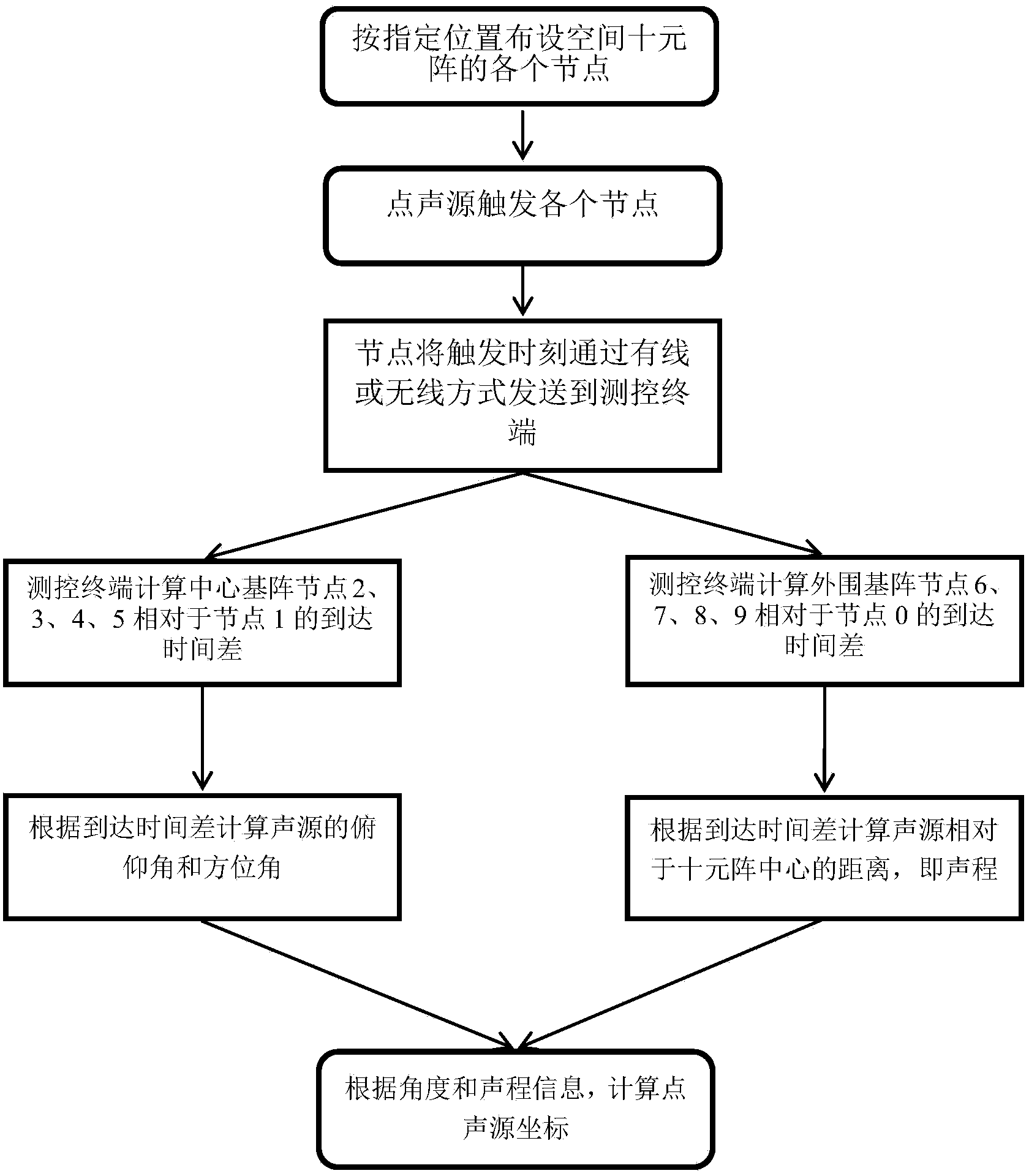

Method for passively positioning point sound source based on spatial ten-element array

The invention provides a method for passively positioning a point sound source based on a spatial ten-element array and belongs to the technical field of sensing and test. The method for passively positioning the point sound source comprises the following steps: calculating a corresponding arrival time difference through all the nodes of a central base array of the spatial ten-element array, and then utilizing the arrival time difference to calculate the pitch angle and the azimuth angle of the point sound source; calculating a corresponding arrival time difference through all the nodes of a peripheral base array of the spatial ten-element array, and then utilizing the arrival time difference to calculate the sonic path distance information of the point sound source; finally calculating the coordinates of the point sound source according to the obtained pitch angle, the azimuth angle and the sonic path distance information. The method for passively positioning the point sound source prevents the condition that the sound source cannot be positioned or a positioning error suddenly changes due to a special sound source position and has the advantages of high precision and strong practicability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

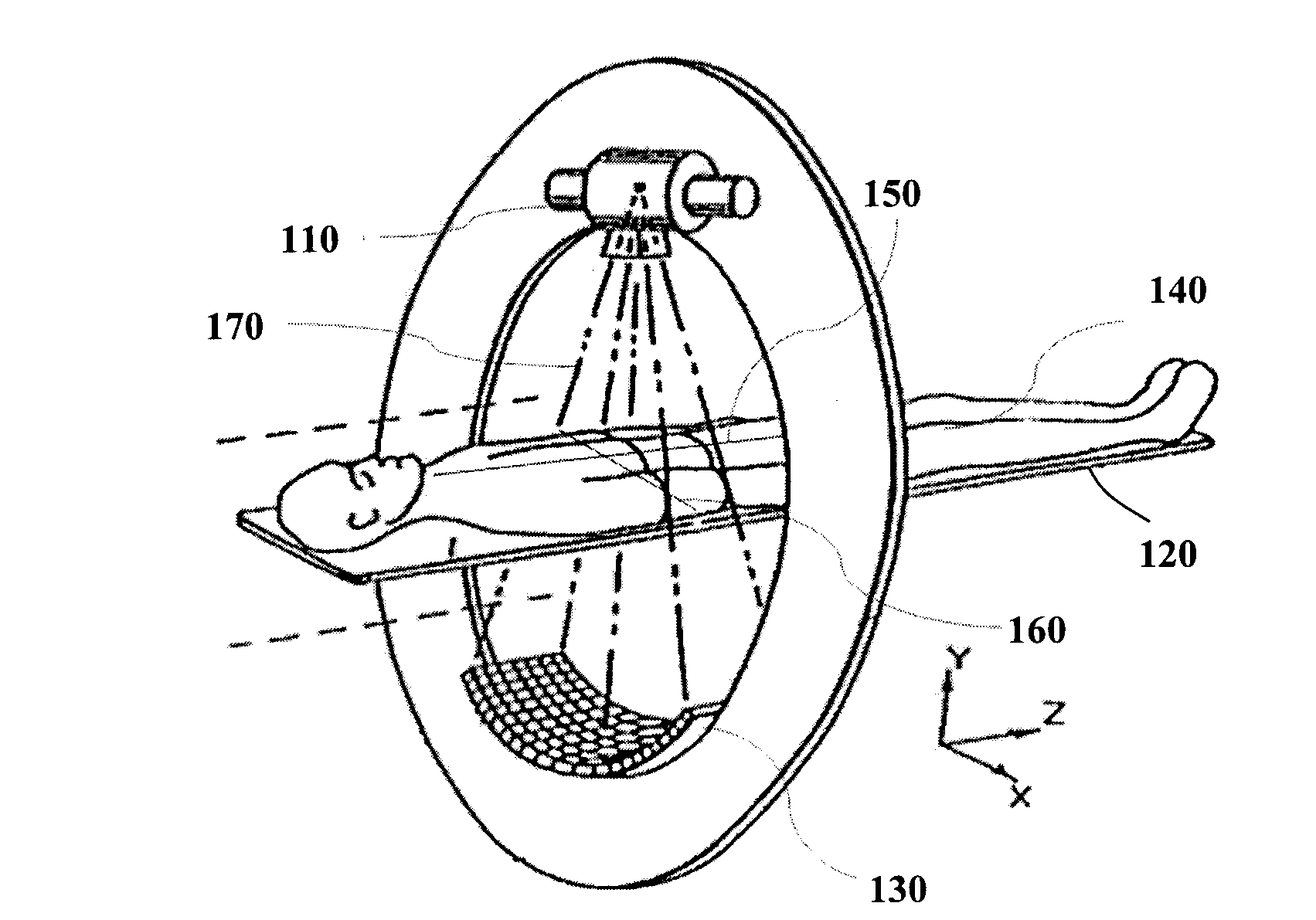

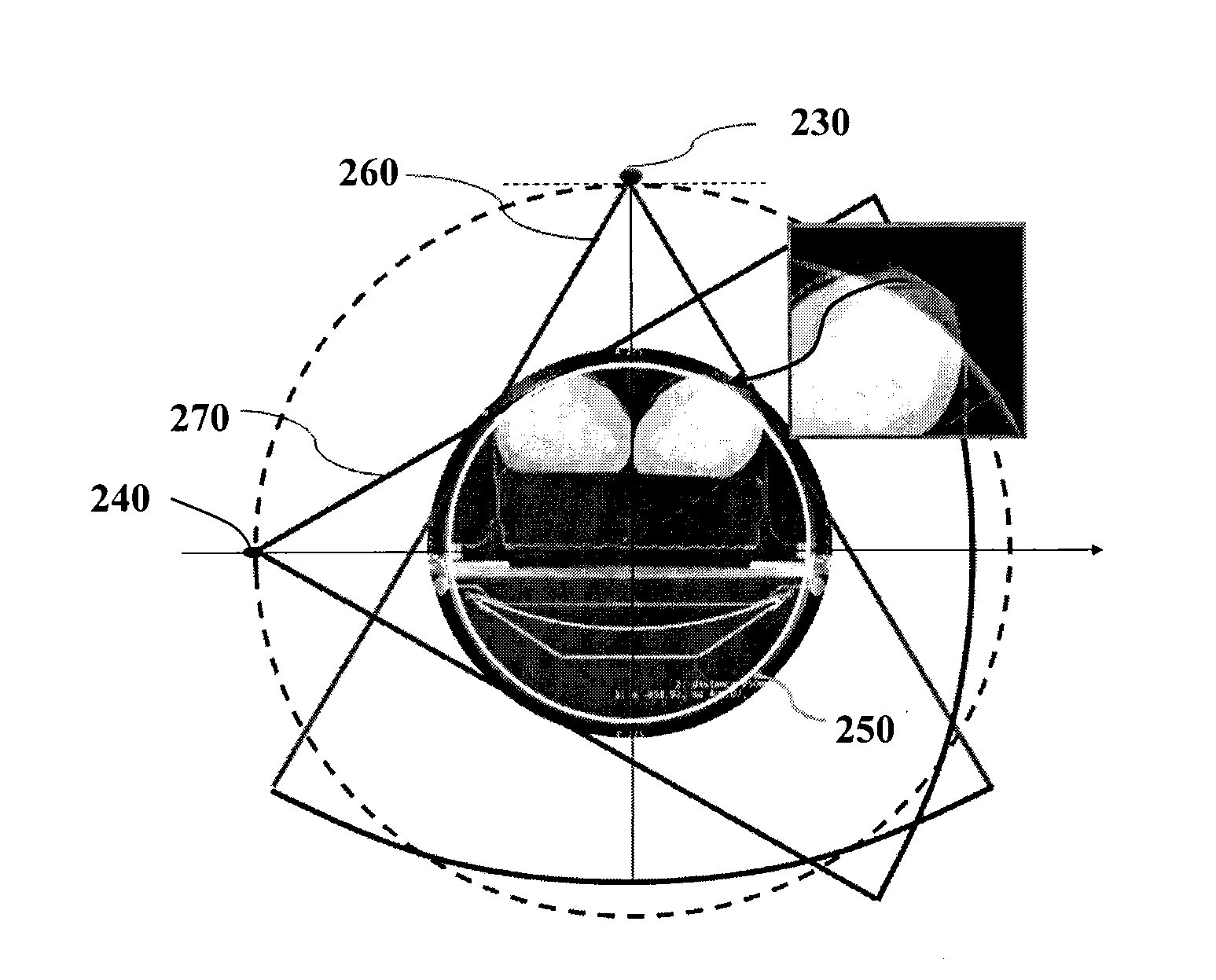

Body laser positioning system and method used for computed tomography (CT) system

ActiveCN103126703AReduce workloadPrecise positioningPatient positioning for diagnosticsComputerised tomographsComputed tomographyField of view

The invention relates to a body laser positioning system and a method used for a computed tomography (CT) system. The body laser positioning system used for the CT system comprises a laser positioning device and a laser piece generation device, wherein the laser positioning device is used for emitting lasers to an object to be scanned and using the emitted lasers to carry out initialization positioning for CT scanning, the laser piece generation device is used for enabling the emitted lasers to be diffused to laser pieces in a CT scanning plane, and edges of the laser pieces along the direction of propagation are at least tangential to a circumference of scanning field of view (SFOV) of the CT system. The body laser positioning method used for the CT system comprises that the lasers are emitted to the object to be scanned, and the emitted lasers are utilized to carry out the initialization positioning for the CT scanning, the emitted lasers are diffused to the laser pieces in the CT scanning plane, and the edges of the laser pieces along the direction of propagation are at least tangential to the circumference of the SFOV of the CT system.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

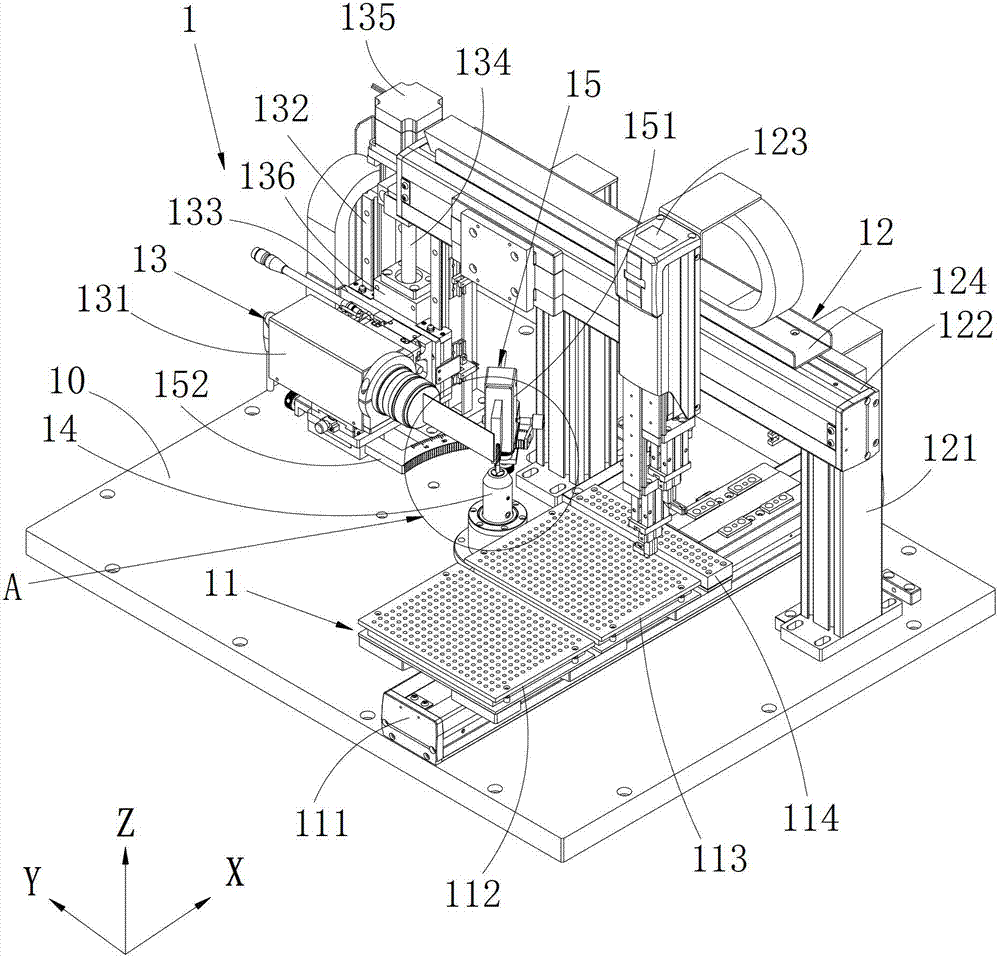

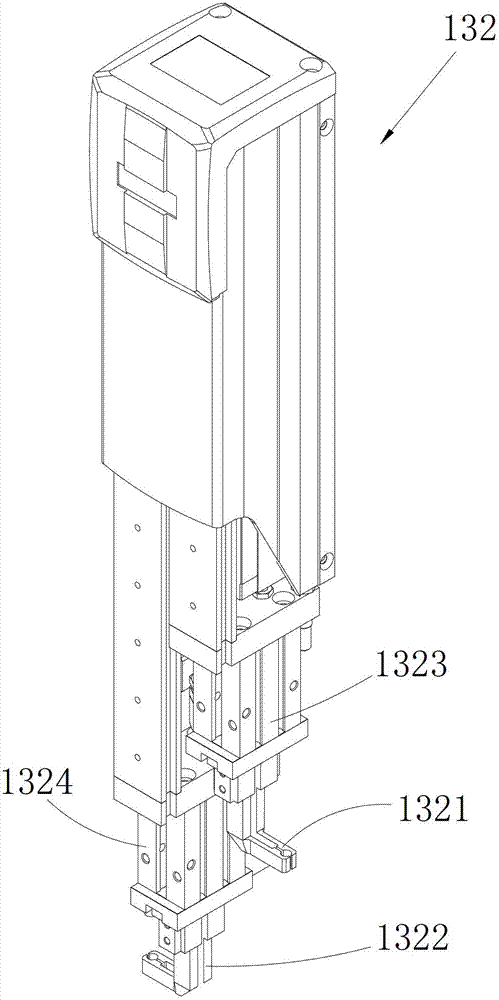

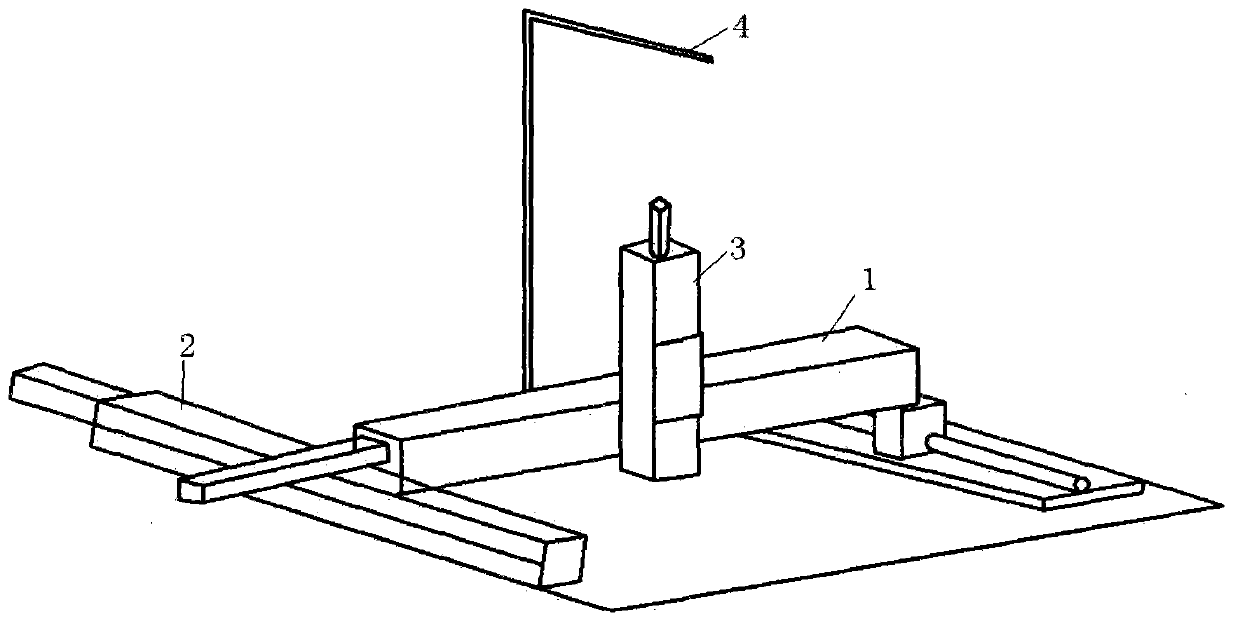

Three-dimensional positioning device based on visual guidance and dispensing equipment

InactiveCN103272739AAvoid the problem of lower precisionLow costLiquid surface applicatorsCoatingsEngineeringMotion system

The invention relates to a three-dimensional positioning device based on visual guidance and dispensing equipment. The three-dimensional positioning device comprises an X axis motion system; a Y axis motion system, wherein the X axis motion system is movably supported on the Y axis motion system, and the Y axis motion system drives the X axis motion system to move along the axial direction of the Y axis motion system; a Z axis motion system, wherein the Z axis motion system is installed on the Y axis motion system, the X axis motion system drives the Z axis motion system to move along the axial direction of the X axis motion system; an image obtaining unit installed above the Z axis motion system and used for obtaining the height position information of a target position and plane center position information of the target position; and a controller electrically connected with the X axis motion system, the Y axis motion system, the Z axis motion system and the image obtaining unit and used for driving the X axis motion system, the Y axis motion system and the Z axis motion system to move according to the height position information and the plane center position information. The three-dimensional positioning device provided by the invention improves the positioning effect of the system.

Owner:WUHAN HUAZHUO BENTENG SCI & TECH

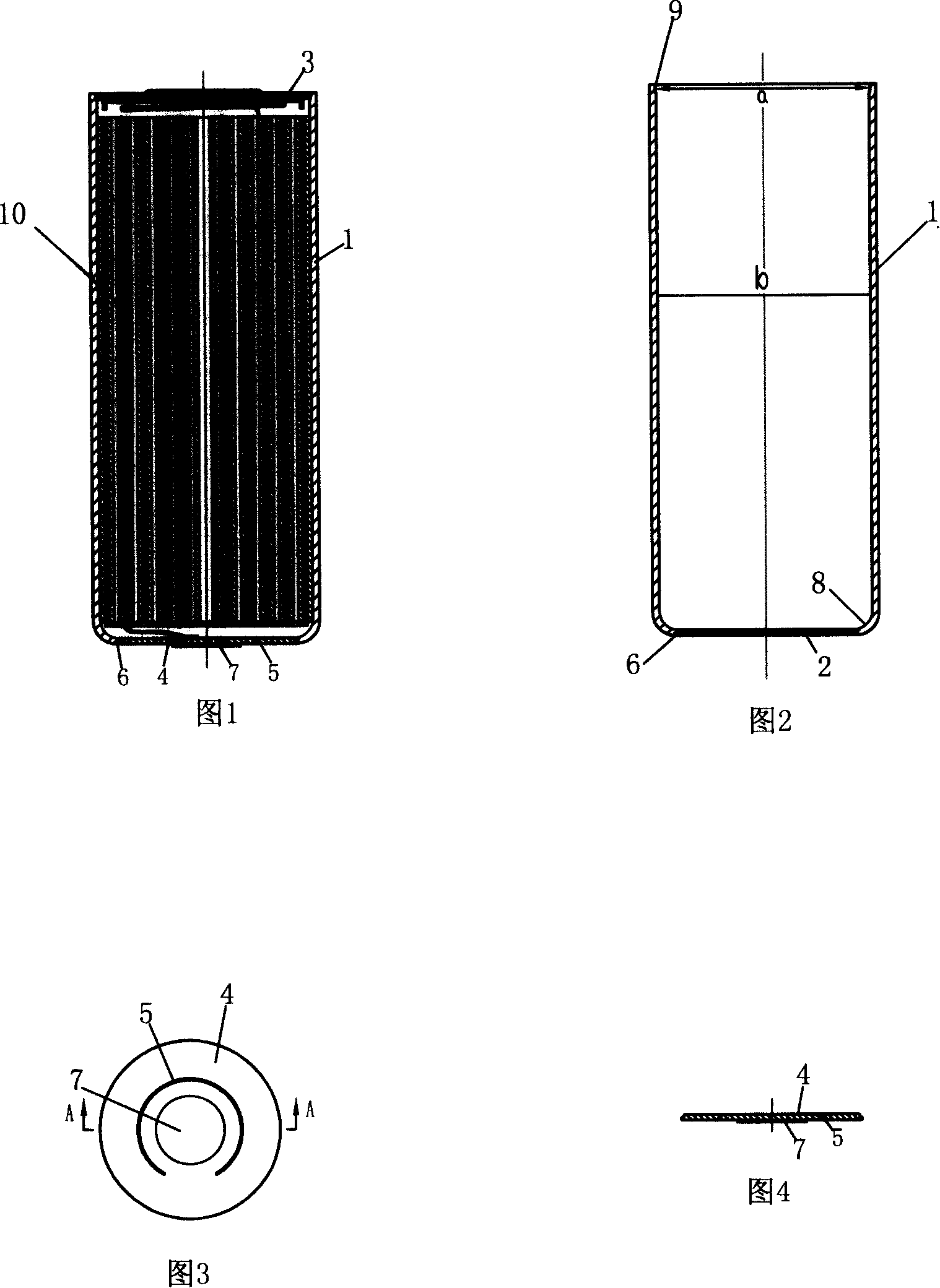

Cylindrical battery housing and cylindrical battery

ActiveCN101114704APrevent slidingAvoid Positioning EffectsSmall-sized cells cases/jacketsSecondary cellsEngineeringOpen mouth

The invention relates to a cylindrical battery shell, comprising a cylinder, an upper cover plate and a lower cover plate, and is characterized in that the head of the cylinder is open and an open supporting table is arranged at the bottom of the cylinder, the lower cover plate is covered on the open mouth of the supporting table, and further more, the open mouth is a step-shaped mouth or a conical mouth, the invention further relates to a cylindrical battery made by the shell. Applying the technic proposal, the invention provides a cylindrical battery shell and a cylindrical battery which is convenient for equipping and locating battery unit, and prevents the battery unit from skipping in the shell.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

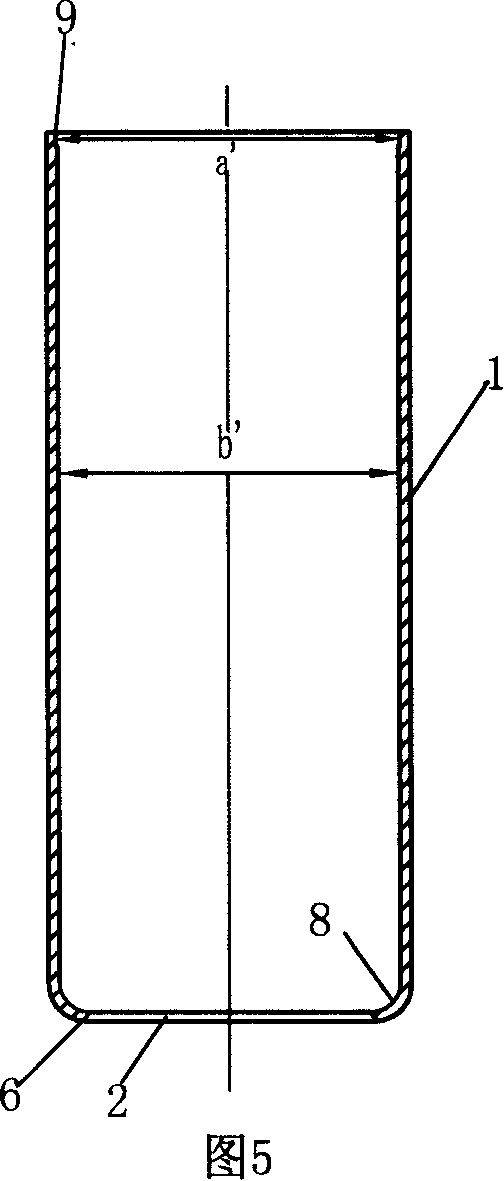

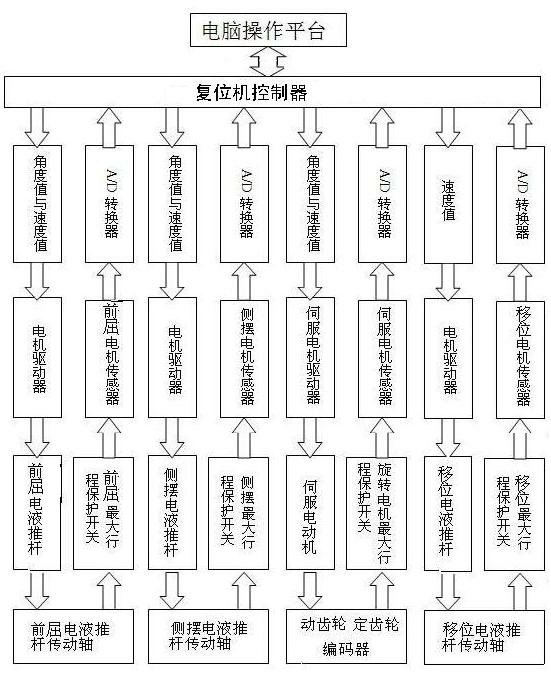

Automatic lumbar fixed-point spinning reduction machine

The invention provides a sitting type automatic lumbar fixed-point spinning reduction machine for treating soft tissue injuries and spinal diseases. The reduction machine comprises a chair, a crotch fixer, leg holddown units, a back fixer, a movable rod, a chest-rest board, a shifting mechanism, a forward bending mechanism, a sideward swaying mechanism, a spinning mechanism and a related electric control system. The shifting mechanism, the forward bending mechanism and the sideward swaying mechanism are driven by electrohydraulic rod type pushers, control is steady, the speed is moderate, the spinning mechanism is controlled by a servo system cooperating with a corresponding transmission mechanism, so that the needed speed and angle of spinning are accurate, and the back fixer is provided with artificial hand models, which are provided with buffer units and an automatic follow-up or withdrawal positioning function. The closed-loop control system comprising related sensors and a programmable controller is communicated with a computer via the RS232 serial communication technology, and cooperates with a computer user interface, and thereby the reduction machine has the advantages of simple operation, high automation degree, accurate control and remarkable efficacy.

Owner:梁伍 +1

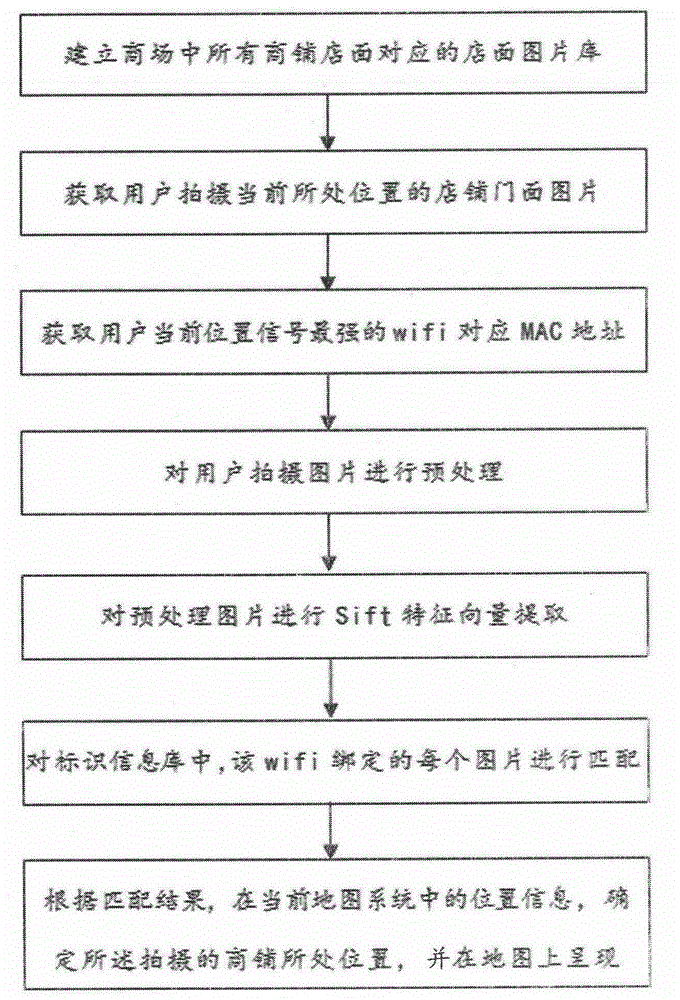

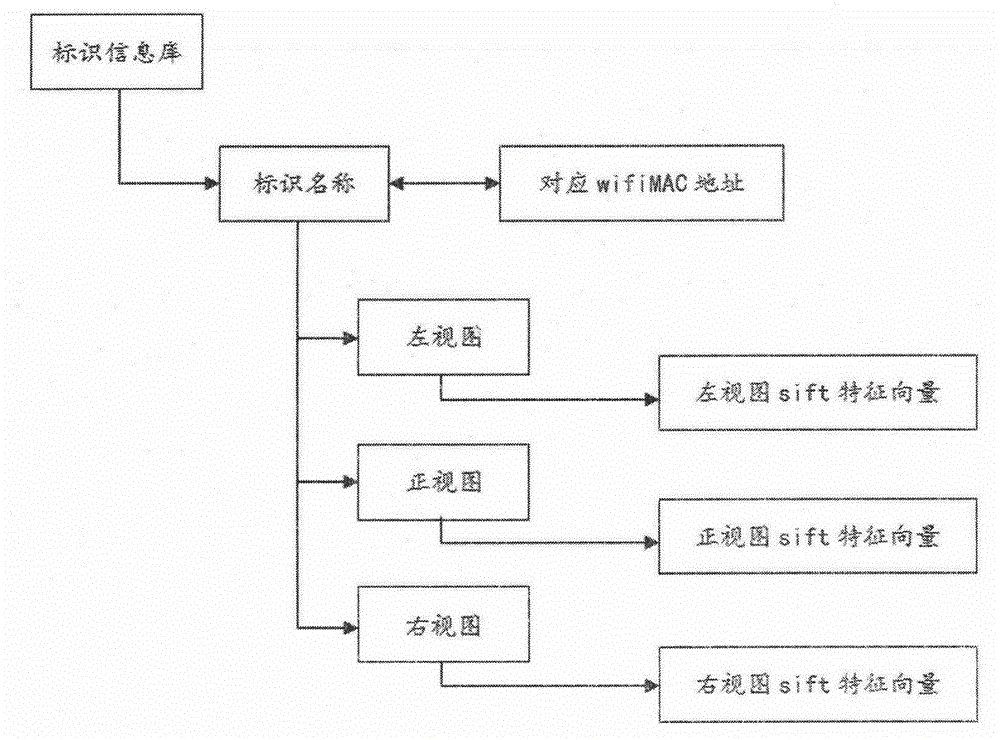

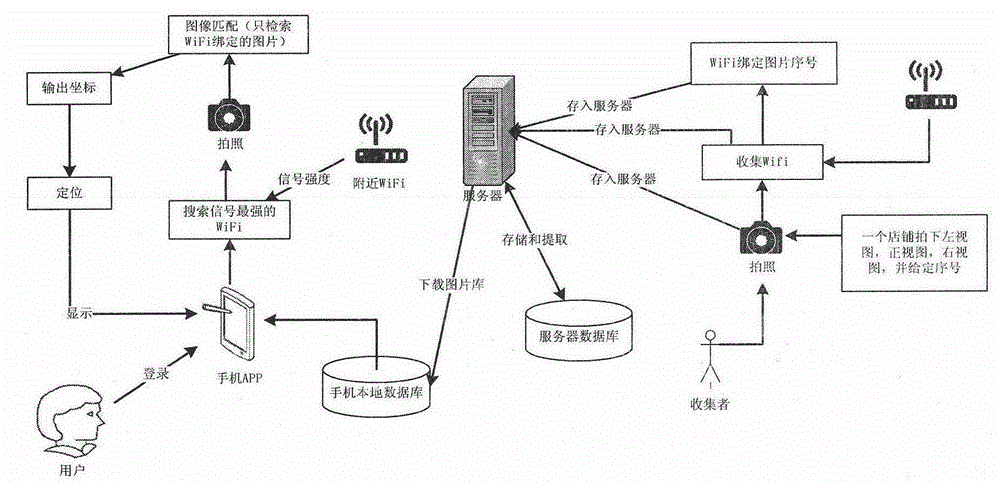

Optimization algorithm based on image matching indoor positioning

InactiveCN104899603ACutting costsImprove accuracyCharacter and pattern recognitionState of artAlgorithm

The invention discloses an optimization algorithm based on image matching indoor positioning, including the following steps: (1) picking store samples; (2) taking a photo of each store; (3) numbering the stores; (4) binding wifiMAC addresses and store images; (5) establishing a database; (6) selecting wifi with the strongest signals; and (7) carrying out image matching traversal. Compared with the prior art, the advantages of the optimization algorithm of the invention lie in that the scope of image matching is narrowed through wifi strength detection, so that unnecessary image matching operation is reduced, and time and cost are reduced; the wifi strength provides assistance, and the influence of unstable factors of wifi strength on positioning is avoided; and the time and cost of positioning are reduced, the stability of positioning is improved, and the optimization algorithm is effective and practical in a mobile platform segment.

Owner:孙思宇

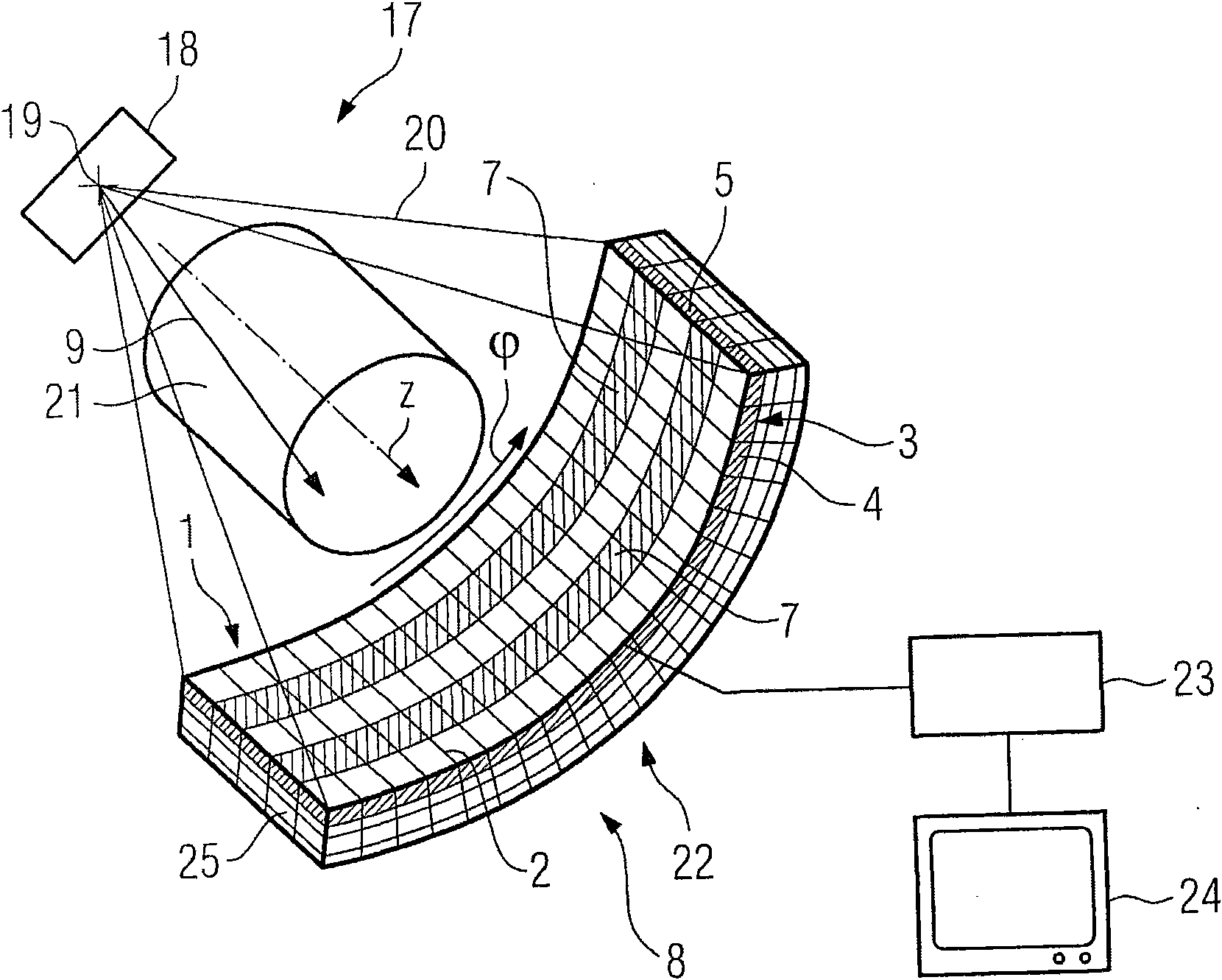

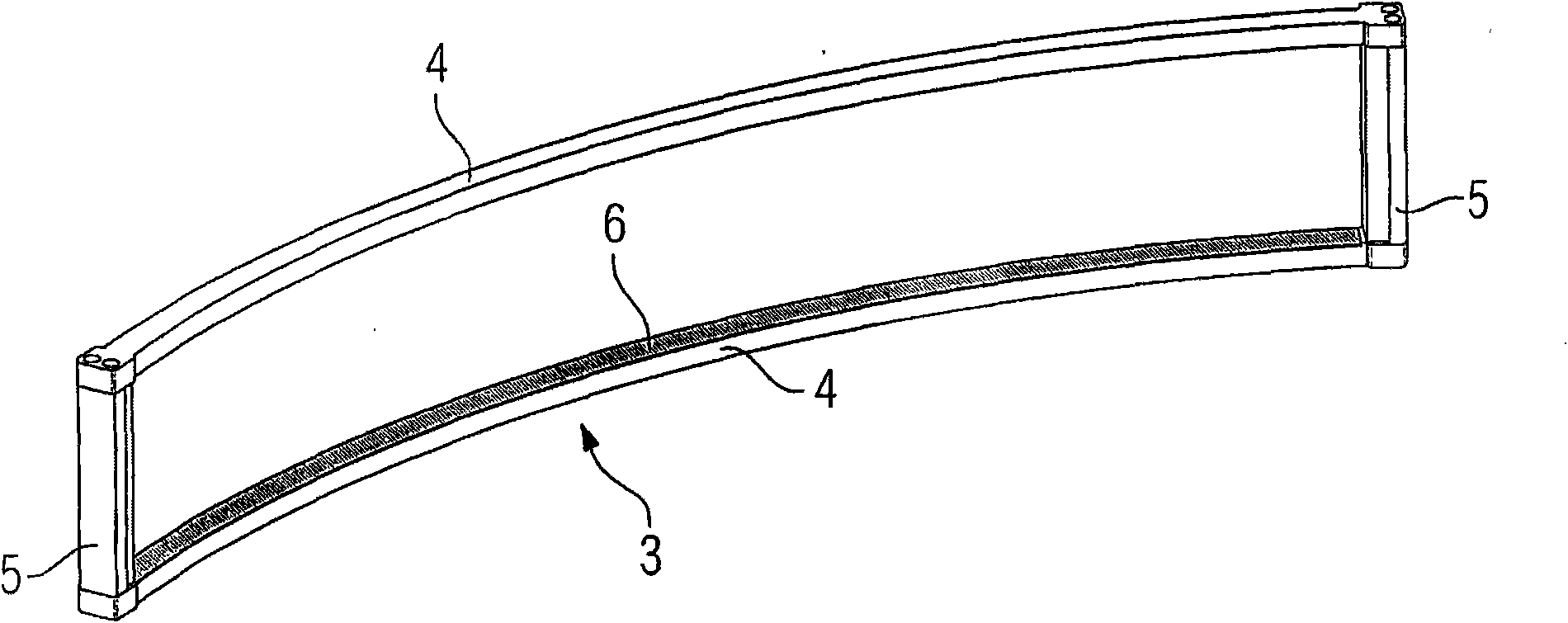

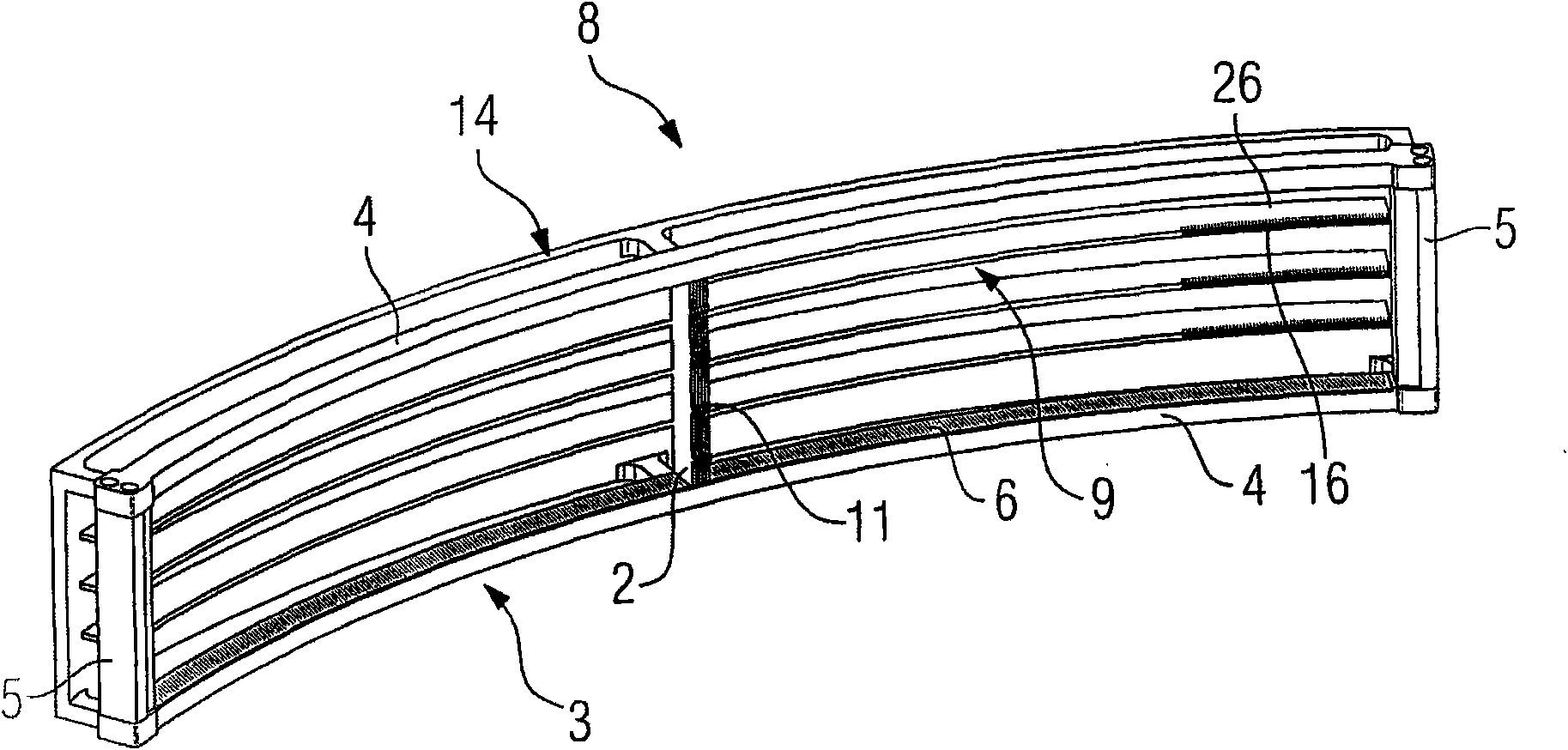

Scattered-radiation collimator and method for producing a scattered radiation collimator

InactiveCN102100563APrevent bucklingStable positionHandling using diaphragms/collimetersComputerised tomographsCentrifugal forceScattering radiation

A scattered-radiation collimator is disclosed for radiological radiation with a multiplicity of absorber elements that are arranged one behind the other in a collimation direction and held in a support frame. In at least one embodiment, the support frame includes a holding device for holding the absorber elements on opposite sides across the collimation direction, and at least one strip-like holding element spans the absorber elements in a collimation direction on the radiation entry side and / or the radiation exit side of the scattered-radiation collimator and additionally fixes the absorber elements on the longitudinal edges thereof in a mechanical fashion. In at least one embodiment, the holding elements prevent deformations of long absorber elements caused by centrifugal forces to a large extent. This affords the possibility of implementing scattered-radiation collimators with a large Z-coverage that meet the demand on the absorber elements in respect of dimensional stability and positional accuracy. Moreover, at least one embodiment of the invention relates to a method for producing such a scattered-radiation collimator.

Owner:SIEMENS AG

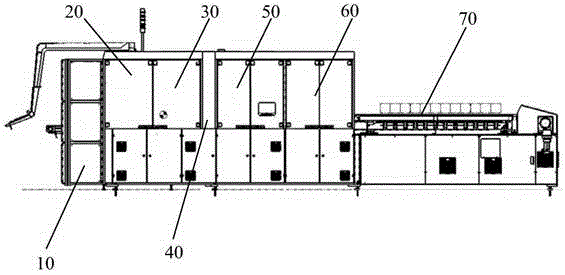

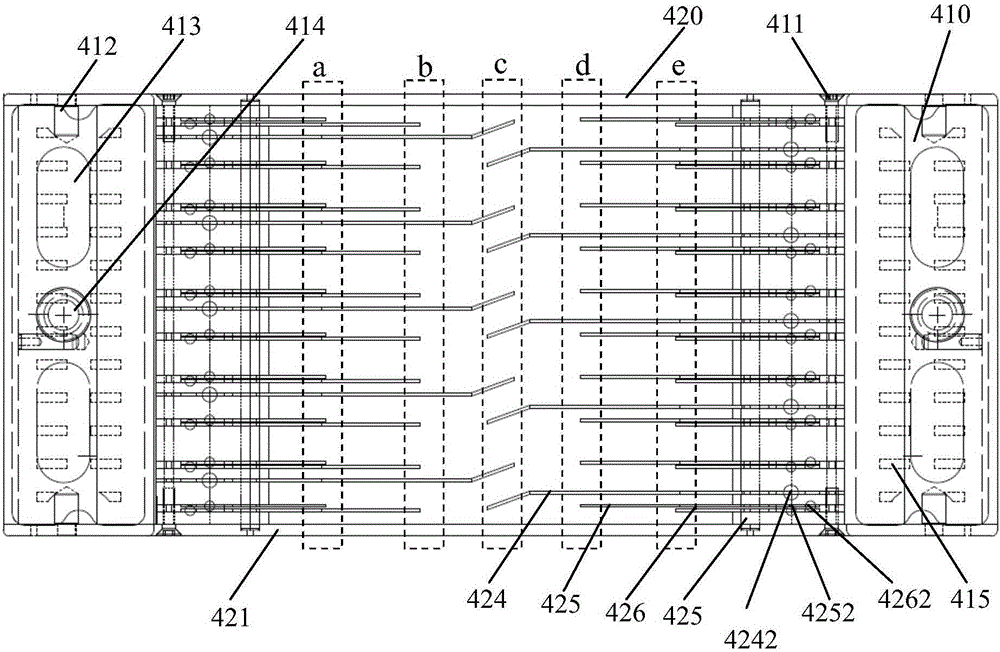

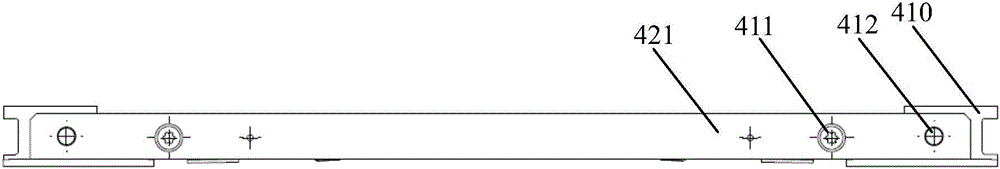

Welding belt welding, transmission and holding device for solar cell series welding machine, and series welding machine

InactiveCN106374016AGuaranteed positional stabilityNo displacementFinal product manufacturePhotovoltaic energy generationTransfer procedureEngineering

The invention provides a welding belt welding, transmission and holding device for a solar cell series welding machine. The welding belt welding, transmission and holding device for the solar cell series welding machine comprises two symmetrically arranged skirt structures and a welding belt pressing needle module connected with the skirt structures. The welding belt pressing needle module comprises a pressing-holding part of the welding belt on five pairs of cell sheets formed by a plurality of pressing needles which have three kinds of length specifications and are relatively arranged. One end of each pressing needle is arranged on an installation shaft in a sleeved mode through a slotted hole, and is jacked up through a spring by using a rotating shaft as a supporting point; the other end of each pressing needle is pressed downward on the welding belt to fix and hold the welding belt to the cell sheets. The bottom surface of the skirt structures is provided with a vacuum adsorption loop formed by a plurality of blind holes. The welding belt welding, transmission and holding device can ensure the fixing and holding of the welding belt in the transmission process, and avoid the inaccurate positioning in the transmission and the poor contact during welding which are caused by displacement.

Owner:苏州佳普硕自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com