Testing device and testing method for automobile gear shifting system performance

A technology for testing device and system performance, which is applied in the testing of machine gears/transmission mechanisms, etc. It can solve the problems that safety hazards cannot be completely eliminated, manufacturing error tests cannot be accurately simulated, etc., and the measurement method is simple and easy, and the cost is low. The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

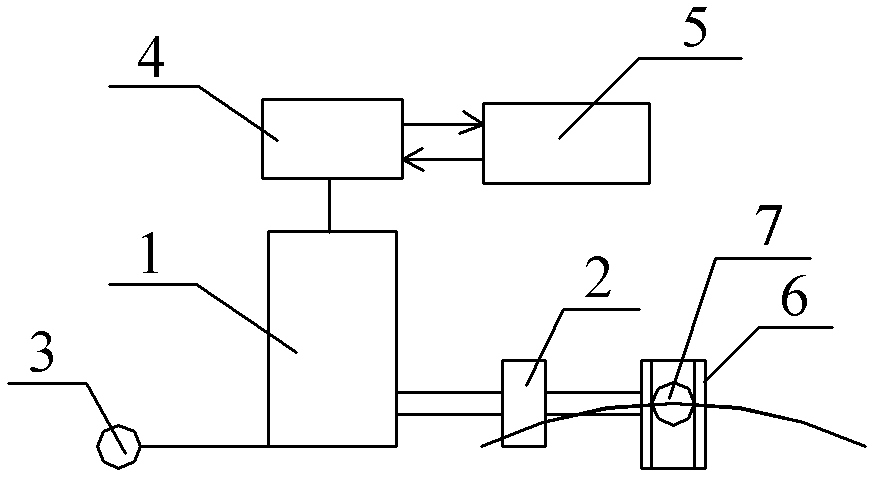

[0038] Use the test device provided by the invention to test the shifting force of the shifter (the test structure schematic diagram is as follows figure 2 shown) the steps are as follows:

[0039] 1) Fix the shifter 9 to be tested on the workbench 10, connect the uniaxial force sensor (50N, resolution 0.1N) 2, the pull wire displacement sensor (500mm, resolution 0.01mm) 3 and the six-axis industrial robot 1, and the clamp 6 connected with the force sensor 2 is correctly nested on the ball head 8 of the shifter handle;

[0040] 2) The test unit 5 calculates the trajectory of the vehicle coordinate system and the coordinate values of each gear point of the handball force point (POF) at each gear point according to the RPS point of the gear shifter 9 to be tested, and then according to the vehicle coordinates The coordinate value of each gear position in the vehicle coordinate system is accurately converted to the coordinate value in the user coordinate system according to t...

Embodiment 2

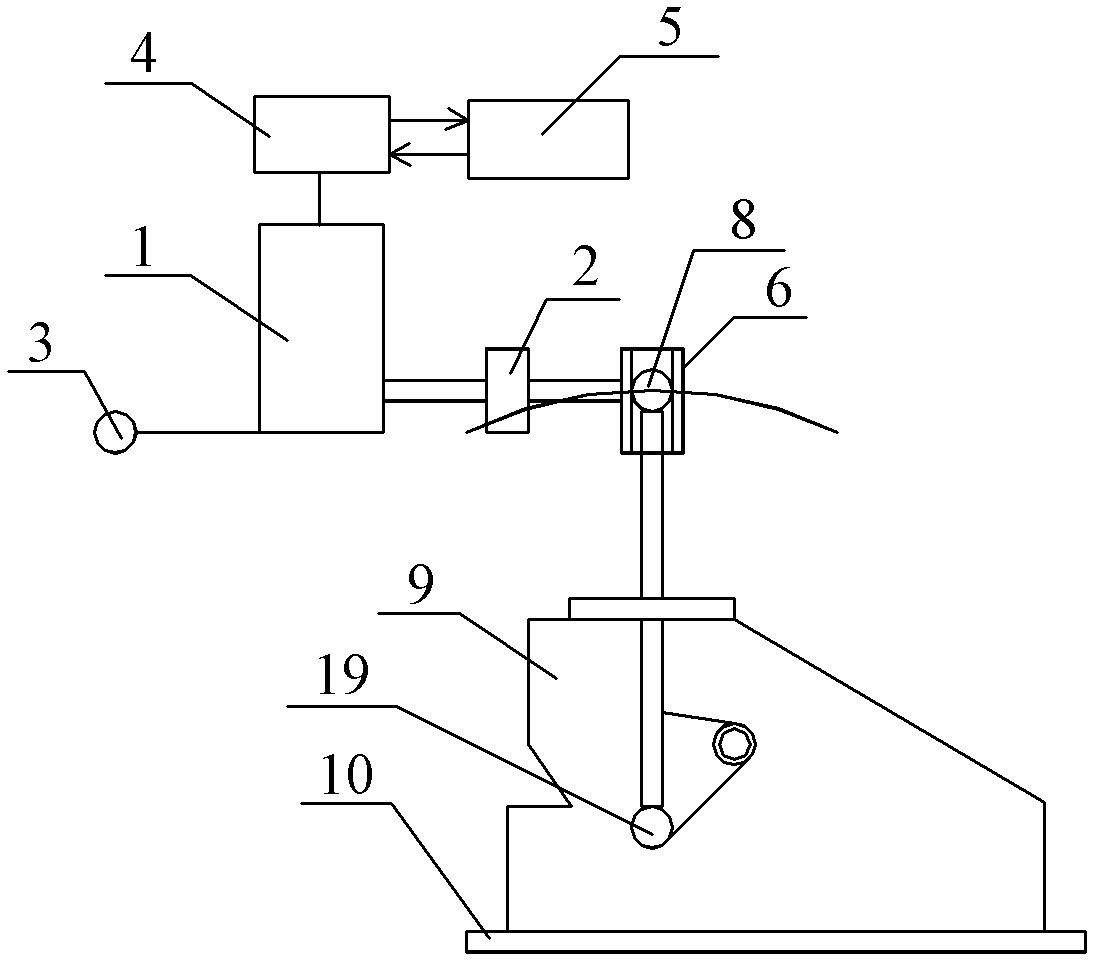

[0044]Use the test device provided by the invention to test each gear gap of the shifter (the schematic diagram of the test structure is as follows: image 3 shown) the steps are as follows:

[0045] 1) Fix the shifter 9 to be tested on the workbench 10, connect the uniaxial force sensor (50N, resolution 0.1N) 2, the grating displacement sensor (100mm, resolution 0.001mm) 3 and the six-axis industrial robot 1, and the clamp 6 connected to the force sensor 2 is correctly nested on the ball head 8 of the shifter handle, and the locking plunger of the shifter 9 is released, and the cable is fixed using the cable fixing piece 12. The ball head 11 is fixed;

[0046] 2) The test unit 5 calculates the coordinate value of the shifter 9 in the vehicle coordinate system according to the RPS point of the shifter 9 to be tested, and then moves the shifter 9 according to the positional relationship between the vehicle coordinate system and the user coordinate system. The coordinate value...

Embodiment 3

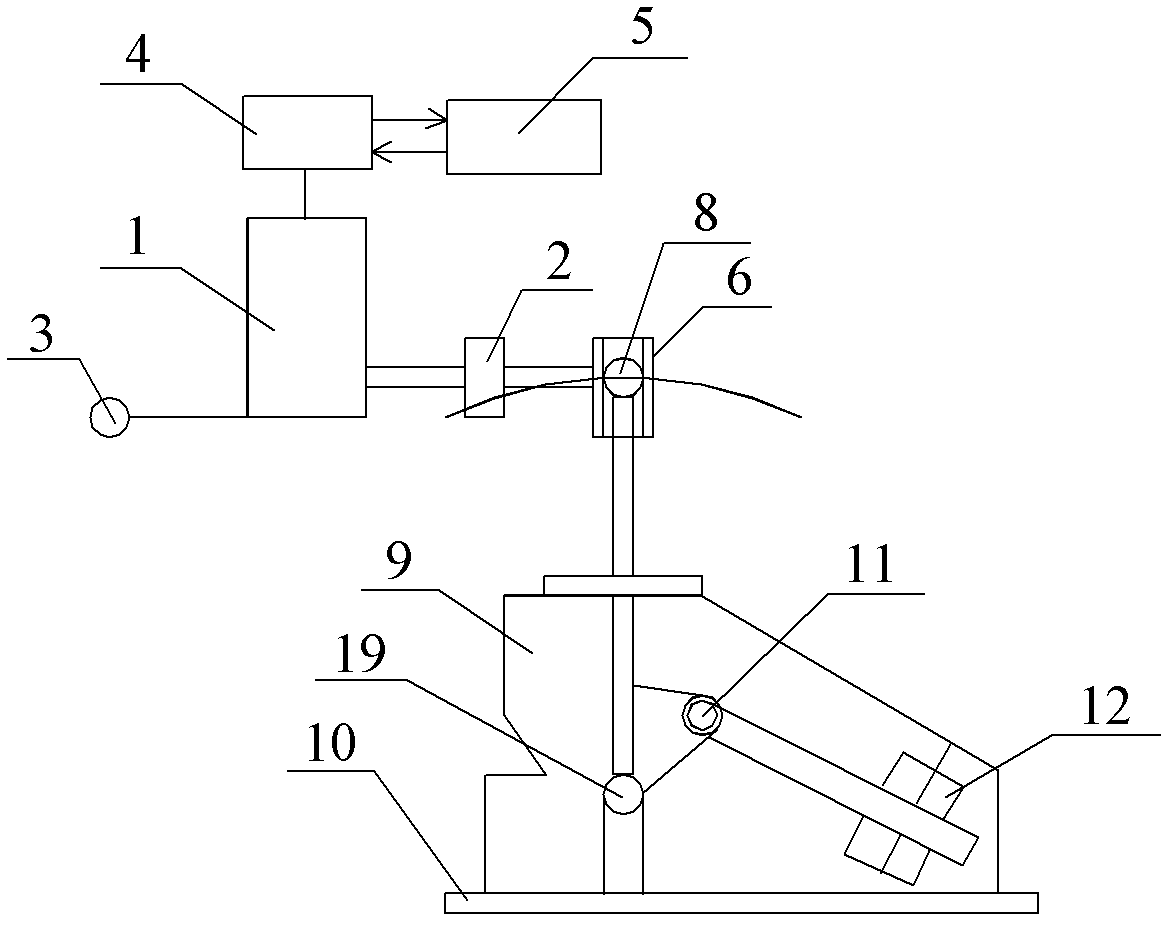

[0050] Use the test device provided by the invention to test the front and rear stroke compliance of the shifter (the schematic diagram of the test structure is as follows: image 3 shown) the steps are as follows:

[0051] 1) Fix the shifter 9 to be tested on the workbench 10, connect the uniaxial force sensor (400N, resolution 0.1N) 2, the grating displacement sensor (100mm, resolution 0.001mm) 3 and the six-axis industrial robot 1, and the clamp 6 connected to the force sensor 2 is correctly nested on the ball head 8 of the shifter handle, and the locking plunger of the shifter 9 is released, and the cable is fixed using the cable fixing piece 12. The ball head 11 is fixed;

[0052] 2) The test unit 5 calculates the coordinate value of the shifter 9 in the vehicle coordinate system according to the RPS point of the shifter 9 to be tested, and then moves the shifter 9 according to the positional relationship between the vehicle coordinate system and the user coordinate syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com